Patents

Literature

46results about How to "High Sulfur Utilization Efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Start working method for hydrocracking process

ActiveCN101492613AHigh vulcanization rateHigh Sulfur Utilization EfficiencyHydrocarbon oil crackingSulfurEconomic benefits

The invention discloses a hydrocracking process operation method. Hydrocracking pre-refining catalyst is treated by precuring outside a reactor while hydrocracking catalyst is not treated or is partially treated by precuring outside the reactor. Curing ingredient introduced by the hydrocracking pre-refining catalyst and the hydrocracking catalyst precured outside the reactor accounts for 90-120% of the theoretical sulfur demand for all the catalyst. The hydro cracking pre-refining catalyst and the hydro cracking catalyst are layered in the reactor and then activated by heating, so that all the catalyst is sulfurated effectively. The method of the invention can precure the hydrocracking pre-refining catalyst outside the reactor or precure the hydrocracking pre-refining catalyst and partial hydrocracking catalyst outside the reactor, thus reducing the catalyst requiring precuring outside the reactor, reducing the production period and production cost of the precuring catalyst and improving the economic benefit and production security.

Owner:CHINA PETROLEUM & CHEM CORP +1

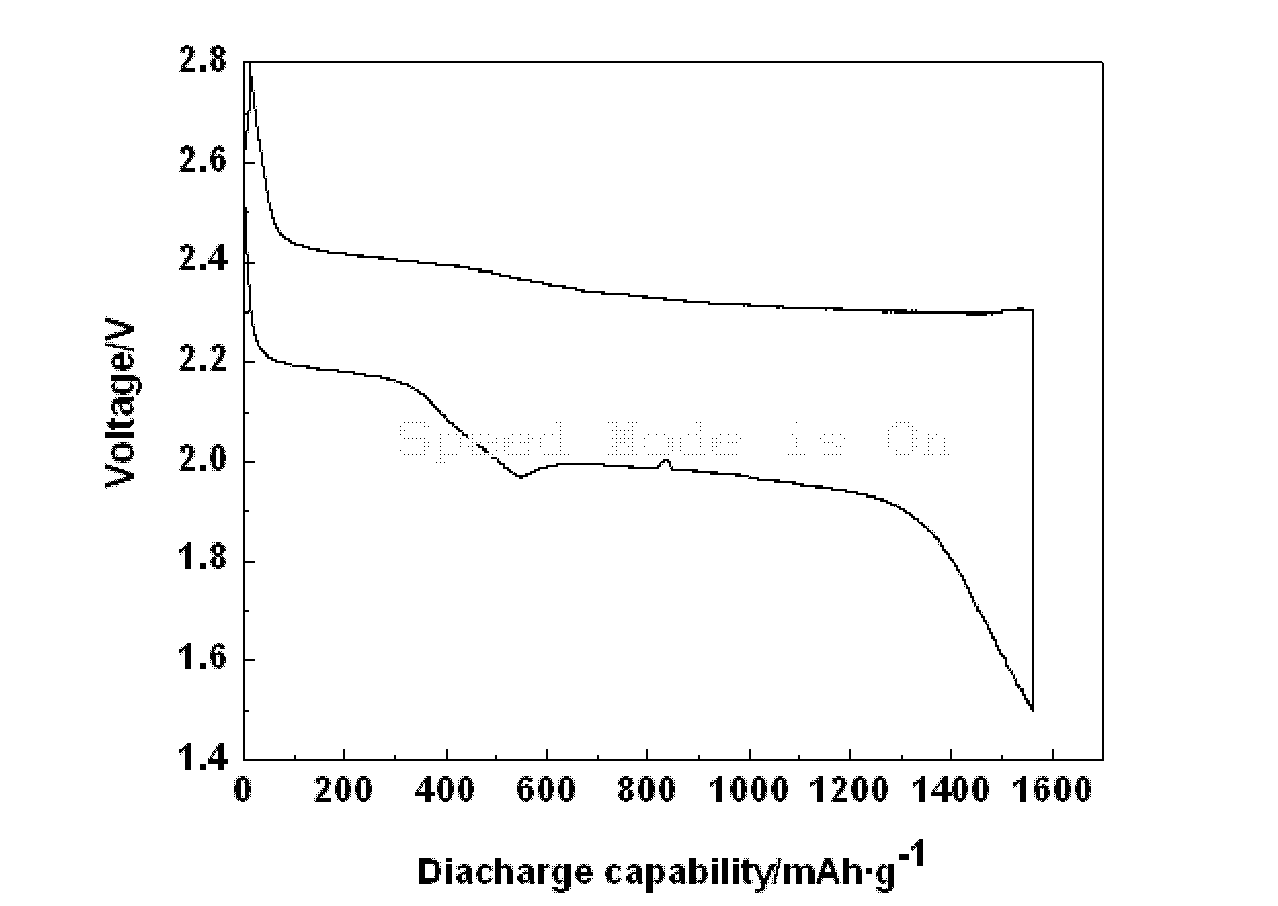

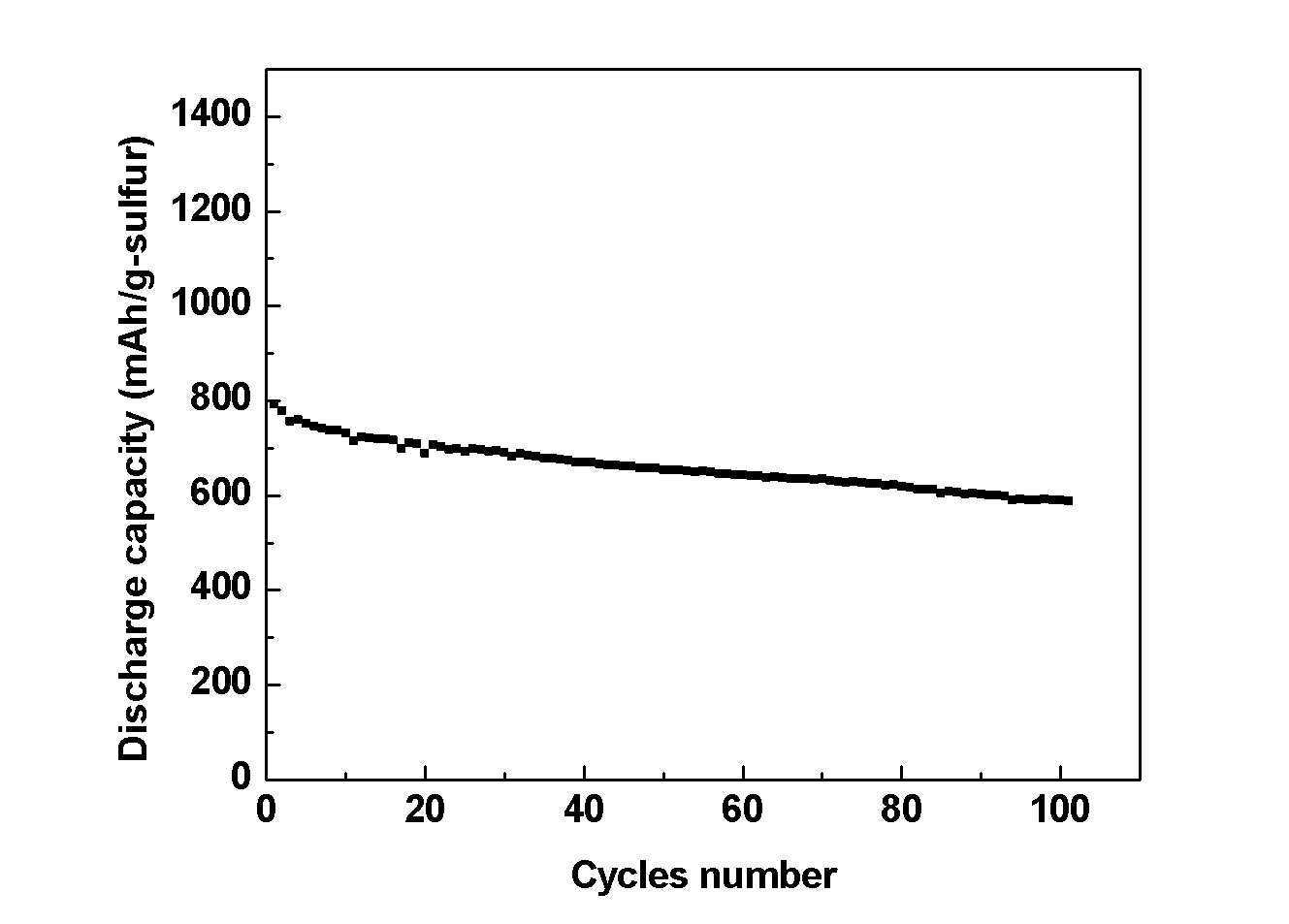

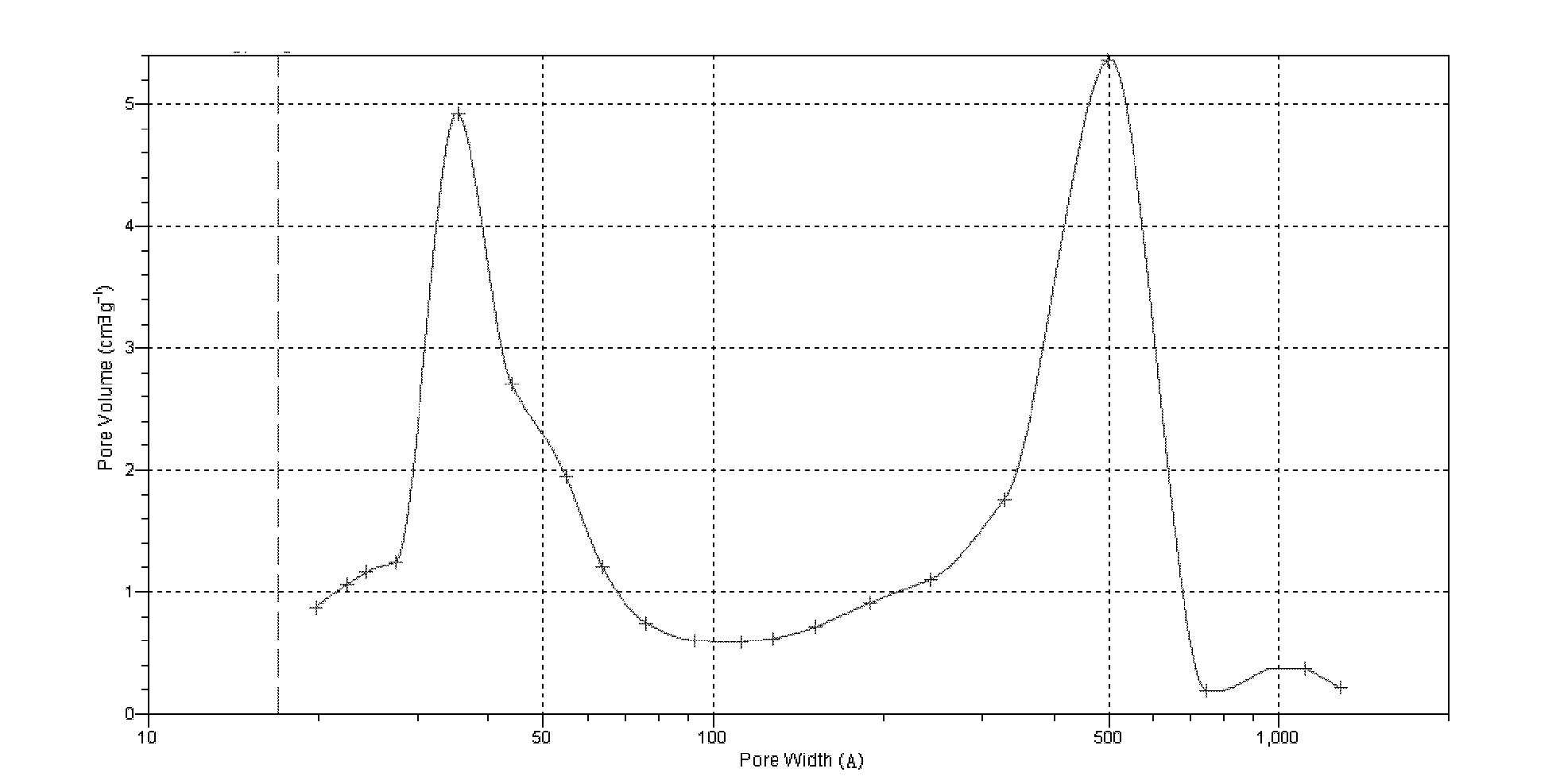

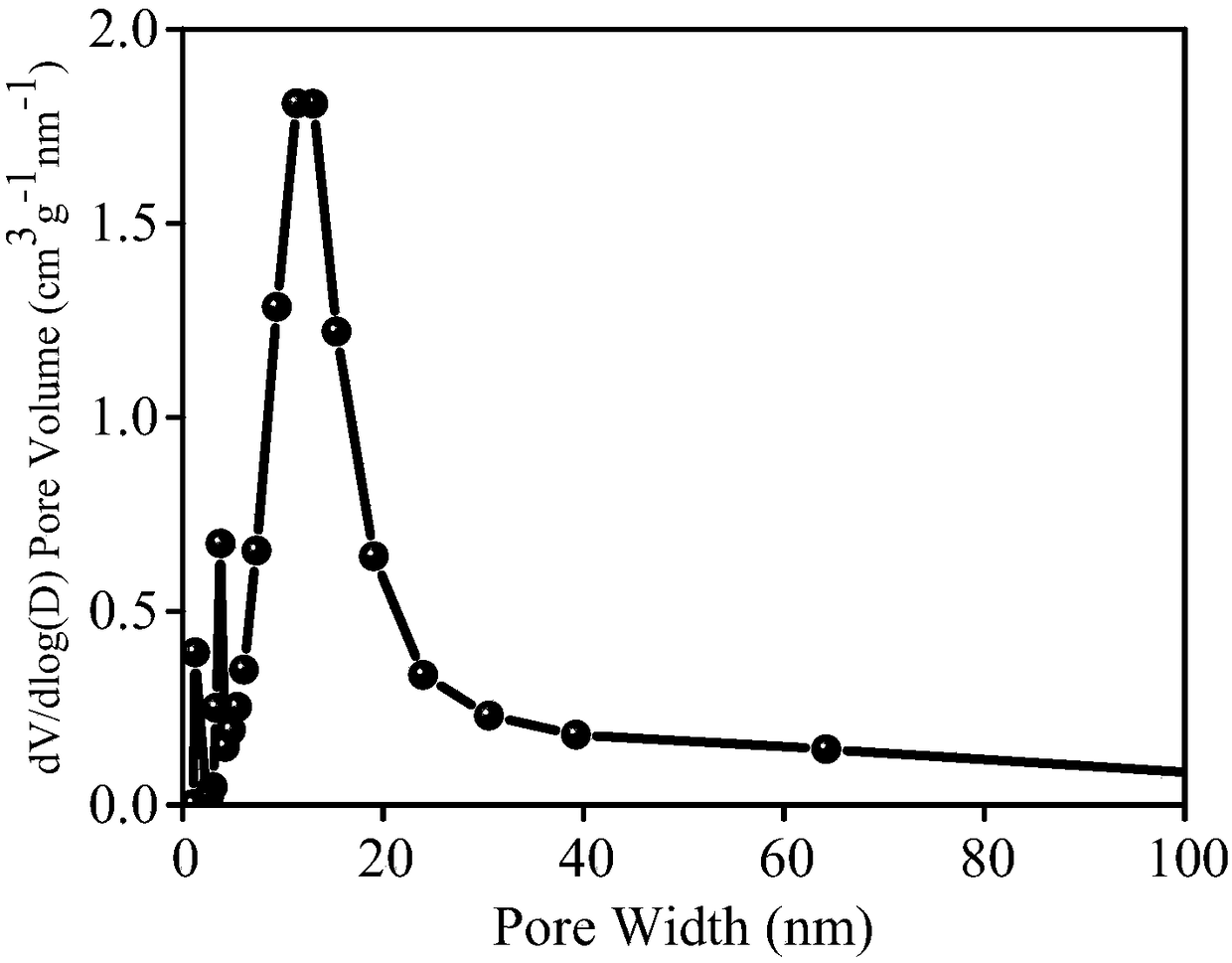

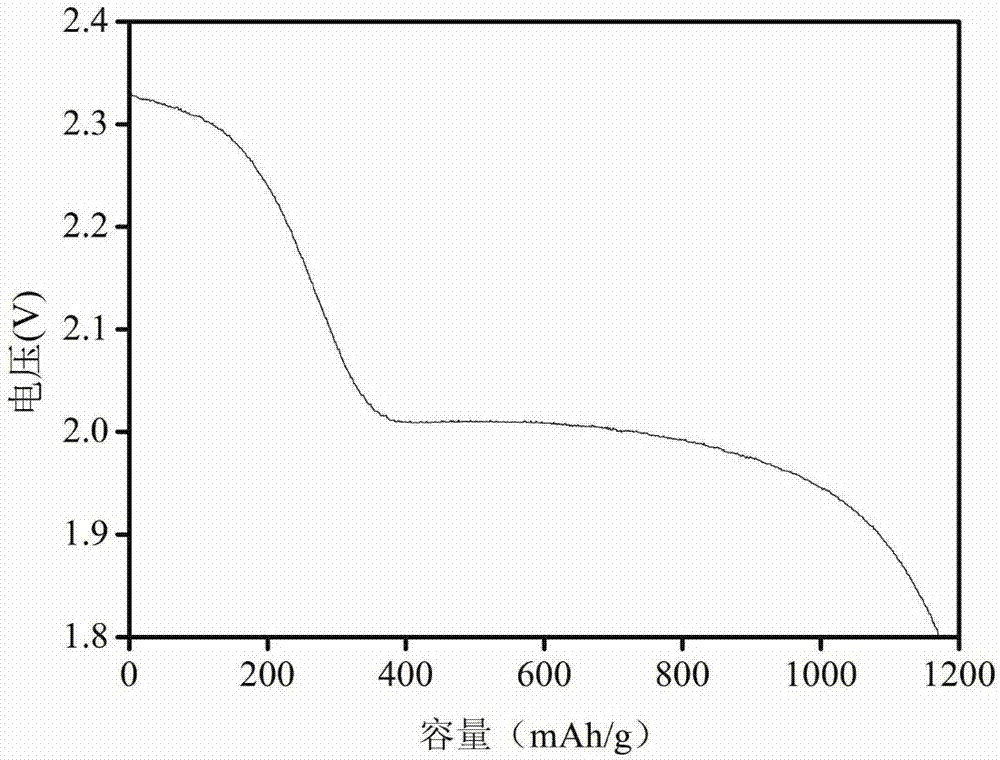

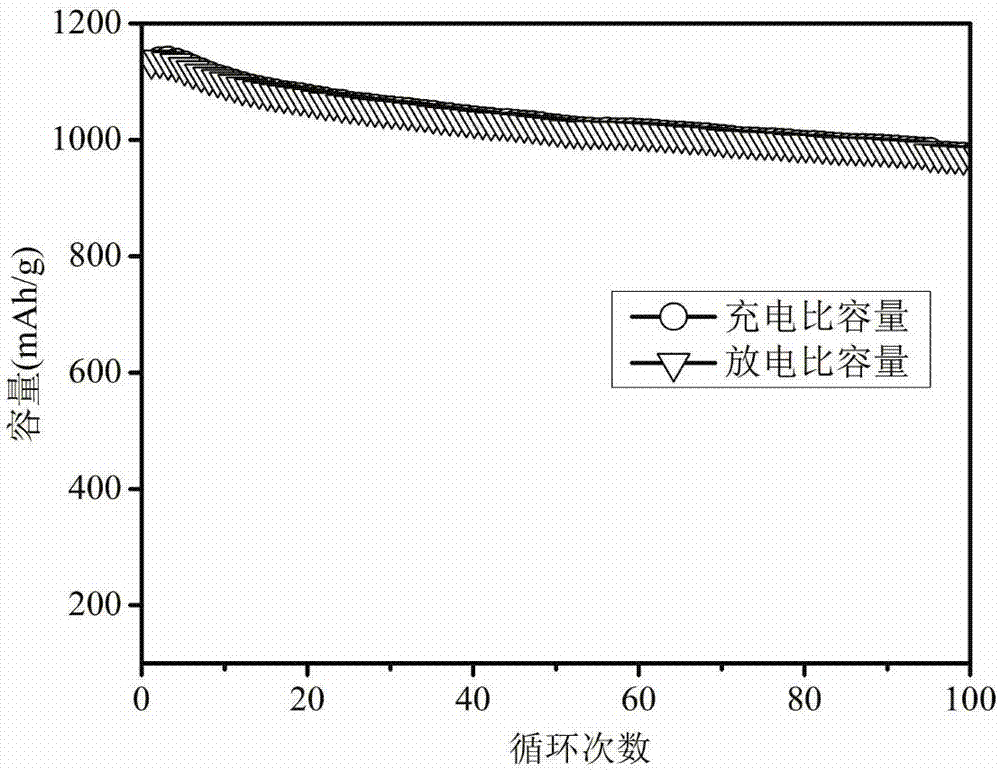

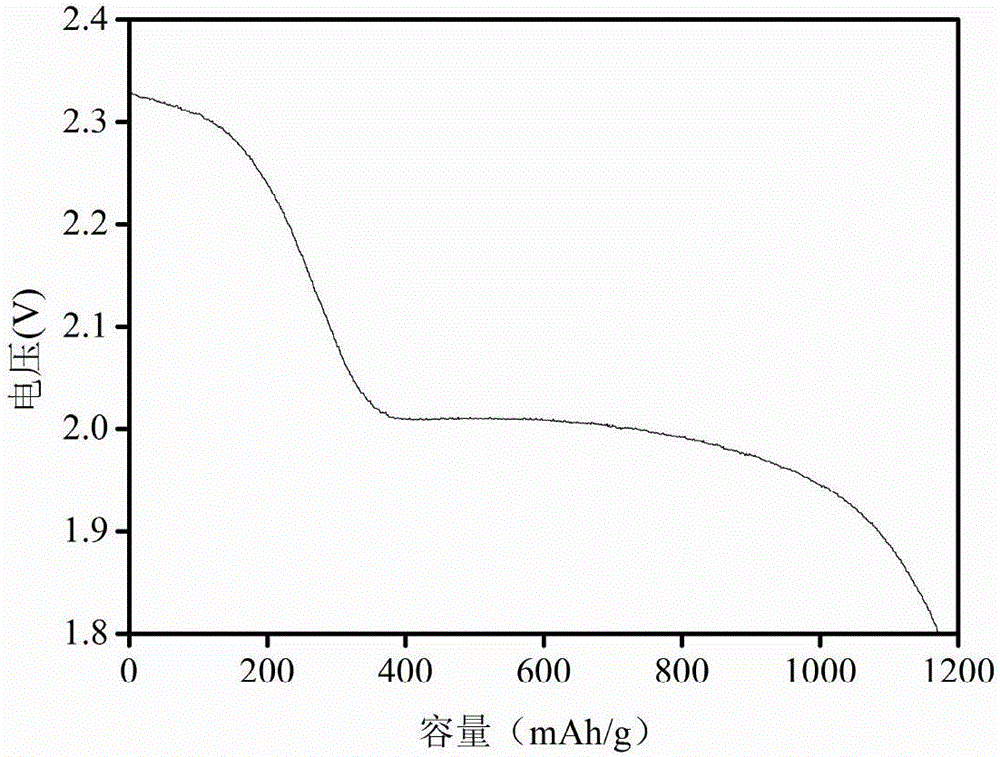

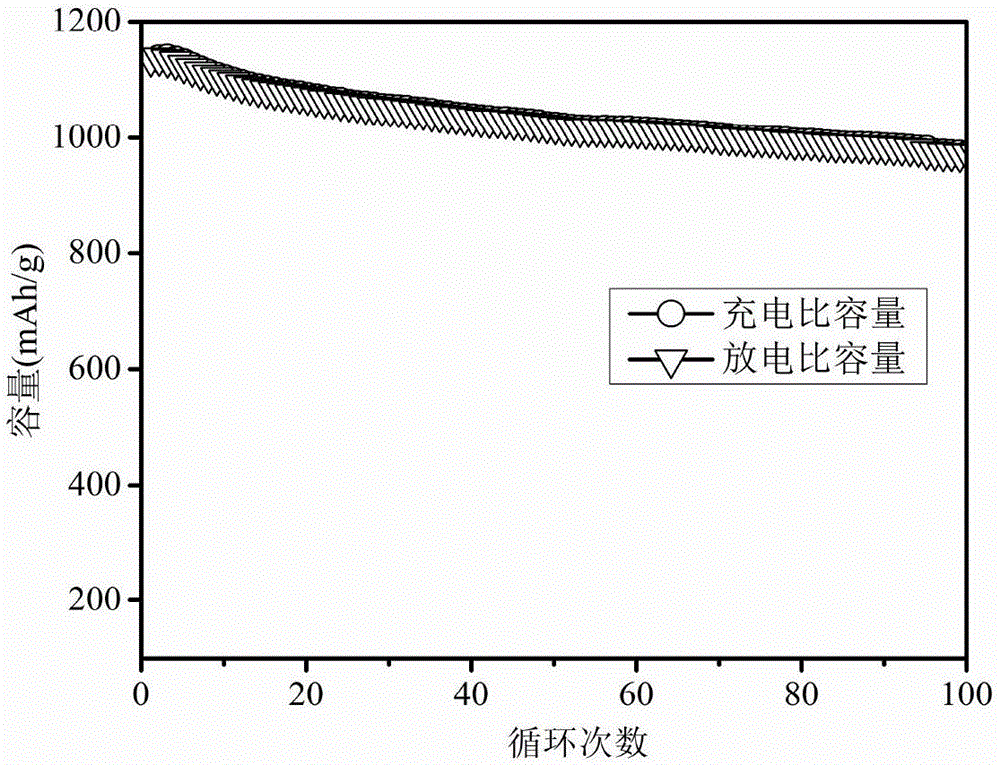

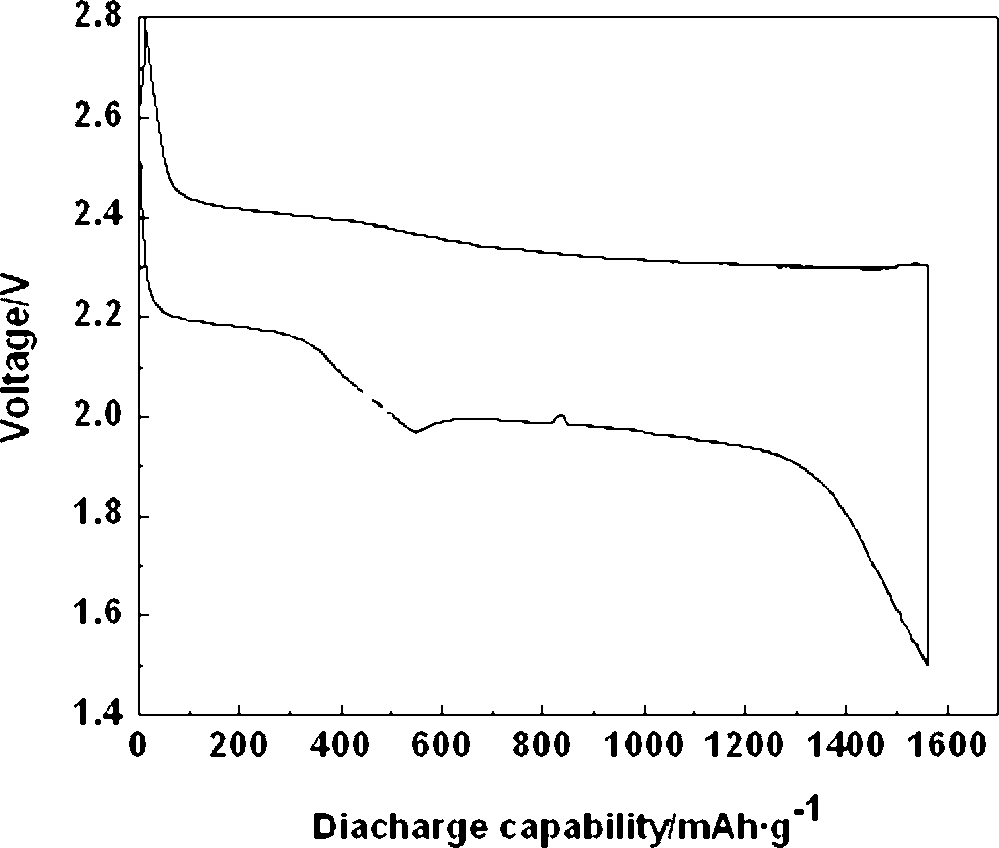

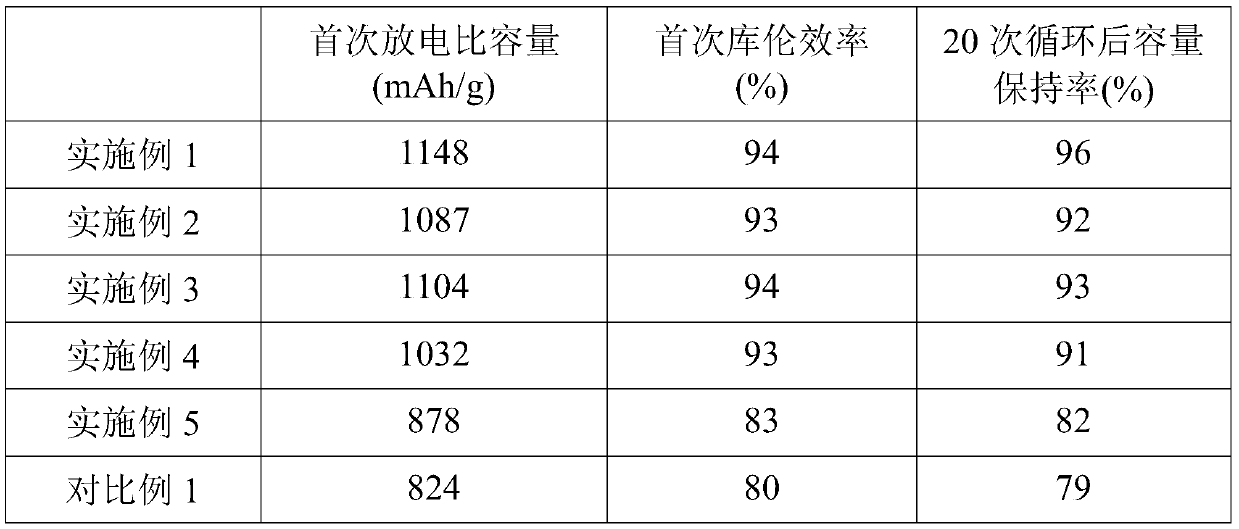

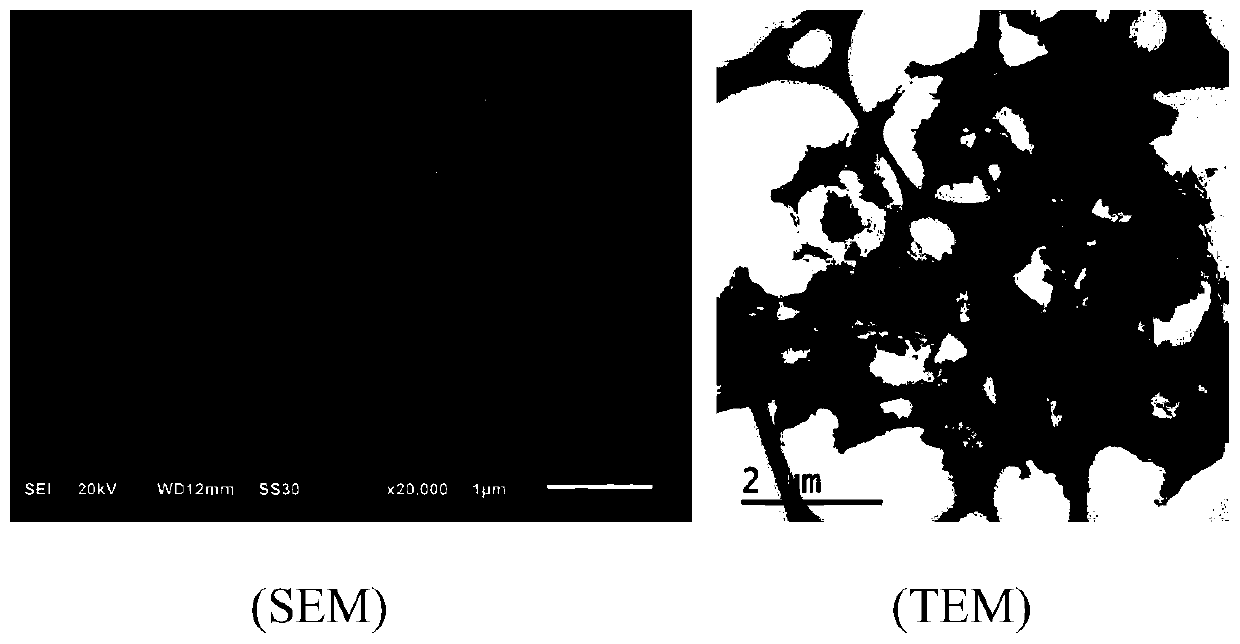

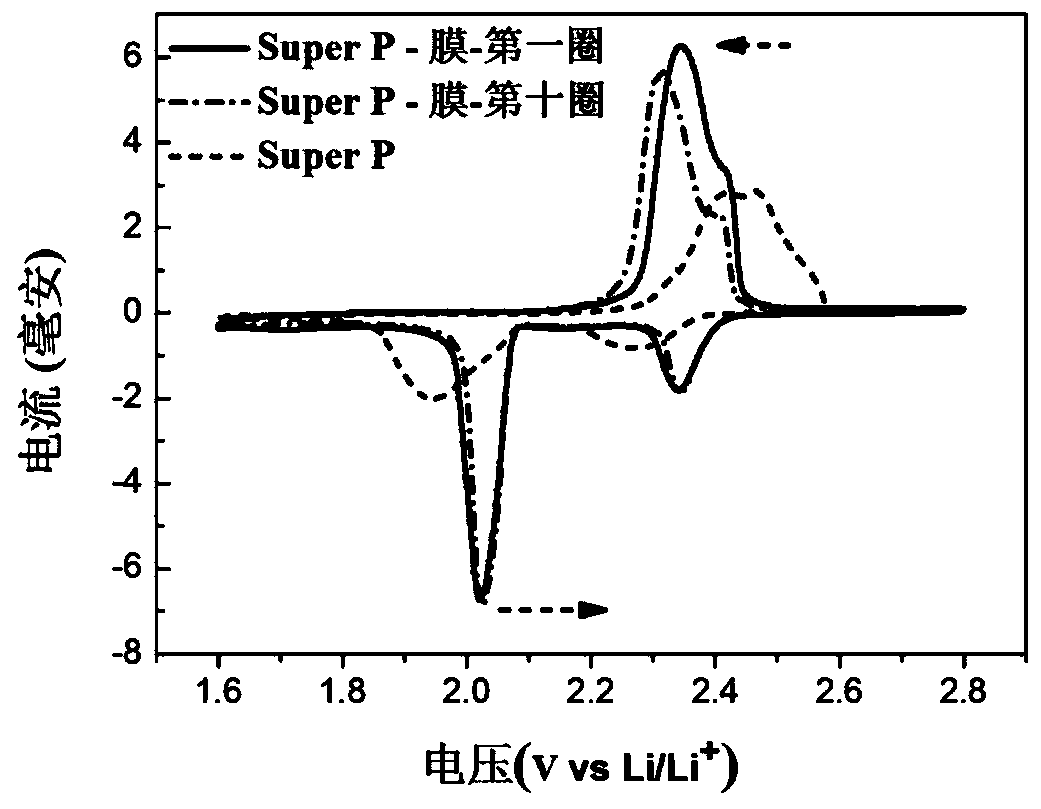

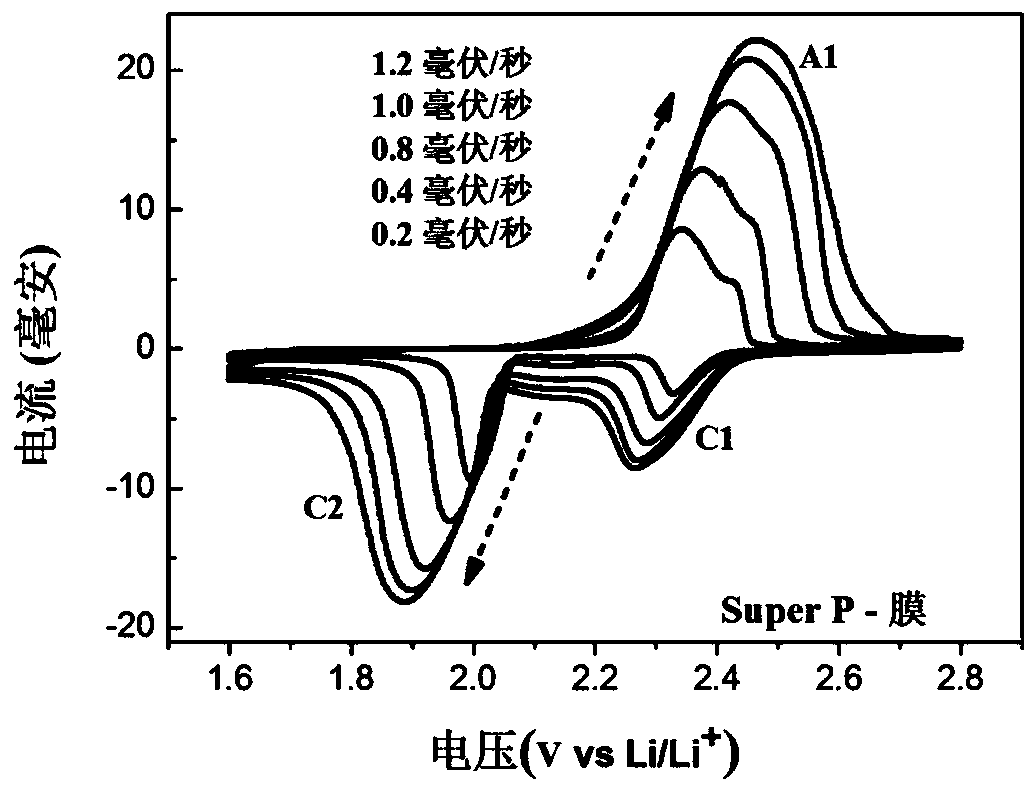

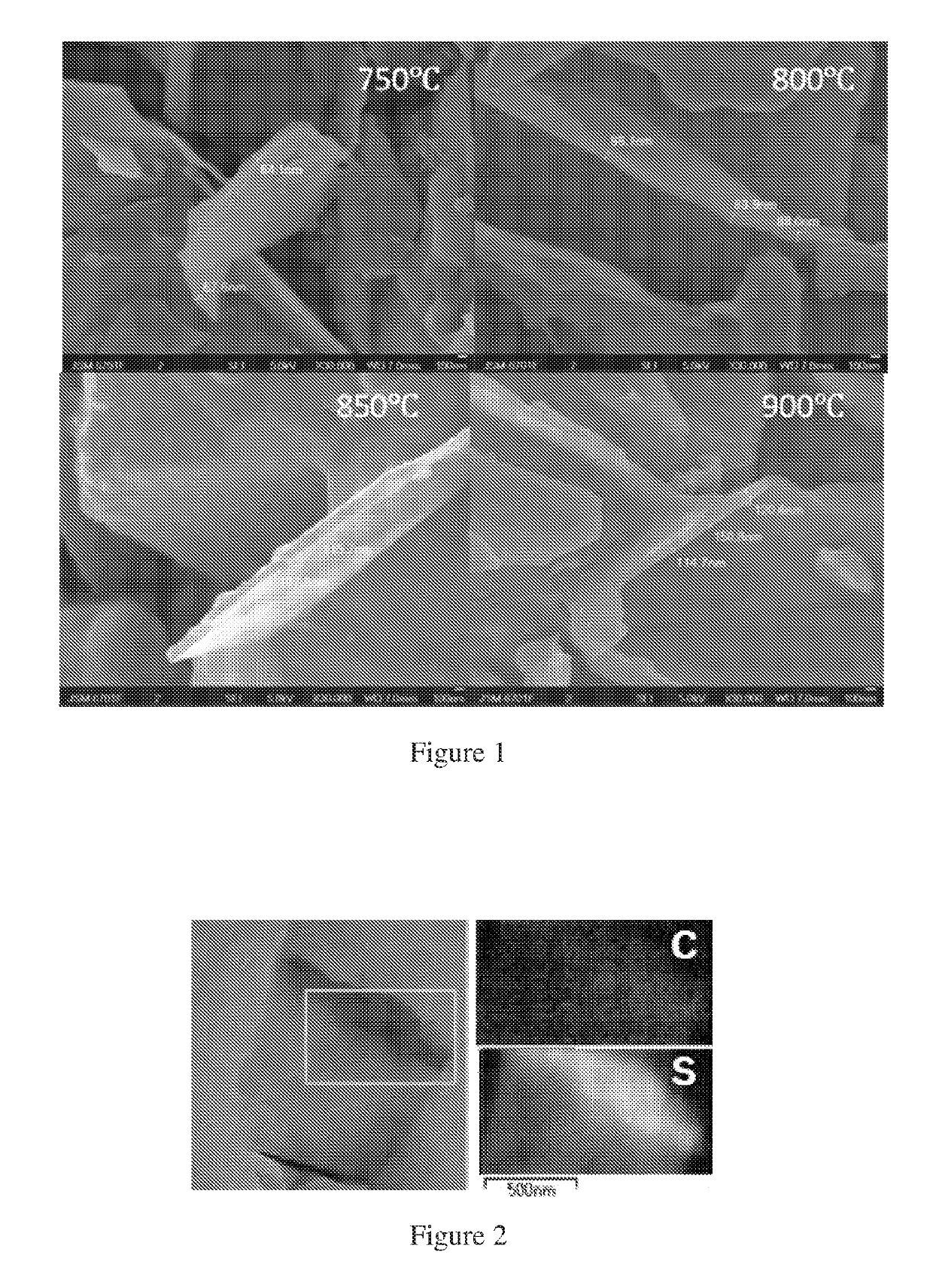

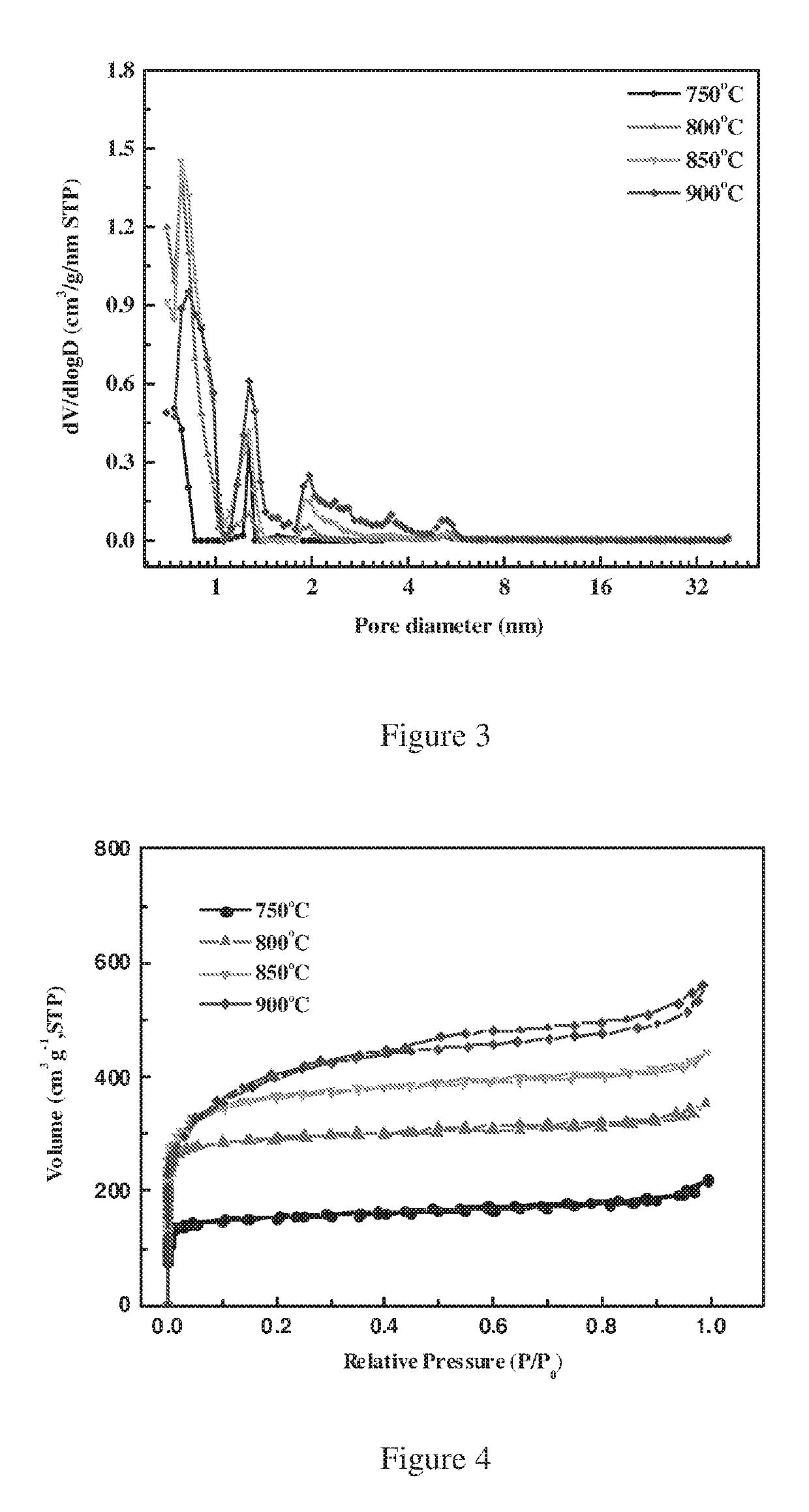

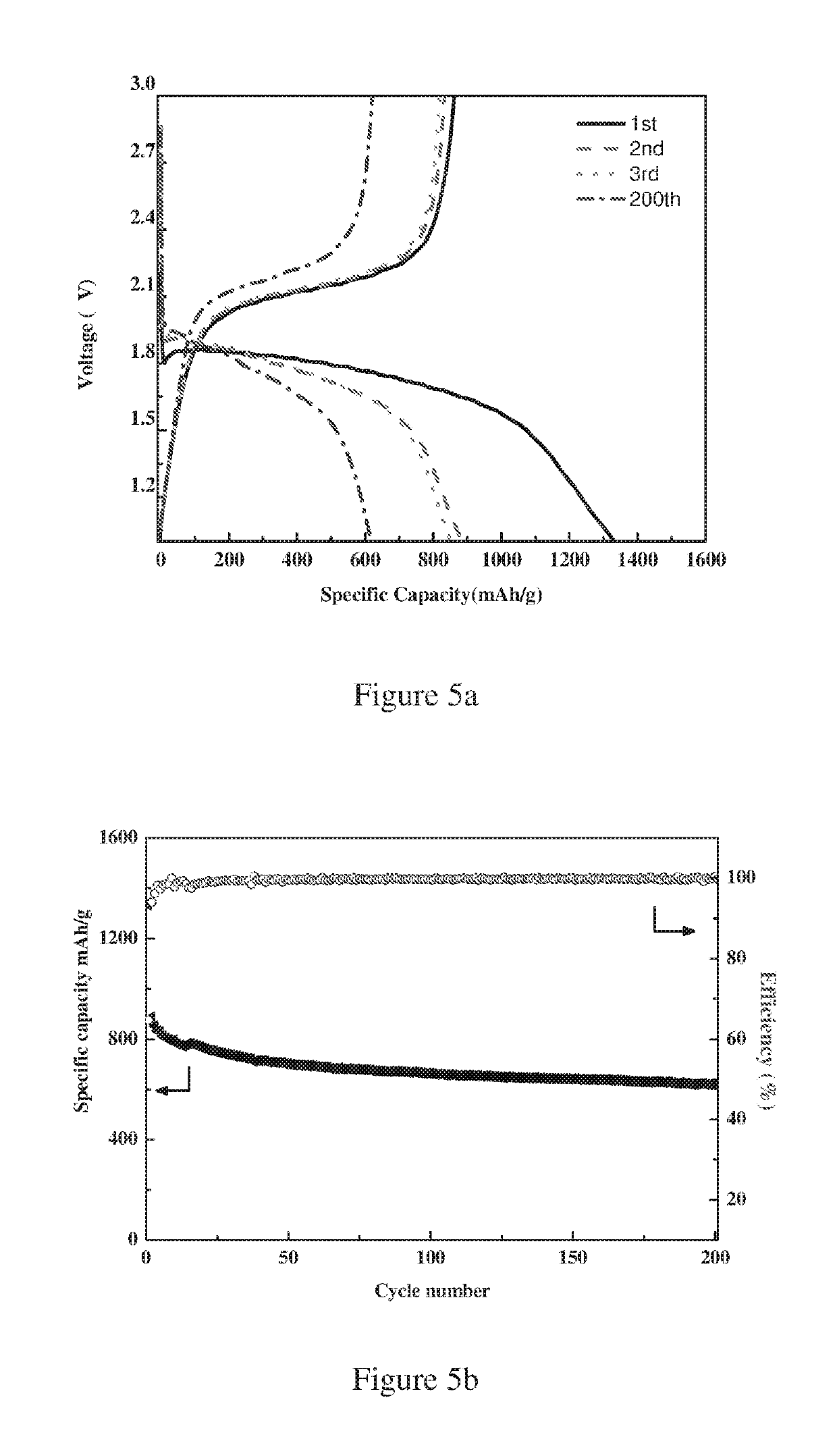

Carbon-sulphur composite used for cathode material of lithium sulphur battery as well as preparation method and application thereof

ActiveCN103050669AImprove discharge capacityLarger than surfaceNon-aqueous electrolyte accumulator electrodesLithium–sulfur batterySulfur electrode

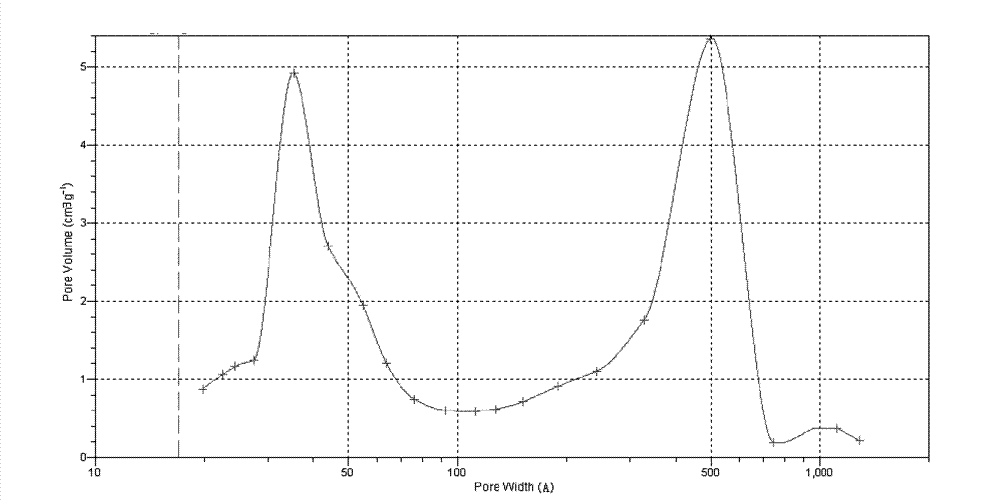

The invention relates to a carbon-sulphur composite used for a cathode material of a lithium sulphur battery as well as a preparation method and application thereof. The carbon-sulphur composite comprises a carbon material and elemental sulphur, wherein the carbon material is formed by doping mesoporous carbon with the aperture of 2-5nm and electroconductive carbon with the aperture of 30-70nm, and the electroconductive carbon with the aperture of 30-70nm contains micropores with the aperture of 0.5-1.7nm; and the elemental sulphur accounts for 10-90wt% of the total quantity of the composite. Abundant micropores guarantee that the carbon material has larger specific surface, adsorption capacity to polysulphide is stronger, and dissolution of the polysulphide can be effectively limited, so that stability of a sulphur electrode is improved. Meso pores in porous distribution can load more sulphur active substances, electrochemical capacity of a composite material is improved, and diffusion and transmission of lithium ions and electrolyte solution can be facilitated, so that reduction polarization of the elemental sulphur is reduced and discharge plateau of the elemental sulphur is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

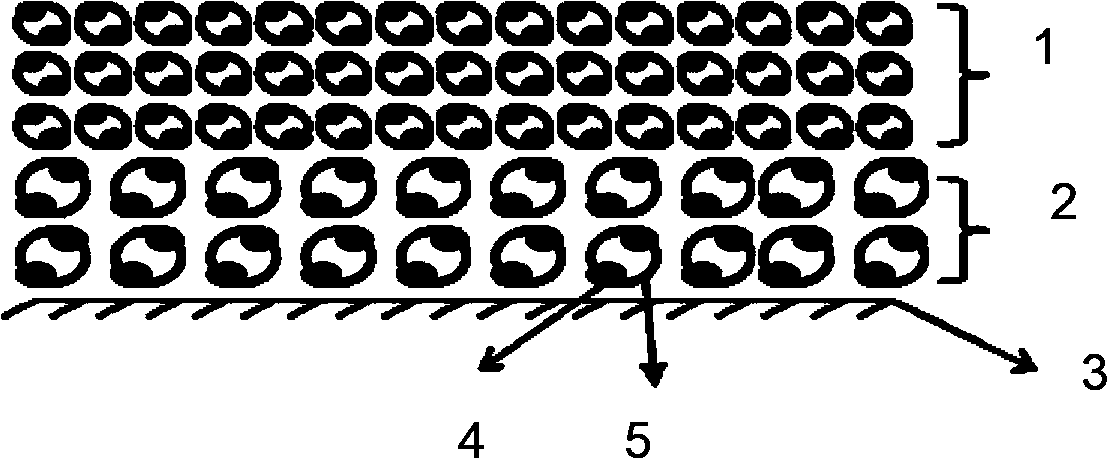

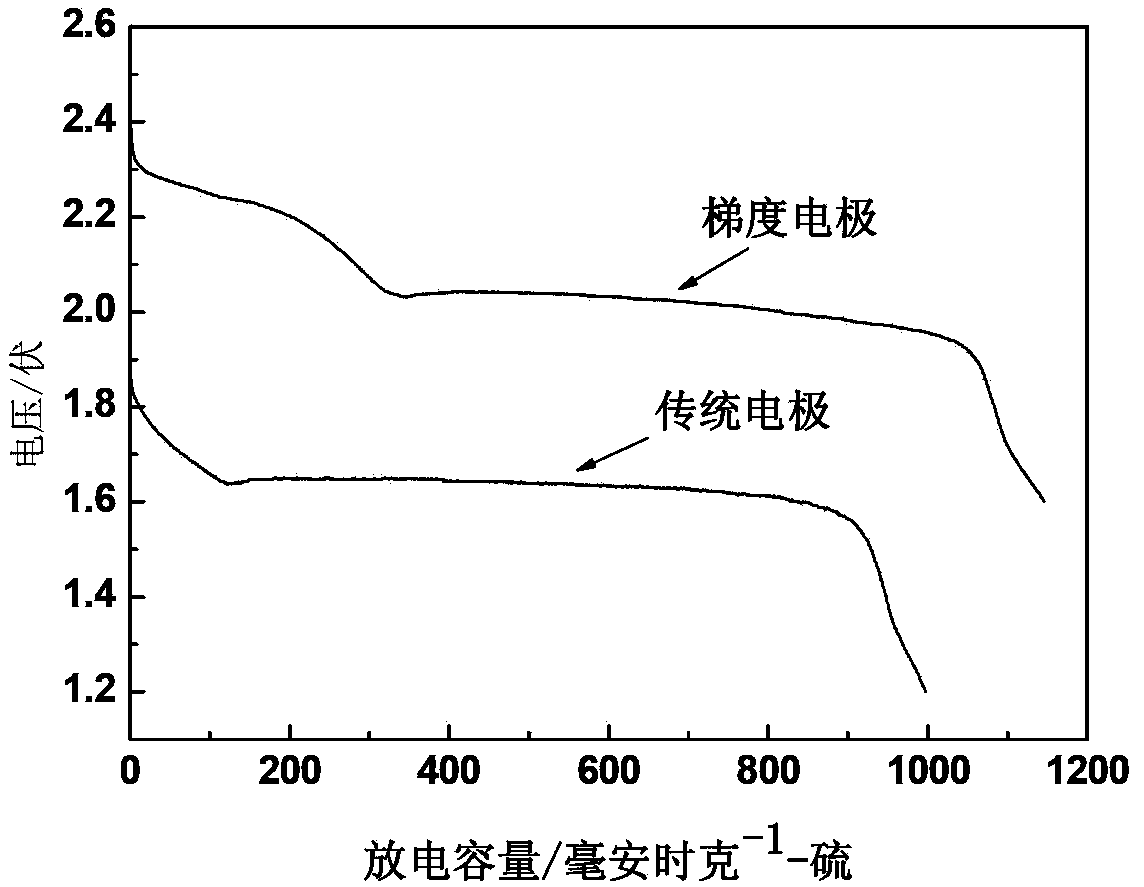

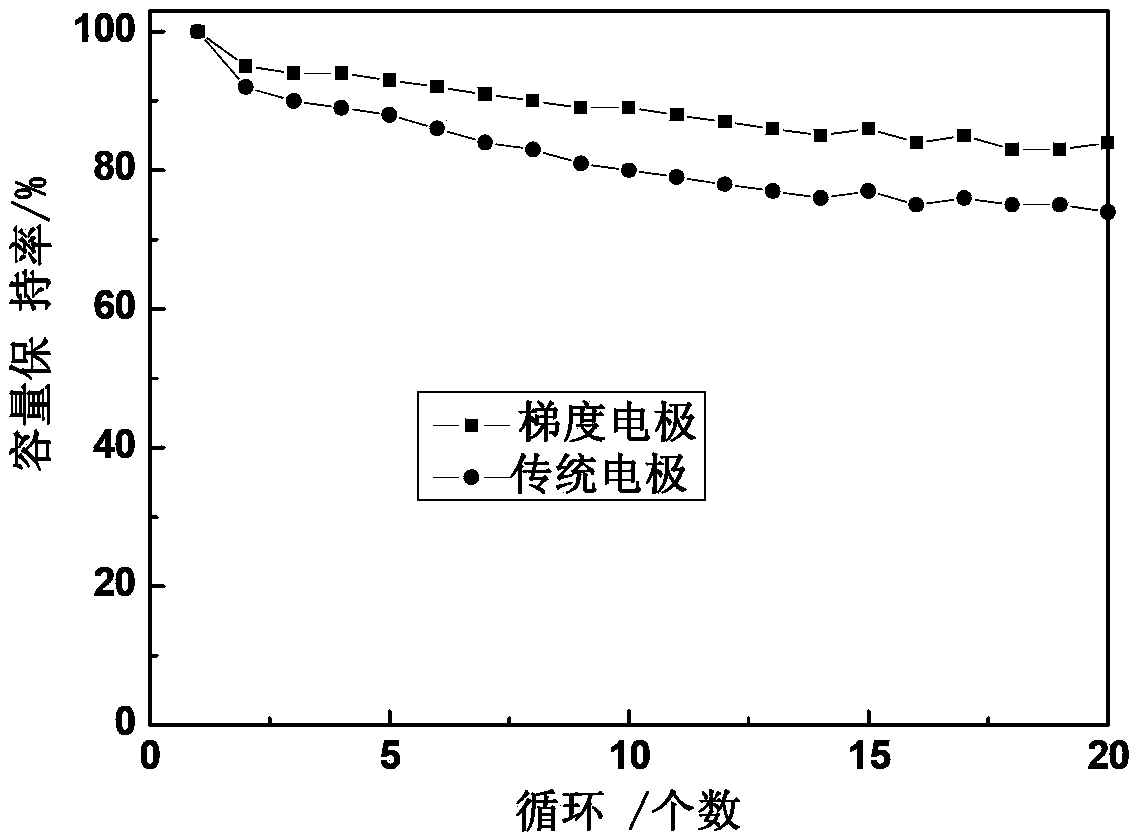

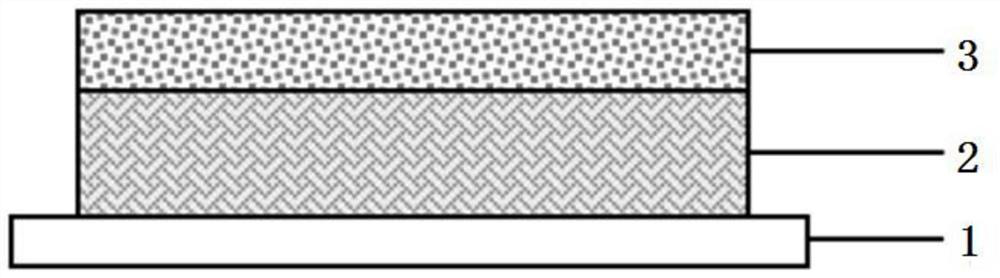

Lithium-sulfur battery positive electrode structure and preparation method thereof

ActiveCN103840125AEasy transferImprove discharge ratePositive electrodesElectrode collector coatingSulfurLithium–sulfur battery

The present invention relates to a lithium-sulfur battery positive electrode structure and a preparation method thereof. According to the lithium-sulfur battery positive electrode structure, a current collector is adopted as a substrate, two carbon-sulfur complex layers with different pore sizes are attached onto the substrate, the structure sequentially comprises the current collector, the large pore size carbon-sulfur complex layer and the small pore size carbon-sulfur complex layer, the thickness of the large pore size carbon-sulfur complex layer is 50-500 mum, the thickness of the small pore size carbon-sulfur complex layer is 10-200 mum, the large pore size carbon material is a carbon material with a pore size of greater than 100 nm and less than 1 mum and a pore volume accounting for 50-90% of the total pore volume, and the small pore size carbon material is a carbon material with a pore size of 0.5-100 nm and a pore volume accounting for more than 50-90% of the total pore volume. With the lithium-sulfur battery positive electrode structure, the mass transfer curvature of the lithium ions in the electrode is effectively increased, the lithium ion transmission path is prolonged, provision of the capacity of the high supporting capacity active substance is easily achieved, and the energy density of the battery is increased.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

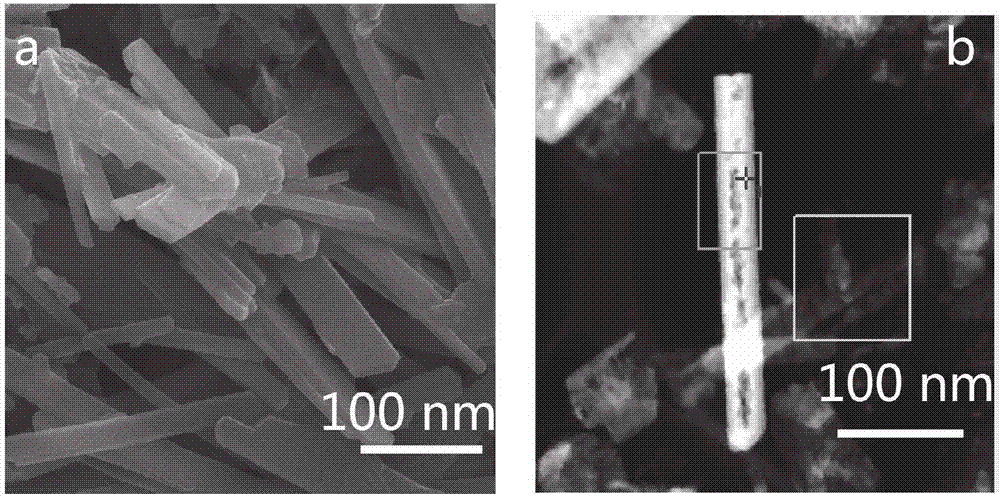

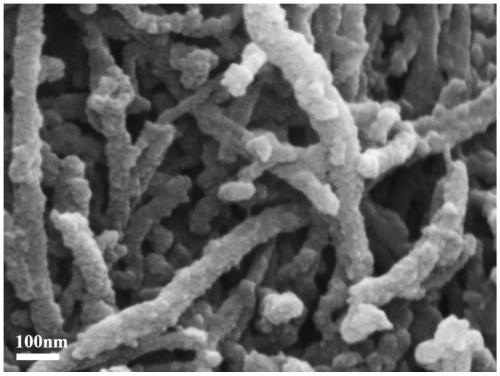

Preparation method of positive electrode material of lithium sulfur battery

InactiveCN104659338AGood dispersionCrystal form controllableMaterial nanotechnologyCell electrodesMass ratioFreeze-drying

The invention belongs to the technical field of lithium sulfur batteries, and particularly relates to a preparation method of a positive electrode material of a lithium sulfur battery. The preparation method comprises the following steps: adding a carbon nano tube into a nitrogen source substance solution with the mass concentration not less than 10%, mixing uniformly, transferring into a hydrothermal / solvent thermal reaction kettle for heat preservation, cooling, and washing and drying a reaction product so as to obtain a carbon nitride nano tube; dissolving sulfur into an organic solvent so as to obtain a sulfur contained organic solution, then adding the carbon nitride nano tube obtained in the step 1 into the sulfur contained organic solution, carrying out ultrasonic dispersion for more than 0.5 hour, and performing ultrasound treatment continuously while dropwise adding an extracting agent, wherein the mass ratio of the extracting agent to the organic solvent is (0.5-10) to 1; and then drying, and carrying out freeze drying on a product after the solvent is evaporated by more than a half. Compared with the prior art, the carbon-sulfur compound obtained by the method is good in circulation stability.

Owner:MCNAIR TECH +2

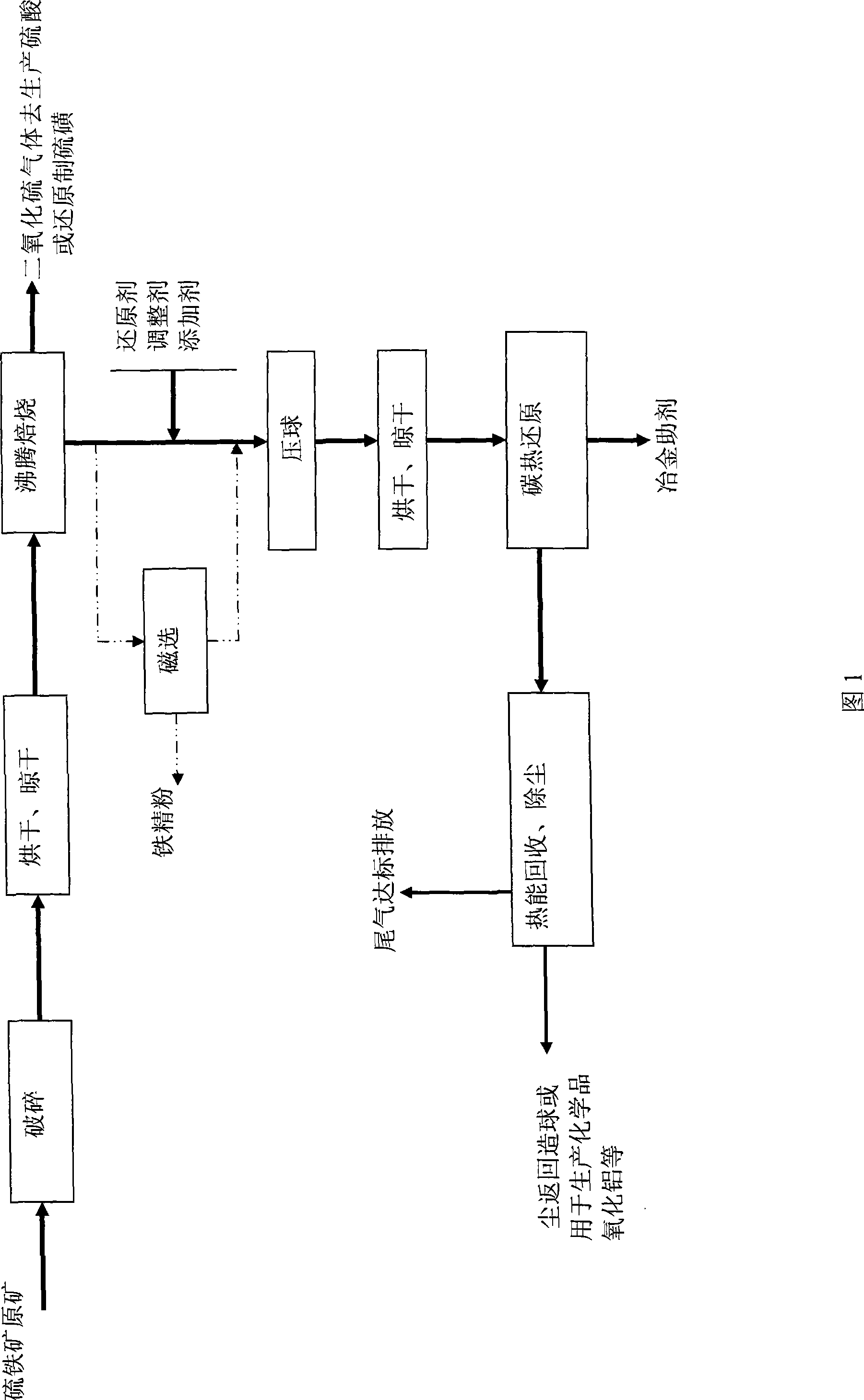

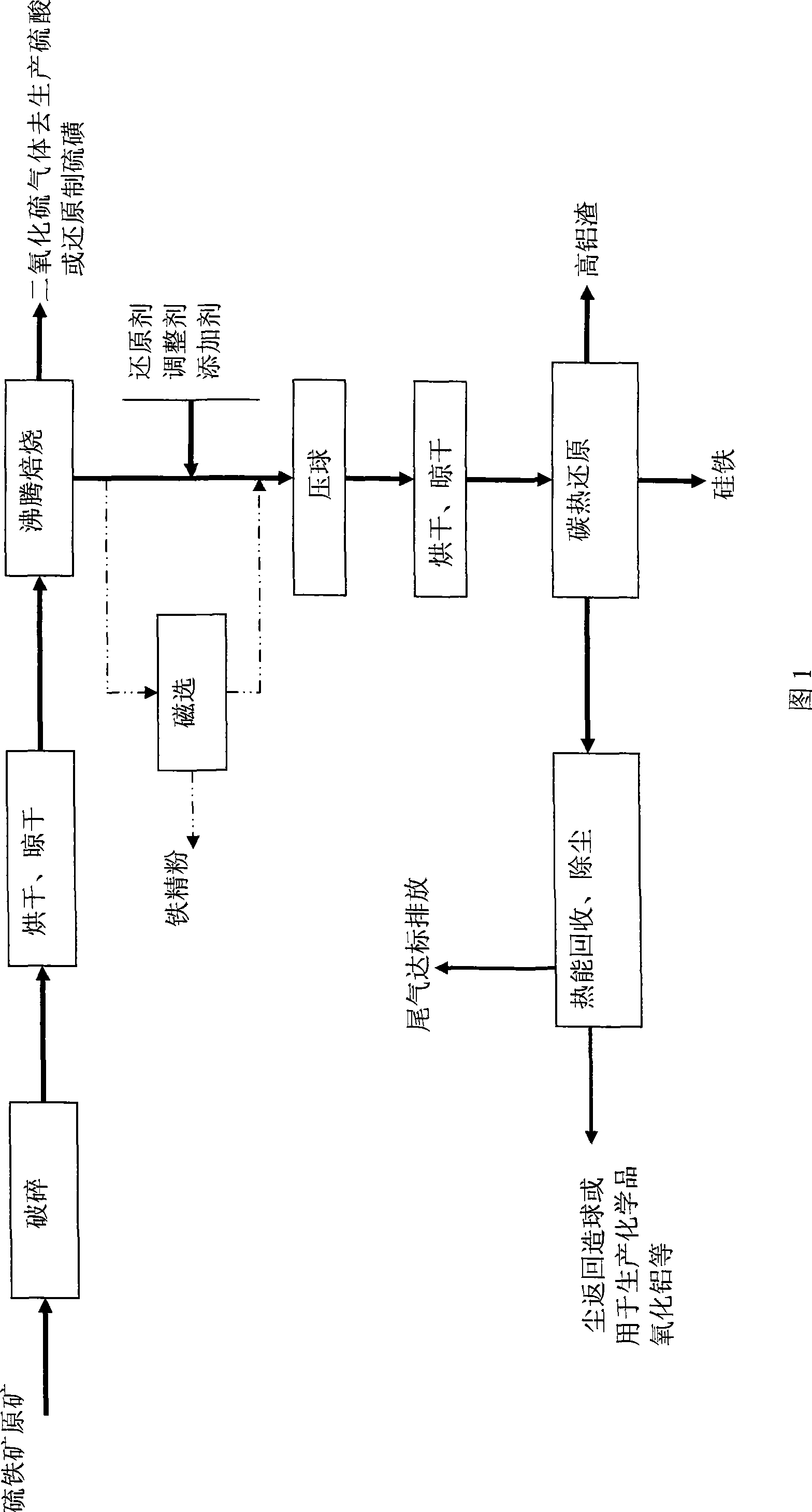

Comprehensive utilization method of middle and low grade ferro-sulphur ore

The invention discloses a comprehensive utilization method of middle-low grade pyrite. The method is characterized in that each layer of the pyrite is exploited, directly smashed and added to a fluidized bed furnace for roasting in the fluidized bed to obtain sulfur dioxide gas and cinder; the sulfur dioxide-containing gas is used for producing sulfuric acid or sulfur; component adjustment is carried out after iron ore concentrate powder is magnetically separated from the cinder, or carried out directly on the cinder by adding metallic mineral or non-metallic mineral according to the subsequent product and the fusion temperature; then, according to the mass of the monoatomic carbon which is needed to reduce each oxide in the adjusted cinder into the monoatomic metal by carbothermic reduction, a reducing agent which is 1.1-3 times of the mass is added; and a deoxidizer and a desulfurizer of high-quality metallurgical composite alloy are produced after reduction. The method solves the environmental pollution problem of the existing utilization technology and realizes each layer exploitation and cyclic comprehensive utilization of the middle-low grade pyrite.

Owner:云南常青树投资有限公司

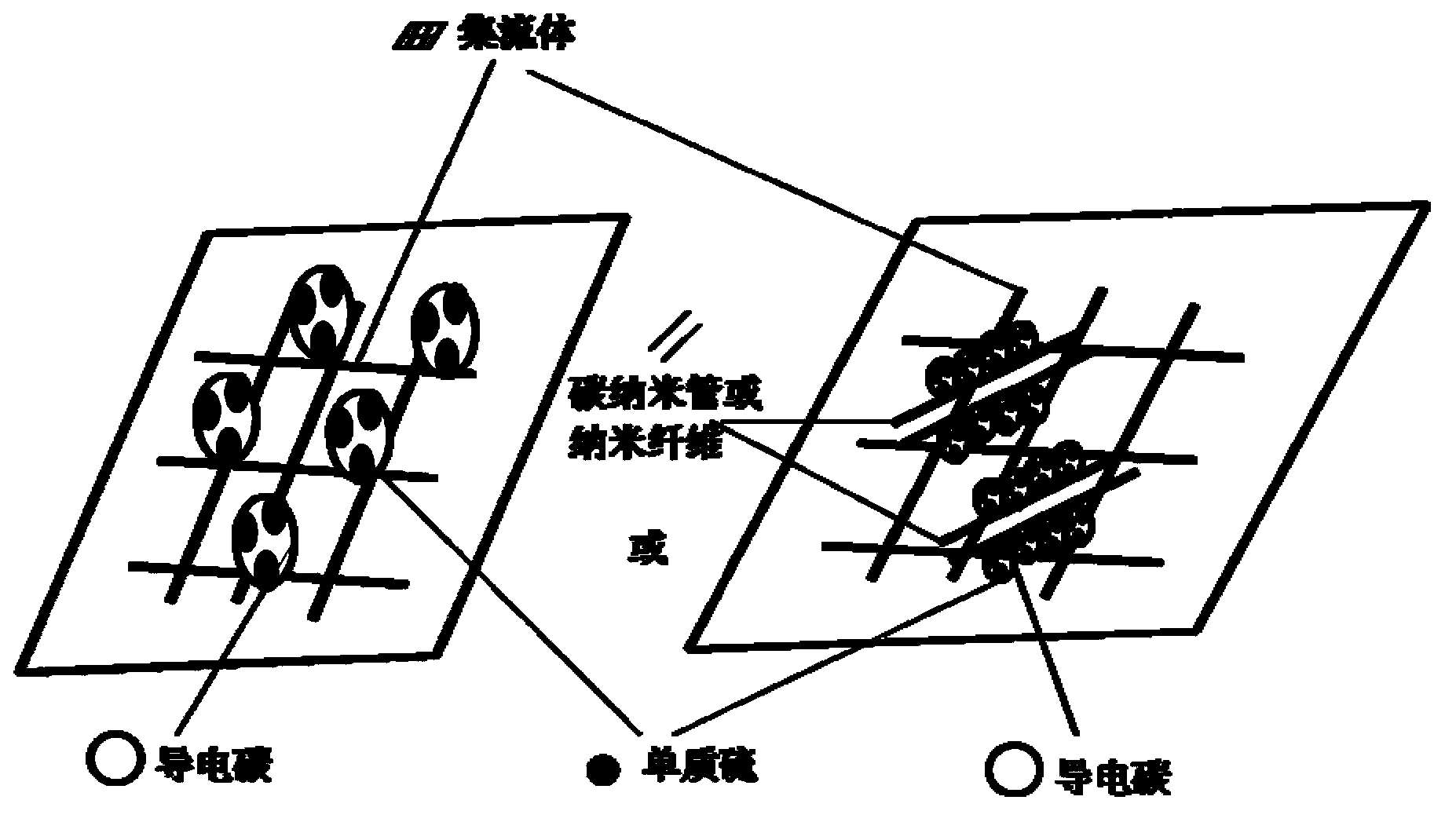

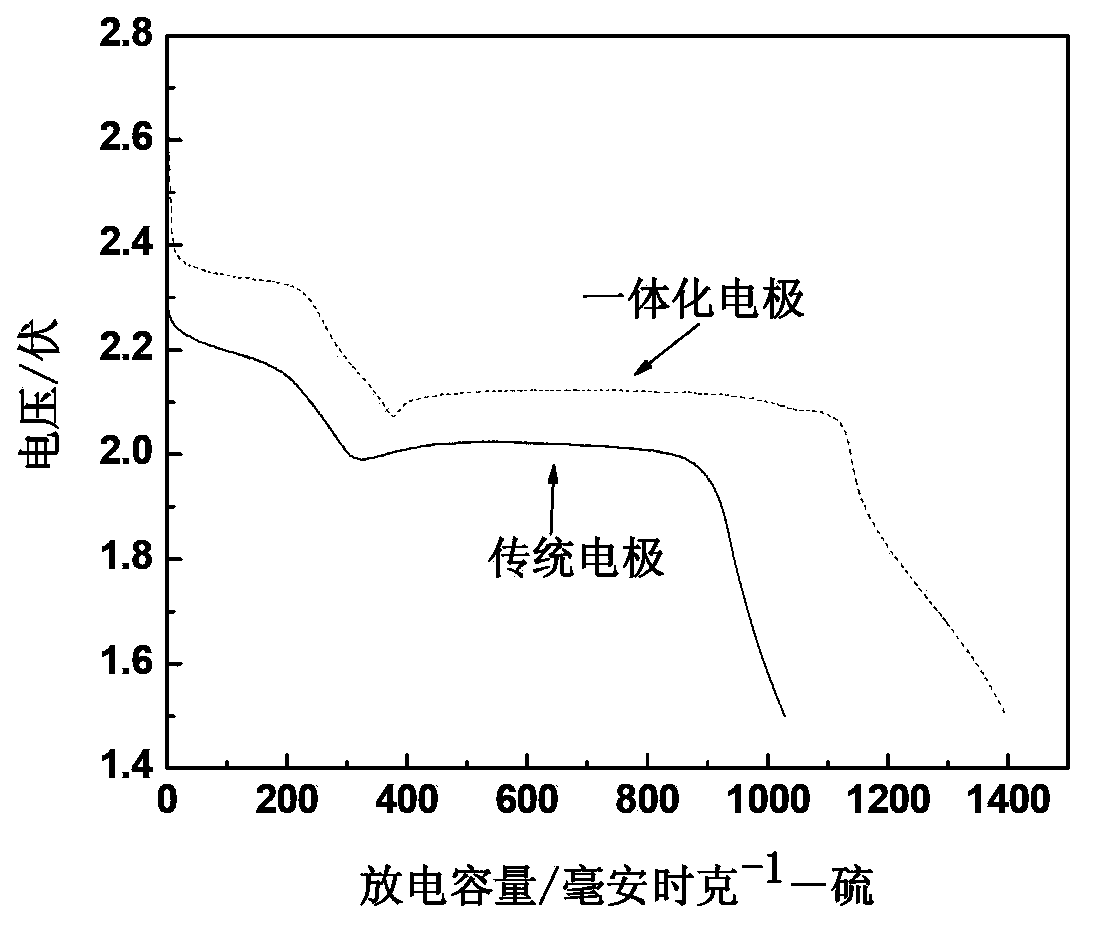

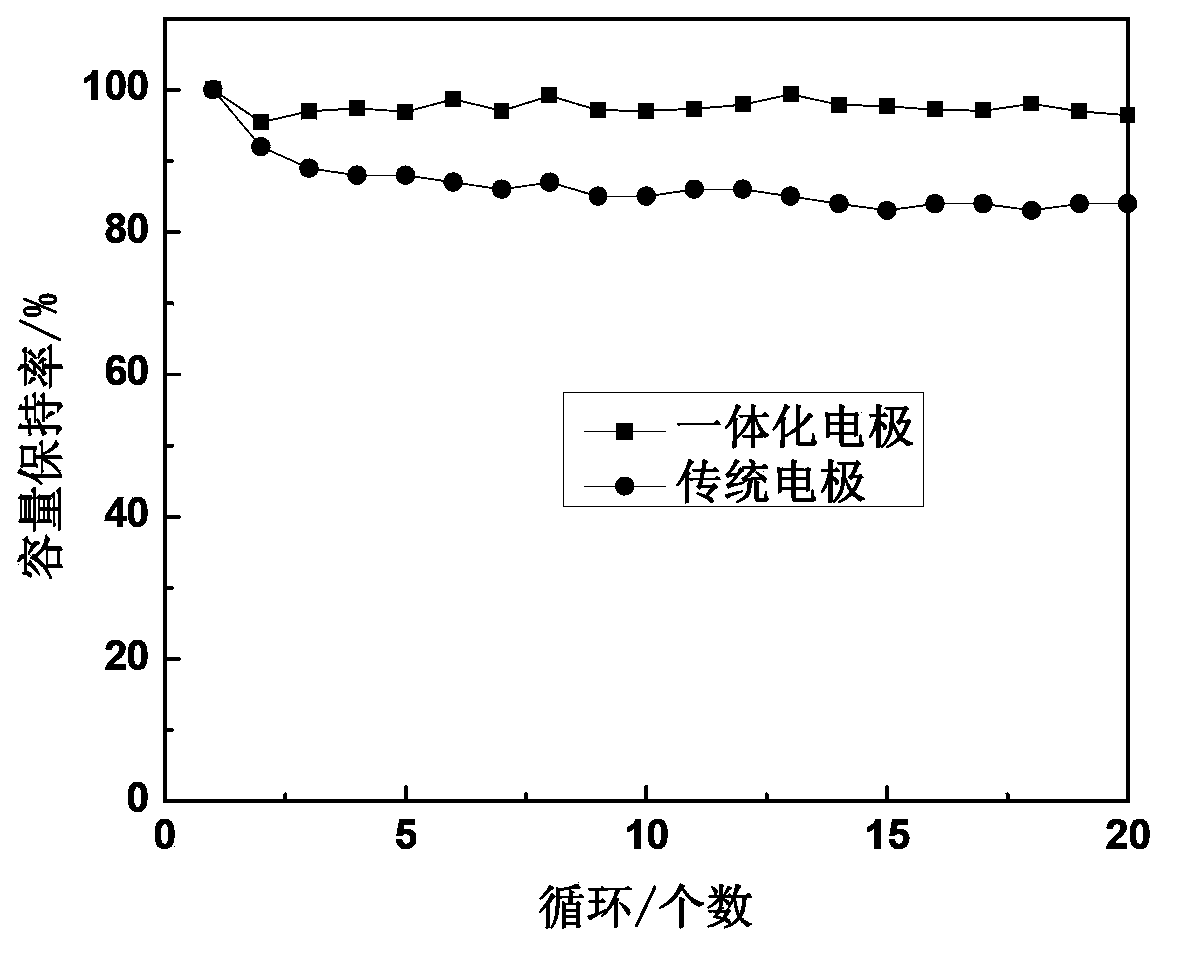

Integrated electrode for lithium sulphur battery and preparation method of integrated electrode

ActiveCN103840141ALight in massIncrease energy densityLi-accumulatorsNon-aqueous electrolyte accumulator electrodesElectrical resistance and conductanceAdhesive

The invention relates to an integrated electrode for a lithium sulphur battery and a preparation method of the integrated electrode. The integrated electrode is composed of a current collector, and a carbon-sulphur compound which is formed by than the current collector is subjected to in-situ growth; the carbon-sulphur compound comprises a conductive carbon material, and elemental sulphur with which a porous structure of the carbon material is filled, wherein the elemental sulphur accounts for 10 to 95% the carbon-sulphur compound in percentage by mass and is of 0.1 to 5mg / cm<2> in equivalent weight based on the current collector. The integrated electrode is simple in process and easy to realize. The electrode prepared by adopting the method is able to obviously reduce the contact resistance between the current collector and the carbon-sulphur compound and the utilization rate of active substance naming sulphur is also increased; in addition, the integrated electrode does not need any adhesive, so that the problem that the battery is poor in cycling stability because of the stability of the adhesive can be avoided, the cost is also saved, and the high commercial value is achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

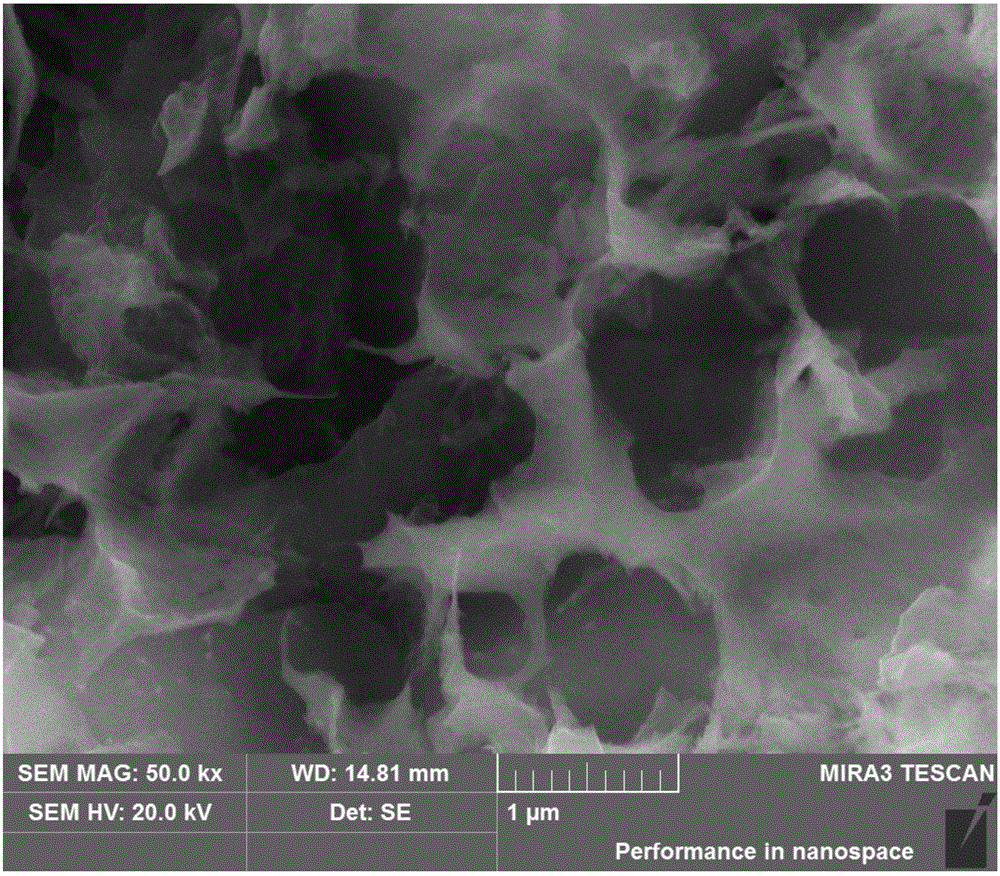

Thin-wall local graphitization porous carbon sphere material, preparation method thereof and application thereof in lithium sulfur battery

The invention discloses a thin-wall local graphitization porous carbon sphere material, a preparation method thereof and application thereof in a lithium sulfur battery. The porous carbon sphere material is a local graphitization porous carbon nanosphere with thin wall holes; the preparation method of the thin-wall local graphitization porous carbon sphere material comprises the steps that water-base resin, water-soluble inorganic salt, a surface active agent and transition metal salts are dissolved into water to obtain a spraying solution; the spraying solution is sprayed and dried to obtaina local graphitization porous carbon nanosphere precursor; the local graphitization porous carbon nanosphere precursor is subjected to pyrolysis to obtain the thin-wall local graphitization porous carbon sphere material. The preparation method is simple in technology and good in repeatability, the prepared thin-wall local graphitization porous carbon sphere material has the advantages of being good in electrical conductivity, large in aperture, high in specific surface area and the like, the thin-wall local graphitization porous carbon sphere material is applied to a lithium sulfur battery sulfur carrier, the high specific capacity, long cycling stability and high rate capability are achieved, and the wide application prospect is achieved.

Owner:CENT SOUTH UNIV

Zinc sulfide nano-belt, preparation and application thereof in preparing anode material of lithium sulfur battery

ActiveCN106927498AEvenly dispersedNot easy to reuniteCell electrodesSulfur preparation/purificationChemistryActive agent

The invention discloses a method for preparing nanometer belt-shaped zinc sulfide, and a method for taking the nanometer belt-shaped zinc sulfide as a template for preparing a nitrogen-doped carbon / sulfur compound anode material, a preparation method and an application thereof. The nanometer belt-shaped zinc sulfide is acquired through the hydrothermal reaction under the condition of zinc source, sulfur source and surface active agent. The nitrogen-doped carbon / sulfur compound anode material is composed of nitrogen-doped coated sulfur. The preparation method comprises the following steps: coating polydopamine on the surface of zinc sulfide and carbonizing under a protective atmosphere condition; adding a ferric salt; separating liquid from solid; and freezing and drying the solid product, thereby acquiring the nitrogen-doped carbon / sulfur compound anode material. The compound anode material is large in nitrogen doped volume, controllable in sulfur capacity, uniform in load and high in use ratio of active substance sulfur, has the advantages of high specific capacity, high energy density and high stability and is capable of greatly improving the cycle performance of the lithium sulfur battery.

Owner:GUANGDONG MIC POWER NEW ENERGY CO LTD

Method for comprehensive utilization of middle and low grade ferro-sulphur ore and by-production of high-alumina slag and ferrosilicon

The invention discloses a comprehensive utilization method of byproduct high alumina slag and ferrosilicon of middle-low grade pyrite. The method comprises the following steps: each layer of the pyrite is exploited, directly smashed and added to a fluidized bed furnace for roasting in the fluidized bed to obtain sulfur dioxide gas and cinder; the sulfur dioxide-containing gas is used for producing sulfuric acid or sulfur; component adjustment is carried out after iron ore concentrate powder is magnetically separated from the cinder, or carried out directly on the cinder, by adding metallic mineral or non-metallic mineral; then, according to the mass of monoatomic carbon which is needed to reduce the ferrosilicon oxide in the adjusted cinder into the monoatomic metal by carbothermic reduction, a reducing agent which is 1.1-3 times of the mass is added; a deoxidizing agent ferrosilicon is produced after reduction; and reducing slag is discharged and cooled to obtain the high alumina slag which is used for producing chemical alumina, extracting gallium metal or being taken as a production raw material of aluminum factories. In the method, the utilization ratio of the sulfur can be improved by 40%-50% without waste slag and waste water produced by the pyrite concentrate, thereby solving the environmental pollution problem of the existing utilization technology; and all the components coexisting with the middle-low grade pyrite are fully used.

Owner:云南常青树投资有限公司

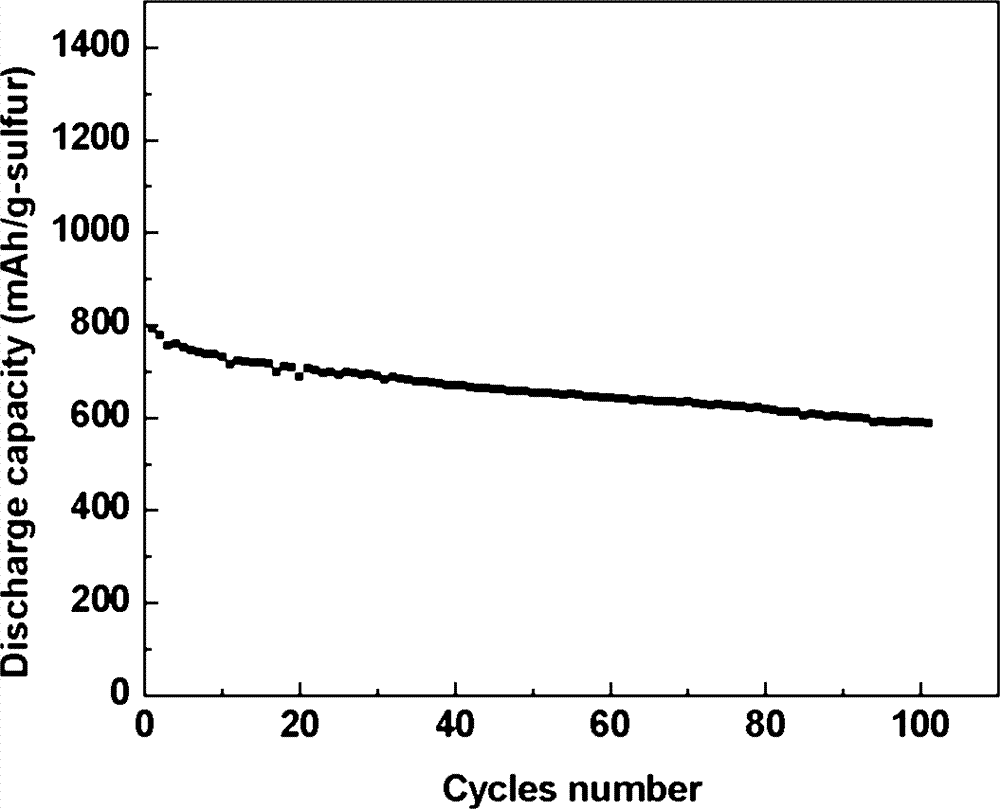

Sulfur-doped three-dimensional porous graphene/sulfur composite positive electrode material and preparation method and application thereof

ActiveCN106654236AMaintain ion transport capacityMaintain conductivityMaterial nanotechnologyCell electrodesPorous grapheneHigh energy

The invention discloses a sulfur-doped three-dimensional porous graphene / sulfur composite positive electrode material and a preparation method and an application thereof. The sulfur-doped three-dimensional porous graphene / sulfur composite positive electrode material is composed of elemental sulfur deposited on a surface of a three-dimensional carbon skeleton of sulfur-doped three-dimensional porous graphene in situ; and the preparation method comprises the steps of first adding sodium bisulfate to a graphene oxide dispersion to react, then adding sodium sulfide to react under a partially neutral condition, carrying out liquid-solid separation, and performing freeze-drying on a solid product, thereby obtaining the sulfur-doped three-dimensional porous graphene / sulfur composite positive electrode material. A sulfur-doped amount of the composite positive electrode material is large, a sulfur loading capacity is controllable, a load is uniform and a utilization rate of an active substance sulfur is high; the sulfur-doped three-dimensional porous graphene / sulfur composite positive electrode material has the advantages of high specific capacity, high energy density, high stability and the like; and the cycle performance of a lithium-sulfur battery is greatly improved.

Owner:CENT SOUTH UNIV

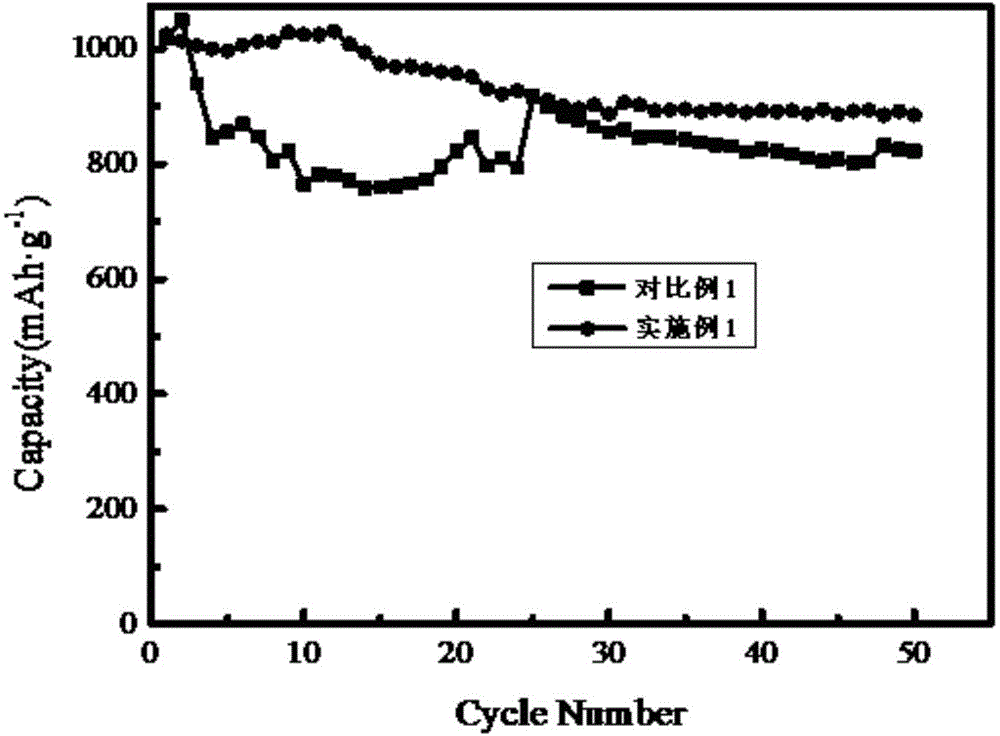

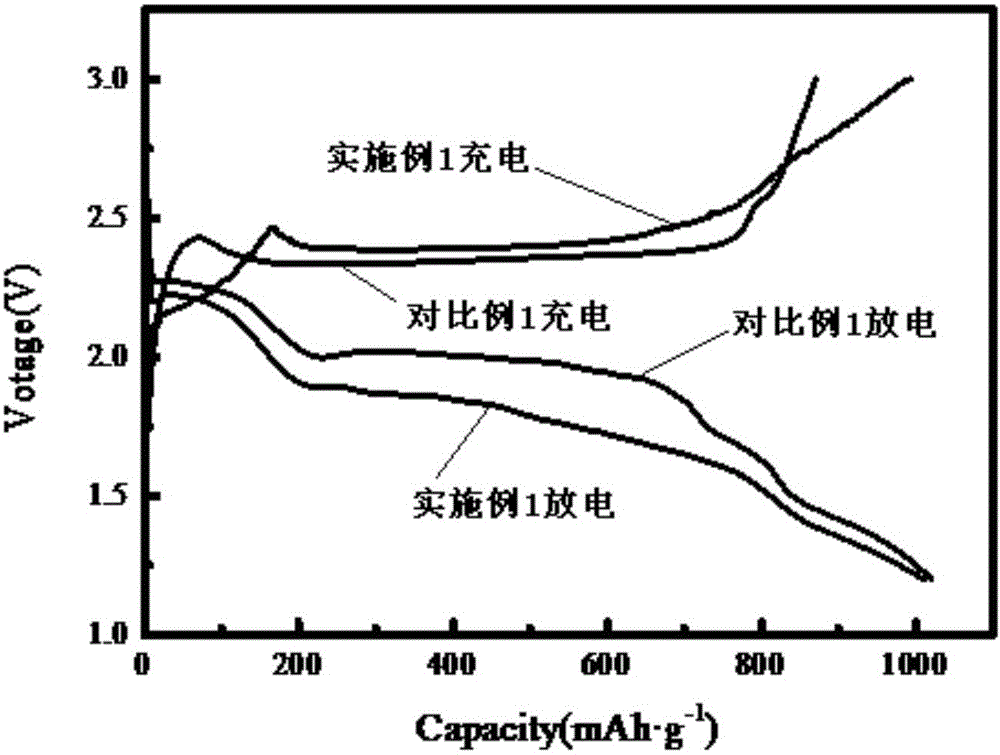

Carbon-sulfur composite positive electrode for lithium-sulfur battery and preparation method of carbon-sulfur composite positive electrode

ActiveCN112072067AImprove cycle lifeOvercoming the low sulfur content in the cathodePositive electrodesLi-accumulatorsCarbon layerLithium–sulfur battery

The invention discloses a carbon-sulfur composite positive electrode for a lithium-sulfur battery and a preparation method of the carbon-sulfur composite positive electrode, and belongs to the technical field of lithium-sulfur batteries. The carbon-sulfur composite positive electrode consists of a carbon-sulfur composite layer and a conductive carbon layer which are sequentially coated on the current collector; the carbon-sulfur composite layer is composed of a sulfur material, a carbon material I and an aqueous binder, and the conductive carbon layer is composed of a carbon material II and anorganic binder. According to the double-layer carbon-sulfur composite positive electrode prepared by the method, the construction of a high-sulfur-capacity, high-sulfur-content, high-specific-capacity and long-cycle-life high-energy-density lithium-sulfur battery can be realized. The preparation method of the composite positive electrode is simple and convenient to operate, low in cost and easy to amplify, the design and preparation of the positive electrode of the lithium-sulfur battery are effectively promoted, and a new possibility is provided for the practicability of the lithium-sulfur battery with high energy density.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

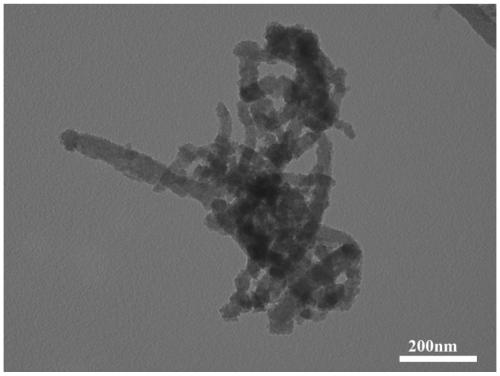

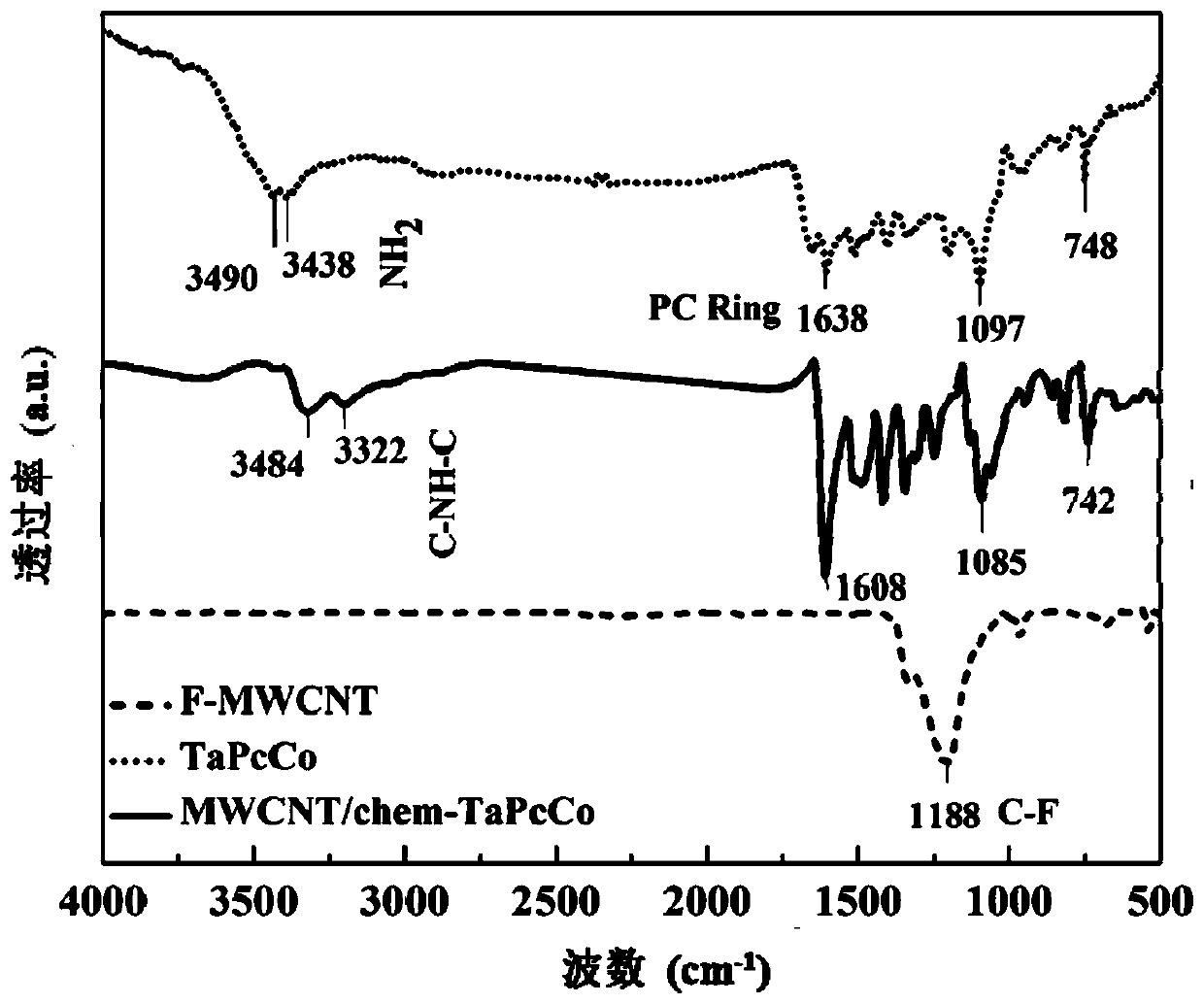

Carbon composite material chemically modified by metal phthalocyanine complex, battery cathode material and preparation method and application thereof

InactiveCN111450888AEasy transferIncrease capacityOrganic-compounds/hydrides/coordination-complexes catalystsSecondary cellsCarbon compositesLithium–sulfur battery

The invention belongs to the technical field of lithium-sulfur batteries and especially relates to a carbon composite material chemically modified by a metal phthalocyanine complex, a battery cathodematerial and a preparation method and application thereof. The composite material comprises a carbon material and a metal phthalocyanine complex attached to the carbon material, and the metal phthalocyanine complex has substituents on the periphery. The cathode material comprises a carbon composite material chemically modified by the metal phthalocyanine complex and a sulfur element loaded on thecomposite material. The metal phthalocyanine complex and the carbon material are combined in a chemical bonding mode, and the obtained material is used as the cathode material of a lithium-sulfur battery after sulfur loading, so that the sulfur utilization rate and the charge-discharge coulombic efficiency can be effectively improved, the specific capacity of the lithium-sulfur battery is remarkably improved, and the cycle life of the lithium-sulfur battery is remarkably prolonged.

Owner:SHANDONG UNIV

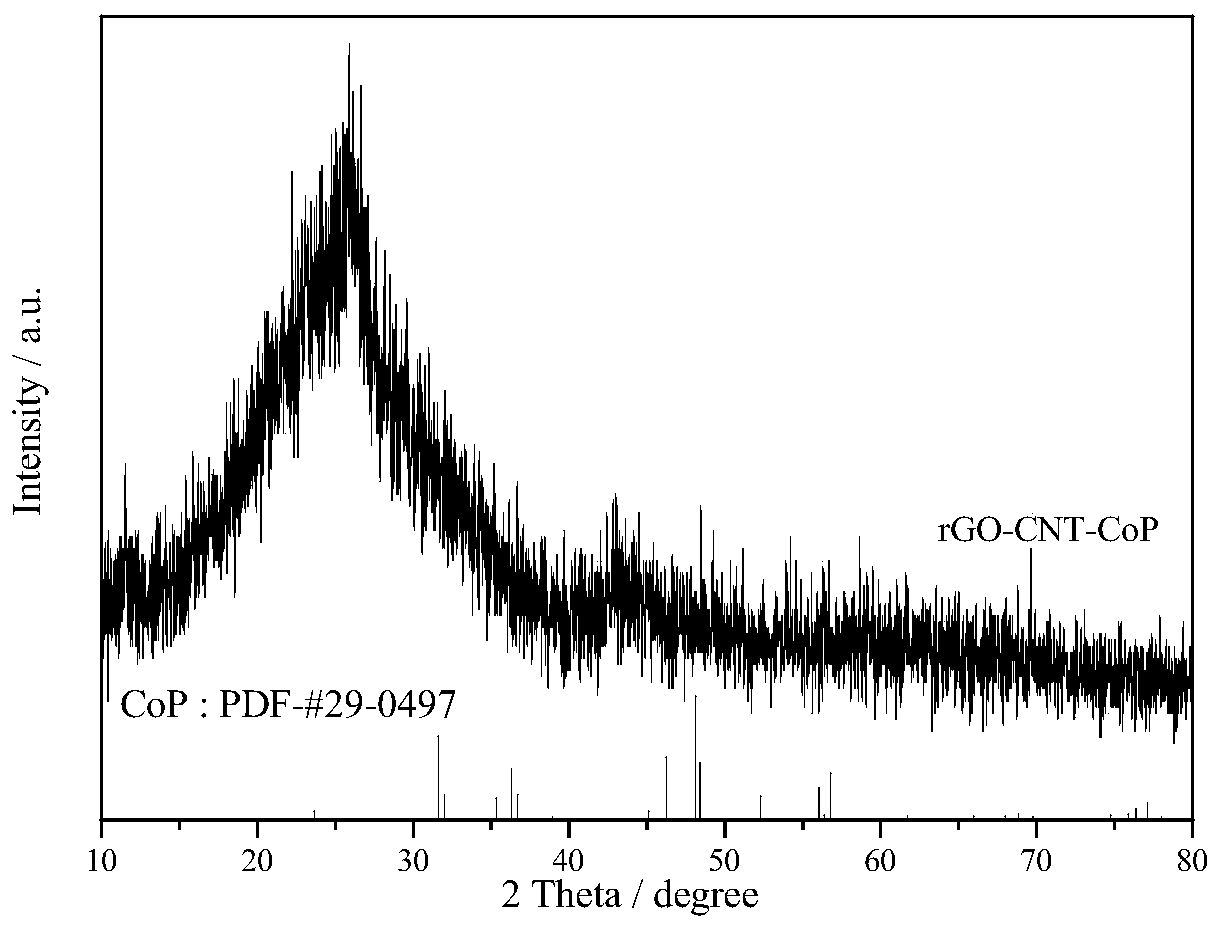

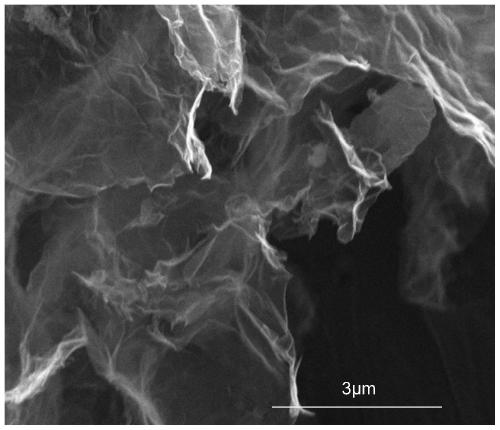

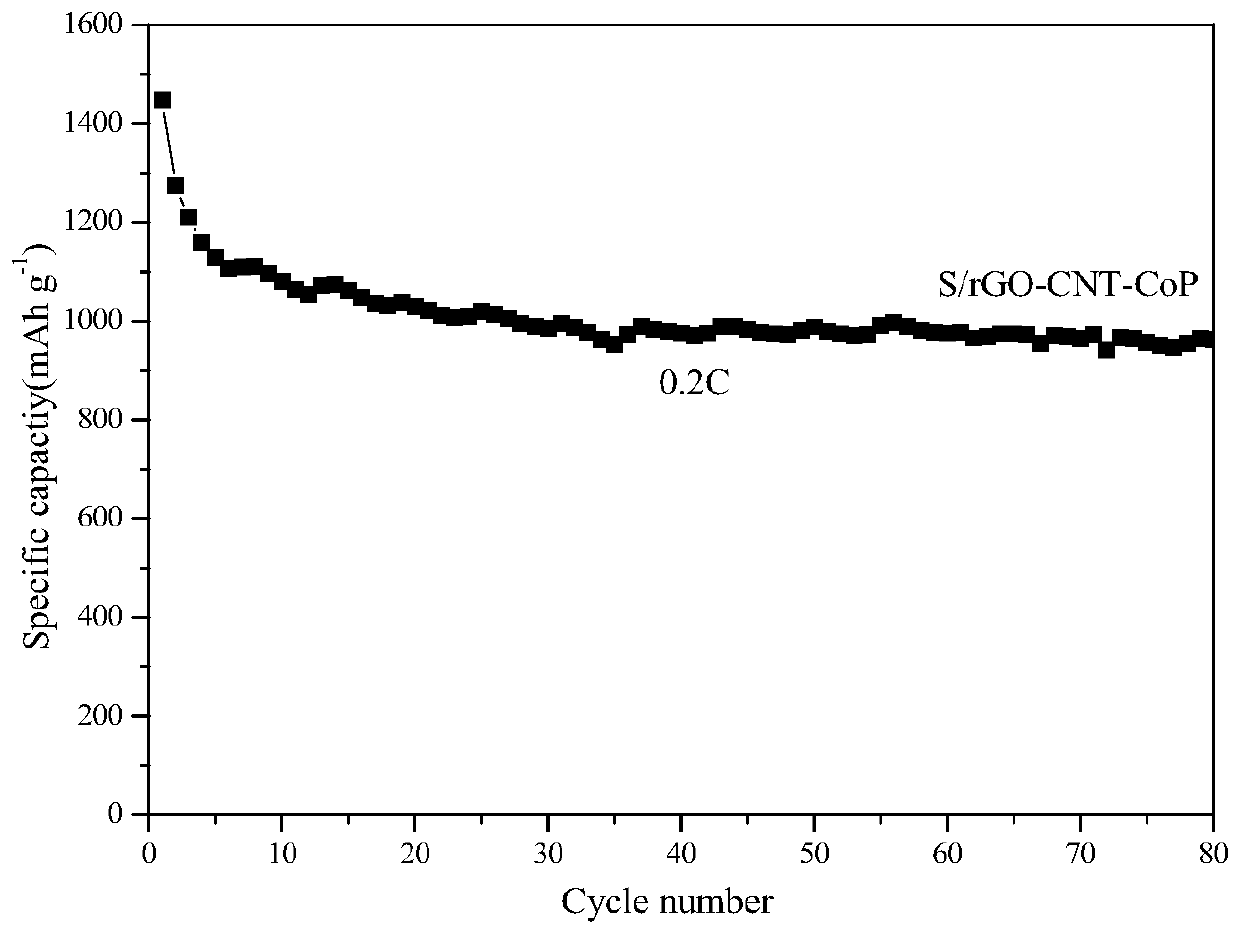

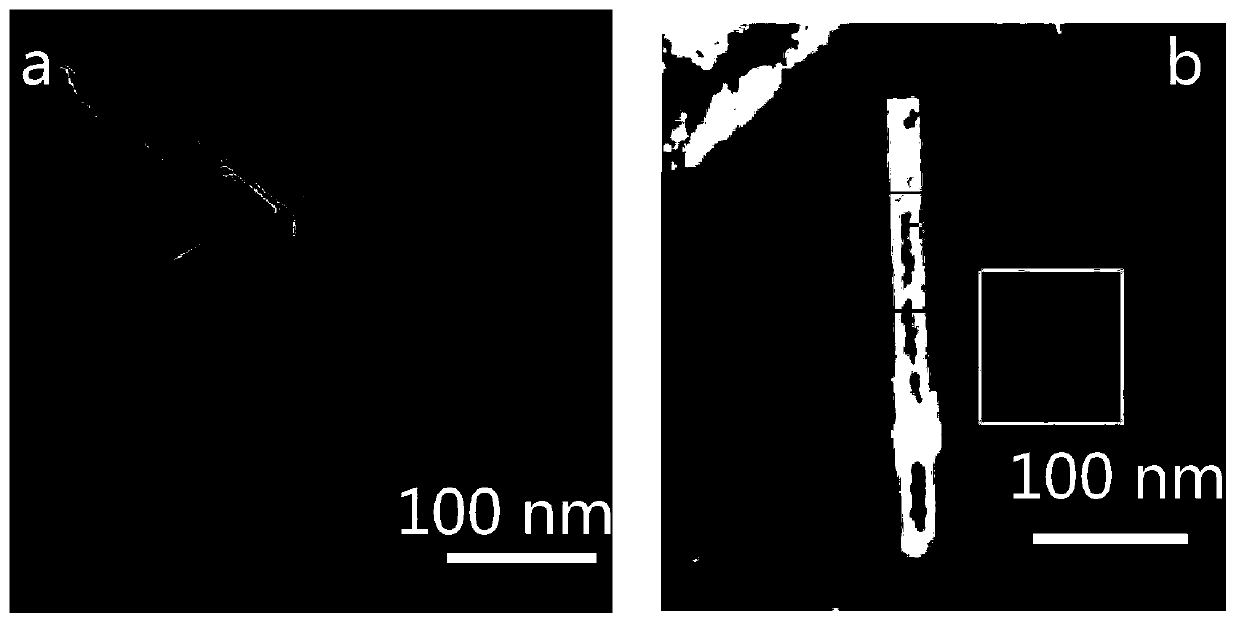

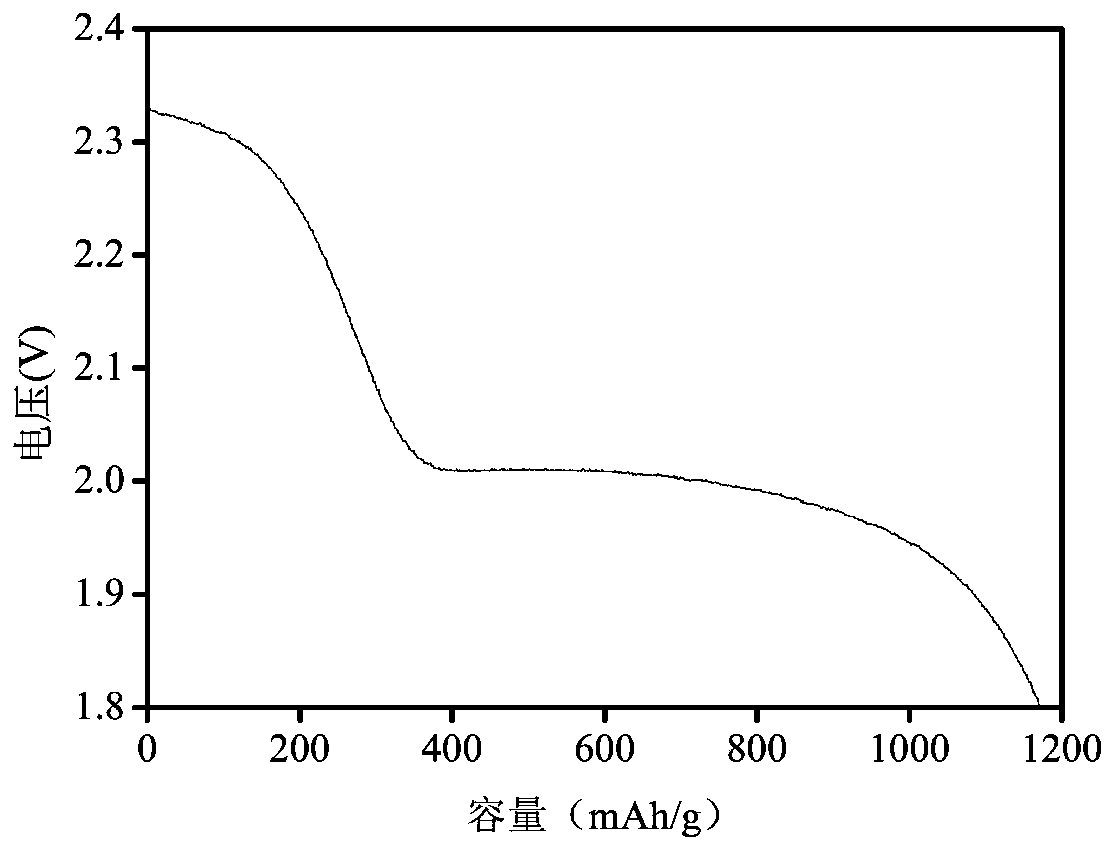

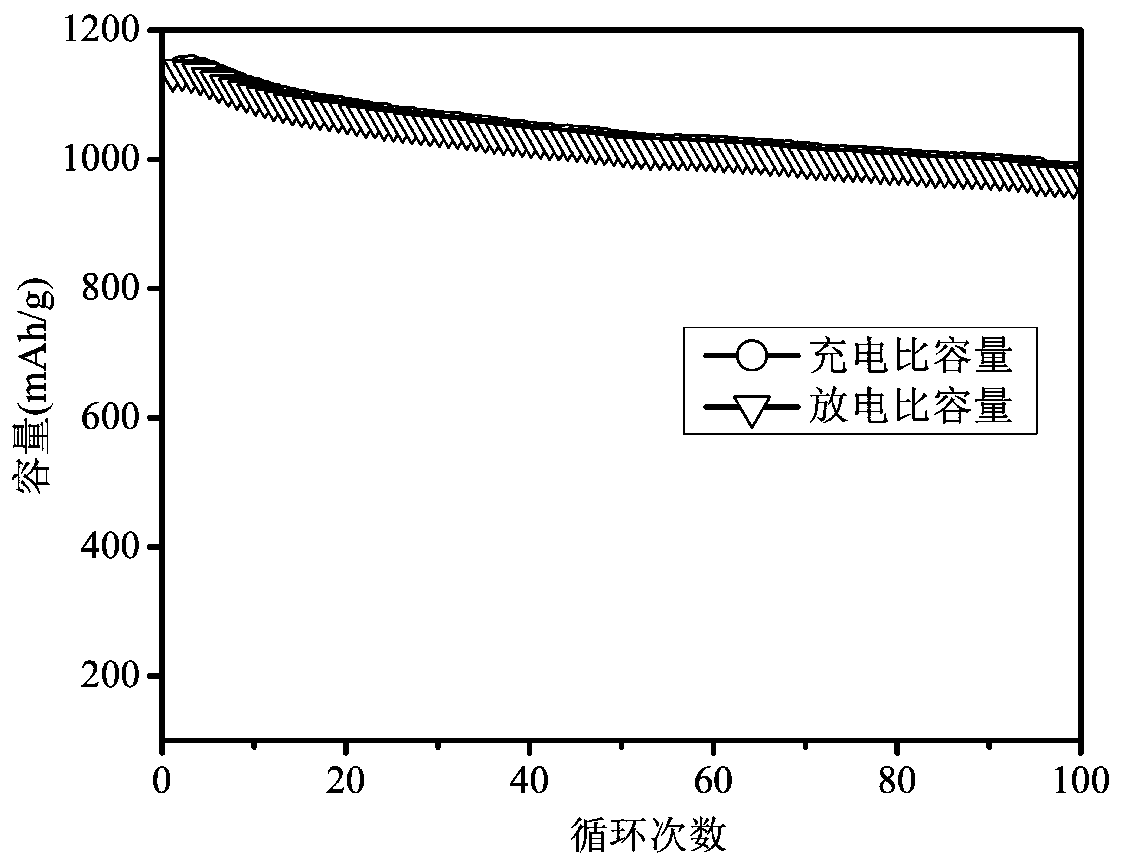

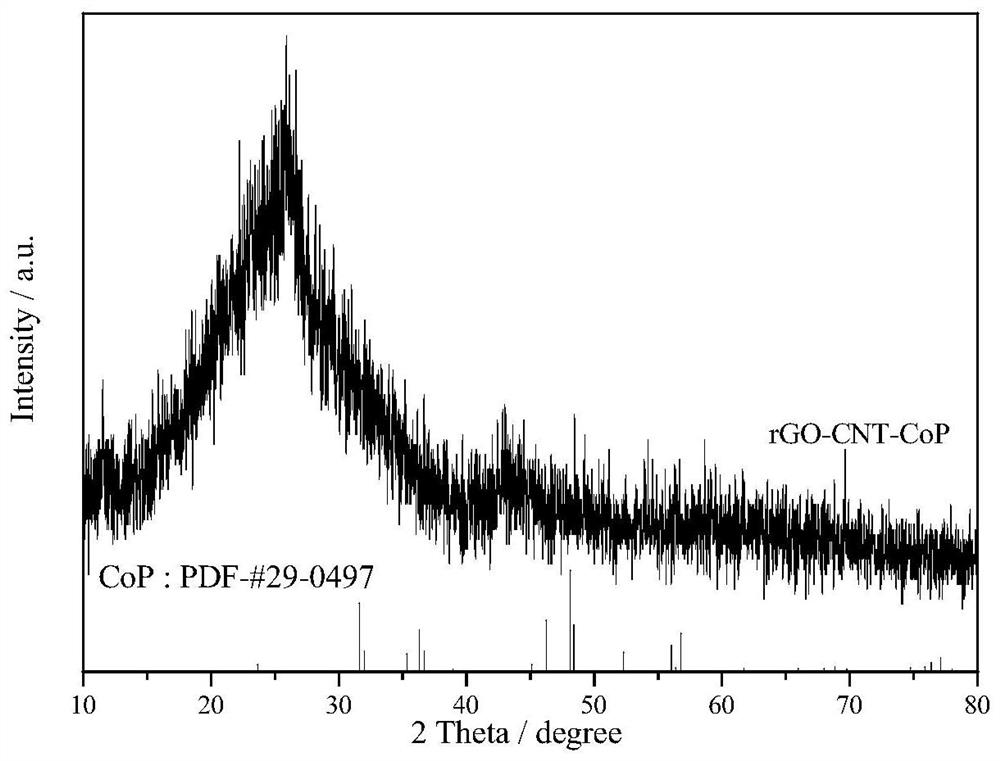

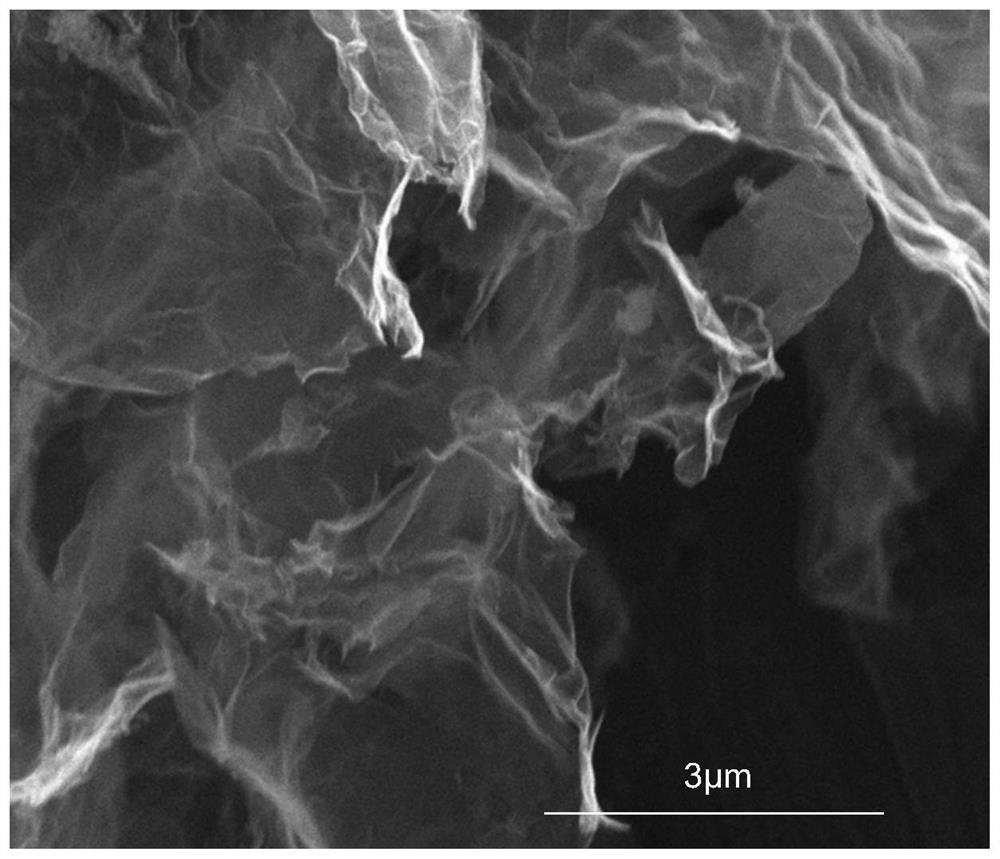

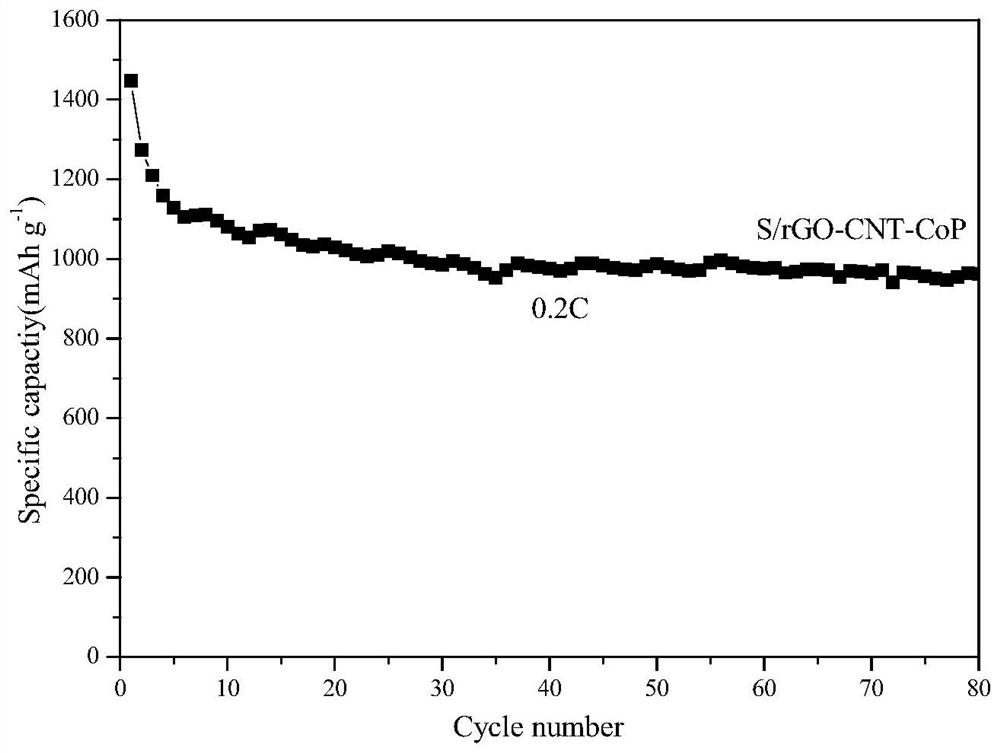

Amorphous cobalt phosphide/nanocarbon composite material and preparation method and application thereof

ActiveCN111517298ALarge specific surface areaRich pore structureMaterial nanotechnologyCell electrodesCarbon compositesNew energy

The invention belongs to the technical field of new energy materials, and particularly relates to an amorphous cobalt phosphide / nanocarbon composite material and a preparation method and application thereof. The composite material is high in specific surface area, rich in pore structure and excellent in conductivity; the conductive carbon network can provide channels for transmission of electronsand ions. The composite material can realize high sulfur loading capacity and high sulfur utilization rate, and can adapt to huge volume change of sulfur in charging and discharging processes. Compared with cobalt phosphide in a high crystalline state, the amorphous cobalt phosphide nanosheet can effectively physically and chemically adsorb polysulfide, reduce the shuttle effect, expose enough catalytic active sites, provide a large number of defect sites, promote electrochemical conversion of polysulfide to the final discharge product and improve the catalytic kinetics of the reaction.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

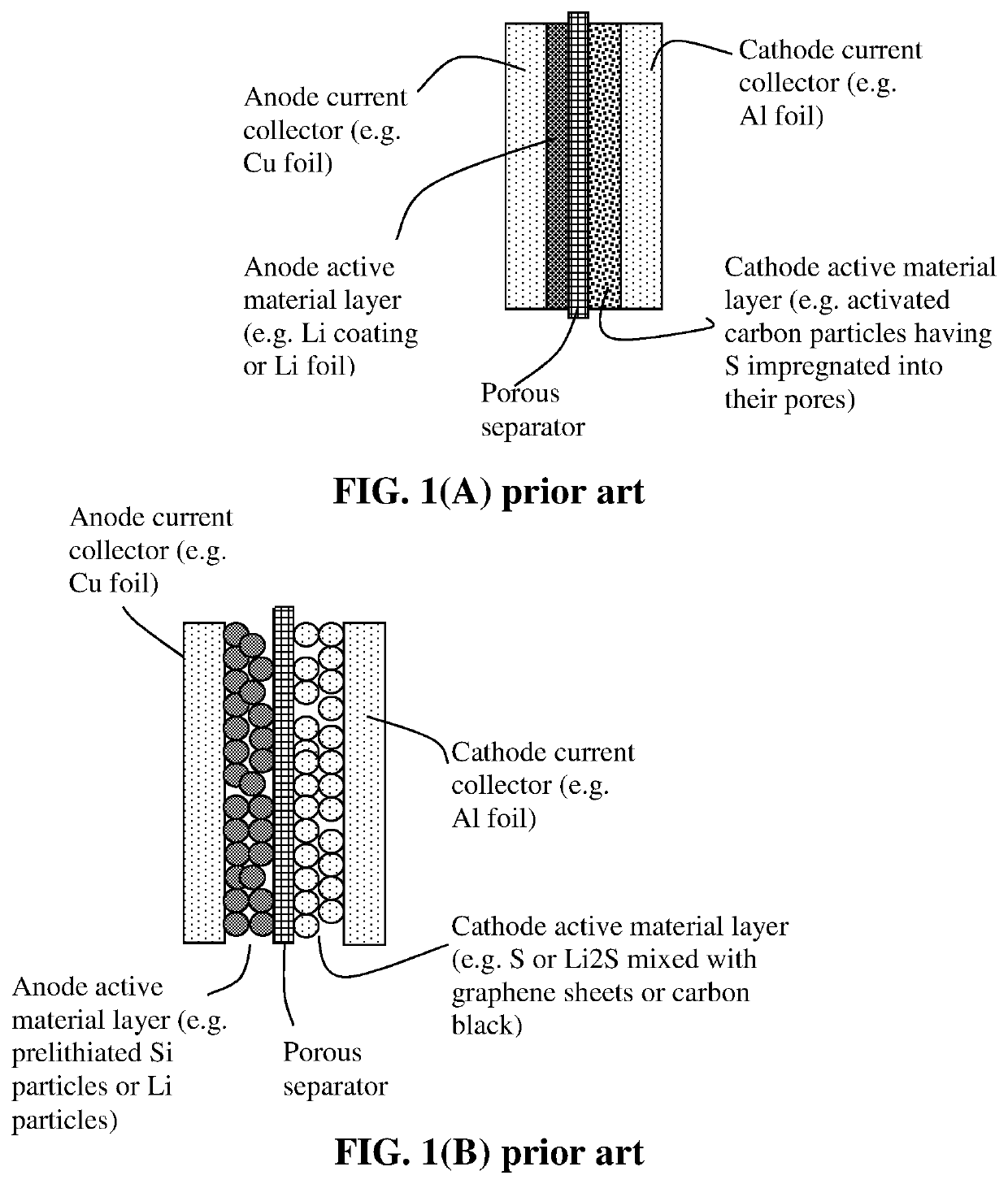

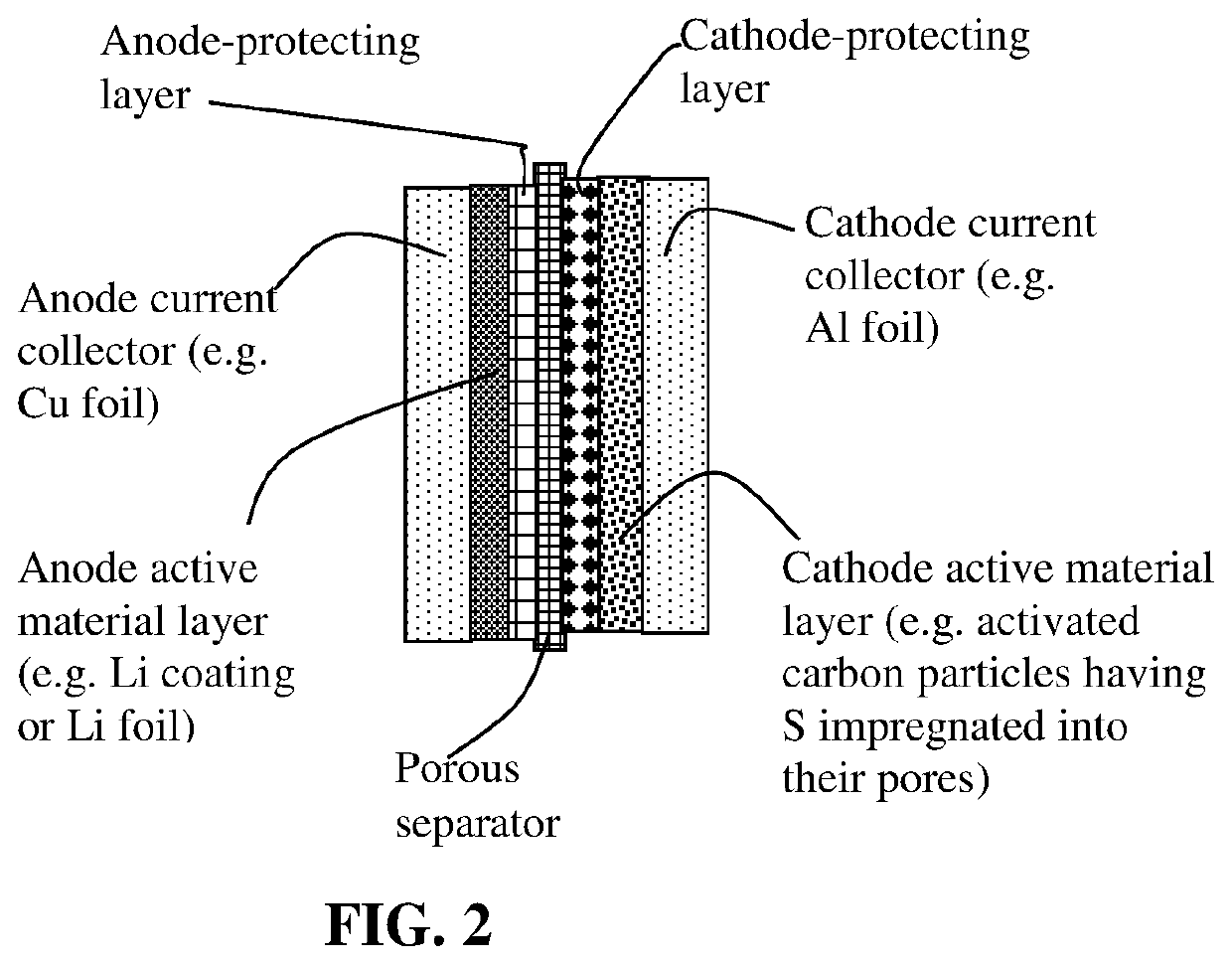

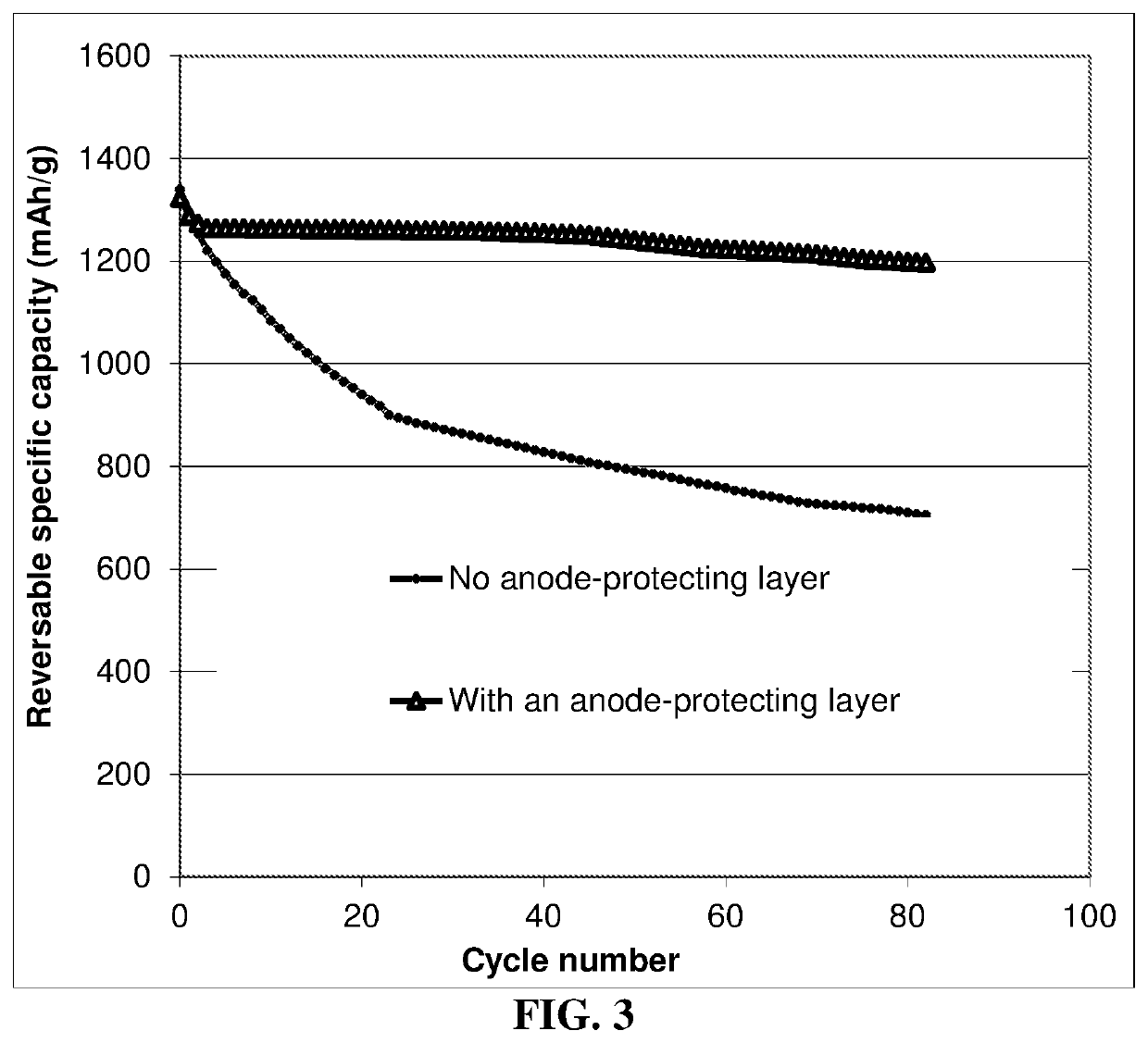

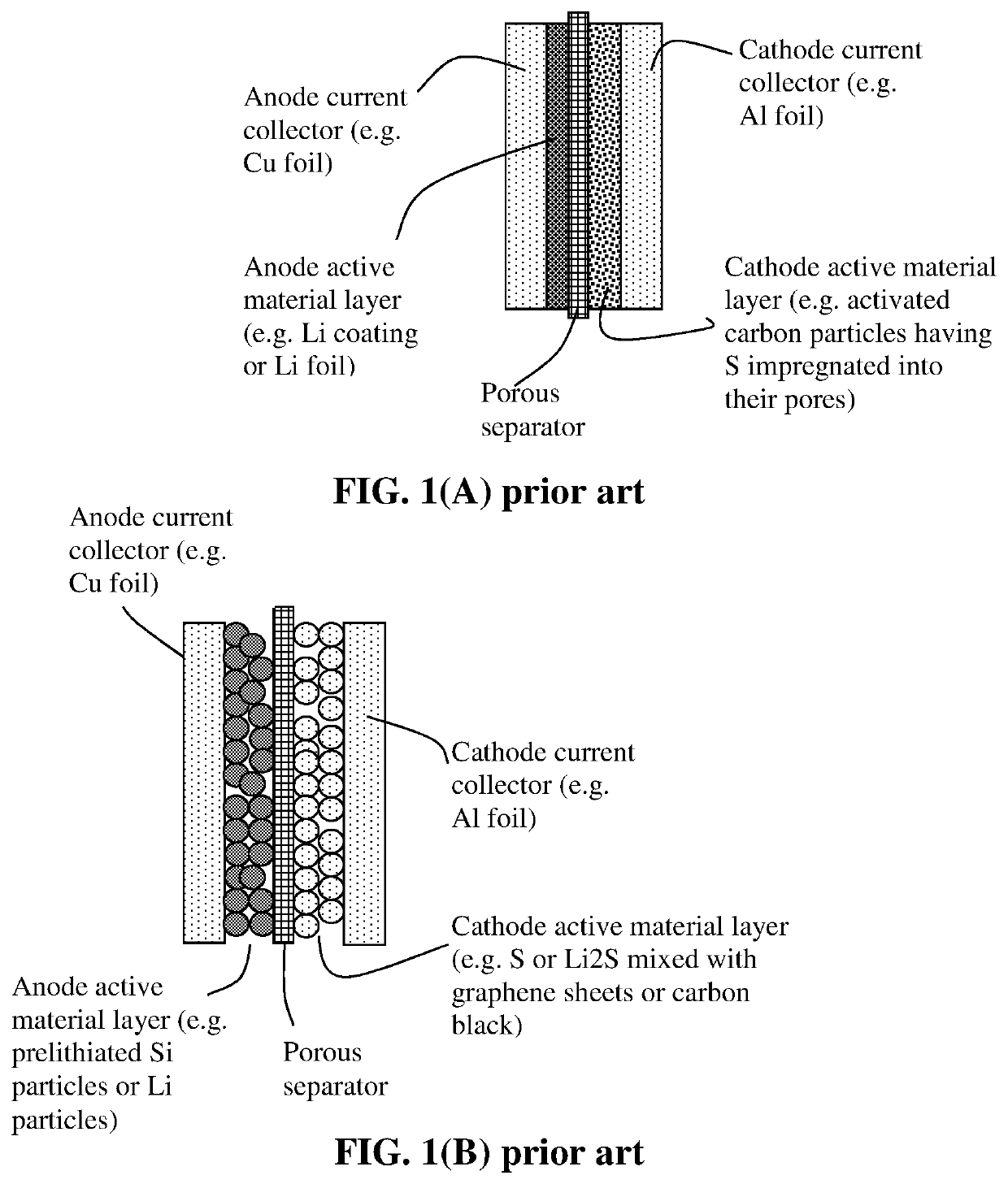

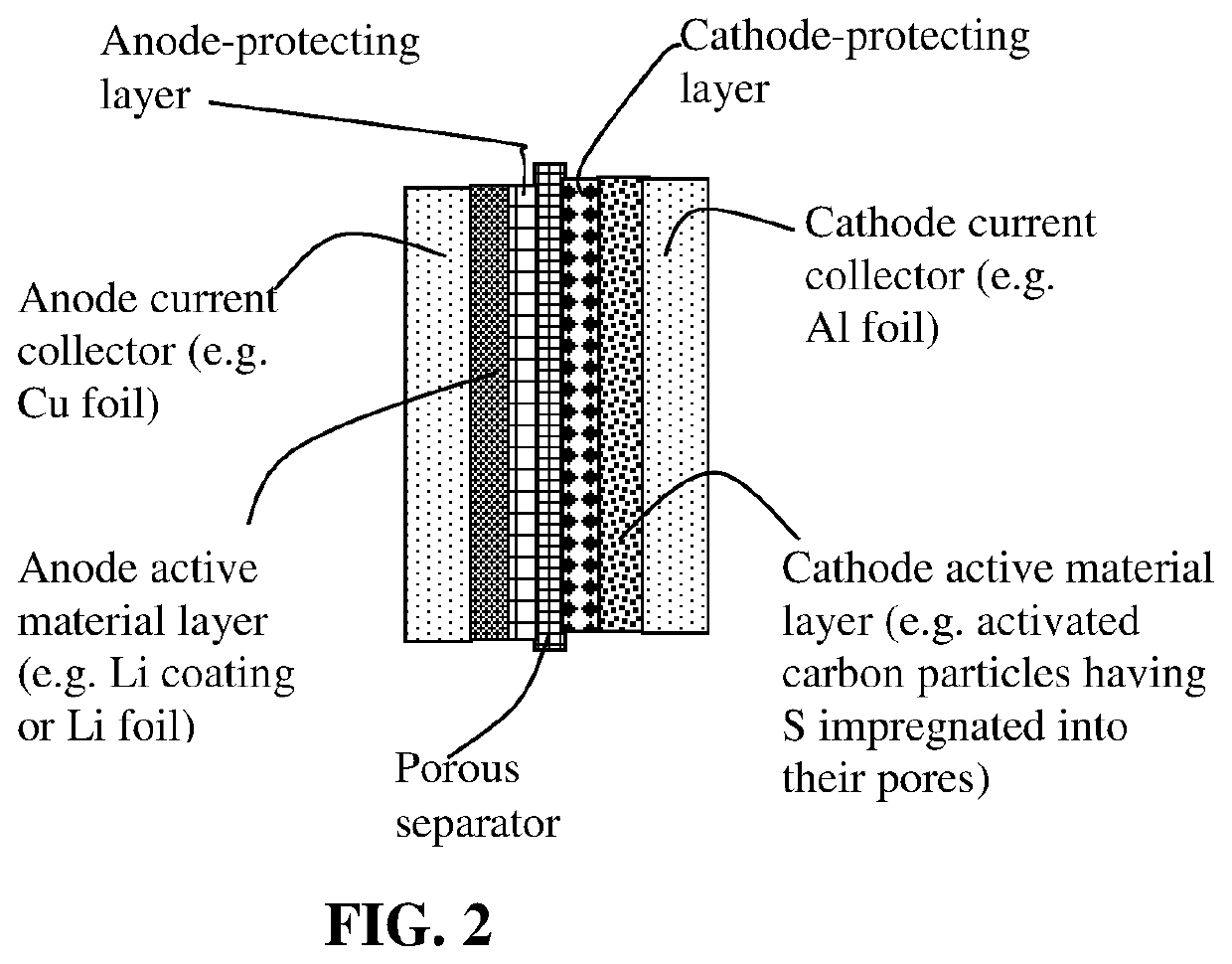

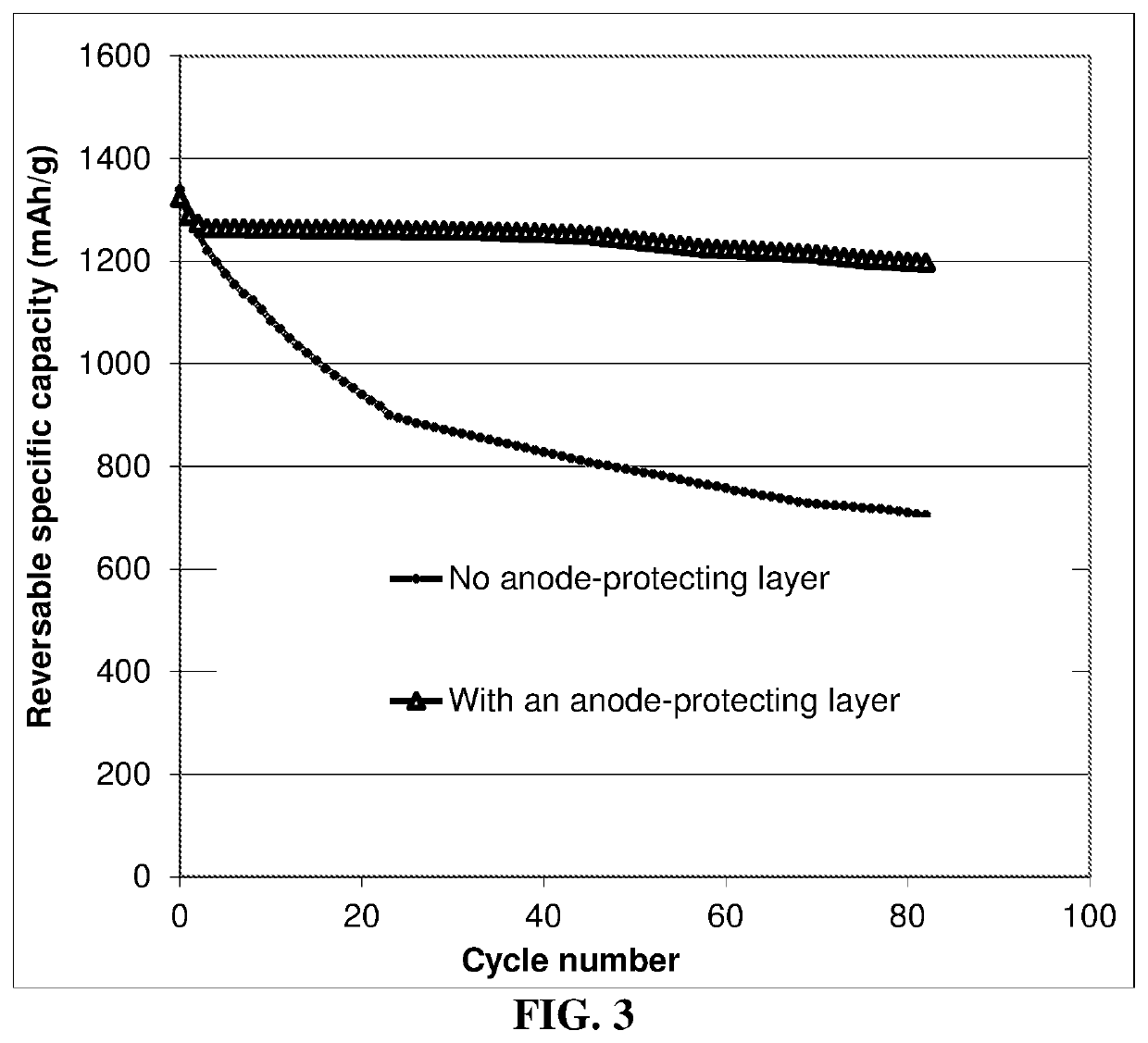

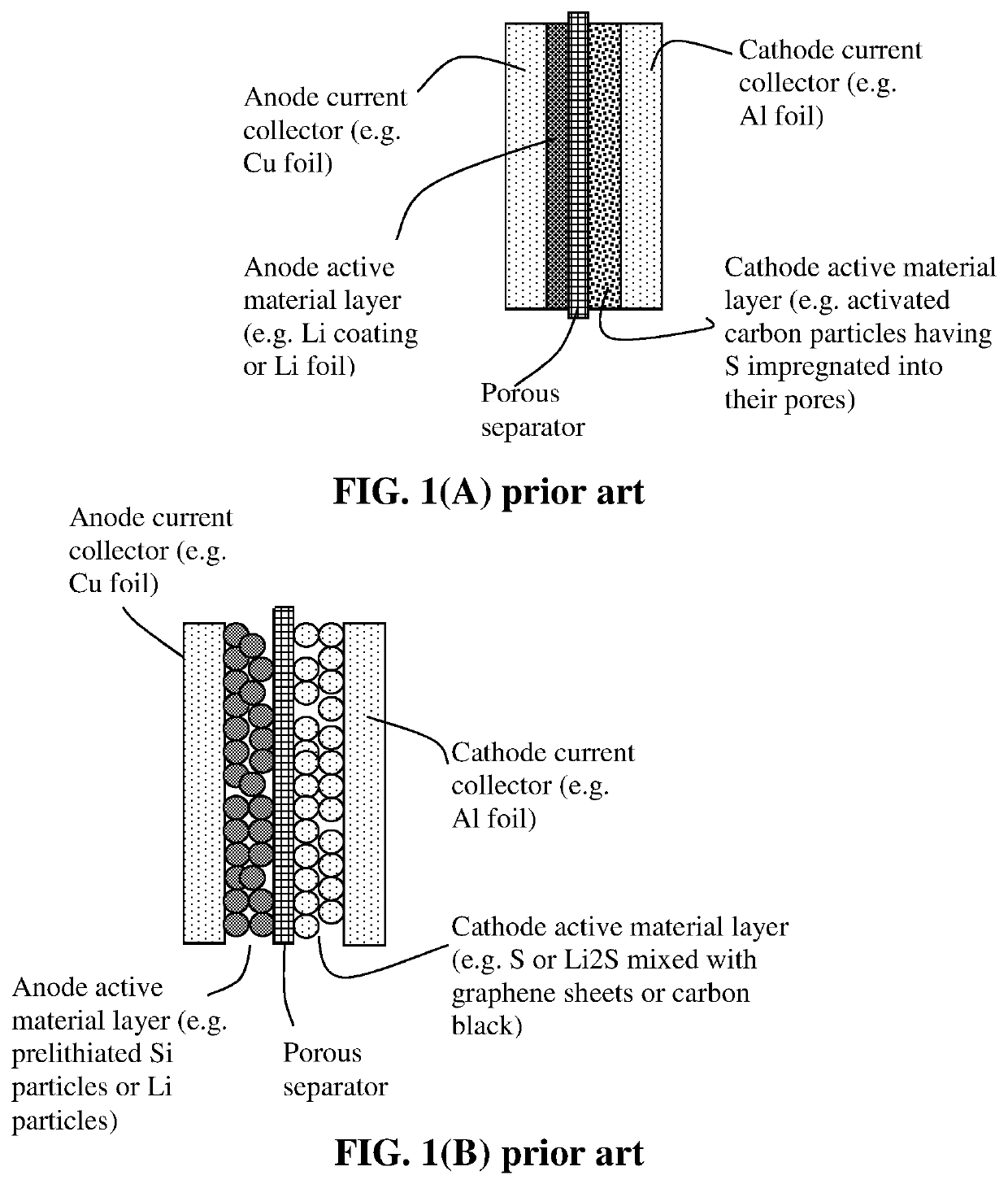

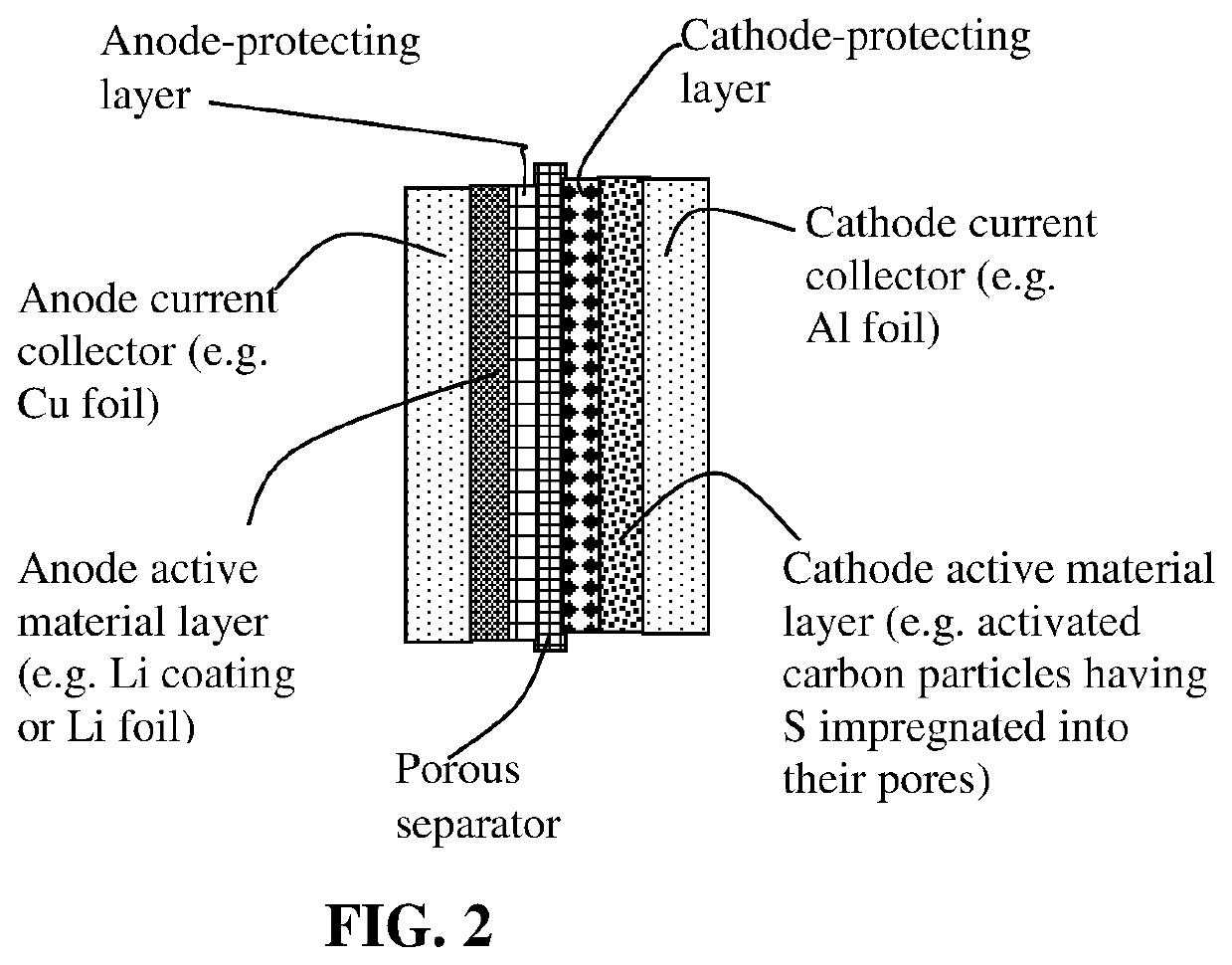

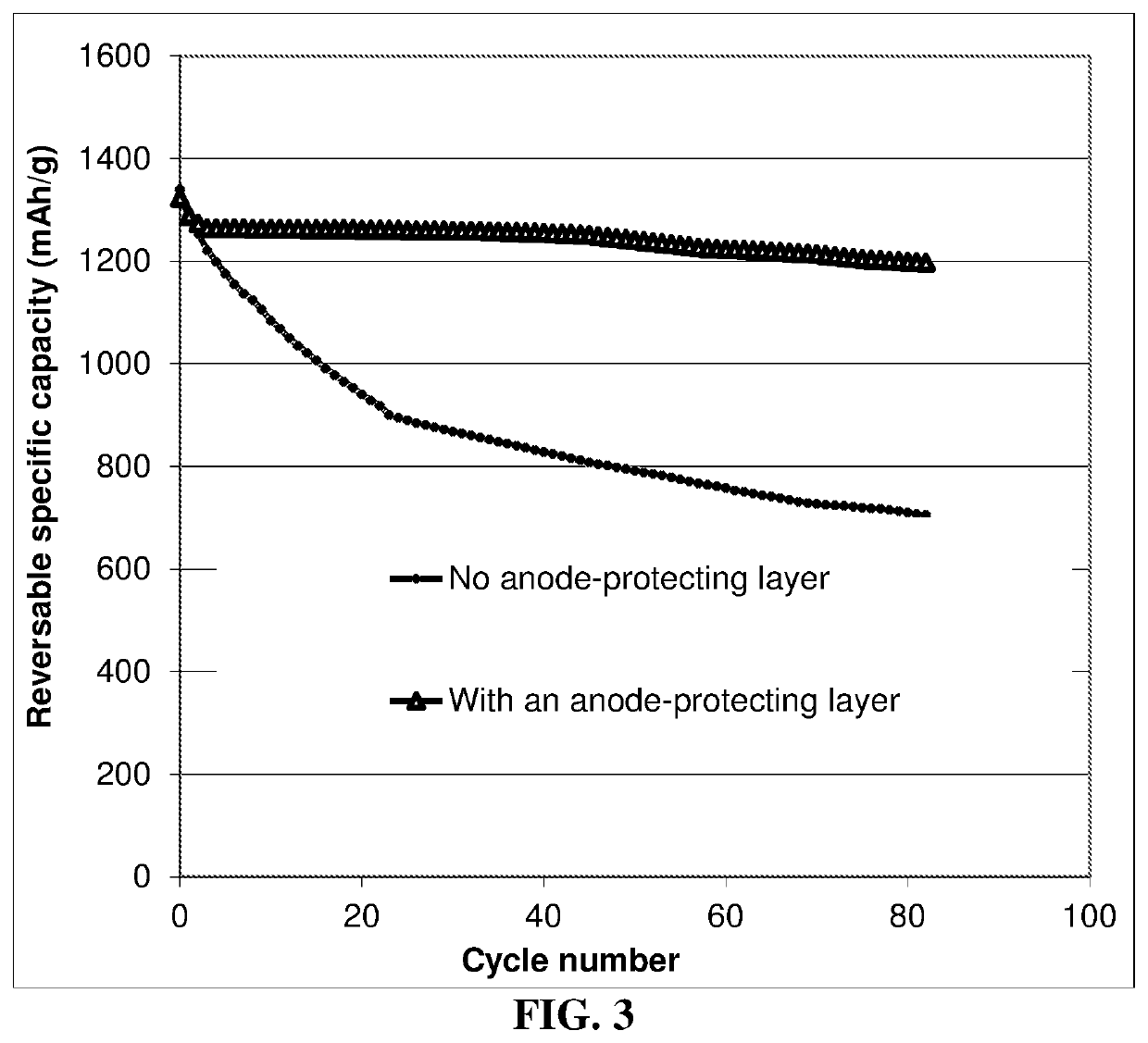

Alkali metal-sulfur secondary battery containing a non-electronically conductive anode-protecting layer

ActiveUS20200220162A1Lower internal resistanceSmooth connectionAlkaline accumulator electrodesLi-accumulatorsConductive polymerHigh energy

Provided is a rechargeable alkali metal-sulfur cell comprising an anode active material layer, a cathode active material layer, a discrete anode-protecting layer disposed between the anode active material layer and the cathode active material layer, and an electrolyte (but no porous separator), wherein the anode-protecting layer has a thickness from 1 nm to 100 μm and comprises an elastomer having a fully recoverable tensile elastic strain from 2% to 1,000% and a lithium ion conductivity from 10−8 S / cm to 5×10−2 S / cm when measure at room temperature. The cathode layer comprises a sulfur-containing material selected from a sulfur-carbon hybrid, sulfur-graphite hybrid, sulfur-graphene hybrid, conducting polymer-sulfur hybrid, metal sulfide, sulfur compound, or a combination thereof. This battery exhibits an excellent combination of high sulfur content, high sulfur utilization efficiency, high energy density, no known dendrite issue, no dead lithium or dead sodium issue, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

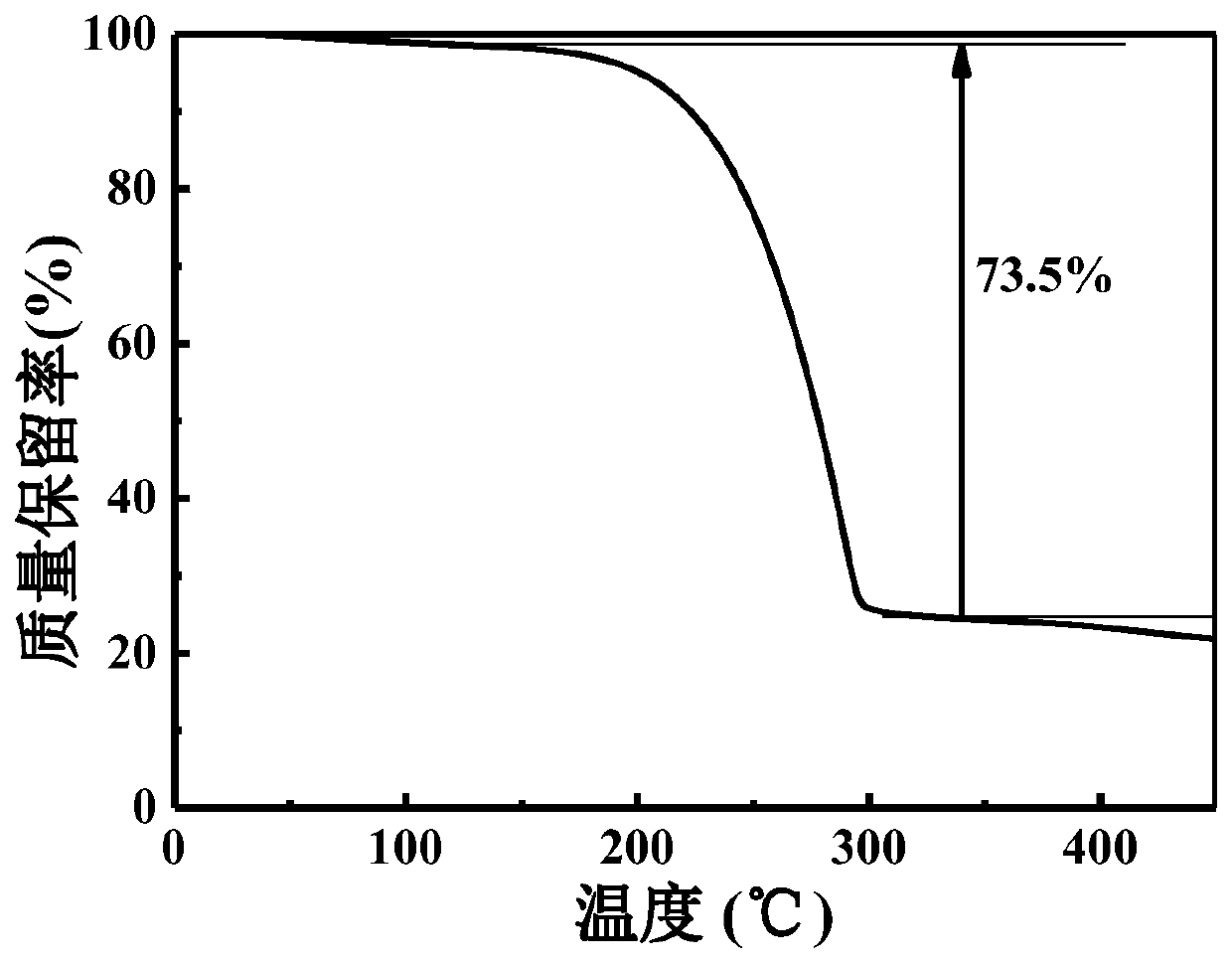

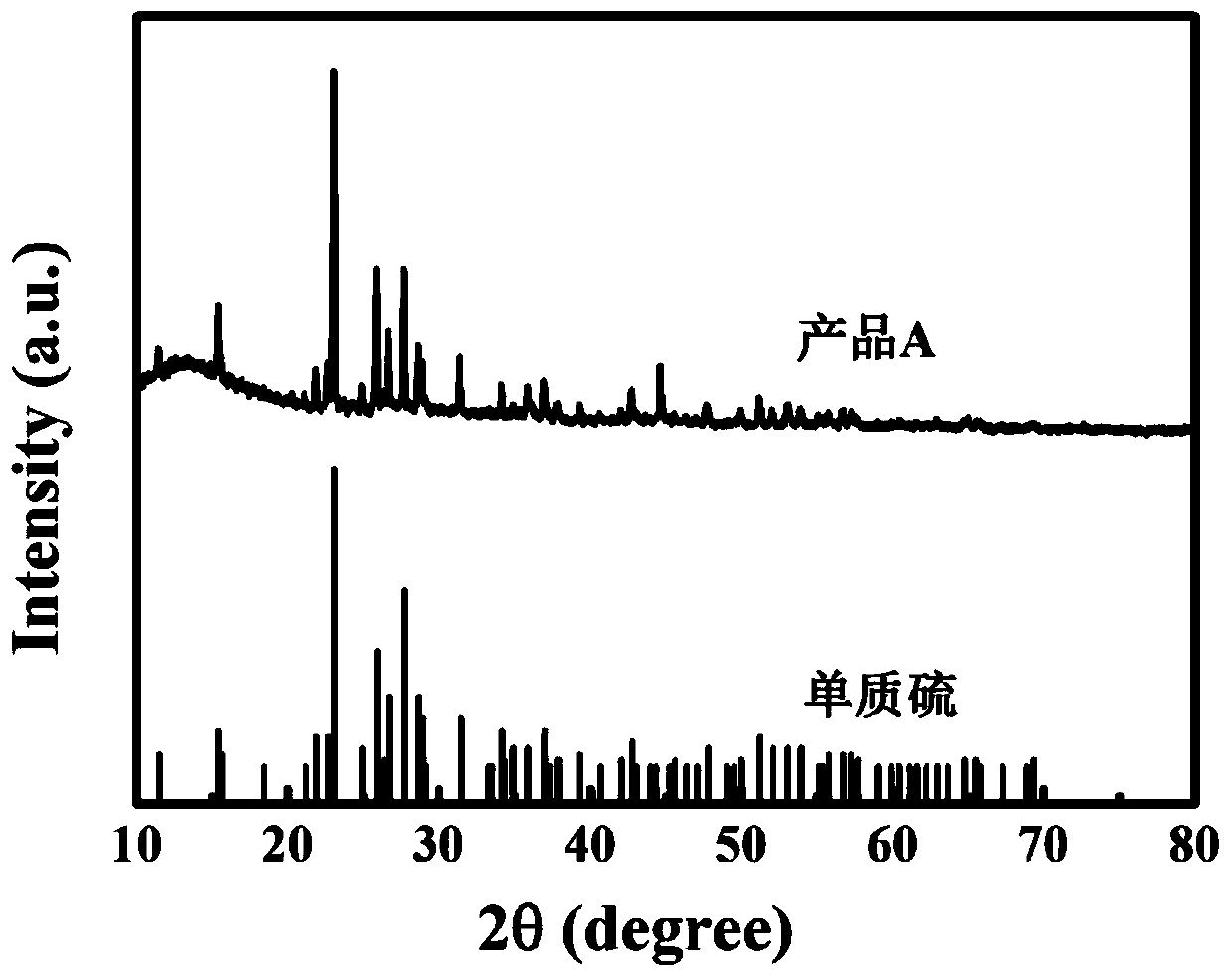

Sulfur-carbon compound and preparation method therefor, and electrode material and lithium-sulfur battery containing sulfur-carbon compound

InactiveCN105552345ASmall apertureStop the "Shuttle Effect"Material nanotechnologyCell electrodesElectrochemical responseFlying shuttle

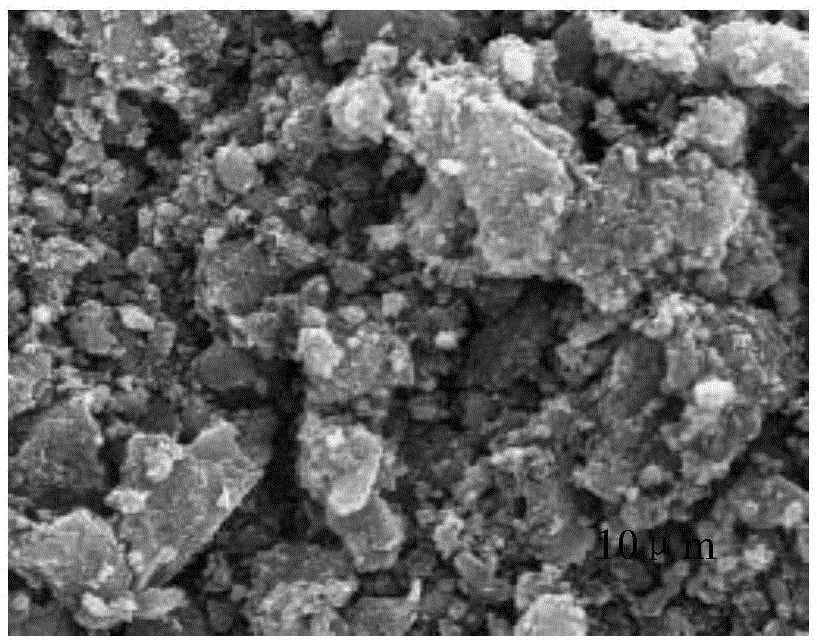

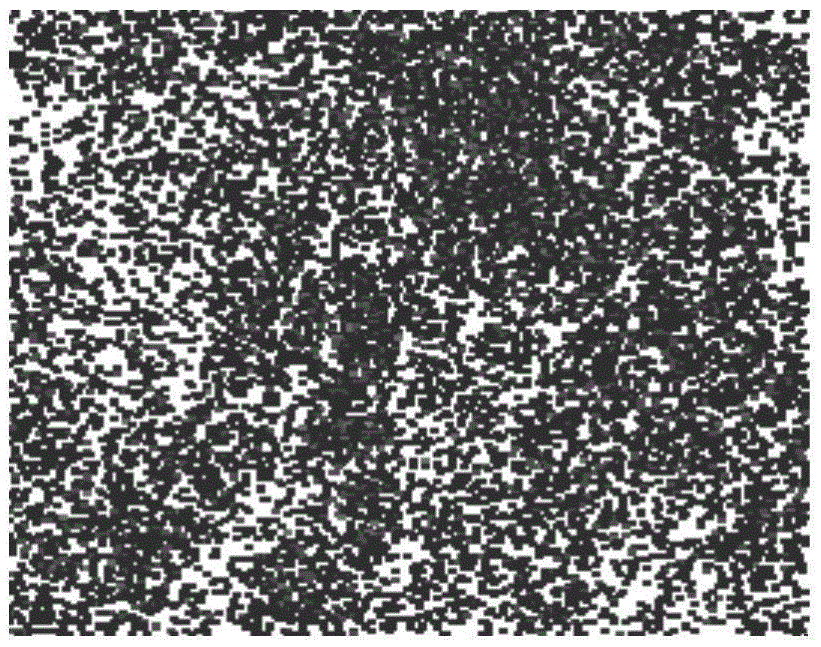

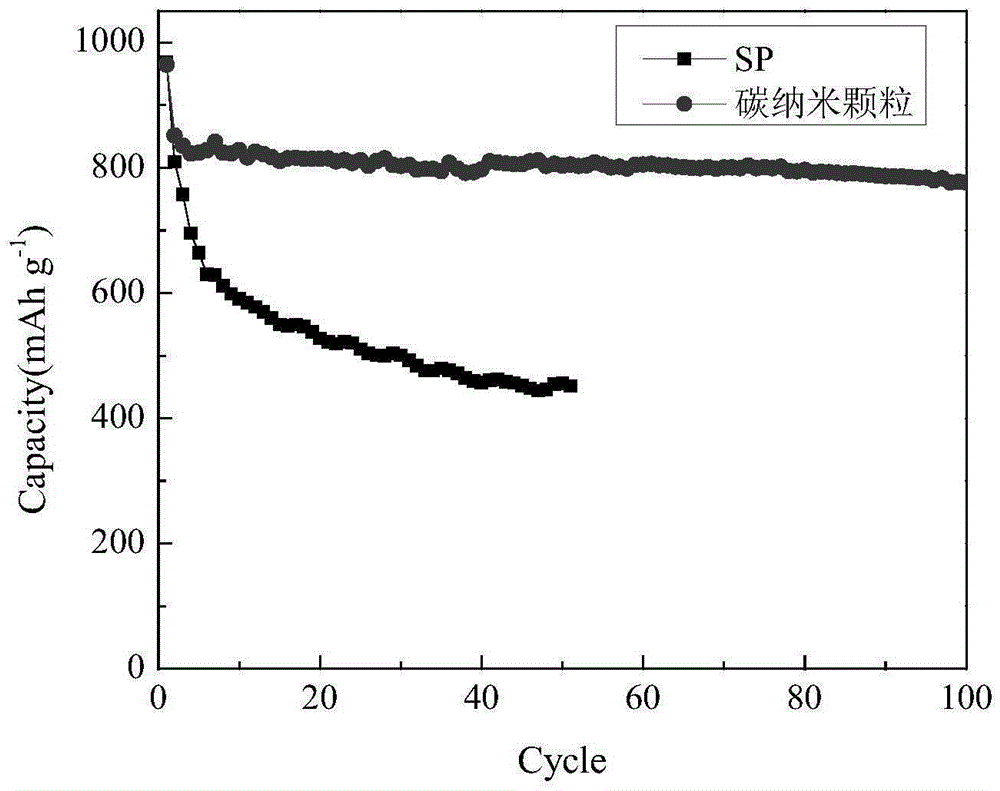

The invention relates to the technical field of a lithium ion battery, and particularly to a sulfur-carbon compound for a lithium-sulfur battery. The sulfur-carbon compound comprises carbon nanoparticles, sulfur loaded in the carbon nanoparticles and silicon dioxide template existing in the carbon nanoparticles in a residual manner, wherein the content of sulfur accounts for 40-70% of the content of the sulfur-carbon compound based on mass percent; and the content of the silicon dioxide template accounts for 0.3-3% of the content of the sulfur-carbon compound based on mass percent. The residual silicon dioxide template in the sulfur-carbon compound is dispersed in the carbon nanoparticles so as to reduce the aperture of the carbon nanoparticles; therefore, the carbon nanoparticles have a relatively high capture capability for polysulfide lithium that is an intermediate product of an electrochemical reaction in use; meanwhile, the residual silicon dioxide template can effectively prevent a flying shuttle effect of polysulfide lithium; and the invention also relates to a preparation method for the sulfur-carbon compound, and an electrode material and the lithium-sulfur battery containing the sulfur-carbon compound.

Owner:MCNAIR TECH +2

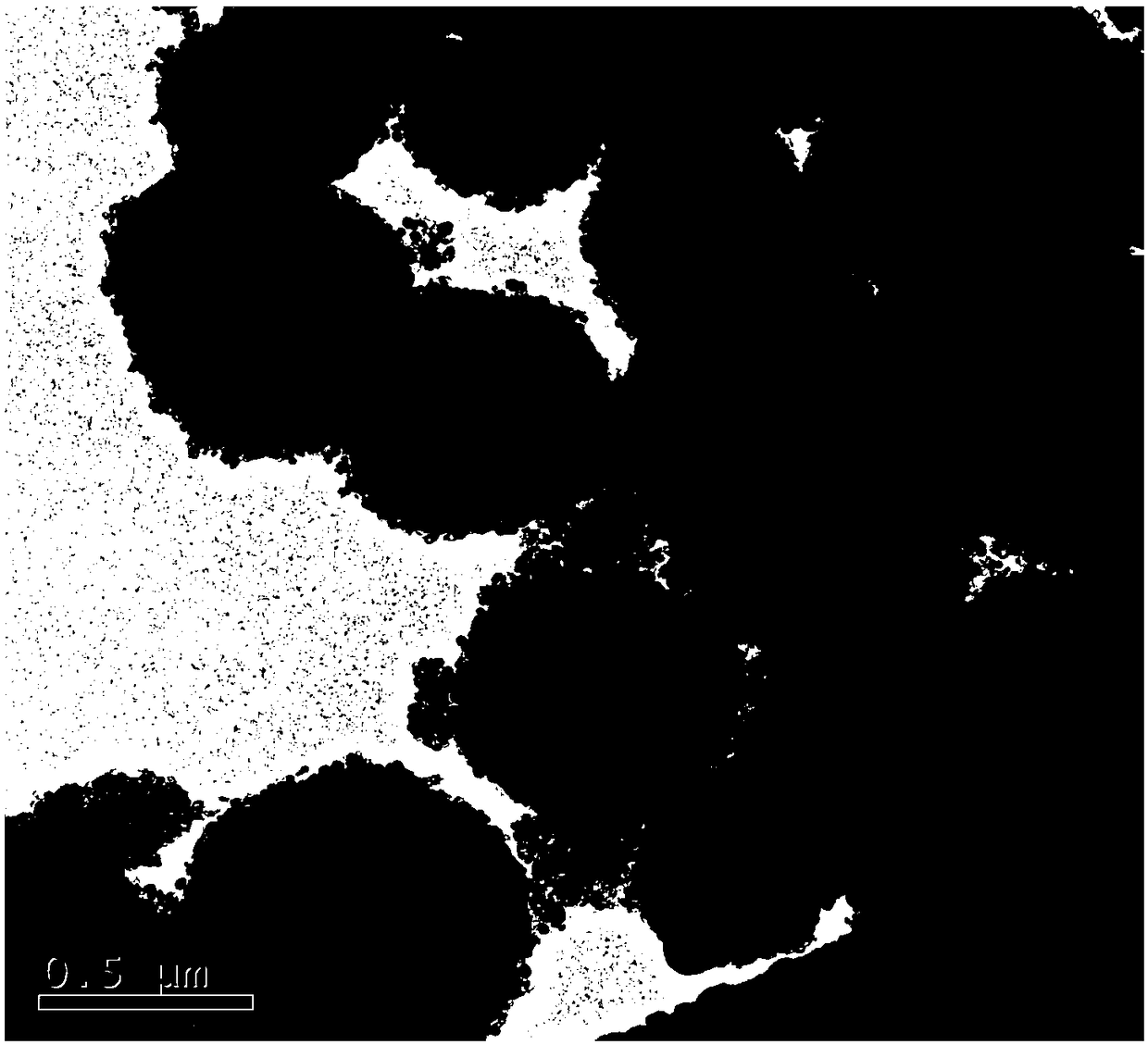

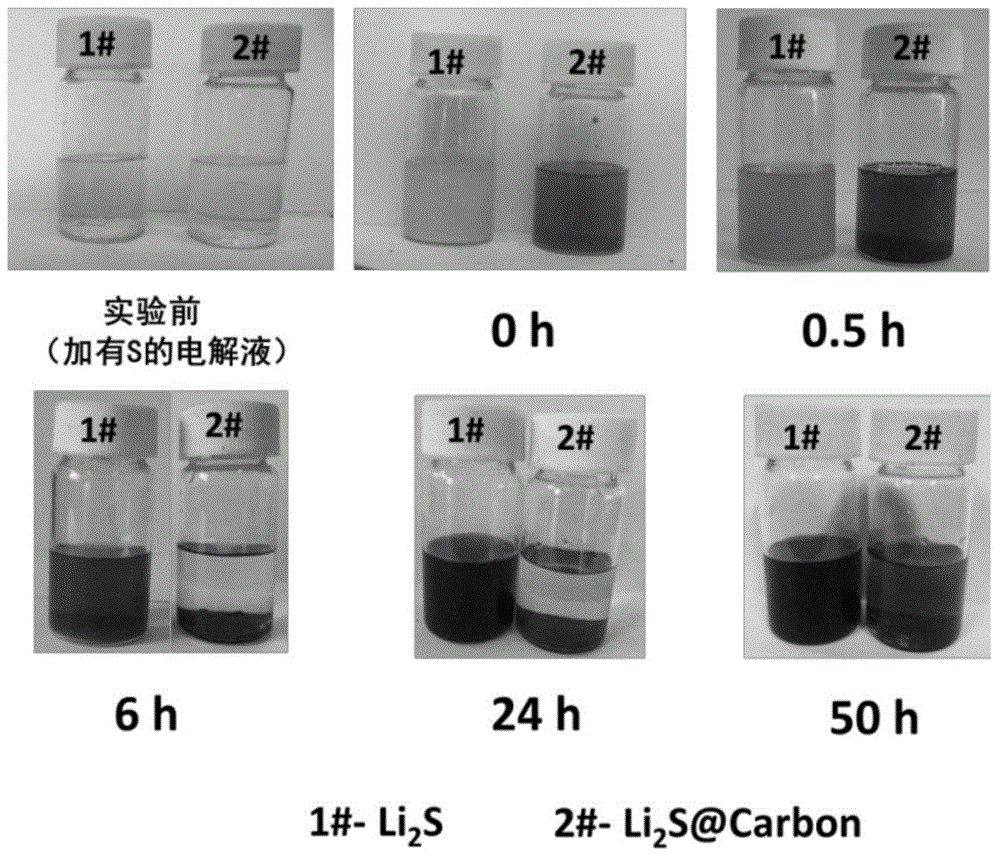

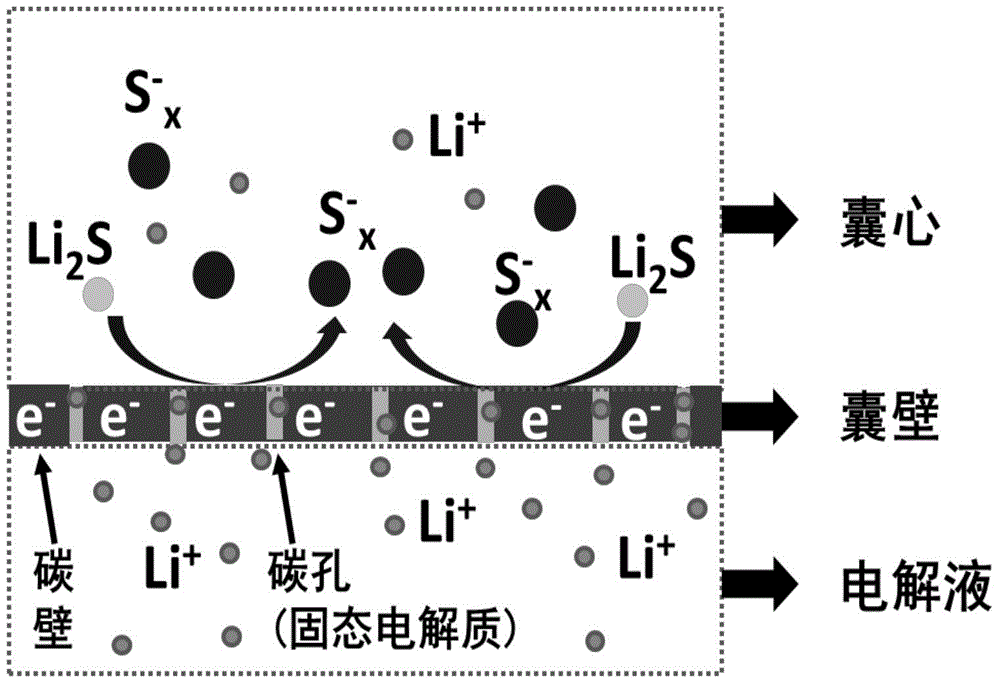

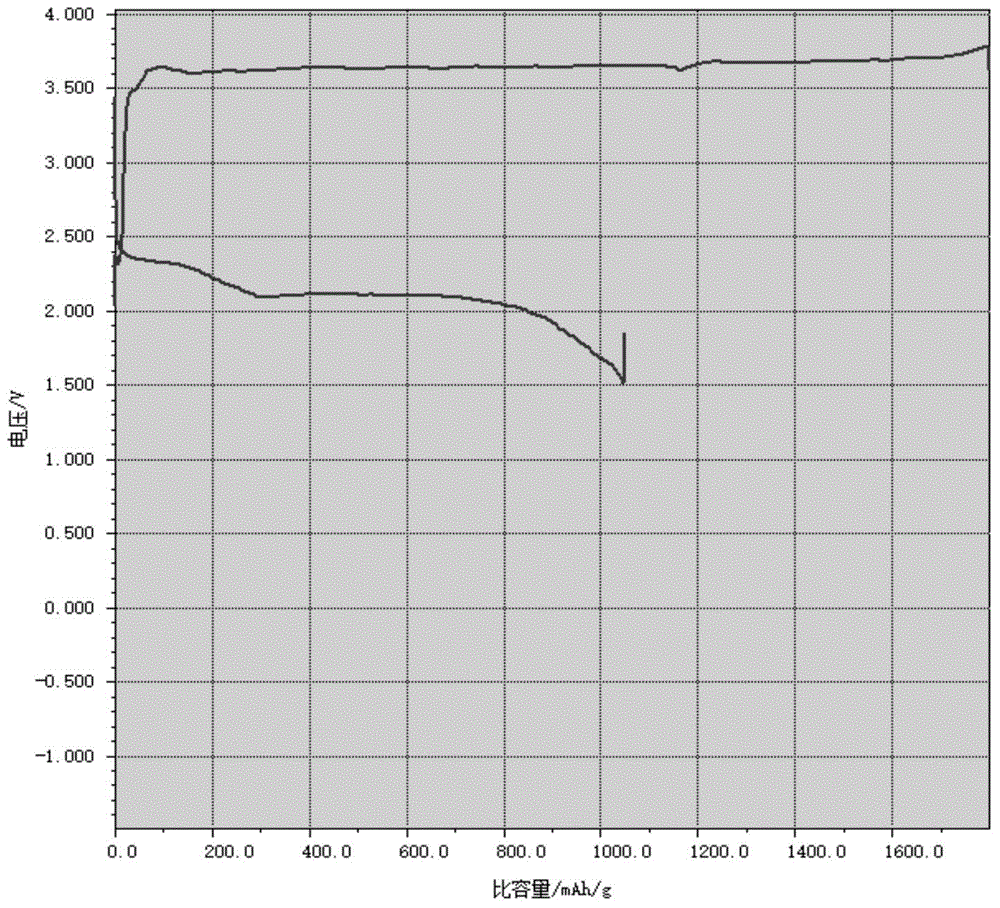

Micro-capsule-structured carbon-sulfur compound and preparation method and application thereof

ActiveCN106505182AIntegrity guaranteedReduce swelling effectMaterial nanotechnologyCell electrodesElectrical conductorMass ratio

The invention relates to a micro-capsule-structured carbon-sulfur compound and a preparation method and an application thereof. The compound takes lithium sulfide as a capsule-core material, and takes a carbon material and a lithium ion conductor as a capsule-wall material; the capsule-core material is positioned in the hollow capsule-wall material, wherein the capsule-core material is 20-300nm in grain diameter; the capsule wall is 2-50nm in thickness; the content of the capsule-core material accounts for 20-80wt% of the carbon-sulfur compound; and the mass ratio of the carbon material to the lithium ion conductor in the capsule-wall material is (1:99) to (99:1). Based on the structural advantage of the "micro-capsule", a positive electrode material design thought of "capsule core sulfur-carrying, capsule wall sulfur-fixing, hole wall electric conduction and hole channel sold-state lithium conduction" is proposed, so that the utilization rate and the cycling stability of the active material sulfur in a lithium-sulfur battery are greatly improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Carbon-sulphur composite used for cathode material of lithium sulphur battery as well as preparation method and application thereof

ActiveCN103050669BImprove discharge capacityLarger than surfaceNon-aqueous electrolyte accumulator electrodesDissolutionPolysulfide

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

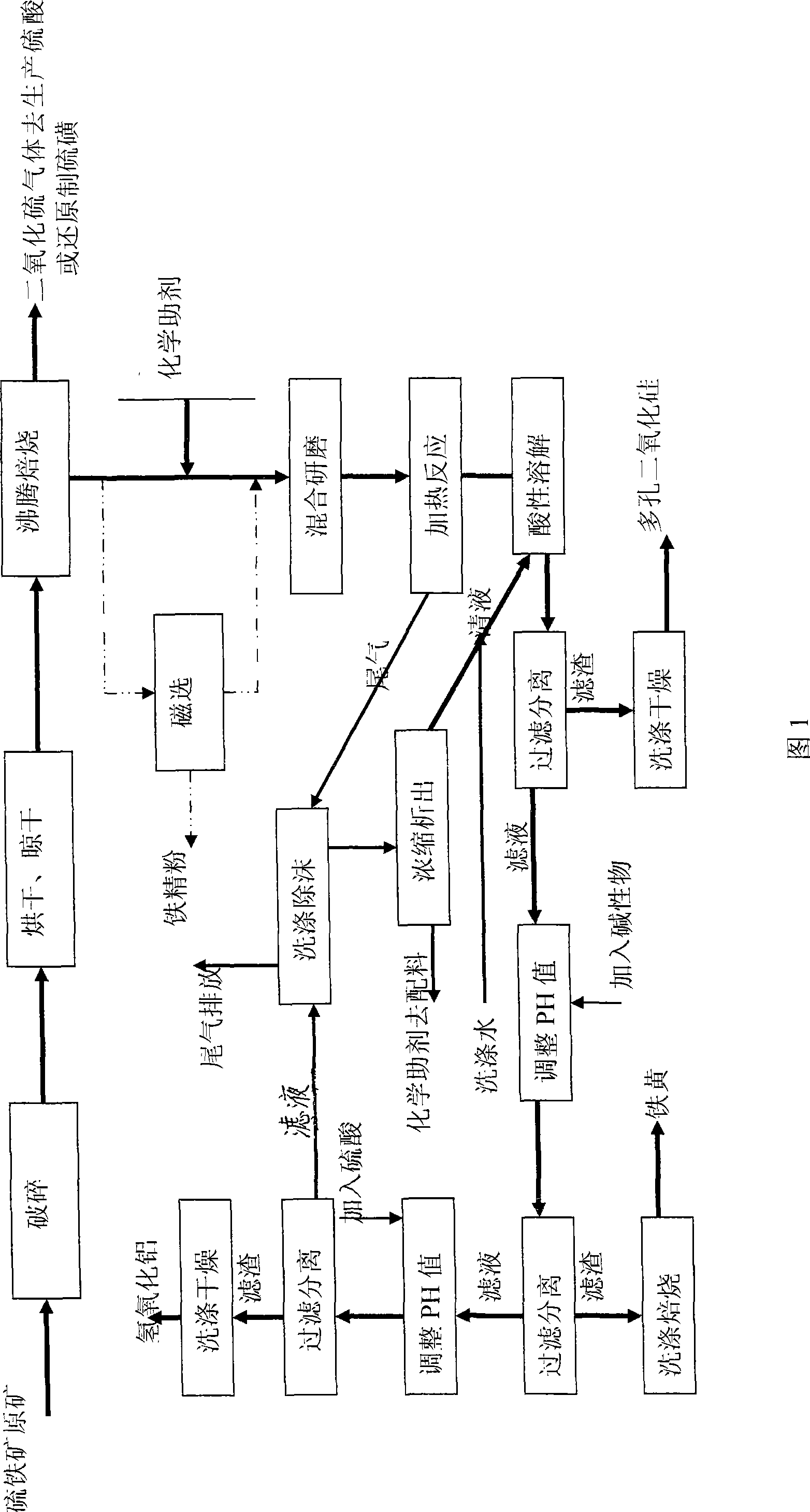

Method for by-producing porous silicon dioxide, aluminum hydroxide and ferrite yellow from middle and low grade ferro-sulphur ore

InactiveCN101456559ARealize full layer miningAchieve recyclingSilicaSulfur-dioxide/sulfurous-acidFerric hydroxideFiltration

The invention relates to a method for coproducing porous silicon dioxide, aluminum hydroxide and ferrite yellow when producing medium and low grade sulfurous iron ores, which comprises: the sulfurous iron ores are crushed and directly enter a fluidized bed furnace for roasting to obtain sulfur dioxide gas and cinder; the sulfur dioxide gas is used for further producing sulfuric acid or reducing production of sulfur; the cinder is subjected to magnetic separation to obtain iron concentrate or directly added with a chemical additive and then subjected to grinding and heating reaction, wherein the addition of the chemical additive is 2 to 4 times of the weight of the cinder; the cinder is dissolved for 1 to 3 hours under the acid condition after heating reaction, and the porous silicon dioxide is obtained after filtration and separation; the pH value of filtrate is adjusted to be between 9 and 12, the filtrate stands and is filtrated, and filter residue ferric hydroxide is washed and roasted to obtain a high-purity ferrite yellow pigment; and the pH value of the filtrate for filtrating the ferric hydroxide is adjusted to be between 4 and 6.5, the filtrate stands and is filtrated and separated to obtain aluminum hydroxide, and the aluminum hydroxide finished product is obtained after washing and drying the aluminum hydroxide. The method can improve the sulfur utilization rate by 40 to 50 percent, solves the problem of environmental pollution in the prior art, and fully utilizes all the compositions coproduced with the medium and low grade sulfurous iron ores.

Owner:云南常青树投资有限公司

Lithium-sulfur battery negative electrode and lithium-sulfur battery comprising same

ActiveCN111540905AImprove cycle performanceExtended service lifeCell electrodesLi-accumulatorsMetallic lithiumLithium–sulfur battery

The invention provides a lithium-sulfur battery negative electrode. A protective layer is arranged on the surface of a negative electrode containing metal lithium, and the protective layer comprises alithium affinity unit, a reducibility unit and an electronegativity unit. The invention also provides a lithium-sulfur battery comprising the negative electrode. According to the invention, the protective layer is arranged on the surface of the negative electrode containing the metal lithium, and the lithium affinity unit contained in the protective layer firmly adsorbs the protective layer to the surface of the negative electrode so as to isolate direct contact between polysulfide ions and the metal lithium; the reducibility unit can shear long-chain polysulfide ions reaching the negative electrode side through the electrolyte through the diaphragm into short-chain polysulfide ions, and then the electronegativity unit reacts with the short-chain polysulfide ions to enable the short-chainpolysulfide ions to continue to return to a positive electrode side, so that more irreversible Li2S is prevented from being formed on the negative electrode side. The lithium affinity unit, the reducibility unit and the electronegativity unit in the protective layer have a synergistic effect, so that the shuttle effect is effectively inhibited, and the sulfur utilization rate is increased. And the cycle performance and the service life of the battery are improved.

Owner:CHINA AVIATION LITHIUM BATTERY RES INST CO LTD

Carbon-based material of graphene-similar three-dimensional porous composite iron oxide, and preparation method

The invention discloses a carbon-based material of graphene-similar three-dimensional porous composite iron oxide, and a preparation method. The method comprises the steps of: adding sodium chloride,carbon source, surfactant and catalyst iron salt into deionized water at room temperature; and adequately stirring for 2-3 hours to form uniform and transparent orange solution. A certain amount of catalyst iron salt is added into the deionized water; and, 7-8g sodium chloride, 1-3g citric acid and 0.2-0.3g polyvinylpyrrolidone are added into each 40ml deionized water. The carbon-based material ofgraphene-similar three-dimensional porous composite iron oxide has rich pore structure, big specific surface area and good electrical conductivity, which are good for improving the loading capacity of sulfur and for transmitting the lithium ion and the electron; and thus, the carbon-based material is suitable to be used in the anode of the lithium-sulfur battery.

Owner:HUBEI UNIV

Lithium-sulfur battery positive electrode material

ActiveCN110931737AInhibition of the shuttle effectImprove electrochemical performancePositive electrodesLi-accumulatorsLithium–sulfur batteryPhysical chemistry

The invention relates to a lithium-sulfur battery positive electrode material, which belongs to the technical field of lithium battery production. The formula of the lithium-sulfur battery positive electrode material is, by weight, 0.1-2 parts of Ni, 0.4-8 parts of GDC, 25-60 parts of C, and 40-75 parts of S. The molecular formula of GDC is Ce<1-x>Gd<x>O<2-delta>. GDC is a GDC precursor prepared by mixing cerium salt and gadolinium oxide through one or more of a sol-gel method, a coprecipitation method, a solid phase method and a hydrothermal method, and then the GDC precursor is heated at thetemperature of 300-500 DEG C to prepare a powdery solid solution. The lithium-sulfur battery positive electrode material has the advantages that the GDC can inhibit the shuttle effect of polysulfideand improve the catalytic performance of the positive electrode material of the lithium-sulfur battery on oxidation reduction, Ni and the GDC can be combined to have relatively high electronic conductivity and ion vacancy, and the conductivity of the positive electrode material of the lithium-sulfur battery is improved.

Owner:NINGBO UNIV

Method of improving the charge/discharge cycle life and safety of an alkali metal-sulfur secondary battery

PendingUS20200220196A1Lower internal resistanceSmooth connectionSolid electrolytesFinal product manufactureElectrical batteryHigh energy

Provided is a method of improving a cycle-life of a rechargeable alkali metal-sulfur cell, the method comprising implementing an electronically non-conducting anode-protecting layer between an anode active material layer and a cathode active material without using a porous separator in the cell, wherein the anode-protecting layer has a thickness from 1 nm to 100 μm and comprises an elastomer having a fully recoverable tensile elastic strain from 2% to 1,000%, a lithium ion or sodium ion conductivity from 10−8 S / cm to 5×10−2 S / cm, and an electronic conductivity less than 10−4 S / cm when measured at room temperature. This battery exhibits an excellent combination of high sulfur content, high sulfur utilization efficiency, high energy density, no known dendrite issue, no dead lithium or dead sodium issue, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Flexible conductive carbon/metal composite nanofiber membrane, preparation method and application thereof, and lithium-sulfur battery

ActiveCN111082063AAvoid inactivationAccelerated Reversible Transformation KineticsMaterial nanotechnologyCell electrodesElectrical batteryHigh energy

The invention provides a flexible conductive carbon / metal composite nanofiber membrane, a preparation method and application thereof, and a lithium-sulfur battery, and belongs to the field of lithium-sulfur batteries. According to the invention, a conductive nanofiber membrane reactor is reasonably designed, chemical adsorption, electro-catalysis and ion (Li+) diffusion of a lithium-sulfur batterymembrane reactor are combined, polysulfide is limited on a nanoscale surface, and reversible conversion kinetics of the polysulfide is accelerated, so that the high sulfur utilization rate is realized, and in a rapid rechargeable, high-energy and high-power future lithium-sulfur battery technology, the flexible conductive carbon / metal composite nanofiber membrane has good rate capability and capacity retention capability under high discharge / charge current density, so that the lithium-sulfur battery is promoted to be developed towards the directions of high capacity and long cycle service life.

Owner:INNER MONGOLIA UNIV FOR THE NATITIES

Method for preparing mercaptoacetic acid

InactiveCN104193658AHigh Sulfur Utilization EfficiencyMild reaction conditionsThiol preparationCarbon disulfideSalt water

The invention relates to a method for preparing mercaptoacetic acid. The method comprises the following steps: (1) adding monochloro acetic acid, sodium chloroacetate and carbon disulfide into a reactor, stirring, dripping an alkali solution, and separating the oil phase from the water phase after the reaction is completed; (2) recycling unreacted carbon disulfide from the separated oil phase mixture for circulation, acidifying the residual mixture into a weak acid solution, adding an organic solvent to extract for 2-3 times, combining organic phases, washing with a salt solution and water, and separating the oil phase and the water phase; and (3) distilling the separated oil phase, and recycling the organic solvent, thereby obtaining residues, that is, the mercaptoacetic acid. As carbon disulfide is adopted to react with alkali to generate sulfydryl, the sulfydryl is further reacted with sodium chloroacetate to generate sodium thioglycollate, and a proper amount of acids, organic solvent and alkali solution are added, the raw material cost is low, and a small amount of reagents are used; as the excessive carbon disulfide can be recycled and circulated, the utilization rate is high, and the method is a clean production process; the reaction conditions are gentle, the reaction time is short, no high temperature or high pressure is needed, and the equipment investment is low.

Owner:湖南立新环保科技发展有限公司

Alkali metal-sulfur secondary battery containing a non-electronically conductive anode-protecting layer

ActiveUS11024840B2Improve cycle lifeHigh sulfur contentAlkaline accumulator electrodesSecondary cells charging/dischargingConductive polymerHigh energy

Provided is a rechargeable alkali metal-sulfur cell comprising an anode active material layer, a cathode active material layer, a discrete anode-protecting layer disposed between the anode active material layer and the cathode active material layer, and an electrolyte (but no porous separator), wherein the anode-protecting layer has a thickness from 1 nm to 100 μm and comprises an elastomer having a fully recoverable tensile elastic strain from 2% to 1,000% and a lithium ion conductivity from 10−8 S / cm to 5×10−2 S / cm when measure at room temperature. The cathode layer comprises a sulfur-containing material selected from a sulfur-carbon hybrid, sulfur-graphite hybrid, sulfur-graphene hybrid, conducting polymer-sulfur hybrid, metal sulfide, sulfur compound, or a combination thereof. This battery exhibits an excellent combination of high sulfur content, high sulfur utilization efficiency, high energy density, no known dendrite issue, no dead lithium or dead sodium issue, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

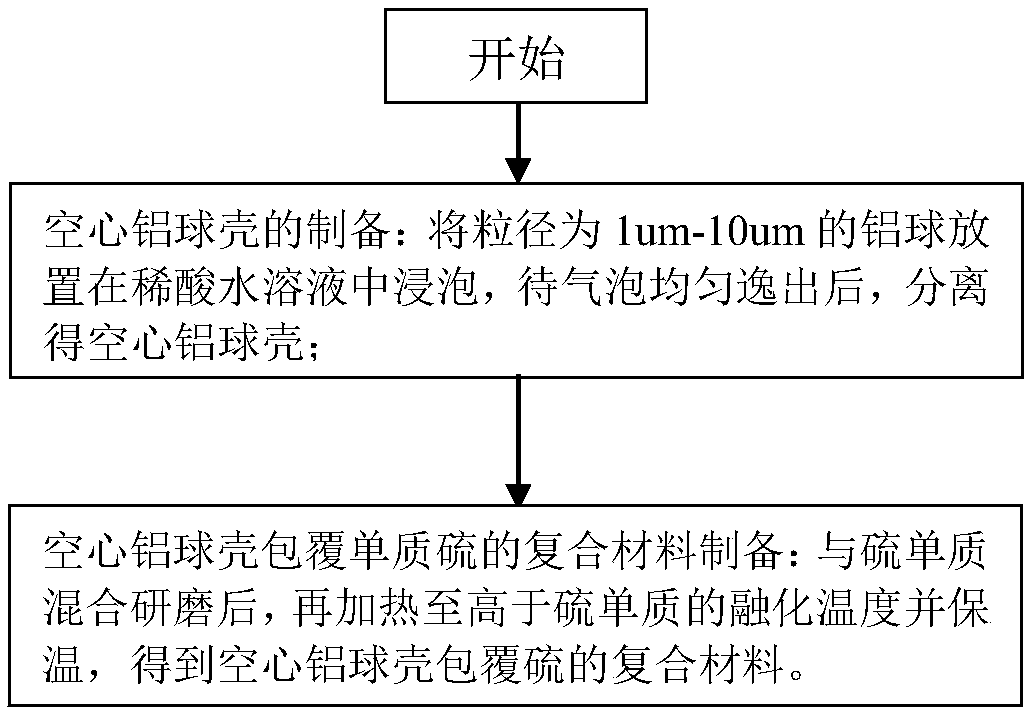

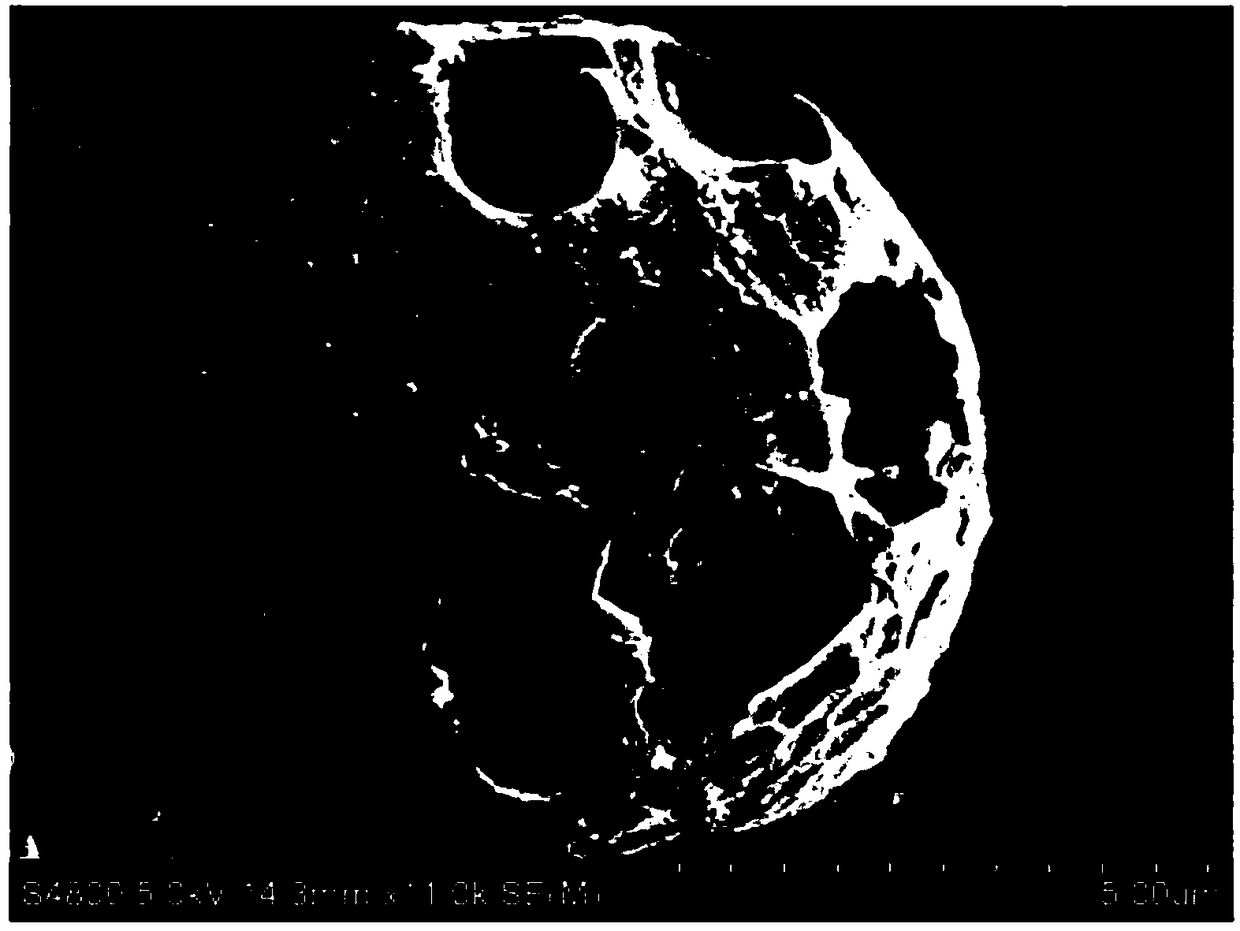

Aluminum sulfur composite material as well as preparation method and application thereof

ActiveCN108134071ASmall volume change rateHigh Sulfur Utilization EfficiencyCell electrodesLi-accumulatorsMicrostructureAluminium

The invention relates to an aluminum sulfur composite material. The aluminum sulfur composite material comprises a hollow aluminum ball shell and elemental sulfur wrapped in the hollow aluminum ball shell; and pores are distributed in the hollow aluminum ball shell. The aluminum sulfur composite material has a composite type microstructure that the elemental sulfur is wrapped by the porous hollowaluminum ball shell; and when the composite material with the structure is made into a positive electrode of a lithium sulfur battery, the sulfur utilization rate of the battery can be increased, andthe rate performance and the cycle performance can be improved.

Owner:SOUNDON NEW ENERGY TECH CO LTD

A zinc sulfide nanobelt, its preparation and its application in the preparation of cathode materials for lithium-sulfur batteries

ActiveCN106927498BEvenly dispersedNot easy to reuniteCell electrodesSulfur preparation/purificationActive agentHigh energy

The invention discloses a method for preparing nanometer belt-shaped zinc sulfide, and a method for taking the nanometer belt-shaped zinc sulfide as a template for preparing a nitrogen-doped carbon / sulfur compound anode material, a preparation method and an application thereof. The nanometer belt-shaped zinc sulfide is acquired through the hydrothermal reaction under the condition of zinc source, sulfur source and surface active agent. The nitrogen-doped carbon / sulfur compound anode material is composed of nitrogen-doped coated sulfur. The preparation method comprises the following steps: coating polydopamine on the surface of zinc sulfide and carbonizing under a protective atmosphere condition; adding a ferric salt; separating liquid from solid; and freezing and drying the solid product, thereby acquiring the nitrogen-doped carbon / sulfur compound anode material. The compound anode material is large in nitrogen doped volume, controllable in sulfur capacity, uniform in load and high in use ratio of active substance sulfur, has the advantages of high specific capacity, high energy density and high stability and is capable of greatly improving the cycle performance of the lithium sulfur battery.

Owner:GUANGDONG MIC POWER NEW ENERGY CO LTD

A kind of preparation method of positive electrode material of lithium-sulfur battery

ActiveCN110993928BInhibition of the shuttle effectImprove electrochemical performancePositive electrodesLi-accumulatorsElectrical batteryPorous carbon

A method for making a positive electrode material for a lithium-sulfur battery, comprising the following steps: making GDC powder; making a nickel-containing carbon solution; adding the GDC powder to the nickel-containing carbon solution and heating and stirring until the solution becomes a paste; drying the paste solution to obtain Powder; heat the powder to 700-900°C for 1-5 hours in an inert gas atmosphere to obtain a black powder; heat the black powder to 600-850°C in an inert gas and hydrogen mixed gas atmosphere, and keep it for 1 ~ 3 hours to get a black powder containing Ni, GDC and porous carbon; react the black powder with sulfur powder to make a finished product; heat the finished product to remove excess sulfur attached to the carbon surface. The advantages of the present invention are: GDC can suppress the shuttle effect of polysulfides, improve the catalytic performance of lithium-sulfur battery positive electrode materials for redox, Ni and GDC can be combined to have higher electronic conductance and ion vacancies, and improve the performance of lithium-sulfur battery positive electrodes. The electrical conductivity of the material.

Owner:NINGBO UNIV

A kind of amorphous cobalt phosphide/nano carbon composite material, preparation method and application thereof

ActiveCN111517298BLarge specific surface areaRich pore structureMaterial nanotechnologyCell electrodesCarbon compositesNew energy

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com