Carbon-sulfur composite positive electrode for lithium-sulfur battery and preparation method of carbon-sulfur composite positive electrode

A carbon-sulfur composite and lithium-sulfur battery technology, applied in battery electrodes, lithium batteries, non-aqueous electrolyte battery electrodes, etc., can solve the problem of large-scale preparation of unfavorable carbon-sulfur composite positive electrodes, increase the cost of electrode production, and increase the complexity of the preparation process, etc. problems, to achieve the effect of rational design and preparation, high sulfur utilization rate, and multiple electrochemical active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

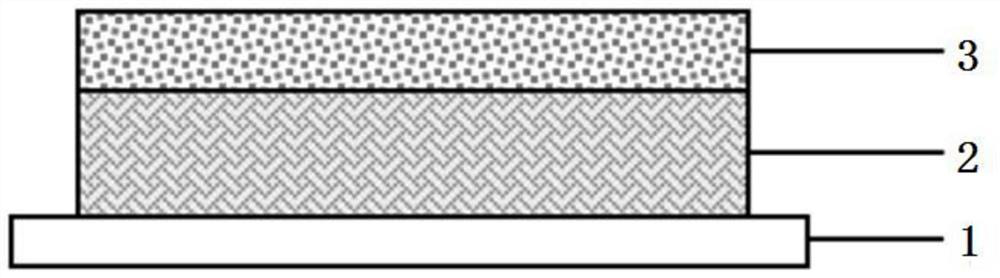

[0038] A method for preparing a lithium-sulfur battery composite positive electrode provided by the invention comprises the following steps:

[0039]1) Mix the carbon material I used in the carbon-sulfur composite layer with elemental sulfur in proportion, seal and heat to 155° C., and heat-melt at a constant temperature for 1 to 5 hours to prepare a carbon-sulfur composite. Add a certain amount of water to the carbon-sulfur composite to obtain a dispersion with a solid content of 20-40%, mill the dispersion for 1-5 hours, add a water-based binder, and homogenize for 10-120 minutes to prepare a carbon-sulfur composite slurry The sulfur in the carbon-sulfur composite slurry is sublimed sulfur; the carbon materials used in the carbon-sulfur composite layer slurry are carbon nanotubes, graphene, carbon black, mesocarbon microspheres, fullerenes, porous carbon and activated carbon One or more of them; the water-based binder in the carbon-sulfur composite slurry is one or more of p...

Embodiment 1

[0045] Polyacrylic acid was used as the binder of the carbon-sulfur composite layer, and polytetrafluoroethylene was used as the binder of the conductive carbon layer to prepare the carbon-sulfur composite positive electrode of the lithium-sulfur battery.

[0046] Carbon nanotubes and sublimed sulfur were mixed at a mass ratio of 6:13, sealed and heated to 155°C, and melted at a constant temperature for 5 hours to prepare a carbon-sulfur composite. Adding a certain amount of water to the carbon-sulfur composite to obtain a dispersion with a solid content of 20%, milling the dispersion for 1 hour, adding polyacrylic acid with a mass fraction of 5%, and homogenizing for 10 minutes to prepare a carbon-sulfur composite slurry;

[0047] The carbon-sulfur composite slurry was scraped on a 15 μm thick aluminum foil with a scraper, and vacuum-dried at 50°C for 24 hours to prepare a carbon-sulfur composite layer. The thickness of the carbon-sulfur composite layer was 20 μm, and the mass...

Embodiment 2

[0052] Carboxymethyl cellulose was used as the binder of the carbon-sulfur composite layer, and polyvinylidene fluoride was used as the binder of the conductive carbon layer to prepare the carbon-sulfur composite positive electrode of the lithium-sulfur battery.

[0053] Graphene and sublimed sulfur were mixed at a mass ratio of 2:7, heated to 155°C, and melted at a constant temperature for 4 hours to prepare a carbon-sulfur composite. Add a certain amount of water to the carbon-sulfur complex to obtain a dispersion with a solid content of 30%, ball mill the dispersion for 2 hours, add carboxymethyl cellulose with a mass fraction of 10%, and homogenate for 30 minutes to prepare a carbon-sulfur complex slurry;

[0054] The carbon-sulfur composite slurry was scraped on a 20 μm thick aluminum foil with a scraper, and vacuum-dried at 60°C for 10 hours to prepare a carbon-sulfur composite layer. The thickness of the carbon-sulfur composite layer was 50 μm, and the mass of sulfur in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com