Patents

Literature

216 results about "Electrode fabrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

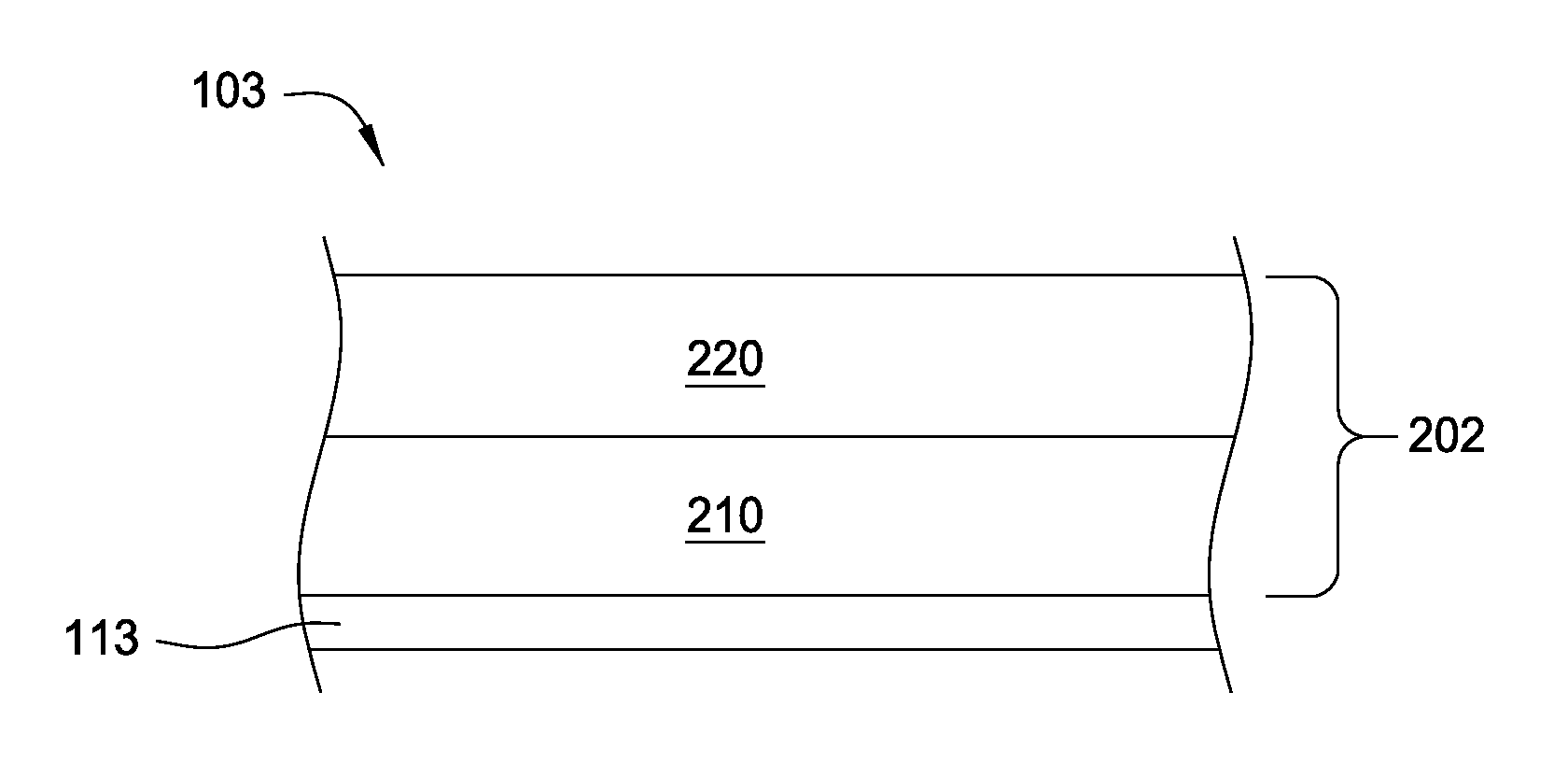

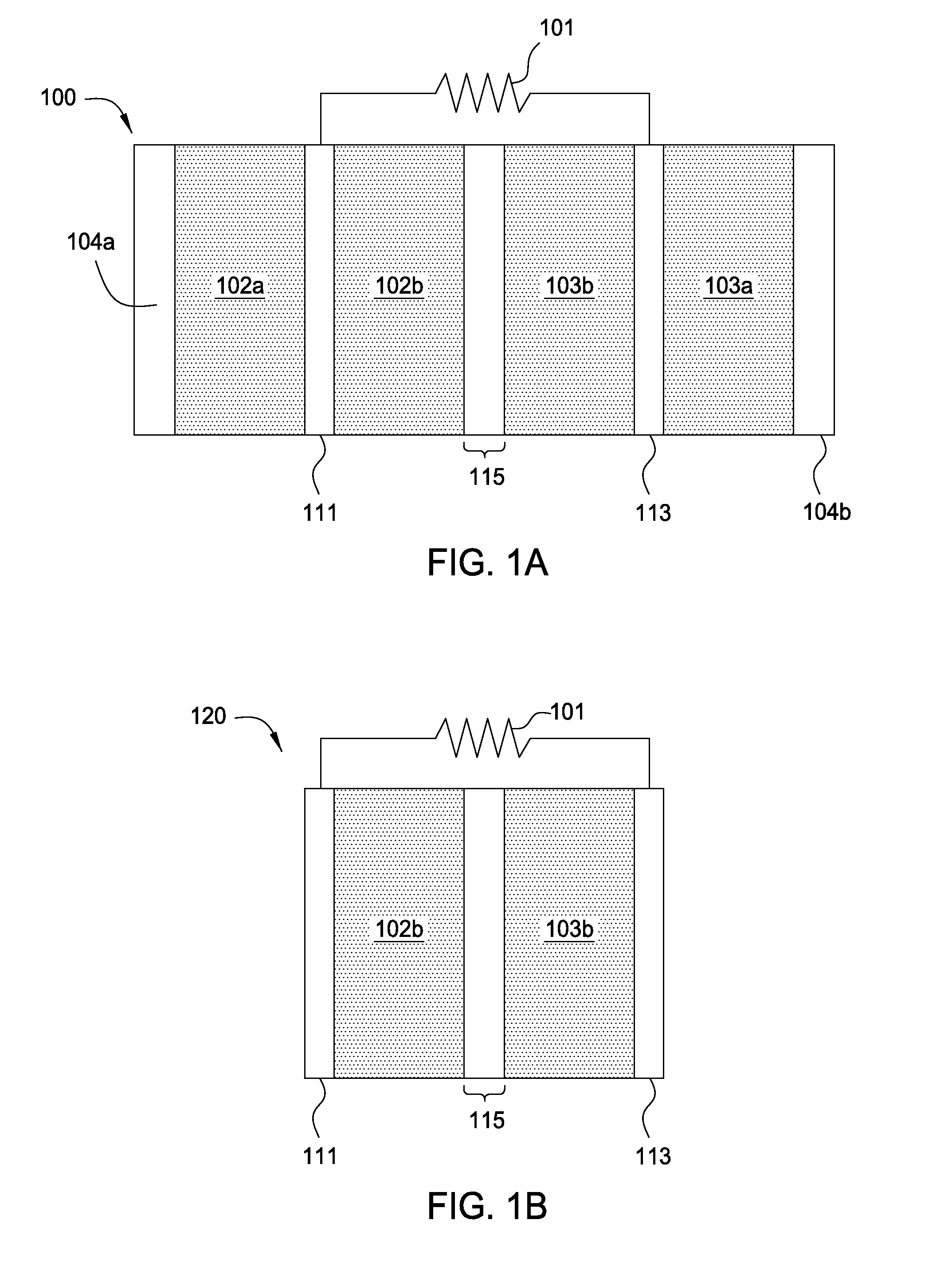

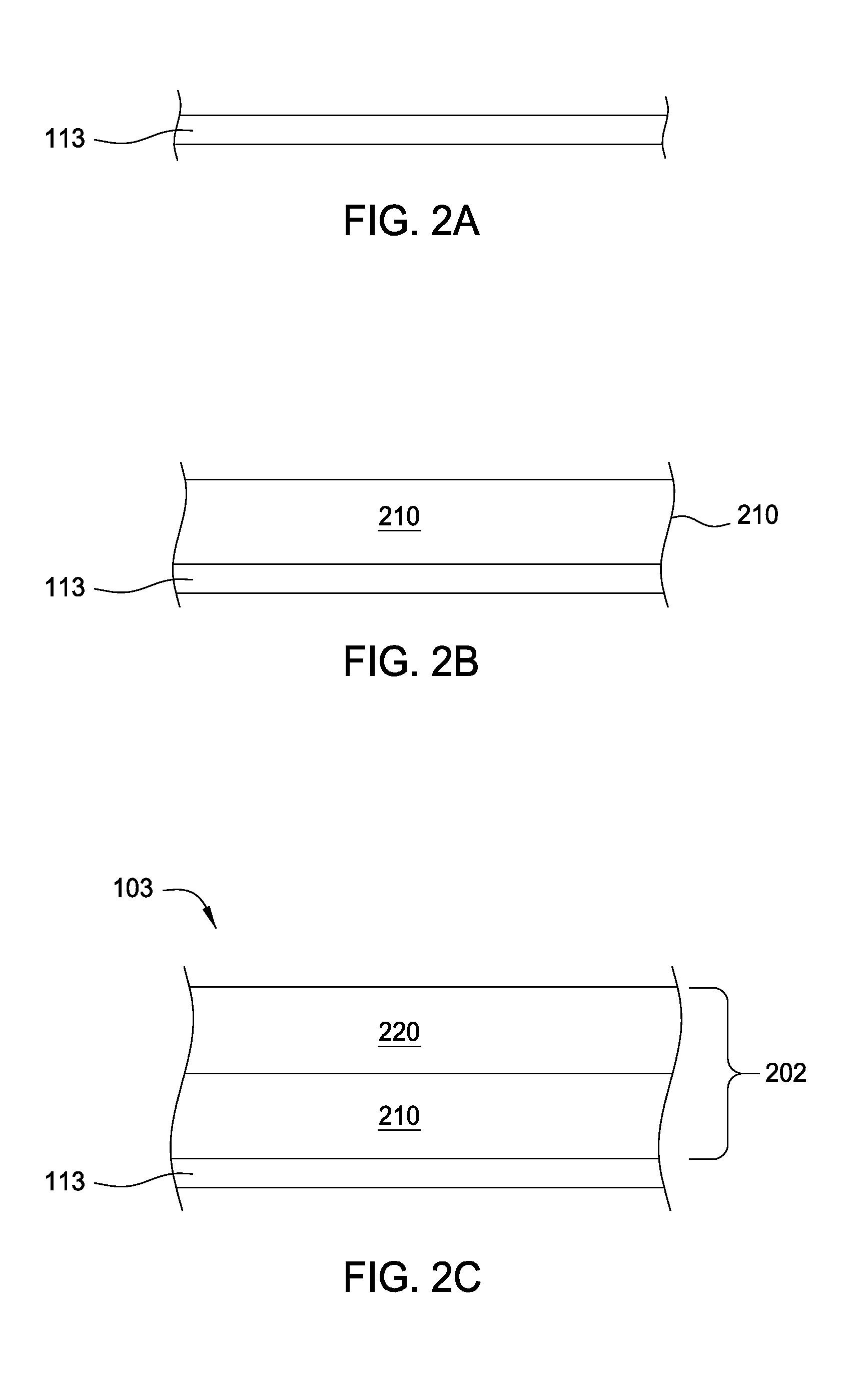

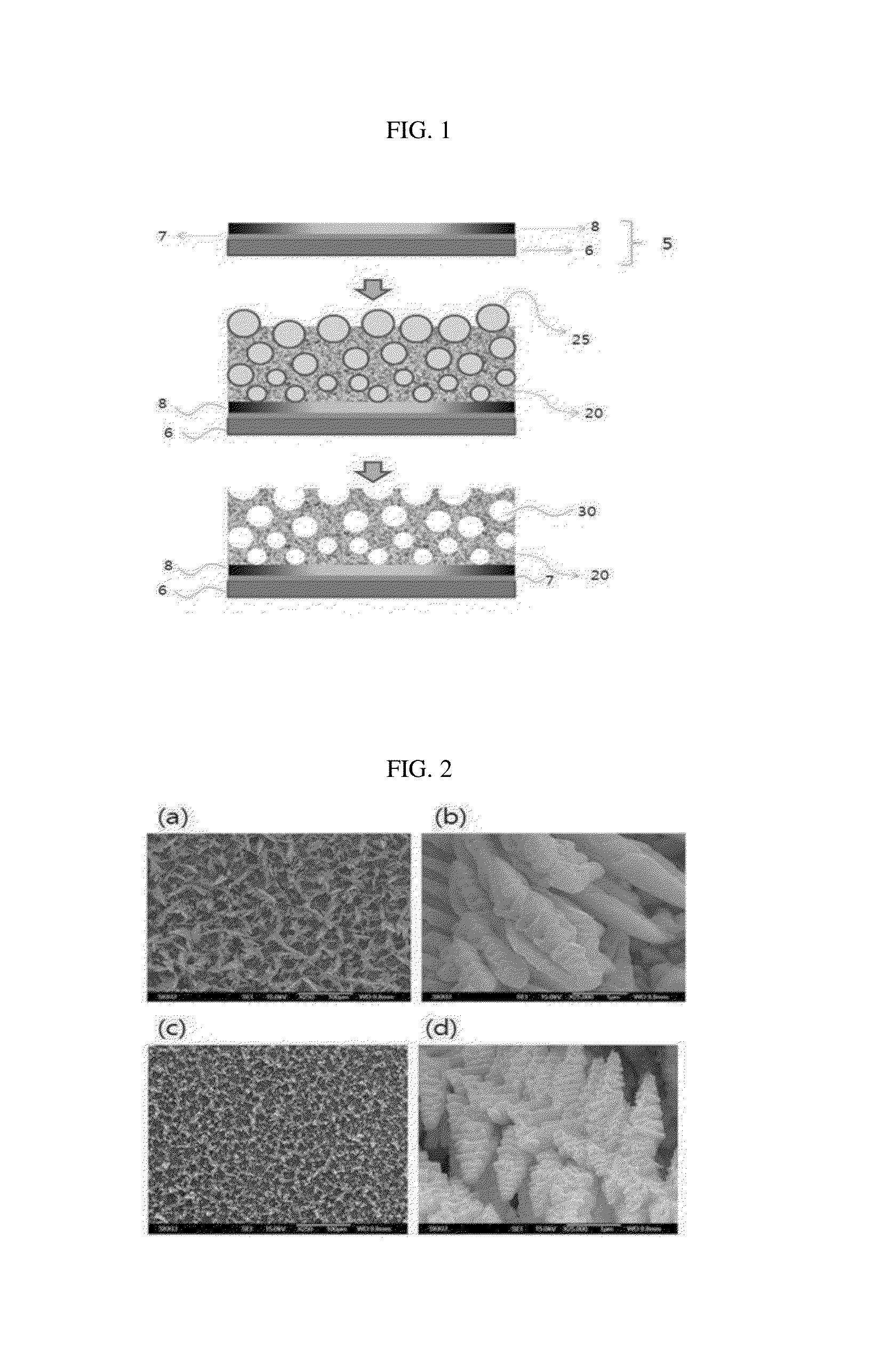

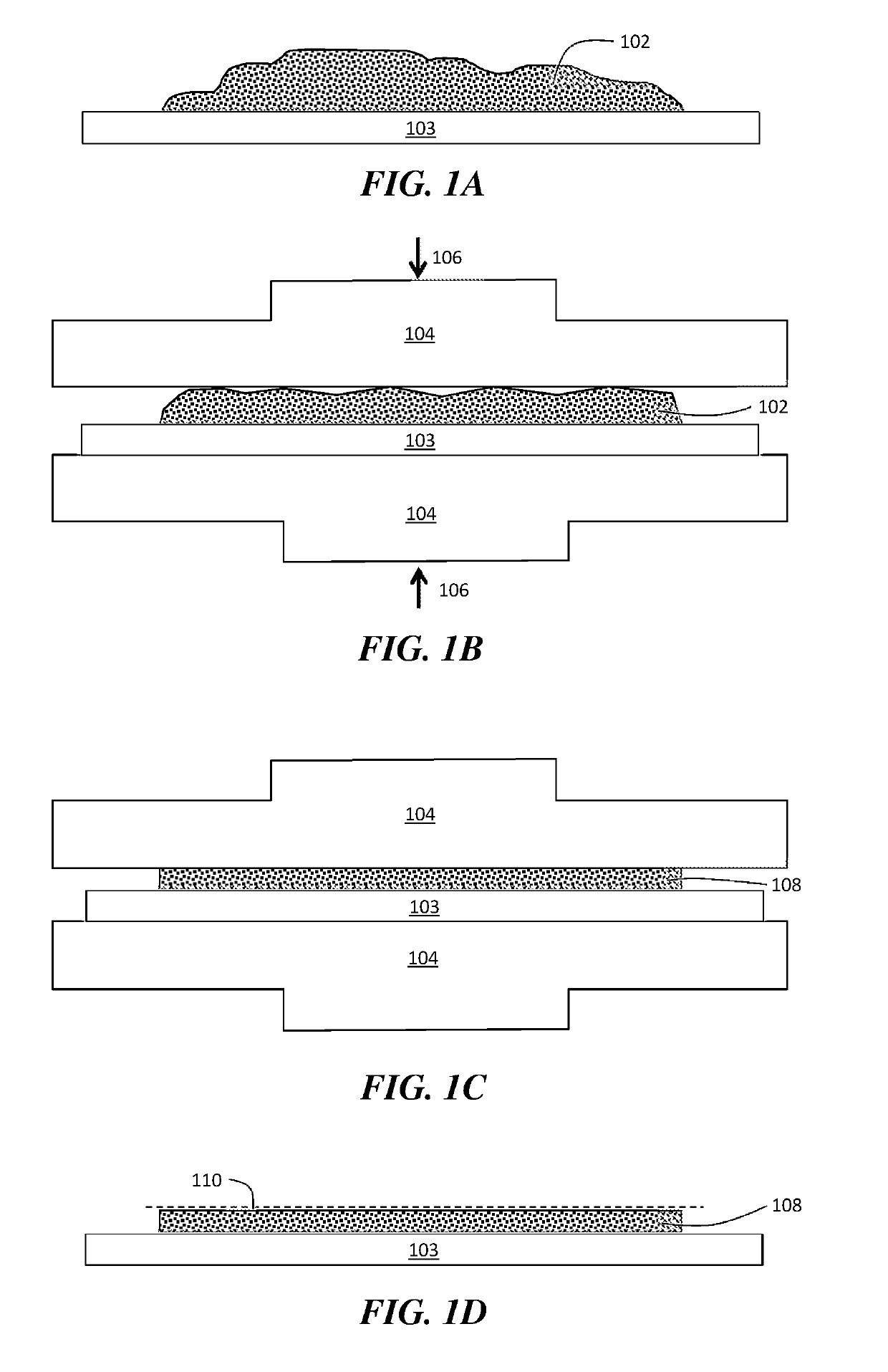

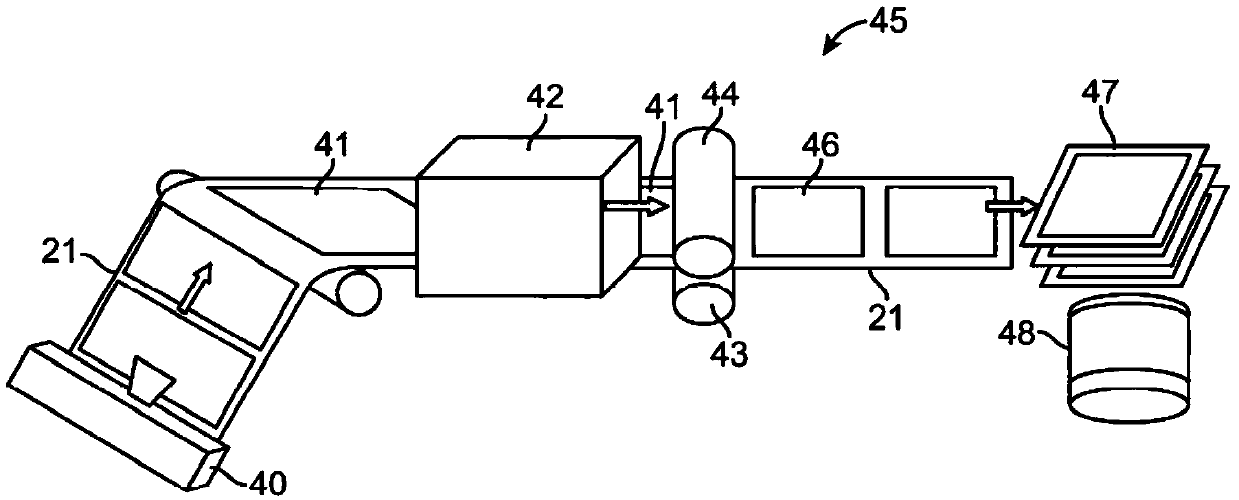

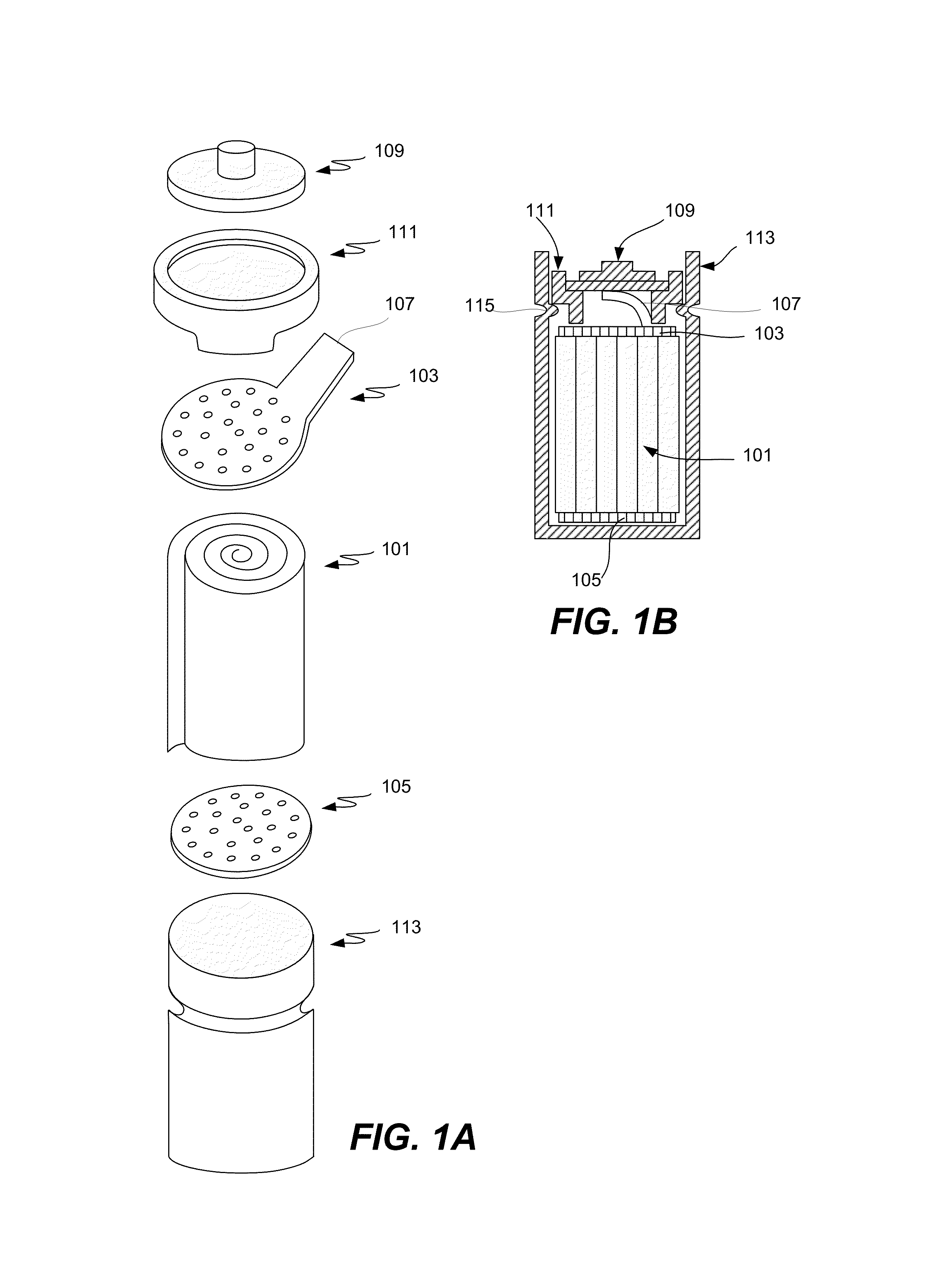

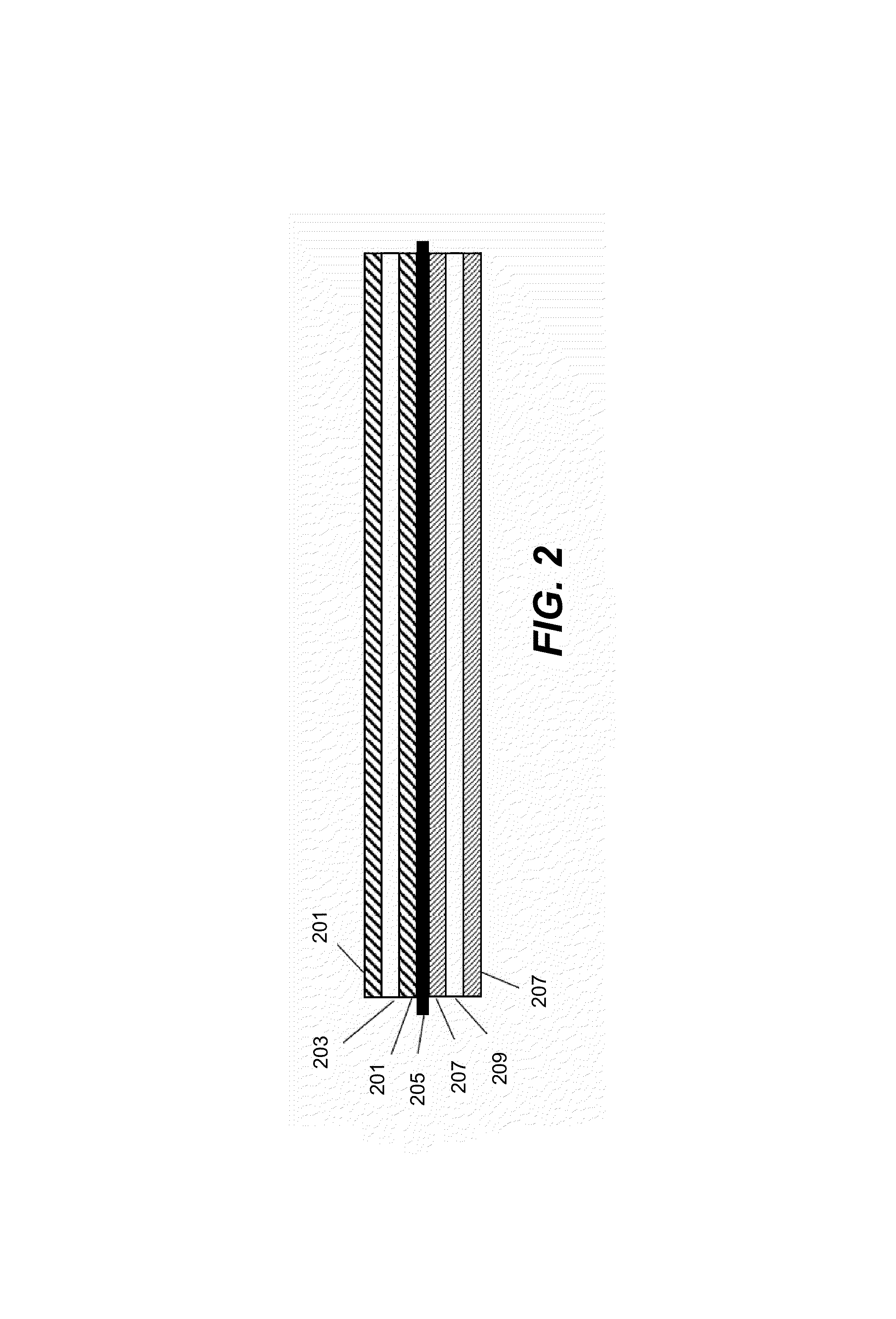

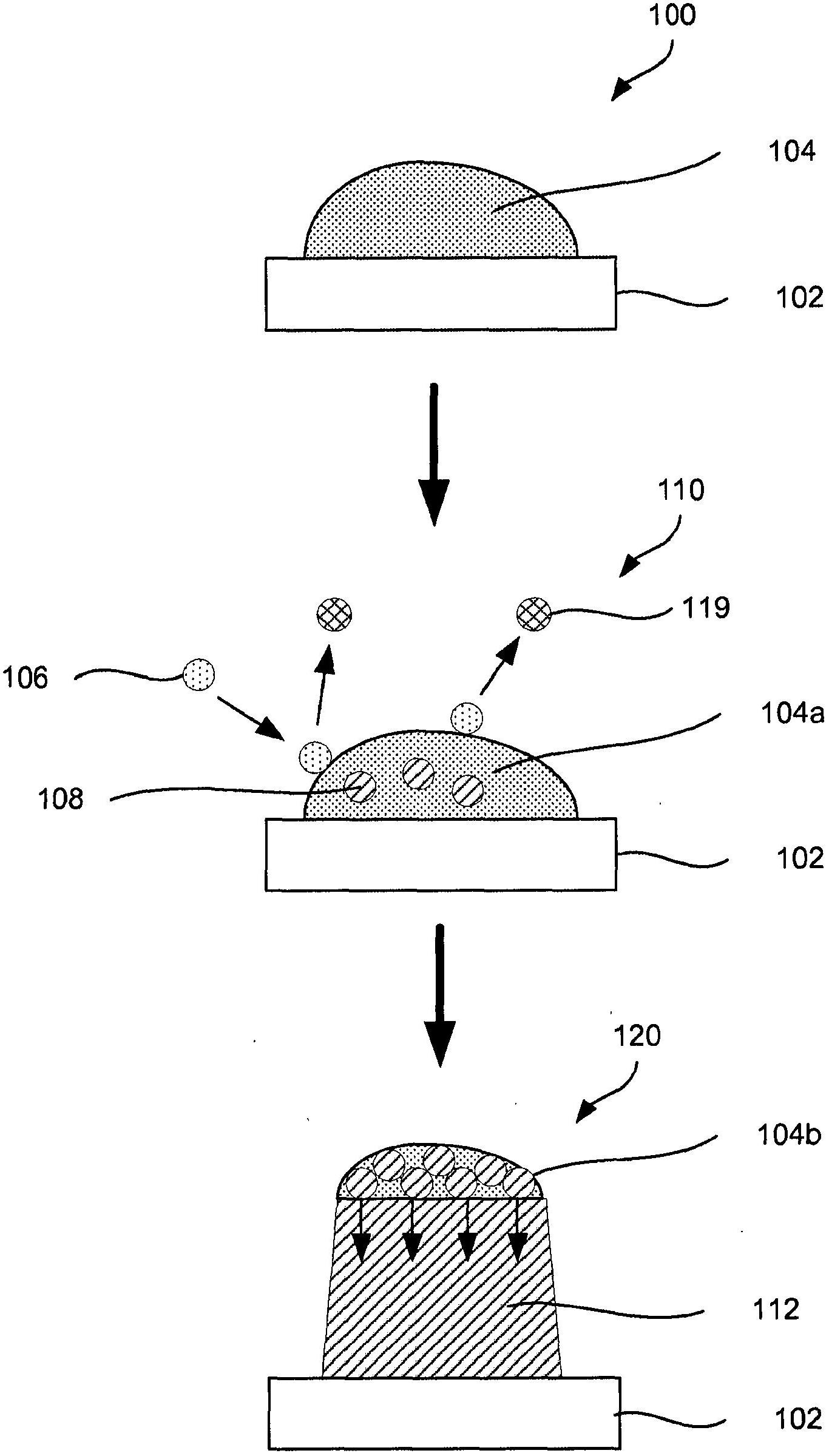

Multi-layer battery electrode design for enabling thicker electrode fabrication

Implementations of the present invention relate generally to high-capacity energy storage devices and methods and apparatus for fabricating high-capacity energy storage devices. In one implementation, a method for forming a multi-layer cathode structure is provided. The method comprises providing a conductive substrate, depositing a first slurry mixture comprising a cathodically active material to form a first cathode material layer over the conductive substrate, depositing a second slurry mixture comprising a cathodically active material to form a second cathode material layer over the first cathode material layer, and compressing the as-deposited first cathode material layer and the second cathode material layer to achieve a desired porosity.

Owner:APPLIED MATERIALS INC

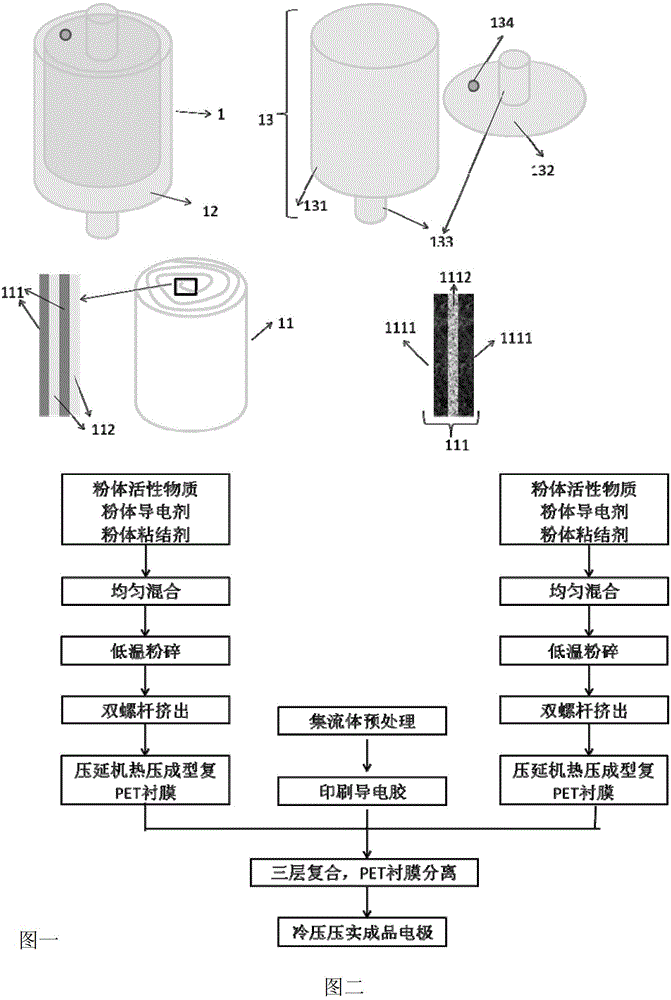

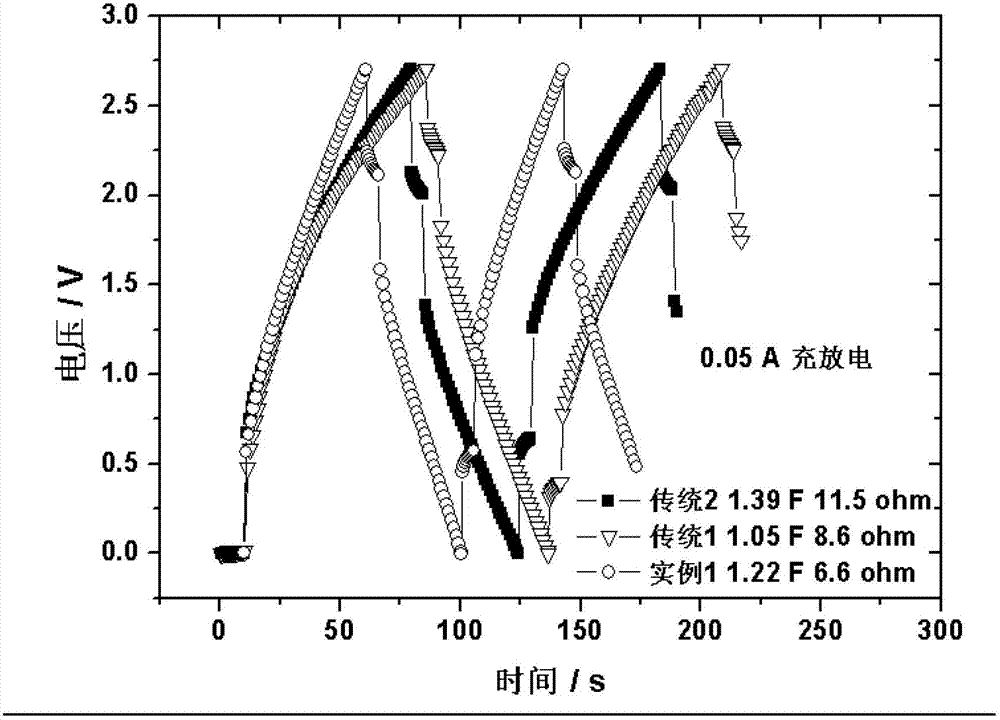

High performance super capacitor and manufacturing process thereof

ActiveCN102723211AWell mixedImprove the mixing effectElectrolytic capacitorsBiochemical engineeringSupercapacitor

The invention relates to a high performance super capacitor and a manufacturing process thereof. The super capacitor comprises an electrode core, an electrolyte and a shell. The manufacturing process comprises steps that: tabs and leading-out terminals of the prepared electrode core positive and negative poles are welded; the electrode core with the well-welded leading-out terminals is encased in the shell; the shell with the electrode core encased is put in a vacuum drying furnace for vacuum drying; and finally a vacuum liquid filling sealing test is carried out. In an aspect of the electrode manufacturing method, the manufacturing process of the invention abandons a method which uses a solvent for assisted processing, thus to the greatest degree, the purity of the electrode material is ensured. In addition, during the production process, the manufacturing process of the invention has no drying energy waste and drying time constraint, and therefore reduces cost, reduces energy loss, and improves working speed. The manufacturing process of the invention further adopts an advanced assembly process to avoid problems such as secondary pollution and processing consistency in the traditional assembly technology, and greatly improves the stability of the super capacitor.

Owner:GMCC ELECTRONICS TECH WUXI CO LTD

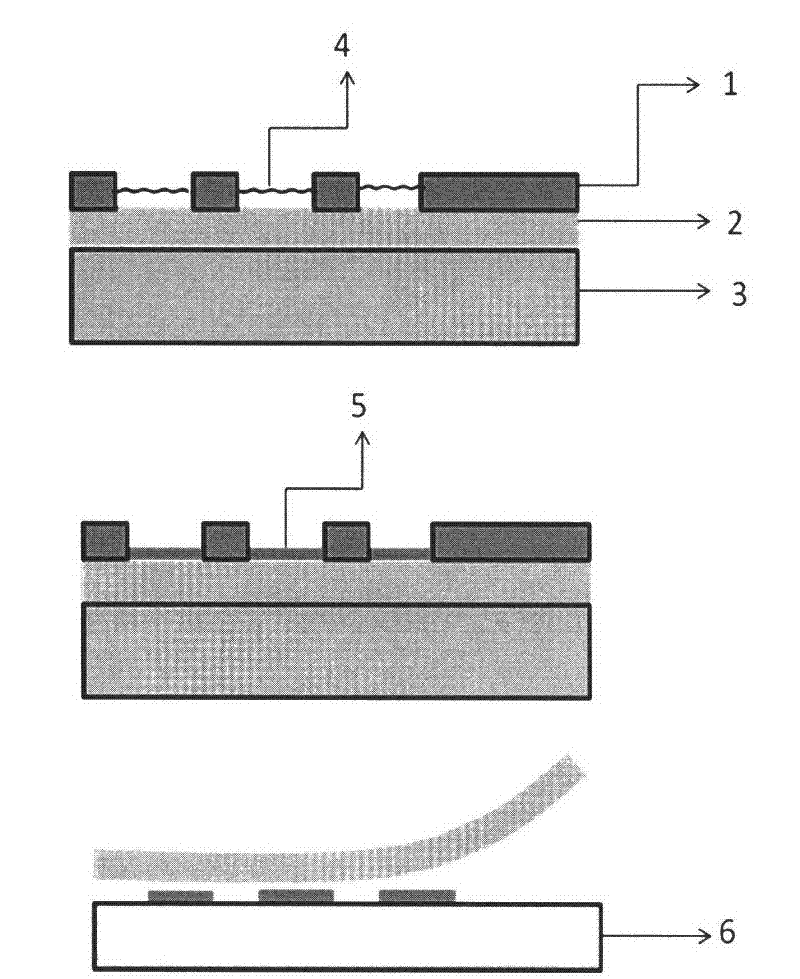

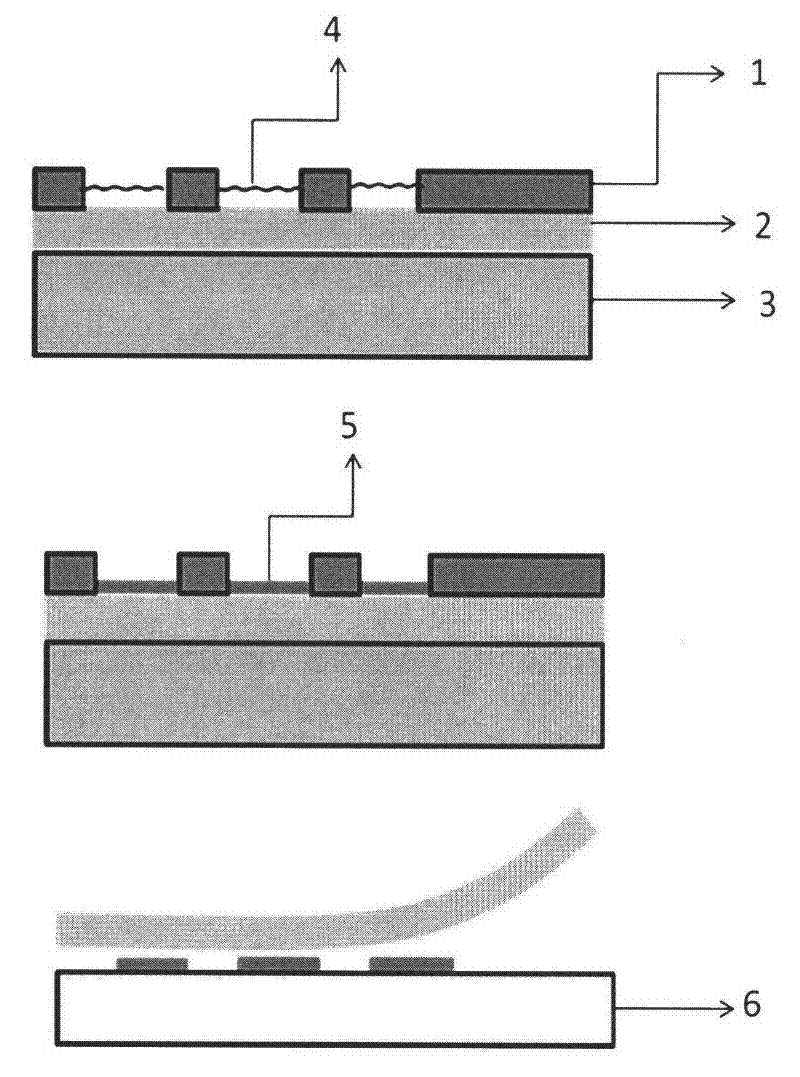

Patterned transparent electrode fabrication method

ActiveCN102543303AEnsure controllabilityEfficient removalConductive layers on insulating-supportsCable/conductor manufactureMaterials scienceNanomaterials

The invention discloses a patterned transparent electrode fabrication method. The method comprises the steps of (1) depositing a conductive nanoparticle dispersion solution on a porous filter membrane with a negative pattern mask to obtain a patterned transparent conductive film adhered on the porous filter membrane; and (2) removing the mask, transferring the patterned transparent conductive film on the porous filter membrane onto a transparent substrate, and removing the porous filter membrane to obtain the patterned transparent electrode; wherein the dispersion solution contains conductive nanoparticles 0.015wt% to 5wt%, dispersing agent 0.15wt% to 20wt%, and water in balance; and the dispersing agent is selected from arbitrary one or the combination of a surfactant, organic acid, high-molecular polysaccharide and DNA macromolecules. The method has the advantages of simple process, low cost and large material selection range, and can accurately design and control the formed pattern according to requirement.

Owner:浙江暖科能源技术有限公司

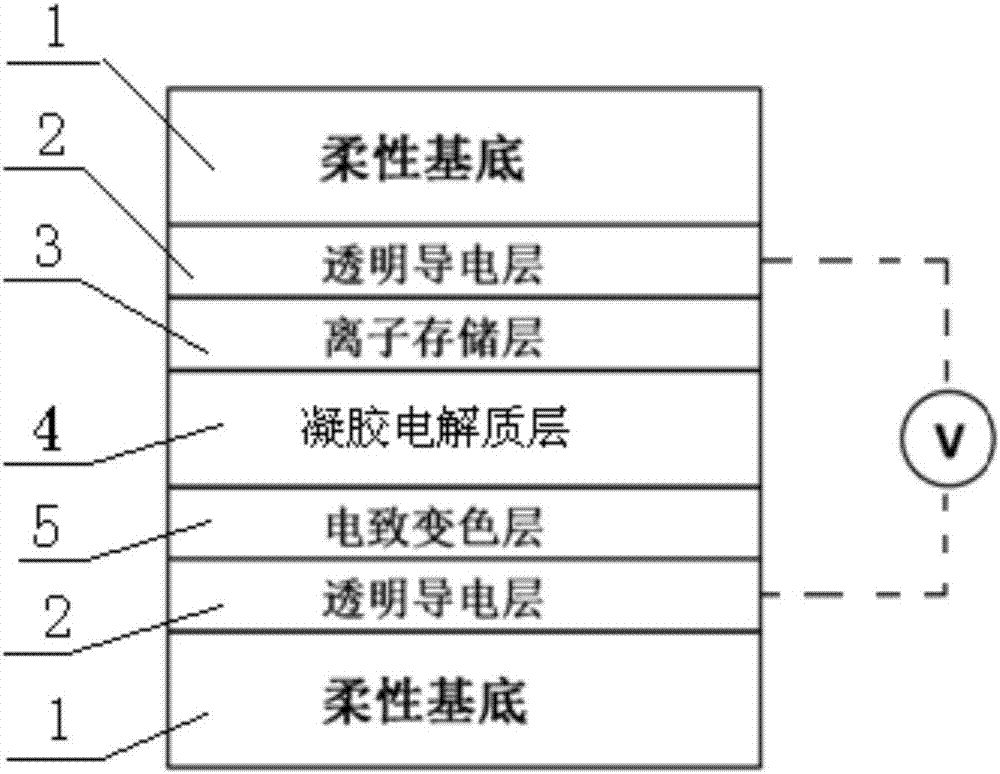

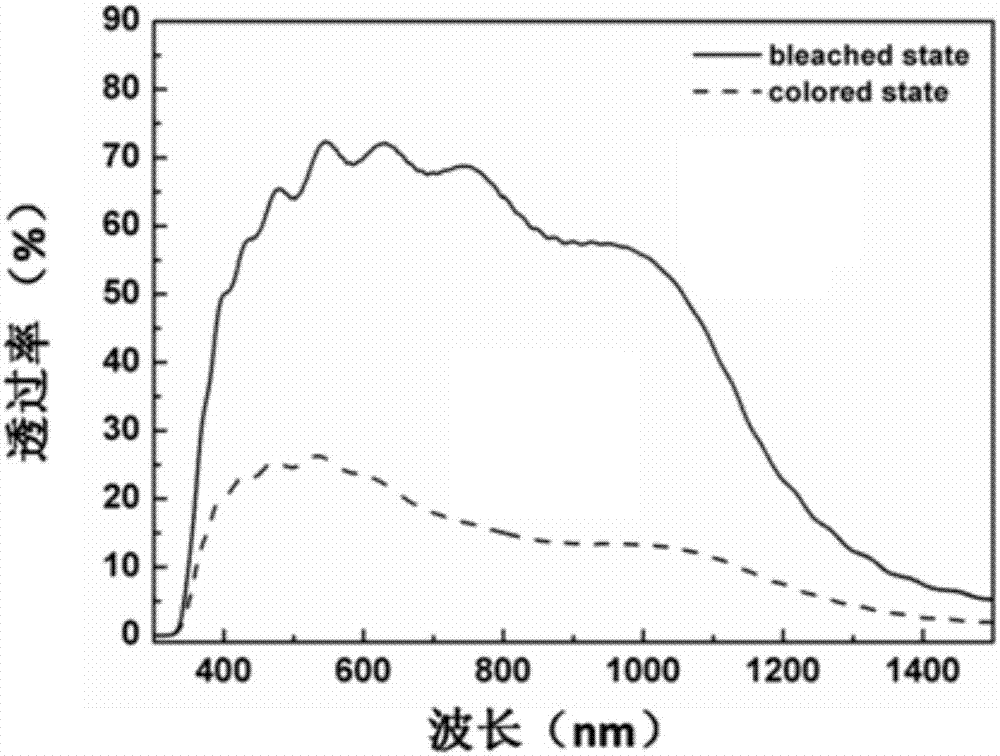

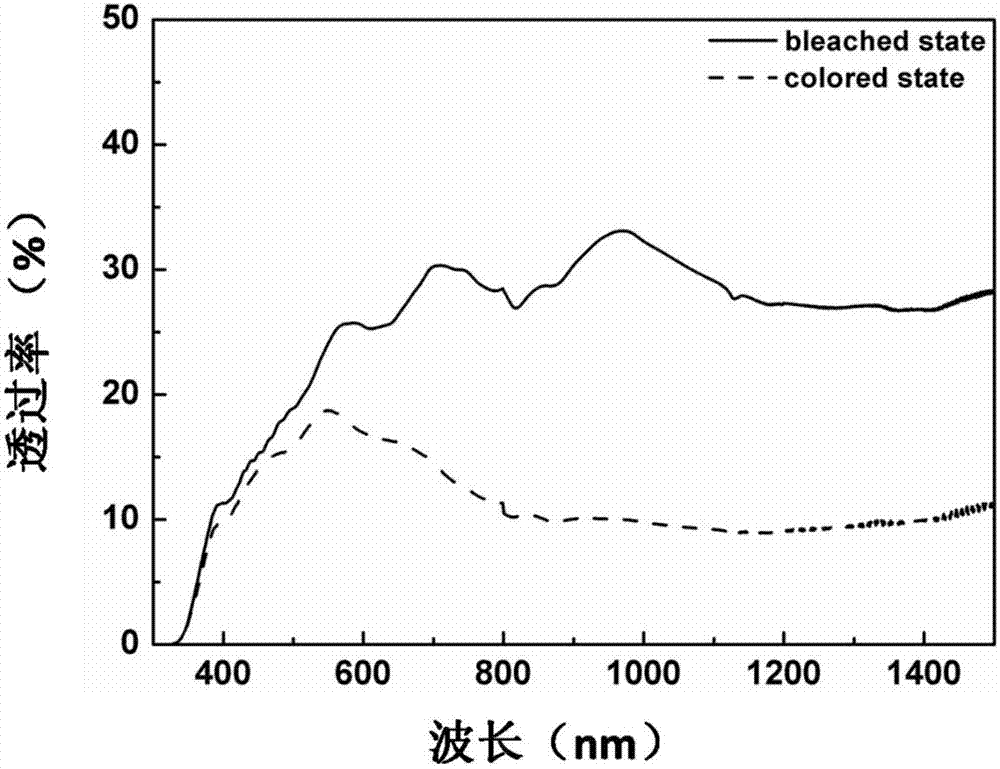

Flexible electrochromic device for regulating and controlling near-infrared light and preparation method

The invention belongs to a electrochromic technology and relates to a flexible electrochromic device for regulating and controlling near-infrared light and a preparation method. The flexible electrochromic device is characterized by being formed by superposing 7 functional layers. The method comprises the preparation steps of manufacturing a counter electrode; manufacturing a work electrode; preparing a gel electrolyte; and assembling devices. The invention provides a preparation method of the flexible electrochromic device for regulating and controlling the near-infrared light. The transmittance of the device in a near-infrared region can be dynamically regulated and controlled.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

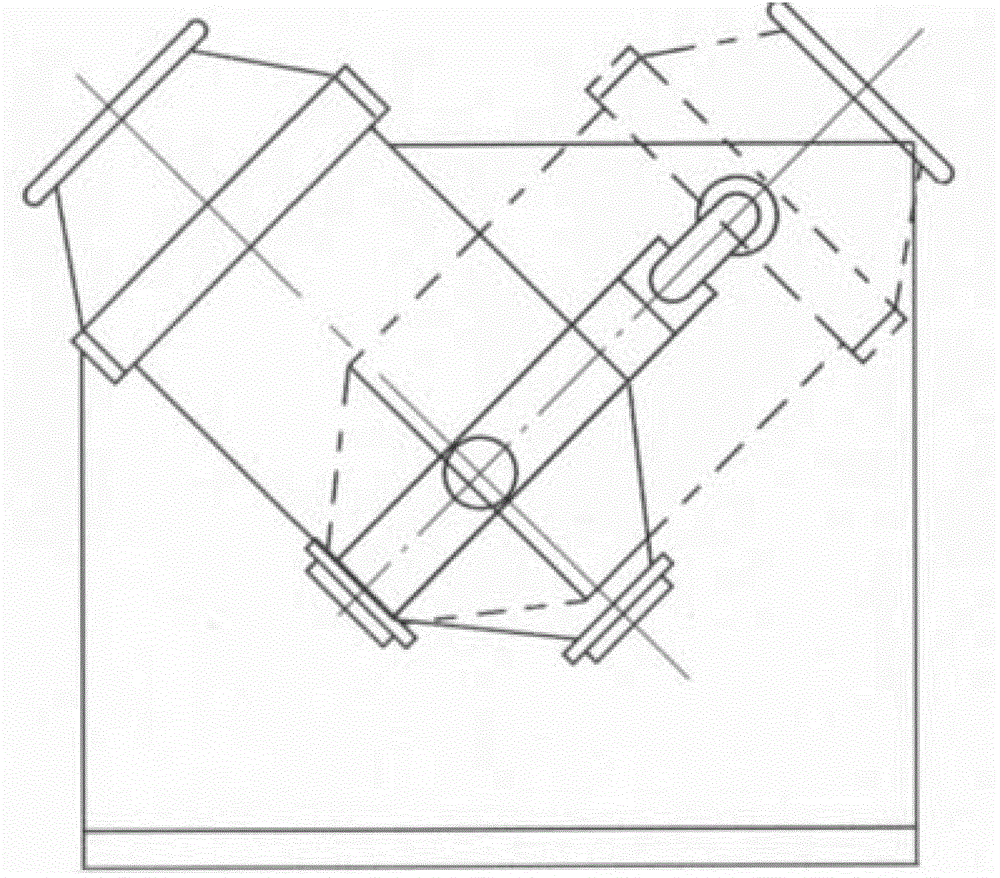

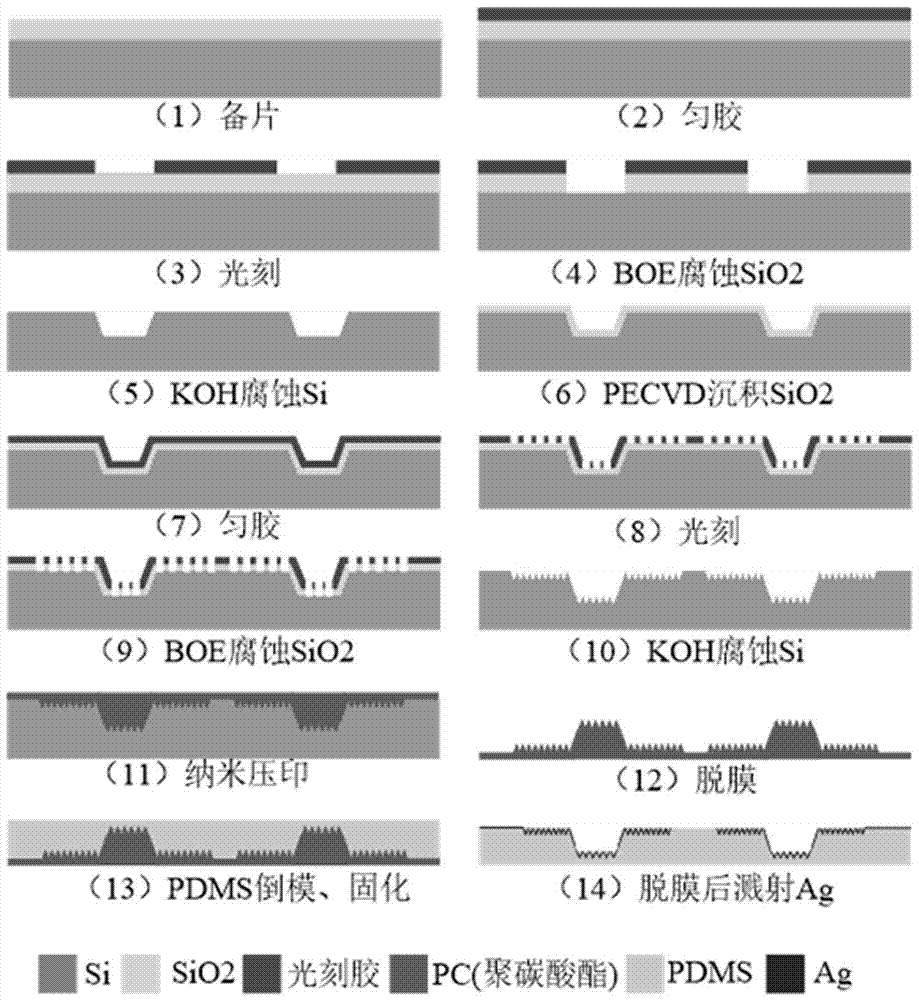

Flexible pressure sensor manufacturing method based on V-shaped groove array electrode

InactiveCN106946221AResolve the breakImprove adhesionDecorative surface effectsPhotomechanical coating apparatusMicro nanoComposite film

The invention belongs to the field of flexible sensing and the field of micro-nano systems, and specifically relates to a method for manufacturing a flexible pressure sensor based on "V" groove array electrodes. The fabrication method of flexible pressure sensor based on "V"-shaped array electrodes, including the preparation of flexible pressure sensor "V"-groove array electrodes and the preparation of carbon nanotubes / PDMS polymers, two flexible pressure sensors "V" The groove array electrodes are used as the upper electrode and the lower electrode respectively, and the carbon nanotube / PDMS composite film is used as the intermediate dielectric layer, and the flexible pressure sensor is formed by packaging. Aiming at the problem of poor adhesion between metal materials and flexible substrates, the present invention selects polydimethylsiloxane (PDMS) as the flexible substrate material, metal Ag as the electrode material, and uses the plasma process to modify the surface of the PDMS flexible substrate The treatment is used to enhance the adhesion between metal Ag and PDMS, and the designed "V" groove array microelectrode structure effectively solves the problem of metal electrode fracture when the flexible pressure sensor undergoes large deformation.

Owner:ZHONGBEI UNIV

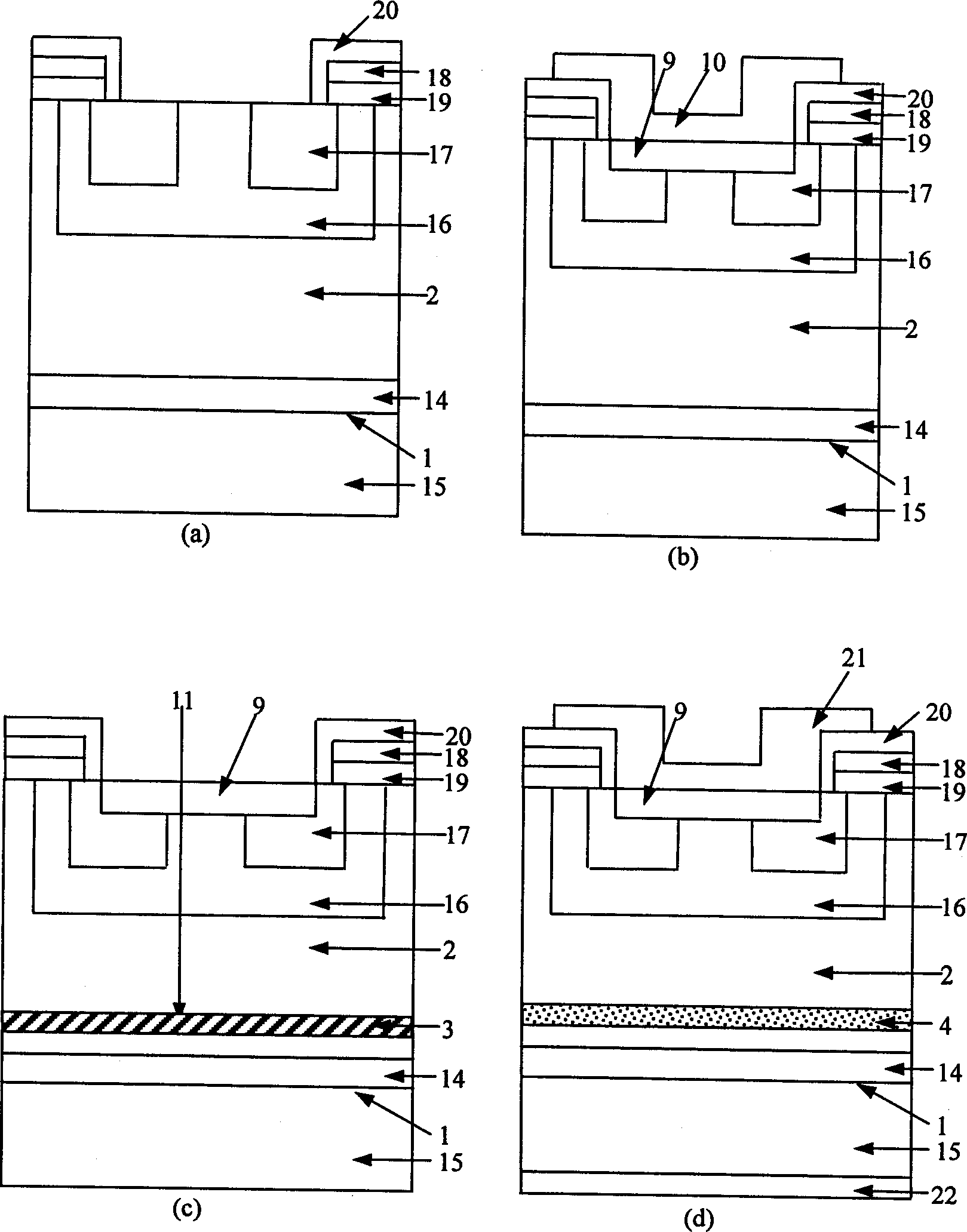

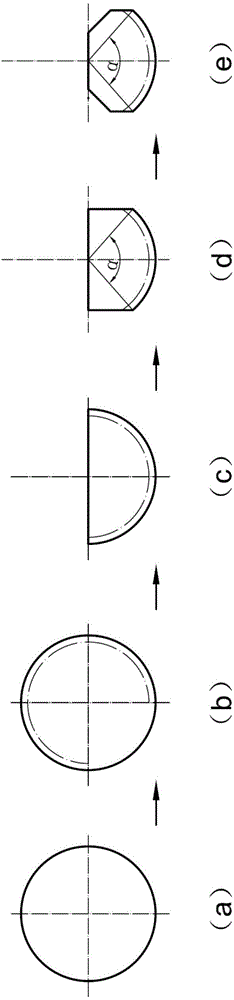

Method for manufacturnig silicon high-speed semiconductor switch device

InactiveCN1471146AExcellent electrical performanceDensity Spatial Distribution OptimizationSemiconductor/solid-state device manufacturingGate turn-off thyristorPlatinum

The method is applicable to manufacture silicon semiconductor binistor with at least one PN junction such as GTO, IGBT etc. General manufacturing steps is carried out till the step of making metalized electrode. Platinum-silicon alloy is made on surface of silicon. Using proton or particle injection forms local high density defect area. Heating and annealing makes the defect area absorb platinum to convert to platinum impurity range. Then, General manufacturing steps is carried out till manufacturing completion. The performances of the invention are better than present life control technique. The parts made by the invention possesses higher switching speed and backward recovery speed, but the forward voltage drop and reverse leakage are not increased visibly.

Owner:BEIJING UNIV OF TECH

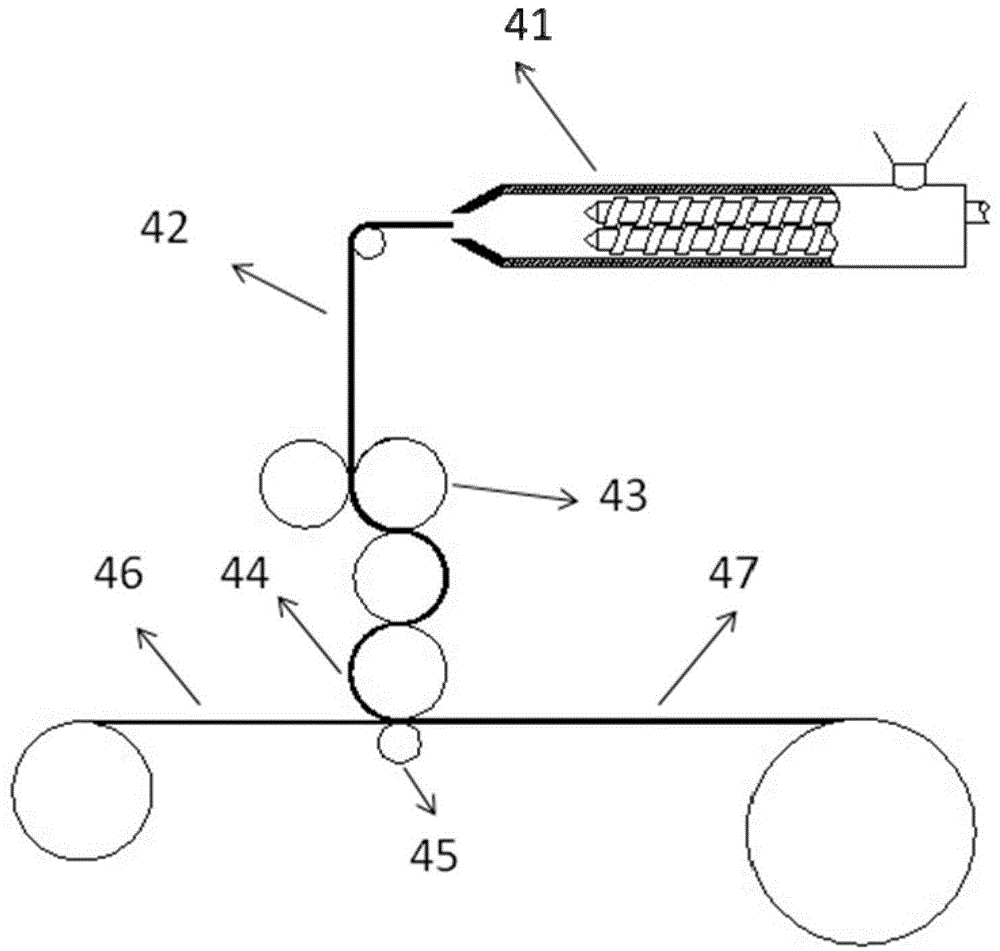

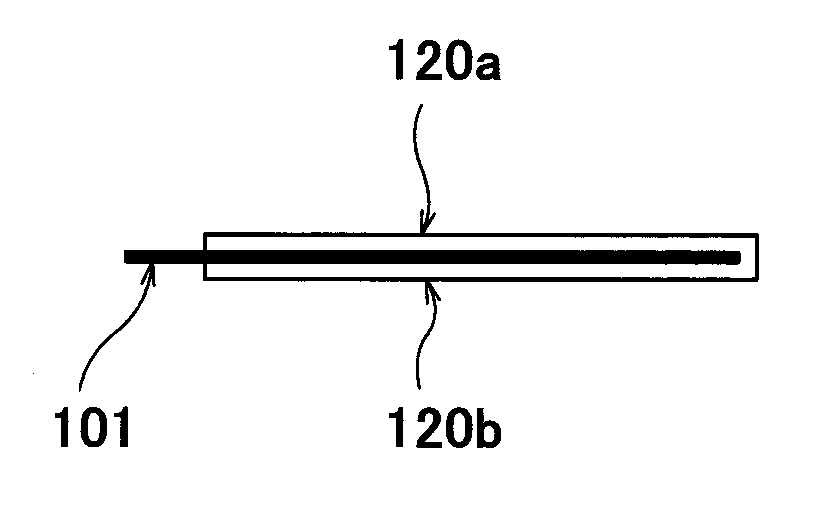

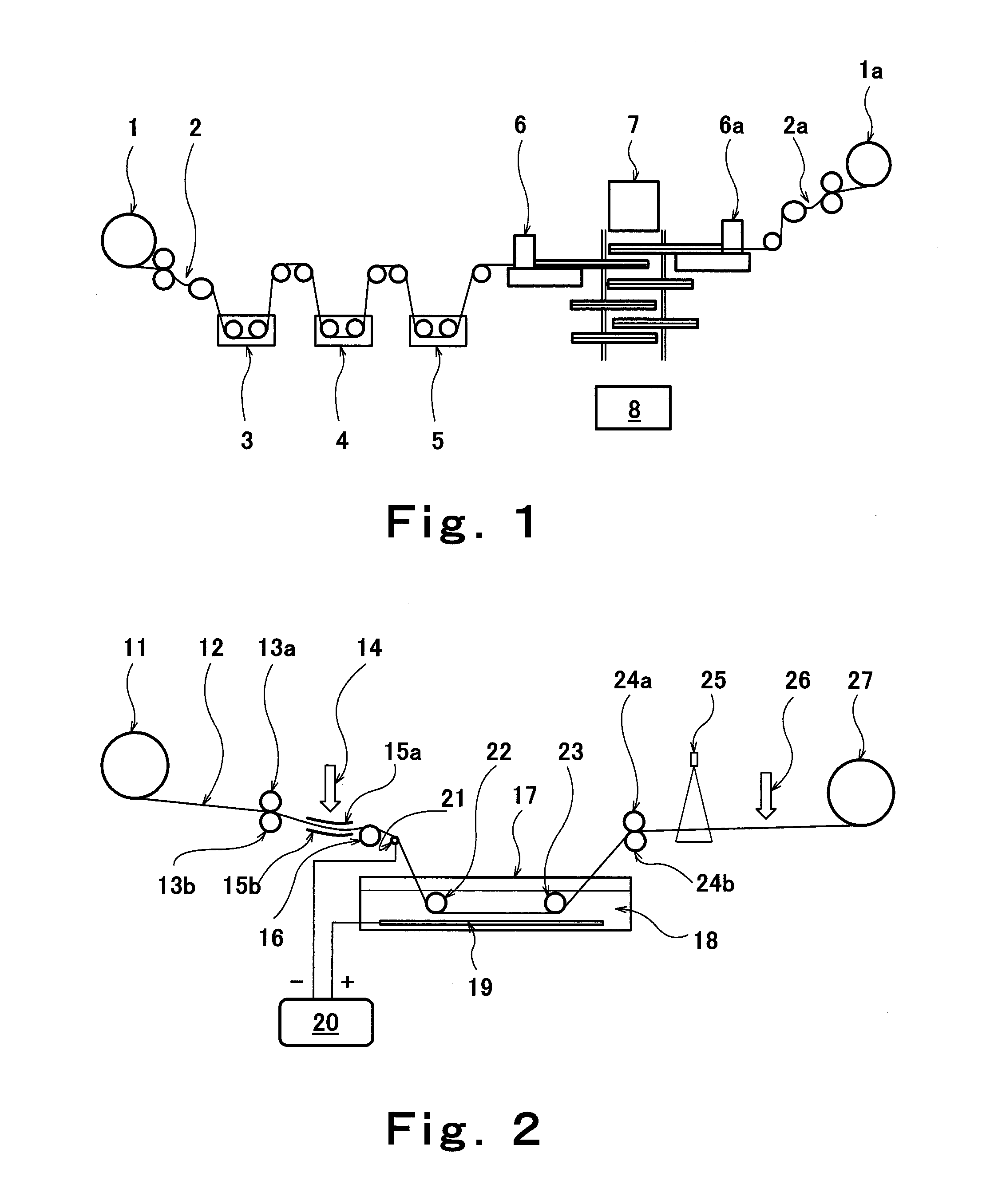

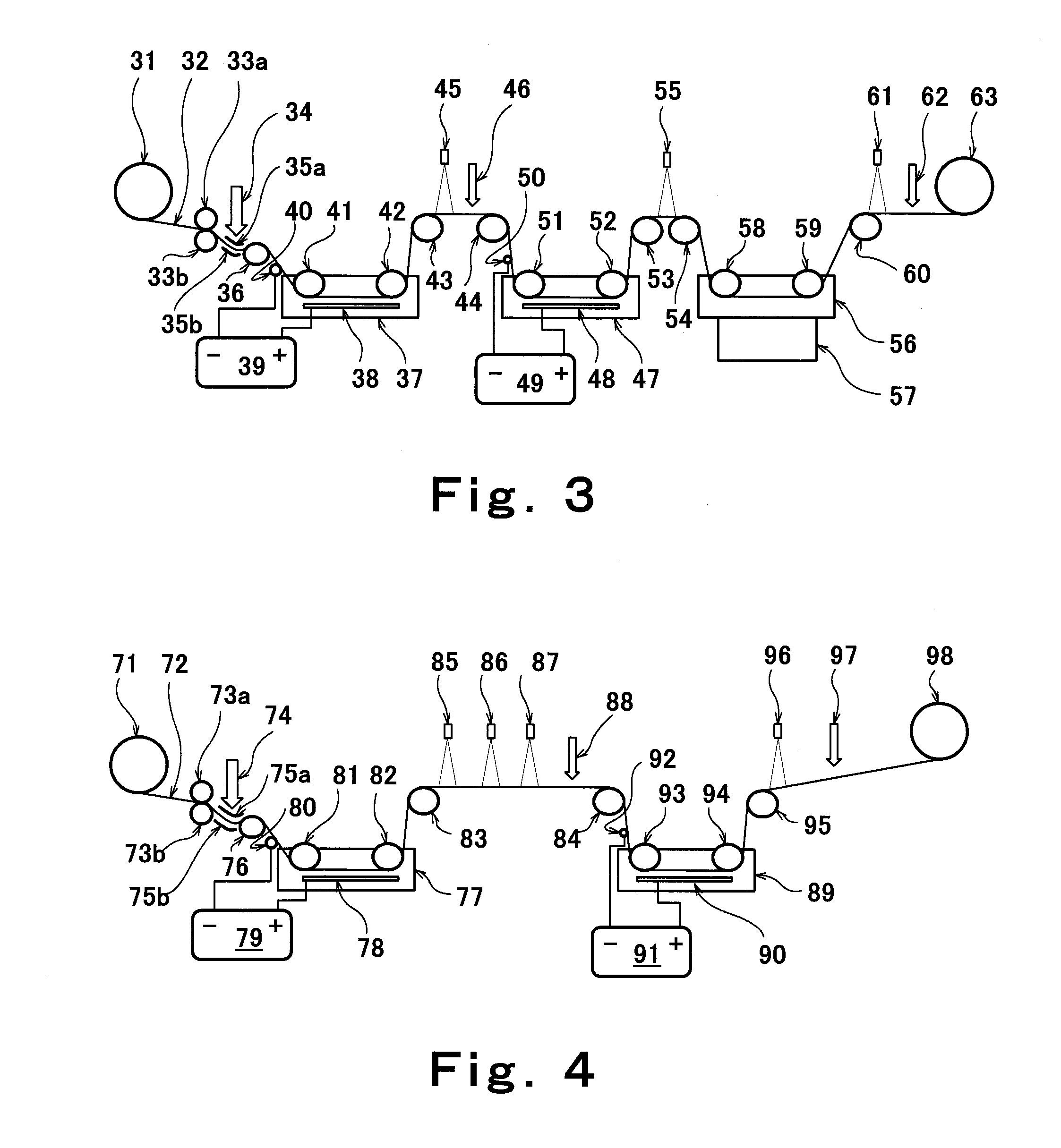

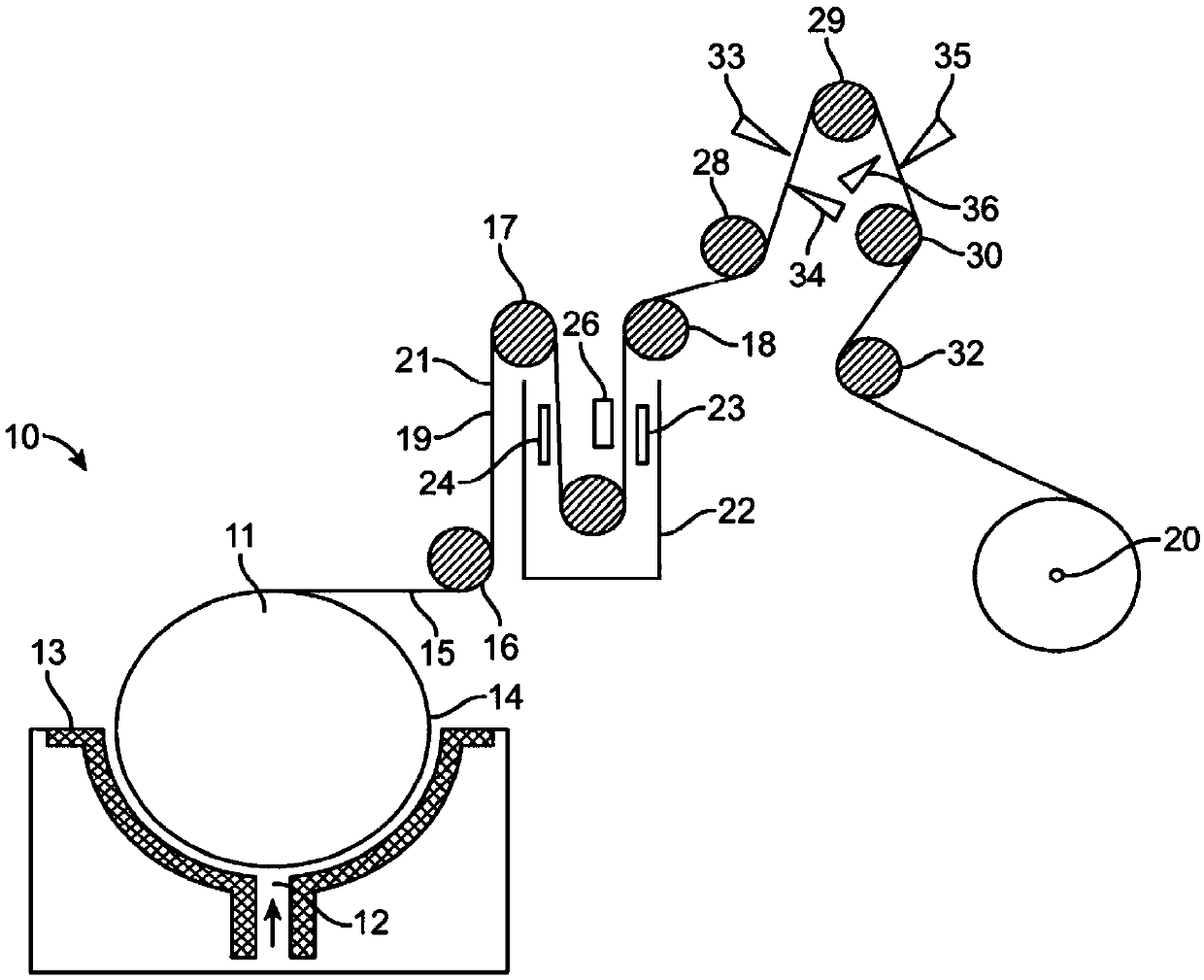

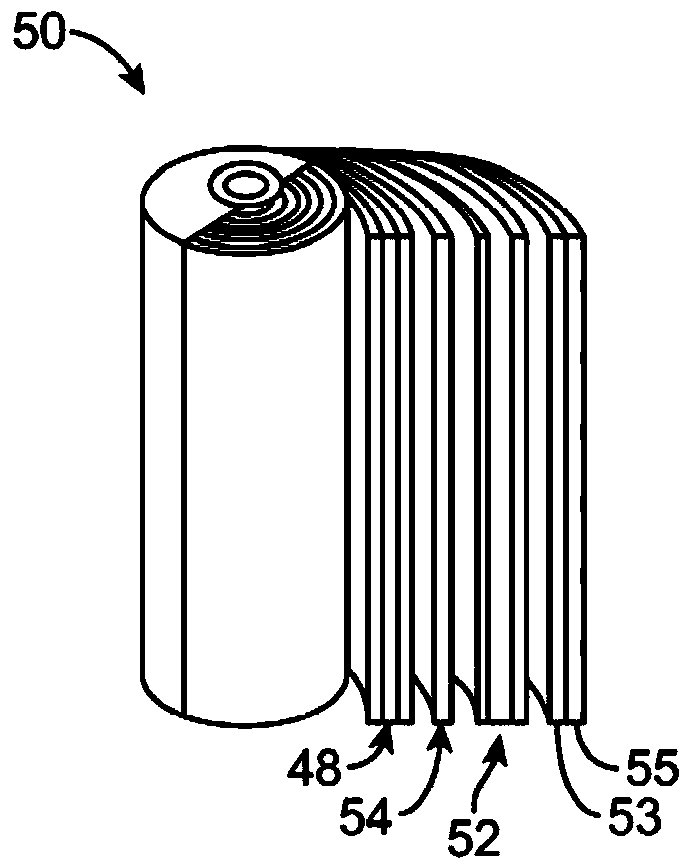

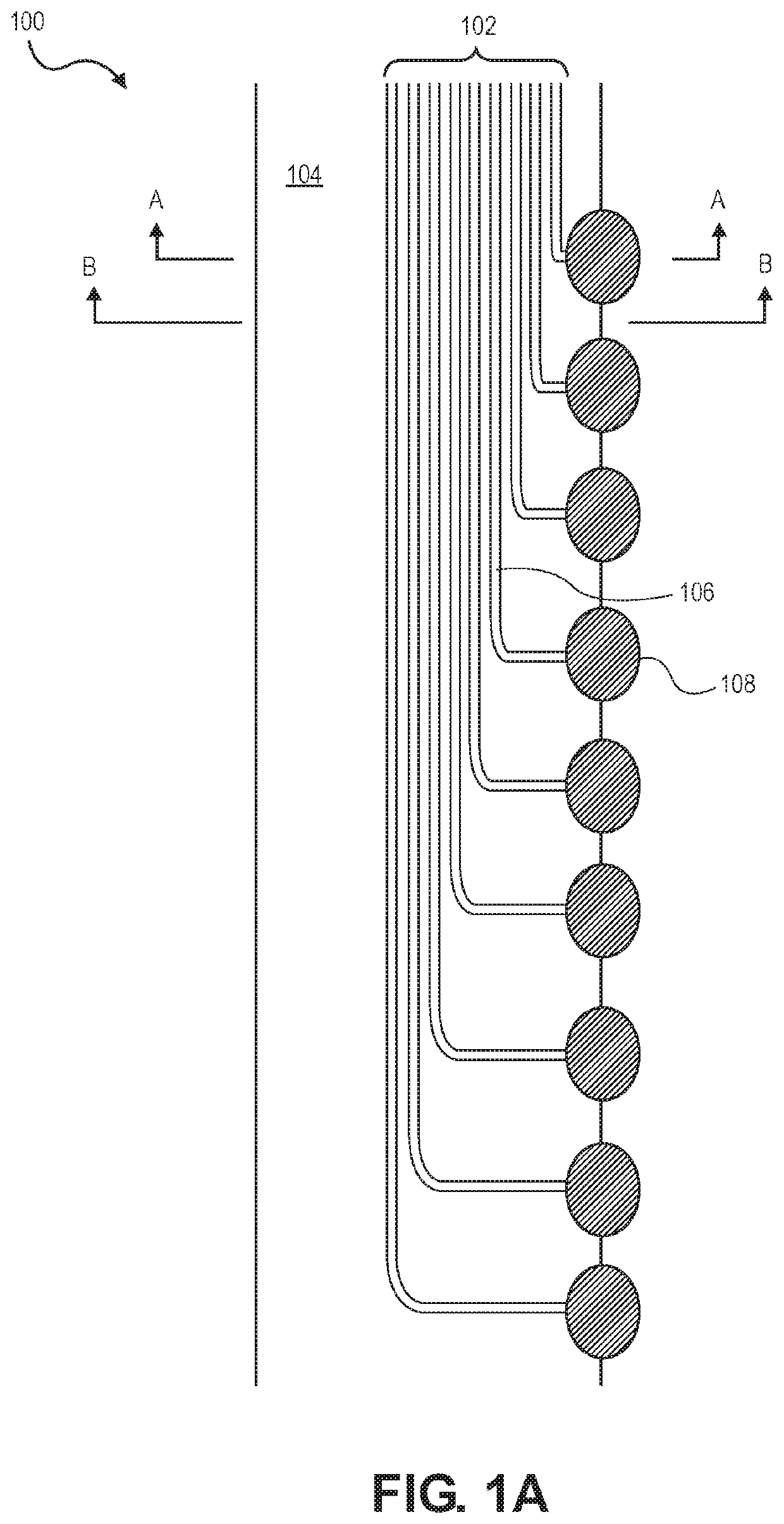

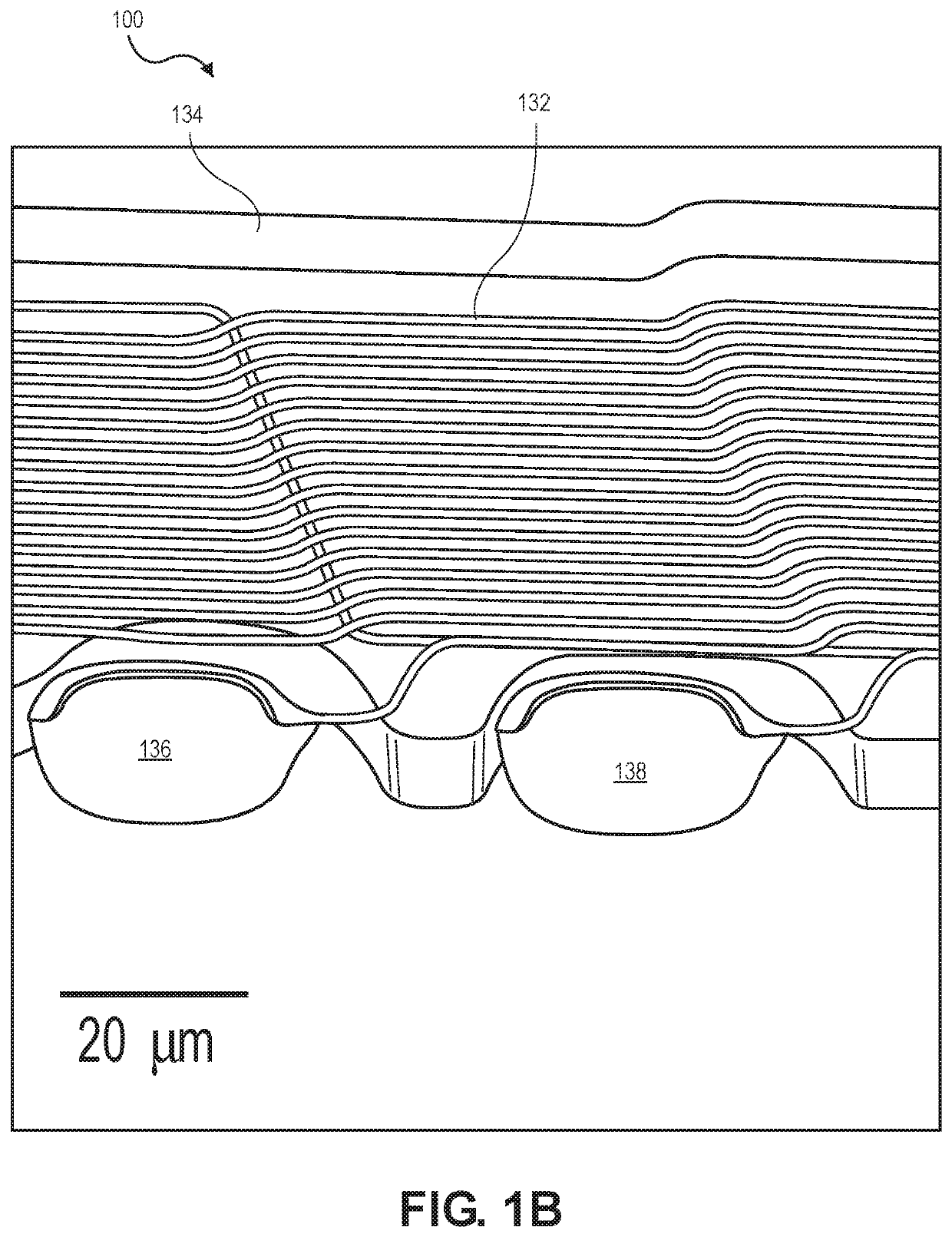

Fiber electrode and fiber battery, method of fabricating the same, and fiber electrode and fiber battery fabrication apparatus

InactiveUS20120214040A1Efficient manufacturingReduce distanceFinal product manufactureElectrode carriers/collectorsSingle fiberOptoelectronics

The present invention provides a method of efficiently fabricating a large number of fiber electrodes at the same time from a large number of fibers while taking advantage of inherent characteristics of fiber electrodes.A fiber electrode fabrication method according to the present invention includes: a step (2, 2a) of spreading a fiber tow; a step (3, 4, 5) of obtaining fiber positive electrodes or fiber negative electrodes by forming a positive electrode active material coating or a negative electrode active material coating on each of single fibers that are obtained by spreading the fiber tow; and a step (6, 6a) of forming a separator coating on the fiber positive electrodes or the fiber negative electrodes.

Owner:KAWASAKI HEAVY IND LTD

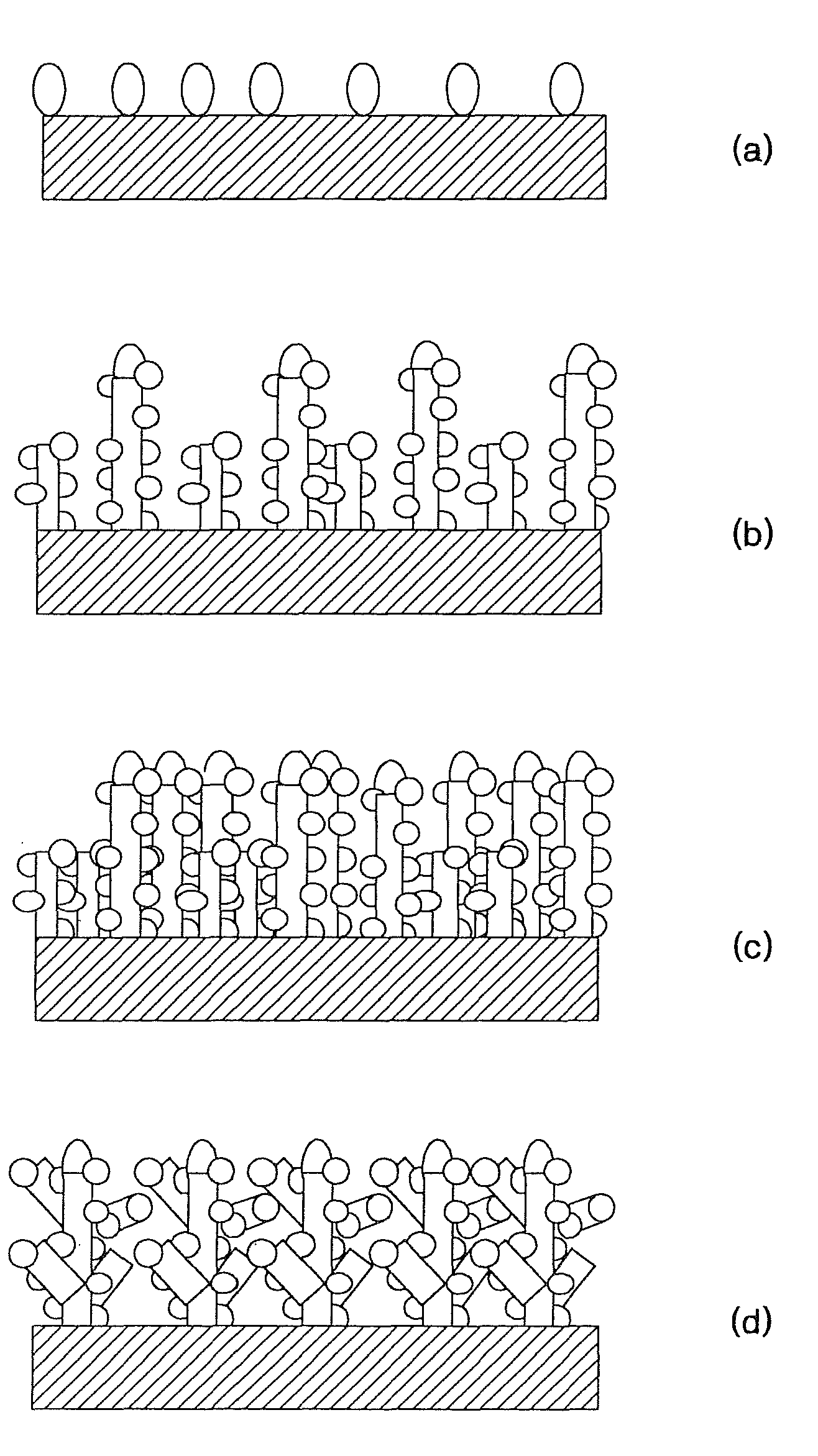

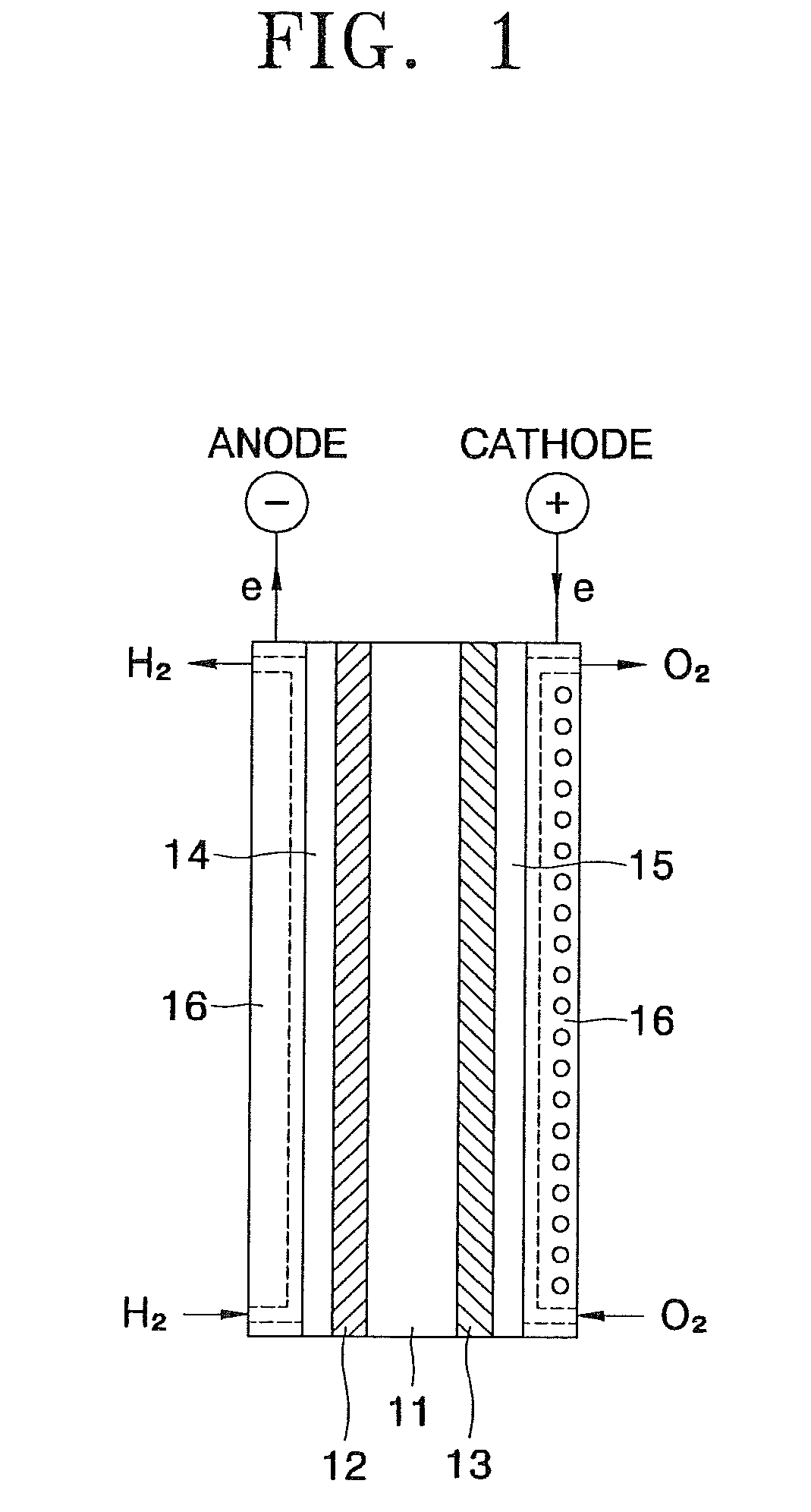

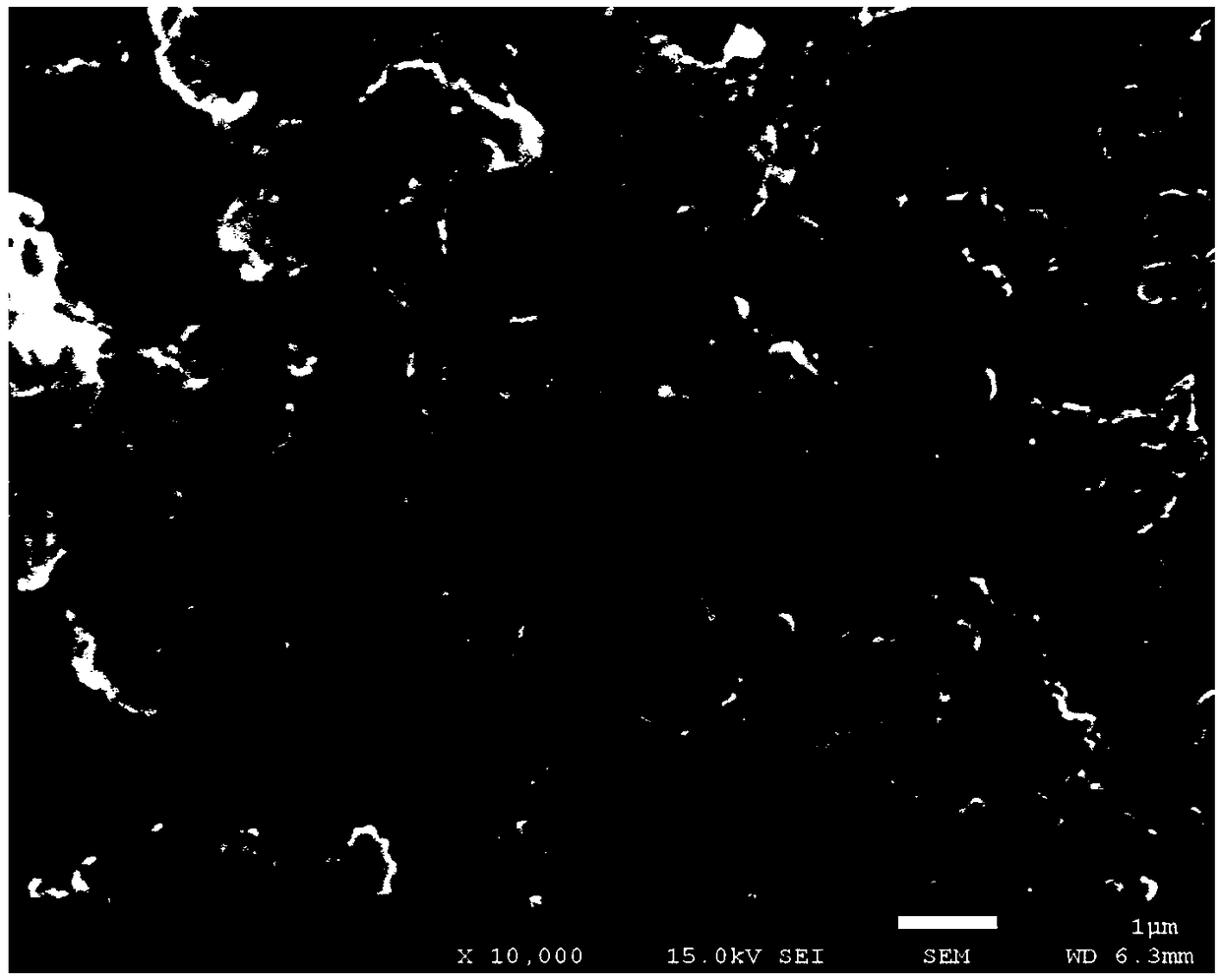

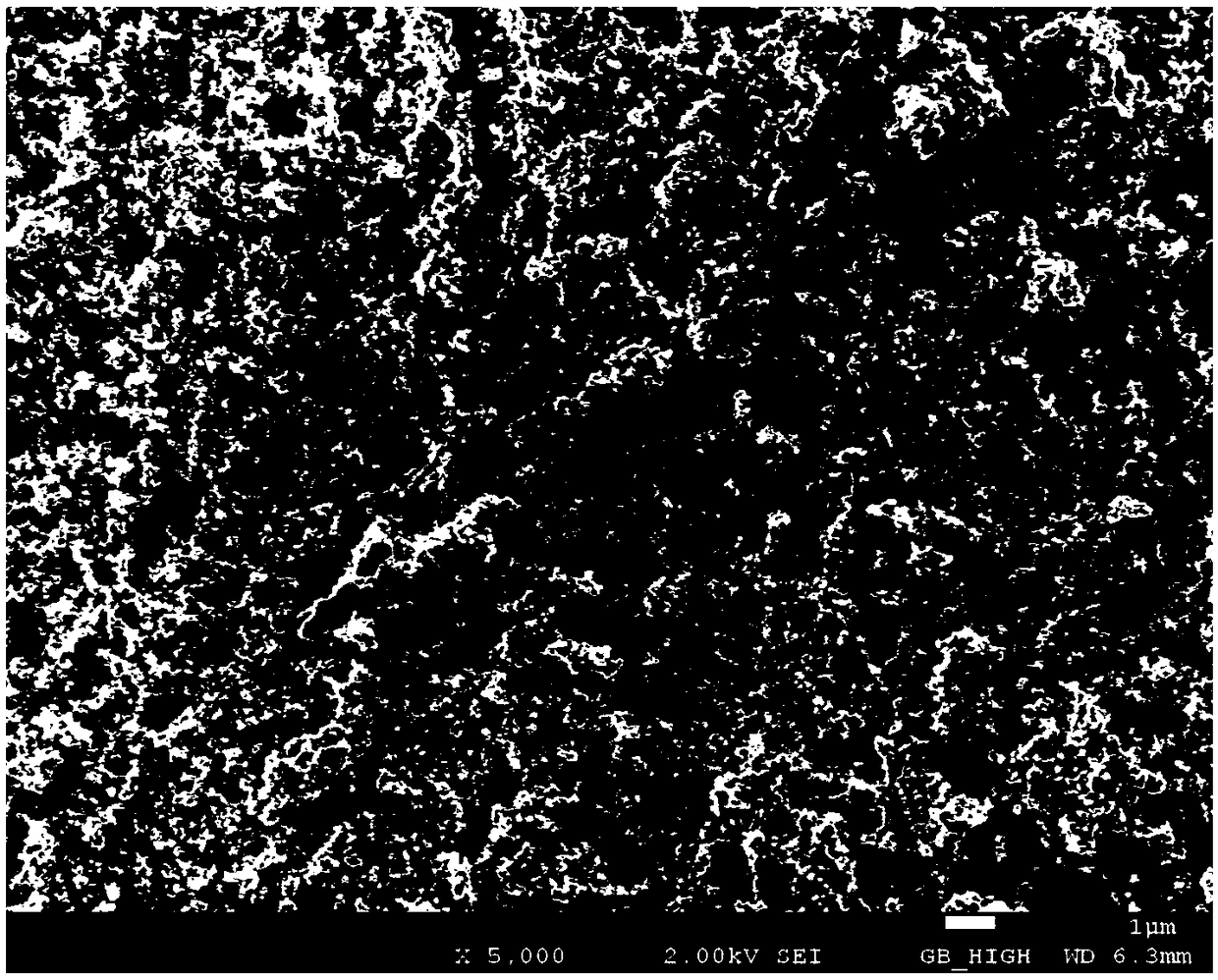

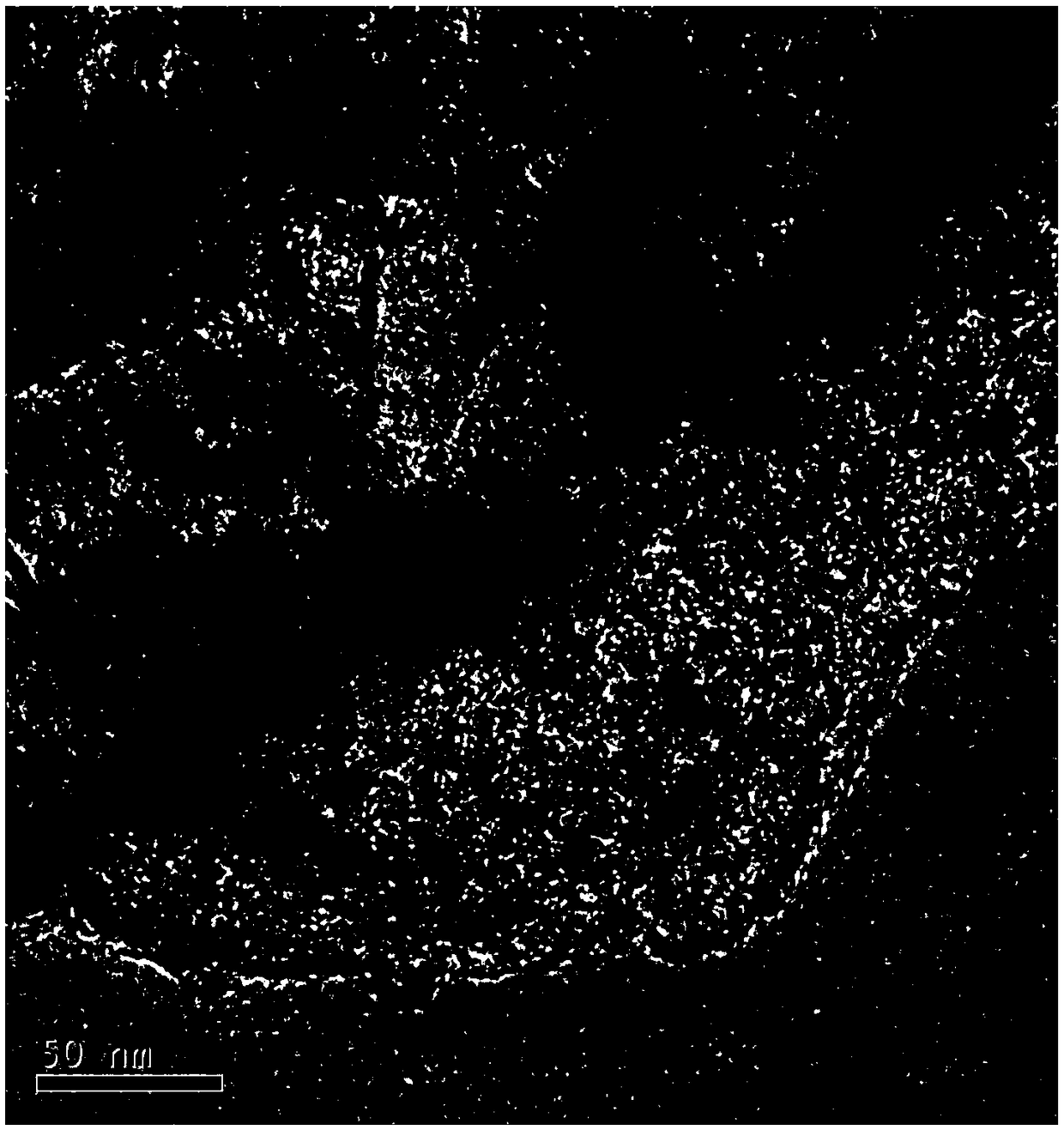

Carbon nanotubes for fuel cells, method for manufacturing the same, and fuel cell using the same

The internal and external walls of the carbon nanotubes are doped with nano-sized metallic catalyst particles uniformly to a degree of 0.3-5 mg / cm2. The carbon nanotubes are grown over a carbon substrate using chemical vapor deposition or plasma enhanced chemical vapor deposition. Since the carbon nanotubes have a large specific surface area, and metallic catalyst particles are uniformly distributed over the internal and external walls thereof, the reaction efficiency in an electrode becomes maximal when the carbon nanotubes are used for the electrode of a fuel cell. The carbon nanotubes fabricated using the method can be applied to form a large electrode. The carbon nanotubes grown over the carbon substrate can be readily applied to an electrode of a fuel cell, providing economical advantages and simplifying the overall electrode manufacturing process. A fuel cell using as the carbon nanotubes for its electrode provides improved performance.

Owner:SAMSUNG SDI CO LTD

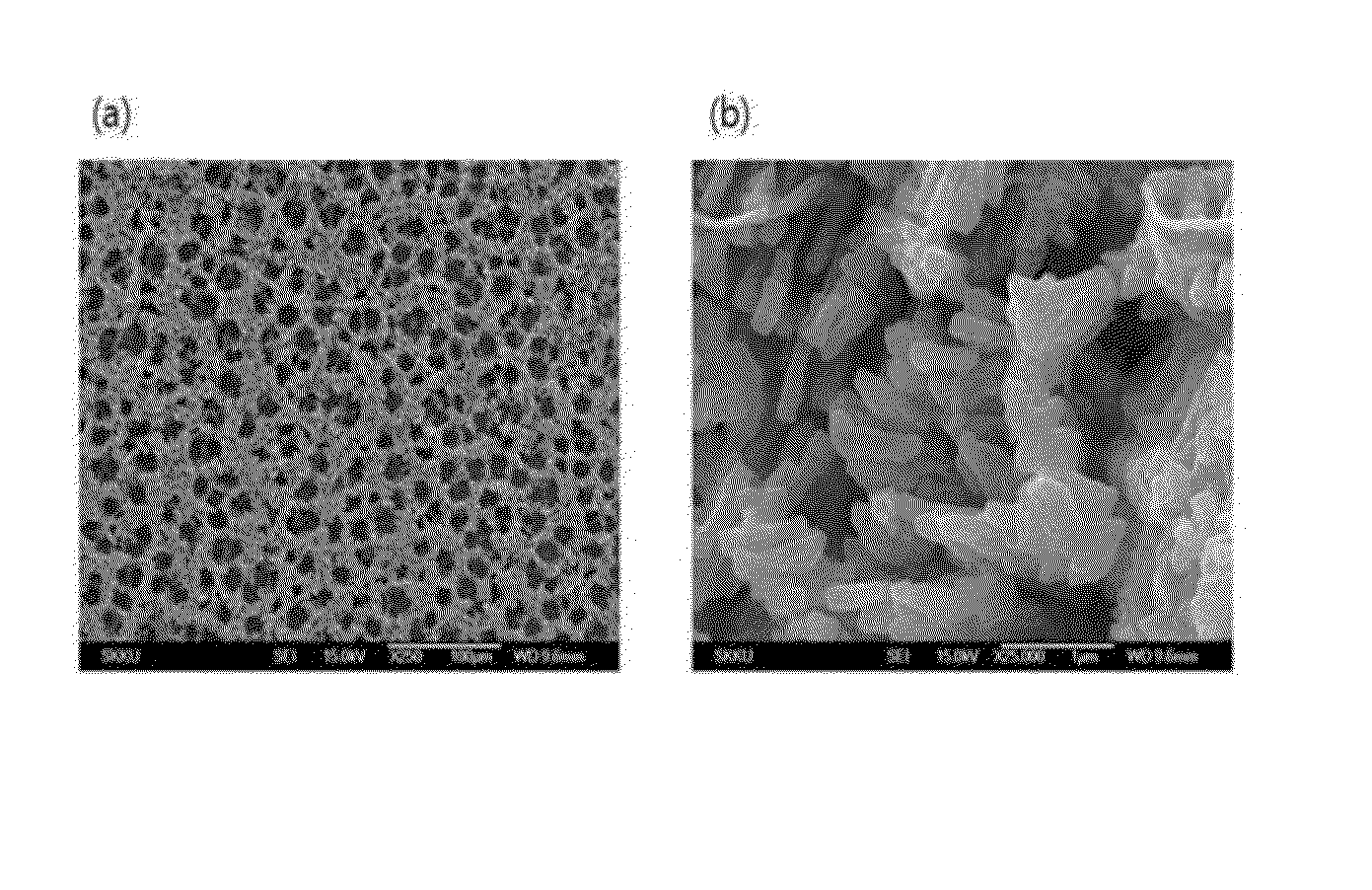

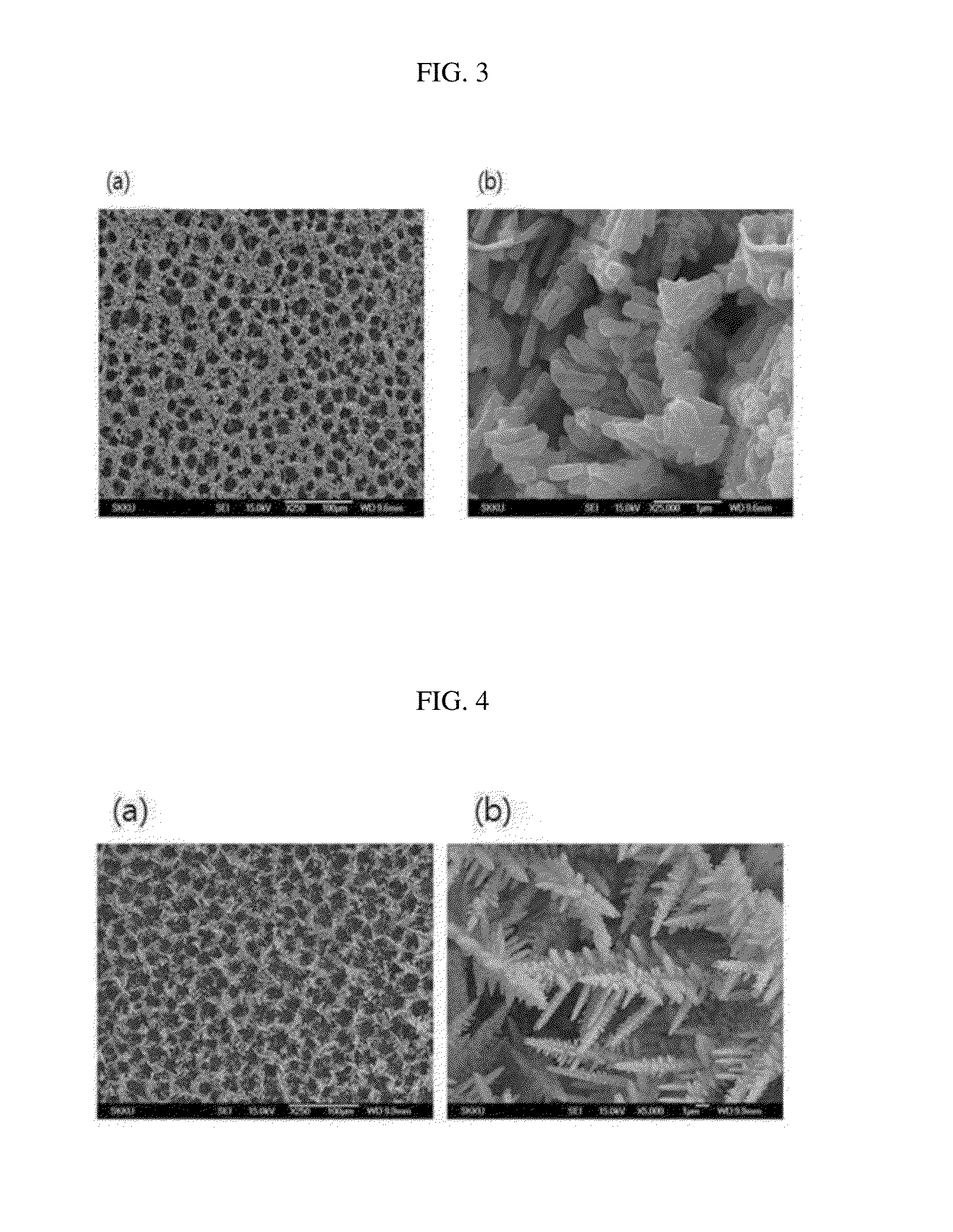

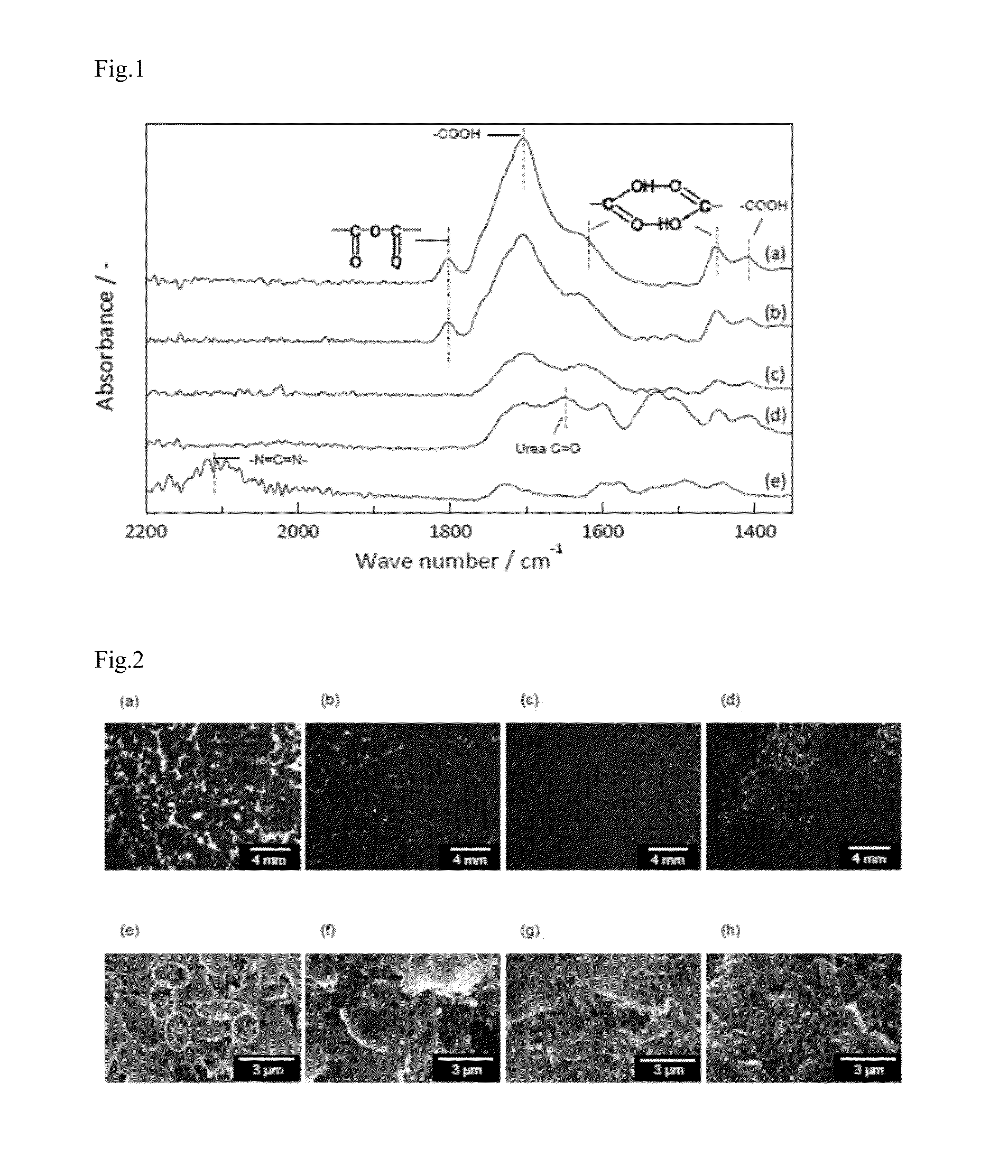

Nano-porous electrode for super capacitor and manufacturing method thereof

ActiveUS20130321983A1Increase surface areaIncrease capacityElectrolytic capacitorsHybrid capacitor electrodesElectricityHydrogen

The present invention relates to a nano-porous electrode for a super capacitor and a manufacturing method thereof, and more specifically, to a nano-porous electrode for a super capacitor and a manufacturing method thereof wherein pores are formed on the surface or inside an electrode using an electrodeposition method accompanied by hydrogen generation, thereby increasing the specific surface area of the electrode and thus improving the charging and discharging capacity, energy density, output density, and the like of a capacitor. The method for manufacturing a nano-porous electrode for a super capacitor according to the present invention manufactures a nano-porous electrode using hydrogen generated by the electrodeposition as a template to minimize the amount of metal used, so that electrode manufacturing costs can be sharply reduced, the specific surface area of the electrode can be adjusted by a simple process, and also the charging and discharging capacity, energy density, output density, and the like of a capacitor can be improved by increasing the specific surface area.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

Graphene dispersion, process for producing same, process for producing particles of graphene/active material composite, and process for producing electrode paste

ActiveUS20180261402A1Easily adsorbedHigh dispersibilityElectrode manufacturing processesHybrid capacitor electrodesIonOptical path length

A graphene material in a specific form is provided that has a high dispersibility and can maintain a high electric conductivity and ion conductivity when used as material for electrode manufacturing. A graphene dispersion liquid is provided including graphene dispersed in a solvent having a N-methyl pyrolidone content of 50 mass % or more and, when diluted with N-methylpyrolidone to a graphene weight fraction of 0.000013, giving a diluted solution having a weight-based absorptivity coefficient, which is calculated by Equation (1) given below, of 25,000 cm-1 or more and 200,000 cm-1 or less at a wavelength of 270 nm:weight-based absorptivity coefficient (cm−1)=absorbance / {0.000013×cell's optical path length (cm)}. (1)

Owner:TORAY IND INC

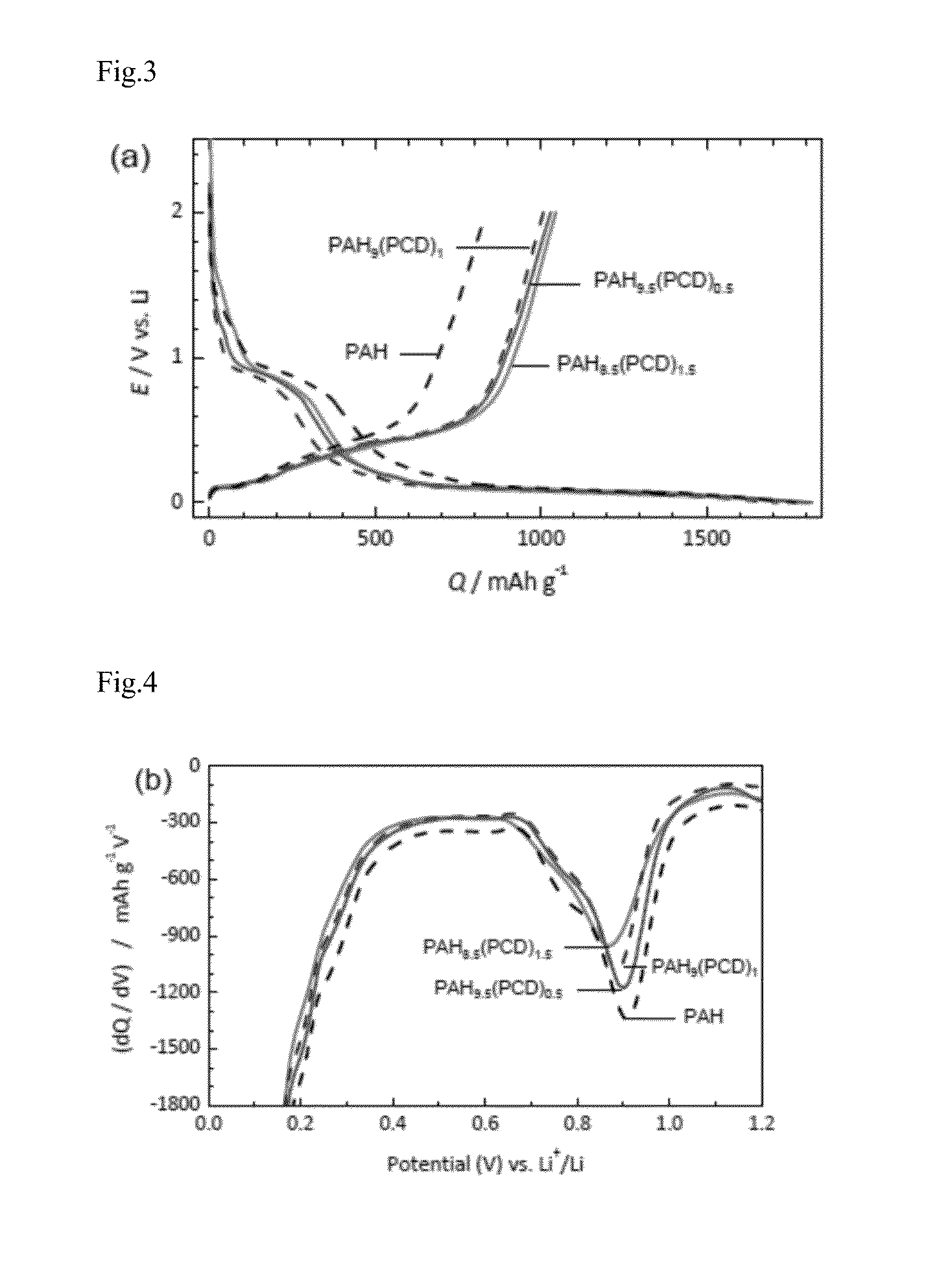

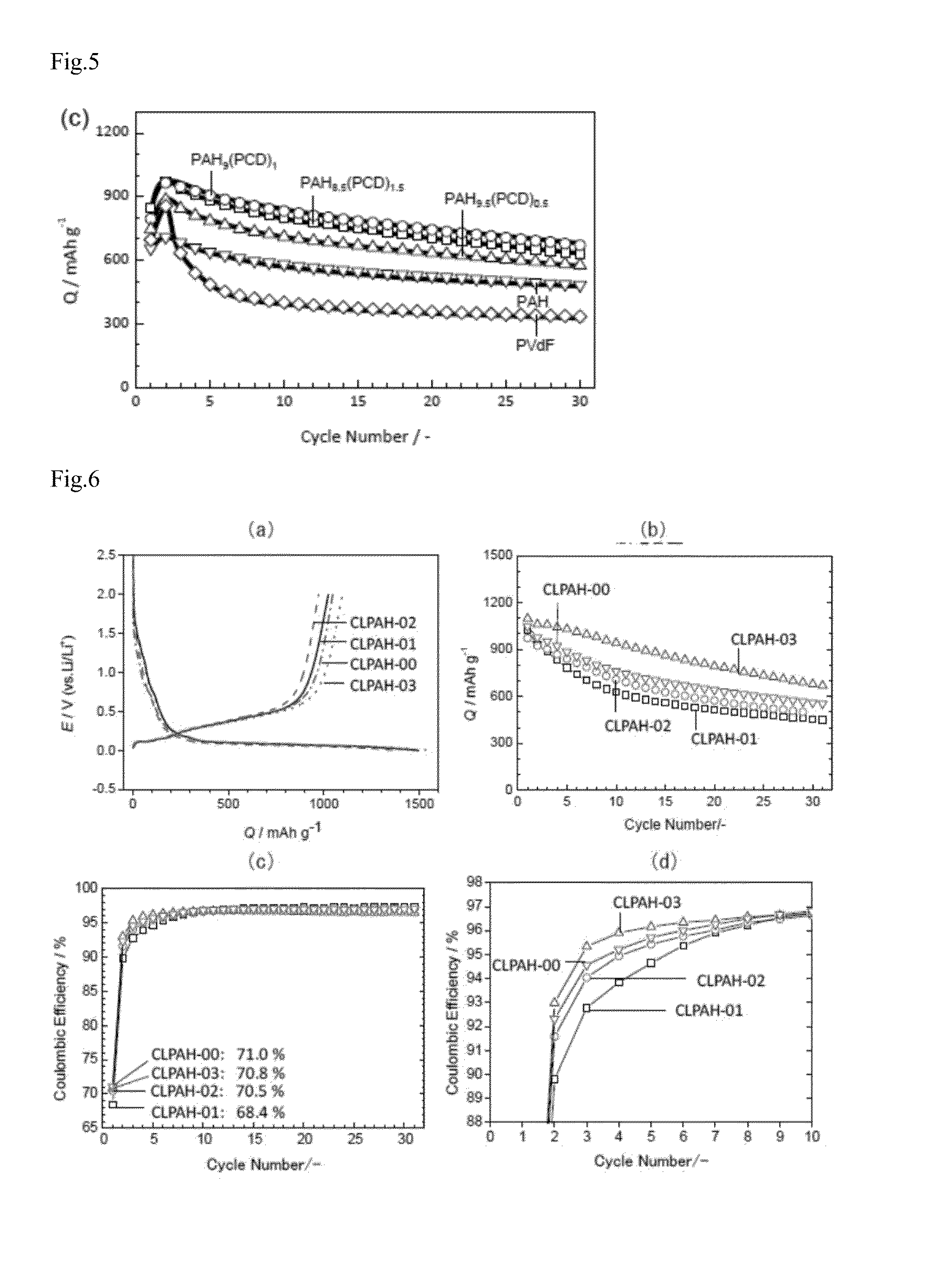

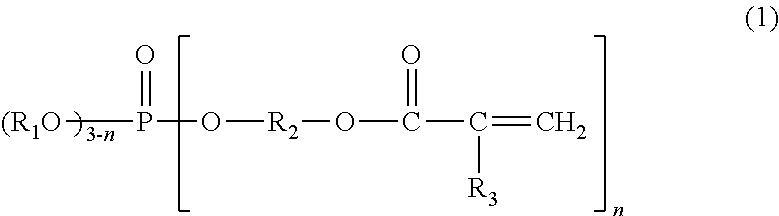

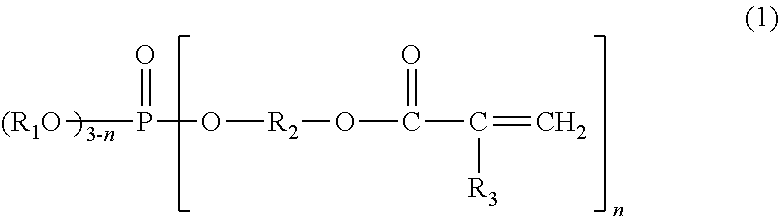

Binder for lithium cell, composition for producing electrode, and electrode

ActiveUS20150287993A1High capacity retentionEarly stabilization of coulombic efficiencyNon-metal conductorsConductive materialCross linkerALLYL SUCROSE

It is an object of the present invention to provide an electrode capable of maintaining superior capacity retention without destruction of an electrode structure, even in the case of using an active material including silicon.The present invention relates to “a binder for a lithium cell, the binder comprising polyacrylic acid cross-liked by a cross-linking agent selected from the compounds described in the general formulae [1] to [13] and the polymer described in the general formula [14] (provided that the one which includes a functional group-containing vinylidene fluoride-based polymer is excluded)”; a “composition for producing an electrode of a lithium cell, the composition comprising 1) an active material containing silicon, 2) a conductive assistant and 3) a cross-linked-type polyacrylic acid (provided that the one containing a functional group-containing vinylidene fluoride-based polymer is excluded)”; and an “electrode for a lithium cell, the electrode comprising 1) an active material containing silicon, 2) a conductive assistant, 3) a cross-linked-type polyacrylic acid, and 4) a current collector (provided that the one containing a functional group-containing vinylidene fluoride-based polymer is excluded)”.

Owner:FUJIFILM WAKO PURE CHEM CORP +1

Binder for secondary battery providing excellent adhesion strength and cycle property

ActiveUS20130122364A1Improve cycle performanceHigh bonding strengthSecondary cellsActive material electrodesDouble bondAdhesion strength

Provided is a binder for secondary battery electrodes comprising a copolymer consisting of 79 to 98% by weight of at least one selected from the group consisting of (a) an ethylenically unsaturated carbonic acid ester monomer and (b) a vinyl monomer and a nitrile monomer, (c) 1 to 20% by weight of an ethylenically unsaturated carbonic acid monomer, and (d) 1 to 20% by weight of a phosphorus (P)-containing monomer including a P═O bond and one or more reactive double bonds in a molecular structure thereof, based on the total weight of the binder. The binder fundamentally improves stability of an electrode in the process of fabricating the electrode, thus providing secondary batteries with superior cycle properties.

Owner:LG CHEM LTD

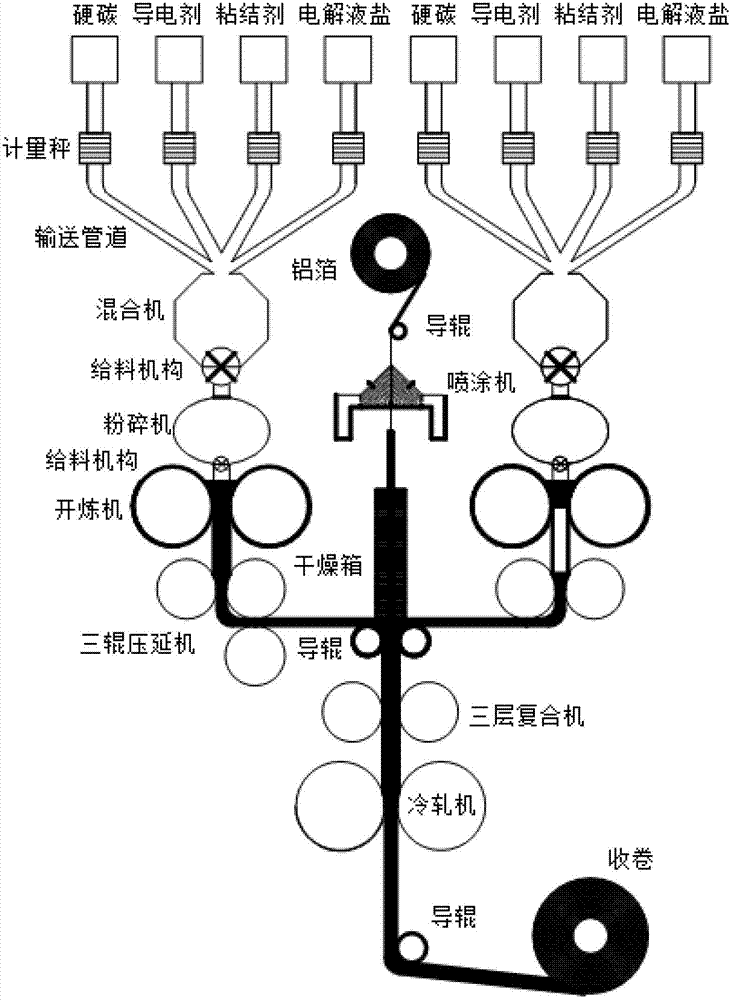

Whole pollution-free manufacturing method for electrode containing electrolyte salt

ActiveCN103093969AGuaranteed purityImprove performanceElectrode manufacturing processesHybrid/EDL manufactureElectrolytic agentElectrolyte

The invention relates to a whole pollution-free manufacturing method for an electrode containing electrolyte salt. No water or solvent is led in a productive process of the electrode, accordingly purity of an electrode material is guaranteed to the maximum degree, and performance of an electrochemical device is improved. An inner wall of a pipe in a full-automatic powder transportation process is made of high-stability and high-wearing inorganic nonmetallic materials, and pollution caused by contact between electrode powder materials and metal is avoided. In all processes comprising powder handling and film processing, the electrode materials are not contacted with the metal in all processes. In addition, the electrolyte salt is evenly distributed in the electrode in an electrode manufacture process, only an electrolyte solvent is injected in a hollowing liquid injection process, and crystallographic problems of the electrolyte salt are solved. Simultaneously, the electrolyte solvent after liquid injection forms a high-speed ion motion channel inside the electrode in a process for dissolving the electrolyte salt, and power density of the electrochemical energy-saving device is greatly improved.

Owner:GMCC ELECTRONICS TECH WUXI CO LTD

Lithium Ion Battery Electrode and Its Fabrication Method

InactiveUS20130252091A1Improves active material utilizationIncrease areal densityActive material electrodesElectrode collector coatingElectrical batteryConductive polymer

The present invention is aimed to provide a complex electrode for a lithium ion battery, consisting of: an electro-conductive current collector with porous three-dimensional network construction, the electrode active materials filled in the porous current collector, and a porous ionic conductive polymer binder coated in the pores of the current collector holding the electrode materials. In the abovementioned lithium ion battery complex electrode construction, the current collector connects with the electrode active materials through its highly porous three-dimensional backbone network and thus greatly improves the utilization of the electrode active materials and obtains high area density and low impedance of the electrode. Another objective of this invention is to disclose a novel electrode fabrication technique for lithium ion batteries.

Owner:LONG POWER SYST SUZHOU

Graphene dispersion, process for producing same, process for producing particles of graphene/active material composite, and process for producing electrode paste

ActiveUS20180269465A1High electronic conductivityExcessive agglomerationMaterial nanotechnologySecondary cellsCvd grapheneIon

A graphene material has a specific form that has a high dispersibility and can maintain a high electric conductivity and ion conductivity when used as material for electrode manufacturing. A graphene dispersion liquid is provided including graphene dispersed in an organic solvent and meeting both 0.5 μm≤S≤15 μm and 1.0≤D / S≤3.0 wherein D is the median diameter (μm) of the graphene measured by the laser diffraction / scattering type particle size distribution measurement method and S is the average size (μm) in the planar direction of the graphene calculated from the arithmetic mean of the longest diameter and shortest diameter of the graphene observed by a laser microscope.

Owner:TORAY IND INC

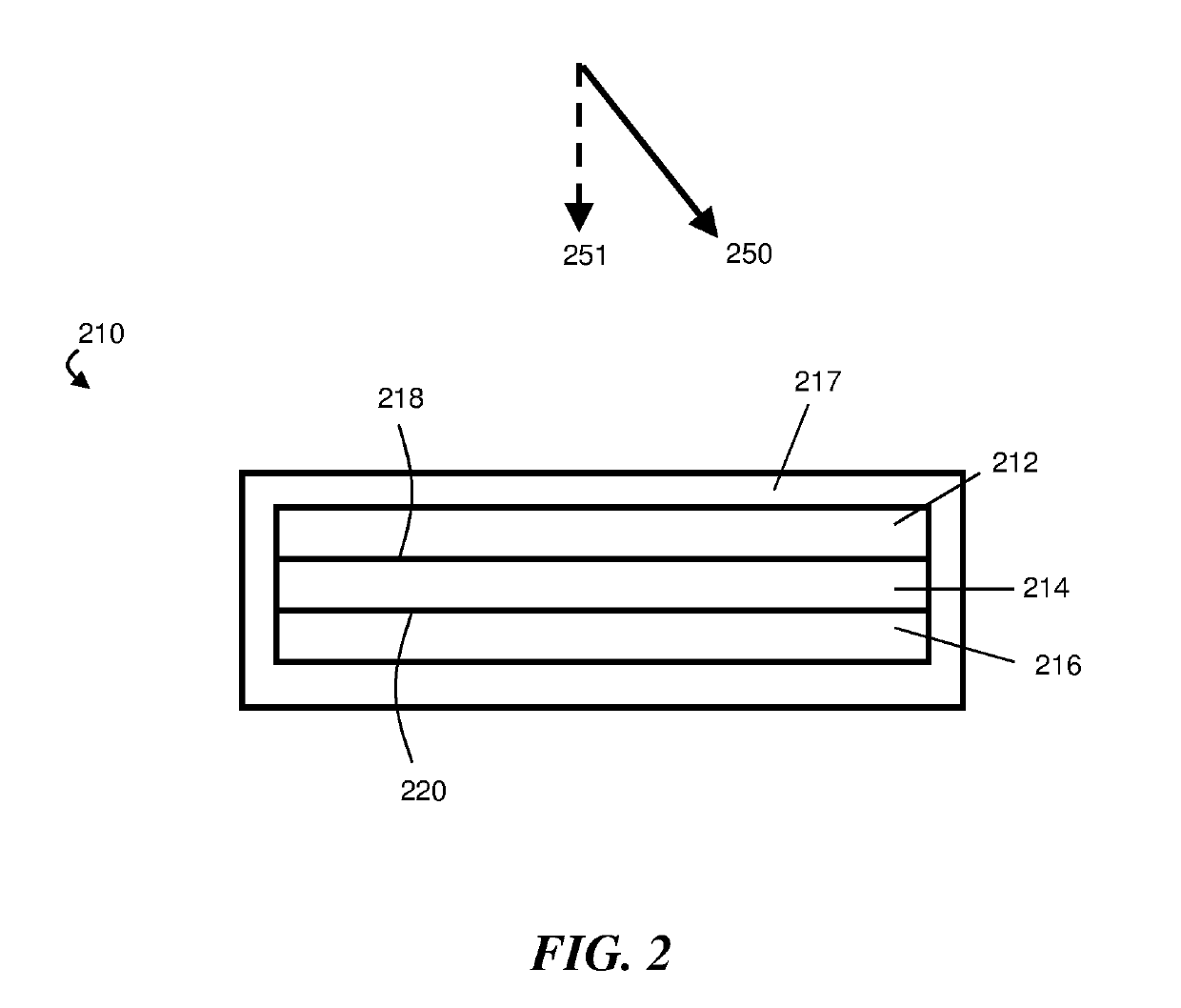

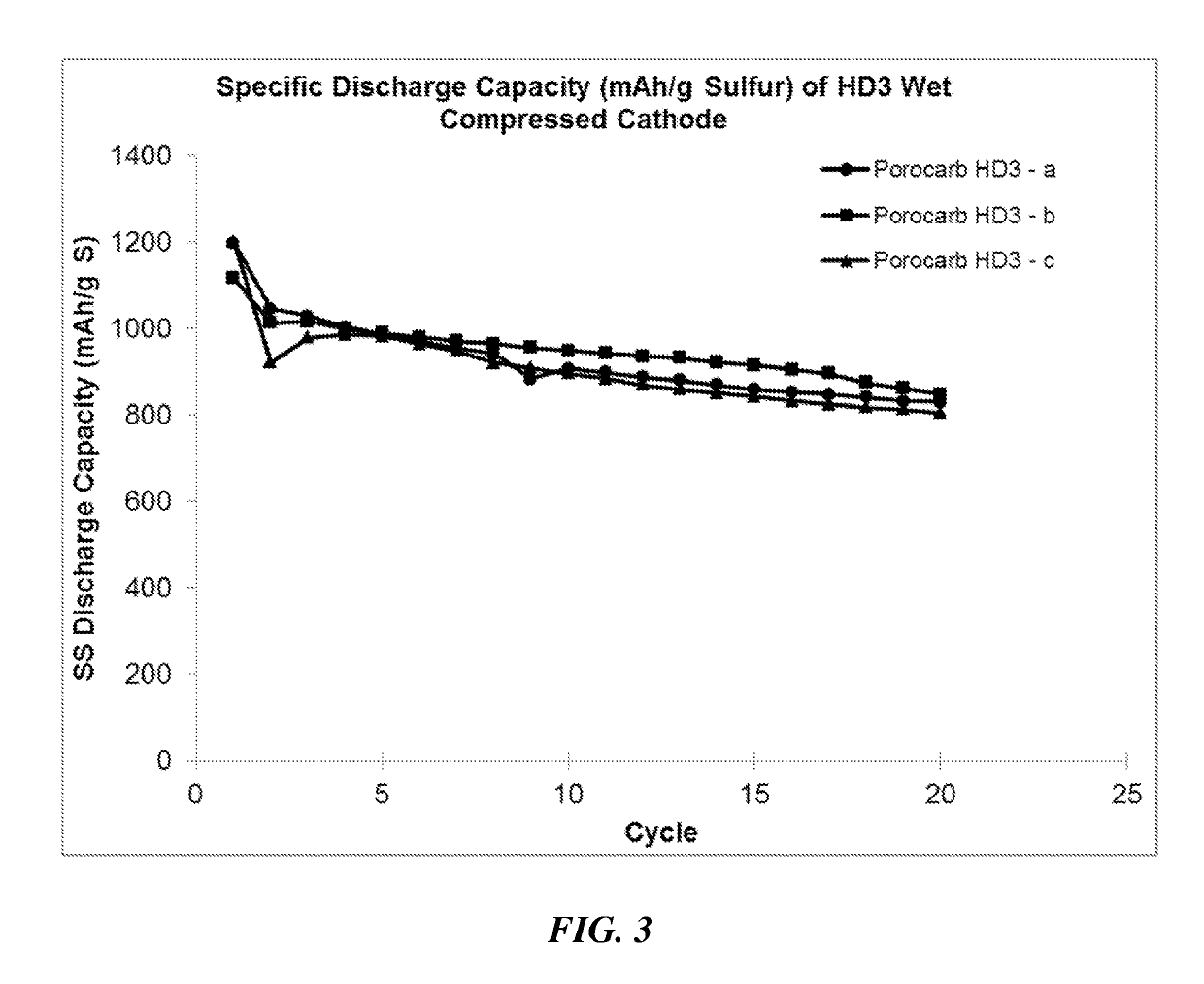

Electrode fabrication methods and associated systems and articles

Sulfur-based electrodes, and associated systems and methods for their fabrication, are generally described. Certain embodiments relate to sulfur-based electrodes with smooth external surfaces. According to some embodiments, relatively large forces can be applied to compositions from which the sulfur-based electrodes are made during the fabrication process. In some such embodiments, the compositions can maintain relatively high porosities, even after the relatively large forces have been applied to them. Methods in which liquids are employed during the electrode fabrication process are also described.

Owner:SION POWER CORP

Non-noble metal catalytic electrode, film electrode and preparation method of non-noble metal catalytic electrode

InactiveCN109346728AExcellent gasExcellent electronicsFinal product manufactureCell electrodesNon platinumNitrogen source

The invention discloses a non-noble metal catalytic electrode, a film electrode and a preparation method of the non-noble metal catalytic electrode, wherein a catalytic layer on the surface of an electrode diffusion layer of the non-noble metal catalytic electrode is formed by thermally treating a precursor mixture of a catalytic layer material at the high temperature and growing or loading a catalytic ingredient on the electrode diffusion layer, the precursor mixture of the catalytic layer material comprises a transition metal precursor, a carbon source material and a nitrogen source material, the catalytic layer is porous ordered large-specific surface area non-platinum high-nitrogen carbon based catalytic ingredient containing transition metal, the catalytic activity is mainly from a multi-component system comprising carbon, nitrogen and the transition metal, a catalytic region is porous and highly ordered, has the characteristic of high hydrophobicity and the excellent performanceof conduction of gas and electrons, the integrally direct forming preparation method directly loads or grows a catalytic activity component on the surface of the electrode diffusion surface at one time, the time is saved, the production steps of the electrode are simplified, the waste of a catalyst is avoided, and the preparation method has the advantages of simple preparation, low cost and excellent performances.

Owner:CHINA-SINGAPORE INT JOINT RES INST

Method for preparing solar cell electrodes, solar cell substrates prepared thereby, and solar cells

InactiveCN102246319AImprove efficiencyLower specific resistanceFinal product manufacturePhotovoltaic energy generationElectrical batterySolar battery

Owner:SSCP CO LTD

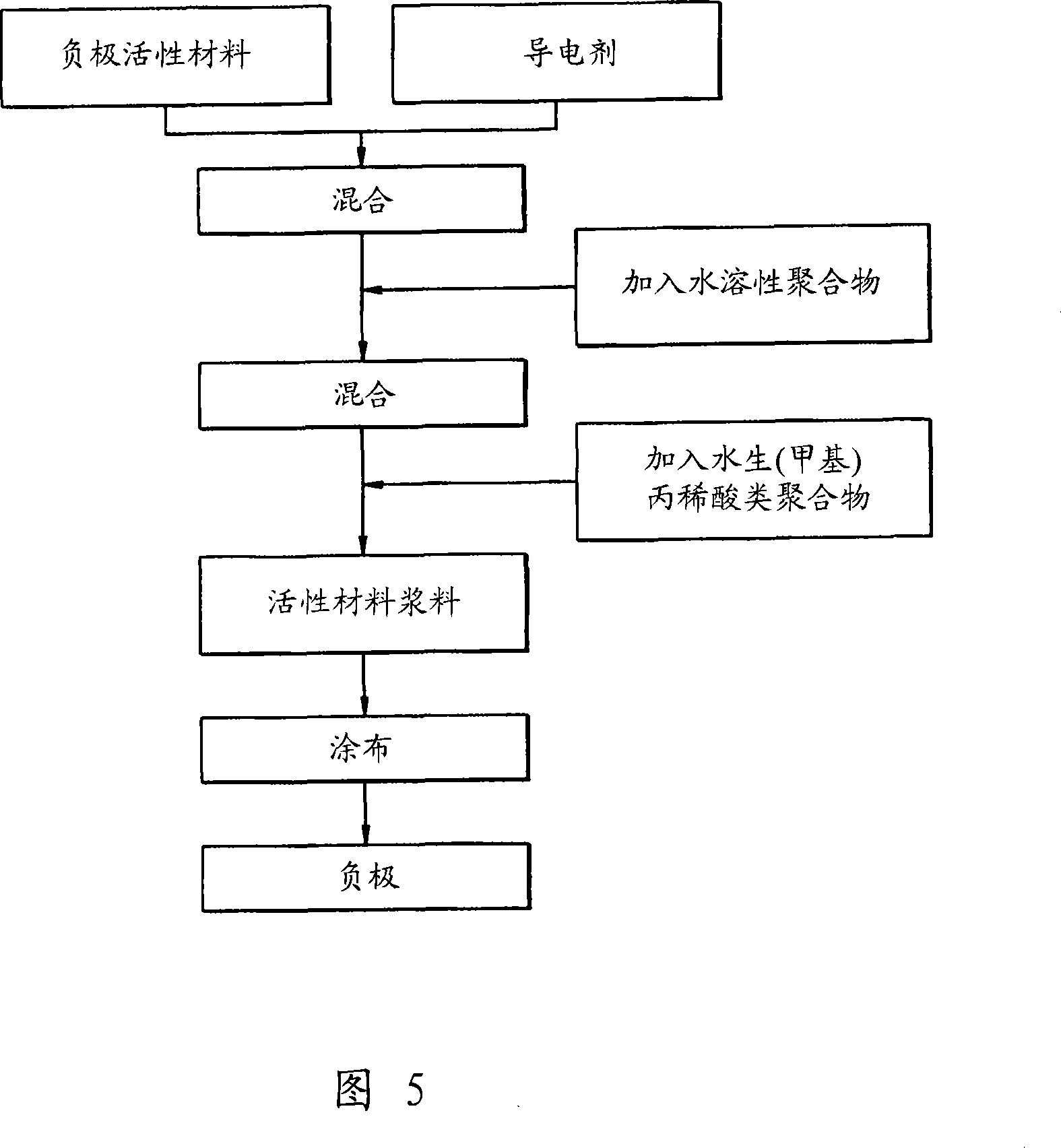

Anode for lithium battery and lithium battery employing the same

InactiveCN101217193AImprove adhesionIncrease capacityElectrode rolling/calenderingNon-aqueous electrolyte cellsHigh energyPhysical chemistry

Anodes for lithium batteries and lithium batteries employing the anodes are provided. In one embodiment, an anode includes an anode active material, and a binder including a waterborne acrylic polymer and a water-soluble polymer. The binder permeates the anode active materials to provide binding force between the anode active materials through point binding. The binder has excellent binding force and elasticity, and does not experience the spring-back phenomenon during electrode manufacture. The anodes have improved assembly density, high capacity and high energy density. Further, the anodes have improved lifetime characteristics since the anode structure is maintained long term over repeated charge / discharge cycles.

Owner:SAMSUNG SDI CO LTD

Copper foil for current collector of lithium secondary battery

ActiveCN109868490AReduce grain size variationReduce the numberElectrochemical processing of electrodesElectrode carriers/collectorsPhysical chemistryCopper foil

Electrodeposited copper foils having adequate puncture strength to withstand both pressure application during consolidation with negative electrode active materials during manufacture, as well as expansion / contraction during repeated charge / discharging cycles when used in a rechargeable secondary battery are described. These copper foils find specific utility as current collectors in rechargeablesecondary batteries, particularly in lithium secondary battery with high capacity. Methods of making the copper foils, methods of producing negative electrode for use in lithium secondary battery andlithium secondary battery of high capacity are also described.

Owner:CHANG CHUN PETROCHEMICAL CO LTD

Electrode, electrolyte thin layer and preparation method thereof

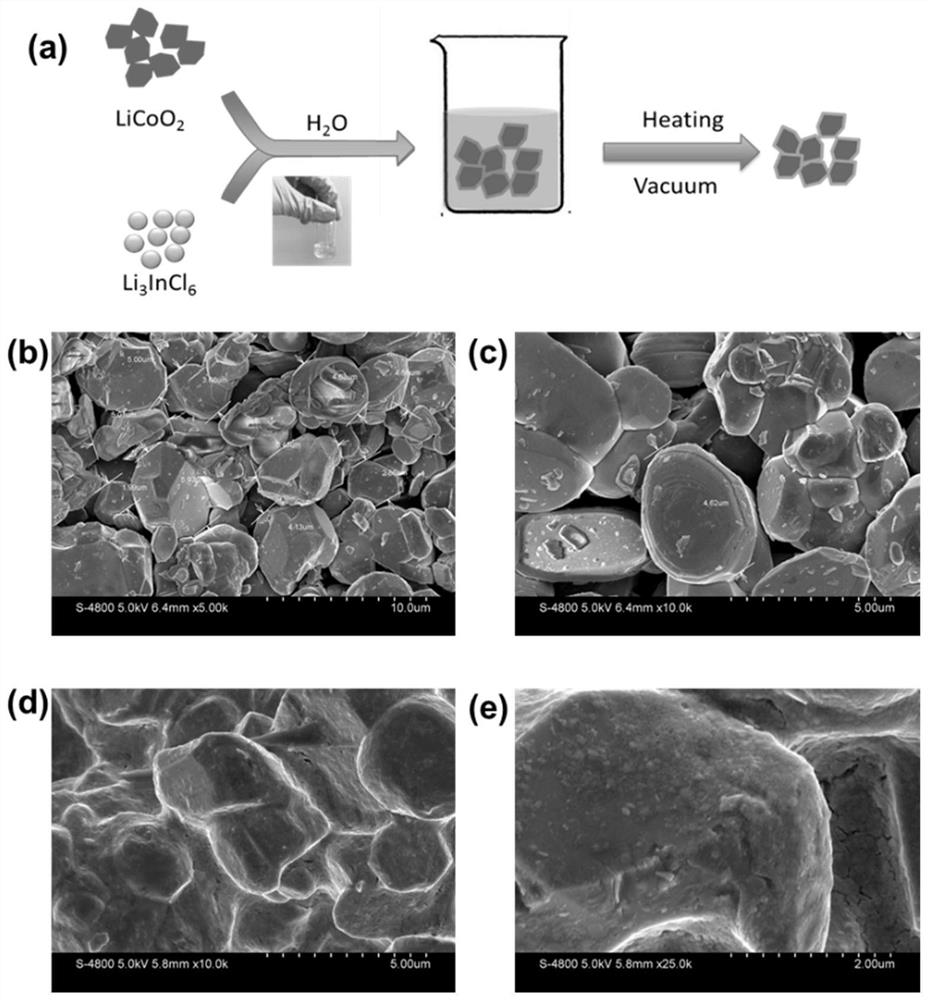

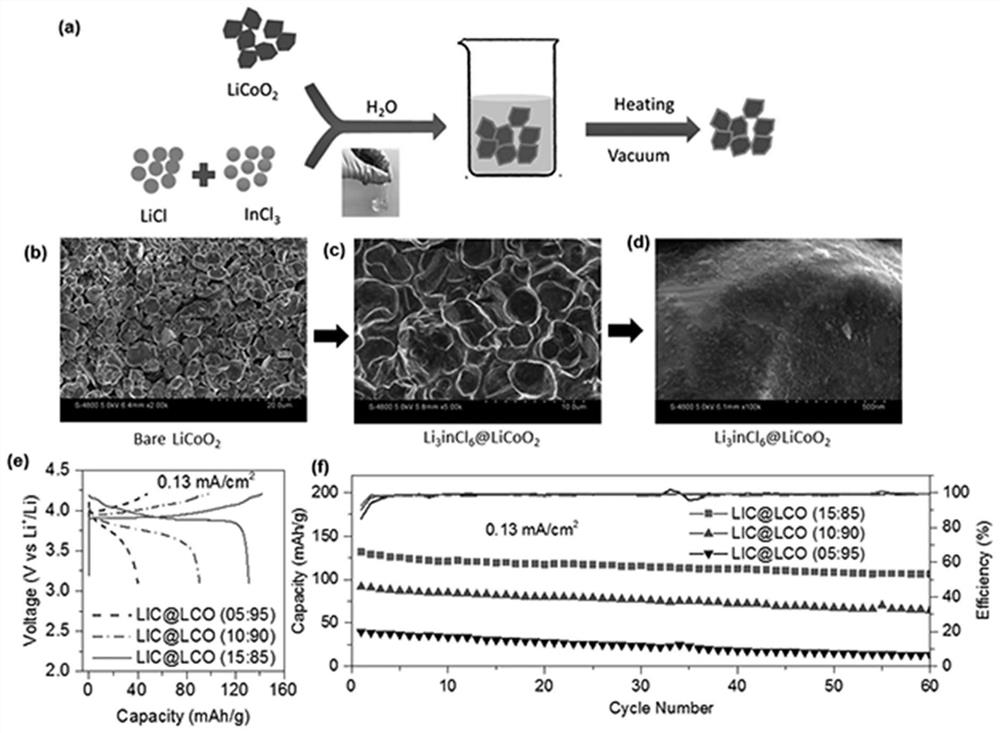

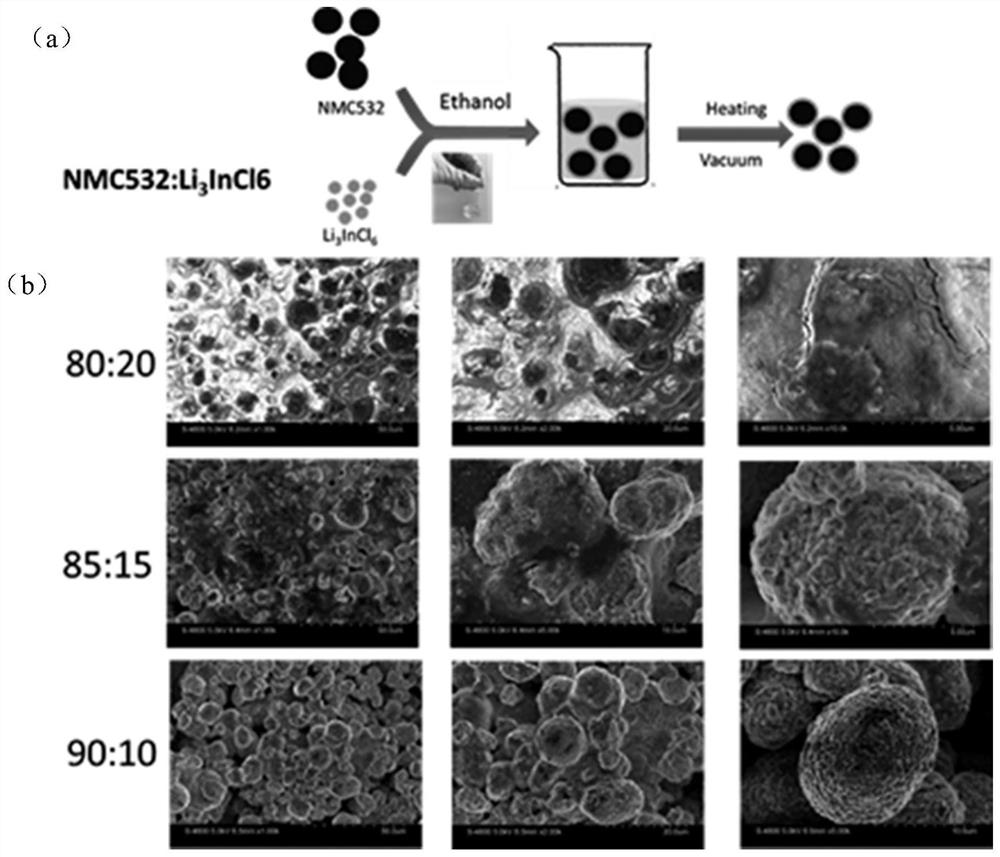

InactiveCN112467074AReduce contentGood solid contactFinal product manufactureCell electrodesSolid state electrolyteManufacturing technology

The invention relates to the technical field of secondary batteries, in particular to an electrode, an electrolyte thin layer and a preparation method thereof. An electrode is prepared from a halide solid electrolyte material, the solid electrolyte material is LiaMXb, M is one or more of Al, Ga, In, Sc, Y and La series, X is one or more of F, Cl and Br, a is greater than or equal to 0 and less than or equal to 10, and b is greater than or equal to 1 and less than or equal to 13. According to the invention, the ionic conductivity, the chemical / electrochemical stability and the plasticity can beremarkably improved; and in the manufacturing process of the electrode and the electrolyte, inert atmosphere protection is not needed, the method is very compatible with a traditional electrode manufacturing technology, the process is simple, the cost is low, the large-scale production capacity is extremely achieved, and therefore the commercial application value is extremely achieved.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD +1

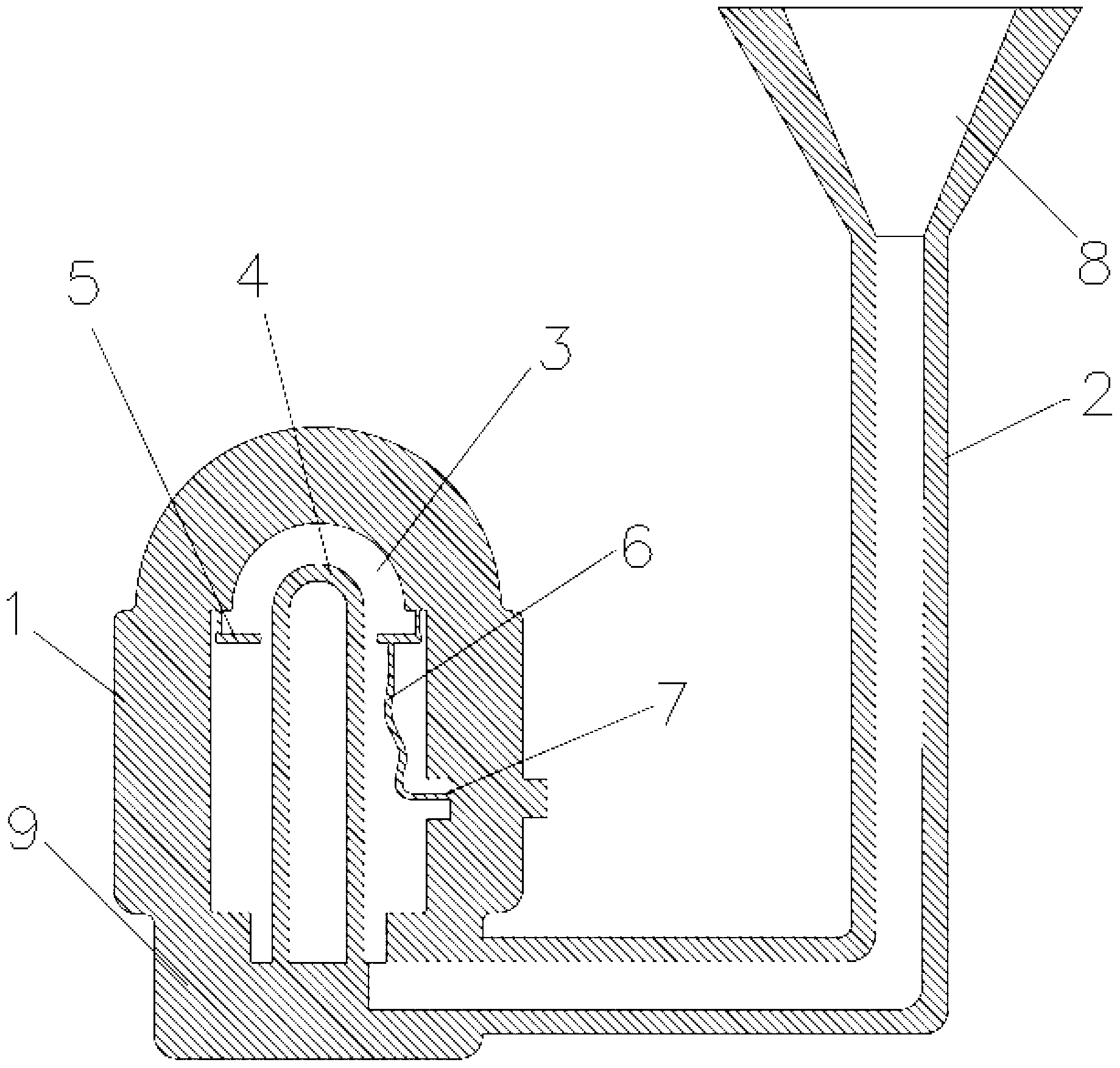

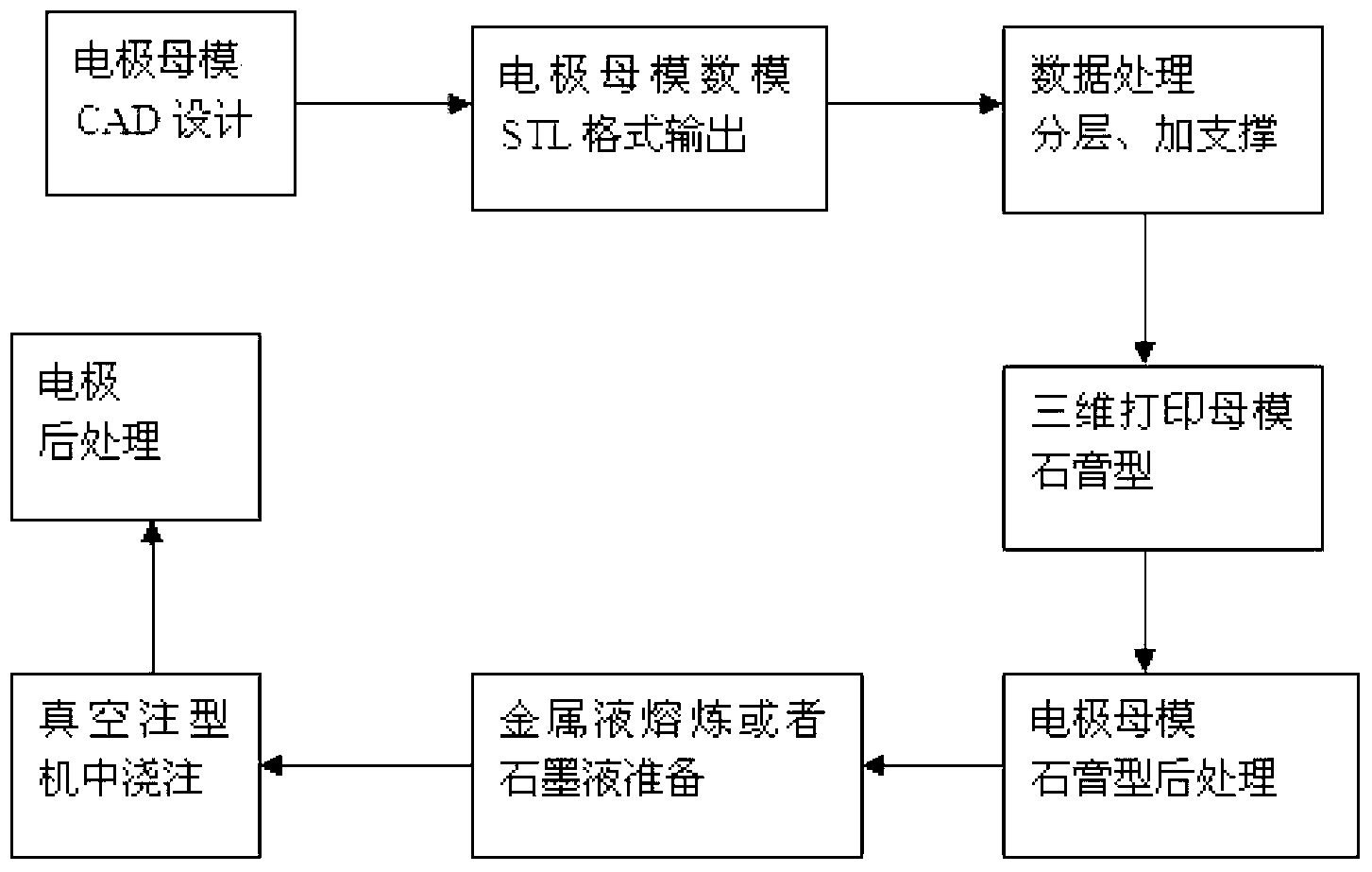

Device and method for quickly fabricating electrode

The invention relates to a method and a device for quickly fabricating an electrode. The method comprises the following steps: fabricating a gypsum part prototype, with completely the same shape as the electrode, as a female mold through three-dimensional printing, and then pouring copper liquid or graphite liquid in vacuum condition, cooling and solidifying the copper liquid or graphite liquid to form the electrode. The method can be used for quickly fabricating electrodes with complicated shapes, and is high in speed and low in cost; and the complicated die splicing process is omitted, the electrode forming is high in precision and high in speed, and the process is simple and applicable to production and processing of single and small-batch special-type electrodes in the electrode manufacturing industry.

Owner:NINGBO HECHUANG RAPID TECH

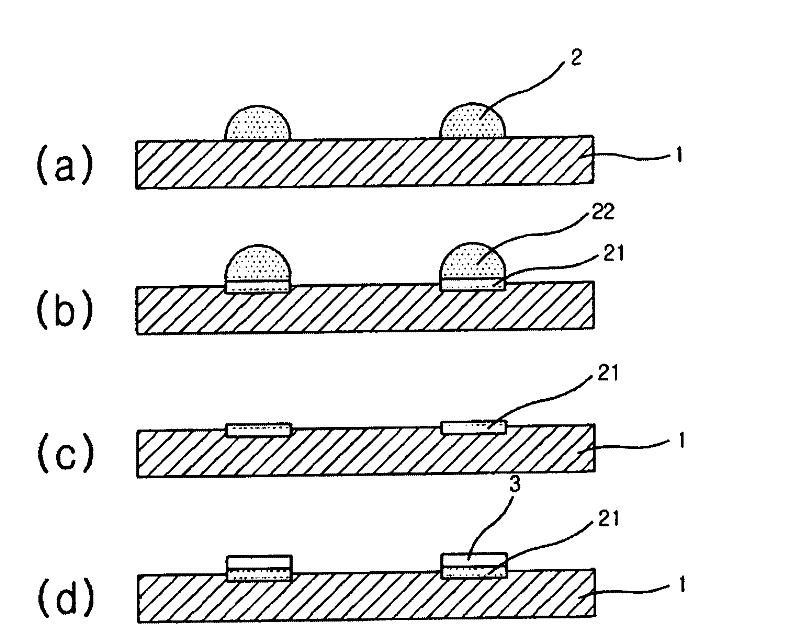

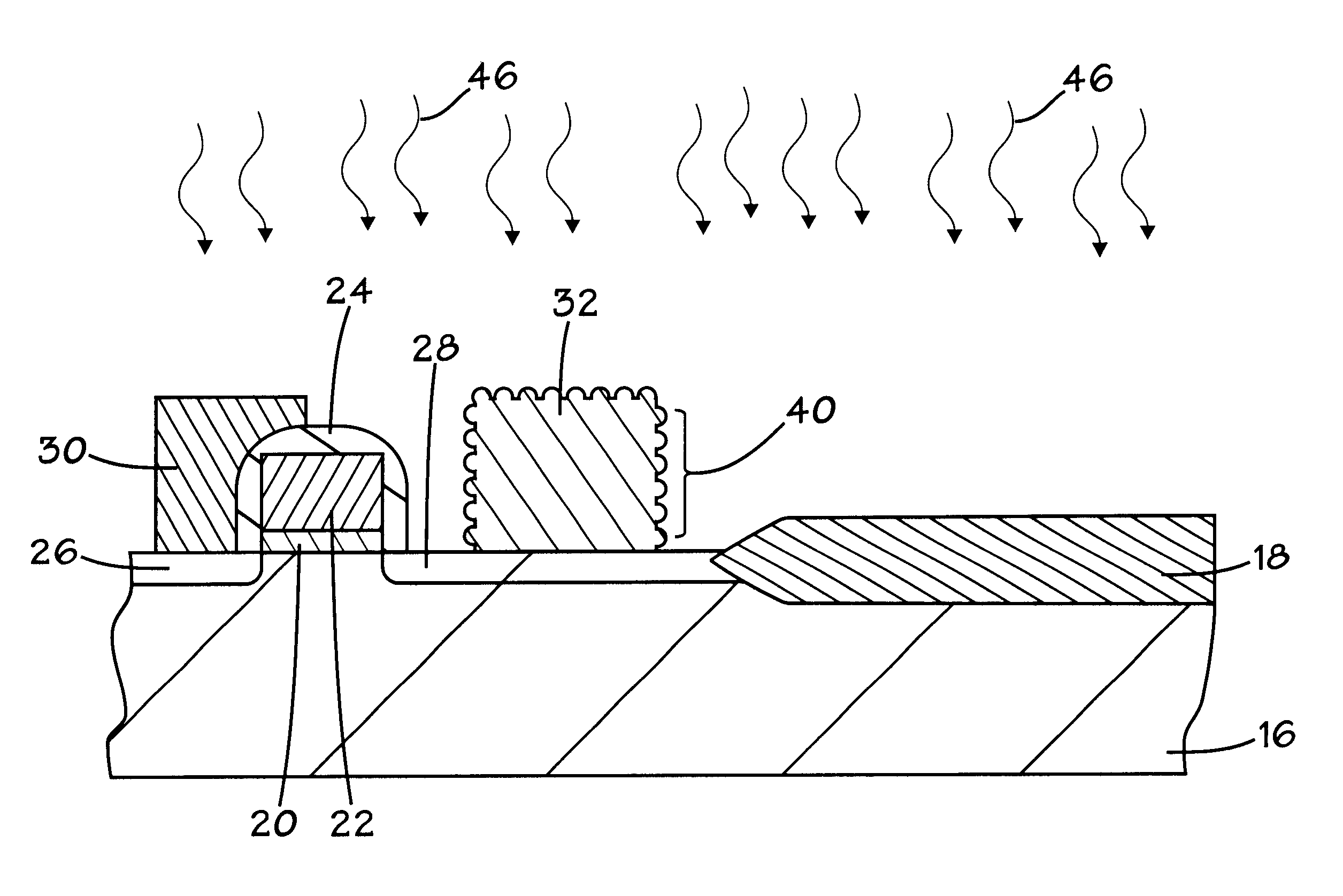

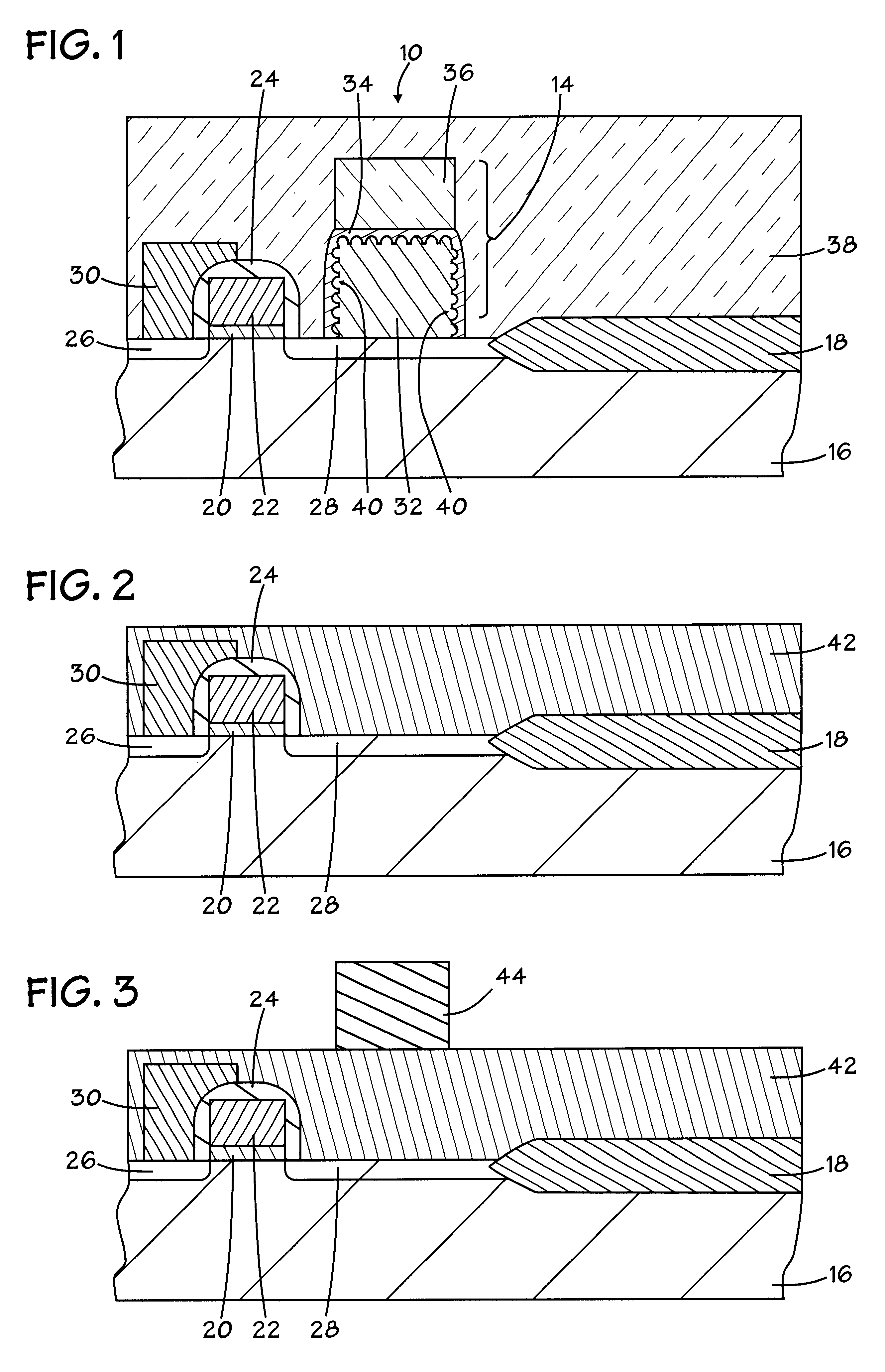

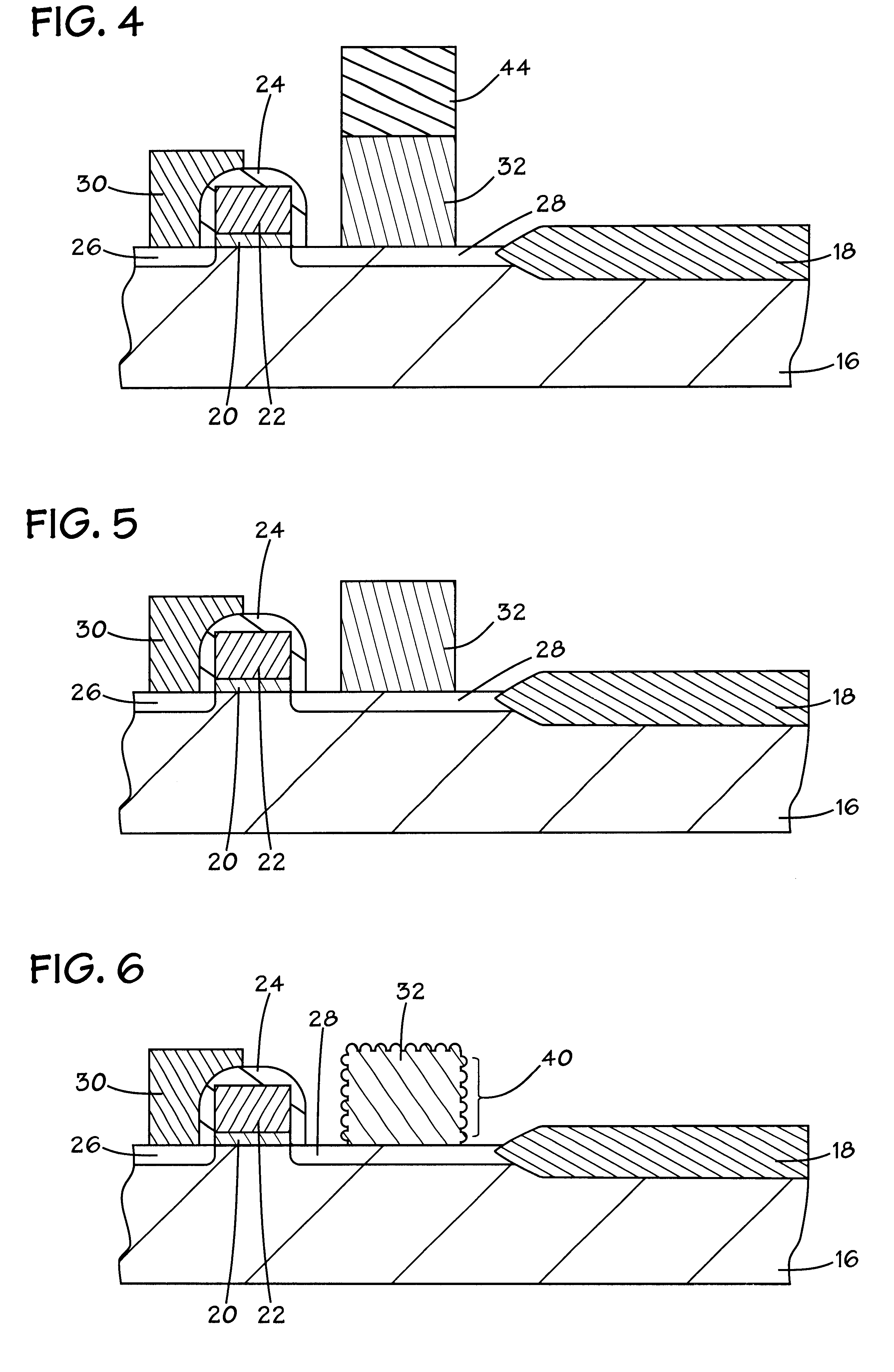

Methods of fabricating a memory device

Various methods of fabricating circuit devices are provided. In one aspect, a method of fabricating a circuit device on a substrate is provided. The method includes forming a doped silicon structure on the substrate and forming a hemispherical grain silicon film on the silicon structure. The substrate is heated from a first temperature to a second temperature while undergoing exposure to a dopant gas to add a dopant to the hemispherical grain silicon film. The method provides for improved capacitor electrode fabrication via concurrent gas exposure and substrate temperature ramp-up. In this way, dopant gas is introduced before the doped silicon structure transitions from an amorphous state to a polycrystalline state.

Owner:SAMSUNG AUSTIN SEMICON

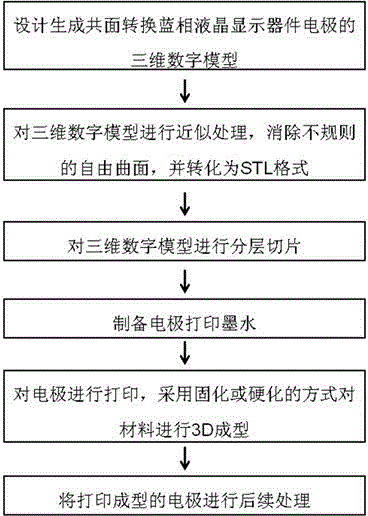

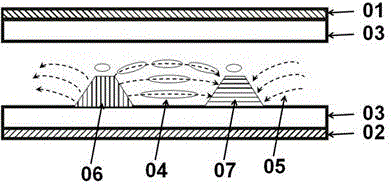

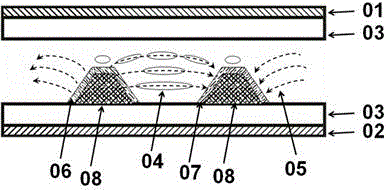

3D manufacturing method for an electrode of an in-planeswitching blue phase liquid crystal display device

InactiveCN104408214ADeep wellReduce the driving voltageSpecial data processing applicationsNon-linear opticsComputer printingDisplay device

The invention relates to a 3D manufacturing method for an electrode of an in-plane switching blue phase liquid crystal display device. The electrode may go deep into the blue phase liquid crystal to reduce a driving voltage. By way of layered manufacturing, the method comprises the steps: (1) designing a three-dimensional digital model; (2) performing an approximating process on the three-dimensional digital model to eliminate an irregular free surface, and converting the model into an STL format that can be accepted and operated by a 3D printer; (3) hierarchically slicing the model into a series of two-dimensional cross-sectional graphs; (4) preparing electrode printing paste; (5) printing the electrode by a 3D printing apparatus, and performing 3D molding on materials by curing or hardening; (6) performing a subsequent process on the printed electrode to form a desired electrode of the in-plane switching blue phase liquid crystal display device. The 3D manufacturing method, with great manufacturing flexibility, effectively reduces the complexity in and the cost of manufacturing the electrode of the in-plane switching blue phase liquid crystal display device.

Owner:FUZHOU UNIV

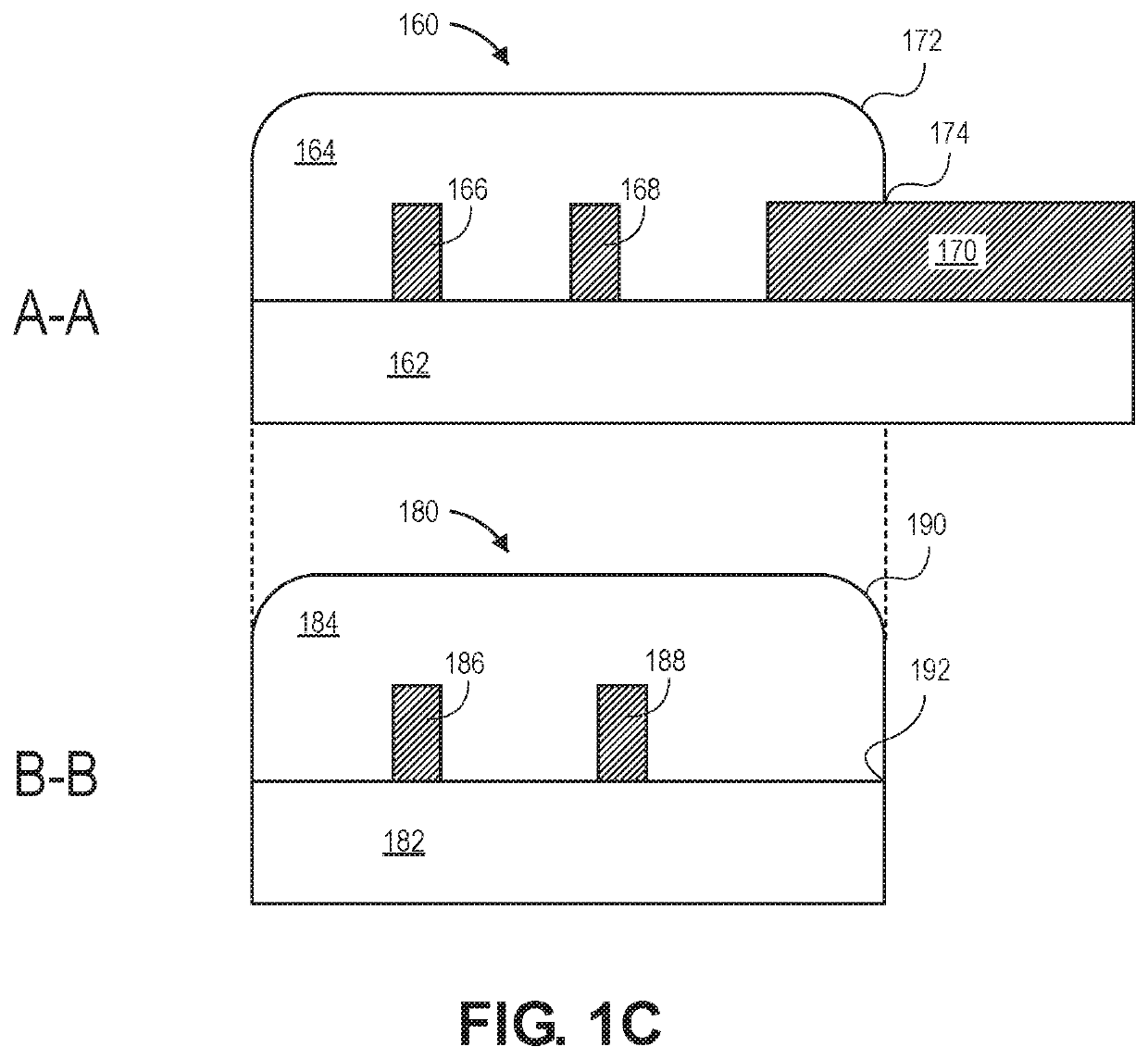

Electrode fabrication and design

PendingUS20200085375A1Good biocompatibilityImprove stabilityHead electrodesImplantable neurostimulatorsDielectricParylene

Disclosed are biocompatible multi-electrode devices capable of being implanted in sensitive tissue, such as the brain, and methods for fabricating such arrays. The disclosed arrays can be implanted in living biological tissue with a single needle insertion. The devices can include linear arrays with contacts along an edge, linear arrays with multiple electrodes per opening in a parylene support layer, multi-thread electrode arrays, tree-like electrode arrays, and combinations thereof. In an embodiment, a compliant electrode apparatus can comprise a biocompatible and bio-implantable compliant dielectric having a top edge defined by a top and a side along a length of the dielectric, insulated electrical traces oriented along the length of the dielectric, and electrode contacts coupled to the traces and situated on the side along the length of the dielectric, wherein an exposed portion of a respective electrode contact protrudes beyond the top edge of the dielectric.

Owner:NEURALINK CORP

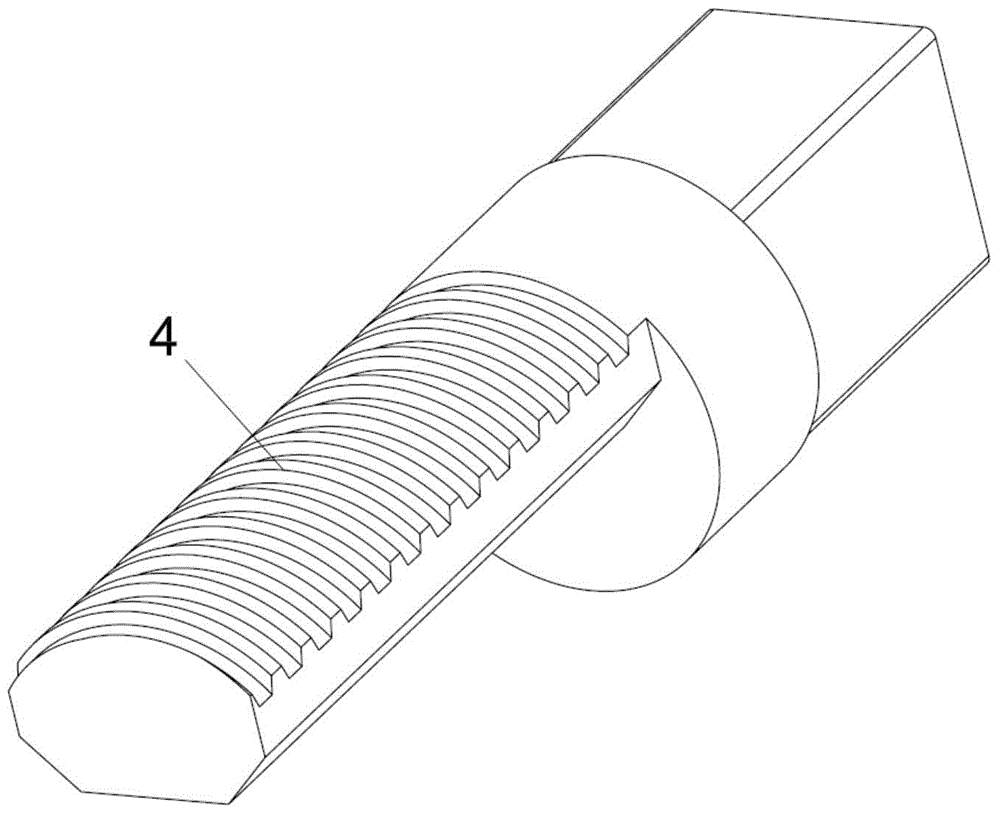

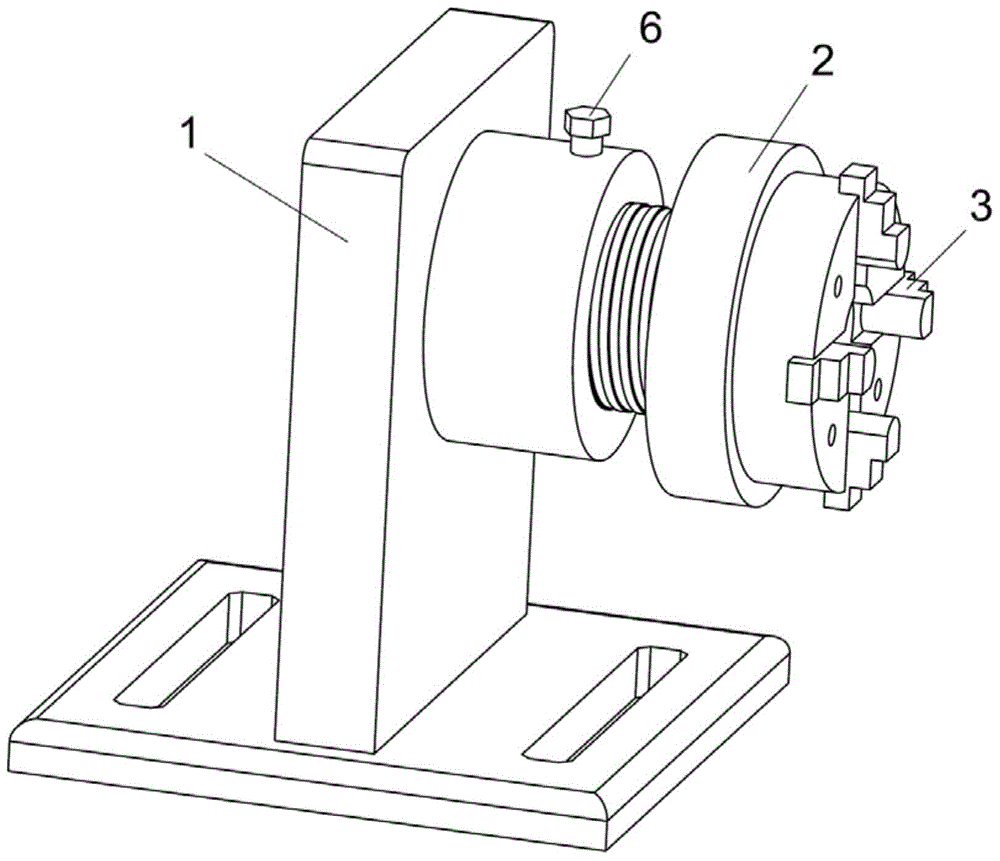

Method and tooling for electric spark machining of internal thread of hard alloy product

The invention discloses a method and a tooling for electric spark machining of an internal thread of a hard alloy product. The method comprises the following steps of S1: thread bottom hole machining; S2: tooling fabrication, including fabricating an electrode for discharging to the hard alloy product and a spiral clamping device for clamping the hard alloy product, and specifically including the following steps of S21: electrode fabrication; S22: spiral clamping device fabrication; S3: tooling installation; S4: product clamping; S5: internal thread machining, wherein the tooling includes the electrode for discharging to the hard alloy product and the spiral clamping device for clamping the hard alloy product. The method and the tooling for electric spark machining of the internal thread of the hard alloy product disclosed by the invention have the advantage that the machining of the internal thread of the hard alloy product and the machining of various internal circular large spiral grooves can be performed on an electric spark machine tool without Z-axis rotation.

Owner:成都科力铁硬质合金有限公司

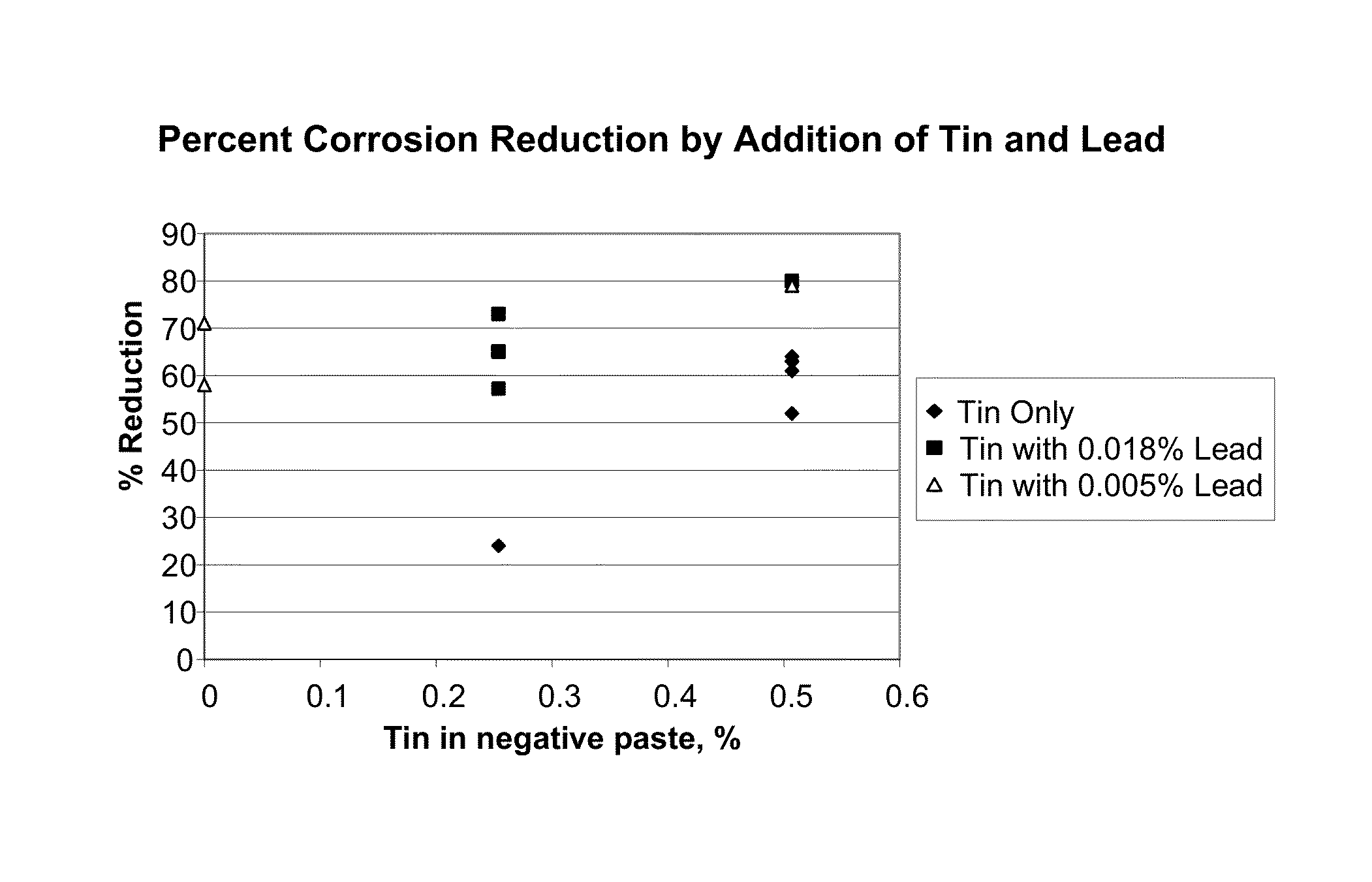

Pasted zinc electrode for rechargeable nickel-zinc batteries

ActiveUS8501351B2High viscositySimple working processFinal product manufacturePrimary cellsElectrolytic agentElectrical battery

Active material for a negative electrode of a rechargeable zinc alkaline electrochemical cell is made with zinc metal particles coated with tin and / or lead. The zinc particles may be coated by adding lead and tin salts to a slurry containing zinc particles, a thickening agent and water. The remaining zinc electrode constituents such as zinc oxide (ZnO), bismuth oxide (Bi2O3), a dispersing agent, and a binding agent such as Teflon are then added. The resulting slurry / paste has a stable viscosity and is easy to work with during manufacture of the zinc electrode. Further, the zinc electrode is much less prone to gassing when cobalt is present in the electrolyte. Cells manufactured from electrodes produced in accordance with this invention exhibit much less hydrogen gassing, by as much as 60-80%, than conventional cells. The cycle life and shelf life of the cells is also enhanced, as the zinc conductive matrix remains intact and shelf discharge is reduced.

Owner:ZINCFIVE POWER INC

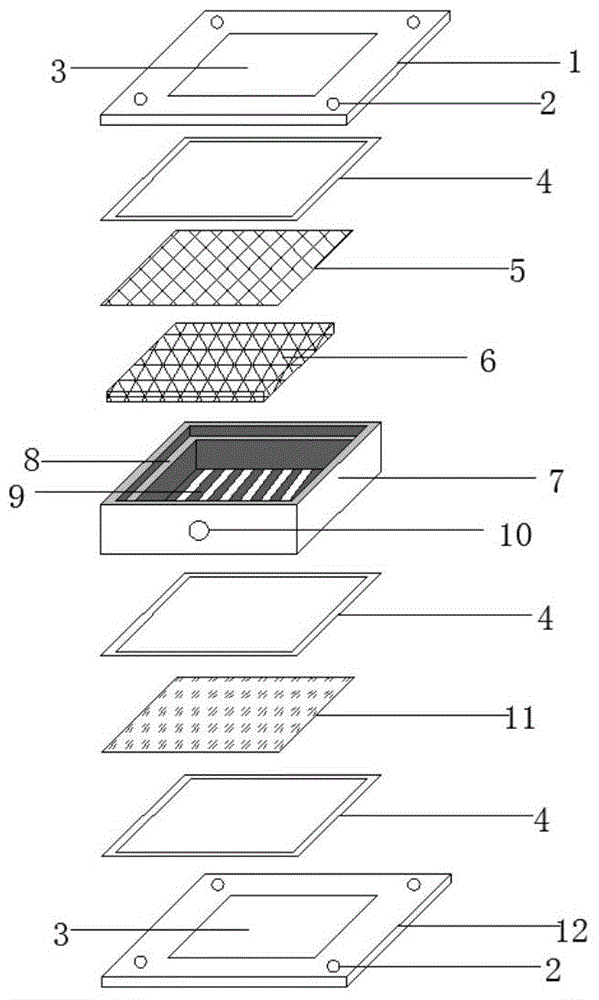

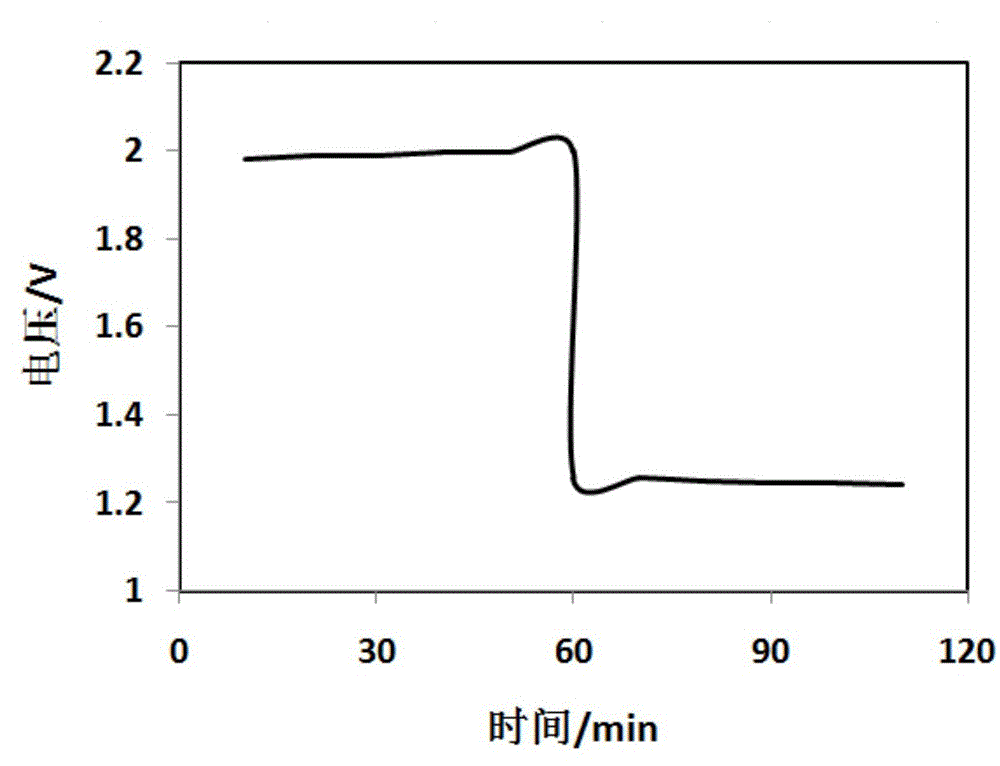

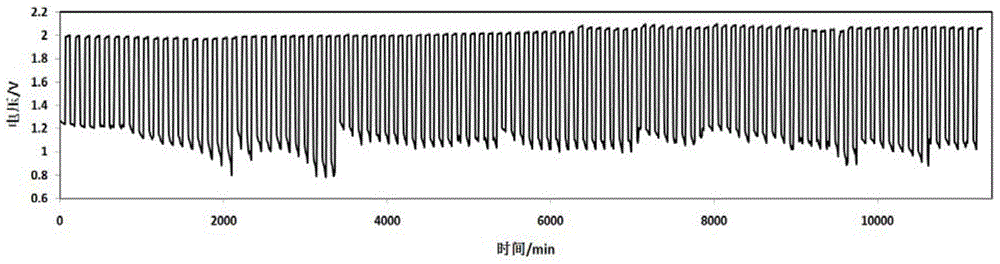

Horizontal three-electrode electrochemical rechargeable zinc-air battery

InactiveCN105098292AEliminate corrosionExtended service lifeFuel and secondary cellsElectrical batteryDendrite

The invention discloses a horizontal three-electrode electrochemical rechargeable zinc-air battery, belonging to the technical field of an electrochemical power supply. The battery comprises an oxygen precipitation electrode, a zinc electrode and a battery module and also comprises an oxygen reduction electrode, wherein the oxygen precipitation electrode, the zinc electrode and the oxygen reduction electrode are all horizontally arranged and assembled together by using the battery module, the zinc electrode and the oxygen precipitation electrode form a working loop during charging, and the zinc electrode and the oxygen reduction electrode form a working loop during discharging. The structure disclosed by the invention is favorable for battery sealing, the gravity effect during the charging and discharging process is eliminated, and zinc dendrite generation and zinc electrode deformation are prevented; by using a three-electrode system, the corrosion of oxygen generated during charging of a two-electrode system to an air electrode and the damage to a physical structure are avoided, and the cycle life of the battery is prolonged; and the horizontally-arranged electrodes are immersed in an electrolyte, thus, an oxygen diffusion channel built on the oxygen precipitation electrode is prevented, the electrode structure is greatly simplified, and the electrode fabrication and amplification is promoted.

Owner:TSINGHUA UNIV

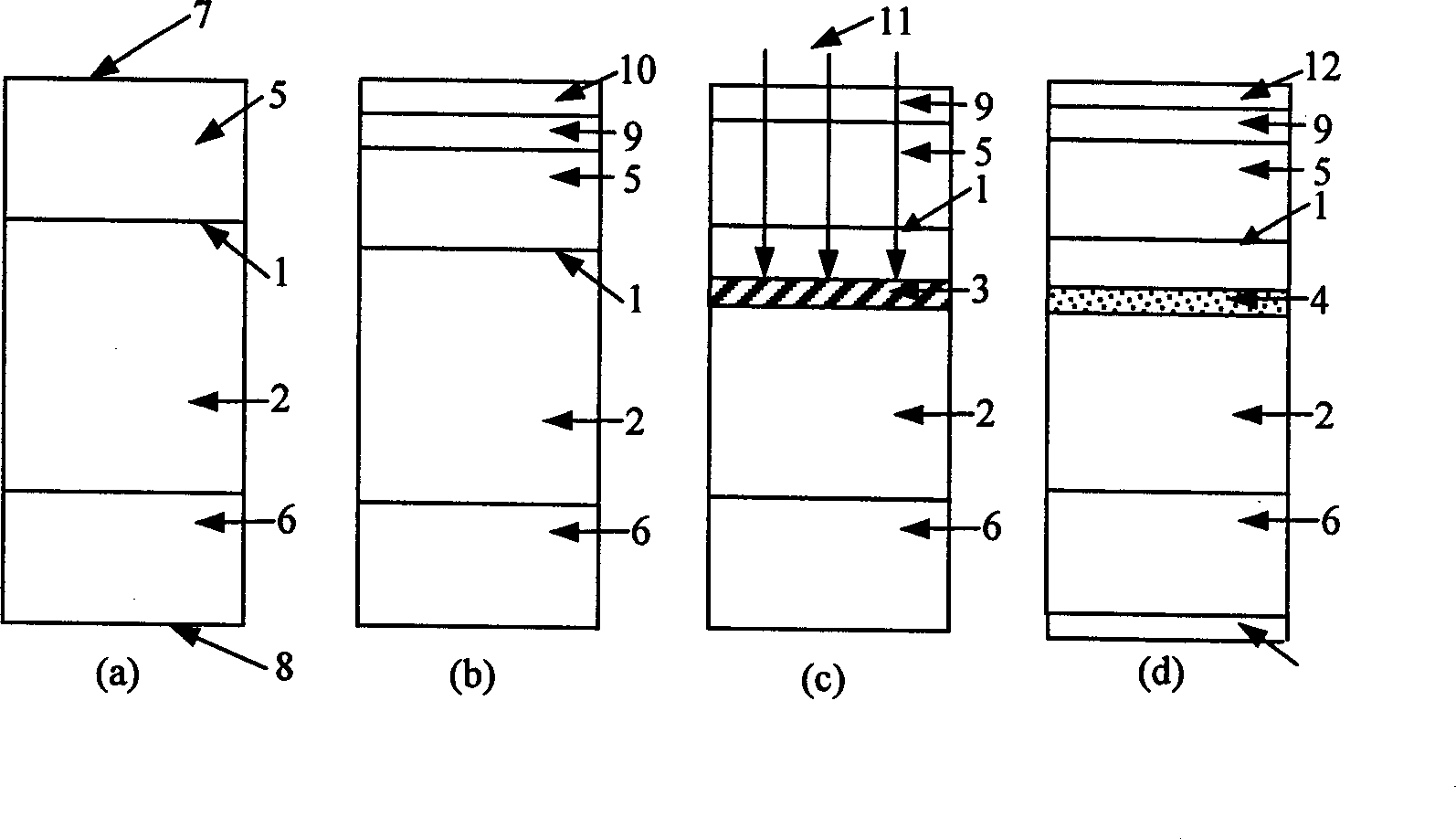

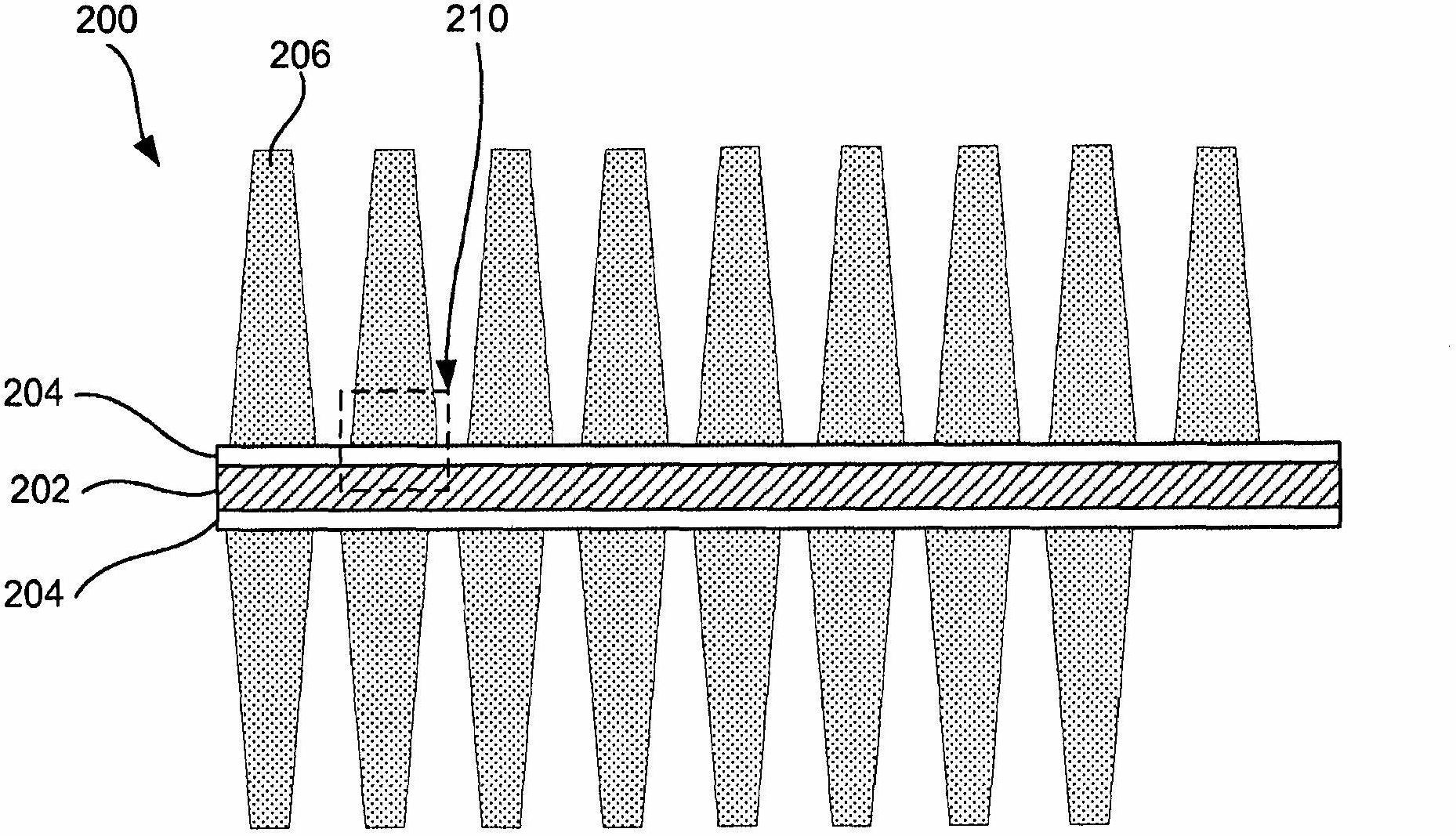

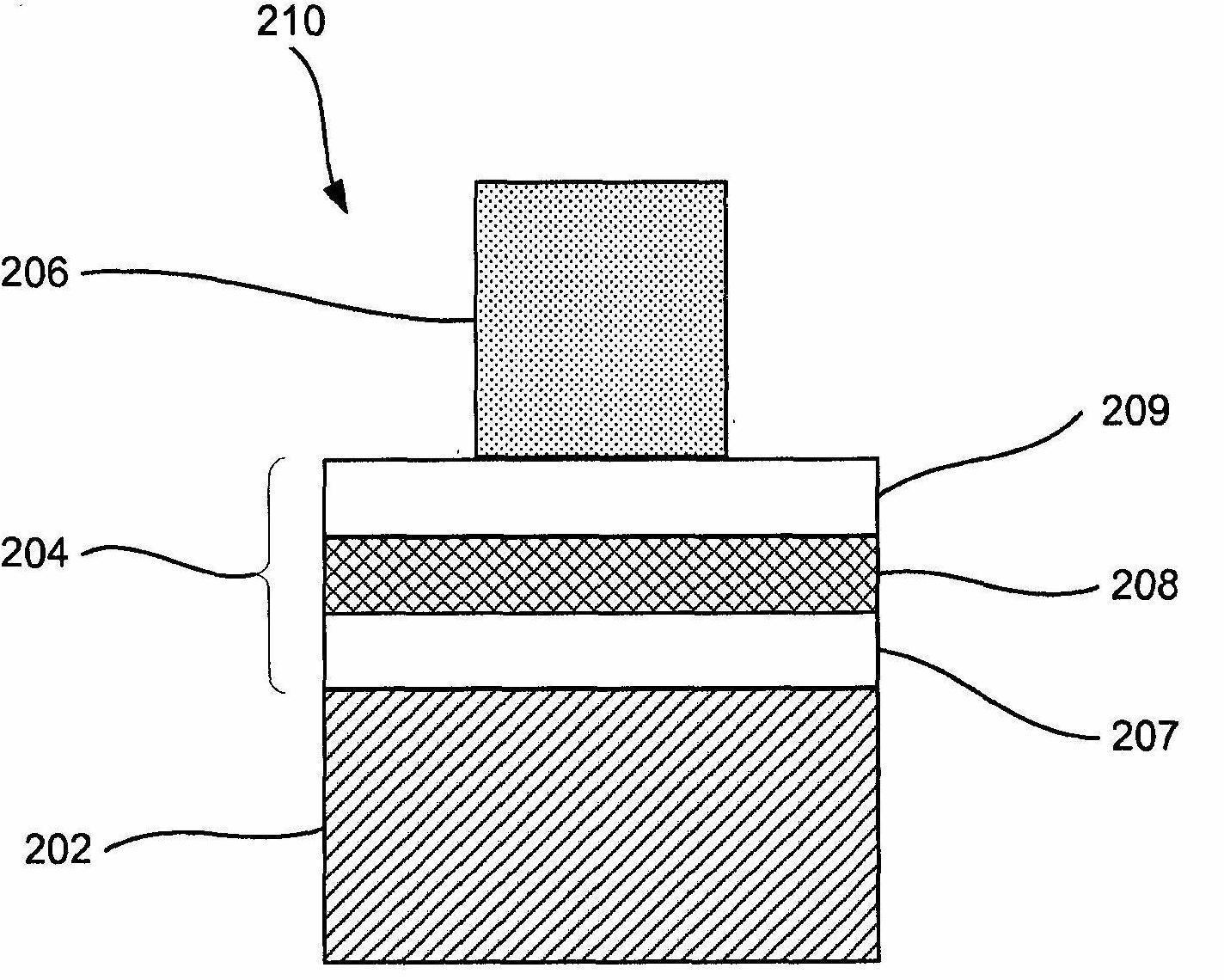

Intermediate layers for electrode fabrication

InactiveCN102687313ANanostructure manufactureElectrode manufacturing processesCyclic processElectrical connection

Provided are novel electrodes for use in lithium ion batteries. An electrode includes one or more intermediate layers positioned between a substrate and an electrochemically active material. Intermediate layers may be made from chromium, titanium, tantalum, tungsten, nickel, molybdenum, lithium, as well as other materials and their combinations. An intermediate layer may protect the substrate, help to redistribute catalyst during deposition of the electrochemically active material, improve adhesion between the active material and substrate, and other purposes. In certain embodiments, an active material includes one or more high capacity active materials, such as silicon, tin, and germanium. These materials tend to swell during cycling and may loose mechanical and / or electrical connection to the substrate.; A flexible intermediate layer may compensate for swelling and provide a robust adhesion interface. Provided also are novel methods of fabricating electrodes containing one or more intermediate layers.

Owner:AMPRIUS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com