Method for preparing solar cell electrodes, solar cell substrates prepared thereby, and solar cells

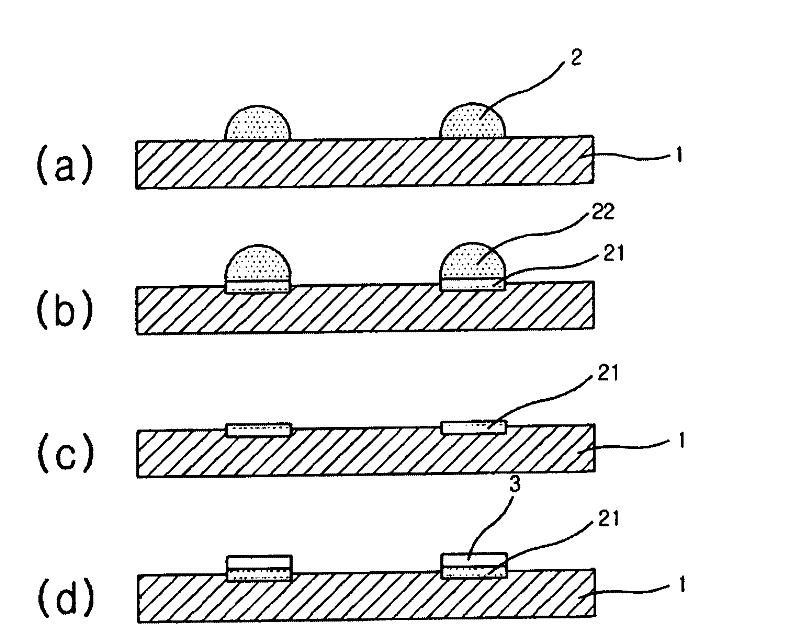

A solar cell and manufacturing method technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problem of weak adhesion of semiconductor wafers, reduce the number of superimposed printing, realize single printing, improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] First, offset printing (gravure offset printing) was performed using a mixture for offset printing (our company's paste name SSCP1672, silver powder 68%, glass frit 17%, adhesive 10%, dilution solvent 3%, dispersant and others 2%). Check the scraping state through the blade pressure and angle of the initial gravure roll, and adjust the Off pressure and Set pressure to the best state through the indirect roll Off nip and Set nip adjustment. 20 g of paste was thrown between the gravure roll and the blade to scrape off at 7 rpm. After the scraping was performed three or more times, the rubber of the intermediate roll was pasted at 7 rpm, and then the intermediate roll was rotated once. The paste on the rubber was fully absorbed during one rotation of the indirect roll and unloaded at 7 rpm. In this way, a conductive paste was printed once on a 5″ wafer fixed to a printed board in vacuum. After the printed substrate was dried, it was fired in an infrared furnace at a tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com