Patents

Literature

266results about How to "Lower specific resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

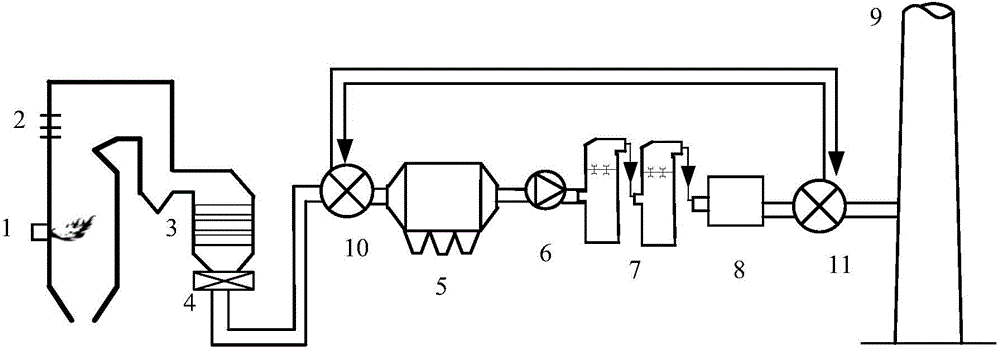

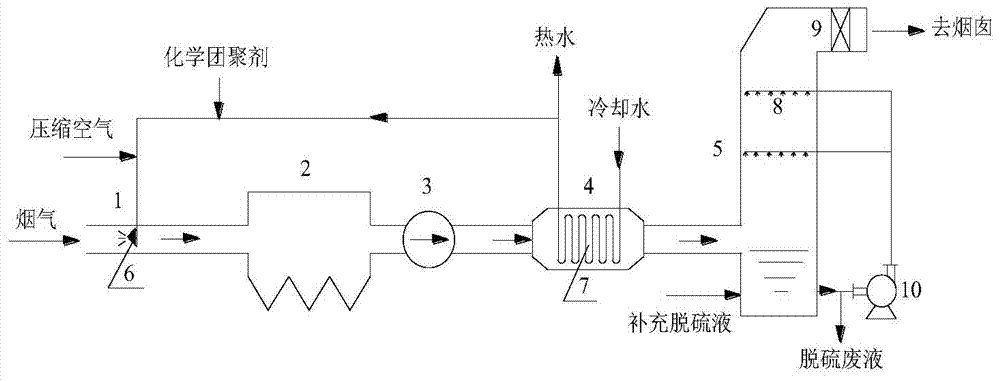

Method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in evaporation manner and device of method

InactiveCN102380278ALow running costConvenient sourceCombination devicesWater/sewage treatmentAir preheaterFlue gas

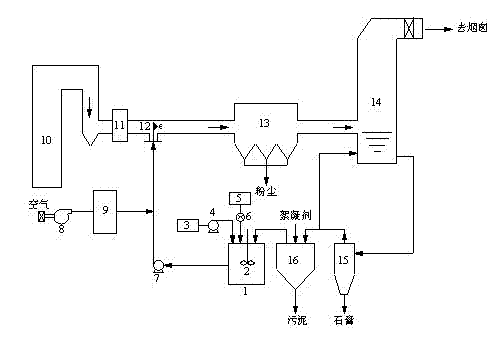

The invention discloses a method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in an evaporation manner and a device of the method. The method particularly includes steps that agglomeration liquor prepared by desulfuration wastewater, high polymer adhesive and wetting agent is sprayed into an inlet flue of an electric precipitator and is evaporated by the aid of heat of flue gas, in an evaporation process, the wetting agent promotes dust to enter drops of the agglomeration liquor, the high polymer adhesive is connected with PM2.5 via a polymer chain with polar groups, the grain diameter of the PM2.5 is prompted to be enlarged, so that the PM2.5 can be gathered by the follow-up electric precipitator, the desulfuration wastewater is evaporated completely, suspended matters and dissolvable pollutants in the wastewater are converted into solid to be dissolved out, and the suspended matters and the dissolvable pollutants in the wastewater, together with dust in the flue gas, are gathered by the electric precipitator. The device consists of a boiler, an air preheater, the electric precipitator, a desulfurizing tower, a hydraulic cyclone, a desulfuration wastewater clarification tank and an agglomeration liquor preparation tank, and a double-fluid atomizing nozzle is arranged in the flue between the air preheater and the electric precipitator.

Owner:SOUTHEAST UNIV

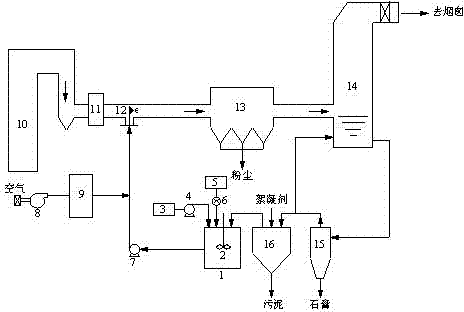

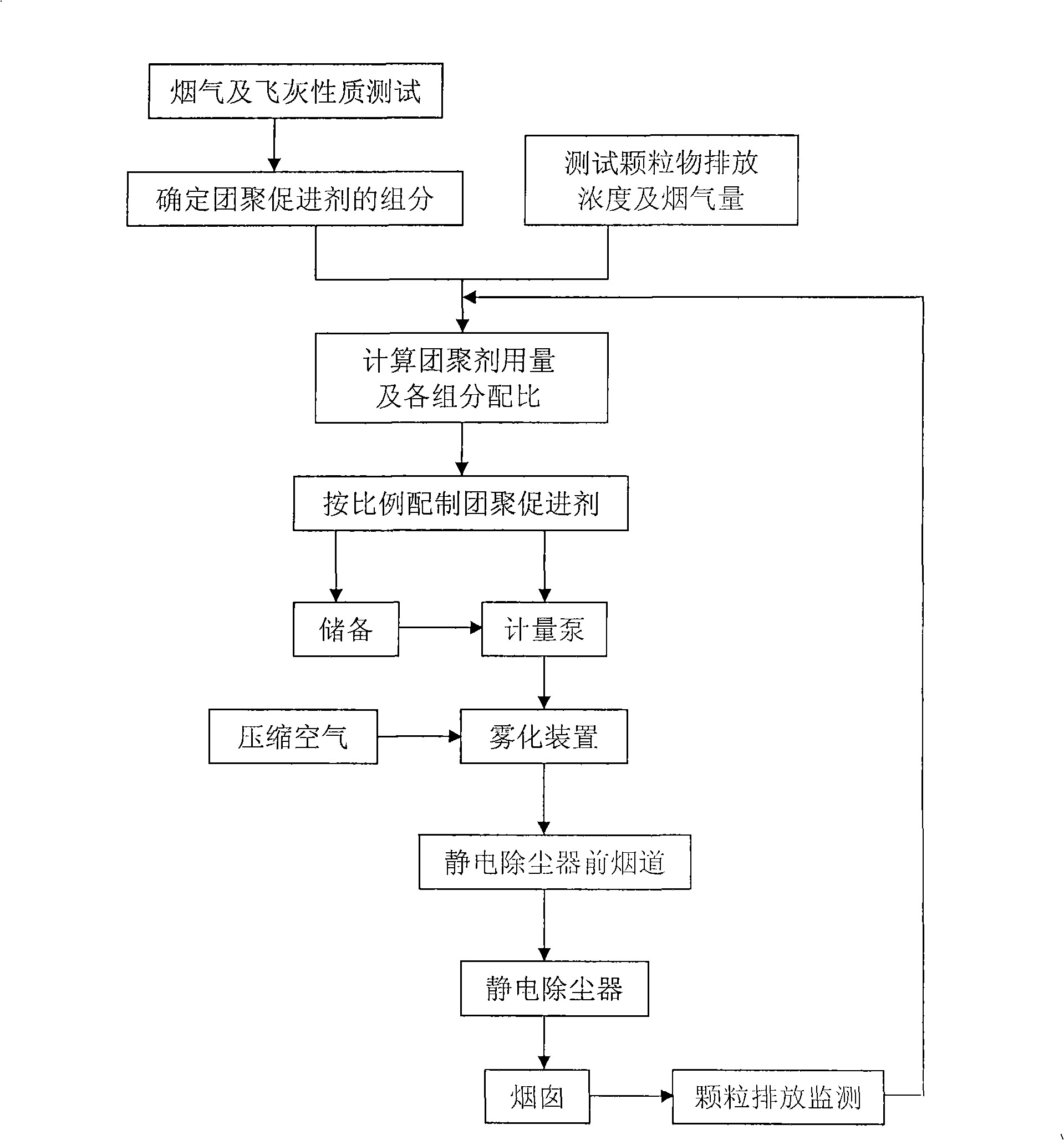

Coal-fired ultrafine grain chemical agglomeration promotor

ActiveCN101513583AWide variety of sourcesEasy to synthesizeAuxillary pretreatmentElectrostatic separationInorganic saltsWater soluble

The invention discloses a coal-fired ultrafine grain chemical agglomeration promotor which comprises the components based on mass percent: 0.001-0.2% of surface active agent, 0.0001-0.01% of water-soluble high molecular compound, 0.001-0.05% of inorganic salt additive and the rest of water. The invention can effectively promote ultrafine grains to agglomerate, improve the removal efficiency of a static precipitator for the ultrafine grains and high specific resistance flying ash, and reduce the soot emission and the charges for disposing pollutant of enterprises. The agglomeration promotor has the components with wide source, economical price, environmental protection, simple synthetic process, easy operation and no environmental pollution.

Owner:武汉天空蓝环保科技有限公司

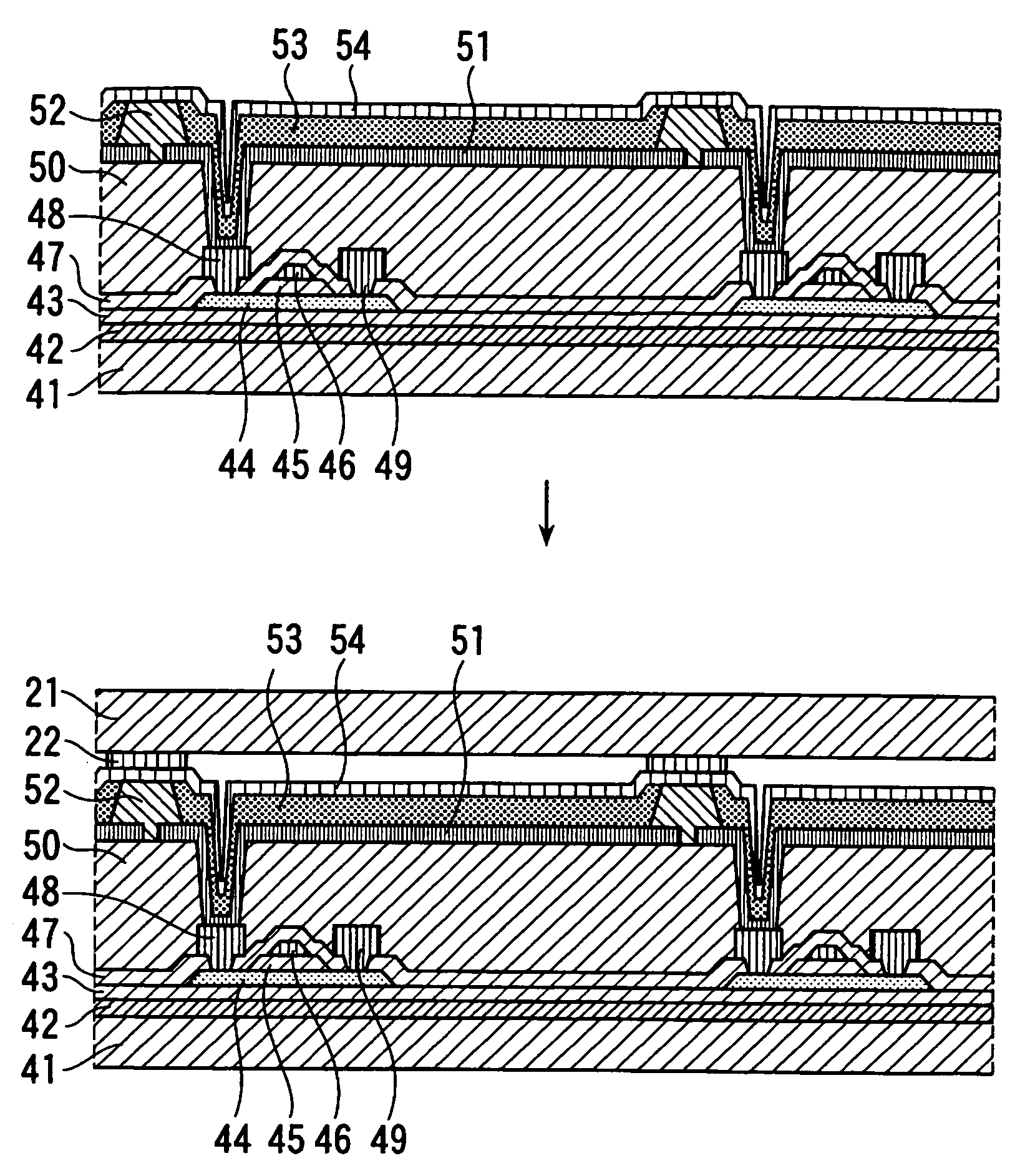

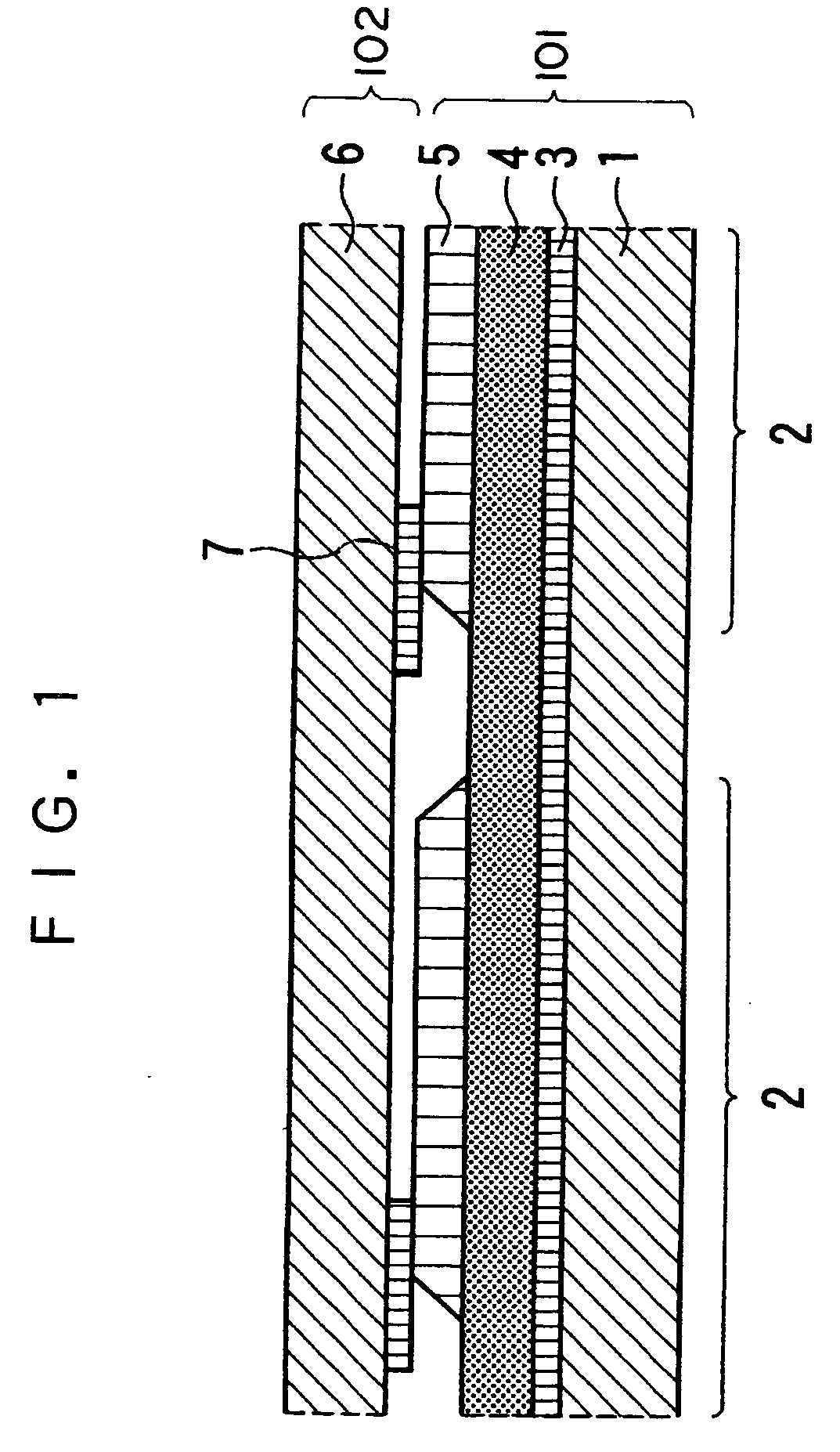

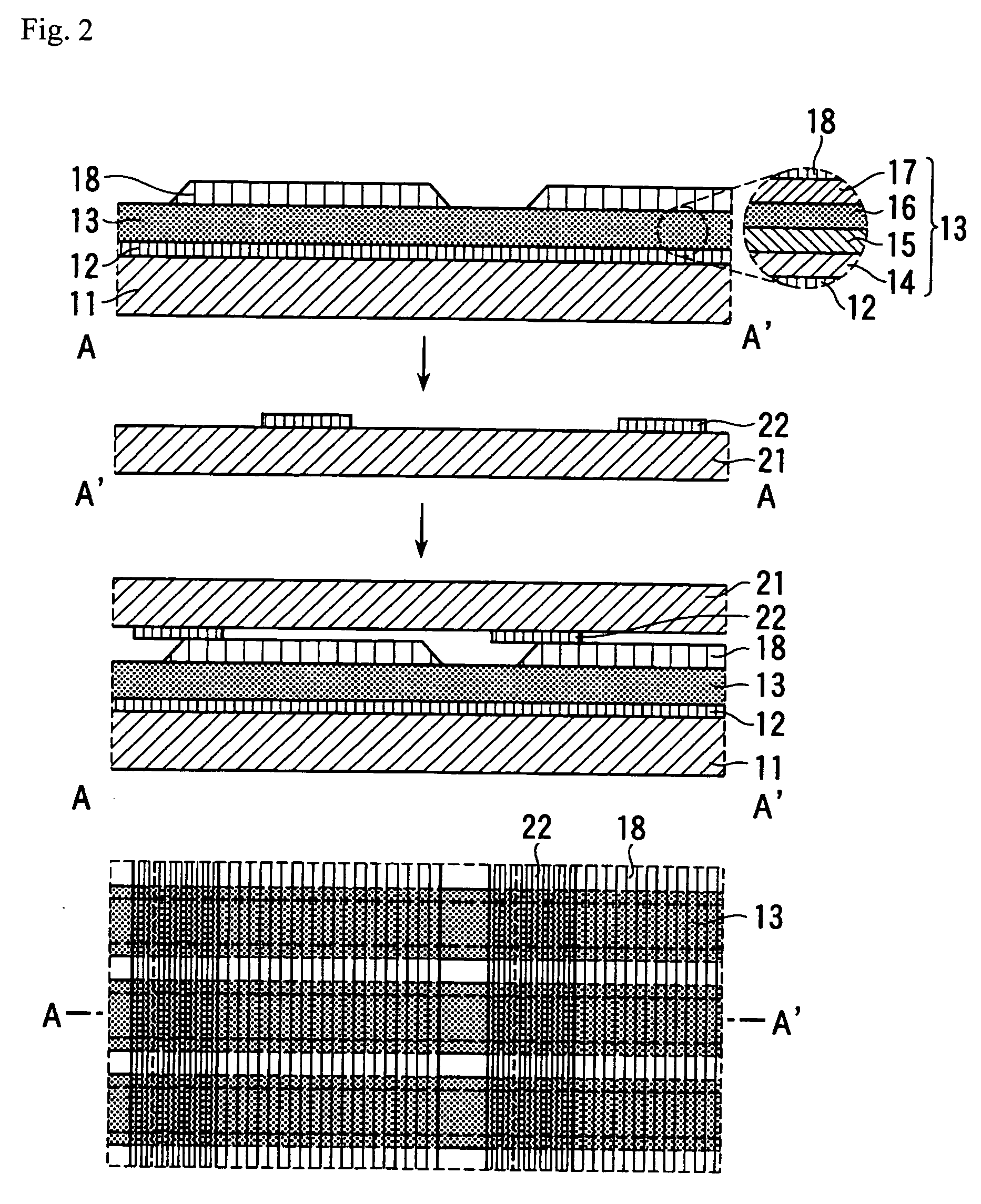

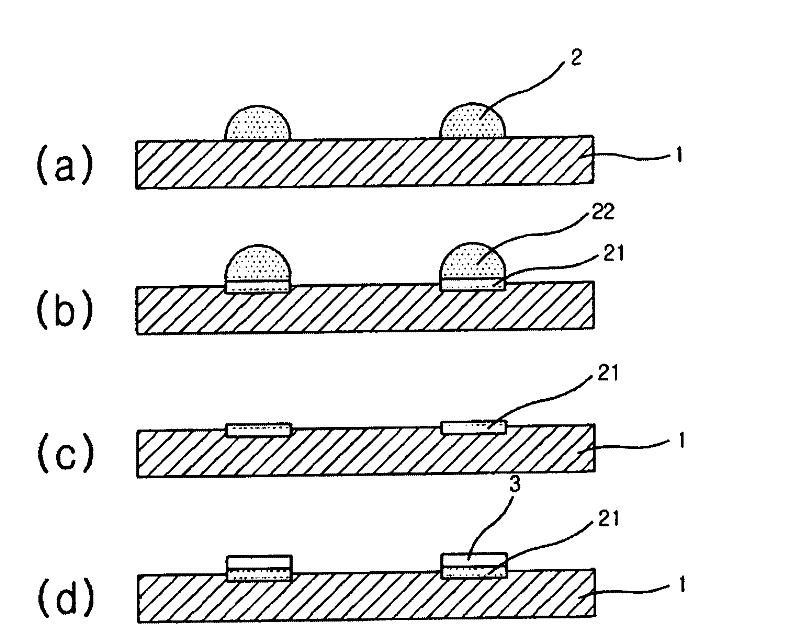

Organic electroluminescence display apparatus

InactiveUS20060273712A1Lower specific resistanceDischarge tube luminescnet screensElectroluminescent light sourcesOptoelectronicsOrganic electroluminescence

An organic electroluminescence display apparatus comprising a first substrate 101 and a second substrate 102 adhered to the first substrate, wherein the first substrate 101 comprises a first base substrate 1 having an organic electroluminescence device 2, the organic electroluminescence device 2 comprises a first electrode 3, an organic electroluminescence layer 4, and a second electrode 5 provided in this order from the first base substrate side, the second substrate 102 comprises a second base substrate 6 and a patterned conductive film 7 provided on the second base substrate 6 such that the patterned conductive film 7 faces the first substrate 101, the patterned conductive film 7 has a lower specific resistance than the second electrode 5, and the conductive film 7 is electrically connected to the second electrode 5.

Owner:FUJIFILM CORP

Synergistic removal system and method for realizing ultra-low emission of multiple pollutants of smoke of thermal power plant

InactiveCN104100964ALower specific resistanceImprove dust removal efficiencyCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelThermal power stationLow emission

The invention discloses a synergistic removal system and method for realizing ultra-low emission of multiple pollutants of smoke of a thermal power plant. By the aid of a synergistic dust-removal system consisting of a smoke cooler, an efficient dust remover, an efficient wet desulphurization system and a wet type electric dust remover, the total particulate matter emission in a chimney can be controlled within 5 mg / m<3>. By the aid of a synergistic mercury-removal system consisting of a selective catalytic reduction denitration system, the efficient dust remover, the efficient wet desulphurization system and the wet type electric dust remover, the emission concentration of mercury in the smoke at the chimney can be lower than 6 mu g / m<3>. By the aid of an efficient denitration system consisting of a low-nitrogen burner, a selective non-catalytic reduction denitration system and the selective catalytic reduction denitration system, the NOx concentration can be controlled within 50 mg / m<3>. A two-stage circulation two-tower limestone-gypsum wet desulphurization system is used, a rotary gas-to-gas heat exchanger is cancelled, the leakage of the original smoke to clean smoke is avoided, and the concentration of SO2 in the smoke can be controlled within 35 mg / m<3>. Besides, the synergistic removal system and method are low in overall investment level, and waste heat in the smoke can be recycled to reduce the energy consumption.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD +1

Potassium permanganate lysis/ferric chloride flocculation/biological carbon skeleton combined conditioning method for municipal sludge

InactiveCN105254153AExcellent net yieldLow costSludge treatment by de-watering/drying/thickeningSludgeMoisture

The invention discloses a potassium permanganate lysis / ferric chloride flocculation / biological carbon skeleton combined conditioning method for municipal sludge, belonging to the technical field of environmental management. The method comprises the step of feeding certain amounts of potassium permanganate, ferric chloride and biological carbon into excess sludge at a certain stirring speed according to a certain feeding sequence, so as to condition the municipal sludge, so that the dehydration property of the municipal sludge is improved. The method has the beneficial effects that the cost of conditioning agents is low, and the operation is simple; meanwhile, the sludge breakage, flocculating constituent reconstruction and filter cake skeleton structure construction are achieved by virtue of three conditioning agents, so that the dehydration property of the sludge is overall improved, and the limitations of a single method and the combination of two methods in the past are broken through; by virtue of combined conditioning of the three conditioning agents, the dehydration property of the sludge can be obviously improved, and the moisture content of dehydrated sludge reaches 62%-67%; the cost is low, and the process is simple. The method is significant for the solving of the pollution problem of sludge.

Owner:HUNAN UNIV

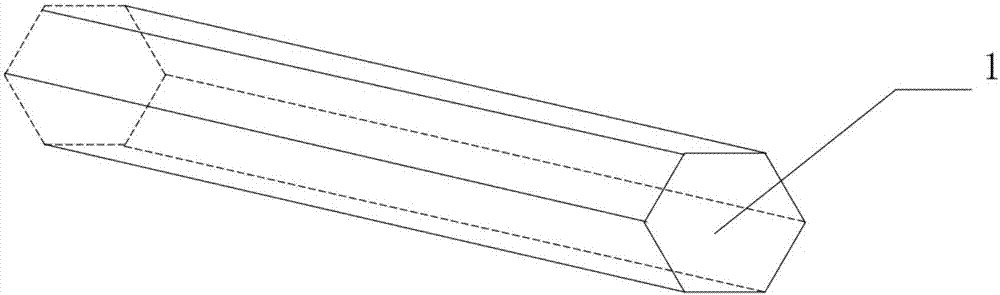

Oxide sintered body, sputtering target, transparent conductive thin film and manufacturing method therefor

InactiveCN1690011ALower specific resistanceImprove permeabilityConductive layers on insulating-supportsElectroluminescent light sourcesElectrical resistance and conductanceThin membrane

There is provided an amorphous transparent conductive thin film with a low resistivity, a low absolute value for the internal stress of the film, and a high transmittance in the visible light range, an oxide sintered body for manufacturing the amorphous transparent conductive thin film, and a sputtering target obtained therefrom. An oxide sintered body is obtained by: preparing In2O3 powder, WO3 powder, and ZnO powder with an average grain size of less than 1 mum so that tungsten is at a W / In atomic number ratio of 0.004 to 0.023, and zinc is at a Zn / In atomic number ratio of 0.004 to 0.100; mixing the prepared powder for 10 to 30 hours; granulating the obtained mixed powder until the average grain size is 20 to 150 mum; molding the obtained granulated powder by a cold isostatic press with a pressure of 2 to 5 ton / cm2, and sintering the obtained compact at 1200 to 1500 degree.C. for 10 to 40 hours in an atmosphere where oxygen is introduced into the atmosphere of the sinter furnace at a rate of 50 to 250 liters / min per 0.1 m3 furnace volume.

Owner:SUMITOMO METAL MINING CO LTD

Method for disposing sludge

InactiveCN102992566ALower specific resistanceGood for dehydration processSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationFlocculationAluminium chlorohydrate

The invention provides a method for disposing sludge. The method comprises the following steps of: mixing sludge to be disposed with an oxidation guide catalyst and an oxidant to carry out redox reaction; and mixing the redox reaction product with a flocculant to carry out coagulation, wherein the flocculant comprises the following components: 0-60wt% of FeCl3, 37-95wt% of aluminium polychlorid and 3-10wt% of cationic polyacrylamide. The method has the beneficial effects that firstly the sludge to be disposed and the oxidant carry out redox reaction in the presence of the oxidation guide catalyst and then the obtained reaction product is mixed with the flocculant to carry out coagulation; the flocculant adopted in the method is beneficial to deposition of small molecular substances in the obtained reaction product to enable the sludge flocs to undergo re-flocculation, thus increasing the volumes of the sludge flocs; and regenerated sludge flocs are conductive to reducing the specific resistance of the sludge as the proteins, polysaccharides and the like in the sludge are reduced.

Owner:湖南清和环保技术有限公司

Method for improving dehydration performance of sludge through oxidizing organic matters in sludge

ActiveCN104003602AStrong oxidizing propertiesHigh reactivitySludge treatment by de-watering/drying/thickeningSludge treatment by oxidationSludgeSoil organic matter

A method for improving dehydration performance of sludge through oxidizing organic matters in the sludge includes the following steps that (1), mixing dilution or concentration is performed; (2), chemical feeding is performed for oxidization; (3), solid-liquid separation is performed; (4), liquid filtering is performed. The method is simple in progress, conditions are easy to control, the dehydration time for the sludge can be shortened, and the sludge can be treated on a large scale.

Owner:湖南葆华环保科技有限公司

Sludge dewatering agent and use method thereof

InactiveCN107032580ALower specific resistanceReduce the amount addedSludge treatment by de-watering/drying/thickeningBio-organic fraction processingPorosityResource utilization

The invention relates to a sludge dewatering agent which is formed by a filter aid, a flocculant and a superoxide, the specific resistance of sludge can be effectively reduced, the sludge dewatering agent can be taken as an accessory for further aerobic composting treatment of the dewatered sludge, the accessory consumption of the composting stage is reduced, the turning times can be reduced due to high porosity, the composting power consumption is reduced, and the sludge dewatering agent has multiple purposes; substances of lime and the like which influence follow-up resource utilization are not contained; ferric chloride is not contained, corrosion to the steel structure is not produced, the colloid structure of the sludge is changed by the superoxide, and the addition of the filter aid is reduced greatly. The invention further relates to a use method of the sludge dewatering agent, the method comprises the following steps that firstly thickened sludge is heated to 40 DEG C to 50 DEG C, then the superoxide is added, the flocculant and the filter aid are added, the treated sludge is subjected to mechanical filter pressing, and the moisture content is reduced to 70% or below.

Owner:北京首创污泥处置技术有限公司

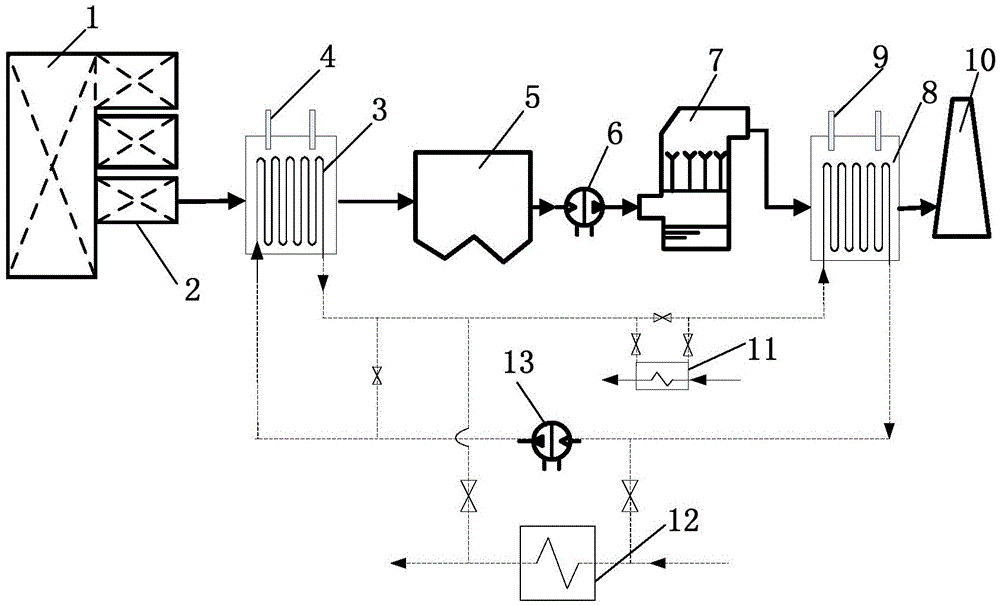

Boiler energy saving and emission reduction system based on flue gas waste heat recovery and reheating technology

ActiveCN104100994ALower specific resistanceReduce trafficCombustion processIndirect carbon-dioxide mitigationProcess engineeringFlue gas

The invention discloses a boiler energy saving and emission reduction system based on flue gas waste heat recovery and the reheating technology. The system comprises an air preheater, a flue gas cooler, an electrostatic dust collector, a desulfurizing tower, a flue gas reheater, and a chimney. A flue gas inlet of the air preheater is communicated with a flue gas outlet of a boiler. A flue gas outlet of the air preheater is communicated with a flue gas inlet of the flue gas cooler. A flue gas outlet of the flue gas cooler is communicated with a flue gas inlet of the electrostatic dust collector. A flue gas outlet of the electrostatic dust collector is communicated with a tail flue gas inlet of the desulfurizing tower. A desulfurized flue gas outlet of the desulfurizing tower is communicated with a flue gas inlet of the flue gas reheater. A reheated flue gas outlet of the flue gas reheater is communicated with a flue gas inlet of the chimney. A hot water outlet of the flue gas cooler is communicated with a hot water inlet of the flue gas reheater. A cold water outlet of the flue gas reheater is communicated with a cold water inlet of the flue gas cooler through a booster pump. The boiler energy saving and emission reduction system based on flue gas waste heat recovery and the reheating technology allows boiler flue gas to be treated and is long in service life, energy efficient and environment friendly.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD +1

Novel sludge dehydrating agent

InactiveCN104829088AGood dehydration synergyReduce dosageSludge treatment by de-watering/drying/thickeningAluminium chlorideSodium Bentonite

The present invention discloses a novel sludge dehydrating agent, a preparation method and applications thereof, and belongs to the sludge treatment field, wherein poly aluminium chloride, calcium oxide, ferric sulfate, bentonite, starch, and polyacrylamide are mixed according to a certain ratio, and then drying is performed for 20-40 min at a temperature of 80-100 DEG C to prepare the novel sludge dehydrating agent. According to the present invention, the novel sludge dehydrating agent has the good dehydrating effect, the water content of the dehydrated sludge is 40-50%, the polyacrylamide content is low, the environmental pollution is low, the preparation process is simple, the cost is low, and the novel sludge dehydrating agent is suitable for large-scale sludge dehydrating treatment.

Owner:唐国萍

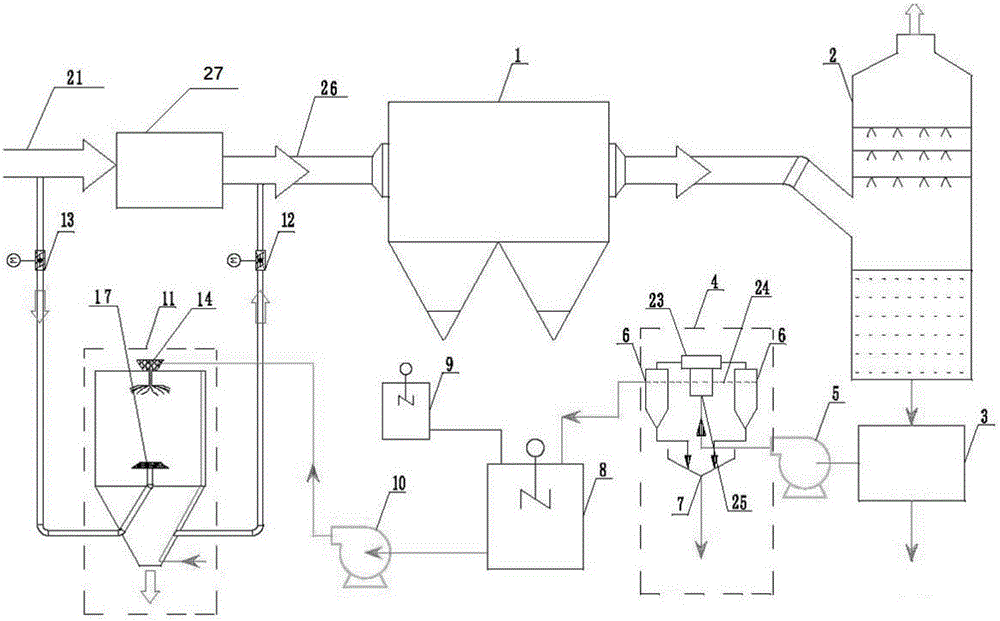

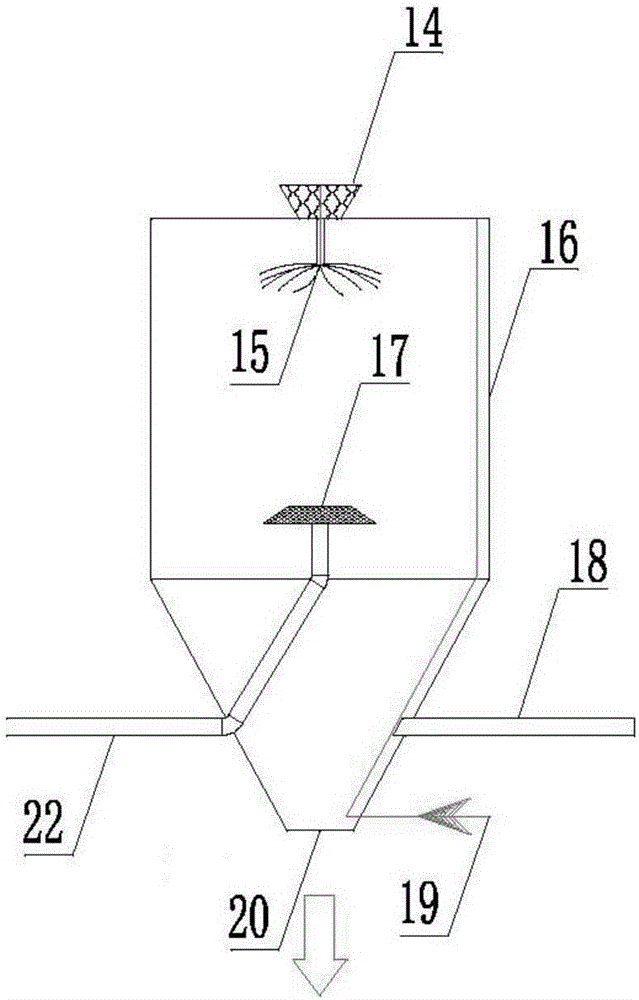

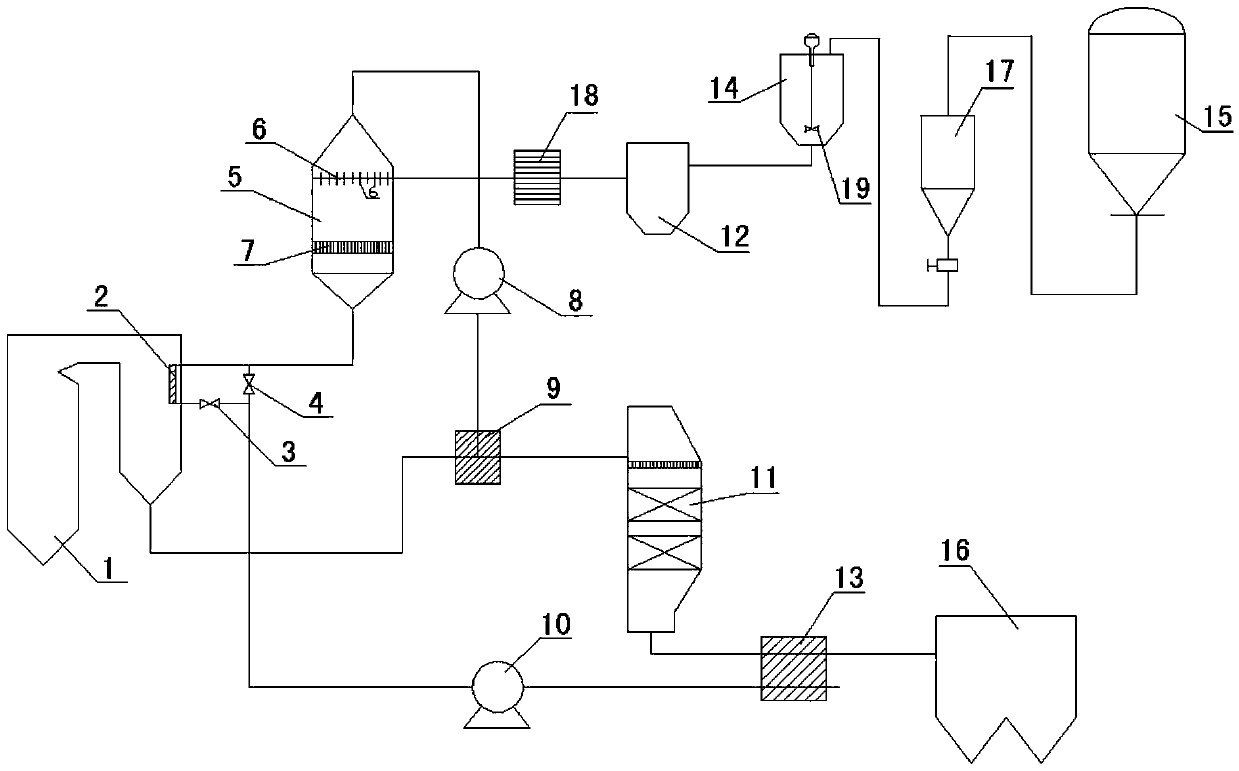

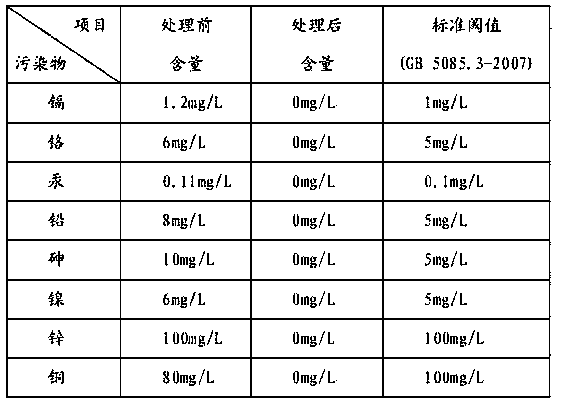

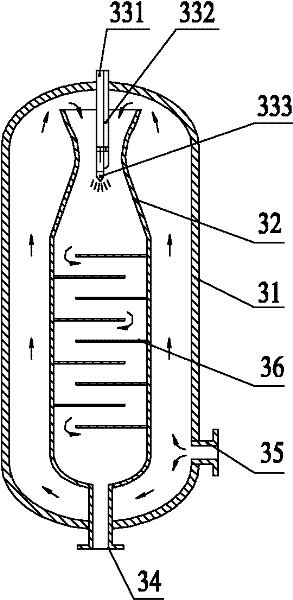

Zero-release coupling humidifying dust-removing synergizing system and method for desulfurization wastewater

PendingCN106630358AAvoid poor evaporationImprove dust removal efficiencyWater/sewage treatment by centrifugal separationElectrostatic separationAir preheaterCyclone

The invention relates to a zero-release coupling humidifying dust-removing synergizing system and a zero-release coupling humidifying dust-removing synergizing method for desulfurization wastewater. The zero-release coupling humidifying dust-removing synergizing system comprises a desulfurizing tower, a gypsum dewatering system, a wastewater cyclone, a wastewater box, a rotary spraying and evaporating tower and a dust remover, wherein wastewater treated through the gypsum dewatering system is treated through the wastewater cyclone; afterwards, one part underflows to the desulfurizing tower to be repeatedly utilized; one part overflows to a wastewater box to be collected; the wastewater is conveyed to a rotary sprayer to be atomized; an atomized fog drop descends, is regressively in contact with a high-temperature fume which is introduced from the front of an air pre-heater; a solid particle in the evaporated wastewater and the fume integrally descend to the lower part of a rotary evaporating tower, and enter a front flue of the dust remover through an outlet flue of the rotary evaporating tower; the wastewater passes through the dust remover in a form of purified water vapor to enter the desulfurizing tower. The zero-release coupling humidifying dust-removing synergizing system and the zero-release coupling humidifying dust-removing synergizing method are high in wastewater treatment stability, and are not influenced by the load of a unit; the investment and running expenses are low; the water consumption and the energy consumption are reduced; the fume humidity is increased while the zero release of the wastewater is realized; the dust removal efficiency of the dust remover is improved.

Owner:ZHEJIANG UNIV

Production method of rabbit hair, cashmere and silk three-in-one face fabric

InactiveCN101225568ASoft and smoothNatural elegant lusterHeating/cooling textile fabricsLiquid/gas/vapor removalYarnEngineering

The invention relates to a triad producing method of clothing face fabric with rabbit hair, cashmere and silk, which is characterized in that: the raw material comprises 14% of the silk, 39% of the rabbit hair, 44% of the wool and 3% of the cashmere, the clothing face fabric with rabbit hair, cashmere and silk is made by the processes of dyeing, garneting, spun yarn, warping, weaving and after-finishing. The triad producing method of clothing face fabric with rabbit hair, cashmere and silk has the advantages of gathering the elasticity and heat retention of the wool, and the excellent properties of the rabbit hair and the silk, soft and satiny hand feeling, natural and elegant luster, excellent heat retention, and suitable for the demand of higher consumption level stratum.

Owner:江阴市天鹅制呢厂有限公司

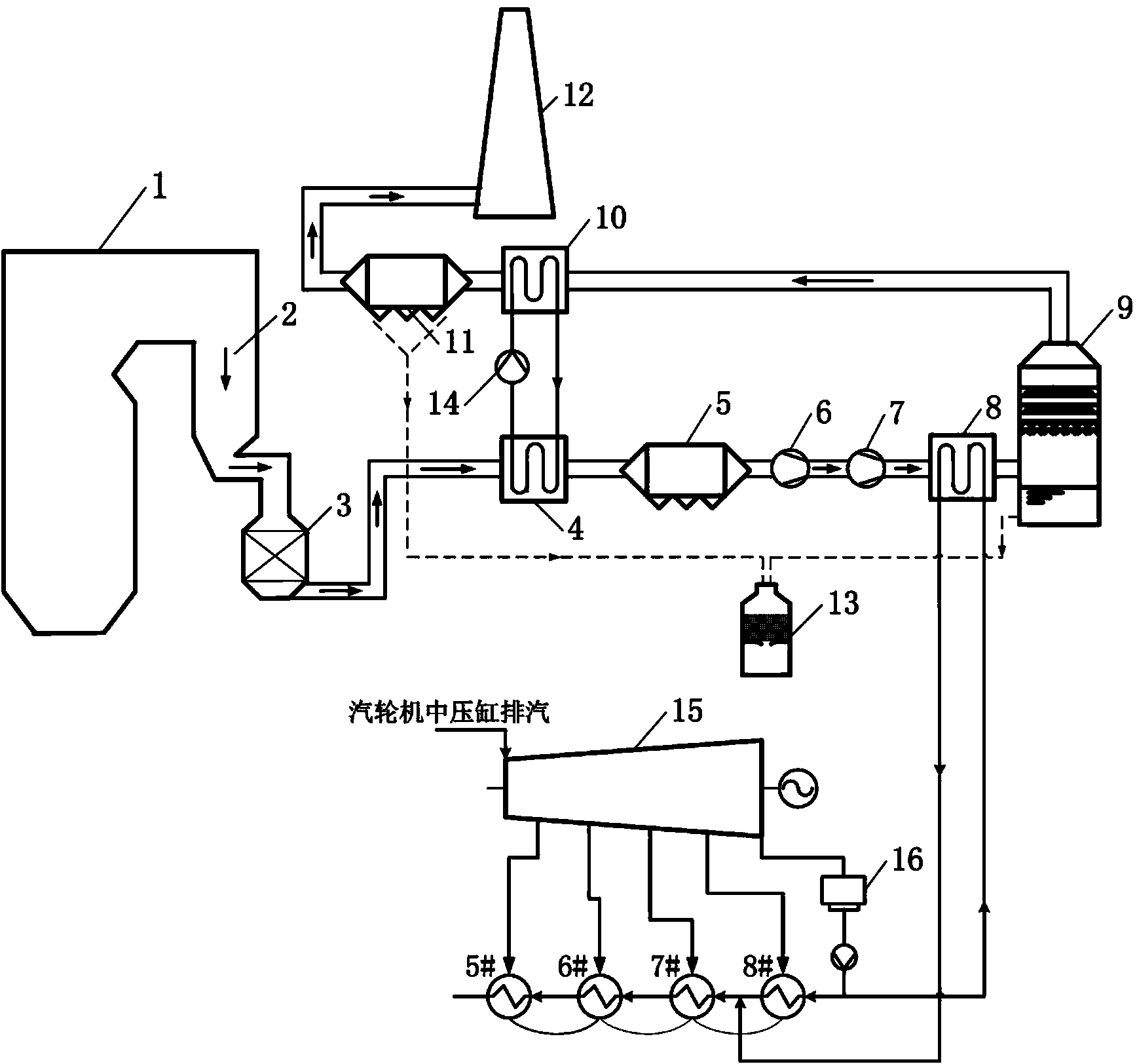

Method and device for cooperatively enhancing PM2.5 (Particulate Matter 2.5) removal and smoke afterheat deep utilization

ActiveCN103868087APromote reunionReduce dust specific resistanceExternal electric electrostatic seperatorFeed-water heatersLiquid temperatureFlue-gas desulfurization

The invention relates to a method and a device for cooperatively enhancing PM2.5 (Particulate Matter 2.5) removal and smoke afterheat deep utilization. The device is composed of a smoke humidifying device, an electric dust remover, a low-temperature coal economizer and a wet desulphurization tower. The method comprises the following steps: before smoke enters the electric dust remover, spraying atomized hot water to carry out humidifying and tempering treatment; enhancing the PM2.5 capturing of the electric dust remover and improving the moisture content of the smoke; providing the atomized hot water by the low-temperature coal economizer; arranging the low-temperature coal economizer between the electric dust remover and the desulphurization tower to recycle the sensible heat released by cooling the smoke to obtain the smoke with high relative humidity; then adjusting an inlet gas-liquid temperature difference and a desulphurization liquid-gas ratio of the subsequent wet desulphurization tower to enable the smoke with the high relative humidity in the desulphurization tower to be over-saturated in a desulphurization and washing process; and carrying out nucleation condensation on over-saturated water steam on the surface of PM2.5 so as to enable the granularity of the PM2.5 to grow and be captured. According to the method and the device, the capturing effect on the PM2.5 by the electric dust remover and a wet smoke desulphurization system can be enhanced and the smoke afterheat can also be recycled.

Owner:SOUTHEAST UNIV

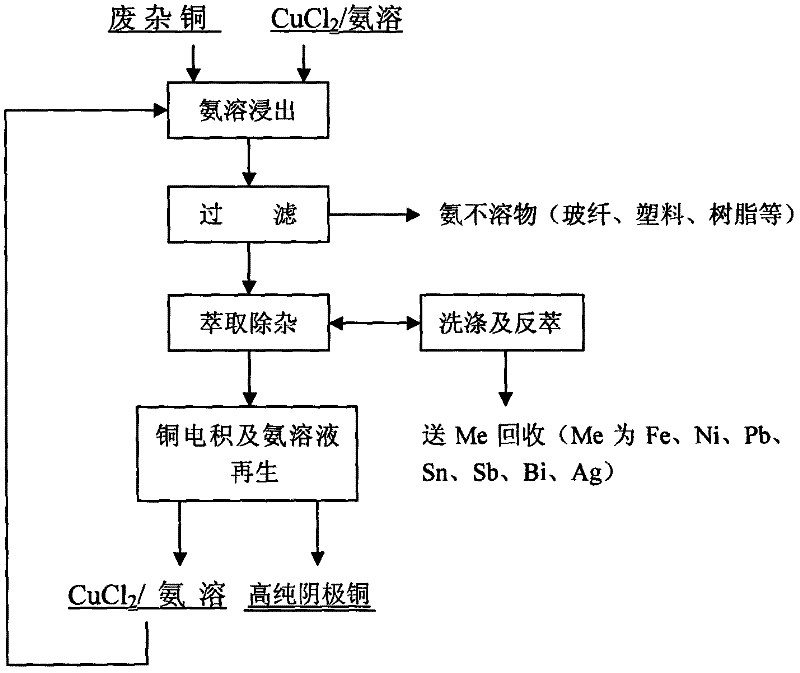

Method for extracting copper from scrap copper through wet process

InactiveCN102443703ALower specific resistanceReduce concentration overpotentialPhotography auxillary processesProcess efficiency improvementEnvironmental resistanceElectrolysis

The invention relates to a method for extracting copper from scrap copper through a wet process. The method comprises the steps of: A) ammonia dissolving leaching: putting scrap copper in a multicomponent solution of ammonia, an ammonia salt, a monovalent chloride, and a divalent copper chloride to form an appropriate electric potential, and reacting the scrap copper with ammonia complex ions so as to be dissolved in the multicomponent solution and generate stable monovalent copper complex ions, filtering out most of metal element impurities Fe, Ni, Al, Sn and Pb from the scrap copper, leaving a small amount of impurities to undergo an oxidation reaction and react with ammonia molecules to generate complex ions of different coordination numbers and exist in the solution; B) extraction for impurity removing: extracting impurities Ag, Fe, Ni, Zn, Bi, Cr, Mn, Sb, Pb, and Sn into an organic phase, and keeping the monovalent copper complex ions in the solution; C) diaphragm electrolytic deposition for preparing high-purity cathode copper: carrying out electrolytic deposition of copper in the cathode chamber of a negative ion membrane electrolyzer, thus obtaining a well crystallized negative copper plate. The method of the invention is characterized by environmental protection and low energy consumption, and can generate high-purity copper directly.

Owner:周毅舟

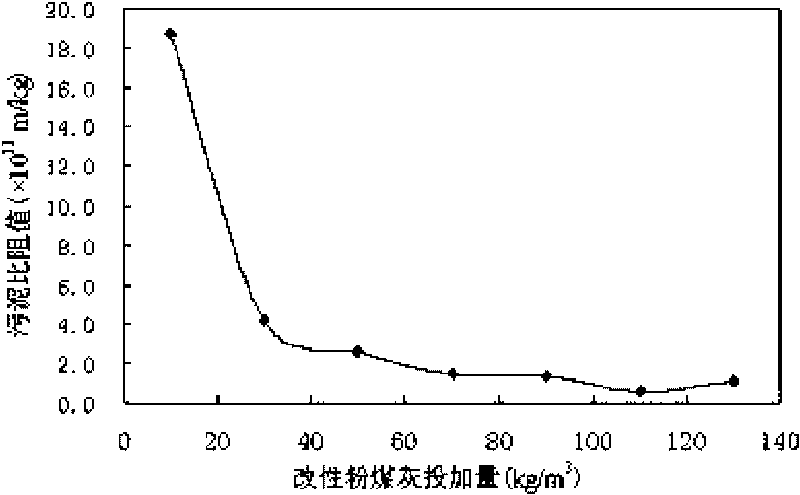

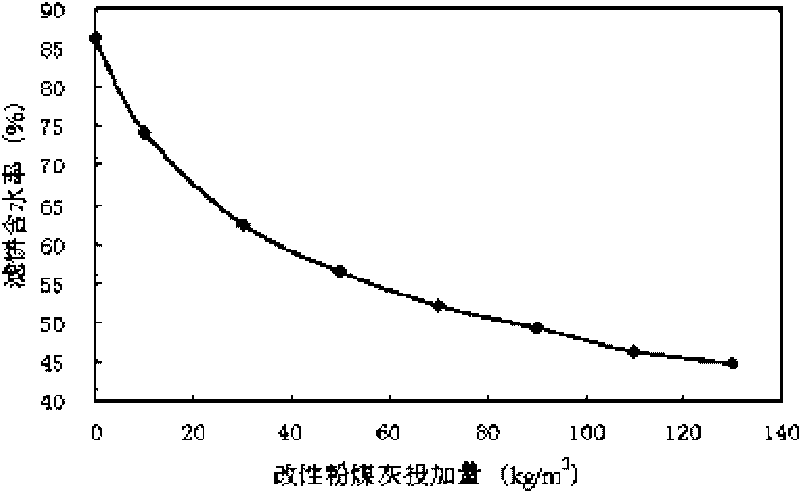

Modified flyash as well as preparation method and application thereof in urban sludge conditioning

InactiveCN101695649ALower specific resistanceBroaden your optionsSludge treatment by de-watering/drying/thickeningOther chemical processesMunicipal sewageEnvironmental chemistry

The invention discloses modified flyash which is obtained by the steps of mixing a modified sulfuric acid solution and flyash, reacting, filtering and drying. The modified flyash can be effectively applied to the conditioning of urban sludge and has the advantages of good conditioning effect, low cost, effective utilization of waste resources, and the like.

Owner:HUNAN UNIV

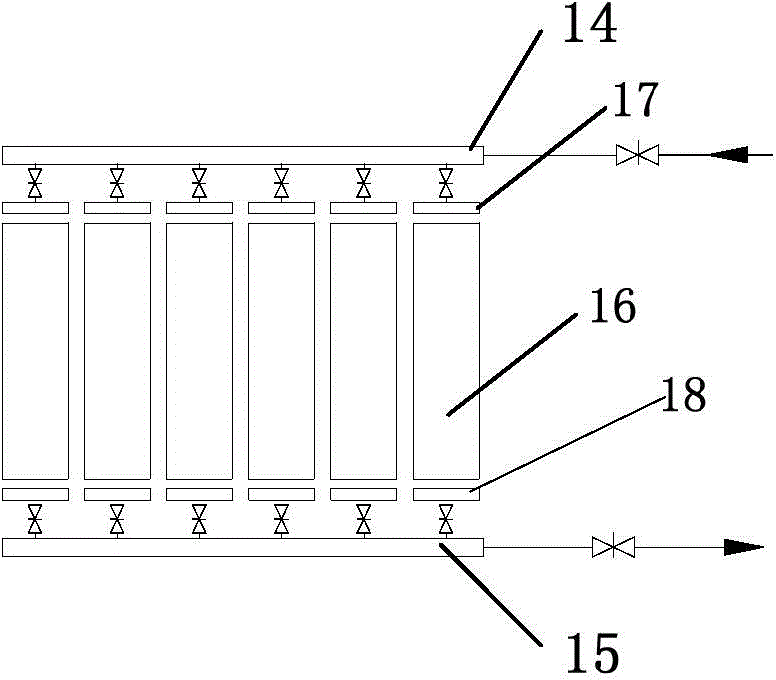

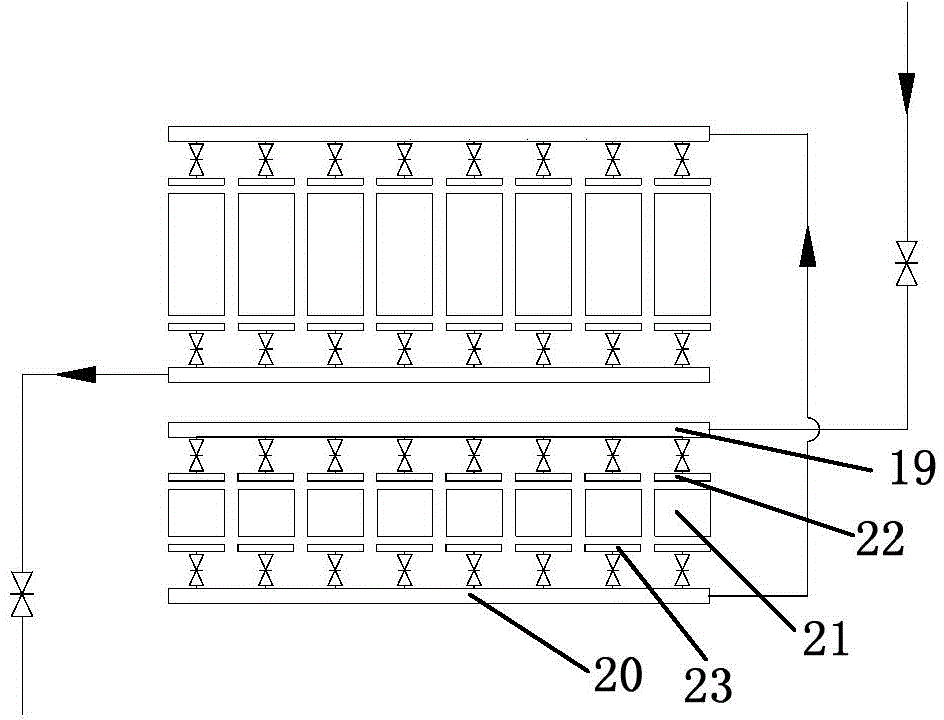

Dedusting, desulfuration and waste-heat utilization integrated system with low PM2.5 emission

ActiveCN103968401APrevention of "Gypsum Rain" PhenomenonEmission controlFeed-water heatersAir preheaterAtmospheric air

The invention discloses a dedusting, desulfuration and waste-heat utilization integrated system with low PM2.5 emission. The system is composed of a boiler rear smoke channel, an air pre-heater, smoke-water heat exchangers, dust extraction devices, a desulphurization device, a low pressure heat regenerative system and a chimney. The outlet of the air pre-heater of the system is connected with the first-level smoke-water heat exchanger, after smoke is cooled through the heat exchanger, large solid particles carried in the smoke are removed through the first-level dust extraction device, then the smoke enters the second-level smoke-water heat exchanger through an induced draft fan and a booster fan to heat a part of power plant condensed water, and finally the smoke enters the desulphurization device. The outlet of the desulphurization device of the system is connected with the third-level smoke-water heat exchanger, after the smoke is heated up, the smoke enters the second-level dust extraction device to remove plaster particles, and finally the smoke is discharged to the atmosphere through the chimney. The dedusting, desulfuration and waste-heat utilization integrated system with the low PM2.5 emission can prevent the phenomenon of plaster rain of coal-fired power plants from occurring, can effectively reduce the emission load of PM2.5 of coal-fired power plants, and has the advantages of being simple in structure, mature in equipment technology and good in dedusting effect.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Automatic control SCR flue gas denitrification urea pyrolysis system

InactiveCN105498532AReduce plant power consumptionSolve the blockageGas treatmentCombustion processAutomatic controlUrea

The invention discloses an automatic control SCR flue gas denitrification urea pyrolysis system. The system is characterized in that a gas-gas heat exchanger is arranged in an inlet flue of an electric precipitator so as to form an air heating unit; a set of flue gas heating tube bundles are arranged in a boiler, so as to form an air reheating unit; after heated by the gas-gas heat exchanger and reheated by the flue gas heating tube bundles, air becomes high-temperature air at the temperature of heat resource required by urea pyrolysis; the high-temperature air is fed into a urea pyrolysis furnace and is mixed with a sprayed atomized urea solution, and then the pyrolysis is performed and an ammonia / air mixture is generated; the ammonia / air mixture is sprayed into an inlet flue of an SCR denitrification reactor through an AIG ammonia injection grating. The automatic control SCR flue gas denitrification urea pyrolysis system has the advantages that the technical structure is simple; the system can be widely applied to an SCR denitrification device of a coal-fired power plant; the urea atomizing pyrolysis efficiency can be effectively increased and the crystal plugging problem can be thoroughly solved; the waste-heat utilization of flue gas can be realized and the electrostatic precipitation efficiency can be increased; water used by a desulfurization system can be reduced.

Owner:ANHUI XINLT POWER TECH CONSULTING +1

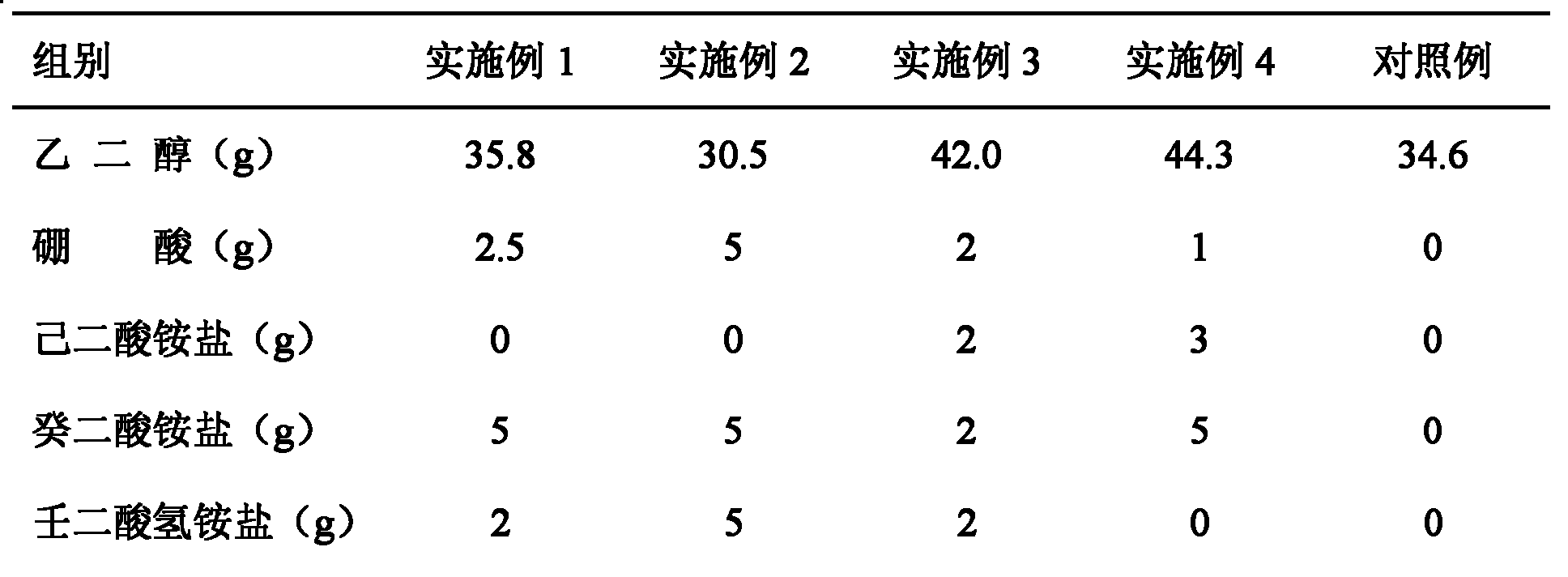

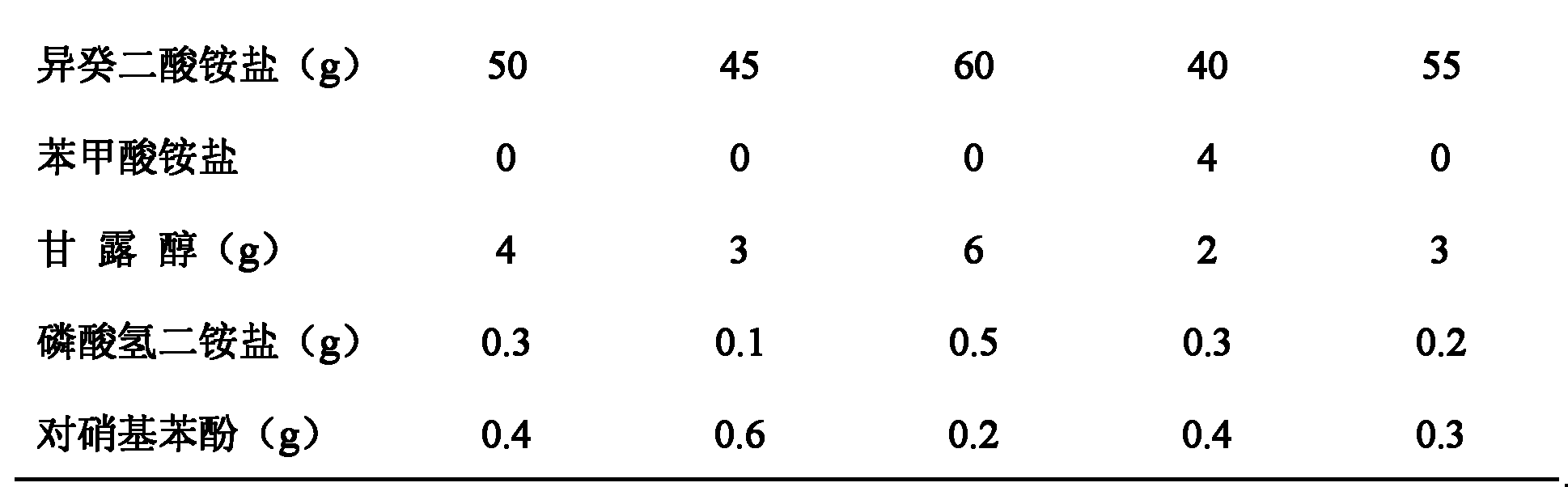

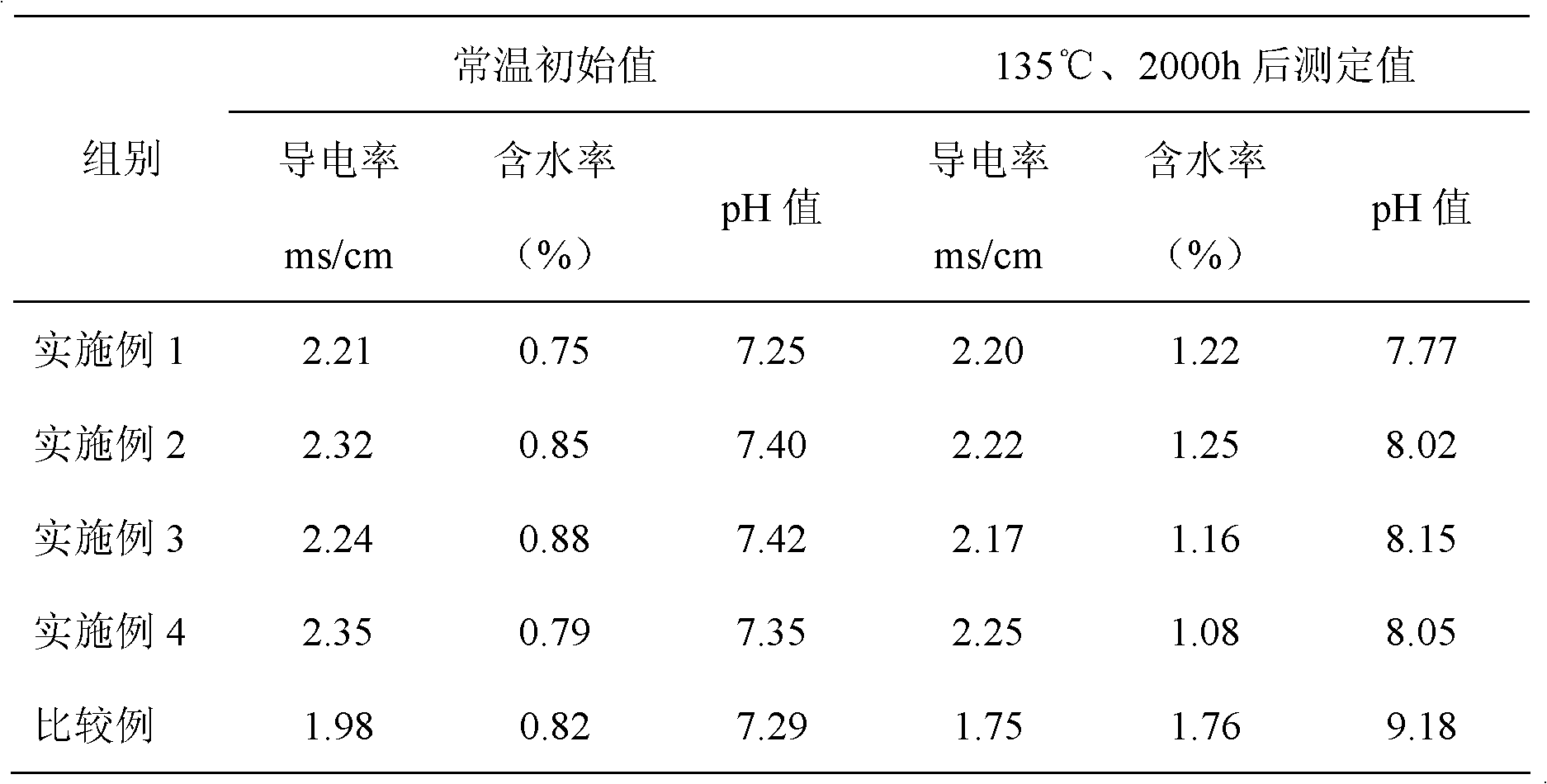

Novel electrolyte

The invention discloses a novel electrolyte, which mainly comprises the following components in parts by weight: 30-45 parts of ethylene glycol, 1-5 parts of boric acid, 4-10 parts of at least one kind of long straight-chain saturated dicarboxylic acid or ammonium salt thereof, 40-60 parts of at least one kind of long straight-chain saturated dicarboxylic acid with branched chains or ammonium salt thereof, 2-6 parts of mannitol, 0.1-0.5 part of phosphate and 0.2-0.6 part of dehydrogenation agent. Since the electrolyte uses ethylene glycol as solvent and uses long straight-chain saturated dicarboxylic acid with branched chains, long straight-chain saturated dicarboxylic acid and boric acid as solute, the invention has the advantages that the forming efficiency and the breakdown voltage of the electrolyte are improved, the solubility of the solute is increased, the electric conductivity is improved, the specific resistance is reduced and the service life of the product is improved.

Owner:FUJIAN YUNXING ELECTRONICS

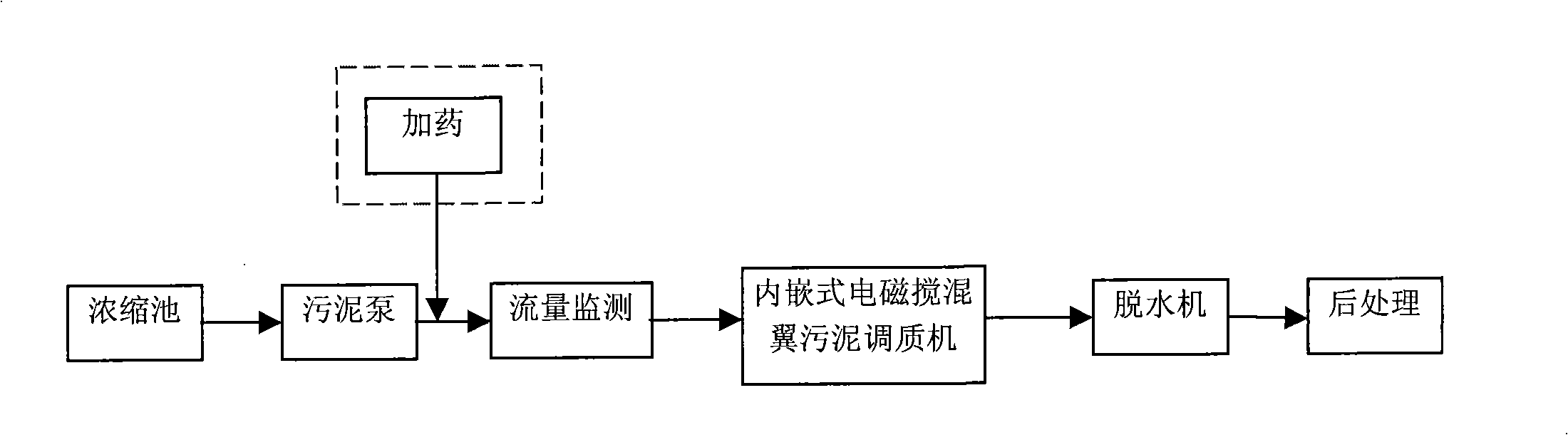

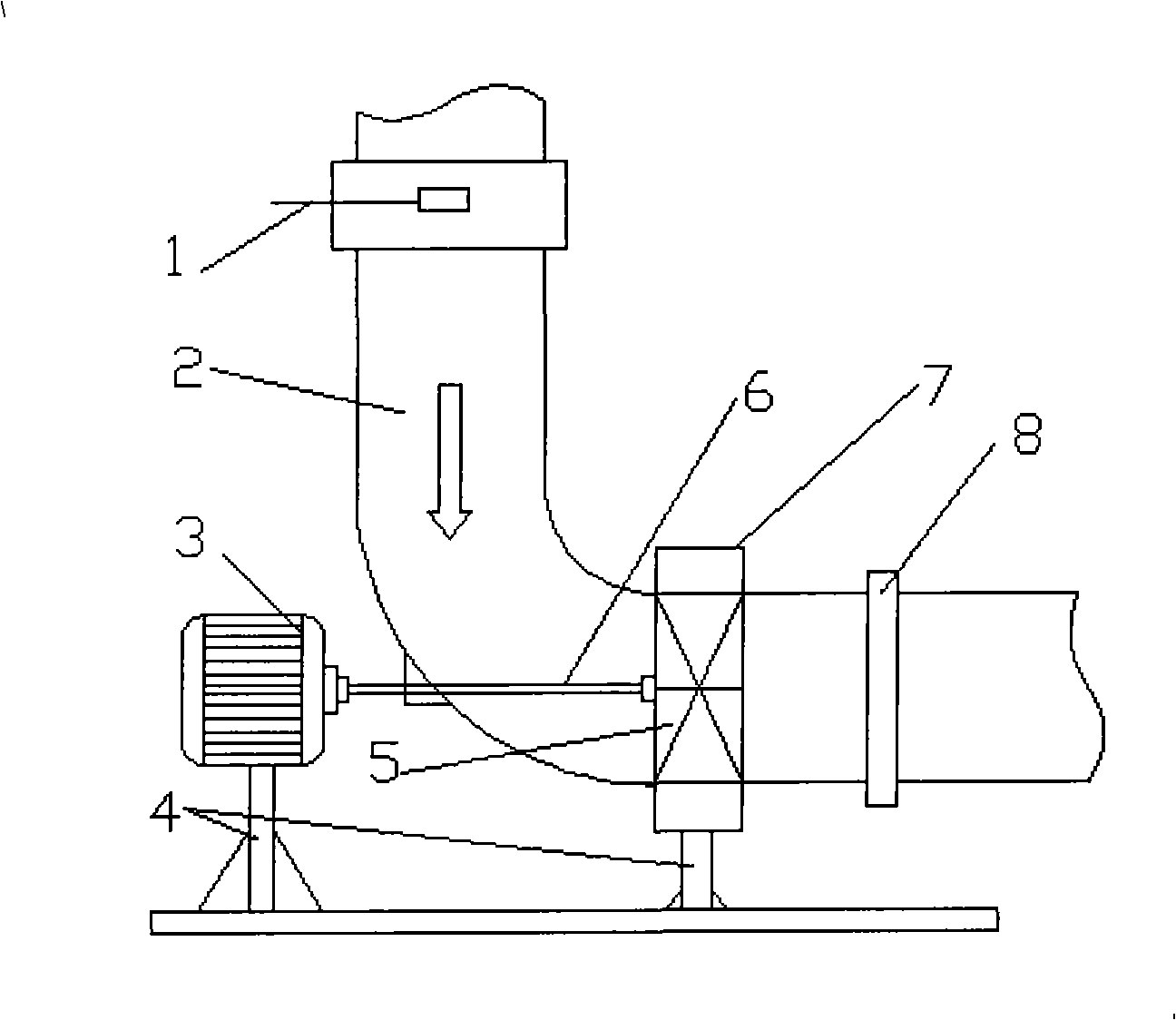

Method and apparatus for improving sludge dehydration

InactiveCN101328002APrecise temperingLower specific resistanceSludge treatment by de-watering/drying/thickeningEnergy expenditureDewatered sludge

The invention discloses a method for improving the dehydrating property of the sludge and equipment thereof. The method is to adopt an inner embedded type electromagnetic swirling wing sludge conditioner arranged in the sludge pipe or an external magnet-rotary sludge conditioner arranged on the sludge pipe to quench and temper the sludge, so as to achieve the purpose of sludge specific resistance reduction and sludge dehydrating property improvement. After the method and the equipment are implemented, the water content of the final dewatered sludge (mud cake) can reach 70-80% which reduces by 2-15% comparing to the technology without conditioner treatment. The work efficiency of the dewaterer is greatly improved, the energy consumption of the dewaterer is reduced by 5-40% and the reagent dosing is reduced by 5-100%. The method and equipment of the invention are not only suitable for the transformation of the old equipment in the prior sludge treatment, but also suitable for the establishment of the new equipment.

Owner:上海滨浦水处理设备有限公司

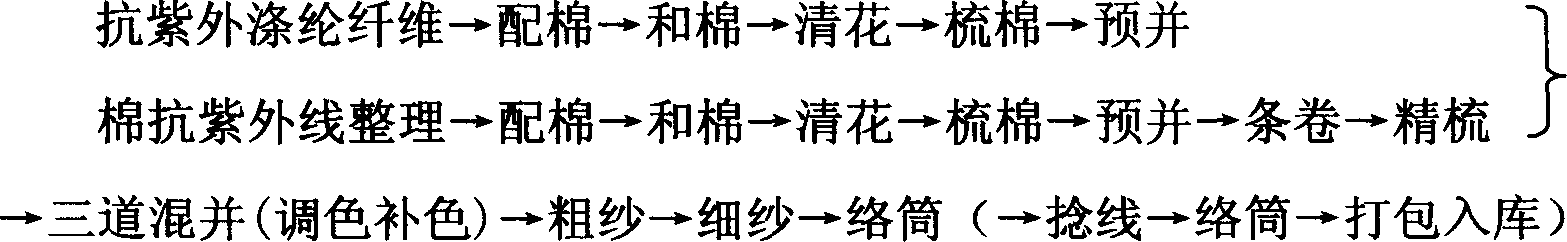

Anti-ultraviolet ray mixed color spinning thread and its producing method

The invention belongs to engineering area in weaving industry in which said uviofast colored spinning thread is characterized in that it includes two or more than two varied colors cotton-dispersing fibres or uviofast polyester fibre, collated with uviofast. Coefficient UPF of plus material of textile, machined by purifying uviofast colored spinning thread, for guarding ultraviolet ray, can reach more than 30 after 10 times wash measuring and the coefficient UPF of polyester fibre can reach more than 50 after 30 times wash measuring. Uviofast colored spinning thread of the invention is widely applied in various clothes, sports suit, sportswear, tame and so on.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

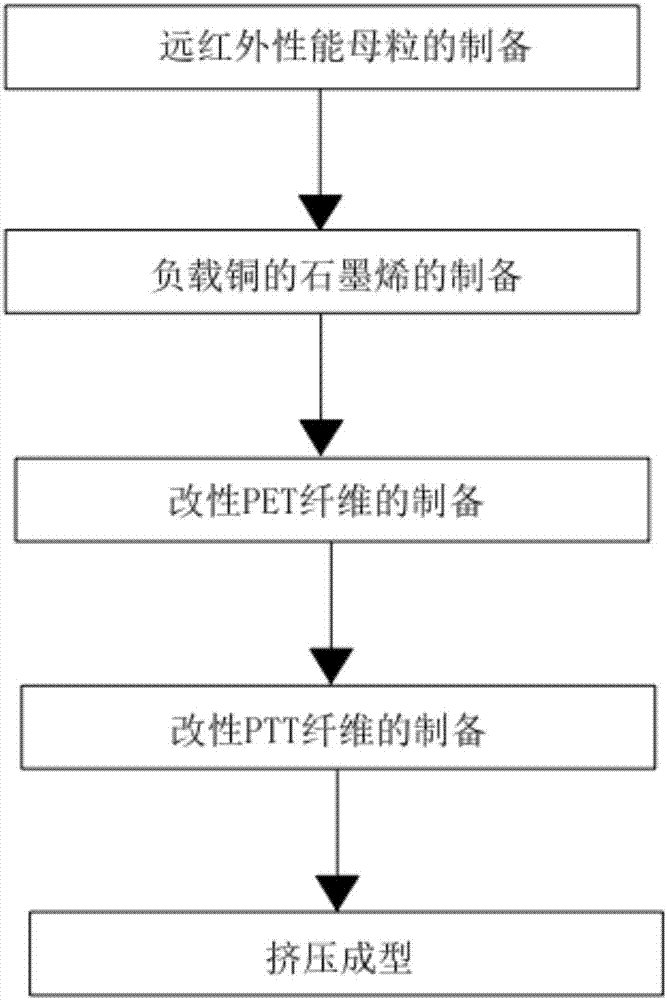

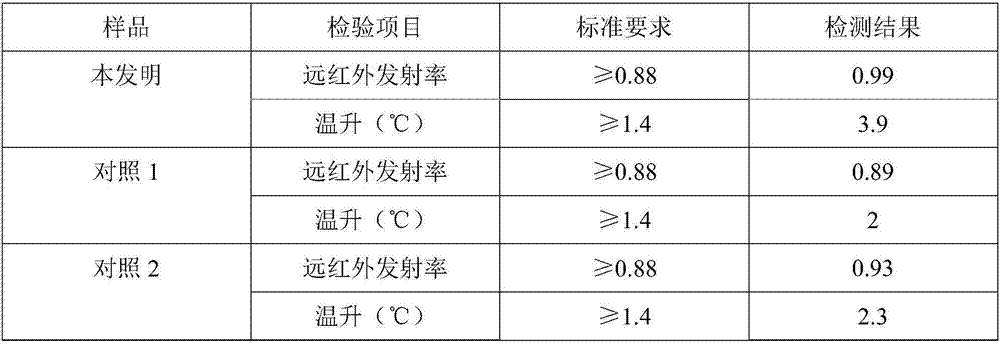

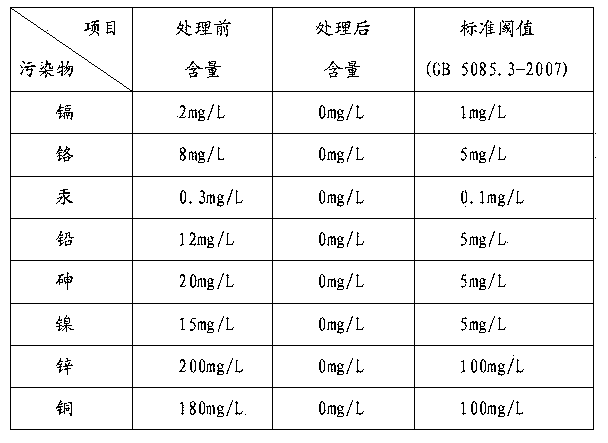

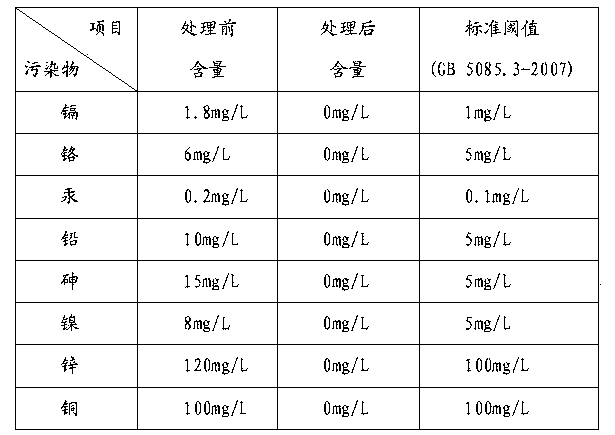

Far-infrared polyester fiber

ActiveCN107059156AGood hygroscopicityImprove dyeing effectElectroconductive/antistatic filament manufactureBiochemical fibre treatmentPolyethylene terephthalate glycolMicroparticle

The invention discloses far-infrared polyester fiber. The far-infrared polyester fiber is prepared by blending PET (polyethylene terephthalate) fiber, PTT (polytrimethylene terephthalate) fiber, far-infrared property master batch and copper-loaded graphene powder, wherein the PET fiber is prepared from dimethyl terephthalic acid and ethylene glycol polyester according to a molar ratio of 1.2:2.3; the PTT fiber is prepared from dimethyl terephthalic acid and propylene glycol polyester according to a molar ratio of 1.5:2.5; the far-infrared polyester fiber is prepared from the following raw materials in percentage by weight: 0.05% to 0.1% of far-infrared property master batch, 0.05 to 25% of copper-loaded graphene powder, and the balance of PET fiber slice and PTT fiber slice, and the raw materials of the far-infrared property master batch are mainly vermiculite and medical stone microparticles. The invention also discloses a preparation method of the polyester fiber. The polyester fiber prepared by the preparation method has excellent far-infrared property, bacteria-resisting and inhibiting properties, and skin-friendly and skid-care properties.

Owner:黄蕊烨

Efficient sludge dewatering flocculant

ActiveCN104261652ARapidly changing microstatesLower specific resistanceSludge treatment by de-watering/drying/thickeningPlant rootsDewatered sludge

The invention relates to an efficient sludge dewatering flocculant. The efficient sludge dewatering flocculant is prepared from a mixture A and a mixture B, wherein the mixture A is prepared from the following components in parts by weight: 100 parts of diatomite containing 1-5 percent of soil fungi, 10-30 parts of activated carbon, 20-50 parts of cement and 2-5 parts of organic flocculants; the mixture B is prepared from at least three of the following components in parts by weight: 16-32 parts of sodium thiosulfate, 16-32 parts of iron oxide, 48-96 parts of calcium sulfate, 32-80 parts of aluminum sulfate and 16-32 parts of alkali carbonate. After the efficient sludge dewatering flocculant is directly added in water containing sludge to be uniformly stirred, mechanical dewatering is carried out, and water content of the sludge can be lowered below 60 percent; the removed water can be discharged to reach standard without needing to be further treated; heavy metals in the sludge are fixed in the sludge and can not be absorbed by plant roots and disperse in soils and water; the dewatered sludge can serve as a fertilizer raw material, a fuel raw material and a building raw material without secondary pollution.

Owner:佑景天(北京)国际水环境研究中心有限公司

System and method for modulating flue gas with sulfur trioxide

InactiveCN102225365AImprove efficiencyImprove dust removal efficiencyElectrostatic separationAir compressorMoisture

The invention discloses a system and a method for modulating flue gas with sulfur trioxide. The system comprises: a storage tank, a sulfuric acid conveying apparatus, a sulfuric acid pyrolysizing furnace, an air compressor for providing compressed air for the sulfuric acid pyrolysizing furnace, a blower and an air heating apparatus for providing hot air for the sulfuric acid pyrolysizing furnace,and an injector. The injector is connected to the sulfuric acid pyrolysizing furnace, and is arranged in the inlet flue of an electrostatic precipitator (ESP). With the flue gas modulating system andmethod provided by the present invention, sulfuric acid solution can be decomposed into a gas mixture of sulfur trioxide and steam under a high temperature; the gas mixture is then injected to the flue gas with the injector arranged in the inlet flue of the ESP; sulfur trioxide and moisture in the flue gas can be combined to form sulfuric acid aerosol attached to the surfaces of the dust particles; specific resistance of the dust can be reduced, and dedusting efficiency of the ESP can be improved. Compared to traditional technologies for modulating flue gas with sulfur trioxide, the method and the system provided by the present invention has advantages of simple operation, good economic benefit, and high improvement efficiency of the ESP.

Owner:FUJIAN LONGKING

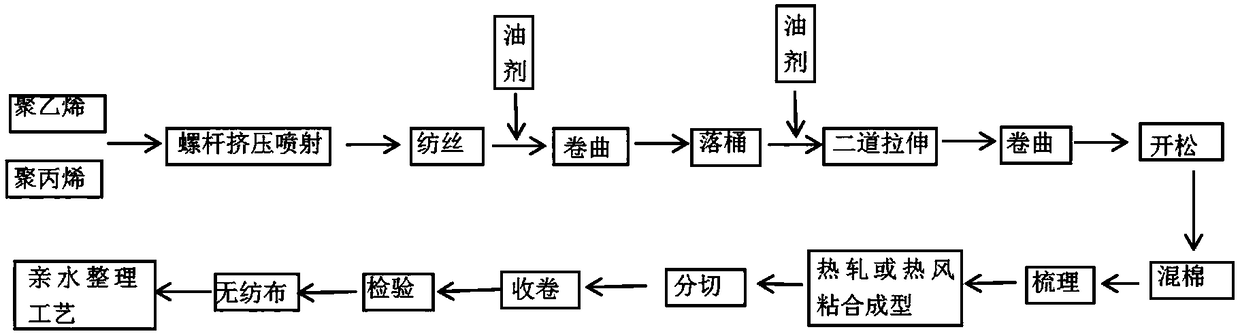

Manufacturing process of ES hydrophilic fiber non-woven fabric

InactiveCN108998889AEasy to wetImprove smoothnessFibre typesNon-woven fabricsNonwoven fabricMaterials science

The invention discloses a manufacturing process of ES hydrophilic fiber non-woven fabric. The non-woven fabric adopts PE and PP as raw materials, the manufacturing process is characterized by comprising following steps of screw extrusion spraying, spinning, pre-spinning oiling, curling, in-barrel treatment, post-spinning oiling, two-way stretching, curling, opening, cotton blending, carding, hot rolling or hot air bonding forming, slitting, winding, inspection, non-woven fabric and hydrophilic finishing process, and lastly, the ES hydrophilic fiber nonwoven fabric is obtained, and the hydrophilic nonwoven fabric produced by the process has high hydrophilicity and good hygroscopicity and can be applied to high-level products.

Owner:JIXI YUANDAO AGRI IND TECH

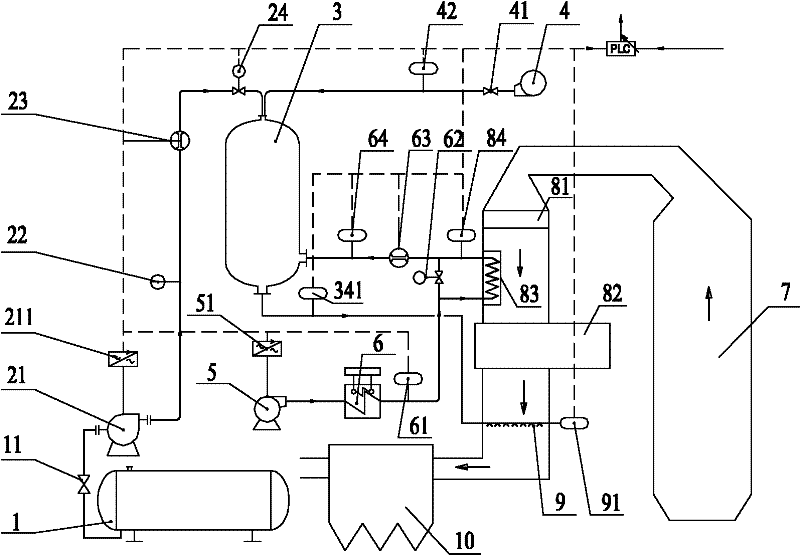

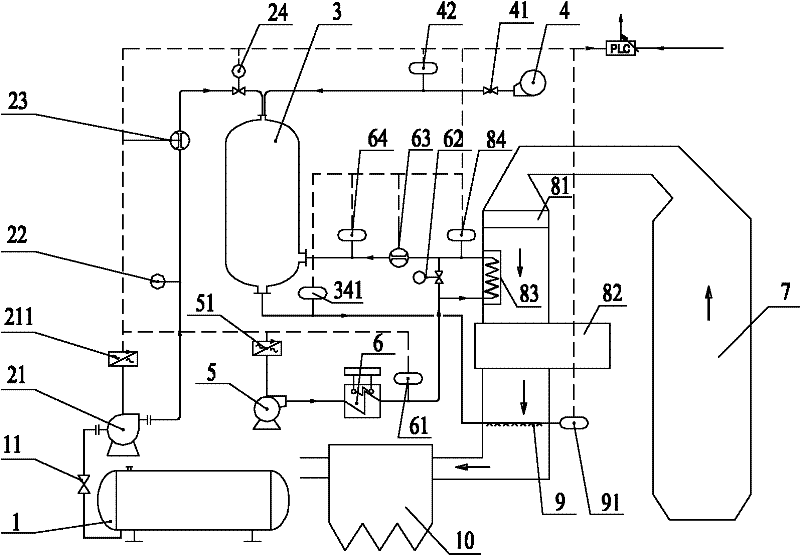

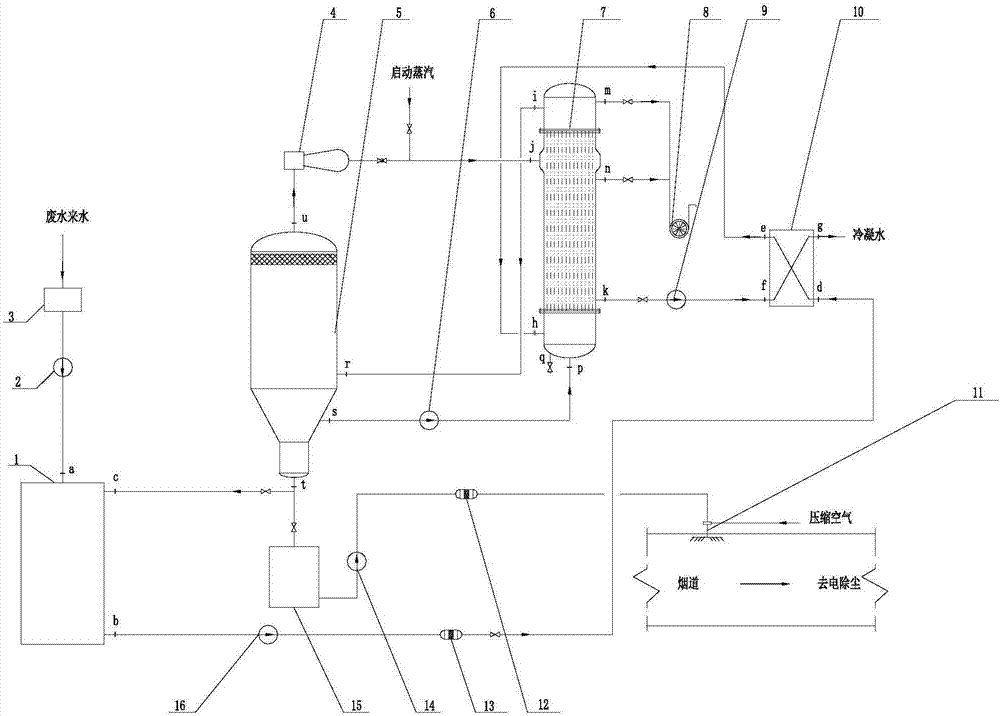

Waste water disposal technique by union of steam recompression evaporation and flue spraying technology

InactiveCN107954560AReduce consumptionLow costElectrostatic separationWater/sewage treatmentVapor–liquid separatorEvaporation

The invention discloses a waste water disposal technique by union of steam recompression evaporation and flue spraying technology. The technique includes steps of removing suspended solid and calciumfrom waste water; then delivering waste water to a raw water tank by a water delivering pump after filtering, delivering waste water to a preheater by a raw water pump and a raw water filter to heat;after preliminarily preheating the waste water, heating in a pipe box at the lower part of the heater without evaporation, and then entering a gas fluid separator to carry out flashing and generate enough steam, absorbing steam to a steam compressor; using the secondary steam compressed and heated by the steam compressor as a new heat source and delivering to a shell side of the heater to releasethe potential heat; closing a steam door and realizing the self-circulation evaporation and heat transfer; drawing waste water without being evaporated in the gas fluid separator at a conical side ofthe lower part; delivering the circulated pump to the heater to circularly absorb heat; after circular evaporation for many times, discharging concentrated waste water from one path of the bottom partof the gas fluid separator to a concentrated water box and then delivering to a flue to spray and evaporate; discharging the other path to the raw water tank to adjust water balance. The waste waterdisposal technique is applicable to the treatment of waste water of a heat-engine plant.

Owner:XIAN XIELI POWER TECH

Compounded sludge dewatering conditioner and application method thereof

InactiveCN105948457ARich sourcesLow priceSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesCompound aAluminium chloride

The invention discloses a compounded sludge dewatering conditioner and belongs to the technical field of sludge treatment. The compounded sludge dewatering conditioner is prepared through compounding a sludge conditioner A and a sludge conditioner B, wherein the sludge conditioner A is prepared through compounding the following ingredients in parts by weight: 20-30 parts of fly ash, 10-20 parts of quicklime powder, 10-20 parts of magnesia, 20-30 parts of polyaluminum ferric chloride; the sludge conditioner B is an acetic solution of chitosan. The invention further discloses a method of application of the compounded sludge dewatering conditioner.

Owner:河南永泽环境科技有限公司

Method for preparing solar cell electrodes, solar cell substrates prepared thereby, and solar cells

InactiveCN102246319AImprove efficiencyLower specific resistanceFinal product manufacturePhotovoltaic energy generationElectrical batterySolar battery

Owner:SSCP CO LTD

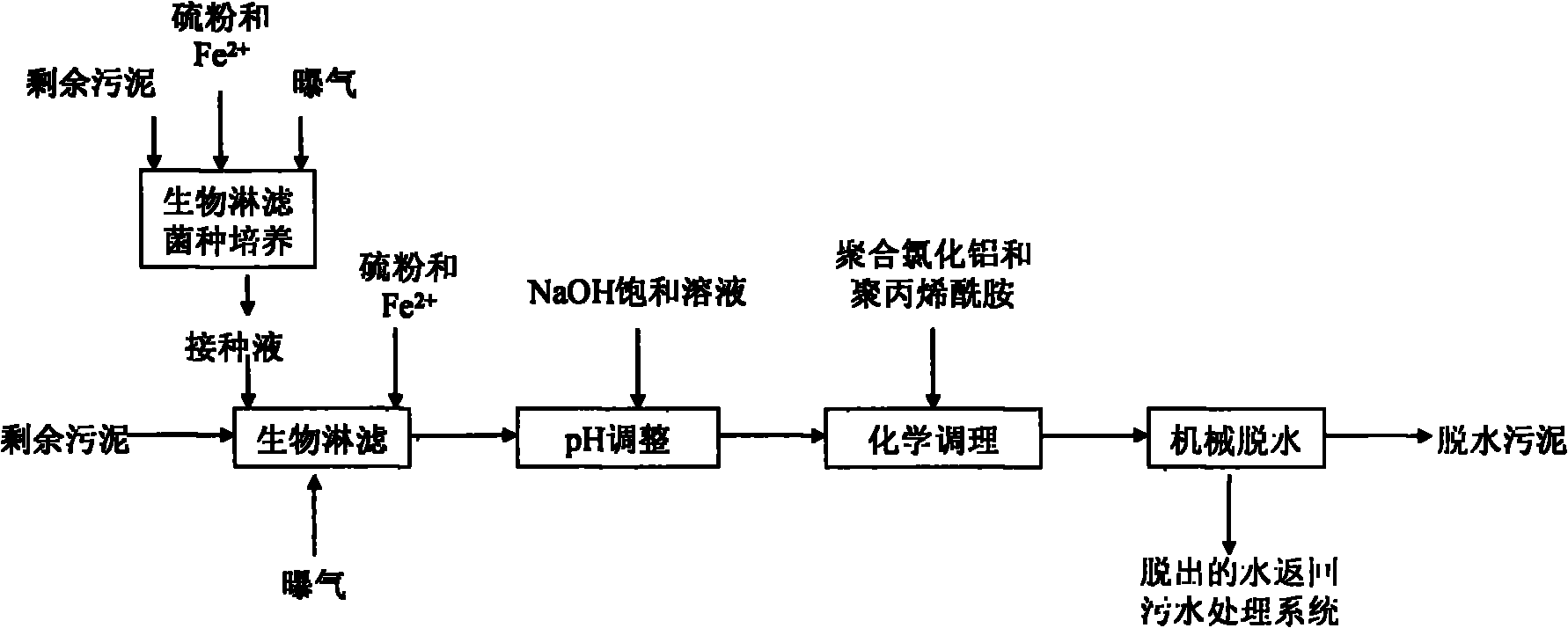

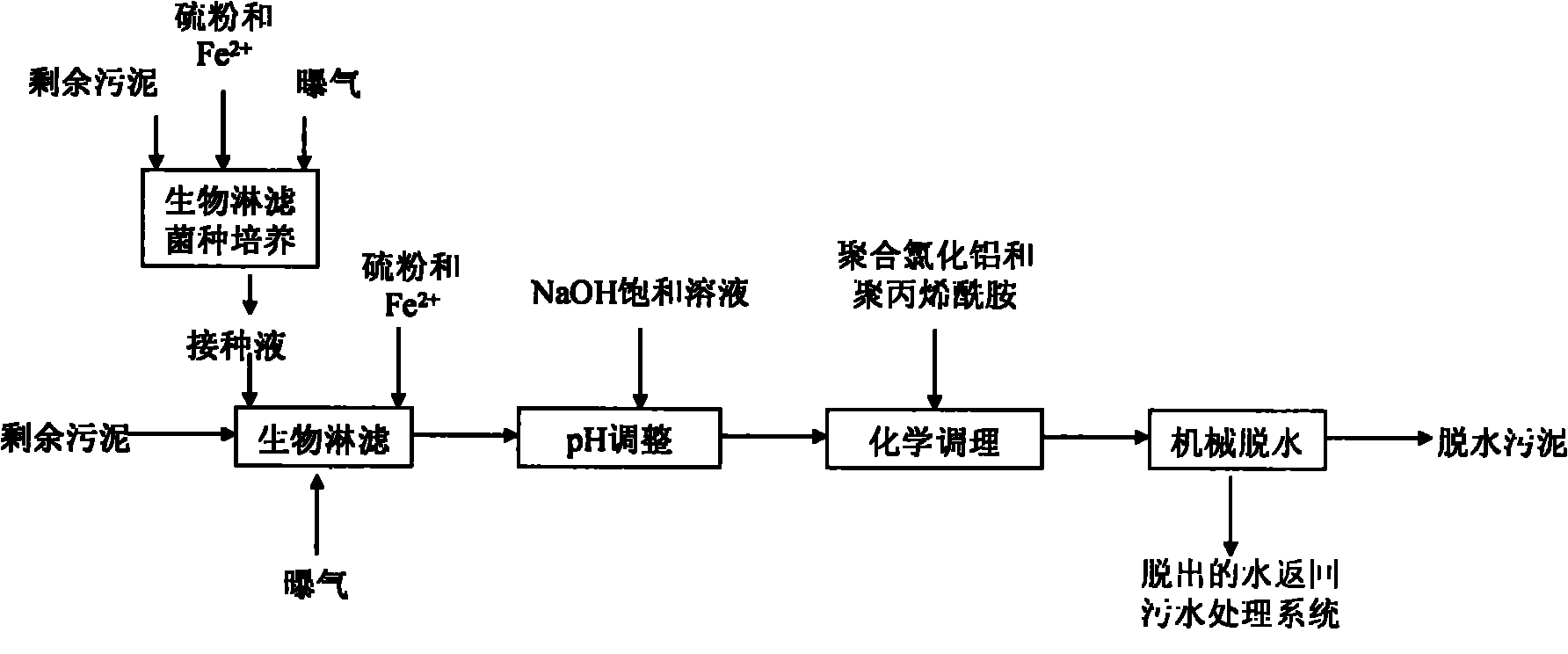

Method for improving sludge dewatering performance by combining bioleaching and dual conditioners

InactiveCN101863612AImprove dehydration effectLower specific resistanceSludge treatment by de-watering/drying/thickeningAluminium chlorohydrateBioleaching

The invention relates to a method for improving sludge dewatering performance by combining bioleaching and dual conditioners, and belongs to the technical field of sludge treatment. The method comprises the following steps of: under the condition of adding sufficient substrates, culturing and domesticating autochthonous bacteria in sludge, and using the autochthonous bacteria as inoculum; adding the inoculums into the residual sludge, and performing bioleaching on the sludge under the conditions of aerob, stirring and proper substrate until the pH of the sludge is about 2; adding saturated NaOH solution into the leached sludge to adjust the pH of the sludge to between 6 and 7; adding aluminium polychlorid and polyacrylamide into the sludge to condition the sludge; and performing mechanical dewatering on the treated sludge by a plate-and-frame filter pressing or centrifugal dewatering method to obtain the dewatered sludge with the moisture content between 65 and 75 percent. The bio-acidification and the dual conditioners are combined to improve the sludge dewatering performance, so the reaction efficiency can be improved, the reaction time can be shortened, the treatment capacity can be improved, and the sludge treatment cost can be reduced.

Owner:BEIJING FORESTRY UNIVERSITY

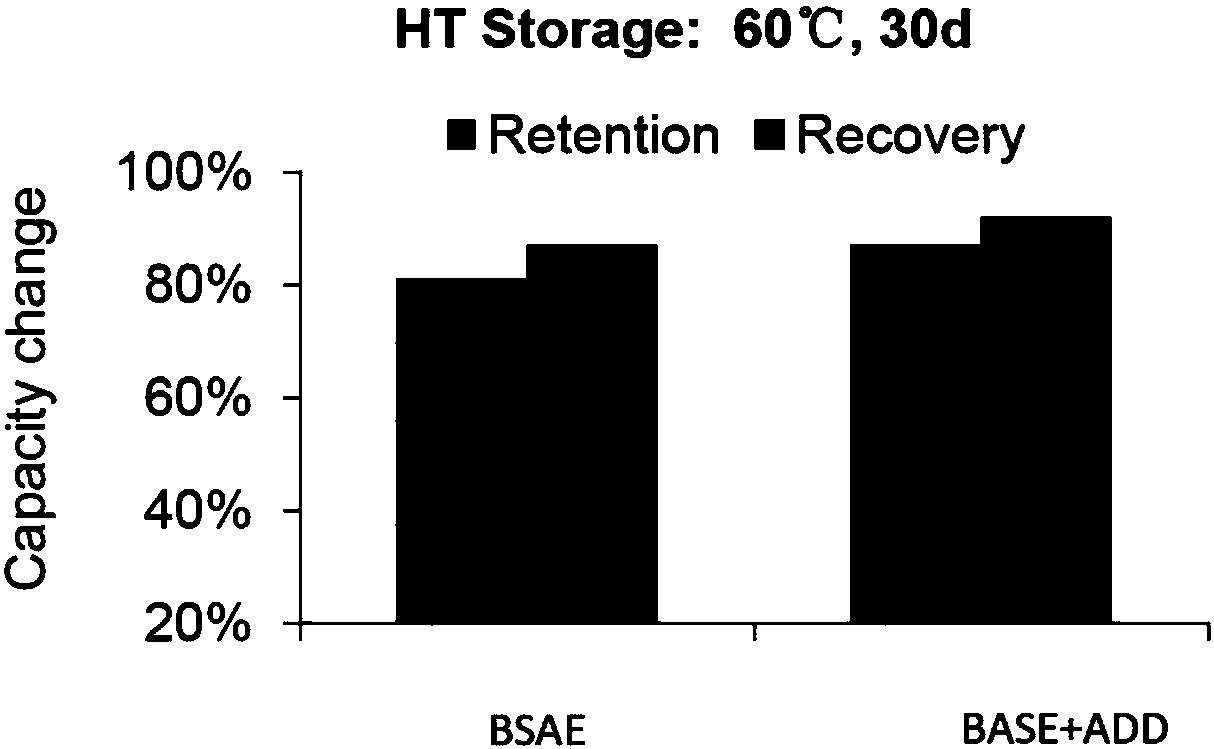

High-temperature resistant lithium ion electrolyte

ActiveCN107910591AImprove low temperature performanceImprove solubilitySecondary cellsDisiloxaneOrganic solvent

A high-temperature resistant lithium ion electrolyte belongs to the technical field of a lithium battery electrolyte and comprises a lithium salt and an organic solvent and also comprises 1,2-bi(trimethylsilyl) ethylene, 1,3-dimethyl-1,1,3,3-tetraethylene disiloxane, 2,4,6-triethylene-2,4,6-trimethylcyclotrisiloxane or 1,3-divinyl-1,1,3,3-tetramethyl-disilazane. In the battery electrolyte, the charge-discharge performance of a lithium battery can be effectively improved due to addition of the substance into the electrolyte, side reaction is reduced, so that the battery bubbling is reduced, andthe cycle lifetime of the battery is prolonged.

Owner:SHIJIAZHUANG SAN TAI CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com