Waste water disposal technique by union of steam recompression evaporation and flue spraying technology

A vapor recompression, evaporation concentration technology, applied in spray evaporation, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of industrial application of desulfurization wastewater treatment process, inconvenient sludge treatment and disposal, and poor operation effect. Ideal and other issues, to achieve the effects of reliable design, reduced chemical consumption, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

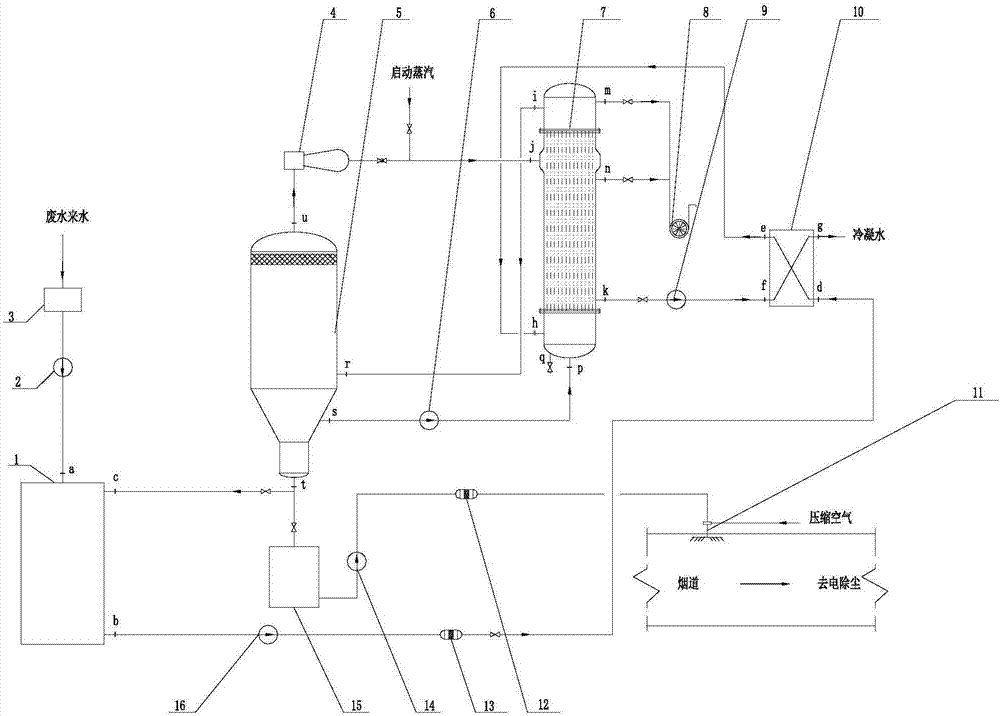

[0021] exist figure 1Among them, the process of steam recompression evaporation concentration combined with flue spraying technology to treat wastewater in the present invention, the incoming water of wastewater enters the entrance of pretreatment system 3 through pipelines, and the pretreatment system 3 of this embodiment only removes suspended solids and double alkali method. Calcium and magnesium are not removed, since the solubility of MgCl2 and MgSO4 at 20°C is more than 20%, and when the pH value is less than 8.0, there will be no magnesium hydroxide precipitation in the evaporative crystallizer, so when removing hardness, it is selectively removed Calcium hardness, magnesium hardness is not removed, which can greatly reduce the consumption of pretreatment chemicals and save costs; the pretreatment system 3 is connected to the inlet a of the raw water tank 1 through the water delivery pump 2 installed on the pipeline, and the outlet b of the raw water tank 1 The raw wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com