Patents

Literature

90 results about "Dairy industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compositions and methods for UV sterilization

ActiveUS20140161663A1Use minimizedEfficiently patternFood preservationLavatory sanitoryDairy industryUv disinfection

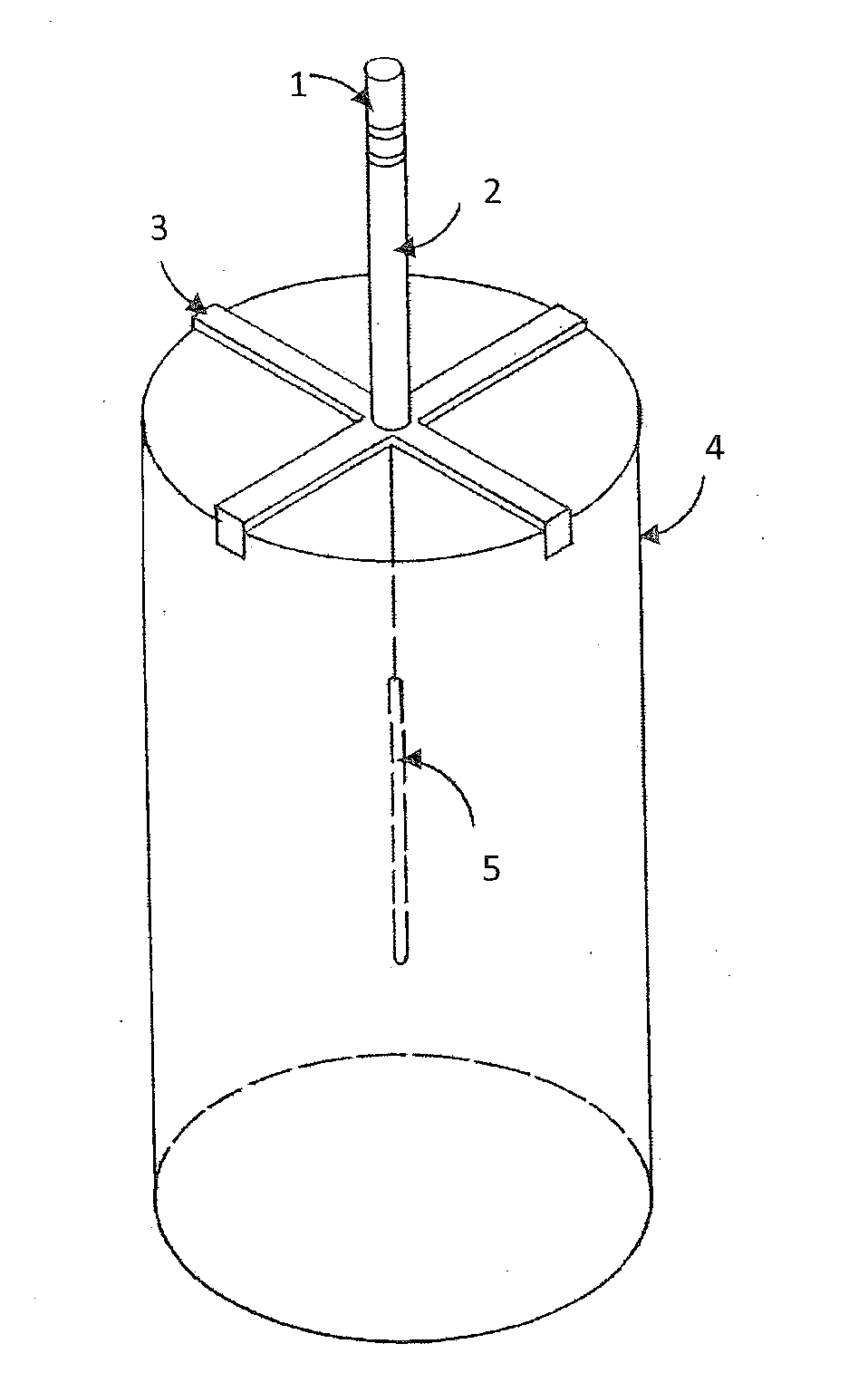

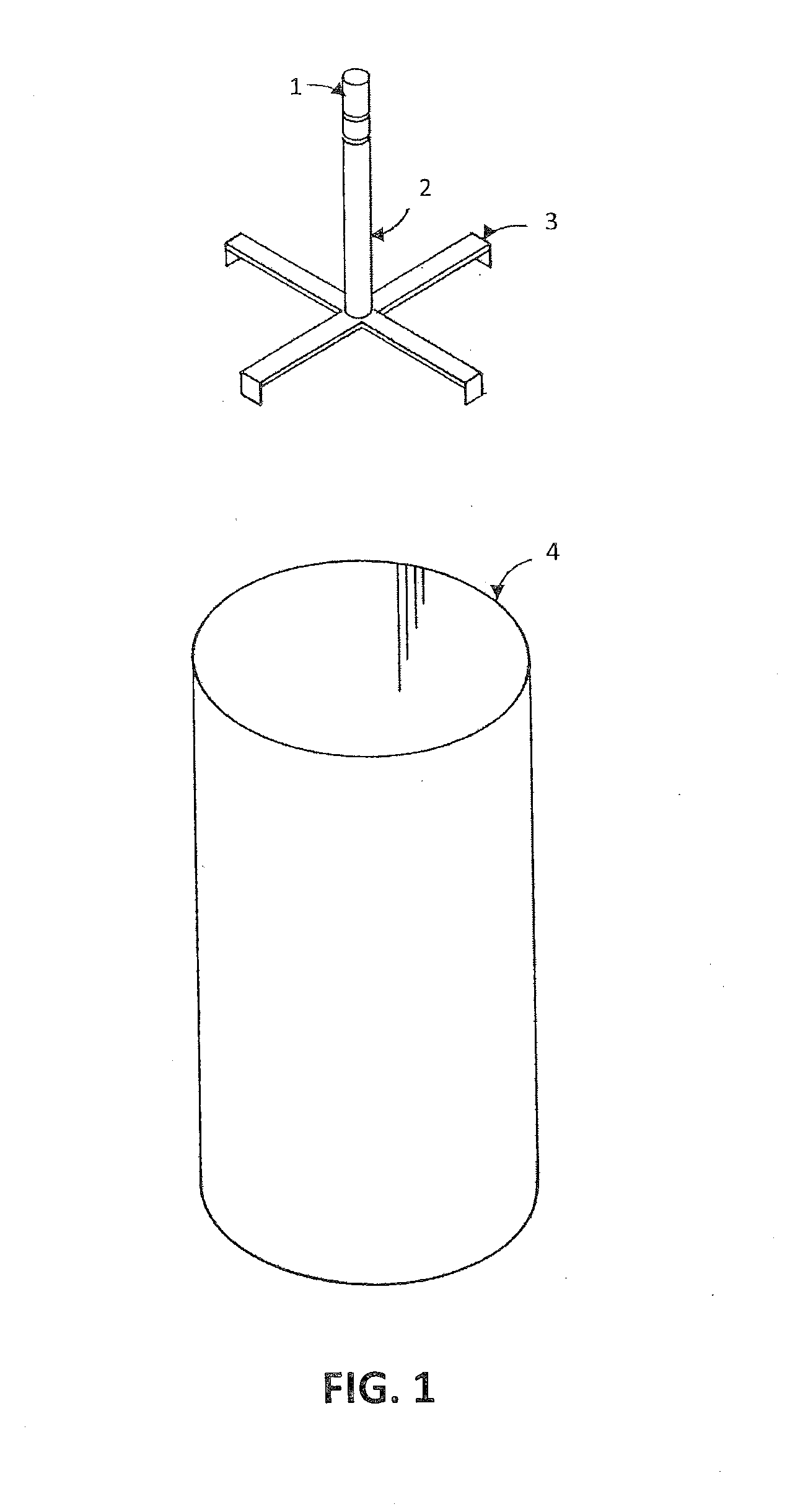

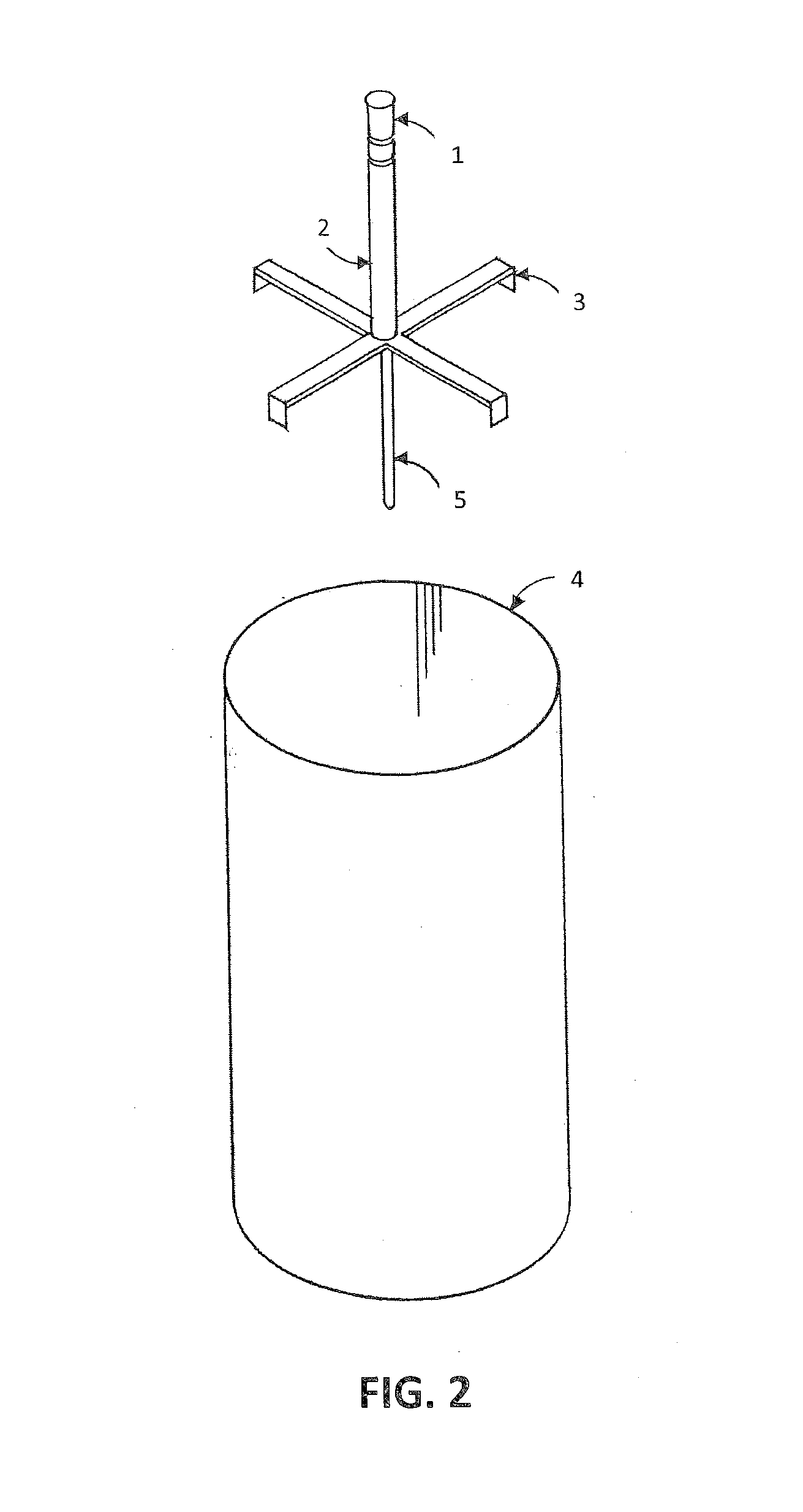

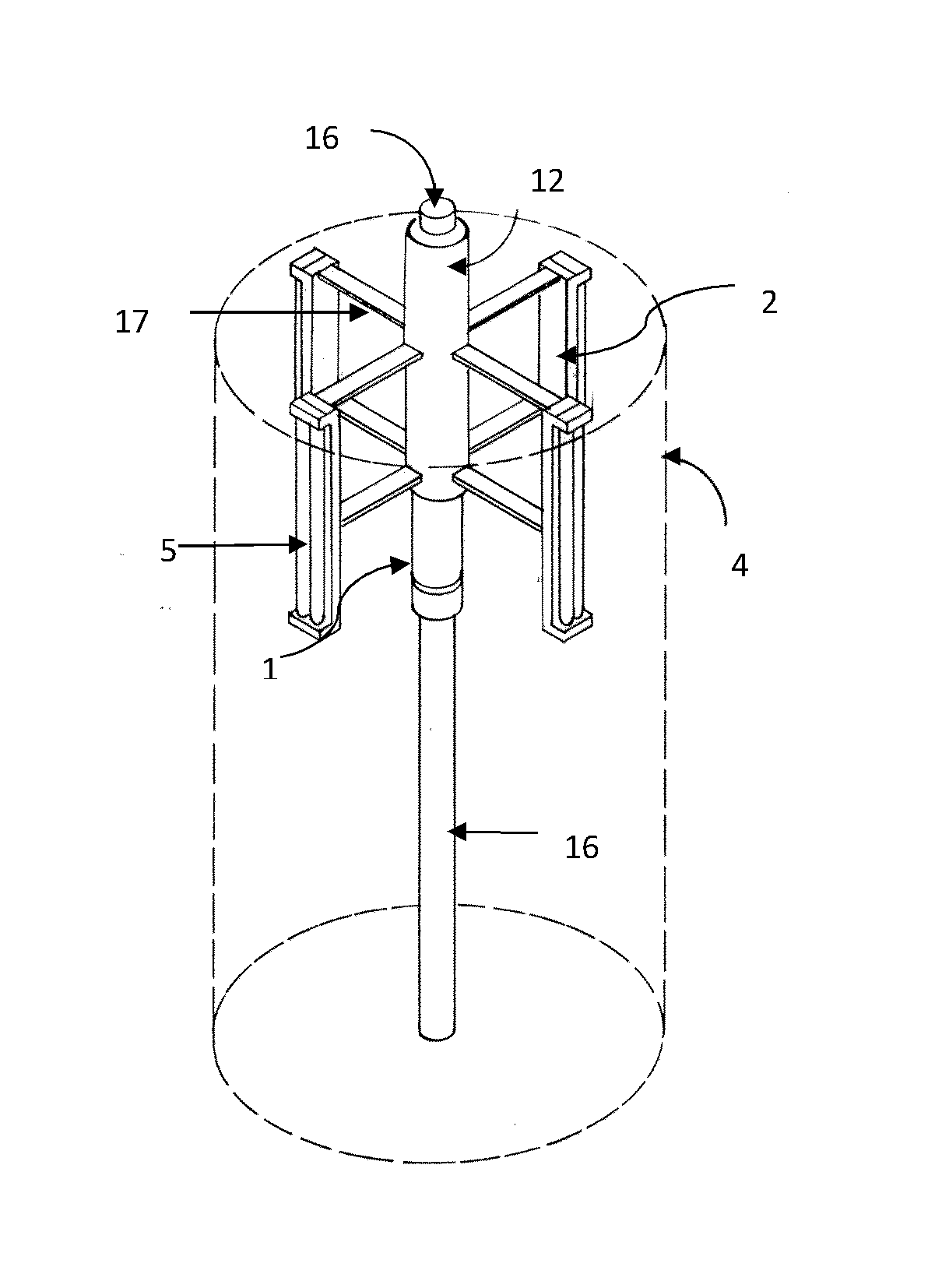

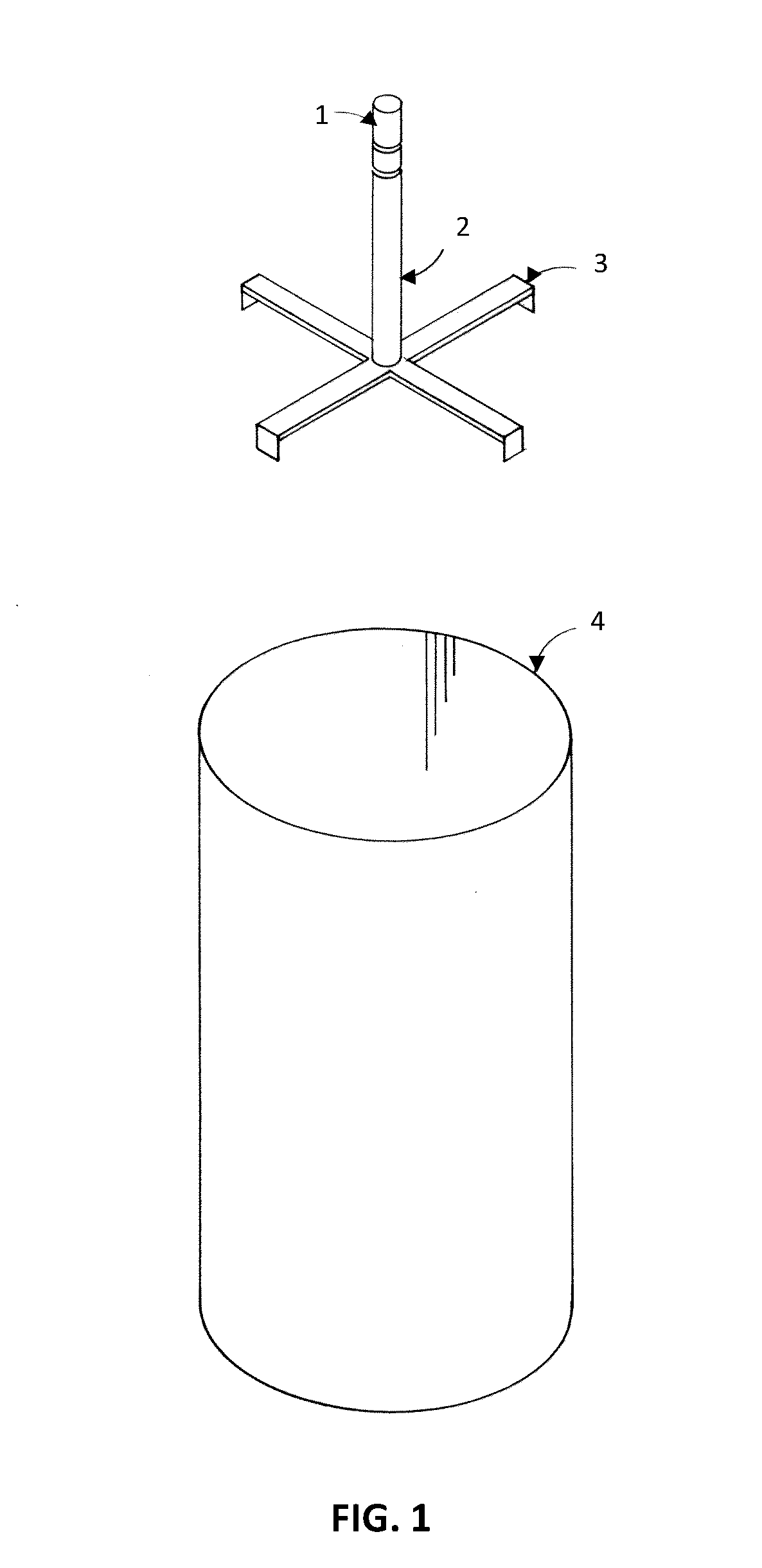

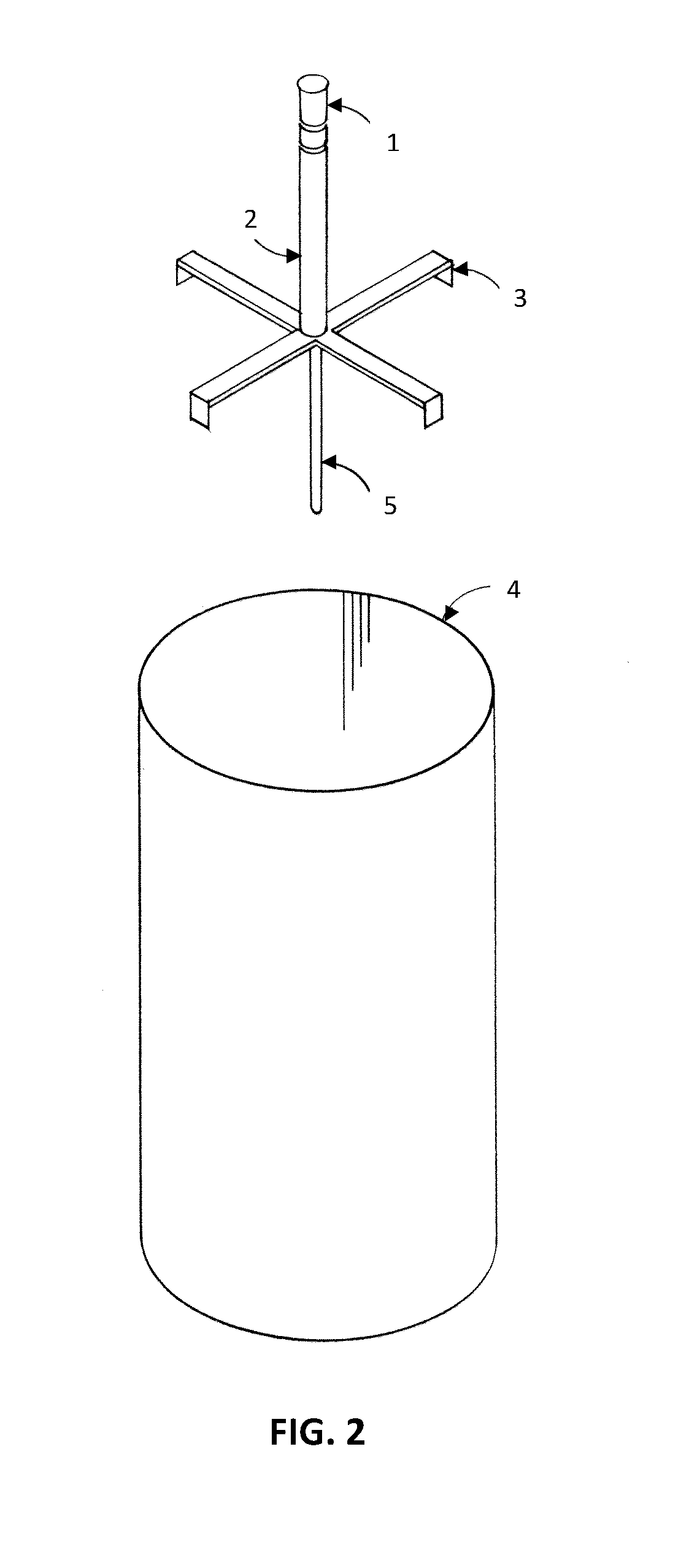

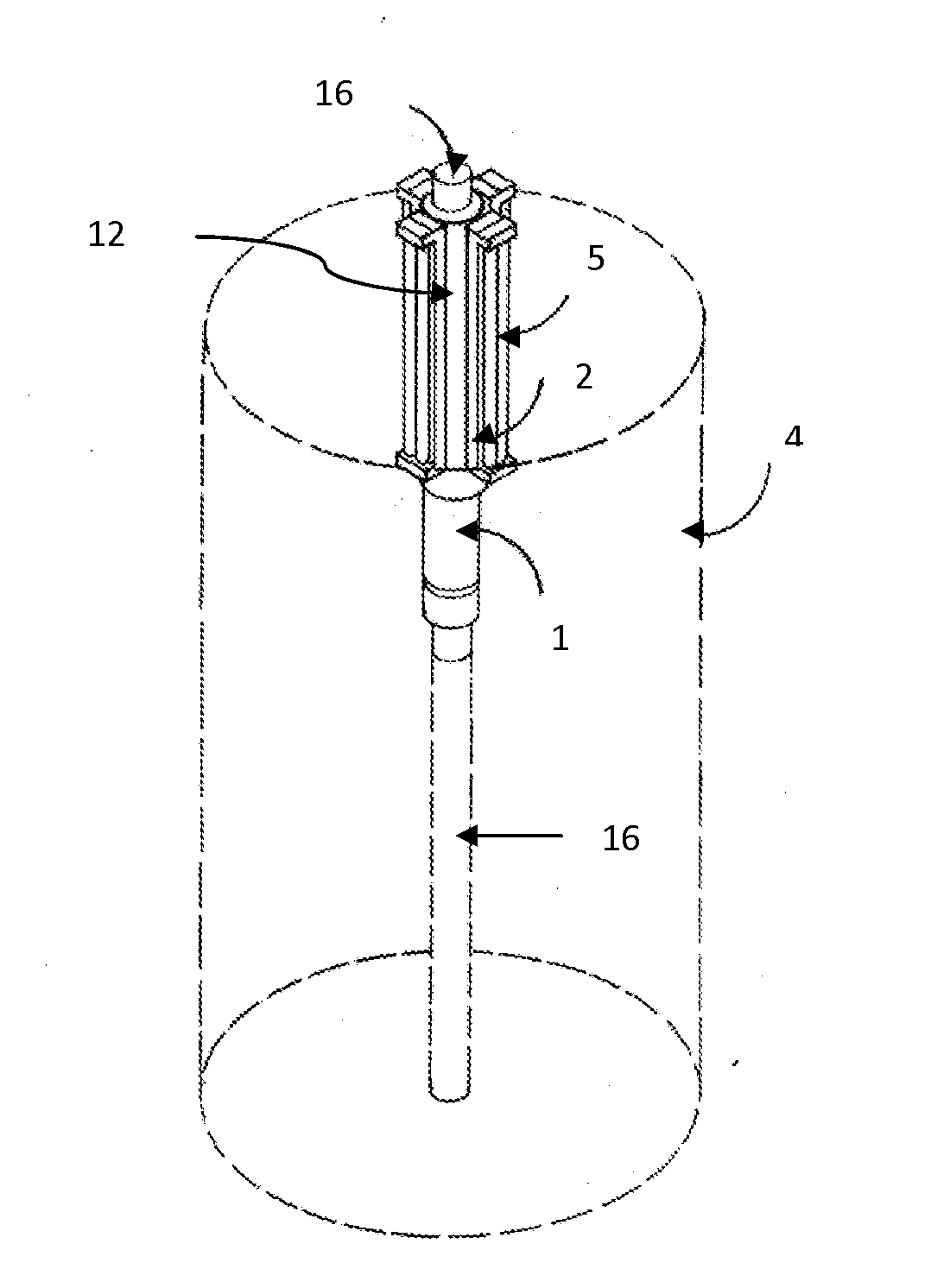

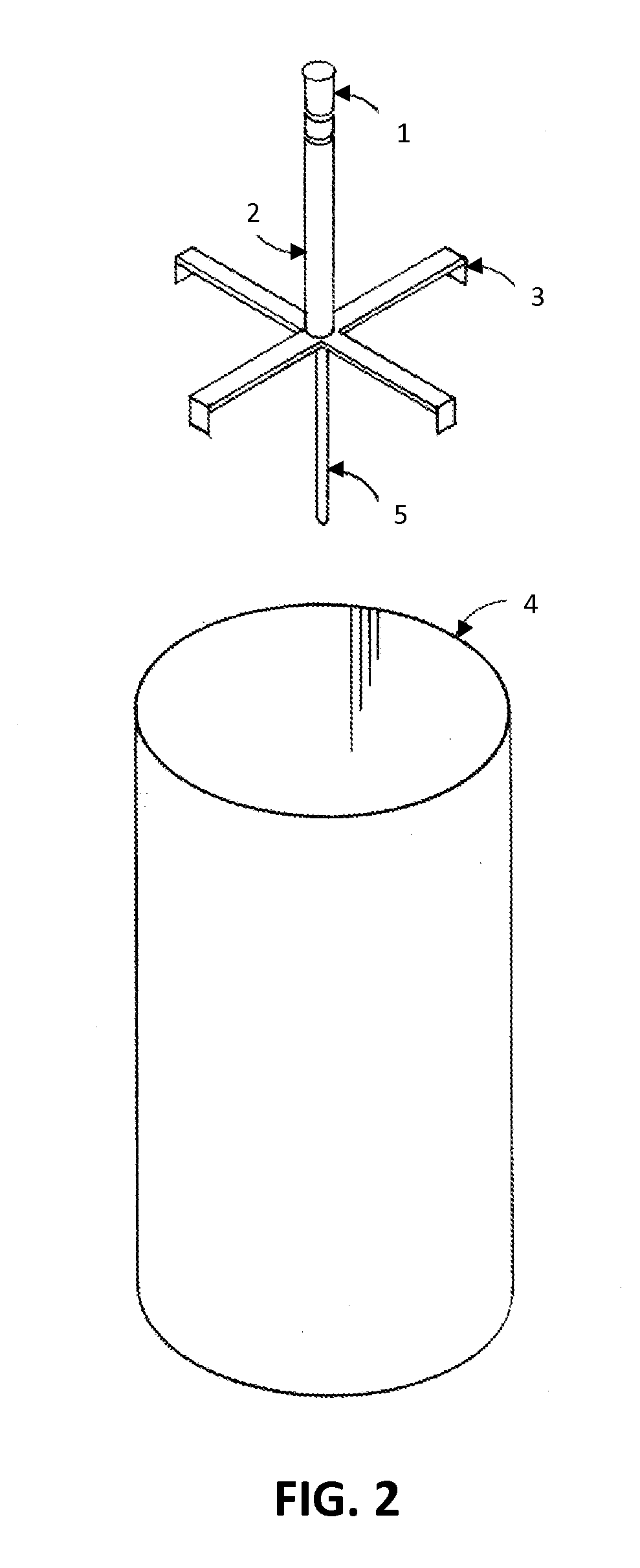

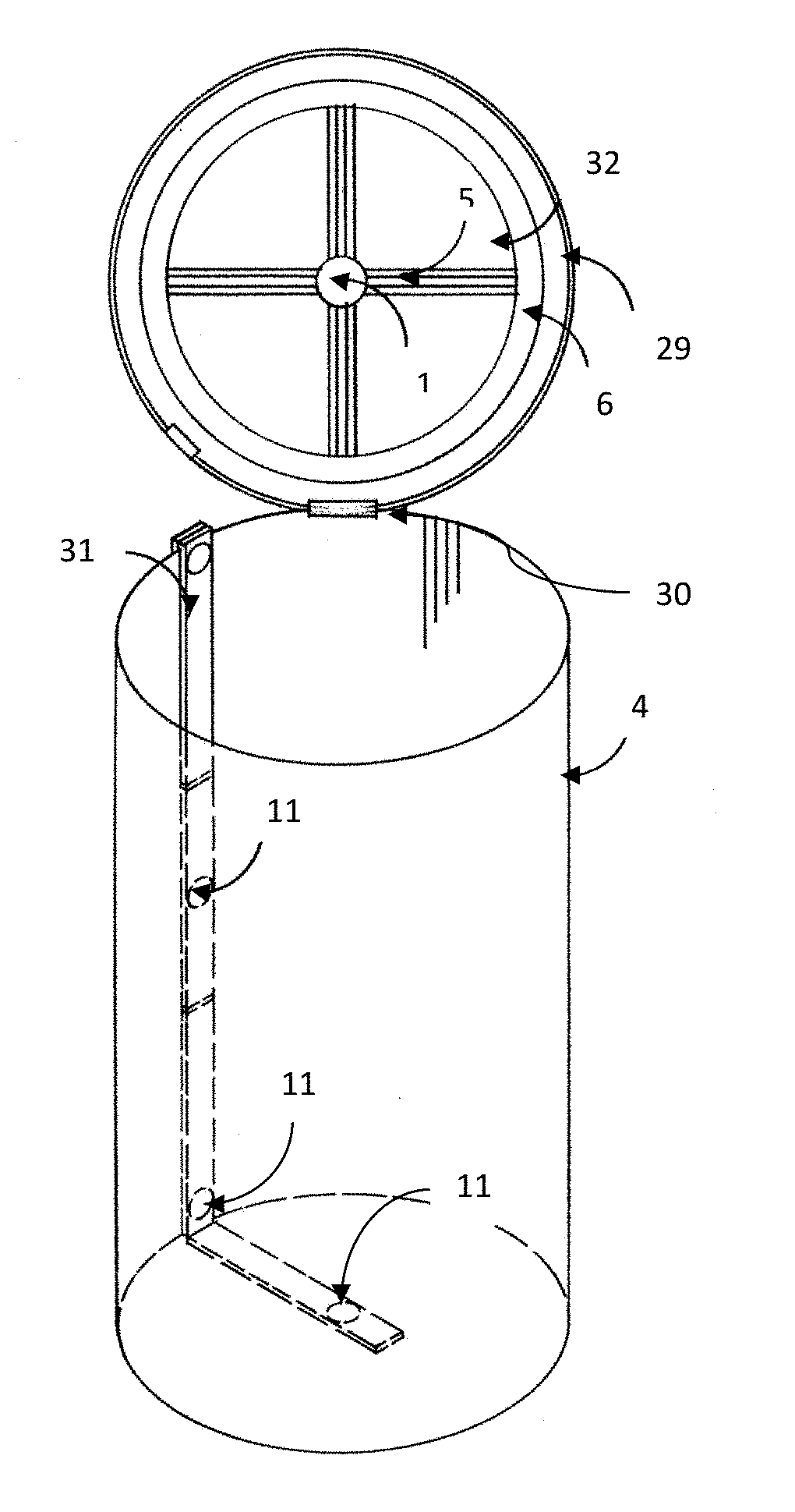

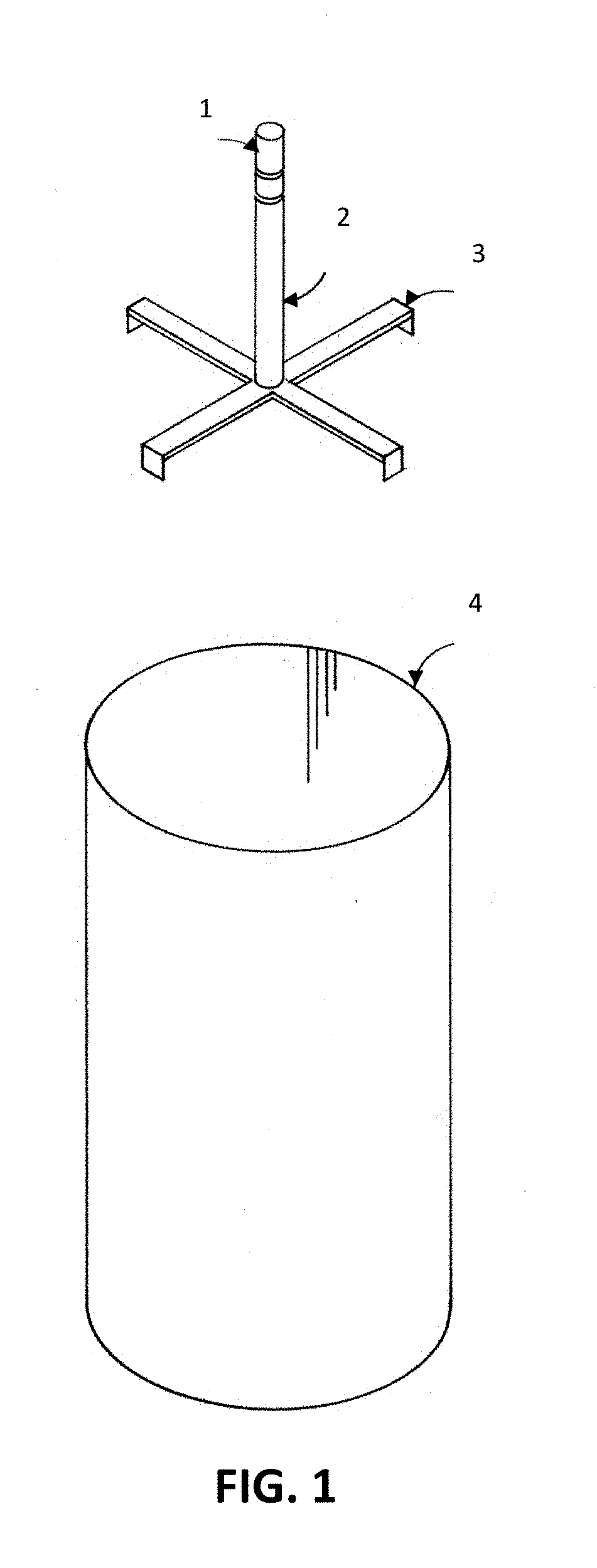

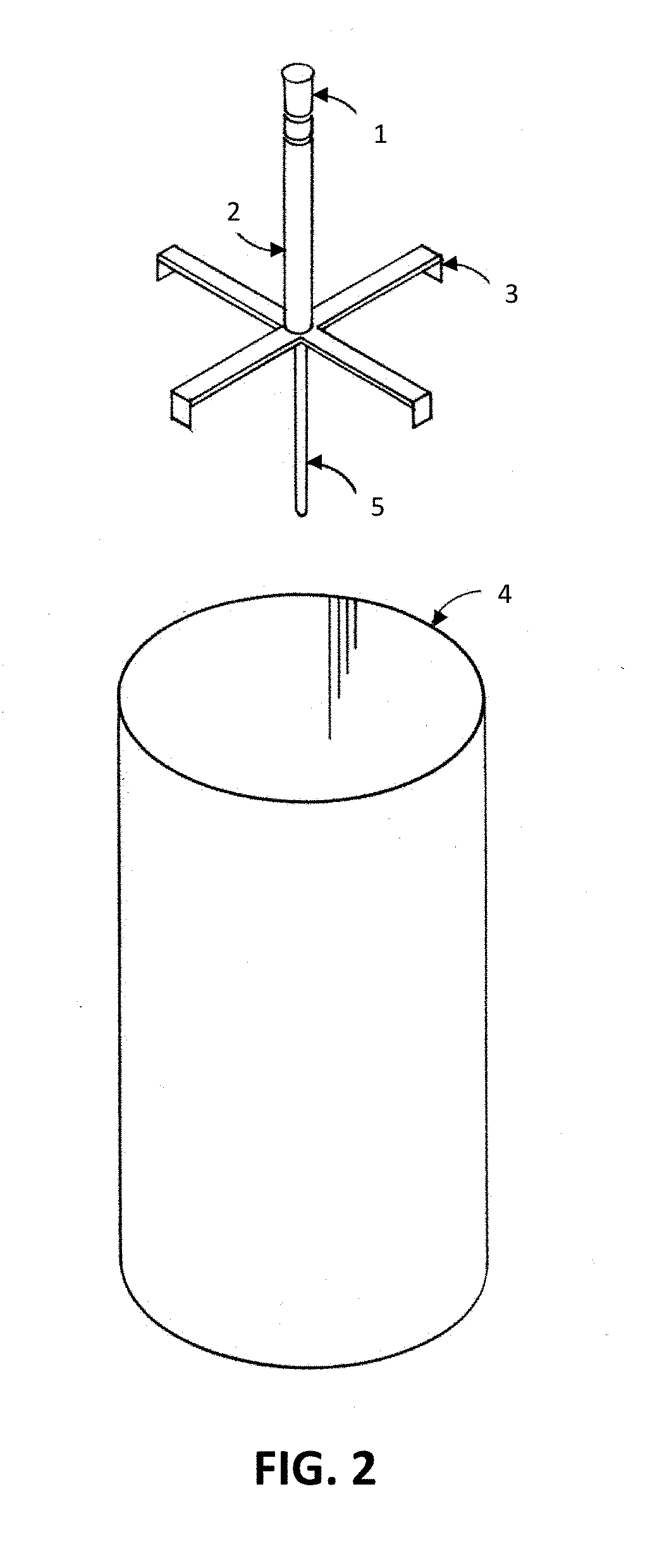

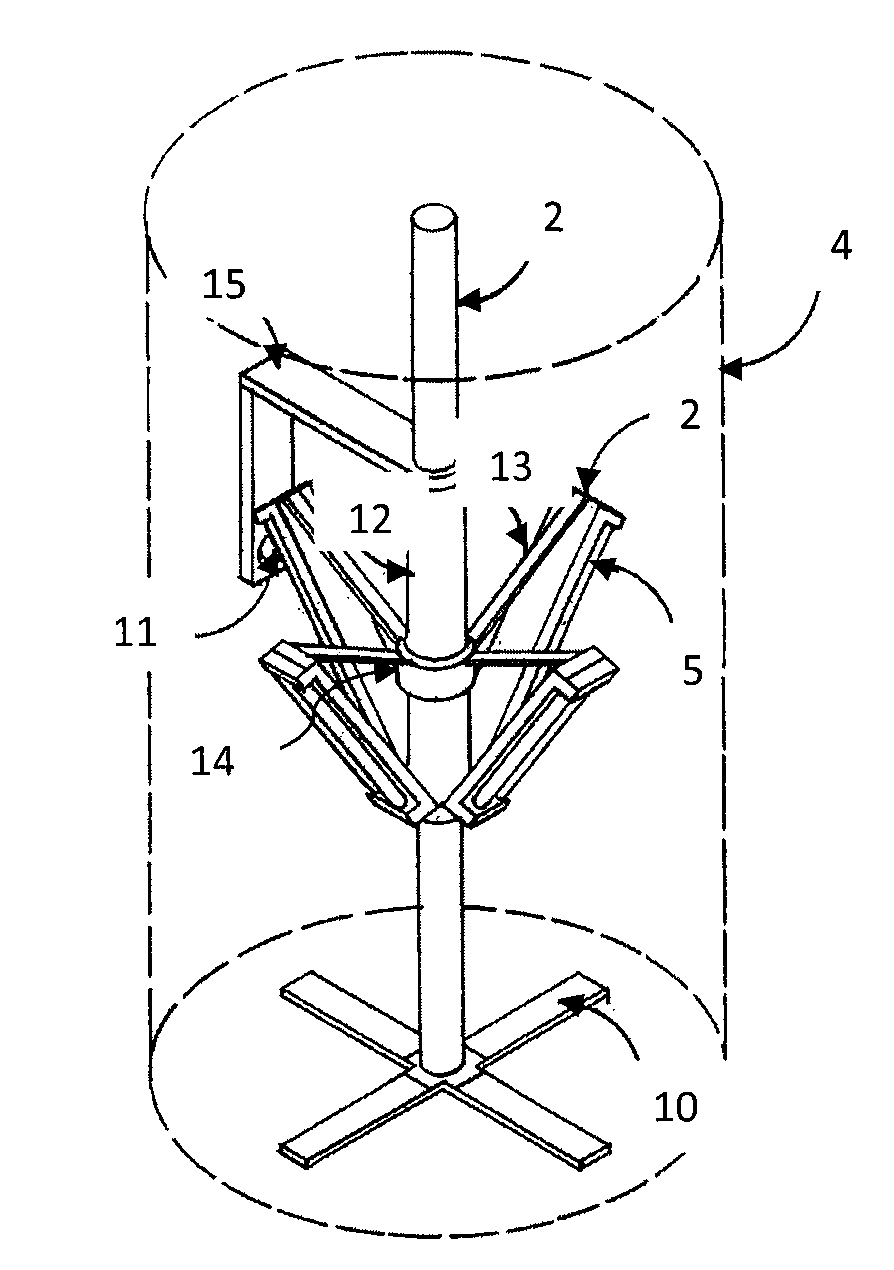

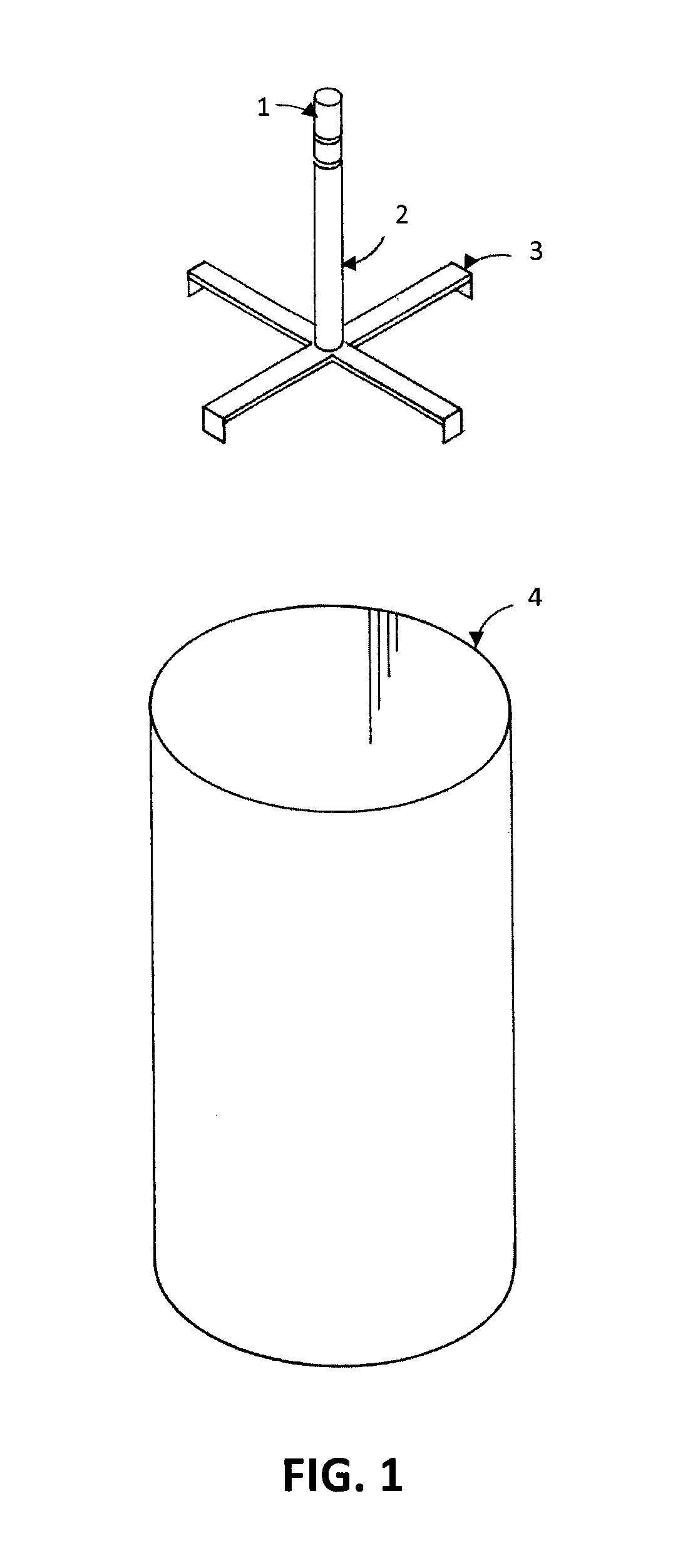

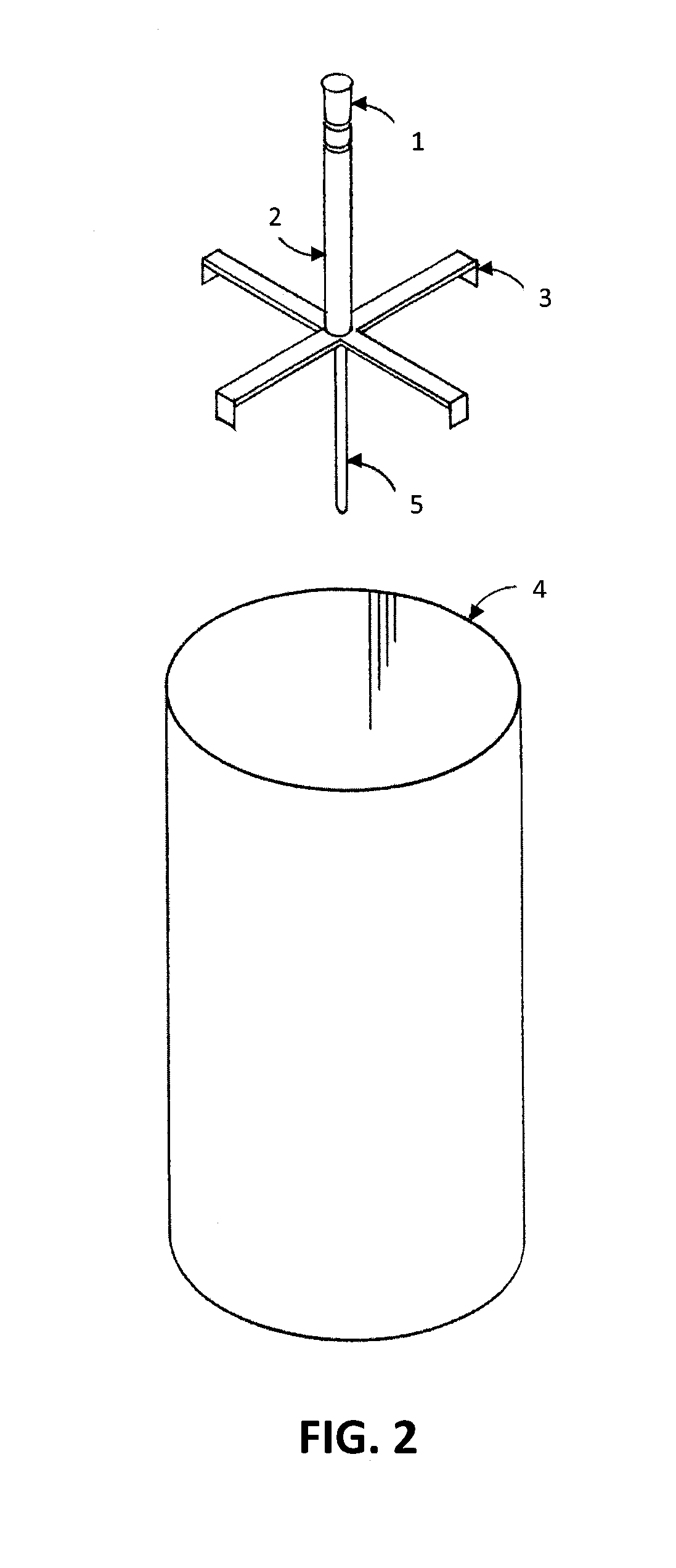

Provided herein are systems, ultraviolet (UV) devices, and methods for UV disinfection and sterilization, more specifically, systems, UV devices, and methods for UV disinfection and sterilization of a container, room, space or defined environment. The systems, UV devices, and methods are particularly useful for the UV disinfection and sterilization of a container used in the food and dairy industry and for containers used in the process of fermentation for an alcoholic beverage. Provided are also systems, UV devices, and methods for inhibiting the growth of one or more species of microorganisms present in a container, room, space or defined environment, preferably for inhibiting the growth of one or more species of microorganisms present on an interior surface of a container, room, space or defined environment.

Owner:BLUEMORPH

Compositions and methods for UV sterilization

ActiveUS20130175460A1Minimal necessary UV doseMinimizing power useRadiation pyrometryFood preservationDairy industryUv disinfection

Provided herein are systems, ultraviolet (UV) devices, and methods for UV disinfection and sterilization, more specifically, systems, devices, and methods for UV disinfection and sterilization of a container, room, space or defined environment. The systems, UV devices, and methods are particularly useful for the UV disinfection and sterilization of a container used in the food and dairy industry and for containers used in the process of fermentation for an alcoholic beverage. Provided are also systems, UV devices, and methods for inhibiting the growth of one or more species of microorganisms present in a container, room, space or defined environment preferably for inhibiting the growth of one or more species of microorganisms present on an interior surface of a container, room, space or defined environment.

Owner:BLUEMORPH

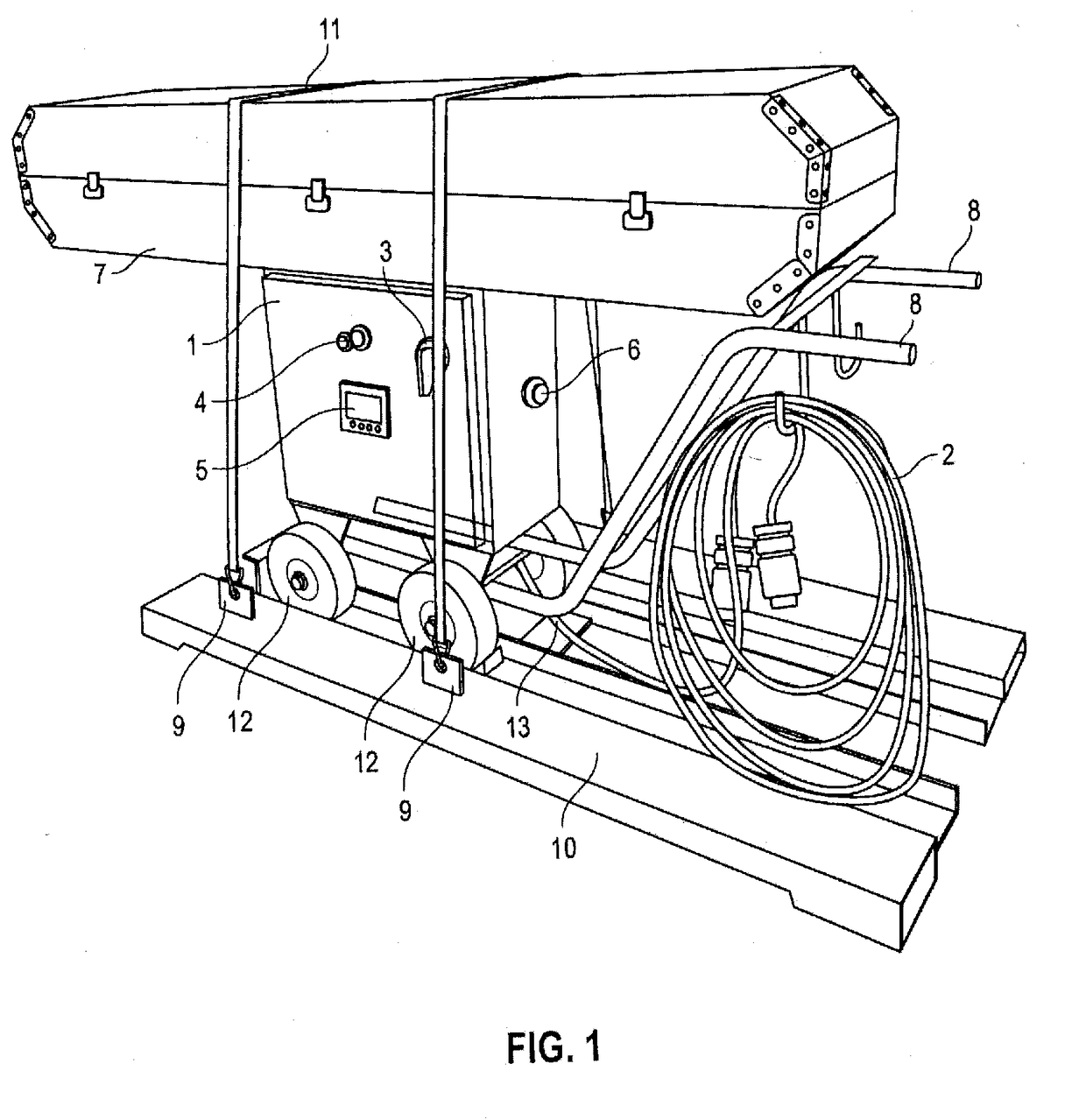

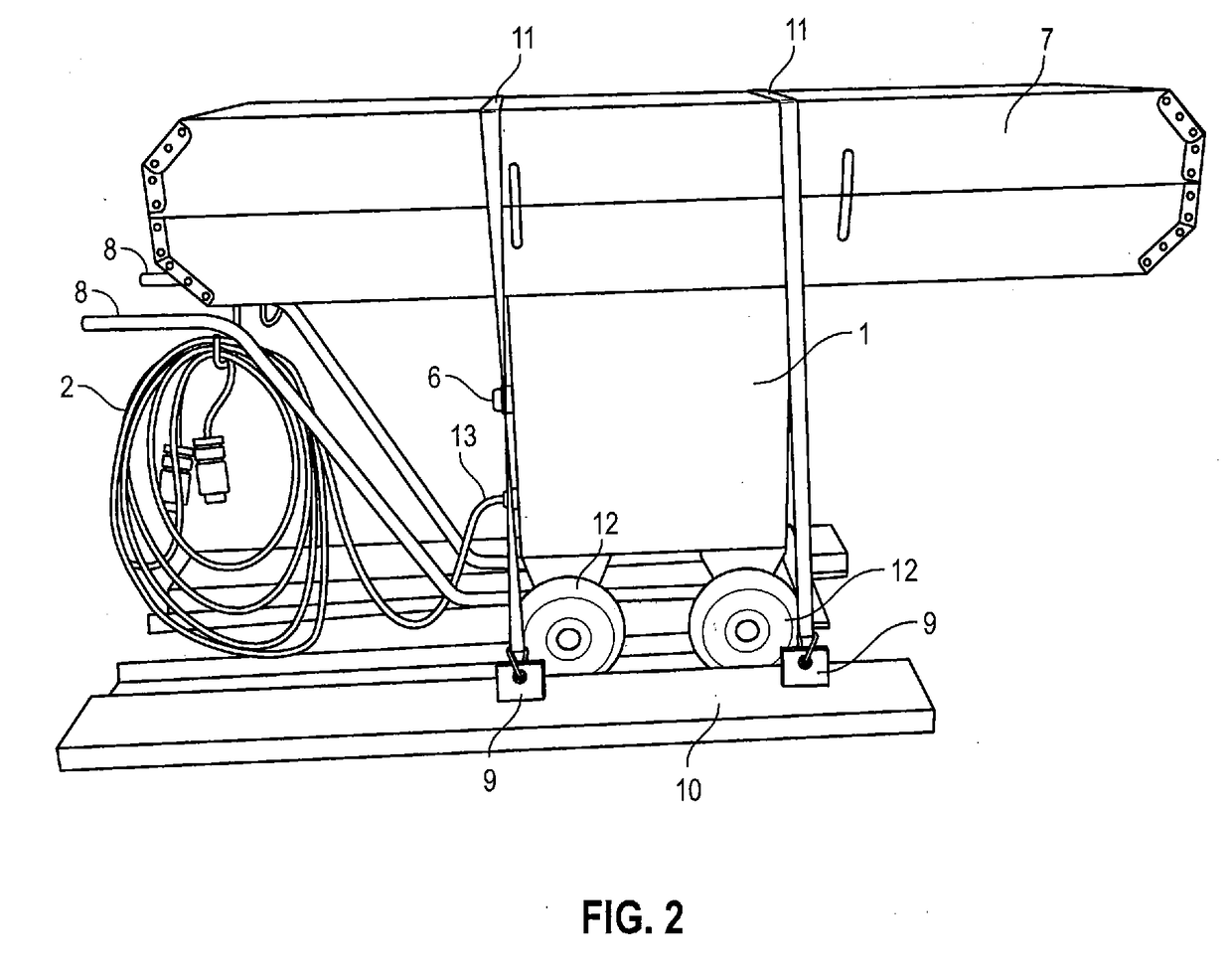

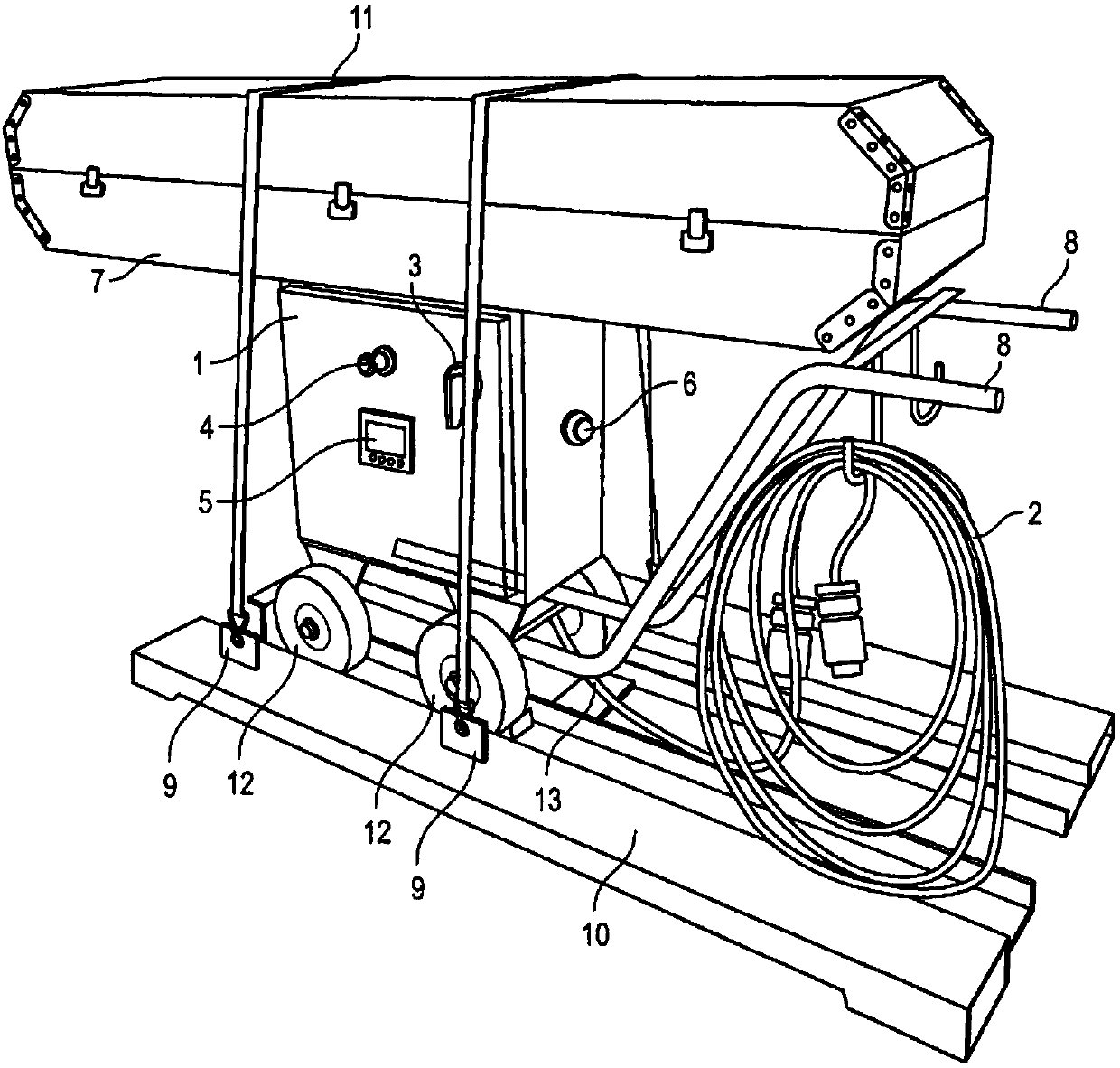

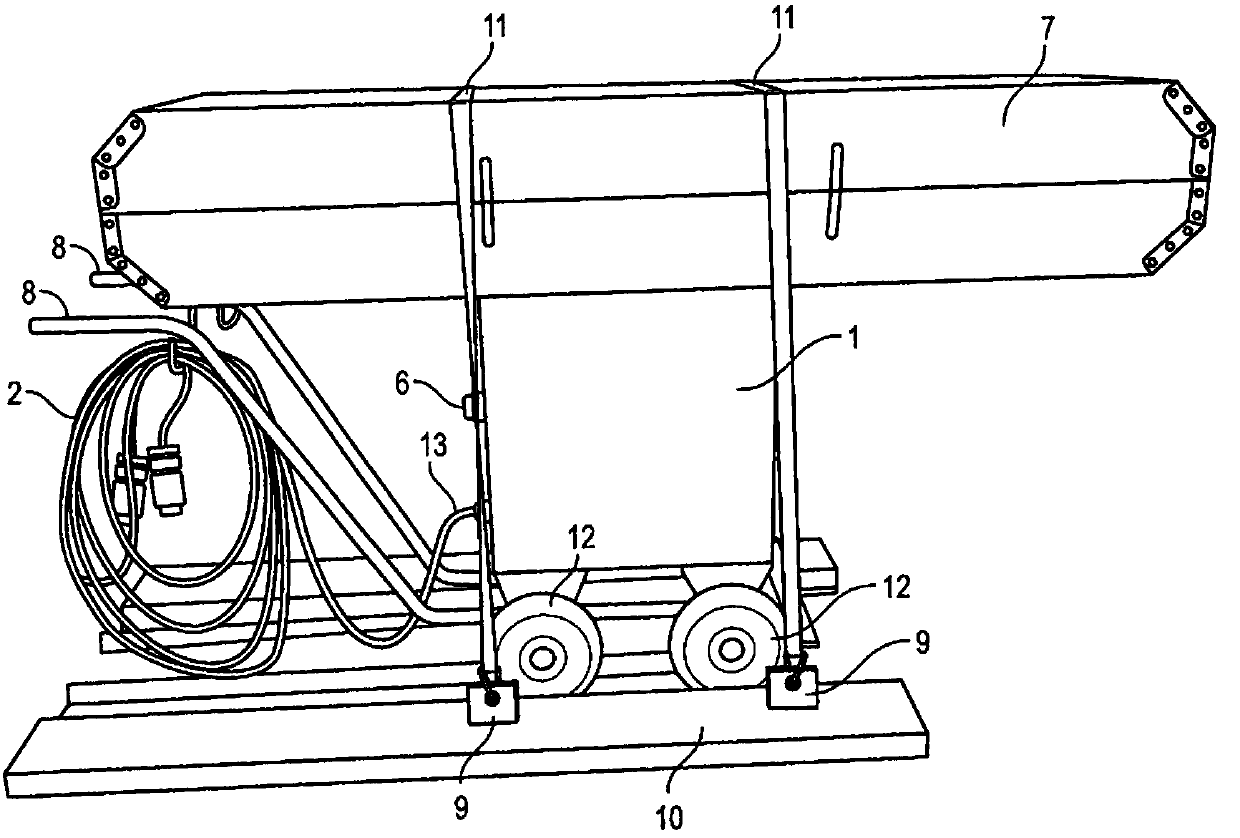

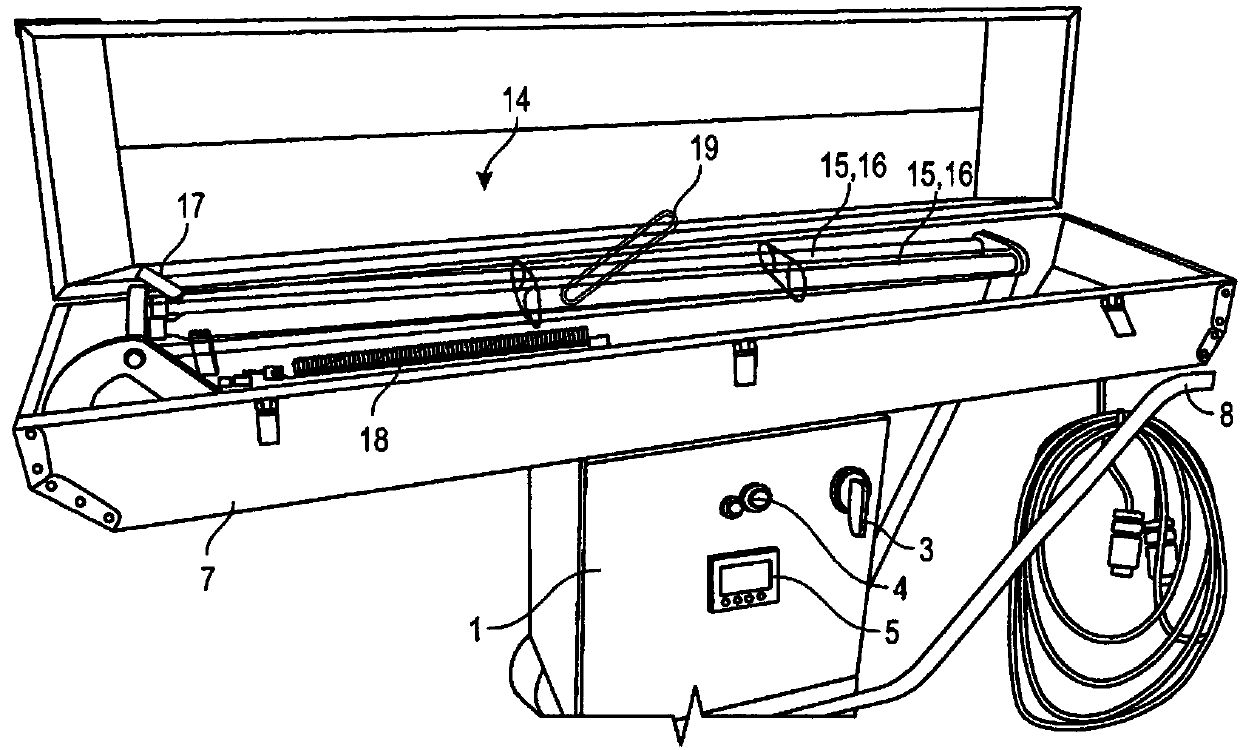

Portable UV devices, systems and methods of use and manufacturing

ActiveUS20150359915A1Promote sportsElectric discharge tubesFood preservationDairy industryUv disinfection

Provided herein are portable ultraviolet (UV) devices, systems, and methods of use and manufacturing same. Methods of use include methods for UV disinfection and sterilization, more specifically, methods for UV disinfection and sterilization of a container, a room, a space or a defined environment. The portable UV devices, systems and methods are particularly useful for the UV disinfection and sterilization of a container, a room, a space or defined environment used in the food, beverage and dairy industry and in the process of fermentation for an alcoholic beverage. Provided are also portable UV devices, systems, and methods for inhibiting the growth of one or more species of microorganisms present in a container, a room, a space or a defined environment, preferably for inhibiting the growth of one or more species of microorganisms present on an interior surface of a container, a room, a space or a defined environment.

Owner:BLUEMORPH

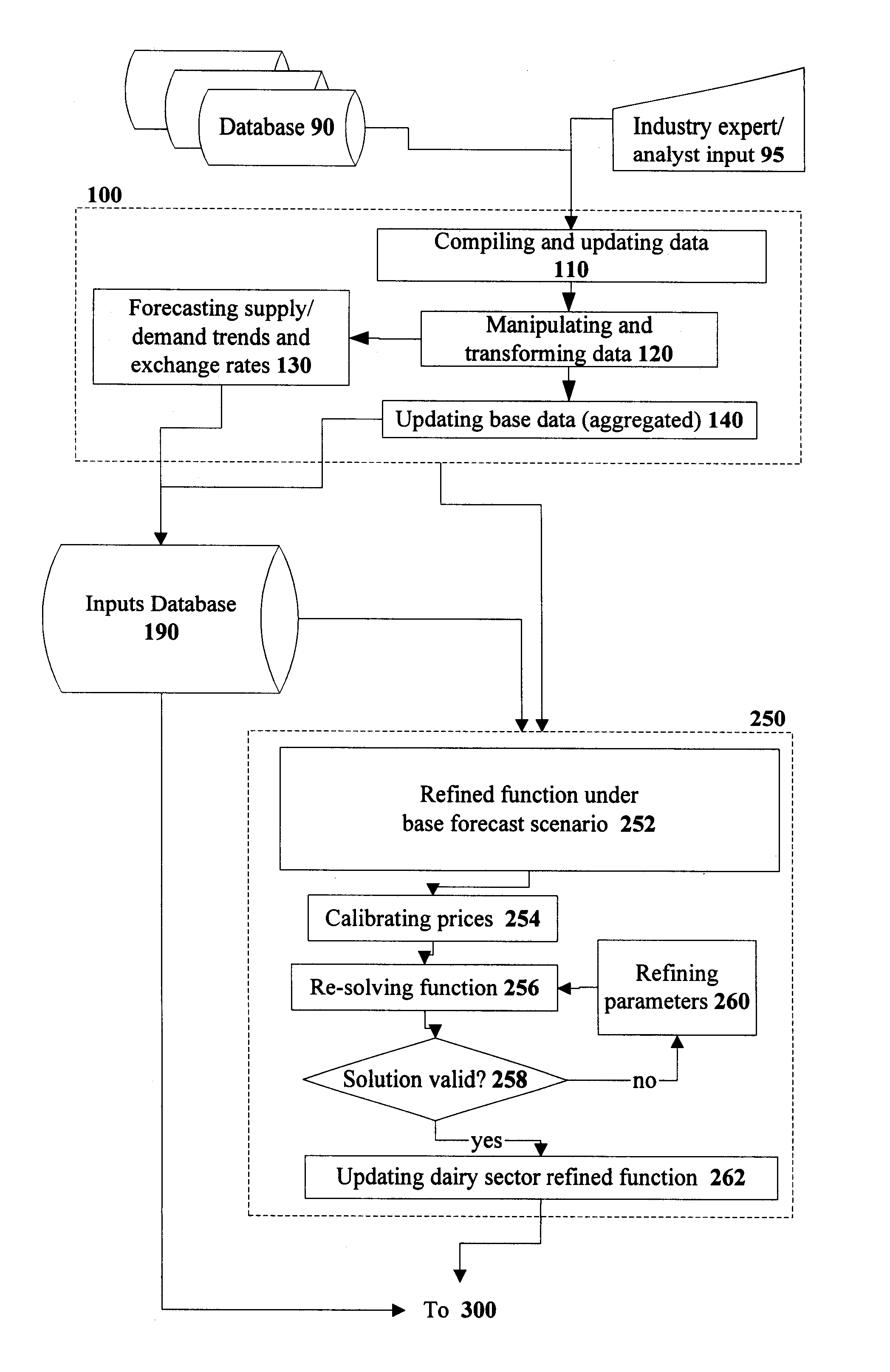

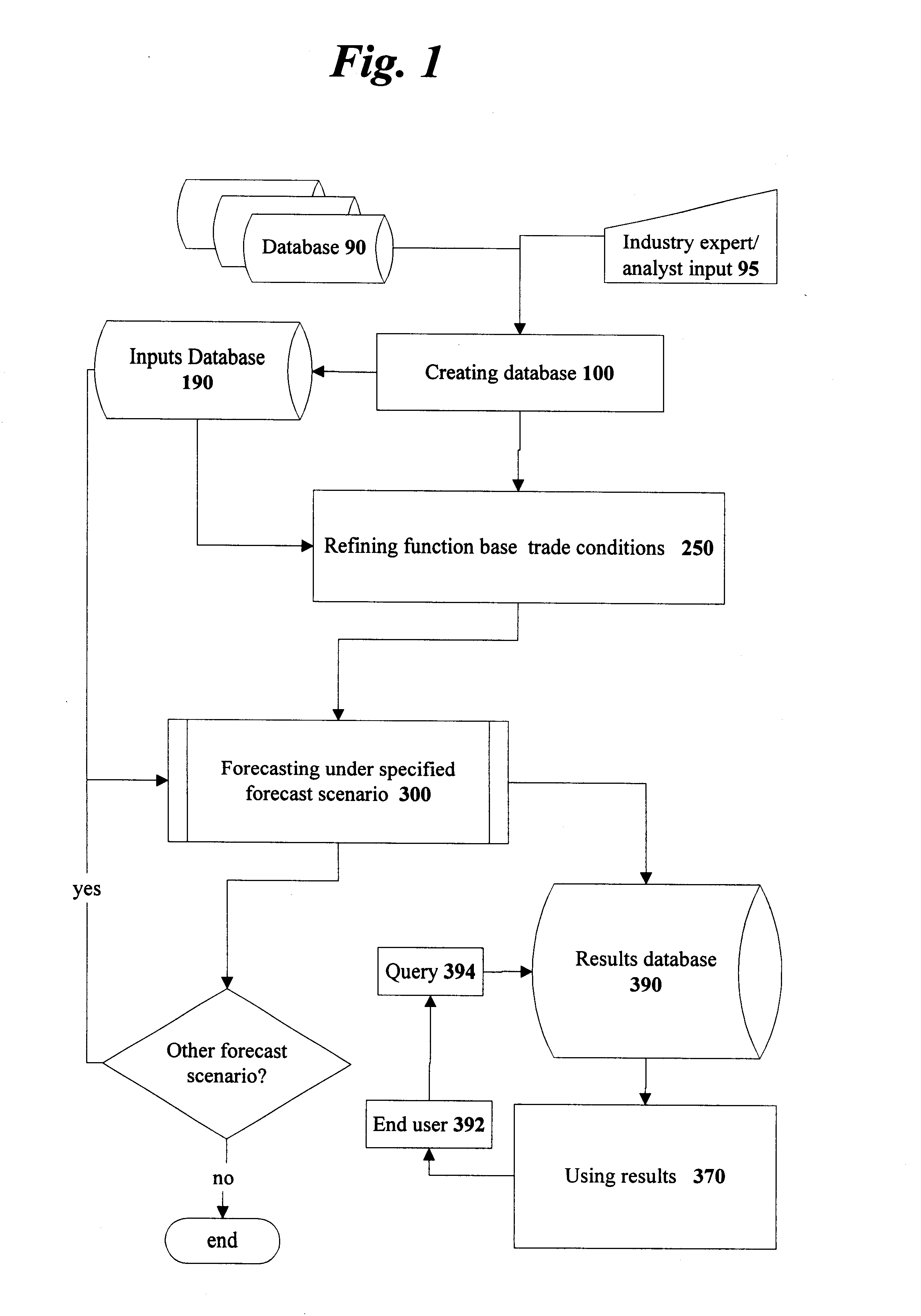

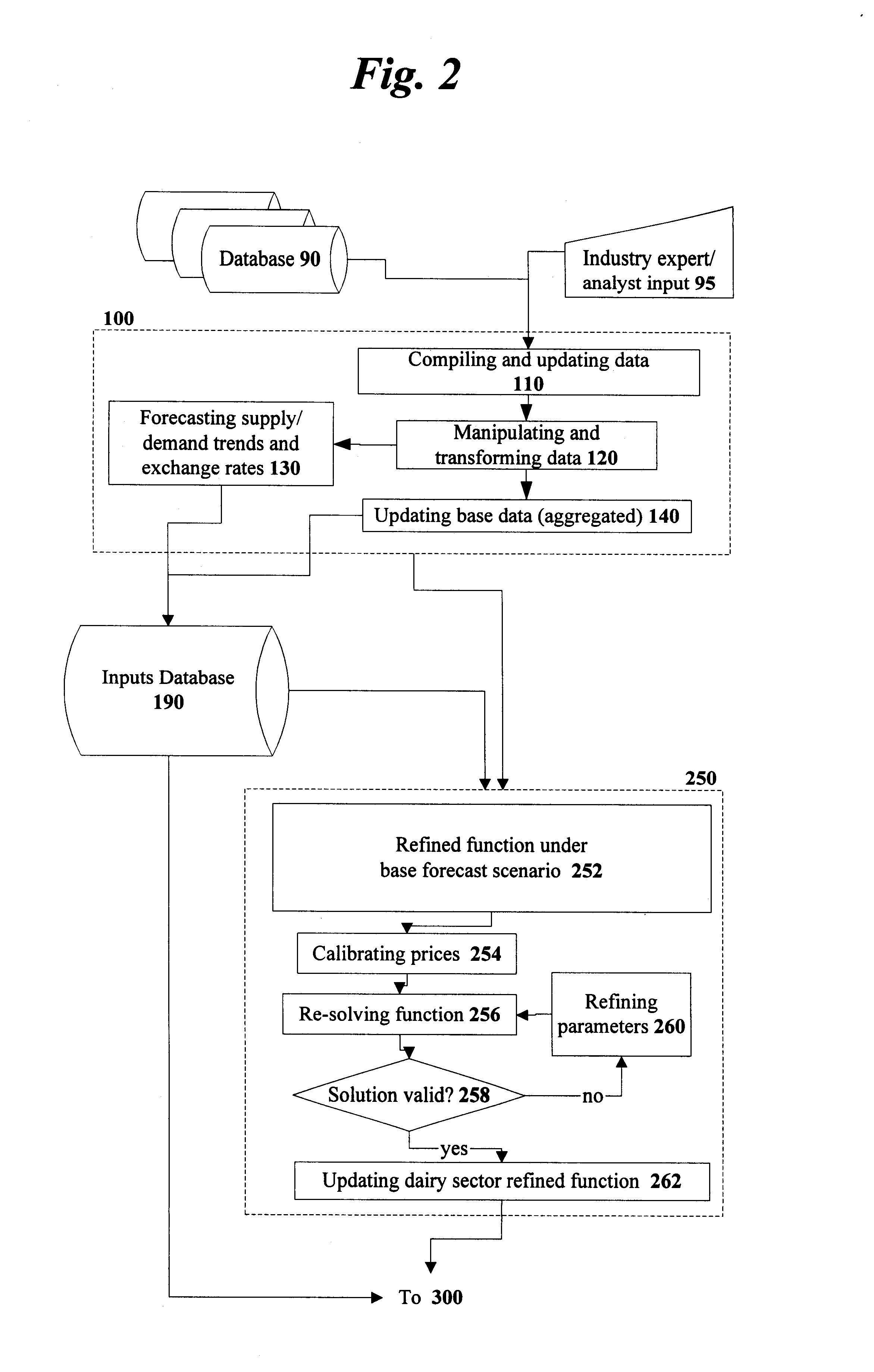

Method and system for accurately forecasting prices and other attributes of agricultural commodities

InactiveUS6865542B2Accurately approximatedAccurate predictionMarket predictionsResourcesGraphicsElectronic form

Using a general-purpose computer, the method and system of the present invention enables the forecasting of agricultural commodity prices and amounts of consumption, production and trade flows across regions, under a variety of supply and demand, trade and domestic policy scenarios and over an at least annual time period. The method employs a multi-component spatial equilibrium function approximating an inter-regional market in agricultural commodities, such as dairy commodities, and enables the setting of trade and domestic policy instruments to enable forecasting under a variety of forecast scenarios. The function further enables the incorporation of intermediate commodities, in addition to primary and processed commodities, to account for the effects of reconstitution technologies on said forecasted values. The method generally comprises creating an inputs database comprising a definition of the regions and forecast scenarios, and a plurality of dairy sector data spanning a number of recent years including commodity prices and amounts of consumption, production and trade flow in the regions; refining the function; solving the refined function by maximizing a consumer and a producer surplus net of all transaction costs, to generate the forecasts; and, outputting the forecasts to a results database. The method may further solve for an optimal amount of intermediate commodities consumed in the making of the final processed commodities by region under an assumption of optimal use to further refine the forecasts. The system outputs in the forms of graphs, spreadsheets, maps, or other formats can be delivered electronically through various media.

Owner:WISCONSIN ALUMNI RES FOUND

UV Sterilization Of Container, Room, Space Or Defined Environment

Provided herein are portable ultraviolet (UV) devices, systems, and methods of use and manufacturing same. Methods of use include methods for UV disinfection and sterilization, more specifically, methods for UV disinfection and sterilization of a container, a room, a space or a defined environment. The portable UV devices, systems and methods are particularly useful for the UV disinfection and sterilization of a container, a room, a space or defined environment used in the food, beverage and dairy industry and in the process of fermentation for an alcoholic beverage. Provided are also portable UV devices, systems, and methods for inhibiting the growth of one or more species of microorganisms present in a container, a room, a space or a defined environment, preferably for inhibiting the growth of one or more species of microorganisms present on an interior surface of a container, a room, a space or a defined environment.

Owner:BLUEMORPH

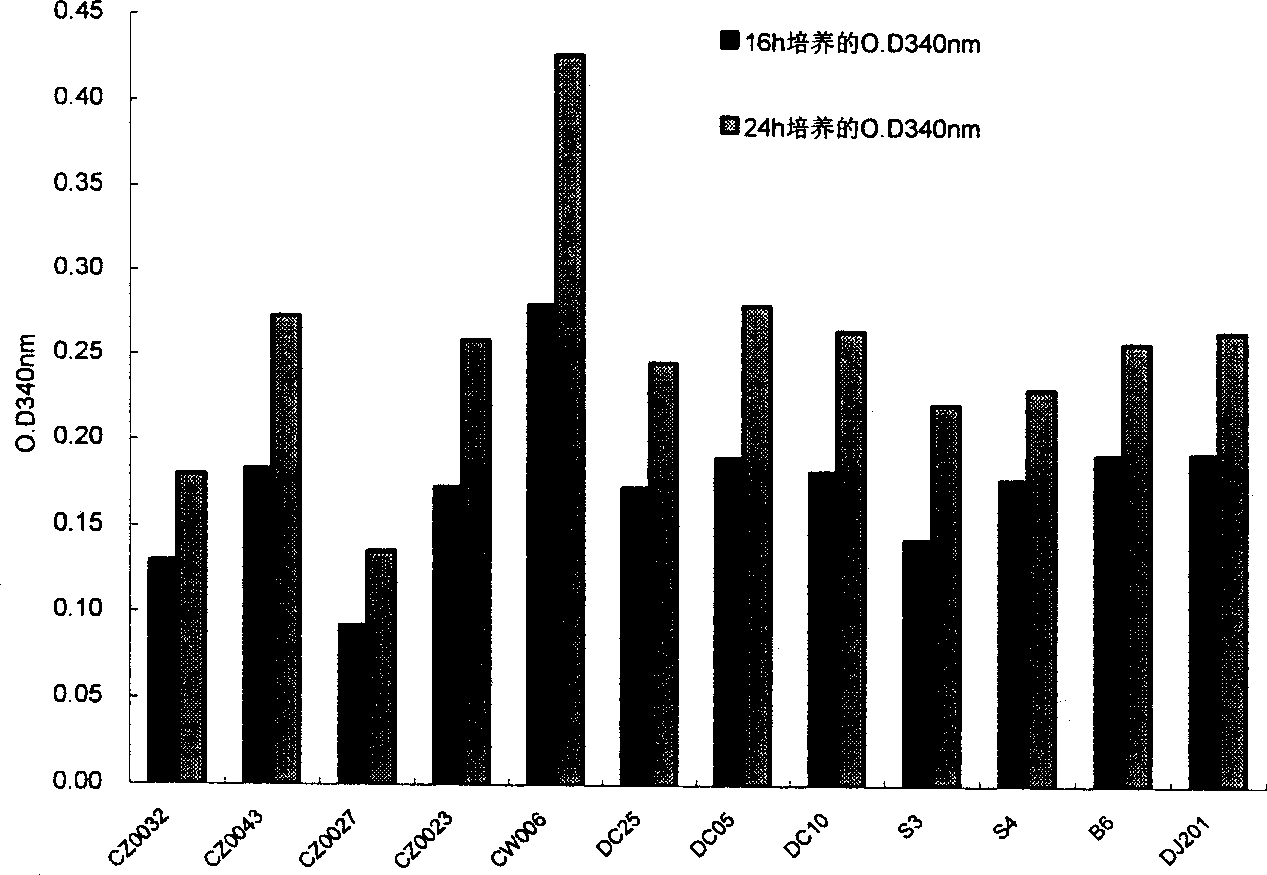

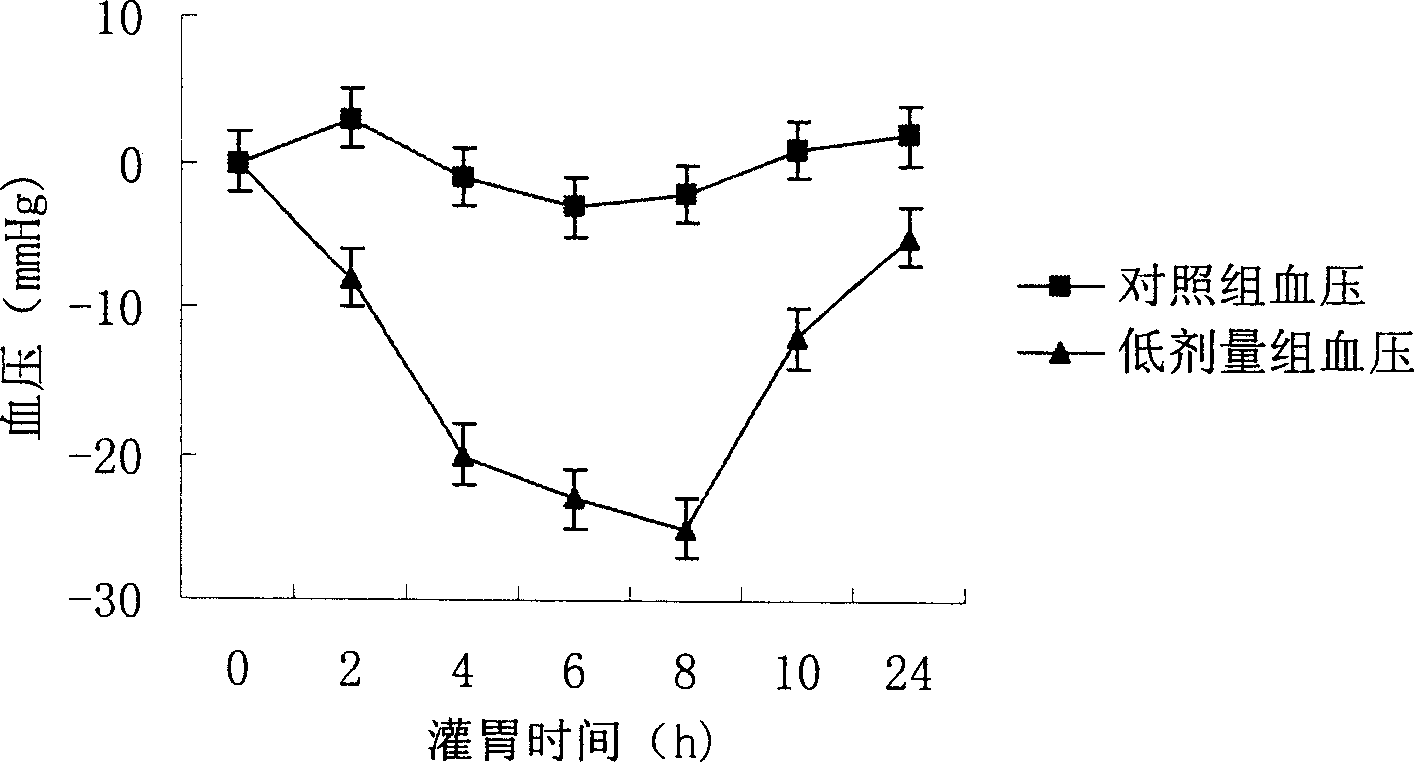

Lactobacillus plantarum CW006 with antihypertensive function

This invention discloses a new Lactobacillus plantarum strain CW006(conservation number CCTCC M 206032) with an antihypertensive effect, and the hygienic and medical agents related, belonging to the micro-biological additives technological field. This Lactobacillus plantarum strain CW006 has a proteolysis activity and can acquire the antihypertensive effect by producing angiotensin-converting enzyme inhibitor via fermentation of raw milk. With these characteristics, it can be used as starting strain in the dairy industry, and applied in various health care products and medical agents as theraputic additives.

Owner:JIANGSU WECARE BIOTECHNOLOGY CO LTD

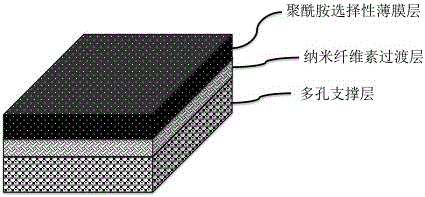

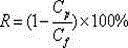

Composite thin membrane with multilayer composite structure and preparation method thereof

InactiveCN106739363ALow energy consumptionPromote formationSemi-permeable membranesLamination ancillary operationsElectrolysisFiltration membrane

The invention belongs to the technical field of semi-permeable membrane separation processes, and relates to a composite thin membrane with a multilayer composite structure and a preparation method thereof. The composite thin membrane is formed by coating nano-cellulose and a transition layer which is formed from a polyelectrolyte by a layer-by-layer assembling method on a porous supporting layer substrate in sequence, and then coating a polyamide selective membrane layer which is formed through a common interface polymerization reaction method. A composite thin membrane structure can be applied to preparation of a nano-filtration membrane, a reverse osmosis membrane and a forward osmosis membrane. The application of the composite thin membrane with the multilayer composite structure comprises tap water purification, municipal water supply, sewage purification, brackish water desalination, seawater desalination, drink juice concentration process, dairy industry, blood dialysis medicine industry and semiconductor industry.

Owner:林小锋

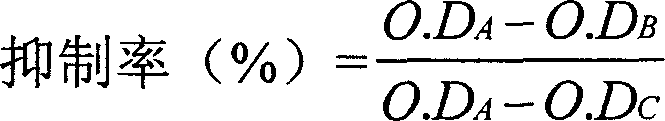

Ultrasensitive fluorescence response method for detecting melamine in milk

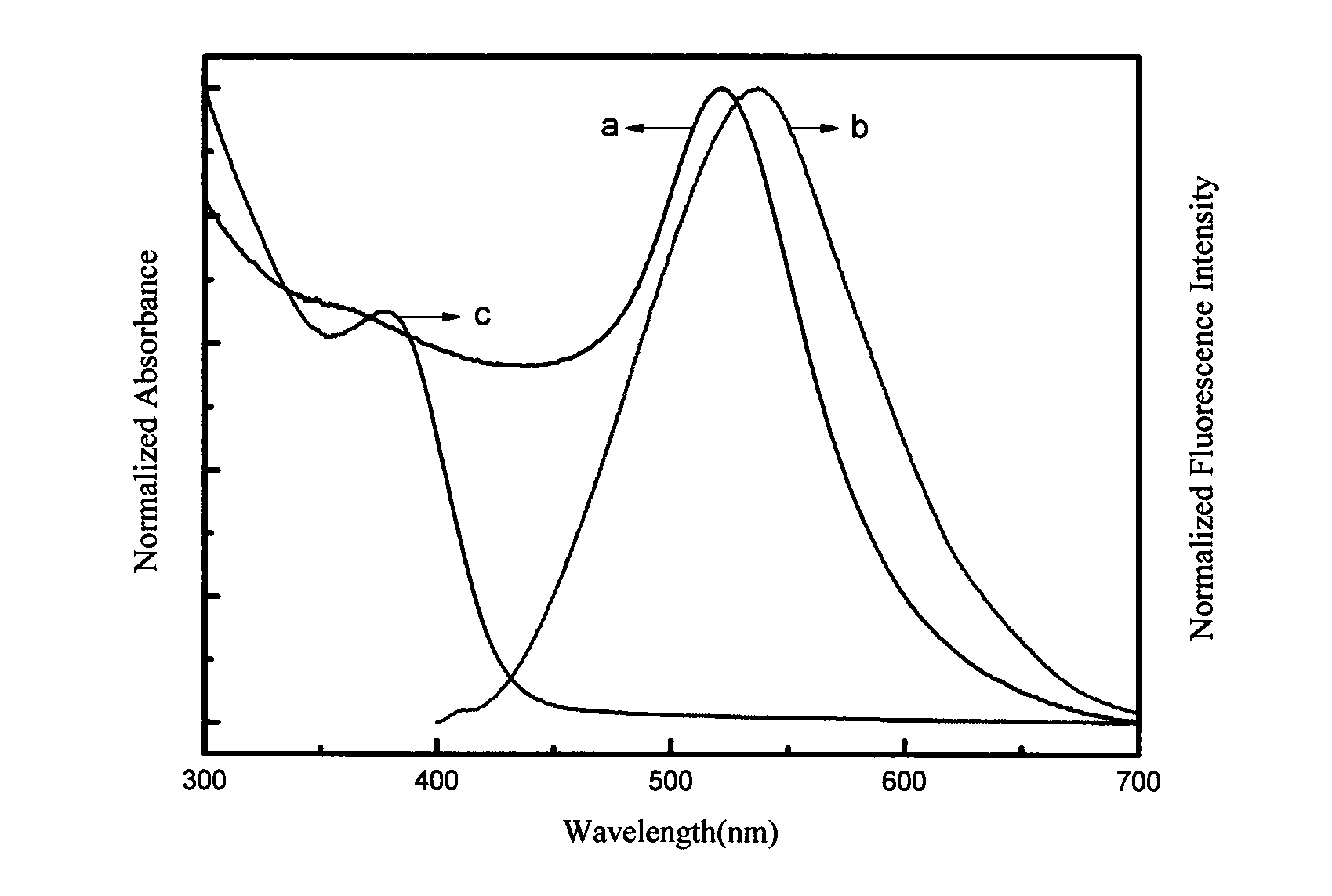

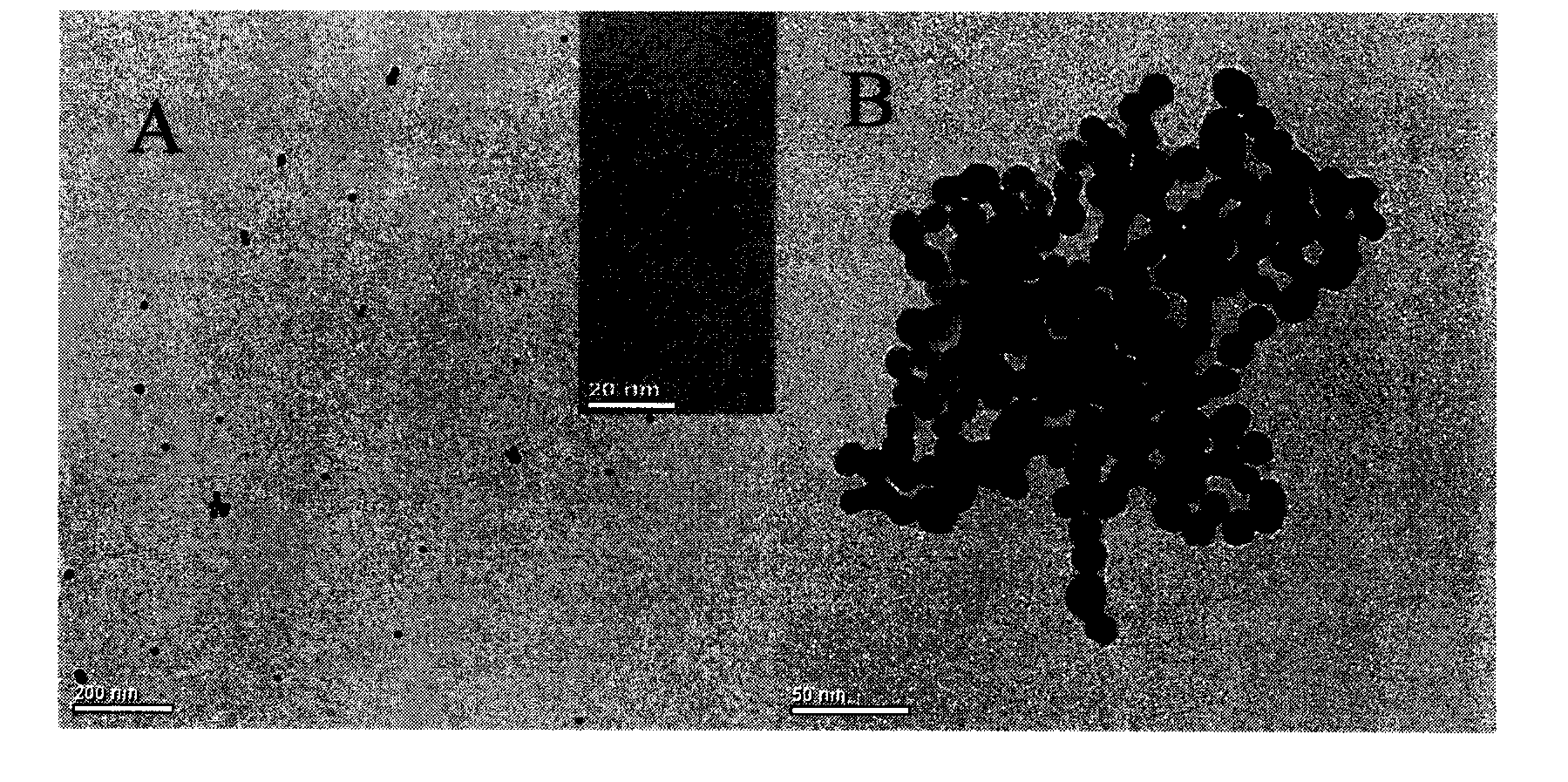

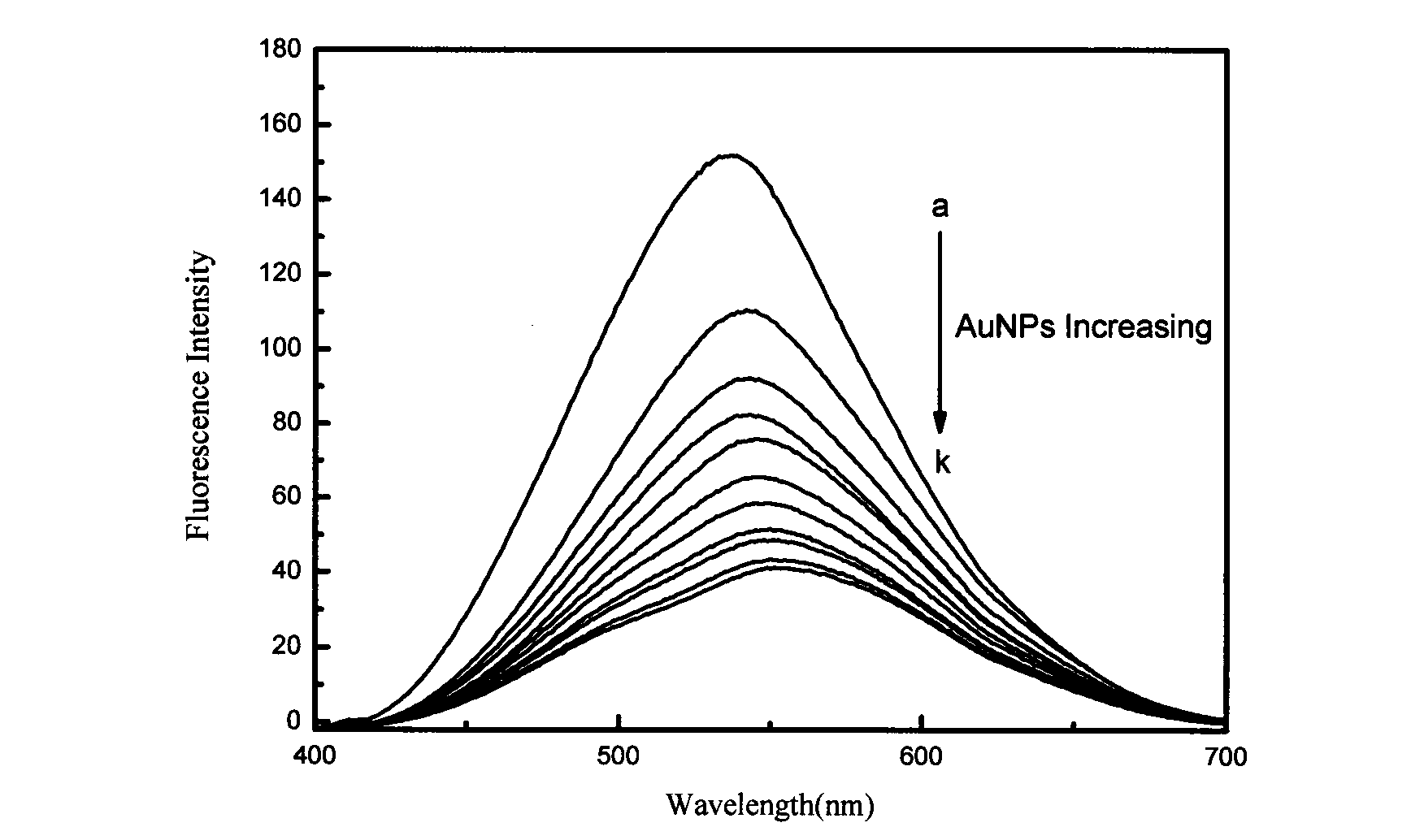

InactiveCN103063643AQuick checkEasy to detectColor/spectral properties measurementsFluorescence/phosphorescenceFilter effectQuenching

The invention relates to a method for detecting melamine in milk which is built based on the inner filter effect (IFE) between cysteine (L-Cys)-modified CdS quantum dots and citric acid ligand coating gold nanoparticles (AuNPs), and belongs to the field of analytical chemistry. The method comprises the detecting steps of preparing the AuNPs, synthesizing and purifying the L-Cys-modified CdS quantum dots, pre-treating a milk sample and detecting the melamine in the milk. According to the principle of recovering the fluorescence intensity of the CdS quantum dots by adopting the AuNPs to cause the fluorescence quenching of the CdS quantum dots and adopting the melamine to induce the aggregation of the AuNPs, the method can simply, quickly and sensitively detect the melamine in the milk so as to provide convenience to future dairy industry.

Owner:JILIN UNIV

Enzyme isolated from a Bifidobacterium

InactiveUS7081355B2High transgalactosylatingImprove scalabilityFungiBacteriaBifidobacteriumDairy industry

The present invention concerns a new β-galactosidase with transgalactosylating activity isolated from Bifidobacterium bifidum and a truncated enzyme where the C-terminal end of the β-galactosidase protein has been deleted, resulting in an enzyme with a higher transgalactosylating activity than hydrolase activity. When lactose is used as a substrate, galacto-oligosaccharides are products of the transgalactosylase activity. Galacto-oligosaccharides enhance growth of health-promoting Bifidobacterium that may be used in a number of applications in the dairy industry.

Owner:ARLA FOODS AMBA

UV devices, systems and methods for UV sterilization

Provided herein are ultraviolet (UV) devices, systems, and methods for UV disinfection and sterilization, more specifically, UV devices, systems, and methods for UV disinfection and sterilization of a container, room, space or defined environment. The systems, UV devices, and methods are particularly useful for the UV disinfection and sterilization of a container used in the food and dairy industry and for containers used in the process of fermentation for an alcoholic beverage. Provided are also UV devices, systems, and methods for inhibiting the growth of one or more species of microorganisms present in a container, room, space or defined environment, preferably for inhibiting the growth of one or more species of microorganisms present on an interior surface of a container, room, space or defined environment.

Owner:BLUEMORPH

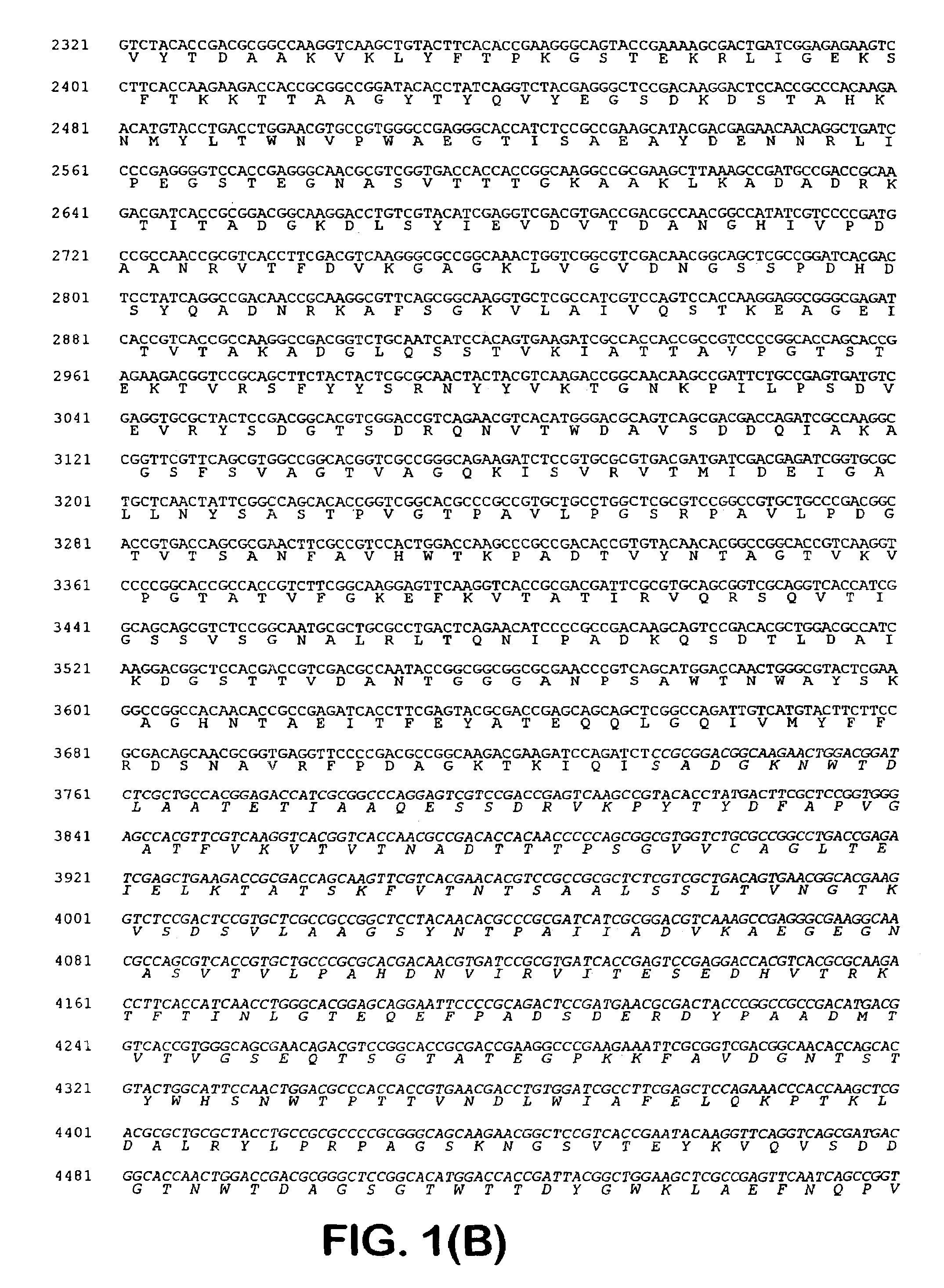

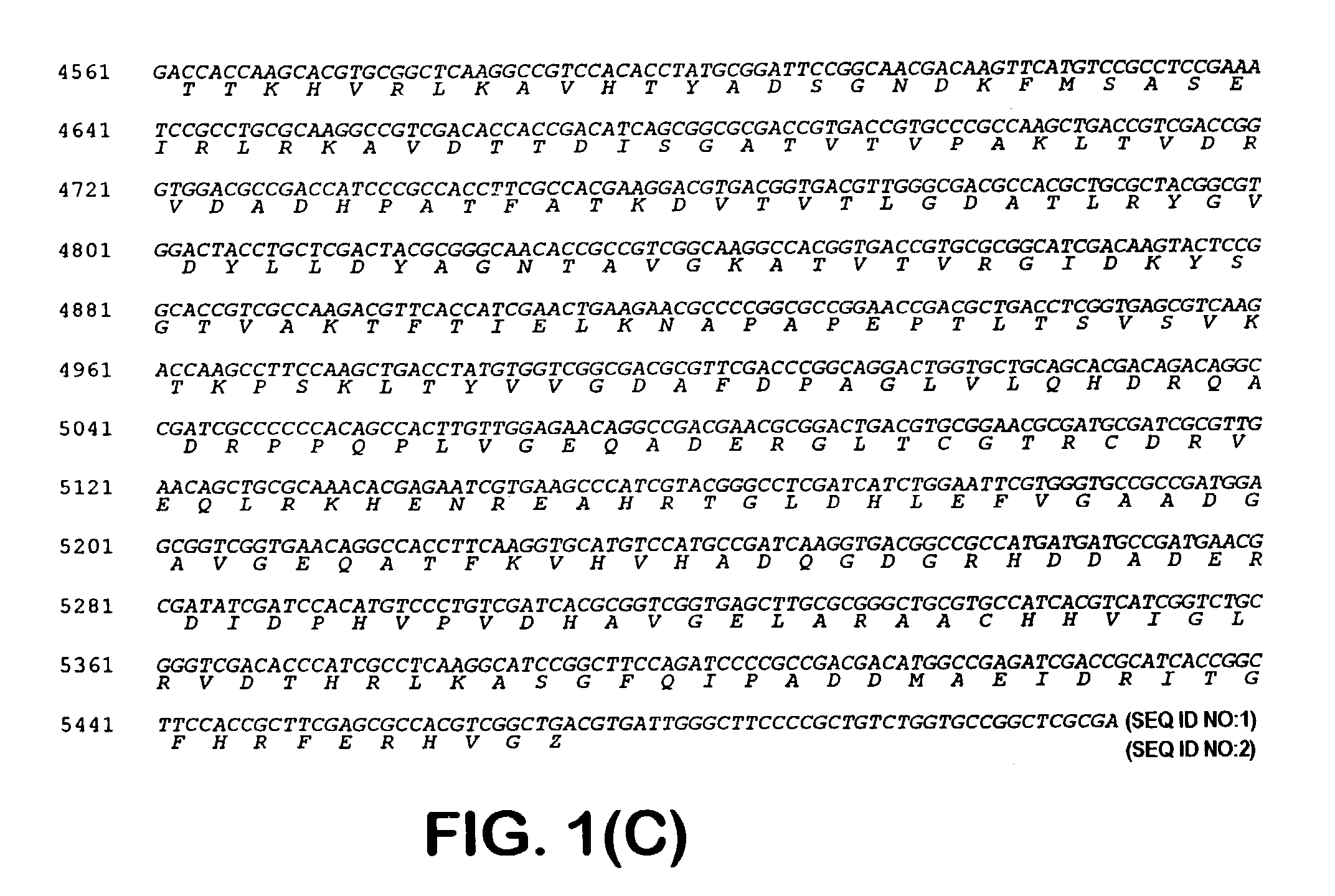

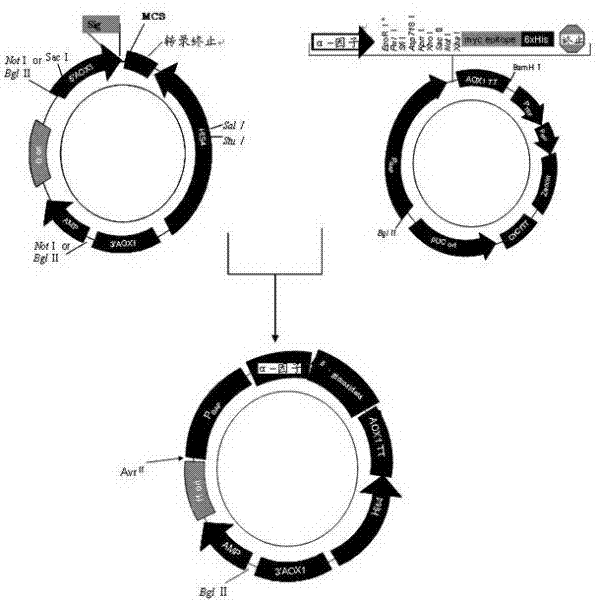

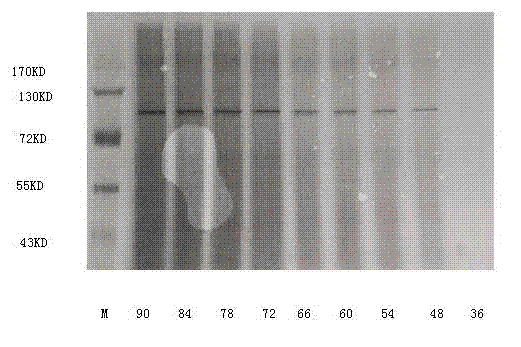

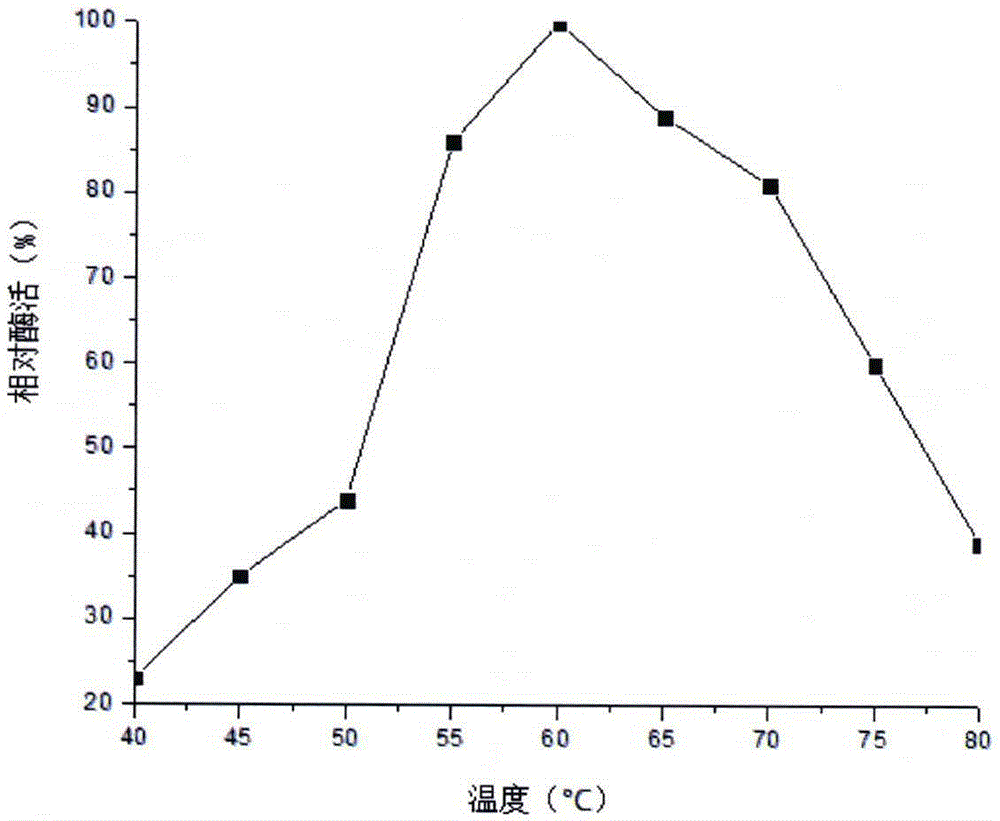

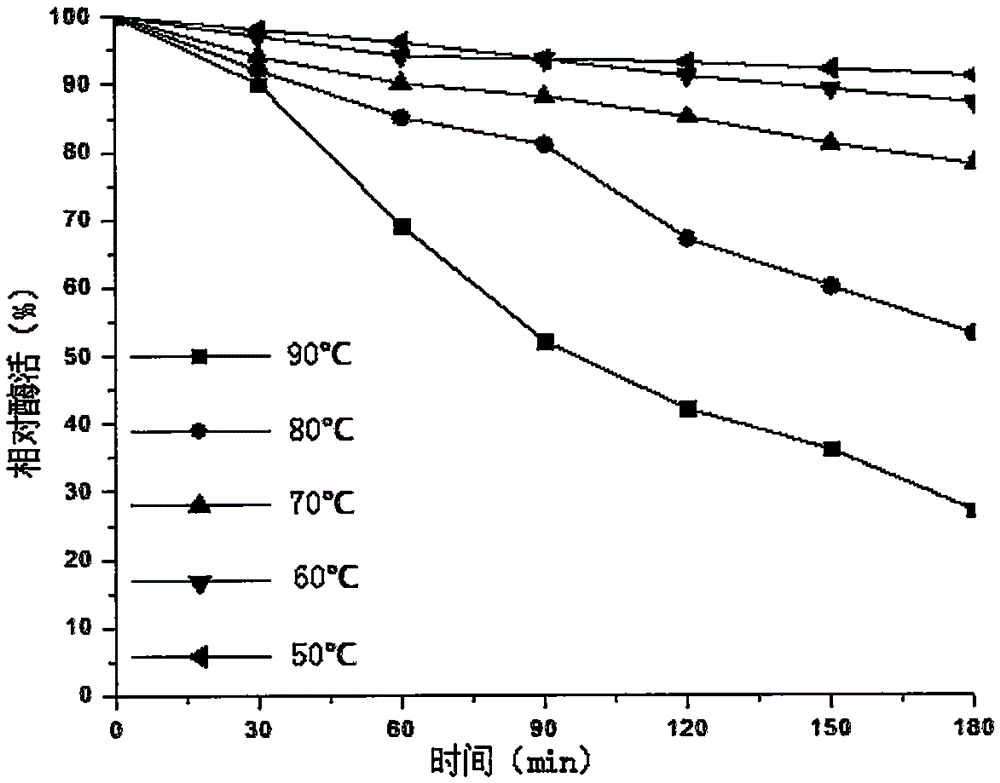

Cloning, expression and application of a β-glucosidase gene

ActiveCN102268421AImprove securityThe follow-up processing process is convenientFungiMicroorganism based processesBeta-glucosidaseHigh activity

The invention belongs to the field of biotechnology, and particularly relates to a beta-glucosaccharase which can decompose lactose and has high activity under both high-temperature and low-temperature conditions, and a gene engineering bacterium capable of efficiently expressing secretion-type beta-glucosaccharase. The invention discloses a beta-glucosaccharase having an amino acid sequence disclosed as SEQ ID NO:2, and constructs a gene engineering bacterium capable of efficiently secreting the beta-glucosaccharase. The gene engineering bacterium is collected in Common Microorganism Center of Committee for Culture Collection of Microorganisms, and the collection number is CGMCC No.4891. The beta-glucosaccharase produced by the method disclosed by the invention has high activity of galactosidase, and can be applied to dairy industry; and meanwhile, the beta-glucosaccharase has stable activity within wide pH value range and temperature range.

Owner:山西恩泽生物技术有限公司

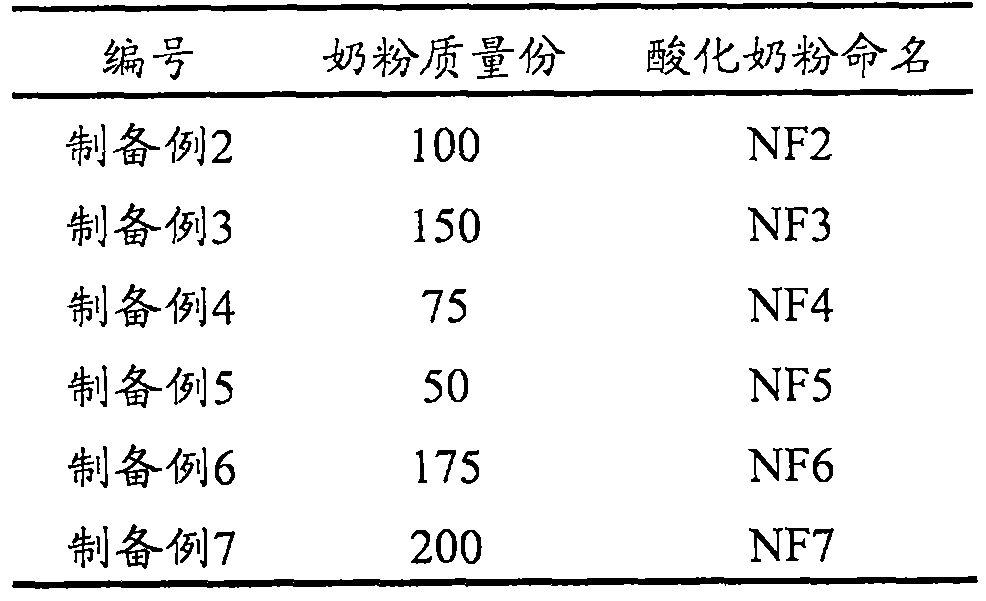

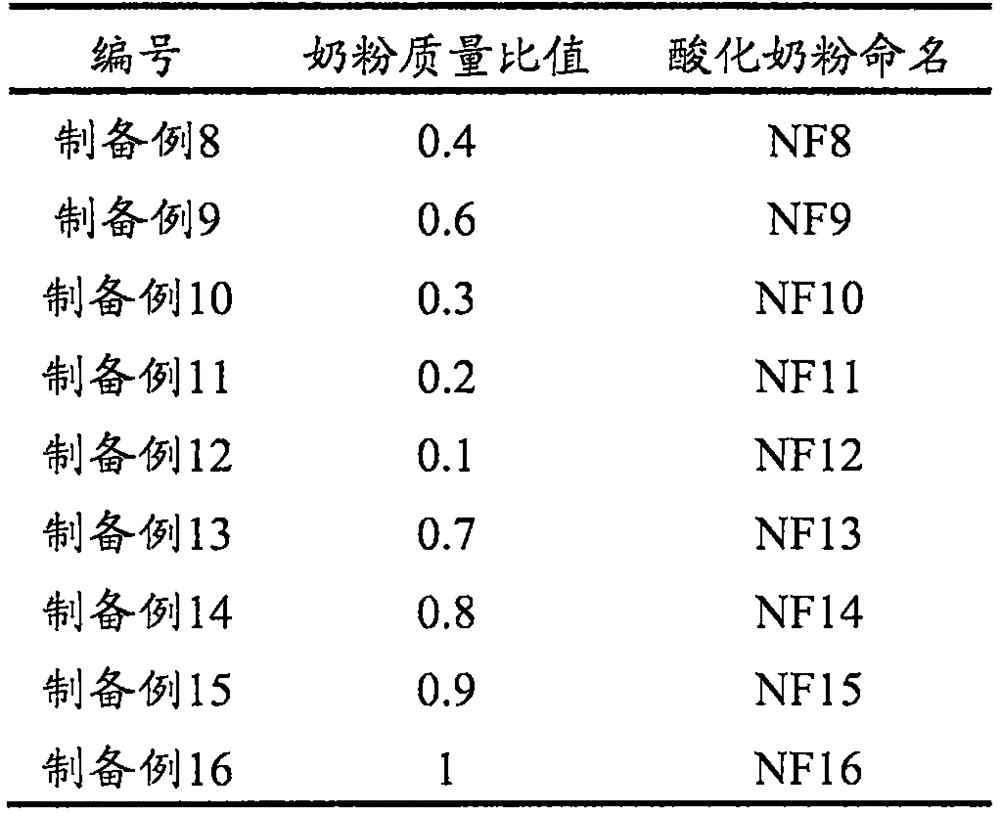

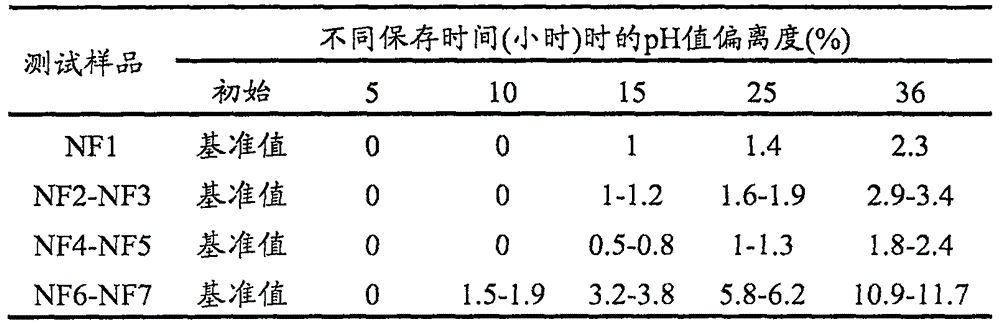

Acidified milk powder fed to calves as well as preparation method of acidified milk powder and feeding method of calves

ActiveCN105053209ACompatible with pH rangeGood storage stabilityMilk preparationAnimal feeding stuffBiotechnologyAnimal science

The invention provides acidified milk powder fed to calves as well as a preparation method of the acidified milk powder and a feeding method of the calves. The preparation method comprises the following steps: A1: respectively weighing milk powder and food-grade solid formic acid, grinding the weighed food-grade solid formic acid, and screening the ground food-grade solid formic acid through a 300-mesh sieve so as to obtain solid formic acid powder; and A2: under the condition that the temperature is below 8 DEG C, compounding the milk powder and the solid formic acid powder in the mass ratio of the milk powder to the solid formic acid powder being 50-200: 1, and thoroughly mixing the milk powder and the solid formic acid powder according to a specific mixing manner so as to obtain the acidified milk powder fed to the calves. The feeding method comprises the following steps: C1: firstly, preparing the acidified milk powder fed to the calves according to the preparation method; C2: pouring the acidified milk powder into water of which the temperature is 10-20 DEG C, and sufficiently stirring the acidified milk powder and the water until the acidified milk powder is melted so as to obtain acidified milk; and C3: supplying the acidified milk to the calves so that the calves freely drink the acidified milk. The acidified milk powder, the preparation method and the feeding method have quite important realistic significance and economic value in the field of breeding industry or dairy industry.

Owner:CHINTEM TECH CONSULTING BEIJING CO LTD

UV devices, systems, and methods of making and use

Provided herein are portable ultraviolet (UV) devices, systems, and methods of use and manufacturing same. Methods of use include methods for UV disinfection and sterilization, more specifically, methods for UV disinfection and sterilization of a container, a room, a space or a defined environment. The portable UV devices, systems and methods are particularly useful for the UV disinfection and sterilization of a container, a room, a space or defined environment used in the food, beverage and dairy industry and in the process of fermentation for an alcoholic beverage. Provided are also portable UV devices, systems, and methods for inhibiting the growth of one or more species of microorganisms present in a container, a room, a space or a defined environment, preferably for inhibiting the growth of one or more species of microorganisms present on an interior surface of a container, a room, a space or a defined environment.

Owner:BLUEMORPH

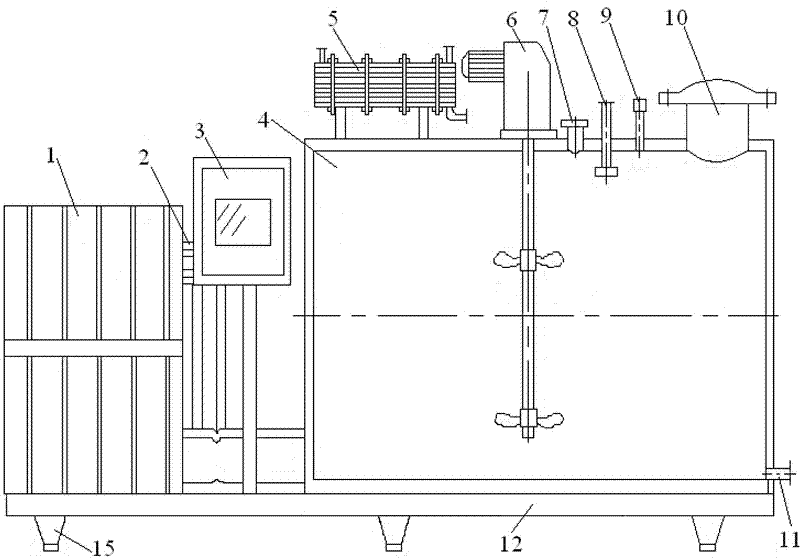

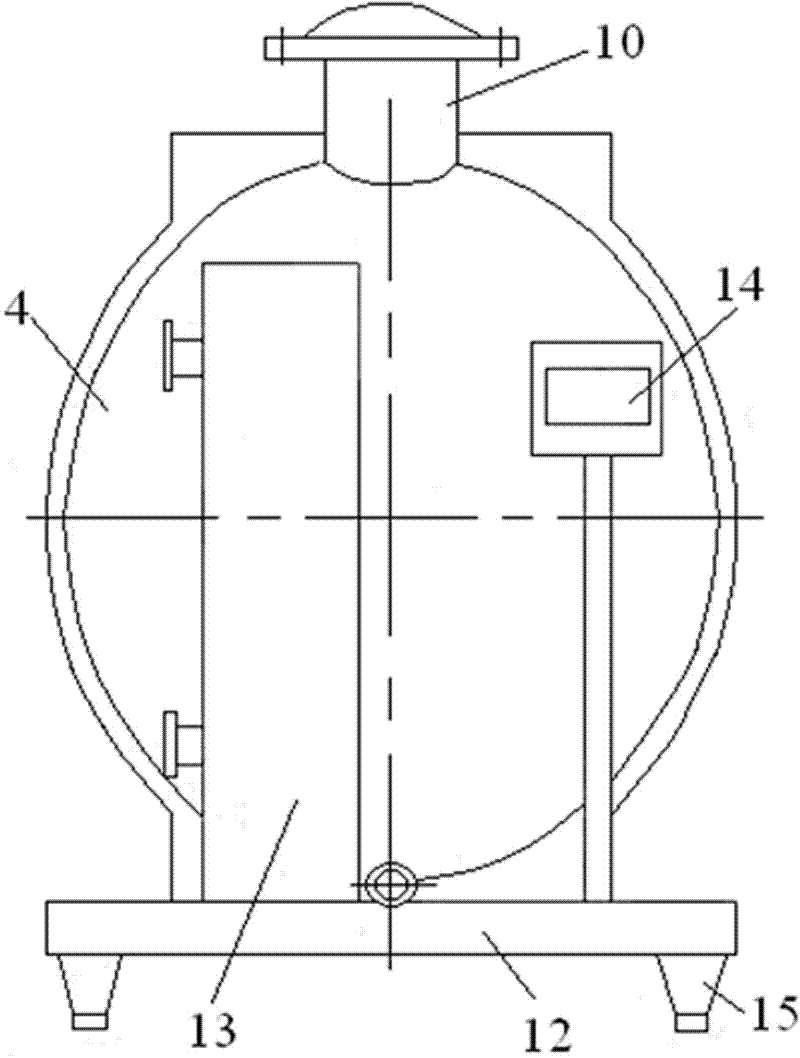

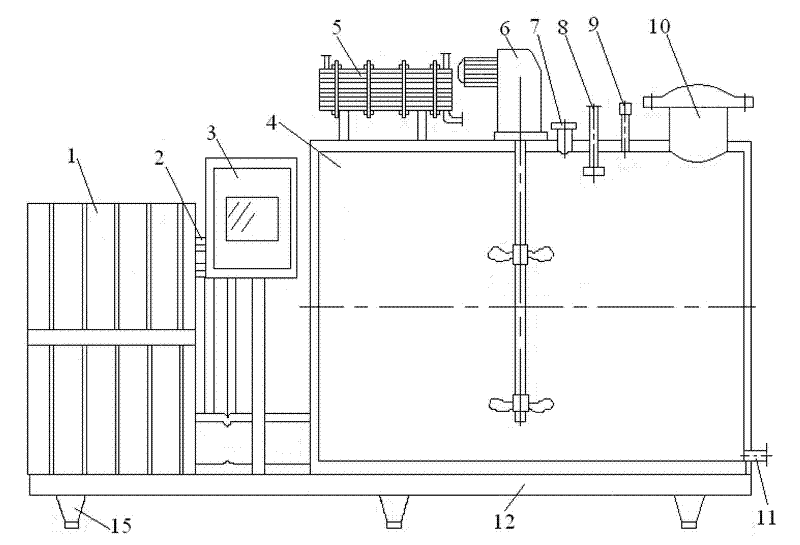

Quick-refrigerating type milk-storing cool storage tank

The invention discloses a quick-refrigerating type milk-storing cool storage tank. The quick-refrigerating type milk-storing cool storage tank comprises a base, wherein a tank body, a compressor set and an electrical control box are installed on the base; a stirring device and a feed inlet are formed on the tank body; a thermoswitch which is electrically connected with the electrical control box is installed inside the tank body; a preposed precooler is arranged on the tank body; and the preposed precooler is communicated with the feed inlet. The milk-storing cool storage tank adopts a refrigerating mode that early circulating cooling by cooling water is combined with direct cooling to quickly reduce the temperature of the milk, so that the fresh milk is cooled and preserved quickly, and the temperature of the milk increases by no more than 2 DEG C within 24 hours; and the milk-storing cool storage tank solves the problem that the raw milk is preserved and has a positive effect of promoting the animal husbandry and aquaculture and the dairy industry and increasing the income of the farming and animal husbandry.

Owner:GANSHU HUAQING LIGHT IND MACHINERY

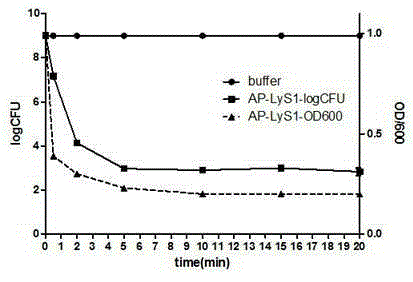

Wide spectrum bacteriophage chimeric lytic enzyme capable of resisting staphylococcus, preparation method and appliance thereof

ActiveCN105238773AReduce disadvantagesImprove the effect of prevention and controlAntibacterial agentsPeptide/protein ingredientsSide effectNucleotide

The invention discloses a wide spectrum bacteriophage chimeric lytic enzyme capable of resisting staphylococcus, wherein a nucleotide sequence wide spectrum bacteriophage chimeric lytic enzyme capable of resisting the staphylococcus as shown in sequence identifier number 1 (Seq ID NO.1), an amino acid sequence as shown in Seq ID NO.2. The wide spectrum bacteriophage chimeric lytic enzyme capable of resisting the staphylococcus is used to prevent various staphylococcus, can be separately used or matched to use, is used to prevent various pollutions and infections caused by the staphylococcus, has extremely high prevention effect to cow mastitis infection caused by the staphylococcus in dairy industry, and is safe without side effects.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

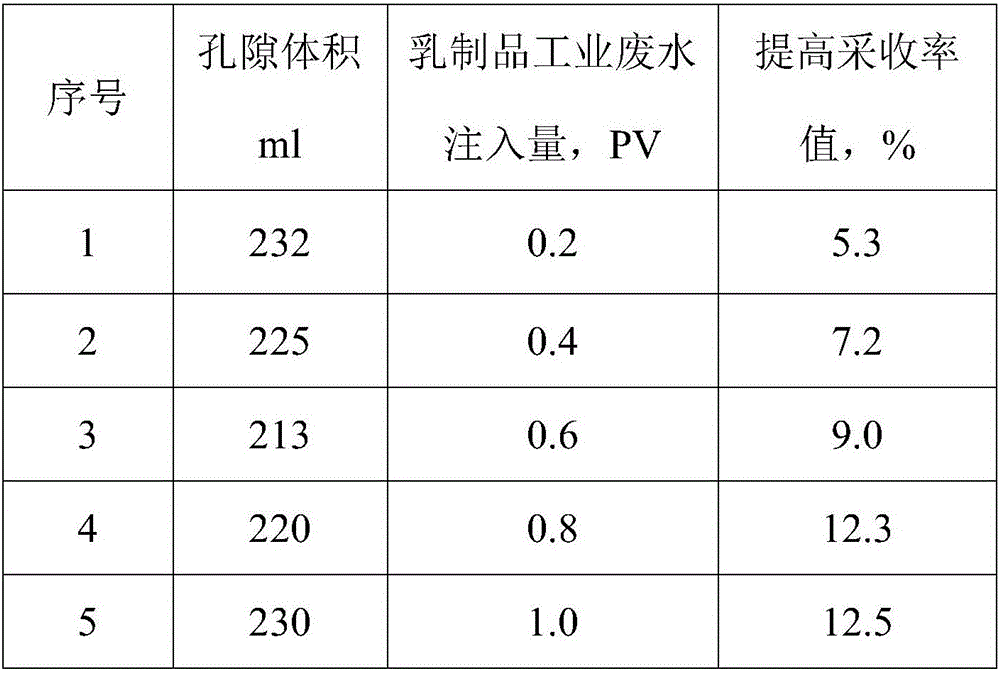

Method for improving oil well yield through dairy industry wastewater

InactiveCN106089169ASimple processSimple and fast operationFluid removalDrilling compositionSuspended particlesDairy industry

The invention discloses a method for improving the oil well yield through dairy industry wastewater. The method comprises the following steps that large-diameter suspended particles in the wastewater are changed into small-diameter suspended particles, the pH of the wastewater is adjusted to 6.5-7.5, and pretreated dairy industry wastewater is obtained; a testing oil well is selected; on-site injection technological parameters are determined, specifically, the on-site injection technological parameters comprise the injection amount of the pretreated dairy industry wastewater, the injection amount of air and the well-closing culture time; and a field test is conducted. The method has the advantages that the construction technique is simple, and the investment and cost are low; the problems that environment pollution is caused by drainage of the dairy industry wastewater, and the treatment cost is too high are solved; and therefore, the method can be widely applied to field tests for improving the oil well yield.

Owner:YANTAI ZHIBEN INTPROP OPERATIONS MANAGEMENT CO LTD

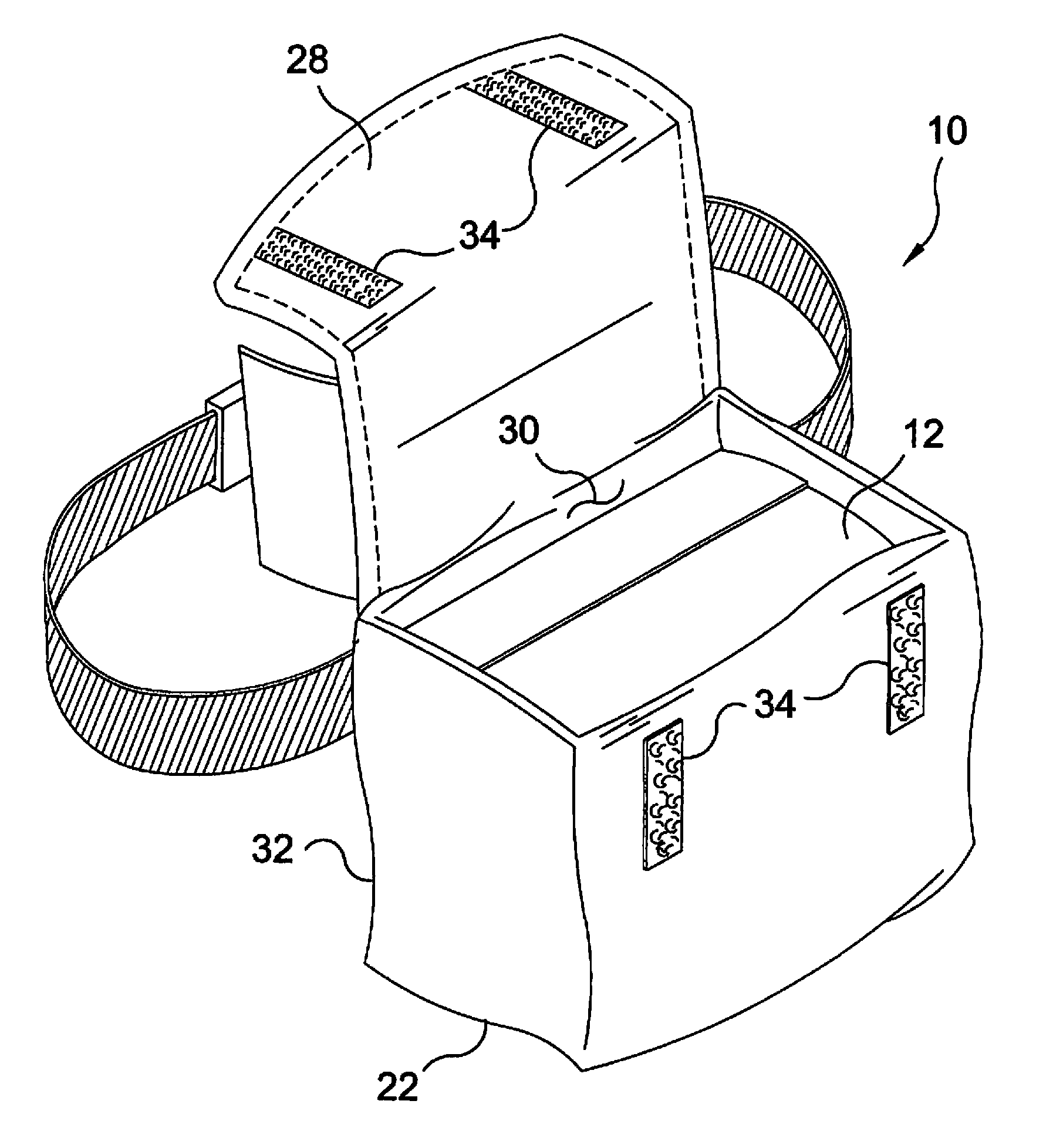

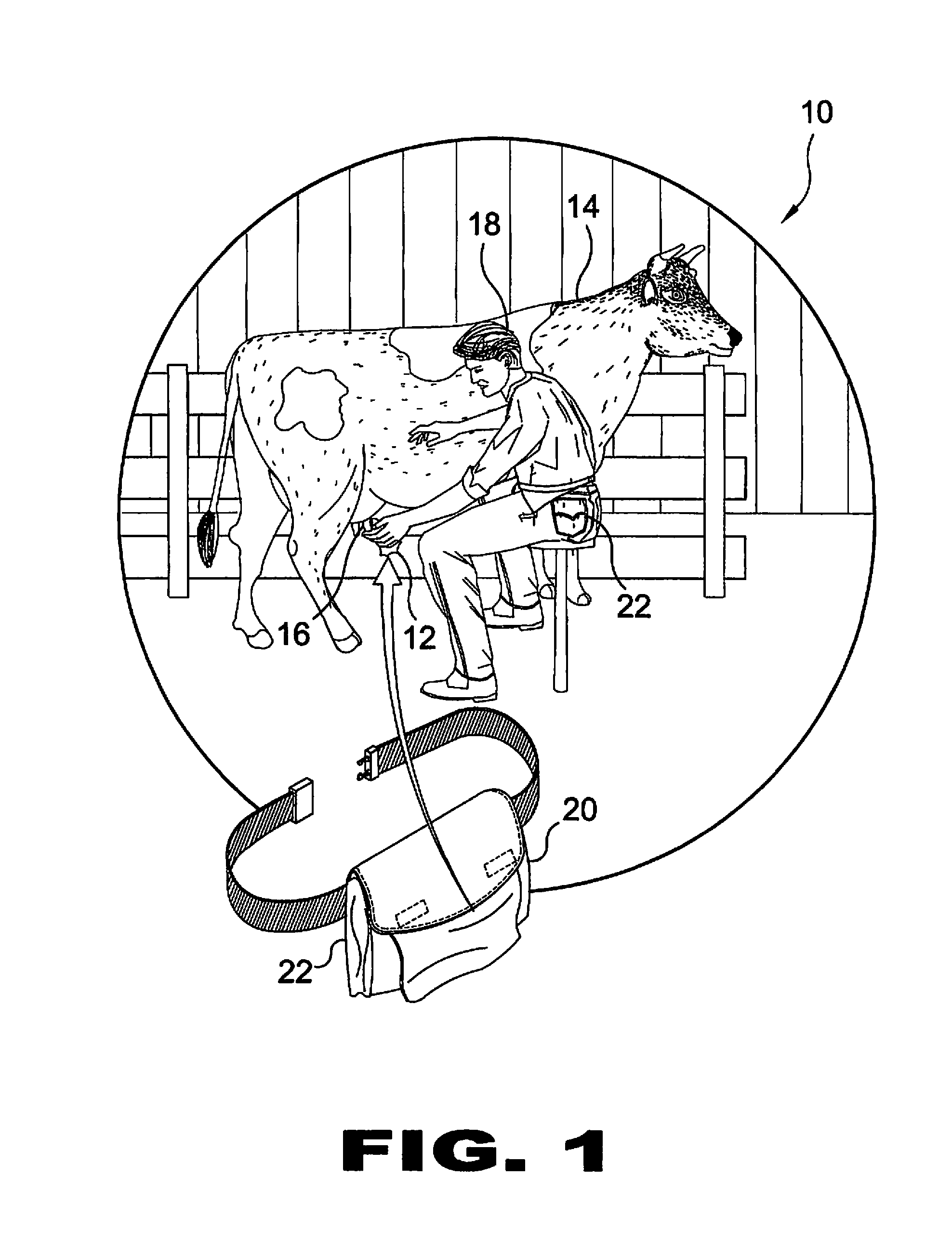

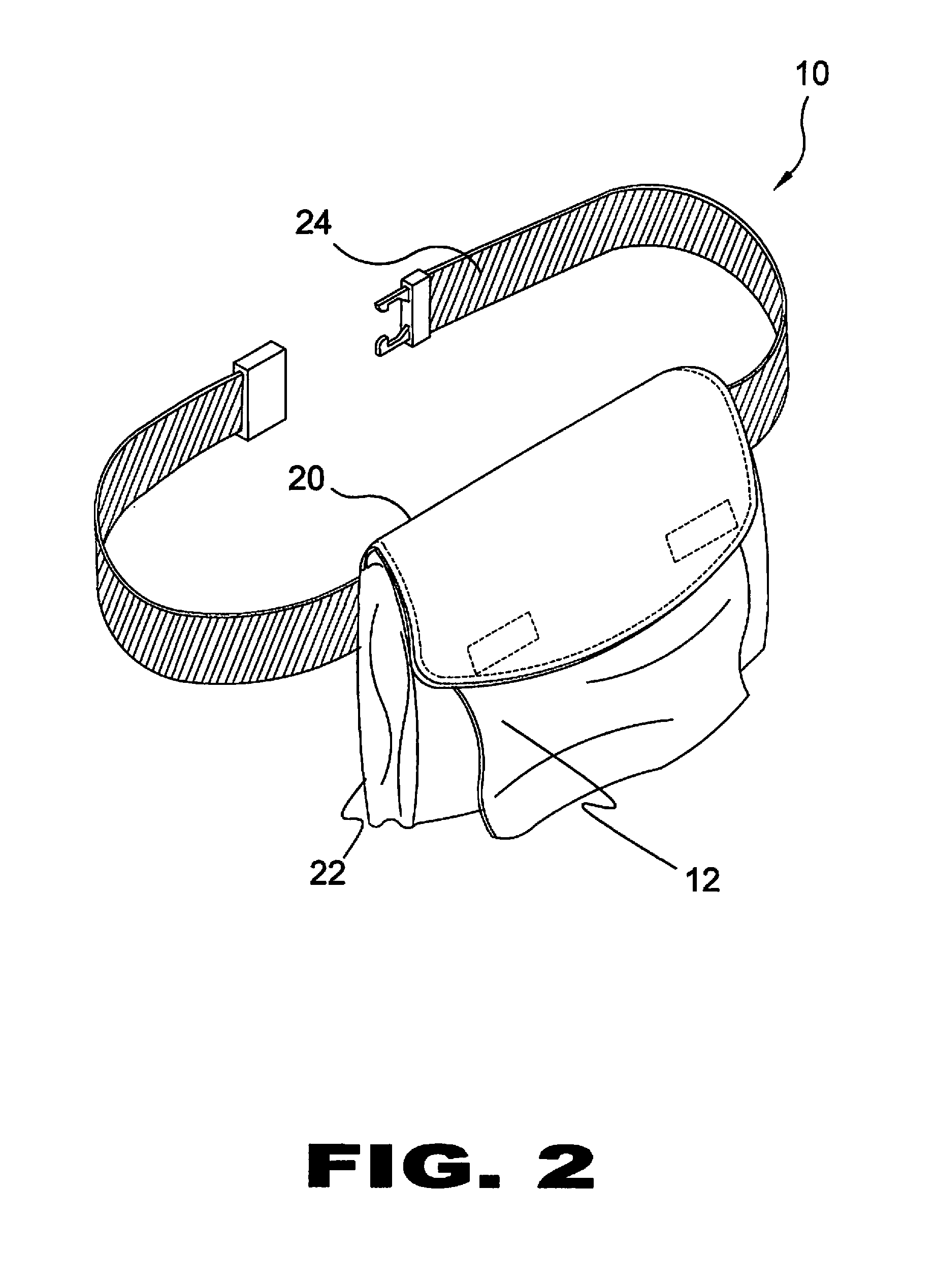

Device for using nonwoven towels in the dairy industry

A method and apparatus for use in the dairy industry to affect the time in preparing a dairy cow for milking and the transference of mastitis in dairy cows with the method the present invention provides: retrieving a quantity of the disposable single fold towels / wipes of the present invention before teat cleaning; extracting a towel / wipe from the quantity and having the maximum surface area of the towel / wipe upon extraction available for use without further manipulation; wiping the udder teats until dry and disposing of the used disposable single fold towel of the present invention. The apparatus of the present invention is a Nonwoven Airlaid or Nonwoven DRC (Double Recreped Cellulose) or 2-6 ply Scrim single fold, interfold towel with a basis weight between 40 GSM (grams per square meter) and 80 GSM, consisting of both virgin pulp (longer fibers) and also recycled pulp (broken or shorter fibers), in the dairy industry.

Owner:VAN TASSELL MARTY

Cleaning agents for equipment of dairy industry

InactiveCN103160393AAvoid depositionEasy to rinseNon-surface-active detergent compositionsAcetic acidDairy industry

The invention relates to cleaning agents for equipment of the dairy industry. The cleaning agents are mainly used for cleaning of inner surfaces of containers and pipelines of raw milk and other equipment for raw milk. The cleaning agents include an acidic cleaning agent and an alkaline cleaning agent. The acidic cleaning agent comprises, by mass, the following components: 10-40% of nitric acid, 1-15% of phosphoric acid, 0.1-1% of an acid chelating agent and 55-85% of water, wherein the acid chelating agent is composed of 1-15% of phosphoric acid, 0.05-11% of ethylenediaminetetra-acetic acid (EDTA), 0.01-0.5% of diethylenetriaminepenta-acetic acid (DTPA) and 74-95% of water. The alkaline cleaning agent comprises the following components: 14-39% of sodium hydroxide, 0.1-1% of an alkaline chelating agent and 60-85% of water, wherein the alkaline chelating agent comprises the following components: 1-15% of potassium hydroxide, 0.01-11% EDTA, 0.01-0.5% DTPA and 74-95% of water.

Owner:INNER MONGOLIA HEXI AEROSPACE TECH DEV

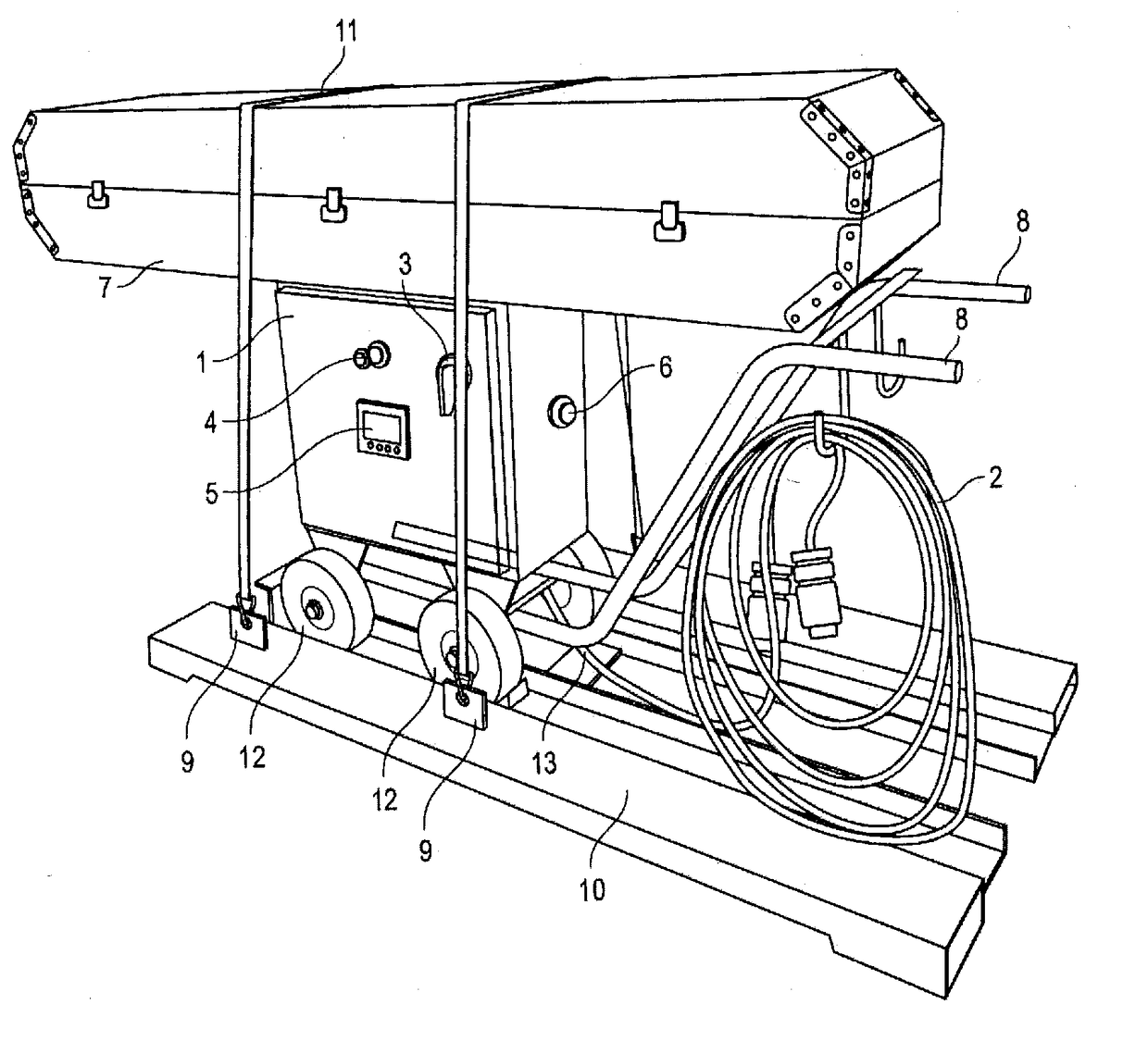

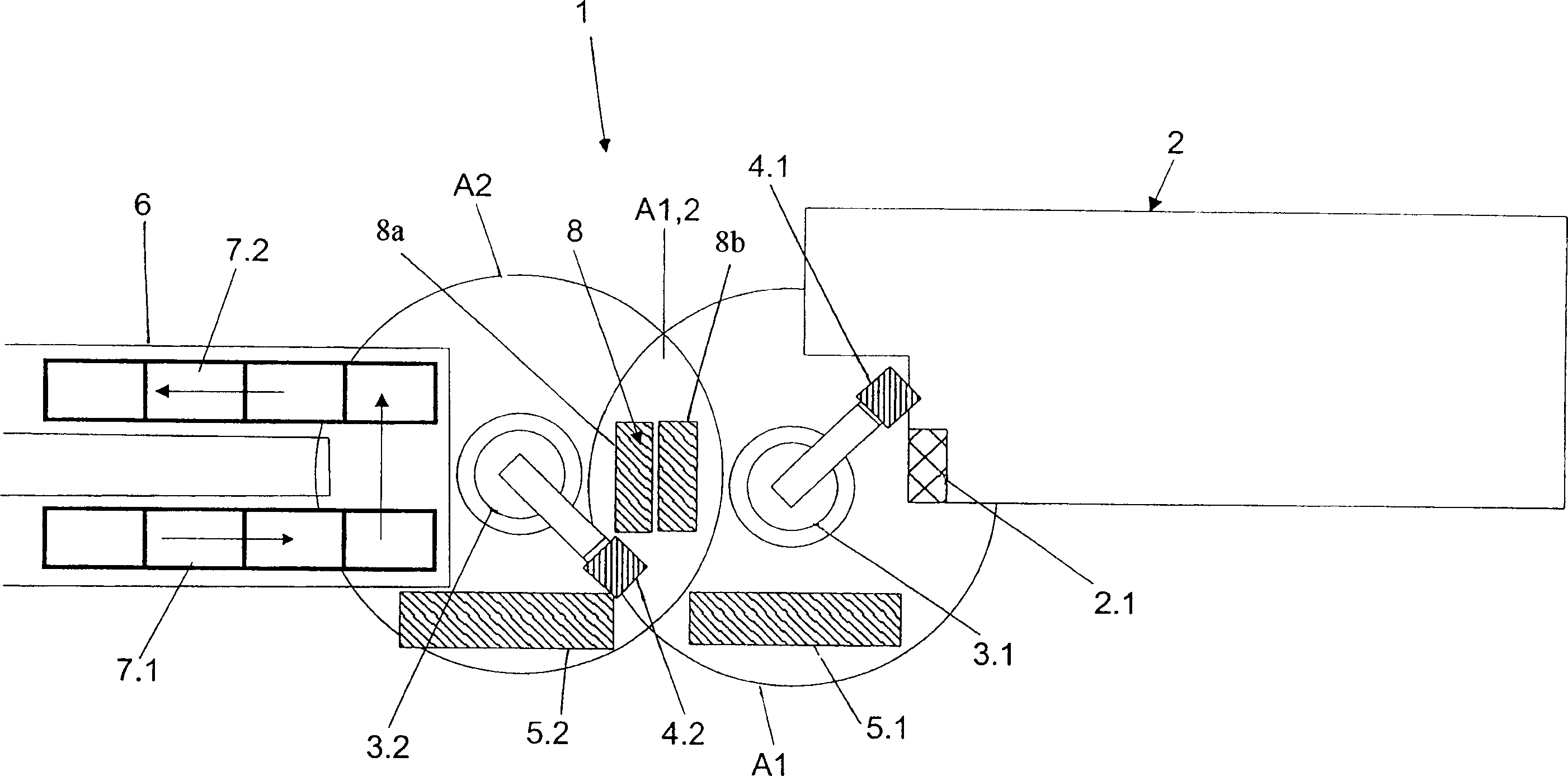

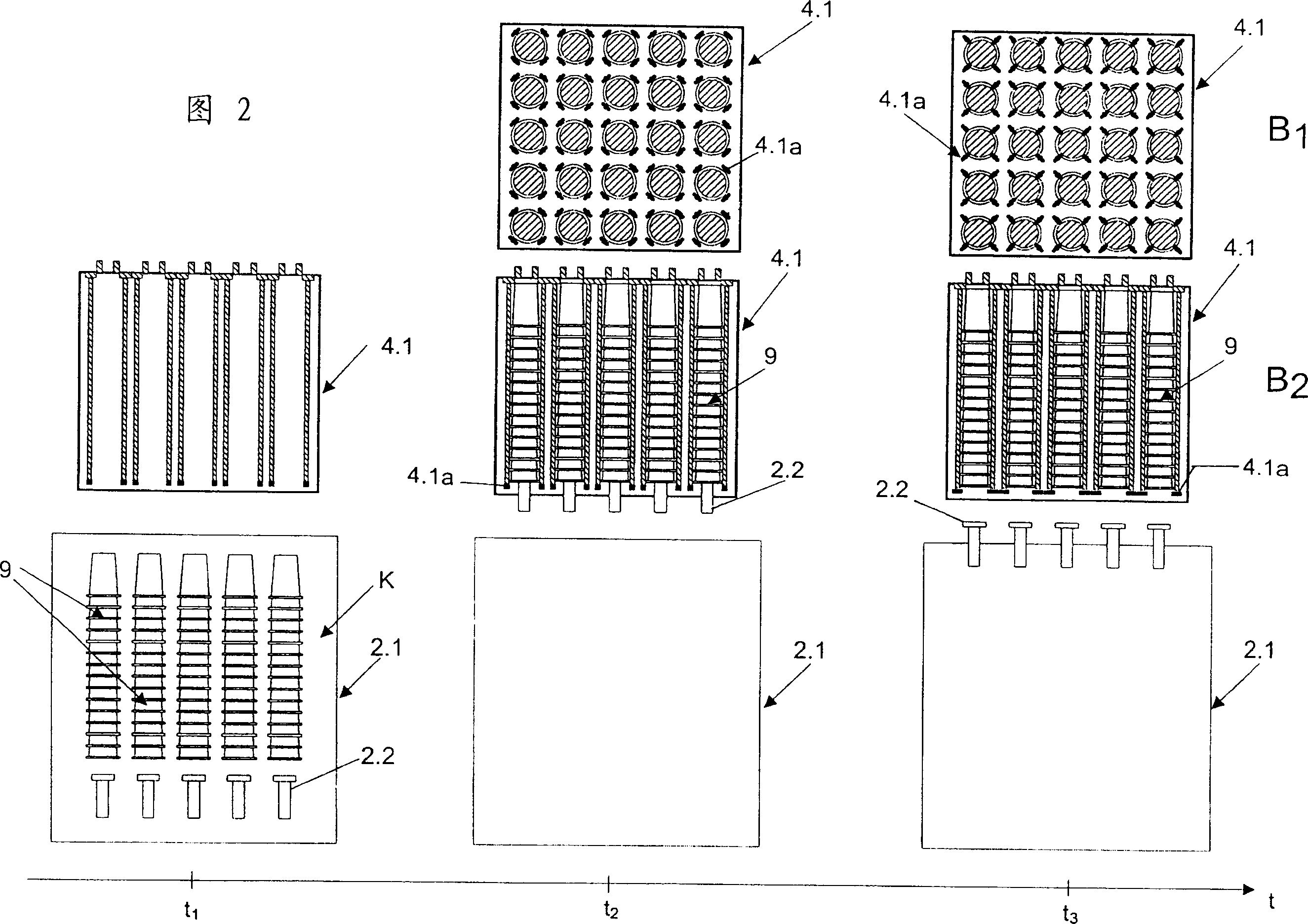

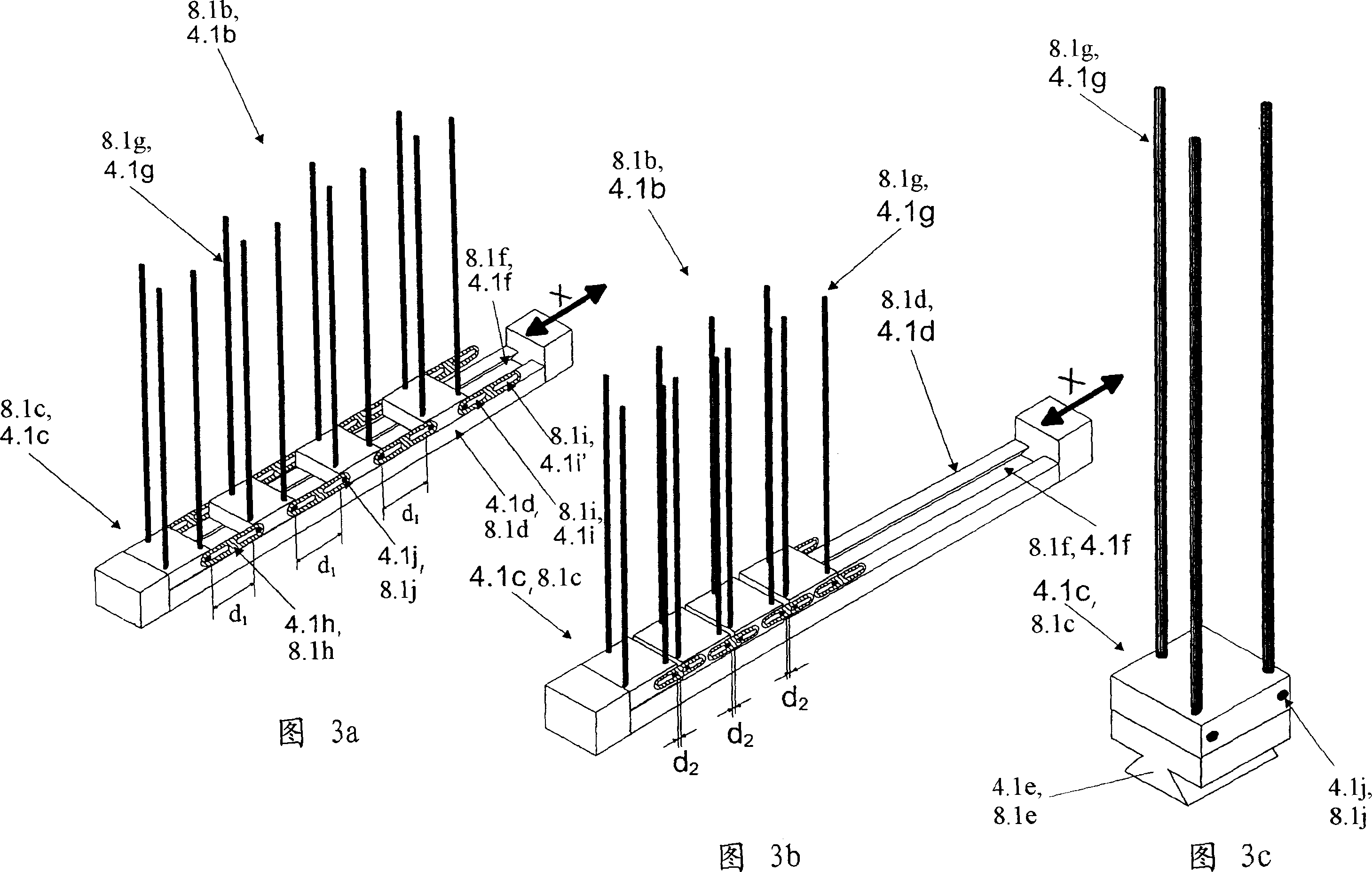

Method and device for handling rod-shaped objects

The invention relates to a completely automatable method for handling essentially rod-shaped objects, particularly rods comprised of articles stacked inside one another in a manner that enables them to be separated, such as plastic cups for use, e.g. in the dairy industry, during loading processes in conjunction with a loading aid, particularly a box. To this end, the objects to be handled are prepared by a manufacturing or processing machine in a first geometric arrangement. The invention is characterized in that at least a portion of the objects are firstly grasped, an arrangement of the objects relative to one another is subsequently modified, and the modified arrangement of the objects is then placed in the loading aid during which the objects are arranged in an upright manner. This permits optimal packing densities for the objects in the loading aid. The invention also relates to a device suited for carrying out said method.

Owner:KUKA ROBOTER

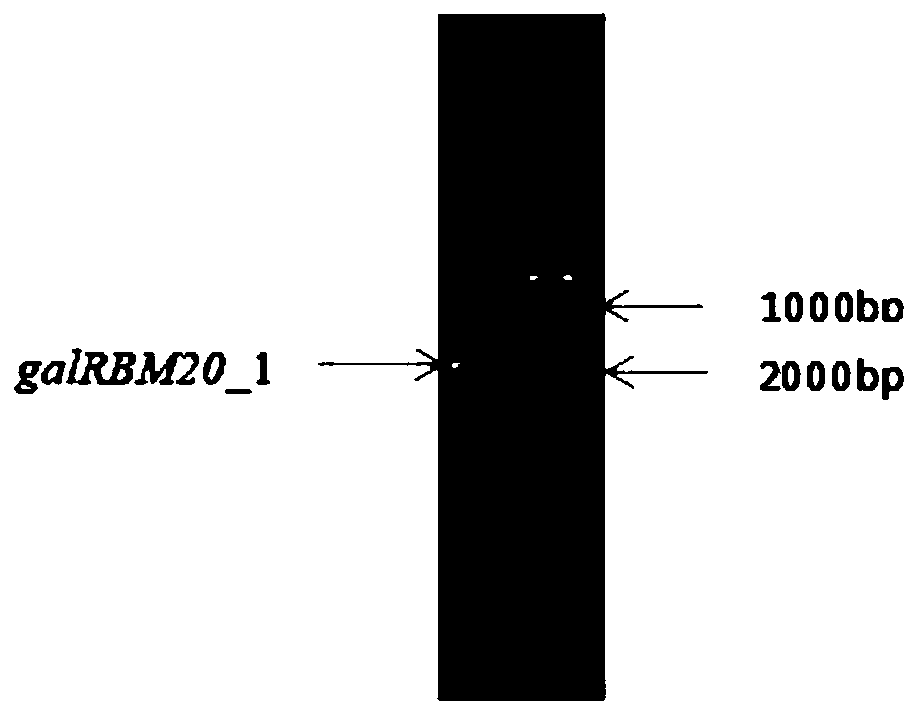

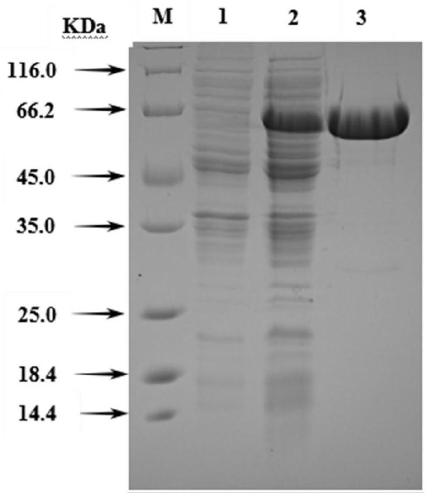

Beta-galactosidase galRBM20_1 and preparation method and application thereof

The invention discloses beta-galactosidase galRBM20_1 and a preparation method and application thereof. The amino acid sequence of the beta-galactosidase galRBM20_1 is as shown in SEQ ID NO.1. Variousenzyme genes are obtained from excrement and urine microorganisms of Yunnan snub-nosed monkeys, and a metagenome Fosmid library of the excrement and urine microorganisms of the Yunnan snub-nosed monkeys is constructed. The beta-galactosidase gene galRBM20_1 is obtained through cloning from the metagenome of the excrement and urine microorganisms of the Yunnan snub-nosed monkeys, and after heterologous expression of escherichia coli, enzymatic property and salt tolerance are researched. The recombinase has higher pH stability and heat stability, and besides, also has favorable salt tolerance.A new source is provided for obtaining the beta-galactosidase gene galRBM20_1, and through efficient recombinant expression, a large number of beta-galactosidase genes galRBM20_1 are provided for industrial production, and can be widely applied to dairy product trade.

Owner:YUNNAN NORMAL UNIV

UV devices, systems, and methods of making and use

InactiveCN107921158AElectric lightingColor/spectral properties measurementsDairy industryUv disinfection

The present invention provides a portable ultraviolet (UV) devices, systems, and methods of use and manufacturing same. Methods of use include methods for UV disinfection and sterilization, more specifically, methods for UV disinfection and sterilization of a container, a room, a space or a defined environment. The portable UV devices, systems and methods are particularly useful for the UV disinfection and sterilization of a container, a room, a space or defined environment used in the food, beverage and dairy industry and in the process of fermentation for an alcoholic beverage. Provided arealso portable UV devices, systems, and methods for inhibiting the growth of one or more species of microorganisms present in a container, a room, a space or a defined environment, preferably for inhibiting the growth of one or more species of microorganisms present on an interior surface of a container, a room, a space or a defined environment.

Owner:BLUEMORPH

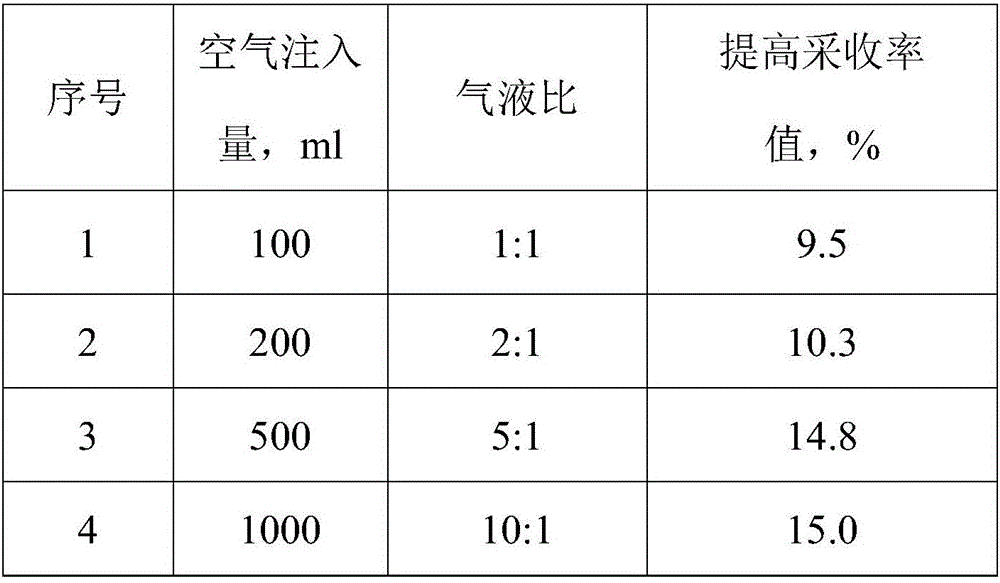

Method for improving crude oil production rate by using dairy industry wastewater

InactiveCN106121607ASimple processSimple and fast operationWater treatment parameter controlTreatment involving filtrationSuspended particlesField tests

The invention discloses a method for improving crude oil production rate by using dairy industry wastewater. The method comprises the following steps: changing large-particle-size suspended particles in the wastewater into small-particle-size suspended particles, and regulating pH of the wastewater to be 6.0-8.0 to obtain pretreated dairy industry wastewater; screening test oil reservoirs; determining the pretreated dairy industry wastewater and injection amount of air; and tracking and analyzing field tests and results of the field tests. A construction process is simple, the cost for improvement of the crude oil production rate by a water-drive reservoir is reduced effectively, the problems that the environment is polluted and the treatment cost is over high due to drainage of the dairy industry wastewater are avoided, and therefore, the method for improving the crude oil production rate by using the dairy industry wastewater can be widely used in the field tests for improvement of the crude oil production rate.

Owner:YANTAI ZHIBEN INTPROP OPERATIONS MANAGEMENT CO LTD

Alkaline cleaner for yoghourt equipment

InactiveCN104479920AAvoid depositionEasy to rinseOrganic non-surface-active detergent compositionsInorganic non-surface-active detergent compositionsPotassiumWater quality

The invention relates to an alkaline cleaner for yoghourt equipment. The alkaline cleaner for yoghourt equipment is mainly used for cleaning the yoghourt equipment. The alkaline cleaner for yoghourt equipment comprises the following composition components in percentage by mass: 20-40% of sodium hydroxide, 1-8% of potassium hydroxide, 2-10% of tetrapotassium pyrophosphate, 0.5-4% of nitrilotriacetic acid, 0.1-1.5% of sodium gluconate, 0-8% of ethylenediamine tetraacetic acid, 0.2-2% of maltodextrin, 1-8% of peregal-20, 0-1% of OP-10, 0-2% of sodium tripolyphosphate and 15.5-75.2% of water, wherein the total sum of the percentages by mass of the various components is 100%. A preparation method comprises uniformly mixing and stirring the various components. The invention aims at providing an efficient and safe alkaline cleaner for yoghourt equipment in the dairy industry. The alkaline cleaner for yoghourt equipment disclosed by the invention is few in foams, easy to wash, capable of improving cleaning efficiency, suitable for water qualities with different hardness, and capable of preventing incrustation sedimentation; the compound is high in content and provides a suspension action on insoluble dirt, thus achieving a great re-sedimentation-resisting capacity; organic substances such as milk fats, proteins and mammary calculus in production residues can be dissolved.

Owner:INNER MONGOLIA HEXI AEROSPACE TECH DEV

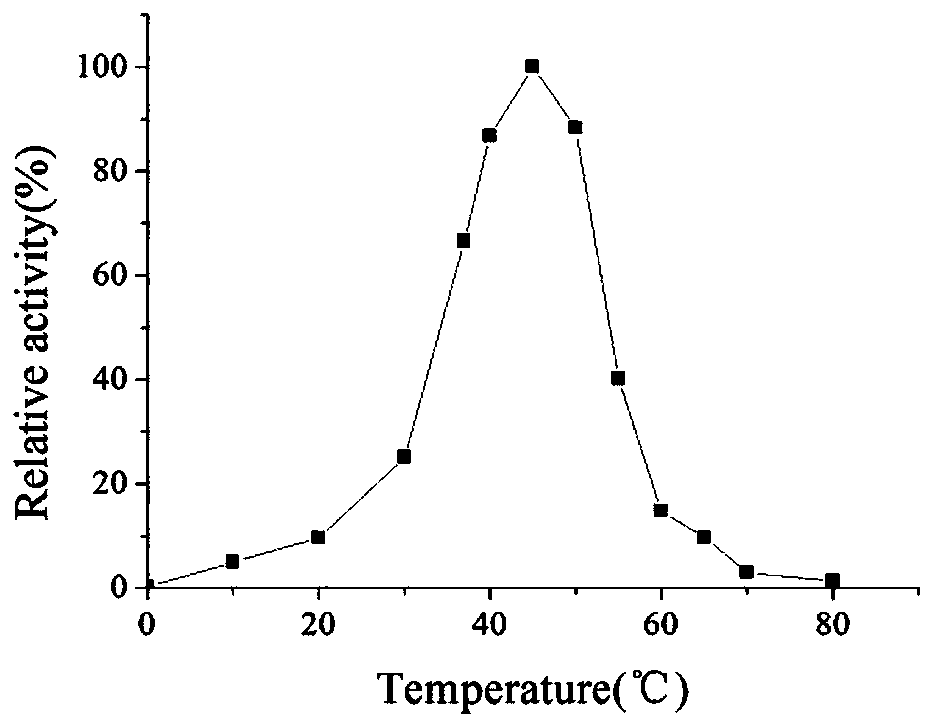

Bacterial strain producing high-temperature-resistant beta-galactosidase and screening method thereof

InactiveCN105400728AImprove thermal stabilityImprove stabilityBacteriaMicrobiological testing/measurementScreening methodBacterial strain

The invention discloses a bacterial strain producing high-temperature-resistant beta-galactosidase and a screening method thereof and belongs to the technical field of biological chemistry and protein engineering. The screening method includes the specific and sequential steps of sample collection, primary screening, secondary screening of culture and beta-galactosidase activity assay. Mainly, soil of hot spring land is collected and boiled, then bacterial colonies are screened, and the technical problem how to produce high-enzyme-activity beta-galactosidase at high temperature is solved through a high-temperature culturing method. The bacterial strain is short in beta-galactosidase production period, high in beta-galactosidase production speed, good in genetic stability, thermal stability and pH stability, high in enzyme catalytic activity and high in production safety, and culturing conditions are simple. The bacterial strain has broad prospects in the fields of food industry and medical and biochemical analysis, in particular to the dairy industry.

Owner:CHONGQING UNIV

Water-based special fatty amine high efficiency lubricant

The invention provides a water-based special fatty amine high efficiency lubricant, which comprises the following components by weight: 5-15 parts of special fatty amine, 1-5 parts of acetic acid, 1-5parts of alkyl dimethyl tertiary amine, 0.1-1 part of a bacteriostatic agent, 0.5-5 parts of a rust inhibitor, 1-5 parts of a surfactant, 0.5-5 parts of a dispersant, 0.5-5 parts of a water softener,0.5-5 parts of a defoamer, and 50-70 parts of water. The water-based special fatty amine high efficiency lubricant provided by the invention can significantly reduce the friction between a packagingcontainer bottle or can and a conveyor belt, and can fully meet the wide needs of glass bottle, packaging box, can and PET plastic bottle production lines in modern food industry production enterprises, like beer, beverage, dairy industries and the like for continuous maintaining of high lubrication, cleanness and sanitation.

Owner:GUANGZHOU JUNHE INDAL

Process for the preparation of galactose

A process for the preparation of high purity galactose is described, comprising the inoculum, of milk or milk serum not previously subjected to any type of preliminary treatment and / or purification procedure and not containing any bactericides or bacteriostats, with not modified micro-organisms commonly used in dairy industry.

Owner:INALCO SPA

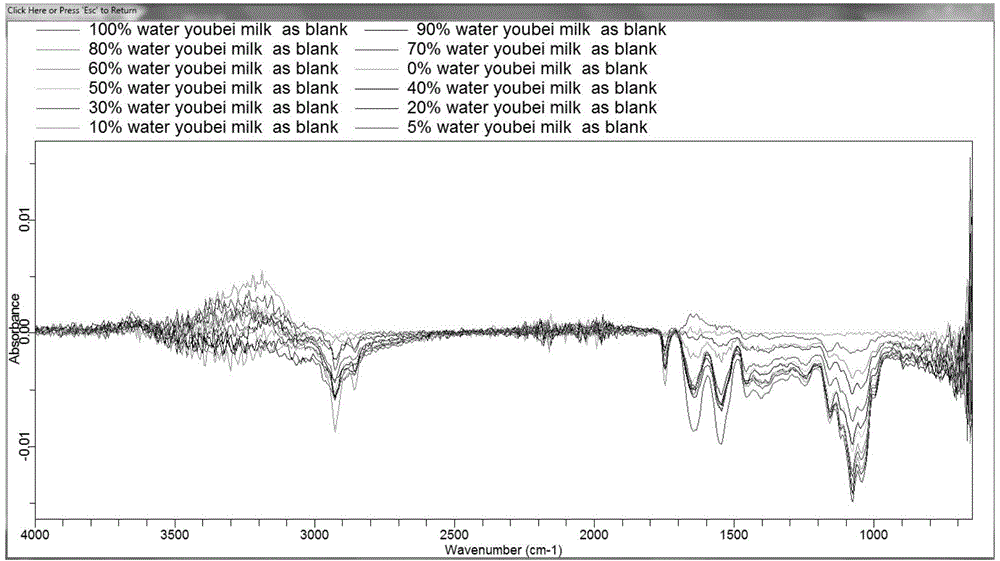

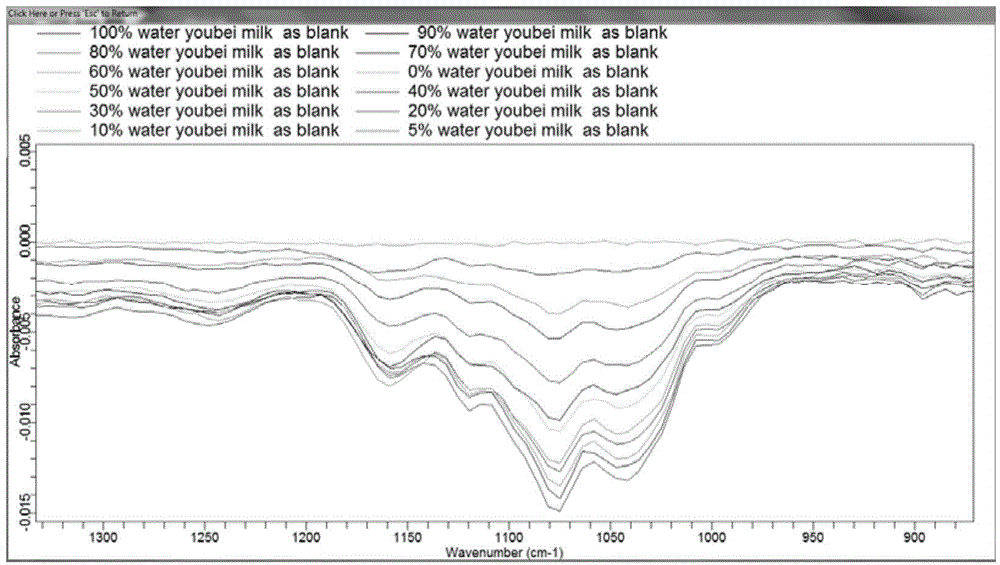

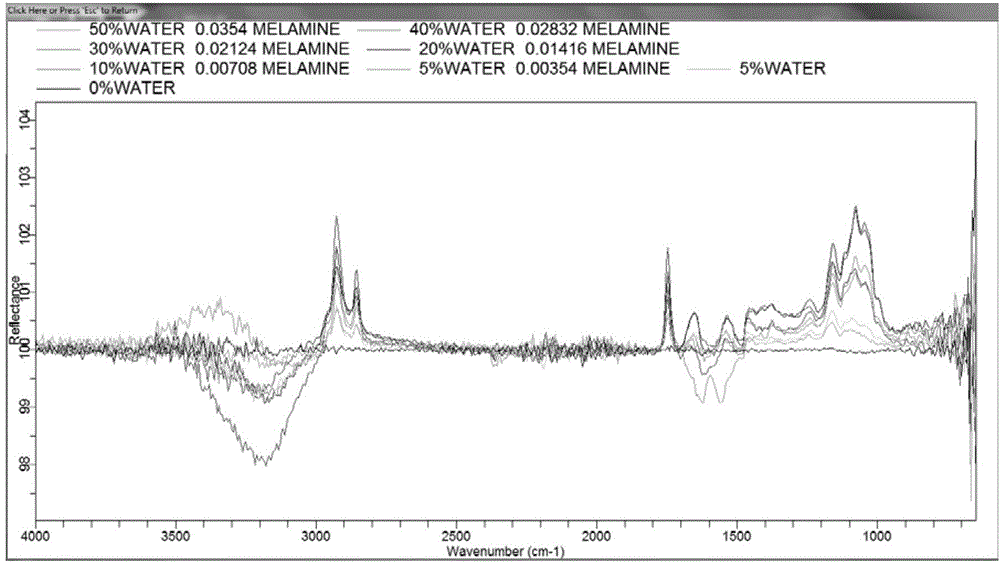

Method for rapidly judging adulteration of milk by virtue of mid-infrared spectrum

InactiveCN106153570AEasy to operateShorten detection timeMaterial analysis by optical meansMilk sampleDairy industry

The invention discloses a method for rapidly judging adulteration of milk by virtue of a mid-infrared spectrum. The method comprises the following steps: qualitatively analyzing a to-be-tested milk sample by virtue of the mid-infrared spectrum, performing spectrogram comparison on the to-be-tested sample and a set background, and rapidly judging whether the milk contains an adulterant or not according to a waveform difference of spectrograms. The judgment method is simple and rapid, whether the milk contains an abnormal additive or not can be rapidly identified within less than 1 minute, a raw milk purchasing link can be rapidly shortened, and a qualified milk source can be guaranteed to be timely and rapidly purchased in the dairy industry.

Owner:SHANGHAI MINHANG HIGH SCHOOL

Artificial breeding technique for cows

InactiveCN104488806ALow costHigh reproductive rateAnimal feeding stuffAnimal housingDiseaseGestation

The invention relates to an artificial breeding technique for cows. The technique comprises the following contents: building a cowshed according to the environment requirement; selecting a cow variety, and paying attention to pasture breeding mode; separately breeding dairy cows after gestation, facilitating nutrition and milking time of the cows, ensuring nutrition and hybridization during dry period, and ensuring the milk yield; and paying attention to daily management and disease prevention. With the adoption of the artificial breeding technique for cows, the milk yield of the artificial breeding cows can be effectively improved, the economic benefits are improved, and the development of the dairy industry is promoted.

Owner:重庆市大足区炫天养殖有限责任公司

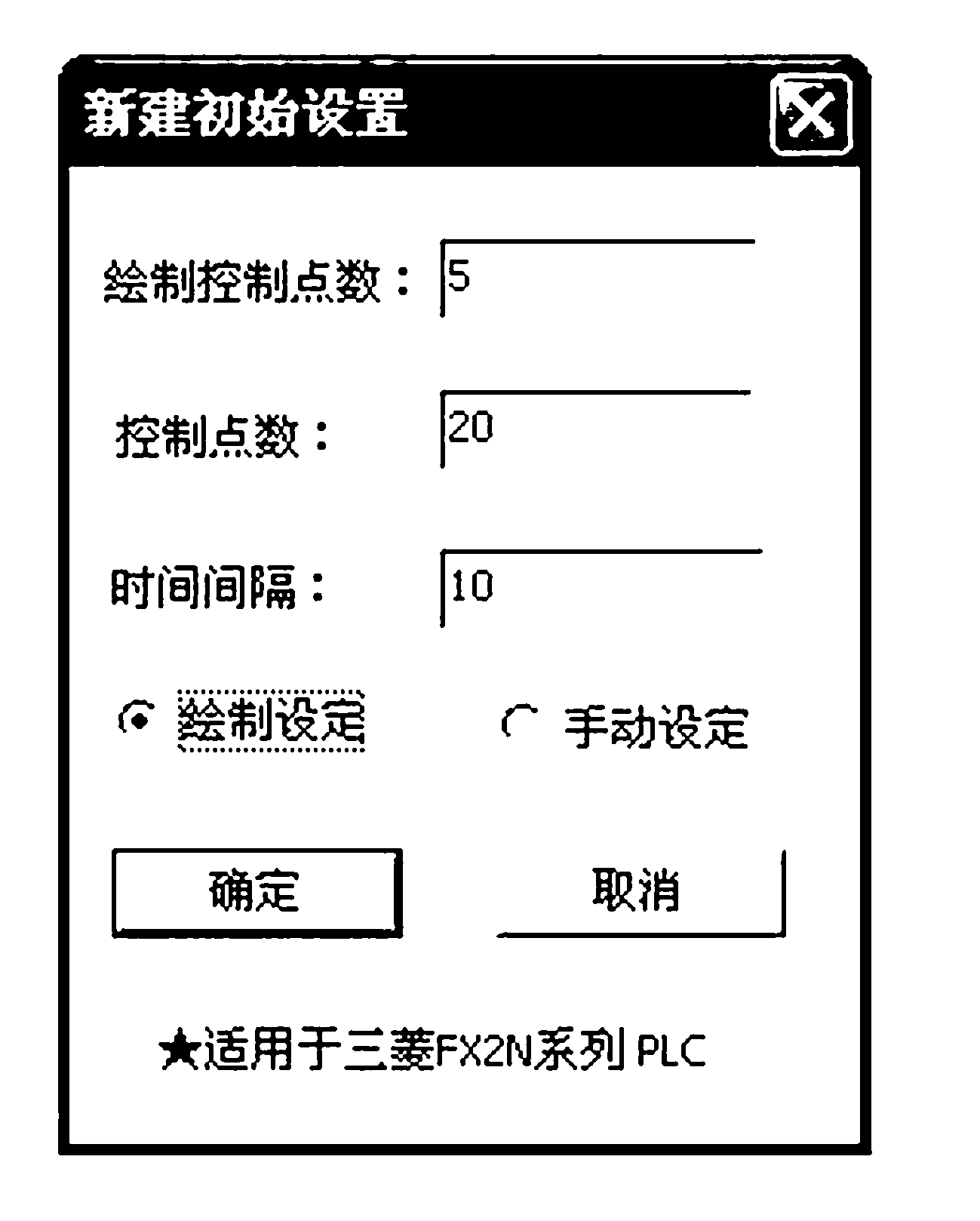

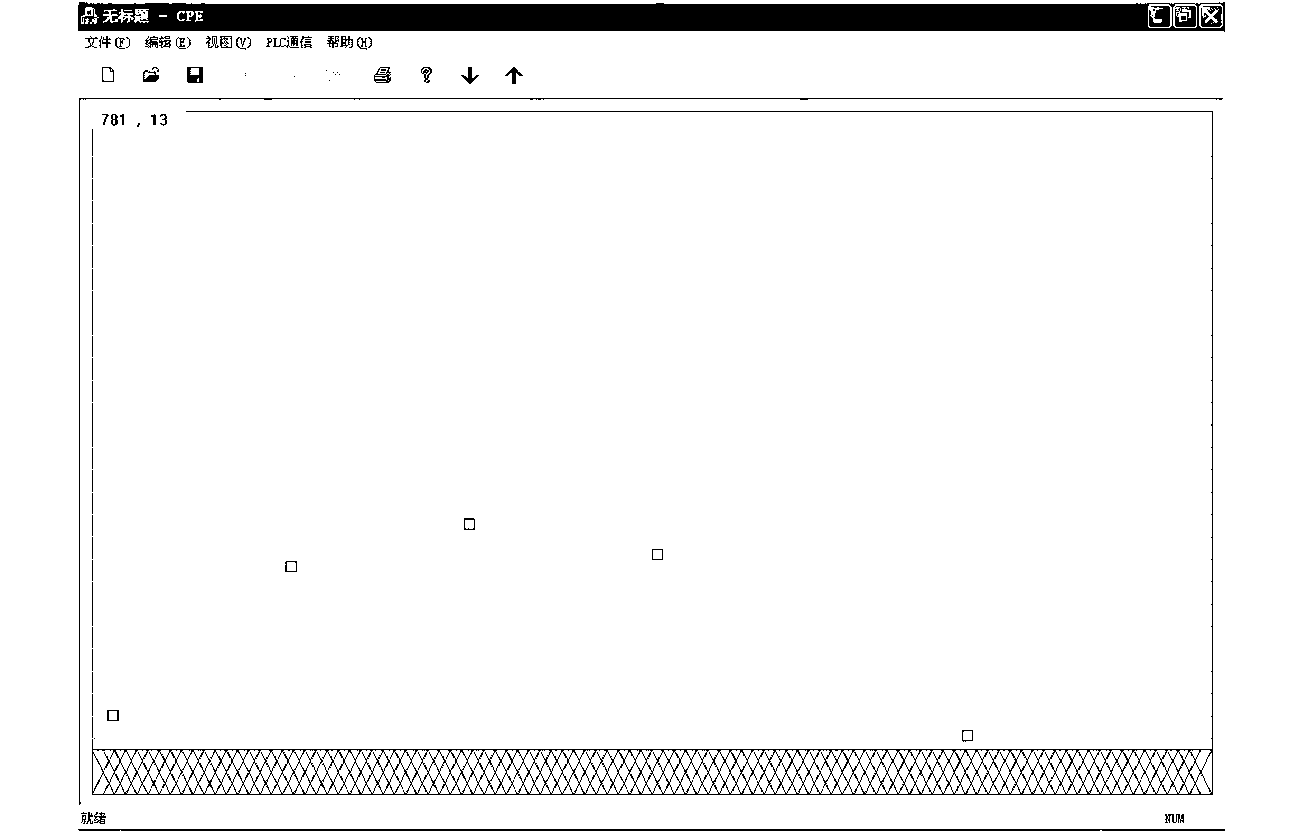

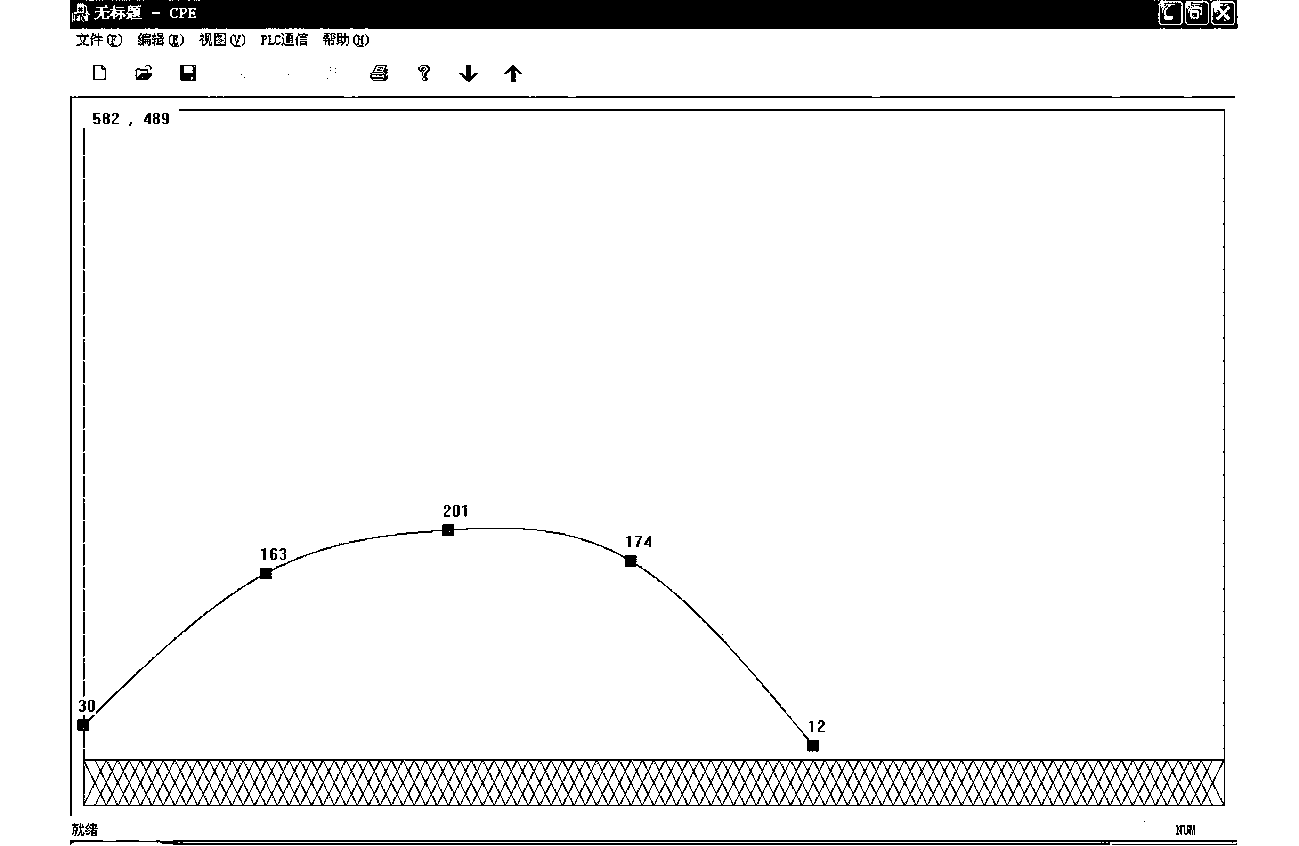

Integrated device for controlling wall thickness by digital cam and servo motor

The invention relates to a plastic extrusion blowing wall thickness control device and particularly relates to an integrated device for controlling wall thickness by a digital cam and a servo motor. The integrated device comprises a digital cam software system and a servo motor control mechanical device, wherein the servo motor control mechanical device comprises the servo motor, a ball screw helical pair, a guide pillar, a fixed support plate, a movable support plate, a piston rod, a movable guide mechanism, a hydraulic gravity balancing mechanism, a cylinder body fixing plate, a precise cylinder body, an extrusion die head device and a stander. The integrated device is mainly used for controlling the wall thickness of a plastic extrusion bottle blowing machine in a dairy industry, the shape of the digital cam can be changed according to different products, and thus plastic products with different wall thicknesses can be produced by extrusion blowing. As the integrated device is provided with the digital cam and the servo motor, not only is the strength of the extruded products with the uniform wall thicknesses of the device greatly improved, but also raw materials are saved, the cooling time of the finished product is shortened, the defective percentage is lowered, and the production rate and the quality of the products are greatly improved.

Owner:浙江机电职业技术学院 +1

Preparation method of pre-prepared active Chinese herbal medicine material-added cow supplement feed

InactiveCN104543558AIncrease milk productionPromote physical activityFood processingAnimal feeding stuffSodium bicarbonateMoisture

The invention discloses a preparation method of a pre-prepared active Chinese herbal medicine material-added cow supplement feed. The preparation method comprises the following steps: after uniformly stirring corn, pre-prepared active Chinese herbal medicine materials, barley flour, edible mushroom dregs, wheat bran, peanut vines, apples, canola oil, tofukasu, vinasse, bone meal, fish meal, black bean flour, sodium alginate, skim milk powder, calcium hydrogen phosphate, sodium bicarbonate, salt, fructose syrup, and compound amino acid, drying until the moisture content is 15-18wt%, and then pelletizing to obtain the pre-prepared active Chinese herbal medicine material-added cow supplement feed. The cow supplement feed is added with the natural pollution-free pre-prepared active Chinese herbal medicine materials, so that the cow lactation is greatly promoted, the cow milking quality is improved, and the requirement of the dairy industry for the high-quality supplement feed is met.

Owner:安徽麒麟正大饲料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com