Patents

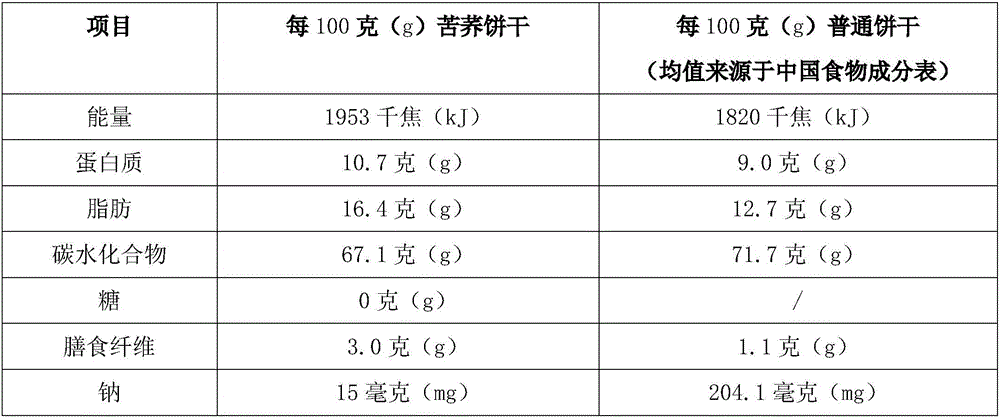

Literature

769 results about "Barley flour" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Barley flour is a flour prepared from dried and ground barley. Barley flour is used to prepare barley bread and other breads, such as flat bread and yeast breads. There are two general types of barley flour: coarse and fine. Barley groats are milled to make coarse barley flour, and pearl barley is milled to make fine barley flour. Additionally, patent barley flour is a finer barley flour that is ground to a greater degree compared to fine barley flour.

Compound mixed grain nourishing food and producing method thereof

InactiveCN101223900AFull of nutritionRich foodDough treatmentBakery productsBiotechnologyPolygonum fagopyrum

The invention relates to a compound coarse cereal nutrition food and a production method thereof. The compound coarse cereal nutrition food can overcome the problems of single variety, insufficient nutrition and poor eating effect of the current coarse cereal food so as to meet different demands of people on coarse cereal foods. The technical proposal to solve the problems is that the food is produced by 4-6 portions of wheat flour, 4-6 portions of purple rice flour, 8-12 portions of rye flour, 7-11 portions of barley flour, 7-11 portions of oat flour, 7-11 portions of buckwheat flour, 8-12 portions of corn flour, 8-12 portions of millet flour, 4-6 portions of sorghum powder, 4-6 portions of pearl barley powder, 2.5-3.5 portions of soybean flour, 1.5-2.5 portions of black soybean powder, 1.5-2.5 portions of pea meal, 0.8-1.2 portions of black sesame seed powder, 1.5-2.5 portions of black rice flour, 7-11 portions of rice flour, 3-5 portions of sweet potato dry powder and water by weight. 3-5 portions of mung bean powder can be added if the food is eaten in spring, summer and autumn. The food has scientific composing prescription, rich nutrition and good taste and is convenient for eating, conducive to the health of people and a great creation of food deep processing, thus having great economic and social benefits.

Owner:单良才

Highland barley ship biscuit and method for making same

InactiveCN102524336ASimple processAvoid difficultiesBakery productsHigh-fructose corn syrupAtmospheric pressure

The invention provides a highland barley ship biscuit and a method for making the same. The highland barley ship biscuit is made by steps: adding, by weight of cooked barley flour or tsamba flour, 20-80% of oil, 30-37% of high fructose corn syrup, 7-10% of granulated white sugar, 30-38% of nut particles, 25-30% of milk powder, 10-20% of cooked peameal and 0.8-1.4% of salt into the tsamba flour or cooked barley flour original from Tibet; and well mixing and feeding the mixture into a ship biscuit maker for pressing under the pressure of 150-250kg / 2cm, and packaging at a vacuum degree of 0.085-0.095MPa. By the improved ship biscuit production process, the process flow of making raw biscuits prior to crushing and pressing to obtain the ship biscuits required in the conventional production process is avoided, the process of pressing the highland barley ship biscuits is simplified greatly, the problem that the raw biscuits are difficult to bake at high altitude and under low atmospheric pressure in Qinghai-Tibet plateau is solved.

Owner:SHANGHAI FOOD RES INST

Breakfast-type comprehensive nutrition powder

InactiveCN102018203AWide variety of sourcesSimple production processFood preparationNervous systemTremella

The invention discloses breakfast-type comprehensive nutrition powder, which comprises the following components in part by weight: 22 to 35 parts of wheat flour, 3 to 8 parts of barley flour, 8 to 19 parts of corn flour, 10 to 30 parts of oat flour, 3 to 11 parts of vegetable powder, 1 to 4.5 parts of tremella powder, 2 to 5 parts of fruit powder, 3 to 10 parts of yam powder, 5 to 10 parts of pumpkin powder, 5 to 10 parts of soybean flour, 2 to 7 parts of sesame powder and 2 to 5 parts of beef powder. The breakfast-type comprehensive nutrition powder integrates the nutrient components and the healthy functions of grains, fruits, vegetables and meat; and the nutrition is comprehensive and balanced. The product contains abundant microelements, vitamins and dietary fibres, can prompt appetite, develop digestion and maintain the normal function of the nervous system, has the effects of lowering glucose, reducing blood fat, losing weight, defaecating, detoxicating, resisting cancer and enhancing disease-resistant ability, and can neutralize human body acid environment, relieve fatigue and increase physical ability.

Owner:刘秀英

Calf forage and preparation method thereof

ActiveCN103229903AFast growthImprove chewing textureAnimal feeding stuffBiotechnologyOnobrychis sativa

The invention discloses a calf forage and a preparation method thereof. The calf forage is composed of the following raw materials, by weight, 50-60 parts of peanut straw, 25-35 parts of Onobrychis viciaefolia Scop, 20-25 parts of orange leaf, 15-20 parts of potato skin, 10-15 parts of bamboo shoot shell, 5-10 parts of traditional Chinese medicinal residue, 10-15 parts of duck manure, 1-2 parts of a starter, 45-55 parts of barley flour, 20-25 parts of rice bran, 15-20 parts of a corn germ cake, 6-8 parts of a soft sweet additive, 3-5 parts of hawthorn powder, 5-10 parts of attapulgite, 4-6 parts of sesame oil, 2-4 parts of sodium alginate, 2-3 parts of calcium carbonate, 1-2 parts of sodium hydrogen phosphate and 0.3-0.5 parts of salt. The forage contains all nutrition required by the growth of calves, guarantees the healthy production of the calves, provides healthcare values, and raises the growth speed of the calves.

Owner:BENGBU DACHENG FOOD

Quick-frozen black sesame rice ball and preparation method thereof

InactiveCN103005275AIncrease viscosityImprove compactnessFood preparationGlucose polymersMaltodextrin

The invention discloses a quick-frozen black sesame rice ball. The quick-frozen black sesame rice ball comprises the following raw materials in part by weight: 55-65 parts of glutinous rice, 10-12 parts of cream, 4-6 parts of glucose, 3-5 parts of maltodextrin, 5-7 parts of black sesame, 4-6 parts of peanut, 1-3 parts of starch, 0.8-1 part of dried rose, 0.6-0.8 parts of matcha powder, 0.6-0.8 parts of salad oil, 0.5-0.8 parts of fried barley flour and a proper amount of water. A proper amount of starch, maltodextrin and fried barley flour is added in a stuffing making process, so that the emulsifying stability is improved, the stickiness and the compactness of stuffing are improved, the impact of the stuffing on a wrapper is reduced and the breakage opportunity of the wrapper is also reduced; the added matcha powder and rose improves the taste and the mouthfeel of the rice ball; and the quick-frozen black sesame rice ball is soaked by a Chinese herbal extract, so that the health-care value of the quick-frozen black sesame rice ball is improved.

Owner:凤台县康志食品有限责任公司

Process for continuously extracting a plurality of products from highland barley

InactiveCN101617787ASave energyReduce energy consumptionPeptide preparation methodsPlant peptidesFiberBARLEY BRAN

The invention relates to a process for continuously extracting a plurality of products from highland barley, which comprises the following steps: (1) pulverizing highland barley raw material and screening highland barley flour and highland barley bran; (2) extracting and centrifugalizing the highland barley flour by alkaline solvent, collecting supernate and depositing and extracting albumen powder by acid; washing, freezing and drying the sediment at low temperature to obtain highland barley starch; (3) after the highland barley bran is extracted by a supercritical carbon dioxide technology or quenched by small polar solvent, obtaining highland barley bran oil; (4) after the degreased bran is ultrasonically extracted or stewed and centrifugalized by taking water as solvent, respectively obtaining powder containing highland barley beta-glucan and concentrated solution containing highland barley flavone and amino acid; and (5) after residues obtained in the step (4) are dried and pulverized in an ultramicro way, obtaining highland barley water insoluble fiber albumen powder. The process can continuously obtain six highland barley deep-processing products, effectively improves the utilization ratio of the highland barley and increases the utilization value of the highland barley.

Owner:青海韵驰检测技术有限公司

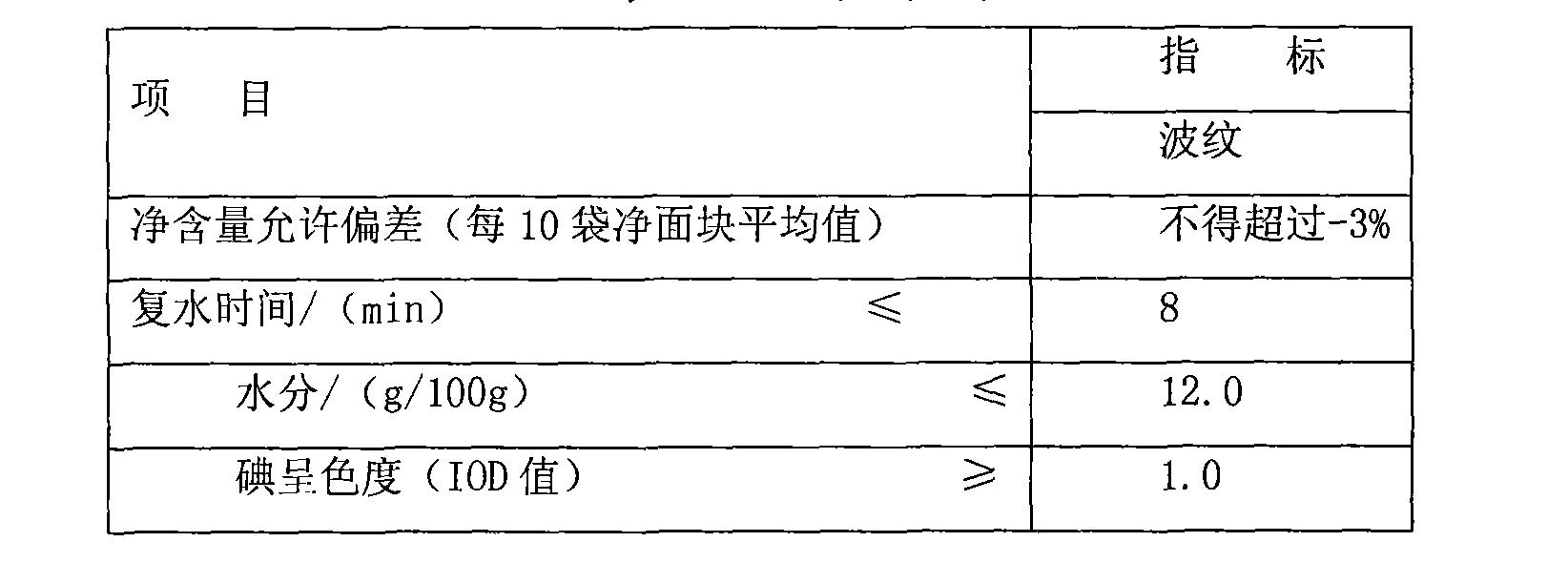

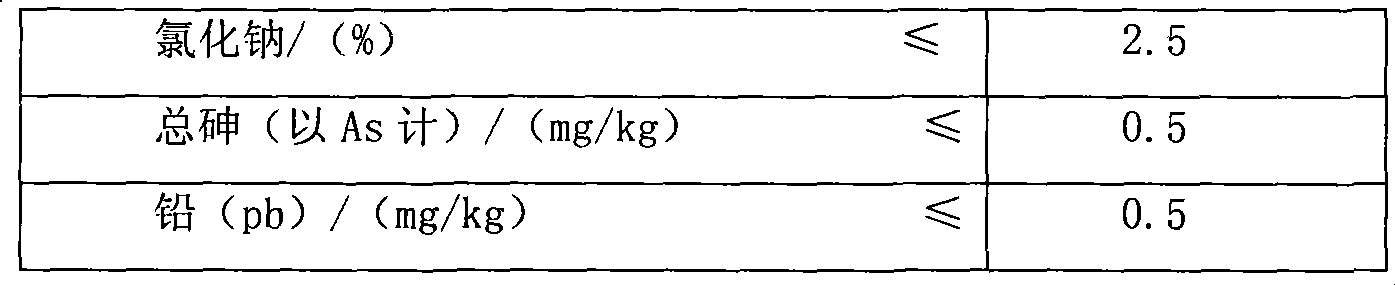

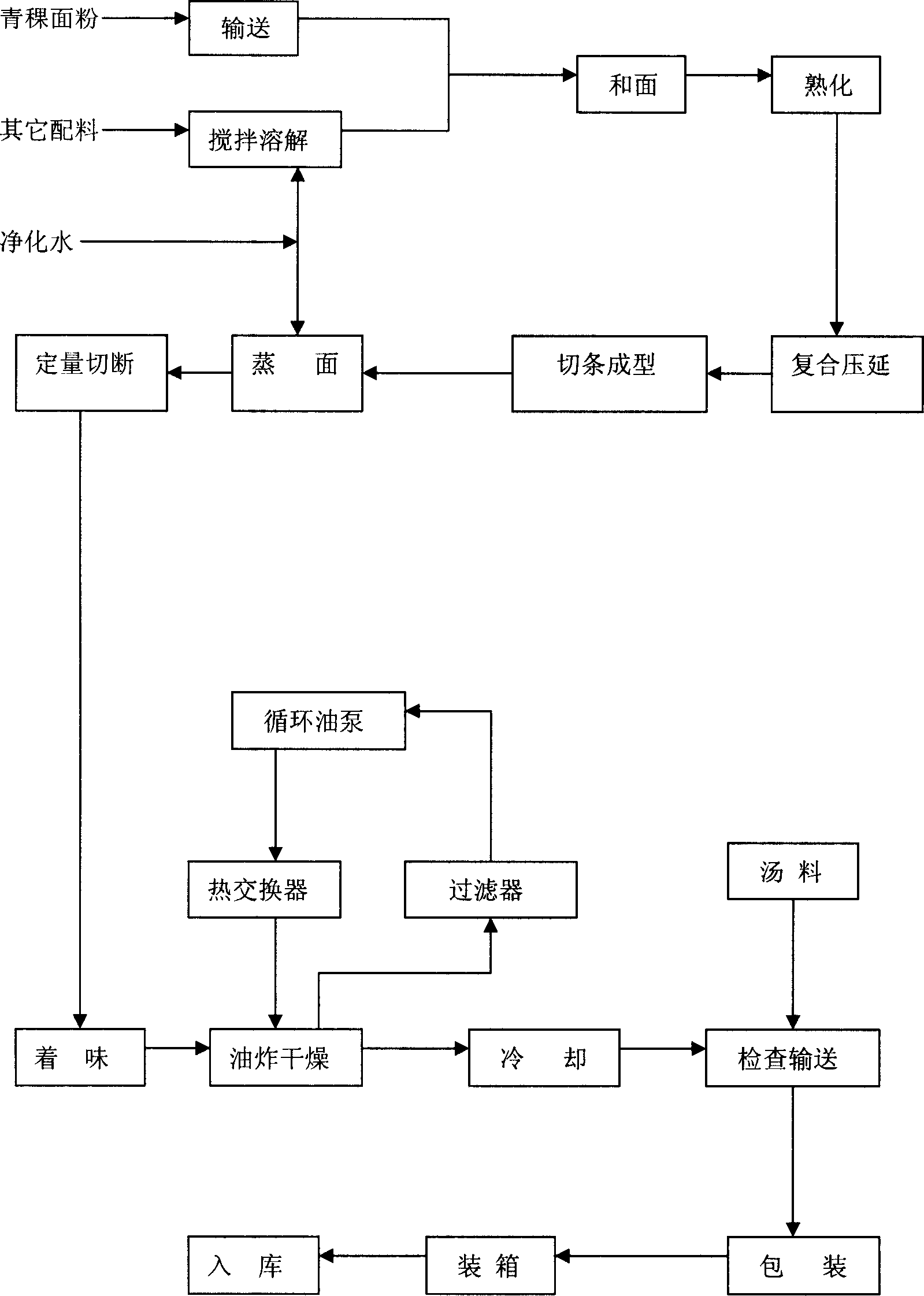

No-fry highland barley instant noodles and production method thereof

ActiveCN101380071AKeep the original colorKeep it authenticFood preparationInstant noodleConvenience food

The invention provides a non-frying highland barley instant noodle which takes highland barley flour as the main raw material and a making method thereof, belonging to the field of food processing; the making method of the non-frying highland barley instant noodle includes the steps of flour milling, charging, dough making, shaping, stewing, drying, and the like, and is characterized in that: the highland barley flour accounts for 50-100 % of the total weight of dry raw materials in the charging step, water which accounts for 30-35 % of the total weight of dry raw materials and has the temperature of 25-30 DEG C is added in the dough making step, the time for dough making is 10-20 minutes, and a piece of non-expansion extrusion equipment is adopted in the shaping step. The technique can be used for producing the non-frying highland barley instant noodle of whole highland barley flour, and can greatly raise the technology content and added value of highland barley flour food, thus the highland barley flour food can turn into health instant food which can be accepted by most people.

Owner:西藏春光食品有限公司

Nutrient biscuit with functions of reducing sugar and reducing fat

InactiveCN101816317AIncrease vitalityLower blood sugarBakery productsSodium bicarbonateVegetable oil

The invention provides a nutrient biscuit with functions of reducing sugar and reducing fat, which belongs to the field of food processing. The nutrient biscuit is prepared by using highland barley flour as a main raw material and matching edible vegetable oil, fresh egg, sodium bicarbonate and water according to a conventional process for preparing biscuit food. The traditional wheat flour is changed into the highland barley flour, and the highland barley flour is rich in beta-glucan, so the biscuit has the functions of reducing blood surfer, reducing blood fat, balancing metabolism and enhancing body vigor. Meanwhile, because the biscuit is rich in various nutrient components of the human body, the biscuit can relieve or eliminate hunger sensation, provides nutrients required for the metabolism of the human body, and is functional food integrating nutrition, health care and food therapy.

Owner:TIBET TIANMAILI HEALTH PROD CO LTD

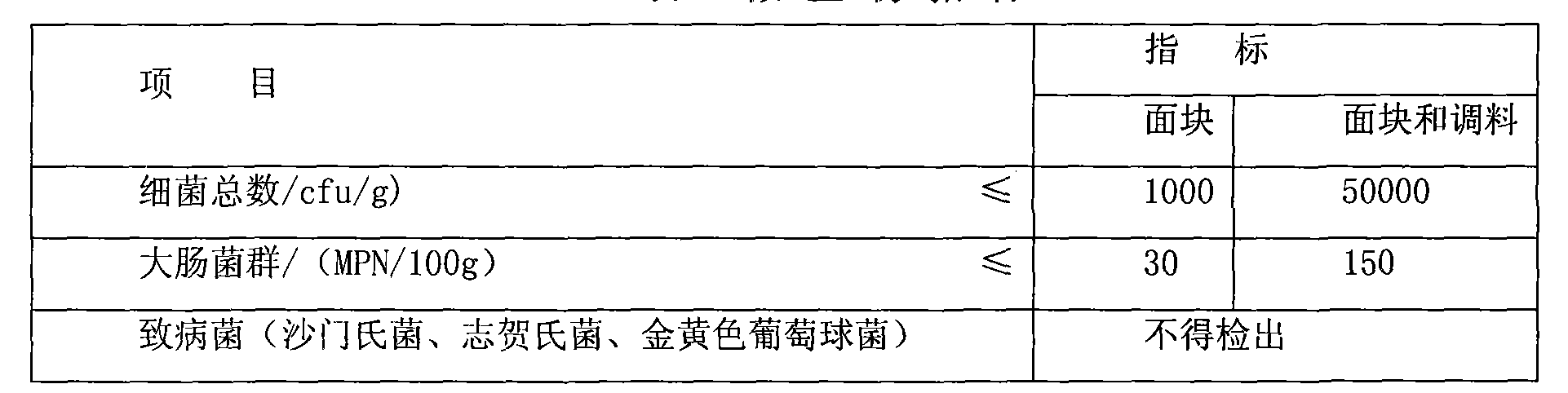

Natural yeast bread and manufacturing method thereof

InactiveCN104782702AAppropriate tasteUniform structureDough treatmentPre-baking dough treatmentNutritive valuesWarm water

The invention relates to a manufacturing method of natural yeast bread. The method includes the steps that a, natural yeast liquid raw materials selected from fruits and cereals at least including glutinous barley are fermented to obtain natural yeast liquid; b, high-gluten flour and glutinous barley flour are mixed to obtain mixed flour, the mixed flour and the natural yeast liquid are mixed to obtain a mixture, and the mixture is fermented to obtain primary natural yeast; c, after the primary natural yeast is fermented, the primary natural yeast, warm water, high-gluten flour and glutinous barley flour are stirred into mixed dough, and the mixed dough is fermented at low temperature to obtain sponge dough; d, high-gluten flour, glutinous barley flour, malt flour, soya bean lecithin and a water solution are stirred and then added into the sponge dough to form bread dough through stirring; e, the bread dough is fermented; f, a conventional method is used for baking to obtain the bread. The invention further discloses natural yeast bread manufactured by adopting the method. The high water absorption rate and the high aerogenesis capacity of the glutinous barley flour, the capacity of promoting yeast aerogenesis of the malt flour and the emulsifying capacity of the soya bean lecithin are used, and low-temperature secondary fermentation is combined to obtain the soft and healthy bread moderate in mouthfeel and high in nutritive value.

Owner:福建安麦高新生物技术有限公司

Low-sugar tartary buckwheat biscuit and making process thereof

InactiveCN106417511AIncreased sensitivityImprove immunityDough treatmentBakery productsVegetable oilAdditive ingredient

The invention belongs to the field of food processing, and particularly relates to a low-sugar tartary buckwheat biscuit and a making process thereof. The low-sugar tartary buckwheat biscuit is characterized in that ingredients of the biscuit include, by weight, 20-65 parts of wheat flour, 12-40 parts of whole-wheat flour, 5-25 parts of tartary buckwheat flour, 1-15 parts of barley flour, 1-15 parts of rye flour, and 1-10 parts of oatmeal, and further, 8-25% of vegetable oil, 0.1-10% of olive oil, 1-15% of butter, 1-10% of milk powder, 25-45% of maltitol, 1.5-4.5% of complex leavening agent, 0.1-5% of sesame, 10-12% of water, and one of 0.1-10% of okra powder, 0.05-10% of tricholoma matsutake powder and 0.02-5% of truffle powder are added into the ingredients by mass. The low-sugar tartary buckwheat biscuit is a food for enriching dietary supplement variety for diabetic patients, provides daily nutrition and also helps the diabetic patients to control postprandial blood sugar well.

Owner:CHENGDU BAOWEI CONTROL SUGAR FOOD CO LTD

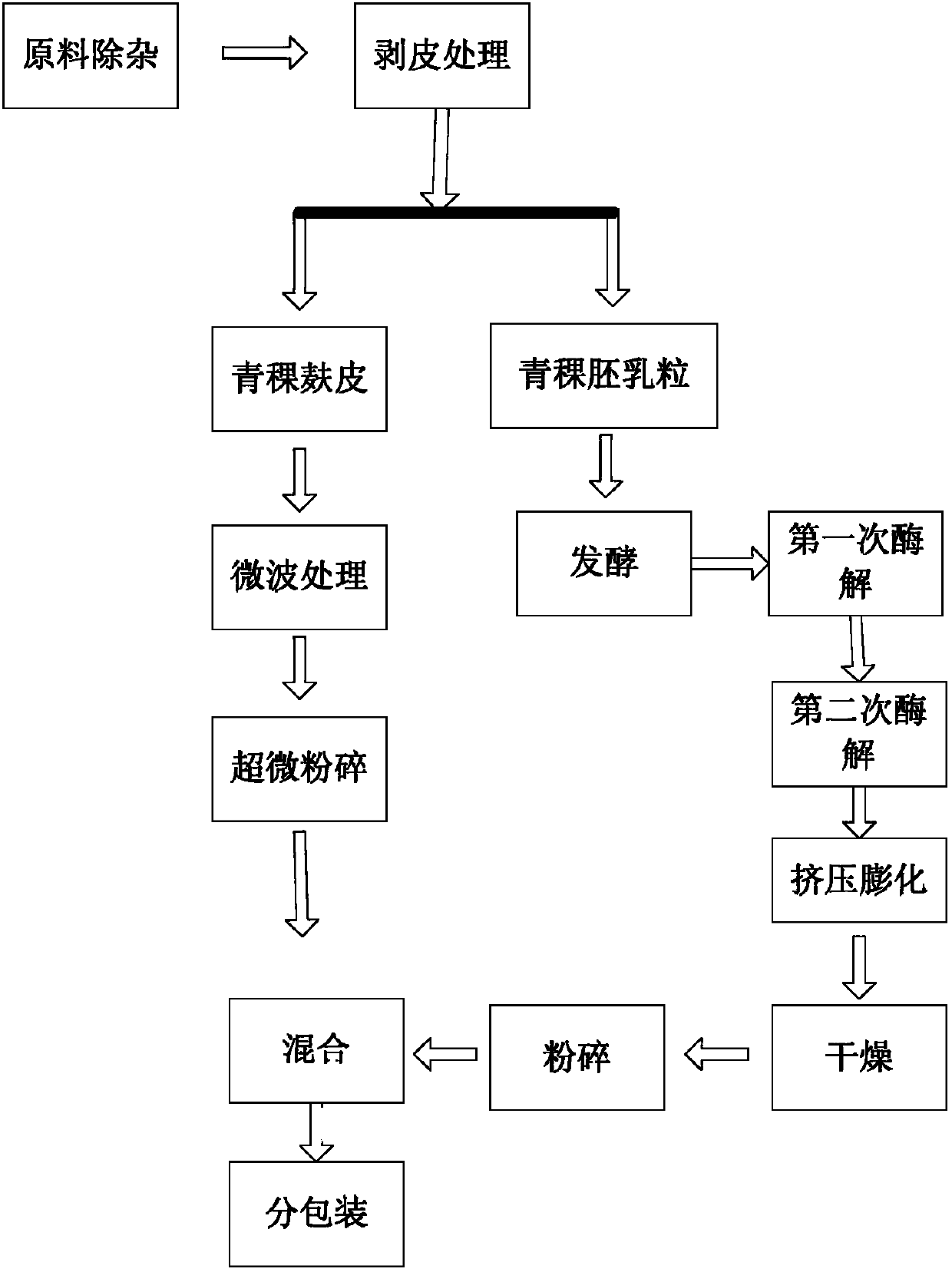

Instant highland barley flour processing technology

InactiveCN103340353ASimple processing methodPromote absorptionFood preparationBARLEY BRANFood science

The invention provides an instant highland barley flour processing technology. The instant highland barley flour processing technology comprises processes such as raw material impurity removing, peeling, highland barley bran microwave crushing, once highland barley endosperm particle fermenting, twice highland barley endosperm particle enzymolysis treating, extrusion expanding, dry crushing, mixed packaging and the like. The instant highland barley flour processing technology is simple, convenient and practicable, and the instant highland barley flour has a good taste and can be easily digested and absorbed by human bodies.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

High-dietary-fiber-content nutritional bread and production method thereof

The invention provides high-dietary-fiber-content nutritional bread and a production method thereof. The bread is produced from the following raw materials in parts by weight: 300 to 400 parts of germinated barley flour, 550 to 650 parts of high gluten wheat flour, 70 to 80 parts of vital gluten, 8 to 12 parts of yeast, 600 to 700 parts of purified water, 280 to 330 parts of germinated barley oatmeal, 80 to 150 parts of eggs, 100 to 150 parts of sugar, 90 to 120 parts of butter, 5 to 15 parts of edible salt, 35 to 45 parts of raisins and 6 to 10 parts of malt extracts. The bread is produced by raw and auxiliary material pretreatment, dough mixing, cutting, fermentation and baking. The nutritional value and the health function of the bread are obviously increased, and the nutritional bread keeps good taste, flavor and texture and is anti-aging.

Owner:天津市汇禾食品有限公司

Bread and preparation process thereof

InactiveCN1736212AExtend freshnessThe texture is dense and elasticBakery productsAdditive ingredientMillet flour

The invention discloses a bread and its preparation process, wherein the end product is prepared from main ingredients, water, hop fermentation liquor and auxiliary materials through mixing, fermenting and baking, the main ingredients include whole wheat flour, naked oat flour and oat flakes, buckwheat flour, millet flour, maize flour, soybean flour and green bean flour, the auxiliary materials include sugar, fresh milk, fruit material, cream, hen's eggs, table salt, vitamin sodium and L-lysine hydrochlorates. The preparing process consists of batchingthe main ingredients and auxiliary materials by weight, mixing, charging hop fermentation liquor, fermenting five times, charging water and baking.

Owner:吴微

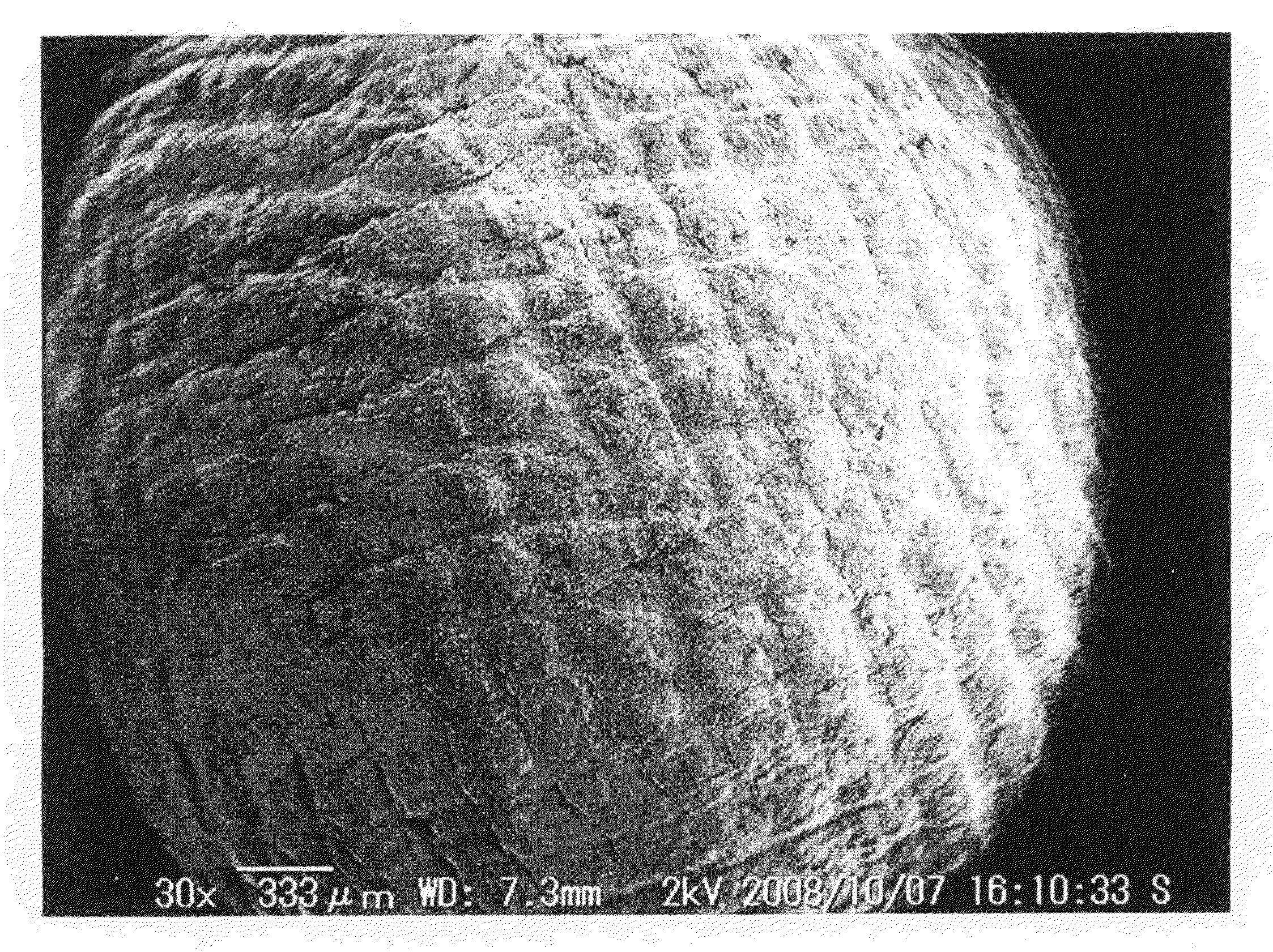

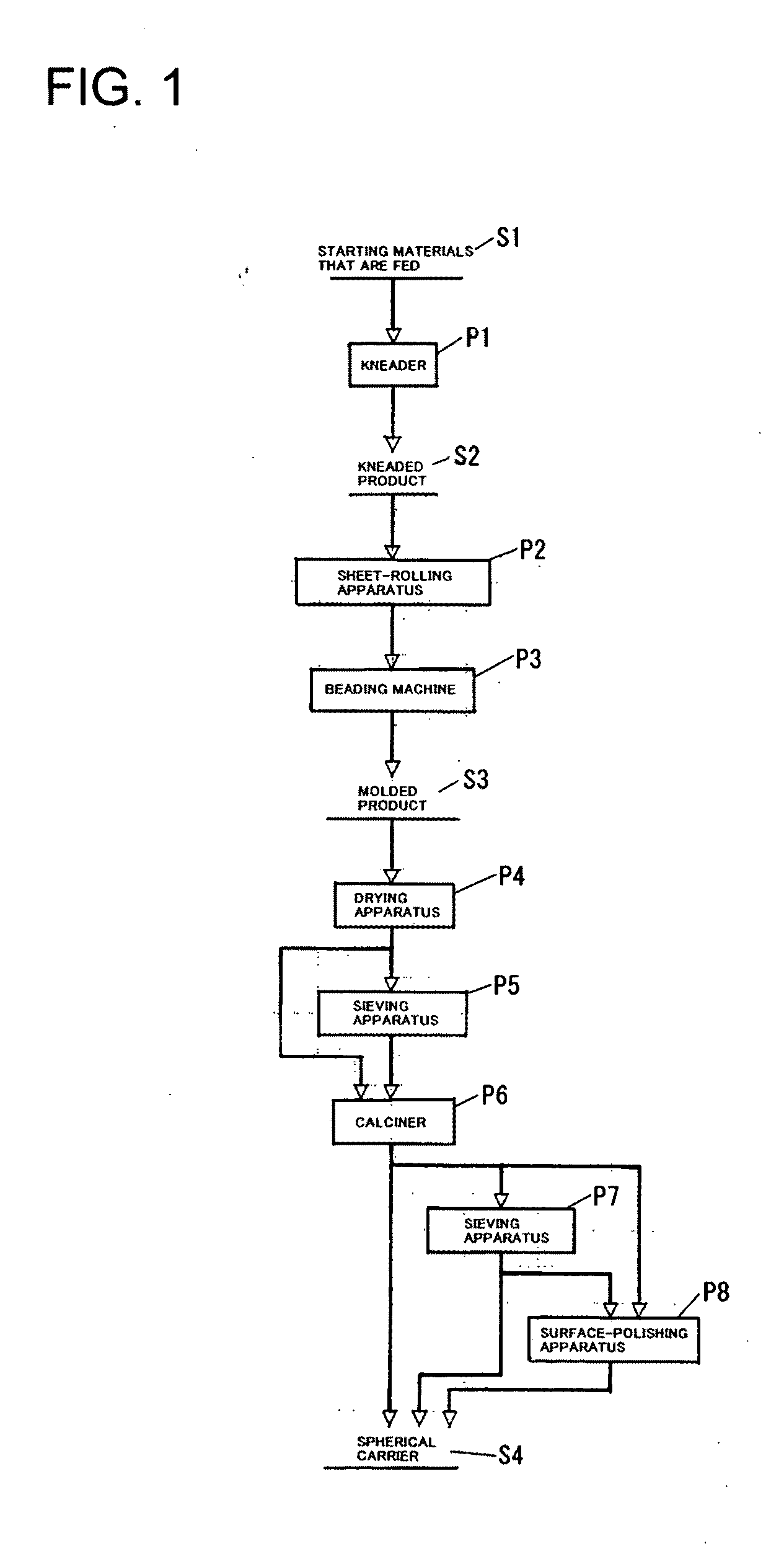

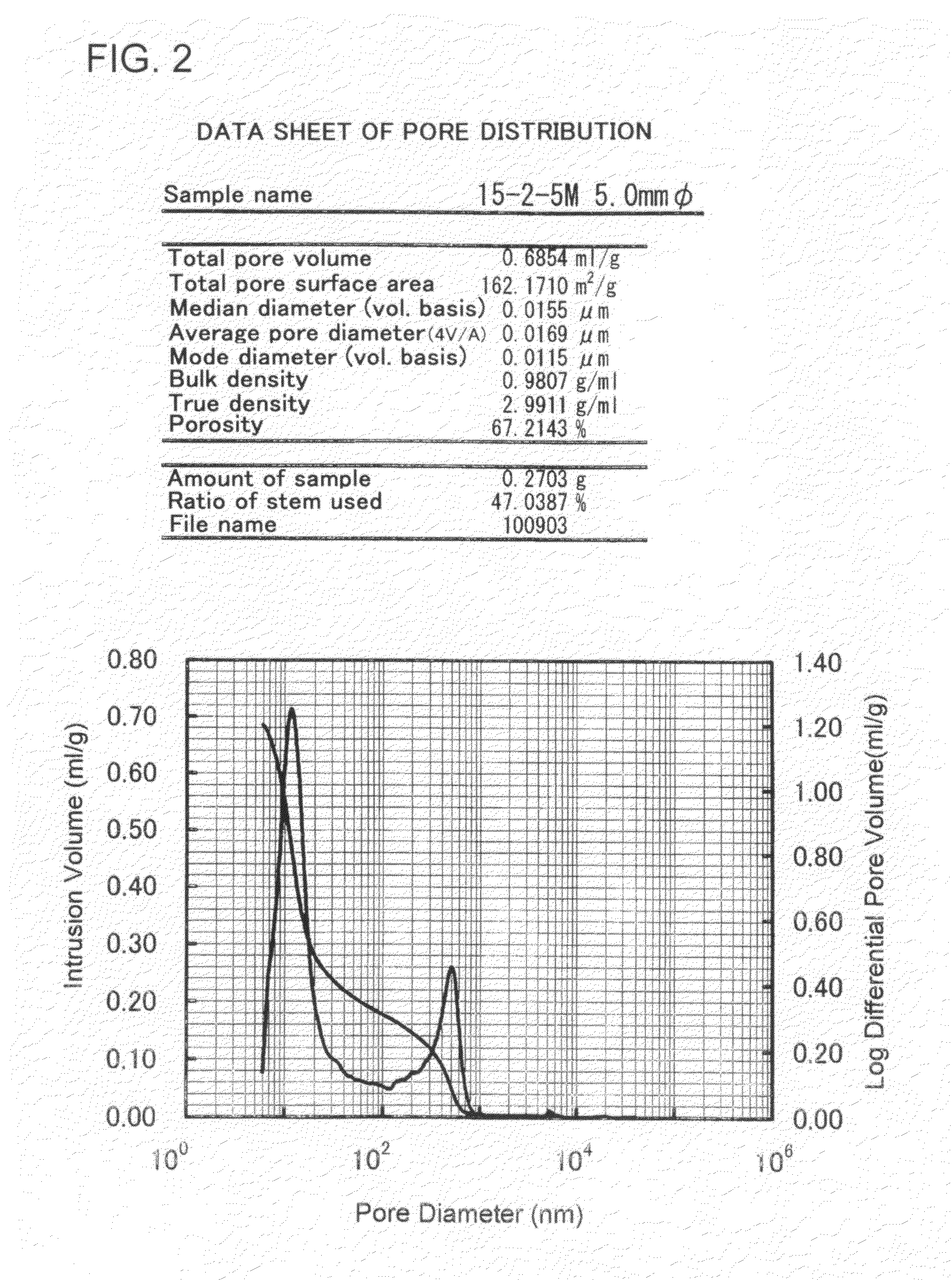

Carrier and method of producing the same

The method of producing a carrier of the invention includes a step of kneading the starting carrier components, solid binding agent, liquid binding agent and diluted nitric acid water. The starting carrier components comprise aluminum hydroxide, pseudoboehmite, γ-alumina, powdery silica gel, powdery natural silica and zeolite. The solid binding agent comprises a powder of α-starch (rice), α-starch (potato), α-starch (tapioca), funori (glue plant), crystalline cellulose and powdery cellulose. The liquid binding agent comprises colloidal alumina, colloidal silica and polyvinyl alcohol. As a de-firing agent, further, there are used wood powder, charcoal powder, rice flour, wheat flour, barley flour, buck wheat flour and corn. The carrier has a pore volume in a range of 0.52 to 0.84 cc / g and a side crushing strength in a range of 2.2 to 11.0 kgf / particle.

Owner:KUREHA YUSHI INDS +1

Laying hen feed and preparation method thereof

The invention discloses a laying hen feed. The laying hen feed is prepared from 20-25 parts of egg shell, 20-25 parts of duck shell, 50-60 parts of calcium carbonate powder, 480-500 parts of wheat flour, 60-70 parts of pearl barley flour, 5-8 parts of almond flour, 5-10 parts of barley flour, 10-14 parts of yeast, 7-10 parts of citric acid, 10-15 parts of white granulated sugar, 5-9 parts of tea leaf, 4-6 parts of bitter gourd, 5-7 parts of amomum tsao-ko, 5-7 parts of ginger peel, 6-9 parts of tenuifolia and 4-5 parts of phagostimulant. The laying hen feed has the advantages that as the egg shells are fermented, calcium in the egg shells is fully dissolved out by fermented acid and nitric acid, the Chinese herbal medicines have nutritional and medicinal functions and can be used for improving the immunity of animal organisms and reducing the occurrence of diseases in a feeding process, the using amount of drugs is reduced, safe animal products are produced, and the produced eggs have thick shells.

Owner:ANHUI MUXIANG POULTRY IND

High-fine sugar-free thick juice highland barley biscuit and its processing method

The invention discloses high-fiber sugar-free syrup highland barley biscuit and a processing method thereof; the weight proportion of the raw materials of the biscuit are as follows: 50 portions to 94 portions of highland barley flour, 5 portions to 30 portions of strong flour, 5 portions to 10 portions of high-fiber sugar-free syrup, 0.5 portion to 4 portions of refined salt, 8 portions to 15 portions of cream, 0.1 portion to 1 portion of saleratus, 5 portions to 8 portions of egg, 0.5 portion to 5 portions of edible plant oil and 30 portions to 70 portions of water; the technological process comprises the following steps: raw material selection, weighing, mixing, processing and shaping by a biscuit machine, drying, sterilization, oil spraying, cooling, packaging and finishing product preparation. The method of the invention improves the strength of gluten by adding strong flour, replaces sucrose with high-fiber sugar-free syrup, and is characterized by sugar free, richness in water soluble dietary fiber, low heat, no decayed tooth, starch aging inhibition, etc. The highland barley biscuit of the invention has rich nutrition and good taste, is convenient to be digested and absorbed, and has the functions of intestine clearing, blood sugar regulating, cholesterin reducing and improvement of the immunity of human body after being often eaten.

Owner:食品行业生产力促进中心

Preparation method of highland barley broad bean fine dried noodles

ActiveCN103110060AGive full play to the value of health careSimple processFood preparationAmyrisAmino acid composition

The invention discloses a preparation method of highland barley broad bean fine dried noodles. The method comprises the following steps of: (1) mixing of raw materials; (2) dough kneading and curing; (3) tabletting; (4) slitting; (5) drying; (6) cutting off; and (8) packaging. The fine dried noodles are manufactured by using highland barleys and broad beans as raw materials, and effective components in the highland barleys and broad beans can be fully utilized; because the content of straight-chain starch in the starch of broad bean powder is high, the characteristics of low content of the straight-chain starch in the highland barleys and high content of branch-chain starch can be supplemented, and the stickiness of the dough is reduced; the proteins in the broad beans can be used for compensating the deficiency of the proteins and amino acid compositions in the highland barleys and intensifying the nutrition of the highland barley flour; and the broad bean powder is added into the highland barley flour to replace the addition of other external source starch and proteins, so that the process is simplified, and the cost is reduced.

Owner:青海高原羚食品有限公司 +1

Grass carp feed and preparation method thereof

InactiveCN103445014AMeet the needs of growthPromote growthClimate change adaptationAnimal feeding stuffNutritive valuesBiotechnology

The invention discloses a grass carp feed and a preparation method thereof. The grass carp feed comprises the following raw materials in parts by weight: 20-30 parts of cotton seed cake flour, 30-35 parts of rice sprout flour, 12-15 parts of bean cake flour, 4-5 parts of rapeseed cake flour, 8-10 parts of silkworm chrysalis meal, 4-5 parts of fish meal, 3-4 parts of barley flour, 1-2 parts of chrysanthemum, 2-3 parts of gynostemma pentaphyllum, 1-2 parts of raisins, 2-3 parts of galium aparine, 2-3 parts of rubiaceae Borreria stricta, 2-4 parts of hawthorn roots, 5-7 parts of kelp root, 2-4 parts of sunflower leaves, 1-2 parts of phlegmariurus petiolatus and 1-3 parts of phagostimulant. The grass carp feed disclosed by the invention is scientific and reasonable in formula, and can meet requirements for growth of grass carps at every growth stage, effectively improve the flesh quality and the nutritive value of the grass carps, promote the growth of the grass carps, enhance the skin antibacterial ability of the grass carps and lower the disease incidence of the grass carps.

Owner:LIXIN XINLIANXIN FORAGE

a multigrain pastry

The invention discloses a coarse cereal cake. The coarse cereal cake is prepared by the steps of: adding edible auxiliary materials and seasonings into flour and coarse cereal powder which are taken as staple food raw materials and roasting. The coarse cereal cake is characterized in that: the coarse cereal powder comprises oat meal, barley flour, mung bean flour and millet flour, the weigh ratioof the flour to the oat meal to the barley flour to the mung bean flour to the millet flour is 6:1:1:1:1, and the edible auxiliary materials and the seasonings comprise eggs, white granulated sugar, water, baking powder, oil and green tea powder which sequentially account for 100, 80, 40, 1.5, 20 and 1.4 percent of the total weight of the staple raw materials.

Owner:ANHUI YANZHIFANG FOOD

Grain puffed particle containing quinoa and preparation method thereof

InactiveCN107198117AMeet the needs of nutrition and healthNutritional diversityFood ingredient functionsVegetable oilSugar

The invention relates to a grain puffed particle containing quinoa and a preparation method thereof. The grain puffed particle is prepared from the following raw materials in parts by weight: 5-9 parts of quinoa flour, 1.5-2.5 parts of whole oat flour, 1-3 parts of highland barley flour, 2-5 parts of naked barley flour, 0.1-1 part of white granulated sugar, 0.1-1 part of soyabean protein powder, 0.1-0.5 part of soluble dietary fiber, 0.5-1.2 parts of vegetable oil, 0.01-0.20 part of phospholipid, 0.1-0.3 part of table salt and 0.05-0.15 part of edible calcium carbonate. The preparation method of the grain puffed particle containing quinoa comprises the steps of preparing flour, carrying out twin-screw extrusion, baking and screening. The prepared grain puffed particle is more complete in nutrition; the requirements of consumers on nutrition and health can be met.

Owner:焦作荣利达食品有限公司

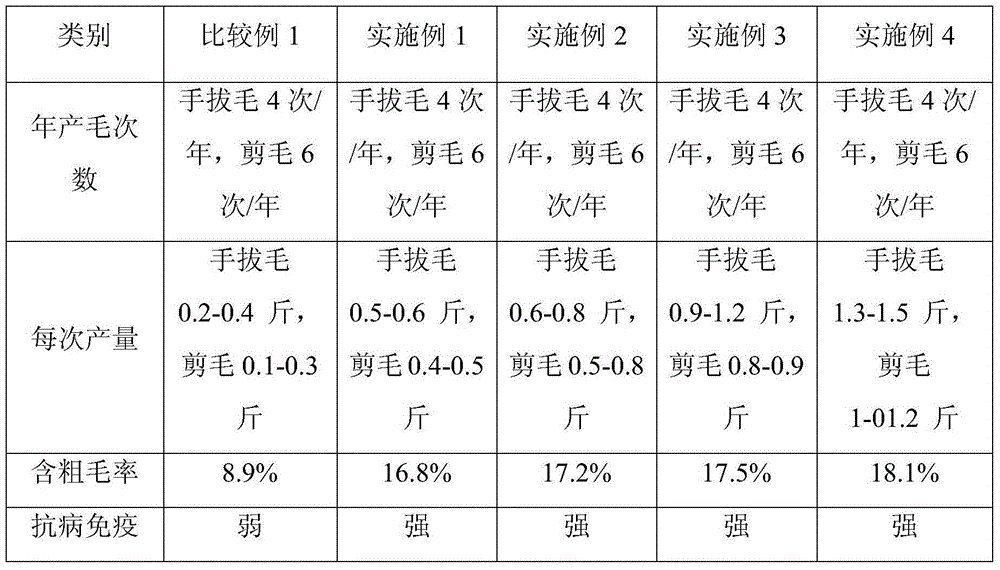

Feed capable of increasing hair growth rate of long-hair rabbits and preparation method thereof

InactiveCN104543592AImprove hair yieldImprove quality colorFood processingAnimal feeding stuffAnimal scienceChaff

The invention provides a feed capable of increasing the hair growth rate of long-hair rabbits and a preparation method thereof. The feed disclosed by the invention is prepared from the following raw materials in parts by weight: 50-100 parts of corn flour, 10-20 parts of barley flour, 25-40 parts of bean pulp, 5-10 parts of green chaff, 20-25 parts of bran, 1-5 parts of alfalfa powder, 1-6 parts of sophora japonica linn. leave powder, 1-10 parts of bagasse, 1-10 parts of tapioca flour, 1-10 parts of sweet potato powder, 1-10 parts of carrot powder, 0.7-1.5 parts of sugar, 1-10 parts of pine needle meal, 0.5-3 parts of fishbone meal, 1-5 parts of yeast powder, 0.1-2 parts of salt, 0.5-3 parts of spirulina, 0.8-8 parts of Chinese herbal medicine additives, 0.5-5 parts of vitamin additives and 0.1-1 part of trace element additive. By means of the feed and the preparation method provided by the invention, the hair growth rate of long-hair rabbits can be obviously increased; and the quality, the color and the luster of rabbit hairs are improved.

Owner:贵州新普科技股份有限公司

Tuckahoe tea beverage

The invention relates to tuckahoe tea beverage which is characterized by being prepared by the following raw materials proportioning by weight: 5000-10000 parts of tap water, 50-100 parts of tuckahoe tea, 10-20 parts of salt, 5-10 parts of zanthoxylum, 5-10 parts of tsaoko cardamon, 5-10 parts of ginger peel, 5-10 parts of barley flour, 5-10 parts of medlar, 5-10 parts of herba schizonepetae, 5-10 parts of rhodiola root, 5-10 parts of red date and 10-20 parts of honey. The tuckahoe tea beverage adopts tuckahoe tea, such as Hunan dark green tea, Chaner tea, Hezang tea, Hubei old green tea, Sichuan bian tea, Yunnan Pu'er tea and Guangxi Liubao tea. When being drunk, the tuckahoe tea beverage can assist digestion, warm the middle-jiao, strengthen the stomach, promote digestion, smooth qi and increase blood circulation. By long-term drinking, the tuckahoe tea beverage can resist senility, tumours and viruses and has the functions of protecting the liver and enhancing the physical strength. When being drunk in a plateau area in tour, the beverage has the functions of resisting oxygen deficiency, fatigue and radiation, improving the functions of cardiac muscles and enhancing the brain function. Simultaneously, the beverage has the functions of sweating and relieving exterior syndrome, has the effect of dispersing pathogenic wind and also has the functions of relieving alcoholism and removing halitosis.

Owner:铁生年

Highland barley instant noodles and processing technique thereof

InactiveCN1907100AImprove qualityNutrients are enhanced and stabilizedFood preparationGlutelinInstant noodle

The invention relates to a highland barley instant noodle and process for preparation comprising steps of mixing highland barley flour, purified water, dissolved palm oil, composite flour modifying agent, glutelin powder, phosphatidy icholine, salt, alkali, guar gum and enzyme, calendaring, boiling, chopping, frying and cooling down.

Owner:杜沛沪

Method for preparing feed for meat pigeons

InactiveCN101617751AFast growthLoud ingredientsFood processingAnimal feeding stuffAnimal scienceCoptis

The invention relates to a method for preparing a feed for meat pigeons. The feed comprises the following components in percentage by weight: 4 to 6 percent of rice albumen powder, 4 to 8 percent of sorghum albumen powder, 2 to 6 percent of soybean albumen powder, 8 to 10 percent of wheat albumen powder, 8 to 11 percent of rice bran, 4 to 6 percent of barley flour, 6 to 10 percent of sunflower seed cake, 12 to 16 percent of fish meal, 3 to 6 percent of eel meal, 4 to 6 percent of seashell meal, 4 to 6 percent of broken rice, 1 to 3 percent of vitamin B complex, 6 to 8 percent of carrot meal, 2 to 4 percent of cod liver oil meal, 1 to 3 percent of cooking salt, 1 to 3 percent of bulbus fritillariae cirrhosae, 1 to 3 percent of coptis root, and 1 to 3 percent of cassia seed. The method for preparing the feed comprises the following steps: taking the powders and meals according to the proportions and putting the same into a multiplex mixer for stirring; taking out the mixture and putting the same into a circular die type crusher for crushing; then taking out the mixture and drying the same in a drying machine; taking out the mixture and bulking the same in a circular die type bulking machine; taking out the mixture and putting the same into a circular die type hard granule machine to produce a deposition hard granulated feed; and screening the feed with a 80-mesh sieve, wherein the each granule of the granulated feed is 0.2 gram so that the feed can be sealed and packaged according to the required weight.

Owner:王嵩

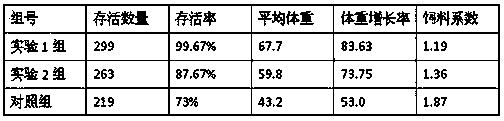

Juvenile tilapia feed

InactiveCN104286595AImprove conversion rateImprove survival rateAnimal feeding stuffSodium BentoniteCorn meal

The invention relates to the field of feeds, in particular to a juvenile tilapia feed. The juvenile tilapia feed consists of the following components in parts by weight: 30 to 40 parts of soybean cake, 20 to 30 parts of bran, 10 to 15 parts of fish meal, 5 to 10 parts of barley flour, 2 to 8 parts of corn meal, 2 to 8 parts of pagoda tree leaf powder, 1 to 3 parts of bone meal, 0.1 to 0.5 part of salt, 0.1 to 1.0 part of multivitamins, 1 to 5 parts of a traditional Chinese medicine additive and 1 to 2 parts of mineral salt. The traditional Chinese medicine additive comprises the following components: excoecaria sebifera, honeysuckle, rheum officinale, garlic, codonopsis pilosula, acanthopanax root, corydalis tuber, cortex albizziae, coptidis rhizoma, astragalus mongholicus, blackberry lily, tobacco, humifuse euphorbia herb, the fruit of Chinese magnoliavine, Chinese gall, chinaberry, golden cypress, medicated leaven, poria cocos, bentonite, malt and Chinese yam. The juvenile tilapia feed has the benefits that through the adoption of the feed disclosed by the invention, the survival rate of juvenile tilapia is effectively increased and the weight of adult fishes is increased, wherein the survival rate reaches 99.67 percent and the weight increase rate also reaches 83.63 percent; a feed coefficient is reduced; the conversion rate of the feed is increased; the cost is reduced; the benefits are increased.

Owner:JINAN CAVIN BIOTECH

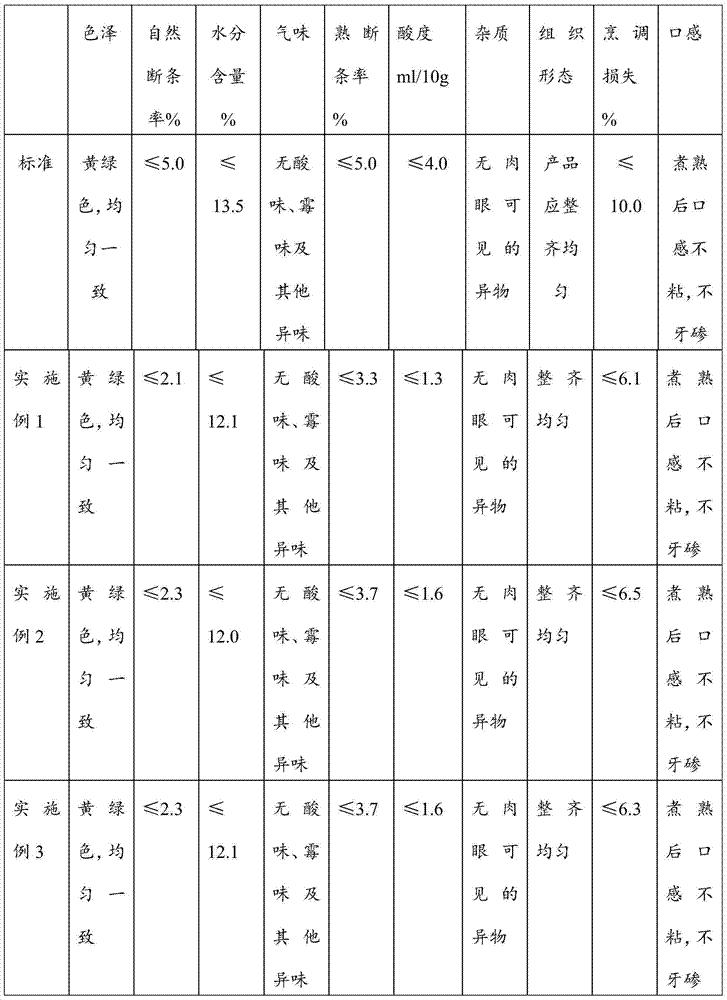

Coix seed barley buckwheat coarse cereal noodle and production method thereof

InactiveCN104323129AChange rheological propertiesOvercome the monotonous tasteFood preparationBiotechnologyPolygonum fagopyrum

The invention discloses a coix seed barley buckwheat coarse cereal noodle and a production method thereof. According to the invention, wheat flour, coix seed flour, barley flour, buckwheat flour, wheat gluten, eggs and other raw materials are selected to prepare the coarse cereal noodle with the nutrition and health care efficacy of coix seed, barley and buckwheat, good taste, and reasonable nutrition collocation. The noodle product has slight red color, is smooth and delicate, has good molding properties, is chewy and elastic, and has a breaking rate of less than 5%, a hint of coarse cereal flavor, and good palatability. The noodle provided by the invention has the advantages that: 1. the coix seed, barley, buckwheat and other coarse cereals are selected to overcome the disadvantages of single taste and low nutritional value in traditional noodles, and the product has the characteristics of reasonable diet, and good nutrition and health care functions; 2. the wheat gluten is added to the product raw materials to change the noodle rheological properties, improve the water absorption of stock, shorten the curing time and reduce the breaking rate, so that the noodle can be delicate, chewy, rich in nutrition, and has the health care functions.

Owner:QINGDAO JIARUI BIOLOGICAL TECH

Tartary buckwheat and highland barley noodle and manufacturing method thereof

InactiveCN104770648AEasy cookingDouble effect sugar controlFood preparationCooking & bakingPolygonum fagopyrum

The invention belongs to the technical field of noodle processing and manufacturing, and specifically relates to a tartary buckwheat and highland barely noodle and a manufacturing method thereof. The method comprises the following steps: (1) preparing the following components in percentage by weight: 60 to 70% of tartary buckwheat flour, 15.9 to 2.59% of wheat flour, 10 to 15% of highland barley flour, 1 to 1.2% of salt, 0.3 to 0.4% of xanthan gum powder, and 0.08 to 0.1% of edible alkali; (2) stirring and aging; (3) rolling: rolling the aged dough, and cutting into noodles; (4) drying: transferring the noodles to a baking chamber, and drying the noodles through a low-temperature moisture-maintaining drying method; (5) strip-cutting: cutting the dried vermicelli into sections with a required length so as to obtain the tartary buckwheat and highland barley noodle. The prepared tartary buckwheat and highland barley noodle has a good taste and is convenient for cooking, the core and the peel of the tartary buckwheat are individually subjected to a refining treatment, before the baking step, the noodles are processed in a wet and low-temperature environment, and thus the noodle breaking rate is largely reduced, compared with the conventional manufacturing technology.

Owner:上海久降堂食品科技有限公司

Preparation method of ultrafine edible mung bean protein powder

The invention discloses a preparation method of ultrafine edible mung bean protein powder. The method can prepare ultrafine edible mung bean protein powder with good biological utilization and remarkable dietotherapy effect on heat clearing, detoxification, pox removal and skin cleaning. The technical scheme comprises the following steps: cleaning mung beans; airing by hot air; grinding; peeling off; extruding and bulking at 70-140 DEG C; pulverizing the extruded, bulked and peeled mung beans by a rough pulverizer until the average granularity is smaller than 100 microns; mixing the following materials in percentage by weight: 50-75 pulverized mung bean with the average granularity smaller than 100 microns 10-25 barley flour, 10-25 black soybean meal, 0.5-5 pearl powder and 1-20 brown sugar; uniformly stirring by a stirrer for 5-20 minutes; taking out; drying in an oven at a drying swelling of 90-130 DEG C for 20-50 minutes; and pulverizing by an ultrafine pulverizer until the average granularity is 1-30 microns.

Owner:SICHUAN UNIV

Preparation method of cooking-free barley noodles

The invention discloses a preparation method of cooking-free barley noodles, belonging to the food field. The preparation method of the cooking-free barley noodles comprises the steps of: (1) uniformly stirring barley flour, refined salt and water to obtain stirred flour; (2) primarily curing the stirred flour in an automatic feeder on the conditions that the temperature is 60 DEG C and the rotation speed of a motor is 700r / min to obtain primarily-cured barley flour; (3) sending the primarily-cured barley flour to a spiral extruder for secondary molding on the conditions that the temperature is 30 DEG C and the rotation speed of the motor is 700r / min to obtain molded noodles; (4) quantitatively cutting the molded noodles, and aging the noodles at the low temperature; and (5) drying and cooling the noodles to the room temperature, checking and packaging the noodles. The method can furthest maintain quality of the barley noodles; the produced noodles can be eaten after being soaked to soft; the noodles can be soaked for a long period, do not dissolve to rot, and have good taste; and the method solves the problem that the noodles are difficult to cook due to low pressure in Tibetan areas.

Owner:RES INST OF AGRO PROD PROCESSING SHANXI ACADEMY OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com