Tartary buckwheat and highland barley noodle and manufacturing method thereof

A production method and technology of highland barley noodles, which are applied in food preparation, application, food science, etc., can solve the problems of low yield, easy breaking, and inability to roll, etc., and achieve the effects of being easy to eat, improving the taste, and simplifying the cooking process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

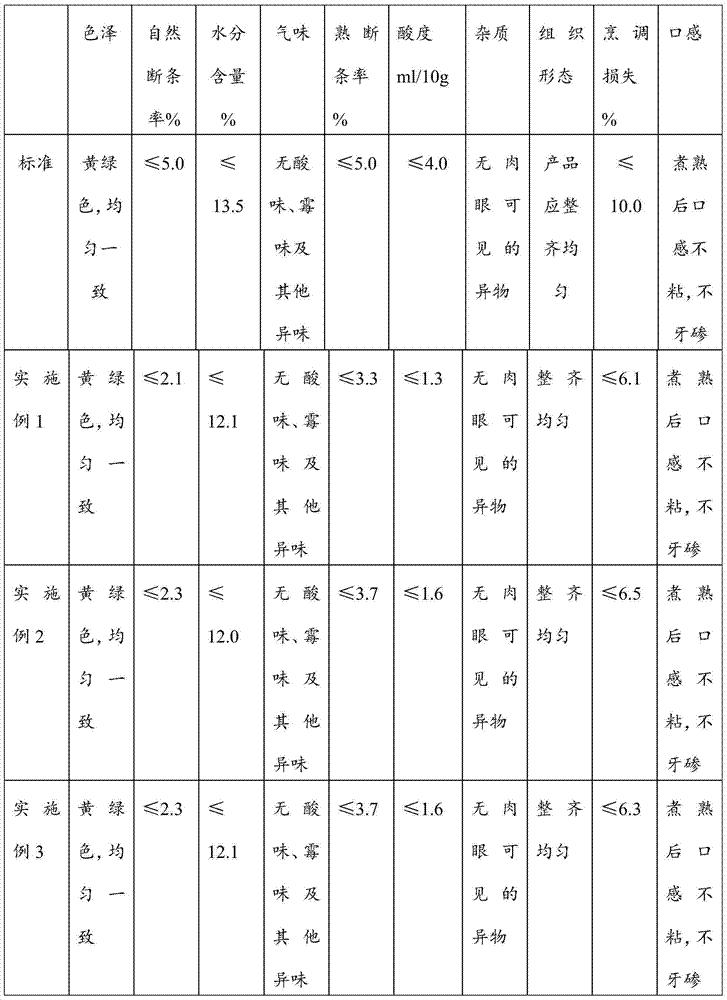

Examples

preparation example Construction

[0027] Preparation of Powdered Raw Materials

[0028] The tartary buckwheat is crushed separately to obtain wheat core powder with a particle diameter of 150 mesh or less and wheat bran powder with a particle diameter of 120 mesh or less, and the tartary buckwheat powder is obtained after mixing.

[0029] Grinding and sieving to obtain wheat flour, highland barley flour, edible salt, xanthan gum powder, and edible alkali with particle diameters less than or equal to 80 mesh.

[0030] A certain amount of the above raw materials is mixed, and insecticidal treatment is carried out with an insecticidal machine to obtain powdery raw materials.

Embodiment 1

[0032] Take 52 parts of wheat core flour, 14 parts of wheat bran powder, 22.5 parts of wheat flour, 10 parts of highland barley flour, 1 part of edible salt, 0.4 part of xanthan gum powder and 0.1 part of edible alkali and mix evenly to obtain powder shaped raw materials. Insecticide treatment is carried out on powdery raw materials with an insecticide machine. The powdery raw materials were evenly mixed and stirred for 5 minutes, then 27 parts of water was added and fully stirred for 15 minutes for kneading to obtain a dough. The dough is rolled after 20 minutes of ripening. Cut the rolled dough into strips, the width of the strips is less than or equal to 2.0mm, and the thickness of the strips is less than or equal to 0.85mm. The strips are kept moist and dried at a low temperature at a maximum temperature of 35 degrees Celsius to obtain tartary buckwheat and highland barley noodles.

Embodiment 2

[0034] Take 48 parts of wheat core powder, 12 parts of wheat bran powder, 23.5 parts of wheat flour, 15 parts of highland barley flour, 1 part of edible salt, 0.4 part of xanthan gum powder and 0.1 part of edible alkali and mix evenly to obtain powder shaped raw materials. Insecticide treatment is carried out on powdery raw materials with an insecticide machine. The powdery raw materials were evenly mixed and stirred for 5 minutes, then 27 parts of water was added and fully stirred for 15 minutes for kneading to obtain a dough. The dough is rolled after 20 minutes of ripening. Cut the rolled dough into strips, the width of the strips is less than or equal to 2.0mm, and the thickness of the strips is less than or equal to 0.85mm. The strips are kept moist and dried at a low temperature at a maximum temperature of 35 degrees Celsius to obtain tartary buckwheat and highland barley noodles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com