Patents

Literature

65 results about "Pasta processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pasta processing is the process in which wheat semolina or flour is mixed with water and the dough is extruded to a specific shape, dried and packaged. Durum wheat semolina or flour, common farina or flour, or combination of both is mixed with water and eggs (for egg noodles) and other optional ingredients (like spinach, tomato, herbs, etc.). Usually 25–30 kg of water is added per 100 kg of semolina. The amounts are measured by computerized dispensers. The mixture is then kneaded by auger extruder equipped with mixing paddles and kneading blades to obtain a homogeneous mass, and after that is extruded through various shaped dies. Drying process begins immediately after the products are shaped to prevent deformation and sticking. The pastas are dried completely in drying chambers and stabilized, then ready for packaging. In modern factories, dry pasta is processed using automatic continuous lines.

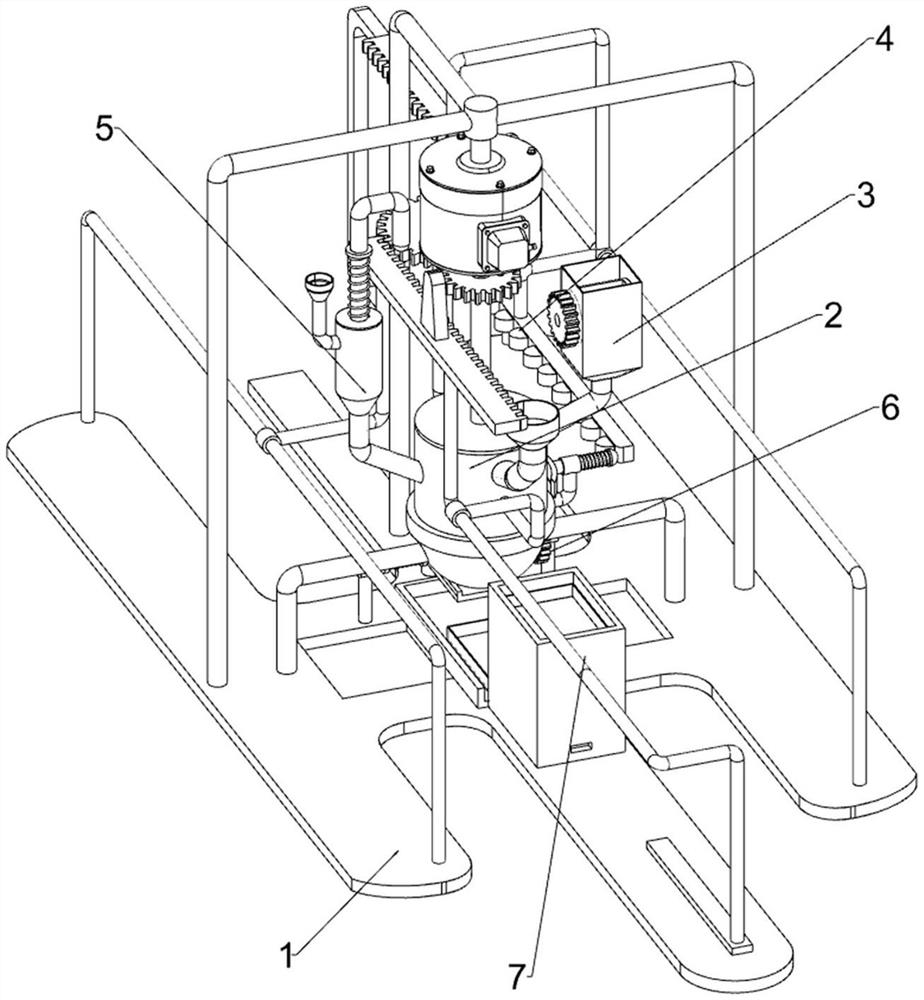

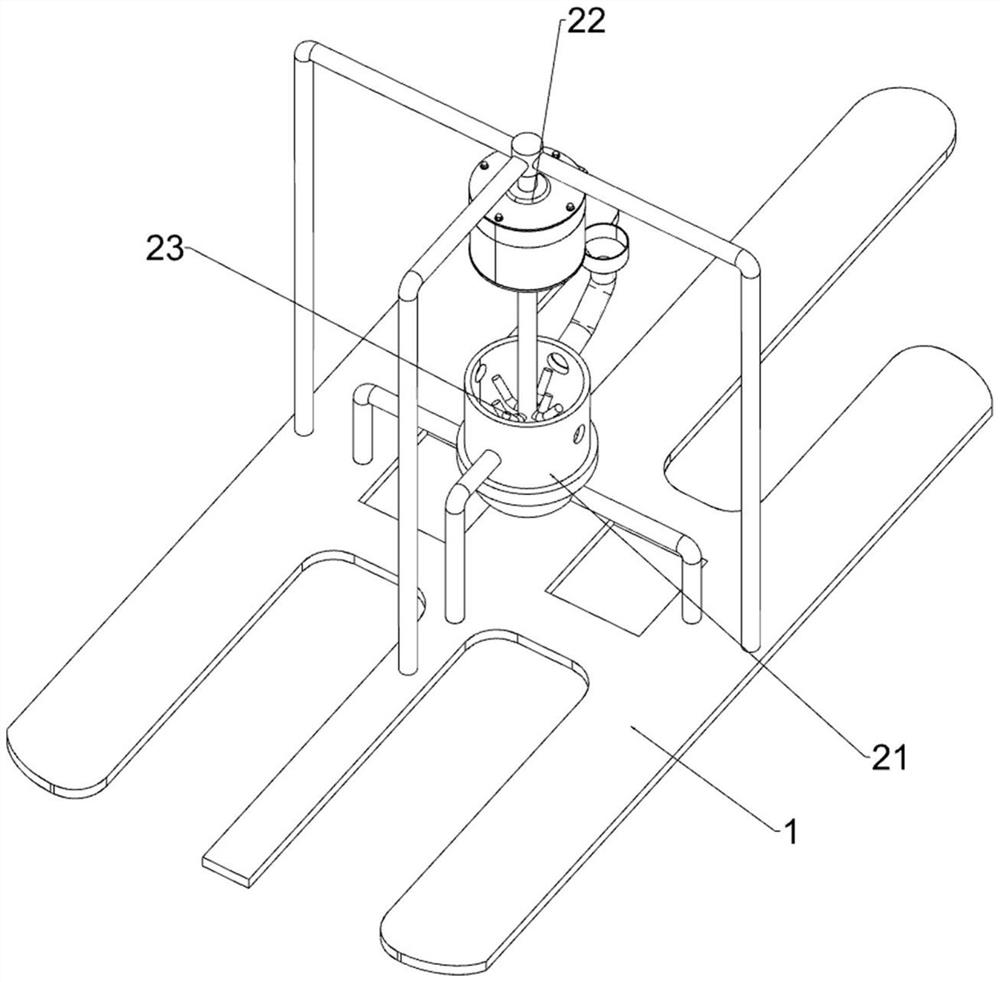

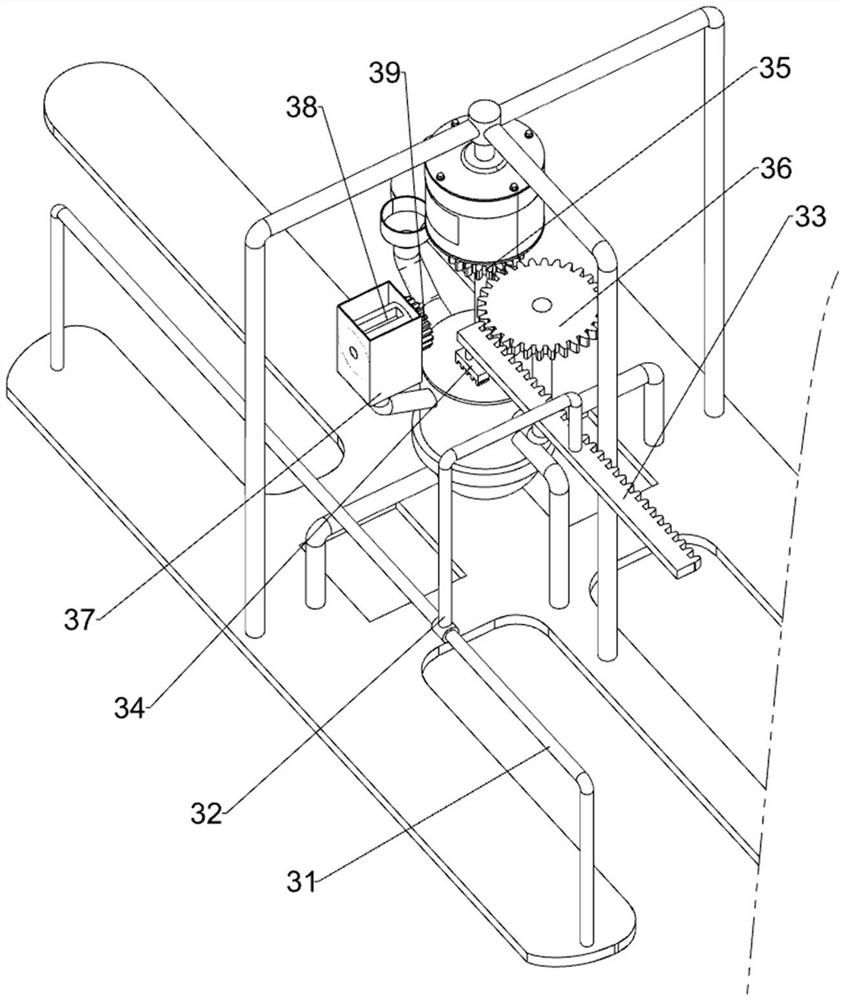

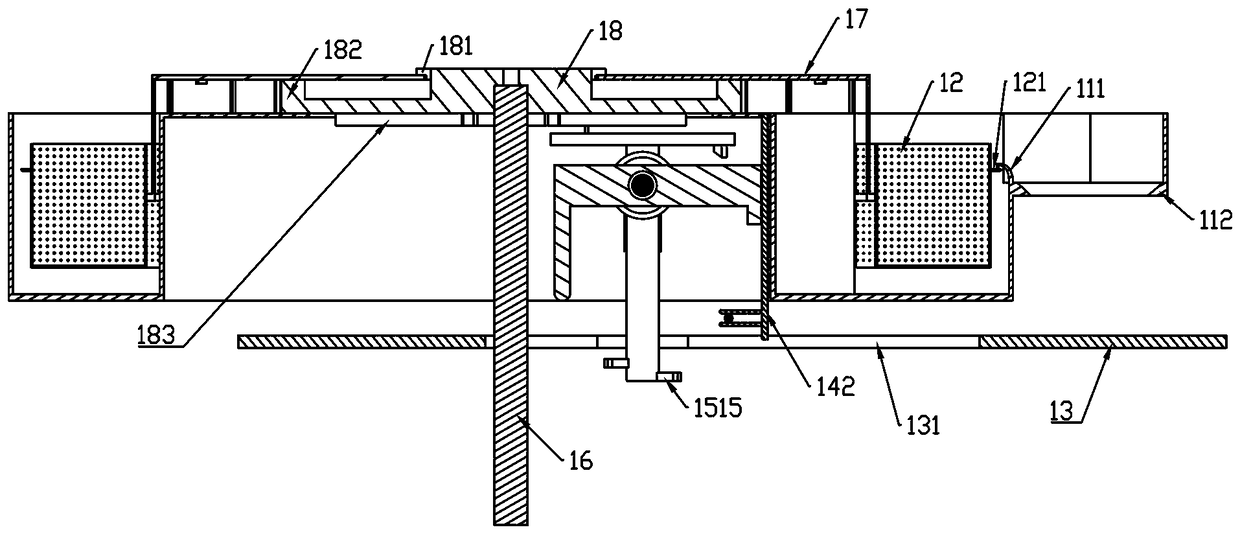

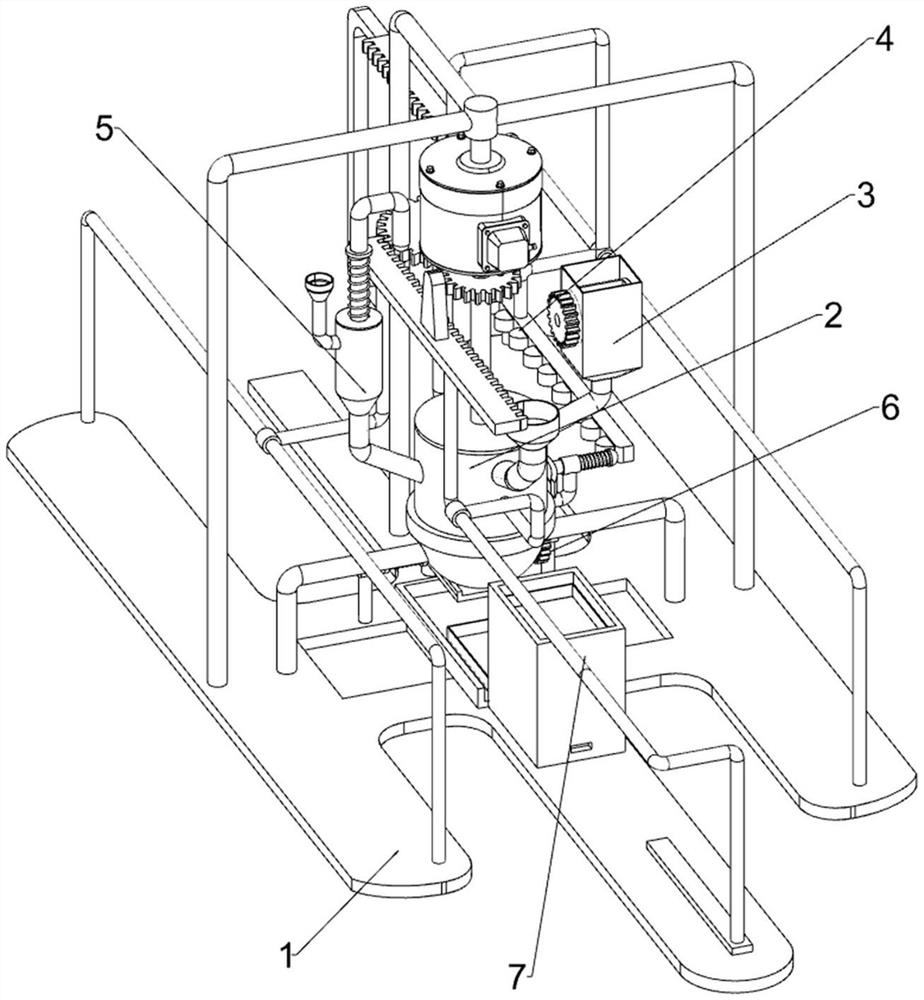

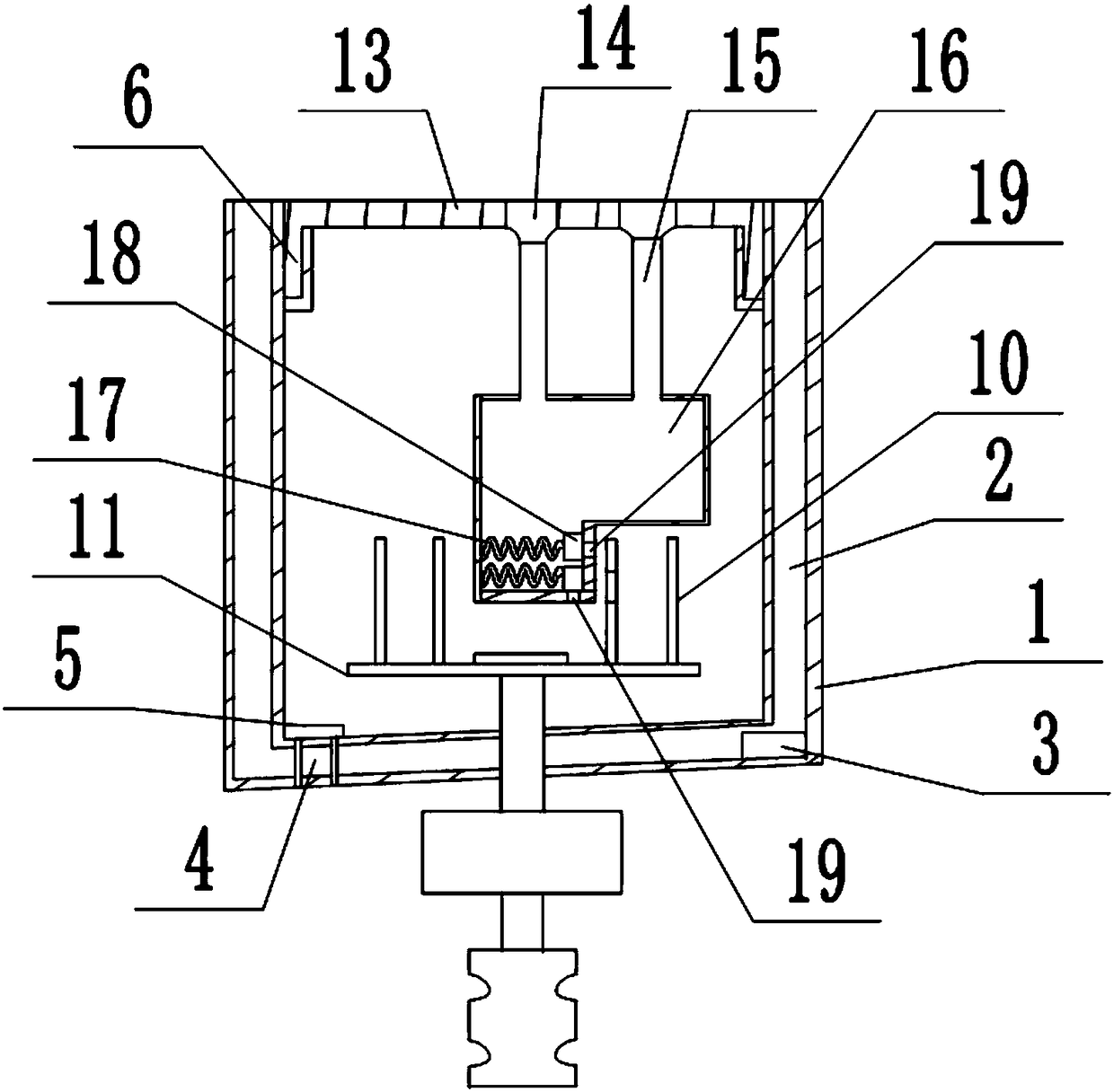

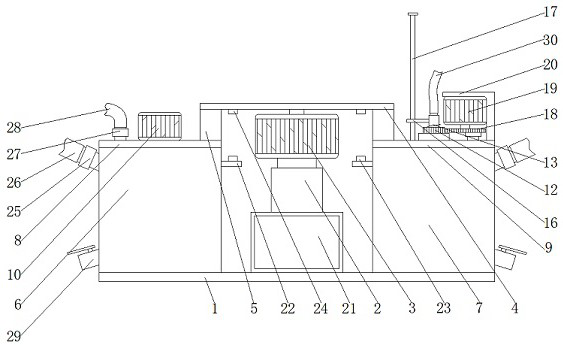

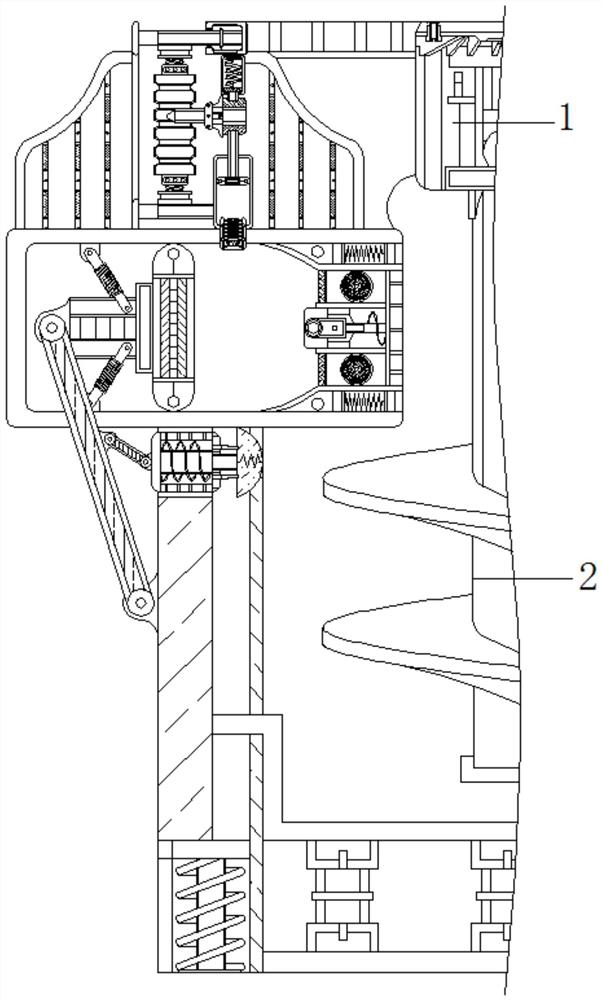

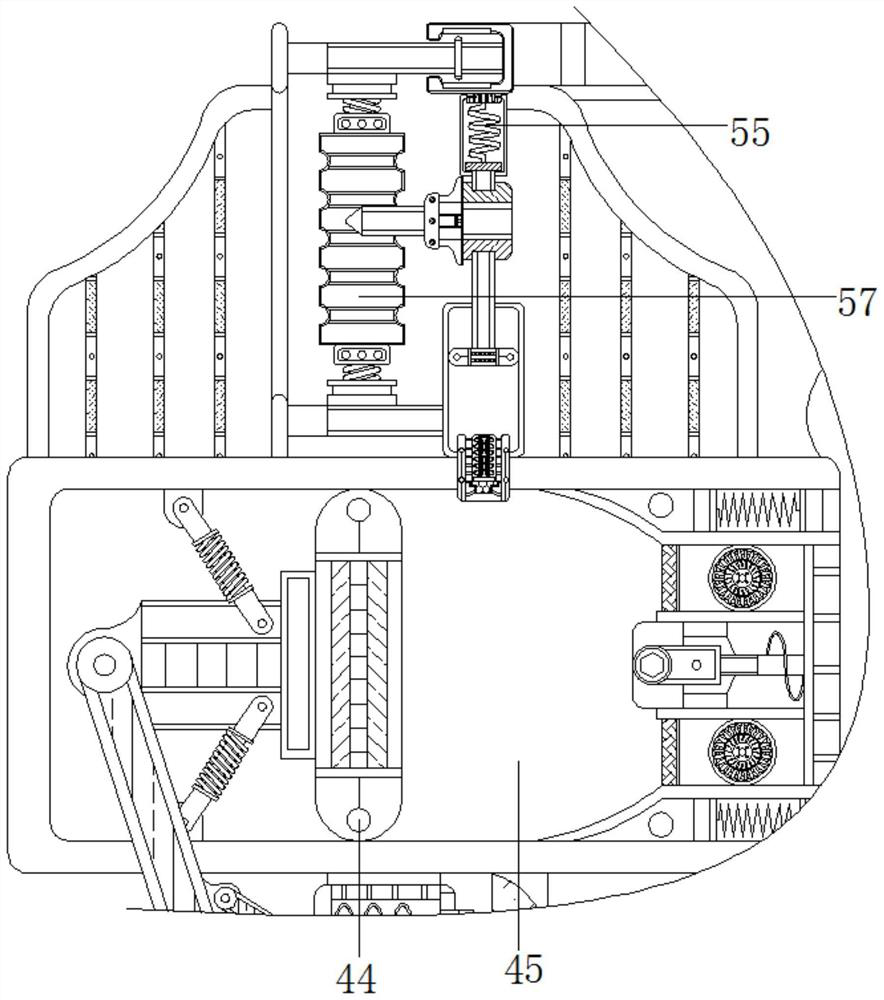

Modified starch stirring making machine for cooked wheaten food processing

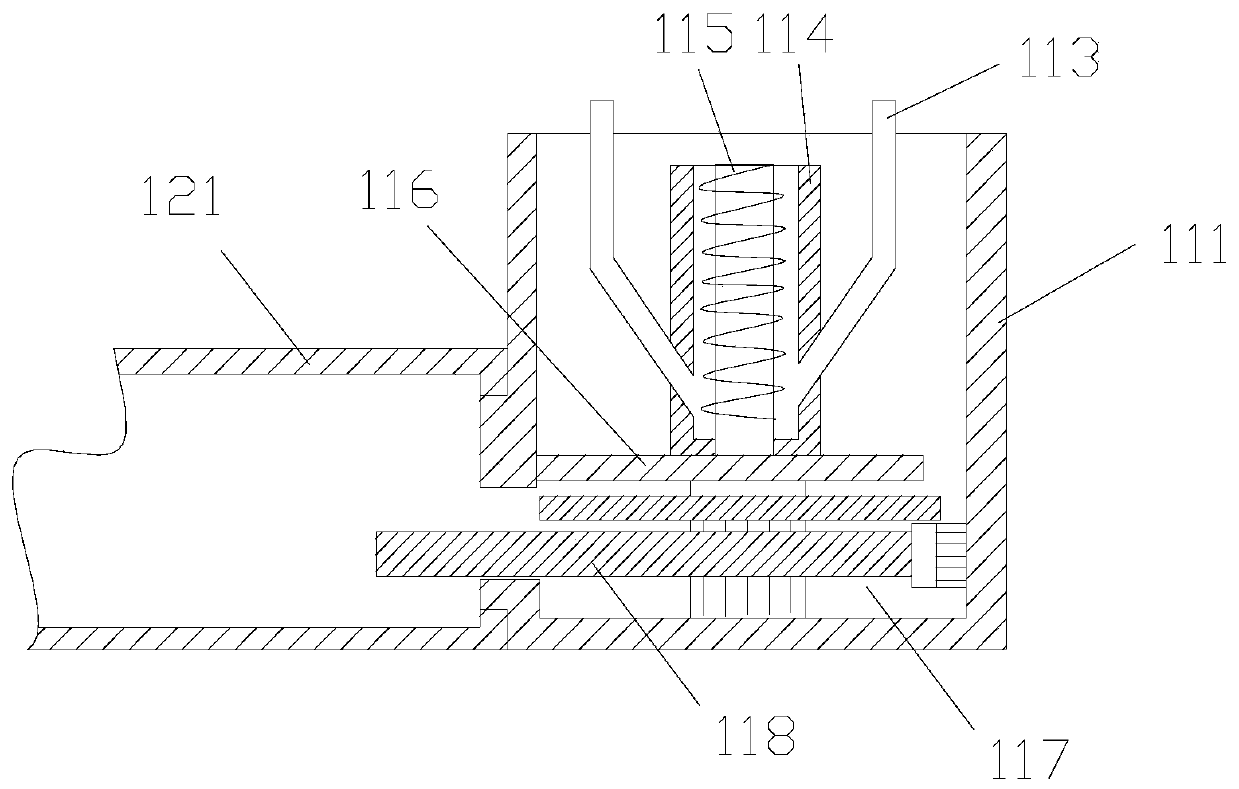

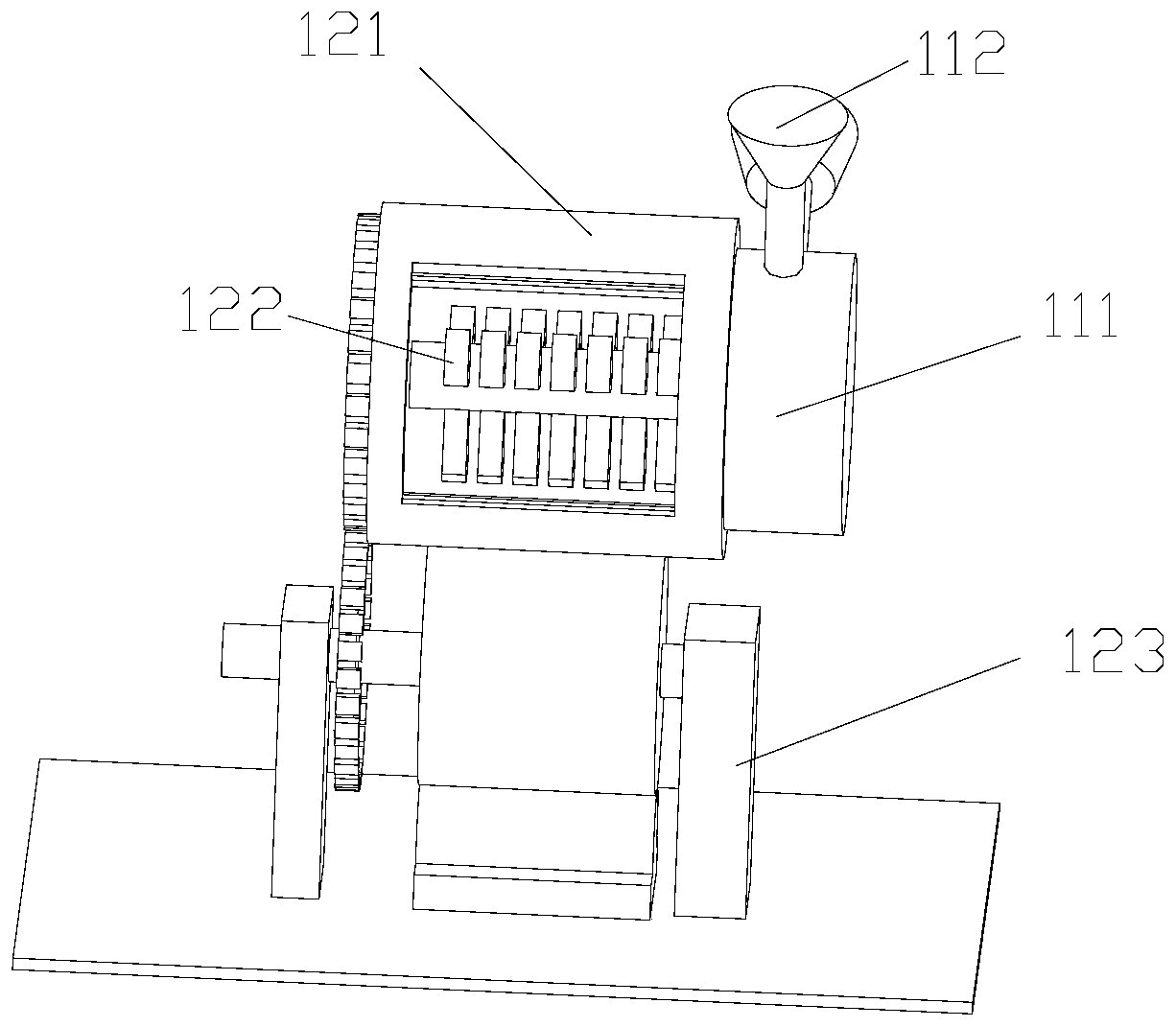

ActiveCN112516855AEasy to take outAutomatic collectionBio-packagingTransportation and packagingEngineeringProcess engineering

The invention relates to a stirring making machine, in particular to a modified starch stirring making machine for cooked wheaten food processing. The modified starch stirring making machine for wheaten food processing is capable of automatically stirring, high in working efficiency and capable of saving a large amount of labor cost. The modified starch stirring making machine for cooked wheaten food processing comprises: a bottom plate; a stirring mechanism which is mounted on the bottom plate and is used for stirring in a rotating manner; and a feeding mechanism which is installed on the bottom plate and conducts feeding in a rotating mode. Starch in a material containing frame can be stirred through the stirring mechanism instead of manpower, a large amount of manpower is saved, and theworking efficiency of people is improved; the feeding mechanism can perform intermittent feeding on the material containing frame; the material containing frame can be knocked through a vibration knocking mechanism, and waste caused by the fact that the starch adheres to the inner wall of the material containing frame is avoided; and water can be added into the material containing frame through awater adding mechanism.

Owner:河北省五星面业有限公司

Processing method of whole-grain cereals type macaroni series foods

The invention provides a processing method of whole-grain cereals type macaroni series foods, and belongs to the field of pasta processing methods. According to the processing method, the mixed grains and beans are adopted and used as the raw materials to produce the macaroni foods by the pasting molding technology based on the 'starch gelatinization' principle. The raw materials are treated to prepare a finished product by the processes, such as removing impurities and sieving once, cleaning and soaking, powdering, dosing, mixing the powder, pasting and molding, carrying out ageing treatment, cutting and receiving materials, drying, balancing the water, carefully selecting, metering, packaging and inspecting. The finished products produced by the processing method provided by the invention have the characteristics of being uniform and regular in lines, free from scar and twisting, smooth in surface, glittering and translucent, excellent in boiling fastness, free from turbidity, draining and adhering, chewy and rich in elasticity, low in broken bar rate, small in size output value, elastic, moisture and smooth in taste, high in flexibility, soft and palatable.

Owner:吉林市老爷岭农业发展有限公司

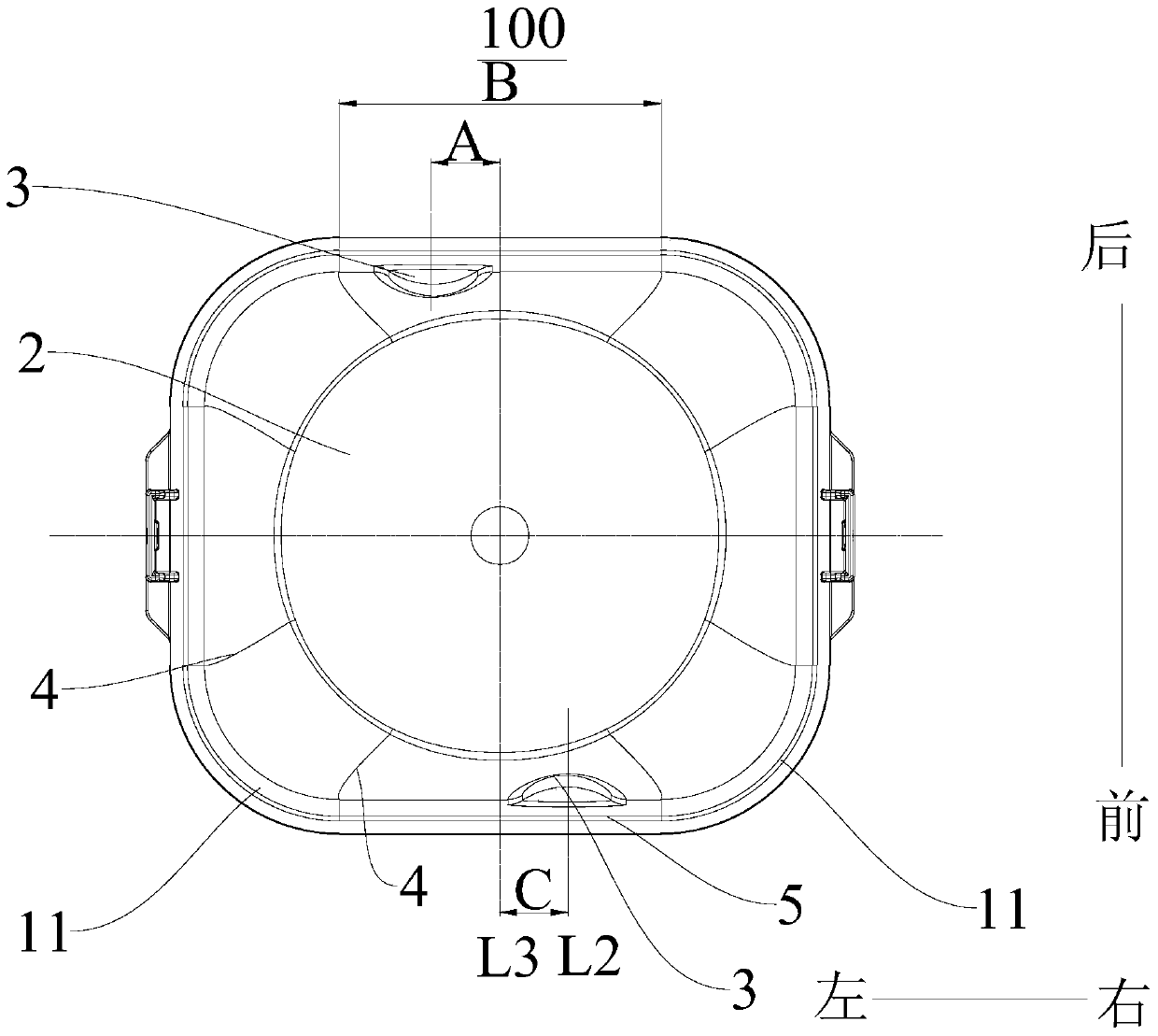

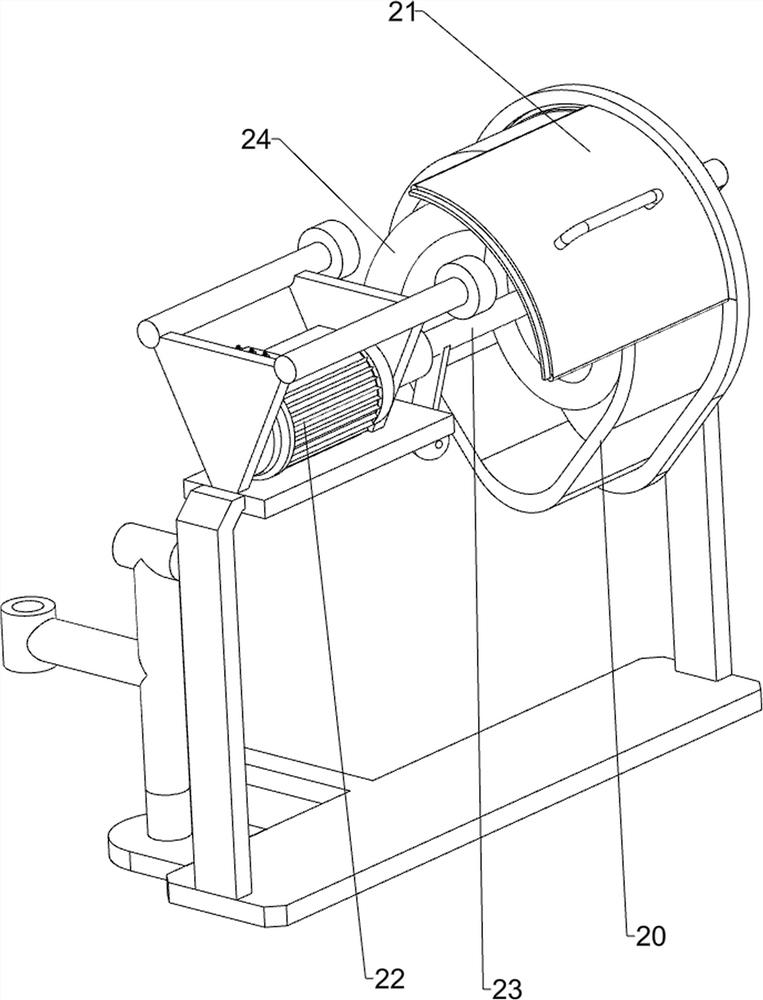

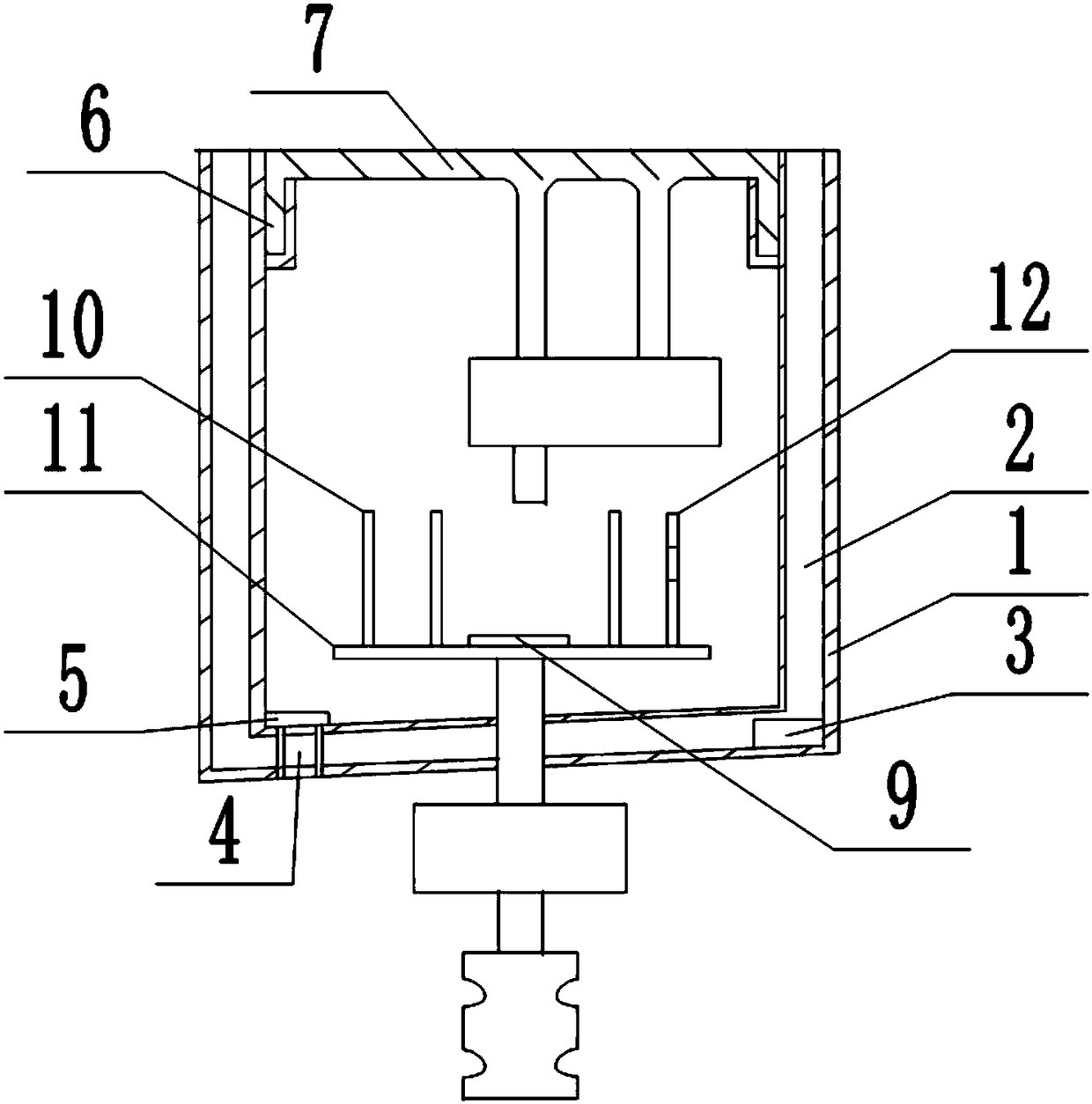

Pasta processing machine

InactiveCN103784031AFunctionalSave spaceSteam cooking vesselsBread-toastersEngineeringPasta processing

The invention provides a pasta processing machine which comprises a machine body, an upper cover, a heating tray, an inner barrel, a heating tube, a power mechanism and a control circuit. A control panel is arranged on the outer surface of the machine body, and an outer barrel is arranged inside the machine body. The heating tray is arranged at the outer bottom of the outer barrel. The inner barrel is located inside the outer barrel, and a mixing vane is arranged inside the inner barrel. The heating tube is located between the outer barrel and the inner barrel. The power mechanism is located at the bottom of the machine body and penetrates the outer barrel and the inner barrel to be connected with the mixing vane. The control circuit is electrically connected with the control panel, the heating tray, the heating tube and the power mechanism respectively. By the arrangement of the heating tray arranged at the outer bottom of the outer barrel and the heating tube arranged between the outer barrel and the inner barrel, the heating tube can be directly started up for baking bread, water can be added into the outer barrel for steaming buns, and functions of a bread maker and a steamed-bun maker are achieved, so that multiple purposes of the pasta processing machine is realized and kitchen space is saved. The structural design can be used for manufacturing of the pasta processing machine.

Owner:周武轩

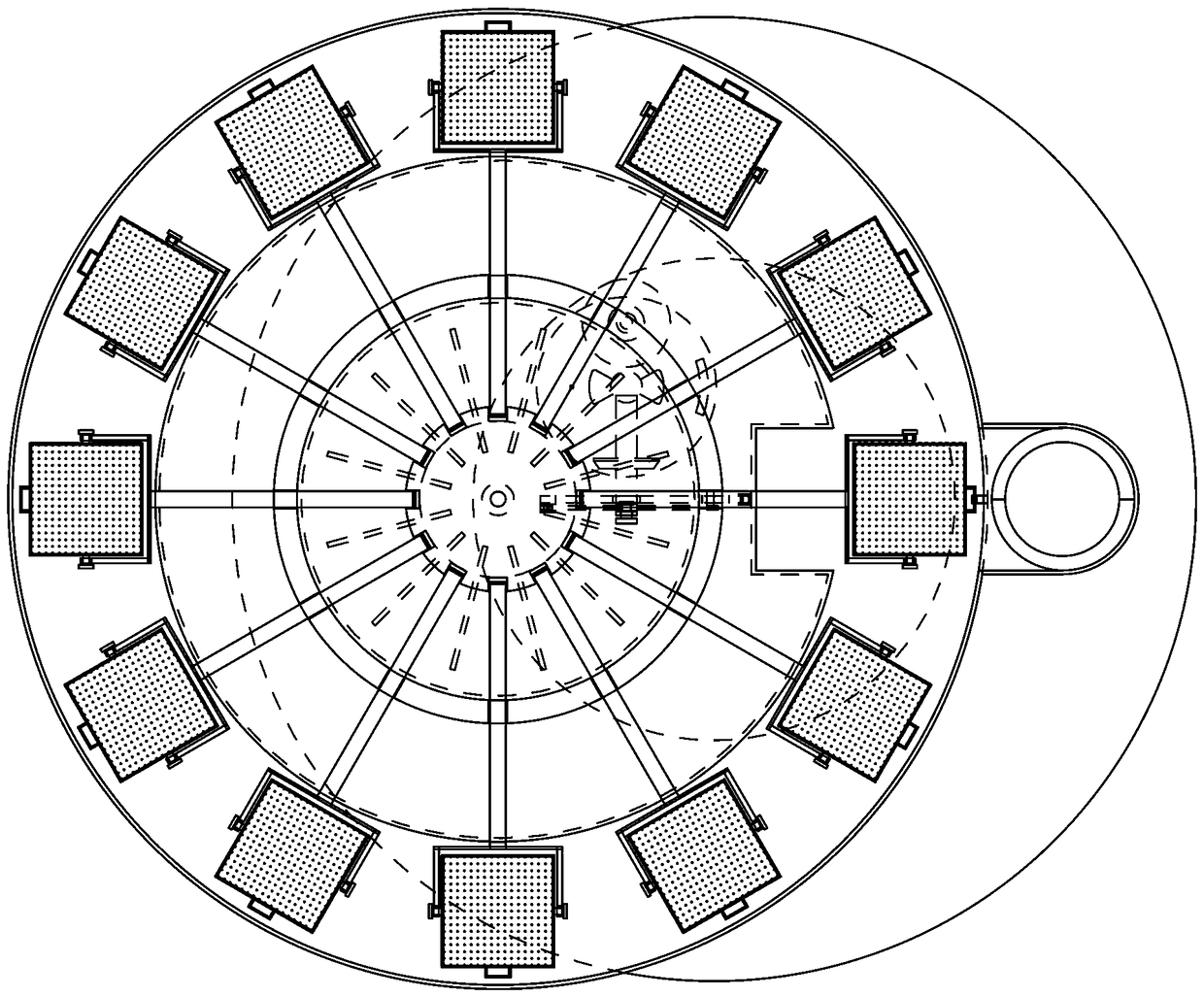

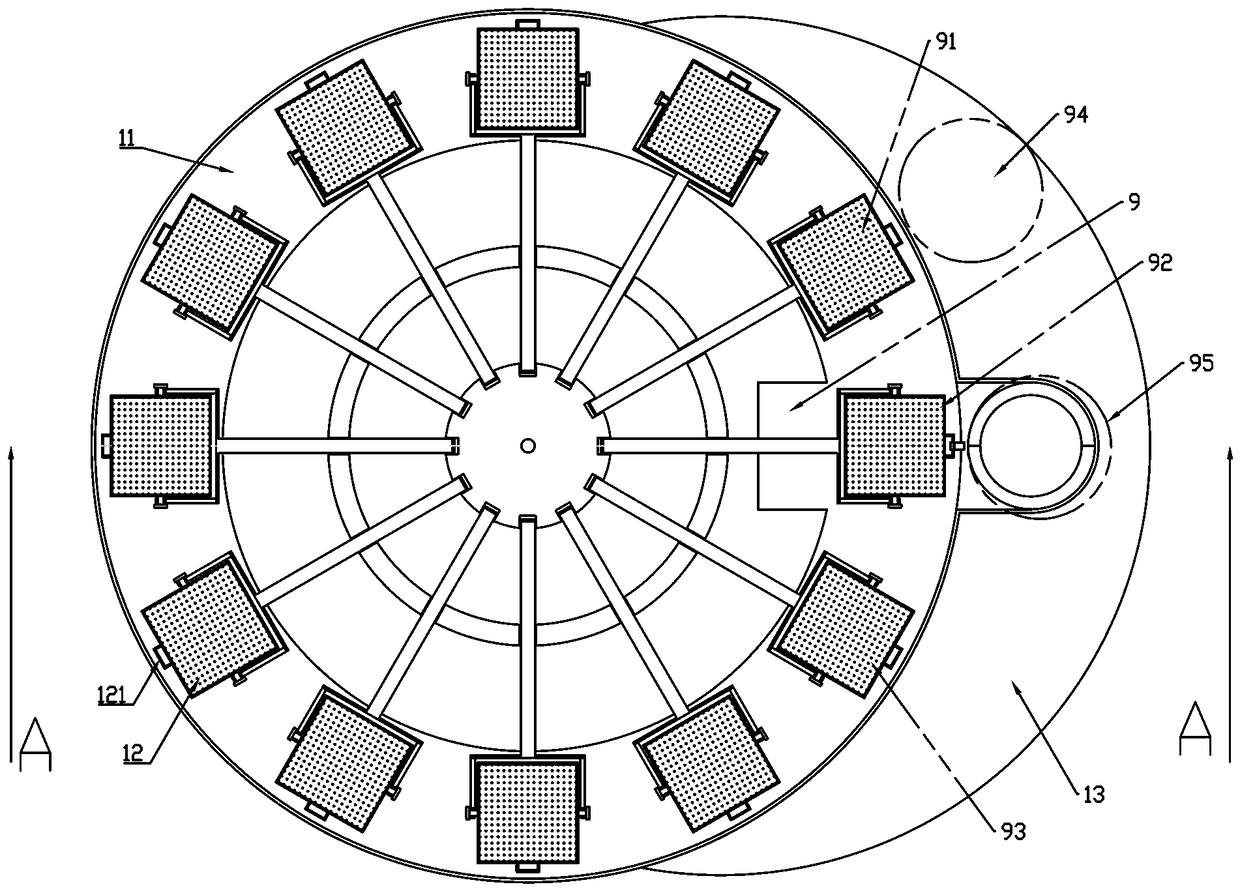

Multifunctional pasta boiling-removing machine and pasta processing system

PendingCN108523650AWith noodle functionSave waterTableware washing/rinsing machine detailsCooking vesselsPasta processingEngineering

The invention discloses a pasta processing system, comprising a multifunctional pasta boiling-removing machine and a dishwasher used with the same. The Multifunctional pasta boiling-removing machine comprises a circular boiling basin, N boiling fences, a bowl holder, a pull-holding device, and a driving device; the circular boiling basin is provided with a removing region; in the removing region,a fastening tongue is arranged on the circular boiling basin, and a gap is arranged between the fastening tongue and the boiling fence; the N boiling fences are arranged within the circular boiling basin, with N> / =3; the boiling fences are provided with front noises used with the fastening tongue; the pull-holding device is used for lifting or pressing down the boiling fences such that openings ofthe boiling fences are turned toward the fastening tongue, and pasta within the boiling fences can fall into dishware placed on the bowl holder; the driving device is used for driving the boiling fences to rotate within the circular boiling basin. The dishwasher is provided with a gate blocking device coupled to the driving device. The pasta processing system is mainly used for pipeline production of pasta.

Owner:刘超锋

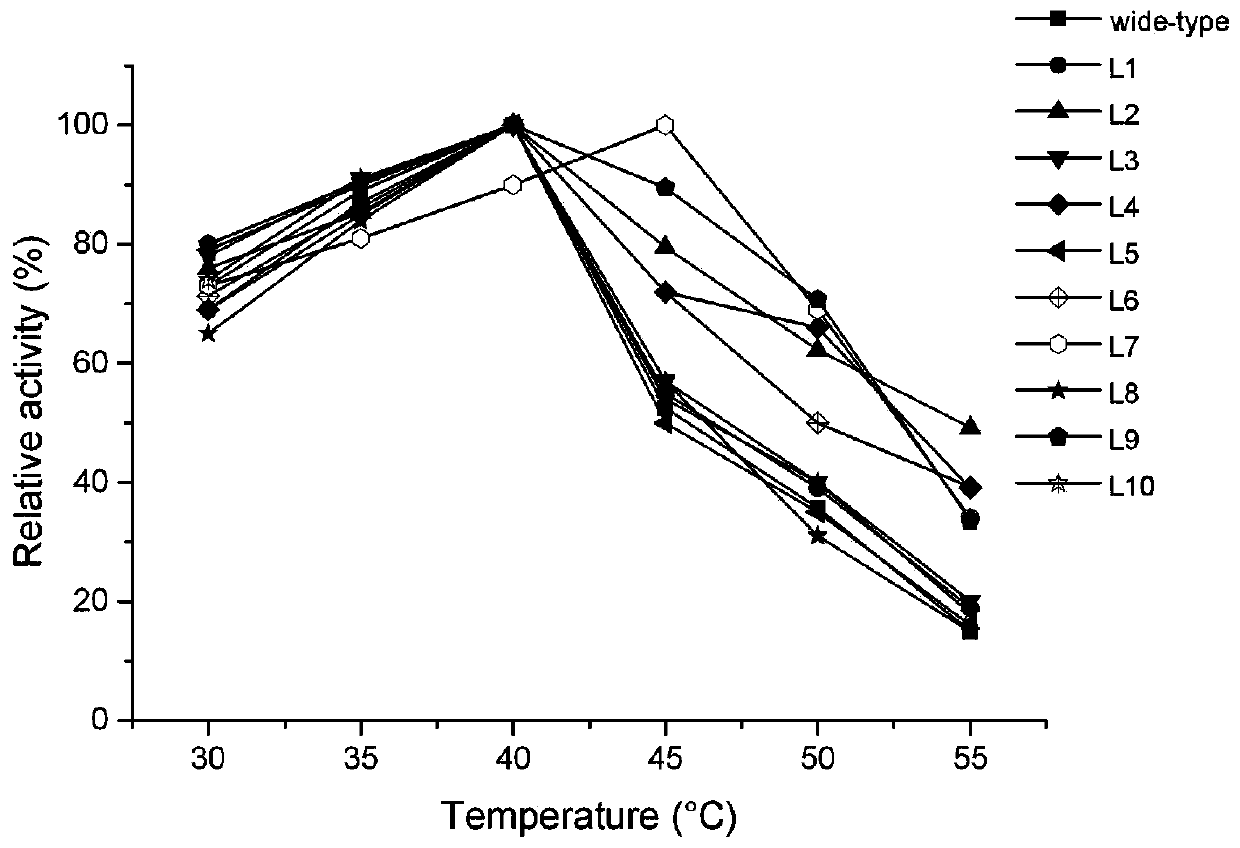

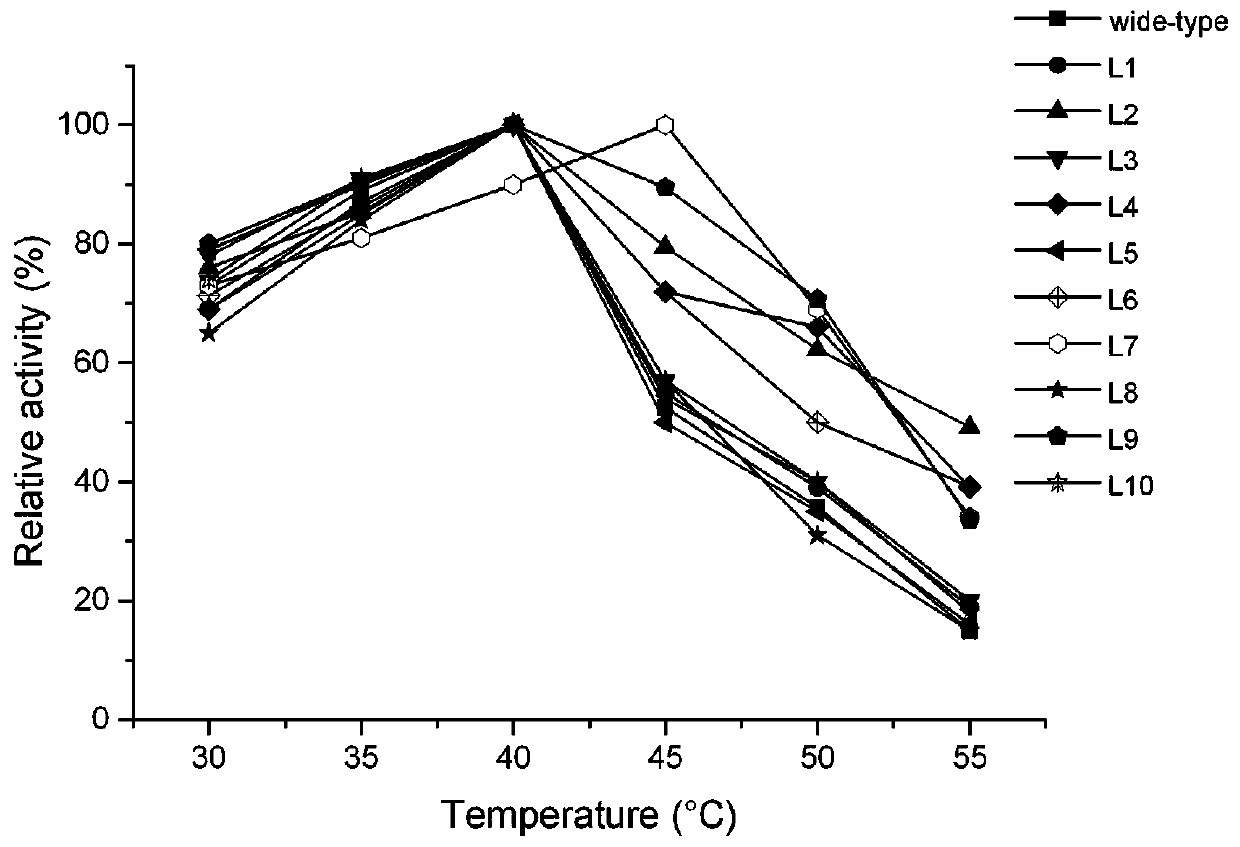

Lipase mutant and application thereof in decontamination

ActiveCN110904074AImprove thermal stabilityImproves pH stabilityHydrolasesNon-surface-active detergent compositionsOil processingSynthetic Polymeric Macromolecules

The invention discloses a lipase mutant and its application in decontamination, and belongs to the technical field of enzyme engineering. The lipase mutant of the invention has good thermal stability,good pH stability and good washing performance. Therefore, the lipase mutant of the invention has very important applications in decontamination, oil processing, dairy processing, pasta processing, meat processing, drug synthesis, diesel oil synthesis, polymer synthesis, chiral compound synthesis, leather production, detergent preparation, papermaking and the like.

Owner:JIANGNAN UNIV

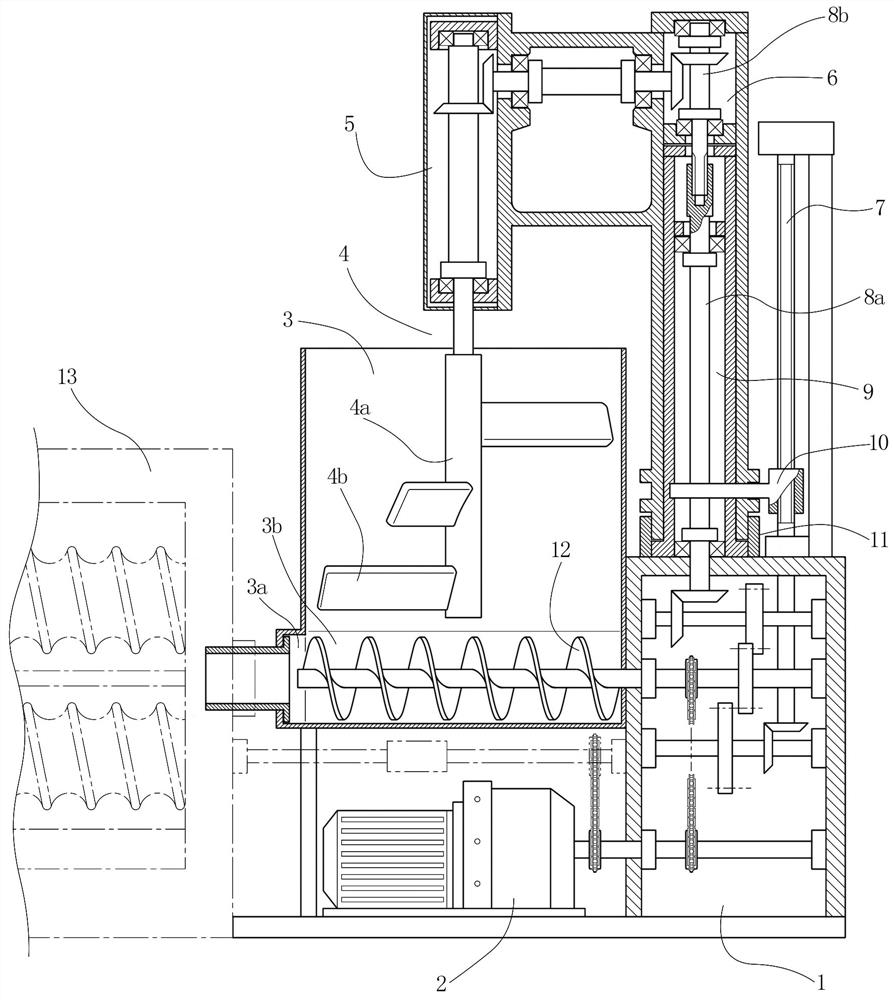

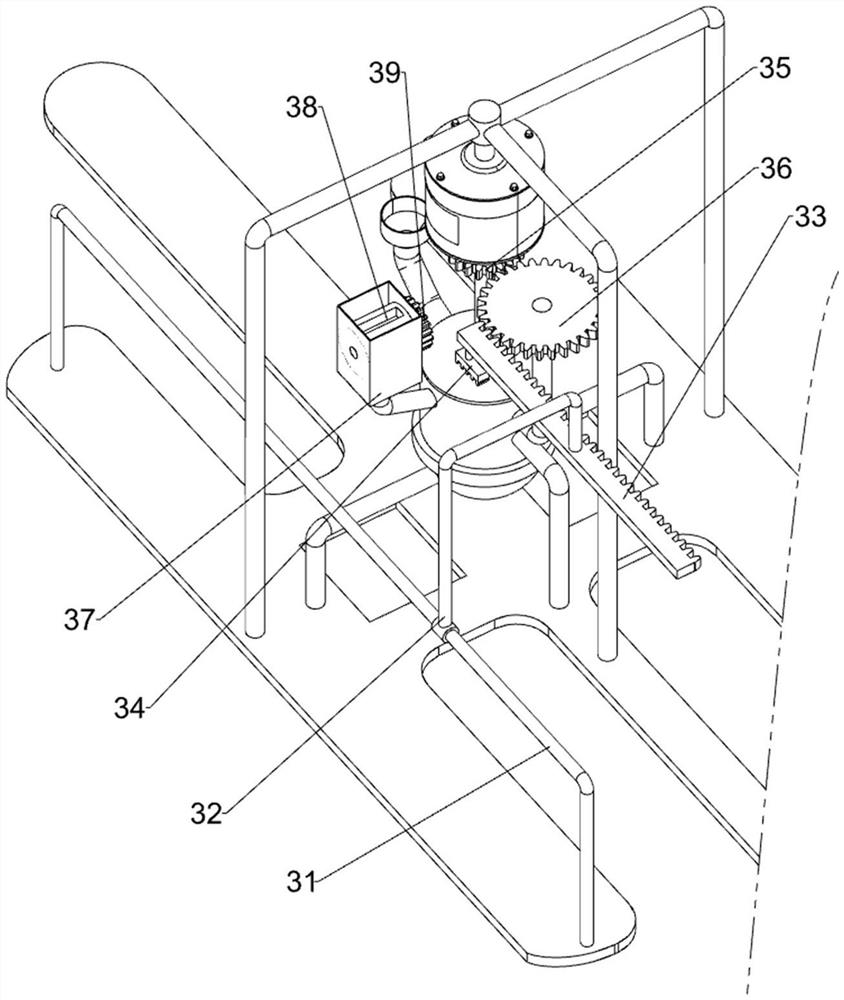

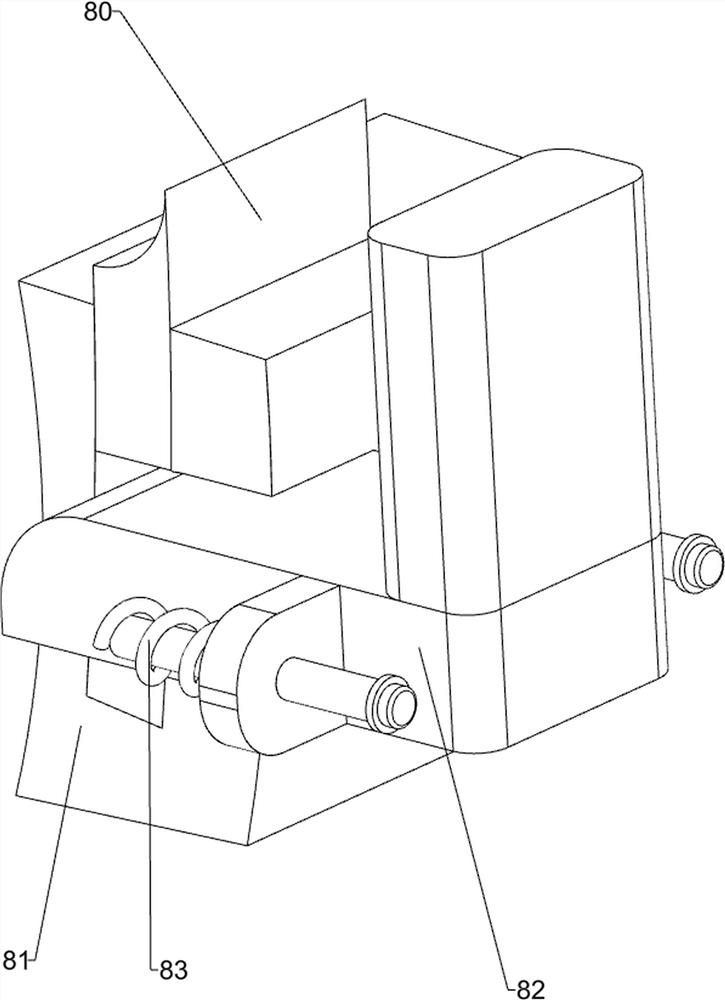

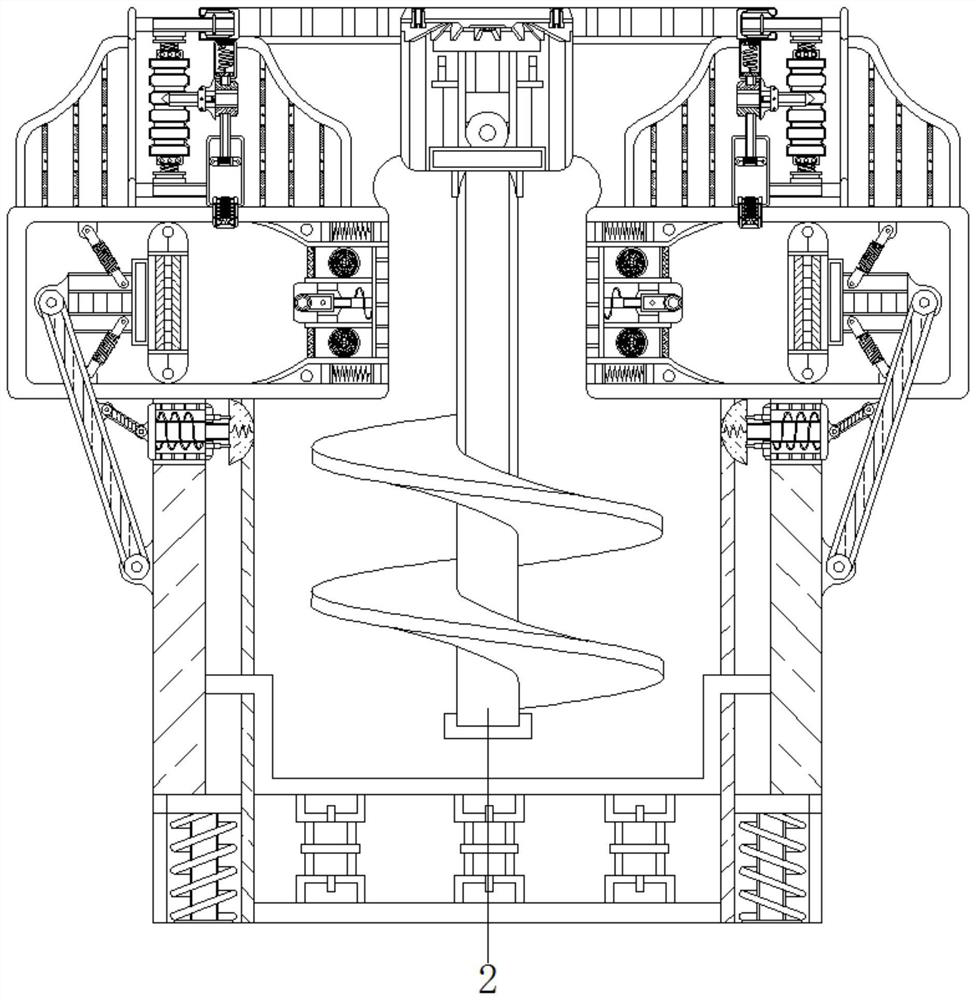

Kneading type wheaten food processing device

PendingCN113273584AAvoid throwing upGreat tasteMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsBiotechnologyEngineering

The invention relates to the technical field of food processing machinery, and particularly relates to a kneading type wheaten food processing device. The common wheaten food processing machinery in the market has the problems of single dough kneading mode, adhesion of wheaten food blanks and stirring components, low dough kneading efficiency, poor mouthfeel of wheaten food finished products and the like. The technical scheme of the invention is that: a spiral push rod is horizontally arranged in a dough kneading barrel; a stirrer support is arranged on the side part of the dough kneading barrel; and a stirrer is vertically suspended above the spiral push rod by using the stirrer support which is connected with a lifter to adjust and control the height of the stirrer. The kneading type wheaten food processing device has the advantages that: the longitudinally arranged stirrer is matched with the transversely arranged spiral push rod, and the dough is pushed and pressed in vertical and horizontal directions and is always transferred between the spiral push rod and the stirrer, so the kneading type wheaten food processing device simulates the conventional manual dough kneading method to repeatedly knead, greatly improves the dough kneading efficiency and enhances the mouthfeel of the wheaten food finished products.

Owner:方绪龙

Lipase mutant and application thereof in decontamination

ActiveCN110904073AImprove thermal stabilityImproves pH stabilityHydrolasesNon-surface-active detergent compositionsOil processingSynthetic Polymeric Macromolecules

The invention discloses a lipase mutant and its application in decontamination, and belongs to the technical field of enzyme engineering. The lipase mutant of the invention has good thermal stability,good pH stability and good washing performance. Therefore, the lipase mutant of the invention has very important applications in decontamination, oil processing, dairy processing, pasta processing, meat processing, drug synthesis, diesel oil synthesis, polymer synthesis, chiral compound synthesis, leather production, detergent preparation, papermaking and the like.

Owner:JIANGNAN UNIV

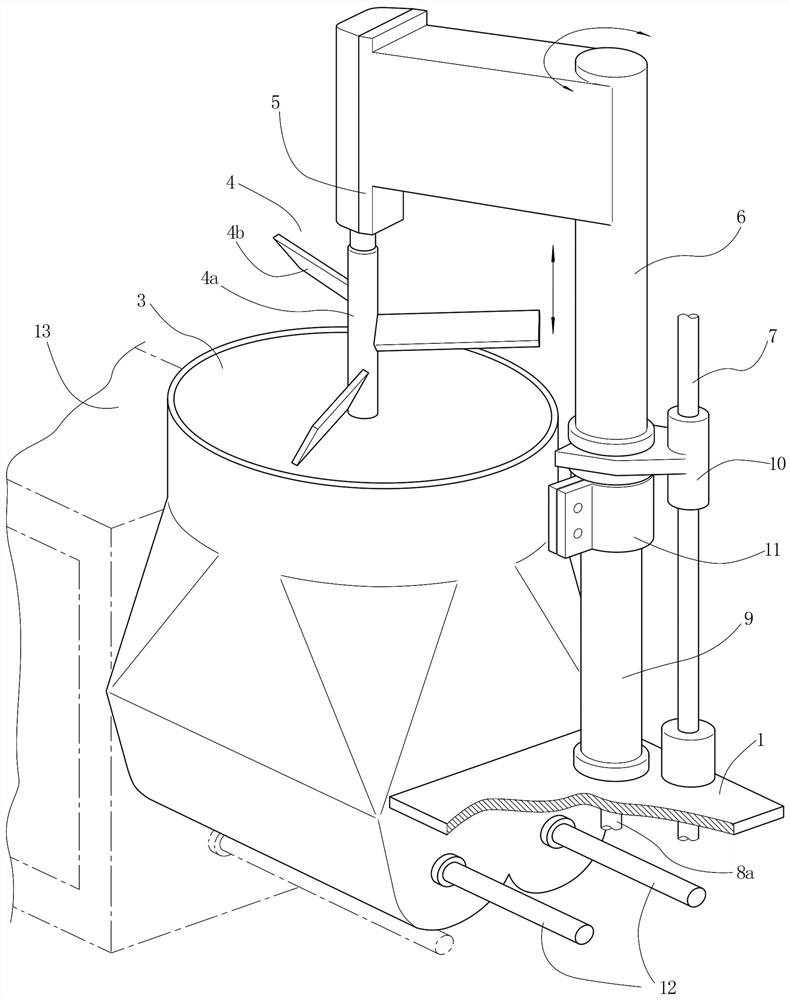

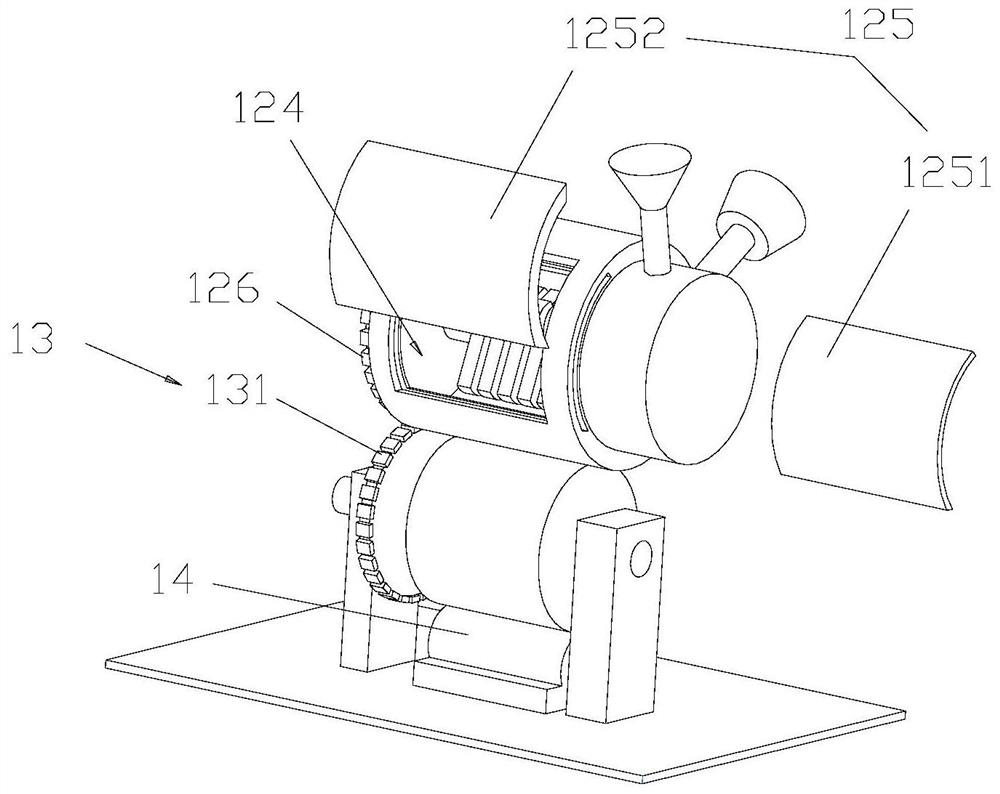

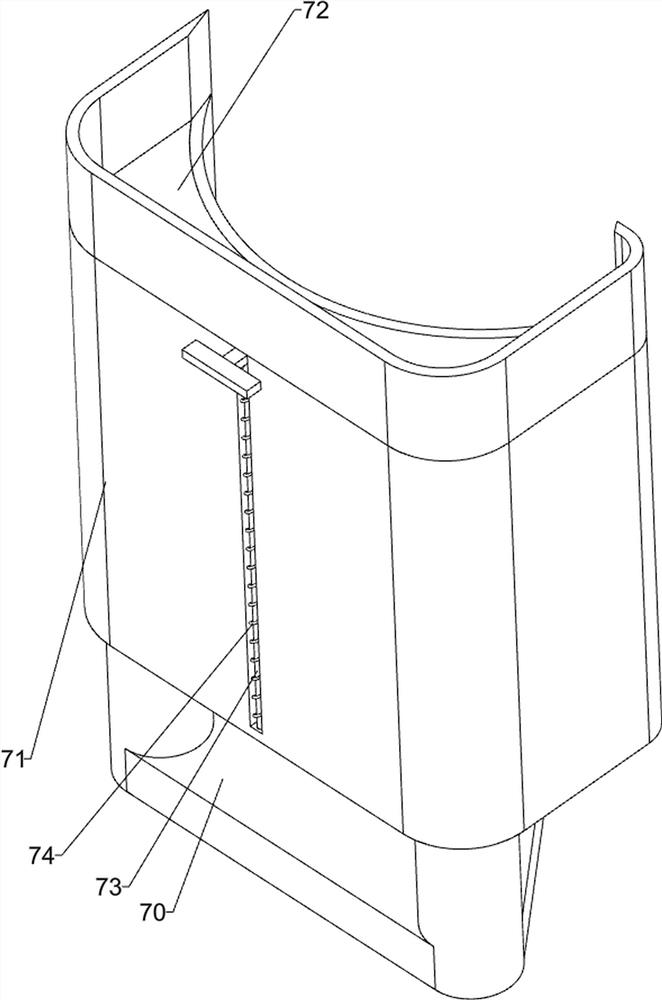

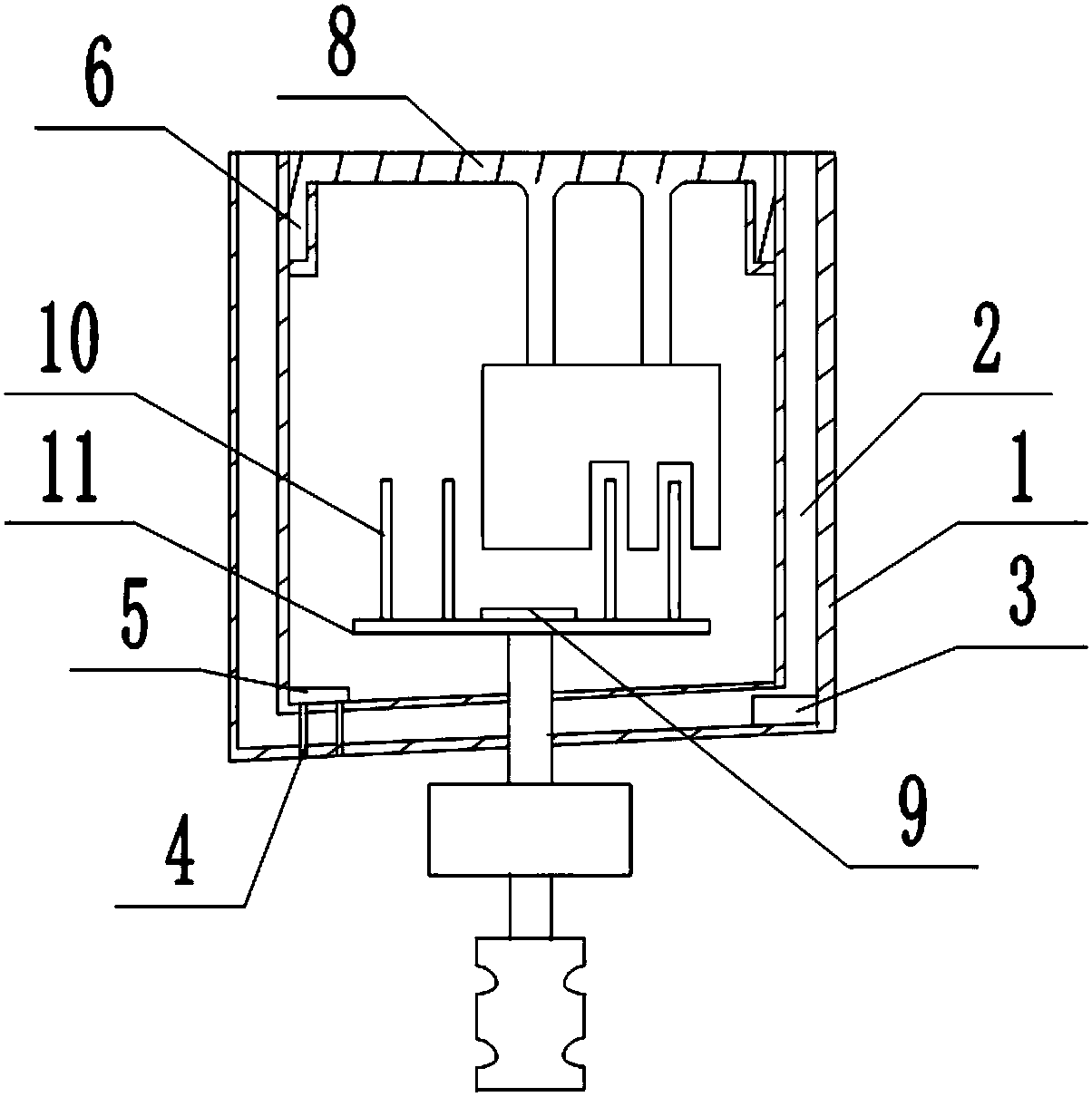

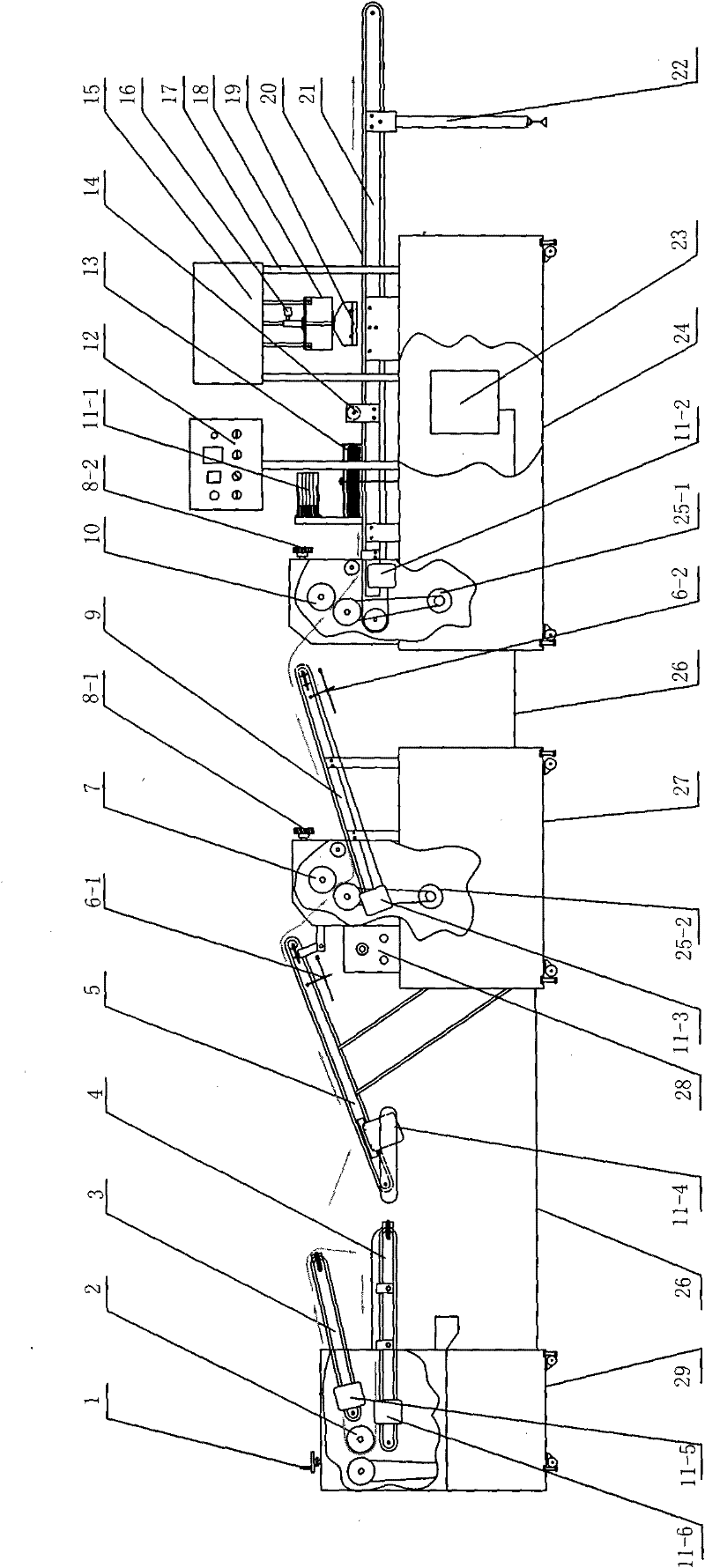

Dough kneading mechanism for kelp noodles and wheaten food processing assembly line

ActiveCN110558348AAvoid reunionReduce reunionMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsAssembly lineEngineering

The invention discloses a dough kneading mechanism for kelp noodles. The dough kneading mechanism comprises a mixing device, and a stirring and dough kneading device, wherein the mixing device is usedfor premixing various raw materials for processing noodles, and the stirring and dough kneading device is used for stirring the materials premixed by the mixing device. The invention further discloses a wheaten food processing assembly line. The dough kneading mechanism has the advantages of sufficient material mixing and strong production streamline property.

Owner:福州盈创信息科技有限公司

Preparation method of pure natural boil-resisting soup spaghetti

ActiveCN109699906AShorten production timeIncrease productivityMixing/kneading with horizontally-mounted toolsDough extruding machinesGlutenMoisture absorption

The present invention mainly relates to the technical field of spaghetti processing and discloses a preparation method of pure natural boil-resisting soup spaghetti. The preparation method comprises the following steps of dough kneading with hot water, vacuum dough kneading, squeezing and shaping, steam drying, cooling and packaging. The provided provided pure natural boil-resisting soup spaghettiis simple in the preparation method, chewy and resistant to boil, not turbid in soup, and not broken in strips, free of any additives, nutritional and healthy and chewy in mouthfeel; firstly, hot water is added to high-gluten powder, dough kneading is conducted in a double-screw warehouse, and viscosity and chewiness of dough are increased; then hot dough is then transferred into a single-screw warehouse through a sealing device to conduct vacuum stirring and dough kneading, even moisture absorption by the dough is promoted, gluten network is rapidly formed, a protein structure is balanced, chewiness, smoothness and transparency of the dough are improved, dough fermentation time is avoided, and production efficiency of the spaghetti is significantly improved; and then the squeezing and shaping, and steam heating and drying are conducted to obtain the soup spaghetti.

Owner:安徽谷优美食品科技股份有限公司

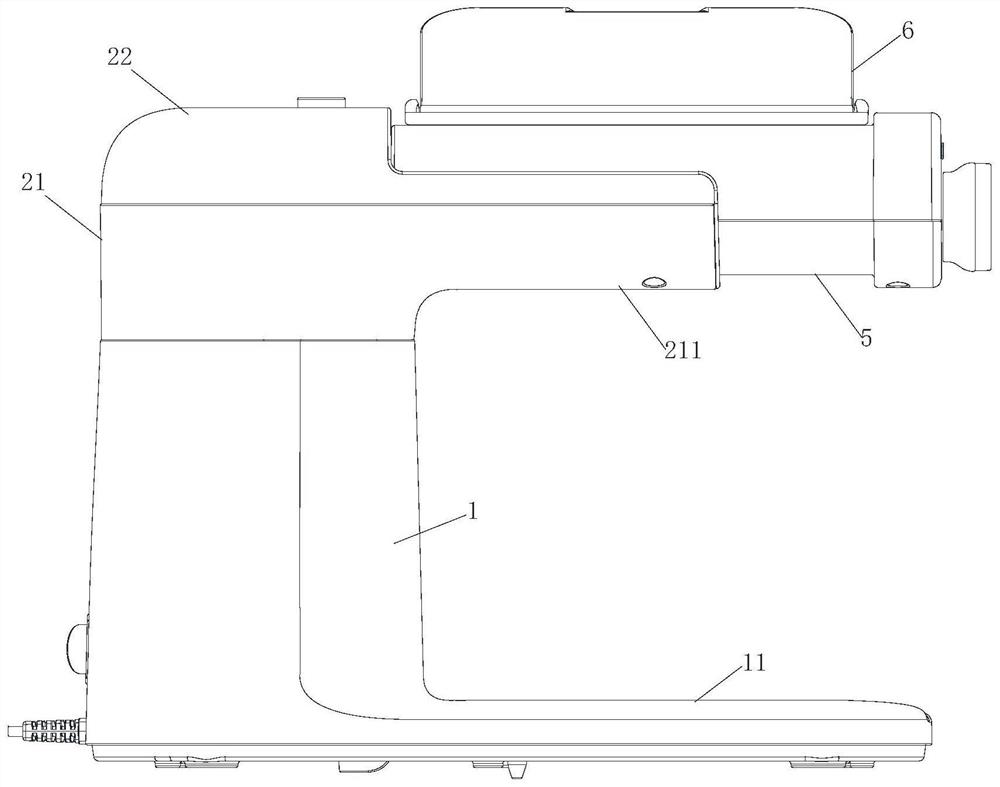

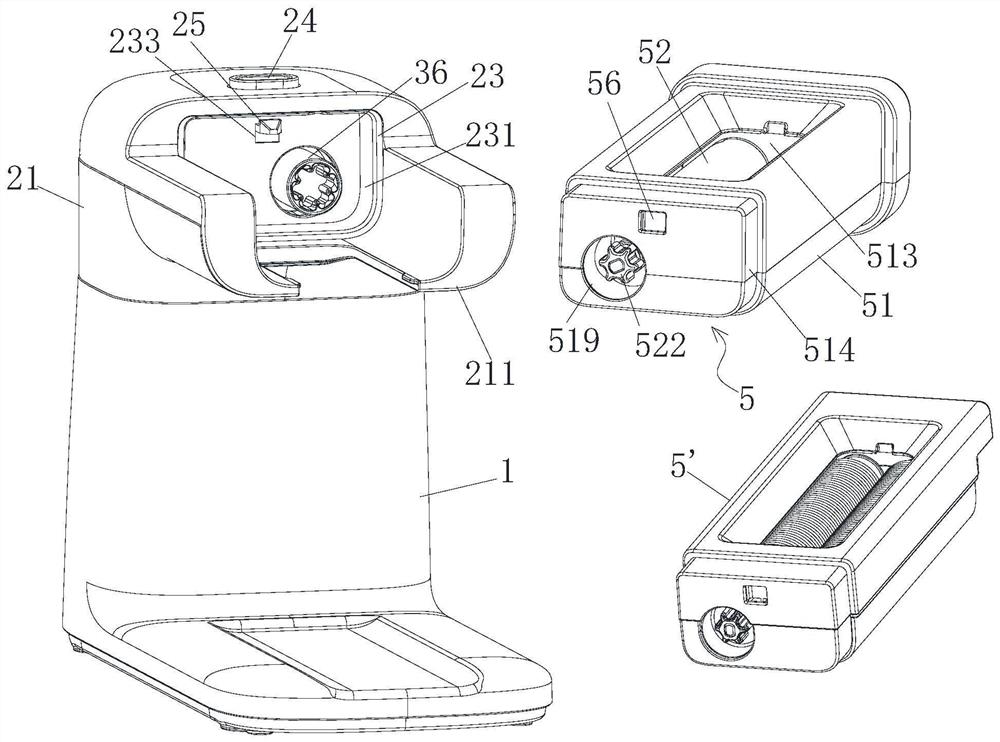

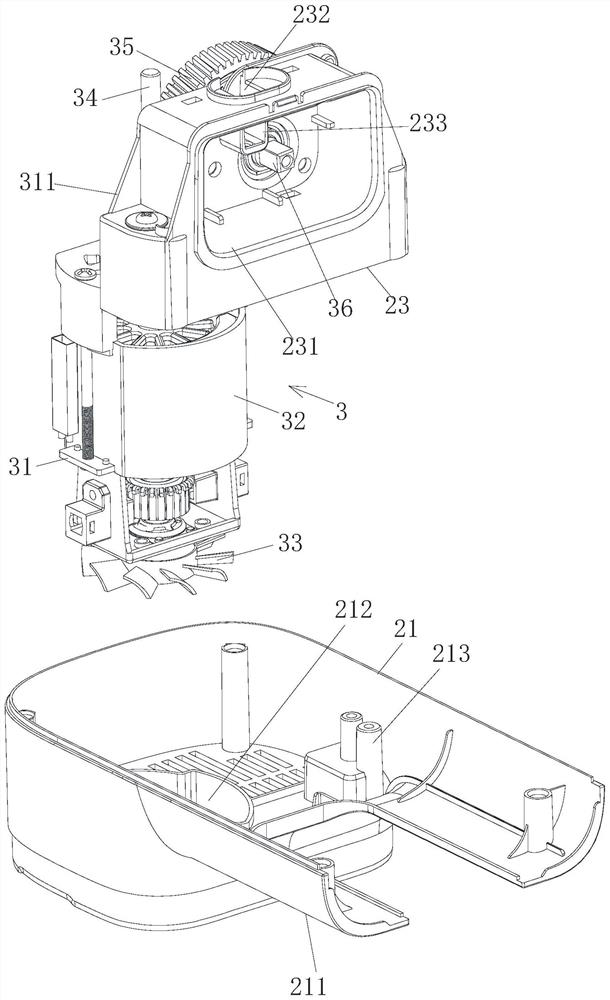

Vertical noodle press

PendingCN112293444AImprove transmission efficiencySimple structureDough-sheeters/rolling-machines/rolling-pinsElectric machineryEngineering

The invention discloses a vertical noodle press. The vertical noodle press comprises a base, a main machine and a driving device, wherein the main machine comprises a lower shell assembled on the base, an assembly connecting piece fixed on the lower shell and a noodle processor detachably assembled on the lower shell, and the assembly connecting piece is provided with an assembly groove; the driving device comprises a support fixedly connected with the assembly connecting piece, a motor fixed to the support and vertically arranged in the base, a power shaft with one tail end arranged in the assembly groove, and a transmission assembly connected between an output shaft of the motor and the power shaft; one tail end of the noodle processor is set to be an assembly tail end matched with the assembly groove, a rotating shaft is arranged on the end surface of the assembly tail end, and the noodle processor is inserted into the assembly groove through the assembly tail end so that the rotating shaft can be in transmission connection with the power shaft. The vertical noodle press is simple in structure and convenient to assemble and use, and can be matched with noodle processors with different functions to meet actual use requirements.

Owner:BEAR ELECTRICAL APPLIANCE CO LTD +1

Mountain fern fine dried noodles and making method thereof

The invention relates to mountain fern fine dried noodles and a making method thereof, and belongs to the technical field of pasta processing. People are enabled to obtain richer nutrition while eating fine dried noodles. The mountain fern fine dried noodles comprise, by weight, 100 parts of flour, 15-20 parts of mountain fern, 25-27 parts of drinking water, 1.8-2 parts of salt and 0.1-0.2 part of dietary alkali. The making method includes the steps of pretreatment of the mountain fern, mixing, dough kneading, resting, tabletting, shredding, racking, drying, removing from rack, metering, packing and inspecting. After eating the mountain fern fine dried noodles conveniently and quickly, people are satisfied in satiety and meanwhile obtain rich nutrition; the mountain fern fine dried noodles are free of any food additives, thereby being safe to eat by people.

Owner:王茗琦

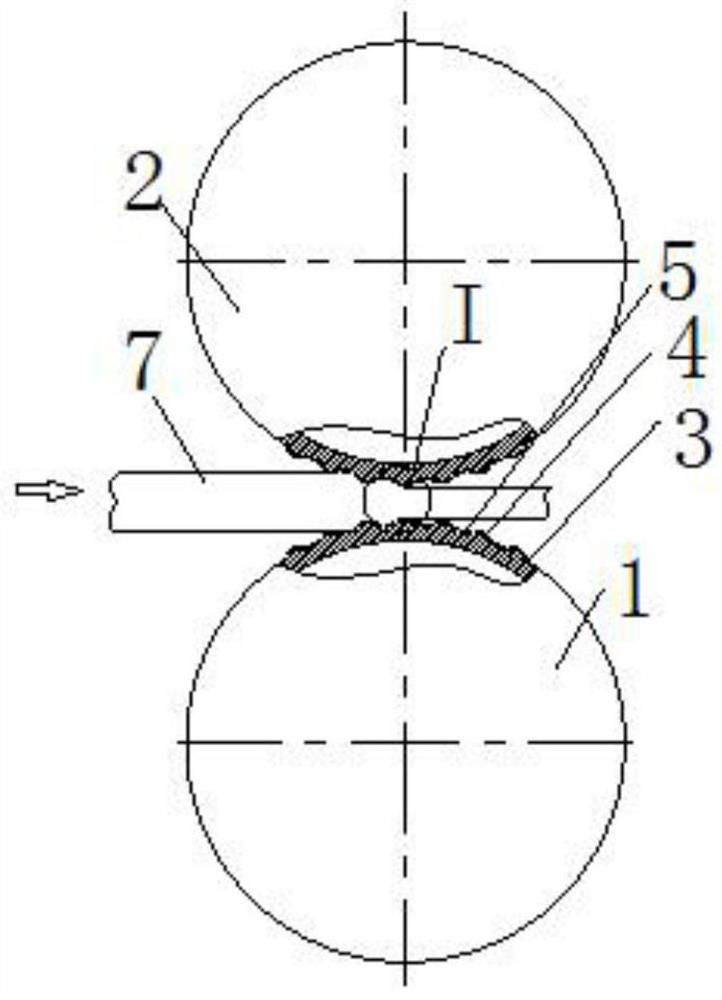

Automatic stuffing filling type stuffed noodle maker

InactiveCN107711957AGuaranteed uniformityImprove processing qualityDough shaping and cutting apparatusNoodles cutting outTransverse grooveDrive motor

The invention provides an automatic stuffing filling type stuffed noodle maker, and solves the problems of uneven stuffing, exposed stuffing, hollow noodles, broken stuffing, blockage of stuffing pipes, and noodle adhesion and non-molding caused by manual stuffing filling of the stuffed noodle maker. The technical scheme is as follows: the automatic stuffing filling type stuffed noodle maker comprises a pair of forming rollers with a plurality of annular grooves and two squeezing rollers with annular ribs, which are laterally assembled in a shell; a stuffing filling device is arranged above the forming rollers, and comprises a funnel-shaped stuffing filling groove, and the lower outlet of the stuffing filling groove is provided with a stuffing feeding roller driven by a drive motor; a gapbetween the stuffing feeding roller and the front wall of the stuffing filling groove forms a transverse narrow gap-shaped stuffing outlet, and the stuffing outlet is correspondingly arranged above anoodle forming channel; and a scraper is elastically arranged along the surface of the stuffing feeding roller behind the lower part of the stuffing feeding roller. The automatic stuffing filling typestuffed noodle maker can continuously, quickly, automatically and uniformly add stuffing, thereby ensuring that the noodle stuffing is full and continuous. The processing quality of stuffed noodles is greatly improved, the operation is simple, manpower is saved and the production efficiency is improved.

Owner:中裹安全应急科技集团有限公司

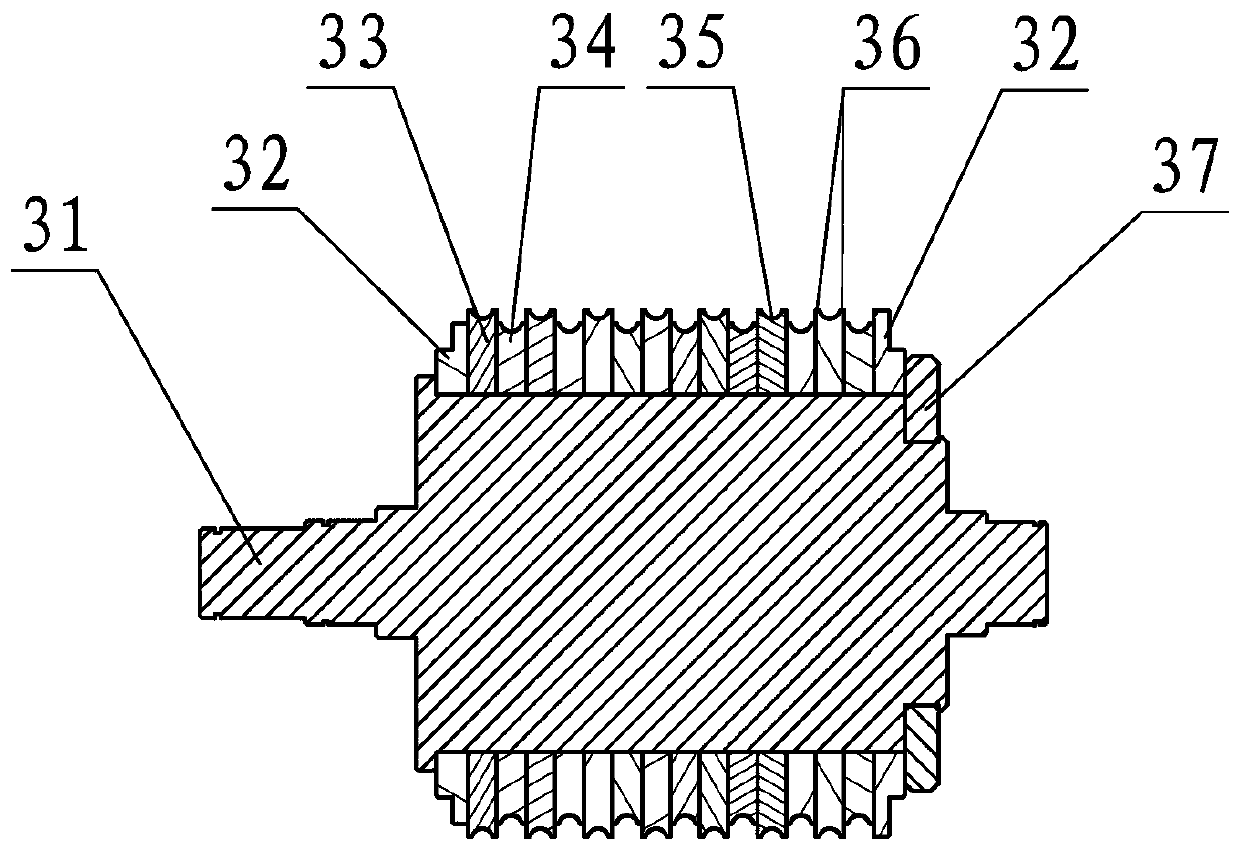

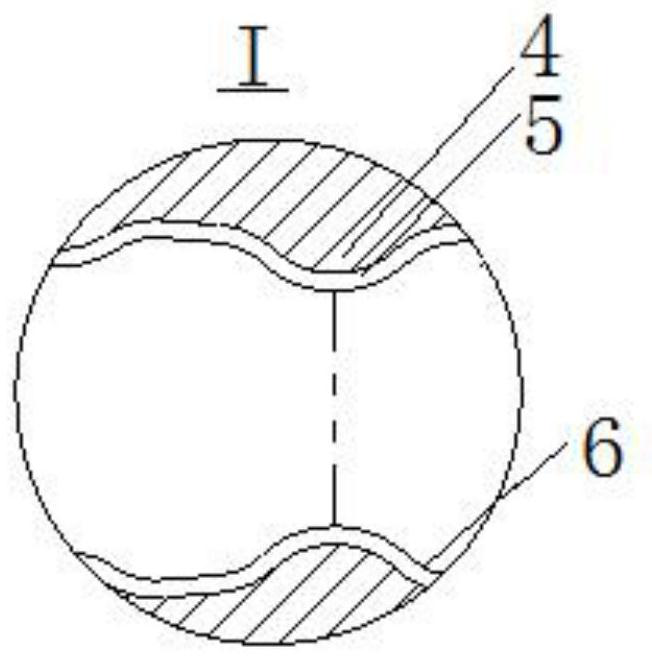

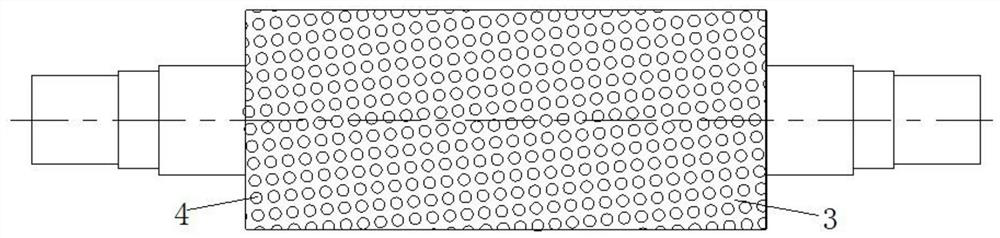

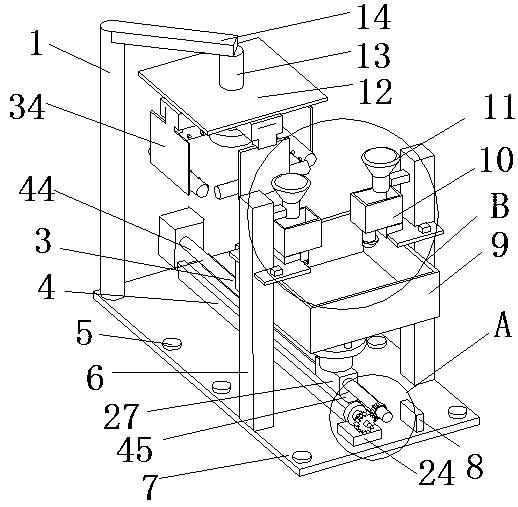

Special calendaring roller for flour food products and manufacturing method thereof

ActiveCN111713523AIncrease contact areaIncrease deformation spaceDough-sheeters/rolling-machines/rolling-pinsChemical vapor deposition coatingEngineeringPasta processing

The invention discloses a special calendaring roller for flour food products and a manufacturing method thereof, and relates to the technical field of flour food processing equipment. The calendaringroller is in symmetrical arrangement, and comprises a first calendaring roller and a second calendaring roller, wherein the two calendaring rollers have the same structure; the calendaring roller comprises two support shafts; a cylindrical base body is arranged between the two support shafts; a calendaring roller tube body is arranged on the cylindrical base body of the calendaring roller in a sleeving way; protruding parts of micro spherical structures are prepared on the outer surface of the calendaring roller tube body; and a low- surface-energy chemical vapor deposition carbon-based dopingfilm coats the outer surface of the calendaring roller tube body. The invention also provides the manufacturing method of the special calendaring roller for flour food products. The calendaring roller manufactured by the manufacturing method has the advantages that a contact angle between water drips and the surface of the calendaring roller is improved through an element doping film; the adhesion capability of flour belts on the surface of the calendaring roller is reduced; and the water addition quantity of machine made flour food products can be greatly improved.

Owner:BEIJING GOLDEN WHEEL SPECIAL MACHINE +1

Filling improving agent, high soup filling, double-layer soup-preserving steamed stuffed bun and preparation method thereof

ActiveCN106962763BStrong water and oilStrong water and oil retentionFood ingredient as thickening agentYeast food ingredientsBiotechnologyFiber

The invention relates to the technical field of cooked wheaten food processing, in particular to a filling improver, soup-stock filling, a double-layer soup-protecting steamed stuffed bun, and a preparation method thereof. The filling improver is prepared by compounding wheat fiber, orange fiber, oat fiber and edible gelatin; and the filling improver is added in the filling. The double-layer soup-protecting steamed stuffed bun by wrapping the filling with two layers of wrappers comprising inner-layer unleavened dough wrapper or spring roll wrapper and outer-layer leavened dough wrapper. Three kinds of dietary fiber and the edible gelatin are compounded and used, high water-retaining property, oil-retaining property, thermal reversibility and freeze-thaw stability are given to the filling, the soup content is not reduced when the soup is reheated after long-time quick-frozen preservation of the filling, the soup is locked and is prevented from being permeated into the wrapper, and the taste of the whole product is improved. The double-layer steamed stuffed bun provided by the invention protects the soup of the filling from permeating outwards, solves the problems that the filling of the quick-frozen steamed stuffed bun is dry and does not have soup and the wrapper absorbs the soup of the steamed stuffed bun and is sticky, and achieves the taste and the state of the fresh steamed stuffed bun.

Owner:天津思念食品科技有限公司

Kelp noodle kneading mechanism, pasta processing line

ActiveCN110558348BIncrease contact timeUniform densityMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsProcess engineeringPasta processing

The invention discloses a noodle kneading mechanism for kelp noodles. The noodle kneading mechanism includes a mixing device and a stirring noodle kneading device; the mixing device is used to pre-mix various raw materials used for processing noodles. The noodle device is used to knead the pre-mixed materials through the mixing device. The invention also discloses a pasta processing line. The invention has the advantages of sufficient material mixing and strong production flow.

Owner:福州盈创信息科技有限公司

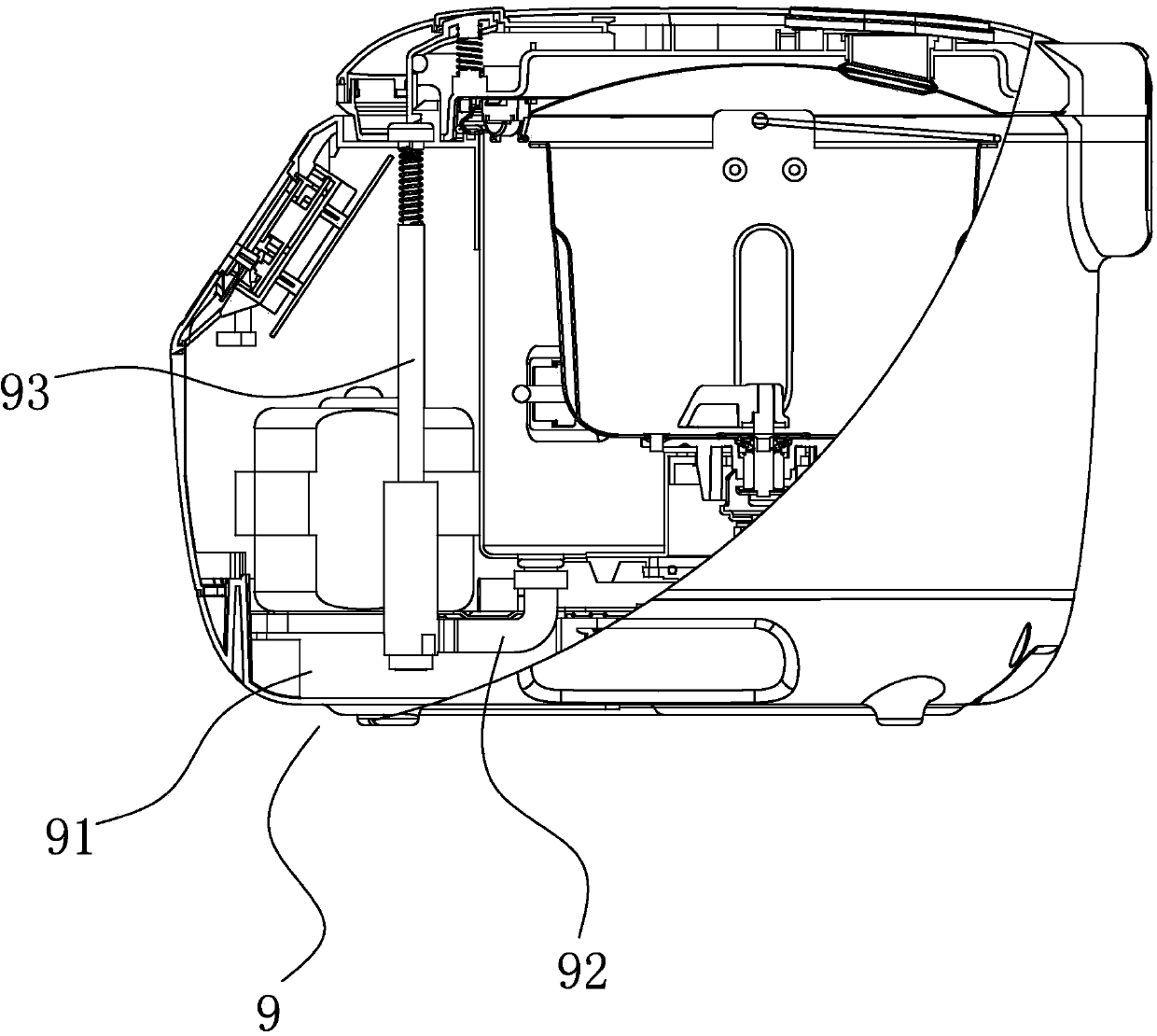

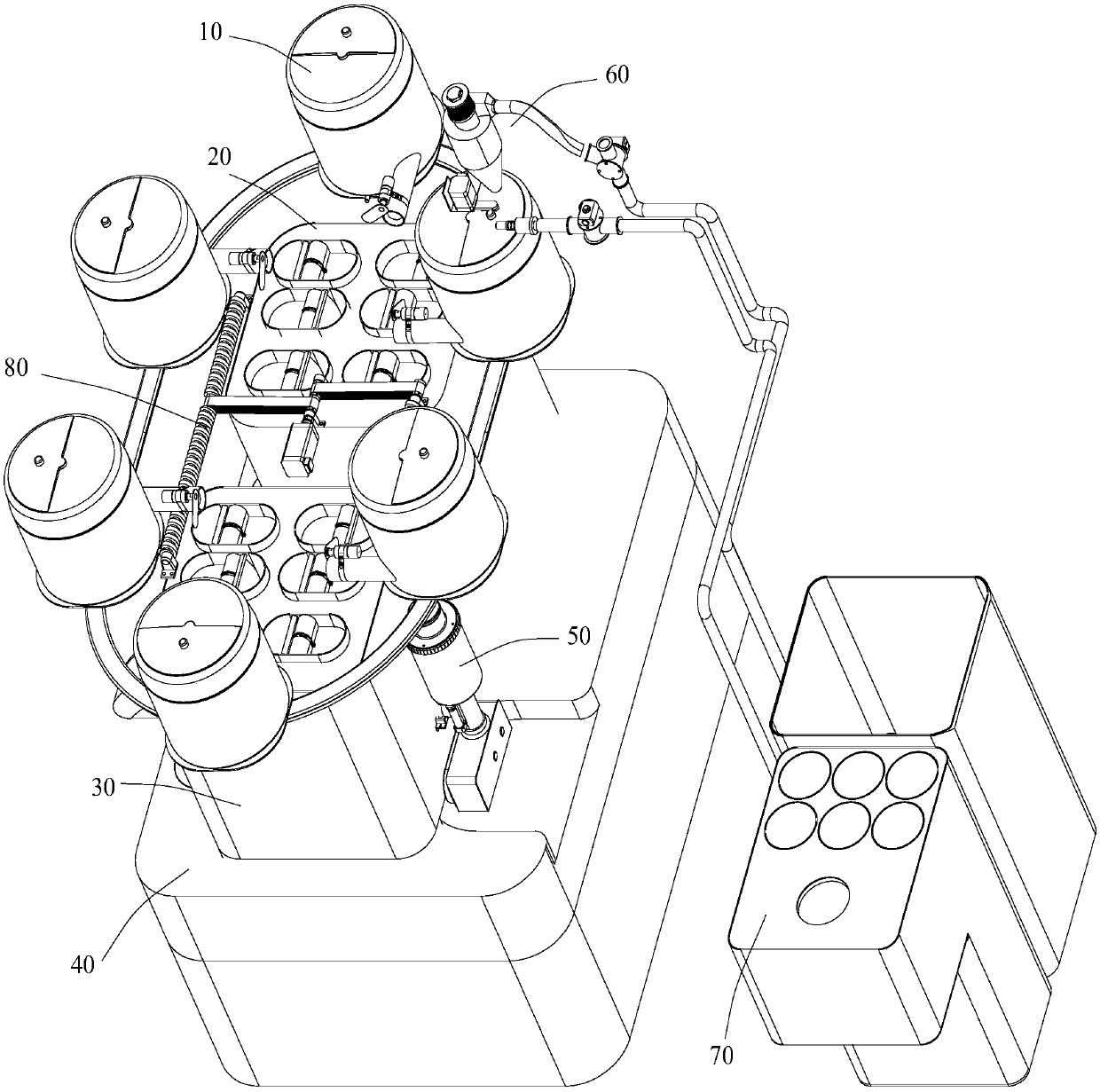

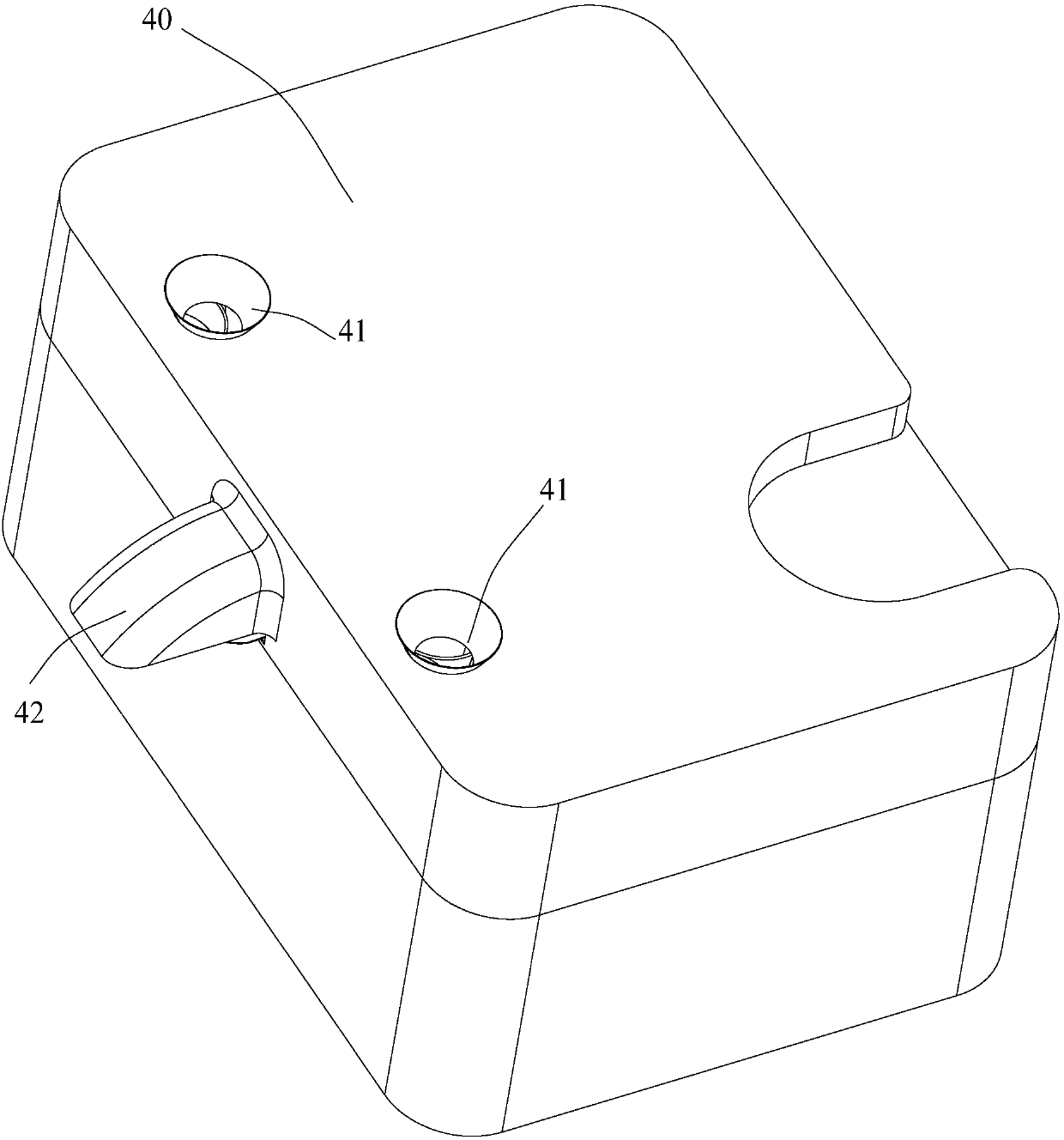

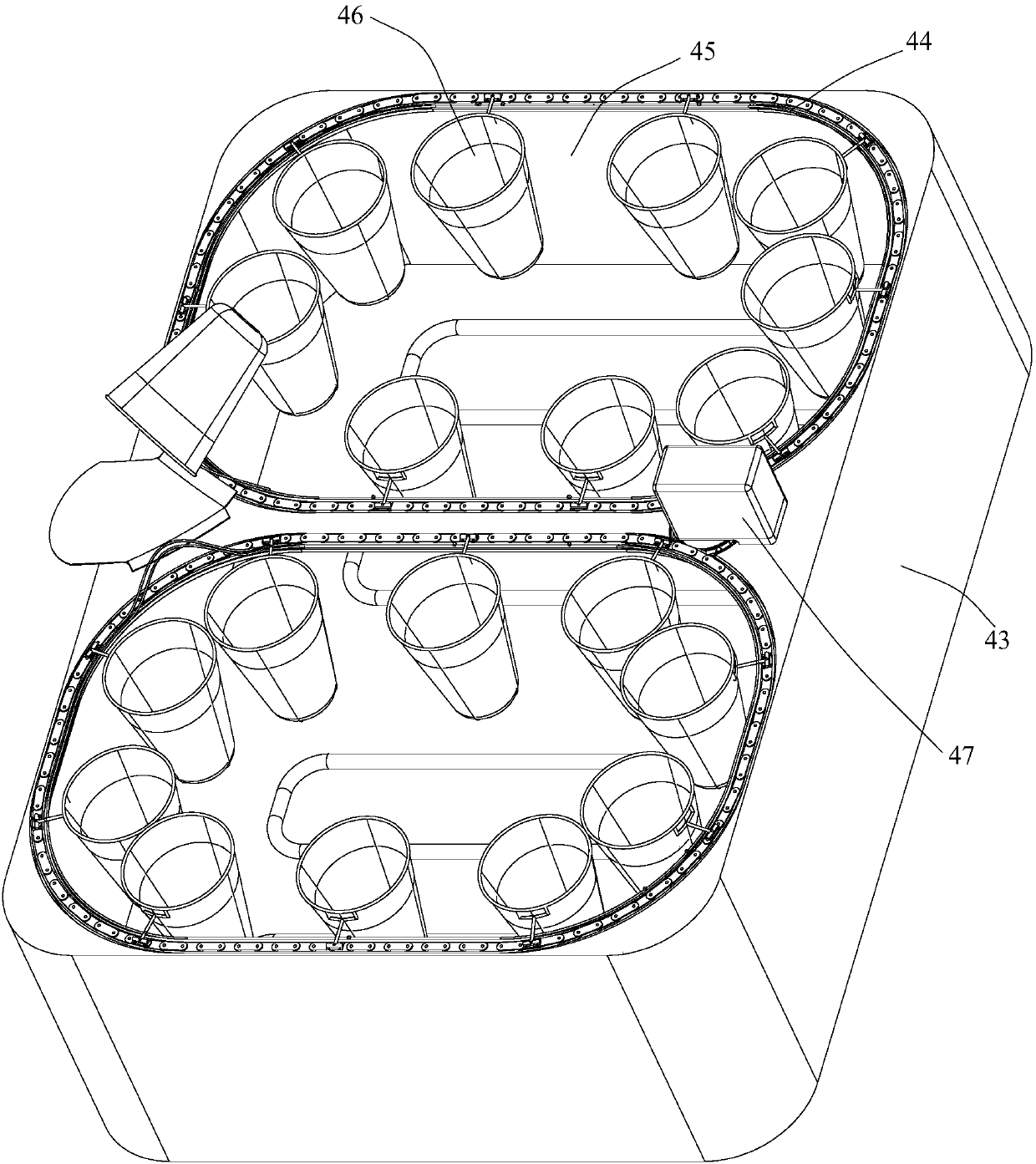

Wheaten food making machine

ActiveCN107751276AImprove processing efficiencyGuaranteed continuityMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsProcess engineeringPasta processing

The invention discloses a wheaten food making machine which comprises at least two dough mixing mechanisms, a first wheaten food forming mechanism, a second wheaten food forming mechanism, and a firstdriving mechanism, wherein the first wheaten food forming mechanism is used for receiving a flour material dropped by the dough mixing mechanisms and forming a first wheaten food; the first wheaten food forming mechanism is provided with a first flour material inlet; the second wheaten food forming mechanism is used for receiving the flour material dropped by the dough mixing mechanisms and forming a second wheaten food; the second wheaten food forming mechanism is provided with a second flour material inlet; and the first driving mechanism drives at least two dough mixing mechanisms to movecircularly and alternately from the first flour material inlet to the second flour material inlet. According to the wheaten food making machine provided by the invention, the provided at least two dough mixing mechanisms can provide a well mixed flour material to the first wheaten food forming mechanism and the second wheaten food forming mechanism, thereby ensuring the continuity of the flour material supply and improving the wheaten food processing efficiency. In addition, the first wheaten food forming mechanism and the second wheaten food forming mechanism can form different wheaten foods,so that the wheaten food making machine can produce different varieties of wheaten foods.

Owner:傅峰峰

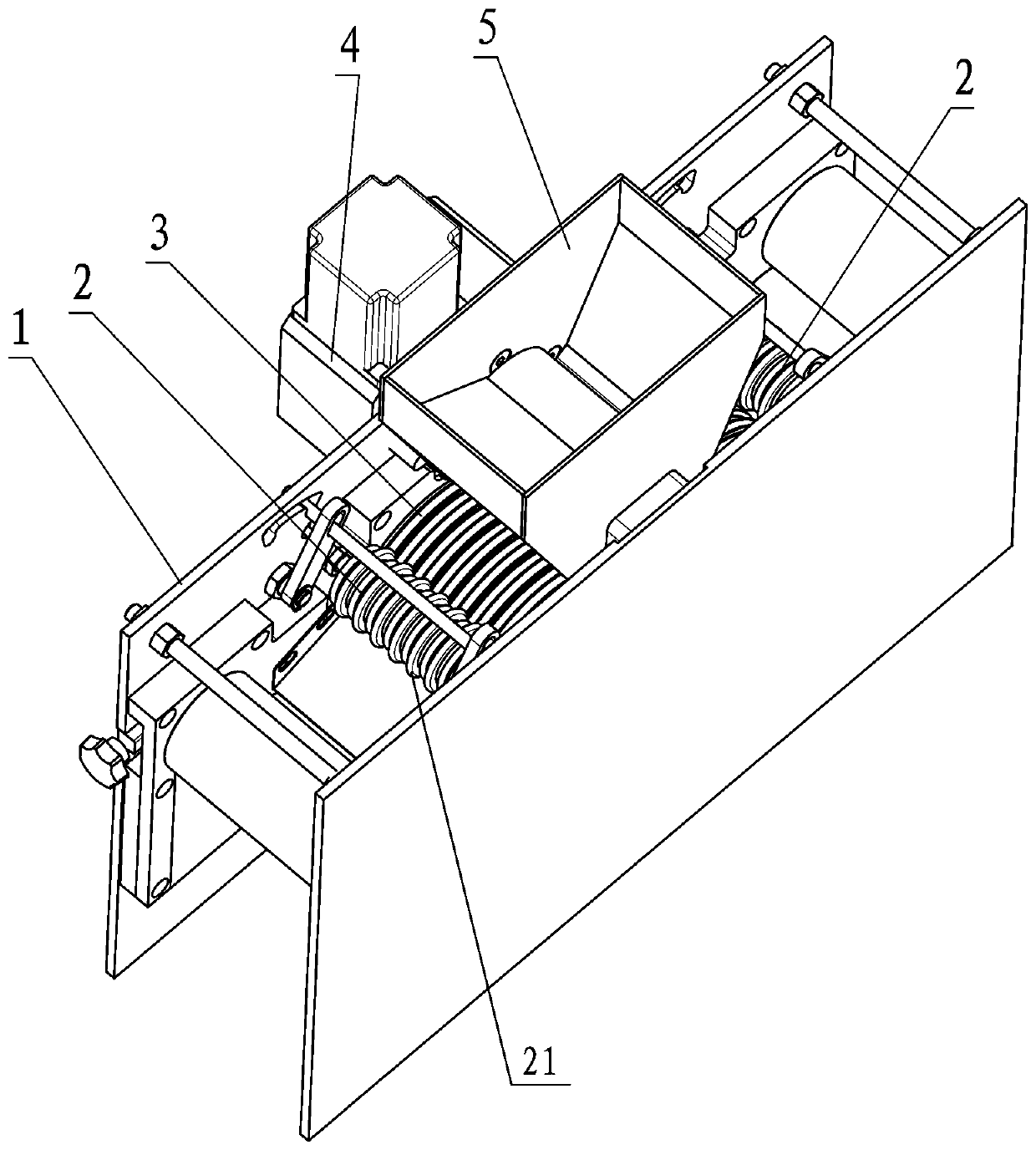

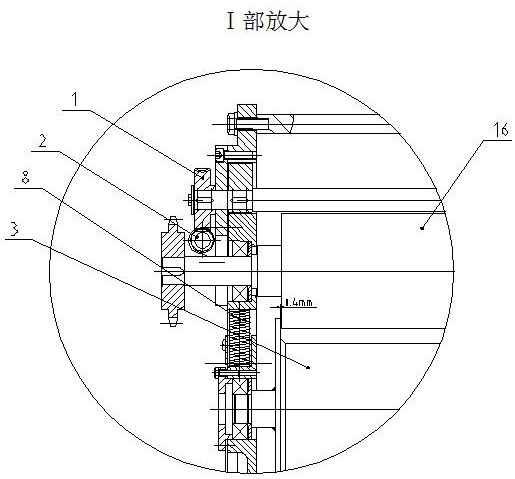

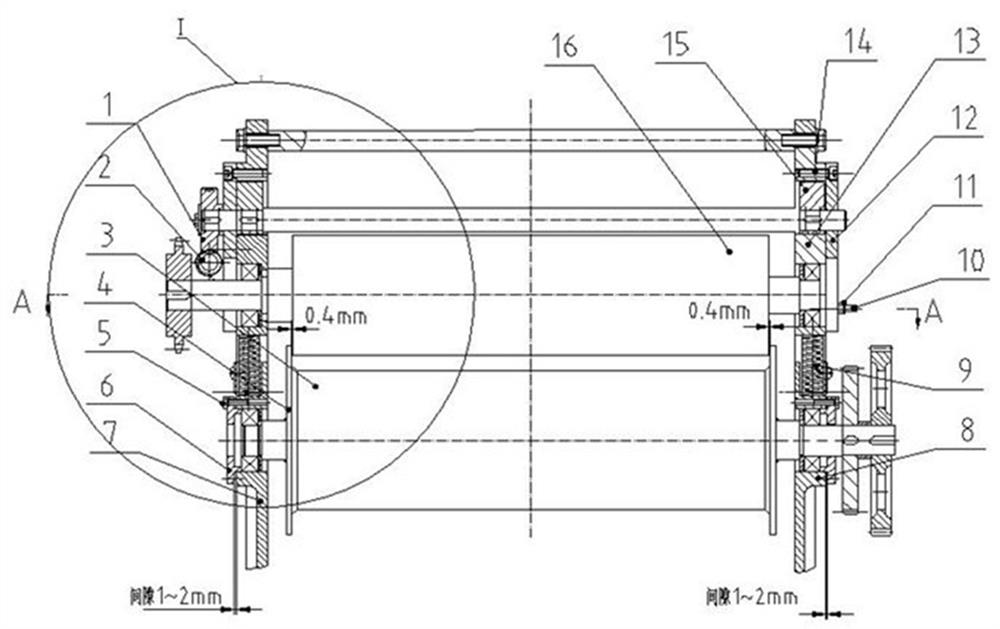

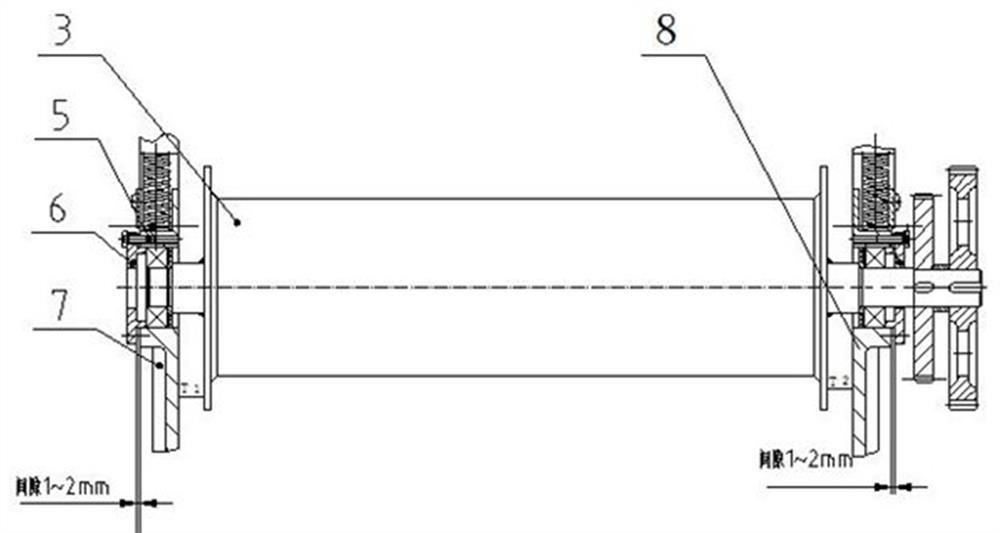

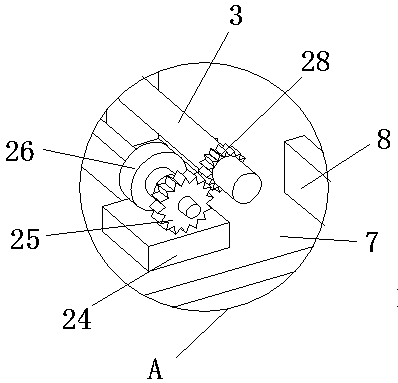

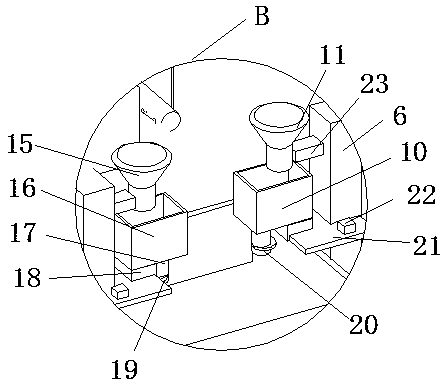

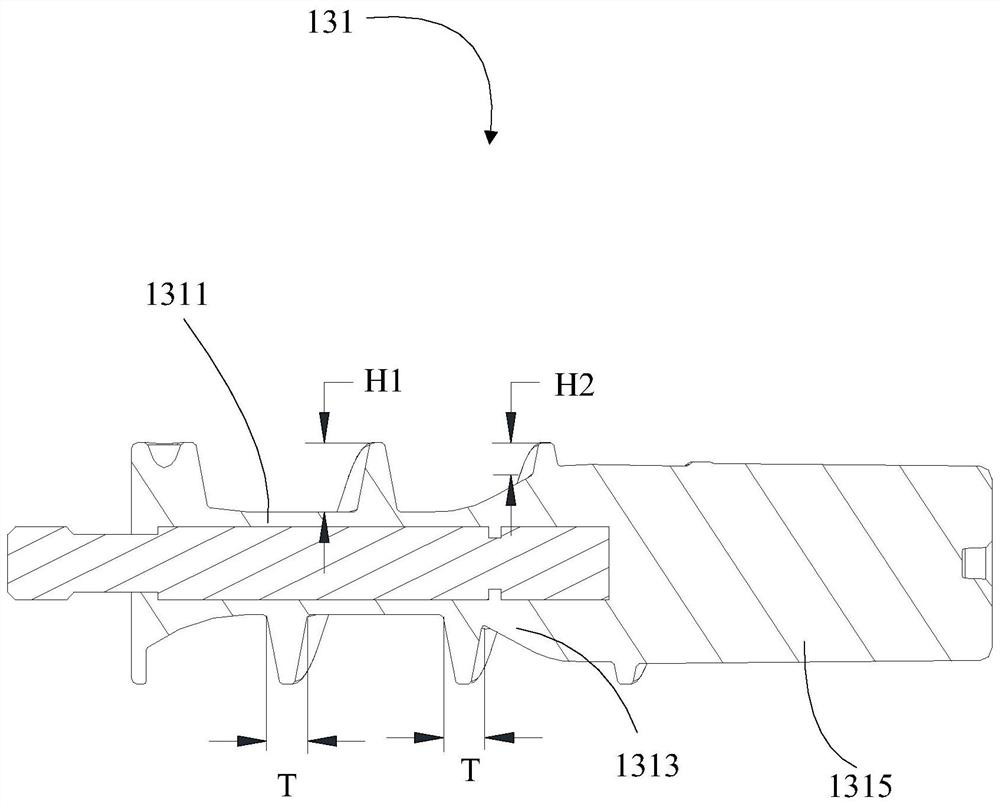

Axial clearance adjusting mechanism of automatic noodle press

PendingCN112998042APrevent grinding black surfacePrevent iron filingsDough-sheeters/rolling-machines/rolling-pinsSet screwEngineering

The invention discloses an axial clearance adjusting mechanism of an automatic noodle press, which comprises an upper roller, an upper roller baffle disc, a worm gear, a worm, a left bracket, a right bracket, a bearing gland, an adjustable roller, a fixed plate, a set screw, a standby nut, a roller bearing seat, a hexagon socket cap screw, a pressure spring and an eccentric wheel; the left bracket and the right bracket are symmetrical, the roller bearing seats are symmetrically mounted in the left bracket and the right bracket; the upper roller penetrates through the left and right brackets, two sides of the upper roller are respectively provided with a bearing gland, the upper roller baffle plates are fixed on the left and right sides of the upper roller, and the axial clearances between the outer end surfaces of the upper roller and the inner end surfaces of the left and right brackets are T1 and T2; the bearing glands are mounted on the outer sides of the left and right brackets through hexagon bolts to form an upper roller axial position adjusting structure; gaps between the inner end face of the bearing gland and the outer end faces of the left and right brackets are adjusted through hexagon bolts, and axial position adjustment of the upper roller is achieved. The product is convenient and easy to adjust and convenient and reliable to use, and sanitation and safety of cooked wheaten food processing machinery are guaranteed.

Owner:SHANDONG YINYING COOKING MACHINERY

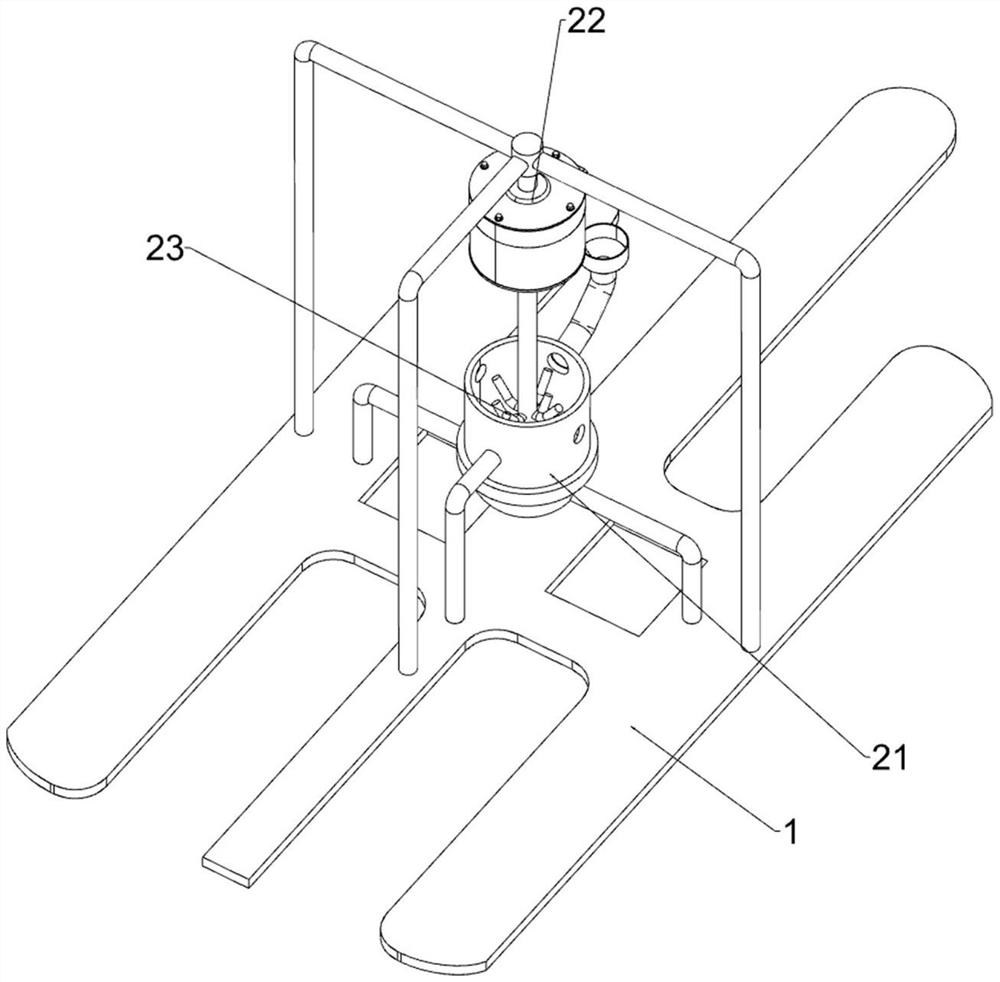

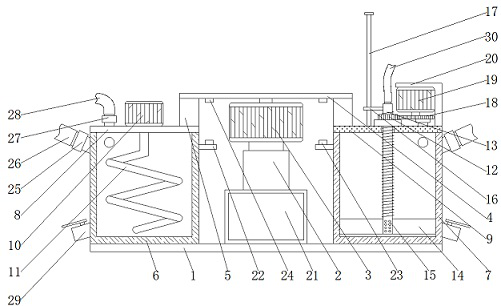

Kneading device for pasta processing

ActiveCN108617724BAccurate quality controlEasy to cleanMixing/kneading structural elementsMixing/kneading with rollersPasta processingSingle chip

The invention discloses a dough kneading device for flour-made food processing. The dough kneading device comprises a base and is characterized in that a transverse slide guide rail is arranged in themiddle of the upper surface of the base, a third fixing plate is arranged on the left side of the slide guide rail, a screw is rotatably connected to the right side of the third fixing plate througha bearing, square support columns are arranged at the front end and the rear end of the right side of the upper surface of the base, a second connecting rod is arranged on the inner side of the upperend of each square support column, a liquid feeding hopper is arranged on the front second connecting rod, a flour feeding hopper is arranged on the rear second connecting rod, and a single-chip microcomputer is arranged on the right side of the upper surface of the base. The dough kneading device has the advantages that the device is provided with an electronic weighing device and an electronic counter, the weight of needed flour and water can precisely controlled, the flour and the water can be automatically mixed according to a certain proportion, production efficiency is increased, dough does not need secondary processing during use, a dough kneading bin can move by the slide guide rail below the dough kneading bin, the kneaded dough can be conveniently taken out, and the dough kneading bin can be conveniently cleaned.

Owner:安徽品滋味食品股份有限公司

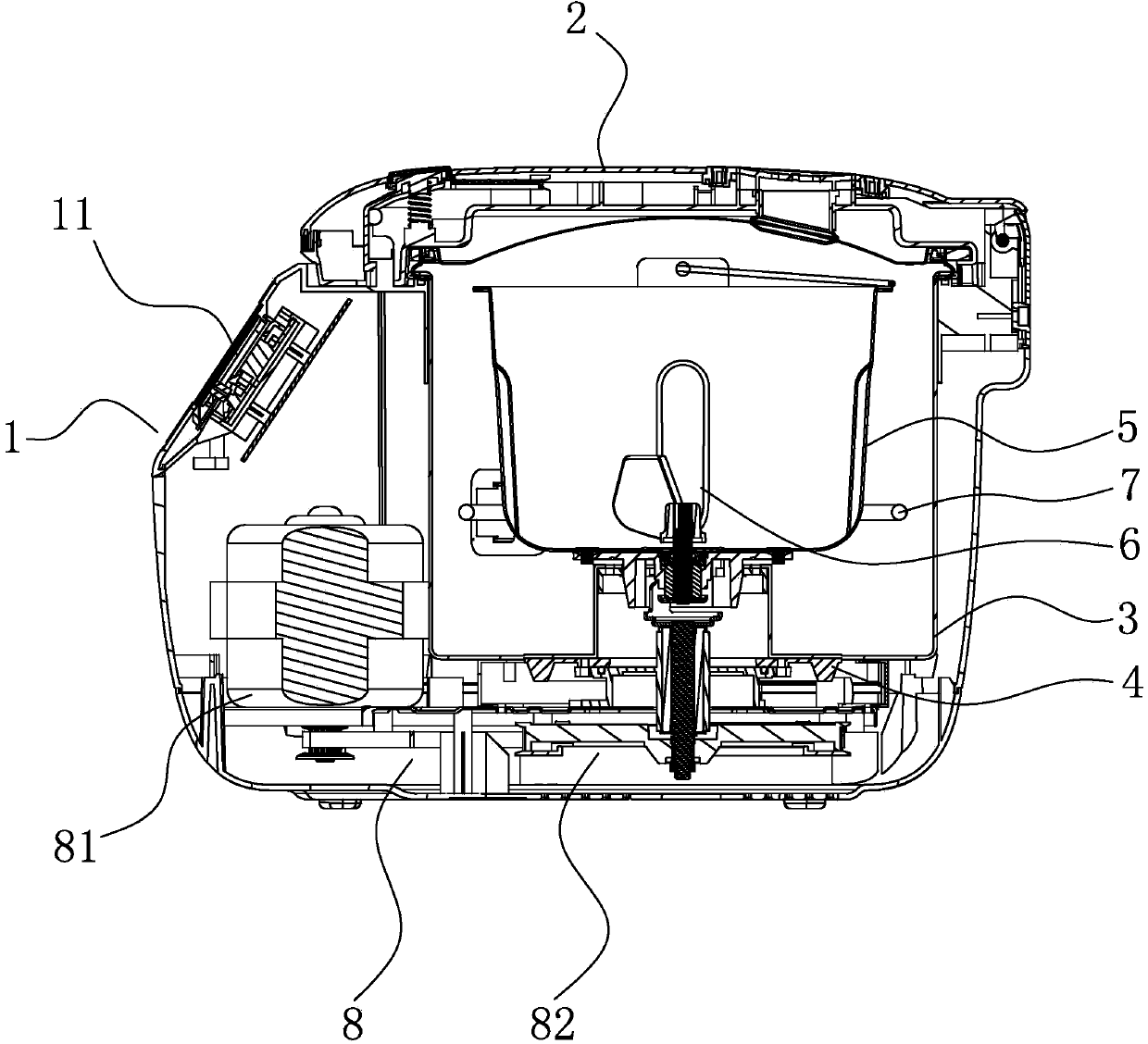

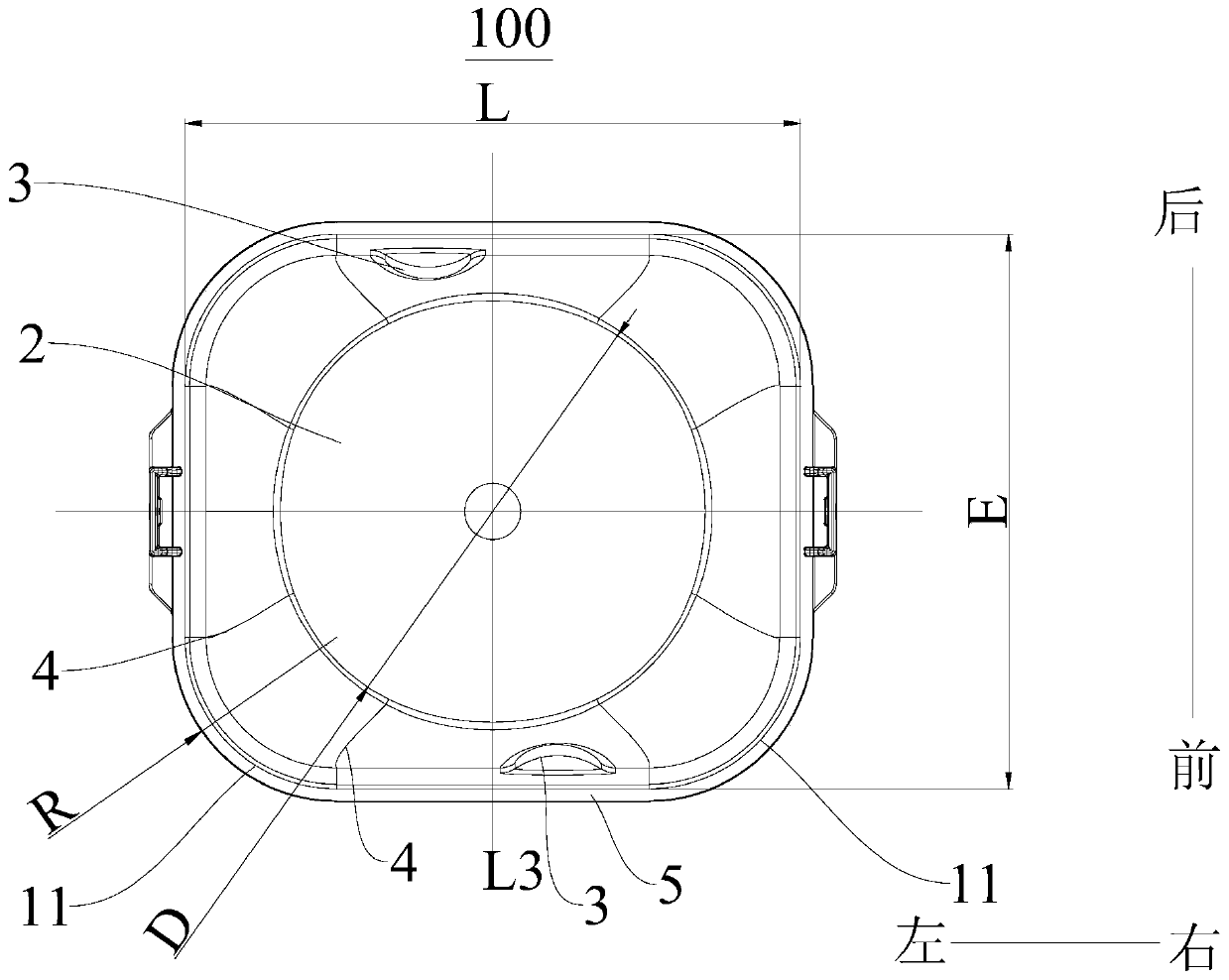

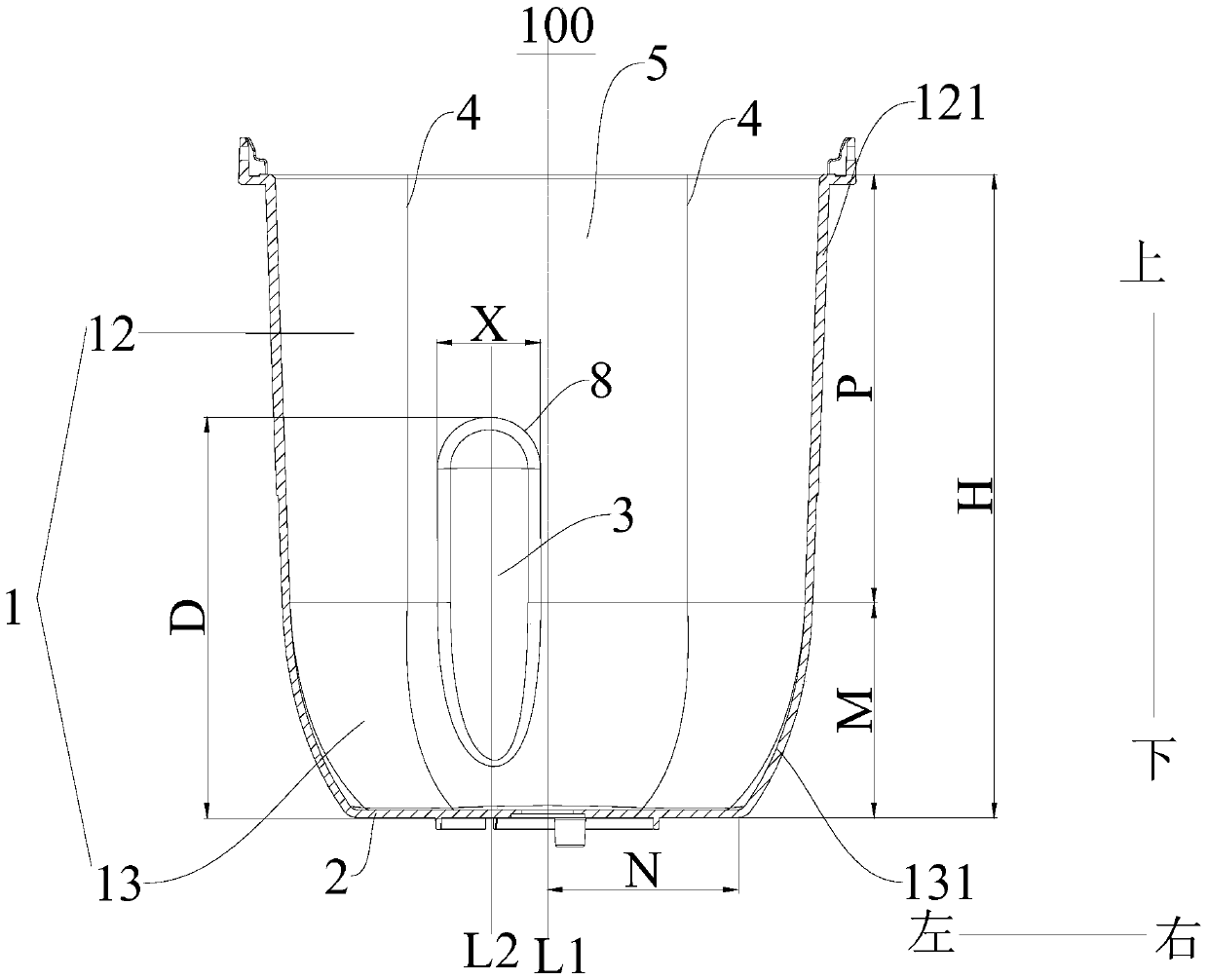

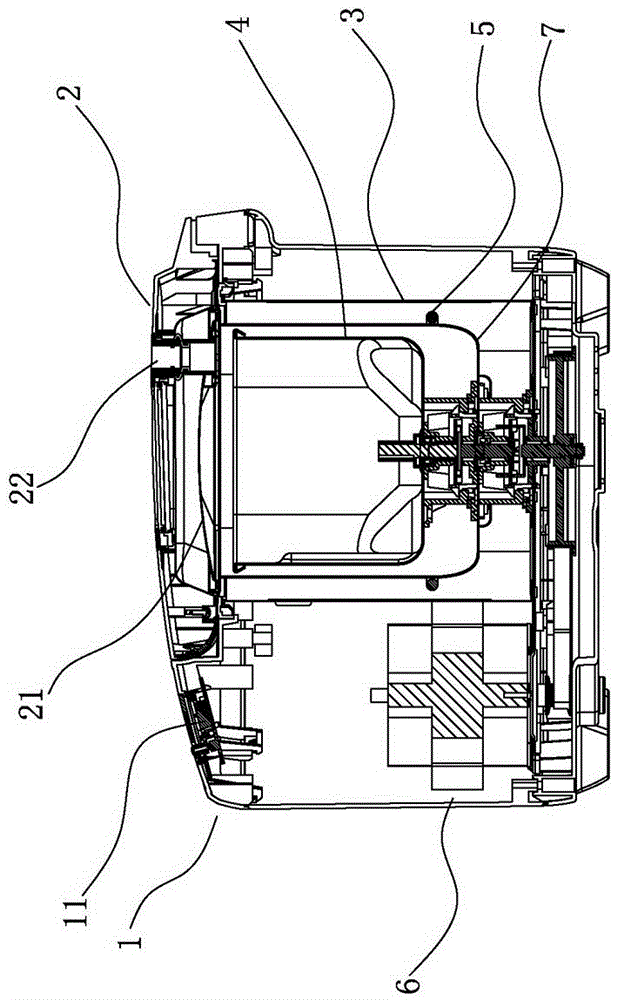

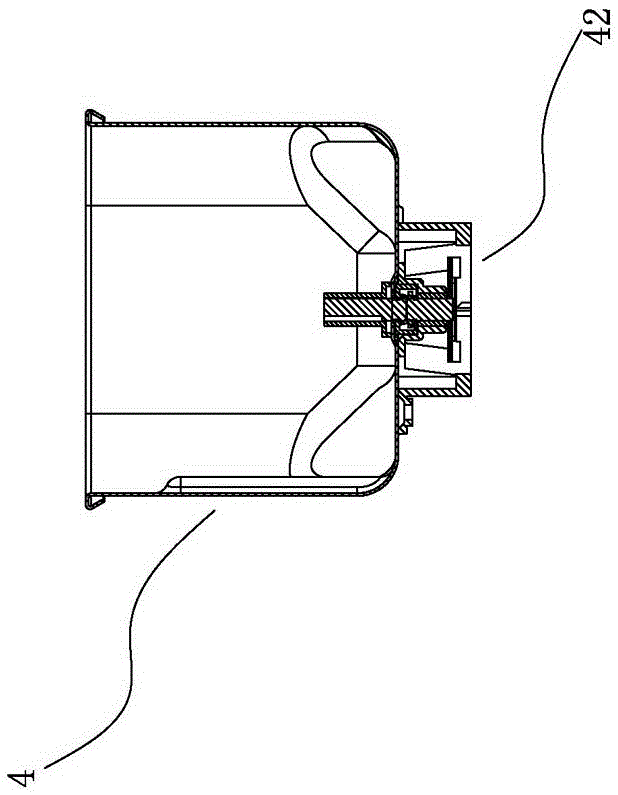

Pasta Processor and Bread Bucket

ActiveCN105794893BBaking vesselsMixing/kneading with vertically-mounted toolsStructural engineeringPasta processing

The present invention discloses a wheaten food processing machine and a bread bucket thereof. The bread bucket of the wheaten food processing machine comprises a bucket body. The bucket body has an upper end opening, the upper end opening of the bucket body is square, protruding convex ribs facing toward the interior of the bucket body are arranged on the side walls of the bucket, and the distances between center lines of the convex ribs and center lines of the side walls are greater than zero. The bread prepared by the bread bucket of the wheaten food processing machine according to the embodiment of the invention is homogeneous in texture and good in taste.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

A kind of preparation method of pure natural anti-cooking Italian noodle soup

ActiveCN109699906BIncrease productivityFast rehydrationMixing/kneading with horizontally-mounted toolsDough extruding machinesBiotechnologyGluten

The invention mainly relates to the technical field of pasta processing, and discloses a preparation method of pure natural boilable pasta noodle soup, including: hot water kneading noodles, vacuum kneading noodles, extrusion molding, steam drying, cooling and packaging; the invention provides The preparation method of pure natural boilable Italian noodle soup is simple, chewy and boilable, not muddy soup, continuous strips, does not contain any additives, nutritious and healthy, and tastes chewy; first add hot water to high-gluten flour, and carry out in the twin-screw warehouse Knead the dough to increase the consistency and texture of the dough; then transfer the hot dough to the single-screw chamber through the sealing device and then carry out vacuum mixing and kneading to promote the dough to absorb water evenly, so that the gluten network is formed quickly, the protein structure is balanced, and the dough is improved. The texture, smoothness and transparency of the dough can avoid the proofing time of the dough and significantly improve the production efficiency of pasta; then the pasta soup can be obtained by extrusion molding and steam heating and drying.

Owner:安徽谷优美食品科技股份有限公司

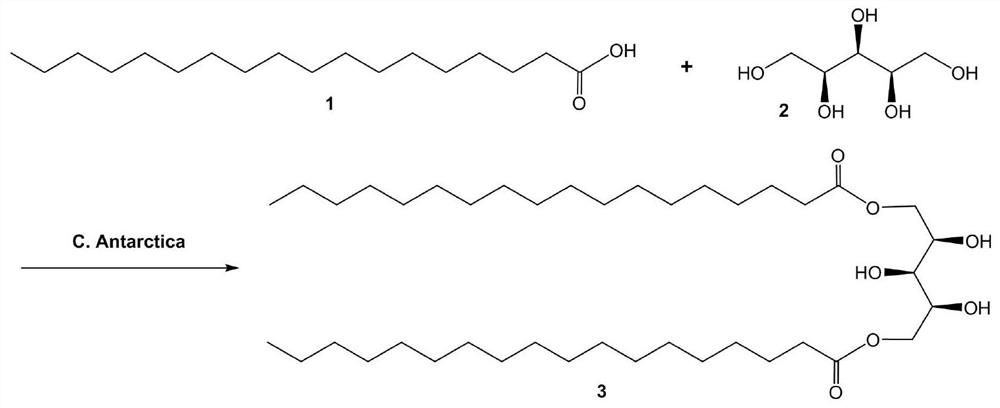

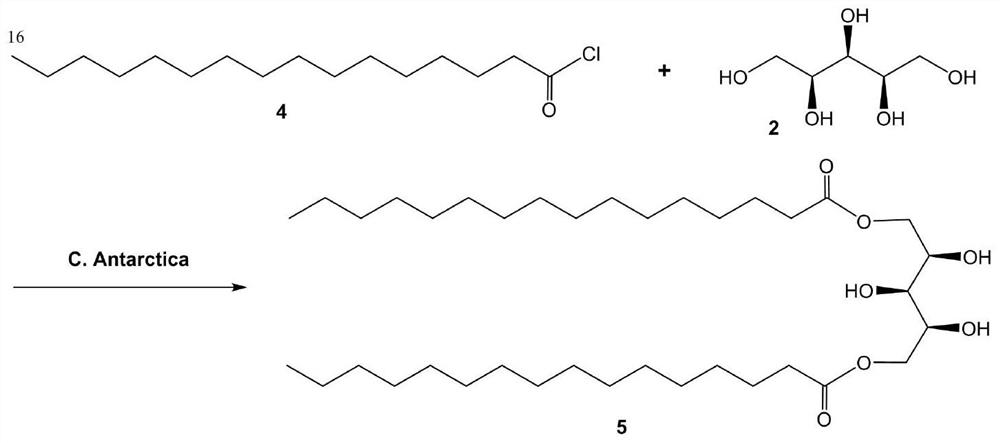

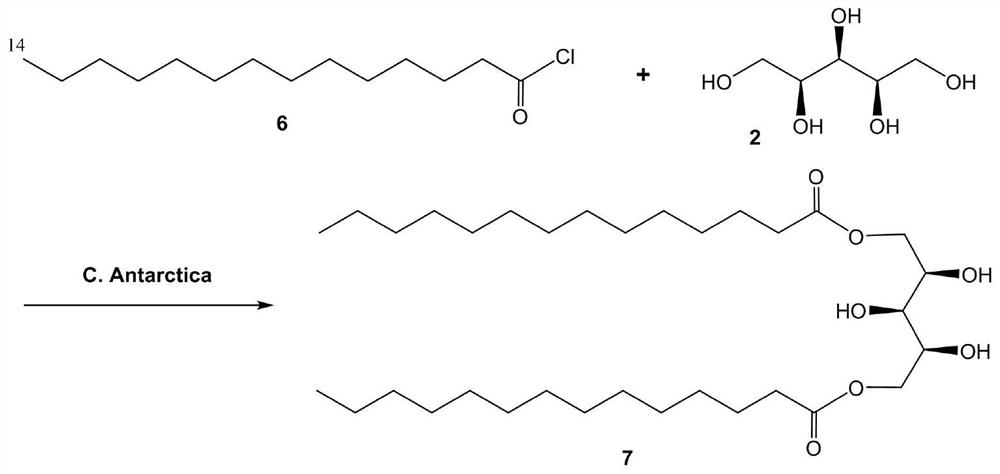

Synthesis and application of novel food emulsifier

PendingCN111909063AIncrease surface tensionExcellent gas productionDough treatmentSulfonic acids salts preparationBiotechnologyNatural source

The invention discloses synthesis and application of a novel food emulsifier. The molecular structure is shown in the specification, wherein m is equal to 5, 6 or 7; n = 5, 6, or 7; the xylitol is structurally characterized in that two primary hydroxyl groups of xylitol from a natural source are respectively connected with fatty acids from C14 to C18; and three secondary hydroxyl groups of the xylitol are sodium salts of sulfate. Through molecular design and chemical preparation experiments as well as tests on surface tension, viscosity, stability, safety, aging resistance to flour and the like of a compound, the screened novel food emulsifier can become a safe novel food emulsifier, can be added into various cooked wheaten foods such as bread baking and the like, and has a wide application prospect. Excellent surface tension and gas yield provide possibility for improvement of wheaten food processing.

Owner:中山市南方新元食品生物工程有限公司

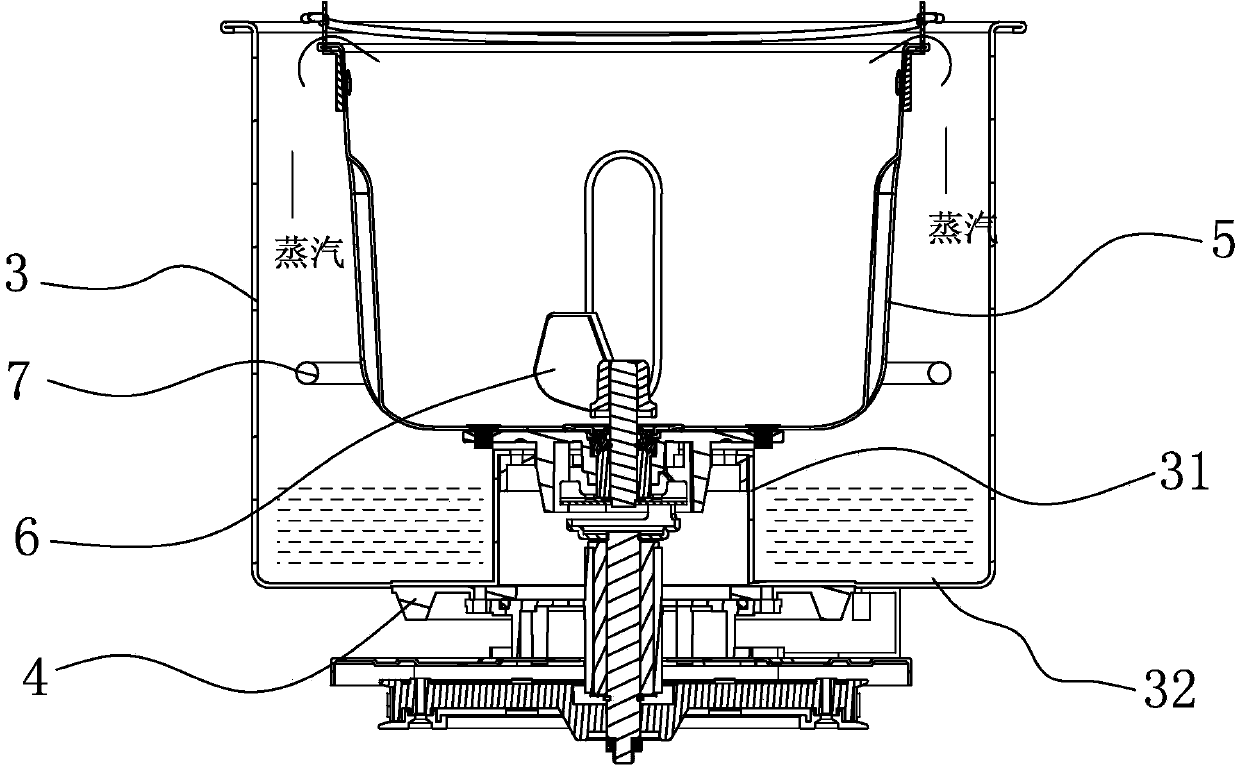

A pasta processing machine with a steam bucket

ActiveCN103799846BRealize steamed bun functionRealize the function of baking breadSteam cooking vesselsBread-toastersDistilled waterEngineering

A pasta processing machine with a steaming barrel, comprising a body and an upper cover, the outer surface of the body is provided with a control panel, and the body includes an outer barrel, an inner barrel, a heat pipe between the outer barrel and the inner barrel, and a power mechanism, And the control circuit that is electrically connected with control panel, heat pipe and power mechanism respectively, is provided with stirring blade in the described inner barrel, and described power mechanism provides power for the stirring blade, and described pasta processing machine also includes that is located between outer barrel and inner barrel steam bucket. The invention discloses a noodle processing machine with a steaming bucket, which is equipped with a steaming bucket, so that the work of replenishing water and removing scale is easy to carry out. Adding water to the steaming barrel can realize the function of steaming steamed buns of the pasta processor, and taking out the steaming barrel can realize the function of baking bread of the pasta processing machine. The invention can be used for pasta processing.

Owner:佛山市活力源电子科技有限公司

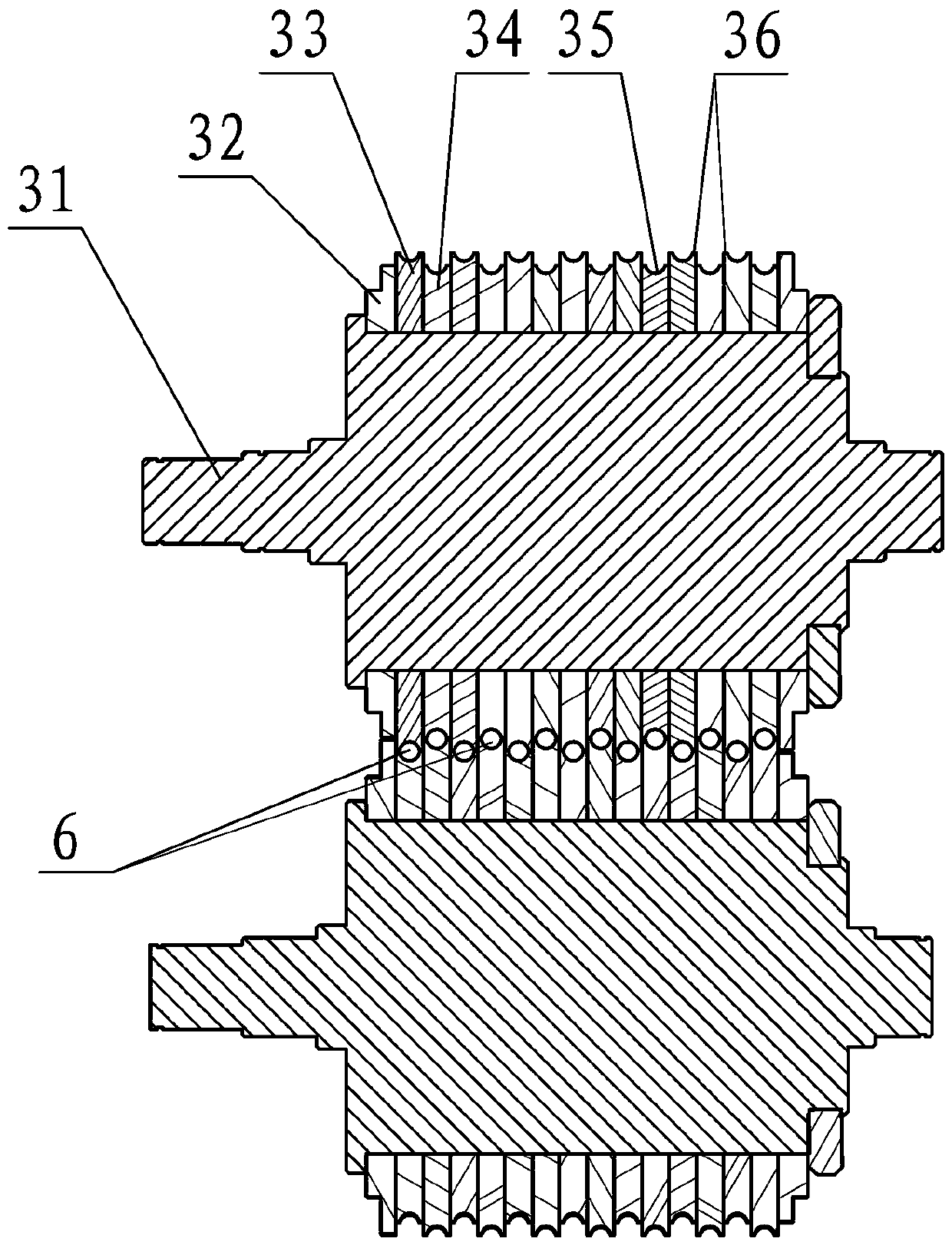

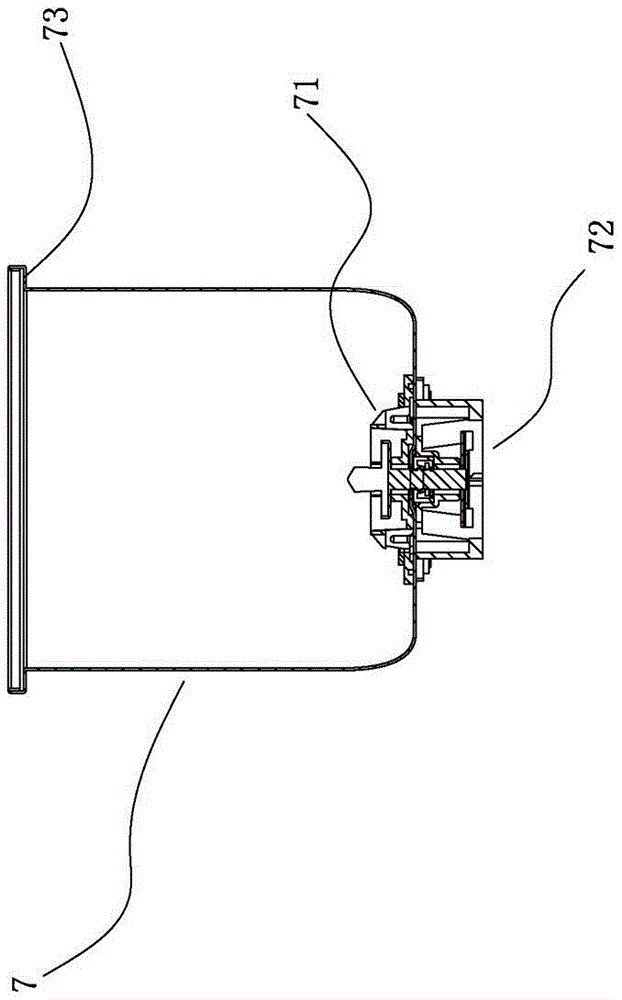

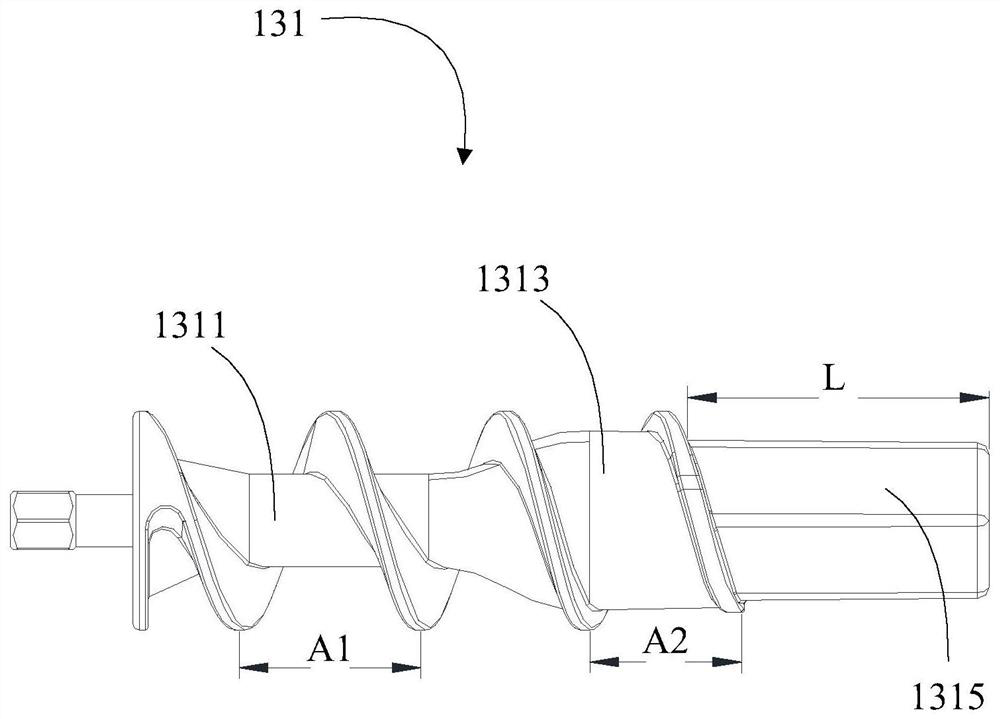

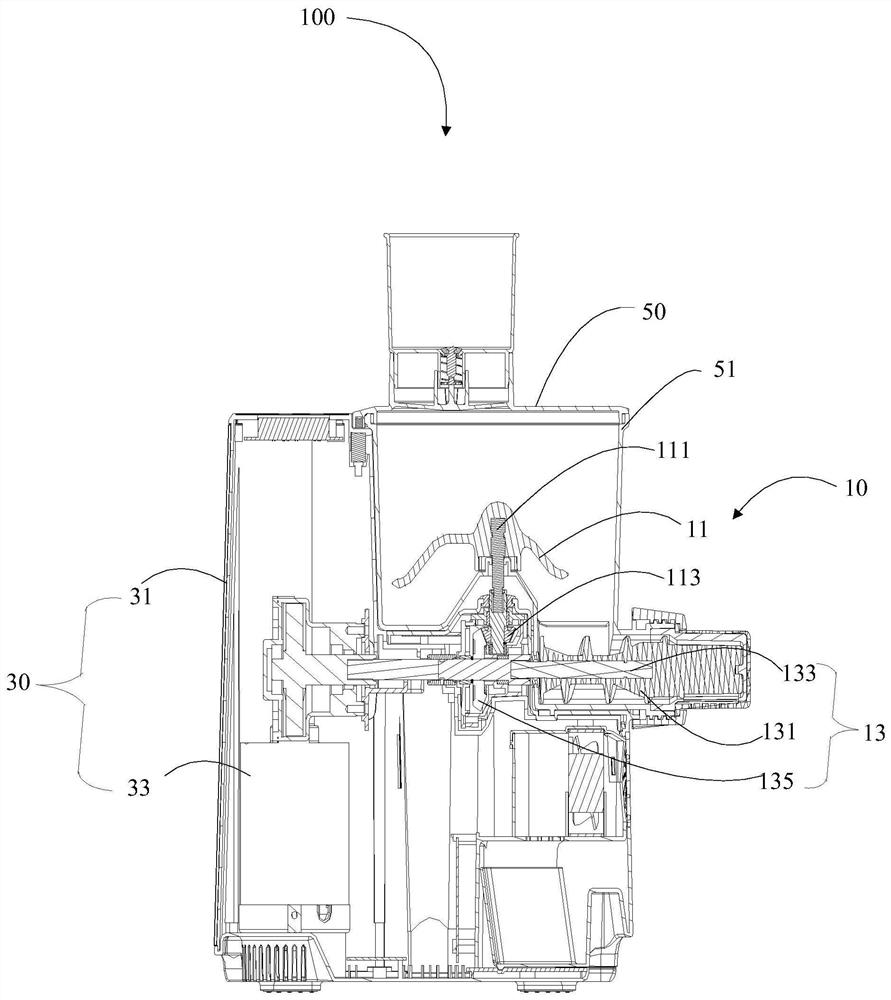

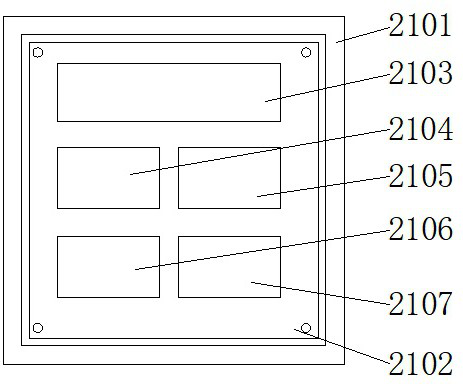

Surface screw assembly and pasta processing appliances

ActiveCN108935565BIncrease elasticityAvoid breakingDough extruding machinesEngineeringPasta processing

The invention discloses a surface screw assembly and a pasta processing appliance using the surface screw assembly. The surface screw assembly is applied to pasta processing appliances. The surface screw assembly includes a transmission shaft and a screw body connected to the transmission shaft. The screw body includes a dough entry section, an extrusion section, and a molding section connected in sequence. The molding section is a polygonal cylinder structure, the dough inlet section, the extrusion section and the molding section are integrally formed, and the transmission shaft at least extends into the dough inlet section and the extrusion section. The pasta processing appliance of the technical solution of the present invention has a better effect of stirring and making noodles.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD

A kind of lipase mutant and its application in decontamination

ActiveCN110172455BImproved pH stabilityImprove thermal stabilityHydrolasesNon-surface-active detergent compositionsOil processingSynthetic Polymeric Macromolecules

The invention discloses a lipase mutant and its application in decontamination, belonging to the technical field of enzyme engineering. The lipase mutant of the present invention has good thermal stability, good pH stability, and good washing performance. Therefore, the lipase mutant of the present invention is useful in decontamination, oil processing, dairy processing, pasta processing, meat processing, drug synthesis, It has important applications in diesel synthesis, polymer synthesis, chiral compound synthesis, leather production, detergent preparation and paper making.

Owner:JIANGNAN UNIV

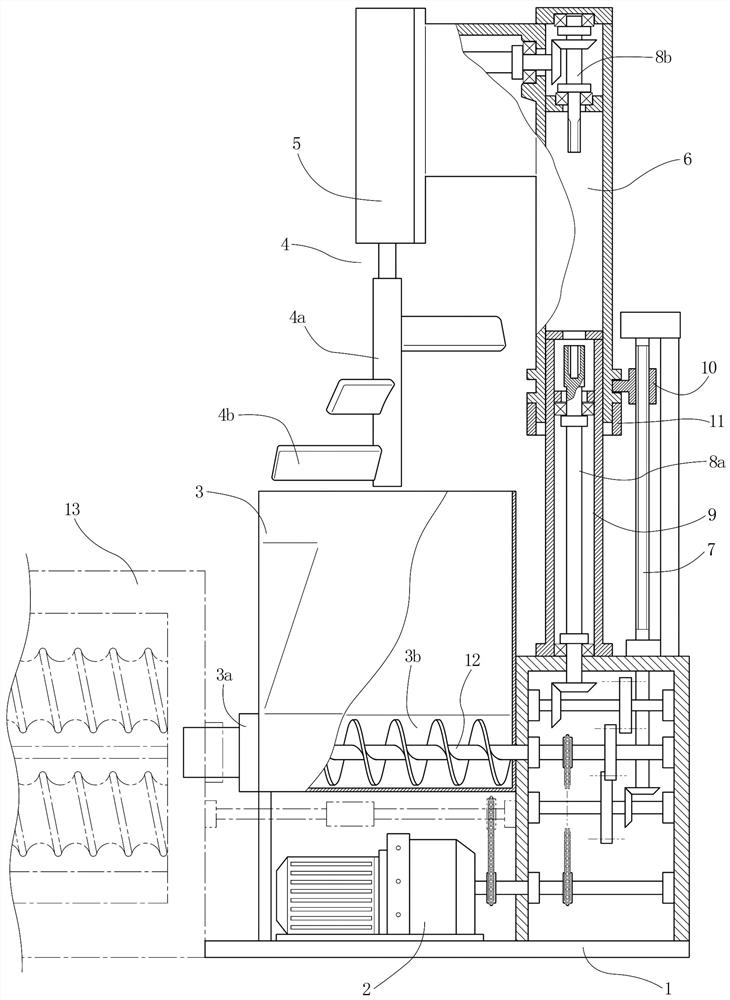

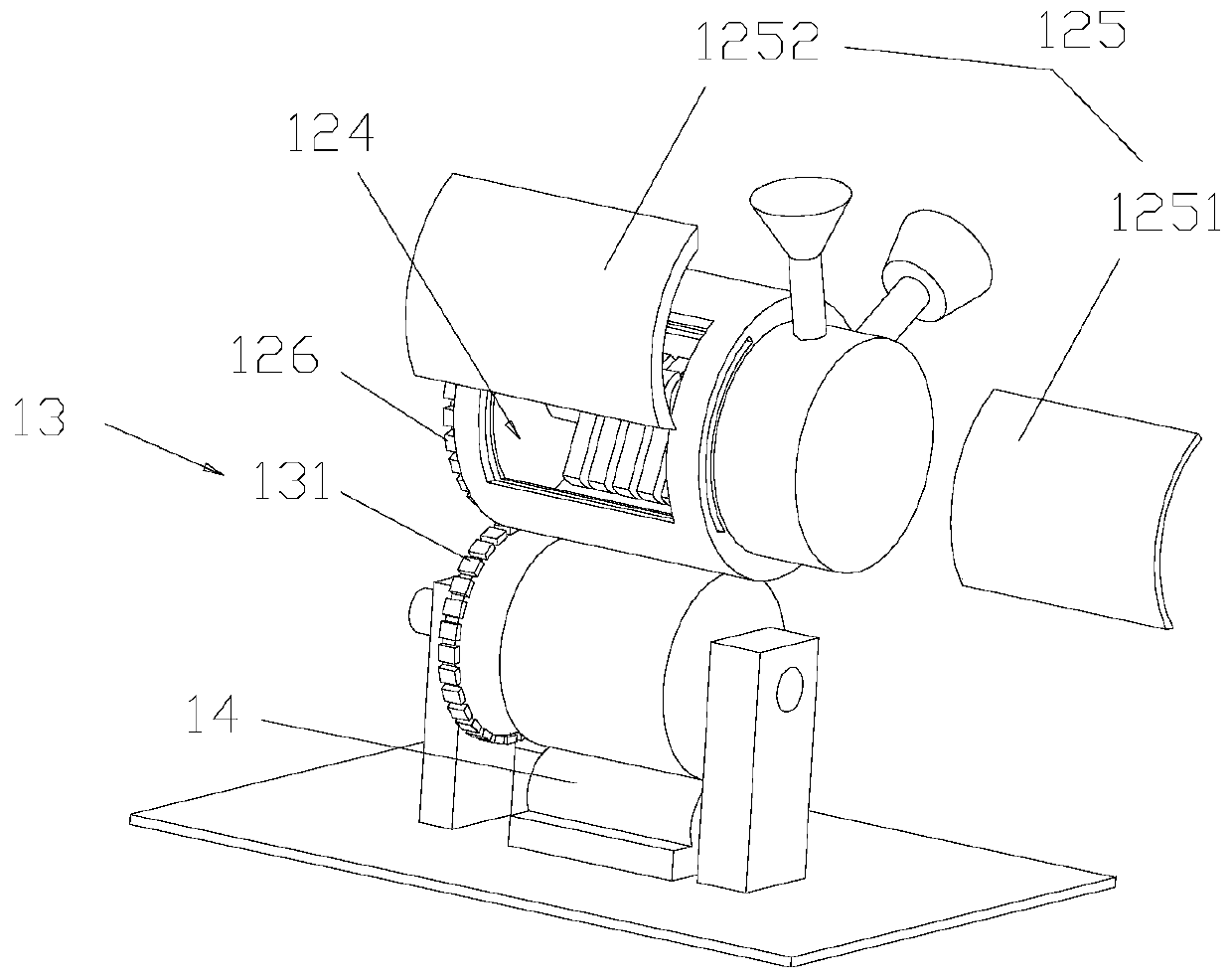

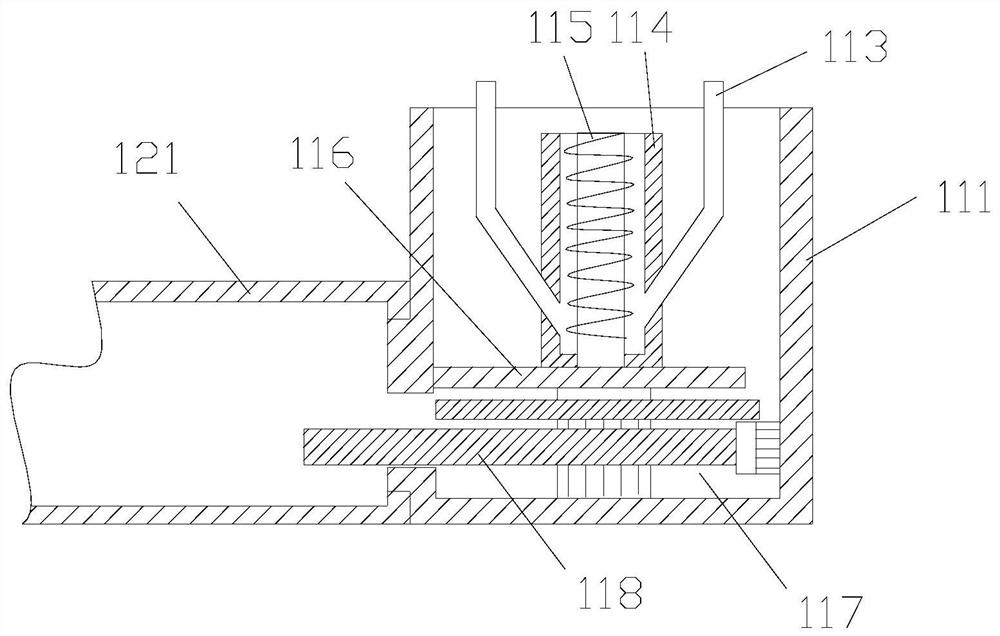

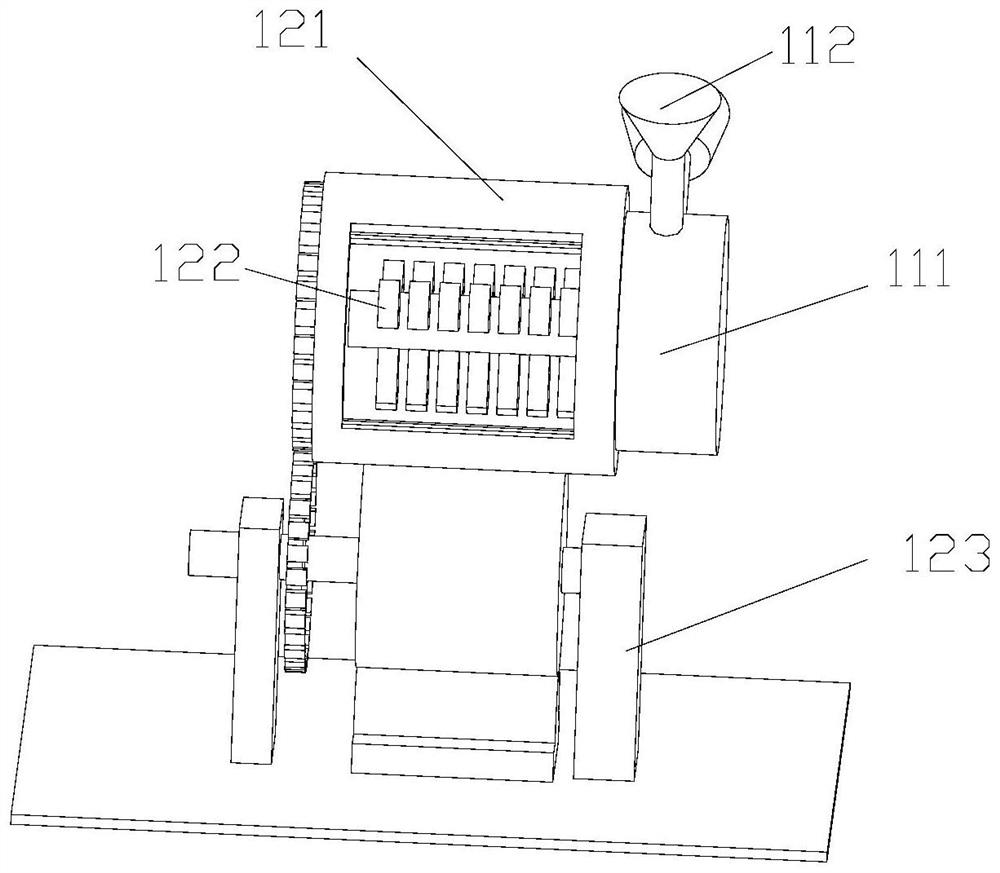

Modified starch stirring machine for pasta processing

ActiveCN112516855BEasy to take outAutomatic collectionBio-packagingRotary stirring mixersProcess engineeringPasta processing

The invention relates to a stirring machine, in particular to a modified starch stirring machine for pasta processing. Provided is a modified starch stirring machine for pasta processing, which can automatically stir, has high work efficiency, and saves a lot of labor costs. A machine for stirring and producing modified starch for pasta processing comprises: a bottom plate; a stirring mechanism, mounted on the bottom plate, and stirring by rotating; a feeding mechanism, mounted on the bottom plate, and feeding by rotating. The invention can replace the manual stirring of starch in the material holding frame through the stirring mechanism, save a lot of manpower, and improve people's work efficiency. The material holding frame can be knocked to prevent starch from sticking to the inner wall of the material holding frame and causing waste, and the water filling mechanism can be used to add water to the material holding frame.

Owner:河北省五星面业有限公司

Kneading equipment for cooked wheaten food processing

InactiveCN113647423AImprove work efficiencyExcellent kneading performanceMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsElectric machineryPasta processing

The invention relates to kneading equipment, in particular to kneading equipment for wheaten food processing. The technical problem of the invention is to provide the kneading equipment for wheaten food processing, which is automatic in kneading, good in kneading effect and convenient to operate. The kneading device for cooked wheaten food processing comprises a support frame; a dough kneading assembly which is arranged on one side of the upper part of the support frame; and a feeding assembly which is arranged on the lower side of the dough kneading assembly. The cover plate is pulled upwards under the action of the dough kneading assembly, and then flour and water are placed in the stirring barrel; then the motor is started, and an output shaft of the motor drives the first transmission shaft to rotate; at the moment, a tool is used for blocking a stop block, a first transmission shaft can drive a stirrer to rotate, and the stirrer can stir flour and water; and the working efficiency of people is effectively improved.

Owner:韦华新

A kind of pasta processing equipment

InactiveCN106472622BAvoid inhomogeneityThorough and convenient cleaningMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsControl valvesPasta processing

The invention belongs to the equipment for making or treating dough, and particularly discloses cooked wheaten food processing equipment. The cooked wheaten food processing equipment mainly consists of a barrel body, a stirring assembly, a dough mixing board assembly, a dough cleaning board assembly and a cleaning assembly, wherein a water inlet is formed in the top of the cleaning assembly, a water inlet pipe is connected to the bottom end of the water inlet, a cleaning water tank is connected to the bottom end of the water inlet pipe, and the cleaning water tank is made of nonmagnetic materials, and can communicate with the stirring assembly in a crossing manner; springs are fixed to one side of the bottom end of the cleaning water tank, an elastic block which can be attracted by magnetic substances is connected to a free end of each spring, a water outlet is formed in one side, close to each elastic block, of the cleaning water tank, and the diameter of each elastic block is larger than that of each water outlet; a magnet is arranged at the top of each stirring tooth at one end of a connecting plate; a cavity is formed in the inner wall of the barrel body, liquid is loaded in the cavity, and a heating device is arranged in the cavity; and a waste discharge opening is formed in the bottom of the barrel body, and a control valve is arranged at the waste discharge waste discharge. According to the cooked wheaten food processing equipment disclosed by the scheme of the invention, dough mixing water temperature can be controlled so that different dough can be made, and the dough is simple and rapid to clean.

Owner:山东娜瑟觅尔食品有限公司

Golden pocket food processing line device

A golden pocket food processing line device belongs to a noodle food processing line device. Contains vertical adjustment handwheel, front pressing roller device, surface conveying frame, entering surface conveying frame, entering surface conveying frame, probe, middle pressure surface roller device, horizontal adjusting handwheel, surface conveying frame, rear pressure Surface roller device, servo motor, main control box, thread composite pressure roller, conveying roller, box body of blanking knife mold device, code counter, column bracket, glass cover, blanking knife mold, conveyor belt, workbench, support frame , integrated circuit, rear pressing device box, motor, electric wire, middle road pressing device box, switch box, front pressing device box. Designed by combining computer closed-loop technology and mechanical principles, the device can automatically press noodles, fold and press, and product forming, getting rid of the original manual operation, and realizing the automatic assembly line production of products. The equipment is advanced and safe, ensuring Product quality and sanitation have improved product production efficiency.

Owner:YANCHENG XIANGLV FOOD

Dough mixer capable of automatically cleaning inner wall and having automatic quantitative feeding function

InactiveCN112913872AConvenient processing workImprove work efficiencyMixing/kneading structural elementsHollow article cleaningElectric machineryProcess engineering

The invention discloses a dough mixer capable of automatically cleaning the inner wall and having an automatic quantitative feeding function. The dough mixer comprises a bottom plate, and a hydraulic telescopic rod is fixedly connected to the axis of the top of the bottom plate. Through cooperative use of a first motor, a connecting plate, a connecting column, a first dough mixing barrel, a second dough mixing barrel, a first cover plate, a second cover plate, a second motor, a dough mixing rod, a driven gear, a threaded rod, a scraping plate, a water spraying hole, a limiting plate, a limiting rod, a driving gear, a third motor, a mounting seat and a controller, the dough mixer can mix dough while cleaning the inner wall, time and labor are saved, and the working efficiency is greatly improved; and through cooperative use of a solid flow meter, a flour inlet pipe, a moisture flow meter and a first water inlet pipe, feeding work can be automatically and quantitatively carried out, manual weighing and feeding by workers are not needed, the dough mixing efficiency is greatly improved, and great convenience is brought to cooked wheaten food processing work.

Owner:滕丽阳

Dough elasticity increasing mechanism based on cooked wheaten food processing

InactiveCN114568454AIncrease elasticityChange powerMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsThermodynamicsPasta processing

The invention relates to the technical field of cooked wheaten food processing, and discloses a dough elasticity increasing mechanism based on cooked wheaten food processing, which comprises a temperature adjusting mechanism, the temperature adjusting mechanism comprises a temperature guide rod, the top of the temperature guide rod is movably connected with a transmission air cavity, and the transmission air cavity is internally and movably connected with a push-pull plug. A sliding block is fixedly connected to the side, away from the transmission air cavity, of the push-pull plug, a reset spring is movably connected to the side, away from the push-pull plug, of the sliding block, an adjusting shifting piece is fixedly connected to the left side of the sliding block, and a rheostat is movably connected to the end, away from the sliding block, of the adjusting shifting piece. And at the moment, the resistance value of the rheostat in a circuit is changed, so that the power of the heating wire is increased or reduced, the heating value of the heating wire is changed, and the effects of automatically adding clear water according to the amount of flour, keeping the water temperature constant and improving the elasticity of dough are achieved.

Owner:李兴江

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com