Dough kneading mechanism for kelp noodles and wheaten food processing assembly line

A technology for noodles and kelp, which is used in dough mixers, structural components of mixing/kneading machines, food science, etc., can solve the problems of slow material discharge rate and small material output, and achieve full contact probability and good uniformity. , the effect of long contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

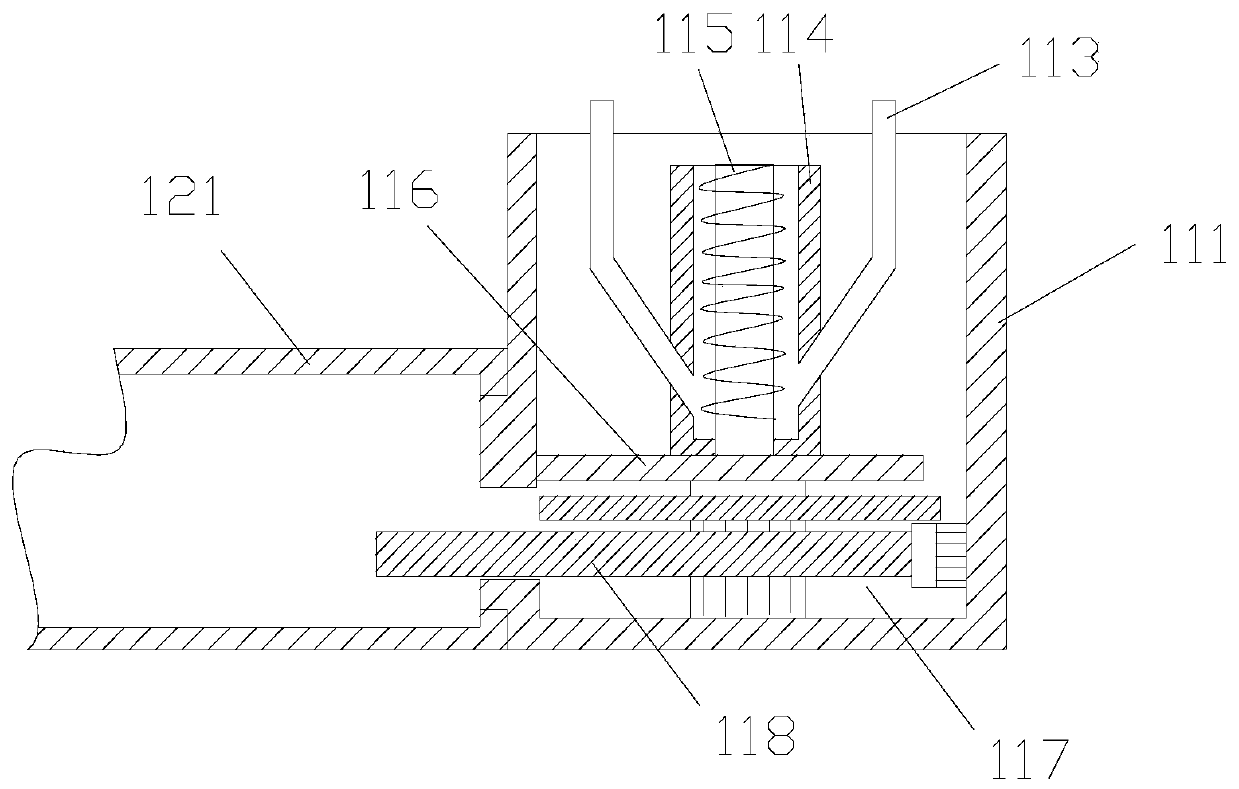

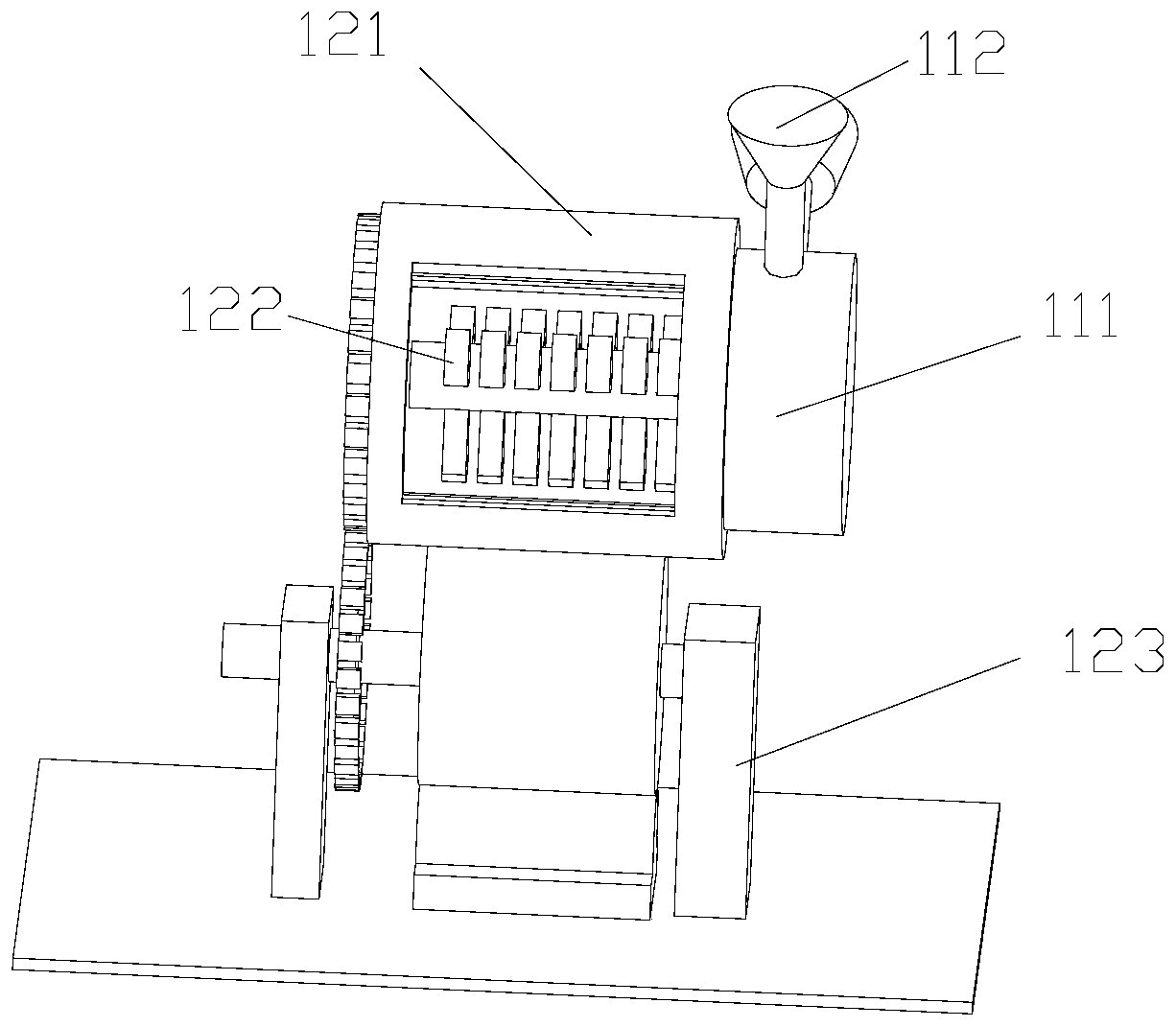

[0039] like figure 1 , 2 As shown, this embodiment discloses a kneading mechanism for kelp noodles, including a mixing device and a stirring and kneading device. The mixing device is used for pre-mixing various raw materials for processing noodles, and the stirring and mixing device is used for mixing the materials pre-mixed by the mixing device.

[0040] The mixing device includes a mixing housing 111 , a feeding funnel 112 , a feeding pipe 113 , a mixing bin 114 , a first auger 115 , a partition 116 , an extrusion bin 117 , and a second auger 118 . The mixing bin 114 is disposed in the inner cavity of the mixing housing 111 , and the top of the mixing bin 114 is open.

[0041] The top of the mixing housing 111 is provided with a plurality of feeding ports, and each feeding port is provided with a feeding funnel 112 . A material guide channel is opened below the left side of the material mixing shell 111 .

[0042] The bottom of the feeding funnel 112 extends into the int...

Embodiment 2

[0049] like figure 2 , 3 , 5, the difference between this embodiment and the above-mentioned embodiment is that: the right end of the dough tube 121 communicates with the material guide channel through the bearing, and the first gear plate 126 is connected with the left end surface of the dough tube 121. A cylinder 13 is arranged at the bottom of the kneading cylinder 121 , and the cylinder 13 is tangent to the kneading cylinder 121 . A second gear plate 131 is connected to the left end surface of the cylinder 13, and the second gear plate 131 meshes with the first gear plate 126, and the first gear plate 126 is driven to rotate by a first motor, and the first motor is installed on the frame 123 .

[0050] The right end of the noodle cylinder 121 is communicated with the material guide channel through the bearing to realize the rotational connection between the noodle cylinder 121 and the mixing device, that is, the rotation of the noodle cylinder 121 will not drive the mix...

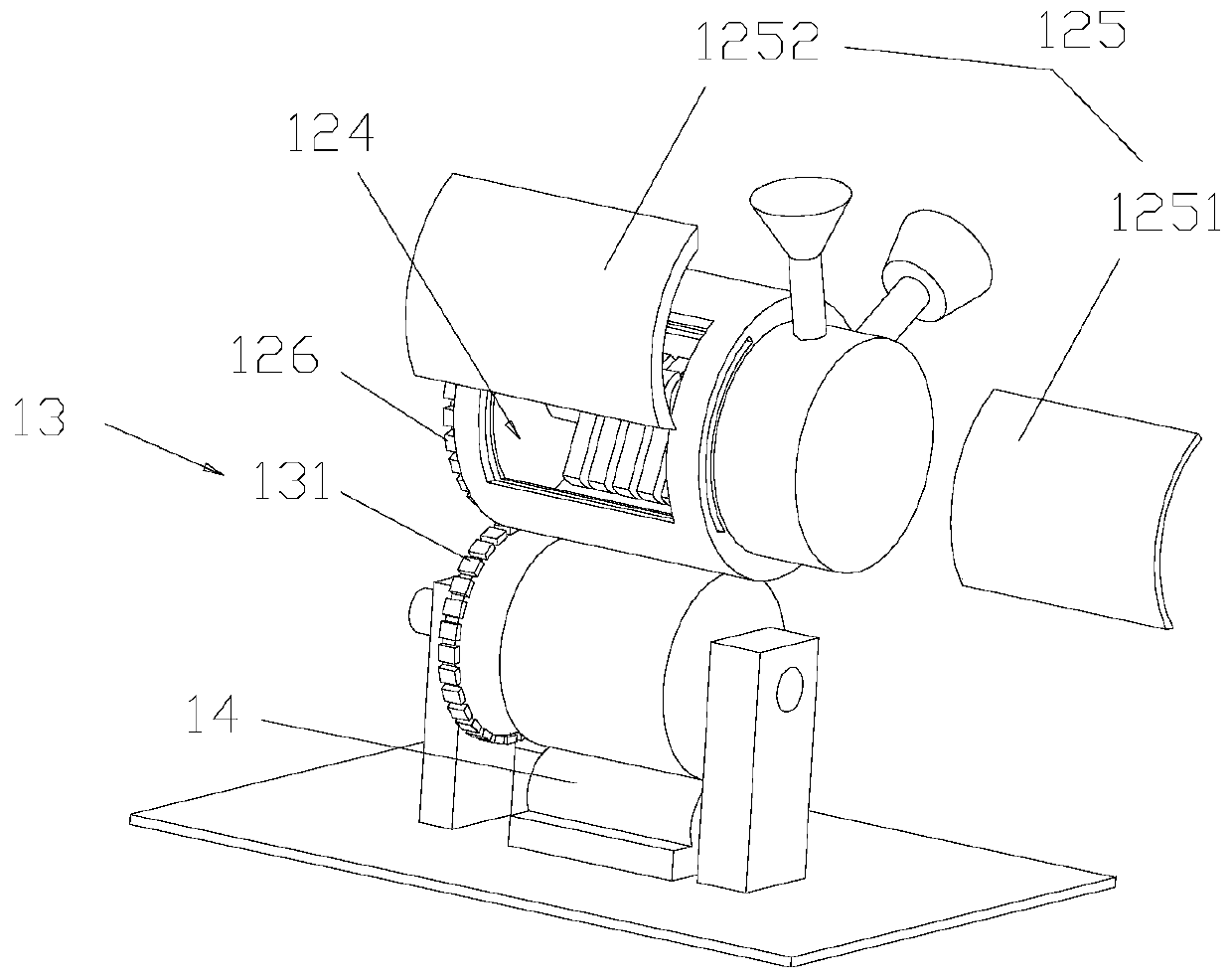

Embodiment 3

[0053] like image 3 , 4 As shown, the difference between this embodiment and the above-mentioned embodiments is that: the front and rear inner surfaces of the blanking opening 124 of the noodle cylinder 121 are all stepped structures, and the inner surfaces of the stepped structure divide the blanking opening 124 into upper ones. The upper discharge port area 1241 and the lower discharge port area 1242 located below. A through hole is also opened on the right side of the kneading cylinder 121 , and the projection of the through hole in the horizontal direction coincides with the projection of the drop opening area 1242 in the horizontal direction. The cover 125 includes a lower cover 1251 and an upper cover 1252 . The lower cover 1251 can completely cover the lower blanking area 1242 through the through hole, and the upper cover 1252 can completely cover the upper blanking area 1241. The inner surfaces are all provided with magnetic blocks capable of attracting each other....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com