Patents

Literature

1292results about "Mixing/kneading structural elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

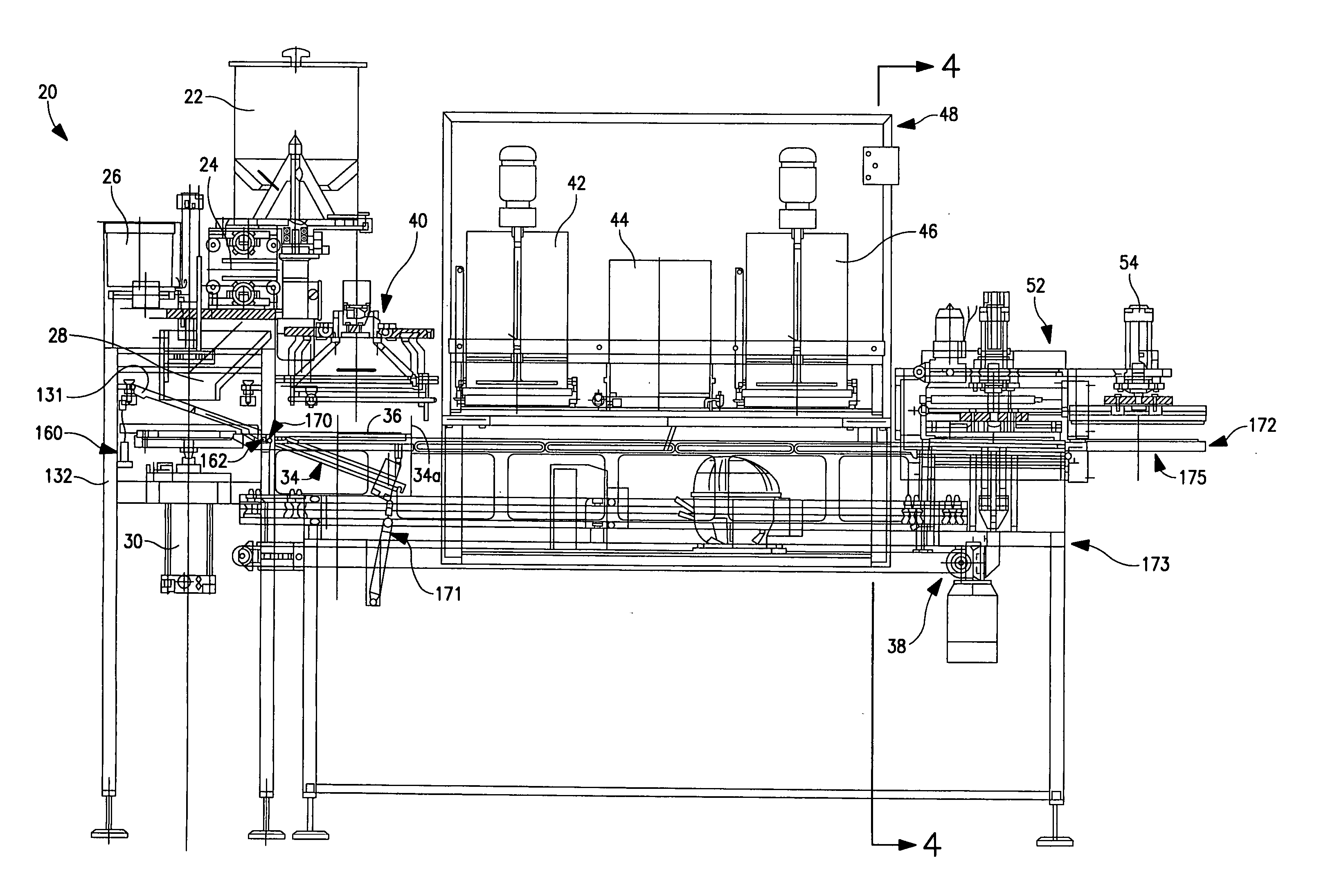

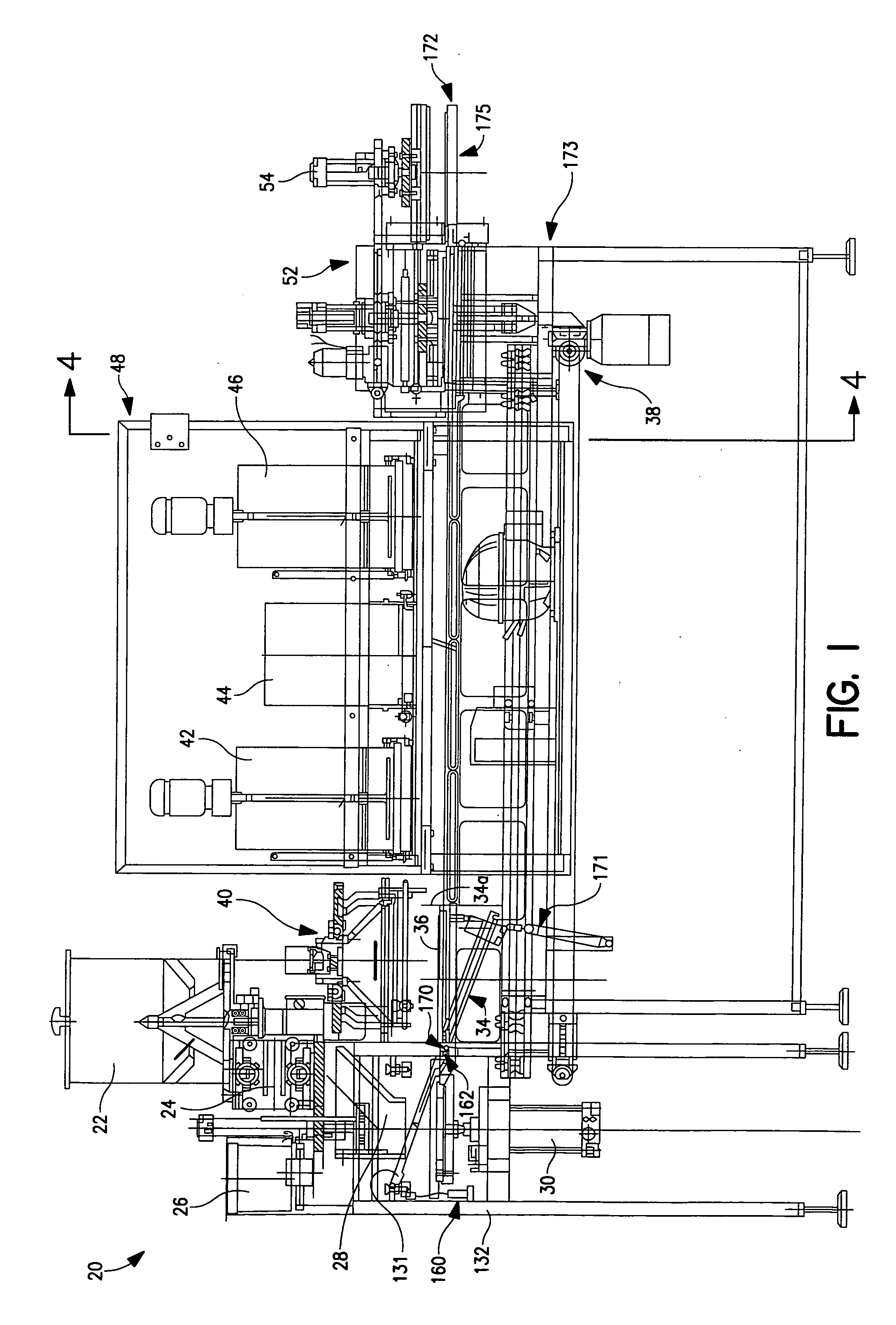

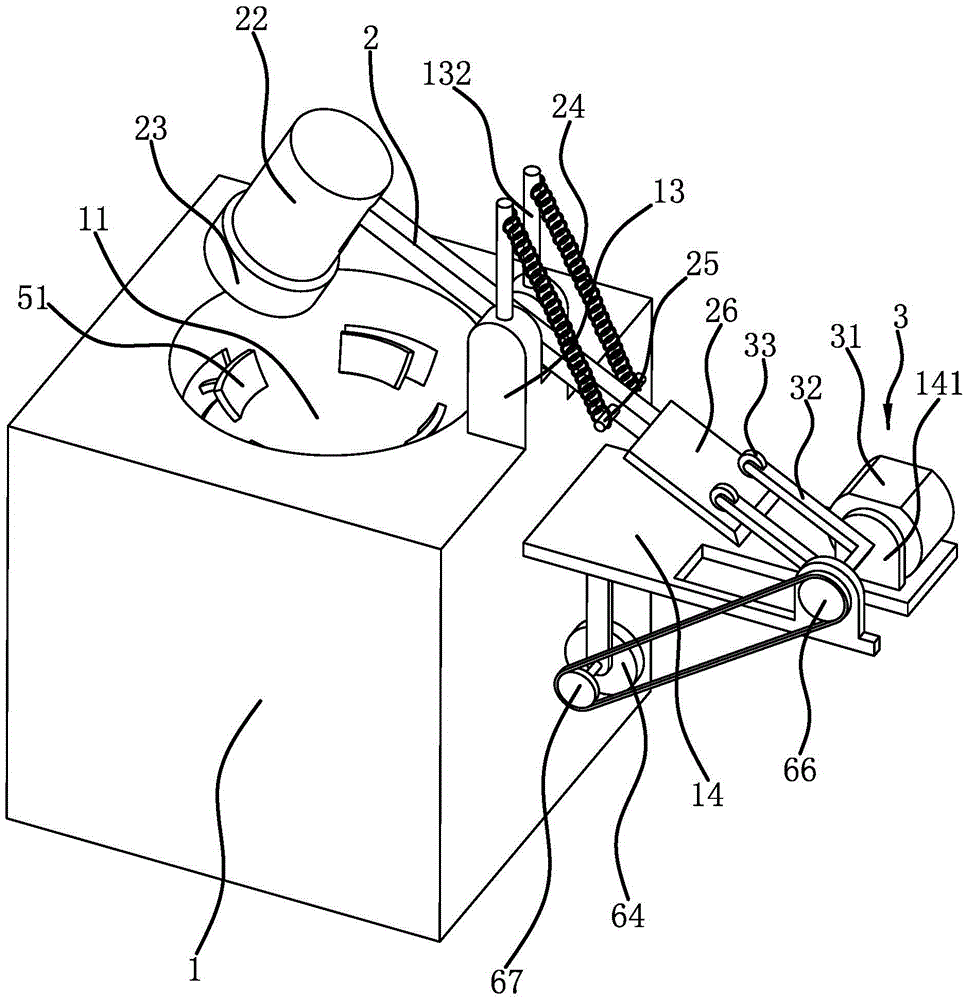

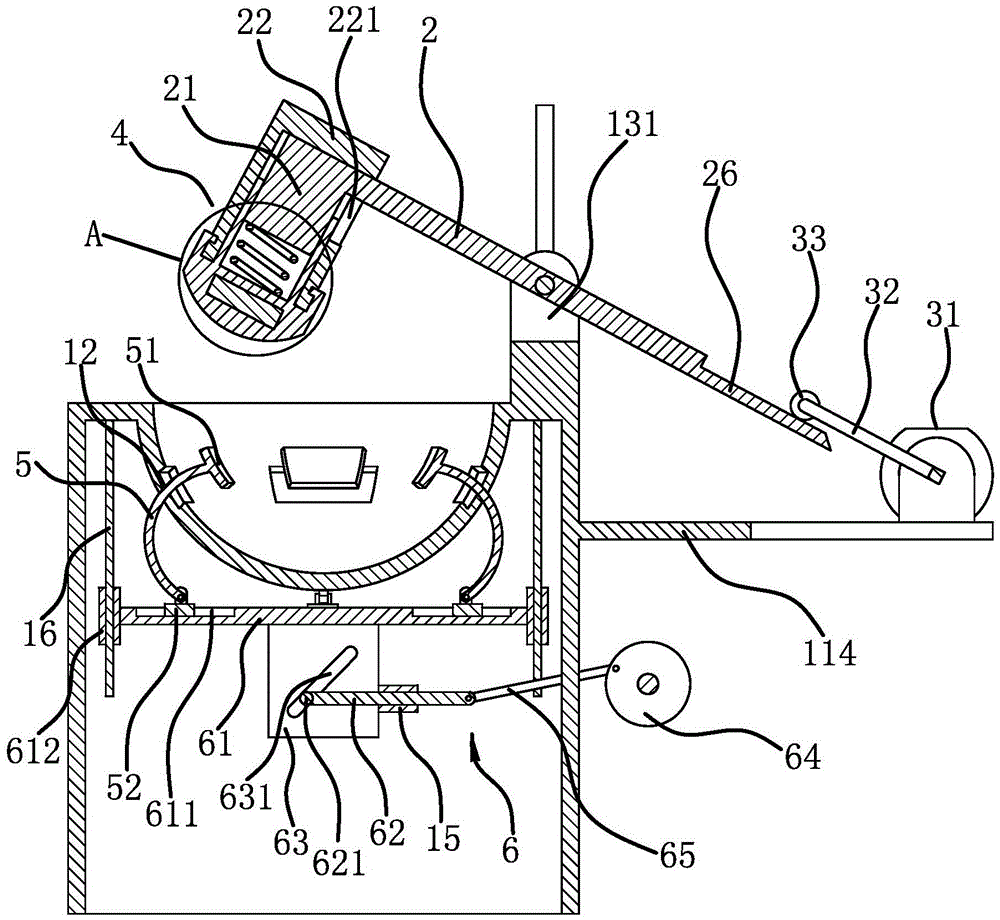

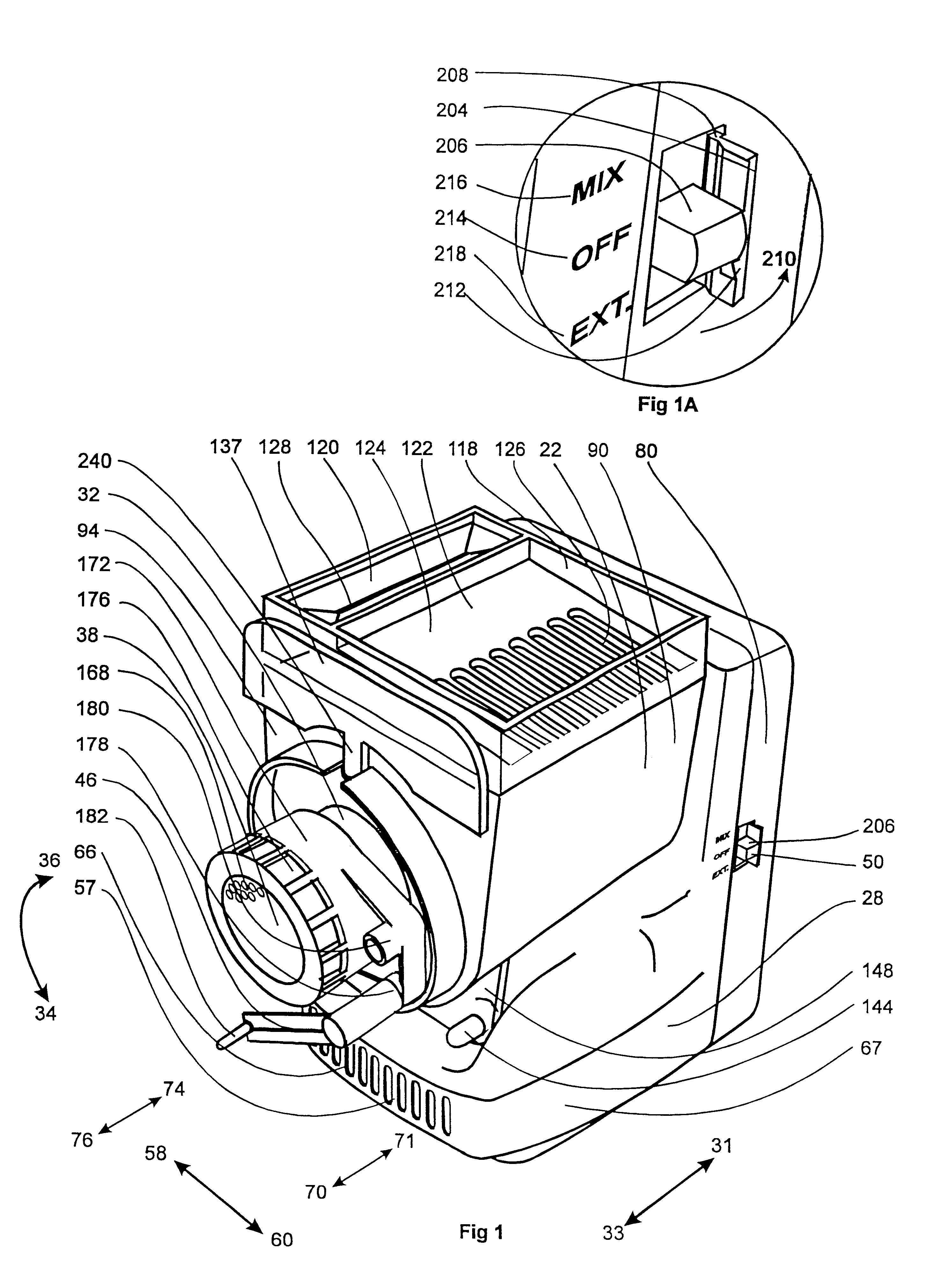

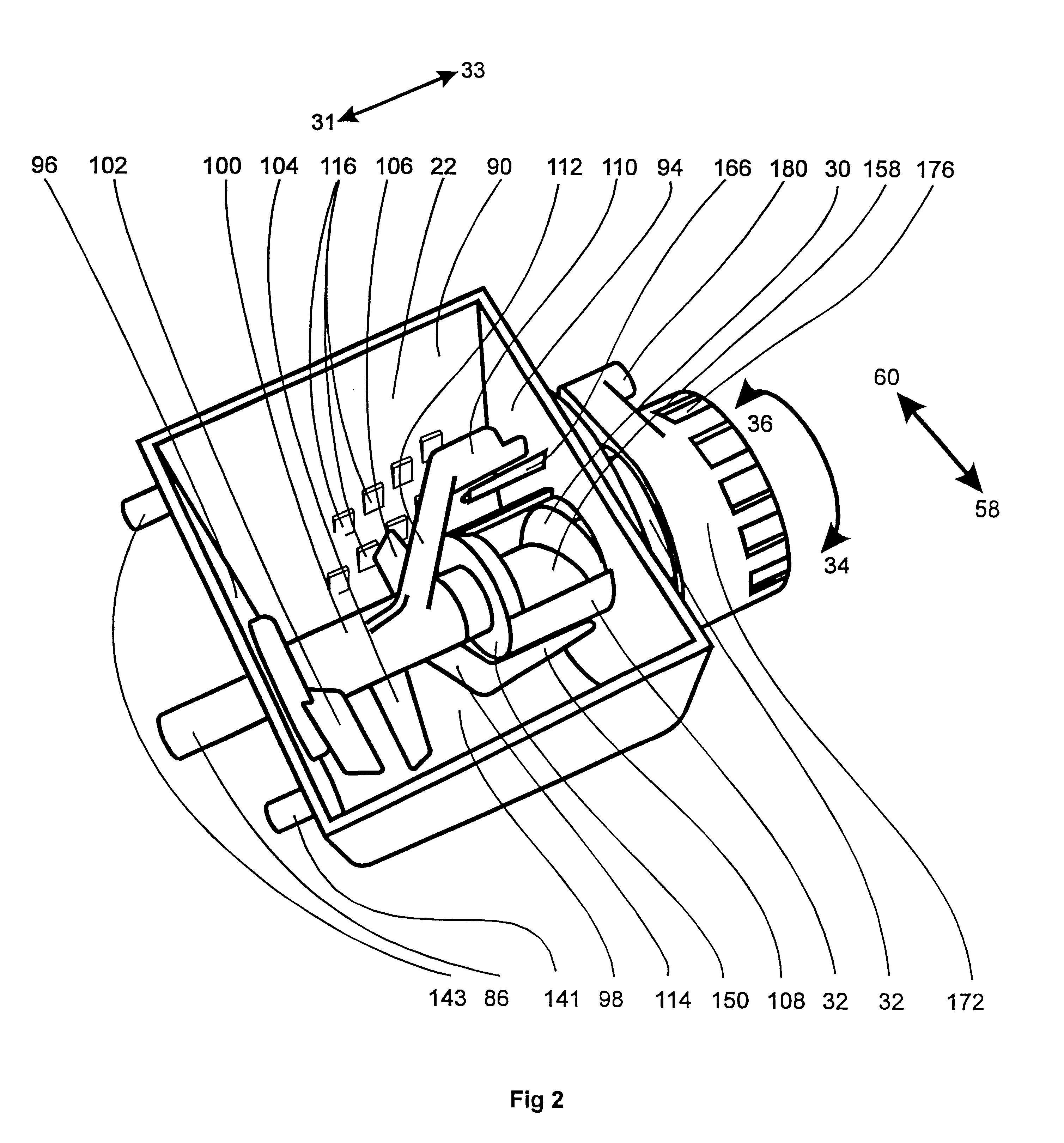

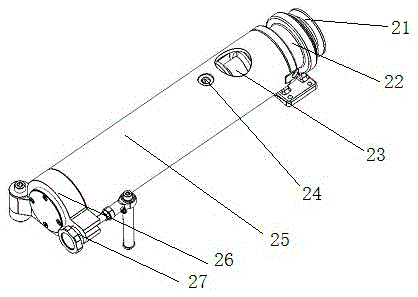

Pizza making method and system

InactiveUS6915734B2Simple and compact designMeet actual needsTransportation and packagingRotary stirring mixersCooking & bakingAdditive ingredient

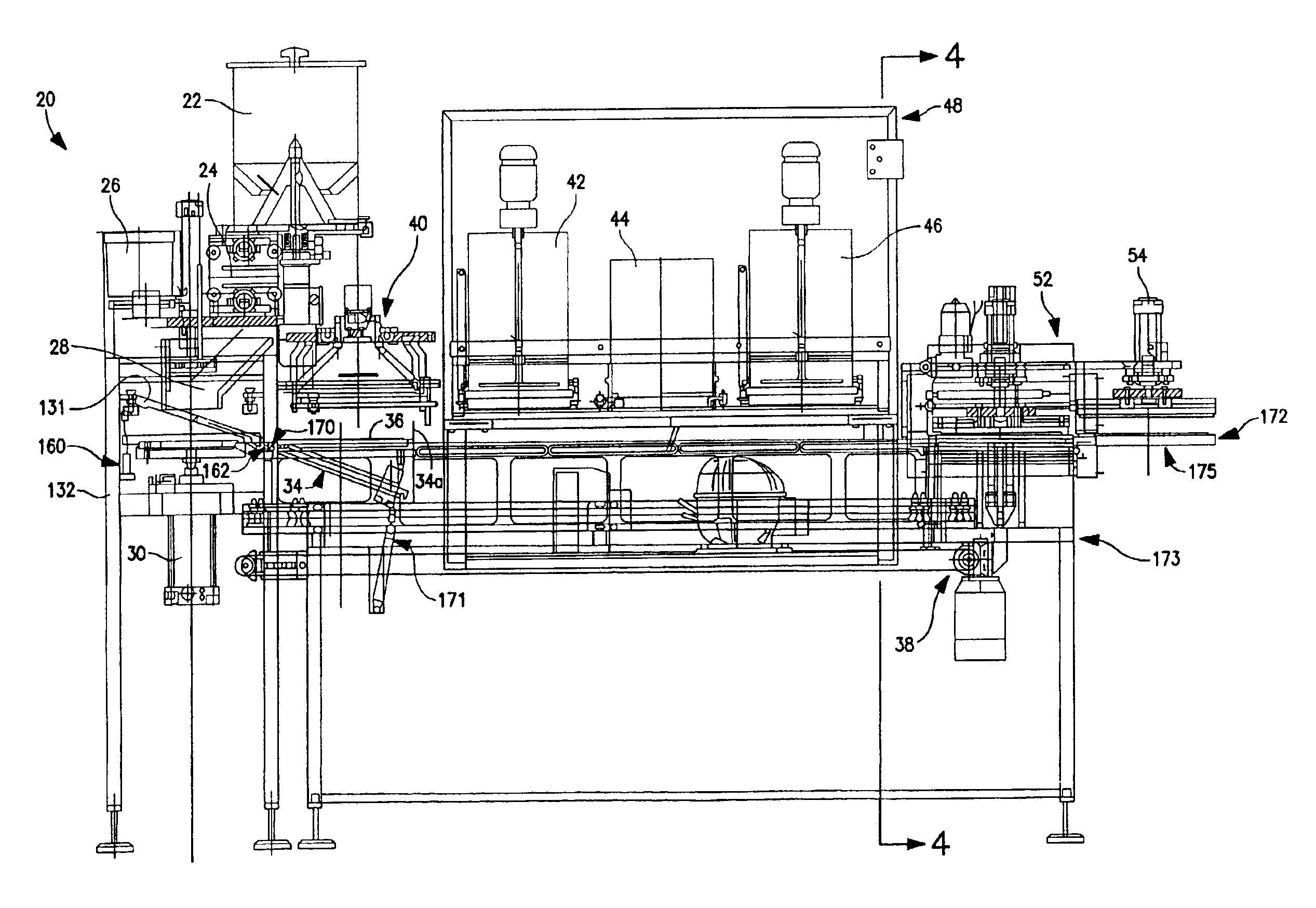

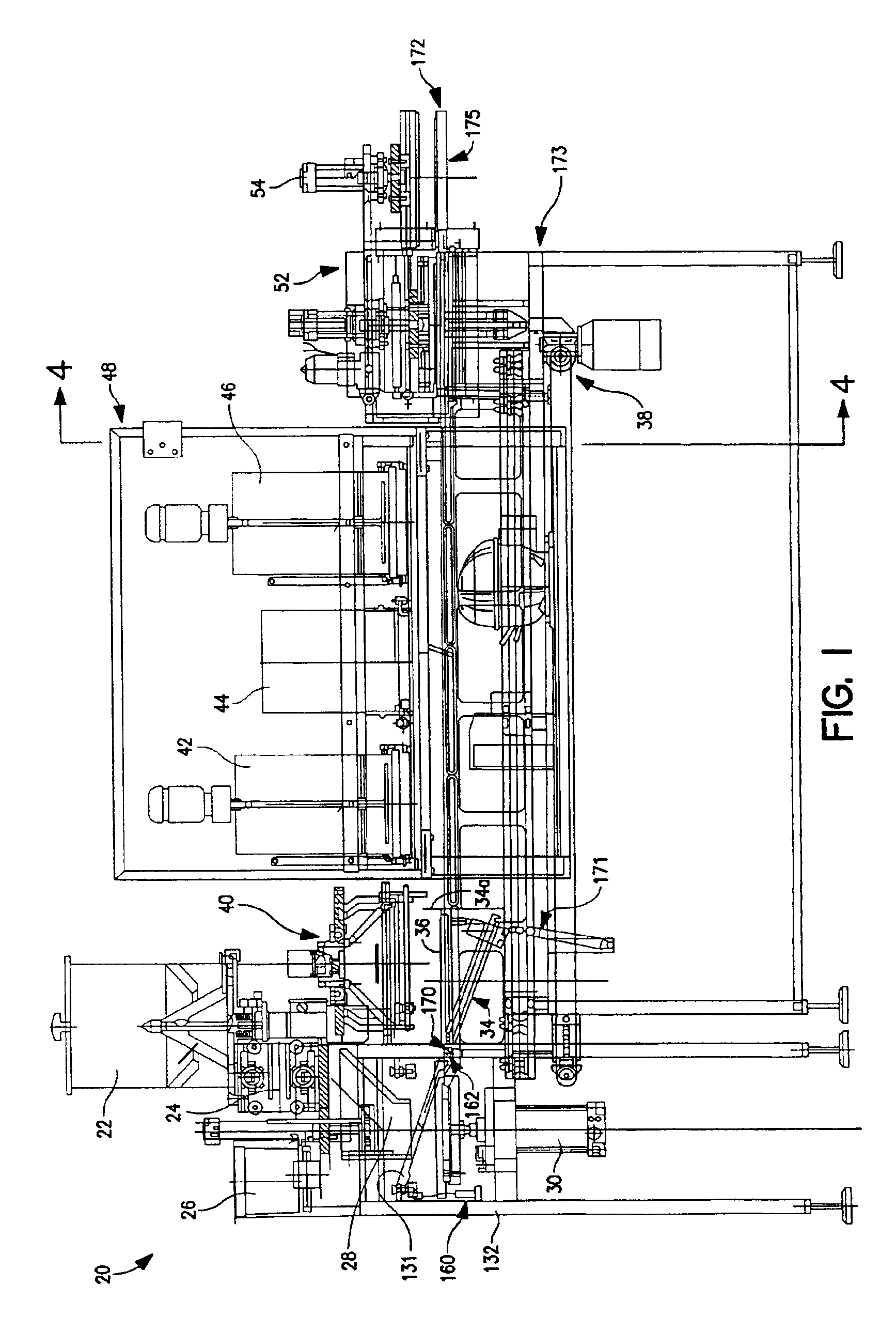

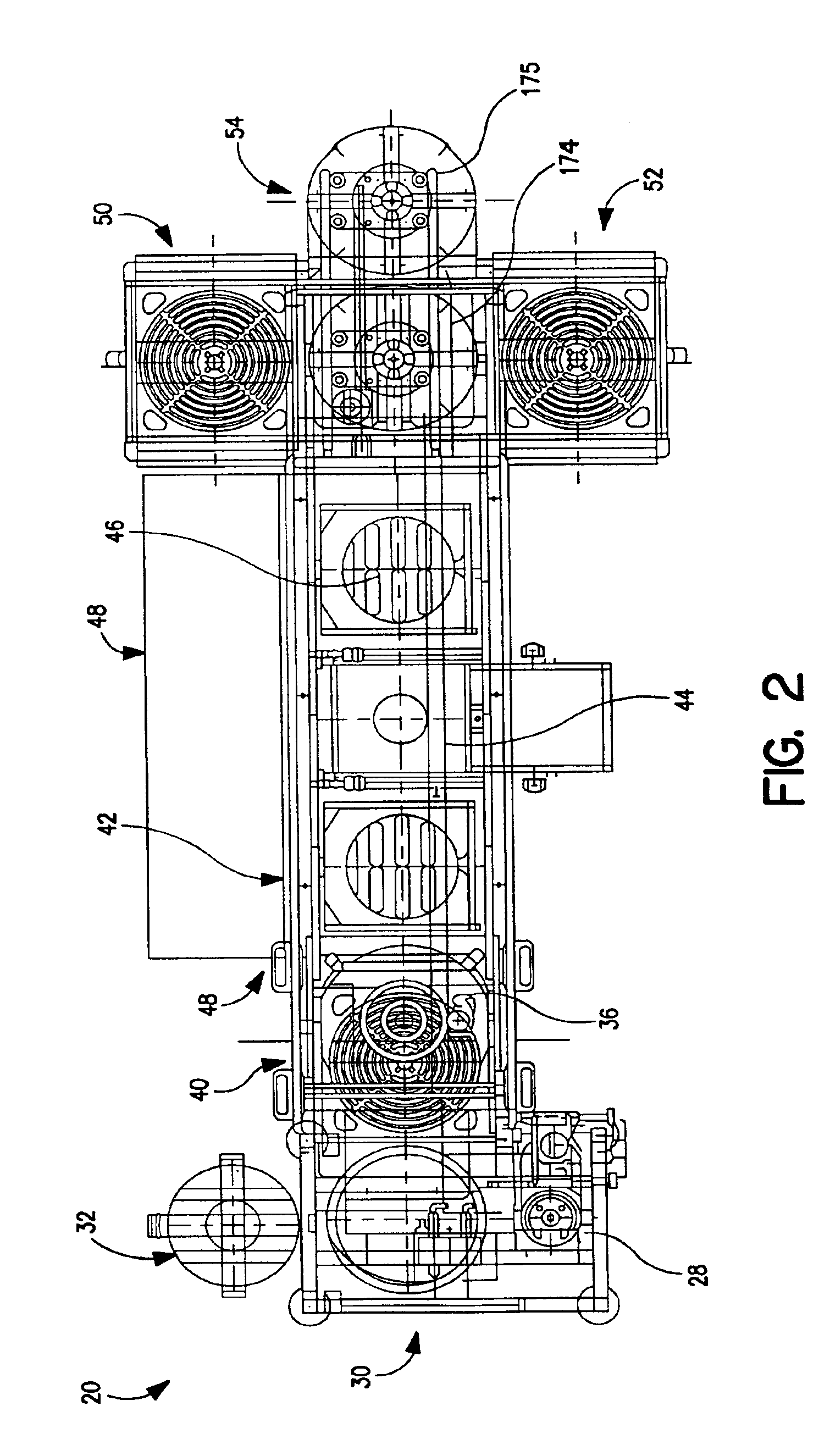

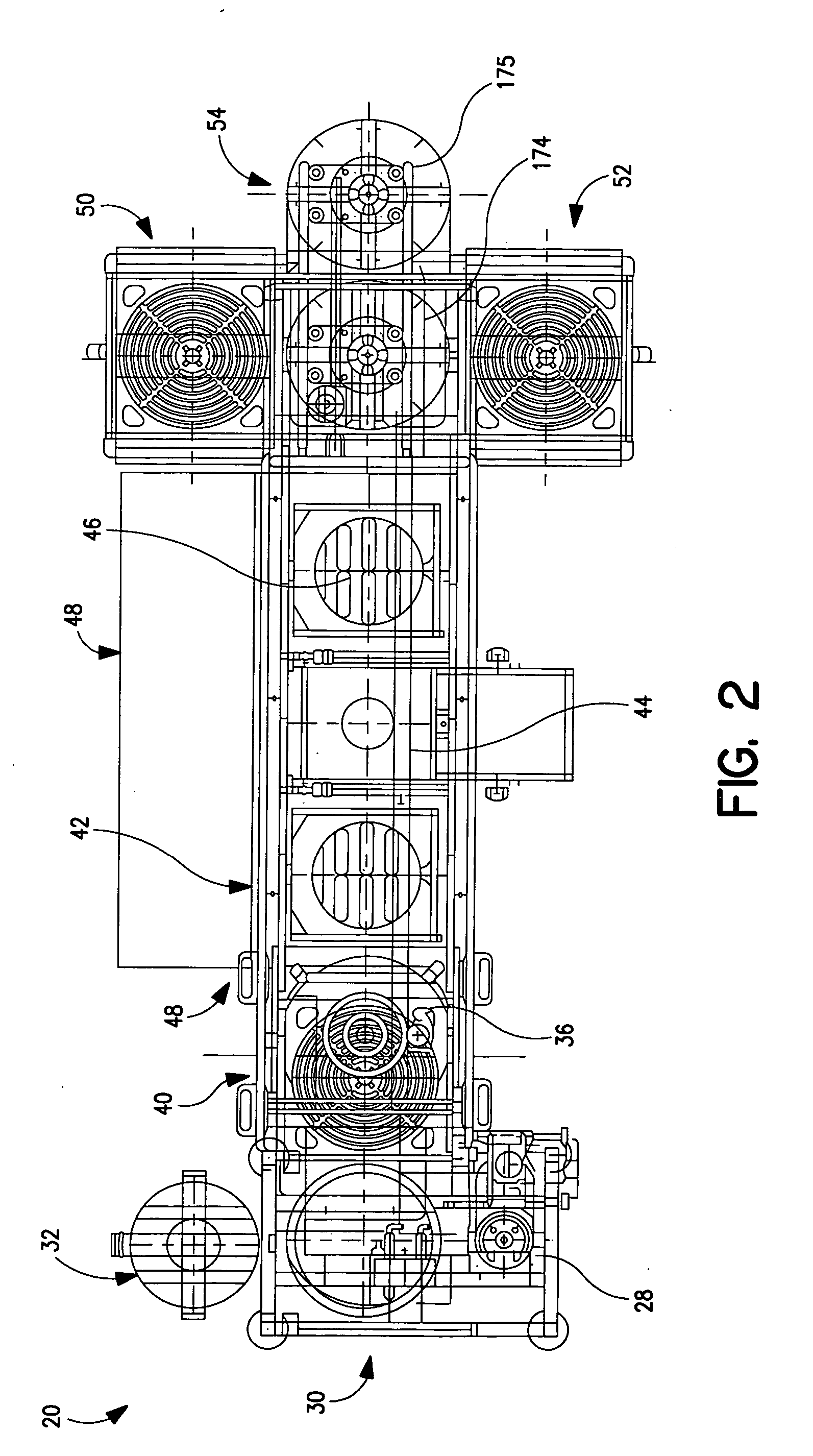

The invention provides an automated method and apparatus for pizza production which is initiated by individual order placement and uses only fresh ingredients (no ingredients are frozen, pre-prepared or pre-cooked). Each dough portion is individually and mechanically prepared from flour and other fresh, pre-proportioned ingredients. The dough portion passes through a series of shaping and pre-heating processing stations to prepare a flattened and partially baked pizza base. Using a preheated or continuously heated conveying tray, the pizza base passes under a number of metering and distribution devices for selected application of tomato sauce and / or various other toppings according to the order. Baking occurs in one of multiple ovens to complete pizza preparation. Multiple ovens are provided to facilitate the automated preparation of multiple pizzas at any given time. A tray conveying system transports one or more trays through the various processing stations to accommodate multiple orders at the same time.

Owner:SITOS

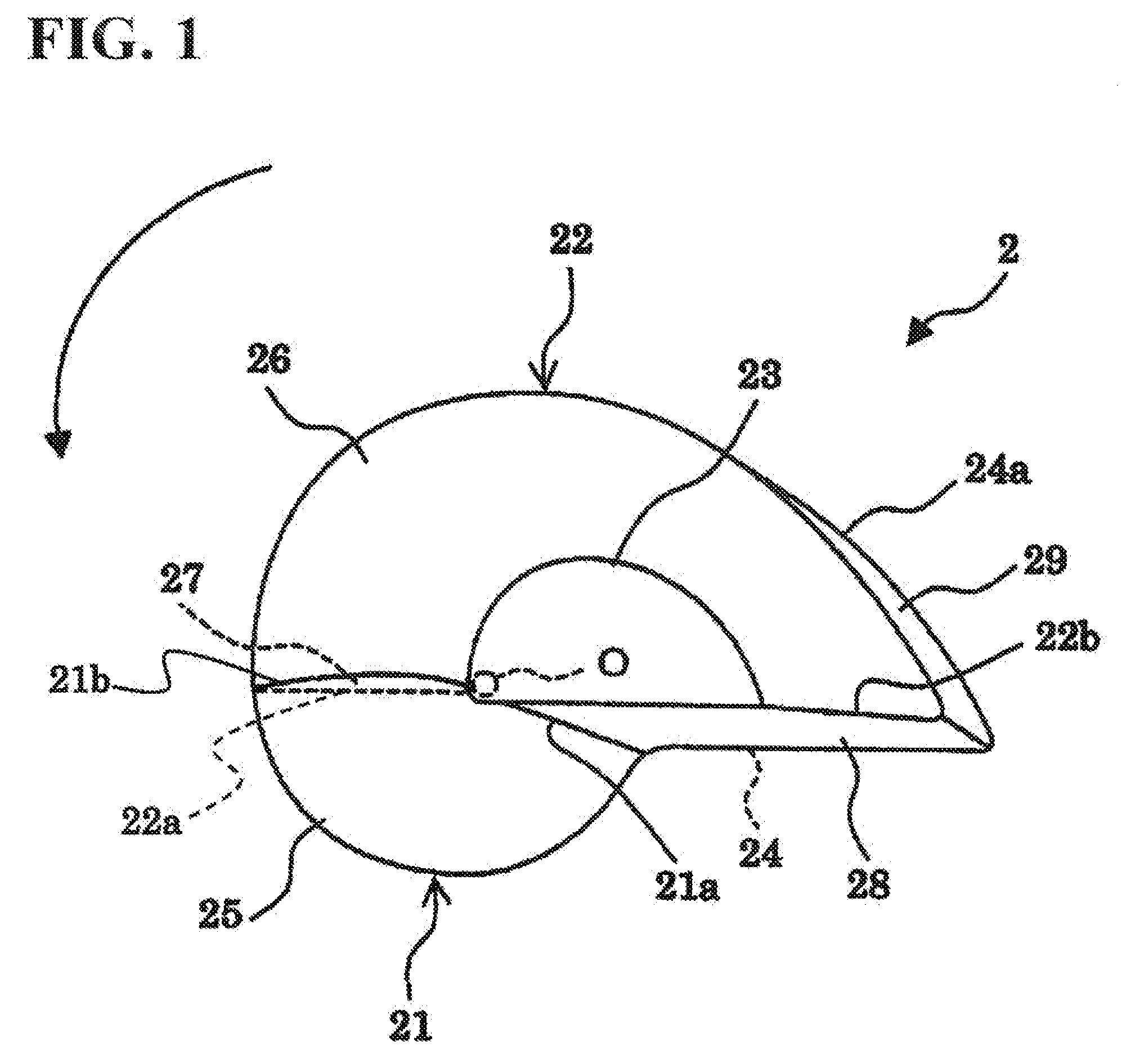

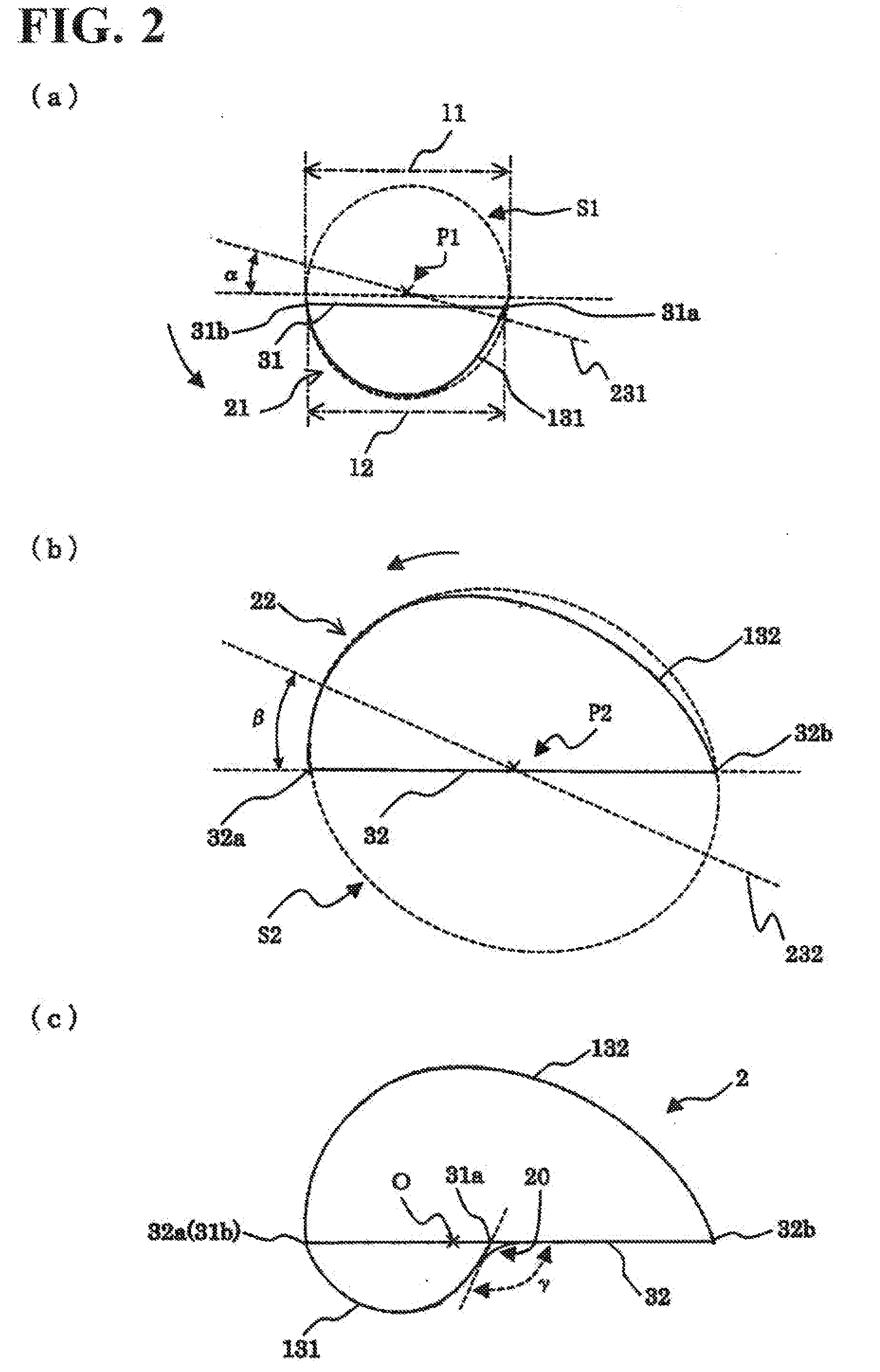

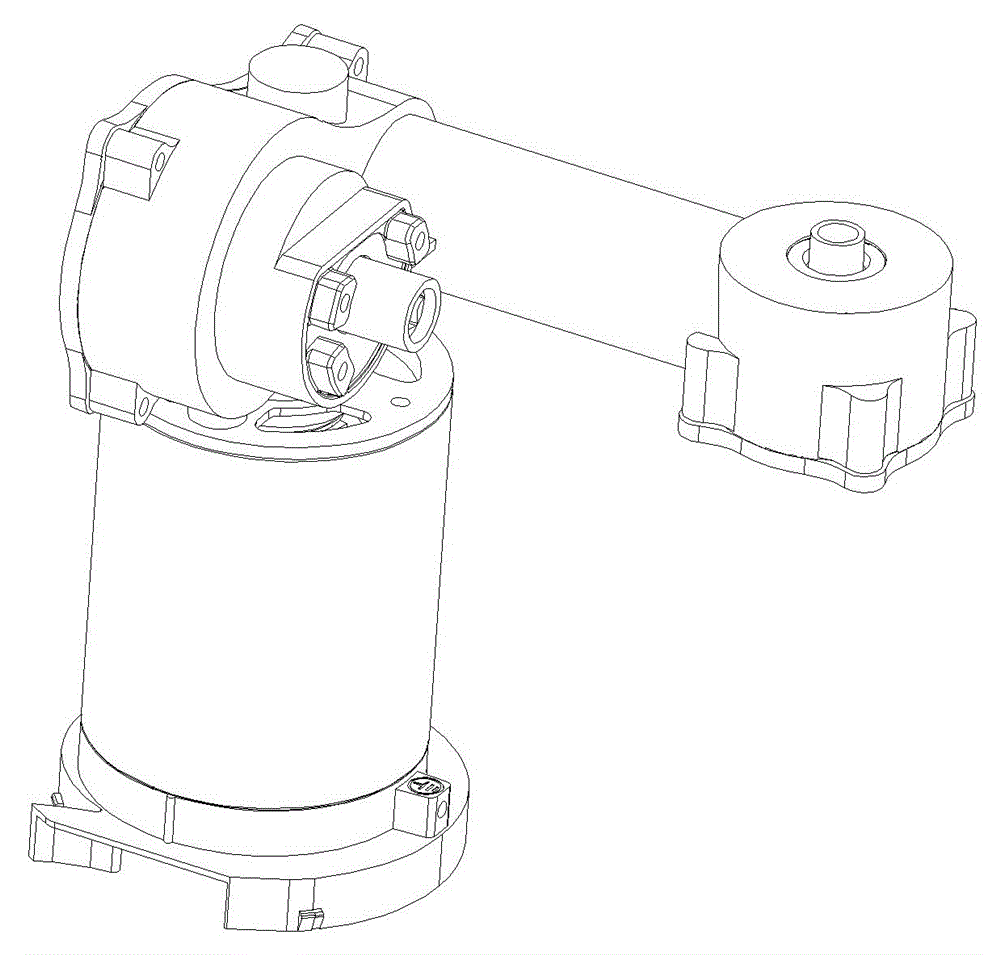

Kneading Element of Kneader, Kneader, and Bread Machine

InactiveUS20100147160A1Efficient kneadingReduce adhesionMixing/kneading structural elementsRotary stirring mixersMechanical engineeringEngineering

Owner:JAPAN KNEADER

Pizza making method and system

InactiveUS20050123659A1Simple and easy-to-clean cuttingEasy to separateRotary stirring mixersTransportation and packagingCooking & bakingAdditive ingredient

The invention provides an automated method and apparatus for pizza production which is initiated by individual order placement and uses only fresh ingredients (no ingredients are frozen, pre-prepared or pre-cooked). Each dough portion is individually and mechanically prepared from flour and other fresh, pre-proportioned ingredients. The dough portion passes through a series of shaping and pre-heating processing stations to prepare a flattened and partially baked pizza base. Using a preheated or continuously heated conveying tray, the pizza base passes under a number of metering and distribution devices for selected application of tomato sauce and / or various other toppings according to the order. Baking occurs in one of multiple ovens to complete pizza preparation. Multiple ovens are provided to facilitate the automated preparation of multiple pizzas at any given time. A tray conveying system transports one or more trays through the various processing stations to accommodate multiple orders at the same time.

Owner:SITOS

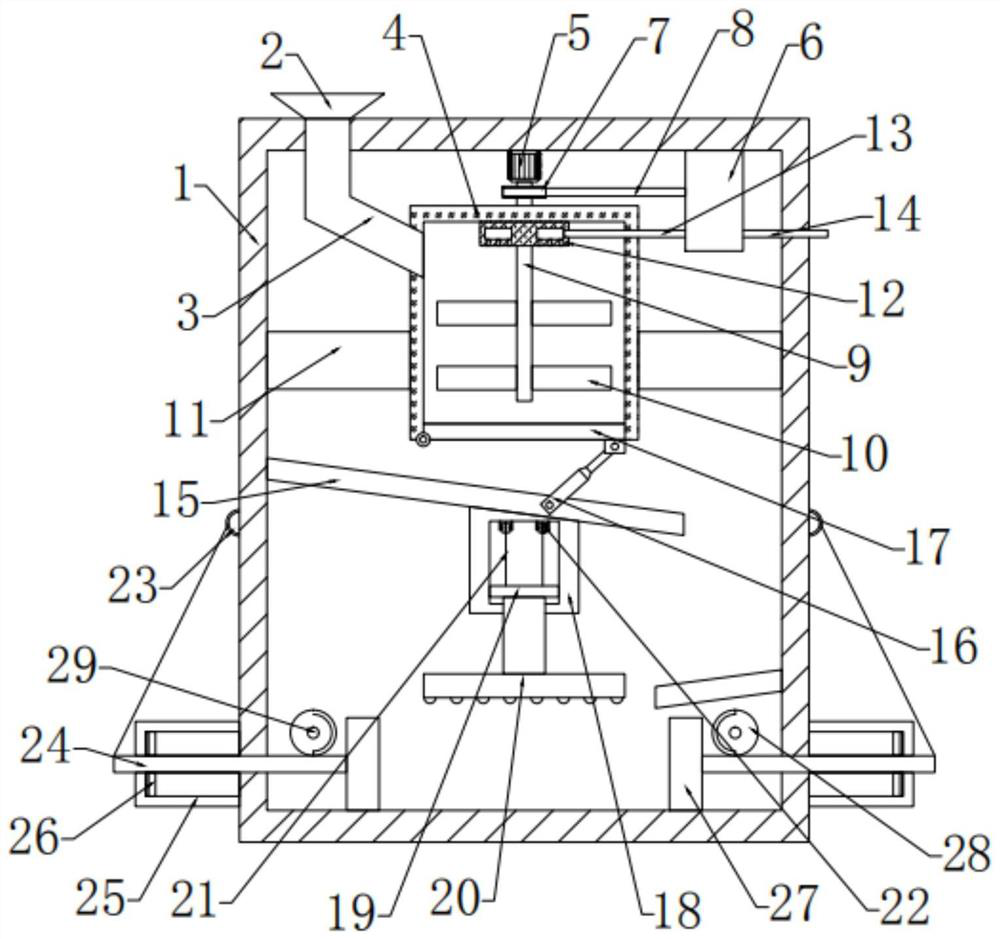

Dough kneading device for noodle production processing

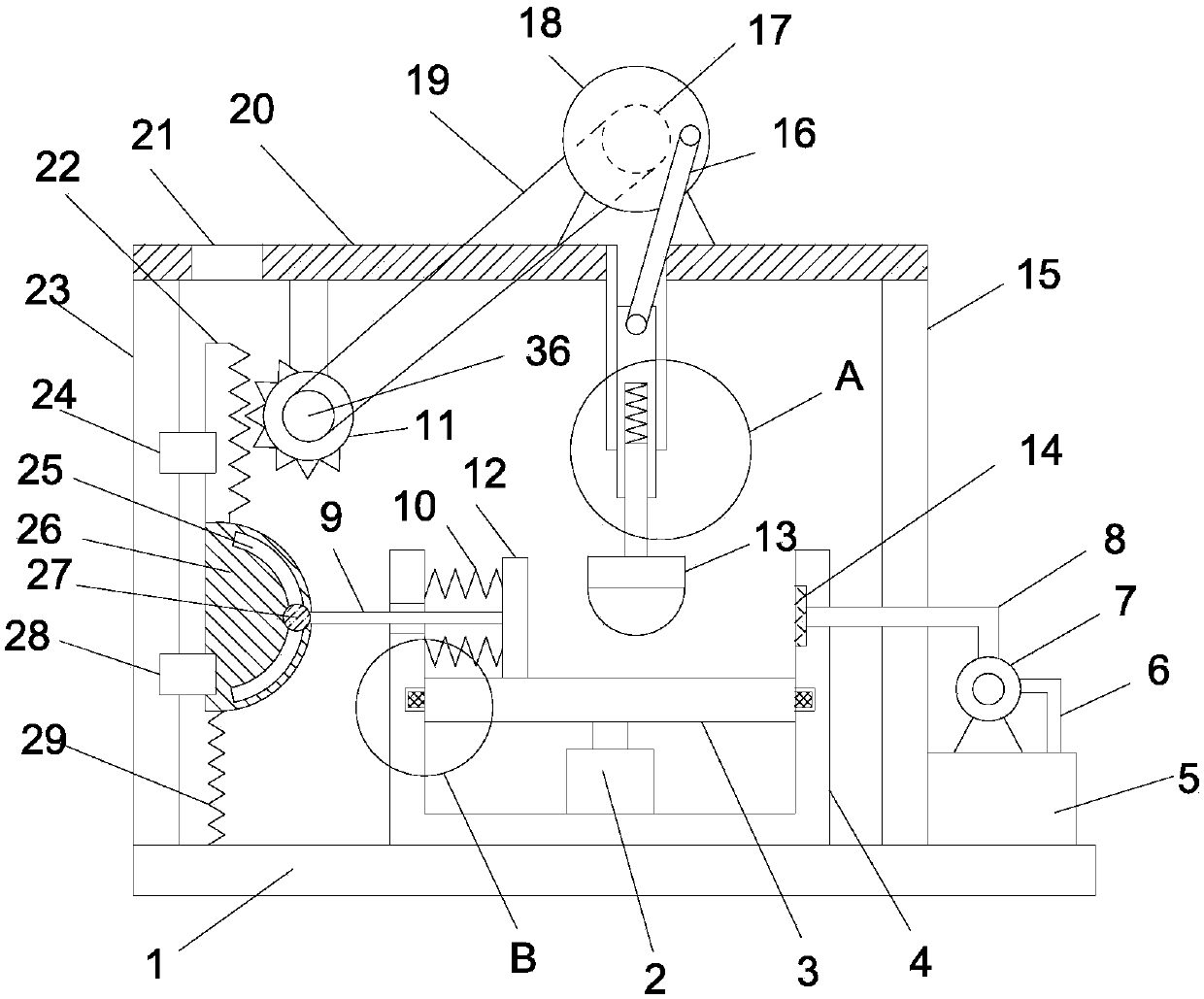

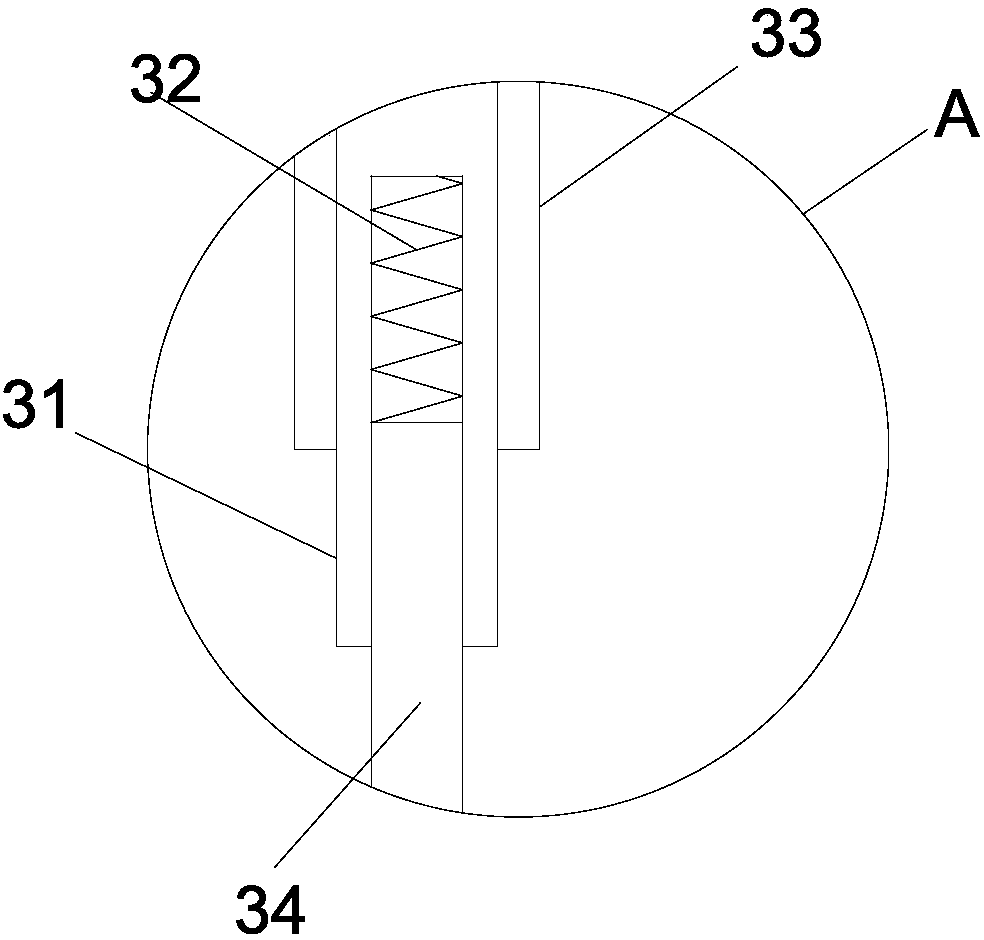

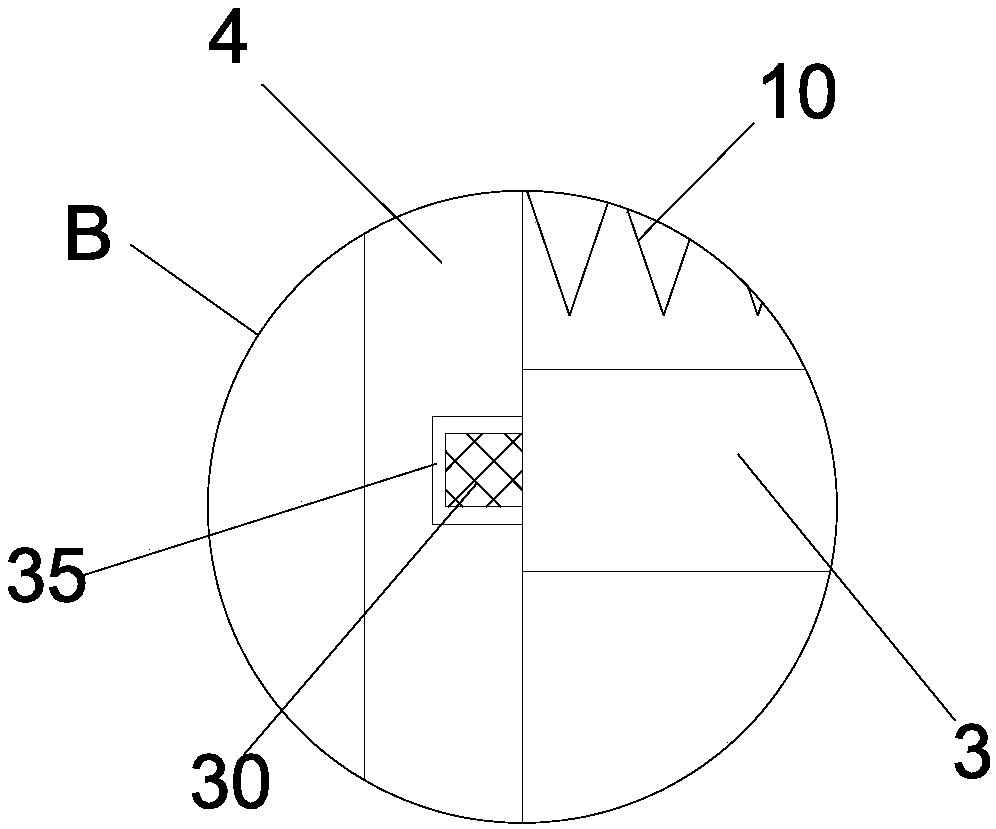

InactiveCN107549224AExtend squeeze timeReduce rigid impactMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsGear wheelReciprocating motion

The invention discloses a dough kneading device for noodle production processing. The device comprises a bottom plate, wherein a slide bar is vertically arranged in a spacing sleeve in a sliding manner; a connecting rod is connected between the slide bar and a rotating wheel; a segment gear is arranged on the lower bottom of a top plate in a rotating manner; a driven belt pulley is coaxially fixedly arranged on the segment gear, a driving belt pulley is coaxially fixedly arranged on the rotating wheel, transmission belts are wound on the driving belt pulley and the driven belt pulley, and a first spacing spring is arranged between a semi-circular block and the bottom plate; a push-pull rod is horizontally fixedly arranged on a spacing pin bolt; a dough kneading groove is fixedly formed inthe bottom plate, and a gear motor is arranged at the bottom of the dough kneading groove. According to the dough kneading device, a dough in the dough kneading groove is repeatedly extruded and kneaded by up-down reciprocating motion of a dough kneading briquette, and the dough is extruded by the dough kneading briquette and is rotated, so that the dough can be extruded in different positions; and the dough is extruded rightward intermittently by a push plate, so that the dough can be concentrated and sufficiently contacted with the dough kneading briquette, and the dough kneading efficiencycan be greatly increased.

Owner:融滋合味(上海)科技有限公司

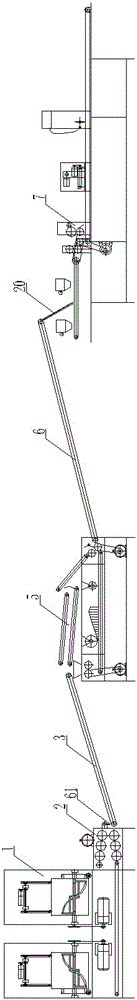

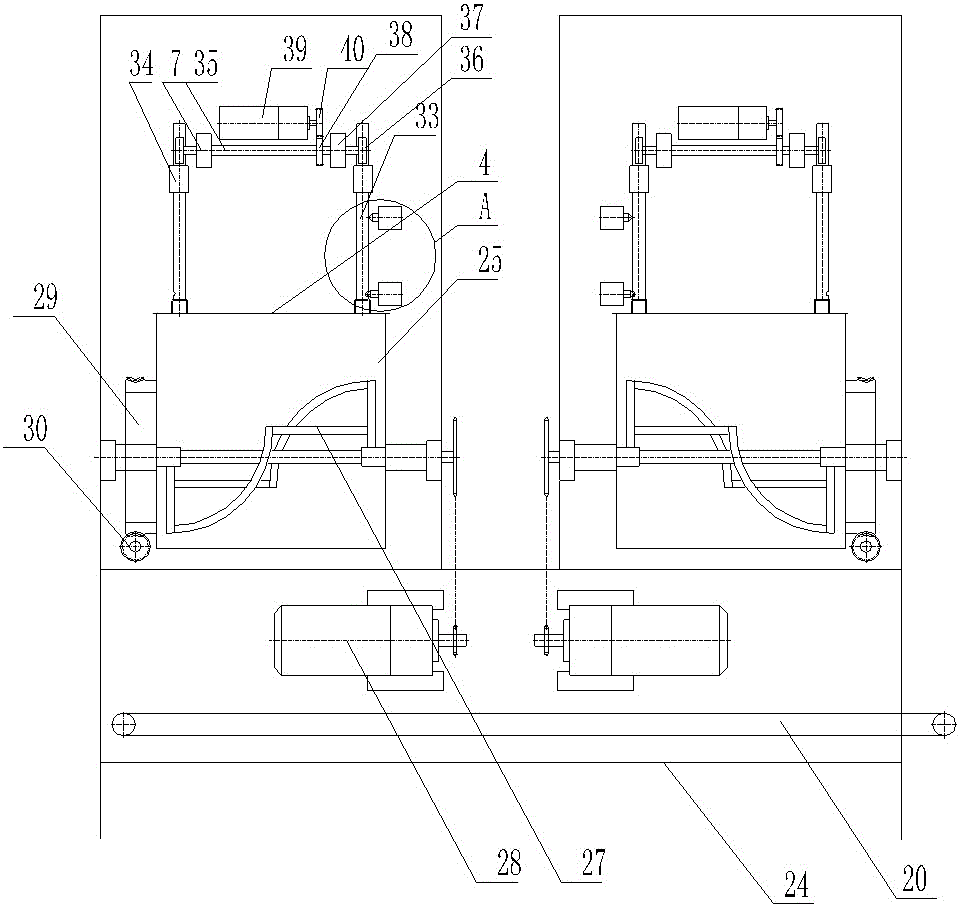

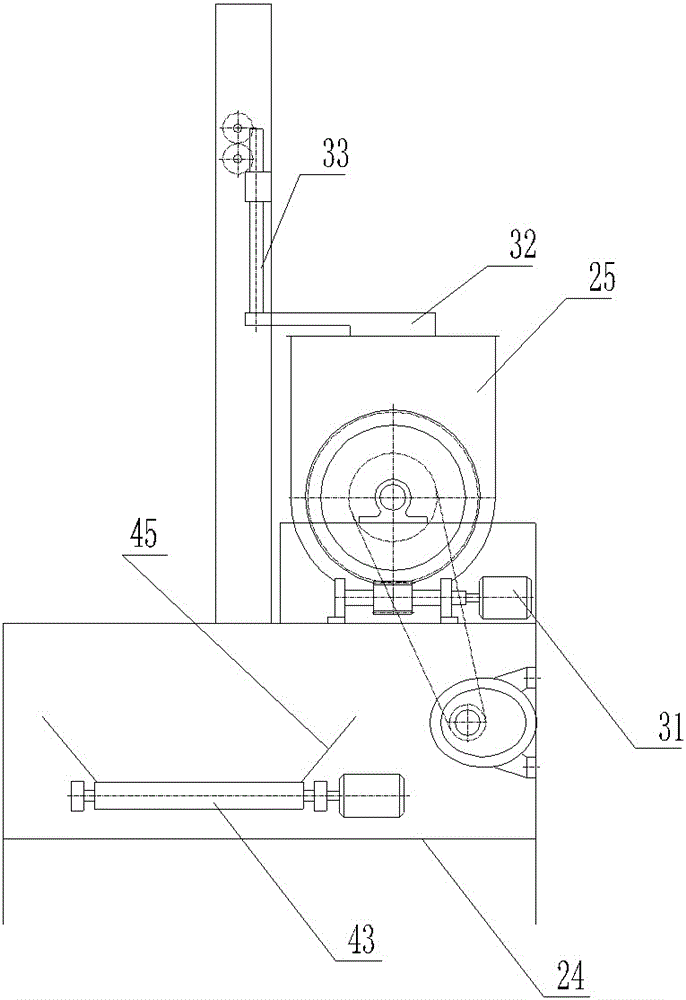

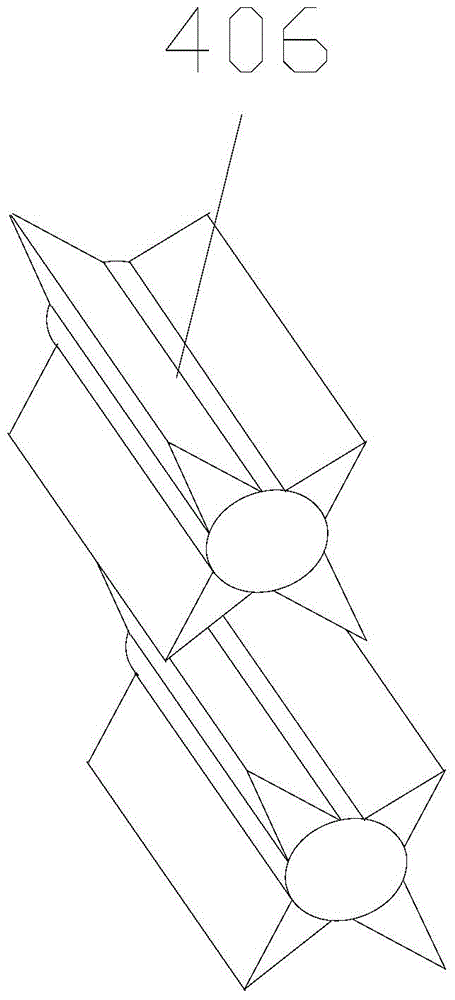

Efficient fully-automatic semi-finished stewed noodle production line

ActiveCN105053104AGood kneading qualityFully automatedMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsReciprocating motionTransverse fracture

The invention discloses an efficient fully-automatic semi-finished stewed noodle production line. The front end of the longitudinal fracture conveying device of the novel double-head fully-automatic cycle dough kneading machine of the production line is provided with a first pair of dough kneading rollers, a longitudinal fracture synchronizing wheel is arranged above the longitudinal fracture conveying device, two sides of the longitudinal fracture conveying device are provided with longitudinal fracture rotating plates inwardly continuously folding to central portions, a longitudinal fracture burdening pressure roller is arranged above the longitudinal fracture conveying device, the rear end of the longitudinal fracture conveying device is provided with a second pair of dough kneading rollers, the second pair of the dough kneading rollers is provided with an obliquely arranged conveying device, a guiding plate is arranged behind the second pair of the dough kneading rollers, the frame of the machine is provided with a transverse fracture one-layer conveying device capable of moving back and forth, a transverse fracture two-layer conveying device is arranged directly below the transverse fracture one-layer conveying device, and the rear end of the transverse fracture two-layer conveying device is connected with the first pair of tough kneading rollers. Dough from the dough kneading machine is automatically sent to the double-head fully-automatic cycle dough kneading machine and is automatically kneaded in a cycle manner in the double-head fully-automatic cycle dough kneading machine, and the kneaded dough is automatically sent to a semi-finished stewed noodle forming machine to realize fully-automatic production of semi-finished stewed noodles.

Owner:王朝民

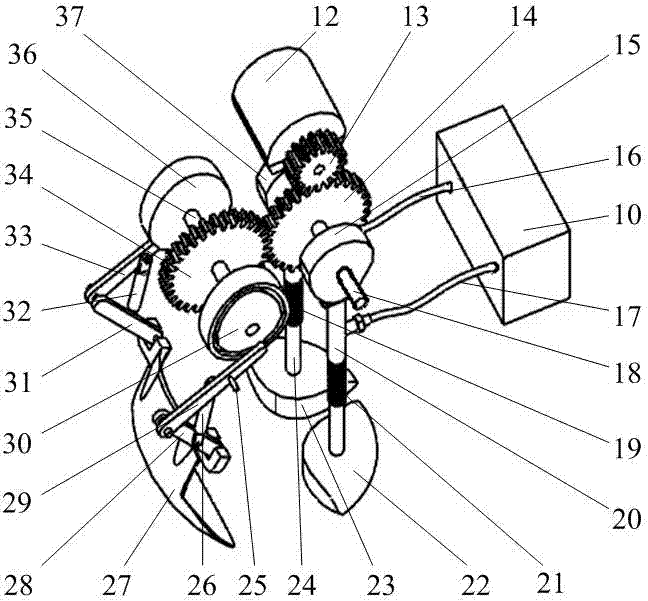

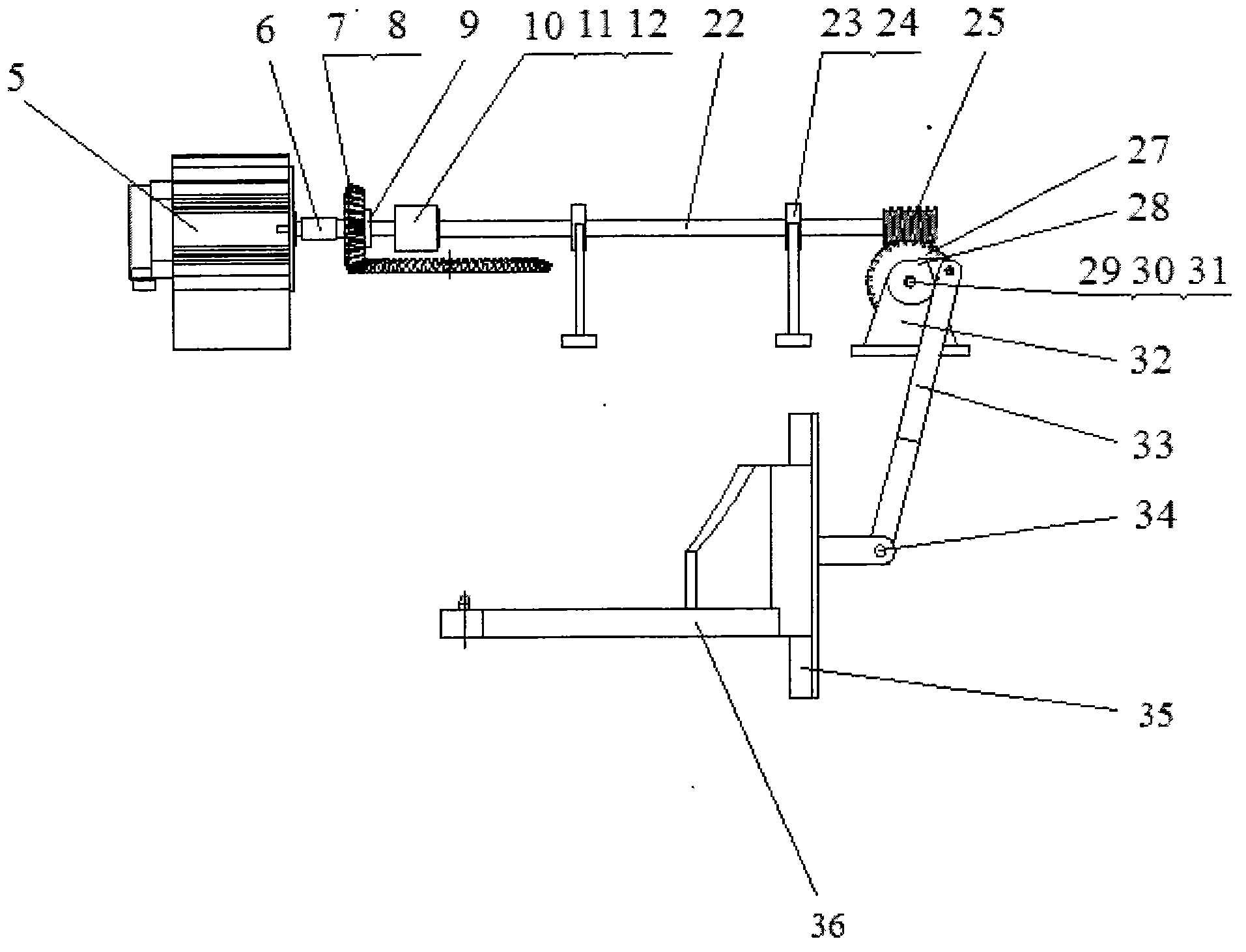

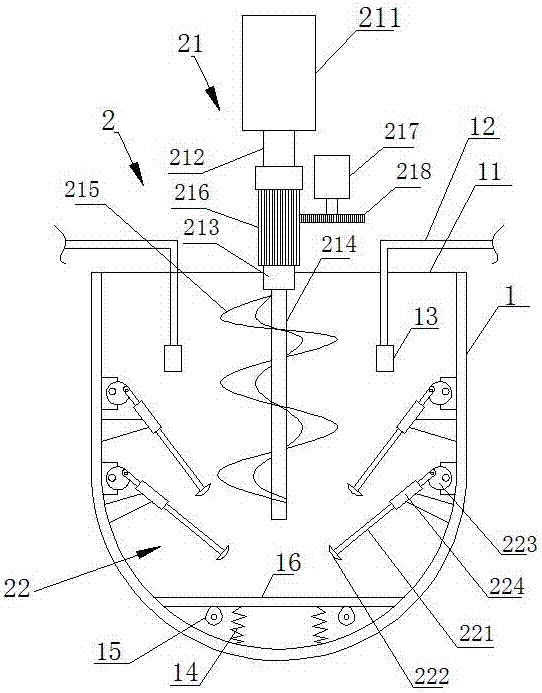

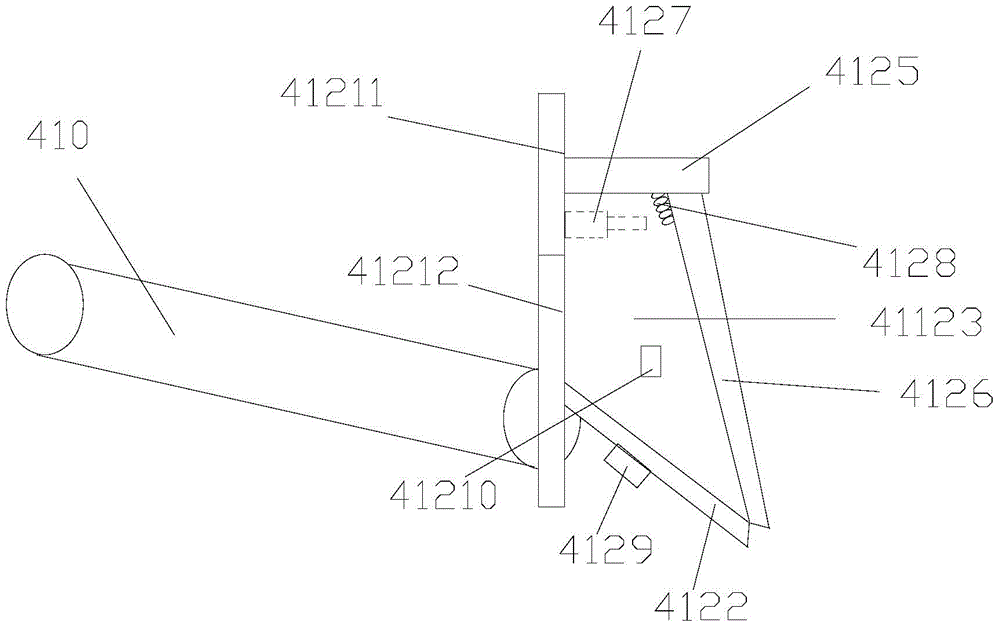

Handwork imitation dough kneading machine based on pneumatic artificial muscle

InactiveCN103168806AIncrease added valueImprove palatabilityMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsGear wheelEngineering

The invention discloses a handwork imitation dough kneading machine based on pneumatic artificial muscle. The handwork imitation dough kneading machine is characterized by comprising a single-chip microcomputer controller, an artificial muscle gas distributor, a gas distribution pipe, a surface hammer ejector rod, a reset spring, a pneumatic artificial muscle surface hammer, a dough kneading motor, a small gear, a large gear, a cam, a cam shaft, a slotting cam, a slotting cam shaft, a roller ejector rod, a connecting rod, a ridge lifting shovel and a ridge lifting shovel support rod. Compared with the prior art, the handwork imitation dough kneading machine has the advantages that (1) the existing rigid kneading part is replaced by the pneumatic artificial muscle surface hammer, so that a novel and reliable dough kneading way is provided; (2) the handwork imitation dough kneading machine fully utilizes the characteristics of flexible contact, controllable extension size and the like of the pneumatic artificial muscle, thus basically realizing handwork imitation dough kneading operation; the flour products are good in palatability and high in additional value; and (3) the handwork imitation dough kneading machine solves the problem of automatic resetting of a dough after being kneaded for once, is relatively high in degree of automation, and improves the production efficiency and the safety.

Owner:SHANDONG UNIV OF TECH

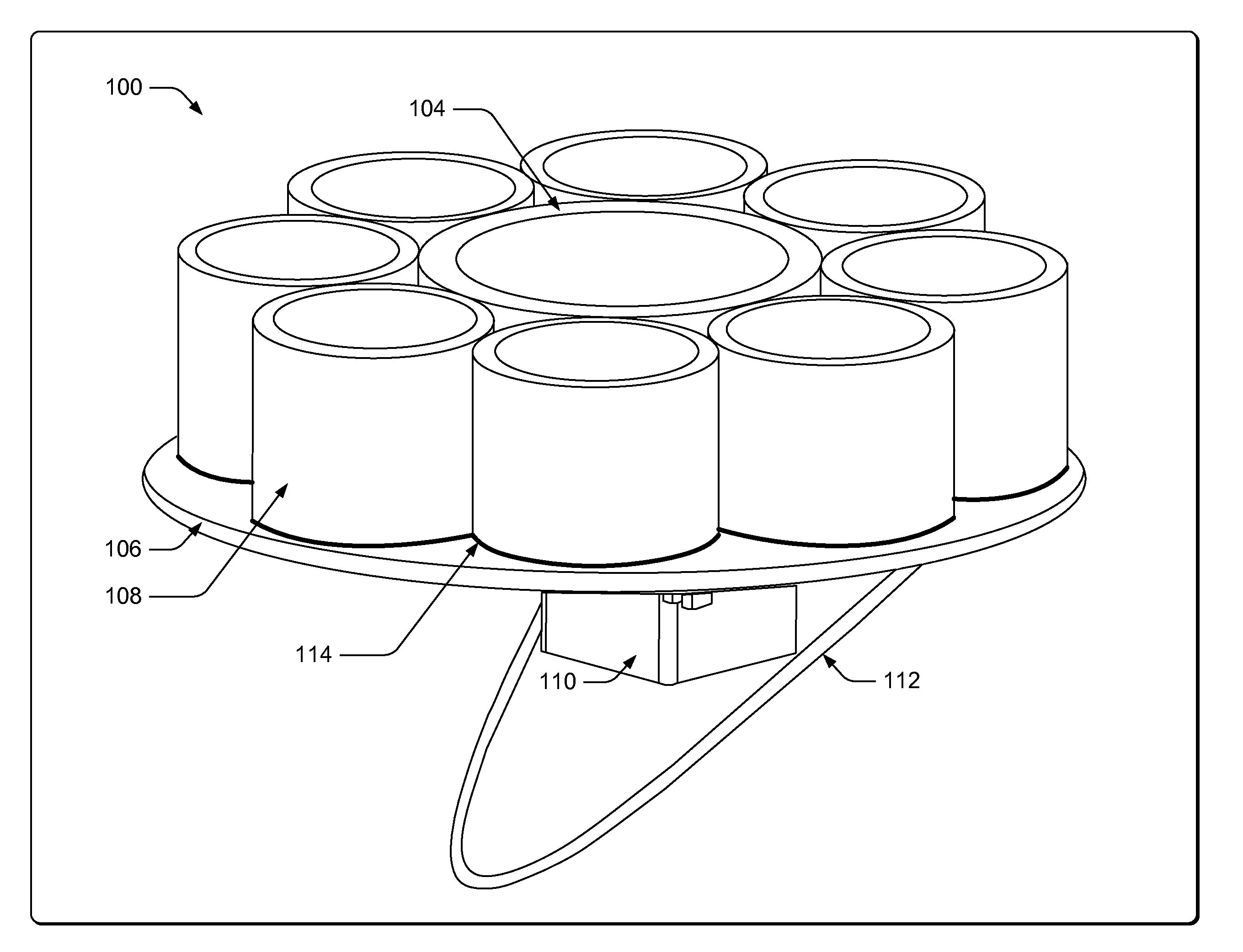

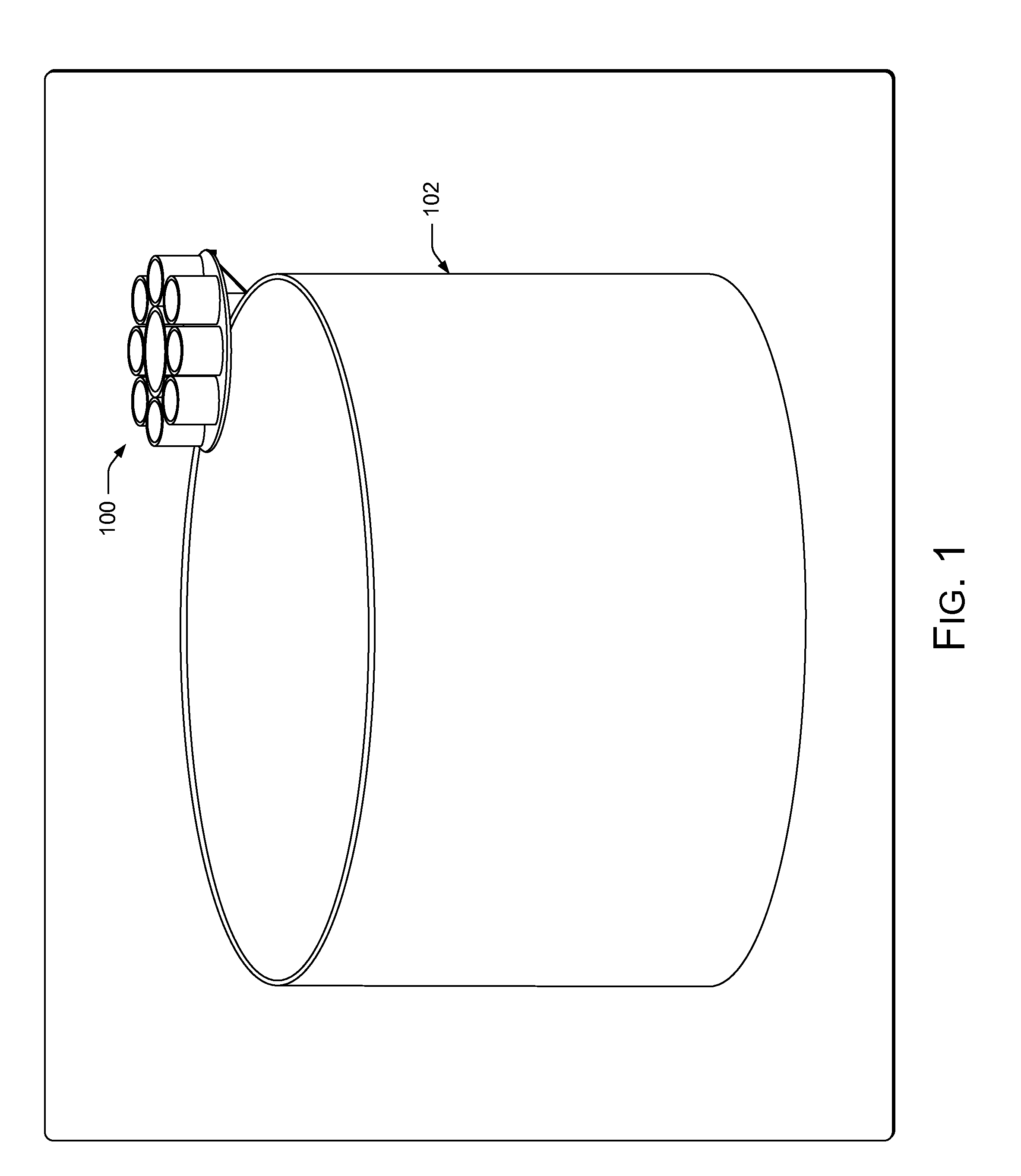

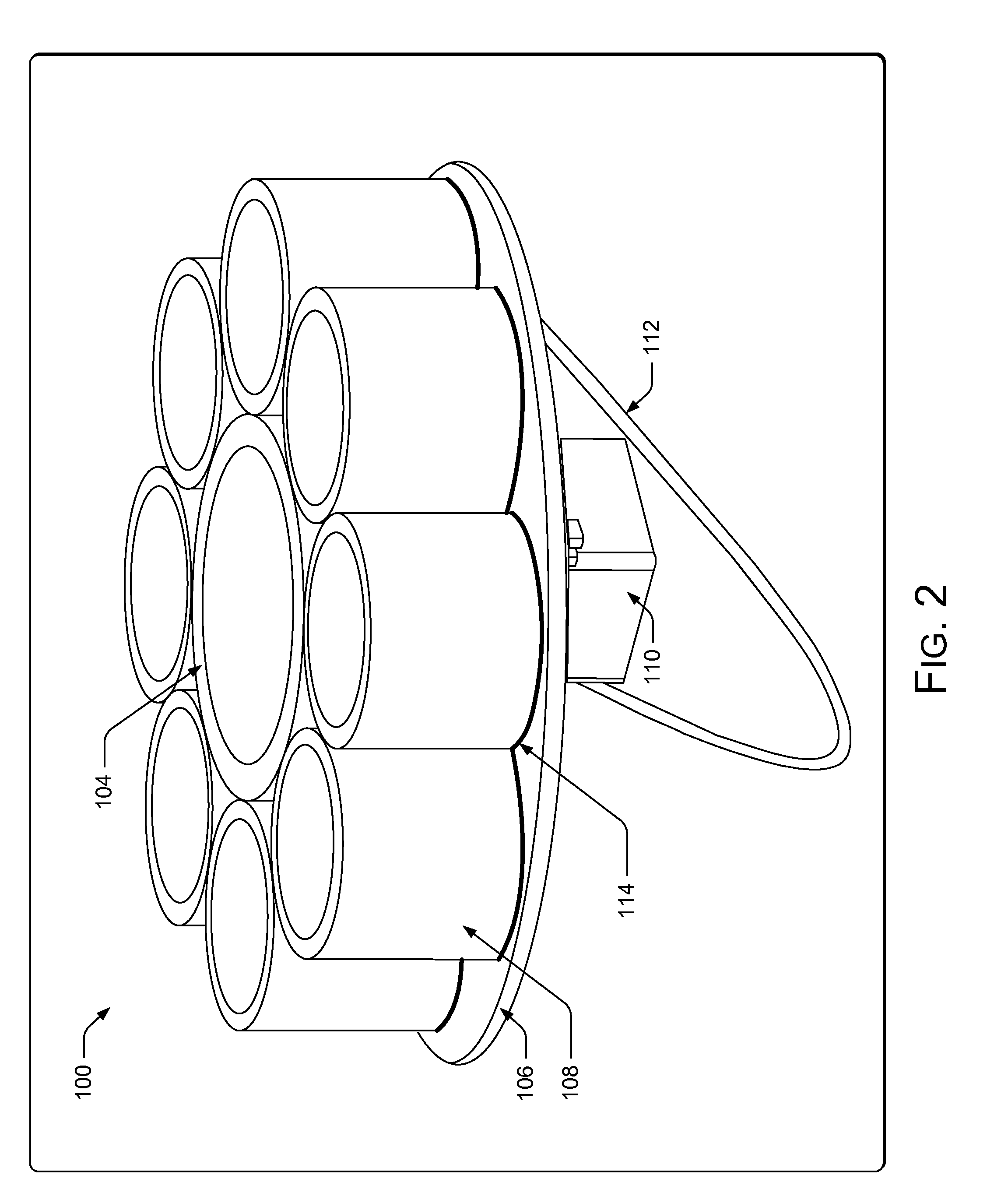

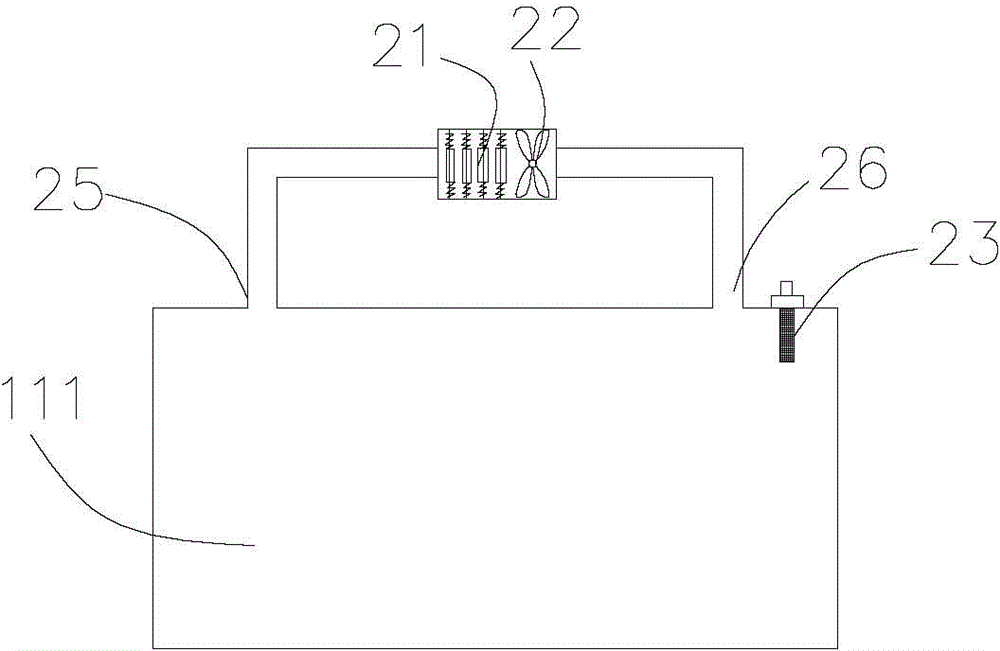

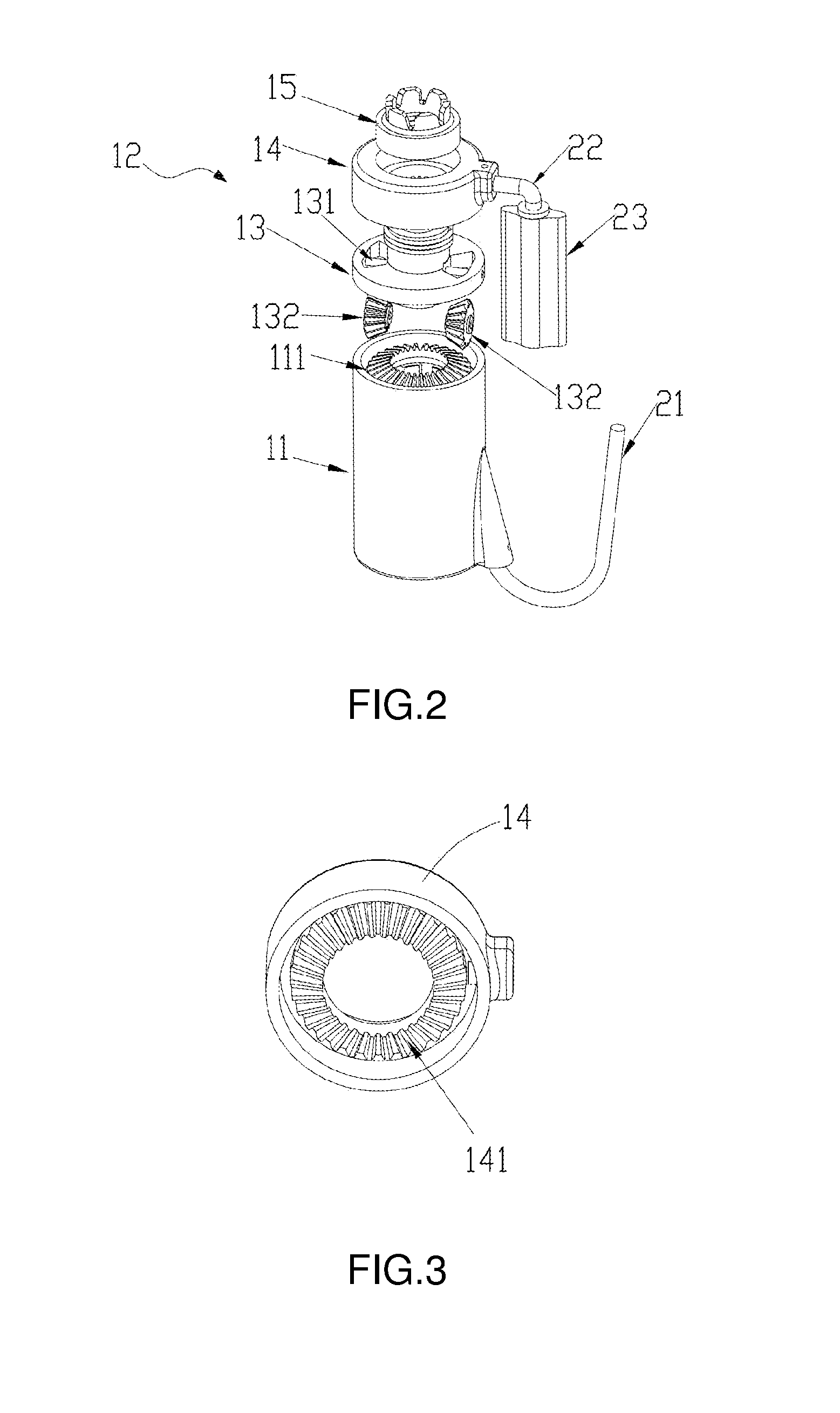

Portable ingredients system

InactiveUS20150298081A1Drive precisionWell formedTime indicationMixing/kneading structural elementsAdditive ingredientEngineering

A portable ingredients system is provided. An example assembly attaches to the side of a kettle, mixing bowl, pot, vat, or vessel and adds ingredients at programmed intervals. In an implementation, only that part of the assembly that adds the ingredients is located over the kettle or vessel. In an implementation, a microprocessor controls a stepper motor to precisely drive a rotary dispenser containing the ingredients to be added separately at time intervals. The example assembly may be preloaded with ingredients for a recipe, such as for mixing a batter, making a soup, or brewing a beer, for example. The assembly may be preprogrammed with one or more electronic recipes for instructing the microprocessor to create the intended food or drink item using ingredients, such as preloaded ingredients.

Owner:MCMATH DANIEL JEFFREY

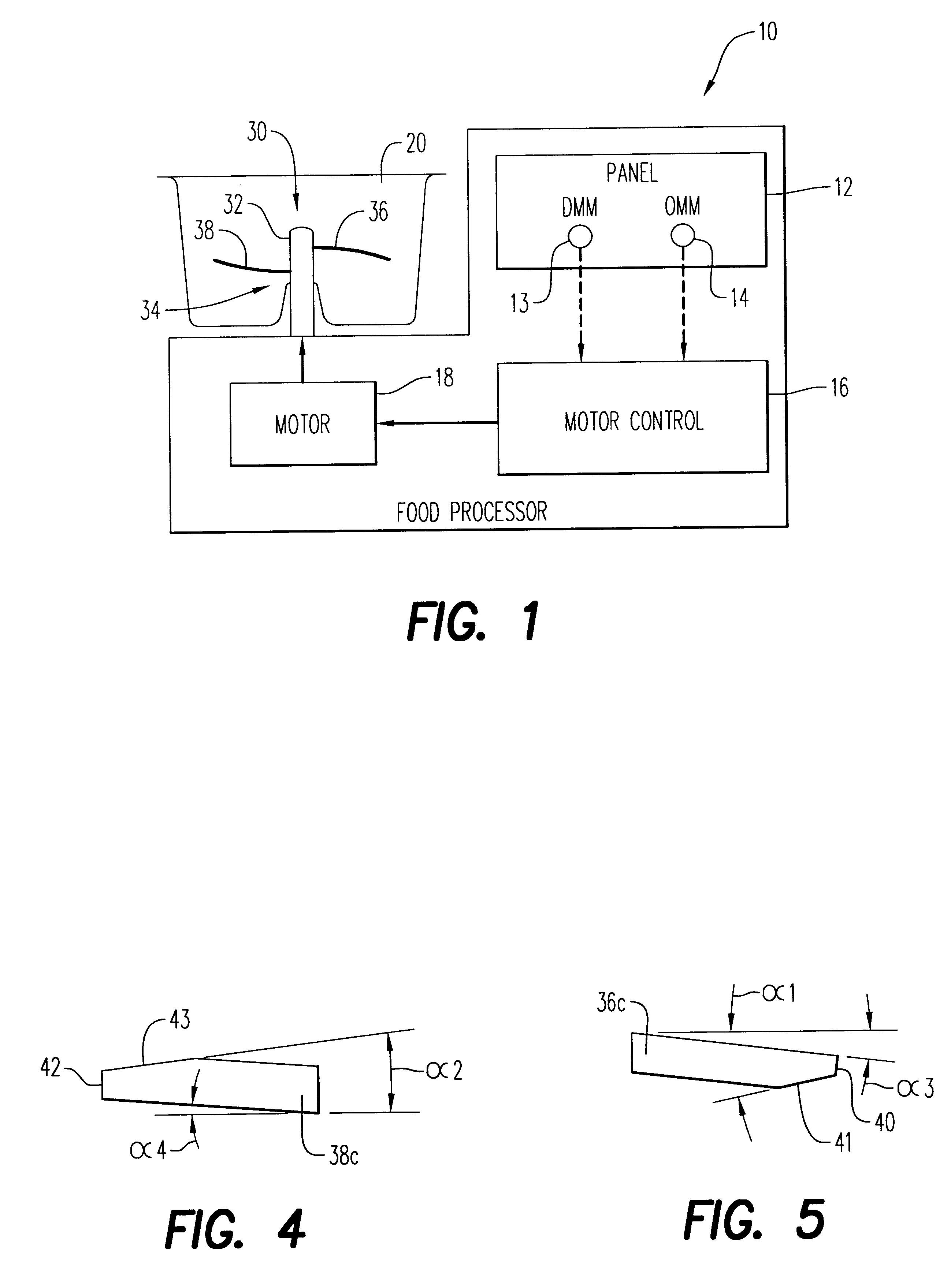

Food processing appliance

InactiveUS6446547B2Shorten speedQuality improvementPropellersRotary stirring mixersImpellerEngineering

Owner:CONAIR CORP

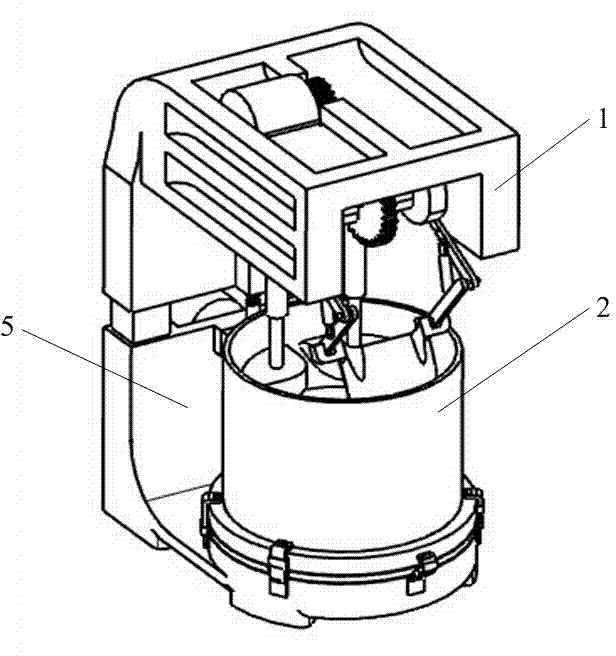

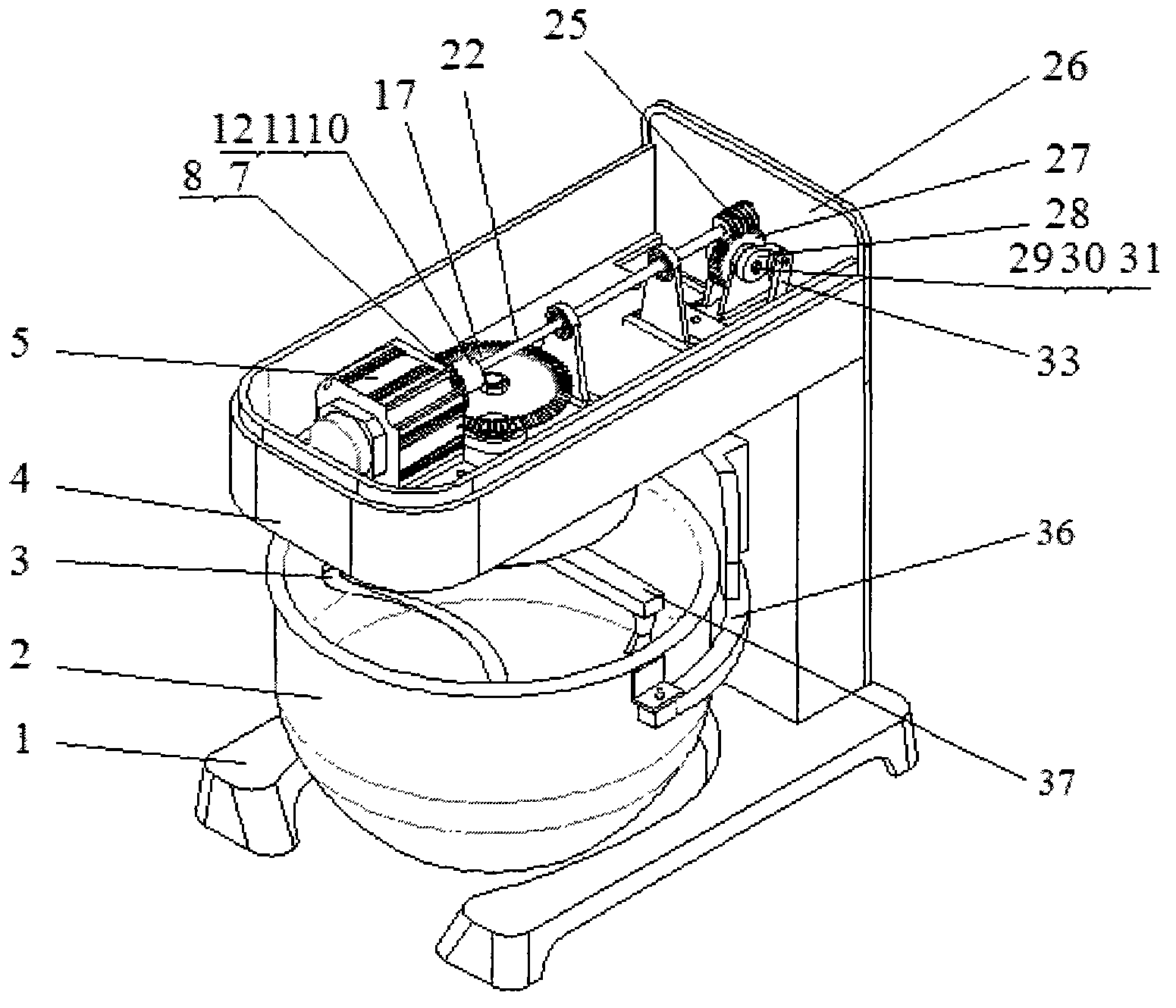

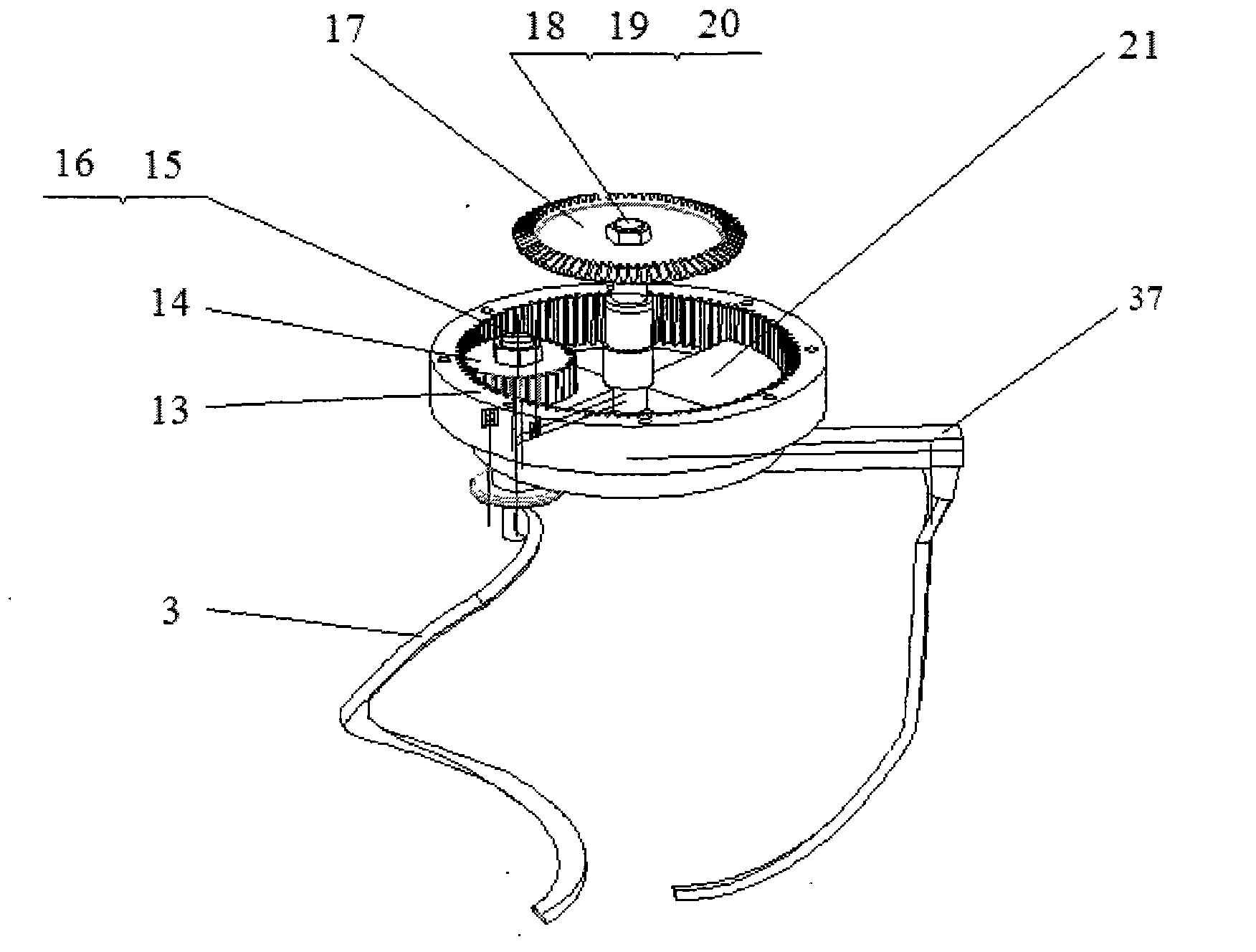

Movement separation spiral multifunctional food mixing machine

InactiveCN103210966AReduce manufacturing costImprove structural performanceMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsMixing effectMechanical engineering

The invention designs a movement separation spiral multifunctional food mixing machine. The movement separation spiral multifunctional food mixing machine comprises a spiral mixer, a mixing tank, a movement separation mechanism, a lifting device and a dough scraping device, wherein the movement separation mechanism can meet the power demand of all movements in the mixing machine by one motor; when the motor rotates forwards, materials are mixed by the mixer at different speeds, and when the motor rotates reversely, the mixing tank ascends or descends; due to the spiral and rodless designs of the spiral mixer, the spiral mixer can be used for mixing in a wide range, overcomes the phenomenon of automatic material climbing, and improves the structural performance of the mixer; and the dough scraping device can accelerate the rolling of the materials in the mixing tank so as to improve the mixing effect. The multifunctional food mixing machine overcomes the shortcomings of a conventional mixing machine that a plurality of power sources are needed and the mixing efficiency is low, thus being very beneficial to the production and generalization of the mixing machine. According to the mixing machine, the production cost is reduced, the mixing is more sufficient, and the mixing time is greatly shortened.

Owner:吴玉国 +6

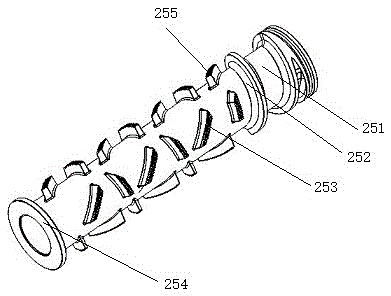

Fully automatic intelligent noodle processing and making method

ActiveCN105341018APromote hydrationWon't change colorMixing/kneading structural elementsDough-sheeters/rolling-machines/rolling-pinsEngineeringFully automatic

The invention relates to the field of food processing equipment, in particular to a fully automatic intelligent noodle processing and making method. The fully automatic intelligent noodle processing and making method is characterized by at least comprising the following steps: an extruding can is arranged, an extruding roller is arranged in the extruding can and can rotate in the extruding can, and a flour inlet is formed in the extruding can; a water inlet is formed in the flour inlet, flour is added from the flour inlet, water is added from the water inlet, the extruding roller is driven to rotate so as to mix the flour and the water, and the flour and the water are extruded to be formed into dough; a forming and cutting mechanism is arranged under the extruding can, and the forming mechanism comprises two dough pressing rollers and two dough cutting rollers, wherein two dough cutting rollers are arranged under the two dough pressing rollers to drive the two dough pressing rollers to rotate; the dough pressing rollers press the dough into wrappers and drive the two dough cutting rollers to rotate; the dough cutting rollers cut the wrappers into noodles. The fully automatic intelligent noodle processing and making method disclosed by the invention has the advantage that the fully automatic processing and making of noodles is realized.

Owner:上海老磨坊餐饮管理有限公司

Fried glutinous pudding beating processing device

InactiveCN105557796AImprove processing qualityImprove efficiencyMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsEngineeringUltimate tensile strength

Owner:张伟滨

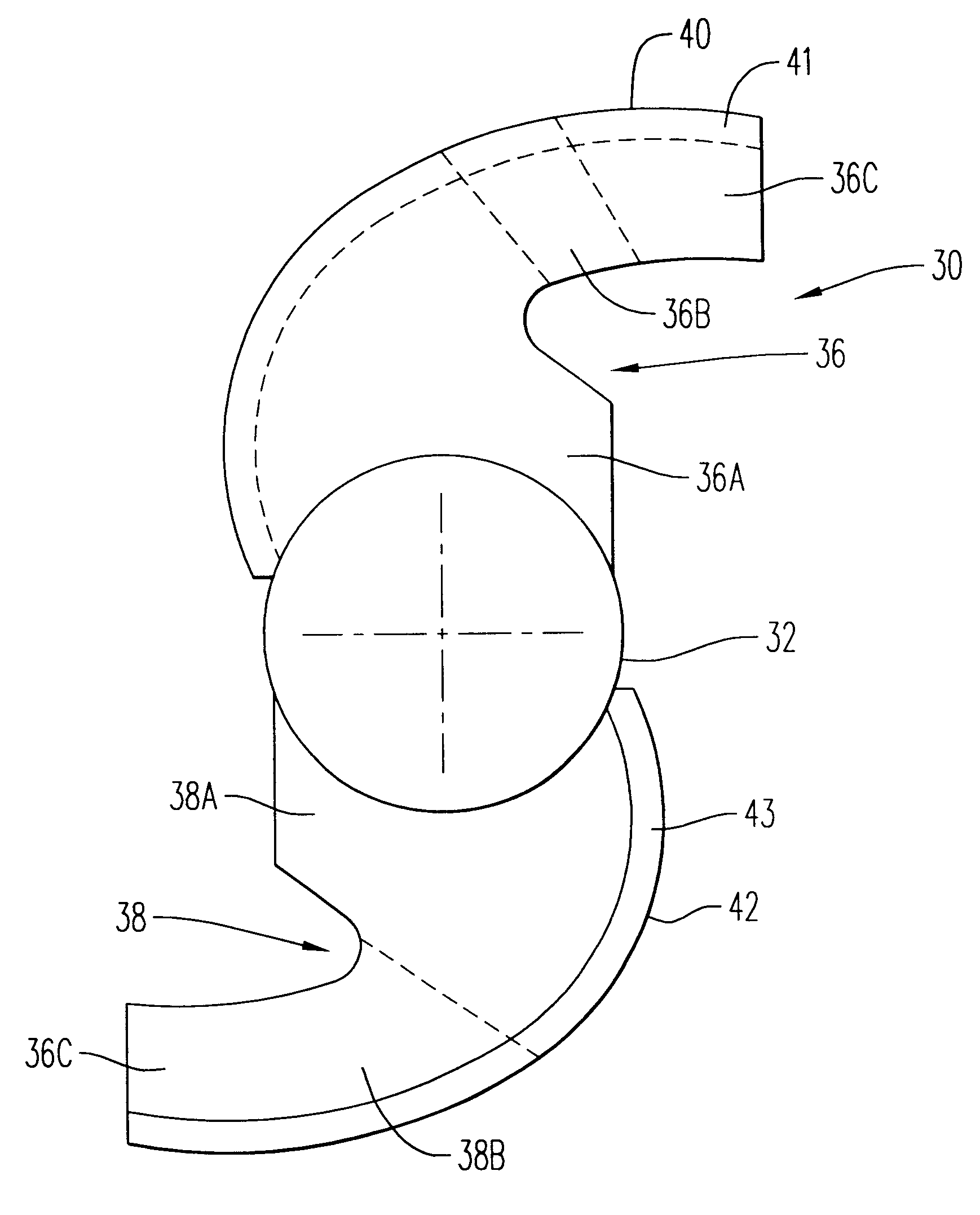

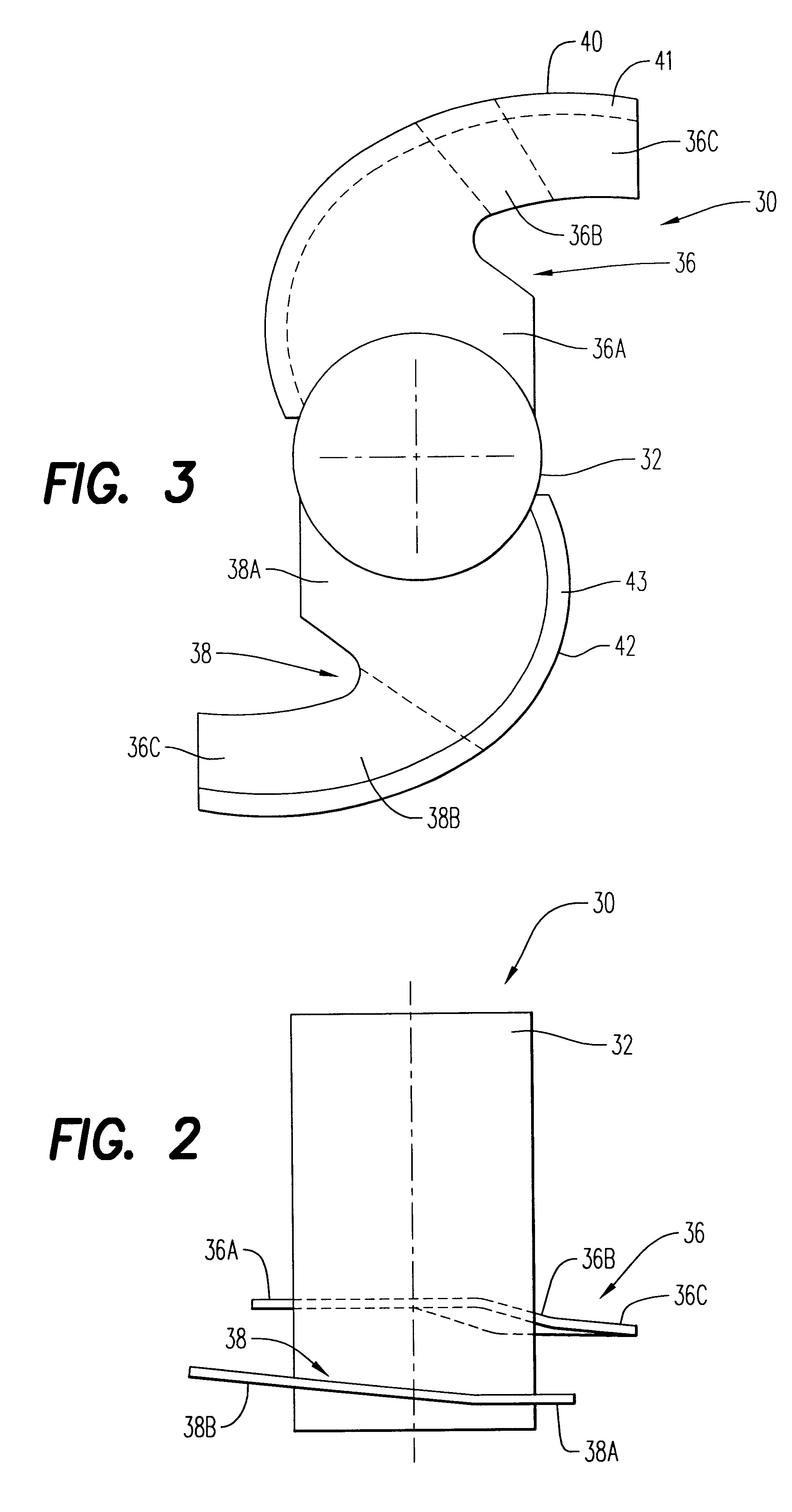

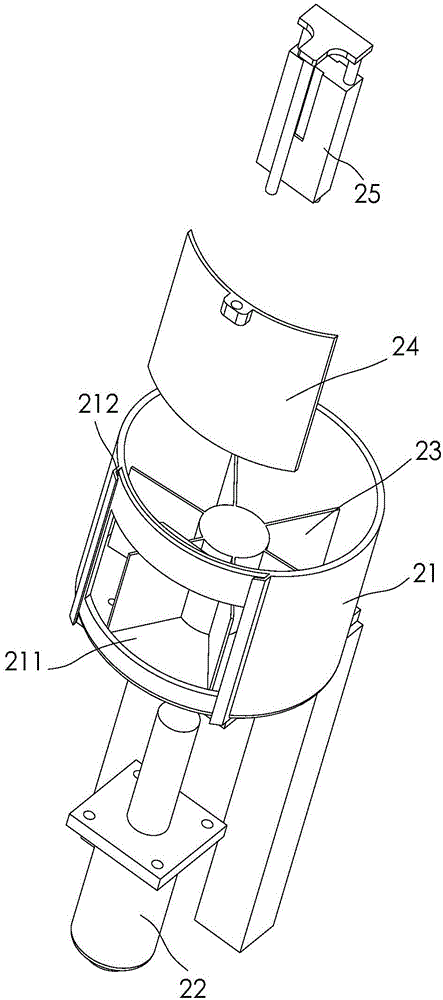

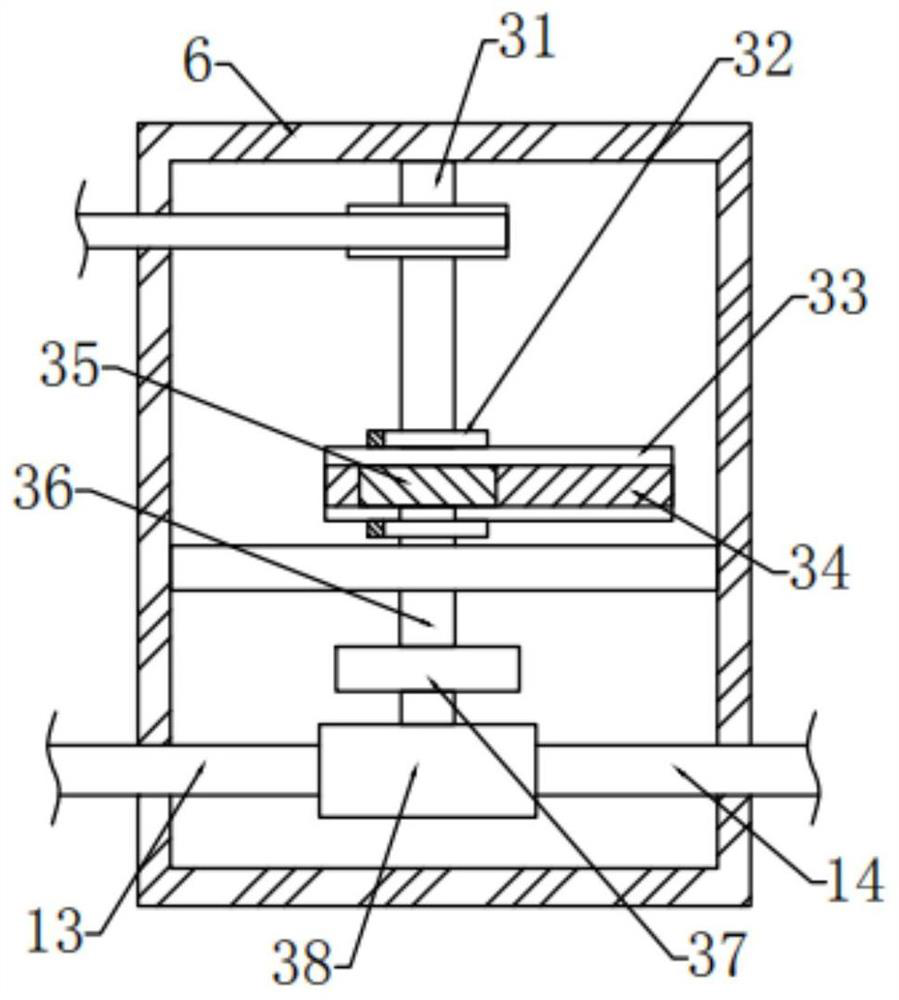

Device for kneading, slowly fermenting and producing sourdough

InactiveUS20070171766A1Improve operationImprove efficiencyMixing/kneading structural elementsRotary stirring mixersEngineeringAir conditioning

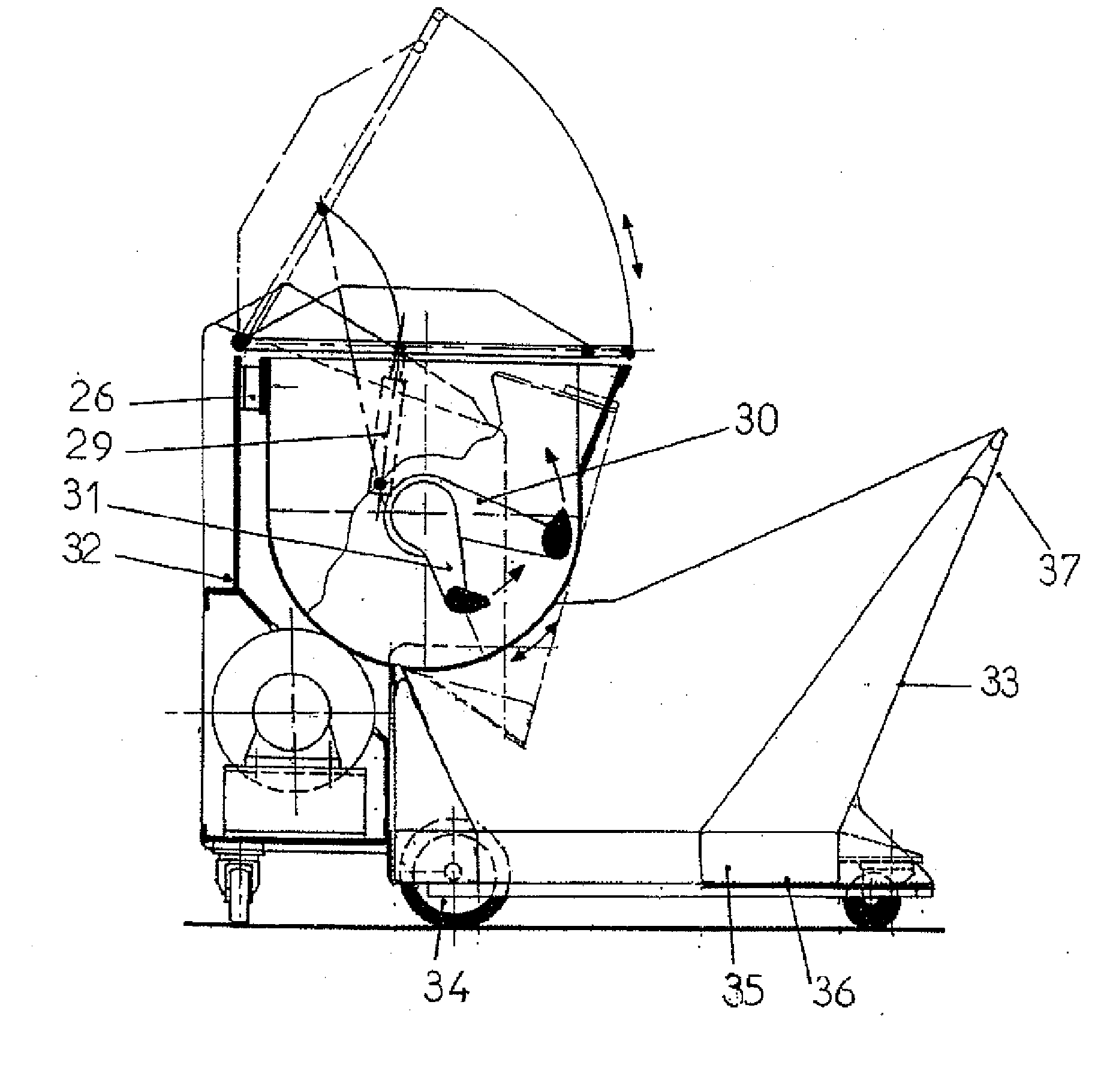

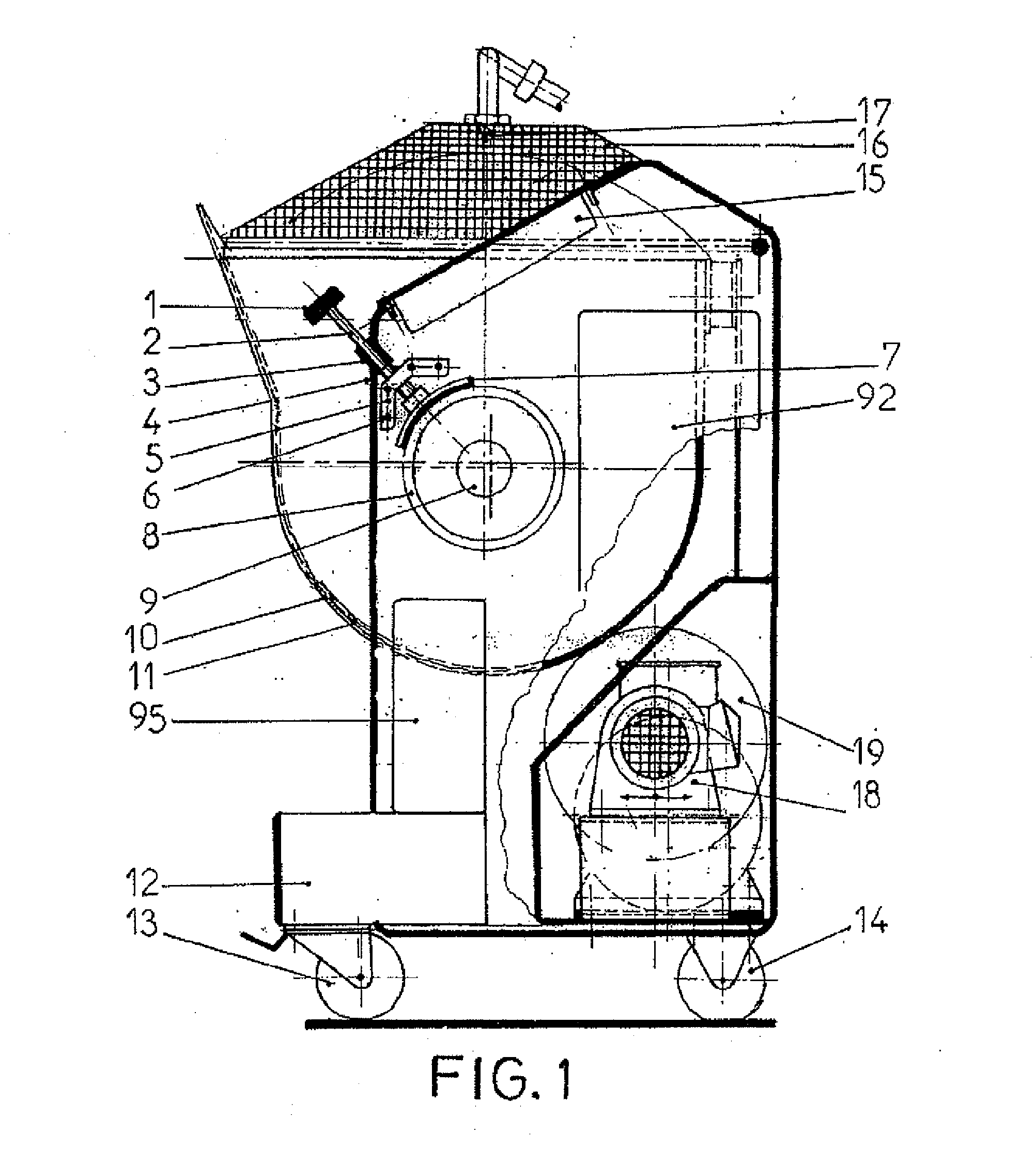

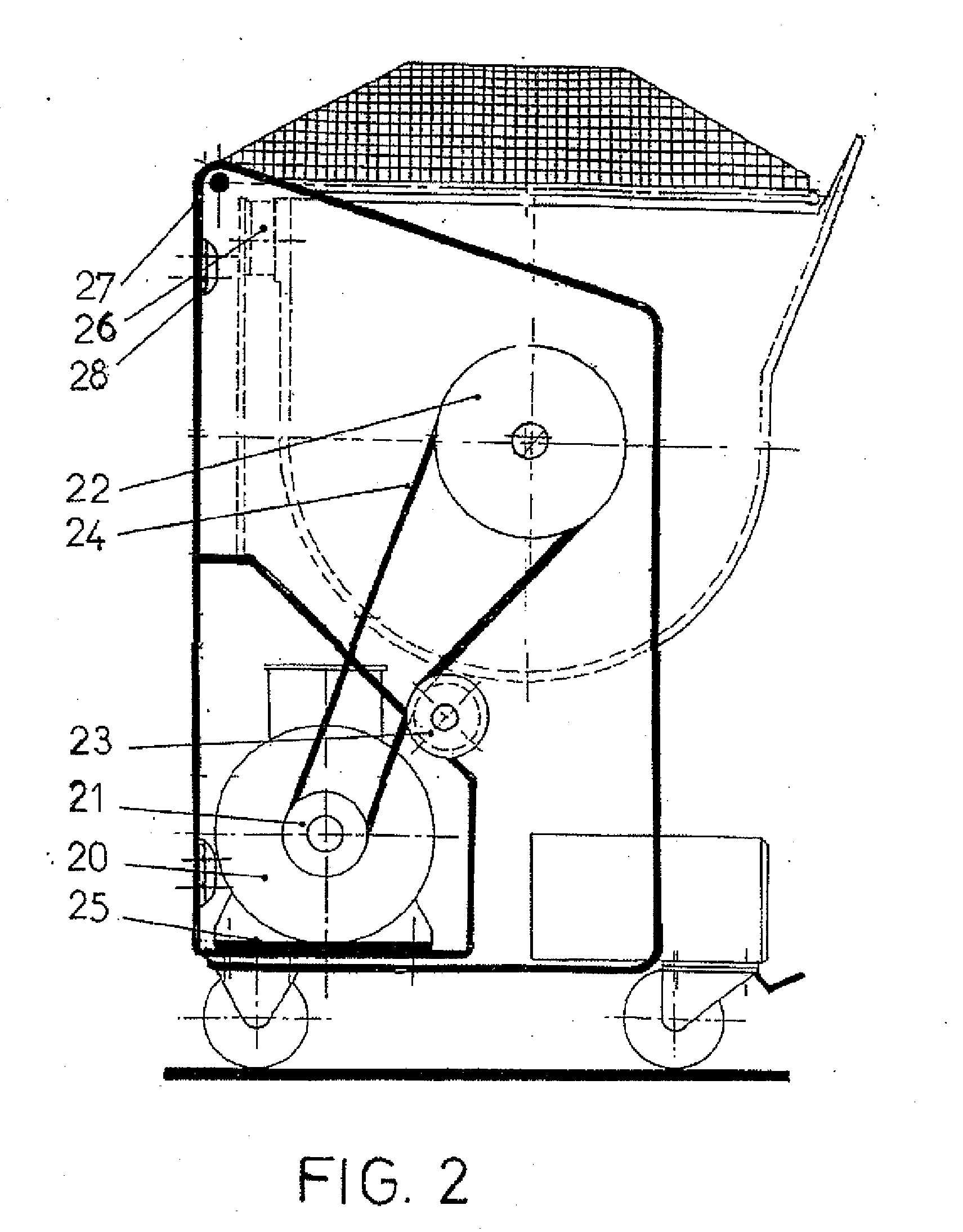

The invention relates to a system of devices for kneading, mixing and fermenting viscoelastic dough comprising a swing tank (10) provided with a driven arm (30) and a helicoidal counter-arm (31) which is driven by a dough mixture flow and associated to a weakly stirring air-conditioning device producing and maintaining a constant temperature of air and dough pieces ranging from 20 to 26° C. during kneading, tempering and storing and corresponding to an accelerated fermentation and from 9 to 16° C. which makes it possible to carry out slow growth of the dough pieces and to produce sourdough corresponding to a second slow fermentation stage.

Owner:LOISELET

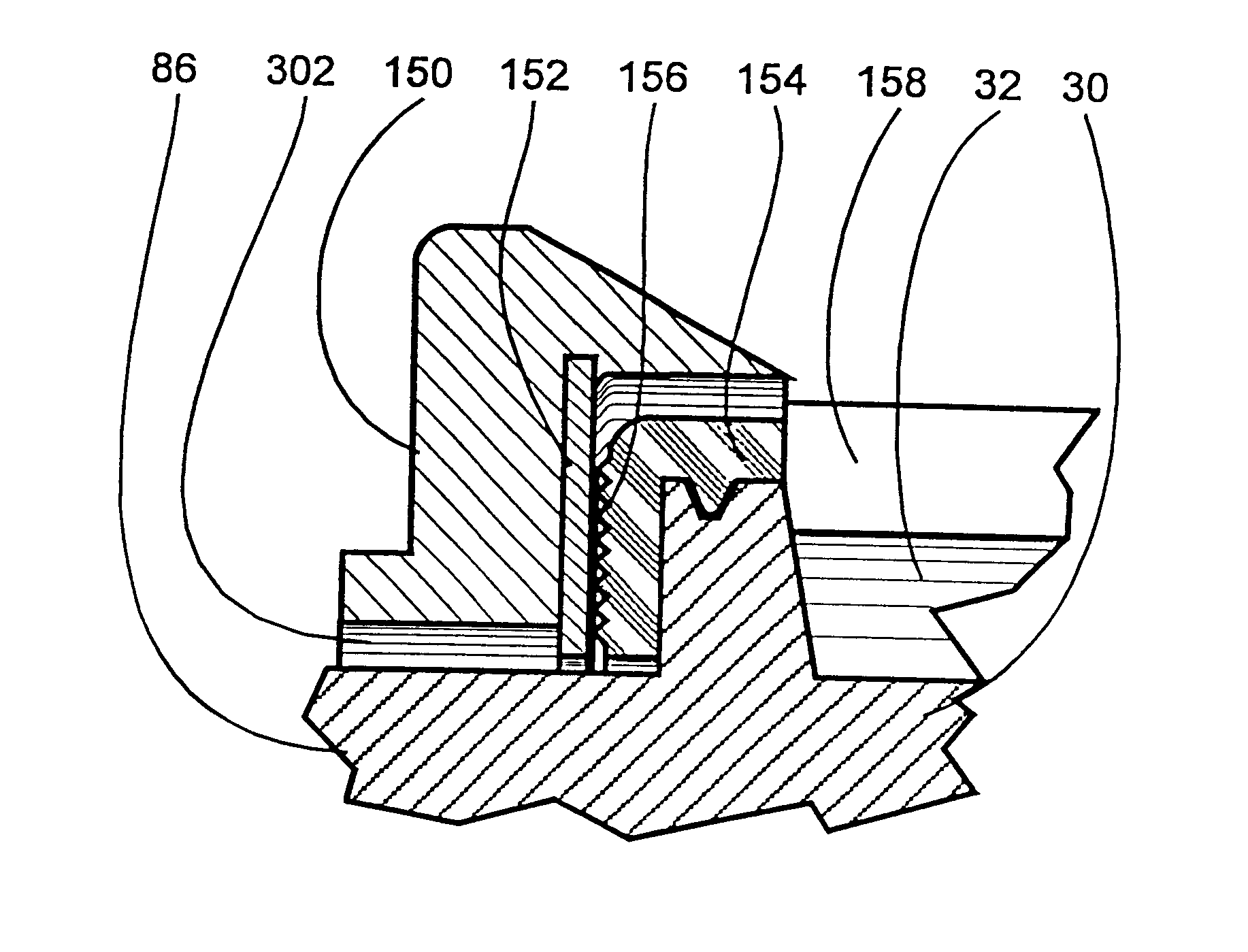

Thrust bearing to be used in a contaminated environment

InactiveUS6280092B1Mixing/kneading structural elementsRotary stirring mixersThrust bearingAxial thrust

A simplified trust bearing to be used in a dry powder contaminated environment such as a pasta maker, with the bearing comprising two plates contacting each other face-to-face and through such face-to-face contact transmitting an axial thrust load.

Owner:LAURUS MASTER FUND

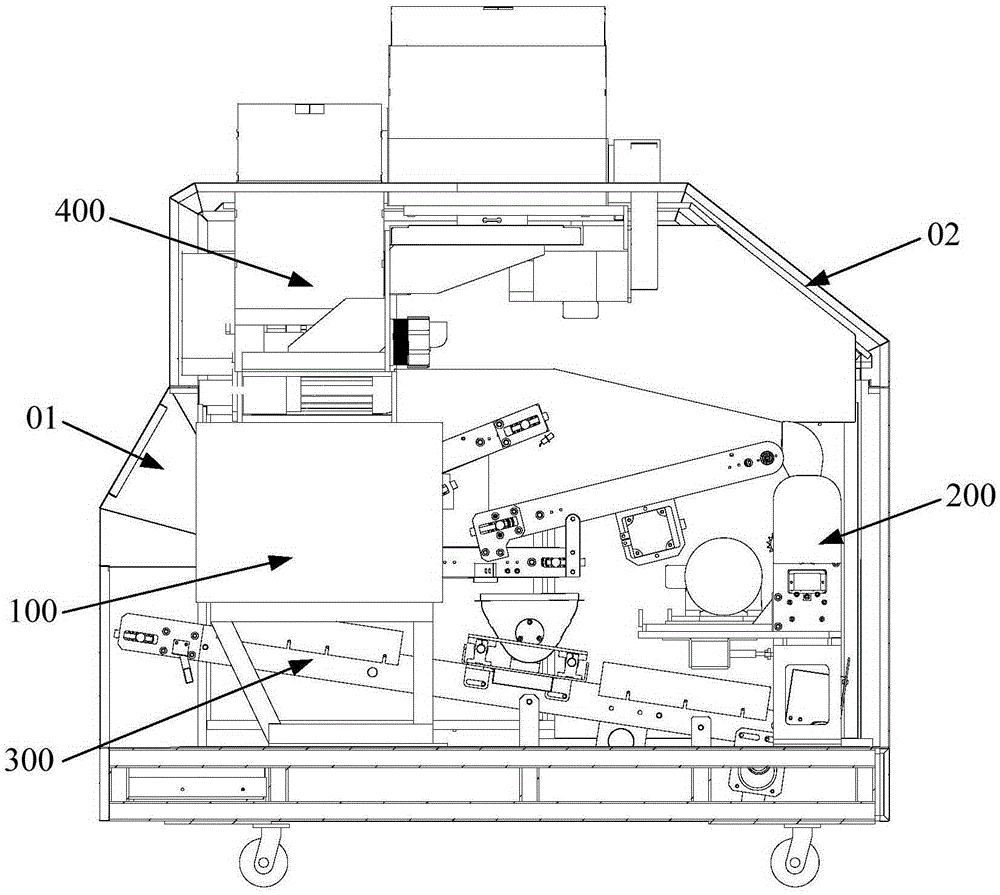

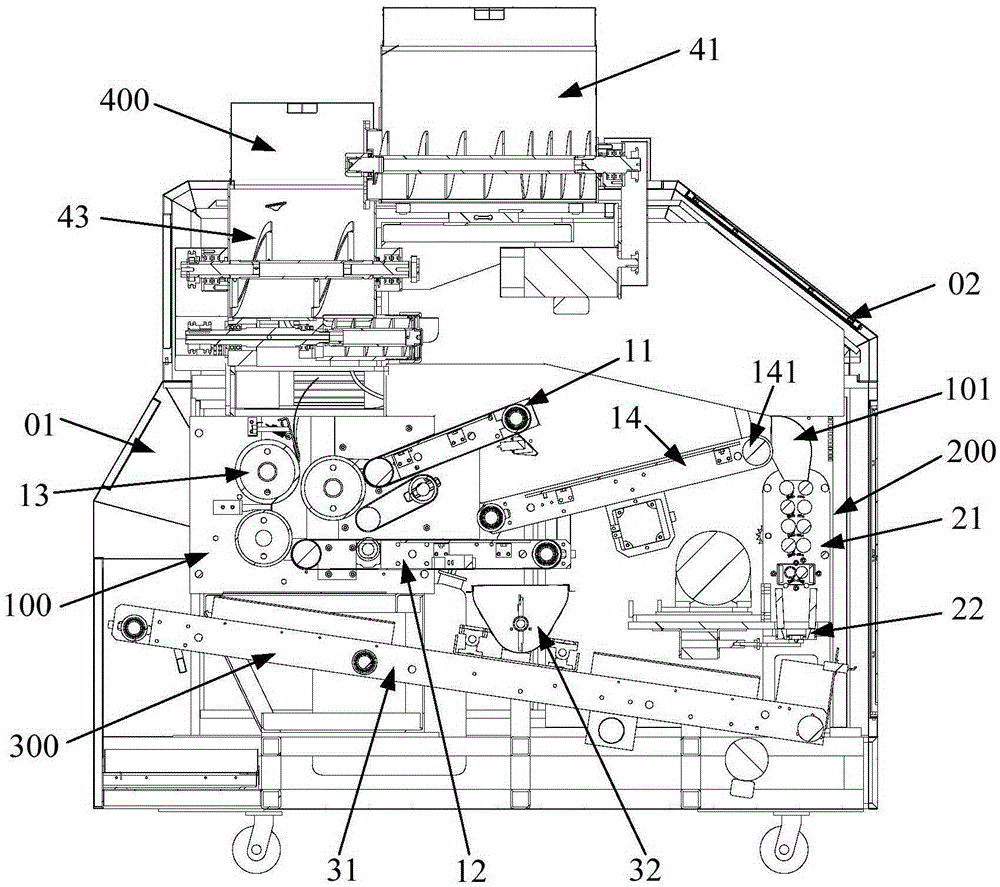

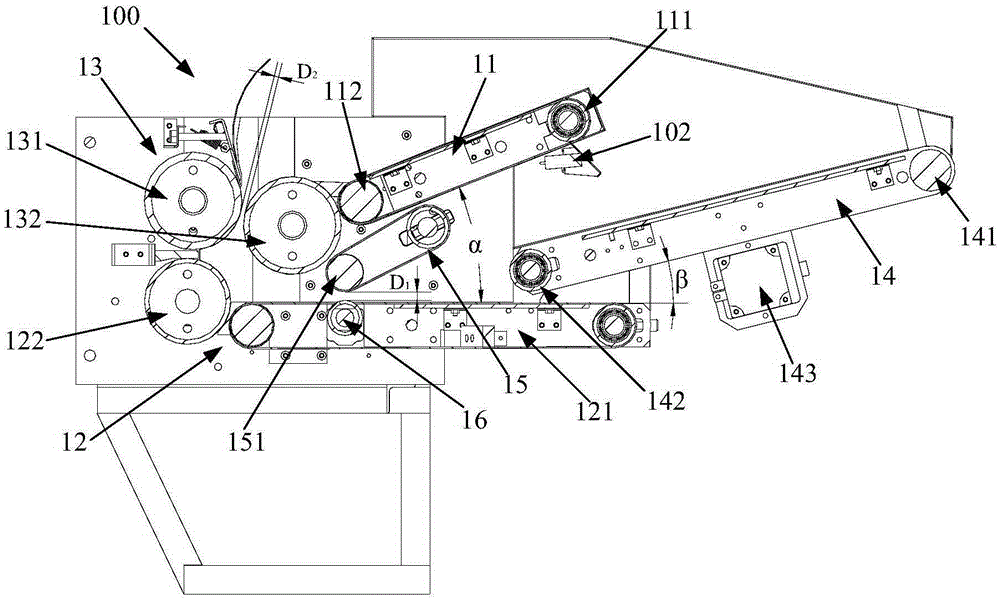

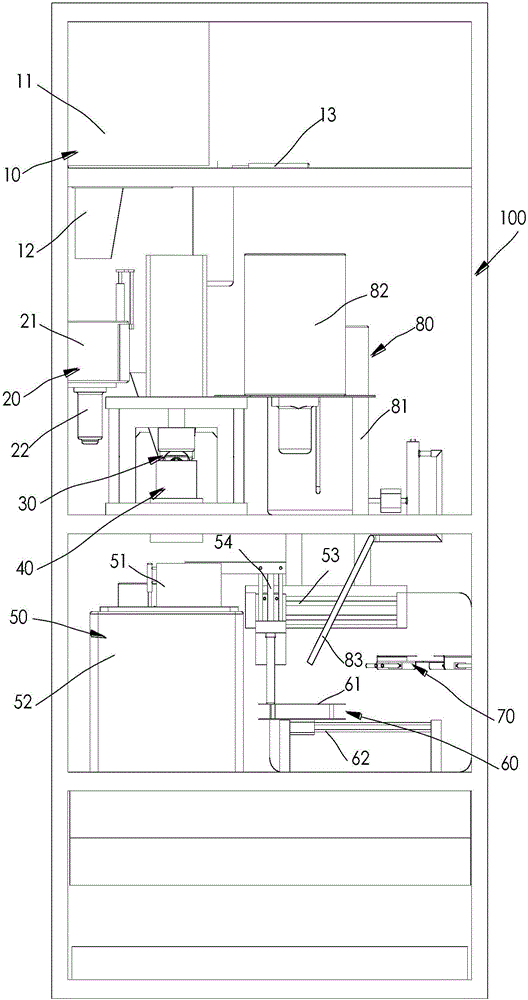

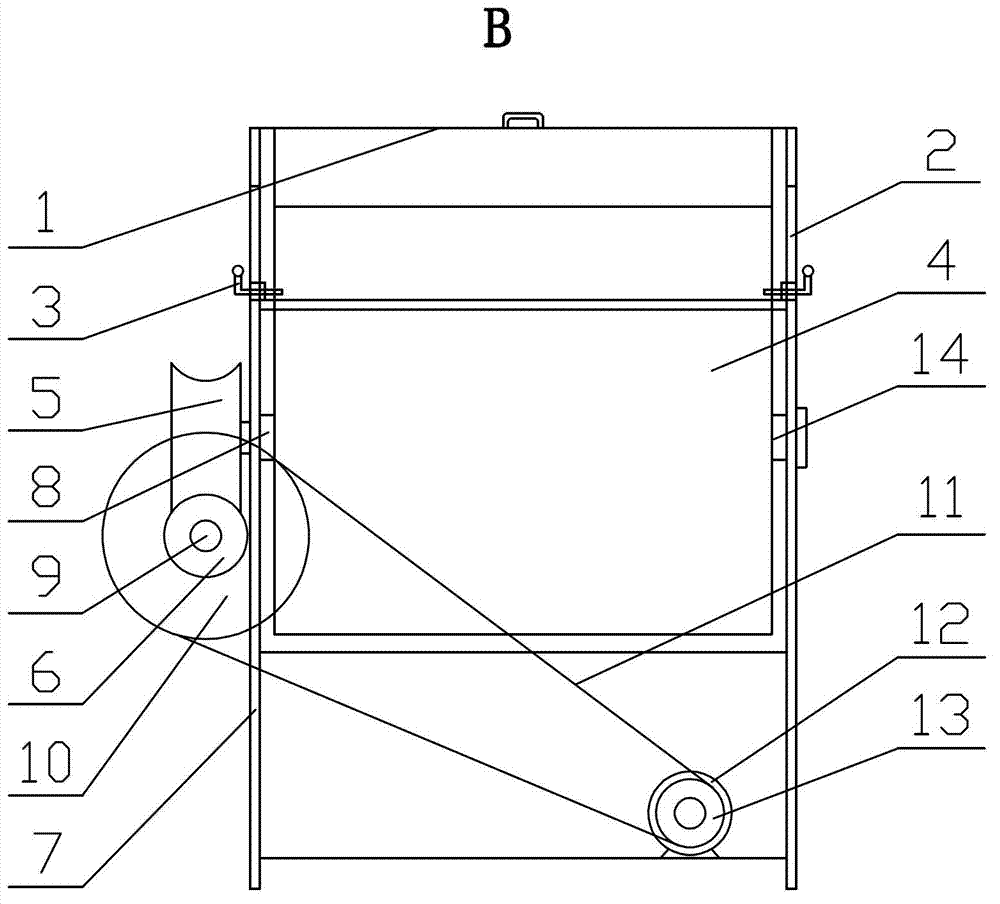

Small-size fresh noodle making and selling machine

ActiveCN105594784AMiniaturization for integrationMixing/kneading structural elementsDough-sheeters/rolling-machines/rolling-pinsControl systemMiniaturization

The invention provides a small-size fresh noodle making and selling machine and belongs to the field of commercial equipment. The small-size fresh noodle making and selling machine comprises a dough falling device, a dough kneading and conveying device, a dough pressing device, a dough cutting device, a noodle receiving device, a rack, a control system, a protective cover and a power and transmission device, wherein the dough falling device is mounted at the upper end of the rack; the dough kneading and conveying device is mounted on the rack; the dough pressing device is mounted on the rack; the dough cutting device is mounted on the rack; the noodle receiving device is mounted on the rack; the control system is mounted on the rack; the protective cover is mounted on the rack; and the power and transmission device is mounted on the rack and is connected with a control system and a power input element of each functional part. The small-size fresh noodle making and selling machine has the characteristics of realizing integrated miniaturization of production and selling equipment of fresh noodles, coin inserting, card swiping, remote payment and automatic field production and selling.

Owner:HENAN WANJIE INTELLIGENT TECH

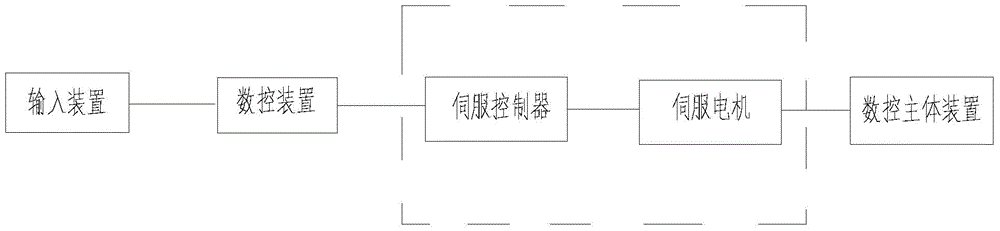

Numerically-controlled fully-automatic noodle maker

ActiveCN105325485AResilientGreat tasteMixing/kneading structural elementsDough-sheeters/rolling-machines/rolling-pinsEngineeringHardness

The invention provides a numerically-controlled fully-automatic noodle maker. The numerically-controlled fully-automatic noodle maker comprises a PLC and a dough stacking and pressing system, and the PLC is electrically connected with the dough stacking and pressing system, wherein the dough stacking and pressing system comprises a first conveyer, a second conveyer, a dough pressing device and a stacking and sending device. The numerically-controlled fully-automatic noodle maker can repeatedly stack and press dough to make noodles made in the invention have sufficient toughness and good mouthfeel; and a series of motions of automatic flour feeding, water feeding and dough kneading are carried out in front of the dough stacking and pressing system, a cake-shaped stacked and pressed dough can directly enter a noodle making and cutting device, so noodles with different hardnesses, different widths and different lengths can be made according to different requirements of clients to completely meet diversified demands of the clients.

Owner:ZHUHAI RUNXINGTAI ELECTRICAL

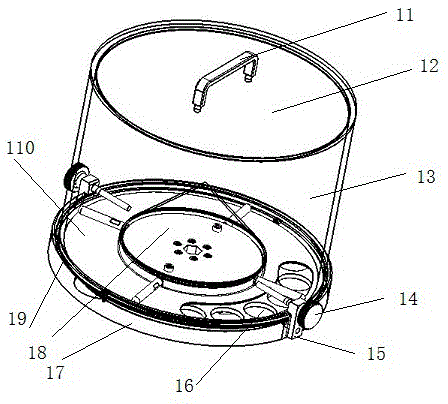

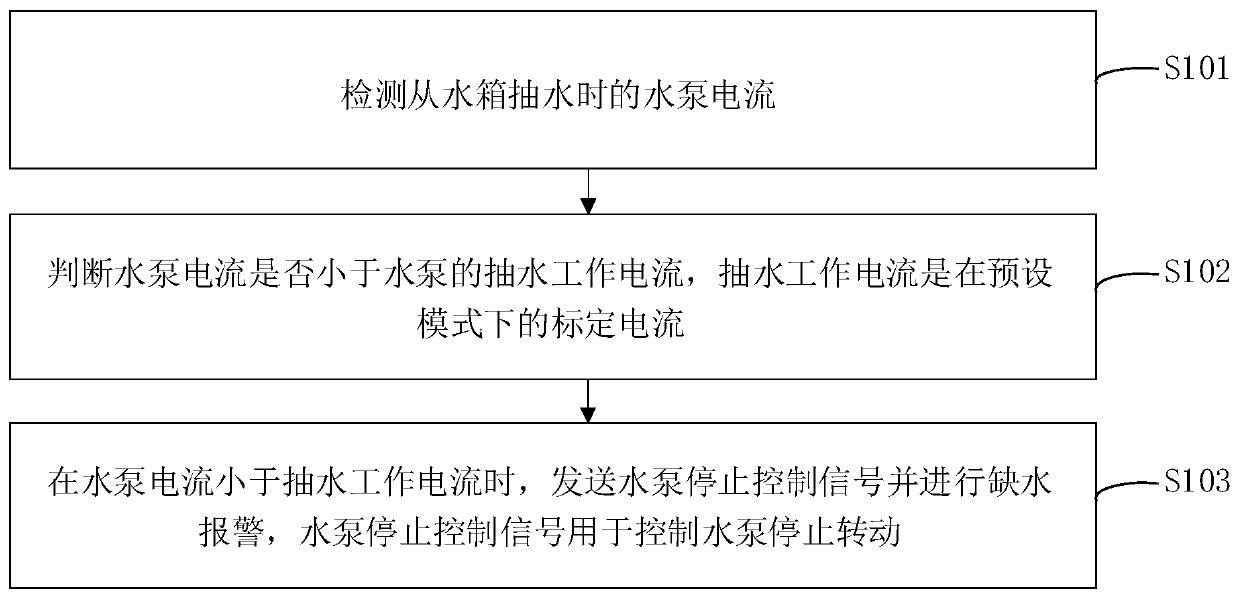

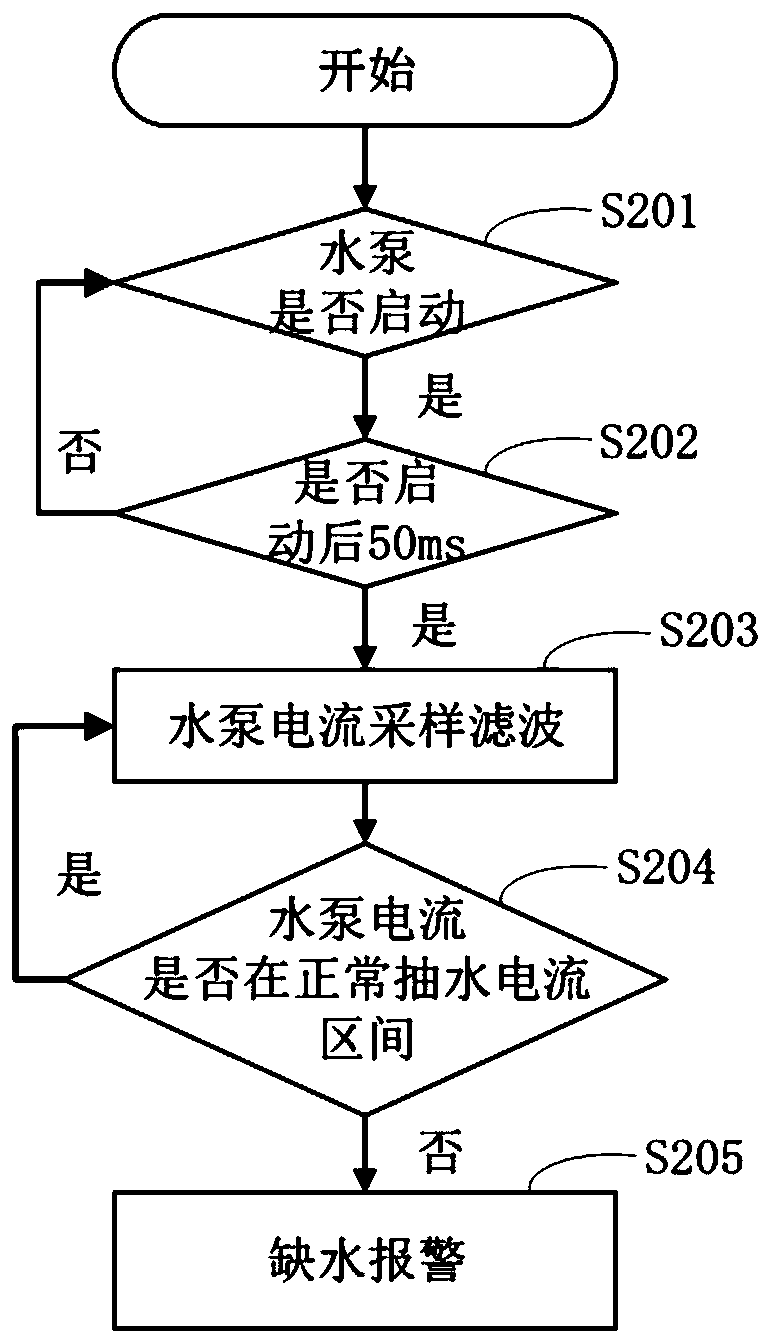

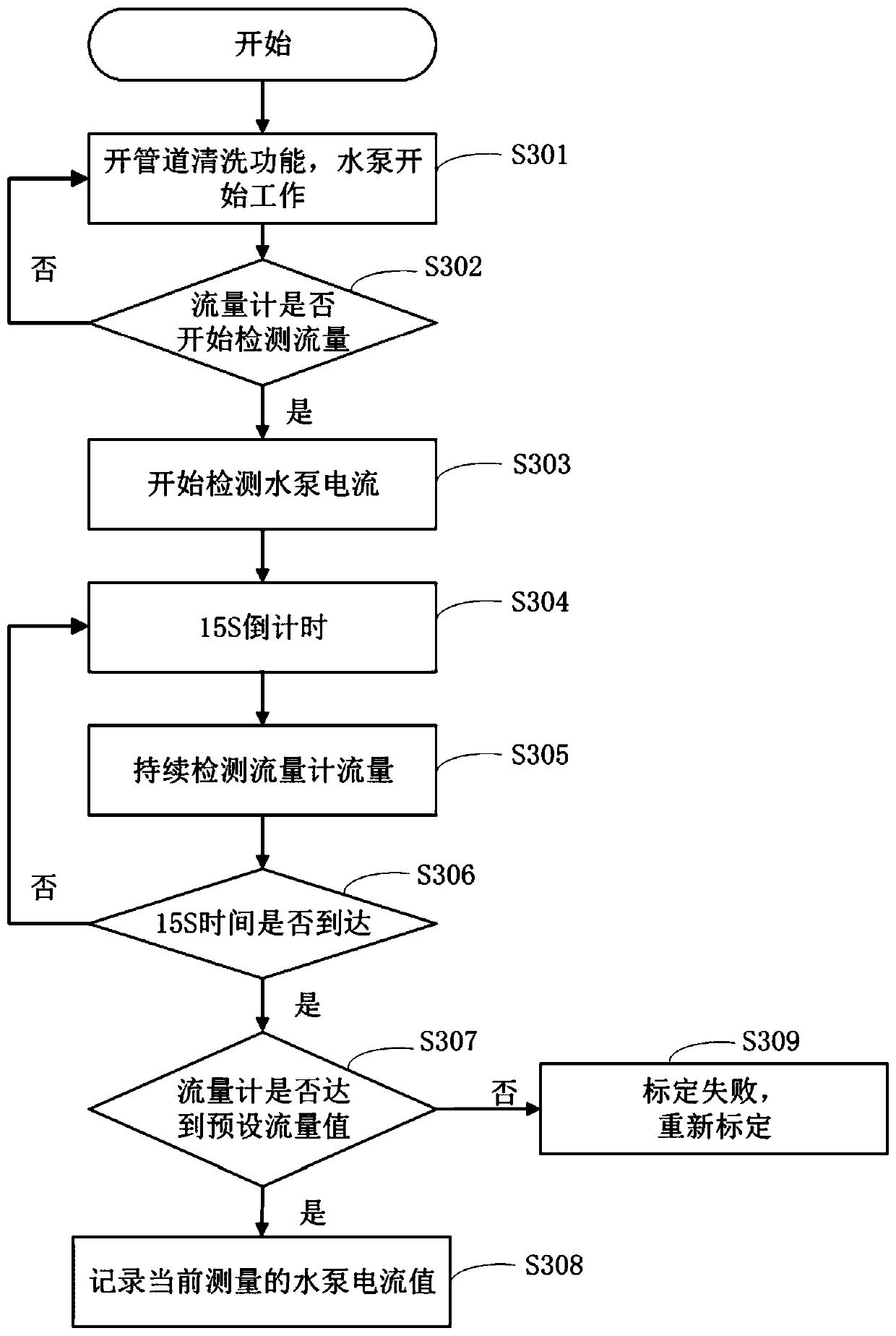

Food processor and water deficiency detection method thereof

ActiveCN110367297AReduce pollutionSimple structureMixing/kneading structural elementsLevel indicators by physical variable measurementControl signalElectrical current

The invention discloses a food processor and a water deficiency detection method thereof. The method includes: detecting water pump current when water is extracted from a water tank; judging whether the water pump current is smaller than water extraction working current of a water pump or not, wherein the water extraction working current is calibrated current in a preset mode; when the water pumpcurrent is smaller than the water extraction working current, sending a water pump stop control signal, and giving a water deficiency alarm, wherein the water pump stop control signal is used for controlling the water pump to stop rotating. No structure is arranged in the water tank, so that water pollution is reduced; the food processor is simple in structure and low in cost.

Owner:JOYOUNG CO LTD

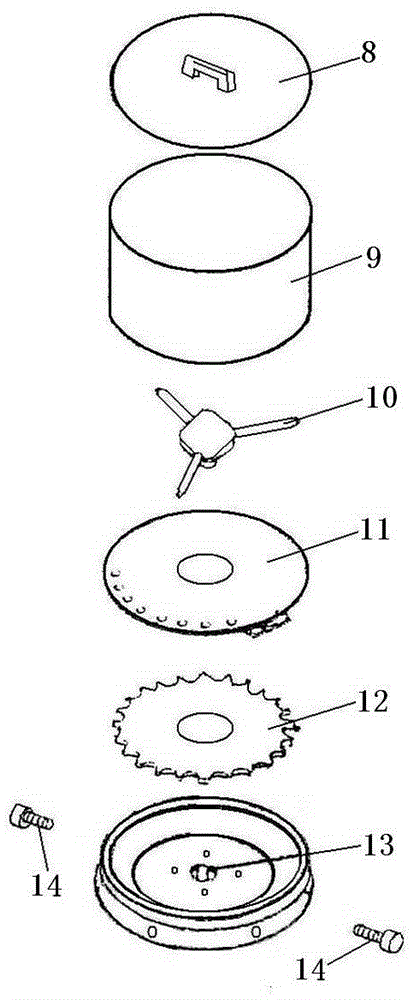

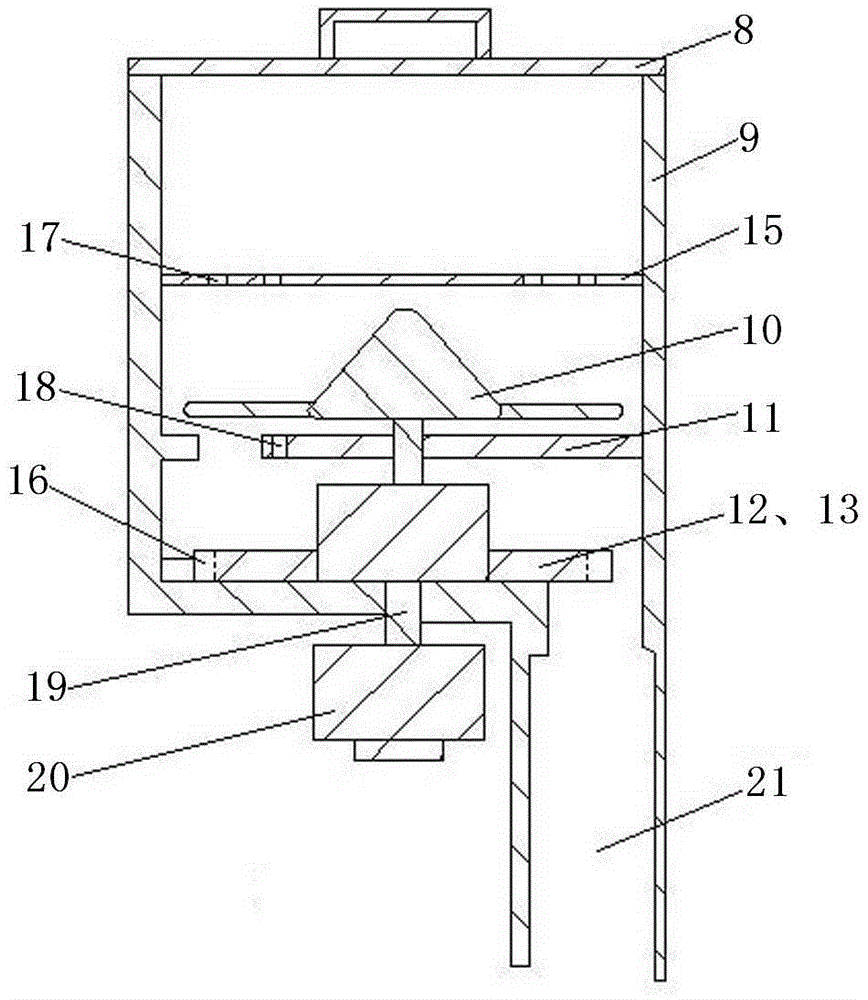

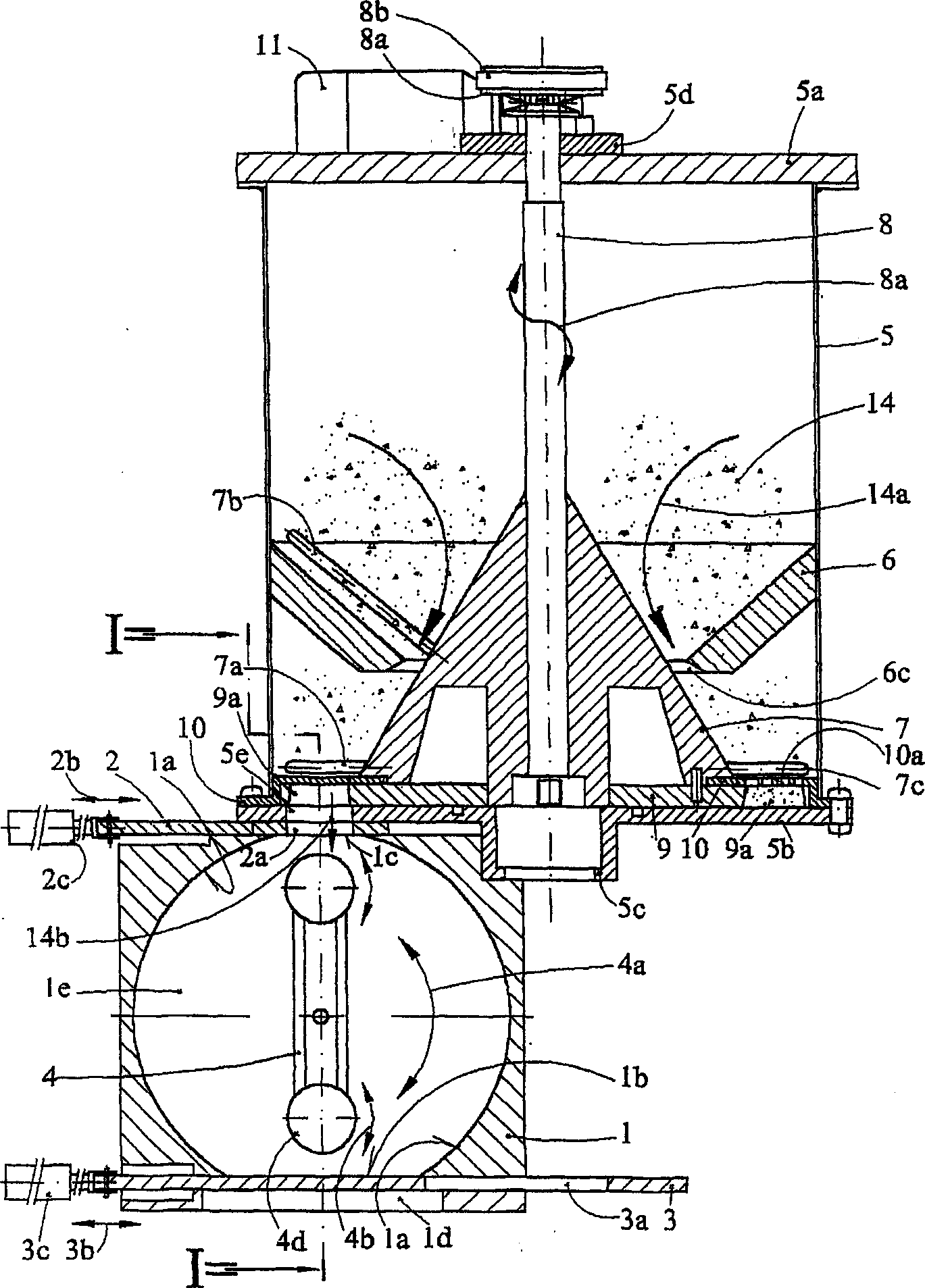

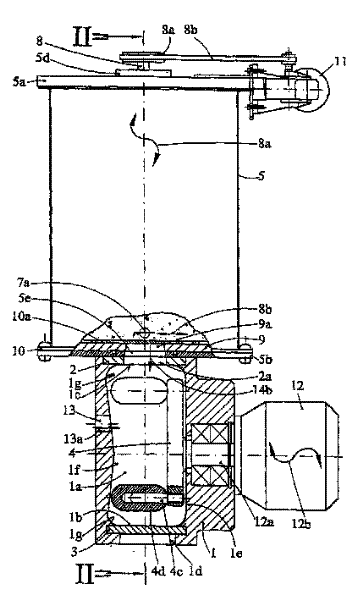

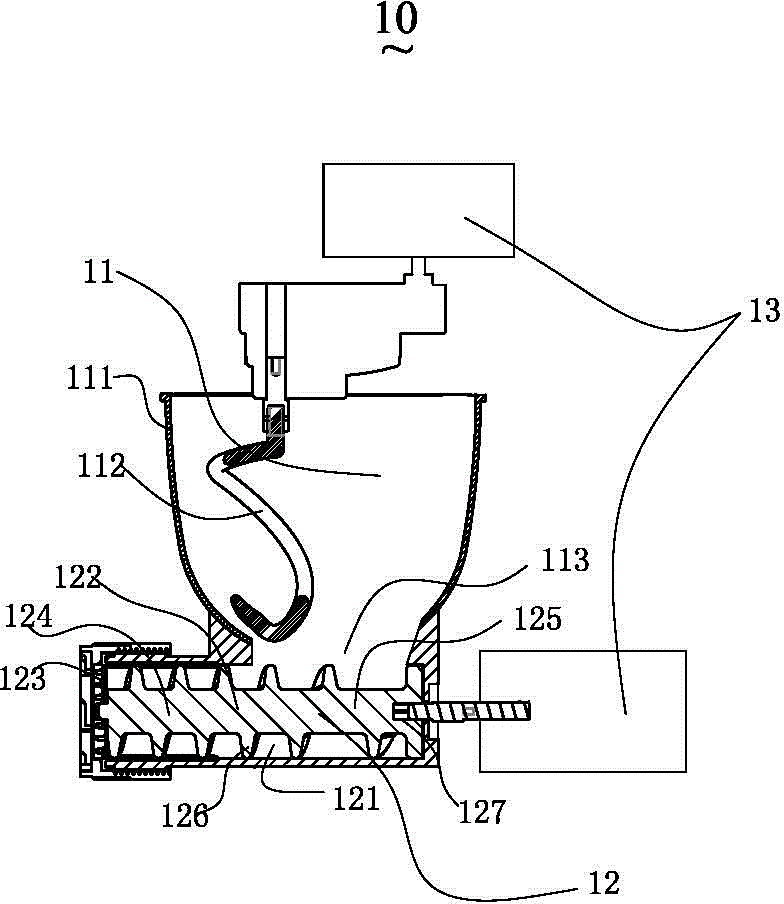

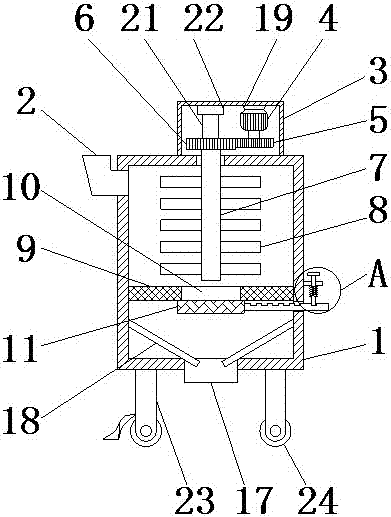

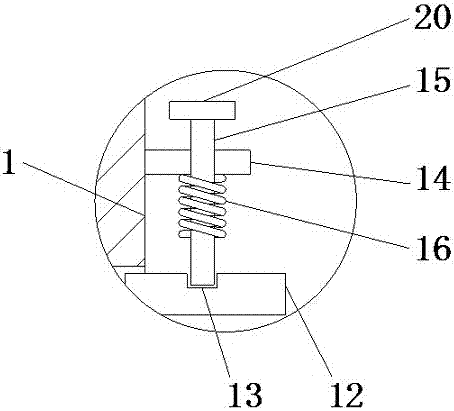

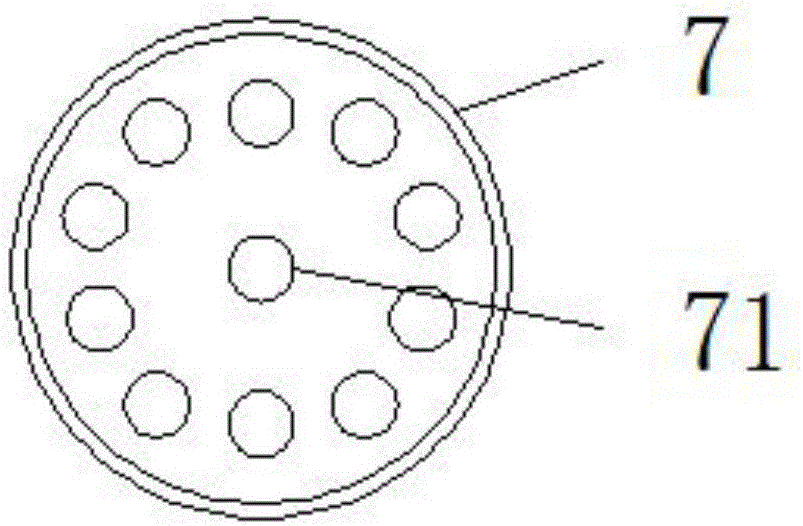

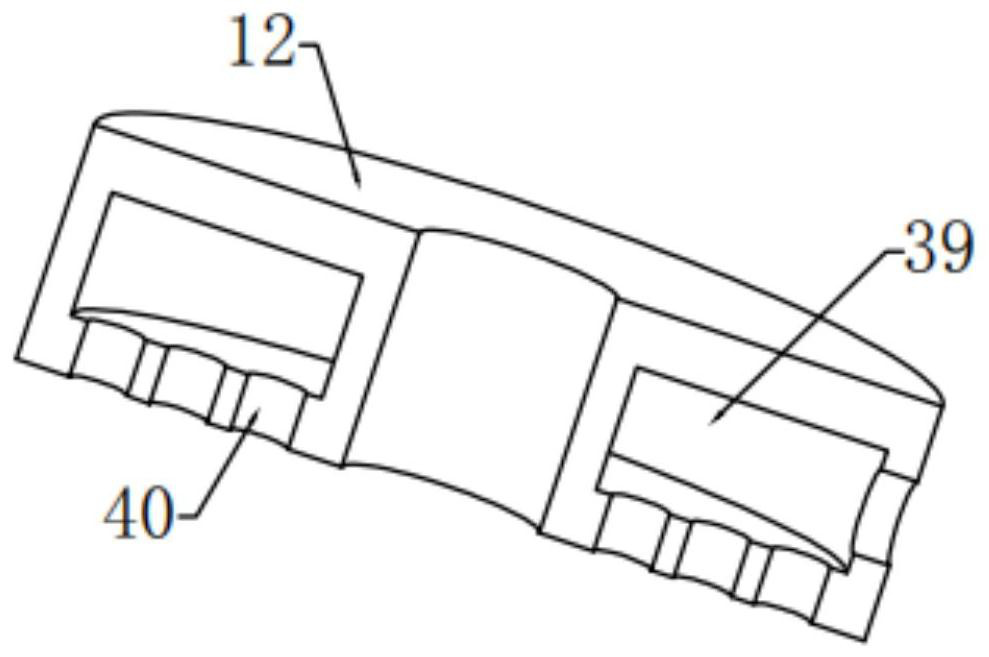

Dough mixer with metering device

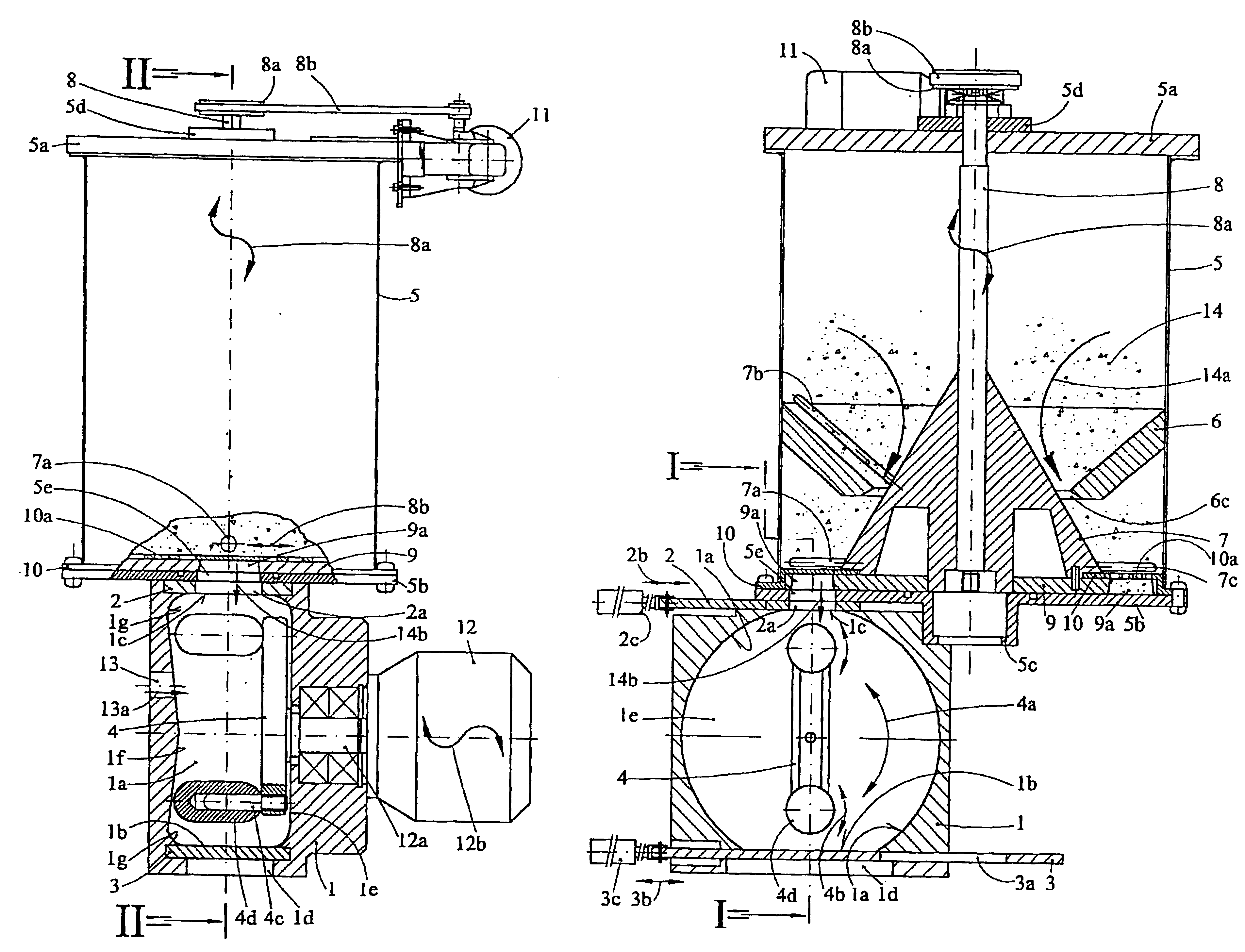

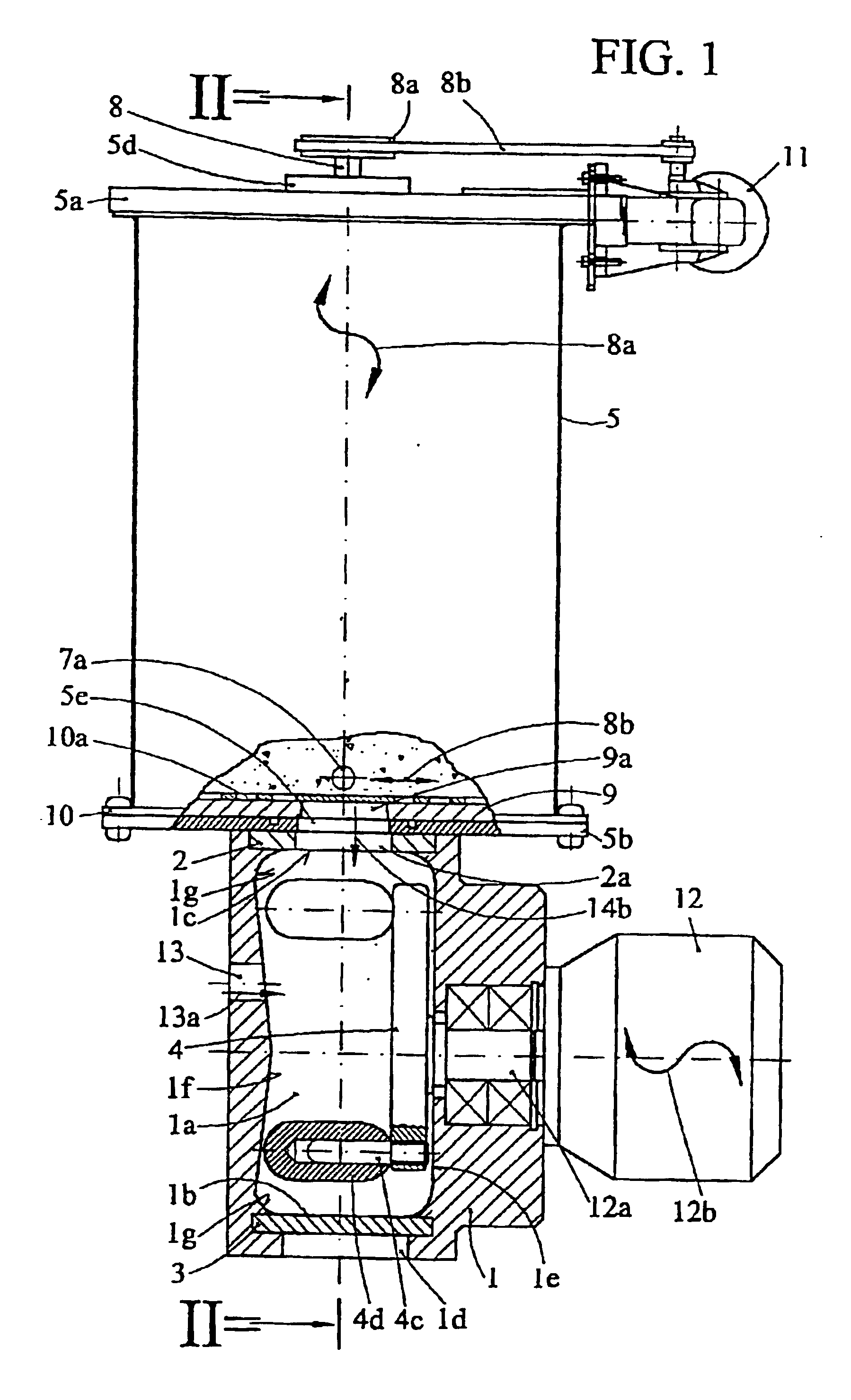

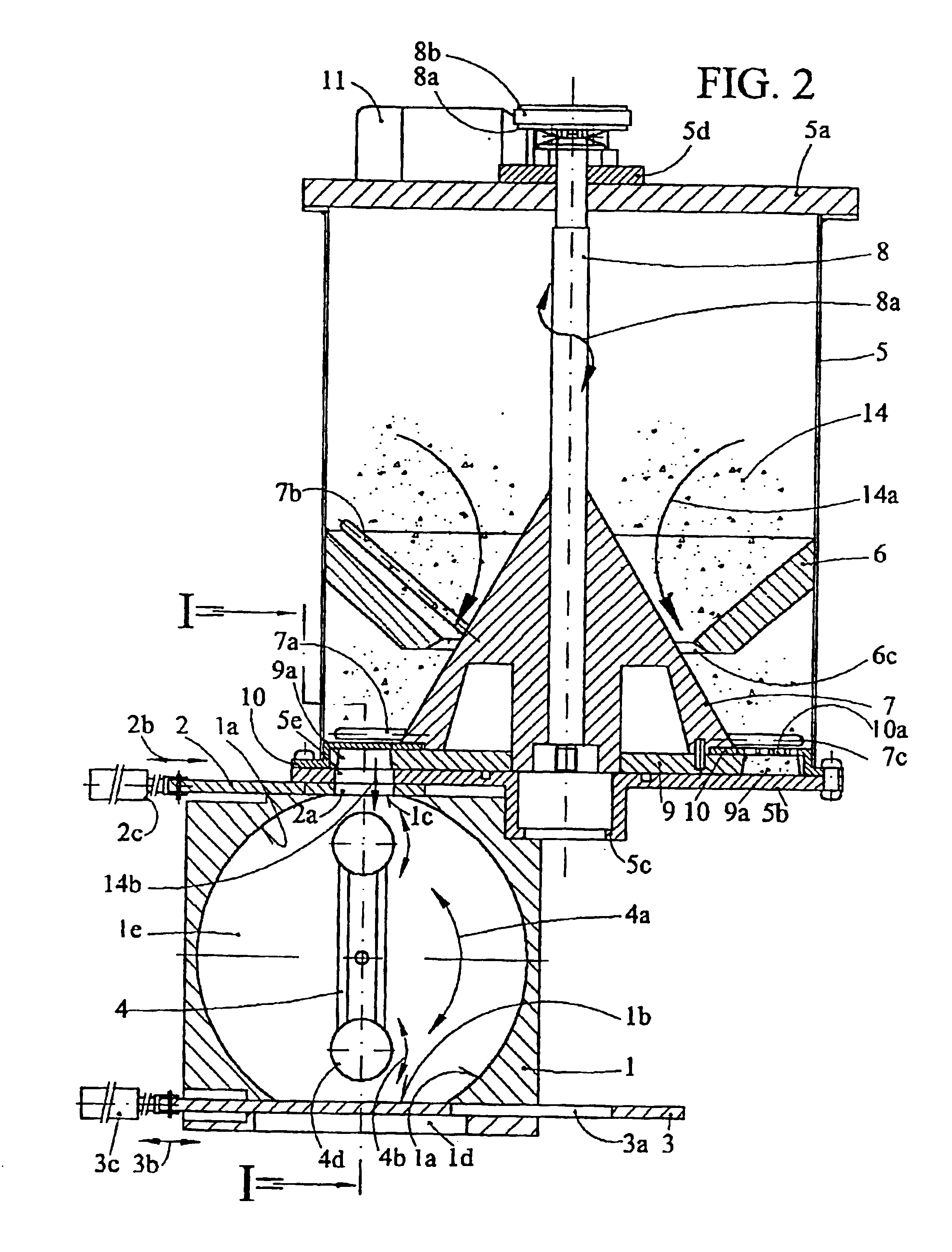

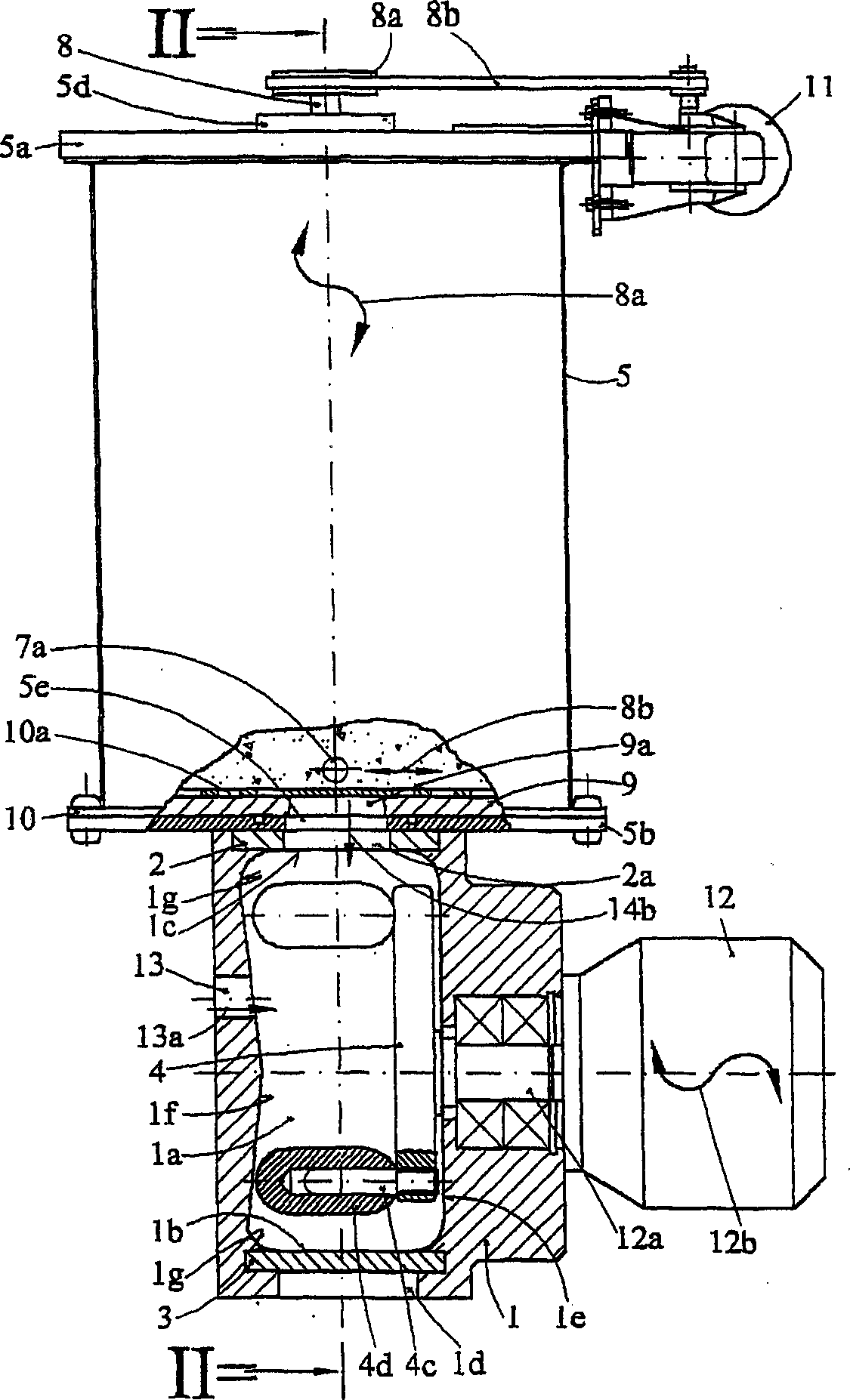

InactiveUS6863429B2Simple and compact designMixing/kneading structural elementsTransportation and packagingHorizontal axisCircular surface

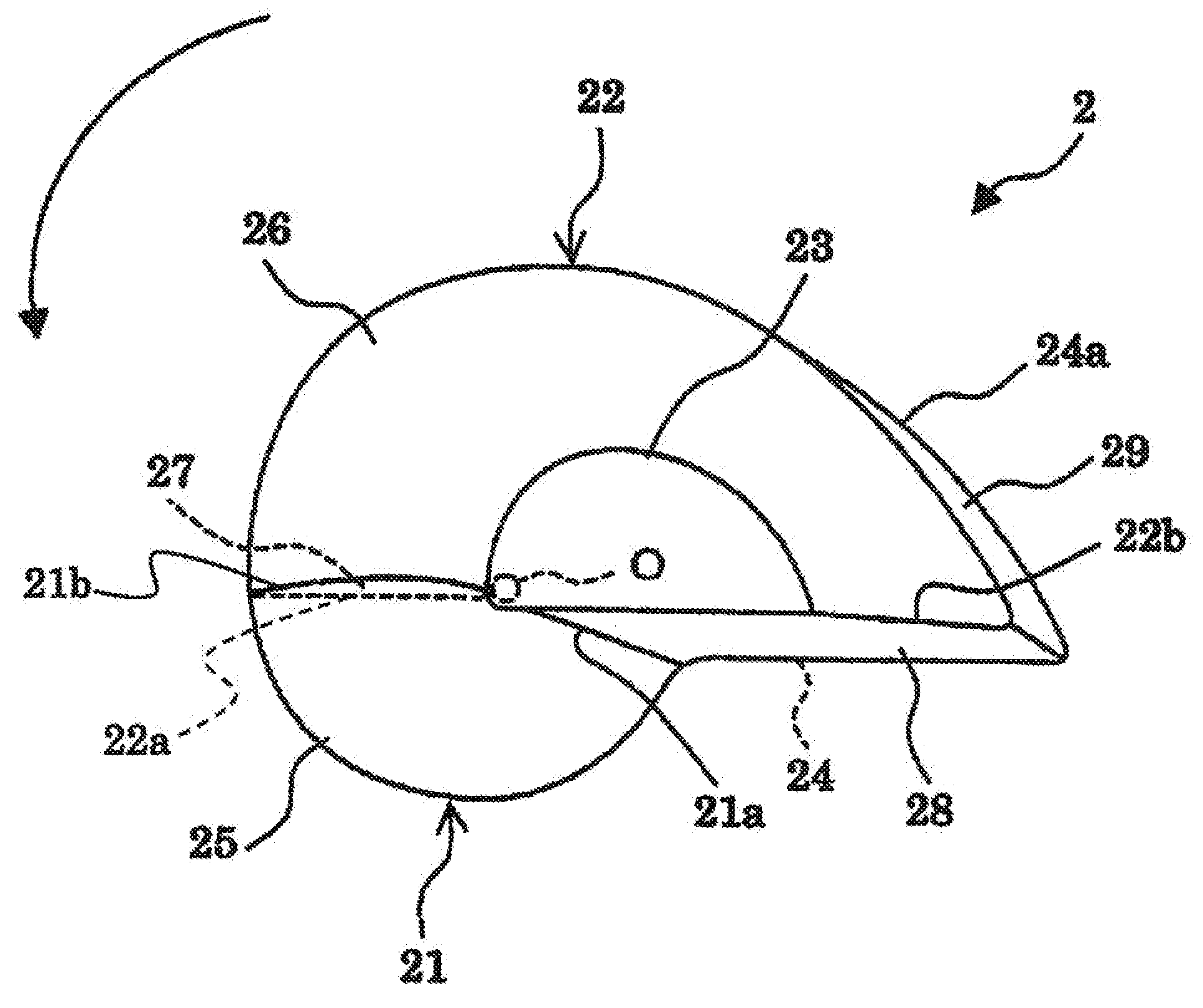

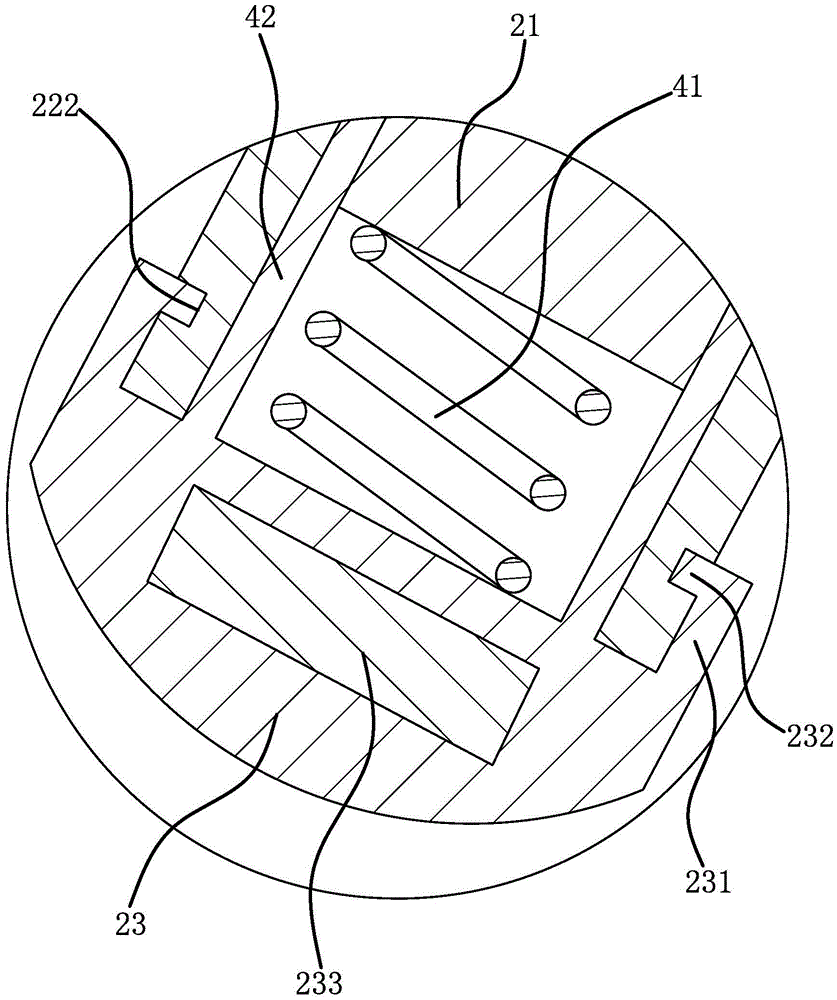

In a dough mixer for preparing dough, the essentially cylindrical chamber with horizontal axis within which kneading elements (4, 4c, 4b) rotate coaxially or parallel to this axis, between two casing surface sections (1a) with the same casing line, two level surface sections (1b, 1c) which are essentially formed by the surface of sliding (2b, 3b) blades (2, 3) with upper charging opening (2a) and lower discharging opening (3a) in closed position, and the aforementioned surfaces (1a, 1b, 1c) turn into two front, coaxial, separated circular surfaces (1e, 1f) via rounded areas (1g) with the largest possible radius, such that, together with the rotating (4a) kneading element (4, 4c, 4d), which likewise has very round forms, they enable the preparing and compressing of dough and rolling into balls of an individual dough portion that is discharged without residue of ingredients or dough. The metering device for charging the dough mixer with volumetric calibrated and the most homogeneous portion of flour-like ingredients has a vertical shaft (8) that rotates coaxially (8a) to the cylindrical container (5, 5a, 5b), which drives stirring elements (7a, 7b), a distribution cone (7) and a metering disk (9a) with metering holes (9a) positioned on the rim that are equidistant both from one another and from the axis. The container of the metering device is divided on the inside by an annular, funnel-like partition (6) into an upper container and a lower, smaller region for the metering mechanism.

Owner:SITOS

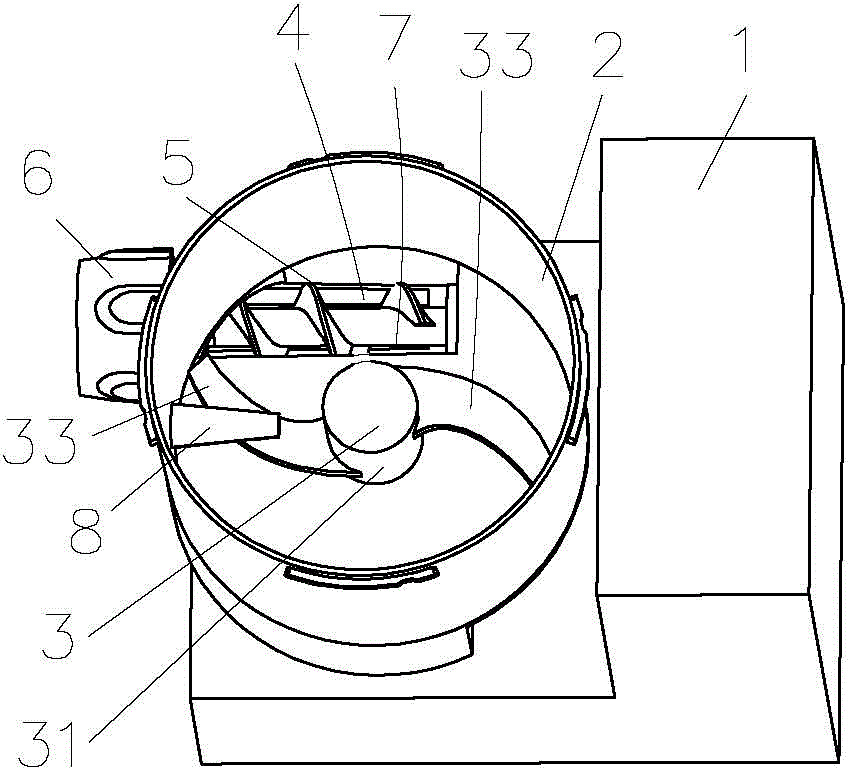

Kneading machine with dosing device

InactiveCN1372489AAbsorb evenlyMix completelyMixing/kneading structural elementsRotary stirring mixersRotational axisVertical plane

A dough or pastry mixer assembly has a main mixing chamber (5) discharging into a high speed single portion lower kneading chamber (1). In one horizontal plane the kneading chamber has essentially ring-shaped sidewalls with mixer paddles rotating through the vertical plane. At right angles to the first horizontal plane, the chamber has two circular facing sidewalls, one slightly conical and the other flat. The top and bottom of the kneading chamber are slightly flattened. The top has an inlet aperture which is kept free of food particles by a slide closure. The chamber bottom has a slide closure for discharge of the kneaded mixture. The slightly conical chamber sidewall terminates in a rounded tip parallel to the axis of mixer paddle rotation.

Owner:ARTOS SA

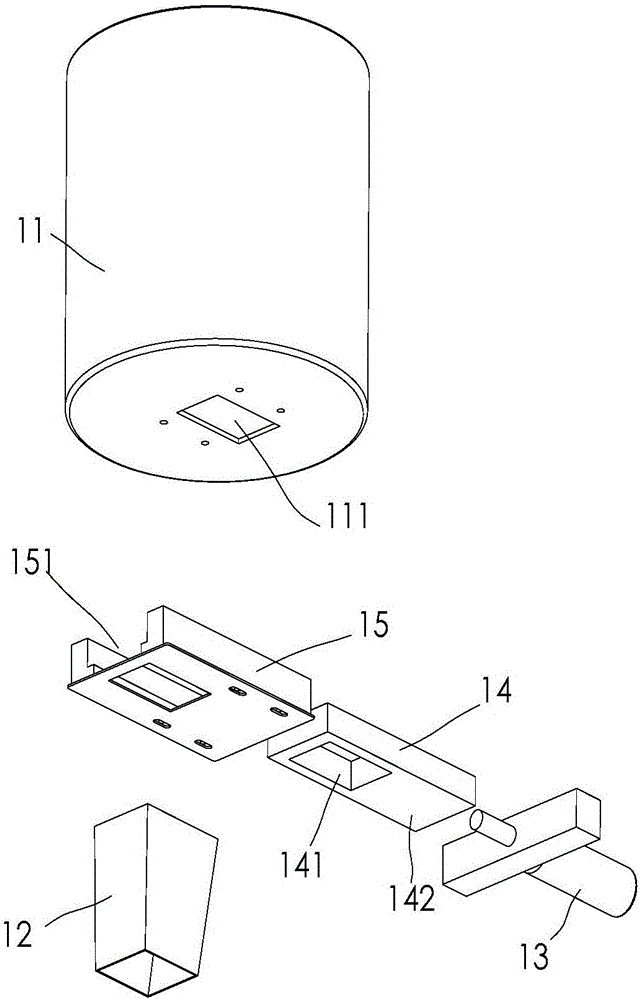

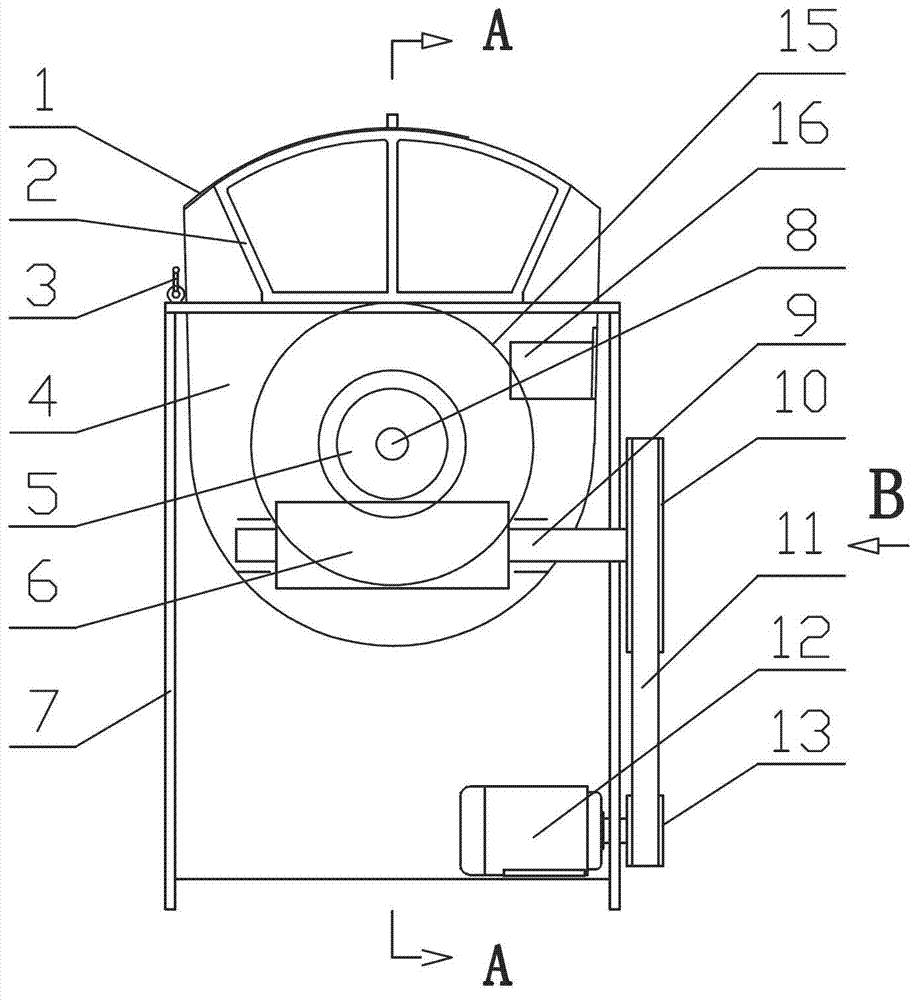

Flour mixing machine

InactiveCN107019010AIncrease elasticityUniform elasticityMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsEngineeringMotor shaft

The invention relates to a noodle kneading machine, comprising a cylinder body and a dough kneading device arranged in the cylinder body; a dough inlet is arranged at the upper end of the cylinder body; a telescopic water inlet pipe which can be stretched The end is a cylindrical self-rotating nozzle; the kneading device includes a stirring device that can be raised and lowered as in the cylinder and a beating device that is evenly distributed on the inner periphery of the cylinder; the beating device includes a plurality of The stroke rod; one end of the stroke rod toward the center of the bottom of the cylinder is provided with a hemispherical hammer, and the other end is hinged on the outer periphery of a turntable; the turntable is driven by a first motor, and the motor shaft is eccentric on the turntable Setting; the middle part of the strike rod is slidingly sleeved in a limit sleeve.

Owner:林娜娜

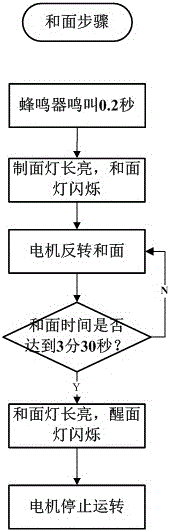

Intelligent noodle making method of household noodle maker

ActiveCN104920527AStable Rotational Inertial ForceAvoid idlingMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsFood science

Owner:JOYOUNG CO LTD

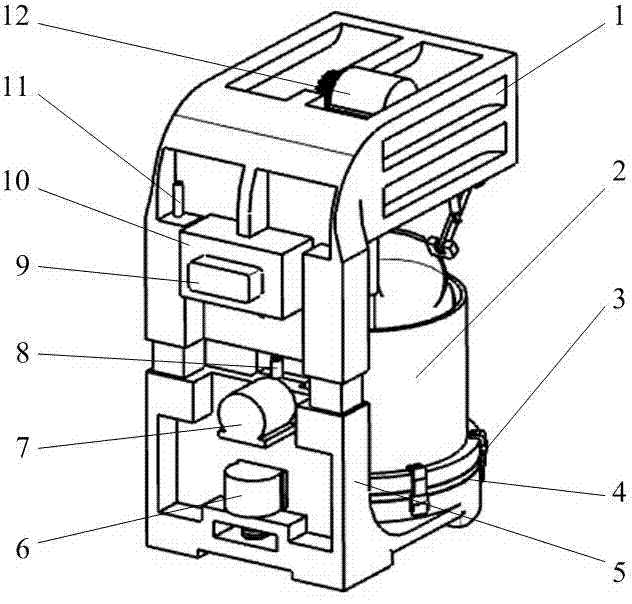

Unattended automatic noodle cooking machine

ActiveCN106037460AMixing/kneading structural elementsWater-bath cooking vesselsReady to eatEngineering

The invention discloses an unattended automatic noodle cooking machine. The unattended automatic noodle cooking machine comprises a frame, a dough kneading mechanism, a noodle forming mechanism, a noodle cooking mechanism, a noodle bowl mechanism and a noodle taking port. The noodle forming mechanism comprises a forming barrel and a pressing part, the forming barrel is used for receiving noodle materials falling from the dough kneading mechanism, the bottom of the forming barrel is provided with a plurality of forming holes, and the pressing part is mounted in the forming barrel and capable of moving along the height direction of the forming barrel to extrude the noodle materials out of the forming hole. The noodle cooking mechanism comprises a noodle cooking vessel and a noodle cooker, the noodle cooking vessel is used for receiving the noodle materials falling from the forming holes, and the noodle cooker is mounted below the noodle cooking vessel to heat the same. The noodle bowl mechanism is mounted on one side of the noodle cooker and used for receiving noodle materials falling from the noodle cooking vessel. The noodle taking port is communicated to the noodle bowl mechanism. By the unattended automatic noodle cooking machine, a whole automatic process for processing flour into ready-to-eat noodles can be realized.

Owner:GUANGDONG SHENTOP INTELLIGENT EQUIP CO LTD

Method for making cooked wheaten food by using domestic multifunctional cooked wheaten food machine

InactiveCN104542768AIncrease exerciseProlong the stress timeMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsEngineeringUtilization rate

The invention relates to a method for making cooked wheaten food by using a domestic multifunctional cooked wheaten food machine. The domestic multifunctional cooked wheaten food machine comprises a stirring system, an extrusion and forming system and a driving system, wherein the stirring system comprises a stirring element and a stirring container; the extrusion and forming system comprises a forming cavity, a dough extrusion screw rod and a forming mold; and the driving system comprises a driving stirring element and a dough extrusion screw rod. The method for making the cooked wheaten food comprises a feeding procedure, a first stirring procedure, a second stirring procedure, a kneading procedure and an extrusion and forming procedure. By setting three different rotation speeds in the first stirring procedure, the second stirring procedure and the kneading procedure, the extruded cooked wheaten food is relatively uniform, smooth and free of layering, the raw material residue amount is also reduced, and the utilization rate is increased.

Owner:JOYOUNG CO LTD

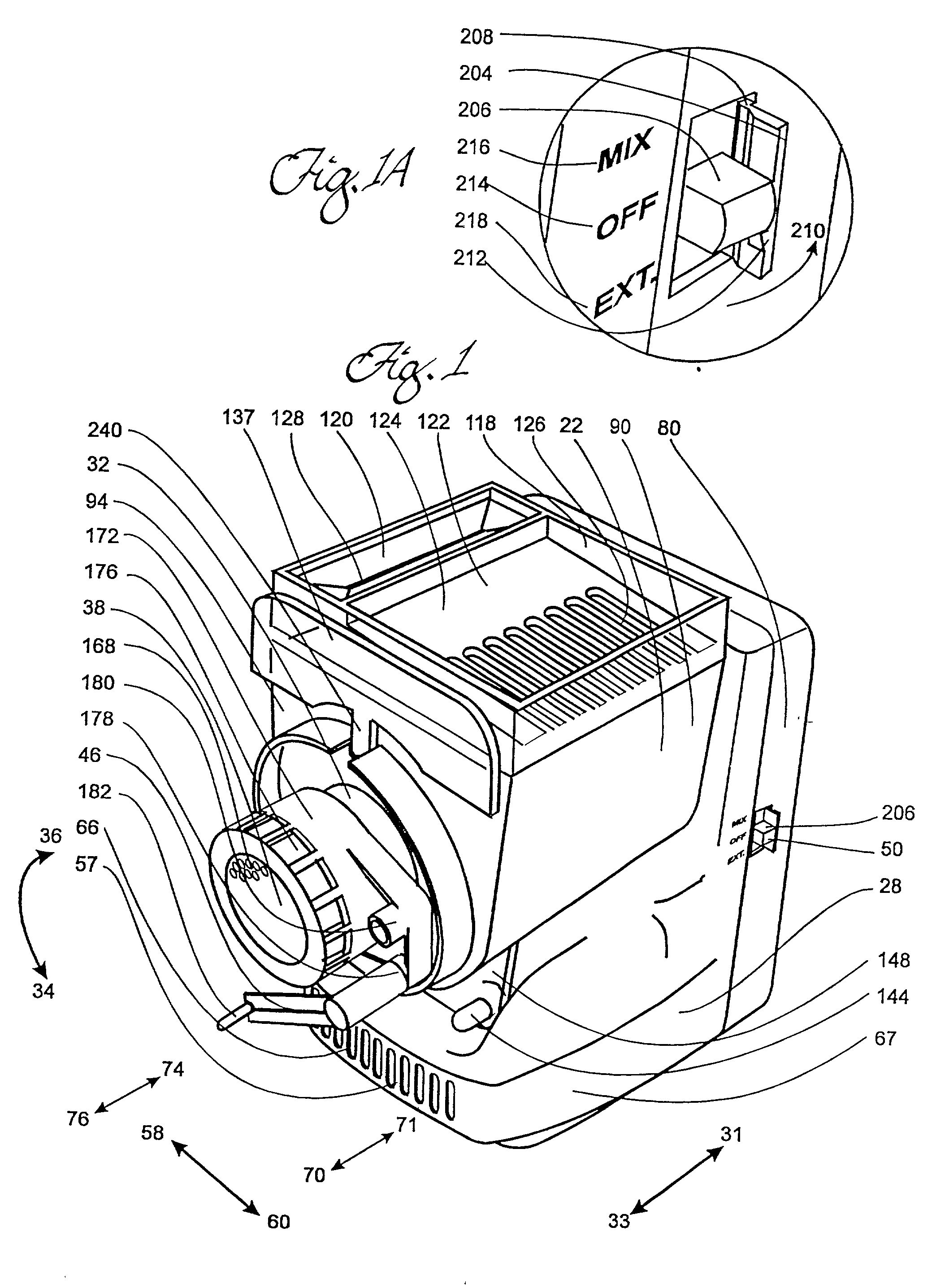

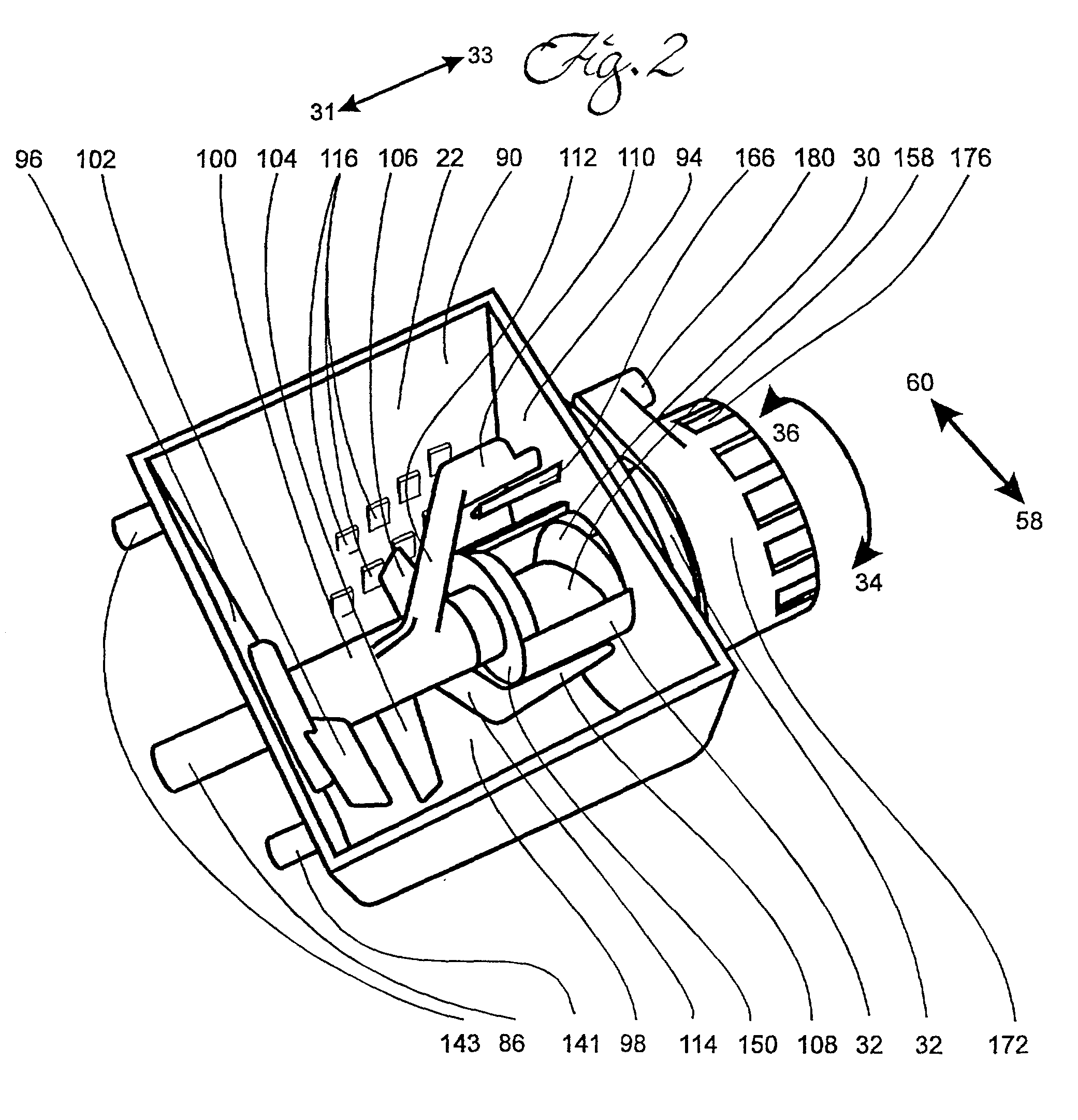

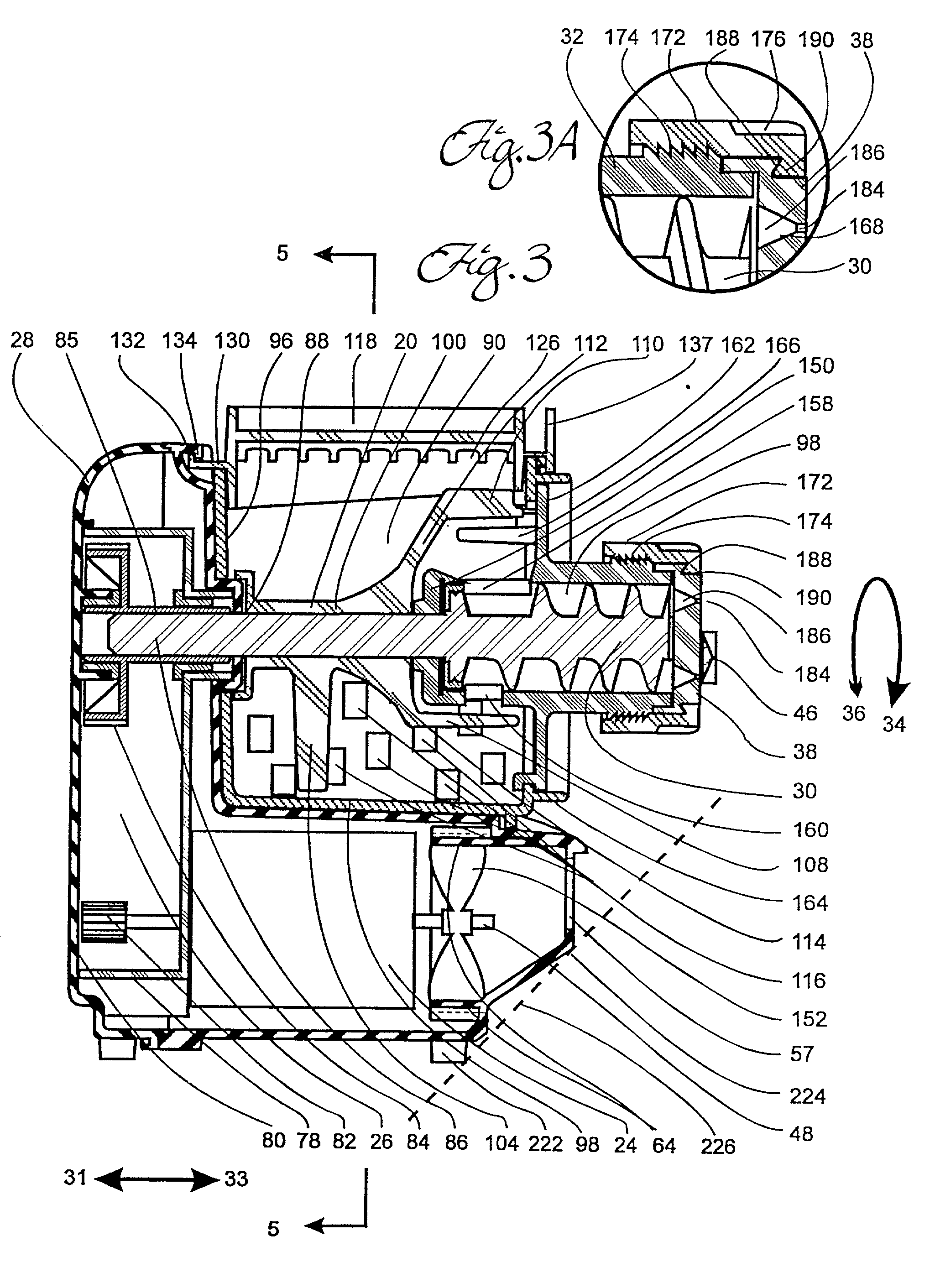

Pasta, pastry, cookie, and hors d'oeuvre maker

InactiveUS20010046337A1Rotary stirring mixersTransportation and packagingAdditive ingredientBaked goods

A device to mix and extrude various ingredients including pastas, pastries, baked goods, hors d'oeuvres, and cookies. The device includes novel measuring, mixing and extrusion arrangements including: an automatic measuring cup; a way to continuously mix and extrude ingredients without intervening cleanings; a mixing and extrusion feed for handling different consistencies of ingredients; an integrated automatic cutter; motor cooling and extruded ingredient drying; as well as various safety devices.

Owner:LAURUS MASTER FUND +1

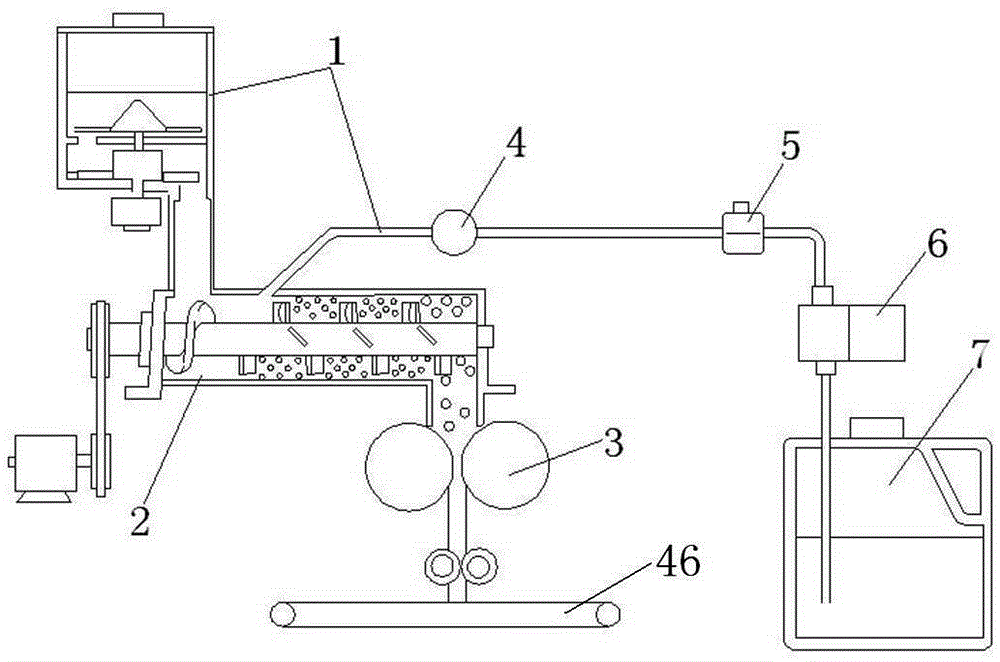

Noodle processing device

ActiveCN104886203AWorkload balanceMake up for lack of motivationMixing/kneading structural elementsDough-sheeters/rolling-machines/rolling-pinsEngineeringMaterial supply

The invention discloses a noodle processing device. The noodle processing device comprises a dough-kneading device, a pre-sheeting device, composite rollers, rollers, noodle tools, cut-off tools, a first conveying device and a drying device. A water supply system supplies water to the dough-kneading device. The dough-kneading device, the pre-sheeting device, the composite rollers, the rollers, the noodle tools, the cut-off tools and the first conveying device are sequentially arranged from front to back according to the technological process. The drying device is arranged on a conveying path of the first conveying device. The noodle processing device has the advantages that the water supply power is sufficient, and noodles are uniformly discharged after dough is kneaded.

Owner:HUAIBEI XUYUAN FOOD CO LTD

Food stirring device

InactiveCN107333825AImprove stabilityExtended service lifeMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsGear wheelEngineering

The invention discloses a food stirring device. The food stirring device comprises a machine body, wherein a feed hopper communicates with the top of the left side of the machine body; a gearbox is fixedly connected to the top of the machine body; a motor is arranged in the gearbox; a first gear is fixedly connected to an output shaft of the motor; a second gear which is engaged with the first gear is arranged on the left side of an inner cavity of the gearbox; a rotary shaft is fixedly connected to an axis of the bottom of the second gear; and stirring rods are fixedly connected to the bottom penetrating through the machine body and extending into the machine body, of the rotary shaft. According to the food stirring device disclosed by the invention, the motor is arranged, so that the first gear and the second gear can be driven to rotate; the second gear is arranged, so that the rotary shaft and the stirring rods can be driven to rotate to stir paste; a through hole is formed, so that the stirred paste can fall out of the machine body through the through hole; and besides, the problem that the effects of uniform and thorough stirring cannot be achieved, so that the working efficiency of the stirring machine is reduced is solved.

Owner:翟端

Efficient flour mixer for food processing

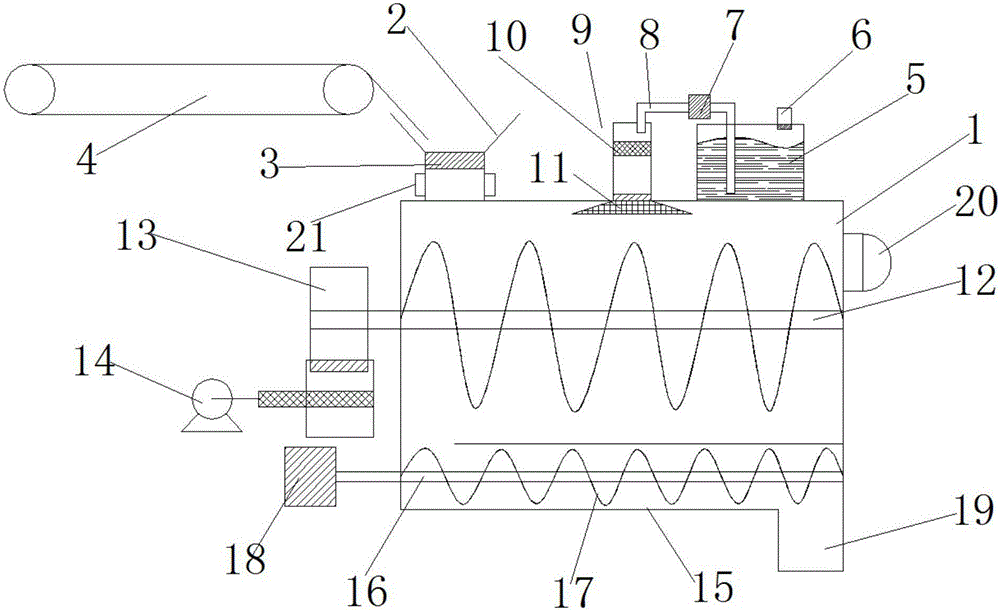

InactiveCN106070404AImprove processing efficiencyImprove work efficiencyMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsSpiral bladeWater storage tank

The invention discloses an efficient flour mixer for food processing. The efficient flour mixer for food processing comprises a flour mixer body, a feeding hopper, a quantitative electronic scale, a feeding device, a water storage tank, a mixing box, a booster water pump, a water pipe, a water inlet pipe, a flow control valve, a nozzle, an auger device, a transmission gear set, a gear motor, a spiral discharging pipe, a spiral rotating shaft, spiral blades, a rotating motor and a discharging pipe. According to the efficient flour mixer for food processing, flour and water can be automatically fed, and flour and water entering the flour mixer to be processed can be quantitatively controlled, so that processed paste is higher in quality, the working efficiency of the flour mixer is improved, and the labor intensity is relieved; the auger device is used for mixing flour and water, so that the effect is good, and the efficiency is high; besides, automatic continuous discharging can be achieved, so that the labor intensity is further relieved, and the working efficiency is improved.

Owner:徐州龙凤缘工贸有限公司

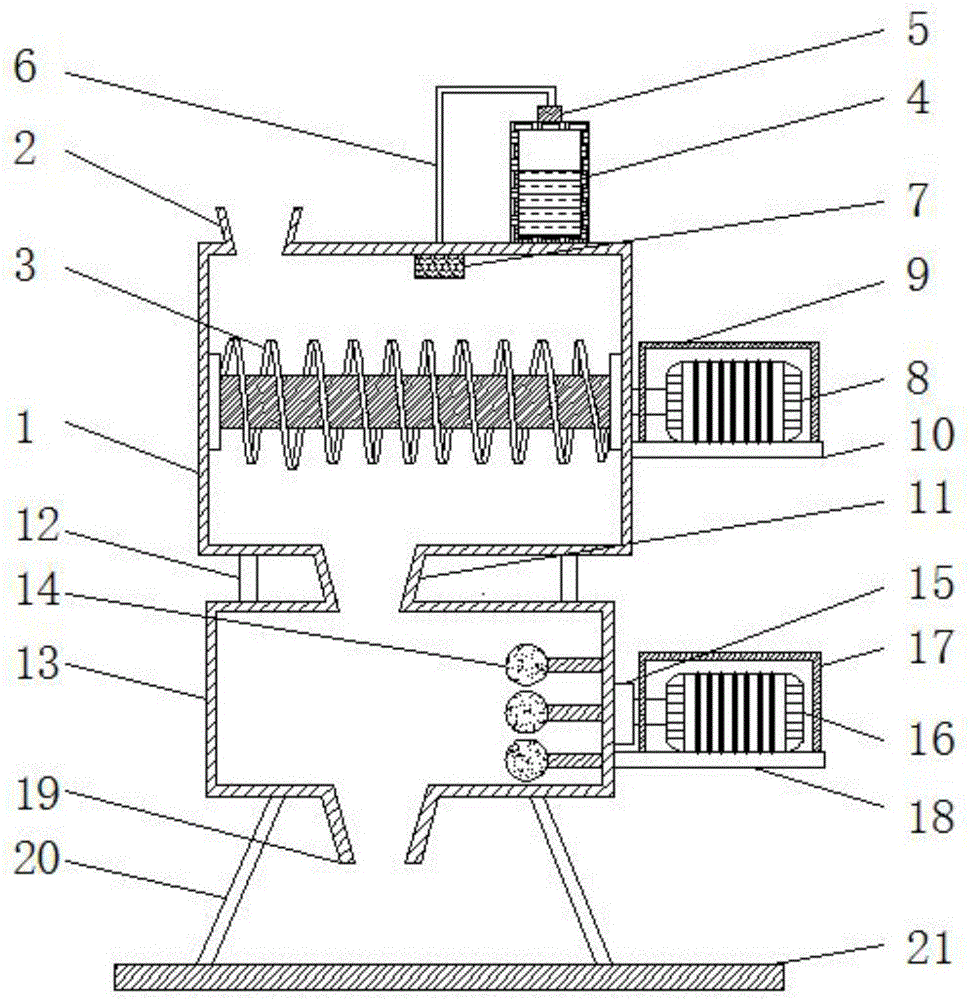

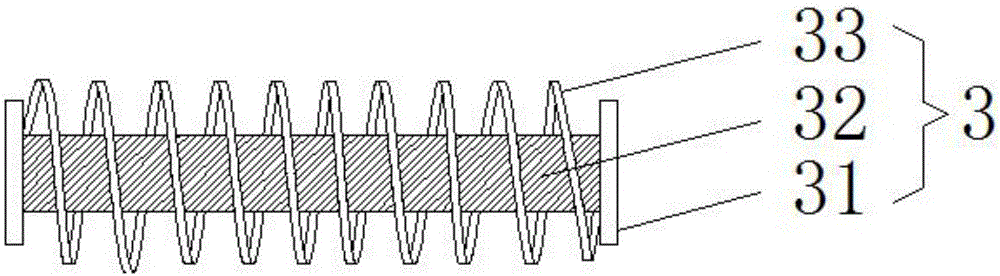

Dough mixer good in dough mixing effects

InactiveCN106359493AIncrease contact areaEvenly kneadMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsEngineeringMixing effect

The invention discloses a dough mixer good in dough mixing effects. The dough mixer comprises a first machine body, wherein a feed opening is formed in one end of the top of the first machine body, an auger device is fixedly connected to an inner cavity of the first machine body, a water tank is fixedly connected to the top end of the outside of the first machine body, a water inlet of a water pump is fixedly connected to the top end of the water tank, one end of a water pipe is fixedly connected to a water outlet of the water pump, and a spray head located at the top of the inner cavity of the first machine body is fixedly connected to the other end of the water pipe; a first fixing table is fixedly connected to one side of the outside of the first machine body, a first motor is fixedly connected to the upper surface of the first fixing table, and a first encloser located on the upper surface of the first fixing table is fixedly connected to the outside of the first motor; and an output shaft, penetrating through and extending to the inner cavity of the first machine body, of the first motor, is fixedly connected to one end of the auger device. According to the dough mixer disclosed by the invention, the spray head is arranged and used for sprinkling water in the water tank onto flour, so that the effect of enlarging the contact area of the flour and the water is achieved, and a uniform dough mixing effect is achieved.

Owner:姜元华

Dough making and kneading device for food processing

InactiveCN111869695AWell mixedImprove mixing efficiencyMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsBiotechnologyElectric machinery

The invention relates to the technical field of food processing, in particular to a dough making and kneading device for food processing. The dough making and kneading device comprises a shell, wherein a feeding hopper is arranged at the top of the shell, the bottom end of the feeding hopper is connected with a dough making mechanism arranged on the inner side of the shell through a material guidepipe, and a dough kneading mechanism is arranged on the lower side of the dough making mechanism. A plurality of guiding plates fixedly connected with the shell are arranged between the dough kneading mechanism and the dough making mechanism. By arranging the dough mixing mechanism, automatic water adding and dough mixing can be achieved, the dough making efficiency is improved, the workload of people is reduced, flour and water can be mixed more uniformly, and the dough making quality is improved; by arranging an adjusting mechanism, intermittent water injection can be achieved in the doughmaking process; and a driving mechanism is arranged, clamping blocks on two sides are made to move left and right repeatedly through a second motor, a pull rod drives the clamping blocks to move, andbesides, up and down repeated movement of a pressing block can be achieved through a connecting mechanism, and therefore, dough is comprehensively extruded, and dough kneading is achieved.

Owner:汪根明

Automatic dough mixing machine

InactiveCN102763696AImprove sealingWon't leakMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsHorizontal axisEngineering

An automatic dough mixing machine belongs to a mechanical device for dough mixing replacing manual mixing and is characterized by comprising a frame, a mixing box, a mixer, a motor and a transmission device. The mixer is disposed in the mixing box by rotating around a horizontal axis. The mixing box is disposed on the frame and is provide with a flour access opening at the top. The inner bottom of the mixing box is an arc face adapting to rotation direction of the mixer. Two lateral edges of the top opening of the mixing box are arc edges upwardly arched, and an arc cover board is disposed at the opening of the mixing box in a matching manner. Two sides of the mixing box are provided with arc rails allowing the arc cover board to slide in an arc direction, and the arc rails are fixedly supported on the frame. A motor and the transmission device are located outside the mixing box and drive the mixer to rotate around the horizontal axis. The airtightness of the automatic dough mixing machine is achieved mainly, flour leakage is avoided, and the automatic dough mixing machine is simple in structure, even in mixing and high in mixing efficiency.

Owner:山东美鹰食品设备有限公司 +1

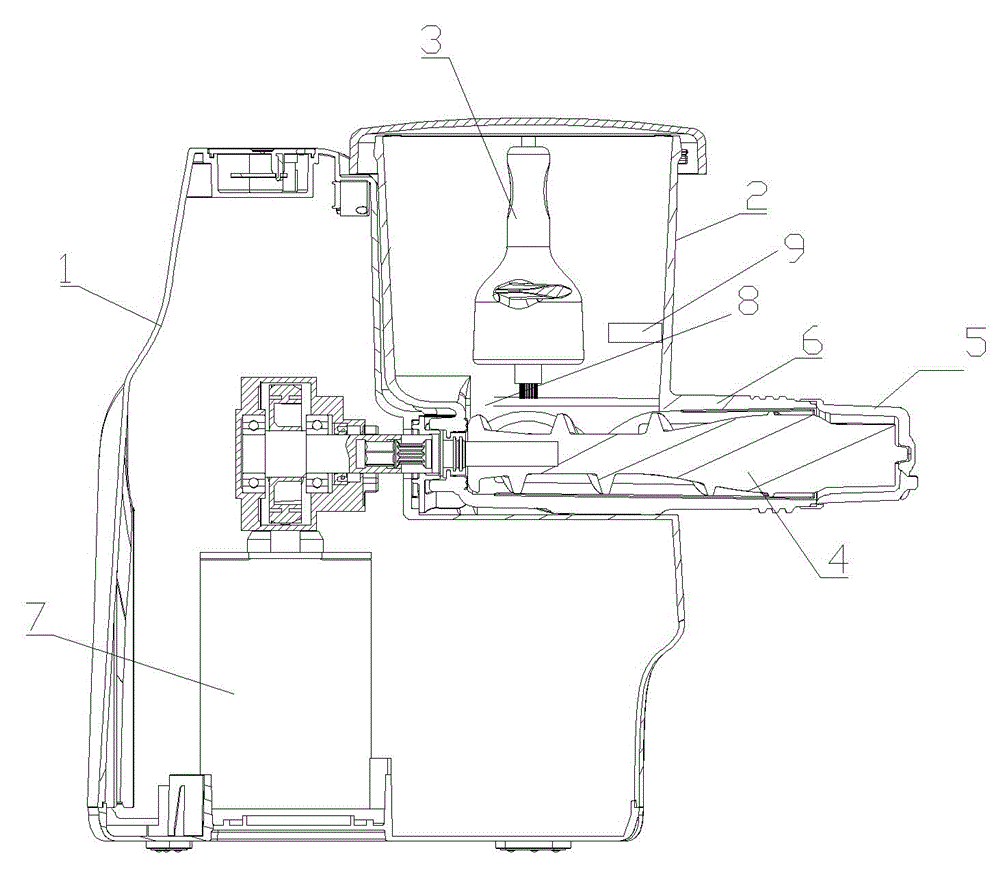

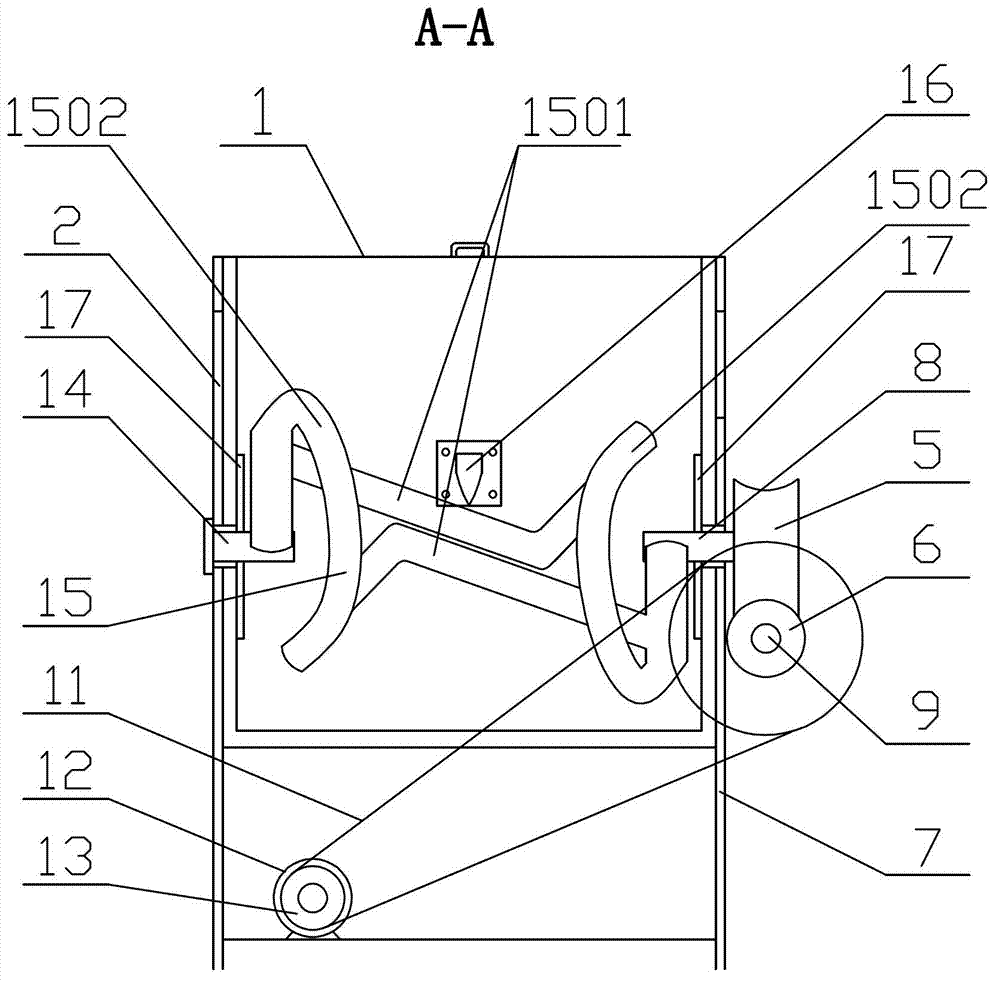

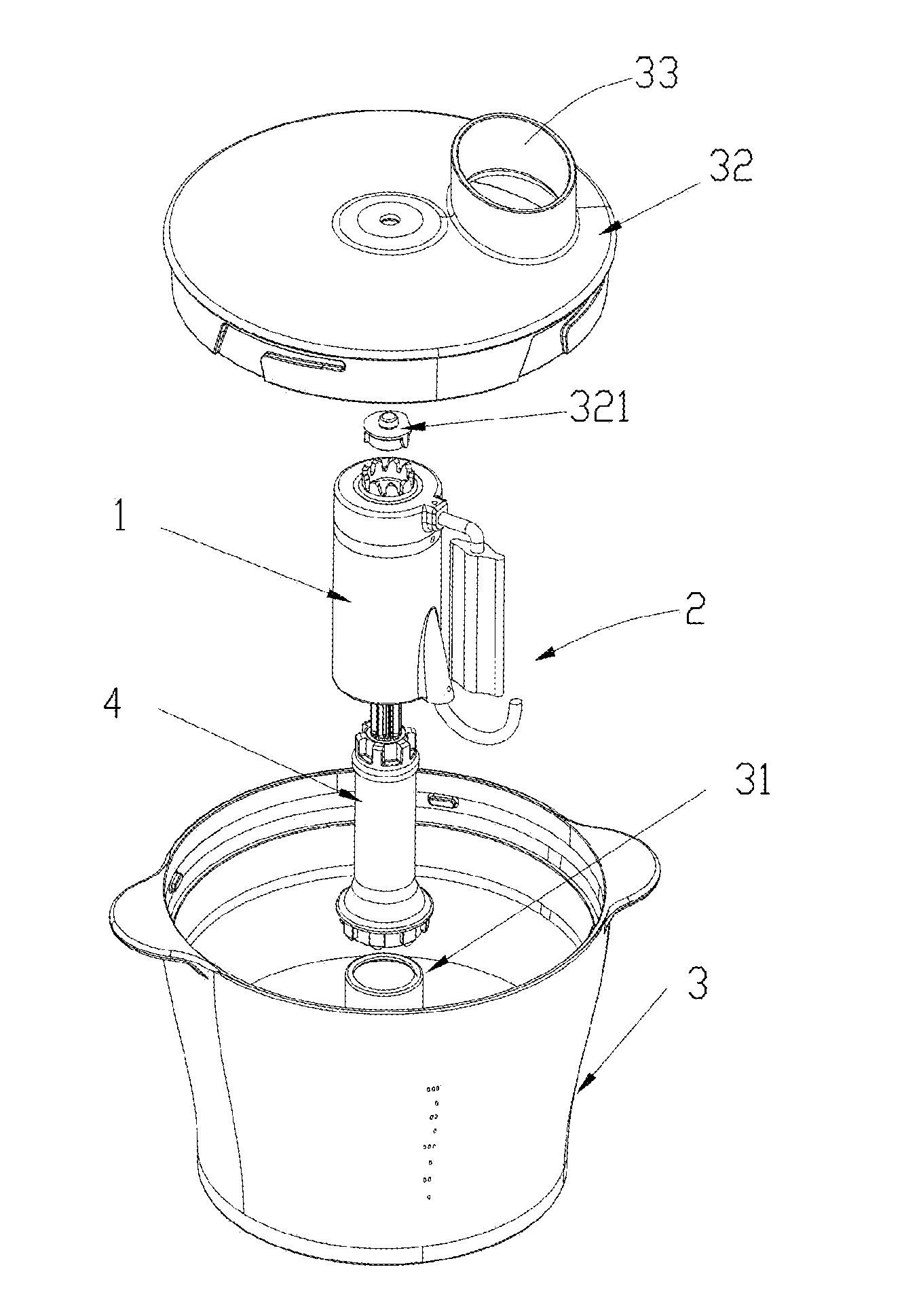

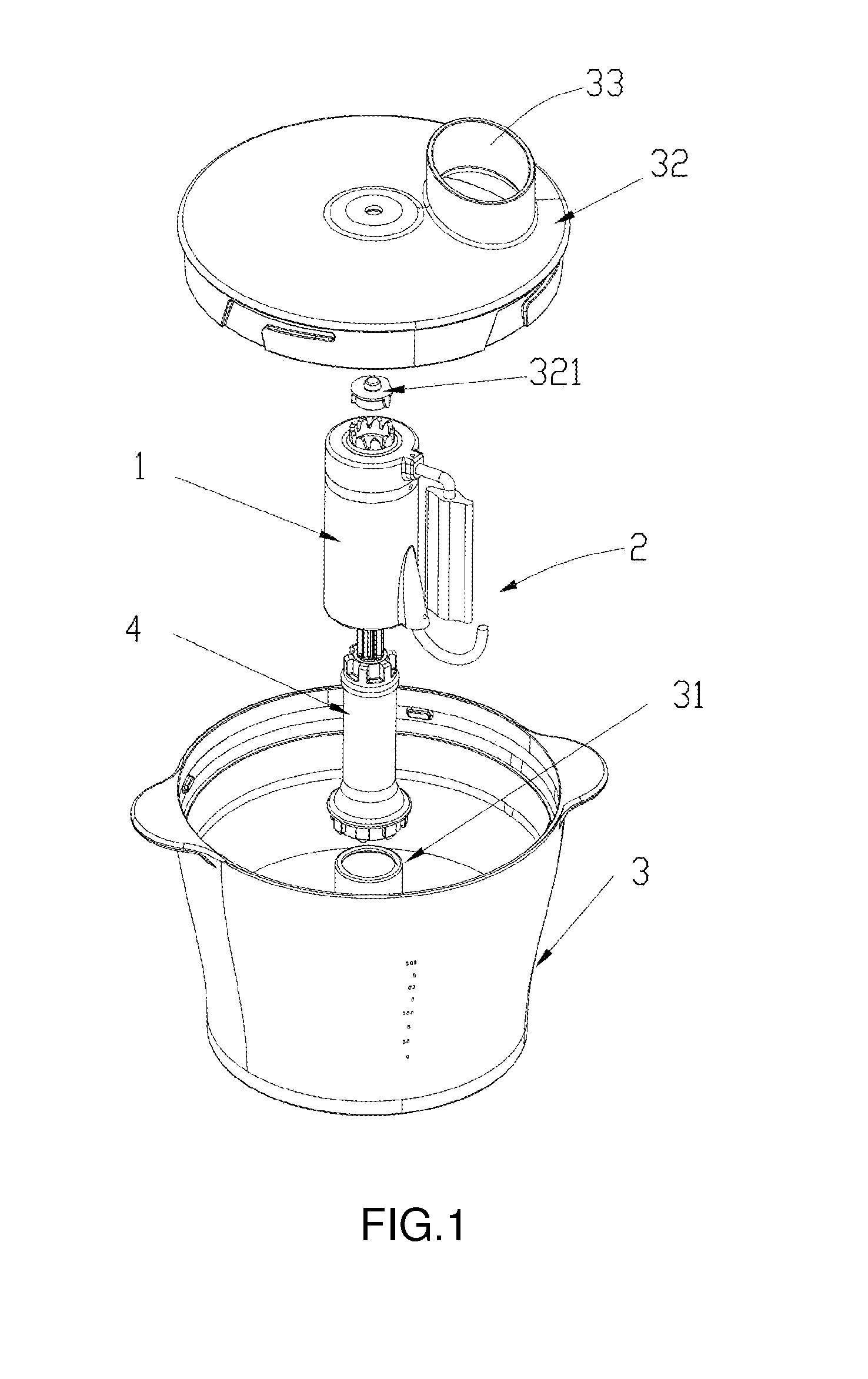

Food kneading appliance

ActiveUS20140219045A1Reduce speedSimilar performanceMixing/kneading structural elementsTransportation and packagingLow speedEngineering

A food kneading appliance especially adapted to mix and knead bread or pizza dough or dough of other types includes a container, a central body located in the center of the container, kneading tools, and a drive unit to rotate the central body. The central body includes a stirring spindle and a kneading spindle which are positioned in the same axis and rotate in opposite directions in operation. The kneading tools include a dough hook disposed on the stirring spindle and a dough mixer disposed on the kneading spindle. The appliance can provide large torque and low speed operation so that the dough can be processed without overheating and Deteriorating. Beyond that, the dough is easy to be thoroughly mixed and achieve high quality dough that is comparable to manual kneading. Another advantage of the invention is that the kneading process is stable and low in noise.

Owner:HUIYANG ALLAN PLASTIC & ELECTRIC INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com