Method for making cooked wheaten food by using domestic multifunctional cooked wheaten food machine

A production method and a multi-functional technology, which can be applied to the structural parts of dough mixers, dough extruders, mixing/kneading machines, etc. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

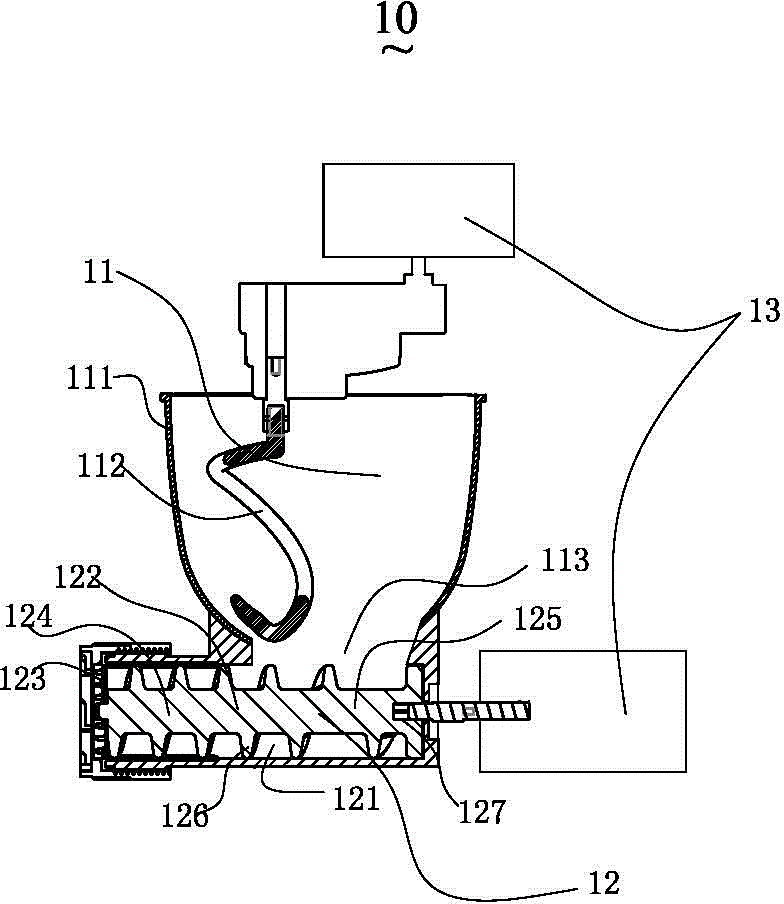

[0038] like figure 1 It is a kind of household multifunctional pasta machine 10 and comprises mixing system 11, extruding molding system 12 and driving system 13, and described mixing system 11 comprises mixing container 111, stirring element 112, and stirring element 112 is a stirring hook, and stirring element 112 stretches into In the mixing container 111, the extrusion molding system 12 includes a molding cavity 121, an extruding screw 122 and a molding die 123, the bottom of the mixing container 111 is provided with a face inlet 113 communicating with the molding cavity 121, and the extruding screw 122 includes The conveying part 124, the feeding part 125 corresponding to the noodle inlet 113, the extruding screw 126 is arranged on the conveying part 124 and the feeding part 125, and the drive system 13 includes two motors, and the two motors drive the stirring element 112 and the extruding surface respectively. The screw 122 rotates.

[0039]The first embodiment of the ...

Embodiment approach 2

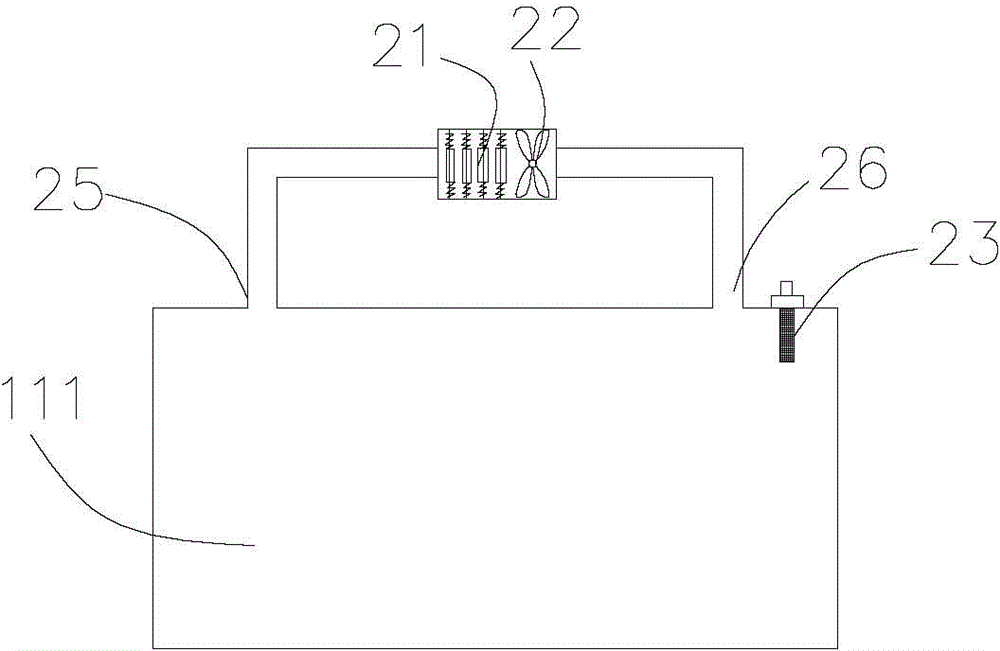

[0054] like figure 2 It is a schematic diagram of a fermentation component, including a heating element 21, an air supply element 22, and a temperature detection element 23. The air supply element 22 communicates with the stirring container 111 through the air inlet pipe 24 and the air outlet pipe 25, combined with the household multifunctional pasta of Embodiment 1 The structure of machine 10 is described, and the pasta making method of a kind of household multifunctional pasta machine comprises the following steps:

[0055] Step 1, feeding stage: adding raw materials into the stirring container 111;

[0056] Step 2, start up: connect the power supply and turn on the switch, start the household multifunctional pasta machine 10;

[0057] Step 3, the first stirring stage: add water to the inside of the stirring container 111, which can be added by the user or the household multifunctional pasta machine 10 is equipped with a water tank and other water adding mechanisms to auto...

Embodiment approach 3

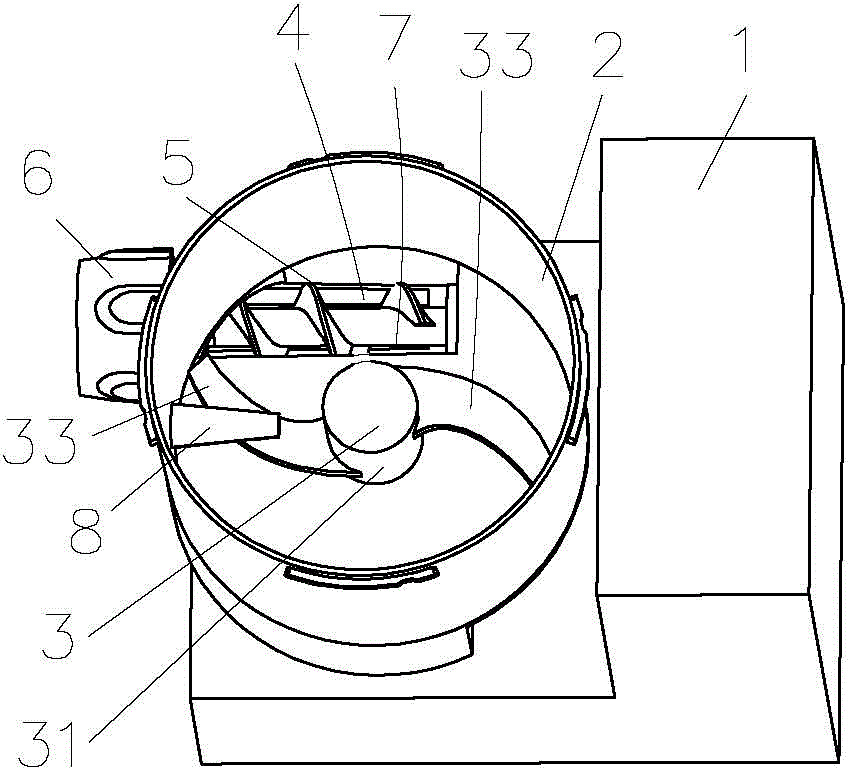

[0070] like image 3 As shown, another kind of household multifunctional pasta machine adopted by the present invention includes a base 1, a motor (not shown in the figure) arranged in the base 1, a stirring container 2 arranged above the base 1, The stirring rod 3 arranged in the stirring container 2, the molding chamber 4 arranged below the stirring container 2, the extruding screw 5 arranged in the molding chamber 4, and the molding die arranged at the end of the molding chamber 4 Head 6, the forming cavity 4 is placed on the lower side of the mixing container 2, in this example, there is one motor, and the motor drives the extruding screw 5 and the stirring rod 3 to move together to complete the stirring and extrusion work, Described stirring rod 3 comprises rod body 31, stirring tooth, and stirring tooth comprises upper stirring tooth 32 and lower stirring tooth 33 in this example, and described upper stirring tooth 32 and lower stirring tooth 33 are arranged on described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com