Patents

Literature

392results about "Provers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

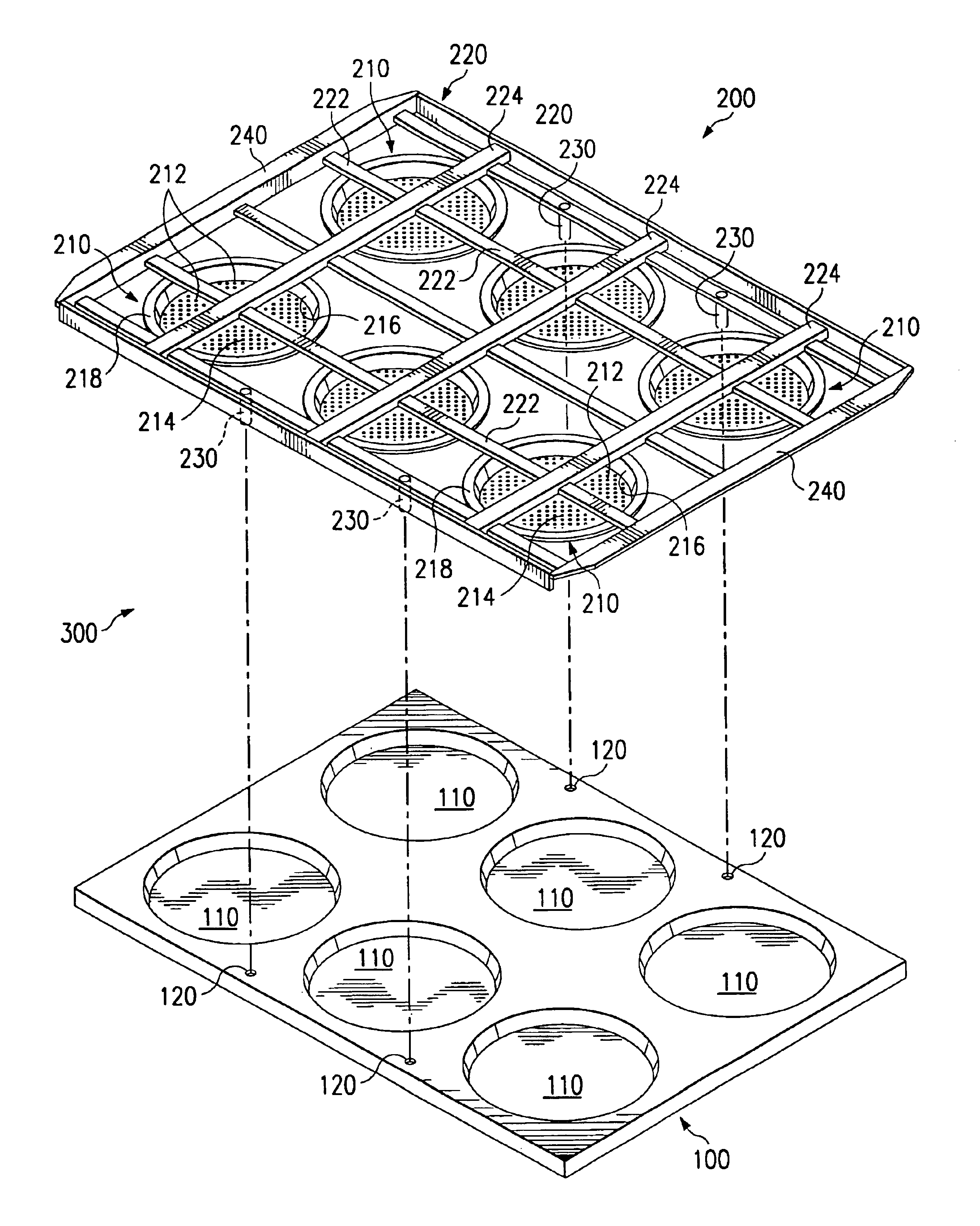

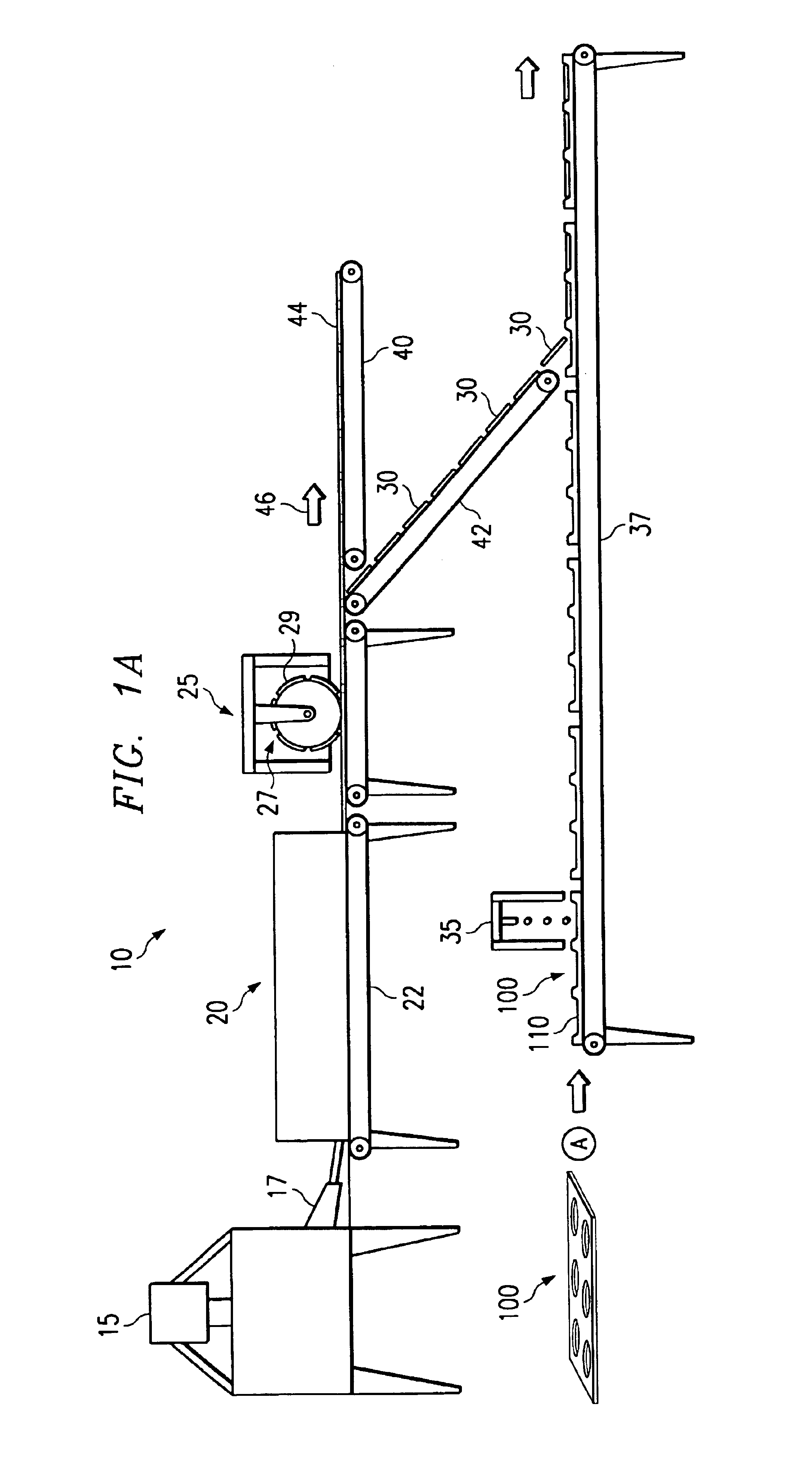

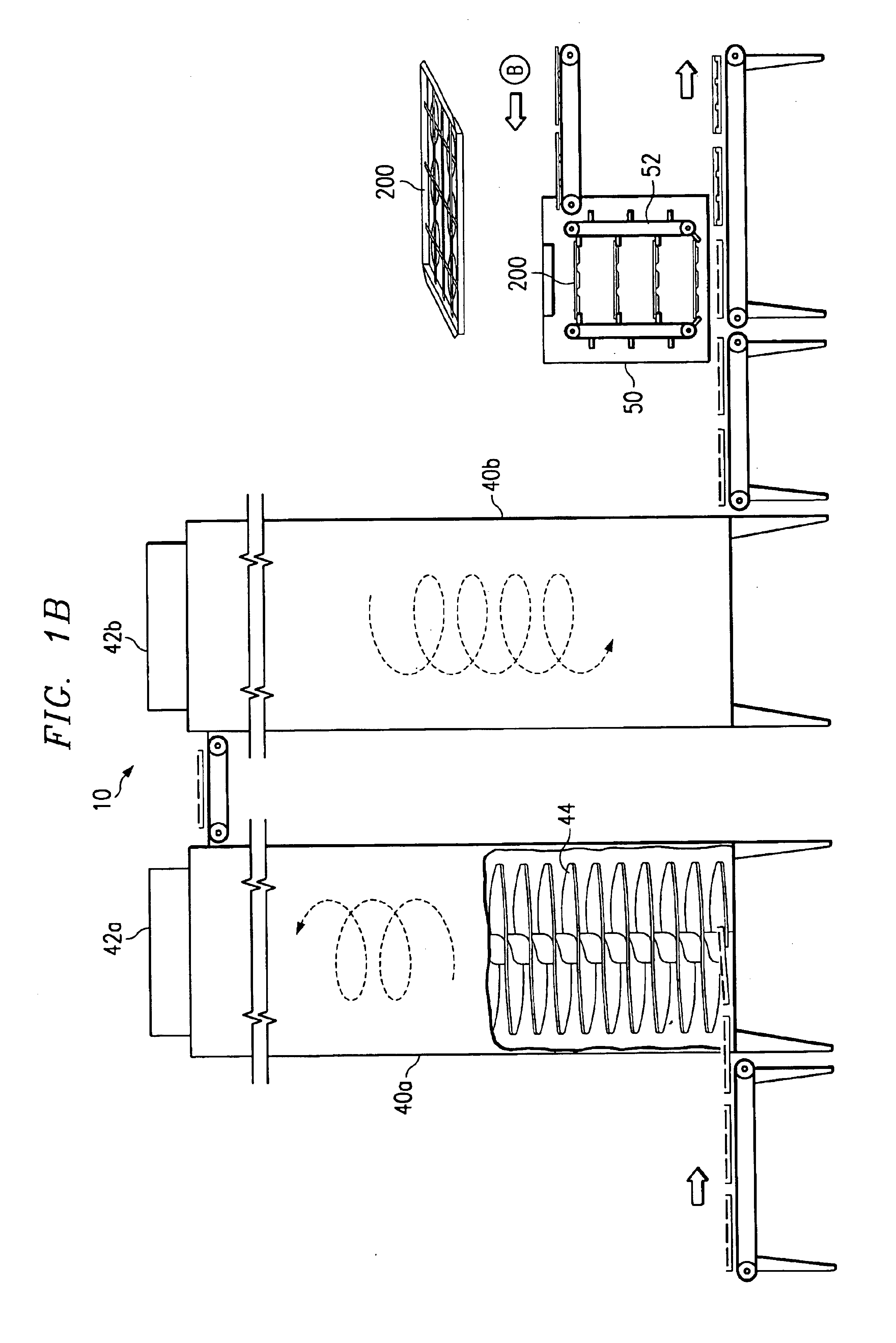

System and method for producing par-baked pizza crusts

InactiveUS6843167B1Reduces final cooking timeFast deliveryFood preservationMeat processingBiomedical engineering

A system for producing par-baked pizza crusts from dough portions includes a pan adapted to support the dough portions. A lid assembly is positioned to contact each dough portion. The dough portions are par-baked in an oven, while the lid assembly contacts the dough portions, in order to produce par-baked pizza crusts.

Owner:PIZZA HUT LLC

Dough conditioning apparatus and method

InactiveUS20080171120A1Reduce the temperatureImprove workabilityDough treatmentMilk preservationProcess engineeringHumidity

A dough conditioning apparatus for frozen dough including: an enclosure; at least one tray or conveyance for supporting at least one frozen dough piece within the enclosure; a means to direct a conditioning gas directly onto frozen dough within the enclosure; humidity and temperature sensors for respectively measuring the humidity and temperature of the conditioning gas; and a gas controller, the gas controller controlling the duration of the conditioning gas onto the frozen dough according to the output of the humidity and temperature sensor.

Owner:MOFFAT

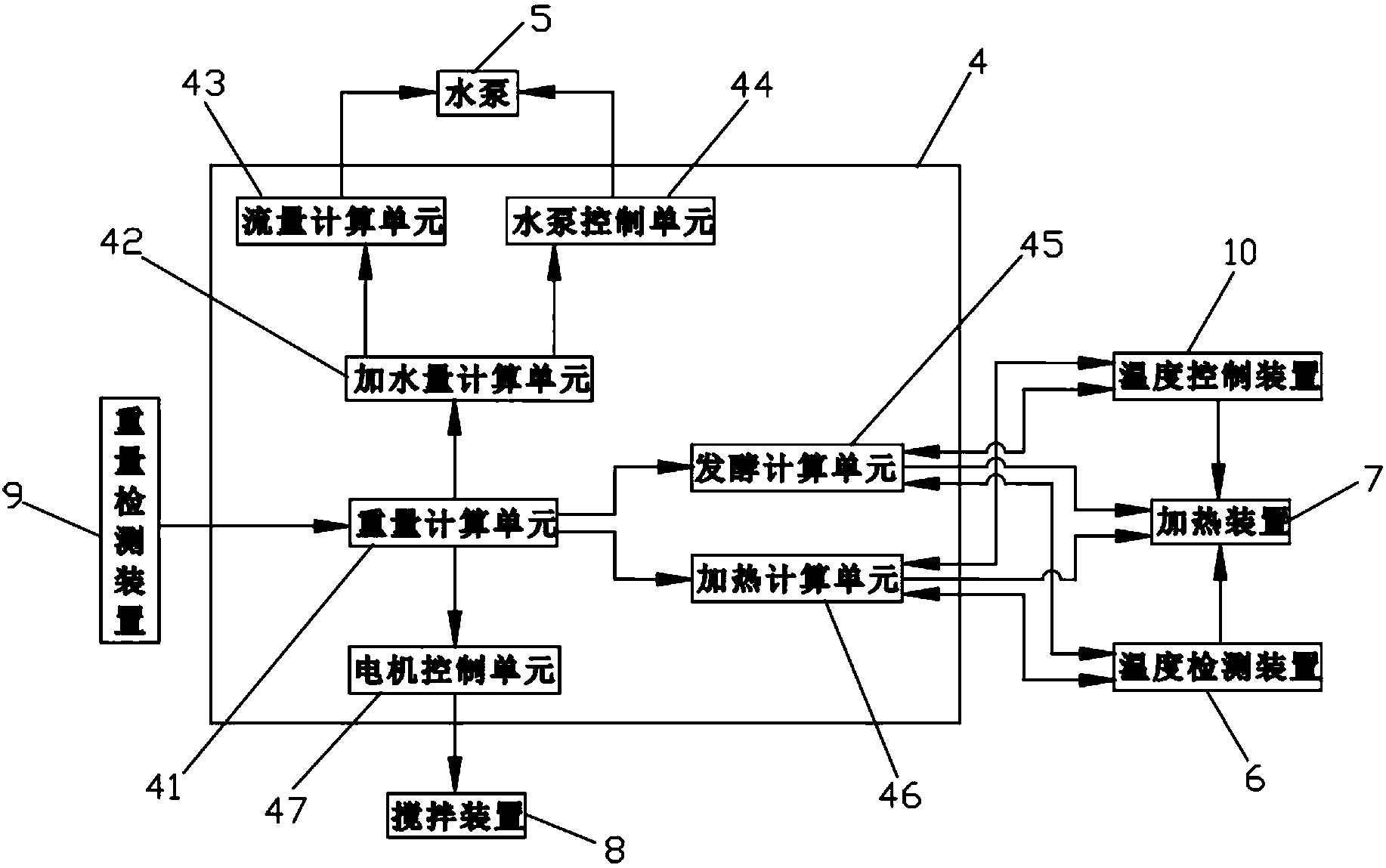

Intelligent bread machine and weighing control method thereof

ActiveCN103004917AManufacturing process intelligenceEasy to makeBakery productsSimultaneous control of multiple variablesElectricityHeating time

Owner:JOYOUNG CO LTD

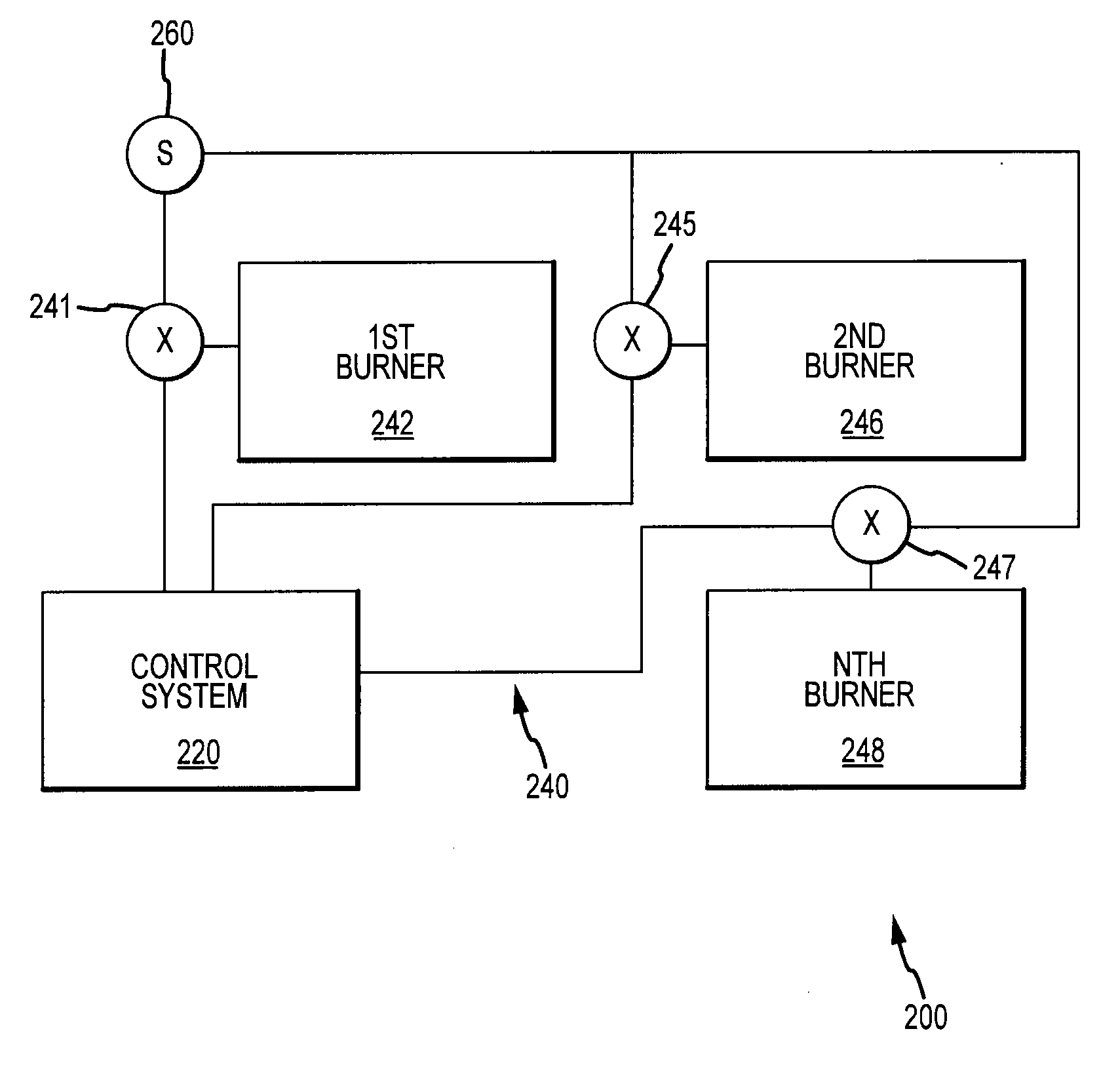

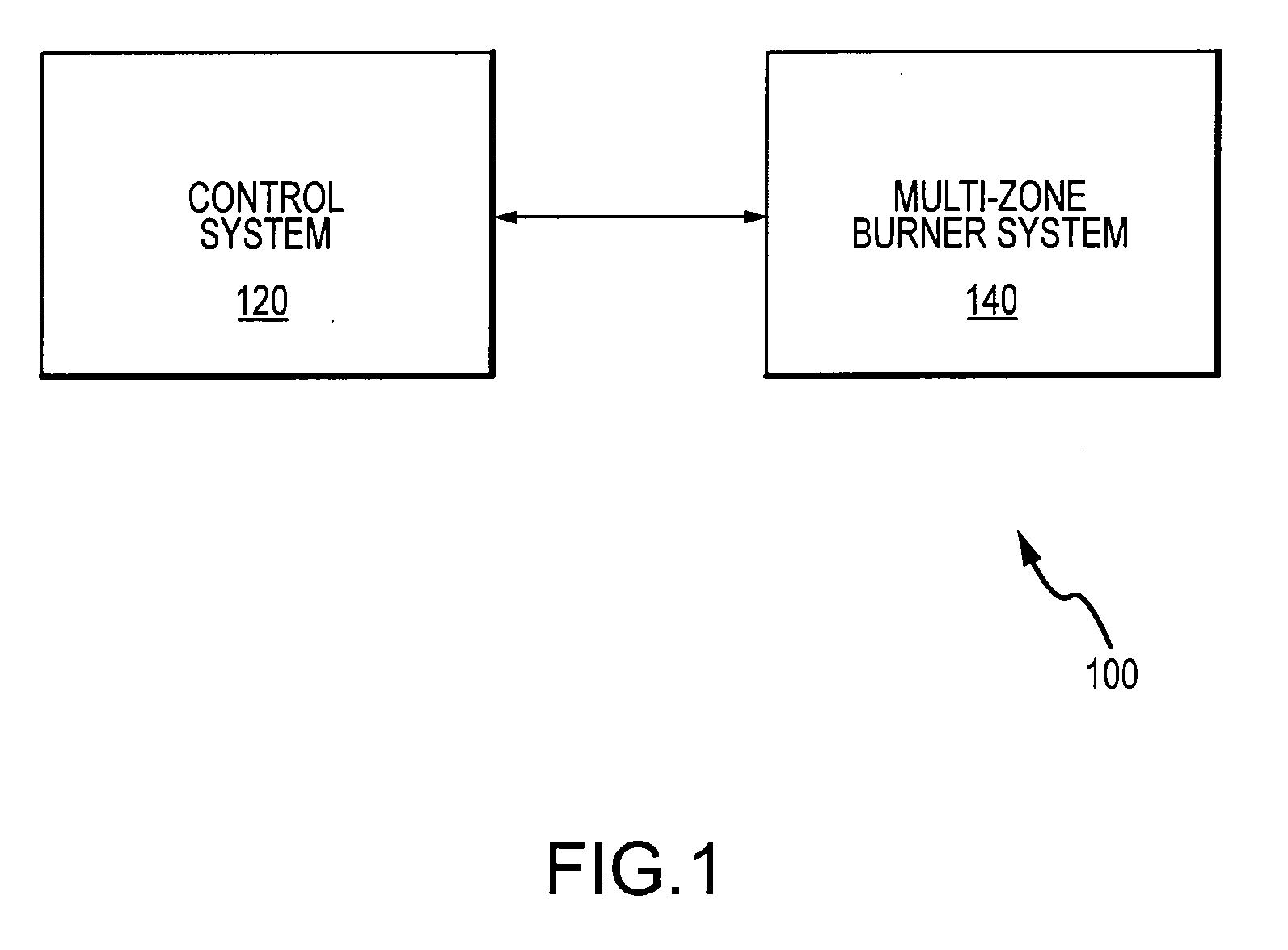

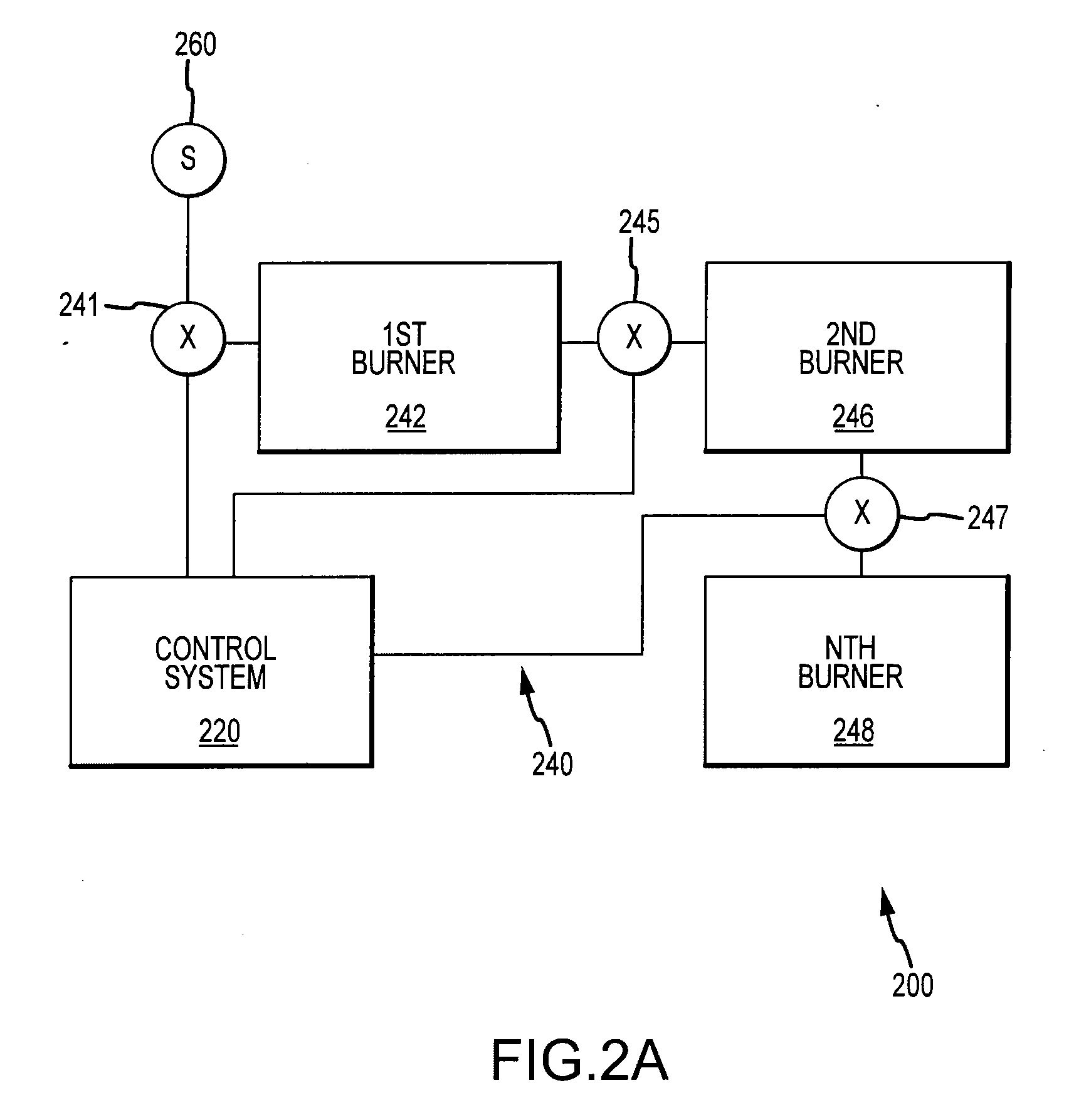

Multi-zone gas fireplace system and method for control

InactiveUS20070235020A1Simulate the realFuel supply regulationDomestic stoves or rangesCombustorUser input

A multi-zone gas fireplace system and method for control are provided. An exemplary embodiment of the multi-zone gas fireplace system comprises a firebox, a multi-zone burner system, and a control system. The multi-zone burner system comprises a plurality of burners located in a plurality of zones, a plurality of control valves coupled to the plurality of burners, a gas supply which supplies a gas to the burners, and an ignition source configured to ignite the gas. The control system comprises an input element responsive to a user input, a processor in communication with the input element, and an output element in communication with the processor, such that the control system is operative to automatically provide a variable flame display in conjunction with the multi-zone burner system.

Owner:FPI FIREPLACE PRODS INT

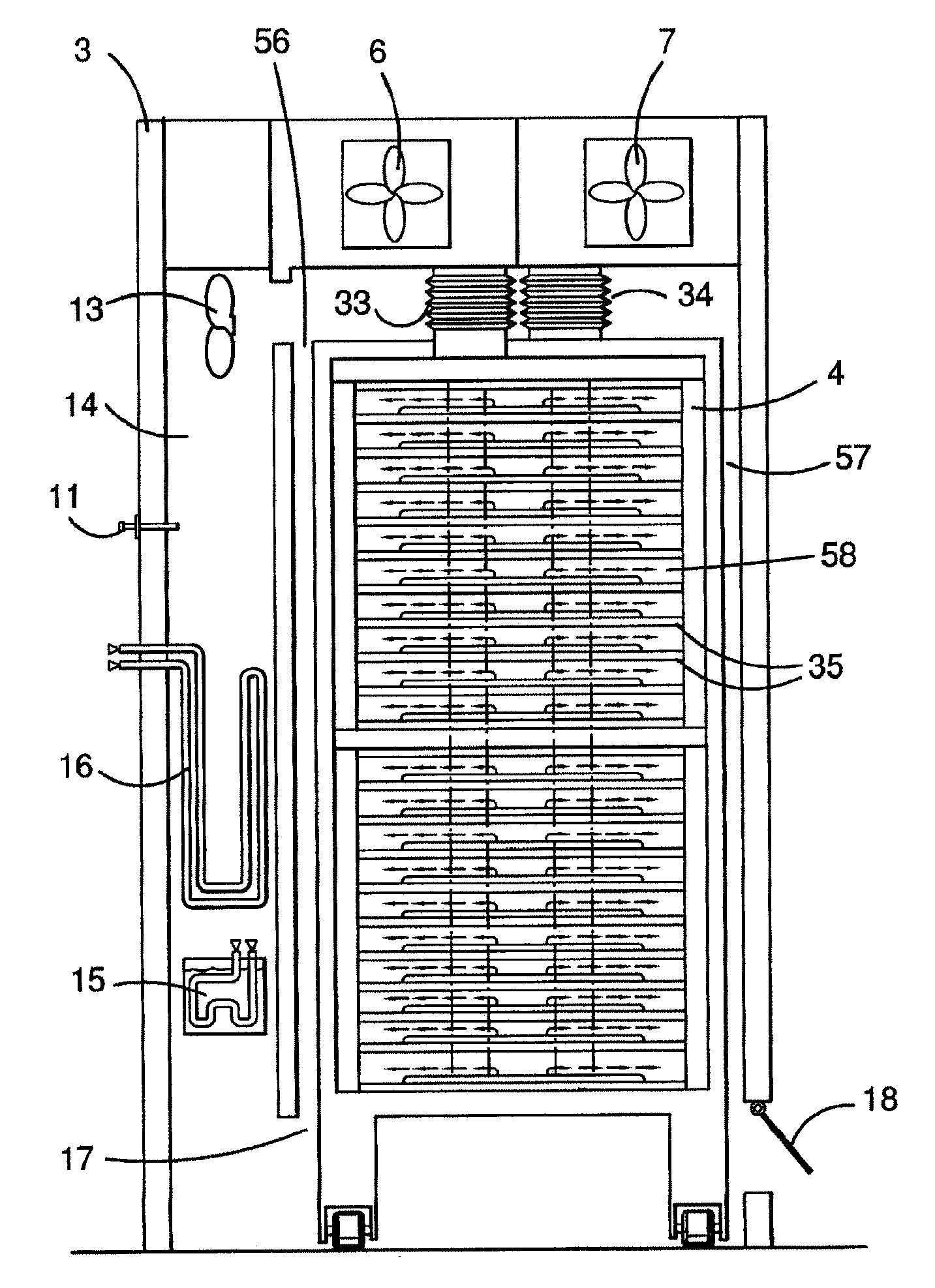

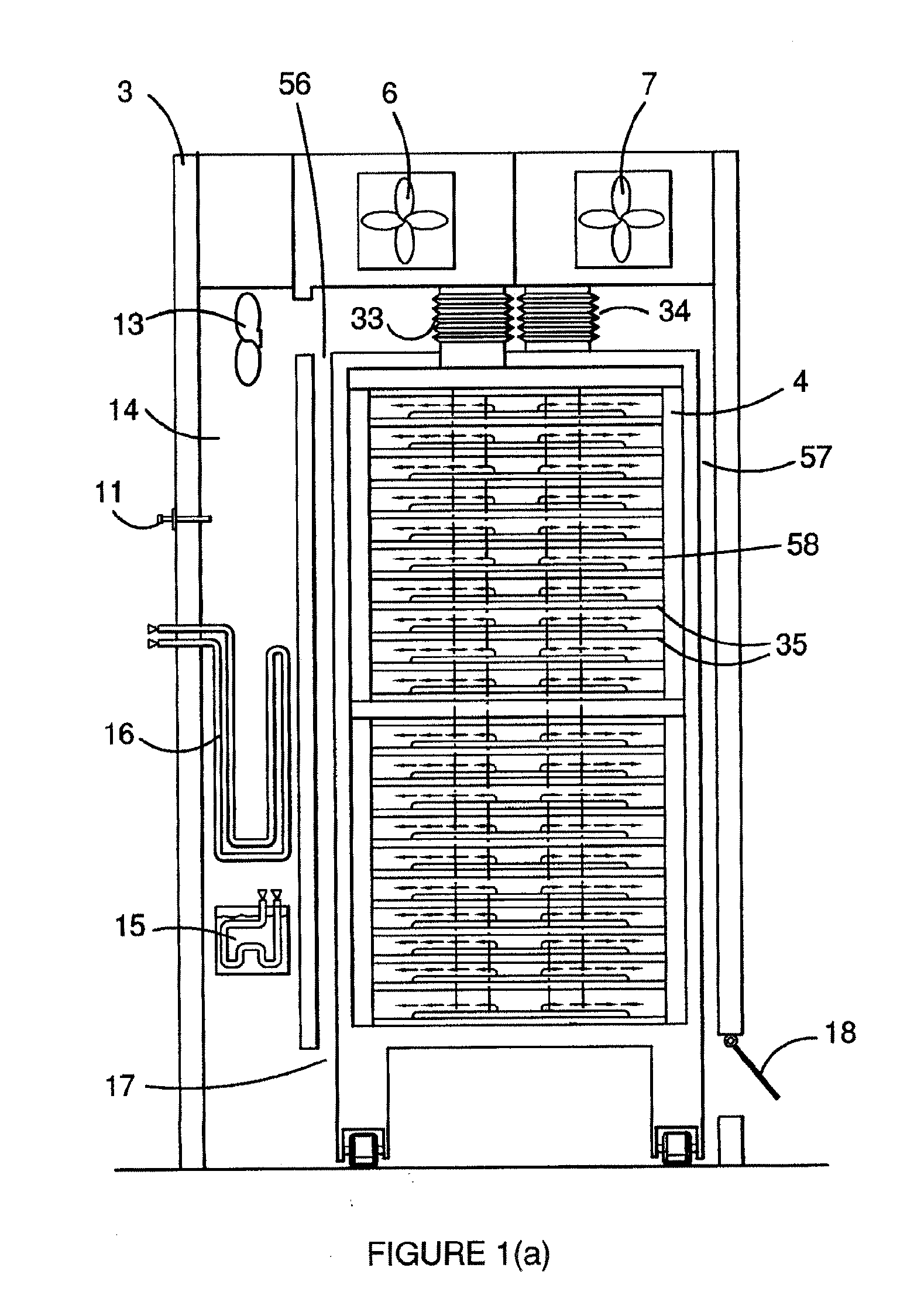

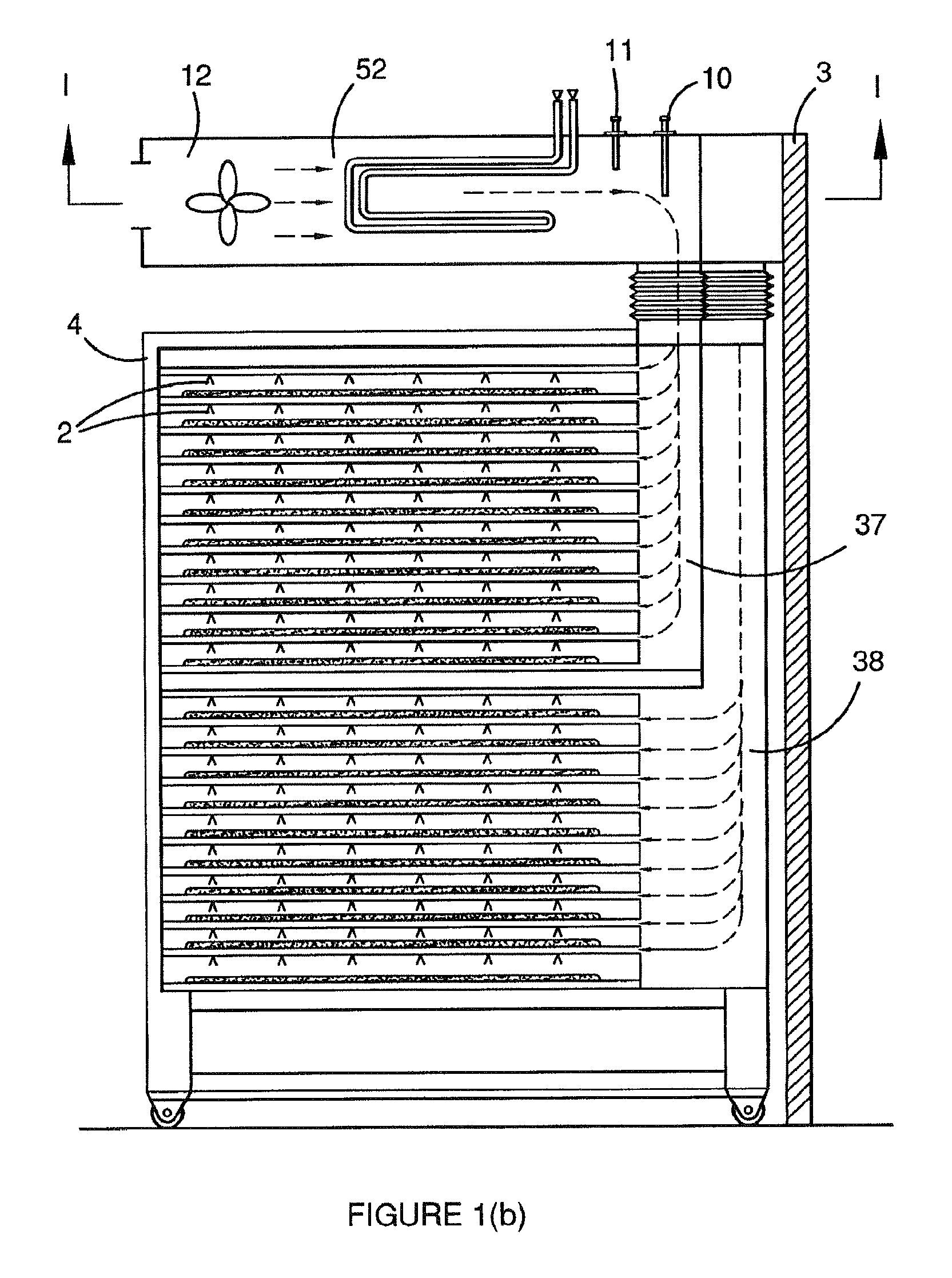

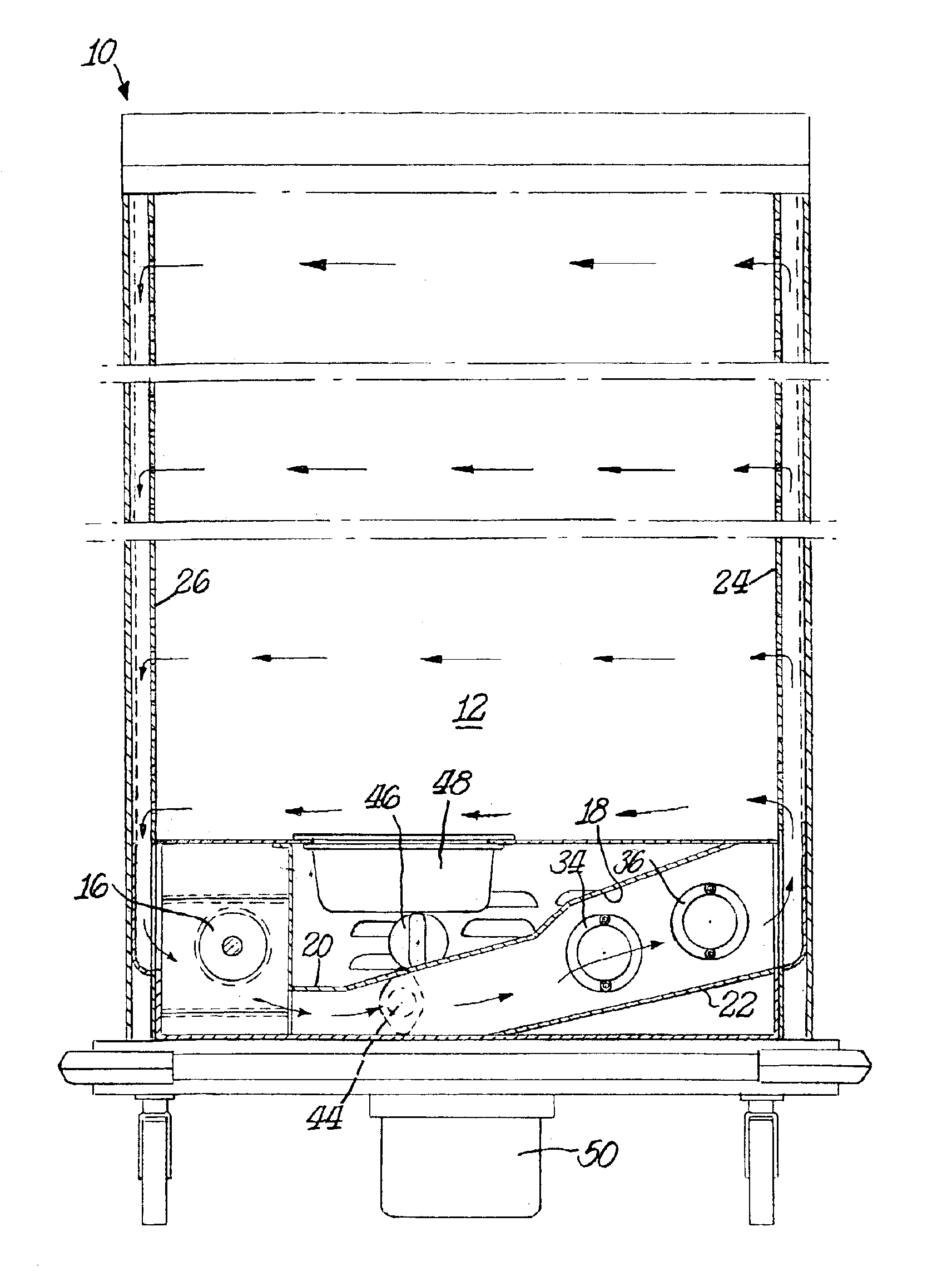

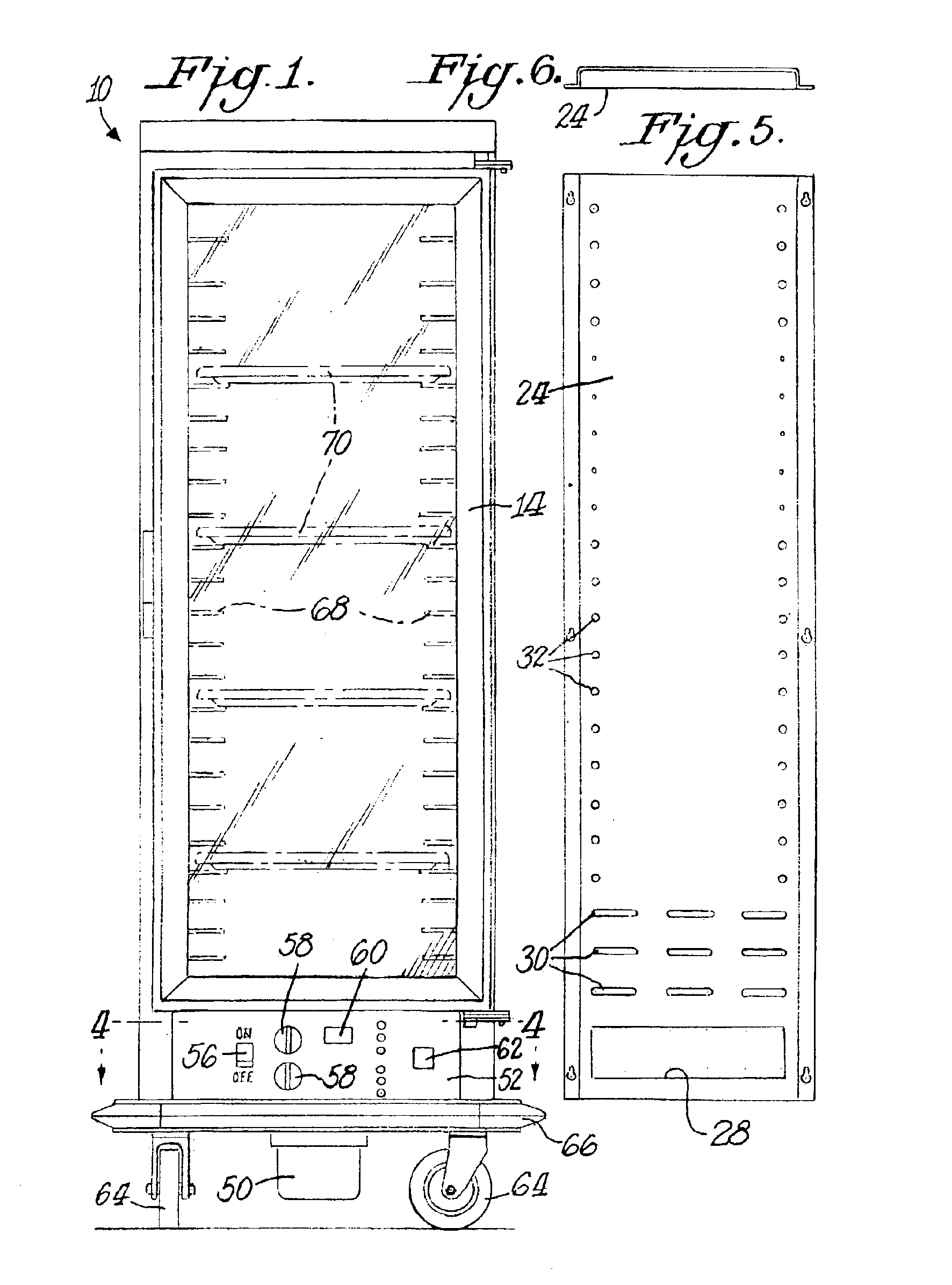

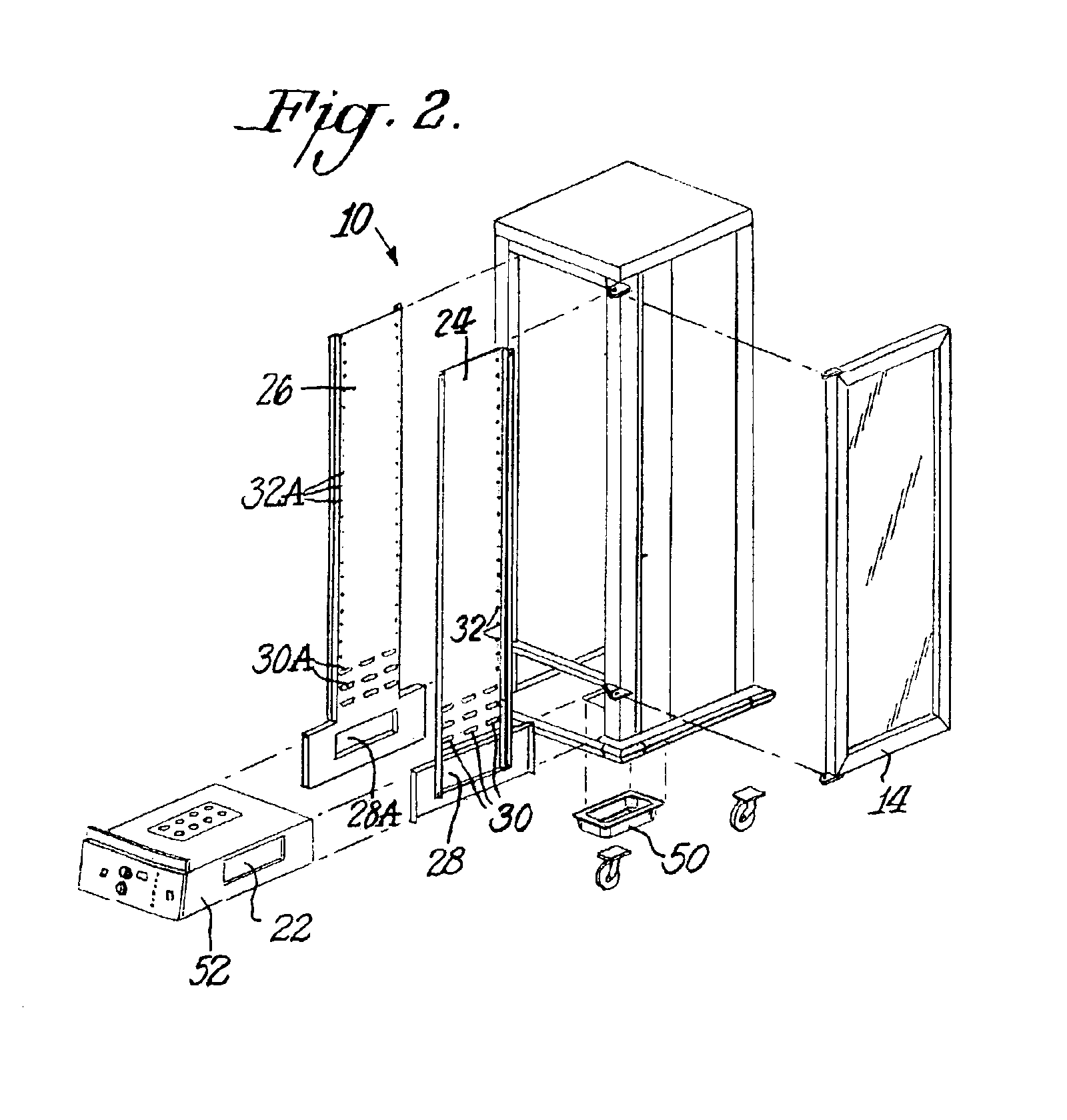

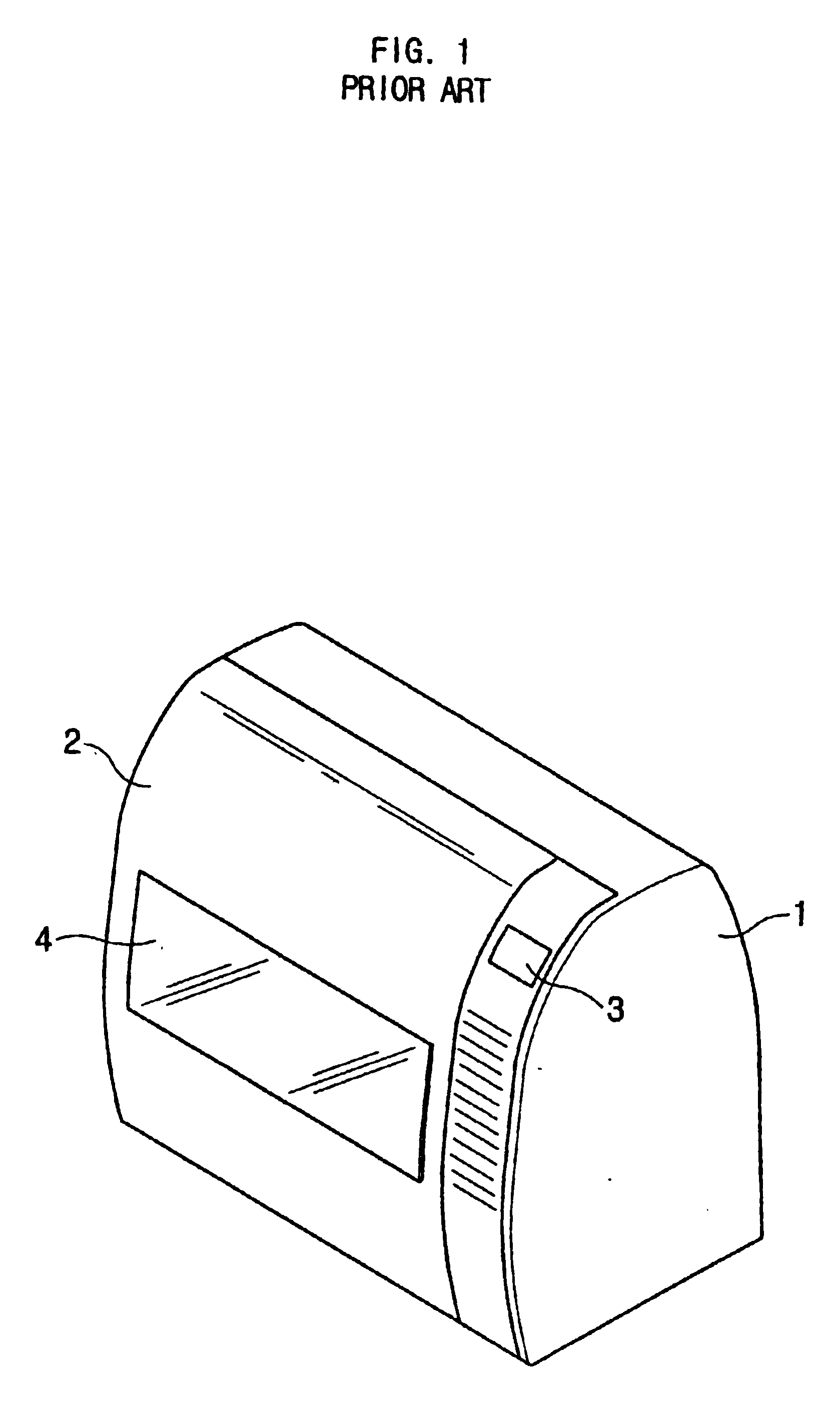

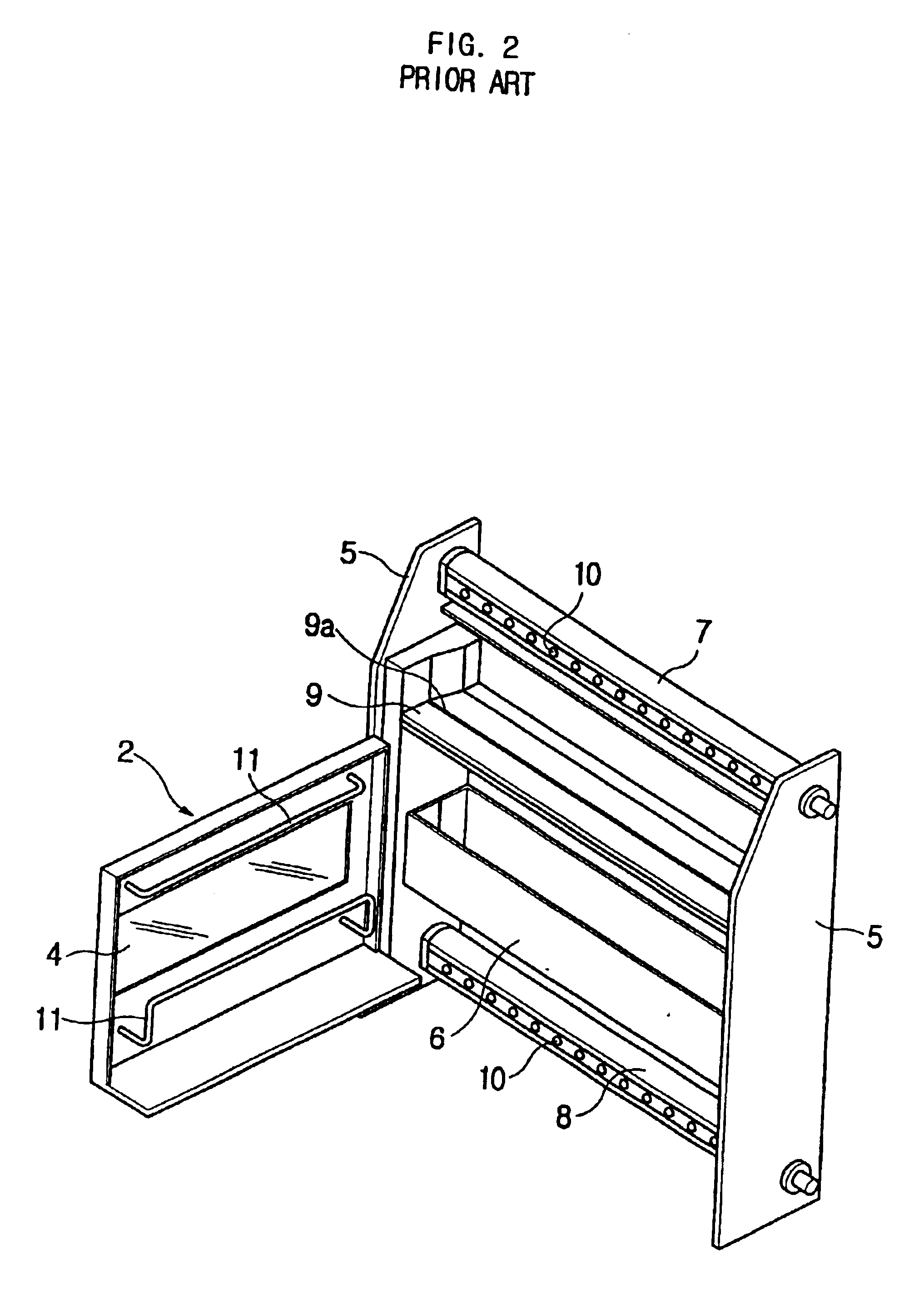

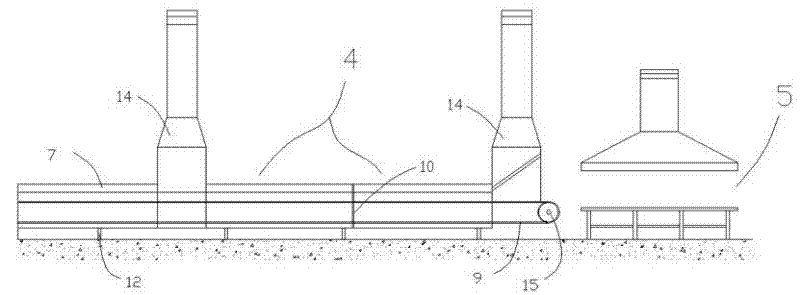

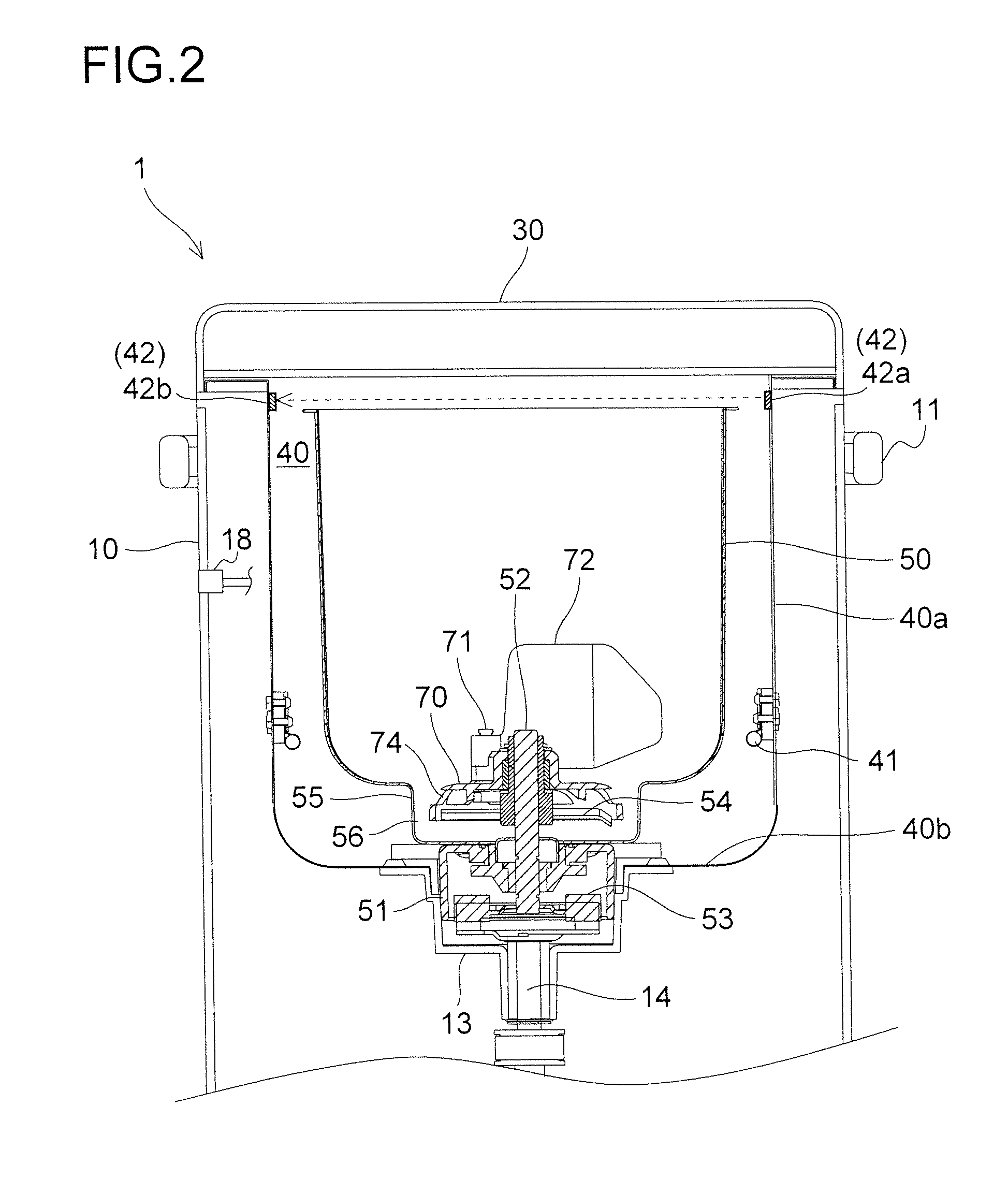

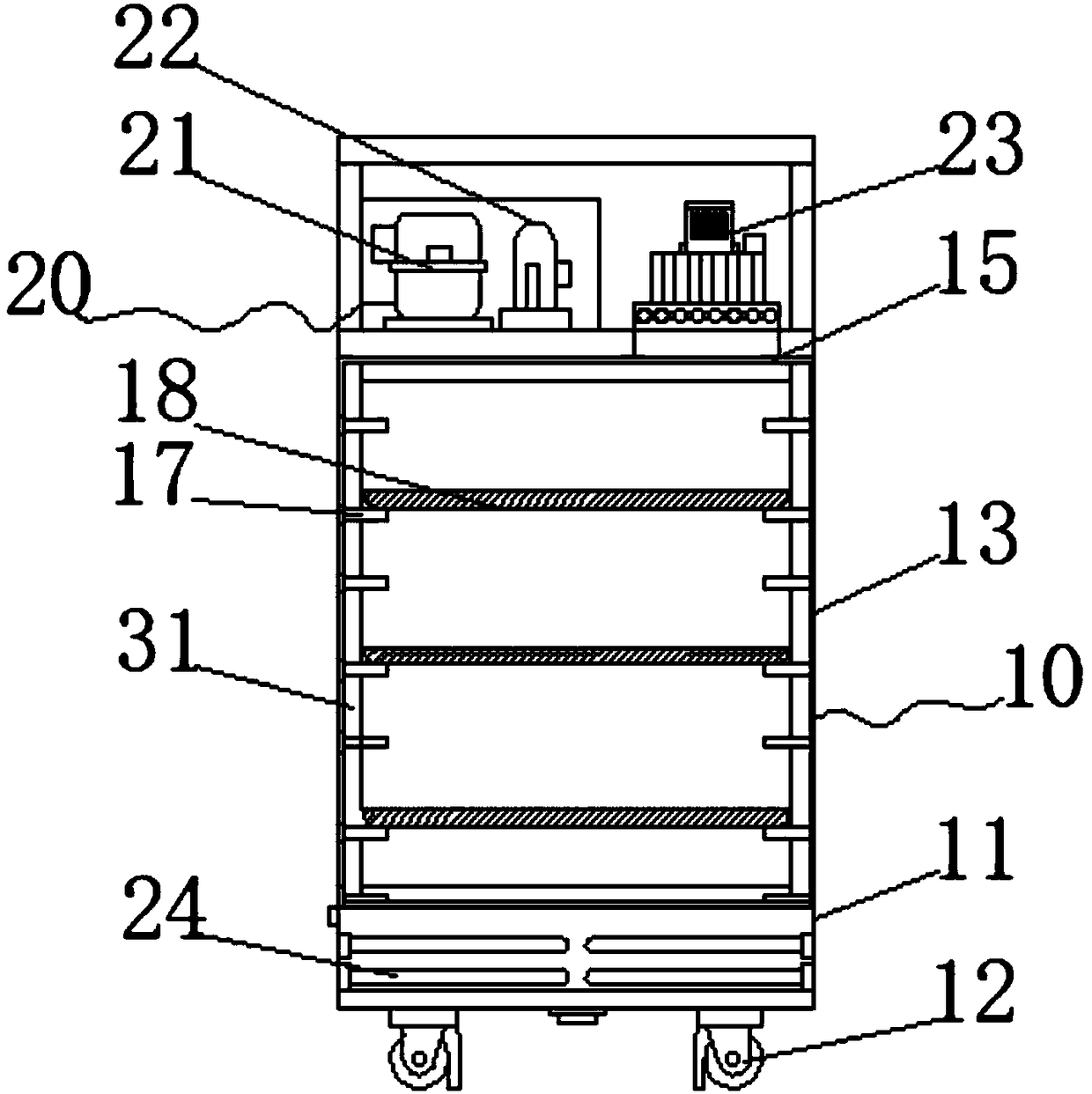

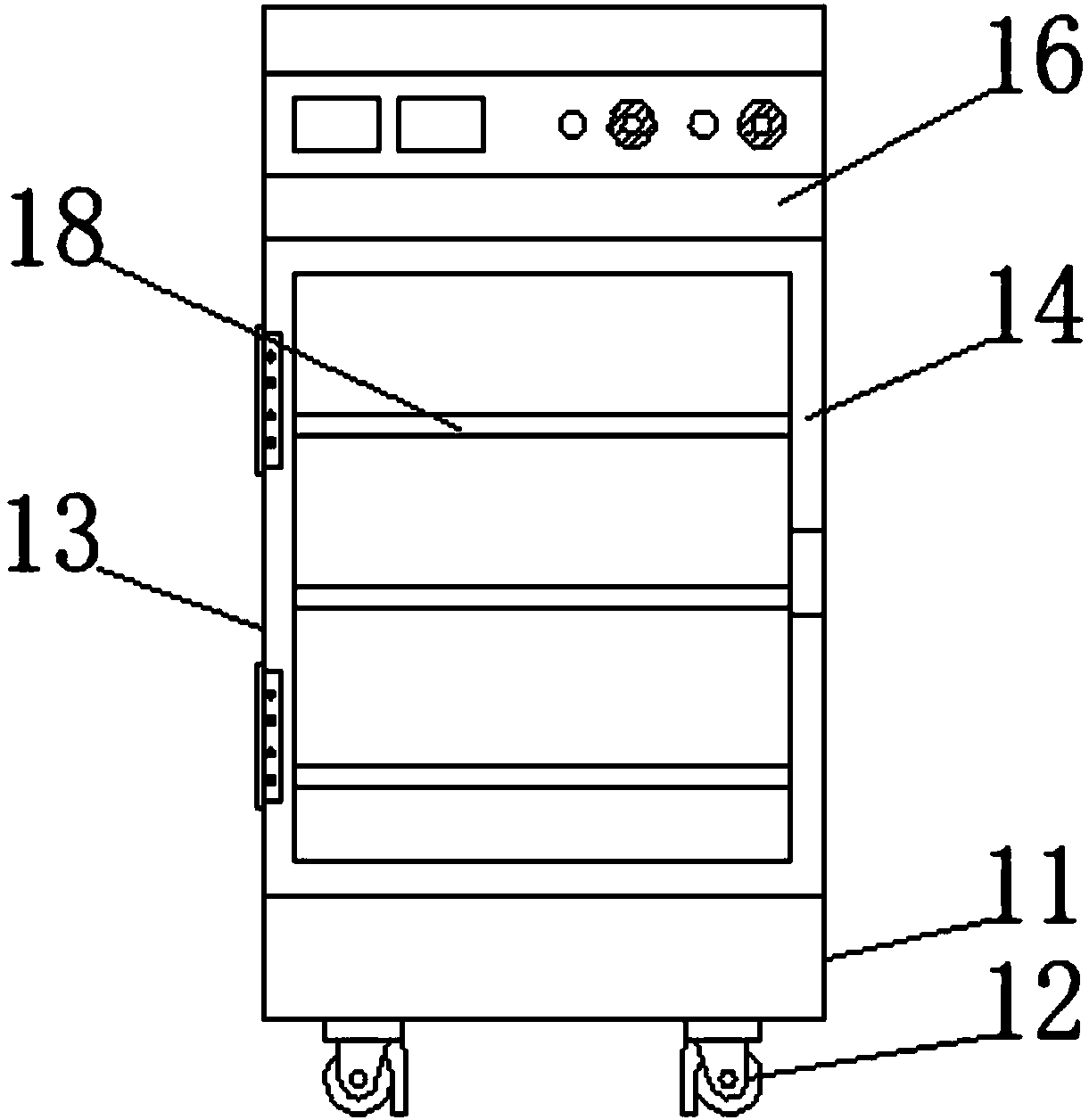

Heated proofing cabinet

InactiveUS6847013B2Increase air circulationEffective regulationAir-treating devicesDomestic stoves or rangesInterior spaceForced-air

A heated proofing cabinet with improved air flow and minimal air leakage comprises an enclosure having an interior space and an access door. A blower is positioned to supply forced air into the interior space of the enclosure and at least one heater is positioned to heat the air. A venturi air flow chamber has an entrance end connected to receive forced air from the blower and an exit end connected to deliver air to the interior space of the enclosure. A first air duct receives air from the exit end of the venturi air flow chamber and distributes the air to the interior space of the enclosure, and a second air duct receives air from the interior space of the enclosure and directs the air to the blower. Temperature and humidity levels within the interior space of the enclosure are controlled.

Owner:METAL MASTERS FOOD SERVICE EQUIP

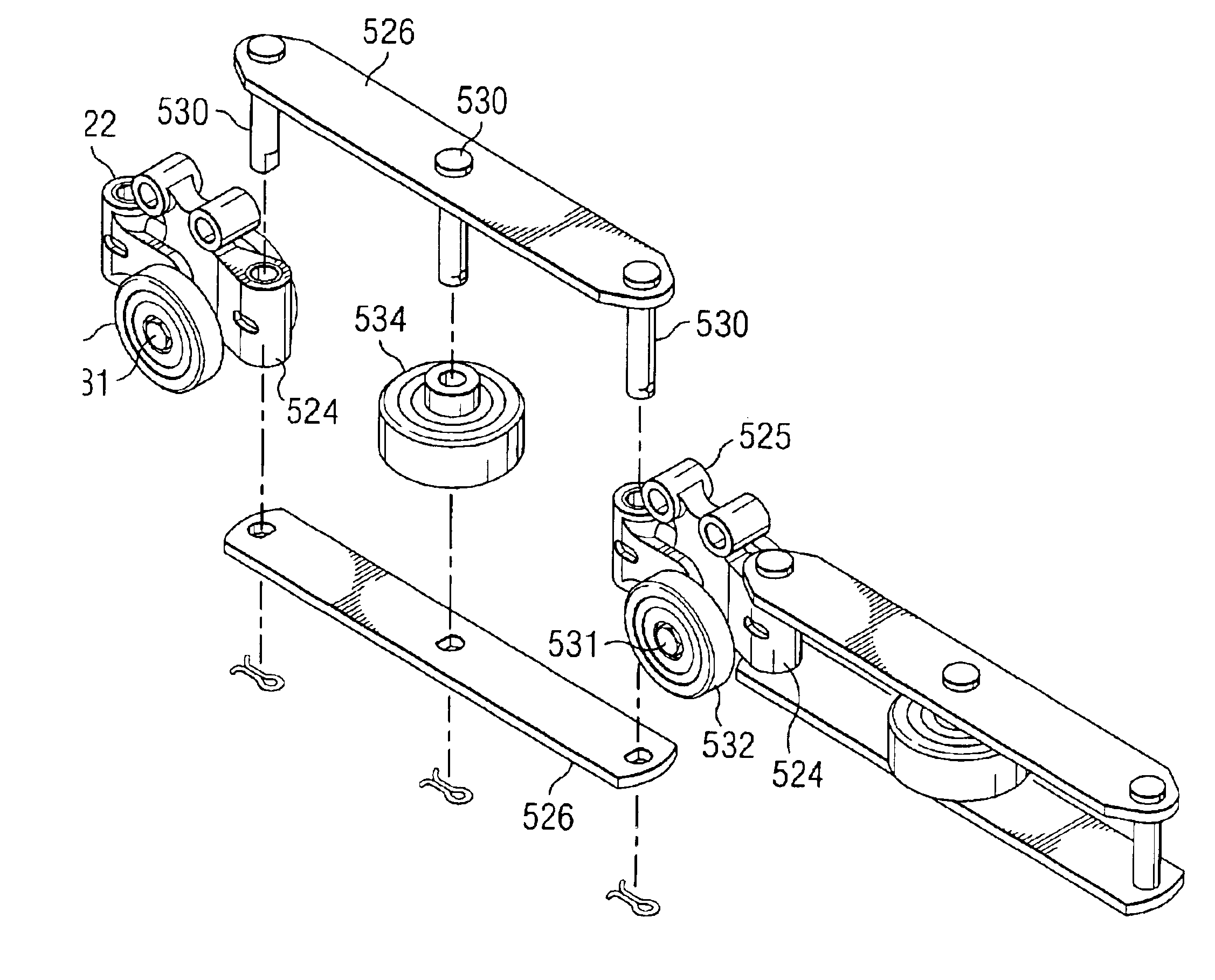

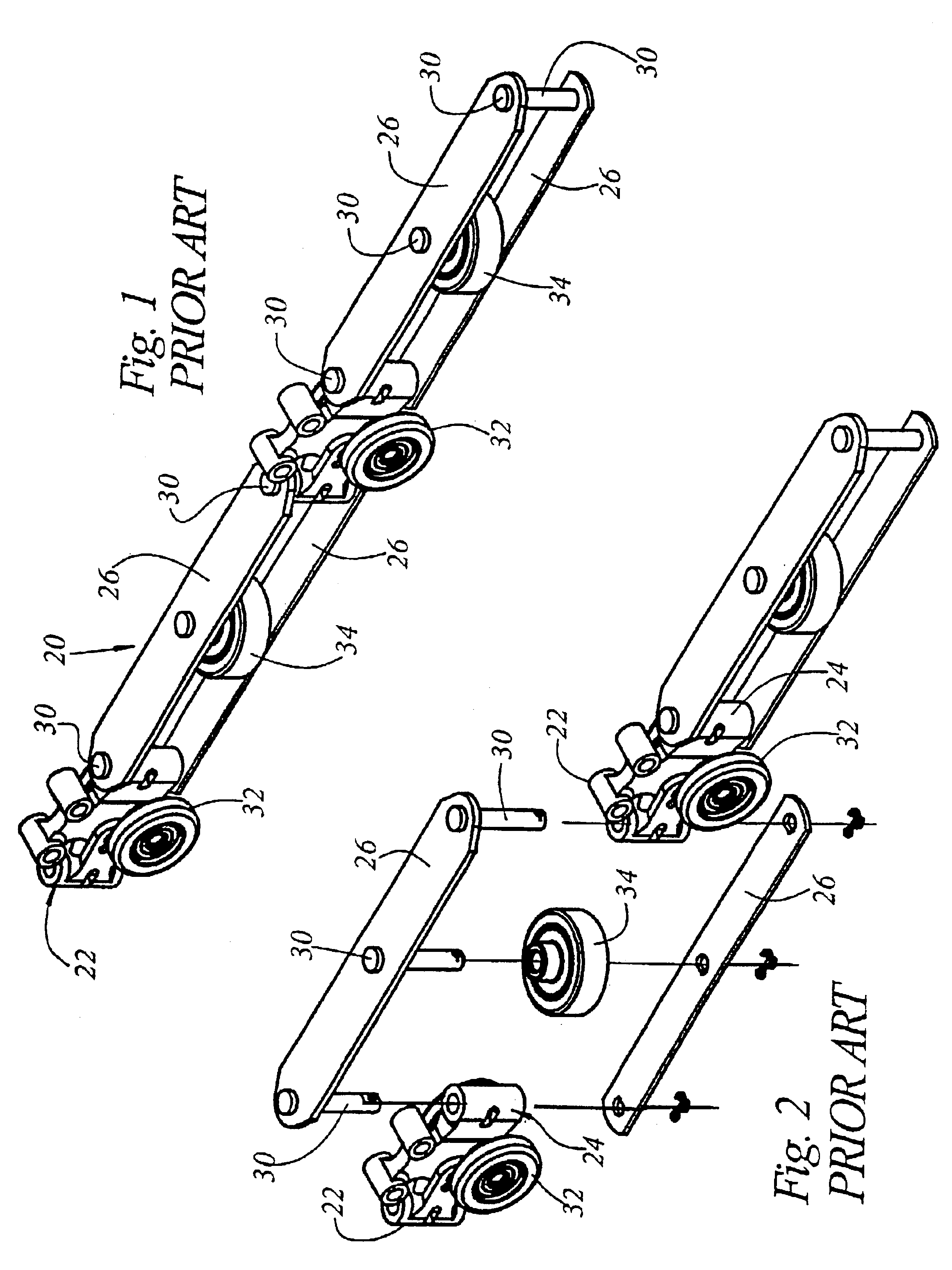

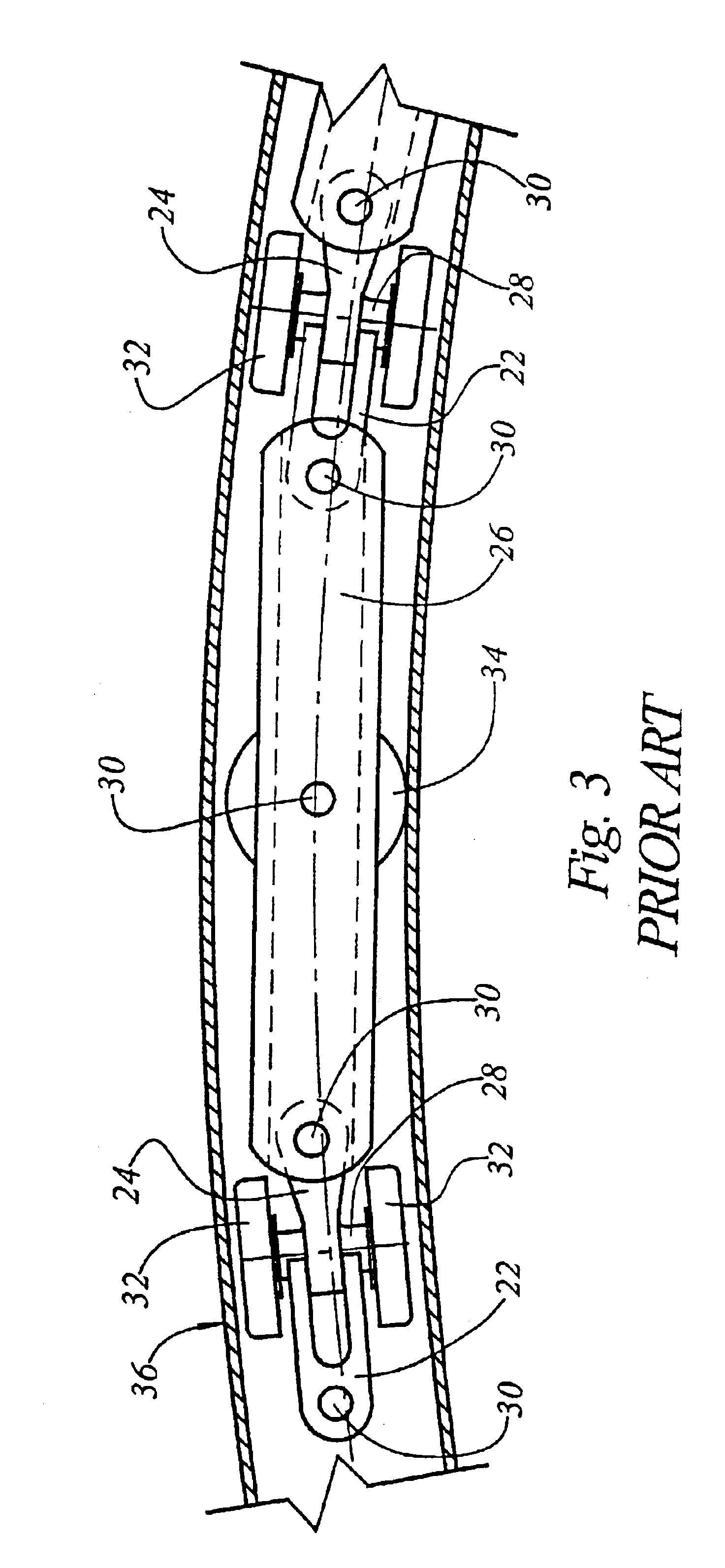

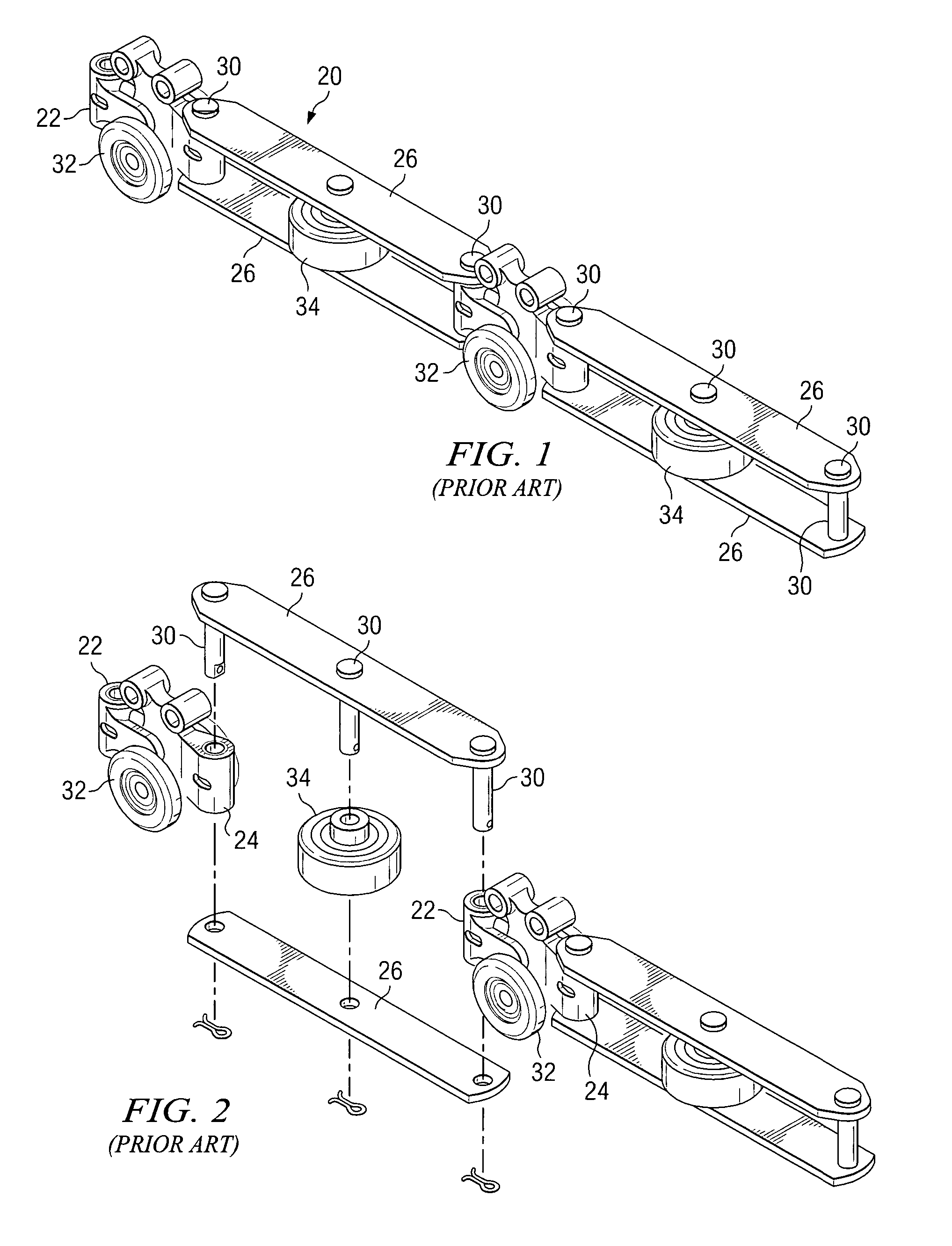

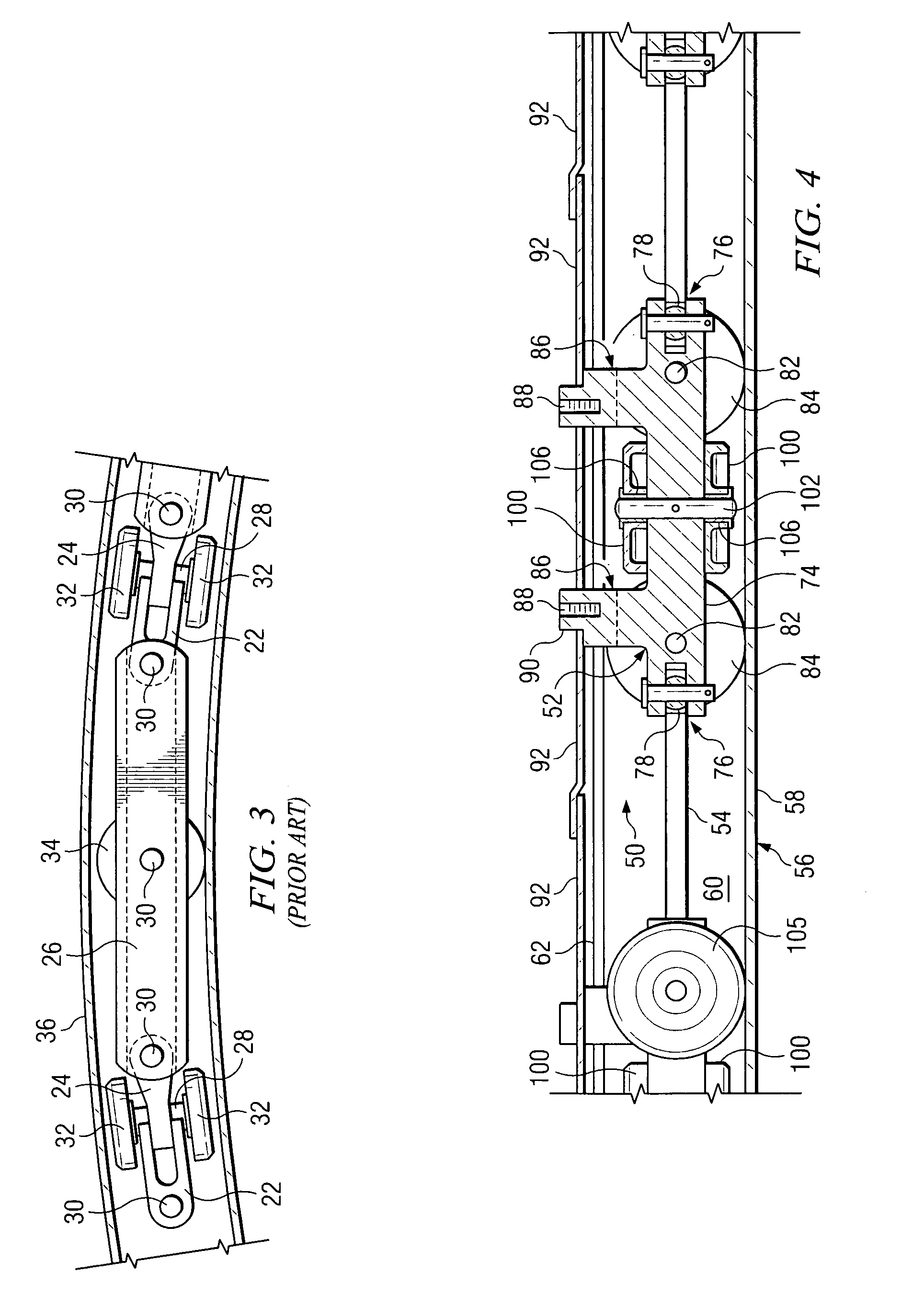

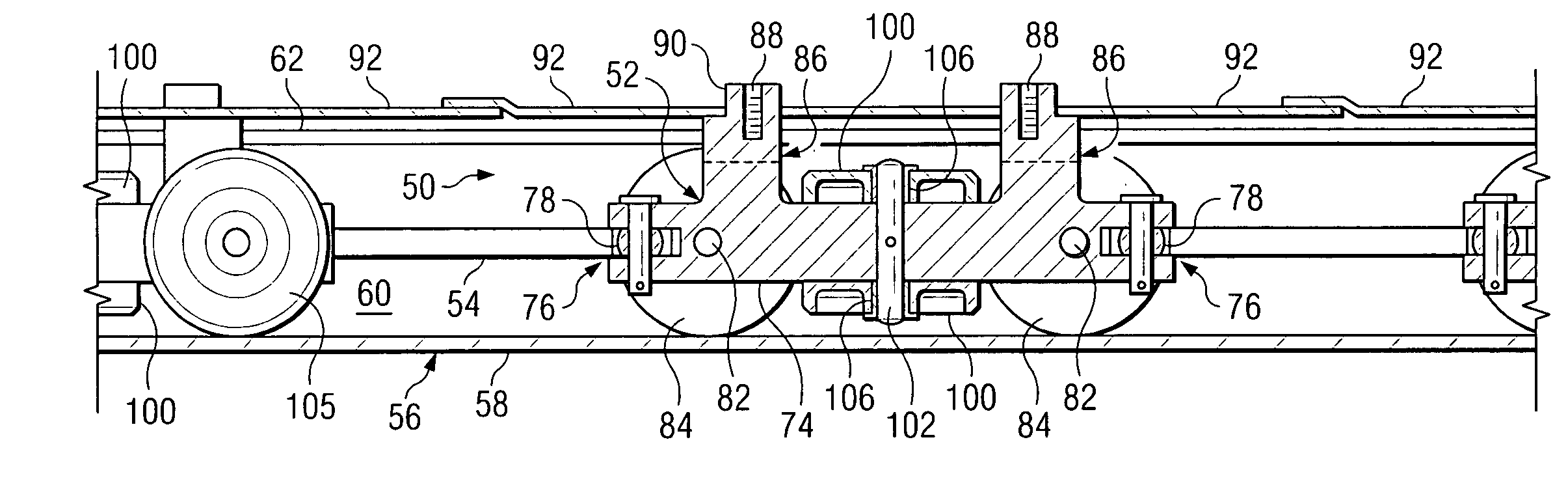

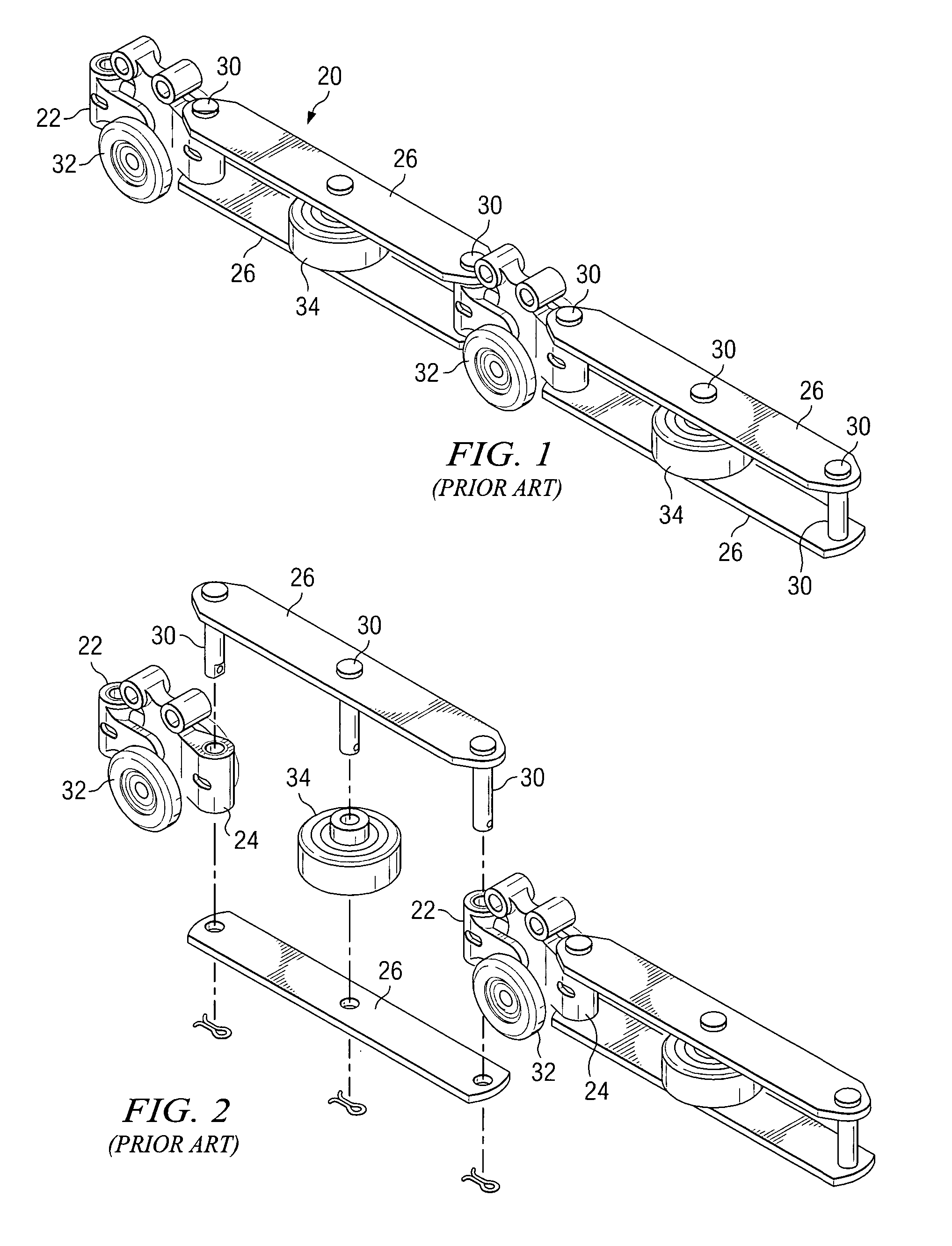

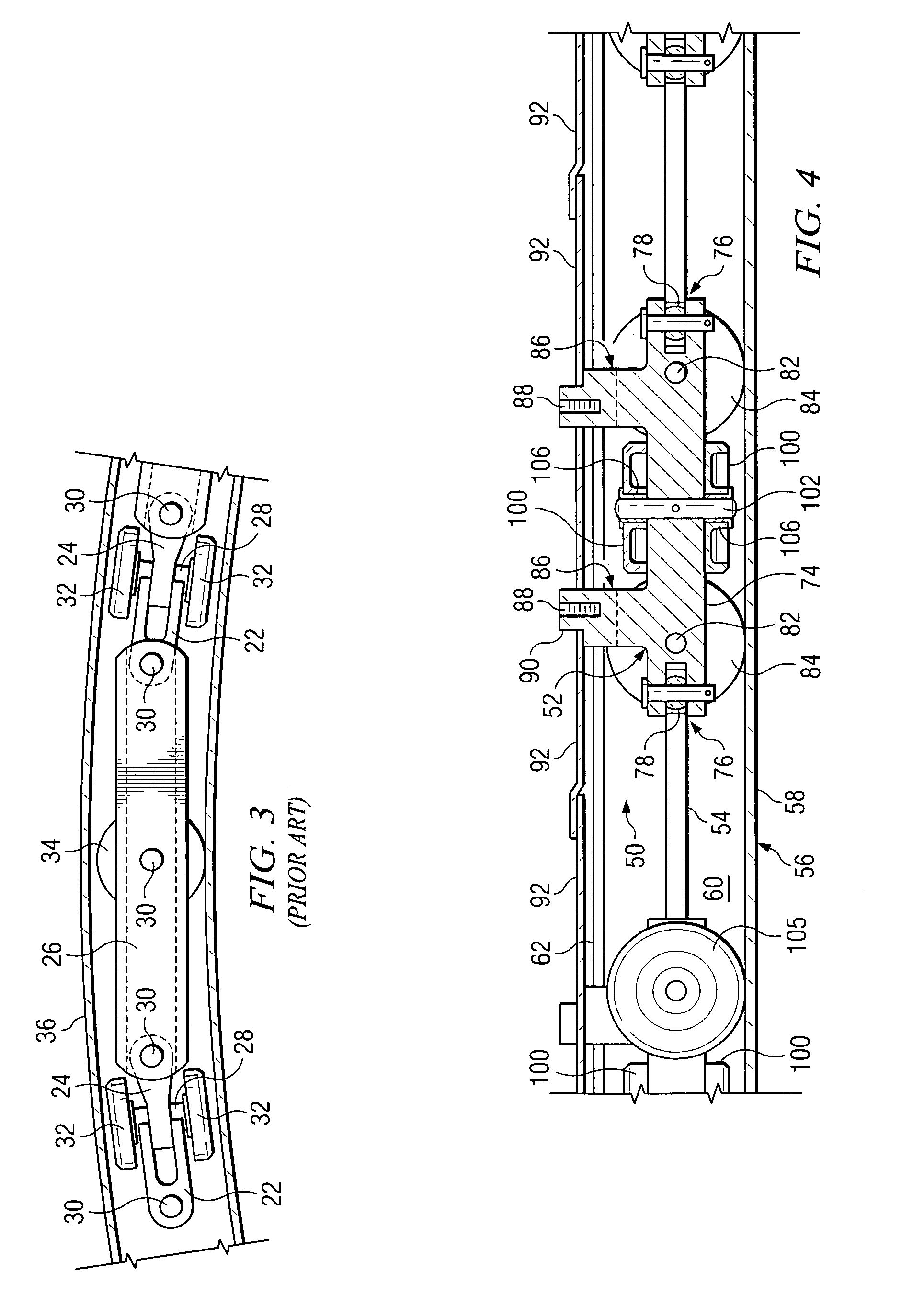

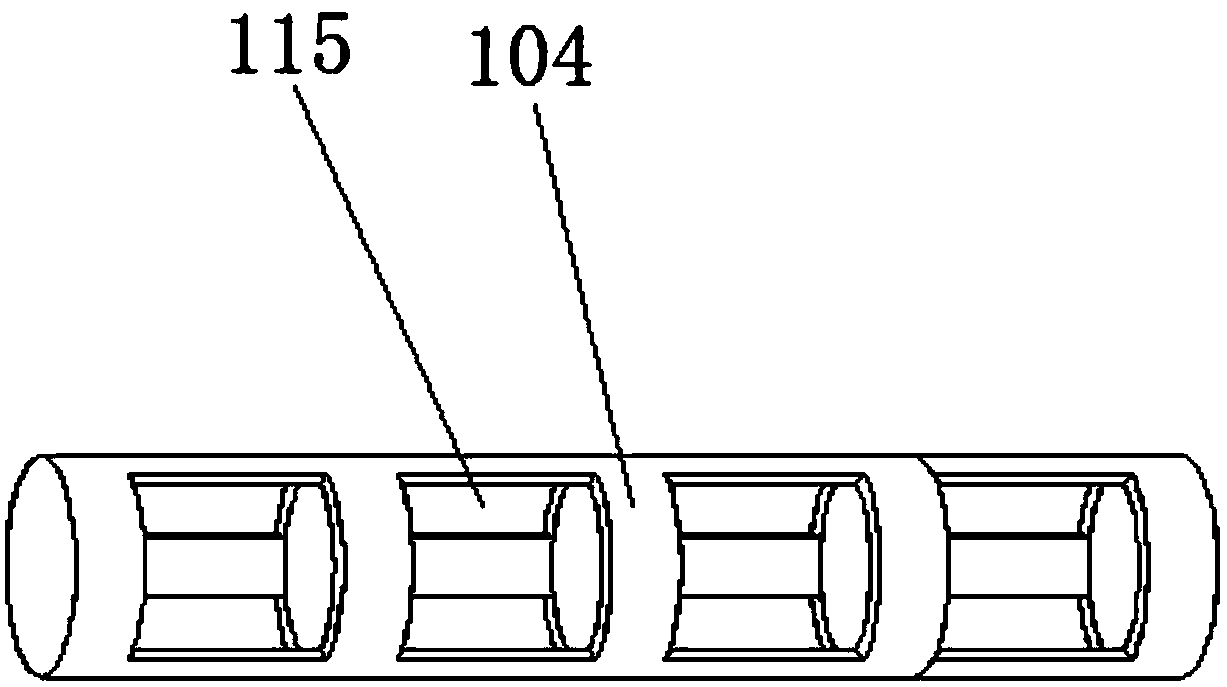

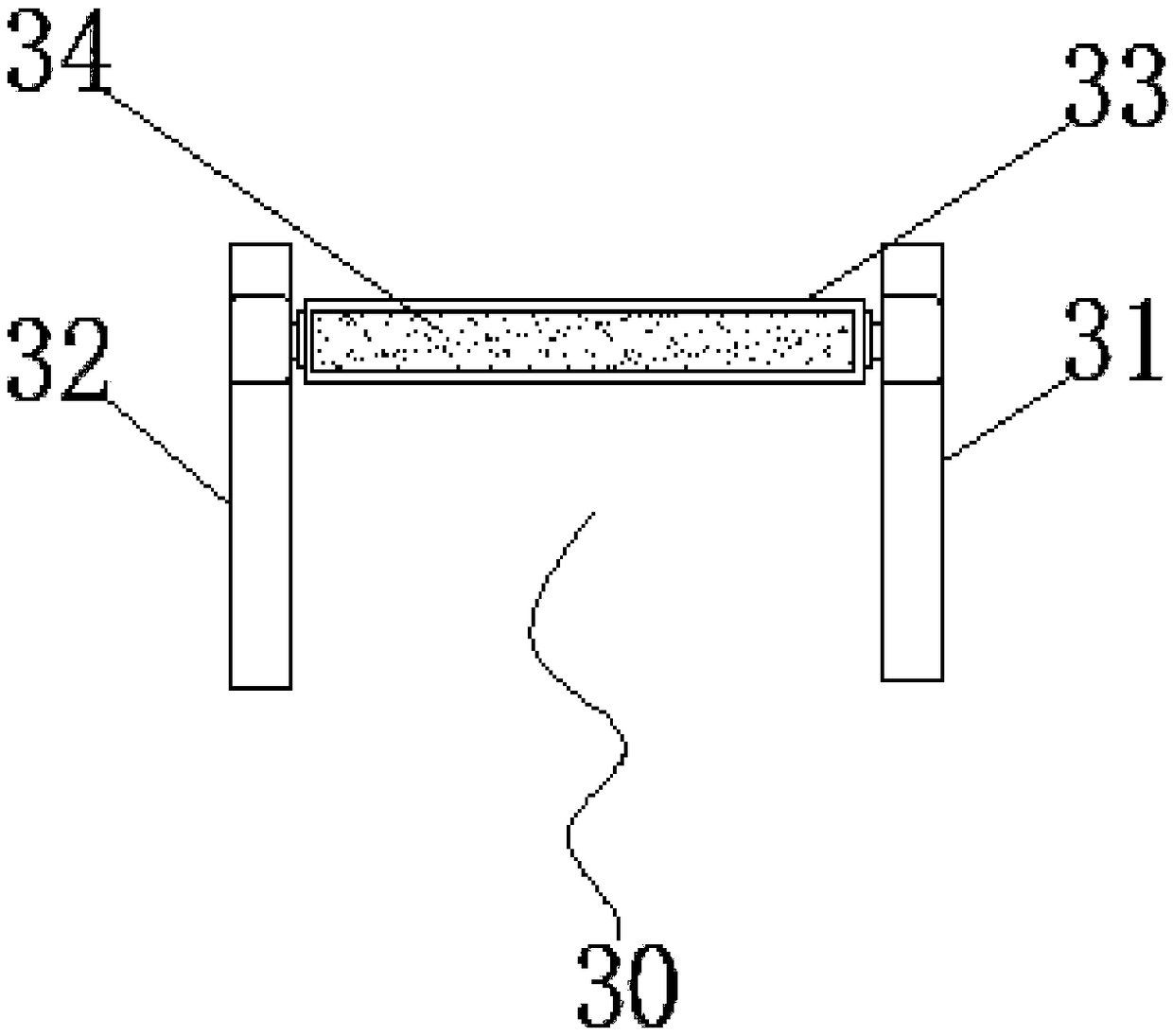

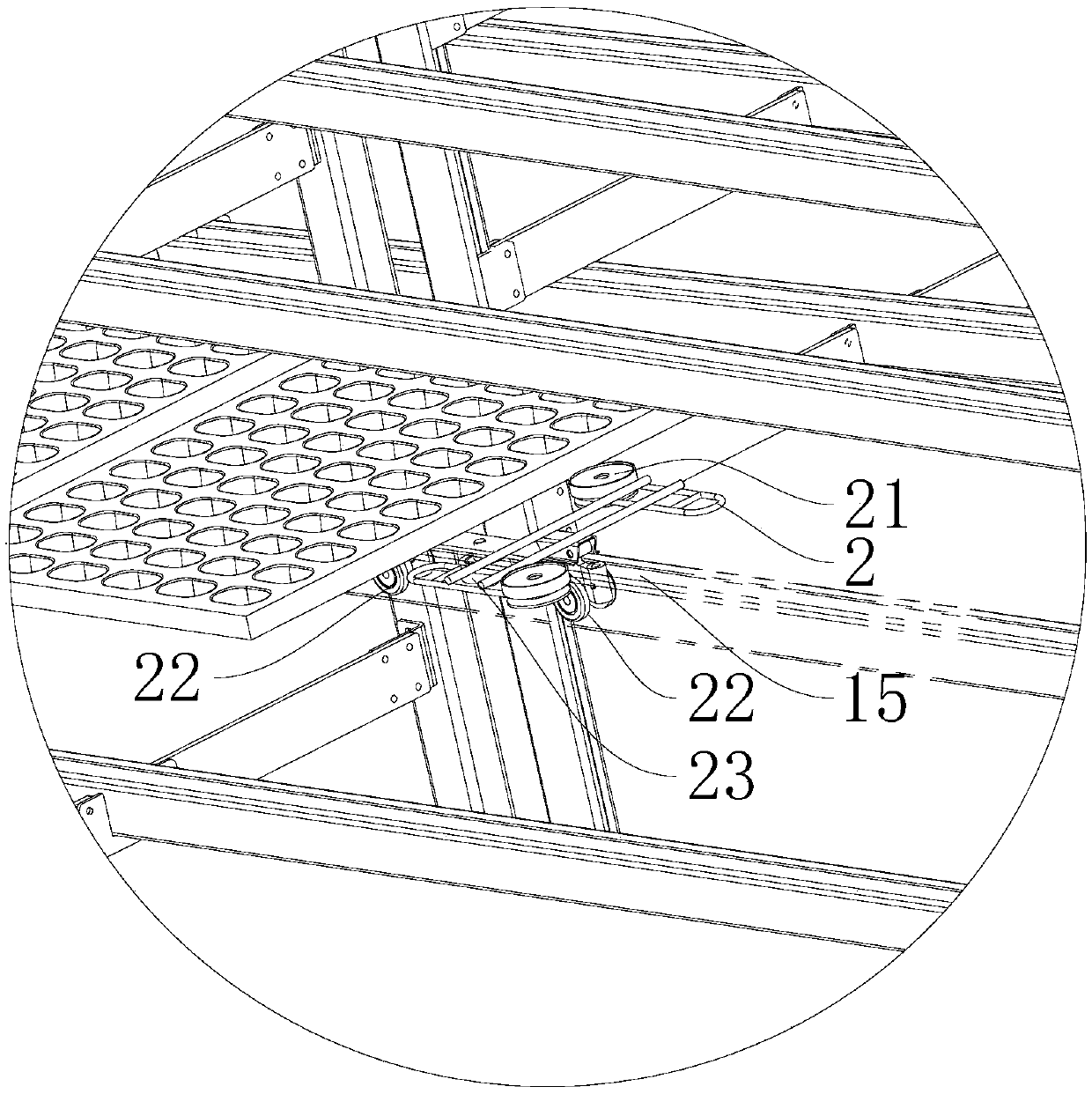

Conveyor for continuous proofing and baking apparatus

InactiveUS6968943B2Save a lot of costEliminate failureBearing componentsRollersEngineeringMechanical engineering

Conveyor chains of the type utilized in commercial ovens and proofers are provided with improved bearing support for the rotating and pivoting components of the chains. The rotating components comprising anti-friction bearings constructed from superior components which support substantial improvements in the service life of the conveyor chains. The pivoting components are provided with plain bearings and / or anti-friction coating which also function to extend the service life of the conveyor chains.

Owner:STEWART SYST GLOBAL LLC A TEXAS LIMITED LIABILITY

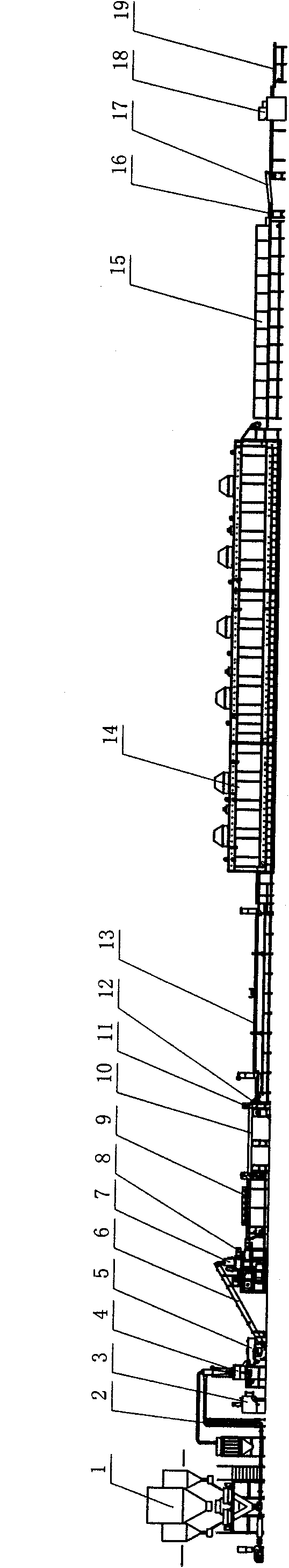

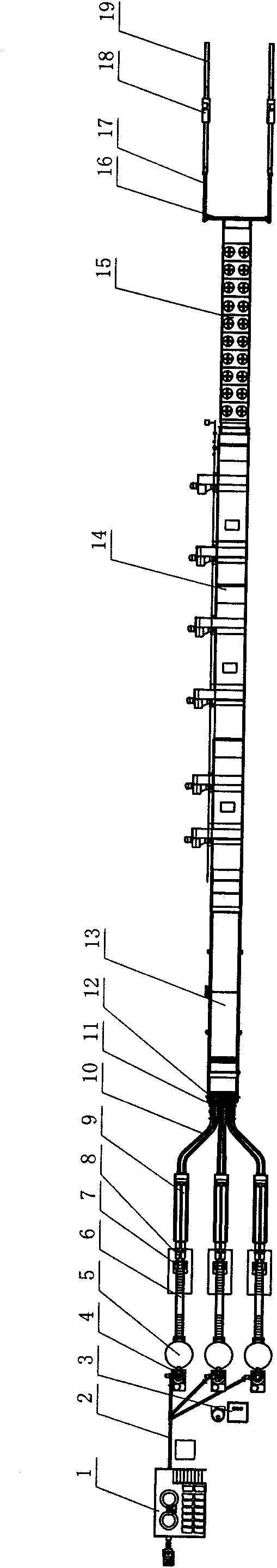

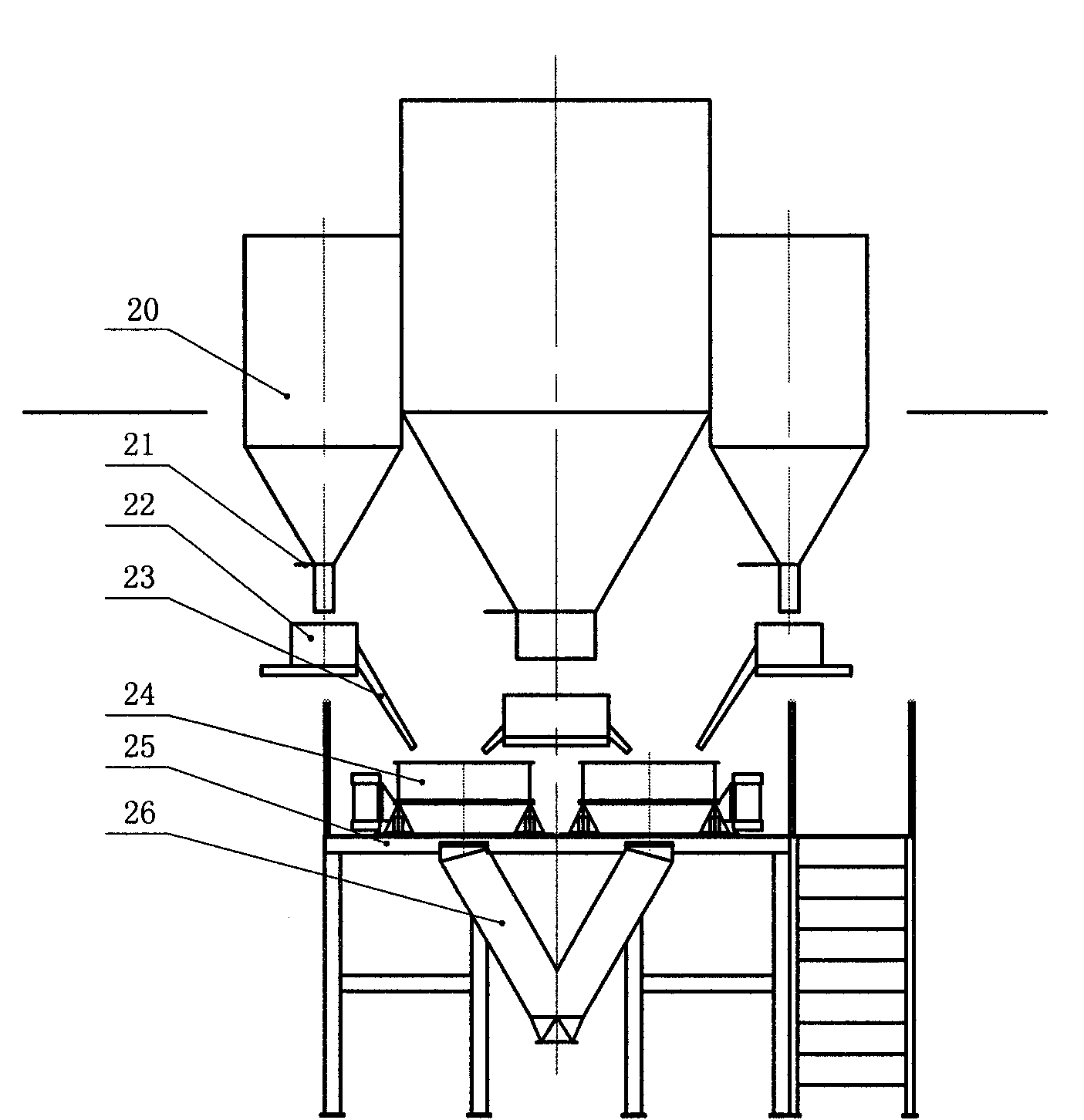

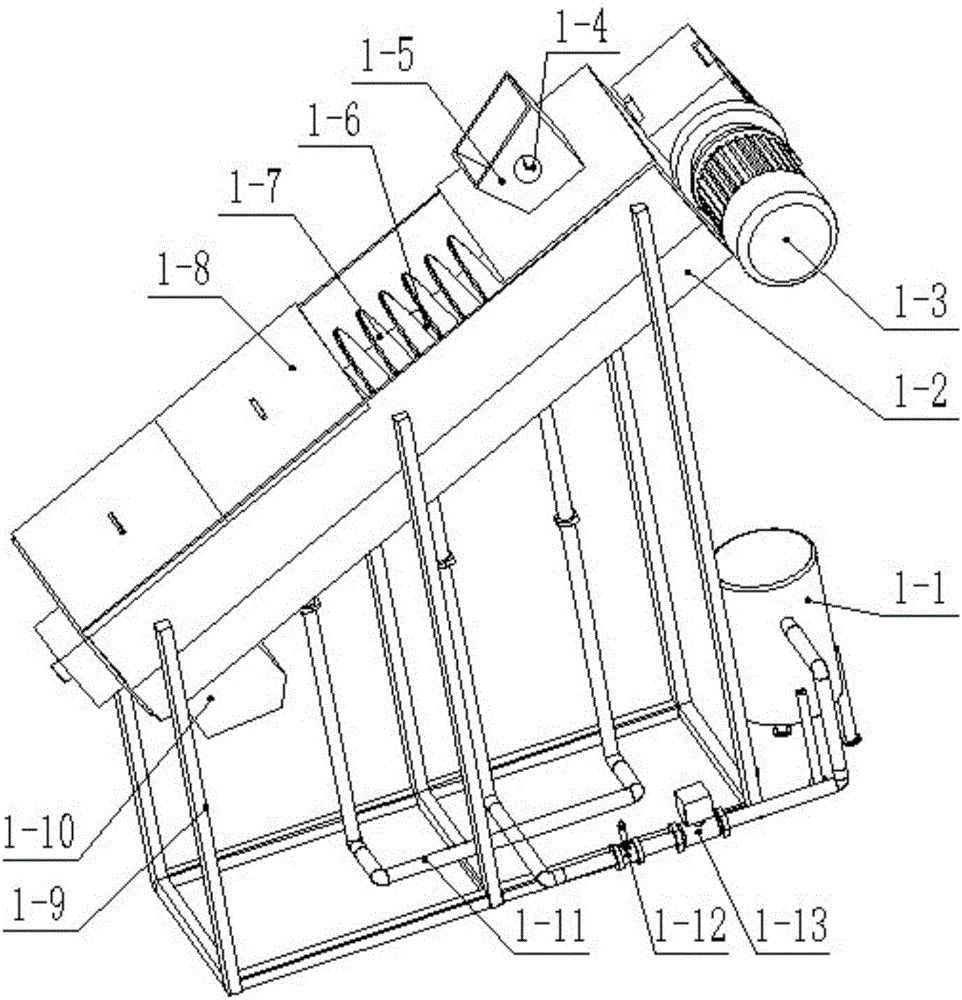

Cereal coarse grain instant noodle processing production line

InactiveCN102058056AGuaranteed uptimeReduce labor intensityDough shaping and cutting apparatusDough extruding machinesAutomatic controlPositive pressure

The invention relates to a cereal coarse grain instant noodle processing production line, comprising a mixing drum, a flour mixing machine, a hoisting machine, a flour feeding machine, an extrusion moulding machine, a quantitative cutting machine, a row combining machine, a pneumatic stopping device, a row separating device, a flour steaming machine, a drying machine, a cooling machine, an inspection conveyor, a packaging machine and a finished product conveyor which are sequentially connected, wherein an automatic weighing blanking device and a positive pressure conveying device are arranged in the procedure before the procedure of the flour mixing machine; a flour softening machine is arranged between the flour mixing machine and the hoisting machine; the extrusion moulding machine is one with automatically controlled temperature and curing degree; the quantitative cutting machine is of high accuracy type; the row separating device is of pneumatic type; the drying machine is a multi-section temperature and humidity controllable drying machine; and a transition conveyor is arranged between the cooling machine and the inspection conveyor. The invention can complete integration continuous production including burdening, conveying powder, mixing flour, softening flour, extruding and curing, high accuracy quantitative cutting, stewing and curing, multi-section drying, cooling and finished product packaging.

Owner:SHENGCHANGDA MACHINERY TIANJIN

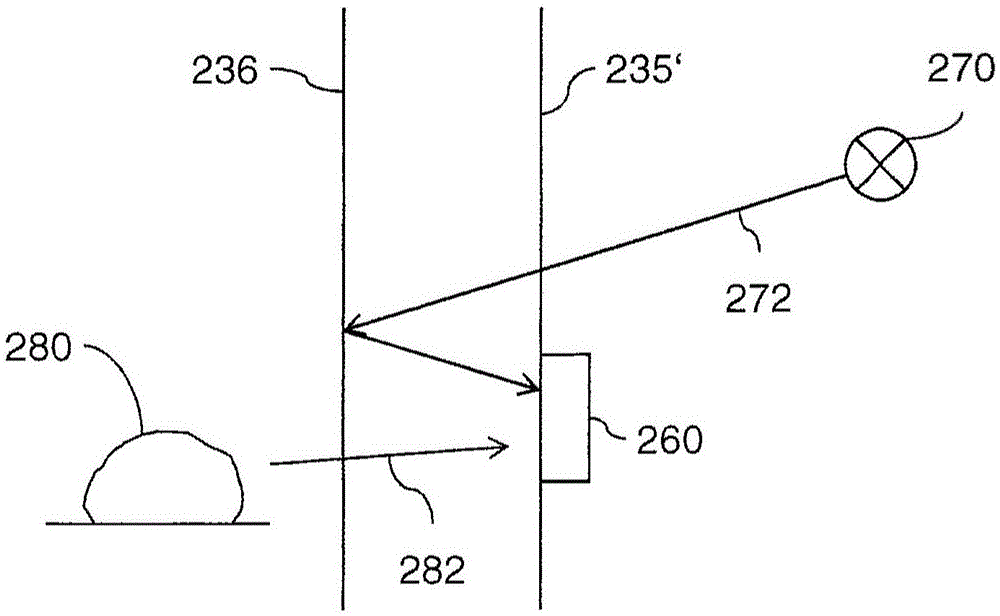

Heat treatment monitoring system

A heat treatment monitoring system comprises a heat treatment machine comprising a heat treatment chamber, a double glass window comprising an inside window and an outside window, and an illumination apparatus for illuminating the inside of the heat treatment chamber, and a monitoring apparatus mounted to the heat treatment machine and comprising a camera to observe the inside of the heat treatment chamber through the inside window, wherein the visible transmittance of the outside window is lower than the visible transmittance of the inside window to reduce reflections within the double glass window structure and outside illumination effects on image processing of images recorded by the camera.

Owner:英戈·施托克格南特韦斯伯格

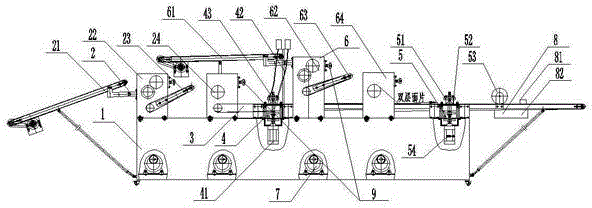

Multi-channel fried bread stick maker

ActiveCN104542764AQuality improvementHigh degree of automationDough shaping and cutting apparatusBaking plantsBrush deviceEngineering

The invention discloses a multi-channel fried bread stick maker. The multi-channel fried bread stick maker comprises a rack, a lower flour pressing conveying mechanism, a main conveyer belt, an oil brushing device, a cutting device, an upper flour pressing conveying mechanism and a transmission device, wherein the lower flour pressing conveying mechanism, the main conveyer belt, the oil brushing device and the cutting device are arranged sequentially on the rack; the upper flour pressing conveying mechanism is arranged on the rack and positioned above the lower flour pressing conveying mechanism and the main conveyer belt; the transmission mechanism is arranged in the rack, is positioned below the lower flour pressing conveying mechanism, and is connected with the upper flour pressing conveying mechanism, the lower flour pressing conveying mechanism, the oil brushing device, the cutting device and the main conveyer belt; the oil brushing device is positioned between the upper flour pressing conveying mechanism and the main conveyer belt and is positioned above the main conveyer belt; the cutting device is positioned above the main conveyer belt. By utilizing the multi-channel fried bread stick maker, a fried bread stick dough is made directly and conveyed to a fryer to fry, the automation degree is high, and the labour intensity is reduced greatly; by the combination of two four pressing mechanisms and the main conveyer belt, and through additionally arranging the oil brushing device between two layers, the occupied space is small, the produced fried bread stick dough is reliable in quality, and the directly fried bred sticks are crisp and delicious.

Owner:蚌埠禹辰科技有限公司

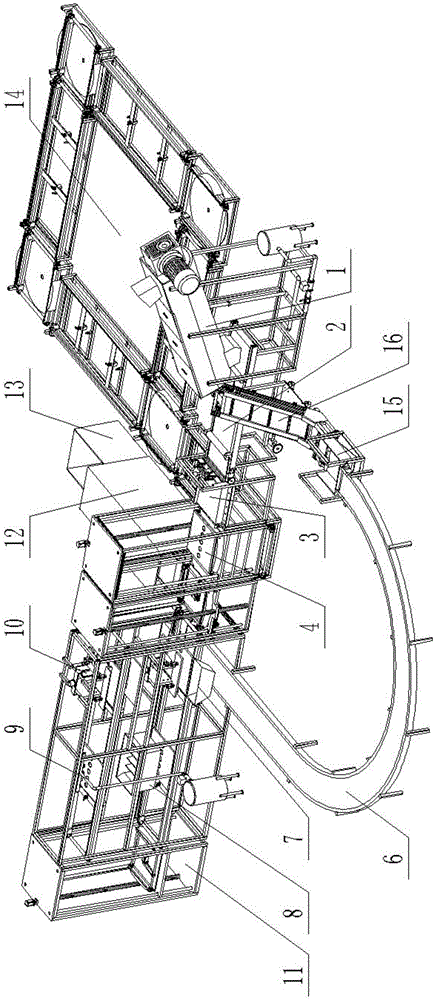

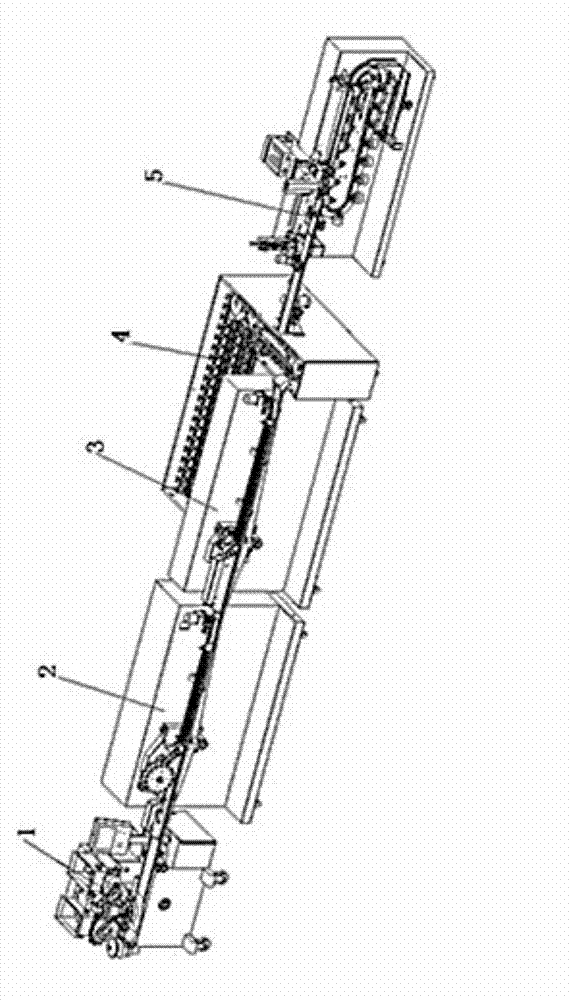

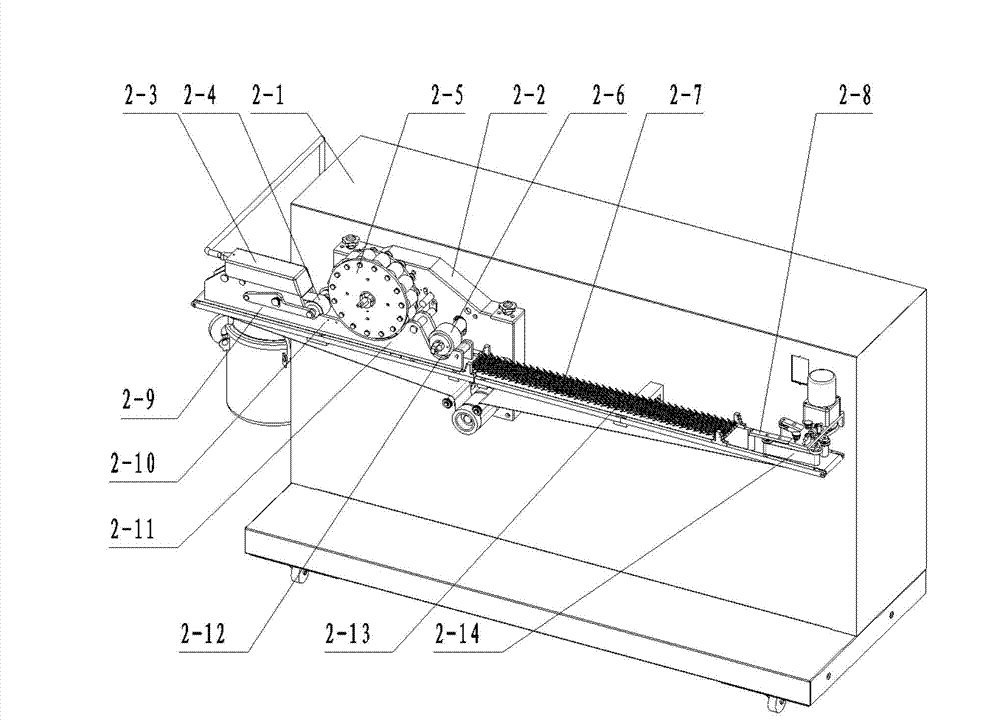

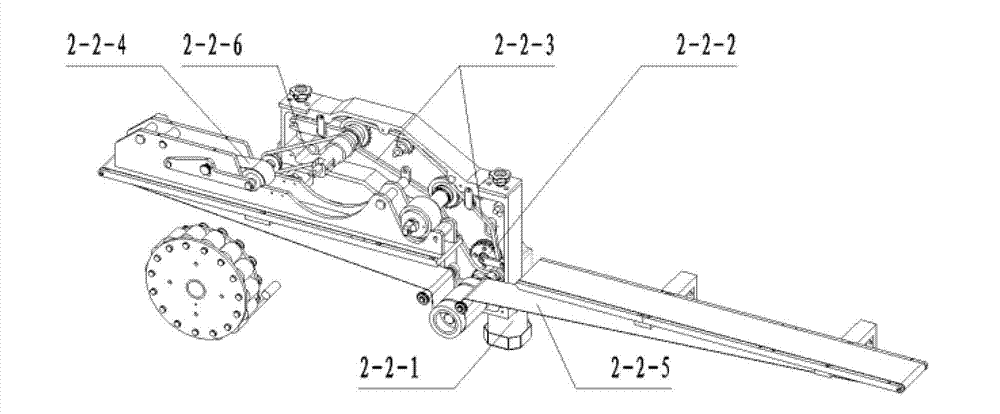

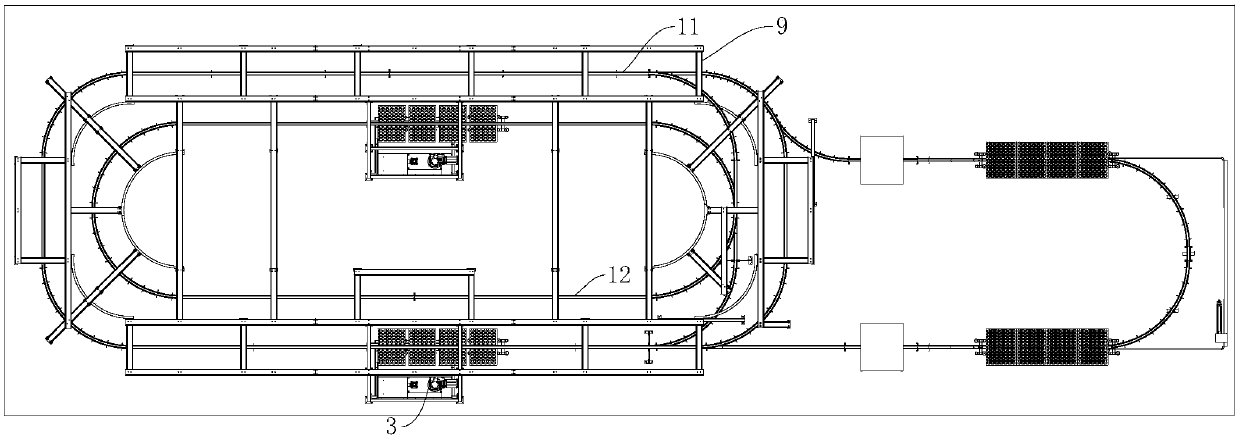

Full-automatic dumpling production line

ActiveCN106614869ASolve the problem of poor taste and chewyIncrease success rateMixing/kneading with vertically-mounted toolsProversEngineeringManufacturing line

The invention discloses a full-automatic dumpling production line. A machine capable of making dumplings instead of the hands, as well as ensuring chewy taste of the dumplings, has been the wish of the people. The full-automatic dumpling production line disclosed by the invention comprises a dough making device, a dough-strip shaping device, a dough-strip sectioning device, transition dough-conveying and dough-leavening devices, a transition collecting device, a first chain transmission device, an annular dough-residue recycling conveyor belt, a dumpling wrapper shaping device, a stuffing filling device, a second chain transmission device, a dumpling-wrapper edge moistening device, a dumpling making and shaping device, an upper and lower conveying device, a quick freezing device, a material storage box, a dough-leavening device track, a recycling transition device, a climbing conveying device, and dumpling mold devices. The full-automatic dumpling production line disclosed by the invention is capable of integrally realizing a processing line of dough making, dough conveying, dough leavening, dumpling wrapper shaping, stuffing filling, wrapper-edge moistening, dumpling making, dough-residue recycling and quick-freezing; thus, the problems of marketed dumpling machines, namely bad taste and lack of chewy taste of the made dumplings caused by absence of the wrapper-edge moistening device and the dough leavening device are solved. Therefore, the full-automatic dumpling production line greatly improves success rates and qualities of the made dumplings.

Owner:ZHEJIANG SCI-TECH UNIV

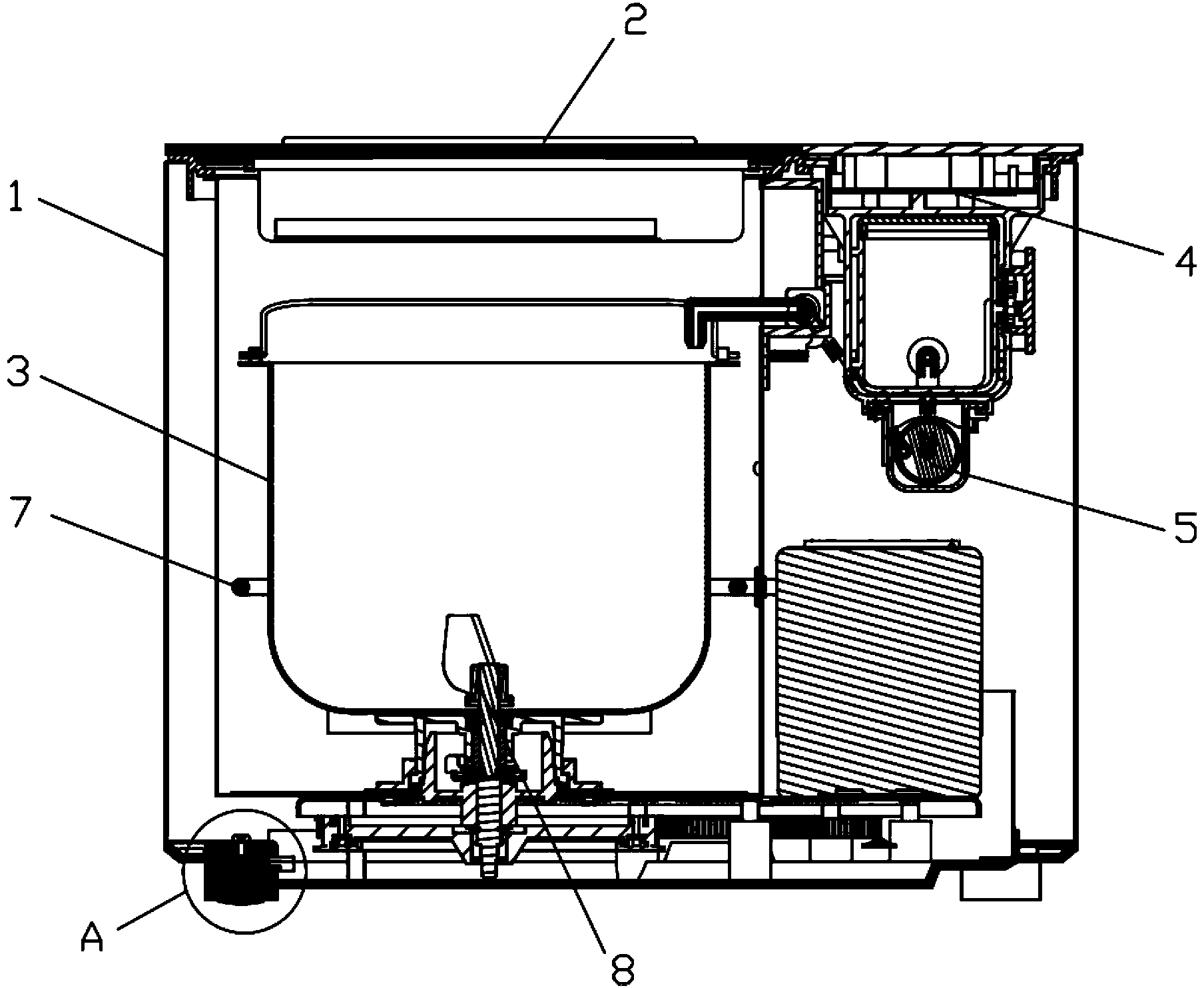

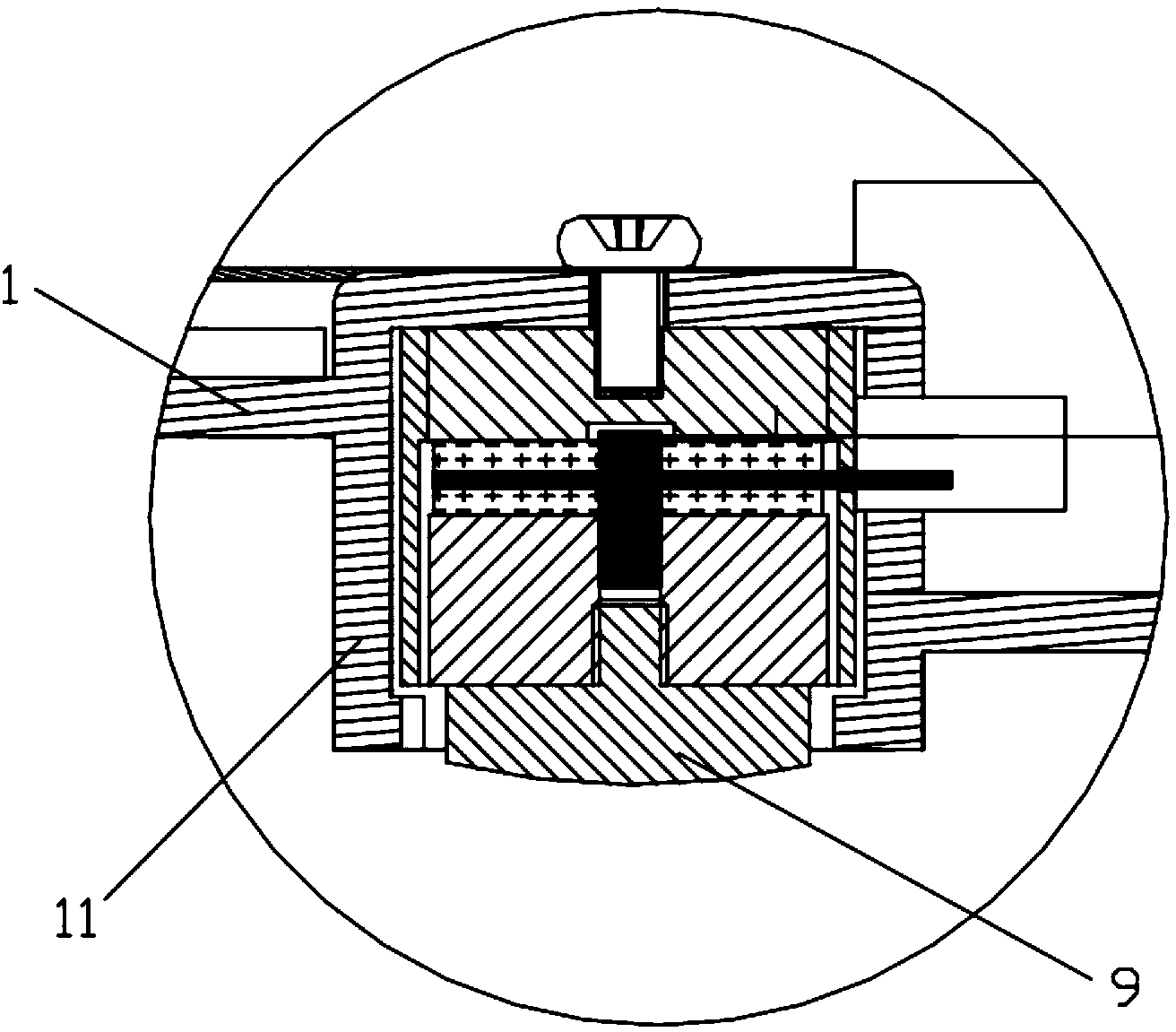

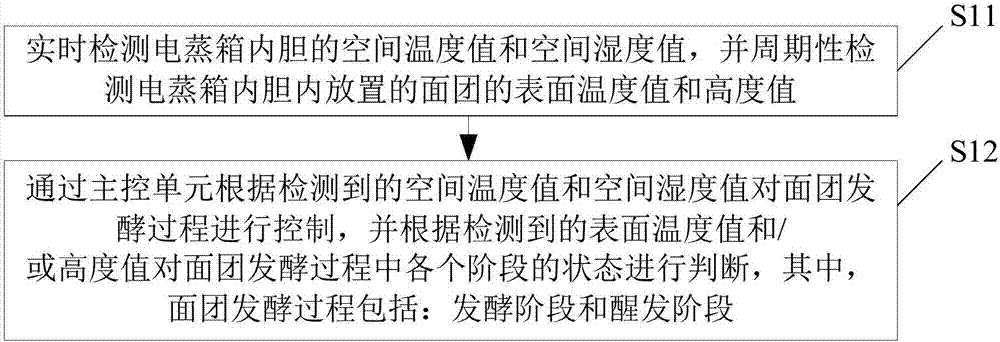

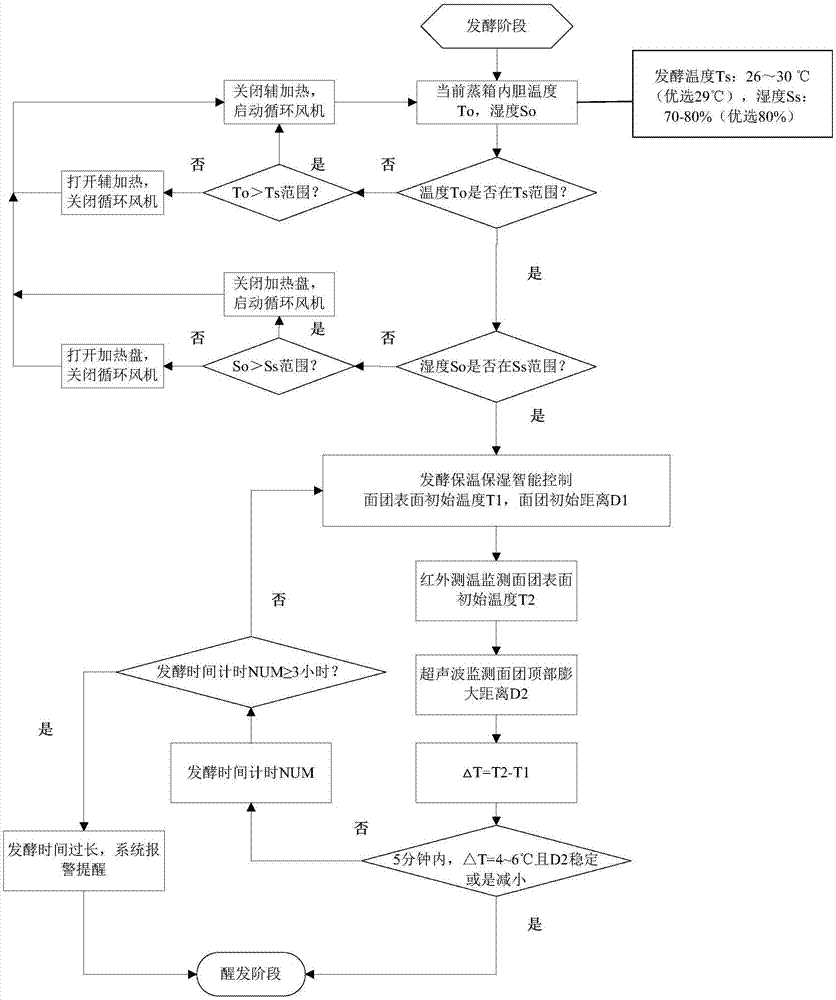

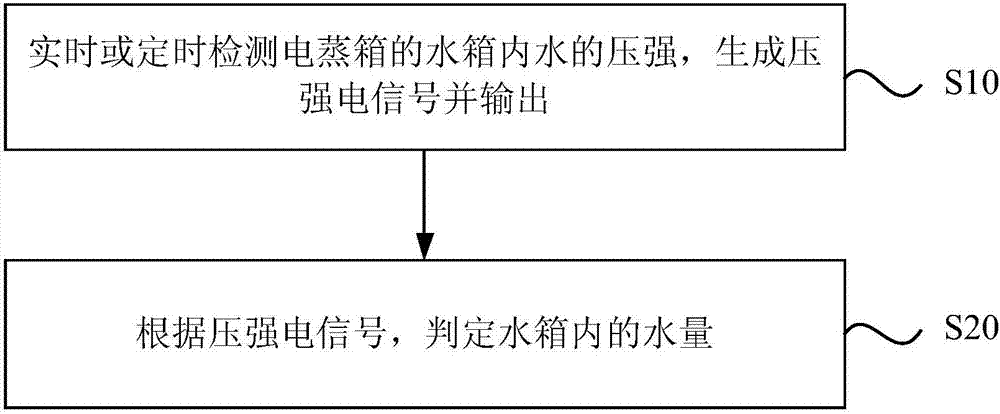

Intelligent electric steaming box and control method thereof

An embodiment of the invention discloses a control method of an intelligent electric steaming box. The control method comprises detecting spatial temperature values and spatial humidity values of an inner container of the electric steaming box in real time; periodically detecting surface temperature values and altitude values of a dough placed in the inner container of the electric steaming box; controlling a dough fermentation process according to the detected spatial temperature values and spatial humidity values; and judging the status of each stage in the dough fermentation process according to the detected surface temperature values and / or altitude values, wherein the dough fermentation process comprises a fermentation stage and a curing stage. The embodiment of the invention also discloses the intelligent electric steaming box.

Owner:JOYOUNG CO LTD

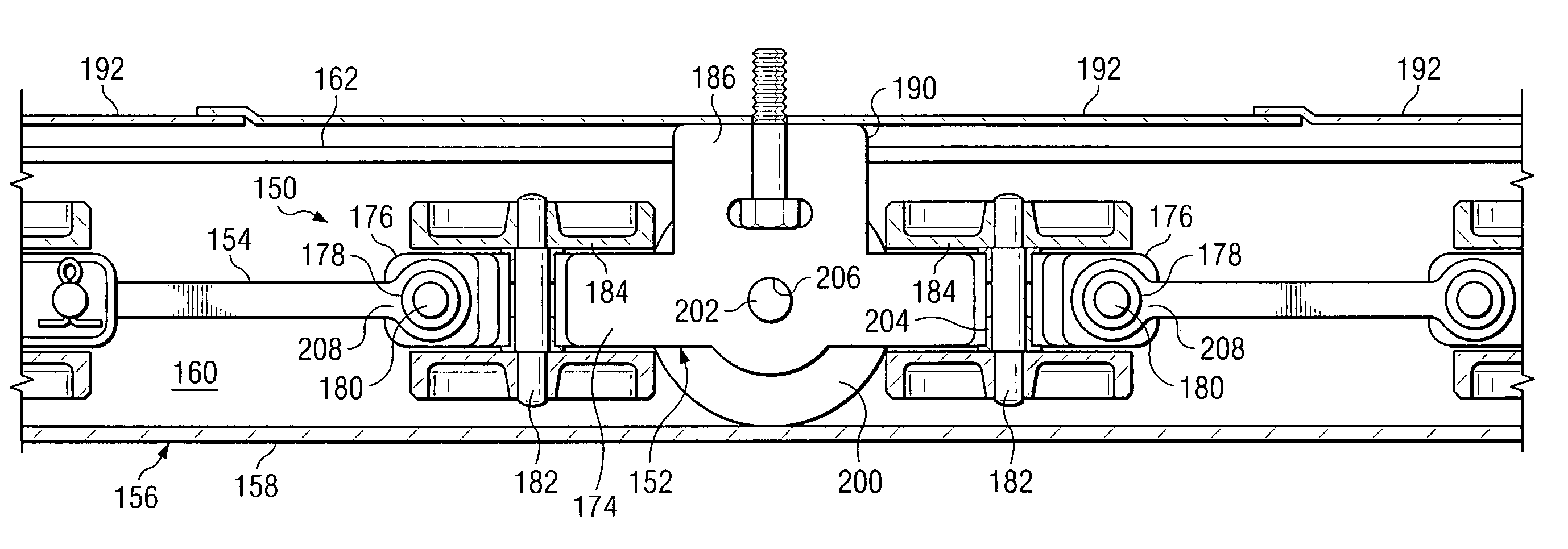

Conveyor for continuous proofing and baking apparatus

InactiveUS7086525B2Low costEliminate failureBearing componentsRollersMechanical engineeringPlain bearing

Conveyor chains of the type utilized in commercial ovens and proofers are provided with improved bearing support for the rotating and pivoting components of the chains. The rotating components comprising antifriction bearings constructed from superior components which support substantial improvements in the service life of the conveyor chains. The pivoting components are provided with plain bearings and / or antifriction coating which also function to extend the service life of the conveyor chains.

Owner:STEWART SYST GLOBAL LLC A TEXAS LIMITED LIABILITY

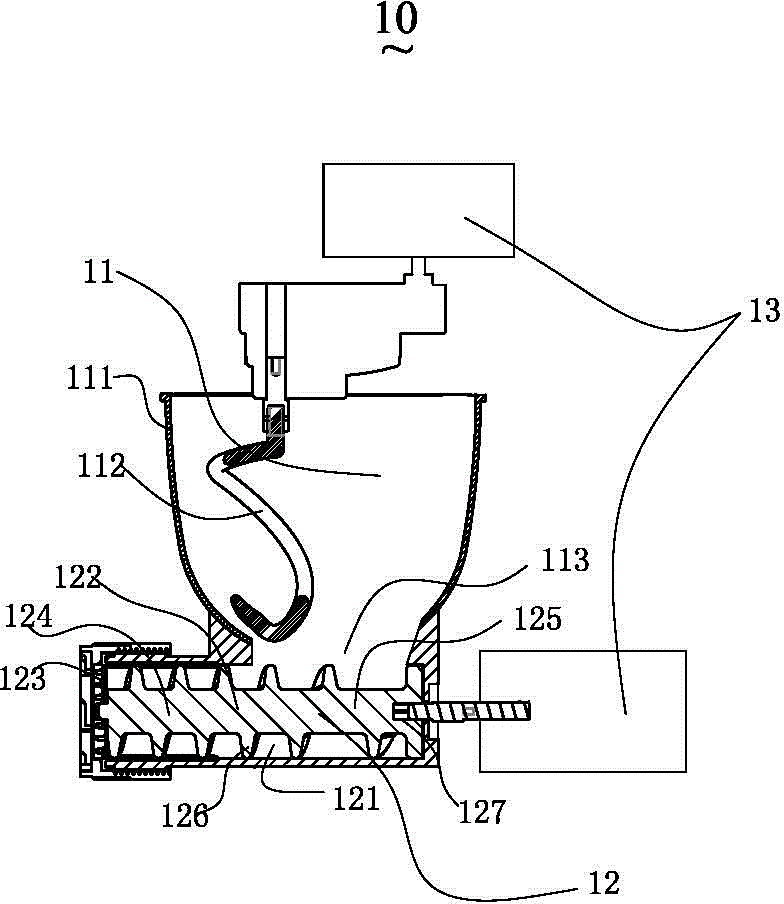

Method for making cooked wheaten food by using domestic multifunctional cooked wheaten food machine

InactiveCN104542768AIncrease exerciseProlong the stress timeMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsEngineeringUtilization rate

The invention relates to a method for making cooked wheaten food by using a domestic multifunctional cooked wheaten food machine. The domestic multifunctional cooked wheaten food machine comprises a stirring system, an extrusion and forming system and a driving system, wherein the stirring system comprises a stirring element and a stirring container; the extrusion and forming system comprises a forming cavity, a dough extrusion screw rod and a forming mold; and the driving system comprises a driving stirring element and a dough extrusion screw rod. The method for making the cooked wheaten food comprises a feeding procedure, a first stirring procedure, a second stirring procedure, a kneading procedure and an extrusion and forming procedure. By setting three different rotation speeds in the first stirring procedure, the second stirring procedure and the kneading procedure, the extruded cooked wheaten food is relatively uniform, smooth and free of layering, the raw material residue amount is also reduced, and the utilization rate is increased.

Owner:JOYOUNG CO LTD

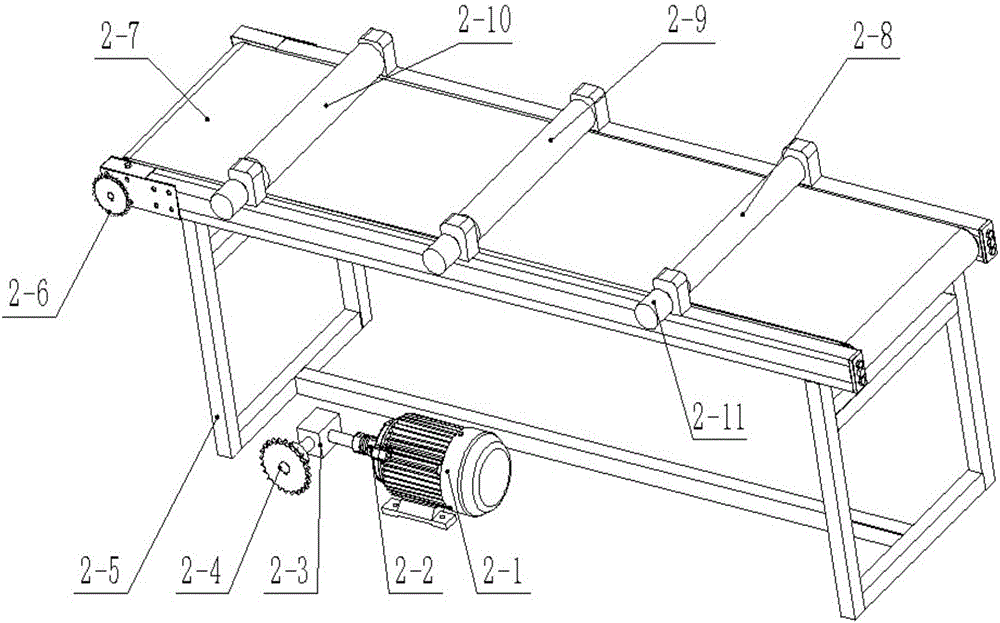

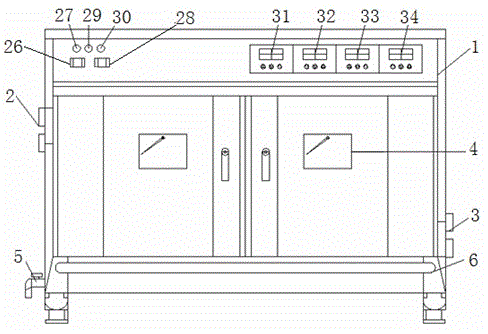

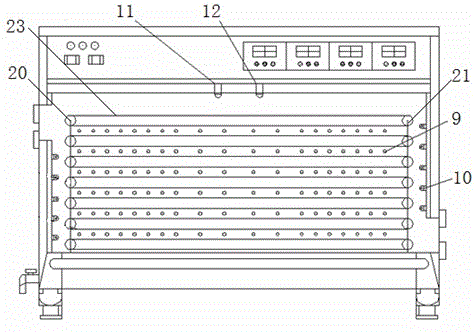

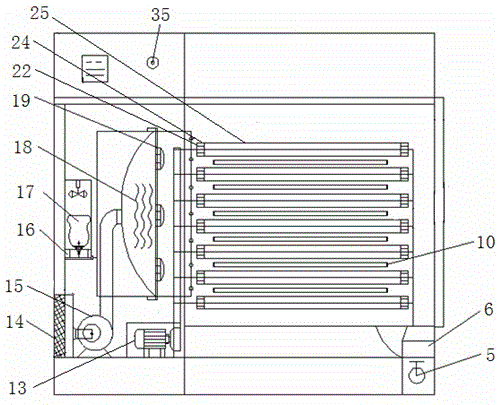

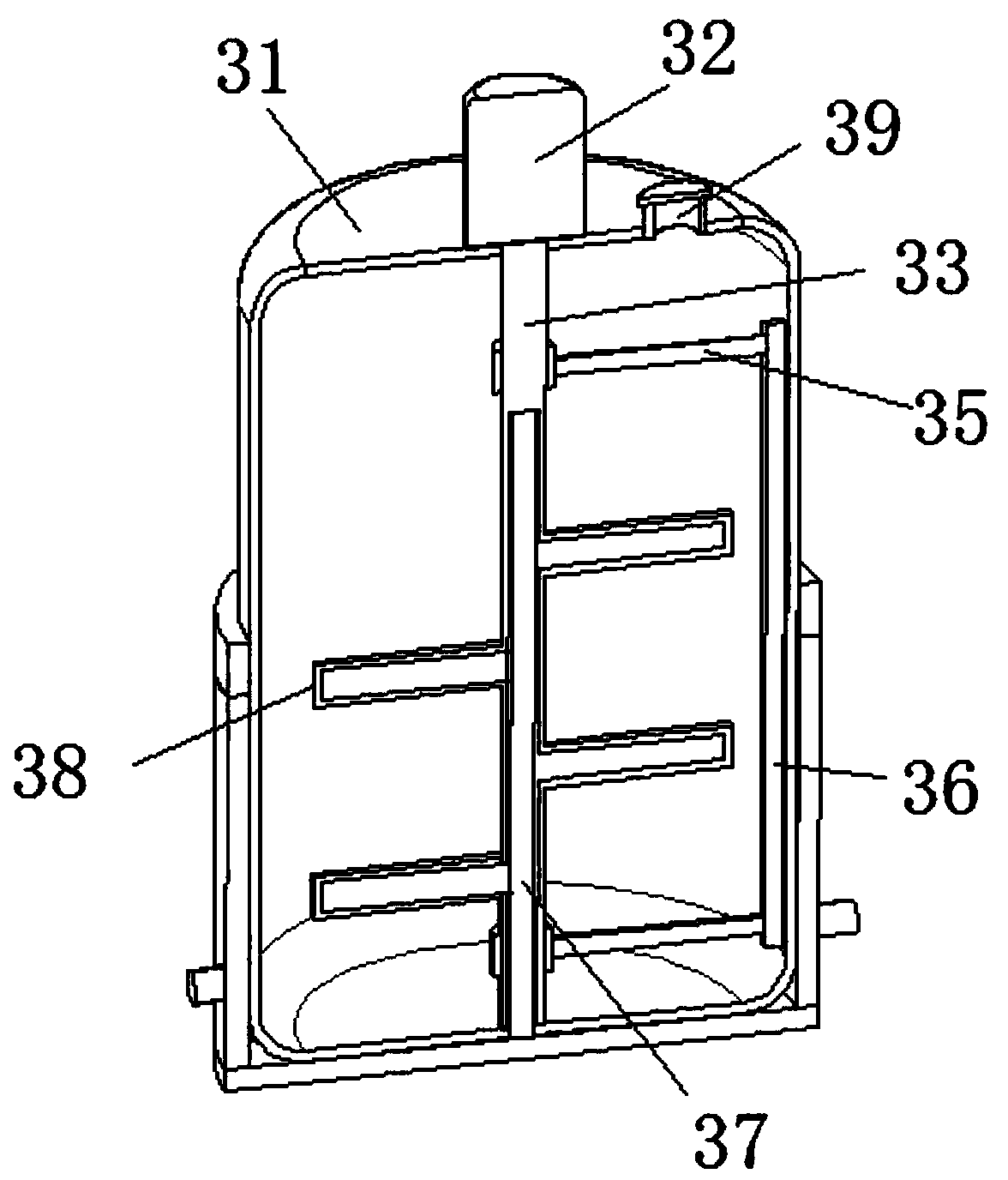

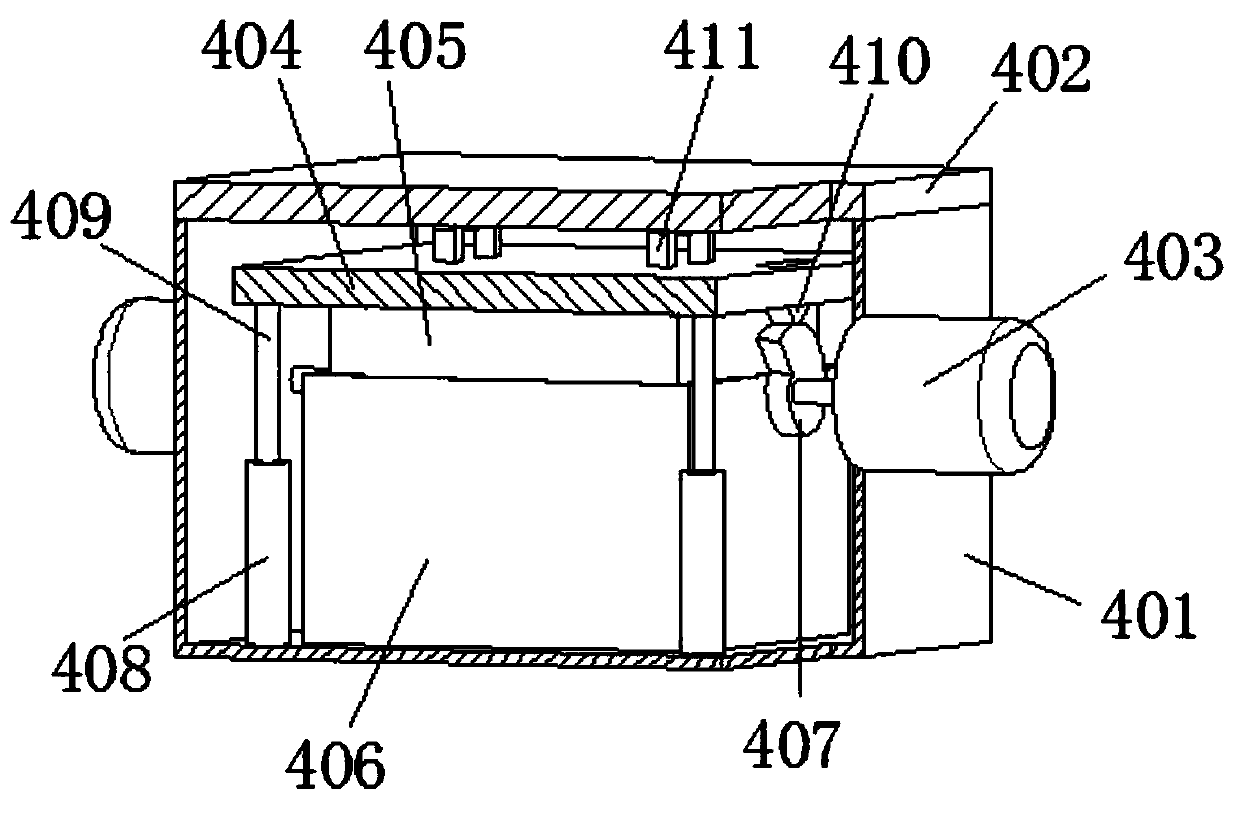

Constant-temperature and constant-humidity fermenting box

ActiveCN103548910AClean up in timeObservation field is clearProversDough processingAir filtrationAir filter

The invention relates to a constant-temperature and constant-humidity fermenting box. The fermenting box comprises a box body, a transmission device, a sterilizing device, a heating device, a humidifying device and a control center, wherein a first push-pull window is arranged at the upper part of the left side of the box body, a second push-pull window is arranged at the lower part of the right side of the box body, box doors are arranged on the front side of the box body, observation windows are arranged on the box doors, a drain valve is arranged at the bottom of the box body, and an exhaust hole is formed in the bottom of the box body and is communicated with the drain valve; the transmission device is mounted in the box body and comprises a motor, a transmission gear set, a series of transmission gears and a series of transmission chains, the transmission gear set is connected with the motor, and the transmission gears and the transmission chains are matched with each other; the heating device comprises an air filter screen, an air blower, a fan cover, heating wires, a partition board and a temperature sensor; the humidifying device comprises a moisture generator, a water tank, a moisture atomizer and a humidity sensor. Fresh wet noodles fermented by the constant-temperature and constant-humidity fermenting box are adequately fermented and are bright in color and long in shelf life, and the chewiness of the noodles is enhanced.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

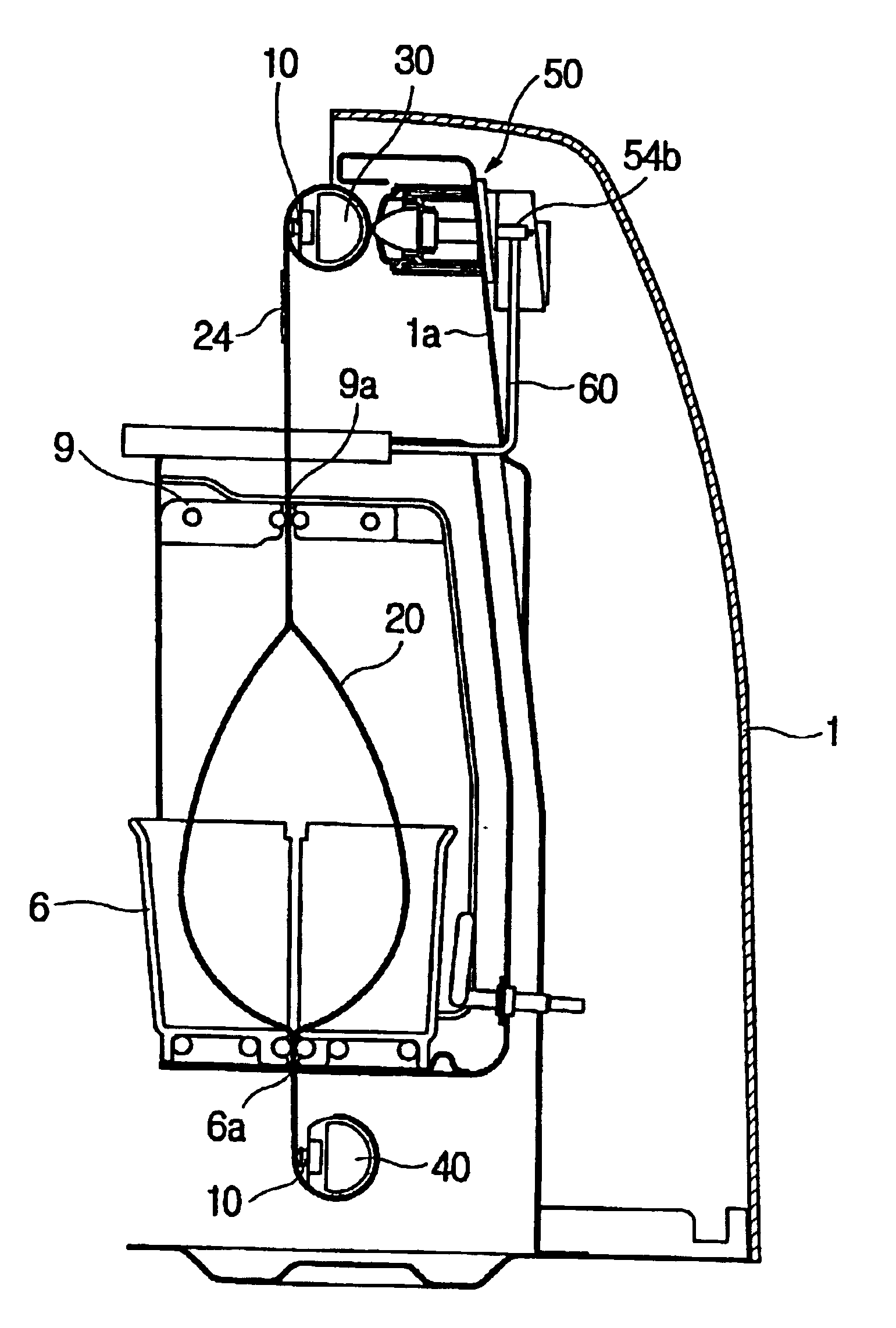

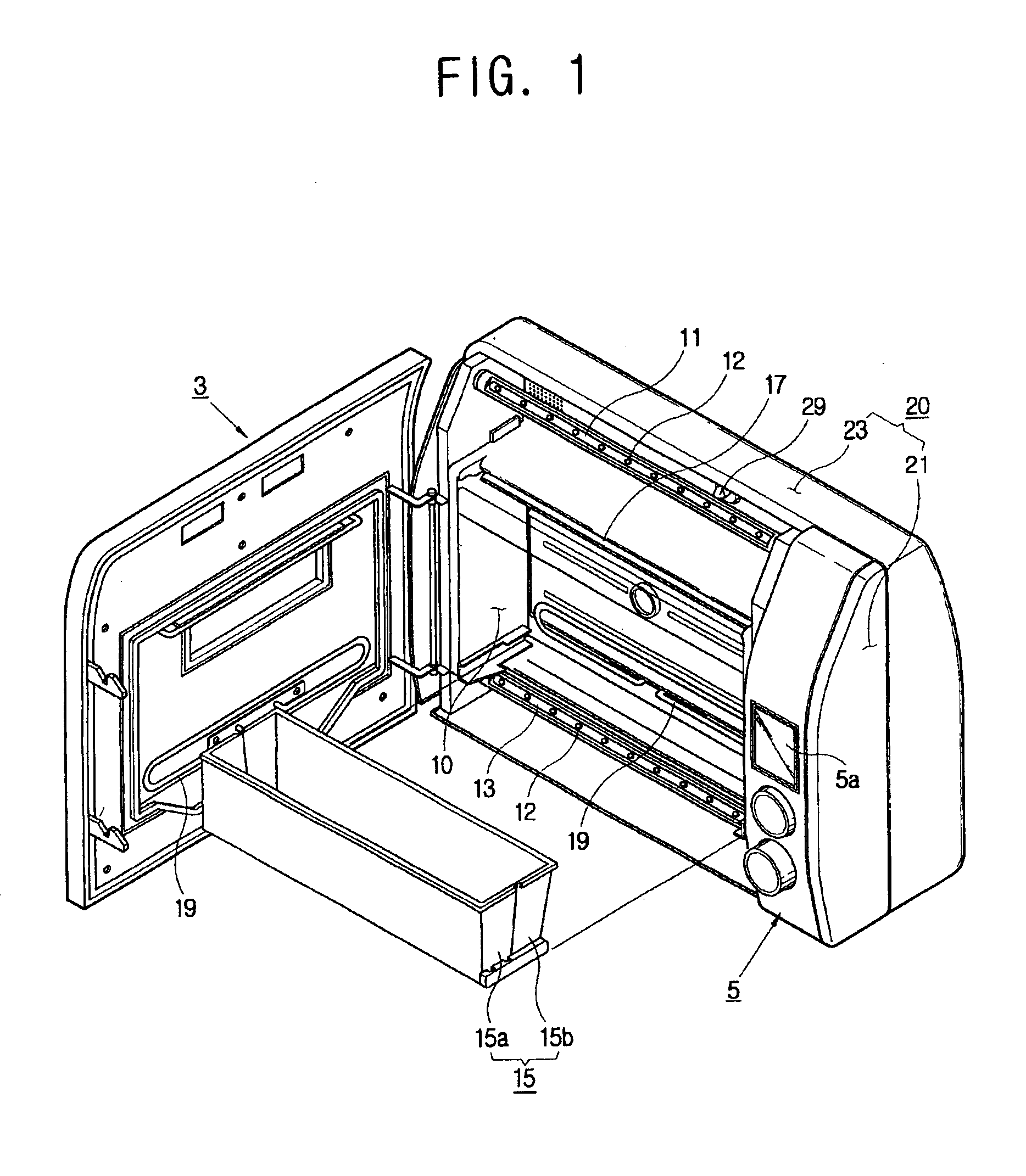

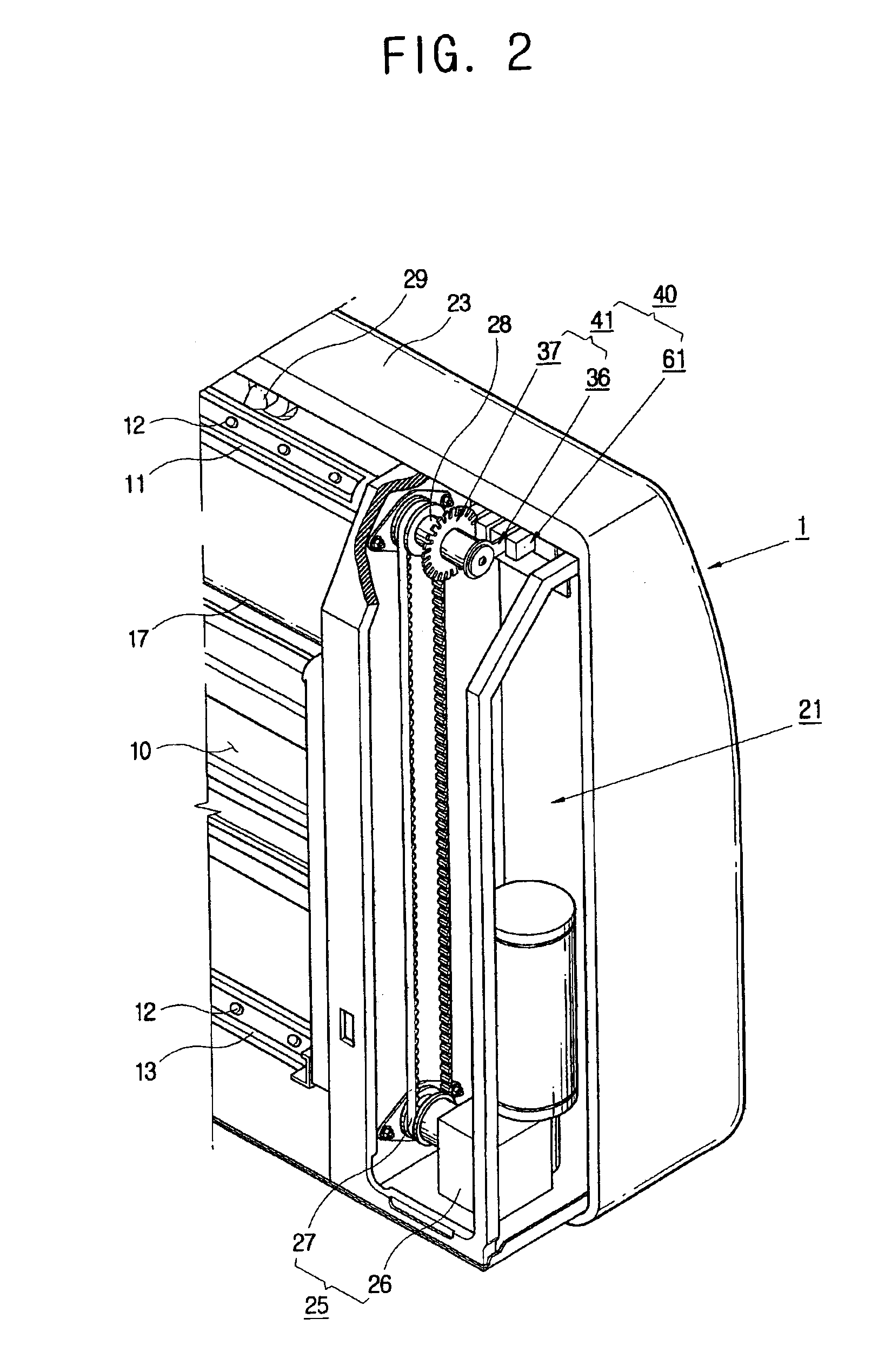

Bread maker with bar code scanner

InactiveUS6845706B2Inhibit wearAbsorb vibrationShaking/oscillating/vibrating mixersTransportation and packagingAdditive ingredientBarcode

A bread maker includes upper and lower rollers and a bar code scanner. The upper and lower rollers wind a mixing bag containing bread ingredients to form dough. The bar code scanner reads a bar code attached to the mixing bag so that, as the mixing bag is wound by rotation of the upper and lower rollers, the bar code scanner reads the bar code while being in contact with the bar code wound around one of the upper and lower rollers. The upper roller includes flat and arcuate portions. The flat portion is provided with an arcuate guide section to form a circular track together with the arcuate portion.

Owner:SAMSUNG ELECTRONICS CO LTD

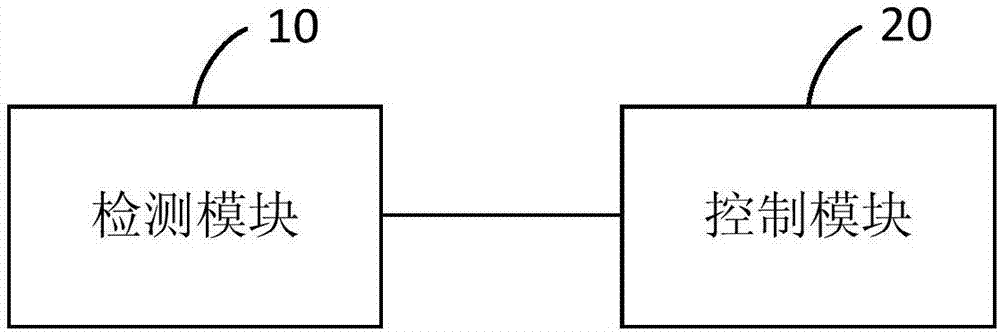

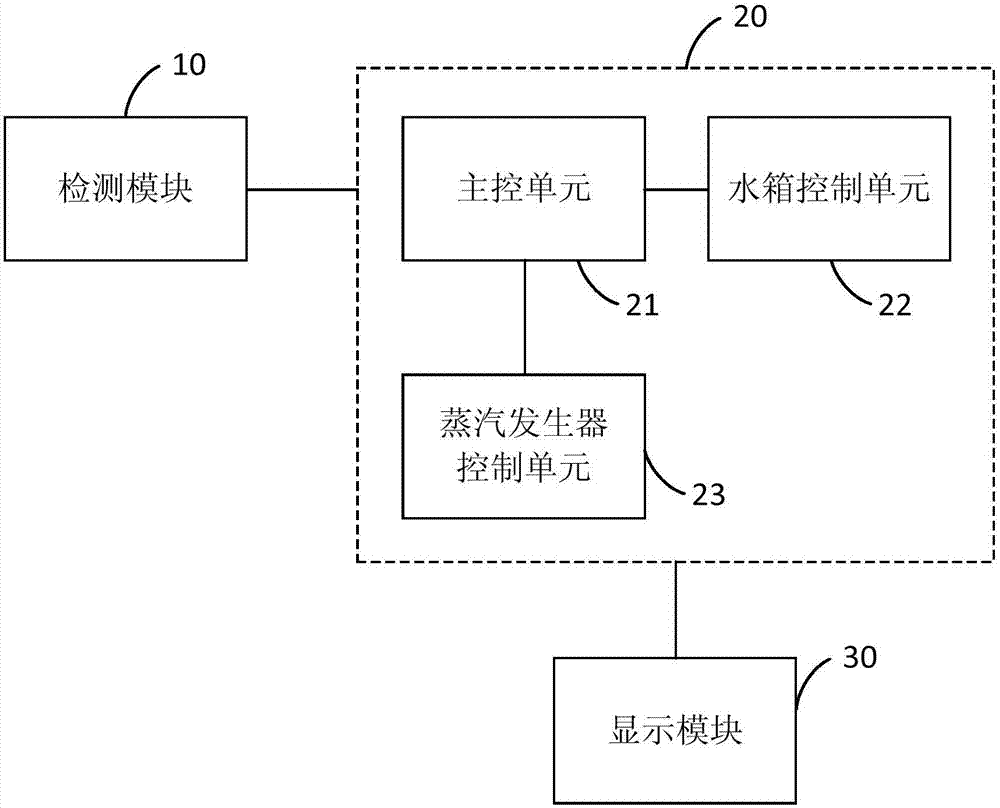

Electric steamer and steam control device and method thereof

ActiveCN107224195AAccurately judge the effect of water volumeSteam cooking vesselsProversElectricityEngineering

The invention discloses an electric steamer and a steam control device and method thereof. The steam control device comprises a detection module and a control module, the detection module is used for detecting pressure intensity of water in a water tank of the electric steamer in real time or regularly, generating a pressure intensity electric signal and outputting the same, and the control module is electrically connected with the detection module and used for receiving the pressure intensity electric signal and judging water quantity in the water tank according to the same. The pressure intensity of the water in the water tank is detected in real time or regularly, so that the problem that a steam control device of an existing electric steamer can only detect lowest water level and highest water level of a water tank and is unitary in detection result is solved, and detection on all water quantity height of the water tank and effect of accurately judging the water quantity in the water tank are realized.

Owner:GREE ELECTRIC APPLIANCES INC

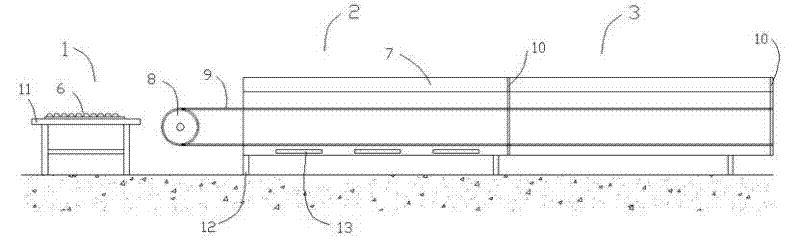

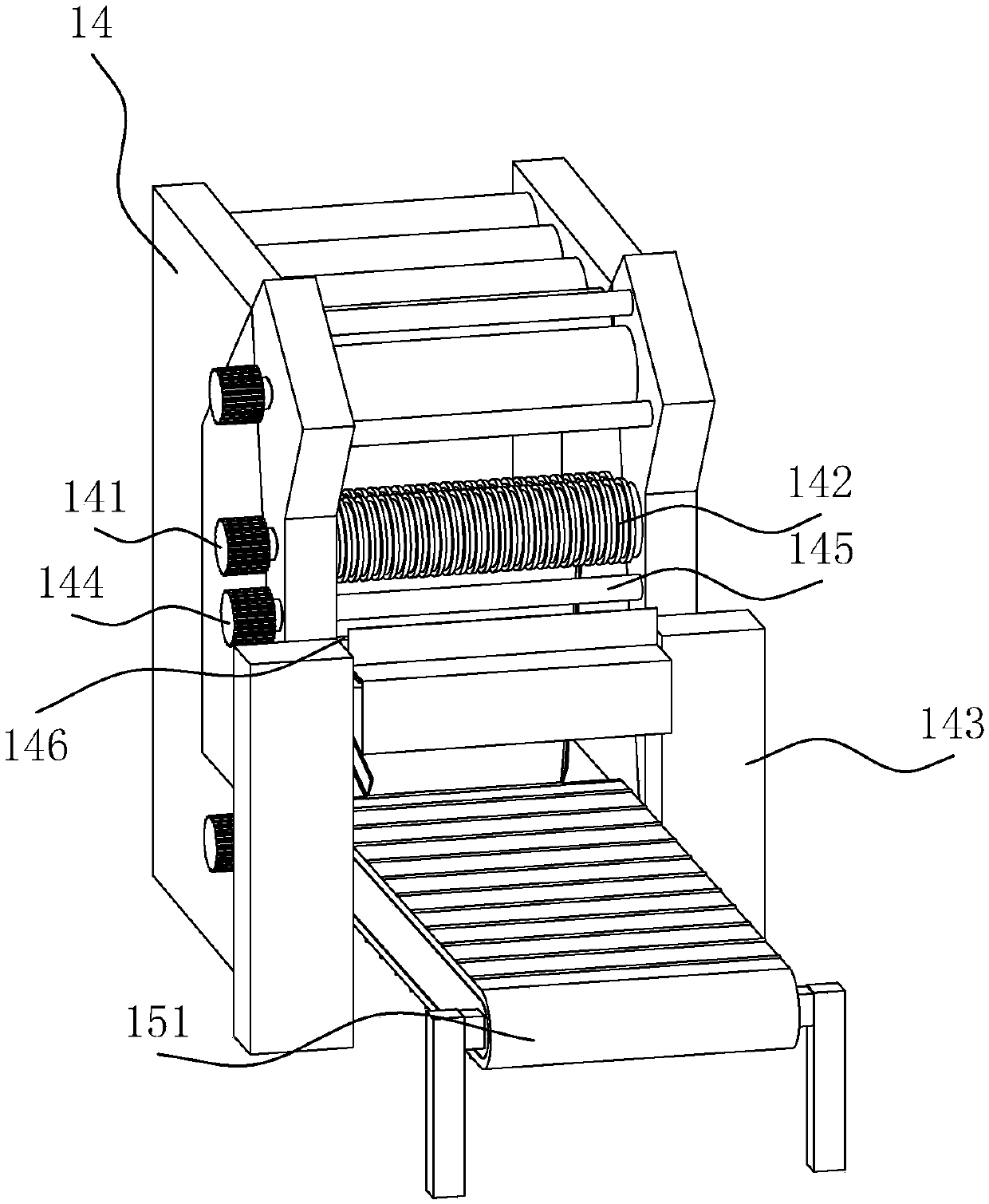

Steamed bun leavening, steaming and airing all-in-one machine

The invention provides a steamed bun leavening, steaming and airing all-in-one machine. The steamed bun leavening, steaming and airing all-in-one machine comprises a dough leavening area, a steaming area, an airing area and a main power system which are connected to be a whole. A plurality of hanging basket assemblies for bearing steamed buns penetrate the dough leavening area, the steaming area and the airing area. The hanging basket assemblies are driven by a conveying chain to perform sequential and continuous cycle operation. According to the all-in-one machine, the steamed bun leavening and steaming process is continuous and unmanned, produced steamed buns are very stable in quality, the guarantee period is prolonged greatly, and the taste is unique. The machine is well welcome by steamed bun production enterprises, and the products produced by the machine are well welcome by consumers.

Owner:QINGDAO ZHENGYA MACHINERY TECH

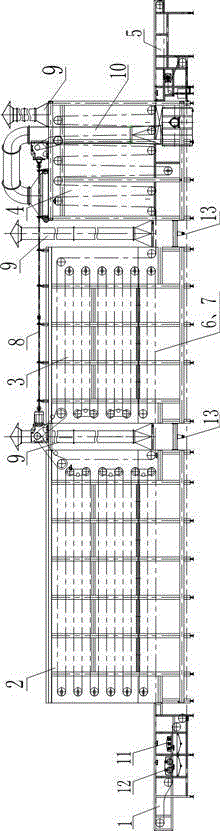

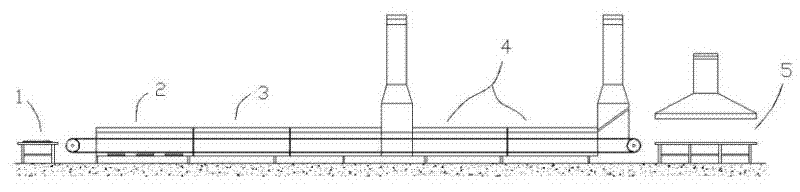

Automatic steaming production line

InactiveCN102228188ALarge amount of processingHigh degree of mechanizationFood preparationProversEngineeringChain type

The invention discloses an automatic steaming production line comprising a closed chain type conveyer; the closed chain type conveyer comprises a closed conveying channel with openings on two ends and a conveying mechanism. An active chain wheel and a passive chain wheel of the conveying mechanism are respectively located on the openings on two ends of the closed conveying channel; the closed conveying channel is sequentially divided into a waking section, a steaming section and a cooling section via spacers; and exhaust channels are arranged on the cooling section. Moreover, a heating and humidifying device is arranged on the waking section. Moreover, the steaming section comprises a steam pipeline nozzle arranged in the closed conveying channel at the steaming section. Moreover, the cooling section is divided into a first cooling section and a second cooling section via a spacer; one of the exhaust channels is arranged in the middle of the first cooling section; and the other exhaust channel is arranged at the exit of the second cooling section. Moreover, the production line further comprises a disc arranging area and a disc discharging area respectively located on the openings on two ends of the closed conveying channel. Through the automatic steaming production line, steamed breads can be continuously and mechanically produced in large quantity.

Owner:菅宪锋

Conveyor for continuous proofing and baking apparatus

InactiveUS20050061637A1Low costEliminate failureBearing componentsRollersEngineeringMechanical engineering

Conveyor chains of the type utilized in commercial ovens and proofers are provided with improved bearing support for the rotating and pivoting components of the chains. The rotating components comprising anti-friction bearings constructed from superior components which support substantial improvements in the service life of the conveyor chains. The pivoting components are provided with plain bearings and / or anti-friction coating which also function to extend the service life of the conveyor chains.

Owner:STEWART SYST GLOBAL LLC A TEXAS LIMITED LIABILITY

Bread maker and control method thereof

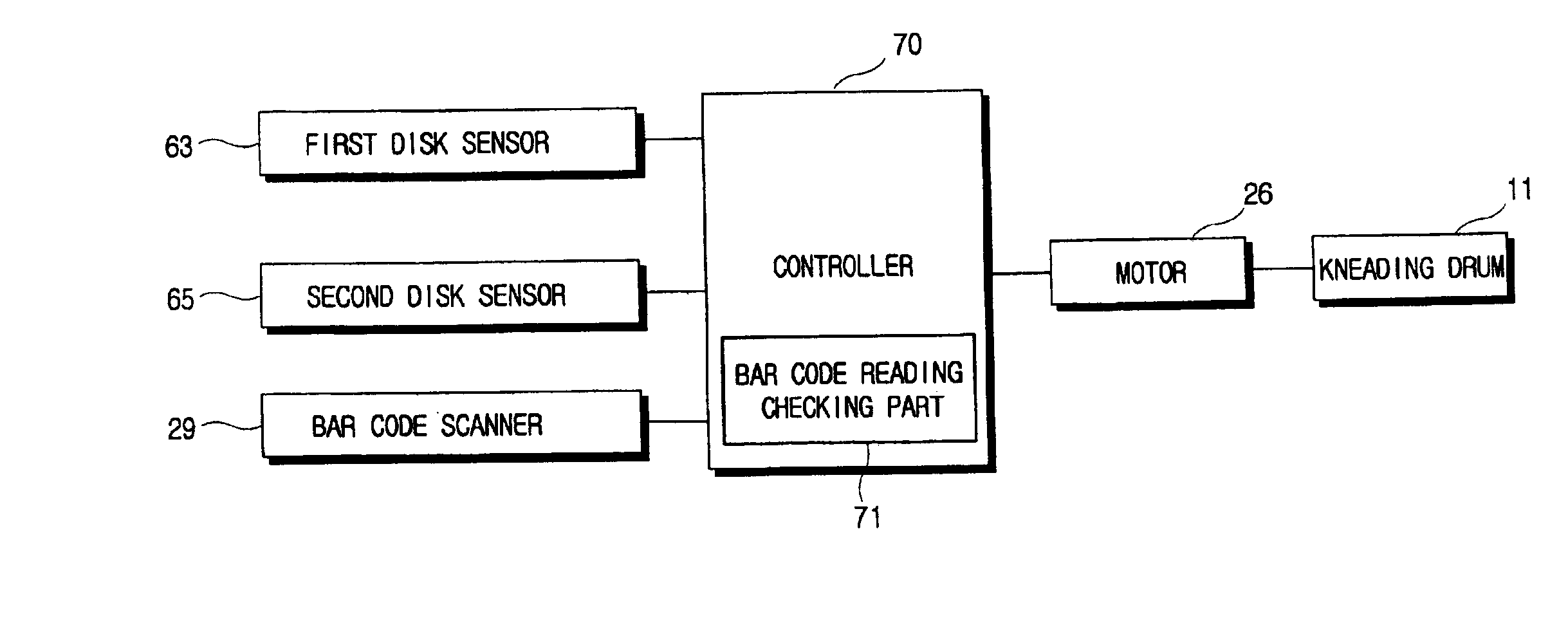

InactiveUS6962290B2Protection from damageShaking/oscillating/vibrating mixersBoiling over preventionAdditive ingredientBarcode

A bread maker including a pair of kneading drums inside an oven compartment, to which are attached opposite ends of a mixing bag containing bread ingredients, the kneading drums reversing rotary direction periodically; a bar code scanner to read a bar code on the mixing bag; a drum driving part rotating the kneading drums in clockwise and counterclockwise directions; a bar code reading checking part sensing whether the bar code scanner is reading the bar code; and a controller determining whether the bar code scanner is reading the bar code based upon a sensed signal output from the bar code reading checking part, and controlling the drum driving part to rotate the kneading drums at a bar code reading speed while the bar code scanner reads the bar code, and at a faster dough kneading speed when the bar code scanner has completely read the bar code.

Owner:SAMSUNG ELECTRONICS CO LTD

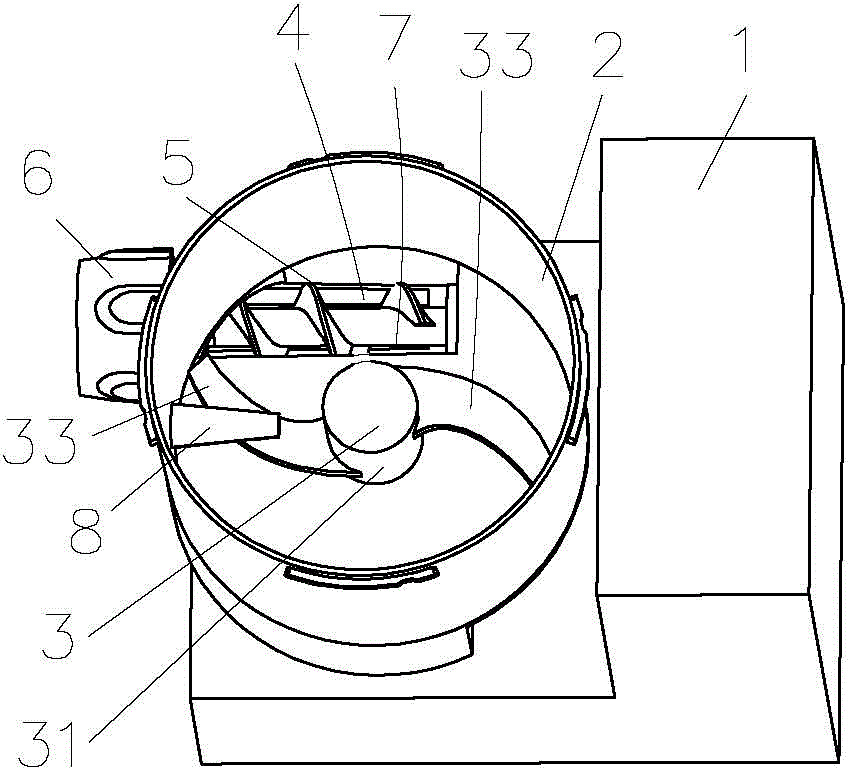

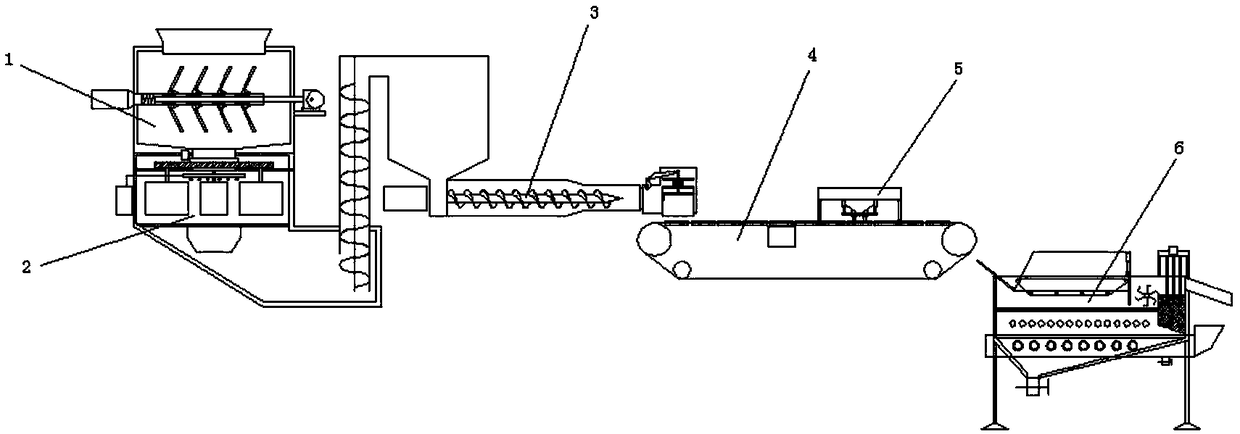

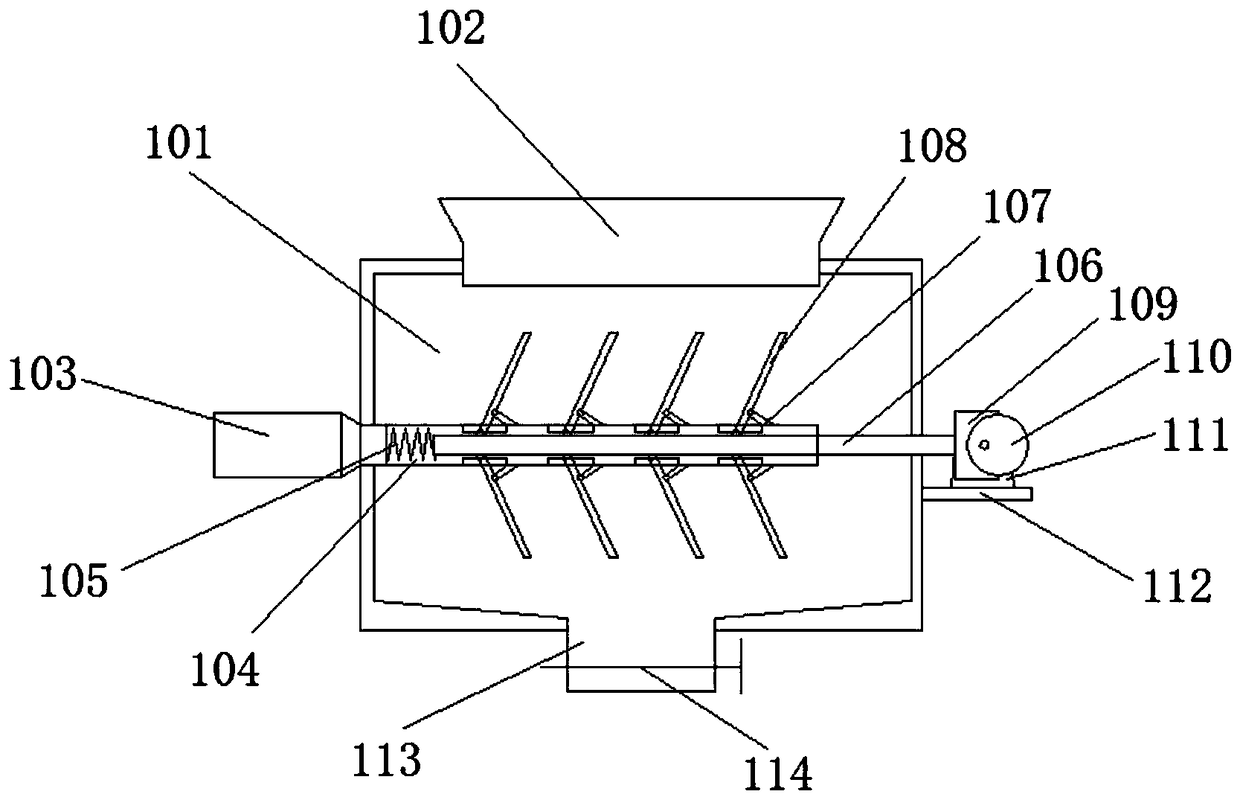

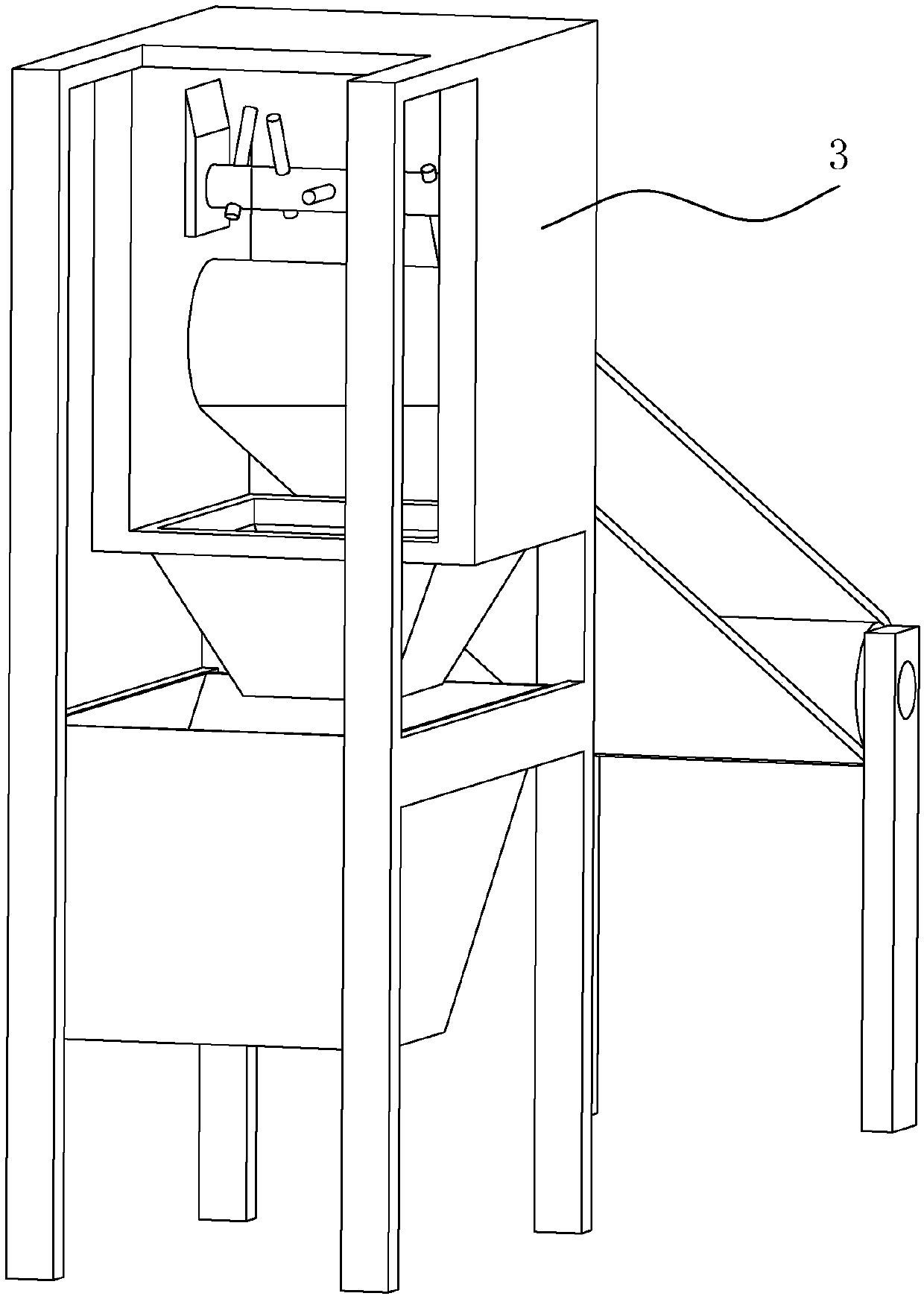

Flour mixing device of deep-fried dough stick machine

ActiveCN109006896AWell mixedImprove the mixing effectMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsDeep fryingAgricultural engineering

The invention discloses a flour mixing device of a deep-fried dough stick machine, and relates to the field of food processing. The flour mixing device includes a mixing mechanism, a dough kneading mechanism is arranged at the bottom of the mixing mechanism, a leavening cabin is connected to the right side of the dough kneading mechanism through a lifting machine, an extrusion machine is fixed tothe bottom of the leavening cabin, a discharging mechanism is arranged at the right end of the extrusion machine, a conveying machine is arranged below the discharging mechanism, a composite shaping mechanism is arranged at the middle of the conveying machine, a stretching detachment mechanism is arranged on the right portion of the conveying machine, and a deep-frying device is arranged at the bottom of the right end of the conveying machine. By adopting the flour mixing device of the deep-fried dough stick machine, a manual deep-fried dough stick making process can be stimulated, after wateris automatically added into flour and is mixed with the flour to make dough, the dough is kneaded, leavened, pressed, shaped and then stretched, finally, the dough is deeply fried, manual labor is greatly reduced, the mouthfeel of deep-fried dough sticks is ensured, the deep-fried dough sticks are efficiently and rapidly made, and the flour mixing device is suitable for being used in breakfast stores.

Owner:张乐

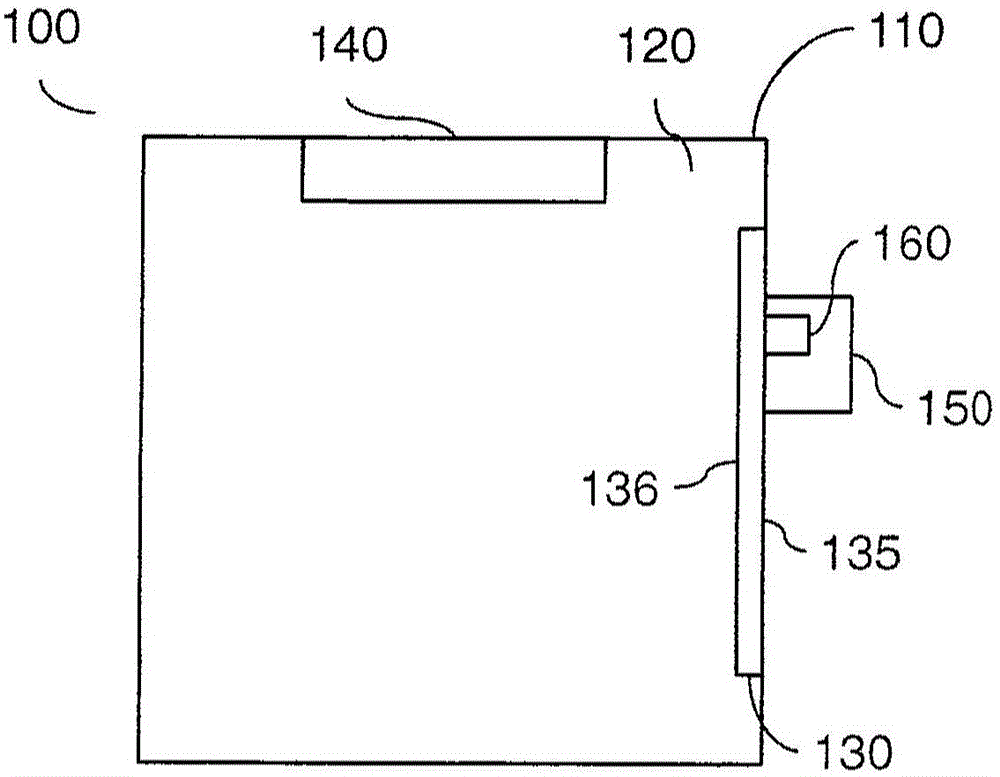

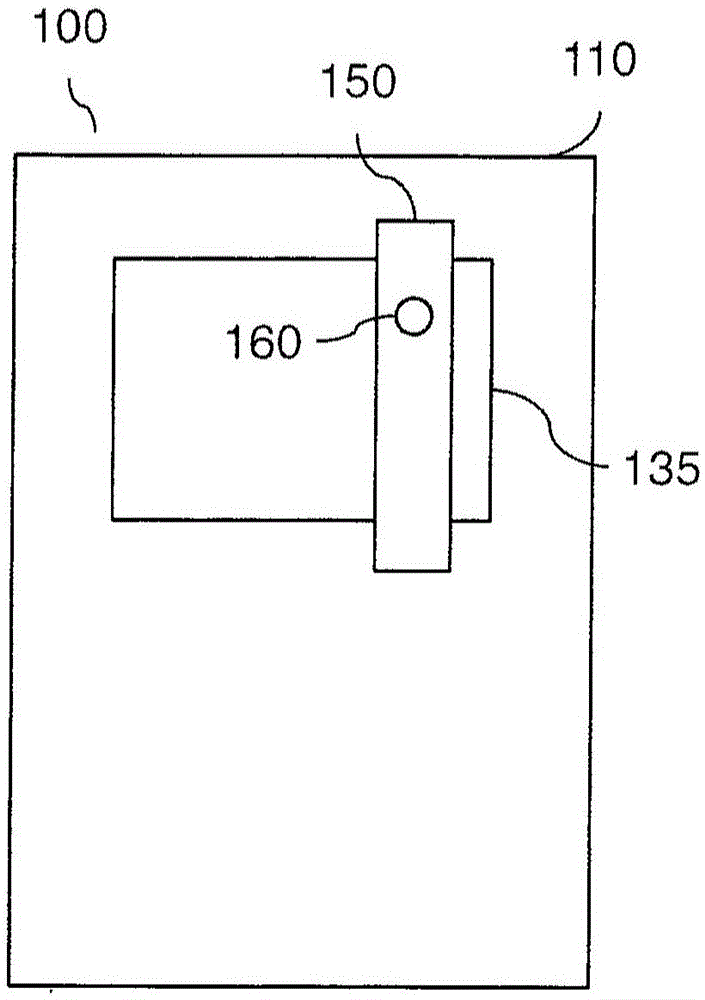

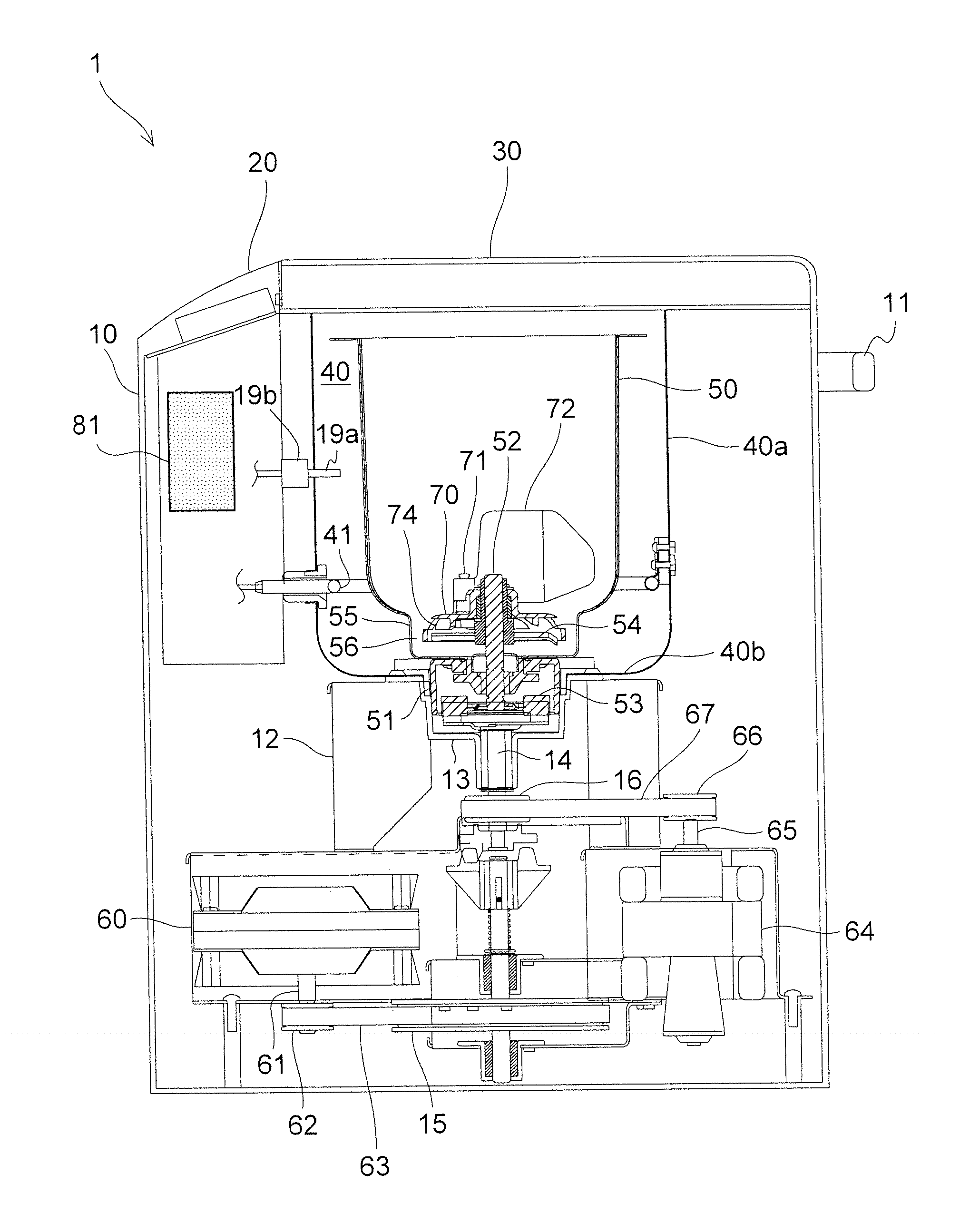

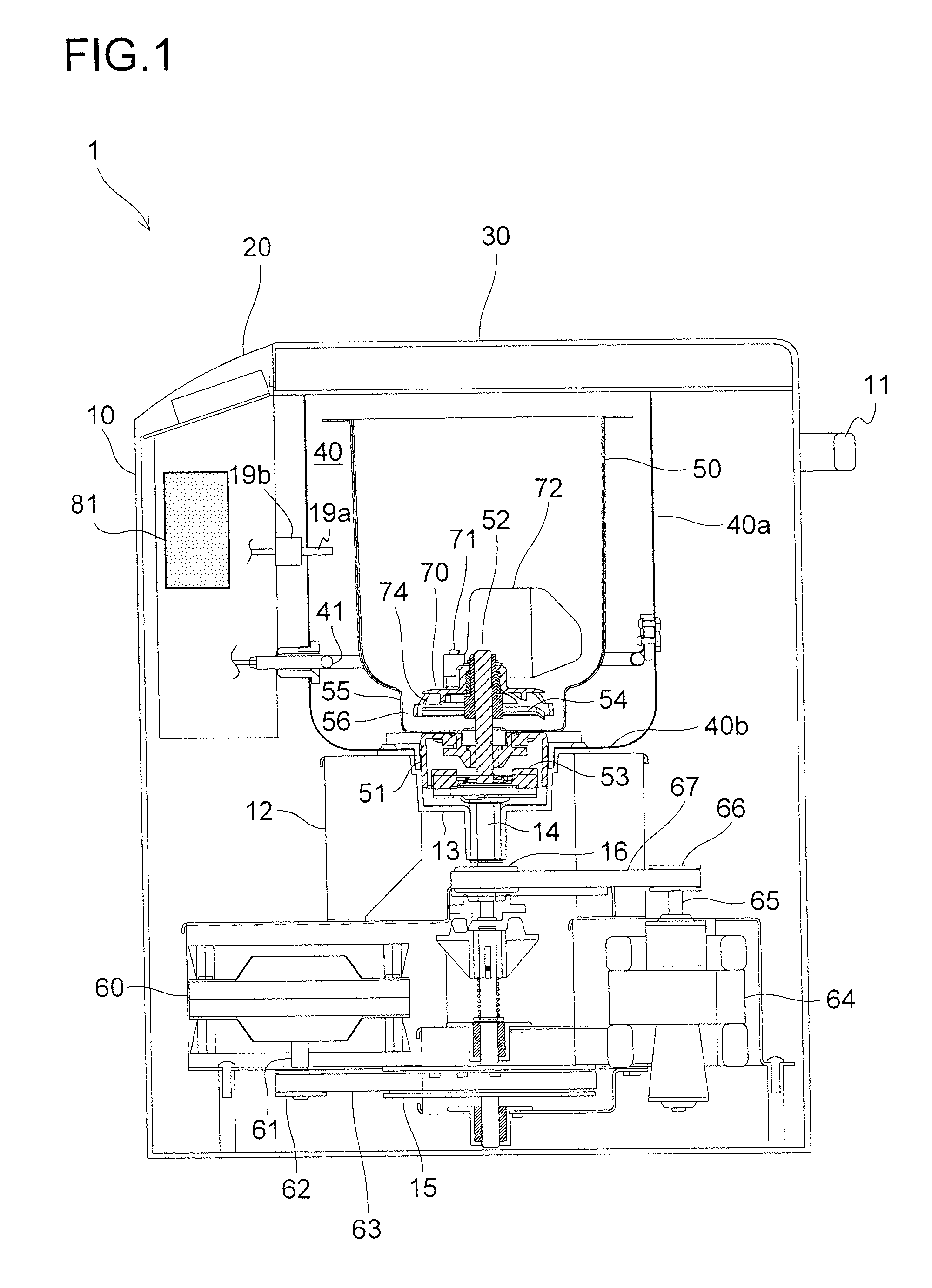

Automatic bread maker

InactiveUS20110174169A1Reduce the possibilityMinimize excessive risingKitchen fruit stoningFruit coringEngineeringMechanical engineering

An automatic bread maker comprises a container in which bread ingredients are fed; a body for accommodating the container; a control unit for carrying out bread-making steps in a state in which the container is accommodated in the body; and a rise detector for detecting that dough has risen to a prescribed height from an upper surface of the container in a state in which the container is accommodated in the body.

Owner:SANYO ELECTRIC CO LTD +1

Multi-station automatic forming system device for multilayer crisp stuffed moon cakes

InactiveCN102885100AIncrease productivityAvoid congestionDough sheet coiling machinesDough-sheeters/rolling-machines/rolling-pinsFood flavorMultiple layer

The invention relates to a multi-station automatic forming system device for multilayer crisp stuffed moon cakes. The multi-station automatic forming system device comprises a dough and crisp packing and discharging machine, a first-time flattening and coiling forming machine, a second-time flattening and coiling forming machine, a crisp layer leavening machine and a follow-up stuffing supplying and sealing machine, wherein a programming controller is connected with the dough and crisp packing and discharging machine, the first-time flattening and coiling forming machine, the second-time flattening and coiling forming machine, the crisp layer leavening machine and the follow-up stuffing supplying and sealing machine respectively to control the five machines. The programming controller is connected with the five machines respectively, and sends out commands to control the five machines to execute processes on line. The five machines are connected by transmission devices on the five machines, and blank or multiple layers of cake blanks are transmitted from an inlet of the multiple players of cake blank to an outlet by the transmission devices after the mechanical action is accomplished. The multi-station automatic forming system device can ensure traditional flavor and taste of the crisp dessert, and realizes the output at the speed of 40-60 desserts per minute. The multi-station automatic forming system device opens up a new technical field of producing the multilayer crisp stuffed moon cakes through mechanical automation.

Owner:上海伟隆机械设备股份有限公司

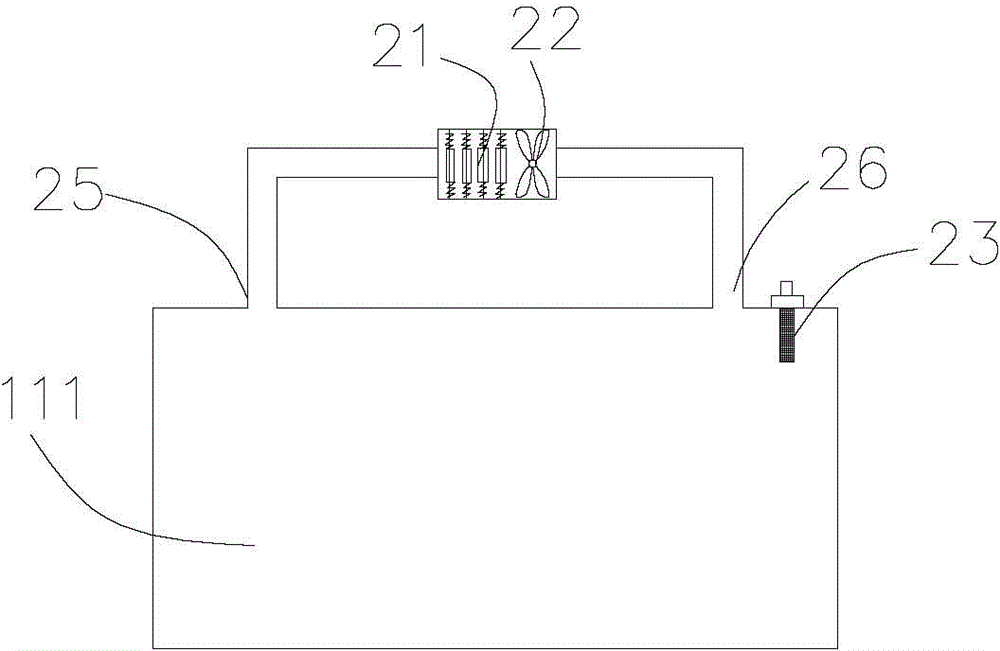

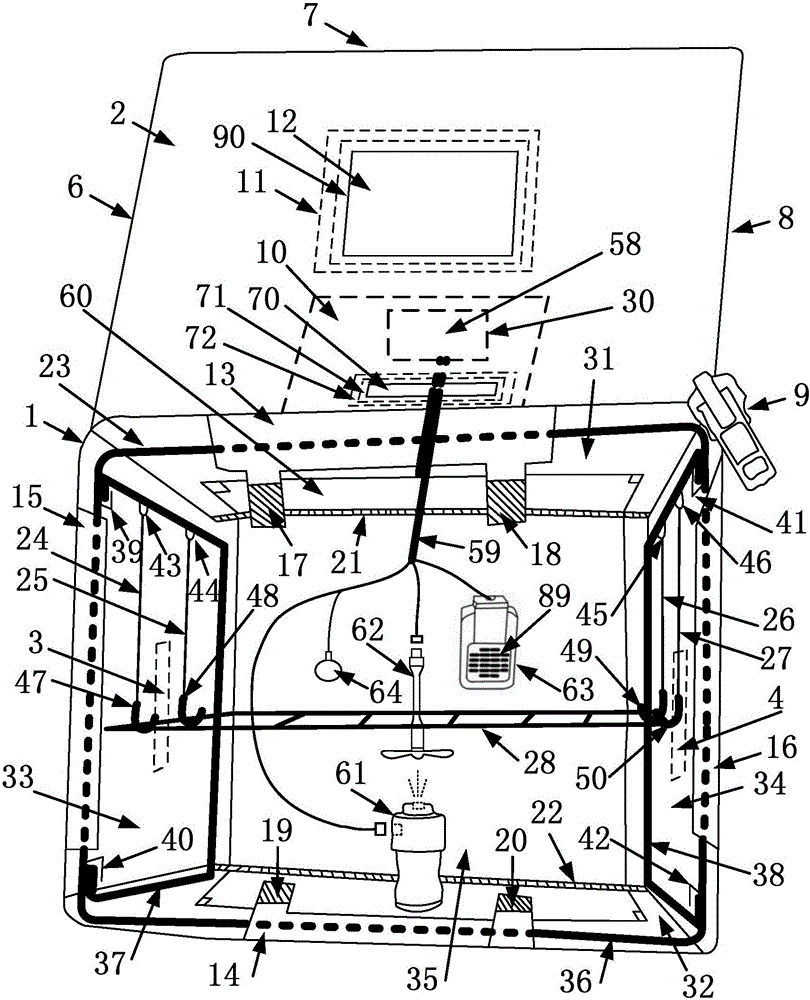

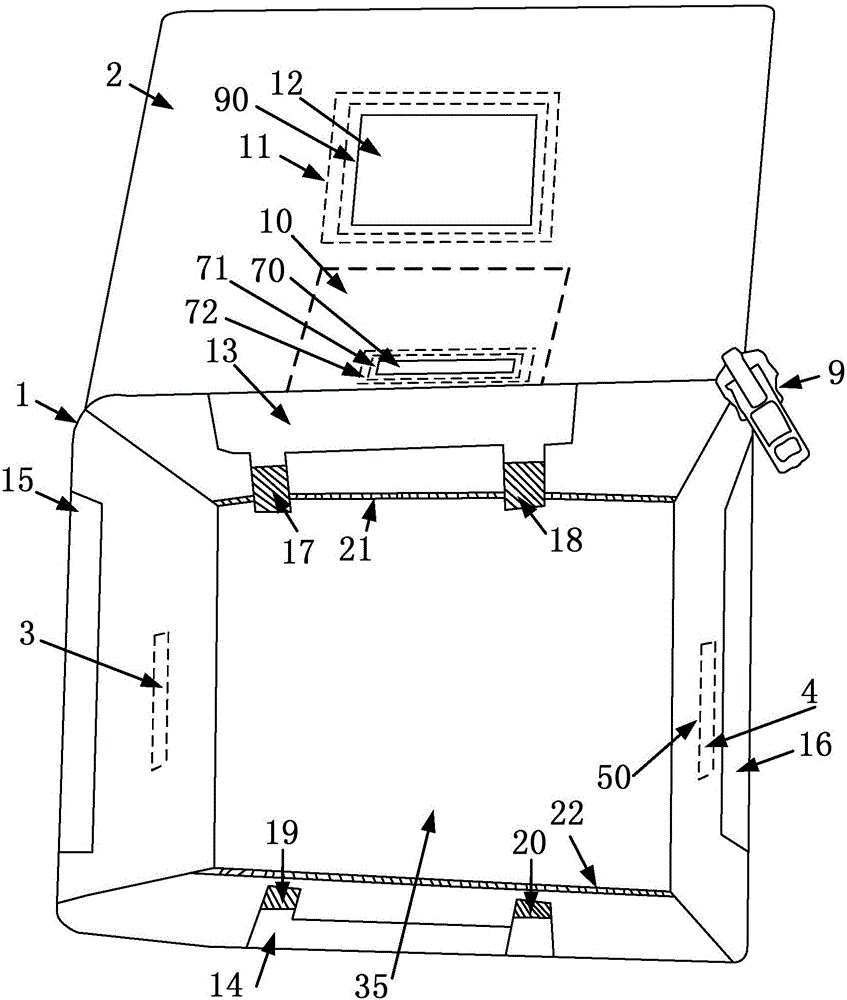

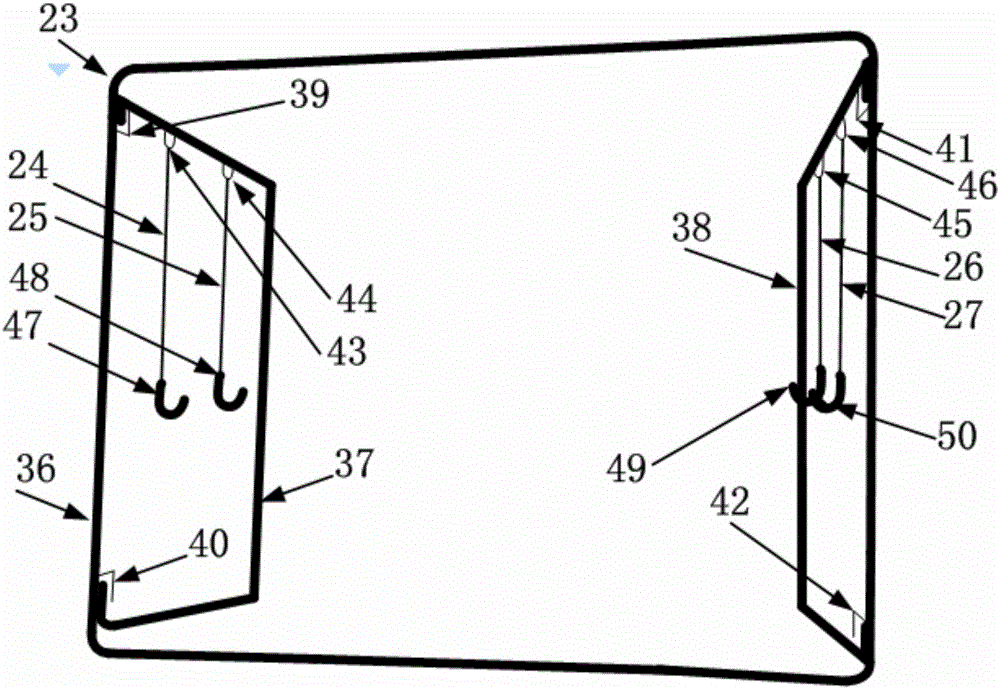

Multifunctional household bread fermentation tank

InactiveCN105660763AReal temperatureReal humidityBread-toastersProversNetwork communicationEngineering

The invention discloses a multifunctional domestic bread fermentation box, which comprises a box body, a box cover, a fixed through pipe, a support frame, a hook, a compartment frame, a fixed ribbon and a control assembly, and the control assembly is controlled by an input power supply, a device, output connection harness, heating device, humidifier, fan, temperature and humidity probe, and lighting lamp. The control assembly is self-contained and can be separated from the box and stored separately. The bread fermentation box provided by the present invention has a built-in Ultrasonic humidifier, fan, large-area heating device and temperature and humidity probe make the temperature and humidity distribution in the box more uniform, and make the temperature and humidity data detected by the controller more real in the box. The bread fermentation box has network communication, Foldable, easy to assemble and disassemble, easy to maintain, evenly heated and humidified, light in weight, easy to observe and economical and practical.

Owner:马发财

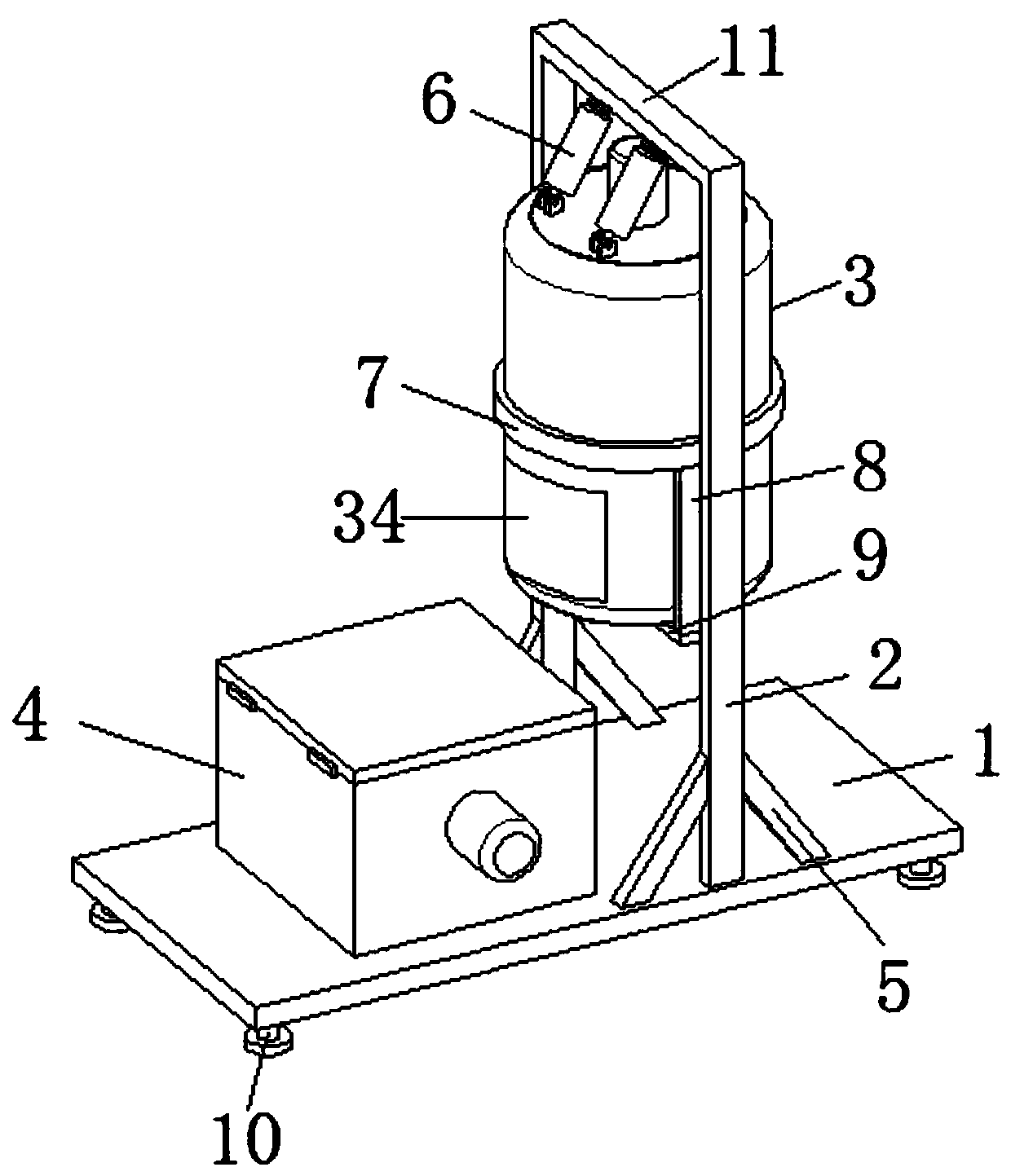

Flour fermentation device for pastry production

InactiveCN108112652AEasy to cleanEfficient and convenient cleaningHollow article cleaningProversAgricultural engineeringFermentation

The invention discloses a flour fermentation device for pastry production. The flour fermentation device comprises a shell assembly, a thermal humidity assembly and a cleaning assembly, wherein the cleaning assembly comprises a first chute, a second chute, cleaning brush fixing plates and a cleaning brush; the first chute is positioned in the rear, which is close to a tray bracket, of a left sidewall inside a fermentation tank; the first chute is fixedly connected with the fermentation tank; and the second chute is positioned in the rear on a left side wall inside the fermentation tank and fixedly connected with the fermentation tank. According to the first chute and the second chute formed in the left side wall and the right side wall inside the fermentation tank, the cleaning brush fixing plates are conveniently connected in a sliding manner, the cleaning brush arranged on the cleaning brush fixing plate is driven, the cleaning brush fixing plates and the first chute and the secondchute are detachable, the cleaning brush fixing plates are conveniently fixed on chutes on the right side wall, the inner upper surface and the lower surface inside the fermentation tank, and the interior of the fermentation tank is conveniently and comprehensively cleaned, so that cleaning is high-efficiency and convenient.

Owner:海宁市麦米米食品有限公司

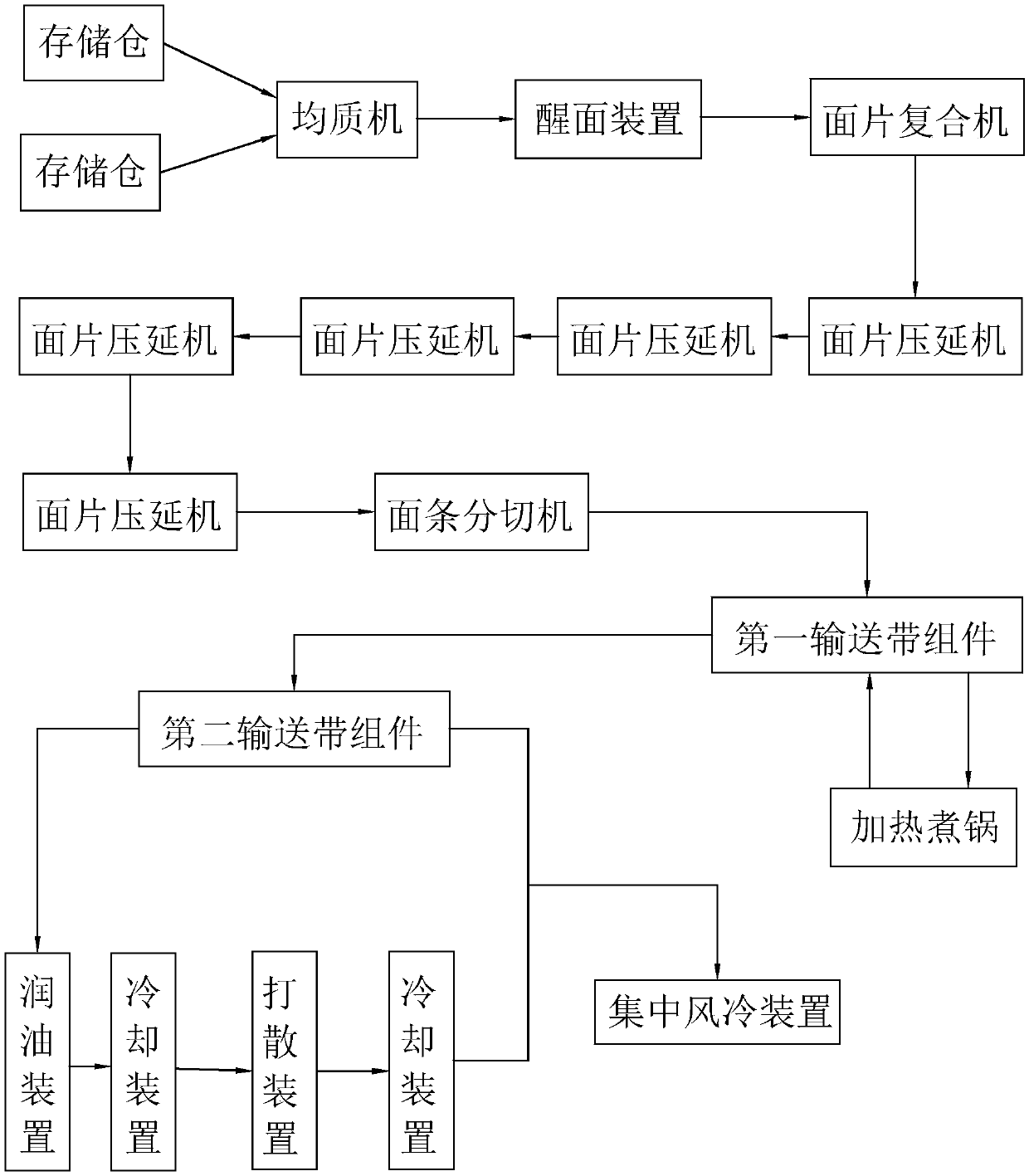

Automatic noodle production system

ActiveCN109601854AImprove process automationProduct quality is easy to controlDough shaping and cutting apparatusNoodles cutting outEngineeringAutomation

The present invention discloses an automatic noodle production system. The automatic noodle production system comprises a flour pretreatment part, a noodle cooking part and a cooling and shaping part,the flour pretreatment part comprises a flour processing station, a flour rolling and pressing station and a dividing and cutting station, the flour processing station comprises a storage bin, a homogenizer communicating with the storage bin, and a dough putting-still device located under the homogenizer, the flour rolling station comprises a dough slice compounding machine communicating with theflour putting-still device and at least a dough slice rolling machine; the noodle cooking part comprises a first conveying assembly, a heating boiling pot arranged on the first conveying assembly; and the cooling and shaping part comprises a second conveying assembly, a plurality of cooling devices, a dispersing device, an oil lubricating device and a concentrated air cooling device. From flour to finished products of noodles, a certain degree of cooking is maintained, the automatic noodle production system is conducive to timely cooking and taking out from pots after transportation and arrival, each step is naturally and smoothly conducted, product quality is high in identity, labor cost and interference degree are reduced, and at the same time, the automatic noodle production system ishigh in automation and conducive to mass production.

Owner:武汉金香园食品有限公司

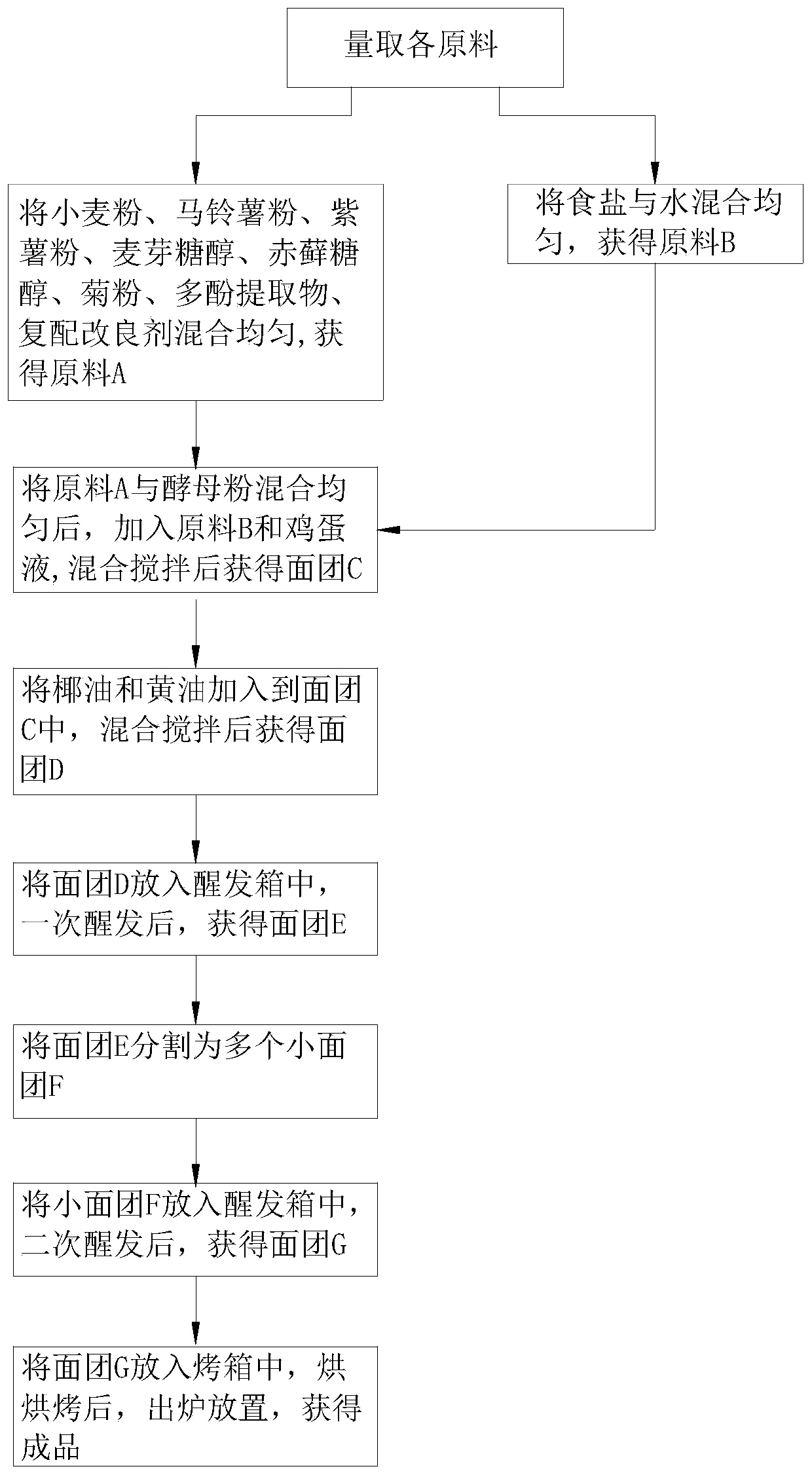

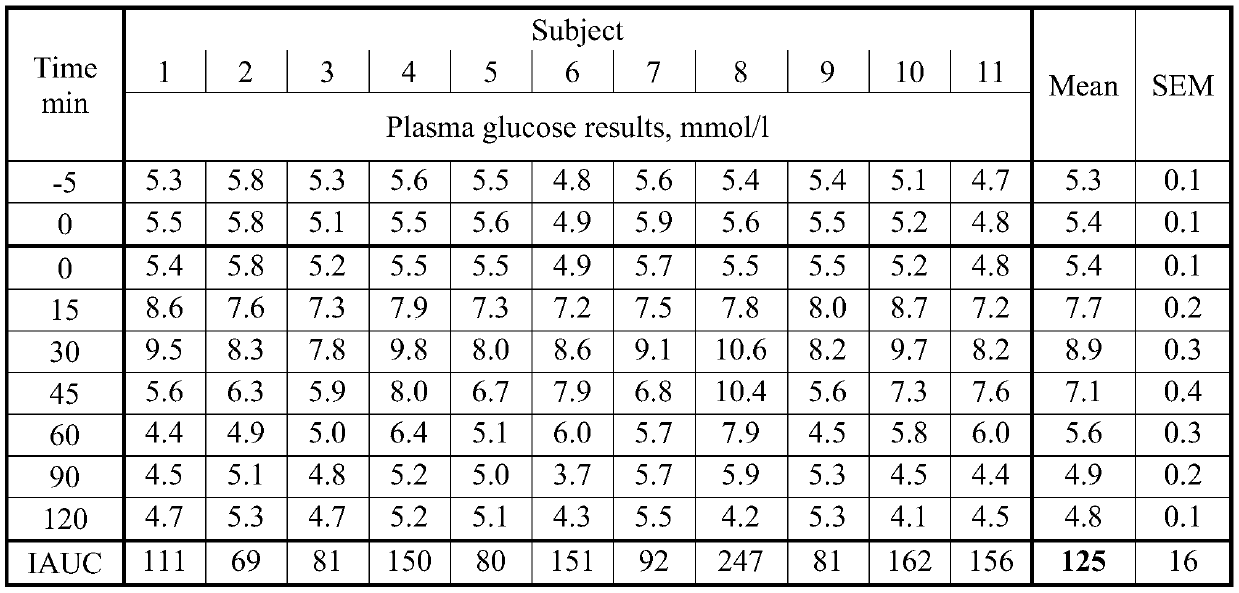

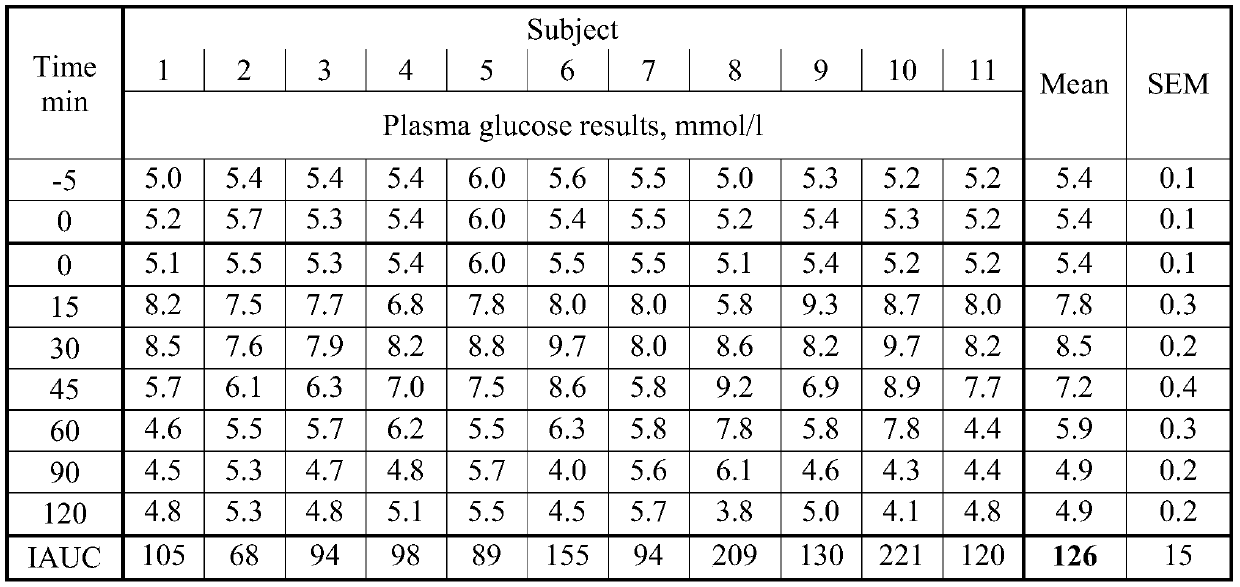

Composition of low GI potato bread and preparation method of composition

InactiveCN110839674AReduce intakeIncrease peristalsisDough irradiationDough heat treatmentBiotechnologyNutritive values

The invention is suitable for the technical field of nutritious food, and provides a composition of low GI potato bread. The composition comprises the following components: wheat flour, potato flour,purple potato flour, maltitol, erythritol, inulin, a polyphenol extract, yeast powder, salt, butter, coconut oil, an egg liquid, a compound modifier and water. Aiming at the defect of high GI value ofcommon wheat flour bread, the low GI potato bread is researched and developed through adjustment of the composition; by adopting potato powder, purple potato powder, sugar alcohol and particularly adding inulin dietary fiber, the low GI potato bread not only has a good supplement effect in the aspects of minerals, vitamins, essential amino acids, dietary fiber and the like, but also a low GI bread product is obtained through reasonable compatibility of raw material components; and the bread does not cause rapid fluctuation of blood sugar after being ate, so that the bread not only can meet the nutritional requirements of common diets of eaters, but also has obvious improvement in the aspects of bread calories, flavor and nutritional value.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD

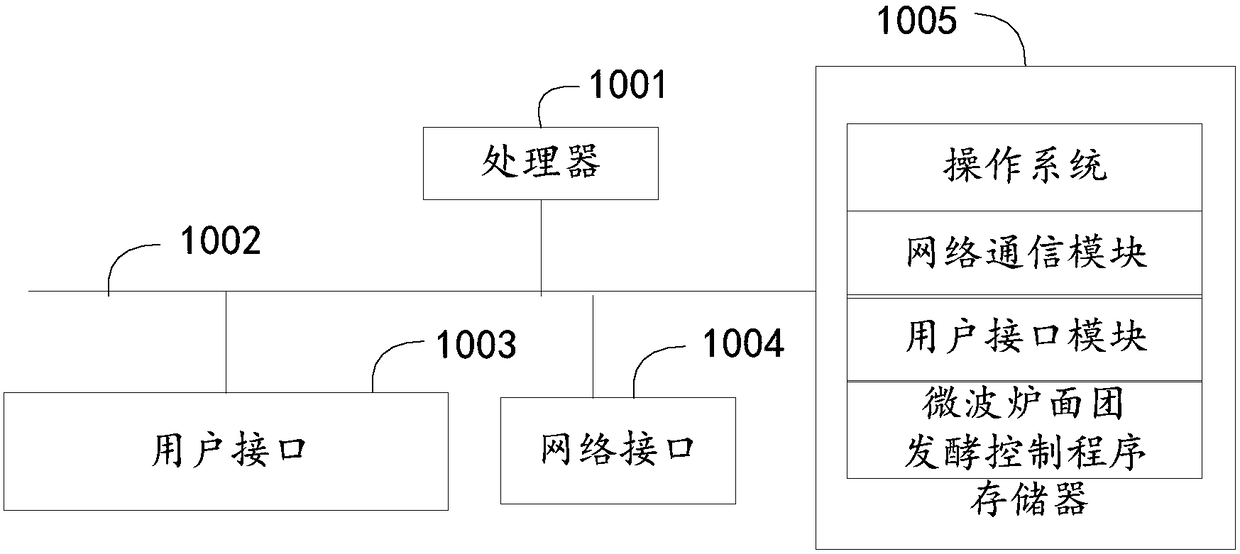

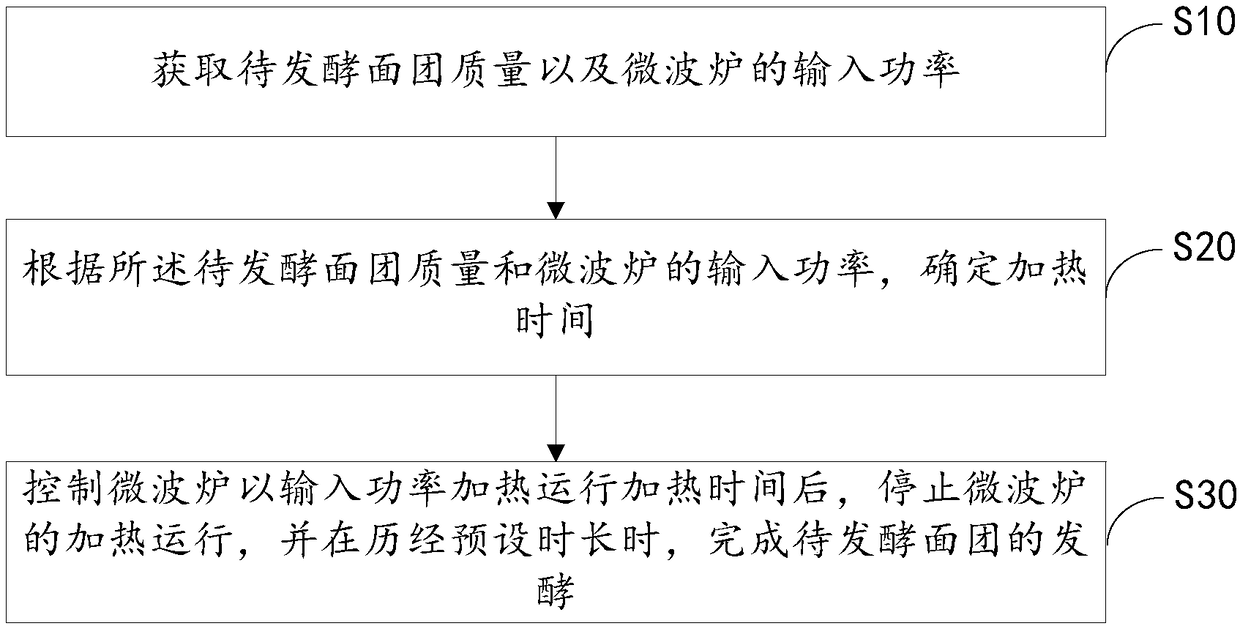

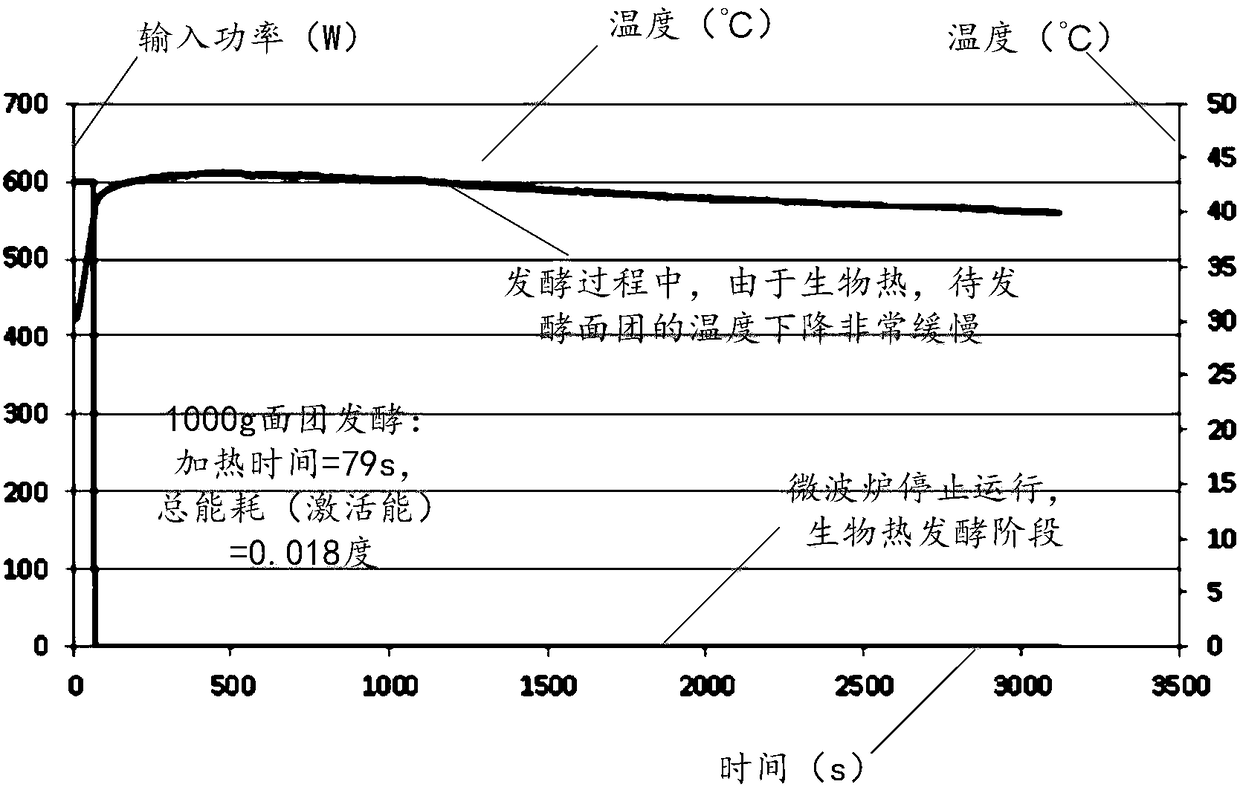

Microwave oven dough fermentation control method, microwave oven, control terminal and storage medium

The invention discloses a microwave oven dough fermentation control method, a microwave oven, a control terminal and a storage medium. The method comprises the following steps: obtaining the mass of dough to be fermented and the input power of the microwave oven; determining a heating time according to the mass of the dough to be fermented and the input power of the microwave oven; and controllingthe microwave oven to perform heating operation at the input power for the heating time, stopping the heating operation of the microwave oven, and fermenting the dough to be fermented for preset duration. The heating time of the microwave oven in the scheme is related to the mass of the dough to be fermented and the input power, and is targeted; the microwave oven is controlled to operate for theheating time, so that a large amount of thalli in the dough to be fermented can be activated to grow, and the heating is stopped at the moment to prevent high-temperature sterilization and to delay thallus senescence; and then the fermentation is carried out within the preset duration with biological heat generated by a large number of thalli and the residual heat of the microwave oven, so that the dry dough surface caused by the long-time heating of the dough to be fermented is avoided, and the power consumption is reduced at the same time.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

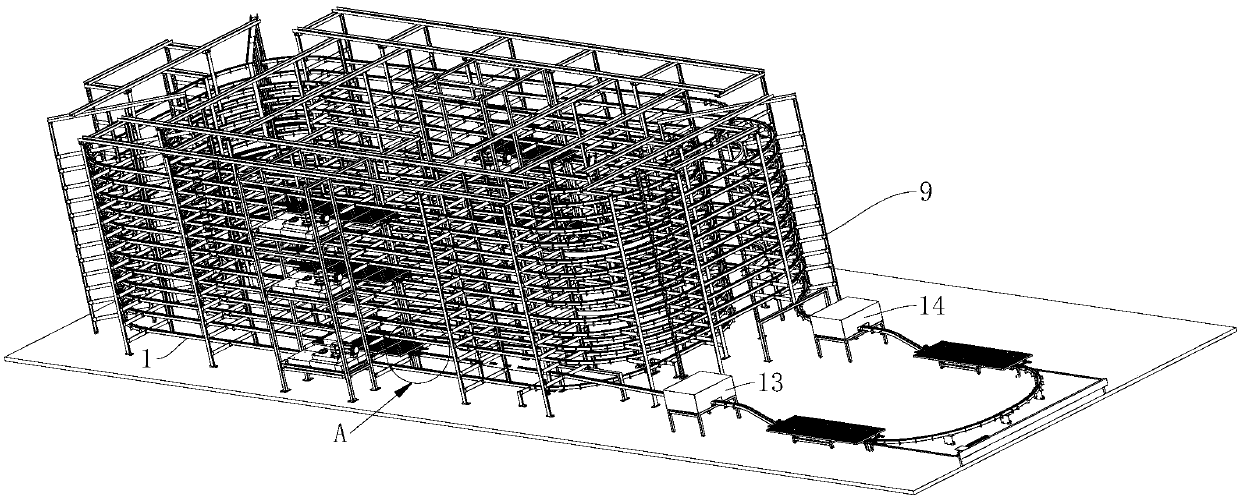

Food transport device

The invention discloses a food transport device. The food transport device is used for being mounted in a fermentation chamber, that is, during operation, the food transport device can be mounted in the fermentation chamber with a large space, and the temperature in the fermentation chamber is suitable for fermentation of package blanks. The food transport device comprises a rack, a guide rail anda transport carrier, wherein the guide rail is mounted on the rack and winds in a spiral structure in the vertical direction, that is, the guide rail is laminated and winds in a spiral structure; thetransport carrier is arranged in the extending direction of the guide rail and used for transporting the package blanks to move in the extending direction of the guide rail. As the guide rail winds in a spiral structure in the vertical direction, the length of the guide rail is extended, so that the food transport device can accommodate more package blanks to ferment in the fermentation chamber,and the occupied area of the food transport device is saved. By means of the food transport device, the package blanks can be conveniently transported to the food transport device, the fermented package blanks can be conveniently taken out of the food transport device, and thus, the workload is reduced.

Owner:GUANGZHOU FUYA MACHINERY

Flour product microbial fermentation device and using method thereof

ActiveCN110250236AUniform deliveryEvenly heatedMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsHeat conductingEngineering

The invention discloses a flour product microbial fermentation device and a using method thereof. The device includes a support bottom plate, a first fermentation mechanism and a second fermentation mechanism, the second fermentation mechanism is fixedly mounted on an upper surface of the support bottom plate, and two longitudinally distributed support rods are symmetrically disposed at the upper surface of the support bottom plate. The device adopts the first fermentation mechanism to stir the raw materials of the flour product, provides a heating rod in the stirring rod, conducts heat through the heat conducting oil to uniformly heat the internal raw materials, and ensures the fermentation effect. A pulley and a cam in the invention are used together, and the cam makes a pressing block to perform the reciprocating rise and the sudden falling during the rotation process for bumping the dough in a material groove, the air in the dough is extruded to ensure the quality of the flour product. The flour product microbial fermentation device does not adopt manpower during a whole process, the device adopts an integrated design, has high automation degree and high production efficiency, and can effectively ensure the fermentation effect of the noodle products.

Owner:安徽皓浩食品科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com