Cereal coarse grain instant noodle processing production line

A technology of instant noodles and production line, which is applied in the fields of dough processing, food science, dough extruder, etc. It can solve the problems of noodle performance and product quality influence, lack of continuous conveying device, and inability to realize continuous production, etc., to meet the temperature and Maturity requirements, good safety and sanitation, and the effect of ensuring continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

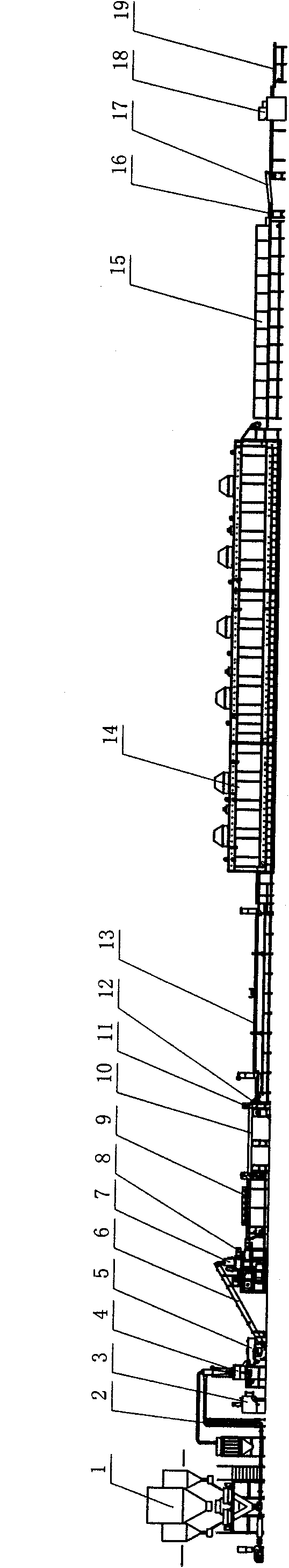

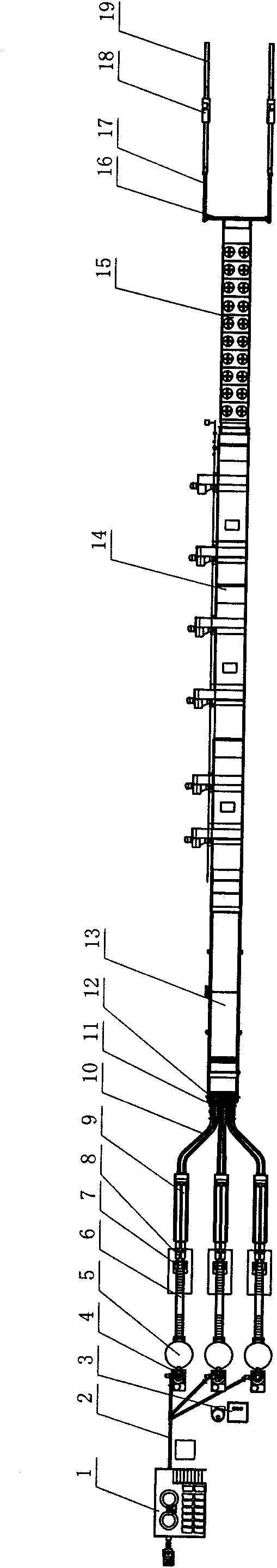

[0043] A cereal instant noodle processing production line, comprising a mixing drum 3, a dough mixing machine 4, an elevator 6, a noodle feeding machine 7, an extrusion molding machine 8, a quantitative cutting machine 9, a side-by-side machine 10, and a pneumatic stop Device 11, sorting device 12, noodle steamer 13, dryer 14, cooler 15, inspection conveyor 17, packaging machine 18 and finished product conveyor 19.

[0044] The innovation of the present invention is:

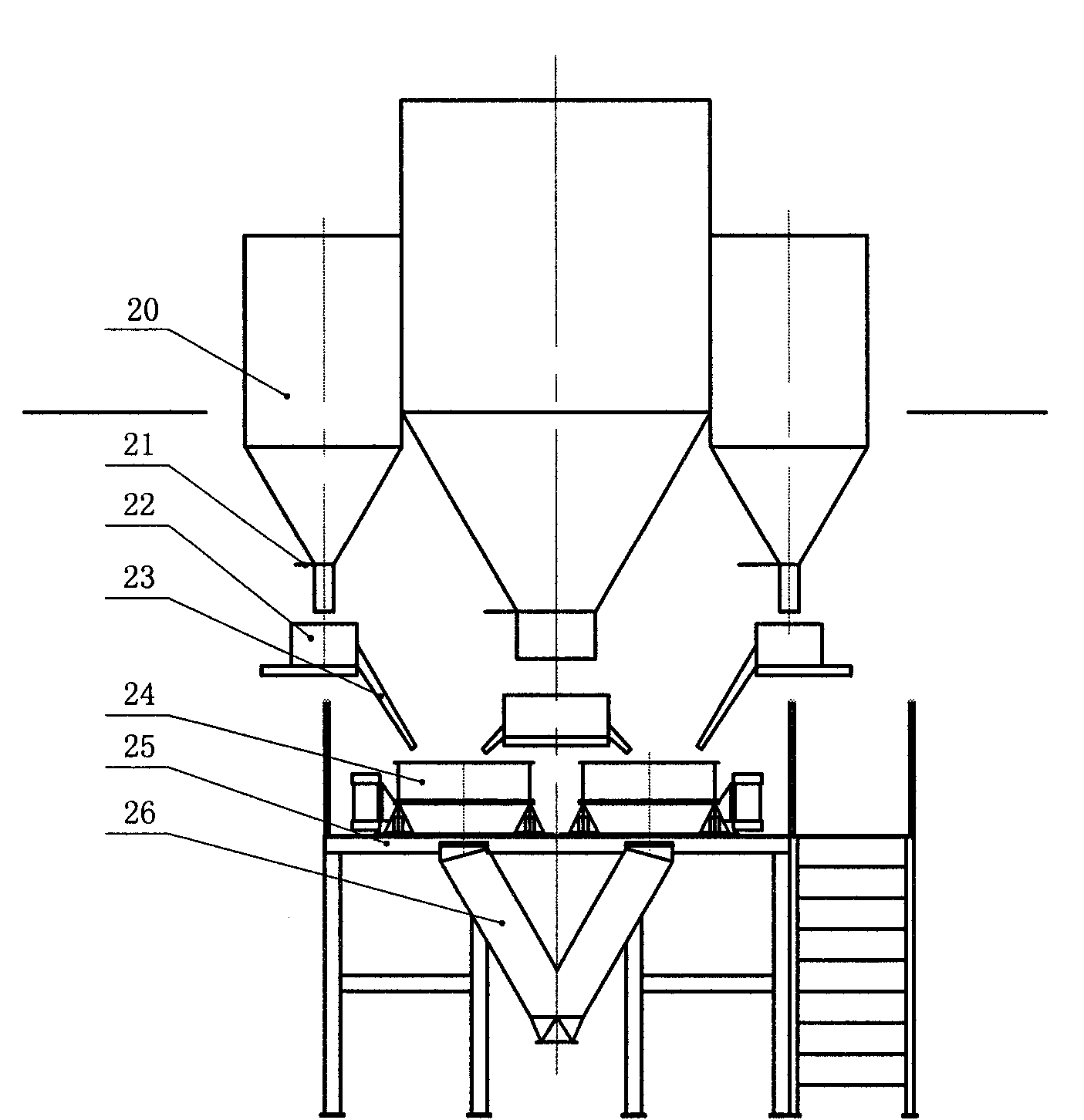

[0045] (1). An automatic weighing and blanking device 1 and a positive pressure conveying device 2 are installed at the front of the dough mixer. The discharge end of the automatic weighing and blanking device is located above the feed end of the positive pressure conveying device, and the positive pressure conveying The discharge end of the device is located above the feed end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com