Patents

Literature

137results about How to "Achieve constant temperature control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

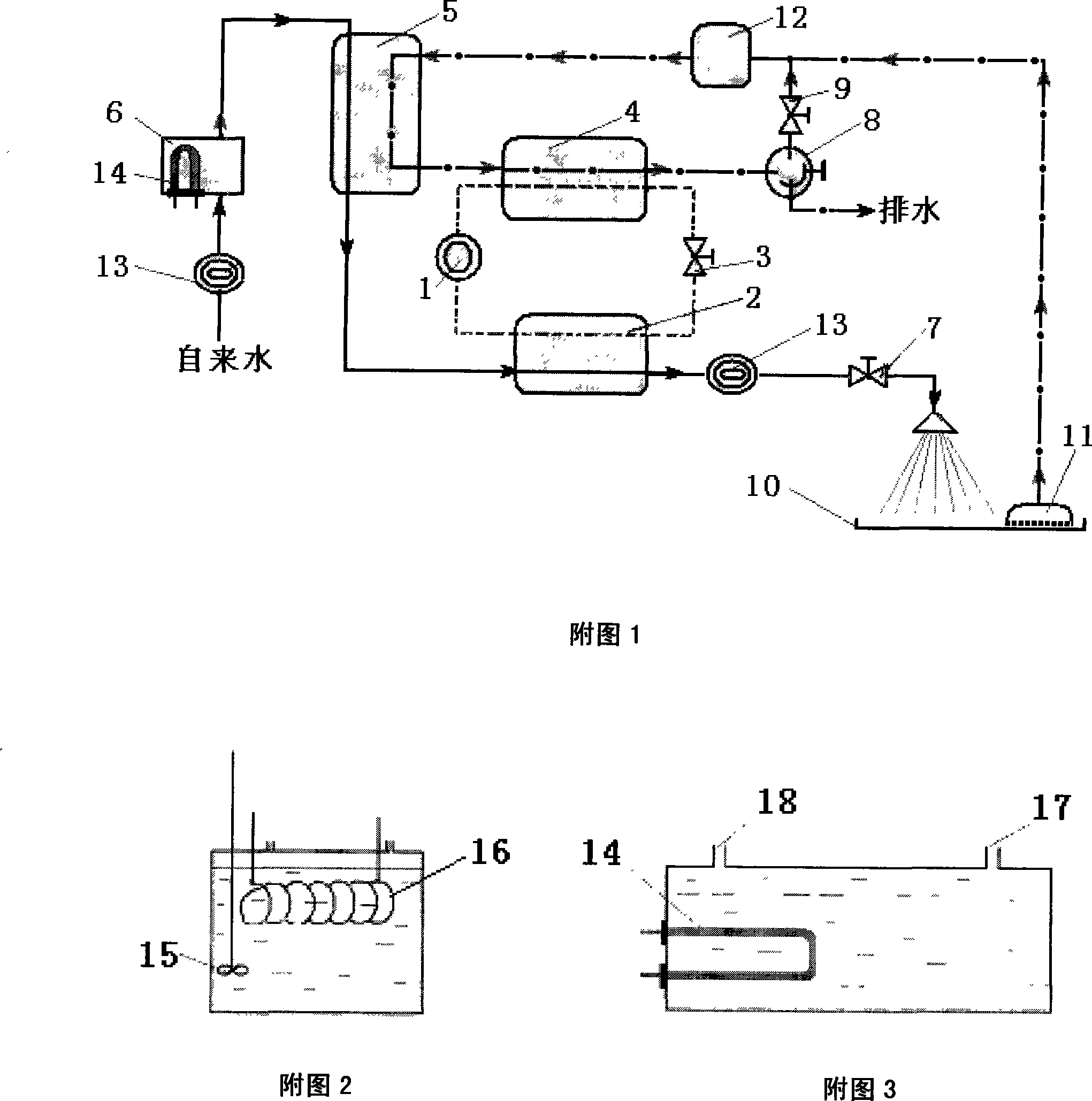

Instant heating type water heater constant temperature control system and method

ActiveCN103727677ARealize constant water temperature controlAchieve constant temperature controlWater heatersHeating systemEngineering

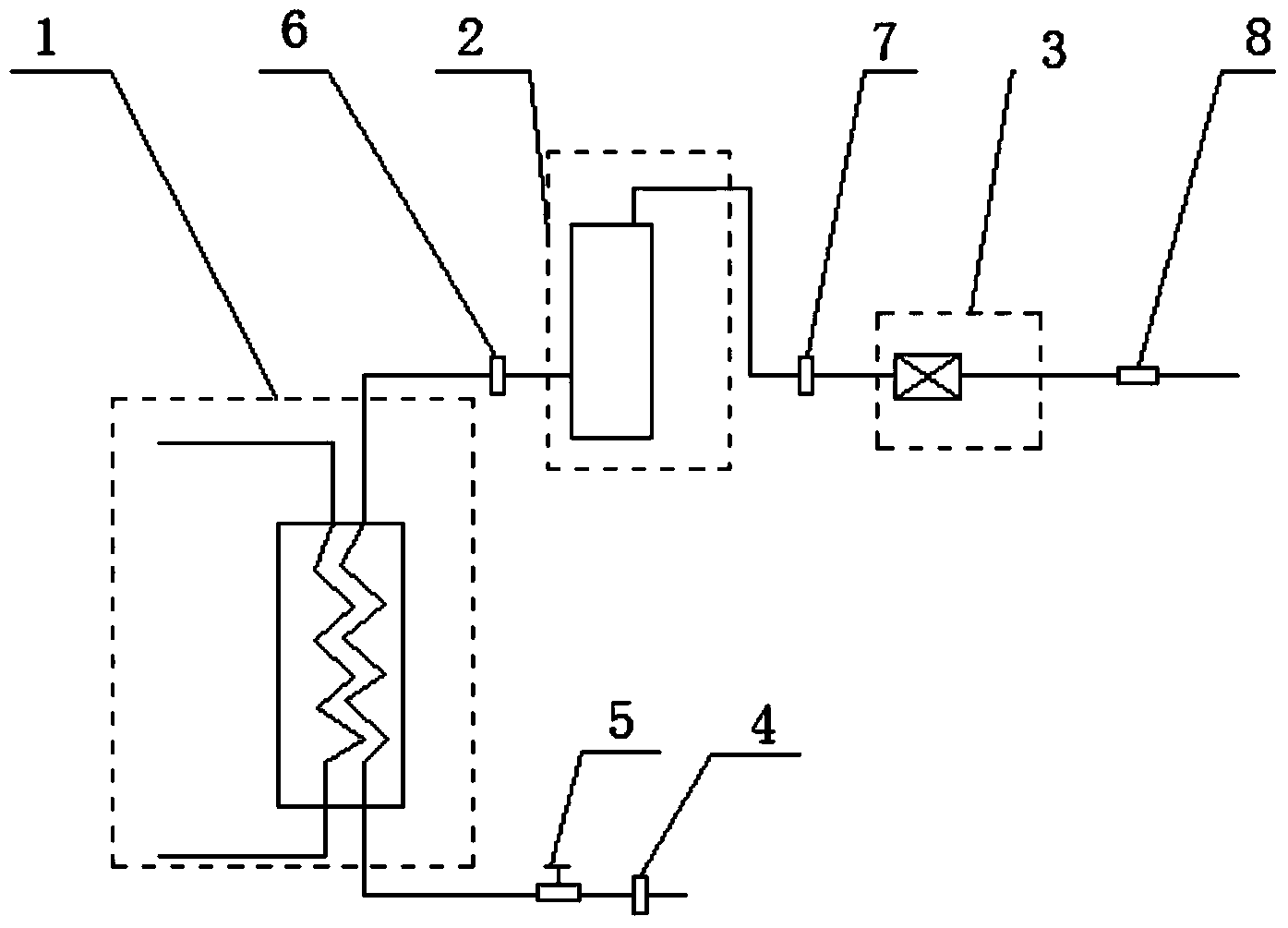

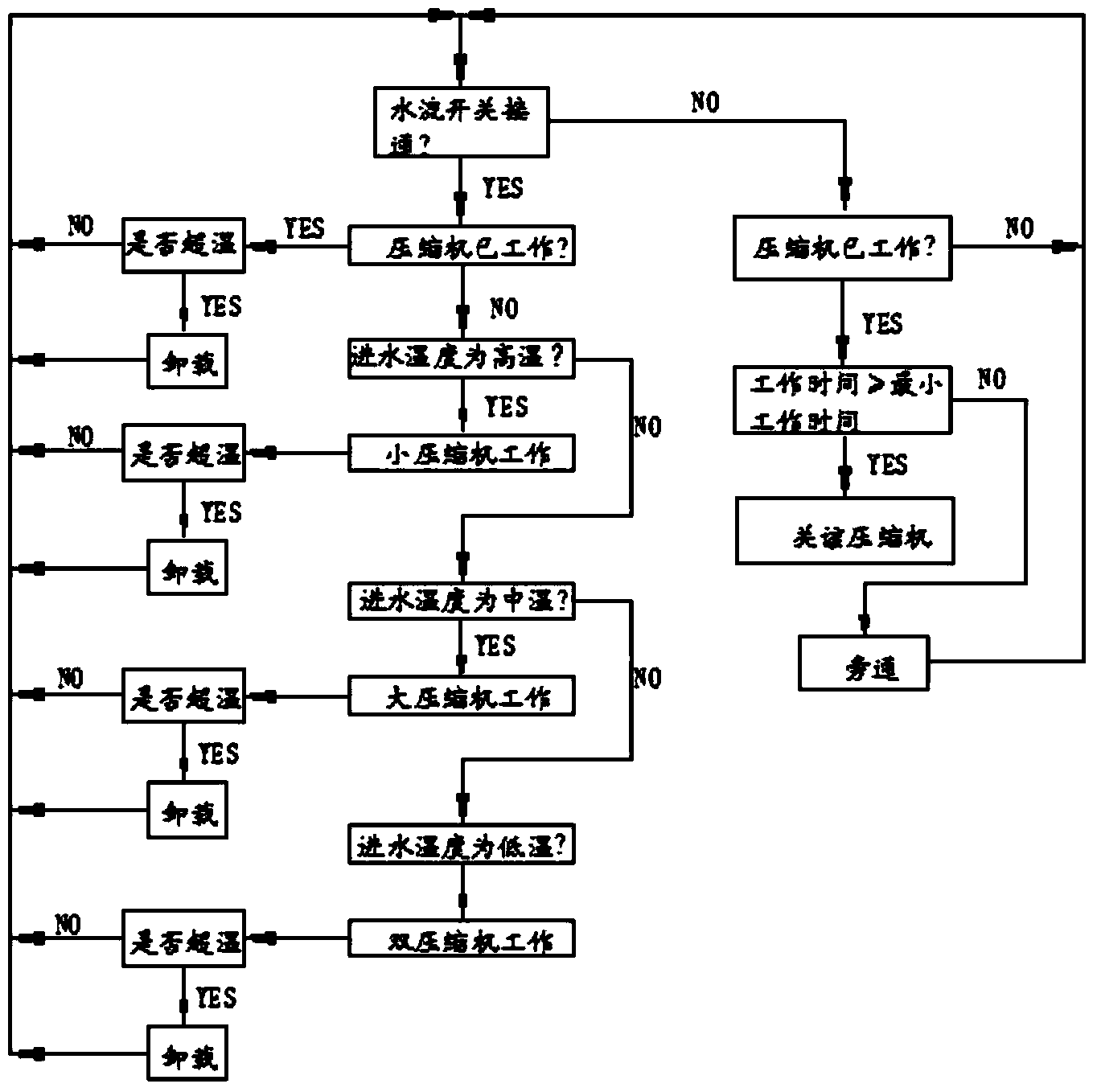

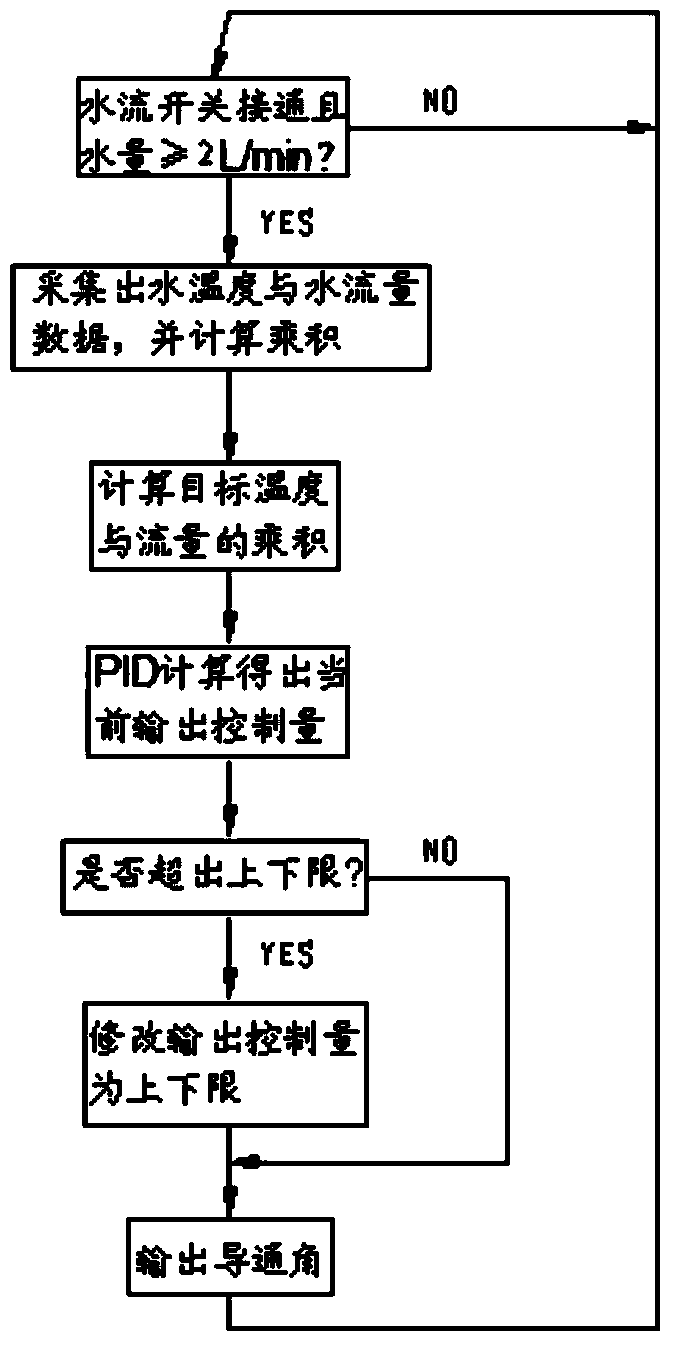

The invention relates to an instant heating type water heater constant temperature control system and method. The control system comprises a heat pump heating system, an instant heating system and a water amount adjusting system which are sequentially arranged in the direction from a water inlet to a water outlet of a water heater. According to the control method, the outlet water temperature, the total water outlet temperature and the water amount of a heat pump and the output power of the instant heating system are detected, and the water volume, the working state of the heat pump heating system and the output power of the instant heating system are adjusted, so that the total outlet water temperature is maintained at preset temperature. Compared with the prior art, the control system and method have the advantages of saving energy due to the fact that the heat pump and the instant heating system are used for heating in a hybrid mode, and being capable of realizing outlet water constant temperature control in the range of wider flow and a preset temperature range through a unique water volume adjusting system.

Owner:FUZHOU AQUAPOWER ELECTRIC WATER HEATER

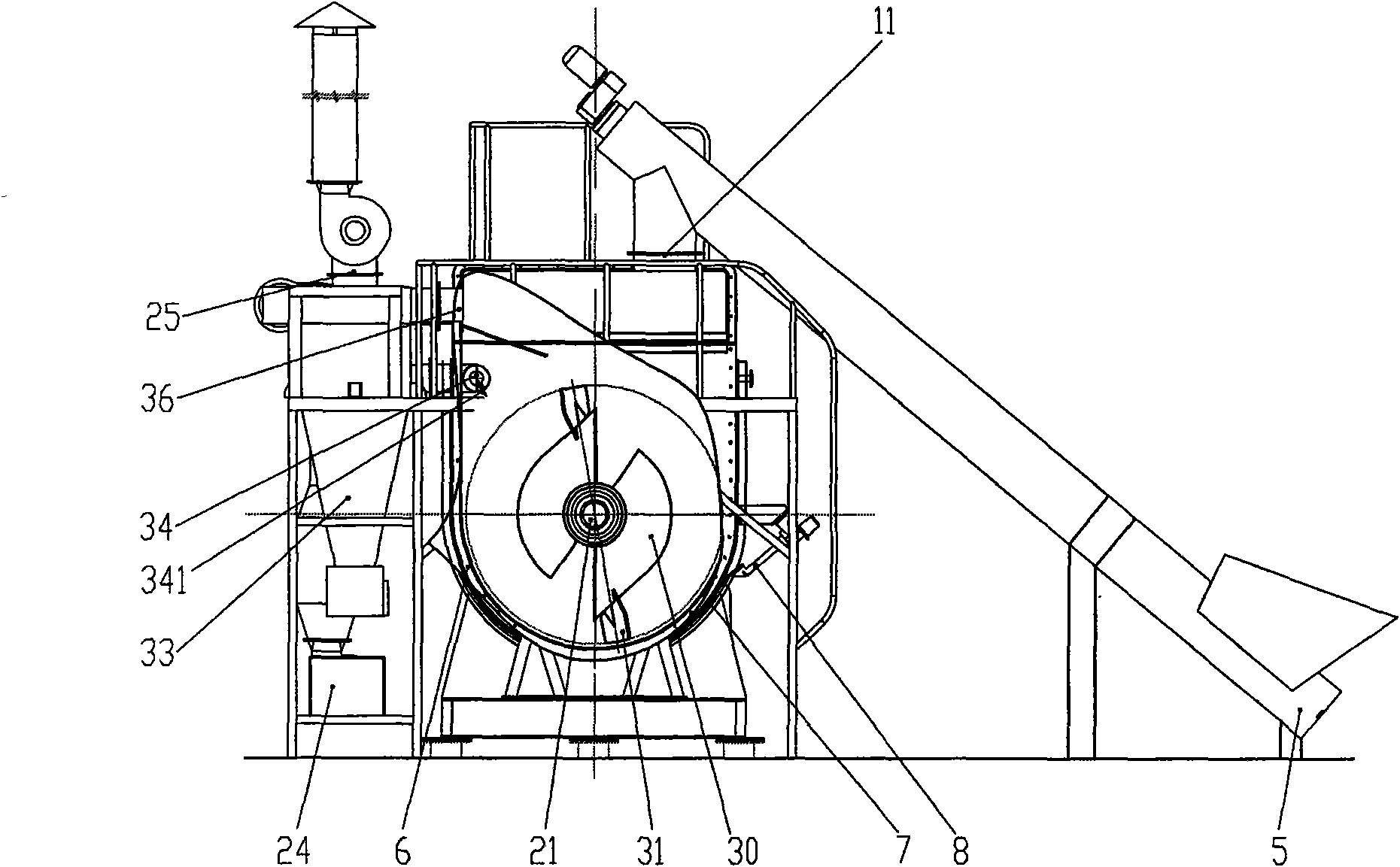

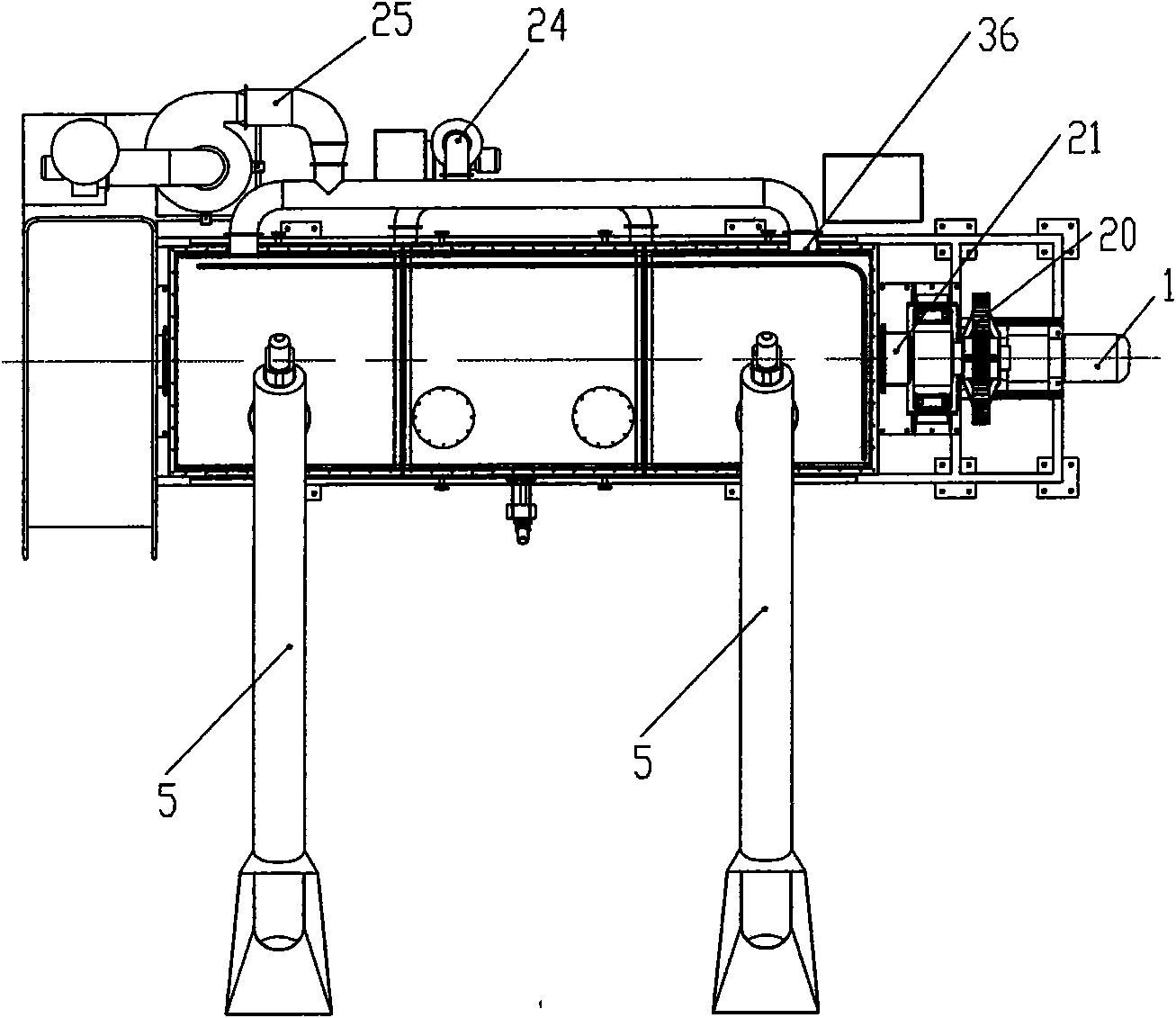

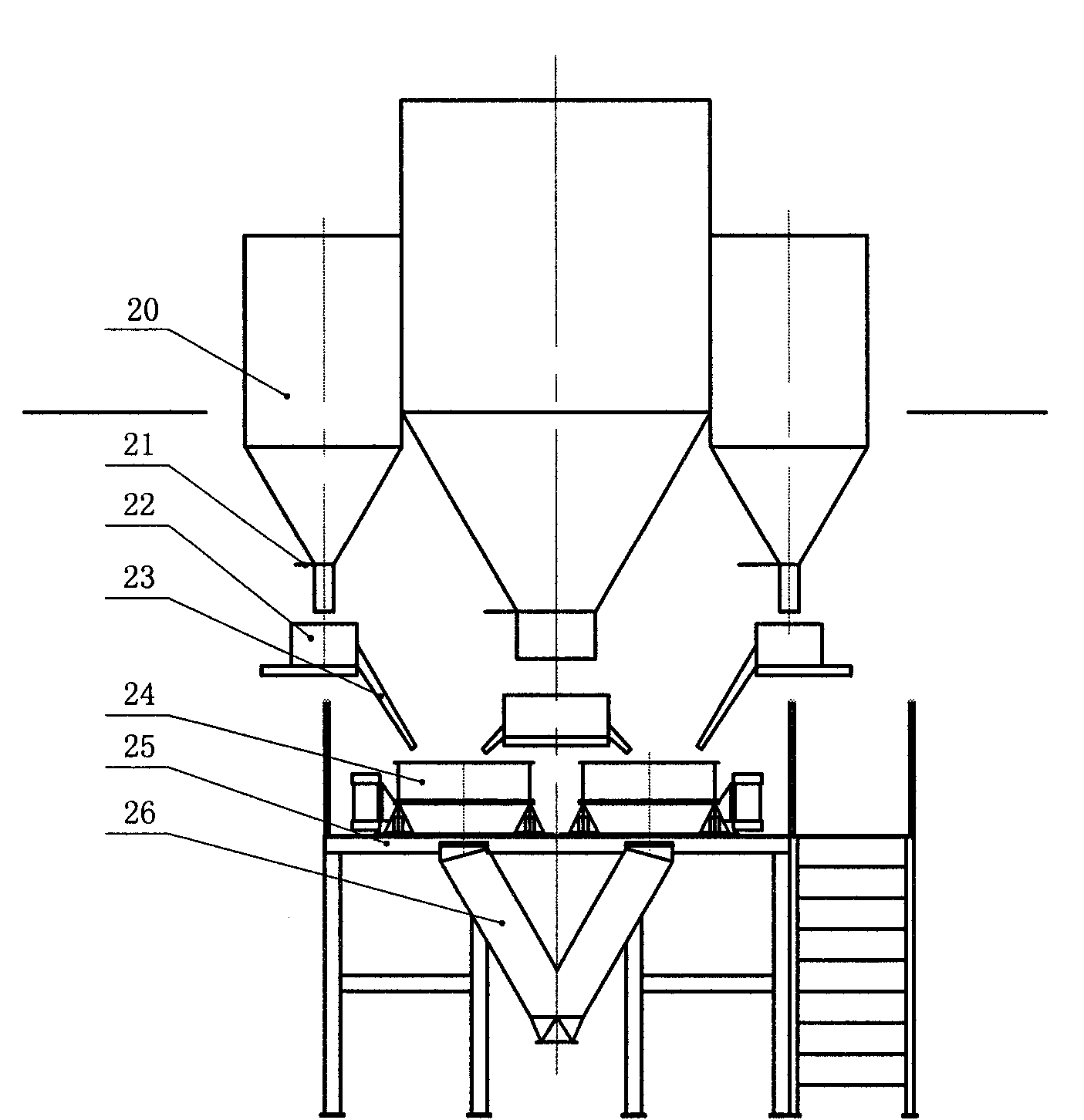

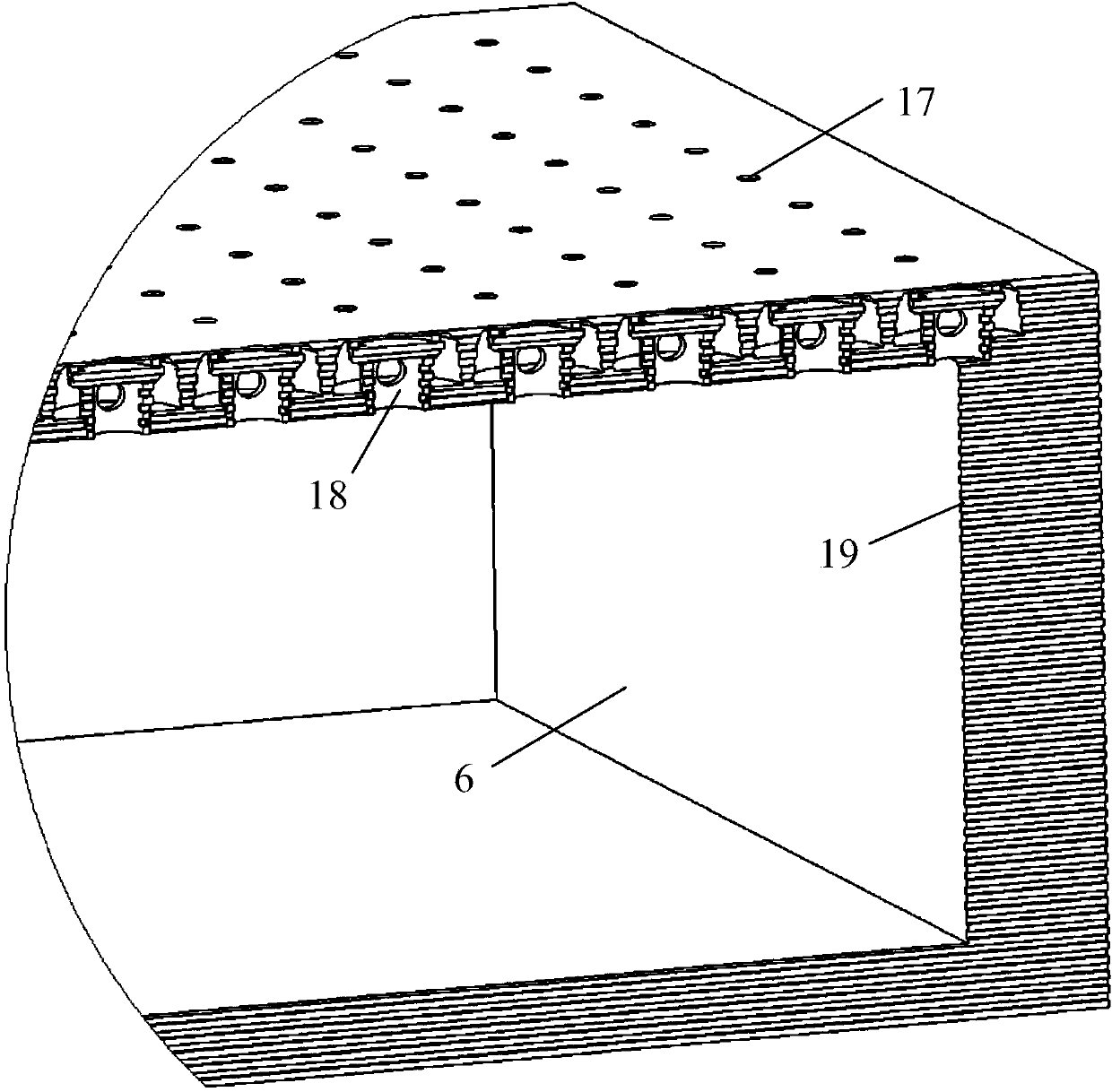

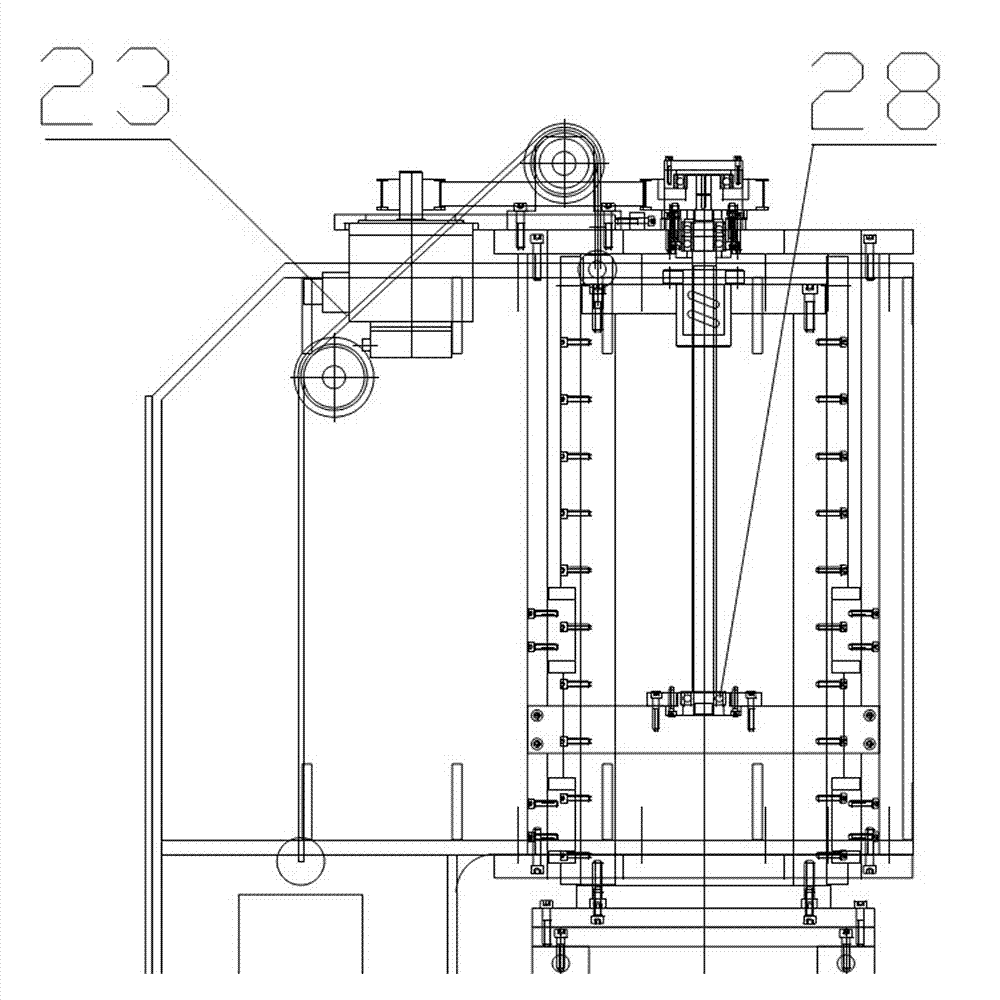

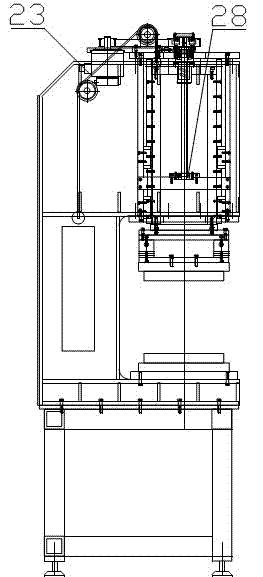

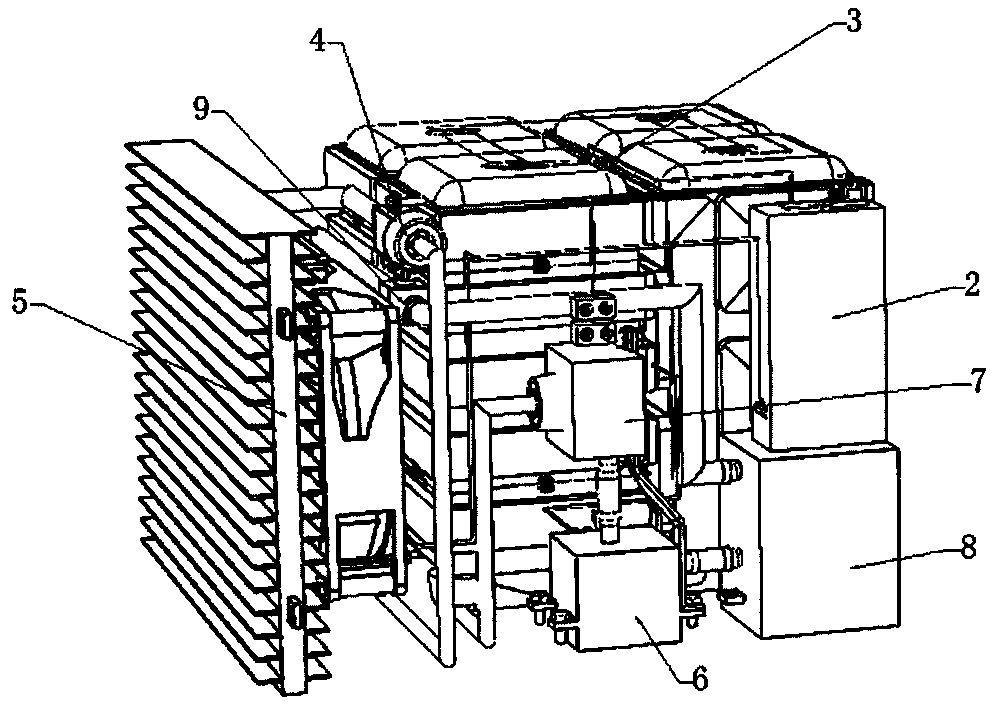

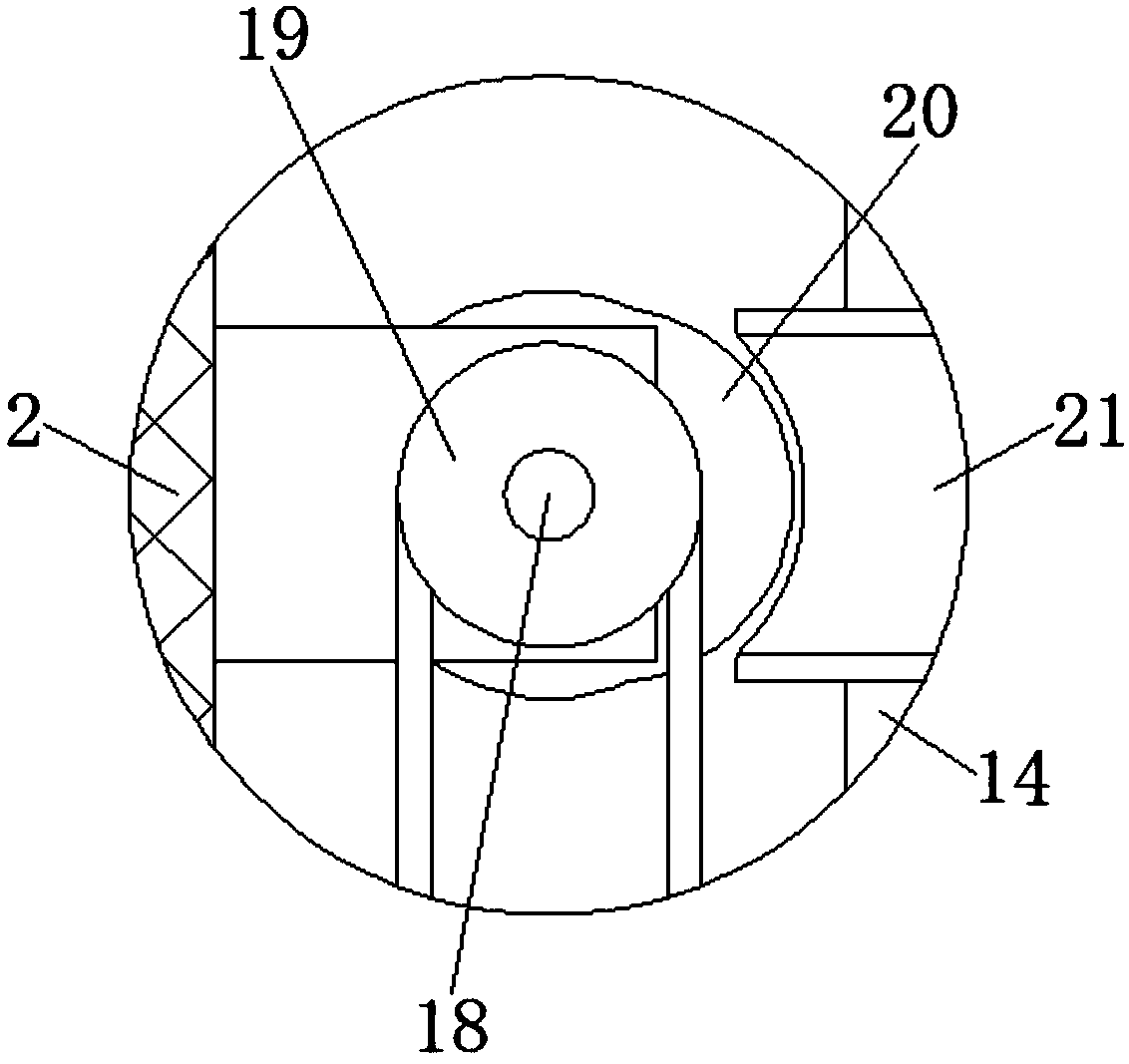

Organic waste biochemical processor

ActiveCN101632997ADecompose fullyIncrease the heat exchange areaBio-organic fraction processingSolid waste disposalOxygenPollution

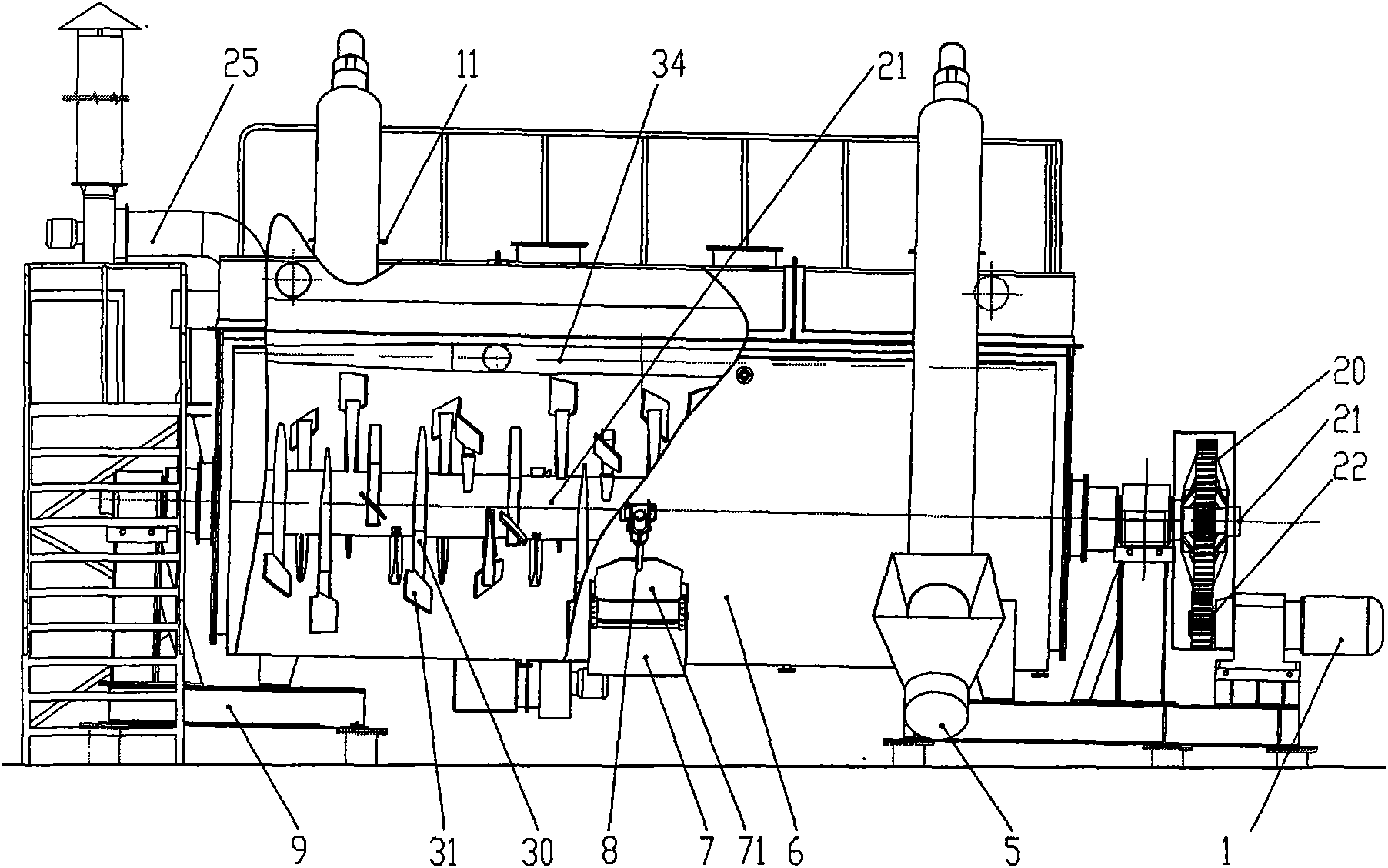

The invention relates to an organic waste biochemical processor comprising a fermenting and drying chamber with a U-shaped cross section, wherein the upper end of the fermenting and drying chamber is provided with a feeding hole, and the lower end of the fermenting and drying chamber is provided with a discharging hole which is sealed by a discharging hole baffle plate; a hollow mixing shaft passes through both sides of the fermenting and drying chamber, the left end and the right end of the mixing shaft are respectively connected with a steam input pipe and a condensed water outlet pipe, the right end of the mixing shaft is connected with a reducing motor by a driving device, a hollow mixing blade is arranged on the mixing shaft, a cavity of the mixing blade is communicated with a cavity of the mixing shaft, the inner upper part of the fermenting and drying chamber is provided with an air distributing pipe, an air inlet of the air distributing pipe is communicated to an air outlet of a heat exchanger outside the fermenting and drying chamber, an air outlet of the air distributing pipe is positioned into the fermenting and drying chamber, and the upper part of the fermenting and drying chamber is provided with a humidity discharging hole which is communicated to an inlet of a dust collector of a waste gas processing device by a humidity discharging duct. The organic waste biochemical processor has low pollution and can sufficiently ferment and dry the organic waste by oxygen.

Owner:BEIJING GOLDENWAY BIO TECH

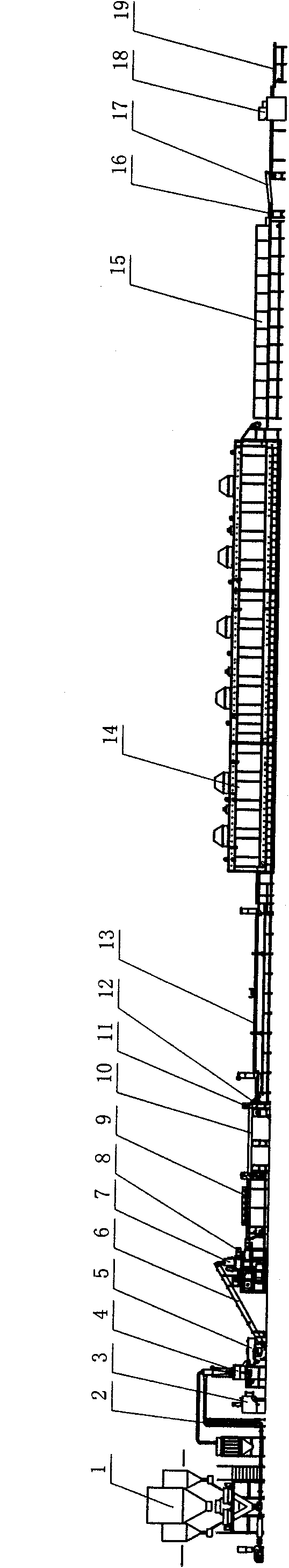

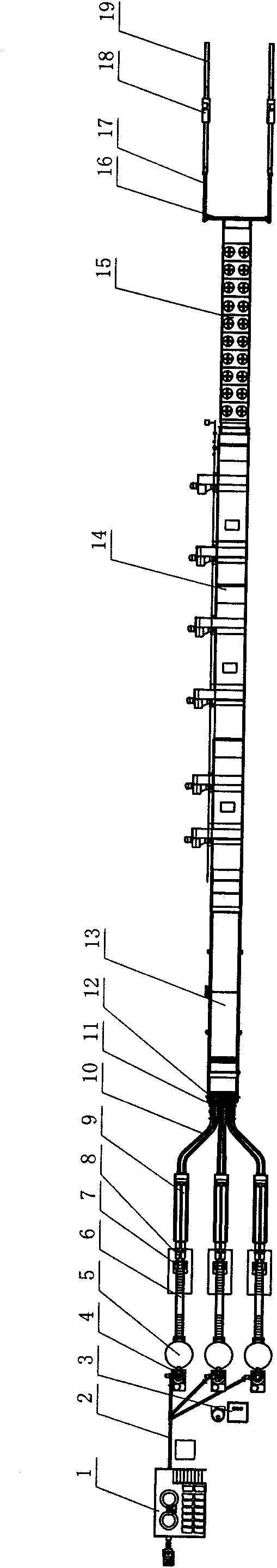

Cereal coarse grain instant noodle processing production line

InactiveCN102058056AGuaranteed uptimeReduce labor intensityDough shaping and cutting apparatusDough extruding machinesAutomatic controlPositive pressure

The invention relates to a cereal coarse grain instant noodle processing production line, comprising a mixing drum, a flour mixing machine, a hoisting machine, a flour feeding machine, an extrusion moulding machine, a quantitative cutting machine, a row combining machine, a pneumatic stopping device, a row separating device, a flour steaming machine, a drying machine, a cooling machine, an inspection conveyor, a packaging machine and a finished product conveyor which are sequentially connected, wherein an automatic weighing blanking device and a positive pressure conveying device are arranged in the procedure before the procedure of the flour mixing machine; a flour softening machine is arranged between the flour mixing machine and the hoisting machine; the extrusion moulding machine is one with automatically controlled temperature and curing degree; the quantitative cutting machine is of high accuracy type; the row separating device is of pneumatic type; the drying machine is a multi-section temperature and humidity controllable drying machine; and a transition conveyor is arranged between the cooling machine and the inspection conveyor. The invention can complete integration continuous production including burdening, conveying powder, mixing flour, softening flour, extruding and curing, high accuracy quantitative cutting, stewing and curing, multi-section drying, cooling and finished product packaging.

Owner:SHENGCHANGDA MACHINERY TIANJIN

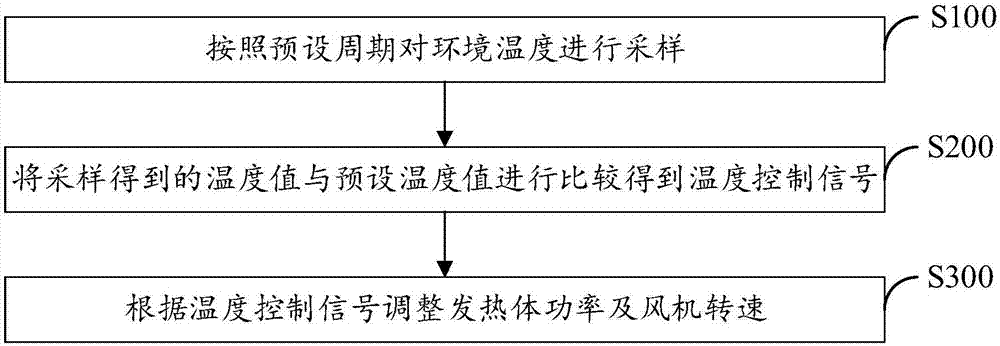

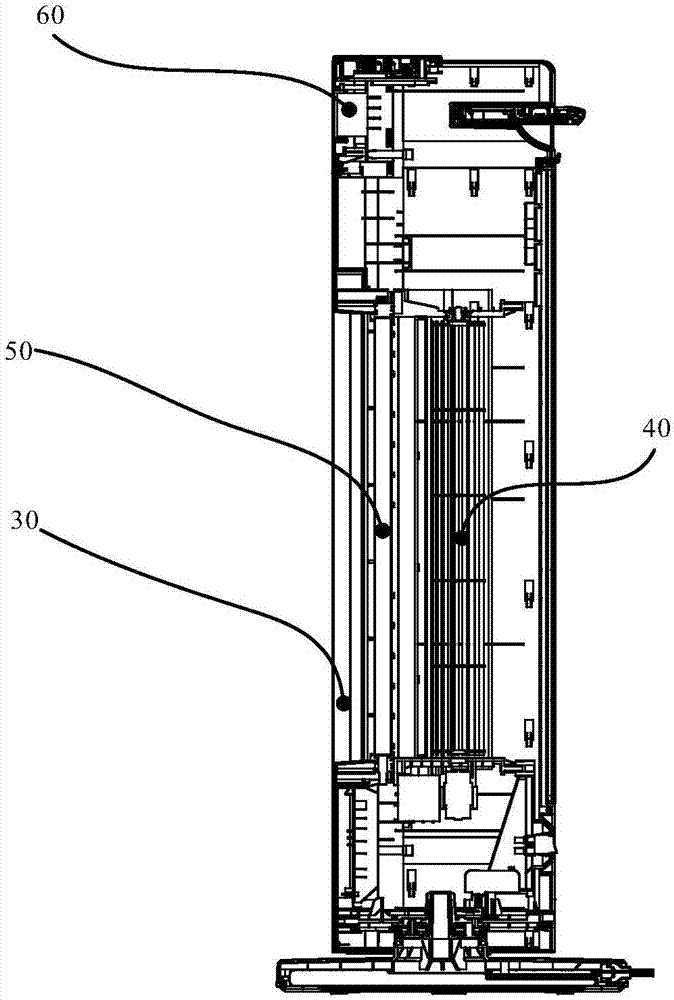

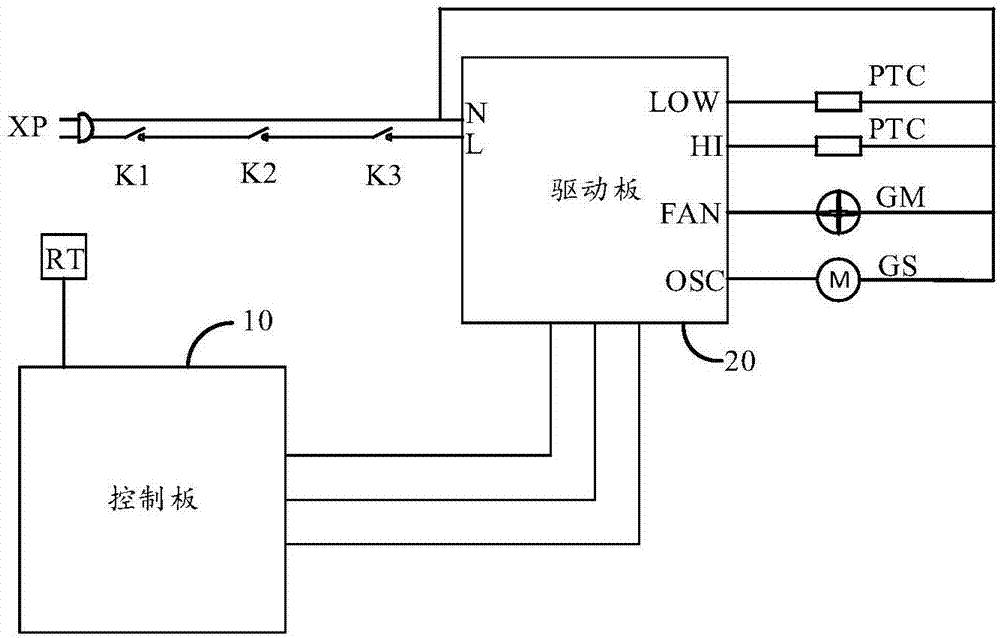

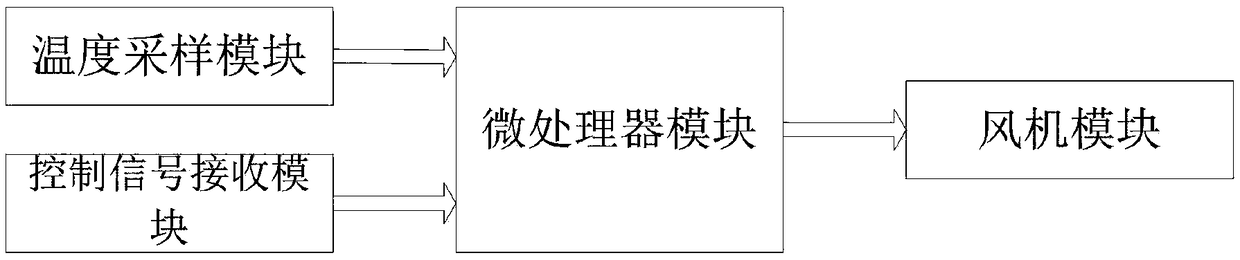

Fan heater control method and device, fan heater and storage medium

InactiveCN107289634AIncrease temperature rise ratePrecise constant temperature controlAir heatersTemperature control using electric meansEngineeringTemperature control

The invention discloses a fan heater control method and device, a fan heater and a storage medium. The method comprises the steps that the ambient temperature is sampled according to the preset period; the temperature value obtained after sampling is compared with the preset temperature value, and a temperature control signal is obtained; and the heating body powder and the fan rotating speed are adjusted according to the temperature control signal. By the adoption of the technical scheme, the temperature rising speed is increased, the control accuracy is improved, and the control frequency is lowered.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

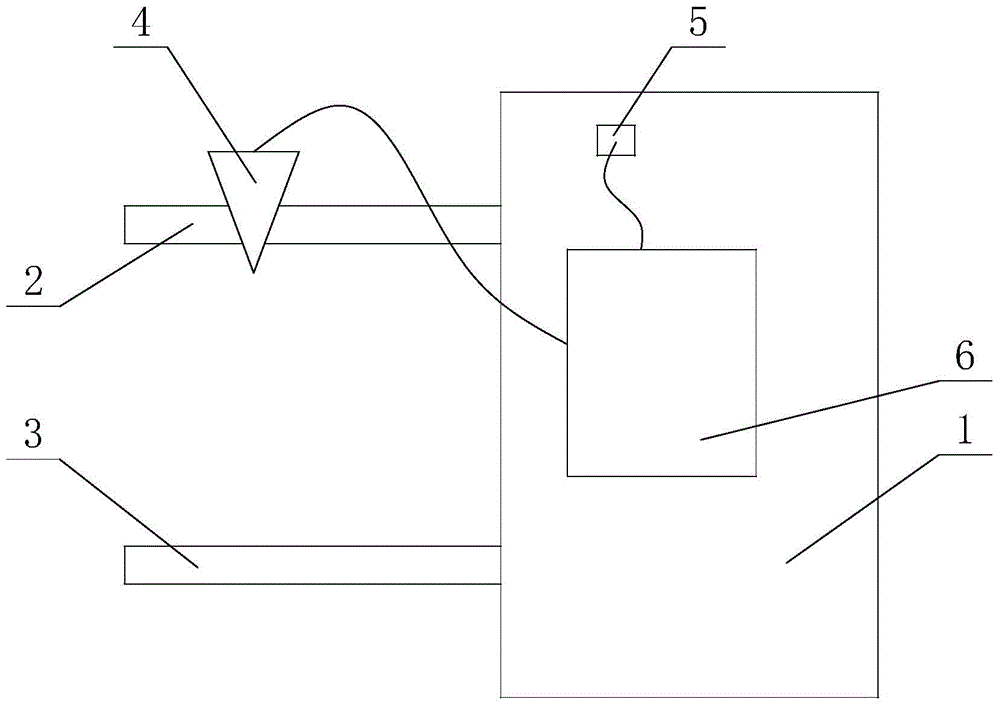

Coolant radiating device, air conditioner with coolant radiating device and temperature control method of coolant radiating device

ActiveCN104566840AAchieve constant temperature controlNo overheating issuesMechanical apparatusEfficient power electronics conversionTemperature controlFrequency changer

The invention discloses a coolant radiating device and belongs to the field of variable-frequency air conditioners. The coolant radiating device comprises a controller, a radiator, a coolant inlet pipe and a coolant outlet pipe. The coolant inlet pipe and the coolant outlet pipe are connected with the radiator. An expansion valve is arranged on the coolant inlet pipe. A temperature sensor is attached on the radiator. The expansion valve and the temperature sensor are connected with the controller. An air conditioner with the coolant radiating device comprises a frequency converter provided with an IPM (intelligent power module) drive belt. One side of the radiator contacts the IPM drive belt. By the use of the coolant radiating device, the frequency converter runs under a preset proper work temperature for long time, so that the overheating or condensation problem never occurs to the frequency converter, and the frequency converter operates at full capacity for long time.

Owner:HAIER GRP CORP +1

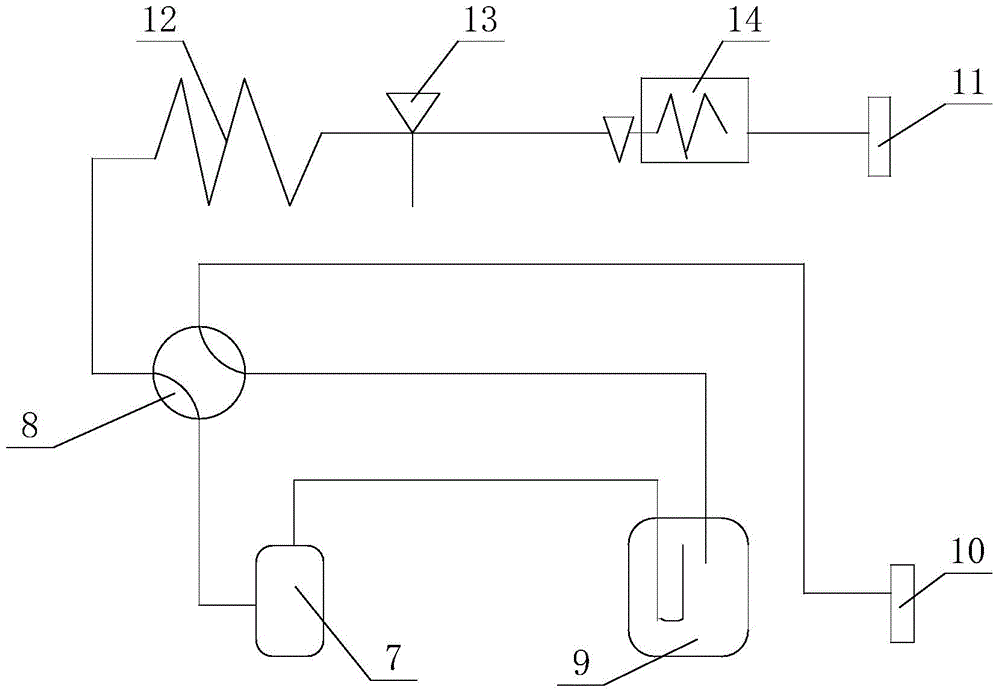

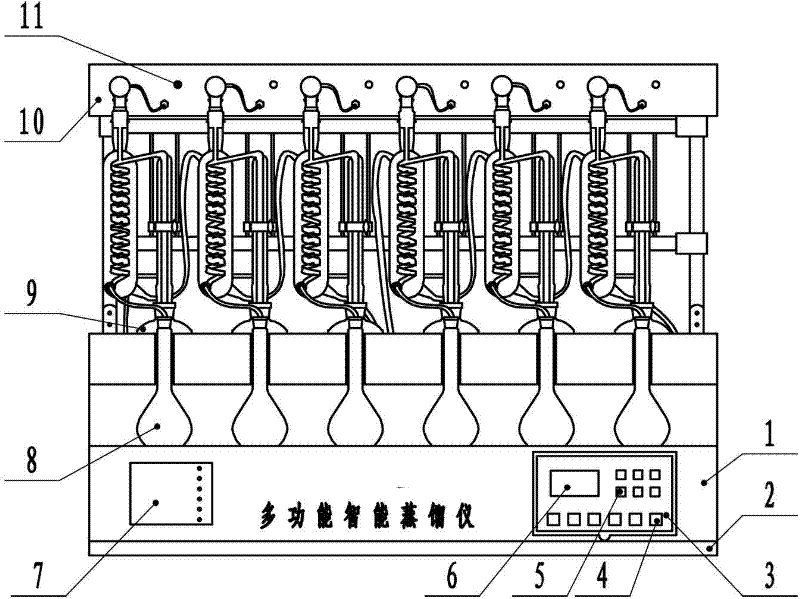

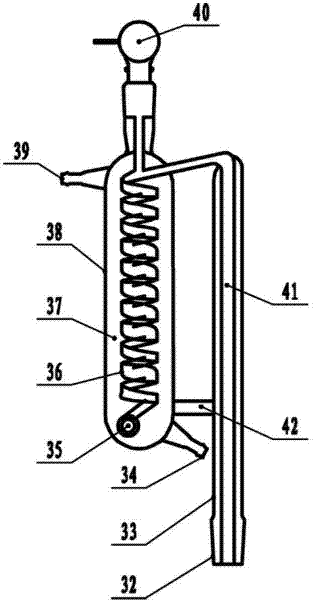

Multifunctional intelligent distillation instrument

InactiveCN102553666AGentle rise in temperatureAvoid burstingLaboratory glasswaresWater in oilDistillation

The invention discloses a multifunctional intelligent distillation instrument. The distillation instrument comprises a shell, a support, heating devices and a cooling device, wherein the heating devices are a plurality of relatively independent heating units, and each heating unit comprises a heating jacket, a heating bar, a heating bowl and a distillation bottle; the heating bowl is arranged in a heating box, the open end of the upper part of the heating bowl is provided with a stove port, and the distillation bottle is arranged in the stove port; the heating jacket is fixed on the periphery of the heating bowl; and the distillation instrument is also provided with a measurement and control device, a temperature sensor is fixed on the top of each heating bowl and connected with a control circuit board through a signal wire and transfers heating temperature to a control chip on the control circuit board, and a liquid level sensor is fixed on a console and senses the liquid level state in a volumetric flask through an optical fiber. The instrument can be widely applied to distillation treatment of projects of volatile phenol, cyanide, ammonia nitrogen, Kjeldahl nitrogen, water in oil and the like in various chemical laboratories requiring distillation treatment in environment friendliness, disease control, water supply and drainage, colleges, research institutions, industrial enterprises and the like.

Owner:山东益源环保科技有限公司

Method for Improving double heat pump hot-water system startup and adjustment performance

The invention discloses a novel method for starting and regulating working performances of a modified double heat pump bath hot-water system (i.e. a device for utilizing waste water and waste heat after bath to produce bath hot water). The method is implemented by adding a temperature-balancing tank and an electric heater at the water inlet end to shorten the start-up time and save water, and utilizing a three-way energy efficiency valve and a solenoid valve to regulate the volume of inlet waste water and thus to control the outlet water temperature. The invention has the advantages of high energy-efficiency ratio, rapid heating, and good start-up and temperature-regulation performances; and can work at a temperature below 5 DEG C.

Owner:党路明

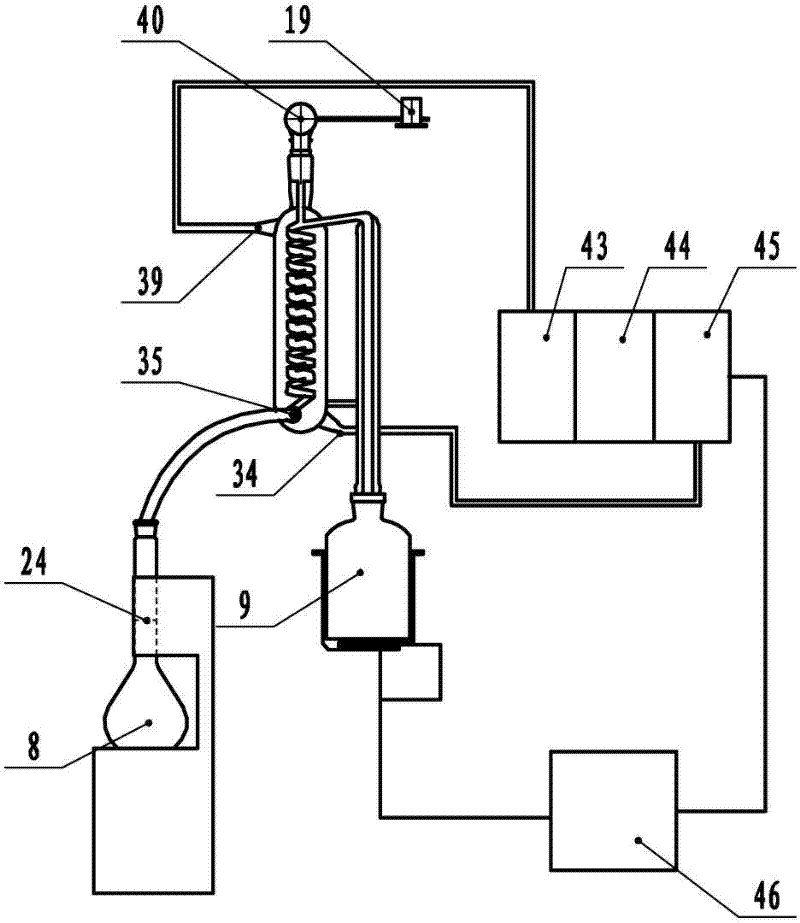

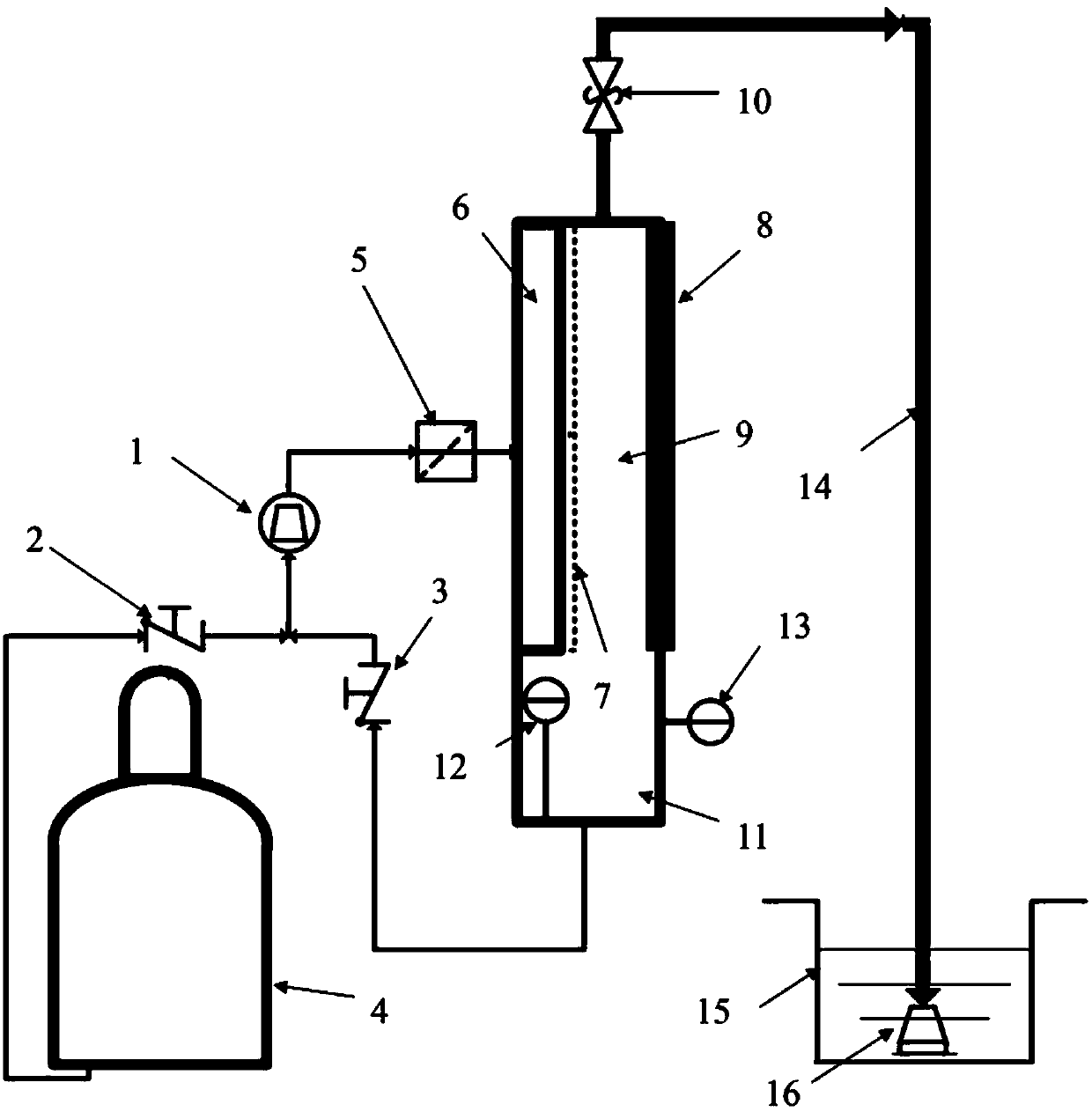

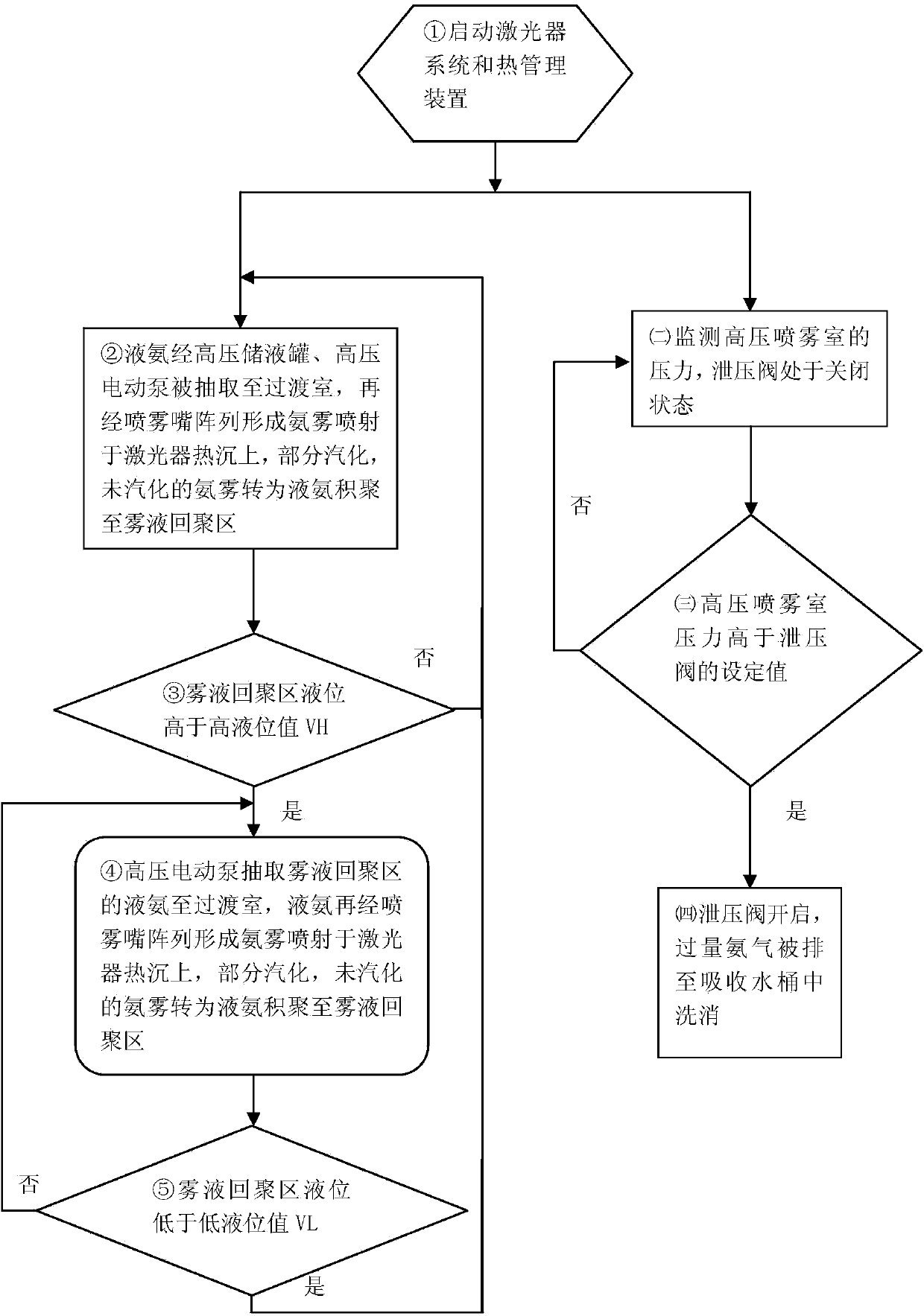

Device and method for high-power laser heat management based on spray evaporation

ActiveCN103441422AOverall small sizeSmall weightLaser detailsSemiconductor lasersHigh power lasersLiquid storage tank

The invention discloses a device and method for high-power laser heat management based on spray evaporation. The device for the high-power laser heat management comprises a high-pressure spray chamber arranged on a laser heat sink, a spray nozzle array and an air pressure sensor are arranged in the high-pressure spray chamber, the high-pressure spray chamber is adjacent to a transitional chamber, the transitional chamber is connected with a high-pressure liquid storage tank through a high-pressure electric pump, a spray liquid returning and accumulating area on the bottom portion of the high-pressure spray chamber is connected with the transitional chamber through the high-pressure electric pump, the high-pressure spray chamber is further connected with an exhaust pipe, and a decompression valve is arranged on the exhaust pipe. The method for the high-power laser heat management is achieved through the device for the high-power laser heat management, and the method is used for maintaining the pressure of gas refrigerants in the high-pressure spray chamber to be constant, and therefore temperature is maintained to be constant to achieve constant temperature control over the laser heat sink. The device is simple and reliable in structure, high in compactness, accurate in temperature control and stable in operation, and the method is simple and easy to implement, high in efficiency and environmentally friendly.

Owner:NAT UNIV OF DEFENSE TECH

Method for synthesizing polyether glycol in microstructure reactor

The invention relates to a method for synthesizing polyether glycol in a microstructure reactor, which comprises the following steps: respectively pumping oxyalkylene and a catalyst liquid generated by reacting an alkaline catalyst and an initiator into the microstructure reactor composed of a micro-mixer and a retention time prolonging pipe, reacting while controlling the reaction temperature and pressure, neutralizing the reaction solution, adsorbing, degassing and filtering to obtain the refined polyether glycol. The hydroxyl value of the refined polyether glycol is 50-550 mgKOH / g, and the relative molecular mass is 300-3300 g / mol. The method overcomes the defects of long initiation time and low operational efficiency in the intermitted technique, solves the problems of complex equipment, high requirements for technological condition control and long retention time in the continuous technique, implements quick and continuous production, and has the advantages of short reaction time, simple technique, high safety, high controllability, high adjustment flexibility, continuous operation and the like.

Owner:上海睿瓦科技有限公司

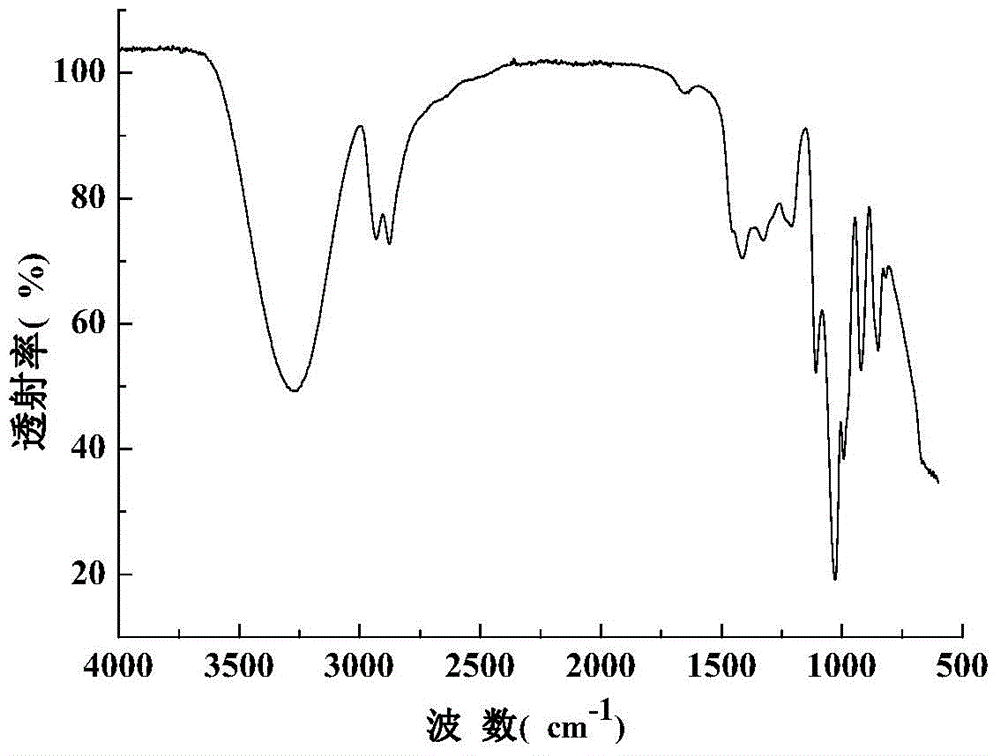

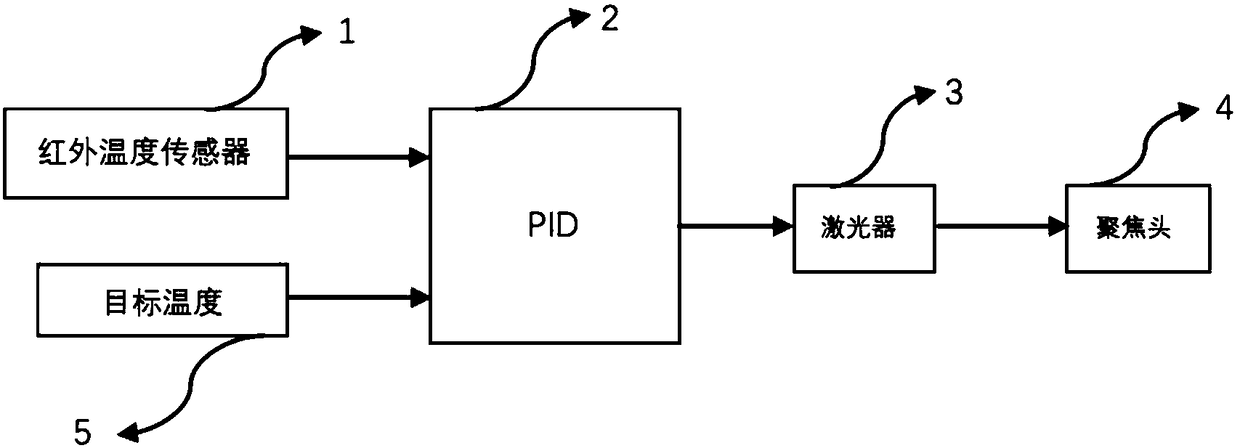

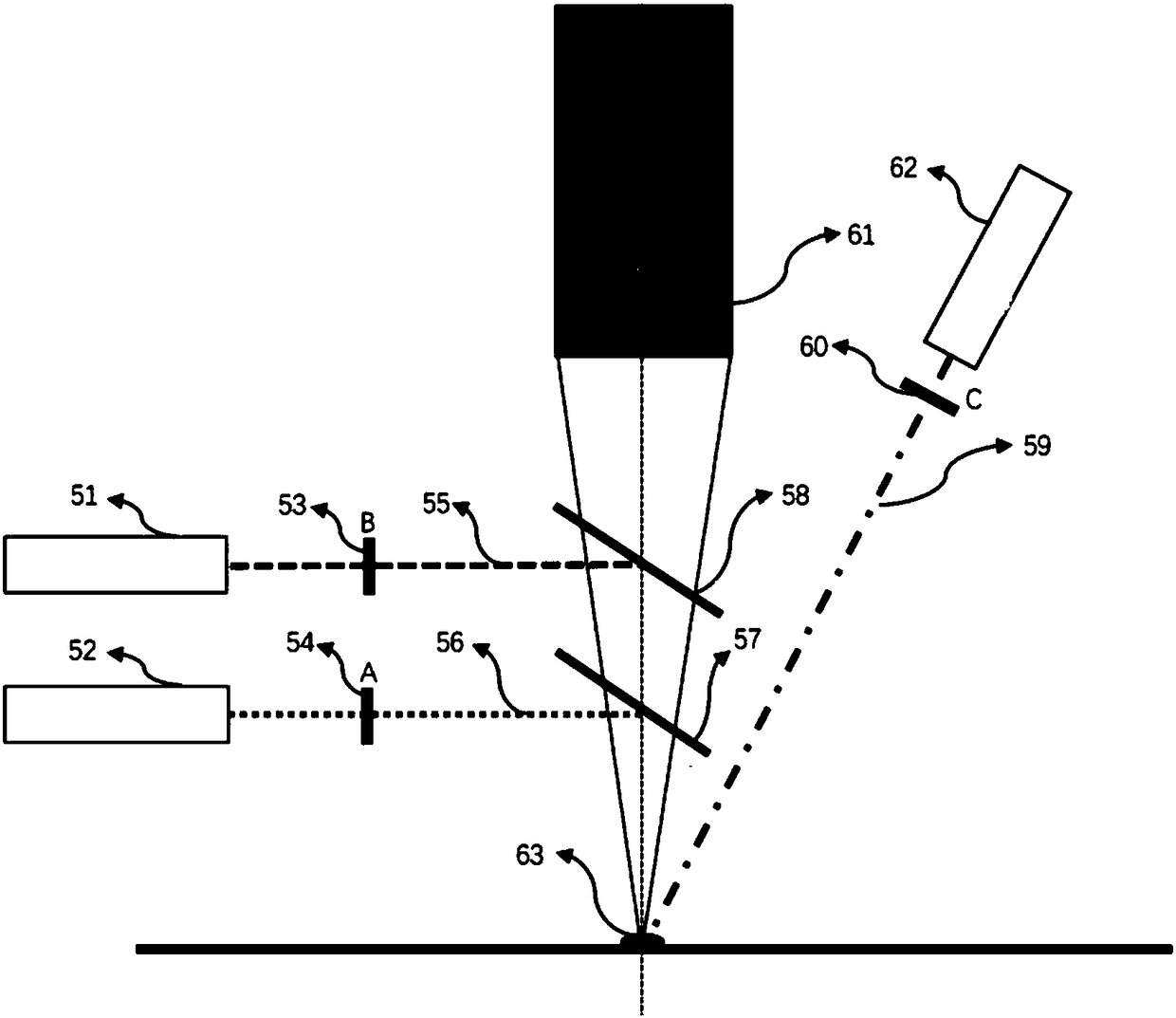

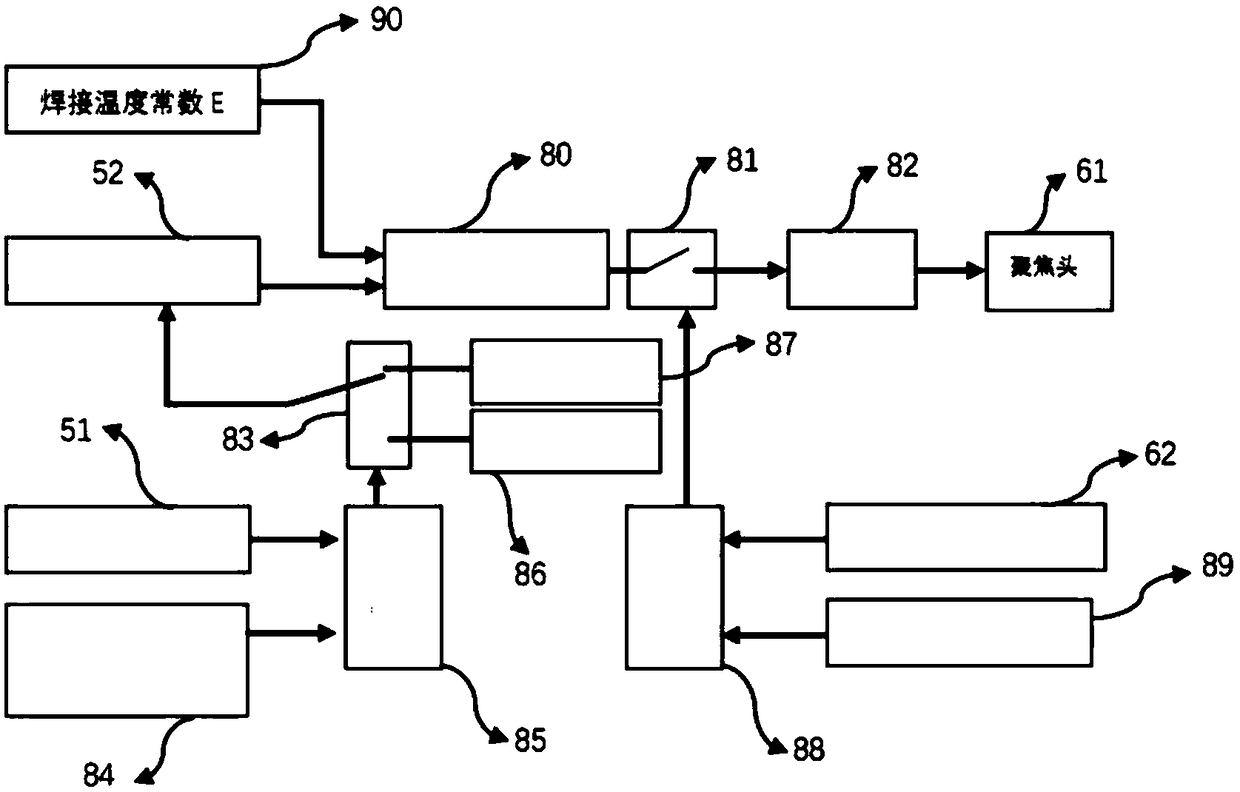

Infrared temperature measurement and variable emittance based laser welding safety control method and system

ActiveCN108311767AEasy to controlAchieve integrationHeating appliancesMetal working apparatusTemperature controlEmissivity

The invention discloses an infrared temperature measurement and variable emittance based laser welding safety control method and system. The method is that the temperature of a welding point of a welded object is detected based on the infrared temperature during laser welding, thus controlling a laser to work based on the feedback result. The method is characterized in that the intensity of reflected light at the welding point of the welded object is detected and compared with the brazing emitting light intensity threshold so as to determine whether a brazing filler metal of the welding pointreaches a melting point; the corresponding emittance constant is selected for infrared temperature detection under different states. According to the method, the state of the welded point is analyzedand determined to realize variable emittance control of an infrared temperature sensor; different emittance is adopted for infrared temperature detection based on different state of the welding point.Therefore, the problem that the temperature of the welding point cannot be accurately detected in the prior art can be solved, and the working state of the laser can be controlled; the system is integrated, so that the space layout of the system is reasonably performed; the space for equipment is small; the state of the welding point can be accurately controlled; and moreover, the constant-temperature control in the laser welding process can be realized.

Owner:WUHAN LINGYUN PHOTOELECTRONICS SYST

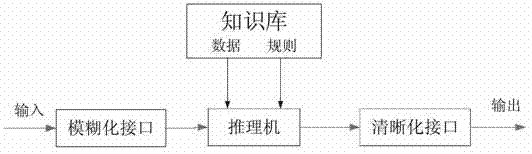

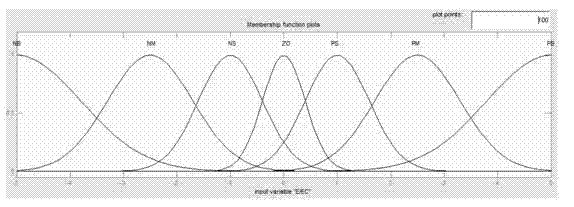

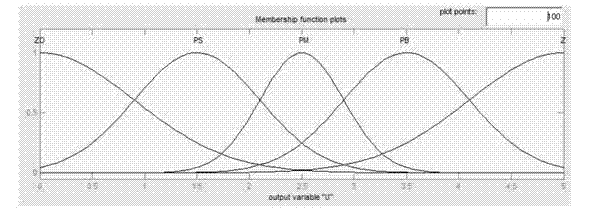

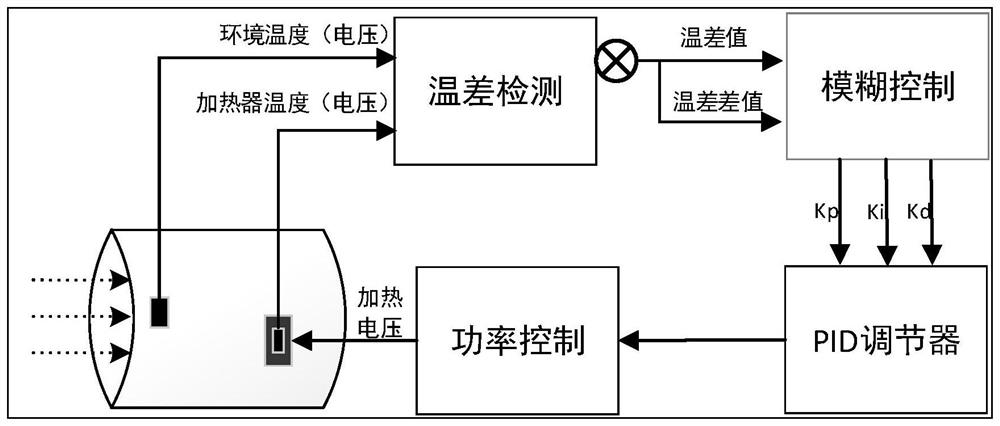

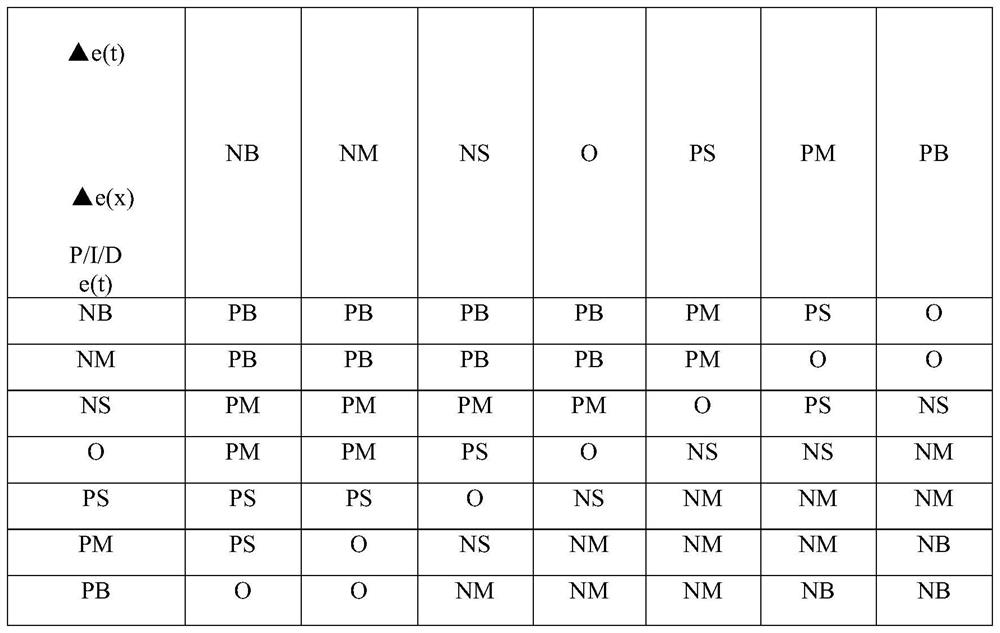

Heat metering wireless temperature control system based on fuzzy control algorithm

ActiveCN103487172AEasy to measureEasy to recordTransmission systemsLighting and heating apparatusEngineeringHeat consumption

The invention provides a heat metering wireless temperature control system based on a fuzzy control algorithm. The heat metering wireless temperature control system comprises a fuzzy controller module, a temperature detection and control module, a wireless communication module, a motor driving valve module and a flow measurement module. The temperature detection and control module detects the indoor temperature in real time, carries out inquiring and displaying of temperature setting and heat energy consumption, and transmits temperature data detected in real time to the wireless communication module; the wireless communication module outputs the temperature data detected in real time to the fuzzy controller module and transmits heat data stored in a fuzzy controller to the temperature detection and control module; the fuzzy controller module calculates according to input indoor actual temperature signals by means of the fuzzy control algorithm, outputs output valve opening signals to the motor driving valve module, drives a motor to operate, and controls valve opening of a radiating device; the flow measurement module is used for measuring heat consumption values and outputting the heat values to the fuzzy controller module.

Owner:ZHEJIANG UNIV OF TECH

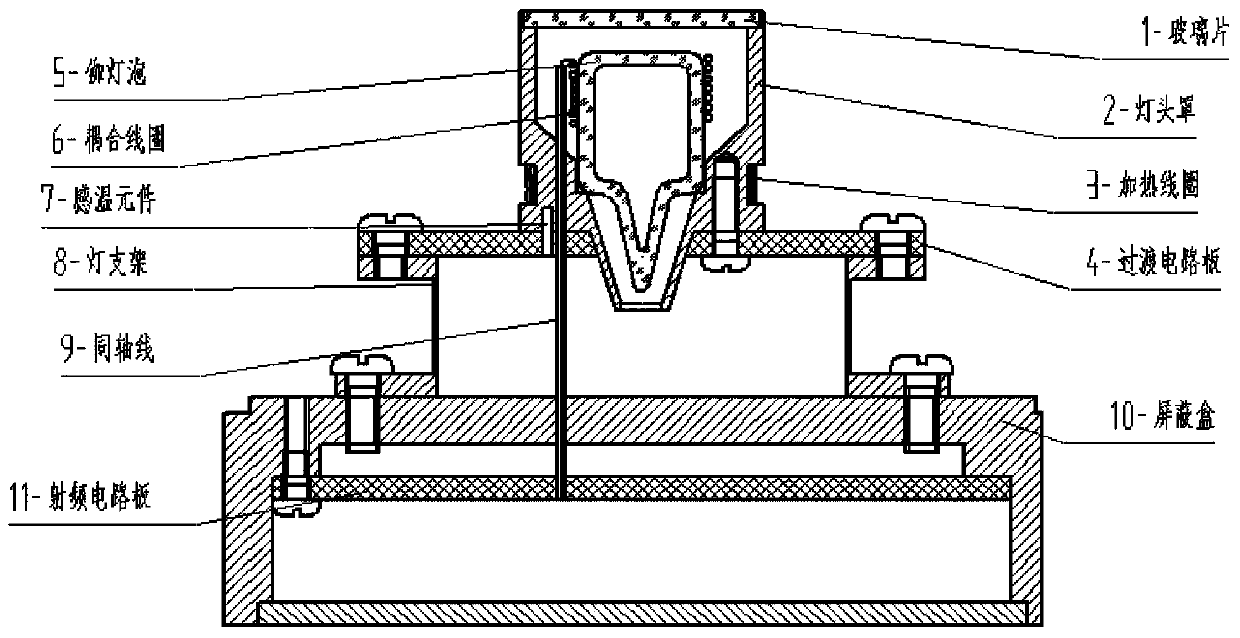

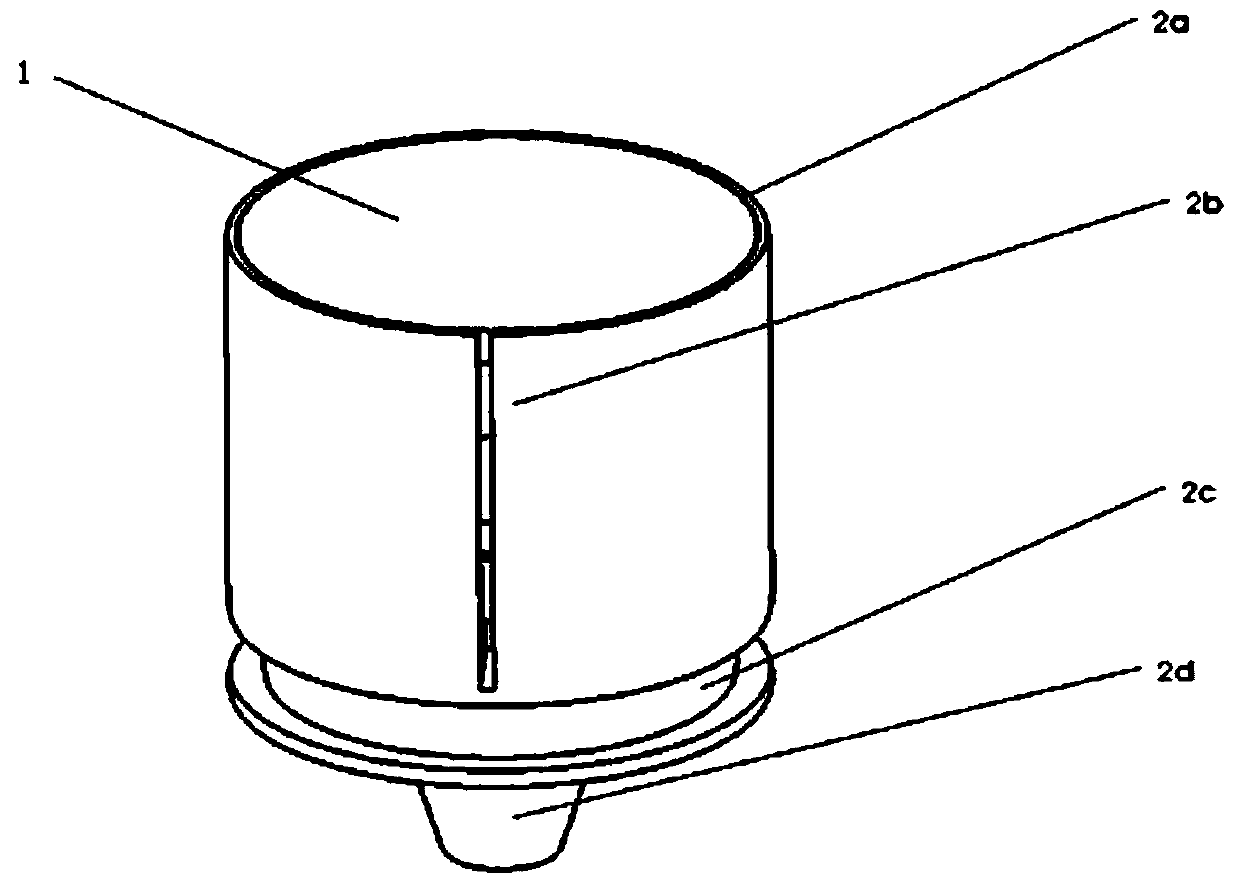

Spectral lamp for rubidium atomic frequency standard

ActiveCN103363359AReduce instabilityImprove transmission efficiencyPulse automatic controlElectric circuit arrangementsCoaxial lineGlass sheet

The invention discloses a spectral lamp for a rubidium atomic frequency standard. A sapphire glass sheet is adhered into a glass sheet clamping opening in the top of a lamp base cover through silicone rubber. A coupling coil is closely wound on the upper part of a bulb. One end of the coupling coil is welded with a core wire of a coaxial wire, and the other end of the coupling coil is welded with the outer wall of the coaxial wire. The coaxial wire penetrates through the lamp base cover, a transition circuit board, a shielding box and a radio frequency circuit board, and is welded at the ground ends of the transition circuit board and the radio frequency circuit board. The lamp base cover is fixedly arranged on the transition circuit board through screws. Leading wires of a heating coil and a temperature sensing element are welded on the transition circuit board. The lamp base cover is fixedly arranged on the transition circuit board through the screws at the bottom of the lamp base cover. The transition circuit board is fixedly arranged on a lamp bracket through screws. The lamp bracket is fixedly arranged on the shielding box through screws. The radio frequency circuit board is fixedly arranged in the shielding box through screws. The spectral lamp is simple in structure, easy to machine, stable in performance and high in environmental adaptability, and can be directly applied to the rubidium atomic frequency standard.

Owner:WUHAN INST OF PHYSICS & MATHEMATICS CHINESE ACADEMY OF SCI

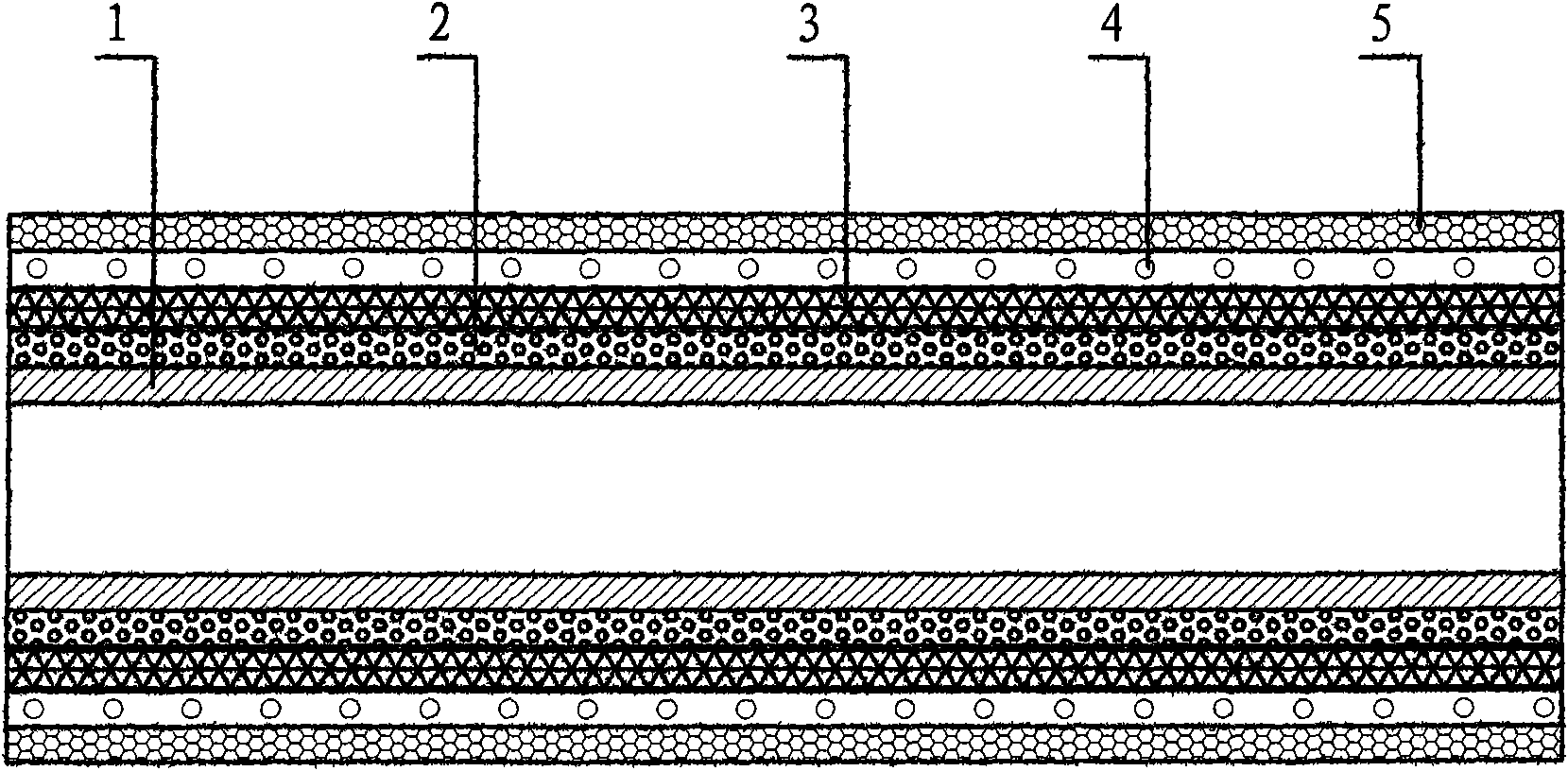

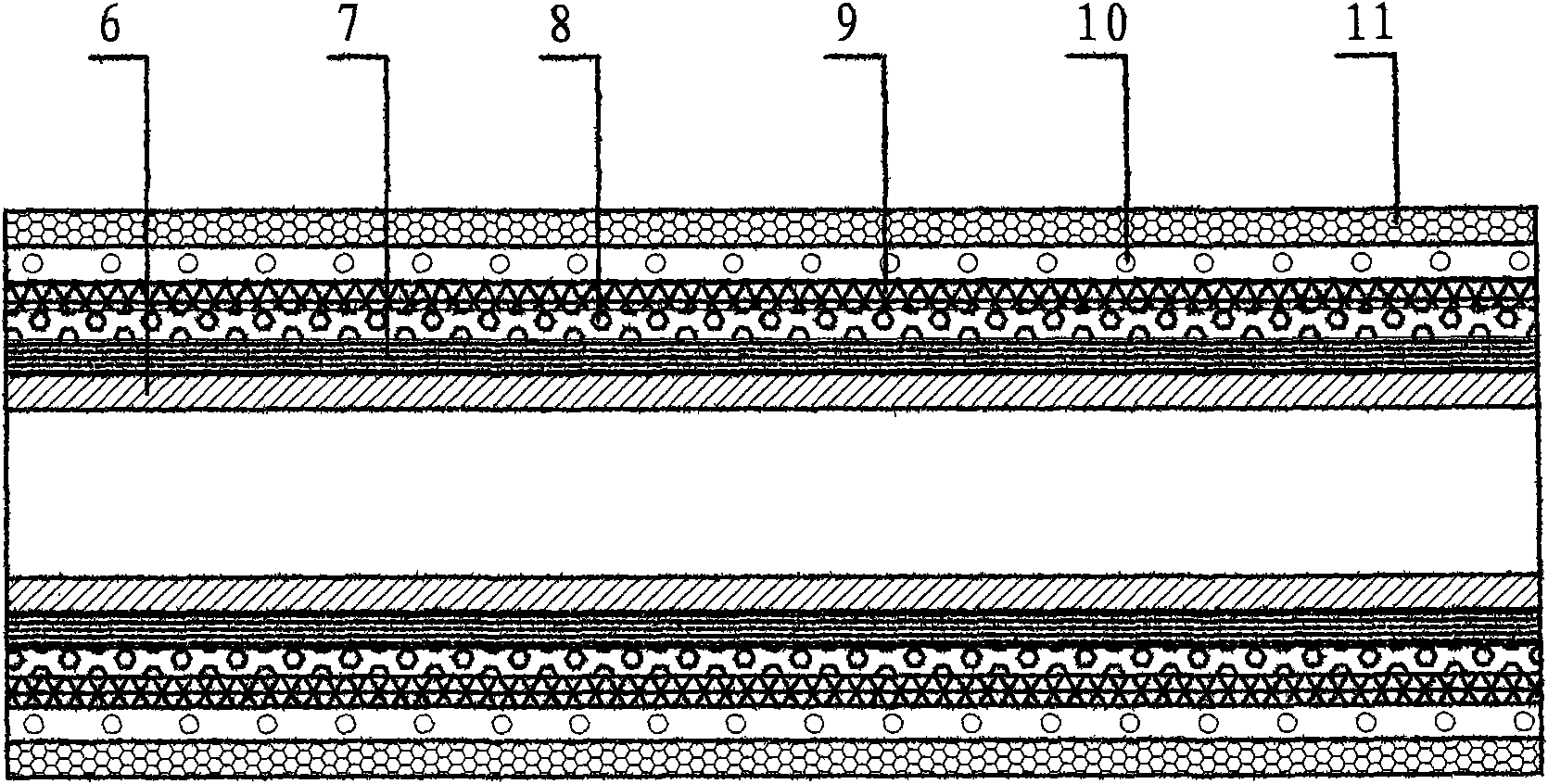

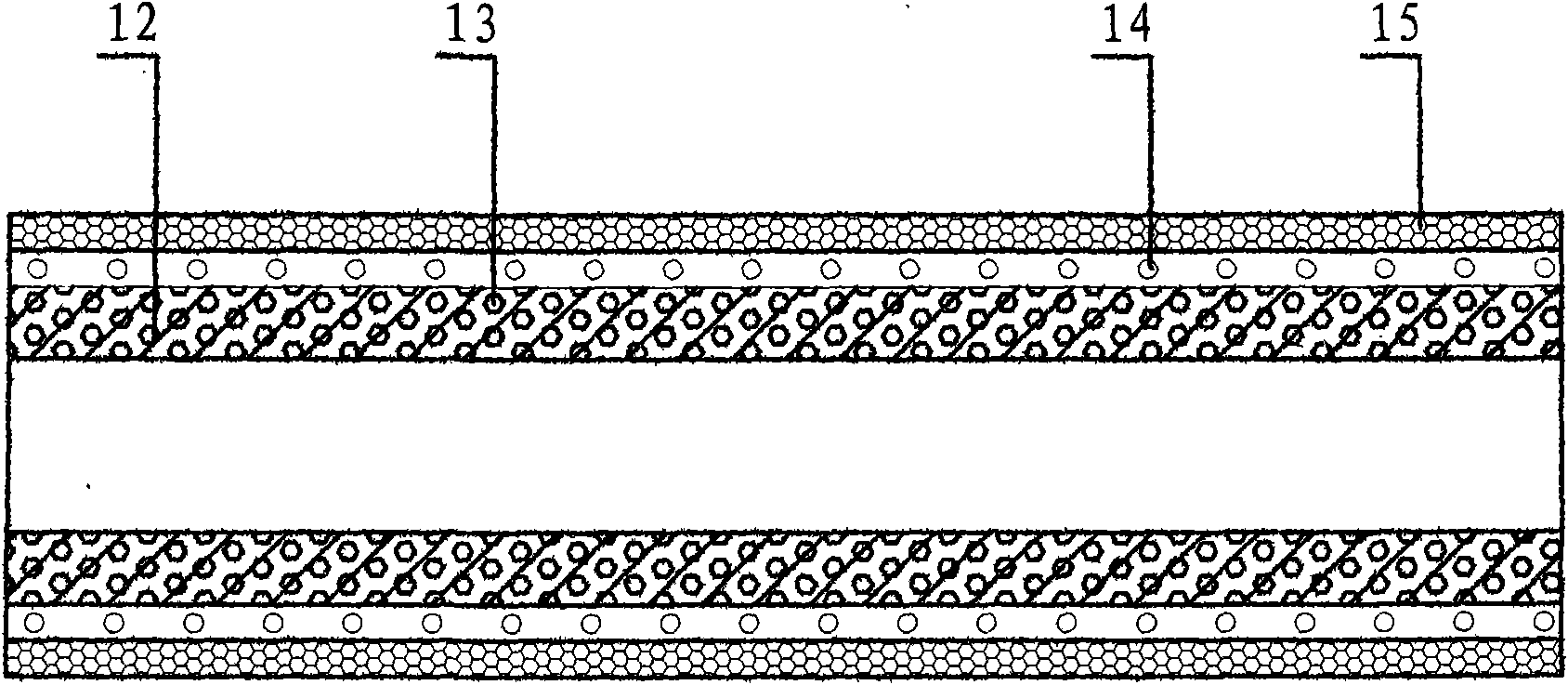

Electromagnetic heating constant temperature transfusion tube

InactiveCN101539229AAchieve constant temperature controlFast heat transferThermal insulationPipe heating/coolingCrucibleElectromagnetic heating

Te invention relates to an electromagnetic heating constant temperature transfusion tube, which comprises a transfusion metal tube, a transfusion organic resin tube, a transfusion ceramic tube or a crucible, a magnetic material, an insulating heat insulating material, an electromagnetic induction coil, and an external protection heat insulating material. The electromagnetic heating constant temperature transfusion tube is characterized in that the transfusion metal tube, the transfusion organic resin tube, the transfusion ceramic tube or the crucible enwraps a magnetic material layer of which the curie point temperature is between 5 and 1,500 DEG C, the insulating heat insulating material is arranged outside the magnetic material, the electromagnetic induction coil is arranged outside the insulating heat insulating material, and the external protection heat insulating material is arranged outside the electromagnetic induction coil.

Owner:王广武

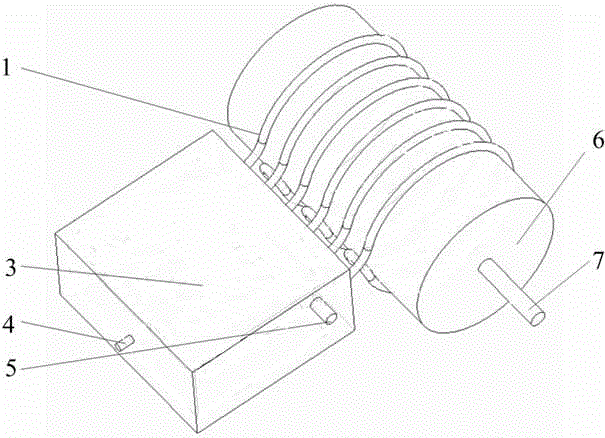

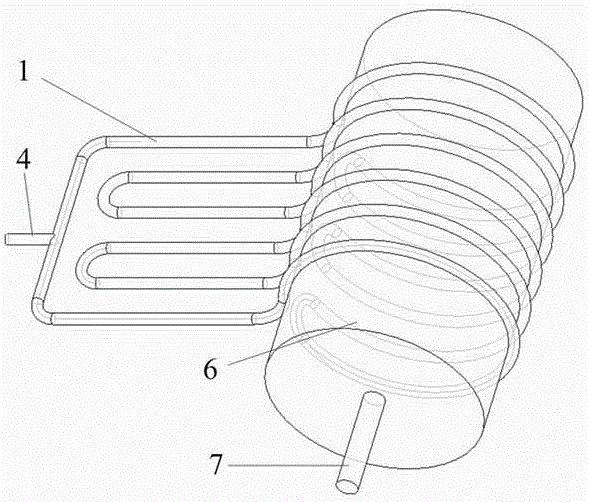

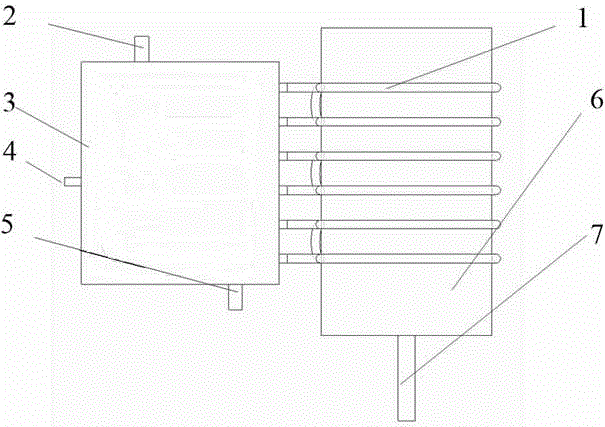

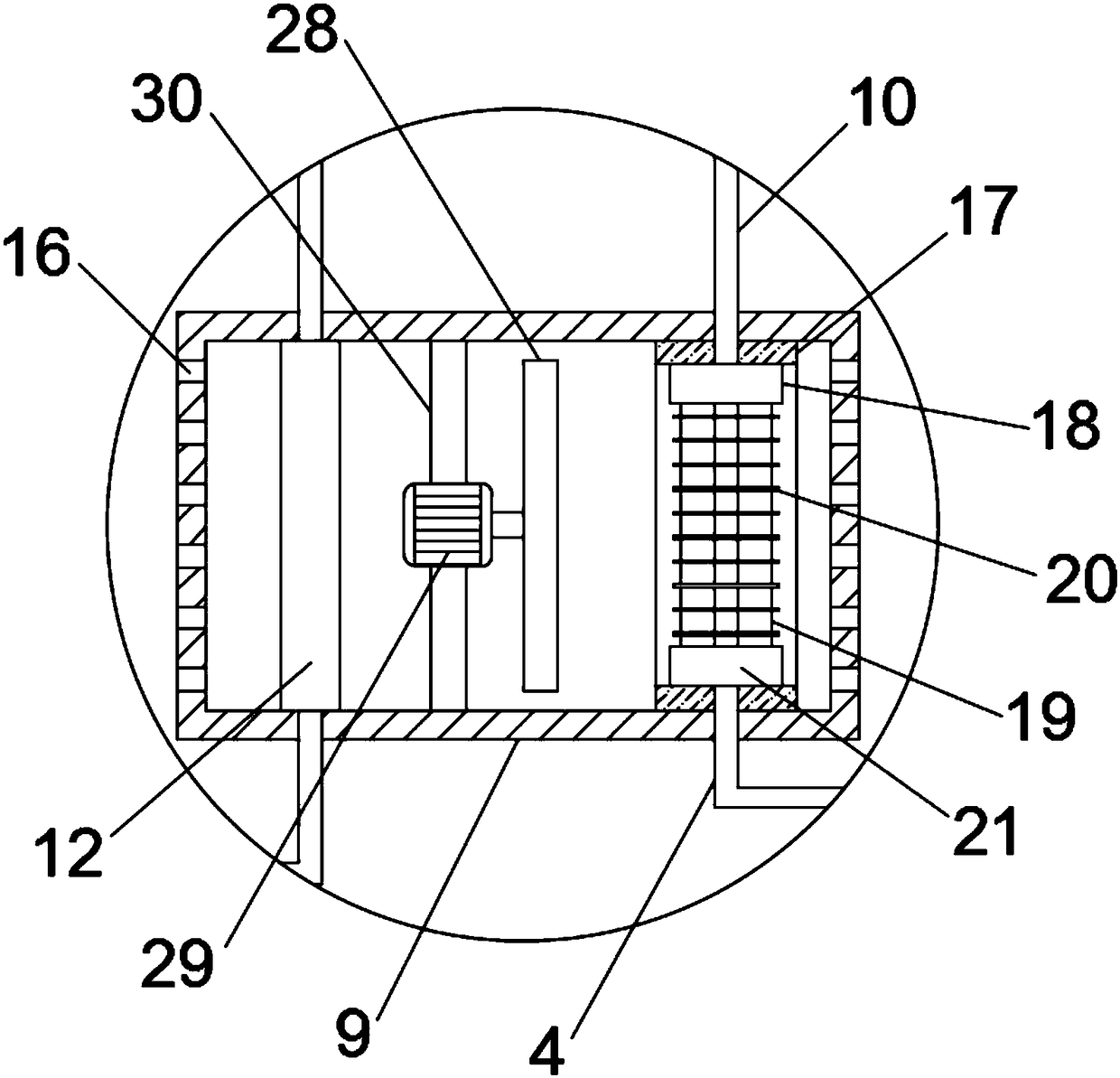

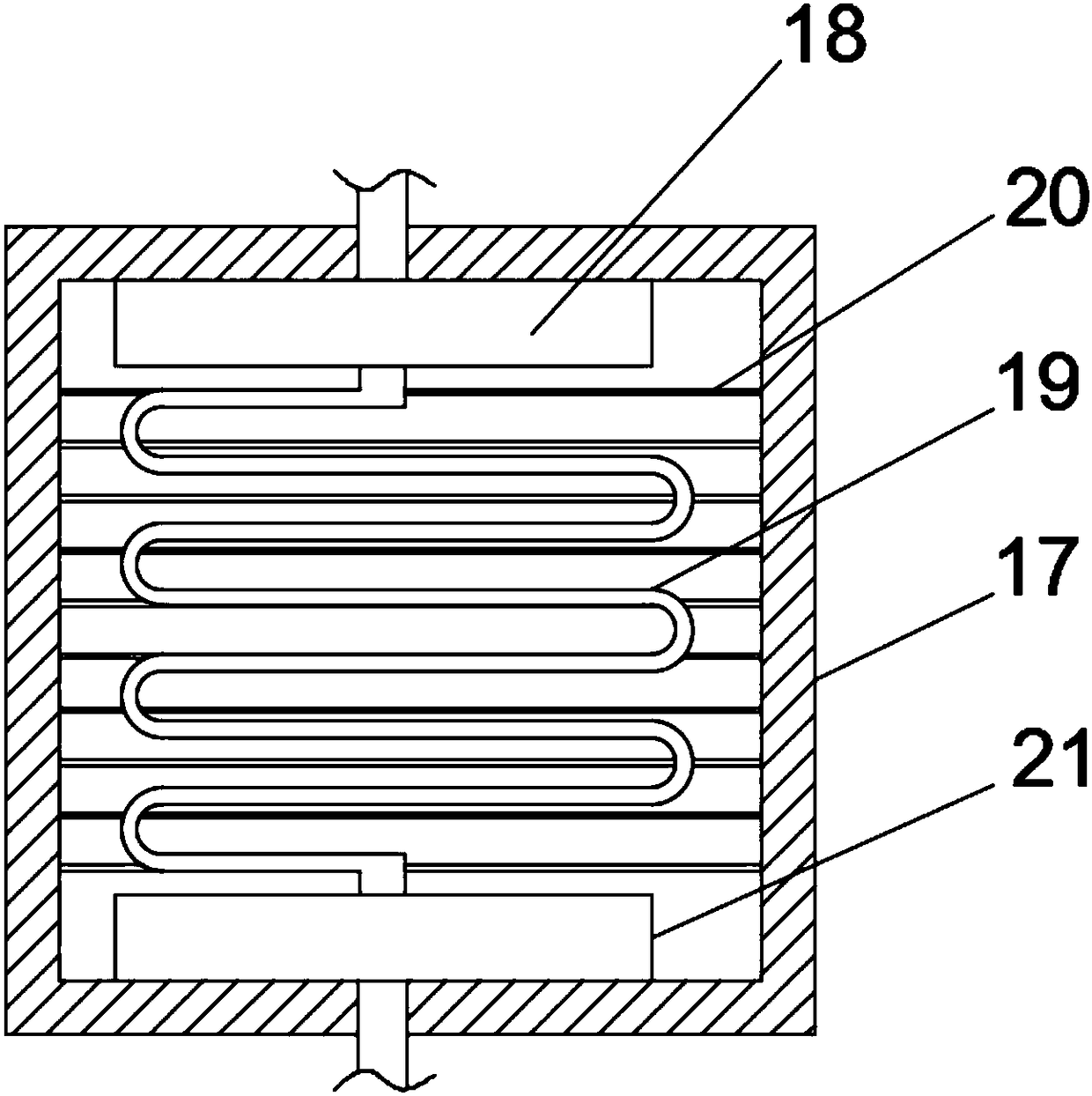

Pump motor cooling noise reduction device based on pulsating heat pipe

InactiveCN106787451AEfficient coolingAchieve cycleCooling/ventillation arrangementTemperature controlLow noise

The invention discloses a pump motor cooling noise reduction device based on a pulsating heat pipe principle. The main structure of the pump motor cooling noise reduction device lies in that a pulsating heat pipe cooling device in spatial arrangement is designed on the shell of a motor; a pulsating heat pipe mainly comprises a spatially warped multi-bend closed passage, wherein the cooling section of the passage is arranged in a water tank, the included angle between the water tank and the horizontal plane is 30 to 90 degrees, and an inlet and an outlet are formed in the water tank, so that circulation and constant-temperature control can be realized. The heating section of the pulsating heat pipe is directly adhered onto the outer surface of a motor shell, the position of a condensation section is always on the upper side of the heating section, and an included angle of 30 to 90 degrees can be presented with the horizontal plane. Moreover, the cross section of the closed passage can be designed into circular and rectangular cross sections. The device is to carry out efficient cooling treatment on the motor, and an existing motor with a fan cooling structure is replaced, so that low noise operation is realized. The structure has the characteristics that the device is detachable and is convenient to maintain.

Owner:JIANGSU UNIV

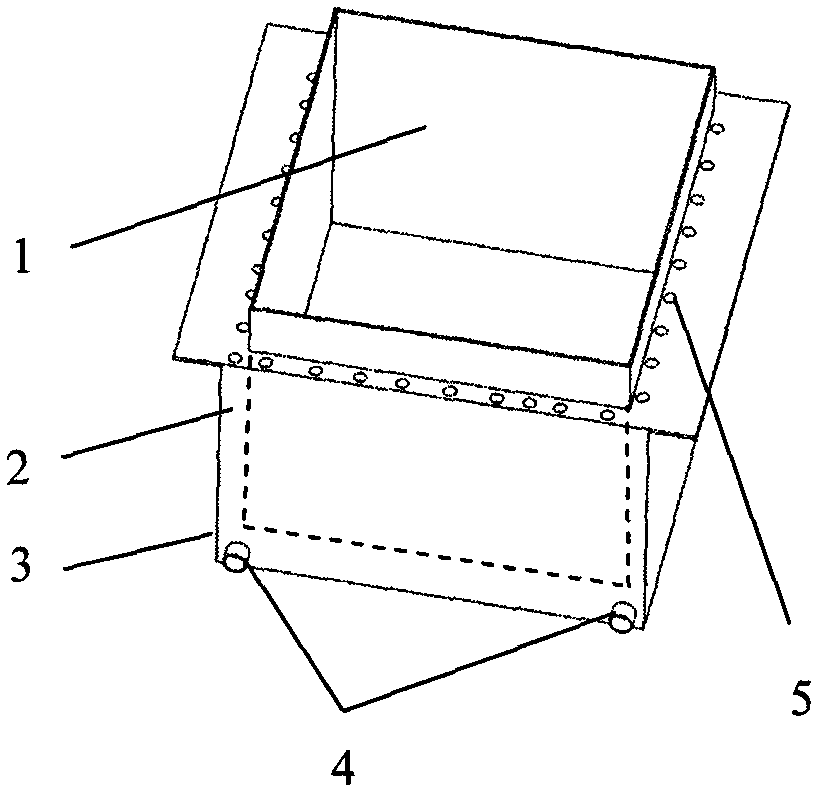

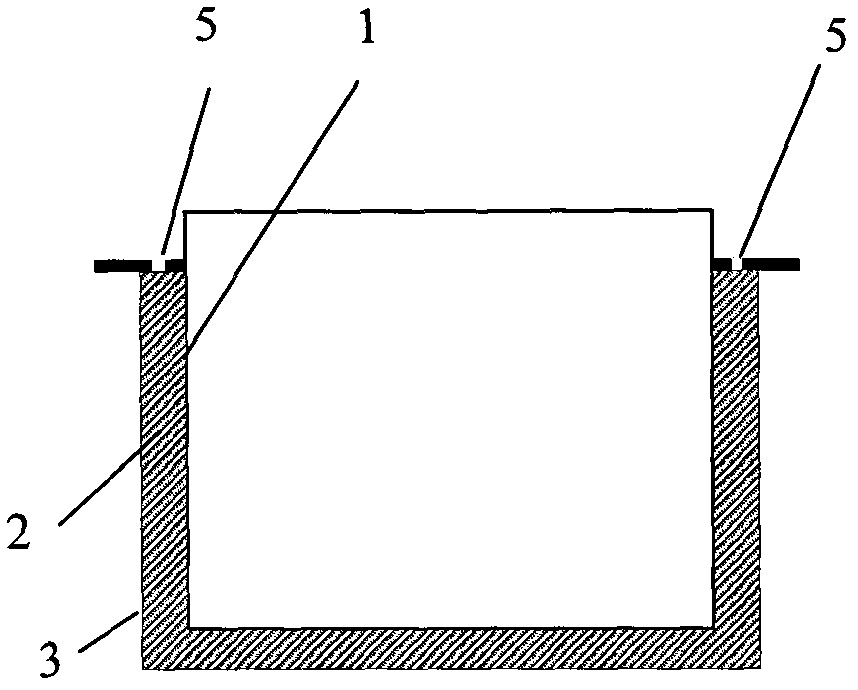

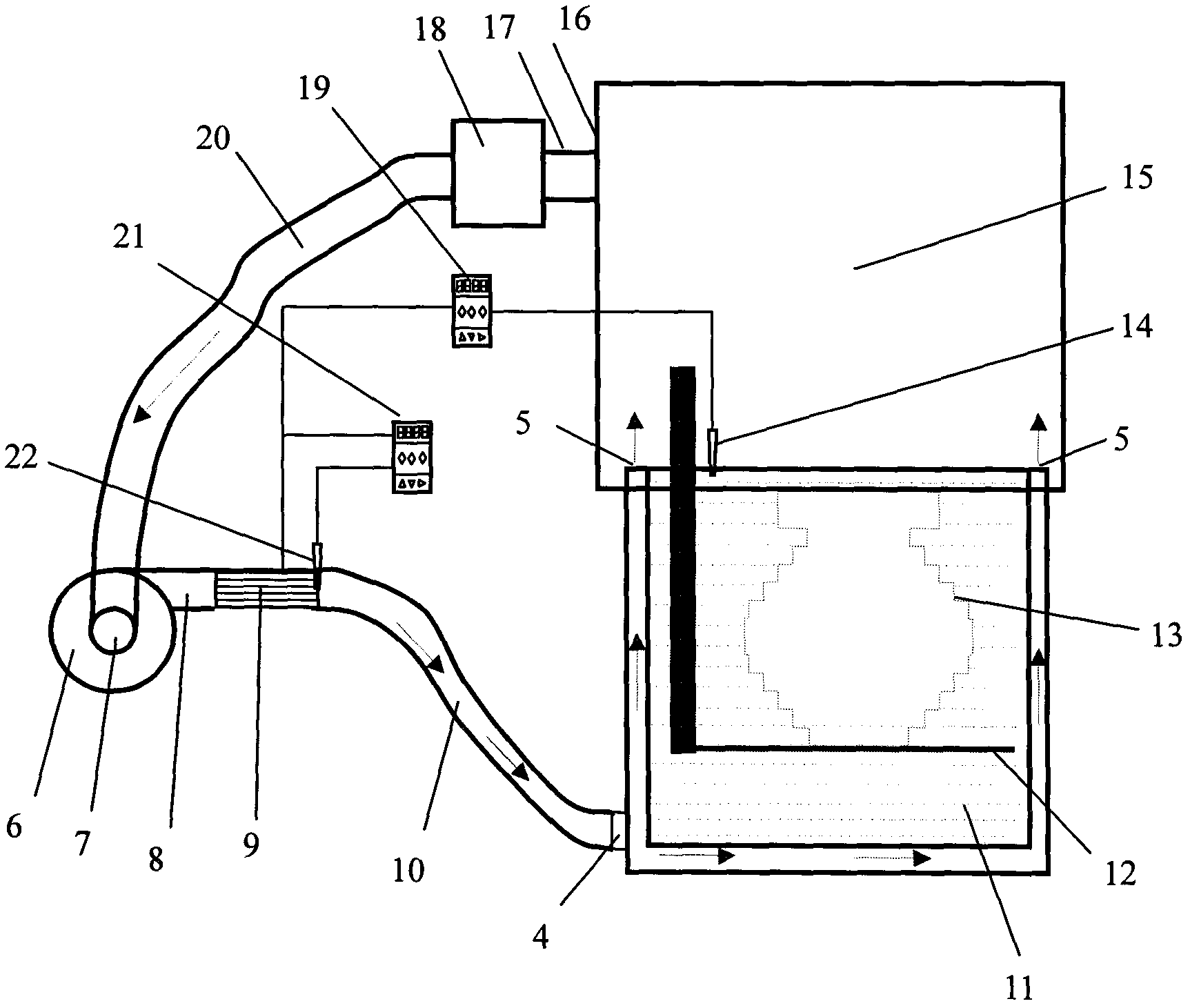

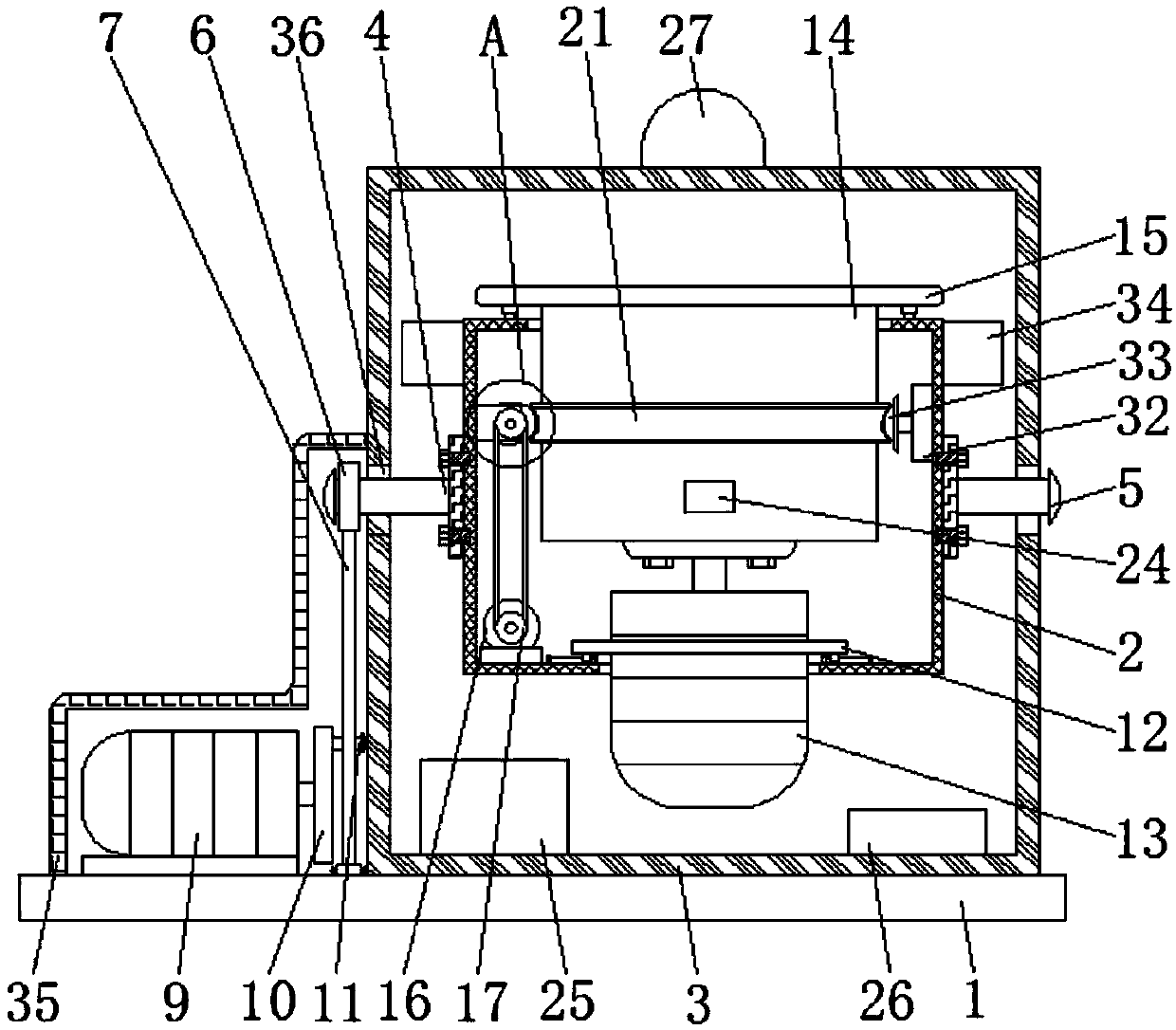

Resin heating and drying system of photo-curing rapid forming equipment

The invention discloses a resin heating and drying system of photo-curing rapid forming equipment. The resin heating and drying system comprises a resin groove, a closed working chamber and an air heating and injection control device, wherein an interlayer is arranged between an inner cavity and an outer cavity of the resin groove, an interlayer air inlet is arranged on the bottom part of the resin groove, and an interlayer exhaust passage is arranged above the resin groove; the closed working chamber a hollow cavity body which is arranged above the resin groove and is in sealed connection with the resin groove, and the top part of the closed working chamber is provided with a working chamber exhaust port; and hot air output by the air heating and injection control device is injected into the interlayer through the interlayer air inlet, flows in the interlayer, is discharged into the closed working chamber through the interlayer exhaust passage, then is discharged by the working chamber exhaust port, and is input into the air heating and injection control device for heating circulation. The resin heating and drying system can realize omnibearing uniform heating and thermostatic control in six directions of resin in the resin groove, ensures that the resin temperature on a light beam scanning plane is kept at an ideal set value, and simultaneously can prevent a photosensitive resin from being exposed in air for along time to absorb moisture in the environment.

Owner:GUANGZHOU ELECTRONICS TECHCAL INST CHINESE ACADEMY OF SCI

Efficient heat radiating device used for car engine

InactiveCN108425735AEfficient heat dissipationAvoid damageLiquid coolingCoolant flow controlTemperature controlEngineering

The invention discloses an efficient heat radiating device used for a car engine. The efficient heat radiating device comprises a cooling device, an installing shell, a water guide pipe, a heat radiating assisting device and a negative pressure device; the cooling device comprises a water storage box, a temperature control device, a water inlet pipe, a water outlet pipe, a cooling water pump, a heat radiating device and a cooling pipe; and the heat radiating device is fixed into the installing shell, the input end of the cooling water pump is connected with the cooling pipe through the water guide pipe, the output end of the cooling water pump is connected with the input end of the cooling device through the water guide pipe, the output end of the cooling device is connected with one sideof the water storage box through the water inlet pipe, the other side of the water storage box is connected with the end, far away from the cooling water pump, of a cold water pipe through the water outlet pipe, the cooling pipe is fixed to the inner side of the engine, and the temperature control device is fixed to the water storage box. By means of the efficient heat radiating device used for the car engine, efficient heat radiating of the engine is achieved, the engine is prevented from being damaged by slow heat radiating when a car is in a high temperature zone, and the service life of the engine is prolonged.

Owner:胡仟惠尹

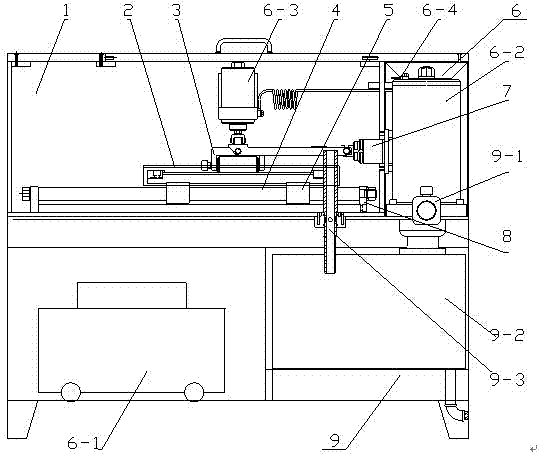

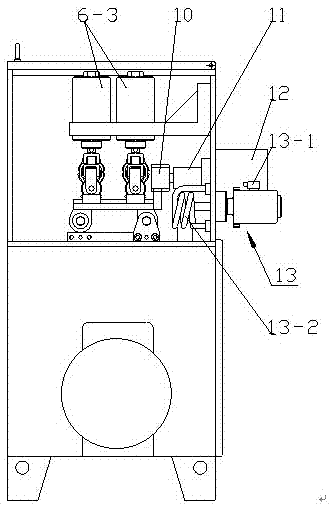

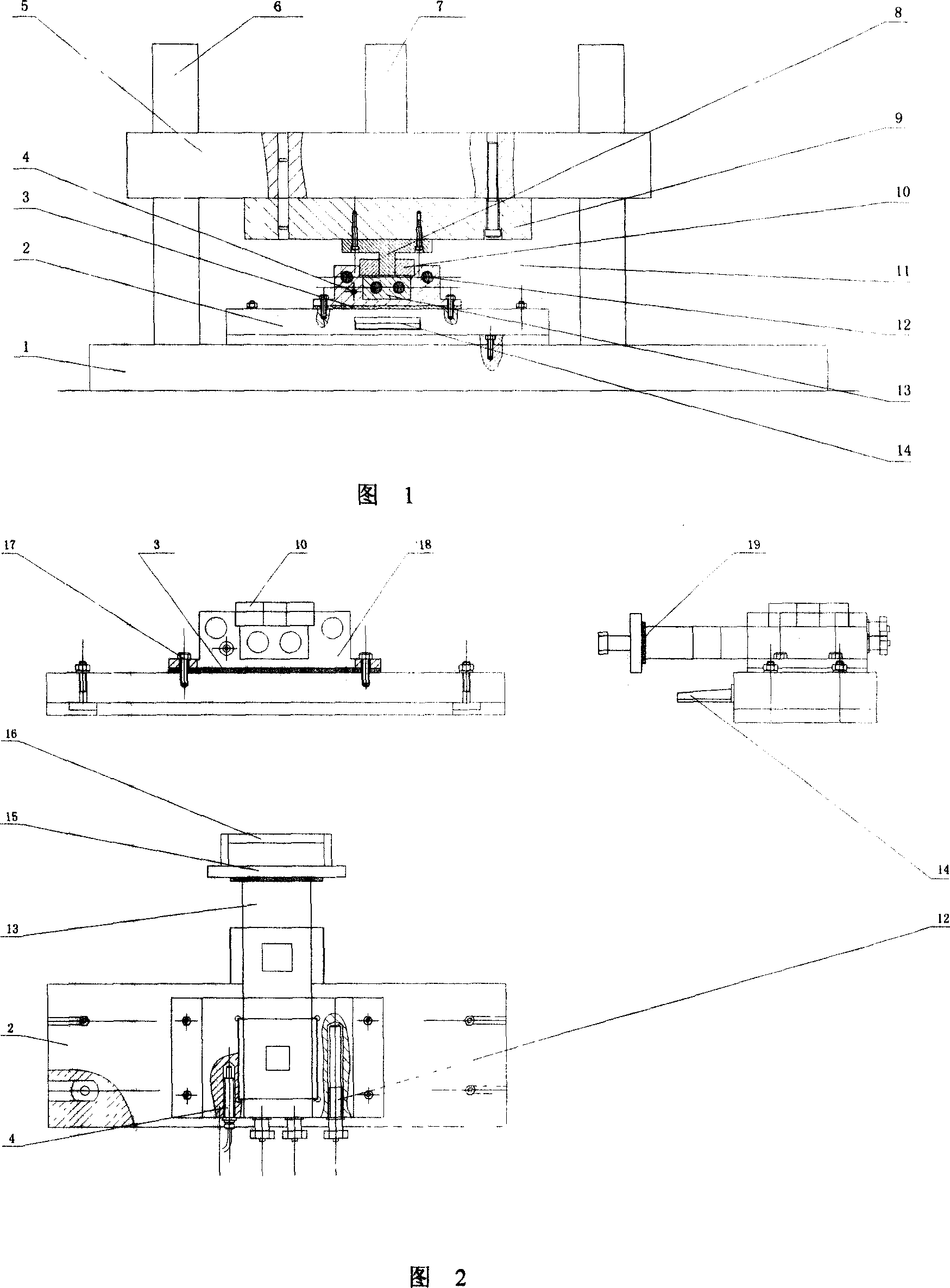

Reciprocating friction-wear test apparatus and method

PendingCN107101901ASimulation is accurateImprove accuracyInvestigating abrasion/wear resistanceOil wellForce transducer

The invention discloses a reciprocating friction-wear test apparatus and method. The apparatus includes a test box, an oil pipe clamping part, a test piece clamping part, an oil pipe reciprocating slide system, a loading system, a frictional force transducer, a medium circulation system and a temperature control system. The oil pipe clamping part and the test piece clamping part are all arranged in the test box, and after the oil pipe clamping part clamps an oil pipe and the test piece clamping part clamps a test piece, the test piece presses the oil pipe. The oil pipe clamping part and the oil pipe are all connected to the oil pipe reciprocating slide system. The loading system is acted on the test piece clamping part, and the frictional force transducer is acted on the oil pipe clamping part. The medium circulation system communicates with the test box, and the temperature control system is installed on the test box for controlling the temperature of a test medium. The apparatus simulates the actual working condition of a sucker rod and oil pipe frictional pair in an oil well and can accurately evaluate the wear resistance of a pipe rod material, so that guide is provided for adopting specific anti-eccentric wear measures for anti-eccentric wells.

Owner:CHINA PETROLEUM & CHEM CORP +1

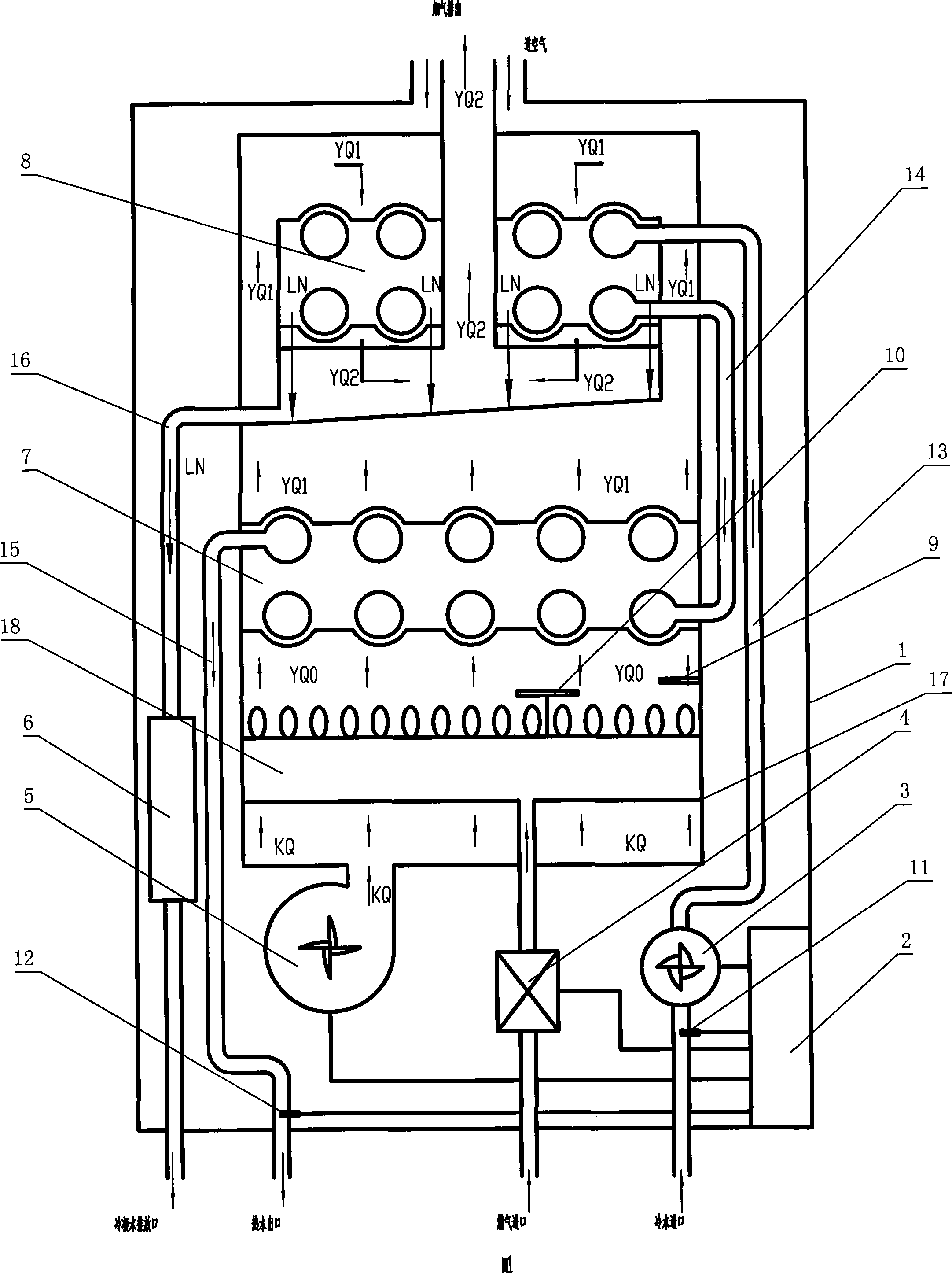

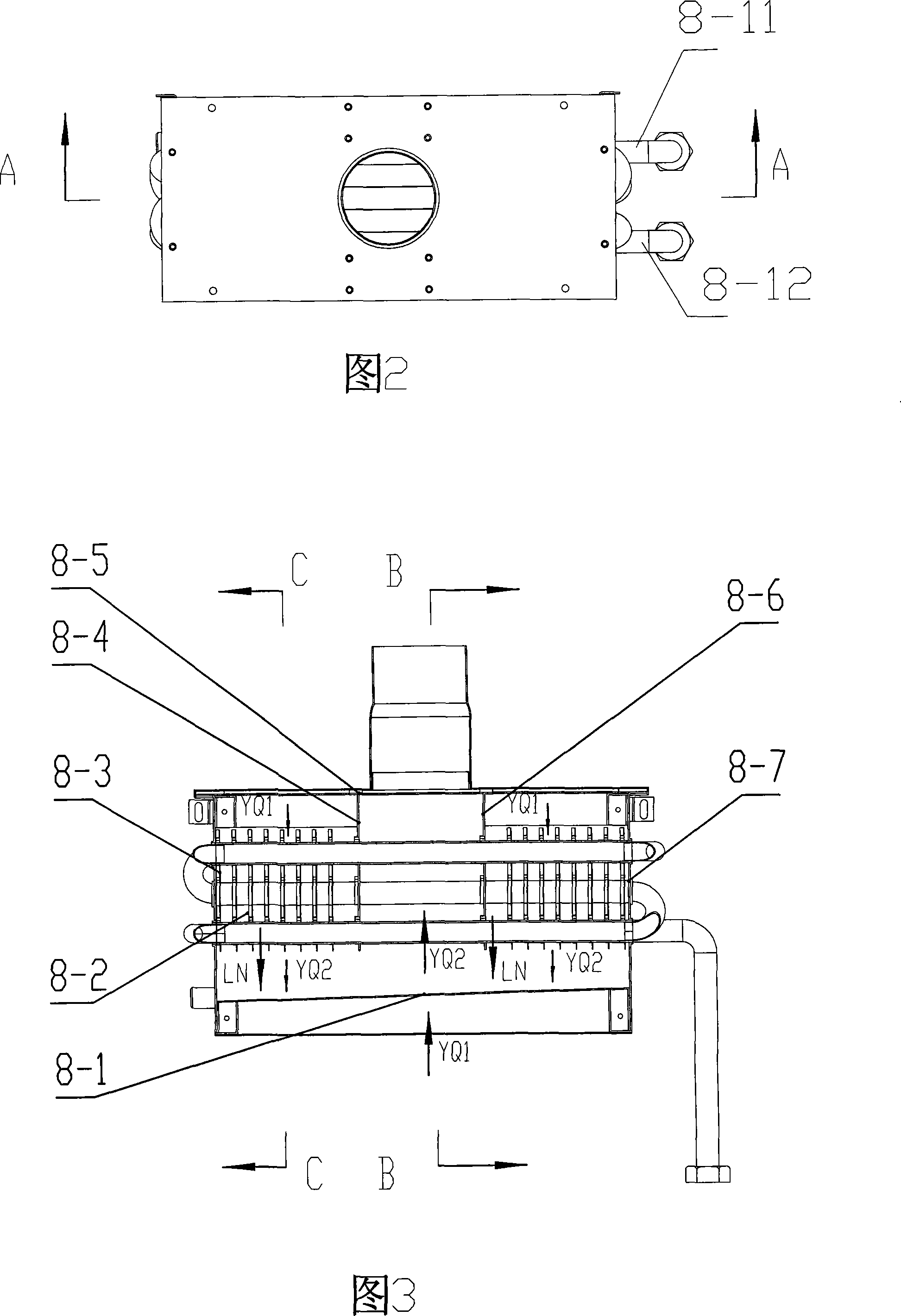

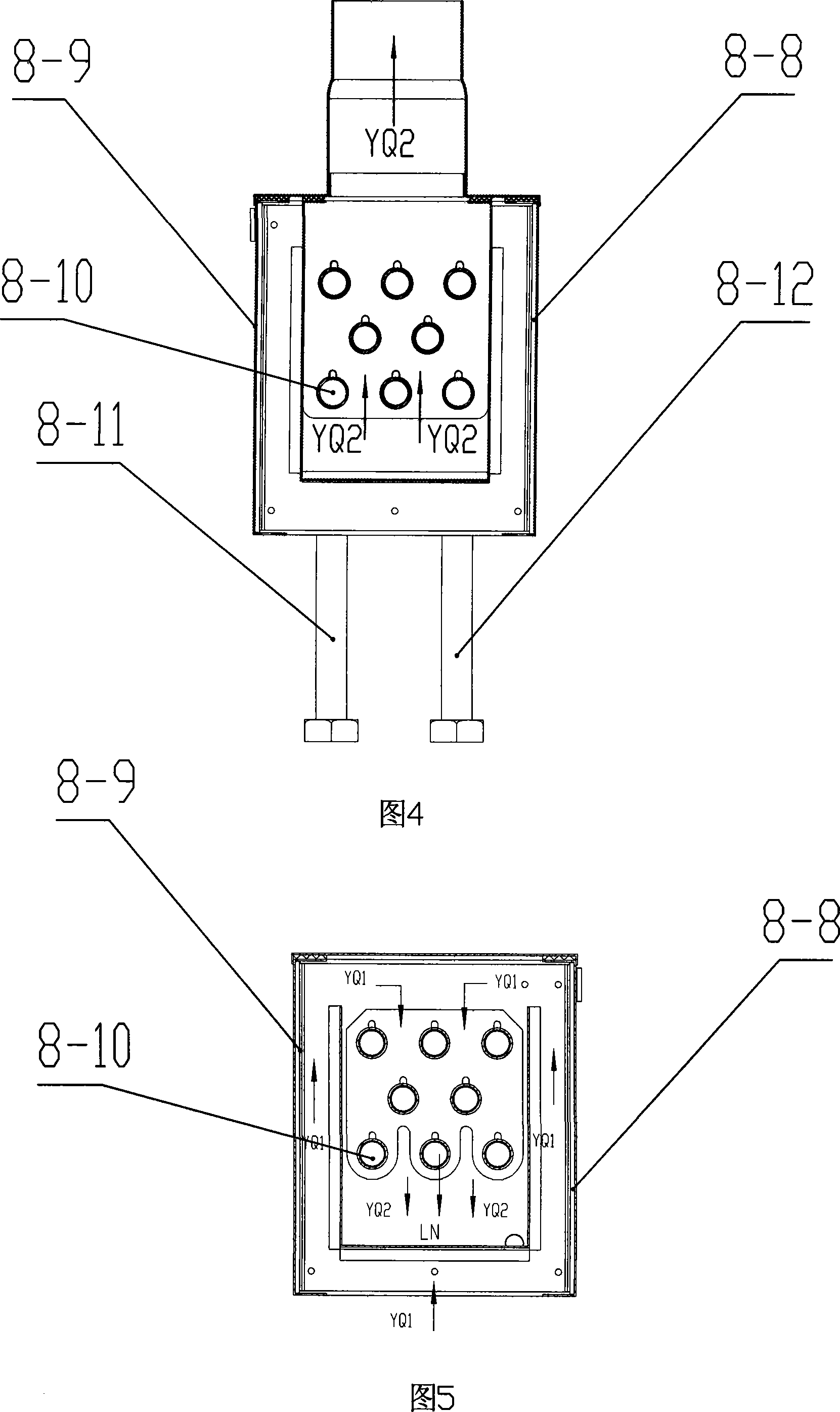

Condensing gas water heater and flue gas flowing mode

The invention discloses a condensed gas water heater, which is characterized in that: a main heat exchanger (7) and an auxiliary heat exchanger (8) inside are arranged from upper to lower in sequence, and waterways of the two are connected through pipelines. The invention is characterized in that: the lower end of the auxiliary heat exchanger (8) is formed with a water collecting cavity (8-1) in one body; a smoke cap is positioned outside the auxiliary heat exchanger (8-1); a smoke discharge cylinder is arranged in the middle of the auxiliary heat exchanger (8), which is communicated with the water collecting cavity (8-1) with the lower end and the upper end extending out from the auxiliary heat exchanger. The invention has the advantages of simple structure, high heat efficiency and the integration of functions as heat collecting and exchanging, condensed water collecting and smoke discharging.

Owner:成都前锋电子有限责任公司

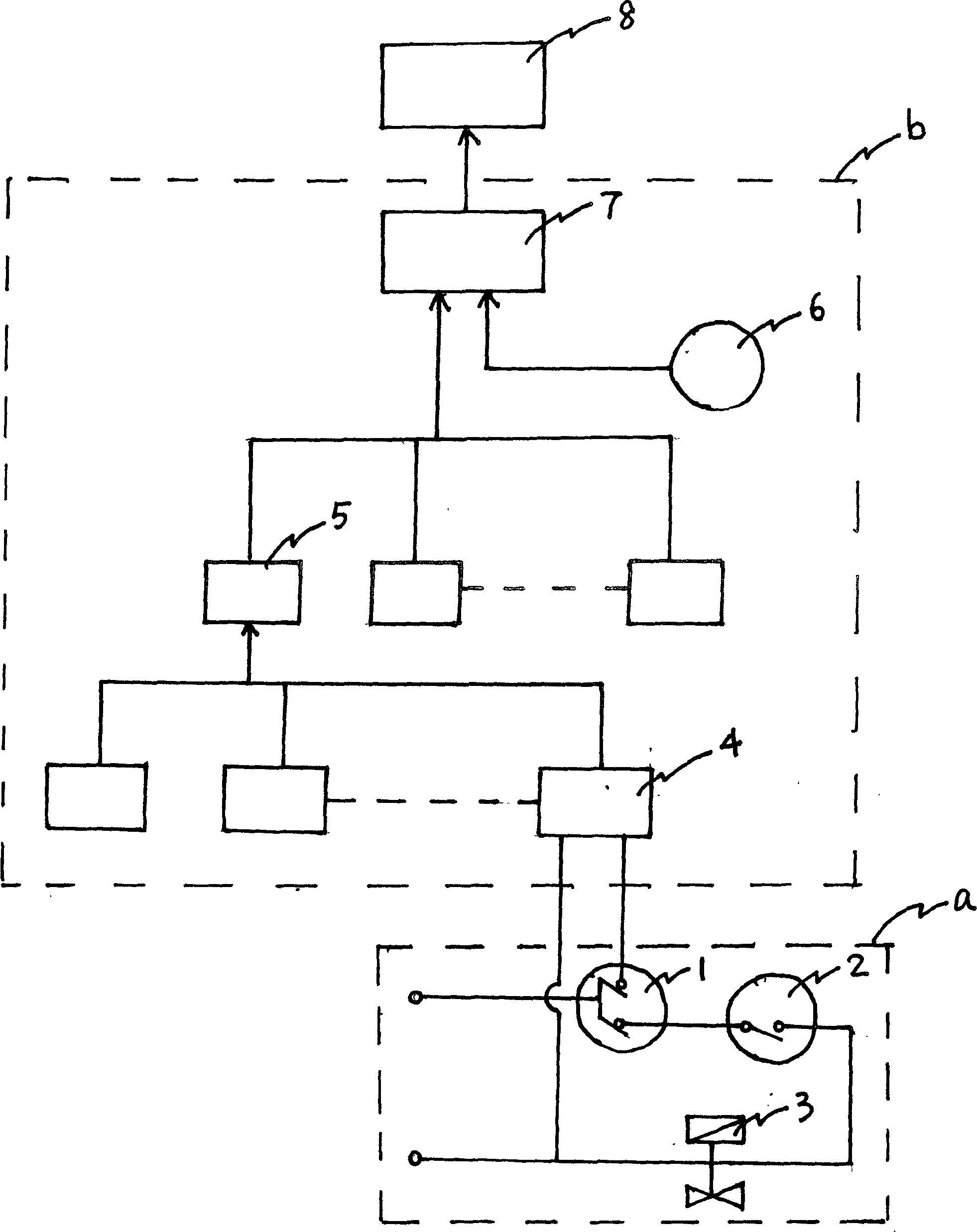

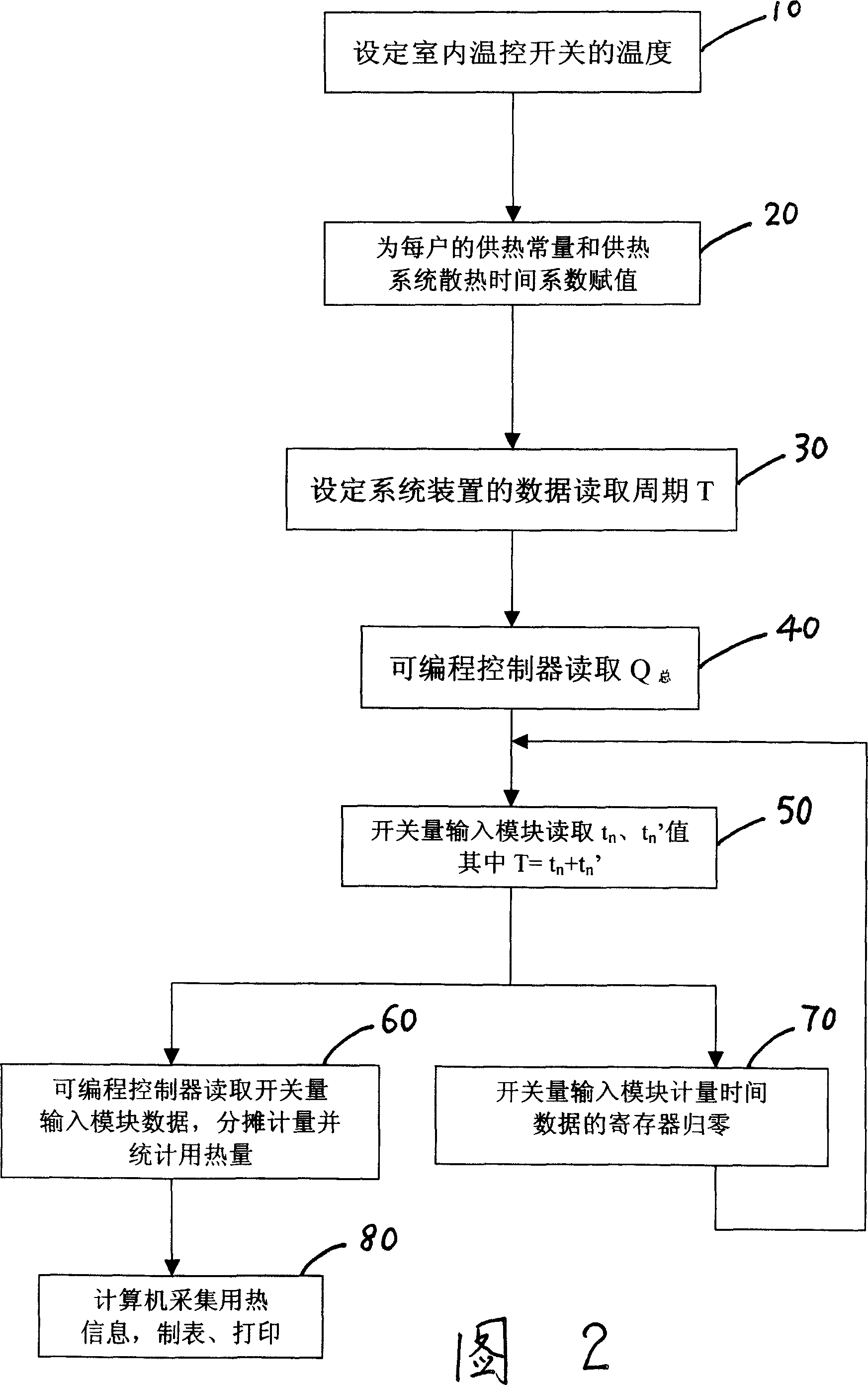

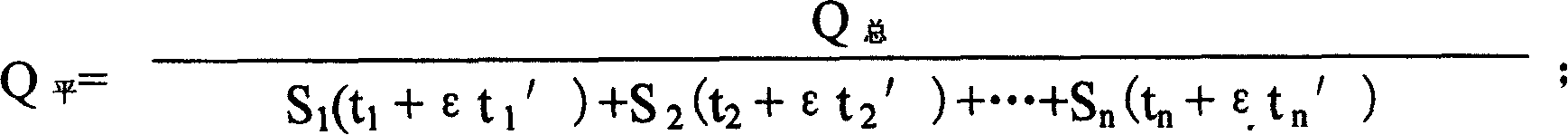

Method for measuring quantity of heat consumed by each home under identical temperature

InactiveCN1687726AAchieve constant temperature controlEasy to understandCalorimeterTemperature controlComputer module

The invention is a method for measuring quantity of heat consumed by each home with the same house temperature. The method is to use indoor constant temperature control circuit a composed of the double-pole switch, the temperature-control switch and the electromagnetic valve series connecting; the signal circuit b composed of the relay, the switch amount input modules and the programming controller and the heat metric form; the system device composed of the terminal reading heat metric computer 8 and the corresponding programs to measure the heating using amount of every user. The measuring method is: first set the temperature switch under the same temperature, then use the system device to record the gross heat using amount and the heating using and non-using times of every user in stated time. Because the heat supplying area is known, so the invention can calculate the heat using amount of every use in the stated time to solve the practical problem.

Owner:吴大河

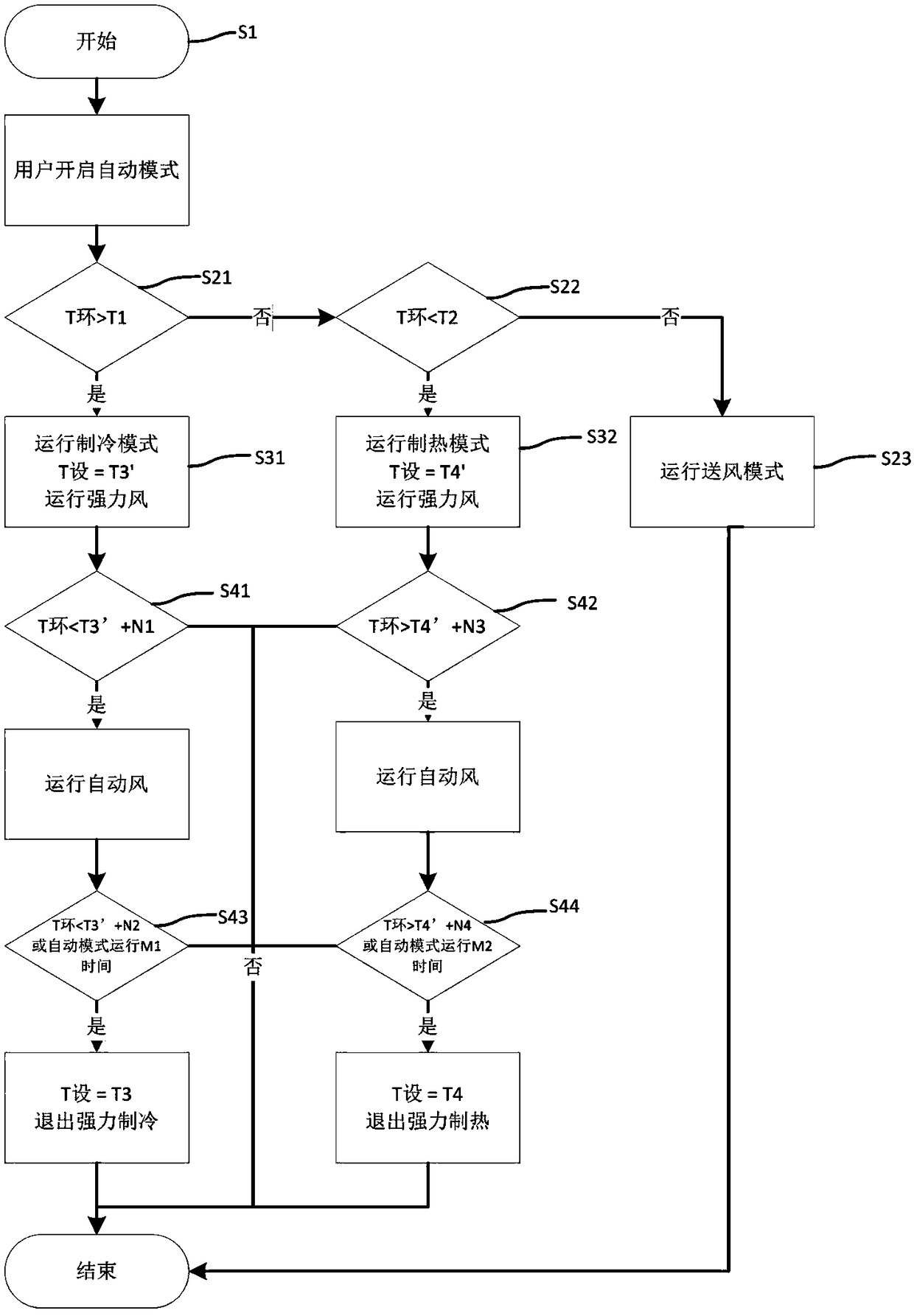

Air conditioner and control method for achieving rapid heating and cooling of air conditioner

InactiveCN108759014ARapid cooling and heatingImprove comfortMechanical apparatusSpace heating and ventilation safety systemsEngineeringOperation mode

The invention provides an air conditioner and a control method for achieving rapid heating and cooling of the air conditioner. The control method comprises the following steps that an operation mode is automatically determined according to current indoor environment temperature, and the current indoor environment is heated or cooled according to the determined operation mode; the indoor environment temperature is increased or decreased to the current indoor environment reference temperature corresponding to the operation mode; and after the indoor environment reference temperature reaches a first preset temperature set by the automatic mode, the temperature is automatically adjusted to a second preset temperature set by the automatic mode, and the operation state of the air conditioner isadjusted according to the second preset temperature set corresponding to the current mode. By means of the control method for achieving the automatic mode of rapid heating and cooling of the air conditioner, the purpose of rapid cooling and heating can be achieved, and the effect that users feel cool or warm rapidly after turning on the air conditioner is achieved.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

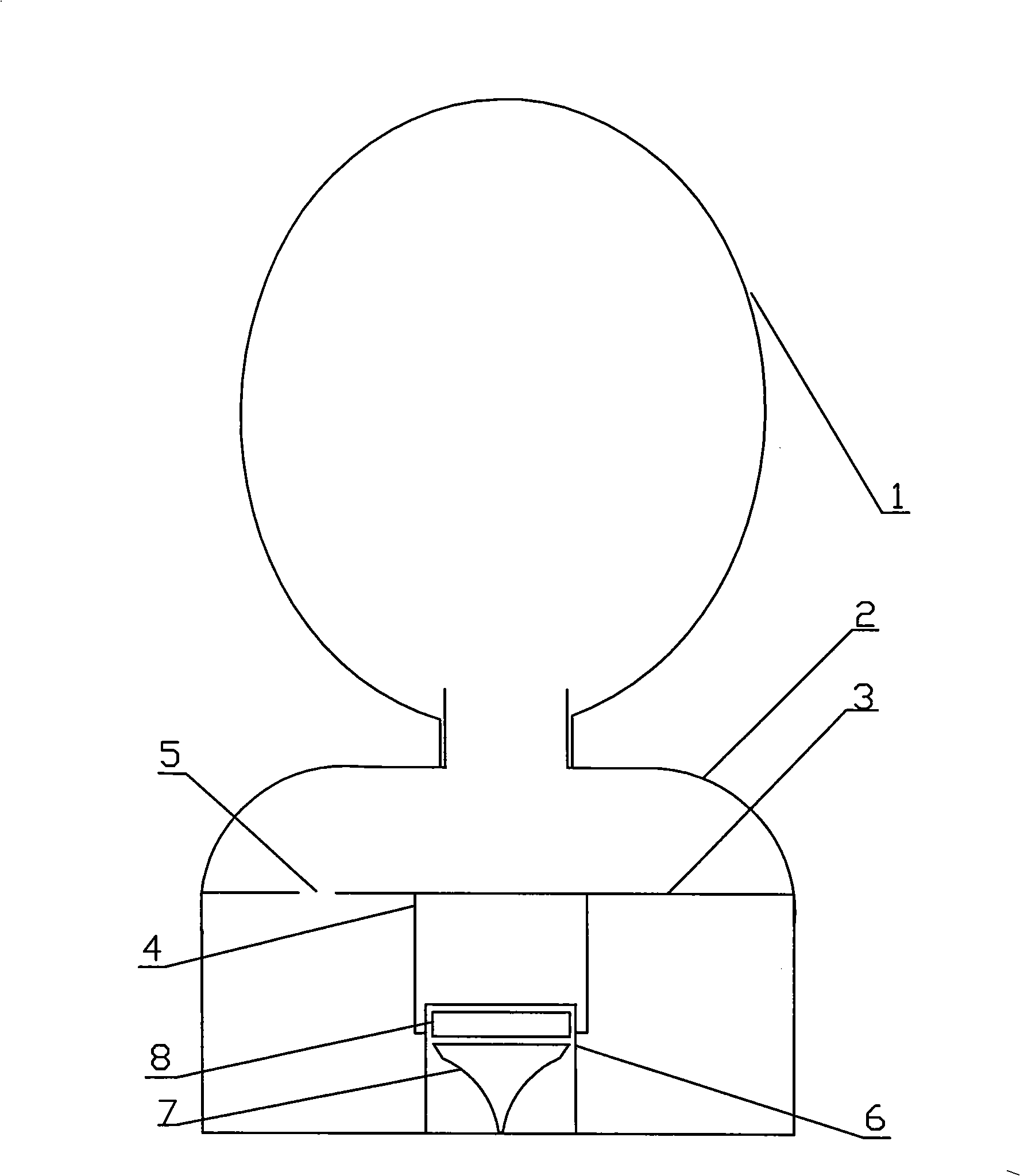

Fire cupping type acupuncture and moxibustion device

InactiveCN101313878AAchieve constant temperature controlThermomagnetic therapy works wellDevices for heating/cooling reflex pointsDevices for pressing relfex pointsNeedle penetrationScars

The invention relates to a cupping type acupuncture instrument, comprising a rubber air bag, a cup body, a fixed plate, magnetic needles, a medicine hopper and a thermostatic apparatus, wherein, the rubber air bag is in closed connection with the cup body; the cup body is provided with the fixed plate which is provided with the thermostatic apparatus; and the magnetic needles are arranged under the thermostatic apparatus. The cupping type acupuncture instrument integrates a cupping, needle warming moxibustion and magnetic needles into a whole, realizes various treating efficacies in one treatment; the magnetic needles do not penetrate into skin, so the patient does not bear the pain caused by the penetration of the needles in the treating process; and the needle warming moxibustion realizes thermostatic control, so the skin can not be scalded due to overhigh temperature in the treatment and scars do not occur on treated positions.

Owner:郭辉

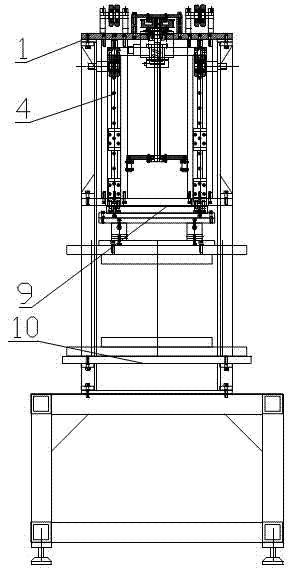

Intelligent hot press and hot pressing control method thereof

ActiveCN102729503AReduce defective rateImprove hot pressing performance and product qualityPress ramHot pressEngineering

The invention provides an intelligent hot press and a hot pressing control method thereof. The intelligent hot press comprises a rack, a control mechanism, a limiting mechanism, a locating and guiding mechanism, an upper workbench plate and a lower workbench plate, wherein the control mechanism is arranged on the rack and realizes segmental hot pressing control on a mold through a servo motor so as to form segmental hot pressing forming; the limiting mechanism is arranged on the rack and used for realizing limiting on the hot pressing position; the locating and guiding mechanism is fixed on the rack and used for realizing locating and guiding of a hot pressing route; the upper workbench plate is connected with the control mechanism and realizes downward pressing and backward pressing movement through the locating and guiding mechanism; and the lower workbench plate is fixedly arranged on the rack. According to the invention, segmental hot pressing control on the mold is realized through the servo motor of the control mechanism so as to form flexible and controllable segmental hot pressing forming, thus enabling hot-pressed products to have no breakage, greatly reducing the rejection ratio, improving the product quality and prolonging the service life.

Owner:SHENZHEN HOCHUEN TECH

Automatic lifting rice frying machine

The invention discloses an automatic lifting rice frying machine. The automatic lifting rice frying machine mainly comprises a stirring strip used for stir-frying food, a roller used for turning the food, a pot body used for driving the roller to conduct stir-frying and rotating, a supporting base used for bearing the pot body and achieving automatic lifting and falling and a base used for controlling the supporting base and the pot body to move. After a power source is plugged into the rice frying machine, a standby state is entered, the lifting button is pressed before work, a turning motoris started, the pot body and the roller are driven to turn downwards to a proper position, a user puts prepared foodstuff (rice, noodles, rice noodles and the like) into the roller, after the startingbutton is pressed, the turning motor is started, the pot body and the roller are driven to turn upwards to the working position, a control board drives a rotary motor and a heating coil to work, so that the roller and the stirring strip conduct differential rotation under the effect of electromagnetic heating, and the food is stir-fried. The automatic lifting rice frying machine also has the advantages of being simple in structure, convenient to operate and low in cost.

Owner:佛山市顺德区天思电器有限公司

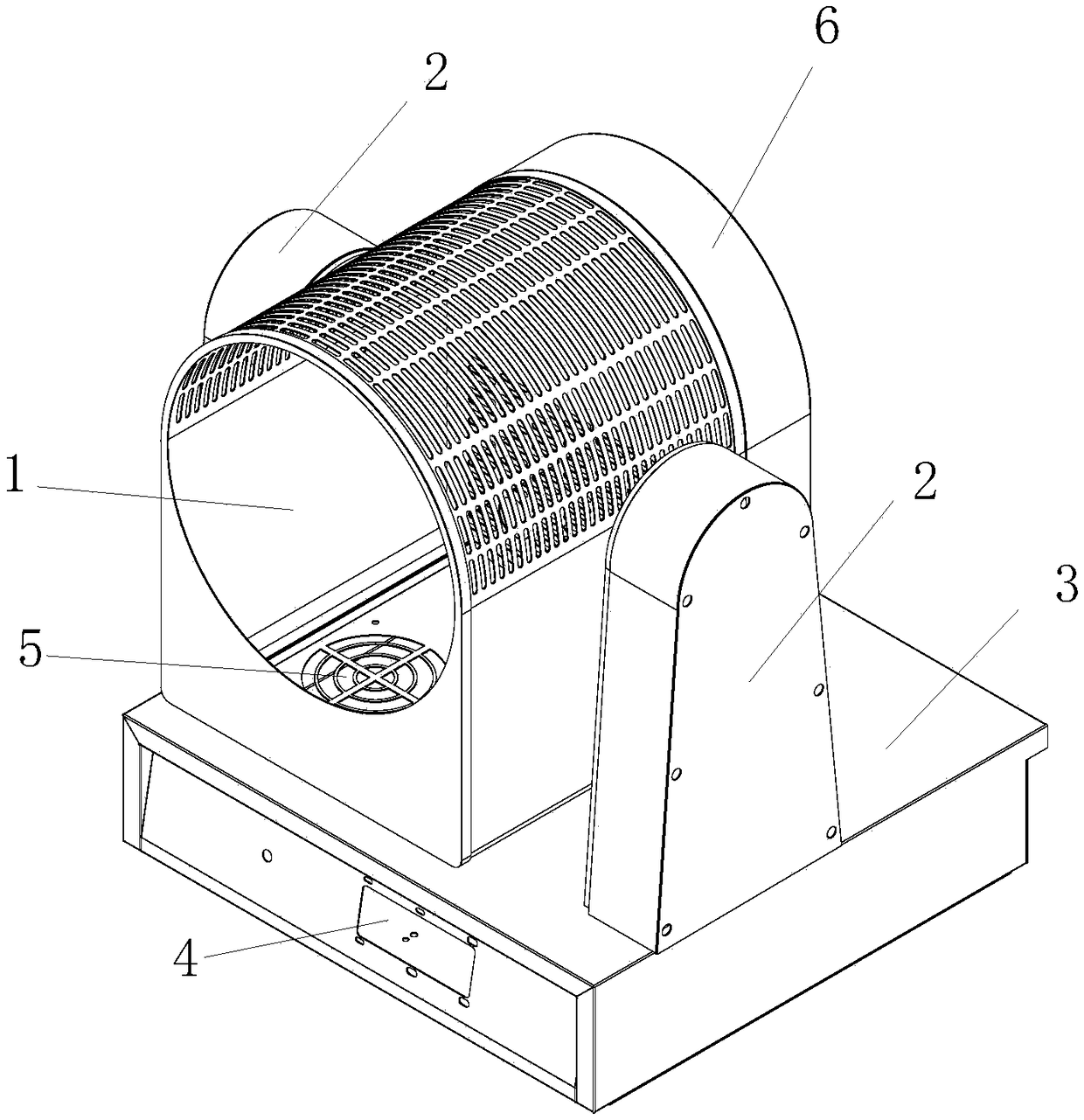

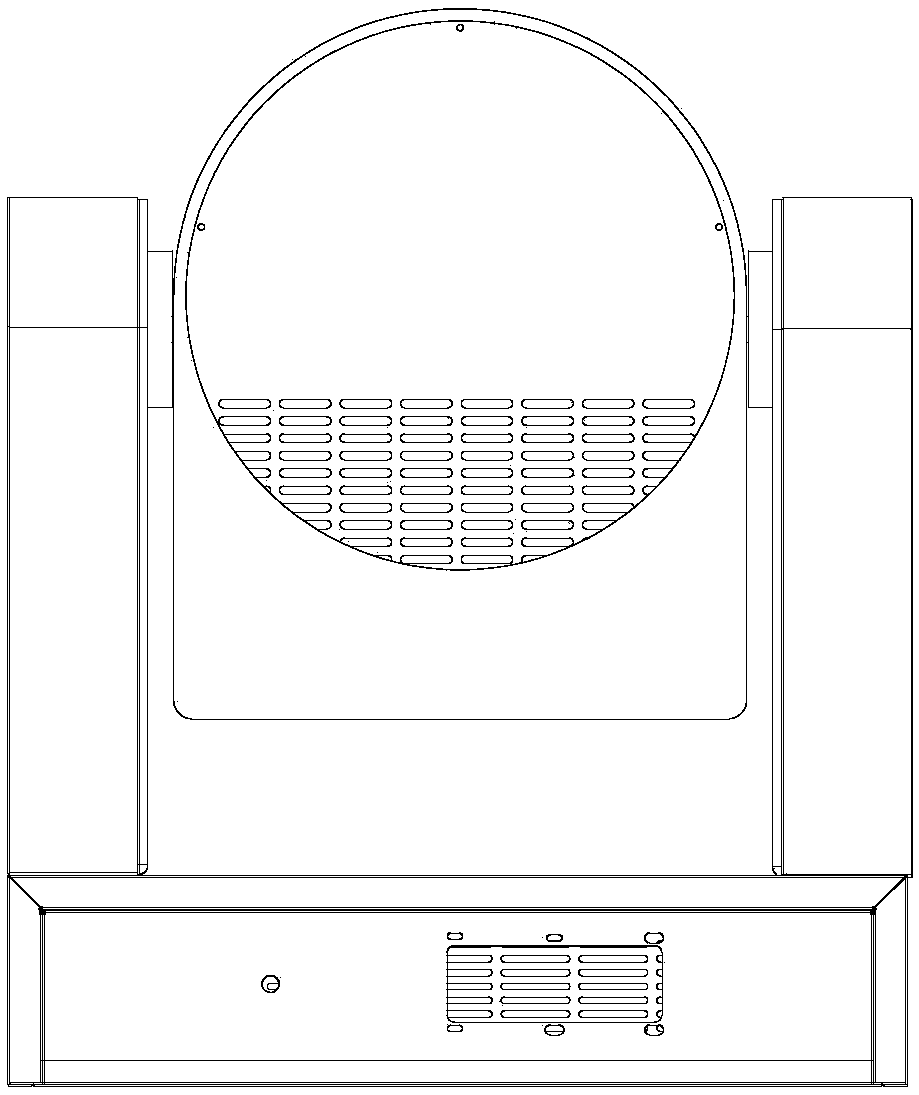

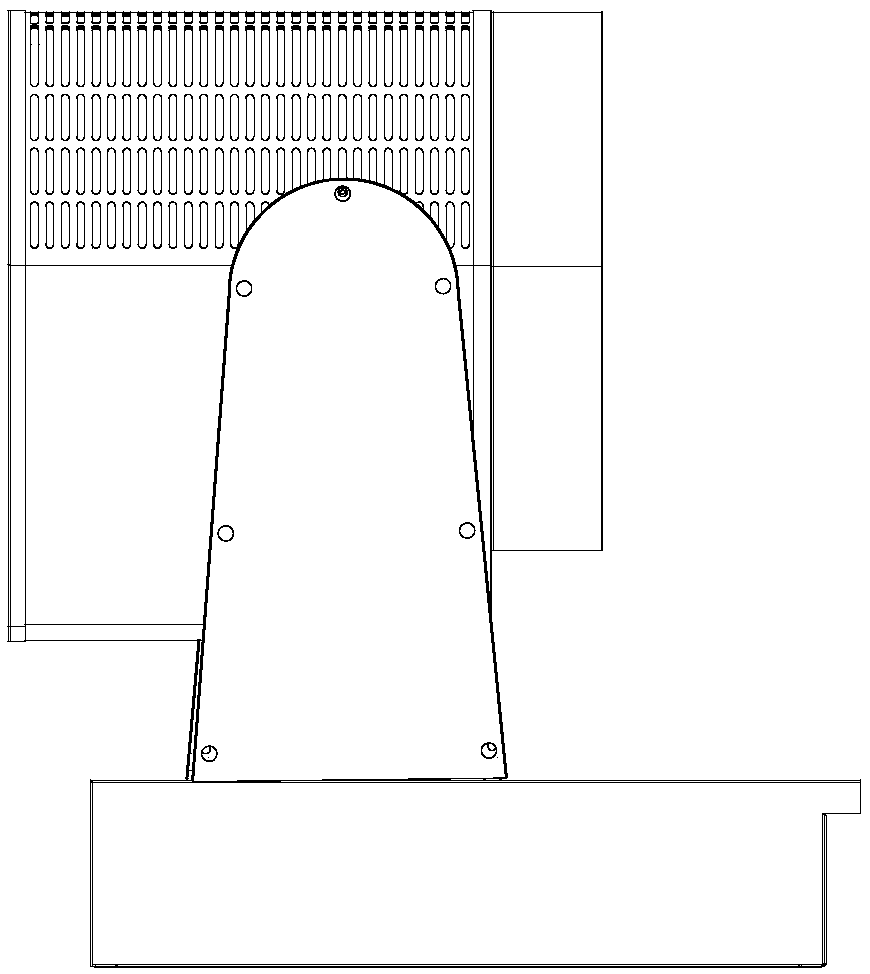

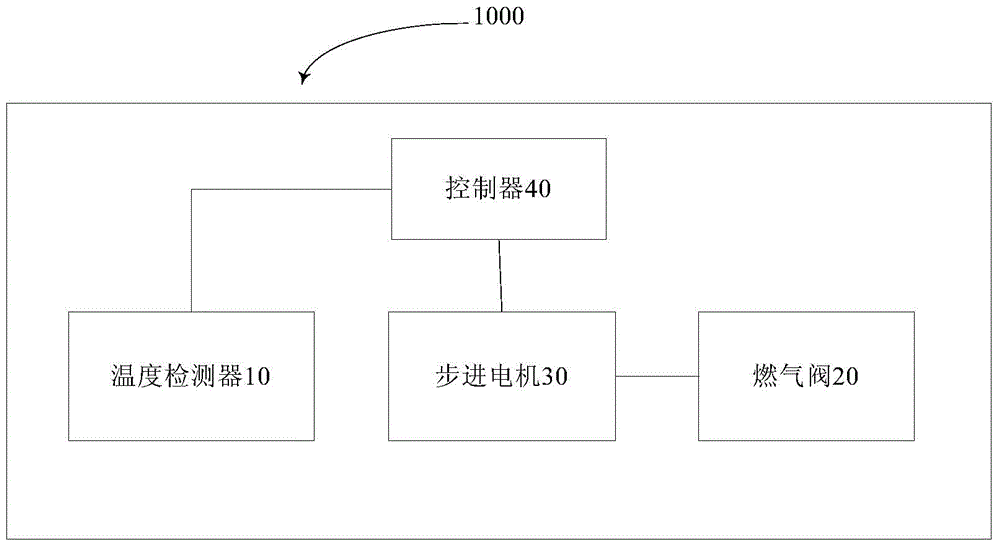

Gas water heater and constant temperature control device and method thereof

The invention discloses a gas water heater and a constant temperature control device and a constant temperature control method thereof. The constant temperature control device for the gas water heater comprises a temperature detector, a stepping motor and a controller, wherein the temperature detector is used for detecting an outlet water temperature of the gas water heater; the stepping motor is used for regulating the opening of a gas valve of the gas water heater; the controller is used for controlling the stepping motor to regulate the opening of the gas valve according to the outlet water temperature and a target temperature of the gas water heater so as to control the outlet water temperature. According to the gas water heater and the constant temperature control device and the constant temperature control method thereof, which are disclosed by the invention, constant temperature control on the outlet water temperature can be implemented, the gas water heater is enabled to output constant-temperature hot water constantly; control is accurate to carry out; the requirements of users are met.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

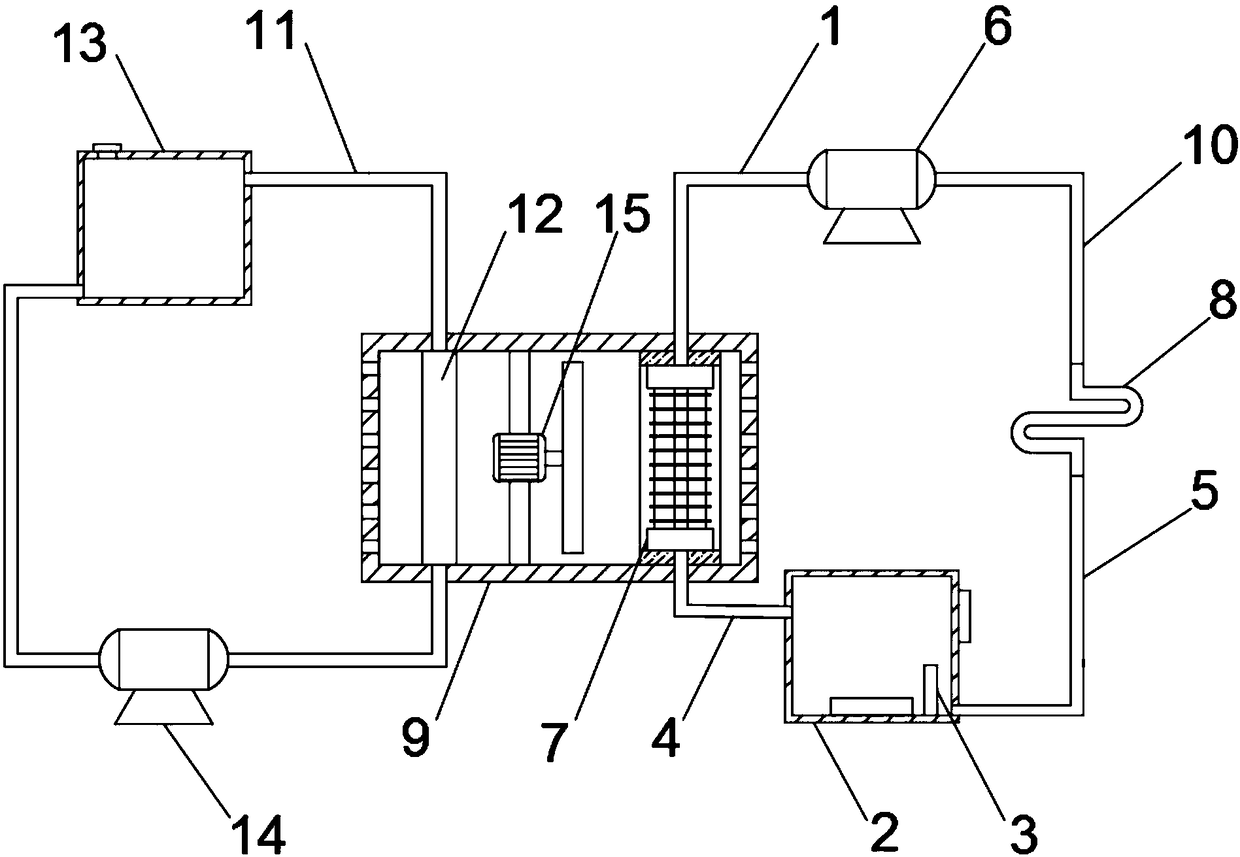

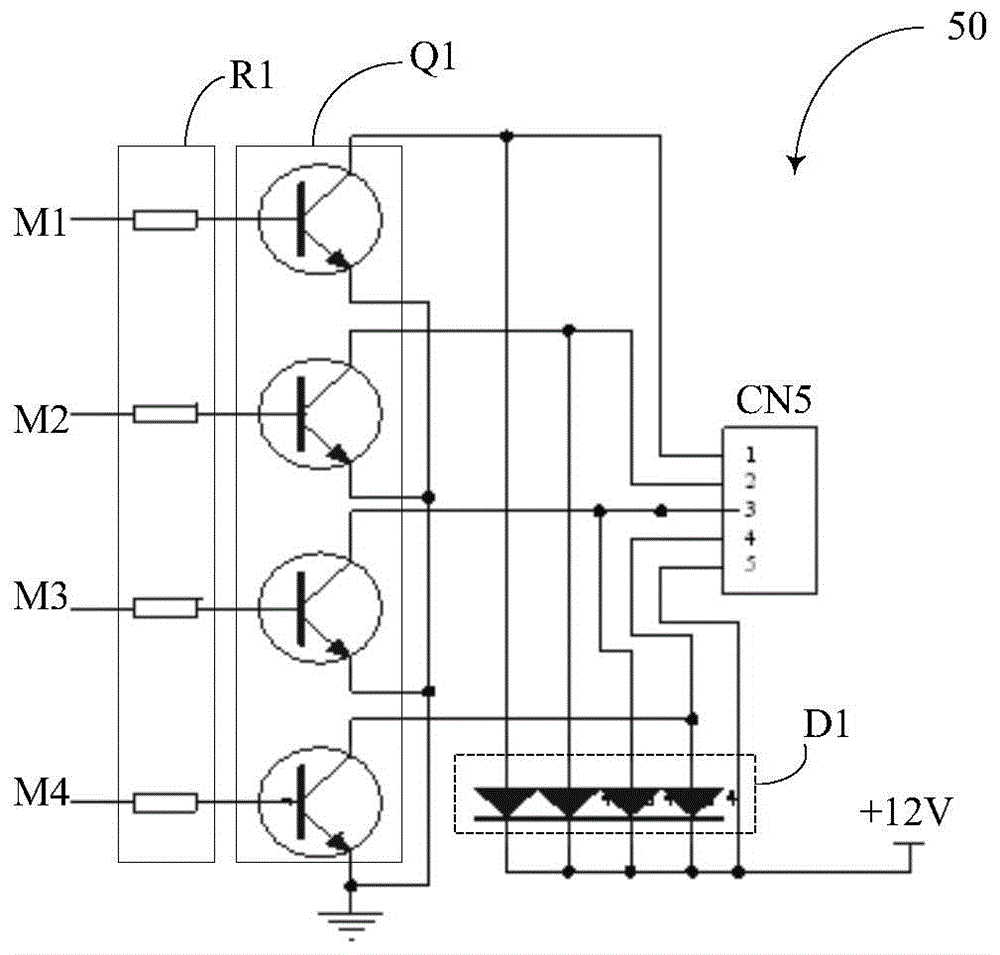

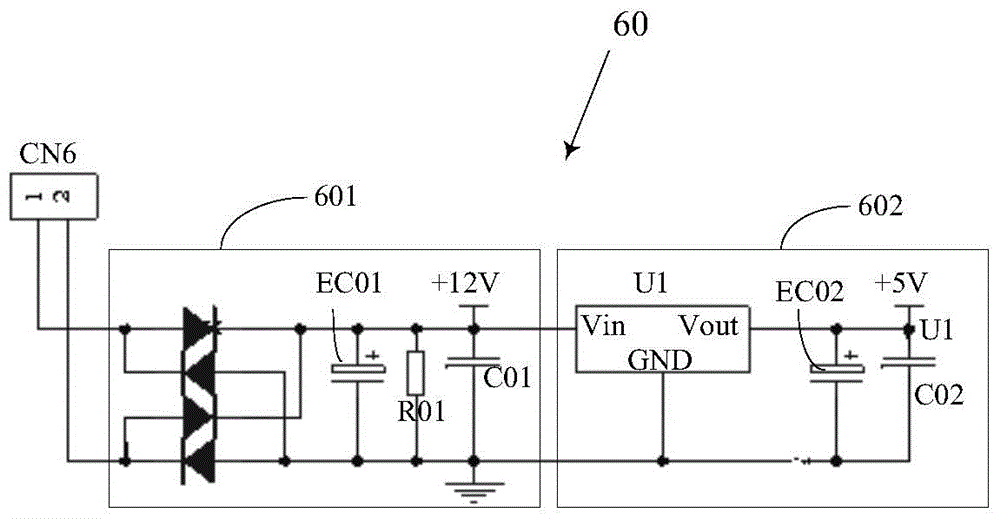

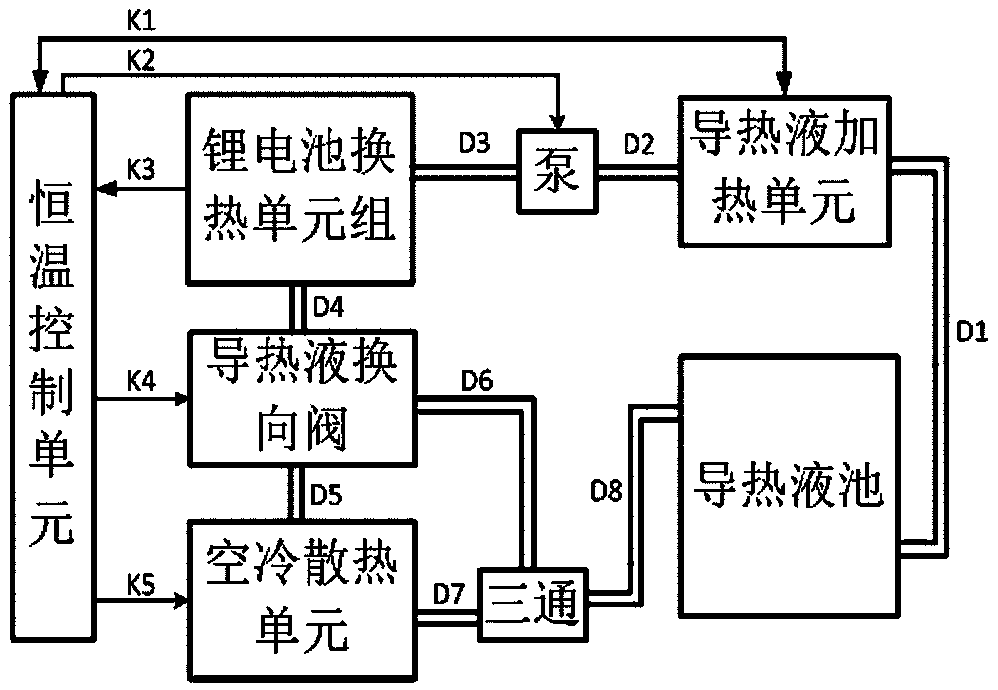

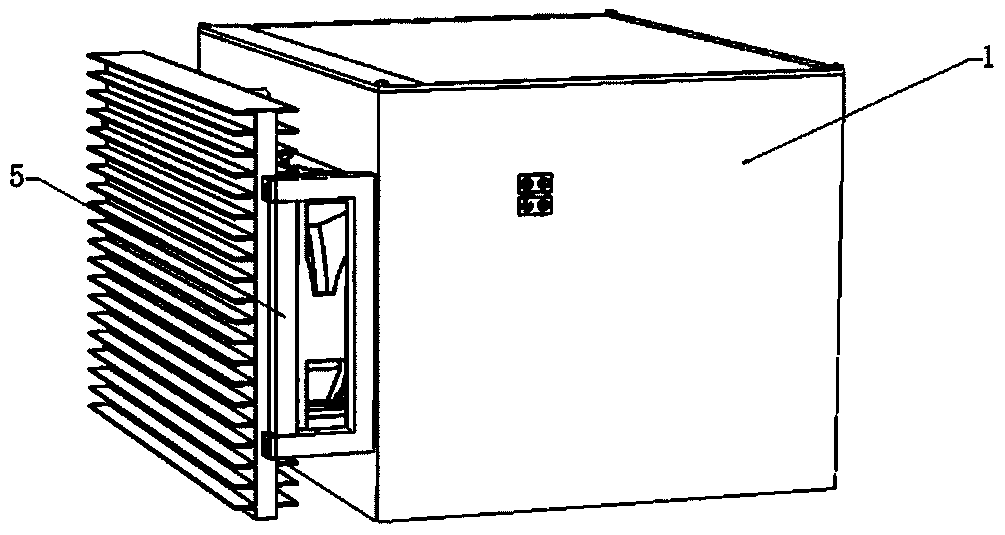

Lithium battery constant temperature device

InactiveCN110444832AAchieve constant temperature controlLittle impact on performanceSecondary cellsCell component detailsTemperature controlElectrical battery

The invention belongs to the field of constant temperature devices, and particularly relates to a lithium battery constant temperature device. The lithium battery constant temperature device comprisesa constant temperature heat insulation box; the constant temperature heat insulation box has a sandwich structure and comprises a heat exchange part and a control part; the constant temperature heatinsulation box is connected with an air-cooled heat dissipation unit; the constant temperature control unit is also connected with a lithium battery heat exchange unit, a heat conducting fluid reversing valve, the air-cooled heat dissipation unit, a pump and a heat conducting fluid heating unit; the lithium battery heat exchange unit is connected with the heat conducting fluid heating unit throughthe pump; the heat conducting fluid reversing valve is connected with the lithium battery heat exchange unit and the air-cooled heat dissipation unit; the heat conducting fluid heating unit is connected with a heat conducting fluid pool; and the heat conducting fluid pool is connected with the heat conducting fluid reversing valve and the air-cooled heat dissipation unit through a tee joint. Thelithium battery pack can be made to constantly work in the best temperature range, the service life of the battery is prolonged, and the safety is improved. The lithium battery constant temperature device is used for constant temperature control on an electric vehicle lithium battery.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

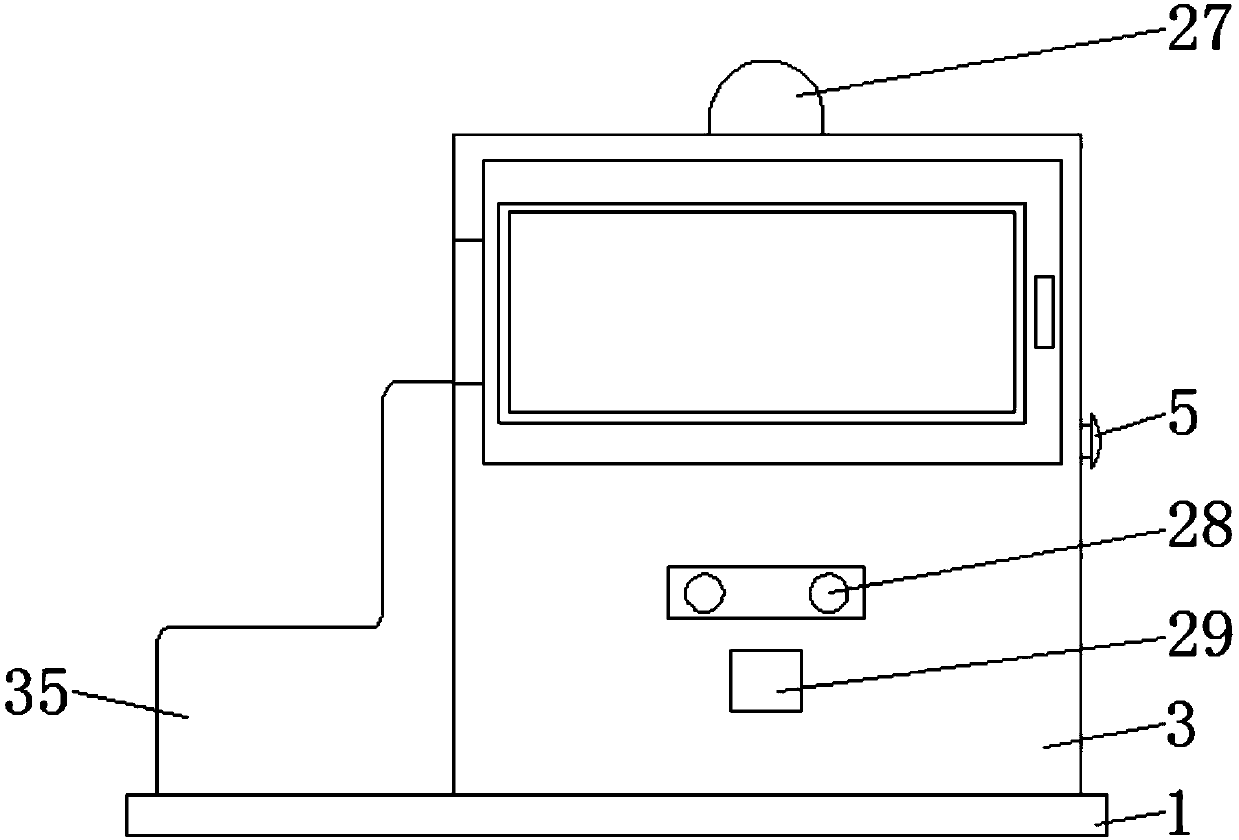

Mini type high temperature extruding forming machine

InactiveCN101091970AHigh replaceabilityAchieve constant temperature controlTemperature controlControl system

The invention is a small high temperature extrusion molding machine, belonging to the field of test apparatus for scientific research labs, comprising: oil pressure system, mould system, temperature control system and pressure control system, and characterized in that: the mould base in the mould system adopts a push-pull slide plate form. And the laboratory apparatus directly adopts proper mould to mould test piece once, thus saving resources and experimental materials, and having higher economic benefits and practicality.

Owner:张雯

Novel incubator with automatic uniform shaking device

ActiveCN107603879ASwing back and forthRealize rotation and shakingBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic controlBiochemical engineering

The invention discloses a novel incubator with an automatic uniform shaking device, relating to the technical field of medical instruments. The novel incubator comprises a bottom plate and a shaking tank, wherein an incubator is fixedly connected with the top of the bottom plate; a first connecting shaft and a second connecting shaft are respectively fixedly connected with two sides of the shakingtank through connecting plates; one end, far away from the shaking tank, of the first connecting shaft, and one end, far away from the shaking tank, of the second connecting shaft, both penetrate through the incubator and extend outside the incubator; and a moveable sleeve is arranged in a sleeve manner on the outer surface of one end extending outside the incubator, of the first connecting shaft. By adopting the novel incubator with the automatic uniform shaking device, the uniform shaking effect is greatly improved, the uniform shaking efficiency is very well improved, cell culture liquid is uniformly shaken by culture operators within a relatively short time, the workload of the culture operators is alleviated, the purpose of rapidly, efficiently, automatically and uniformly shaking the culture liquid is achieved, and thus great convenience can be brought to cell culture operation of the culture operators.

Owner:广州和能生物科技有限公司

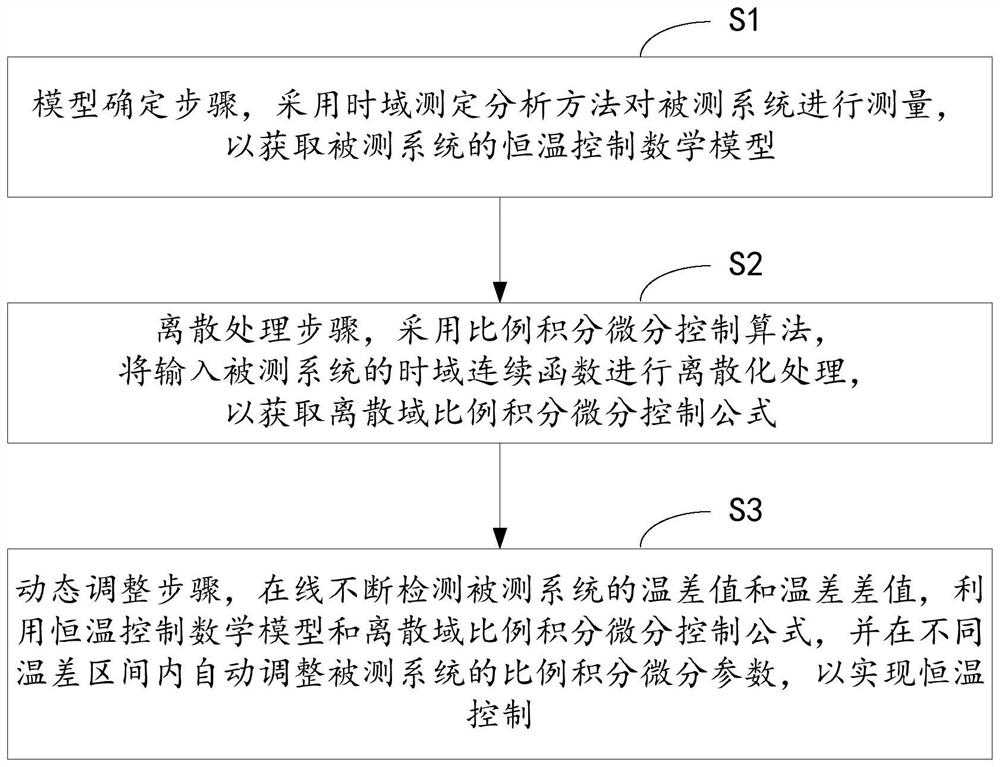

Constant temperature difference temperature control method and system, industrial control equipment and storage medium

PendingCN112578667AOvercoming Heat Transfer HysteresisAchieve constant temperature controlTemperature control using electric meansControllers with particular characteristicsProcess engineeringDiscretization

The invention provides a constant temperature difference temperature control method and system, industrial control equipment and a storage medium, and the method comprises a model determination step:employing a time domain measurement and analysis method to measure a measured system, so as to obtain a constant temperature control mathematic model of the measured system; a discretization processing step: adopting a proportional integral differential control algorithm to discretize the time domain continuous function input into the tested system so as to obtain a discrete domain proportional integral differential control formula; and a dynamic adjustment step: continuously detecting a temperature difference value and a temperature difference value of the measured system on line, and automatically adjusting proportional-integral-differential parameters of the measured system in different temperature difference intervals by utilizing the constant-temperature control mathematical model anda discrete domain proportional-integral-differential control formula so as to realize constant-temperature control. According to the technical scheme provided by the invention, the PID parameters areautomatically set in different temperature difference intervals by continuously detecting the temperature difference value and the temperature difference value on line, so that the hysteresis of heattransfer is overcome, and constant-temperature control is realized.

Owner:SHENZHEN HPMONT TECH

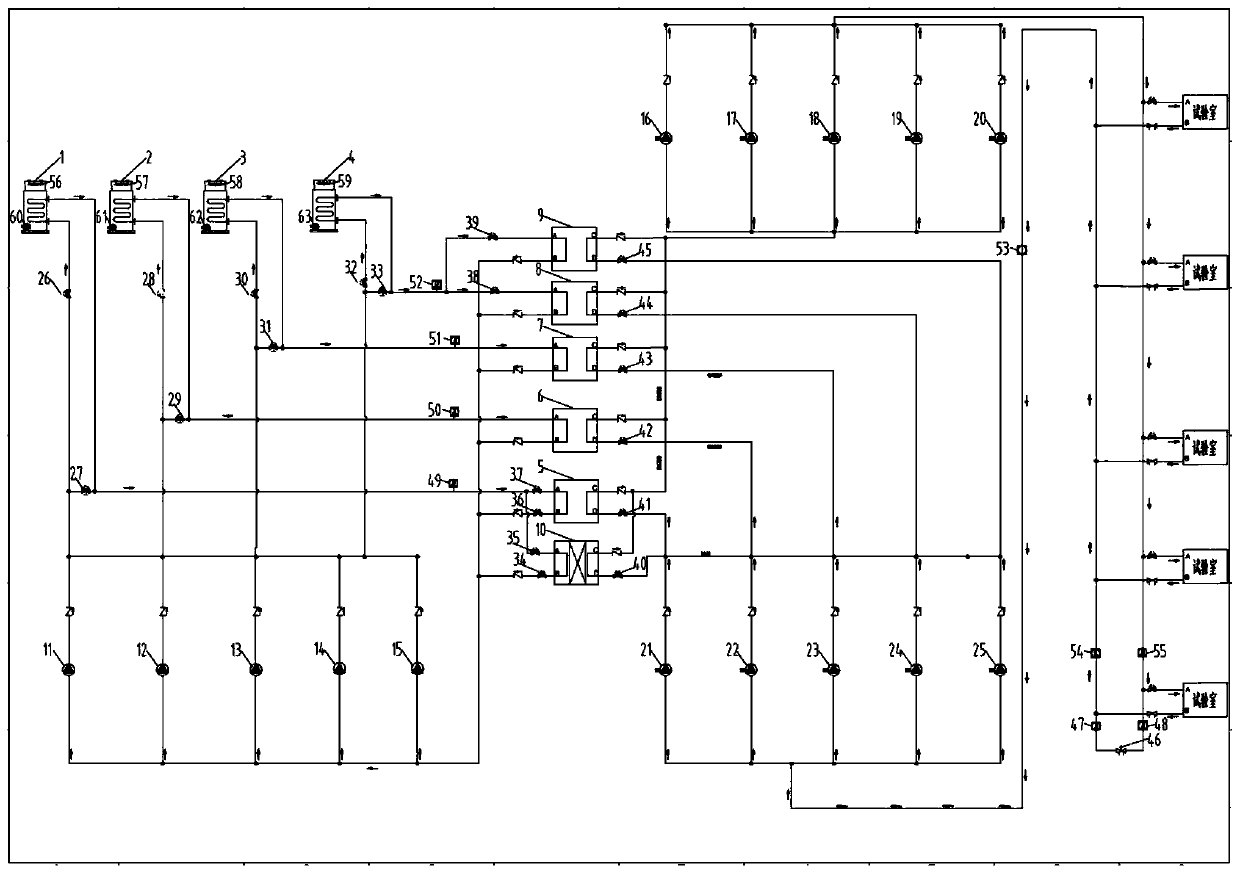

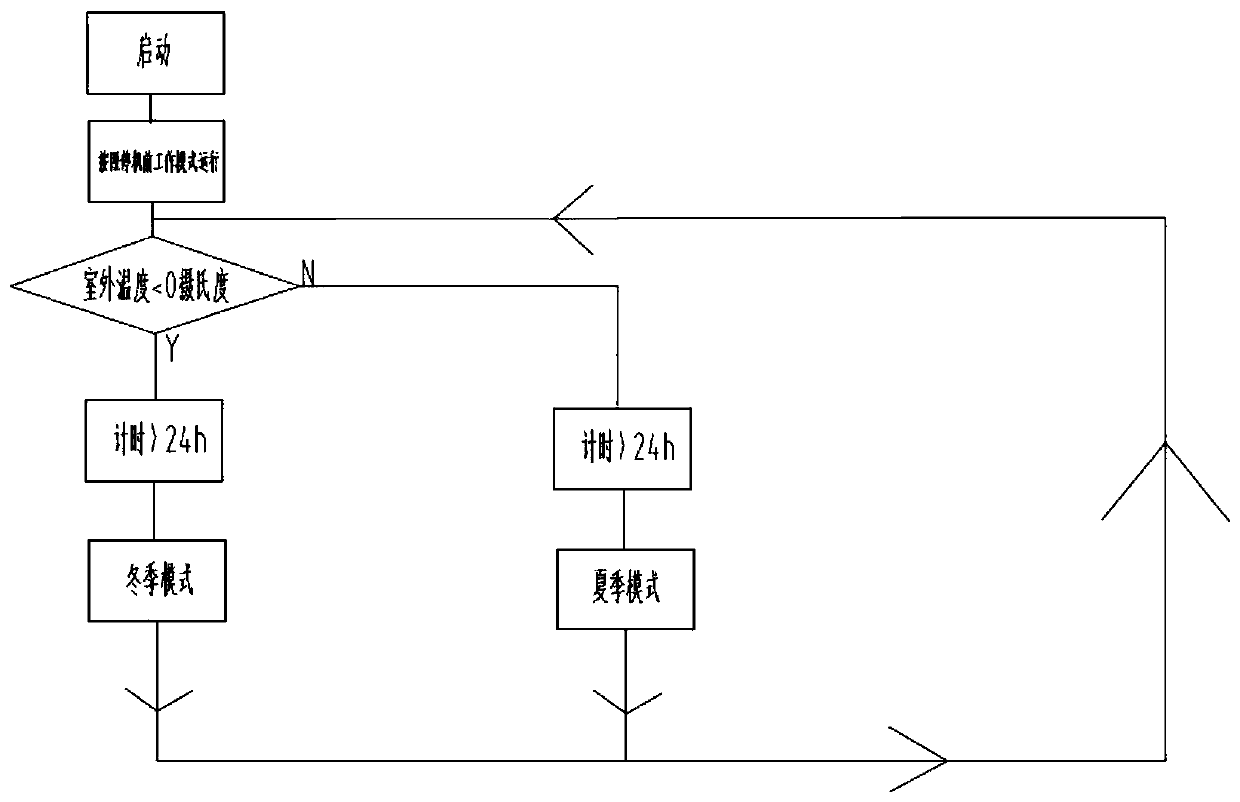

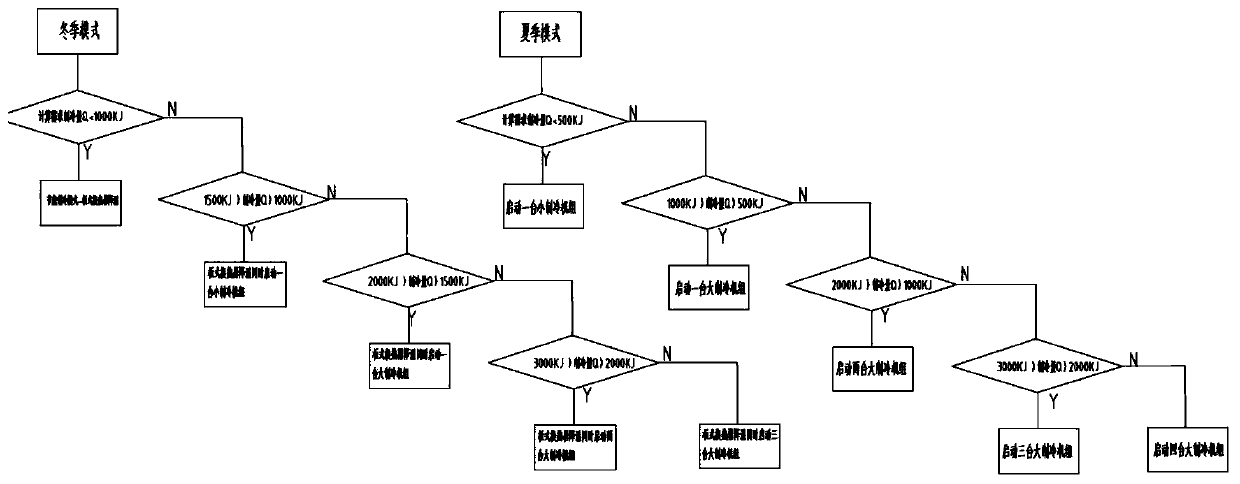

Process water energy-saving constant-temperature control system and control method

InactiveCN110195956AAchieve precise temperature controlSave electricityFluid circulation arrangementRefrigeration devicesEvaporatorMode control

The invention belongs to the technical field of laboratory process water systems, and relates to a process water energy-saving constant-temperature control system and control method. The system comprises a refrigerating unit cooling system and a process water system, wherein the refrigerating unit cooling system comprises four cooling towers, five refrigerating units and a plate heat exchanger; the process water system comprises a primary circulating pump and a secondary side circulating water pump; condenser outlets of the refrigerating units are connected with the cooling towers through water collectors of water inlets of the circulating water pumps, and return to condenser inlets of the refrigerating units through upper water tower valves and bypass valves; and evaporator outlets of therefrigerating units and a water collector pipeline of the primary circulating pump are connected with water supply of a laboratory, and the secondary side circulating water pump is connected to a laboratory water return pipeline through the water collector pipeline, is connected with a switch valve and is connected with evaporator inlets of the refrigerating units. The control method comprises the steps of working mode judgment, winter mode valve water pump control and summer mode control. According to the system, the constant-temperature control of the process water system is realized, namely, accurate temperature control is realized, and the electric energy is saved.

Owner:CHINA FIRST AUTOMOBILE

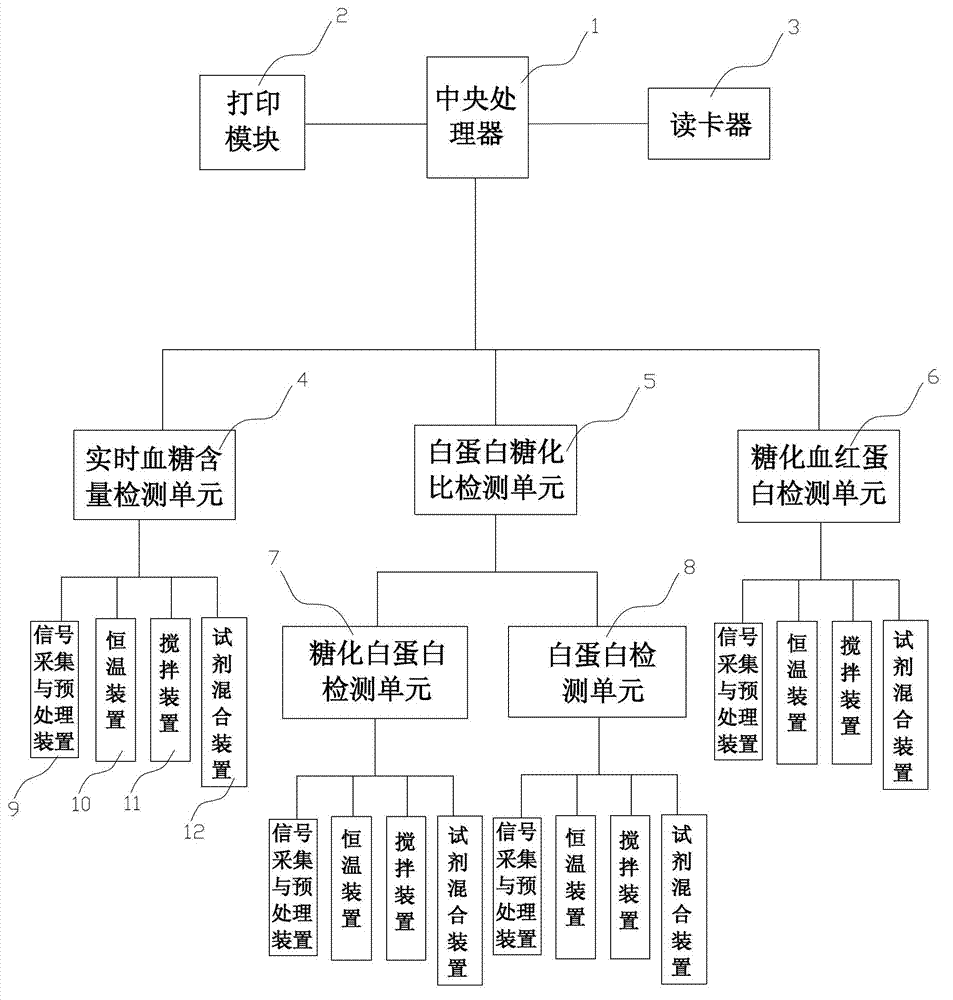

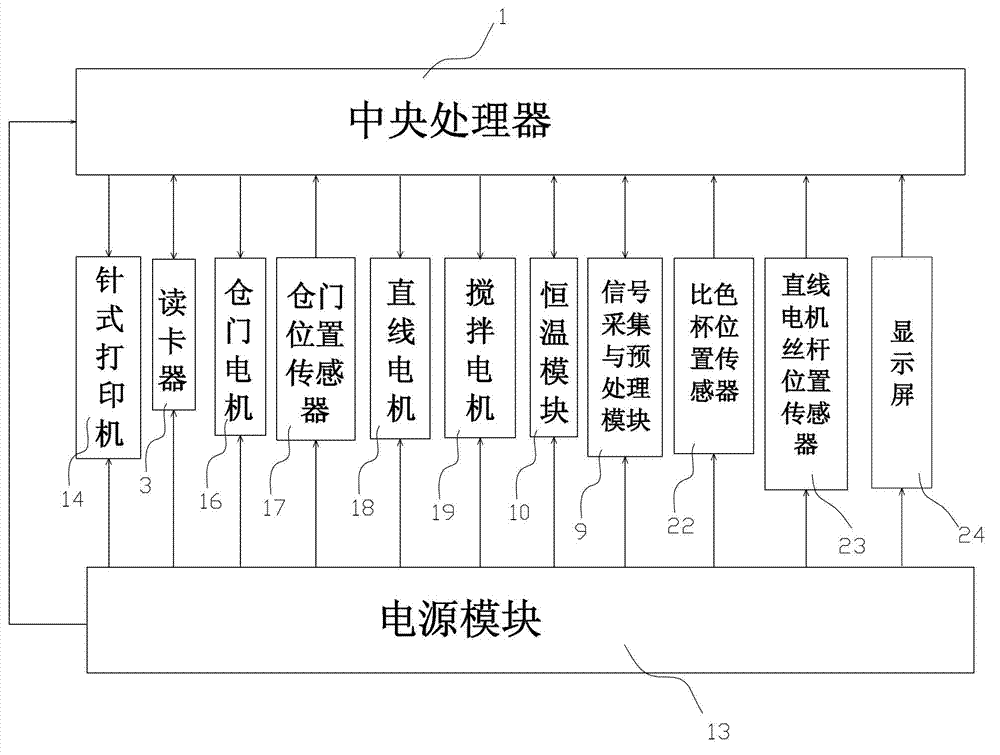

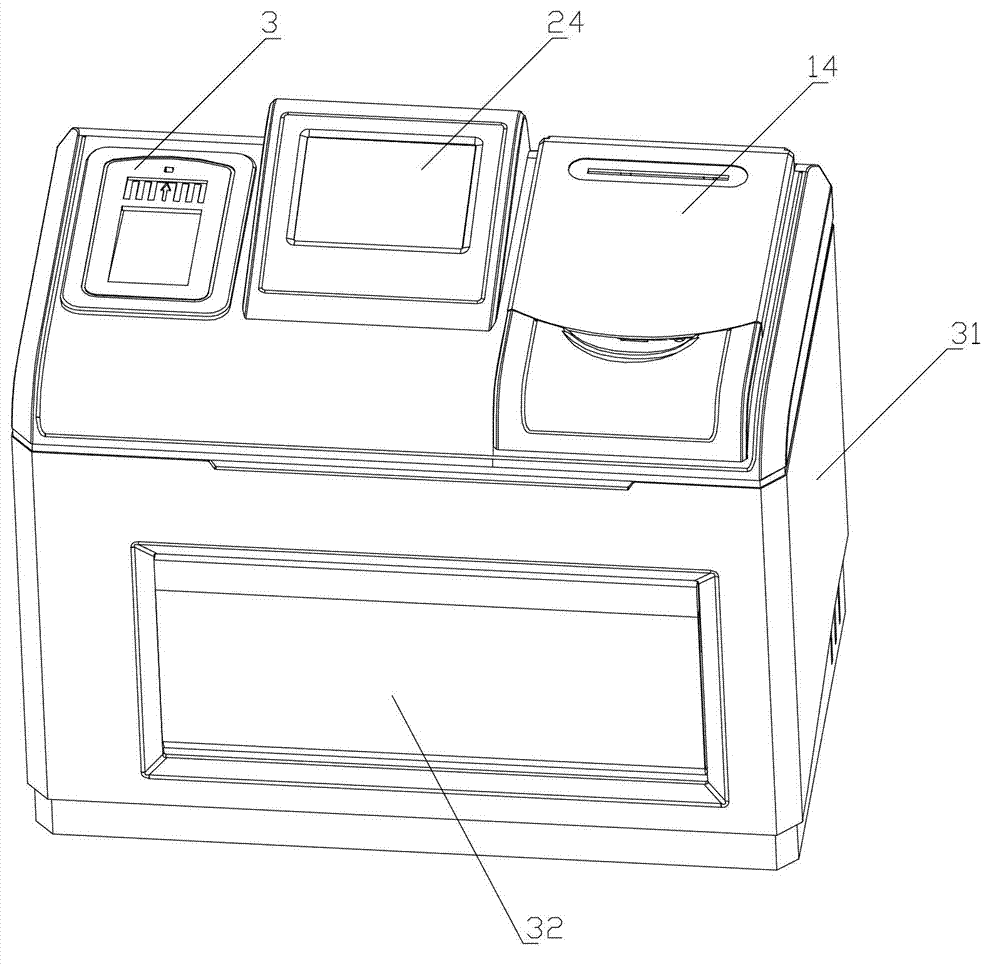

Diabetes detection analyzer

The invention relates to a diabetes detection analyzer, which comprises a detection analyzer body; a central processor, a power module and a real-time blood sugar content detection unit are arranged in the detection analyzer body; the real-time blood sugar content detection unit comprises a signal acquisition and preprocessing device based on a reagent absorbance analysis principle, a constant temperature device and a stirring device; a reagent cavity used for mounting a reagent to be tested is arranged on the constant temperature device; an albumin glycation ratio detection unit used for detecting the average blood sugar content of a patient in 2-3 weeks is also arranged in the detection analyzer body; and the albumin saccharification ratio detection unit comprises a glycated albumin detection unit and an albumin detection unit which have the same structure as the real-time blood sugar content detection unit. The diabetes detection analyzer is low in price and simple and convenient to use, and can be used for detecting the real-time blood sugar content and the average blood sugar content of 2-3 weeks in a blood sample of the patient at the same time.

Owner:宁波美康盛德生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com