Mini type high temperature extruding forming machine

A molding machine, high temperature technology, applied in the field of small high temperature extrusion molding machines, can solve the problems of inconvenient, non-specialized and non-automatic mold removal by a single mold, and achieve high economic efficiency and practicability, saving resources and saving. Effects of experimental materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

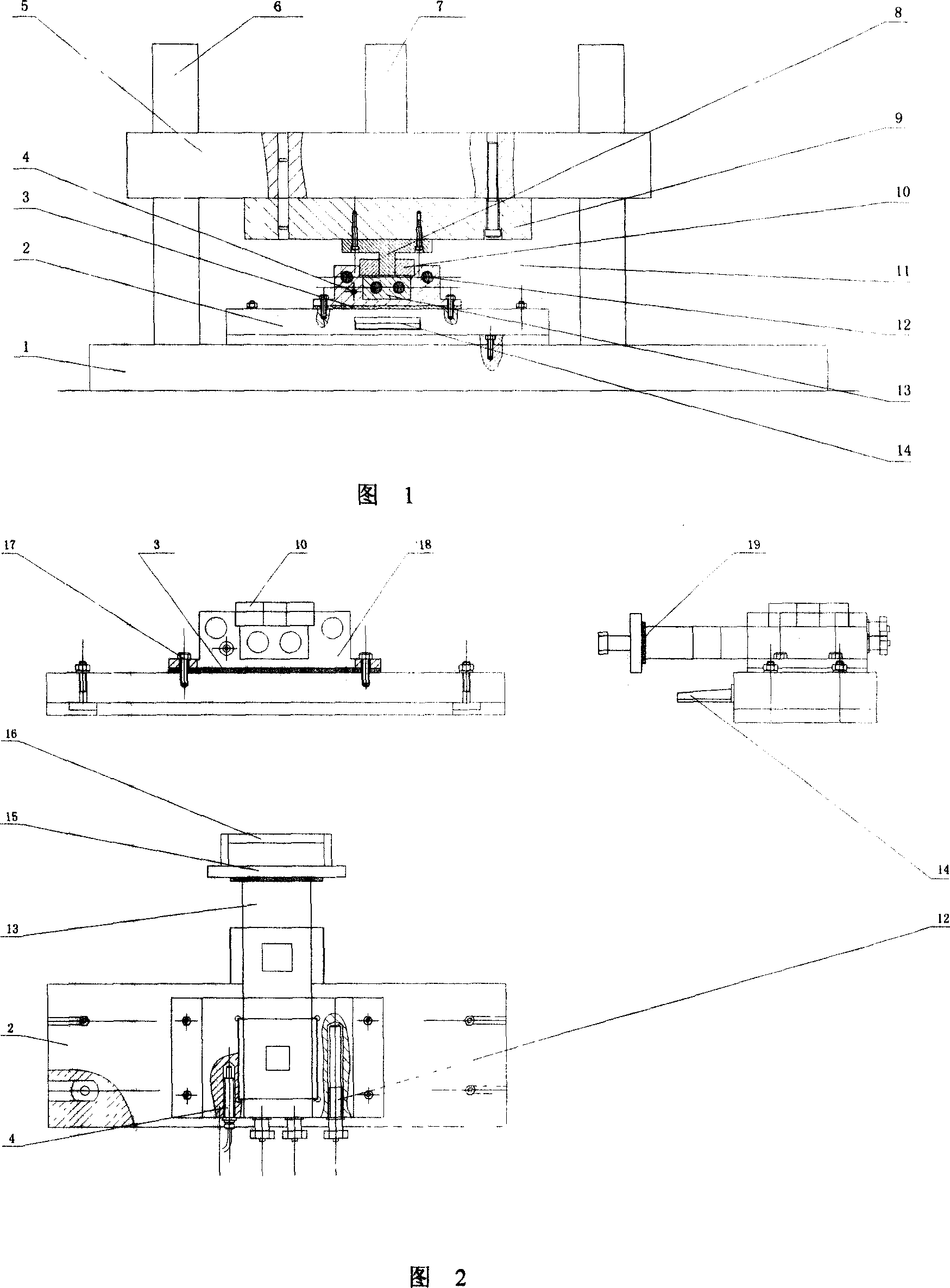

[0014] Below in conjunction with Fig. 1-2, the present invention is further described:

[0015] As shown in Figure 1, the invention connects the die upper die 8 with the upper die fixed plate 9, and directly fixes it on the movable beam 5 of the hydraulic press. Rely on the hydraulic press piston to drive the upper die 8 to press down. Lower mold 10 is placed on the lower mold base 18, and lower mold base 18 is fixed on the lower mold base fixed platform 2 with fastening screws 17. The lower mold base fixing platform 2 is an inverted T-shaped groove plate, which is directly fixed on the hydraulic press workbench 1.

[0016] As shown in Figure 2, a push-pull slide plate 13 with an electric heat pipe 12 is installed below the lower mold groove of the lower mold base 18. The push-pull slide plate 12 is divided into front and rear parts, and the front half has a hollow hole, which is slightly larger in size than the hollow hole of the lower mold. The half part is a solid plane p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com