Combined type high-power semiconductor laser side pumping source and preparation method thereof

A side-pumped semiconductor technology, applied in the field of laser optoelectronics, can solve the problems of inconvenient disassembly and maintenance, low yield rate, and low pass rate, and achieve the effect of convenient reliability testing, high yield rate, and simple testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

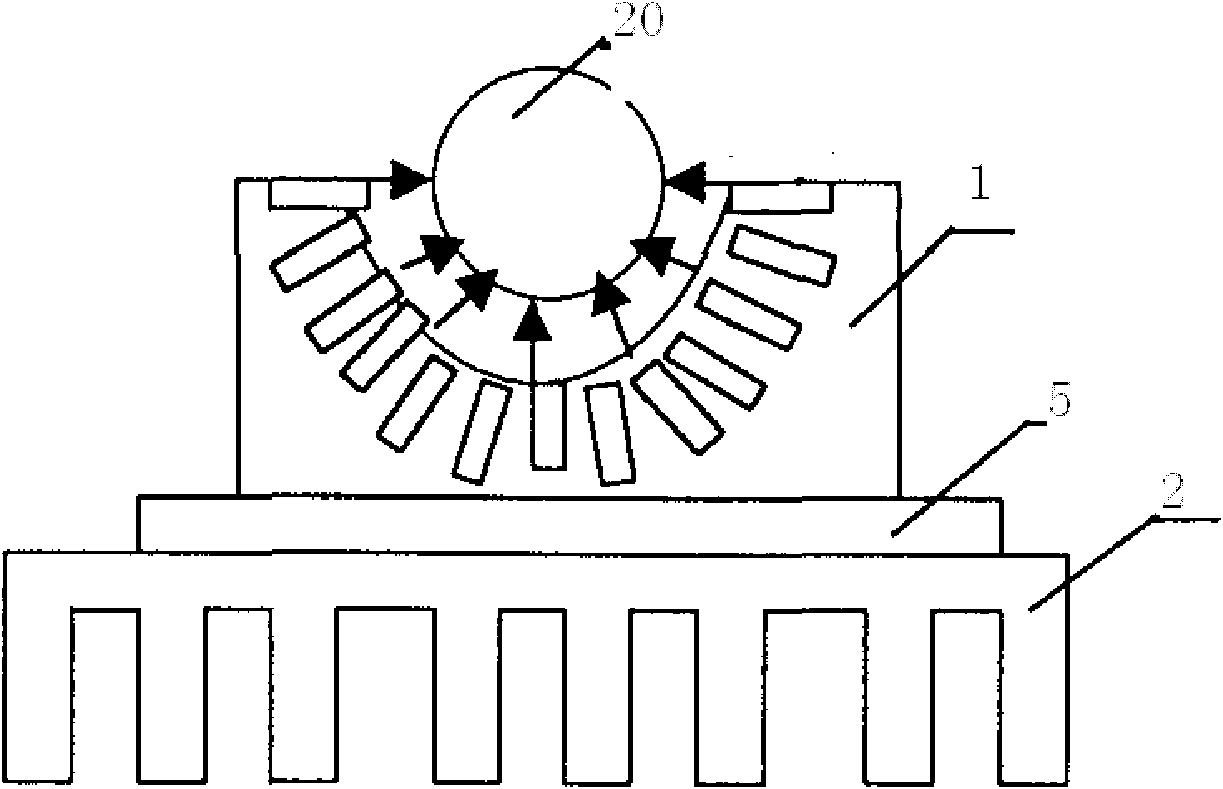

[0066] Such as Figure 4 , Figure 5 and Figure 6 The combined high-power semiconductor laser side pump source shown (compared with figure 1 The layout shown in the schematic diagram is more compact), including the semiconductor laser module group 1 and the heat sink 2. The semiconductor laser module 1 is fixed on the heat sink 2 through a movable connection method (such as a limiting groove, snap joint or other known mechanical connection methods).

[0067] The semiconductor laser module group 1 is composed of semiconductor laser modules 6, 7, 8, 9, 10 and 11;

[0068] The above-mentioned semiconductor laser modules 6, 7, 8, 9, 10, 11 are pre-tested and aged and screened out semiconductor laser modules with known performance;

[0069] The semiconductor laser modules 6, 7, 8, 9, 10, 11 are composed of chips 4 and substrates 5 with different wavelengths respectively.

[0070] Chip 4 is selected to be formed by connecting 6-10 bar chips, and may also be formed by connectin...

Embodiment 2

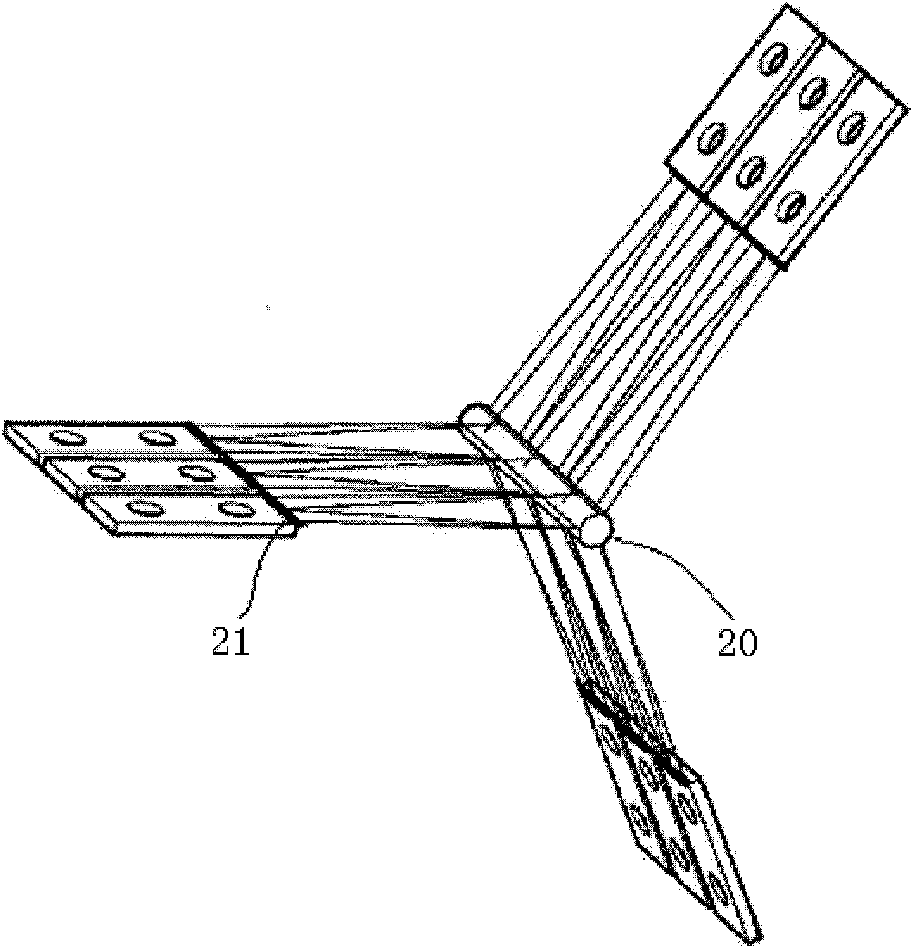

[0079] Such as Figure 7 The combined high-power semiconductor laser side pump source shown in the figure is triangular in shape.

[0080] The semiconductor laser module group 1 is composed of semiconductor laser modules 12 , 13 , 14 arranged in an arrangement.

[0081] Semiconductor laser modules 12, 13, 14 are composed of chip 4 and substrate 5 respectively.

[0082] The material of the substrate 5 is a material with high thermal conductivity.

[0083] What chip 4 selects for use is that 10 bar chips are connected to form.

[0084] The semiconductor laser modules 12 , 13 , 14 are semiconductor laser modules with known good performances that are screened out after testing and aging in advance.

[0085] Fixing the semiconductor laser modules 12, 13, 14 on the heat sink 2 by screws can also be fixed on the heat sink 2 by welding.

[0086] Above-mentioned radiator 2 can select the material conduction refrigeration of high thermal conductivity.

Embodiment 3

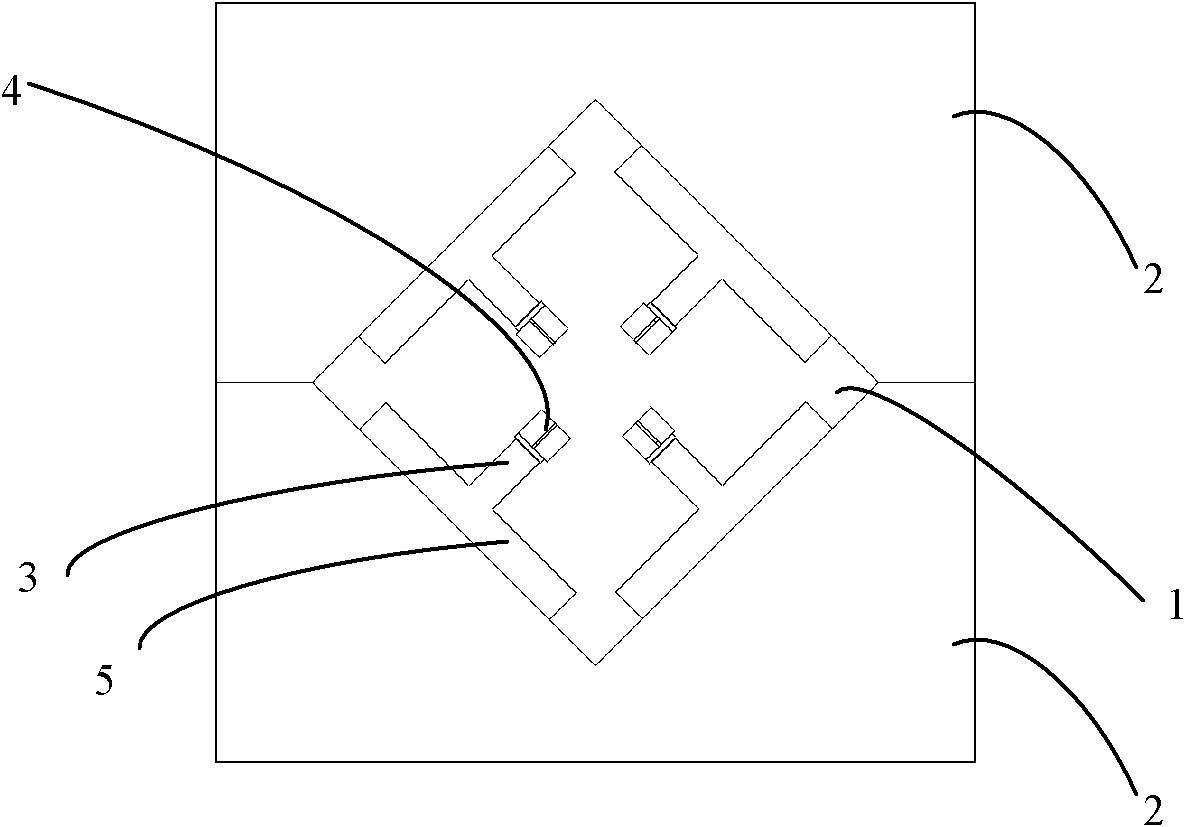

[0088] Such as Figure 8 The combined high-power semiconductor laser side pumping source shown is in the shape of a pentagon, which includes a semiconductor laser module group 1 and a heat sink 2 .

[0089] The semiconductor laser module group 1 is composed of semiconductor laser modules 15, 16, 17, 18 and 19;

[0090] The semiconductor laser modules 15 , 16 , 17 , 18 , and 19 are semiconductor laser modules with known good performances that are screened out after testing and aging in advance.

[0091] The semiconductor laser modules 15, 16, 17, 18, 19 can be fixed on the heat sink 2 by screws or can be fixed on the heat sink by welding.

[0092] Semiconductor laser modules 15, 16, 17, 18, 19 are composed of chip 4 and substrate 5 respectively.

[0093] What chip 4 selects for use is that 7 micro-bar chips are connected to form.

[0094] The material of the substrate 5 is a material with high thermal conductivity.

[0095] Above-mentioned radiator 2 can select the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com