Patents

Literature

2429 results about "Geometric modeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Geometric modeling is a branch of applied mathematics and computational geometry that studies methods and algorithms for the mathematical description of shapes. The shapes studied in geometric modeling are mostly two- or three-dimensional, although many of its tools and principles can be applied to sets of any finite dimension. Today most geometric modeling is done with computers and for computer-based applications. Two-dimensional models are important in computer typography and technical drawing. Three-dimensional models are central to computer-aided design and manufacturing (CAD/CAM), and widely used in many applied technical fields such as civil and mechanical engineering, architecture, geology and medical image processing.

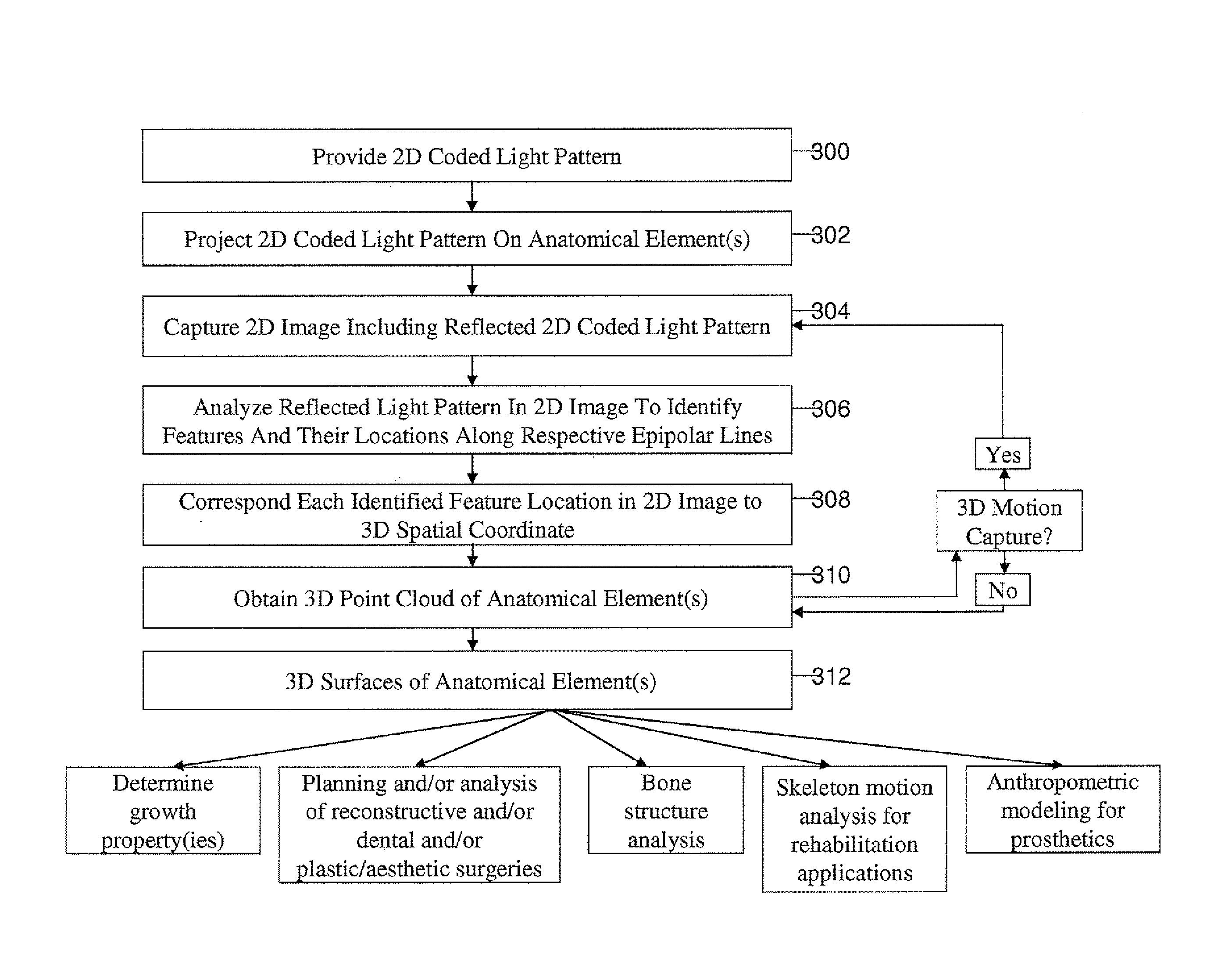

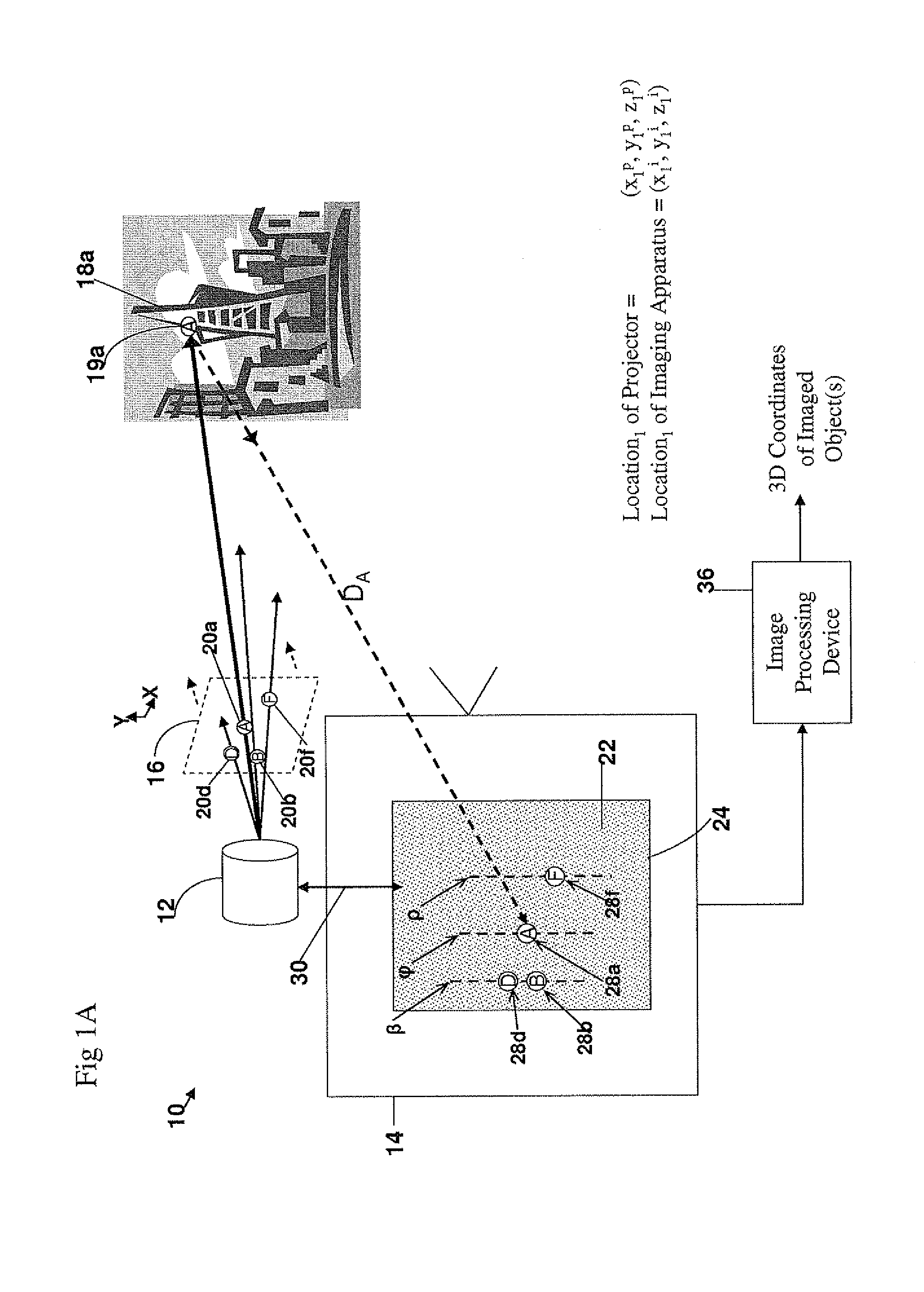

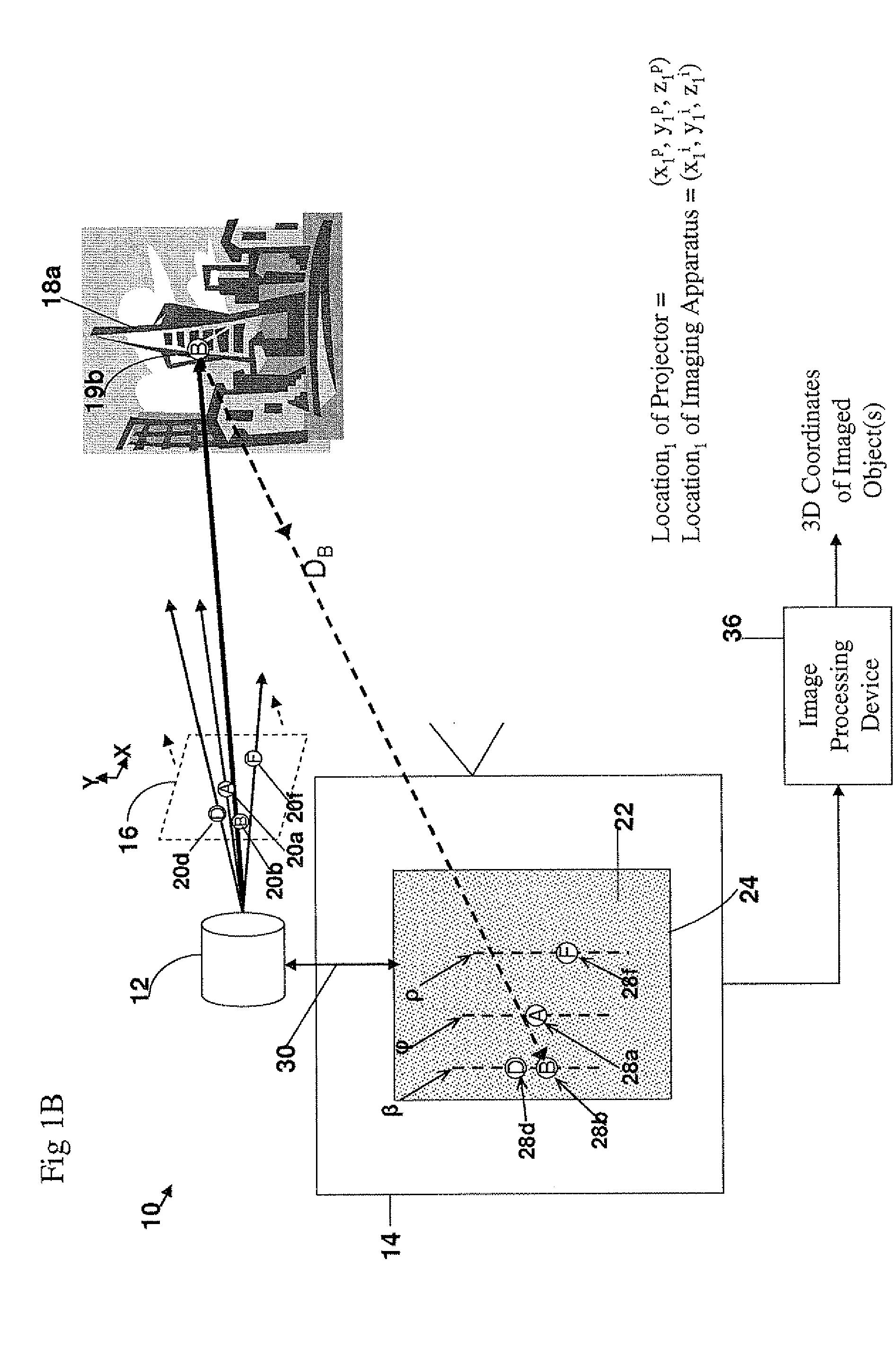

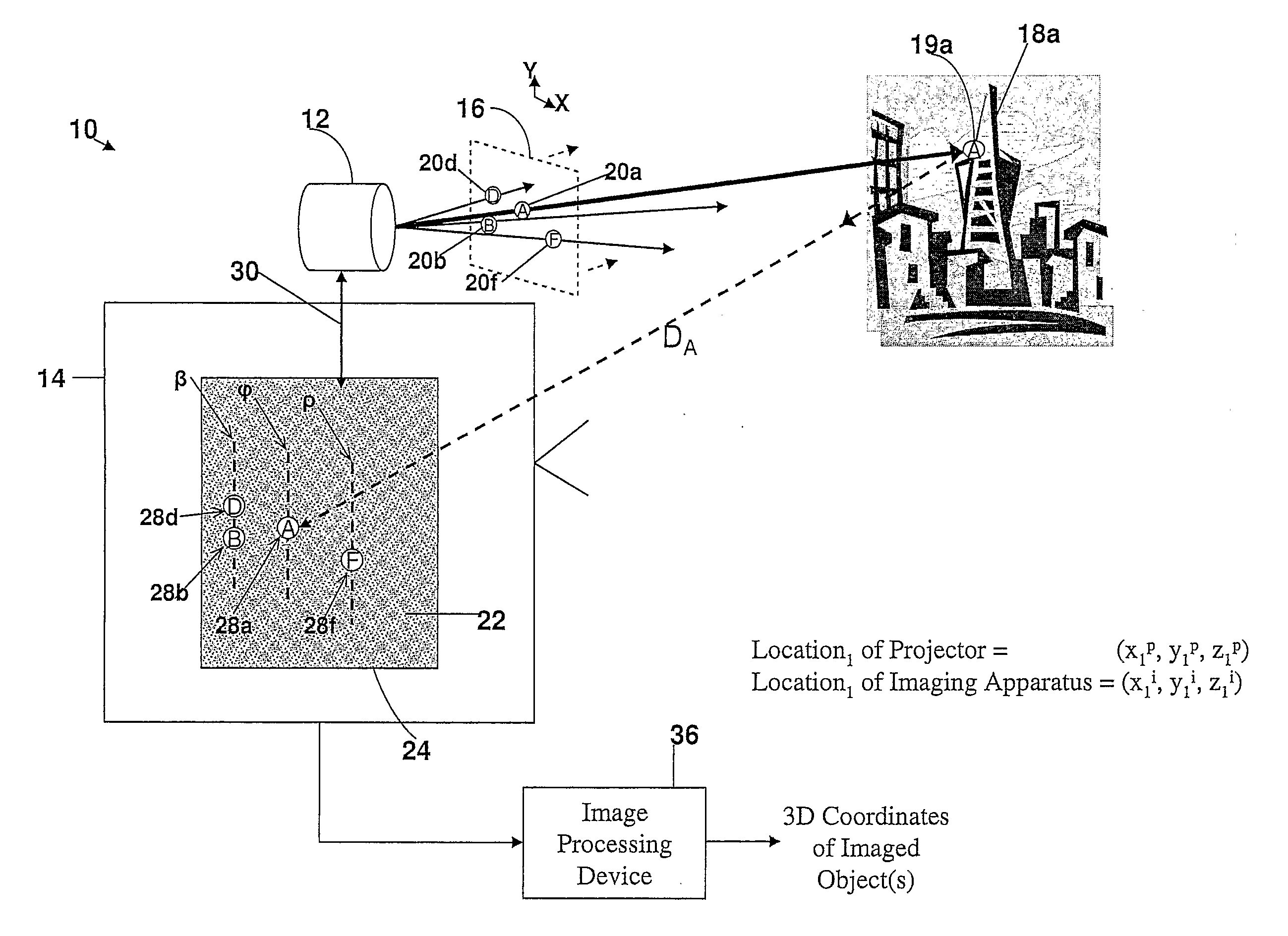

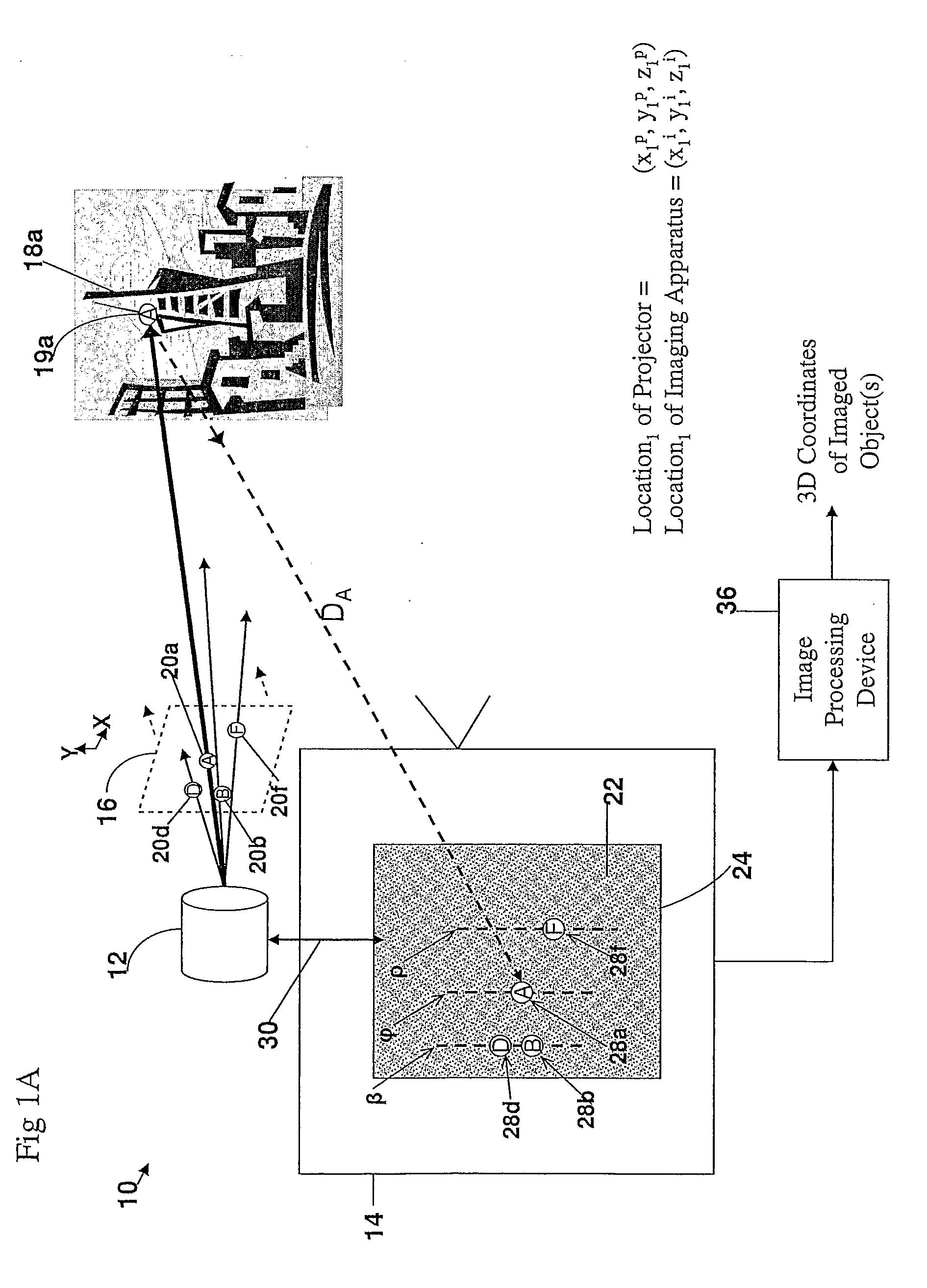

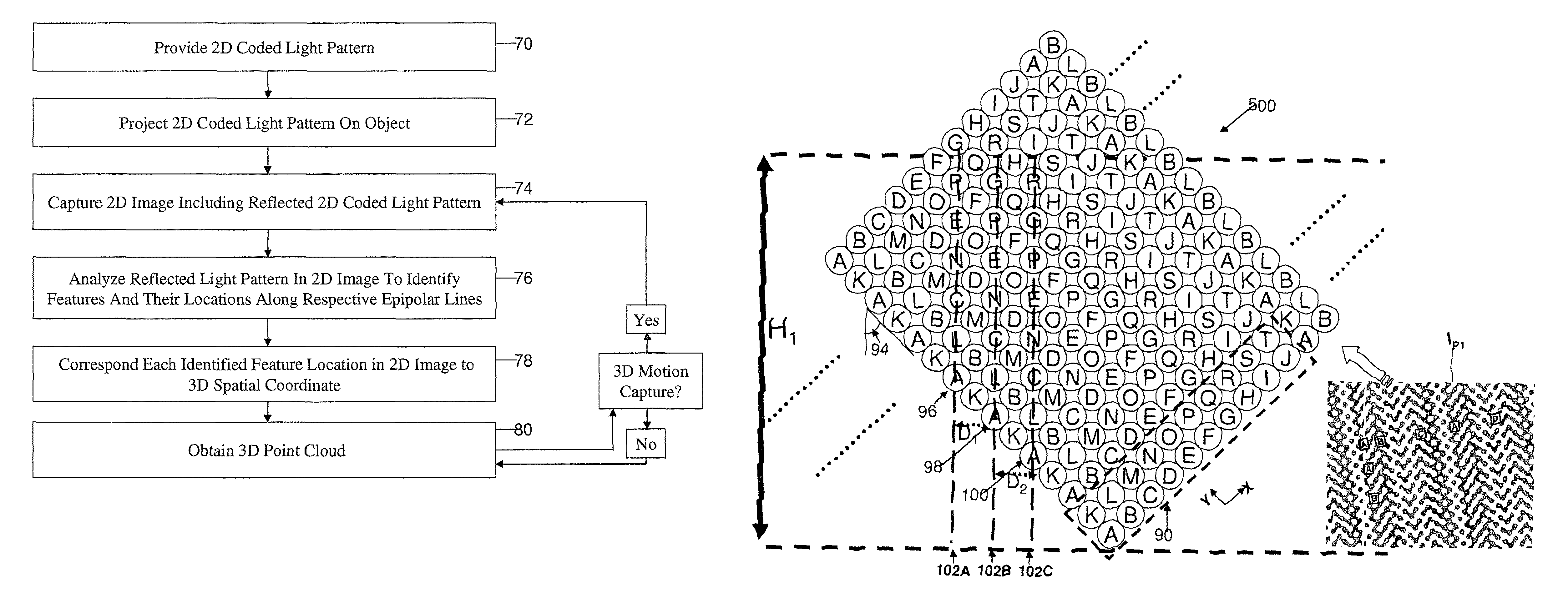

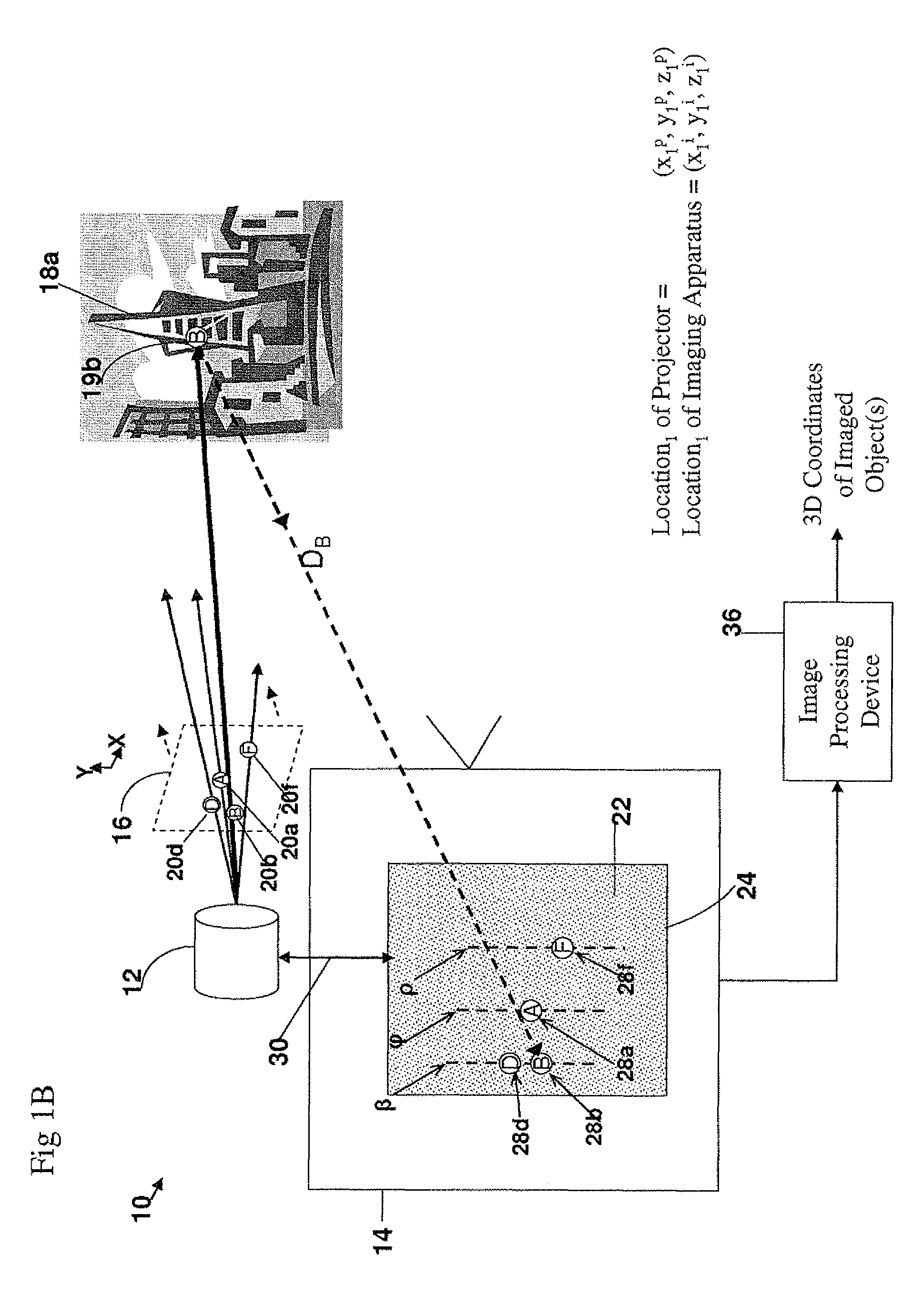

3D Geometric Modeling And Motion Capture Using Both Single And Dual Imaging

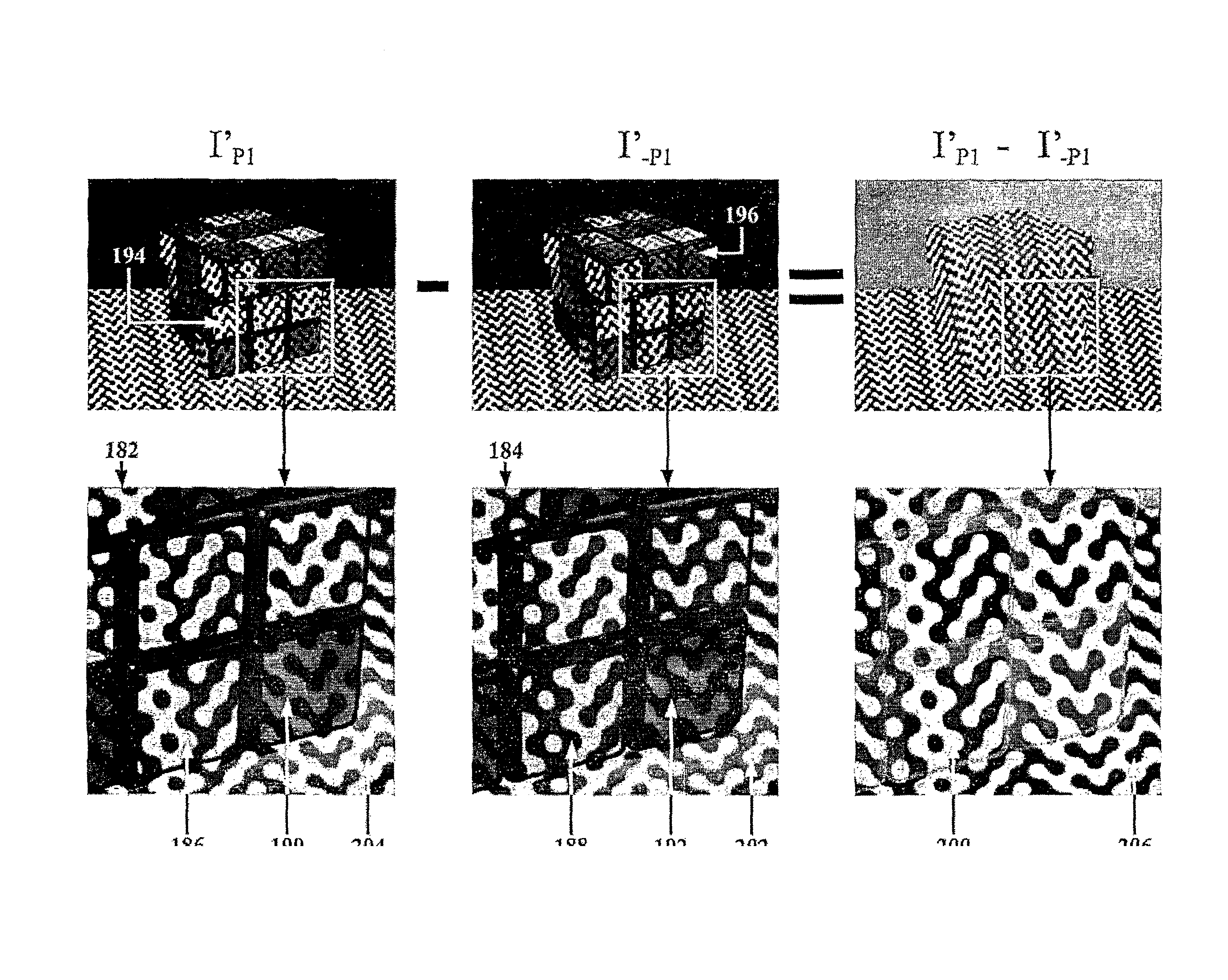

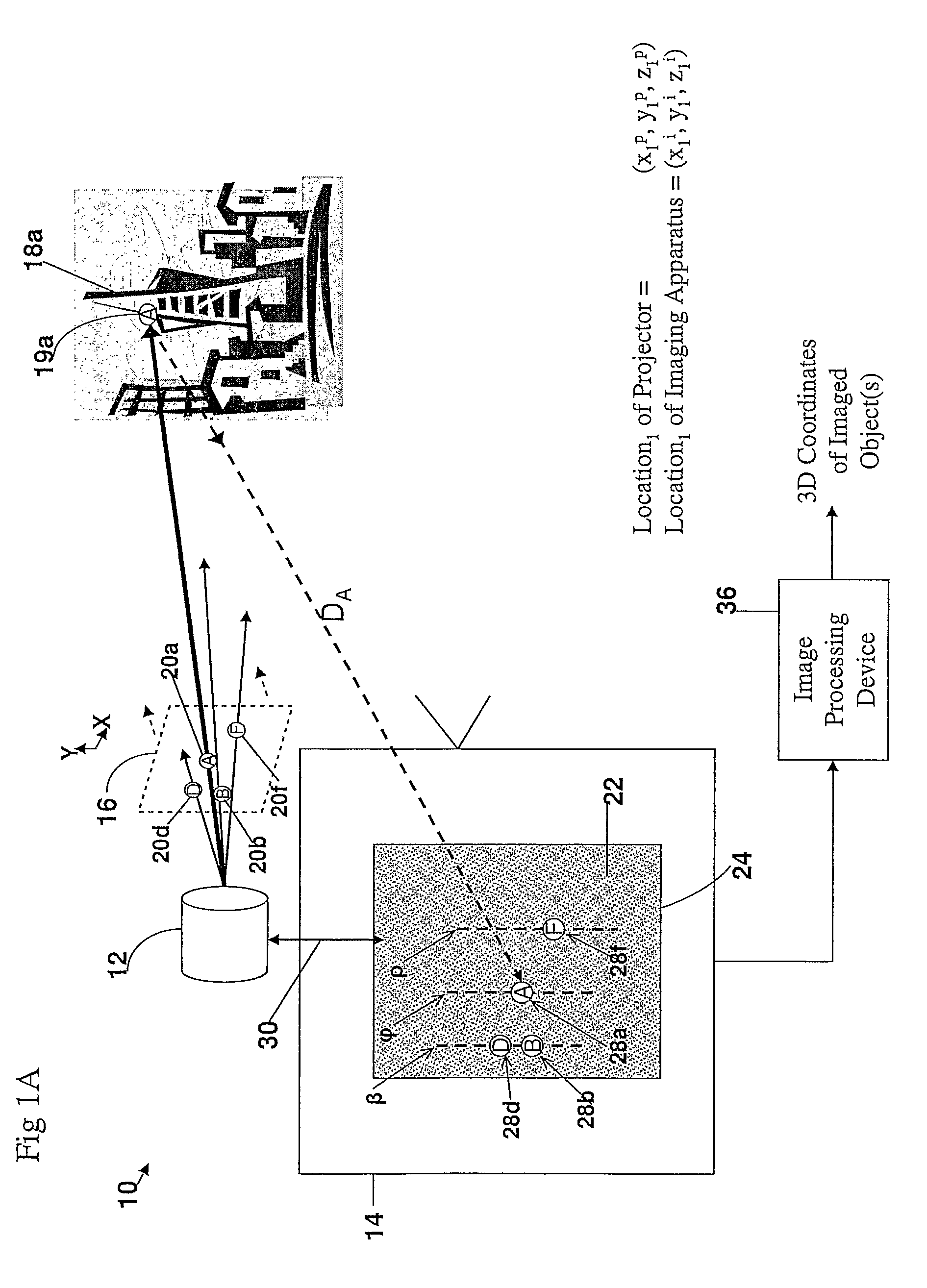

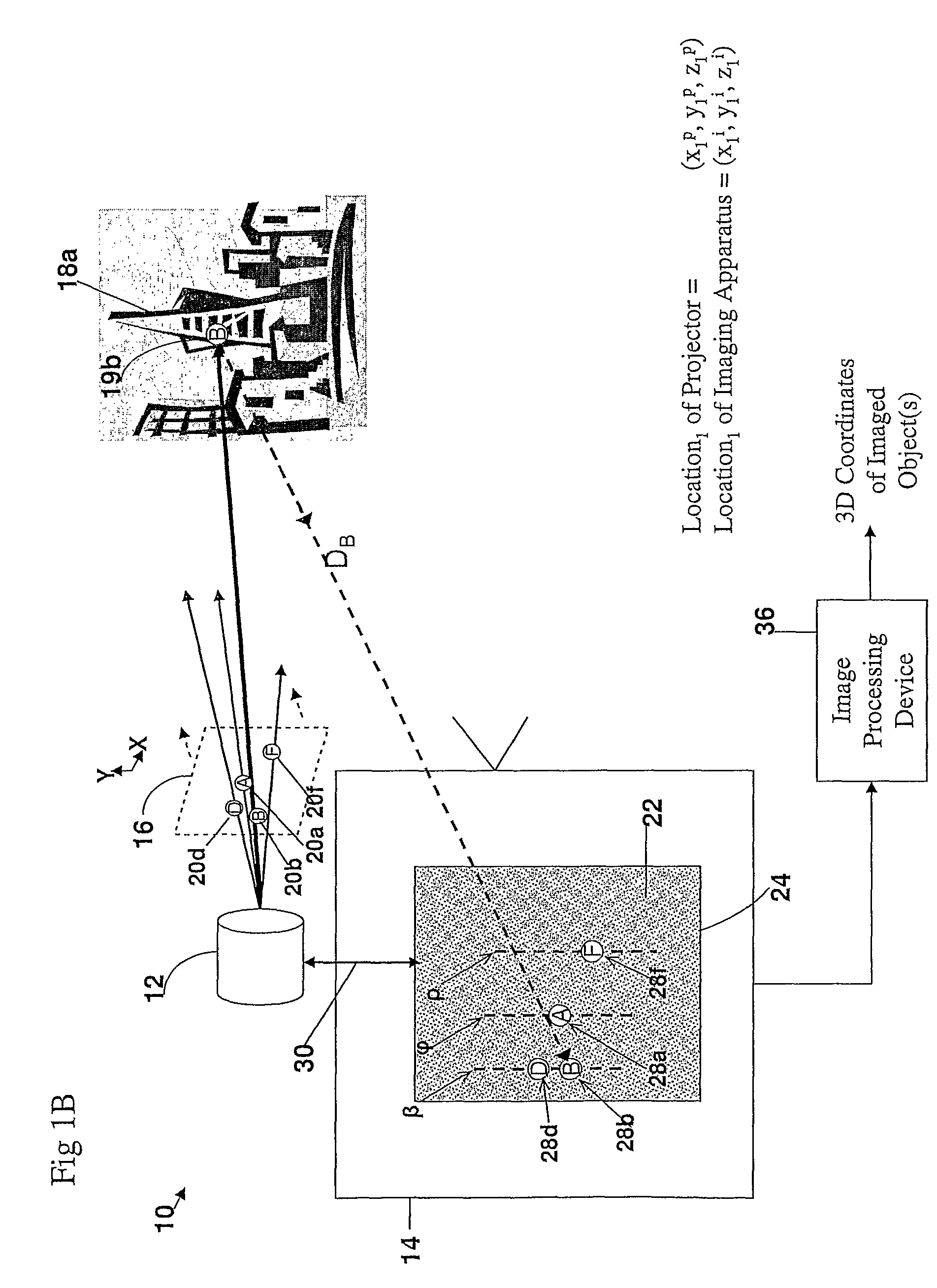

A method and apparatus for obtaining an image to determine a three dimensional shape of a stationary or moving object using a bi dimensional coded light pattern having a plurality of distinct identifiable feature types. The coded light pattern is projected on the object such that each of the identifiable feature types appears at most once on predefined sections of distinguishable epipolar lines. An image of the object is captured and the reflected feature types are extracted along with their location on known epipolar lines in the captured image. Displacements of the reflected feature types along their epipolar lines from reference coordinates thereupon determine corresponding three dimensional coordinates in space and thus a 3D mapping or model of the shape of the object at any point in time.

Owner:MANTIS VISION LTD

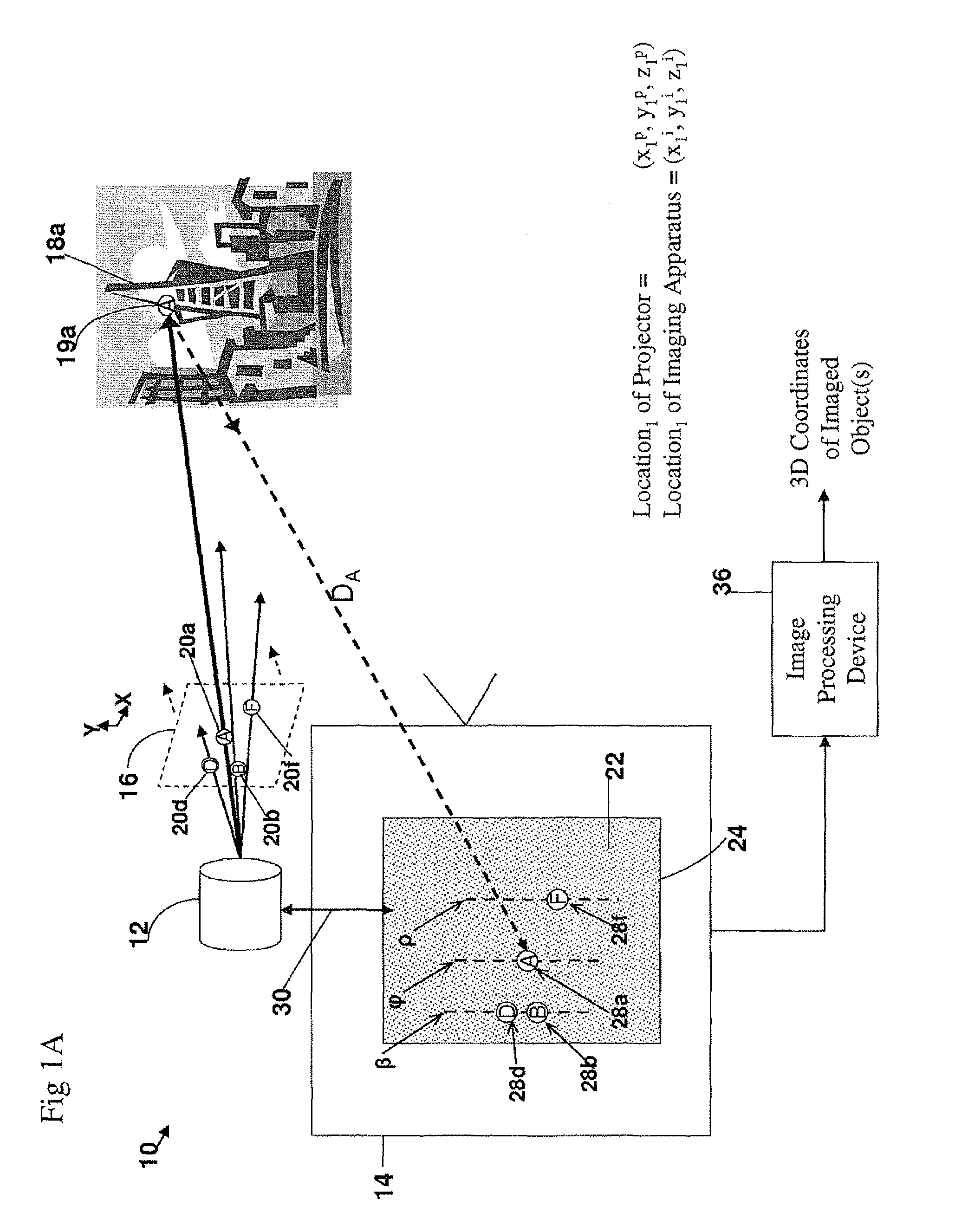

3D geometric modeling and 3D video content creation

A system, apparatus and method of obtaining data from a 2D image in order to determine the 3D shape of objects appearing in said 2D image, said 2D image having distinguishable epipolar lines, said method comprising: (a) providing a predefined set of types of features, giving rise to feature types, each feature type being distinguishable according to a unique bi-dimensional formation; (b) providing a coded light pattern comprising multiple appearances of said feature types; (c) projecting said coded light pattern on said objects such that the distance between epipolar lines associated with substantially identical features is less than the distance between corresponding locations of two neighboring features; (d) capturing a 2D image of said objects having said projected coded light pattern projected thereupon, said 2D image comprising reflected said feature types; and (e) extracting: (i) said reflected feature types according to the unique bi-dimensional formations; and (ii) locations of said reflected feature types on respective said epipolar lines in said 2D image.

Owner:MANTIS VISION

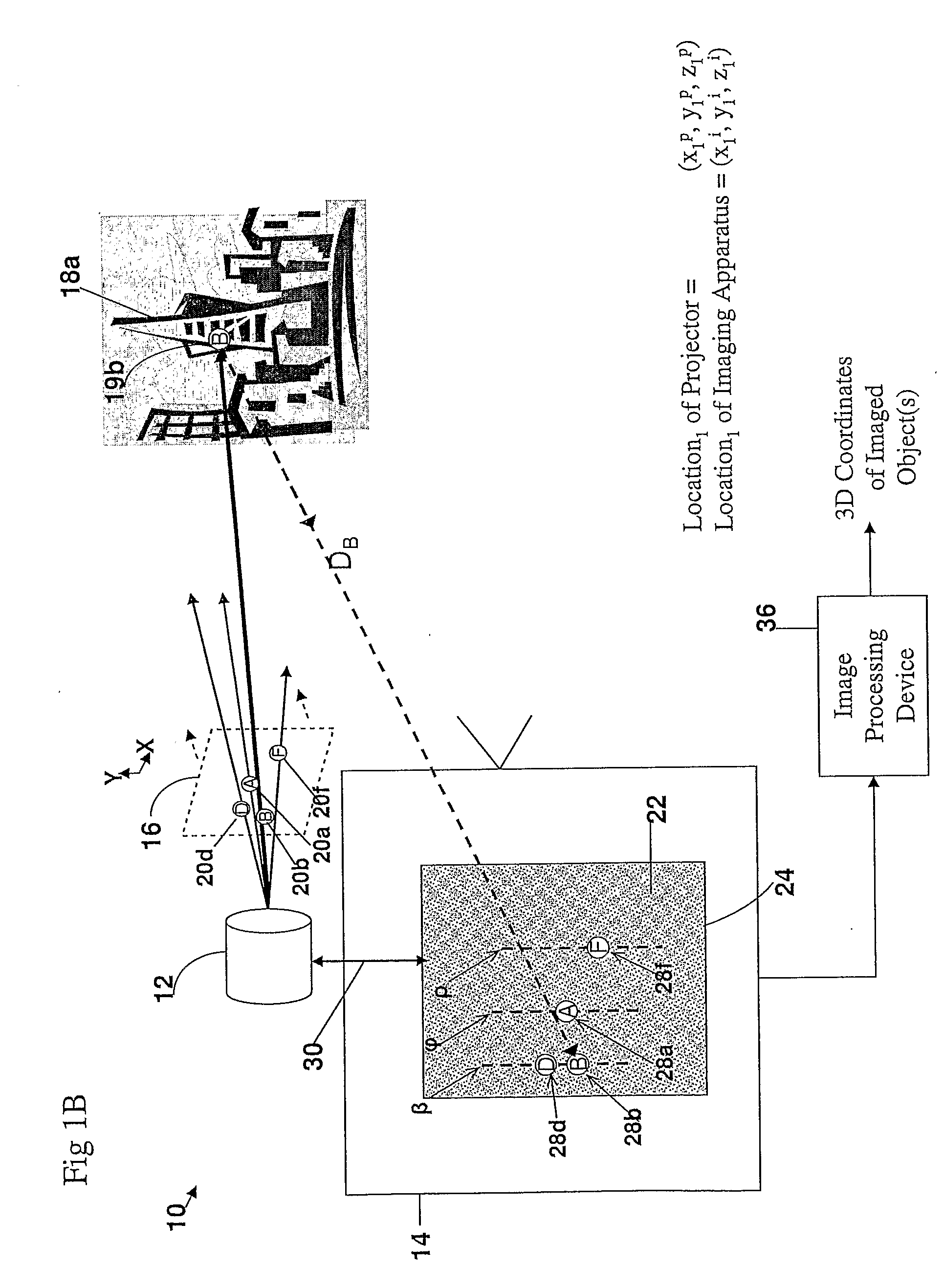

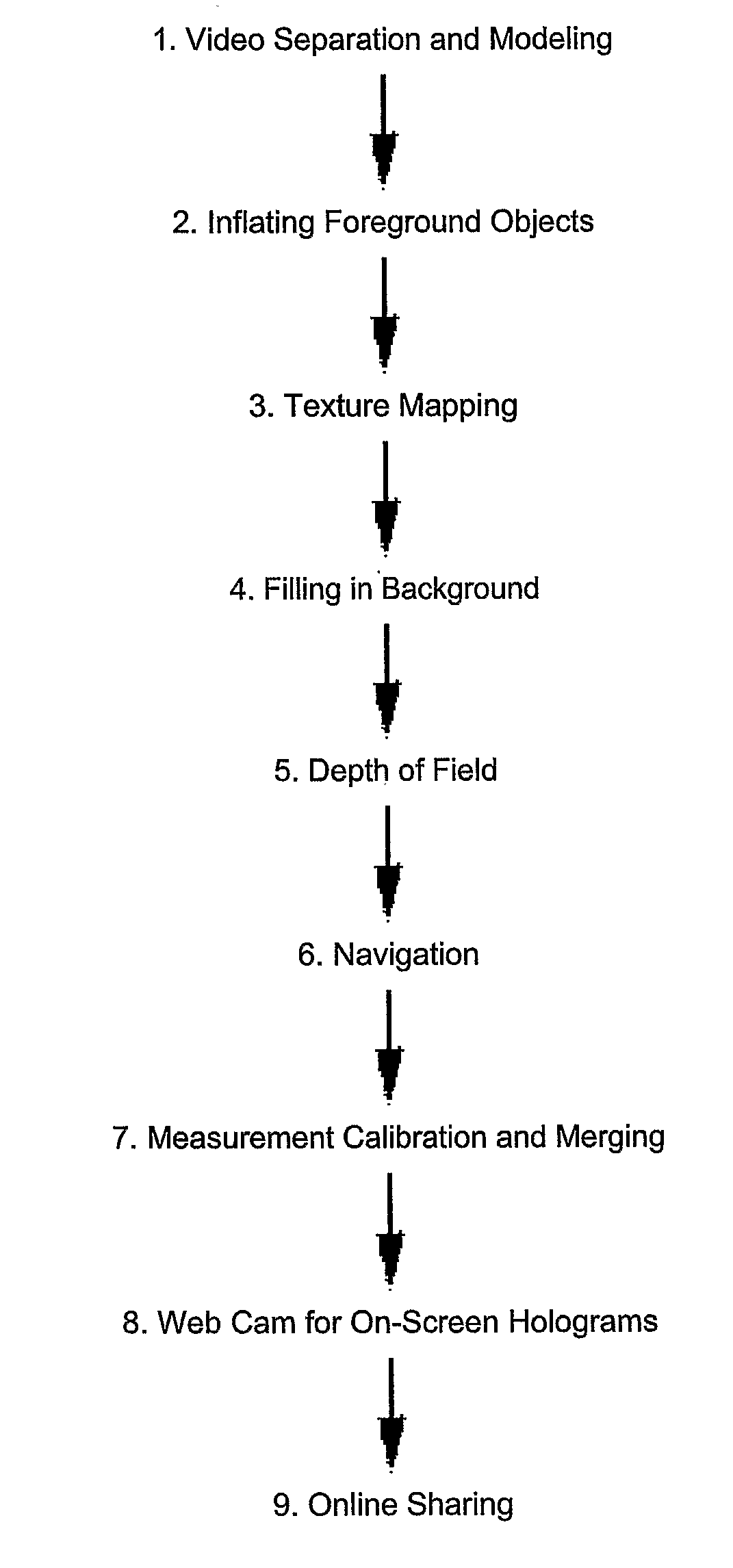

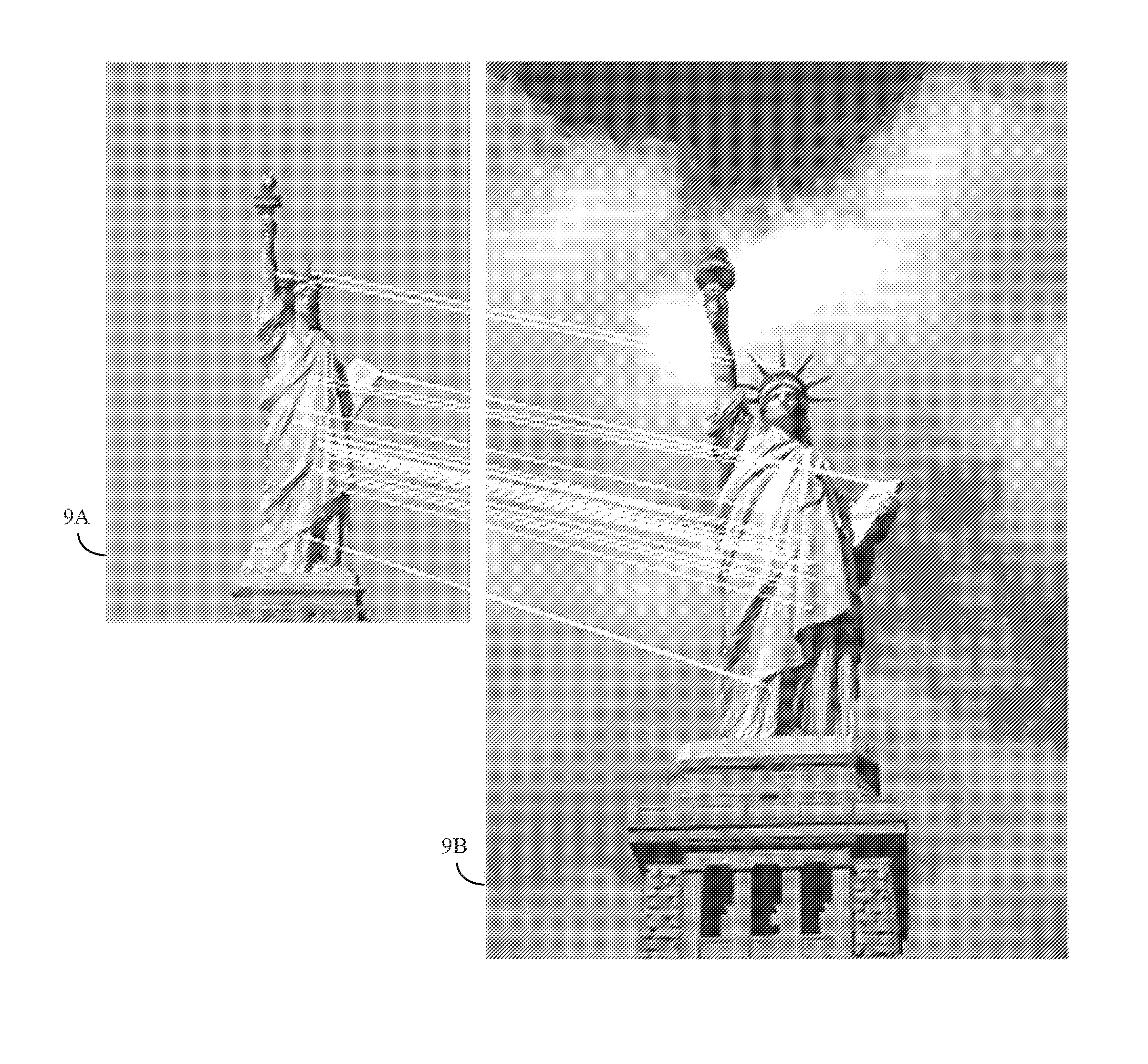

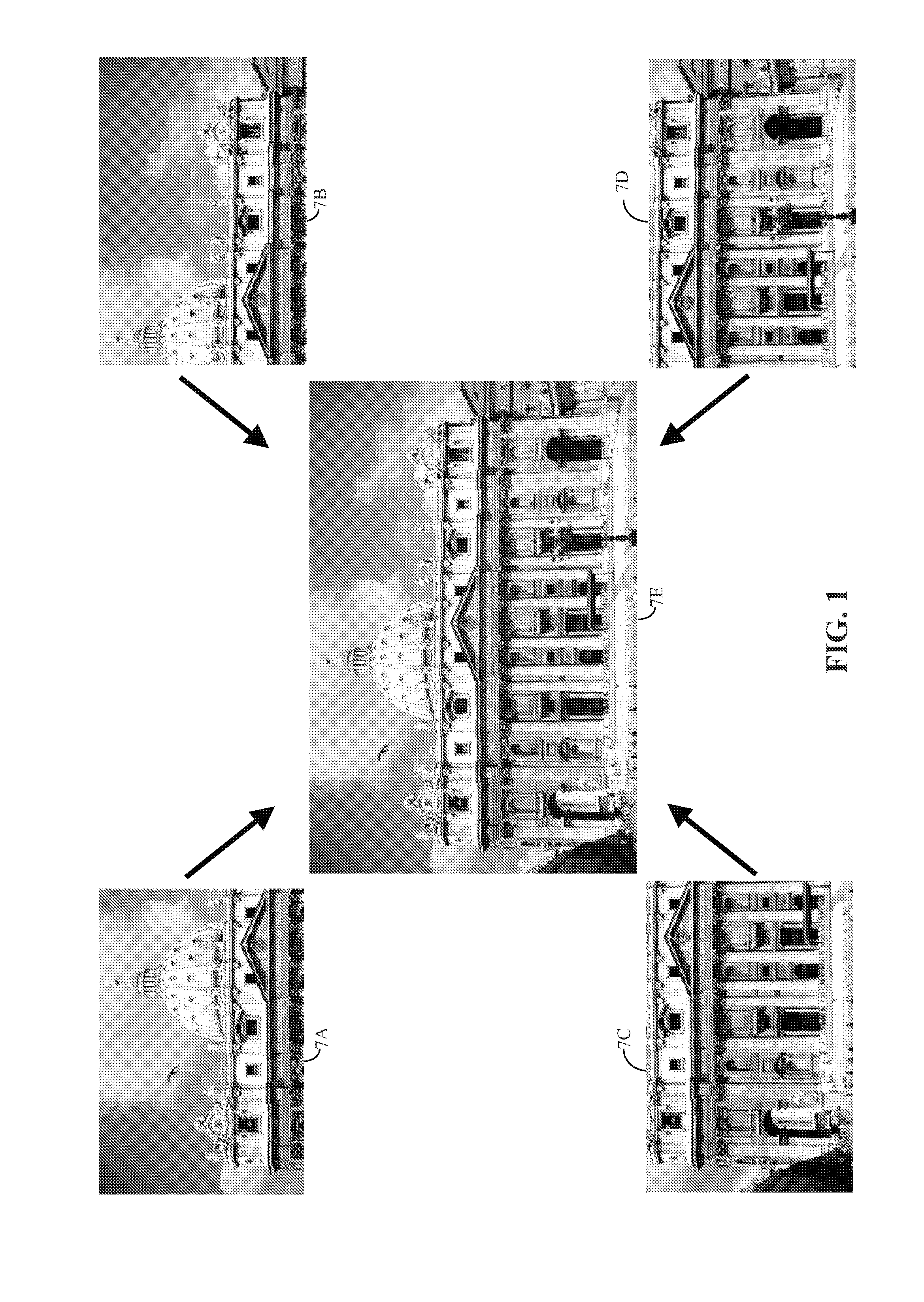

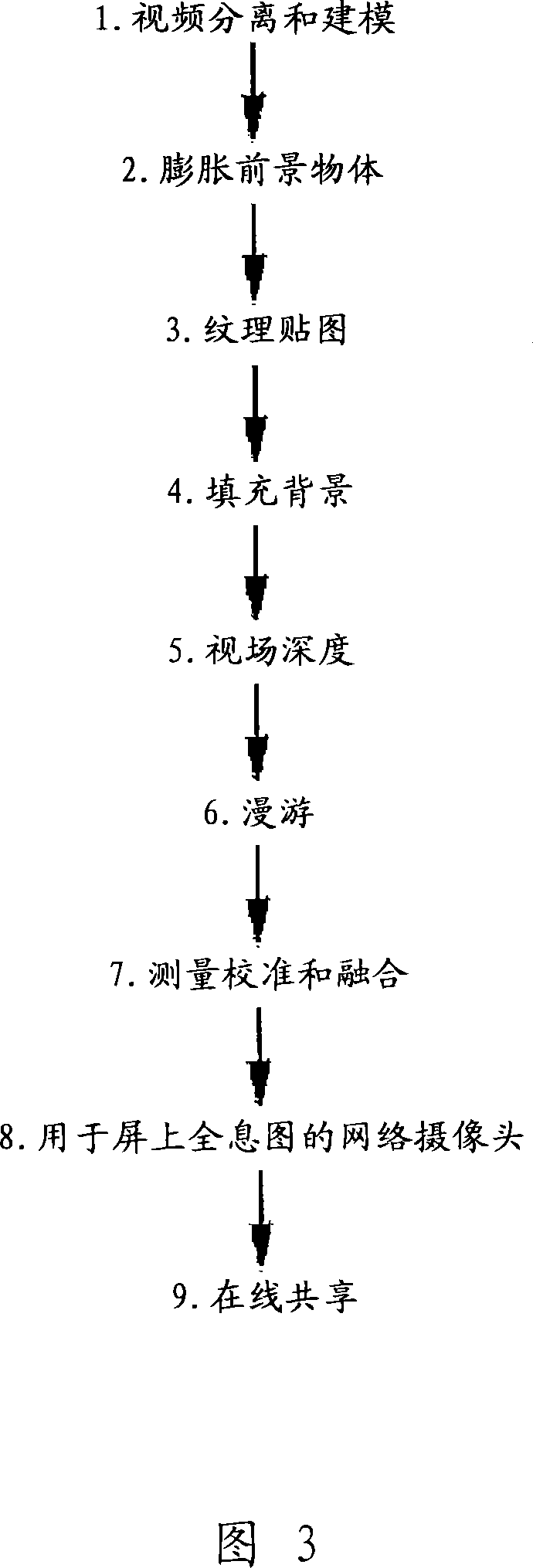

Automatic Scene Modeling for the 3D Camera and 3D Video

InactiveUS20080246759A1Reduce video bandwidthIncrease frame rateTelevision system detailsImage enhancementAutomatic controlViewpoints

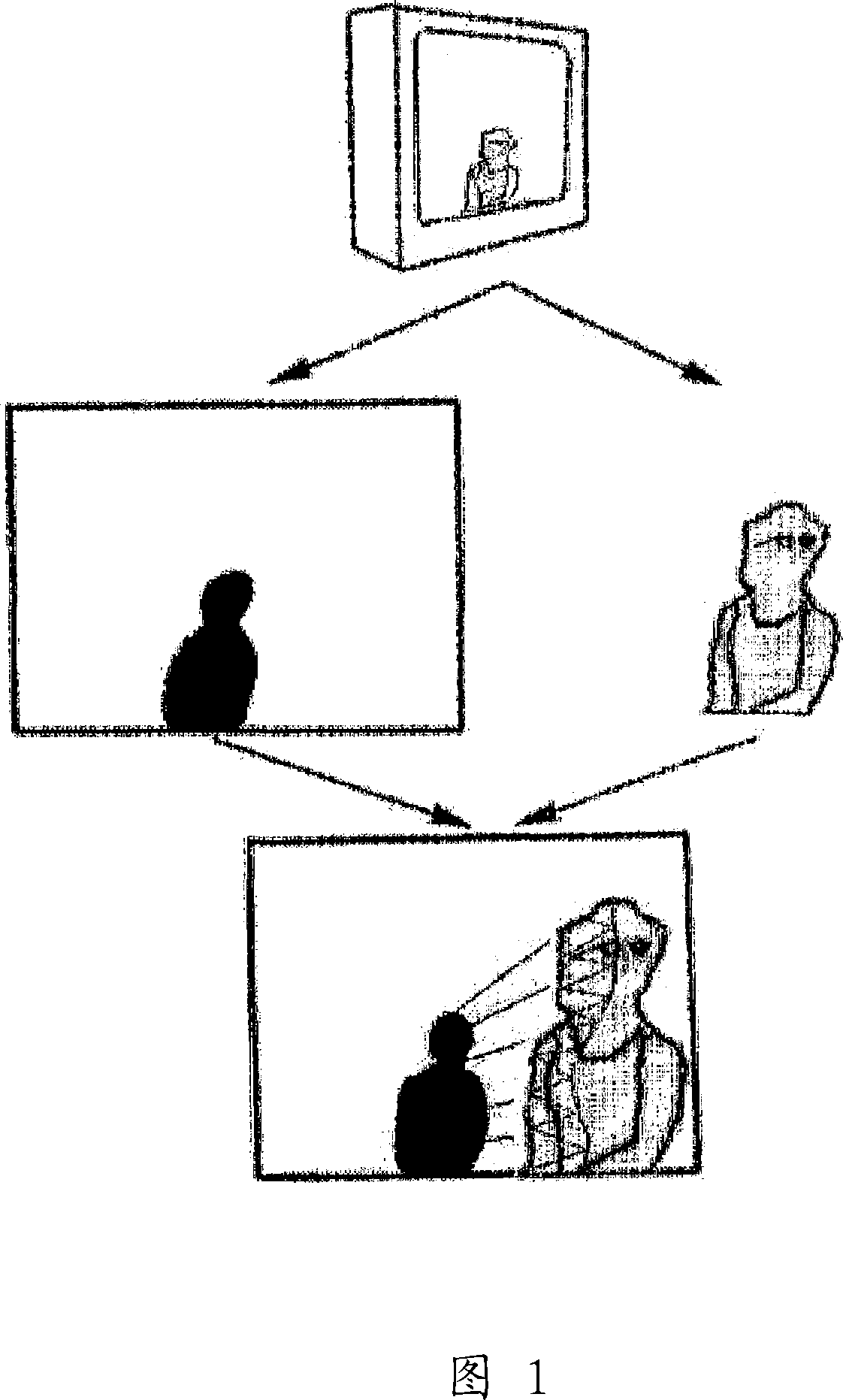

Single-camera image processing methods are disclosed for 3D navigation within ordinary moving video. Along with color and brightness, XYZ coordinates can be defined for every pixel. The resulting geometric models can be used to obtain measurements from digital images, as an alternative to on-site surveying and equipment such as laser range-finders. Motion parallax is used to separate foreground objects from the background. This provides a convenient method for placing video elements within different backgrounds, for product placement, and for merging video elements with computer-aided design (CAD) models and point clouds from other sources. If home users can save video fly-throughs or specific 3D elements from video, this method provides an opportunity for proactive, branded media sharing. When this image processing is used with a videoconferencing camera, the user's movements can automatically control the viewpoint, creating 3D hologram effects on ordinary televisions and computer screens.

Owner:SUMMERS

Apparatus and method for registering two medical images

ActiveUS8620055B2Time requiredShorten the timeImage enhancementMaterial analysis using wave/particle radiationGeometric modelingOrgan surface

Owner:UCL BUSINESS PLC

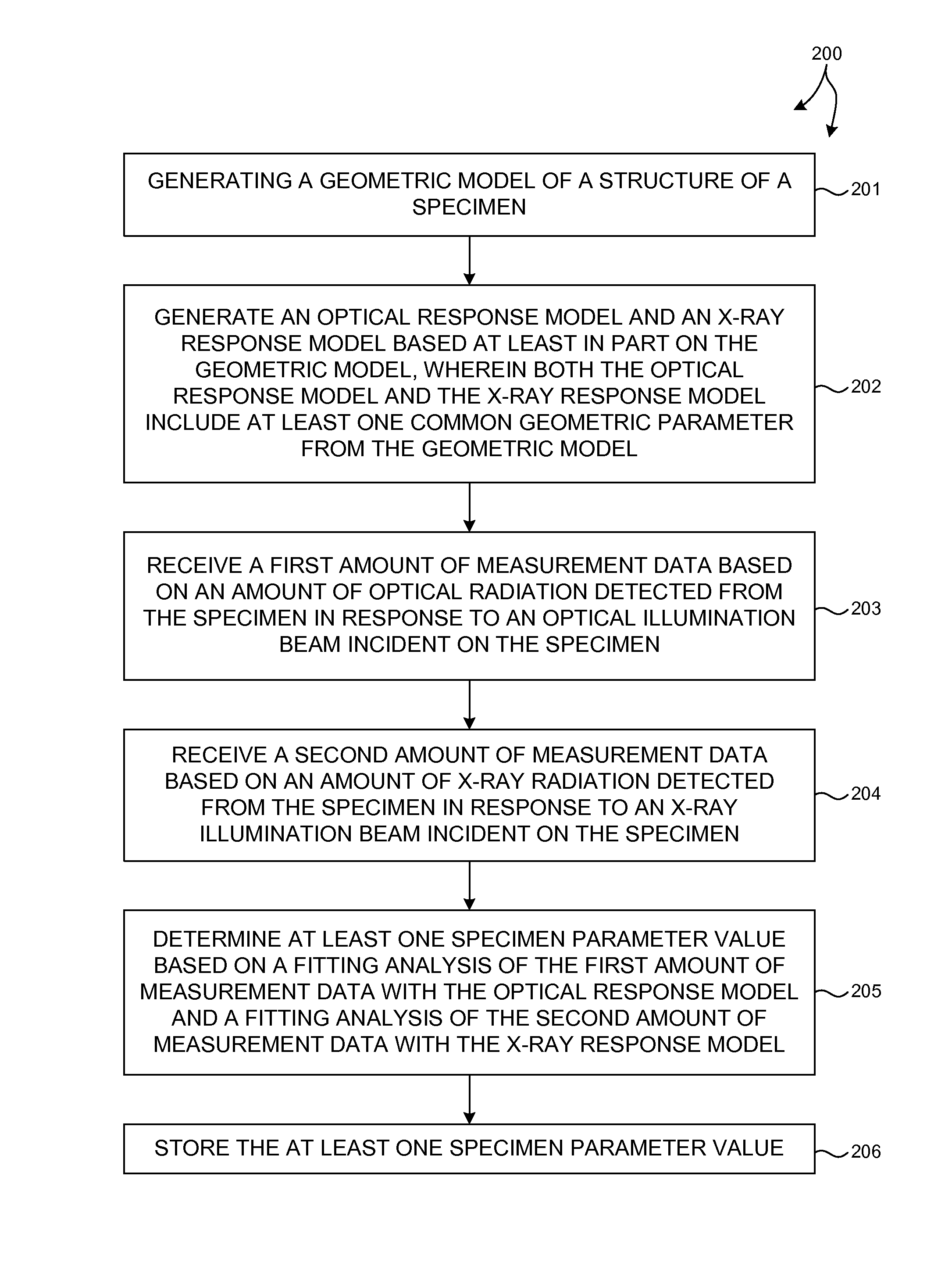

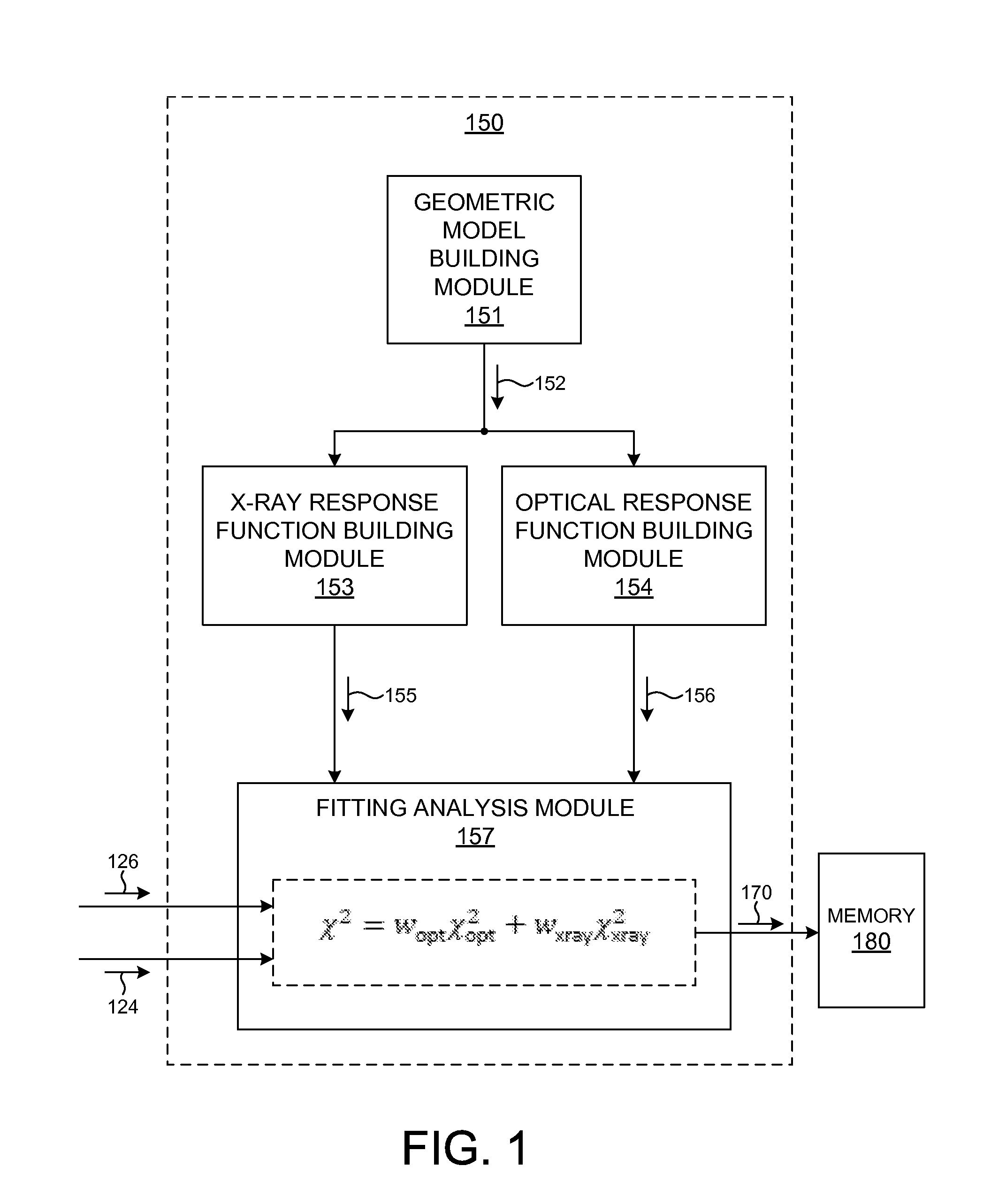

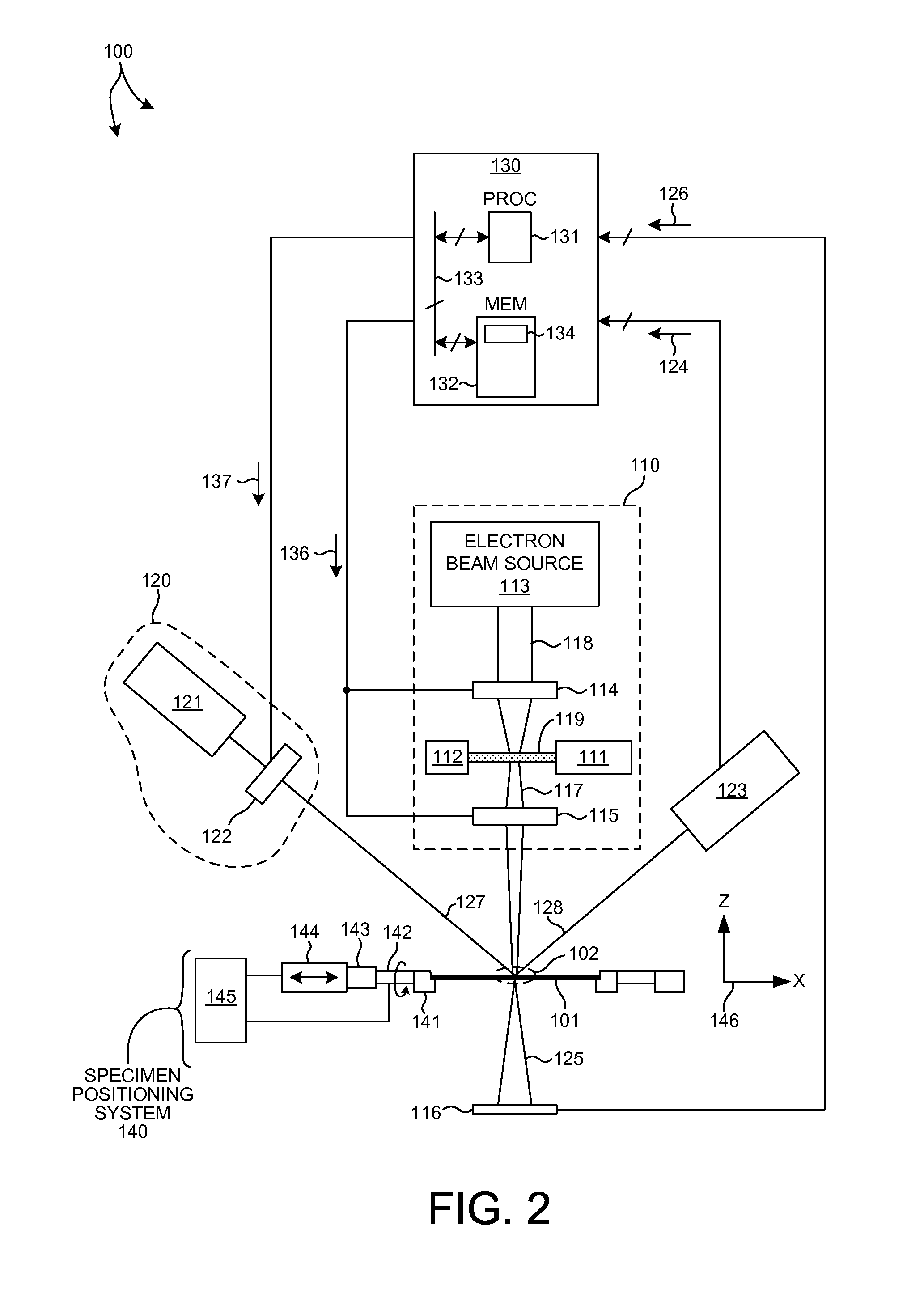

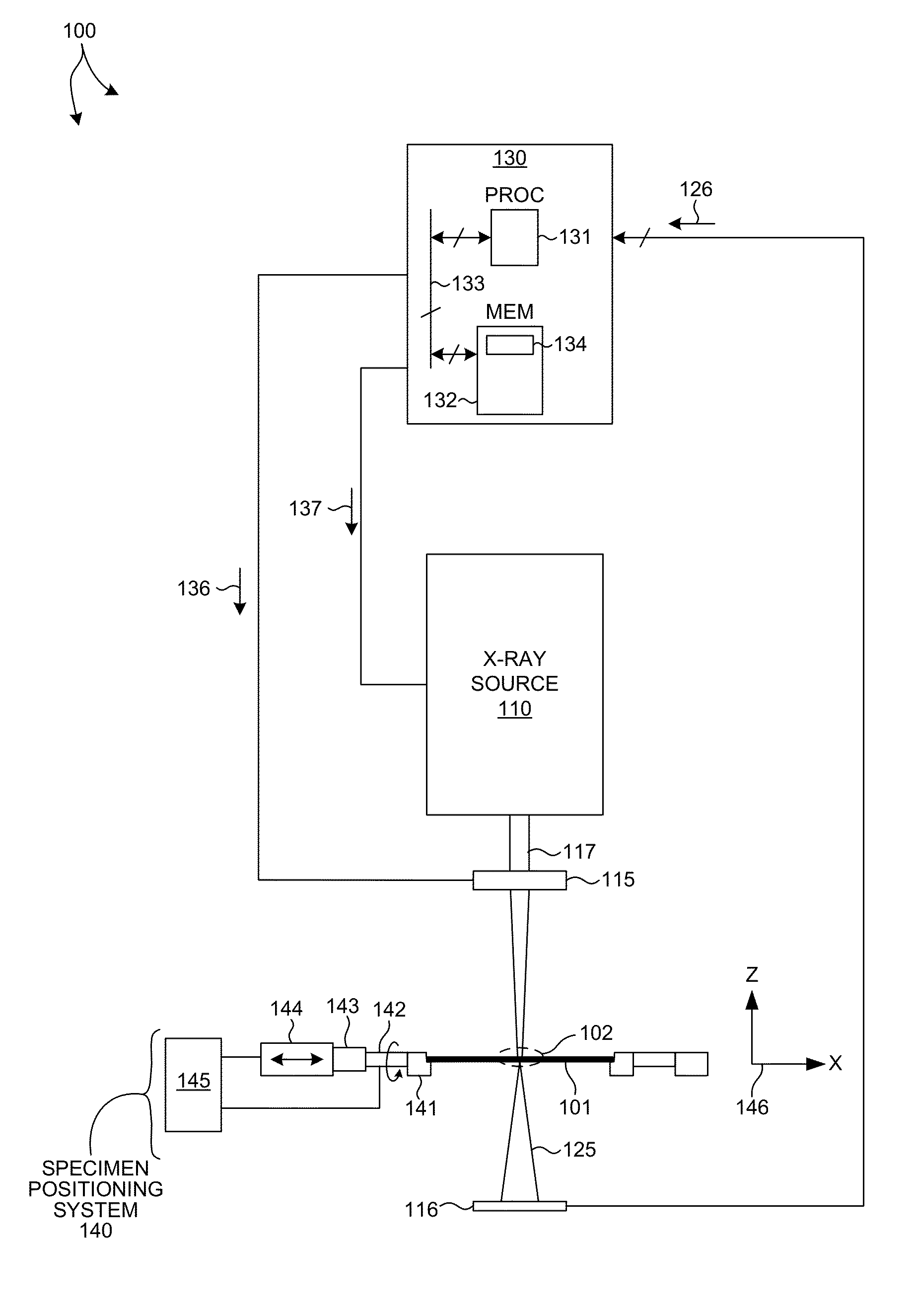

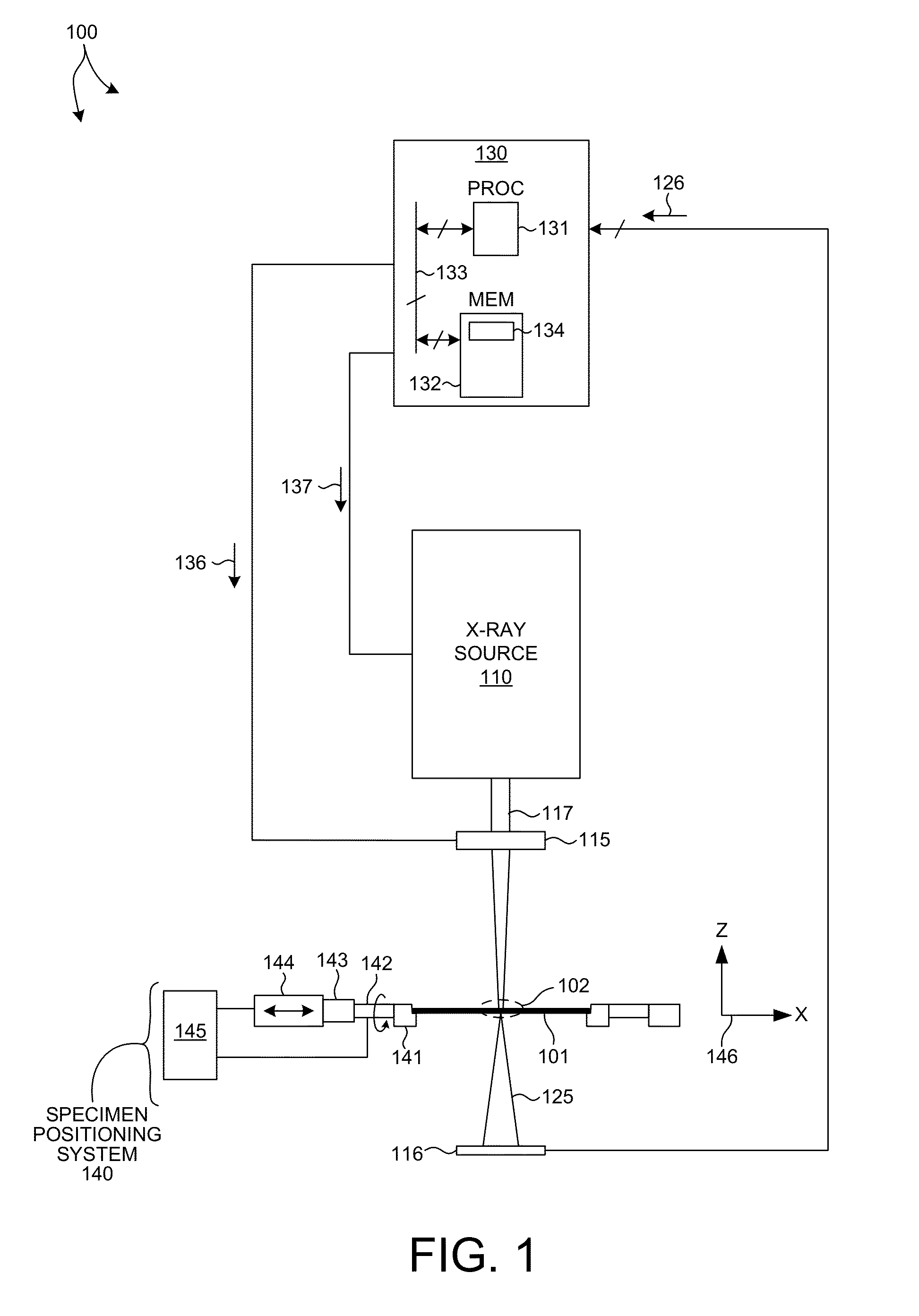

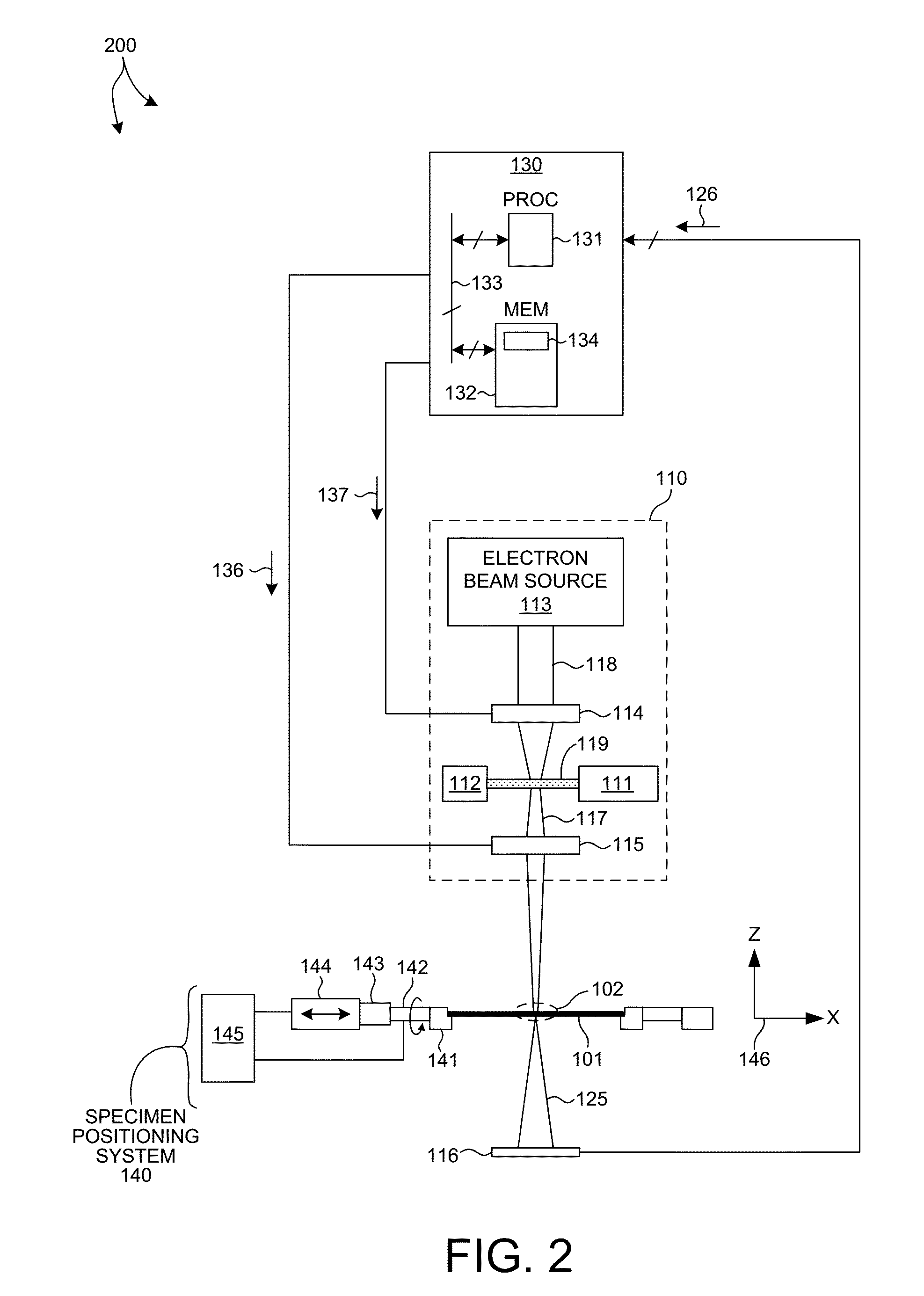

Model building and analysis engine for combined x-ray and optical metrology

ActiveUS20140019097A1Reduce in quantityReduce correlationMaterial analysis using wave/particle radiationPhotomechanical apparatusX-rayGeometric modeling

Structural parameters of a specimen are determined by fitting models of the response of the specimen to measurements collected by different measurement techniques in a combined analysis. Models of the response of the specimen to at least two different measurement technologies share at least one common geometric parameter. In some embodiments, a model building and analysis engine performs x-ray and optical analyses wherein at least one common parameter is coupled during the analysis. The fitting of the response models to measured data can be done sequentially, in parallel, or by a combination of sequential and parallel analyses. In a further aspect, the structure of the response models is altered based on the quality of the fit between the models and the corresponding measurement data. For example, a geometric model of the specimen is restructured based on the fit between the response models and corresponding measurement data.

Owner:KLA TENCOR TECH CORP

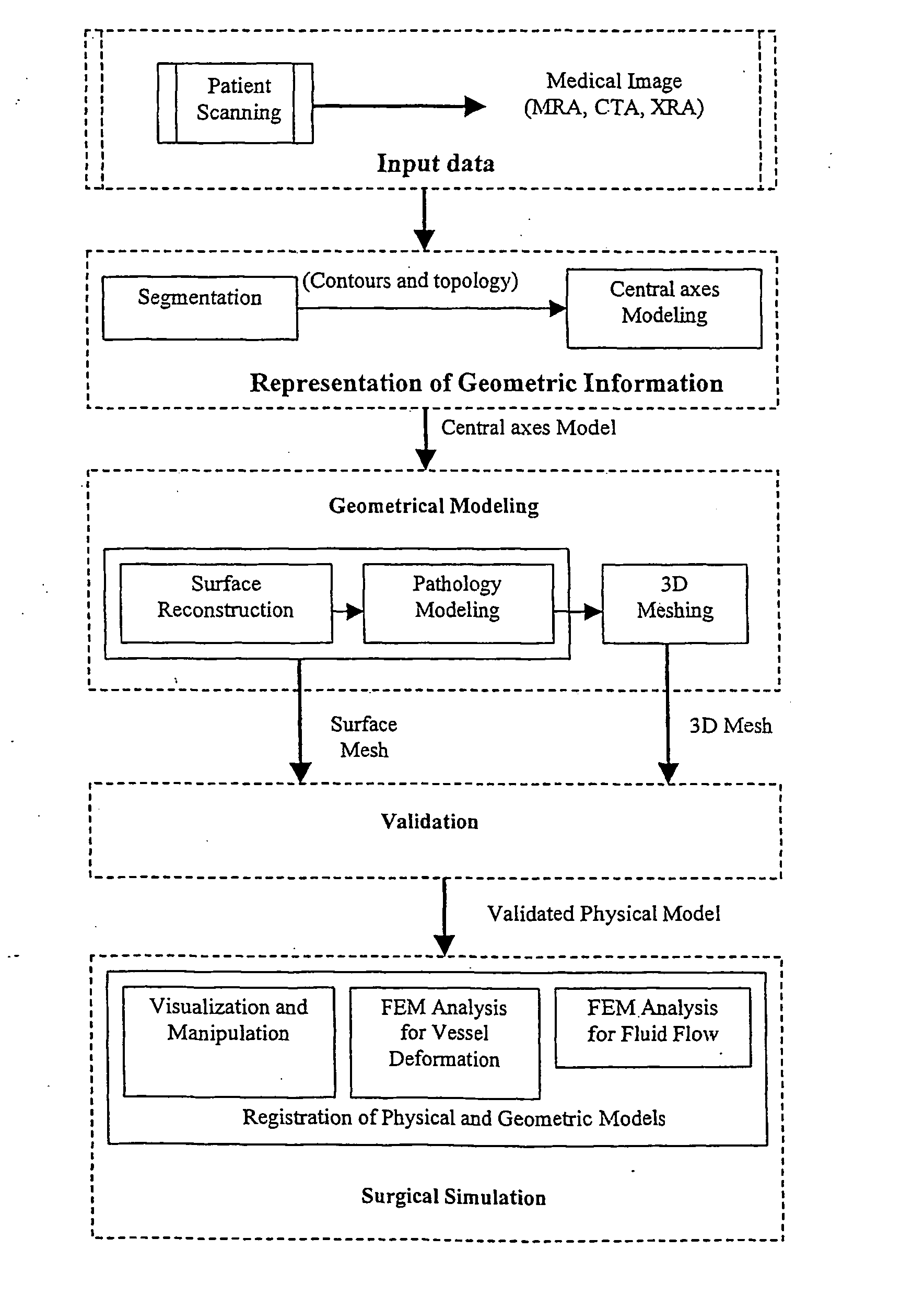

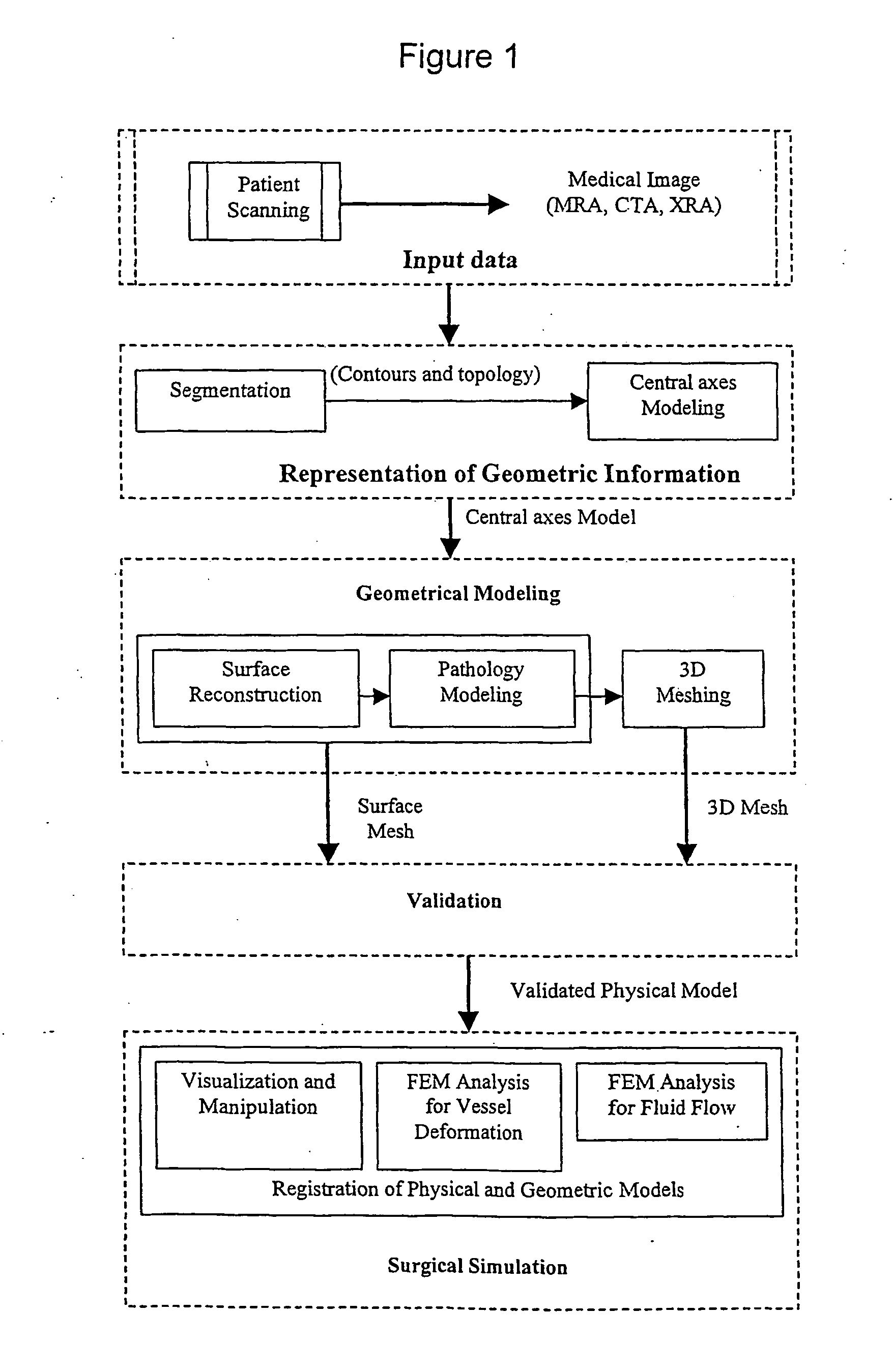

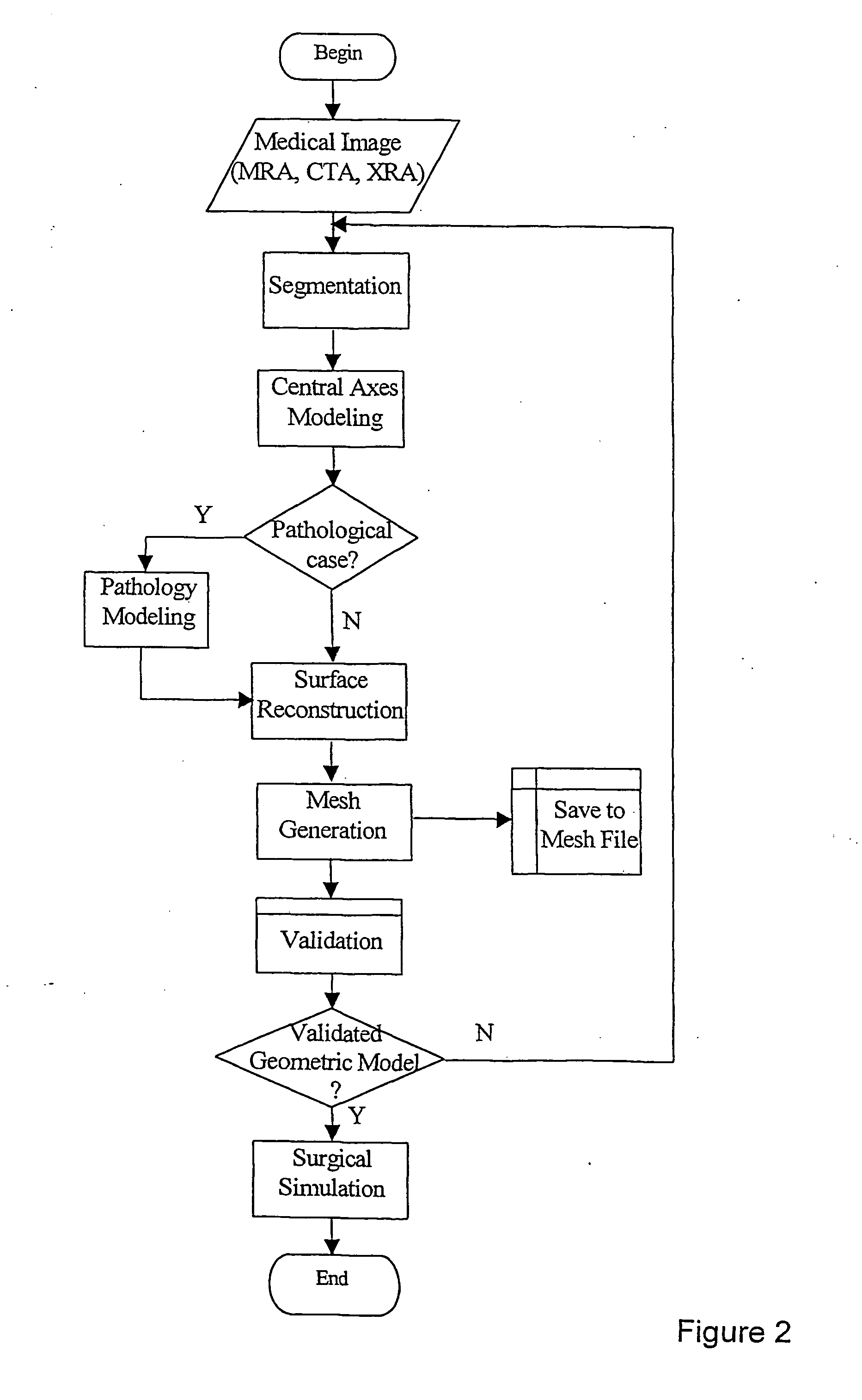

System and method of anatomical modeling

InactiveUS20050018885A1Conveniently stored and compiledFlexible performanceCharacter and pattern recognition3D modellingAnatomical structuresElement analysis

Methods of modeling anatomical structures, along with pathology including the vasculature, spine and internal organs, for visualization and manipulation in simulation systems. A representation of on the human vascular network is built up from medical images and a geometrical model produced therefrom by extracting topological and geometrical information. The model is constructed using topological and geometrical information. The model is constructed using segments containing topology structure information, flow domain information contour domain information and skeletal domain information. A realistic surface is then applied to the geometric model, by generating a trajectory along a central axis of the geometric model, conducting moving trihedron modeling along the generated trajectory and then creating a sweeping surface along the trajectory. A novel joint reconstruction approach is also proposed whereby a part surface sweeping operation is performed across branches of the joint and then a surface created over the resultatn holes therebetween. A 3-D mesh may also be generated, based upon this model, for finite element analysis and pathology creation.

Owner:AGENCY FOR SCI TECH & RES

HMD Calibration with Direct Geometric Modeling

ActiveUS20160012643A1Reduce complexityCathode-ray tube indicatorsImage data processingPattern recognitionGeometric modeling

An optical see-through (OST) head-mounted display (HMD) uses a calibration matrix having a fixed sub-set of adjustable parameters within all its parameters. Initial values for the calibration matrix are based on a model head. A predefined set of incremental adjustment values is provided for each adjustable parameter. During calibration, the calibration matrix is cycled through its predefined incremental parameter changes, and a virtual object is projected for each incremental change. The resultant projected virtual object is aligned to a reference real object, and the projected virtual object having the best alignment is identified. The setting values of the calibration matrix that resulted in the best aligned virtual object are deemed the final calibration matrix to be used with the OST HMD.

Owner:SEIKO EPSON CORP

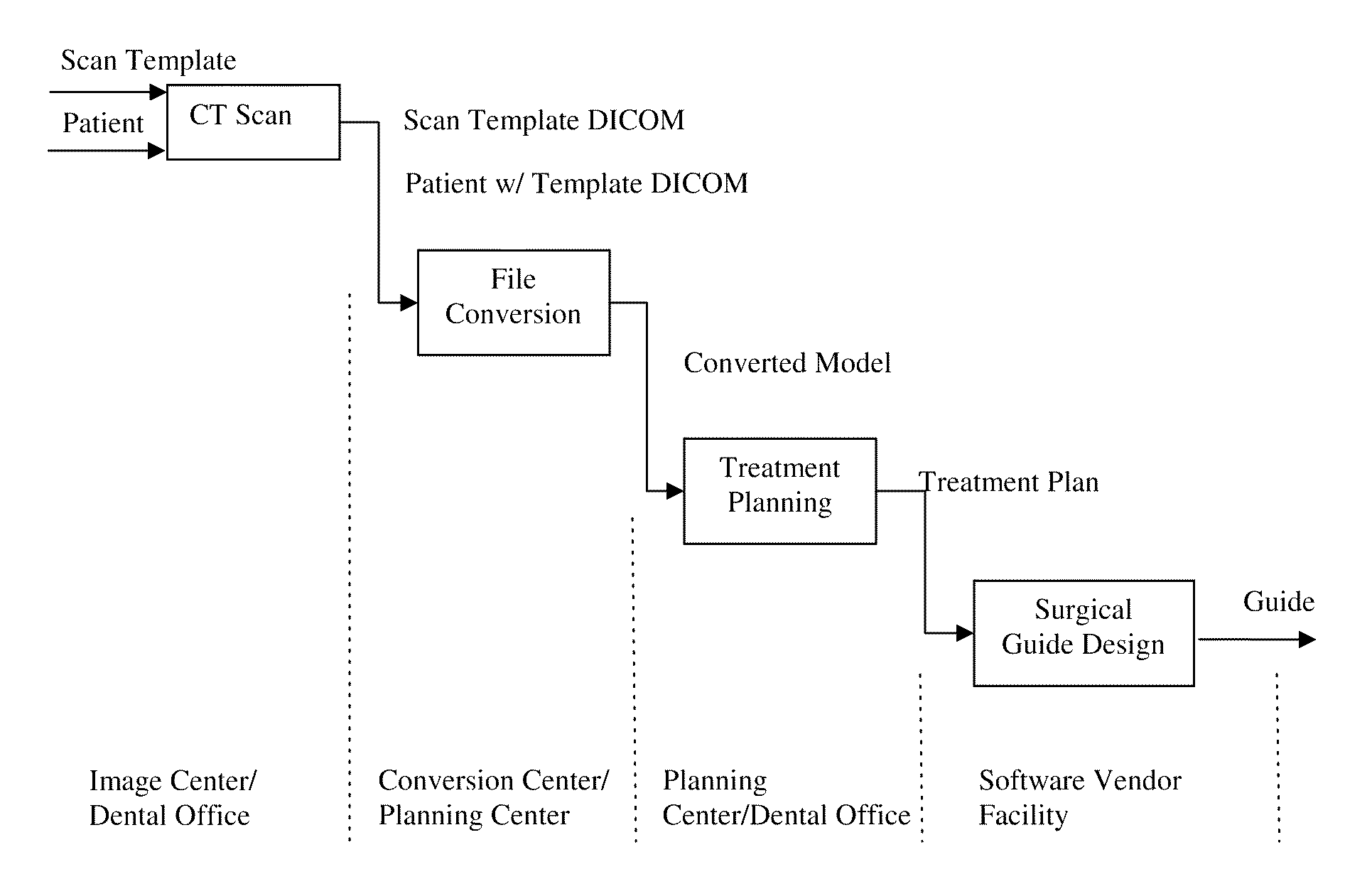

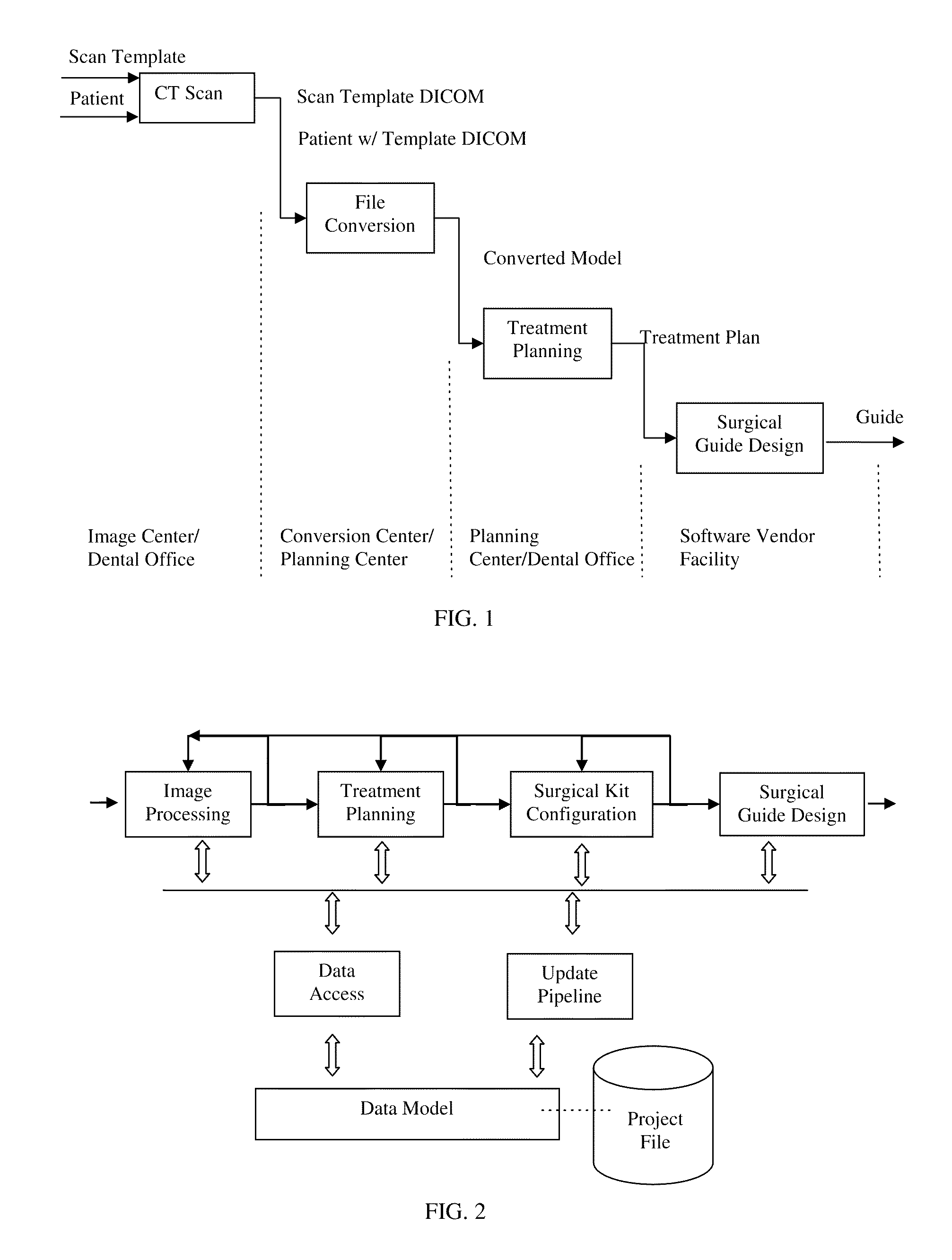

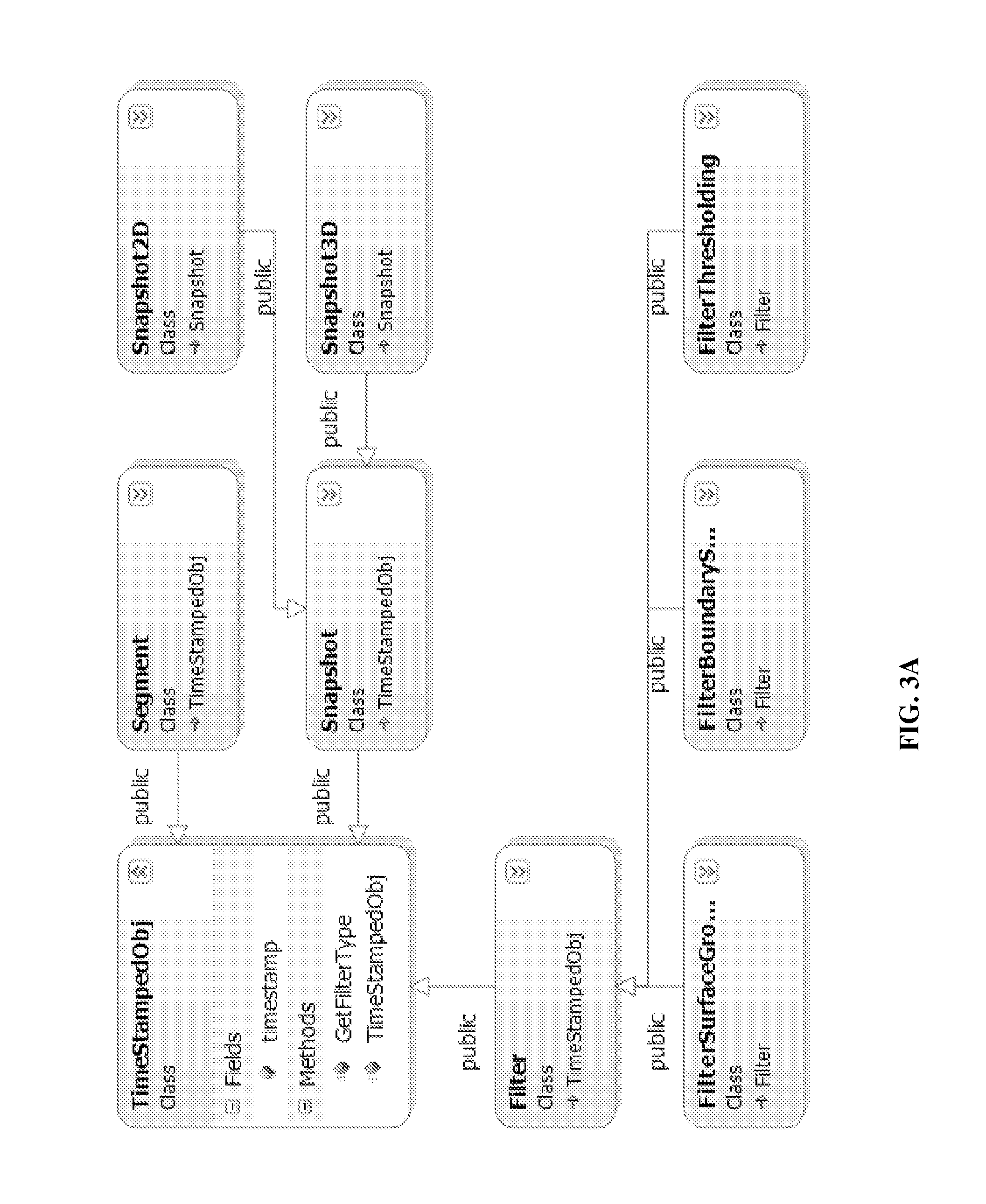

Method and software system for treatment planning and surgical guide CAD/CAM

ActiveUS8543234B2Process controlMedical simulationAdditive manufacturing apparatusImaging processingSoftware system

A method and interactive computer system for dental implant treatment planning, surgical guide design and manufacturing. In the heart of the method is a fully associative workflow integrating image processing, treatment planning, surgical kit configuration and surgical guide CAD / CAM in one single computer system. In this workflow, any changes of image processing parameters and implant information in the earlier stage are automatically propagated to the downstream. This characteristic is referred as associativity. The software aspect of the system is built upon this concept and its corresponding data model. This invention also includes an image processing and geometric modeling approach that is characterized as design for manufacturability and applicability. The integration of treatment planning and surgical guide CAD is further on integrated with manufacturing equipment to constitute a complete CAD / CAM solution, which is also fully associative.

Owner:GUIDEMIA TECH

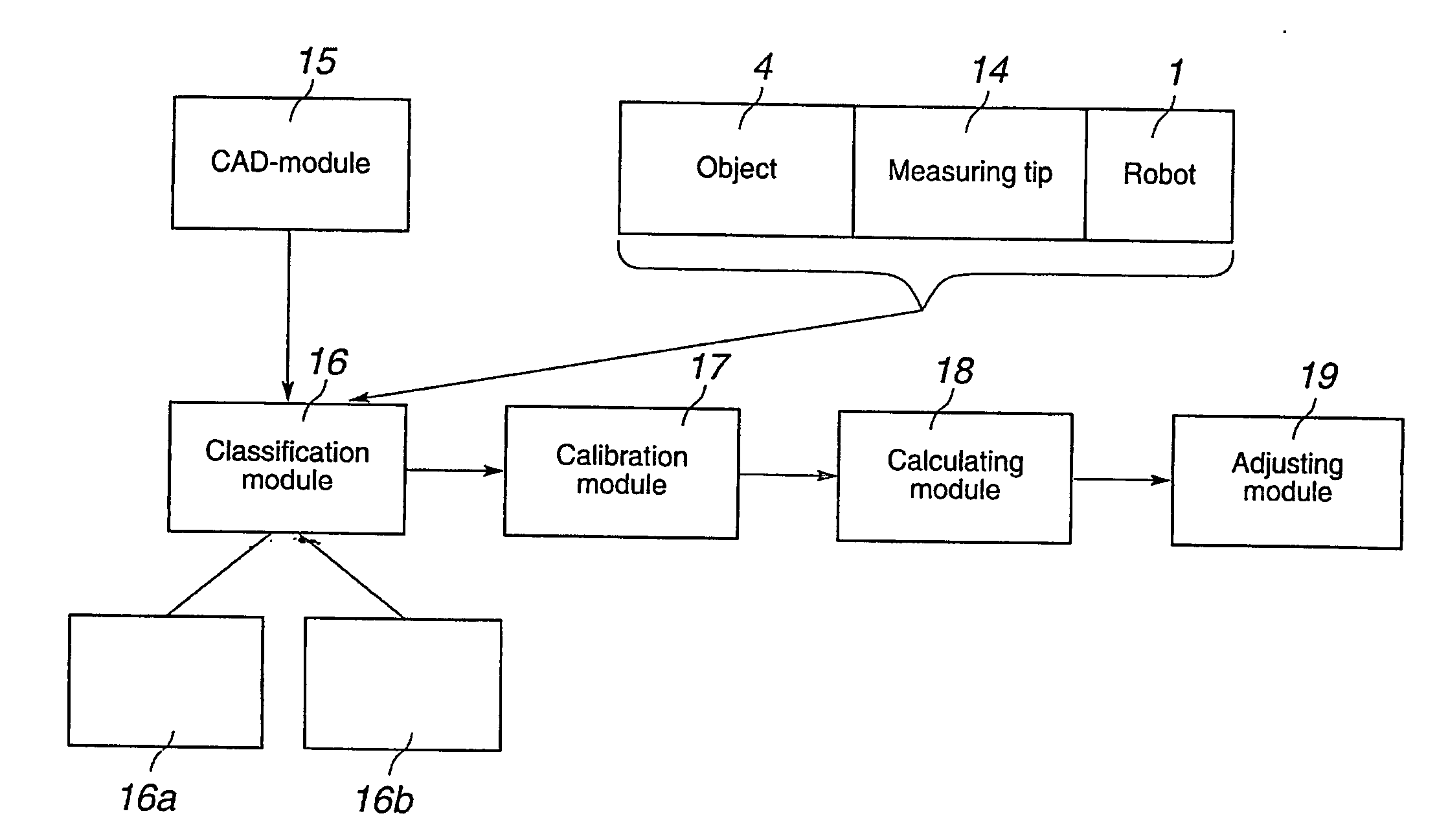

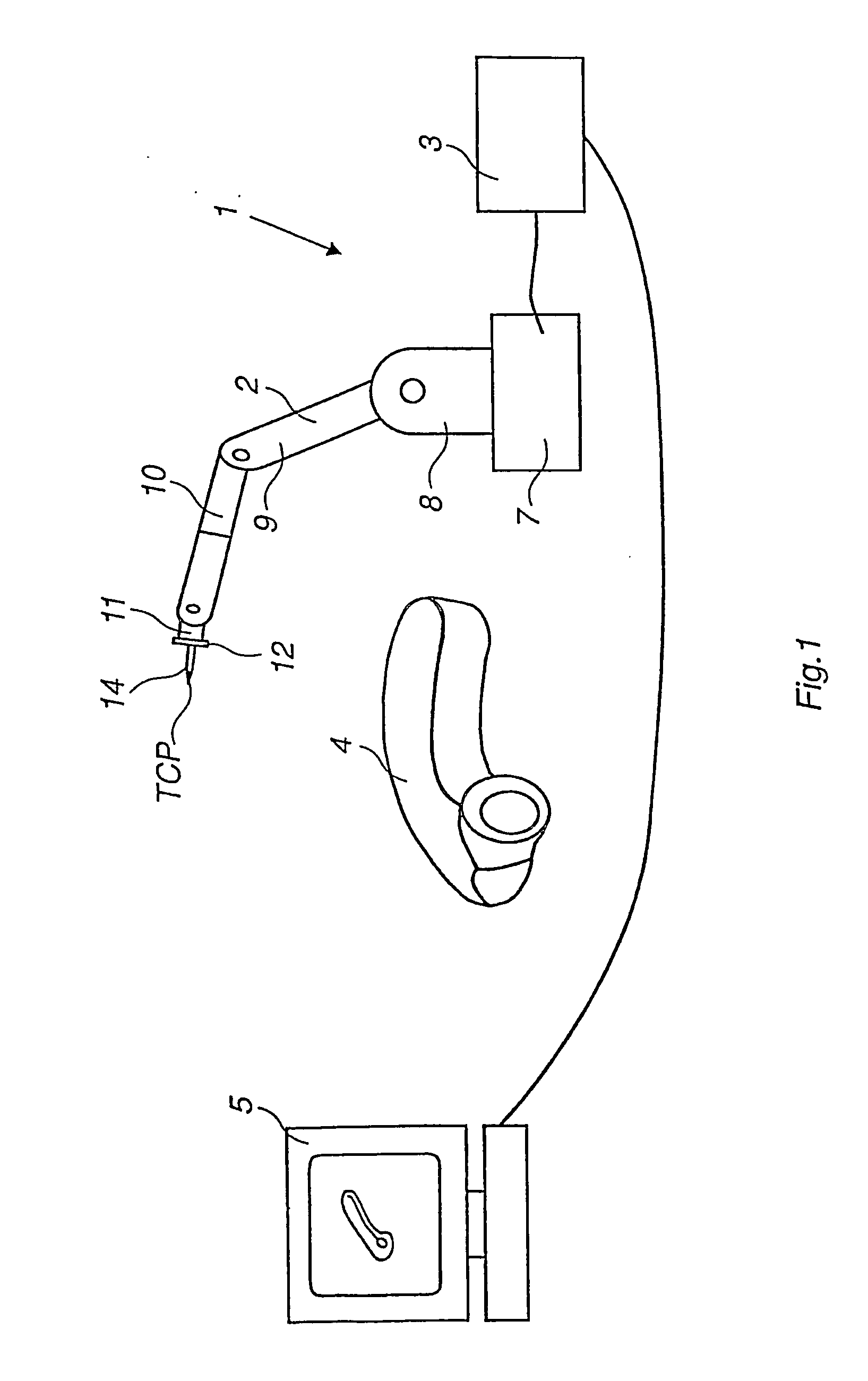

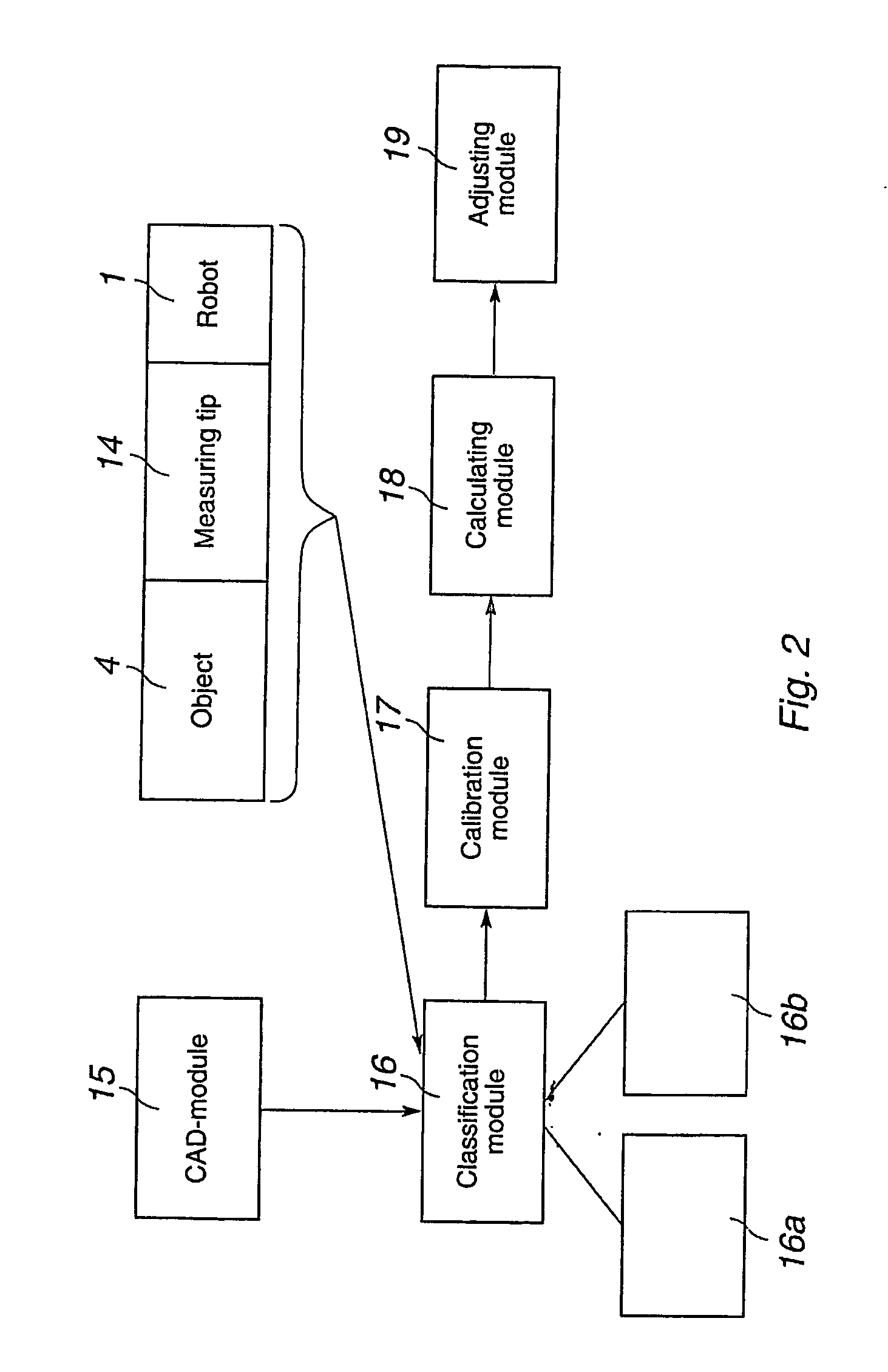

Method and a system for programming an industrial robot to move relative to defined positions on an object, including generation of a surface scanning program

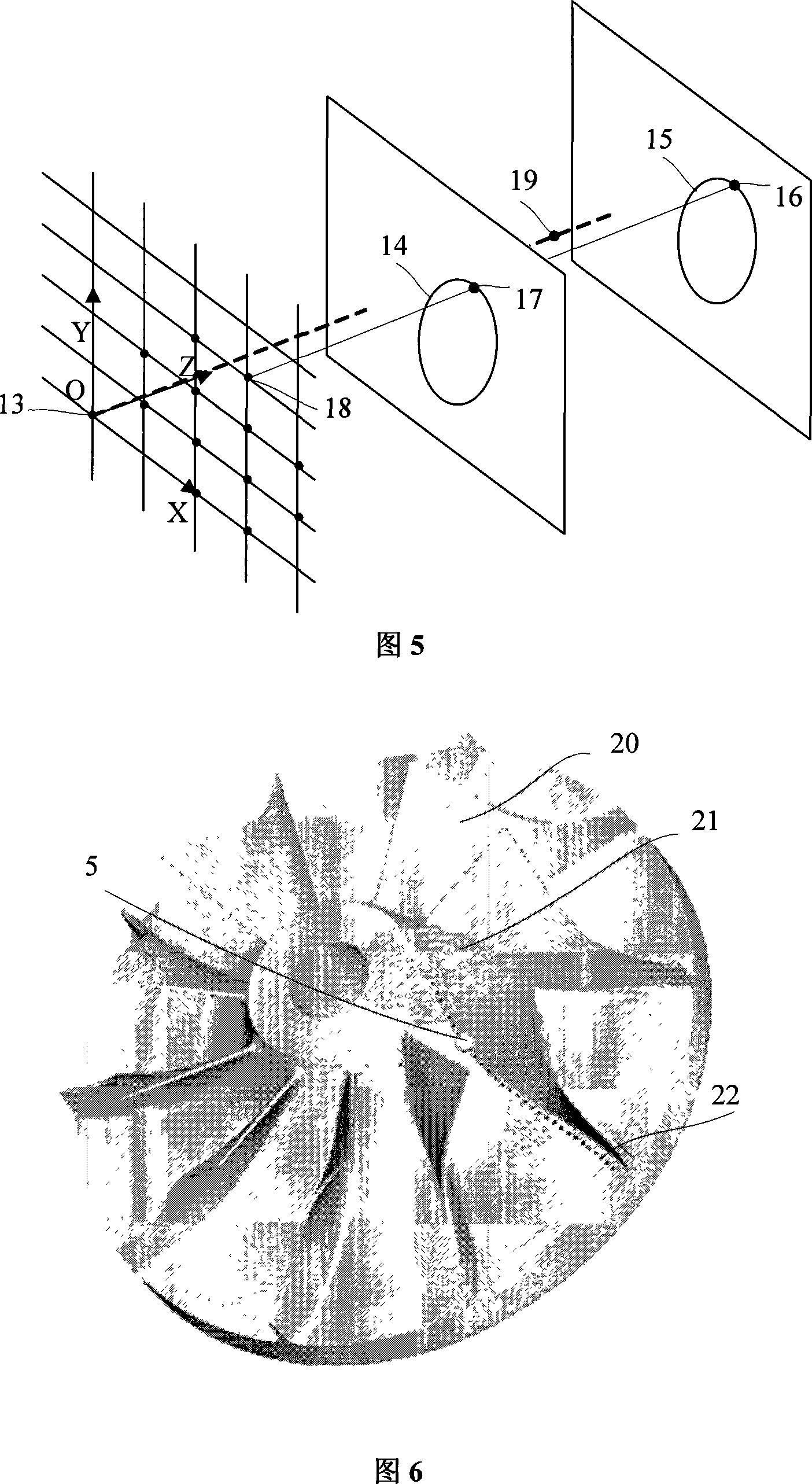

ActiveUS20060181236A1Easy CalibrationSimple programmingProgramme-controlled manipulatorComputer controlMeasurement pointSimulation

A method and a system for programming an industrial robot to move relative to defined positions on an object. The system includes a geometrical model of the object, the real object, and an industrial robot. A plurality of measuring points are generated corresponding to different points on the surface of the real object expressed in a coordinate system associated with the robot. The system further includes a calibration module arranged to determine orientation and position of the geometrical model of the object relative to the coordinate system associated with the robot, a calculating module arranged to calculate the deviation between the measuring points and corresponding points on the geometrical model, and an adjusting module arranged to adjust the defined positions based on the calculated deviations.

Owner:ABB (SCHWEIZ) AG

Scatterometry-Based Imaging and Critical Dimension Metrology

ActiveUS20150300965A1Improve the measurement effectMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementDiffraction orderMetrology

Methods and systems for performing measurements of semiconductor structures and materials based on scatterometry measurement data are presented. Scatterometry measurement data is used to generate an image of a material property of a measured structure based on the measured intensities of the detected diffraction orders. In some examples, a value of a parameter of interest is determined directly from the map of the material property of the measurement target. In some other examples, the image is compared to structural characteristics estimated by a geometric, model-based parametric inversion of the same measurement data. Discrepancies are used to update the geometric model of the measured structure and improve measurement performance. This enables a metrology system to converge on an accurate parametric measurement model when there are significant deviations between the actual shape of a manufactured structure subject to model-based measurement and the modeled shape of the structure.

Owner:KLA TENCOR TECH CORP

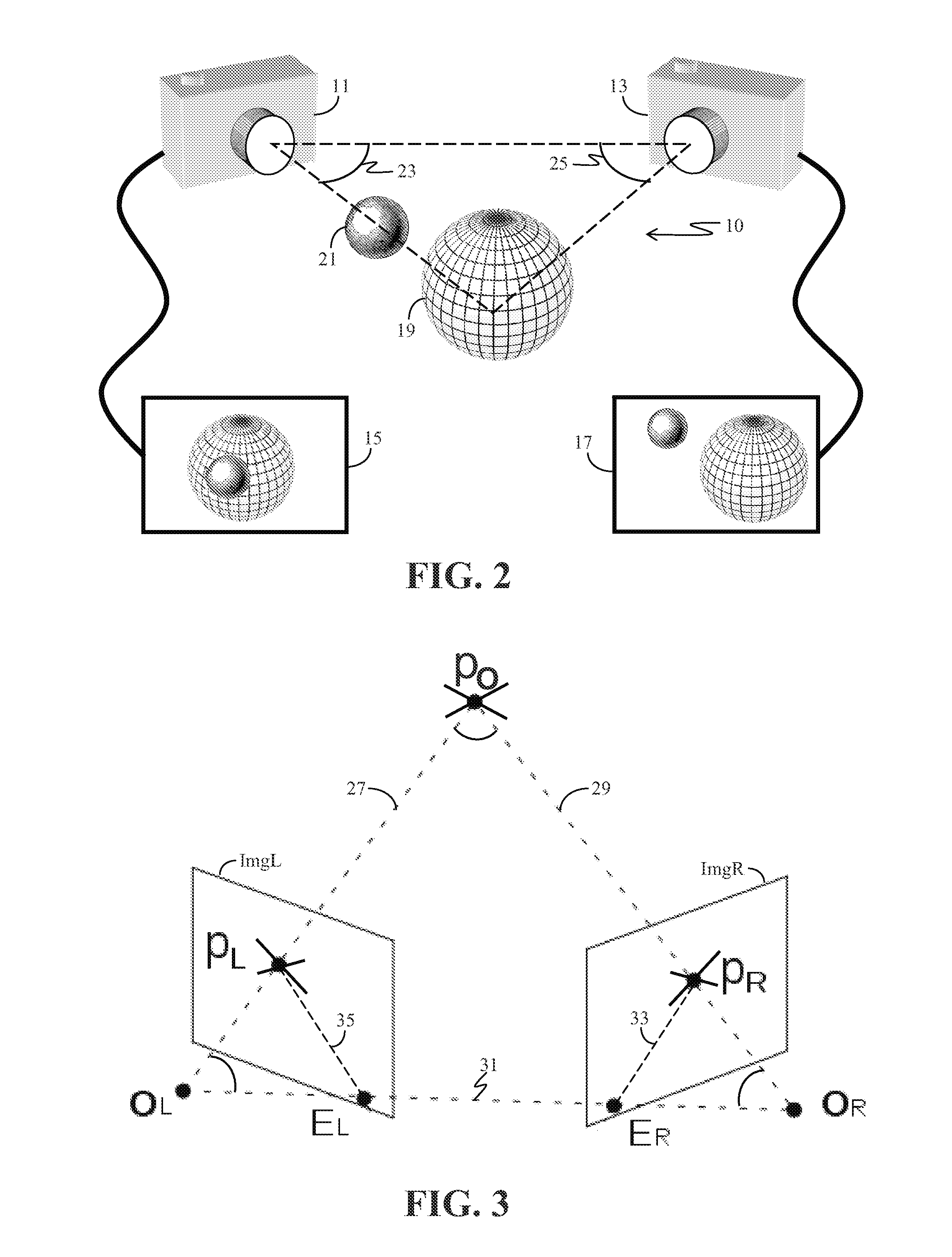

3D geometric modeling and motion capture using both single and dual imaging

Owner:MANTIS VISION LTD

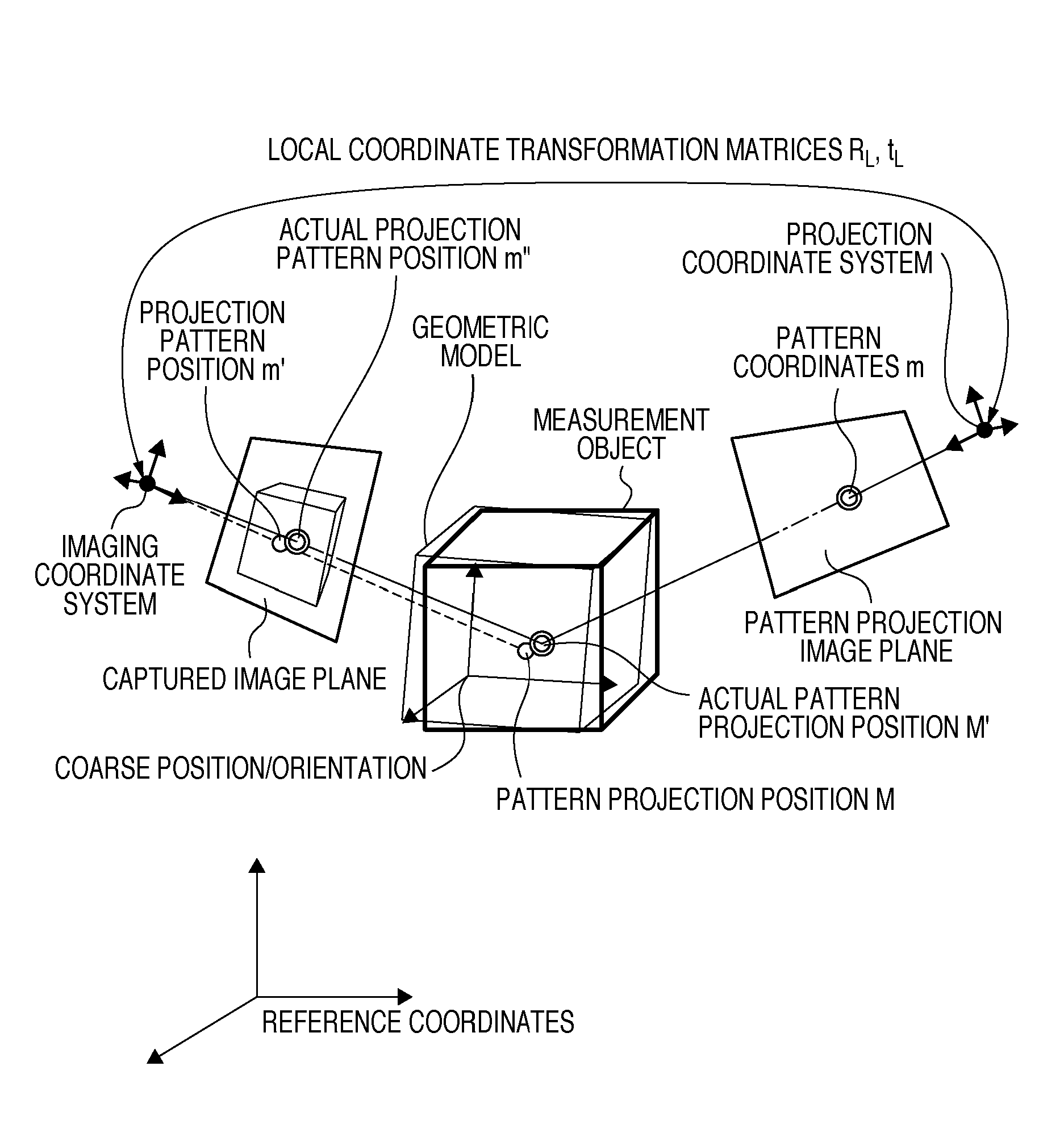

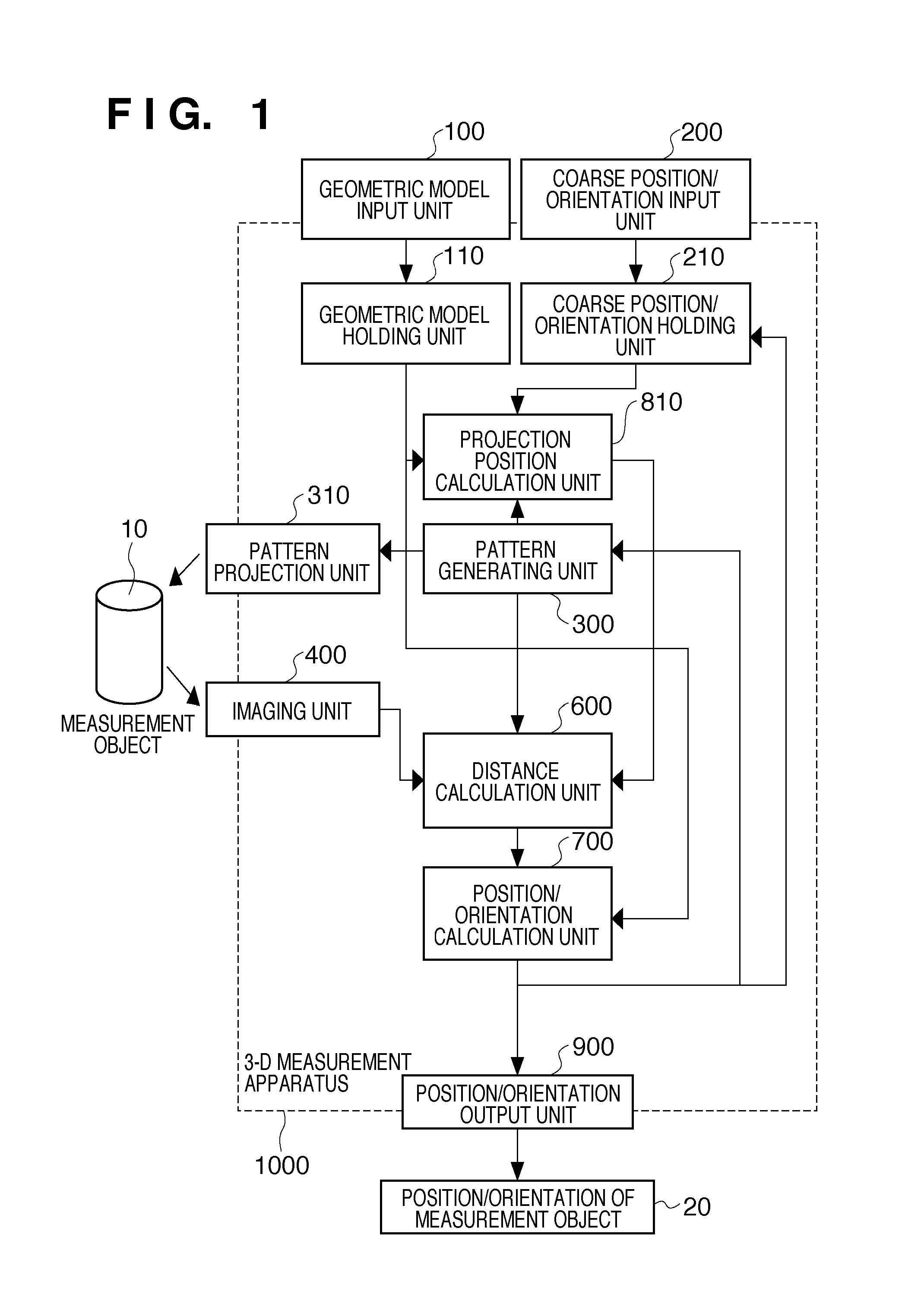

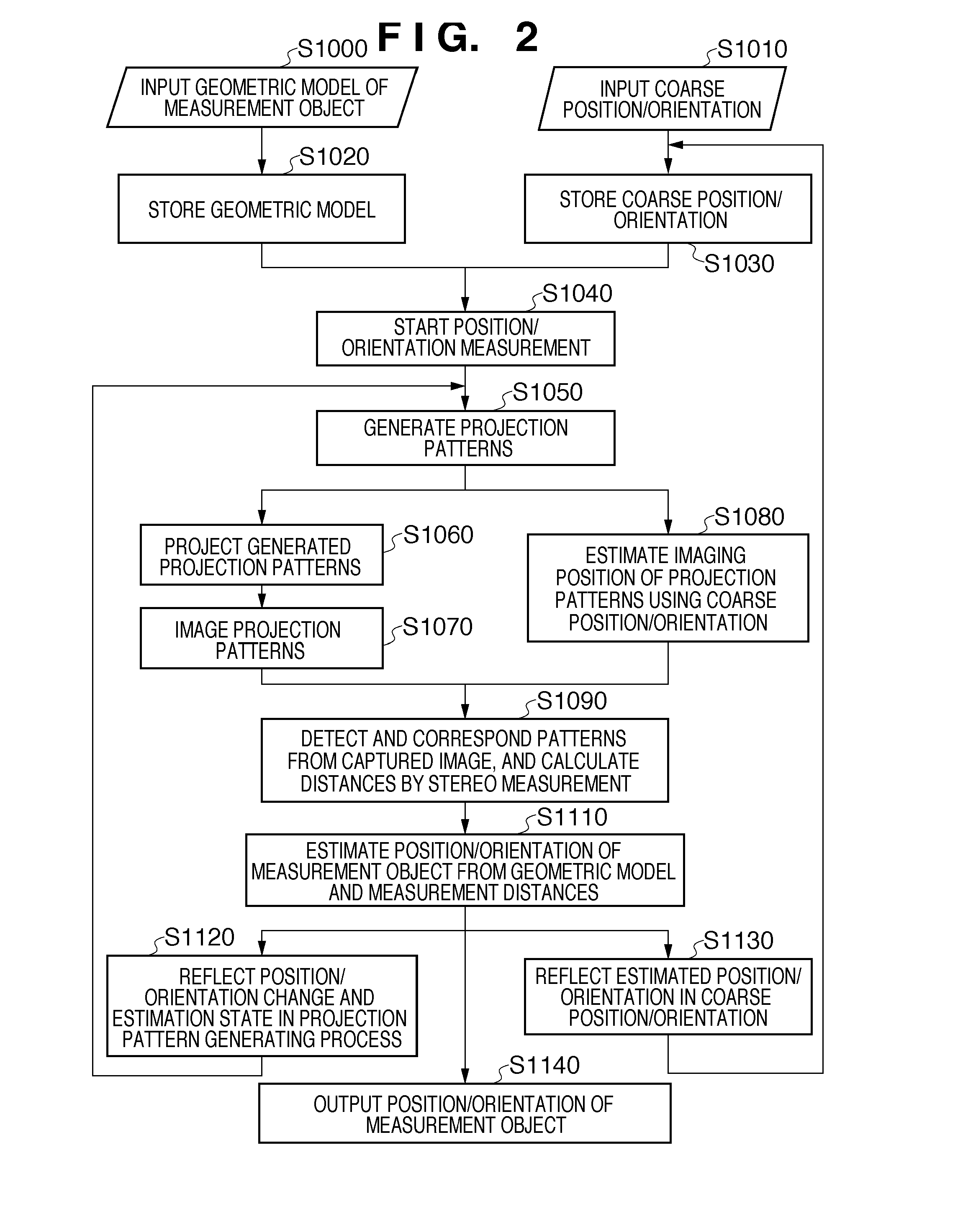

Three-dimensional measurement apparatus and control method therefor

ActiveUS20110164114A1Using optical meansSteroscopic systemsGeometric modelingThree dimensional measurement

Owner:CANON KK

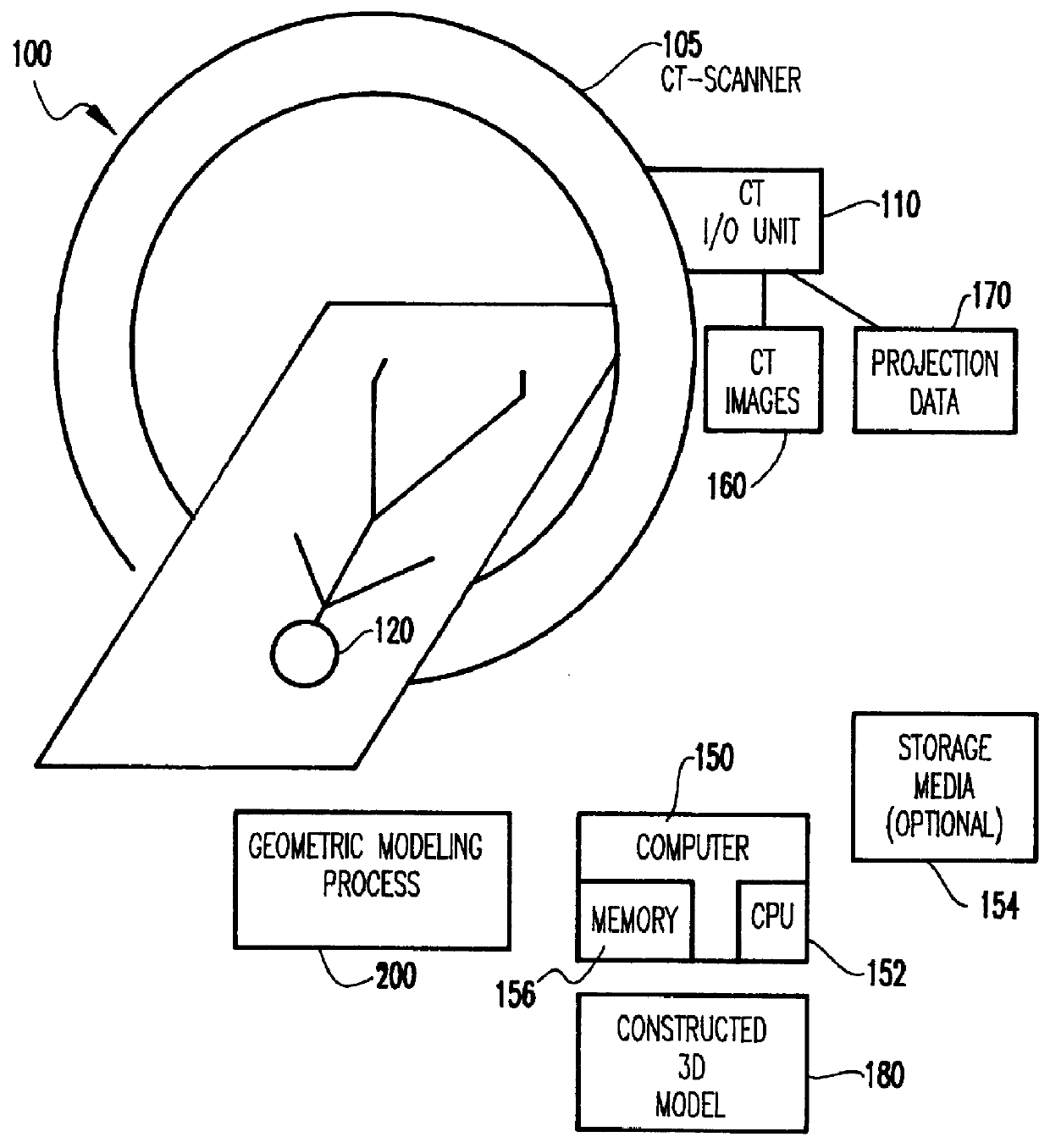

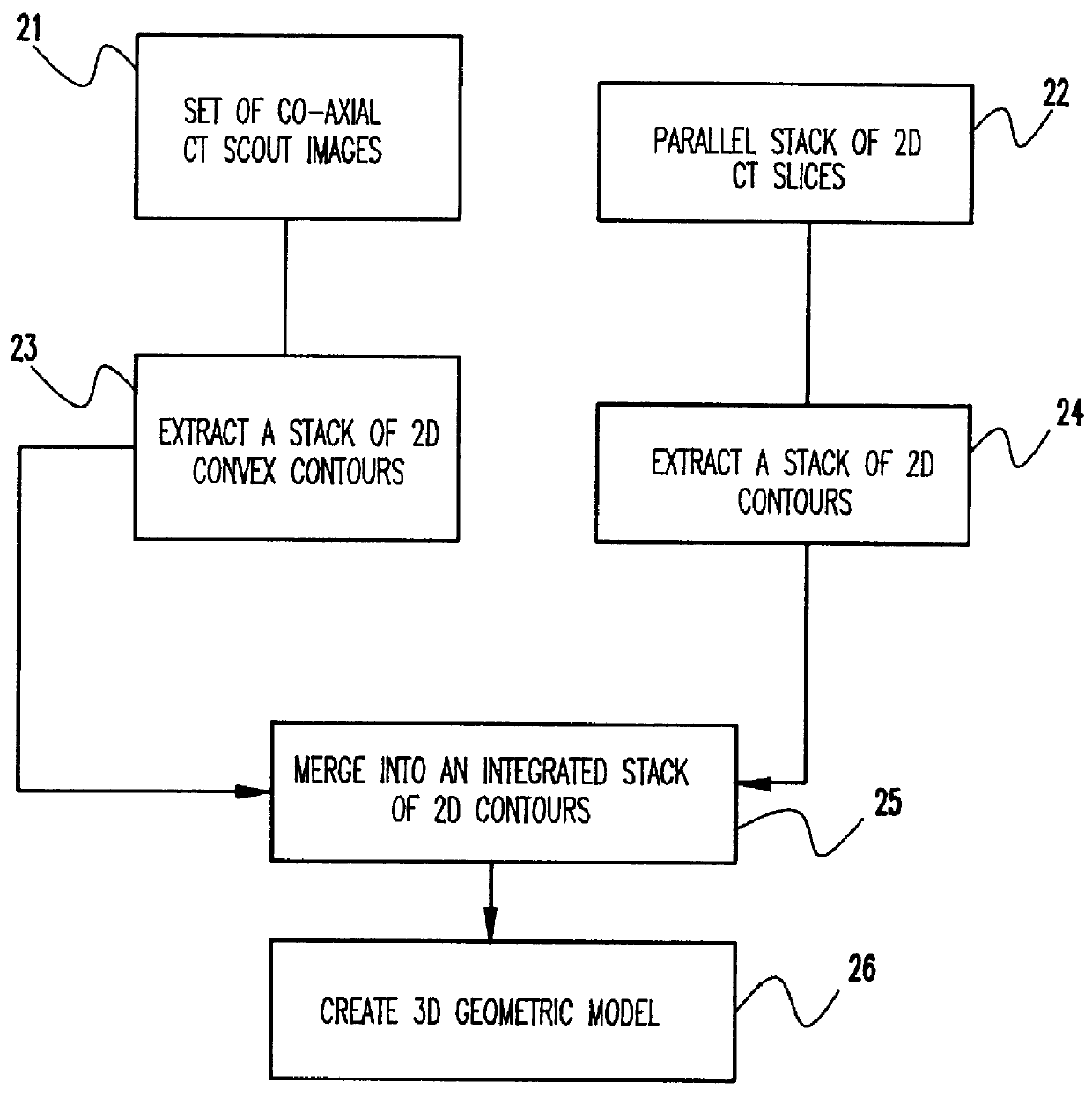

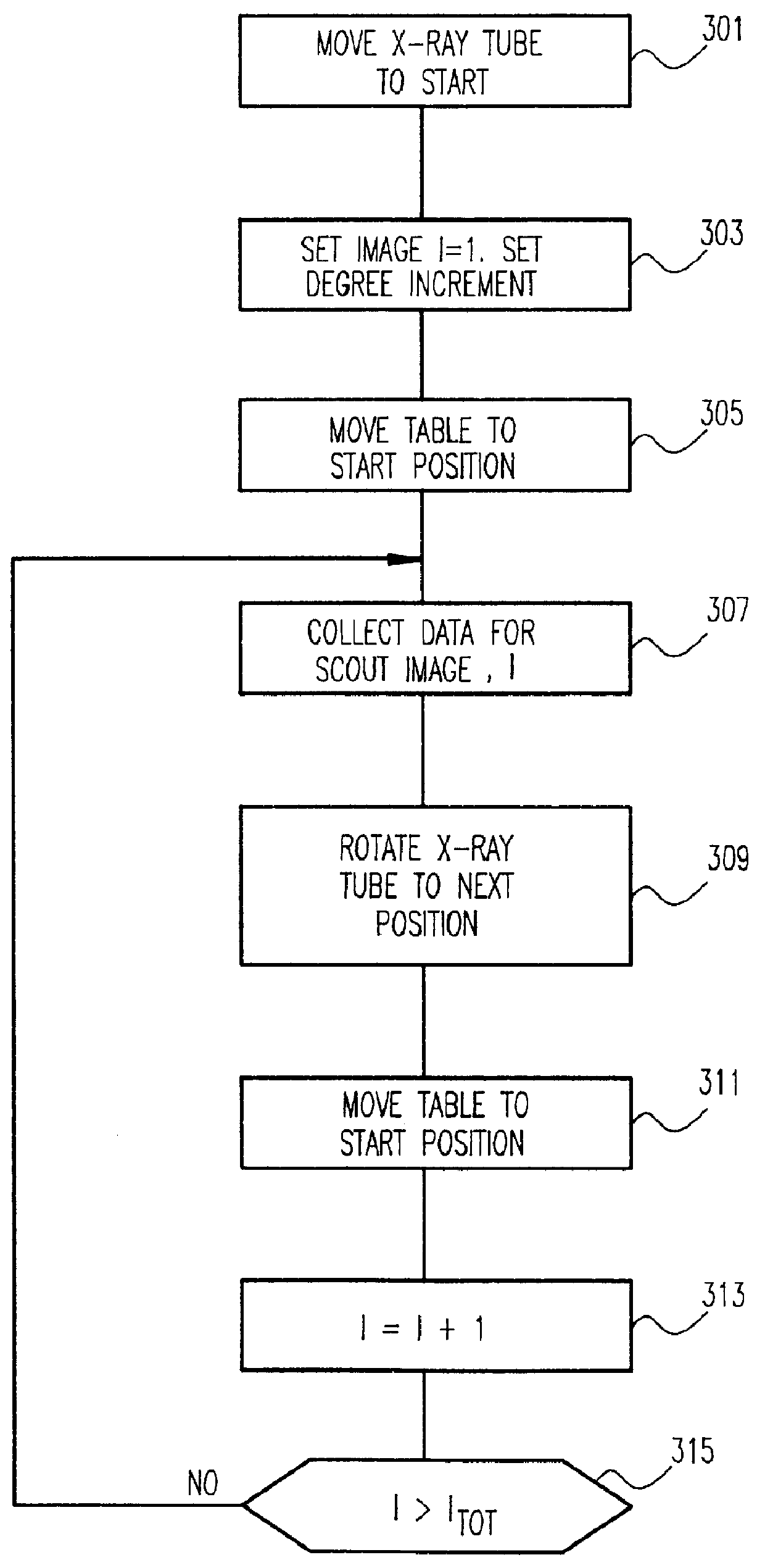

System and method for three-dimensional geometric modeling by extracting and merging two-dimensional contours from CT slice data and CT scout data

InactiveUS6028907AMaterial analysis using wave/particle radiationRadiation/particle handlingCt scannersGeometric modeling

A computer system and method solve the problem of getting a useful three-dimensional representation of an object like the spine using a small amount of data. This is done by gathering three-dimensional data in the form of a set of 2D computer tomography (CT) slices of a patient's bones and a coaxial set of 2D CT scout images, which are digital two-dimensional X-ray images that can be produced by a CT scanner; extracting from each of these three-dimensional data sets a corresponding stack of 2D contours; and constructing a 3D geometric model of the object. The main features of spinal deformation are captured by integrating these two sets of three-dimensional data, and constructing from them a three-dimensional geometric model of the spine. Scouts are usually used to monitor CT scan acquisition. Here, they are also used as an essential source of data.

Owner:GOOGLE LLC

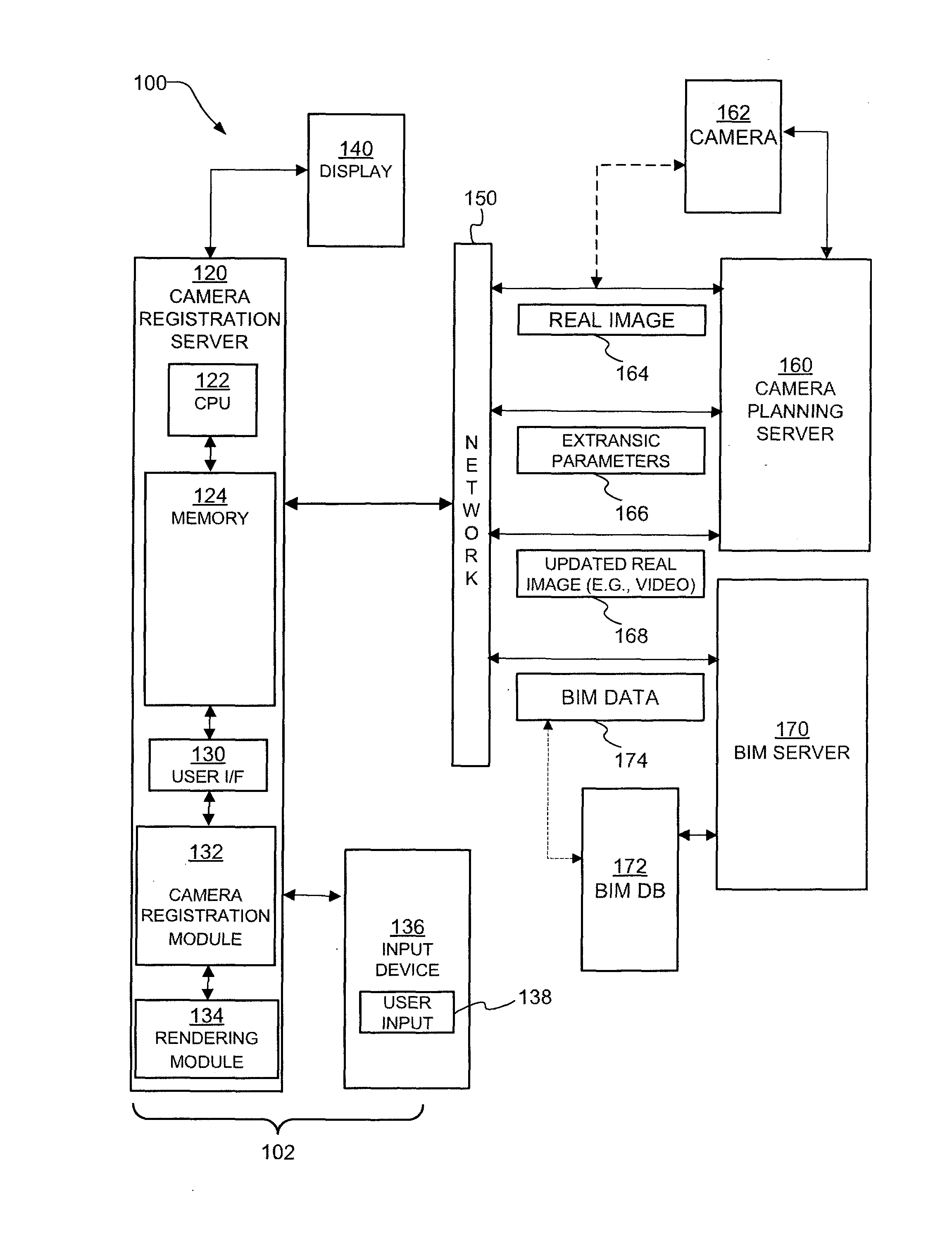

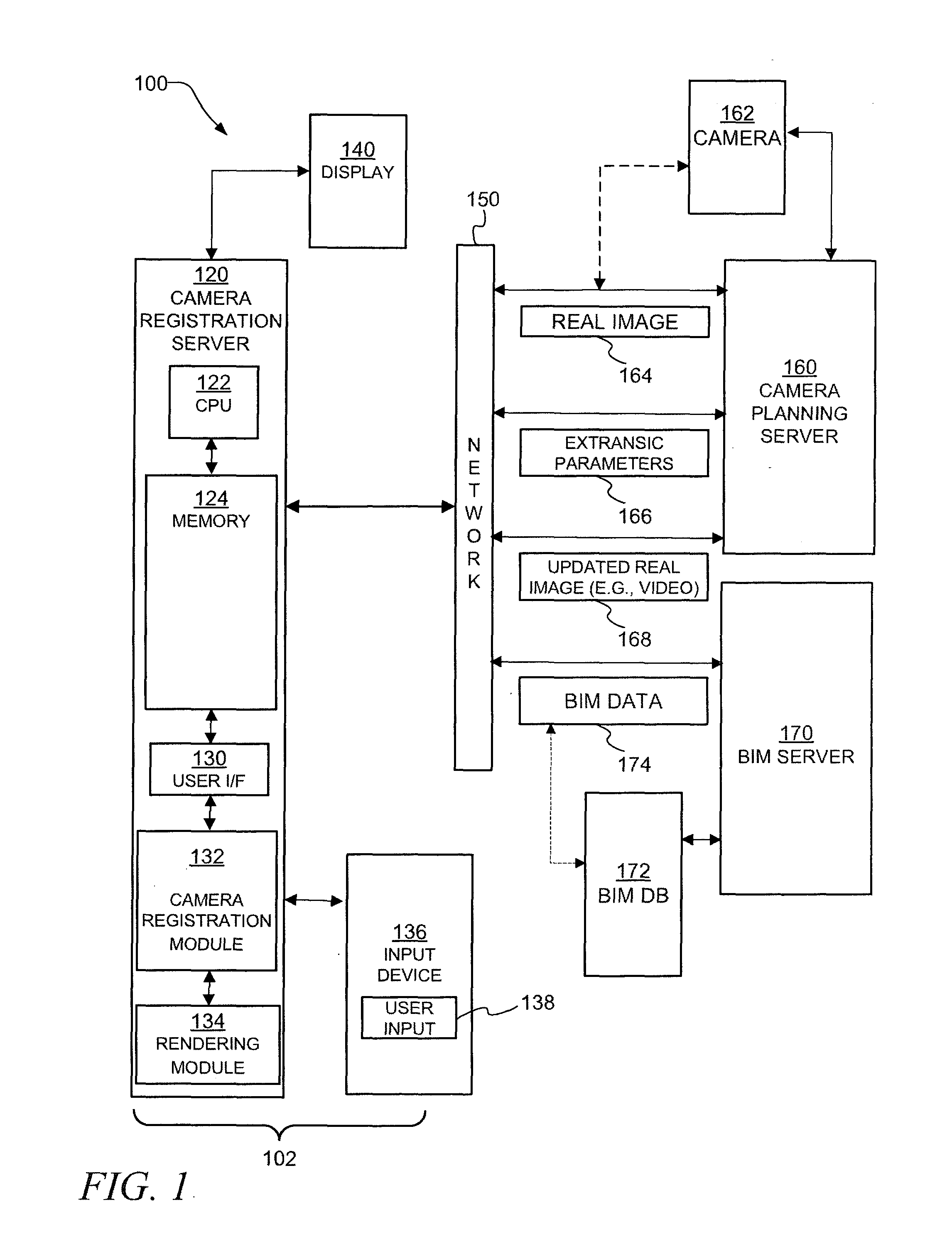

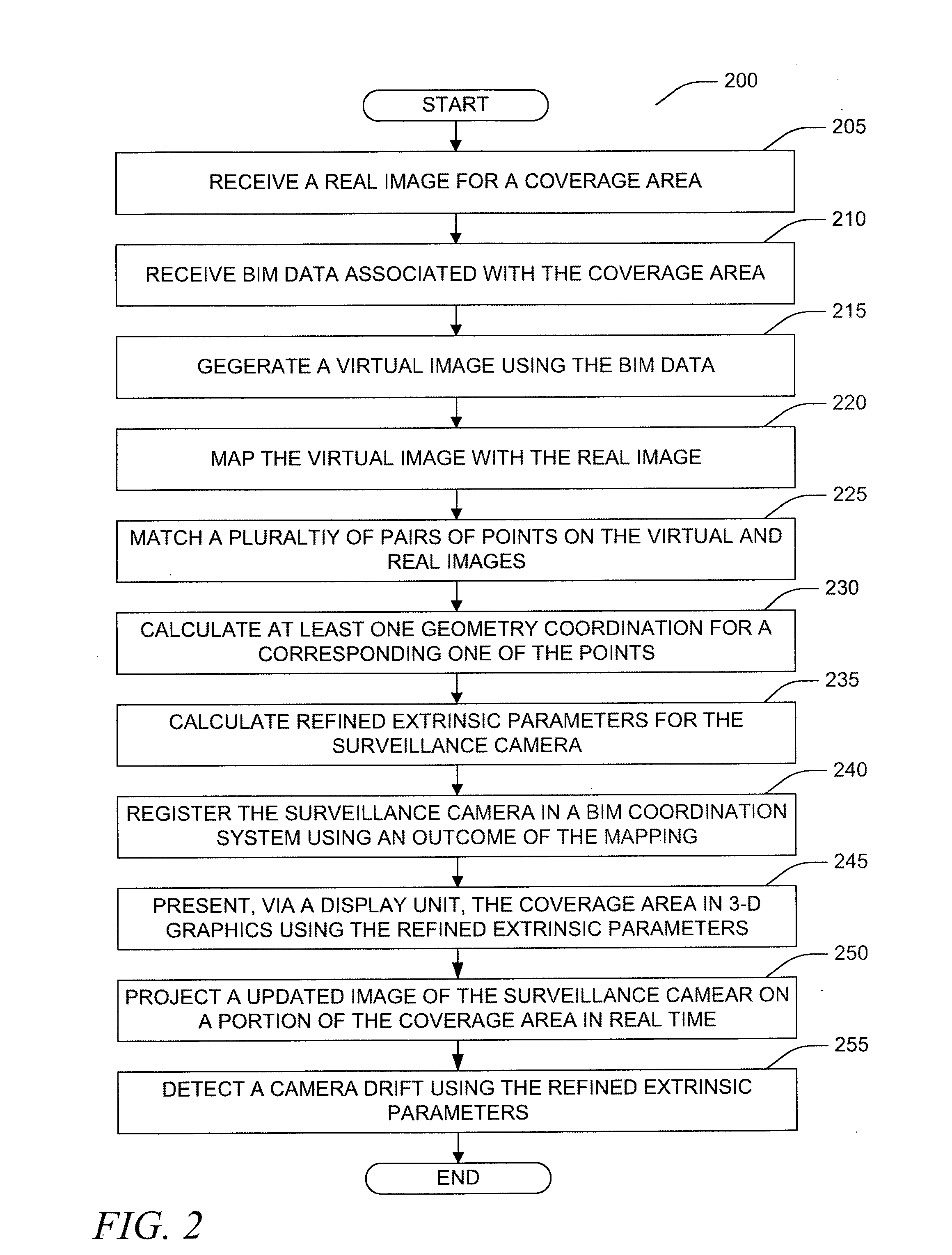

Camera registration and video integration in 3D geometry model

Apparatus, systems, and methods may operate to receive a real image or real images of a coverage area of a surveillance camera. Building Information Model (BIM) data associated with the coverage area may be received. A virtual image may be generated using the BIM data. The virtual image may include at least one three-dimensional (3-D) graphics that substantially corresponds to the real image. The virtual image may be mapped with the real image. Then, the surveillance camera may be registered in a BIM coordination system using an outcome of the mapping.

Owner:HONEYWELL INT INC

Modeling and analysis of objects having heterogeneous material properties

InactiveUS20050060130A1Easy to useComputation using non-denominational number representationDesign optimisation/simulationGeometric modelingMaterials science

Owner:WISCONSIN ALUMNI RES FOUND

Numerical value simulation method of vibration and acoustic characteristics of speaker

ActiveCN102004823ASpeed up the design processOvercome the disadvantage of being limited to low frequenciesSpecial data processing applicationsElement modelGeometric modeling

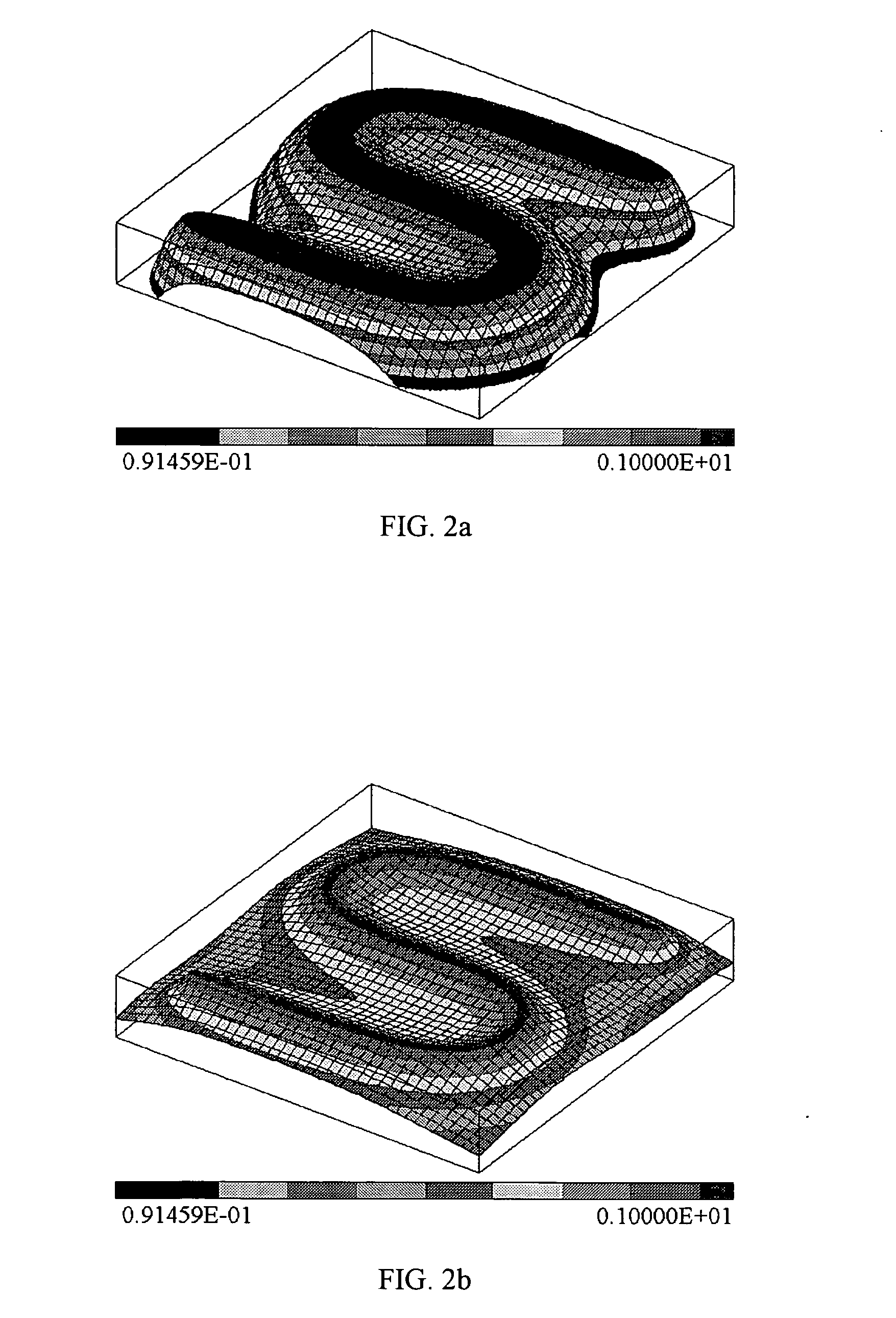

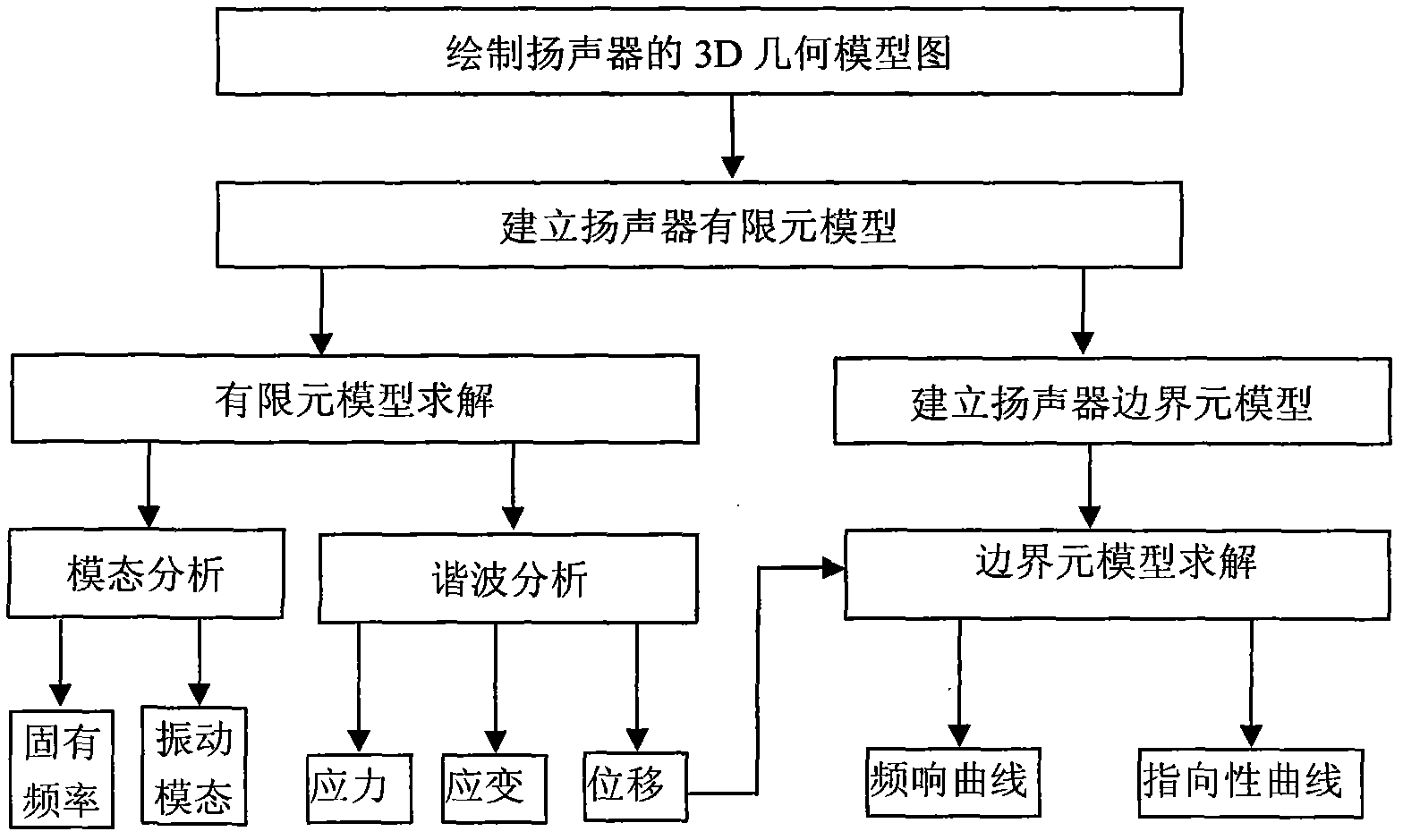

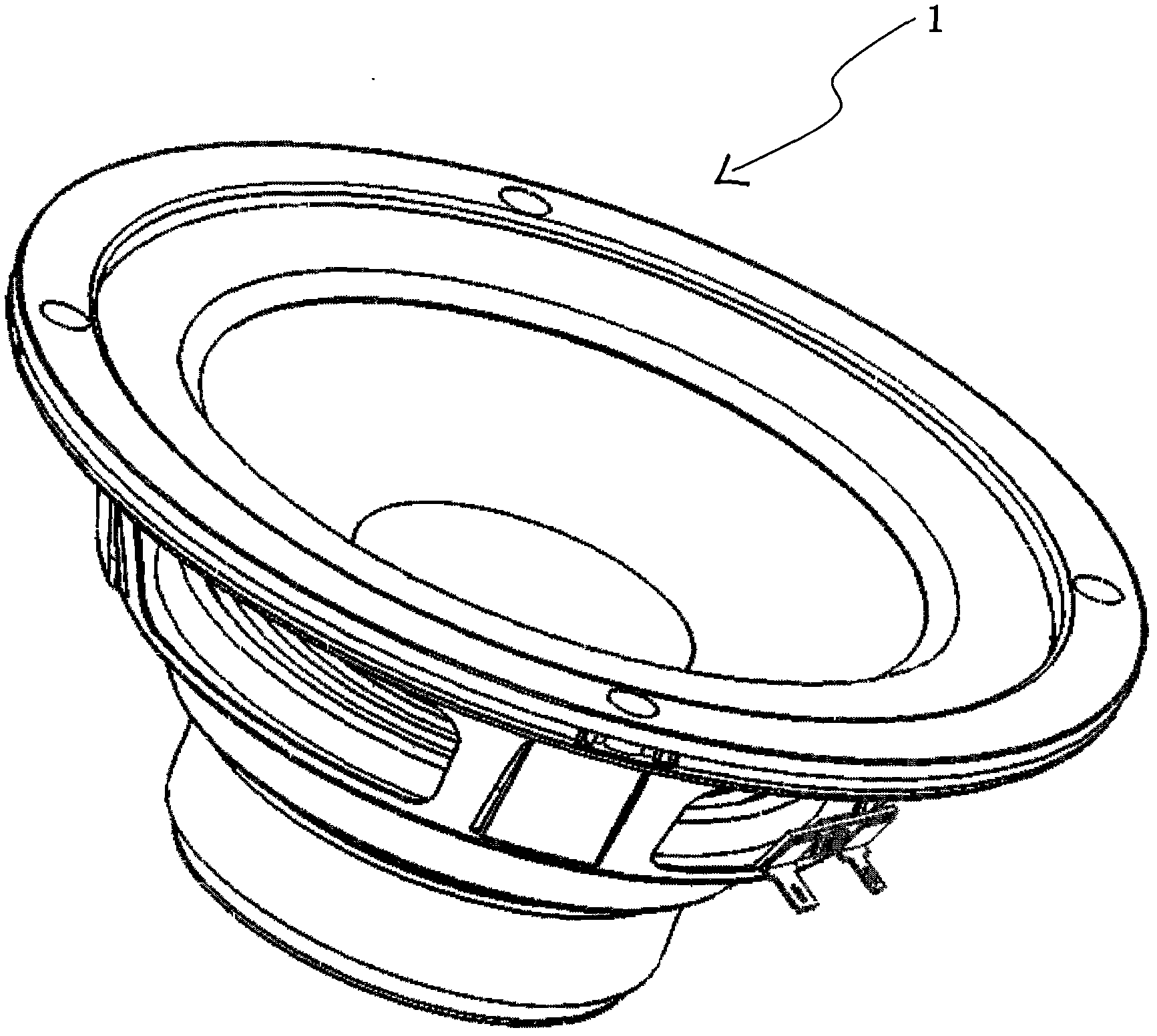

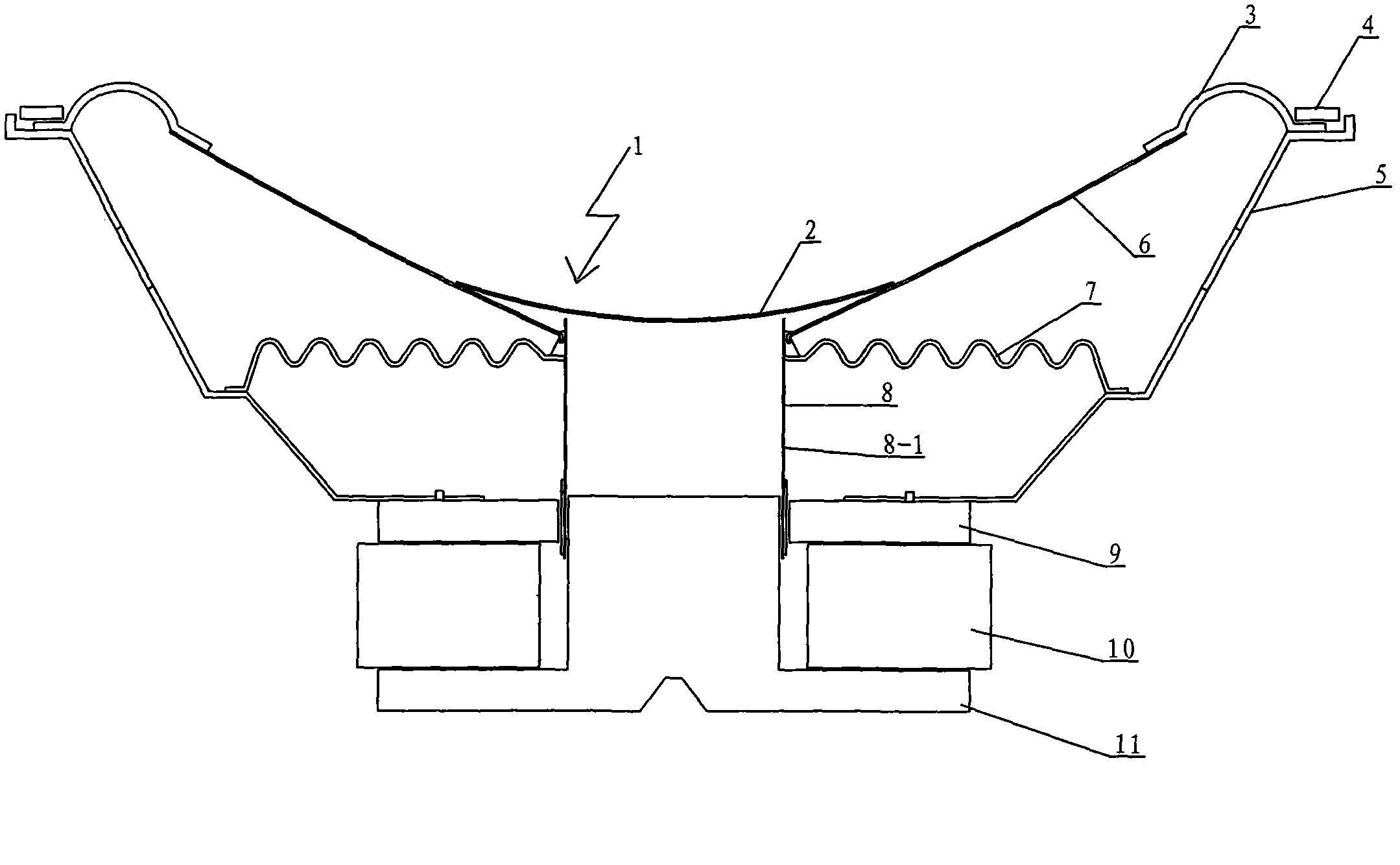

The invention provides a numerical value simulation method of the vibration and acoustic characteristics of a speaker. The method comprises the following steps of: firstly, drawing a 3D (Three-Dimensional) geometric model diagram of the speaker by using 3D drawing software; then, adding the 3D geometric model diagram of the speaker to meshing software to mesh the 3D geometric model diagram into body elements, defining element types, materials and boundary conditions and applying a load to acquire a finite element model; establishing a boundary element model matched with the finite element model; and finally, solving the finite element model with a finite element solver to acquire the vibration characteristics of the speaker, and solving the boundary element model with a boundary element solver to acquire the acoustic characteristics of the speaker, wherein the vibration characteristics include the natural frequency, the vibration mode (vibration type), the displacement, the strain and the stress, and the acoustic characteristics include a frequency response curve and a directivity curve.

Owner:ZHEJIANG ELECTRO ACOUSTIC R&D CENT CAS +1

3D geometric modeling and 3D video content creation

A system, apparatus and method of obtaining data from a 2D image in order to determine the 3D shape of objects appearing in said 2D image, said 2D image having distinguishable epipolar lines, said method comprising: (a) providing a predefined set of types of features, giving rise to feature types, each feature type being distinguishable according to a unique bi-dimensional formation; (b) providing a coded light pattern comprising multiple appearances of said feature types; (c) projecting said coded light pattern on said objects such that the distance between epipolar lines associated with substantially identical features is less than the distance between corresponding locations of two neighboring features; (d) capturing a 2D image of said objects having said projected coded light pattern projected thereupon, said 2D image comprising reflected said feature types; and (e) extracting: (i) said reflected feature types according to the unique bi-dimensional formations; and (ii) locations of said reflected feature types on respective said epipolar lines in said 2D image.

Owner:MANTIS VISION LTD

Automatic scene modeling for the 3D camera and 3D video

InactiveCN101208723AReduce computational intensityTexture Mapping EasyTelevision system detailsImage enhancementMediaFLOTelevision set

Single-camera image processing methods are disclosed for 3D navigation within ordinary moving video. Along with color and brightness, XYZ coordinates can be defined for every pixel. The resulting geometric models can be used to obtain measurements from digital images, as an alternative to on-site surveying and equipment such as laser range-finders. Motion parallax is used to separate foreground objects from the background. This provides a convenient method for placing video elements within different backgrounds, for product placement, and for merging video elements with computer-aided design (CAD) models and point clouds from other sources. If home users can save video fly-throughs or specific 3D elements from video, this method provides an opportunity for proactive, branded media sharing. When this image processing is used with a videoconferencing camera, the user's movements can automatically control the viewpoint, creating 3D hologram effects on ordinary televisions and computer screens.

Owner:克雷格・萨默斯

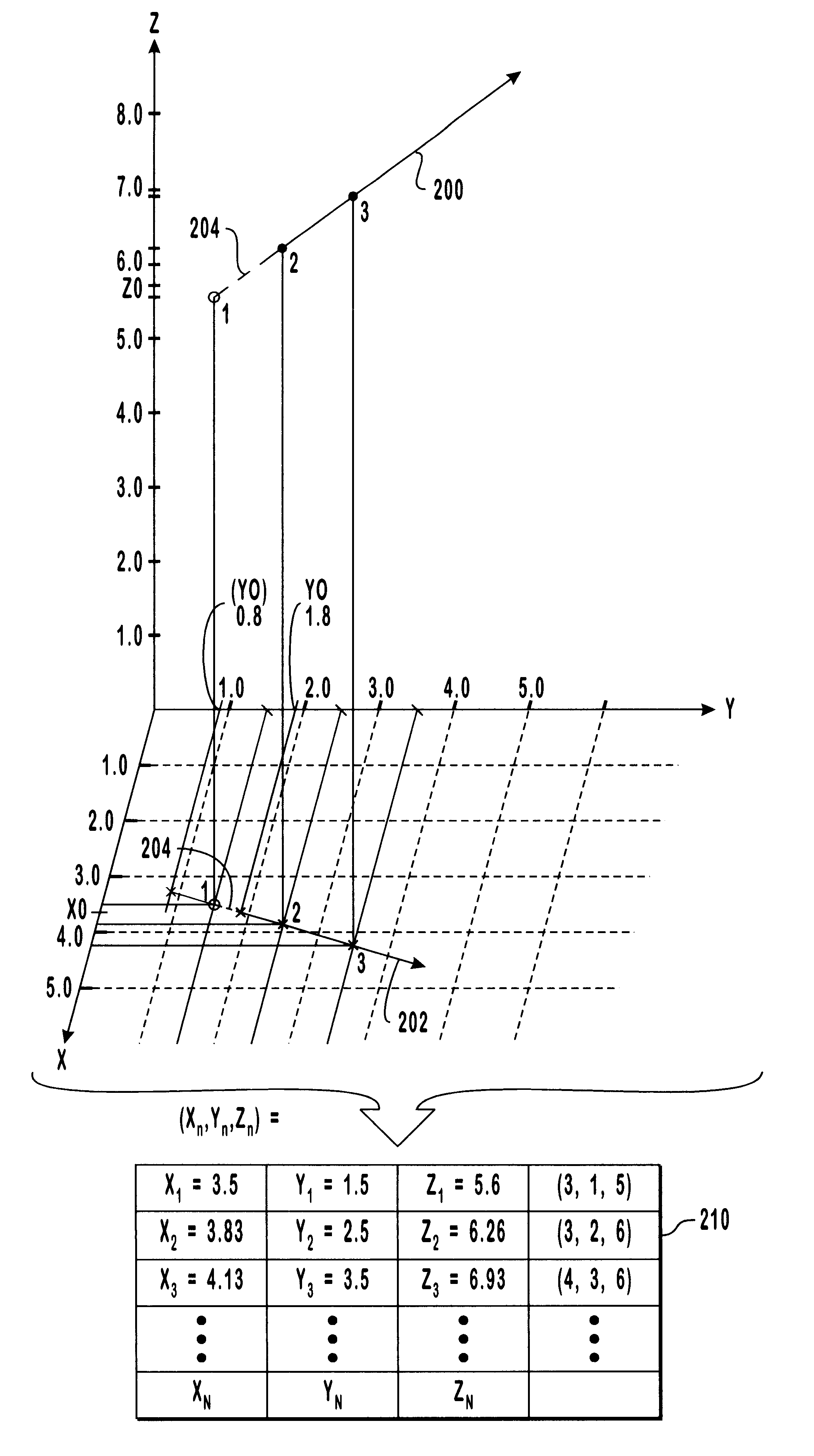

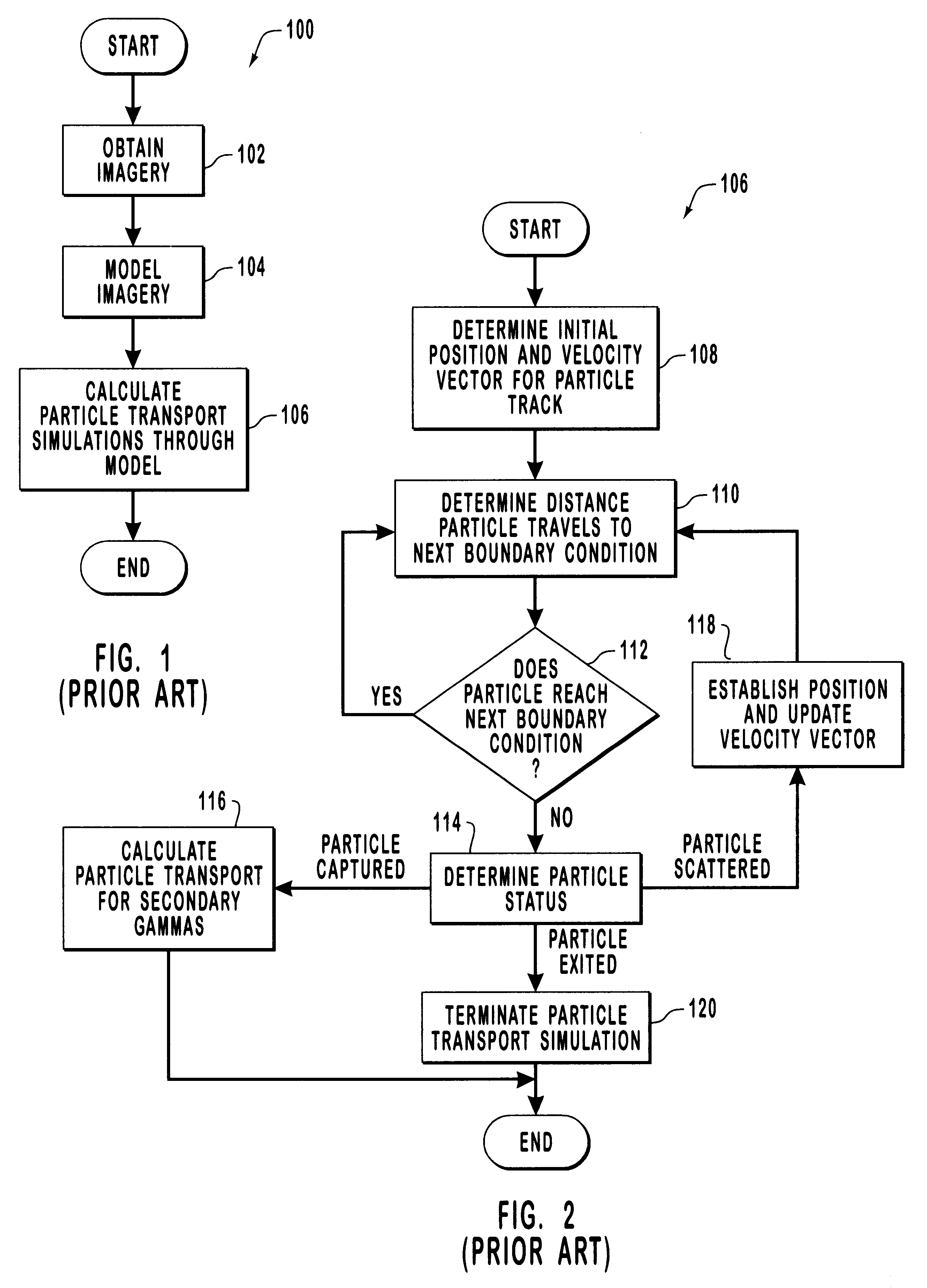

Methods and computer executable instructions for rapidly calculating simulated particle transport through geometrically modeled treatment volumes having uniform volume elements for use in radiotherapy

InactiveUS6175761B1Reduce computing timeImprove calculation accuracyData processing applicationsSurgeryPlan treatmentDosimetry radiation

Methods and computer executable instructions are disclosed for ultimately developing a dosimetry plan for a treatment volume targeted for irradiation during cancer therapy. The dosimetry plan is available in "real-time" which especially enhances clinical use for in vivo applications. The real-time is achieved because of the novel geometric model constructed for the planned treatment volume which, in turn, allows for rapid calculations to be performed for simulated movements of particles along particle tracks there through. The particles are exemplary representations of neutrons emanating from a neutron source during BNCT. In a preferred embodiment, a medical image having a plurality of pixels of information representative of a treatment volume is obtained. The pixels are: (i) converted into a plurality of substantially uniform volume elements having substantially the same shape and volume of the pixels; and (ii) arranged into a geometric model of the treatment volume. An anatomical material associated with each uniform volume element is defined and stored. Thereafter, a movement of a particle along a particle track is defined through the geometric model along a primary direction of movement that begins in a starting element of the uniform volume elements and traverses to a next element of the uniform volume elements. The particle movement along the particle track is effectuated in integer based increments along the primary direction of movement until a position of intersection occurs that represents a condition where the anatomical material of the next element is substantially different from the anatomical material of the starting element. This position of intersection is then useful for indicating whether a neutron has been captured, scattered or exited from the geometric model. From this intersection, a distribution of radiation doses can be computed for use in the cancer therapy. The foregoing represents an advance in computational times by multiple factors of time magnitudes.

Owner:BATTELLE ENERGY ALLIANCE LLC

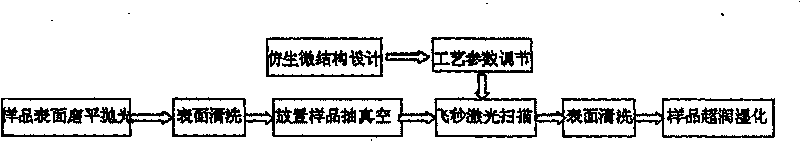

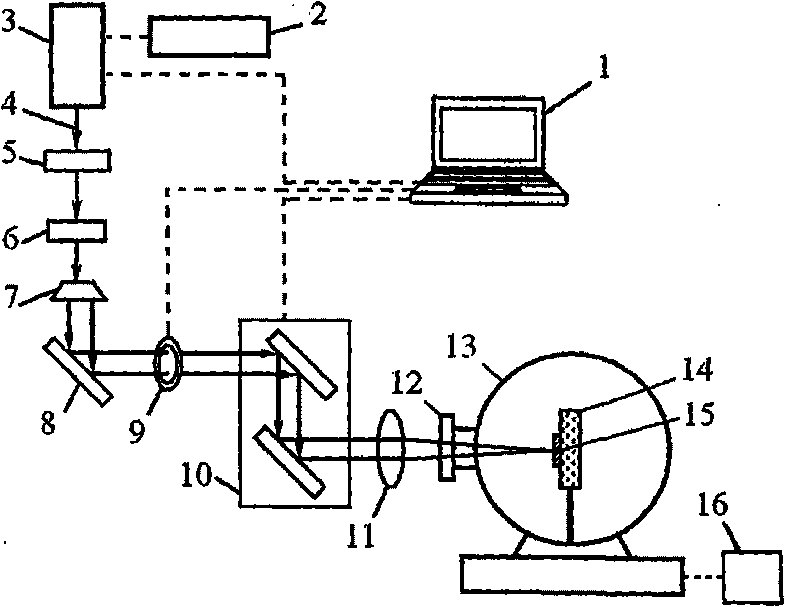

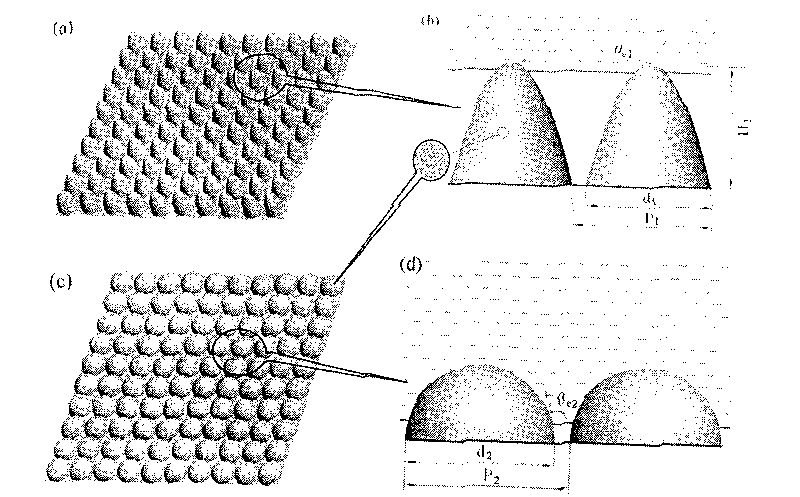

Bionic metal ultra-wetting trans-scale structure design method and preparation method

InactiveCN101712102AEasy to analyze and calculateIdeal wettability structureLaser beam welding apparatusMacroscopic scaleScale structure

The invention relates to the technical field of laser microprocessing, in particular to a method for obtaining a metal-based ultra-wetting surface by designing the trans-scale structure of a metal surface, preparing a laser microstructure on the metal surface and carrying out necessary ultra-wetting decoration to the metal surface. The method comprises the following steps: firstly, designing a macroscopical large-area superficial periodical mastoid structure which simulates a locus leaf surface; constructing a micronano periodical structure on the microstructure of the mastoid structure to obtain a macroscopical-micronano trans-scale geometric model; adjusting laser parameters and a laser scanning path according to geometric parameters acquired after the bionic metal ultra-wetting trans-scale structure is designed; scanning the plane first time; rotating a sample 90 degrees; and scanning the plane again with low-energy laser. The trans-scale microstructure approaches to the surface appearance of a natural organism, is easy to calculate and analyze a contact angle and has a simple and controllable preparation process.

Owner:JIANGSU UNIV

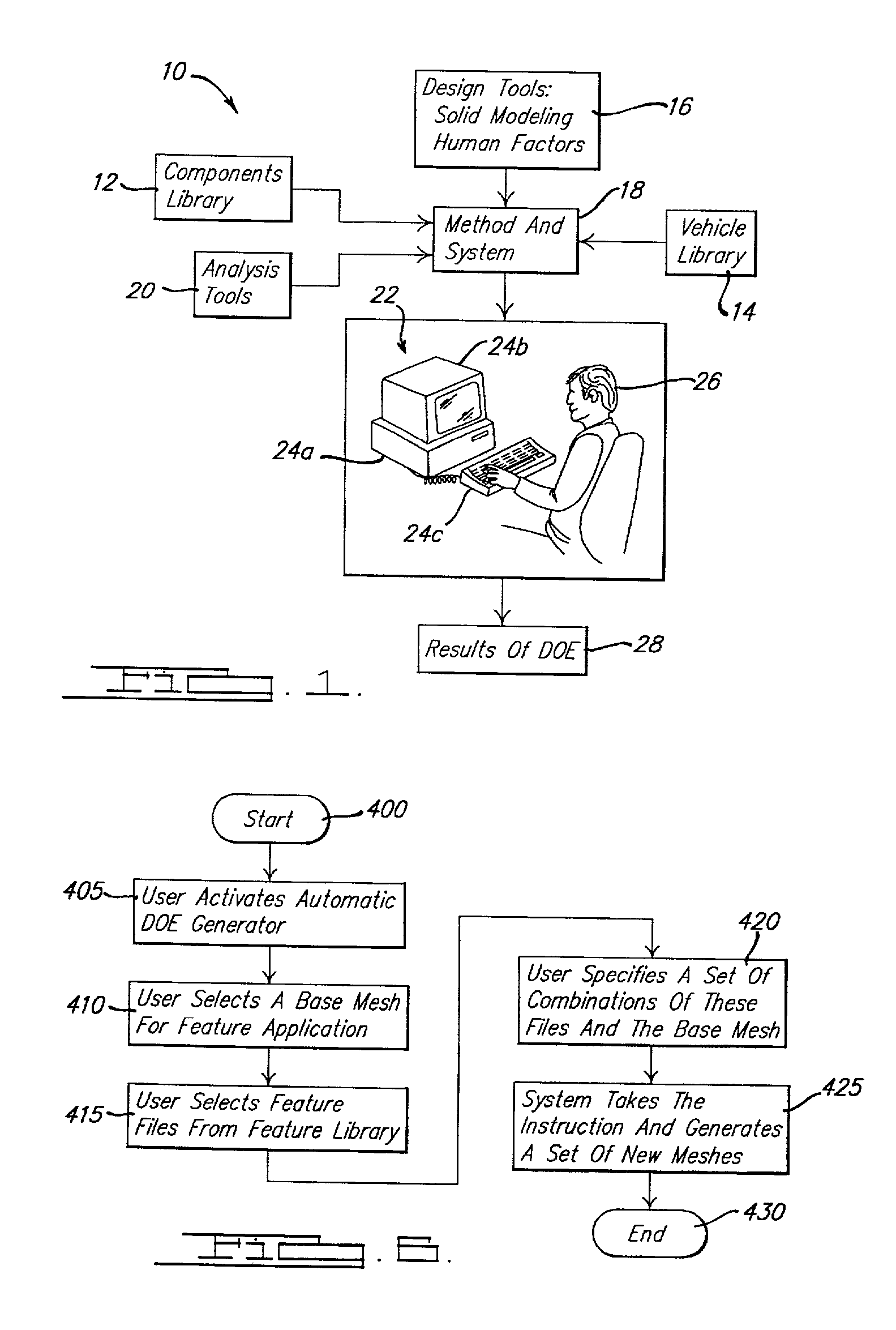

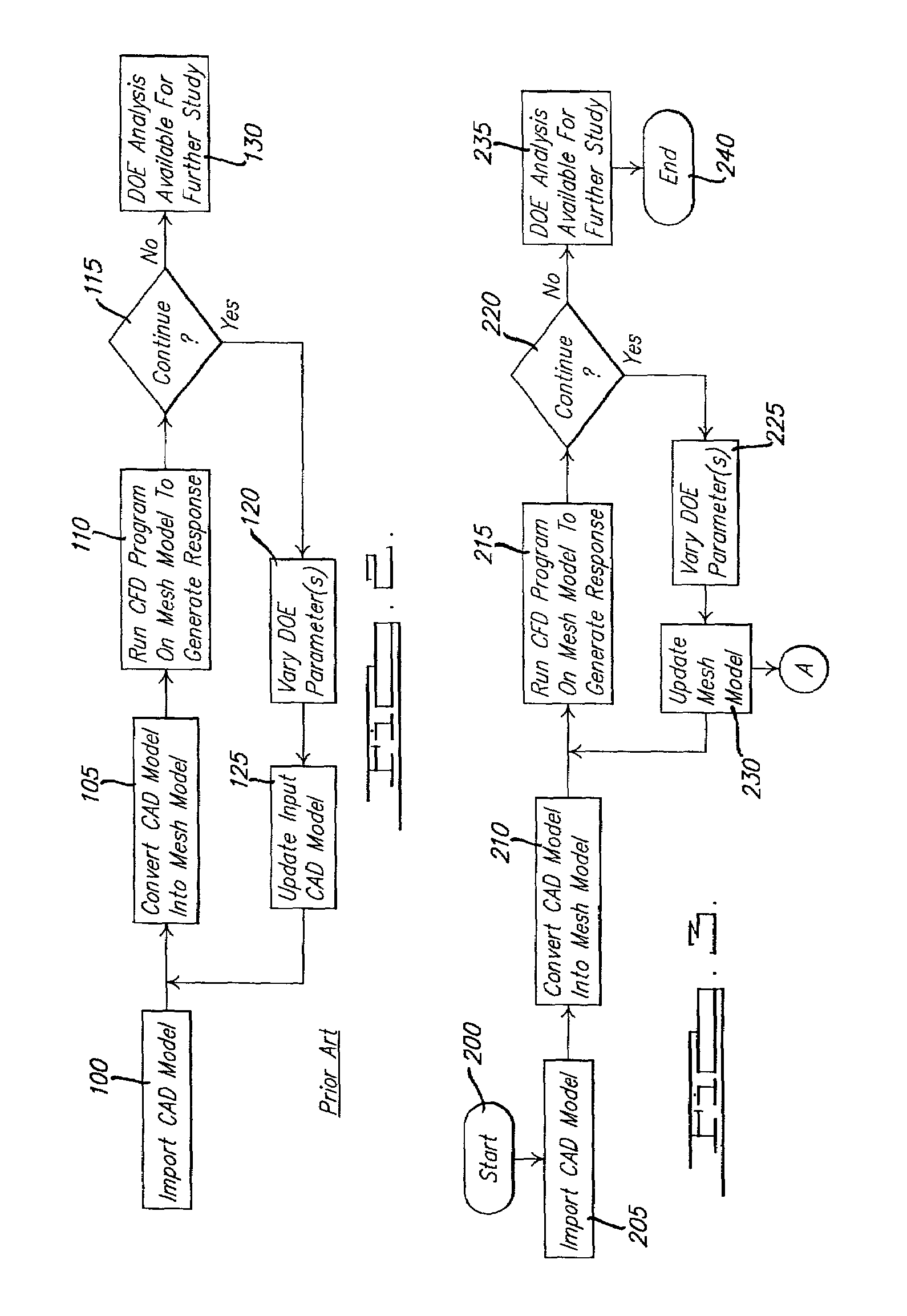

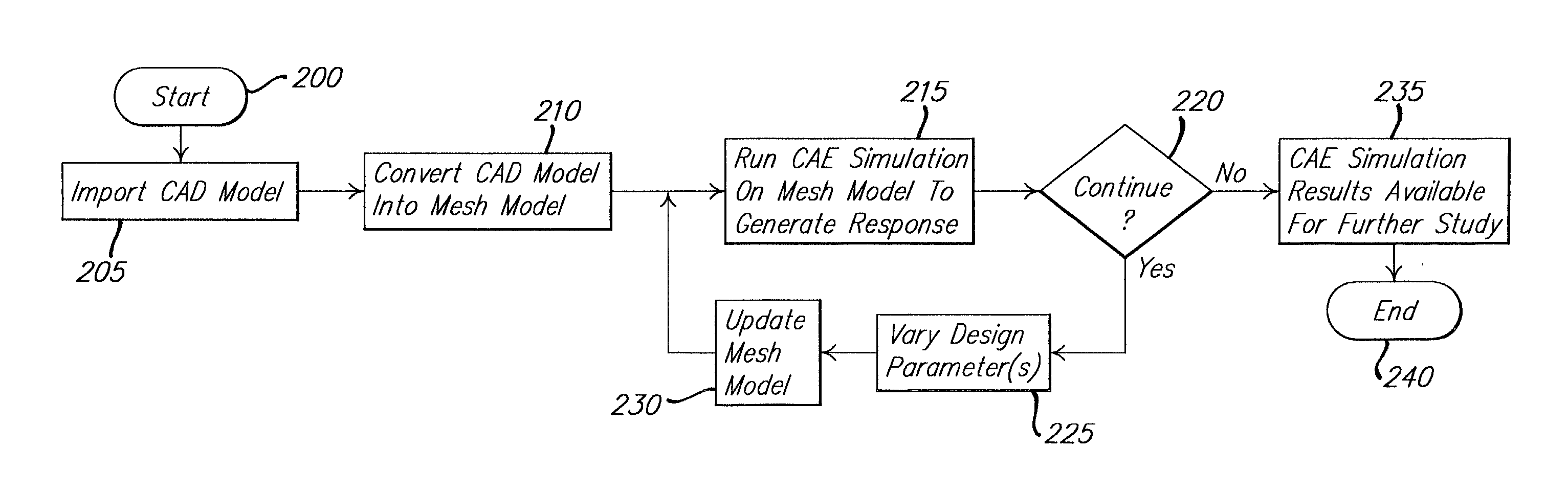

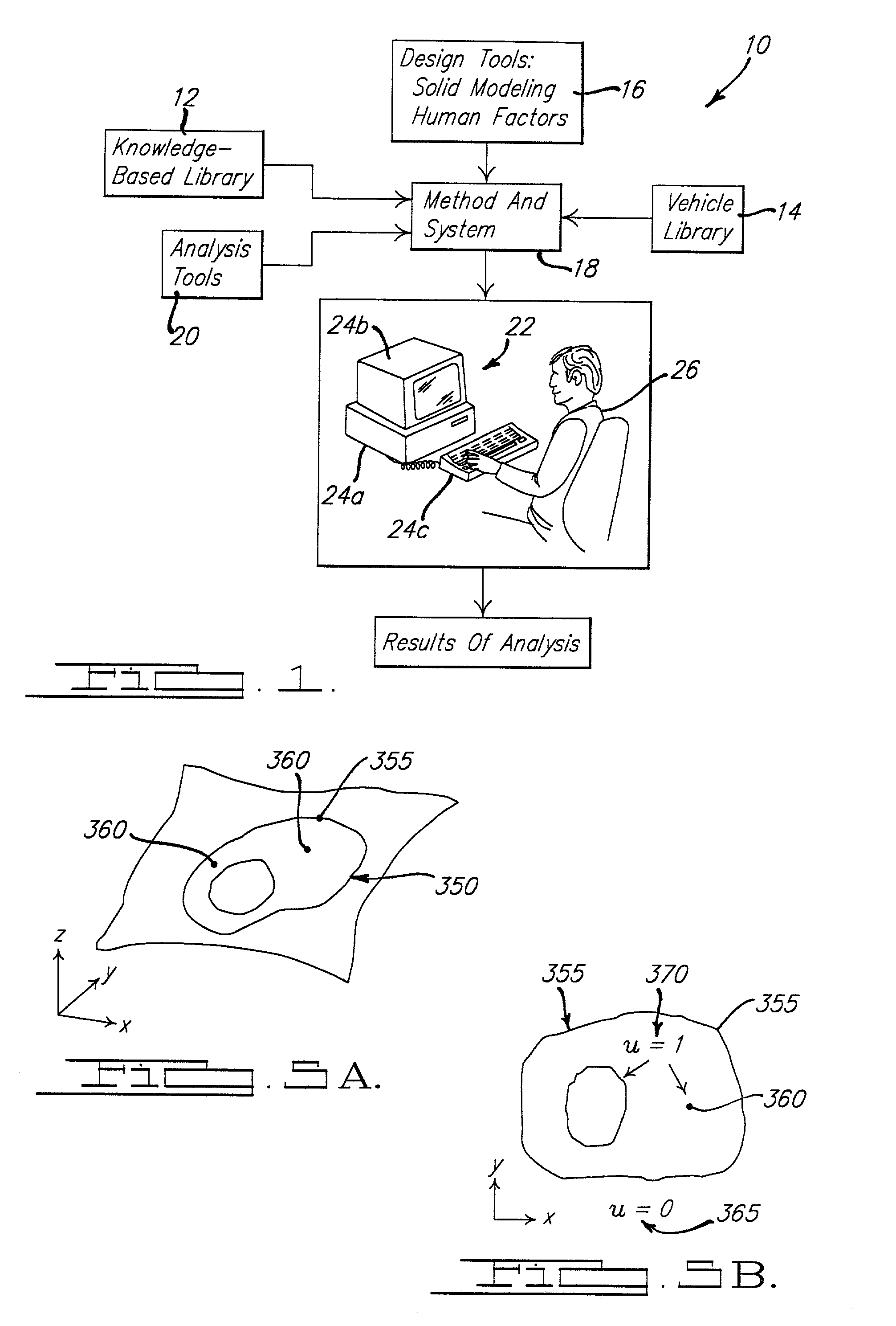

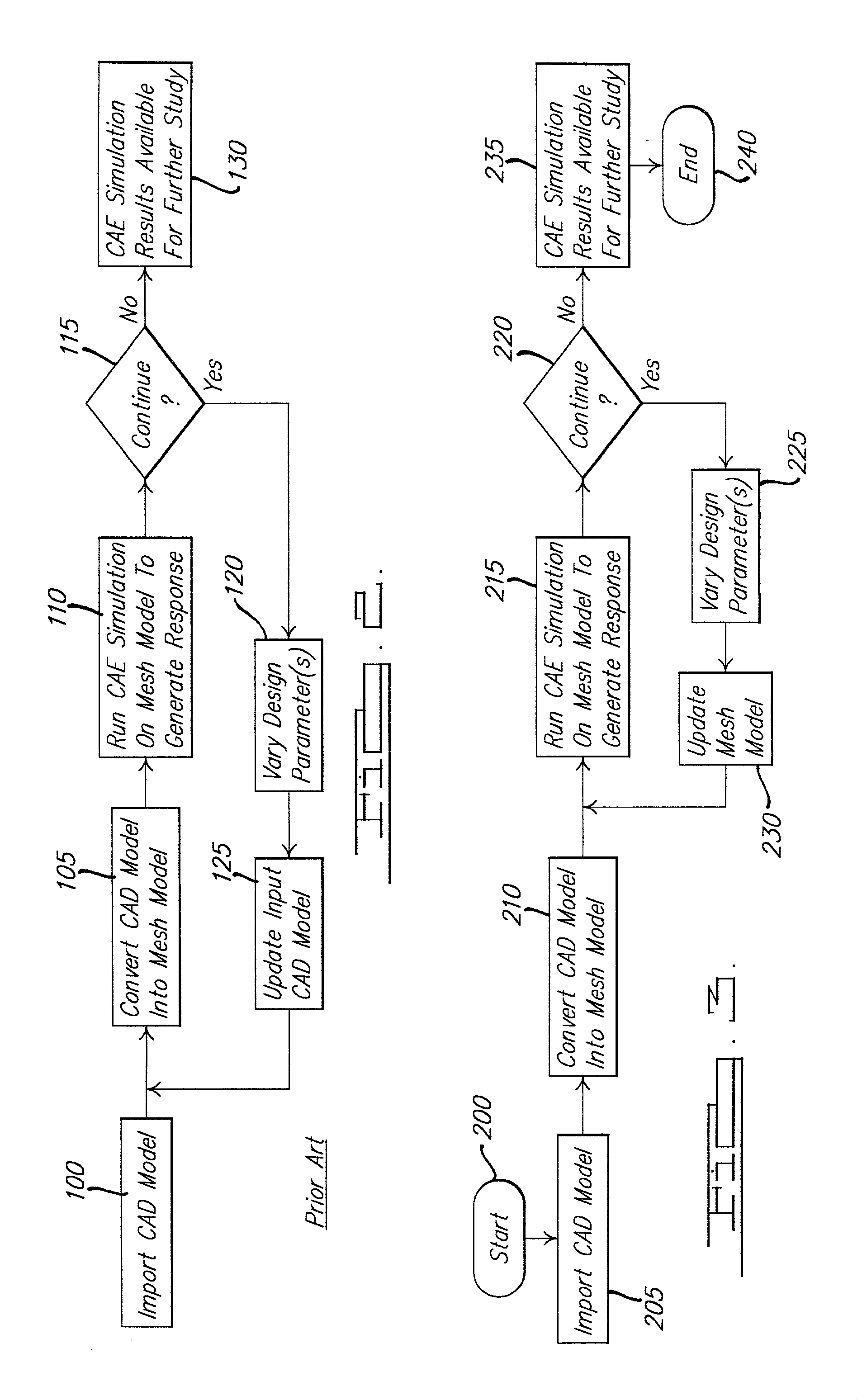

System and method for design of experiments using direct surface manipulation of a mesh model

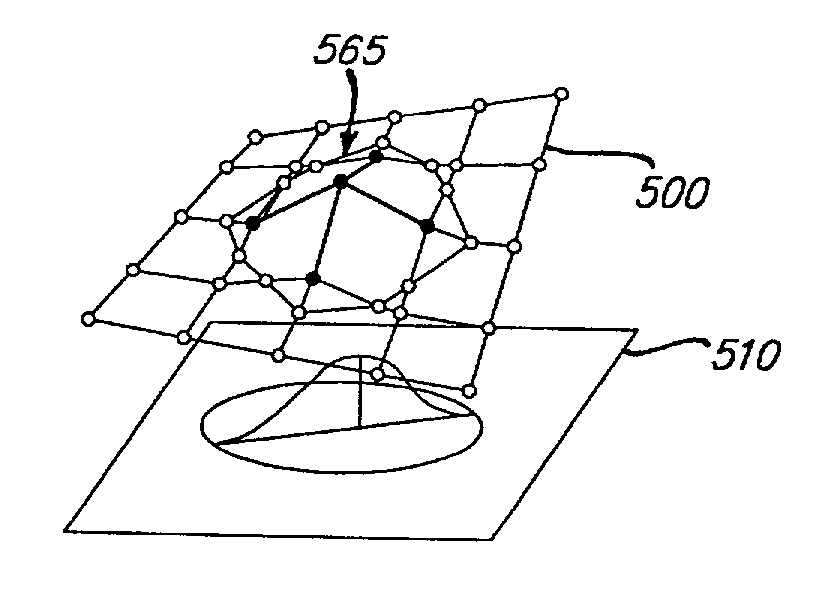

InactiveUS7079996B2Easy to appreciateGeometric CADCathode-ray tube indicatorsComputer Aided DesignGeometric modeling

A system and method for design of experiments (DOE) using direct surface manipulation of a mesh model. The method includes the steps of selecting a geometric model in a computer-aided design (CAD) format, converting the geometric model into a mesh model and evaluating the mesh model using a computer-aided engineering (CAE) analysis. The method also includes the steps of determining whether to continue generating the design of experiments response, and modifying a surface of the mesh model by varying a predetermined parameter, wherein the surface is modified using direct surface manipulation (DSM), the mesh model is updated and the updated mesh model is used in continuing generating the design of experiments response, if determined to continue the design of experiments. The method further includes the steps of using the results of the CAE analysis for the design of experiments.

Owner:FORD GLOBAL TECH LLC

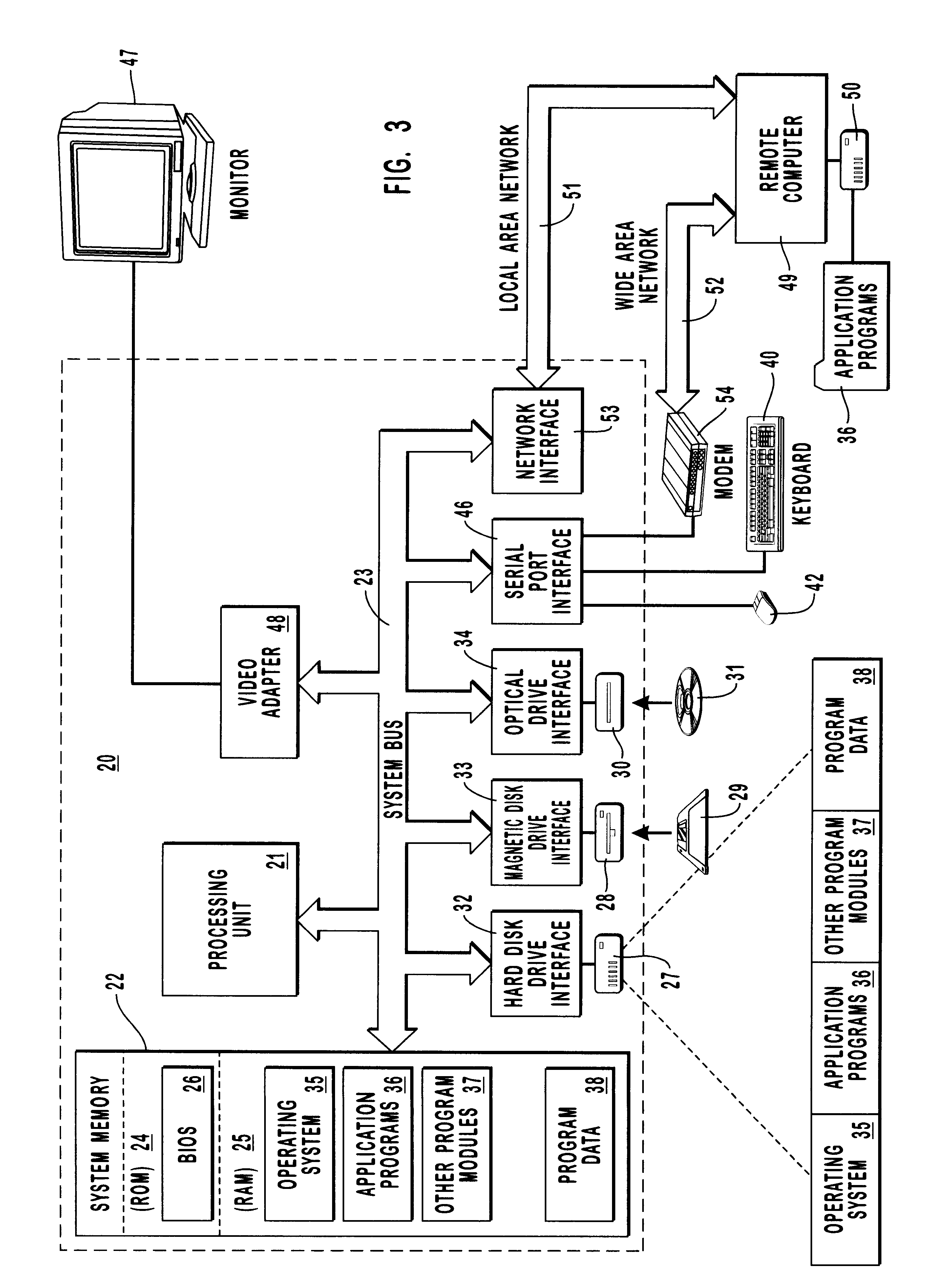

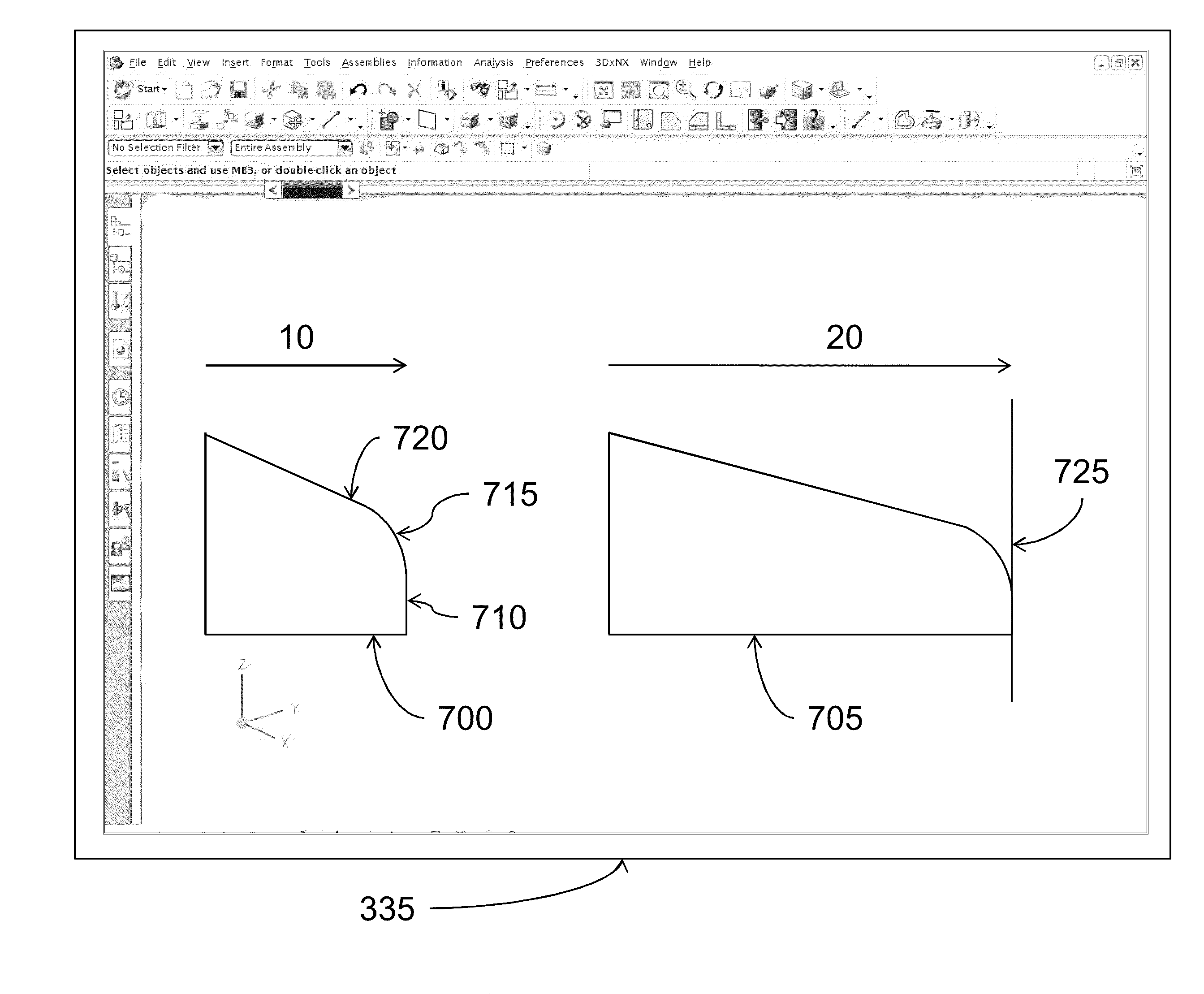

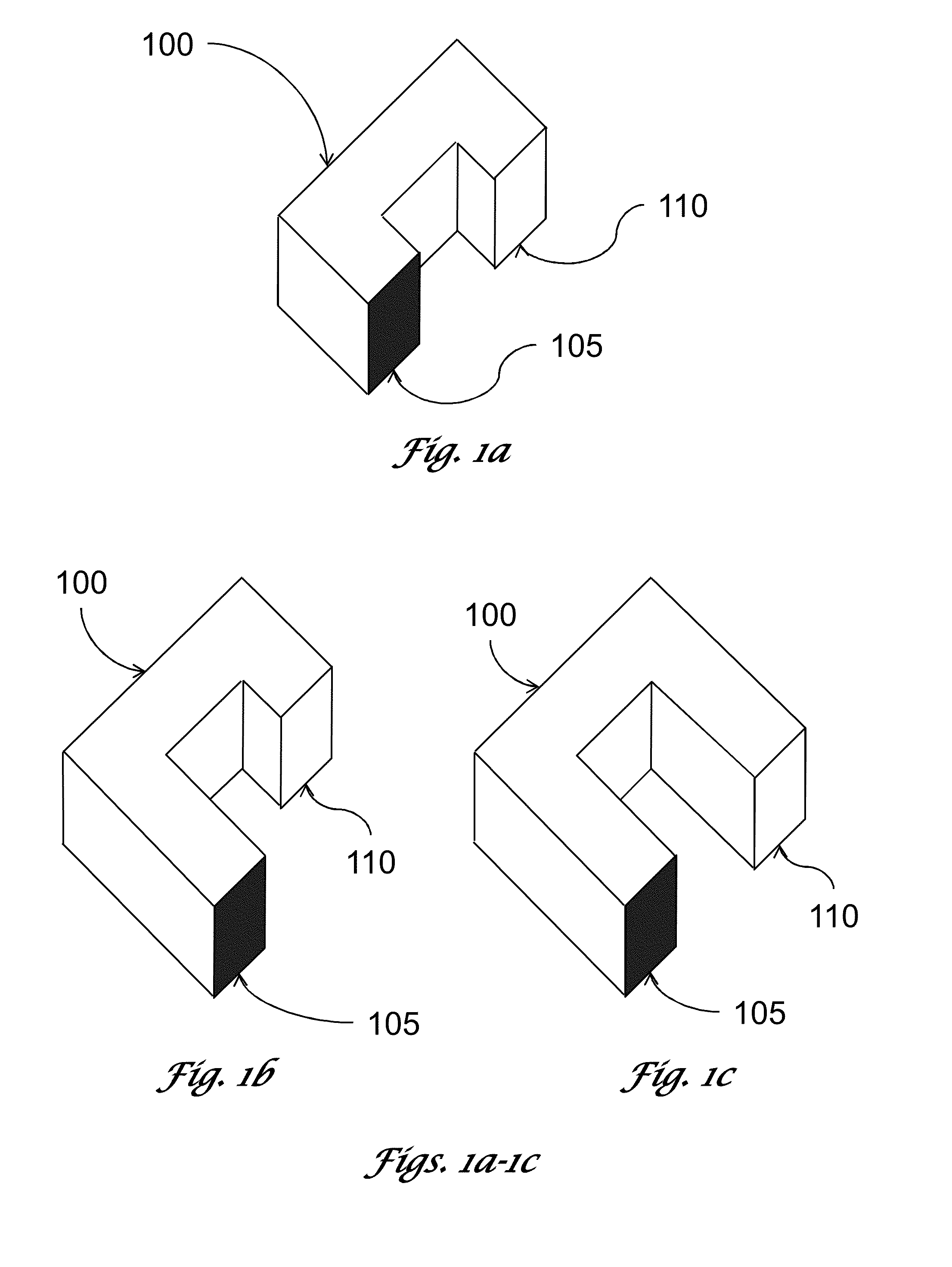

System and method of direct mesh manipulation

ActiveUS20030080957A1Geometric CADData processing applicationsComputer Aided DesignComputer graphics (images)

A system and method for computer-aided engineering analysis using direct mesh manipulation of a mesh model is provided. The system includes a computer system having a memory, a processor, a user input device and a display device. The method includes the steps of selecting a geometric model in a computer-aided design (CAD) format, converting the CAD model into a mesh model and evaluating the mesh model using a computer-aided engineering (CAE) analysis. The method also includes the steps of modifying a surface of the mesh model by varying a predetermined parameter using direct surface manipulation (DSM), updating the mesh model and using the updated mesh model in further CAE analysis. Three techniques are provided for modifying a surface feature, including using a Dirichlet parameter distribution to determine the displacement of the surface feature; modeling the surface feature as an elastic sheet to determine deformation; and enclosing the feature within a lattice structure and using lattice deformation to determine surface deformation.

Owner:FORD GLOBAL TECH LLC

System and method for geometric editing

ActiveUS20090259442A1Constraint-based CADSpecial data processing applicationsComputer graphics (images)User input

A system, method, and computer program for modifying a solid model representation that is manipulated in a computer having software instructions for design, comprising: a computer system, wherein the computer system includes a memory, a processor, a user input device, and a display device; a computer generated geometric model stored in the memory in the memory of the computer system; and wherein the computer system receives user input and accesses at least one data file having a plurality of geometric model definitions that define a geometric model; converts the geometric model definitions into a geometric representation of the geometric model; calculates a plurality of geometric conditions between at least one geometry identified by a user and the geometric model to create a set of constraints; and calculates a modified geometric model with a modified geometry according the set of constraints to display to the user; and appropriate means and computer-readable instructions.

Owner:SIEMENS PROD LIFECYCLE MANAGEMENT SOFTWARE INC

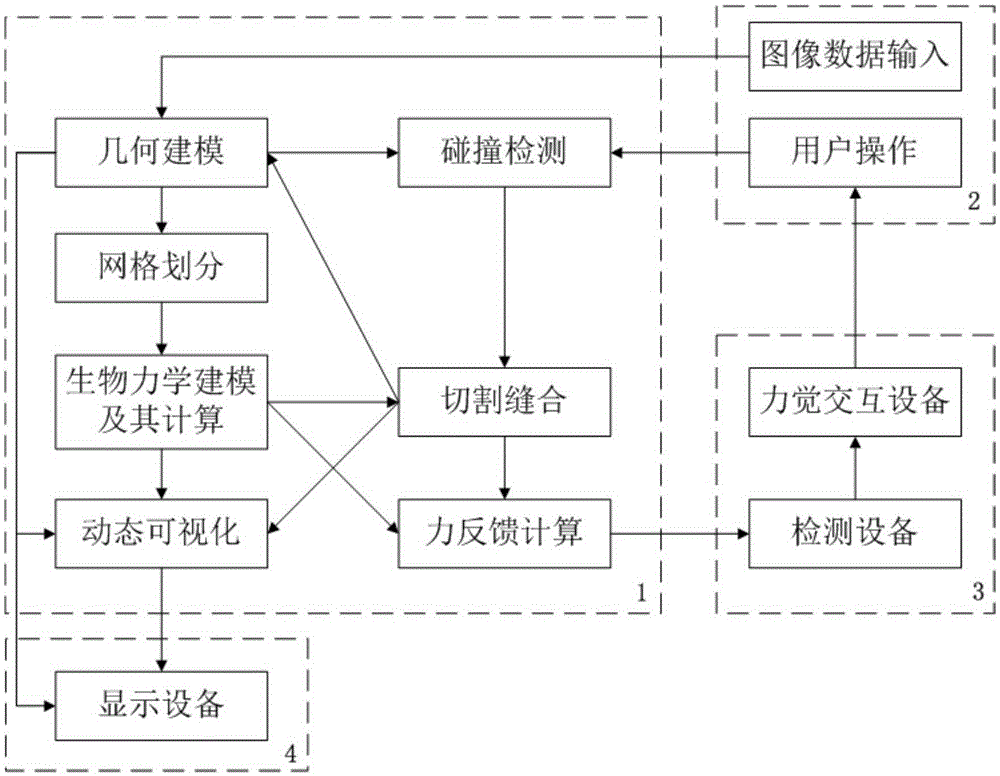

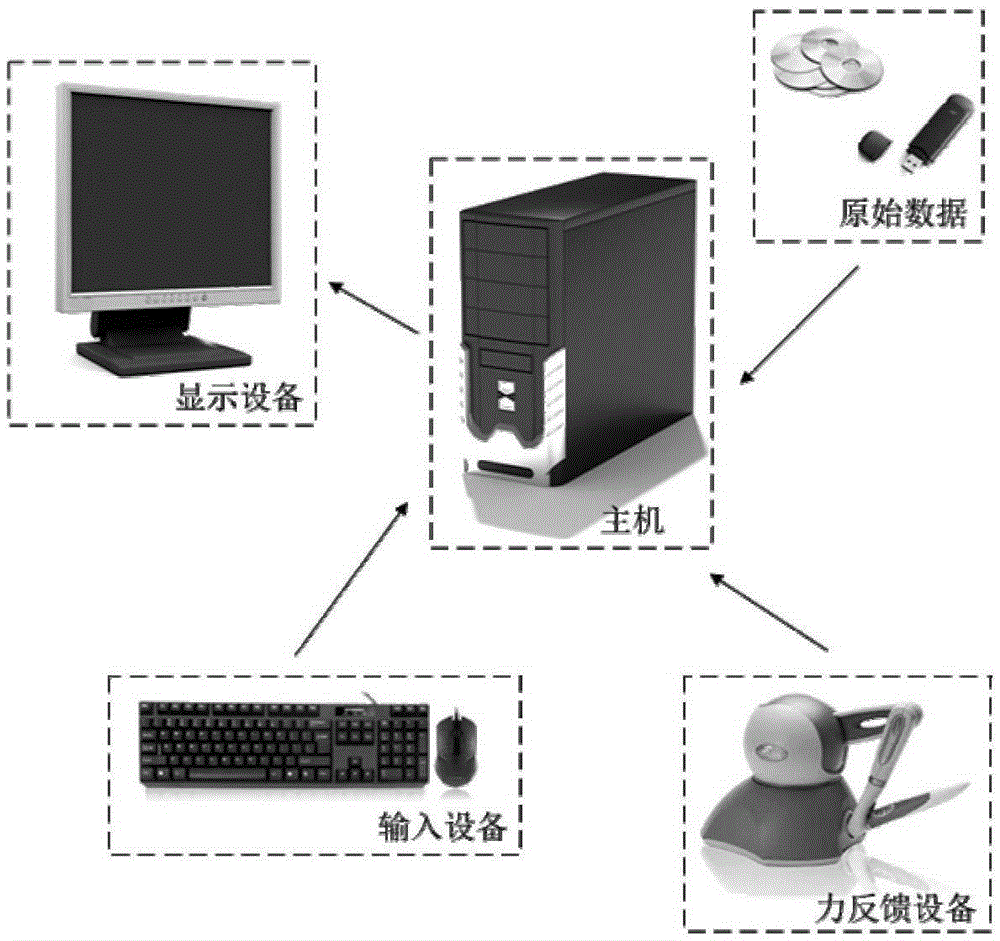

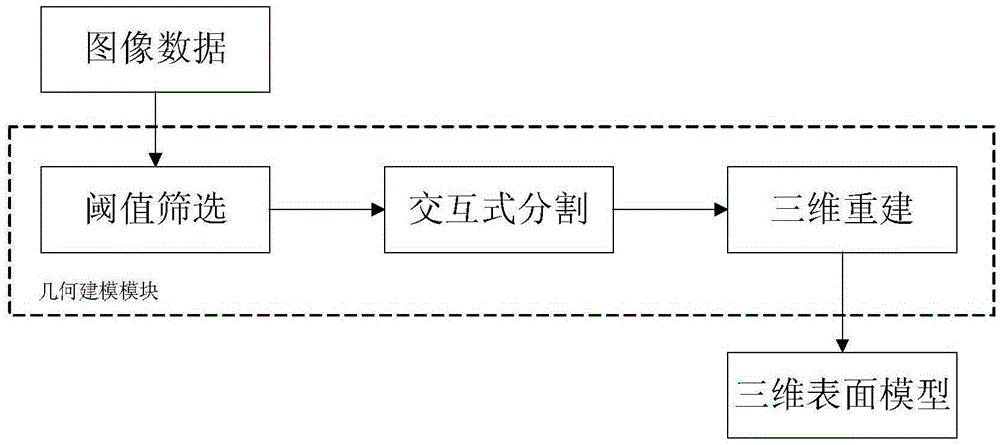

Orthopedic surgery operation simulation system on the basis of force feedback

InactiveCN105303605AGood effectImprove the success rate of surgeryCosmonautic condition simulationsSimulatorsCollision detectionBiomechanics

The present invention provides an orthopedic surgery operation simulation system on the basis of force feedback, relating to the field of the virtual operation system development technology. The objective of the present invention is to allow users to truly sense biomechanical characteristics of human tissues so that the effect of operation training and the success rate of operations are improved. The orthopedic surgery operation simulation system comprises a virtual orthopedic operation simulation subsystem, an input module, a force feedback module and a display module. The virtual orthopedic operation simulation subsystem is configured to realize geometric modeling, mesh generation, biomechanics modeling and calculation thereof, collision detection, cutting and stitching and dynamic state visualization, force feedback calculation and the like of the human tissues required in the operation simulation process. According to the scheme of the invention, geometric modeling, mesh generation, biomechanics modeling and calculation thereof, deformation cutting, force feedback calculation and the like of virtual human tissues may be realized through independent programming on the basis of a visual studio development platform. The cost and the complexity of an operation system may be reduced.

Owner:HARBIN UNIV OF SCI & TECH

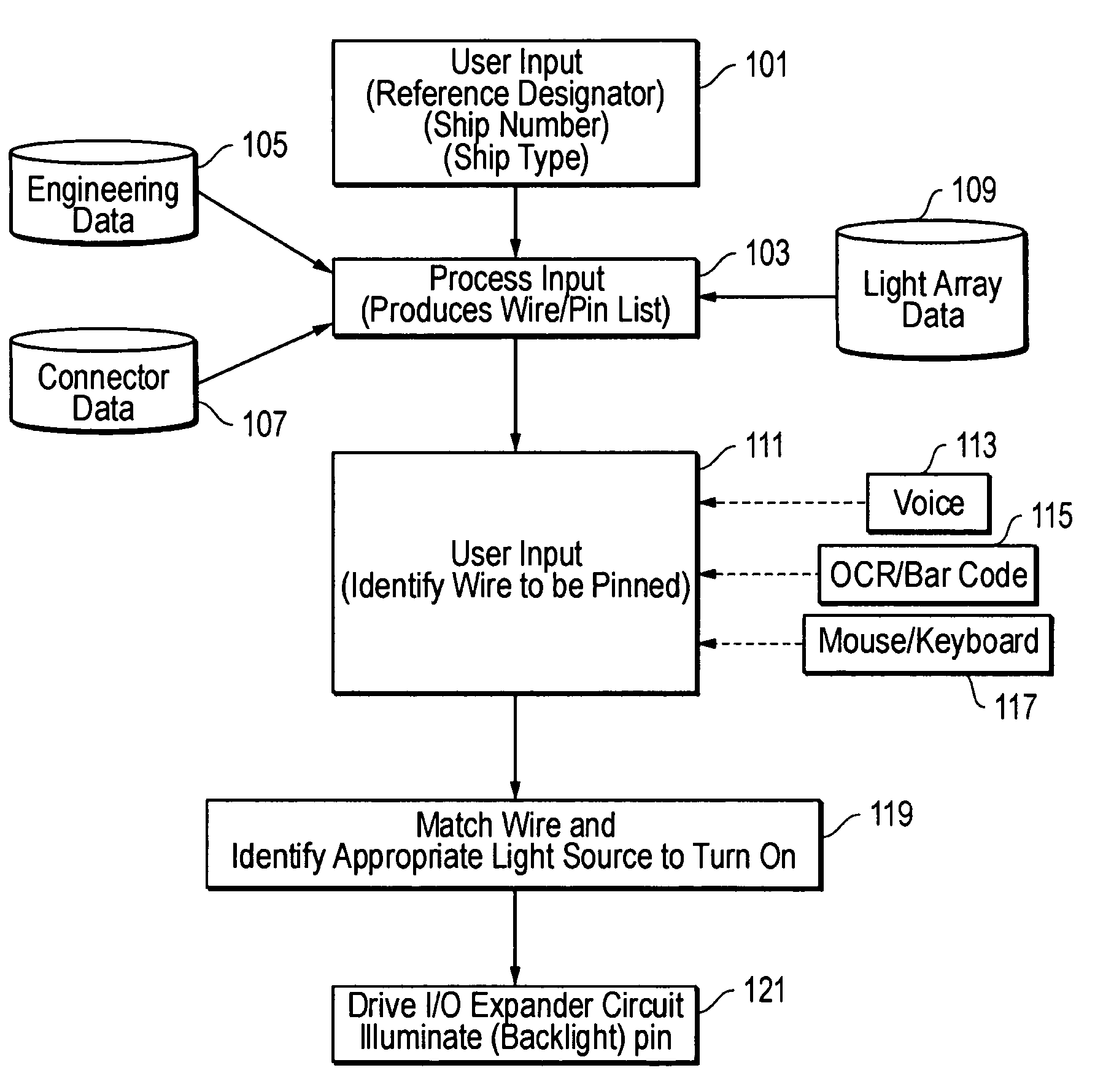

Method of matching harnesses of conductors with apertures in connectors

ActiveUS7647695B2Easy to identifyFacilitates precise registrationPrinted circuit assemblingLine/current collector detailsElectrical conductorGeometric modeling

Owner:LOCKHEED MARTIN CORP

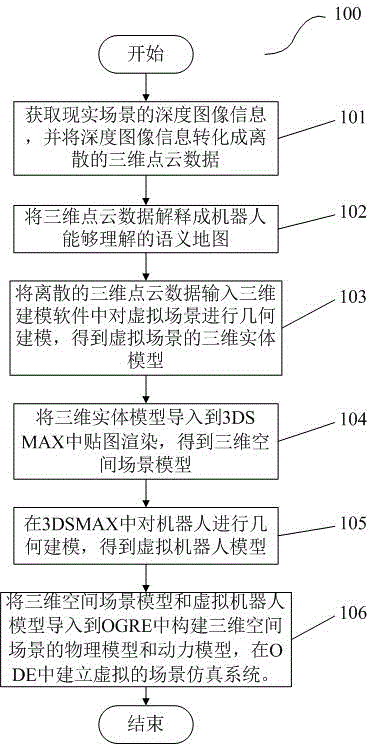

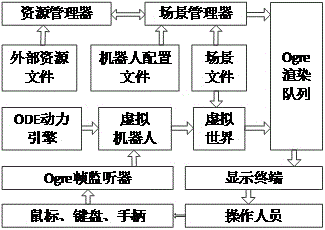

Method for building robot simulation drilling system based on reality scene

InactiveCN104484522AFast modelingGood at texture renderingSpecial data processing applications3D modellingPoint cloudThree-dimensional space

The invention discloses a method for building a robot simulation drilling system based on a reality scene. The method comprises the following steps: obtaining depth image information of the reality scene, and transforming the depth image information into discrete three-dimensional point cloud data; interpreting the three-dimensional point cloud data into a semantic map which can be understood by a robot; inputting the discrete three-dimensional point cloud data into three-dimensional modeling software, and carrying out geometric modeling on a virtual scene, so as to obtain a three-dimensional entity model of the virtual scene; introducing the three-dimensional entity model into a 3DS MAX to map and render, so as to obtain a three-dimensional space scene model; carrying out geometric modeling on the robot in the 3DS MAX, so as to obtain a virtual robot model; introducing the three-dimensional space scene model and the virtual robot model into an OGRE (object-oriented graphics rendering engine), building a physical model and a power model of the three-dimensional space scene, and building a virtual scene simulation system.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

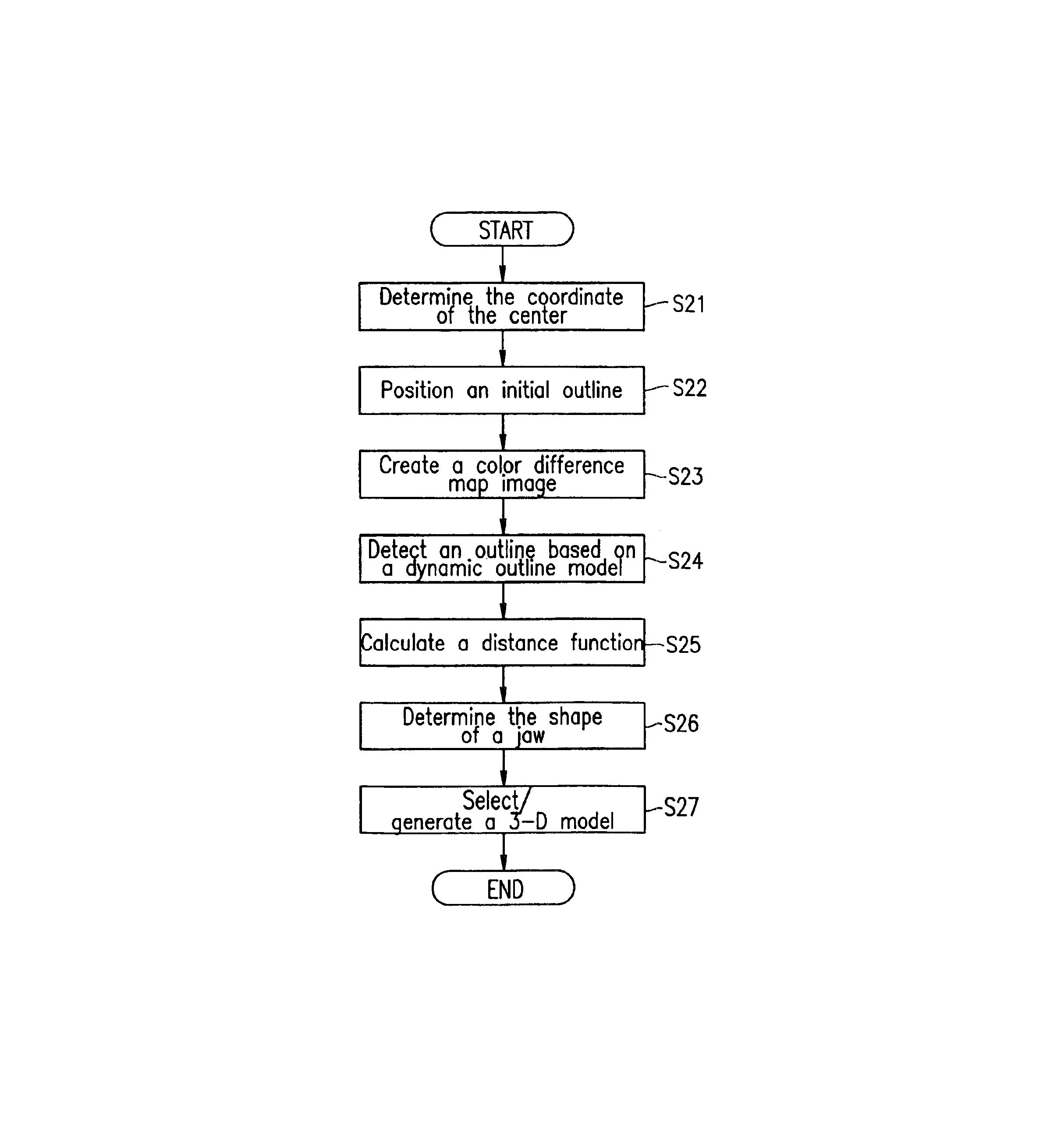

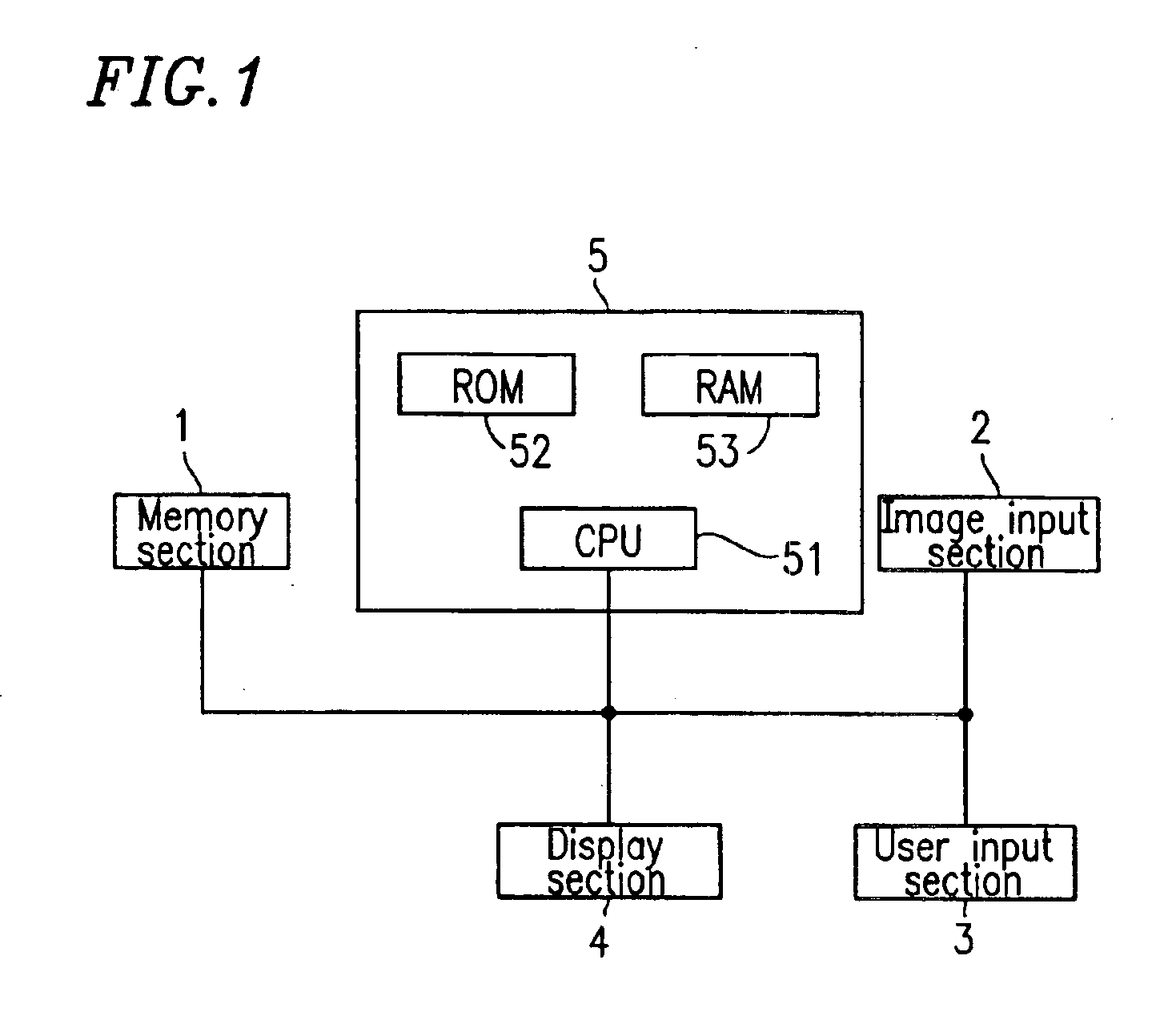

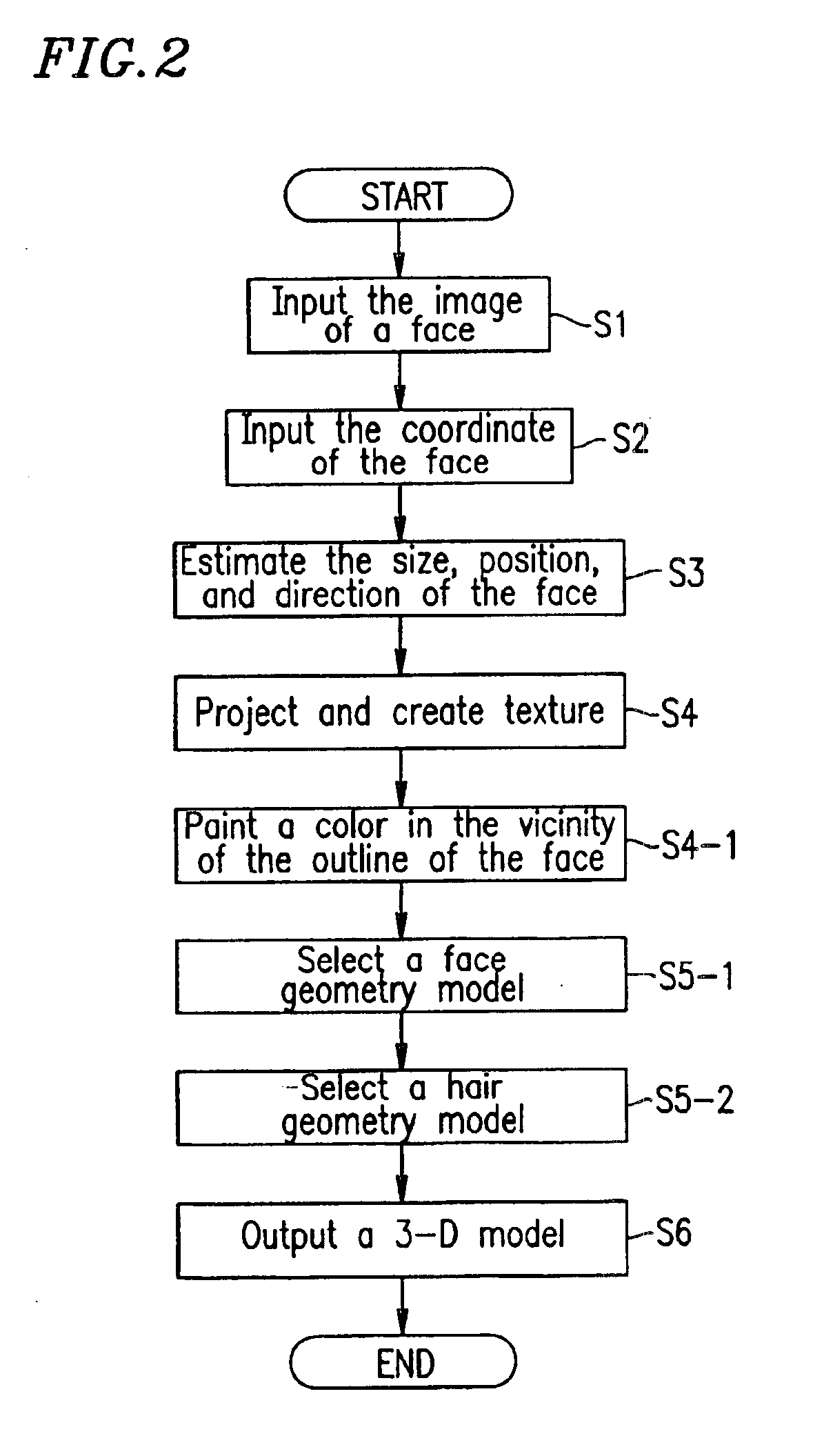

Three-dimensional model generation device, three-dimensional model generation method, and recording medium for storing the three-dimensional model generation method

InactiveUS6879323B1Promote generationElectric signal transmission systemsImage analysisComputer graphics (images)Geometric modeling

Owner:SHARP KK

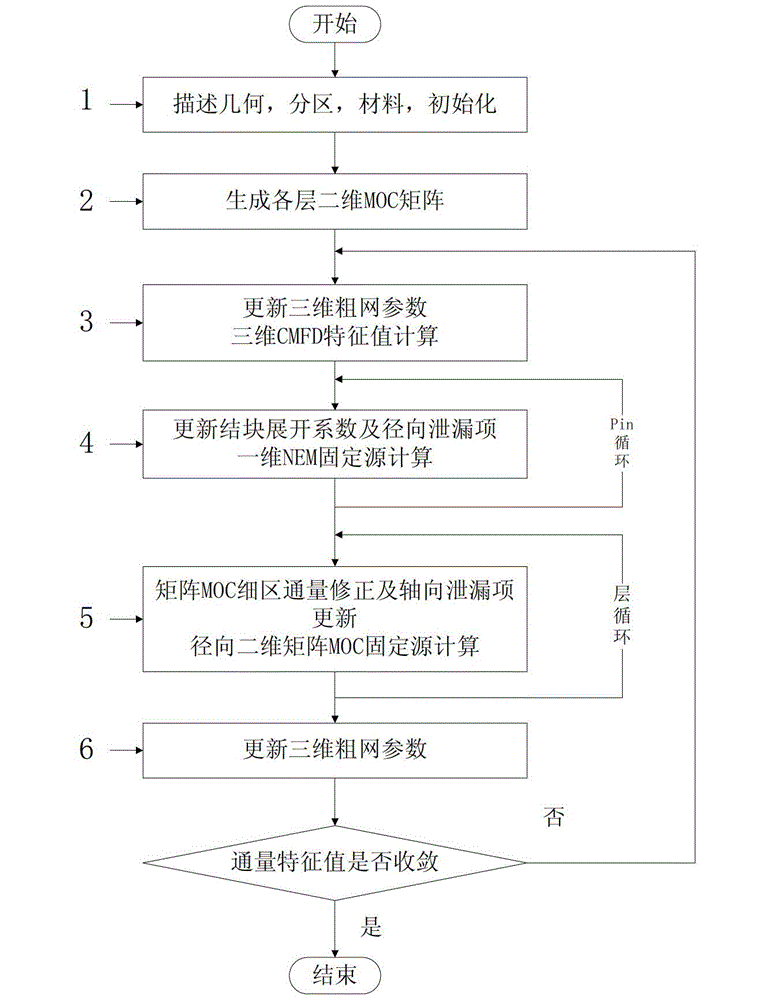

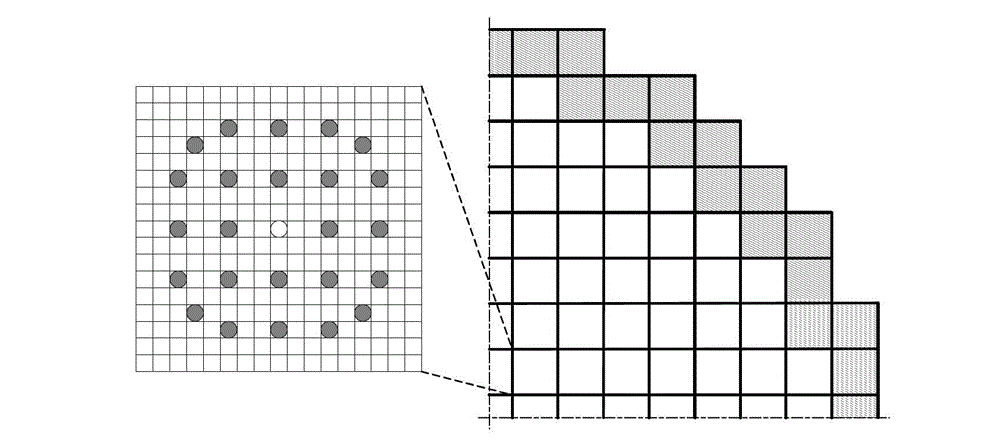

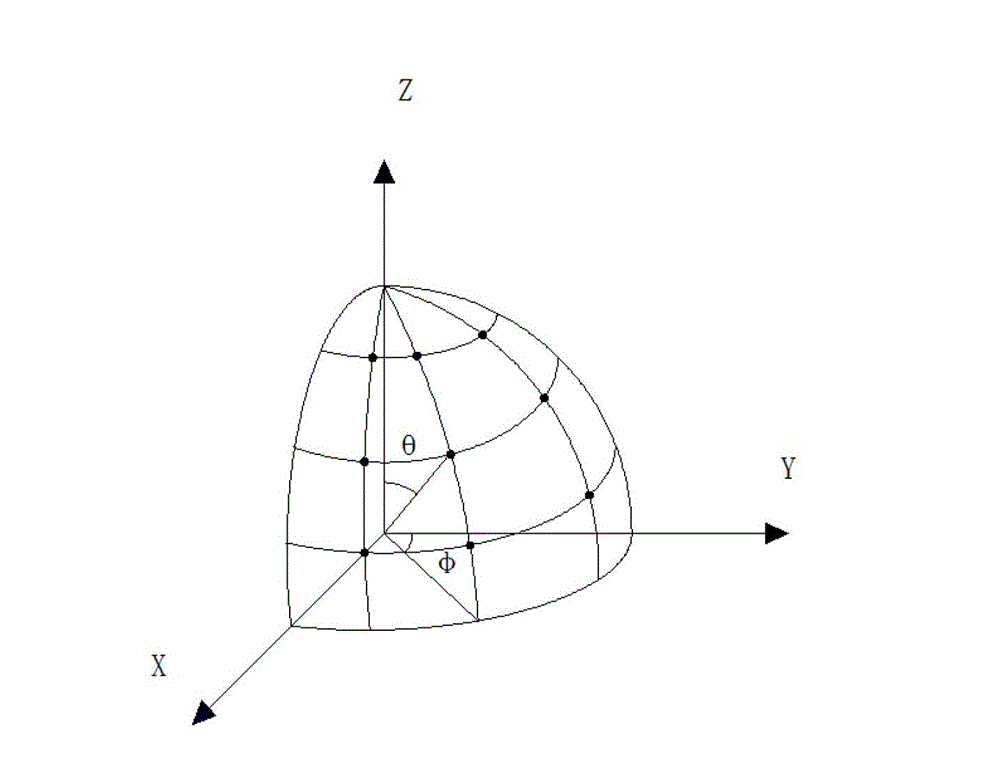

Method for acquiring fine distribution of reactor core three dimensional neutron flux density of reactor

ActiveCN103150424AAvoid repeated iterative calculationsImprove computing efficiencySpecial data processing applicationsMatrix methodGeometric modeling

A method for acquiring fine distribution of the reactor core three dimensional neutron flux density of a reactor comprises the following steps: 1, carrying out geometric modeling to a reactor core, dividing computational domain, dispersing angle space, generating characteristic line, appointing materials for all computing regions, obtaining macroscopic section parameters and setting initial values for neutron flux density flux of a computed region, terminal condition of reactor and characteristic value; 2, calculating coefficient matrix required by the matrix method of each sub region and a part which is positioned at the right end and cannot be changed with the iterative computation; 3, seeking the density of thicknet neutron flux and correcting the density of one-dimensional and two dimensional thinnet neutron flux; 4, seeking the density of one-dimensional neutron flux of each lattice cell; 5, iterative solution of the density of the two dimensional thinnet neutron flux of each layer; and 6, updating three dimensional thicknet parameters, judging whether a characteristic value and the density of a three dimensional neutron flux are in convergence or not, if in convergence, turning to the step 3 for continuous iteration under convergence is achieved, namely, fine distribution of three dimensional neutron flux density can be obtained; and the fine distribution of the reactor core three dimensional neutron flux density of a reactor can be obtained quickly.

Owner:XI AN JIAOTONG UNIV

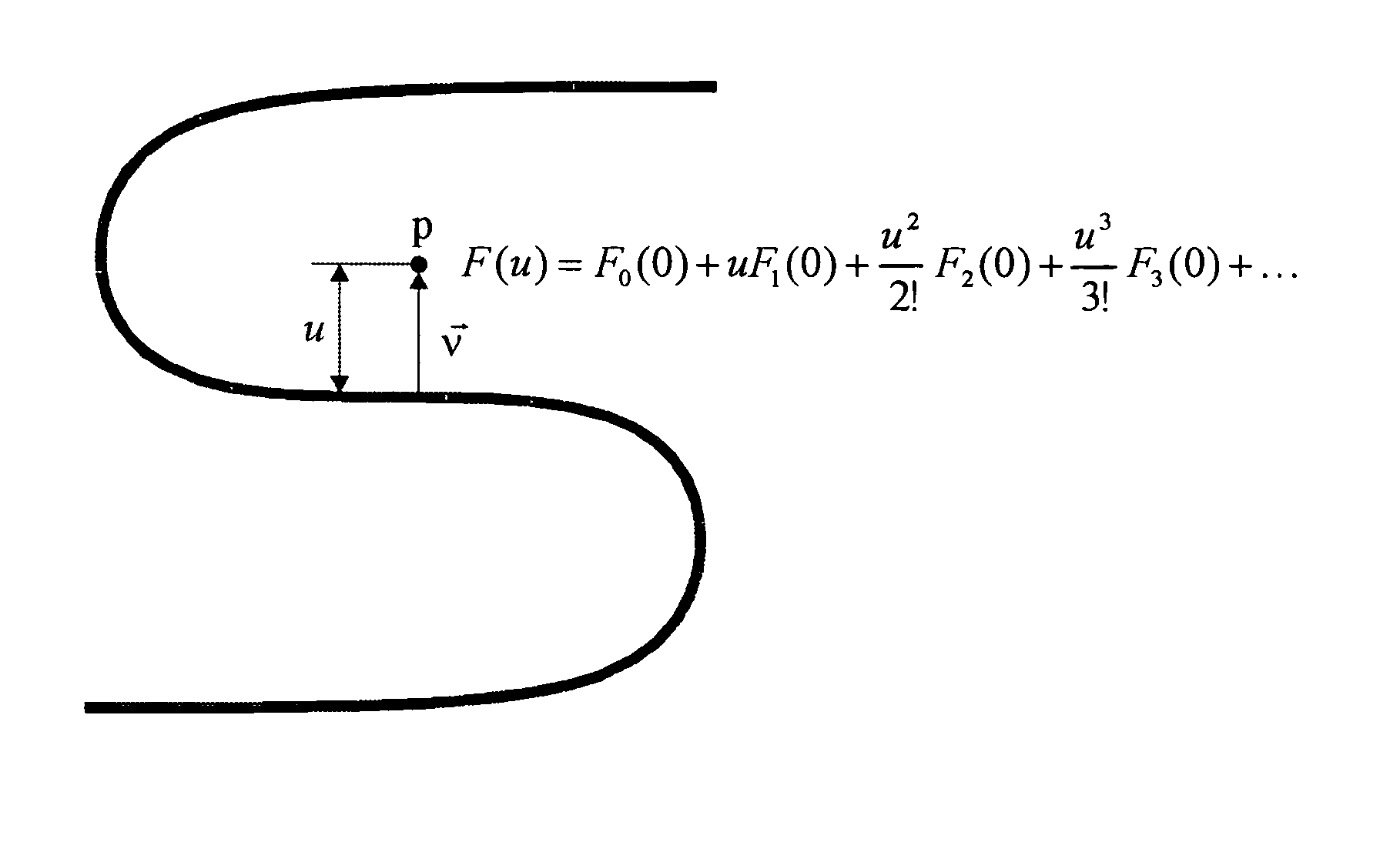

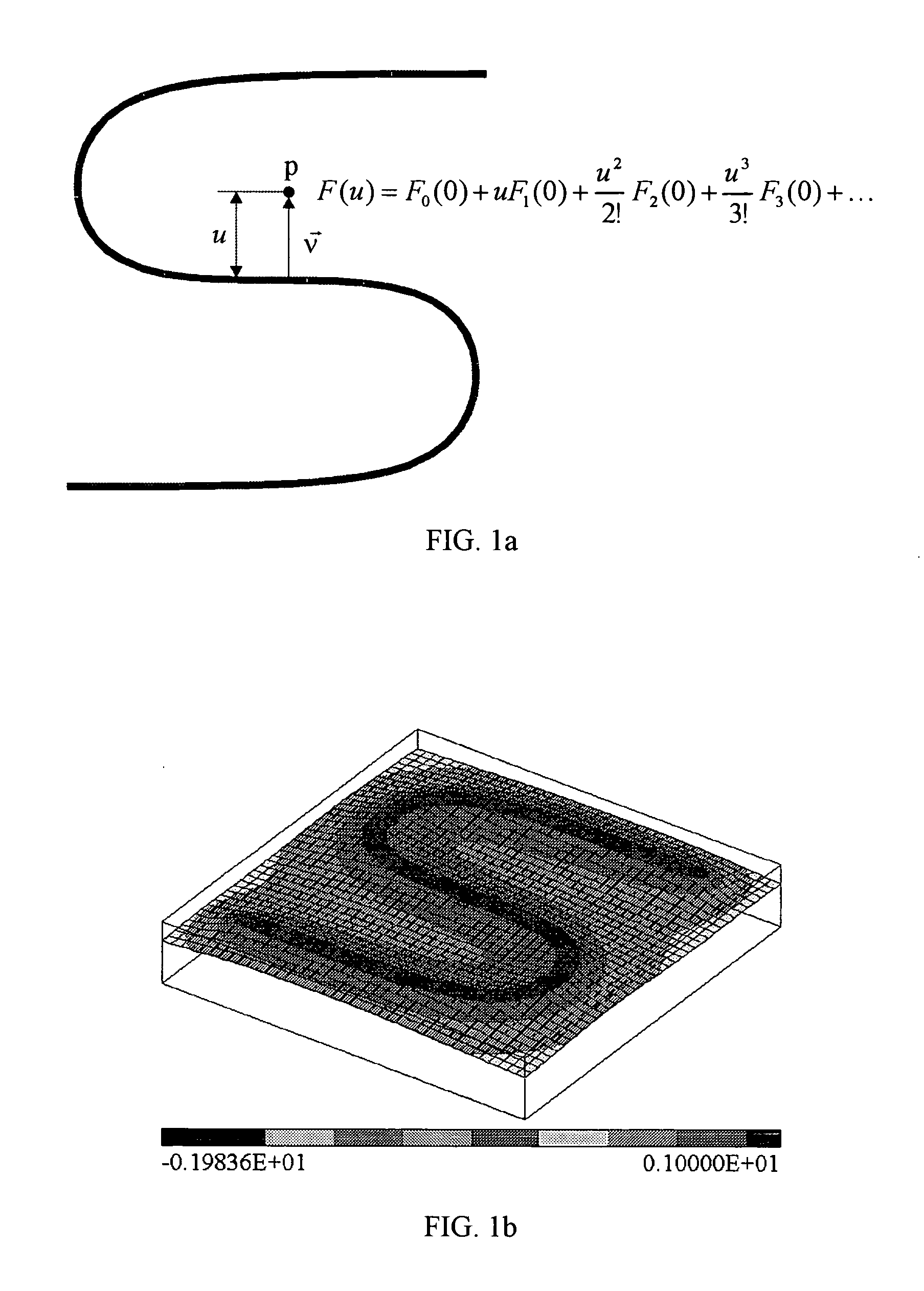

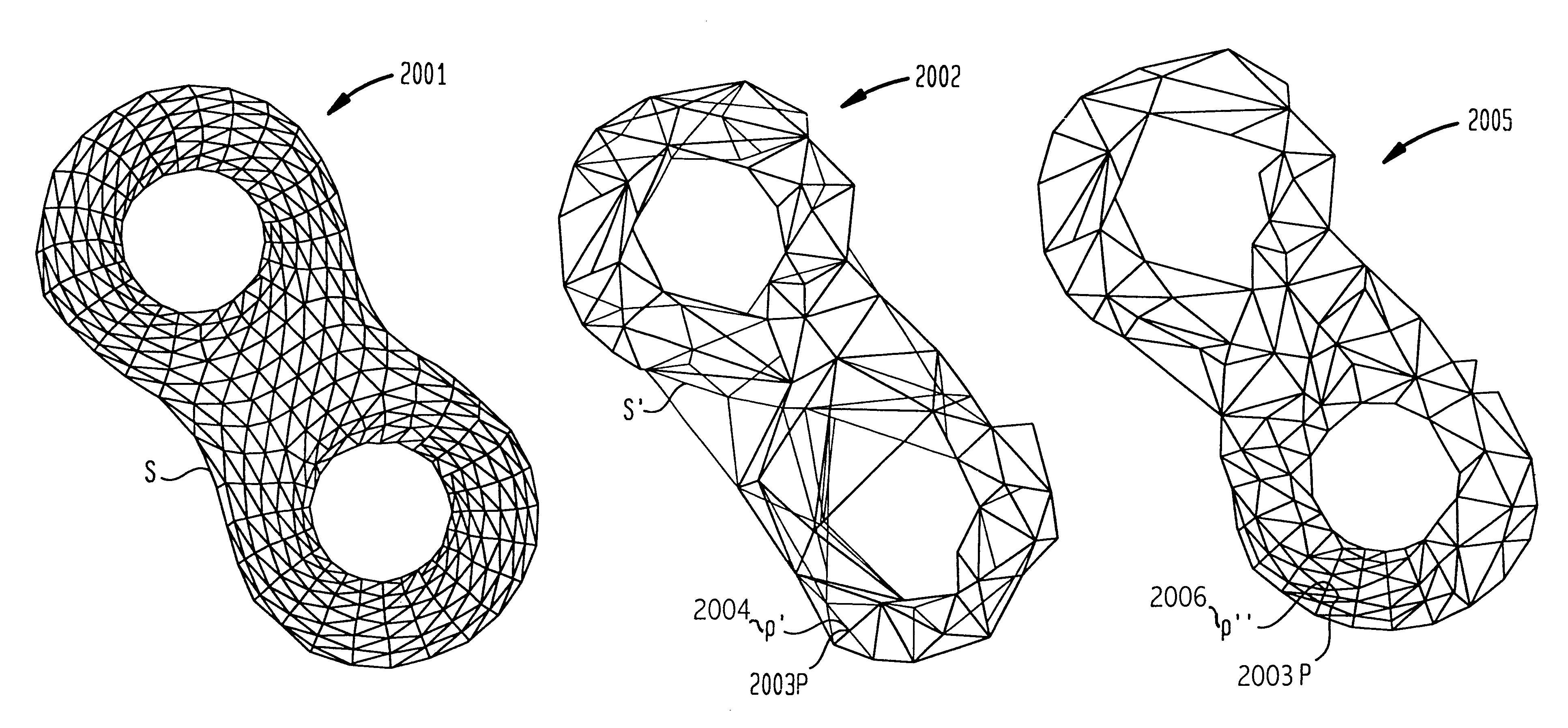

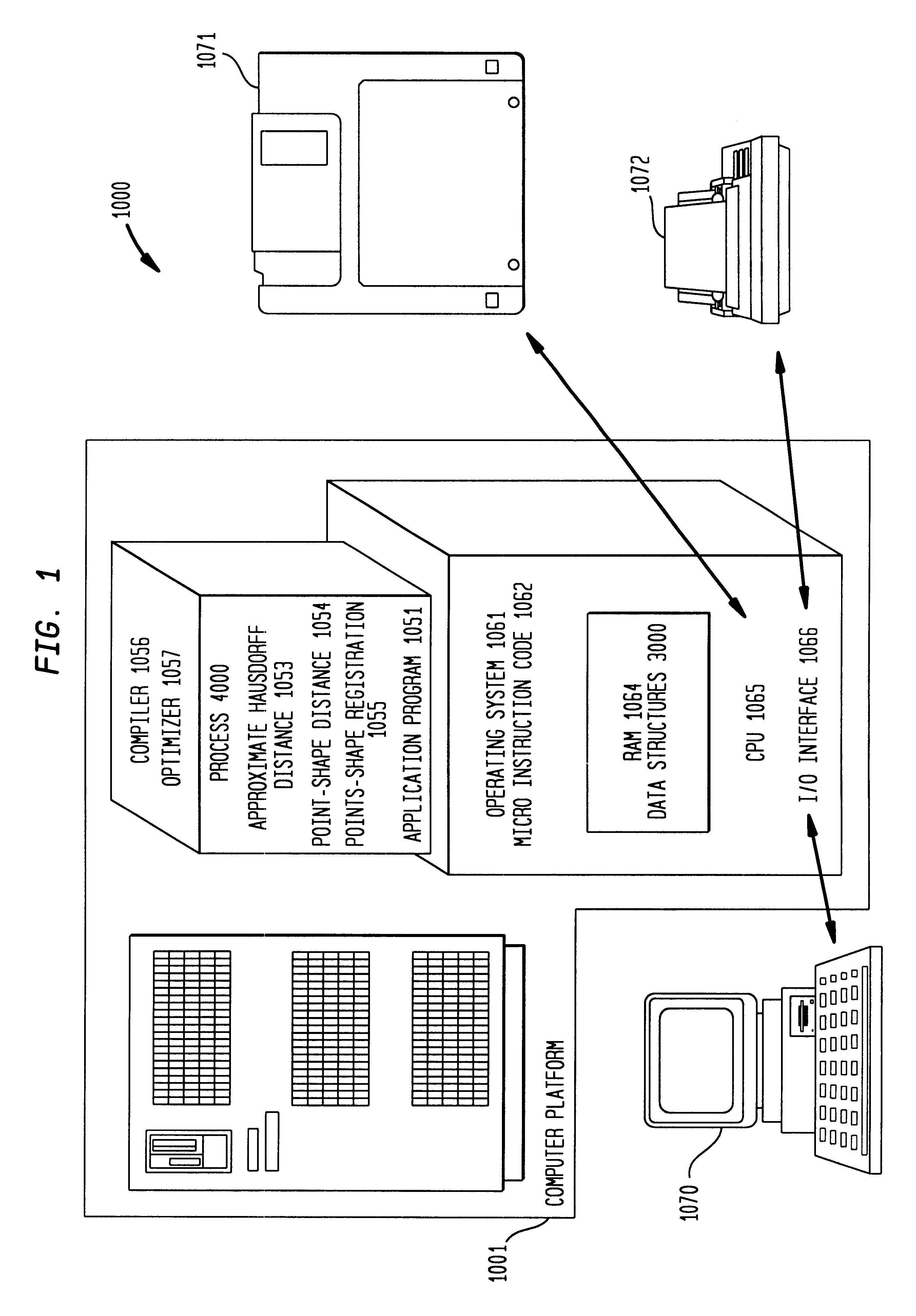

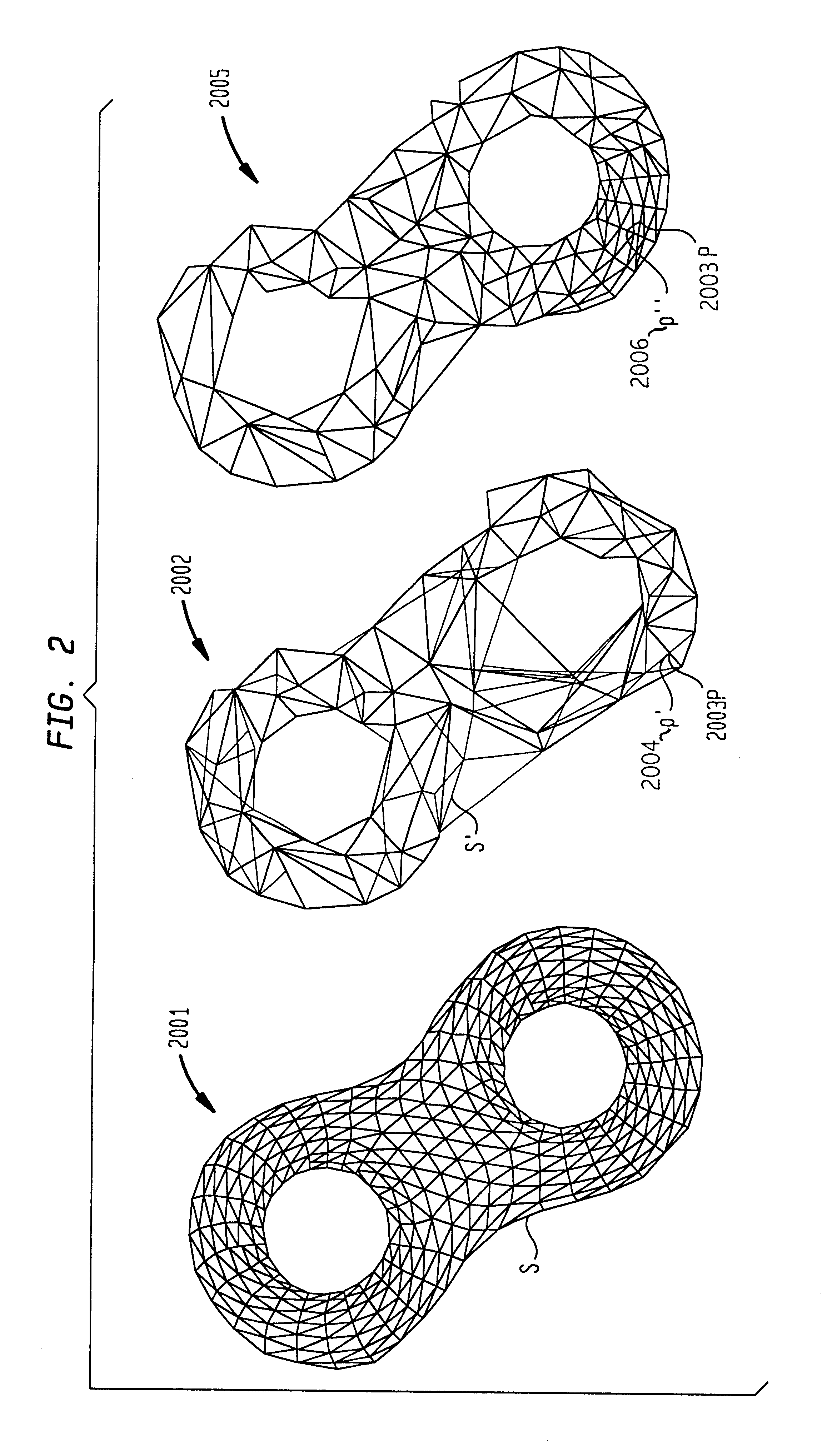

System and method for finding the distance from a moving query point to the closest point on one or more convex or non-convex shapes

The present invention is a computer system and method for determining the closest point on a shape (2 dimensional or 3 dimensional surface) to any general query point. The system has one or more central processing units (CPUs), one or more memories, and one or more geometric model portions stored in one or more of the memories. The geometric model portions have a plurality of line segments (polygons), each of the line segments (polygons) being between a first and a second endpoint (having a polygon boundary). The line segments and end points (polygons and polygon boundaries) are connected to form a shape (in 3 dimensions, a surface) with one or more parameters. Parameters can include geometric position, time, temperature, pressure, flow, color, texture, or any other descriptive value. A multiresolution process that creates one or more models of the shape (surface). The models having a hierarchy of resolutions. Each model has one or more model line segments (model polygons) that approximate one or more of the line segments (polygons). Each model line segment (model polygons) is associated with an error. A distance process, for every model line segment (polygon), determines a distance between a closest point on one or more of the model line segments and a query point. The distance represents one or a combination of two or more of the parameters. The process further determines a confidence level in terms of an upper bound and a lower bound of an envelope enclosing the segment (polygon). The closest point is within the envelope-the upper bound representing an upper limit of the parameter in the envelope determined by an upper error of the respective model containing the model line segment and the lower bound representing a lower limit of the parameter in the envelope determined by a lower error of the respective model. A priority process orders the model line segments (polygons) according to their respective lower bounds and if a maximum error for every one of the model line segments is less than a threshold. The priority process also selects the smallest distance as the minimum distance between the query point and the shape.

Owner:UNILOC 2017 LLC

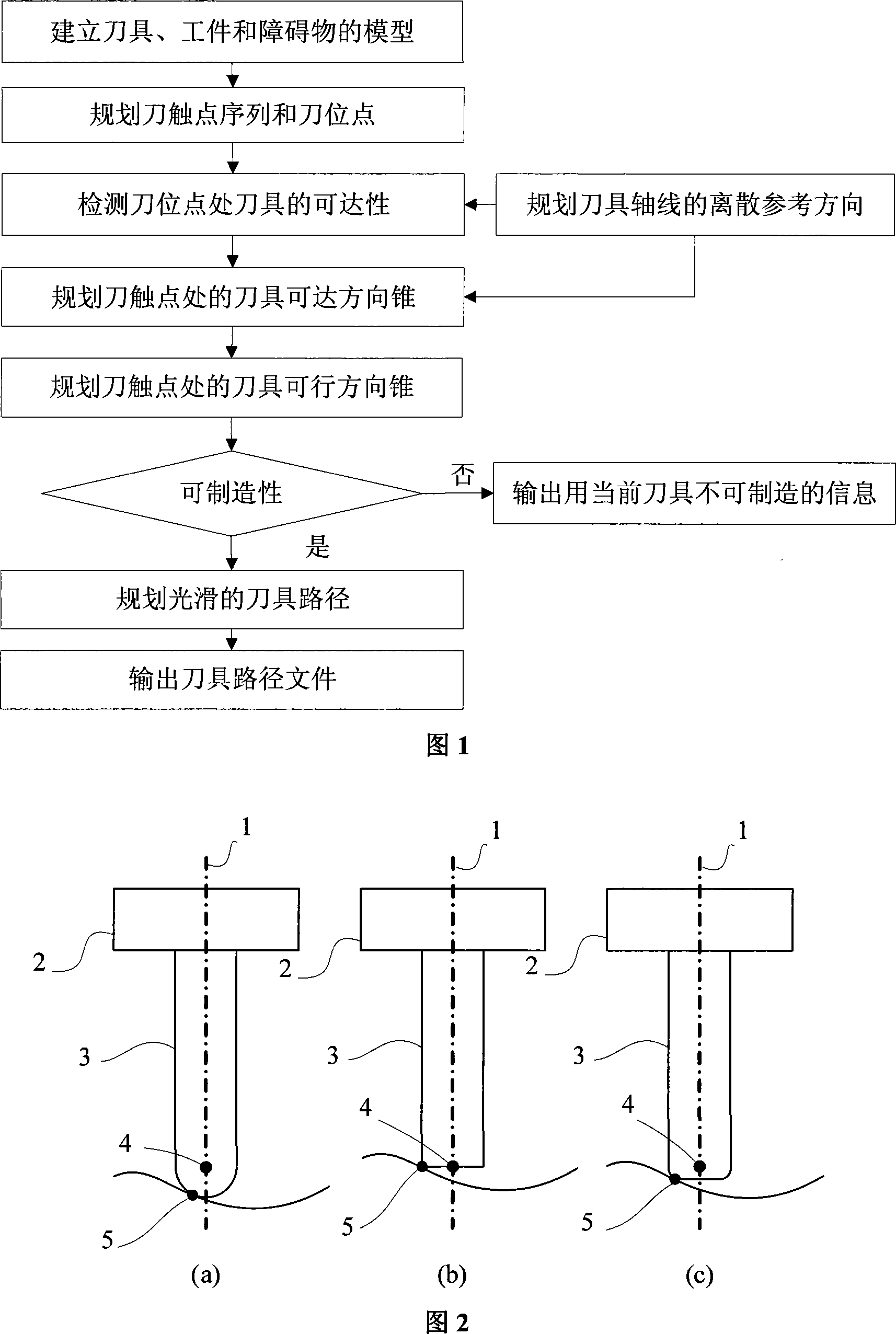

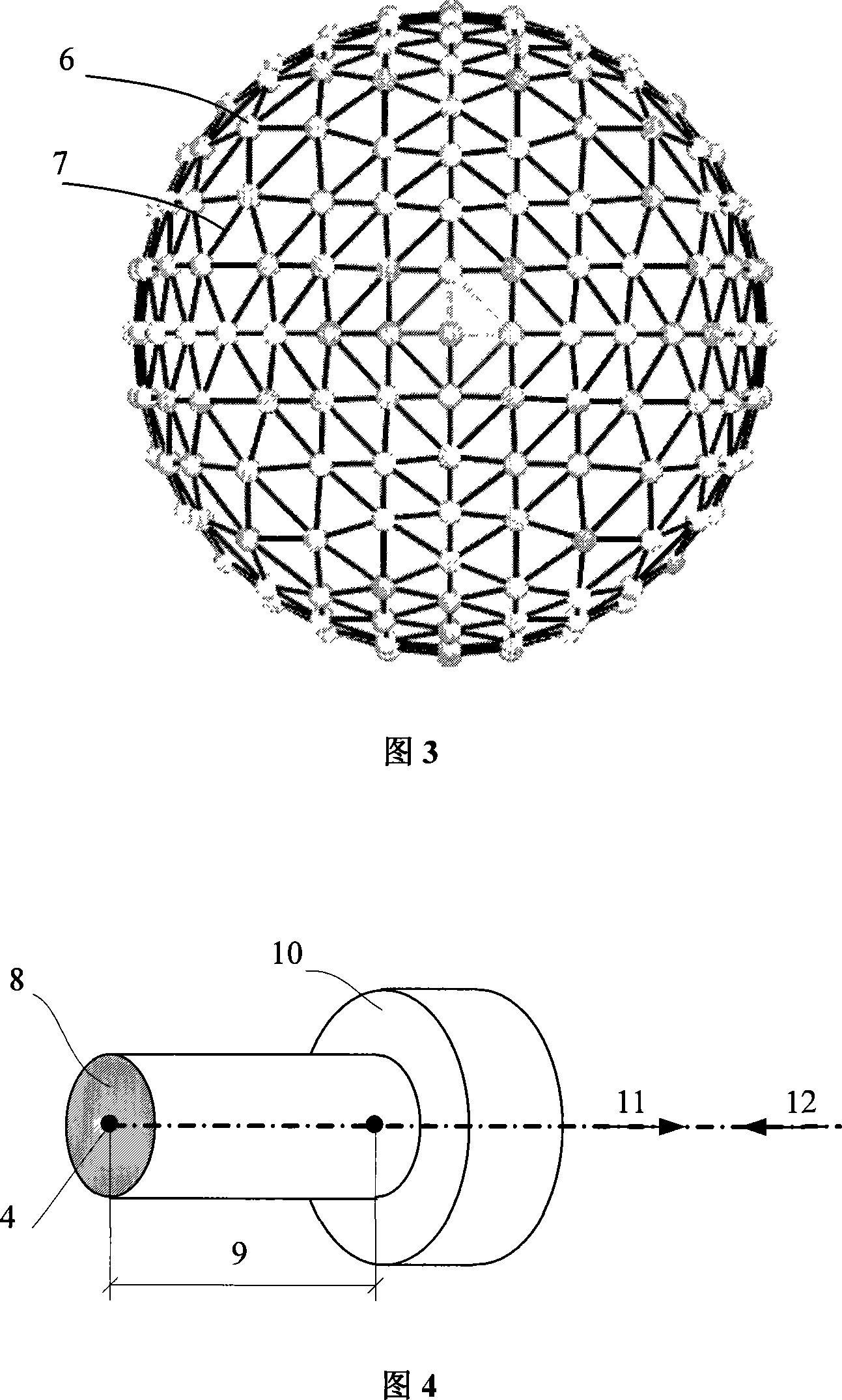

Method for planning smooth and non-interference tool route of 5-axis numerical control machining

ActiveCN101109944AShorten the timeAvoid repeated adjustmentsNumerical controlNumerical controlCircular disc

The utility model relates to a five-axle digital controlled tool path planning method of which the processing is smooth and free of interference as well as the analysis on the producibility of the components. Firstly, the geometrical models for the cutting tools, the work pieces and the obstacles are established. Along the negative direction of the scattered reference direction, griding the obstacle and the disc of the cutting tool turning circle cylindrical surface at the cutter spacing point. Based on the test in depth, the visual information can be obtained to judge the accessibility of the cutting tool along the scattered reference direction. Also, the directional cone for the attainability of the cutting tool can be planned at the cutting tool contact. Based on the continuity constraint of the direction and the restriction of the processing surroundings, the cone for the feasible direction can be calculated and the producibility can be judged. If the producibility is available, the smooth and the non-interference tool path can be planed in the directional cone as per the principle of the minimum change of direction in the tool path so as to output the tool path document. The utility model has a high computational efficiency and a simple programming, so as to be suitable to the wantonly rendered geometrical models such as the polygon grid and the free curved surface. Also, the interference of the clip and the toolbar can be avoided.

Owner:CHENGDU USEFUL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com