Patents

Literature

519results about How to "Improve the measurement effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

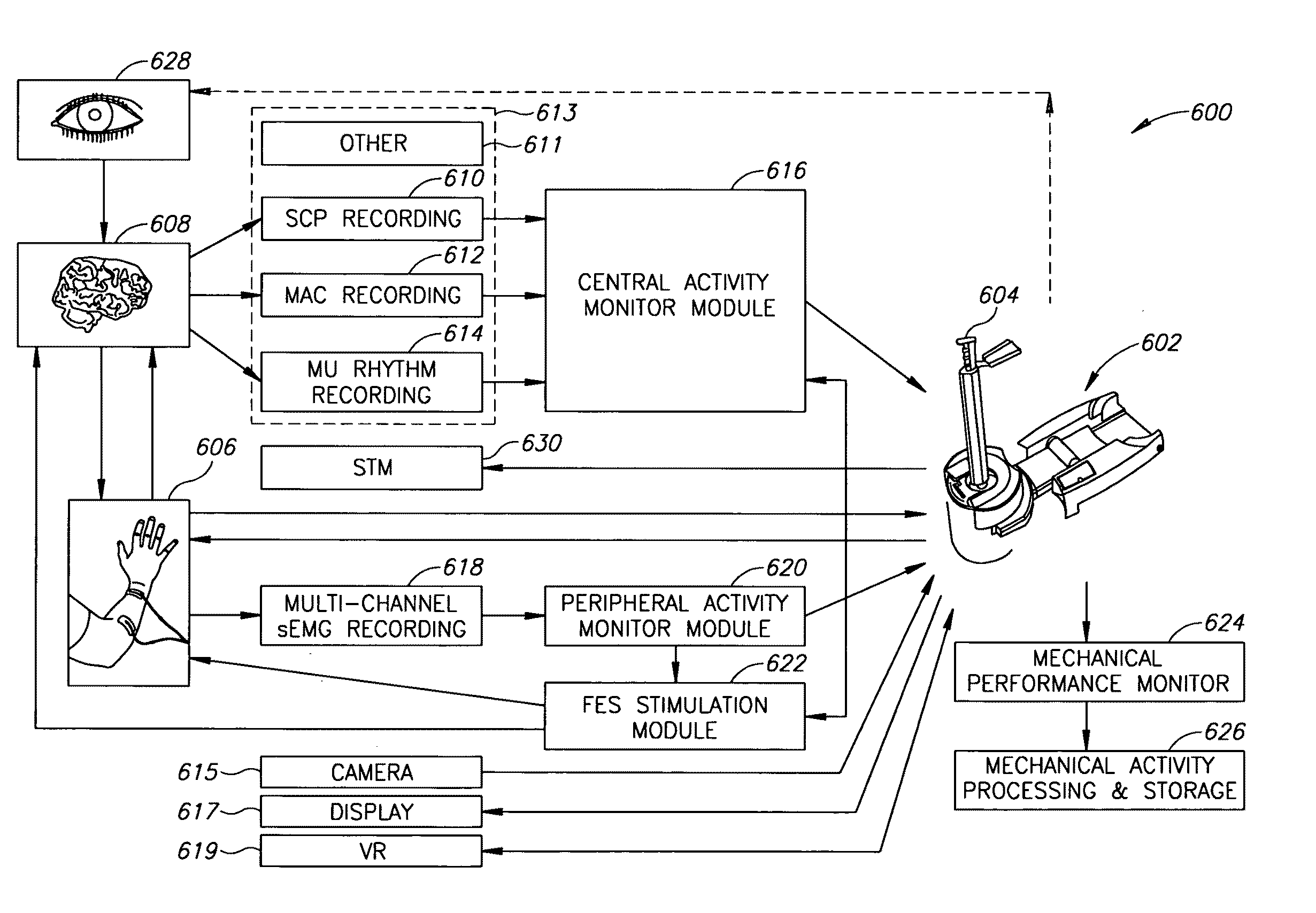

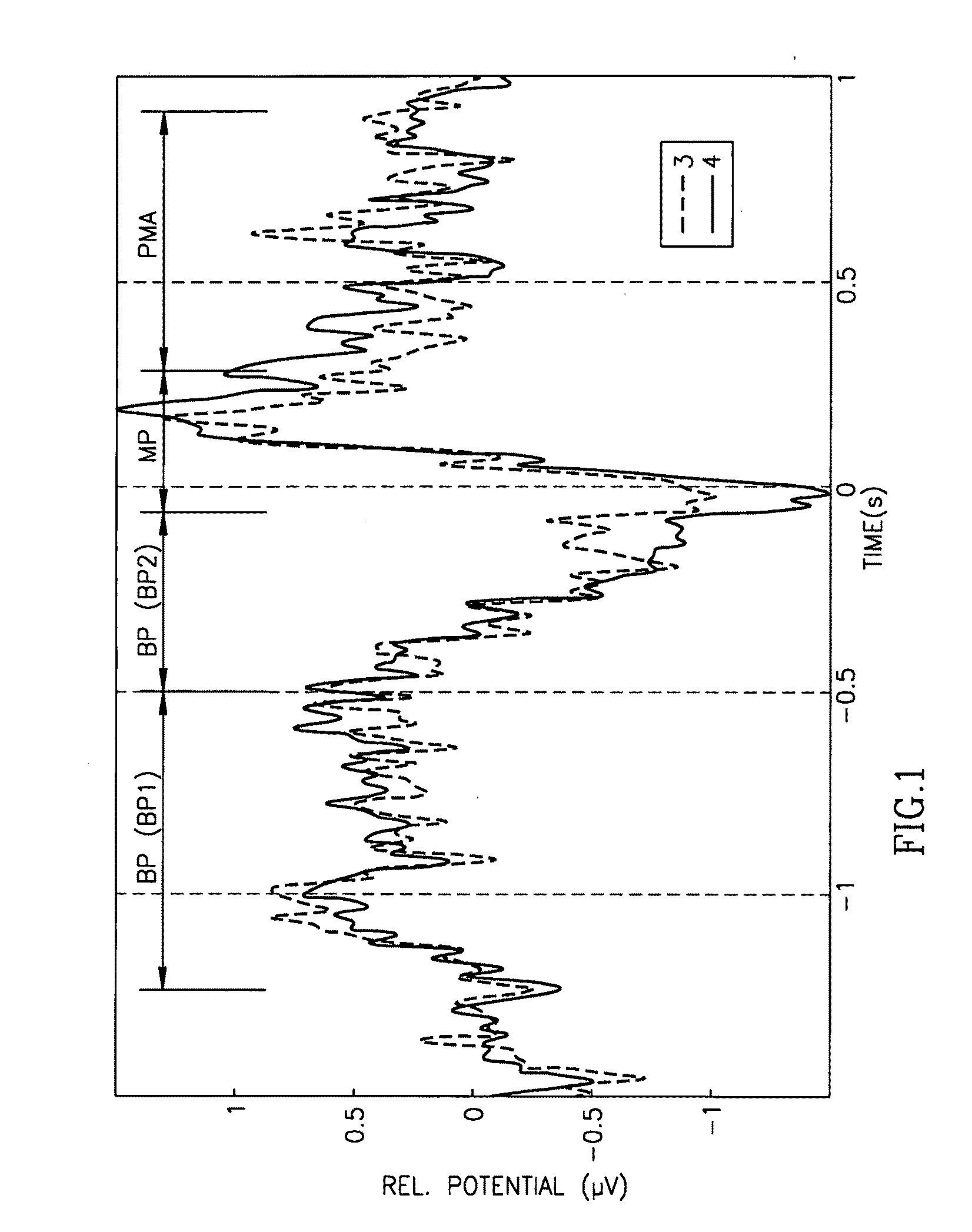

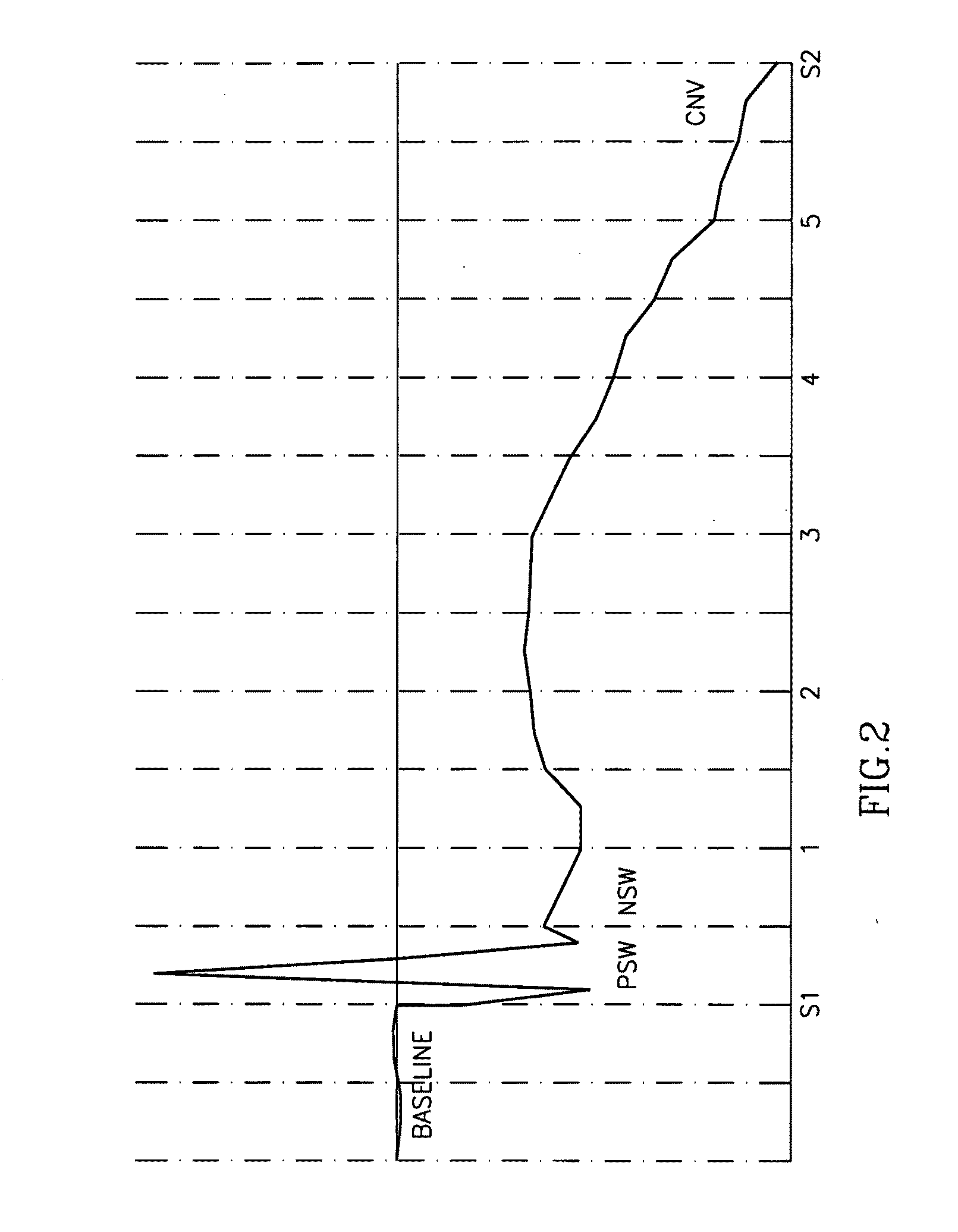

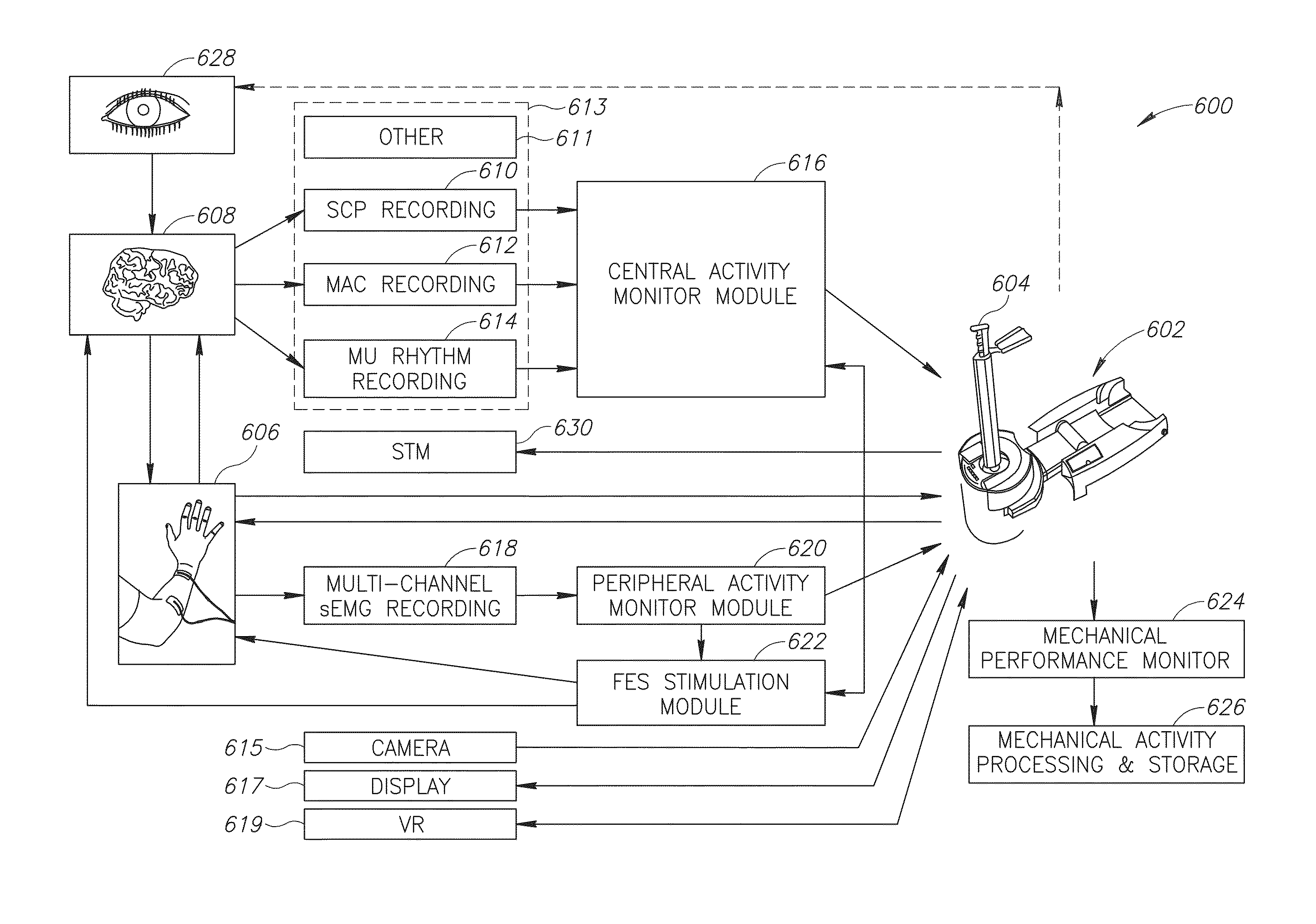

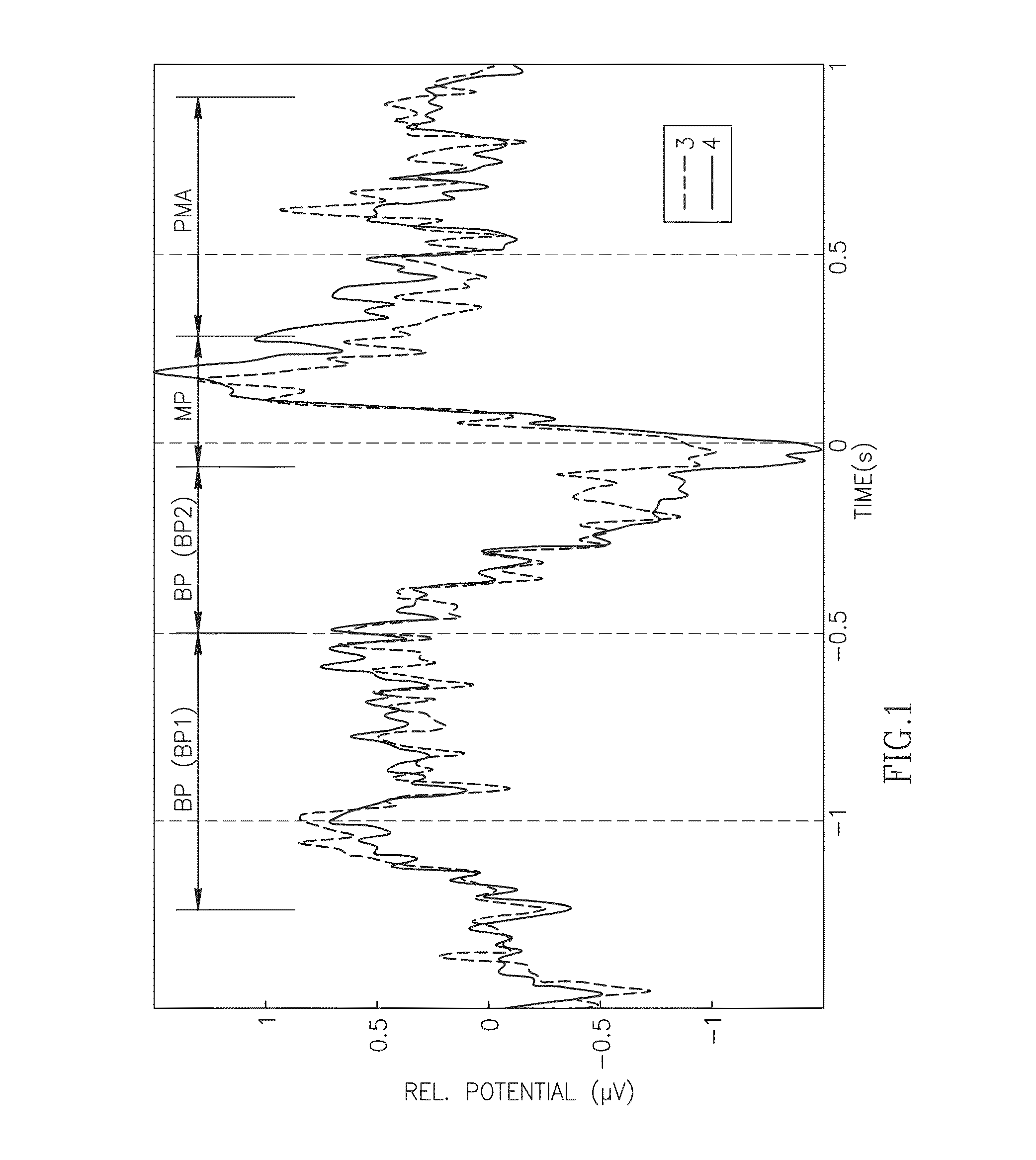

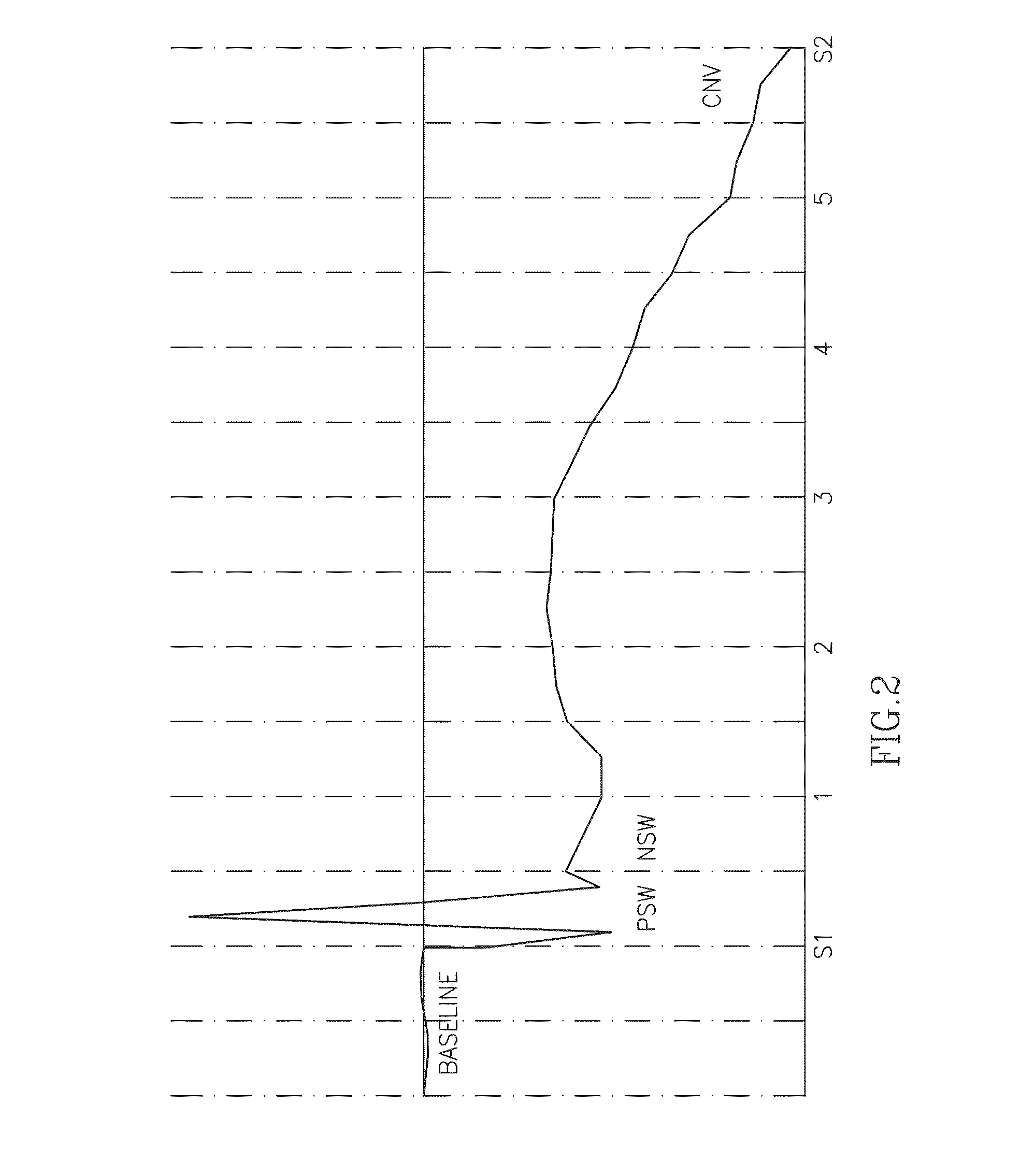

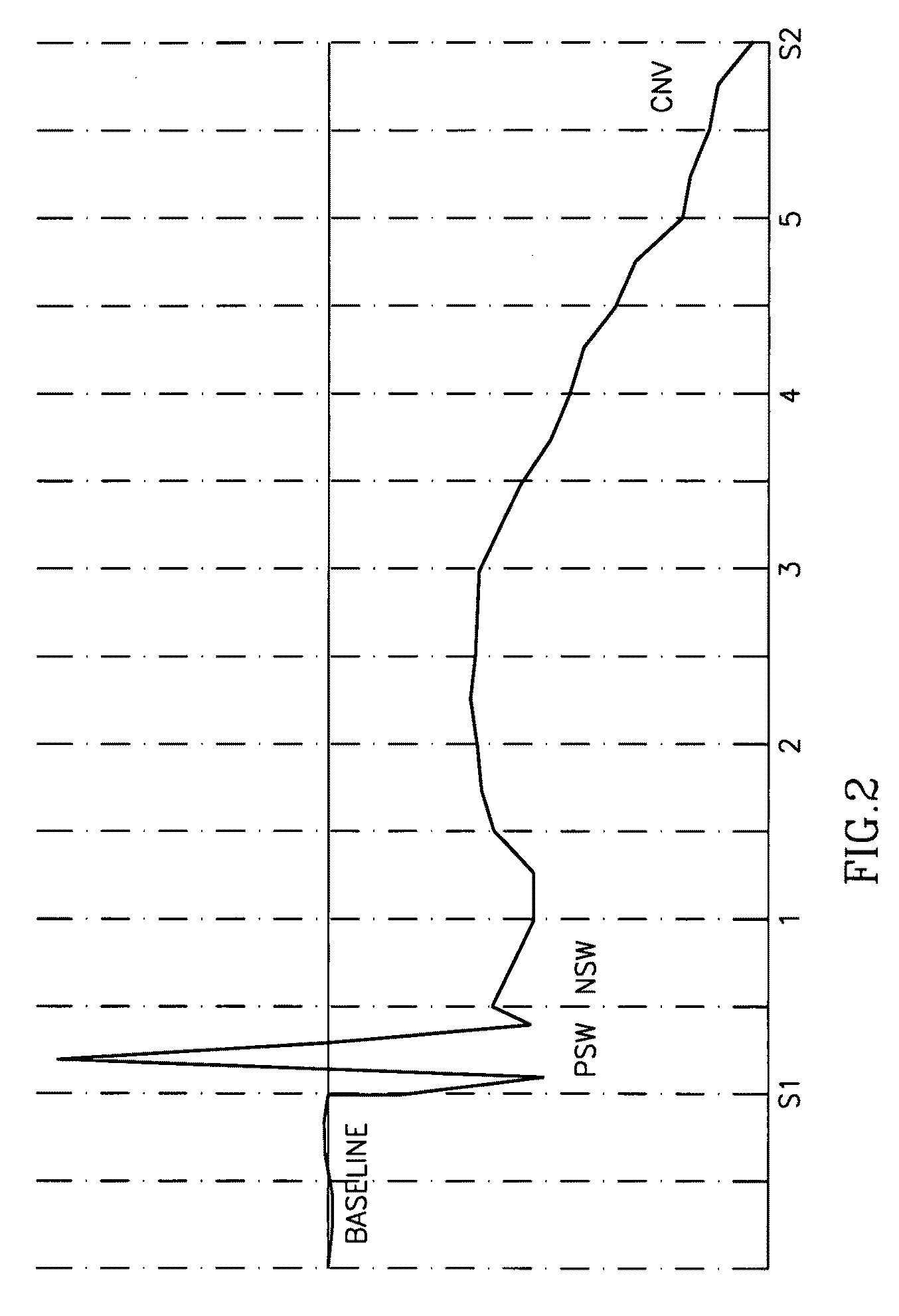

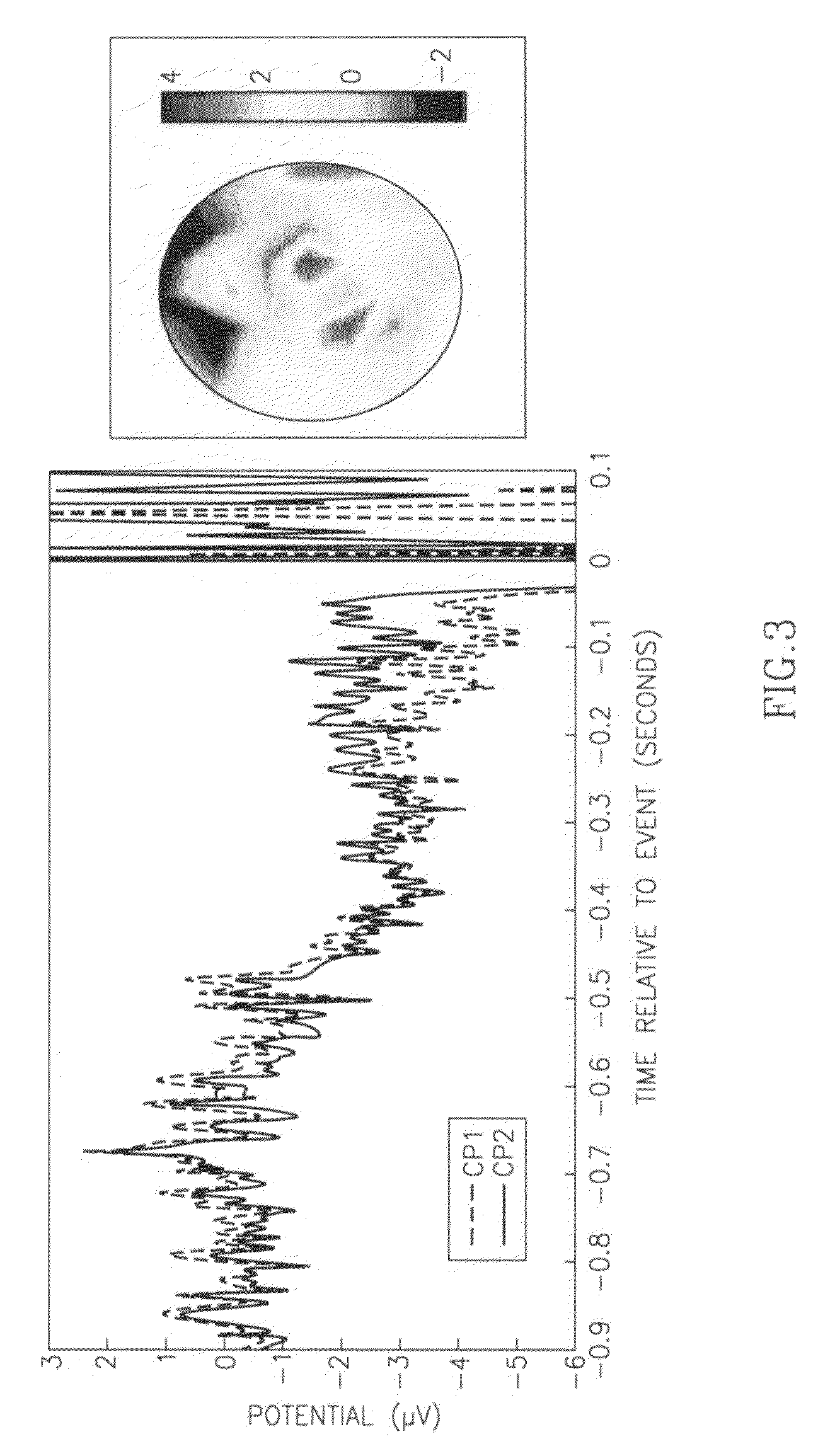

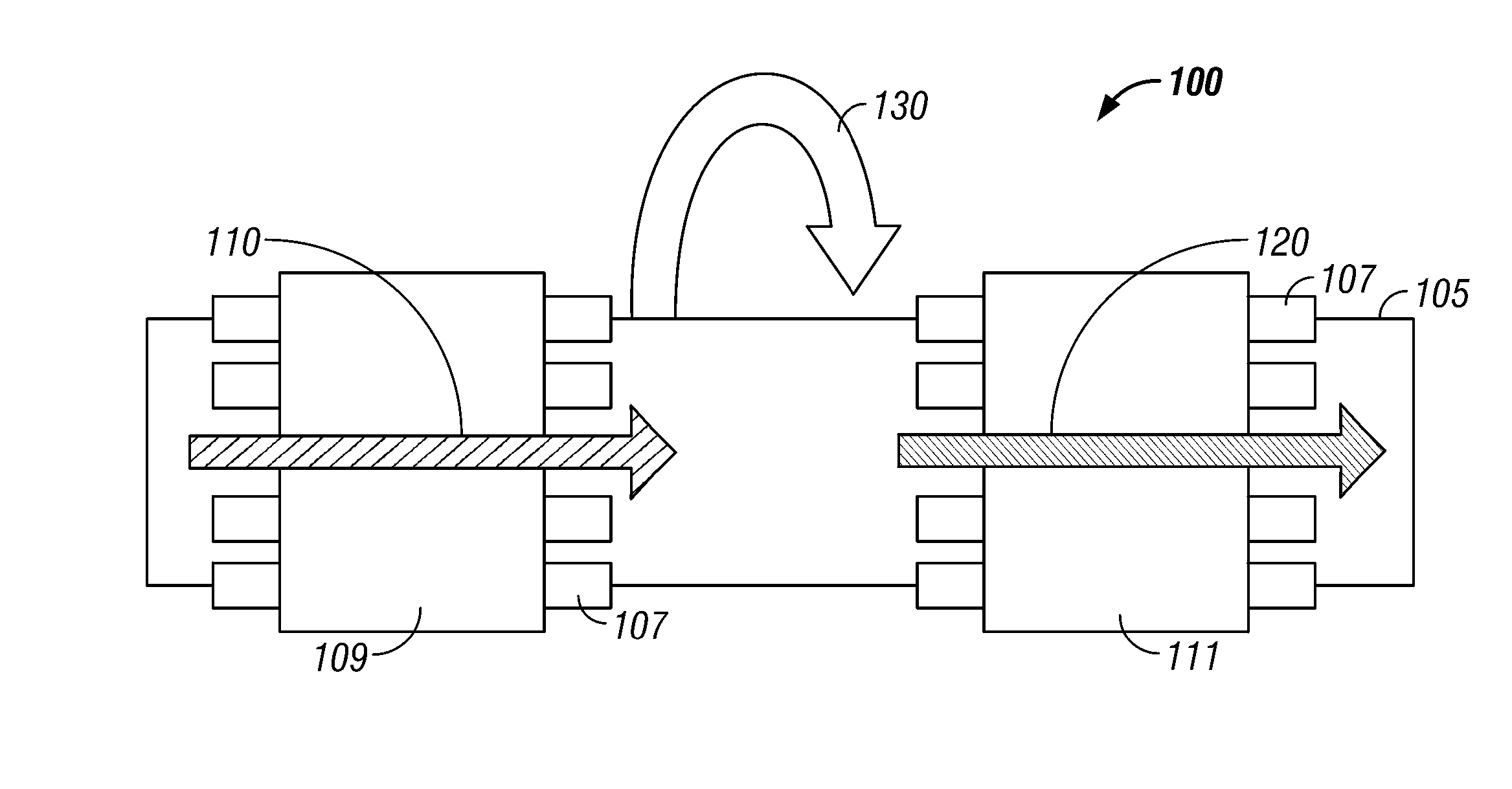

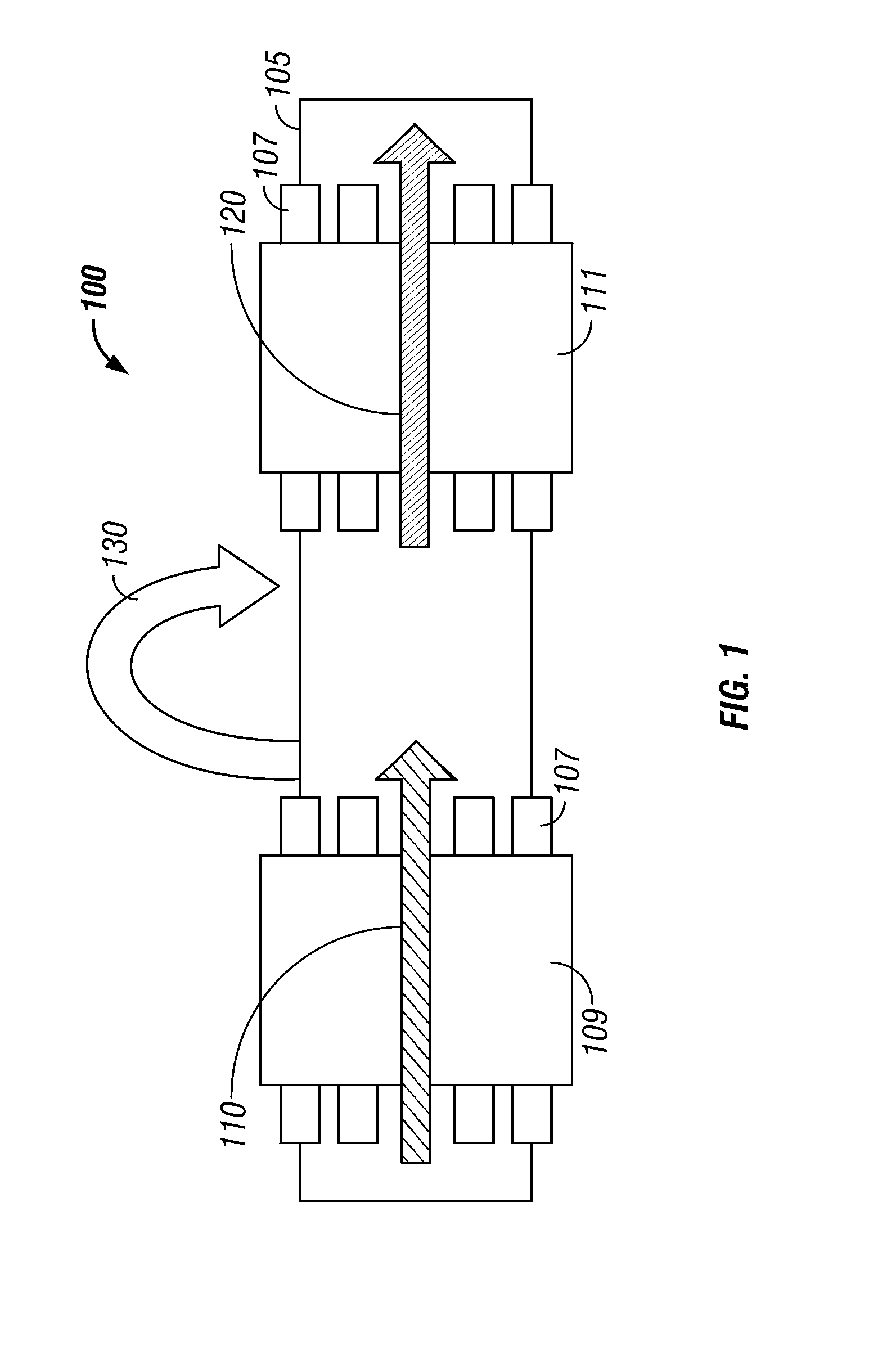

Motor training with brain plasticity

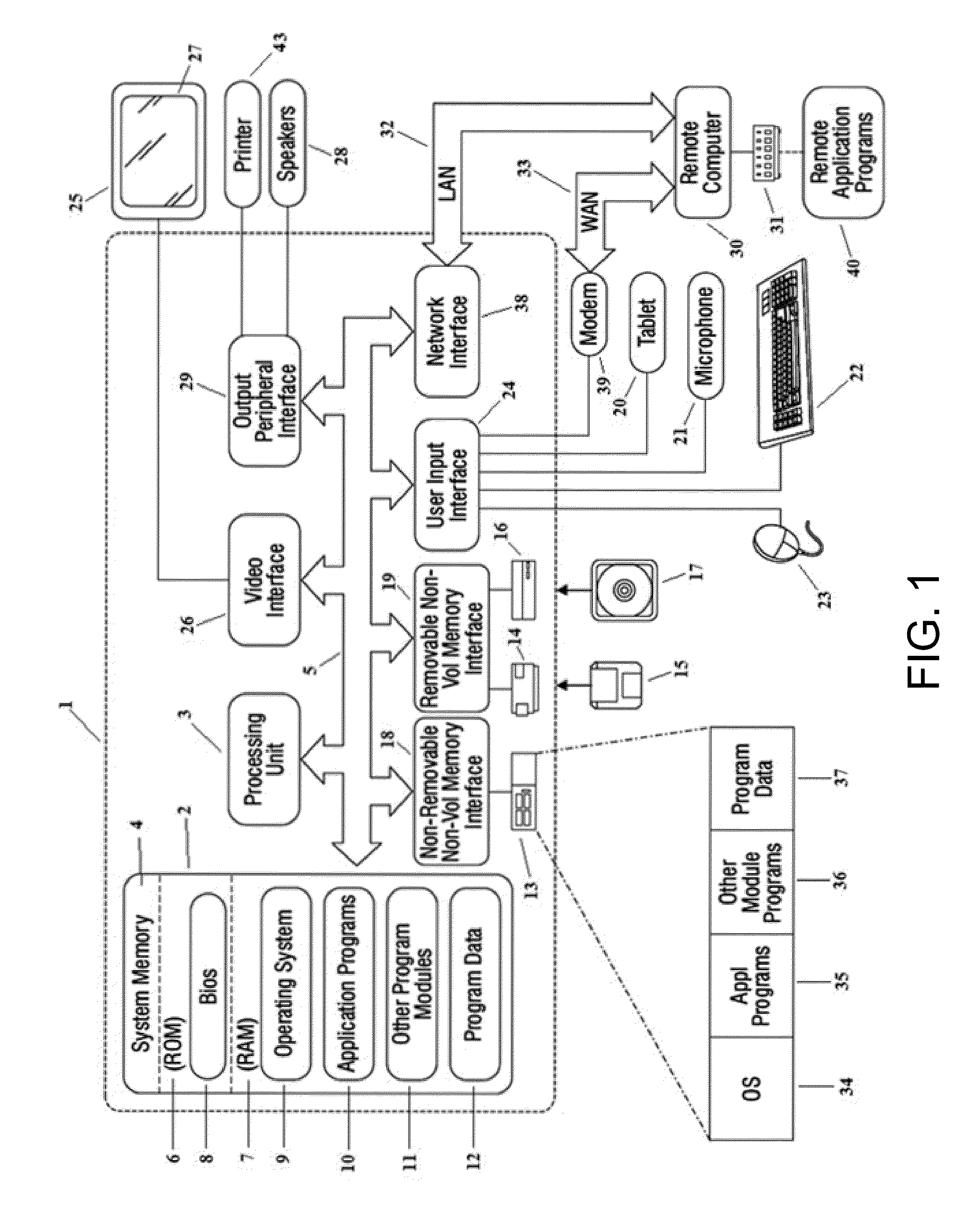

InactiveUS20090221928A1Increase activityImprove motor functionElectroencephalographyElectromyographyPhysical medicine and rehabilitationCerebrum

A rehabilitation device, comprising a movement element capable of controlling at least one motion parameter of a portion of a patient; a brain monitor which generates a signal indicative of brain activity; and circuitry including a memory having stored therein rehabilitation information and which inter-relates said signal and movement of said movement element as part of a rehabilitation process which utilizes said rehabilitation information.

Owner:MOTORIKA

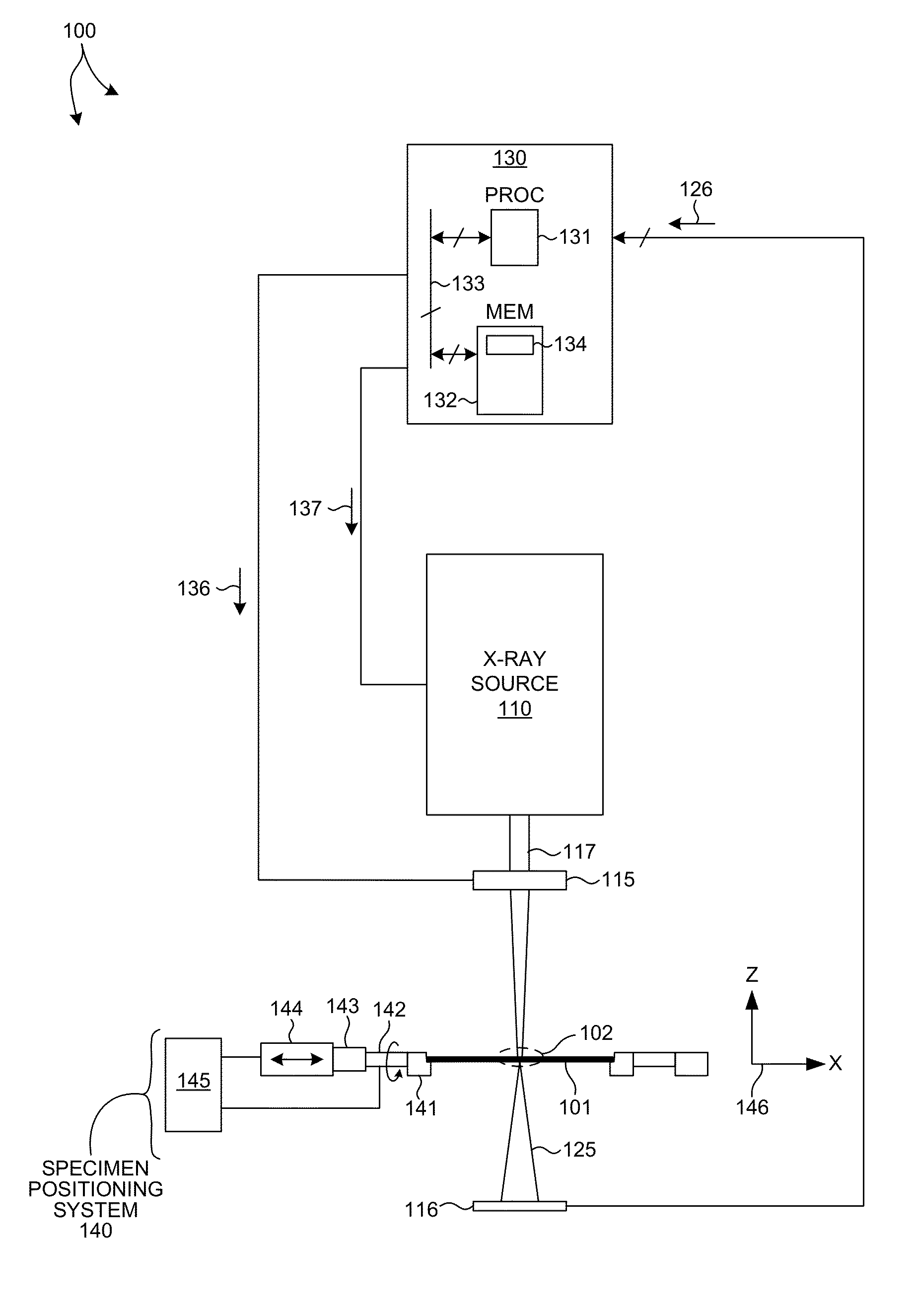

Scatterometry-Based Imaging and Critical Dimension Metrology

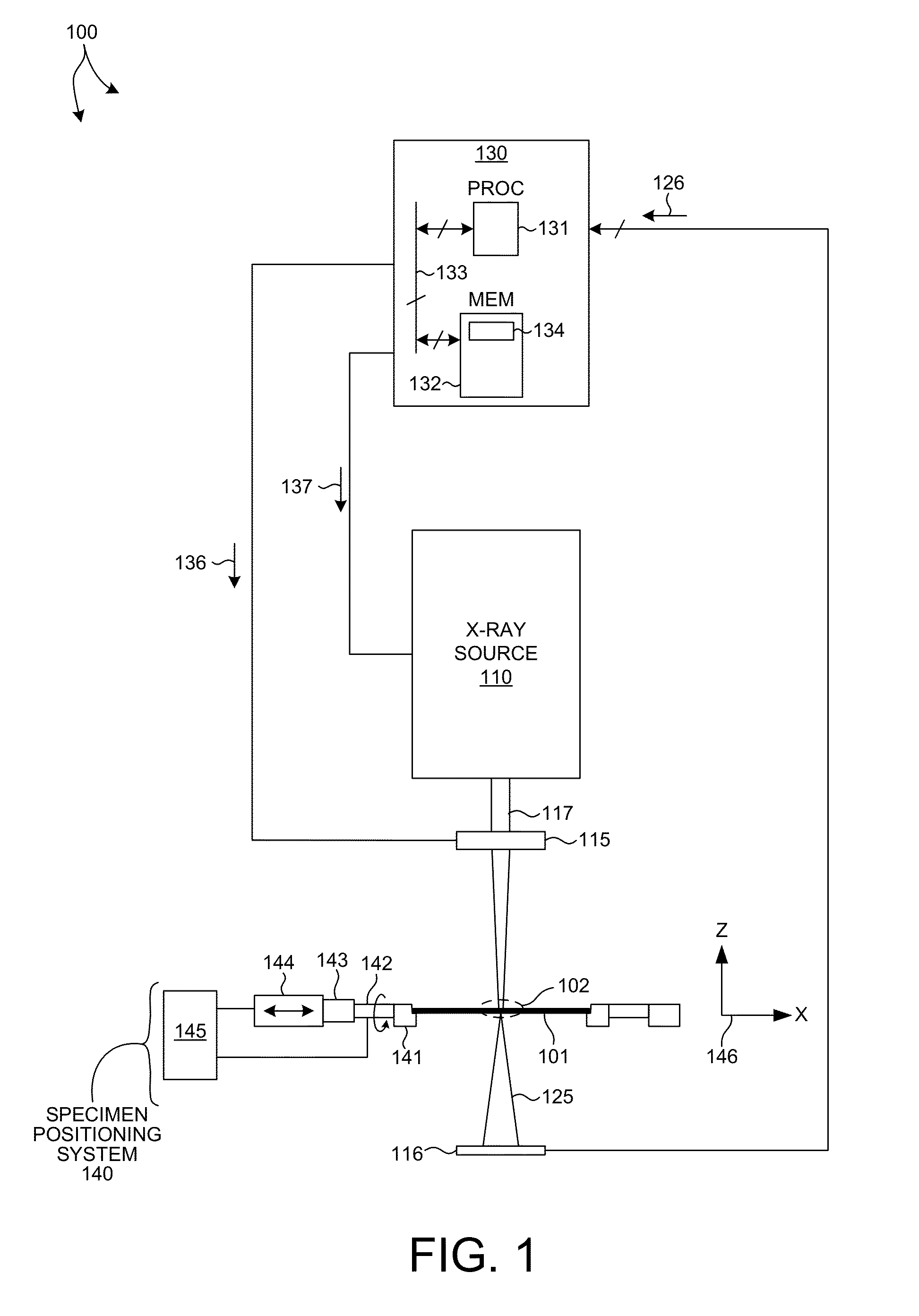

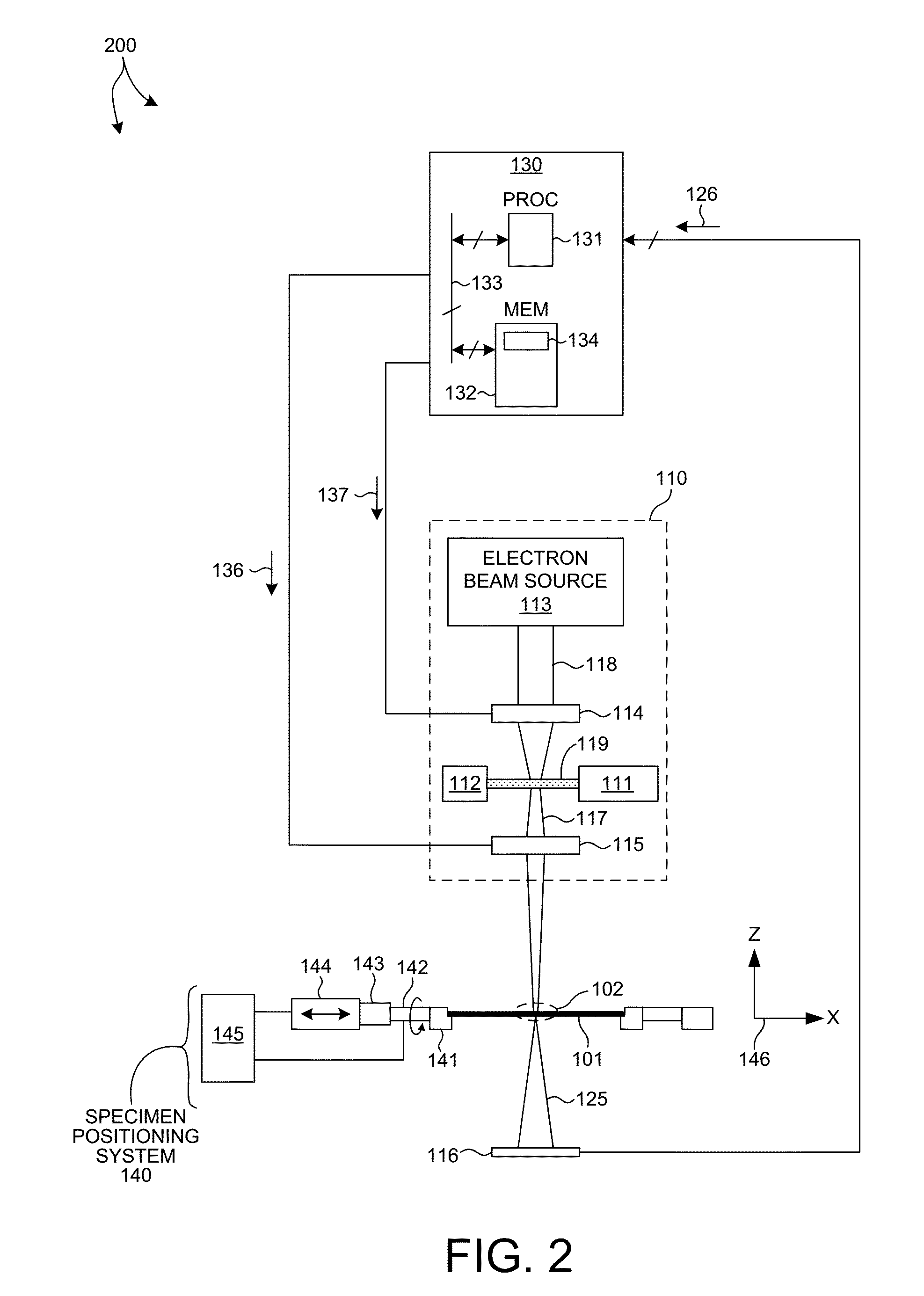

ActiveUS20150300965A1Improve the measurement effectMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementDiffraction orderMetrology

Methods and systems for performing measurements of semiconductor structures and materials based on scatterometry measurement data are presented. Scatterometry measurement data is used to generate an image of a material property of a measured structure based on the measured intensities of the detected diffraction orders. In some examples, a value of a parameter of interest is determined directly from the map of the material property of the measurement target. In some other examples, the image is compared to structural characteristics estimated by a geometric, model-based parametric inversion of the same measurement data. Discrepancies are used to update the geometric model of the measured structure and improve measurement performance. This enables a metrology system to converge on an accurate parametric measurement model when there are significant deviations between the actual shape of a manufactured structure subject to model-based measurement and the modeled shape of the structure.

Owner:KLA TENCOR TECH CORP

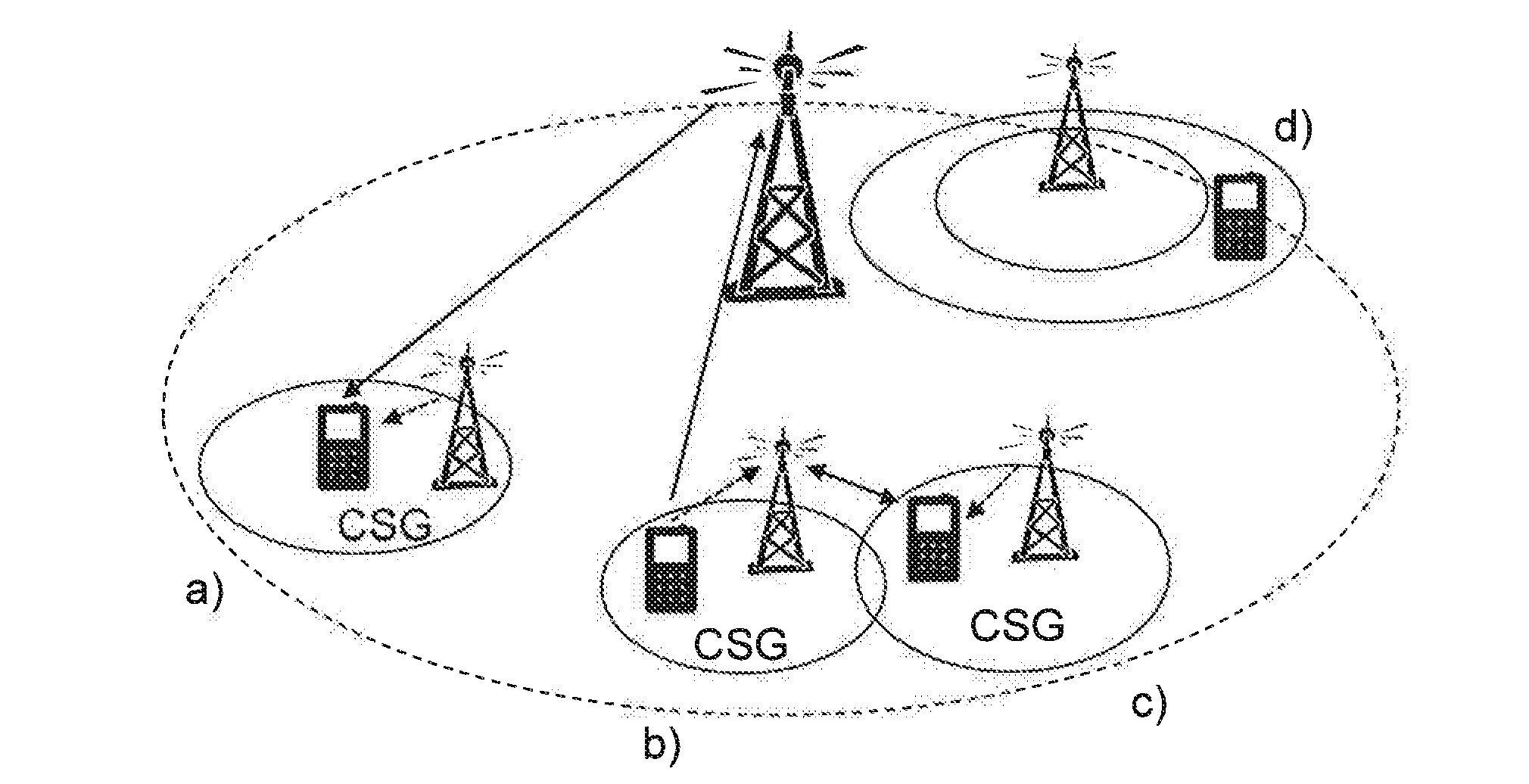

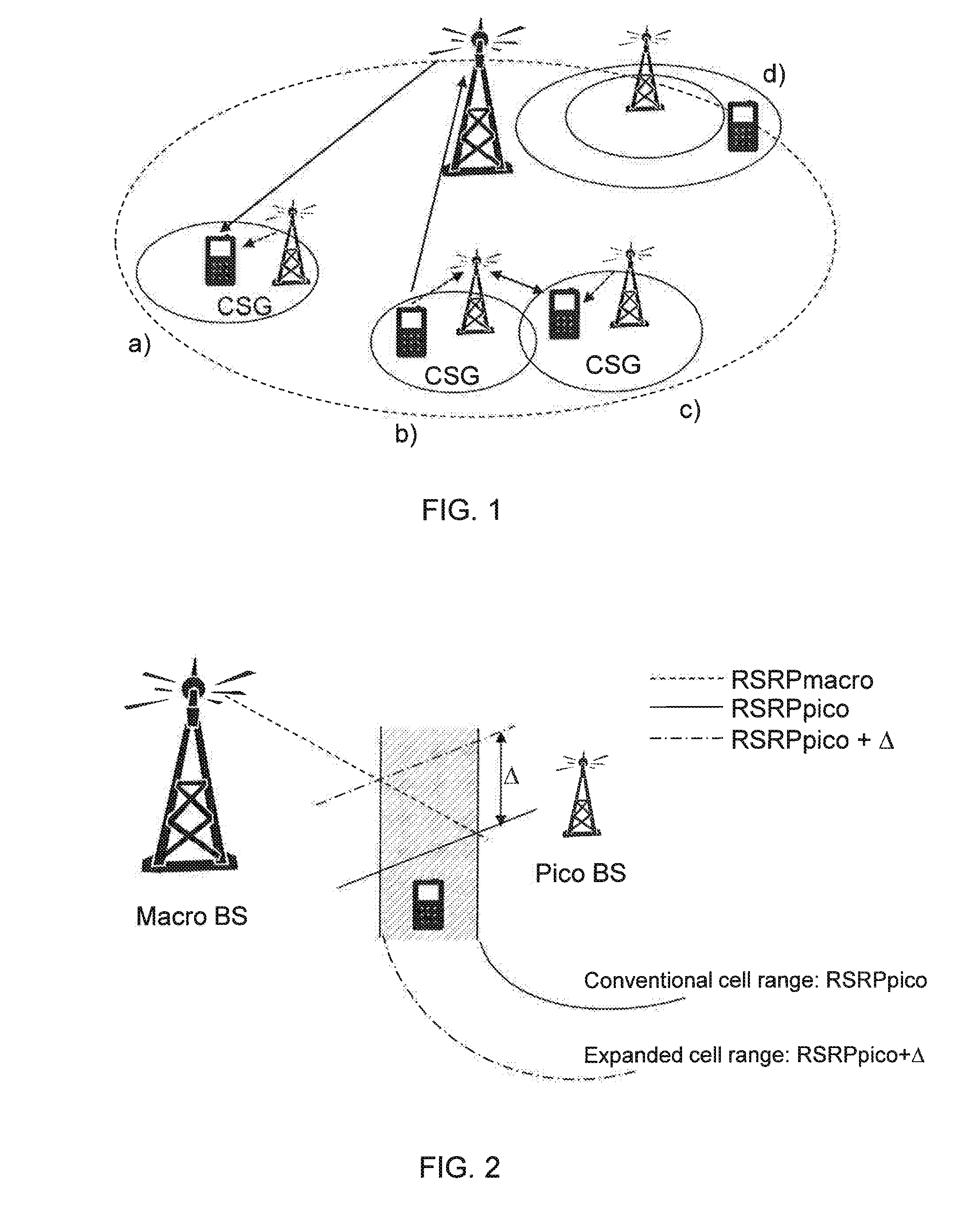

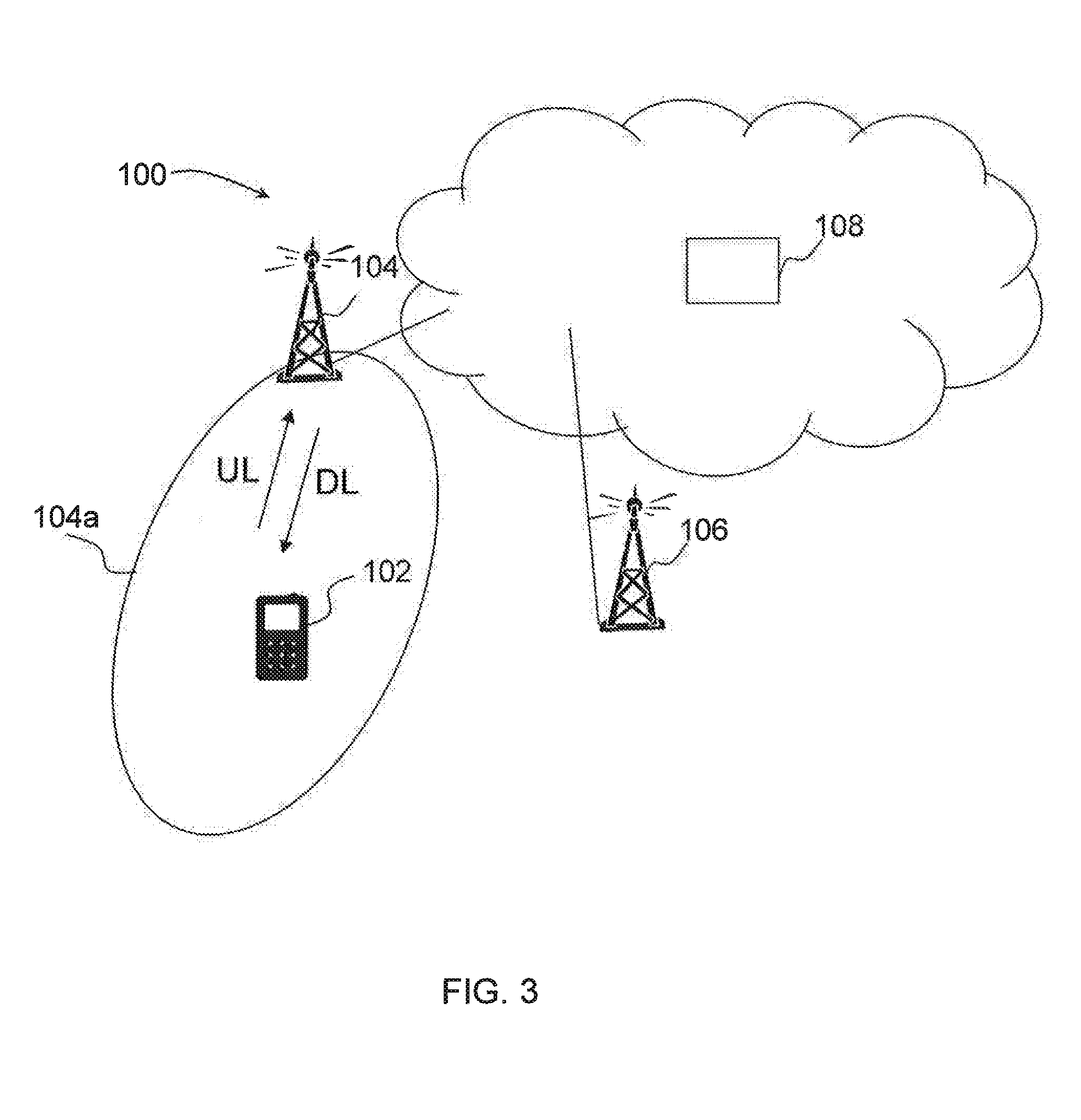

Methods and apparatus for performing measurements in adaptive downlink power transmission

ActiveUS20140286219A1Improve interference controlImprove the measurement effectPower managementTransmission systemsSelf adaptiveTransmitted power

A wireless device, and a method therein, for performing a measurement on a first type of radio signal. The wireless device is comprised in a communications network. The wireless device receives at least two resource specific parameters for the first type of radio signal. The at least two resource specific parameters indicate different transmit power levels of the first type of radio signal and the different transmit power levels relate to two different resources in two different time periods for the first type of radio signal. Further, the wireless device receives a first type of radio signal transmitted at two different transmit power levels, and performs at least one measurement on the received first type of radio signal using the at least two resource specific parameters.

Owner:TELEFON AB LM ERICSSON (PUBL)

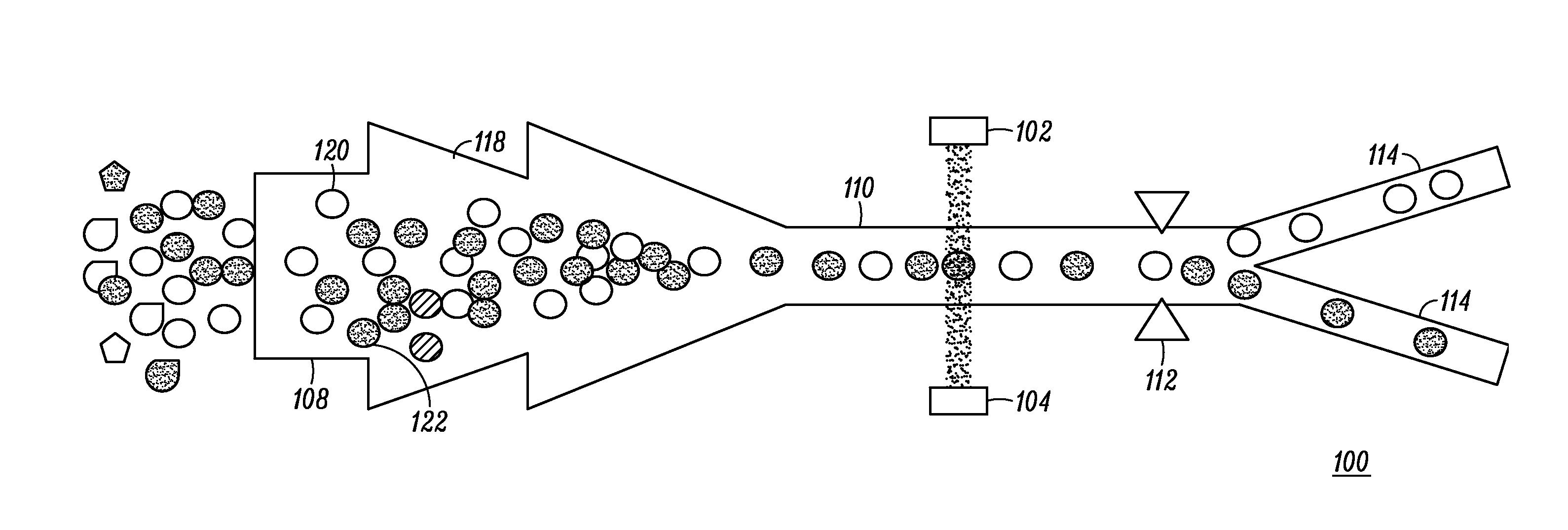

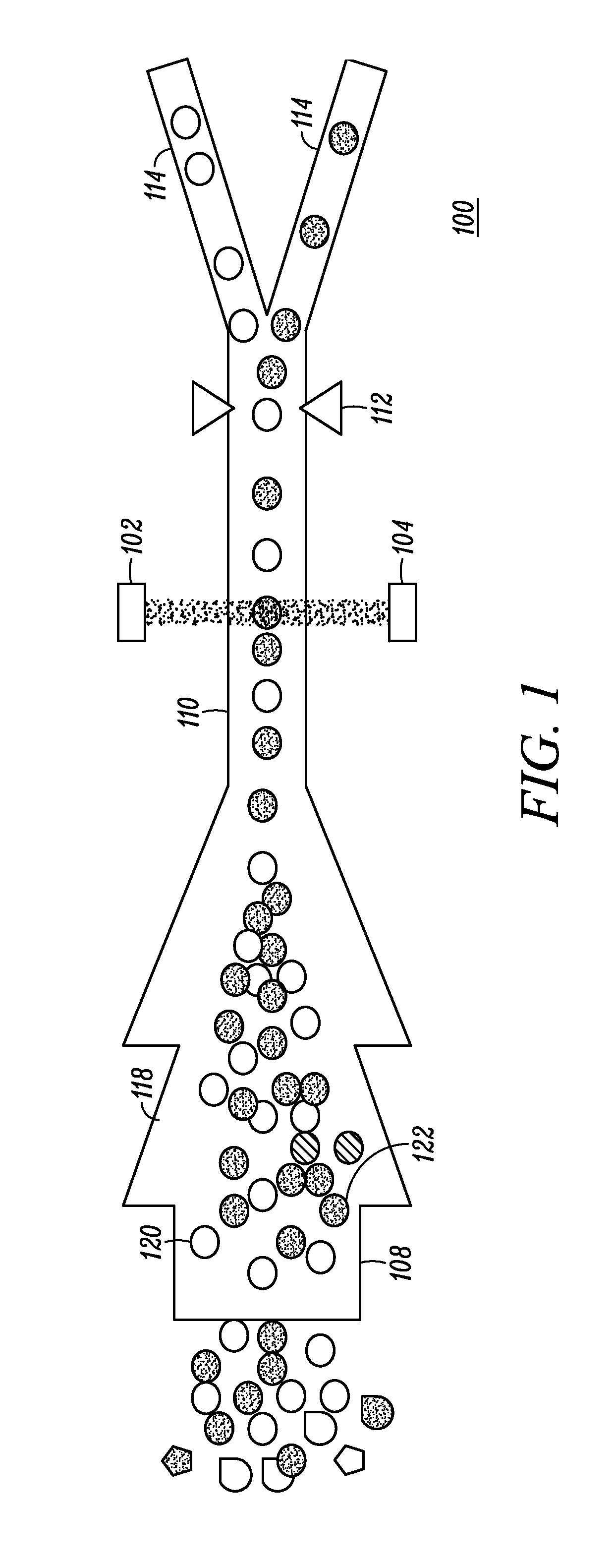

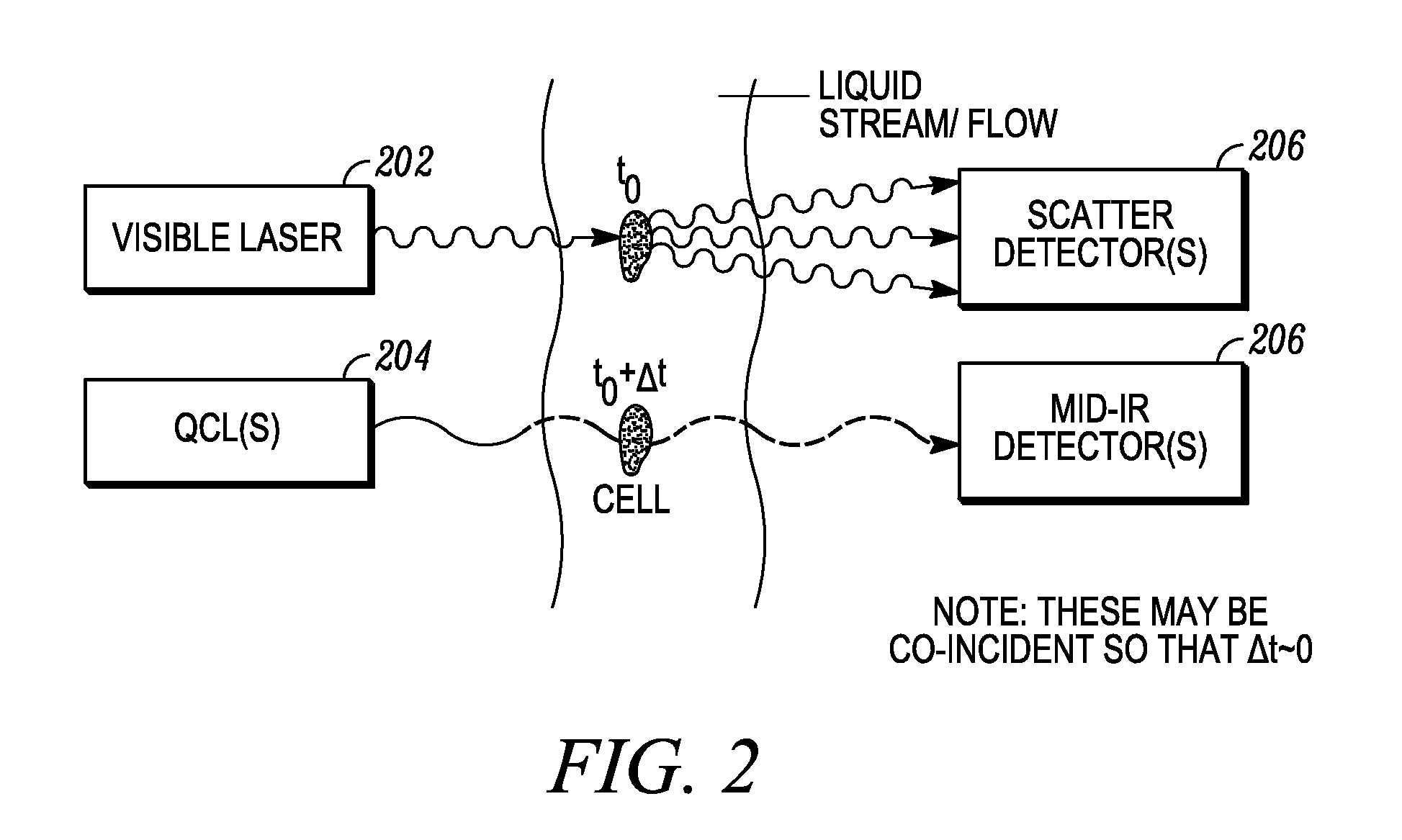

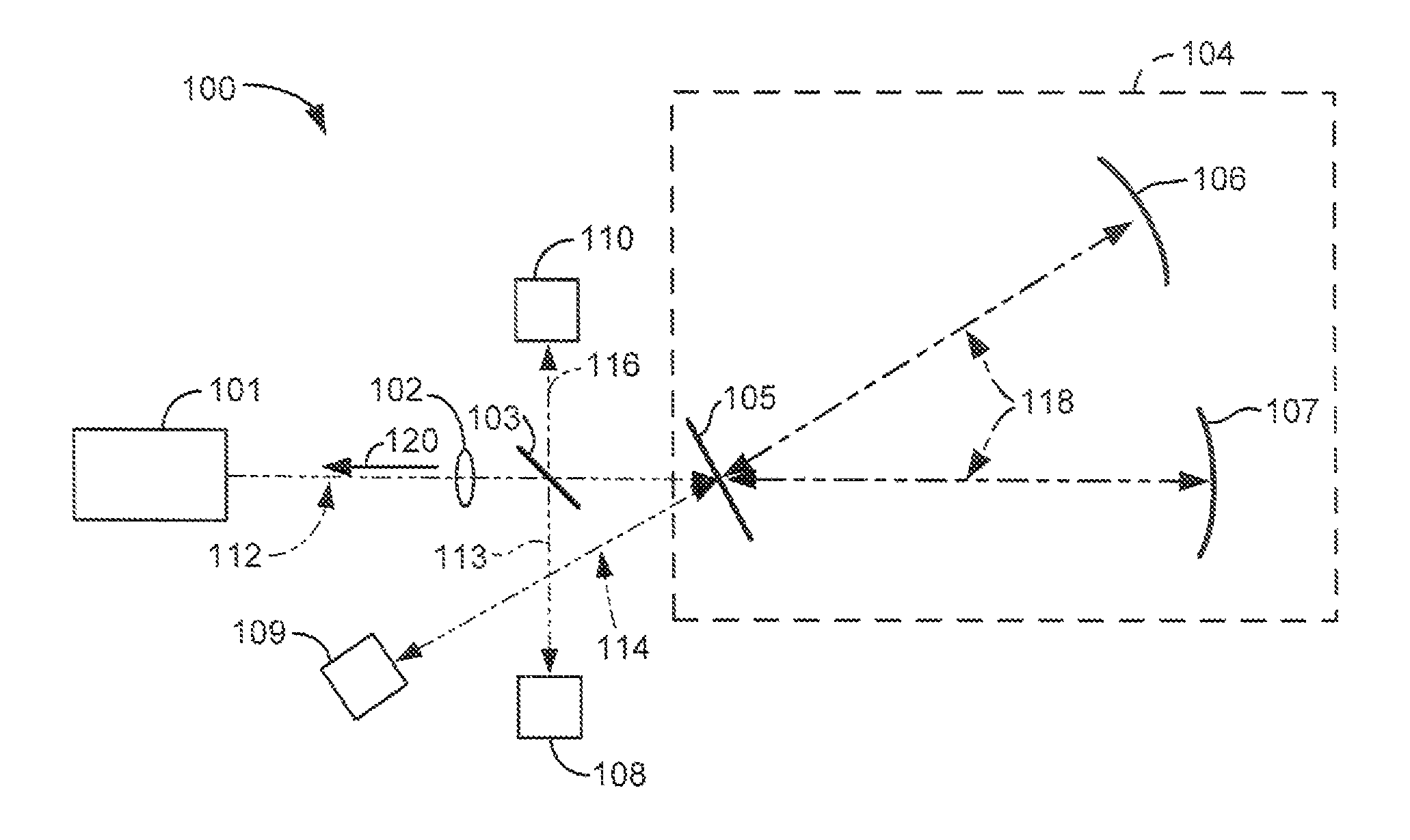

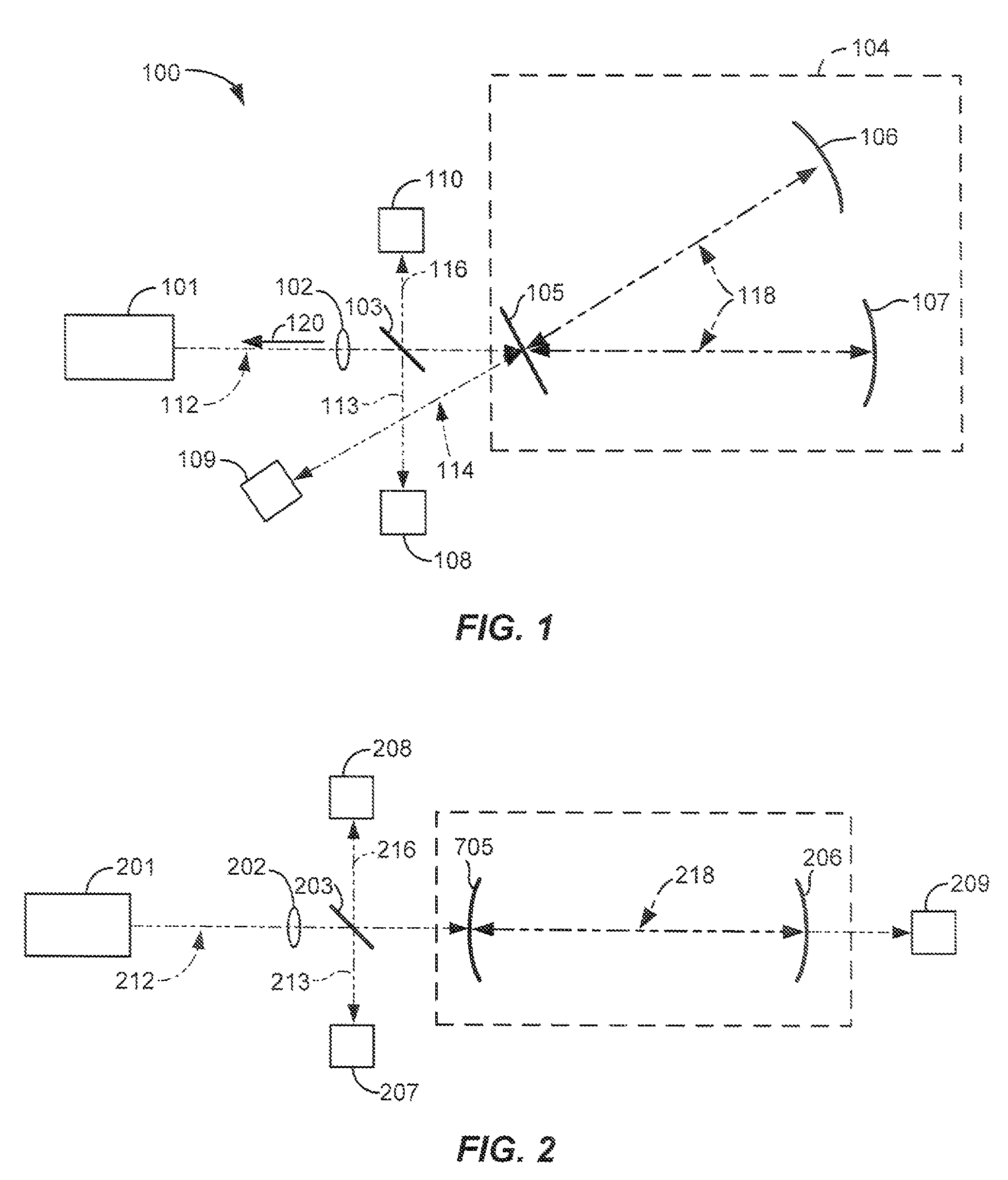

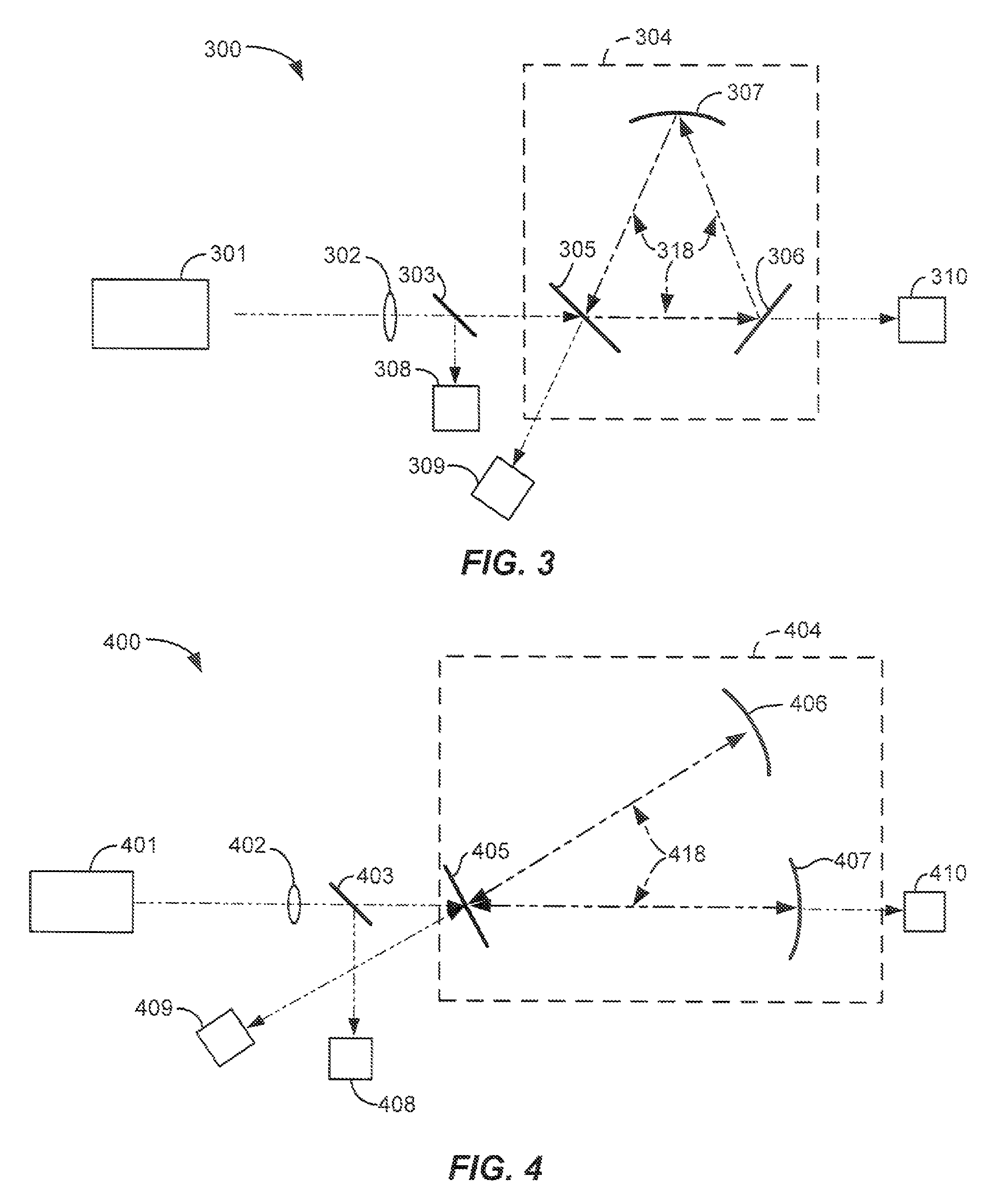

Cytometry system with interferometric measurement

ActiveUS20130252237A1Reduce light energyEasy to handleBioreactor/fermenter combinationsBiological substance pretreatmentsSignal-to-noise ratio (imaging)Phase difference

This disclosure concerns methods and apparatus for interferometric spectroscopic measurements of particles with higher signal to noise ratio utilizing an infrared light beam that is split into two beams. At least one beam may be directed through a measurement volume containing a sample including a medium. The two beams may then be recombined and measured by a detector. The phase differential between the two beams may be selected to provide destructive interference when no particle is present in the measurement volume. A sample including medium with a particle is introduced to the measurement volume and the detected change resulting from at least one of resonant mid-infrared absorption, non-resonant mid-infrared absorption, and scattering by the particle may be used to determine a property of the particle. A wide range of properties of particles may be determined, wherein the particles may include living cells.

Owner:1087 SYST

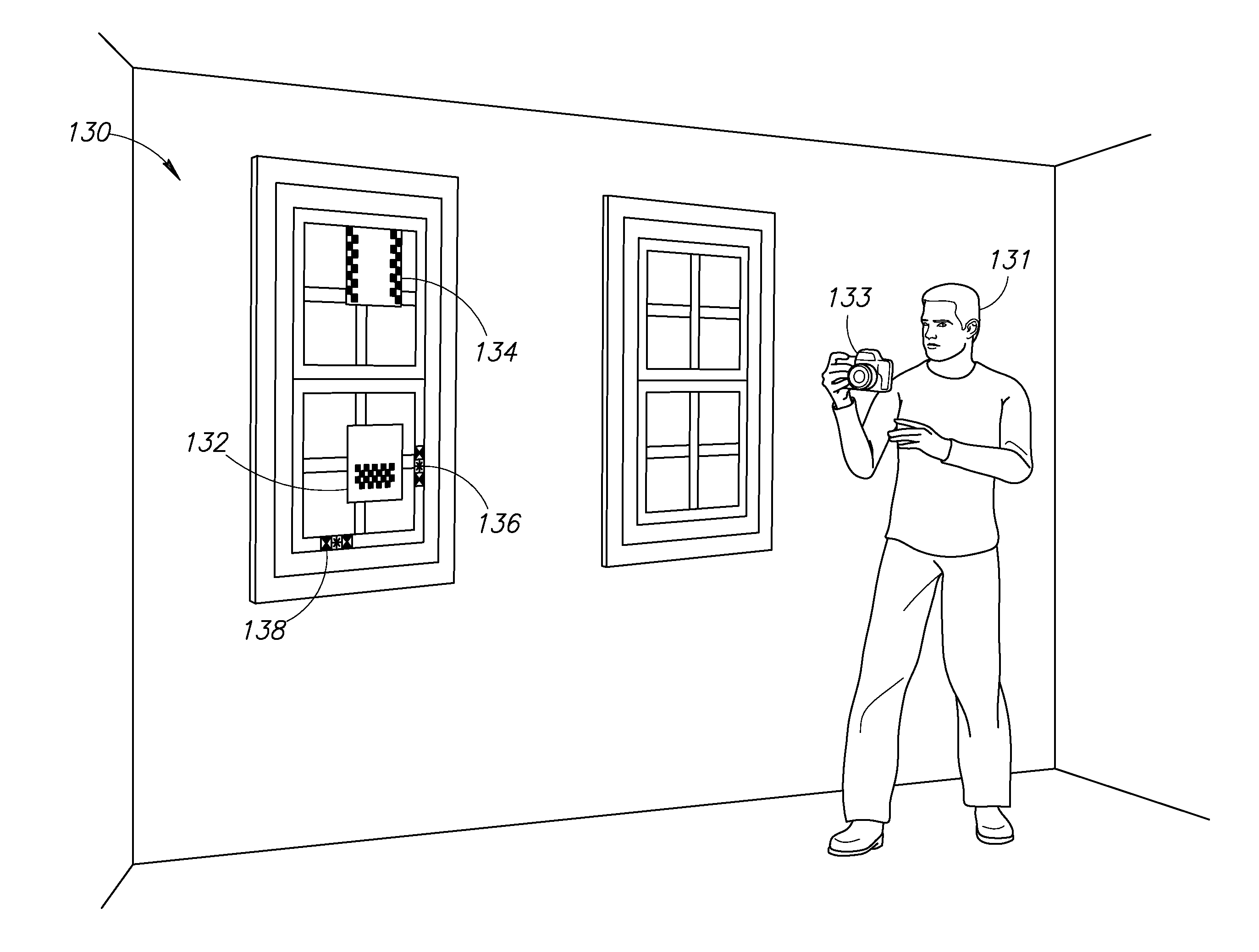

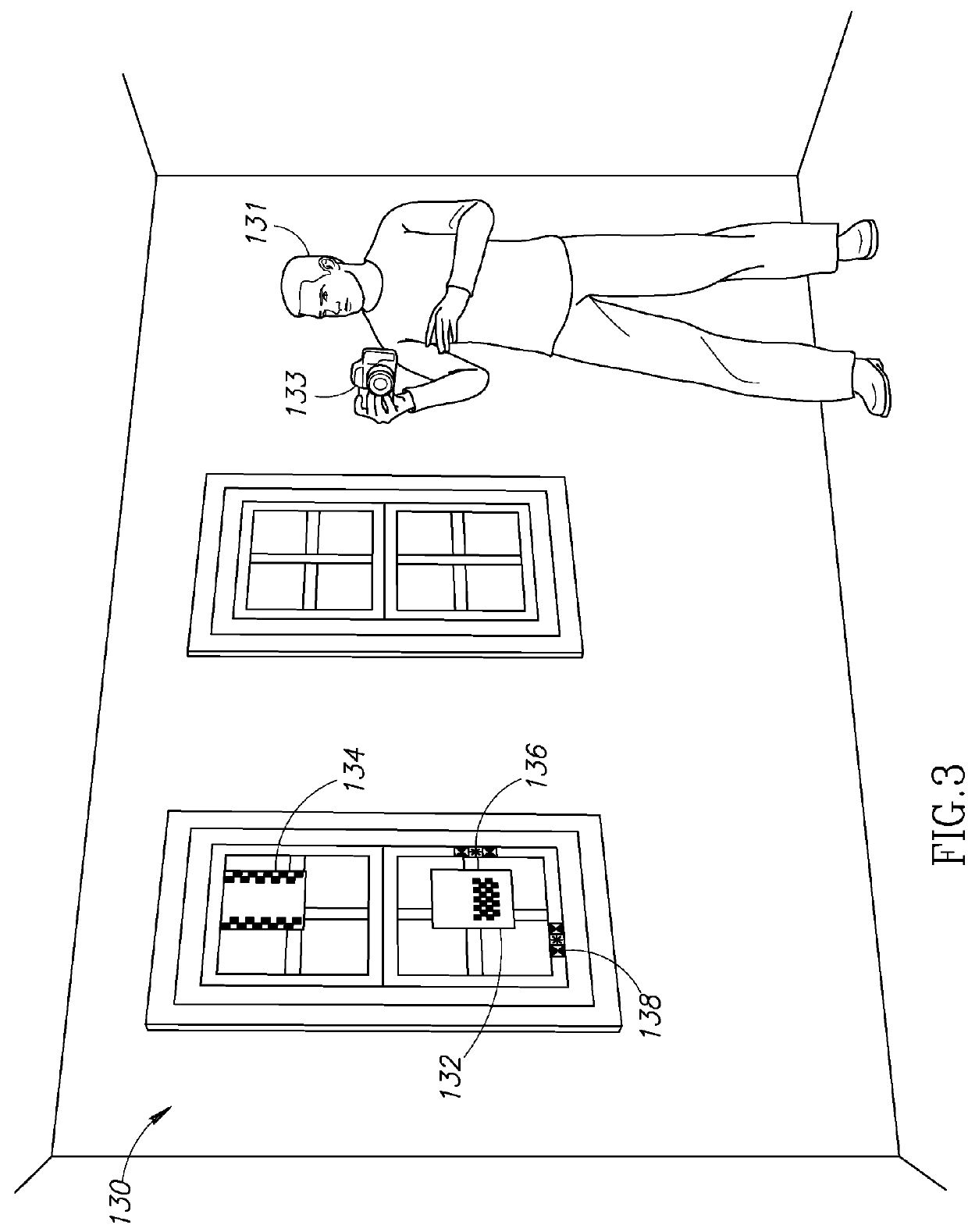

System and method of measuring distances related to an object

ActiveUS20140314276A1Improve specificationEasily associate and maintainImage enhancementImage analysisImage analysisImaging analysis

A system and method for measuring distances related to a target object depicted in an image and the construction and delivery of supplemental window materials for fenestration. A digital image is obtained that contains a target object dimension and a reference object dimension in the same plane. The digital image may contain a target object dimension identified by an ancillary object and a reference object dimension in different planes. Fiducial patterns on the reference and optional ancillary objects are used that are recognized by an image analysis algorithm. Information regarding a target object and its immediate surroundings is provided to an automated or semi-automated measurement process, design and manufacturing system such that customized parts are provided to end users. The digital image contains a reference object having a reference dimension and calculating a constraint dimension from the digital image based on a reference dimension. The custom part is then designed and manufactured based on a calculated constraint dimension.

Owner:WEXENERGY INNOVATIONS

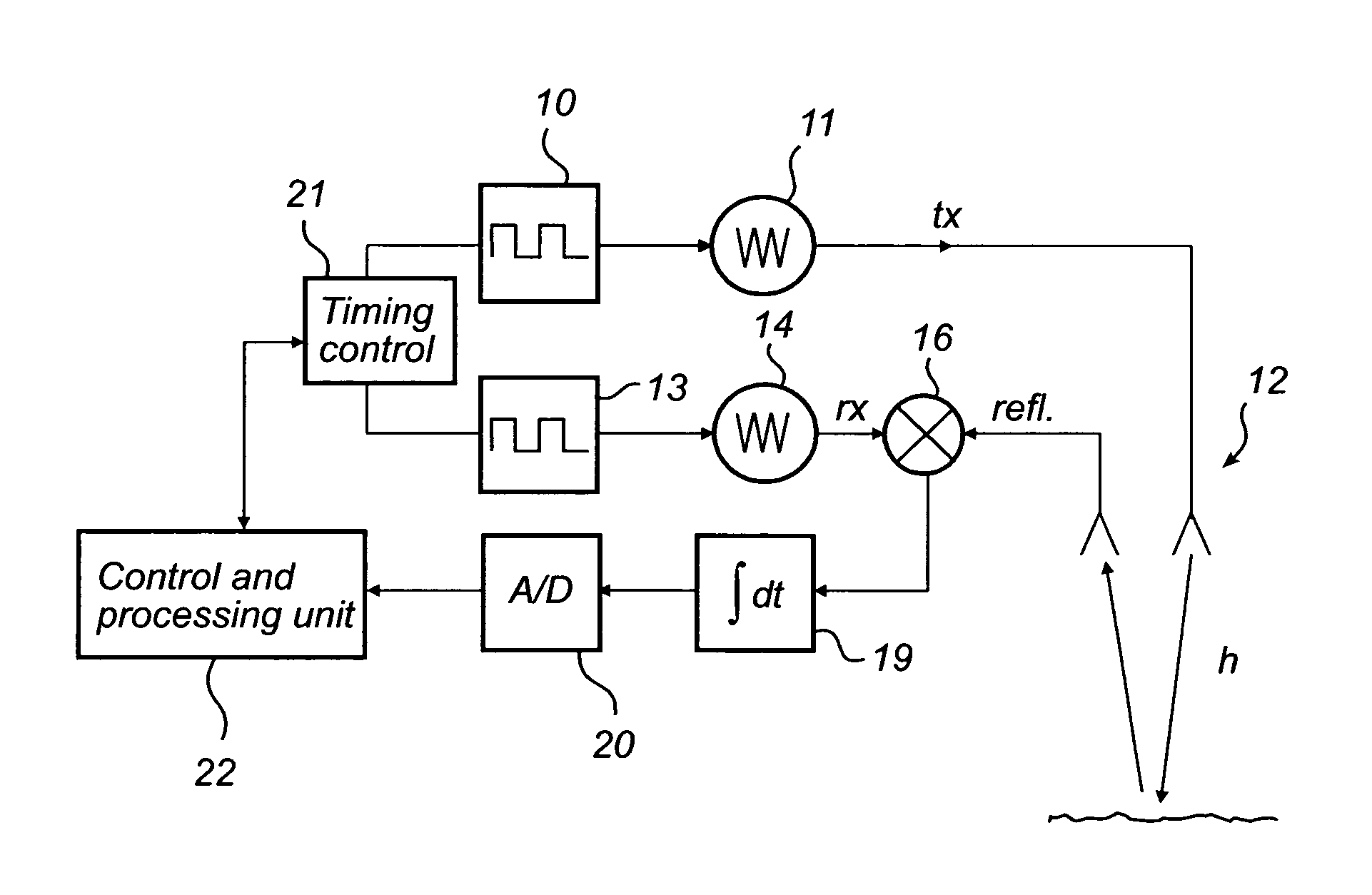

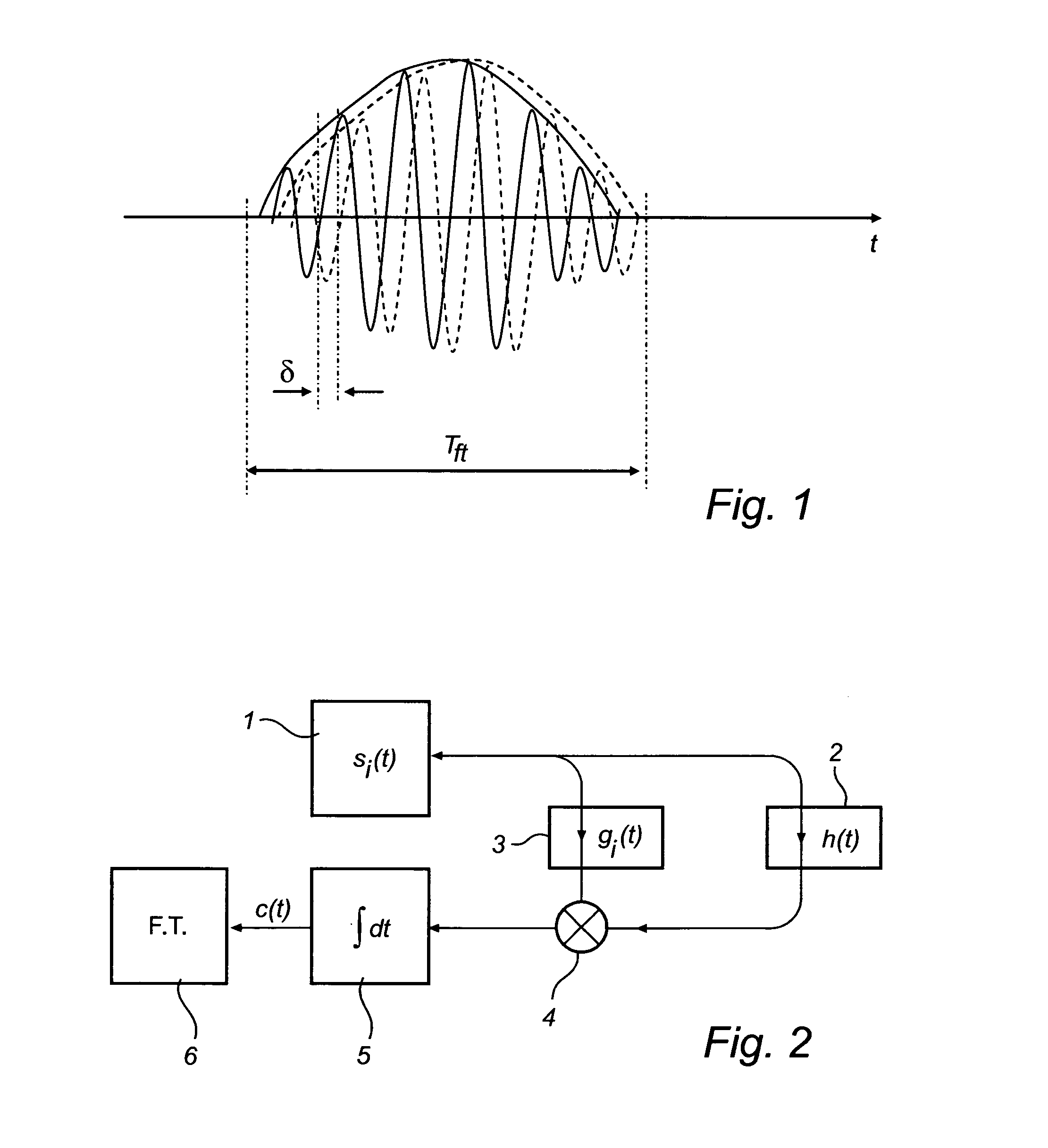

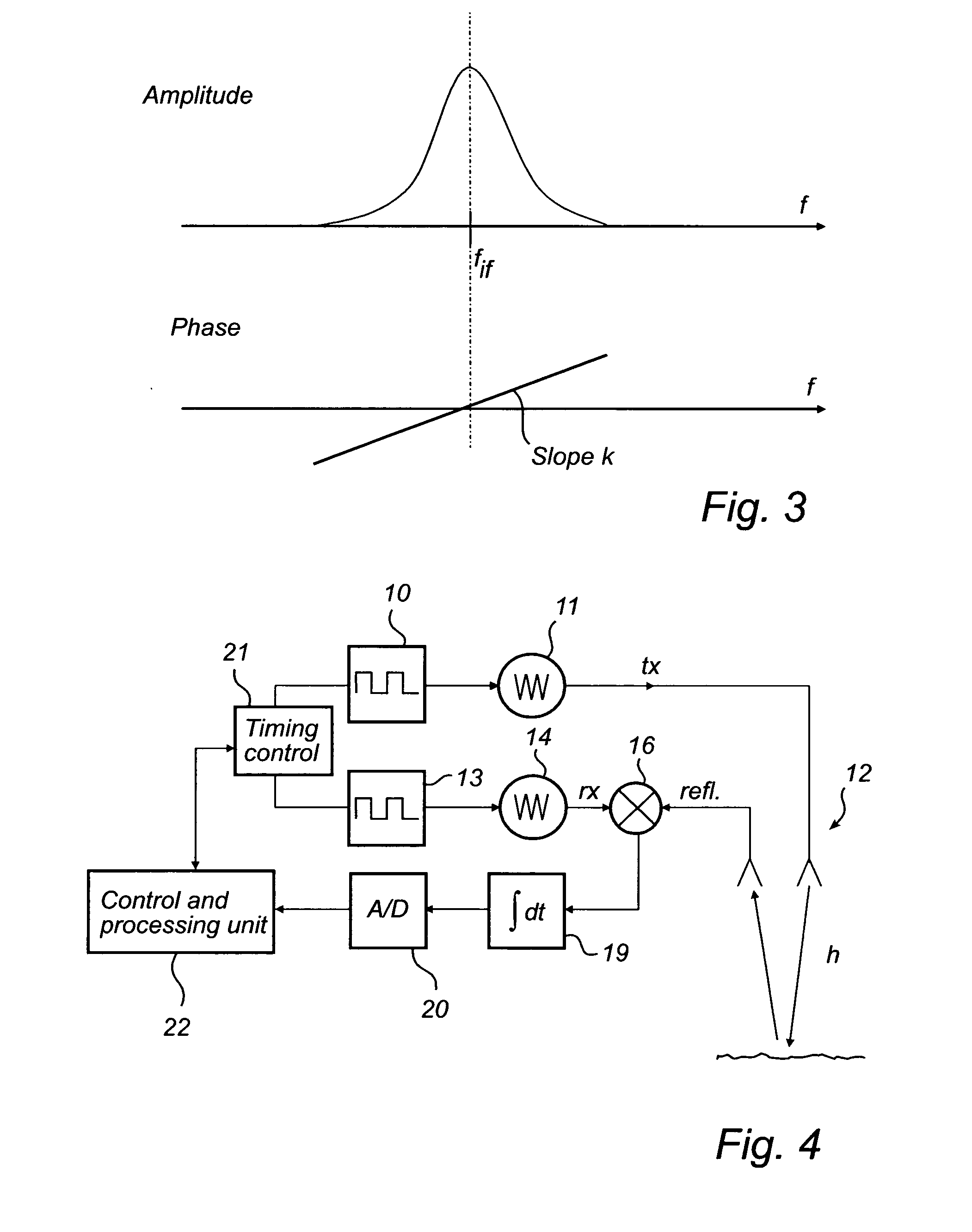

Pulsed radar level gauging with relative phase detection

InactiveUS20080105048A1Accurate detectionLower requirementMachines/enginesLubrication indication devicesFrequency spectrumTime correlation

A method for determining a process variable of a product in a tank based on a time delay of electromagnetic waves. The method further comprises forming a measurement signal comprising a sequence of values, each value representing a time correlation between a pulse of a reference signal and a reflected signal, sampling and digitizing this measurement signal to form a digital signal, identifying a time window of the digital signal including the surface echo peak, determining a relative time period between a reference time corresponding to the predefined reference and a beginning of the time window, time-to-frequency transforming the digital signal in the time window to obtain a phase spectrum, determining a relative phase shift of the spectrum and using the relative phase shift to calculate a corresponding time shift, and determining the time delay by adding the relative time period and the time shift.The invention is based on the realization that major improvement of measurement performance, compared to amplitude detection only, can be achieved by discrimination of the phase difference between the reflected signal and a reference. The detection is further independent of the pulse waveform and modulation, significantly reducing the requirements on pulse modulation.

Owner:ROSEMOUNT TANK RADAR

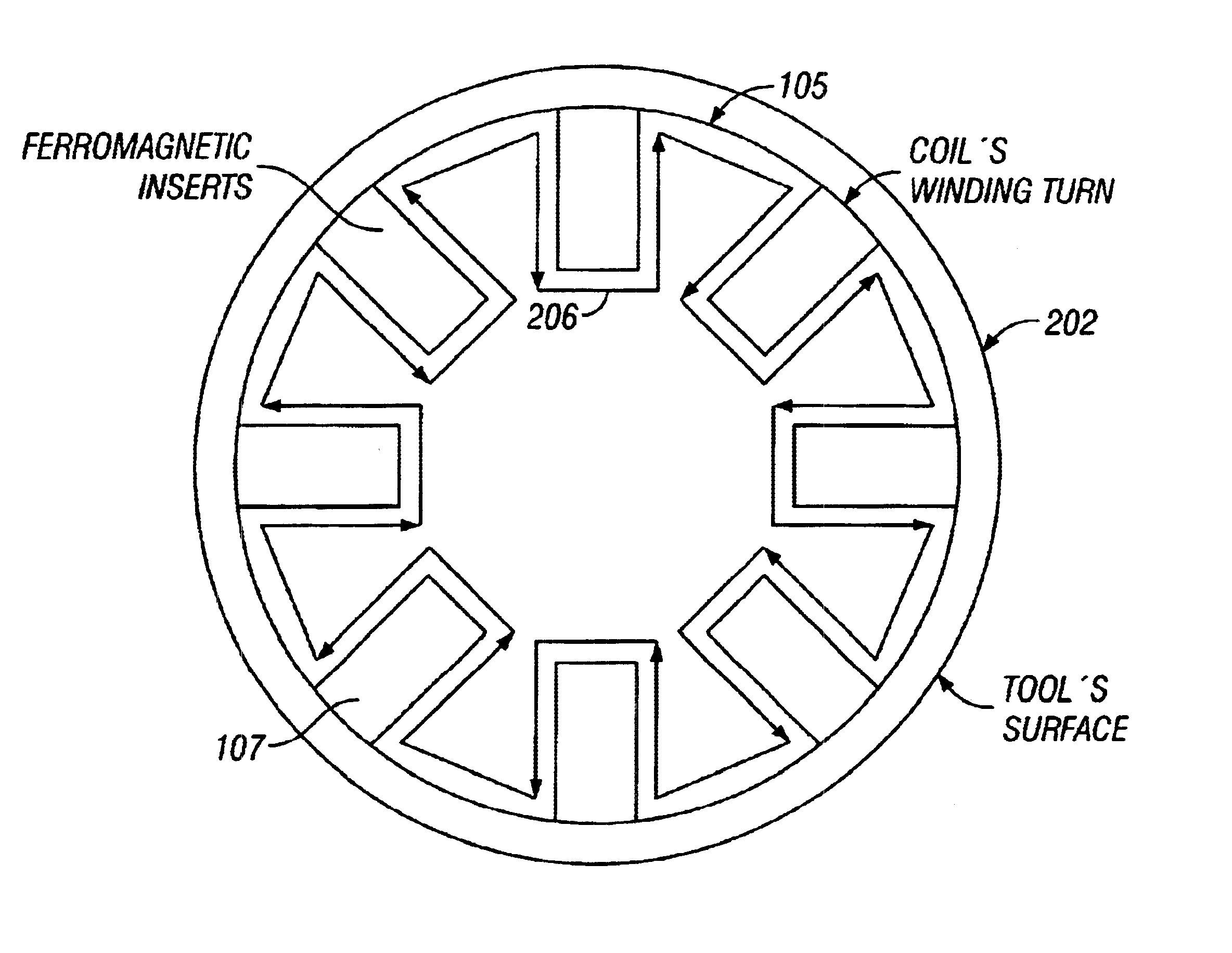

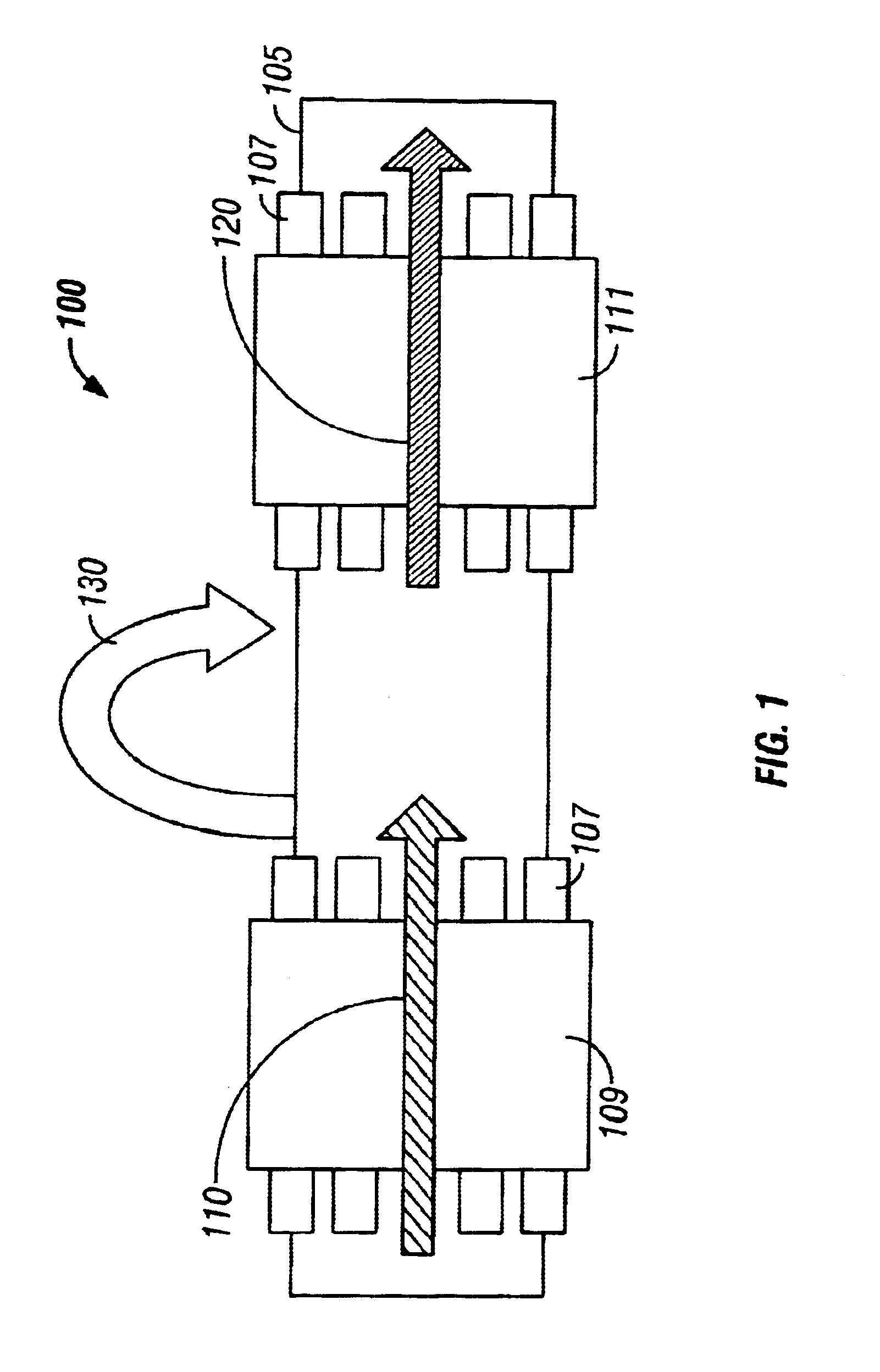

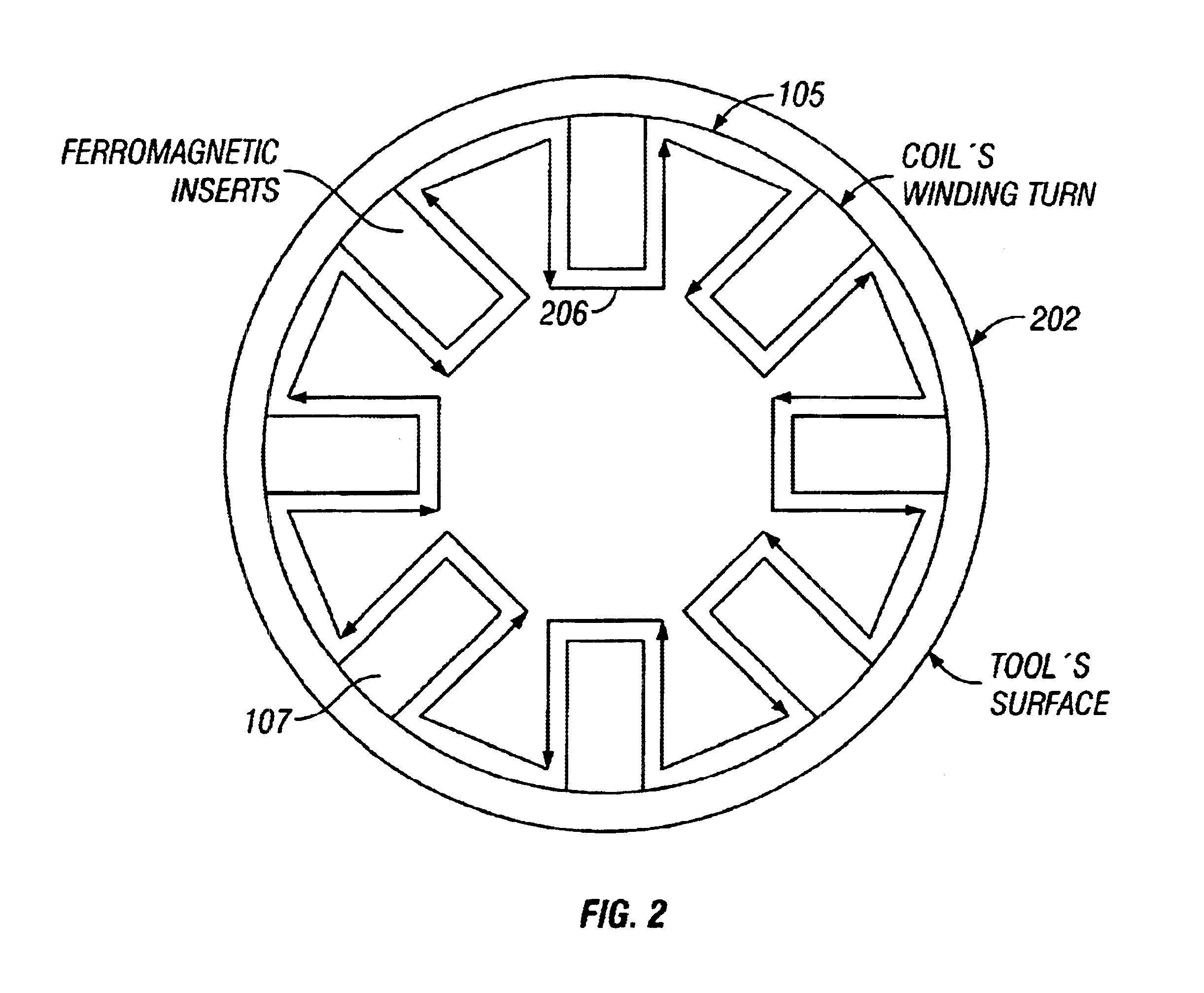

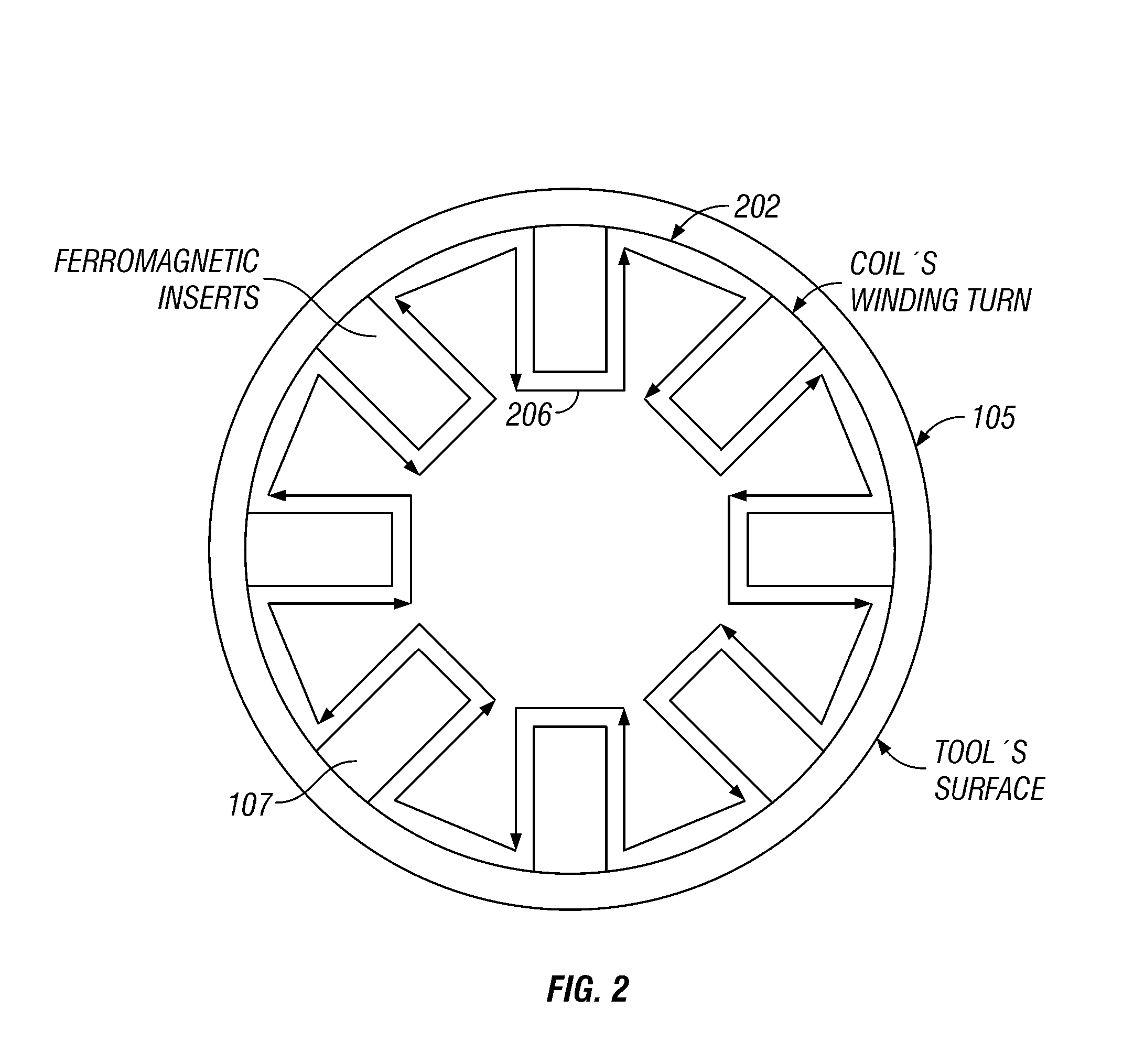

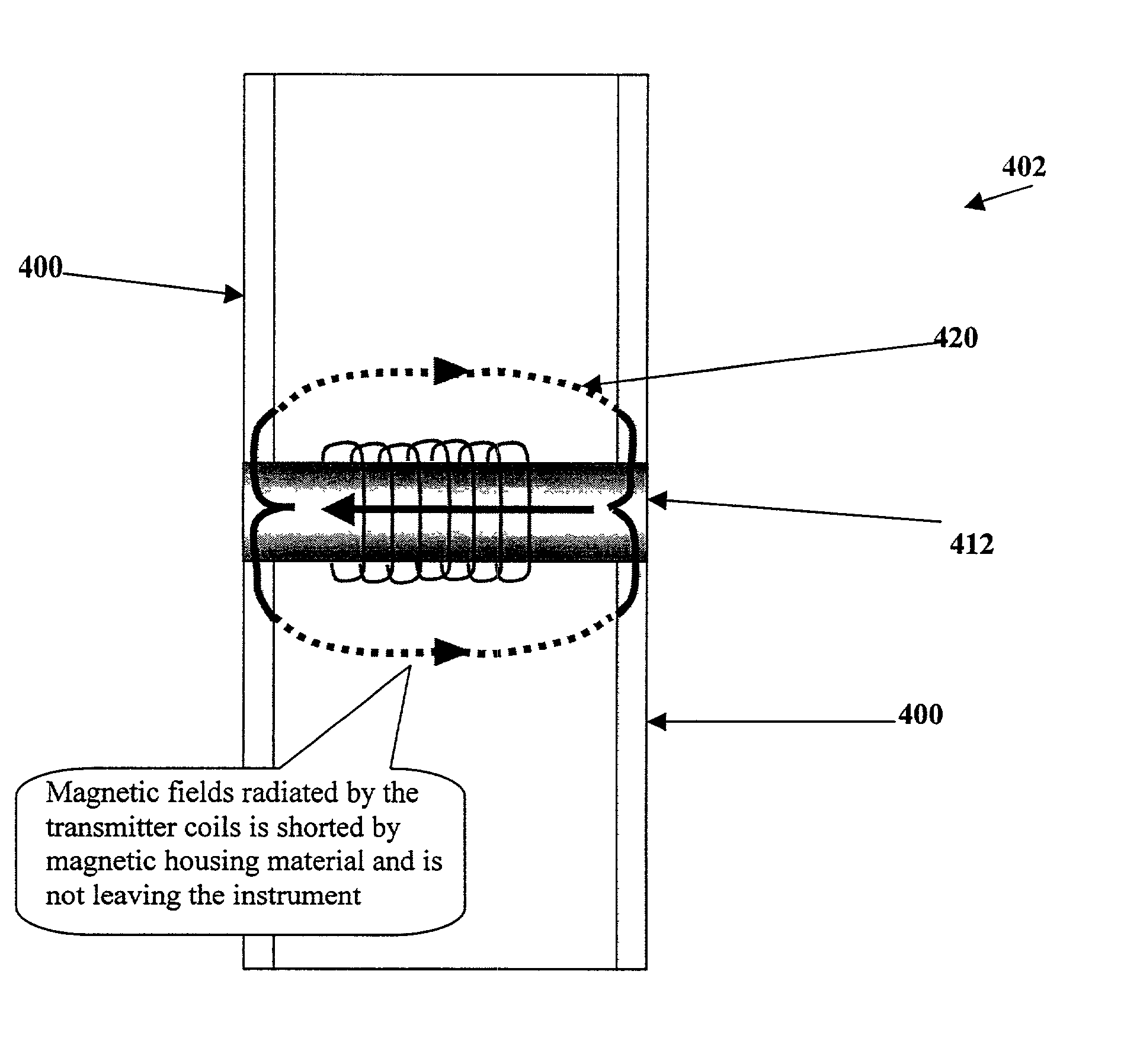

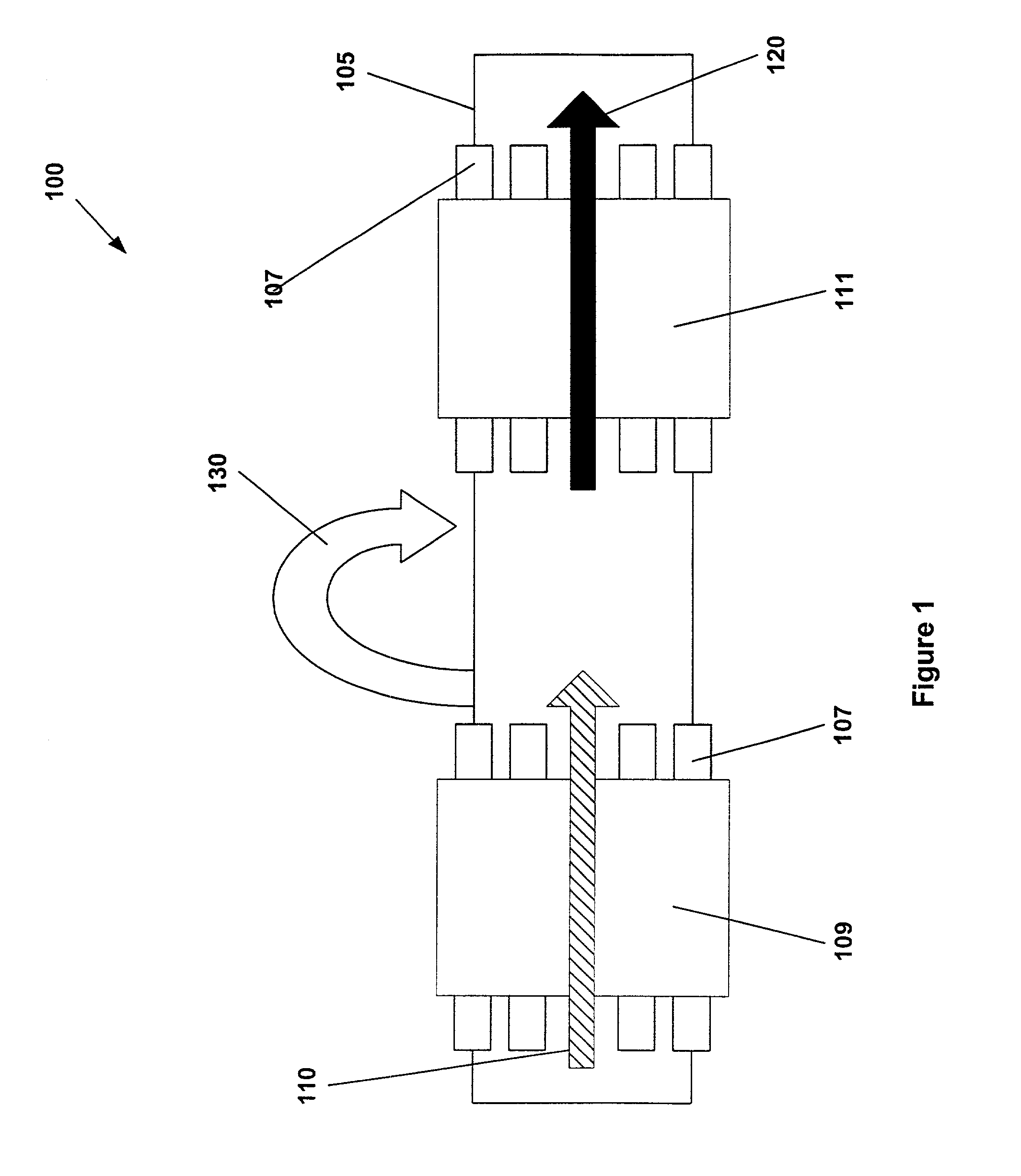

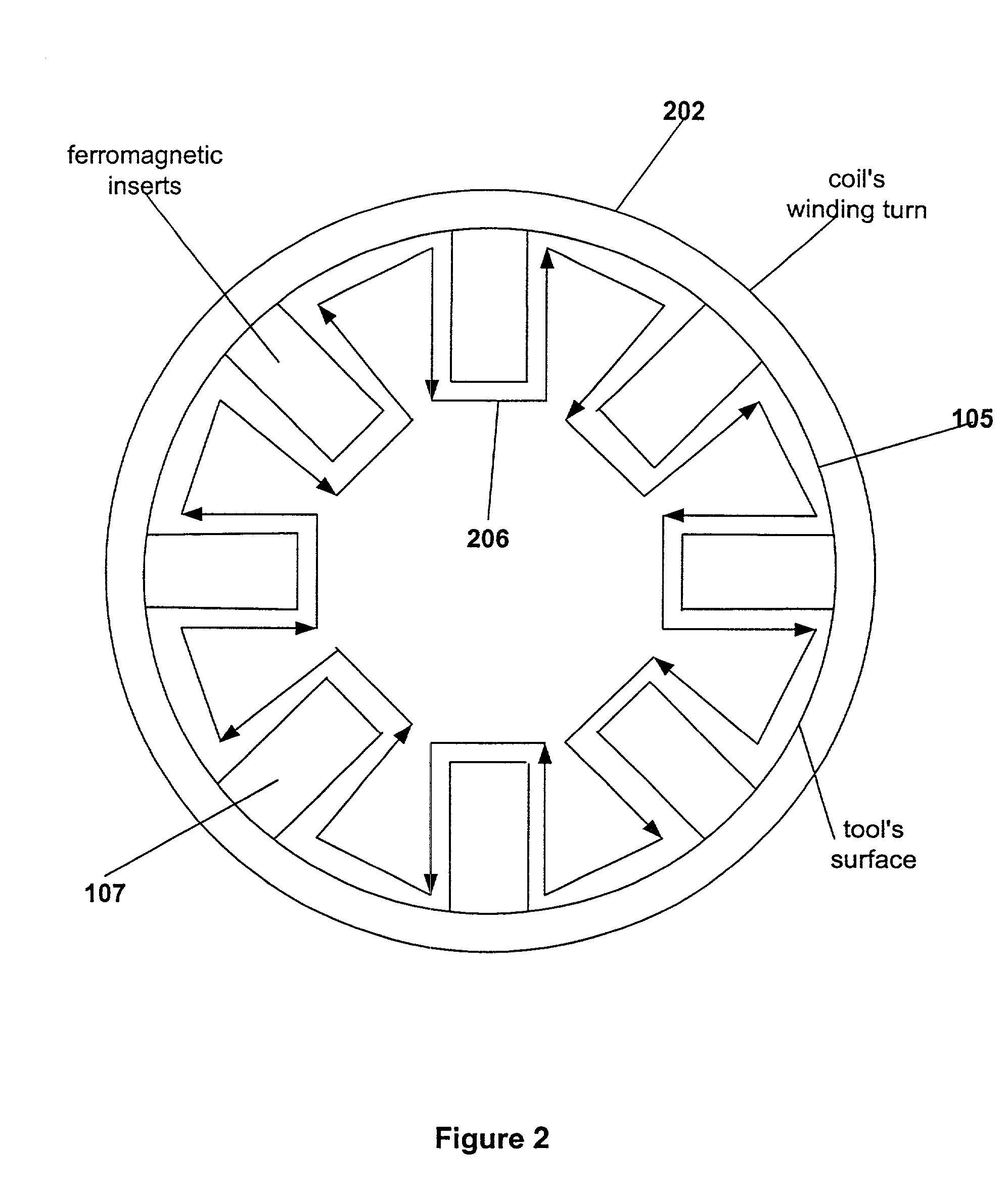

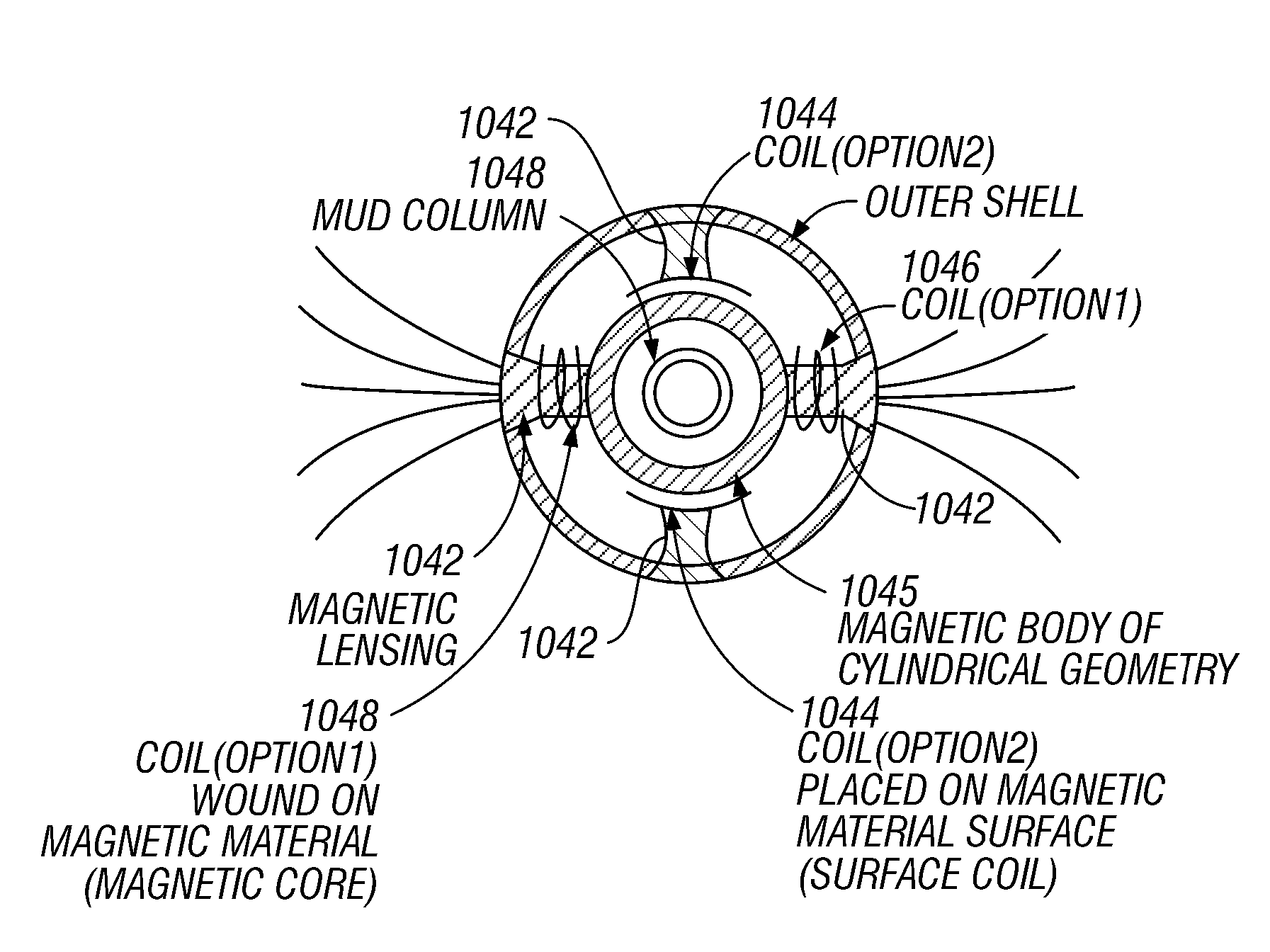

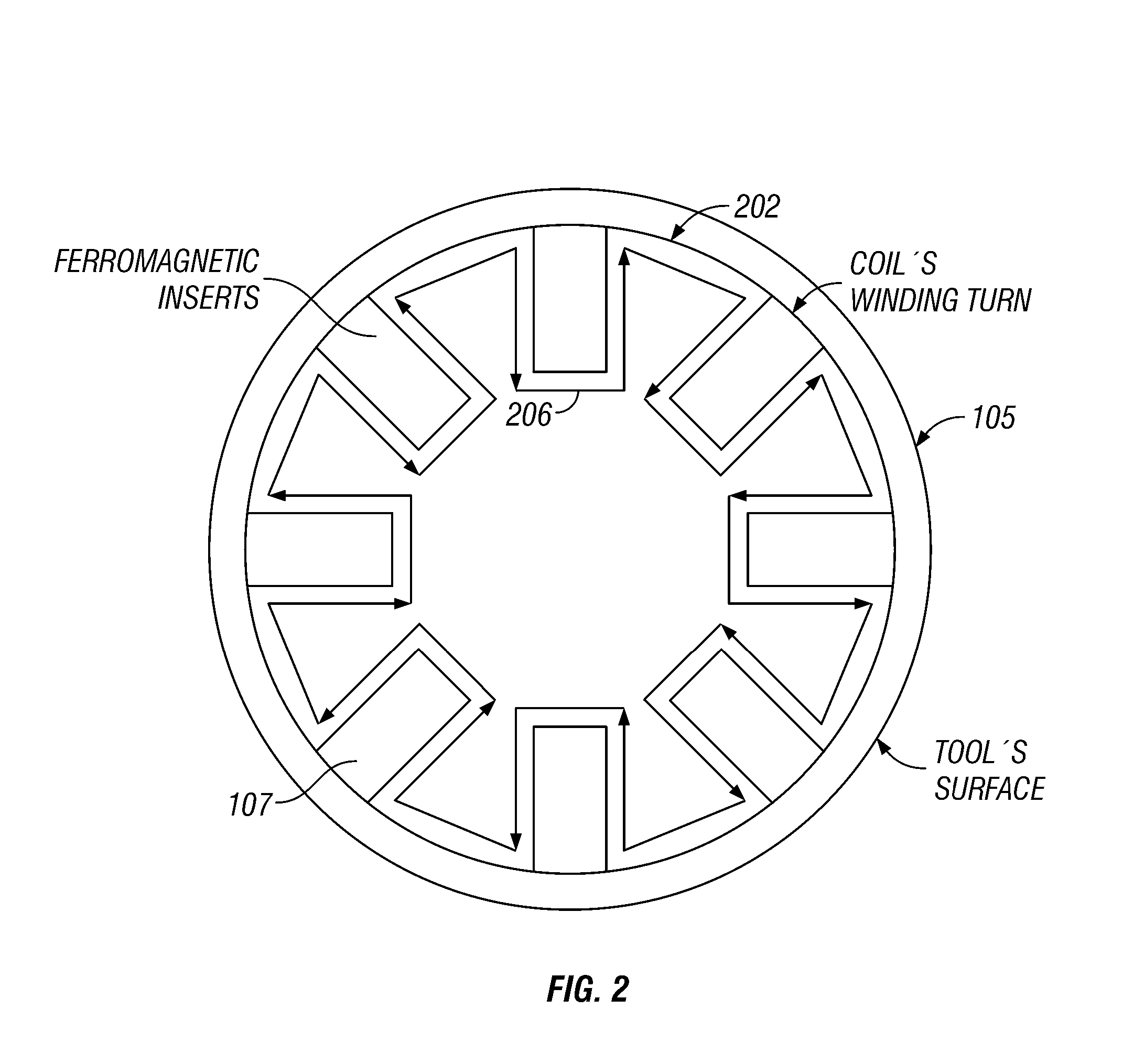

Multi-component induction instrument

InactiveUS6677756B2High degreeEnhanced couplingElectric/magnetic detection for well-loggingAcoustic wave reradiationReceiver coilConductive materials

An improved induction tool for formation resistivity evaluations. The tool provides electromagnetic transmitters and sensors suitable for transmitting and receiving magnetic fields in radial directions that are orthogonal to the tool's longitudinal axis with minimal susceptibility to errors associated with parasitic eddy currents induced in the metal components surrounding the transmitter and receiver coils. The present invention provides increased effective tool surface impedance by increasing self-inductance of the paths in which induced eddy currents flow on the surface of the multi-component induction instruments. The tool enables downhole tool designers to build more effective and better-protected radial induction arrays for existing and future downhole instruments operating in the frequency and / or time domains. In this case the array measurement results contain information primarily about the formation's vertical resistivity. The tool makes it possible to combine radial arrays with coaxial arrays that conventionally measure horizontal formation resistivity. This combination enables obtaining a full resistivity tensor to evaluate formation resistivity anisotropy. The tool provides a composite non-conductive housing to reduce or even avoid the effects of parasitic eddy currents flowing on the tool surface. The tool provides a non-magnetic housing that is conductive which reduces the effects of conductive materials near coils and, primarily, the receiver. The tool provides a non-conductive coating is placed over the housing to prevent high frequency eddy currents from leaking from the housing in the conductive mud of the adjacent wellbore and returning to the housing.

Owner:BAKER HUGHES INC

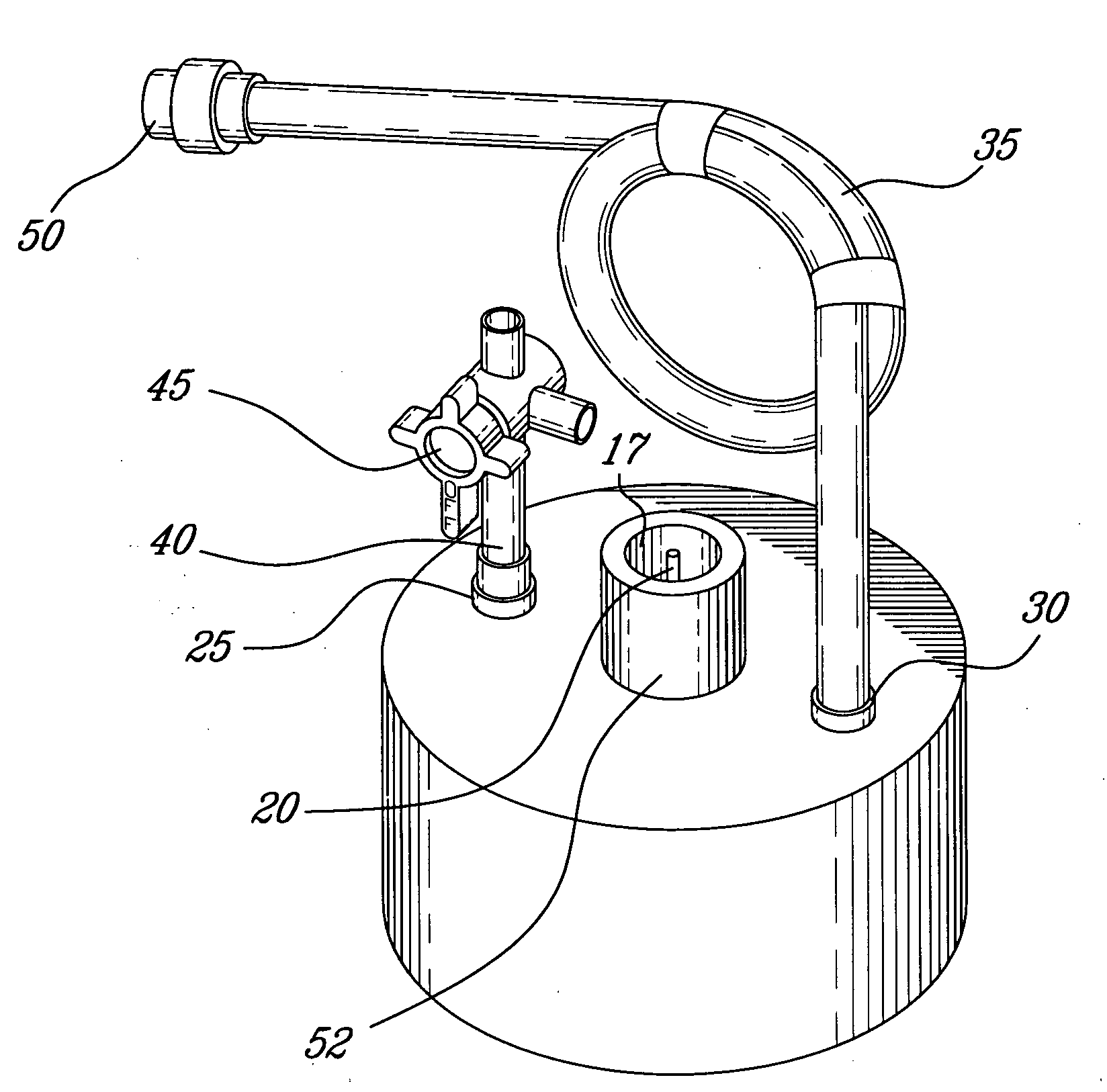

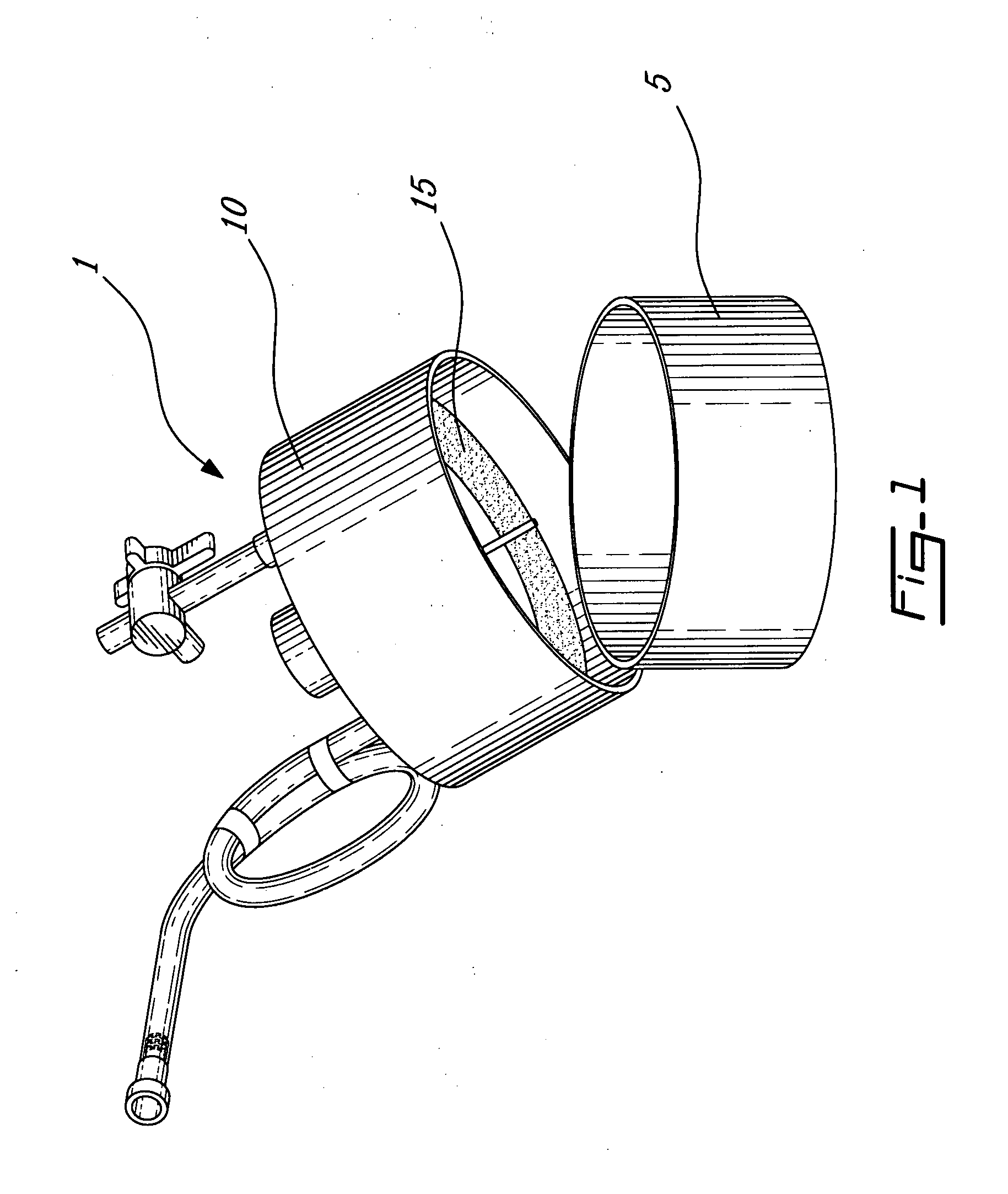

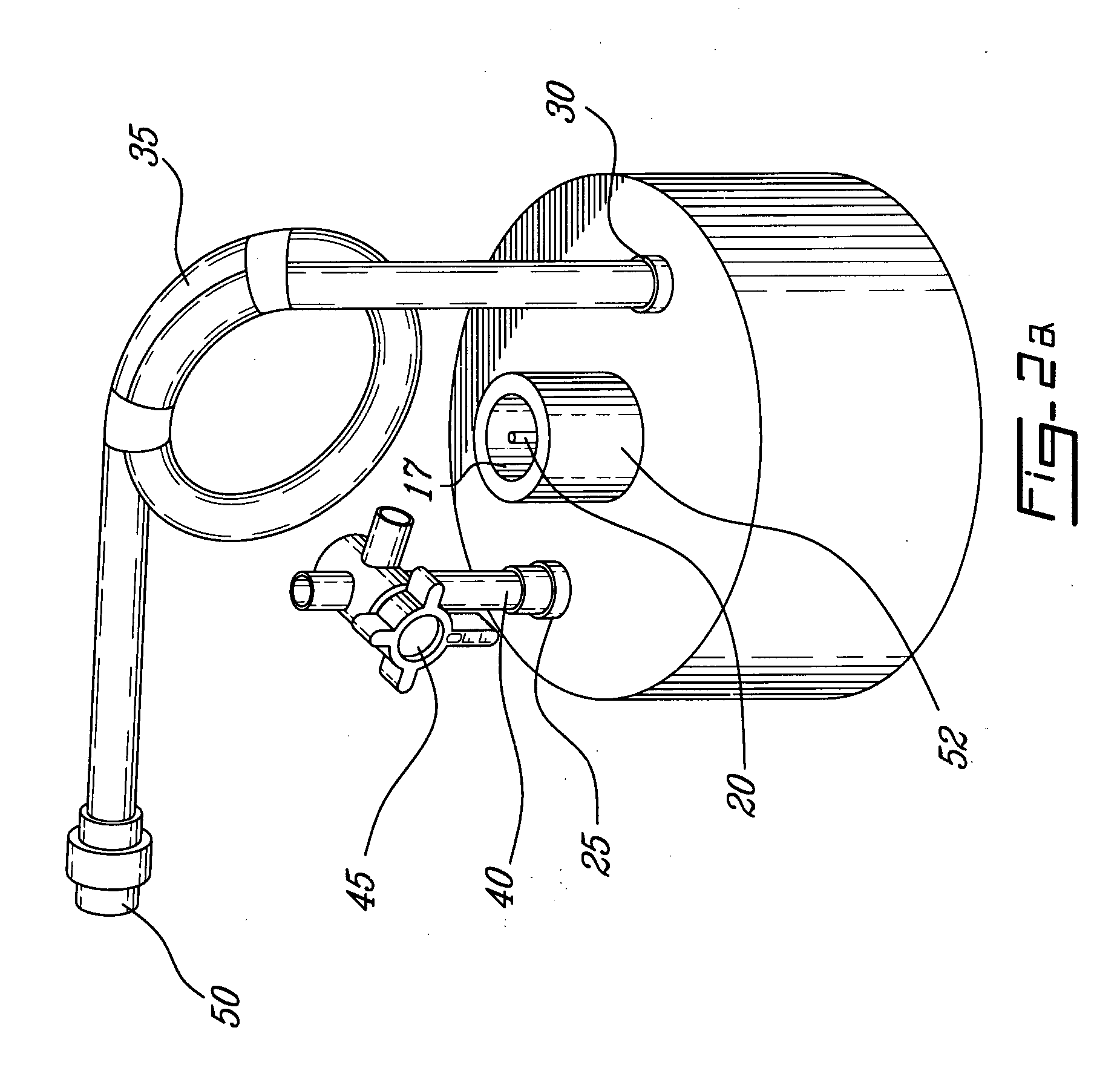

Apparatus and method for measuring the surface flux of a soil gas component

InactiveUS20090301234A1Improve accuracyExpand measurement capabilityWithdrawing sample devicesEarth material testingPhysicsSoil gas

A method of measuring the surface flux of a component of a soil gas comprises placing a chamber for collecting said gas sealably in contact with a soil the chamber initially containing atmospheric gas. Then, the chamber is connected to a purging apparatus to purge the chamber of all measurable traces of the component. Then the soil is permitted to enter the chamber. The method uses a system for measuring the surface flux of the component. The system comprises a chamber having an open bottom for collecting soil gas, a venting port, an exhaust port having a valve and means to purge the chamber of the component.

Owner:ST FRANCIS XAVIER UNIV

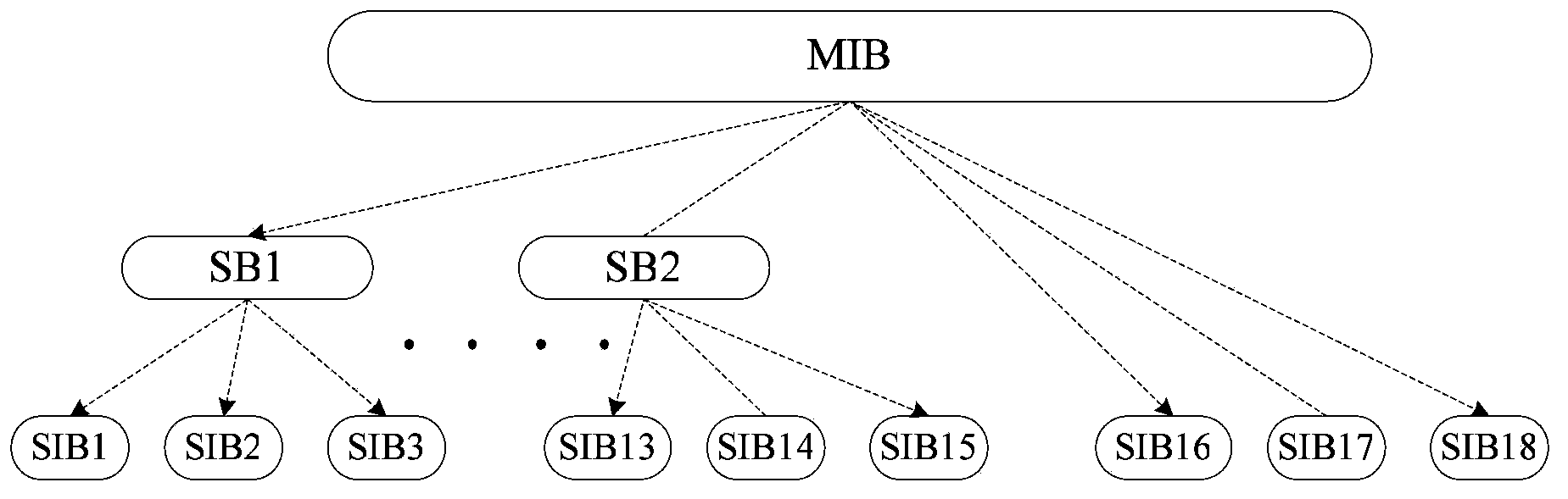

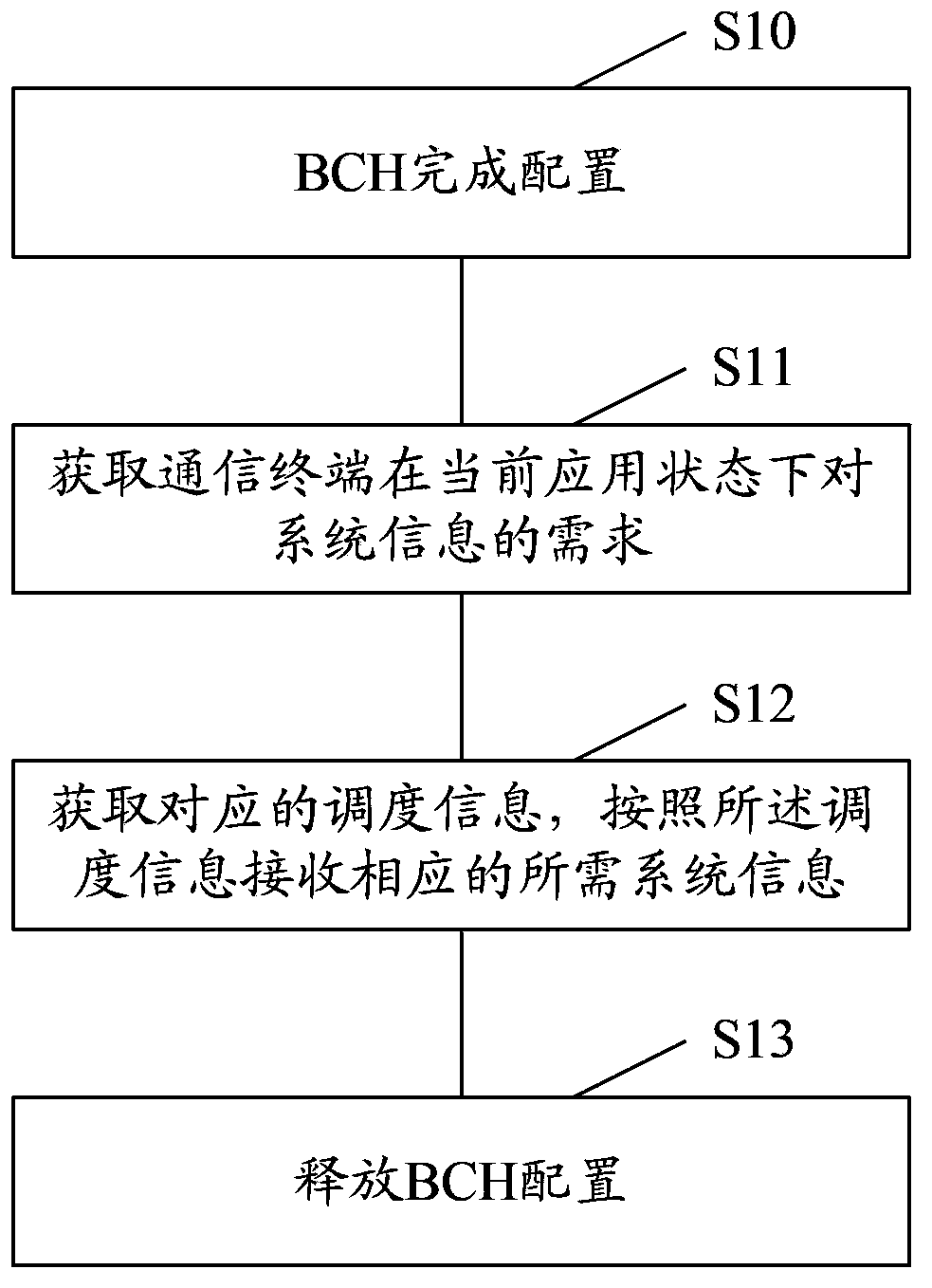

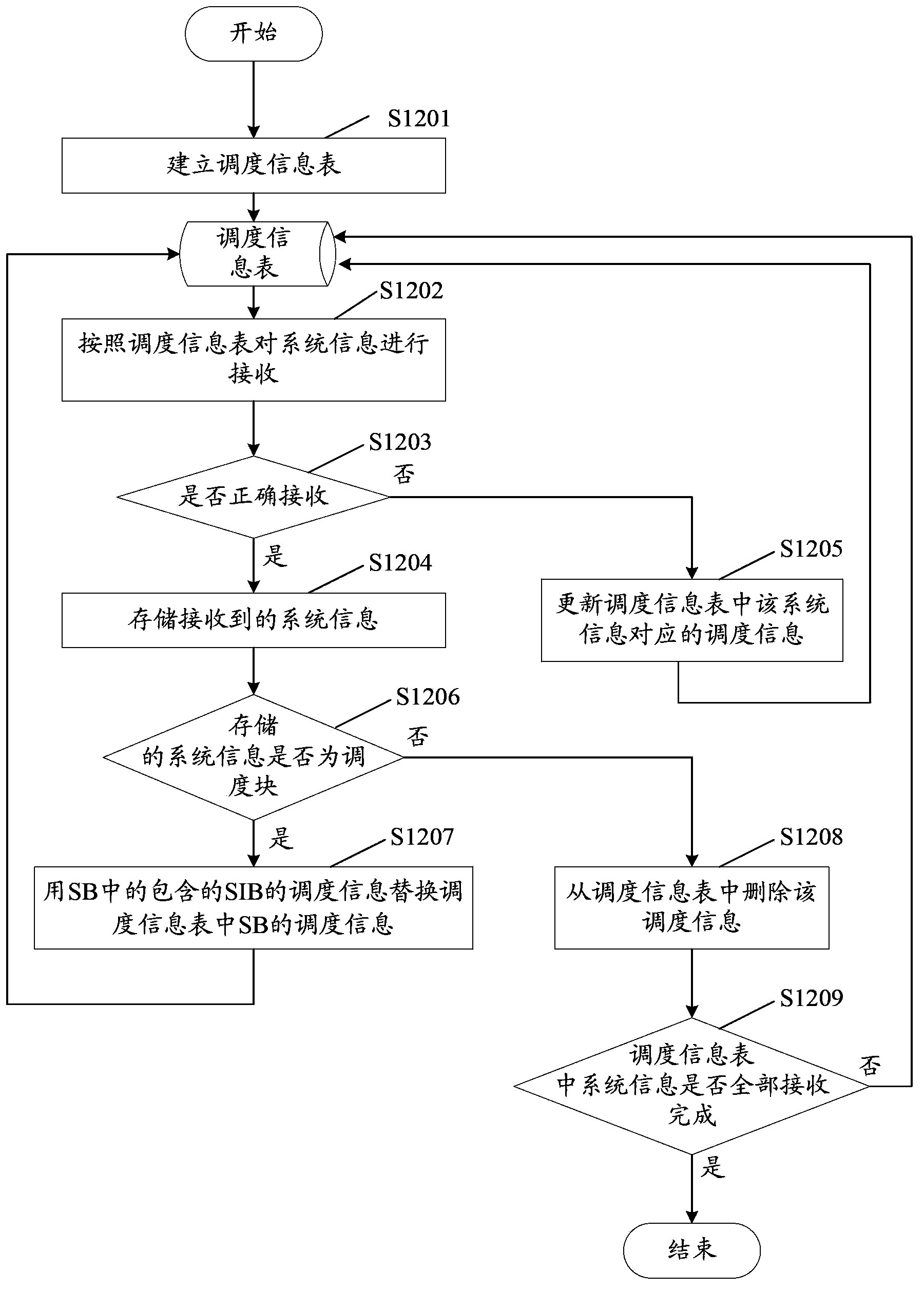

Communication terminal and method and device thereof for receiving system information

ActiveCN104349420ARealize on-demand reception from time to timeImprove receiving efficiencyAssess restrictionHigh level techniquesComputer hardwareRequirements elicitation

The present invention provides a communication terminal and a method and device thereof for receiving system information. The method for receiving system information of the communication terminal comprises: after completing configuration of a broadcasting channel, acquiring corresponding scheduling information according to the demand of the communication terminal for system information under present application state; and receiving relative desired system information based on the scheduling information. The technical solutions of the present invention can improve the efficiency of the communication terminal for receiving system information, save software and hardware resources for the communication terminal and reduce power consumption during the receiving process.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

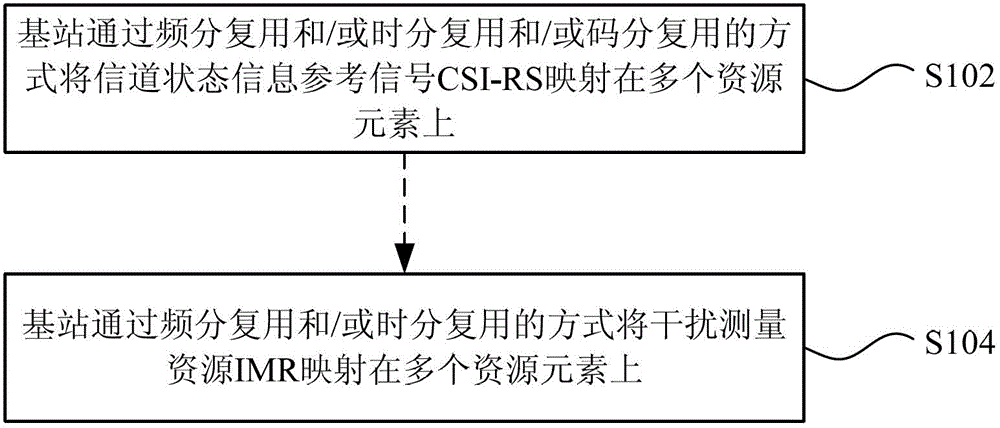

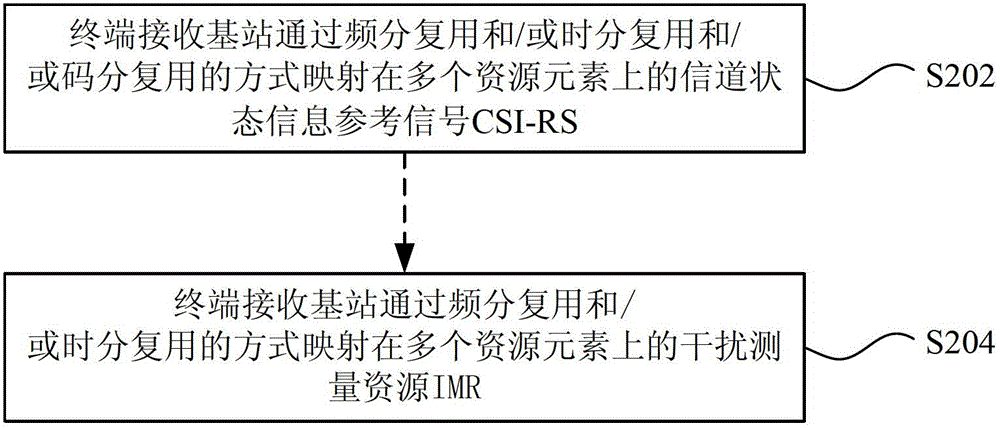

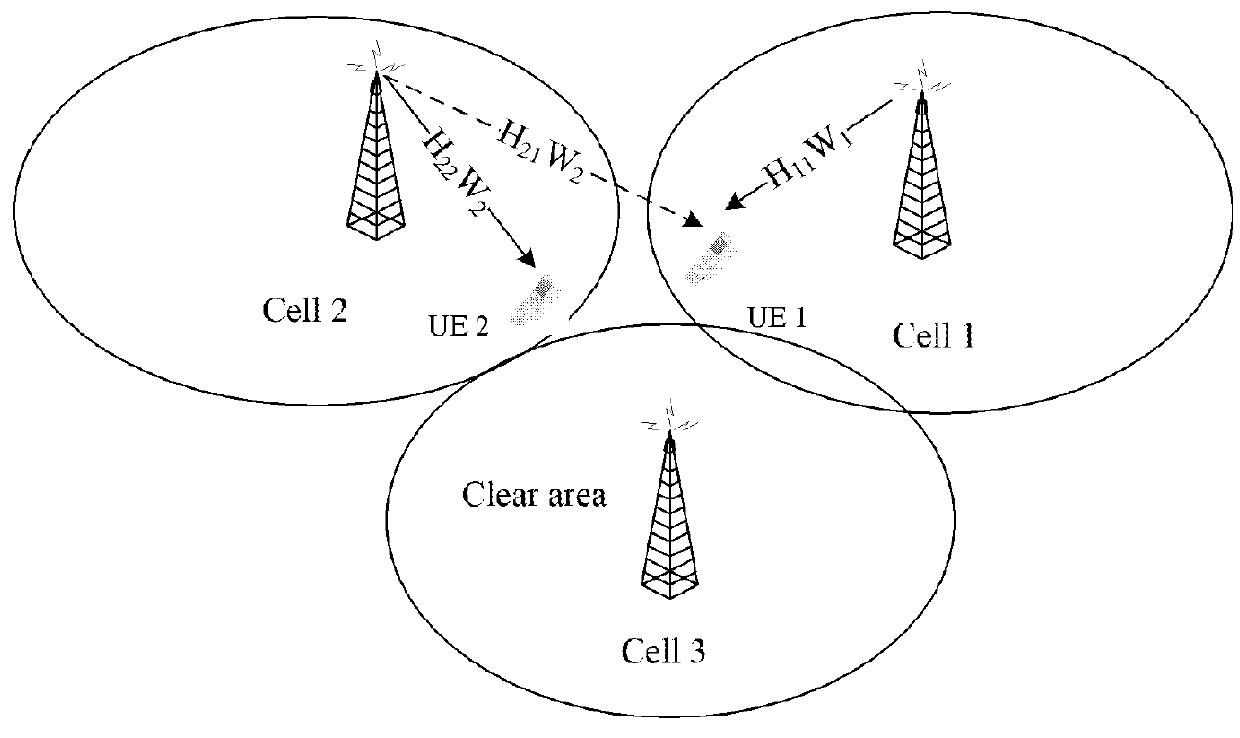

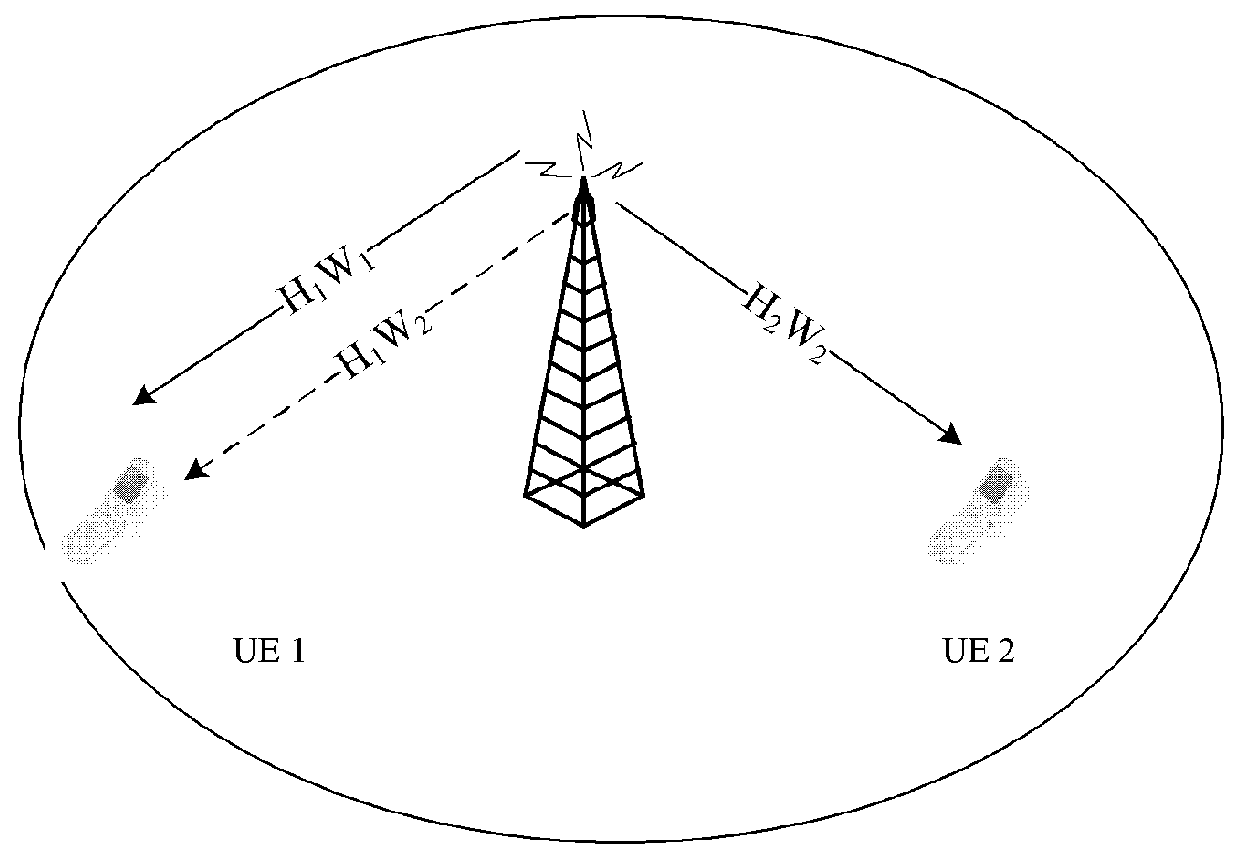

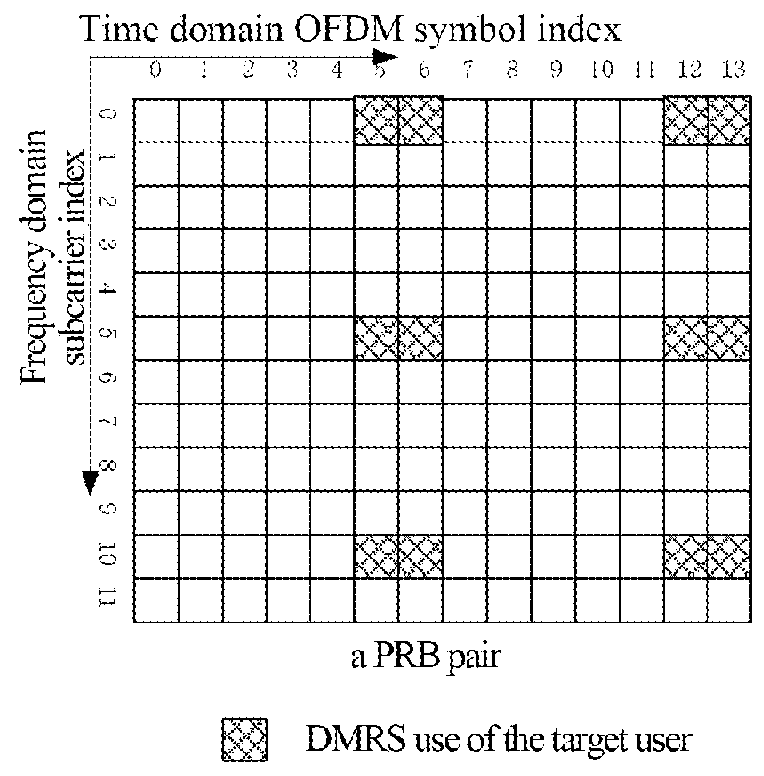

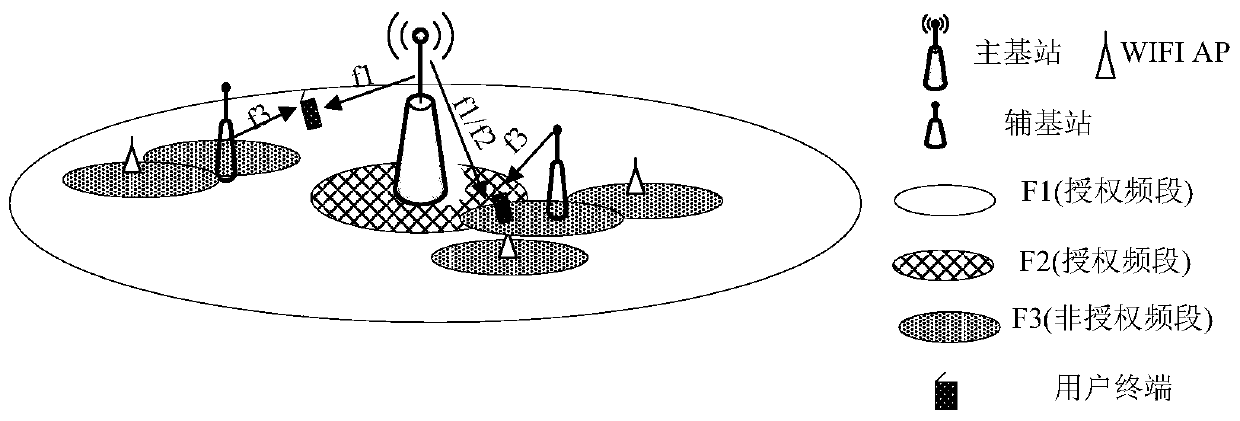

Resource mapping method and apparatus, resource receiving method and apparatus, signaling notifying method and apparatus, and signaling obtaining method and apparatus

ActiveCN104038320AImprove measurement performanceImprove spectral efficiencyCriteria allocationSignal allocationSelf adaptiveFrequency-division multiplexing

Disclosed are a method and apparatus for mapping and receiving resources, as well as a method and apparatus for notifying and acquiring signaling. The method for mapping resources comprises: a base station maps a channel state information reference signal (CSI-RS) onto a plurality of resource elements by means of frequency division multiplexing and / or time division multiplexing and / or code division multiplexing; and / or the base station maps interference measurement resources (IMR) onto a plurality of resource elements by means of frequency division multiplexing and / or time division multiplexing. By virtue of the method and apparatus for mapping and receiving resources, as well as the method and apparatus for notifying and acquiring signaling of the present invention, the effects of improving the measurement performance of a system, ensuring more accurate self-adaptive transmission, and increasing the spectral efficiency of the system are achieved.

Owner:ZTE CORP

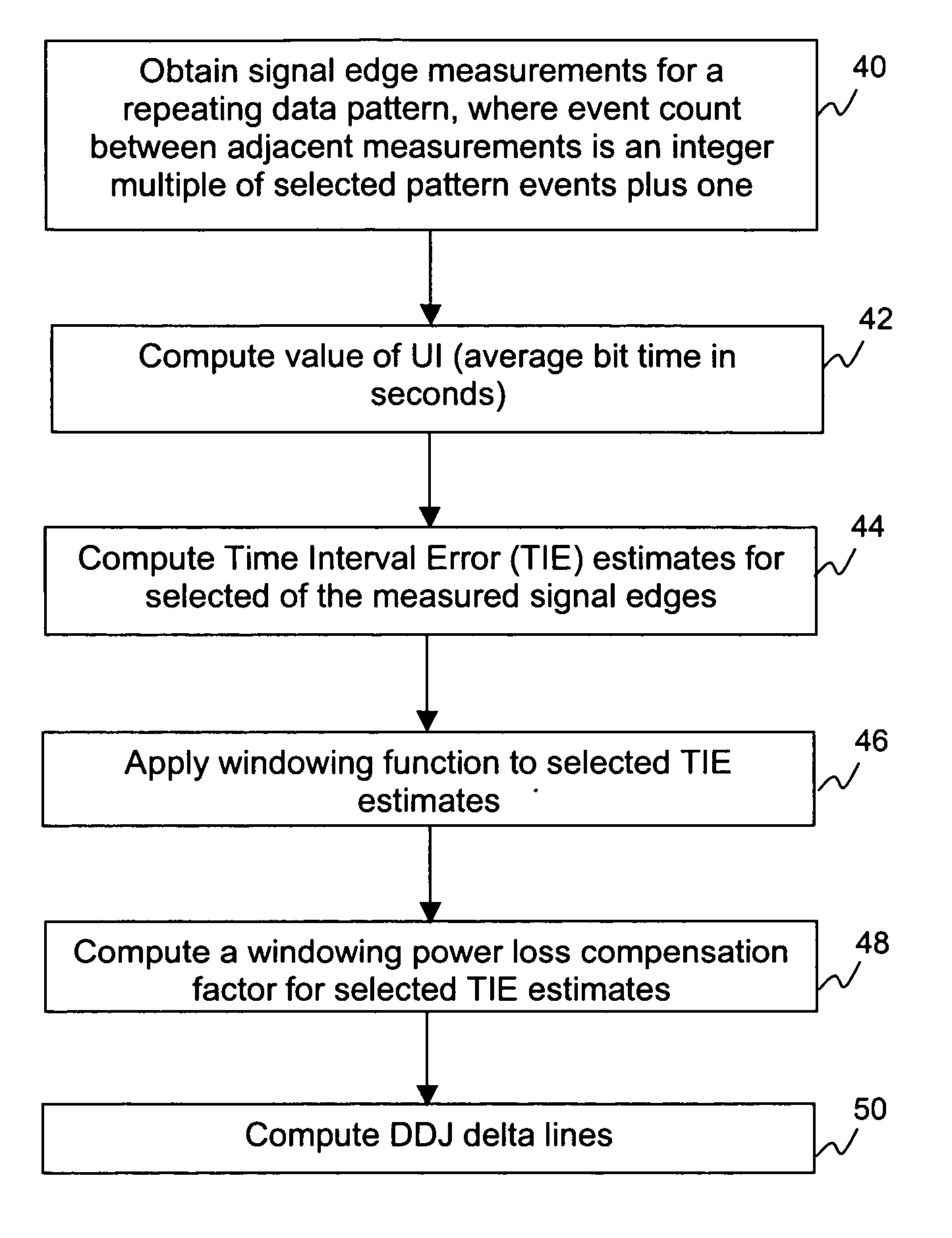

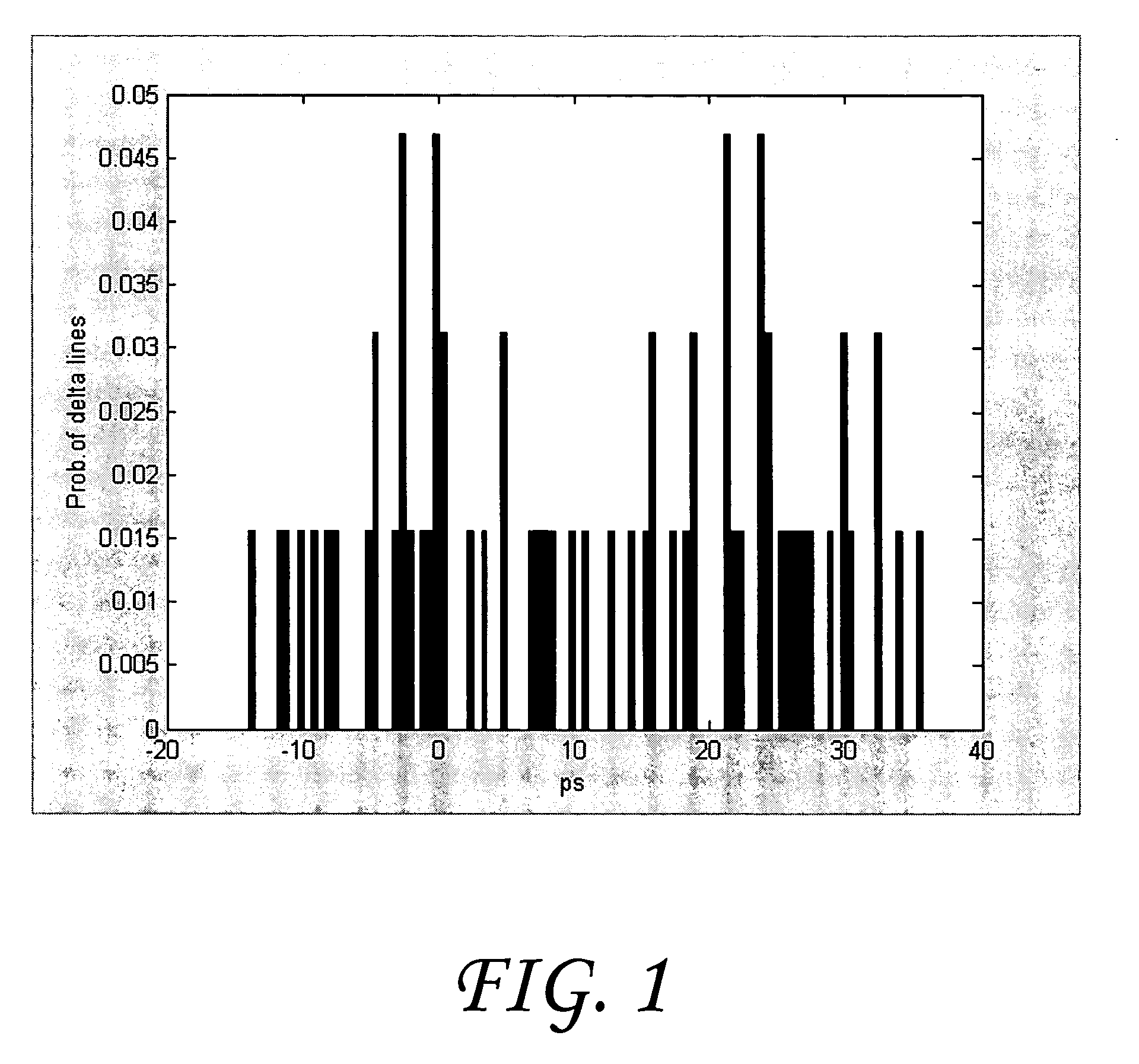

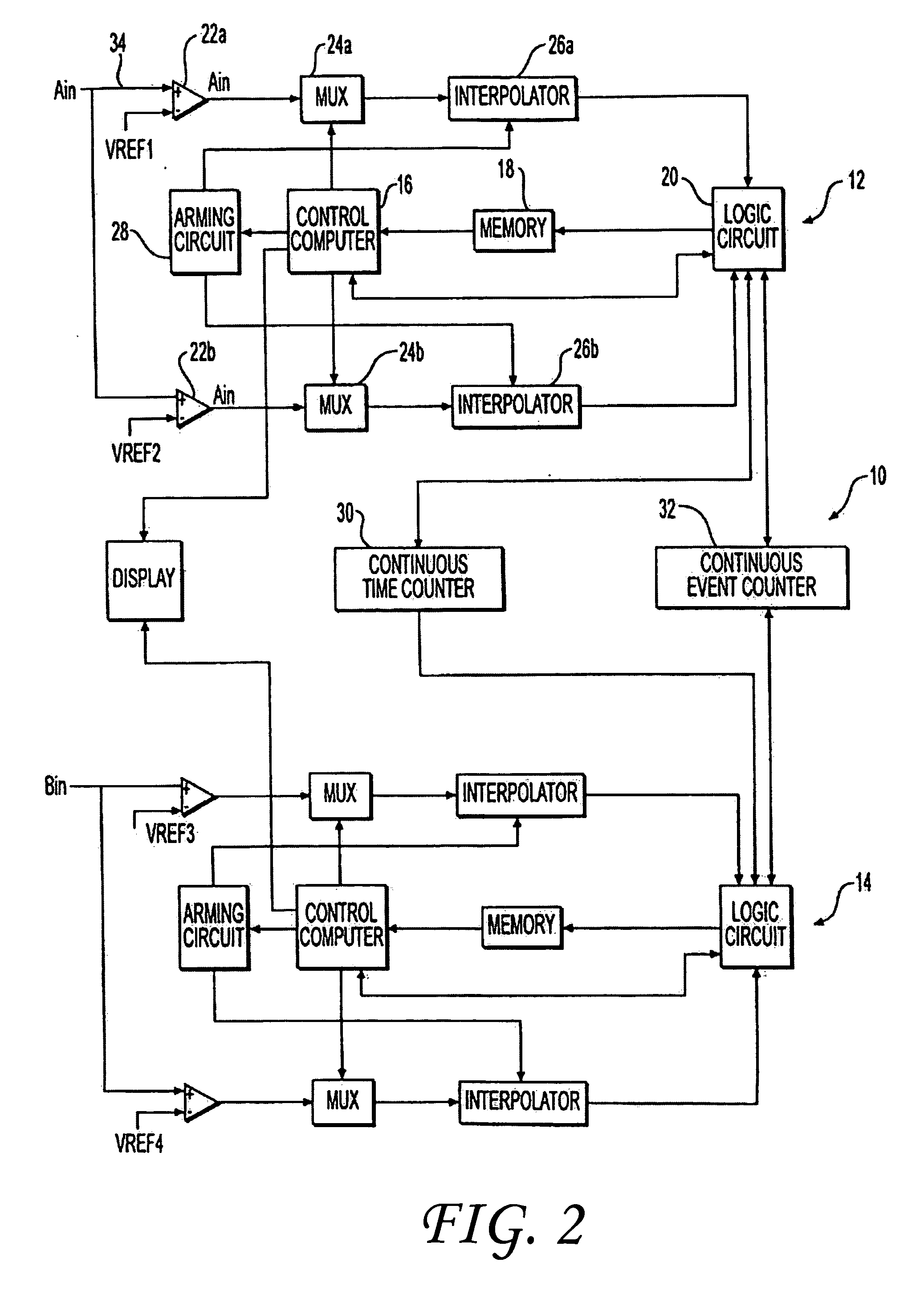

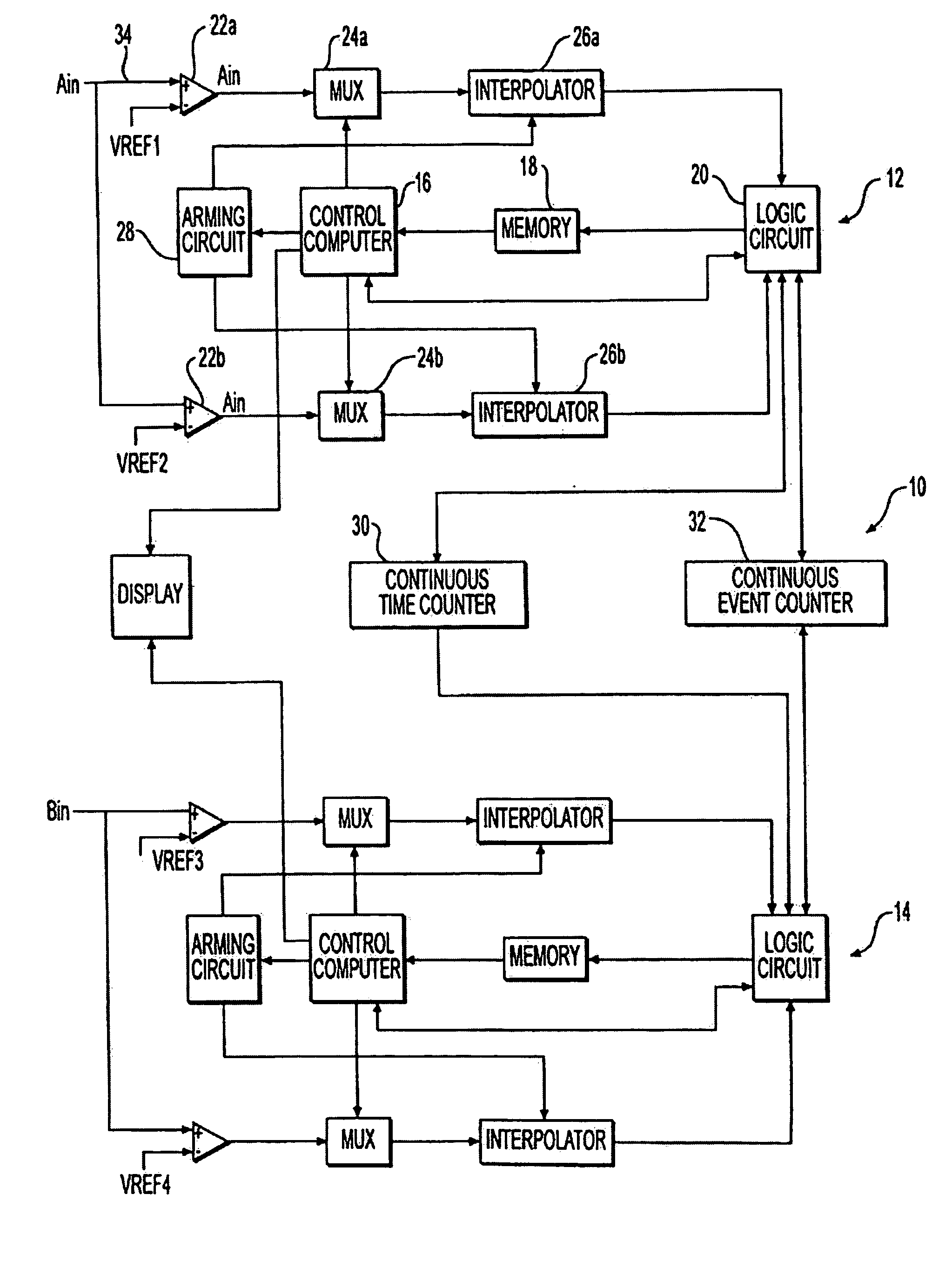

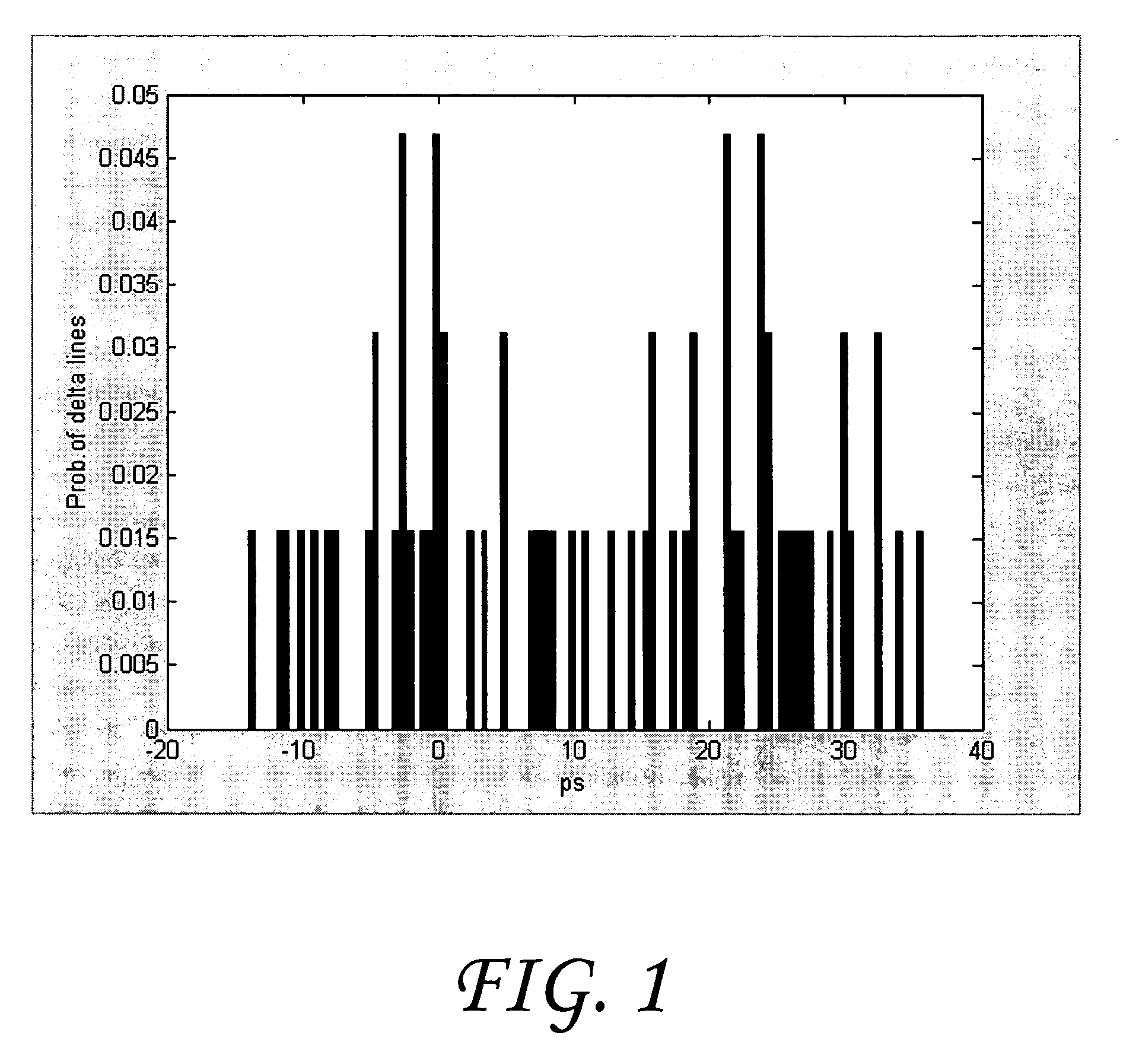

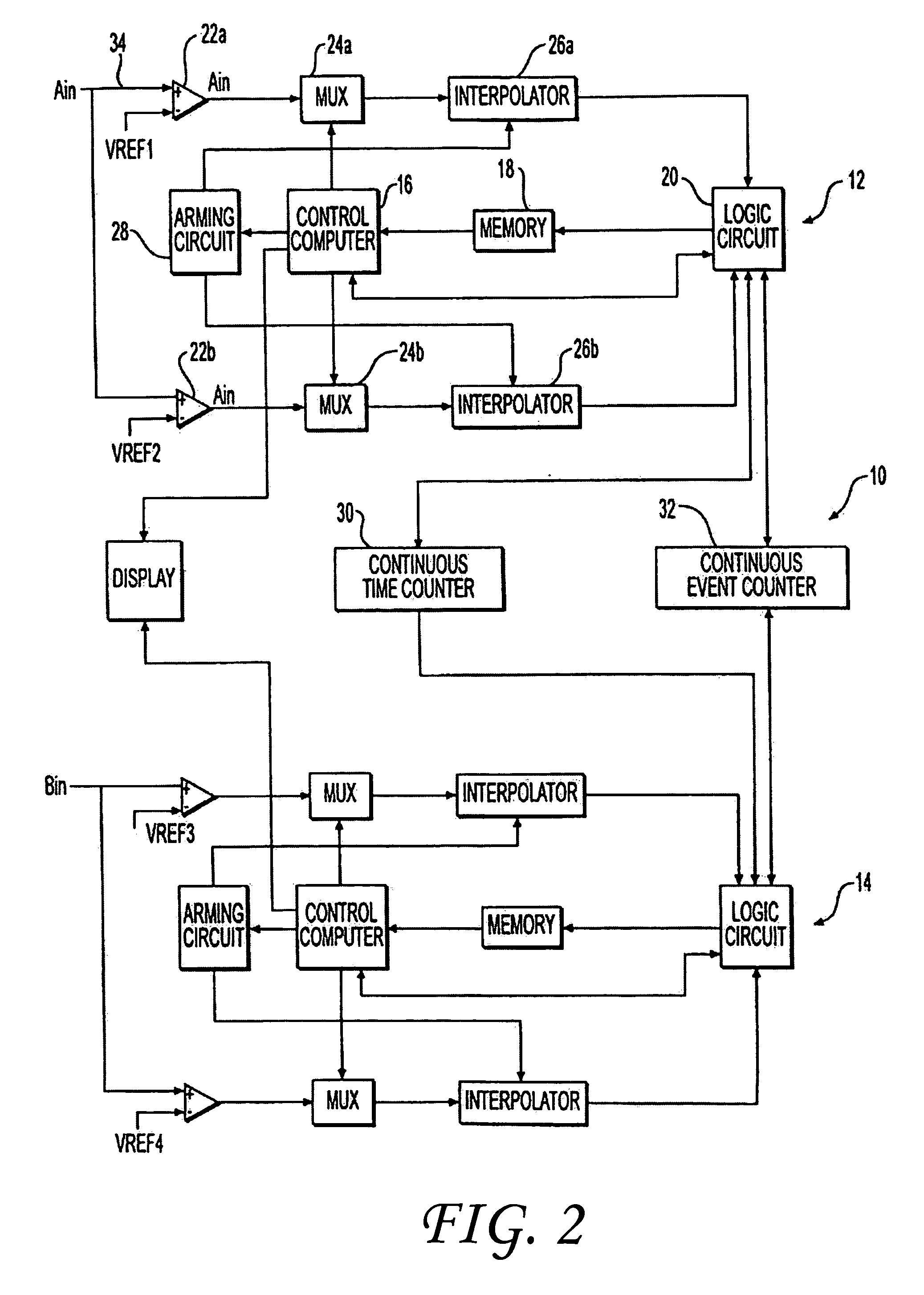

System and method of obtaining data-dependent jitter (DDJ) estimates from measured signal data

InactiveUS20060047450A1Improve robustnessImprove measurement capabilityNoise figure or signal-to-noise ratio measurementElectrical testingDuty cycle distortionData-dependent jitter

Methods for estimating data-dependent jitter (DDJ) from measured samples of a transmitted data signal include a first exemplary step of obtaining a plurality of measurements (e.g., time tags and event counts for selected pulse widths in the data signal). Such measurements may be obtained at predetermined intervals within a transmitted signal or may be obtained at randomly selected intervals, and should yield measurements for each data pulse in a repeating data pattern. An average unit interval value representative of the average bit time of the transmitted signal is determined. Time interval error estimates representative of the timing deviation from each signal edge's measured value relative to its ideal value (determined in part from the calculated average unit interval value) are also determined, as well as a classification for each measured signal edge relative to a corresponding data pulse in the repeating data pattern. DDJ delta lines are then calculated for signal edges of each pulse width in the transmitted data pattern, from which peak-to-peak DDJ values and / or estimates of duty-cycle-distortion (DCD) can be determined.

Owner:GUIDE TECH

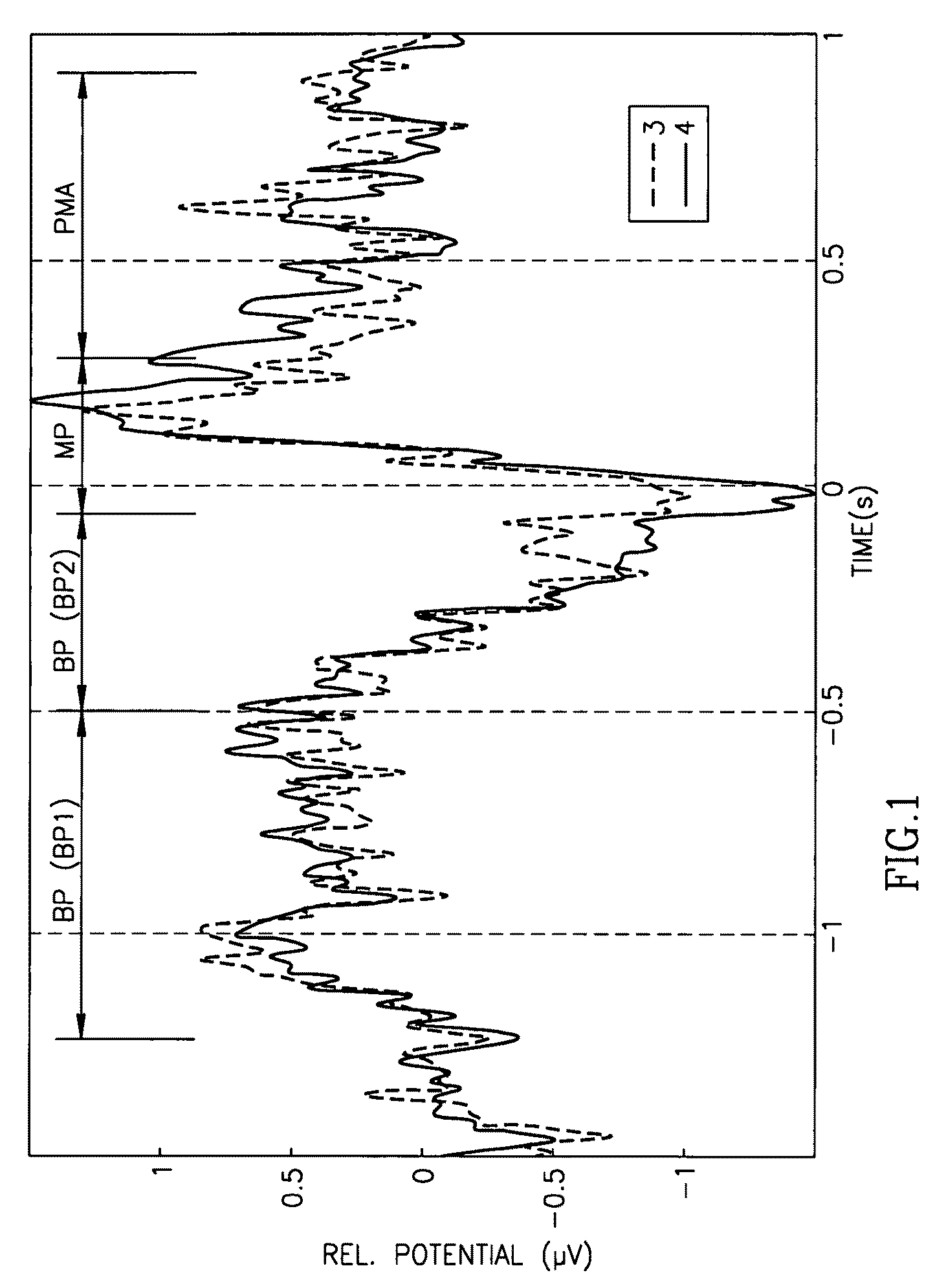

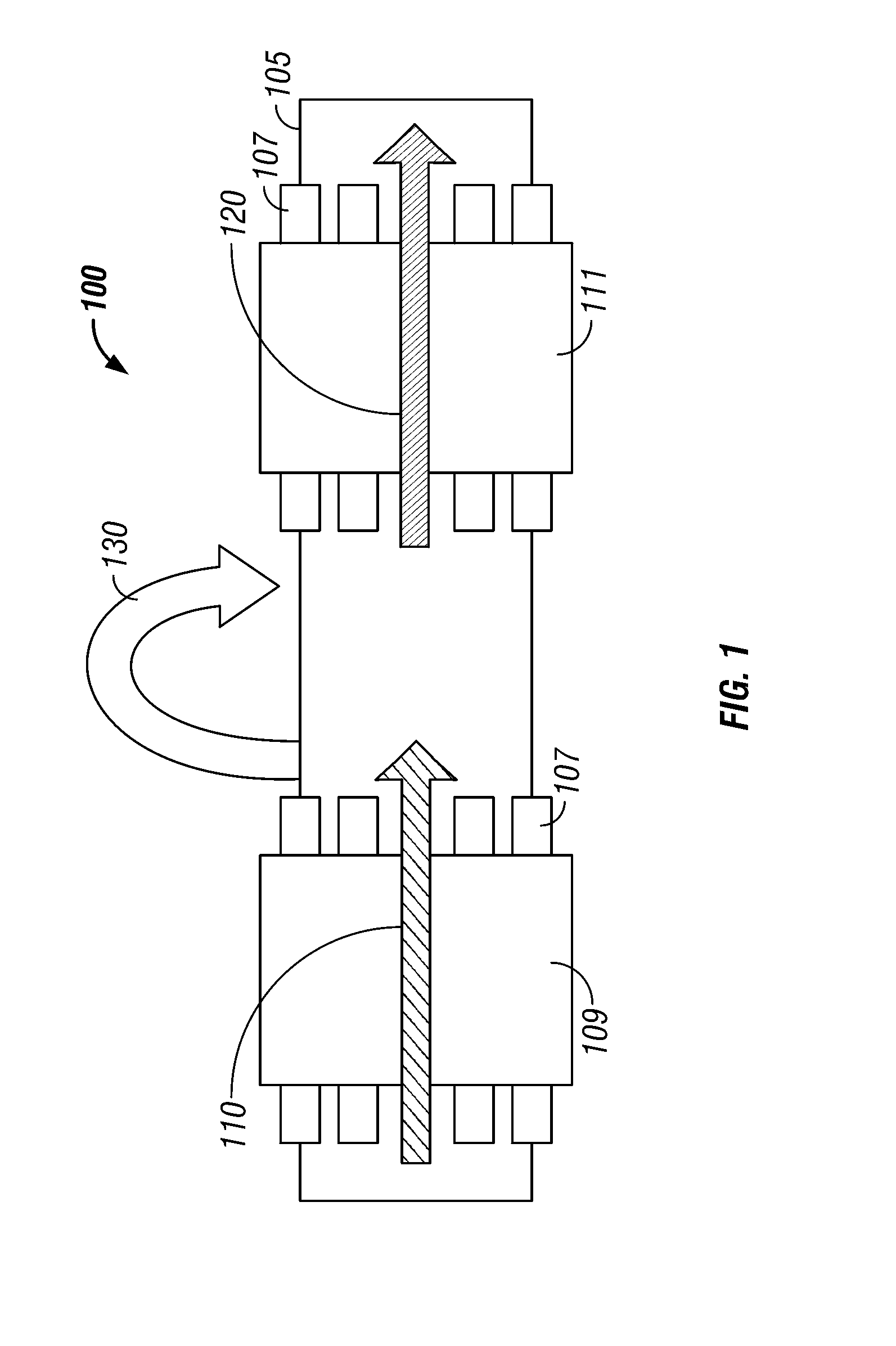

Motor training with brain plasticity

InactiveUS20150141773A1Increased activationHigh activityElectroencephalographyPerson identificationPhysical medicine and rehabilitationMotion parameter

A rehabilitation device, comprising a movement element capable of controlling at least one motion parameter of a portion of a patient; a brain monitor which generates a signal indicative of brain activity; and circuitry including a memory having stored therein rehabilitation information and which inter-relates said signal and movement of said movement element as part of a rehabilitation process which utilizes said rehabilitation information.

Owner:MOTORIKA

Interference Measurement Method, Network-Side Device And Terminal Device

ActiveUS20160036542A1Improve interference measurement effectEliminate the effects ofSite diversityTransmission monitoringTerminal equipmentEngineering

An interference measurement method, a network side device and a terminal device are disclosed. The interference measurement method includes: a network side sending interference measurement indication information to a terminal, and indicating the terminal to perform interference measurement, wherein the interference measurement indication information is used for indicating one or more kinds of the following information to the terminal: interference measurement modes used for performing interference measurement; and parameter configuration information used for interference measurement.

Owner:ZTE CORP

Motor training with brain plasticity

InactiveUS8938289B2Improve the measurement effectEasy to detectElectroencephalographyElectromyographyPhysical medicine and rehabilitationMedicine

A rehabilitation device, comprising a movement element capable of controlling at least one motion parameter of a portion of a patient; a brain monitor which generates a signal indicative of brain activity; and circuitry including a memory having stored therein rehabilitation information and which inter-relates said signal and movement of said movement element as part of a rehabilitation process which utilizes said rehabilitation information.

Owner:MOTORIKA

Method and Apparatus for a Multi-component Induction Instrument Measuring System for Geosteering and Formation Resistivity Data Interpretation in Horizontal, Vertical and Deviated Wells

InactiveUS20070257679A1Improve signal to noise ratio and measurement stabilityImprove signal contentElectric/magnetic detection for well-loggingDetection using electromagnetic wavesReceiver coilEngineering

An improved induction tool for formation resistivity evaluations. The tool provides electromagnetic transmitters and sensors suitable for transmitting and receiving magnetic fields in radial directions that are orthogonal to the tool's longitudinal axis with minimal susceptibility to errors associated with parasitic eddy currents induced in the metal components surrounding the transmitter and receiver coils. Various transmitter receiver combinations are provided to select sensitivity to a desired reservoir formation properties, for example, different orientations xy, xz, yz, 20-40, 20-90, and combinations, such as, Symmetric-symmetric; Asymmetric-symmetric; and Asymmetric-asymmetric. Measurements made with a multi-component logging instrument when used in a substantially horizontal, vertical or deviated borehole in earth formations are diagnostic of the direction of resistive beds relative to the position of the borehole. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b)

Owner:BAKER HUGHES INC

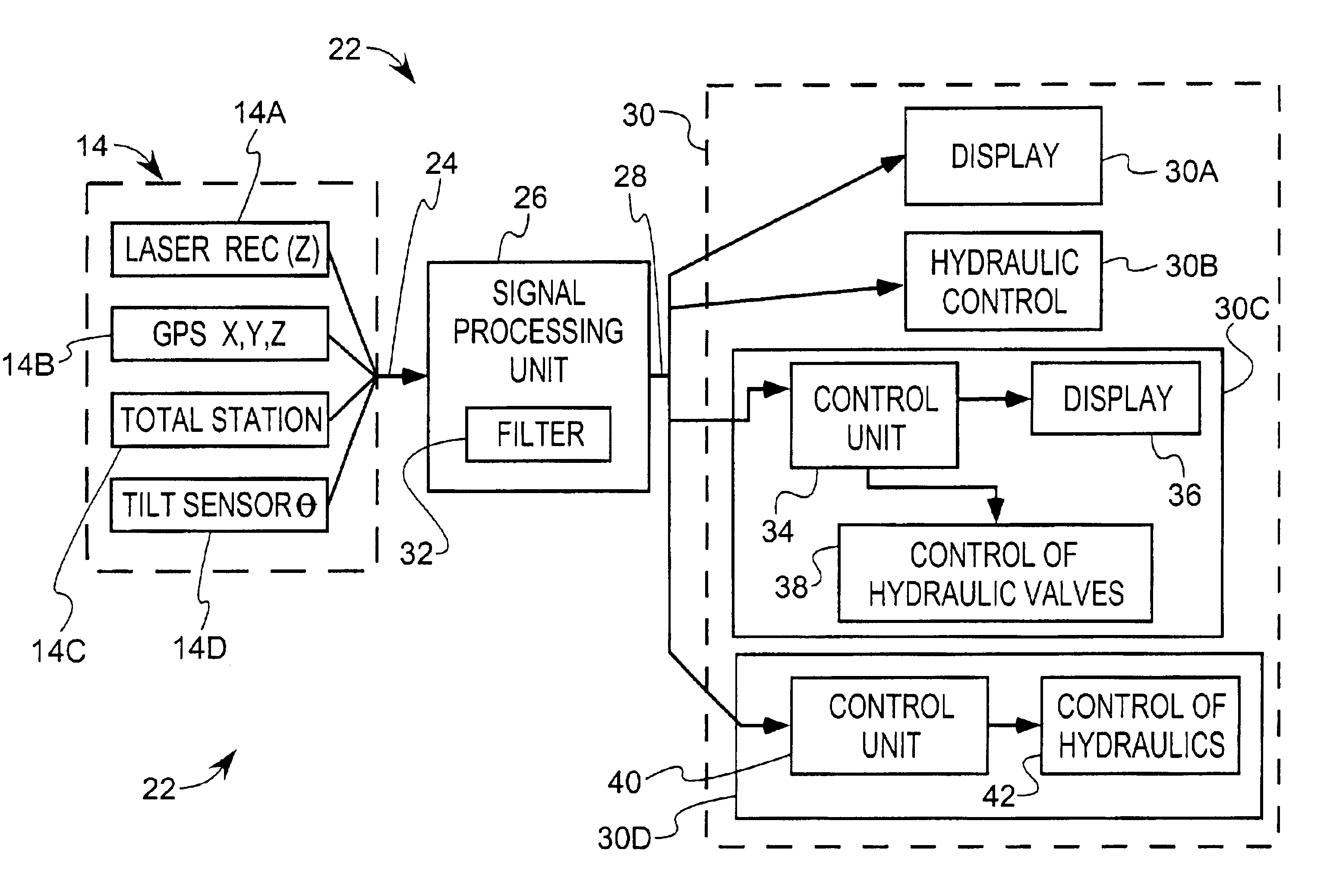

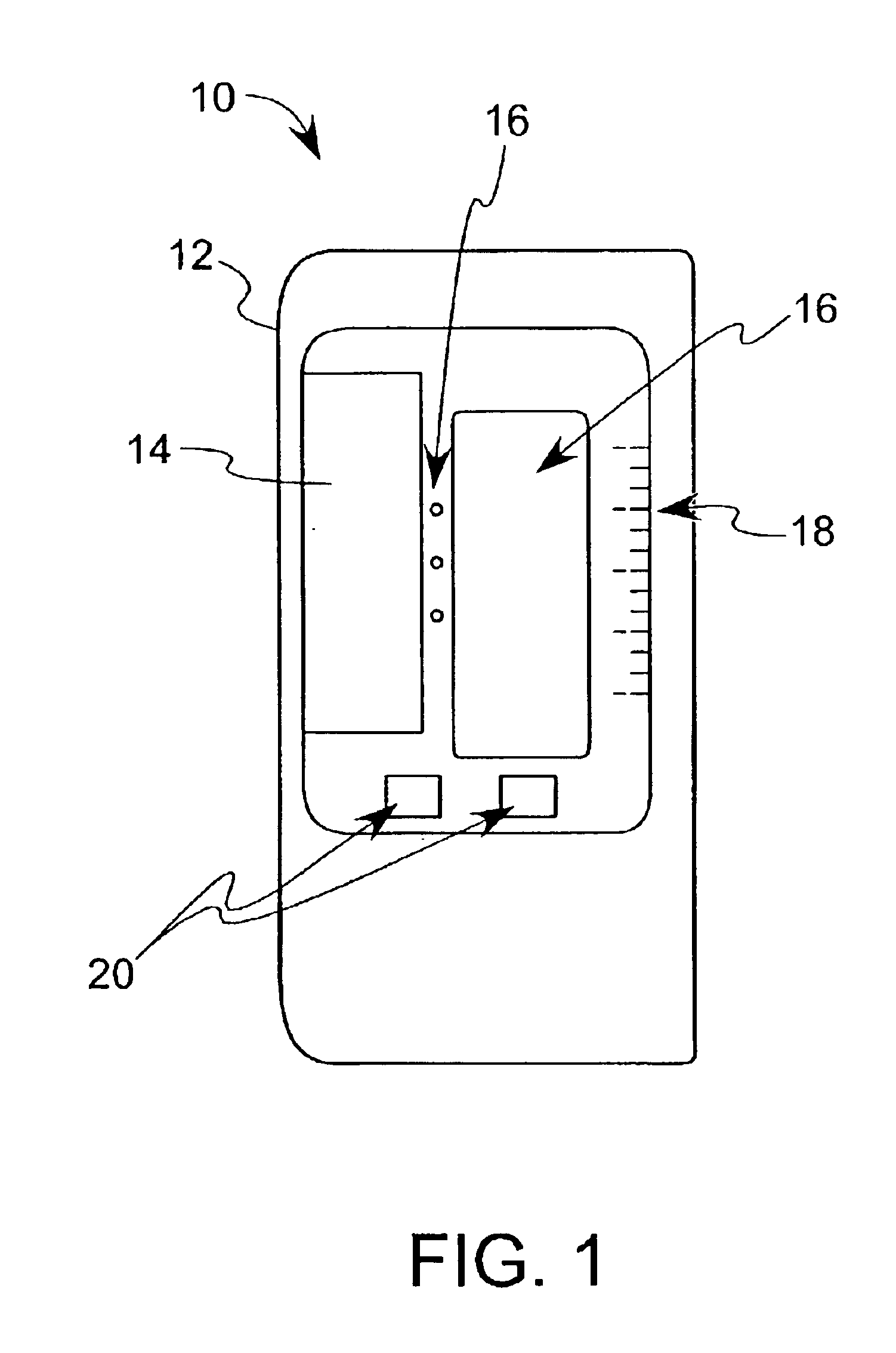

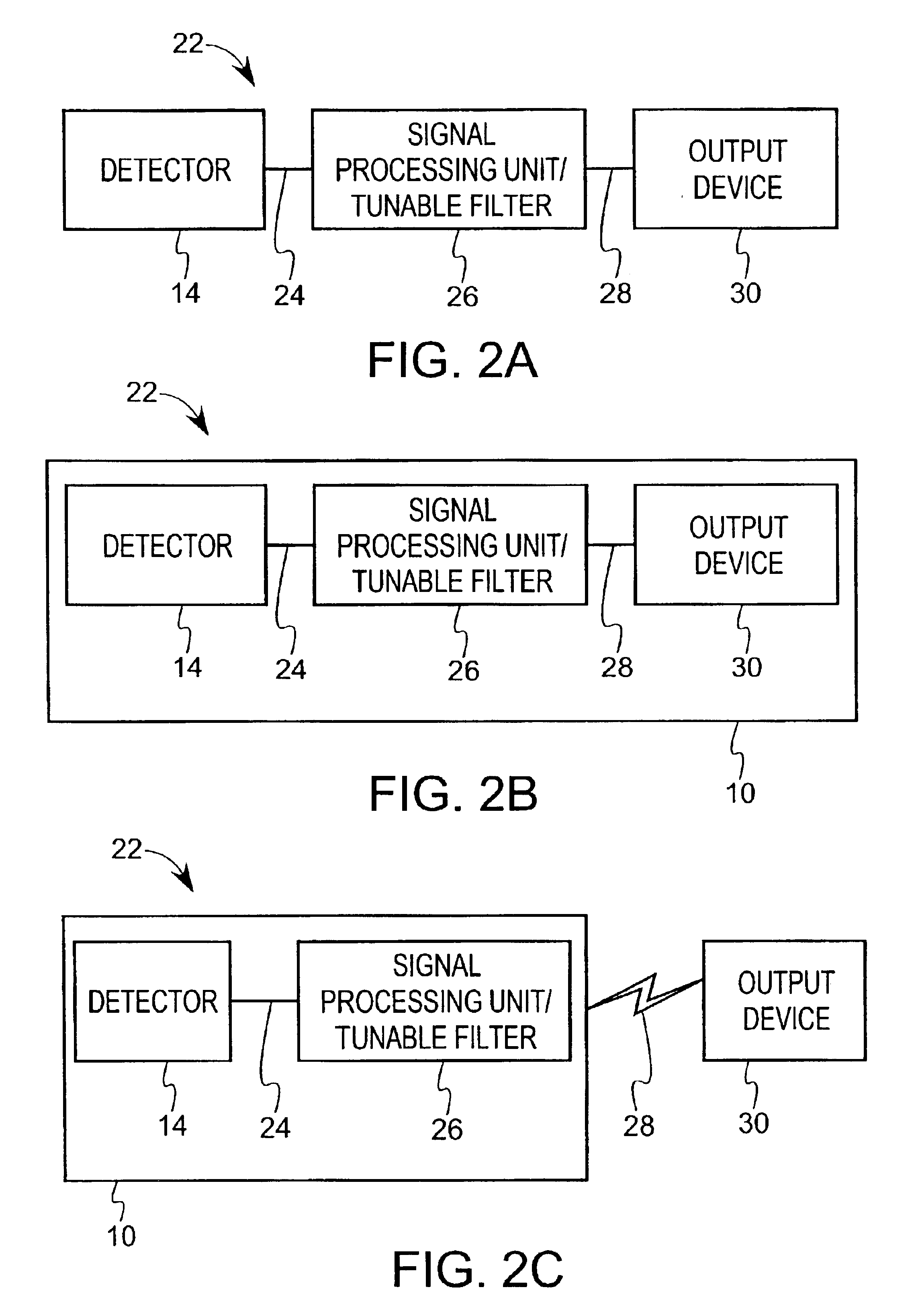

Tunable filter device for spatial positioning systems

InactiveUS6889175B2Improve the measurement effectReduce noiseModulated-carrier systemsAmplifier modifications to reduce noise influenceSpatial positioningGlobal Positioning System

A device for spatial positioning systems includes a programmable measurement filter that is dynamically tuned by the device signal processing unit. The signal processing unit analyzes available data including the measurement signal to determine the likelihood that a detected measurement comprises true device movement and adjusts the measurement filter bandwidth accordingly.

Owner:TRIMBLE NAVIGATION LTD

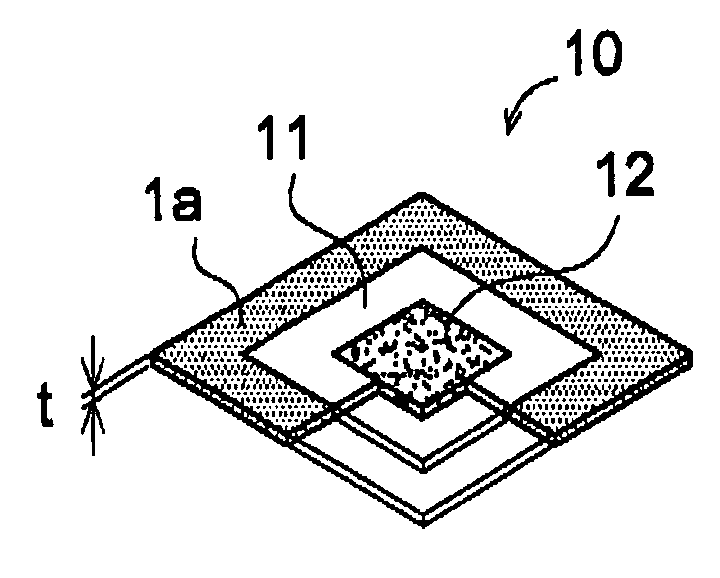

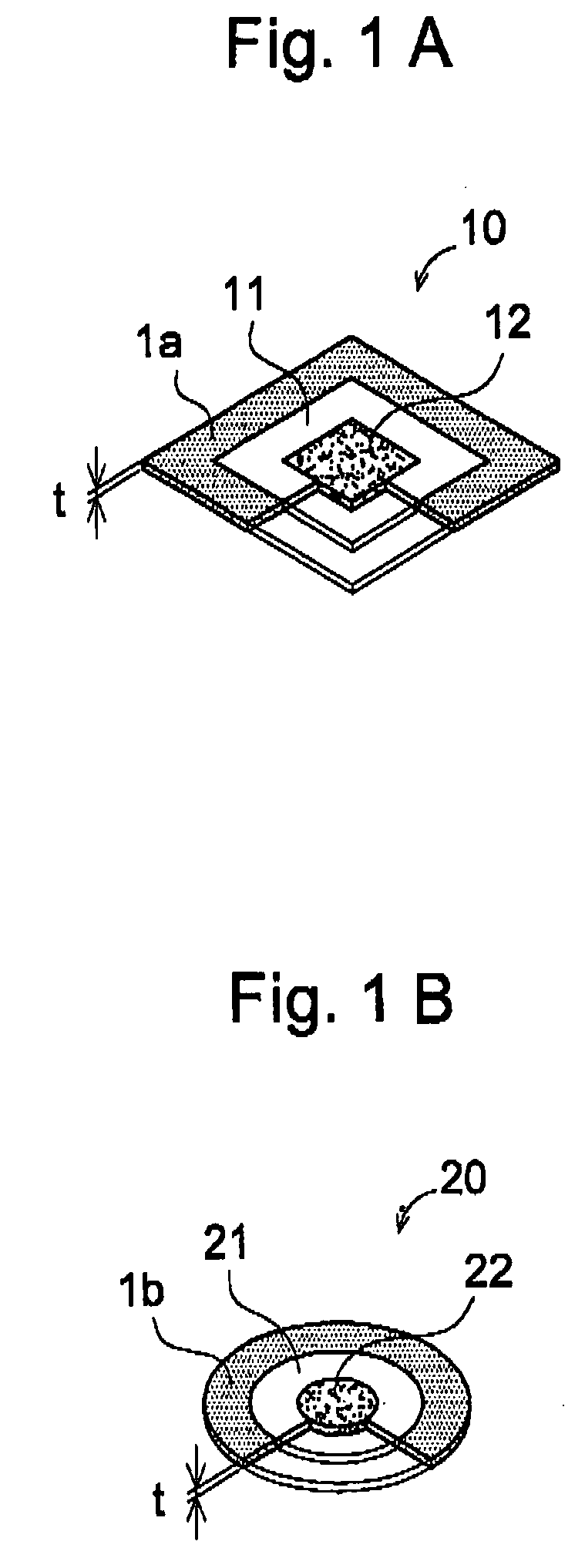

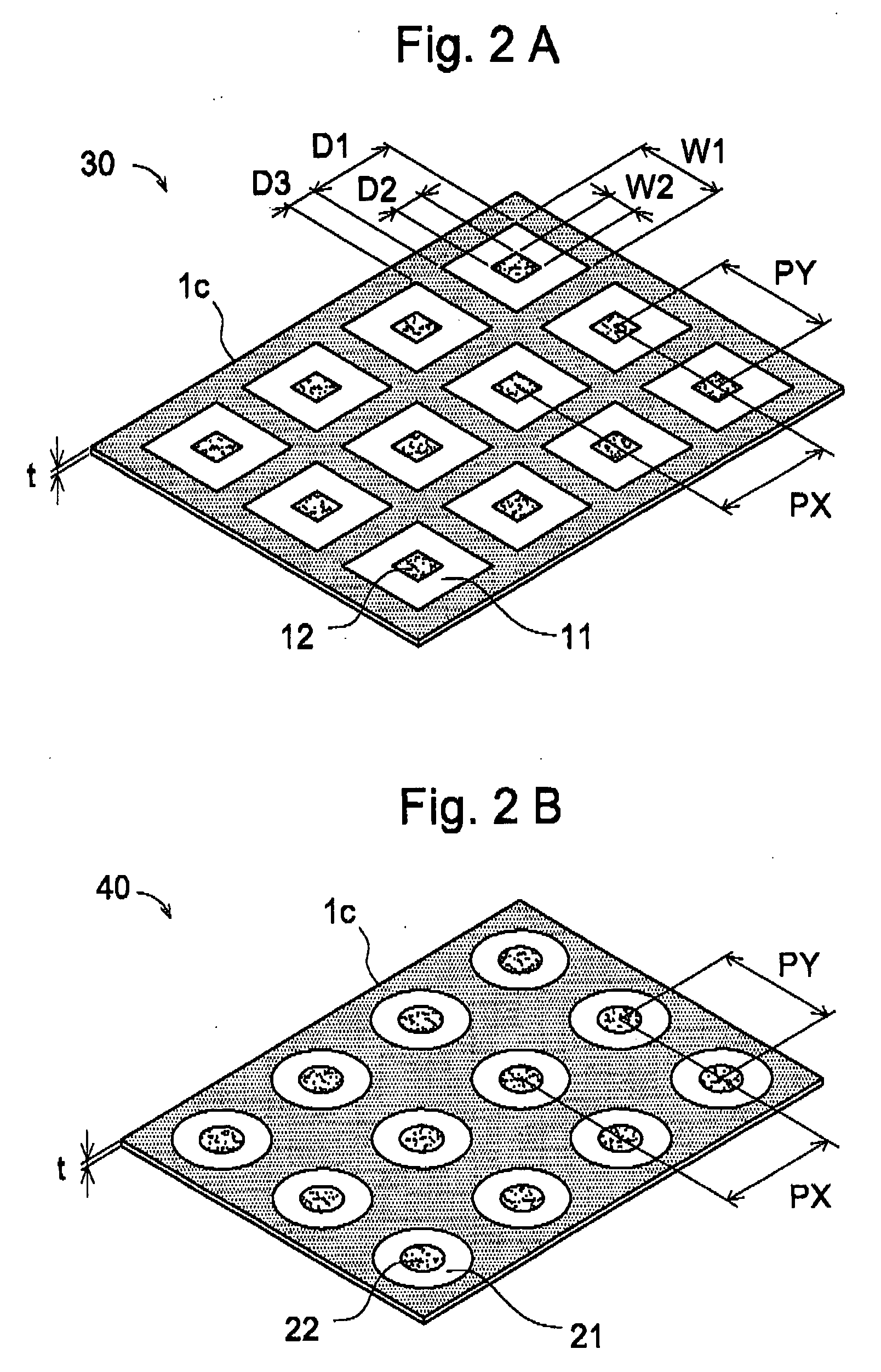

Anisotropic conductive sheet

InactiveUS20060162287A1Noise from junctionAvoid noiseCapsCoupling contact membersElastomerEngineering

An anisotropic conductive sheet for high frequencies is provided as elastomer for connecting high-integrated circuit boards and fine pitch electronic components of recent years. Anisotropic conductive sheet (30) has a sheet-shaped elastomer (1c), and a non-conductive rectangular first penetrating region (11) is formed vertically and horizontally in a state surrounded by the sheet-shaped elastomer (1c). In addition, an electrically-conductive second penetrating region (12) is formed in a rectangular manner in a state surrounded by the first penetrating region (11). The first penetrating region 11 can be a high-dielectric rectangular third penetrating region. The anisotropic conductive sheet (30) has an effect in that electrostatic shield is provided between connected electronic components.

Owner:JST MFG CO LTD

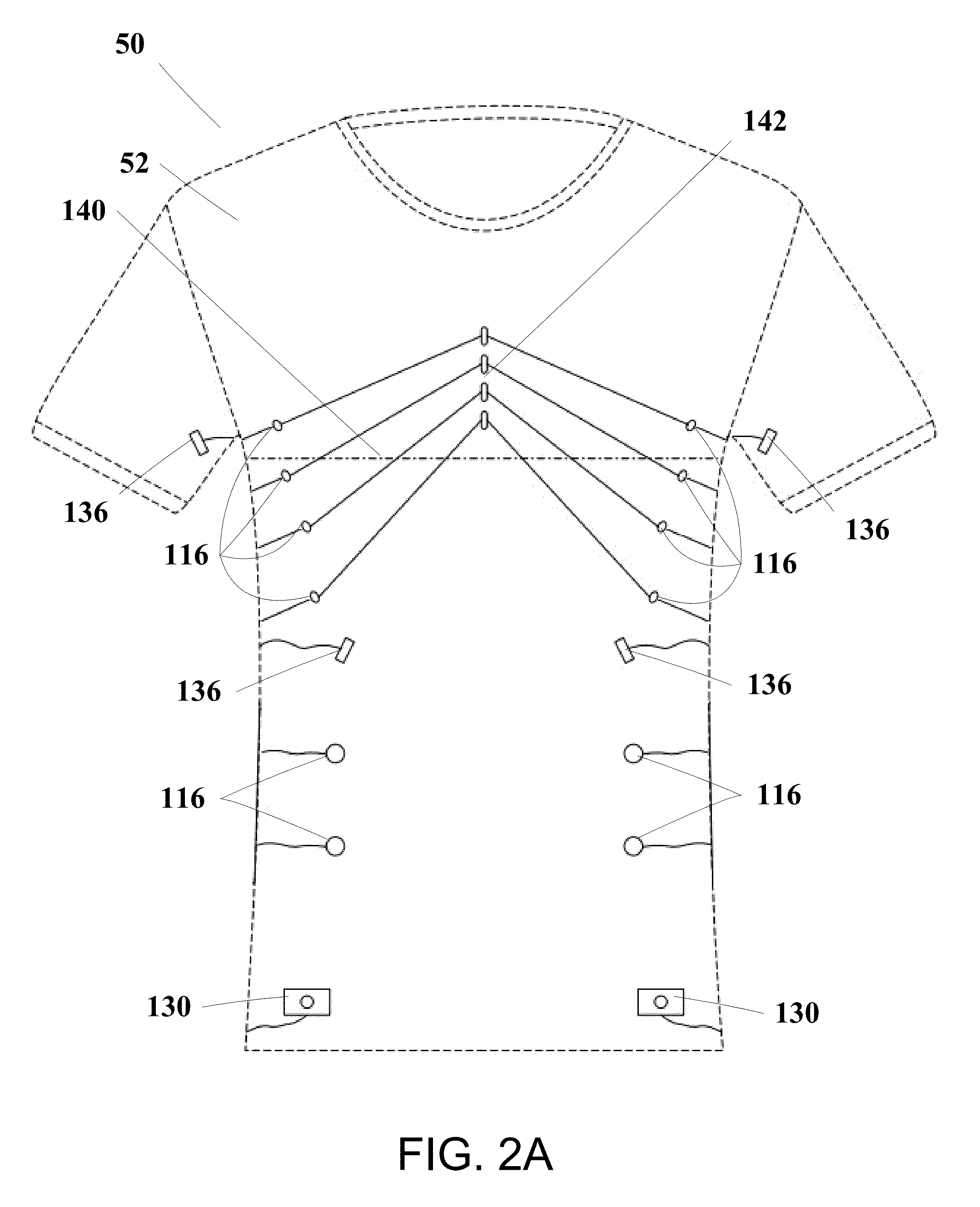

Garment System With Electronic Components and Associated Methods

ActiveUS20160120470A1Improve the measurement effectElectric signal transmission systemsTelemetry/telecontrol selection arrangementsAbdominal movementsBiometric data

The disclosure provides a wireless biometric monitoring system that may be capable of acquiring, compiling, analyzing, and transmitting biometric data in near real time / real time. The system may utilize either the most up-to-date Bluetooth protocol (currently Bluetooth Smart) or a similar wireless protocol. The system may further integrate through this wireless protocol with peripheral devices to expand the measurement capacity of the system.In embodiments, the system may be capable of monitoring multiple biometric responses including, but not limited to: skin temperature, core temperature, respirations, heart rate, predicted tidal volume, chest wall movement, abdominal movement in conjunction with inspiration, abdominal movement in conjunction with expiration, HRR (heart rate reserve), HRV (heart rate variability), body position relevant to perpendicular, shoulder position relevant to hip position, general body posture, up time, down time, and malfunctions.

Owner:CIPHER SKIN

System and method of obtaining data-dependent jitter (DDJ) estimates from measured signal data

InactiveUS7203610B2Enhanced low frequencyImprove the measurement effectNoise figure or signal-to-noise ratio measurementVoltage-current phase angleDuty cycle distortionData signal

Methods for estimating data-dependent jitter (DDJ) from measured samples of a transmitted data signal include a first exemplary step of obtaining a plurality of measurements (e.g., time tags and event counts for selected pulse widths in the data signal). Such measurements may be obtained at predetermined intervals within a transmitted signal or may be obtained at randomly selected intervals, and should yield measurements for each data pulse in a repeating data pattern. An average unit interval value representative of the average bit time of the transmitted signal is determined. Time interval error estimates representative of the timing deviation from each signal edge's measured value relative to its ideal value (determined in part from the calculated average unit interval value) are also determined, as well as a classification for each measured signal edge relative to a corresponding data pulse in the repeating data pattern. DDJ delta lines are then calculated for signal edges of each pulse width in the transmitted data pattern, from which peak-to-peak DDJ values and / or estimates of duty-cycle-distortion (DCD) can be determined.

Owner:GUIDE TECH

Laser based cavity enhanced optical absorption gas analyzer

ActiveUS8659759B2Promote absorptionImprove the measurement effectMaterial analysis using wave/particle radiationMaterial analysis using microwave meansSpectroscopyLaser light

Cavity enhanced absorption spectroscopy systems and methods for detecting trace gases. When the frequency of laser light approaches the frequency of a resonance cavity mode, the laser begins to fill the cavity to that mode. Optical intensity inside the cavity reflects total cavity loss when the laser light frequency coincides with the cavity mode transmission peak. The intra-cavity optical power also depends on the coupling efficiency of the laser beam to the particular cavity mode. Measurement of intensities of three optical signals, namely, intensity of the light incident on to the cavity, intensity of the light reflected from the cavity, and intensity of the intra-cavity optical power, with their appropriate normalization advantageously significantly reduce effects of baseline calibration and drift as the normalized signal only depends on total cavity loss, and not the coupling efficiency, as in traditional approaches.

Owner:LI COR

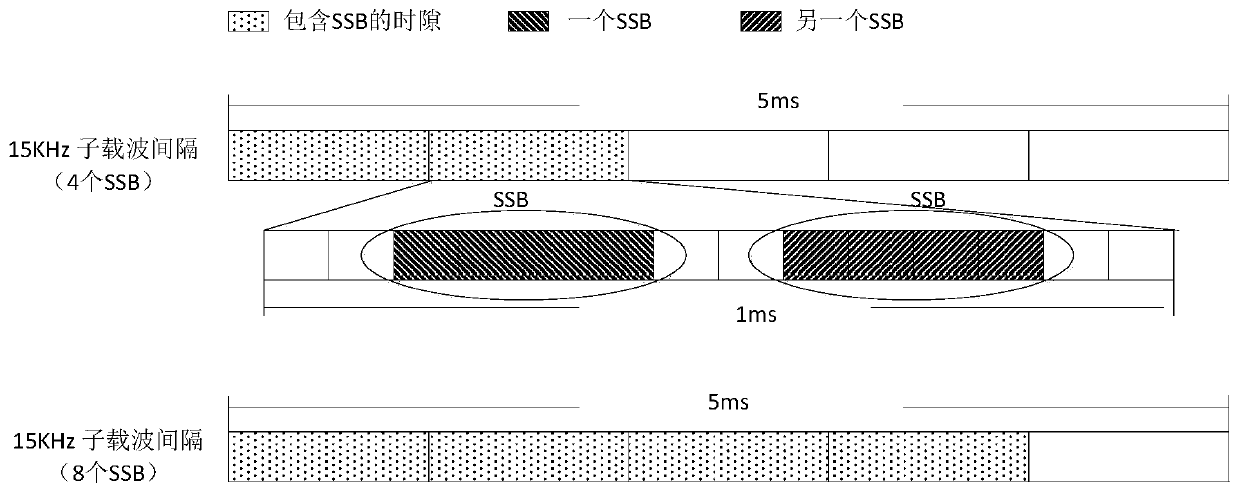

Methods and apparatus for synchronizing signal transmission and reception

PendingCN110167134AImprove sending efficiencyImprove the measurement effectSynchronisation arrangementBroadcast channelsCommunications system

The invention discloses a method and apparatusequipment for sending and receiving synchronous signals. The method comprises the following steps of: performing listen before talk (LBT) operation in a predefined time window; if the LBT operation is successful, sending an SSB in the time window; wherein the SSB comprises a synchronization signal SS, or the SSB comprises the SS and a physical broadcast channel PBCH. Compared with the prior art, the method and the apparatus device have the advantages that the time for implementing the LBT by the base station is relaxed, namely, the a base station is allowed to implement the LBT in the a predefined time window, and the SSB is sent after the LBT is successful, so that the data sending efficiency and the access performance of a communication system are remarkably improved.

Owner:BEIJING SAMSUNG TELECOM R&D CENT +1

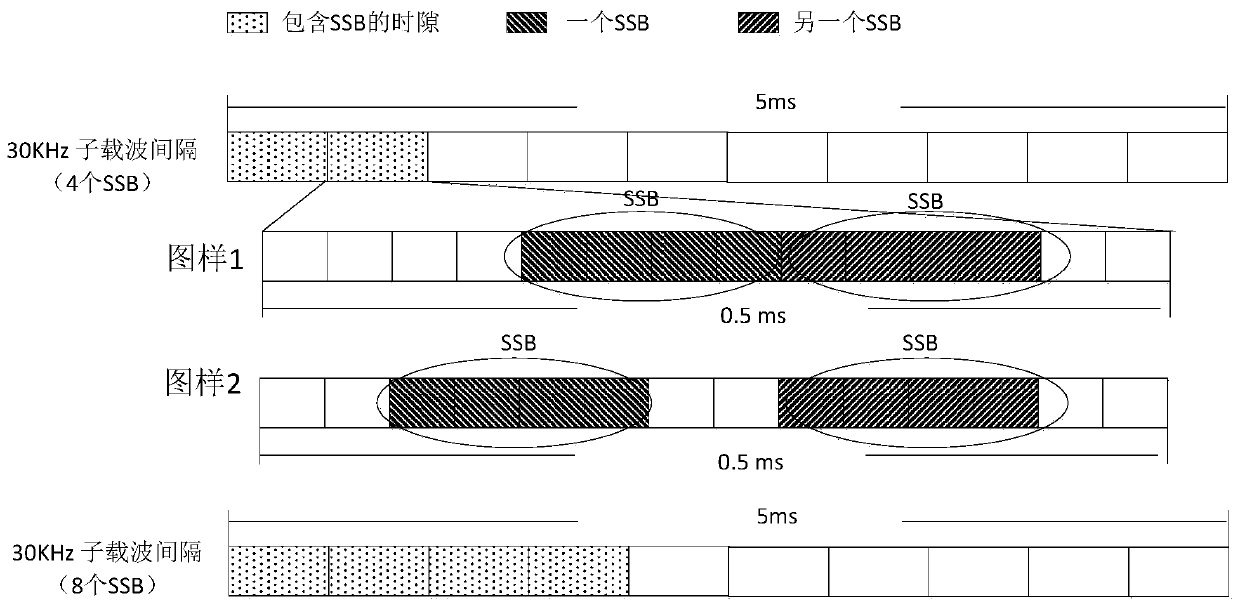

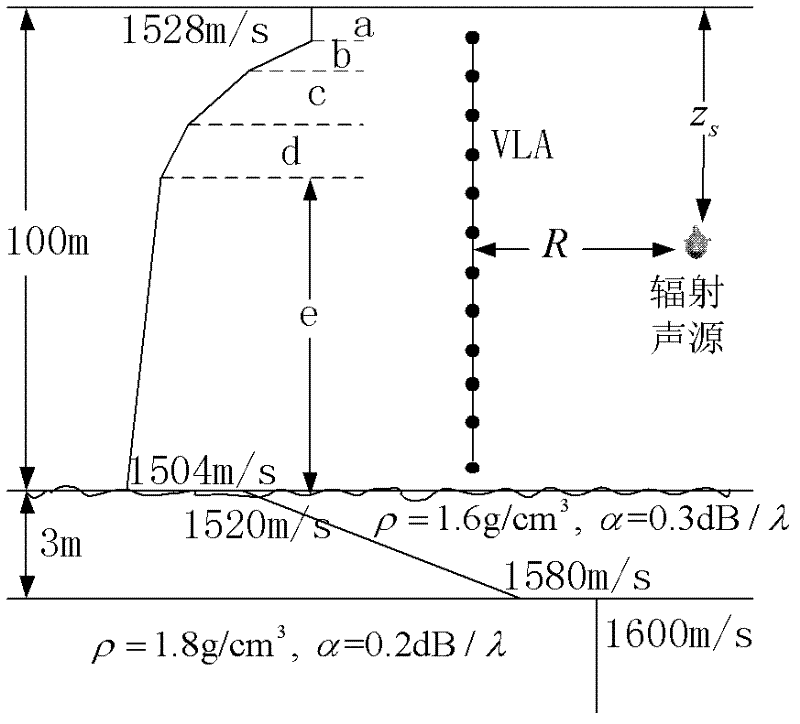

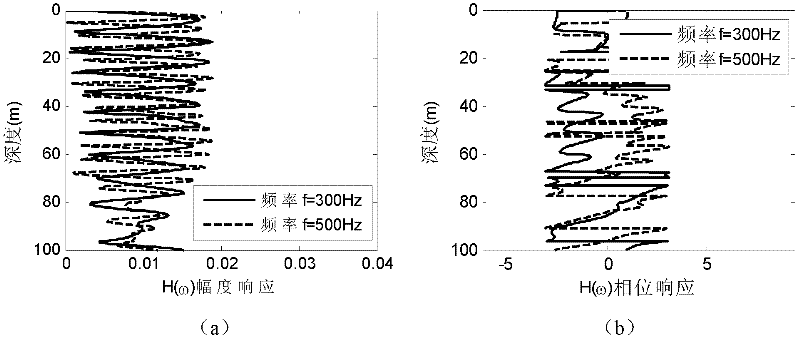

Ship radiated noise level measuring method based on virtual time reversal mirror

InactiveCN102645265AOffset measurement errorRestoring the signal waveformVibration measurement in fluidDistortionChannel transfer function

The invention discloses a ship radiated noise level measuring method based on a virtual time reversal mirror. The ship radiated noise level measuring method comprises the following steps of: presetting ocean environmental parameters; calculating a channel transfer function and an impulse response function among a radiated sound source and measurement hydrophones; obtaining a received signal of each measurement hydrophone of a vertical array; carrying out virtual time reversal treatment on the received signal of the measurement hydrophone by the impulse response function; and carrying out summation treatment on an output signal of the received signal after virtual time reversal treatment of each measurement hydrophone so as to calculate ship radiated noise level. With the adoption of the ship radiated noise level measuring method, the influence on ship radiated noise measurement by distortion of a transmission signal caused by multipath and medium in a shallow sea can be eliminated or weakened so as to reduce measurement error.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

System and method of measuring distances related to an object

ActiveUS9230339B2Facilitate inventionImprove the measurement effectImage enhancementImage analysisImaging analysisManufacturing systems

A system and method for measuring distances related to a target object depicted in an image and the construction and delivery of supplemental window materials for fenestration. A digital image is obtained that contains a target object dimension and a reference object dimension in the same plane. The digital image may contain a target object dimension identified by an ancillary object and a reference object dimension in different planes. Fiducial patterns on the reference and optional ancillary objects are used that are recognized by an image analysis algorithm. Information regarding a target object and its immediate surroundings is provided to an automated or semi-automated measurement process, design and manufacturing system such that customized parts are provided to end users. The digital image contains a reference object having a reference dimension and calculating a constraint dimension from the digital image based on a reference dimension. The custom part is then designed and manufactured based on a calculated constraint dimension.

Owner:WEXENERGY INNOVATIONS

Multi-component induction instrument

InactiveUS20030025503A1High degreeEnhanced couplingElectric/magnetic detection for well-loggingAcoustic wave reradiationConductive materialsReceiver coil

An improved induction tool for formation resistivity evaluations. The tool provides electromagnetic transmitters and sensors suitable for transmitting and receiving magnetic fields in radial directions that are orthogonal to the tool's longitudinal axis with minimal susceptibility to errors associated with parasitic eddy currents induced in the metal components surrounding the transmitter and receiver coils. The present invention provides increased effective tool surface impedance by increasing self-inductance of the paths in which induced eddy currents flow on the surface of the multi-component induction instruments. The tool enables downhole tool designers to build more effective and better-protected radial induction arrays for existing and future downhole instruments operating in the frequency and / or time domains. In this case the array measurement results contain information primarily about the formation's vertical resistivity. The tool makes it possible to combine radial arrays with coaxial arrays that conventionally measure horizontal formation resistivity. This combination enables obtaining a full resistivity tensor to evaluate formation resistivity anisotropy. The tool provides a composite non-conductive housing to reduce or even avoid the effects of parasitic eddy currents flowing on the tool surface. The tool provides a non-magnetic housing that is conductive which reduces the effects of conductive materials near coils and, primarily, the receiver. The tool provides a non-conductive coating is placed over the housing to prevent high frequency eddy currents from leaking from the housing in the conductive mud of the adjacent wellbore and returning to the housing.

Owner:BAKER HUGHES INC

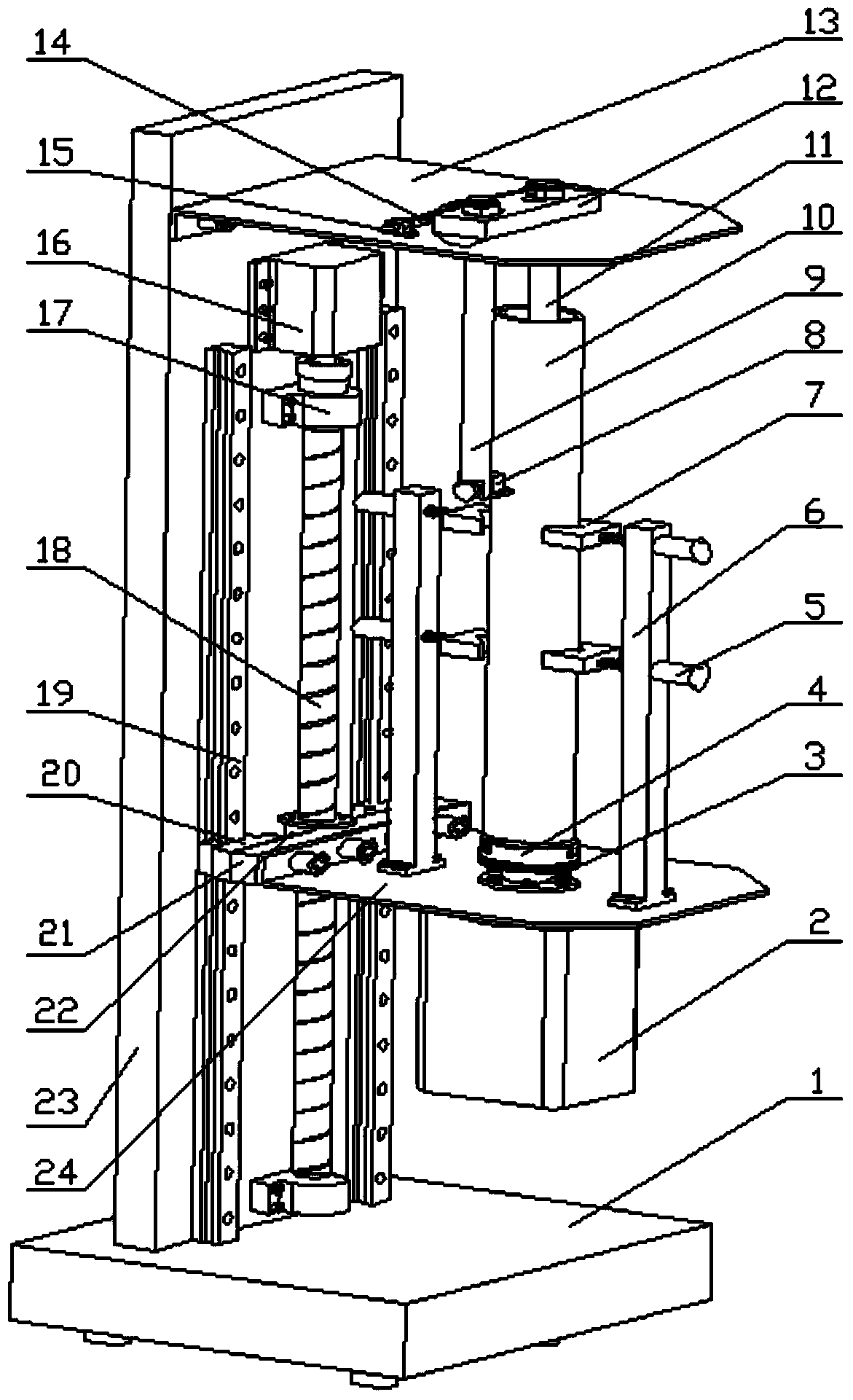

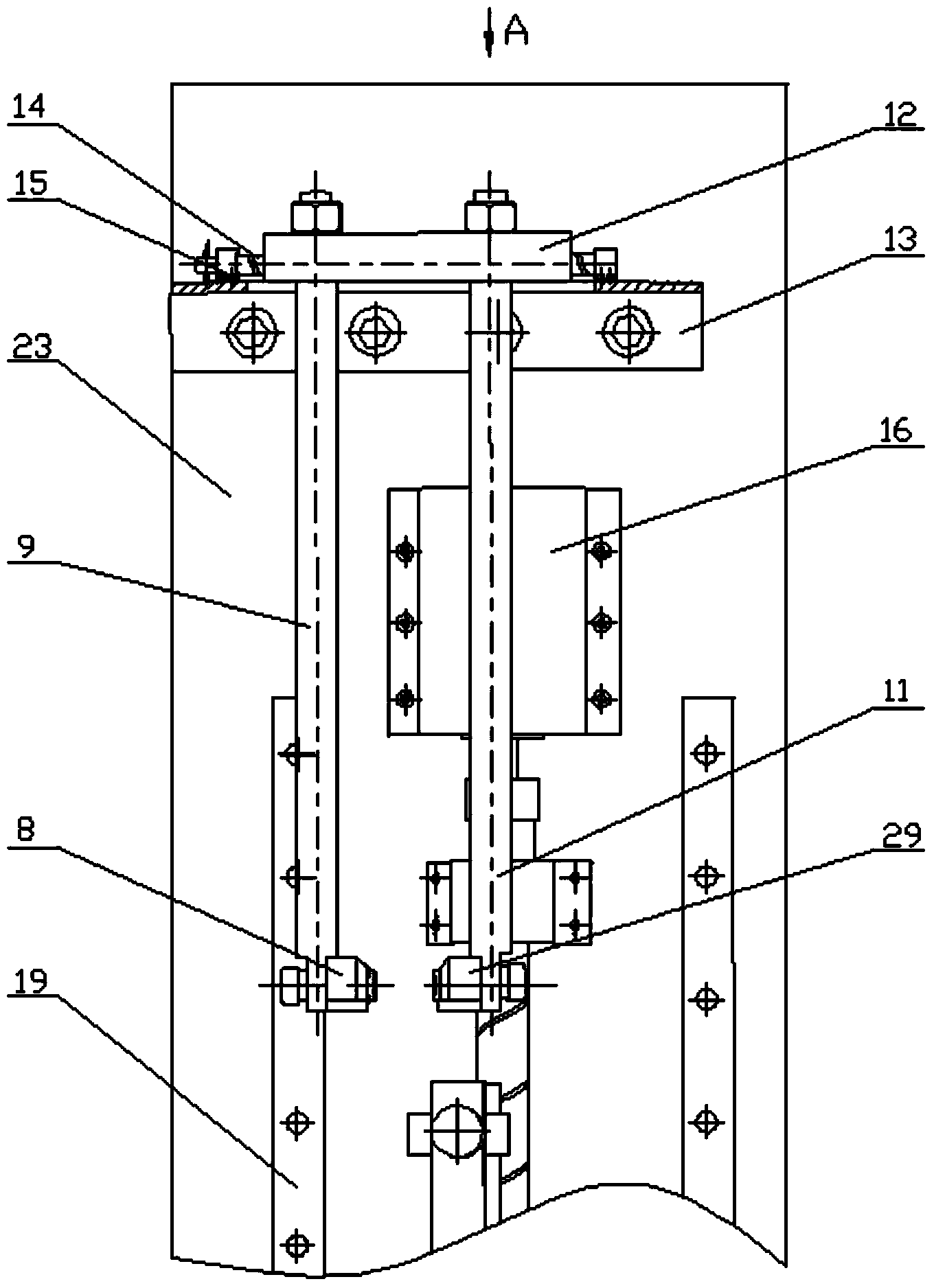

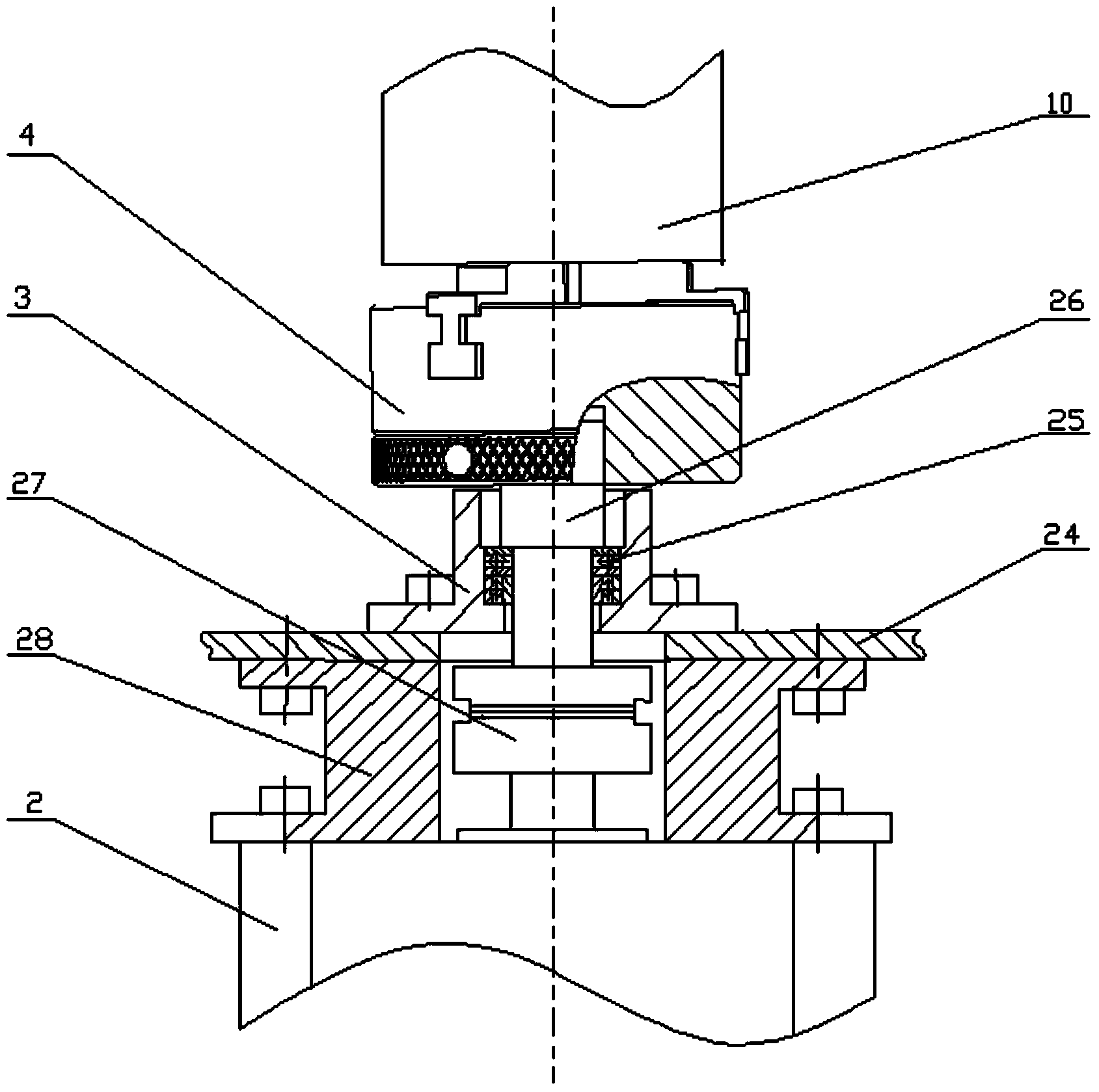

Automatic cylinder wall thickness measurement device based on laser sensor

ActiveCN104006754AGuaranteed measurement accuracyAvoid vibration and transmission errorsUsing optical meansMeasurement deviceBiomedical engineering

The invention discloses an automatic cylinder wall thickness measurement device based on a laser sensor. The device comprises a machine frame, a transmission unit, a rotating mechanism, a guide bearing mechanism and a measurement and adjustment mechanism. On one hand, the defect that a measurement instrument is abraded due to contact measurement is overcome, on the other hand, influences of unevenness of materials on measurement precision are avoided, measurement efficiency and precision are greatly improved, and automatic pipelining measurement is easy to achieve. The measurement device is improved in the following aspects: (1) the transmission structure of the measurement device and the motion relation between the laser sensor and a workpiece to be tested, (2) the distribution and automatic measurement feeding mode of the laser sensor, (3) automatic positioning, clamping and rotating of the workpiece to be tested and the anti-collapsing or anti-tilt structure, and (4) function extensibility, measurement universality and implantation of an automatic production line. The measurement device has the advantages of being simple in structure, high in reliability and easy to obtain.

Owner:SHANGHAI JIAO TONG UNIV

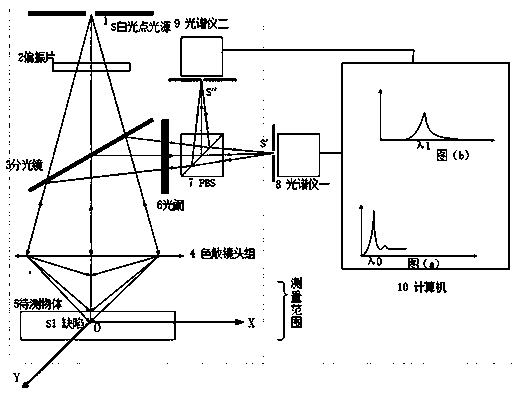

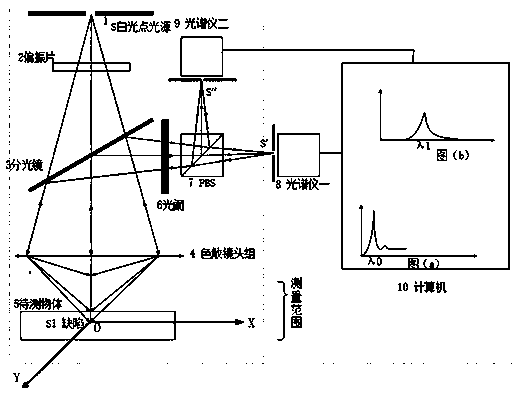

Detection method and device of optical component surface topography and subsurface defect information

ActiveCN109916909AImprove measurement efficiencyHigh speed scanOptically investigating flaws/contaminationUsing optical meansLength waveTopography

The invention relates to a detection method and device of optical component surface topography and subsurface defect information. The method comprises the following steps that wavelength information is used to measure a distance, one beam of compound color light (white) with a broad spectrum is emitted by a light source, spectral dispersion is generated through a dispersive lens to form monochromatic light with different wavelengths, and a focal point of each wavelength corresponds to one distance value; measurement light is reflected back from a surface of an object, the monochromatic light satisfying a confocal condition can be sensed by a spectrometer through a small hole, and the acquired distance value is converted through calculating the wavelength of the sensed focal point; and thetwo spectrometers are used to receive a surface of a component to be tested and light wave information of an internal defect so as to obtain surface information of the optical component, a position ofthe internal defect, depth information and the like simultaneously.

Owner:XIAN TECHNOLOGICAL UNIV

Method and apparatus for multi-component induction instrument measuring system for geosteering and formation resistivity data interpretation in horizontal, vertical and deviated wells

InactiveUS7719282B2Minor susceptibilityIncreased effective tool surface impedanceElectric/magnetic detection for well-loggingAcoustic wave reradiationGeosteeringHorizontal wells

An improved induction tool for evaluating formation resistivity. The tool provides electromagnetic transmitters and sensors suitable for transmitting and receiving magnetic fields in radial directions that are orthogonal to the tool's longitudinal axis with minimal susceptibility to errors associated with parasitic eddy currents induced in the metal components surrounding the transmitter and receiver coils. A magnetic lens is provided to select sensitivity to a desired reservoir formation property.

Owner:BAKER HUGHES INC

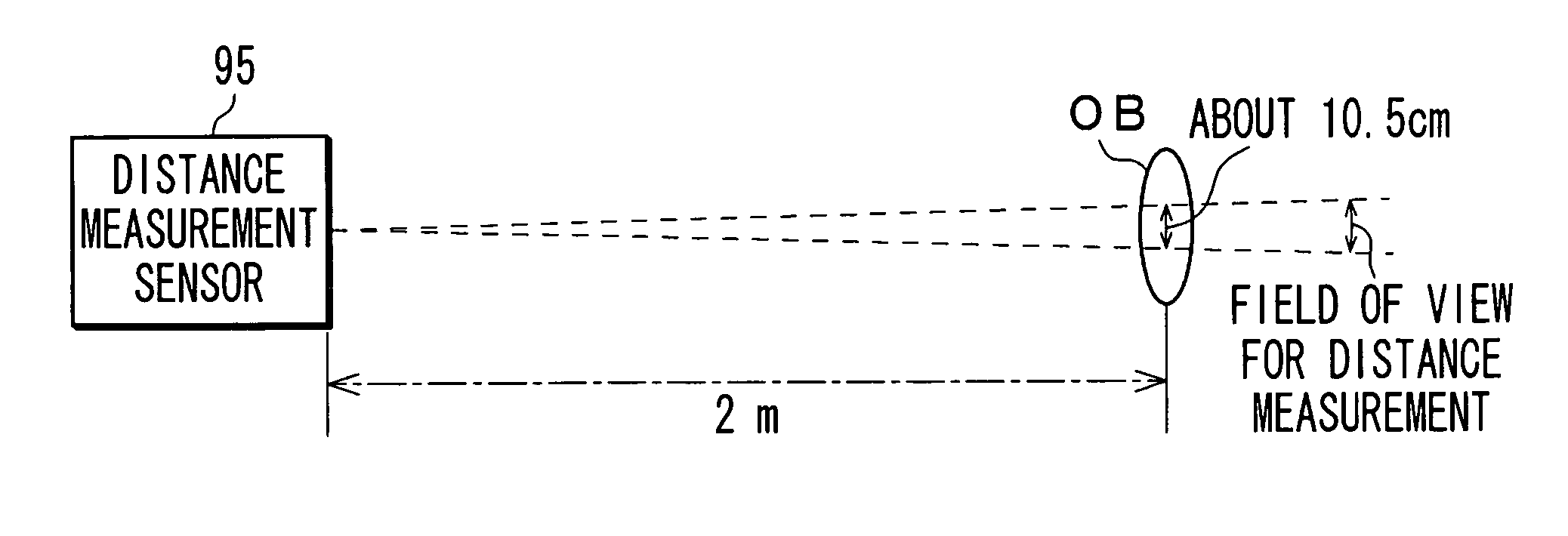

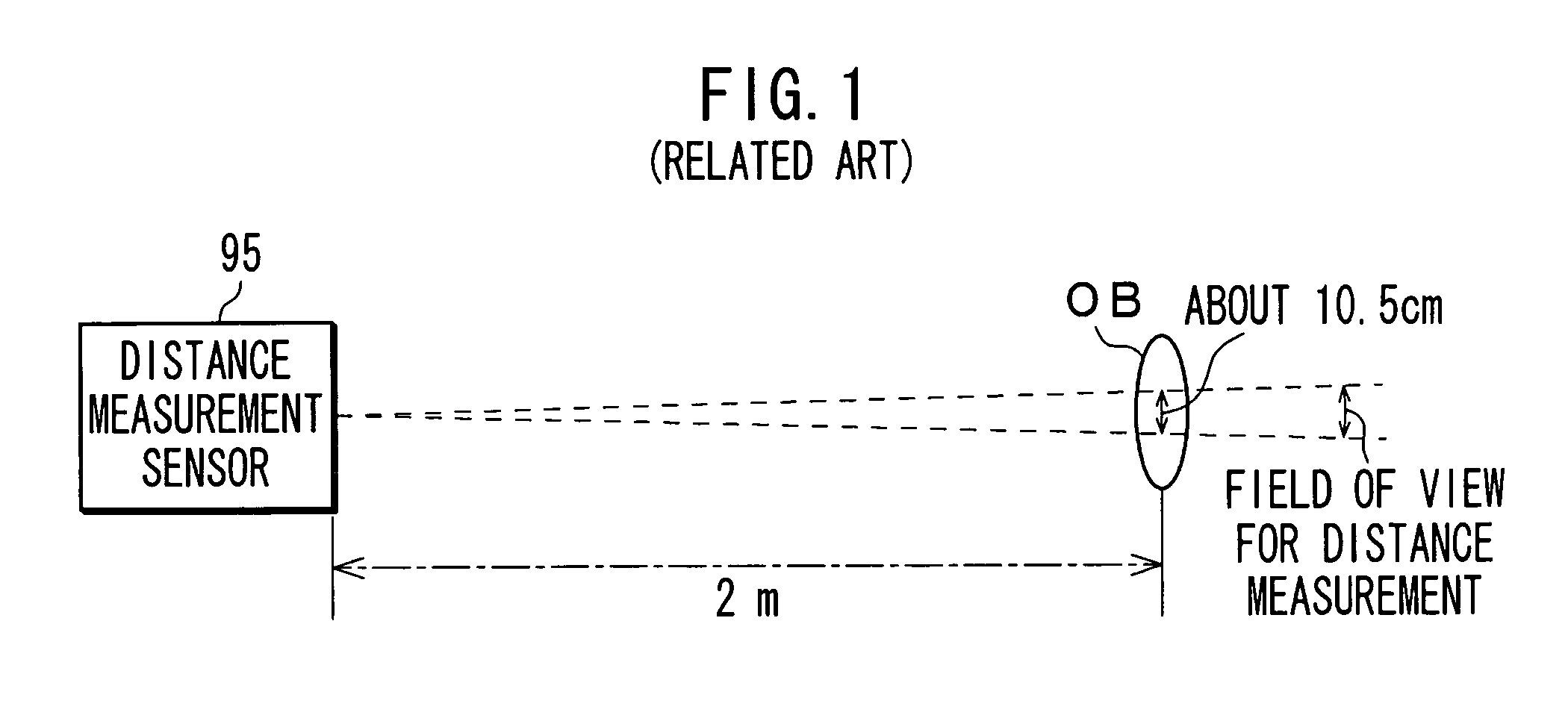

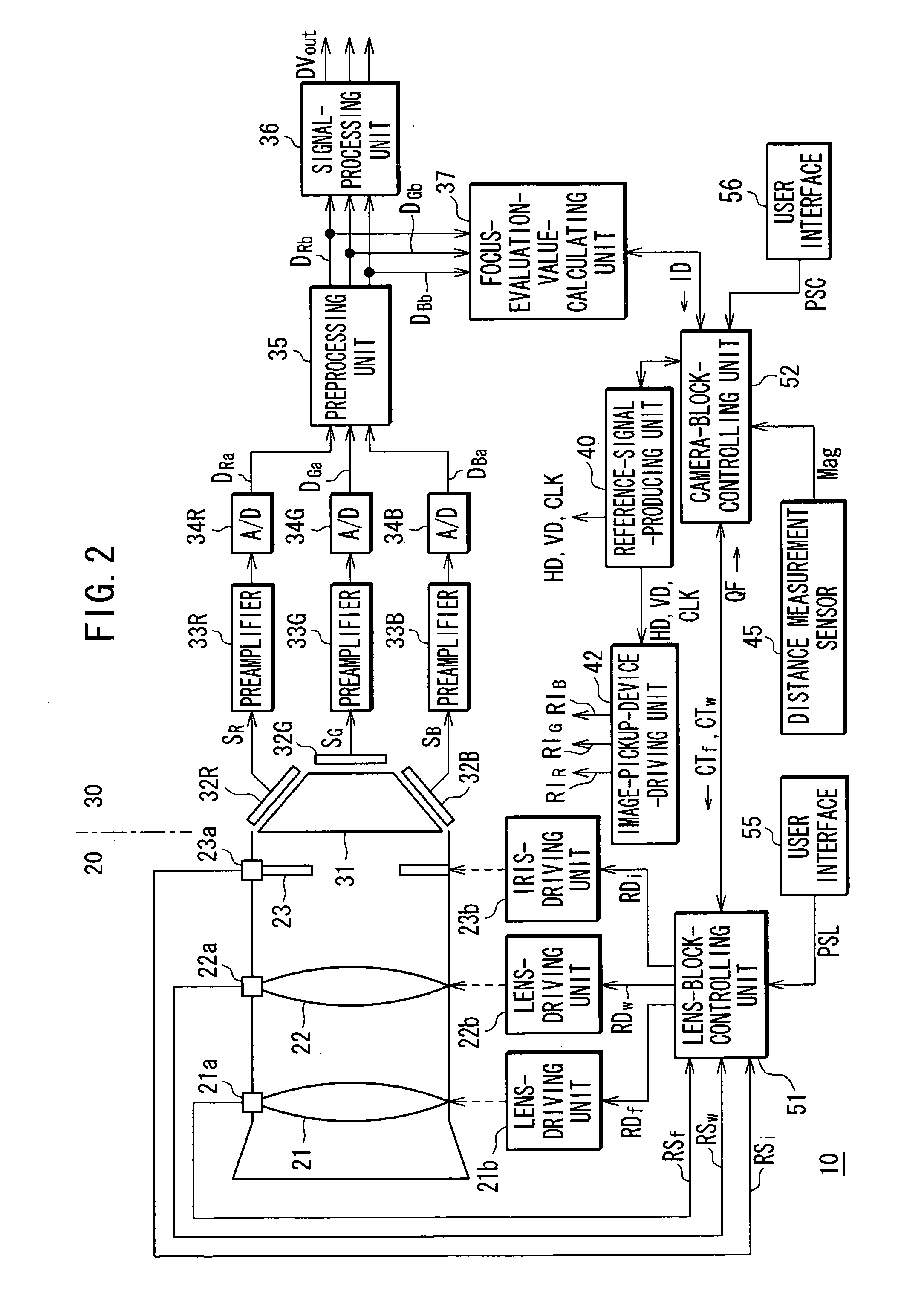

Autofocus device and method

InactiveUS20060232700A1Improve ranging accuracyAccurate focusTelevision system detailsProjector focusing arrangementCamera lensReference field

Autofocus device has a lens-driving unit, a focal-point-position-detecting unit that detects a position of a focal point of the lens, and a distance measurement sensor. The sensor measures a distance to a subject based on a reference field of view for distance measurement and a field of view for distance measurement being offset outwardly from the reference field of view and / or a field of view for distance measurement having a field of view that is different from the reference field of view. The device has a control unit that controls the lens-driving unit to drive the lens to meet the position of the focal point of the lens to an in-focus position thereof. The focusing operation starts by setting the lens drive based on a representative value selected from measured distance results obtained by the distance measurement sensor and the position of the focal point of the lens.

Owner:SONY CORP

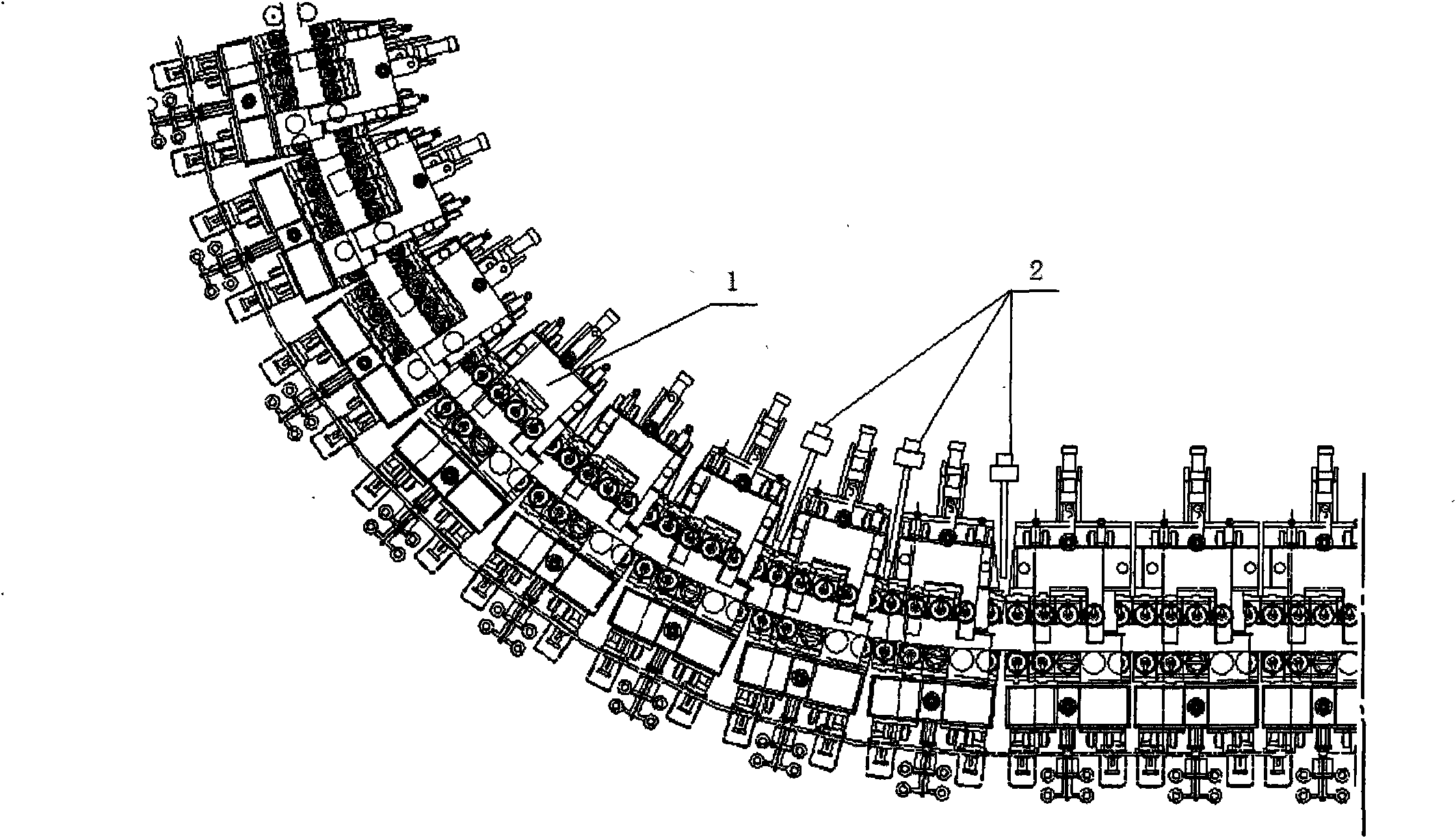

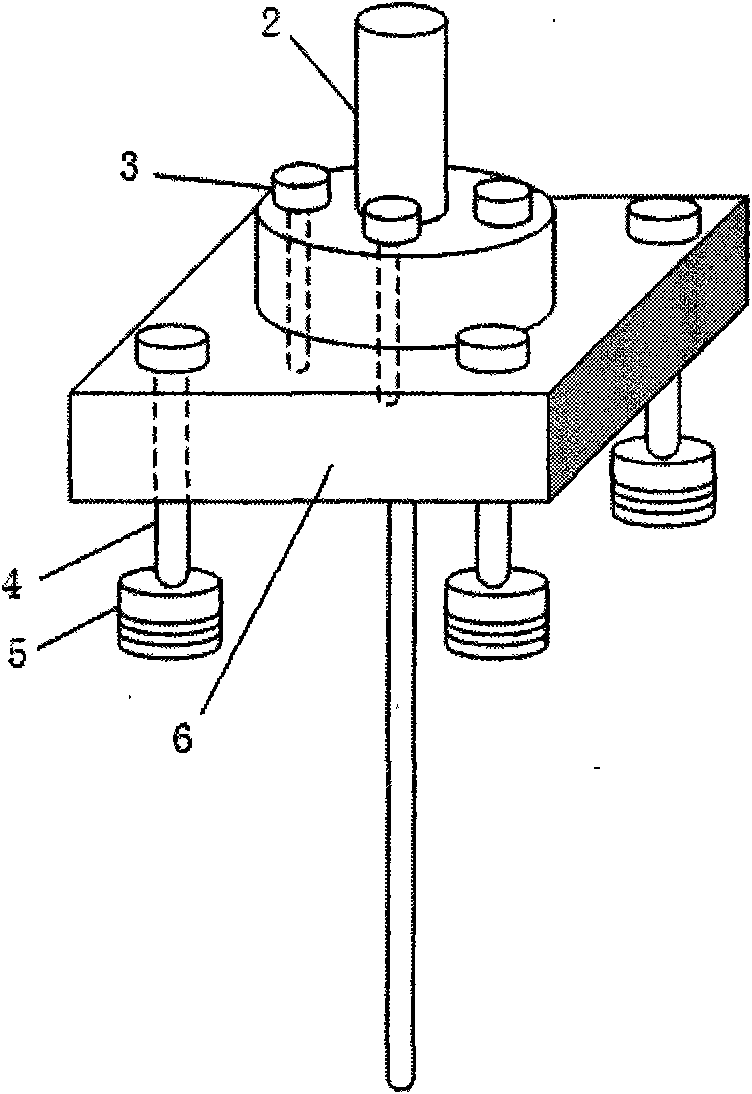

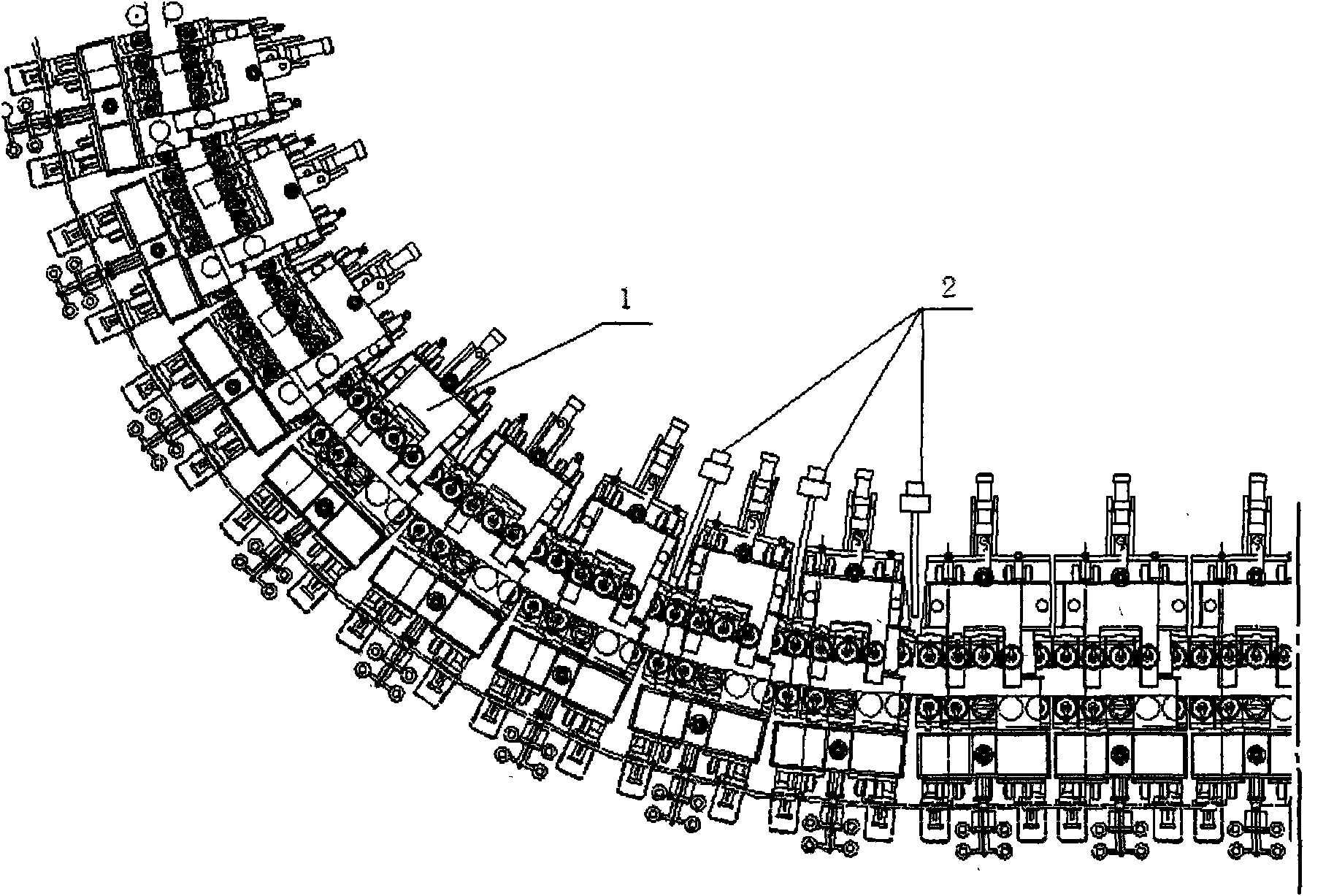

Method and device for measuring thickness of continuous casting shell

ActiveCN101992281AReasonable designGood measurement effectCasting parameters measurement/indication devicesShootEngineering

The invention relates to a method and a device for measuring the thickness of a continuous casting shell. Shoot nails are centralized on a set position by using at least two continuously arranged shoot nail guns, accurately calculating and controlling the shooting time every time so as to accurately measure the thickness of the casting shell at any time after analysis. The invention has the advantages of high measurement precision, simple and convenient operation, simple structure, convenient production, reasonable design in the measurement method and accurate analysis result. The thickness of a condensed casting shell of an actual casting blank can be followed and measured, and the measurement result provides sufficient basis for casting process personnel to analyze the production and the quality. The invention is particularly suitable for measuring the thickness of the casting shell of an arc-shaped continuous casting machine.

Owner:ANGANG STEEL CO LTD

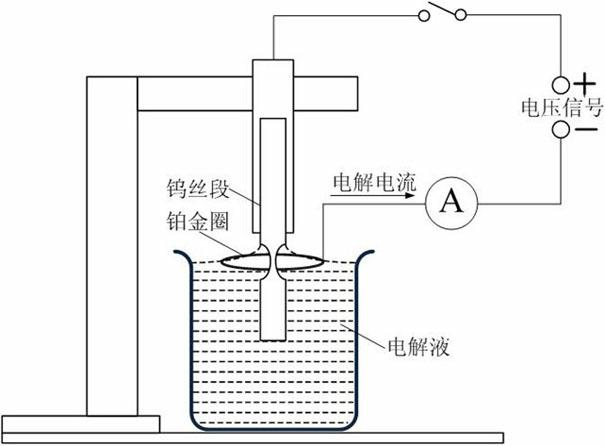

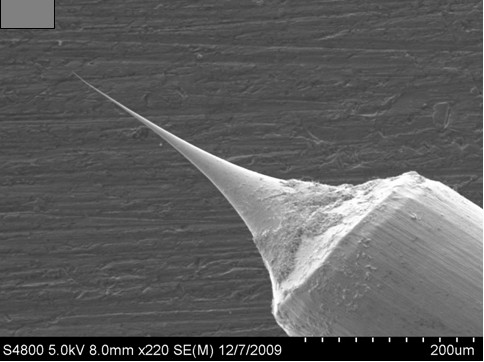

Preparation process for tunneling scanning microscope probe with reverse exponent shape and depth-to-length-diameter ratio

InactiveCN102181914AHigh-precision measurement capabilityImprove the measurement effectScanning probe microscopyMicro nanoElectrolysis

The invention discloses a preparation process for a tunneling scanning microscope probe with reverse exponent and depth-to-length-diameter ratio. The process comprises the following steps: taking tungsten wire as the material for manufacturing the probe, immersing the tungsten wire into alkaline electrolytic solution to be taken as anode, winding a corrosion-resistance platinum wire on the periphery of the tungsten wire to be taken as cathode, sequentially adopting pulse width voltage signals with adjustable current and duty ratio to determine the immersing depth, the electrolytic voltage, solution concentration and the like of the tungsten wire, detecting the electrolytic current in real time, and automatically shunting down the voltage signals, thus stopping the electrolysis process when the slope of curve of the electrolytic current is larger than 0.8mA / ms. The process can be utilized for manufacturing tunneling scanning microscope probe with a reverse-exponent outline, wherein the radius of the probe tip is smaller than 20nm, and the length-to-diameter ratio is higher than 100-1, so that a tunneling scanning microscope has the capability of achieving the atomic-scale image resolution ratio, and measuring the depth-to-width ratio micro-nano structure.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com