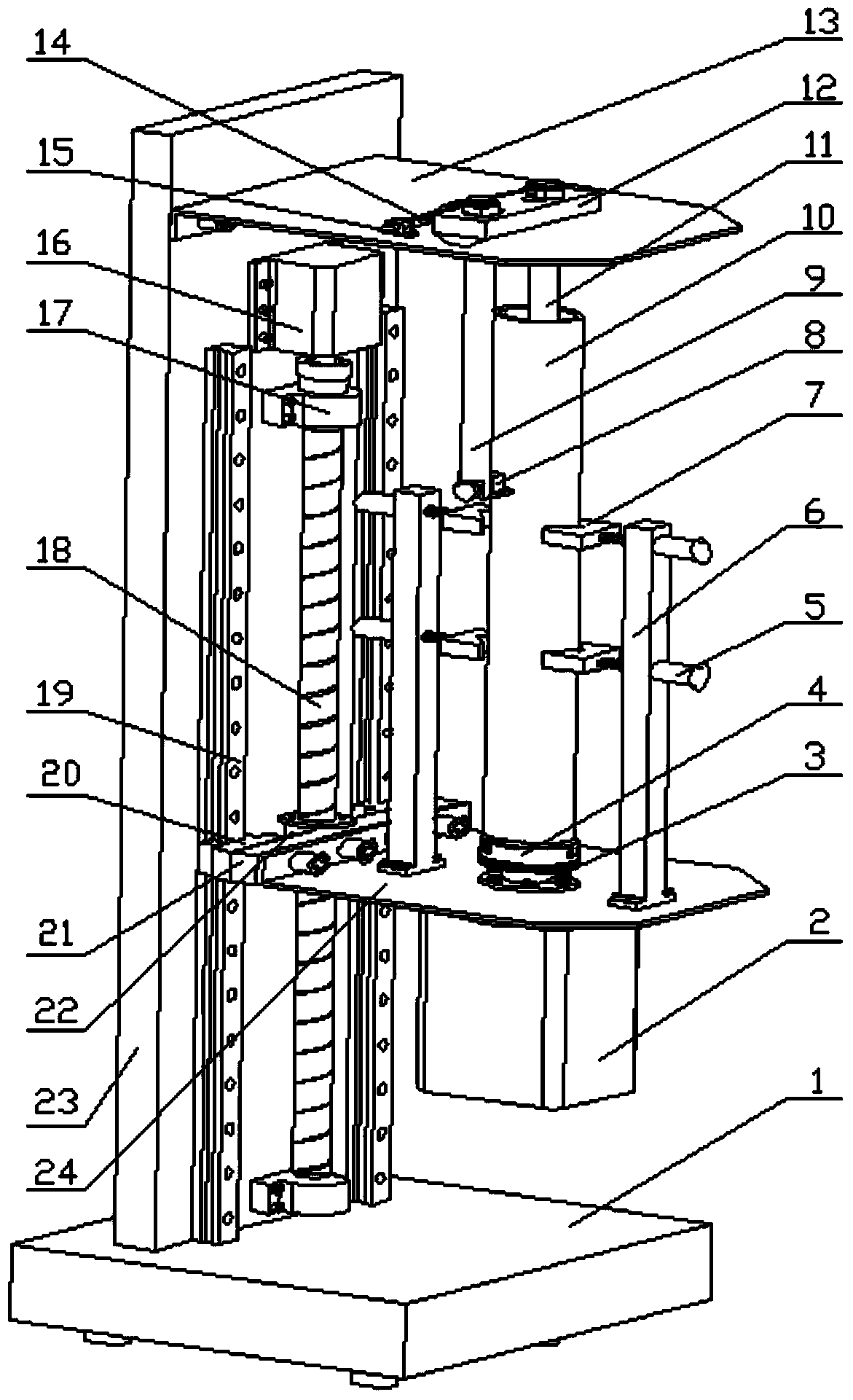

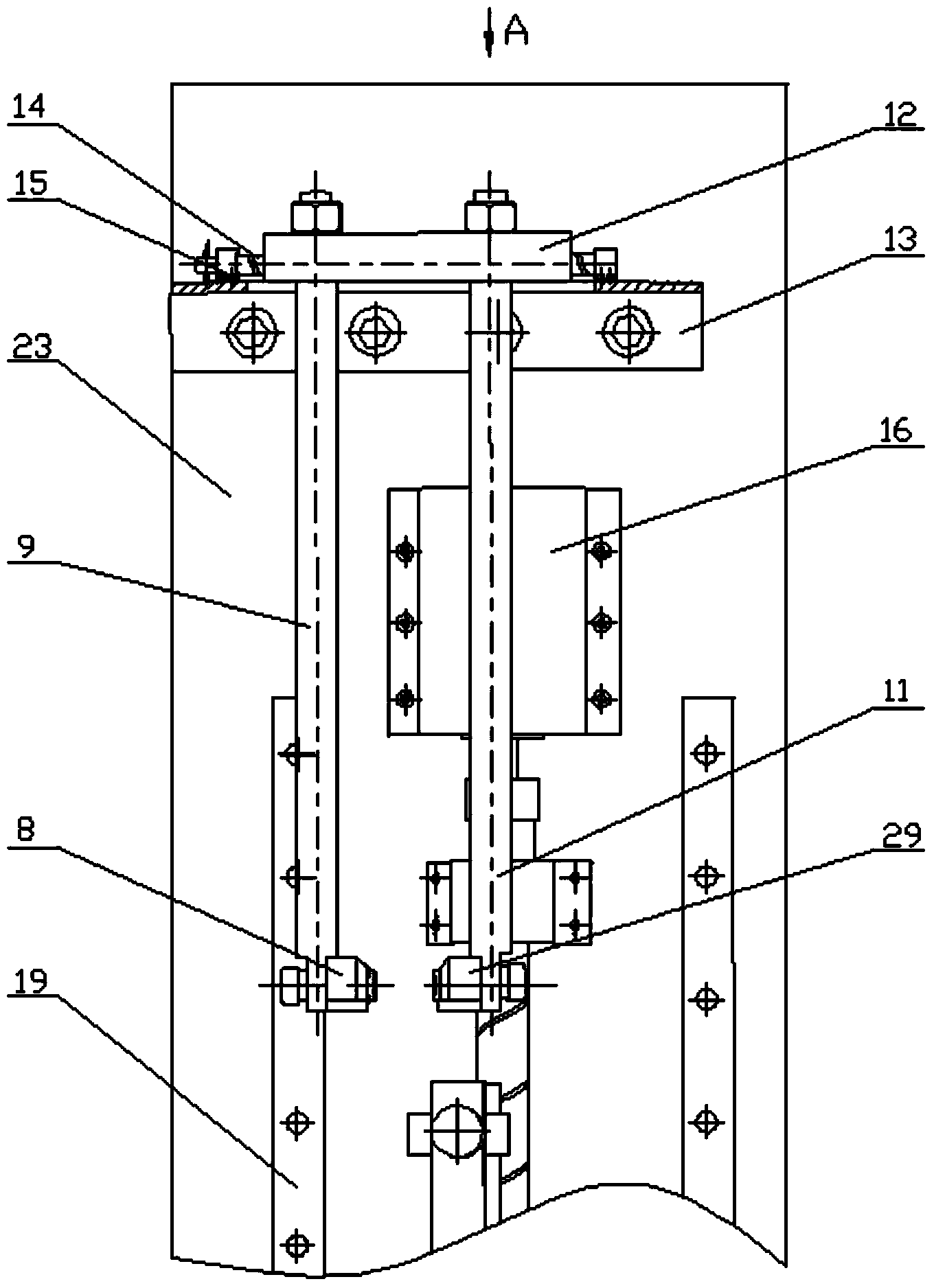

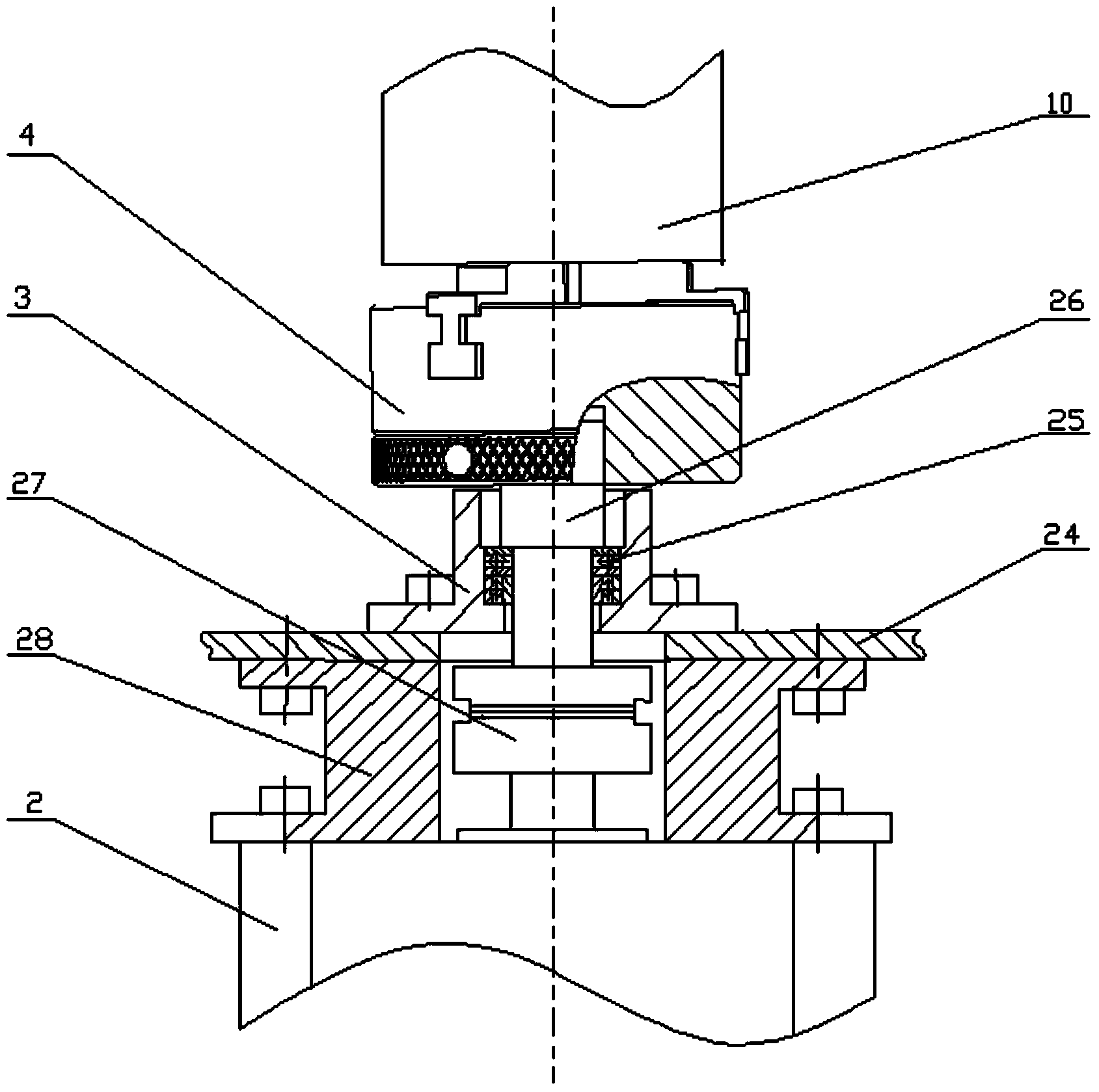

Automatic cylinder wall thickness measurement device based on laser sensor

A laser sensor and measuring device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems affecting measurement accuracy and difficulty in obtaining high-precision measurement results, so as to ensure measurement accuracy, improve measurement efficiency, and improve automation The degree and effect of robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A workpiece is a cylindrical part, its outer wall is a metal structure, the inner wall is a glass fiber reinforced plastic structure, its axial length is close to 1000mm, and its diameter is less than 70mm. When using manual measurement of wall thickness, put the cylindrical part on the measuring mandrel, use the dial gauge to withstand the outer wall, and at the same time apply radial force manually to make it close to the measuring mandrel, because the dial gauge and measuring mandrel If the zero position is calibrated between, the reading of the dial gauge is the wall thickness. This method cannot be automated and continuous measurement, and the efficiency is low and a large number of dial gauge heads are worn.

[0041] And use the cylinder wall thickness automatic measuring device based on laser sensor described in the present invention, from loading (furnished with automatic loading and unloading manipulator in addition), to the clamping of workpiece, location and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com