Czochralski single crystal silicon diameter measurement method

A Czochralski single crystal silicon, diameter measurement technology, applied in single crystal growth, chemical instruments and methods, self-melting liquid pulling method, etc., can solve problems such as large measurement errors, aperture image distortion, and errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

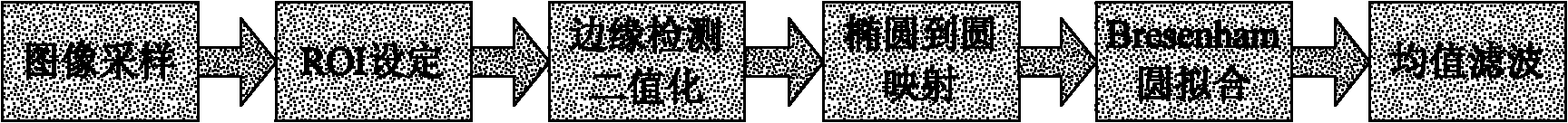

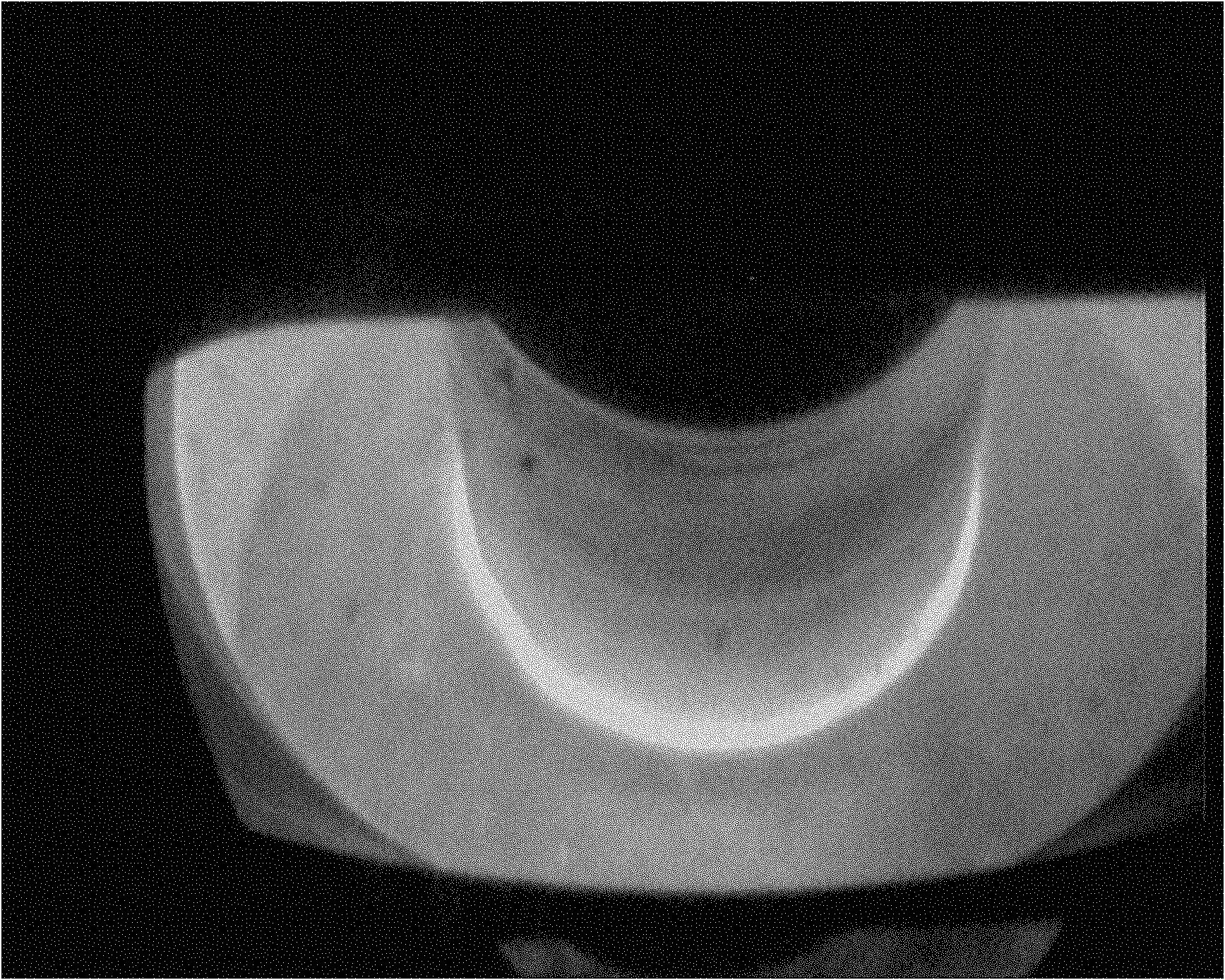

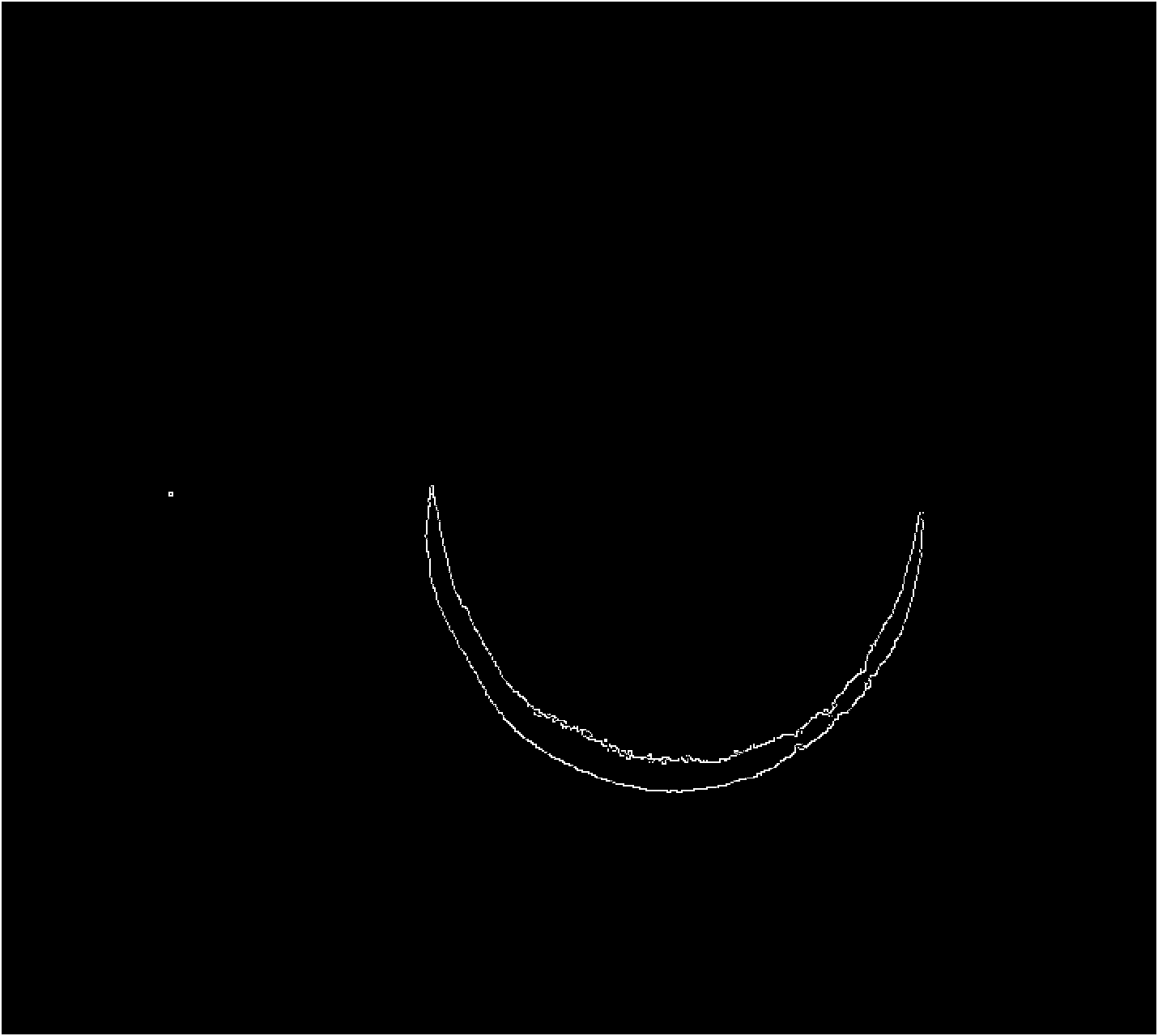

[0042] figure 1 It is the overall flow chart of the implementation of the present invention. First, the image is sampled, and then the ROI region of interest is set, and the edge detection and binarization of the ROI region are performed to obtain a single-sided image of the single crystal. According to the clipping between the camera and the liquid surface of the single crystal The angle is mapped from an ellipse to a circle, the aperture point is fitted with Bresenham's sub-pixel circle, and the diameter of the circle is average-filtered to obtain the optimal diameter of the aperture image.

[0043] Specific steps are as follows:

[0044] 1. The resolution of the general industrial analog camera is 720*576. Due to the large difference in the size of the crystals in the isodiameter and seeding stages, two lenses with different focal lengths ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com