Preparation process for tunneling scanning microscope probe with reverse exponent shape and depth-to-length-diameter ratio

A technology of scanning tunneling and preparation technology, which is applied in the field of preparation technology of scanning tunneling microscope probes with high aspect-to-diameter ratio, and can solve problems such as complex devices, lack of probe preparation technology, and poor controllability of probes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

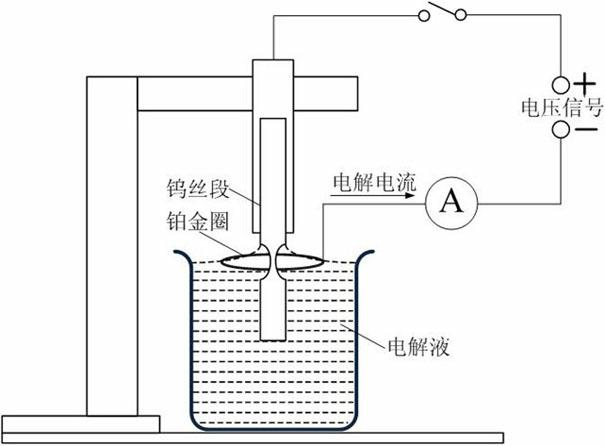

[0023] The preparation device of the scanning tunneling microscope probe with inverted exponential shape and high length-to-diameter ratio is as follows: figure 1 shown.

[0024] 1) Straighten a tungsten wire with a mass percent purity of 99.9999% and a diameter of 0.25mm and cut it into a 10mm tungsten wire segment as the anode, wind a 0.5mm platinum wire into a platinum ring with a diameter of 8mm as the cathode, and use a concentration of 1mol / L of KOH solution as electrolyte;

[0025] 2) Put the platinum ring on the liquid surface of the electrolyte and ground it, put the tungsten wire segment through the center of the platinum ring and immerse it in the electrolyte, apply a voltage signal to electrolyze the tungsten wire segment, when the slope of the electrolysis current curve is greater than 0.8mA / ms , the voltage signal is automatically cut off, and the electrolyzed tungsten wire segment is soaked in hydrofluoric acid solution or acetone solution for 1 minute to remo...

Embodiment 2

[0031] The preparation device of the scanning tunneling microscope probe with inverted exponential shape and high length-to-diameter ratio is as follows: figure 1 shown.

[0032] 1) Straighten a tungsten wire with a mass percent purity of 99.9999% and a diameter of 0.50 mm and cut it into a 15 mm tungsten wire segment as an anode, wind a 1 mm platinum wire into a platinum ring with a diameter of 10 mm as a cathode, and use a concentration of 3 mol / L of KOH solution as electrolyte;

[0033] 2) Put the platinum ring on the liquid surface of the electrolyte and ground it, put the tungsten wire segment through the center of the platinum ring and immerse it in the electrolyte, apply a voltage signal to electrolyze the tungsten wire segment, when the slope of the electrolysis current curve is greater than 0.8mA / ms , the voltage signal is automatically cut off, and the electrolyzed tungsten wire segment is soaked in hydrofluoric acid solution or acetone solution for 2 minutes to re...

Embodiment 3

[0038] The preparation device of the scanning tunneling microscope probe with inverted exponential shape and high length-to-diameter ratio is as follows: figure 1 shown.

[0039] 1) Straighten the tungsten wire with a mass percentage purity of 99.9999% and a diameter of 0.3 and cut it into 12 tungsten wire segments as the anode, wind a 0.8 platinum wire into a platinum circle with a diameter of 9 mm as the cathode, and use KOH with a concentration of 2mol / L solution as electrolyte;

[0040] 2) Put the platinum ring on the liquid surface of the electrolyte and ground it, put the tungsten wire segment through the center of the platinum ring and immerse it in the electrolyte, apply a voltage signal to electrolyze the tungsten wire segment, when the slope of the electrolysis current curve is greater than 0.8mA / ms , the voltage signal is automatically cut off, and the electrolyzed tungsten wire segment is soaked in hydrofluoric acid solution or acetone solution for 1-2 minutes to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com