Method and device for measuring thickness of continuous casting shell

A technology for thickness measurement and continuous casting slabs, which is applied in the configuration of indicating equipment/measuring equipment, casting equipment, manufacturing tools, etc. It can solve the problem of inability to describe the continuous variation of the slab shell, and the inability to fix it at the same position by nailing, etc. To solve the problem, to achieve the effect of reasonable design of measurement method, accurate analysis results and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] The operating conditions of the embodiment are: on a continuous casting machine with the number of segments N=15, the length of the segments is 1850mm, and the distance from the starting point of the flame cutting machine of the continuous casting machine to the exit of the casting machine is L 0 = 2m, billet doubler B is 20m.

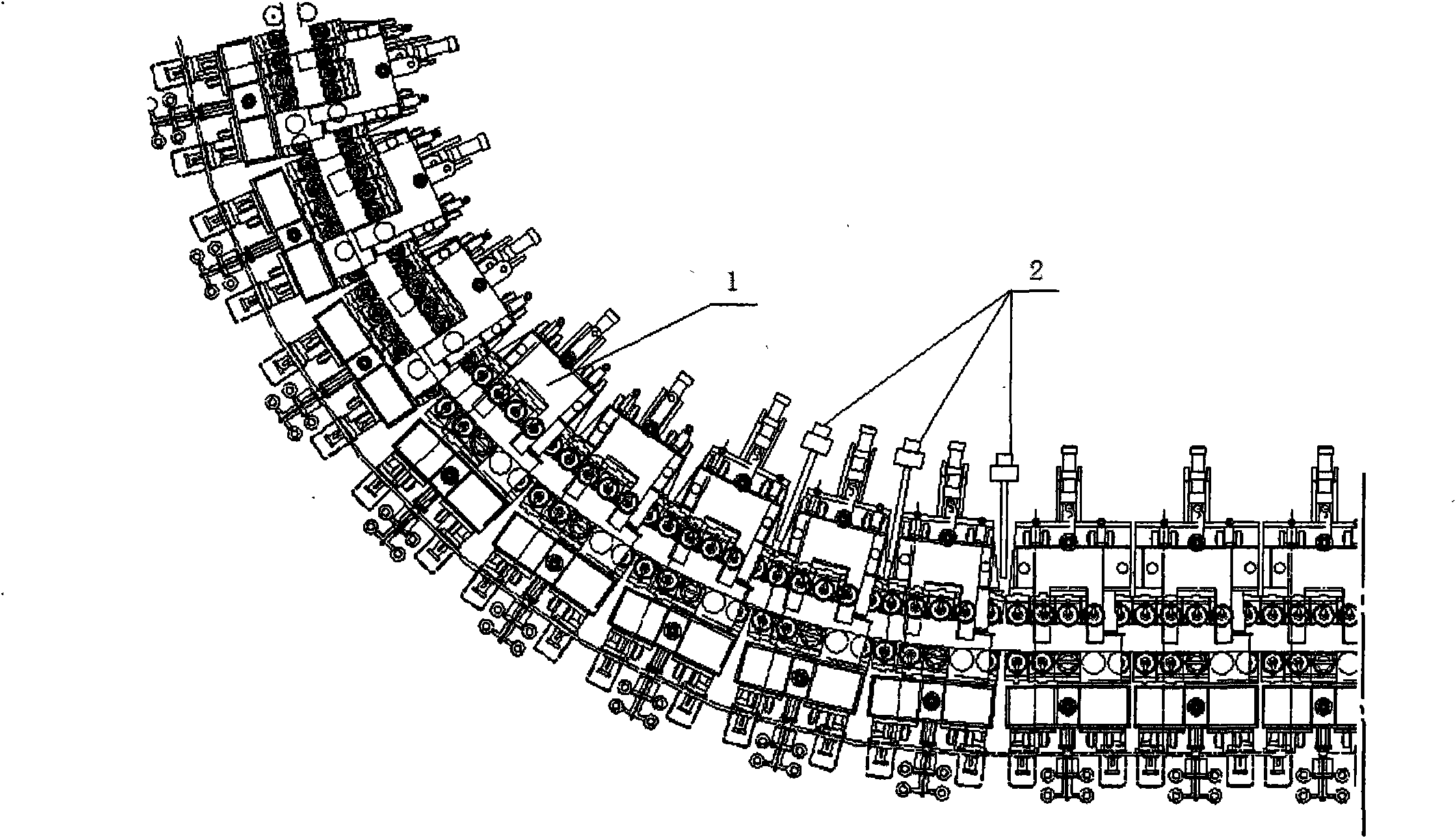

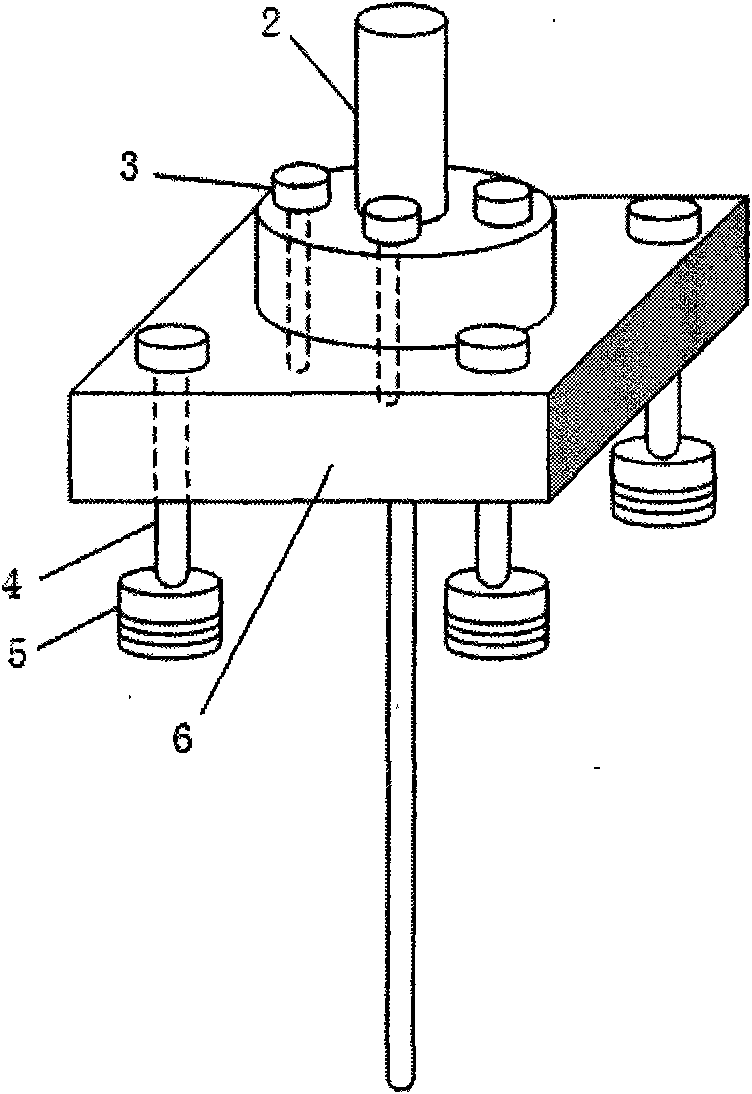

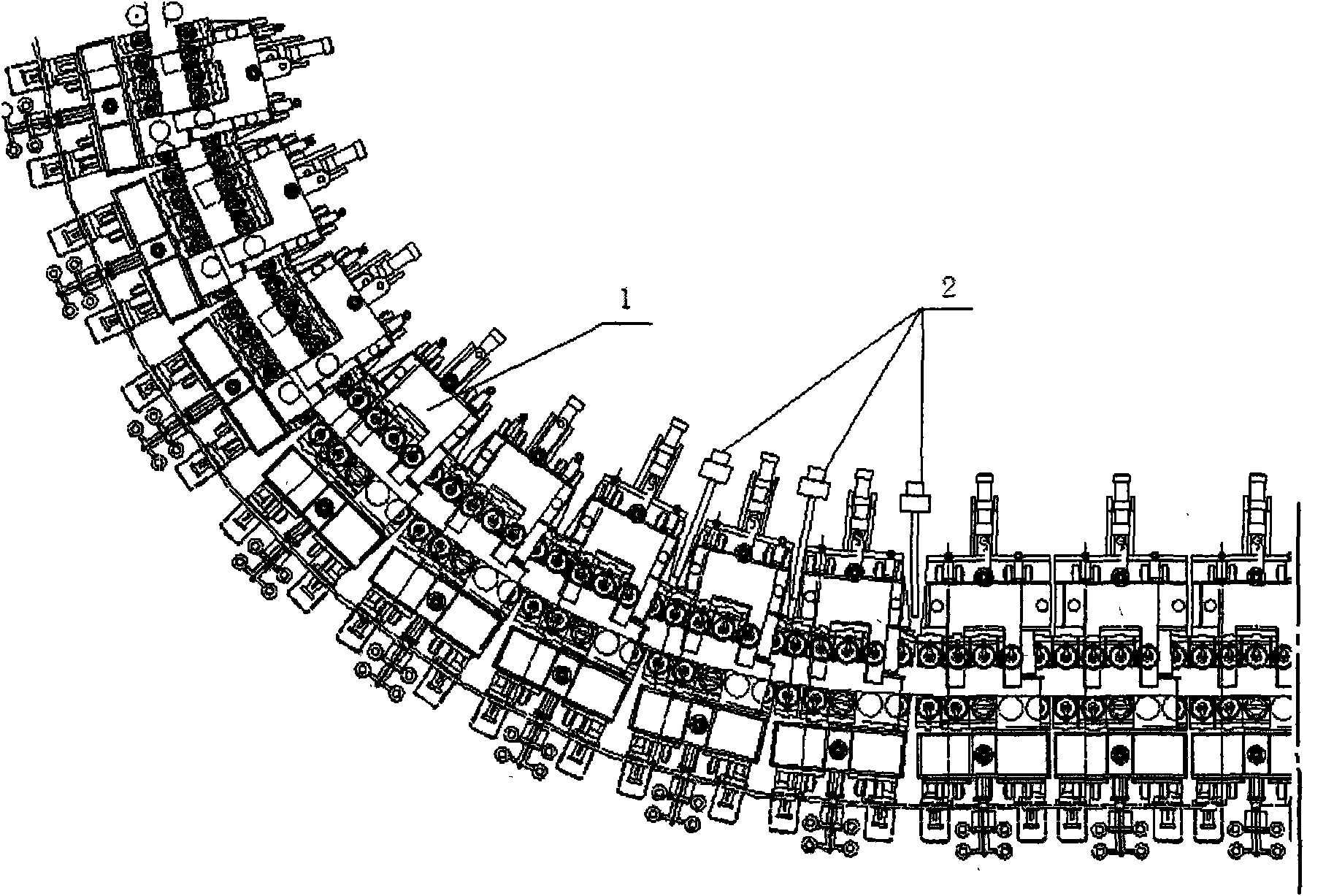

[0023] Depend on figure 1 It can be seen that the continuous casting slab shell thickness measuring device of the present invention is composed of three nail guns 2 arranged along the casting direction of the continuous casting slab, and the three nail guns 2 are sequentially fixed in parallel on two adjacent Between segment 1. figure 2 It is shown that the special support is composed of the support body 6, the foot bolt 4 and the adjusting gasket group 5. The overall shape of the support body 6 is a square flat plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com