Patents

Literature

80results about How to "Speed up the design process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Numerical value simulation method of vibration and acoustic characteristics of speaker

ActiveCN102004823ASpeed up the design processOvercome the disadvantage of being limited to low frequenciesSpecial data processing applicationsElement modelGeometric modeling

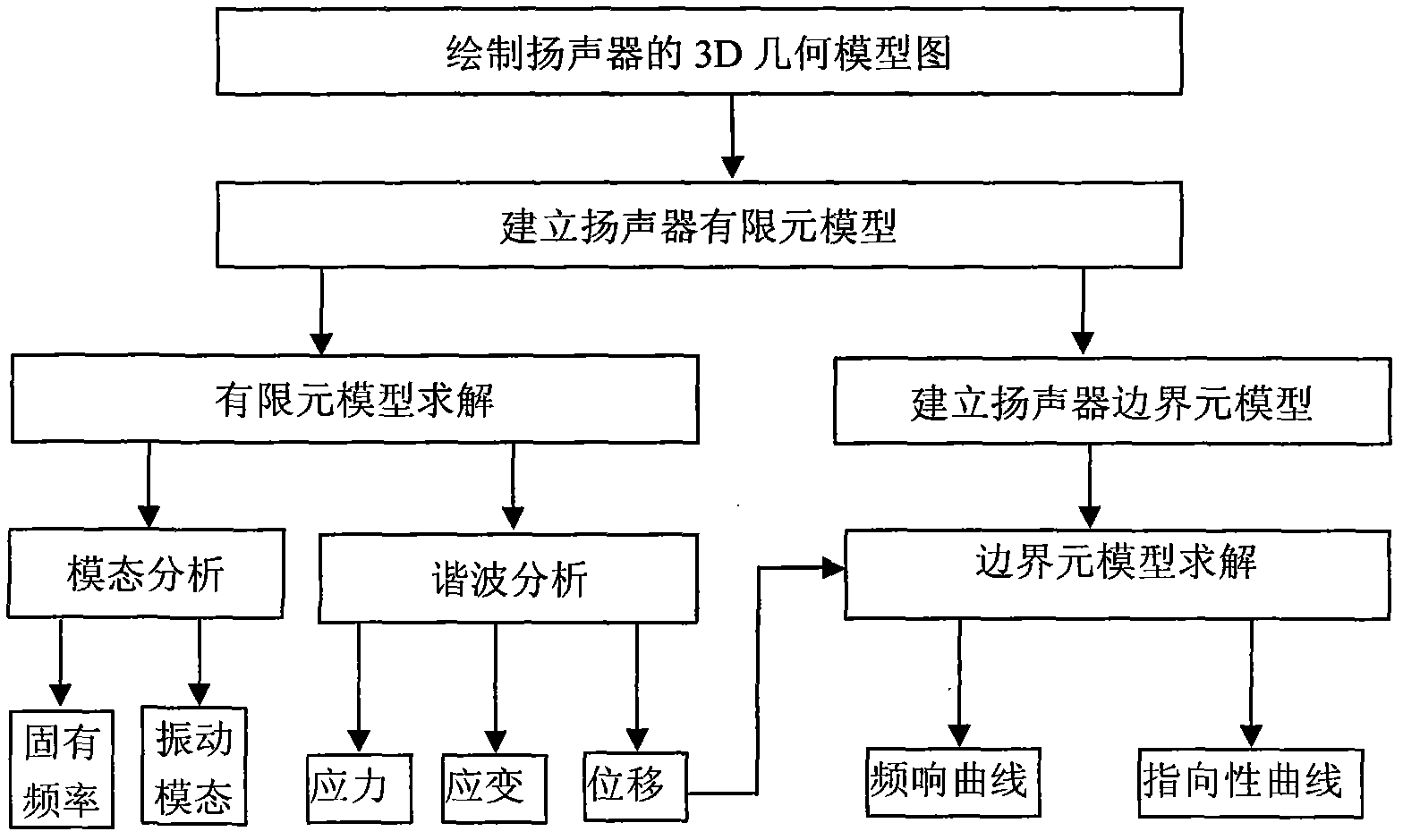

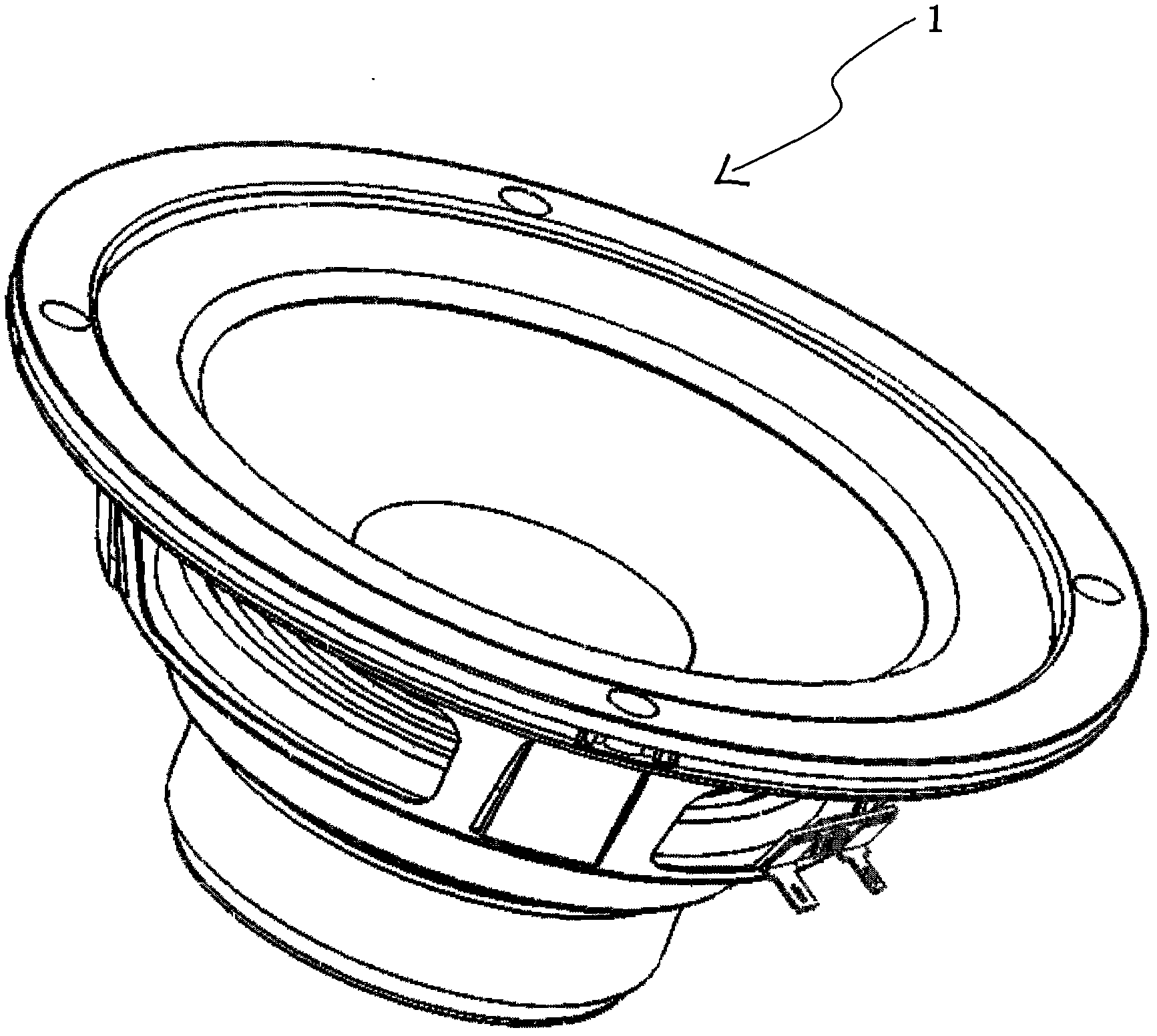

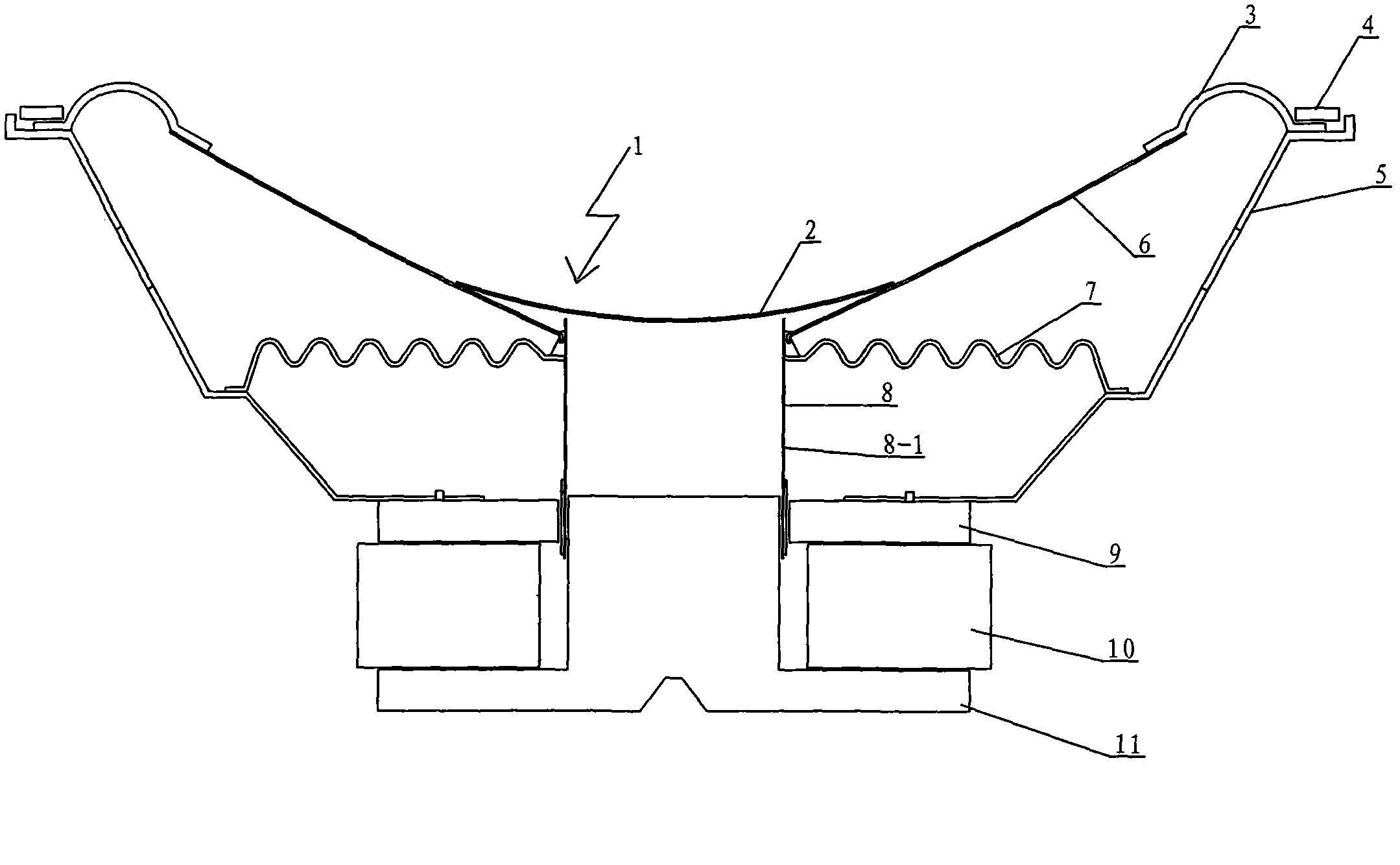

The invention provides a numerical value simulation method of the vibration and acoustic characteristics of a speaker. The method comprises the following steps of: firstly, drawing a 3D (Three-Dimensional) geometric model diagram of the speaker by using 3D drawing software; then, adding the 3D geometric model diagram of the speaker to meshing software to mesh the 3D geometric model diagram into body elements, defining element types, materials and boundary conditions and applying a load to acquire a finite element model; establishing a boundary element model matched with the finite element model; and finally, solving the finite element model with a finite element solver to acquire the vibration characteristics of the speaker, and solving the boundary element model with a boundary element solver to acquire the acoustic characteristics of the speaker, wherein the vibration characteristics include the natural frequency, the vibration mode (vibration type), the displacement, the strain and the stress, and the acoustic characteristics include a frequency response curve and a directivity curve.

Owner:ZHEJIANG ELECTRO ACOUSTIC R&D CENT CAS +1

Numerical value simulating method for loudspeaker magnetic circuit system

ActiveCN102368281ASpeed up the design processOvercome the problem of magnetic circuit defectImage data processingSpecial data processing applicationsElement modelFinite element software

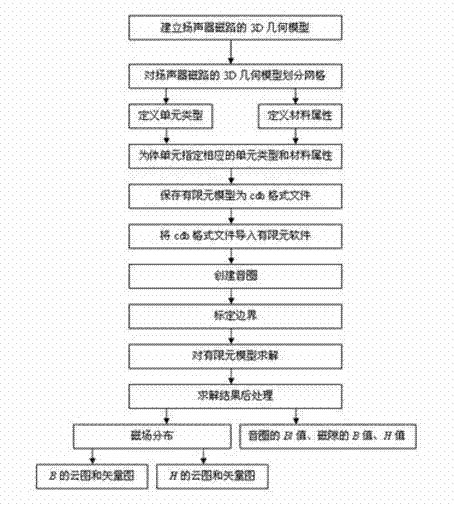

The invention discloses a numerical value simulating method for a loudspeaker magnetic circuit system. The method comprises the following steps of firstly drawing a three-dimensional (or two-dimensional) geometric model of a loudspeaker magnetic circuit system by a three-dimensional drawing software; leading the geometric model in a mesh generation software to perform mesh generation to obtain a body unit (or a facet unit); defining the unit type, material property and associating to the corresponding body unit (or facet unit) to obtain a limit element model of a magnetic circuit system; saving the limit element model as a file type capable of being identified by unit software; and then leading the limit element model in limit element software, adding a voice coil mark, calibrating the absorbing boundary, and finally defining a static analysis to perform solving and obtaining the results of magnetic field distribution situation, voice coil B1 value, B value on certain points an the like of the loudspeaker magnetic circuit system after post-processing, and displaying the results in image forms.

Owner:ZHEJIANG ELECTRO ACOUSTIC R&D CENT CAS +1

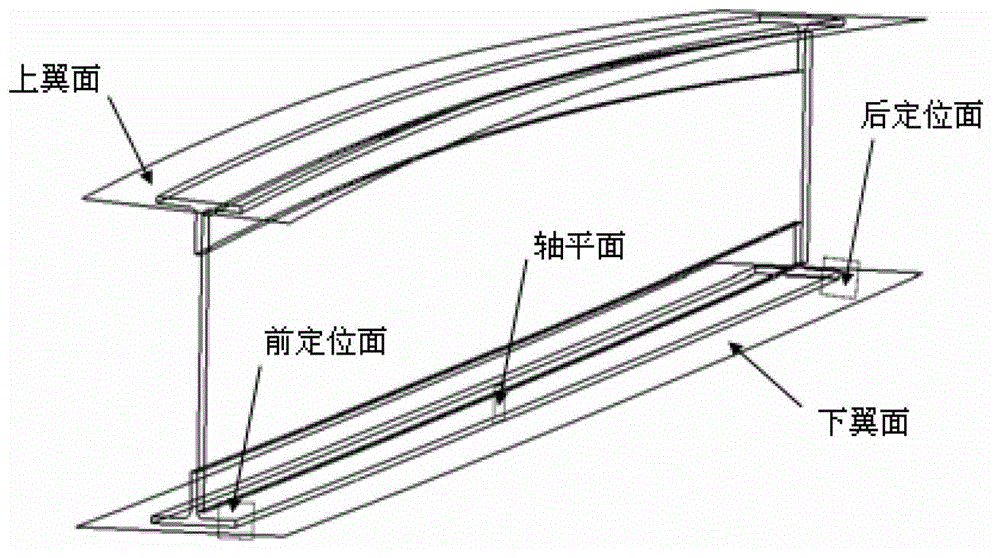

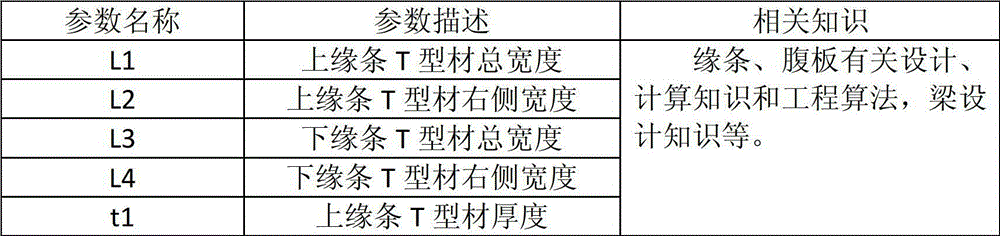

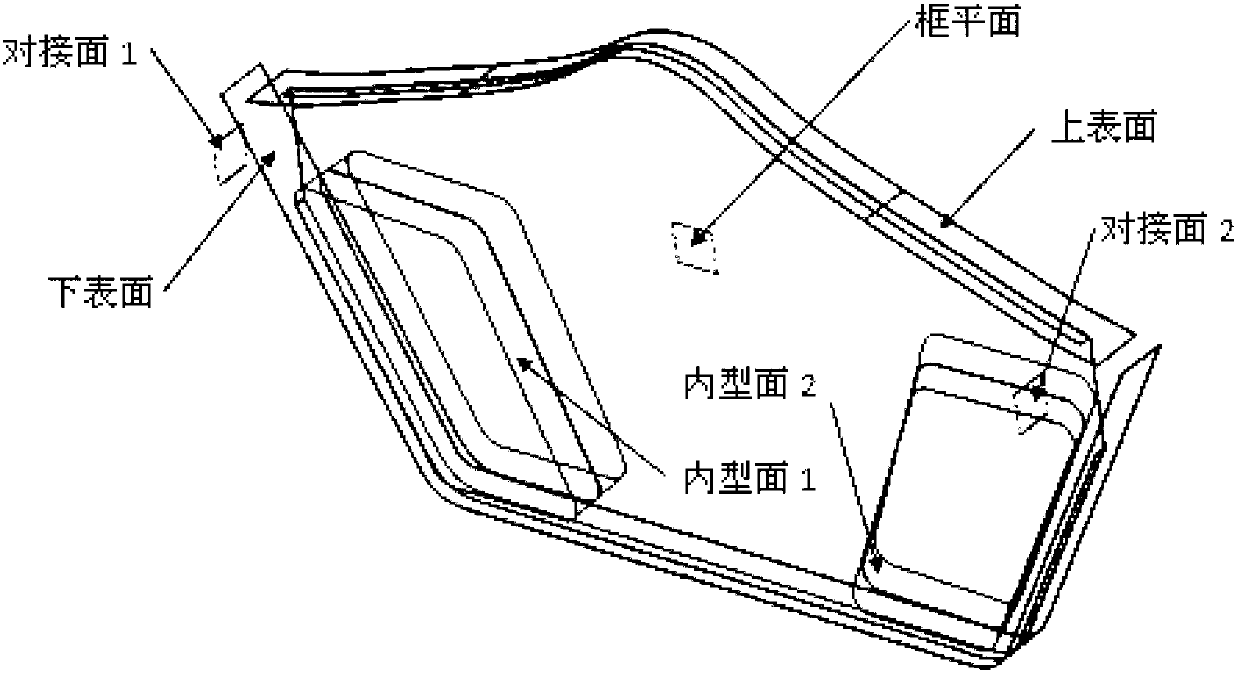

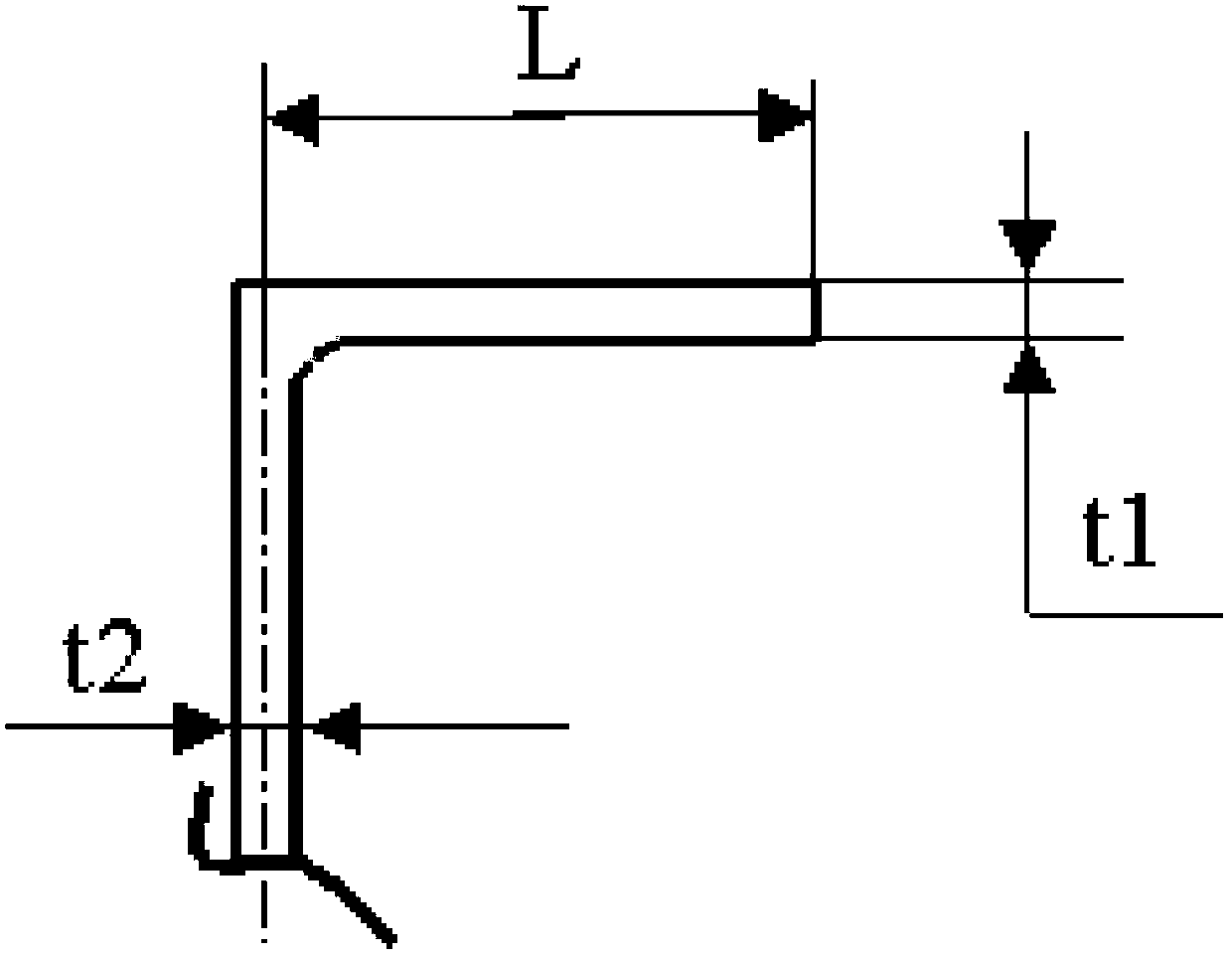

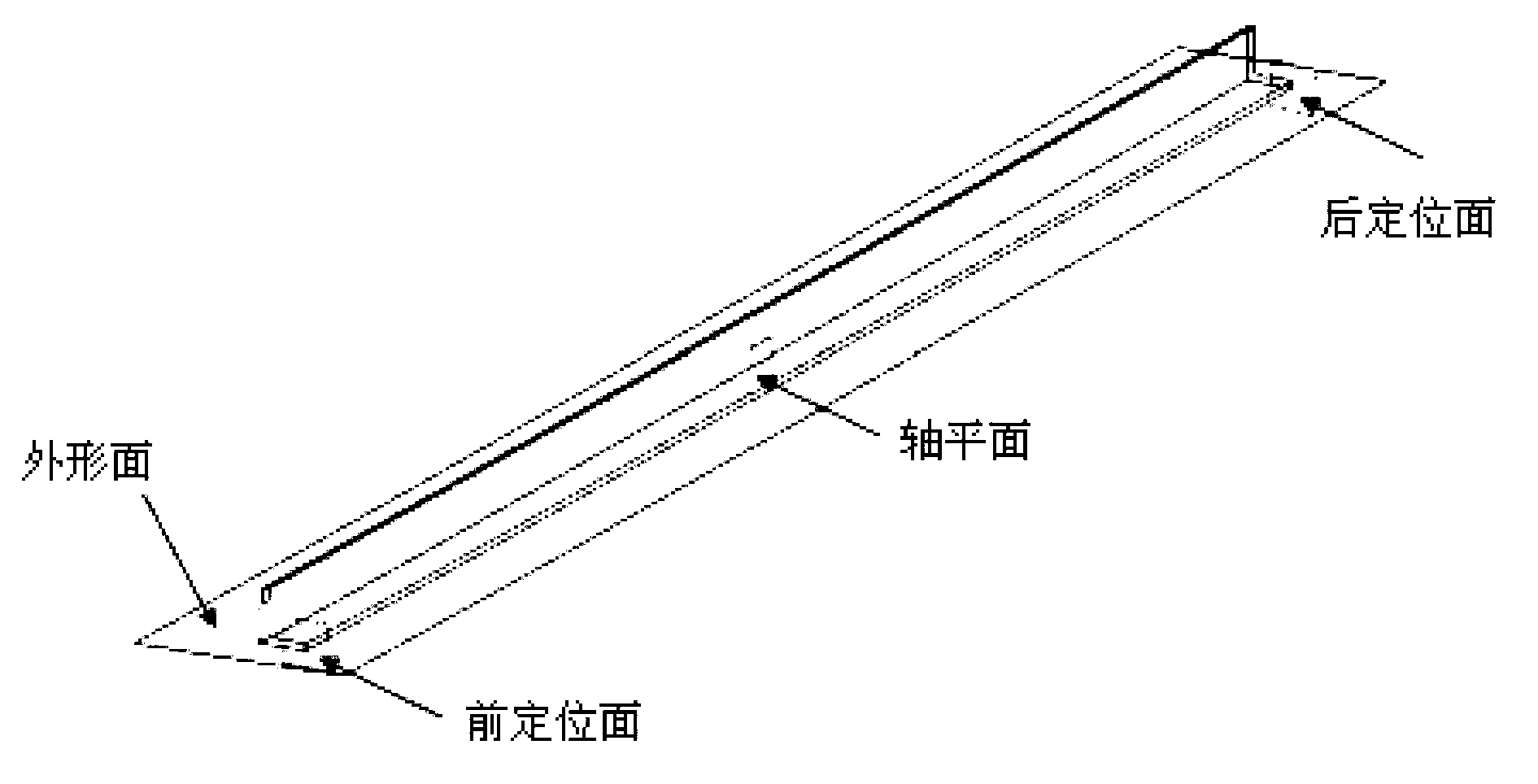

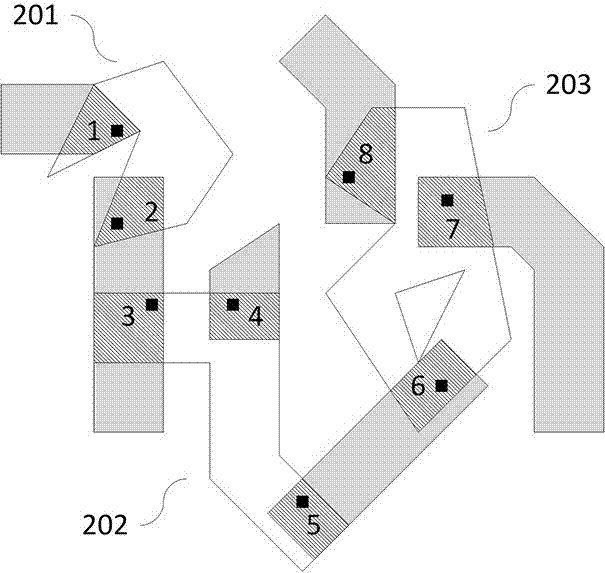

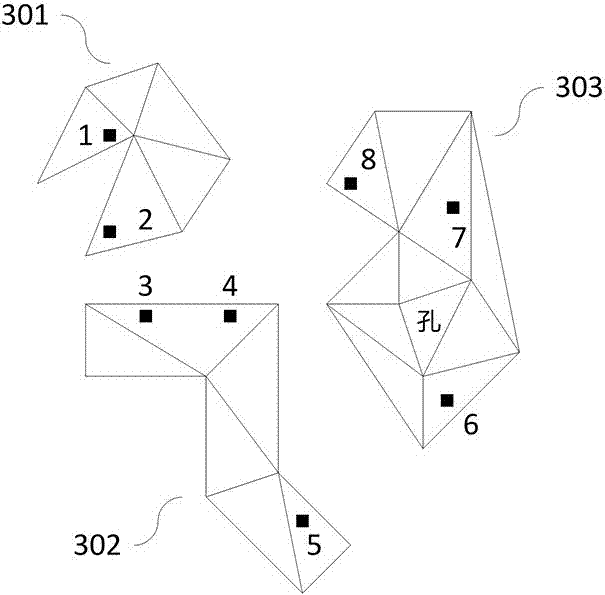

Parametrization design method of first-level member of beam, wall and rib type parts of airplane

ActiveCN102982219AStandardize the digital definition processRich modeling methodsSpecial data processing applicationsDecompositionQuality by Design

The invention discloses a parametrization design method of first-level member of beam, wall and rib type parts of airplane. The parametrization design method comprises the following steps of: stating the beam, wall and rib type parts in the airplane structure by using parametrization members, wherein the parametrization statement of the first-level members of the beam, wall and rib parts of the airplane specifically relates to contents of four parts as follows: 1) the basic attributes specifically comprise the names of the members, the version numbers, the establishment time, the member description, the manufacturing process and the remarks; 2) the geometric attributes specifically consist of two parts of positioning parameters and cross-section parameters; 3) non-geometric attributes specifically relate to decomposition schemes and non-geometric attribute information corresponding to the decomposition schemes; and 4) a two-dimensional sectional drawing is used for helping a user to correctly understand the physical meaning of the parameters of the members in member instantiation. The parametrization design method is helpful in establishing a member bank system, functional and performance model data basis for the standardization and simulation analysis in airplane design is provided, the coordination of data of a geometric model machine and a functional model machine / performance model machine is ensured, the design quality of the airplane is improved, and the research and manufacturing period is shortened.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

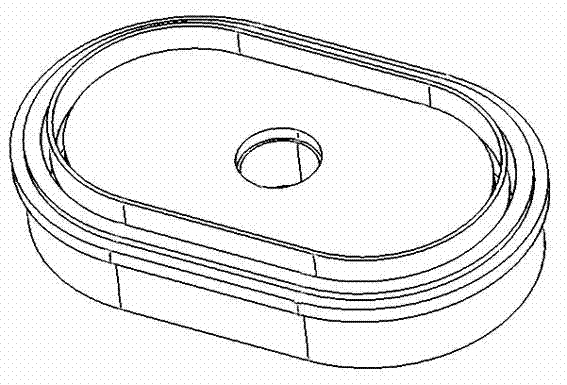

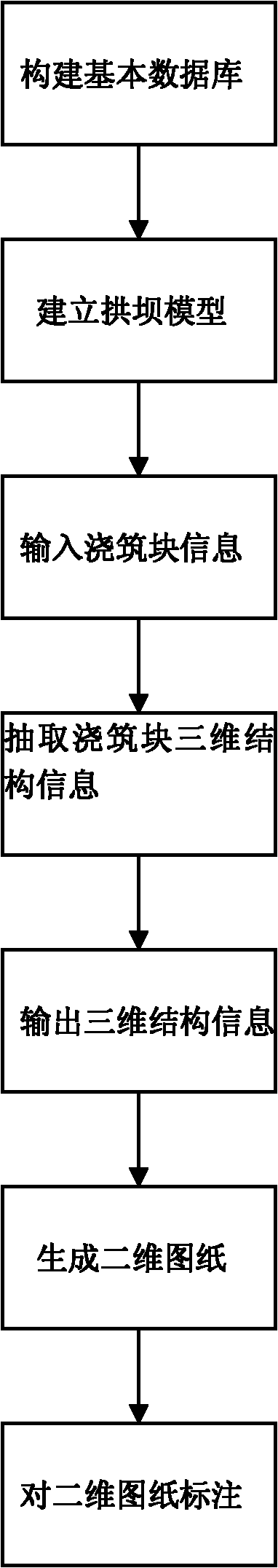

Numerical simulation analysis method for carrying out numerical simulation analysis on nonlinear characteristic of stiffness coefficient of centering disk of loudspeaker

ActiveCN103310052ASpeed up the design processOvercome design gapsSpecial data processing applicationsAxial displacementStiffness coefficient

The invention discloses a numerical simulation analysis method for carrying out numerical simulation analysis on the nonlinear characteristic of stiffness coefficient of a centering disk of a loudspeaker and belongs to the field of loudspeaker design. The method completes static analysis by establishing a geometric model of the centering disk and defining a nonlinear material module and considering the geometric nonlinearity through a finite element method and can obtain axial displacement of the centering disk under the action of different loading forces, so that a changing curve of the stiffness coefficient of the centering disk along with the axial displacement can be obtained by post-processing. By the method, the nonlinear characteristic K(x) of the centering disk can be analyzed and obtained on the initial stage of design, i.e. before a sample is not produced and manufactured, so that the centering disk is rapid and convenient to design and manufacture.

Owner:嘉善恩益迪电声技术服务有限公司 +1

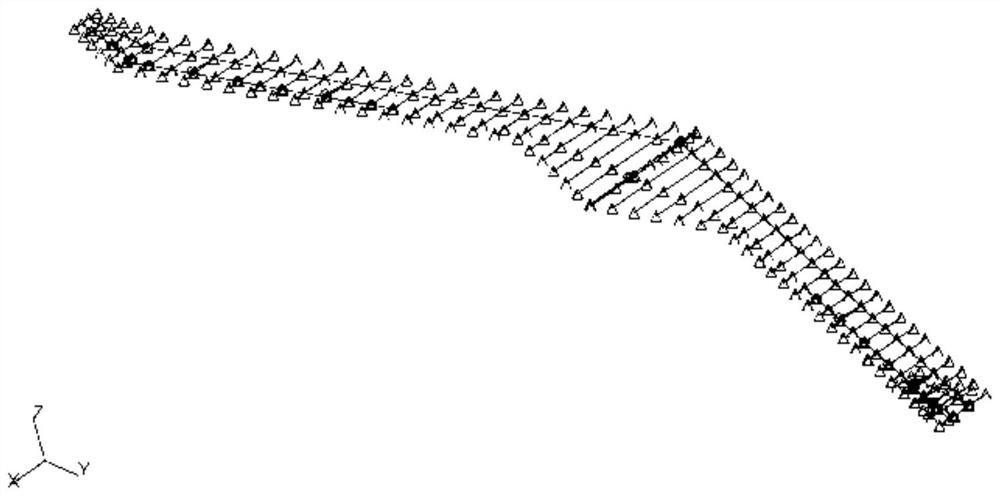

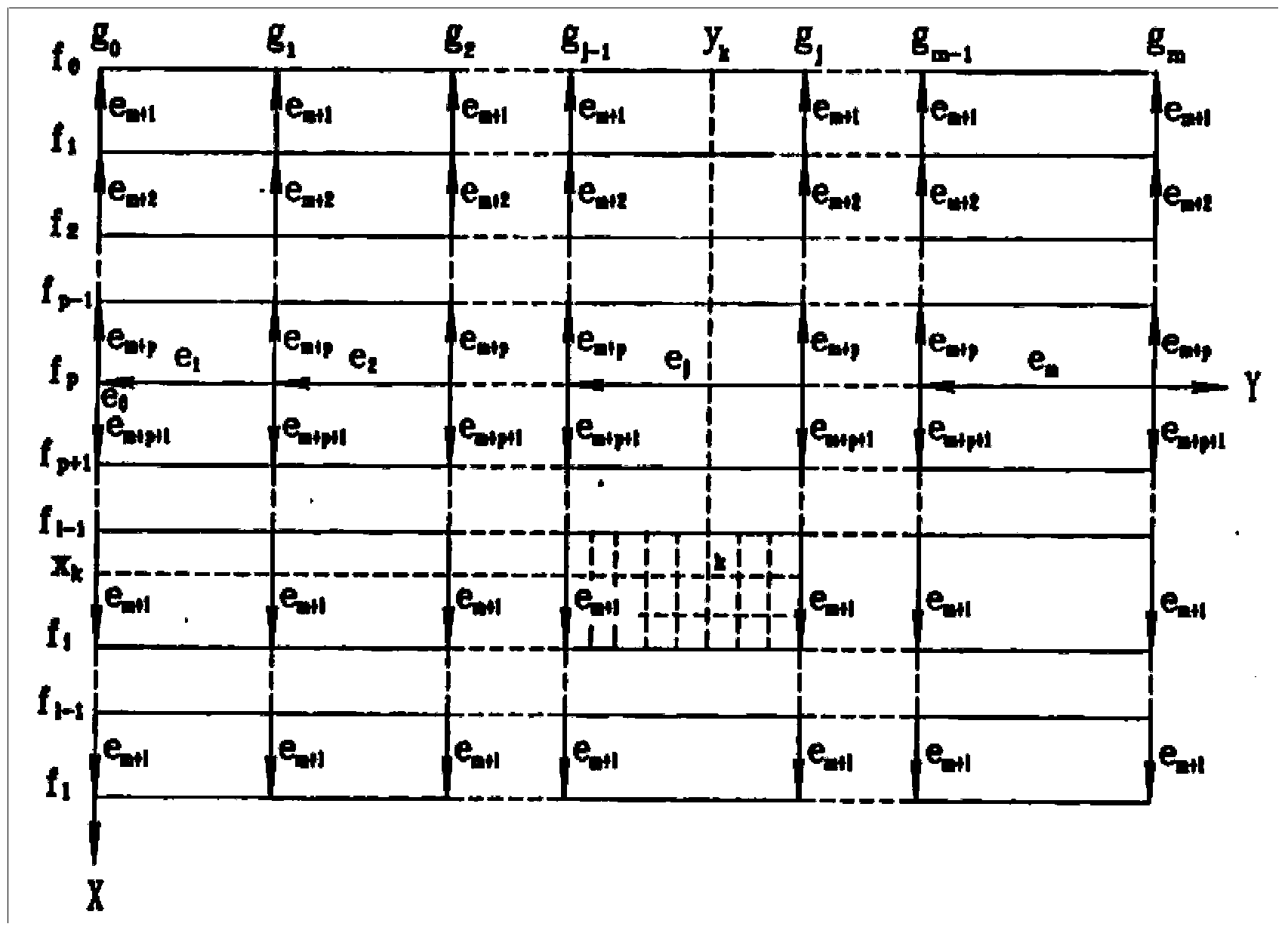

System and method for optimization design of terrain of large multi-track and multi-taxi-track airport

ActiveCN103729542AEasy to solve math problemsSolve math problemsSpecial data processing applicationsTerrainMathematical model

The invention discloses a system and method for optimization design of the terrain of a large multi-track and multi-taxi-track airport. The system for the optimization design of the terrain of the large multi-track and multi-taxi-track airport comprises an automatic optimizing unit, an automatic calculating unit, an automatic drawing unit and interactive units. The method for the optimization design of the terrain of the large multi-track and multi-taxi-track airport comprises the steps that a spatial continuous twisted surface is adopted to symbolize the terrain designing surface of the airport, nonlinear mathematical programming is adopted to summarize the design variables such as the gradient and technical indexes into one mathematical model, and the design gradient and the control point elevation of the airport are solved with the working constraint set method. The system and method for the optimization design of the terrain of the large multi-track and multi-taxi-track airport are applied to terrain design of almost hundreds of domestic and foreign airports, such as the New Luanda International Airport in the capital of Angola and the International Airport of Xianyang in Xi'an; compared with a traditional section method or a traditional lattice method, the method has the advantages that the designing earth volume of the airport can be saved by about 15% on the premise that any take-off and landing requirements of planes are not lowered, the design process can be shortened to about ten days from the original one month, and drawing quality can be improved remarkably.

Owner:AIR FORCE UNIV PLA

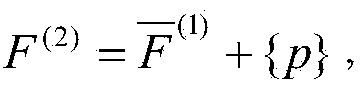

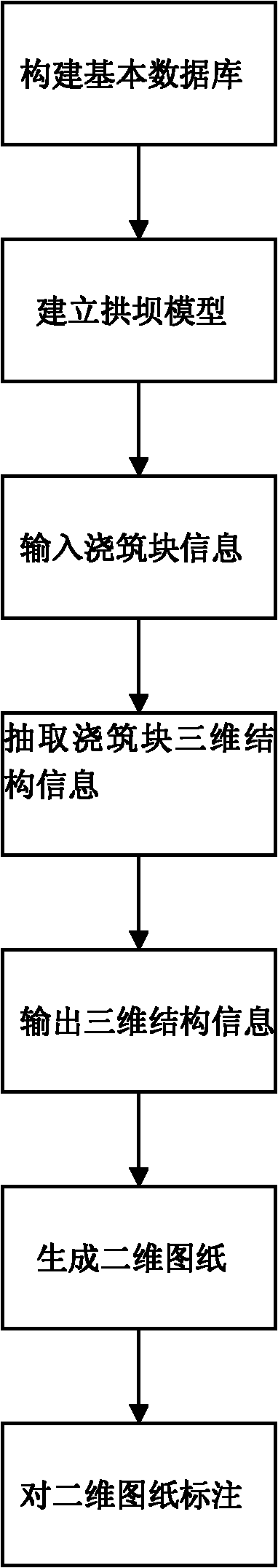

Automatic arch dam pouring block plotting device and plotting method

InactiveCN102073768ASpeed up the design processReduce design costSpecial data processing applications3D modellingThree dimensional modelData information

The invention relates to the technology of modeling, and discloses an automatic arch dam pouring block plotting method, and solves the problems of heavy workload, high difficulty and prone errors caused by manual drawing in the prior art. The technical scheme comprises the main points that: the arch dam pouring block plotting method comprises the following steps of: a. constructing a basic database including arch dam modeling-related data information; b. establishing a three-dimensional model of an overall arch dam; c. inputting the information of a pouring block which needs to be plotted, and extracting the three-dimensional structural information of the pouring block from the three-dimensional model of the overall arch dam; d. outputting the acquired three-dimensional structural information of the pouring block, and generating two-dimensional drawing paper through a two-dimensional plotting module; and e. marking the generated two-dimensional drawing paper and counting basic information, and indicating on a drawing. In addition, the invention also discloses an automatic arch dam pouring block plotting device. The method and the device realize automatic arch dam pouring block plotting, speed up a design schedule, reduce design cost, reduce error rate, improve production efficiency and are suitable for planning to build an arch dam.

Owner:POWERCHINA CHENGDU ENG

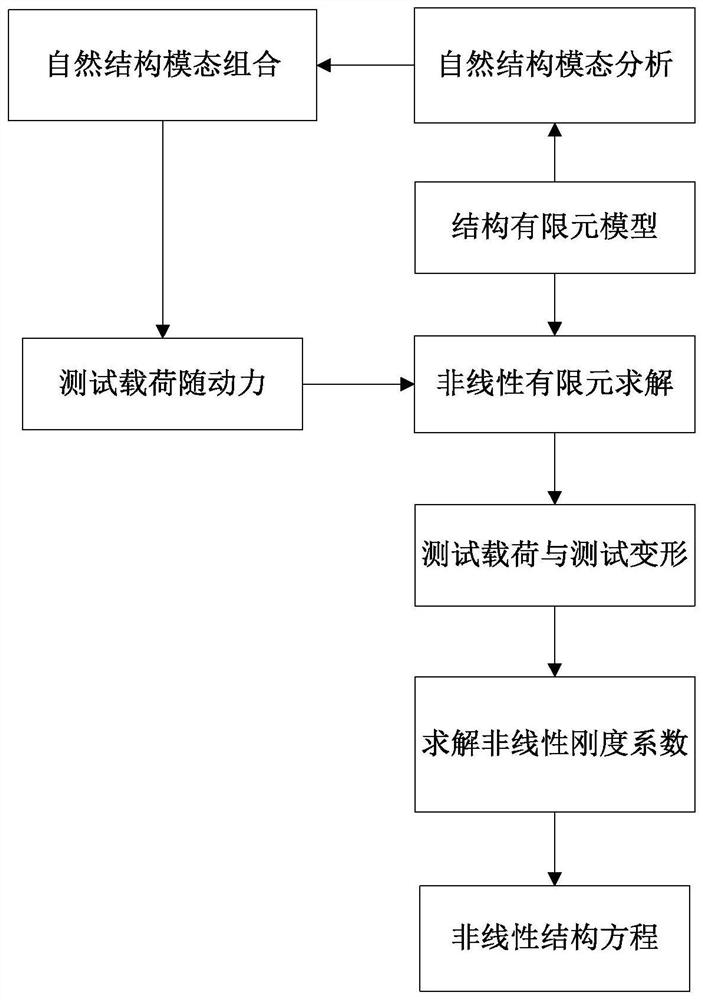

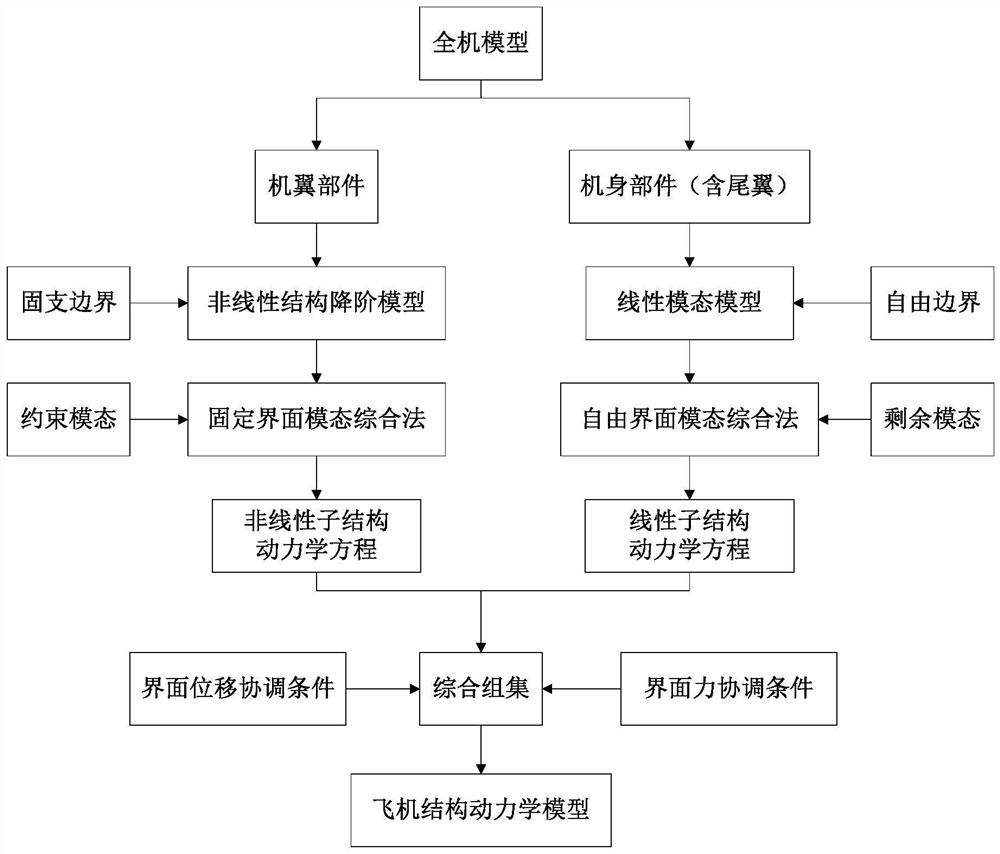

Nonlinear substructure method suitable for complex large flexible aircraft modeling

ActiveCN112580240AReduce the amount of analysis calculationImprove computing efficiencyGeometric CADDesign optimisation/simulationStructural deformationStructure analysis

The invention discloses a nonlinear substructure method suitable for complex large flexible aircraft modeling. A large flexible aircraft model is divided into wing components and fuselage components (including empennages and the like); a wing part is modeled by adopting a nonlinear structure reduced-order model; a large-deformation structure kinetic equation is constructed by utilizing a nonlinearrigidity coefficient, and a test load is constructed by utilizing a mode of multiplying a modal combination by a proportionality coefficient; on the basis, a nonlinear stiffness coefficient is solvedby adopting a method for carrying out regression analysis on an input test load and corresponding structural deformation, and a nonlinear structure order reduction model is formed; and linear modal modeling is carried out on the fuselage component. A constraint mode is solved by applying a fixed interface mode comprehensive method to a wing component, a residual mode is solved by applying a freeinterface mode comprehensive method to a fuselage component, and then a structural kinetic equation is formed through an interface displacement and force coordination condition comprehensive set. According to the method, the modeling cost is greatly reduced, and the modeling and structure analysis efficiency is improved.

Owner:BEIHANG UNIV

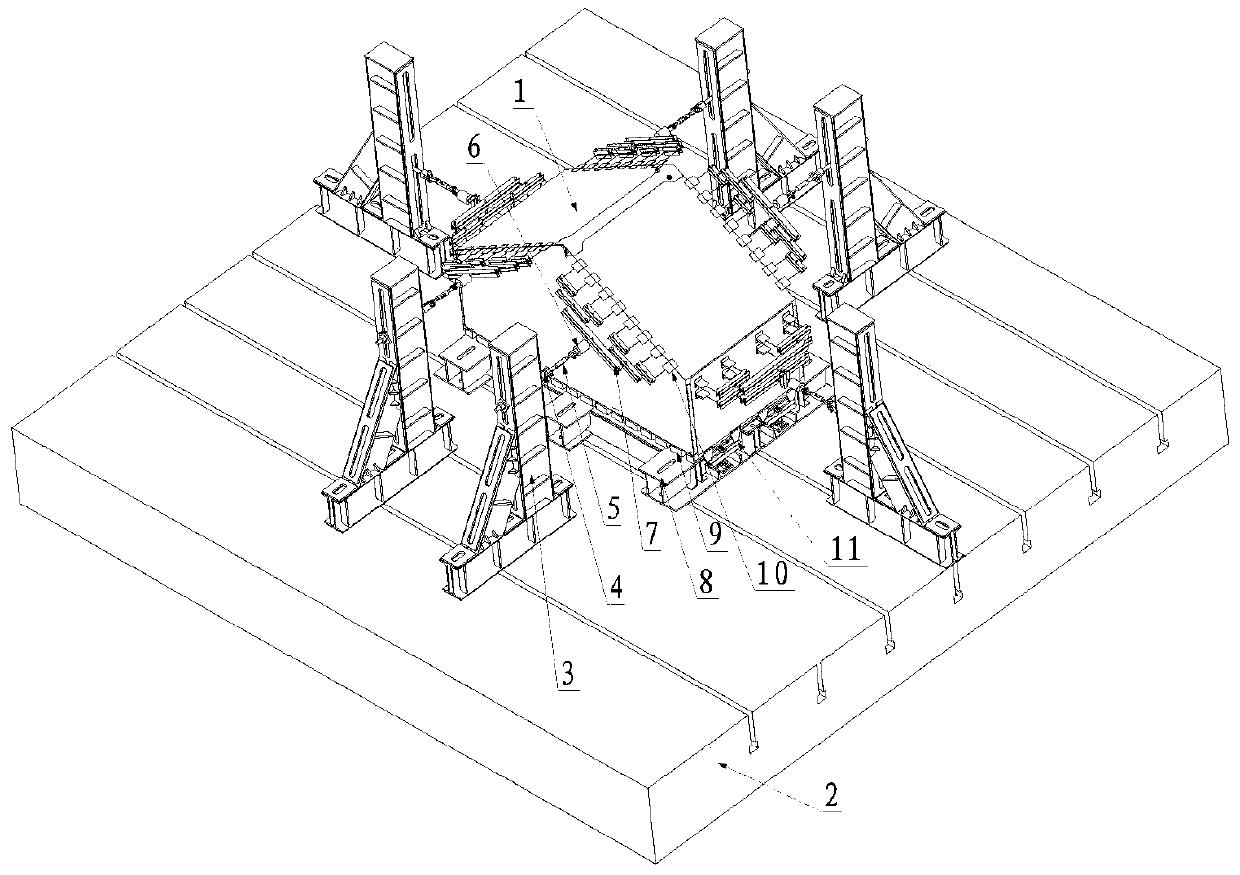

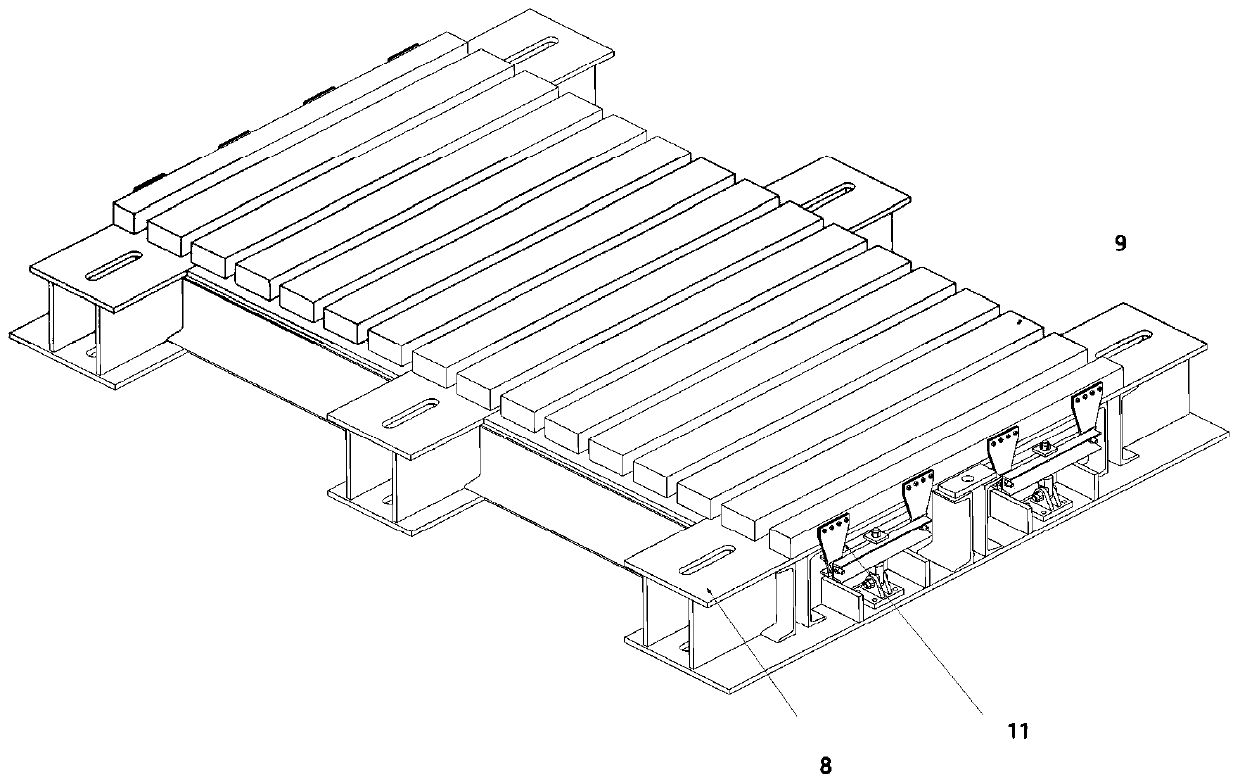

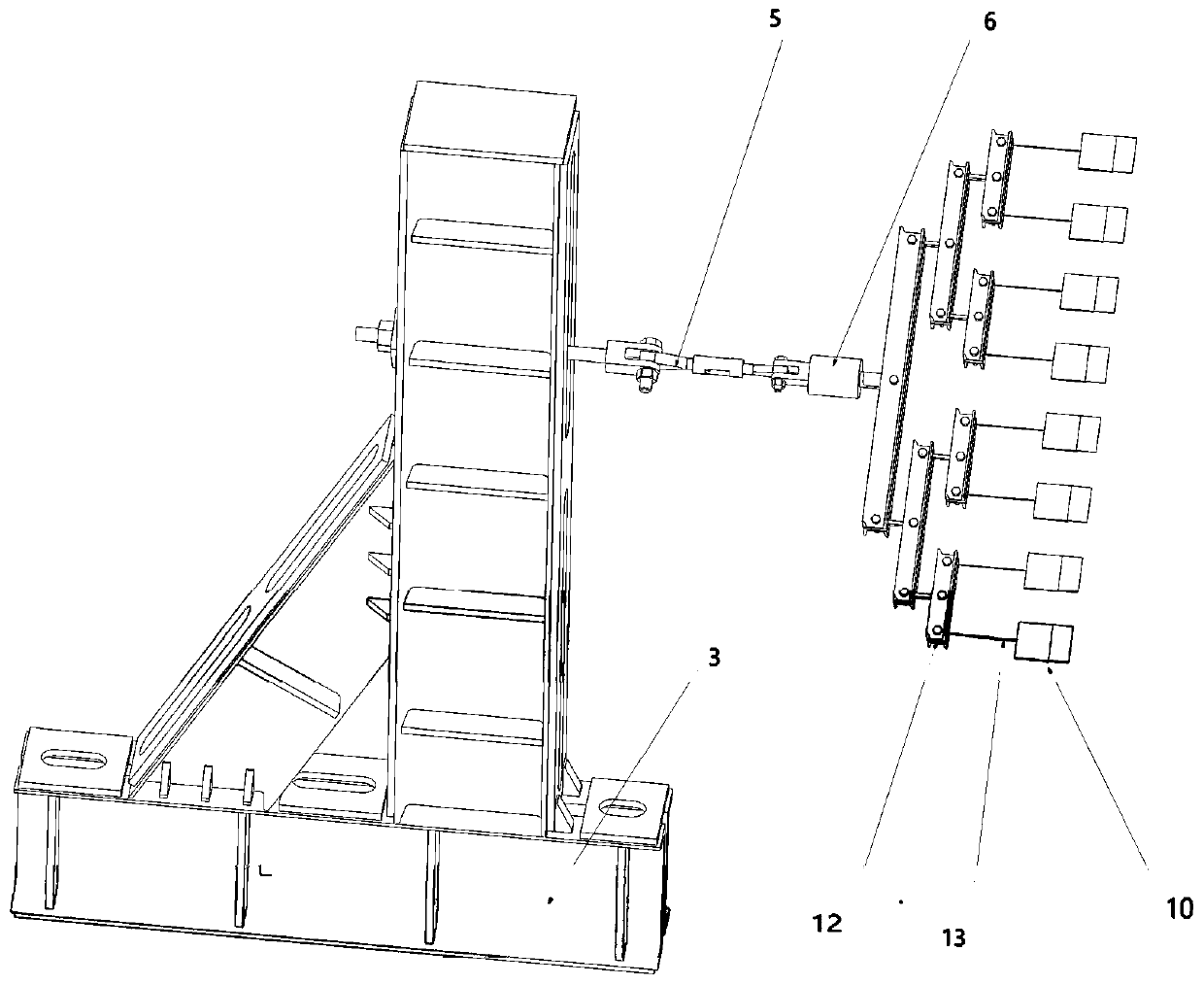

Fuselage cabin section structural strength test constraint system

ActiveCN111409856ASpeed up the design processReduce processing costsWeight reductionAircraft components testingClassical mechanicsRight lateral position

The invention belongs to the field of structural strength tests and particularly relates to a fuselage cabin section structural strength test constraint system. The system comprises a bearing terrace,M stand columns, M fastening structures, M load conversion mechanisms, a fixed base, an adhesive tape and a vertical constraint mechanism, wherein the fixed base is arranged on the bearing terrace, the vertical restraining mechanisms are arranged at two ends of the fixed base and connected with the fuselage cabin section through bolts, the M stand columns are distributed at the front-back headingposition and the left-right lateral position of the fuselage cabin section correspondingly, lower ends of the stand columns are fixed to the force bearing terrace, the adhesive tape is adhered to a skin end frame and two sides of the fuselage cabin section, upper ends of the stand columns are connected with one ends of the load conversion mechanisms through a fastening structure, and the other ends of the load conversion mechanisms are connected with the adhesive tape. The system is advantaged in tht constraints meeting requirements can be provided, the constraint load of a fuselage cabin section end frame and a side wall boundary is effectively reduced, and the boundary is prevented from being damaged earlier than an assessment area.

Owner:CHINA AIRPLANT STRENGTH RES INST

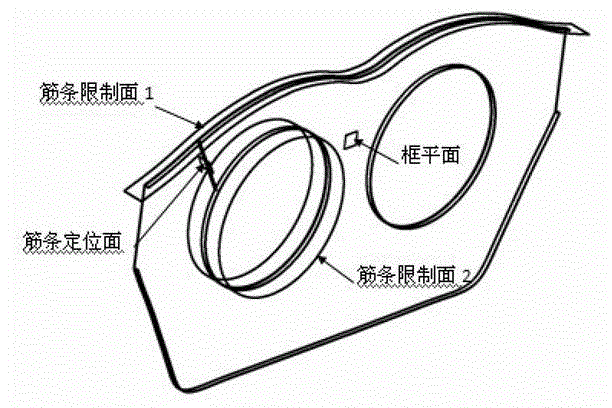

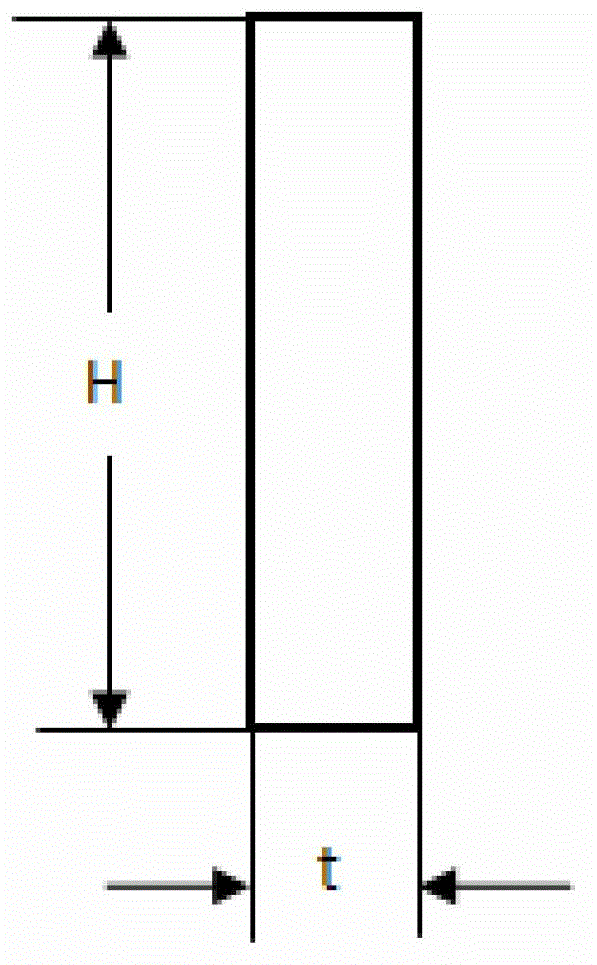

First-level construction member parametrization design method for airplane frame-type parts

ActiveCN102999677AStandardize the digital definition processRich modeling methodsSpecial data processing applicationsManufacturing technologyQuality by Design

A first-level construction member parametrization design method for airplane frame-type parts comprises that the frame-type parts in an airplane structure is described by parametrization construction members. First-level construction member parametrization description of the airplane frame-type parts particularly relates to contents as the following four parts: (1) essential attributes comprise construction member names, version numbers, creating time, construction member description, manufacture technology and remarks; (2) geometric attributes comprise location parameters and section parameter; (3) non-geometric attributes particularly relate to decomposion schemes and non-geometric attribute information; and (4) a two-dimensional sectional view is used for enabling a user to correctly understand physical significances of each parameter of the construction member when construction member instantiation is carried out. The first-level construction member parametrization design method contributes to building a component base system of an airplane, provides function and performance model data basis for airplane design standardization, simulated analysis and optimizing, guarantees consistency of data between a geometric model machine a d a functional model machine / performance model machine, improves design quality of the airplane, and shortens development period.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

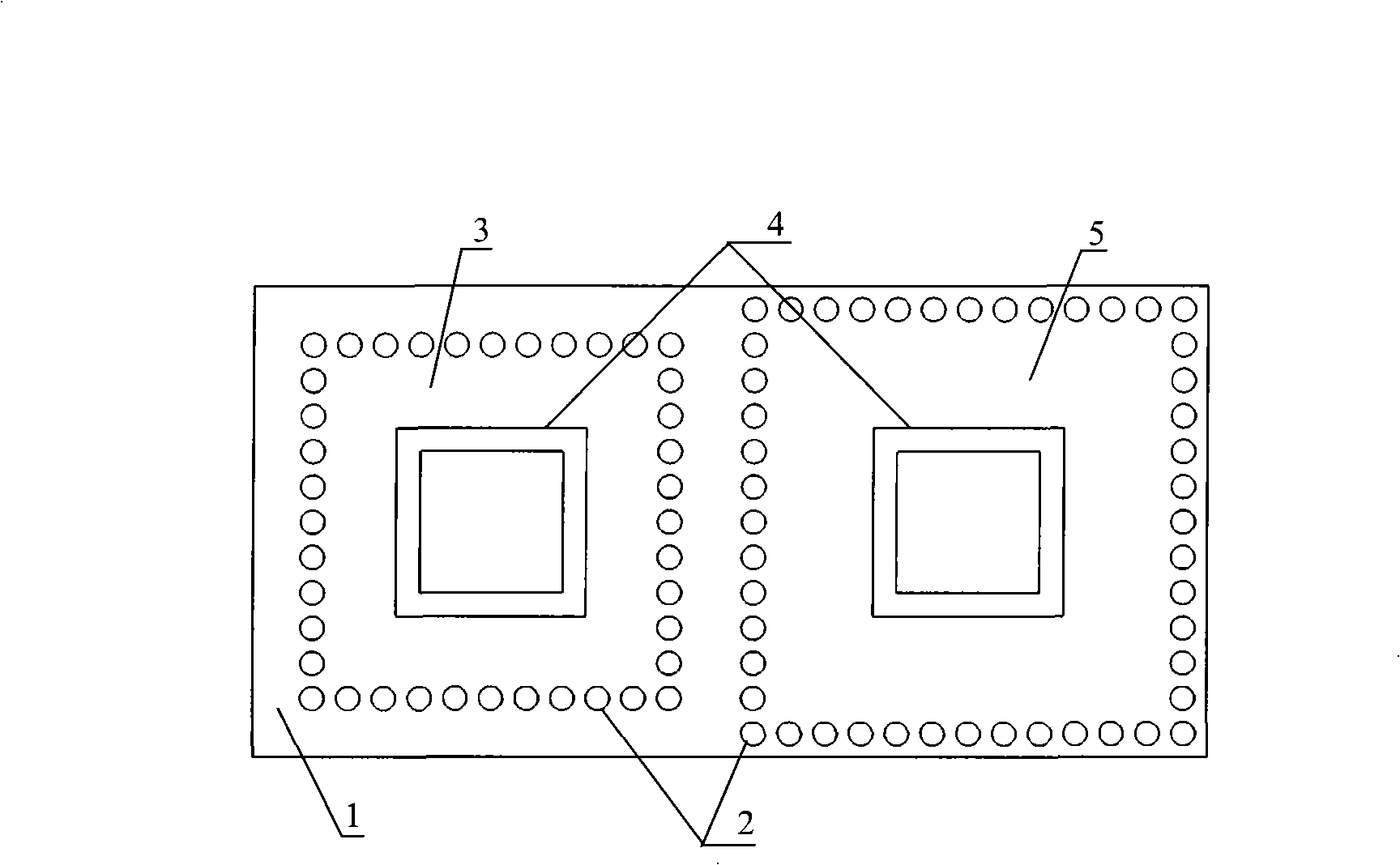

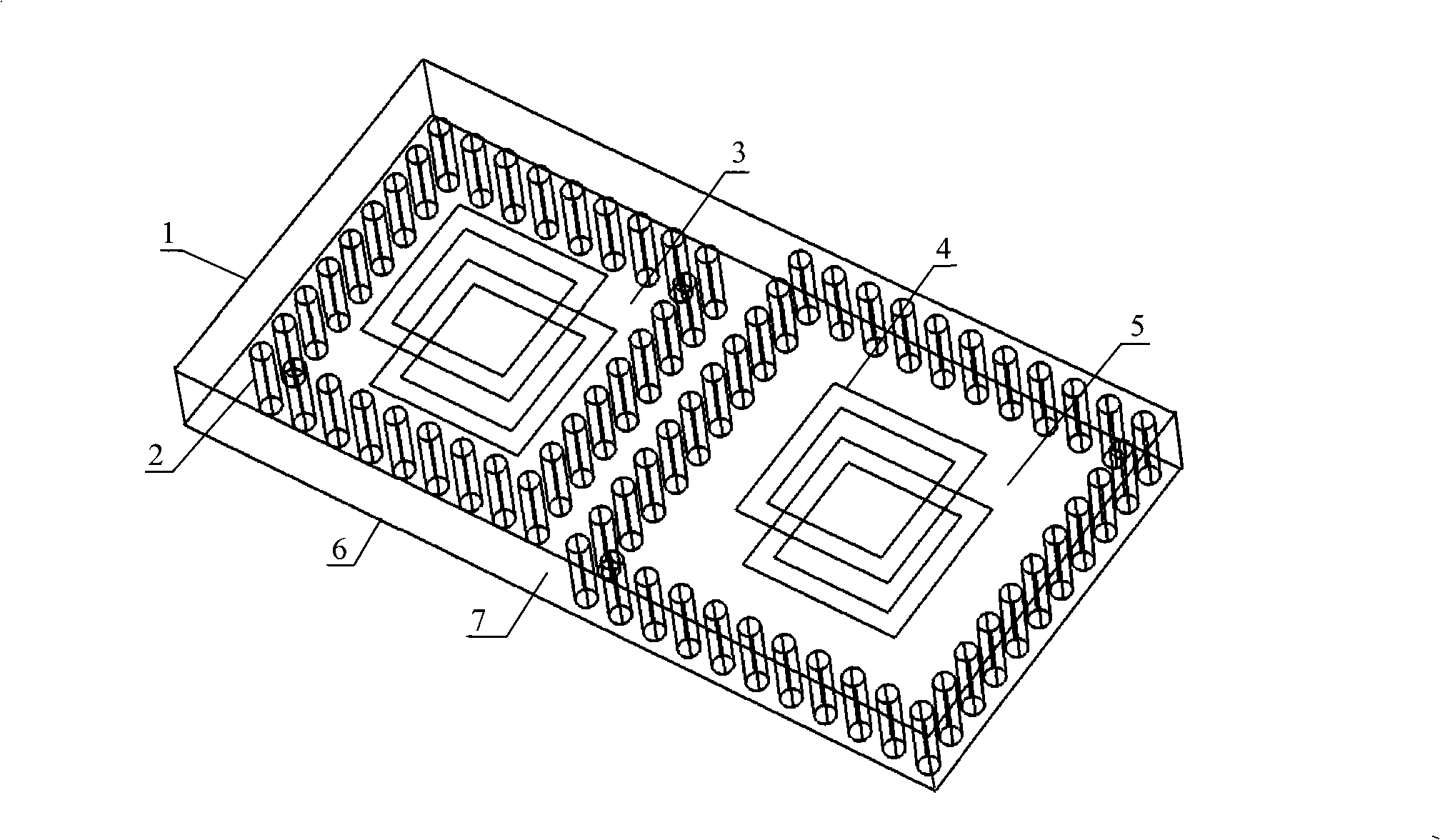

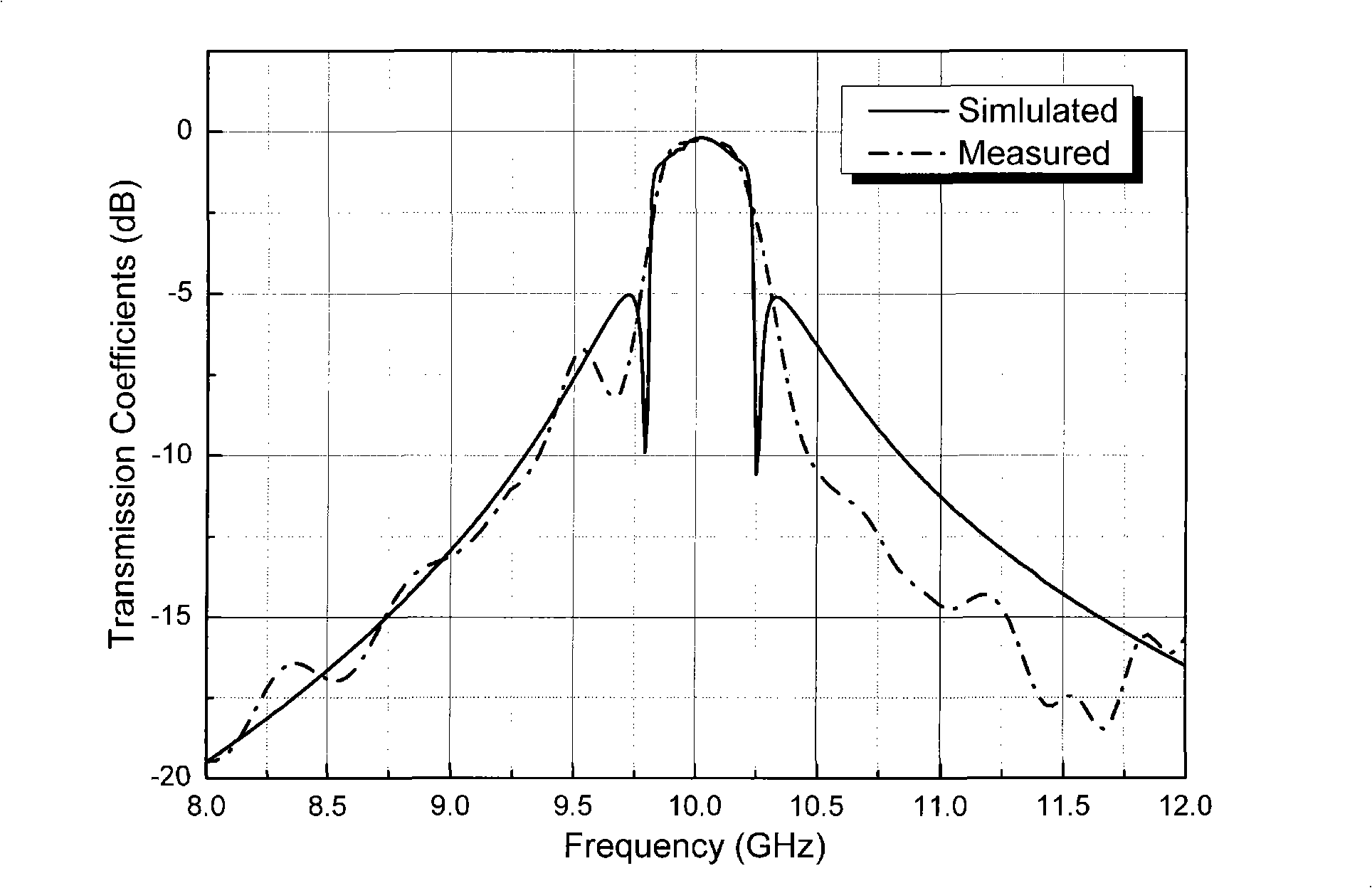

Novel bilateral frequency selecting surface having sudden drop characteristic

InactiveCN101286584AIncrease insensitivityFrequency selective surface enhancementCoupling devicesDielectric substrateEngineering

The invention relates to a novel frequency selective surface with steep drop characteristic in both sides thereof. In the traditional frequency selective surface, the problems of low selectivity, poor performance stability and large volume exist. The novel frequency selective surface is characterized in that: metal layers are plated on both surfaces of a dielectric substrate; plated-through holes arranged in the patterns of large or small square groups run through the whole dielectric substrates to form a variety of high-frequency and low-frequency substrate integrated waveguide cavity groups; same square-shaped coupling gaps are etched for the upper and the lower metal layers in the adjacent high-frequency and low-frequency cavity. Compared with the general dual-band frequency selective surface formed by periodic patches or gaps of different sizes, since a cavity resonant mode is introduced into the new structure, the novel frequency selective surface with steep drop characteristic in both sides thereof realizes the steep drop characteristic of both sides of passbands and greatly improves the selection characteristic of the passbands, with excellent stability to the angles and the polarizability of incident waves.

Owner:HANGZHOU DIANZI UNIV

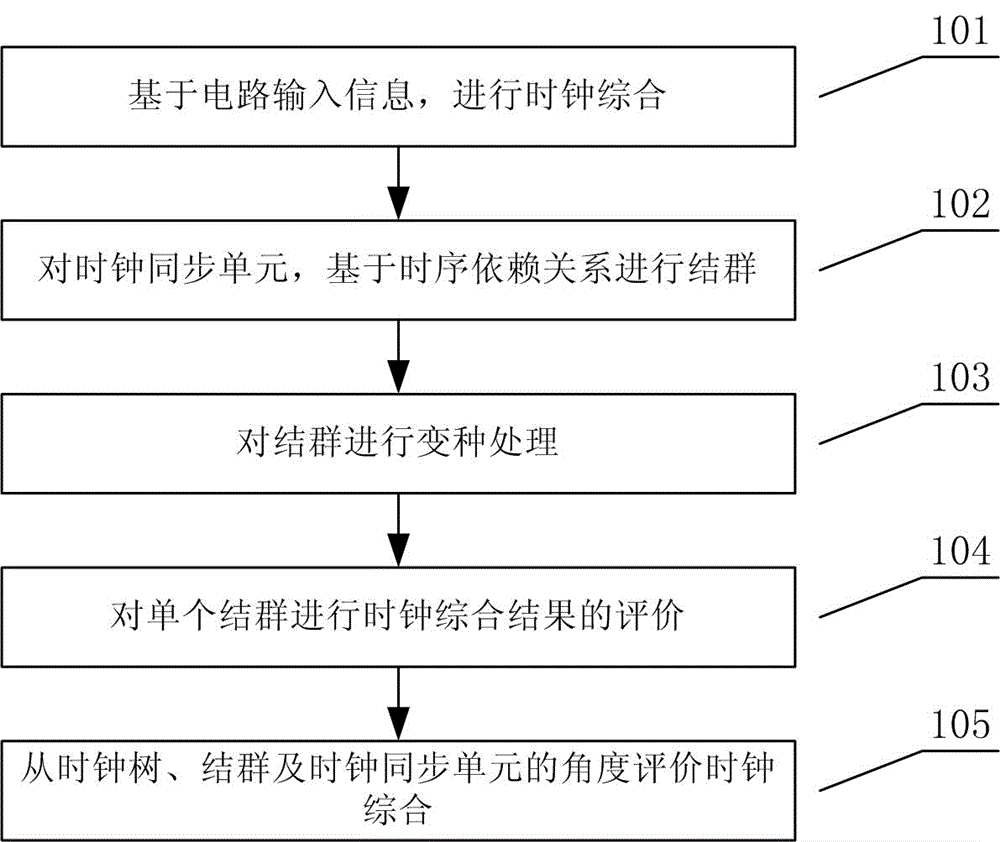

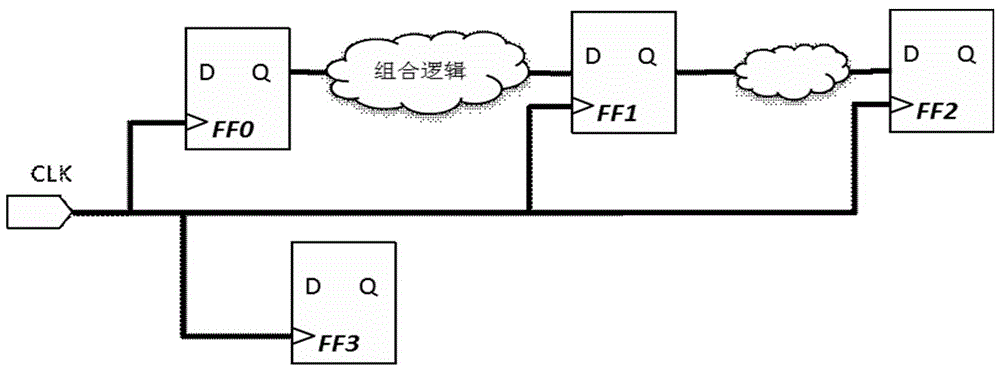

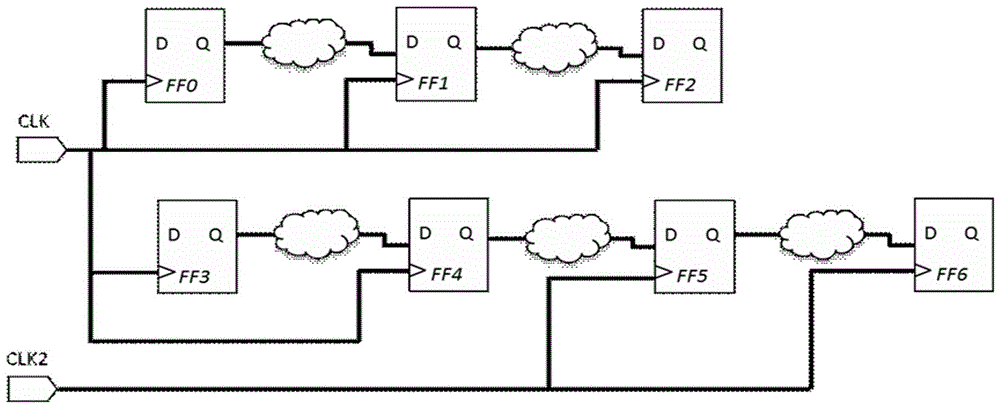

Clock comprehensive result evaluation method based on time sequencing dependency relation

ActiveCN106650111AValid Constraint ConfigurationAvoid process iterationCAD circuit designSpecial data processing applicationsTime sequenceTheoretical computer science

The invention discloses a clock comprehensive result evaluation method based on a time sequencing dependency relation. The method comprises the steps of conducting clustering on a clock synchronization unit based on a time sequencing dependency relation; conducting an evaluation of a clock comprehensive result on a single cluster. According to the clock comprehensive result evaluation method based on the time sequencing dependency relation, the evaluation method can be applied in rich and traditional clock comprehensive evaluation, the data path omitted in the clock comprehensive (CTS) process is integrated into final clock comprehensive evaluation in the form of clustering, a user of a clock comprehensive tool can have clearer and more accurate cognition of the result of the clock comprehensive (CTS) by combining time sequencing constraints to some degree, thus the most effective constraint configuration can be executed, the meaningless process iteration is avoided, and thus the purpose that the design process is accelerated and the design efficiency is improved is achieved.

Owner:北京华大九天科技股份有限公司

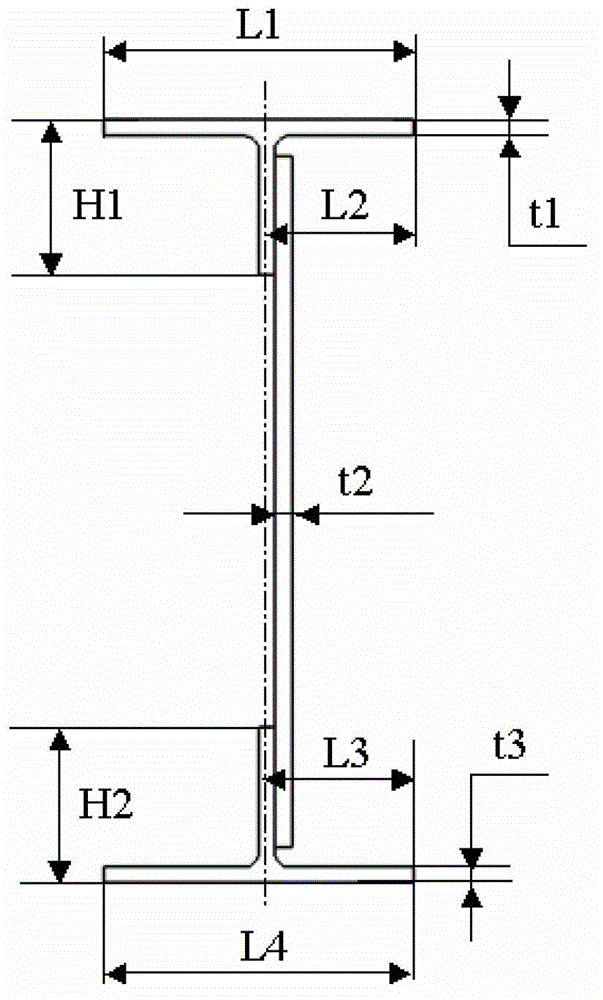

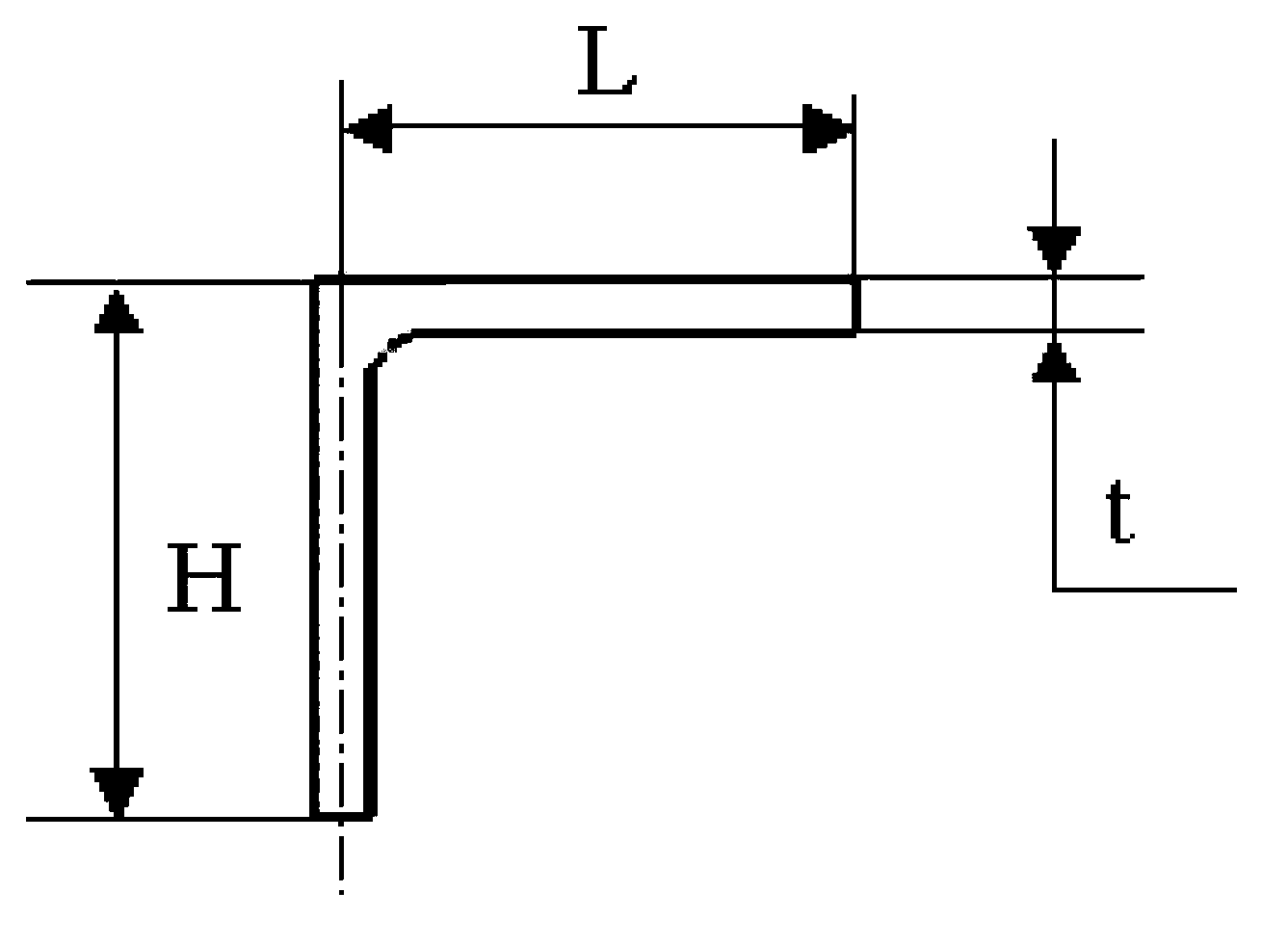

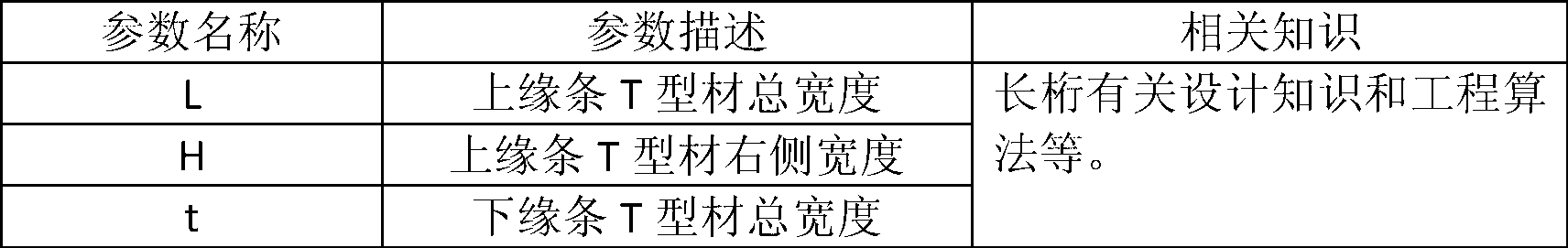

Method for parametrically designing primary components of airplane long truss-type parts

ActiveCN103020375AStandardize the digital definition processRich modeling methodsSpecial data processing applicationsManufacturing technologyQuality by Design

The invention discloses a method for parametrically designing primary components of airplane long truss-type parts. The long truss-type parts in an airplane structure are expressed by parametric components, and the parametric expression for the primary components of the airplane long truss-type parts specifically comprises the following four parts 1, essential attribute: the essential attribute specifically comprises the name of components, the version number, the creation time, the description of the components, a manufacturing technology and remarks; 2, geometric attribute: the geometric attribute is specifically divided into two parts of location parameters and section parameters; 3, non-geometric attribute: the non-geometric attribute specifically relates to a disassembling scheme and non-geometric attribute information corresponding to the disassembling scheme; and 4, two-dimensional sectional view: the two-dimensional sectional view is used for helping a user correctly understand the physical significance of each parameter of the components when the components are in instantiation. According to the method disclosed by the invention, a component base system of an airplane is facilitated to be built, function and performance model data foundation is provided for the standardization, the simulated analysis and the optimization of the airplane design, the consistency between a geometric model machine and a function model machine / performance model machine is ensured, the designing quality of the airplane is increased, and the development time is shortened.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

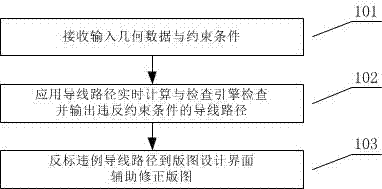

Conductor path real-time calculation and inspection method and engine

ActiveCN107220448AFast resultsMeet real-time inspection requirementsCAD circuit designSpecial data processing applicationsComputer scienceReal-time computing

The invention discloses a conductor path real-time calculation and inspection method and engine. The method includes the steps: (1) receiving inputted geometric data and constraint conditions; (2) inspecting and outputting a conductor path breaking the constraint conditions by the traverse path real-time calculation and inspection engine; (3) back-annotating the conductor path breaking the constraint conditions to a layout design interface and assisting in correcting layout. According to the conductor path real-time calculation and inspection method and engine, when layout data are incomplete, results can be rapidly obtained only by inspecting the geometric data (including conductor polygonal shapes and conductor contact points) of a conductor material layer, real-time inspection requirements are met, and calculation amount is small.

Owner:SHENZHEN HUADA EMPYREAN TECH CO LTD

Parametrization design method of first-level member of rib type part of airplane

ActiveCN102982220AStandardize the digital definition processRich modeling methodsSpecial data processing applicationsDecompositionQuality by Design

The invention discloses a parametrization design method of first-level members of rib type parts of an airplane. The parametrization design method comprises the following steps of: stating the rib type parts in the airplane structure by using parametrization members, wherein the parametrization statement of the first-level members of the rib type parts of the airplane specifically relates to contents of four parts as follows: 1) the basic attributes specifically comprise the names of the members, the version numbers, the establishment time, the member description, the manufacturing process and the remarks; 2) the geometric attributes specifically consist of two parts of positioning parameters and cross-section parameters; 3) non-geometric attributes specifically relate to decomposition schemes and non-geometric attribute information corresponding to the decomposition schemes; and 4) a two-dimensional sectional drawing is used for helping a user to correctly understand the physical meaning of the parameters of the members in member instantiation. The parametrization design method is helpful in establishing a member bank system, functional and performance model data basis for the standardization and simulation analysis in airplane design is provided, the coordination of data of a geometric model machine and a functional model machine / performance model machine is ensured, the design quality of the airplane is improved, and the research and manufacturing period is shortened.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

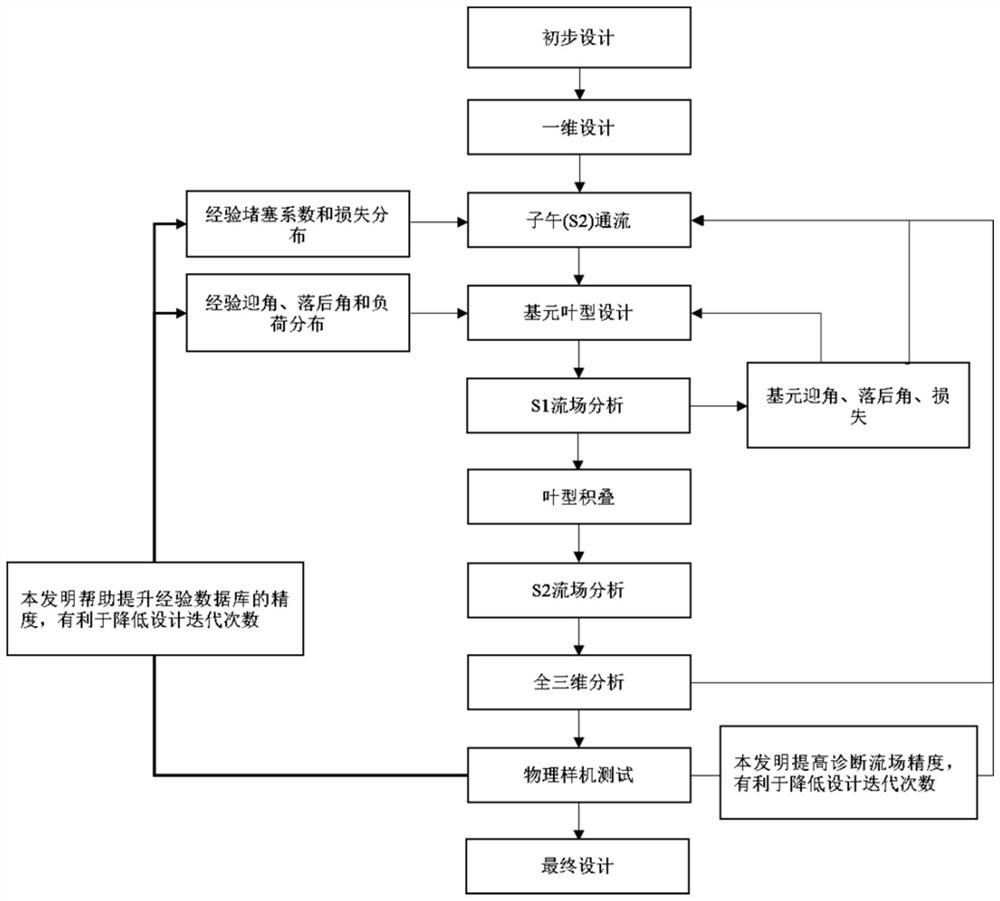

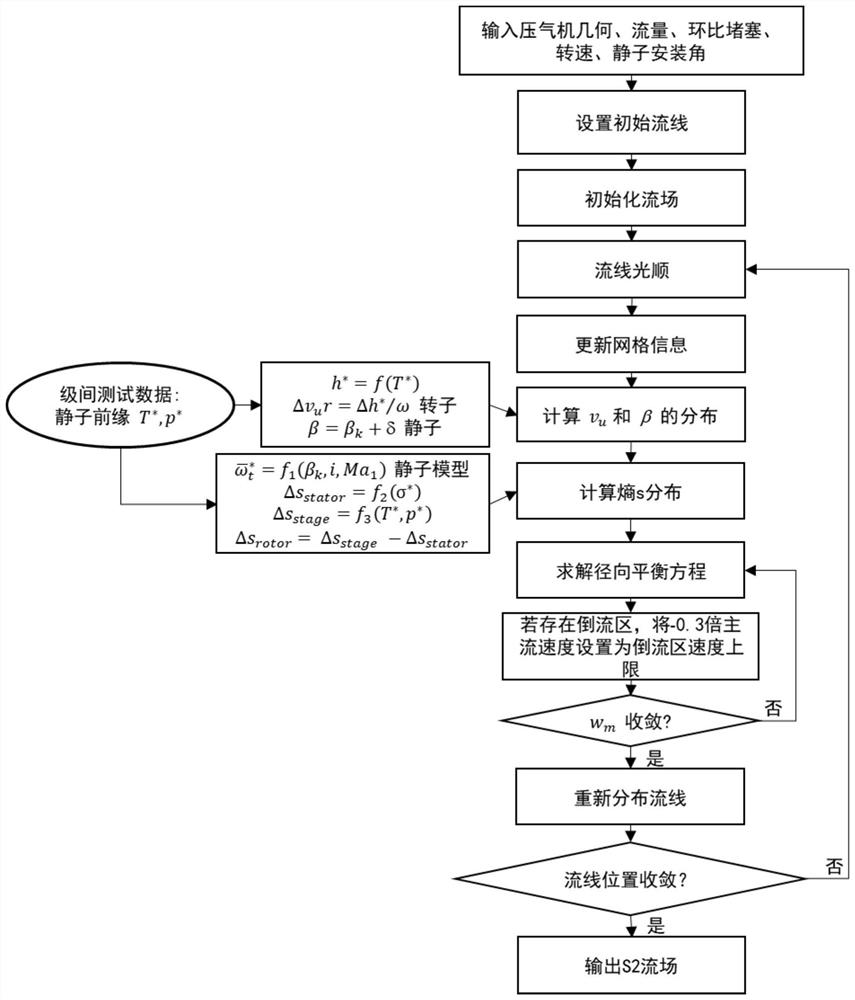

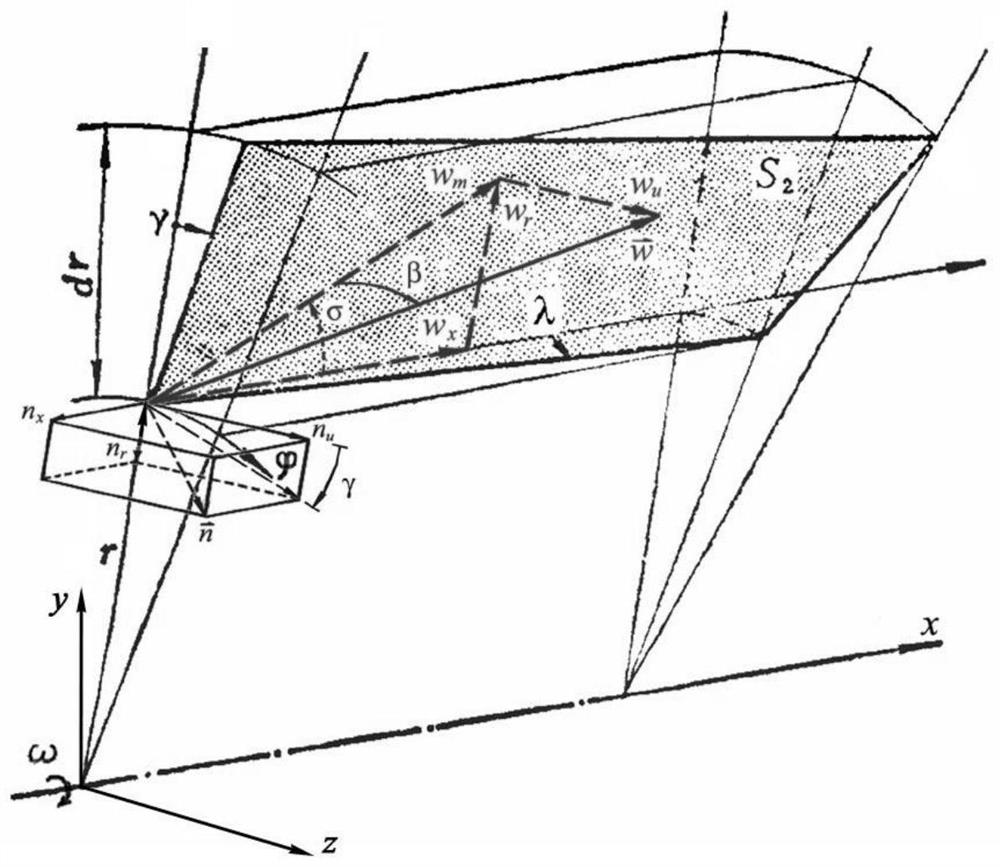

S2 flow field diagnosis method based on inter-stage measurement parameters of axial flow compressor

ActiveCN112594064AHigh precisionSpeed up the design processGas turbine plantsPump controlEngineeringMechanical engineering

The invention discloses an S2 flow field diagnosis method based on inter-stage measurement parameters of an axial flow compressor. The S2 flow field diagnosis method specifically comprises the steps of 1, establishing a corresponding S2 flow field calculation streamline curvature control equation according to the inter-stage measurement parameters of the multi-stage axial flow compressor; 2, according to the fact that the possible total temperature rise of the multi-stage compressor is high, considering the influence of inter-stage measurement parameters by adopting a variable specific heat working medium; 3, obtaining stator lag angle and entropy distribution parameters in the flow field according to a thermodynamic relationship and a stator model; 4, performing flow field calculation toobtain an axial flow compressor S2 flow field inversion result according to the inter-stage measurement parameters; and 5, performing analysis and diagnosis according to calculation results such as flow field parameters and performance parameters obtained by inversion. According to the method, the variable specific heat working medium is adopted, and the accuracy is higher when the conditions thatthe stage number of the compressor is large and the temperature rise is large are treated; and the assumption that the static pressure of measuring points at different heights is equal to the wall surface static pressure in the multi-stage compressor test is broken through, the flow field result automatically meets the radial balance equation, the S2 flow field diagnosis precision is higher, andthe compressor design cycle is reduced.

Owner:BEIHANG UNIV

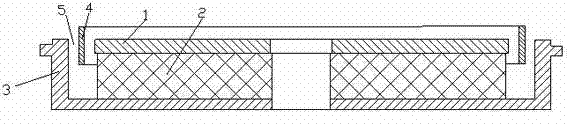

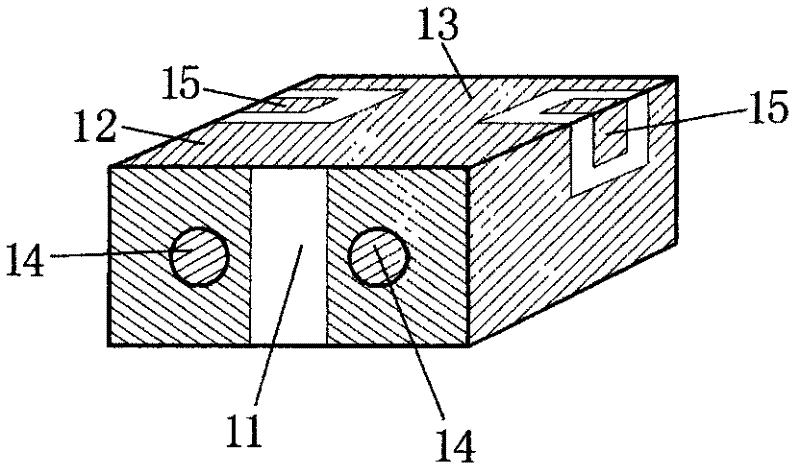

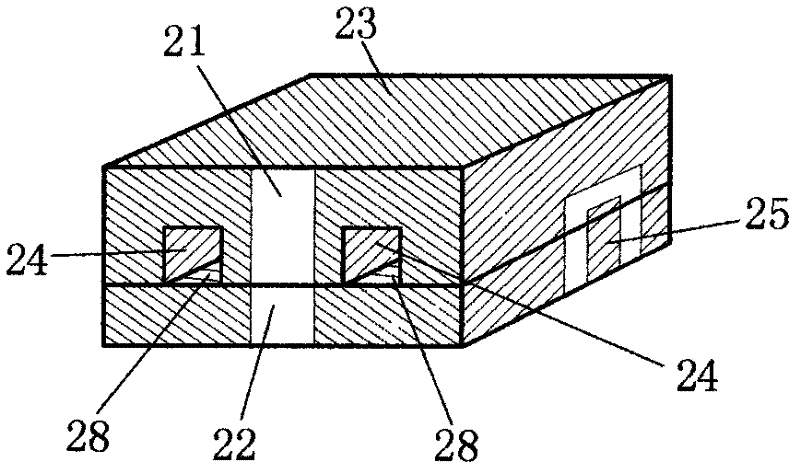

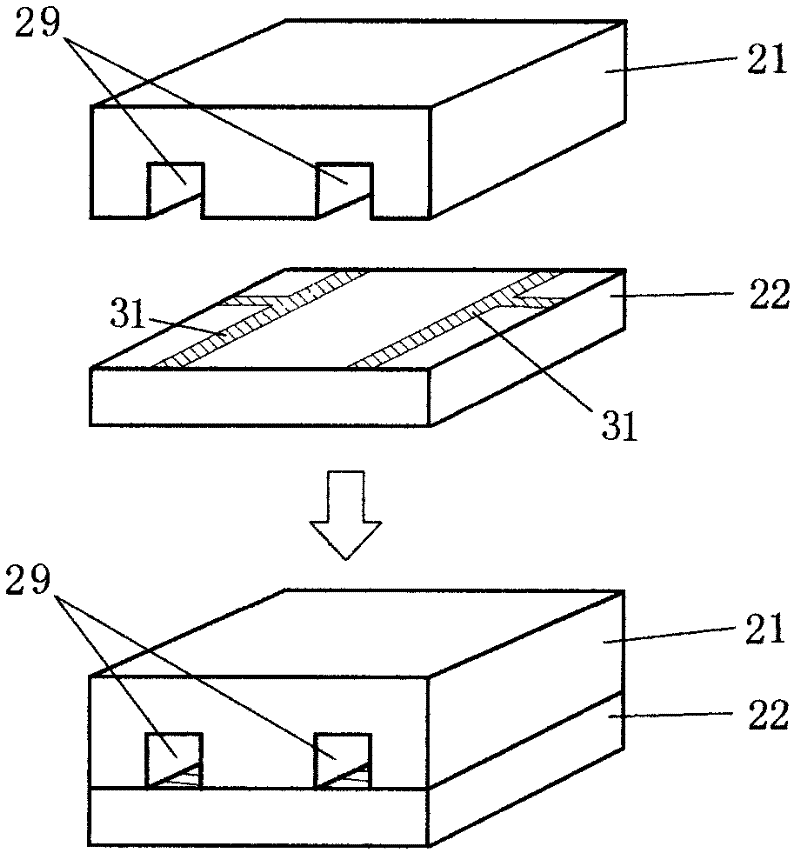

Transverse electromagnetic (TEM)-mode coaxial dielectric ceramic filter and manufacturing method for same

InactiveCN102509820AHigh dimensional accuracyGood parameter consistencyWaveguide type devicesDielectricFrit

The invention discloses a transverse electromagnetic (TEM)-mode coaxial dielectric ceramic filter, which comprises a dielectric ceramic block and a surface metal layer. Two dielectric ceramic bodies (21 and 22) are bonded by glass frit, and are sintered to form the dielectric ceramic block. Two grooves (29) with rectangular sections are formed on the bonded face of one dielectric ceramic body (21). After the two dielectric ceramic bodies are bonded, coupling holes (28) are formed. Coupling internal electrodes (31) are arranged on the bonded face of the other dielectric ceramic body (22). The manufacturing method comprises the following steps of: manufacturing the coupling internal electrodes and coupling external electrodes at positions at which the grooves are reserved to form cavities on a large dielectric ceramic block, bonding two large dielectric ceramic pieces by using the glass frit, and sintering the bonded large dielectric ceramic pieces into a whole; cutting the large dielectric ceramic block into strip-shaped dielectric ceramic bodies, and manufacturing side electrodes; and cutting the strip-like dielectric ceramic bodies into single elements, and manufacturing end electrodes. The manufactured product has high dimensional accuracy and high parameter consistency. The coupling internal electrodes on the bonded faces can be designed according to needs, so that the performance of the product can be further improved, and design flexibility can be enhanced.

Owner:ZHEJIANG JIAKANG ELECTRONICS CO LTD

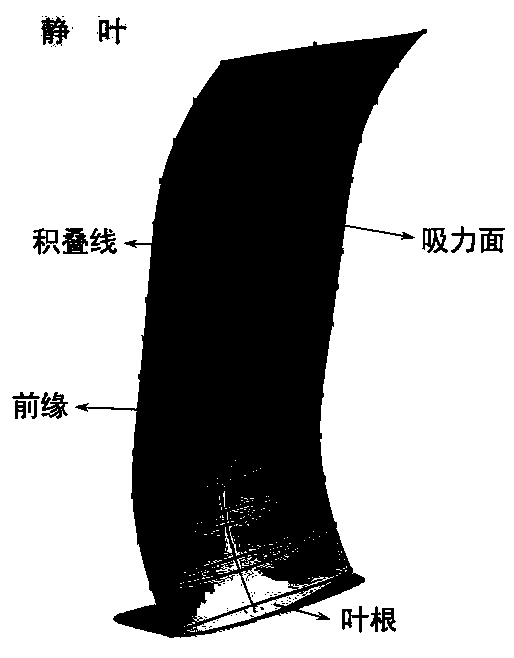

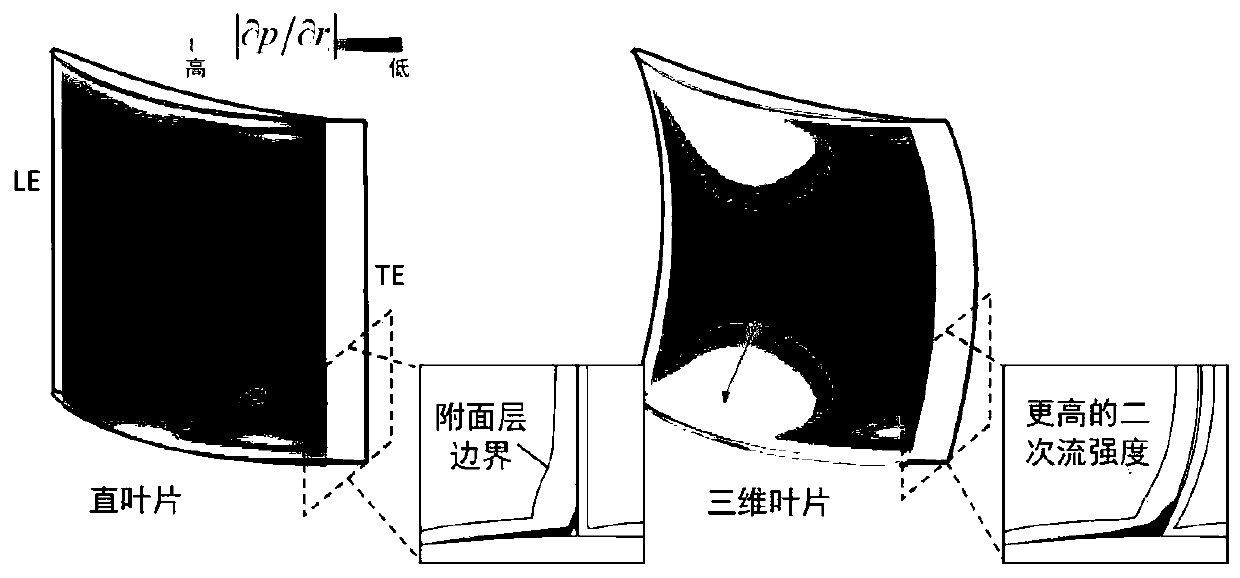

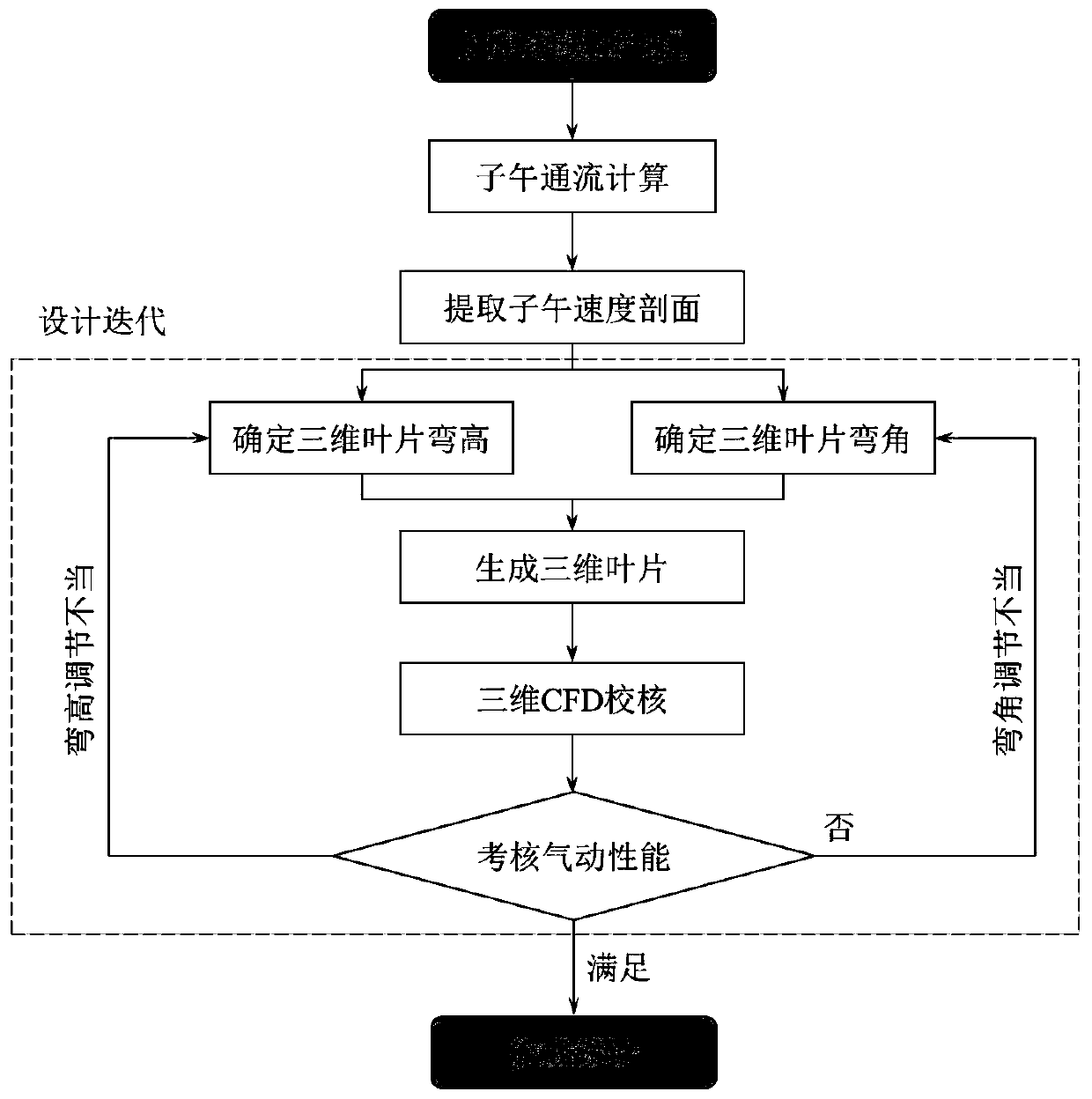

A three-dimensional blade modeling method for a multistage axial flow compressor based on an end region boundary layer and a blade

PendingCN109815590ASpeed up the design processImprove flow propertiesPump componentsPumpsRadial gradientEngineering

The invention relates to a three-dimensional blade modeling method for a multistage axial flow compressor based on an end region boundary layer. The three-dimensional blade modeling method is characterized by comprising the following steps of step 1, analyzing the meridian through-flow performance of the prototype multistage axial flow compressor; secondly, extracting the radial gradient of the meridian velocity profile through the through-flow performance in the first step, so that the boundary of a boundary layer is determined, and calculating the displacement thicknesses of the wheel flangeand the boundary layer of the wheel hub side; and step 3, determining initial three-dimensional blade modeling parameters, determining the bending height of the three-dimensional blade according to the relative blade height of the boundary of the corresponding side boundary layer, determining the bending angle of the three-dimensional blade according to the displacement thickness of the corresponding side boundary layer, and forming three-dimensional deformation of a stacking line according to the bending height and the bending angle to obtain the three-dimensional modeling of the blade. Theintegrated modeling design of the three-dimensional blade of the multistage axial flow compressor is realized, the multistage influence of the multistage axial flow compressor is considered, and the flow efficiency of the compressor is improved while the stable work of the compressor is ensured.

Owner:HANGZHOU TURBINE POWER GRP

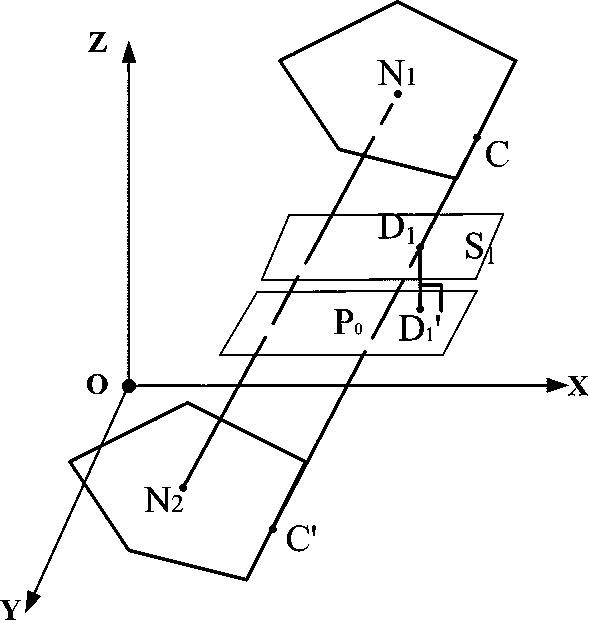

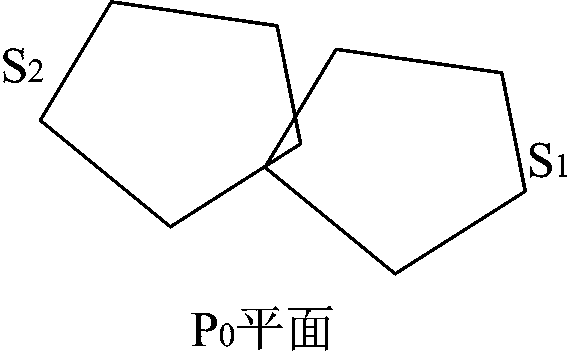

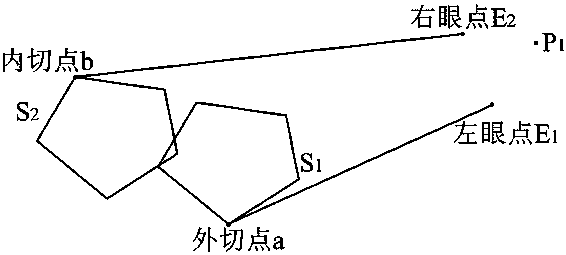

Method for calculating vehicle body A column obstacle angle

ActiveCN106991207AShorten the design cycleSpeed up the design processGeometric CADSpecial data processing applicationsDesign cycleAlgorithm

The invention relates to a method for calculating a vehicle body A column obstacle angle, and belongs to the field of vehicle body design of automobiles. The method includes: firstly determining a driver head key point Pm, rotating a plane upward and downward to acquire a plane P1 and a plane P2; acquiring an intersection point according to the plane P1 and a spatial linear equation of an upper fixing point and a lower fixing point of an A column, using a z coordinate of the intersection point as an equation of a horizontal cross section S1; acquiring a linear equation of a random point C of an upper and lower fixing point cross section and a corresponding point C' according to the spatial linear equation of the upper fixing point and the lower fixing point of the A column, calculating an intersection point D1 between the A column and the horizontal cross section S1 through simultaneous solution of the CC' linear equation and the horizontal cross section S1, and projecting the point to a horizontal plane P0 to acquire a projection point D1'; approximatively determining an inner tangent point a and an outer tangent point b, determining coordinates of a left eye point E1 and a right eye point E2 of a driver according to a geometrical relationship formed by an inner tangent line and an outer tangent line, and calculating an included angle alpha as a dual eye obstacle angle of a vehicle body A column. The method is suitable for all the passenger vehicles, can provide a new method for design of enterprise vehicle body A columns, can shorten the design cycle of A column cross sections, and can accelerate the design process.

Owner:JILIN UNIV

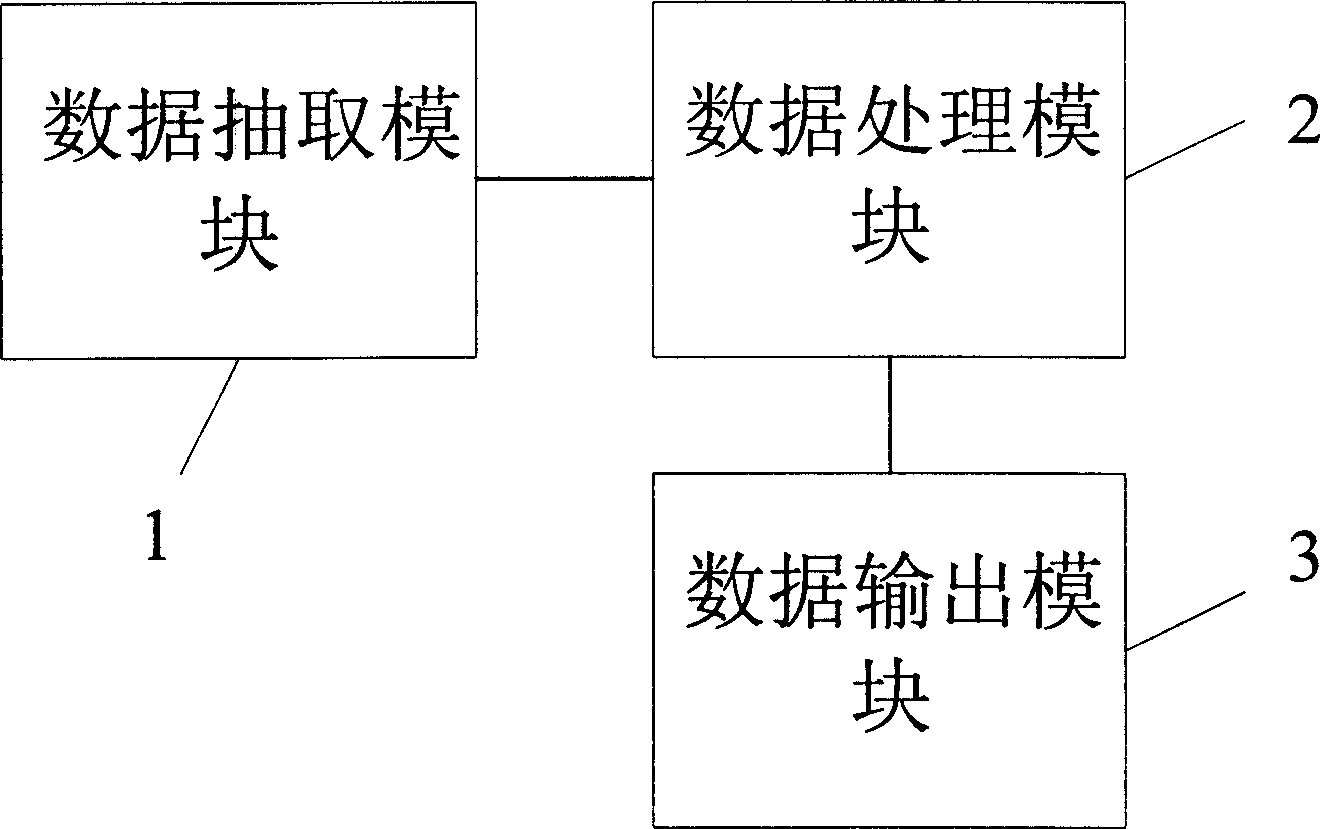

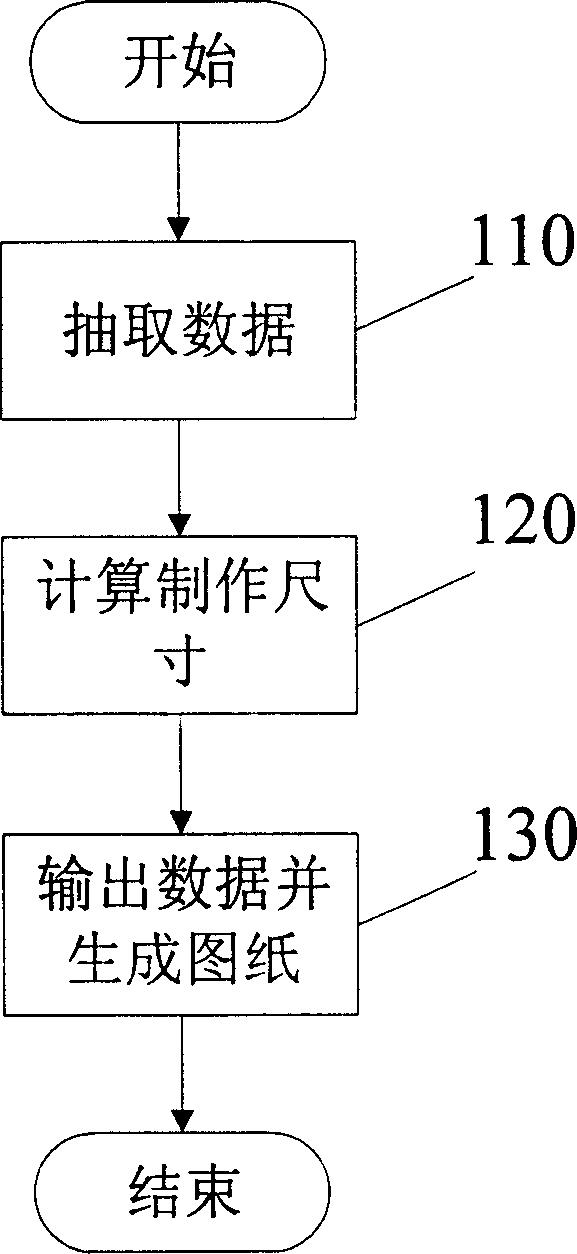

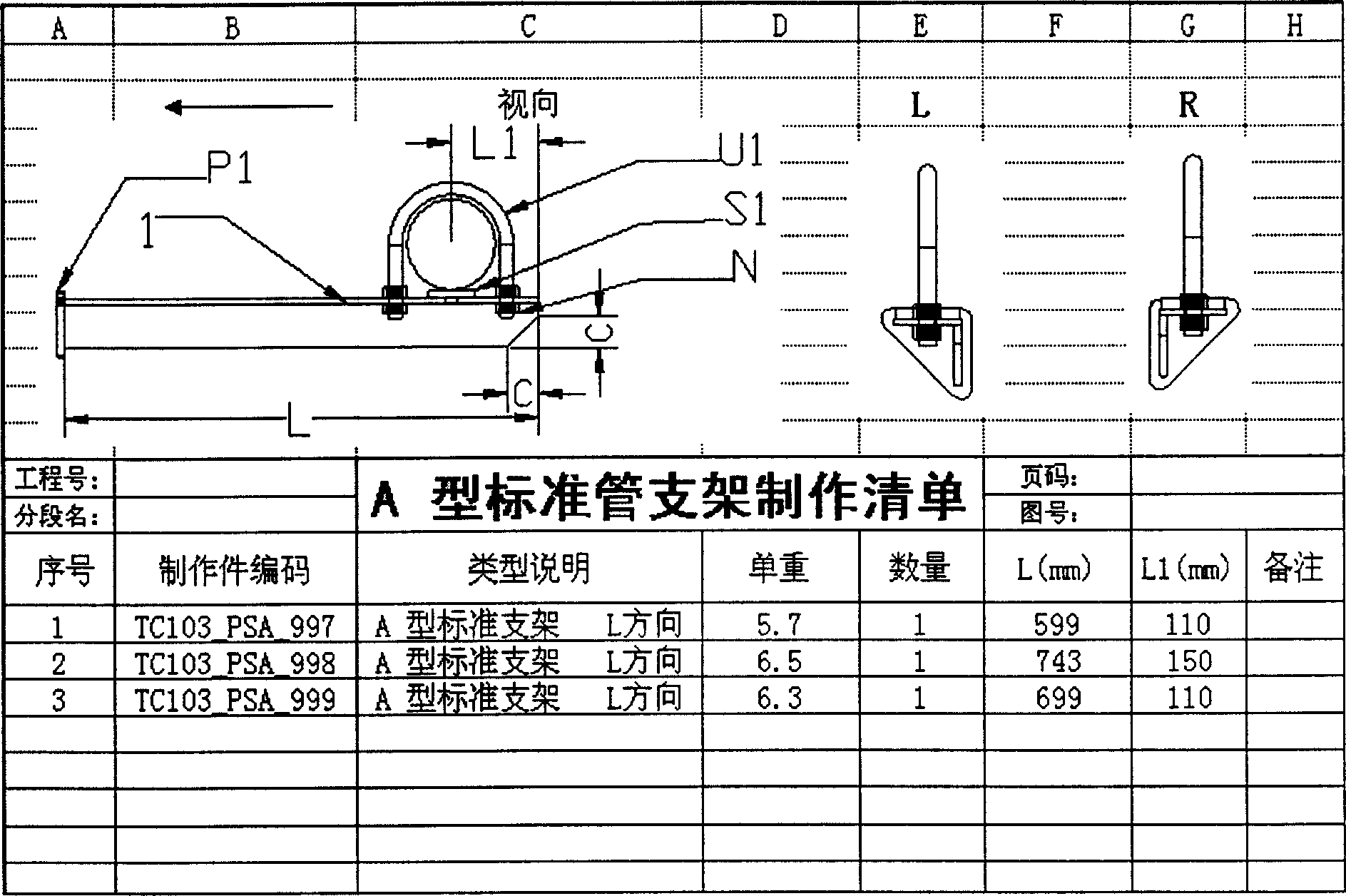

Automatic map delivery device for rack

InactiveCN1822007ALighten the design burdenSpeed up the design processSpecial data processing applicationsProcess moduleDesign load

This invention discloses an automatic plotting device for frames including a data pick-up module picking up data in the preset frame search information, a data process module computing said data to get the manufactured sizes of the frames, a data output module outputting the computed and pick-up data to generate a blueprint, which expresses the same kind of frames on a same drawing to reduce the design load and speed up the design.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

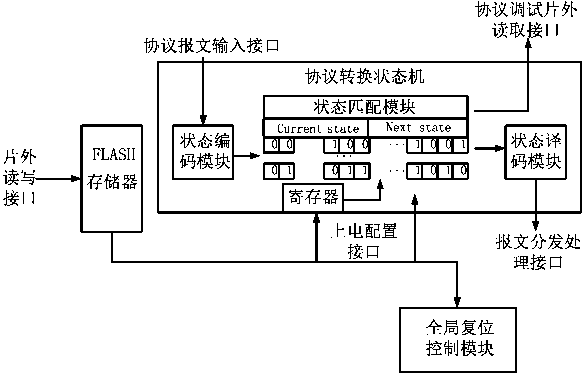

Configurable protocol conversion state machine circuit structure and protocol configuration method

InactiveCN105516158ASimple structureSpeed up the design processTransmissionCode moduleProcessor register

The invention particularly relates to a configurable protocol conversion state machine circuit structure and a protocol configuration method. The configurable protocol conversion state machine circuit structure comprises a flash storer, a global reset control module and a protocol conversion state machine. The protocol conversion state machine comprises a register, a state coding module, a state matching module and a state decoding module. The register, the state coding module and the state decoding module are all connected to the state matching module. According to the configurable protocol conversion state machine circuit structure and the protocol configuration method, the chip protocol conversion is realized, so that risks in chip design can be well controlled; verification requirement on protocol details is lowered, so that the whole chip design process is faster, demand on verification resources is lowered accordingly, the circuit structure is simplified, overall, design difficulty of the whole chip system is lowered, and development time is remarkably shortened.

Owner:SHANDONG HAILIANG INFORMATION TECH RES INST

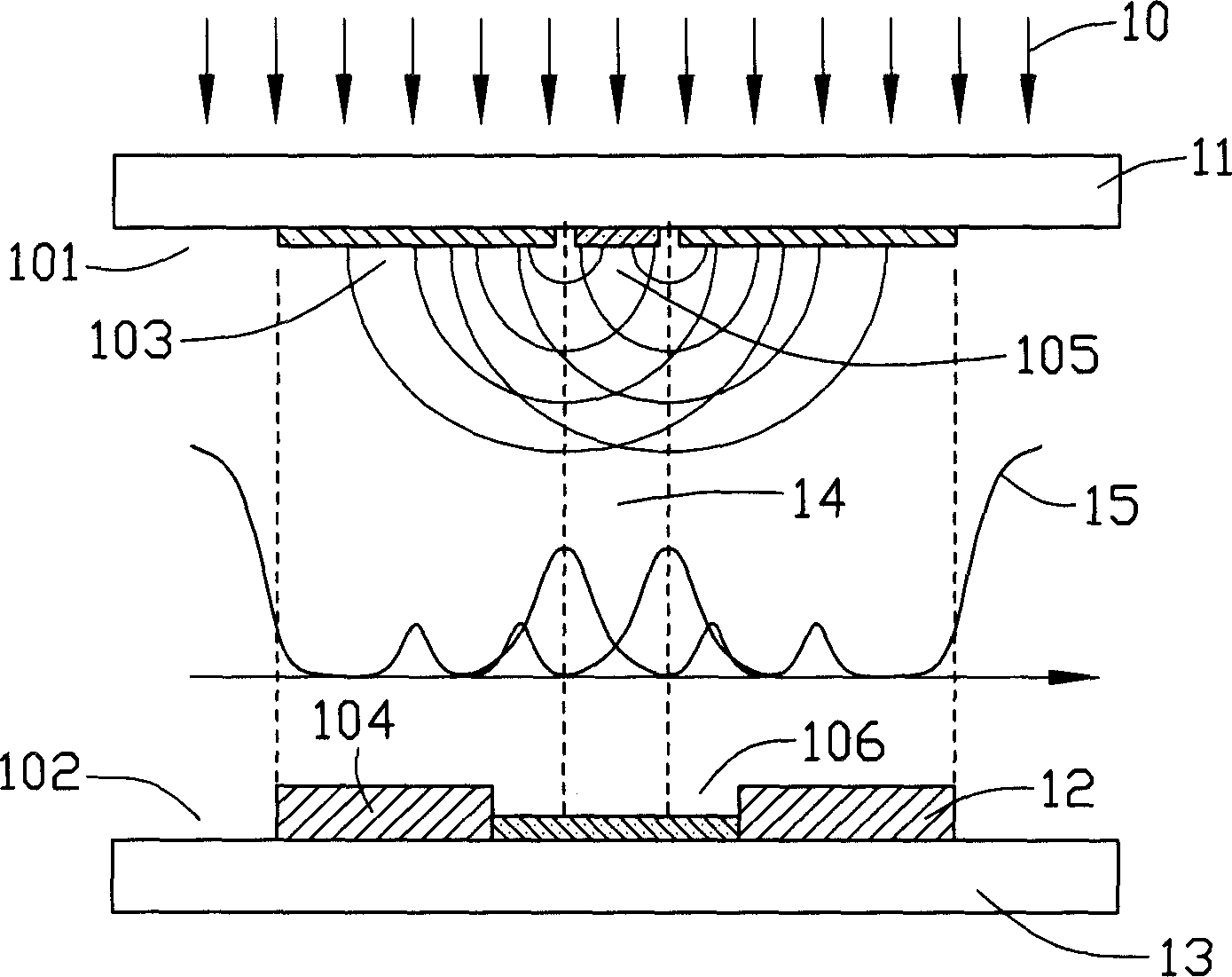

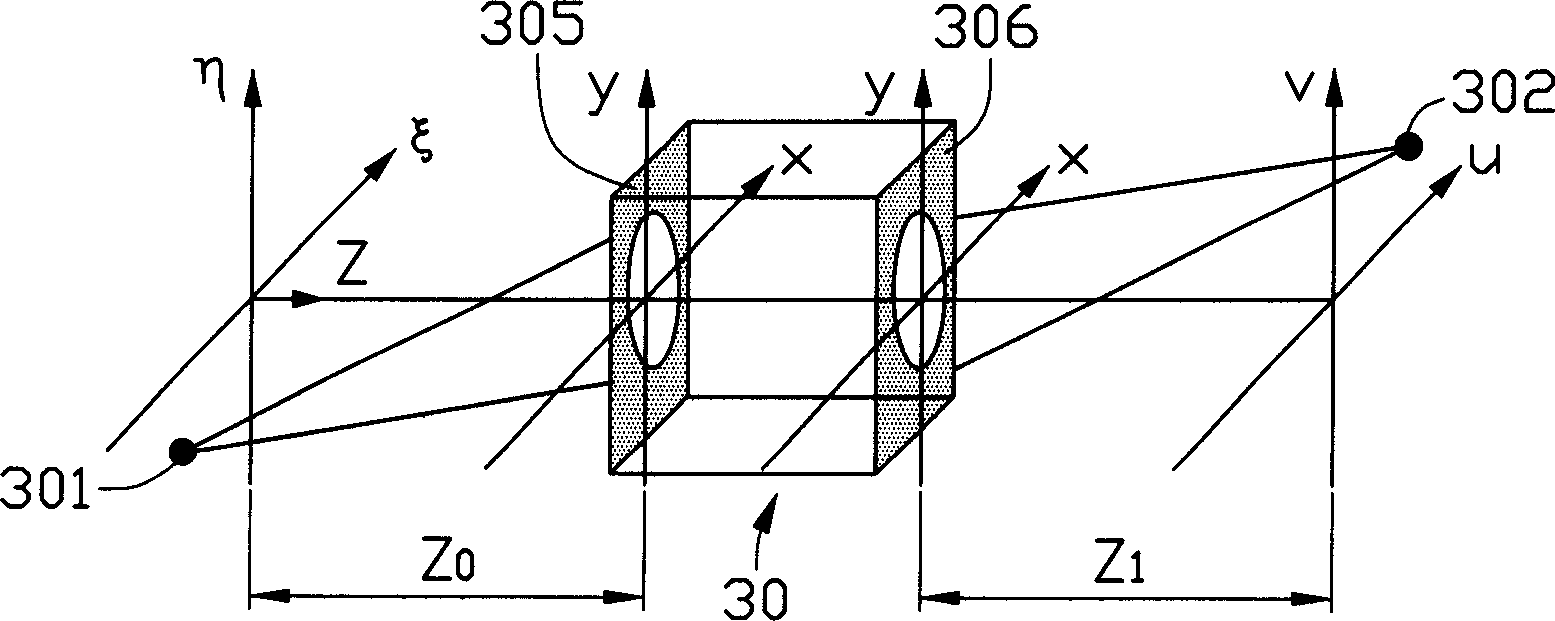

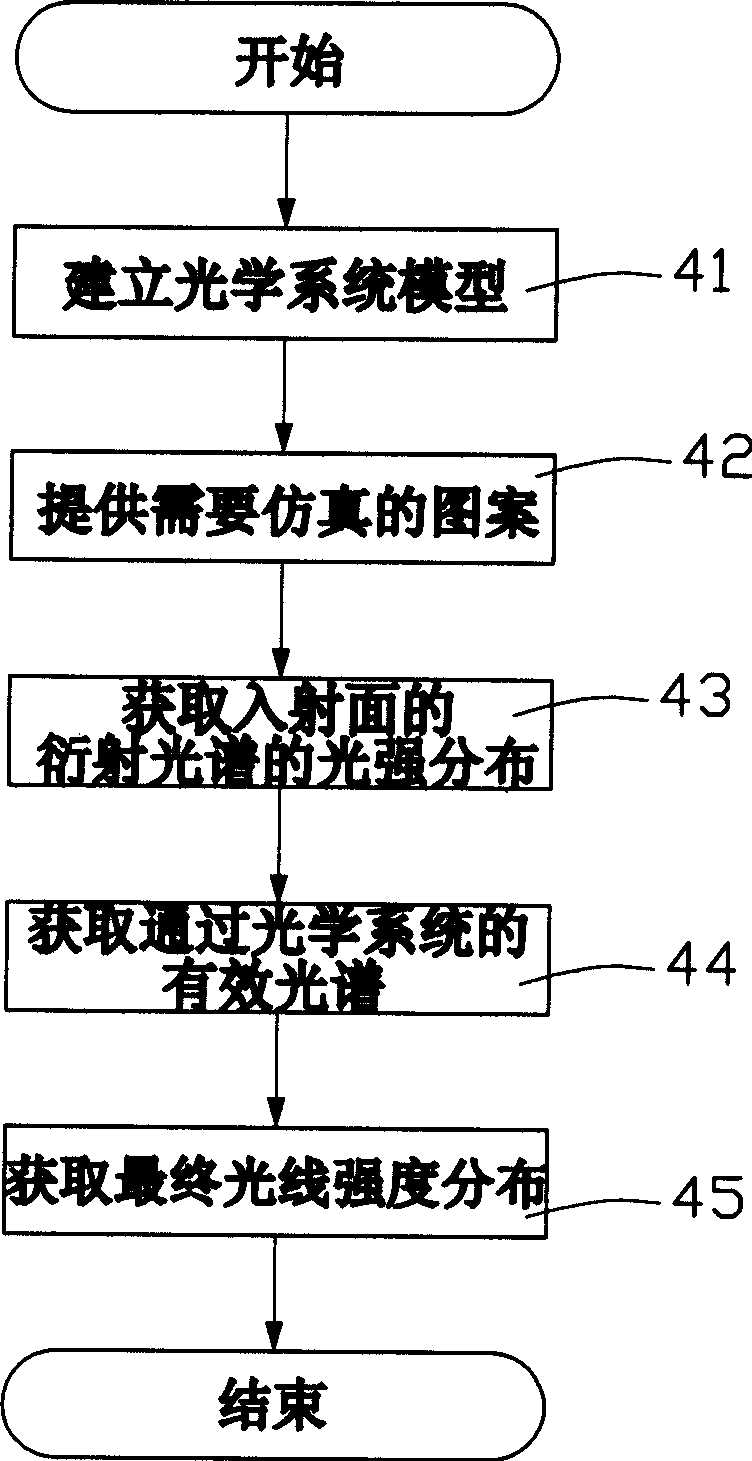

Emulating method and device for exposure system

InactiveCN1716098AImprove accuracySpeed up the design processStatic indicating devicesSemiconductor/solid-state device manufacturingComputer scienceDiffraction spectrum

The simulating method of exposure system includes the following steps: establishing optical system model; initializing one data processing device; setting the relevant parameters of the optical system in the data processing device; providing pattern to be simulated; analyzing the pattern; analyzing the input pattern, and transforming the pattern to obtain the light strength distribution spectrum of the far field diffracted light in the incident plane of the optical system; multiplying the diffraction spectrum and the transfer function of the optical system to obtain the effective diffraction spectrum of the optical system; and performing corresponding inverse transformation of the effective diffraction spectrum to obtain the final light intensity distribution.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

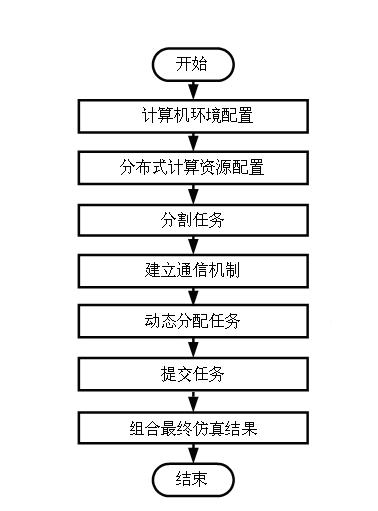

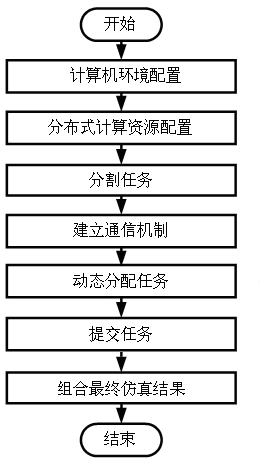

Method for improving three-dimensional electromagnetic simulation speed by using distributed computing

InactiveCN102662758AEnsure Simulation AccuracyReduced simulation timeResource allocationComputer resourcesParallel computing

The invention discloses a method for improving three-dimensional electromagnetic simulation speed by using distributed computing, mainly comprising the following steps: a corresponding computer environment is configured according to current communication protocol; computer resource used for distributed computing is configured; the computer resource is segmented into tasks; a mode of communication between a task allocation host machine and a task doer in distributed computing is established; the task allocation host machine allocates tasks dynamically; and submitted simulation results are combined into a final S parameter file. The method for improving three-dimensional electromagnetic simulation speed by using distributed computing provided by the invention is used for improving existing electromagnetic simulation process, and can make full use of existing computer resources and reduce three-dimensional electromagnetic simulation time.

Owner:SUZHOU XINHE ELECTRONICS TECH CO LTD

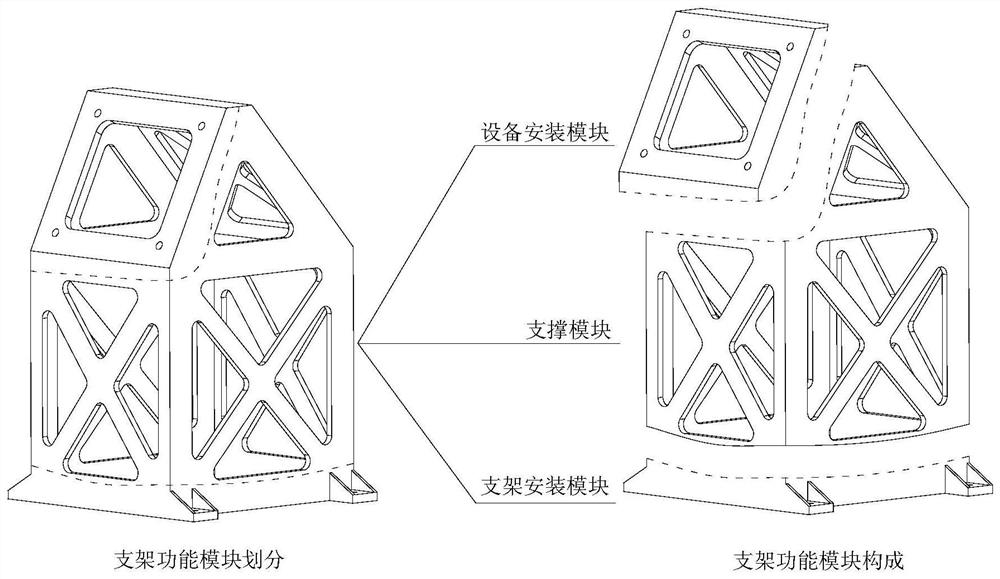

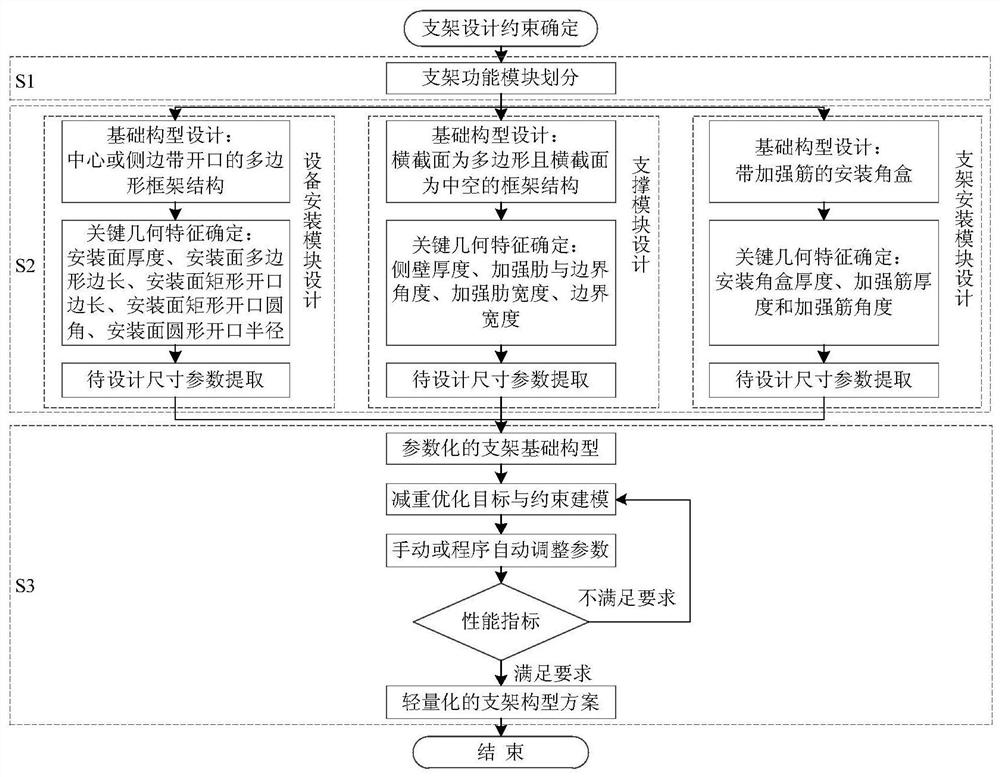

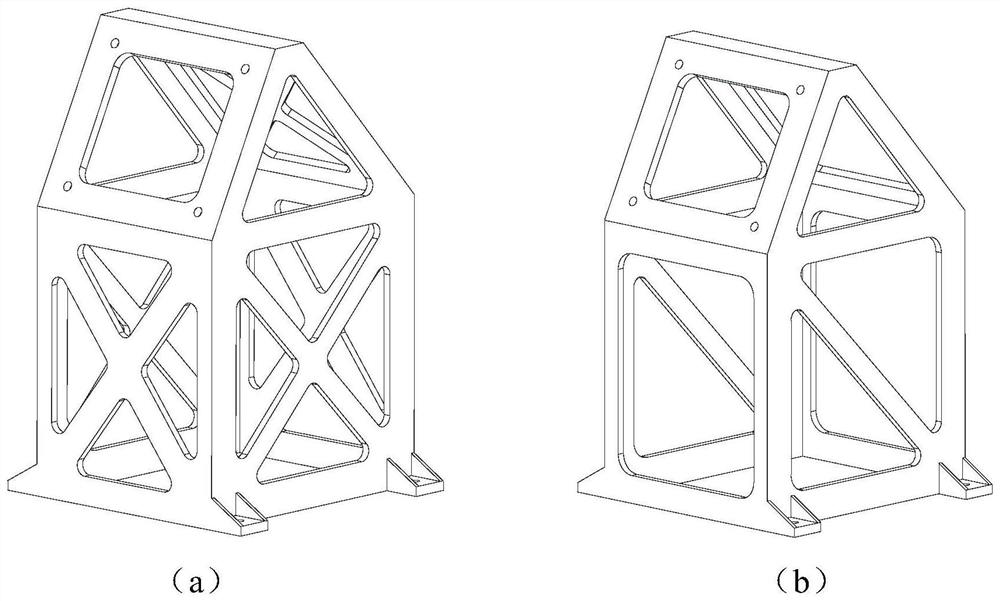

Universal parameterized configuration design method for spacecraft equipment mounting bracket

PendingCN113283023AReduce dependencyVersatileGeometric CADConstraint-based CADSpacecraftMechanical engineering

A universal parameterized configuration design method for a spacecraft equipment mounting bracket comprises the following steps: S1, decomposing functional components of the spacecraft equipment mounting bracket according to functions of the spacecraft equipment mounting bracket; S2, setting a basic configuration of the spacecraft equipment mounting bracket, determining key geometric features of the basic configuration, and extracting size parameters of the key geometric features to obtain a parameterized configuration of the spacecraft equipment mounting bracket; and S3, taking weight reduction as a target, automatically adjusting size parameters to drive the parameterized configuration of the spacecraft equipment mounting bracket to change, and obtaining the lightweight configuration of the spacecraft equipment mounting bracket. The problems of high configuration design difficulty, complex design process, large geometric model modification workload, non-visual optimization design result and the like are solved.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

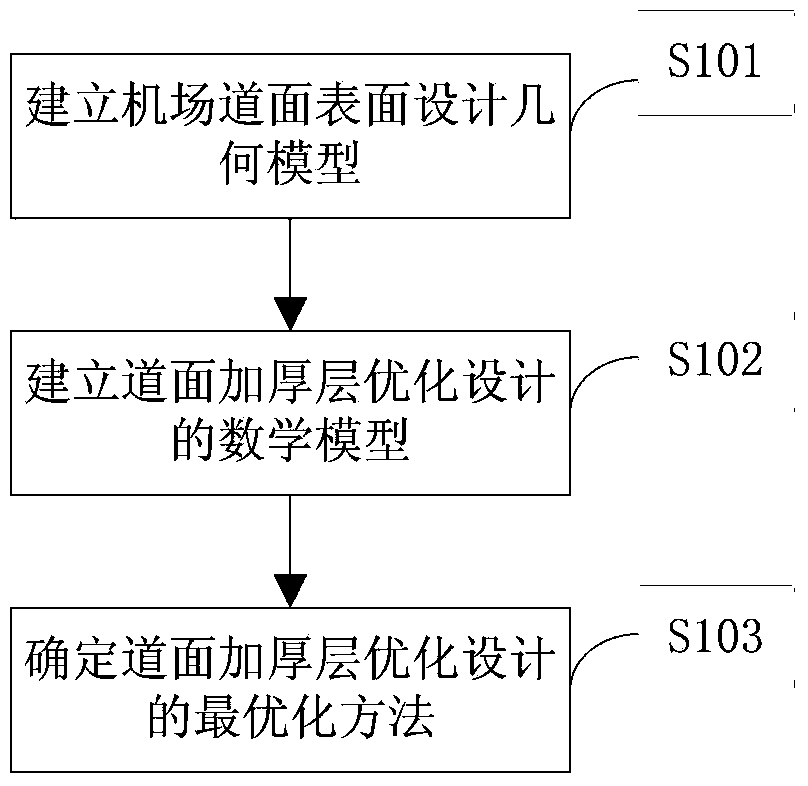

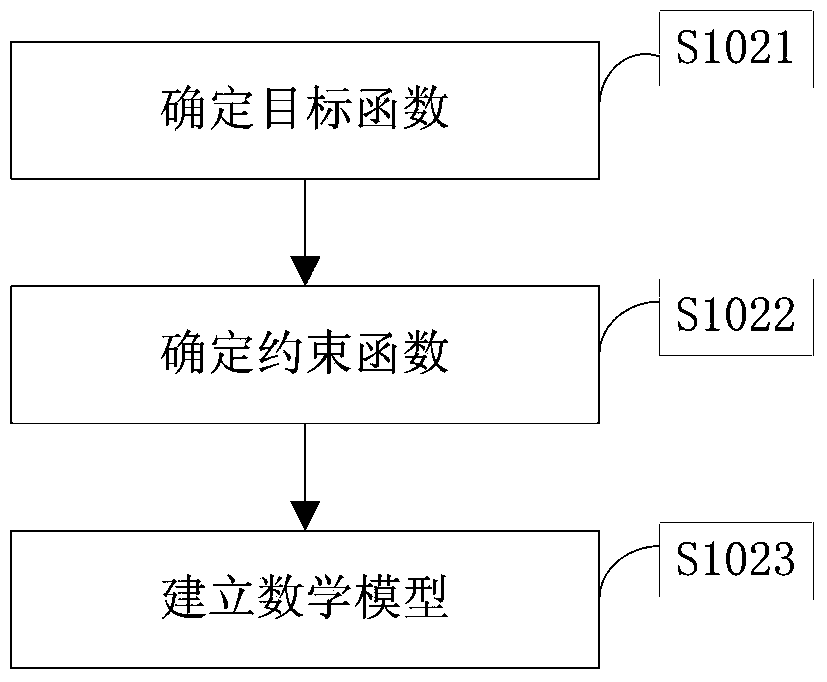

System and method for optimally designing thickening layers of airport pavements

InactiveCN103761373AReliable calculationEasy to useSpecial data processing applicationsMathematical modelGeometric modeling

The invention discloses a system and a method for optimally designing thickening layers of airport pavements. The system for optimally designing the thickening layers of the airport pavements comprises an automatic optimizing unit, an automatic computing unit, an interactive unit and an automatic drawing unit. The method for optimally designing the thickening layers of the airport pavements includes steps of using spatial curved surfaces as the surfaces of the pavements with the thickening layers and designing geometrical models; building mathematical models for optimally designing the thickening layers of the pavements by means of using design grade and elevation of control points as design variables; creating constraint conditions which conform to relevant specifications of current military aviation and civil aviation; providing the optimal process for optimally designing the thickening layers of the pavements. The system and the method have the advantages that the system and the method are applied to designing more than ten rebuilt or expanded airports such as the Baita airport in Hohhot, the concrete thickening layer engineering quantity can be saved by about 5%, all design drawing can be implemented, an acquired design scheme completely conforms to technical standards, and the design period can be shortened and is about 10 days.

Owner:AIR FORCE UNIV PLA

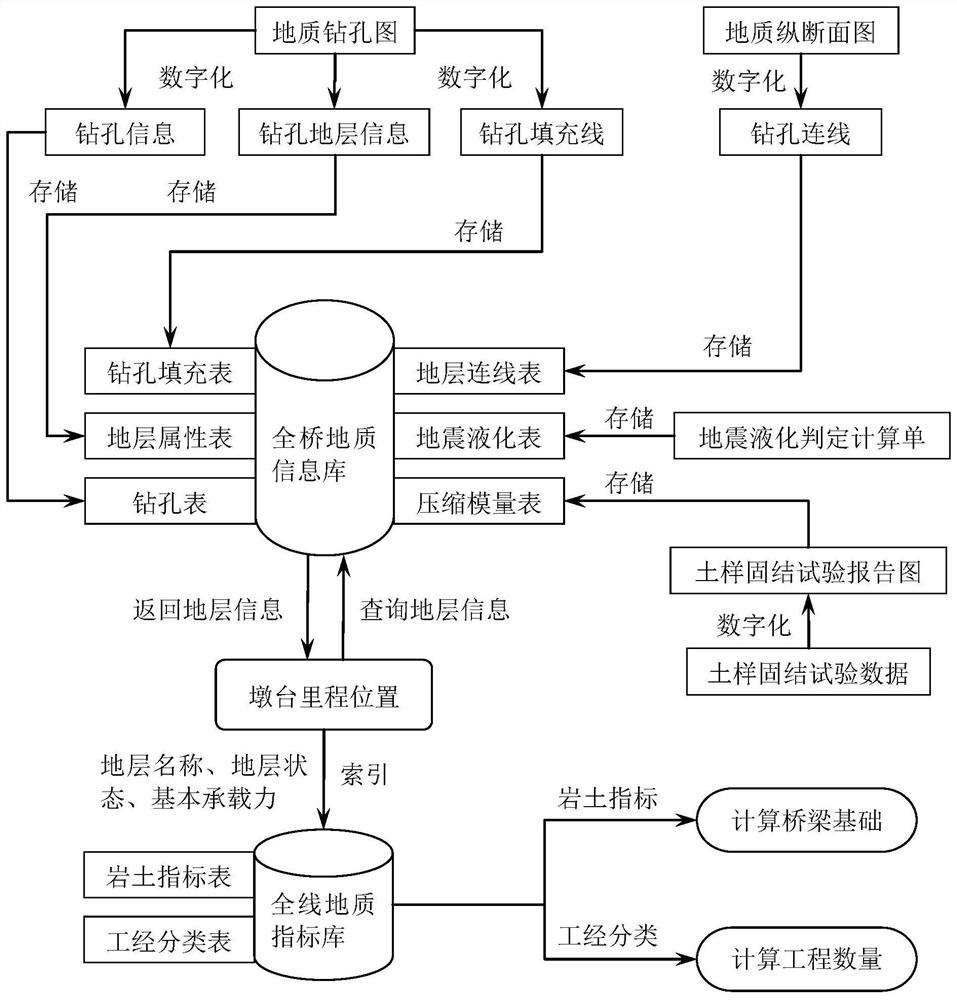

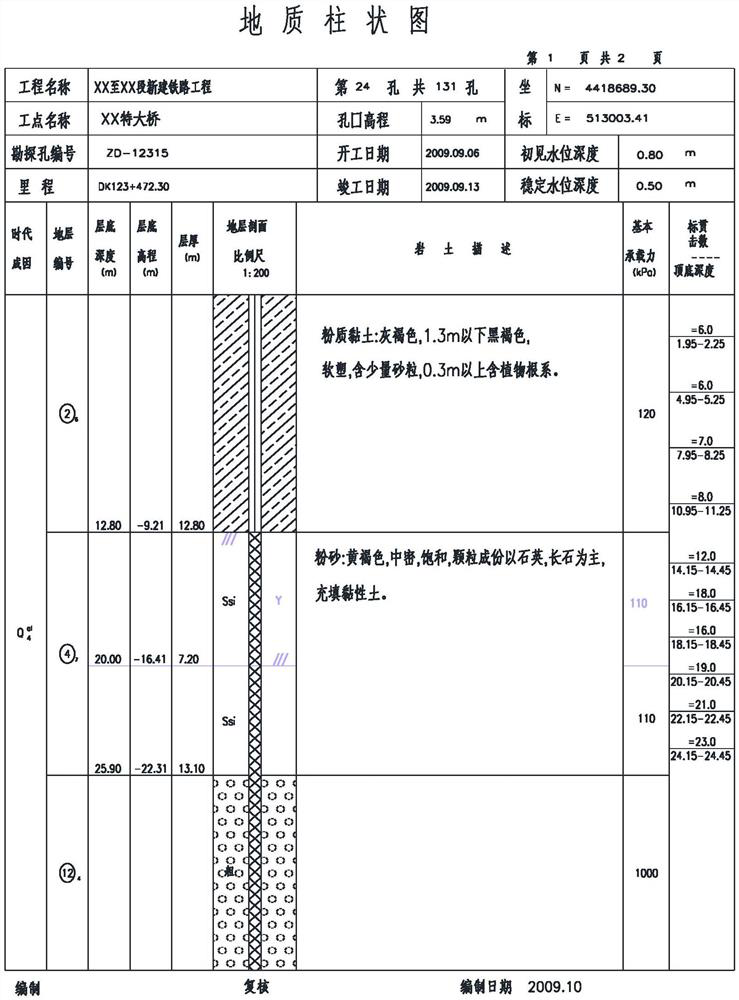

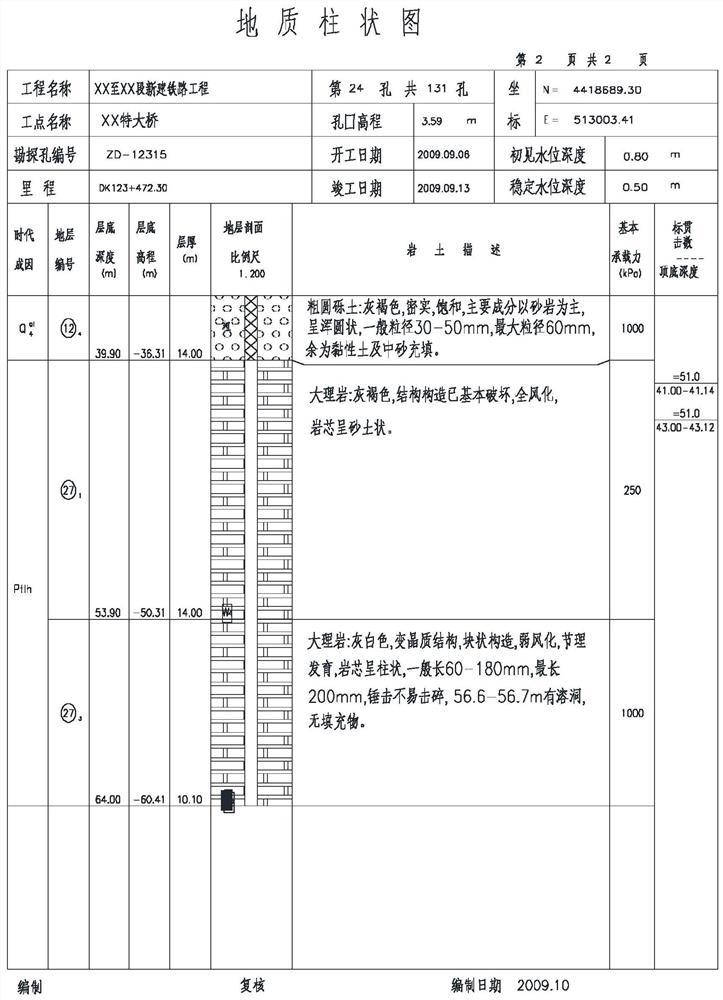

Railway bridge geological graph digital storage and application method

PendingCN113626546AGuaranteed calculation accuracySpeed up the design processGeographical information databasesSpecial data processing applicationsDrill holeTest report

The invention discloses a railway bridge geological graph digital storage and application method, which comprises the following steps of: the geological condition of the whole railway project line is counted, and a stratum index library of the whole line is established by taking the stratum name, the stratum state and the basic bearing capacity as indexes; geological data provided by the geological specialty are sorted, and a full-bridge geological information base is established with a single bridge as a unit; basic characteristics of the geological drilling map are analyzed, drilling information is stored in a drilling table, drilling stratum information is stored in a stratum attribute table, and drilling filling lines are stored in a drilling filling table; basic characteristics of the geologic profile diagram are analyzed, and drill hole connecting lines are stored in a stratum connecting line table; an earthquake liquefaction judgment calculation sheet is designed and stored in an earthquake liquefaction table, and a digital soil sample consolidation test report graph is stored in a compression modulus table; and bridge calculation is performed according to the pier mileage position in the bridge table, the stratum index library and the full-bridge geological information library. The method guarantees the calculation accuracy, accelerates the design progress, improves the labor efficiency of workers, and reduces the labor intensity.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

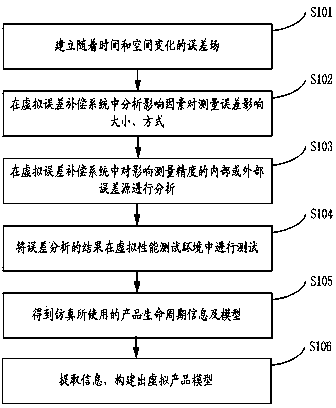

Method for creating virtual prototype product of CMM (coordinate measuring machine)

InactiveCN103646142ASpeed up the design processImprove performanceSpecial data processing applicationsObservational errorCoordinate-measuring machine

The invention discloses a method for creating a virtual prototype product of a CMM (coordinate measuring machine). The method comprises the steps as follows: an error field changing with time and space is established; the magnitude and the manner of an influence of an influence factor on a measuring error are analyzed in a virtual error compensation system; an internal or external error source influencing the measurement accuracy is analyzed in the virtual error compensation system; a result of error analysis is tested in a virtual performance test environment; product life-cycle information and a model which are used during simulation are obtained; and the information is extracted to create a virtual product model. According to the method, the high cost is reduced, and the time for tests is shortened. A CMM design process is accelerated, and the performance of the CMM is improved. Finally, CMM developers can reflect market changes promptly.

Owner:XIAN TECH UNIV

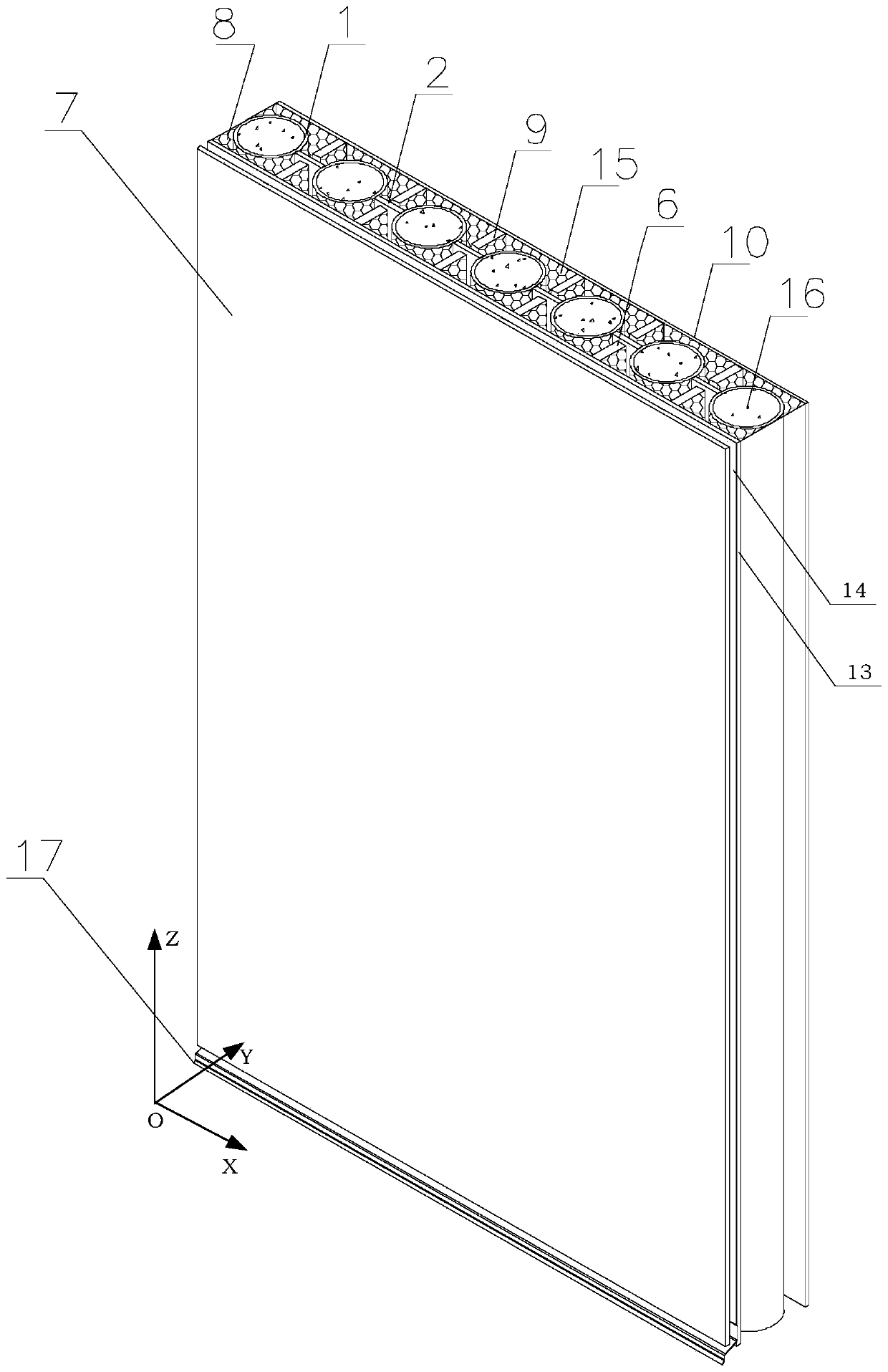

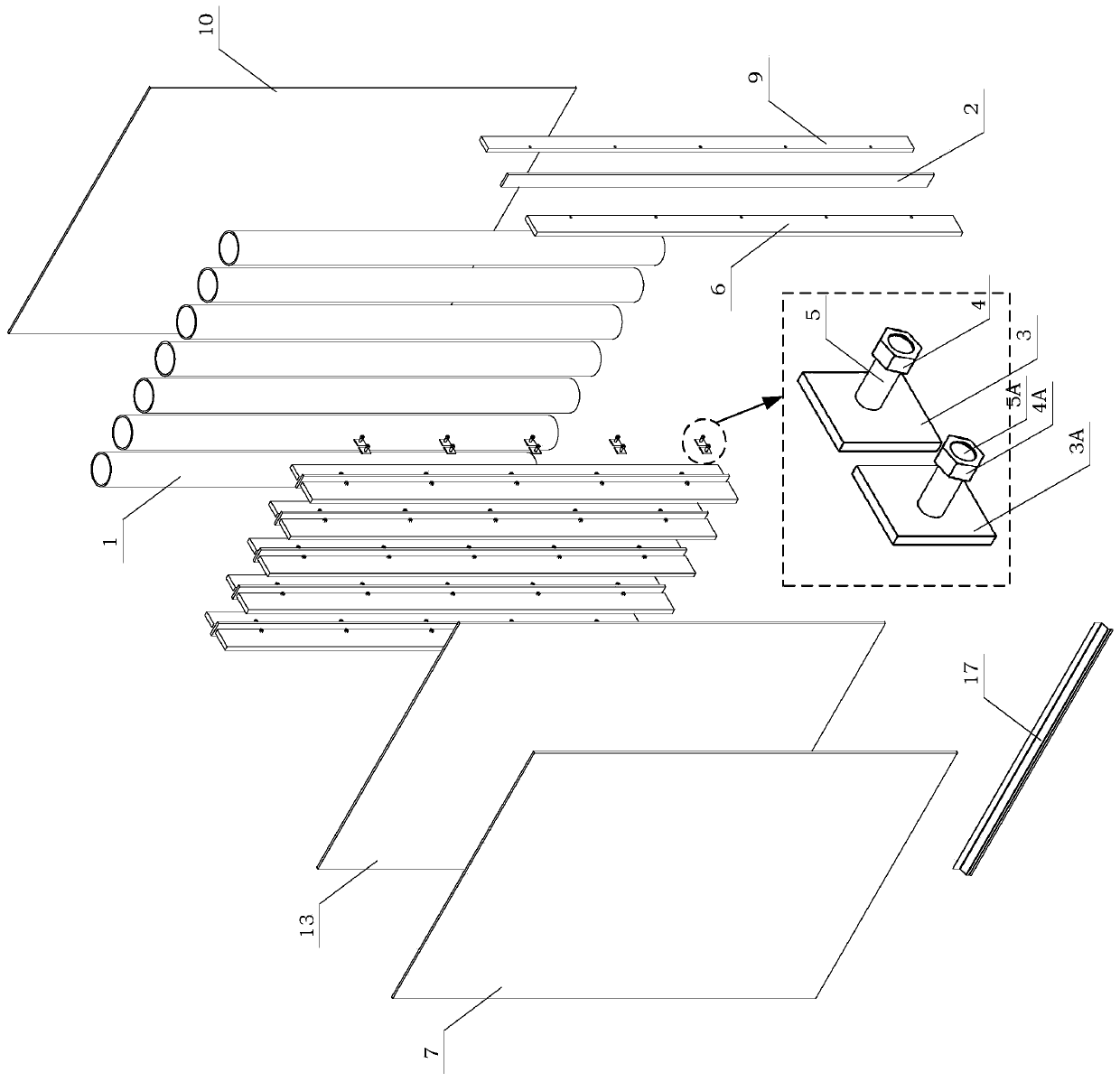

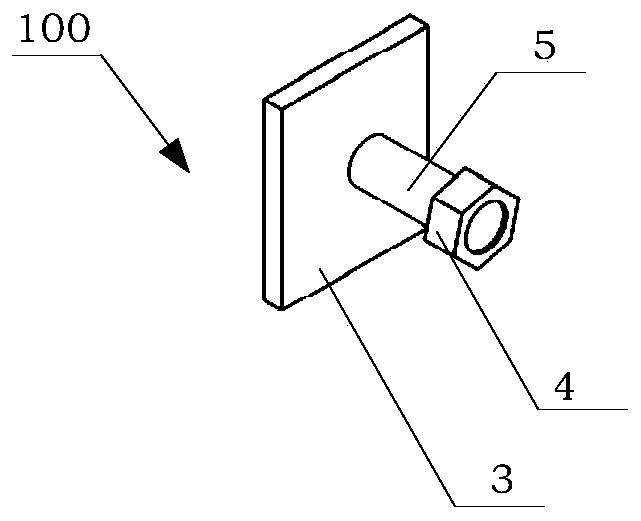

Assembled steel pipe concrete-wood composite wall for building house and manufacturing method thereof

InactiveCN111042373AReduce weightImprove seismic performanceCovering/liningsWallsEarthquake resistanceArchitectural engineering

The invention discloses an assembled steel pipe concrete-wood composite wall for a building house and a manufacturing method thereof. The composite wall comprises a wall panel, a chair rail, a prefabricated part, an inner decorative sheet and an eyebrow. An air pressure balancing layer is arranged between the wall panel and the chair rail; the prefabricated part is arranged between the chair railand the decorative sheet; and the lower ends of the wall panel and the chair rail are mounted on the eyebrow. The prefabricated part comprises round steel pipes, a batten plate, an exterior wall bonecolumn, an interior wall bone column, an insulating and sound-isolating material, a pipeline channel and a connecting part. The pipeline channel is arranged in the insulating and sound-isolating material; the batten plate is welded between the adjacent two round steel pipes; connecting rails in a plurality of connecting parts are welded to the batten plate in the Z-axis direction; the exterior wall bone column and the interior wall bone column are fixed to the batten plate through the connecting parts, and the exterior wall bone column and the interior wall bone column are separately located on two sides of the batten plate. The assembled steel pipe concrete-wood composite wall combines three building materials steel, concrete and wood perfectly to exert advantages thereof, so that the assembled steel pipe concrete-wood composite wall has the excellent characteristics of being high in strength, light in weight, good in anti-seismic property, safe and reliable, attractive, green and environment-friendly and sustainable.

Owner:张效思

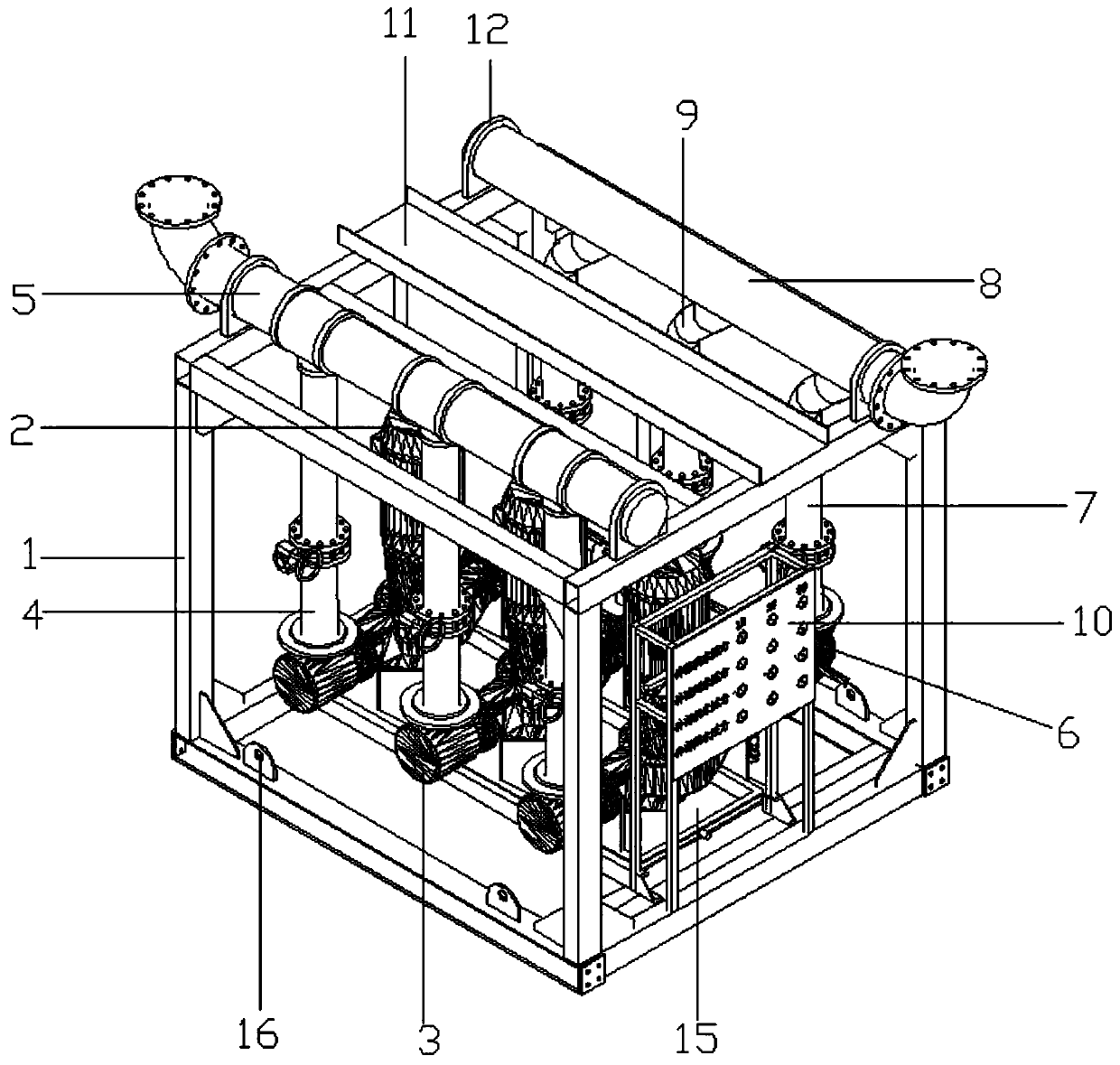

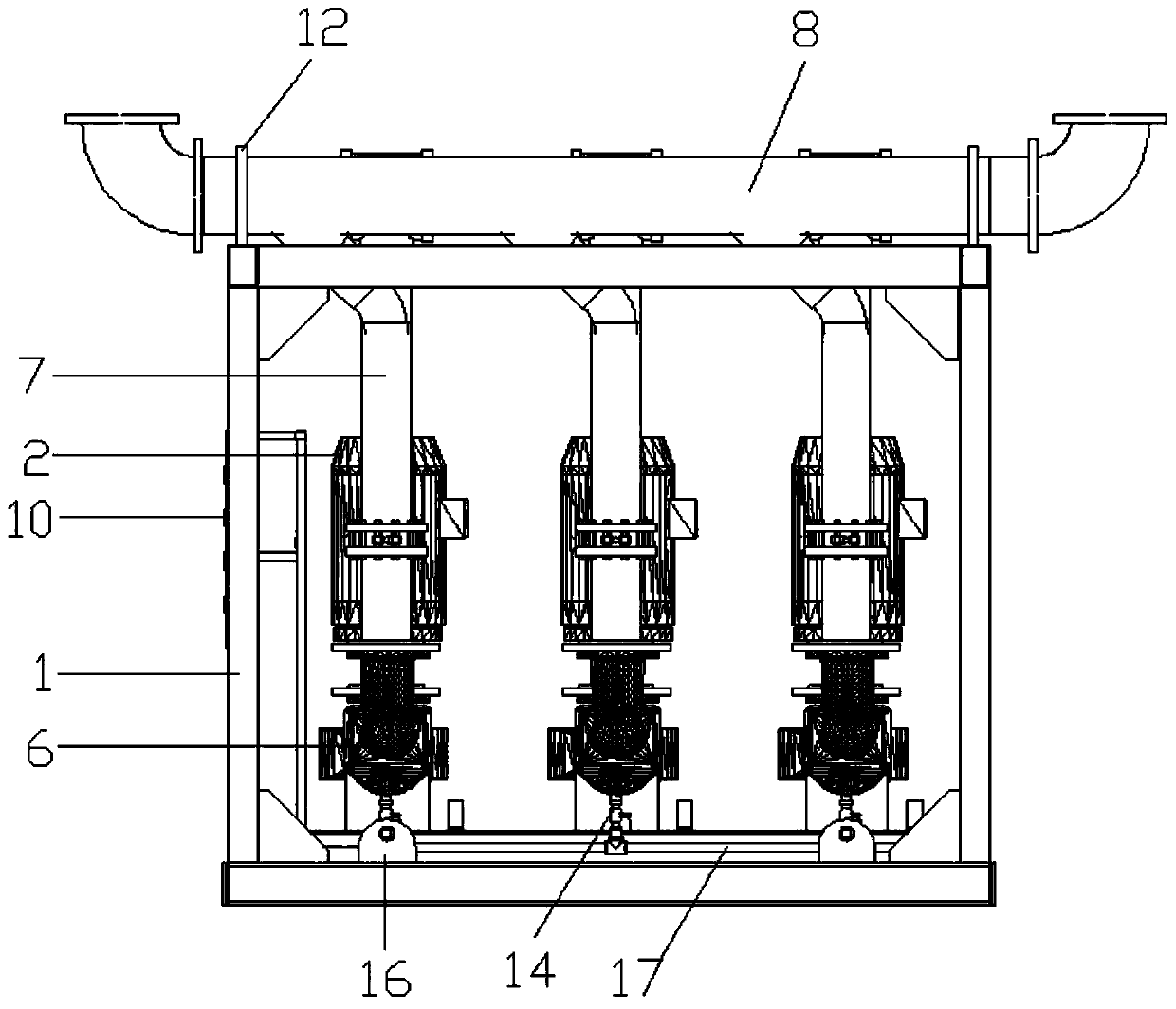

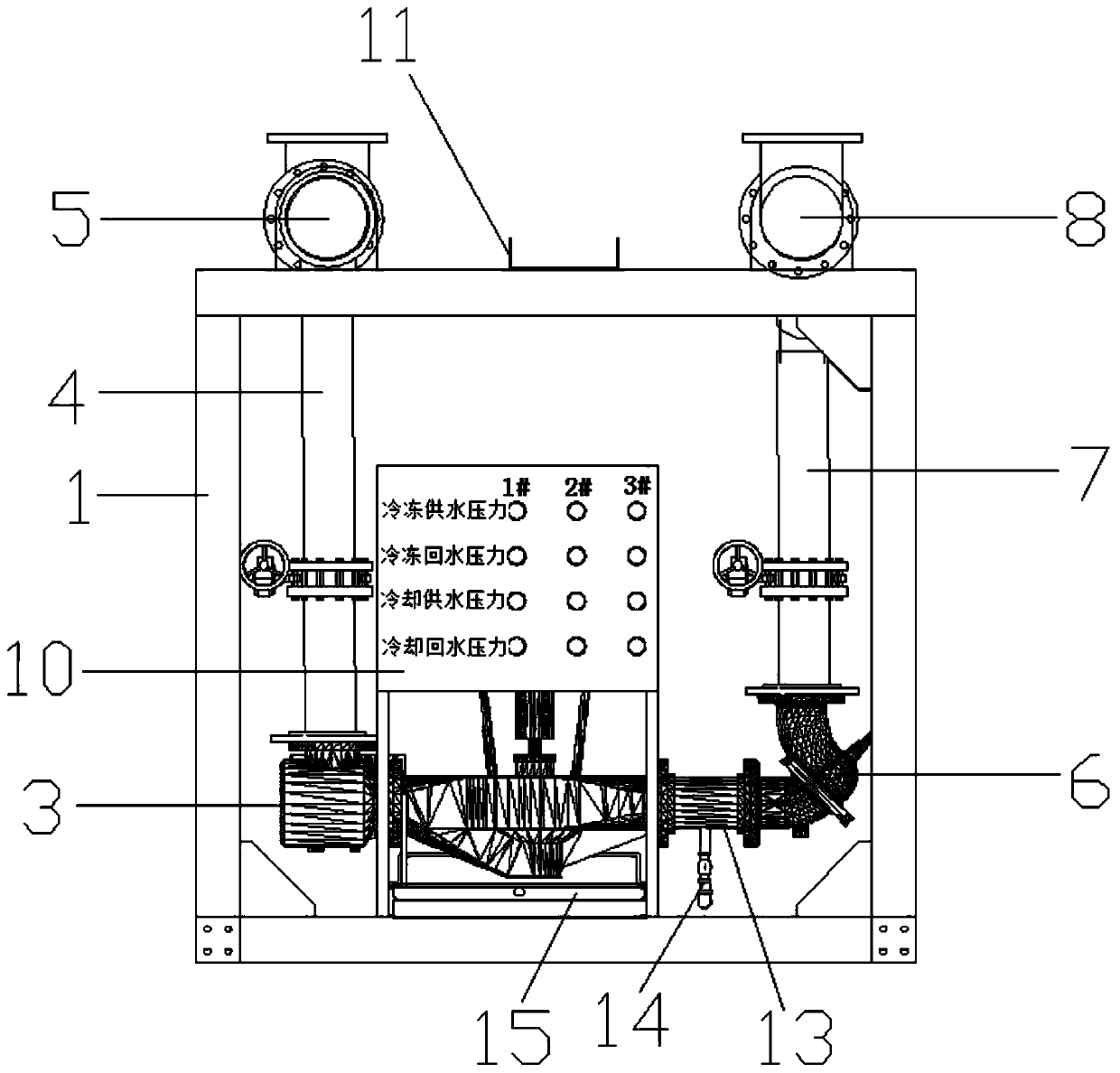

Intelligent fluid pump group

PendingCN110425152AHigh concentricitySimple designSubstation/switching arrangement detailsPump componentsImpellerDynamic balance

The invention provides an intelligent fluid pump group. The intelligent fluid pump group comprises an H steel frame, and at least two intelligent variable-frequency pumps are installed at the bottom of the H steel frame; water inlets of the intelligent variable-frequency pumps are connected with suction fluid directors, and the suction fluid directors are connected with a first water collection pipe installed at the top end of the H steel frame through first vertical pipes; and water outlets of the intelligent variable-frequency pumps are connected with connecting pipes, the connecting pipes are connected with multifunctional valves, and the multifunctional valves are connected with a second water collection pipe installed at the top end of the H steel frame through second vertical pipes.According to the intelligent fluid pump group, noise and vibration are low in the running process, the occupied area and space are small, the intelligent fluid pump group does not need to depend on anexternal sensor, and therefore the pumping efficiency is improved to the maximum limit; and the concentricity of the intelligent variable-frequency pumps is high, pump shafts and motor shafts are positioned by adopting machining connecting steel frames and connected through rigid couplers, impellers achieve dynamic balance design, and flow channels achieve optimization design.

Owner:济南金孚瑞供热工程技术有限公司

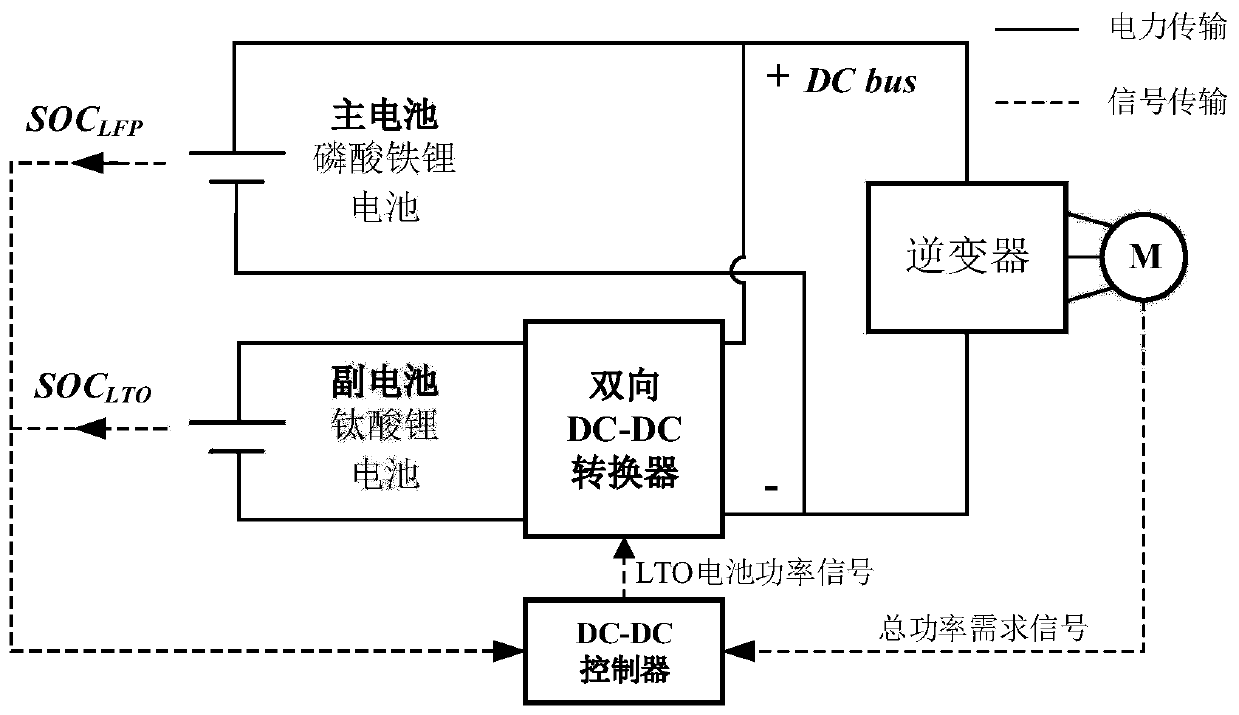

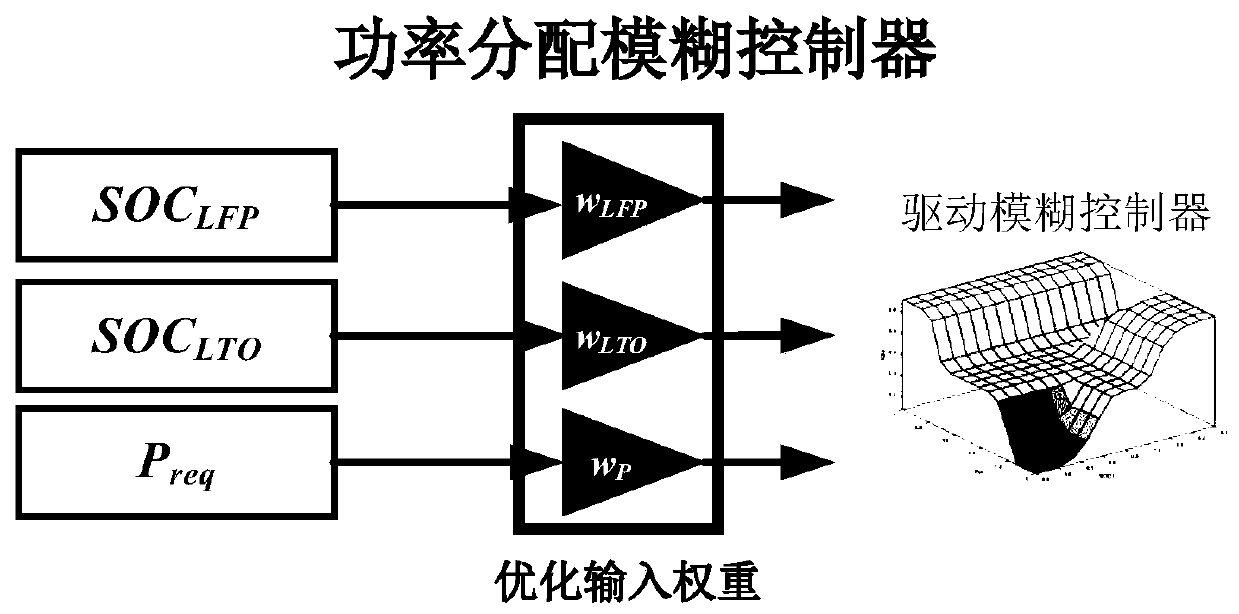

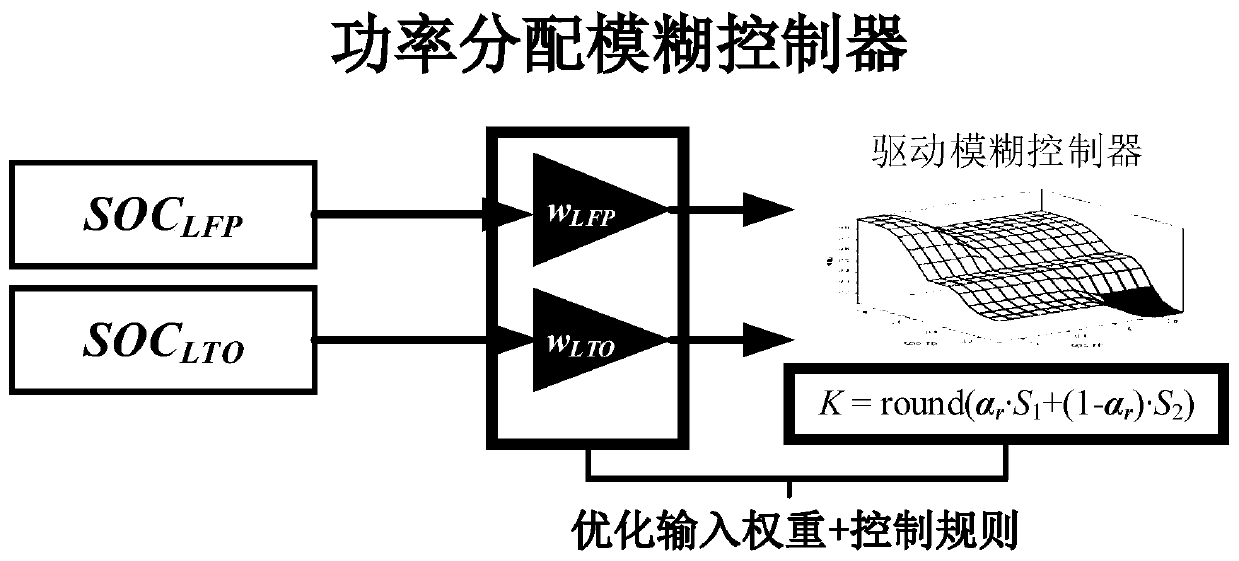

Parameter optimization design method for fuzzy controller of composite power supply system

ActiveCN111137171AImprove performanceSpeed up the design processDesign optimisation/simulationConstraint-based CADControl engineeringFuzzy control system

The invention discloses a parameter optimization design method for a fuzzy controller of a composite power supply system. The method comprises the following steps: step 1, selecting the service life as an optimization target according to function demands of a composite power supply system, and optimizing controller parameters of a fuzzy controller; step 2, constructing a power distribution fuzzy controller, and setting the controller as a three-input-single-output structure; step 3, keeping the fuzzy control rule unchanged, and optimizing the weight of an input variable; step 4, optimizing a fuzzy control rule and input and output variable weights at the same time; and step 5, substituting the optimized input variable weight and the fuzzy control rule back to the fuzzy controller, and verifying the optimized control effect. According to the method, the controller parameters of the HESS fuzzy controller can be optimized, the performance of the HESS in the operation process can be improved, and the comprehensive performance of the electric vehicle is improved.

Owner:开沃新能源汽车集团股份有限公司

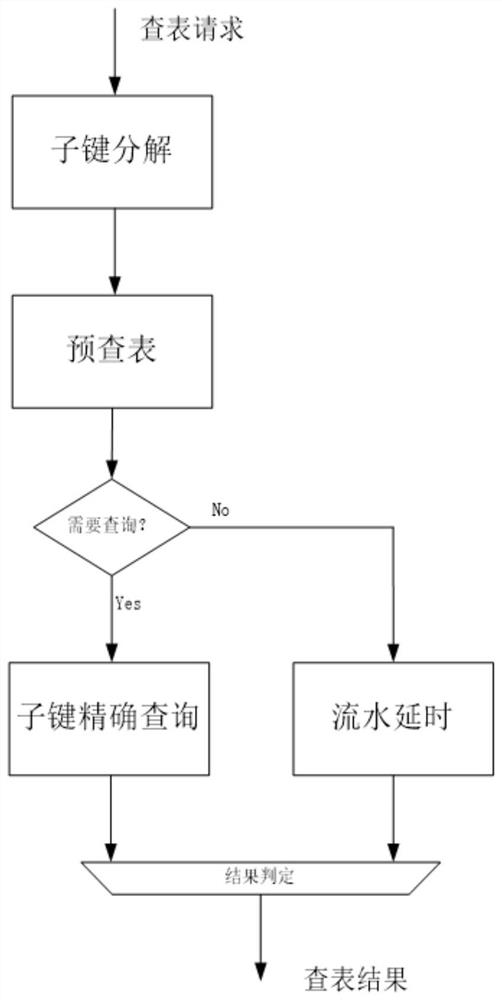

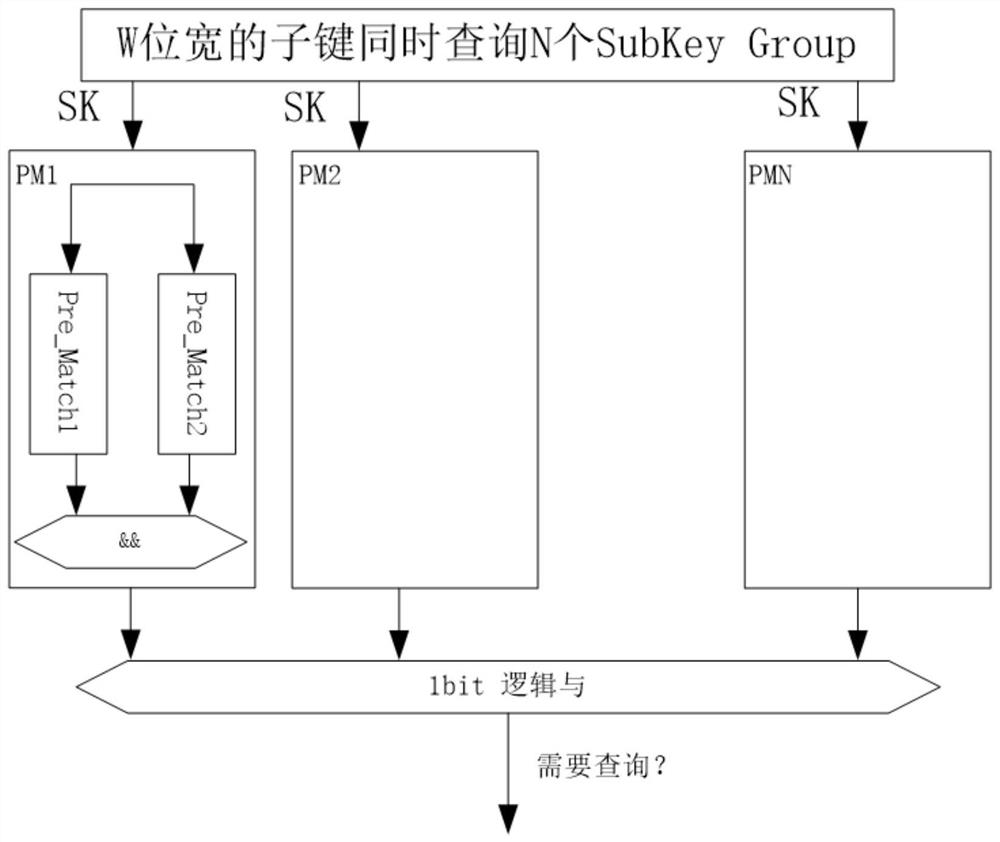

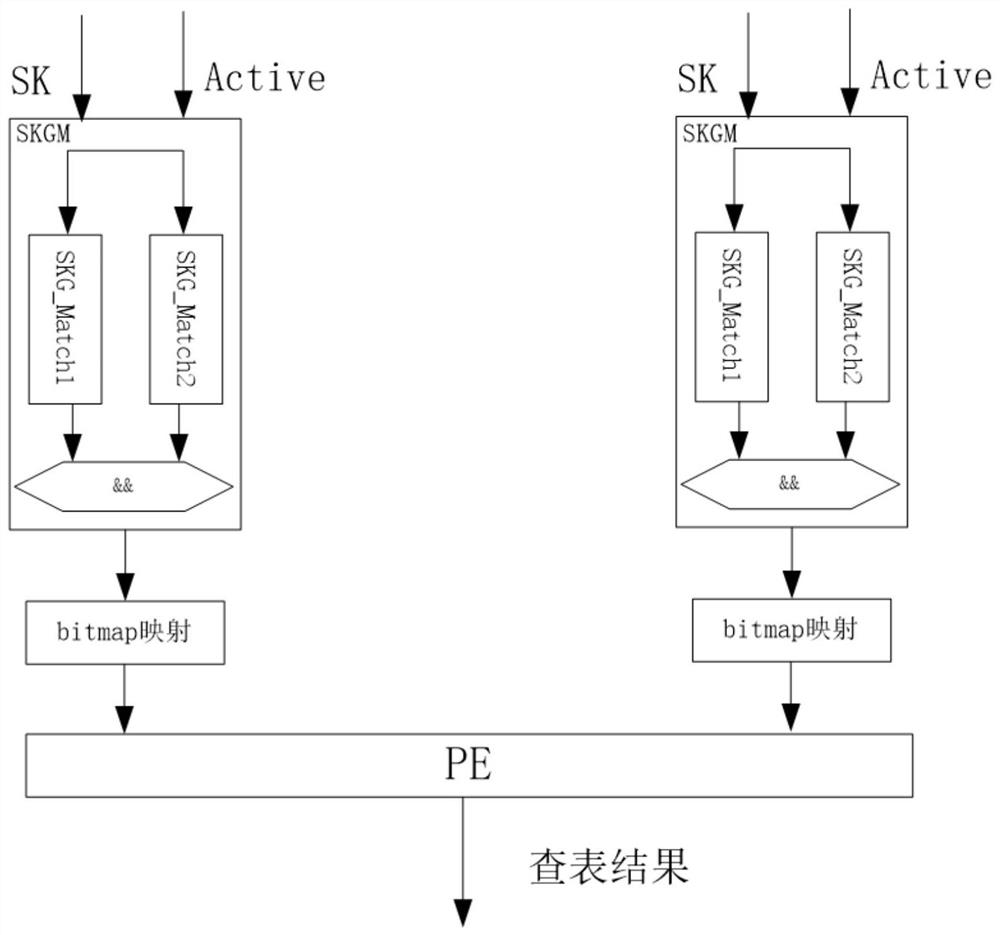

Efficient TCAM implementation method based on SRAM

PendingCN112769703ASpeed up the design processOverall area and power consumption controllableData switching networksTime delaysEngineering

The invention discloses an efficient TCAM (Ternary Content Addressable Memory) implementation method based on an SRAM (Static Random Access Memory). The method comprises the following steps: cutting an input table look-up key value into N sub-keys with W bit width according to a standard; judging whether the key value needs to be queried or not through a pre-table-look-up module; when the table pre-lookup result is that query is not needed, needing to insert a pipeline time delay module, simulating time delay generated by table lookup, and guaranteeing that the sequence of all table lookup results is consistent with that of input when the table lookup results are output; inquiring the SRAM table according to a table pre-lookup mode, performing logical AND on the found bitmap, and then mapping the final bitmap to a specific hit index. According to the method, the TCAM function can be realized by using the SRAM, a TCAMIP does not need to be additionally purchased, the size of the SRAM can be flexibly adjusted according to the table item specification, the limitation of the specific TCAM specification is avoided, and the chip project design progress can be effectively improved; and the overall area and the power consumption are more controllable.

Owner:芯河半导体科技(无锡)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com