Emulating method and device for exposure system

A technology of an exposure system and a simulation method, which is applied to a photoplate-making process exposure device, a microlithography exposure device, and an input/output process of data processing, etc., can solve the problem of low accuracy of the simulation device and low accuracy of the simulation method of the exposure system. and other problems to achieve the effect of shortening the design cycle, speeding up the design progress and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

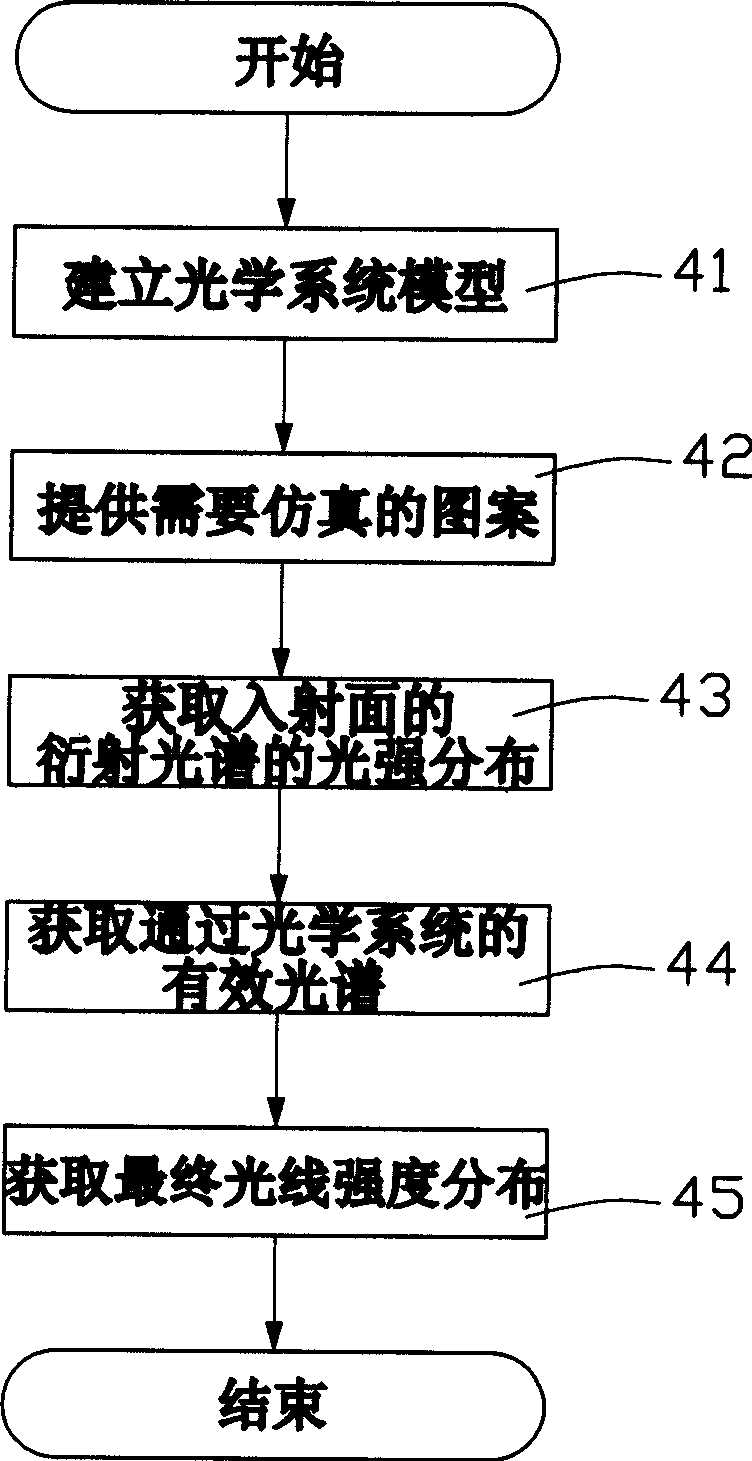

[0031] Generally, the exposure system includes an optical system and a carrier, and the optical system includes several optical lenses and a light source.

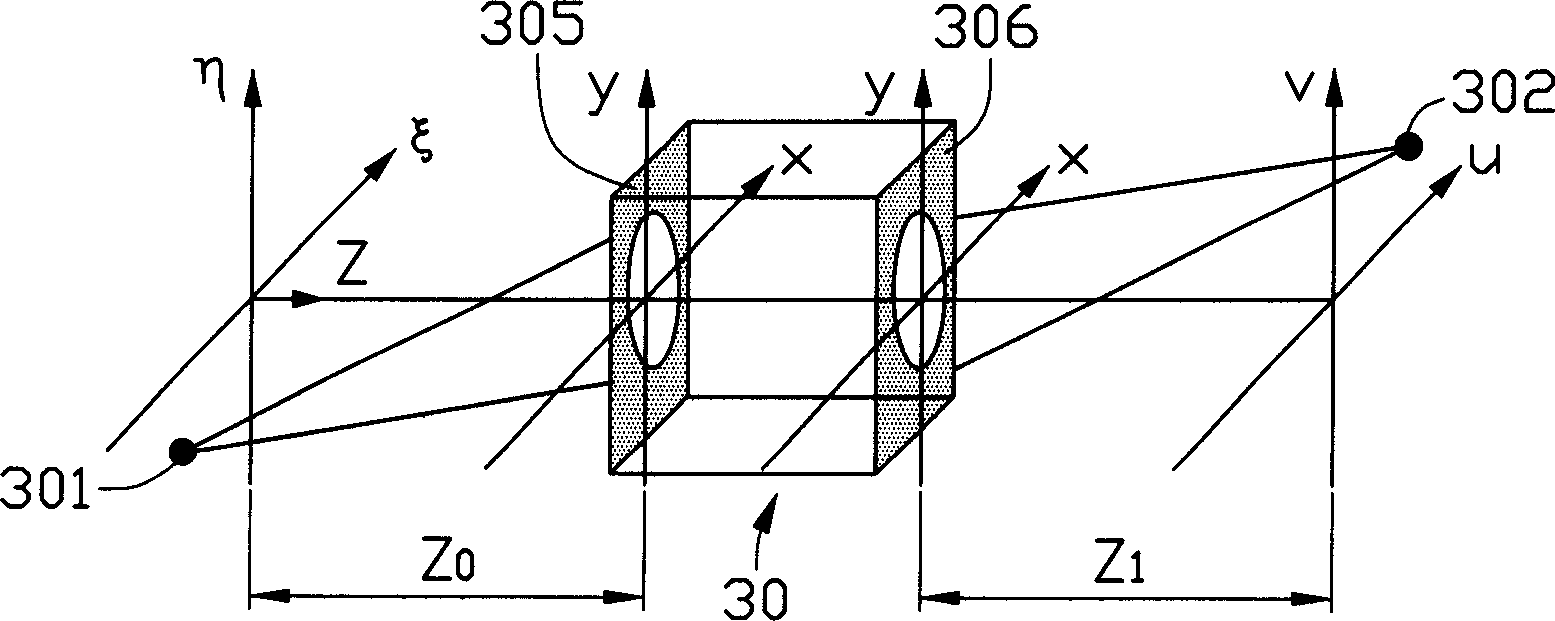

[0032] see figure 2 , is a schematic diagram of the optical system of a commonly used exposure machine. The light emitted by the light source 301 enters the optical system 30 of the exposure machine from the incident surface 305 of the optical system 30 , and then exits from the output surface 306 of the optical system 30 , and forms a projection 302 on the projection surface behind the optical system 30 . Z0 represents the distance between the light source 301 and the incident surface 305 of the optical system 30 , that is, the object distance; Z1 represents the distance between the projection 302 and the outgoing surface 306 of the optical system 30 , that is, the image distance.

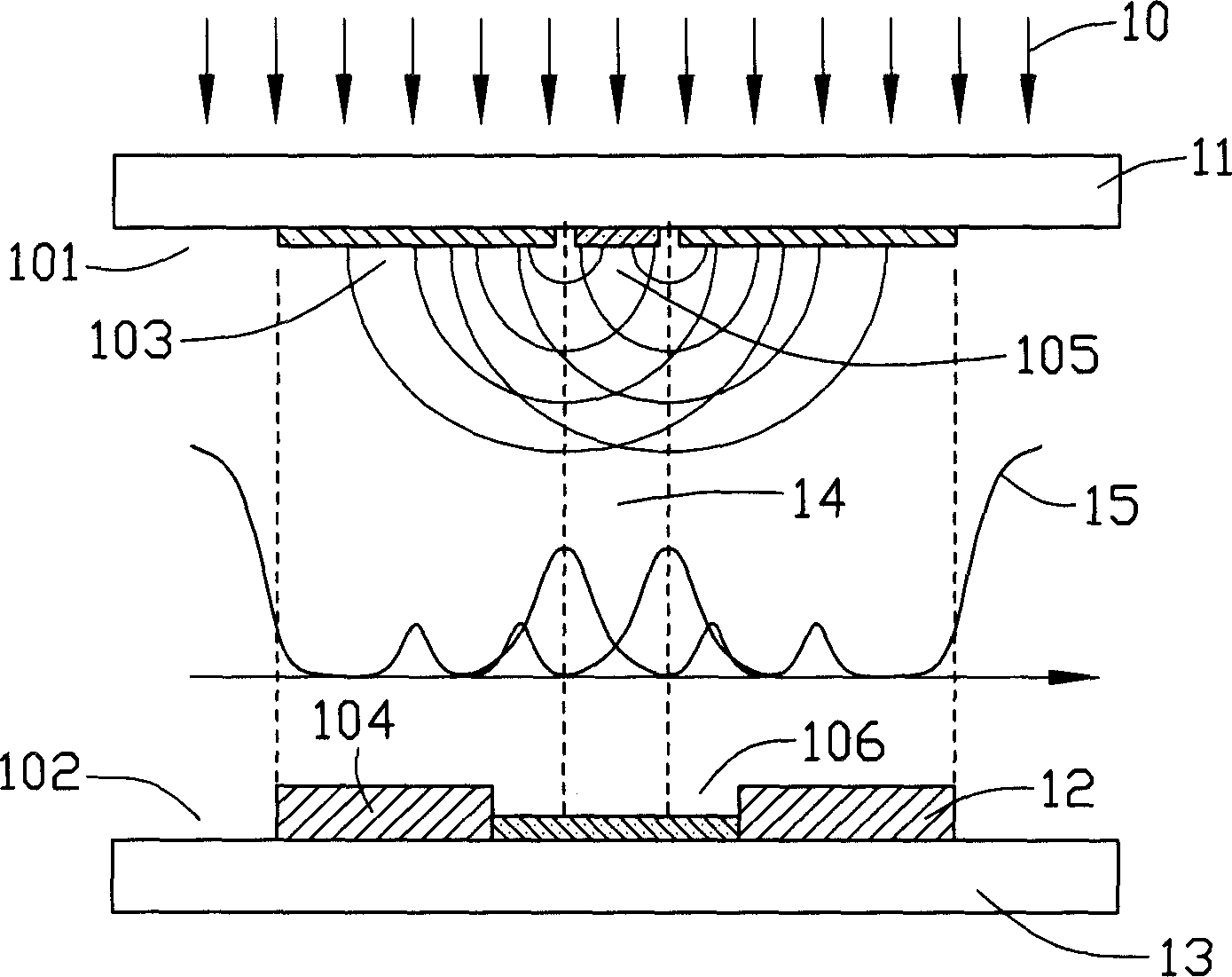

[0033] In the exposure process, among various factors affecting the exposure resolution, the influence of slit diffraction is more obvious....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com