Patents

Literature

100results about How to "Guaranteed design quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

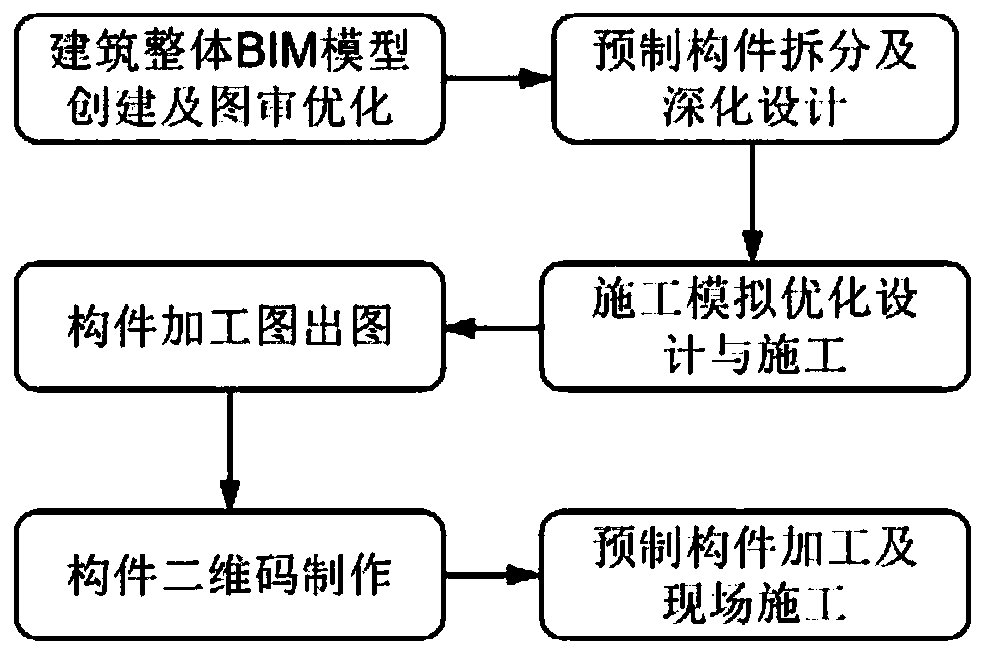

BIM-based concrete fabricated building construction method

PendingCN110929328AGuaranteed design qualityGuaranteed constructabilityGeometric CADDesign optimisation/simulationConstruction engineeringCollaborative design

The invention discloses a BIM-based concrete fabricated building construction method, comprising the following steps: creating a building full-professional integral BIM model, optimizing integral design, splitting prefabricated parts, deepening prefabricated part nodes, performing construction simulation optimization design, performing engineering quantity statistics, drawing a prefabricated partprocessing drawing, and manufacturing a prefabricated part two-dimensional code. By creating the visual informationized BIM model, the BIM-based concrete fabricated building construction method improves the collaborative design of information of the building, the structure and the electromechanical specialty, avoids the problems of mistakes, omissions, collisions and lacks of the design specialties, and improves the design quality. Meanwhile, the assembly type construction process is visually simulated through BIM, and the problem optimization design in construction is found in time, and the design and construction barrier is broken through. Besides, the BIM technology can perform rapid drawing according to the model, and the design quality is improved through automatic statistics of the engineering quantity, and visual construction simulation can further guide field construction, and the generated two-dimensional code can be used for information tracing of the prefabricated part, andthe overall construction quality of the prefabricated building is improved.

Owner:中国电建集团江西省水电工程局有限公司

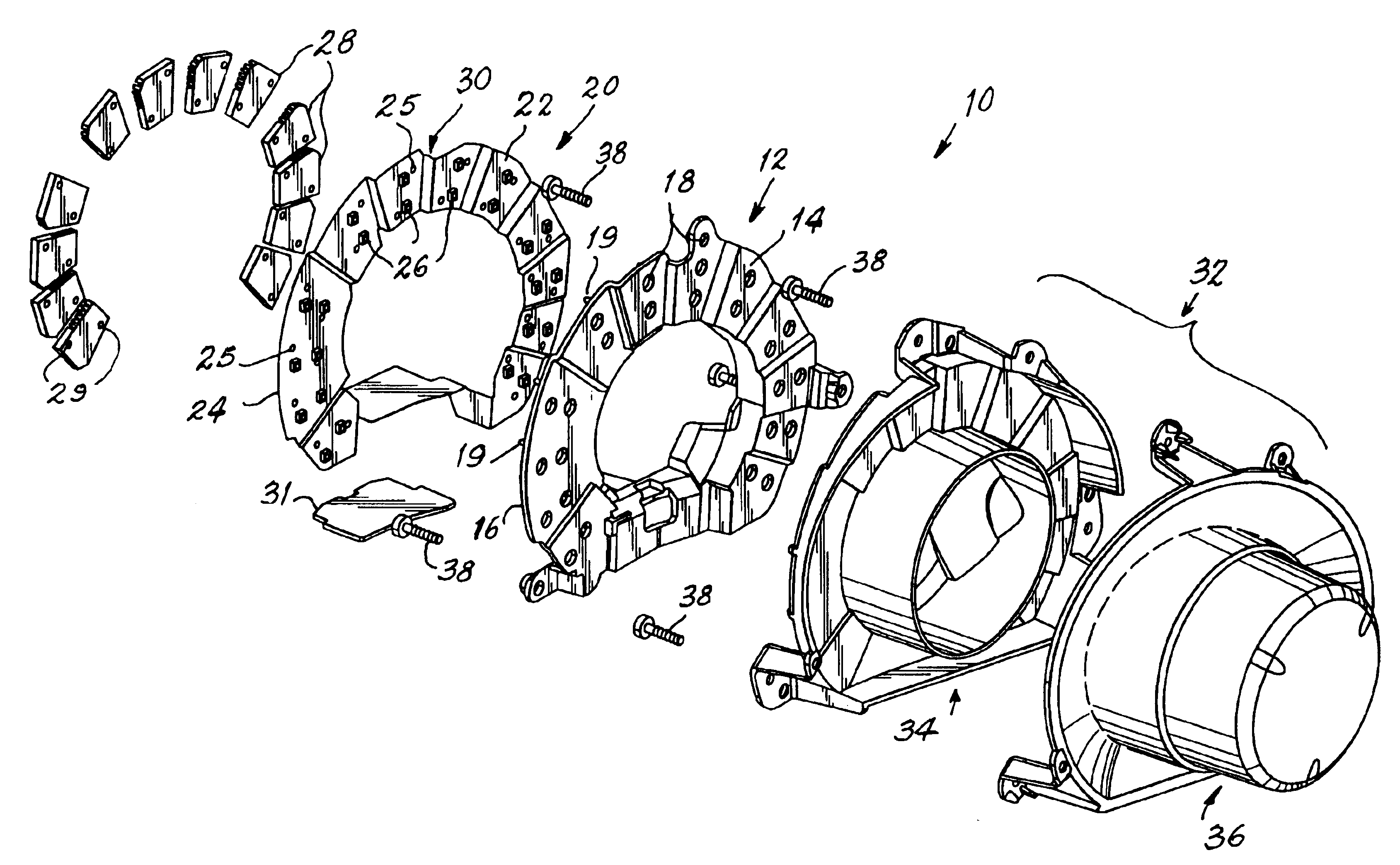

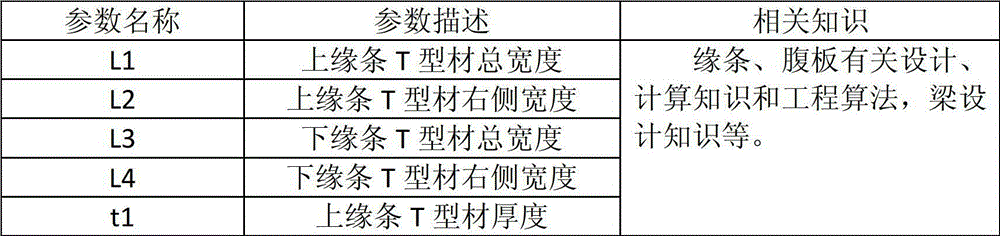

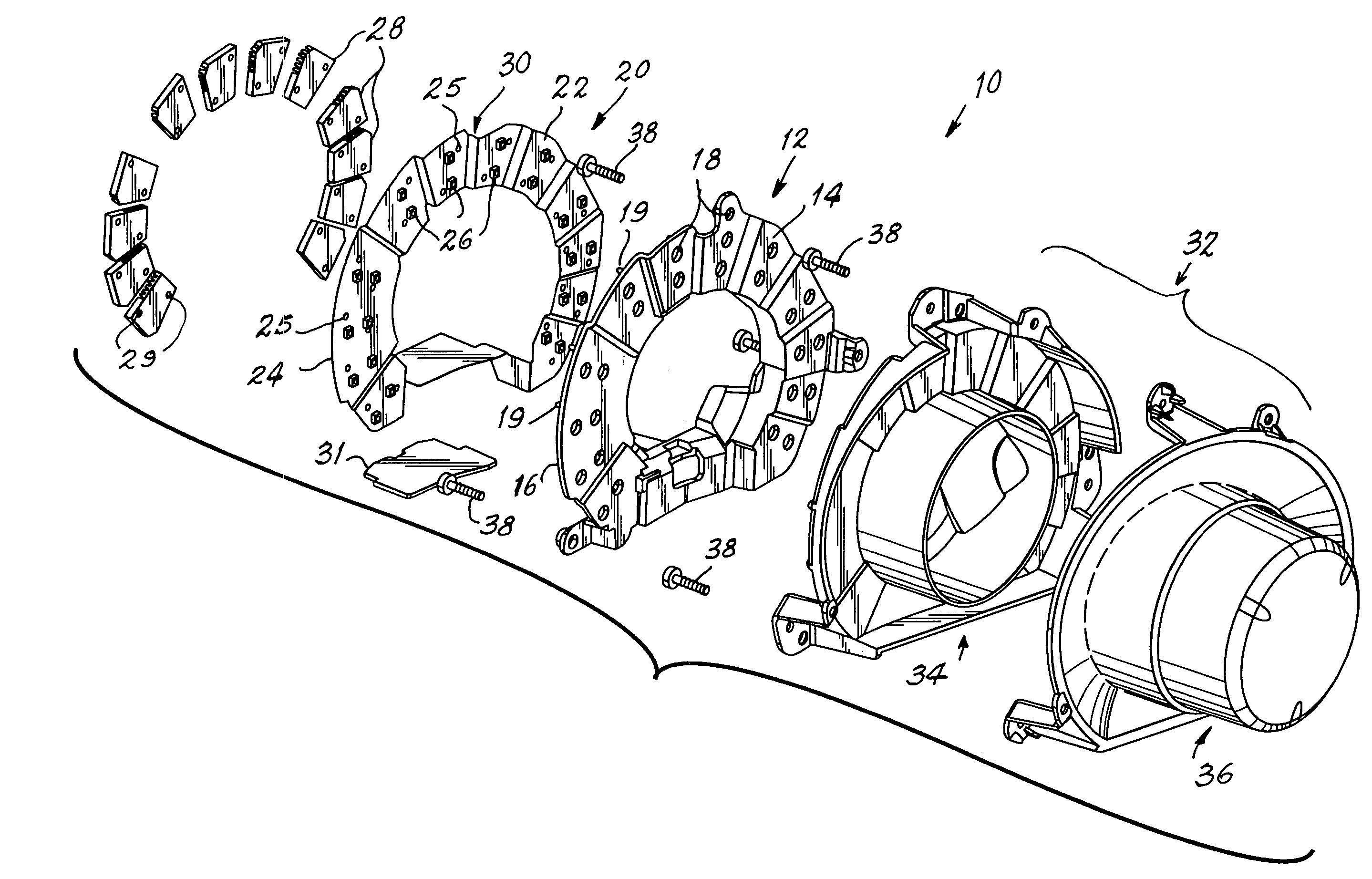

Light emitting diode carrier

ActiveUS6964499B2Enhance assembly and operationGuaranteed design qualityLighting support devicesPoint-like light sourceEngineeringHeat sink

A lamp assembly (10) has a carrier (12) with a front side (14) and a backside (16) provided with a plurality of passages (18) therethrough. A circuit board (20) includes a first surface (22) and a second surface (24). A plurality of light sources (26) is mounted on the first surface (22), and the first surface (22) of the circuit board (20) is aligned with the backside (16) of the carrier (12). The plurality of light sources (26) is aligned with the plurality of passages (18) in one-to-one relationship. At least one heat sink (28) is mounted in thermal contact with at least one of the plurality of light sources.

Owner:VALEO SYLVANIA L L C

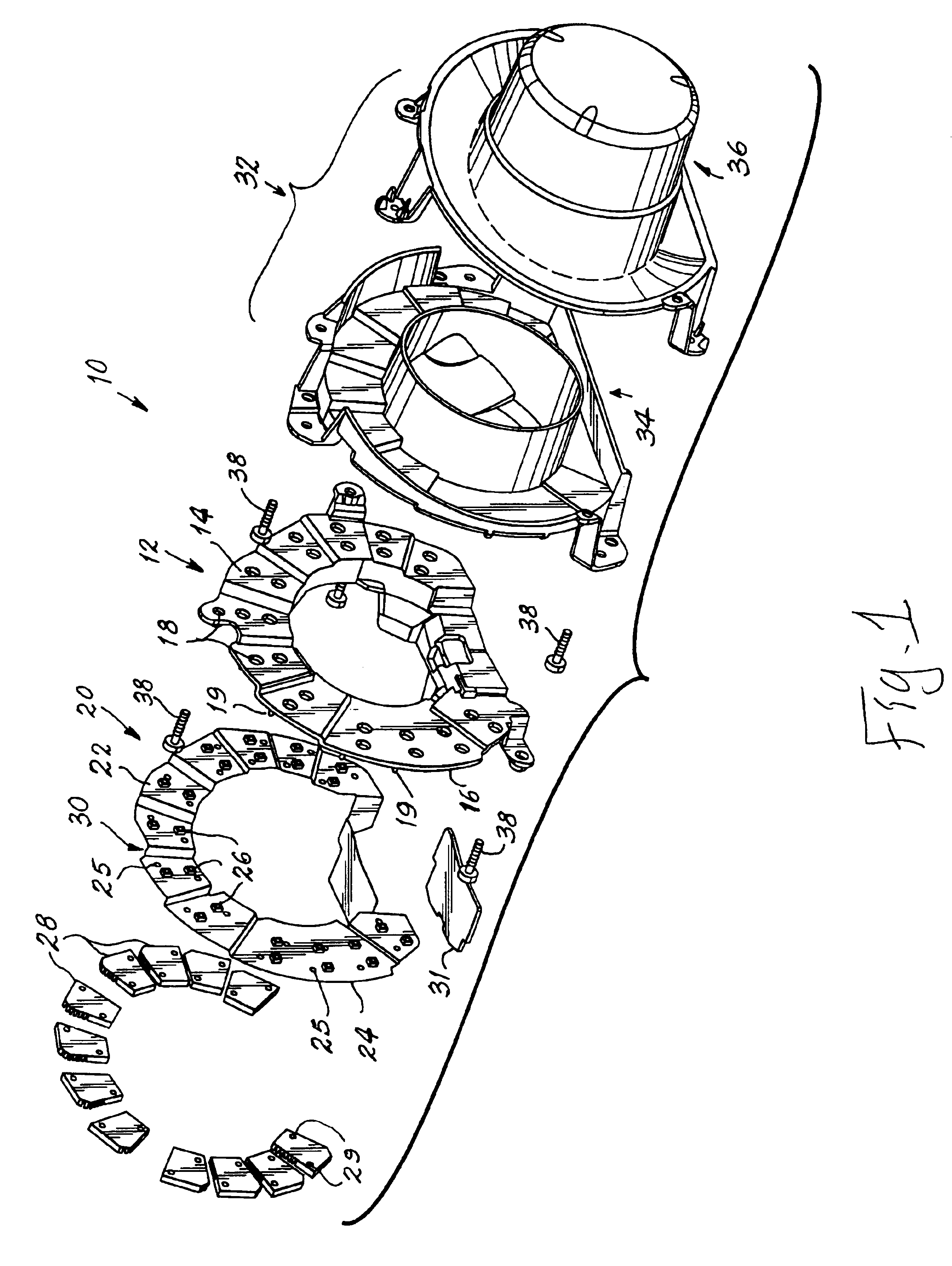

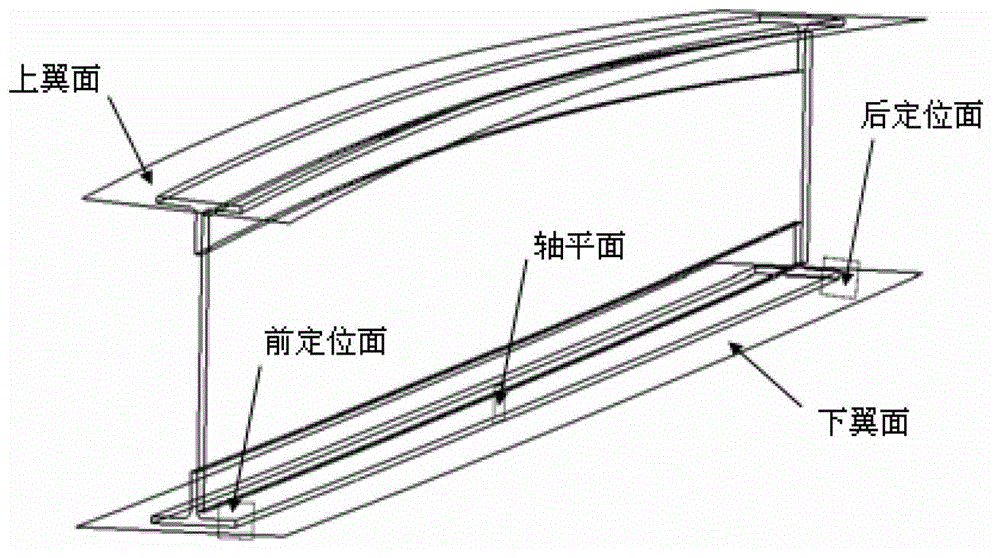

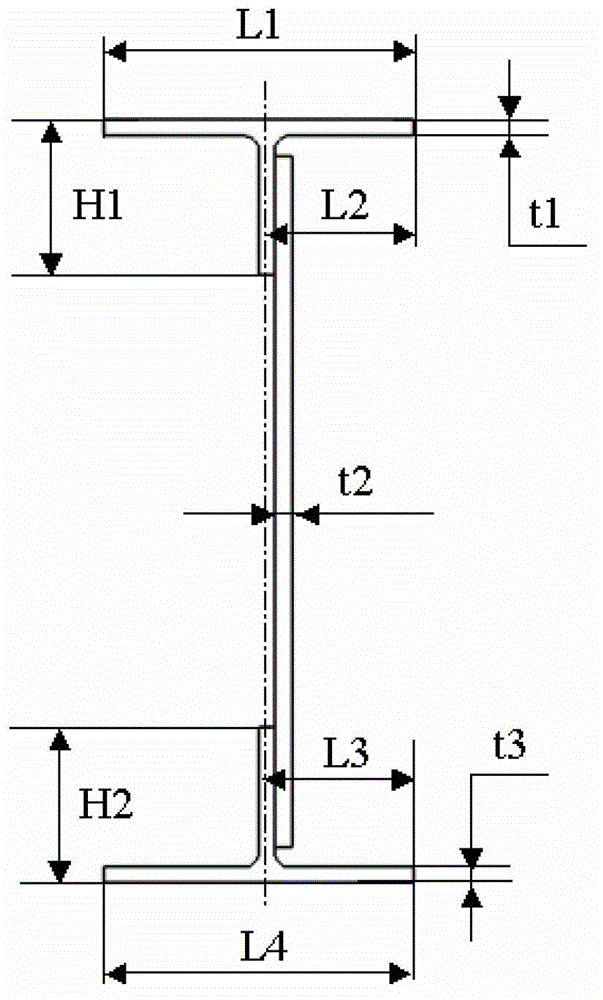

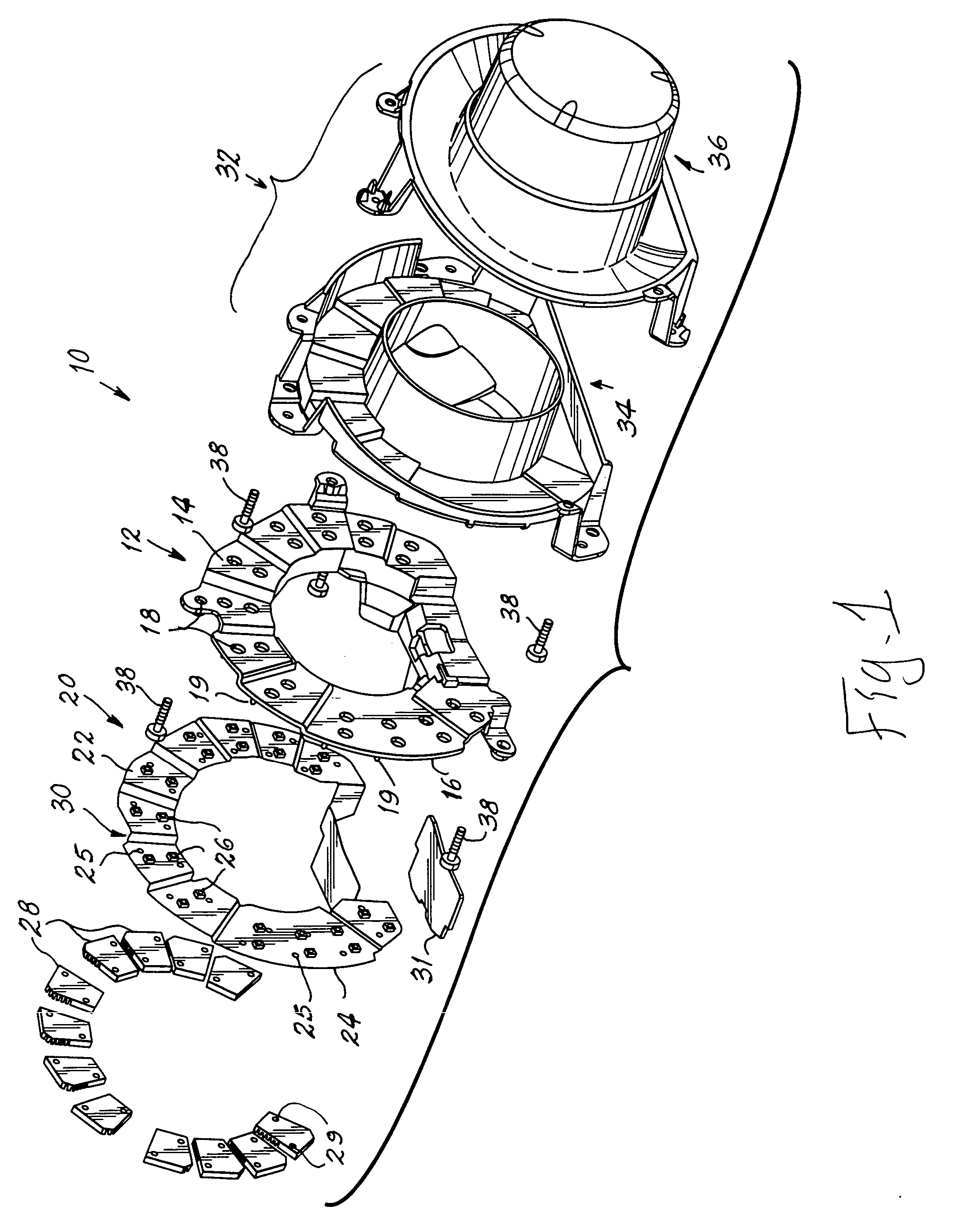

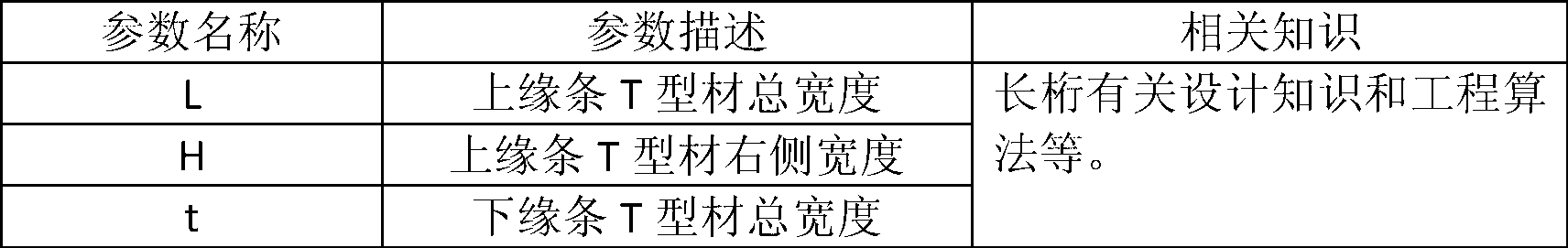

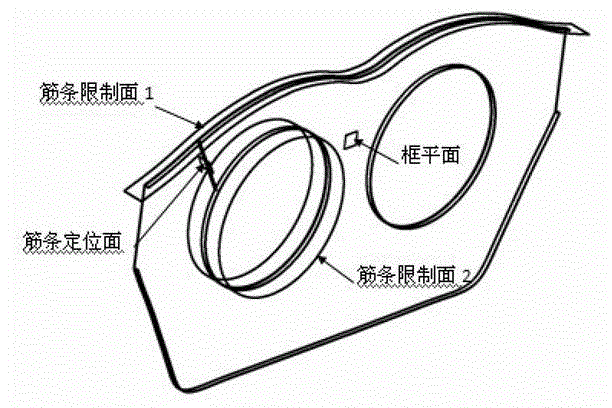

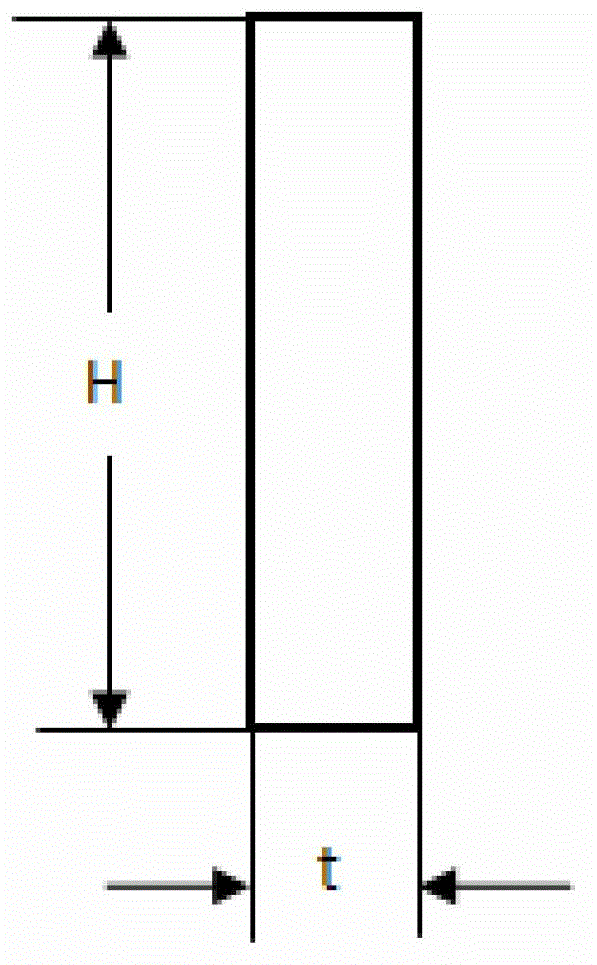

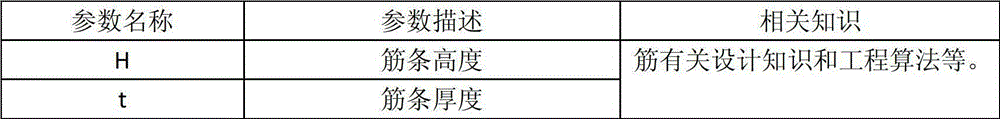

Parametrization design method of first-level member of beam, wall and rib type parts of airplane

ActiveCN102982219AStandardize the digital definition processRich modeling methodsSpecial data processing applicationsDecompositionQuality by Design

The invention discloses a parametrization design method of first-level member of beam, wall and rib type parts of airplane. The parametrization design method comprises the following steps of: stating the beam, wall and rib type parts in the airplane structure by using parametrization members, wherein the parametrization statement of the first-level members of the beam, wall and rib parts of the airplane specifically relates to contents of four parts as follows: 1) the basic attributes specifically comprise the names of the members, the version numbers, the establishment time, the member description, the manufacturing process and the remarks; 2) the geometric attributes specifically consist of two parts of positioning parameters and cross-section parameters; 3) non-geometric attributes specifically relate to decomposition schemes and non-geometric attribute information corresponding to the decomposition schemes; and 4) a two-dimensional sectional drawing is used for helping a user to correctly understand the physical meaning of the parameters of the members in member instantiation. The parametrization design method is helpful in establishing a member bank system, functional and performance model data basis for the standardization and simulation analysis in airplane design is provided, the coordination of data of a geometric model machine and a functional model machine / performance model machine is ensured, the design quality of the airplane is improved, and the research and manufacturing period is shortened.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

Light emitting diode carrier

ActiveUS20050052864A1Simple designReduce probabilityLighting support devicesPoint-like light sourceEngineeringHeat sink

A lamp assembly (10) has a carrier (12) with a front side (14) and a backside (16) provided with a plurality of passages (18) therethrough. A circuit board (20) includes a first surface (22) and a second surface (24). A plurality of light sources (26) is mounted on the first surface (22), and the first surface (22) of the circuit board (20) is aligned with the backside (16) of the carrier (12). The plurality of light sources (26) is aligned with the plurality of passages (18) in one-to-one relationship. At least one heat sink (28) is mounted in thermal contact with at least one of the plurality of light sources.

Owner:VALEO SYLVANIA L L C

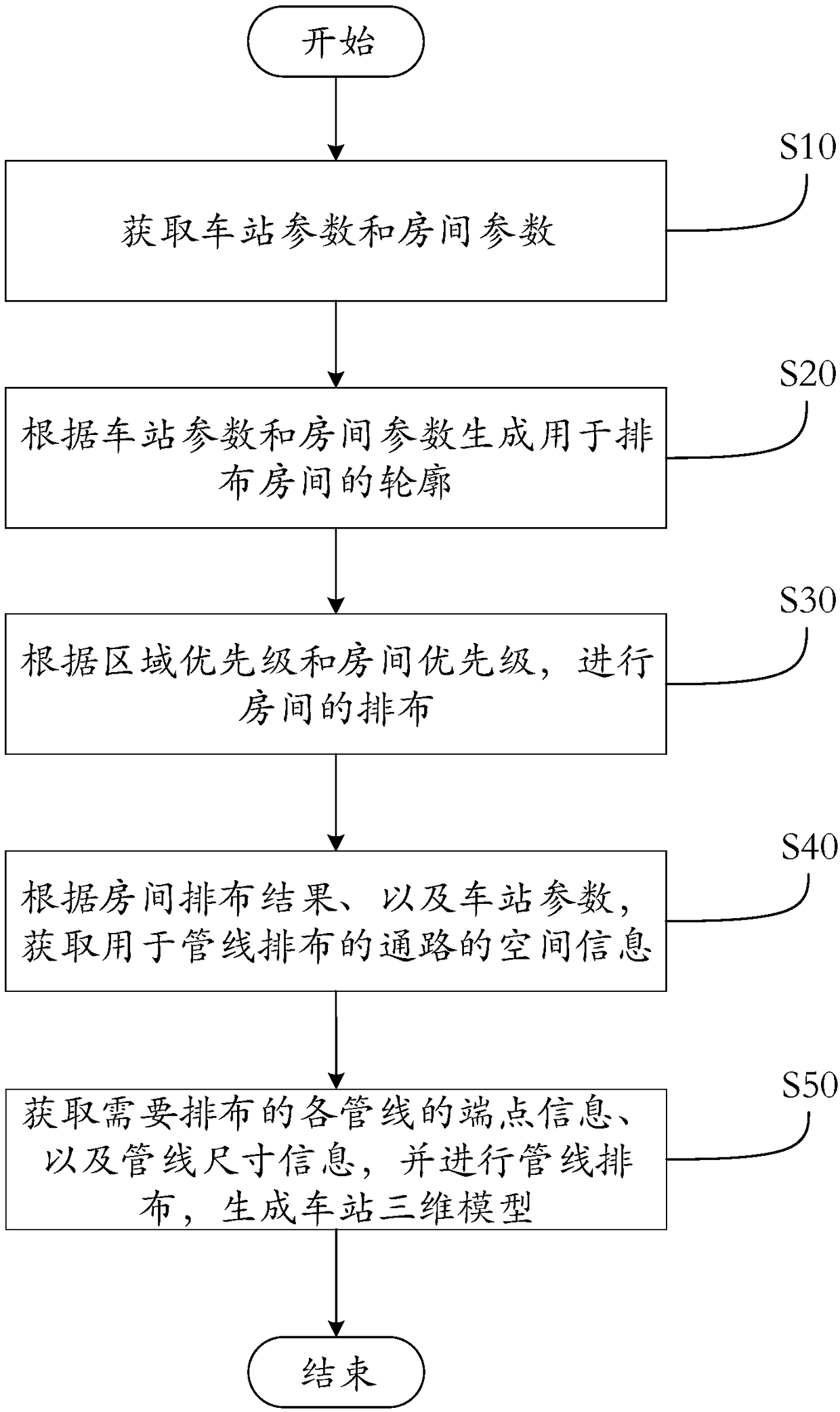

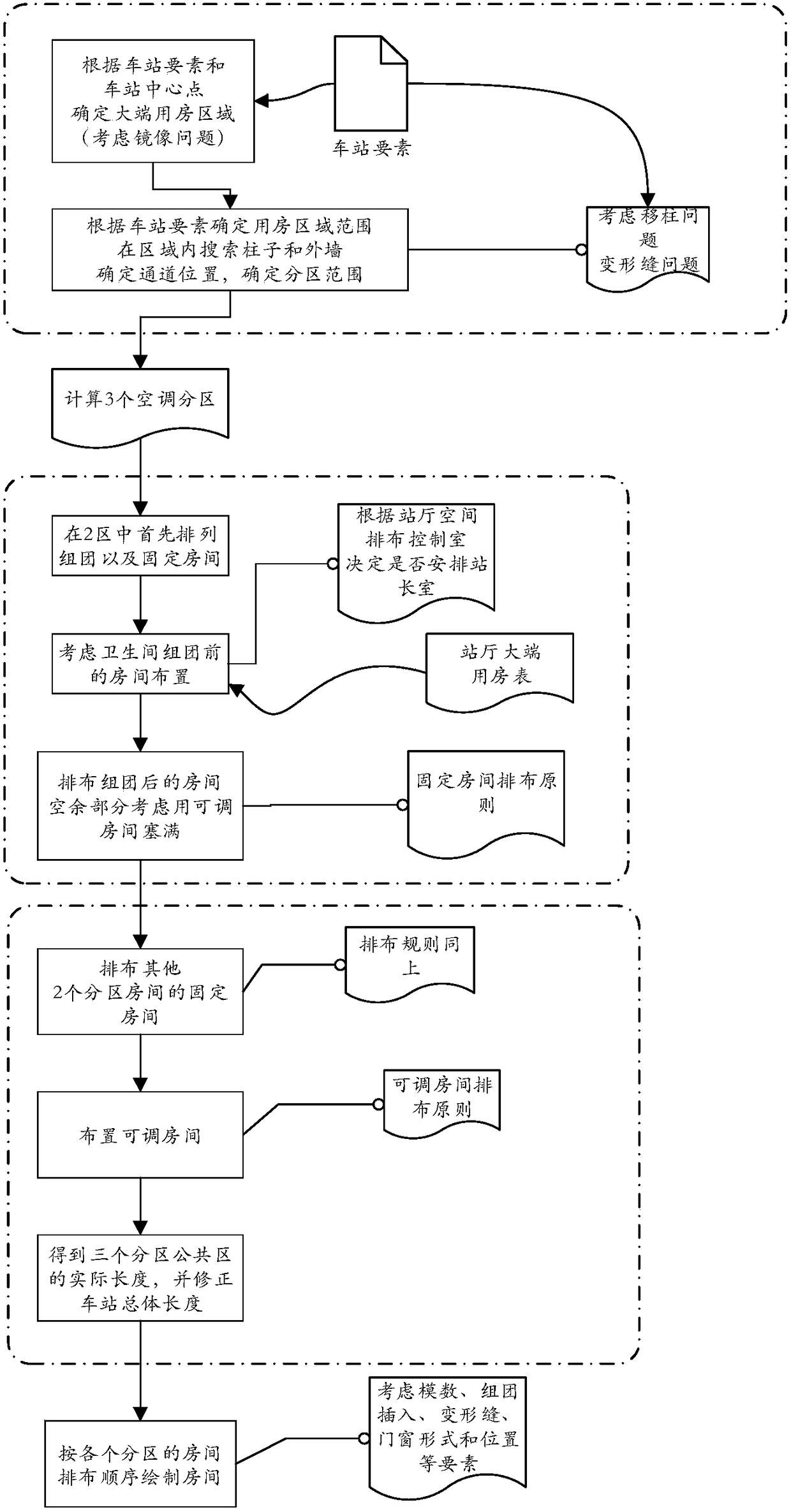

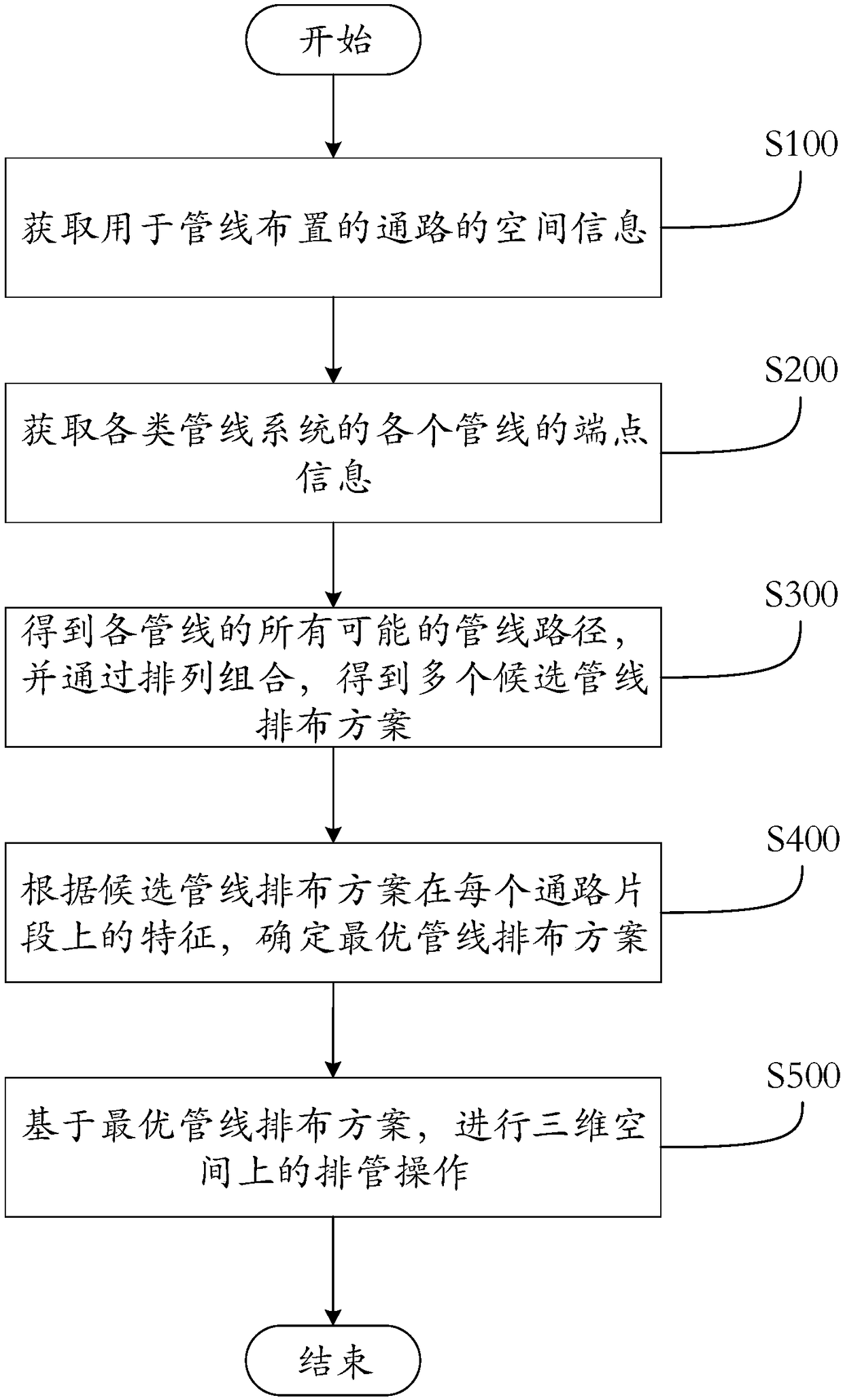

Metro station three-dimensional model automatic generation method

ActiveCN108335356AFast layoutImprove efficiencyGeometric CADSpecial data processing applicationsMetro stationEngineering

The invention relates to a metro station three-dimensional model automatic generation method. The method comprises the following steps of 1, obtaining station parameters and room parameters; 2, generating contours used for room arrangement according to the station parameters and the room parameters; 3, according to types and room priorities of station rooms and region priorities of different regions of the contours, performing the room arrangement in the different regions of the generated contours; 4, according to a room arrangement result in the step 3 and the station parameters, obtaining spatial information of a path used for pipeline arrangement, wherein the path is divided into multiple path segments, and the spatial information includes path segment information used for recording thepositions of the path segments; 5, obtaining end point information and pipeline size information of pipelines needed to be arranged; and 6, according to the information obtained in the steps 4 and 5,performing the pipeline arrangement, and according to the room and pipeline arrangement results, generating a metro station three-dimensional model.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO +1

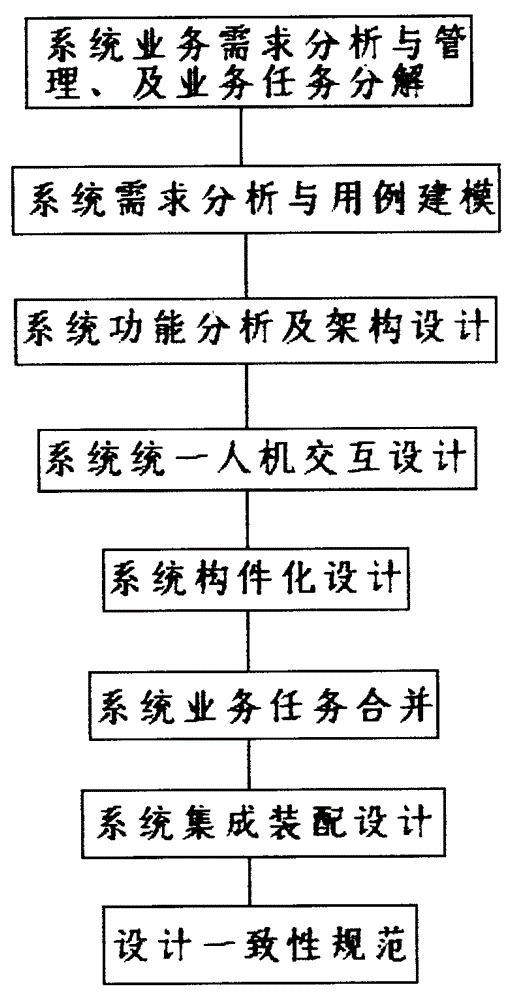

Modeling method of complex equipment system

ActiveCN103984814AOrdered parallel designEfficient Parallel DesignSpecial data processing applicationsSystems analysisModel method

The invention discloses a modeling method of a complex equipment system. According to the method, the analysis of the complex equipment system is defined; the activities, the specifications and the interfaces of each link, and adopted models and views are designed; the design efficiency is improved, and the design quality is guaranteed; the concurrent design of the system can be performed by a design team orderly and effectively.

Owner:燕雪峰

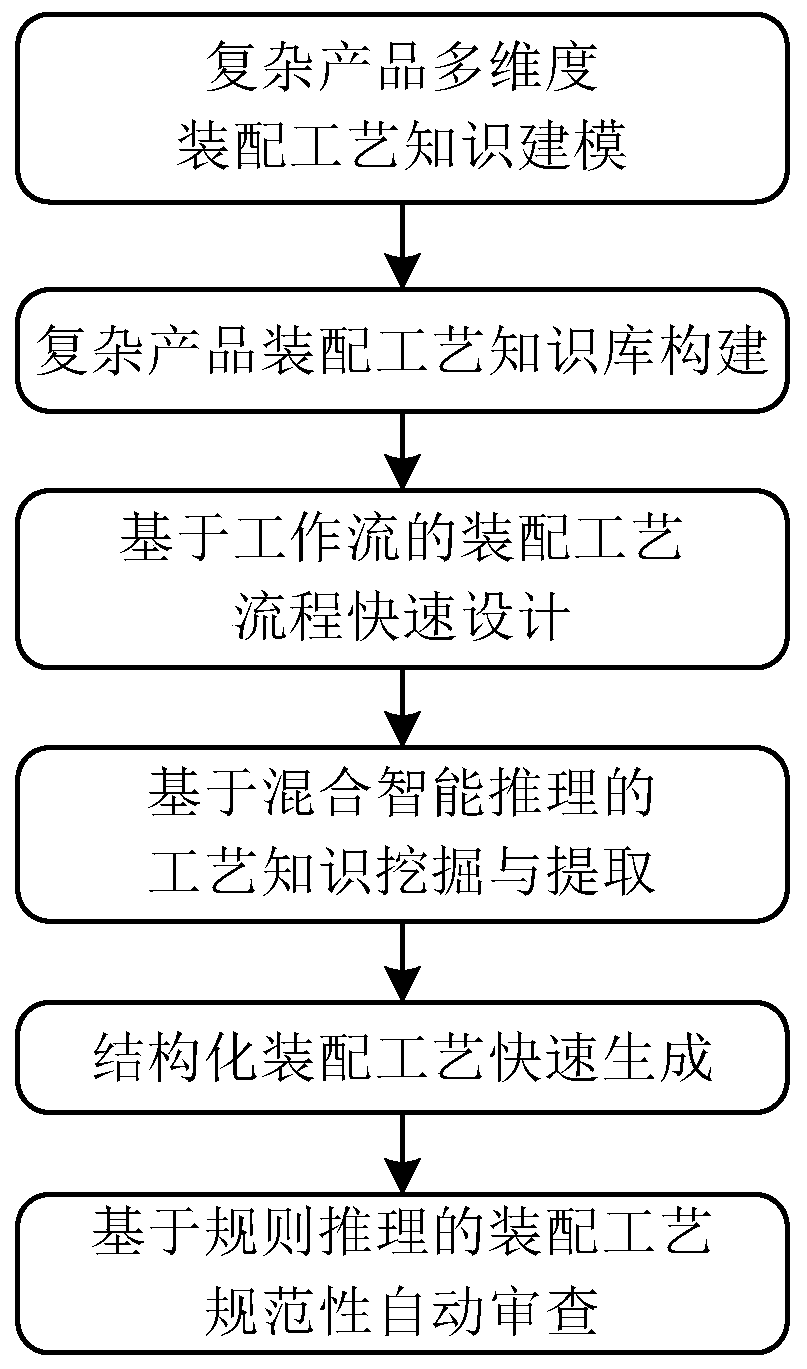

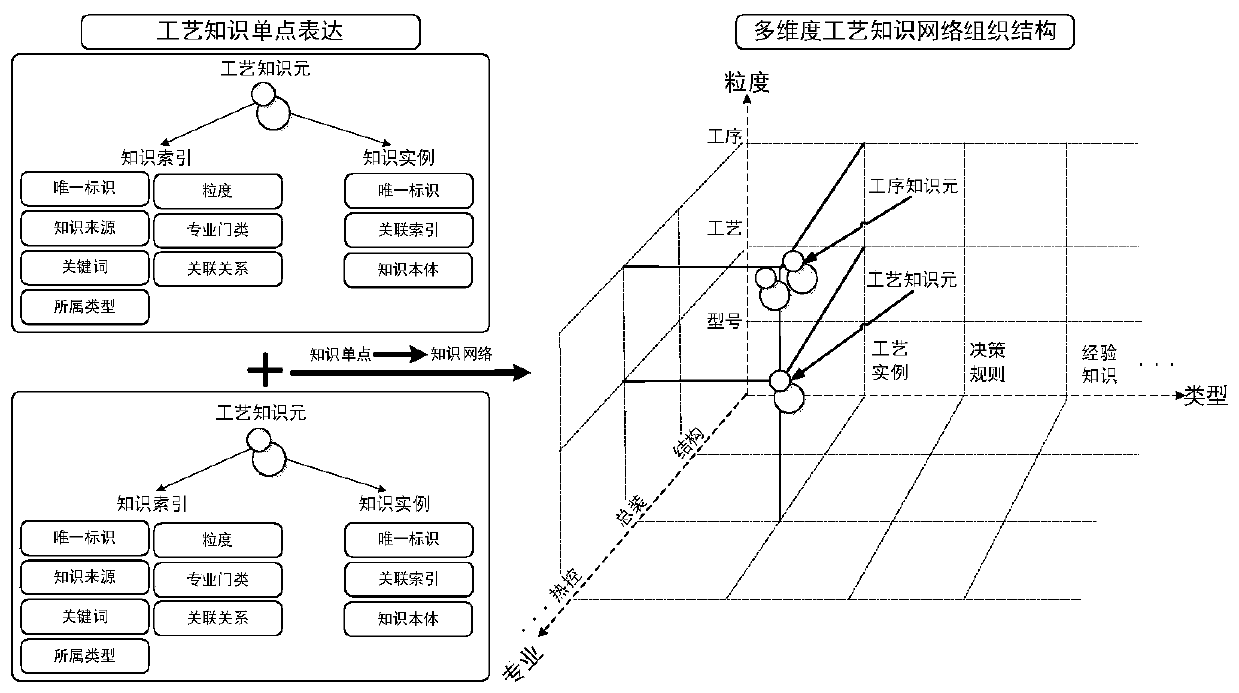

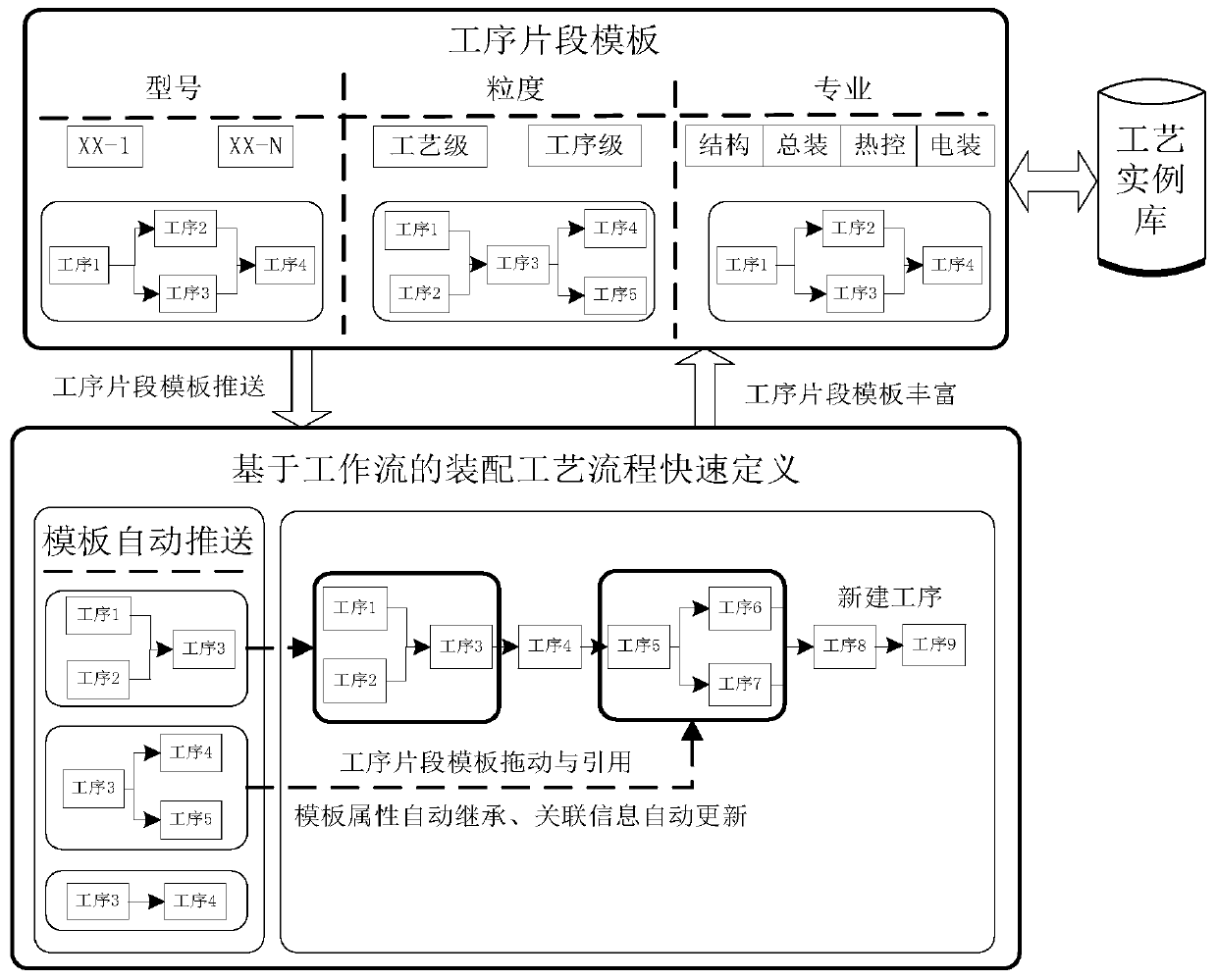

Knowledge-based assembly process design method and system and medium

PendingCN110851499ARapid process designIntelligent assembly process designRelational databasesKnowledge representationProcess engineeringProcess definition

The invention provides a knowledge-based assembly process design method and system and a storage medium. The knowledge-based assembly process design method comprises the following steps: a process knowledge modeling step: constructing an assembly process knowledge model; a process knowledge base building step: building an assembly process knowledge base; a process flow defining step: defining an assembly process flow to obtain an assembly process flow diagram; a process knowledge screening step: screening the assembly process knowledge to obtain an optimal process instance; an assembly processstructuralization step: generating a structuralized assembly process according to the optimal process instance; and a normativity examination step: automatically examining the normativity of the assembly process. Expression, association and storage of a large amount of complex heterogeneous process knowledge are realized, a unified spacecraft assembly process knowledge base is constructed, and knowledge-based rapid process design is supported. Knowledge-based and intelligent assembly process design based on the process flow and knowledge is realized, so that the process design efficiency is greatly improved. The design quality of the process file is effectively ensured.

Owner:SHANGHAI INST OF SATELLITE EQUIP

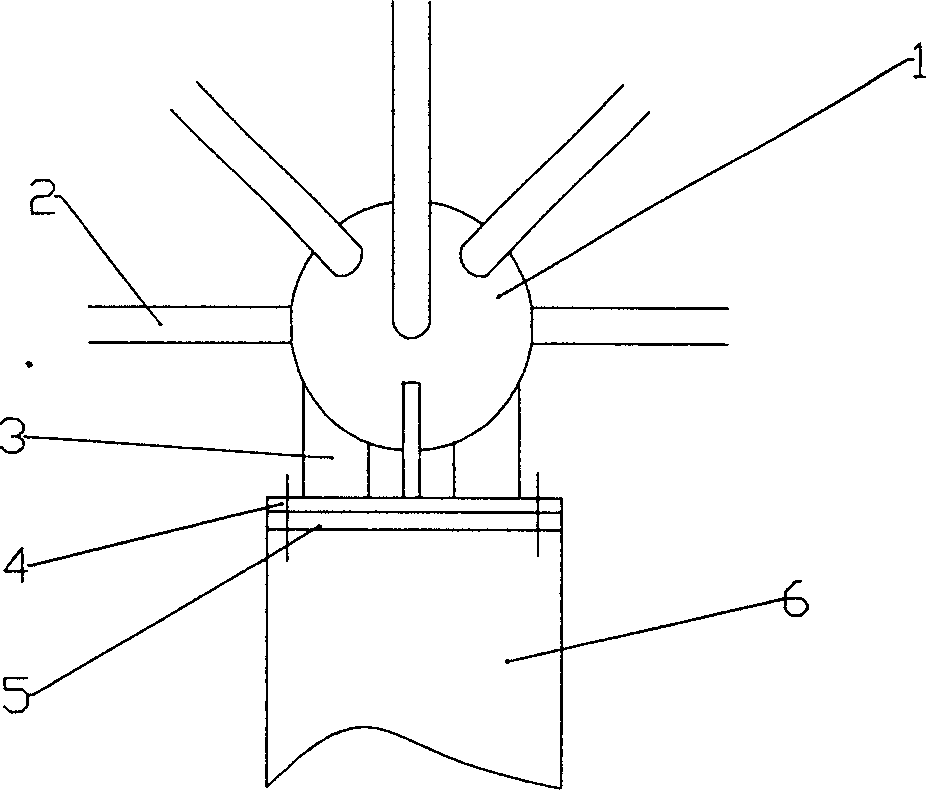

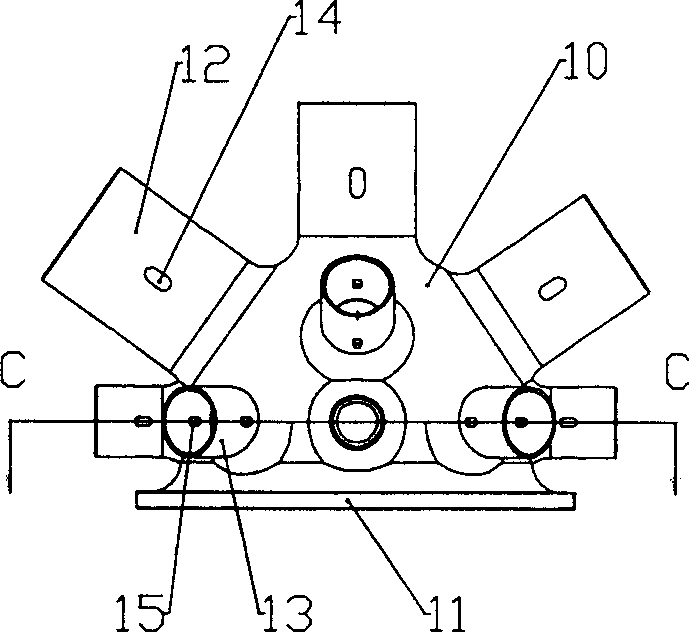

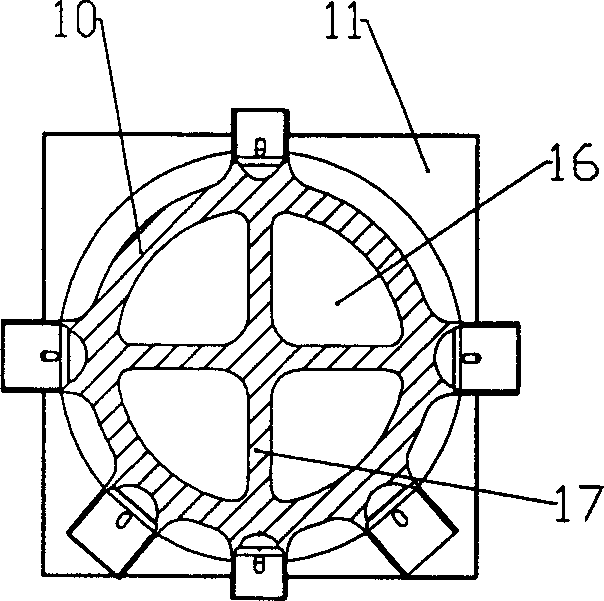

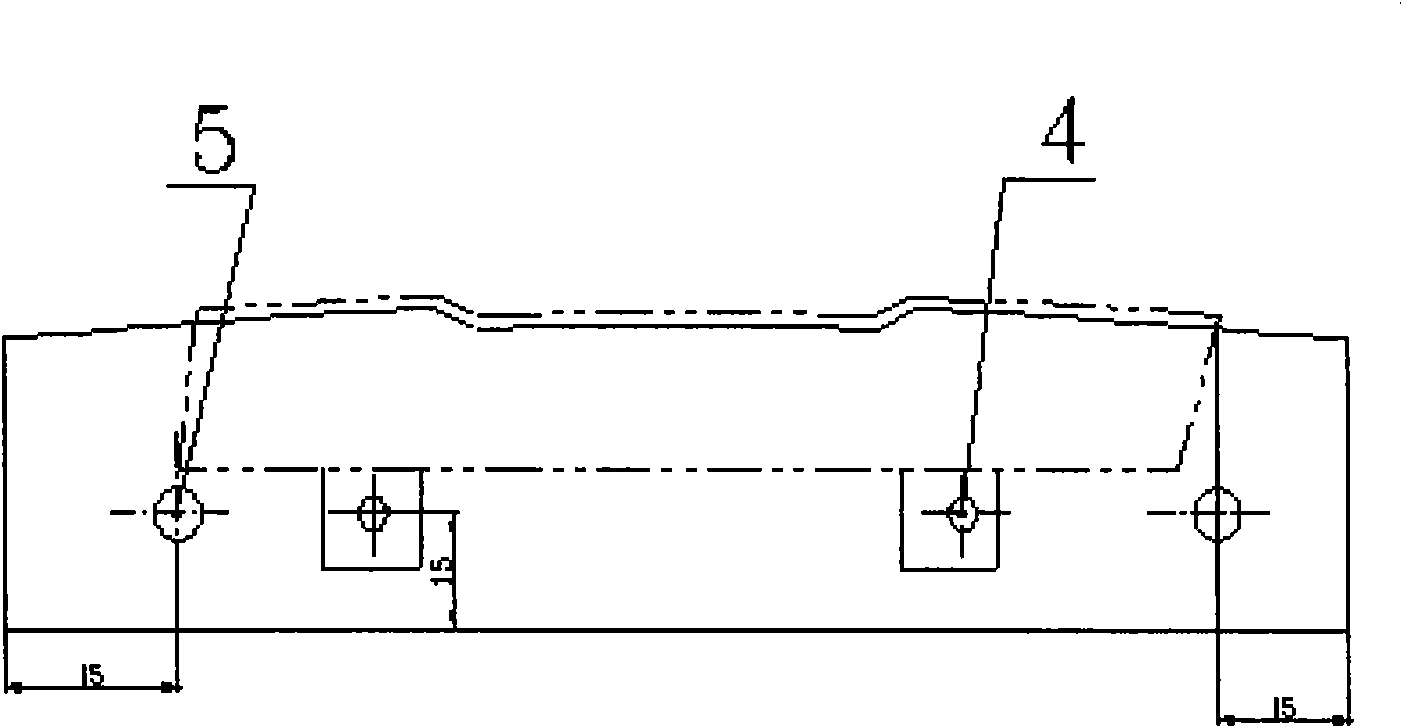

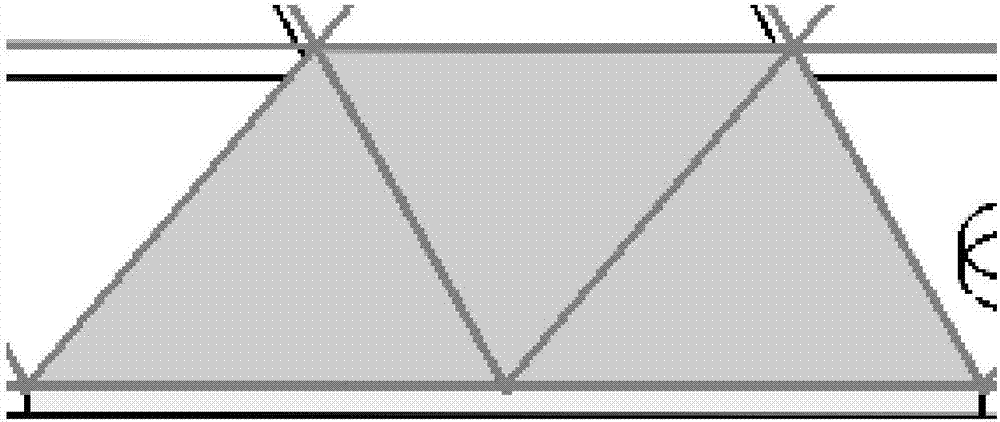

Supporting node

This invention discloses a supporting joint used in girders or rack, characterized in that it comprises an erection support connected with a supporting member, and connected with several joints formed from the integrated component. Said supporting joint is easy to manufacture and install, and it has firm structure and high precision, in addition, it can be used for force analysis and computing.

Owner:徐国彬 +1

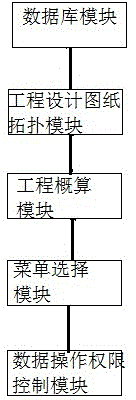

Intelligent electric power engineering design method and system

InactiveCN104679932AShorten design timeGuaranteed design qualitySpecial data processing applicationsPower engineeringDesign systems

The invention discloses an intelligent electric power engineering design system comprising a database module, an engineering design paper topology module, an engineering estimating module, a menu selecting module and a data operation limit control module. The database module contains a standard design, an expandable design, regulations and standards. The engineering estimating module, in an excel format form, automatically exports a typical design cost, a standard design cost and an equipment material list which is generated by the relative regulations and standards and calculates costs. The invention further discloses an intelligent electric power engineering design method. According to the arrangement, according to the standard database and the typical design cases, an electric power engineering paper and cost calculation are intelligently achieved; design time is remarkably shortened for the electric power engineering designer, a plan guidance is provided for decision makers of the electric power engineering program, and through intelligent analysis and data comparison, a comprehensive and systematical reference is supported for the program plan.

Owner:GUANGZHOU ZHONGWANG ELECTRIC POWER ENG DESIGN

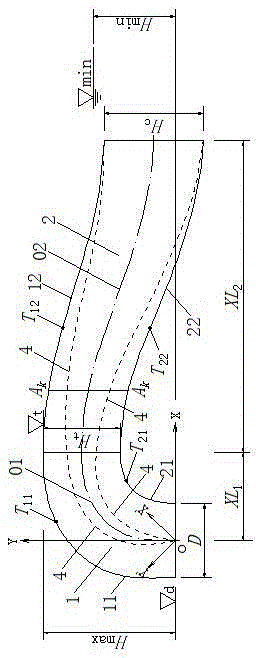

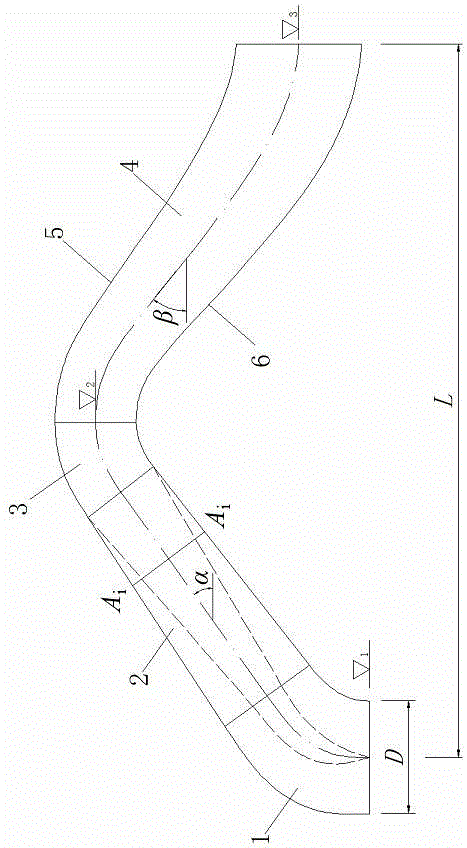

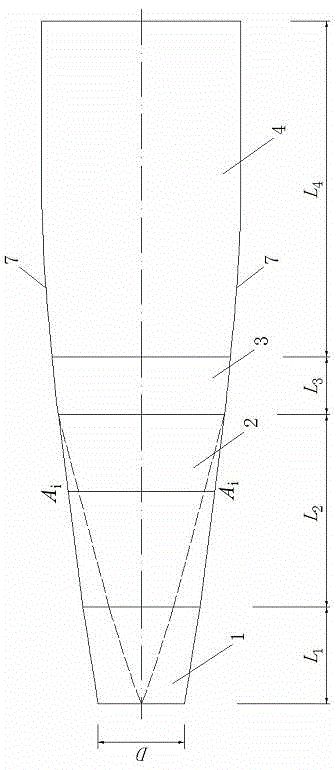

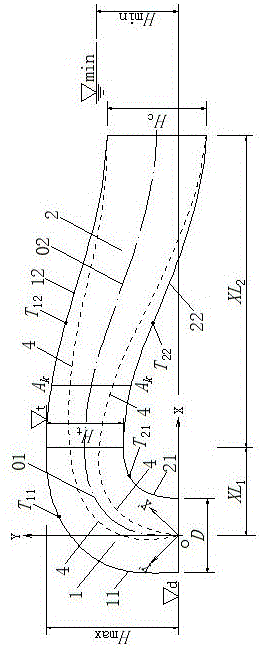

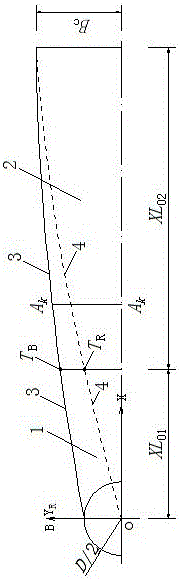

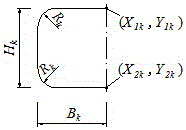

Shaping algorithm for quartic curvilinear equation of three-dimensional shape of low hump type water draining flow way and application of shaping algorithm

ActiveCN104615831AGood hydraulic performanceGuaranteed design qualitySpecial data processing applicationsWater flowThree dimensional shape

The invention relates to a shaping algorithm for a quartic curvilinear equation of a three-dimensional shape of a low hump type water draining flow way and application of the shaping algorithm, and belongs to the technical field of pump stations of water conservancy projects. The low hump type water draining flow way is designed by the shaping algorithm. The shaping algorithm is characterized in that an upper side line and a lower side line of a longitudinal section of the flow way, a width changing curve of the flow way and a transitional circle center track line of the cross section, which is changed into square from circle, of the flow way are respectively set into the quartic curvilinear equation; the flow way is divided into a rising turning section and a falling section, the rising turning section turns at an angle of 90 degrees, influences of a centrifugal force on water flow are reduced to a maximum extent, the height of the rising turning section is increased as much as possible under the condition of arrangement permission of a pump room, and a turning radius of the rising turning section is increased; the falling section guides the water flow to be connected with a water draining pond gently and orderly, so that the crest level of the cross section of an outlet of the flow way is lower than the minimum water level of the water draining pond by 0.5m; and the water flow of the designed low hump type water draining flow way turns orderly and is scattered uniformly, loss of a water head of the flow way is low, and the hydraulic performance is excellent.

Owner:YANGZHOU UNIV

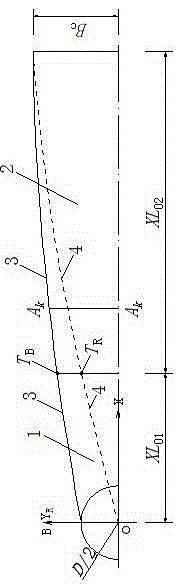

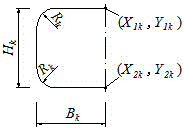

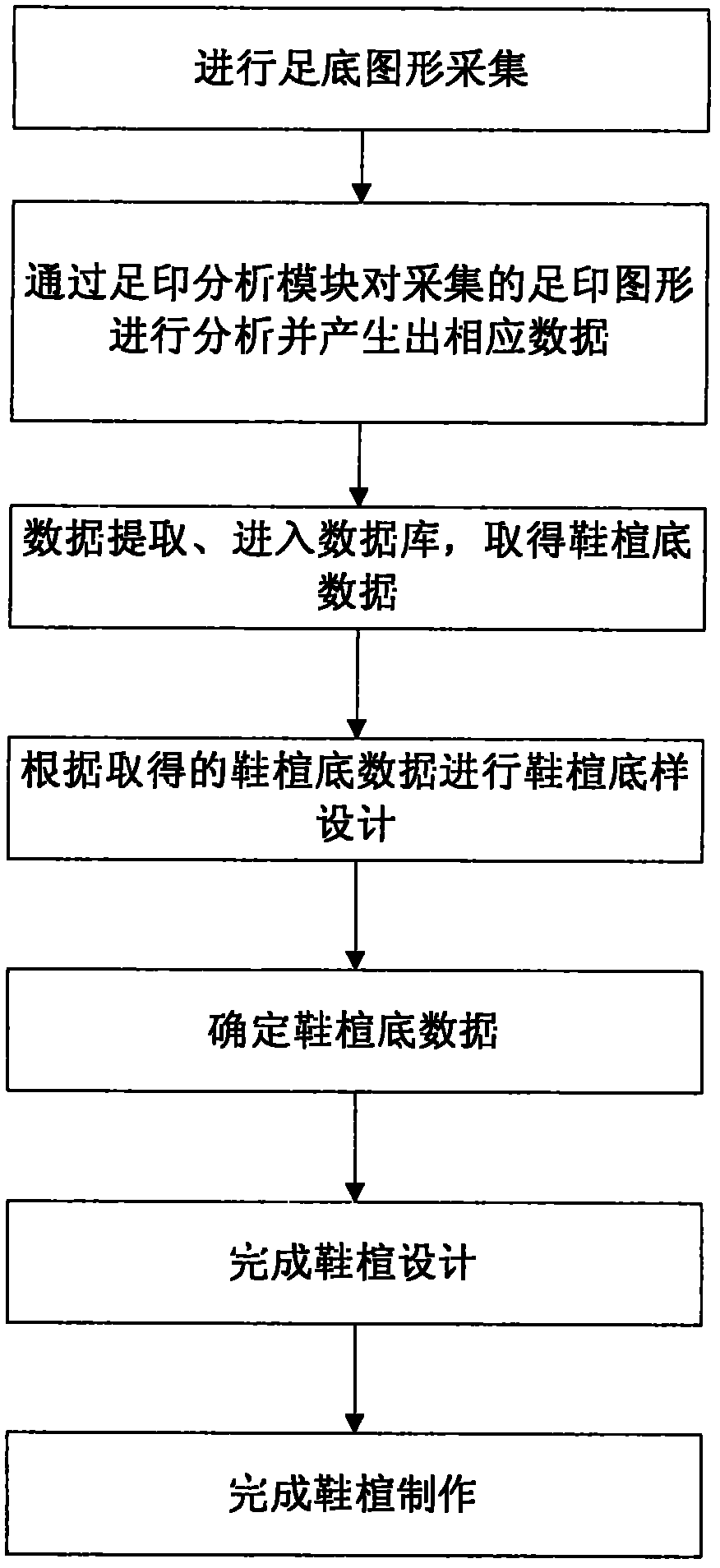

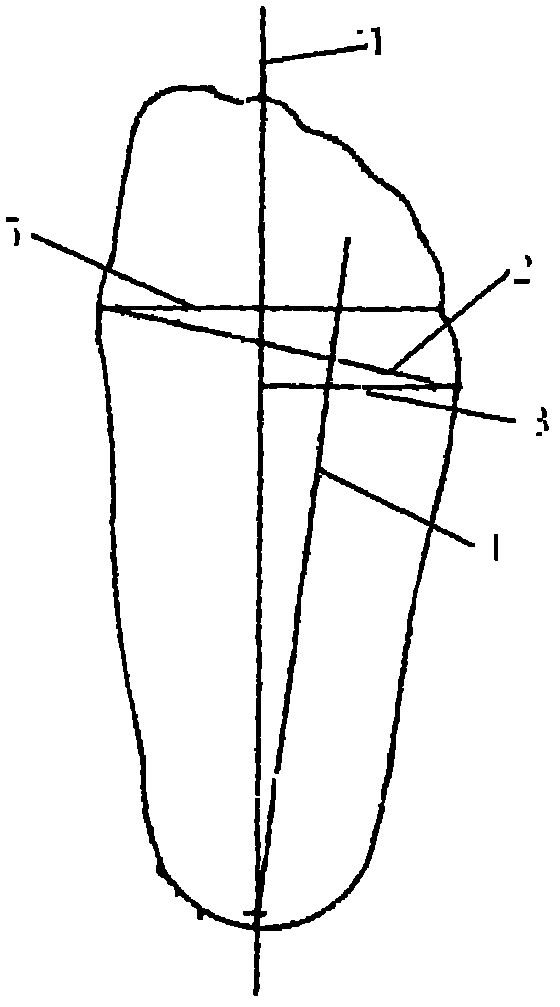

Method for designing shoe tree according to pelma image analysis data

InactiveCN102063533ACorrectly designedRapid designSpecial data processing applicationsGraphicsSize measurement

The invention relates to a method for designing a shoe tree according to pelma image analysis data. The method comprises the steps of pelma image collection, footprint analysis, data extraction, shoe tree ground pattern design and shoe tree design, i.e., utilizing a pelma scanning system; measuring foot characteristic size and characteristic lines through a footprint analyzing module in the footprint analysis step, and carrying out location analysis and relative size measurement on the size of the pelma stressed position to generate corresponding data; extracting the measured, analyzed and calculated size data of the foot pattern characteristic position and the size of the pelma stressed position, and inputting the size data and the size into a database; carrying out statistics and calculation on the comprehensive maximum, minimum and average, and comparing with empirical values according to the statistical and calculated data to obtain the ground data of the shoe tree; designing the ground pattern of the shoe tree according to the obtained ground data of the shoe tree; determining the ground data of the shoe tree; and completing the design and the manufacture of the shoe tree. The invention provides a precise, simple, convenient and feasible shoe tree designing method for shoe tree manufacturing and shoemaking enterprises.

Owner:温州市鹿艺鞋材有限公司

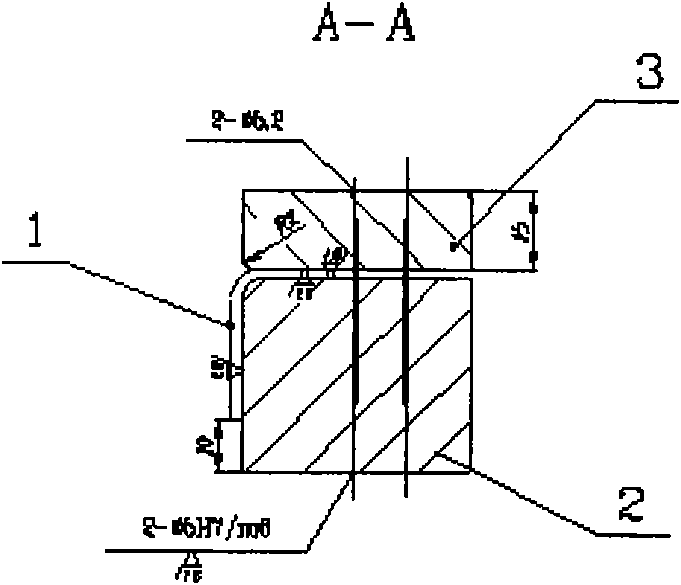

Siphoning type water outlet runner with excellent hydraulic property and application method thereof

ActiveCN104480918AImprove hydraulic performanceEasy to useWater-power plantsHydro energy generationStream flowWater flow

The invention discloses a siphoning type water outlet runner with excellent hydraulic property and an application method thereof, and belongs to the technical field of a hydraulic engineering pump station. The siphoning type water outlet runner comprises an inlet section, a linear section, a hump section and a descent section. A runner vertical view (including cross hatch), a plane expanded view (including cross hatch) and a section data table are provided; based on the thought of converting runner distribution size and cross section with different conversion ratios, the distribution size and section size of the siphoning type water outlet runner provided by the invention are properly respectively converted to obtain siphoning type water outlet runners suitable for large pump stations with different flows, lifts and water outlet pond level amplitudes. The water flow of the converted runner is ordered in steering, even in diffusion, small in water loss, excellent in hydraulic property, wide in application range and convenient for use. The design quality of the siphoning type water outlet runner can be guaranteed, and a great significance is provided for guaranteeing the safe, stable and efficient running of middle and large pump stations.

Owner:YANGZHOU UNIV

Rapid design method of tyre mould

The invention provides a rapid design method of a tyre mould, which comprises the following steps of: 1) simplifying the expressed mould design pattern, classifying the shape related characteristics of the tyre mould, and drawing and establishing a CAD (computer-aided design) pattern library of the typical structure of various types of tyres; 2) compiling a special tyre designing and manufacturing specification, attaching tyre typical structure legends corresponding to the tyre typical structure pattern library and the pattern of the simplified drawing work order, and classifying and numbering the typical structure legends; and 3) correspondingly selecting a legend number from the typical structure specification according to the product shape, calling the CAD pattern from the typical structure pattern library and filling the CAD pattern into the simplified drawing work order according to the number, and finally filling an order number, a fixture pattern number and other simple information into the work order to finish the design. As the tyre typical structures in the invention are strictly classified, the classes nearly include all tyre structure types and the compiling idea is novel, the tyre mould is convenient and quick to use by designers, the design speed is increased by 6-10 times than that before, and the manual labor and material resources are saved. The invention can greatly shorten the production preparation period, and provides solid technical storage for the development of new products.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

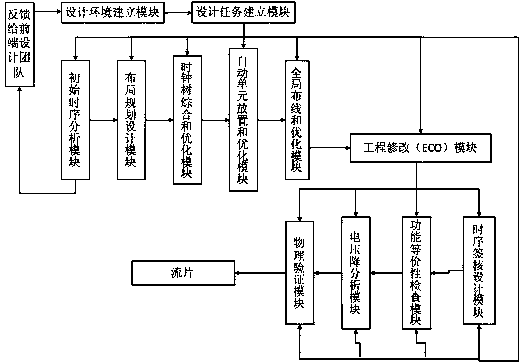

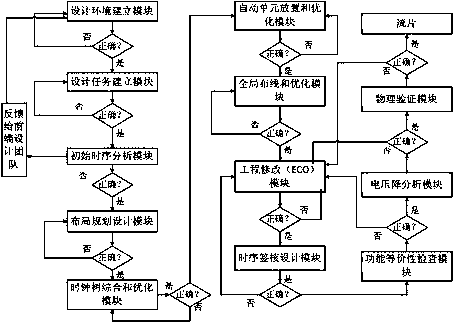

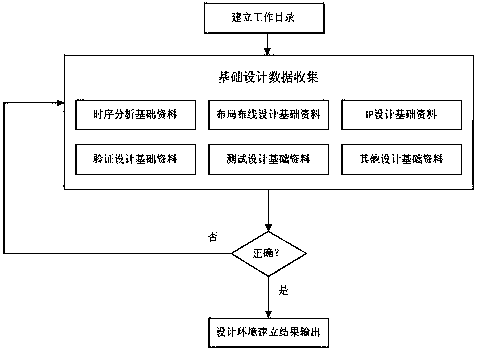

Integrated circuit back end design system and method

InactiveCN108133069AVersatileLower Design BarriersSpecial data processing applicationsLayout planningUltrasound attenuation

The invention discloses an integrated circuit back end design system. The system comprises an environment building module, a design task module, a layout planning design module, an automatic unit placement optimization module, a clock tree synthesis optimization module, a global routing optimization module, a functional equivalence checking module, a timing sign-off design module, a voltage attenuation design module and a physical verification module. According to the integrated circuit back end design system, design sequence standardization is carried out on the main design links of the backend design, so that the design has good universality, thus the design threshold of the back end design is greatly reduced, the labor cost is reduced, the design efficiency is improved, and the designquality is ensured.

Owner:嘉兴倚韦电子科技有限公司

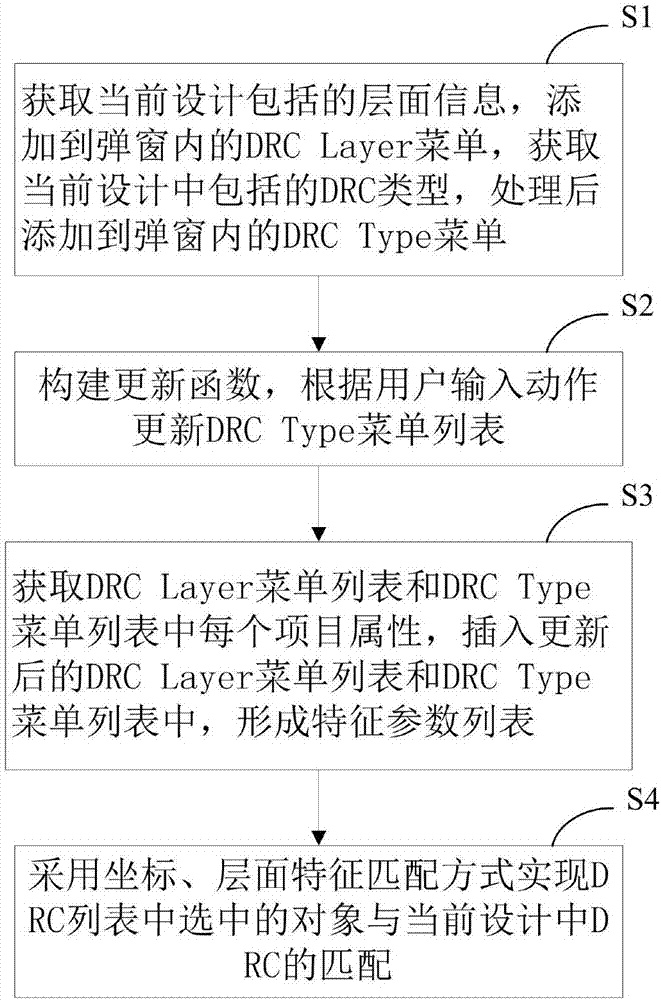

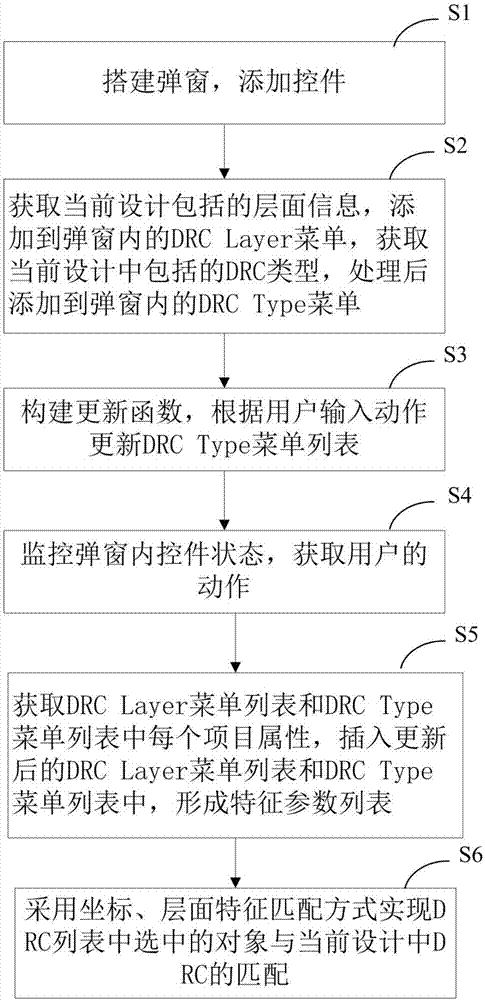

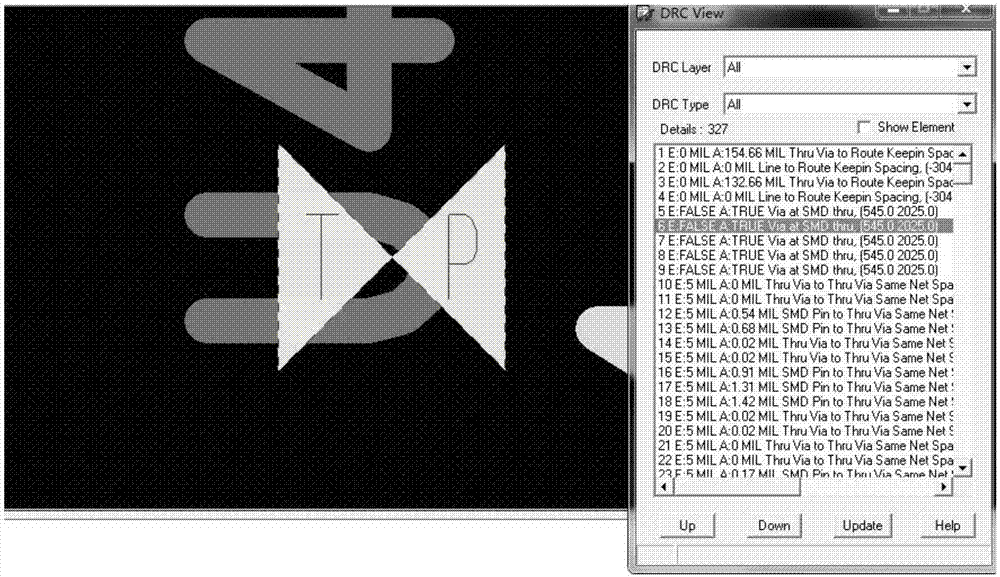

Designing method and operating method for DRC classification displaying in PCB designing

ActiveCN107480369AImprove work efficiencyAvoid bugsCAD customisation/personalisationCAD circuit designTyping ClassificationUser input

The invention discloses a designing method for DRC classification displaying in PCB designing. The designing method includes the following steps of obtaining layer information included by current design, adding the layer information into a DRC Layer menu in a pop-up window, obtaining a DRC type included in the current design, processing the DRC type, and then adding the processed DRC type into a DRC Type menu in the pop-up window; establishing an updating function, and updating a DRC Type menu list according to a user input action; obtaining all item attributes in the DRC Layer menu list and the DRC Type menu list, and inserting the item attributes into the updated DRC Layer menu list and the DRC Type menu list to form a characteristic parameter list; matching objects selected in the DRC lists with DRC in the current design in a coordinate and layer characteristic matching mode. DRC classification displaying including type classification and layer classification of the DRC is achieved, the two kinds of classification can be simultaneously conducted, single classification can also be conducted, working efficiency is greatly improved, unmodified bugs of the important DRC are avoided to a certain degree, and design quality is guaranteed.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

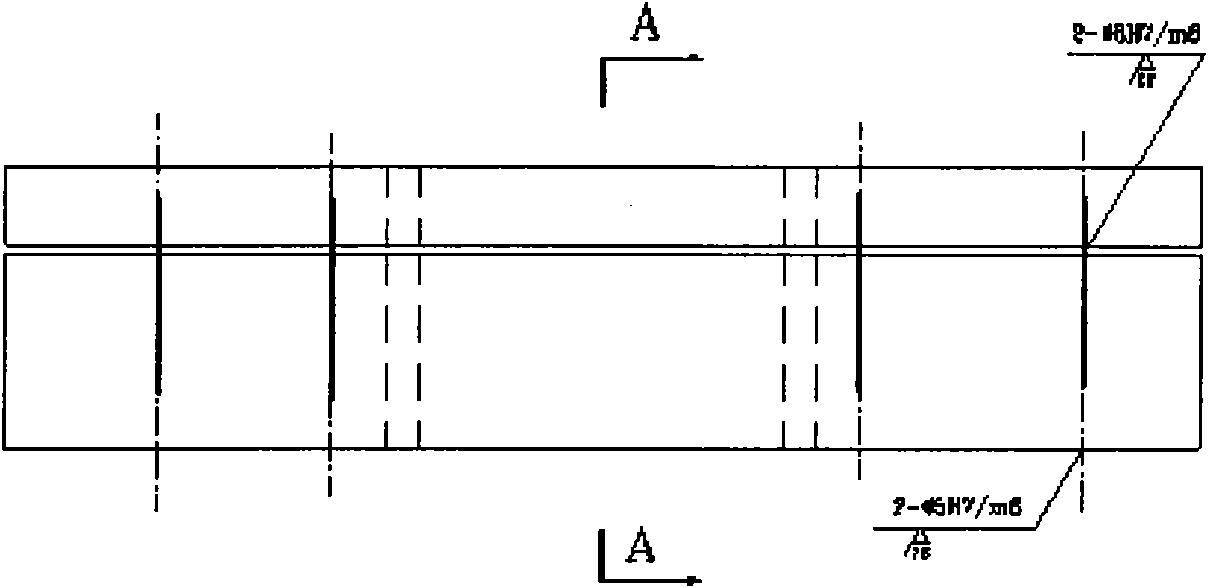

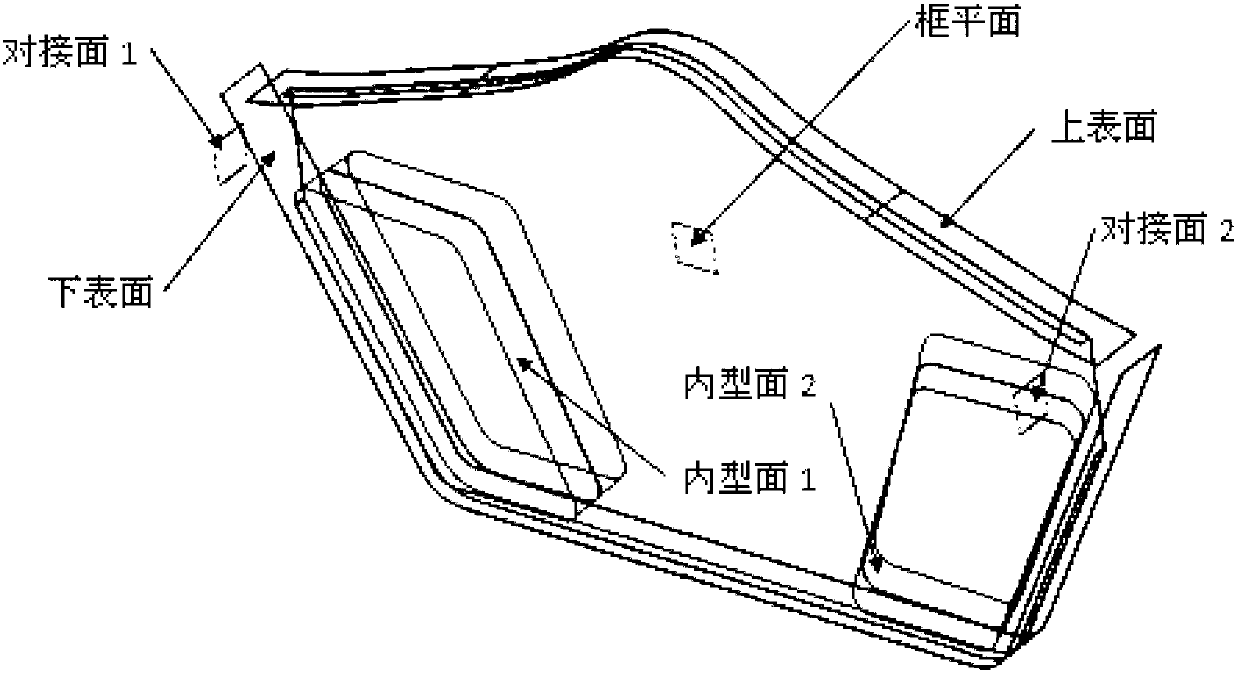

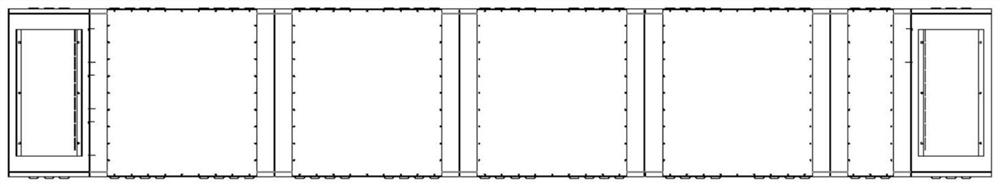

First-level construction member parametrization design method for airplane frame-type parts

ActiveCN102999677AStandardize the digital definition processRich modeling methodsSpecial data processing applicationsManufacturing technologyQuality by Design

A first-level construction member parametrization design method for airplane frame-type parts comprises that the frame-type parts in an airplane structure is described by parametrization construction members. First-level construction member parametrization description of the airplane frame-type parts particularly relates to contents as the following four parts: (1) essential attributes comprise construction member names, version numbers, creating time, construction member description, manufacture technology and remarks; (2) geometric attributes comprise location parameters and section parameter; (3) non-geometric attributes particularly relate to decomposion schemes and non-geometric attribute information; and (4) a two-dimensional sectional view is used for enabling a user to correctly understand physical significances of each parameter of the construction member when construction member instantiation is carried out. The first-level construction member parametrization design method contributes to building a component base system of an airplane, provides function and performance model data basis for airplane design standardization, simulated analysis and optimizing, guarantees consistency of data between a geometric model machine a d a functional model machine / performance model machine, improves design quality of the airplane, and shortens development period.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

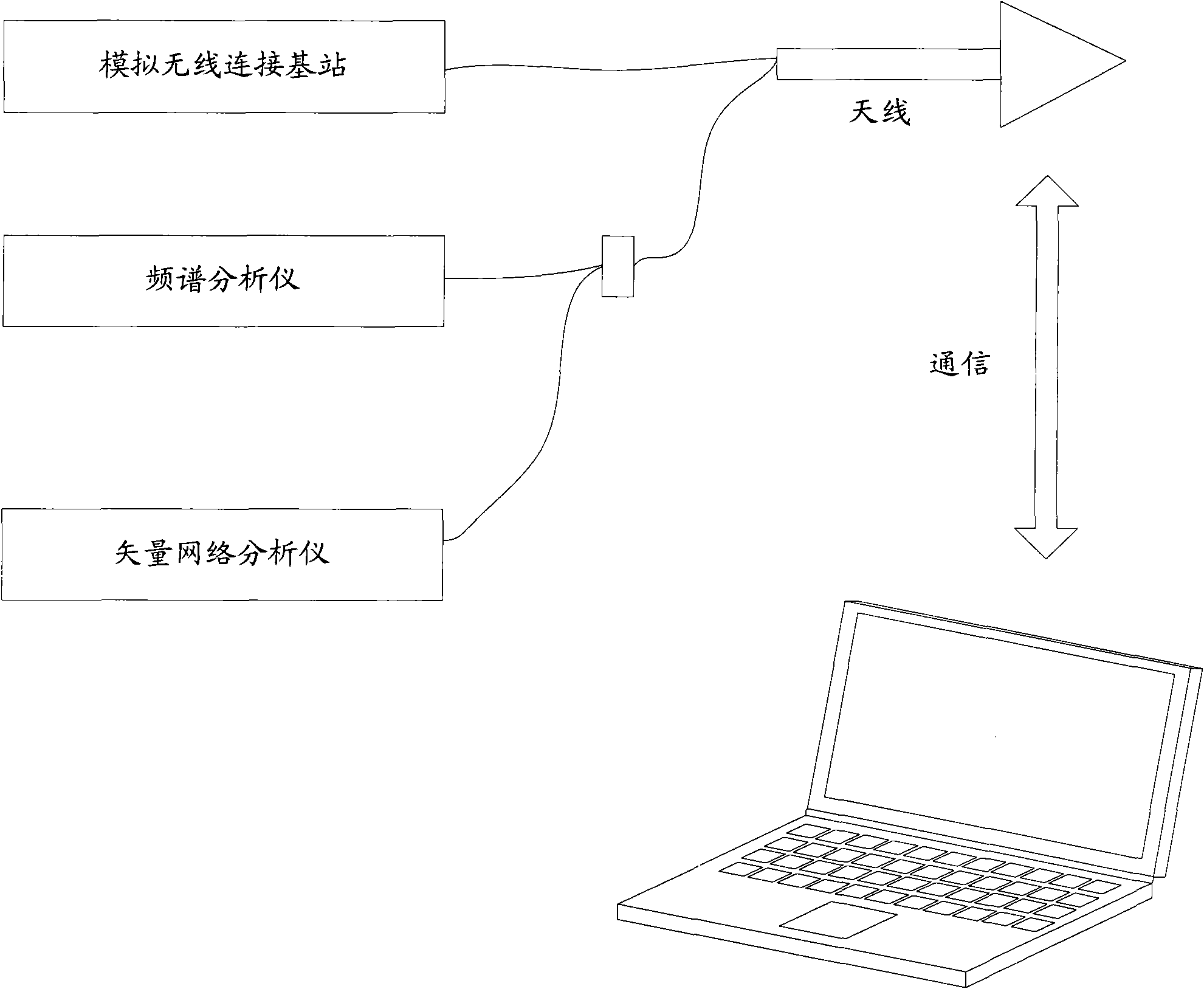

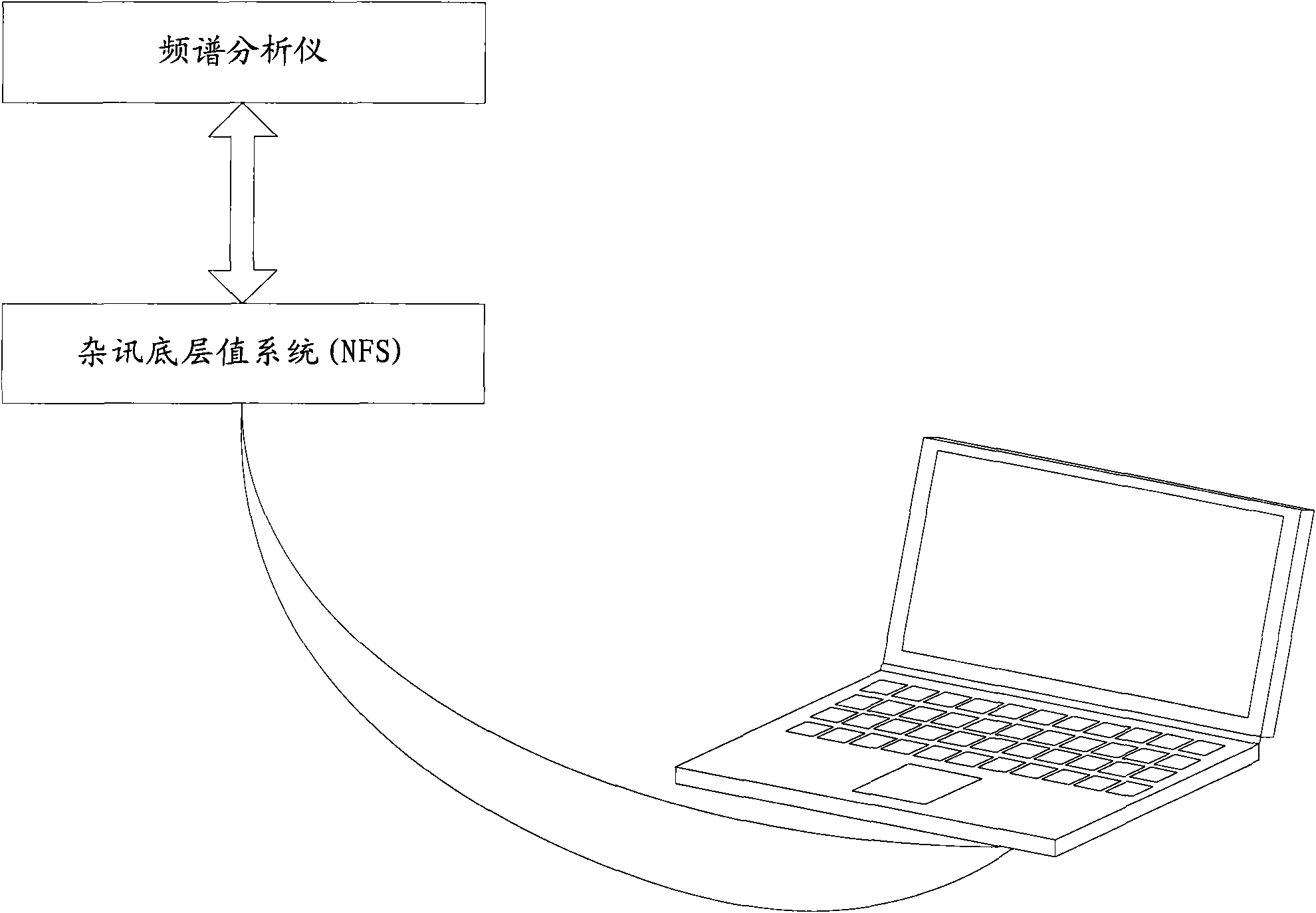

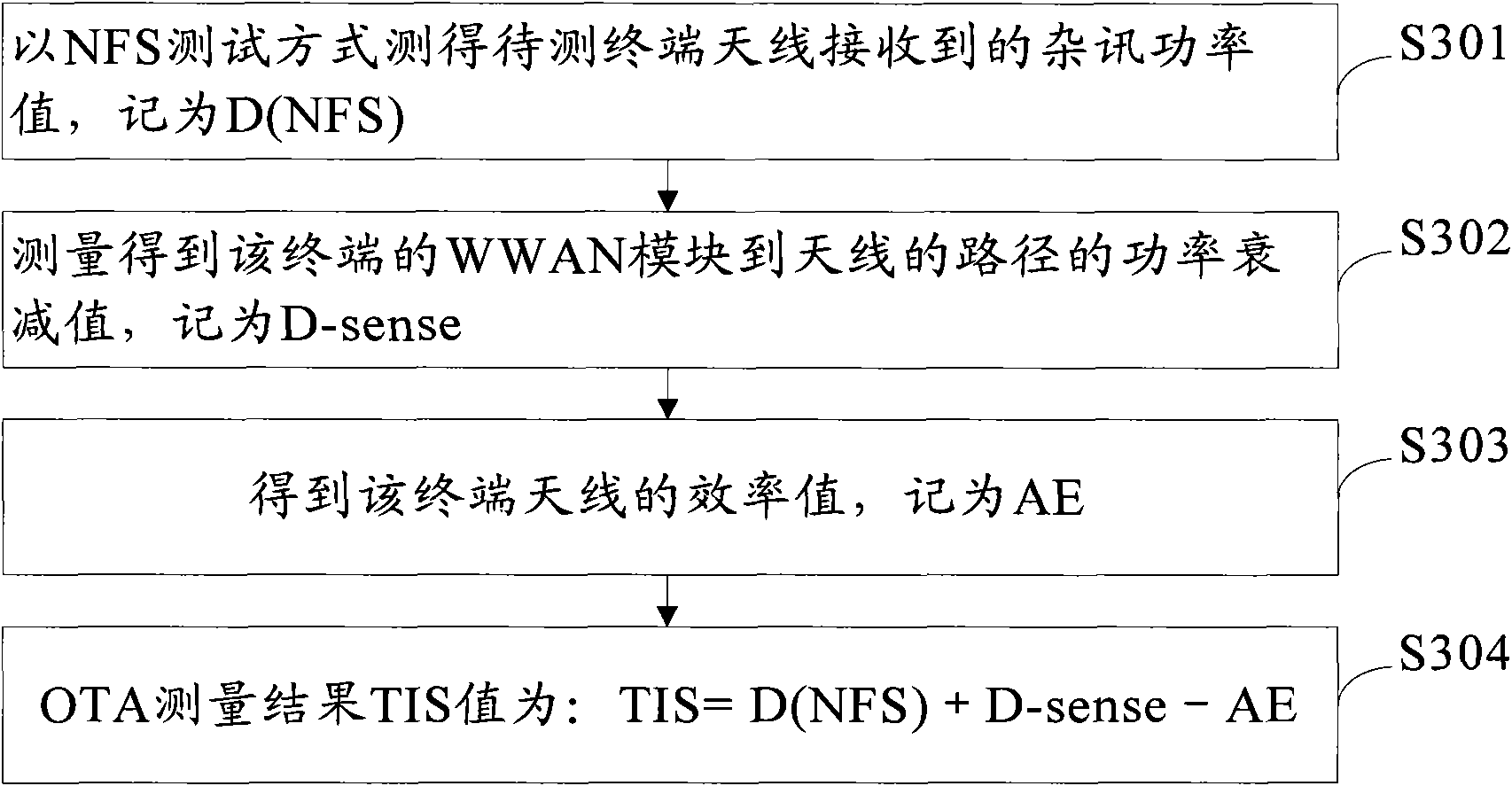

WWAN test method and test system thereof

ActiveCN102469472AGuaranteed design qualityReceivers monitoringNetwork traffic/resource managementUltrasound attenuationWide area network

The embodiment of the invention, which belongs to the communication field, provides a wireless wide area network (WWAN) test method and a test system thereof. The method and the system are suitable for the product research and development phase; and a quantitative data relation between a noise floor system (NFS) test result and an over the air (OTA) test result can be obtained. The WWAN test method comprises the following steps that: an NFS test method is utilized to obtain a noise power value received by a to-be-tested terminal antenna and the obtained noise power value is expressed as D (NFS); a power attenuation value of a path between a WWAN module of the terminal and the antenna is obtained by measurement and is expressed as D-sense; an efficiency value of the terminal antenna is obtained and is expressed as AE; and a TIS value of a measurement result of the OTA is expressed as the following formula: TTIS= D (NFS) + D-sense - AE. According to the embodiment of the invention, the method and the system can be applied to an NFS test.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

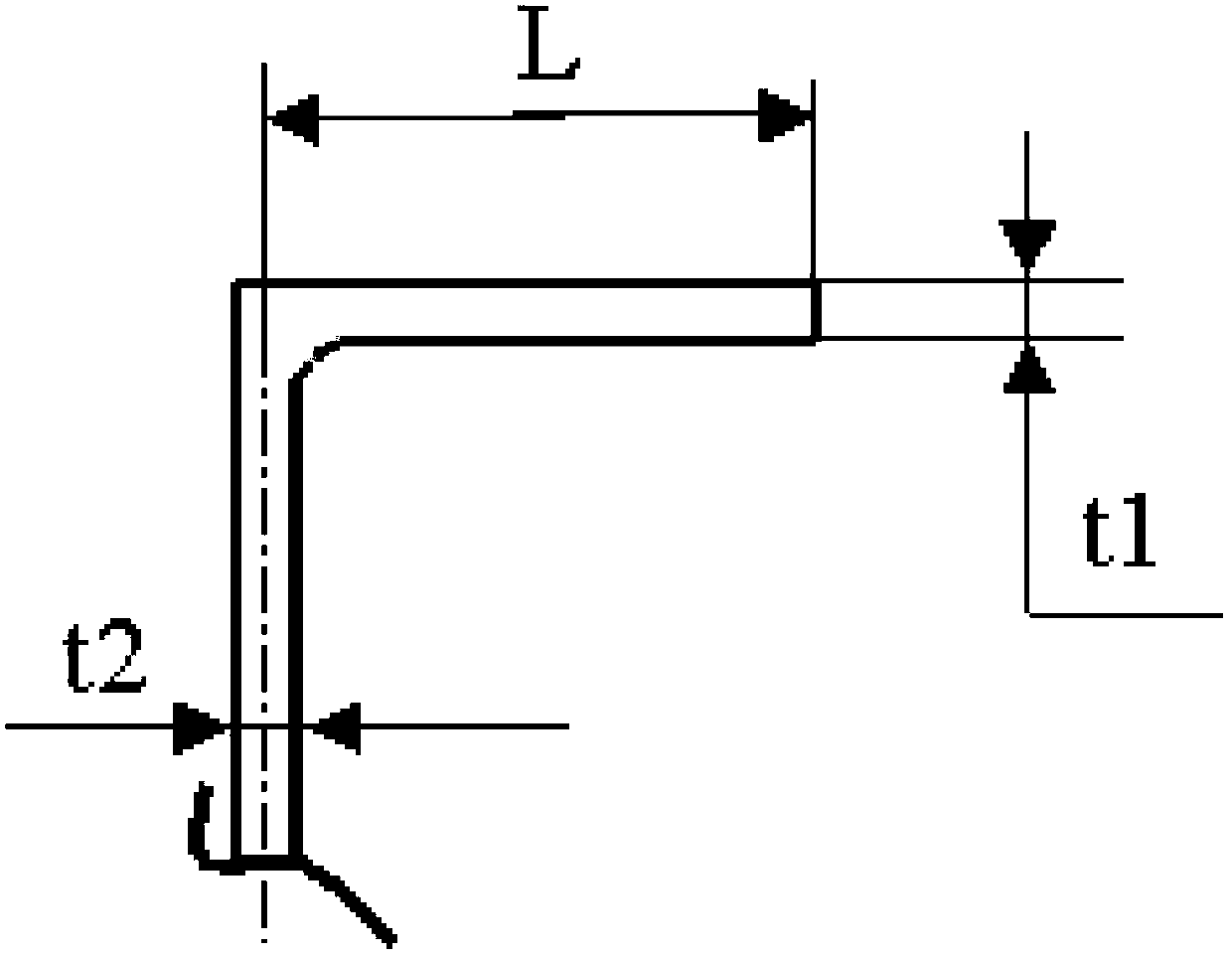

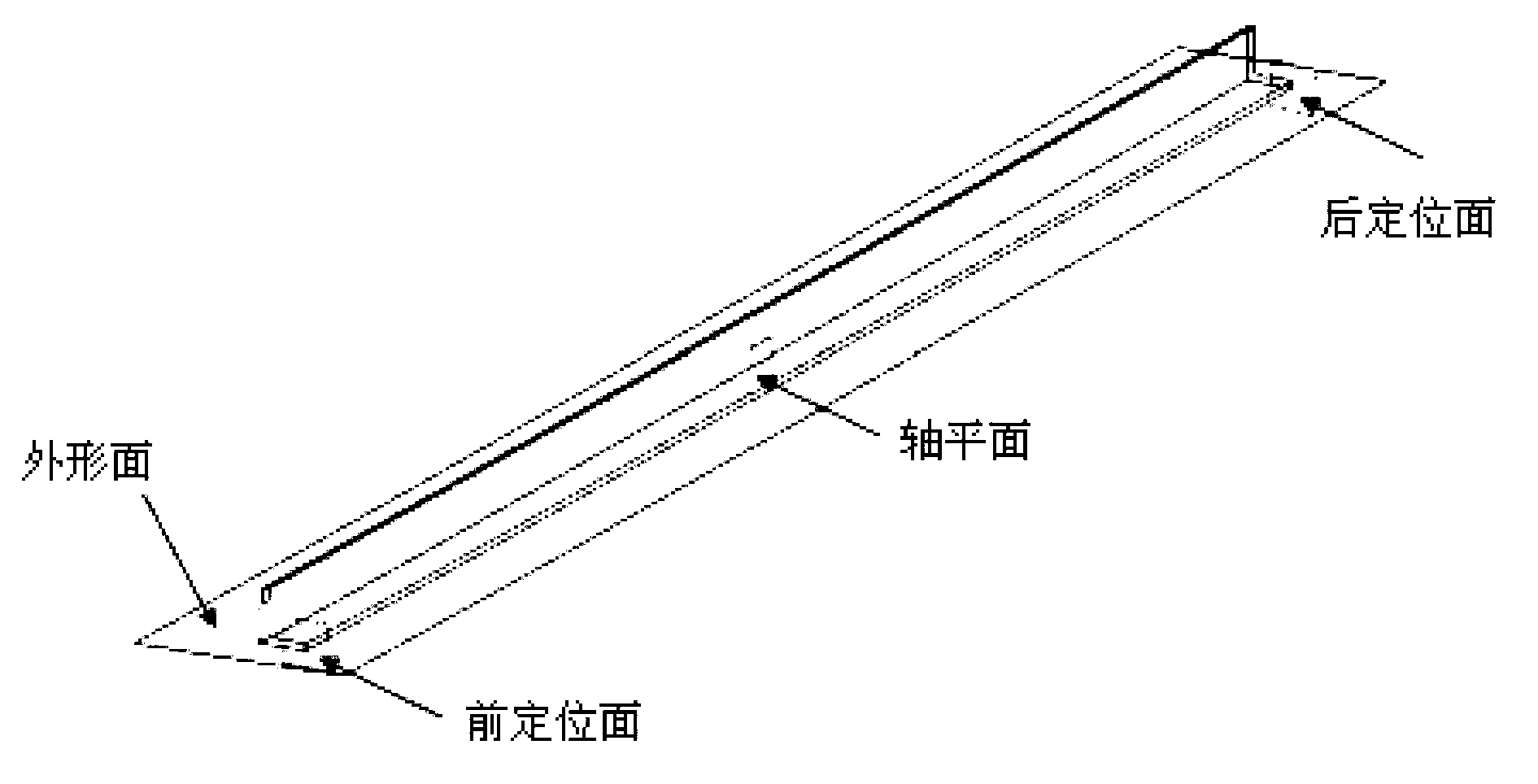

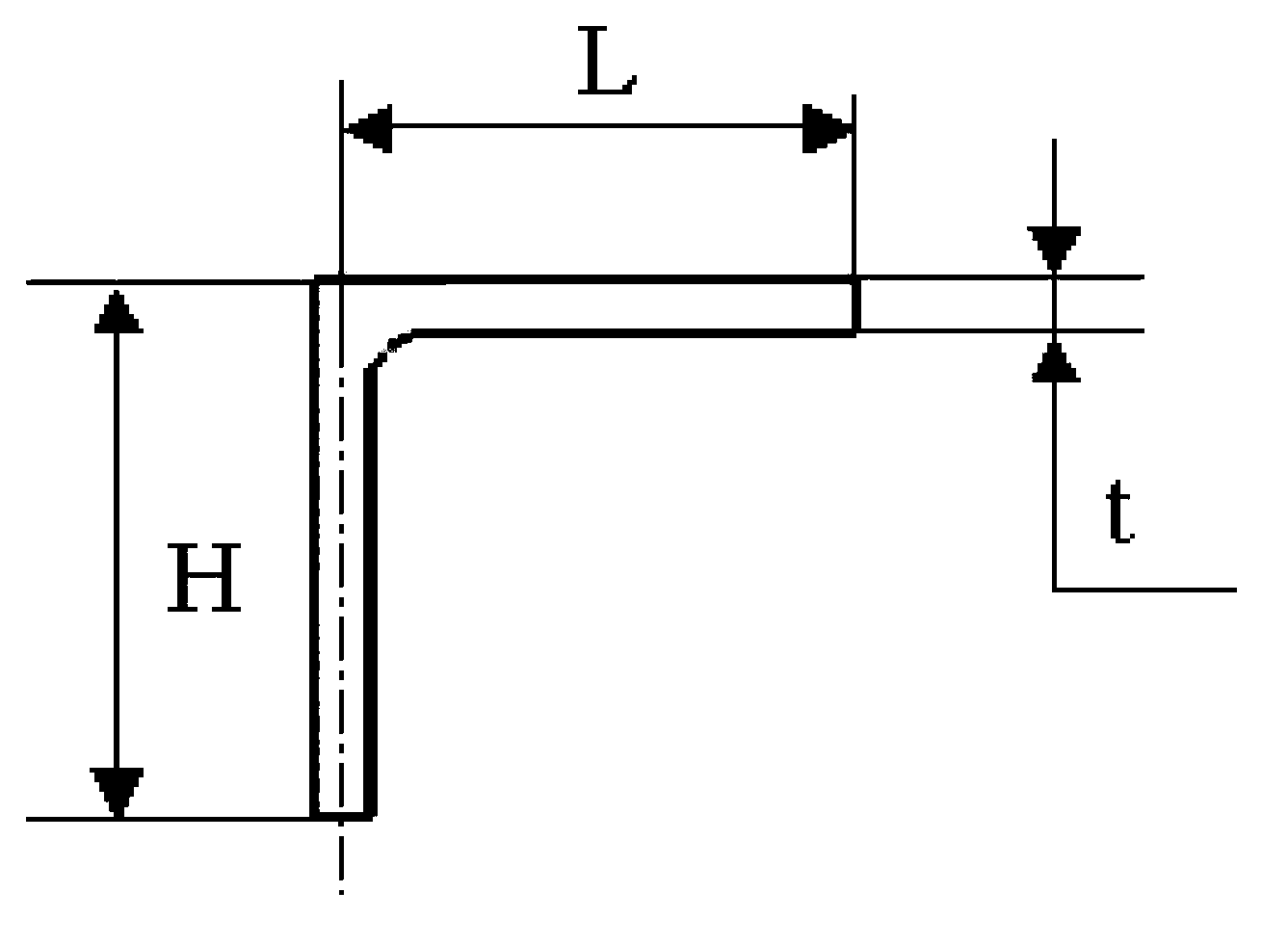

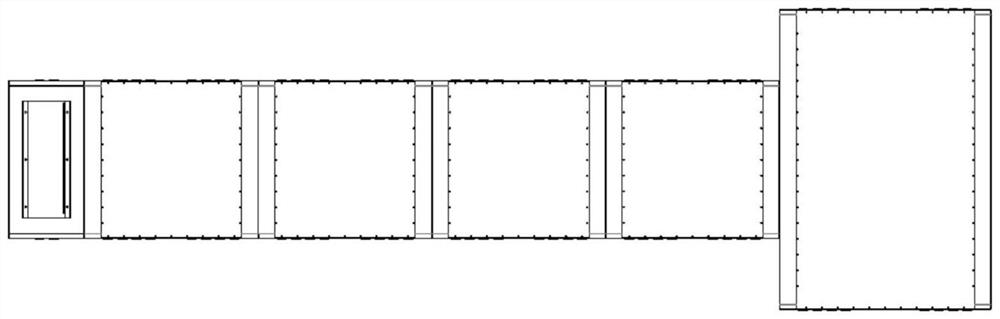

Method for parametrically designing primary components of airplane long truss-type parts

ActiveCN103020375AStandardize the digital definition processRich modeling methodsSpecial data processing applicationsManufacturing technologyQuality by Design

The invention discloses a method for parametrically designing primary components of airplane long truss-type parts. The long truss-type parts in an airplane structure are expressed by parametric components, and the parametric expression for the primary components of the airplane long truss-type parts specifically comprises the following four parts 1, essential attribute: the essential attribute specifically comprises the name of components, the version number, the creation time, the description of the components, a manufacturing technology and remarks; 2, geometric attribute: the geometric attribute is specifically divided into two parts of location parameters and section parameters; 3, non-geometric attribute: the non-geometric attribute specifically relates to a disassembling scheme and non-geometric attribute information corresponding to the disassembling scheme; and 4, two-dimensional sectional view: the two-dimensional sectional view is used for helping a user correctly understand the physical significance of each parameter of the components when the components are in instantiation. According to the method disclosed by the invention, a component base system of an airplane is facilitated to be built, function and performance model data foundation is provided for the standardization, the simulated analysis and the optimization of the airplane design, the consistency between a geometric model machine and a function model machine / performance model machine is ensured, the designing quality of the airplane is increased, and the development time is shortened.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

Parametrization design method of first-level member of rib type part of airplane

ActiveCN102982220AStandardize the digital definition processRich modeling methodsSpecial data processing applicationsDecompositionQuality by Design

The invention discloses a parametrization design method of first-level members of rib type parts of an airplane. The parametrization design method comprises the following steps of: stating the rib type parts in the airplane structure by using parametrization members, wherein the parametrization statement of the first-level members of the rib type parts of the airplane specifically relates to contents of four parts as follows: 1) the basic attributes specifically comprise the names of the members, the version numbers, the establishment time, the member description, the manufacturing process and the remarks; 2) the geometric attributes specifically consist of two parts of positioning parameters and cross-section parameters; 3) non-geometric attributes specifically relate to decomposition schemes and non-geometric attribute information corresponding to the decomposition schemes; and 4) a two-dimensional sectional drawing is used for helping a user to correctly understand the physical meaning of the parameters of the members in member instantiation. The parametrization design method is helpful in establishing a member bank system, functional and performance model data basis for the standardization and simulation analysis in airplane design is provided, the coordination of data of a geometric model machine and a functional model machine / performance model machine is ensured, the design quality of the airplane is improved, and the research and manufacturing period is shortened.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

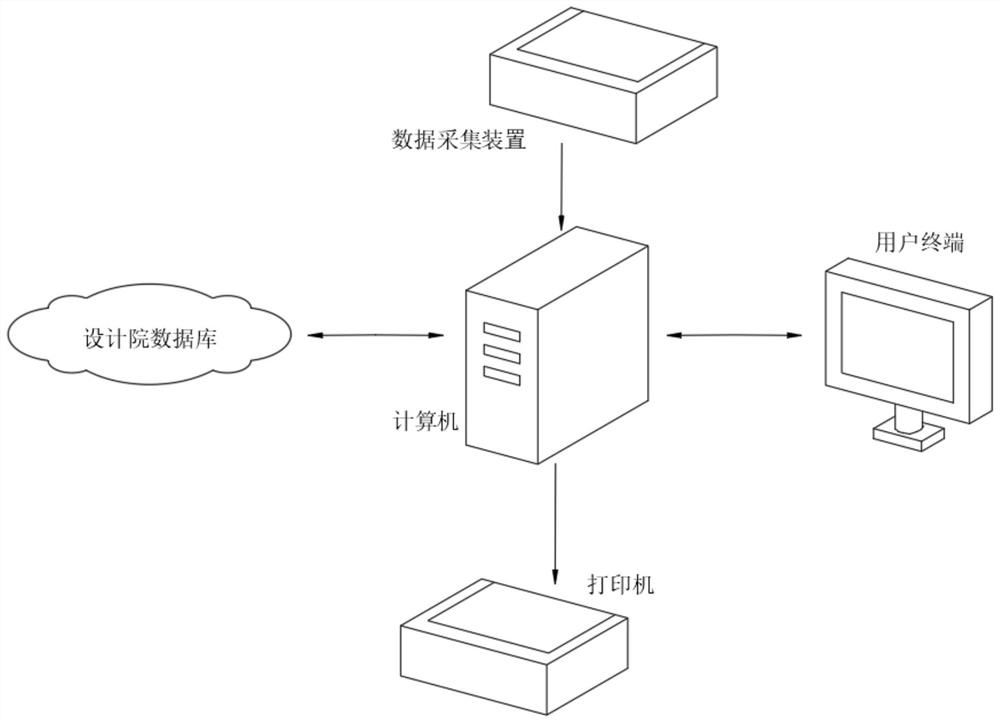

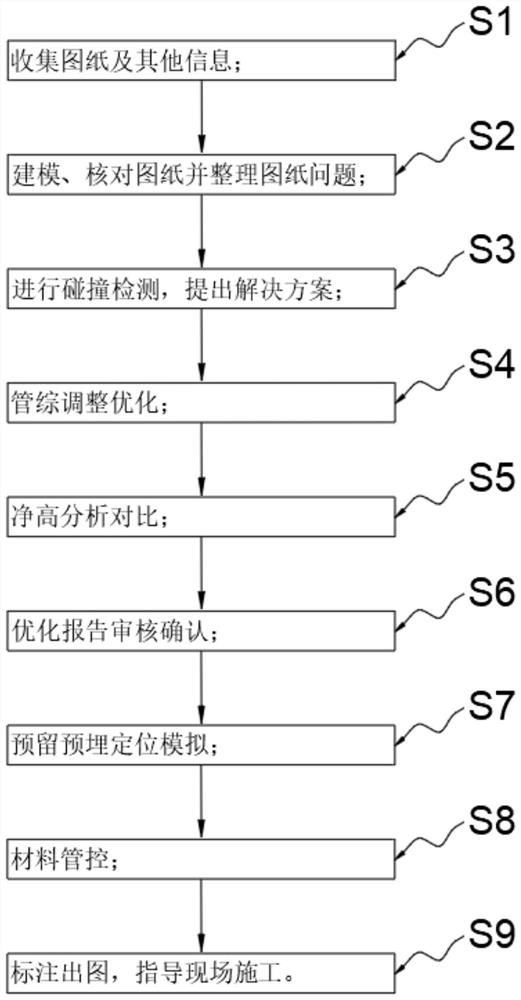

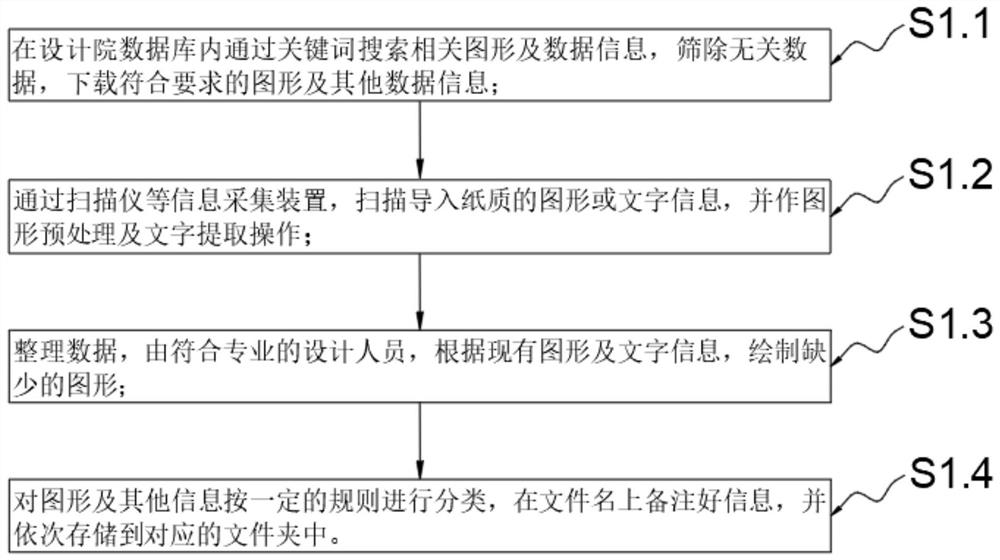

Electromechanical integrated management optimization method based on BIM (Building Information Modeling) technology

PendingCN112926166ABeautiful arrangementArrangement coordinationGeometric CADConfiguration CADProject completionCollision detection

The invention relates to the field of building electromechanical technologies, in particular to an electromechanical comprehensive optimization method based on a BIM technology. Comprising the steps of drawing collection, modeling, collision detection, pipe comprehensive adjustment and optimization, net height analysis, comparison and optimization report auditing and confirmation, reserved pre-embedded positioning simulation, material management and control, marking and drawing output and the like. According to the design, the design problem can be avoided in advance, the design quality can be improved, meanwhile, the professional subpackage construction procedure can be deduced, the field management problem of each professional can be effectively coordinated, and then the problem of cross collision of each professional in the field construction process is avoided; in addition, material management and other resource allocation are reasonably arranged, pipe section prefabrication is achieved, the workload can be reduced, and the construction period and cost are saved; therefore, a series of problems from design to construction can be effectively solved, the construction quality is ensured, and the clear height comfort degree of project completion is met.

Owner:云南云岭工程造价咨询有限公司

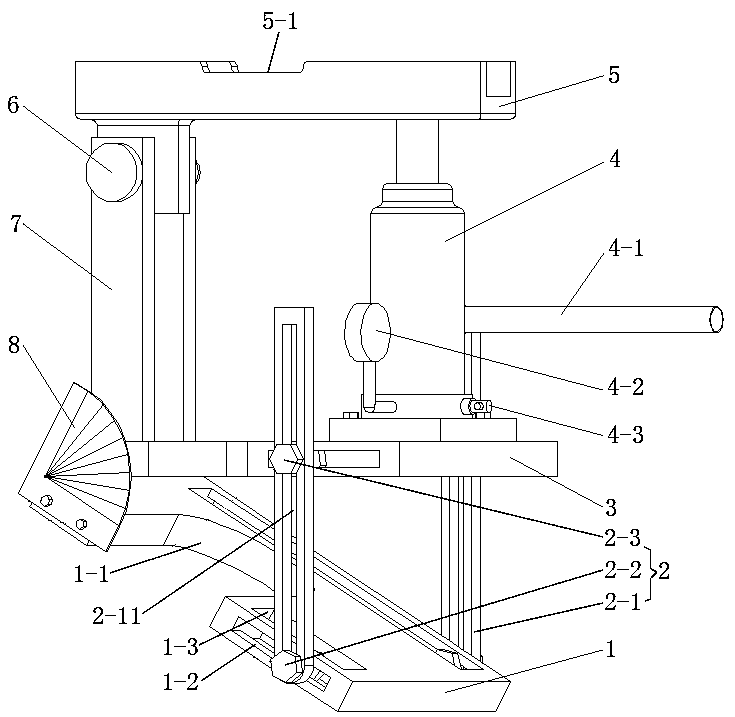

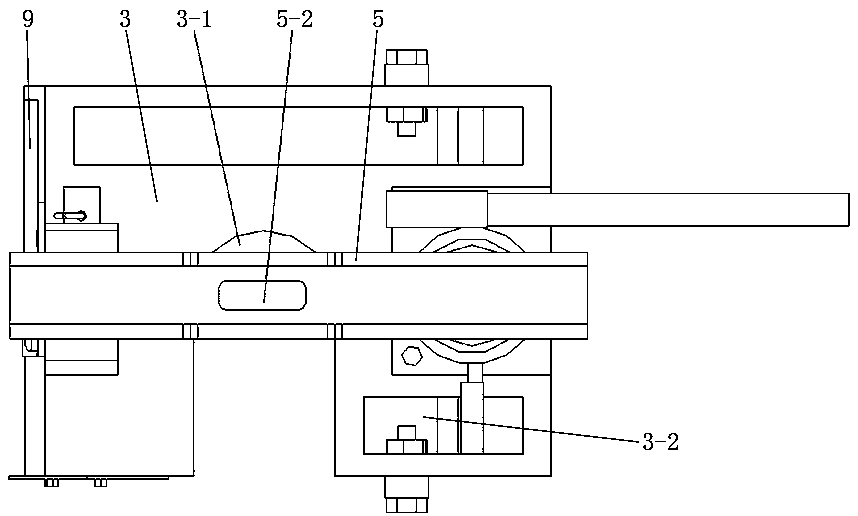

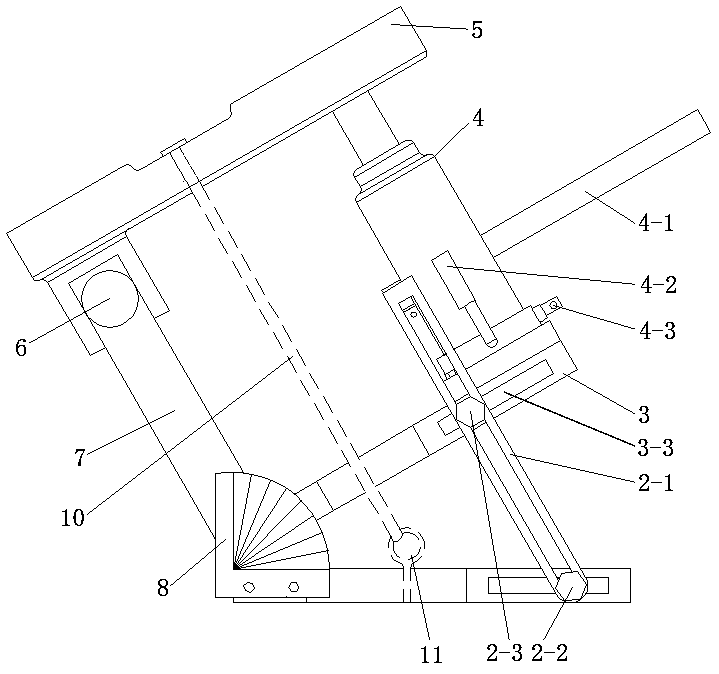

Automobile seat belt pull-out force detecting device

InactiveCN109781437ARealize pull-off force testEasy to detectVehicle testingMaterial strength using tensile/compressive forcesSeat beltVehicle detection

The invention discloses an automobile seat belt pull-out force detecting device, which relates to the technical field of automobile part detection. The automobile seat belt pull-out force detecting device comprises a base and a vertical column and a jack installed on two opposite sides of the upper end face of the base respectively, wherein the jack is equipped with a pressure gauge; the top end of the vertical column is hinged with a cross beam through a rotating shaft; the cross beam is fixedly connected with the extension end of the jack; the base is provided with an avoidance notch for enabling an installation belt to pass through; and the cross beam is provided with an installation belt limiting long hole. The problems that the existing automobile seat belt pull-out force technical indexes need to be subjected to whole vehicle detection on a test bench repeatedly, the cost is high, and the detection period is long can be solved.

Owner:DONGFENG LIUZHOU MOTOR

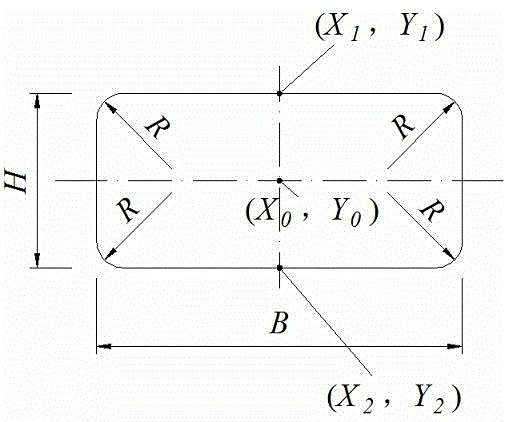

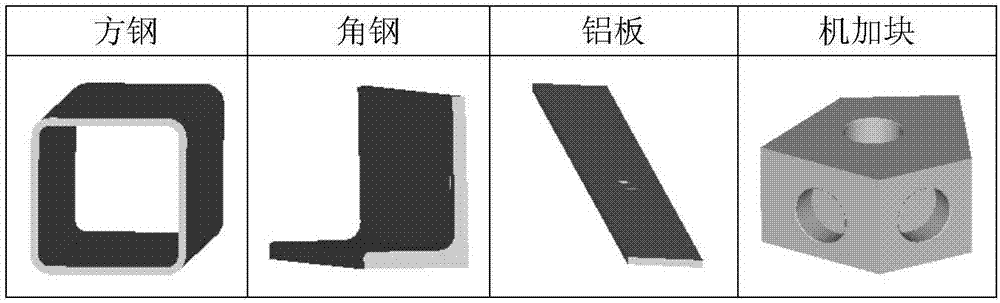

Automatic special-shaped ceiling modeling method

ActiveCN107066644AImprove design efficiencyGuaranteed design qualityGeometric CADSpecial data processing applicationsAbnormal shapedComputer science

The invention discloses an automatic special-shaped ceiling modeling method. The method comprises the following steps of: 1) establishing an initial data template, a part template, an engineering drawing template and a material detail list template; 2, obtaining a DXF grid file of an original unit; 3) projecting the DXF grid file to the initial data template and updating the DXF grid file; 4) calculating part parameters and classifying and outputting the part parameters in a binary file flow form; 5) generating parts; 6) carrying out part assembling according to location information carried by the generated parts; and 7) generating an engineering drawing to complete automatic special-shaped ceiling modeling. According to the method, predefined templates and a calculation rule are used to automatically complete the generation of the ceiling unit parts and the engineering drawing and the assembling of the parts; through simple dialog box interaction operation and parameterized programming, automatic ceiling unit design is realized, so that the design flow is greatly simplified; and a lot of similar repeated design work is processed by a computer, so that the ceiling unit design efficiency is improved by 5-6 times.

Owner:西安精雕软件科技有限公司

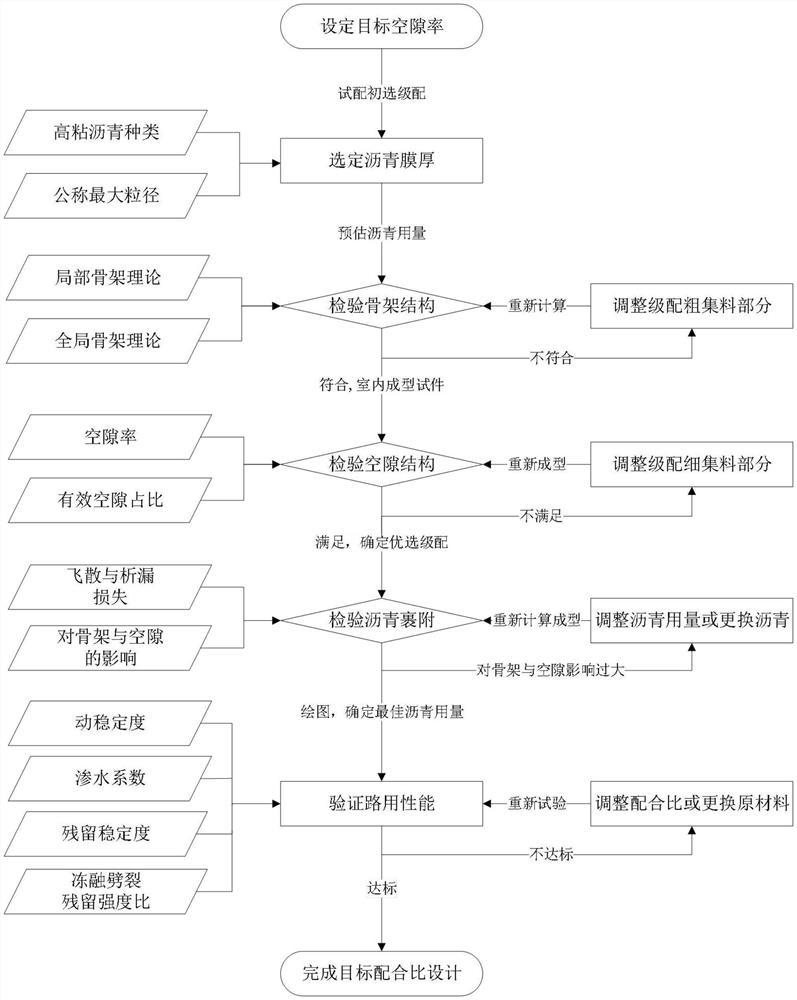

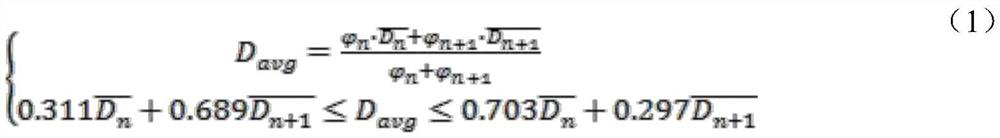

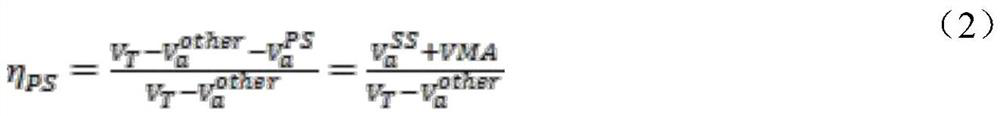

Drainage asphalt mixture optimization design method based on composition mechanism

InactiveCN111892335AGuaranteed design qualityNarrow down the range of available gradesRatio controlStructural engineeringAsphalt

The invention discloses a drainage asphalt mixture optimization design method based on a composition mechanism. The method comprises the following steps: (1) setting a target void ratio, and carryingout grading trial; (2) selecting a corresponding asphalt film thickness according to the type of the used high-viscosity asphalt and the nominal maximum particle size, and estimating the asphalt consumption; (3) checking a skeleton structure, sequentially checking a local skeleton and a global skeleton of each primary gradation according to a gradation skeleton theory suitable for the drainage asphalt mixture, and determining a gradation coarse aggregate part; (4) inspecting the void structure, forming a Marshall test piece, sequentially inspecting the void ratio and the effective void ratio according to the effective void ratio requirements of different nominal maximum particle sizes PAC, and determining optimal gradation; (5) determining the optimal asphalt-aggregate ratio, and inspecting asphalt coating; and (6) performing a performance test, and verifying the pavement performance. According to the method, each design link corresponds to each key performance, optimization and adjustment can be carried out in a targeted manner, and the test time and consumables are saved while the design quality of the drainage asphalt mixture is ensured.

Owner:SOUTHEAST UNIV

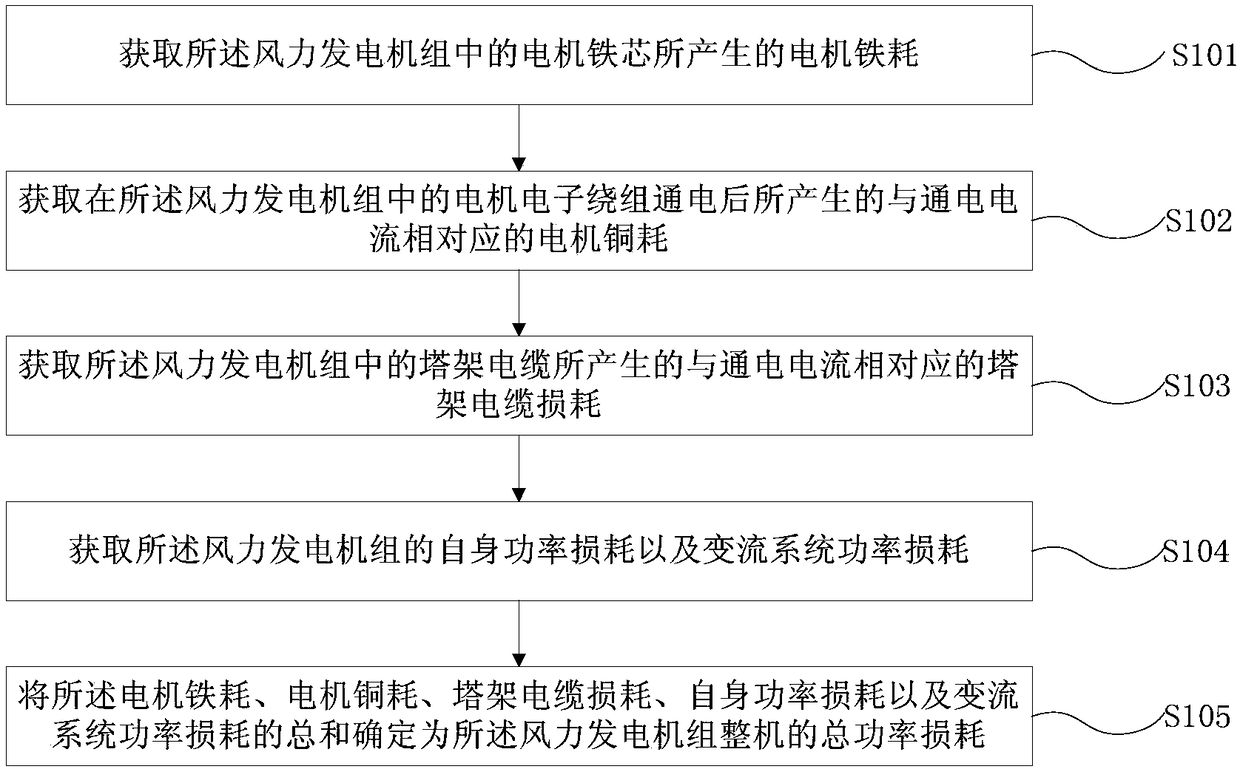

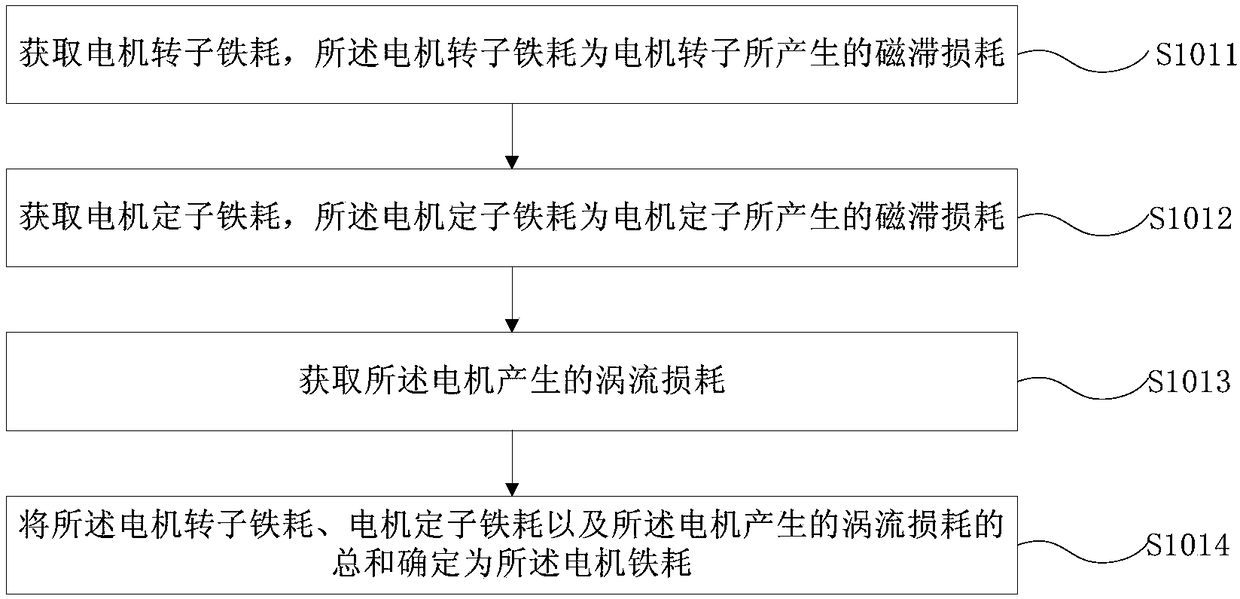

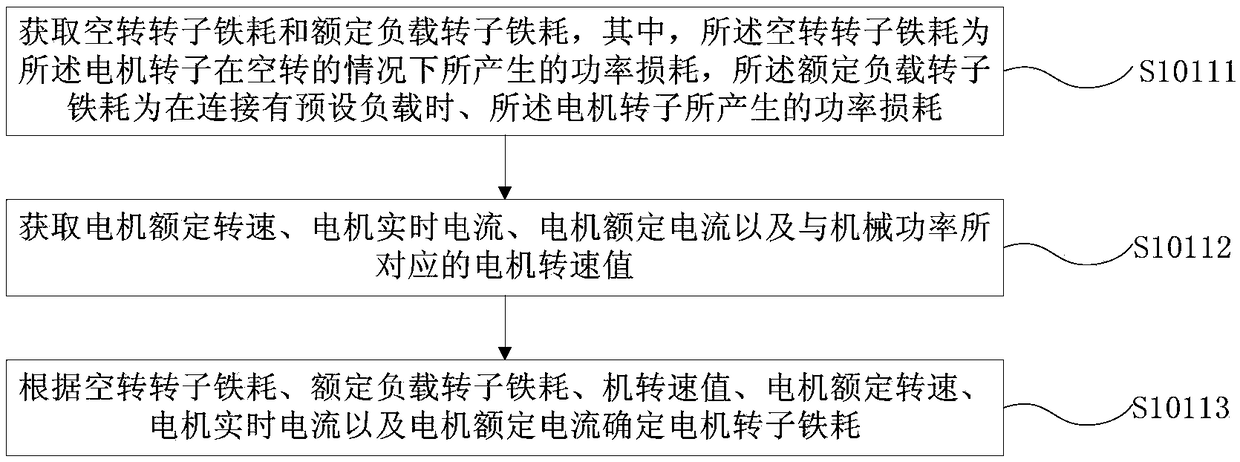

Calculation method and device for whole power loss of wind turbine generator

InactiveCN108241088AThe power loss of the whole machine is accurateReliable overall power lossElectric devicesElectric power measurementEngineeringElectron

The invention provides a calculation method and device for whole power loss of a wind turbine generator. The method comprises steps: the motor iron loss generated by a motor iron core in the wind turbine generator is acquired; the motor copper loss corresponding to electrifying current and generated after a motor electronic winding in the wind turbine generator is electrified is acquired; the tower cable loss corresponding to the electrifying current and generated by a tower cable in the wind turbine generator is acquired; the self power loss of the wind turbine generator and the converter system power loss are acquired; and the sum of the motor iron loss, the motor copper loss, the tower cable loss, the self power loss and the converter system power loss is determined to be the total power loss of the whole wind turbine generator. According to the calculation method and the device for the whole power loss of the wind turbine generator, different part configuration in the wind turbinegenerator, different operation states or environment temperature changes are considered, the calculated power loss is more accurate and reliable, and the wind turbine generator design quality and theefficiency are ensured.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Method for moving assembly layer text in batch in printed circuit board (PCB) design

InactiveCN107220439AMove quicklySimplify complex processesCAD circuit designSpecial data processing applicationsPrinted circuit boardComputer science

The invention particularly relates to a method for moving assembly layer text in batch in a PCB design. The method for moving the assembly layer text in batch in the PCB design includes the steps of traversing all devices one by one and the text attached to the devices by using a traversing nesting method, and acquiring all the text attached to the devices; checking the text in the traversal process to determine whether or not the text belongs to an assembly layer; if the text belongs to the assembly layer, executing the operation of calculating and moving; if the text does not belong to the assembly layer, skipping the current text; finally, writing the skill program for moving the assembly layer text in batch, adding function buttons for moving the assembly layer text in batch into wiring tool Allegro of the PCB design, and then achieving moving the assembly layer text in batch. The method for moving the assembly layer text in batch in the PCB design can quickly move the text of the assembly layers to the centers of the devices, thereby simplifying the complex process of moving manually one by one in the design, and improving the efficiency while being beneficial to guaranteeing the design quality.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Parameterized bus bridge model design and modification method

ActiveCN113051864AReduce labor intensityImprove design efficiencyComputer aided designSpecial data processing applicationsBusReliability engineering

The invention discloses a parameterized bus bridge model design and modification method. The method comprises the following steps: S1, overall 3D sketch layout is carried out on a bus bridge; S2, after the 3D sketch layout of the bus bridge structure is completed, a datum plane is set by means of points and lines of the 3D layout, and the specific position of each part of the bus bridge in the space is determined; and S3, after the spatial positions of the bus bridge parts are determined, each part is drawn in sequence, the contour of each drawn part is restrained through the points and the lines of the 3D sketch layout in the step S1, and the contours of the parts and the 3D sketch layout generate an incidence relation. According to the method, parameterization of the bus bridge is convenient, rapid and efficient, continuous and repeated work is avoided, some unnecessary and repeated workloads are abandoned, the unnecessary labor intensity of technicians is reduced, the design efficiency is improved, the design quality of products is ensured, and the practicability is enhanced.

Owner:HEBEI ELECTRIC POWER EQUIP

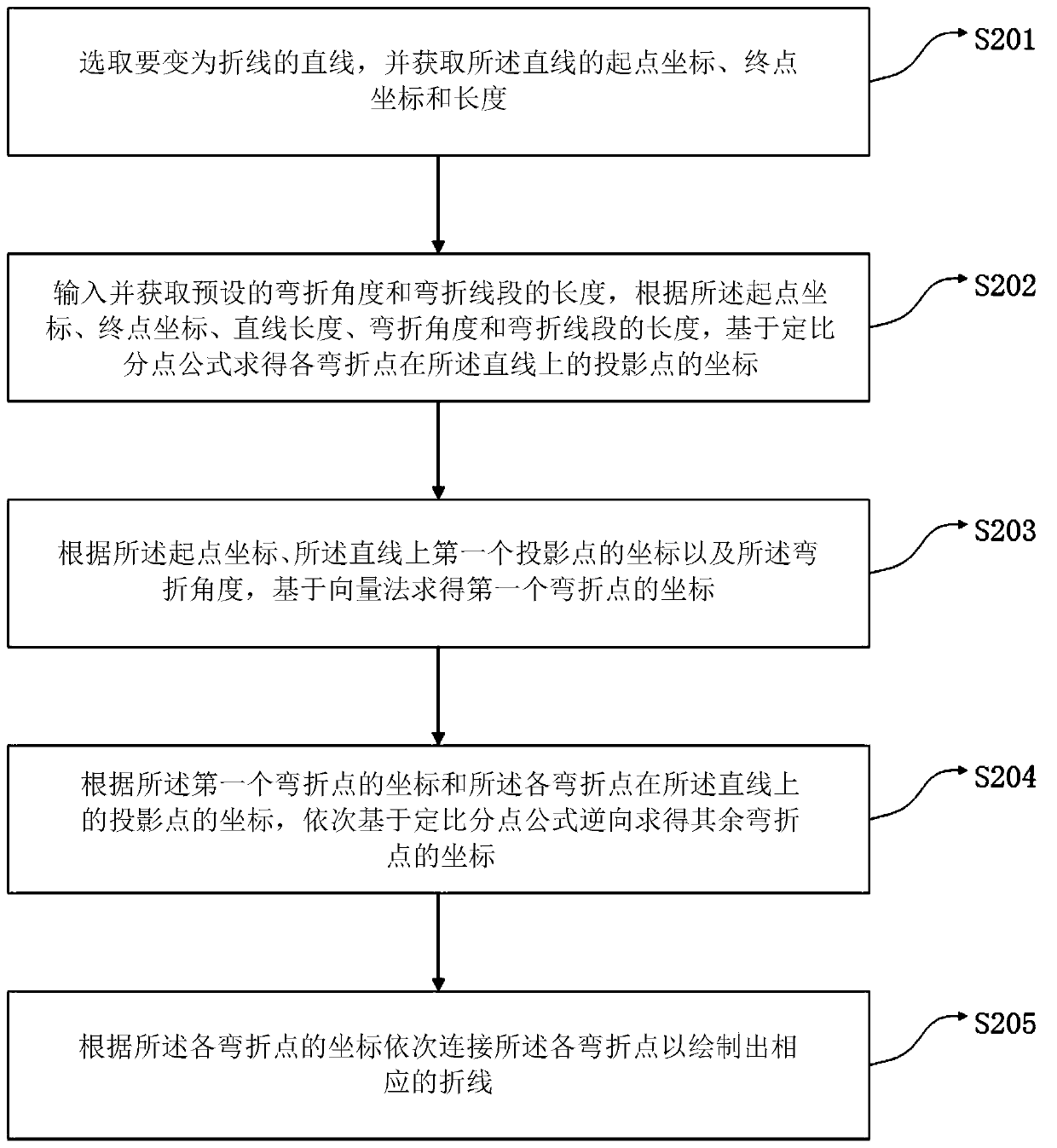

Method and device for changing straight line into arbitrary-angle broken line in PCB design

ActiveCN111368496AImprove design efficiencyGuaranteed design qualityCAD circuit designSpecial data processing applicationsStructural engineeringStraight segment

The invention provides a method and device for changing a straight line into a broken line at any angle in PCB design, and the method comprises the following steps: selecting a straight line to be changed into a broken line, and obtaining the starting point coordinate, end point coordinate and length of the straight line; inputting and obtaining a preset bending angle and the length of a bending line segment, and according to the starting point coordinate, the terminal point coordinate, the straight line length, the bending angle and the length of the bending line segment, solving the coordinate of a projection point of each bending point on the straight line based on a definite proportion score formula; according to the starting point coordinate, the coordinate of the first projection point on the straight line and the bending angle, solving the coordinate of the first bending point based on a vector method; according to the coordinate of the first bending point and the coordinate ofthe projection point of each bending point on the straight line, reversely solving the coordinates of the rest bending points in sequence based on a definite proportion score formula; and sequentiallyconnecting the bending points according to the coordinates of the bending points so as to draw corresponding broken lines. The method can automatically change the straight line segment into the broken line so as to guarantee the design quality.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

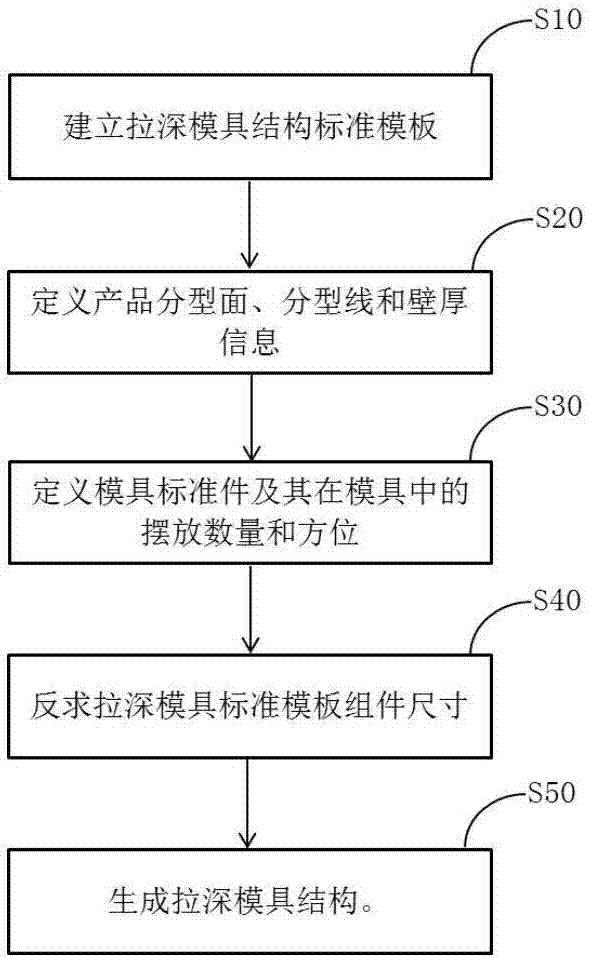

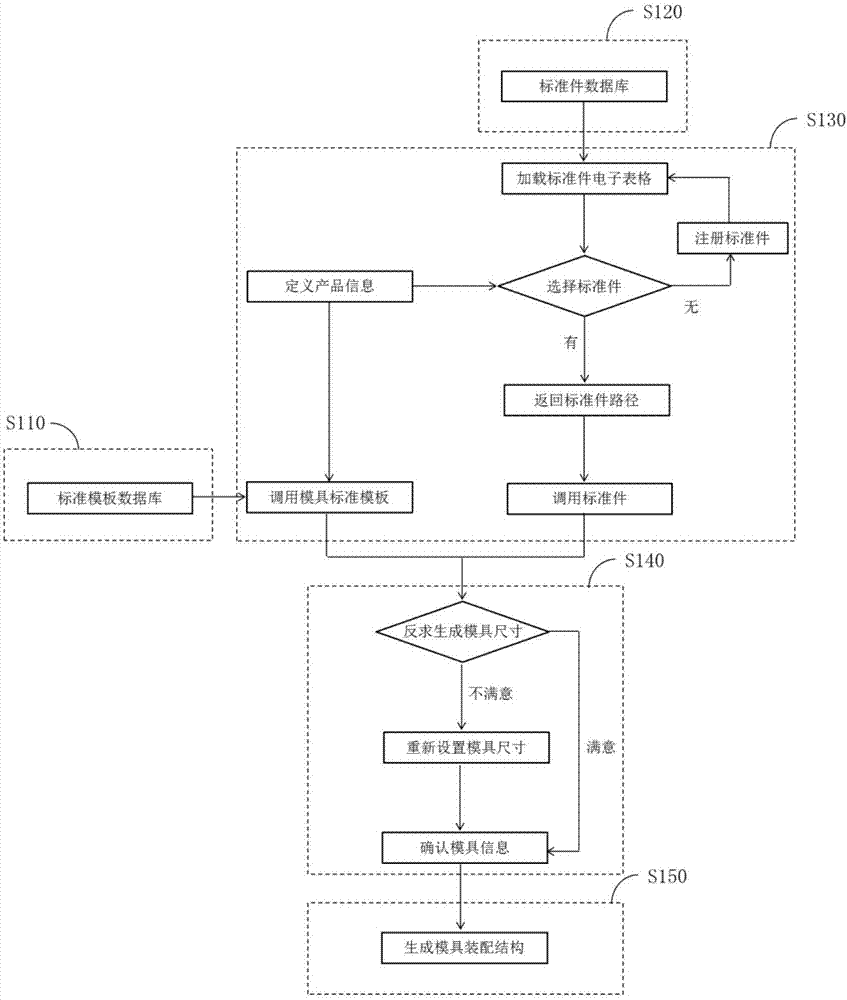

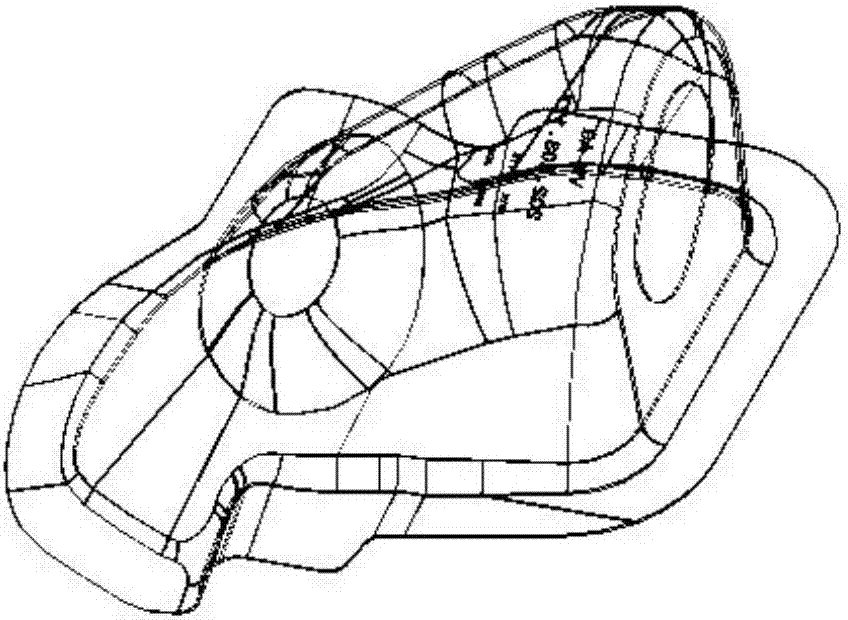

Deep drawing die structure generating method and system

InactiveCN107577898AReduce duplication of effortAdaptableShaping toolsSpecial data processing applicationsDesign cycleEngineering

The invention discloses a deep drawing die structure generating method and system. According to the technical scheme, a deep drawing die standard template is established, a product parting surface, aparting line and wall thickness information are defined; according to product sizes and specifications, die standard parts and the placing quantity and orientation of the die standard parts in a die are defined; through product information and standard part information, sizes of all parts of the standard template are reversely solved; through the product information, sizes of a convex die portion,a concave die portion and an edge pressing portion of the standard template are determined; according to the placing position of the standard part and the product information, the size of a die baseis determined, and then the size of the whole die frame portion is determined; according to the reversely solved standard template and the standard part information, a deep drawing die structure is generated; the deep drawing die structure comprises the reversely solved standard template, the product parting surface, the parting line and the selected standard parts. The drawing line structure generating method and system help shorten the design cycle of the deep drawing die and increase the standardization degree of the deep drawing die.

Owner:SOUTH CHINA UNIV OF TECH +1

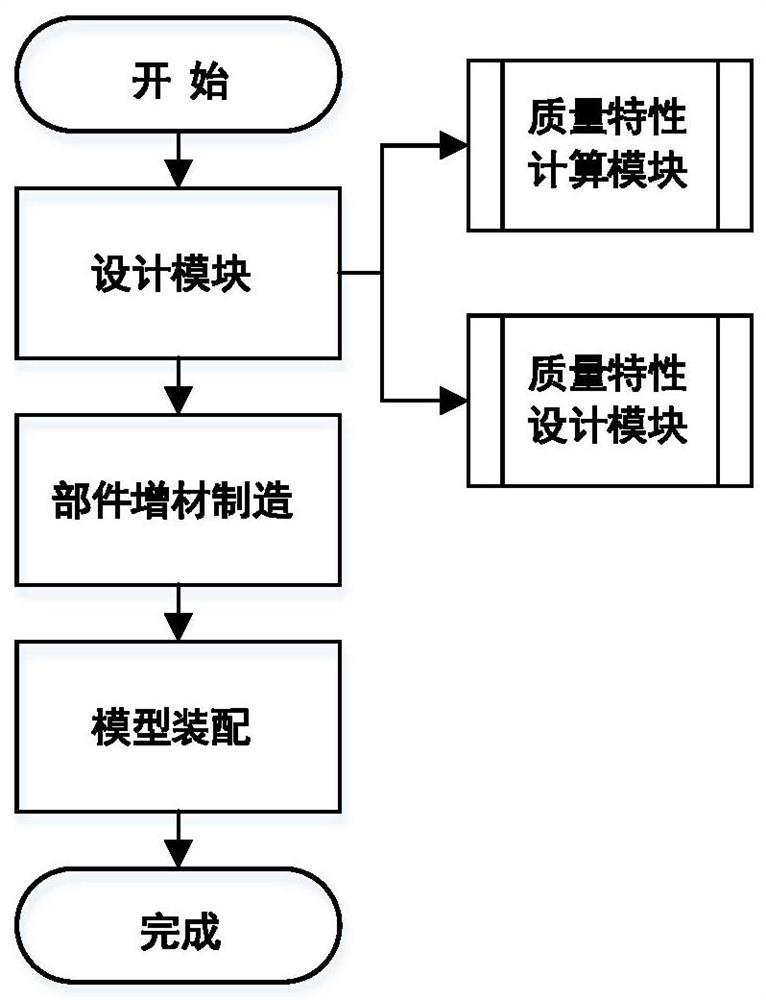

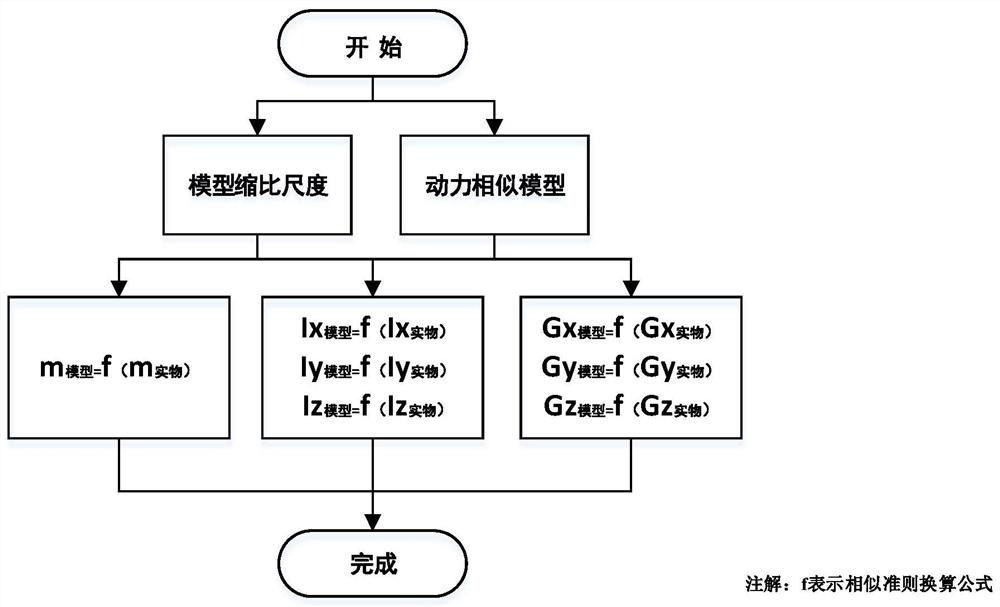

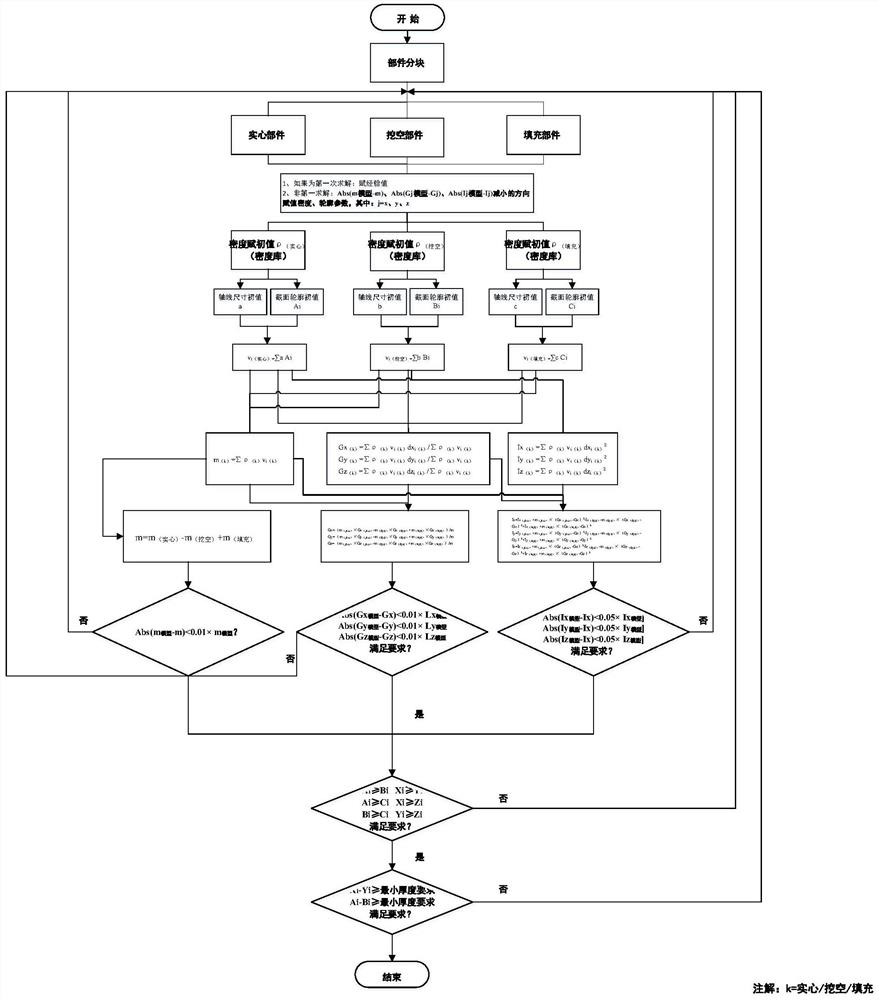

Design and processing method suitable for extremely light mass delivery model

ActiveCN112906142AHigh precisionImprove design efficiencyGeometric CADDesign optimisation/simulationEngineeringGravity center

The invention belongs to a design and processing method suitable for an extremely light mass delivery model. The design and processing method is characterized in that the process sequence of the whole method comprises a design module, part additive manufacturing and part assembling, and wherein the design module comprises two subprograms of a mass characteristic calculation module and a mass characteristic design module; the mass characteristic calculation module calculates the weight, the gravity center and the rotational inertia of the model according to the model scaling proportion and the dynamic similarity criterion, and takes the calculated weight, gravity center and rotational inertia as target parameters of the mass characteristic design module. The core idea of the mass characteristic calculation module is that the middle of a solid body model is hollowed to form a shell, the hollowed-out part is continuous, the basic thickness requirement of the shell needs to be met, and the shape is not limited. The filling part is placed in the hollowed out part, and the contour shapes of the hollowed out part and the filling part are iteratively calculated by adopting a self-adaptive program so as to configure the weight, the gravity center and the rotational inertia of the model to meet the requirements of a design target.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Calculation method for quaternary curve equation forming of three-dimensional shape of low hump outlet channel

ActiveCN104615831BGuaranteed design qualityGuaranteed uptimeSpecial data processing applicationsWater flowThree dimensional shape

The invention relates to a shaping algorithm for a quartic curvilinear equation of a three-dimensional shape of a low hump type water draining flow way and application of the shaping algorithm, and belongs to the technical field of pump stations of water conservancy projects. The low hump type water draining flow way is designed by the shaping algorithm. The shaping algorithm is characterized in that an upper side line and a lower side line of a longitudinal section of the flow way, a width changing curve of the flow way and a transitional circle center track line of the cross section, which is changed into square from circle, of the flow way are respectively set into the quartic curvilinear equation; the flow way is divided into a rising turning section and a falling section, the rising turning section turns at an angle of 90 degrees, influences of a centrifugal force on water flow are reduced to a maximum extent, the height of the rising turning section is increased as much as possible under the condition of arrangement permission of a pump room, and a turning radius of the rising turning section is increased; the falling section guides the water flow to be connected with a water draining pond gently and orderly, so that the crest level of the cross section of an outlet of the flow way is lower than the minimum water level of the water draining pond by 0.5m; and the water flow of the designed low hump type water draining flow way turns orderly and is scattered uniformly, loss of a water head of the flow way is low, and the hydraulic performance is excellent.

Owner:YANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com