Patents

Literature

41results about How to "Improve process design efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for building dynamic three-dimensional process model

ActiveCN102722614AFastImprove interactivitySpecial data processing applications3D modellingReference model3D modeling

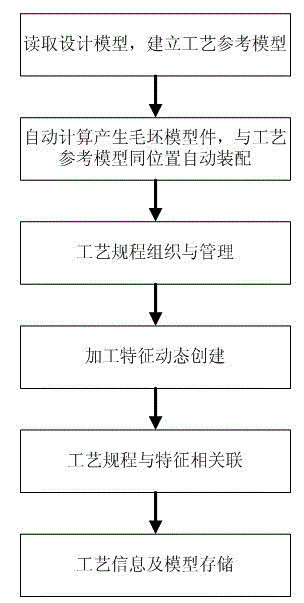

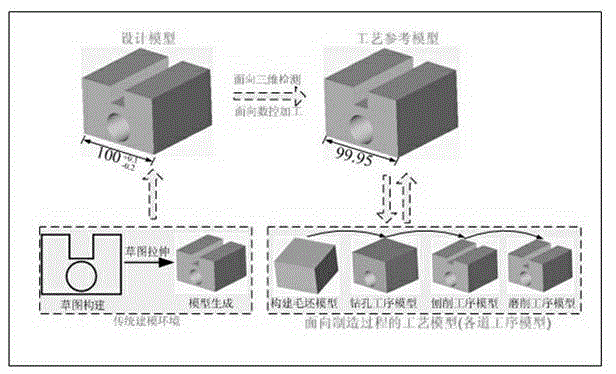

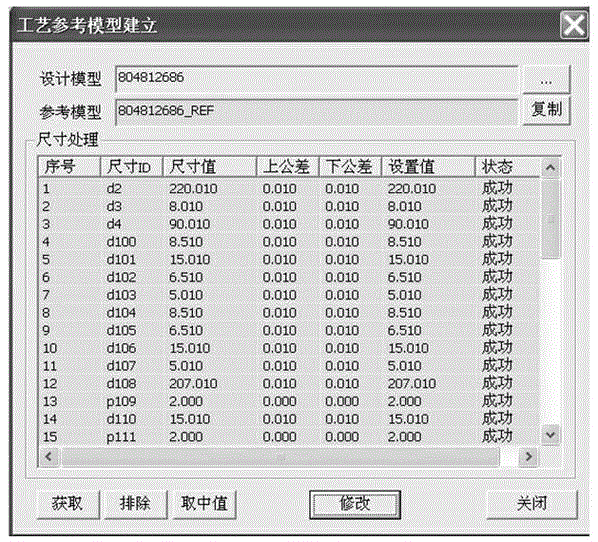

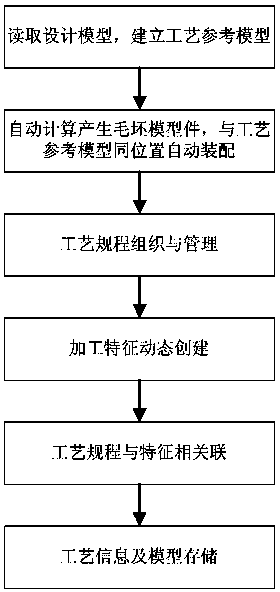

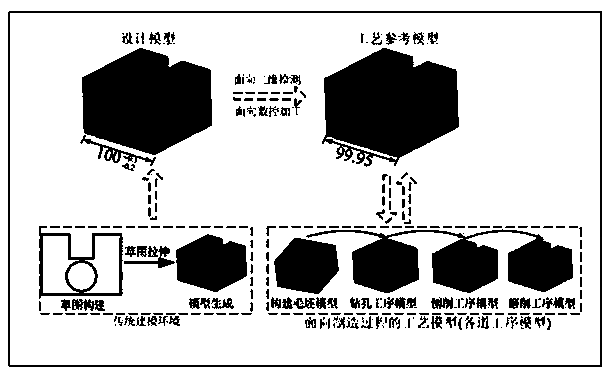

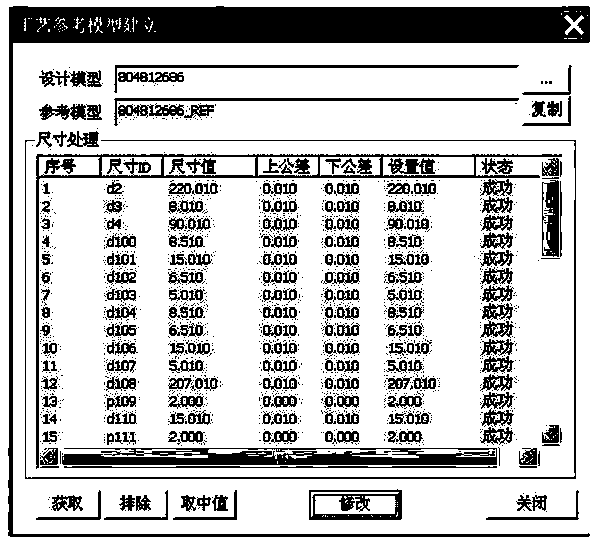

The invention belongs to the field of the technological process of a three-dimensional design model, and relates to a method for building a dynamic three-dimensional process model, which is characterized in that the method for building the dynamic three-dimensional process model is carried out according to the following six steps of: reading the design model, and building a technological reference model; automatically calculating the produced blank model, and automatically assembling the produced blank model with the technological reference model at the same position; organizing and managing the technical schedule; dynamically creating processing the characteristic; correlating the technical schedule with the characteristics; and storing the processing information and the model. The method for building the dynamic three-dimensional process model solves the problem that the two-dimensional technological design and the three-dimensional technological design are disjoined at present, and a two-dimensional model is taken to directly guide production and manufacturing, the traditional mode of 'three-dimensional design plus two dimensional' is broken through, and accordingly, the technological design efficiency is obviously improved; and moreover, the manufacturing staff can directly obtain the machining features and the corresponding technological information on the basis of the three-dimensional technological design, so the preparation periods of production and manufacture are greatly shortened, and the production efficiency is improved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

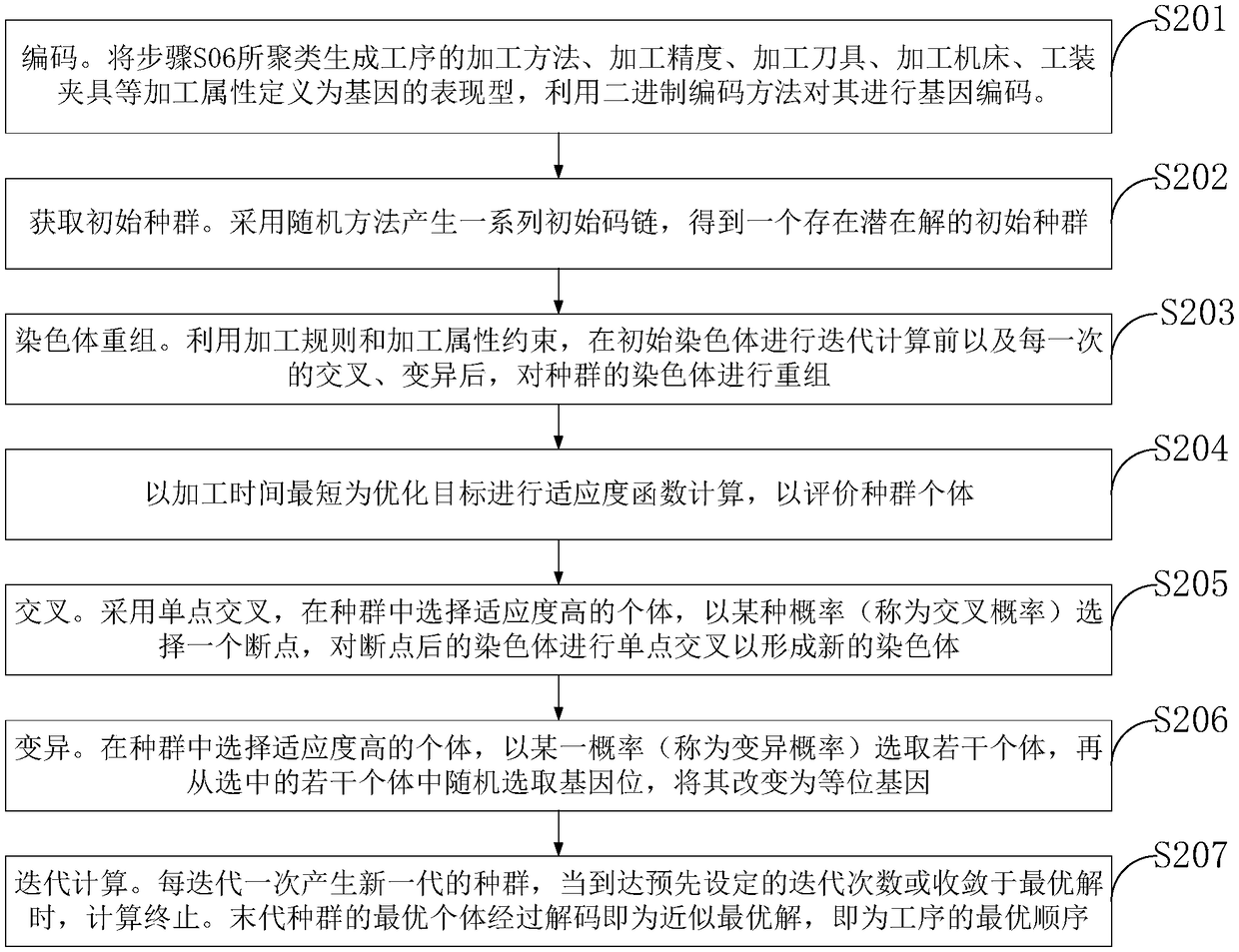

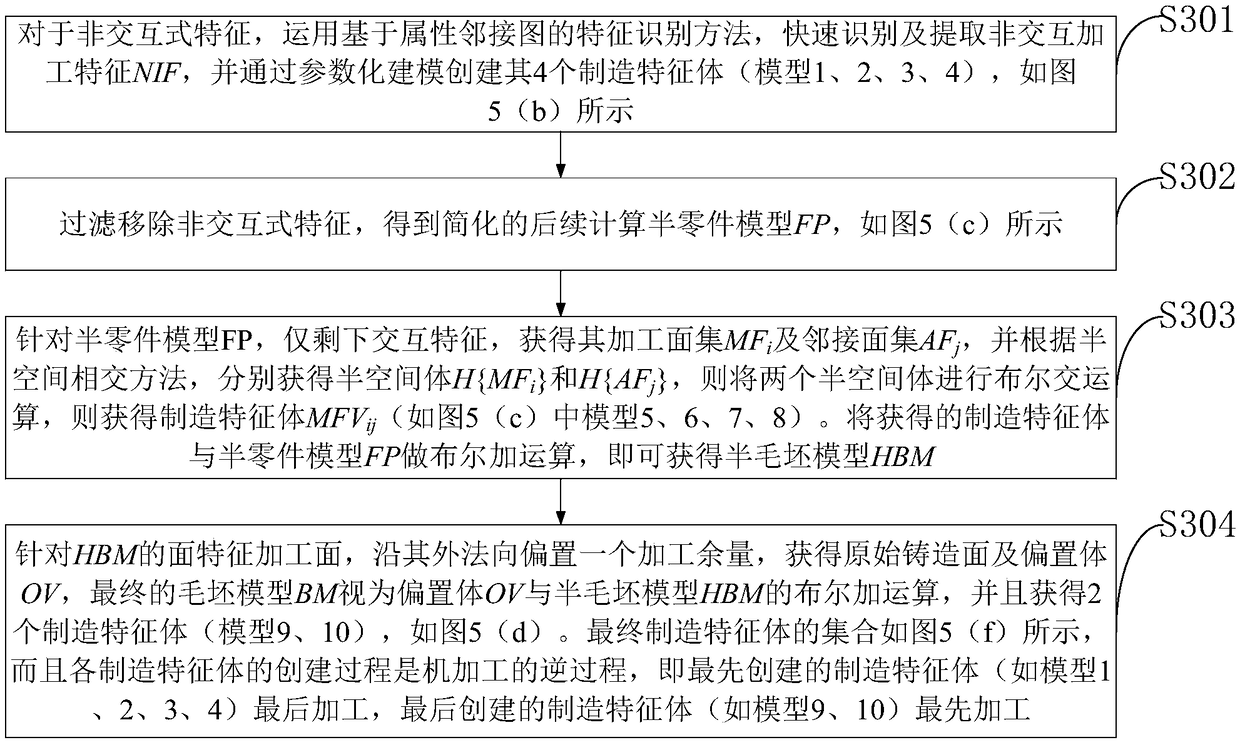

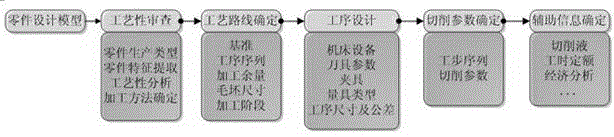

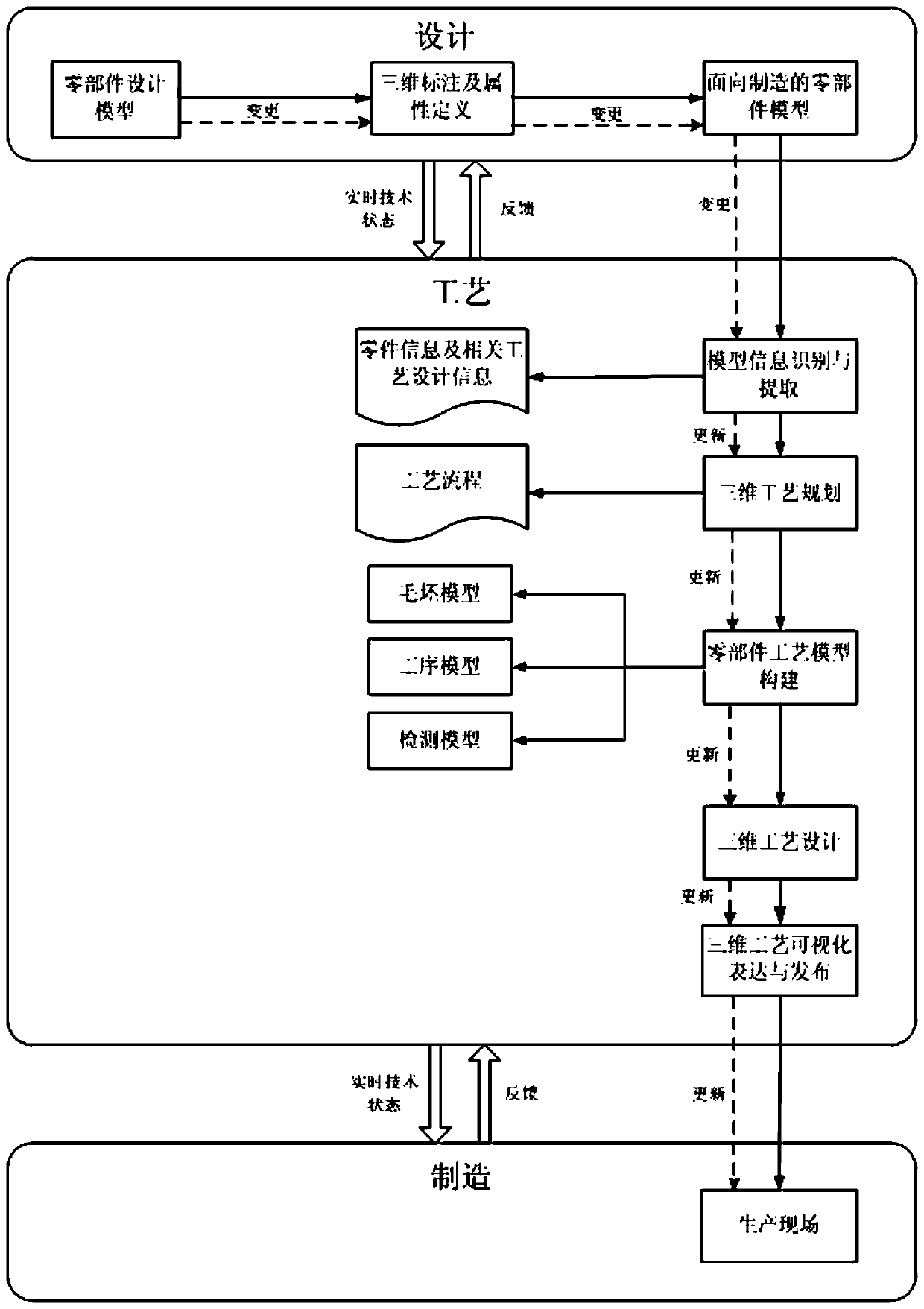

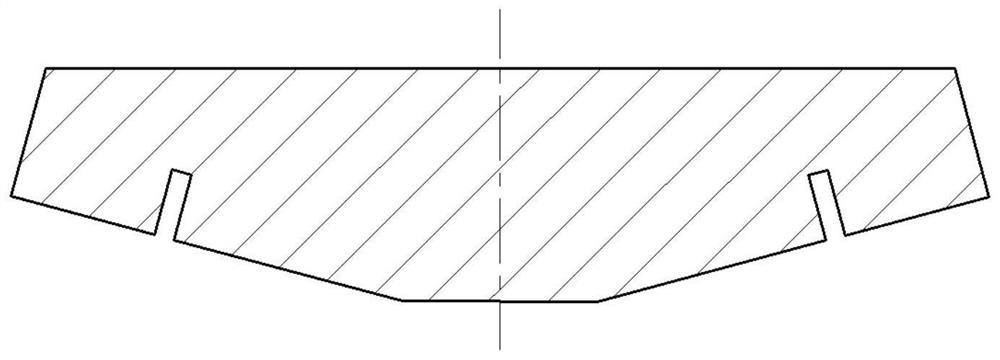

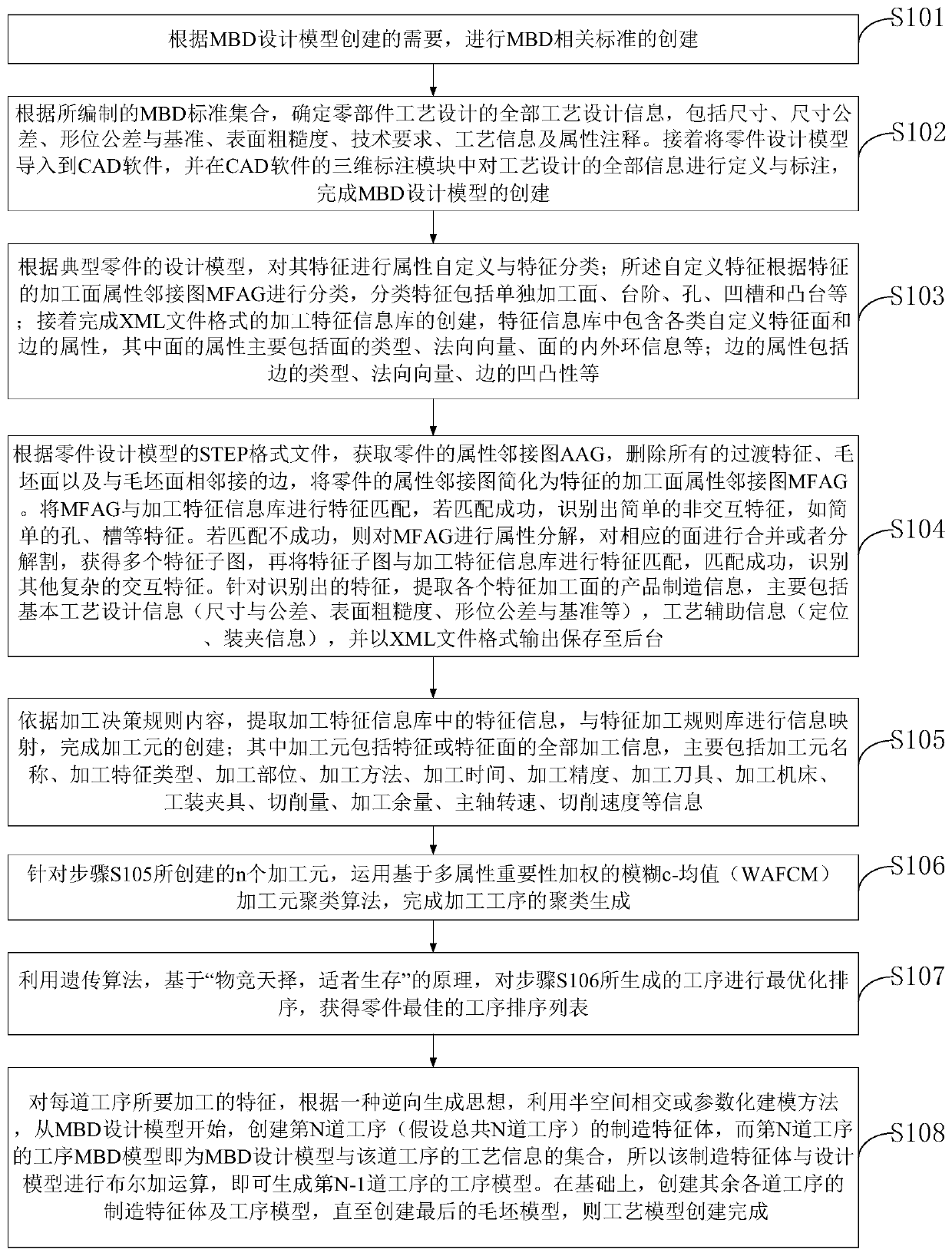

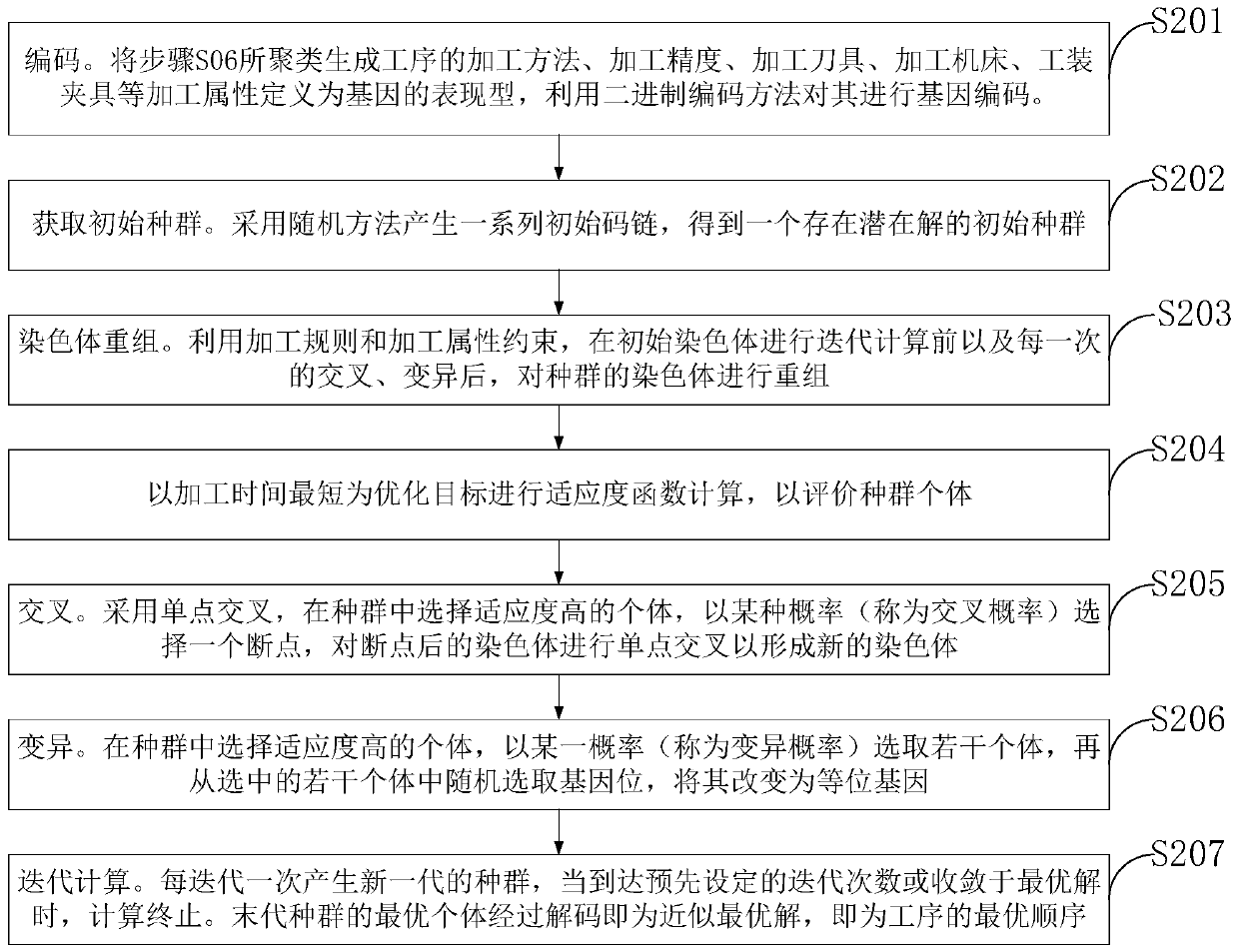

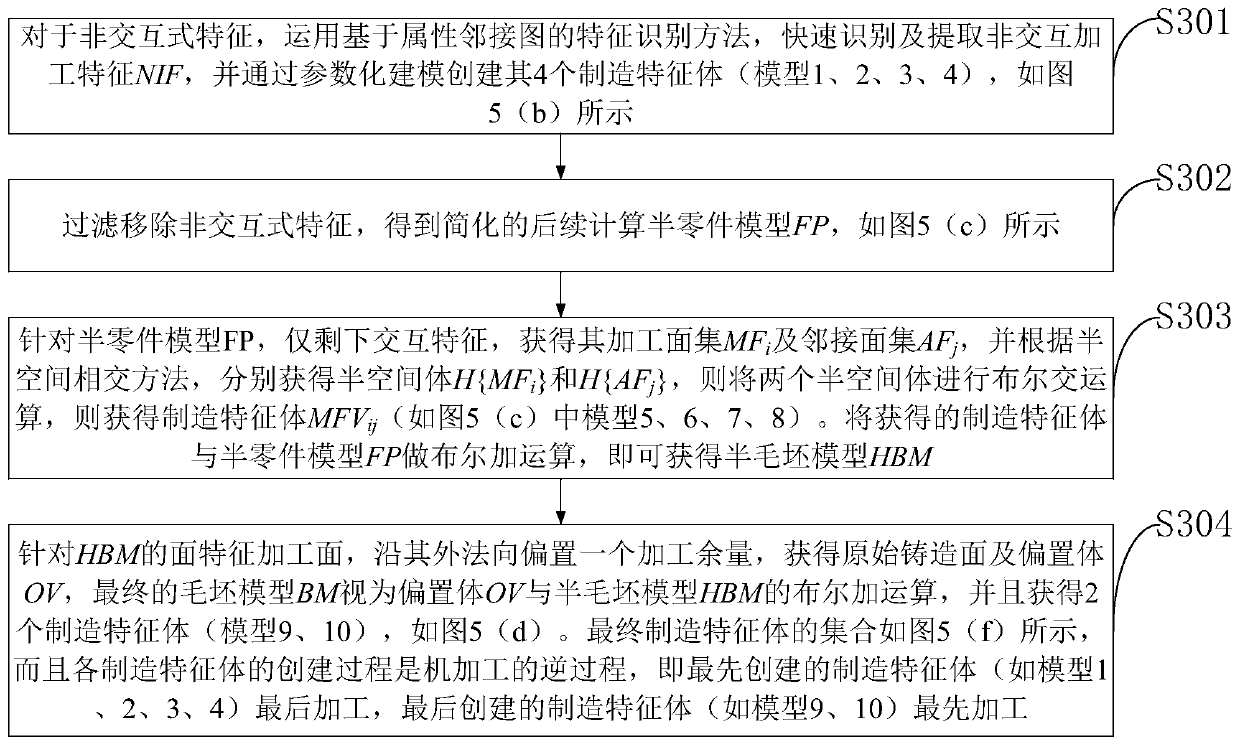

Three-dimensional process planning method and platform for typical automobile machined parts based on MBD

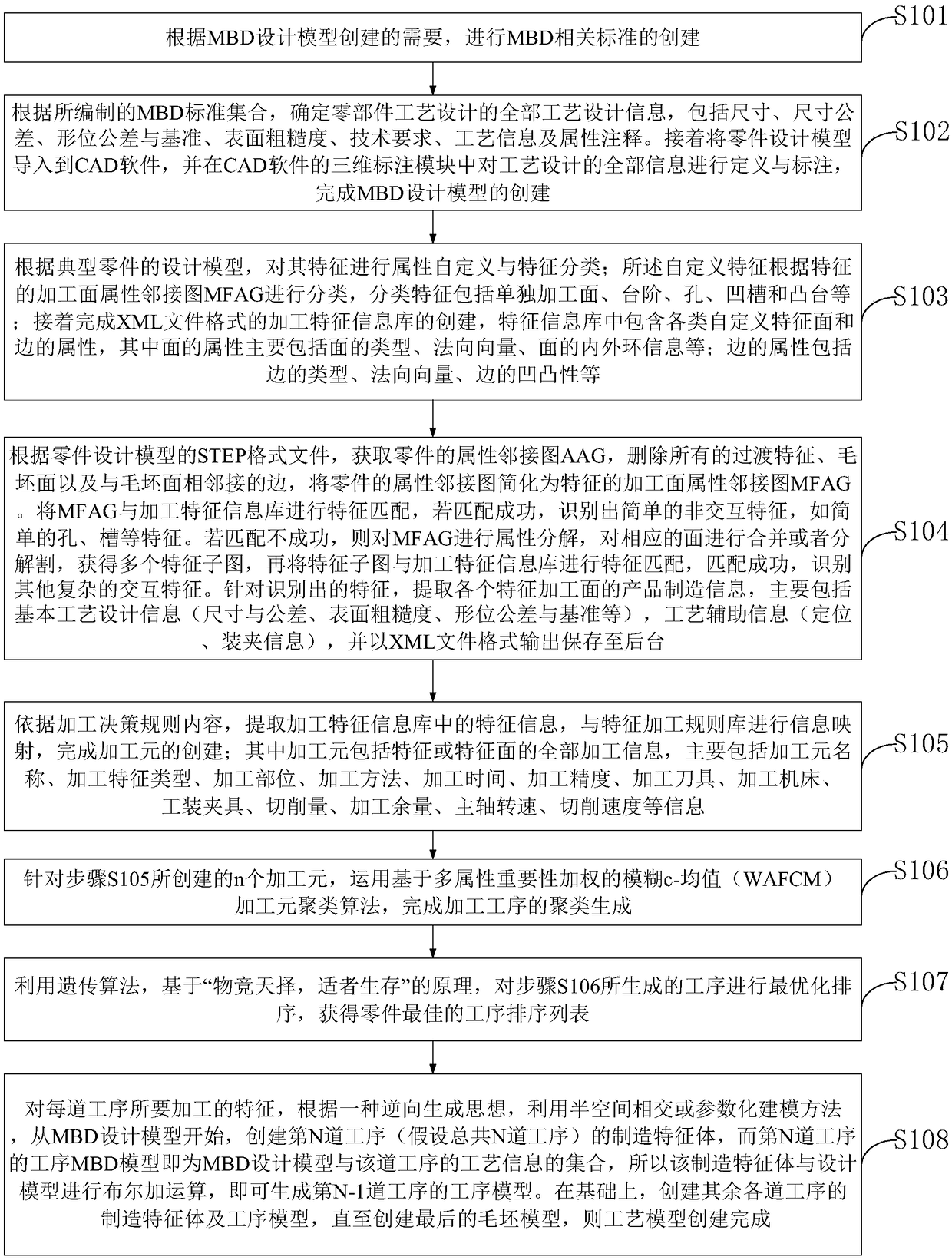

ActiveCN109117560ADesign specificationGuaranteed accuracyGeometric CADDesign optimisation/simulationMachine partsComputer-aided

The invention belongs to the technical field of computer-aided process planning, the invention discloses a three-dimensional process planning method and a platform for typical automobile machined parts based on MBD, based on 3D CAD software, with the MBD design model as the sole data input, the process MBD model is used as the data output, and the design process includes the establishment of MBD related standards, the creation of MBD design model, feature classification and feature database, feature recognition and information extraction, the generation of machining elements, the generation ofmachining elements clustering process, process sequencing, manufacturing features, the creation of process model and so on. The final application example of the present invention is in the case whereNX is used as a carrier, C + + and NXopen language, the invention can quickly generate a process MBD model which integrates a process model and a manufacturing feature body, can realize the visualization of the process design flow, improve the process design efficiency, and lays a foundation for the integration of CAD / CAPP / CAM. The invention can be used in the three-dimensional CAPP system developed by C + + and NXopen language.

Owner:WUHAN UNIV OF TECH

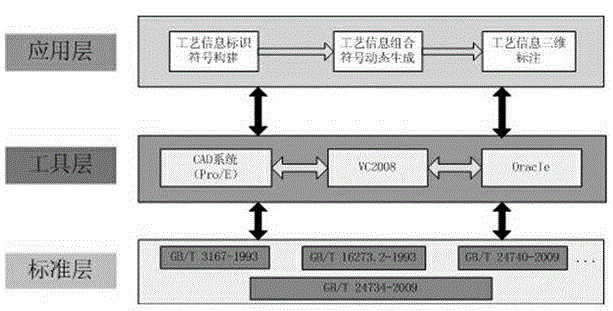

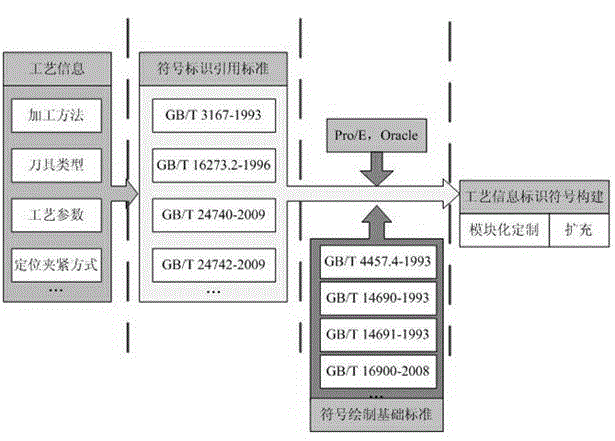

Technique information expressing method based on three-dimensional model

ActiveCN102722615AIntuitive imageEasy to implementSpecial data processing applicationsDimensional modelingComputer science

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

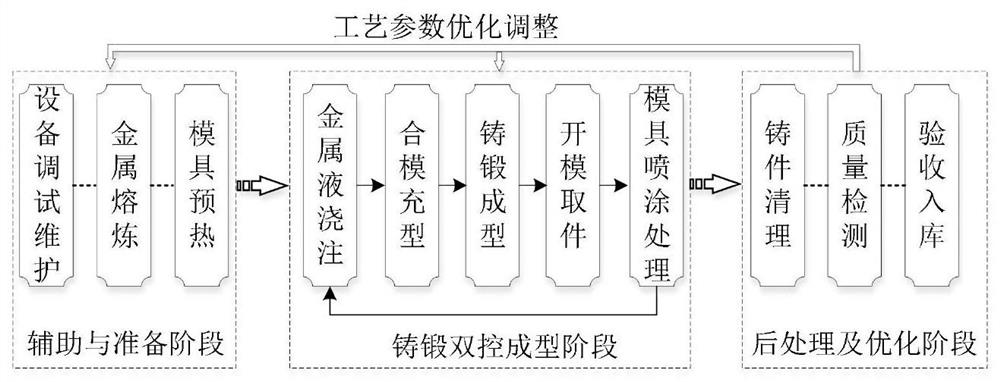

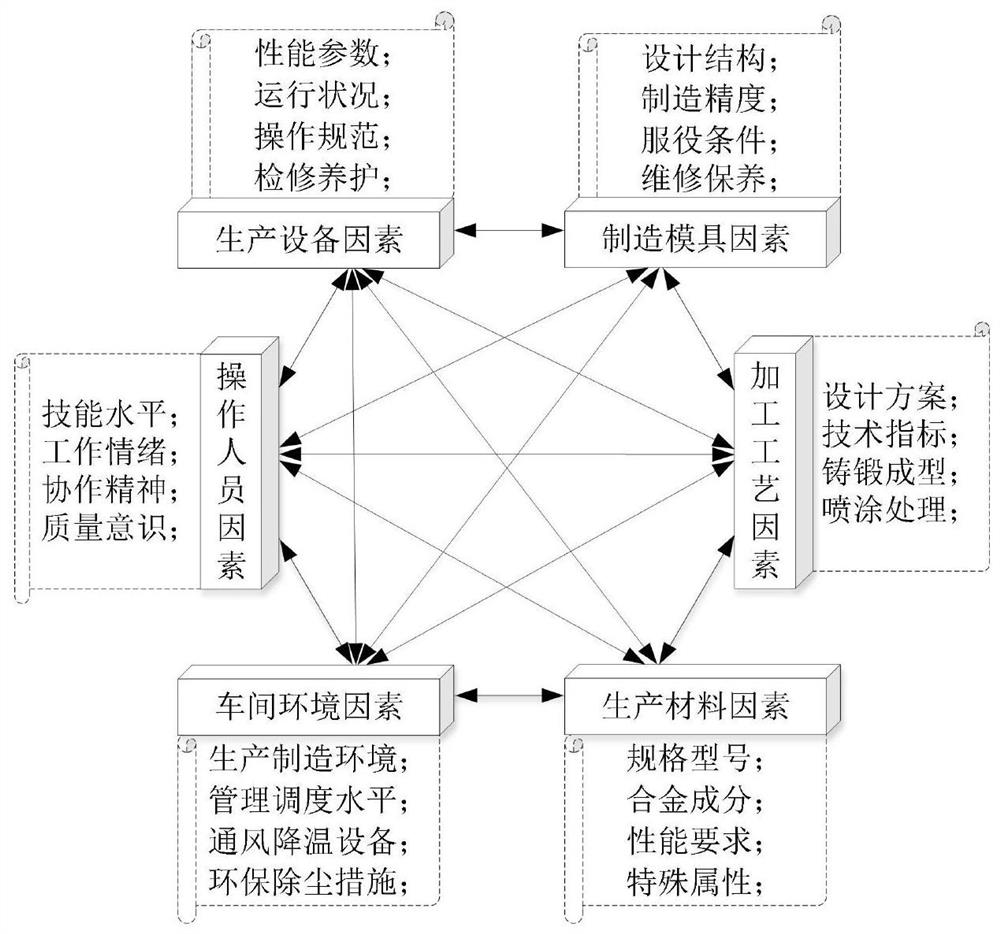

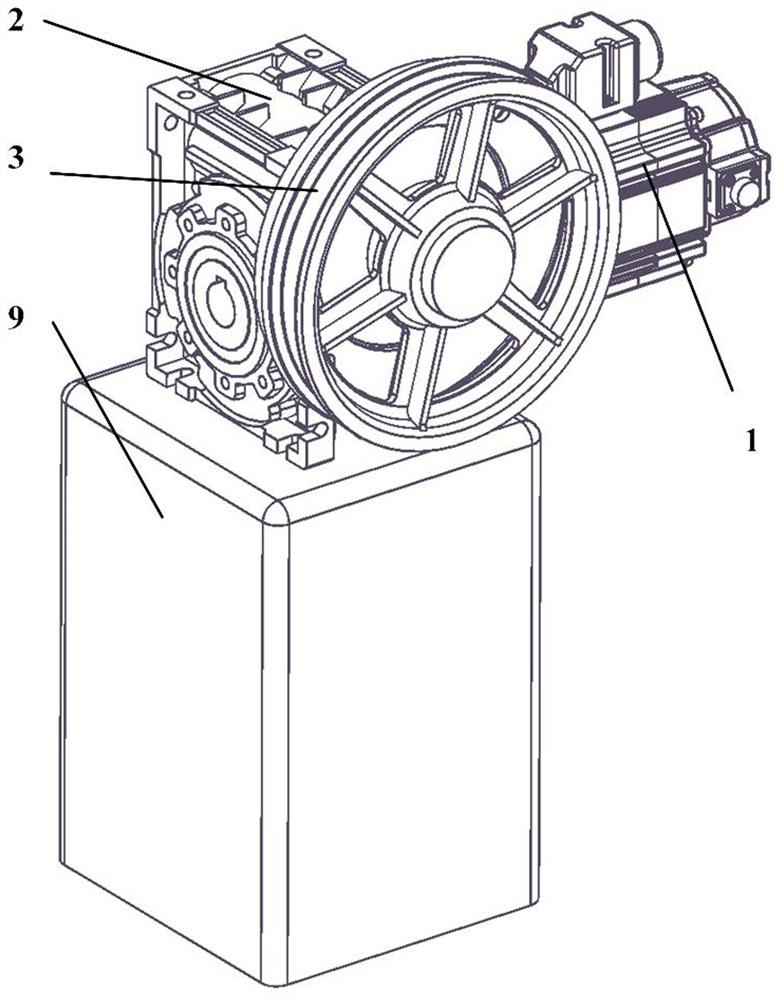

Casting and forging double-control forming system based on digital twinning and parameter optimization method

ActiveCN112427624AReduce investmentReduce production processCasting safety devicesArtificial lifeProcess engineeringTransmission system

The invention relates to a casting and forging double-control forming system based on digital twinning and a parameter optimization method, and belongs to the field of automation. The system comprisesa physical entity system, a data sensing system, a network transmission system and a digital twinning system. The data sensing system collects information data in the operation process of the physical entity system and transmits the information to the digital twinning system through the network transmission system. A virtual model of a physical entity is established in the digital twinning system, and dynamic analogue simulation of a casting and forging double-control forming process is carried out to realize virtual-real interaction mapping; and meanwhile, key process parameters of the casting and forging double-control forming process are intelligently optimized and adjusted, an optimization scheme is fed back to the production process to guide actual production operation, closed loop of the production process is improved, and management is optimized. The casting and forging double-control forming system is small in equipment and die investment, intelligent and networked productioncan be achieved easily, the mechanical performance and the product precision of workpieces are greatly improved, and the casting and forging double-control forming system has good application value.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI +1

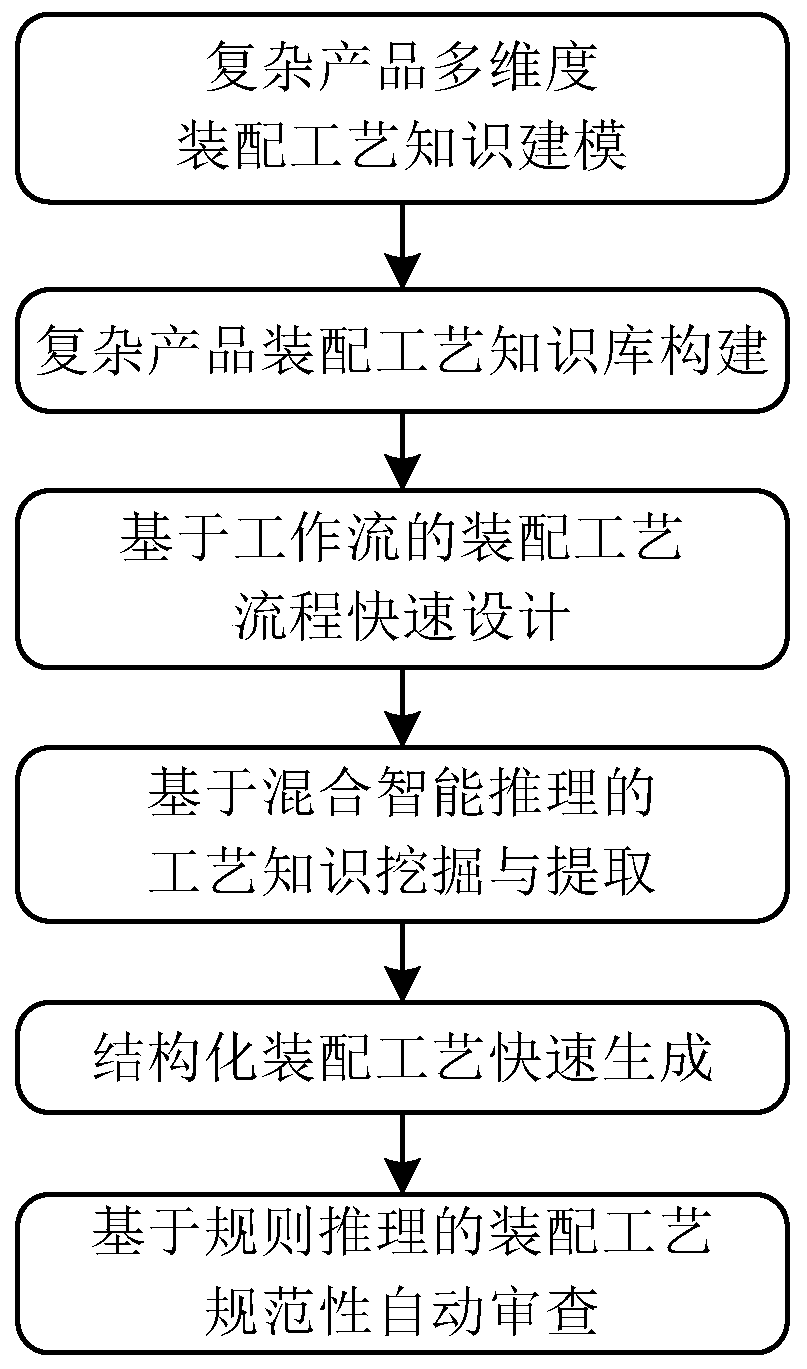

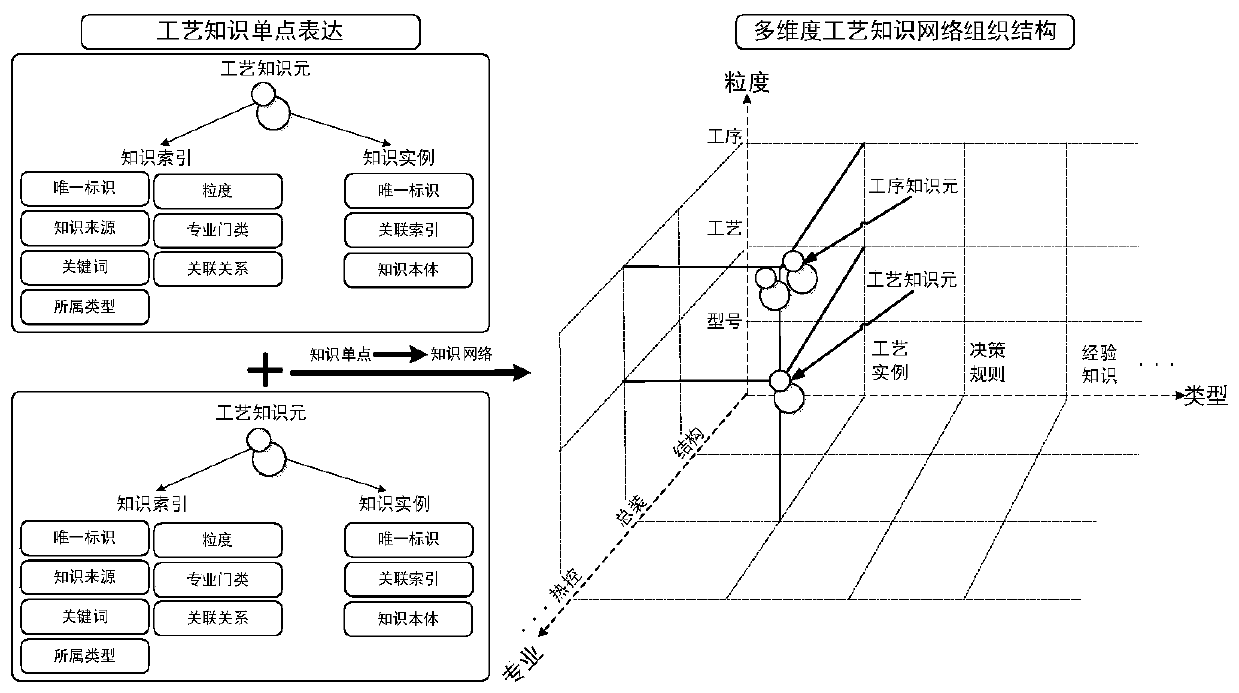

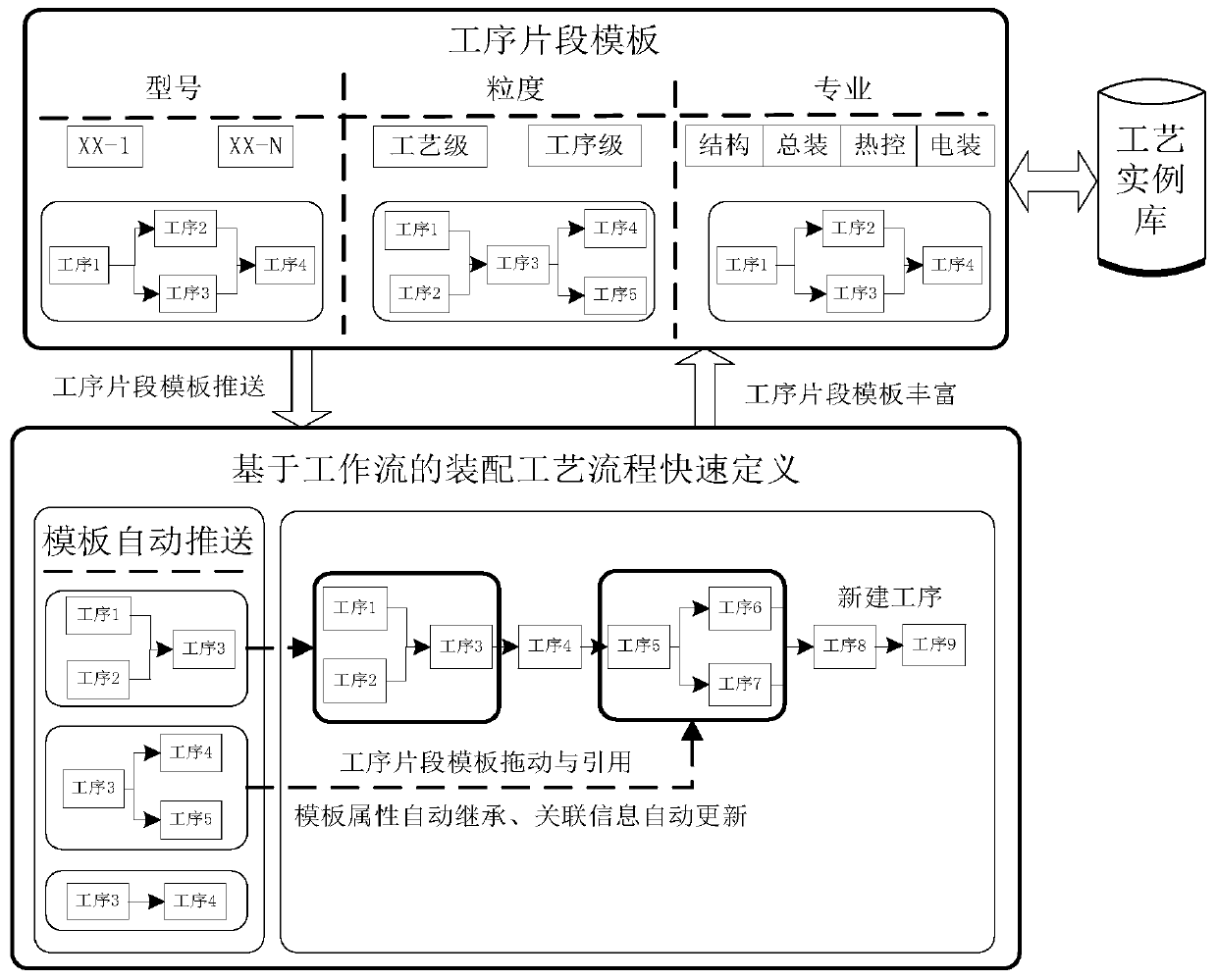

Knowledge-based assembly process design method and system and medium

PendingCN110851499ARapid process designIntelligent assembly process designRelational databasesKnowledge representationProcess engineeringProcess definition

The invention provides a knowledge-based assembly process design method and system and a storage medium. The knowledge-based assembly process design method comprises the following steps: a process knowledge modeling step: constructing an assembly process knowledge model; a process knowledge base building step: building an assembly process knowledge base; a process flow defining step: defining an assembly process flow to obtain an assembly process flow diagram; a process knowledge screening step: screening the assembly process knowledge to obtain an optimal process instance; an assembly processstructuralization step: generating a structuralized assembly process according to the optimal process instance; and a normativity examination step: automatically examining the normativity of the assembly process. Expression, association and storage of a large amount of complex heterogeneous process knowledge are realized, a unified spacecraft assembly process knowledge base is constructed, and knowledge-based rapid process design is supported. Knowledge-based and intelligent assembly process design based on the process flow and knowledge is realized, so that the process design efficiency is greatly improved. The design quality of the process file is effectively ensured.

Owner:SHANGHAI INST OF SATELLITE EQUIP

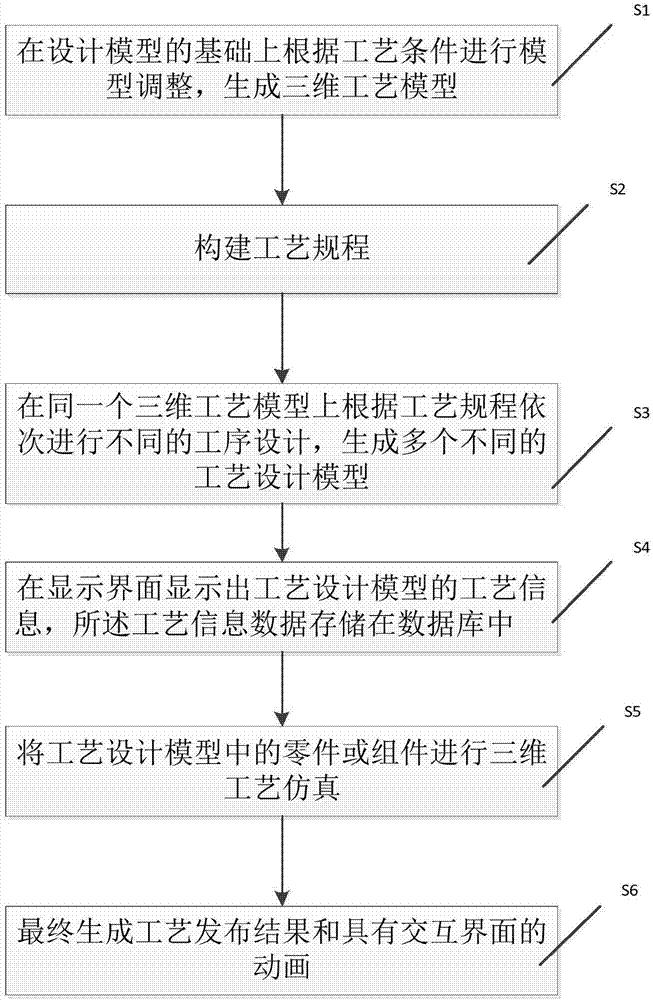

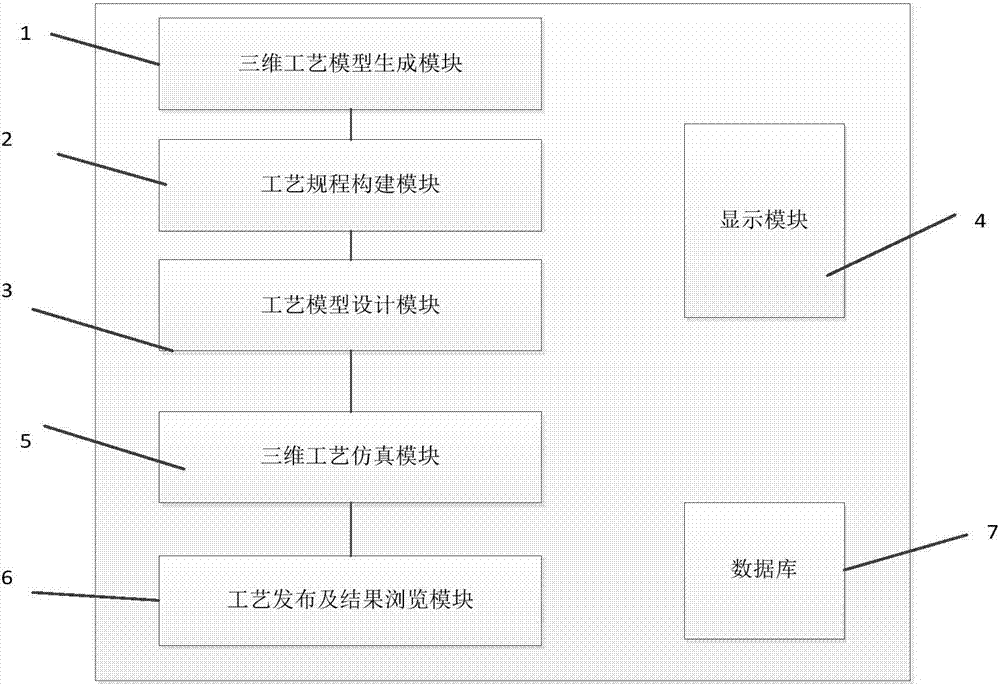

Technology design method based on three-dimensional model and system thereof

PendingCN107392998ASolve the problem that the intermediate state of the product formation process cannot be expressedImprove efficiencyDesign optimisation/simulationSpecial data processing applicationsAnimationIntermediate state

The invention discloses a technology design method based on a three-dimensional model. The method comprises the following steps of based on a design model, according to a technology condition, carrying out model adjusting and generating a three-dimensional technology model; constructing a technological procedure; in the same three-dimensional technology model, according to the technological procedure, successively carrying out different operation designs, classifying the technology models based on operation and generating a plurality of different technology design models; displaying technology information of a technology design model in a display interface, wherein technology information data is stored in a database; carrying out three-dimensional technology simulation on parts or components in the technology design model; and finally generating a technology publishing result and animations possessing an interaction interface. The three-dimensional model is used to visually and accurately describe a formation process of a product from a blank state to a final state; a problem that a traditional two-dimensional technology can not express an intermediate state of a product formation process is solved; characteristics that intuition is good and interactivity is high are possessed; technology design work efficiency is greatly increased; and an optimization degree of a technology design scheme is improved.

Owner:上海湃睿信息科技有限公司

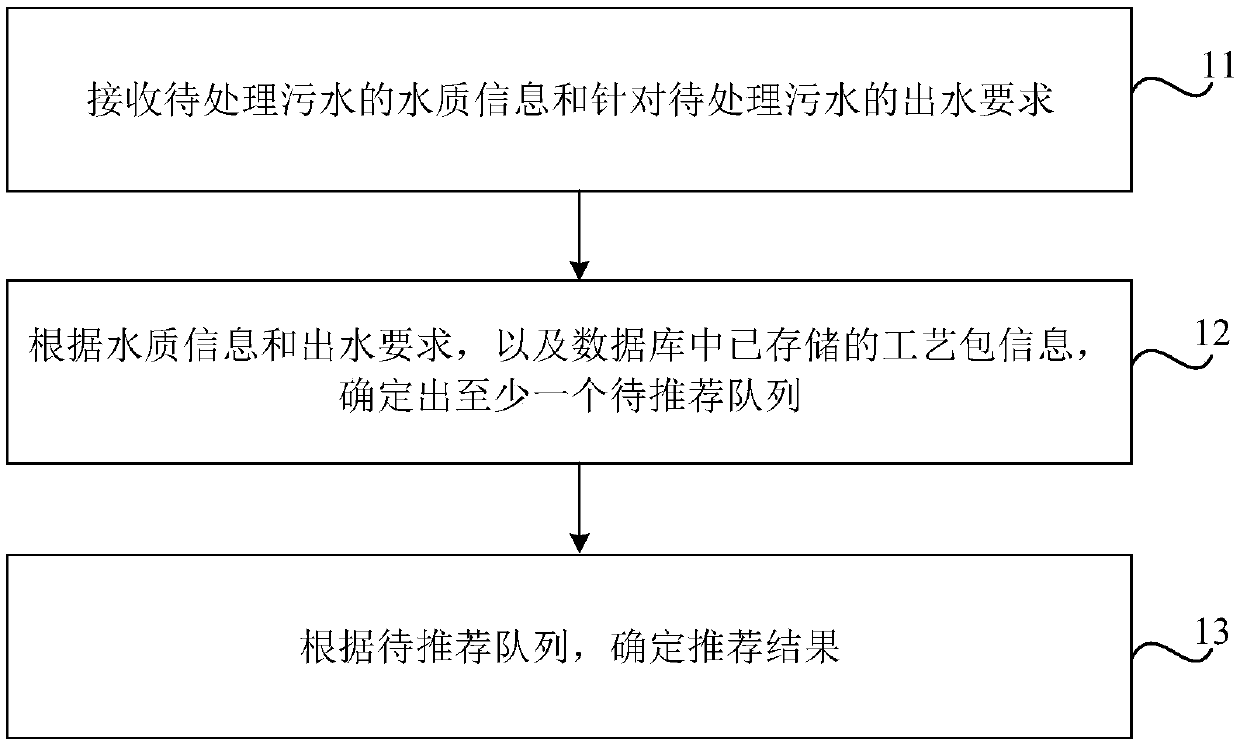

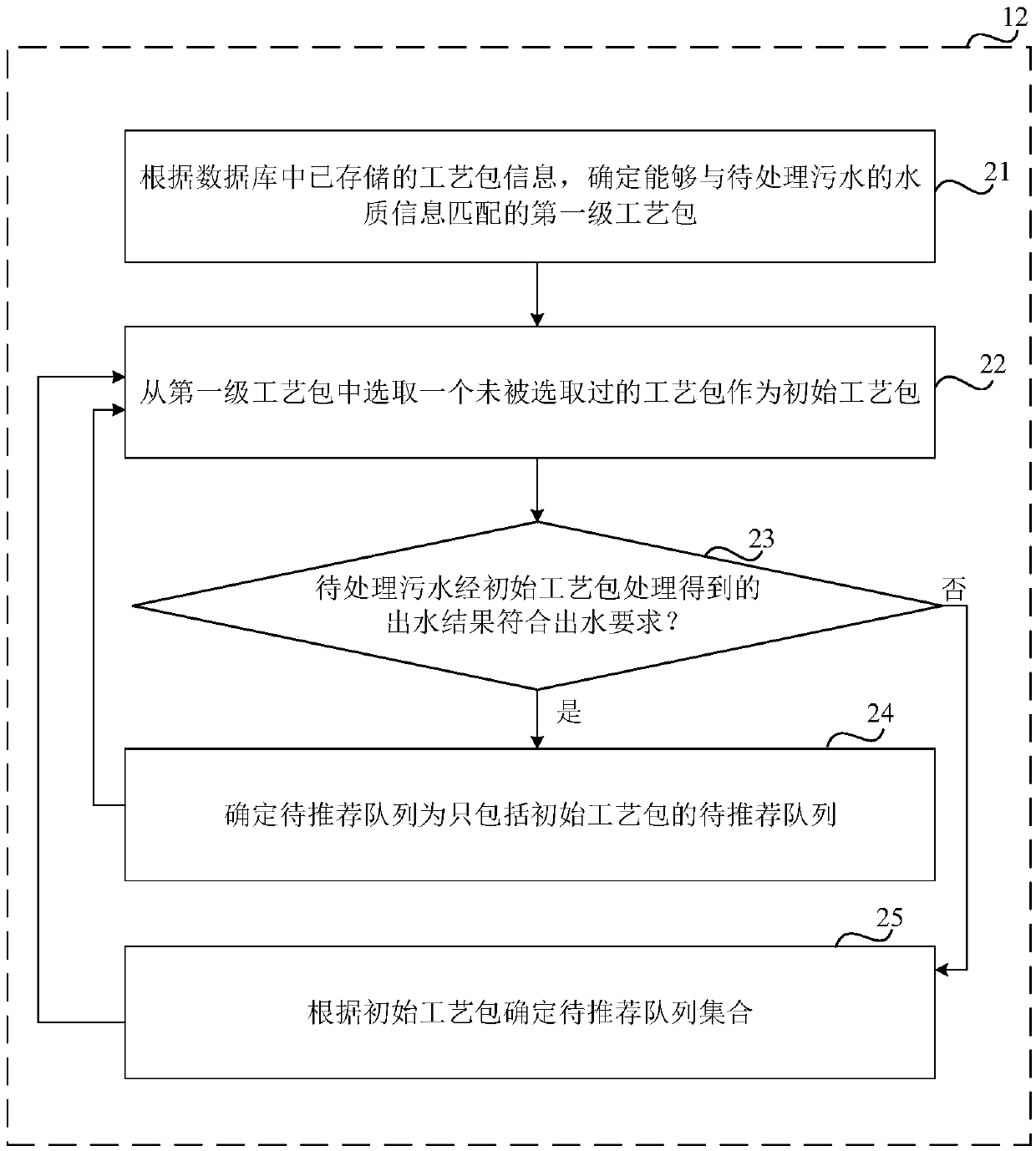

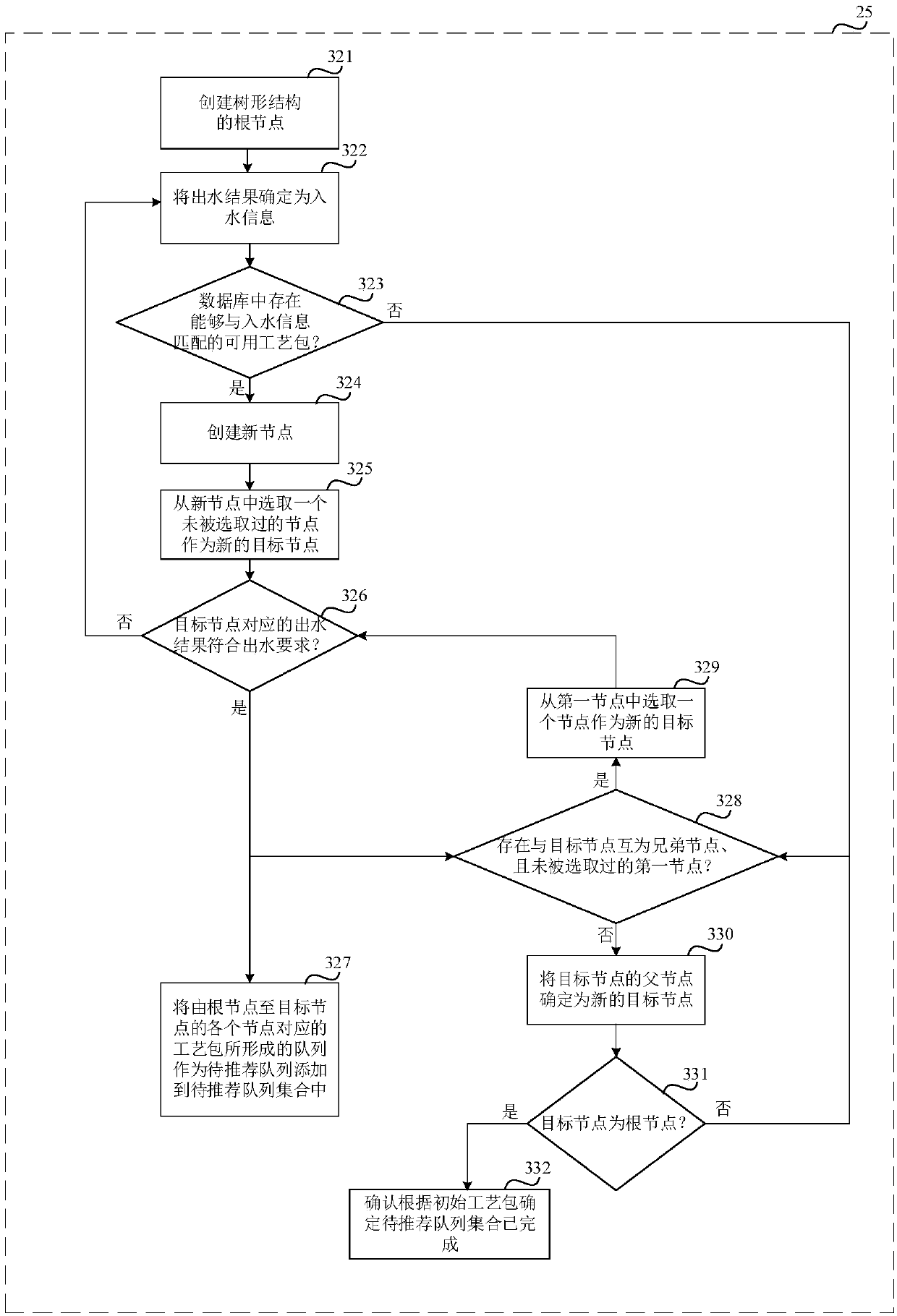

Sewage treatment process recommendation method and device

ActiveCN110968578AImprove experienceImprove process design efficiencyResourcesDatabase indexingWater qualitySewage

The invention relates to a sewage treatment process recommendation method and device. The method comprises the following steps: receiving water quality information of to-be-treated sewage and an effluent requirement for the to-be-treated sewage; water quality information and water outlet requirements are met; and process package information stored in a database, determining at least one to-be-recommended queue, wherein each to-be-recommended queue corresponds to one sewage treatment process flow, each to-be-recommended queue comprises at least one process package and is used for forming the sewage treatment process flow, and the effluent result of the to-be-treated sewage obtained through the sewage treatment process flow corresponding to each to-be-recommended queue meets the effluent requirement; and determining a recommendation result according to the to-be-recommended queues, the recommendation result being used for indicating at least one to-be-recommended queue. Thus, the sewagetreatment process flow capable of meeting the water outlet requirement can be determined according to the water quality information of the sewage and the water outlet requirement, recommendations areautomatically generated for the user for selection, the process design efficiency is improved, and the user experience is improved.

Owner:中建生态环境集团有限公司

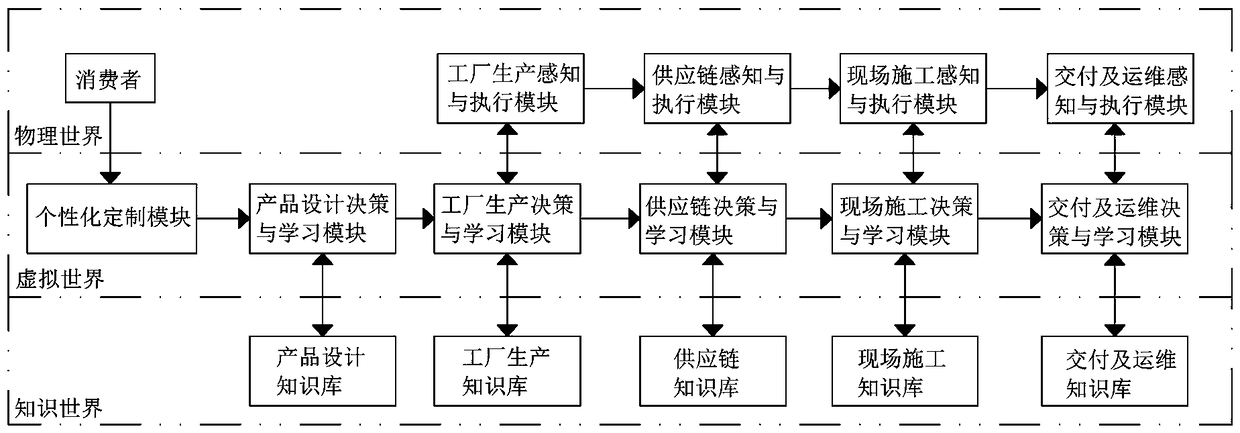

Intelligent constructing system based on CPS

ActiveCN108198093AImprove design efficiencyImprove process design efficiencyData processing applicationsComputer moduleVirtual world

The invention discloses an intelligent constructing system based on CPS (Cyber-Physical Systems). The intelligent constructing system comprises a consumer personalized customization module, a productdesign decision-making and learning module, a factory production decision-making and learning module, a supply chain decision-making and learning module, a site construction decision-making and learning module, a delivery-and-operation-and-maintenance decision-making and learning module, a factory production perceiving and executing module, a supply chain perceiving and executing module, a site assembly perceiving and executing module, a delivery-and-operation-and-maintenance perceiving and executing module, a product design knowledge base, a factory production knowledge base, a supply chain knowledge base, a site construction knowledge base and a delivery-and-operation-and-maintenance knowledge base, wherein the consumer personalized customization module, the product design decision-making and learning module, the factory production decision-making and learning module, the supply chain decision-making and learning module, the site construction decision-making and learning module and the delivery-and-operation-and-maintenance decision-making and learning module belong to the virtual world; the factory production perceiving and executing module, the supply chain perceiving and executing module, the site assembly perceiving and executing module and the delivery-and-operation-and-maintenance perceiving and executing module belong to the physical world; the product design knowledgebase, the factory production knowledge base, the supply chain knowledge base, the site construction knowledge base and the delivery-and-operation-and-maintenance knowledge base belong to the knowledge world. According to the intelligent constructing system based on the CPS, the intelligent computation and analysis capacity of a computer is used for replacing manual empirical judgment or decision,full industry chain designing is achieved, decision-making mistakes in the building construction process are reduced, unnecessary production waste is reduced, the construction period is shortened, the invest is reduced, and the real-time efficiency of building construction engineering is improved.

Owner:墨点狗智能科技(东莞)有限公司

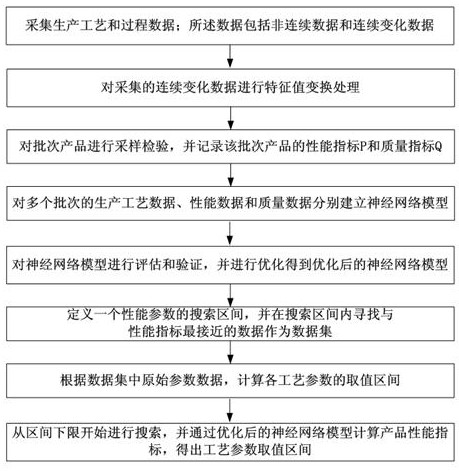

Resin process prediction method and device based on product performance and process data model

InactiveCN113919601AReduce trial production costsImprove stabilityForecastingResourcesData setQuality data

Disclosed is a resin process prediction device based on product performance and process data model which comprises the following steps: collecting a production process and process data; transforming characteristic value of the collected continuous change data; carrying out sampling inspection on batch products, and recording performance indexes and quality indexes of the batch products; respectively establishing neural network models for the production process data, the performance data and the quality data of the plurality of batches; evaluating and verifying the neural network model, and optimizing the neural network model; defining a search interval of a performance parameter, and searching data closest to the performance index in the search interval as a data set; according to the original parameter data in the data set, calculating a value interval of each process parameter; and searching from the lower limit of the interval, and calculating product performance indexes through the optimized neural network model to obtain a process parameter value interval. According to the invention, the problems of difficult optimization of the current production process and low efficiency of the formula experiment process are solved, and the product quality and the performance stability are improved.

Owner:YANTAI JIERUI NETWORK TRADING

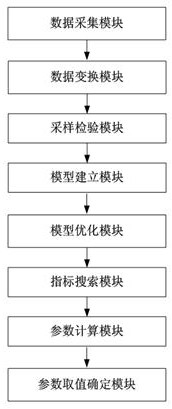

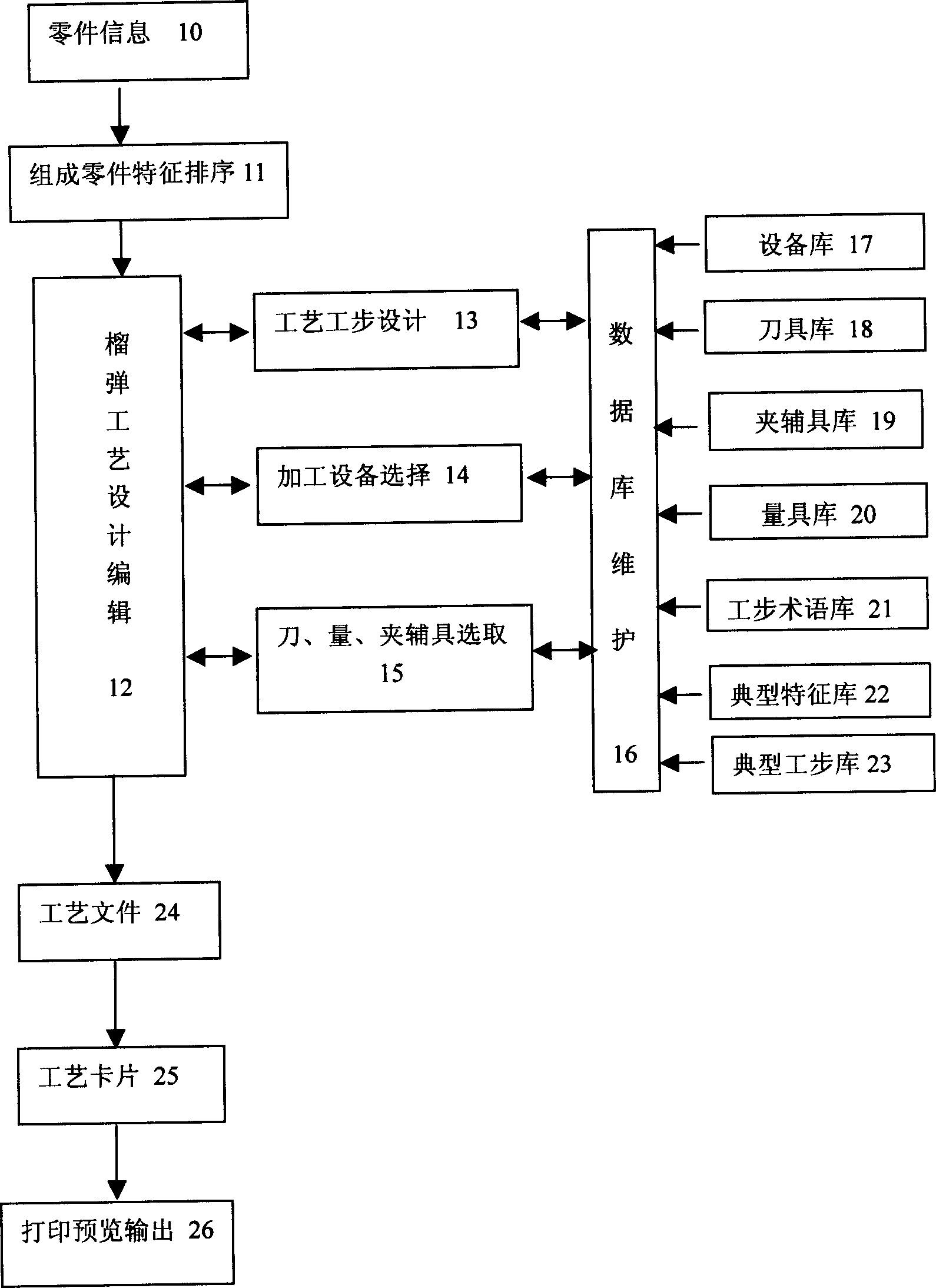

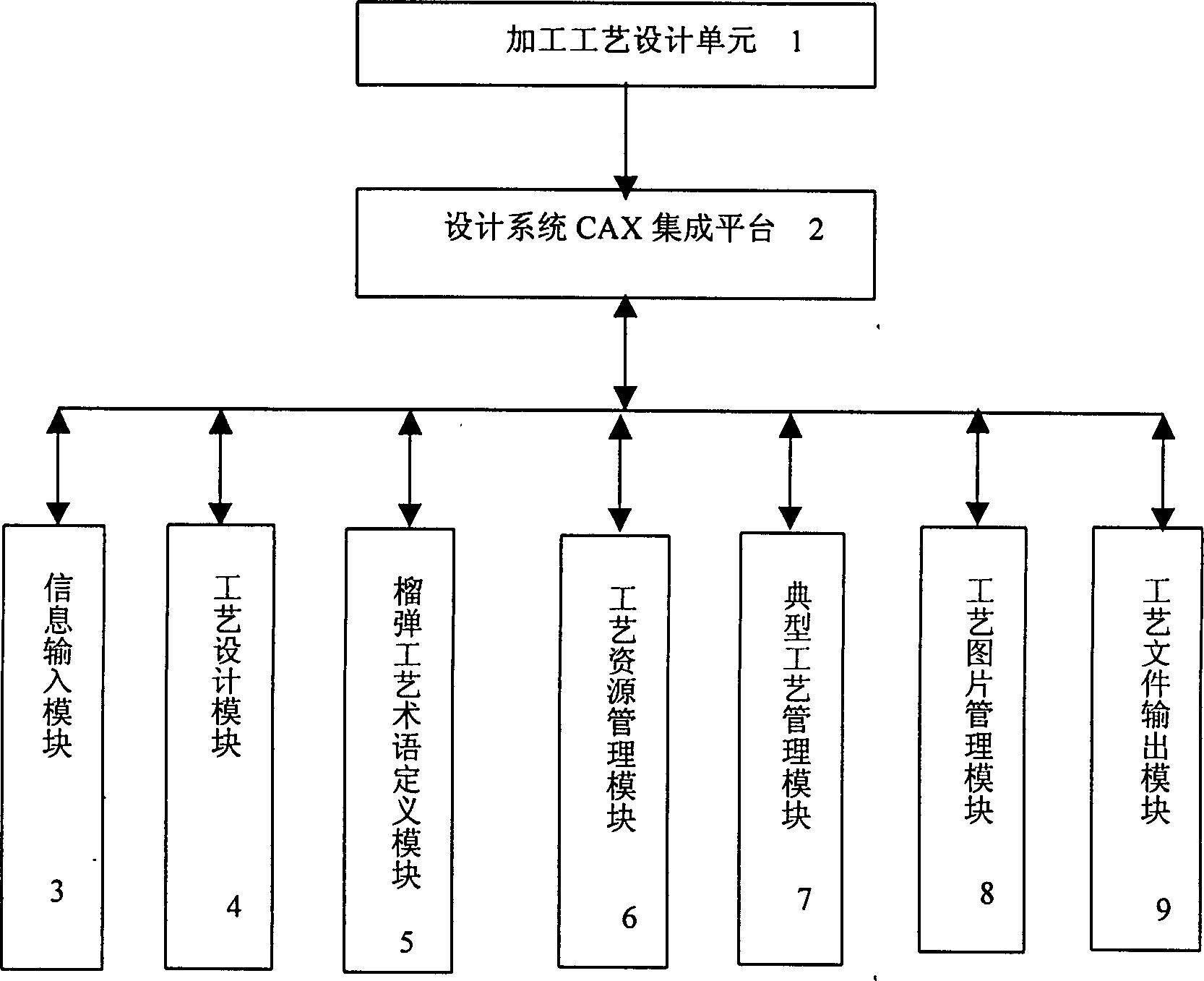

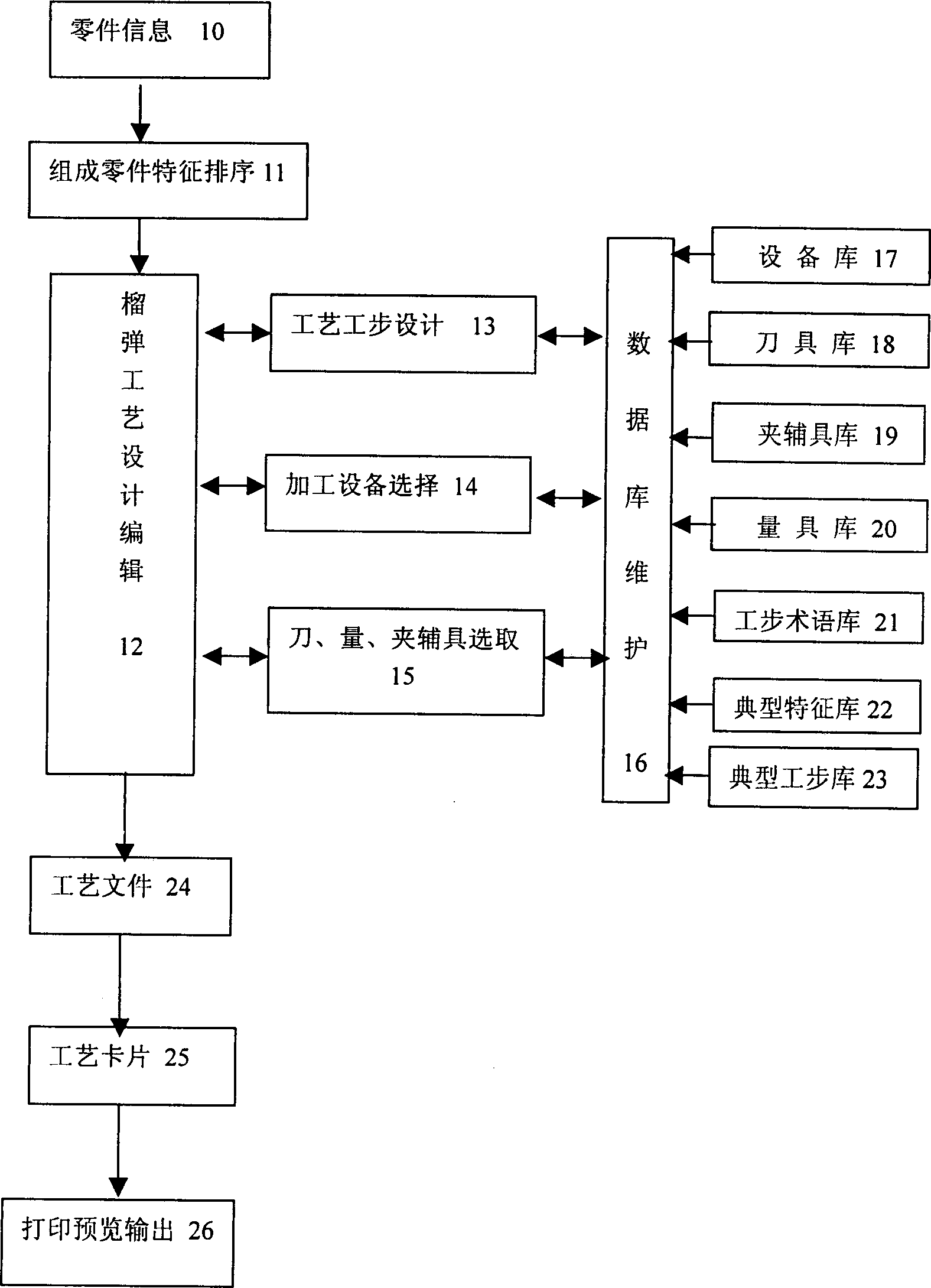

Grenade processing process design system and process design method

InactiveCN1588377AIntelligent processing technology designShorten the process design cycleSpecial data processing applicationsComplete dataRelevant information

The present invention is shrapnel making process design system and method. In the design system, the data are fed from the making process design unit via I / O access module to the design system CAX integrating platform, and the design system CAX integrating platform completes data exchange with information input module, process design module, shrapnel term defining module, technological resource managing module, typical technique managing module, technological photo managing module and technological file outputting module via the data bus. The system creates various technological cards based on relevant information. The present invention has the advantages of high technological design efficiency, high quality, etc.

Owner:SHENYANG LIGONG UNIV

Intelligent kaolin wet powdering method for ceramic raw material

InactiveCN110357572AImprove process design efficiencyIncrease throughputClaywaresProcess equipmentKaolin clay

The invention relates to the technical field of intelligent kaolin wet powdering, and especially relates to an intelligent kaolin wet powdering method for a ceramic raw material. The method comprisesthe following steps: breaking kaolin mineral into powder by utilizing a jaw breaker, wherein the viscosity of kaolin can be changed by adopting a dispersing agent, machining and surface modification and other methods since the increased specific area and increased viscosity of the broken mineral are bad for the subsequent processing; conveying the materials through a double-helix feeding machine,feeding the raw materials into the double-helix feeding machine, and orderly conveying the powdery kaolin mineral to the process equipment of the next step, feeding the kaolin raw material into a pulping unit, wherein the pulping unit is composed of three stages. The method disclosed by the invention has the advantages of being efficient in process design, high in throughput, energy-saving, economic, reasonable and the like; at the same time, the process design is high in cost performance, the fine powder content and yield are guaranteed, the production cost is low, the pollution is small, theinvestment is small, the production efficiency is high, the product quality is stable, and the economic benefit is obvious, therefore, the method is a relatively ideal production mode.

Owner:佛山市万佳德科技有限公司

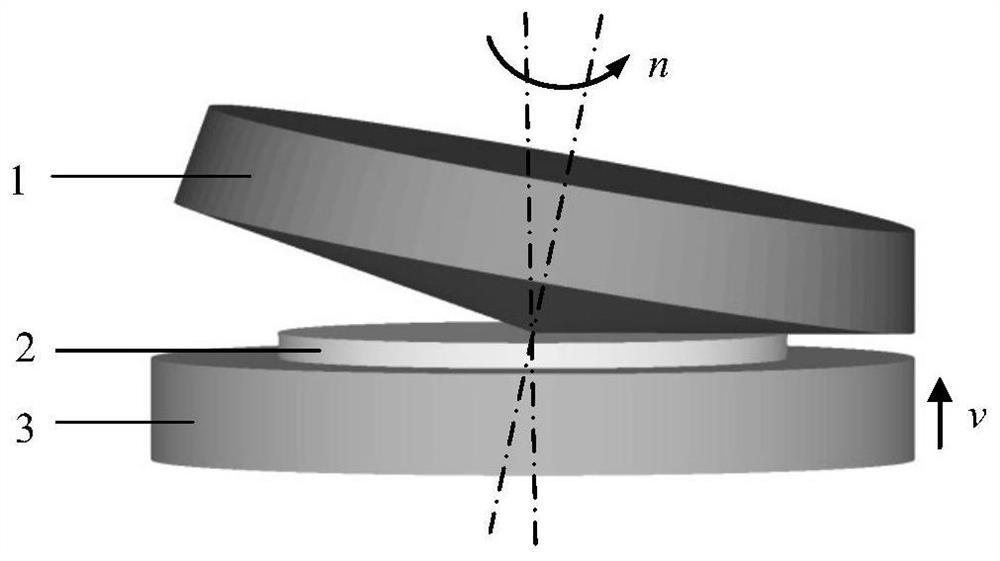

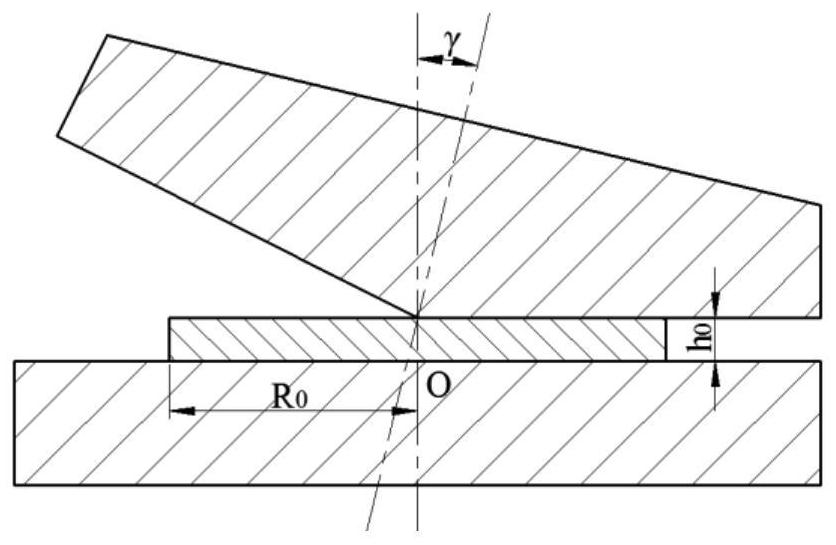

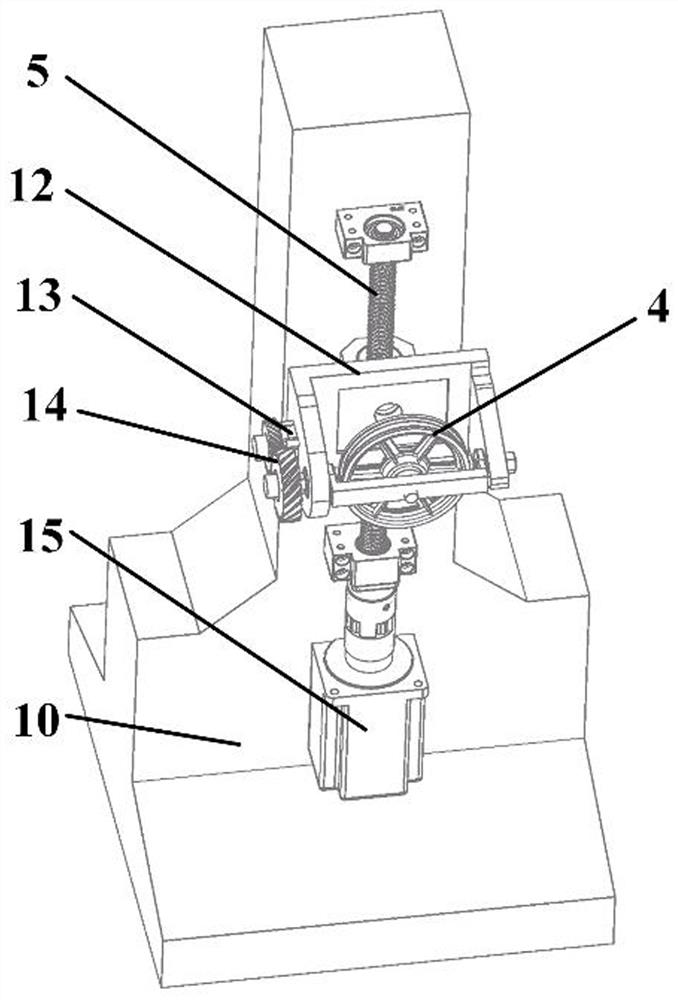

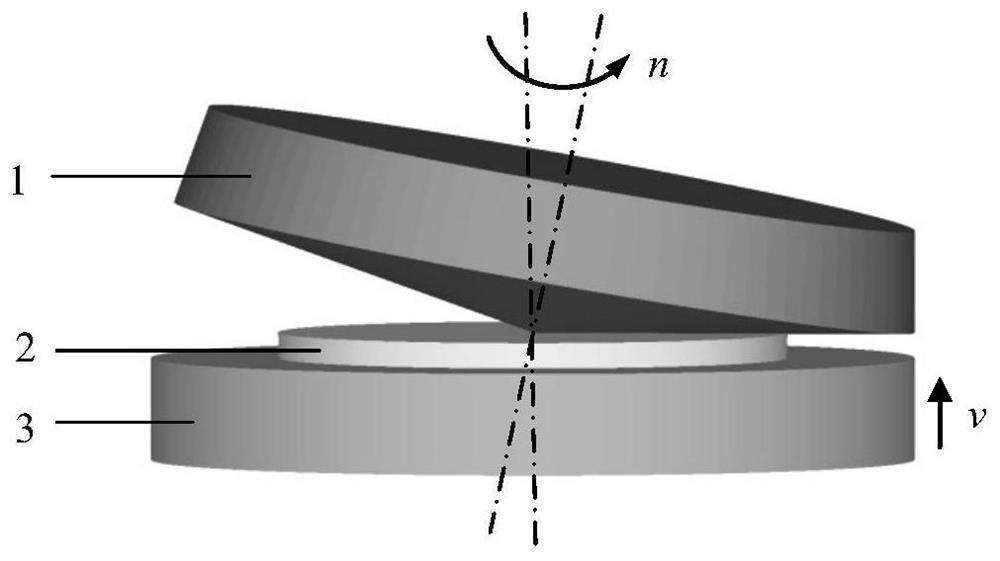

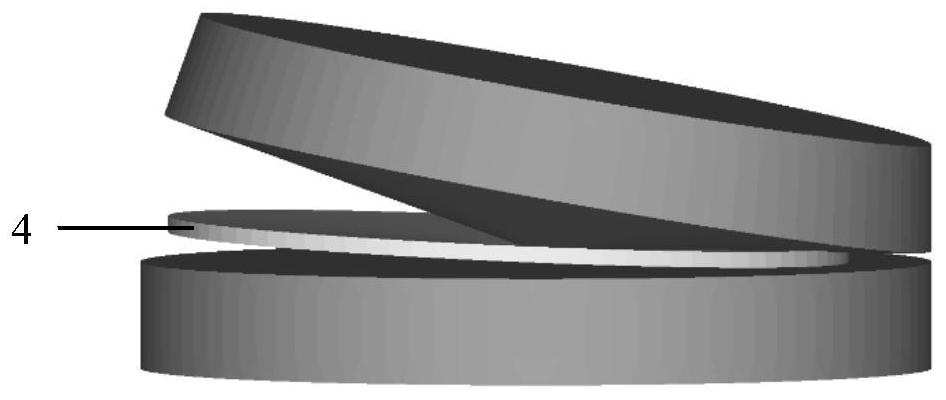

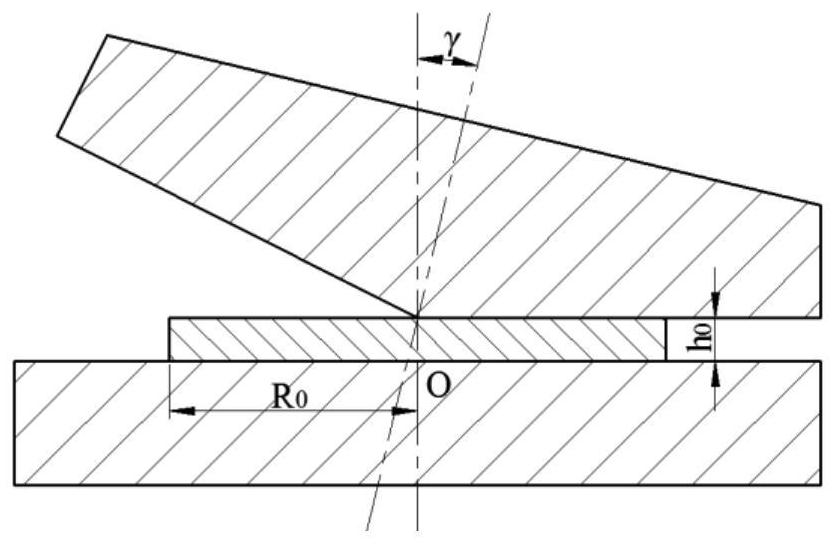

Thin-wall component space envelope forming buckling deformation prediction method

ActiveCN113032908AImprove envelope forming accuracyHigh forming precisionGeometric CADDesign optimisation/simulationMechanical engineeringOptimal design

The invention relates to a thin-wall component space envelope forming buckling deformation prediction method, which comprises the following steps: firstly, determining the geometric dimension of a time-varying contact area between an envelope model and a blank in a space envelope forming process, and calculating the stress of any position of the blank contact area part under a specific coordinate system; and on this basis, calculating the stress of any position of the non-contact area part of the blank, constructing a warping equilibrium differential equation of the non-contact area part of the blank, solving the warping equilibrium differential equation by combining boundary conditions of the non-contact area part of the blank, and obtaining the space envelope forming warping amount of the thin-wall component. According to the method, the spatial envelope forming buckling deformation of the high-performance thin-wall component can be accurately predicted, so that the spatial envelope forming precision of the thin-wall component is improved, and a basis is provided for optimal design of spatial envelope forming process conditions of the thin-wall component.

Owner:WUHAN UNIV OF TECH

Method for determining ideal chemical reinforcement process of high aluminosilicate glass and application thereof

ActiveCN106673459APrecise determination of ideal chemical strengthening processReduce in quantityChemical processes analysis/designSpecial data processing applicationsMaterials scienceAluminosilicate

The invention provides a method for determining an ideal chemical reinforcement process of high aluminosilicate glass. The method comprises the following steps: determining a to-be-satisfied condition 1 of a chemical reinforcement process according to the stress layer depth of target chemical reinforcement glass and by means of a stress layer depth prediction formula DOL=F(t,T); determining a to-be-satisfied condition 2 of the chemical reinforcement process according to the surface microhardness of the target chemical reinforcement glass and by means of a microhardness prediction formula HV=F(t,T); and determining an ideal chemical reinforcement process of high aluminosilicate glass, namely values of the chemical reinforcement time t and the chemical reinforcement temperature T. The invention also provides application of the method in preparation of chemically reinforced high aluminosilicate glass. The method provided by the invention can reduce the sample preparation amount, can lower the preparation cost and testing cost of a sample and can realize accurate prediction of the ideal chemical reinforcement process of high aluminosilicate glass, thereby providing important support for determination of the chemical reinforcement process of high aluminosilicate glass.

Owner:ZHEJIANG UNIV

A Construction Method of Dynamic 3D Process Model

ActiveCN102722614BFastImprove interactivitySpecial data processing applications3D modellingReference modelMachining

The invention belongs to the field of the technological process of a three-dimensional design model, and relates to a method for building a dynamic three-dimensional process model, which is characterized in that the method for building the dynamic three-dimensional process model is carried out according to the following six steps of: reading the design model, and building a technological reference model; automatically calculating the produced blank model, and automatically assembling the produced blank model with the technological reference model at the same position; organizing and managing the technical schedule; dynamically creating processing the characteristic; correlating the technical schedule with the characteristics; and storing the processing information and the model. The method for building the dynamic three-dimensional process model solves the problem that the two-dimensional technological design and the three-dimensional technological design are disjoined at present, and a two-dimensional model is taken to directly guide production and manufacturing, the traditional mode of 'three-dimensional design plus two dimensional' is broken through, and accordingly, the technological design efficiency is obviously improved; and moreover, the manufacturing staff can directly obtain the machining features and the corresponding technological information on the basis of the three-dimensional technological design, so the preparation periods of production and manufacture are greatly shortened, and the production efficiency is improved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Nuclear-related operator path planning method and system based on BIM (Building Information Modeling) technology

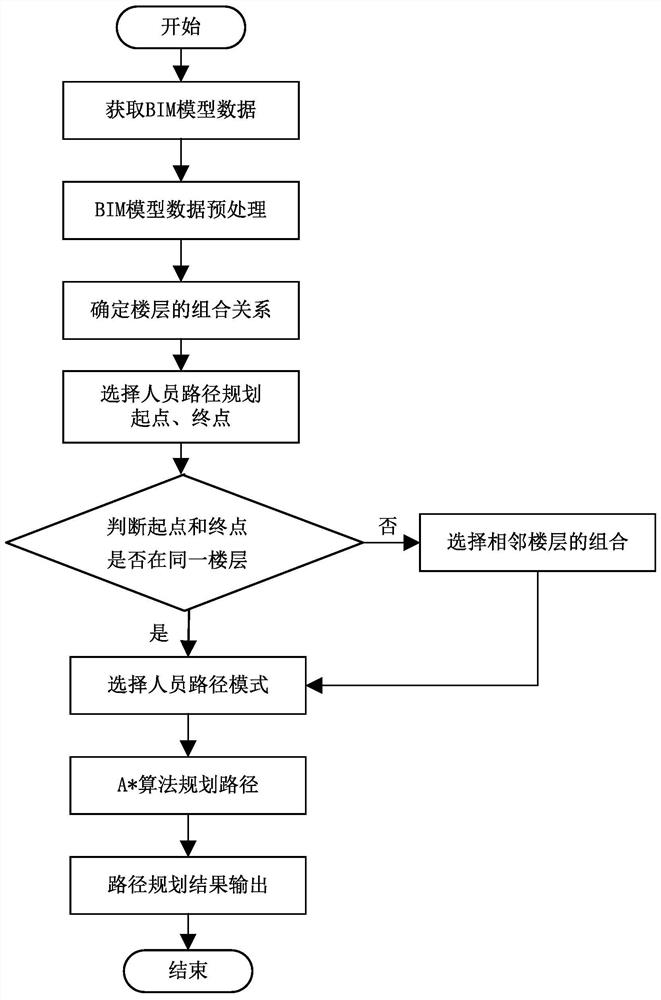

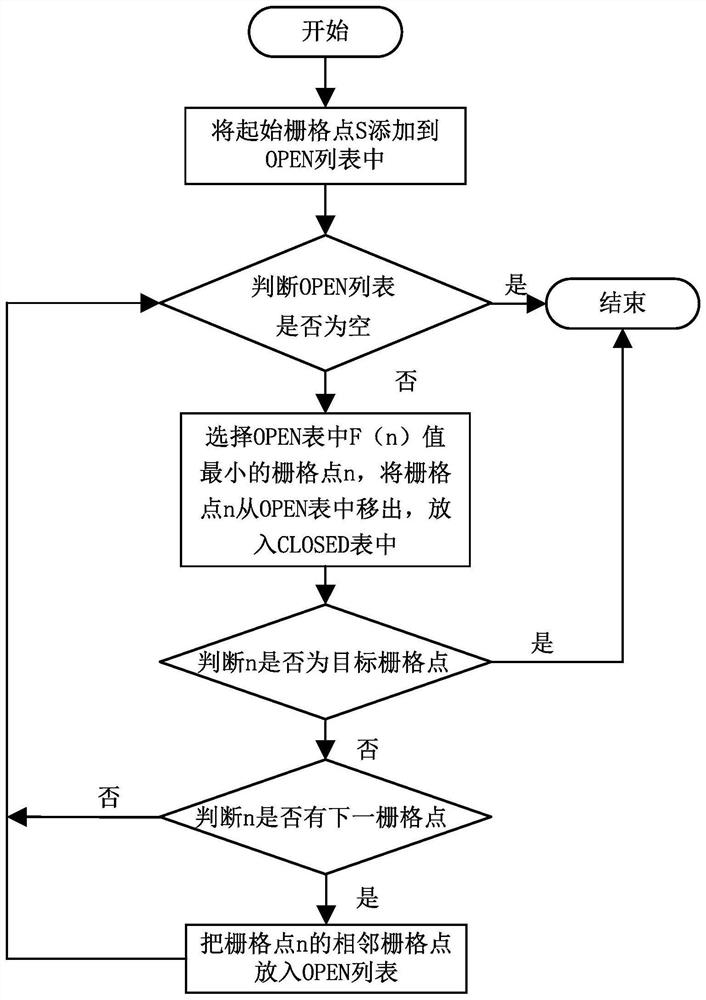

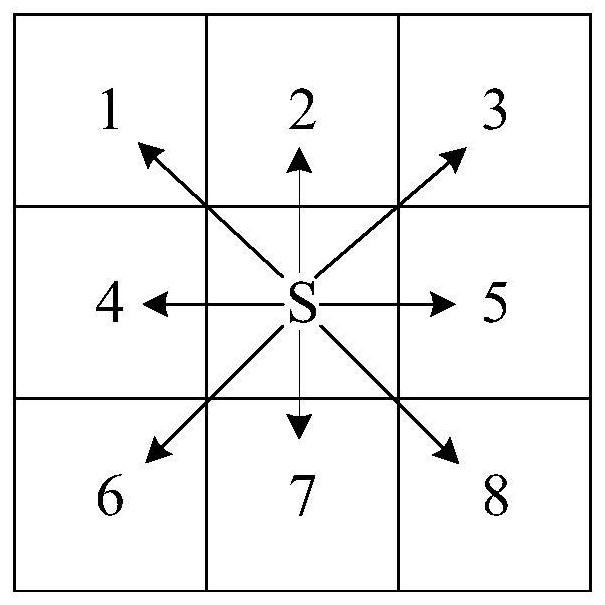

PendingCN113485352AReduce exposure doseProtection securityPosition/course control in two dimensionsVehiclesProcess engineeringIndustrial engineering

The invention discloses a nuclear-related worker path planning method and system based on a BIM technology, and the method comprises the steps: S1, obtaining related parameter data of a nuclear-related plant from a BIM scene model, and carrying out the preprocessing; S2, according to the preprocessed data, the combination relation of nuclear-related plant floors is determined; S3, selecting an operator path planning starting point and an end point according to a combination relation of nuclear-related plant floors; judging whether the starting point and the ending point of the operator are on the same floor, and if so, selecting an operator path planning mode; if not, selecting the combination of the adjacent floors, and then selecting an operator path planning mode; and S4, performing operator path planning by adopting an A* algorithm to obtain a path planning result. According to the method, the walking path of the operating personnel and the exposure dose of the operating personnel are used as evaluation basis, the three-dimensional path of nuclear facility maintenance / retired personnel is planned and optimized, the exposure dose of the personnel is reduced, and the safety of the personnel and the environment is protected.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Technical state linkage method in product manufacturing process

PendingCN110717976AEnsure consistencyGuaranteed validityGeometric CAD3D modellingProcess qualityProduct base

The invention relates to a technical state linkage method in a product manufacturing process. The method comprises the following steps: firstly, designing an interactive integrated interface between aproduct design system and a three-dimensional process design system; establishing a three-dimensional design model of a product based on a product design system, and transmitting an EBOM, a model anda design file in a part model to a three-dimensional process design system through an integrated interface; and when the product data of the product design system is changed, updating the part modelin time, and meanwhile, dynamically updating the three-dimensional process in the three-dimensional process design system through the integrated interface. According to the invention, the three-dimensional model is used as an information carrier, and reasonable data organization is carried out on the three-dimensional model to realize linkage under the technical state change of design data, process data and manufacturing data. The process design period of the product is shortened, the process quality is improved, the loss and cost caused by design errors are greatly reduced, and the process design efficiency is greatly improved.

Owner:内蒙古第一机械集团股份有限公司

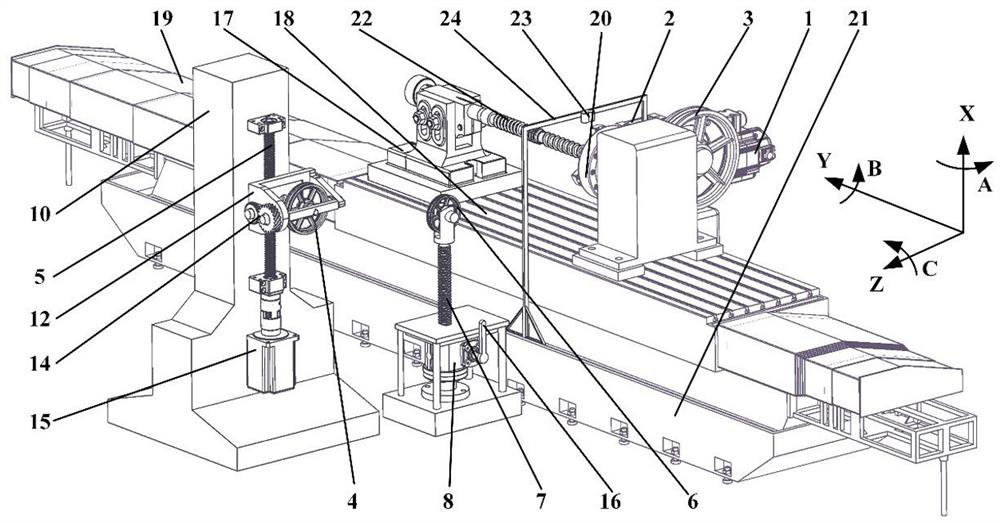

Visual servo feeding special-shaped spiral curved surface screw abrasive belt polishing device and method

ActiveCN114310493AReduce usageReduce purchasesGrinding carriagesBelt grinding machinesPolishingEngineering

The invention discloses a visual servo feeding special-shaped spiral curved surface screw abrasive belt polishing device which comprises a lathe bed and further comprises an abrasive belt driving mechanism, a screw feeding mechanism, a binocular vision collecting mechanism and a data processing unit. The invention discloses a visual servo feeding abrasive belt polishing method for a special-shaped spiral curved surface screw. The method comprises the steps that (1) a whole machine is installed, and a camera is calibrated; 2) acquiring three-dimensional information; 3) calibrating a workpiece coordinate system; 4) thread segment segmentation; the special-shaped screw rod polishing machining method has the advantages that good feasibility is achieved, the special-shaped screw rod polishing machining method can meet the market requirements of small-batch production, automation, high precision and high efficiency of current special-shaped screw rod polishing machining, and the competitiveness of enterprises is effectively improved in the aspects of production flexibility, machining efficiency, environmental protection and economic benefits.

Owner:YANGZHOU UNIV

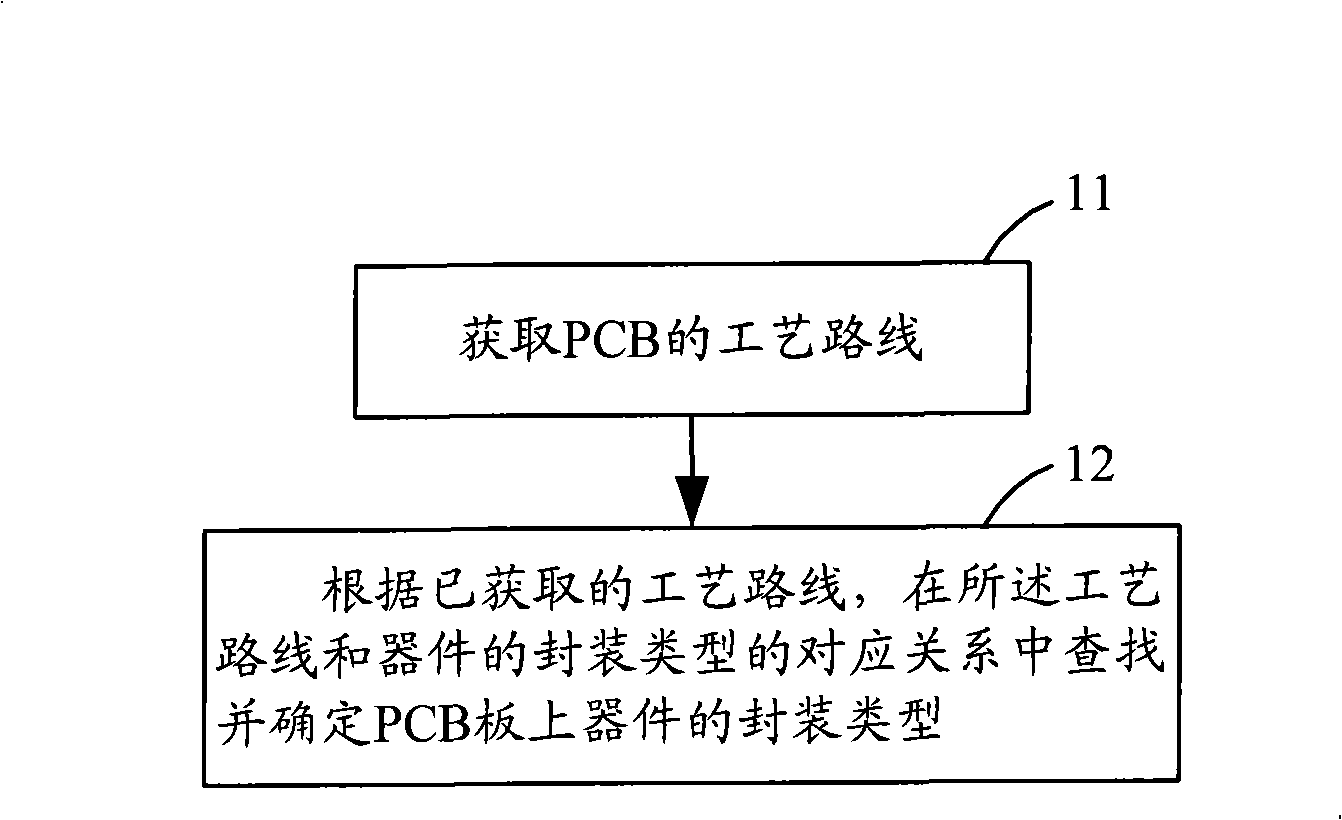

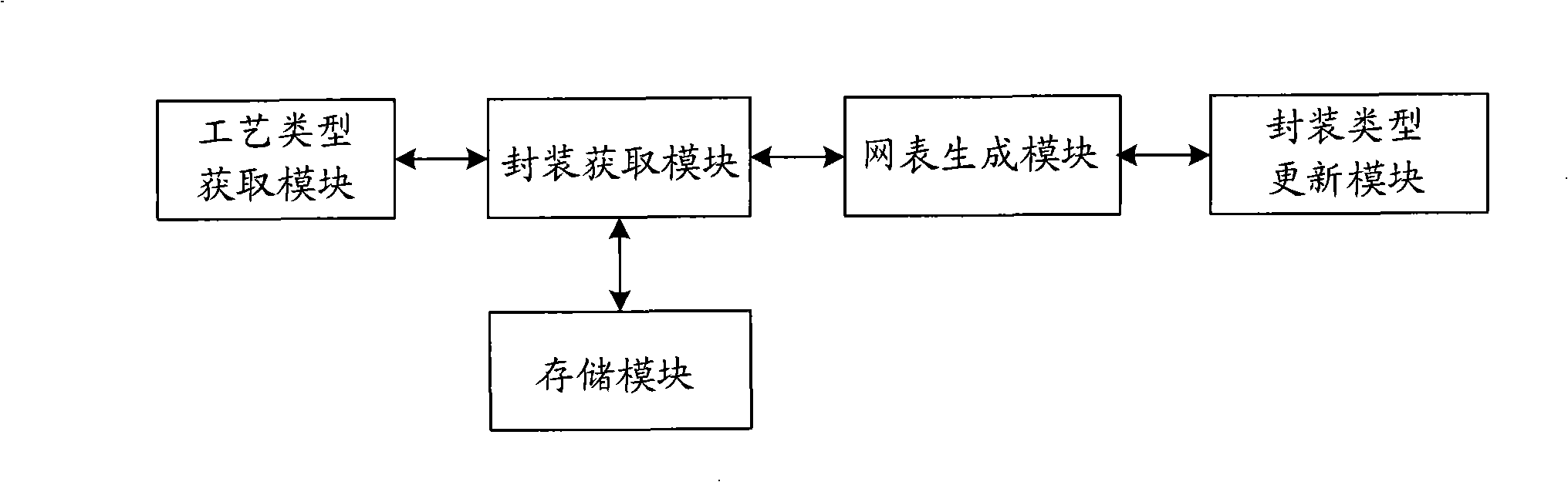

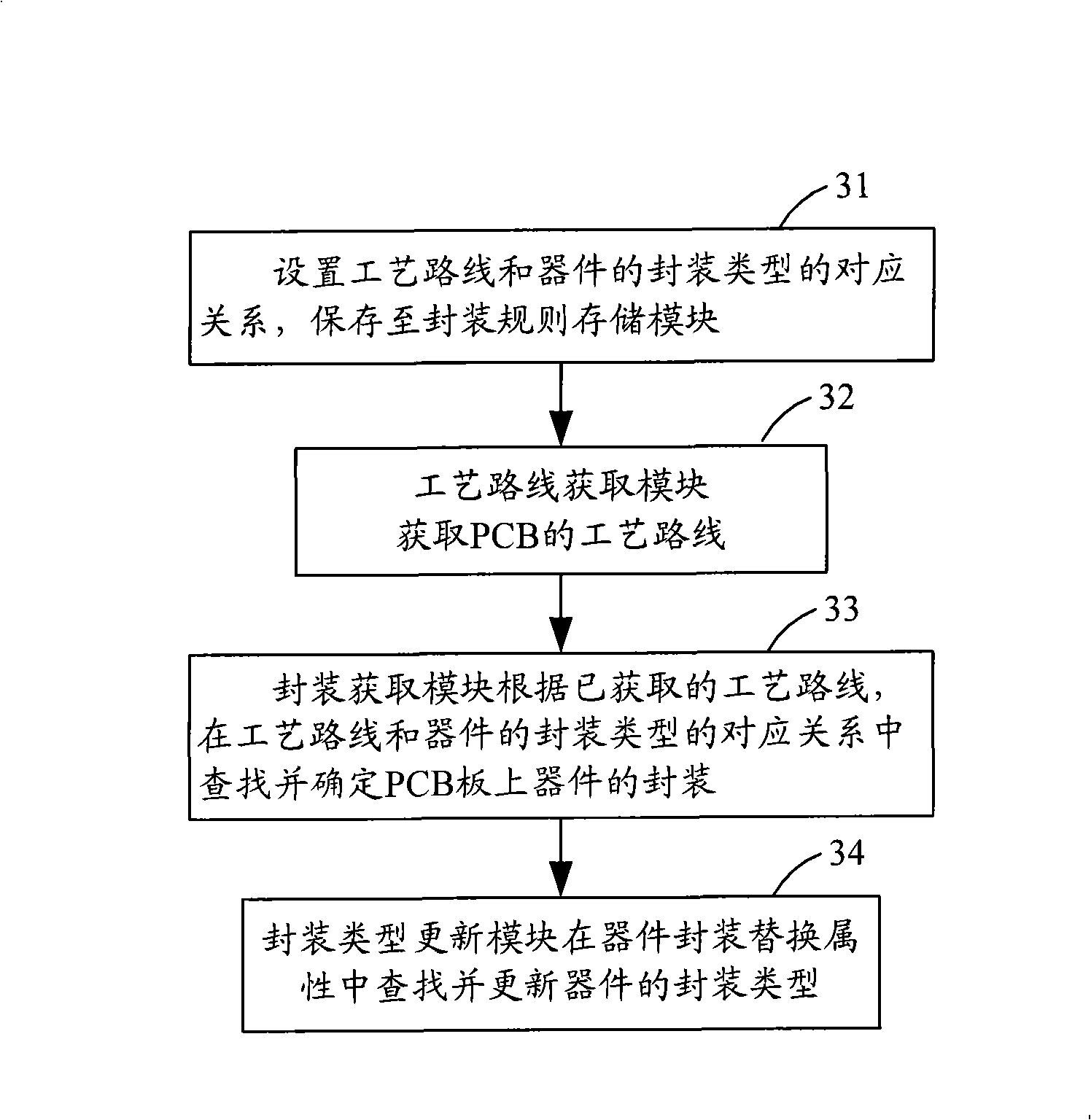

Method and device for obtaining device packaging types

InactiveCN101339573AFlexible process designImprove efficiencySpecial data processing applicationsEmbedded systemPrinted circuit board

The invention discloses a method for acquiring the encapsulation types of a device. The method comprises acquiring the types of technology of a printed circuit board (PCB), and searching and determining the encapsulation types of the device arranged on the PCB in the corresponding relation of the types of technology and the encapsulation types of the device according to the acquired types of technology. The invention also discloses a device for acquiring the encapsulation types of the device. By adopting the invention, the process route of the PCB can be acquired in the process of designing the schematic diagram and the encapsulation types of the device can be determined according to the acquired process route, thus satisfying the need of PCB process design and improving the efficiency and the quality of the PCB process design.

Owner:HUAWEI TECH CO LTD

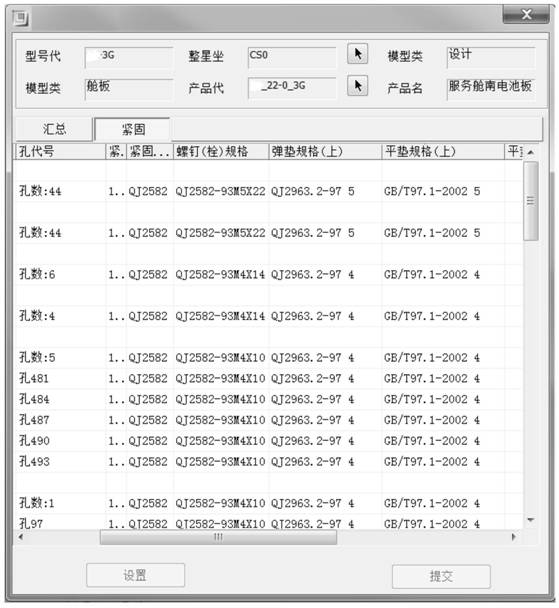

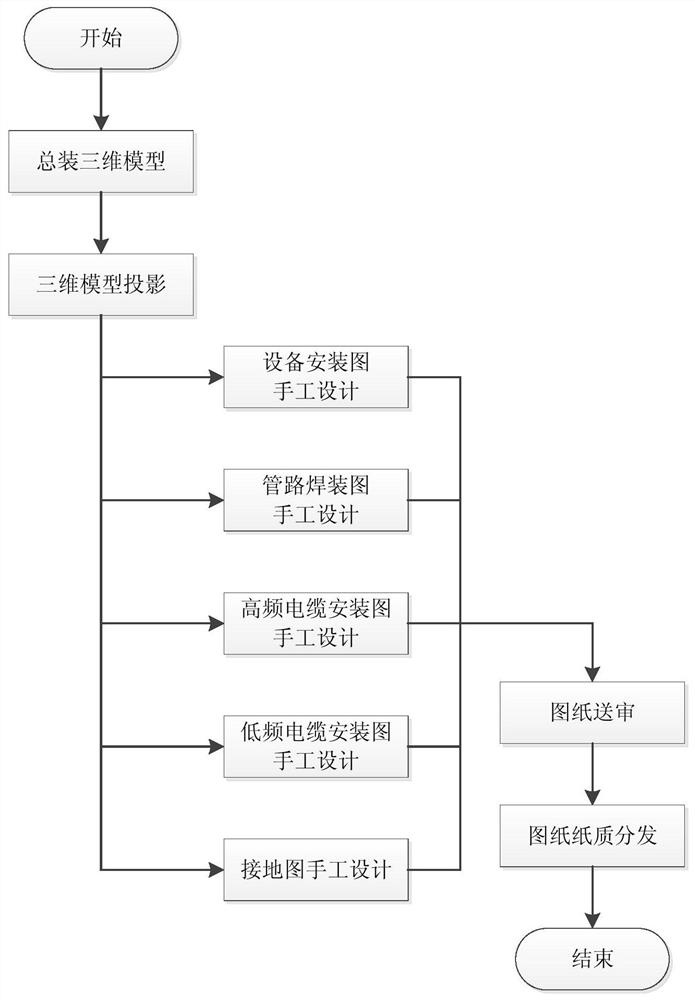

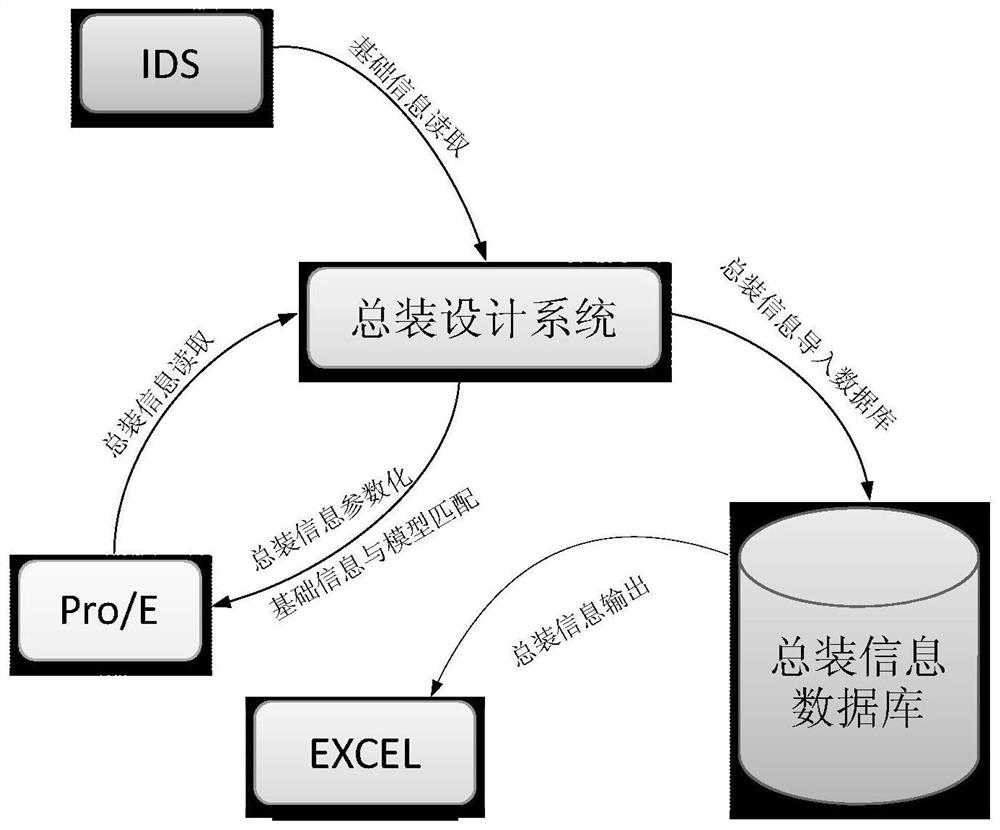

General assembly design system and spacecraft general assembly design information control method

PendingCN113420365AImprove acquisition efficiencyImprove accuracyGeometric CADSpecial data processing applicationsInformation controlGeneral assembly

The invention discloses a general assembly design system and a spacecraft general assembly design information control method. A basic information reading module in the system obtains basic information of equipment from an IDS system; the cabin plate assembly is used as a general assembly design unit, and the general assembly design unit is opened in PRO / E; the general assembly information setting module traverses the PRO / E model tree, identifies all equipment models and support models in the final assembly design unit and creates corresponding final assembly parameters, matches the identified equipment model with the read basic information, determines the basic information of all the equipment models, receives input basic information of the support model, determines general assembly parameter value according to all the basic information, and assigns the general assembly parameter values to the corresponding equipment model and the support model and stores the general assembly parameter values; the general assembly information reading module reads general assembly parameter values from the equipment model and the support model opened by the PRO / E, and displays the general assembly parameter values in a preset form; and the general assembly information output module outputs the general assembly parameters and parameter values stored by the general assembly information setting module to a general assembly information database for storage.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

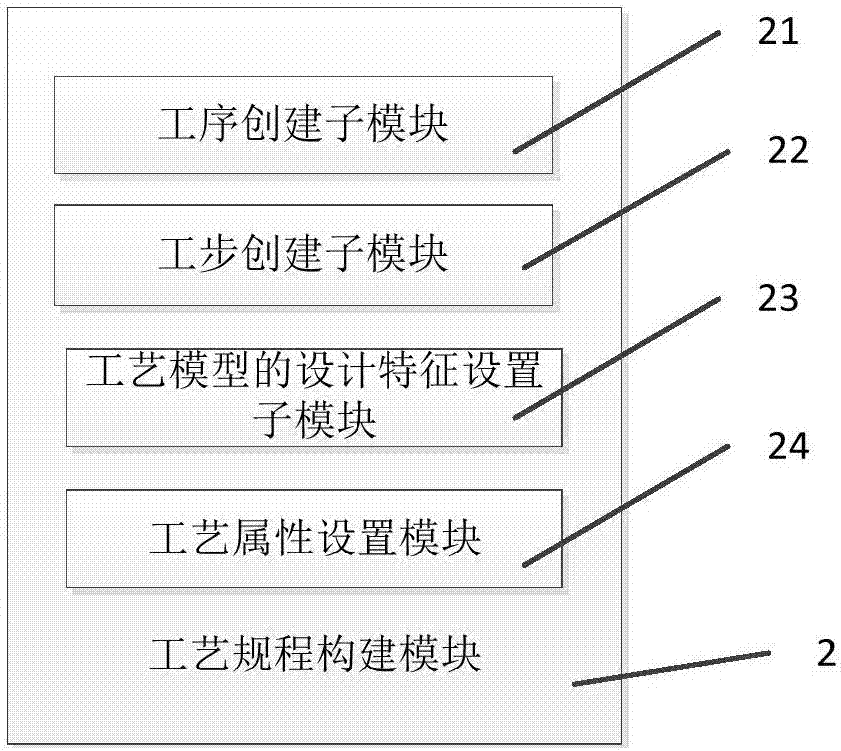

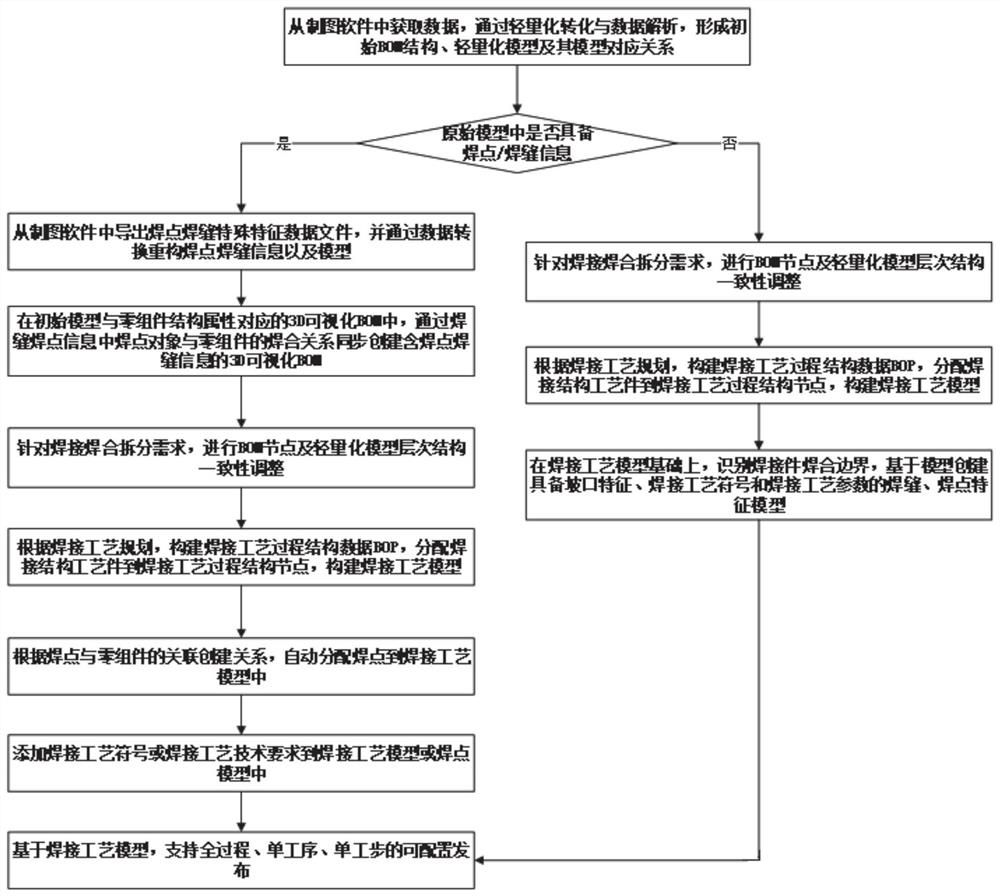

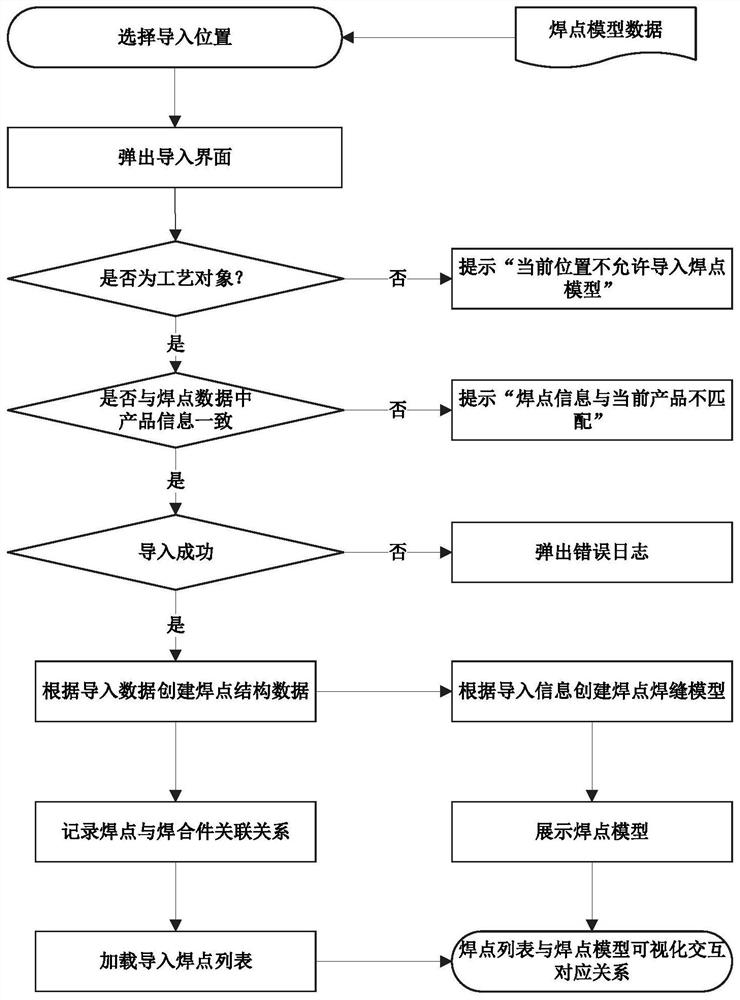

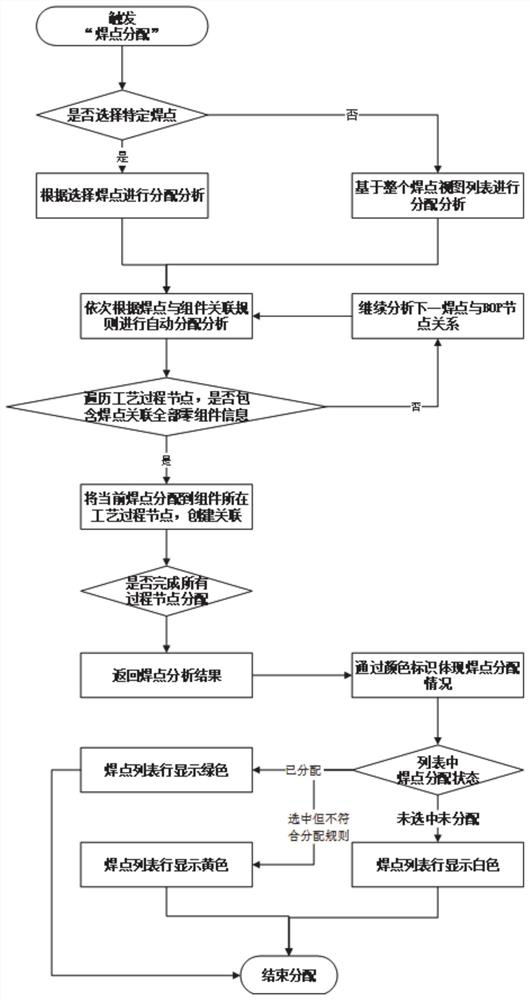

MBD-based welding process modeling and process design method and system

PendingCN113868804AImprove process design efficiencyProcess knowledge accumulationGeometric CADDesign optimisation/simulationProcess engineeringIndustrial engineering

The invention belongs to the technical field of digital processes, and provides a MBD-based welding process modeling and process design method and system, and the system comprises a welding process model based on MBD and a welding process modeling system based on MBD. The MBD-based welding process model realizes consistent expression, storage and management of welding services, and the MBD-based welding process modeling system realizes specific PBOM establishment, welding model definition, visual interaction and output; and rapid addition, deletion, modification and check and visual interaction of the three-dimensional welding process model can be achieved, inheritance and application expansion of the MBD model from design to process are achieved, and a welding feature construction and expression method based on a lightweight model is provided in the field of welding process design application.

Owner:山东山大华天软件有限公司

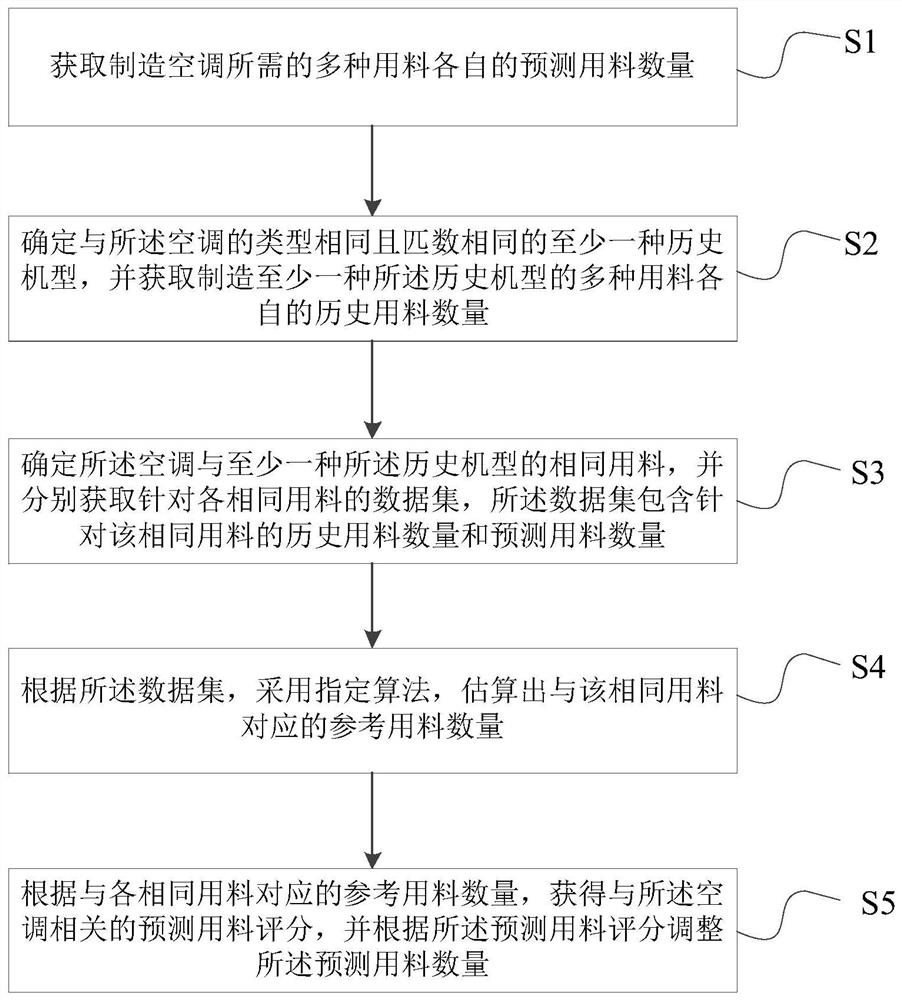

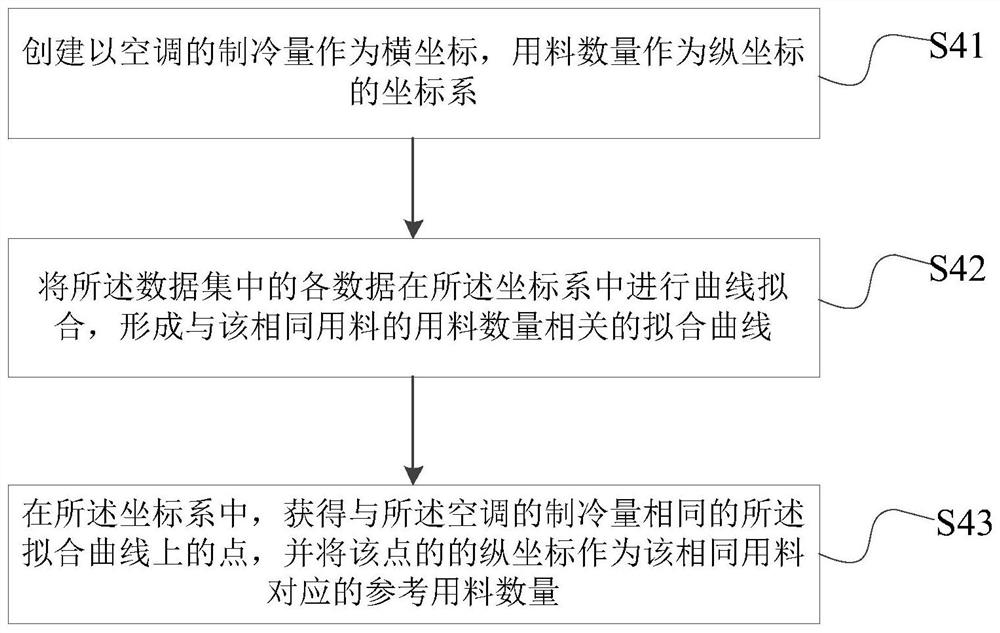

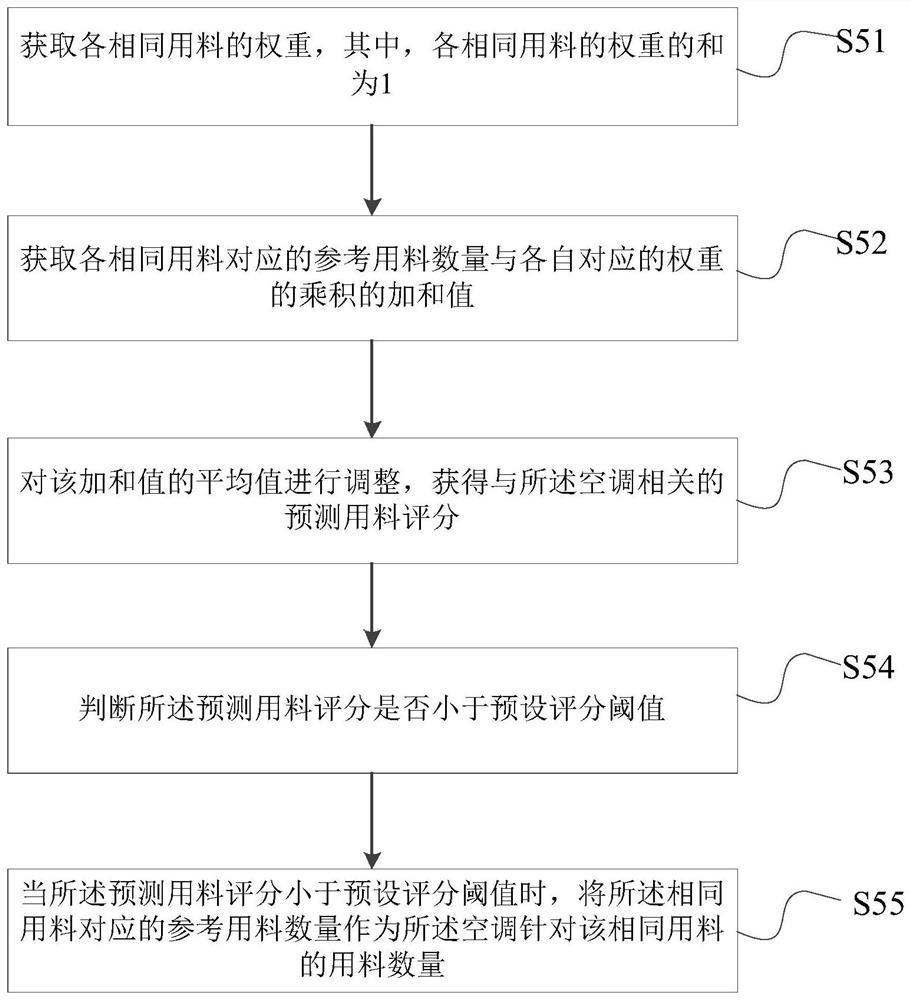

Method, system and storage medium for forecasting air-conditioning materials

ActiveCN111105151BThe quantity is accurate and reasonableSave on estimated costsResourcesManufacturing computing systemsHistorical modelData set

The present invention provides a method, system, and storage medium for forecasting air-conditioning materials. The method includes: obtaining the predicted quantities of various materials required for manufacturing air-conditioners; determining at least A historical model, and obtain the historical material quantities of various materials used to manufacture at least one of the historical models; determine the same materials for the air conditioner and at least one of the historical models, and obtain For each data set of the same material, the data set includes the historical material quantity and the forecast material quantity for the same material; according to the data set, use a specified algorithm to estimate the reference corresponding to the same material Quantity of materials used: According to the quantity of reference materials corresponding to the same materials, a predicted material score related to the air conditioner is obtained, and the predicted material quantity is adjusted according to the predicted material score. The invention makes the quantity of air-conditioning materials accurate, saves the estimated cost, and improves the estimated efficiency.

Owner:GREE ELECTRIC APPLIANCES INC +1

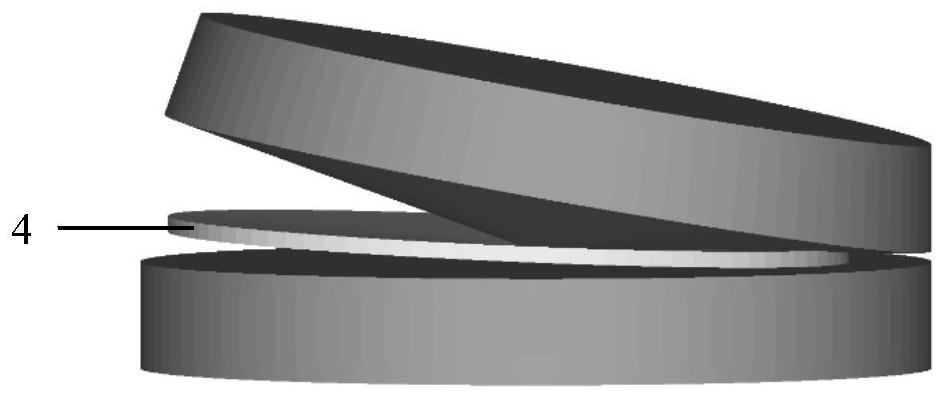

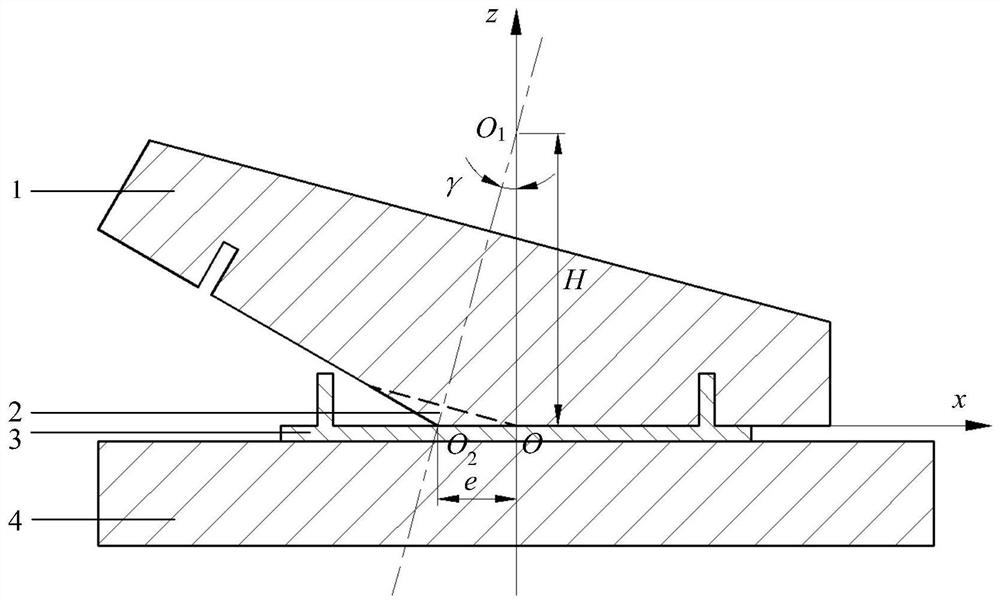

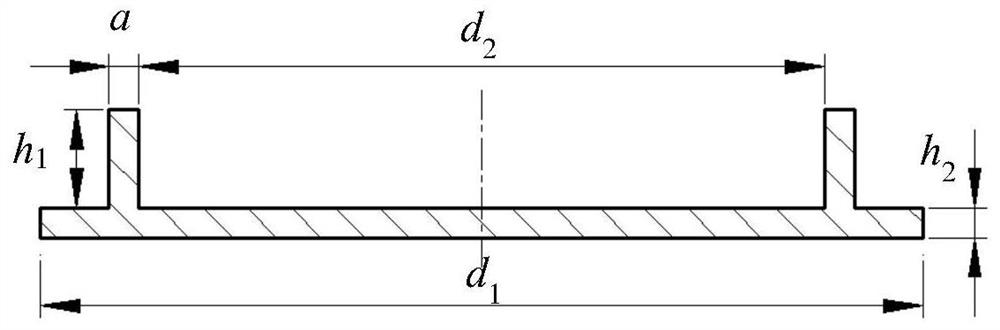

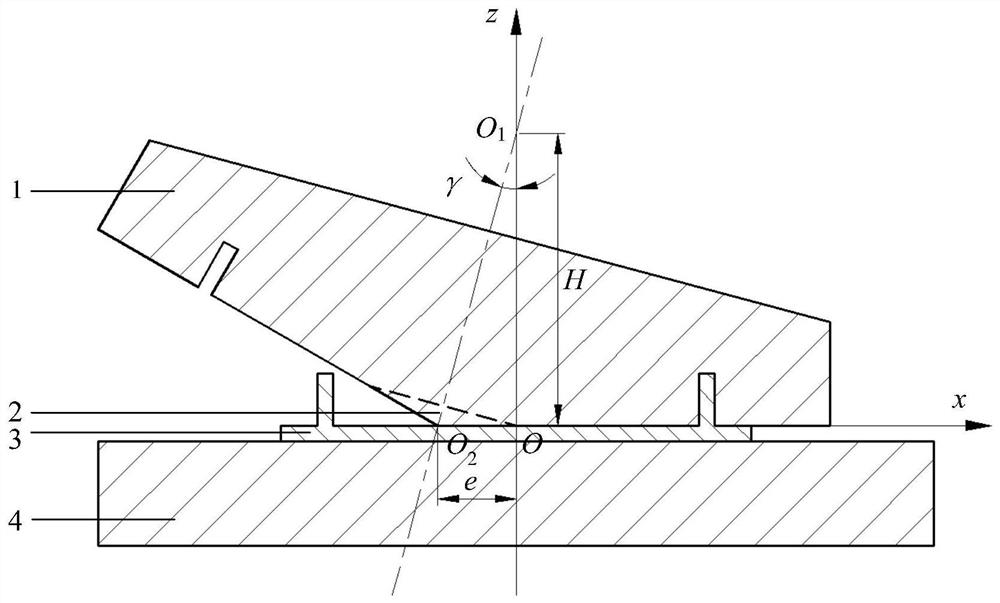

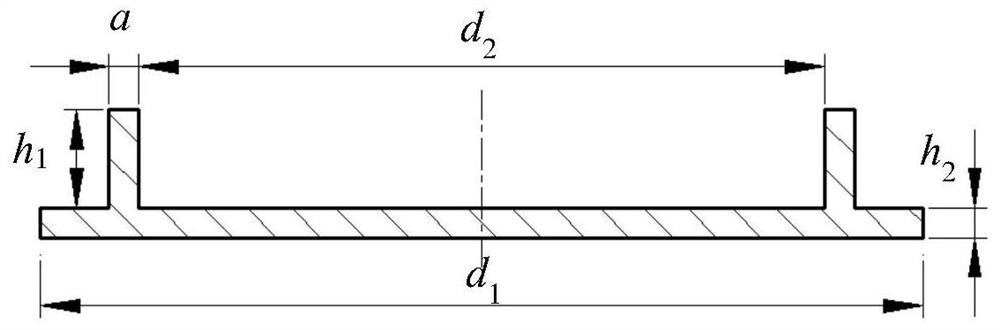

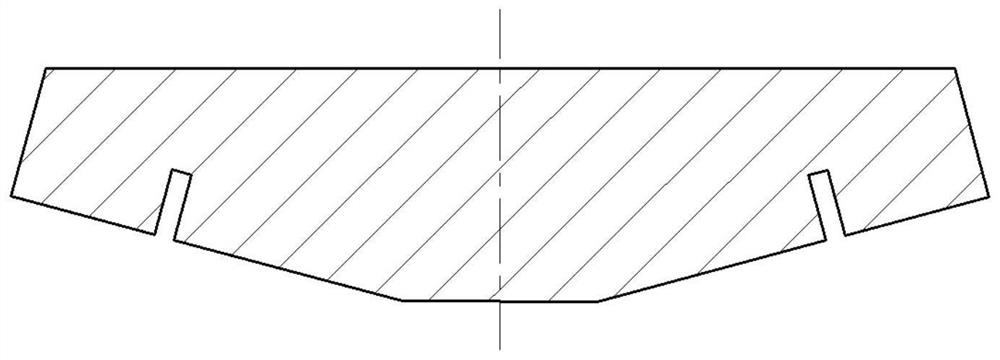

Warping deformation control method of space envelope forming of thin-walled components

ActiveCN113065210BIncrease contactPrecise control of forming warpageGeometric CADSpecial data processing applicationsEngineeringDeformation control

The invention relates to a method for controlling warpage deformation of a thin-walled component space envelope forming, comprising the following steps: S1, establishing a rectangular coordinate system; S2, enveloping center O of the envelope mold 1 On the z axis, the center of the envelope mode envelope O 1 The distance between the coordinate origin O and the coordinate origin O is H; S3, the offset of the envelope mold cone point; S4, the design of the main part of the envelope mold; S5, the design of the front part of the envelope mold; S6, the optimization of process parameters; S7, the thin-walled component space Warpage deformation control in envelope forming; plastic deformation with reduced wall thickness and increased diameter occurs during the envelope forming process of thin-walled components. The contact area between the main part of the envelope mold and the blank is on the side of the central axis, and the front end of the envelope mold The contact area between the part and the blank is on the other side of the central axis, so that the warpage deformation control of the space envelope forming of the thin-walled member can be realized. The invention can realize precise control of warping deformation of the thin-walled component space envelope forming, and further improve the space envelope forming precision and yield of the thin-walled component.

Owner:WUHAN UNIV OF TECH

3D process design method and platform for typical automotive machined parts based on mbd

ActiveCN109117560BDesign specificationGuaranteed accuracyGeometric CADConfiguration CADMachine partsComputer-aided

The invention belongs to the technical field of computer-aided process design, and discloses an MBD-based three-dimensional process design method and platform for typical machined parts of automobiles. The three-dimensional CAD software is used as the carrier, the MBD design model is used as the only data input, and the process MBD model is used as the Data output, the design process includes the establishment of MBD-related standards, the creation of MBD design models, the creation of feature classification and feature library, feature recognition and information extraction, generation of processing elements, processing element clustering generation procedures, process sequencing, manufacturing features Body, process model creation and other steps. The final application example of the present invention is realized in the three-dimensional CAPP system developed by C++ and NXopen language with NX as the carrier. The present invention can quickly generate a process MBD model that integrates process models and manufacturing features, and can realize the visualization of the process design process , improve process design efficiency, and lay the foundation for the integration of CAD / CAPP / CAM.

Owner:WUHAN UNIV OF TECH

Warpage deformation prediction method for thin-walled components in space envelope forming

ActiveCN113032908BImprove envelope forming accuracyHigh forming precisionGeometric CADDesign optimisation/simulationEngineeringMechanical engineering

Owner:WUHAN UNIV OF TECH

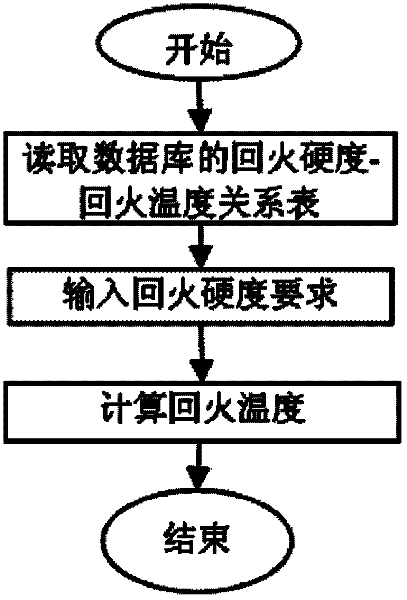

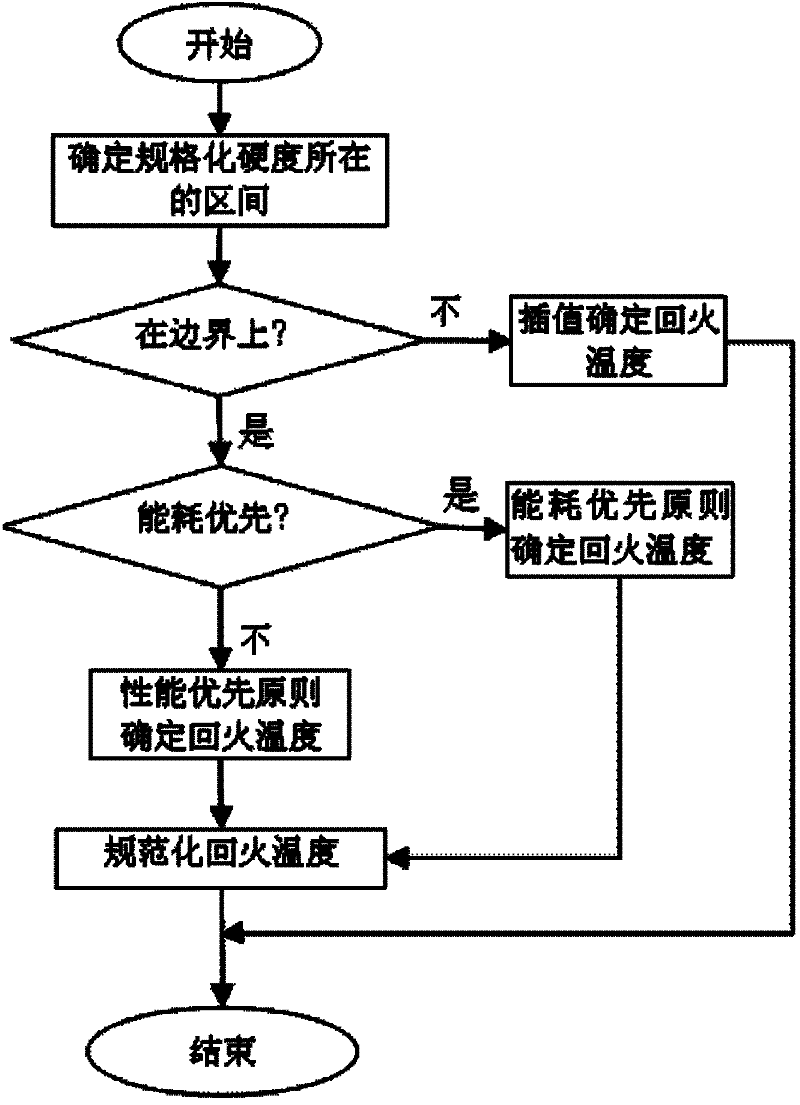

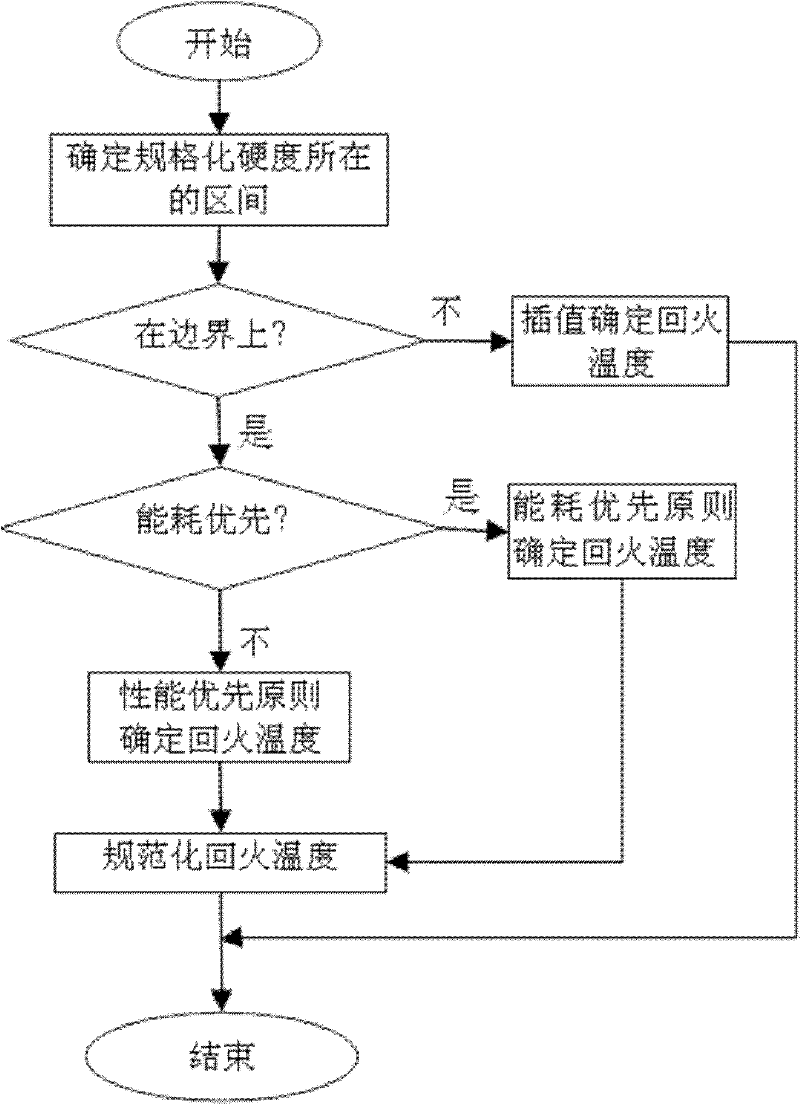

Method for determining tempering temperature

ActiveCN102344999BChoose reasonableImprove consistencyHeat treatment process controlHardnessProcess design

The invention discloses a method for determining tempering temperature, which comprises the following steps: reading a relation table of tempering hardness-tempering temperature in a database according to a material of a part; and determining the tempering temperature according to the tempering hardness. The tempering temperature can be determined according to the material and the tempering hardness requirement inputted by users, so that the process design efficiency is enhanced and the design error can be avoided, the selection of tempering temperature is more reasonable without the phenomenon of columns crossing, the obtained technological parameter has good consistency, scientific and standard design result.

Owner:NANJING DEV ADVANCED MFG

Grenade processing process design system and process design method

InactiveCN1266637CIntelligent processing technology designShorten the process design cycleSpecial data processing applicationsComplete dataRelevant information

The present invention is shrapnel making process design system and method. In the design system, the data are fed from the making process design unit via I / O access module to the design system CAX integrating platform, and the design system CAX integrating platform completes data exchange with information input module, process design module, shrapnel term defining module, technological resource managing module, typical technique managing module, technological photo managing module and technological file outputting module via the data bus. The system creates various technological cards based on relevant information. The present invention has the advantages of high technological design efficiency, high quality, etc.

Owner:SHENYANG LIGONG UNIV

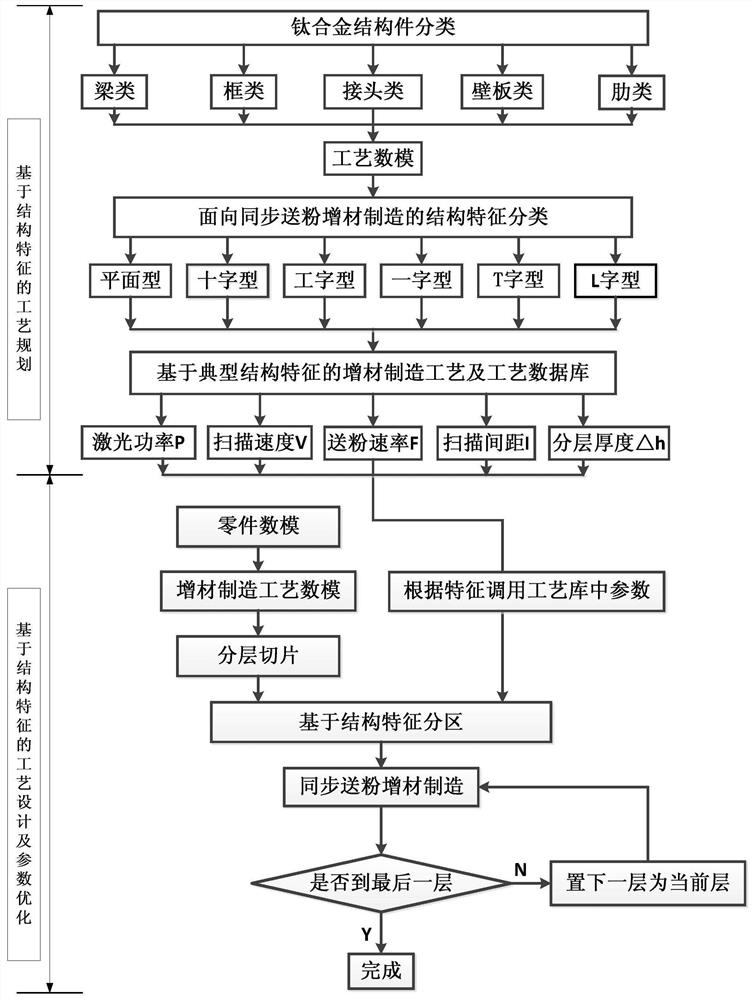

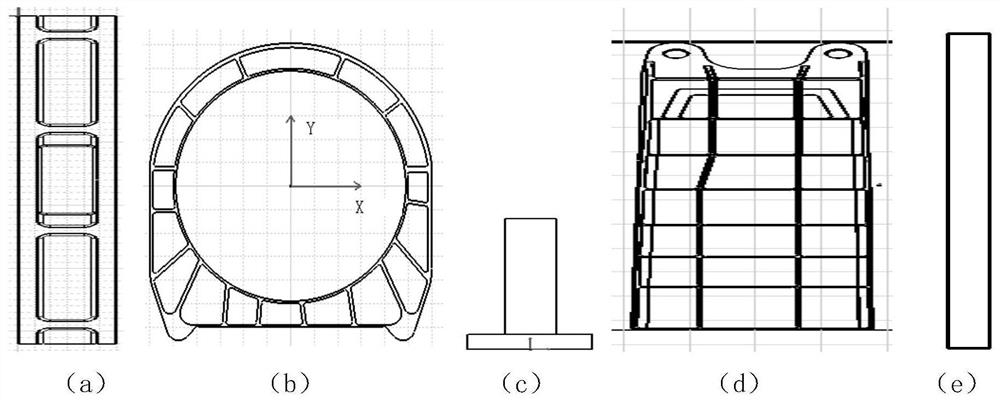

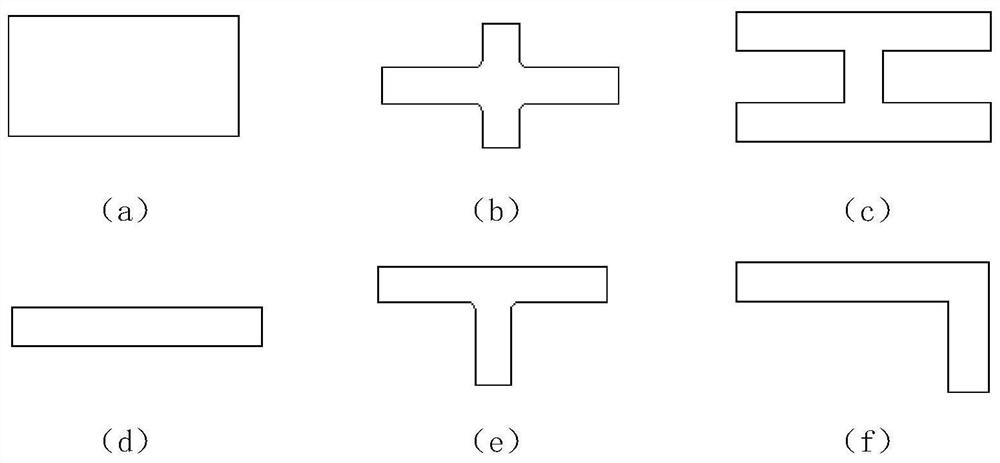

A Process Planning Method for Synchronous Powder Feeding Additive Manufacturing Based on Structural Features

ActiveCN109128168BReliable inheritanceDifficulty of SimplificationAdditive manufacturing apparatusIncreasing energy efficiencyProcess engineeringTitanium alloy

The invention provides a synchronous powder feeding additive manufacturing process planning method based on structural features, and relates to the technical field of additive manufacturing. In this method, titanium alloy structural parts are first divided into beams, frames, joints, wall panels and ribs, and the digital model of the parts is designed into a process digital model according to the characteristics of the synchronous powder feeding additive manufacturing process; then the process digital model Carry out layered slicing processing, divide the data of each layer according to the structural characteristics, and divide each type of titanium alloy structural parts into planar, cross, I-shaped, one-shaped, T-shaped and L-shaped ;Finally, the synchronous powder-feeding additive manufacturing process of structural features and optimization of process parameters are formed into a database, which is used for the follow-up investigation of the additive manufacturing process design of specific parts, and the efficient and high-quality completion of the additive manufacturing process design. The synchronous powder feeding additive manufacturing process planning method based on structural features provided by the present invention simplifies the difficulty of additive manufacturing process design, shortens the process design cycle, and improves the efficiency of process planning.

Owner:SHENYANG AEROSPACE UNIVERSITY

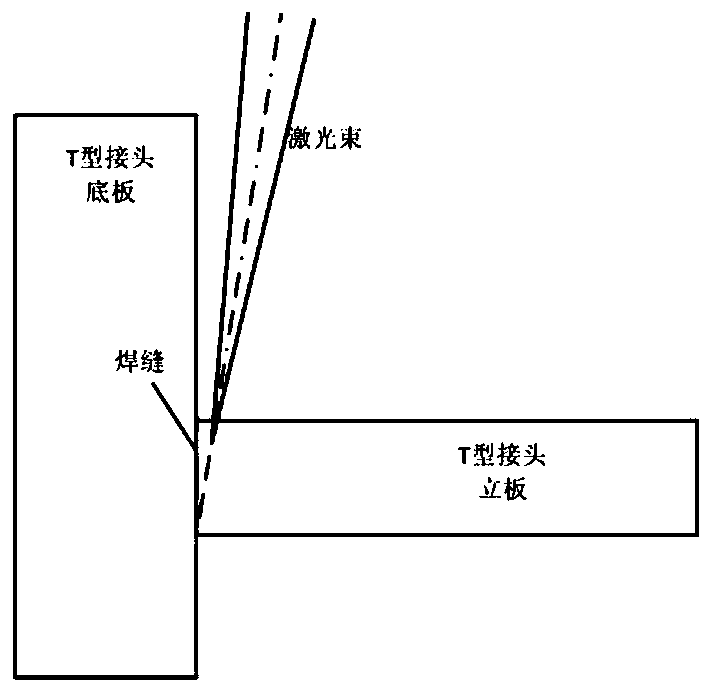

Laser incident angle determination method for T-joint full penetration laser hybrid welding

ActiveCN109366010BImprove design efficiencyReduce dependenceLaser beam welding apparatusLaser-hybrid weldingAngle of incidence

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

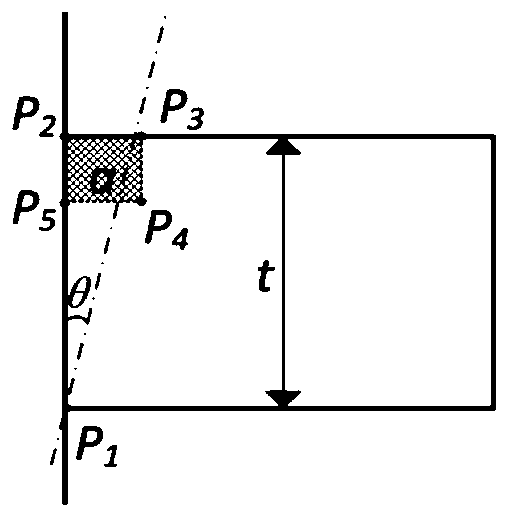

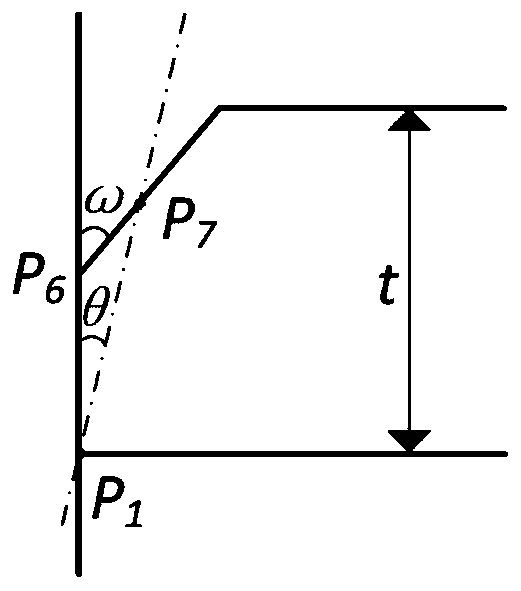

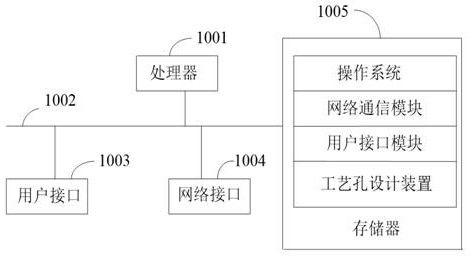

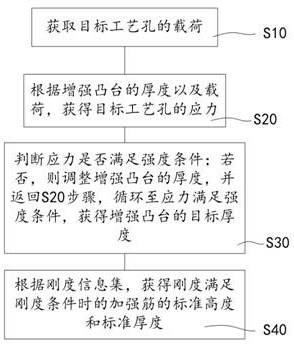

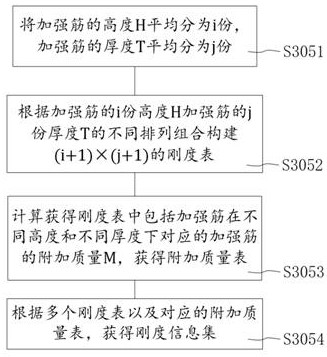

Process hole design method, device, equipment and storage medium

ActiveCN114065406BMeet the intensityRealize the standard process design processGeometric CADAircraft assemblyDesign planDesign standard

The invention discloses a process hole design method, device, equipment and storage medium, including S10, obtaining the load of the target process hole; S20, obtaining the stress of the target process hole according to the thickness and load of the boss; S30, judging Whether the stress satisfies the strength condition; if not, adjust the thickness of the boss, and return to step S20, cycle until the stress meets the strength condition, and obtain the target thickness of the boss; S40, according to the stiffness information set, obtain the reinforcement when the stiffness meets the stiffness condition The standard height and standard thickness of the rib; the stiffness information set includes the stiffness of the target process hole corresponding to the rib at different heights and different thicknesses. A clear standard is put forward, and the technological design scheme of this scheme forms a unified design standard, so that the technological holes processed by this scheme can meet the rigidity and strength, and at the same time, the technological design efficiency of the holes can be improved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Thin-wall component space envelope forming buckling deformation control method

ActiveCN113065210AIncrease contactPrecise control of forming warpageGeometric CADSpecial data processing applicationsRectangular coordinatesDeformation control

The invention relates to a thin-wall component space envelope forming buckling deformation control method. The method comprises the following steps: S1, establishing a rectangular coordinate system; S2, the envelope center O1 of the envelope model being on the z axis, and the distance between the envelope center O1 of the envelope model and the coordinate origin O being H; S3, enveloping die cone point offset being carried out; S4, designing a main body part of the envelope model; S5, designing the front end part of the envelope mode; S6, optimizing process parameters; and S7, thin-wall component space envelope forming buckling deformation control being carried out. In the space enveloping forming process of the thin-wall component, plastic deformation with the wall thickness reduced and the diameter increased occurs, a contact area of a main body part of an enveloping mold and a blank is located on one side of a center shaft, a contact area of the front end part of the enveloping mold and the blank is located on the other side of the center shaft, and therefore space enveloping forming buckling deformation control over the thin-wall component is achieved. According to the method, accurate control over the spatial envelope forming buckling deformation of the thin-wall component can be achieved, and then the spatial envelope forming precision and the yield of the thin-wall component are improved.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com