Technology design method based on three-dimensional model and system thereof

A technology of process design and three-dimensional model, applied in the field of process design method and system based on three-dimensional model, can solve the problems that the design model does not consider the process requirements, the process design does not use the design model, and the process and design are out of touch, so as to achieve the degree of improvement and optimization , good intuition, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

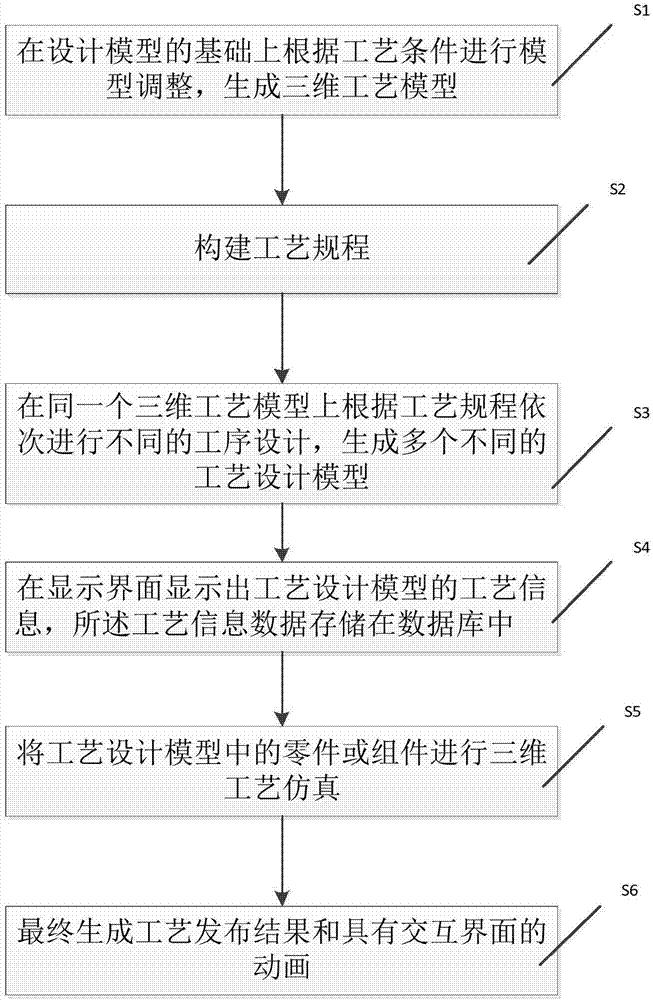

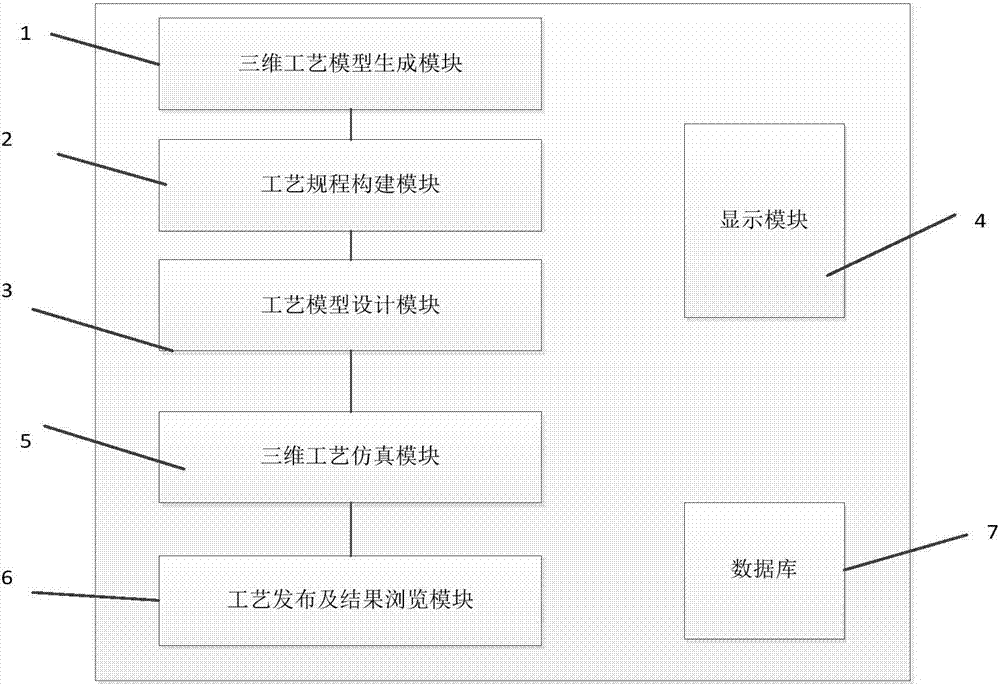

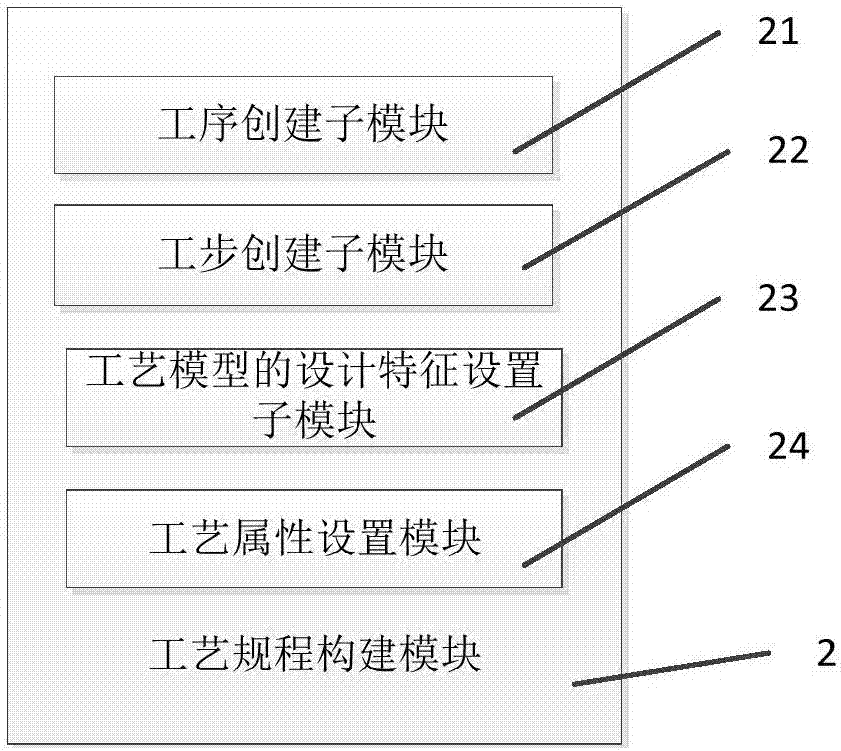

Method used

Image

Examples

example 1

[0036] According to the process design method based on the 3D model mentioned above, the process design method of the part: step 1, open the part design model, create the part process model, select the current model, clear the memory of the manufacturing model and process model, and check the blank size parameters and offset With the rotation parameters, the software generates a process model including the design model by default. If there is an exception, adjust the parameters of the generated process model to realize that the process model and the design model form an assembly.

[0037] Step 2, choose to open the process model, implement process feature construction on the basis of the process model blank, implement feature construction on the blank according to the smooth processing, and add annotation information on the basis of each process, and add audio data annotation The information can also be a description in Chinese characters, and the label information can be added...

example 2

[0042] The process design method for components according to the process design method based on the three-dimensional model: step 1, open the component design model, select the assembly process model, select the required formwork assembly process model and design model, and generate the process model.

[0043] Step 2: Design the process rules under the assembly process model, use the right key to add process steps or use shortcut keys to add process steps, and design the process steps required for assembly components.

[0044] Step 3, right-click the model included in the process step, or use the shortcut key to include the process model of the component. The model contained in the corresponding process step is the model required for assembly and processing. The software will automatically arrange the process content in a default way , from the previous process content to superimposed in sequence, and complete all the parts required for component assembly in sequence.

[0045]...

example 3

[0048] According to the above 3D model-based process design method, the method of sheet metal process design for parts: Step 1, open the sheet metal design model, select the sheet metal process model in the tool, input the design model in sequence, expand the design model, and the sheet metal process template model , to create a sheet metal process.

[0049] Step 2, the process design of the bending situation can be carried out on the sheet metal process model interface, and the bending design, sheet metal hole patching, sheet metal allowance, bending simulation, forming simulation, sheet metal segmentation, Continuous bending and other sheet metal operations.

[0050] Step 3, compile the sheet metal process specification, including the sheet metal process features, and include the corresponding process features into the required process specification.

[0051] Step 4: Publish the sheet metal process results. The sheet metal process results use process steps as a tree structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com