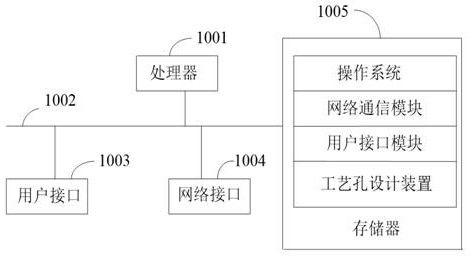

Process hole design method, device, equipment and storage medium

A design method and technology of process holes, applied in the design method of process holes, equipment and storage media, and device fields, can solve the problems of lack of systematic process design methods, inconsistent process hole indicators, and affect assembly accuracy, etc., to achieve improved The effect of process design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] It should be understood that the specific embodiments described herein are only used to explain the present application, but not to limit the present application.

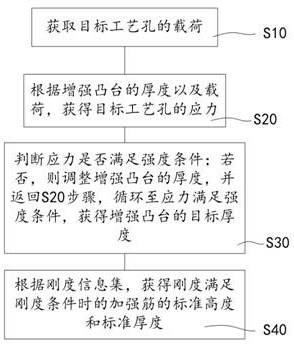

[0053] Aiming at the problem that the existing process holes lack the process design method of the systematic process design method, the present embodiment proposes a process hole design method, device, equipment and storage medium. The specific ideas are as follows:

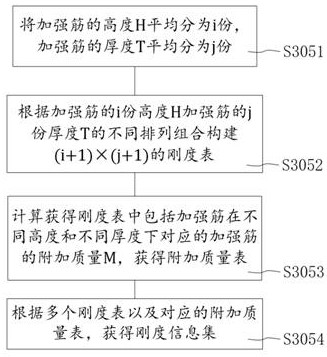

[0054] By obtaining the load of the target process hole 2, according to the thickness of the boss 5 and the load, the stress of the target process hole 2 is obtained, and the target thickness of the boss 5 corresponding to the stress satisfying the strength condition is obtained; And according to the stiffness information set, the standard height and standard thickness of the stiffener 6 when the stiffness meets the stiffness conditions are obtained.

[0055]In the existing process design process of the process hole, it mainly relies on the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com