Patents

Literature

39results about How to "Guaranteed emulsifying effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Emulsified oil composition and use thereof

InactiveCN104342261AGood synergyGuaranteed lubrication effectLubricant compositionActive agentPhysical chemistry

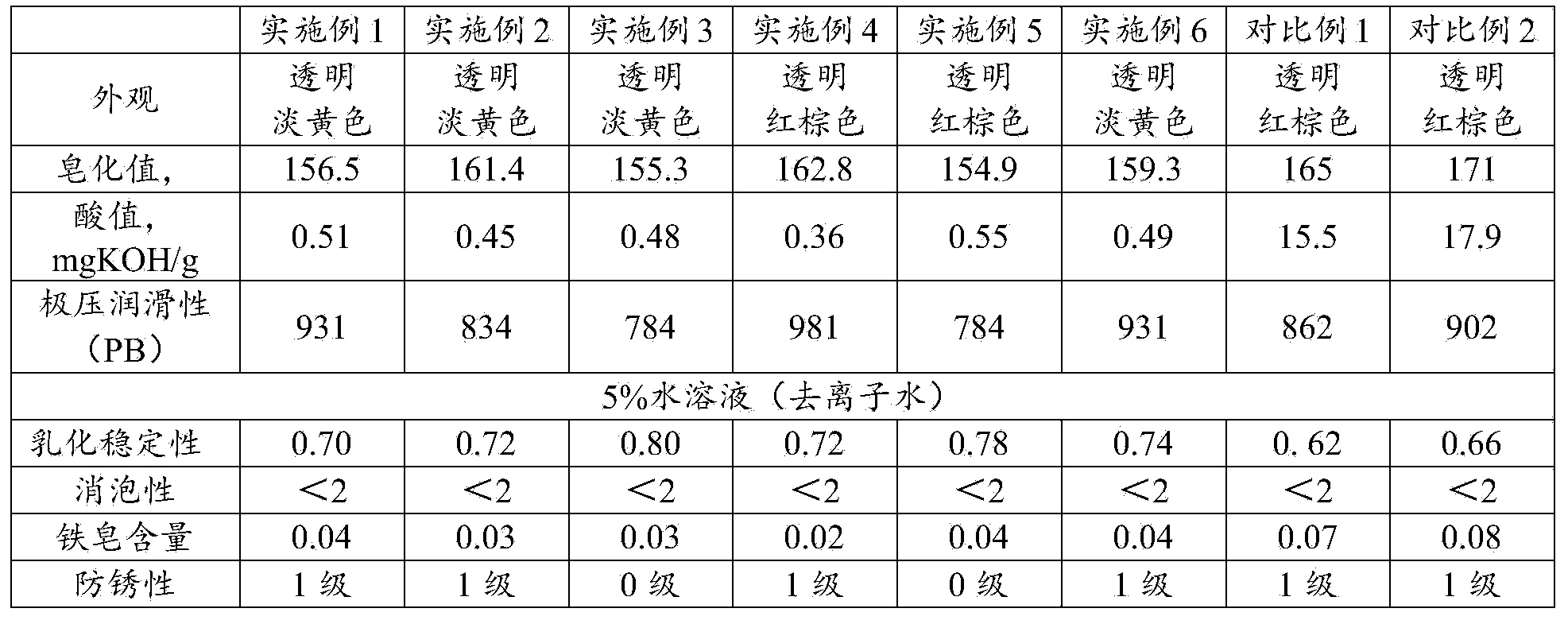

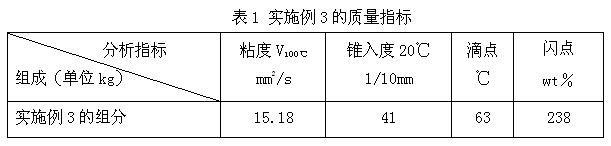

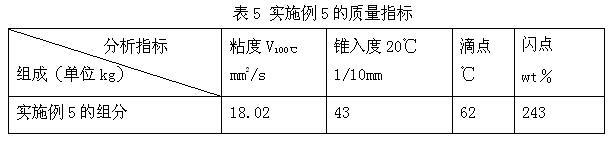

The invention relates to an emulsified oil composition and use thereof. The emulsified oil composition is mainly used for solving the problem that the quality of plate faces and the use performance of emulsified liquid are affected due to the fact that iron soaps are excessive, block pipelines and are difficultly filtered during the use of the existing emulsified liquid technologies. By adopting the technical scheme that the emulsified oil composition contains the following ingredients in parts by weight: (a) 30-40 parts of base oil, (b) 40-50 parts of non fatty acid type lubricant, (c) 2-5 parts of extreme pressure agent, (d) 1-5 parts of anti-rust agent, (e) 5-10 parts of surfactant and (f) 0.1-5 parts of antioxidant, the problem is better solved, the requirements of a straight carbon steel cold-rolling rolling process are met, and the emulsified oil composition can be applied to a rolling process of a modern large-sized multi-rack continuous-rolling rolling mill and a rolling process of a multi-roller mono-rack reversible rolling mill.

Owner:CHINA PETROLEUM & CHEM CORP

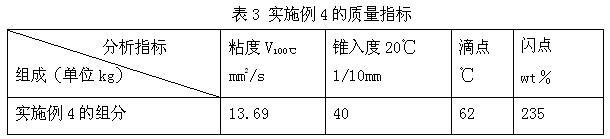

Integrated oil phase for emulsion explosive and preparation method thereof

InactiveCN102079681AGuaranteed emulsifying effectGuaranteed emulsification stabilityNon-explosive/non-thermic compositionsParaffin waxMicrocrystalline wax

The invention discloses an integrated oil phase for emulsion explosive and a preparation method thereof. The integrated oil phase for the emulsion explosive comprises the following components in part by mass: 10 to 18 parts of paraffin, 1 to 6 parts of microcrystalline wax, 45 to 65 parts of cerate and 25 to 35 parts of complex additive. The preparation method for the integrated oil phase for the emulsion explosive comprises the following steps of: preparing the components; adding the paraffin and the microcrystalline wax into an adjustable dehydrator, and heating for melting; adding the cerate, and fully stirring until the components are mixed and dissolved; raising the temperature for dehydration, and reducing the temperature; adding the complex additive, and stirring at a high speed until the components are mixed and dissolved; and filtering, discharging, cooling, forming and packaging. The integrated oil phase for the emulsion explosive integrates various components, has generality, and easily operates and controls the quality of the emulsion explosive, and can ensure the emulsifying property and emulsion stability in the production process of the emulsion explosive; the raw materials are easily obtained, low in cost and convenient to use; and the preparation method provides favorable guarantee for popularization and promotion in the industry.

Owner:GUANGDONG SUNION CHEM & PLASTIC

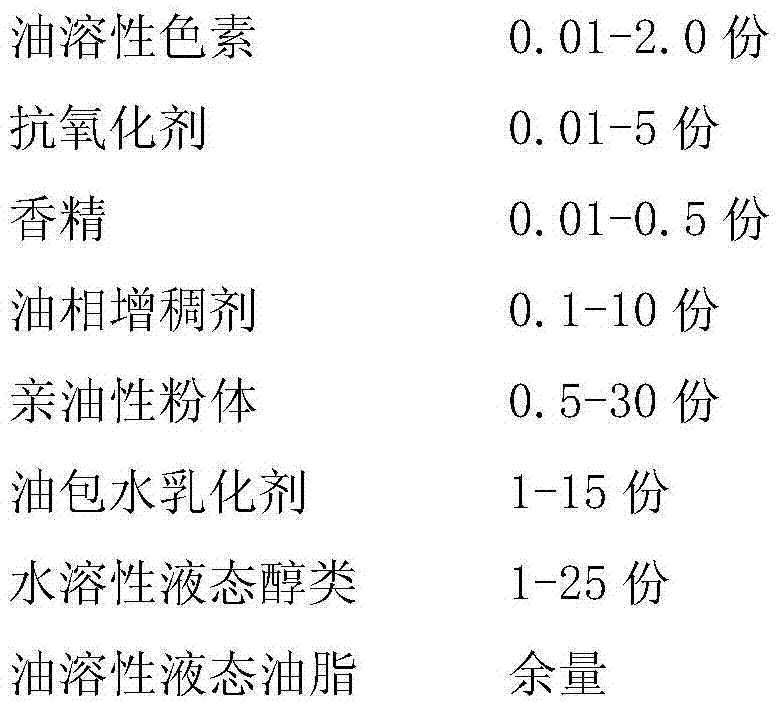

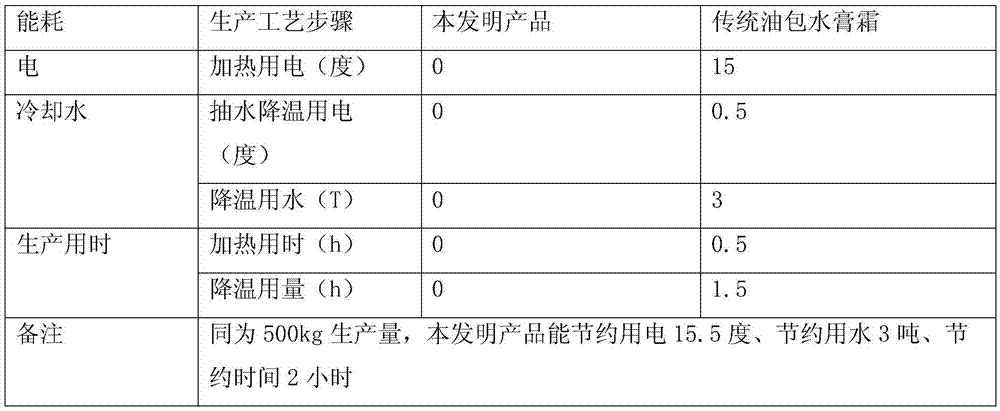

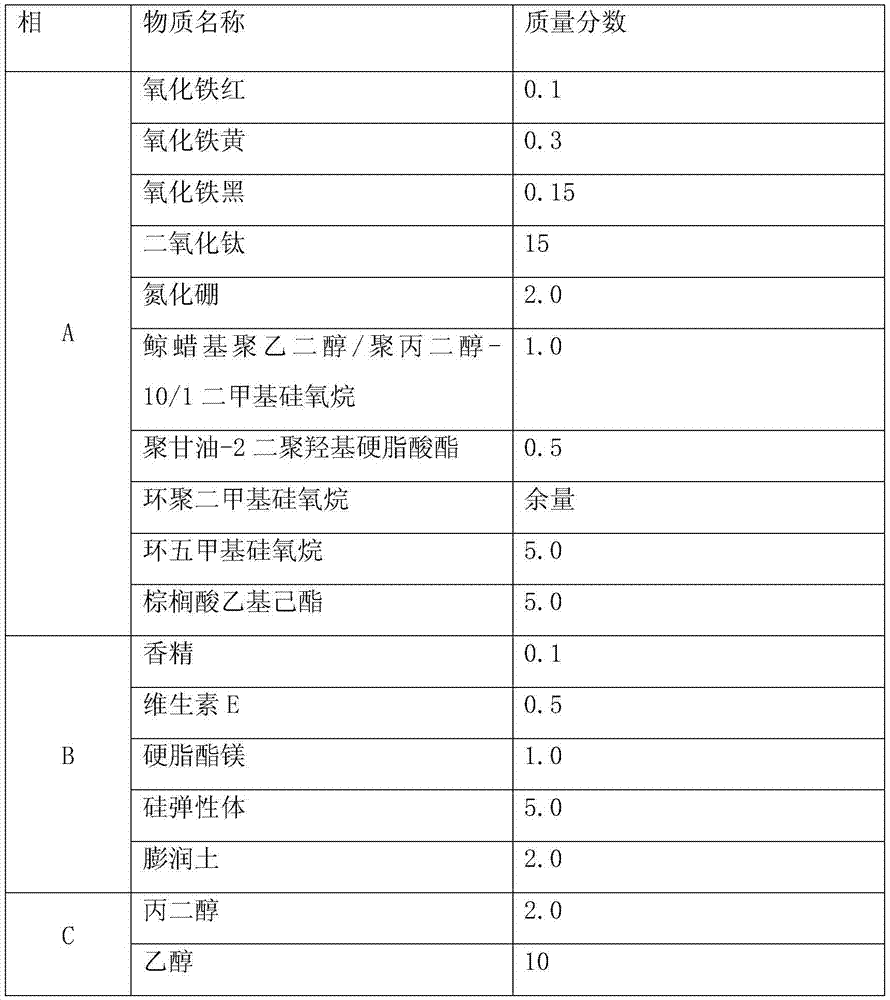

Dual-layer water-free skin-care composition and preparation method thereof

ActiveCN105434181AImprove freshnessReduce greasy feelingCosmetic preparationsMake-upOil and greaseAlcohol

The invention discloses dual-layer water-free skin-care composition. The dual-layer water-free skin-care composition comprises an oil phase layer and a non-oil phase layer, wherein the oil phase layer at least contains one kind of oil-soluble liquid grease immiscible with water, and the non-oil phase layer at least contains one liquid alcohol or a derivative of the liquid alcohol. The composition can form the obvious dual-layer structure during placement and can form an emulsion through shaking during usage. The composition contains no preservative or water, has the good moisture effect and is oily but not greasy, the production technology is simple, and the energy consumption is low.

Owner:GUANGZHOU KENENG COSMETICS RES CO LTD +1

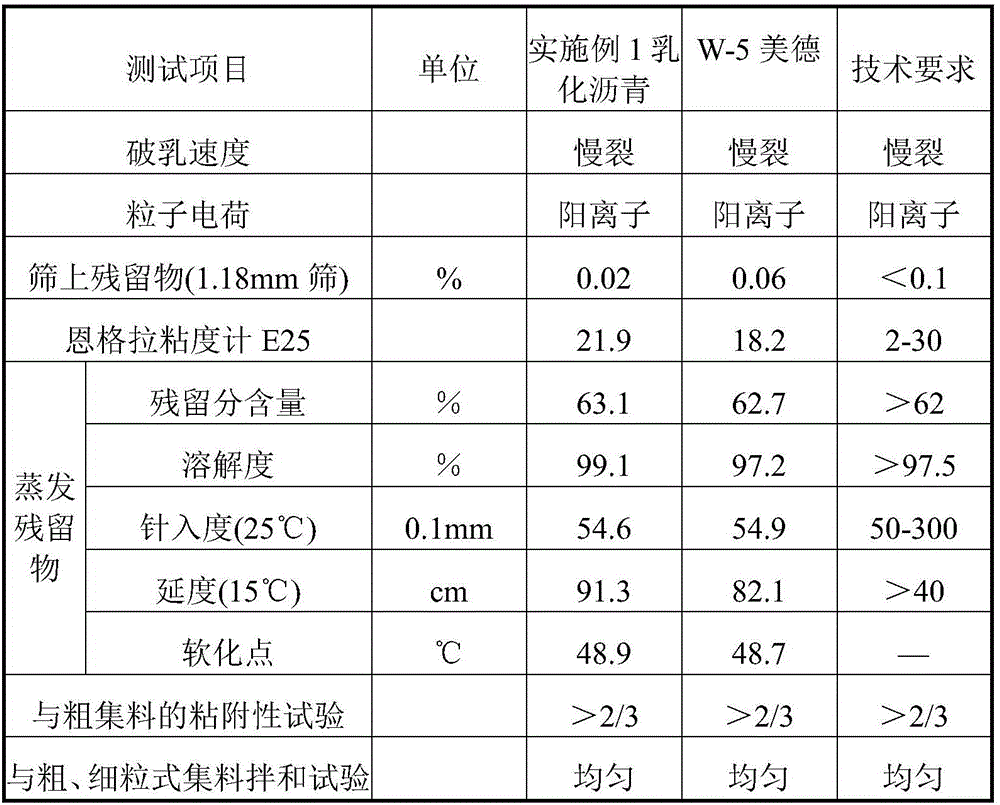

Preparation method and application of lignosulfonate cold-recycled asphalt emulsifier

InactiveCN105885059AExtended working hoursGuaranteed emulsifying effectBuilding insulationsSulfonateLignosulfonates

The invention discloses a preparation method and application of a lignosulfonate cold-recycled asphalt emulsifier. The method comprises the following steps: (1) adding amine to a lignosulfonate solution, wherein the molar mass of the added amine accounts for 0.125%-0.5% of mass of lignosulfonate; (2) heating and dropwise adding aldehyde; then, heating again and reacting to obtain an intermediate lignosulfonate polyethylene polyamine, wherein the molar ratio of the added aldehyde to the added amine in step (1) is (1:1)to (4:1); (3) cooling, adding a lignosulfonate solution which is identical to the solution in the step (1) in concentration and mass, and stirring evenly; and (4) heating, dropwise adding aldehyde to the mixed solution obtained in the step (3), and then carrying out heating reaction to obtain a target product. The fluidity loss caused by a sulfonate radical is compensated by increasing the steric hindrance of the lipophilic group of the lignosulfonate emulsifier; the operable time of the cold-recycled asphalt mixture can be greatly prolonged; and the haul distance of the cold-recycled mixture is prolonged. By adjusting proper preparation conditions, the emulsification effect of the product is ensured while the yield is improved.

Owner:JIANGSU ZHONGLU NEW MATERIAL SCI & TECH DEV CO LTD

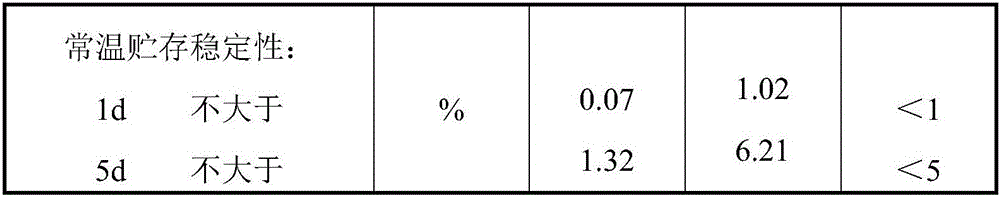

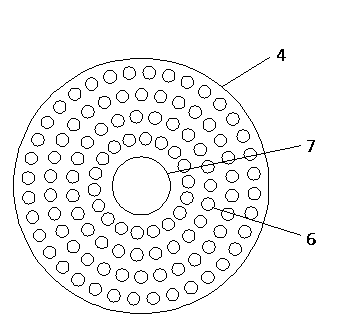

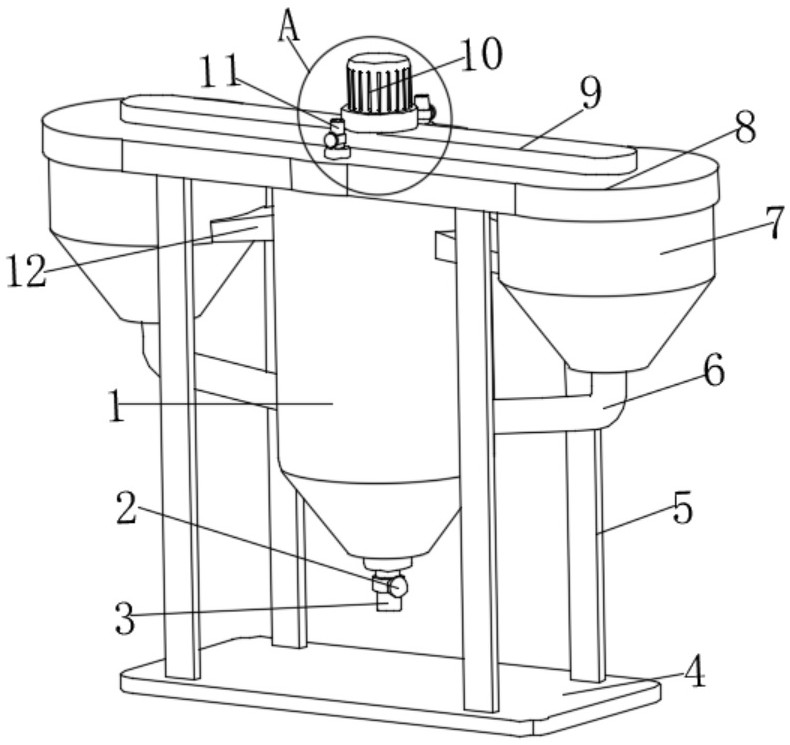

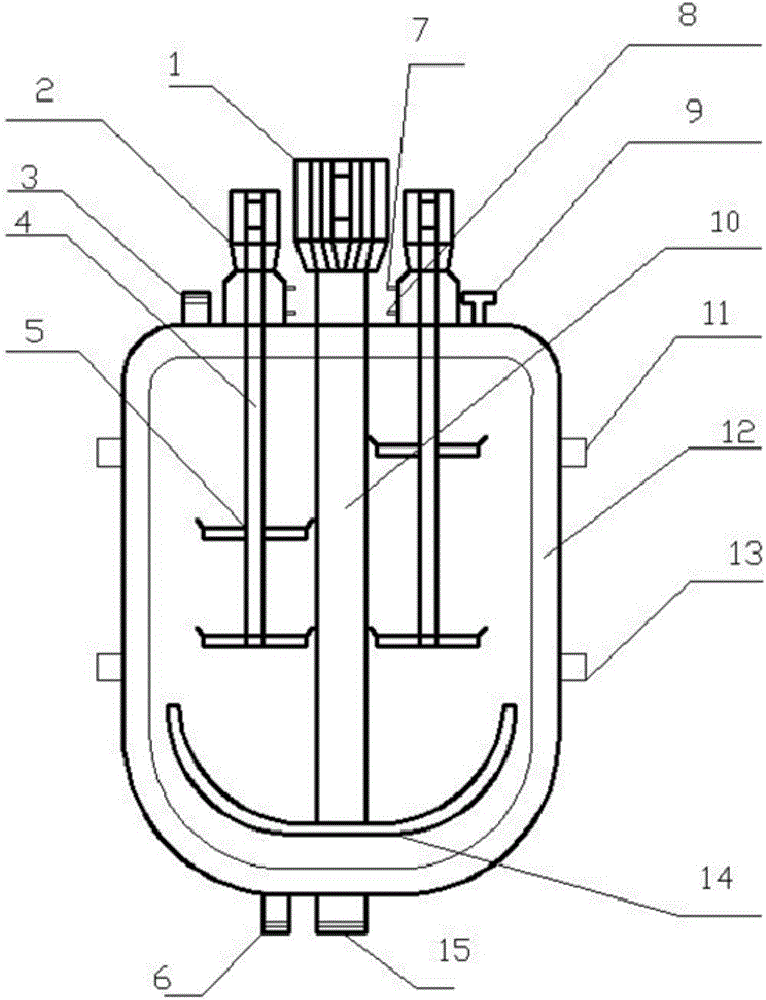

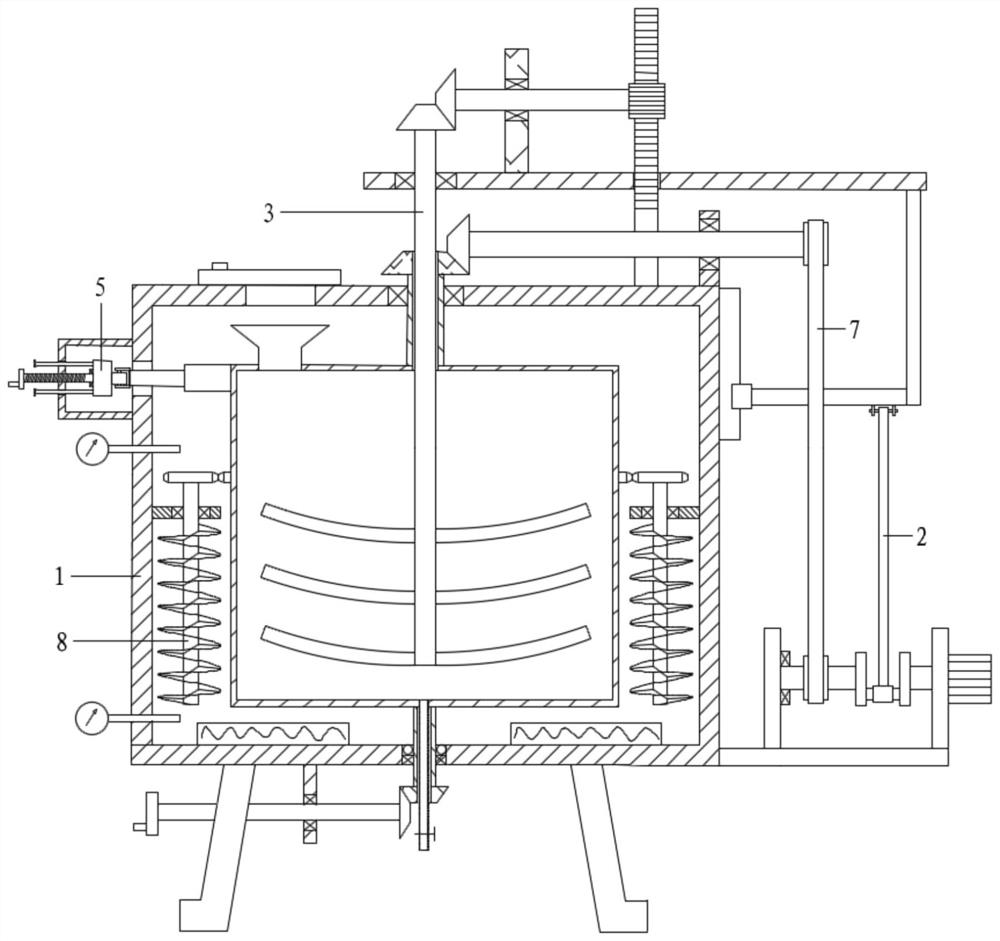

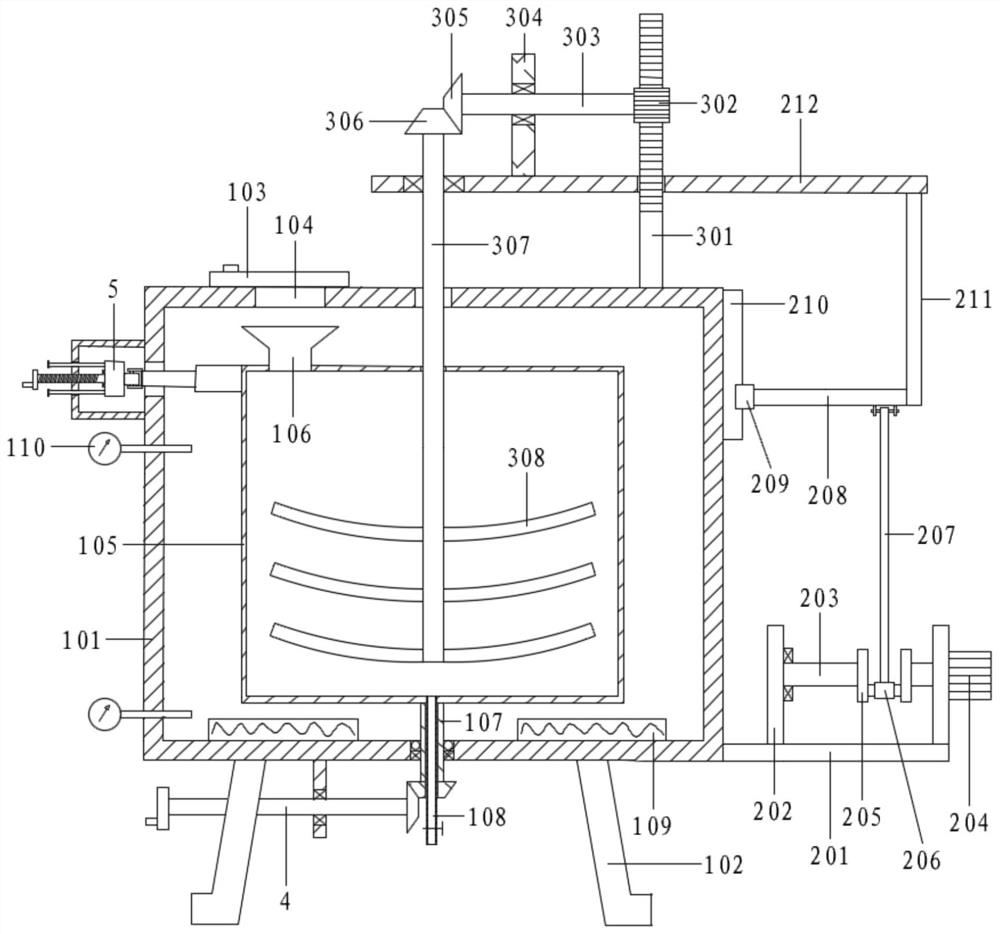

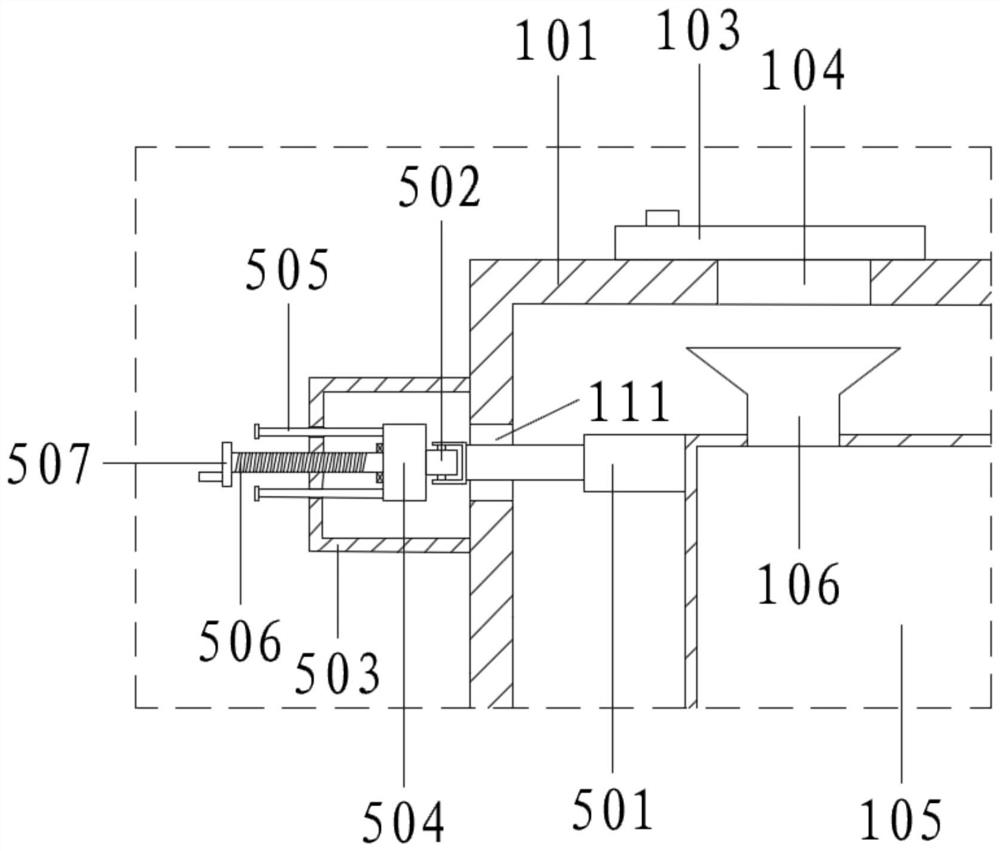

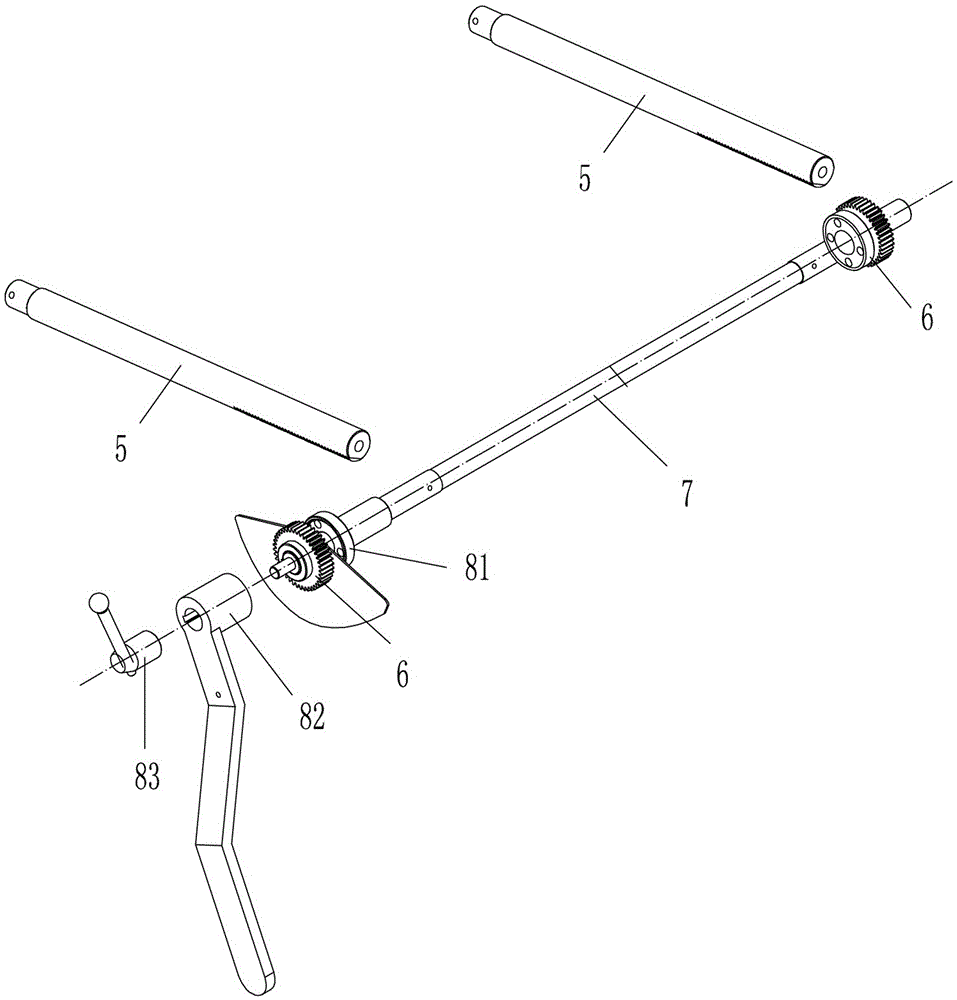

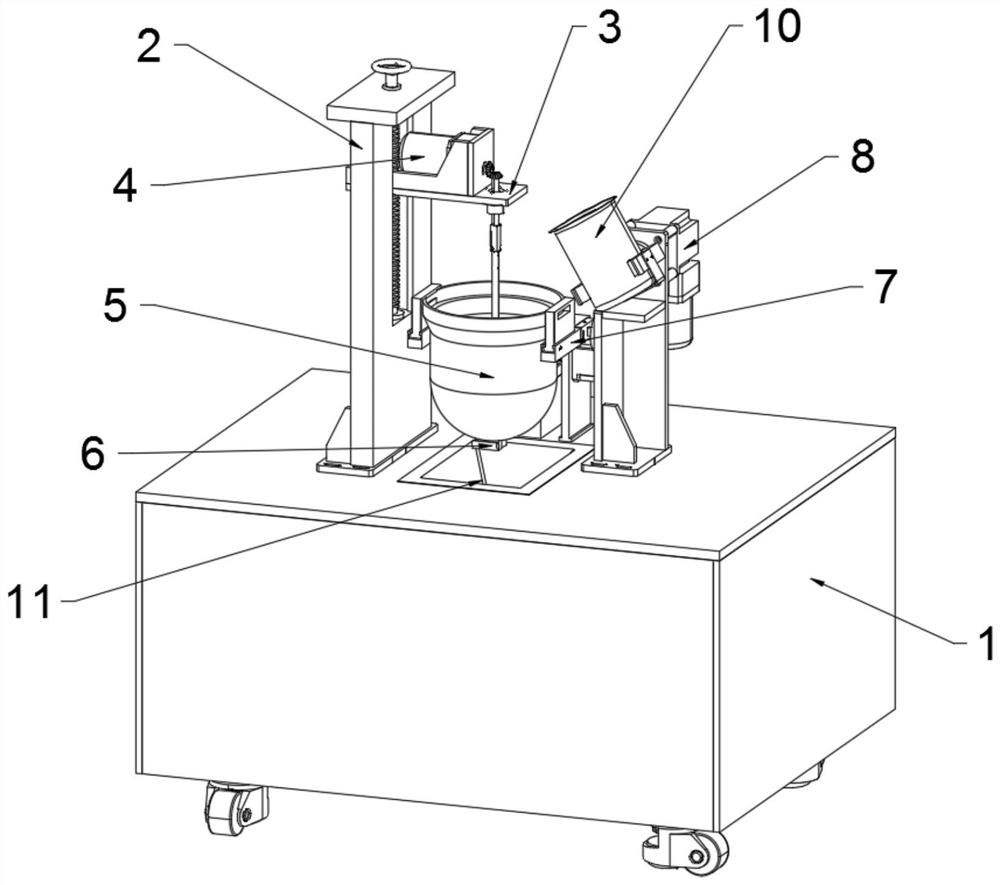

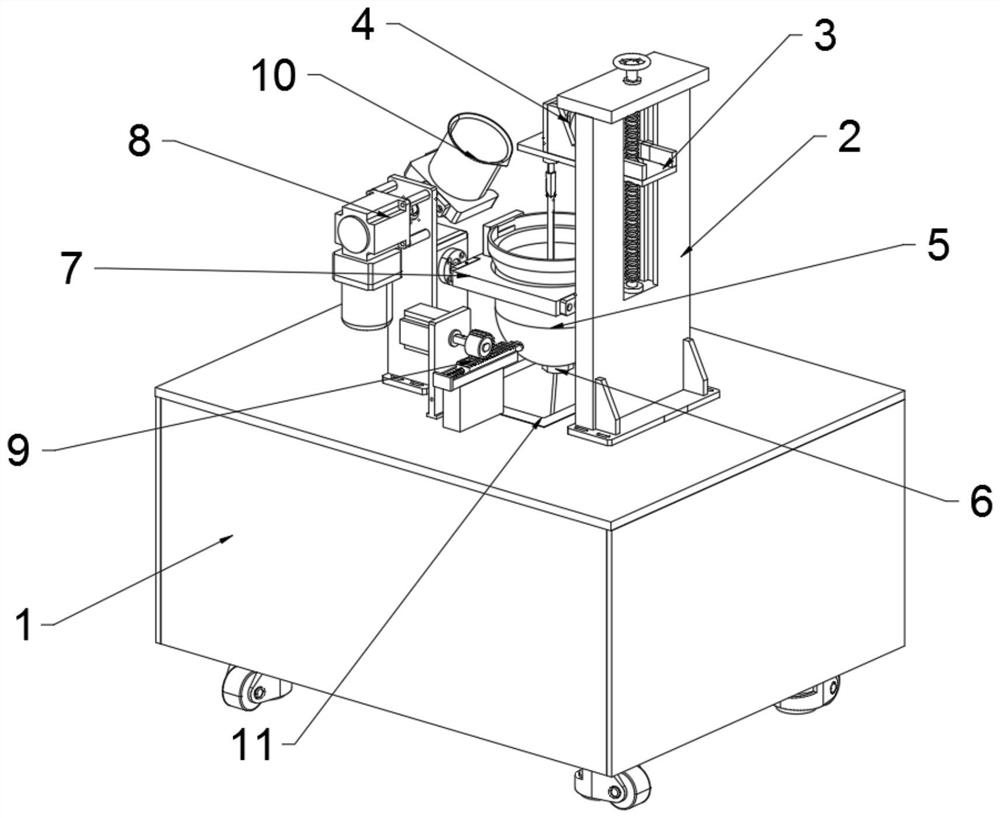

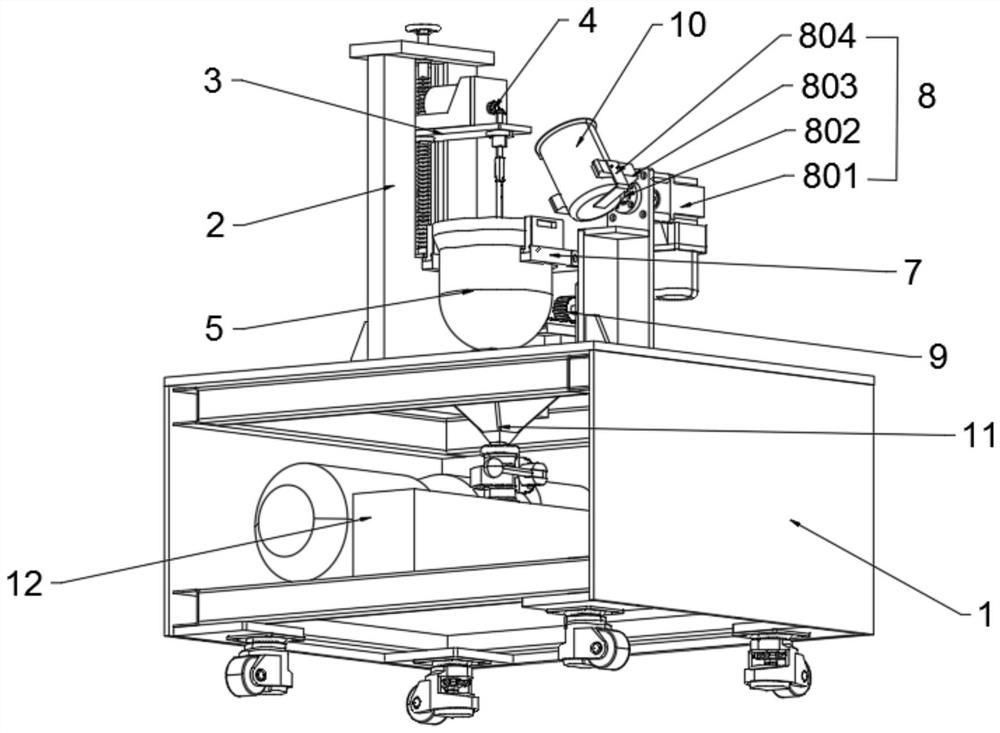

High-efficiency emulsifying machine capable of guaranteeing emulsifying effect

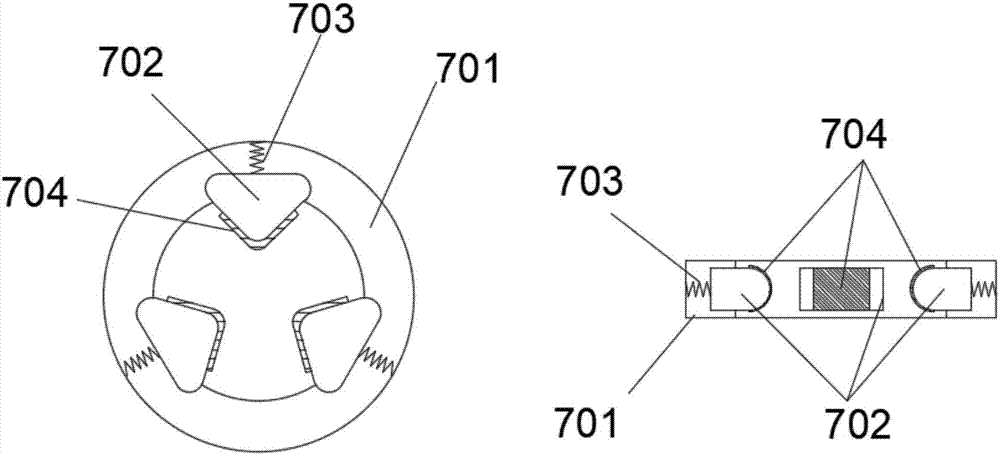

InactiveCN103432924AGuaranteed emulsifying effectHigh industrial practical valueRotary stirring mixersMixing methodsEngineeringMultiple layer

The invention discloses a high-efficiency emulsifying machine capable of guaranteeing an emulsifying effect. The high-efficiency emulsifying machine comprises an emulsifying cavity, a stator and a rotor, wherein the rotor is connected with the motor; a charging port is formed at the upper part of the emulsifying cavity, and a discharging port is formed at the lower part of the emulsifying port. The high-efficiency emulsifying machine is characterized in that the emulsifying cavity is divided into multiple layers by partitioning plates with filtering nets in the middles; the radiuses of holes of the filtering nets which are arranged from top to bottom are reduced gradually; the middle part of each filtering net is provided with a round hole through which a rotor connecting rod can penetrate. The high-efficiency emulsifying machine disclosed by the invention has the advantages that when materials are charged for emulsifying, only particles sheared and crushed to certain size can enter next layer through the filtering net for further emulsification, the radiuses of the holes of the filtering nets are reduced gradually from top to bottom, particles can be controlled in a layer-by-layer manner, and multiple layers can be utilized simultaneously as quick as possible to accelerate the crushing and emulsifying.

Owner:NANJING WEIAN NEW MATERIAL SCI & TECH

Formula and making method of paste material for frozen cheese creammy snow cap

The invention discloses a formula and making method of a paste material for a frozen cheese creammy snow cap. The making method comprises the following steps of mixing raw materials of milk, cream andthe like, through combination of intermittent ultrasonic waves with a chopping technology, making semi-finished products of the paste material for a frozen cheese creammy snow cap, and through a decompressing quick-freezing technology, making finished products of the paste material for a frozen cheese creammy snow cap. After being unfrozen, the paste material for a frozen cheese creammy snow capis mixed with coffee cream in a certain proportion, and whipping is performed, so that cheese creammy snow cap, cheese creammy snow cap coffee or other beverages, being delicious, can be made. Throughcombination of the intermittent ultrasonic waves with the chopping technology, the raw materials are heated, and then the heated raw materials are mixed, so that the juice separation rate of the products can be effectively reduced, the emulsifying effect is guaranteed, and the elasticity and the fine and smooth degree of the products can be strengthened; decompressing quick-freezing is performed,so that the temperature of the products can be rapidly reduced, the flavor and the nutritional quality of the products can be maintained, and the shelf life can be prolonged. The formula and the making method are suitable for large-scale industrialized production. The paste material is stable in quality, rich in nutrition, delicious in mouth feel, convenient to use and convenient to transport andsell, and the problems that losses during on-site making are high, the products are instable, and the food hygiene security cannot be guaranteed, are solved.

Owner:青岛德信食品有限公司

Continuous-rolling silicon steel high-detergency rolling oil and preparation method thereof

ActiveCN106833845APrevent agingInhibition of polymerizationLubricant compositionAntioxidantSURFACTANT BLEND

The invention provides continuous-rolling silicon steel high-detergency rolling oil and a preparation method thereof. The composition comprises the following components in percentage by weight: 50 to 60 percent of synthetic ester, 35 to 45 percent of refined fat, 0.5 to 3.0 percent of an antioxidant, 1.0 to 5.0 percent of an antirust agent, 1.0 to 8.0 percent of an extreme pressure antiwear additive, 1.0 to 5.0 percent of a detergent dispersant and 1.0 to 3.0 percent of a surfactant. The continuous-rolling silicon steel high-detergency rolling oil has high detergency while guaranteeing lubricating property and antirust property, and can obviously improve the detergency of a rolling mill.

Owner:SHANGHAI PARKER CHEM IND

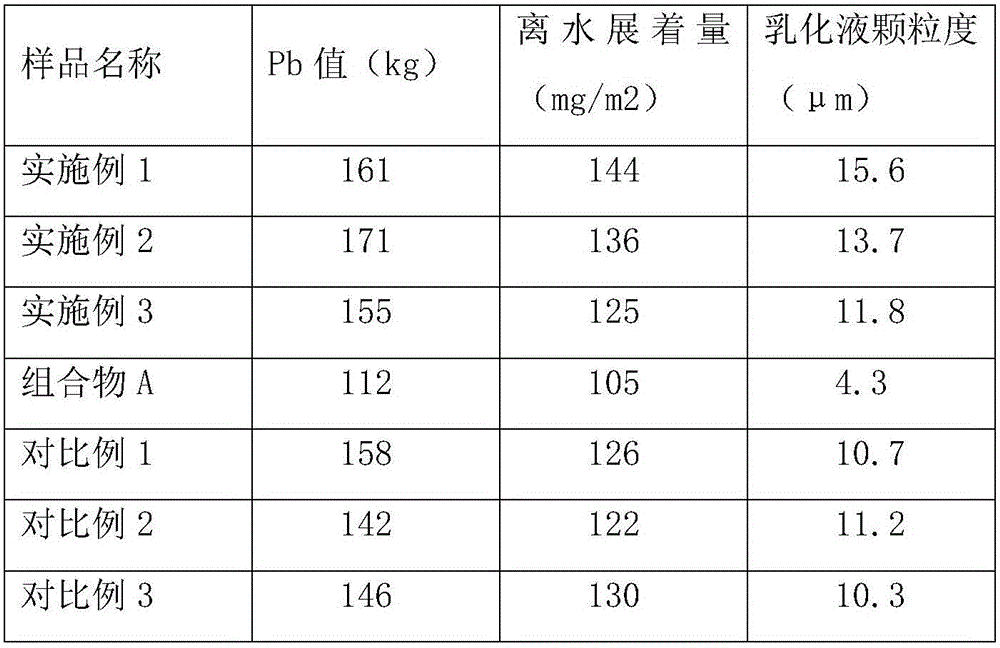

Production method of special soybean protein powder for tofu pudding

PendingCN111938016AHigh yieldImprove efficiencyCheese manufactureVegetable proteins working-upBiotechnologyNeutral protease

The invention discloses a production method of special soybean protein powder for tofu pudding. The production method specifically comprises the following steps: (1) soaking soybeans in water for 14-16 hours, then smashing and grinding into thick liquid, filtering to remove residues, performing high-pressure steam sterilization on filtrate, and cooling to obtain soybean milk; (2) dropwise adding citric acid into the soybean milk to adjust the pH value to 5.0-6.0, then adding neutral protease for enzymatic hydrolysis, and filtering to obtain soybean milk enzymatic hydrolysate; and (3) sequentially performing enzyme deactivation treatment and spray drying on the soybean milk enzymatic hydrolysate to obtain the special soybean protein powder. The production method disclosed by the invention significantly improves the yield and efficiency of soybean protein and removes impurity components in the soybeans, thereby ensuring the functional characteristics of solubility, gel property, emulsibility and the like of the soybean protein; and furthermore, the production method is advanced in process, reasonable in process, controllable in operation and suitable for large-scale production.

Owner:黑龙江冰泉多多保健食品有限责任公司

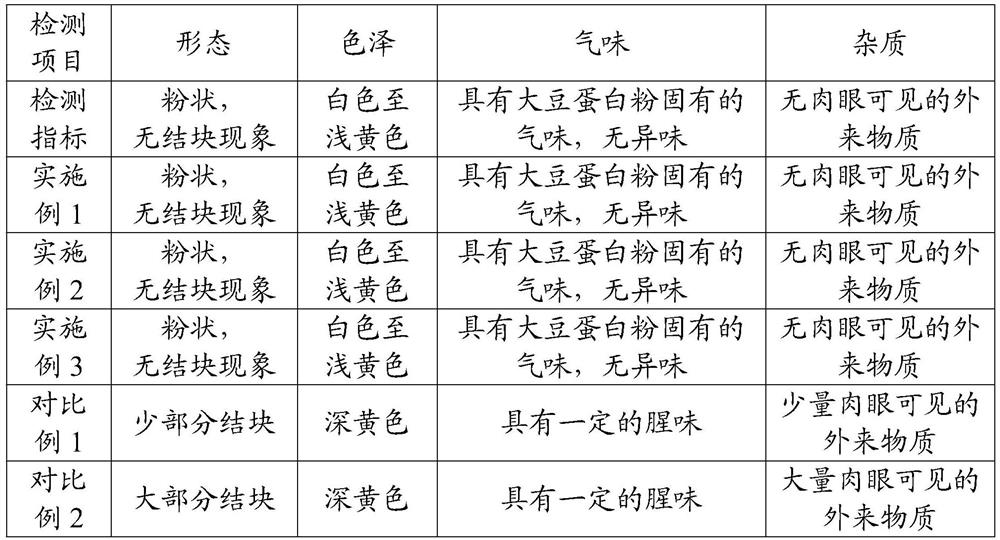

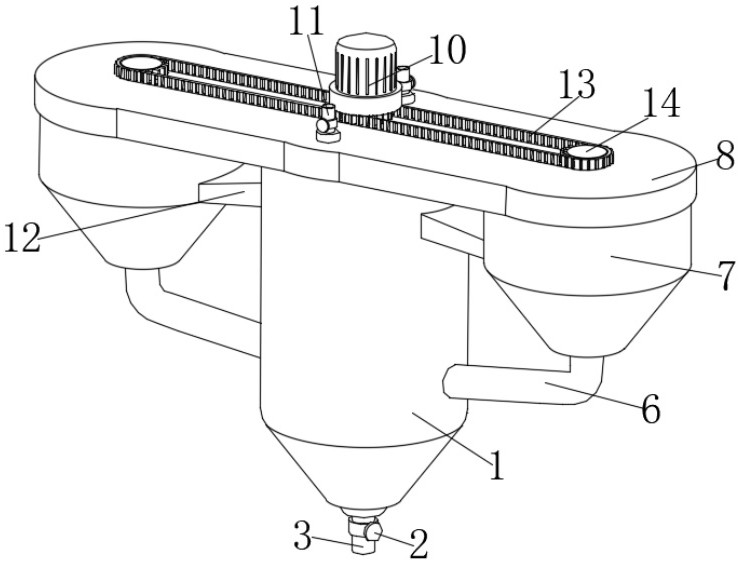

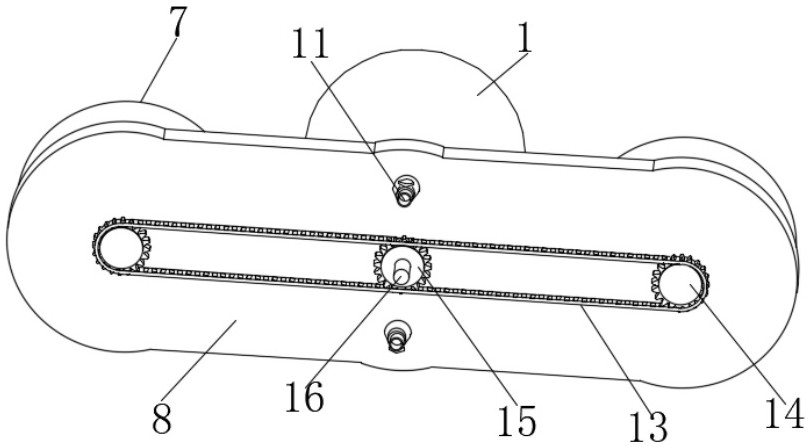

Emulsifying device for cosmetic liquid processing production line

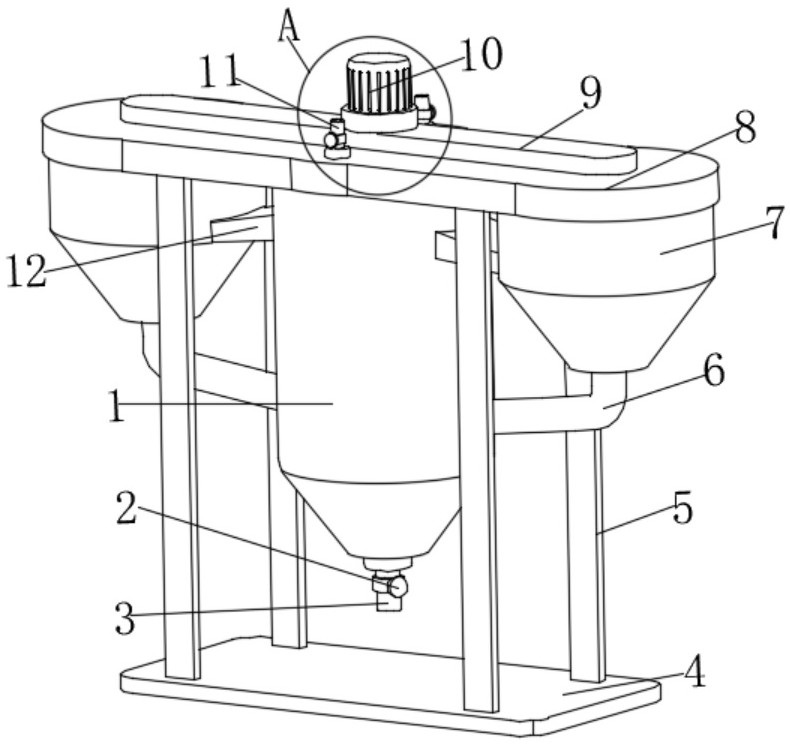

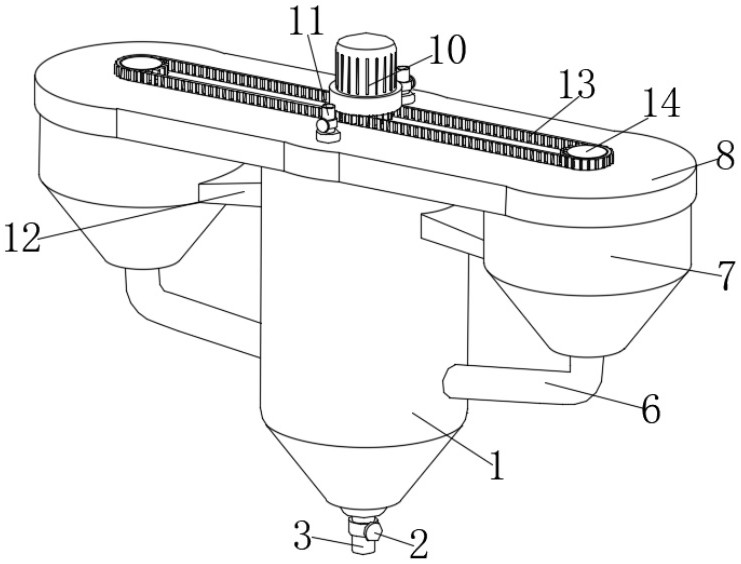

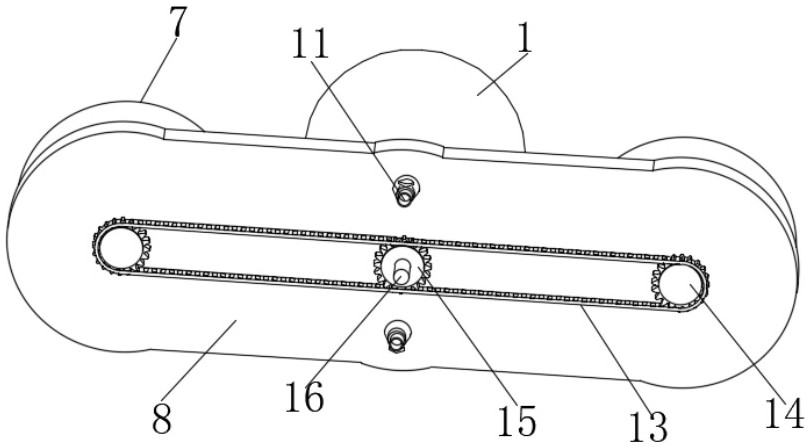

ActiveCN112090307AGuaranteed emulsifying effectImprove the mixing effectFlow mixersRotary stirring mixersThermodynamicsEngineering

The invention relates to the technical field of cosmetic liquid processing, in particular to an emulsifying device for a cosmetic liquid processing production line. The emulsifying device comprises anemulsifying cylinder, flow promoting cylinders are symmetrically arranged on the two sides of the top of the emulsifying cylinder, the bottom ends of the flow promoting cylinders and the emulsifyingcylinder are conical, and the tops of the flow promoting cylinders and the emulsifying cylinder are jointly and fixedly sleeved with a sealing cover; and the bottom of the sealing cover is supported by a supporting frame, a material injection structure is arranged at the top end of the sealing cover at the corresponding position of the emulsifying cylinder, a material discharging structure is arranged at the bottom end of the emulsifying cylinder, and a stirring mechanism is arranged between the emulsifying cylinder and the interiors of the two flow promoting cylinders. The stirring mechanismdesigned by the invention has a repeated stirring function, the stock solution emulsifying effect is ensured, and meanwhile, the two flow promoting mechanisms can be driven to rotate through the arranged linkage mechanism, so that stock solutions falling from the interiors of the two flow promoting cylinders 7 are impacted, and the stock solution emulsifying efficiency is improved.

Owner:杭州未可品牌管理有限公司

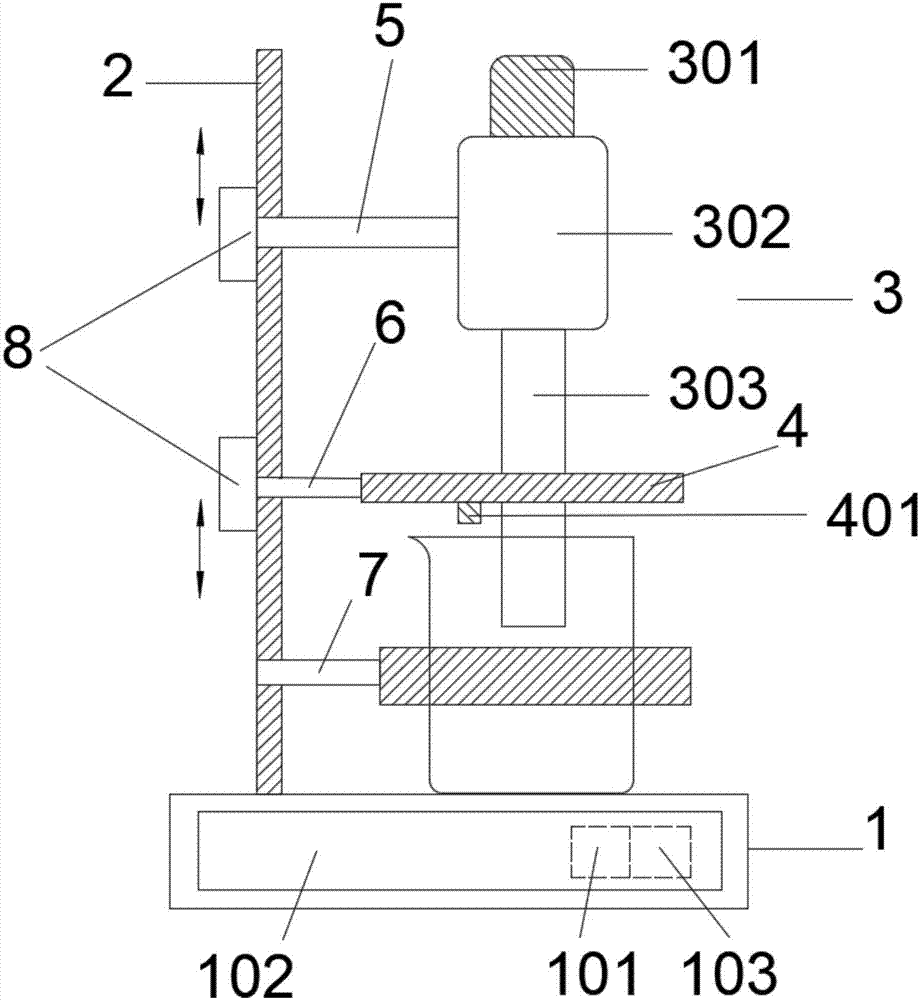

Automatic high-shear emulsifying machine

InactiveCN107970859ASave human effortShorten the timeRotary stirring mixersTransportation and packagingEngineeringAutomation

The invention discloses an automatic high-shear emulsifying machine. The automatic high-shear emulsifying machine comprises a console, a bracket, an emulsifying device and an annular cover plate, wherein the console comprises a micro control chip and a touch screen embedded on a lateral surface of the console; the bracket is fixed on the console, the emulsifying device is provided with a motor, afixed cylinder and a rotor from the top down, wherein the motor penetrates through the fixed cylinder to be connected with the rotor, and the rotor penetrates through the middle part of the annular cover plate; a photoelectric sensor is arranged on the lower surface of the annular cover plate, the fixed cylinder and the annular cover plate are connected with the bracket through a first clamping device and a second clamping device respectively, a container is fastened on the console through a third clamping device under the second clamping device; transmission modules sliding up and down are further arranged at both the connecting parts of the first clamping device and the second clamping device with the bracket. The emulsifying machine realizes the automation of the emulsification processthrough the touch screen to effectively save manpower; the container is firmly fixed to avoid damage of the container; each emulsification parameter is precisely controlled to maximally improve the emulsification effect; and the annular cover plate can prevent liquid from splashing.

Owner:武汉纤然生物科技有限公司

An emulsifying device for a cosmetic liquid material processing production line

ActiveCN112090307BGuaranteed emulsifying effectImprove the mixing effectFlow mixersRotary stirring mixersBLENDER/MIXERProduction line

The invention relates to the technical field of cosmetic liquid material processing, in particular to an emulsifying device for a cosmetic liquid material processing production line, comprising an emulsifying cylinder, and two sides of the top of the emulsifying cylinder are symmetrically provided with flow-promoting cylinders. The bottom ends are all arranged in a conical shape, and the tops are jointly fixed and sleeved with a sealing cover. The bottom of the sealing cover is supported by a support frame. The top of the sealing cover at the corresponding position of the emulsification cylinder is provided with a material injection structure. A discharge structure is arranged at the end, and a stirring mechanism is jointly arranged between the emulsification cylinder and the interior of the two flow urging cylinders. The stirring mechanism designed in the present invention has the function of repeated stirring, which ensures the emulsification effect of the raw liquid, and at the same time, the linkage mechanism provided can drive the rotation of the two flow urging mechanisms, so as to cause impact on the falling raw liquid inside the two flow urging cylinders 7, thereby Increase the emulsification efficiency of the stock solution.

Owner:HANGZHOU WEIKE BRAND MANAGEMENT CO LTD

Formula and making method of frozen burnt cheese paste

InactiveCN107535615AFormulation ScienceGood emulsifying effectCheese manufactureFlavorCooking & baking

The invention discloses a formula and making method of frozen burnt cheese paste. The making method comprises the following steps of mixing cream with butter, reprocessed cheddar cheese, cheddar cheese, sugar and other ingredients, then making burnt cheese paste semi-finished products through an intermittent ultrasonic-assisted chopping technology, performing decompressed rapid freezing to obtainthe frozen burnt cheese paste, and performing packaging to obtain products. The frozen burnt cheese paste is unfrozen, the unfrozen burnt cheese paste is applied on bread or cakes, and baking is conducted so as to obtain delicious burnt cheese products. Through the intermittent ultrasonic-assisted chopping technology, raw materials are heated, and then the heated materials are mixed, so that the juice isolation rate of products can be effectively reduced, the emulsifying effect can be guaranteed, and the elasticity and the fine and smooth degree of the products can be strengthened; through decompressed rapid freezing, the temperature of the products can be rapidly reduced, the flavor and the nutrient quality of the products can be maintained, and the shelf life can be prolonged; the frozenburnt cheese paste can be suitable for large-scale factory production, is stable in quality, rich in nutrition, tasty in mouth feel, convenient to use, and convenient to transport and sell; and the problems that loss caused by on-site making is large, the product yield is instable and the food hygiene and safety cannot be guaranteed are solved.

Owner:青岛德信食品有限公司

High cut disperse emulsification tank and application method thereof

InactiveCN105664758AEasy to operateGuaranteed emulsification and dispersion effectMixing methodsTransportation and packagingAgricultural engineering

The invention provides a high cut disperse emulsification tank and an application method thereof. The high cut disperse emulsification tank is provided with a stirring shaft along the middle axis of a tank body, stirring teeth are arranged at the bottom end of the stirring shaft, the top end of the stirring shaft is connected with a stirring motor, a feed inlet is formed in the top of the tank body, a discharge opening is formed in the bottom of the tank body, one or more shear shafts are arranged in the tank body, each shear shaft is provided with one or more cut disperse teeth, and the top end of each shear shaft is connected with a corresponding shear motor. The high cut disperse emulsification tank can be used for preparing a special fatting agent for fur, and the prepared special fatting agent for fur is good in shear emulsification effect and stable in property.

Owner:北京泛博清洁技术研究院有限公司

Preparation method of acifluorfen water aqua

InactiveCN104126581AGuaranteed decentralizationGuaranteed uniformityBiocideAnimal repellantsAcifluorfenSolvent

The invention relates to a preparation method of an acifluorfen water aqua. The method comprises the following steps: 1) first mixing a raw material of acifluorfen with a solvent of calixarene at the temperature of 10 DEG to 40 DEG C; 2) mixing evenly, adding an emulsifier carboxylic ester, and stirring evenly; and 3) and filtering the sediment to obtain the water aqua. The invention has the following advantages: 1) the invention uses calixarene as the solvent, the cup-shaped structure of calixarene can form good surrounding around the acifluorfen, and has certain concentration performance while maintaining dispersion properties of the acifluorfen water aqua, so as to keep the uniformity of pesticide properties in the application process, ensure the concentration of pesticide properties, and improve the control effect; and 2) acifluorfen is added to the emulsifier to guarantee the emulsifying effect of acifluorfen, and improve the dispersion performance.

Owner:JIANGSU CHANGQING AGROCHEMICAL CO LTD

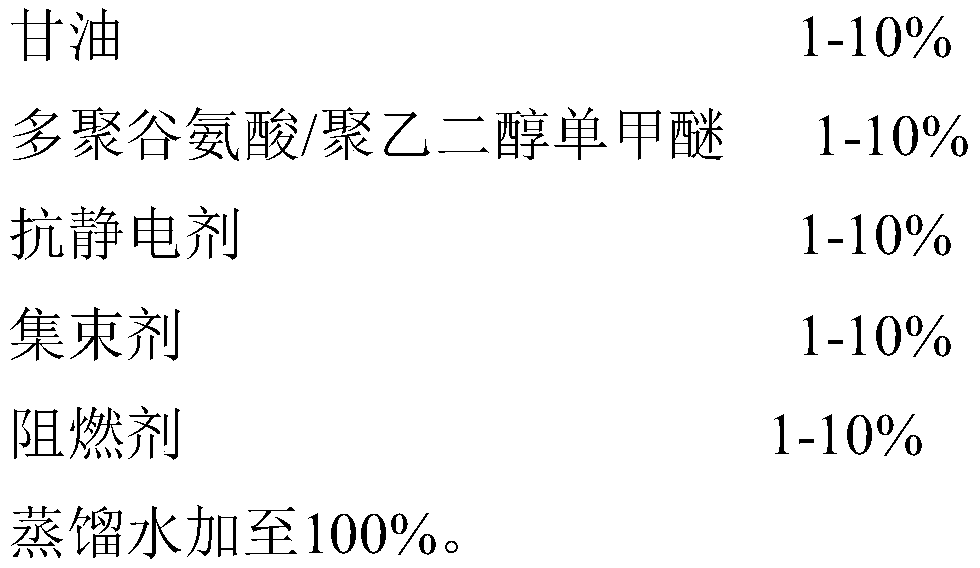

Spinning oil for processing regenerated polyester fiber

InactiveCN110241485AImprove smoothnessGood flexibilityHeat resistant fibresGrip property fibresPolyesterFiber

The invention discloses spinning oil for processing regenerated polyester fiber, and relates to the technical field of regenerated polyester fiber processing. The spinning oil is formed by mixing, by weight, 1-10% of glycerin, 1-10% of polyglutamic acid / polyethylene glycol monomethyl ether, 1-10% of an antistatic agent, 1-10% of a custer agent, 1-10% of fire retardant and the balance distilled water. By means of the spinning oil, the smoothness and softness of the polyester fiber can be remarkably improved, the kinetic friction coefficient between the fiber and metal is reduced, the static friction coefficient between the fiber is increased, and static electricity is reduced.

Owner:ANHUI SHUANGFAN HIGH FIBER CO LTD

Water bath type emulsifying machine for cosmetic production and emulsifying method

InactiveCN111729589APrecise feedingChange and expand the area of effect of stirringShaking/oscillating/vibrating mixersMixing methodsEngineeringProcess engineering

The invention relates to the technical field of cosmetic production and emulsification, in particular to a water bath type emulsifying machine for cosmetic production and an emulsifying method. The plug is moved leftwards through the positioning assembly, so that the positioning hole is opened; the second tank is driven to rotate through the manual adjustment assembly; when the rolling wheel movesto the positioning hole, the spring rod automatically extends to penetrate through the positioning hole to limit the second tank, and at the moment, the feeding hopper is aligned with the feeding port, so that accurate feeding is facilitated; and the servo motor is started, so that the lifting assembly drives the lifting plate to ascend and descendin a reciprocating manner, the lifting plate synchronously drives the emulsifying assembly to move up and down, and the emulsifying assembly rotates to fully stir and emulsify raw materials in the second tank.

Owner:朱苗苗

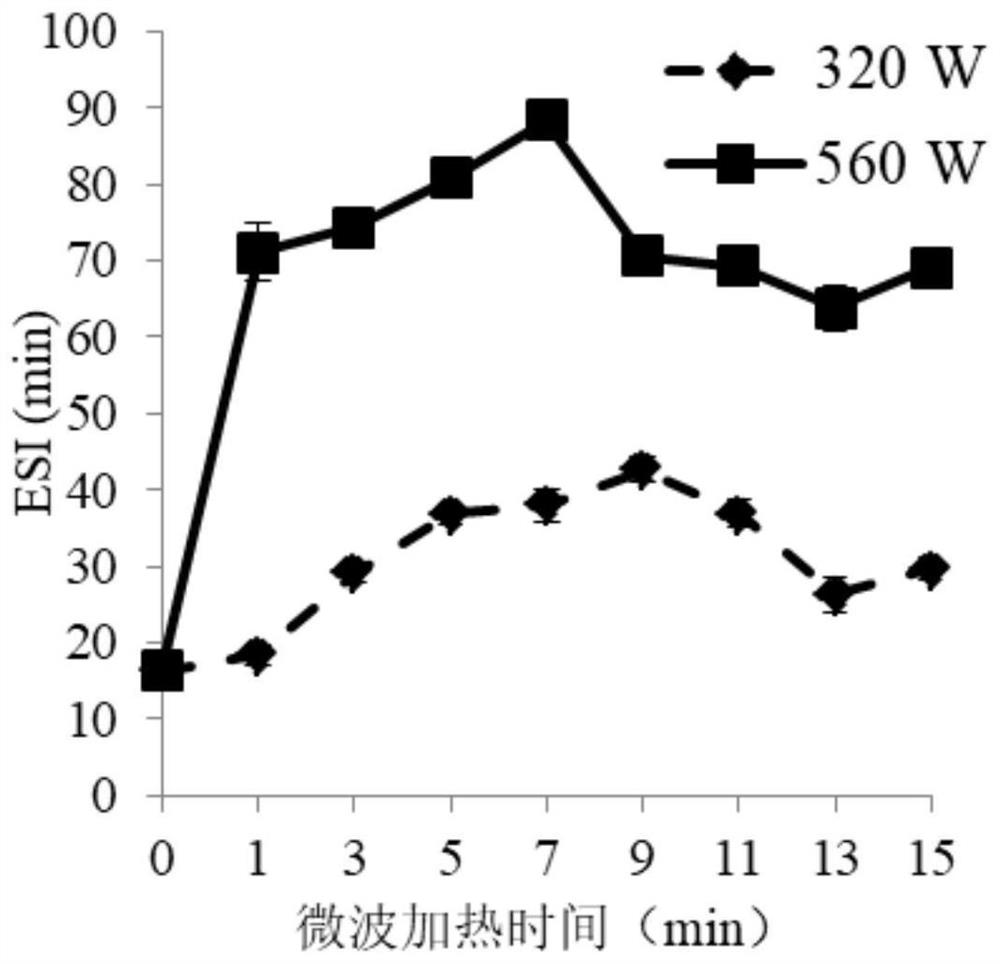

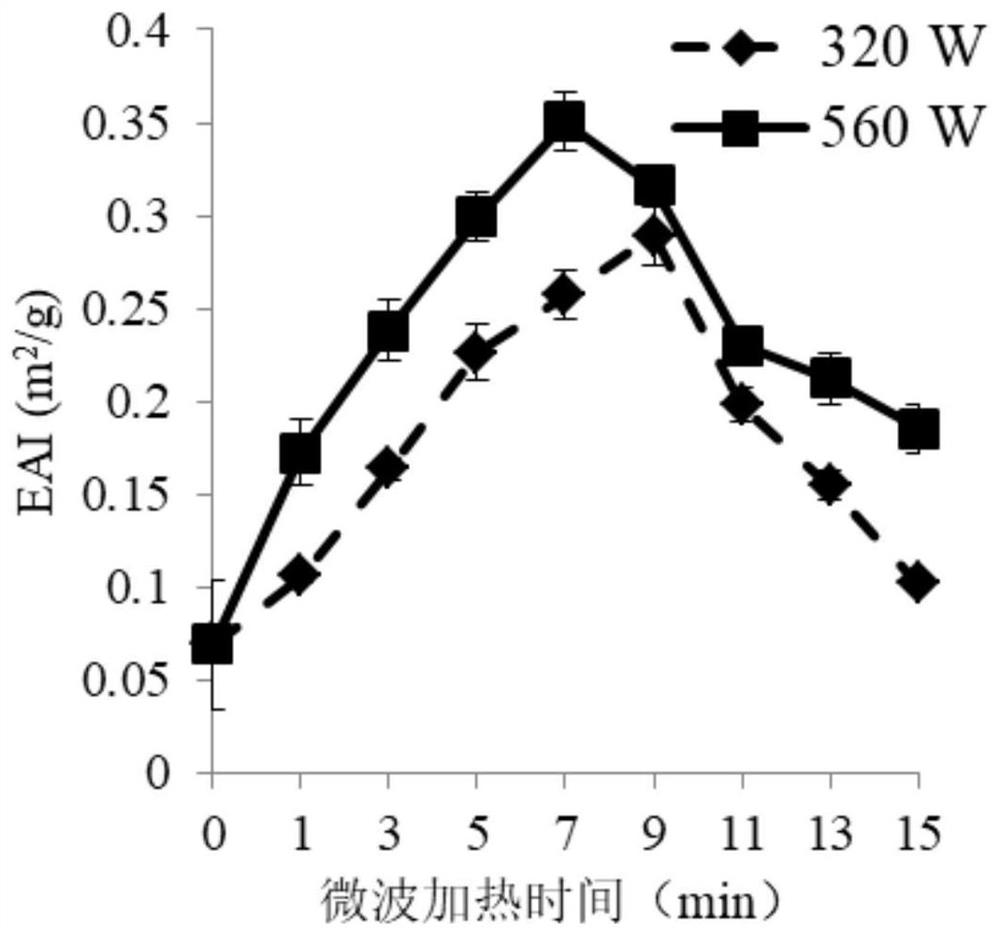

Simple method for quickly improving functional properties of whey isolated protein

ActiveCN112868884AShort reaction timeIncrease reaction rateFood processingPeptide preparation methodsBiotechnologyFreeze-drying

The invention discloses a simple method for quickly improving functional properties of whey protein isolate. The method comprises the following operation steps: adding water to dissolve the whey protein isolate, adding lactose, uniformly stirring and mixing, adjusting the pH value, carrying out microwave heating, taking out the whey protein isolate, cooling, and freeze-dried to obtain the modified whey protein isolate. Compared with a traditional method, the method has the advantages that the production period is greatly shortened, the process is simple, the cost is low, and the popularization value is high. The modified whey protein isolate prepared by the method has high emulsibility and antioxidant activity, and the application range of the whey protein isolate can be greatly expanded.

Owner:JIANGXI SCI & TECH NORMAL UNIV

Water-based nano insulating paint as well as preparation method and application thereof

The invention provides water-based nano insulating paint as well as a preparation method and application thereof, and relates to the technical field of water-based insulating paint. The water-based nano insulating paint is prepared from the following raw materials in parts by weight: 75 to 142 parts of solid epoxy resin, 15 to 30 parts of an emulsifier, 18 to 45 parts of a coalescing agent, 38 to 105 parts of water, 5.5 to 20 parts of a closed curing agent and 0.5 to 4 parts of an anti-sagging agent, the solid epoxy resin is bisphenol A type epoxy resin, and the molecular weight of the bisphenol A type epoxy resin is 1000 to 10000 g / mol; the emulsifier is a nonionic reaction type epoxy resin emulsifier. The insulating paint has the advantages of high insulation grade, high temperature and high pressure resistance, stretching and bending resistance, good adhesiveness, excellent chemical resistance and the like.

Owner:广东顺德大地缘新材料有限公司

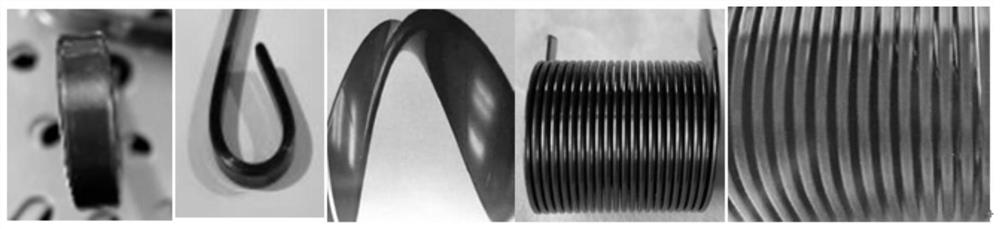

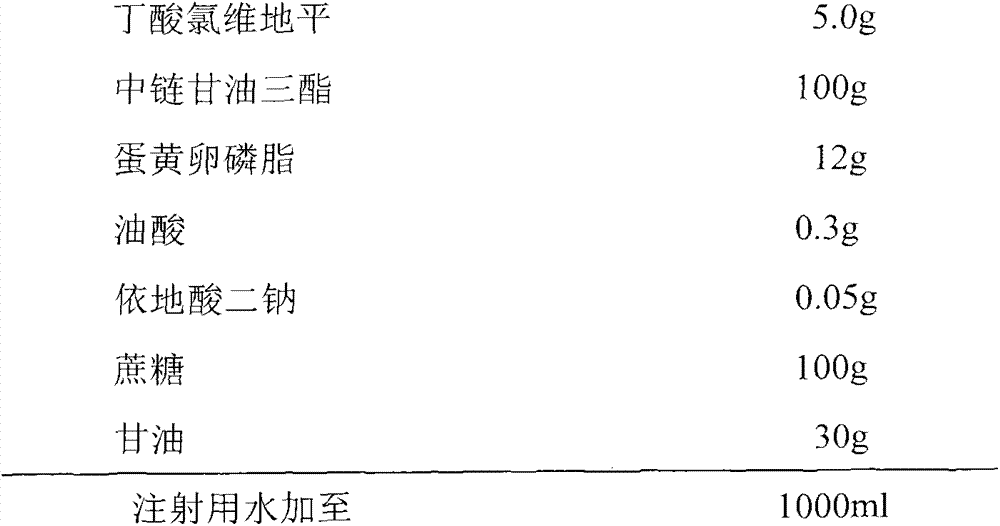

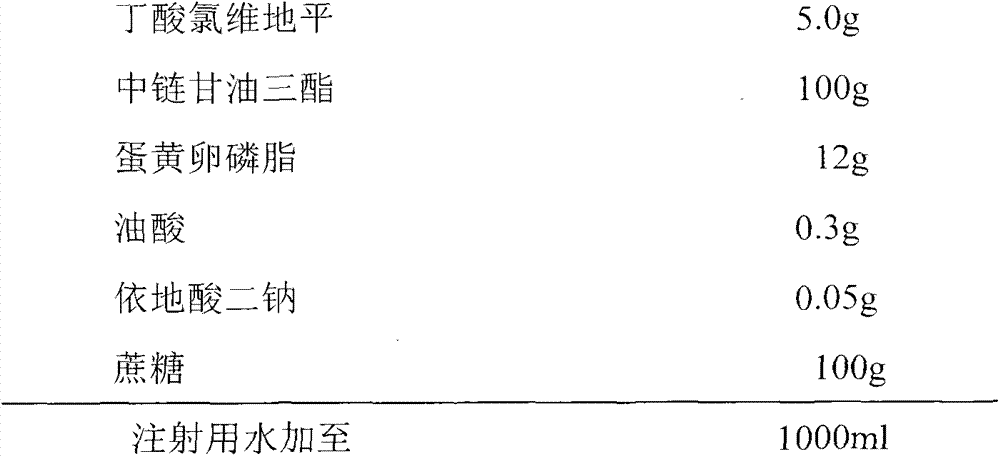

Clevidipine butyrate composition for injection and preparation method thereof

ActiveCN104546707BEasy to operateReduce leakageOrganic active ingredientsPharmaceutical non-active ingredientsDisodium EdetateFreeze-drying

The invention relates to a clevidipine butyrate composition for injection, which consists of the following raw and auxiliary materials in the weight ratio: 25-50 parts of clevidipine butyrate, 100-1000 parts of oil for injection, and 6-180 parts of egg yolk lecithin , 0.3-9 parts of oleic acid, 0.05-5 parts of edetate disodium, 50-4000 parts of lyoprotectant. The present invention removes the highly irritating water-phase surfactant and uses oil-phase auxiliary emulsifier oleic acid instead, which not only ensures the emulsification effect, but also improves safety; the glycerin is removed, the freeze-drying process is not easy to collapse, and the freeze-drying process is increased. The workability of the dry product, while, unexpectedly, the removal of glycerol improved the product's encapsulation efficiency and reduced drug leakage.

Owner:BEIJING LANDAN PHARMA TECH

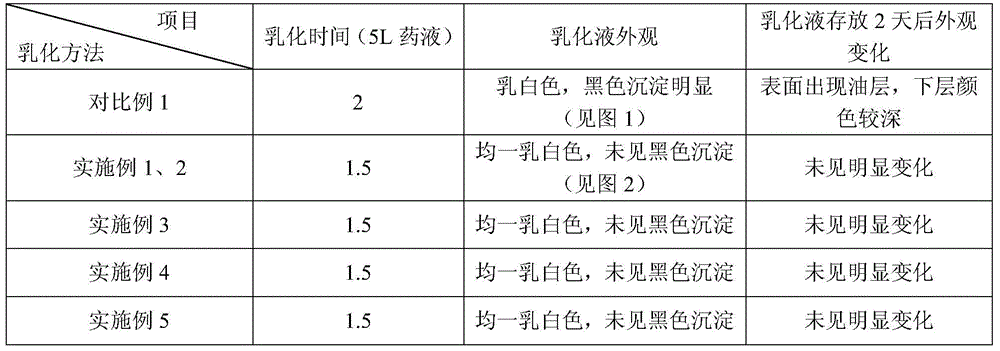

A kind of production improvement method of Nocardia rubrum skeleton emulsion

ActiveCN104083407BGood emulsificationGuaranteed emulsifying effectBacteria material medical ingredientsEmulsion deliveryFiltrationHigh pressure

The invention discloses a method for improving production of nocardia rubra frame emulsion. The method comprises the following steps: (1) preparing raw materials according to the prescription; (2) pre-treating a liquid medicine by utilizing a high-speed shearing machine at a shearing speed of 10000-20000rpm (Revolutions Per Minute) for 10-30 minutes; (3) homogenizing by utilizing a high-pressure homogenizer at a pressure of 1000-2000bar for 2-4 times; (4) performing three-stage filtration on the emulsion, wherein the first-stage granularity is 0.8-1.0 mu m, the second-stage granularity is 0.45-0.65 mu m, and the third-stage granularity is 0.22 mu m. The nocardia rubra frame emulsion does not contain titanium powder impurities, has a stable emulsification effect, and can conveniently realize sterilization and filtration.

Owner:FUJIAN SHANHE PHARMA

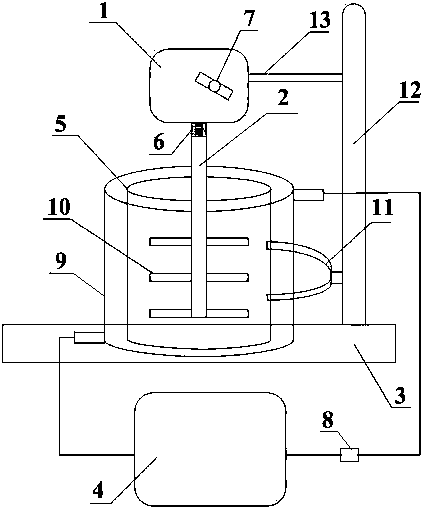

Emulsifying device for emulsion matrix experiment

PendingCN109224897AImprove stability and securitySimple structureRotary stirring mixersTransportation and packagingEmulsionWater storage tank

The invention discloses an emulsifying device for an emulsion matrix experiment. The emulsifying device comprises a motor, a shearing paddle, a base and a beaker, wherein the beaker is arranged in a container for heating; hot water is filled into the container; the container is arranged on the base; a supporting rod is arranged at one side of the base; the motor is transversely and horizontally mounted at the upper end of the supporting rod; an output shaft of the motor is vertically and downward connected with the shearing paddle; a shearing blade is arranged at the lower end of the shearingpaddle; the shearing blade stretches into the beaker; a constant-temperature water storage tank is arranged at one side of the container; a water outlet of the water storage tank is connected with a water inlet of the container through a pipeline; the pipeline is provided with a water pump; a water outlet of the container is connected with a water inlet of the water storage tank through a pipeline. The motor is used for controlling the shearing paddle to carrying out emulsifying stirring and the shearing speed is adjustable; the constant-temperature water storage tank ensures that the emulsifying temperature is accurate and the difficulties that an existing emulsion matrix emulsifying device in a laboratory has a complicated technology, low emulsifying stability and the like are overcome.

Owner:GUIZHOU XINLIAN BLAST ENG GRP

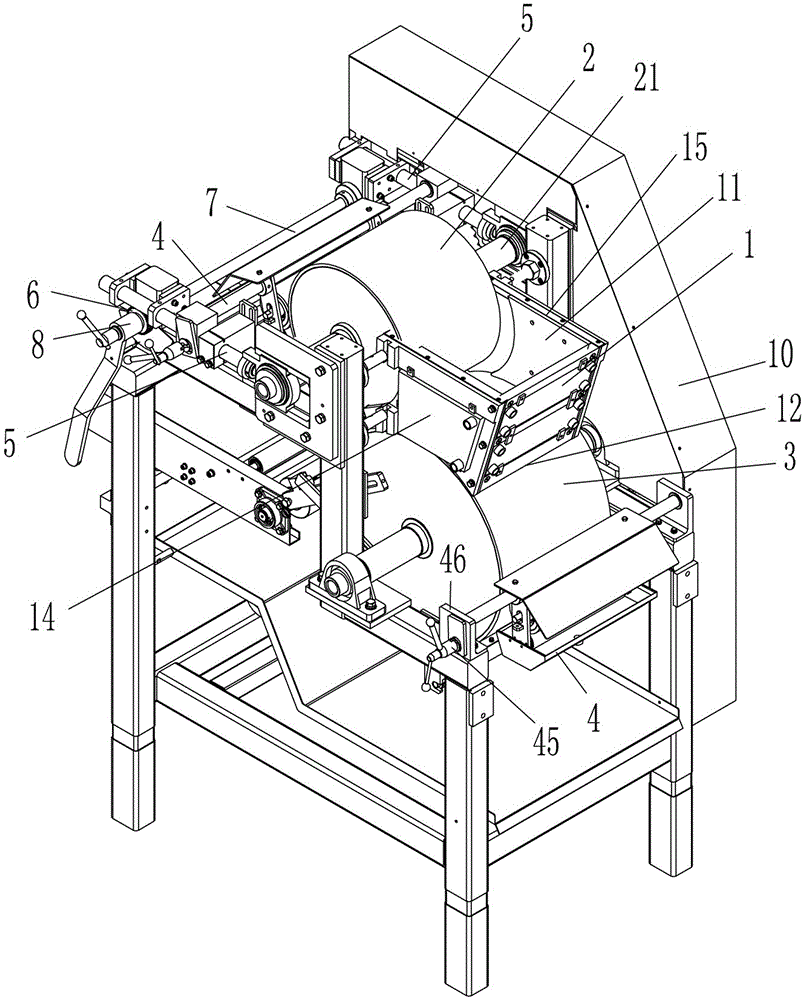

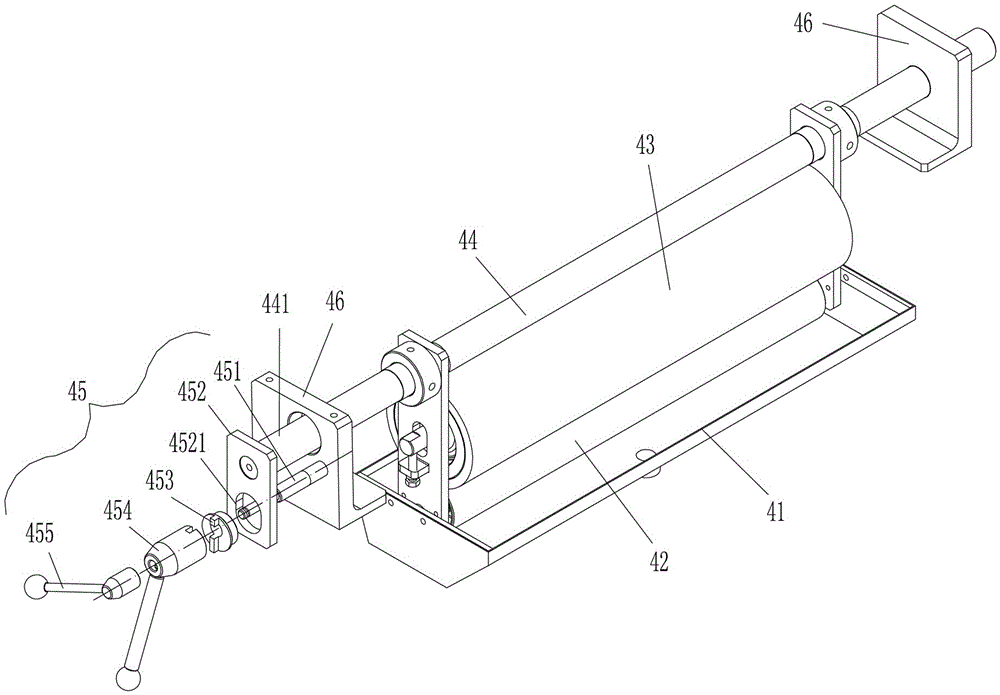

Making process and product of high-butterfat-content crisp pralines and device

ActiveCN105639020AGuaranteed emulsifying effectGuaranteed plasticityConfectionerySweetmeatsFlavorSucrose

The invention discloses a making process of high-butterfat-content crisp pralines. According to the making process, different HLB values of emulsifiers are adopted to fully emulsify oleophylic and hydrophilic materials, and sucrose fatty acid ester S370, sucrose fatty acid ester S770, sucrose fatty acid ester S570 and soybean phosphatide are mixed to prepare a compound emulsifier for ensuring an emulsifying effect and plasticity. By arranging oiling mechanisms beside upper and lower press rollers of a massecuite roller press adopted in the making process, rubber rollers are close to the press rollers adjacent to the rubber roller under the drive of eccentric adjusting assemblies, then the rubber rollers are driven to rotate by utilizing the friction between the rubber rollers and the press rollers and drive polish rollers fit with the rubber rollers to rotate, so that oil in oil storage tanks is finally and automatically carried to the press rollers through the polish rollers and the rubber rollers, the press rollers are coated with uniform and thin oil layers to prevent massecuite from adhering to the press rollers, and the rolling efficiency of the roller press is improved. The made pralines has a crisp taste and a burnt flavor and is not sticky or sweet-greasy, and the variety of candies on the market are enriched.

Owner:金冠健康产业股份有限公司

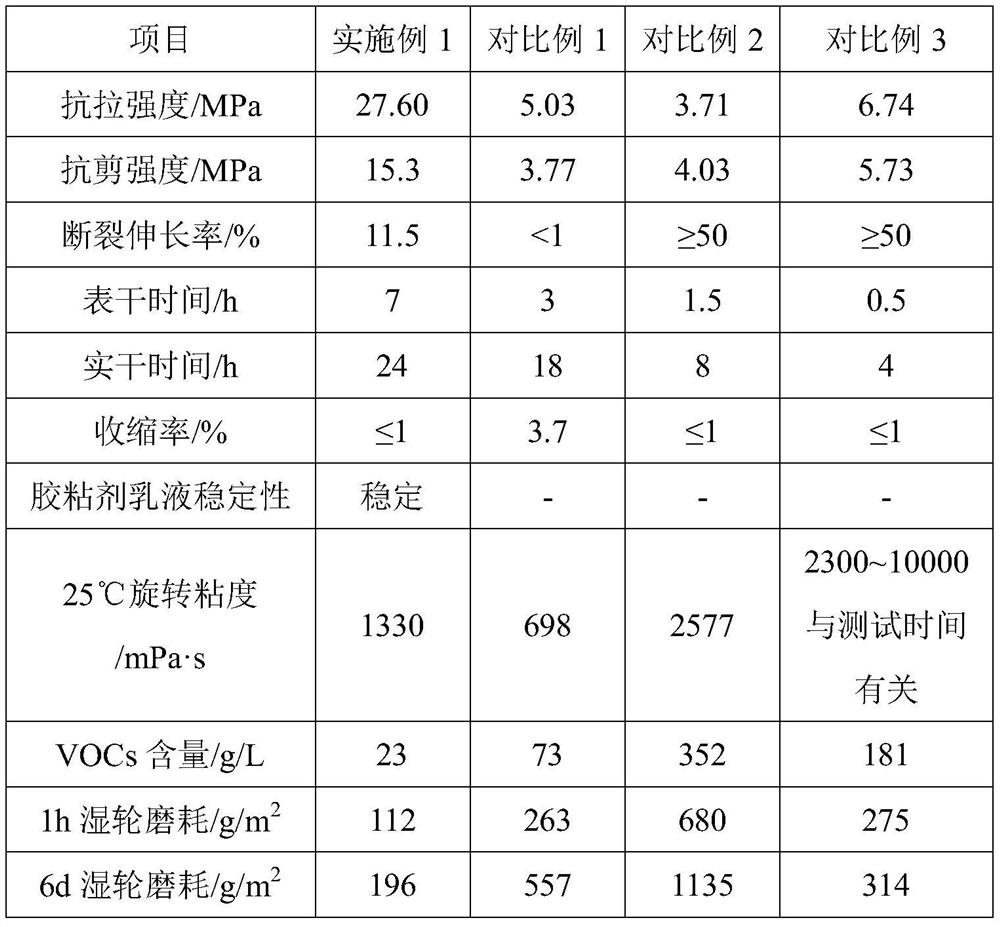

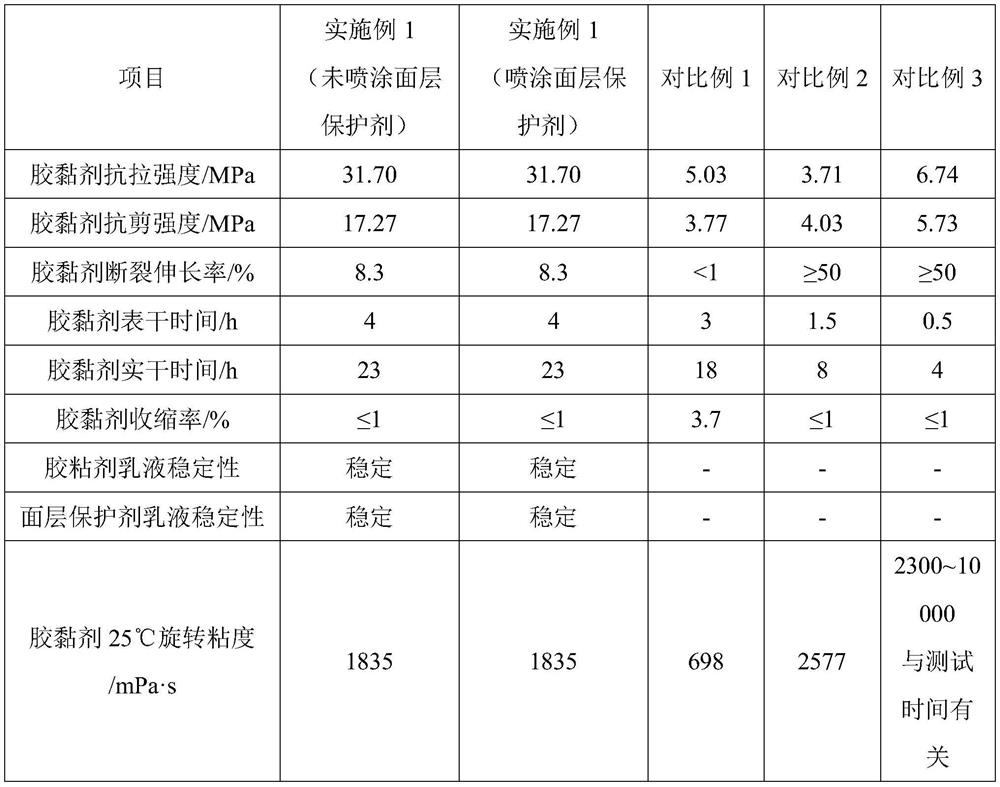

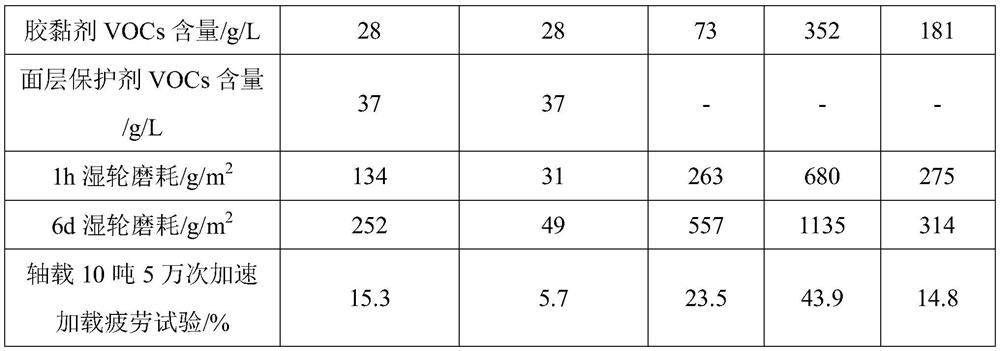

Environment-friendly adhesive capable of being mixed for construction and preparation method of environment-friendly adhesive

ActiveCN112778949AImprove toughnessHigh elongation at breakNon-macromolecular adhesive additivesSolid waste managementEpoxyAdhesive cement

The invention discloses an environment-friendly adhesive capable of being mixed for construction and a preparation method of the environment-friendly adhesive. The adhesive is composed of a component A and a component B. When the adhesive is used, 100 parts by mass of the component A, 150 parts by mass of the component B, 100 parts by mass of tap water and 10 parts by mass of pigment are mixed, then colored ceramic particles with the particle size being 1-3 mm are added, the mixture is stirred evenly, then the mixture is poured on a construction road surface, and the mixture is scraped to be flat through a flat rubber scraper. The environment-friendly adhesive capable of being mixed for construction is waterborne epoxy resin toughened and modified by polyurethane, the elongation at break and the shear strength are remarkably improved compared with those of commercially available waterborne epoxy resin, the crack resistance and the fatigue resistance of a colored anti-skid pavement prepared from the environment-friendly adhesive are remarkably improved, and the introduction of hydrophilic molecular chains is controlled, so that the water damage resistance can be effectively improved. Compared with a conventional colored anti-skid pavement , the colored anti-skid pavement constructed by mixing has the advantages that the anti-stripping capability is higher, and the use amount of the ceramic particles is greatly reduced.

Owner:山西省交通科技研发有限公司 +3

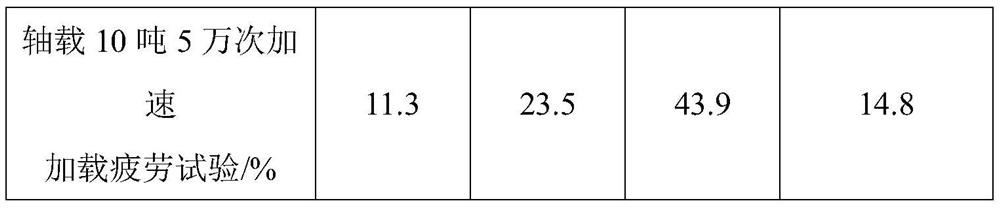

Pomegranate fruit powder preparation method

InactiveCN107198176AGood colorGood emulsifying effectFood ingredient as antioxidantFood preservationFruit juiceVitamin C

The invention discloses a pomegranate fruit powder preparation method. The pomegranate fruit powder preparation method comprises the following steps: taking and peeling a pomegranate, washing with water, adding pre-treated mulberries, performing uniform mixing, performing pulping, grinding and filtering, and taking fruit juice; and adding an anti-oxidant and a Chinese herbal medicine extract into the fruit juice, performing uniform mixing, regulating the pH of the fruit juice to be 3.8-4.0, performing sterilization, adding a drying aid and a flavoring agent, and performing drying to obtain pomegranate fruit powder. The prepared pomegranate fruit powder is high in content of vitamin C and nutritional ingredients, good in taste, excellent in emulsifying property and loose in powder.

Owner:WUHU JINCHENG AGRI TECH CO LTD

High-speed emulsifying device applied to polyurethane coating

InactiveCN114272818AEasy to operateSimple structureShaking/oscillating/vibrating mixersMixing methodsPolymer scienceForward sliding

The invention provides a high-speed emulsification device applied to a polyurethane coating, relates to the technical field of emulsification mechanical equipment, and aims to solve the problems that the emulsification effect is reduced and the emulsification time is shortened due to the fact that the stirring process is not strong enough and a surfactant and a material are not uniformly mixed when an existing emulsification device for the polyurethane coating is actually used. The problems that in the prior art, materials cannot be conveniently added into a stirring barrel in the stirring process, the materials are prone to splashing, meanwhile, a large number of materials are prone to being attached to the inner wall of the stirring barrel, and the stirring barrel is complex in installation structure and inconvenient to disassemble and clean are solved, the emulsifying device comprises a base, the base is of a rectangular through cavity structure, and an emulsifying box is arranged in a cavity of the base. Power is provided by the third motor, the rack is driven by the missing gear to slide forwards in the sliding sleeve, the rack is made to return to the initial position under the elastic action of the restoring spring, the stirring barrel is driven by the rack to swing front and back with the shaft rod as the axis, and under strong vibration stirring, materials are fully mixed, and the emulsifying effect is guaranteed.

Owner:王飞洋

Anti-stripping environment-friendly colored antiskid pavement and preparation method thereof

ActiveCN112832084AImprove crack resistanceImprove fatigue resistanceIn situ pavingsPolyureas/polyurethane adhesivesEpoxyAdhesive cement

The invention discloses an anti-stripping environment-friendly colored antiskid pavement and a preparation method thereof. The method comprises the following steps: firstly, repairing and sweeping a pavement; then paving an environment-friendly colored antiskid pavement adhesive, and spreading colored ceramic particles on the adhesive; and after the adhesive is cured, spraying the environment-friendly colored antiskid pavement surface layer protective agent. The environment-friendly colored antiskid pavement adhesive is toughened and modified by polyurethane, the elongation at break and the shear strength have better matching property, and the crack resistance and the fatigue resistance of a paved colored antiskid pavement are remarkably improved. By using the surface layer protective agent, the anti-stripping capability of the ceramic particles of the colored anti-skid pavement is effectively improved, and the water damage resistance of the environment-friendly colored anti-skid pavement is further improved. Compared with a conventional colored antiskid pavement and a water-borne epoxy resin colored antiskid pavement, the colored antiskid pavement disclosed by the invention is more excellent in environmental protection performance, crack resistance and durability.

Owner:山西省交通科技研发有限公司 +3

Emulsion explosive based on polymer emulsifier and preparation method thereof

ActiveCN112028721AGuaranteed emulsifying effectImprove stabilityNon-explosive stabilisersPolymer scienceO-Phosphoric Acid

The invention discloses an emulsion explosive based on a polymer emulsifier and a preparation method of the emulsion explosive. The emulsion explosive comprises the following raw materials in parts byweight: 72-78 parts of ammonium nitrate, 8-12 parts of sodium nitrate, 5-15 parts of water, 0.5-1.5 parts of a composite polymer emulsifier, 3-7 parts of a composite oil phase, 0.1-0.3 part of expanded perlite, 0.05-0.1 part of sodium nitrite and 0.1-0.3 part of phosphoric acid. Wherein the composite polymer emulsifier is prepared by compounding polyisobutylene succinic anhydride triethanolamine,polyisobutylene succinic anhydride pentaerythritol ester and polybutylene succinic anhydride xylitol ester according to a ratio of 1: 3-5: 1-3. The emulsifier provided by the invention has a good emulsifying effect, and the prepared emulsion explosive has good storage stability.

Owner:HENAN HUATONG CHEMICAL CO LTD

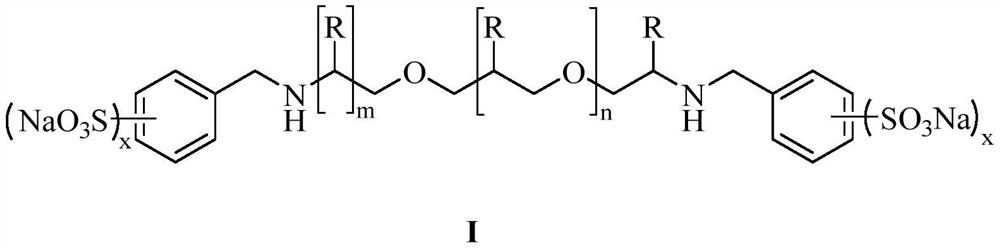

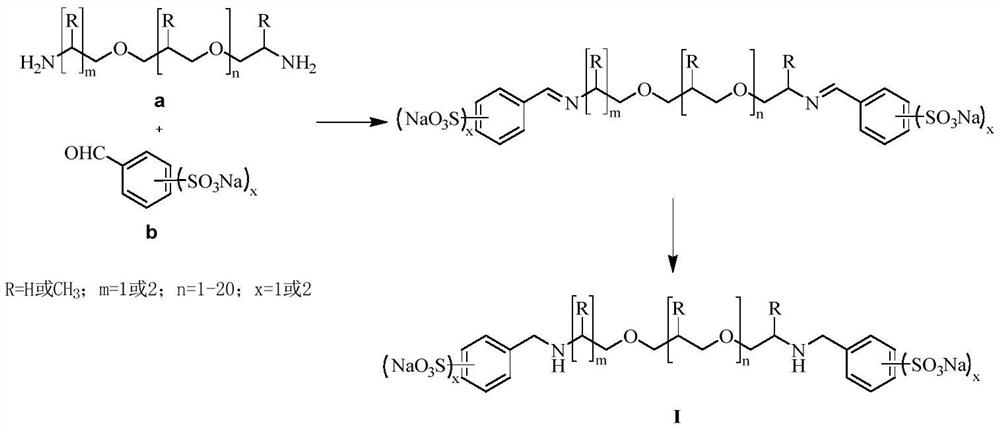

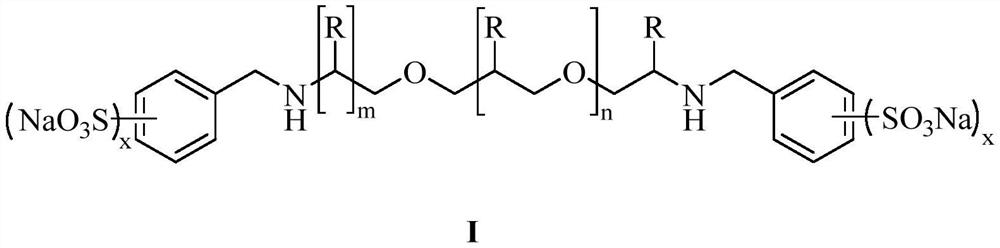

Flexible sulfonic acid type hydrophilic chain extender as well as preparation method and application thereof

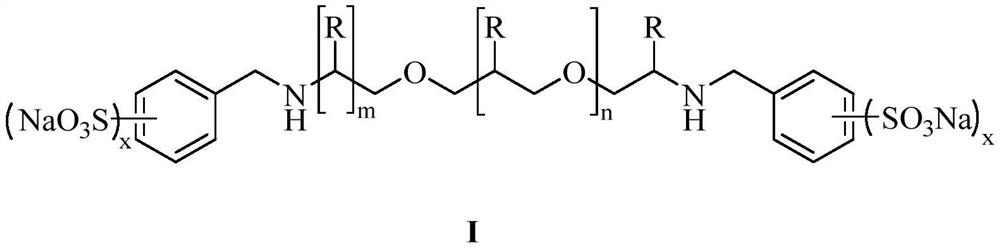

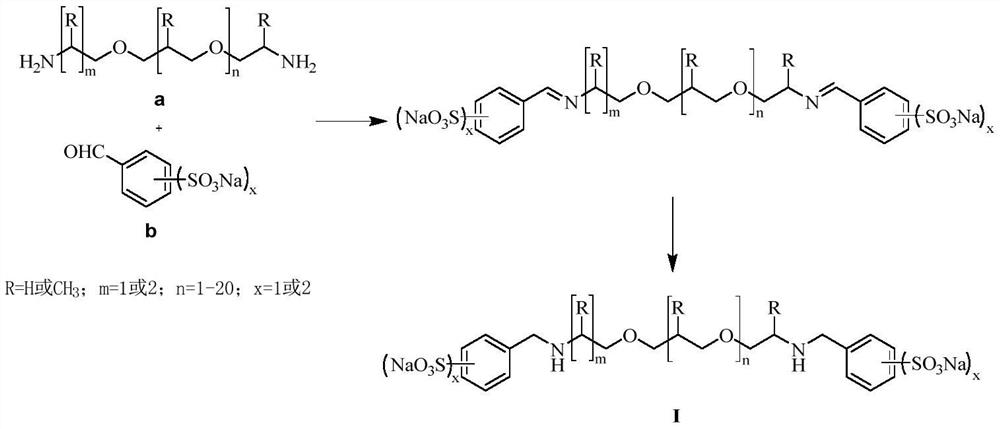

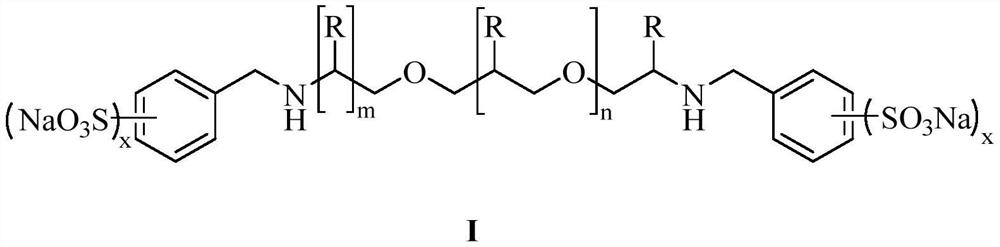

ActiveCN112300353AGuaranteed emulsifying effectGuaranteed long-term stabilitySulfonic acids salts preparationPolyurethane dispersionPolymer science

The invention relates to a flexible sulfonic acid type hydrophilic chain extender as well as a preparation method and application thereof. The molecular structural general formula of the flexible sulfonic acid type hydrophilic chain extender is shown as I in the description, wherein R is H or CH3; m is equal to 1 or 2; n is any integer of 1-20; and x is equal to 1 or 2. The preparation method comprises the steps of reacting aldehyde containing sulfonic acid ion groups with ether diamine under the action of an acidic catalyst to generate an aldimine intermediate product, and reducing the aldimine intermediate product by using a reducing agent to obtain the flexible sulfonic acid type hydrophilic chain extender. The invention also provides application of the flexible sulfonic acid type hydrophilic chain extender or the flexible sulfonic acid type hydrophilic chain extender prepared by the preparation method in synthesis of a waterborne polyurethane dispersion. Through the chain extender,the toughness of polyurethane is further improved on the basis of improving the emulsifying property and water resistance of polyurethane.

Owner:JIANGHAN UNIVERSITY

Environment-friendly adhesive for colored anti-skid pavements and preparation method of environment-friendly adhesive

ActiveCN112778961AImprove crack resistanceImprove fatigue resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyAdhesive cement

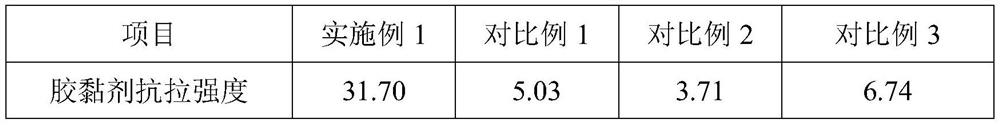

The invention discloses an environment-friendly adhesive for colored anti-skid pavements and a preparation method of the environment-friendly adhesive. The adhesive is composed of a component A and a component B. When the adhesive is used, 100 parts by mass of the component A, 150 parts by mass of the component B, 100 parts by mass of tap water and 10 parts by mass of pigment are mixed, stirred at the rotating speed of 1000-1500 rpm for 3-5 min and then poured on a construction road surface, and colored ceramic particles with the particle size of 1-3 mm are spread after the mixture is spread. The adhesive prepared by the invention is waterborne epoxy resin toughened and modified by polyurethane, the elongation at break can reach 8.3%, the tensile strength is kept at a relatively high value of 31.7 MPa, and the shear strength is remarkably improved compared with the commercially available waterborne epoxy resin and can reach 17.27 MPa. The crack resistance and the fatigue resistance of a colored anti-skid pavement prepared from the adhesive are remarkably improved.

Owner:山西省交通科技研发有限公司 +3

A kind of flexible sulfonic acid type hydrophilic chain extender and its preparation method and application

ActiveCN112300353BGuaranteed emulsifying effectGuaranteed long-term stabilitySulfonic acids salts preparationPolyurethane dispersionPolymer science

The invention relates to a flexible sulfonic acid type hydrophilic chain extender and its preparation method and application. The molecular structure general formula of this flexible sulfonic acid type hydrophilic chain extender is shown in I: wherein, R=H or CH 3 ; m=1 or 2; n is any integer from 1-20; x=1 or 2. The preparation method comprises the reaction of an aldehyde containing a sulfonic acid ion group and an ether diamine under the action of an acidic catalyst to generate an aldimine intermediate product, and then the aldimine intermediate product is reduced by a reducing agent to obtain the flexible sulfonate Acid type hydrophilic chain extender. The present invention also proposes the application of the above flexible sulfonic acid type hydrophilic chain extender or the flexible sulfonic acid type hydrophilic chain extender prepared by the above preparation method in the synthesis of aqueous polyurethane dispersion. The toughness of the polyurethane is further improved by the chain extender on the basis of improving the emulsification and water resistance of the polyurethane.

Owner:JIANGHAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com