Patents

Literature

765 results about "Kinetic friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Kinetic friction is a force that acts between moving surfaces. An object that is being moved over a surface will experience a force in the opposite direction as its movement. The magnitude of the force depends on the coefficient of kinetic friction between the two kinds of material. Every combination is different.

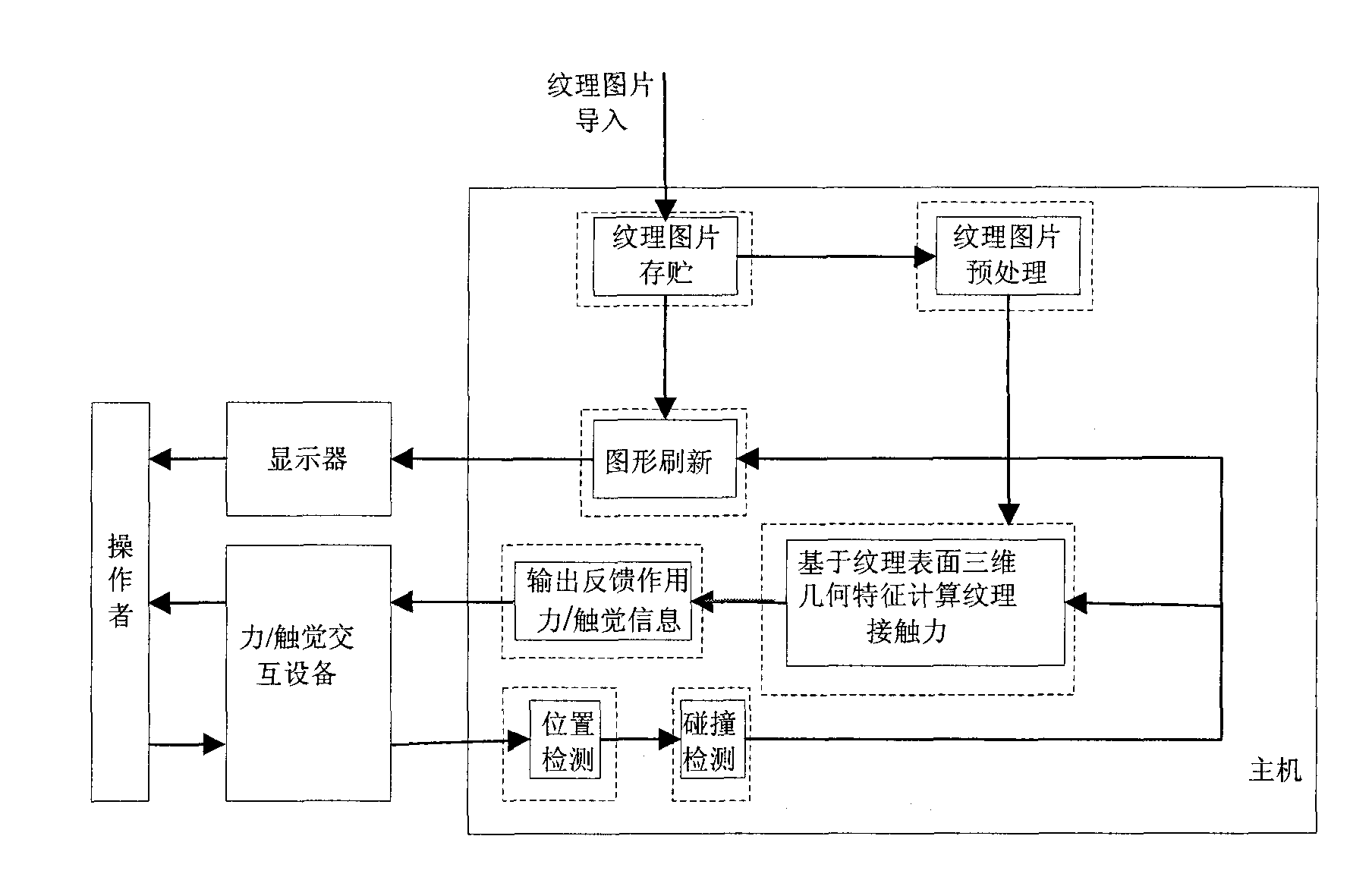

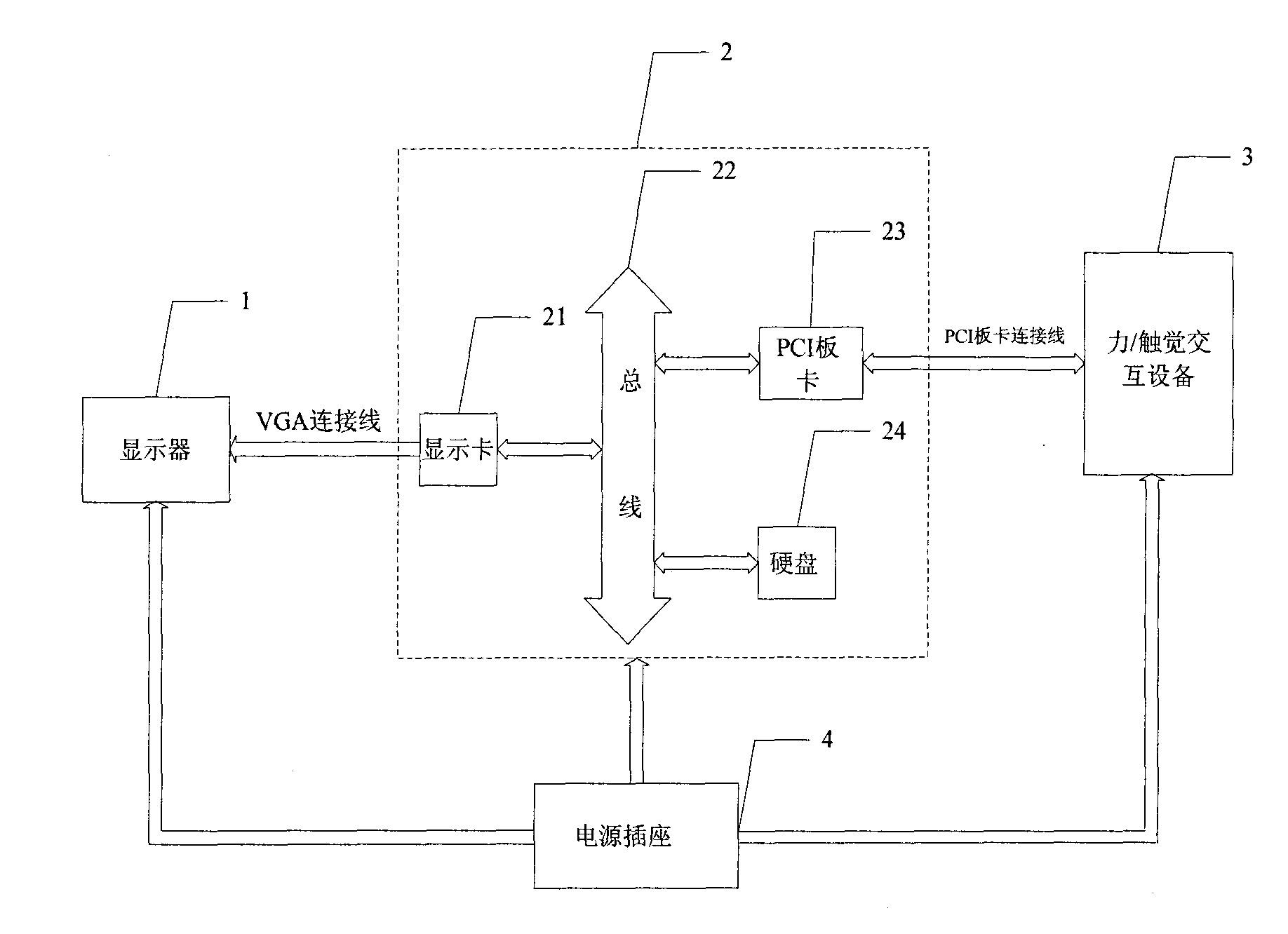

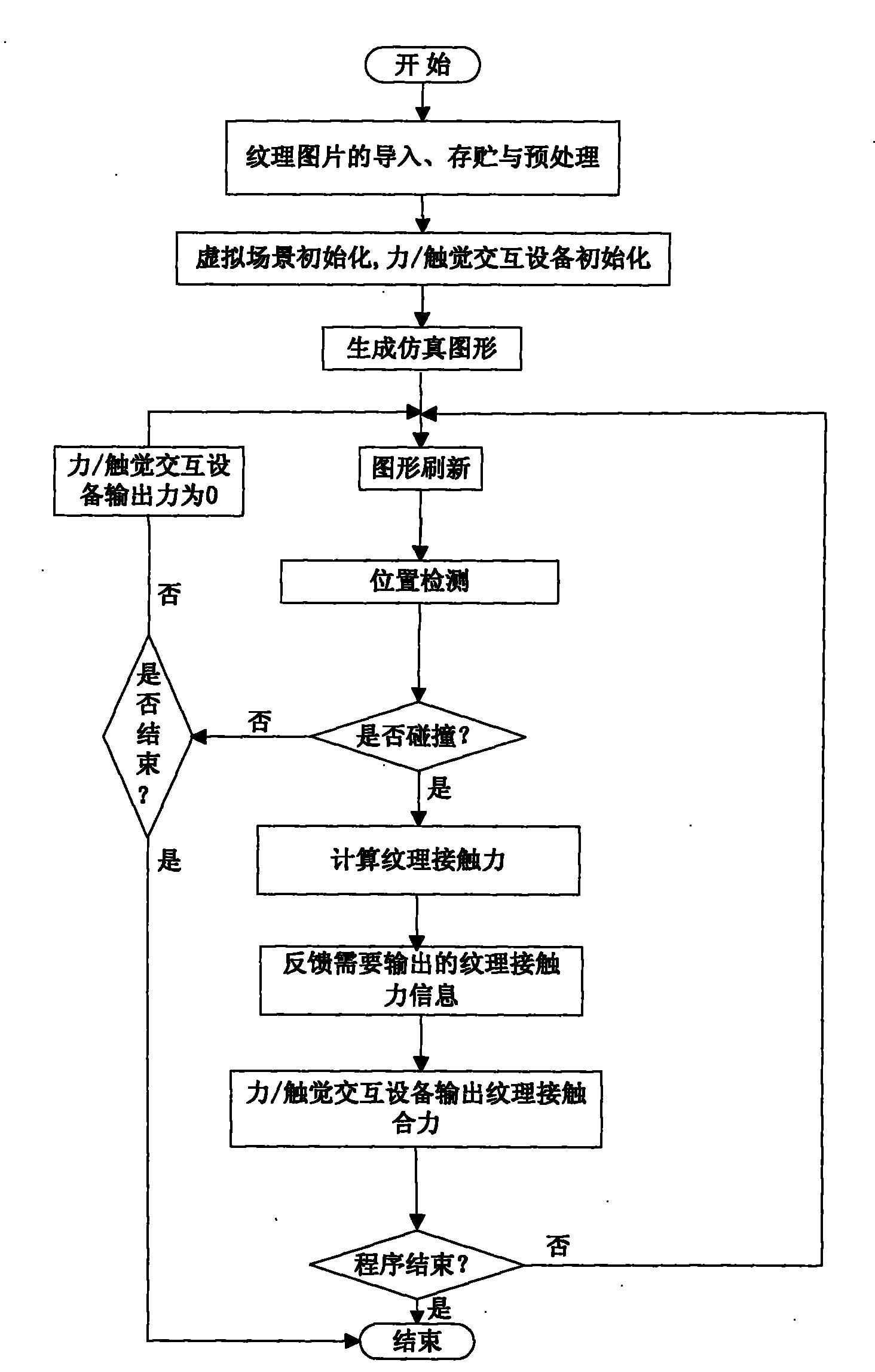

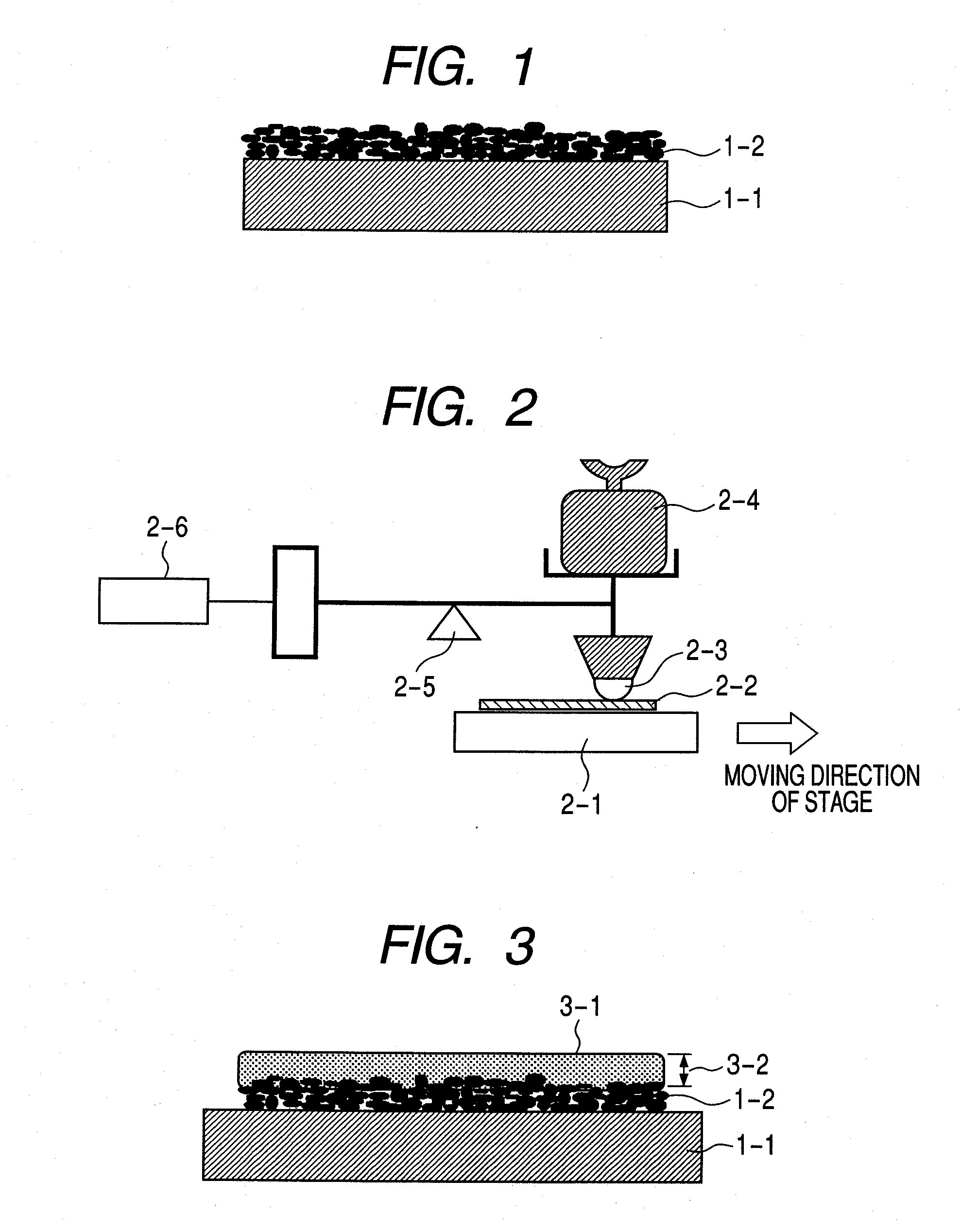

Image texture tactile representation system based on force/haptic interaction equipment

ActiveCN101819462AImprove realismImprove stabilityInput/output for user-computer interactionGraph readingInteraction systemsImaging processing

The invention discloses an image texture tactile representation system based on force / haptic interaction equipment for virtual reality human-computer interaction, which is characterized in that when the virtual proxy of the force / haptic interaction equipment slides on a texture surface of a virtual object in a virtual environment, the surface height of the object texture corresponding to the contact point and a coefficient of kinetic friction for reflecting the rough degree of the contact point are firstly obtained on the basis of an image processing method, a continuous normal contact force model reflecting the concave-convex degree of the contact point and a tangential friction model reflecting the rough degree of the contact point are respectively established, and finally the texture contact force is fed back to an operator in real time through the force / haptic interaction equipment so as to realize the force haptic express and reappear when fingers slide over the surface texture of the virtual object. The feedback continuous change normal force not only enables the human-computer interaction to be more real, but also enables an interaction system to be more stable, and the feedback friction related to the rough degree of the contact point also further enhances the sense of reality when the texture reappears.

Owner:NANTONG MINGXIN CHEM +1

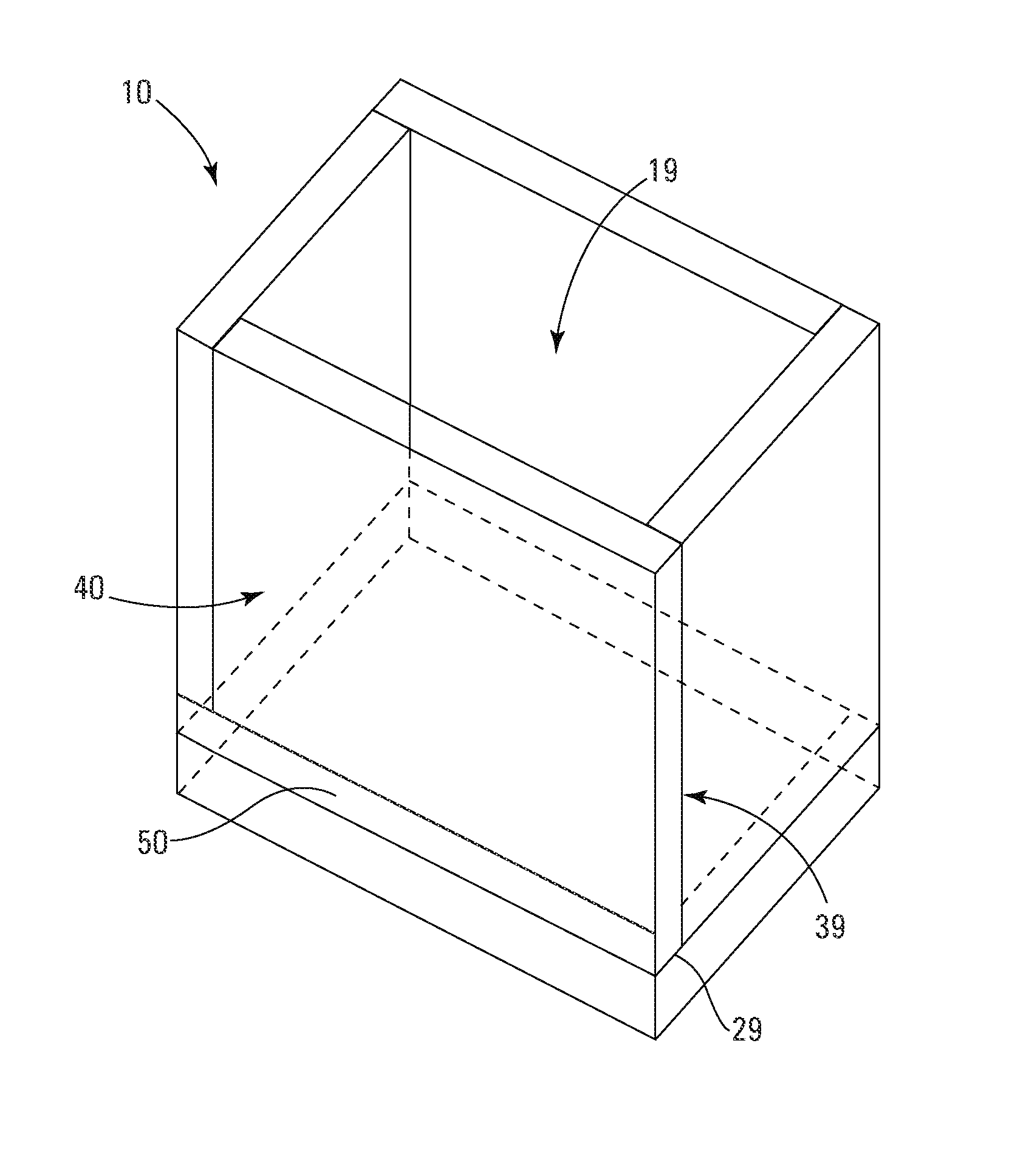

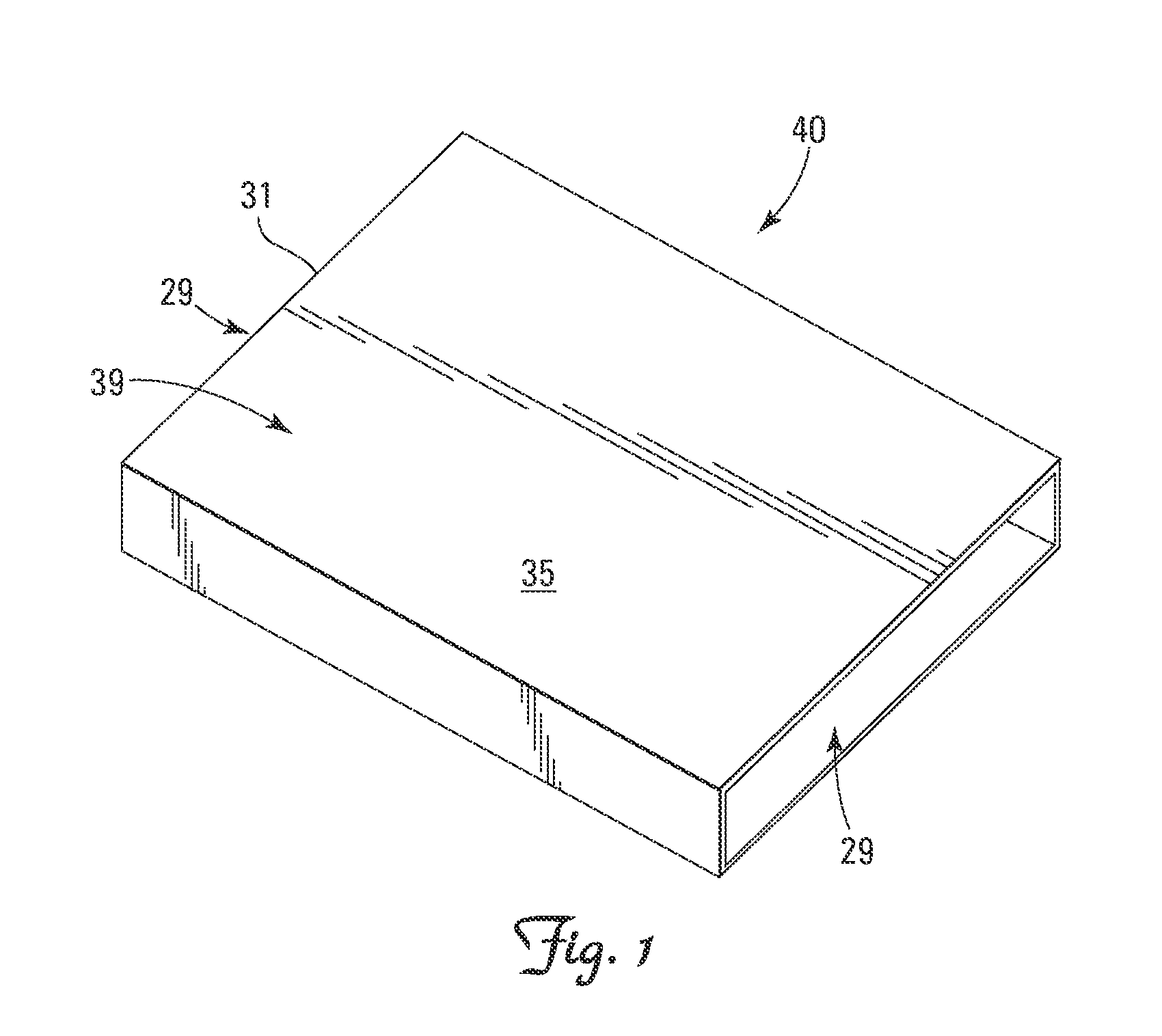

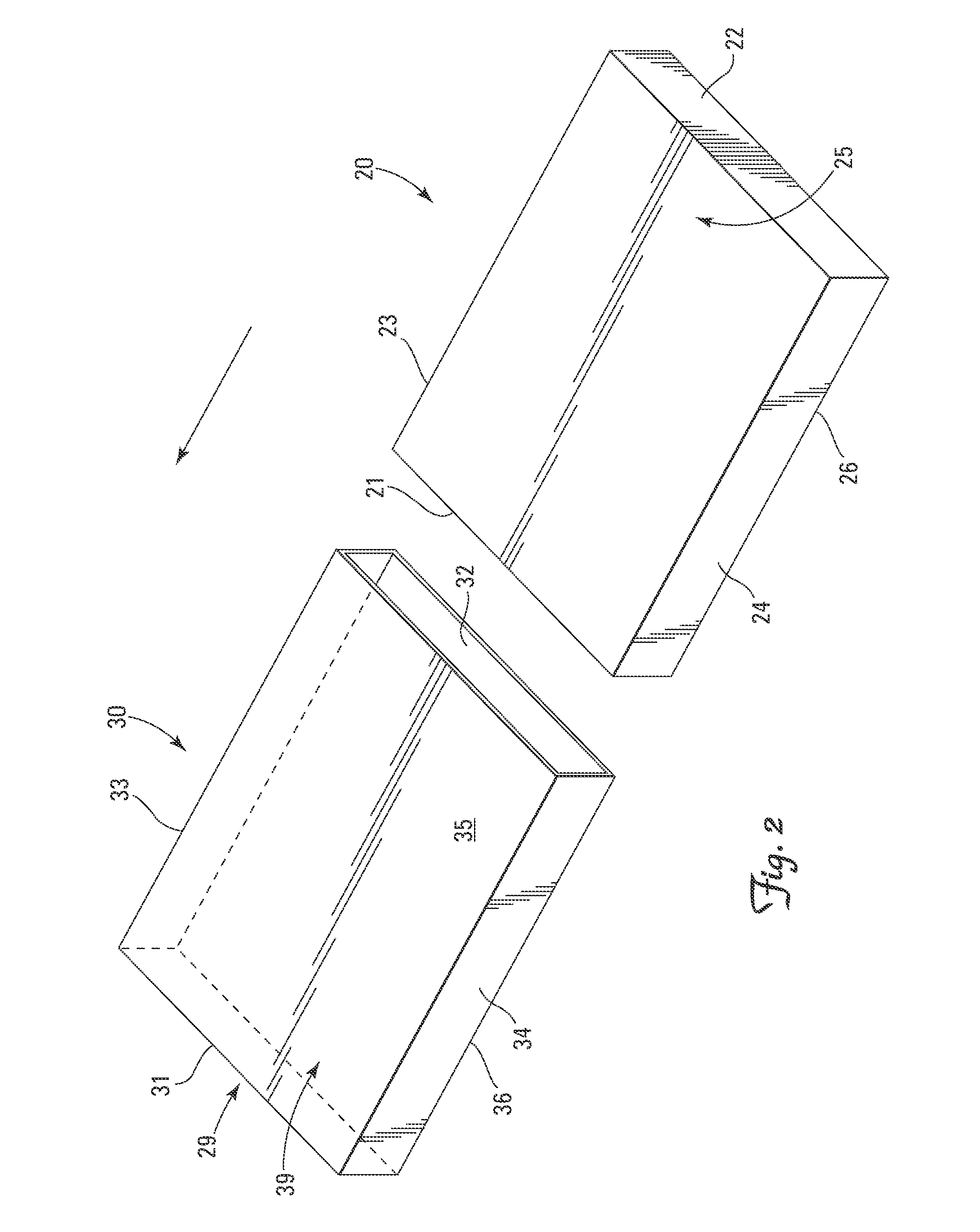

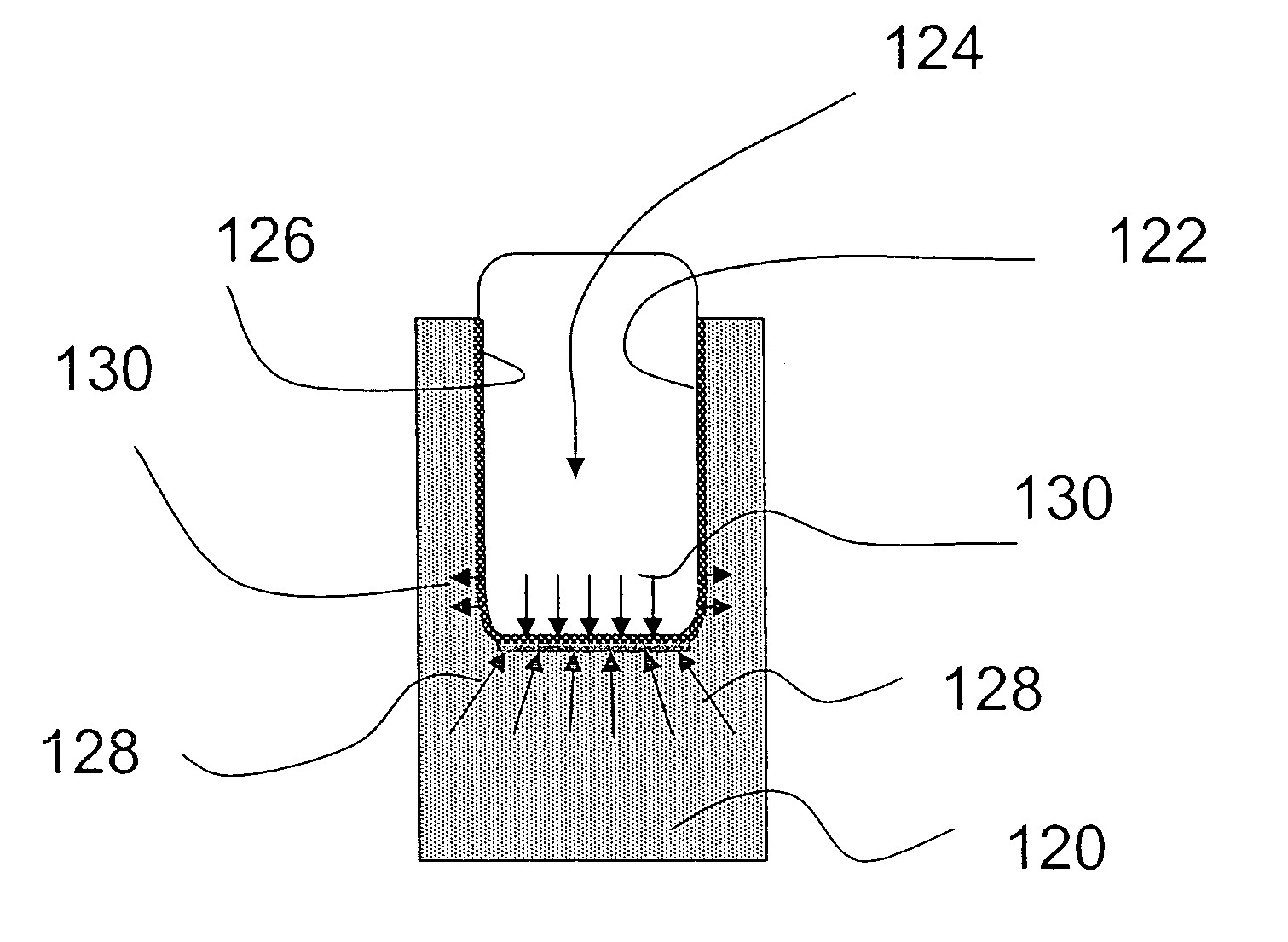

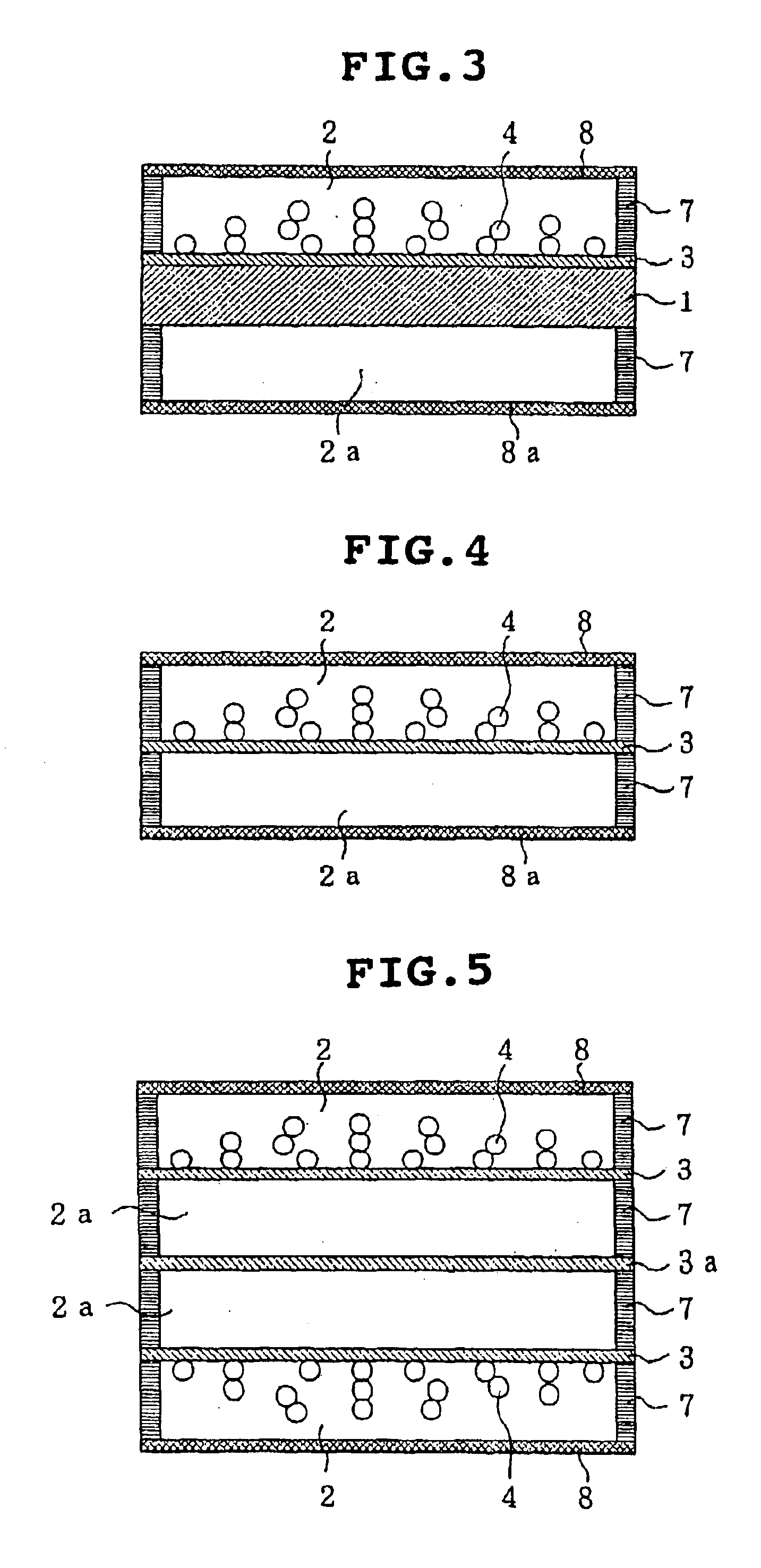

Assembly of abutting vacuum insulated panels arranged to form a retention chamber with a slip surface interposed between the panels

ActiveUS7950246B1Decrease abrasive wearReduce abrasive wearLighting and heating apparatusDomestic refrigeratorsEngineeringVacuum insulated panel

The invention is an assembly of abutting vacuum insulated panels configured and arranged to form a retention chamber with a slip surface providing a low kinetic coefficient of friction interposed between the panels within the abutment areas.

Owner:PELI BIOTHERMAL LLC

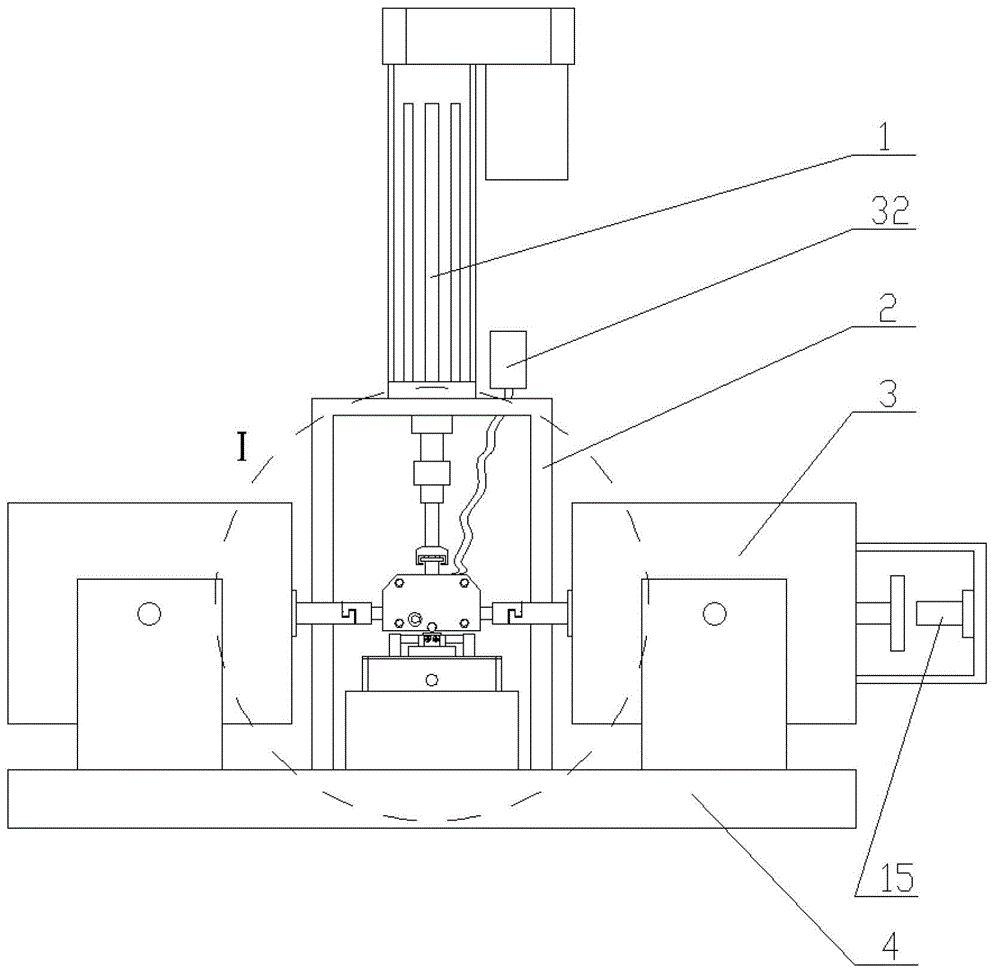

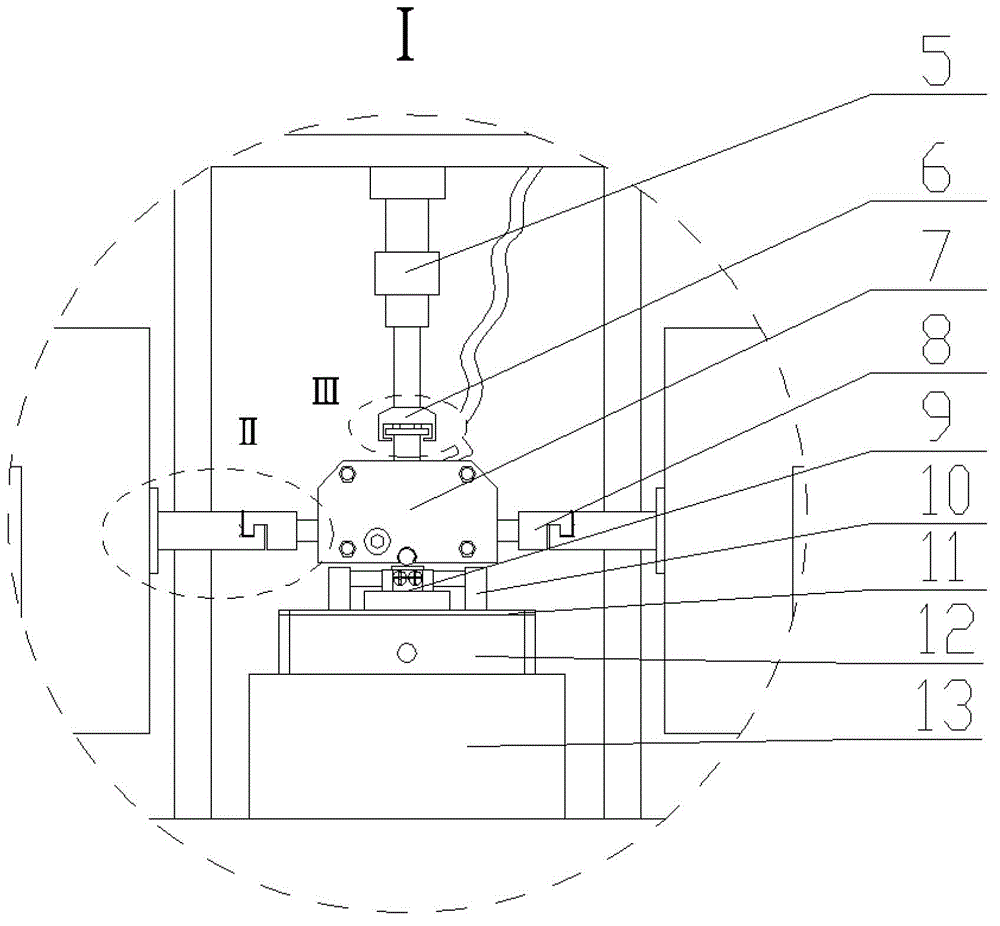

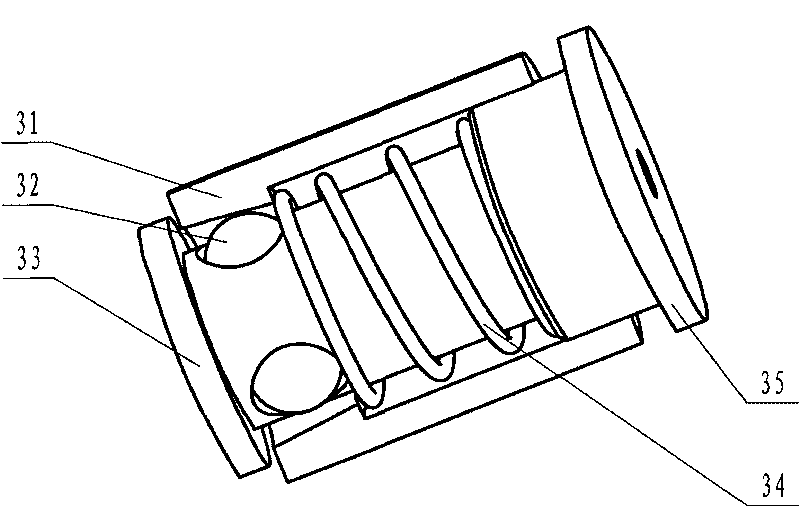

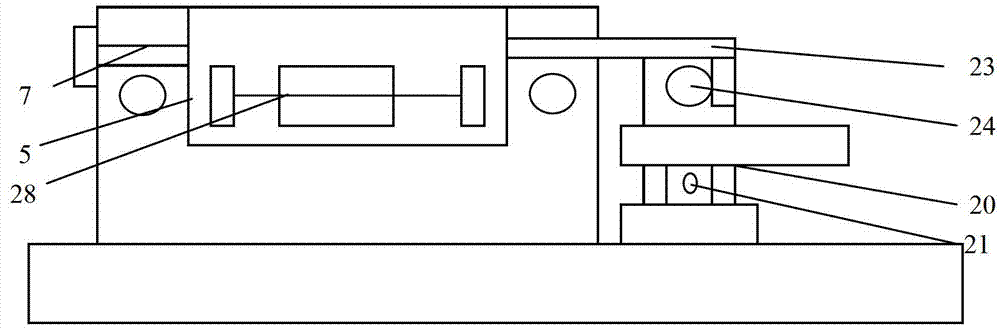

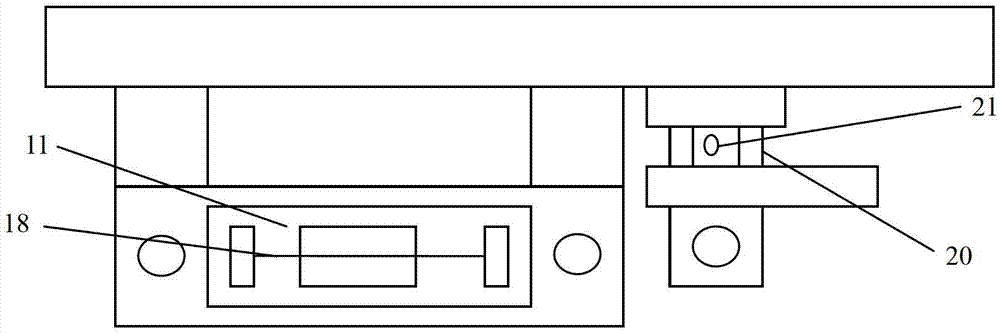

Micro-movement friction and abrasion testing machine

InactiveCN103063530AThe excitation amplitude is adjustableAdjustable vibration modeUsing mechanical meansInvestigating abrasion/wear resistanceClosed loop feedbackEngineering

The invention discloses a micro-movement friction and abrasion testing machine. The micro-movement friction and abrasion testing machine is that two symmetrically arranged electric vibration exciters are adopted and used as excitation sources for generating micro-movement friction between friction pairs; a loading device is adopted and used for applying positive pressure to the friction pairs; a force sensor is adopted and used for collecting a positive pressure signal; a computer data processing device is arranged and produces a closed-loop feedback control together with the acquired positive pressure signal, and the load applied by the loading device is kept constant. In addition, the computer data processing device is used for recording and analyzing the positive pressure signal acquired by the sensor, a micro-movement friction force signal, and a displacement signal, acquired by a displacement sensor, of each electric vibration exciter and then are automatically outputting the signals to generate abrasion performances for a sample A and a sample B of the friction pairs; and therefore, the micro-movement friction and abrasion testing machine has the characteristics of being adjustable in vibration excitation amplitude, variable in vibration mode, convenient to operate and move, high in loading precision, and reproducible in project service condition, the experimental data is high in repeatability and can be used for evaluating the micro-movement friction and abrasion performance of a material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

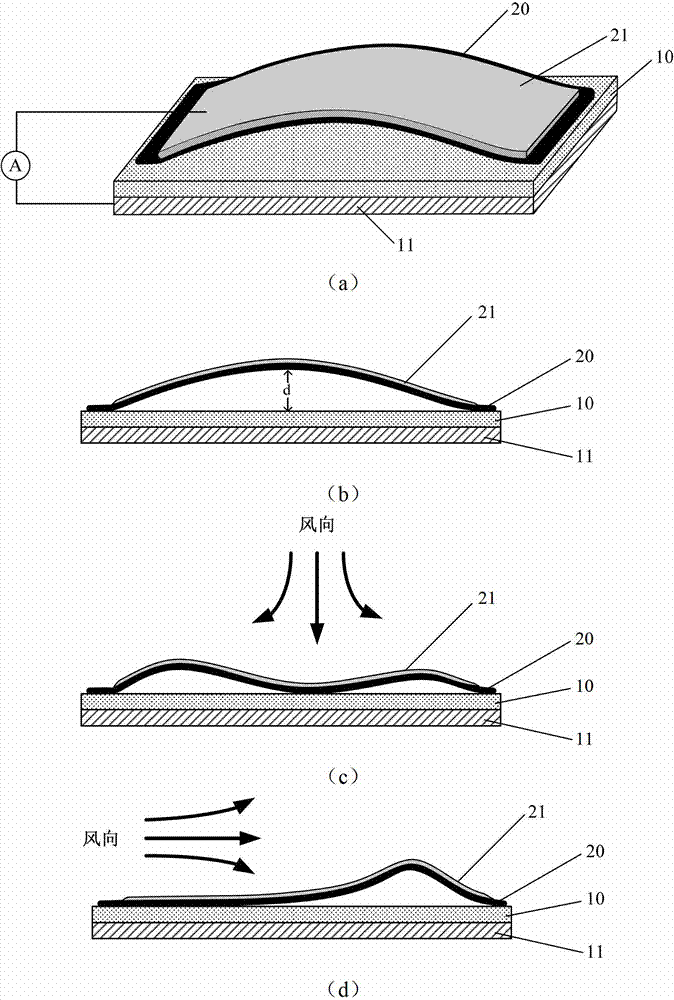

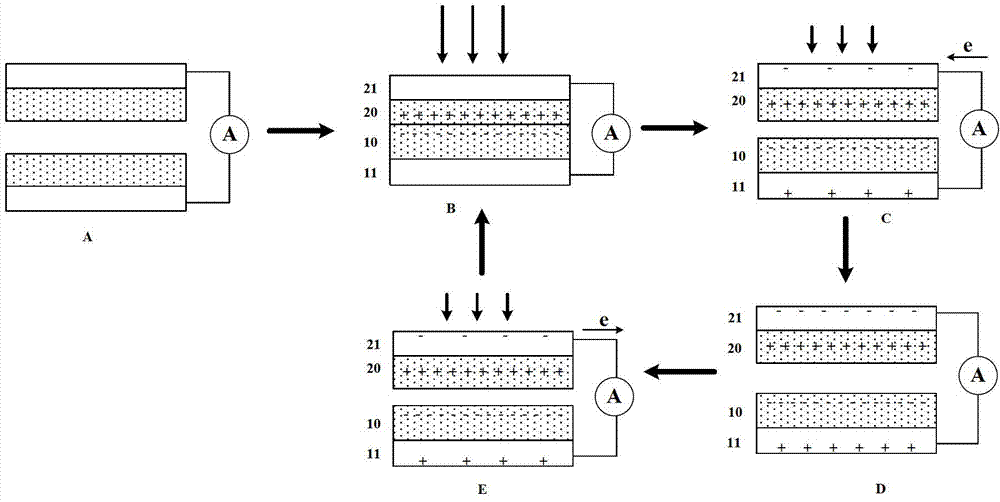

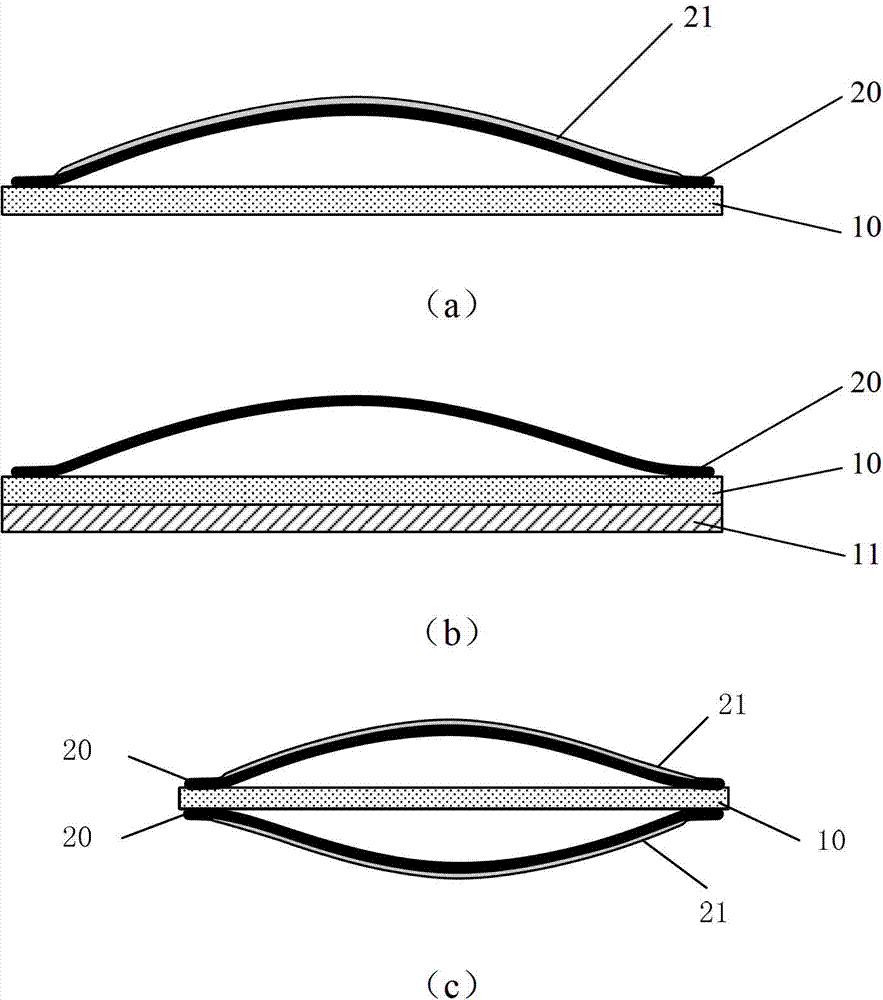

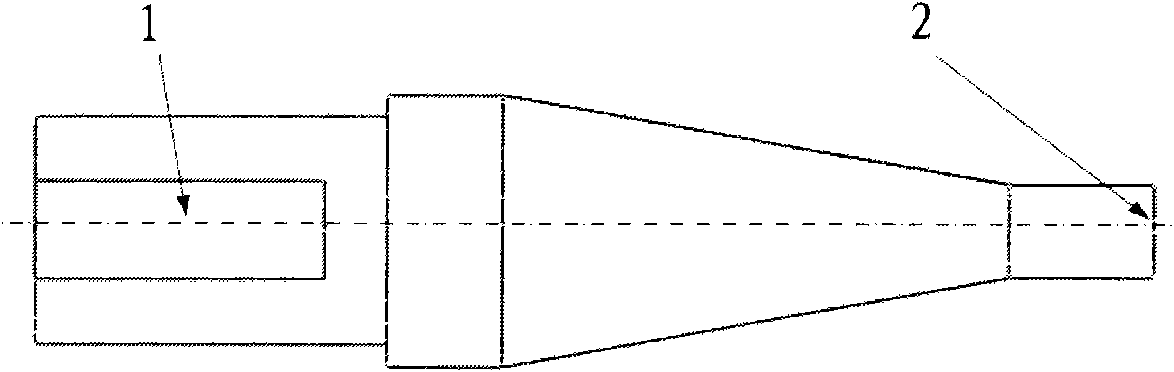

Wind power friction nanometer generator

ActiveCN103780128AThe purpose of normal work in realityEfficient use ofFriction generatorsNanogeneratorAlternating current

This invention provides a wind power friction nanometer generator comprising a first part and a second part which can perform elastic bending deformation. The first part comprises a first conducting element and a first friction layer which is directly attached to the upper surface of the first conducting element; the second part comprises a second friction layer and a second conducting element which is directly attached to the upper surface of the second friction layer; at least one of the first part and the second part is relatively fixed, and the first friction layer and the second friction layer are opposite to each other; at least part of the upper surface of the first friction layer and the lower surface of the second friction layer form a contact-separate circulation under the action of the wind force, and electric signals are outputted to an external circuit through the first conducting element and the second conducting element. When tangential periodic external forces are applied on the sliding friction nanometer generator, alternating current pulse signal output is formed between the first conducting element and the second conducting element.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

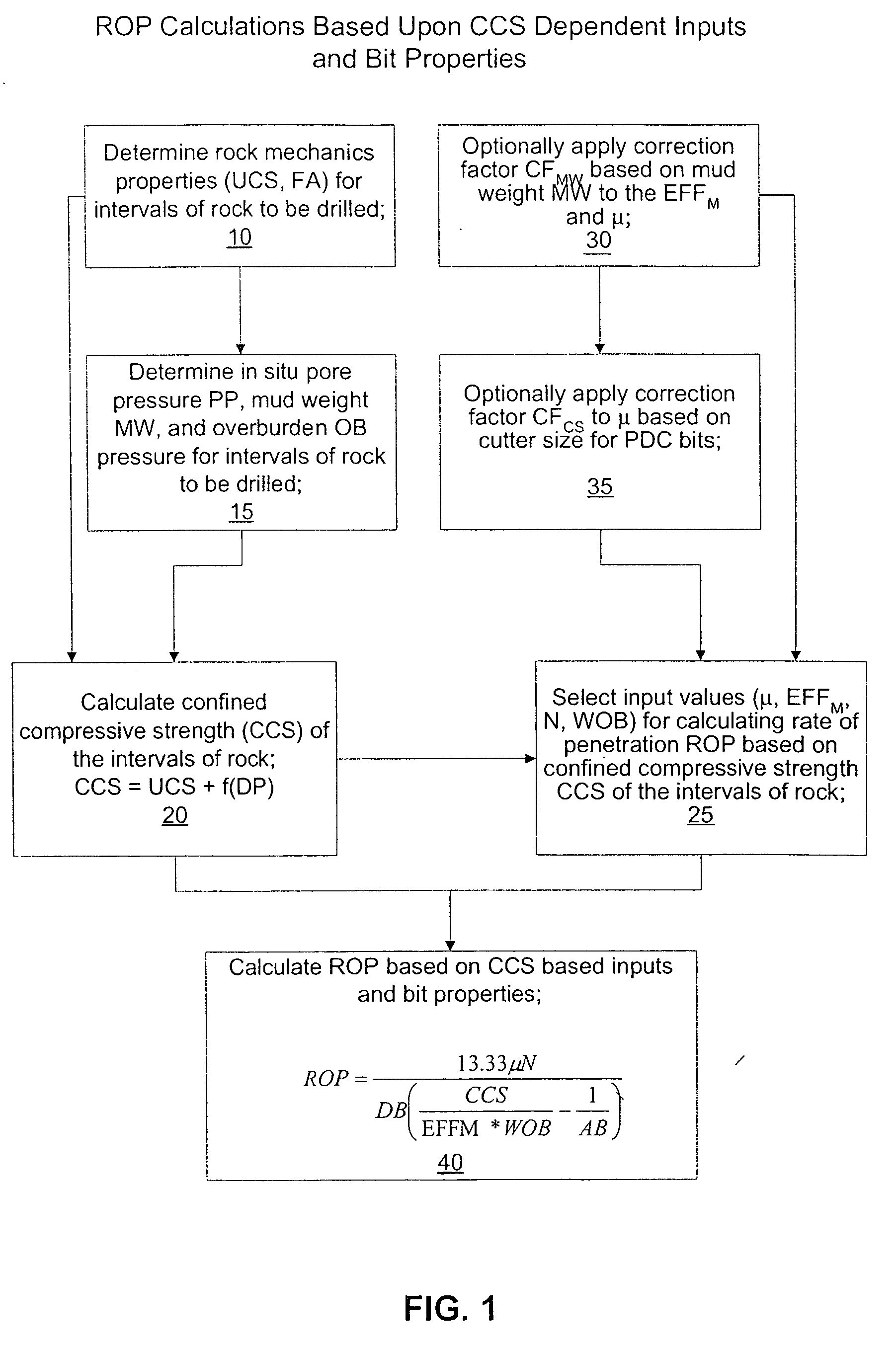

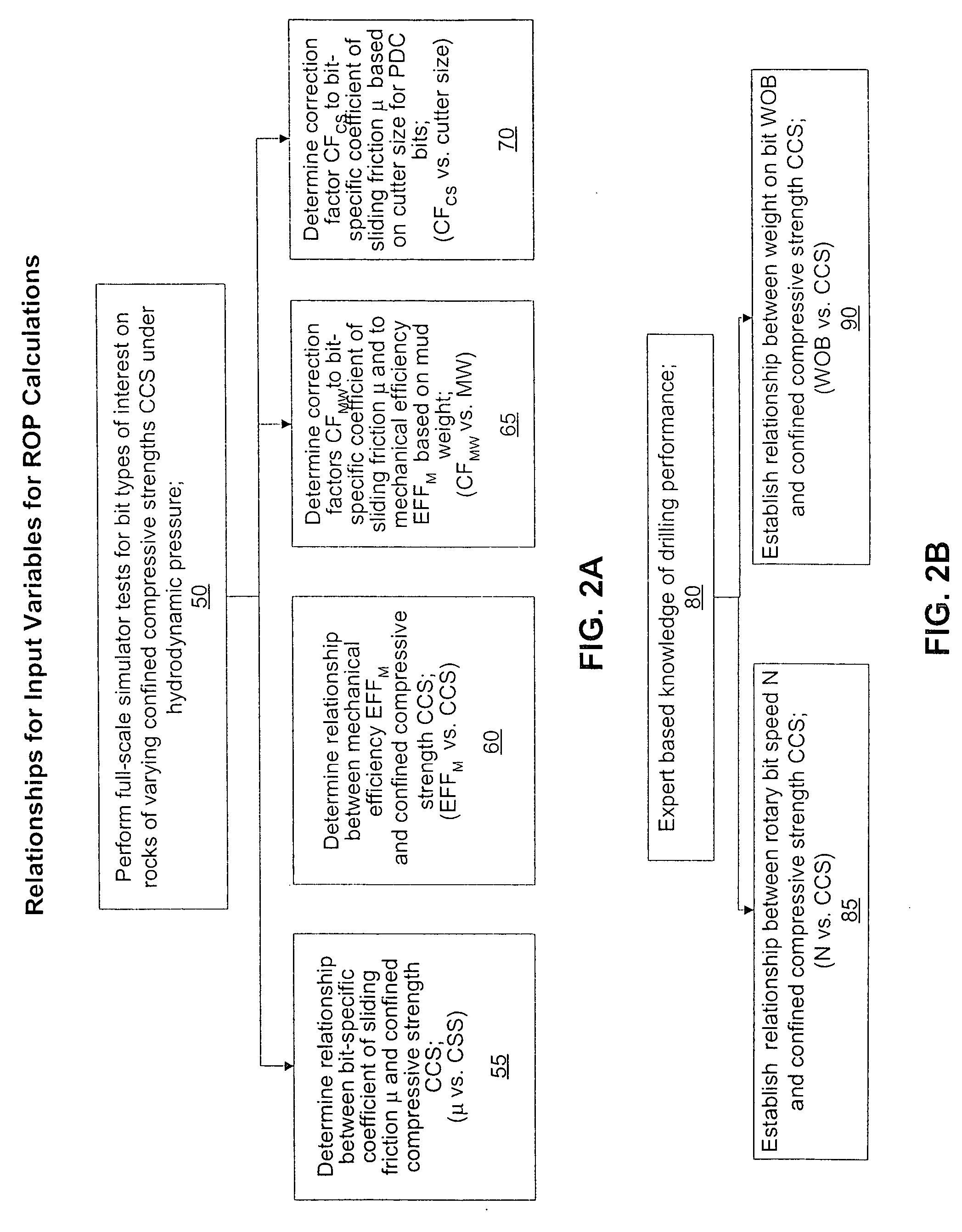

Method for predicting rate of penetration using bit-specific coefficient of sliding friction and mechanical efficiency as a function of confined compressive strength

InactiveUS20060149478A1Electric/magnetic detection for well-loggingSeismology for water-loggingRate of penetrationCompressive strength

A method for predicting the rate of penetration (ROP) of a drill bit drilling a well bore through intervals of rock of a subterranean formation is provided. The method uses an equation based upon specific energy principles. A relationship is determined between a bit-specific coefficient of sliding friction μ and confined compressive strength CCS over a range of confined compressive strengths CCS. Similarly, another relationship for the drill bit is determined between mechanical efficiency EFFM and confined compressive strength CCS over a range of confined compressive strengths CCS. Confined compressive strength CCS is estimated for intervals of rock through which the drill bit is to be used to drill a well bore. The rate of penetration ROP is then calculated utilizing the estimates of confined compressive strength CCS of the intervals of rock to be drilled and those determined relationships between the bit-specific coefficient of sliding friction μ and the mechanical efficiency EFFM and the confined compressive strengths CCS, as well as using estimated drill bit speeds N (RPM) and weights on bit (WOB).

Owner:CHEVROU USA INC

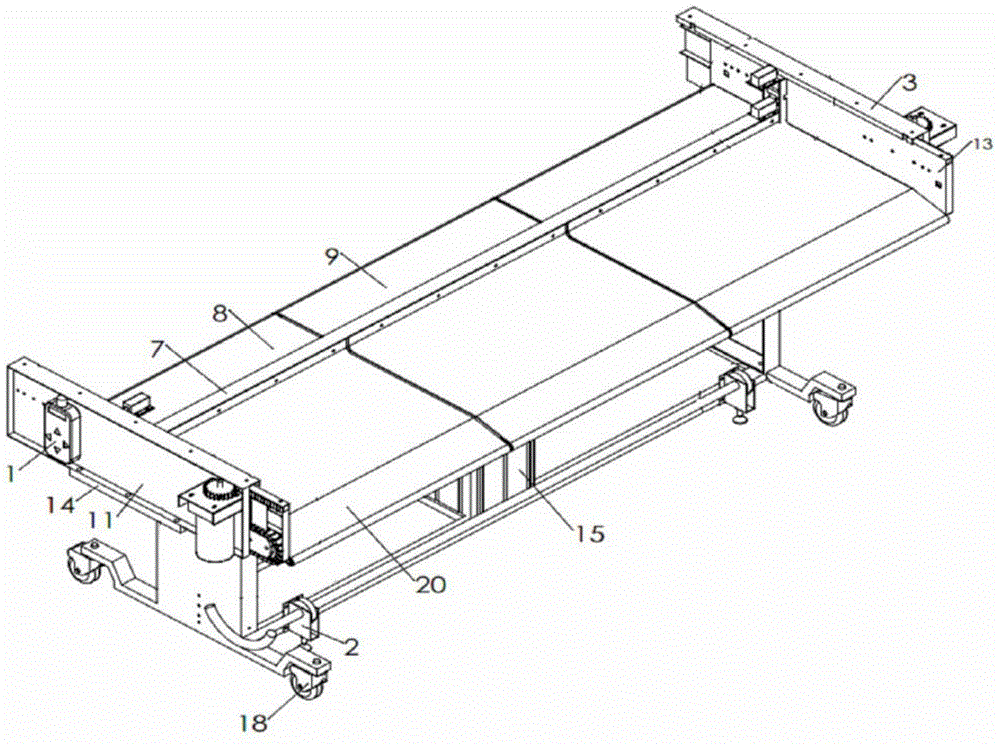

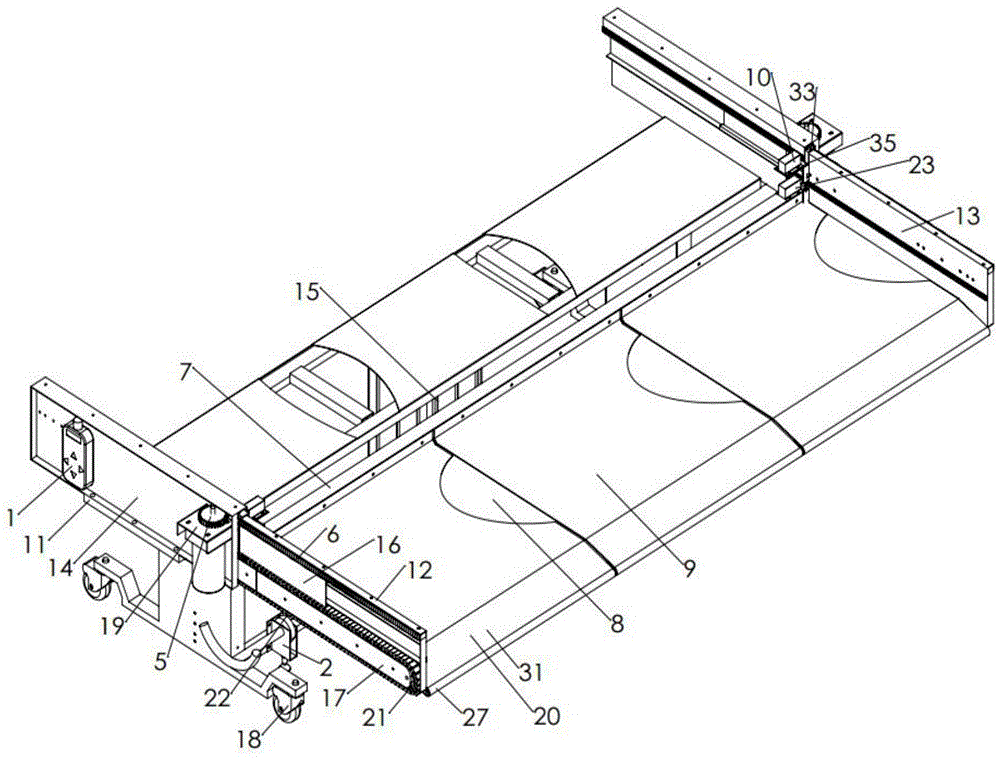

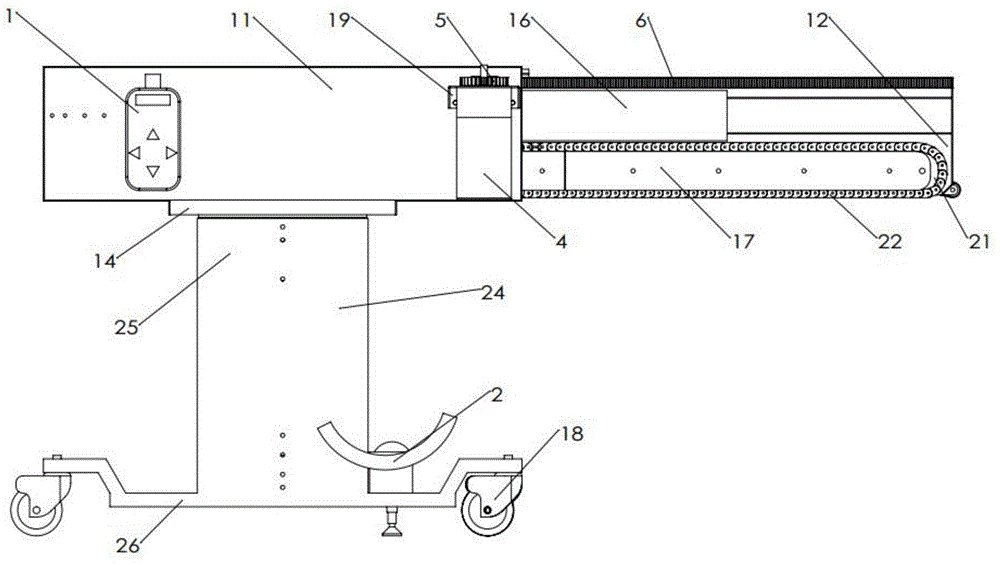

Patient ferry bed

The invention discloses a patient ferry bed which comprises a vehicle body, wherein the vehicle body is provided with a lifting mechanism and universal casters. The ferry bed that can move horizontally is installed on the vehicle body. The ferry bed comprises a bed board mechanism, a bed head and a bed tail beam mechanism. The patient ferry bed is of a single-layer mobile bed board structure and is simple in structure, needed parts are less, and the patient ferry bed is low in production cost and failure rate and convenient to maintain; the friction force caused by the single-layer mobile bed board structure is very small, a belt does not generate kinetic friction with the bed surface and the body of a patient, a bed sheet cannot be wound up, the safe transfer of the patient is achieved, and secondary injury is avoided; operators almost do not need to be in contact with the patient in the process, and the propagation of infecting bacteria is effectively avoided.

Owner:TIANJIN QIRUITONG TECH CO LTD

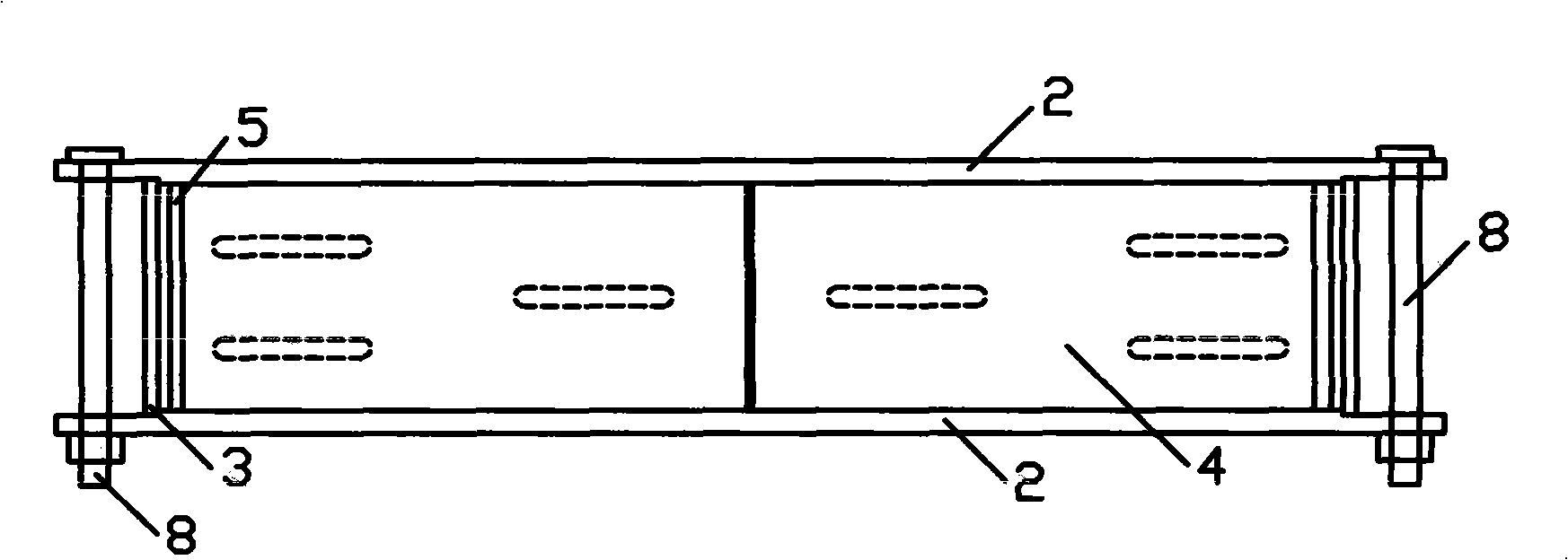

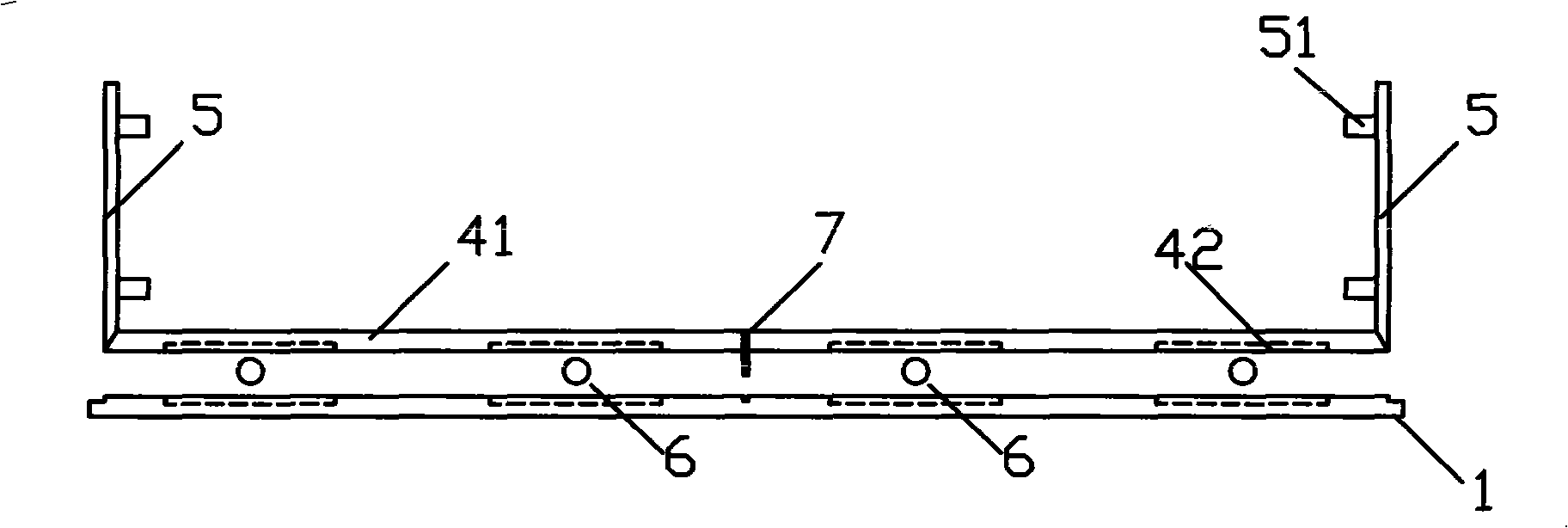

Device and method for measuring early age period linear deformation of cement based material

InactiveCN101344371AReduce frictionHigh measurement accuracyMaterial thermal coefficient of expansionMaterial testing goodsMeasurement deviceEngineering

The invention discloses a measurement device and a measurement method of early-age linear deformation of cement-based materials; the measurement device comprises: a measurement containing cavity which is provided with an opening at the upper end and composed of a bottom board, a side board and an outer end board, wherein, a sliding template is further arranged on the bottom board, inner end boards are arranged at the both ends of the template, and a separation groove is arranged in the middle of the template for dividing the template into two sliding templates. Compared with the prior art, the sliding template is arranged on the bottom board of the measurement device of the invention, the template is divided into two by the separation groove, when a cement-based material sample is deformed, the displacement thereof can be measured by the sliding template which is bonded with the cement-based materials, the properties of the early-age linear deformation of the cement-based materials can be accurately reflected without the need of waiting for hardening of the cement-based materials. Sliding slots are respectively arranged on the bottom board and the template, rolling balls are arranged in the sliding slots, thereby changing sliding friction into rolling friction, greatly reducing the friction and improving the measurement precision.

Owner:HOHAI UNIV +1

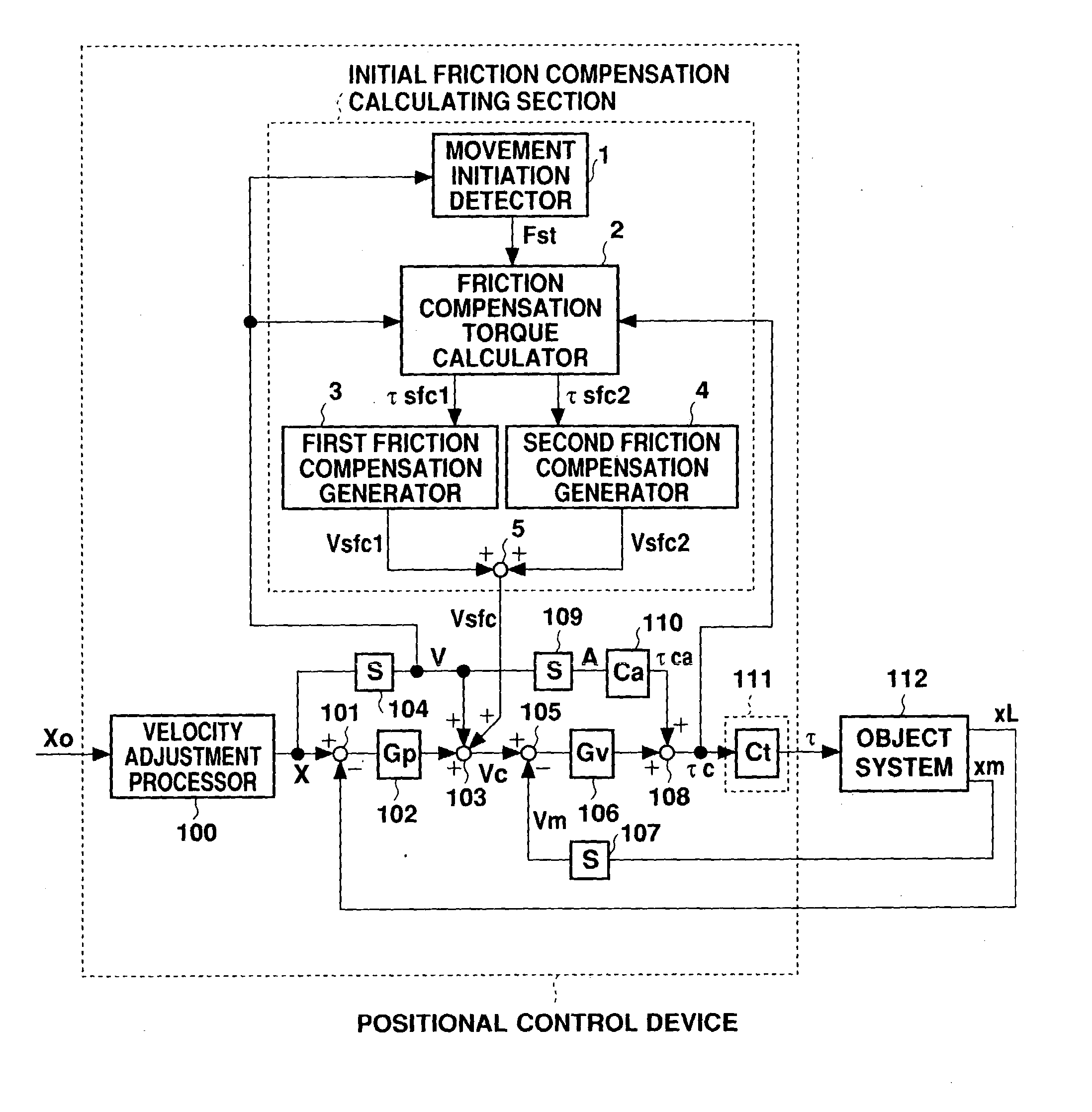

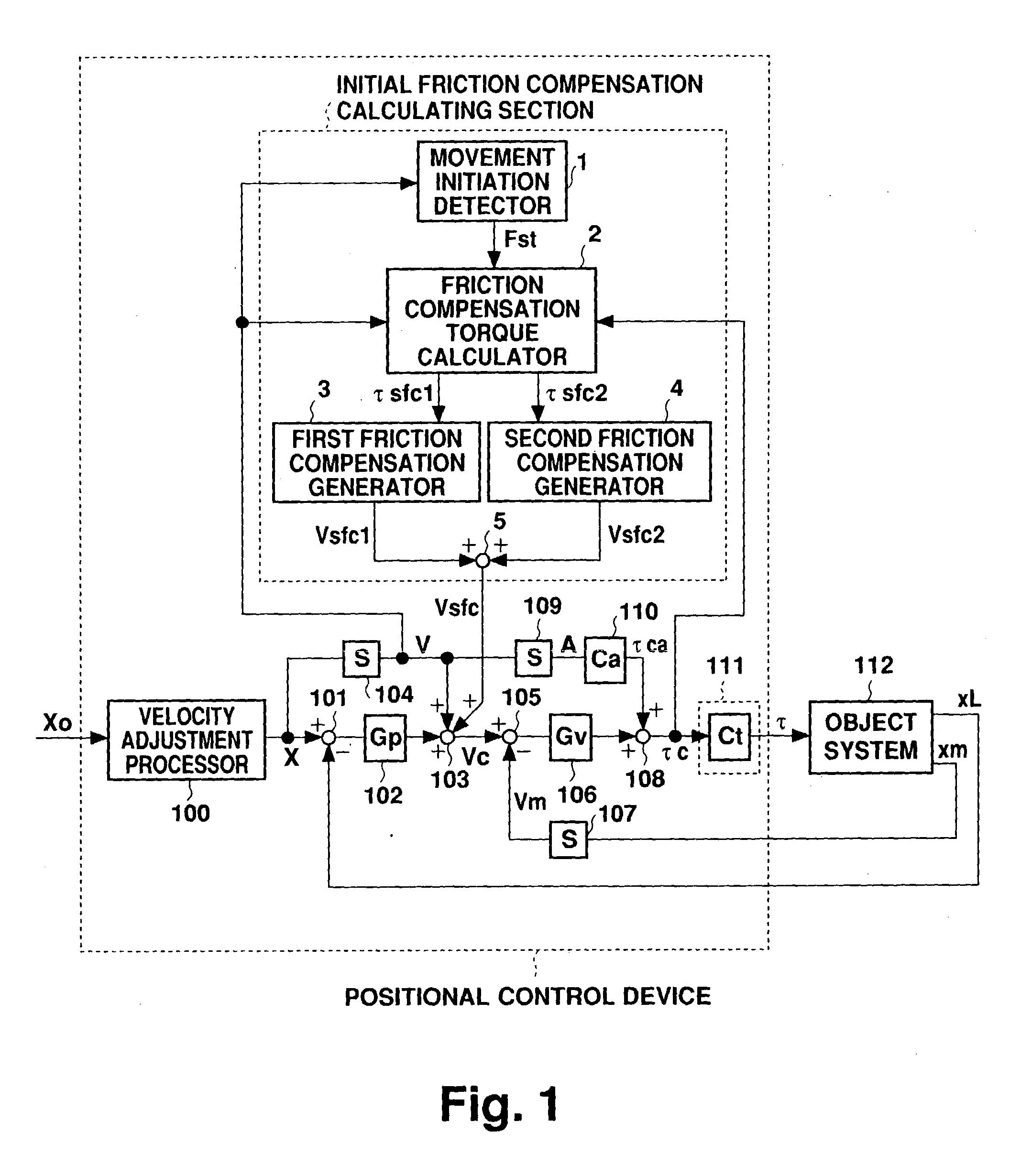

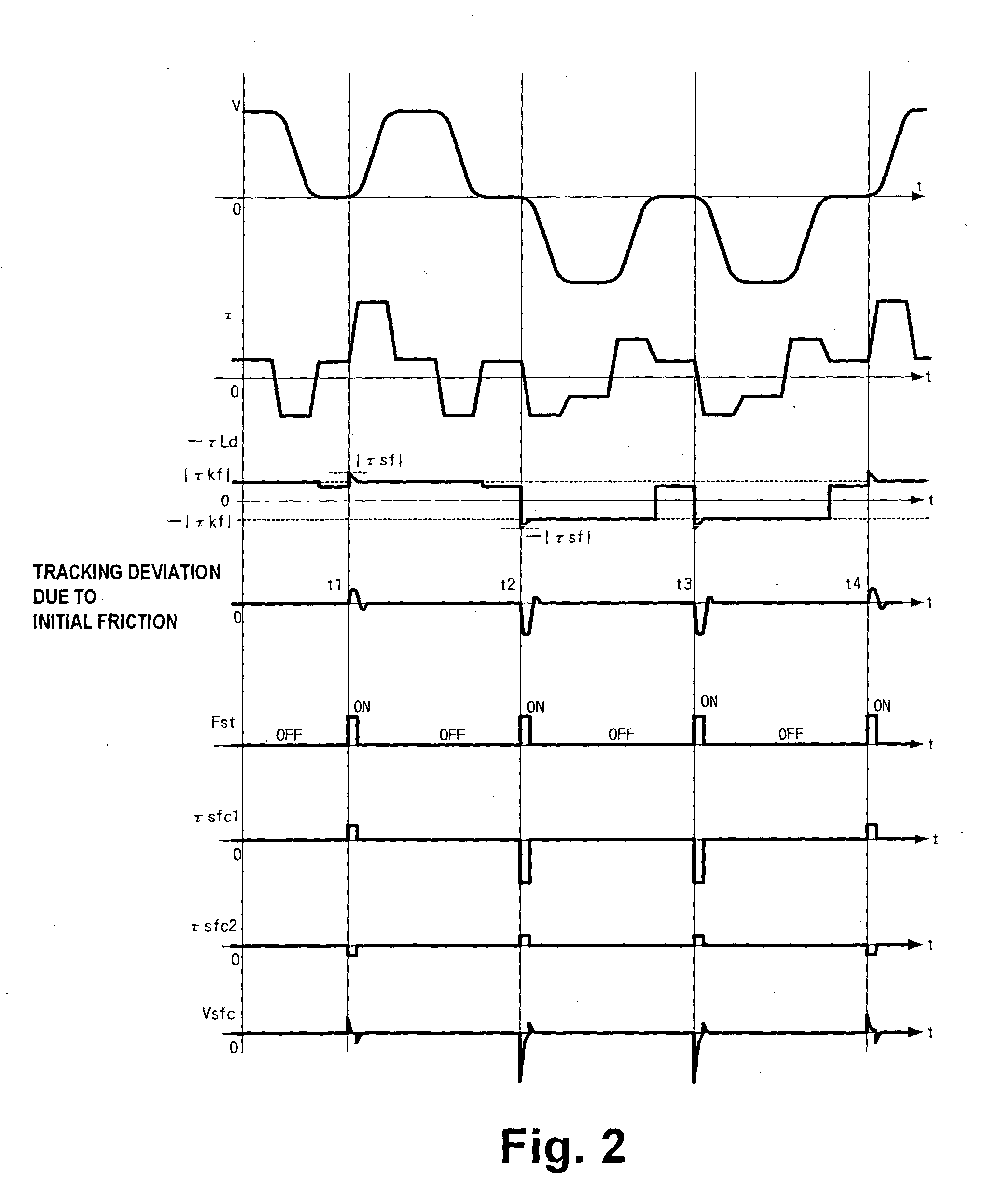

Positional control of a controlled object during movement initiation

In a positional control device for controlling a position of a controlled object using a motor, when generating a torque command value tauc which serves as the command value for the servo motor of the controlled object system (112), a friction compensation value for use when the controlled object initiates a movement is calculated based on a velocity command value V and a torque command value tauc determined according to a positional command value Xo supplied from a superordinate device. More specifically, an initial friction compensation calculating section calculates a torque compensation amount Vsfc1 corresponding to a difference between torque being generated during the standstill state and torque required by the controlled object to initiate the movement, and a torque compensation amount Vsfc2 corresponding to an amount of change in friction that occurs during a transition from static friction to kinetic friction in a period immediately before and after initiation of the movement. Vsfc1 and Vsfc2 are then used to calculate compensated values of the torque command value tauc. Positional tracking deviation generated due to friction during a movement initiation can thereby be reduced, regardless of operational conditions during the standstill state or of the movement direction and velocity effected thereafter.

Owner:OKUMA CORP

Polyvinyl alcohol film and method for producing the same

ActiveCN101056918AExcellent transferability and no light defectsPolarising elementsFlat articlesPolymer sciencePVA - Polyvinyl alcohol

Disclosed is a polyvinyl alcohol film having a film thickness of 30-70 m and a kinetic friction coefficient against stainless-steel roll of not more than 0.03. Also disclosed is a method for producing such a polyvinyl alcohol film.

Owner:MITSUBISHI CHEM CORP

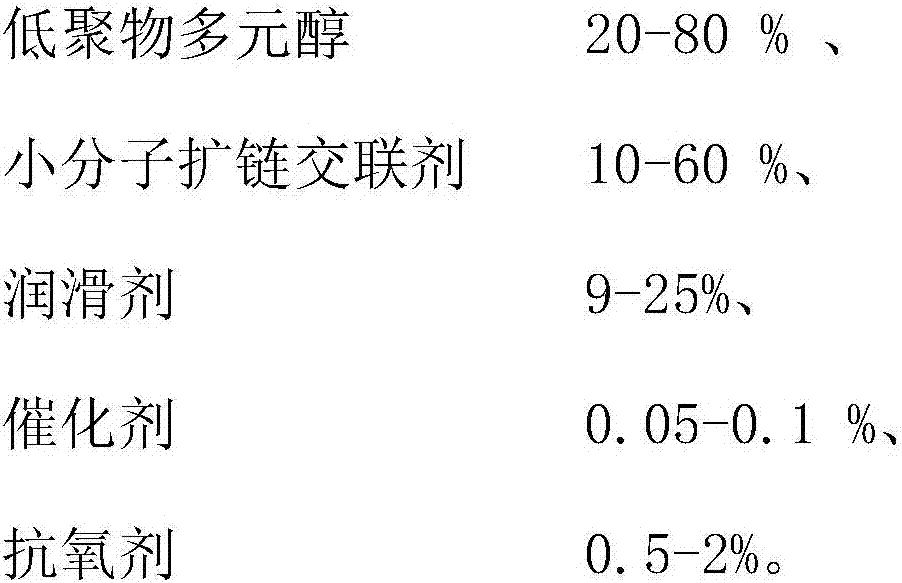

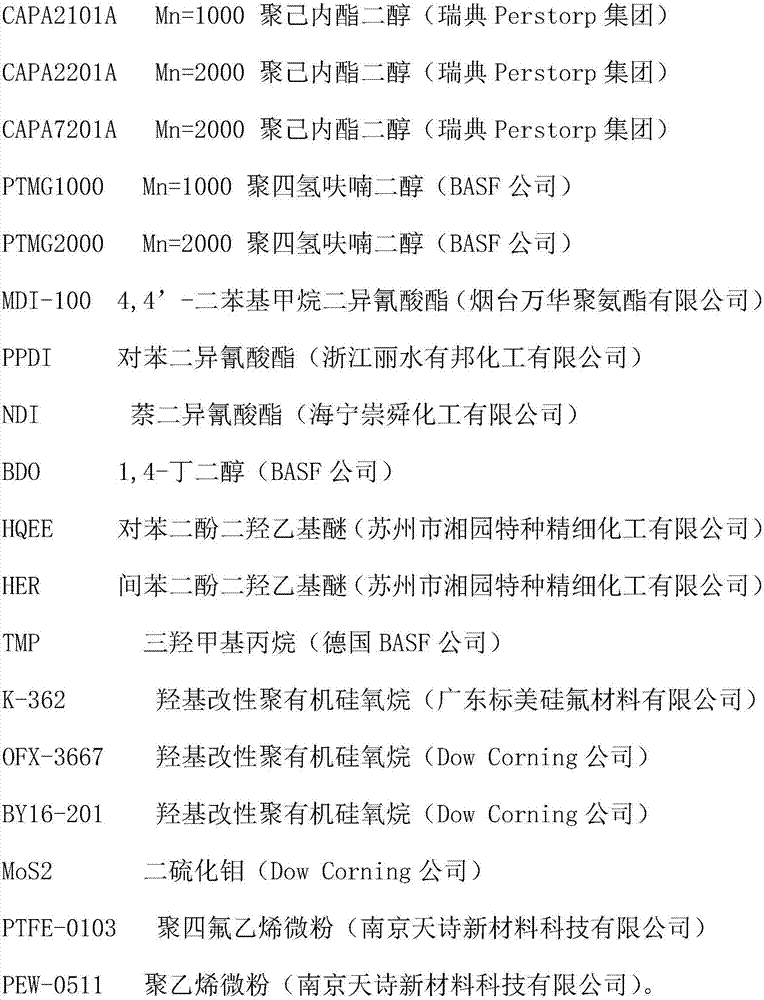

High-hardness self-lubricating polyurethane elastomer and preparation method thereof

The invention discloses a high-hardness self-lubricating polyurethane elastomer and a preparation method thereof. The polyurethane elastomer includes, by weight, 100 parts of polyurethane hemi-prepolymer and 30-100 parts of a polymer containing active hydrogen, wherein the content of free isocyanate in the polyurethane hemi-prepolymer is 9-16 wt% and water content in the polymer containing active hydrogen is less than 0.05 wt%. The polyurethane elastomer can reach up to 65D in hardness, has high mechanical strength and high wear resistance, is very low in friction coefficient which can be controlled to about 0.050, and is very small in difference between kinetic friction and static friction coefficients, so that the polyurethane elastomer can be widely applied in the fields in which reductions on abrasion and friction coefficient are required, especially in sealing members.

Owner:WINSIN MATERIALS INC

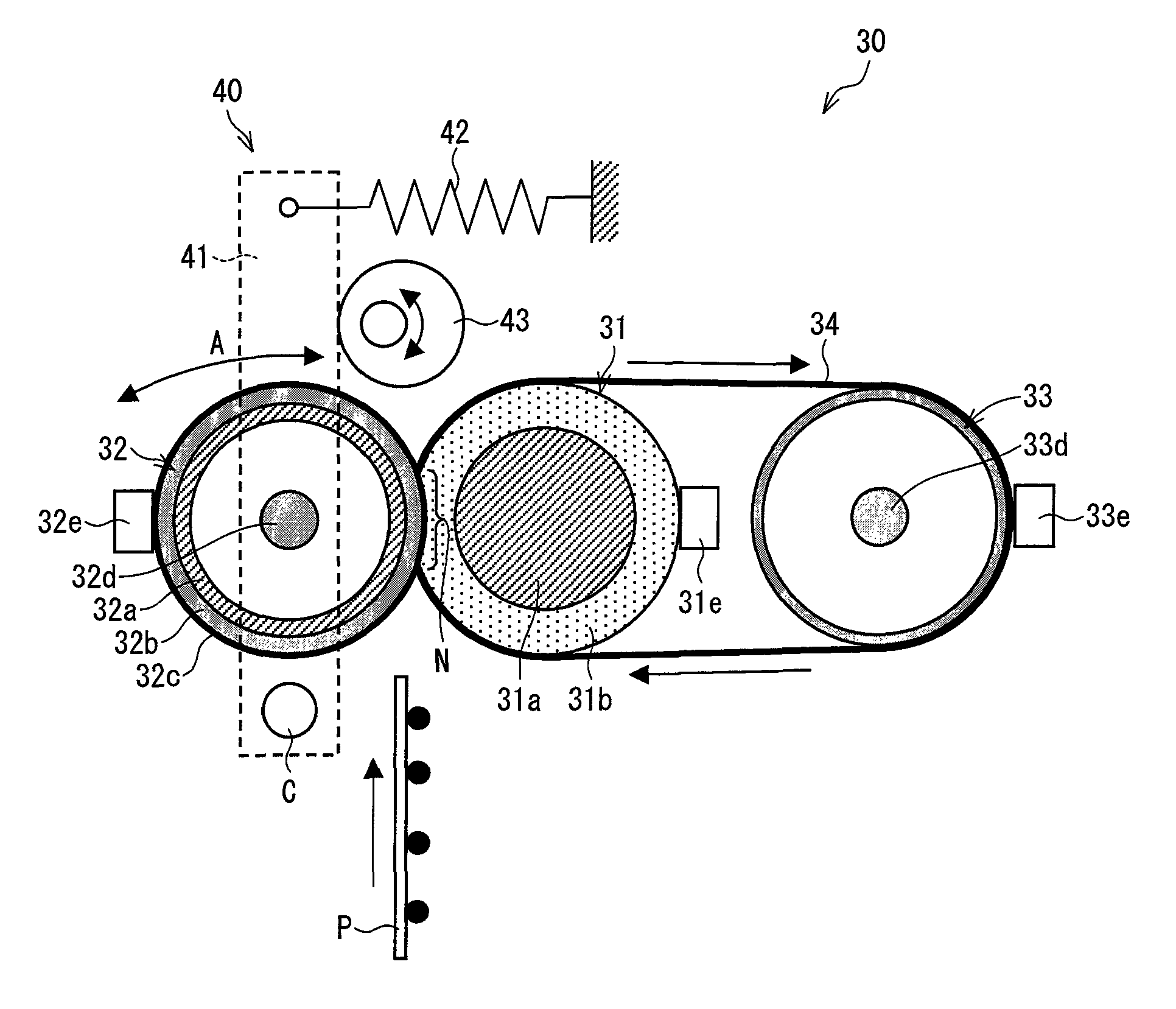

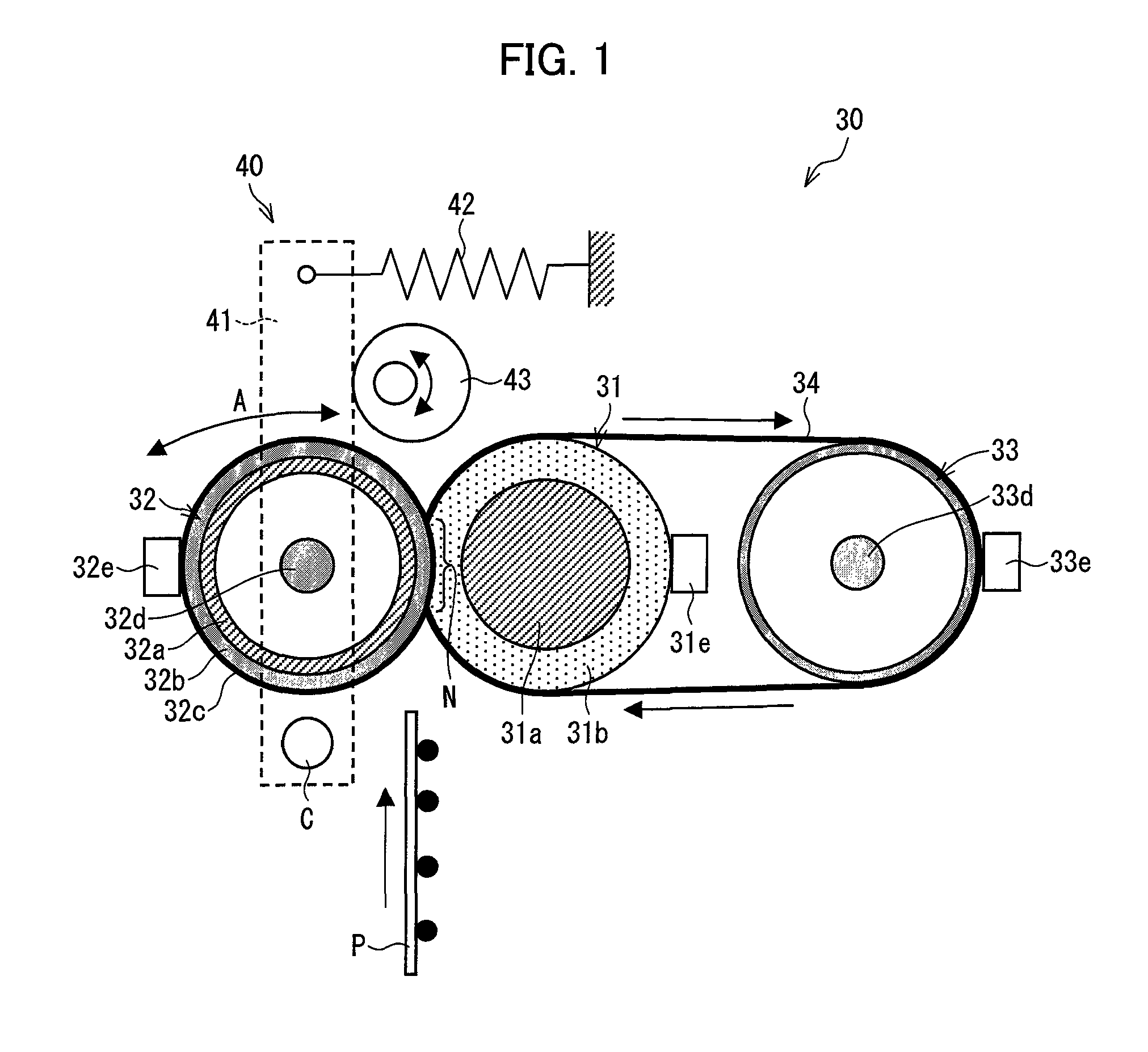

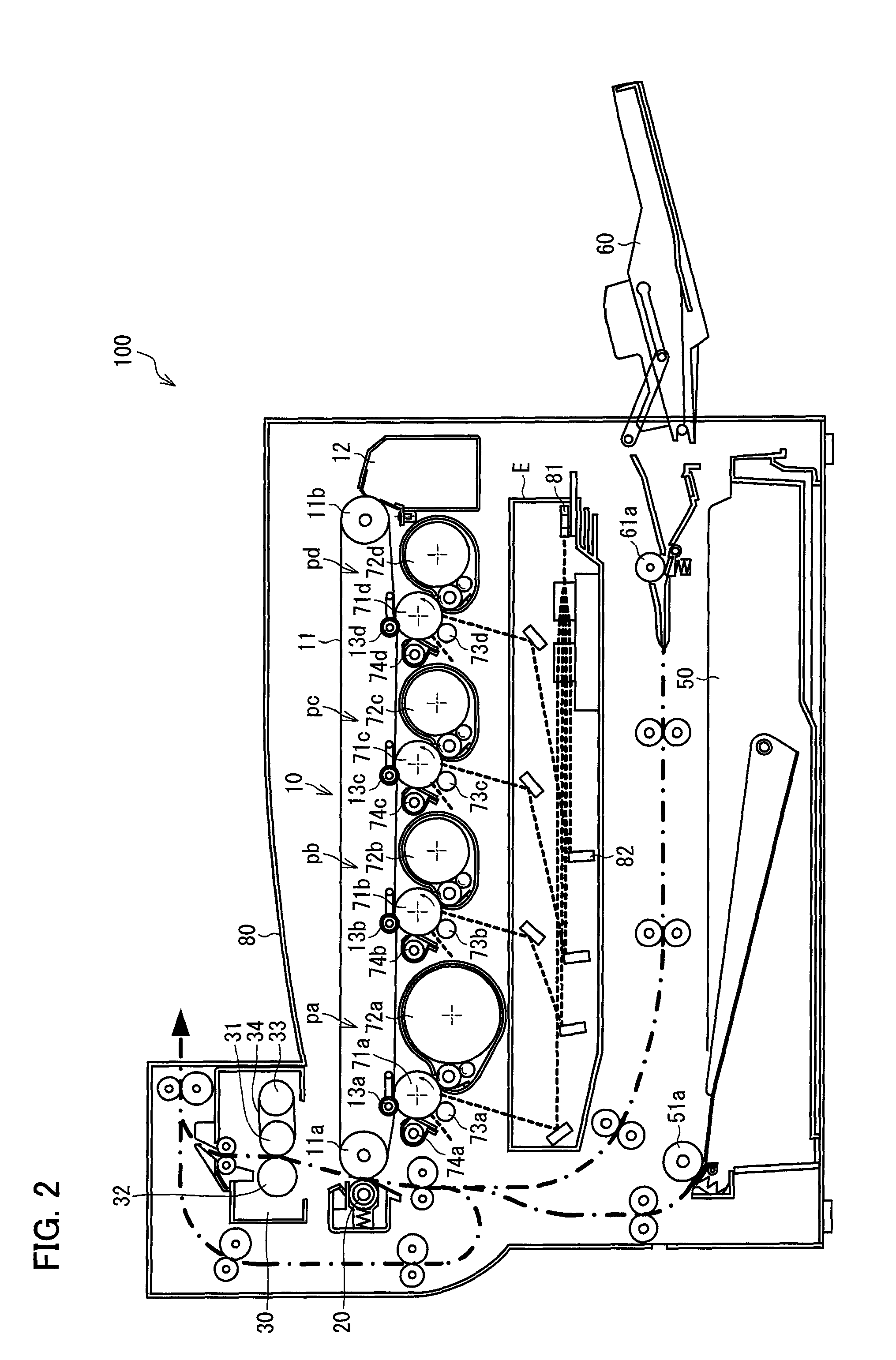

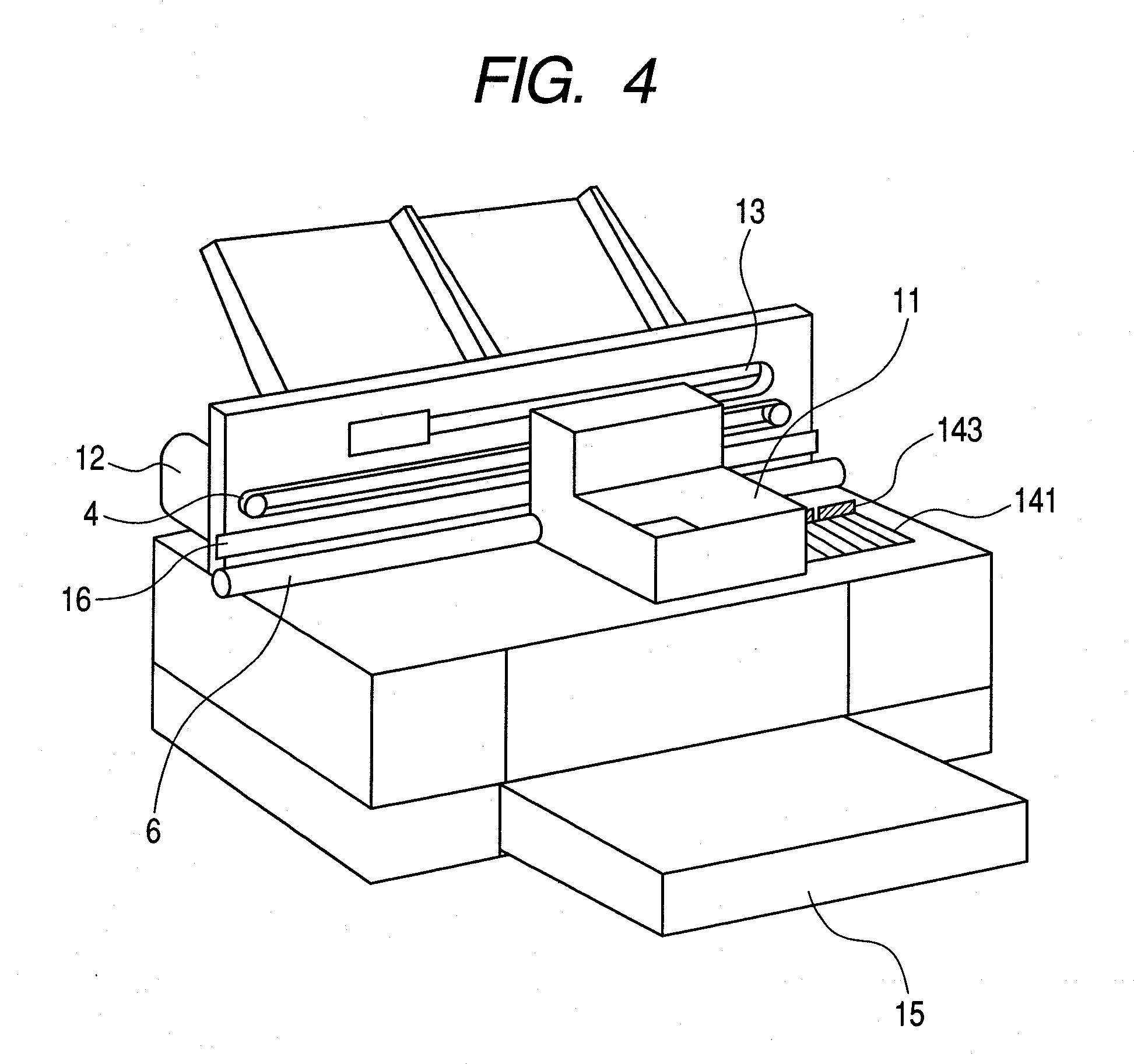

Fixing device having an endless fixing belt and two-position disjunction mechanism

ActiveUS8295753B2Solution to short lifeShorten warm-up timeElectrographic process apparatusEngineeringKinetic friction

A fixing device having a fixing belt which satisfies 42.2≧ER≧0.1044×D×μ−0.5174, where: D represents an inner diameter of the fixing belt; A represents a second inner diameter of the fixing belt; ER represents an elongation rate of the fixing belt and is formulated as ER=(A−D) / D×100; and μ represents a coefficient of kinetic friction between the fixing belt and the fixing roller. The fixing device is thus arranged so that the fixing belt is driven by the fixing roller to rotate in a state where the pressing roller is separated from the fixing belt. This makes it possible to lengthen a life of a fixing belt, to shorten a warm-up time, and to reduce power consumption in a fixing device using a belt fixing method.

Owner:SHARP KK

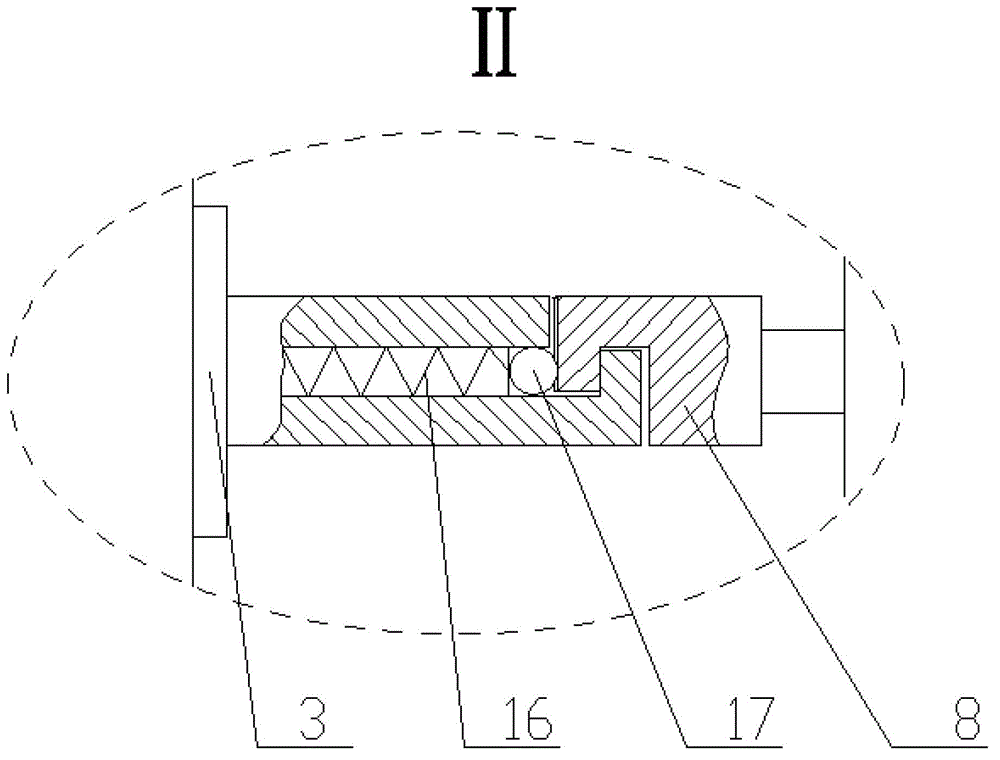

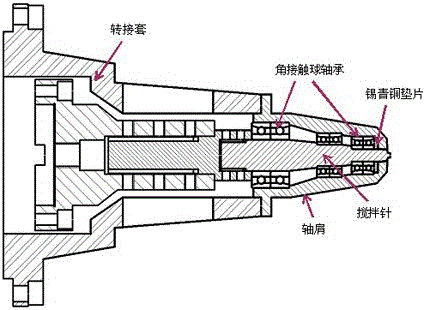

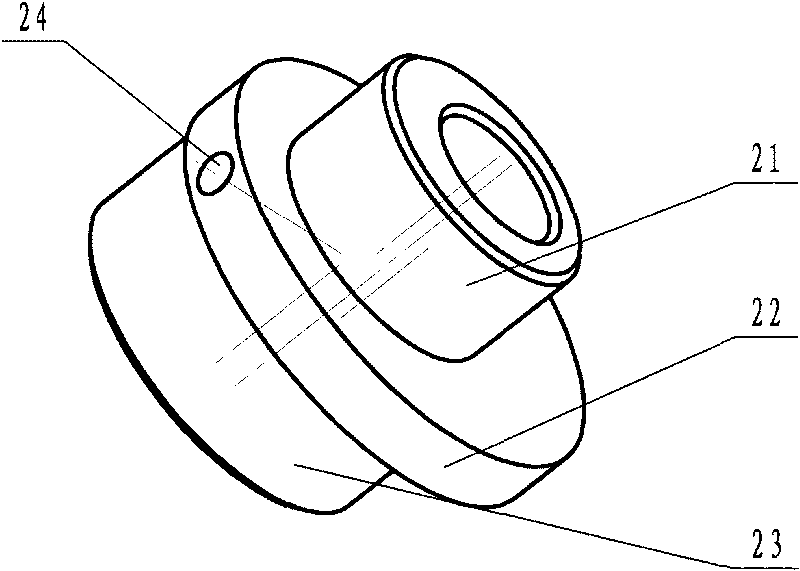

Novel stir friction welding tool for non-thinned post-welded material surface

The invention discloses a novel stir friction welding tool for a post-welded material surface nearly free of differences. A shaft shoulder of the stir friction welding tool is connected with a main machine through a special reducing sleeve, kinetic friction matching of a stirring needle and the shaft shoulder can be achieved, and the stirring needle and the shaft shoulder are designed and manufactured in a split mode; the stirring needle rotates along with a spindle at a high speed, and the shaft shoulder is fixed to a non-rotating part of a main machine head; and the stirring needle and the shaft shoulder move reliably and oppositely through a bearing set. According to the novel stir friction welding tool for the non-thinned post-welded material surface, the effect that reliable kinetic friction matching of the stirring needle and the shaft shoulder is achieved is ensured through bearing selection and structural design; the split type stirring needle is specially designed and based on the static shaft shoulder, a small shaft shoulder of an inclined surface structure is machined at the end of the split type stirring needle, and a spiral line is machined on the end surface of the small shaft shoulder, so that upsetting force is applied to weld metal, and material closing up is conducted at the same time; and through the shaft shoulder based on special material selecting and structural design, the forward resistance of the novel stir friction welding tool is reduced, flashes are eliminated, and good forming of a weld surface is ensured.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

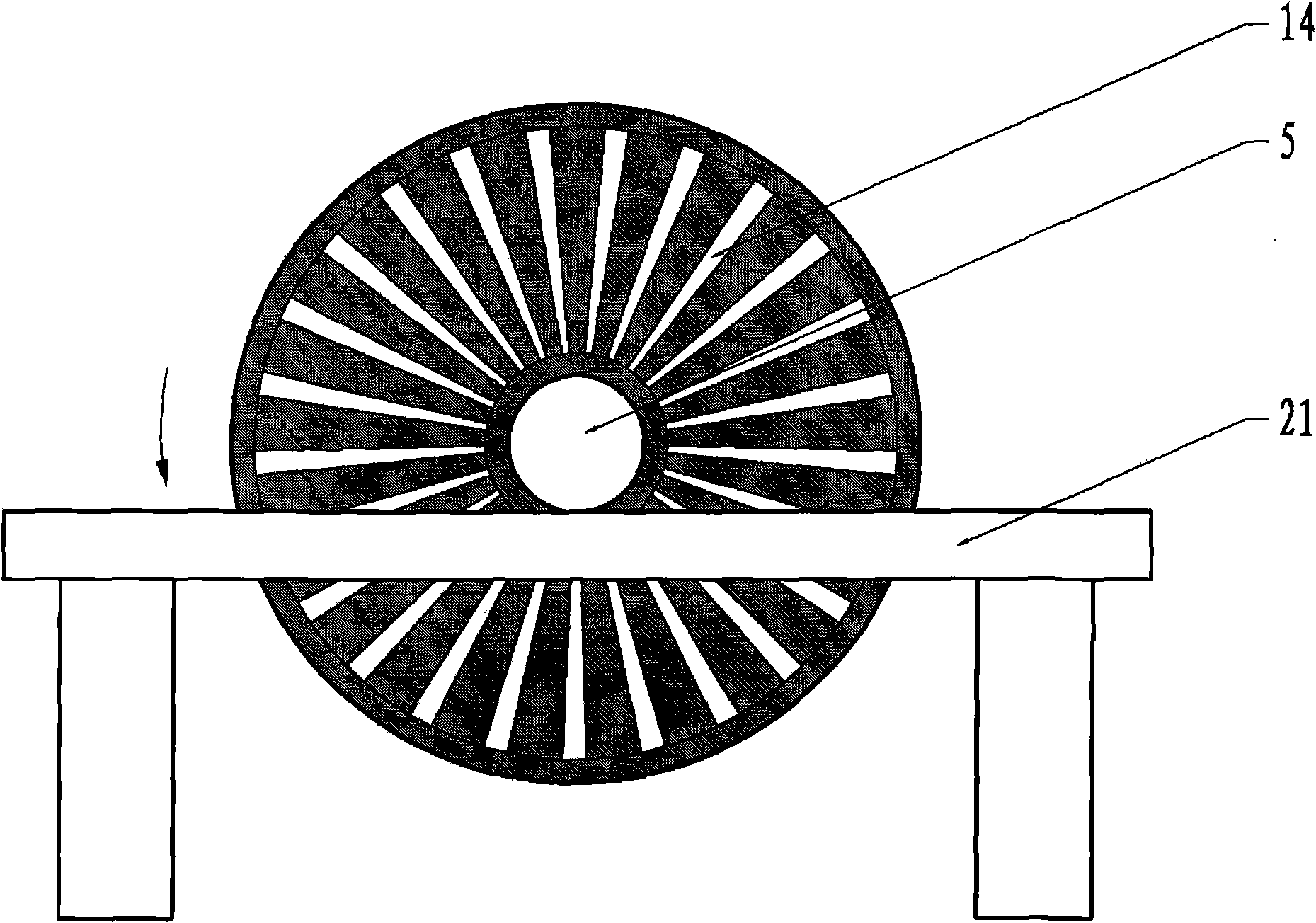

Measuring method for static balance of turbine vane wheel and device thereof

InactiveCN101576425AEliminate systematic errorsLink to reduce errorsStatic/dynamic balance measurementAir bearingDrive motor

The invention relates to a static balance measuring technique for a turbine vane wheel, which belongs to the technical field of precision finishing and measuring. The device comprises a vane wheel, a driving motor, a torque sensor, a data-processing system, an air journal bearing, an air journal bearing supporting mechanism, air-bearing guide ways, an air-bearing guide way supporting mechanism, a hydro bearing, a constant-force generator, and a hydro bearing supporting mechanism. The driving motor is used for driving the air journal bearing, driving the vane wheels for uniform rotation, measuring the output torque of the driving motor during one circle of rotation of the vane wheels, and calculating the amount of unbalance of the vane wheels so as to remove the amount of unbalance quantificationally. The invention has the advantages that the independent rotation of the vane wheels eliminates the system error caused by the amount of unbalance of other parts; fluid lubrication adopted in the main running gear of the measuring system greatly decreases kinetic friction force, reduces the minimum amount of unbalance of measurable vane wheel, improves measurement precision and sensitivity, realizes quantification of measuring results by transmission and measurement of toque, and raises working efficiency. The invention can be widely applied to the checkout gear of static balance for the turbine vane wheel.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

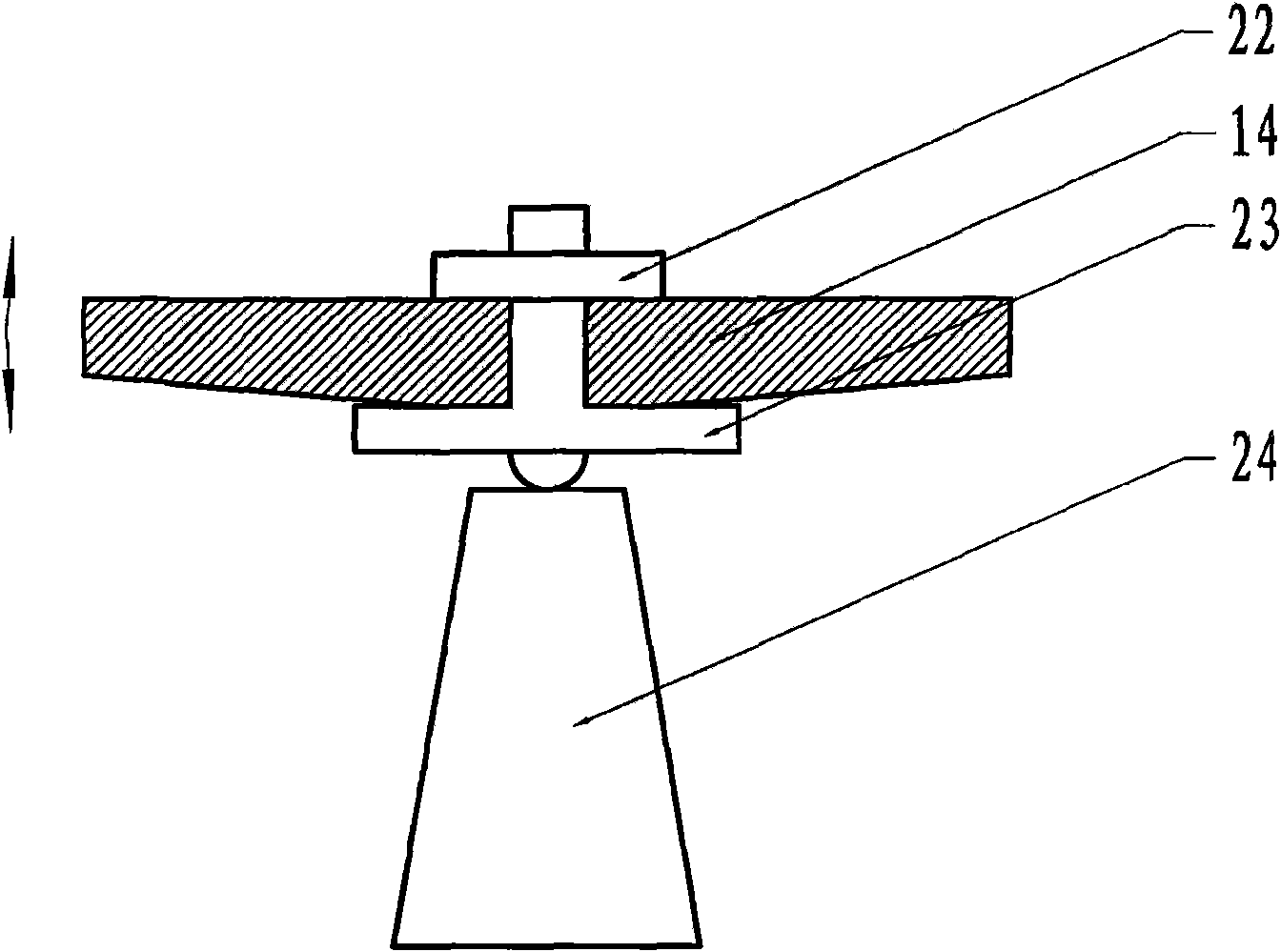

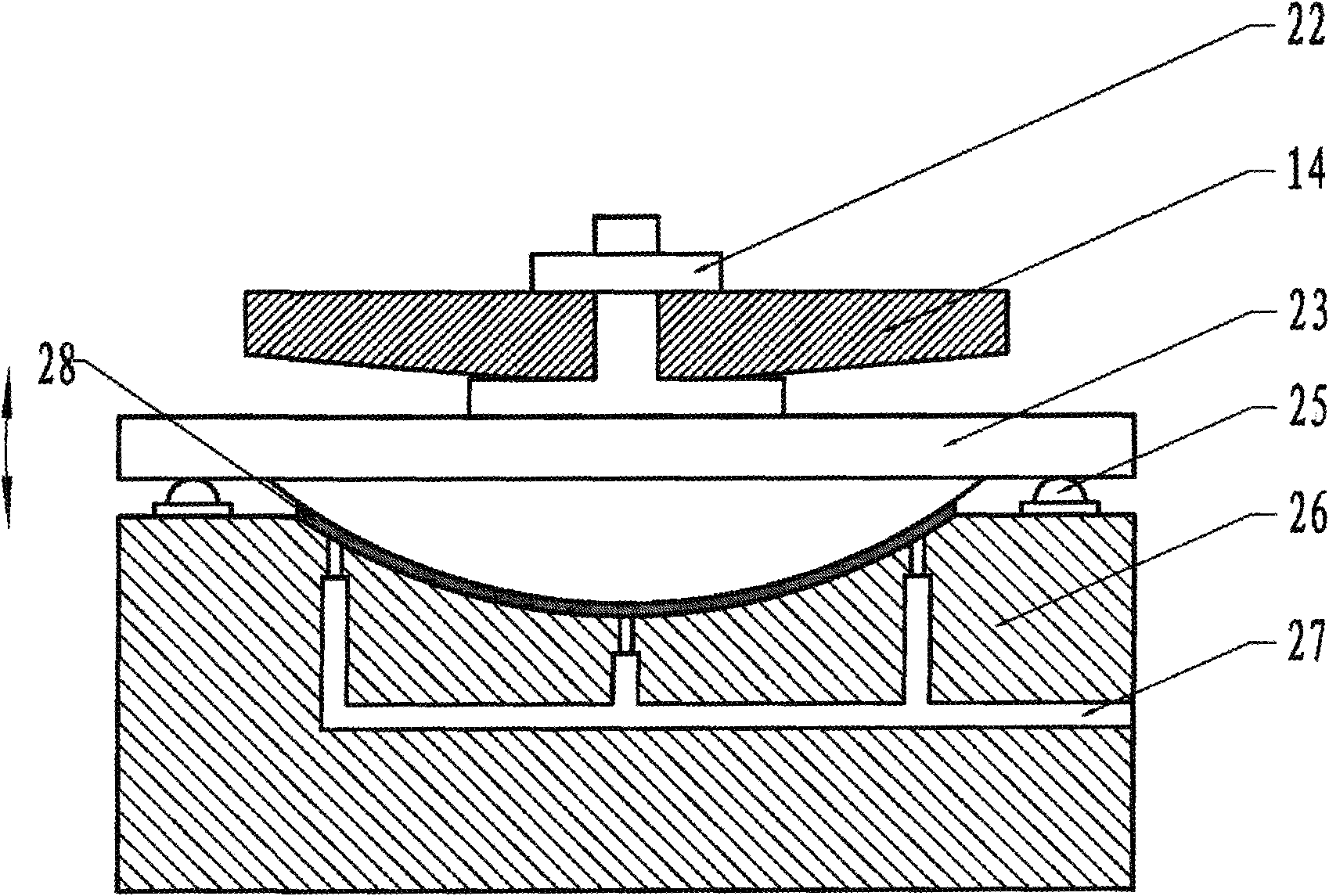

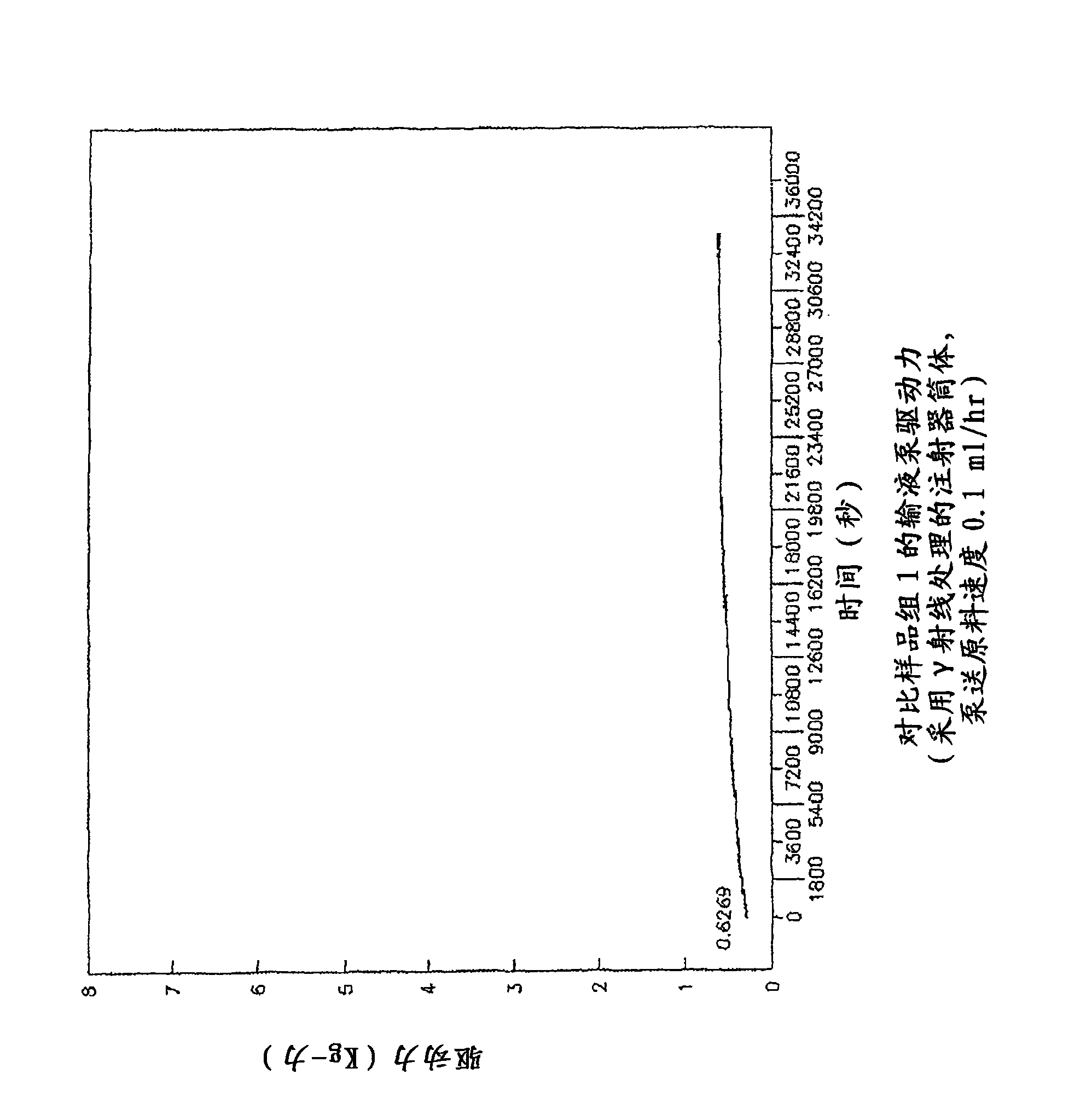

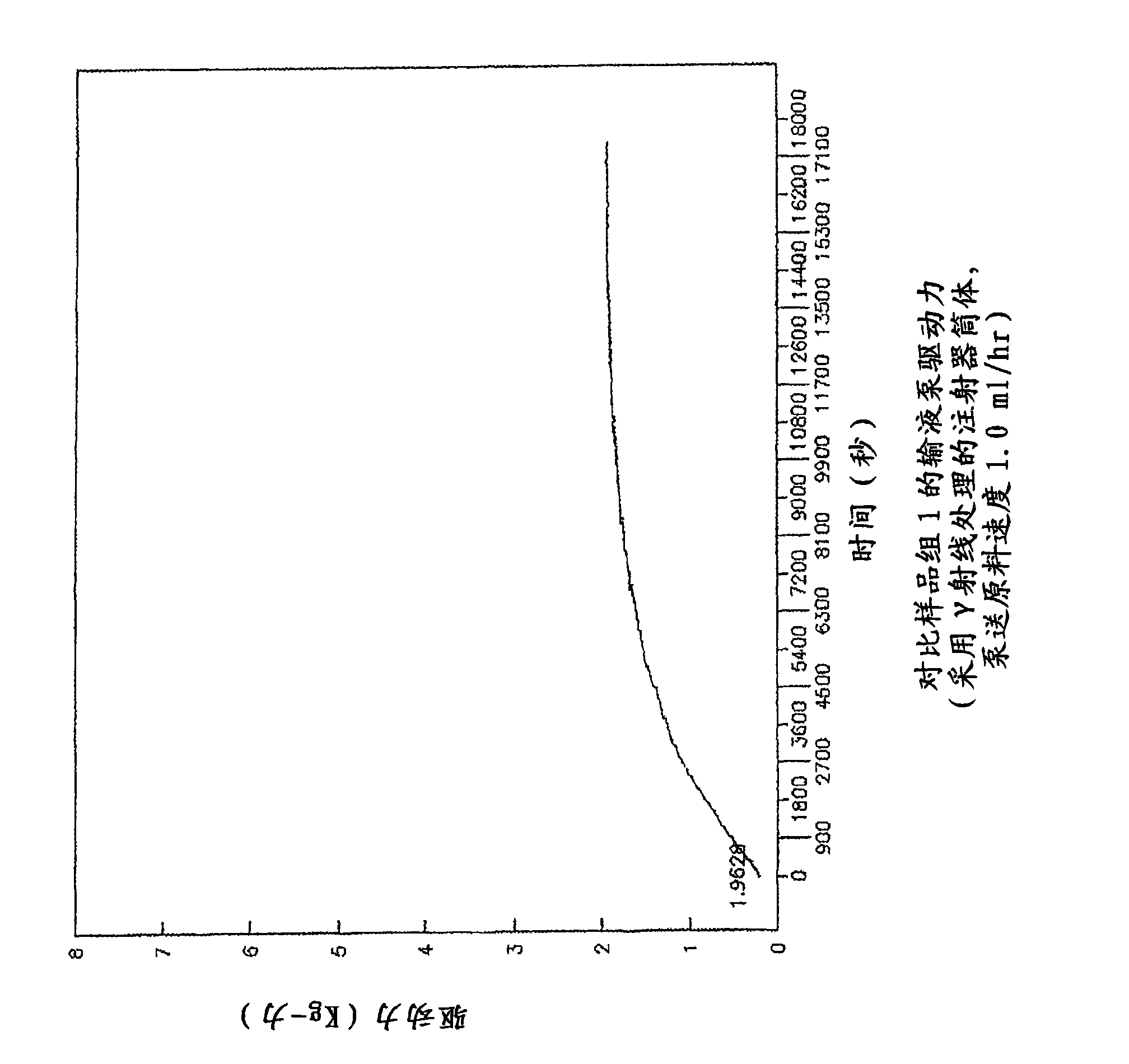

Medical components having coated surfaces exhibiting low friction and methods of reducing sticktion

This invention relates to components useful for medical articles, such as a syringe assembly, having sliding surface(s) coated with a composition including organopolysiloxane(s), the coating being adhered to the surface(s) of the component by crosslinking induced by oxidative treatment and irradiation with an isotope, electron beam or ultraviolet radiation or heat treatment; medical articles including the same; methods to reduce static and kinetic friction between slidable surfaces; and articles of low friction prepared thereby.

Owner:BECTON DICKINSON & CO

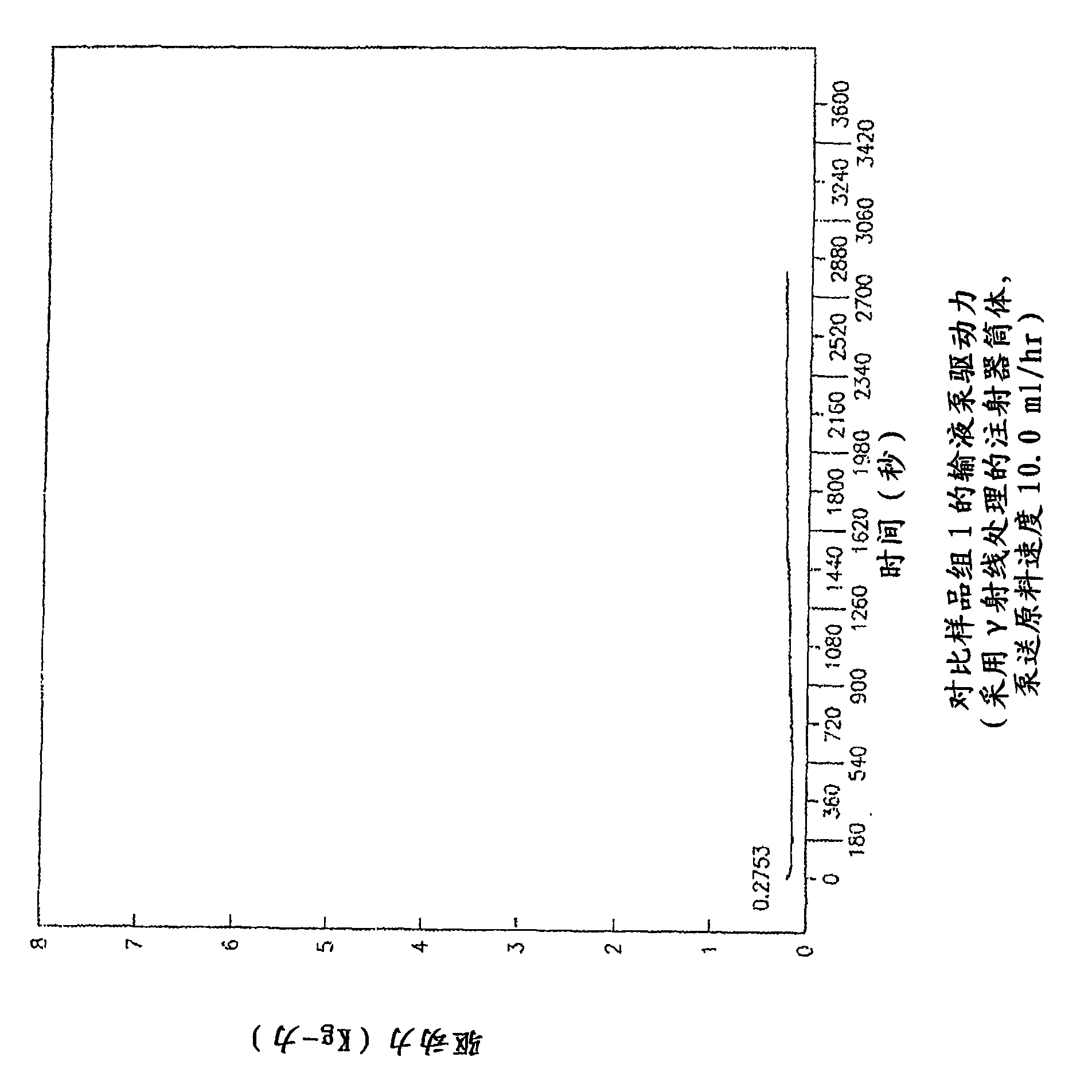

Heat shrinking polyester film

InactiveUS20060063008A1Good printabilityHigh transparencySynthetic resin layered productsFlat articlesPolyesterEngineering

A heat-shrinkable polyester type film has a dynamic friction coefficient of at least one face with one face of another film of μd≦0.27 and range R≦0.05 and a weight loss of less than 0.24 g / m2 after 10 reciprocation times with 400 g load using a color fastness rubbing tester comprising a friction element bearing a sand paper with #1000 particle diameter.

Owner:TOYOBO CO LTD

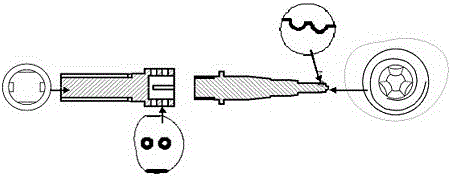

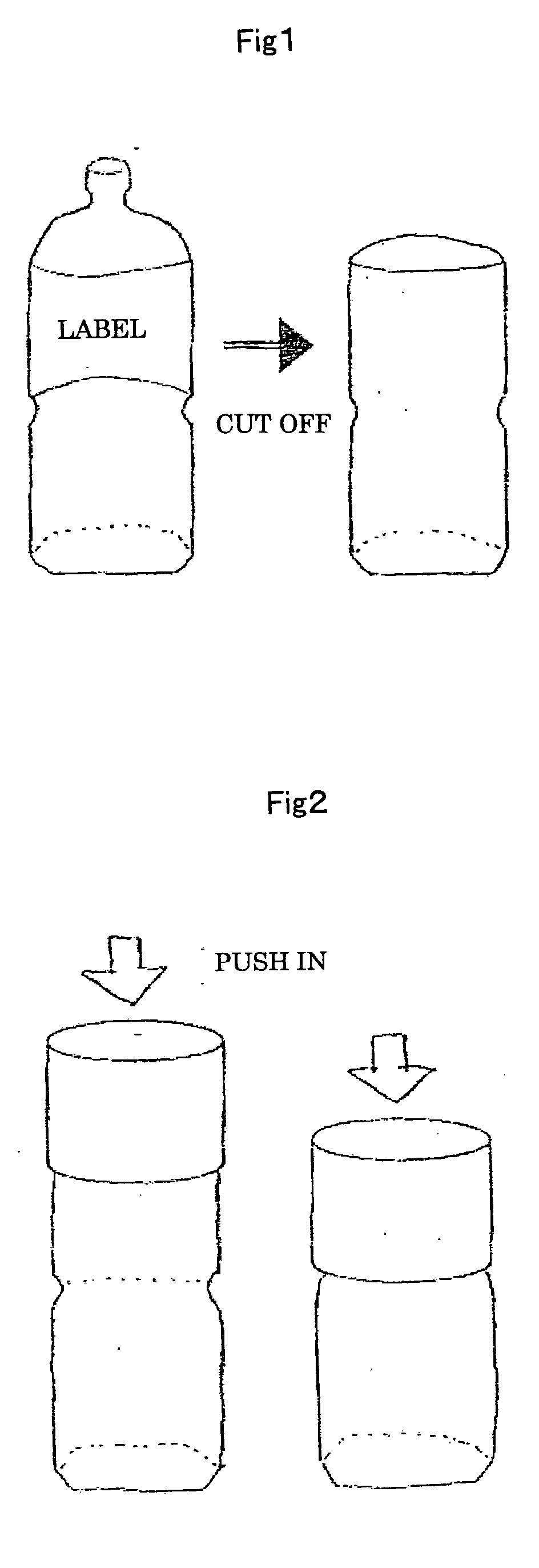

Double eccentric wheel type push-pull pulsed wire feeding method and device

The invention provides a double eccentric wheel type push-pull pulsed wire feeding method and a double eccentric wheel type push-pull pulsed wire feeding device, which realize the feeding and retracting of a welding wire, and achieve the effect of pulsed feeding by more feeding and less retracting of the welding wire. The method is characterized in that: a motor 14 drives an eccentric shaft 8 to rotate; the eccentric shaft 8 is provided with two eccentric wheels with different eccentricities and the same eccentric direction; when the eccentric shaft 8 drives a feed chuck 10 and a retraction chuck 3 to move forwards, the feed chuck 10 drives the welding wire 1 to feed forwards, and the retraction chuck 3 and the welding wire 1 generate sliding friction; and when the eccentric shaft 8 drives the feed chuck 10 and the retraction chuck 3 to move backwards, the feed chuck 10 does not clamp the welding wire 1, and the retraction chuck 3 and the welding wire 1 drive the welding wire 1 to retract by virtue of a static frictional force generated by a pressing force of a spring 4. A feed distance and a retraction distance of the welding wire 1 are determined by the eccentricity of the eccentric wheel. The device has the characteristics of reliable action, high reciprocating frequency, simple and light structure, less vibration and low cost.

Owner:HANGZHOU KAIERDA ELECTRIC WELDING MACHINE

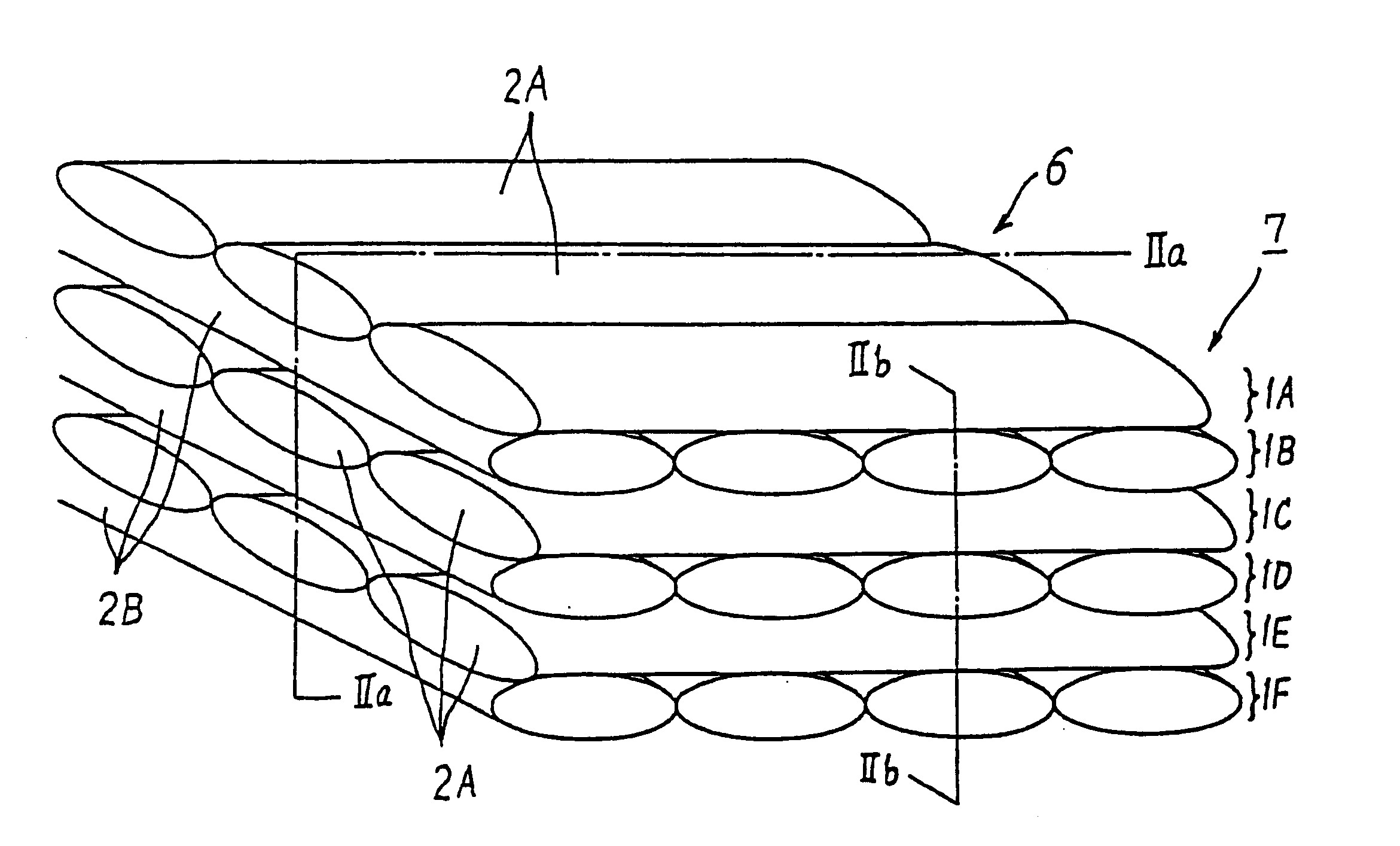

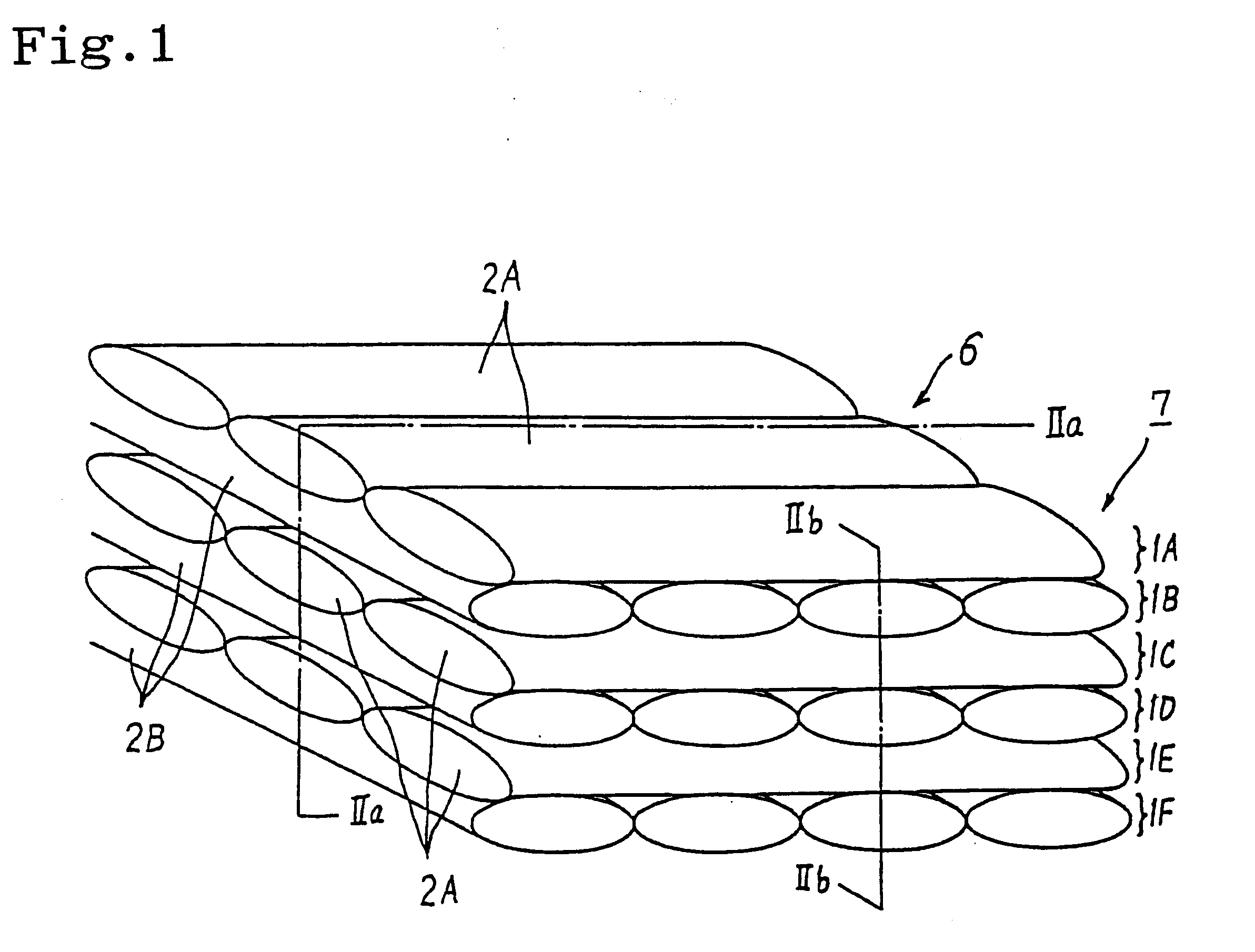

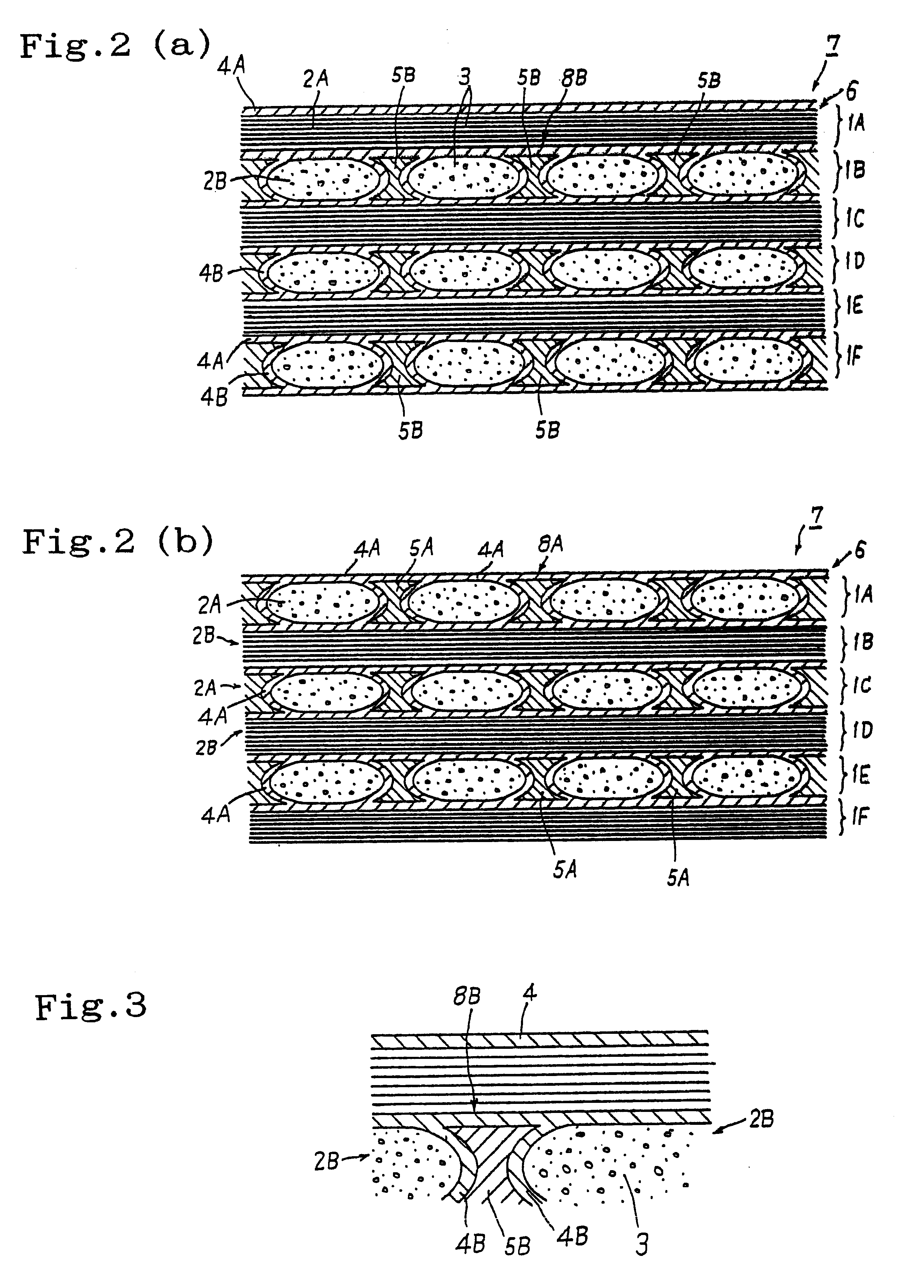

Fiber-composite material and method for producing the same

A fiber-composite material includes: 55-75 wt % of carbon, 1-10 wt % of silicon and 10-50 wt % of silicon carbide, and the matrices including Si-SiC-based materials formed integrally among assemblages of yarns include carbon fibers integrally formed and combined three-dimensionally so as not to separate from each other. The fiber-composite material has a coefficient of kinetic friction of 0.05-0.6 and a porosity of 0.5-10%.

Owner:NGK INSULATORS LTD +1

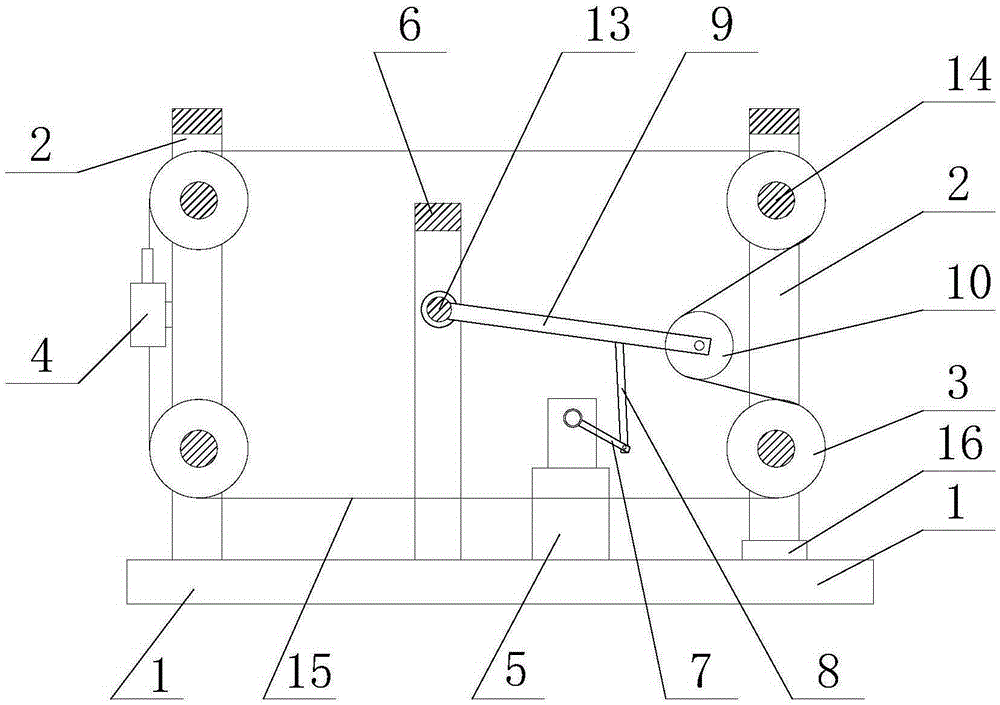

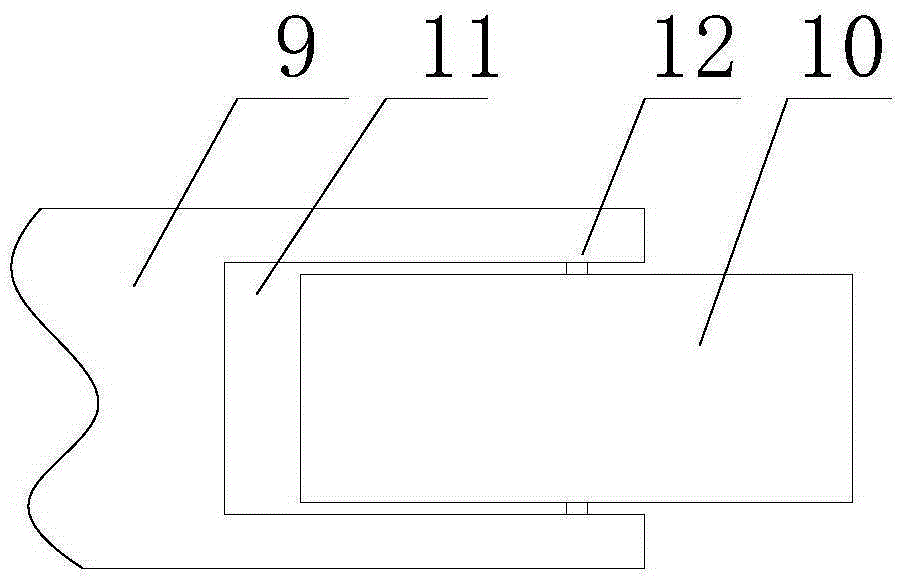

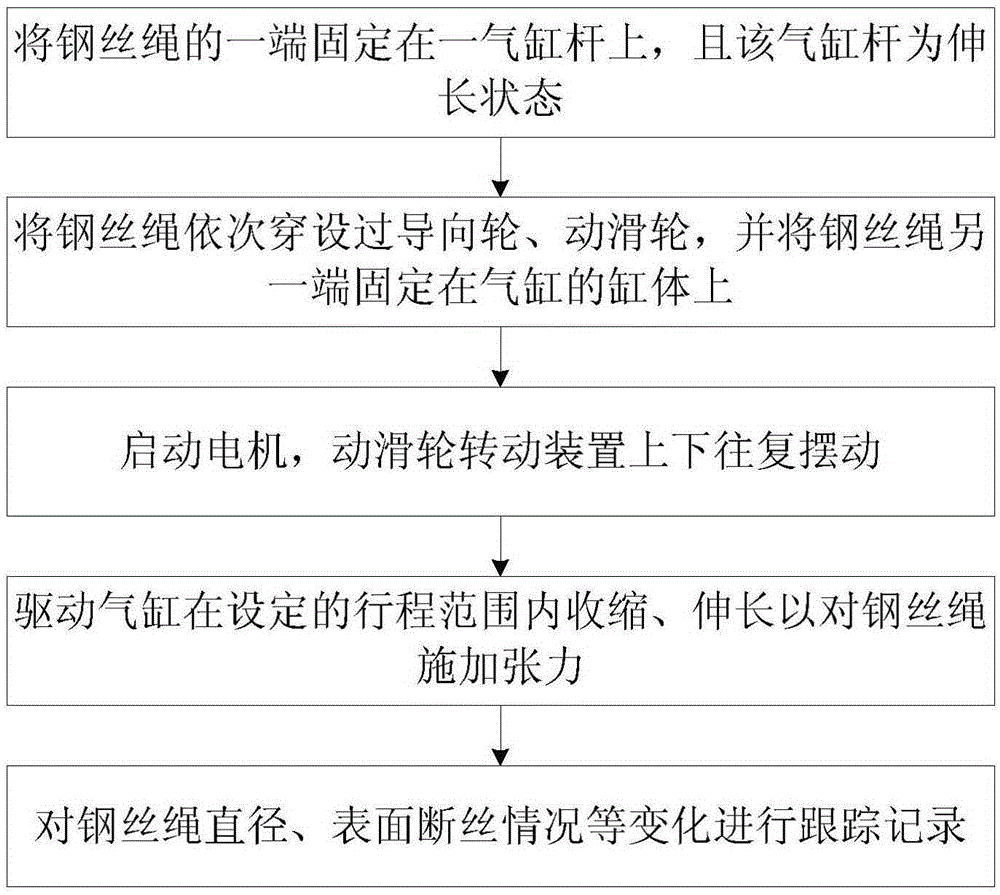

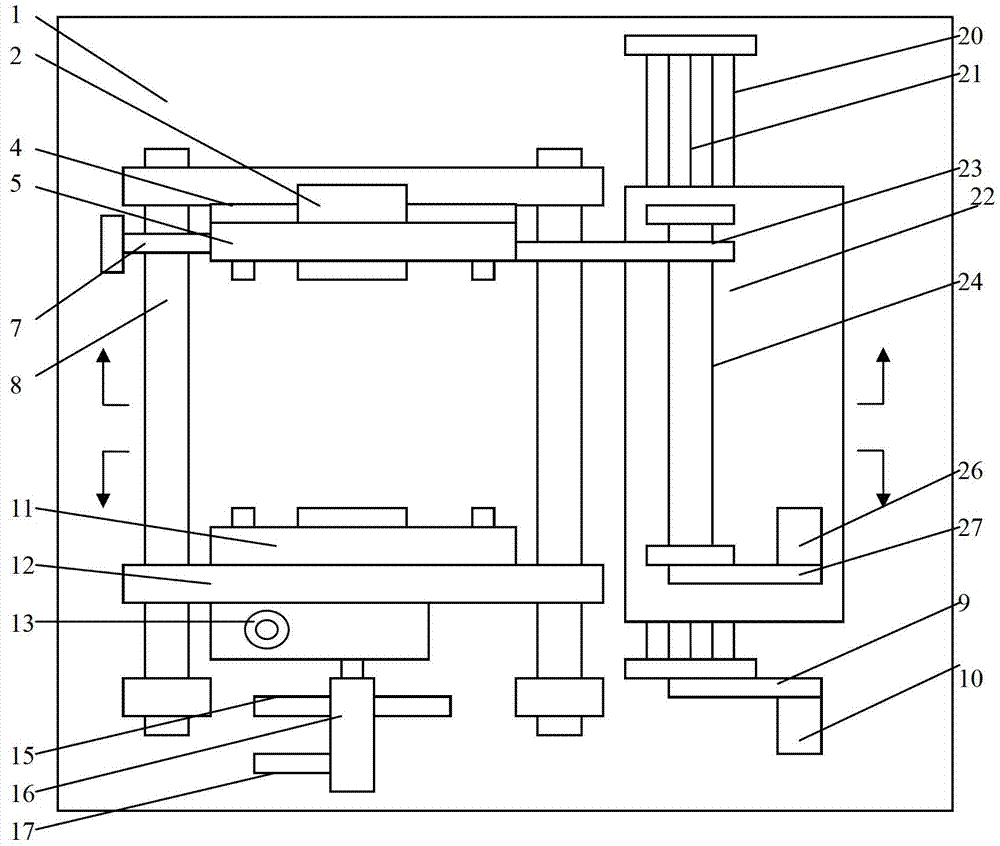

Wire rope fatigue testing apparatus and method

ActiveCN105300806AAutomatic tension adjustmentThere will be no falling and smashing objectsMaterial strength using tensile/compressive forcesInvestigating abrasion/wear resistanceEngineeringHeavy load

The invention relates to the technical field of wire ropes, especially to a wire rope fatigue testing apparatus and method. The wire rope fatigue testing apparatus comprises an apparatus bench and first rectangle frame bodies arranged on the apparatus bench, wherein the first rectangle frame bodies are respectively arranged on two ends of the apparatus bench and both provided with a rotatable directive wheel; the wire rope fatigue testing apparatus also comprises a draw gear which is fixedly arranged on the first rectangle frame bodies; and the wire rope fatigue testing apparatus further comprises a movable pulley rotating device. According to the invention, through arrangement of the draw gear, the draw gear can tighten the wire rope through dragging, kinetic friction occurs between a movable pulley and the wire rope, so friction between the wire rope and the pulley under the action of a certain tensile force can be authentically simulated; the apparatus has a simple structure and can automatically adjust the tensile force of the wire rope; and since the wire rope is not connected with a heavy object, the problem of potential safety hazards does not occur during usage. The testing method provided by the invention can authentically simulate the friction between the wire rope and the pulley under the action of a certain tensile force and comprises simple steps.

Owner:JIANGSU SAFETY STEEL WIRE ROPE

Self-lubricating heat-resistnat and wear-resistant materials

InactiveCN1818117AHigh temperature strength and hardnessIncreased high temperature strength and hardnessBearing componentsOxidation resistantWear resistant

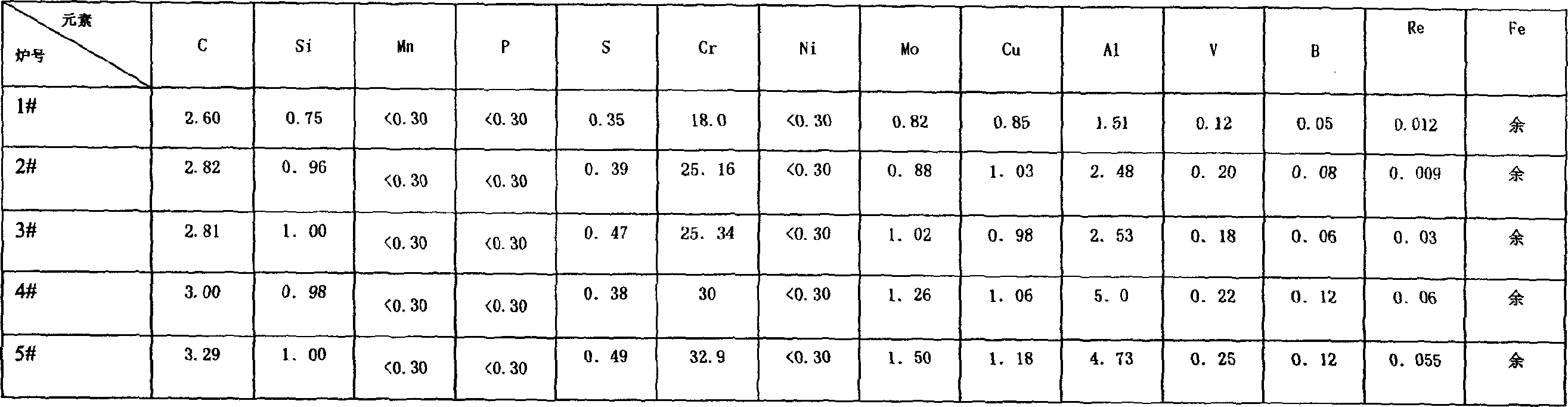

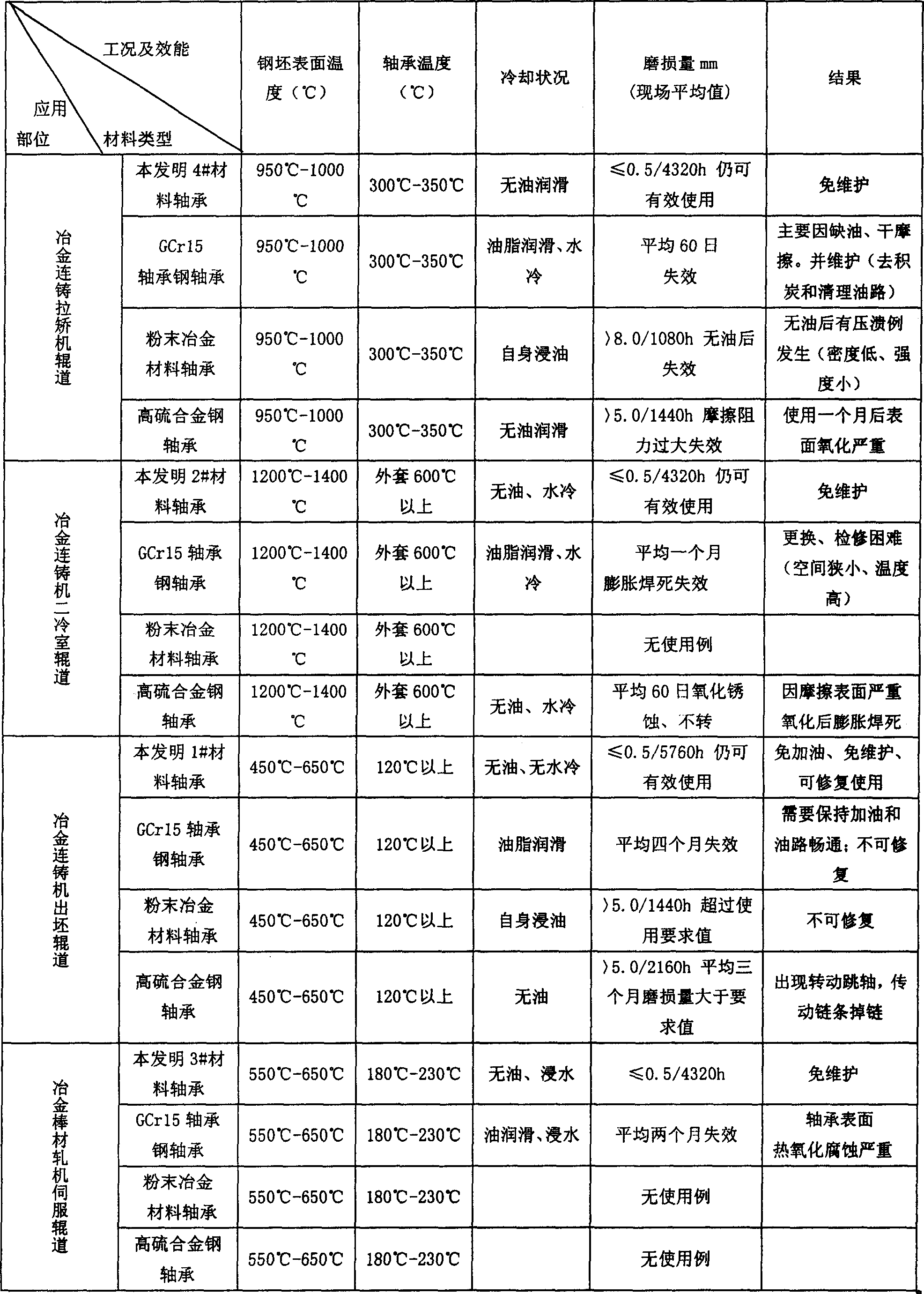

The invention opened a heat-proof and wearing self-lubricating material. It can be used to the shafting bearing, bearing bush, axile bush and the other break-away friction parts of the metallurgy, mining area and machine, especially for the parts of the high temperature (350 DEG C-800 DEG C).the weight ration of the composition is C 2.6-3.%, S 0.35-0.49%, Si 0.5-1.0%, Cr 18-35%, Mo 0.8-1.5%, Cu 0.8-1.2%, Al 1.5-5.0%, V 0.1-0.25%, B 0.05-0.15%, RE 0.008-0.08%, P<=0.3%, Ni<=0.3%, Mn<=0.3%, the residue is Fe. The weight ratio of Cr / C is 5.5-10. The material has the good resistance to heat and wearing character, also it can resist the corrosion of the CO2 and SO2.

Owner:BEIJING CISRI GAONA TECH

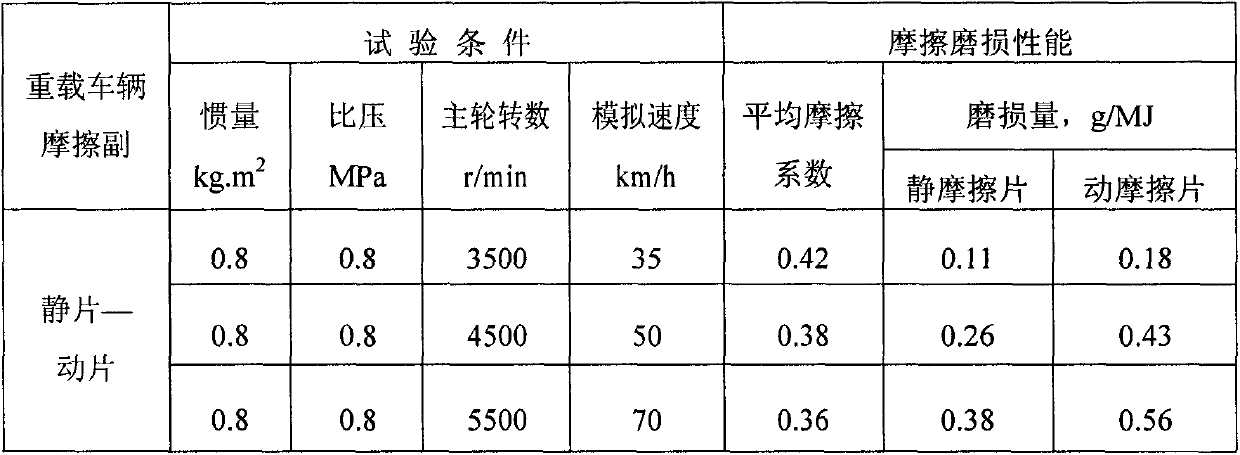

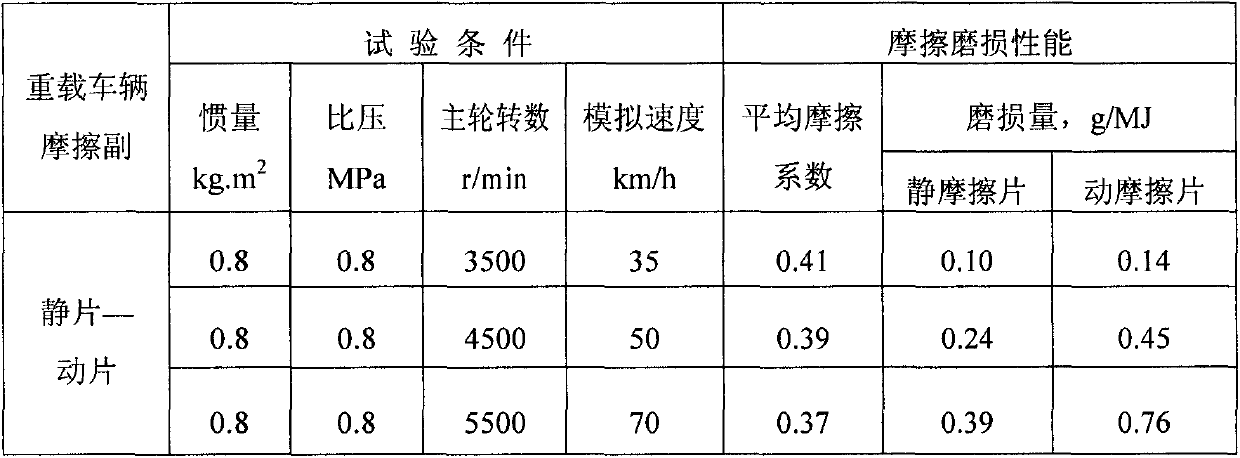

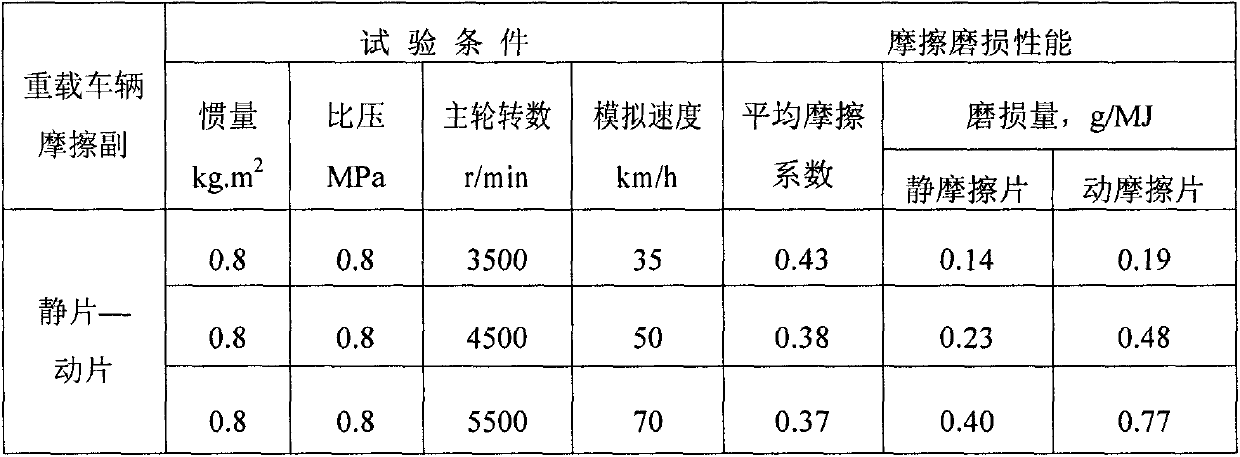

Powder metallurgy friction pair for braking of heavy-load vehicle and preparation technology thereof

ActiveCN103785824AGuaranteed uniformityGuaranteed friction and wear performanceAdditive ingredientHeat conducting

The invention relates to a powder metallurgy friction pair for braking of a heavy-load vehicle and a preparation technology thereof. A static friction piece comprises, by weight, 60-70 parts of reduced iron powder, 12-18 parts of electrolytic copper powder, 2-4 parts of molybdenum disulfide powder, 1-3 parts of ferro-manganese alloy powder, 1-3 parts of electrolytic nickel powder, 3-5 parts of silicon dioxide powder and 6-10 parts of crystalline flake graphite powder. A kinetic friction piece comprises, by weight, 14-18 parts of the reduced iron powder, 40-60 parts of the electrolytic copper powder, 2-4 parts of the molybdenum disulfide powder, 4-6 parts of tin powder, 1-3 parts of ferro-chrome alloy powder, 2-4 parts of the ferro-manganese alloy powder, 1-3 parts of the electrolytic nickel powder, 1-3 parts of chromium powder, 1-3 parts of aluminum oxide powder, 4-7 parts of the silicon dioxide powder and 10-14 parts of the crystalline flake graphite powder. The preparation technology of the powder metallurgy friction pair for braking of the heavy-load vehicle includes the steps of production, sand blasting, reshaping and electroplating of a steel backing and the steps of compounding, mixing, chemical analysis on ingredient uniformity, prepressing shaping, pressure sintering, mechanical processing, product finishing and checking of the power materials. Known from an MM1000 test that the prepared powder metallurgy friction pair for the heavy-load vehicle has the advantages of excellent frictional wear resistance, stable braking performance, low energy consumption and wear rate, good material uniformity and heat-conducting performance and long service life, and the problems of a large breaking wear rate, short service life and the like resulted from severe decline of a high-temperature friction coefficient of an existing friction pair for the heavy-load vehicle are solved.

Owner:北京优材百慕航空器材有限公司

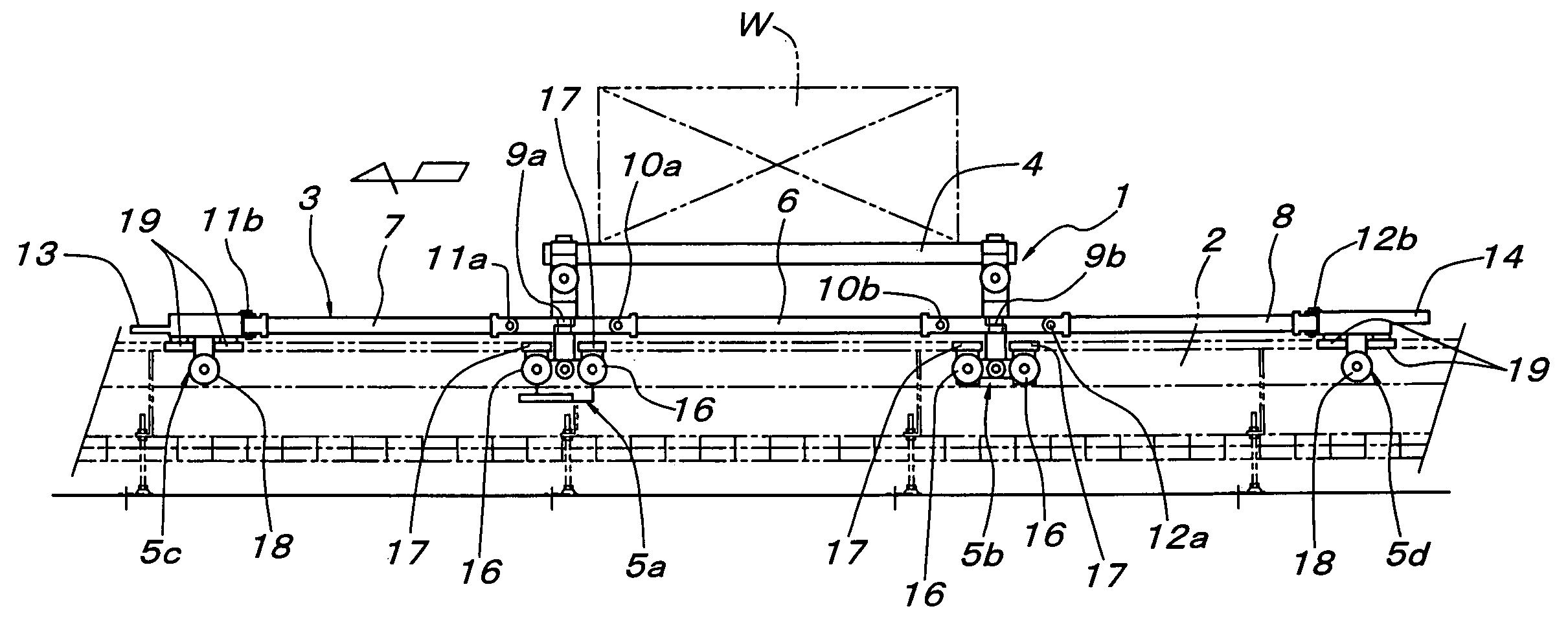

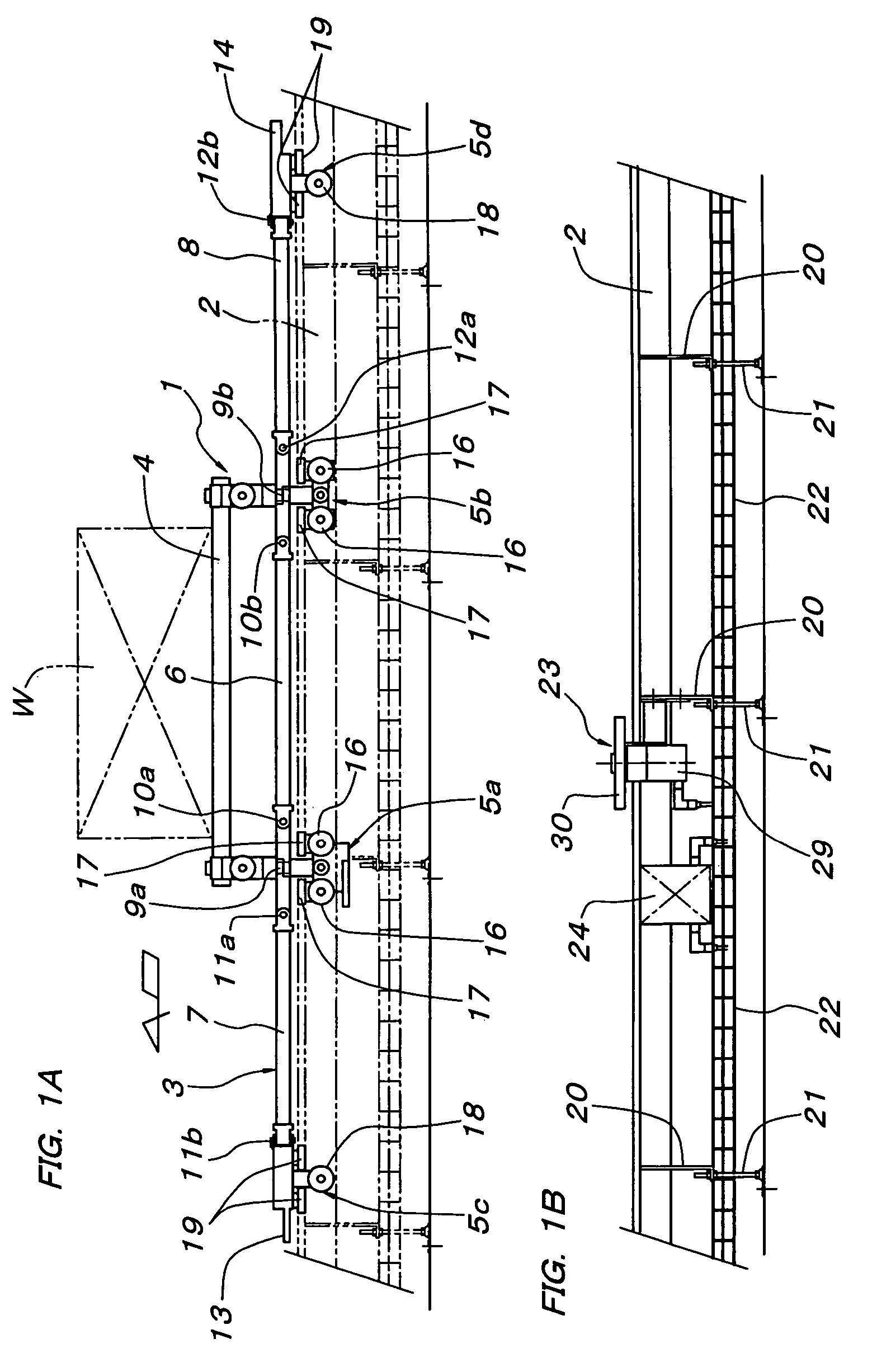

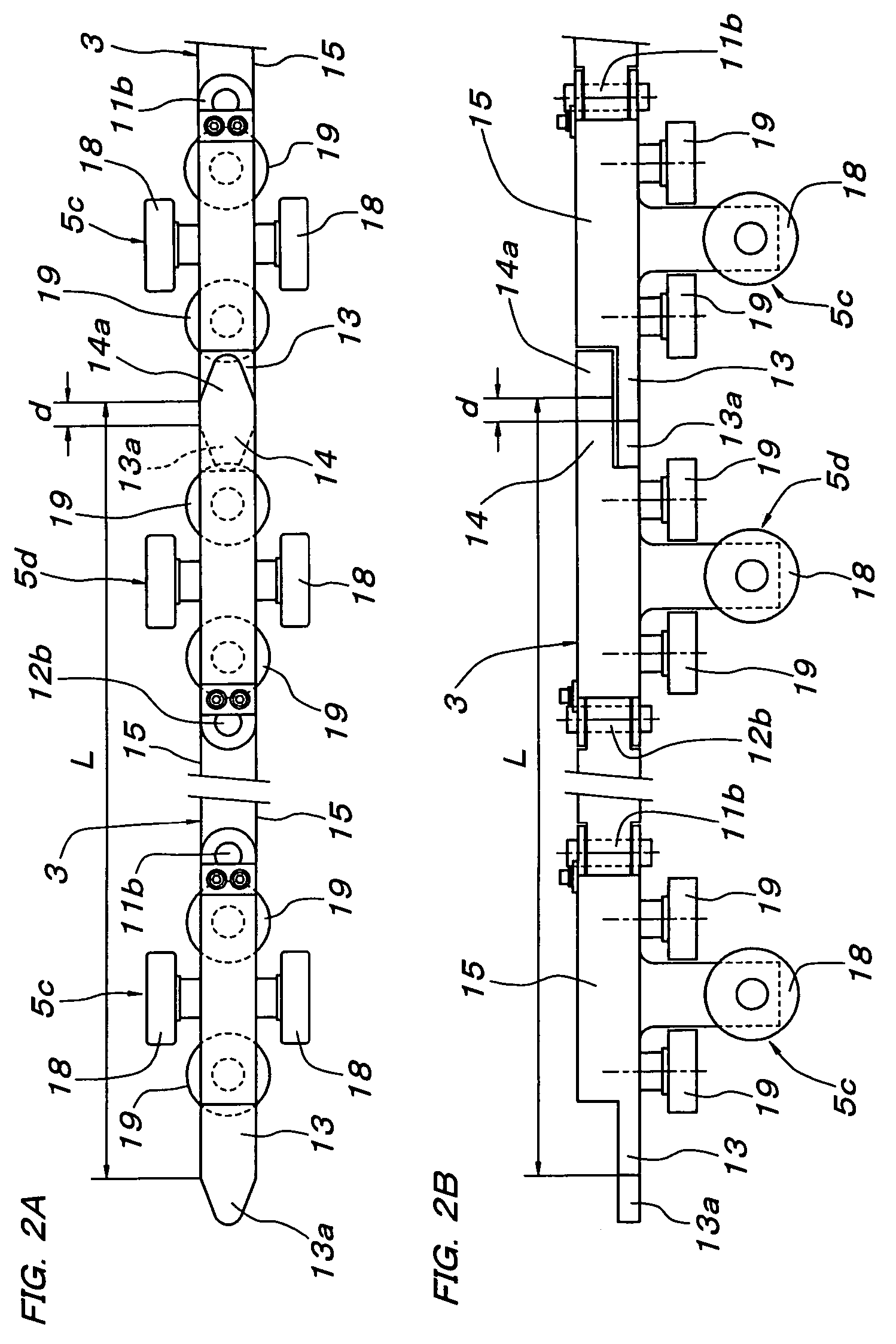

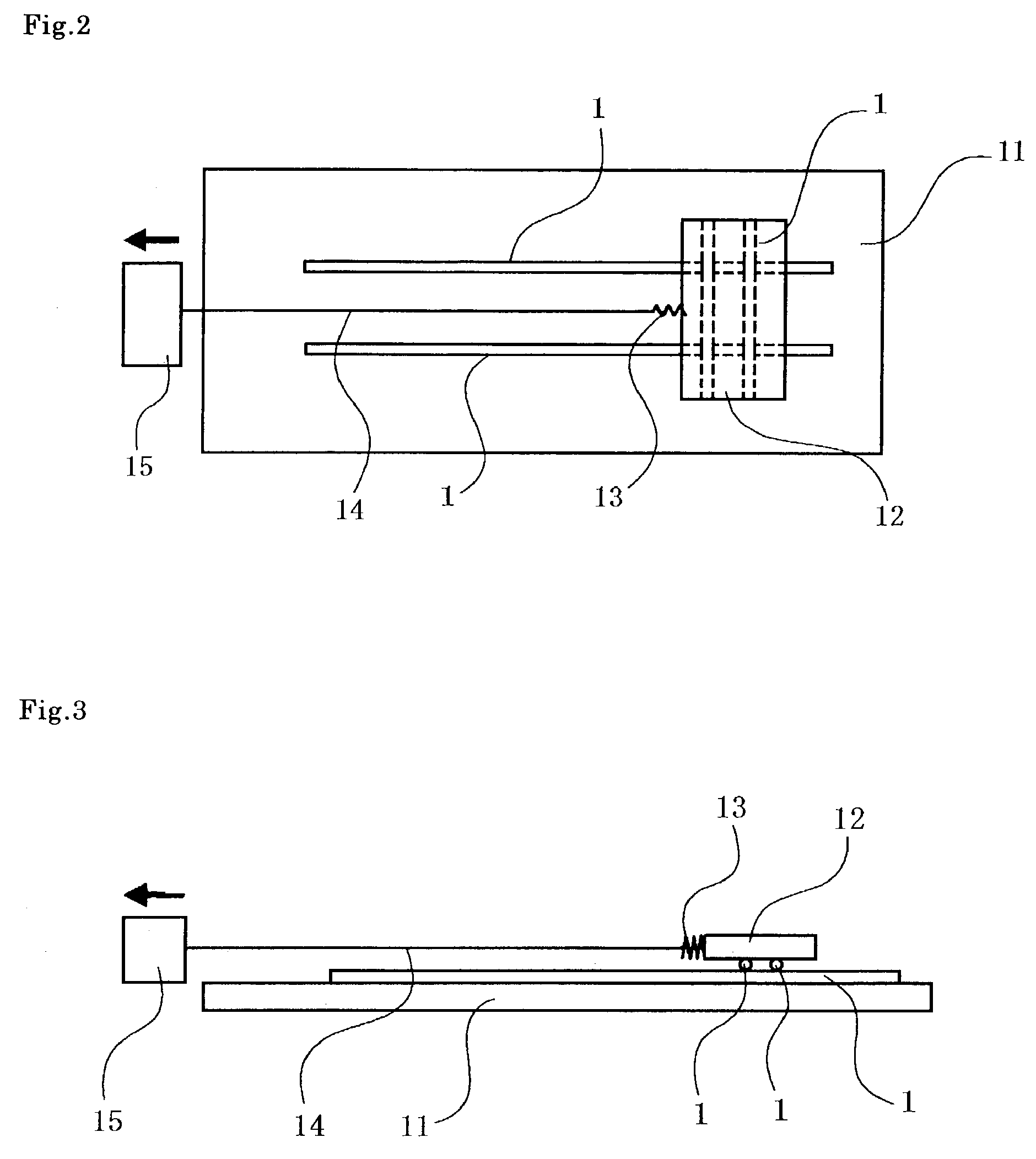

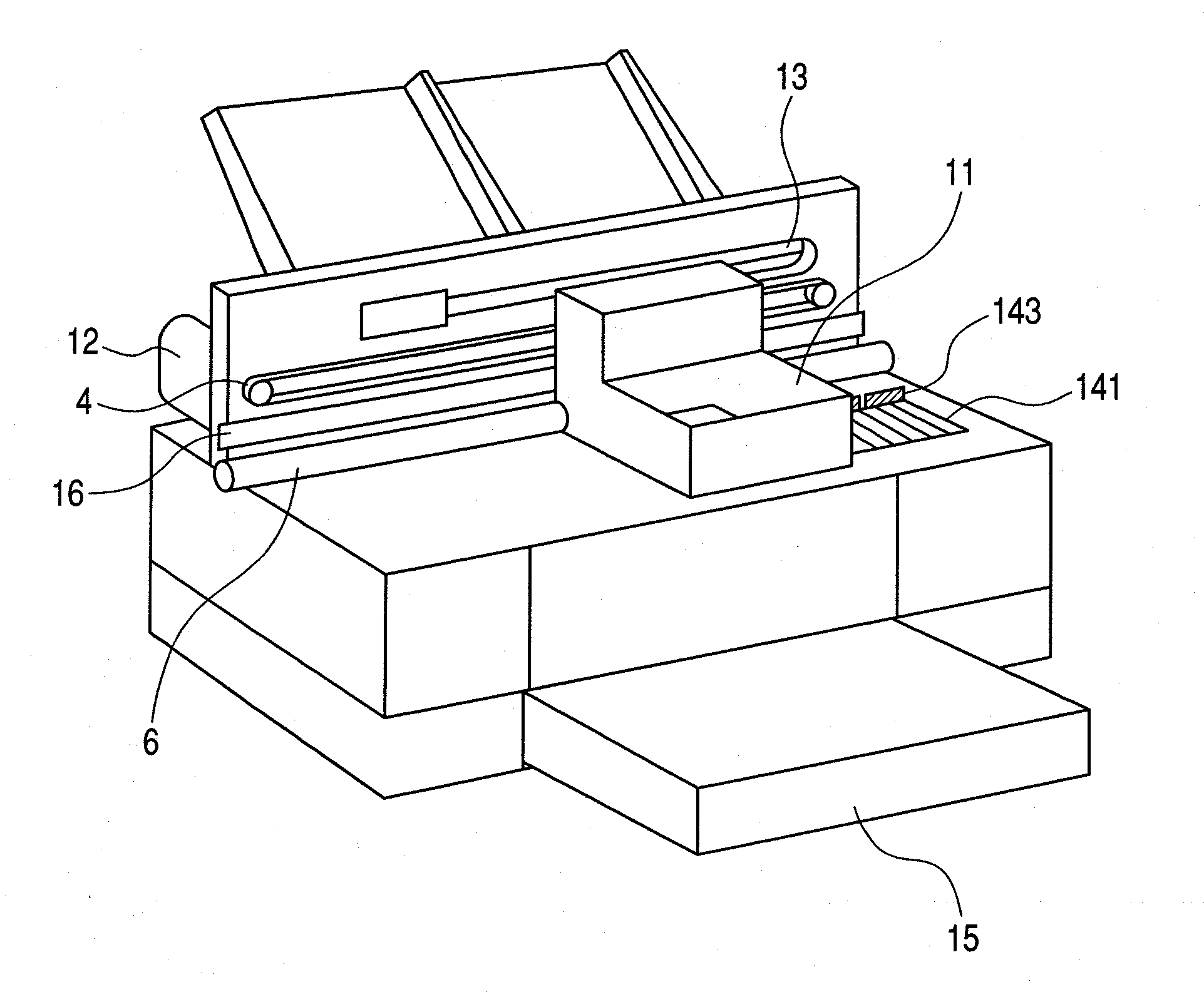

Friction drive conveyor

ActiveUS7127997B2Easily and efficiently carry-outSimple structureRailway componentsTramway railsEngineeringFriction drive

The present invention relates to a friction drive conveyor including carriers 1, which can be propelled along a track by frictional wheels 30 fitted along the track. Each frictional wheel 30 can be driven by a brakeless motor 29. A sensor 32 senses whether each frictional wheel 30 is in contact with any one frictional surface 15 of the carriers 1. The track includes a section along which the frictional wheels 30 are supported at regular intervals equal to or slightly shorter than the total length L of the frictional surfaces 15 on each side of each carrier 1. On the basis of a signal output from each sensor 32, a controller 24 so controls the associated brakeless motor 29 as to start rotating the associated frictional wheel 30 in contact with any one frictional surface 15 when the forward next wheel 30 gets free of the frictional surfaces 15, and as to stop driving the frictional wheel 30 having got free of the frictional surfaces 15.

Owner:DAIFUKU CO LTD

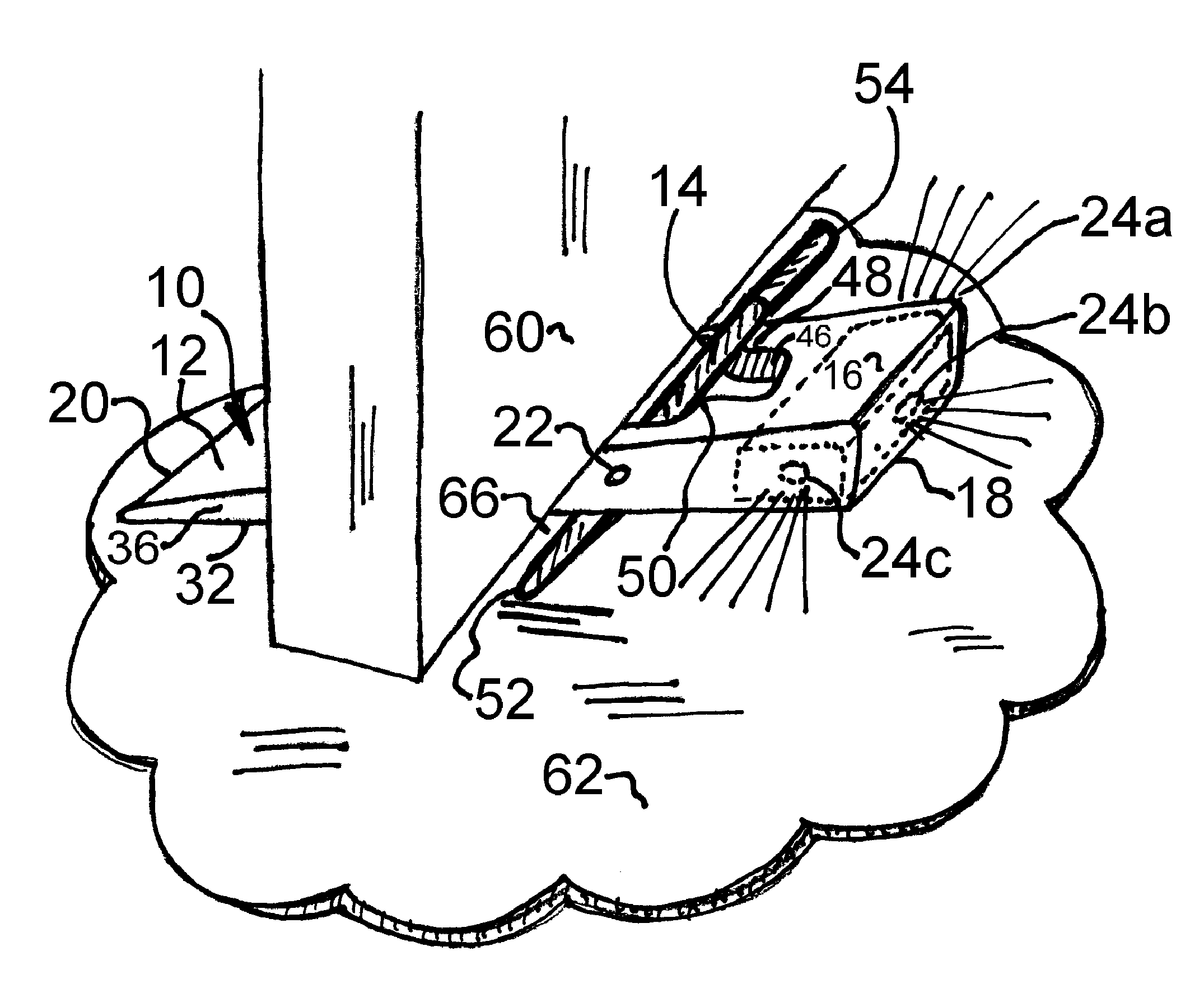

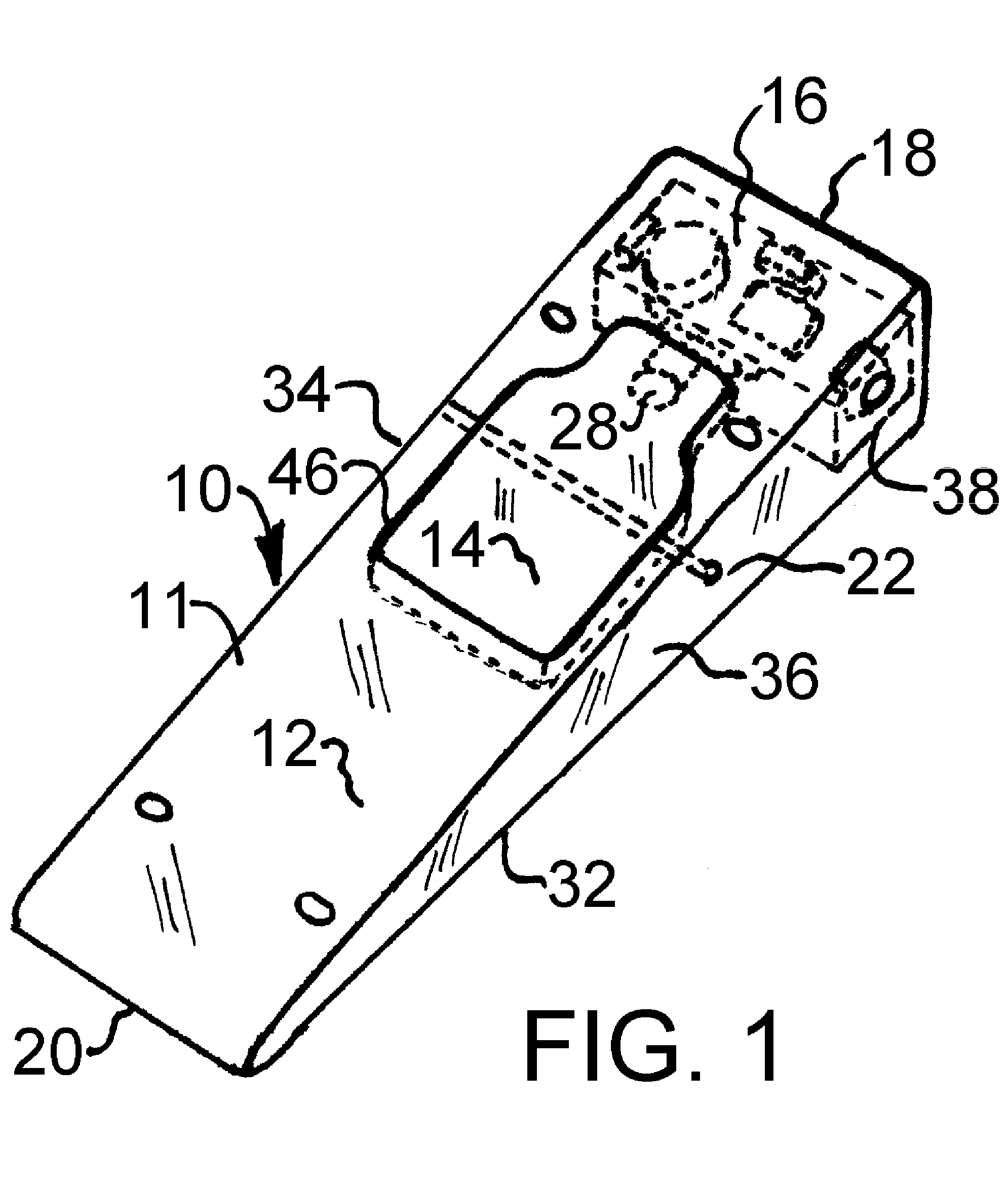

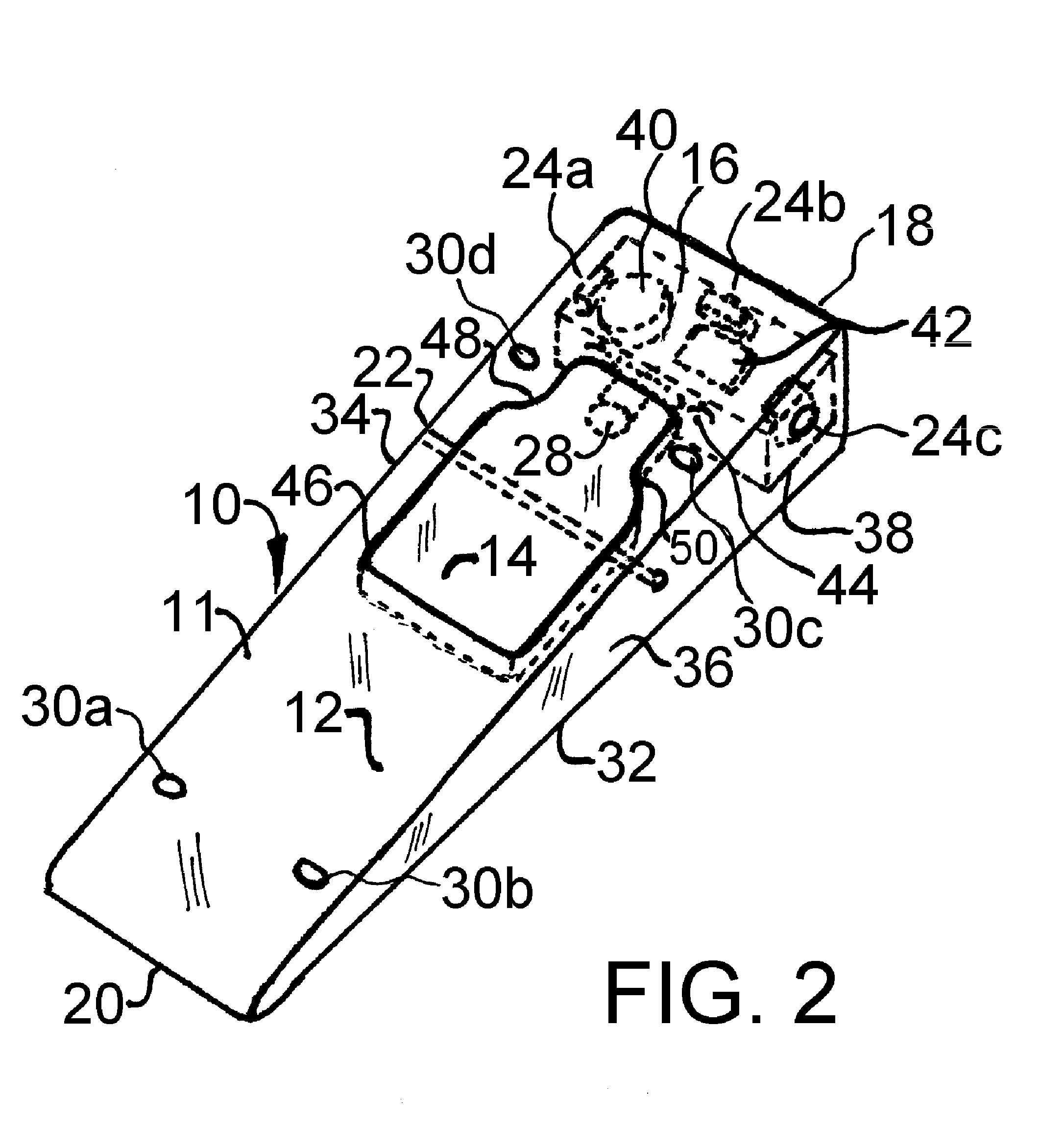

Intrinsically-safe ramp for use by rescue personnel

InactiveUS20090113672A1Intrinsically safeSmall sizePicture framesWing handlesIntrinsic safetyEngineering

An intrinsically-safe ramp or door prop (10) characterized by a light-weight, transparent ramp having an acutely-angled frontal edge (20), at least one rotatable member or rocker-plate (14) pivotally-attached, for increasing its height, further comprising a kinetic-friction lock, and wireless interface control (28) between an adjacently-housed electronic circuit (16). The circuit (42) is replaceable and sealed and intrinsically-safe for deployment in potentially-flammable or ignitable environments. The electronic circuit further comprises a plurality of multi-colored lamps (24) that visually communicate tactically-significant color signals and bears circuitry (42) to extend battery life wherein lamps may continuously operate for multiple hours. The ramp further comprises attachment points (30) (31) to gang-together a multiplicity of identical ramps whereby fashioning one contiguous block (FIG. 6) of ramps. The block or ramps further being easily manipulated by a user wearing gloves and easily transportable within a utility pocket.

Owner:IBEY JERRY ALAN

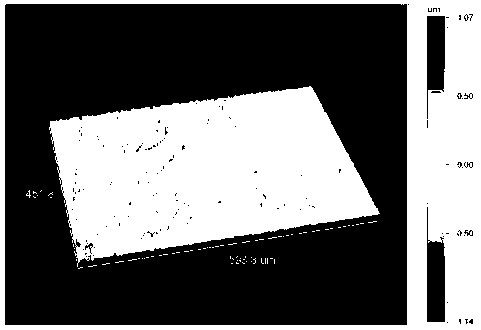

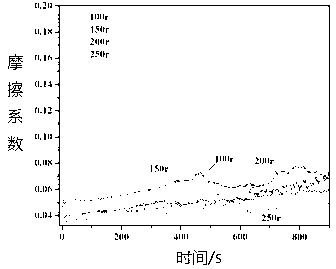

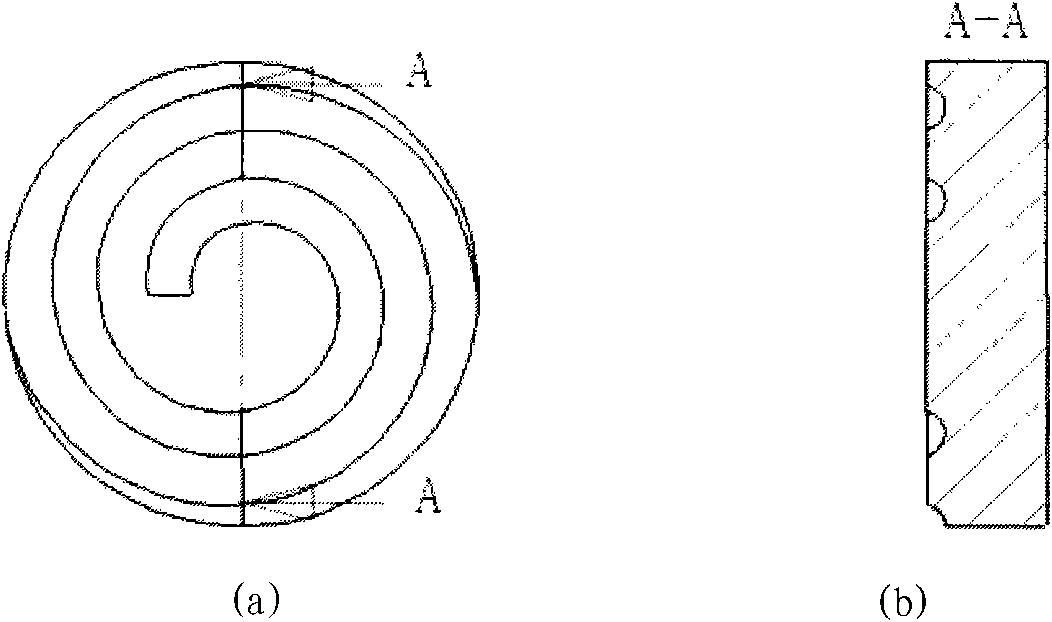

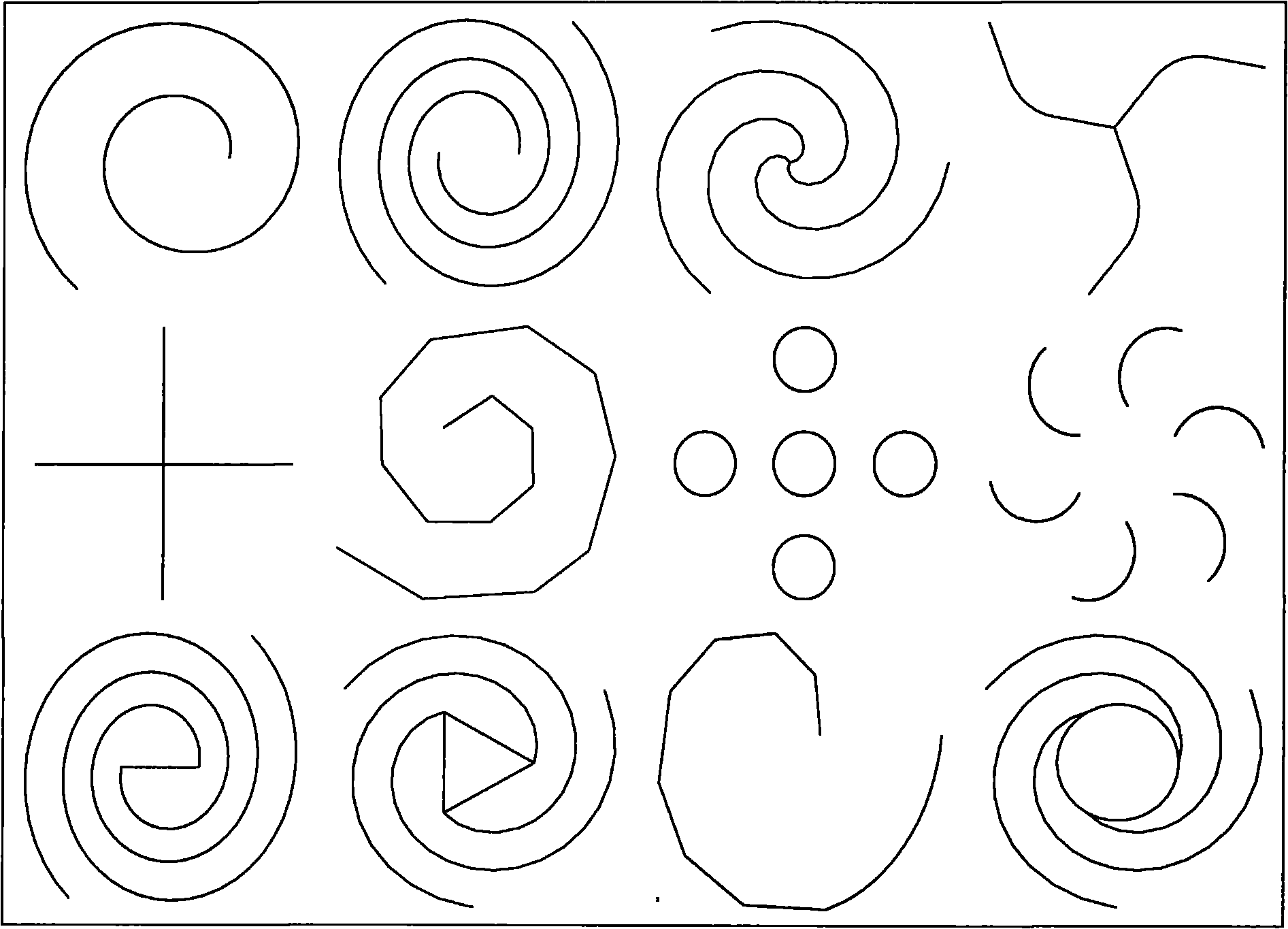

Laser micro-texturing self-lubricating treatment method for friction pairs

InactiveCN103322047AReduce coefficient of frictionBearing componentsLaser beam welding apparatusFrictional coefficientKinetic friction

The invention discloses a laser micro-texturing self-lubricating treatment method for friction pairs, which relates to a friction pair self-lubricating technology. According to the invention, the surface of a friction pair is subjected to laser micro-texturing treatment, the diameter of a micro pit is 45-130 microns, the depth of the micro pit is 10-80 microns, the area-occupied rate of the micro pit is 20-38%, the distance between the micro pits is 110-300 microns, and a self-lubricating composite material is embedded in the surface of the friction pair by using a secondary thermal pressurizing method, so that the surface friction coefficient of the obtained friction pair is low, thereby reducing friction and abrasion and improving the antifriction and wear-resistance combination properties of the friction pair.

Owner:JIANGSU UNIV

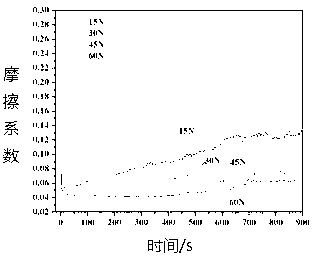

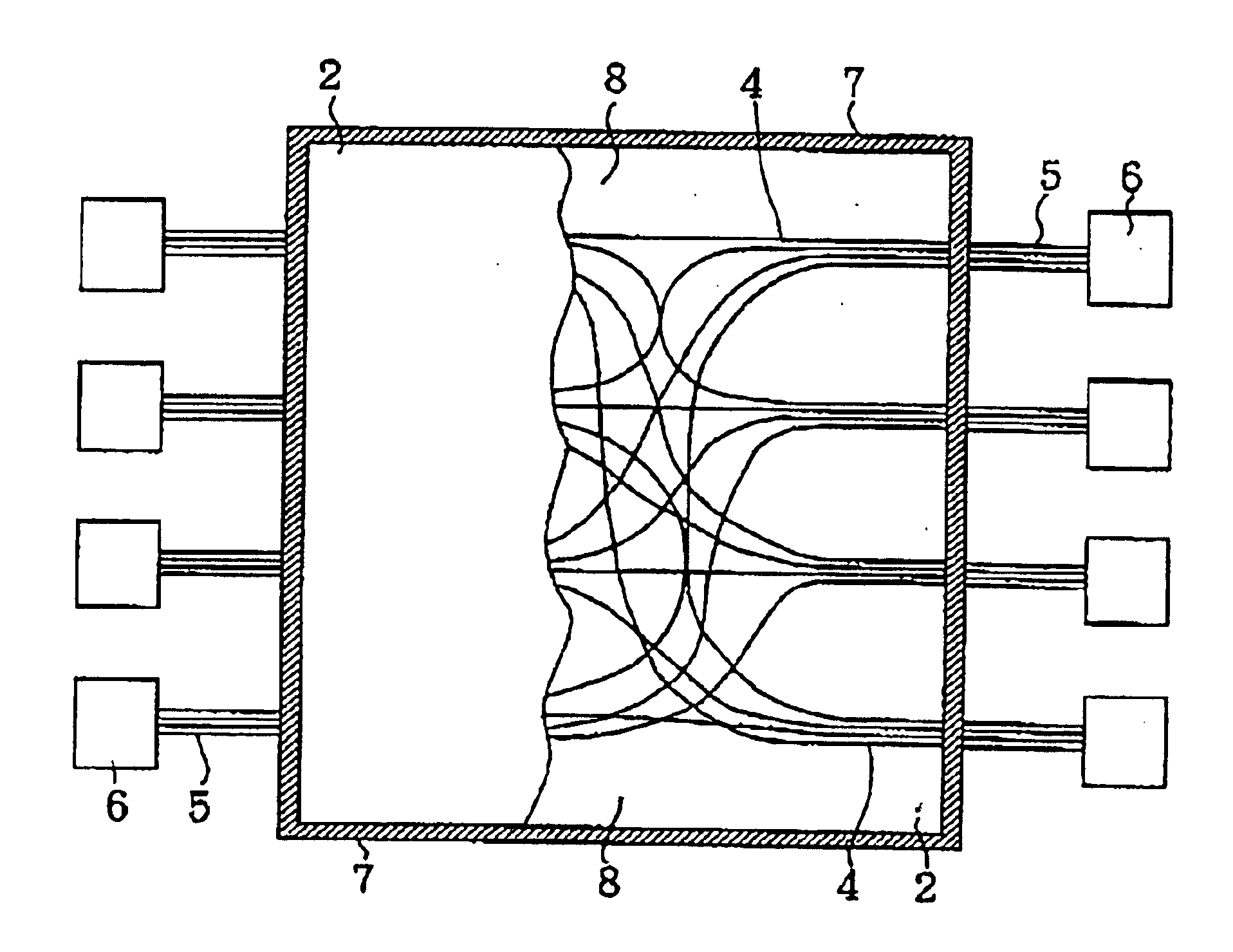

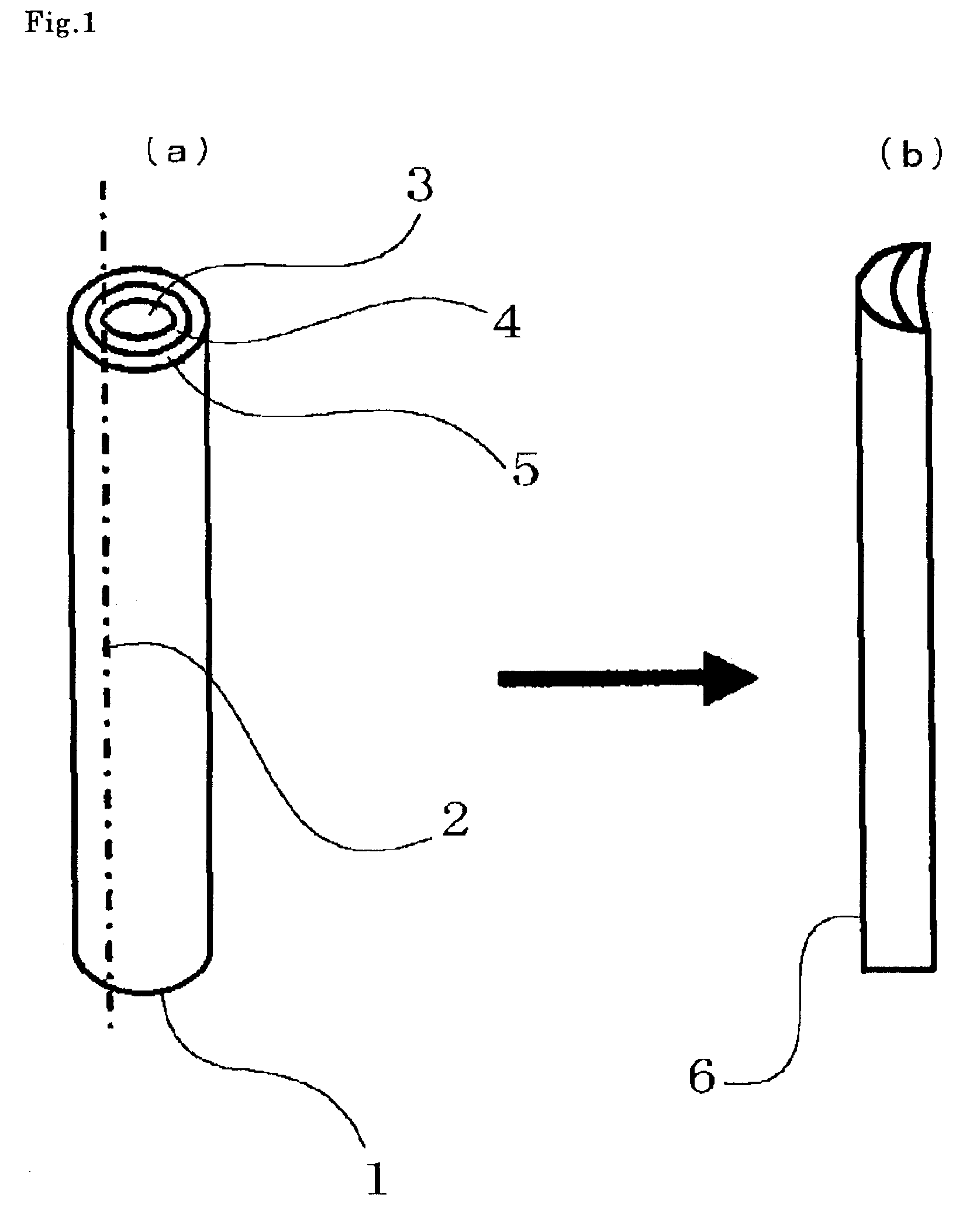

Optical connection component

InactiveUS6839475B2Easy to handleIncrease flexibilityCoupling light guidesOptical waveguide light guideSurface layerEngineering

The present invention provides an optical interconnection apparatus free from attaching, fixing or adhering when come into contact with each other or with another material, and easy to handle. The optical interconnection apparatus according to the invention comprises a substrate (1), a protective resin layer (2) composed of a silicone based rubber-like or gel-like material on one side or both sides of said substrate, and plural optical fibers (4) which are routed two-dimensionally routed on the substrate and provided at ends thereof with end portions (5) adapted to permit optical interconnections, and said optical fibers being held in place by said protective resin layer, wherein a non-tacky surface layer (8) is provided on the surface of said protective resin layer. The non-tacky surface layer is preferred to be composed of a silicone-based material and having a kinetic friction coefficient of 3.0 or less.

Owner:TOMOEGAWA PAPER CO LTD +1

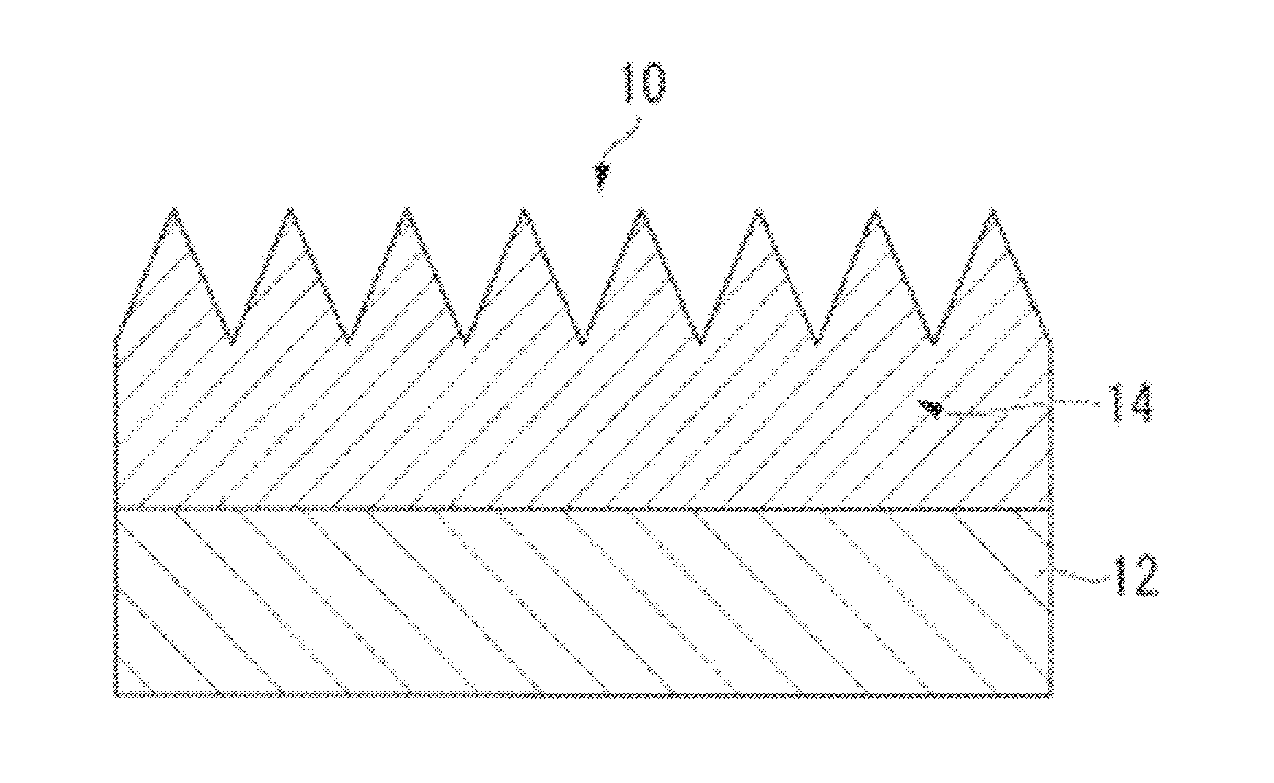

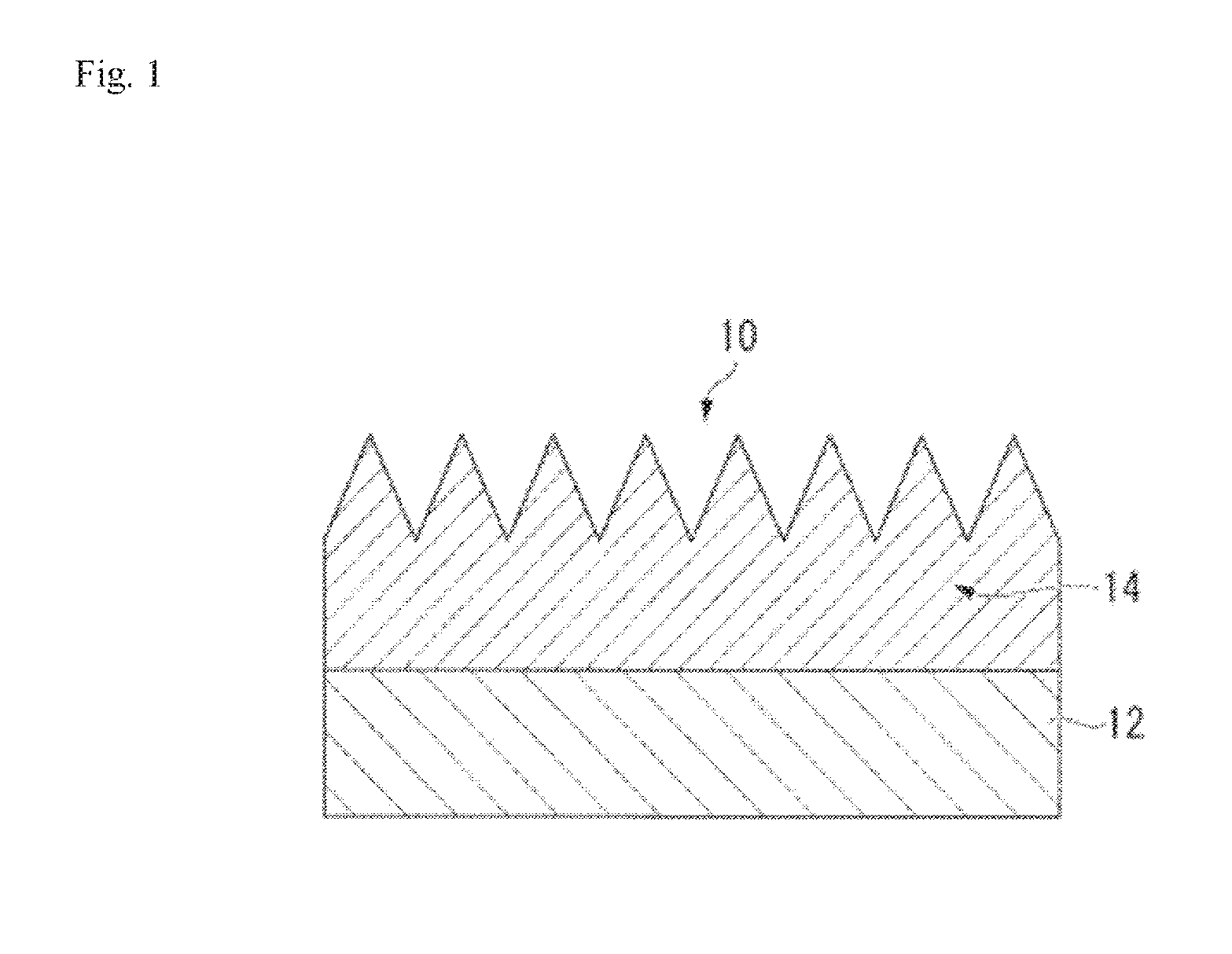

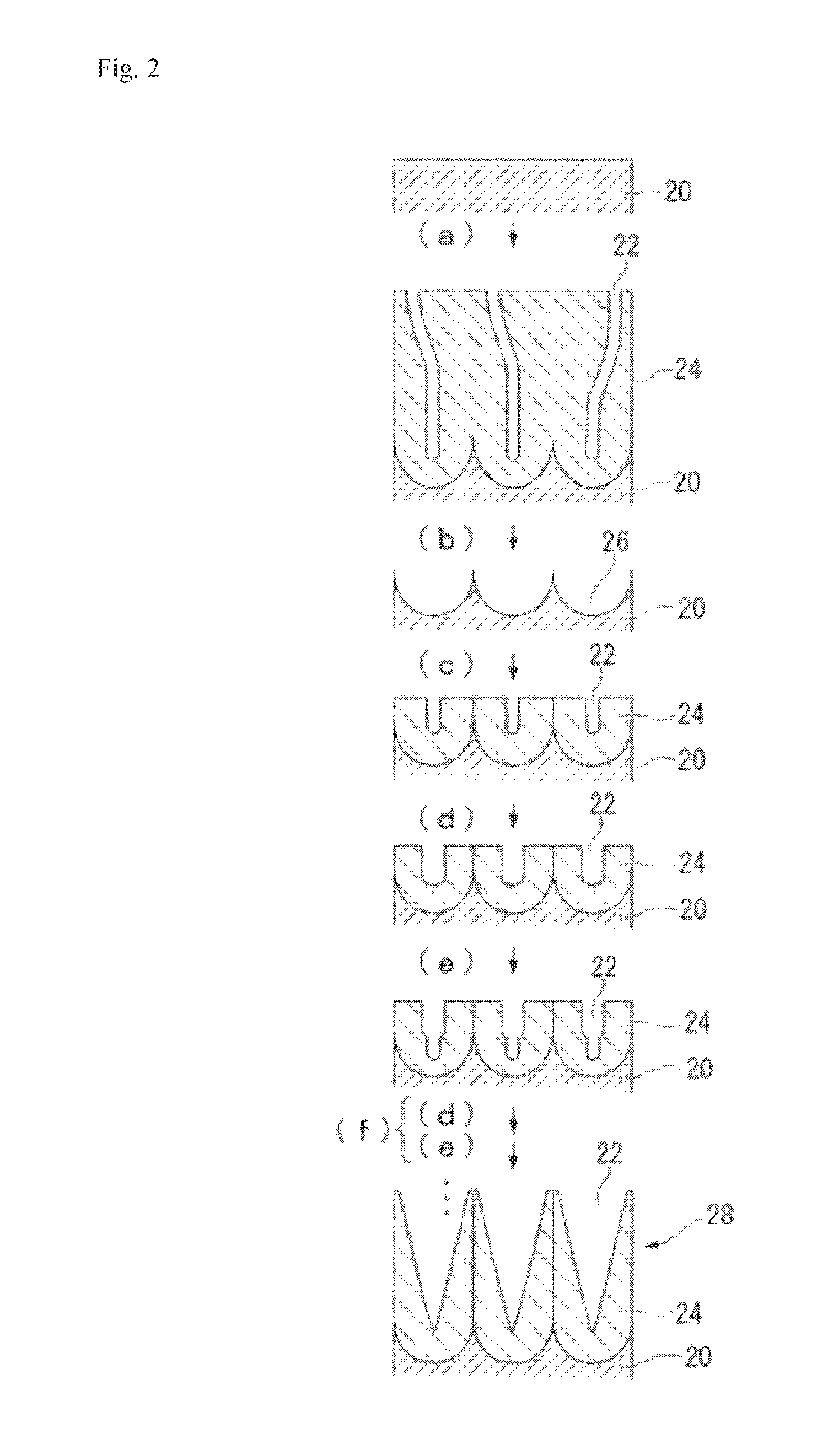

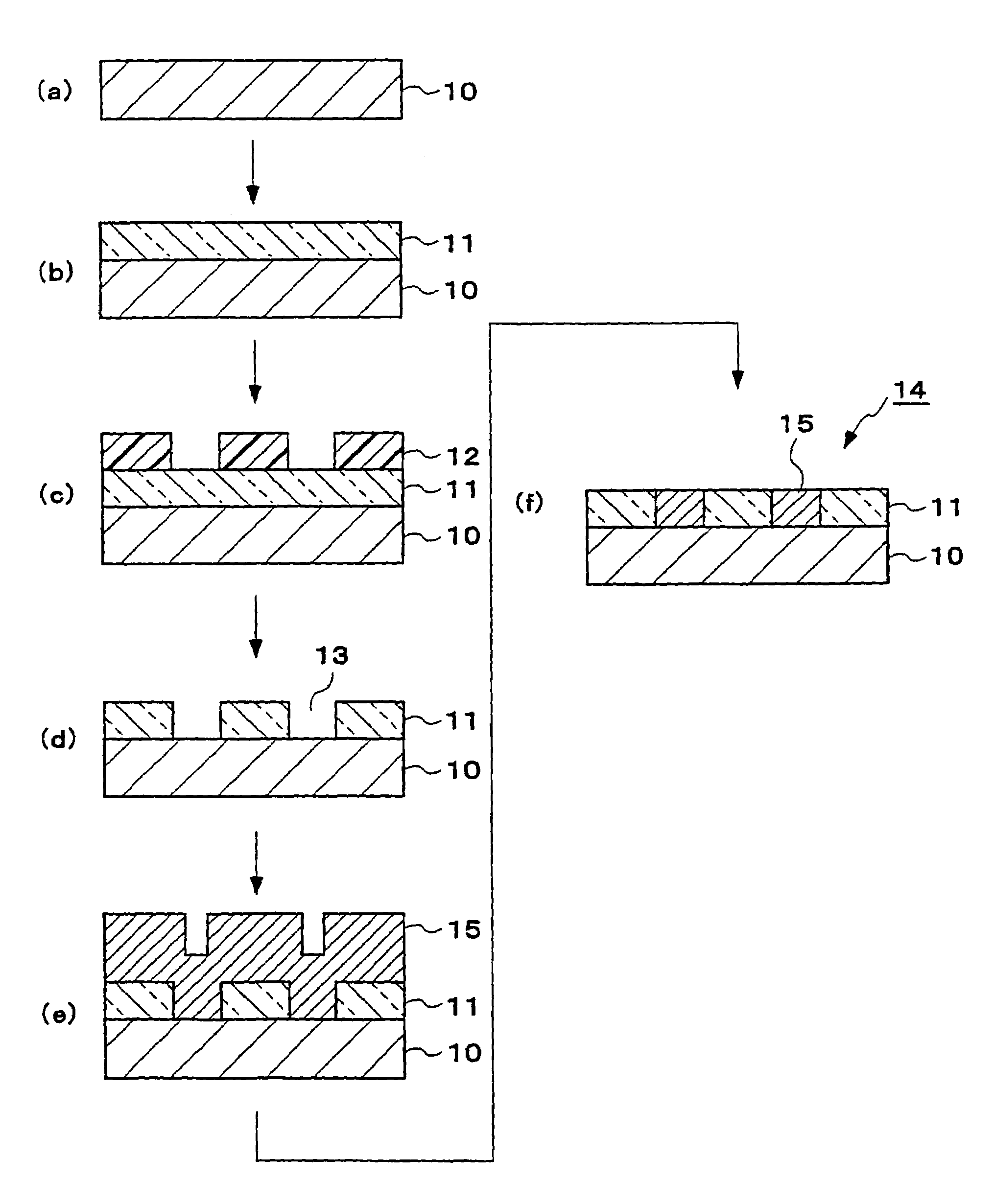

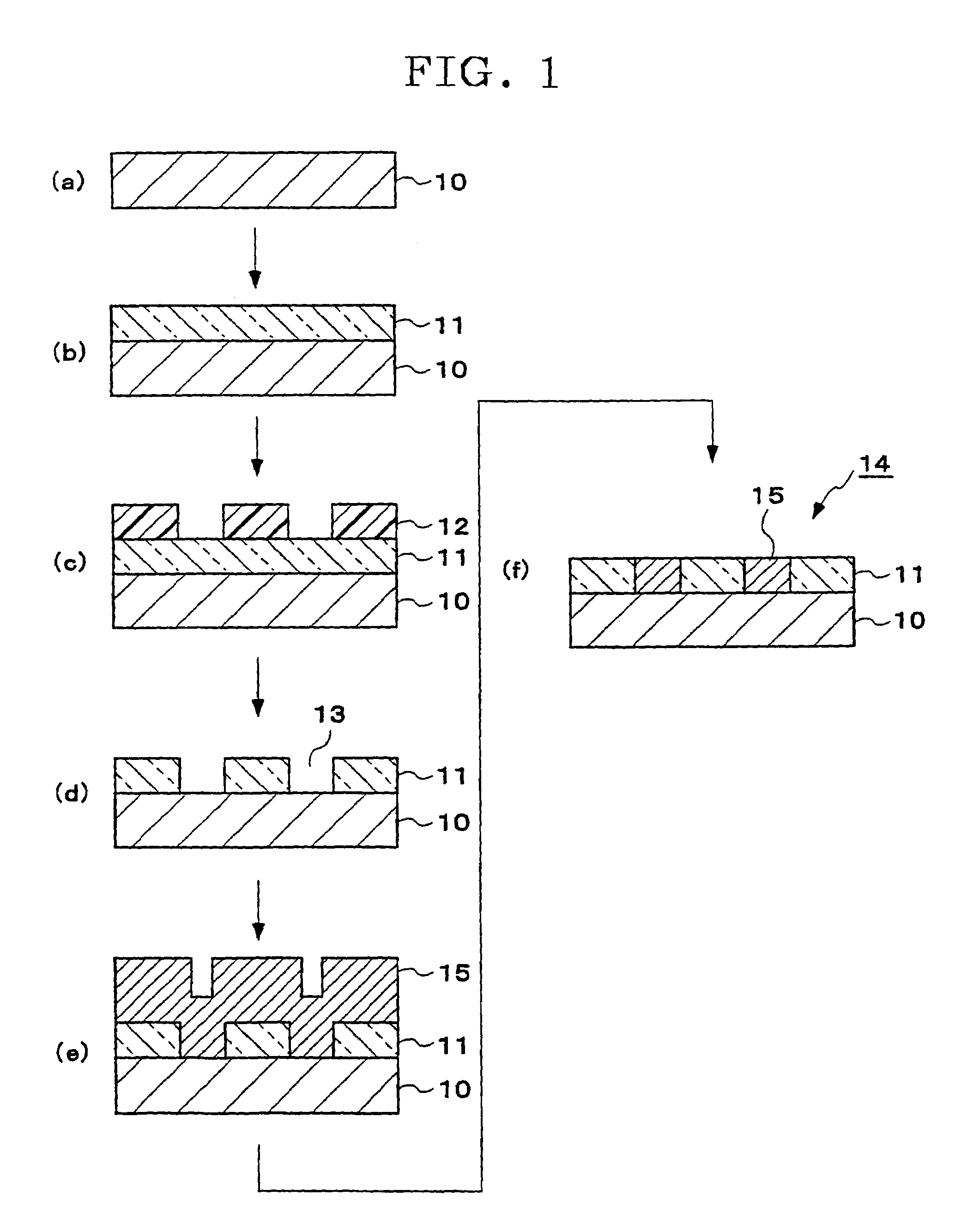

Structure, production method thereof, and article provided with said structure

ActiveUS20160229095A1Improve scratch resistanceSynthetic resin layered productsSurface reaction electrolytic coatingEngineeringKinetic friction

A structure with a substrate, and a fine-unevenness-structure layer provided to at least one surface of the substrate, wherein the fine-unevenness-structure layer is disposed at a surface of the structure, the indentation elastic modulus of the structure is 1-1300 MPa, and the ratio (Δμ) of the rate of change of the coefficient of kinetic friction of the surface of the structure is 0.15-1.05, wherein Δμ=Δμf / Δμs: Δμs represents the rate of change of the coefficient of kinetic friction of the surface of the structure at an initial-abrasion stage of a reciprocating abrasion test; and Δμf represents the rate of change of the coefficient of kinetic friction of the surface of the structure immediately prior to the end of the reciprocating abrasion test. This structure exhibits excellent scratch resistance without compromising on the optical performance thereof, such as the antireflection performance.

Owner:MITSUBISHI CHEM CORP

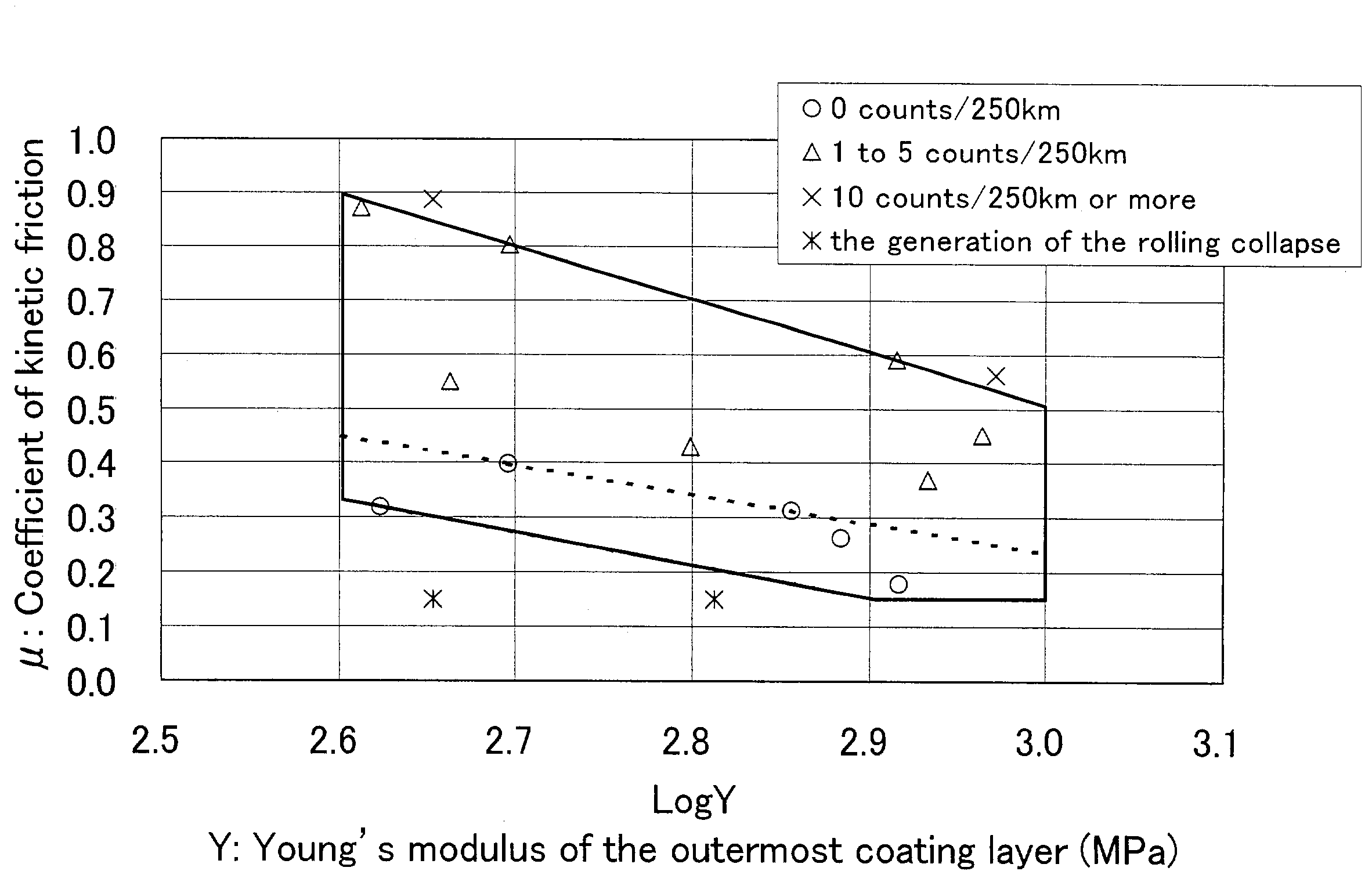

Optical fiber and method of measuring coefficient of kinetic friction of optical fiber

InactiveUS7085465B2Low rate of occurrenceVariationGlass optical fibreOptical fibre with multilayer core/claddingUltrasound attenuationFrictional coefficient

An optical fiber of the present invention comprising a bare optical fiber and one or plural coating layers on the bare optical fiber, wherein Y, the Young's modulus of the outermost coating layer is in the range of 400 to 1000 and μ, a coefficient of kinetic friction which occurs between the outermost coating layers is equal to or larger than 0.15, and further satisfying the following formulas (a) and (b);μ≦−0.9822 Log Y+3.45156 (a)μ≧−0.5418 Log Y+1.74128, (b)wherein the unit of Y is MPa.By the present invention, optical fibers with a low rate of occurrences of the attenuation discontinuity in a measurement result by OTDR and the method of measuring the coefficient of kinetic friction of optical fiber with high reliability are offered.

Owner:FURUKAWA ELECTRIC CO LTD

Coating liquid, ink jet recording method and ink jet recording apparatus

ActiveUS20080134935A1Improve scratch resistanceWithout impairing the feel inherent in paperMeasurement apparatus componentsInksOrganic solventImage formation

A coating liquid for use in an ink jet recording method comprising an image forming step of forming an image on a recording medium by an ink jet system with an ink comprising at least a pigment and a coating layer forming step of applying a coating liquid at least to a region including the image to form a coating layer having a film thickness of from 0.10 μm or more to 1.0 μm or less in at least a part thereof. The coating liquid comprises at least a slippery compound, water and a water-soluble organic solvent. The coating layer has a coefficient of kinetic friction of 0.40 or less.

Owner:CANON KK

Steel wire micro-kinetic-friction abrasion testing machine

InactiveCN103196766ASimple structureEasy to operateInvestigating abrasion/wear resistancePosition/direction controlReciprocating motionMaterials science

The invention discloses a steel wire micro-kinetic-friction abrasion testing machine which comprises a main rack, and an upper working platform and a lower working platform which are arranged on the main rack, wherein an upper sample steel wire is fixed on the upper working platform, a lower sample steel wire is fixed on the lower working platform, and the upper sample steel wire is in contact with the lower sample steel wire. The steel wire micro-kinetic friction abrasion testing machine also comprises a micro inching displacement frequency regulating mechanism and a micro inching displacement amplitude regulating mechanism, wherein the micro inching displacement frequency regulating mechanism is used for driving the upper working platform to reciprocate relative to the lower working platform so as to form friction between the upper sample steel wire and the lower sample steel wire for carrying out a steel wire friction abrasion test, the micro inching displacement frequency regulating mechanism is also steplessly regulating the reciprocating frequency of the upper working platform, and the micro inching displacement amplitude regulating mechanism is used for steplessly regulating the reciprocating amplitude of the upper working platform.

Owner:SHENZHEN INST OF SPECIAL EQUIP INSPECTION & TEST

Polishing compound for chemimechanical polishing and polishing method

InactiveUS7232529B1Highly reliable buried metal film patternsImprove efficiencyOther chemical processesDetergent mixture composition preparationTectorial membraneFilm-forming agent

This invention provides a polishing medium for CMP, comprising an oxidizing agent, a metal-oxide-dissolving agent, a protective-film-forming agent, a water-soluble polymer, and water, and a polishing method making use of this polishing medium. Also, it is preferable that the water-soluble polymer has a weight-average molecular weight of 500 or more and the polishing medium has a coefficient of kinetic friction of 0.25 or more, a Ubbelode's viscosity of from 0.95 mPa·s (0.95 cP) to 1.5 mPa·s (1.5 cP) and a point-of-inflection pressure of 5 kPa (50 gf / cm2).

Owner:RESONAC CORPORATION

Flowing friction welding method and tool thereof

The invention belongs to a welding technique, in particular to a flowing friction welding method suitable for connecting and processing homogeneous or heterogeneous thermoplastic materials and repairing workpiece defects and a tool thereof. The welding method comprises the following steps of: placing a flowing friction tool on welding equipment and rotating the flowing friction tool by 40-4000 turns / minute; contacting the axis of the flowing friction tool with the surface of a welded workpiece by the included angle of 0-15 degrees, and then applying the normal pressure of 0.1-100 kN to the workpiece by using the flowing friction tool; making the flowing friction tool keep the normal pressure and continuous rotation and remain 2-30 seconds on the workpiece, and then welding. The end surface of a friction head of the flowing friction tool used in the invention is provided with a spiral or radial tank. Because the flowing friction tool does not extend into the workpiece, no keyholes in stirring friction welding exist in the invention. The invention can be widely applied in the fields of spot welding, overlapping joint, abutting joint, defect repairing, material processing and the like.

Owner:BEIJING FSW TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com