Powder metallurgy friction pair for braking of heavy-load vehicle and preparation technology thereof

A technology of powder metallurgy and friction pair, which is applied in the field of powder metallurgy friction pair for heavy-duty vehicle braking and its preparation technology, can solve the problems of short life of friction pair, unstable friction coefficient at high temperature, insufficient heat resistance limit, etc., and achieve heat conduction Good performance, low wear rate, guaranteed friction and wear performance and heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

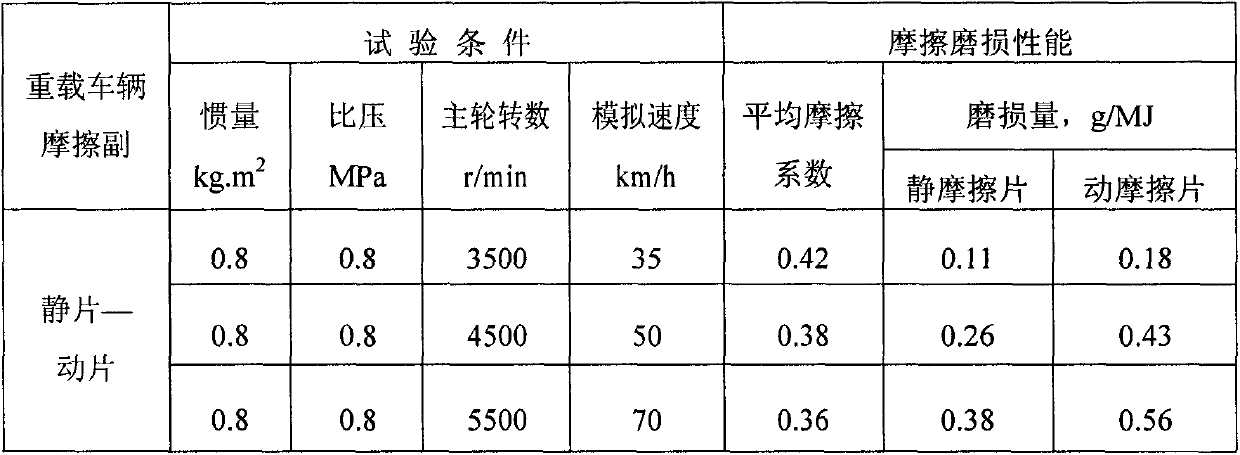

Embodiment 1

[0022] The weight of each component of the static friction plate of the powder metallurgy friction pair for heavy-duty vehicles: 62 parts of reduced iron powder, 15 parts of electrolytic copper powder, 4 parts of molybdenum disulfide powder, 2 parts of iron-manganese alloy powder, 2 parts of electrolytic nickel powder, 5 parts of silicon powder, 10 parts of flake graphite.

[0023] The weight of each component of the powder metallurgy friction pair dynamic friction plate for heavy-duty vehicles: 14 parts of reduced iron powder, 54 parts of electrolytic copper powder, 3 parts of molybdenum disulfide powder, 5 parts of tin powder, 1 part of iron-chromium alloy powder, iron-manganese alloy 3 parts of electrolytic nickel powder, 2 parts of electrolytic nickel powder, 1 part of chromium powder, 2 parts of aluminum oxide powder, 4 parts of silicon dioxide powder, and 11 parts of flake graphite.

[0024] Manufacturing process:

[0025] (1) batching: take each component with electro...

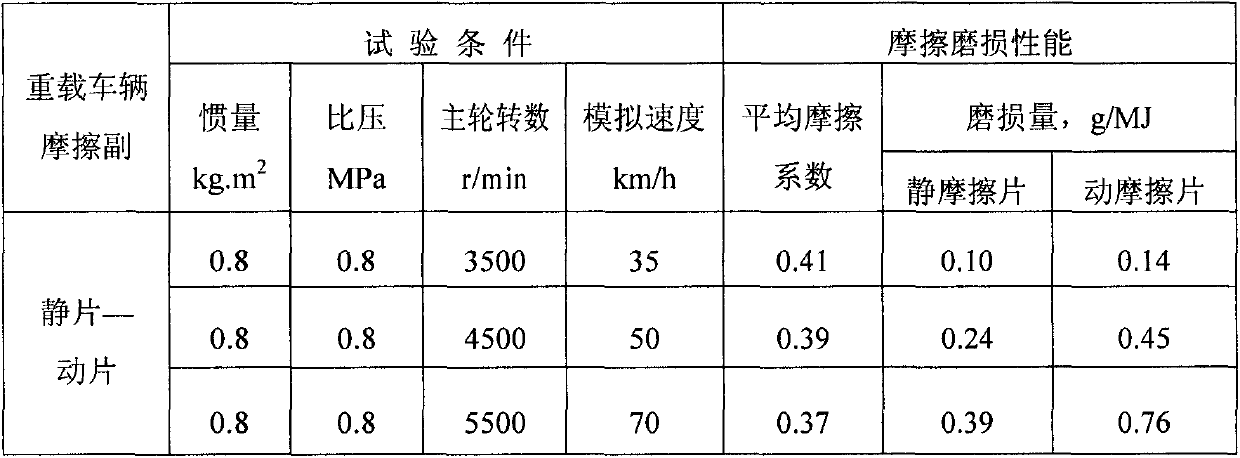

Embodiment 2

[0038] The weight of each component of the static friction plate of powder metallurgy friction pair for heavy-duty vehicles: 66 parts of reduced iron powder, 14 parts of electrolytic copper powder, 2 parts of molybdenum disulfide powder, 3 parts of iron-manganese alloy powder, 3 parts of electrolytic nickel powder, 4 parts of silicon powder, 8 parts of flake graphite.

[0039] The weight of each component of the powder metallurgy friction pair dynamic friction plate for heavy-duty vehicles: 15 parts of reduced iron powder, 53 parts of electrolytic copper powder, 2 parts of molybdenum disulfide powder, 4 parts of tin powder, 1 part of iron-chromium alloy powder, iron-manganese alloy 2 parts of electrolytic nickel powder, 1 part of electrolytic nickel powder, 1 part of chromium powder, 3 parts of aluminum oxide powder, 6 parts of silicon dioxide powder, and 12 parts of flake graphite.

[0040] Manufacturing process:

[0041] (1) batching: take each component with electronic sc...

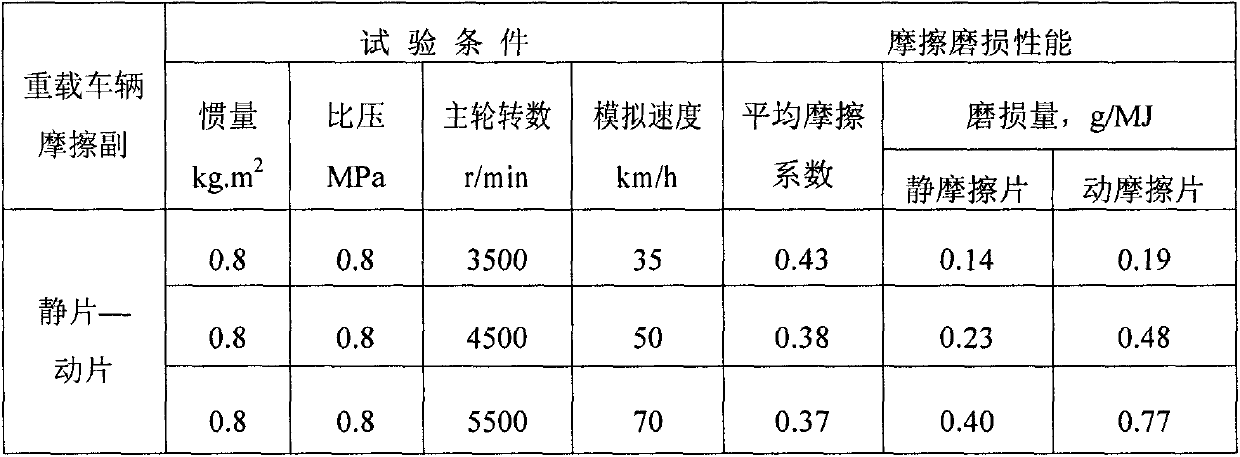

Embodiment 3

[0054] The weight of each component of the static friction plate of the powder metallurgy friction pair for heavy-duty vehicles: 68 parts of reduced iron powder, 13 parts of electrolytic copper powder, 4 parts of molybdenum disulfide powder, 2 parts of iron-manganese alloy powder, 2 parts of electrolytic nickel powder, 5 parts of silicon powder, 6 parts of flake graphite.

[0055] The weight of each component of the powder metallurgy friction pair dynamic friction plate for heavy-duty vehicles: 16 parts of reduced iron powder, 43 parts of electrolytic copper powder, 2 parts of molybdenum disulfide powder, 4 parts of tin powder, 3 parts of iron-chromium alloy powder, iron-manganese alloy 4 parts of electrolytic nickel powder, 3 parts of electrolytic nickel powder, 3 parts of chromium powder, 3 parts of aluminum oxide powder, 6 parts of silicon dioxide powder, and 13 parts of flake graphite.

[0056] Manufacturing process:

[0057] (1) batching: take each component with electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com