Patents

Literature

85results about How to "Reduce abrasive wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

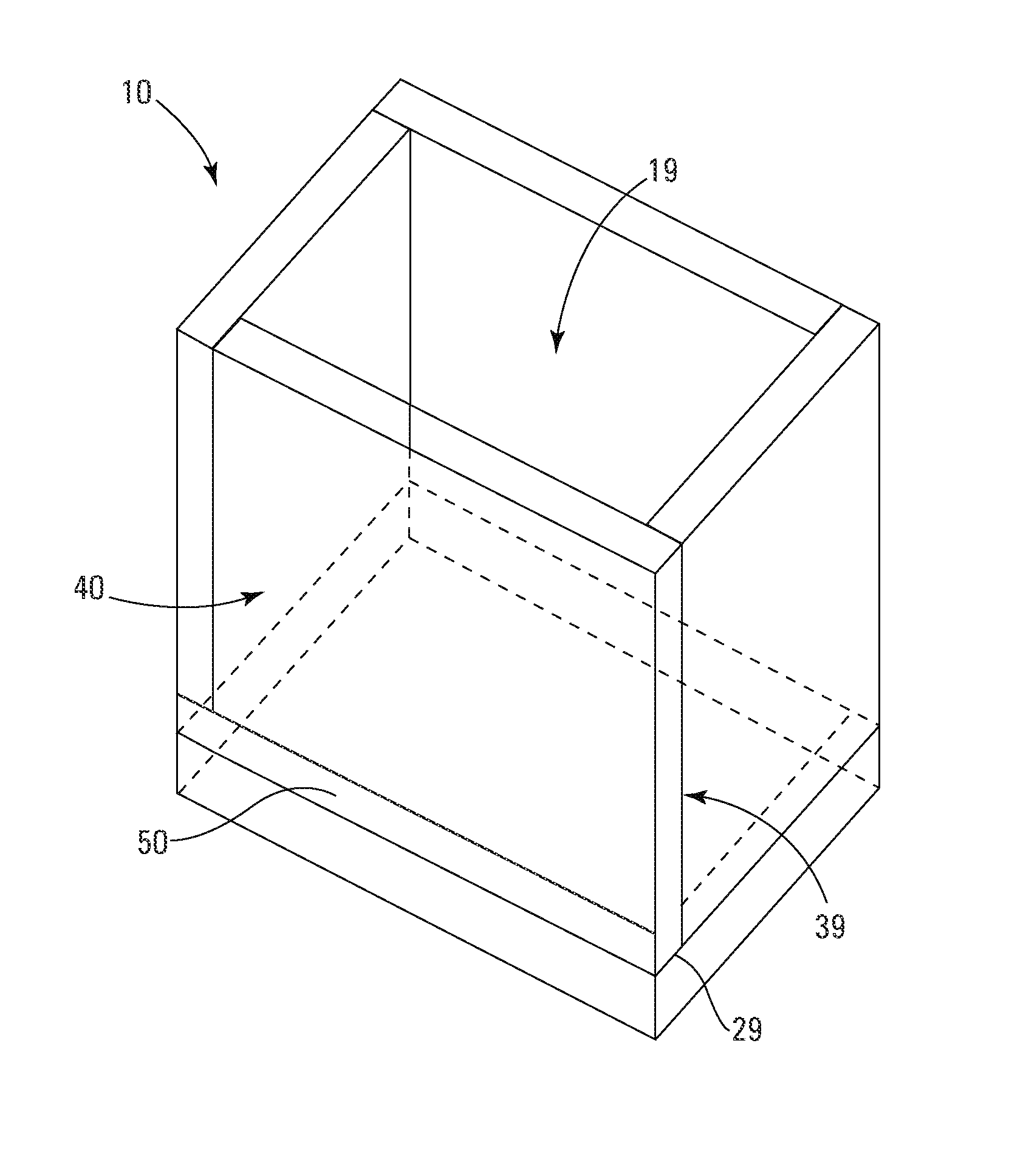

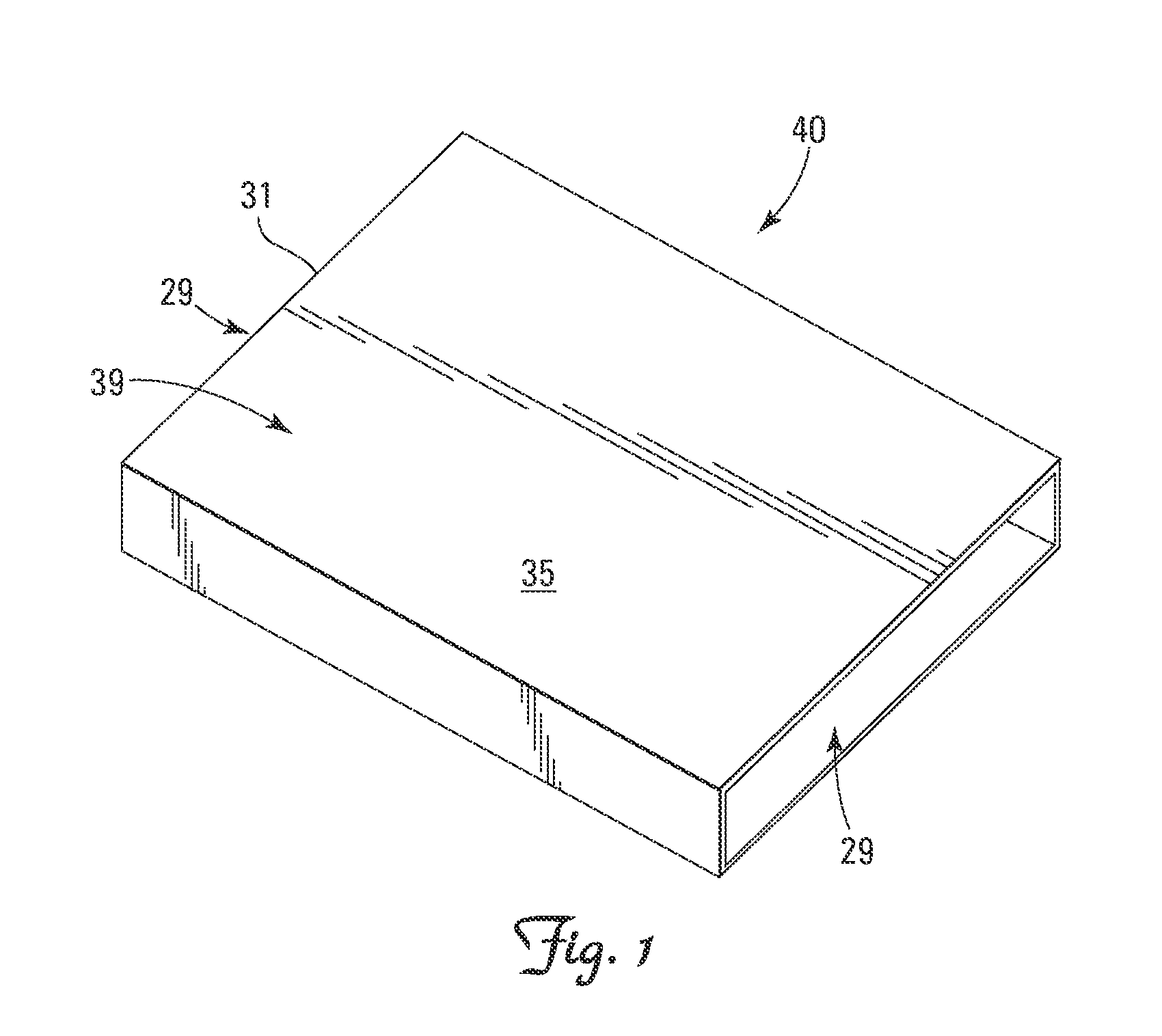

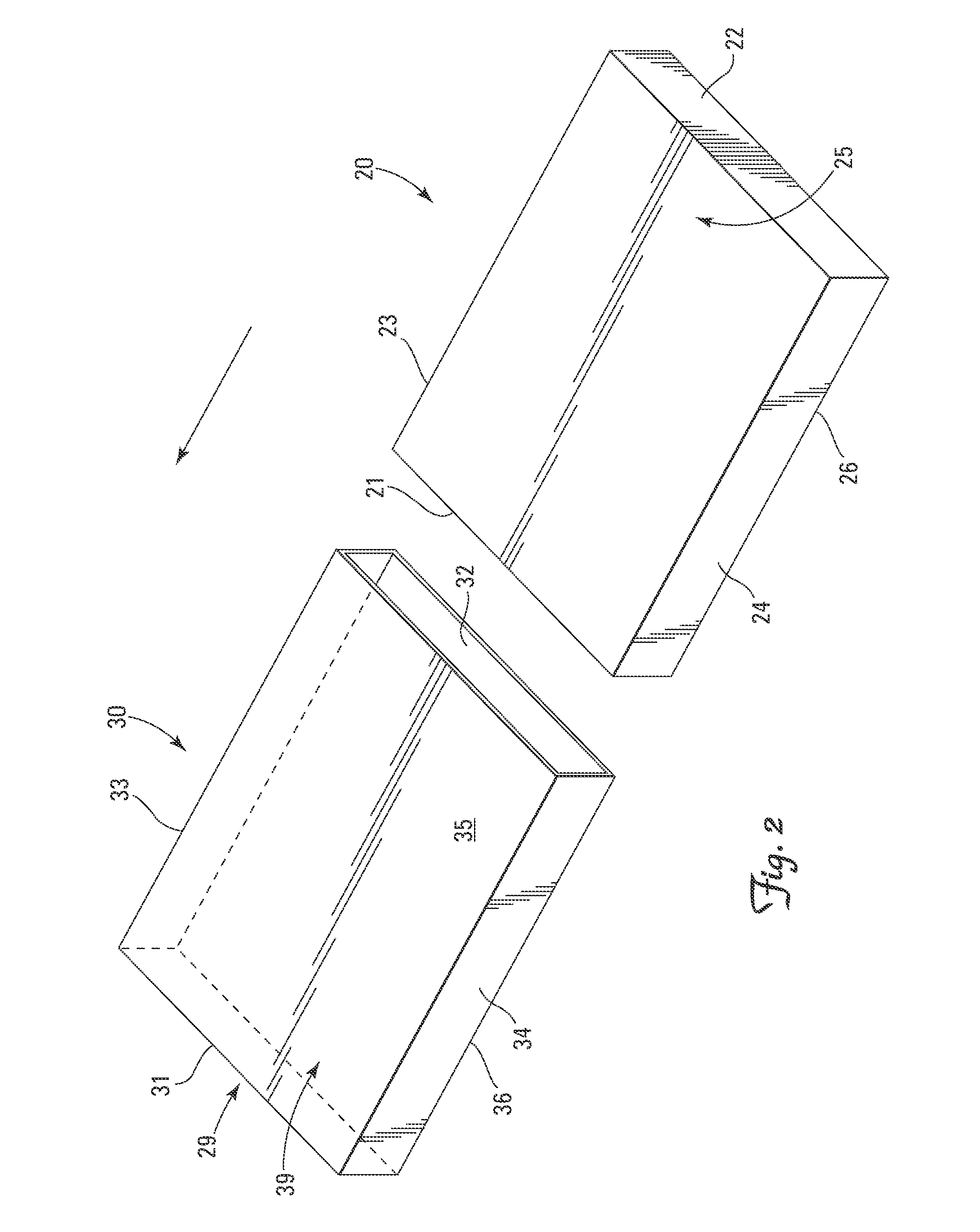

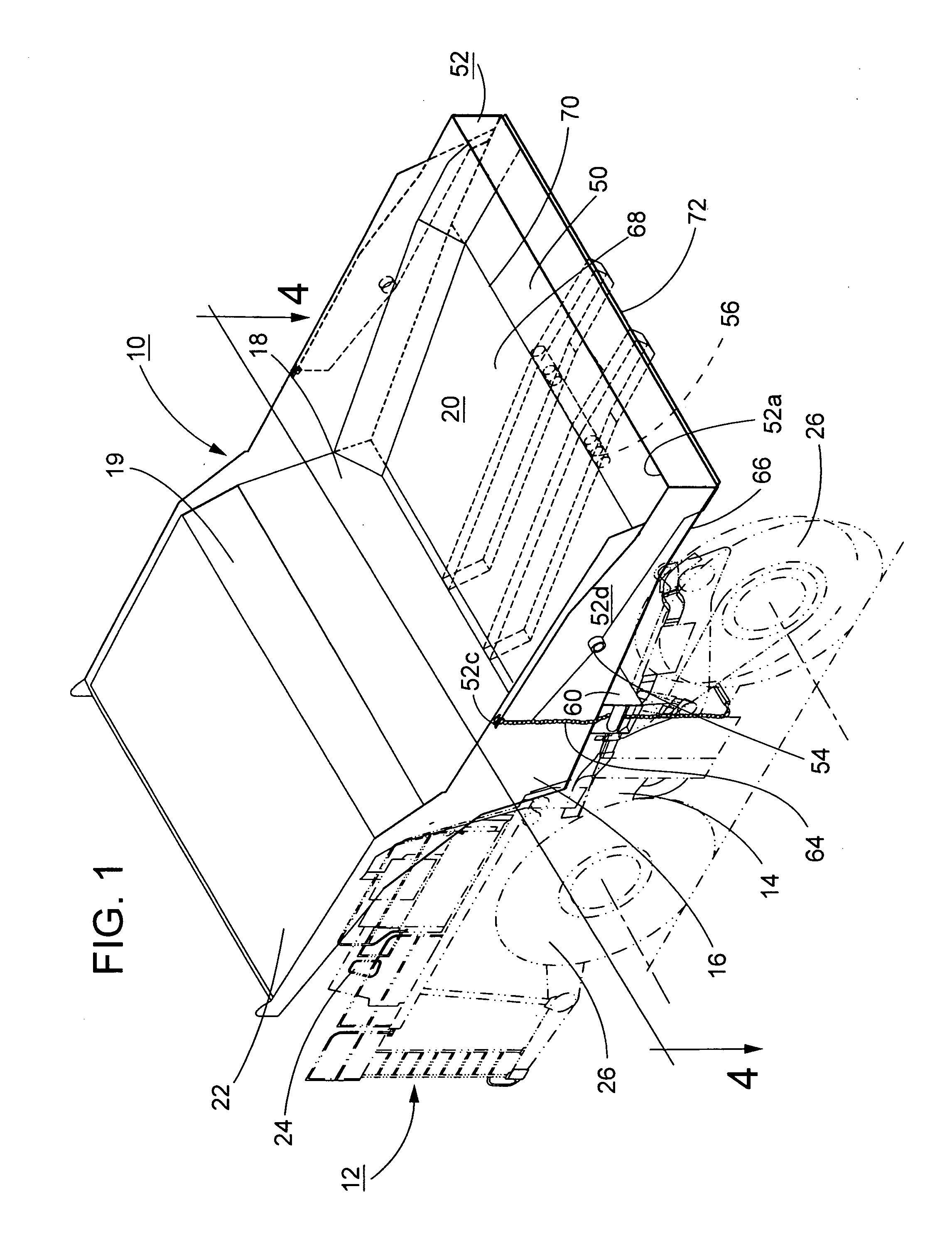

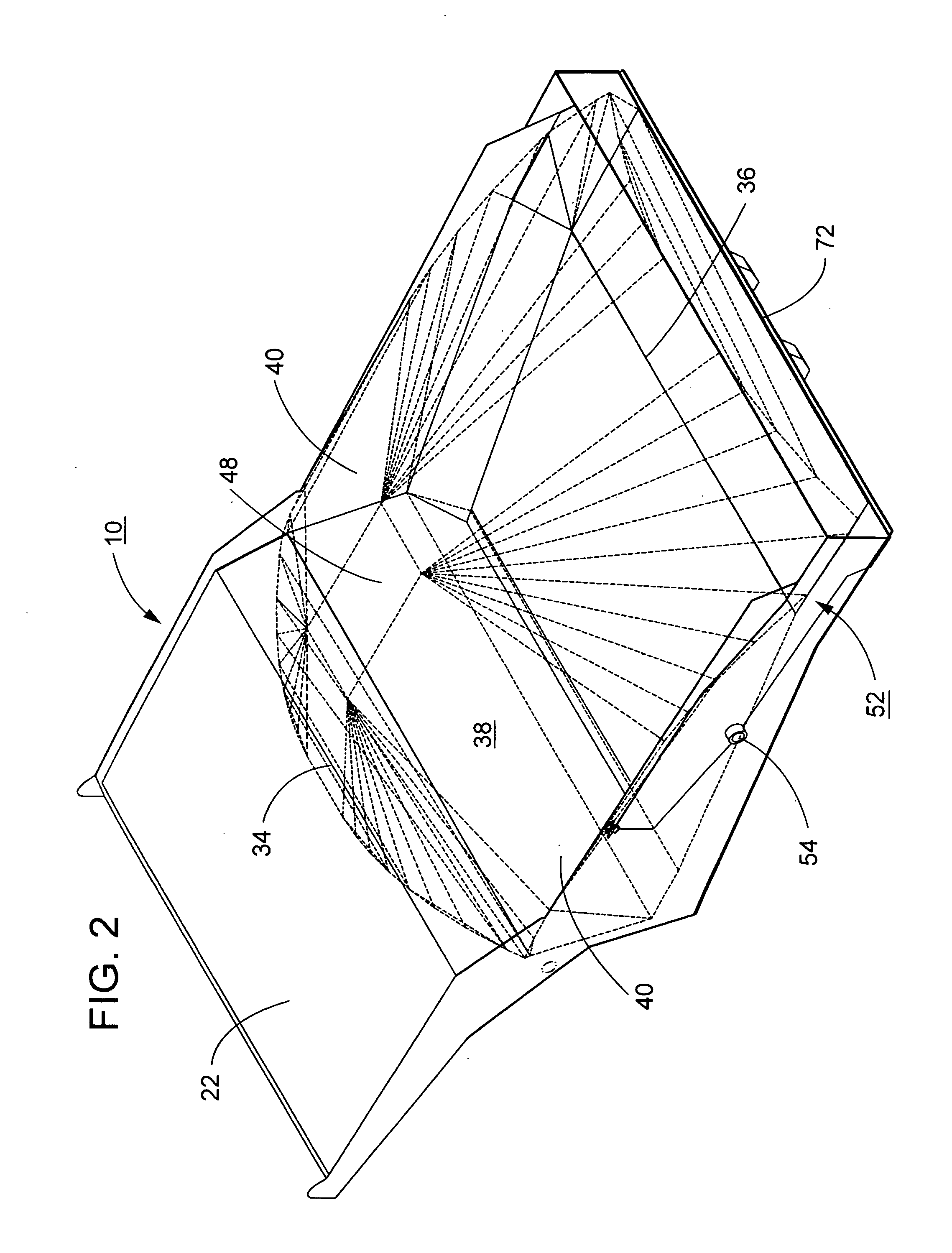

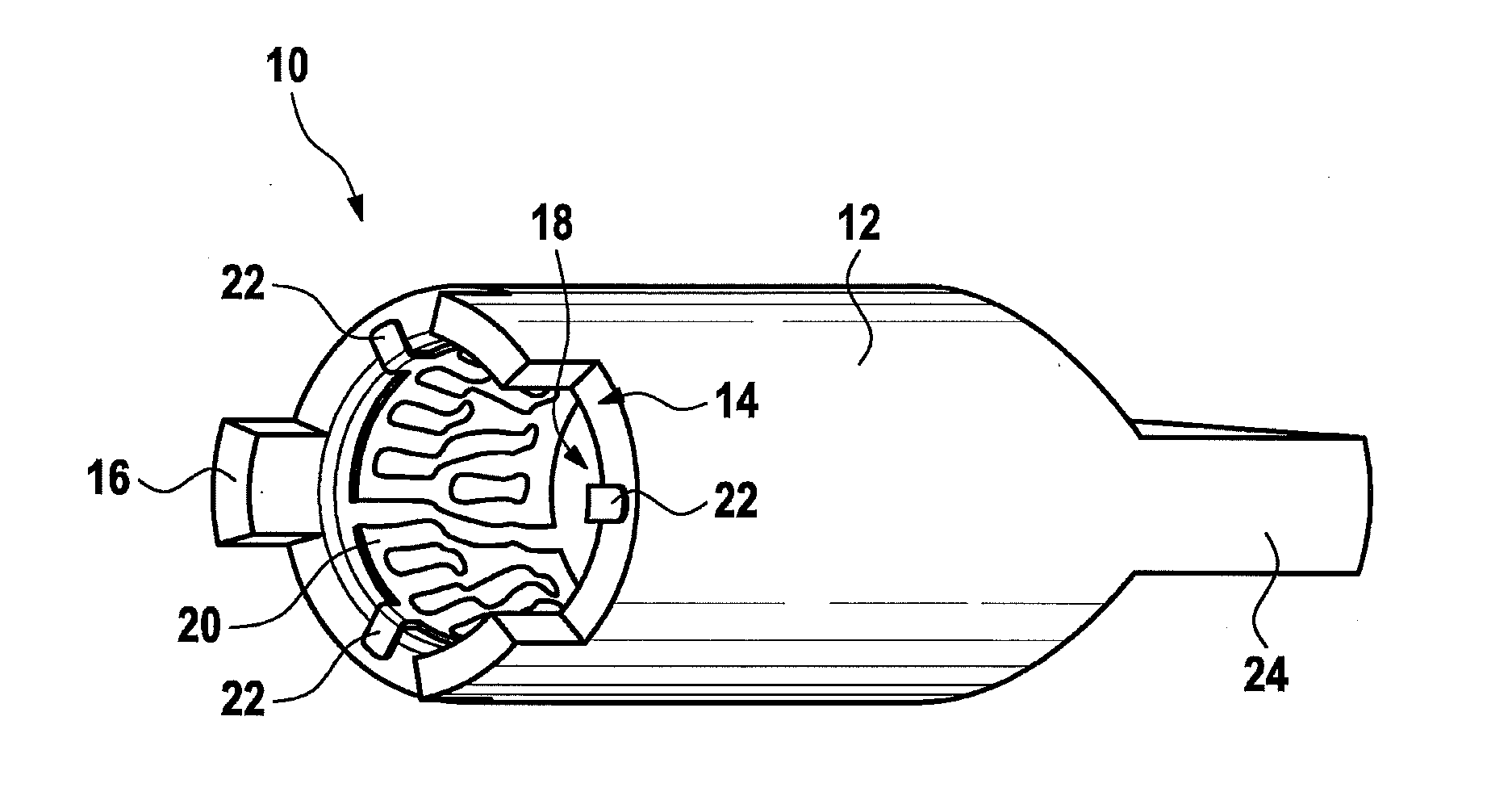

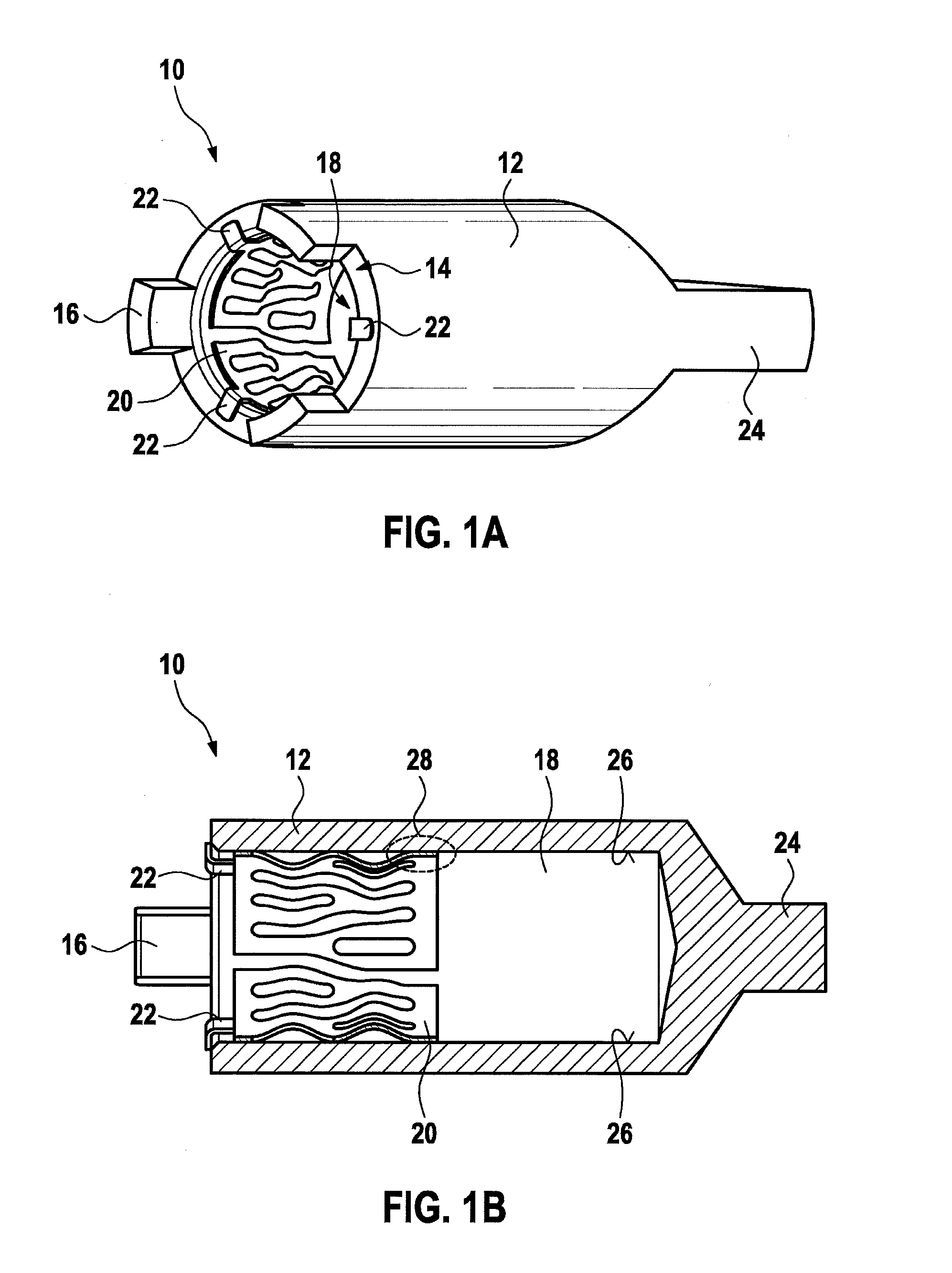

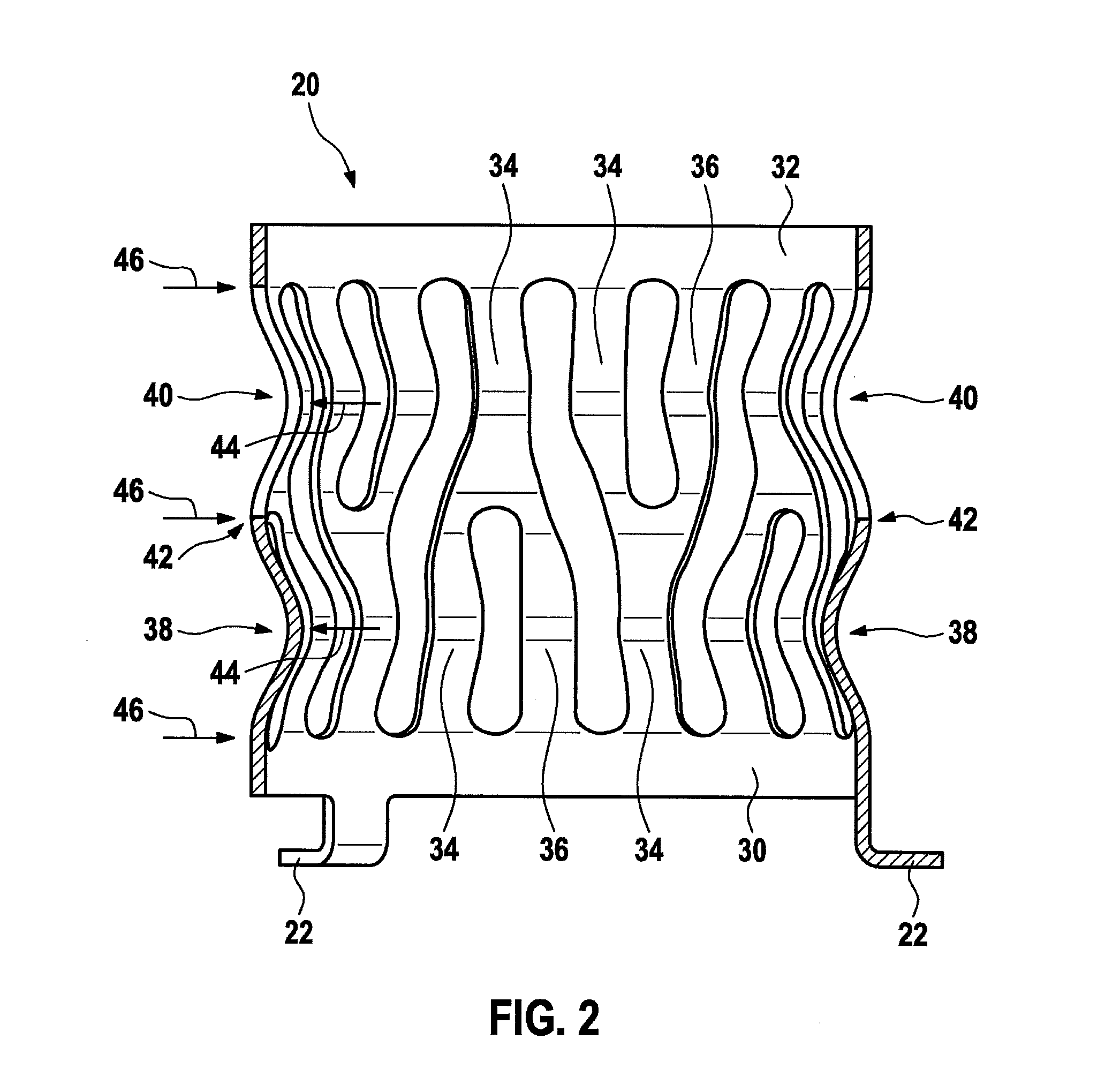

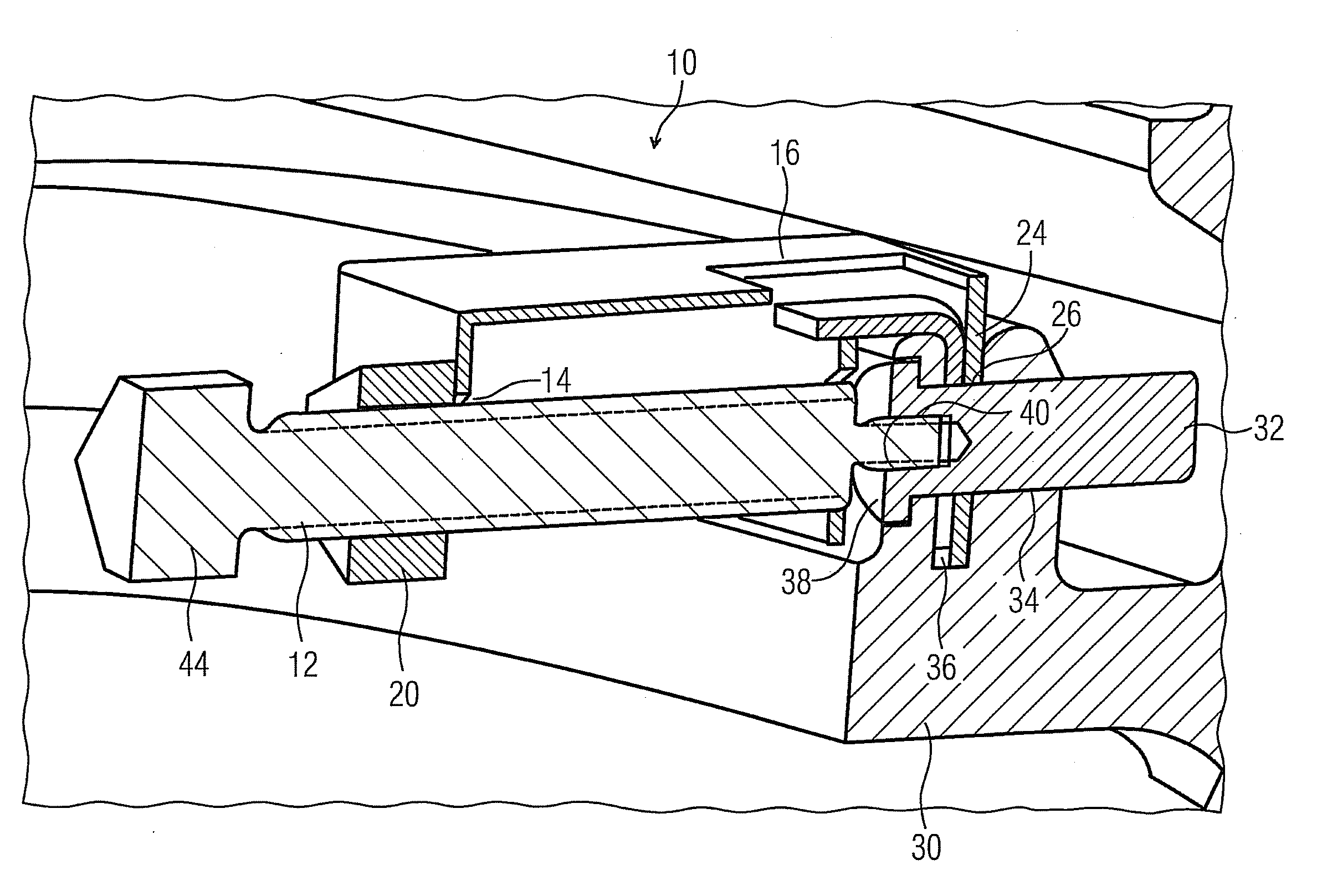

Assembly of abutting vacuum insulated panels arranged to form a retention chamber with a slip surface interposed between the panels

ActiveUS7950246B1Decrease abrasive wearReduce abrasive wearLighting and heating apparatusDomestic refrigeratorsEngineeringVacuum insulated panel

The invention is an assembly of abutting vacuum insulated panels configured and arranged to form a retention chamber with a slip surface providing a low kinetic coefficient of friction interposed between the panels within the abutment areas.

Owner:PELI BIOTHERMAL LLC

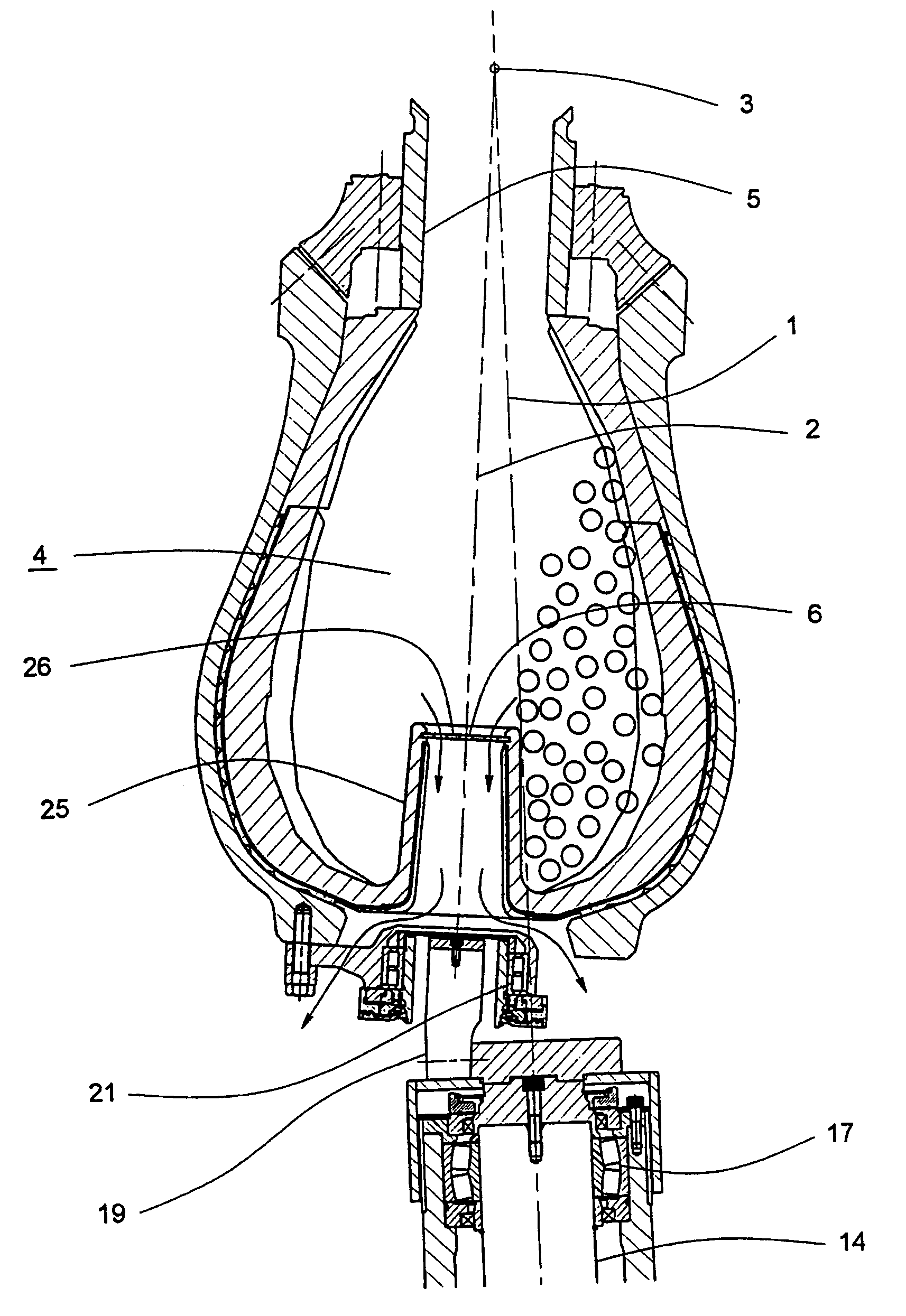

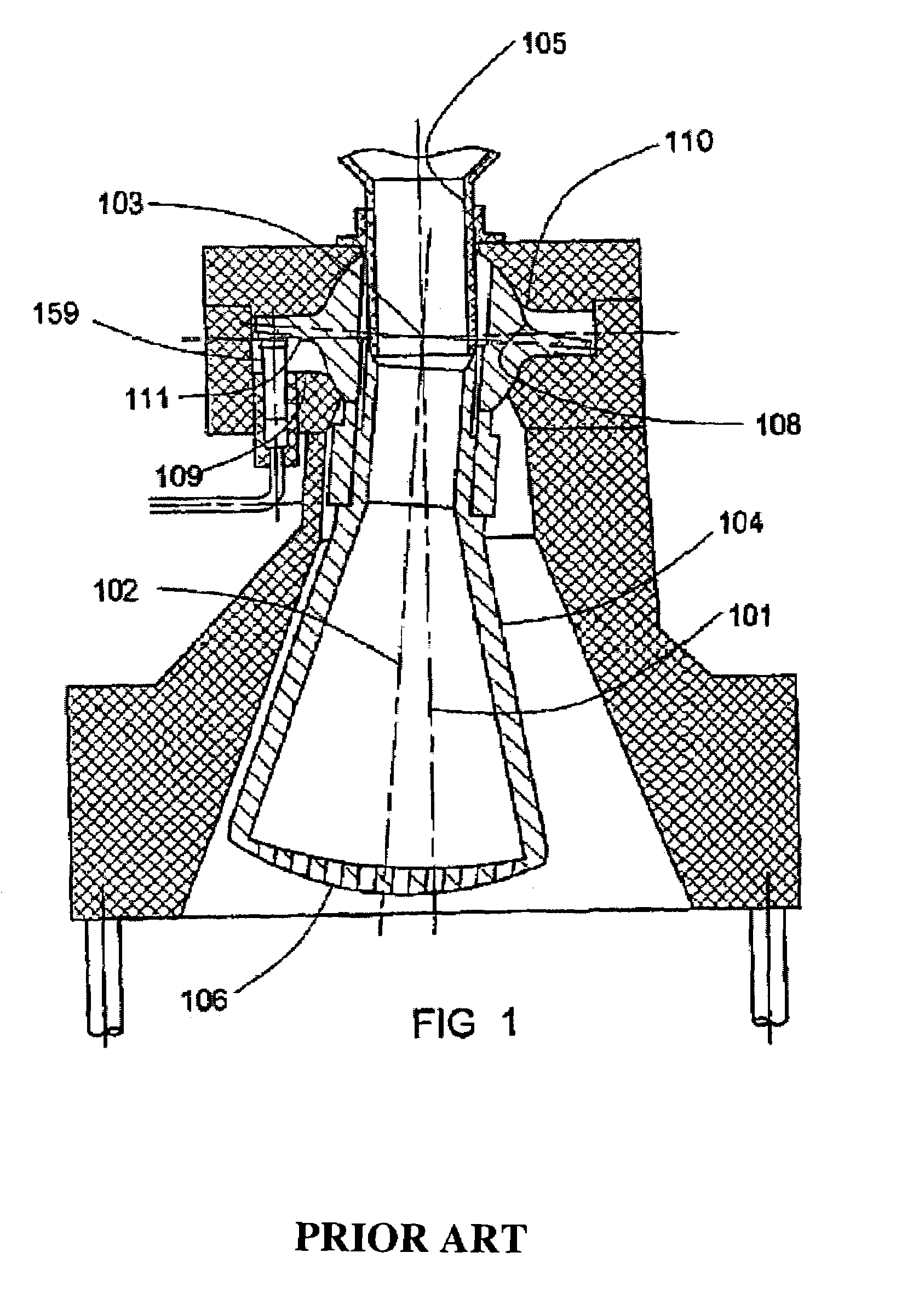

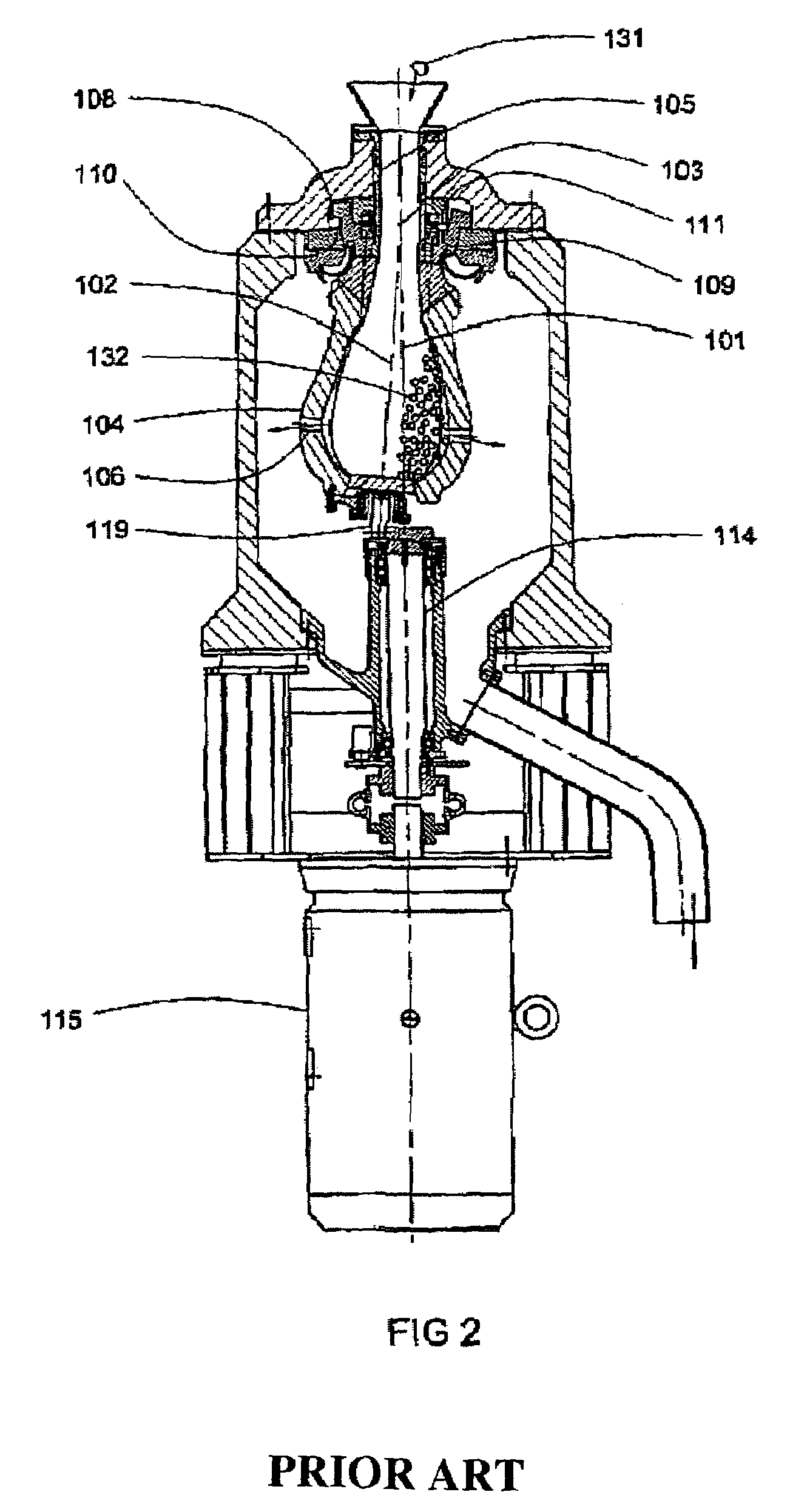

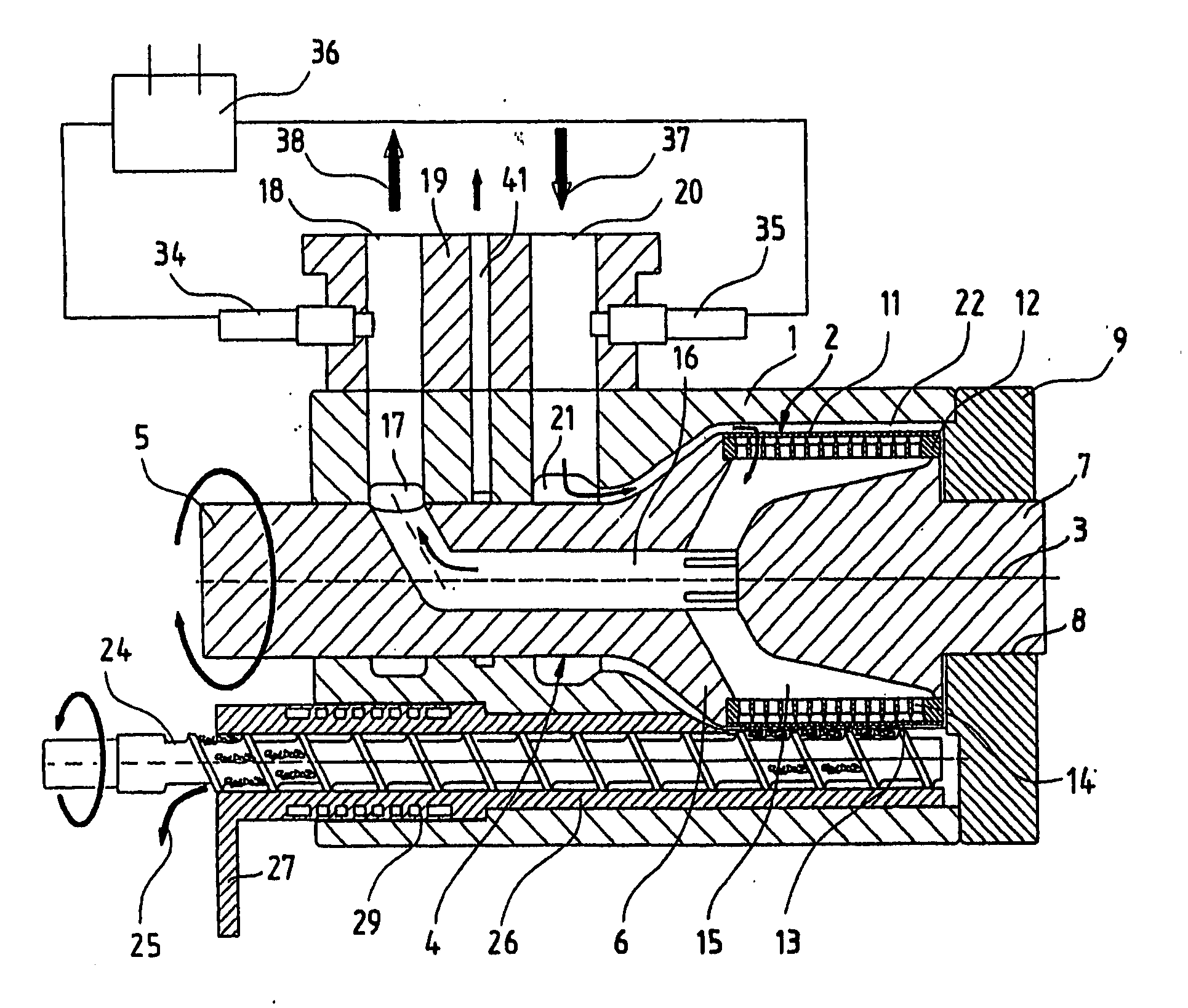

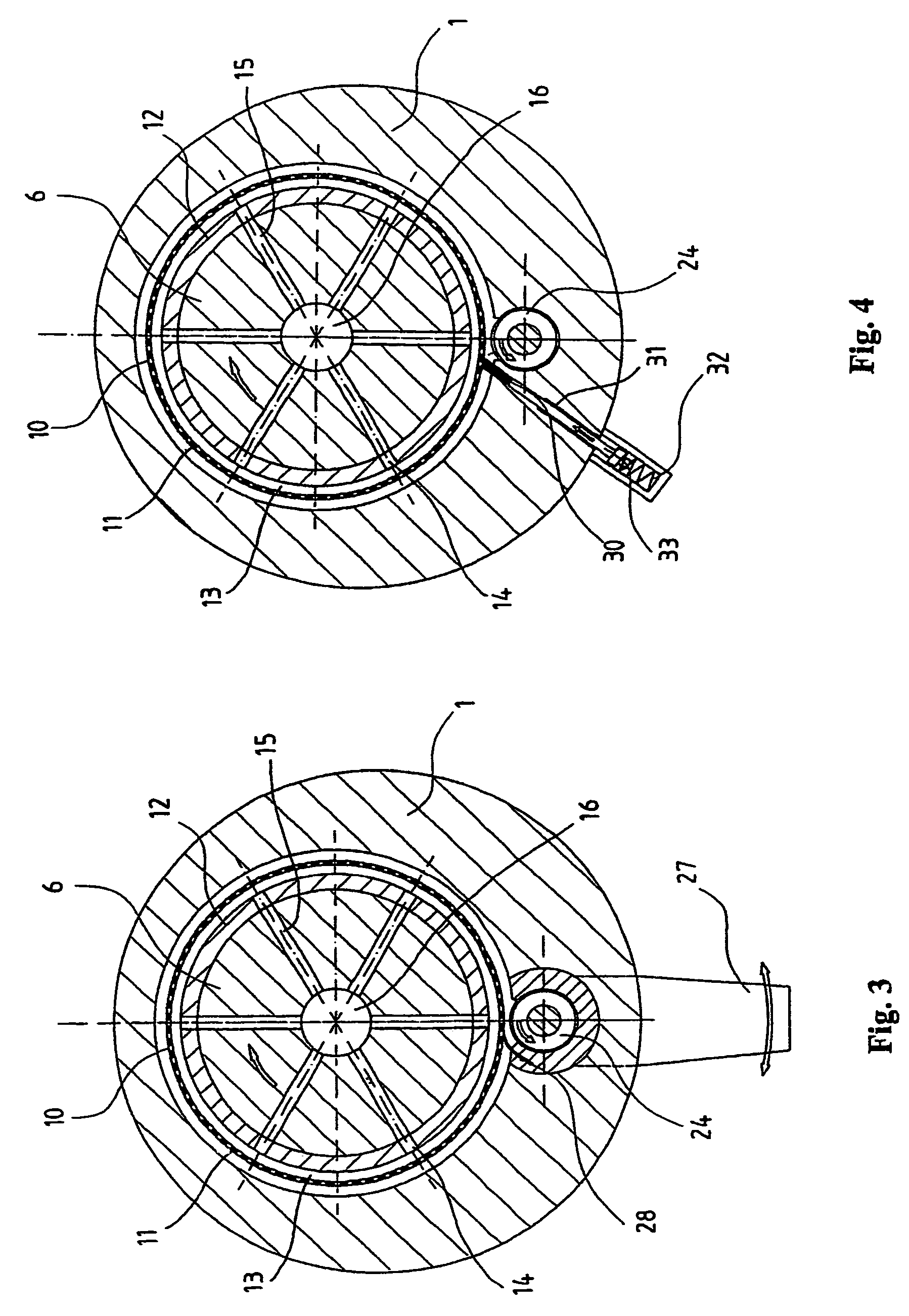

Centrifugal grinding mills

InactiveUS7070134B1Reduce shock pressureReduce abrasive wearGrain treatmentsNutationMaximum diameter

The present invention relates to a centrifugal grinding mill comprising a vertical axis of revolution (1), a nutating axis (2) intersecting axis (1) at a point of nutation symmetry (3), a grinding chamber (4) symmetrical about axis (2) connecting with feed passage (5) at its upper end and having discharge openings (6) of a screening element (26) located within a plane area aligned normal to, symmetrical with, and intersected by the axis (2), and adjacent the plane containing the maximum diameter of the grinding chamber (4).

Owner:F L SMIDTH & CO AS

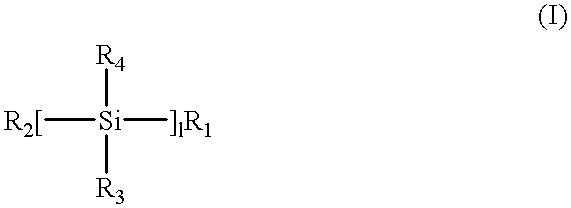

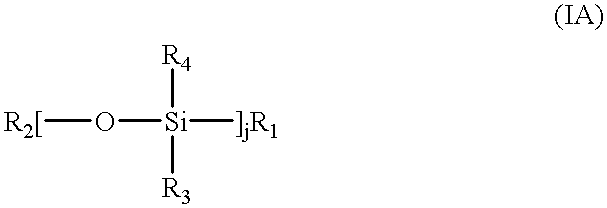

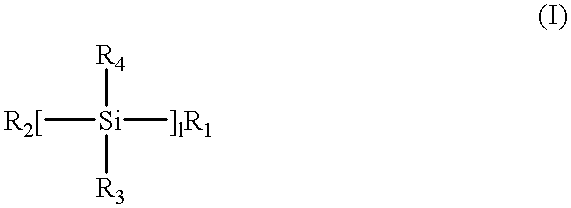

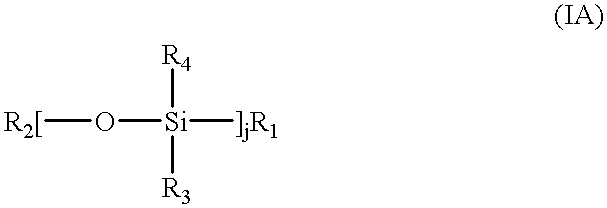

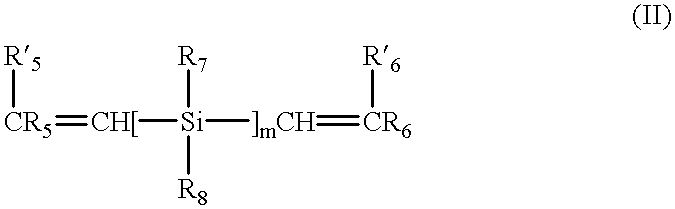

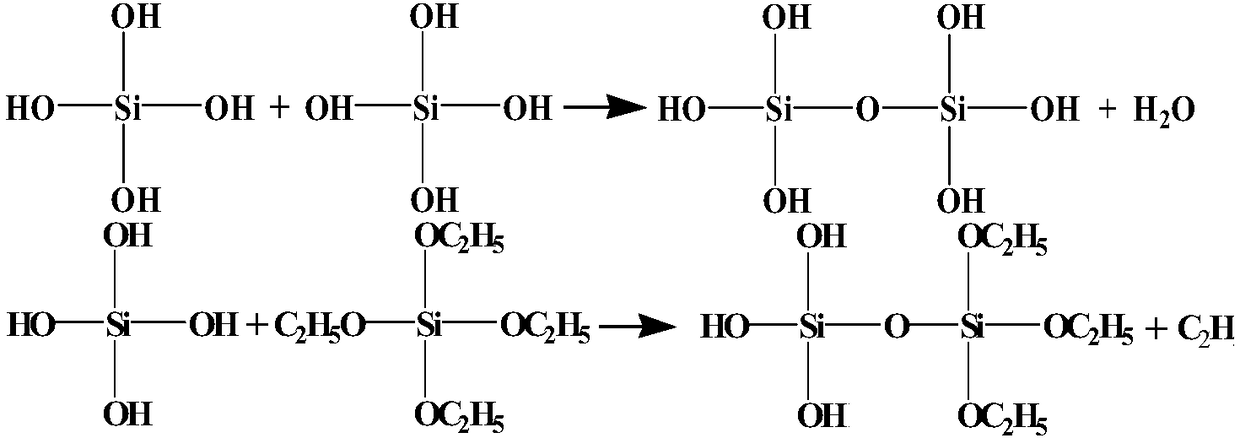

Abrasion resistant dental composition product and process

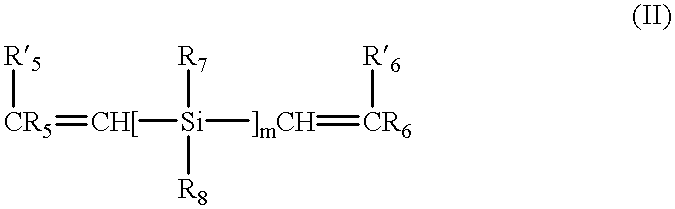

InactiveUS6384107B2Superior physical and aesthetic characteristicReduce abrasive wearCosmetic preparationsImpression capsSilanesProsthesis

Dental composition, product and process using a silicon containing abrasion resistant material. The dental products formed are abrasion resistant and self-lubricating across their entire cross sections. Dental compositions useful for forming dental products in accordance with the invention preferably includes an ethylenically unsaturated silane. The composition is formed into a dental prosthesis, such as an artificial tooth, inlay, onlay, facing, crown or bridge.

Owner:DENTSPLY RES DEVMENT

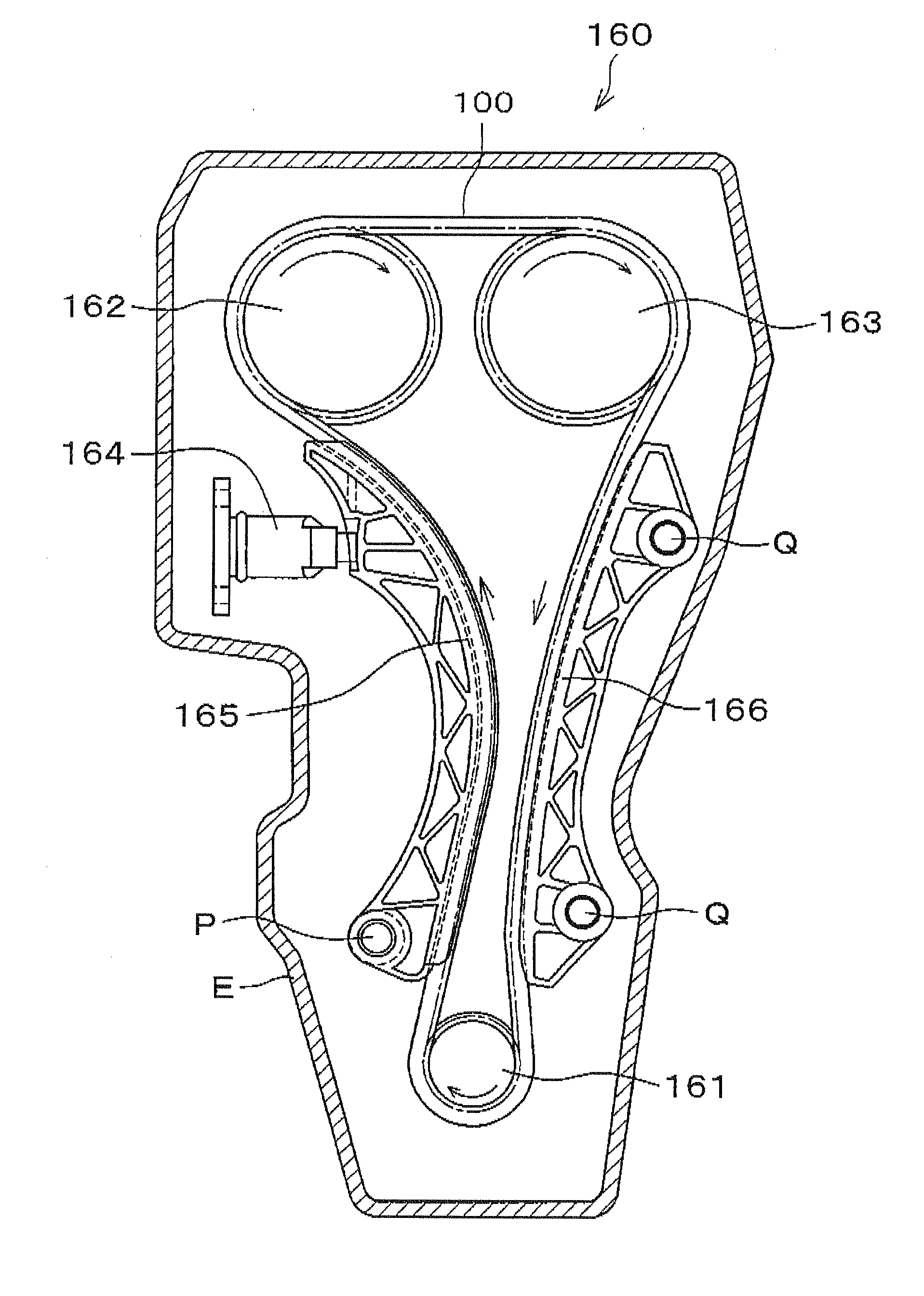

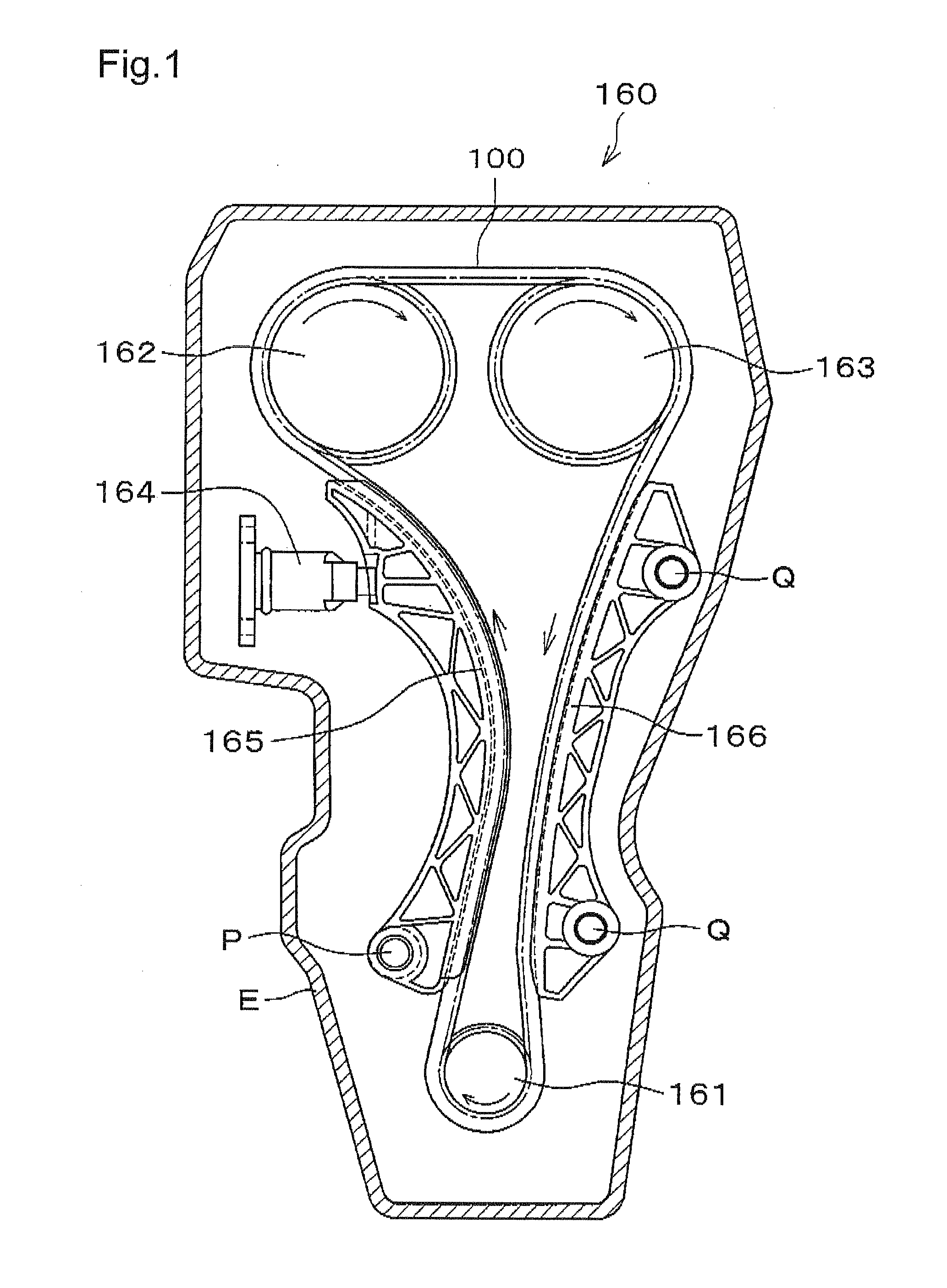

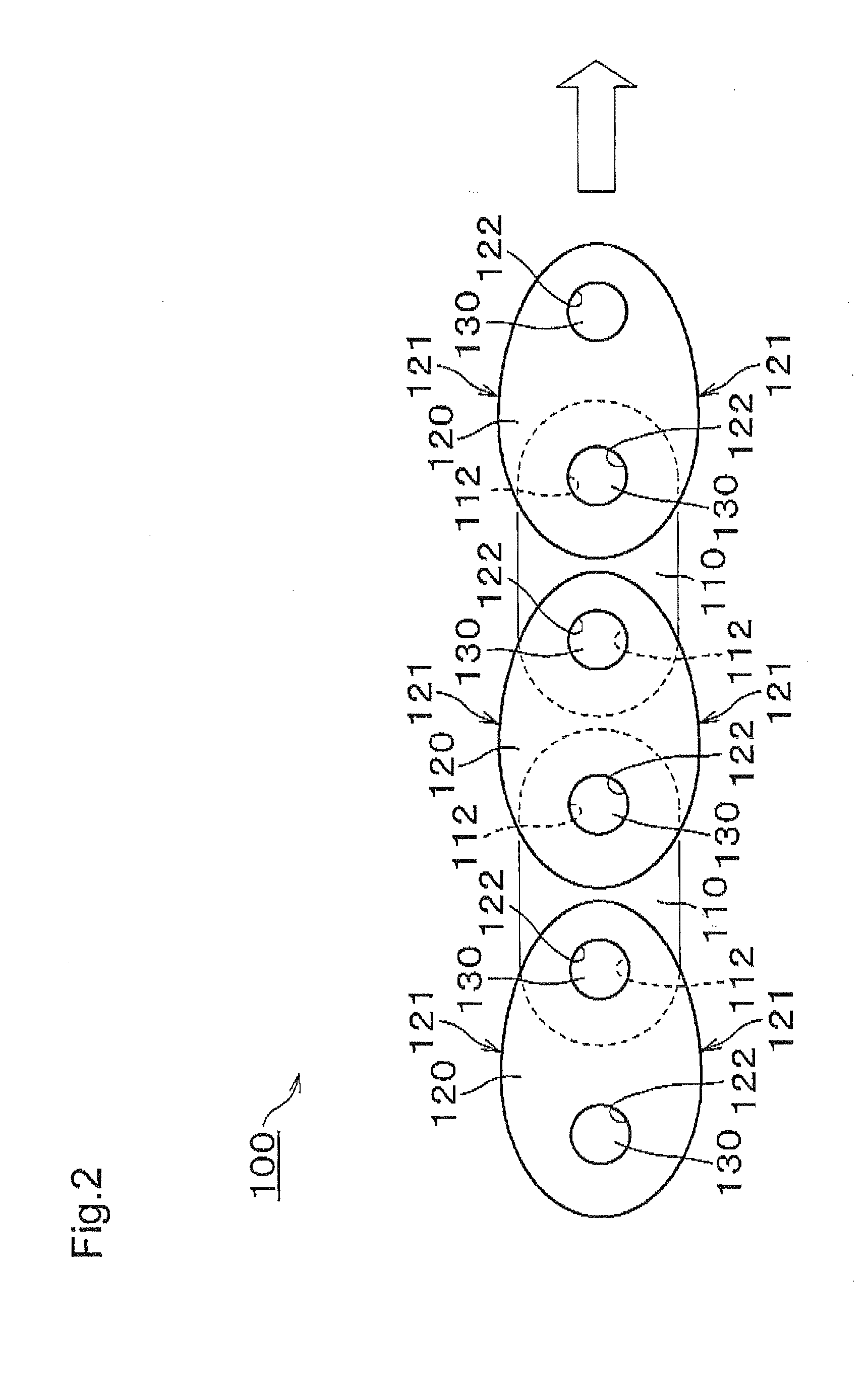

Chain

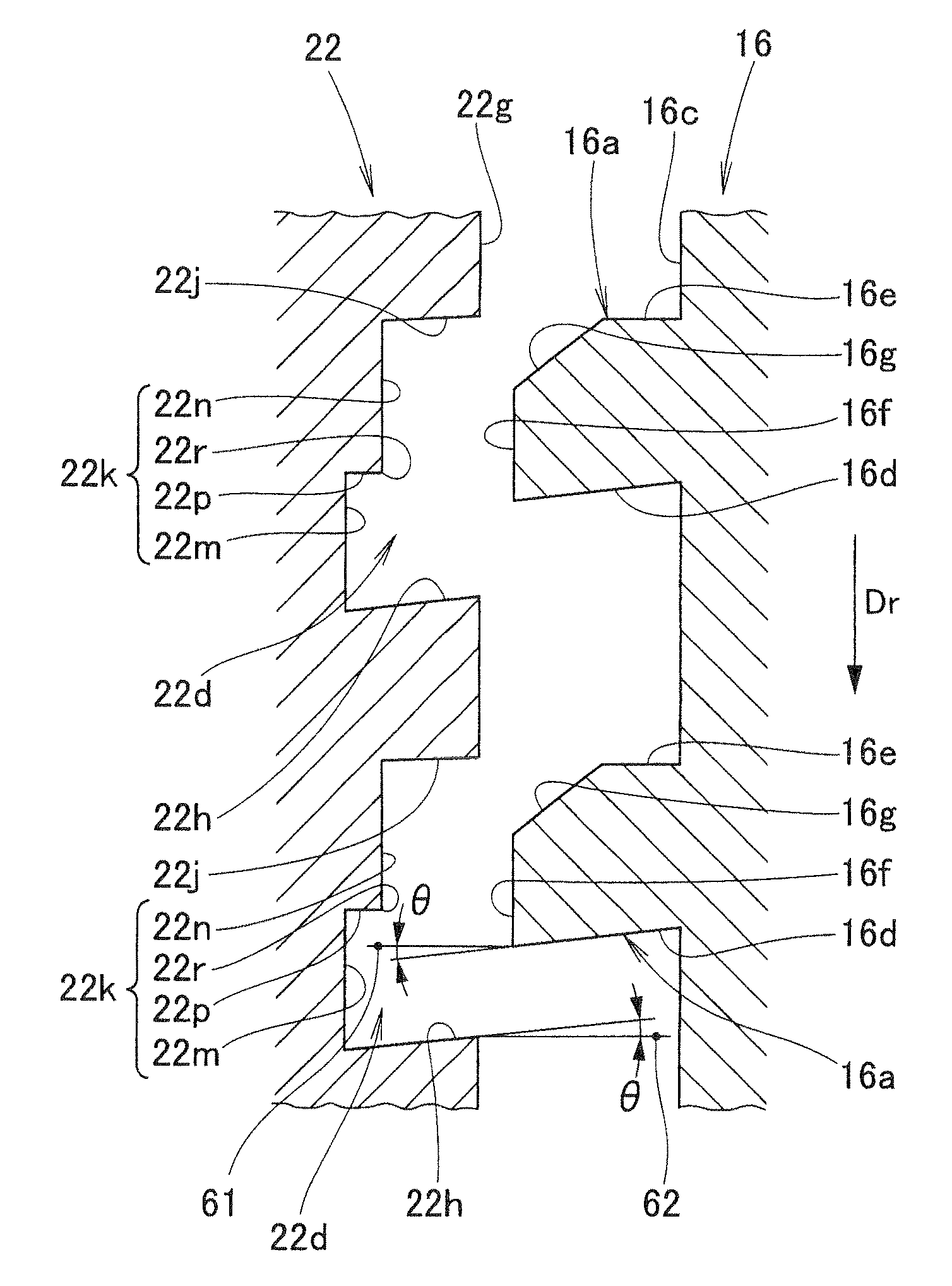

ActiveUS20100267504A1Effective of contact noiseEffective vibrationGearingDriving chainsAbutmentEngineering

In a transmission chain having link plates with convex edges for sliding contact with a guide surface, the plates are asymmetric in shape so that the distance from a line connecting the centers of the connecting holes and the convex edge is greatest at a position other than at the midpoint between the connecting holes. A pivoting action of the link plates takes place as they slide over a guide surface, changing the abutment point.

Owner:TSUBAKIMOTO CHAIN CO

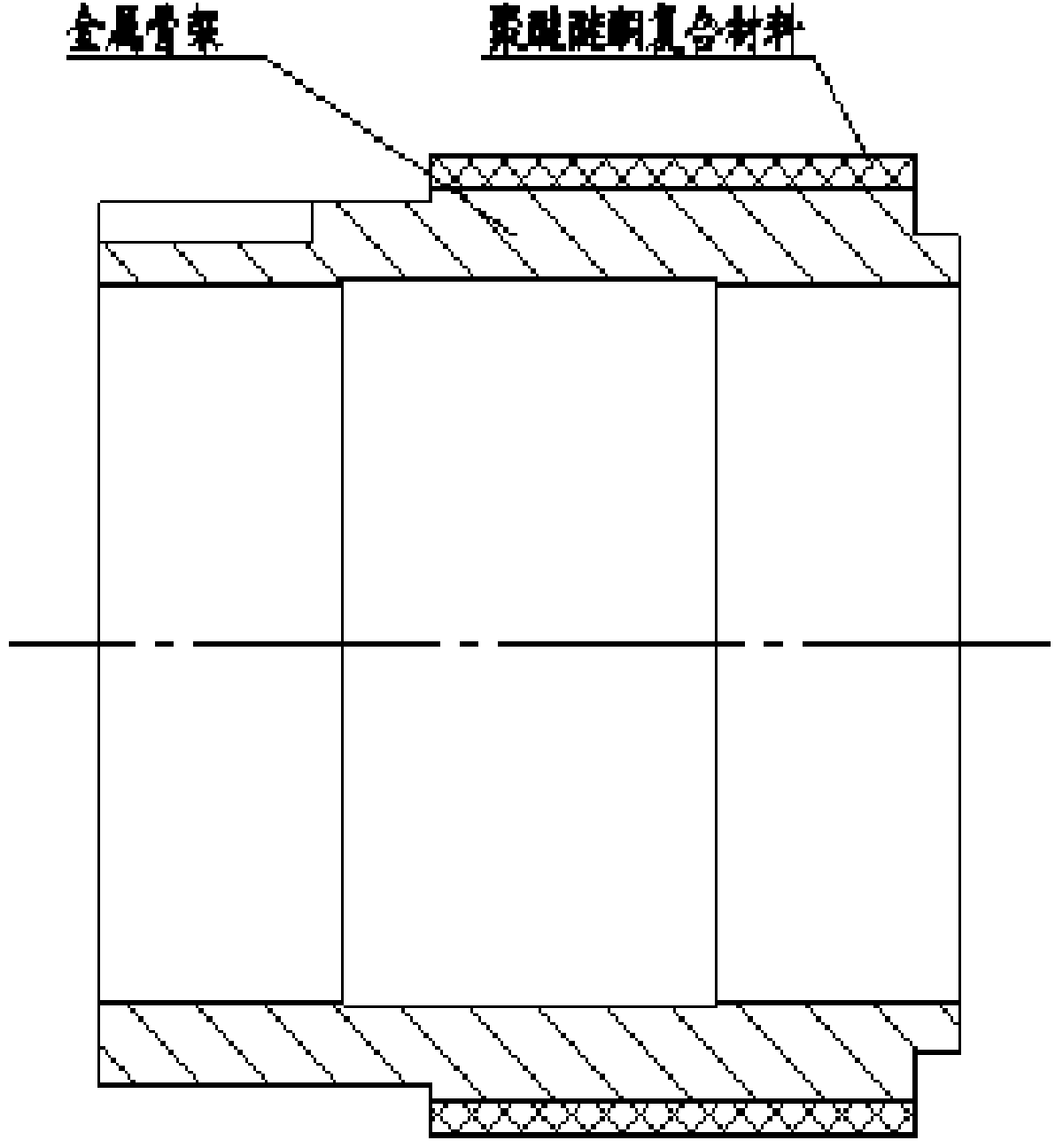

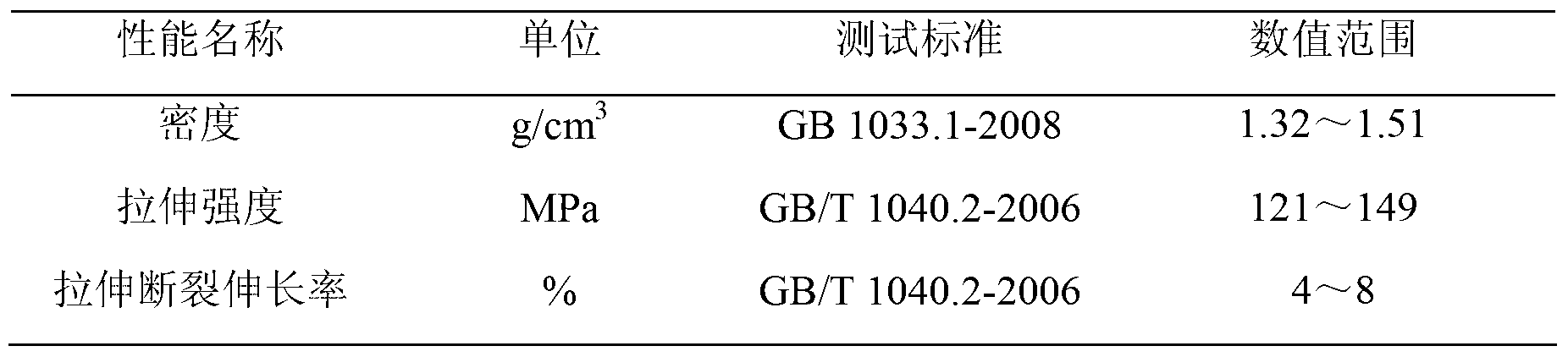

Wear-resistant, high-strength and light-weight poly (ether-ether-ketone) composite material

The invention discloses a wear-resistant, high-strength and light-weight poly (ether-ether-ketone) composite material. The poly (ether-ether-ketone) composite material comprises the following raw materials in parts by weight: 71-83 parts by weight of poly (ether-ether-ketone) resin, 5-10 parts by weight of suspension polytetrafluoroethylene resin, 7-12 parts by weight of carbon fiber powder and 5-7 parts by weight of aluminum oxide powder, as well as a silane coupling agent with the adding quantity of 0.8-1.5% of the weight of the aluminum oxide powder. The poly (ether-ether-ketone) composite material disclosed by the invention has the performance characteristics of wear resistance, high strength, self-lubrication, light weight, corrosion resistance and the like, is used for replacing a hard alloy and a metal framework to assemble a novel sliding bearing, effectively reduces the cost and weight of a bearing product (the weight is reduced by 30%) under the situation of meeting the requirements for service life, and can obviously reduce the power consumption and noise of a pump and achieve the purposes of saving energy and reducing consumption.

Owner:HEFEI GENERAL MACHINERY RES INST

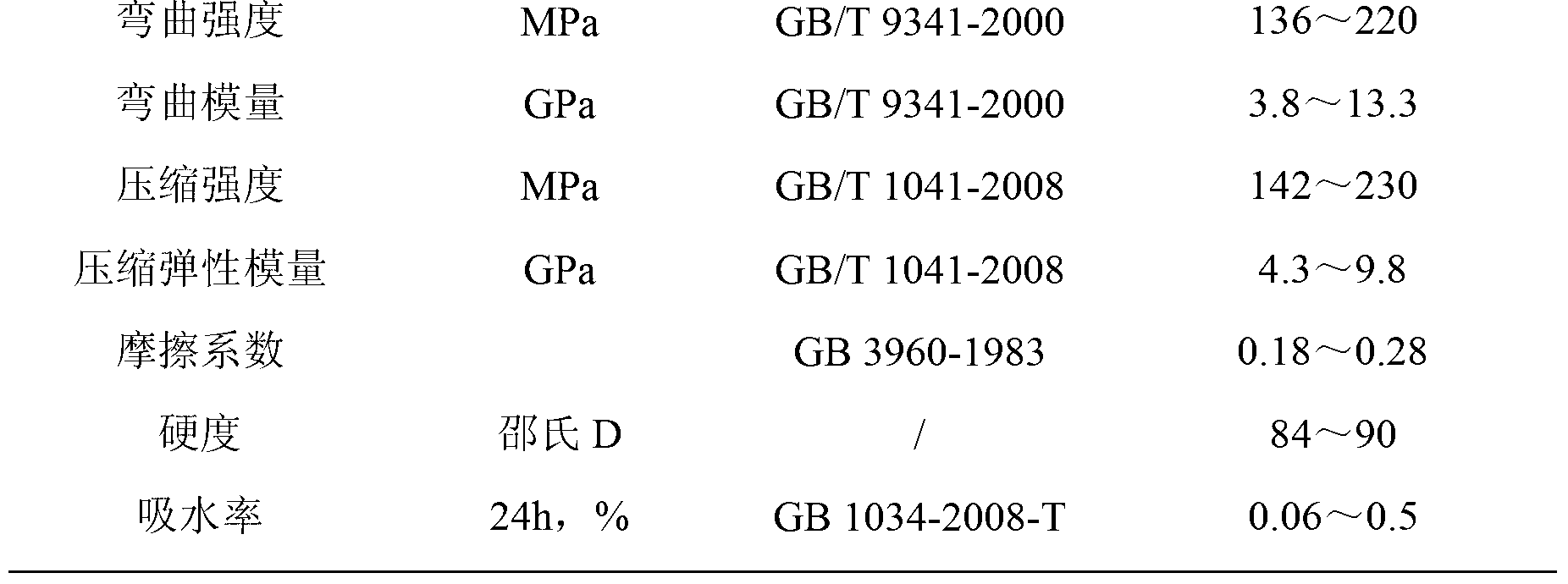

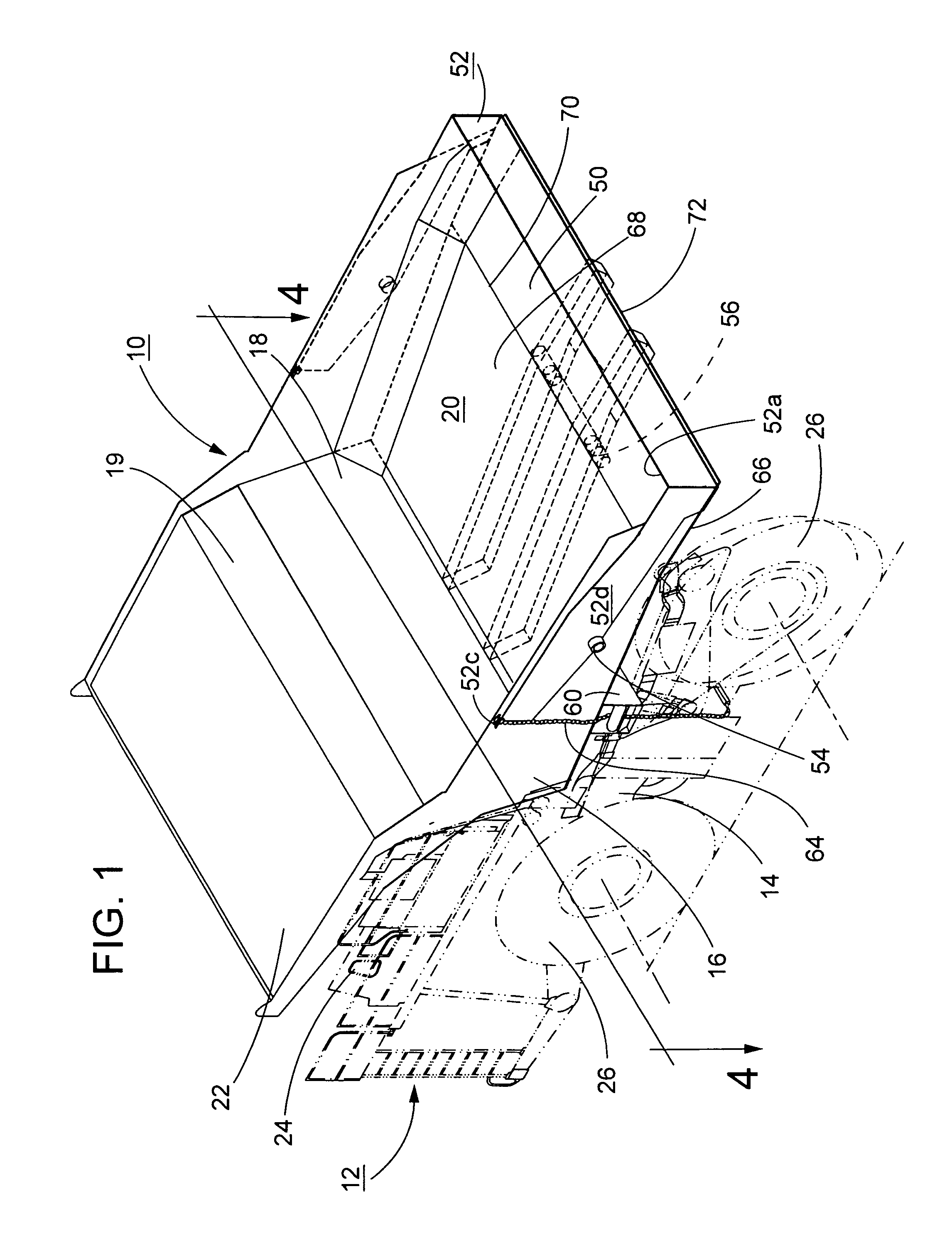

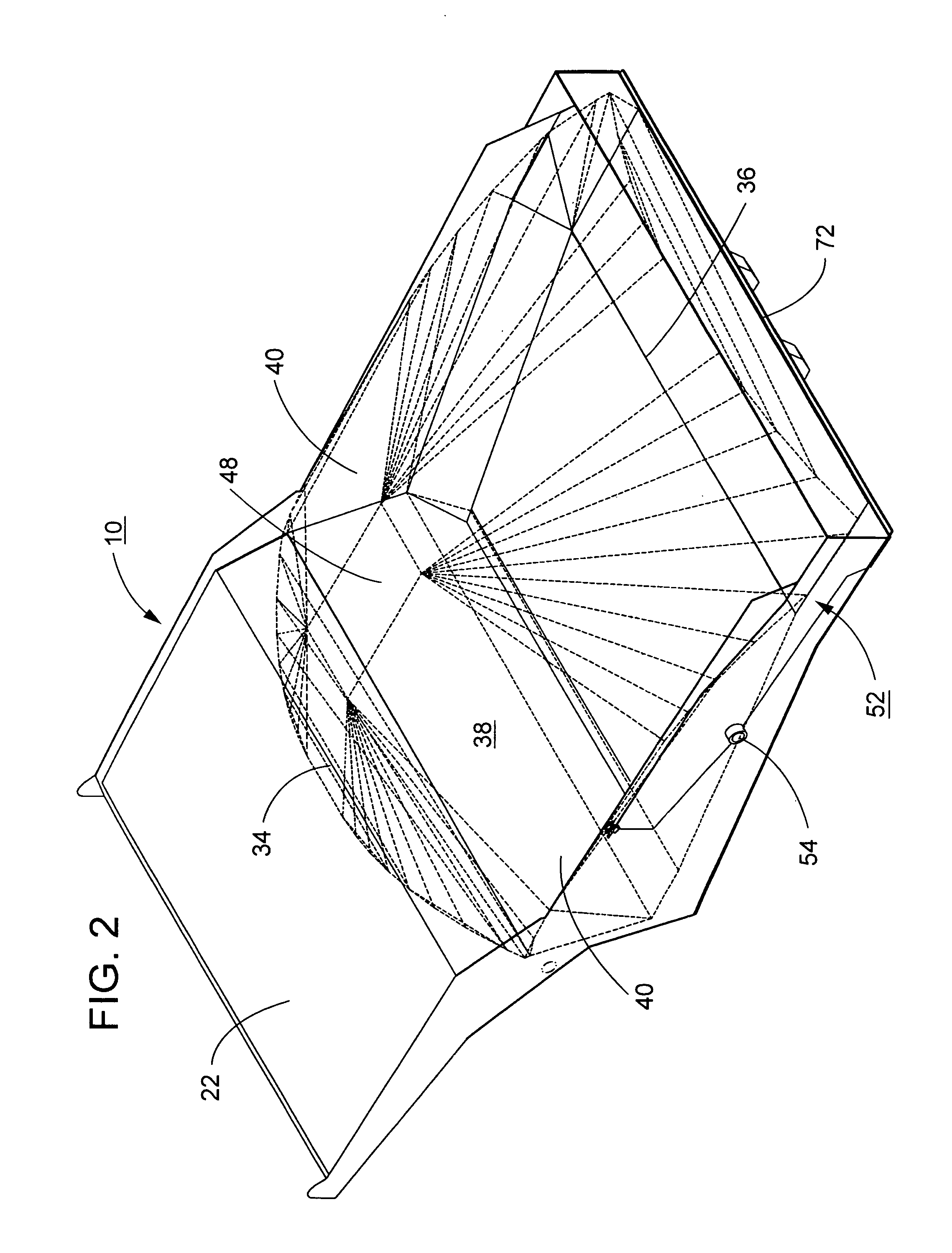

Severe application off-highway truck body

InactiveUS20080067856A1Wear minimizationAvoid excessive wearMonocoque constructionsVehicle bodiesHigh densityEngineering

An open top body of an off-highway haulage vehicle is described for severe hauling applications such as hauling of high density, abrasive material. The body has a floor divided into at least two sections with first and second sections angled at different inclinations. The second section extends to the rear edge of the floor and is at an angle of inclination greater than the first section. The opposing sidewalls of the body extend vertically from the floor are flared or taper along their length such that the body floor is wider at the rear of the body than it is at the front. The body includes a tailgate pivotally attached to the sidewalls for rotation between closed and opened positions in response to the bumping of the load by the body.

Owner:HAGENBUCH LEROY G

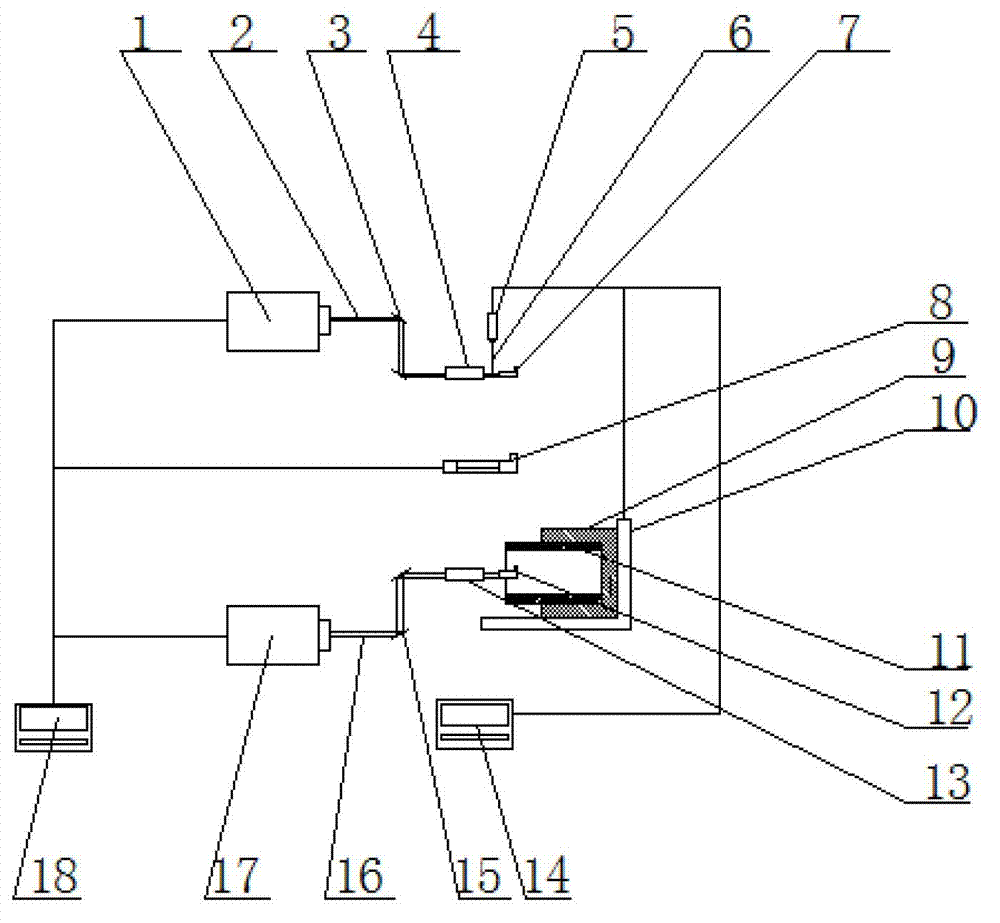

Method and device for forming micro-texture in composite mode on inner surface of cylinder sleeve through laser

InactiveCN103111752AImprove mechanical propertiesImprove friction performanceLaser beam welding apparatusFriction reductionShock wave

The invention provides a method for forming micro-texture in a composite mode on the inner surface of a cylinder sleeve through laser. The method comprises the following steps: step (1), a femtosecond laser device is used for processing a needed microcosmic shape on the inner surface of the cylinder sleeve; and step (2), a nanosecond laser device is used for strengthening the area of the microcosmic shape processed in the step (1) through laser shock waves. Under the condition of dry friction, micro-concave surface texture can be used as a storage device for storing wear particles to reduce abrasive wear and furrows on the friction surface, and therefore the wear rate is lowered. The laser shock waves can eliminate residual tension after the micro-texture is formed on the inner surface of the cylinder sleeve, and therefore deep residual compressive stress is formed, grain refinement is enabled to be more uniform, the hardness, the abrasive resistance and the anti-fatigue performance of the cylinder sleeve are improved, and the service life of the cylinder sleeve is prolonged. The invention further provides a device for forming the micro-texture in the composite mode on the inner surface of the cylinder sleeve through the laser at the same time.

Owner:WENZHOU UNIVERSITY +1

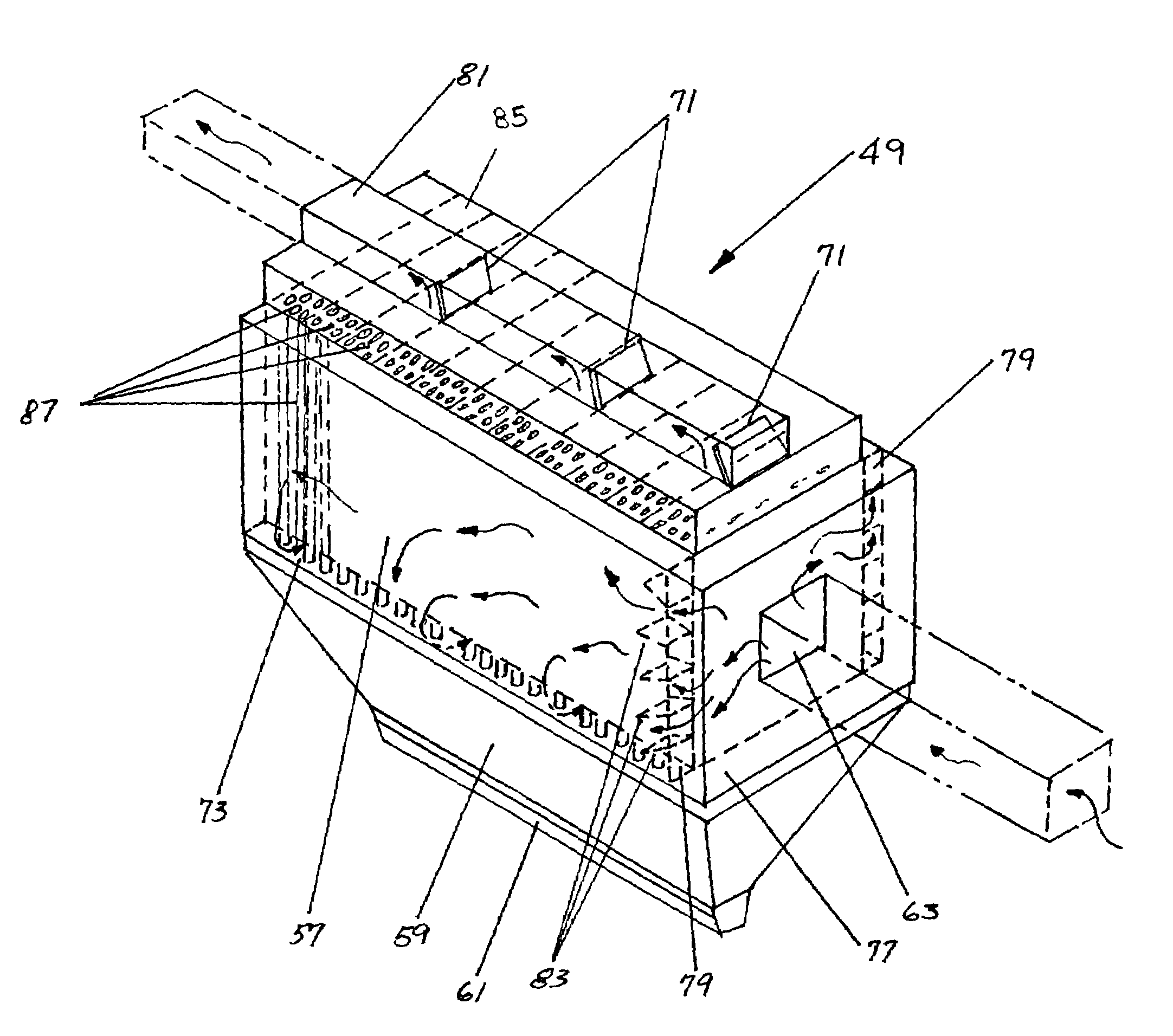

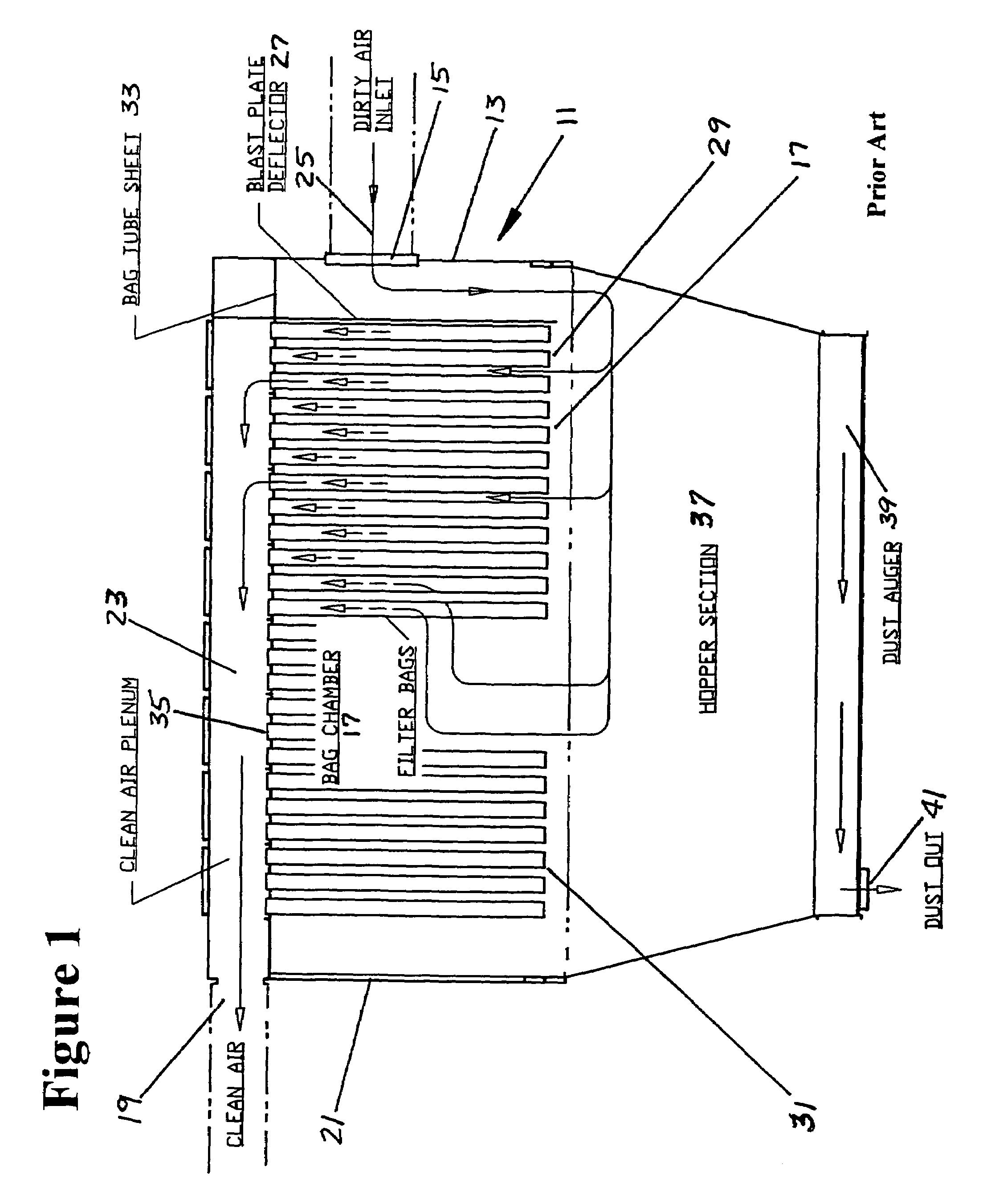

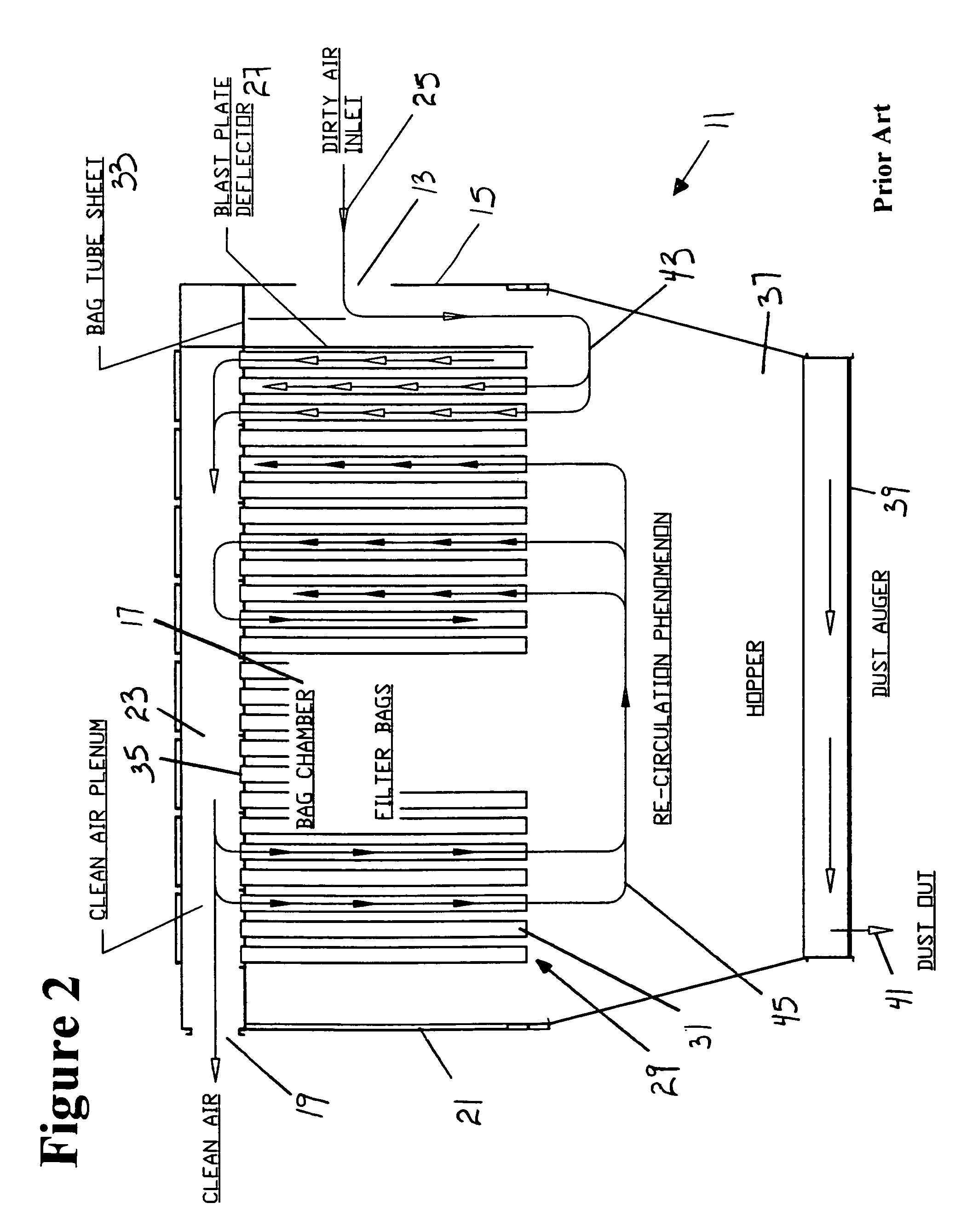

Modular up-draft pressure pulse bag house

InactiveUS7479170B1Simplifies bag cleaning operationIncrease pressureCombination devicesAuxillary pretreatmentAir filtrationAutomatic control

A bag house air filtration system with minimal recirculation uses new inlet airflow patterns and cleaning processes. Inlet air enters the bag house. An input plenum changes the velocity profile. Dirty inlet air is split into two plenums, and then passed through guide vanes. A clean air plenum contains a series of individual compartments with a pre-set number of filter bags that are effectively cleaned during a single cleaning cycle. Each individual compartment has a door or louver mounted above the bag openings that is opened and closed during the cleaning cycle. An automatic control system continuously senses bag house pressure drop and activates the cycle when needed. The doors open and close in a pre-set pattern to drop the dust cakes from the bags and restore air flow to normal pressures. Closing a door mounted above the bags creates a reversal of pressure that removes the dust cake.

Owner:COLLETTE JERRY R

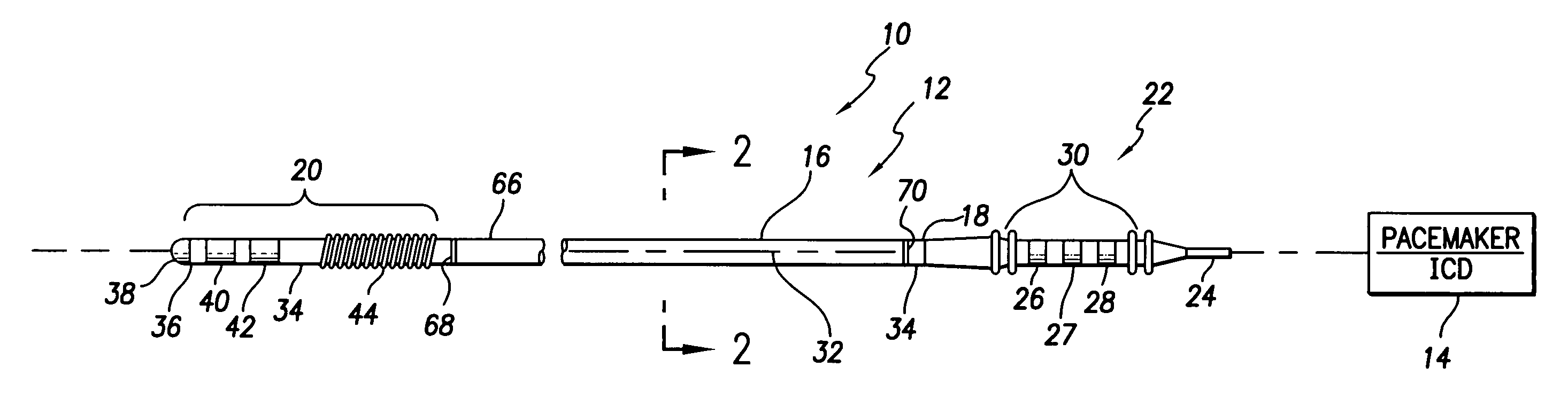

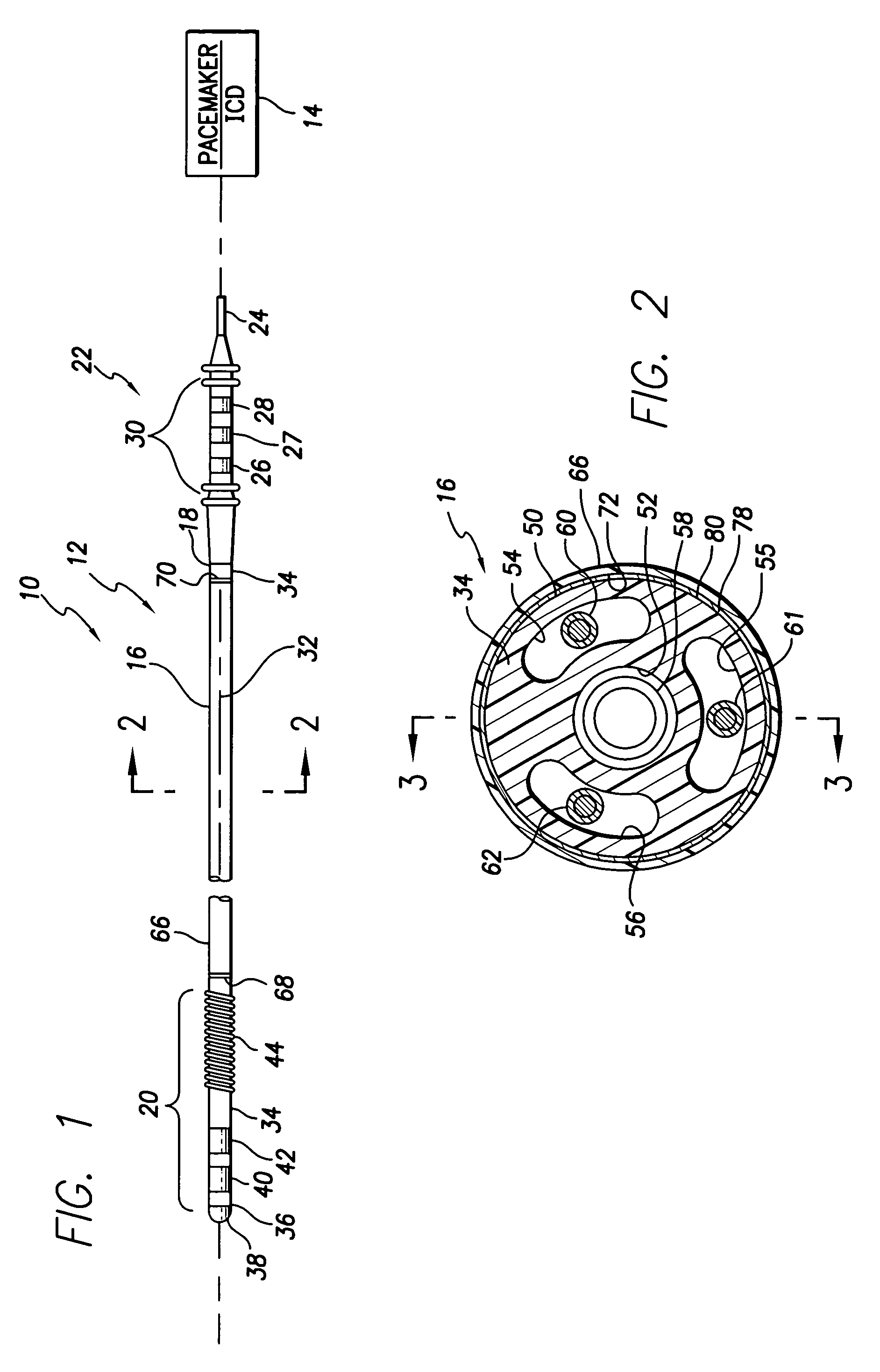

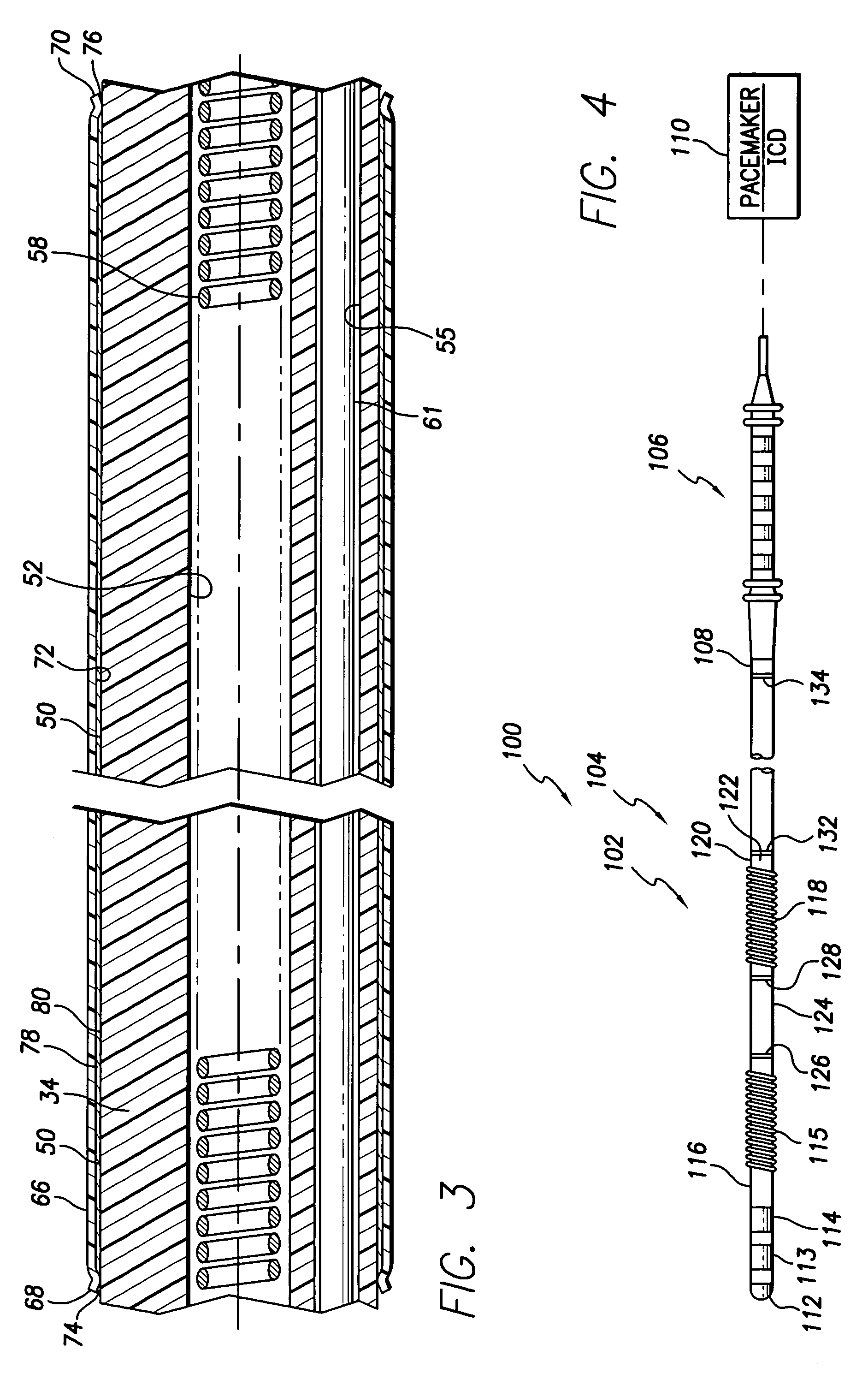

Abrasion-resistant implantable medical lead and a method of fabricating such a lead

ActiveUS6990378B1Facilitate movementReduce abrasive wearTransvascular endocardial electrodesExternal electrodesMembrane configurationBiomedical engineering

Owner:PACESETTER INC

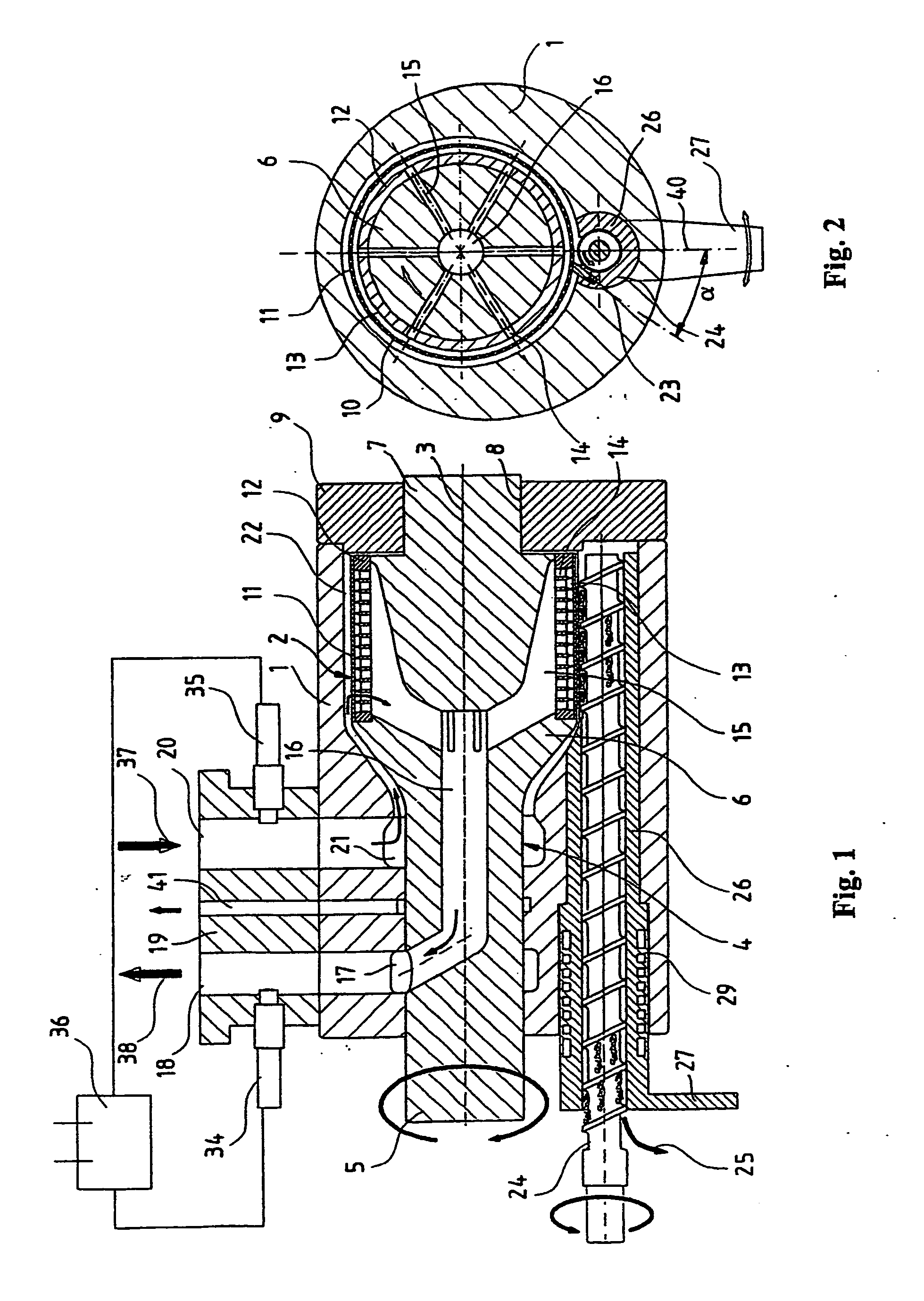

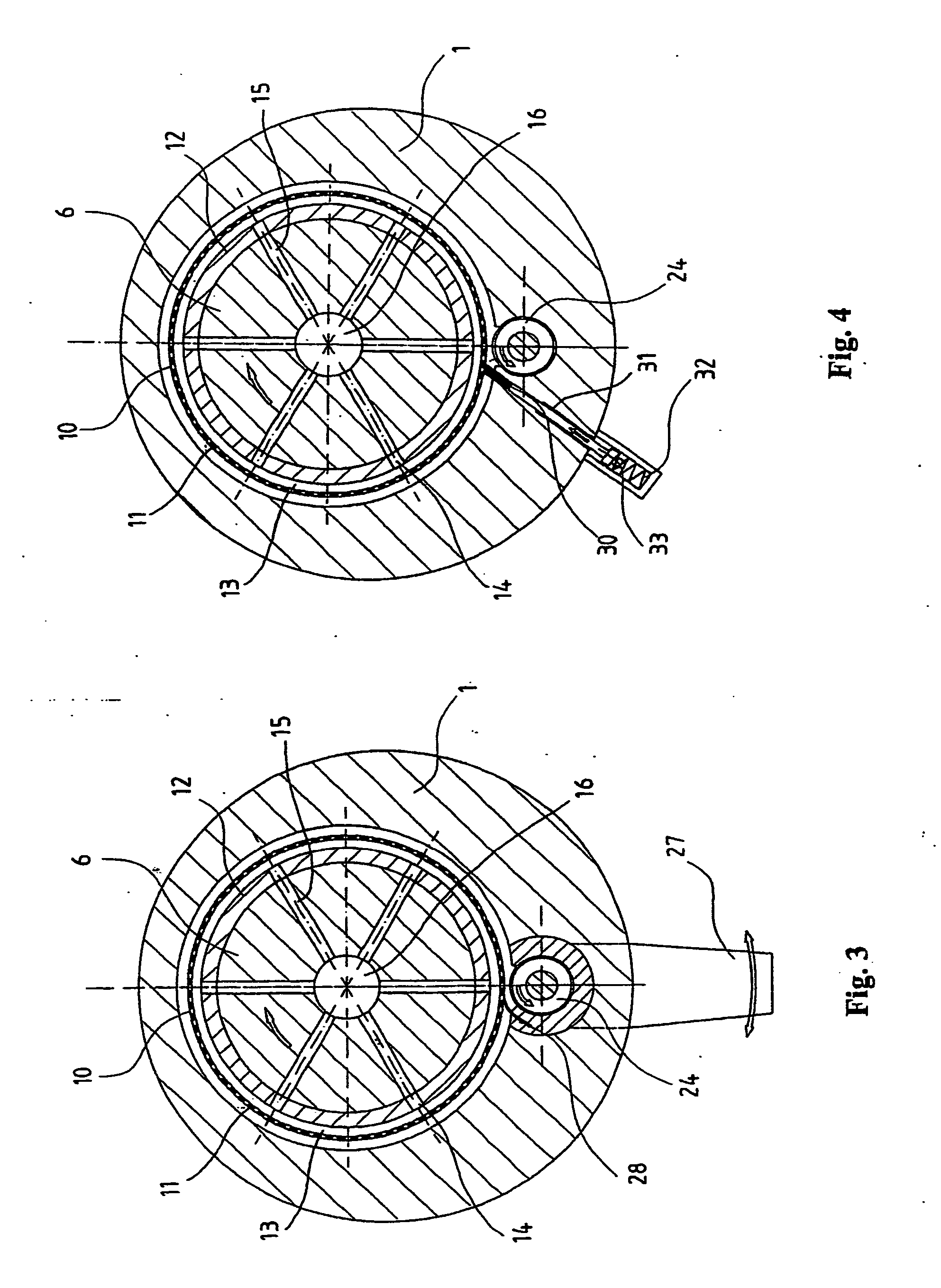

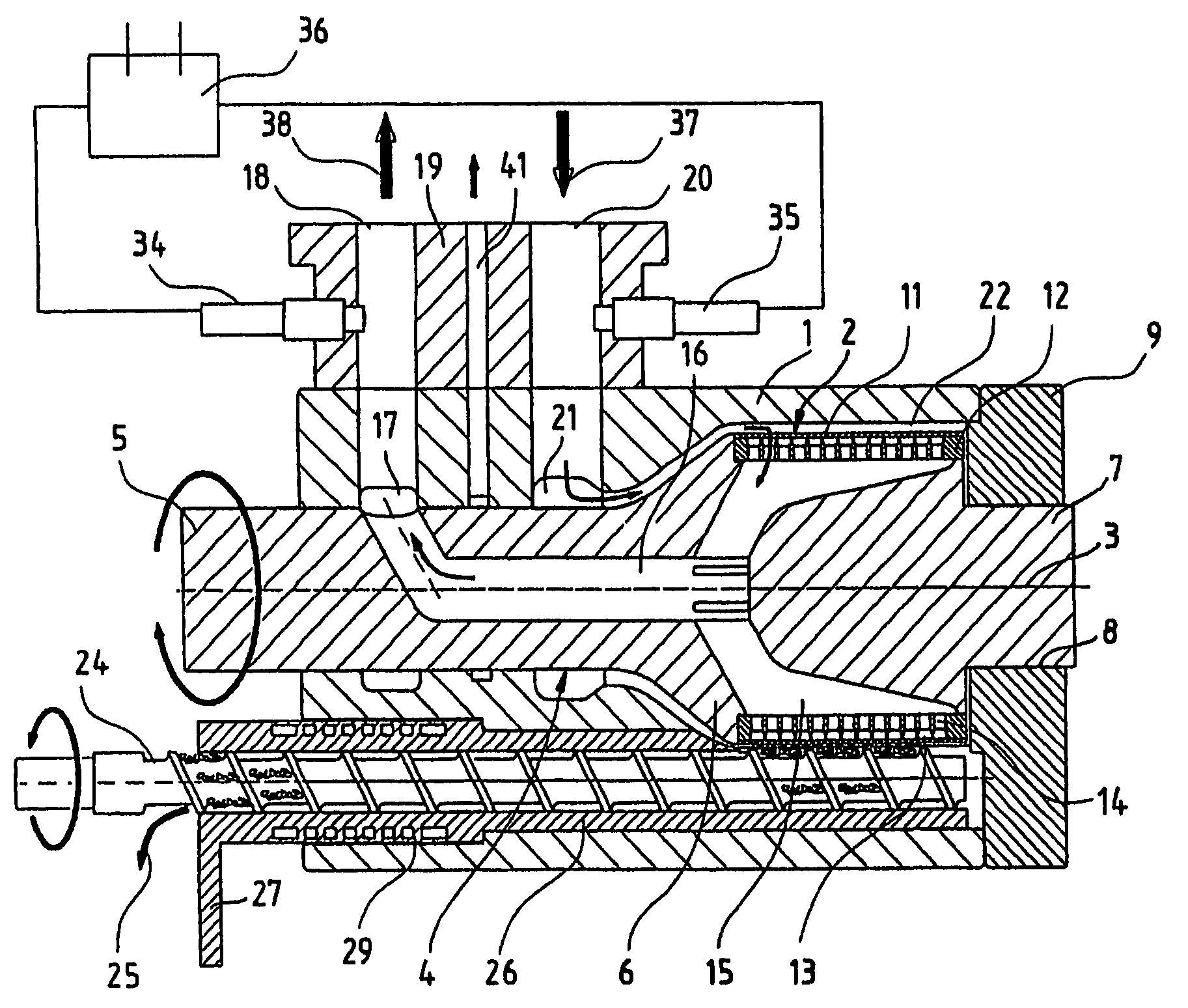

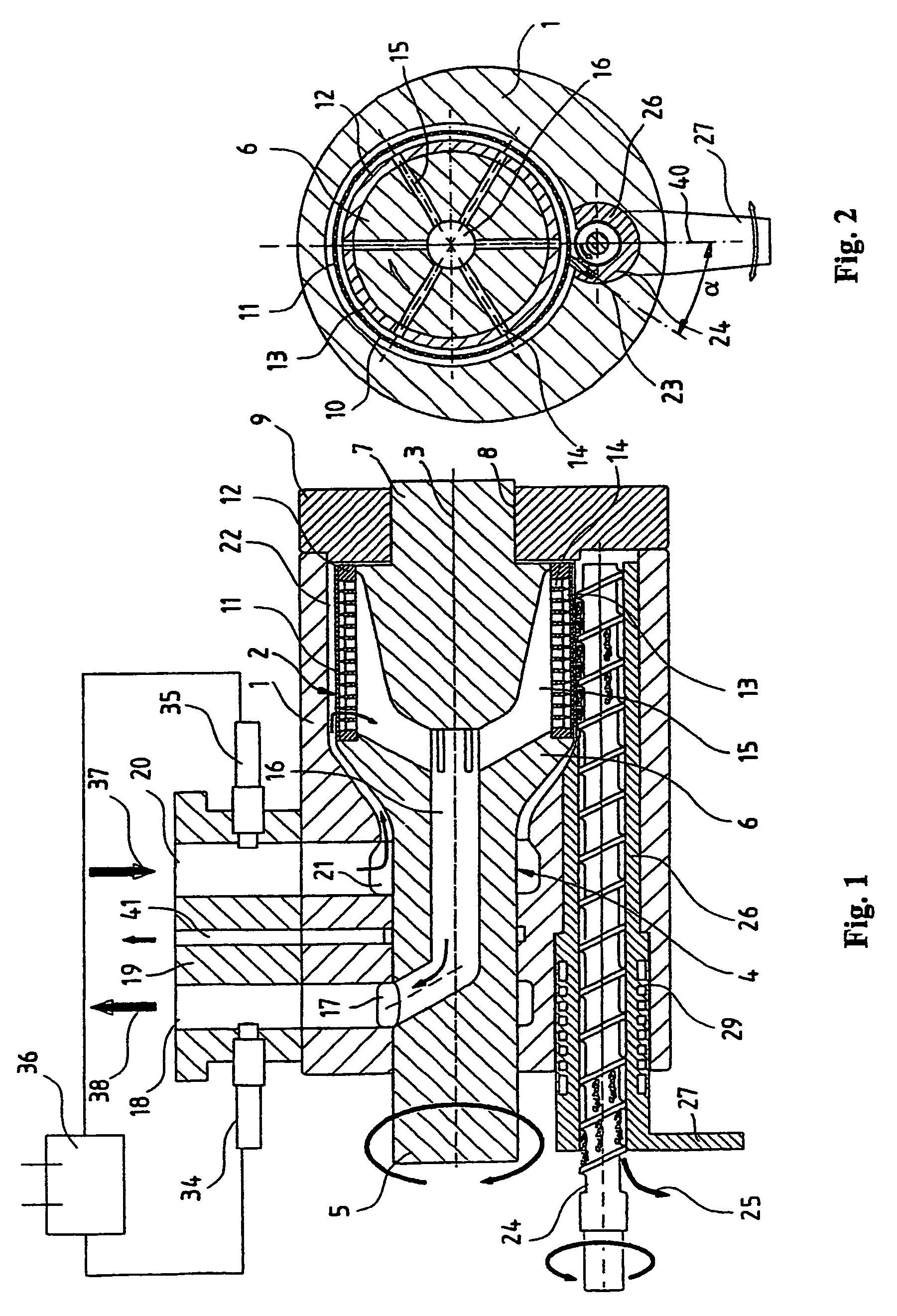

Device for continuous filtration of material blends

ActiveUS20050161391A1Reduce wearReduce tearingWrappingMoving filtering element filtersMotor driveFiltration

A device for the continuous filtration of material blends, in particular for separating impurities from plastic melts. A housing has a hollow cylindrical filter disposed inside. An inside chamber is disposed inside the filter. An annular chamber is defined by the outer surface of the filter and an inside wall of the housing. A cleaning device removes the impurities retained on the filter by a motor driving about an axis coupled to pivot the filter inside the housing. The cleaning device has at least one wiper for removing in the radial direction impurities retained on the filter. A conveying device transports off the impurities removed from the filter by the wiper. The motor-driven filter and the conveying device are driven separately of each other.

Owner:ETTLINGER KUNSTSTOFFMANSCHINEN GMBH

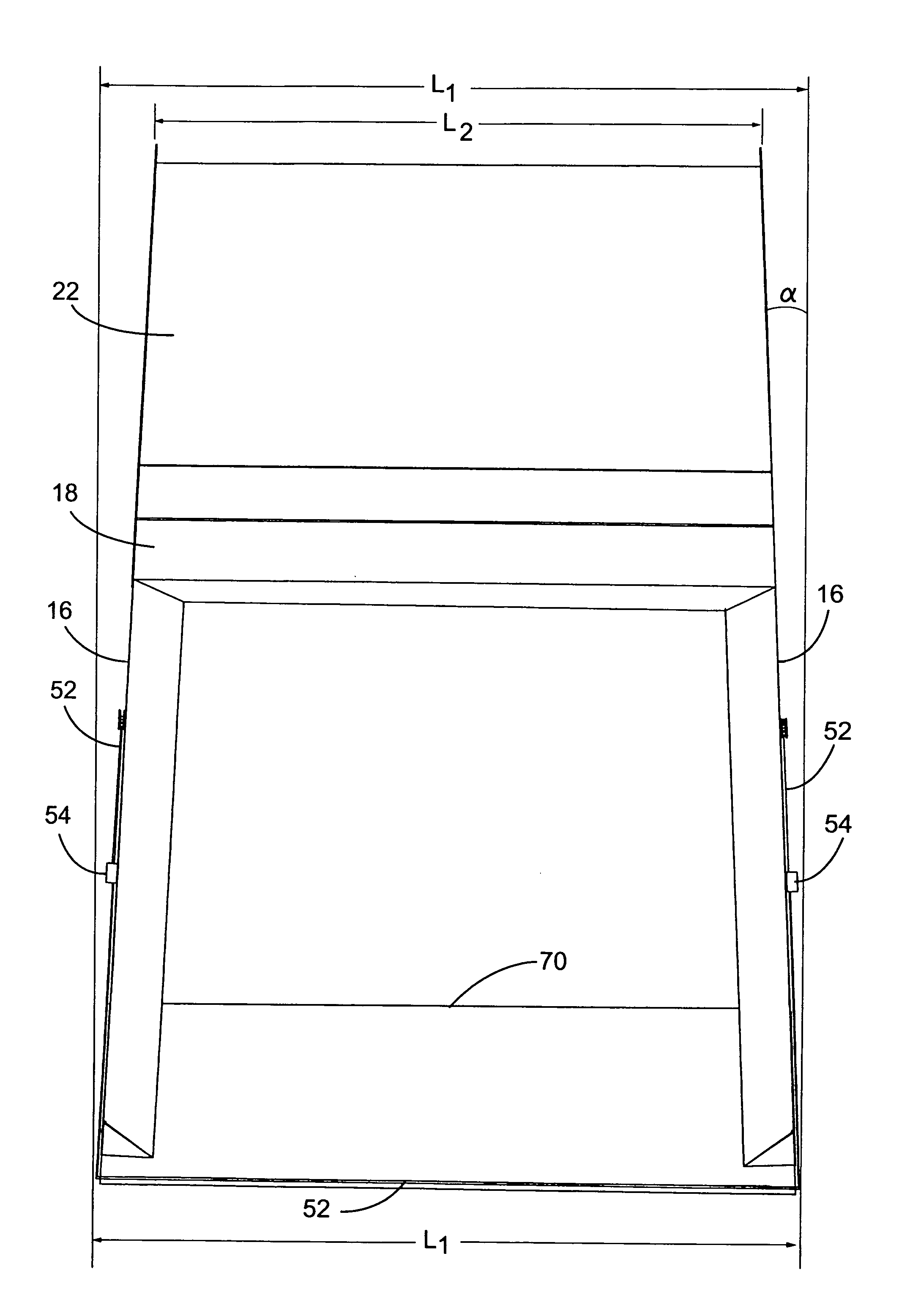

Severe application off-highway truck body

InactiveUS7901009B2Wear minimizationAvoid excessive wearMonocoque constructionsVehicle bodiesHigh densityTruck

An open top body of an off-highway haulage vehicle is described for severe hauling applications such as hauling of high density, abrasive material. The body has a floor divided into at least two sections with first and second sections angled at different inclinations. The second section extends to the rear edge of the floor and is at an angle of inclination greater than the first section. The opposing sidewalls of the body extend vertically from the floor are flared or taper along their length such that the body floor is wider at the rear of the body than it is at the front. The body includes a tailgate pivotally attached to the sidewalls for rotation between closed and opened positions in response to the bumping of the load by the body.

Owner:HAGENBUCH LEROY G

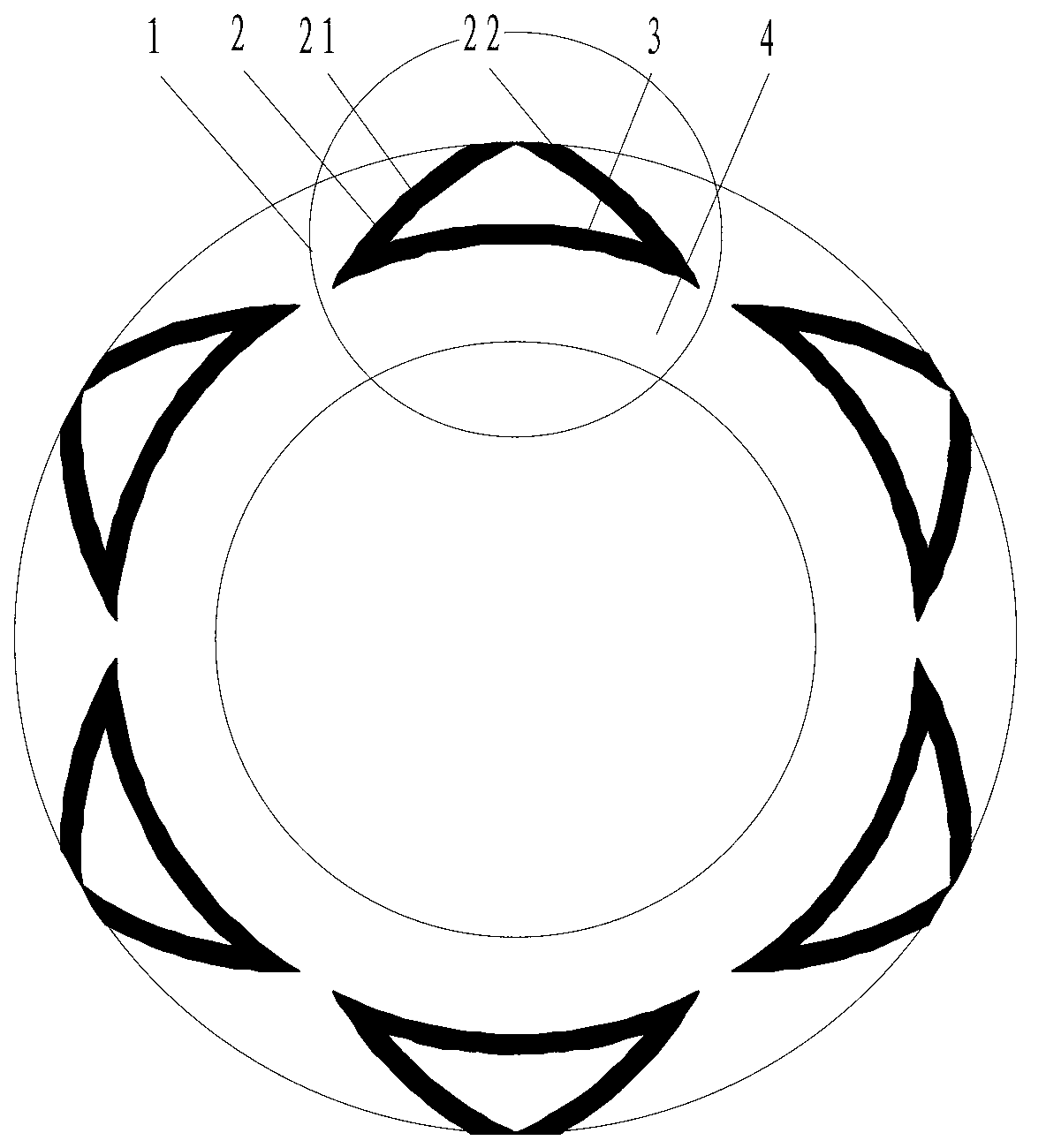

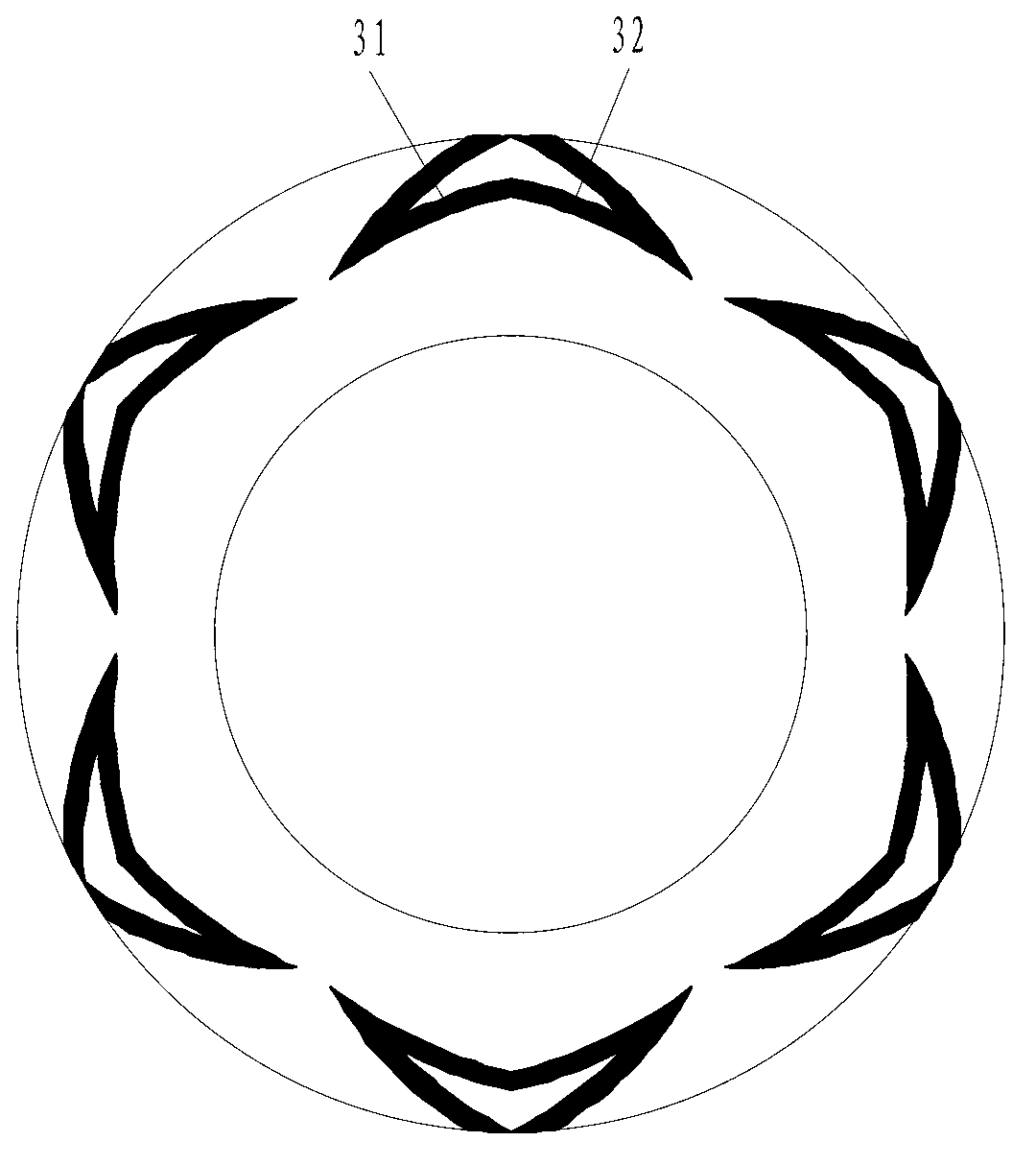

Bilaterally rotatable end surface mechanical sealing structure with dovetail grooves

ActiveCN103133697AImprove compression performanceImprove carrying capacityEngine sealsEngineeringHigh pressure

Owner:ZHEJIANG UNIV OF TECH

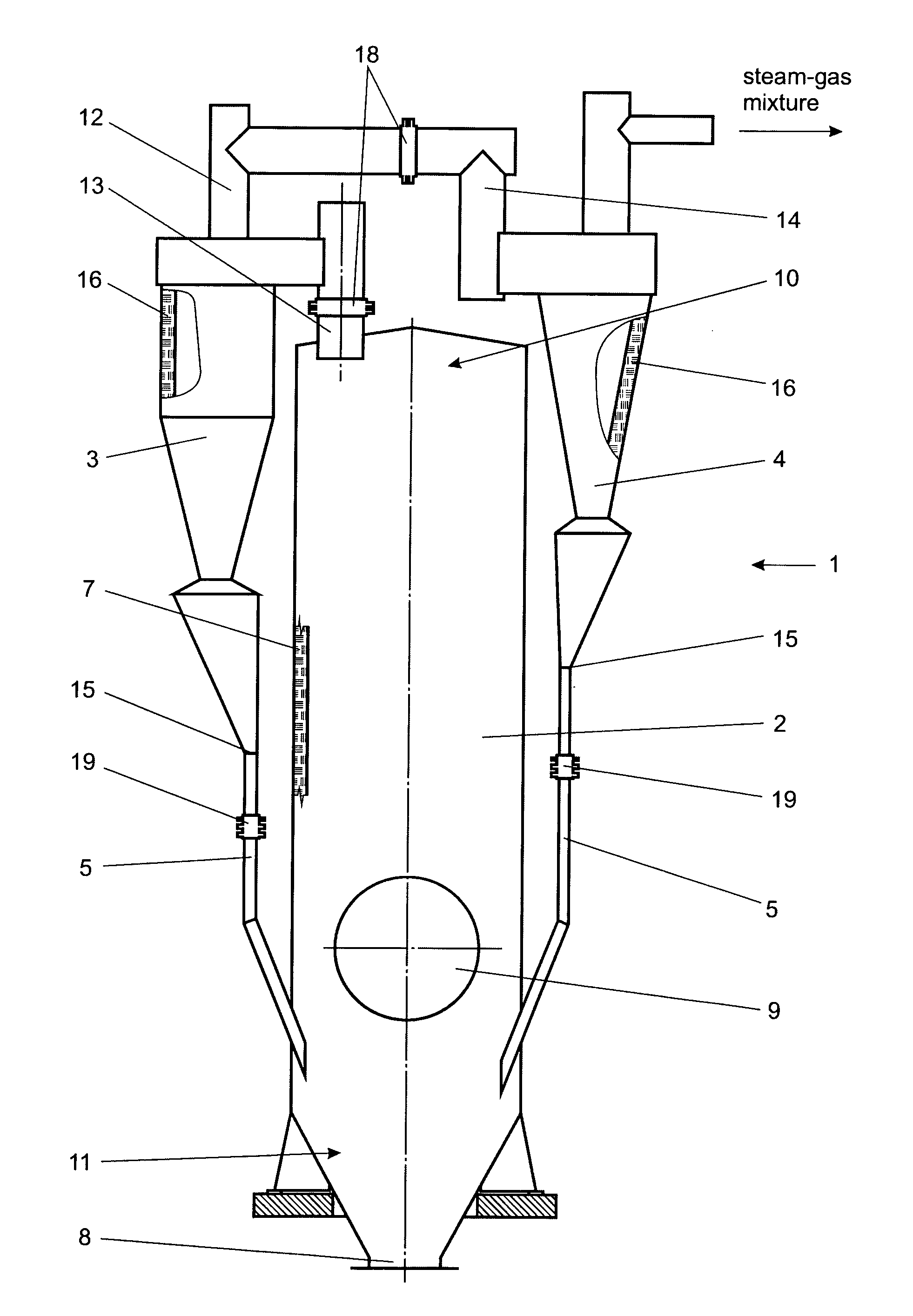

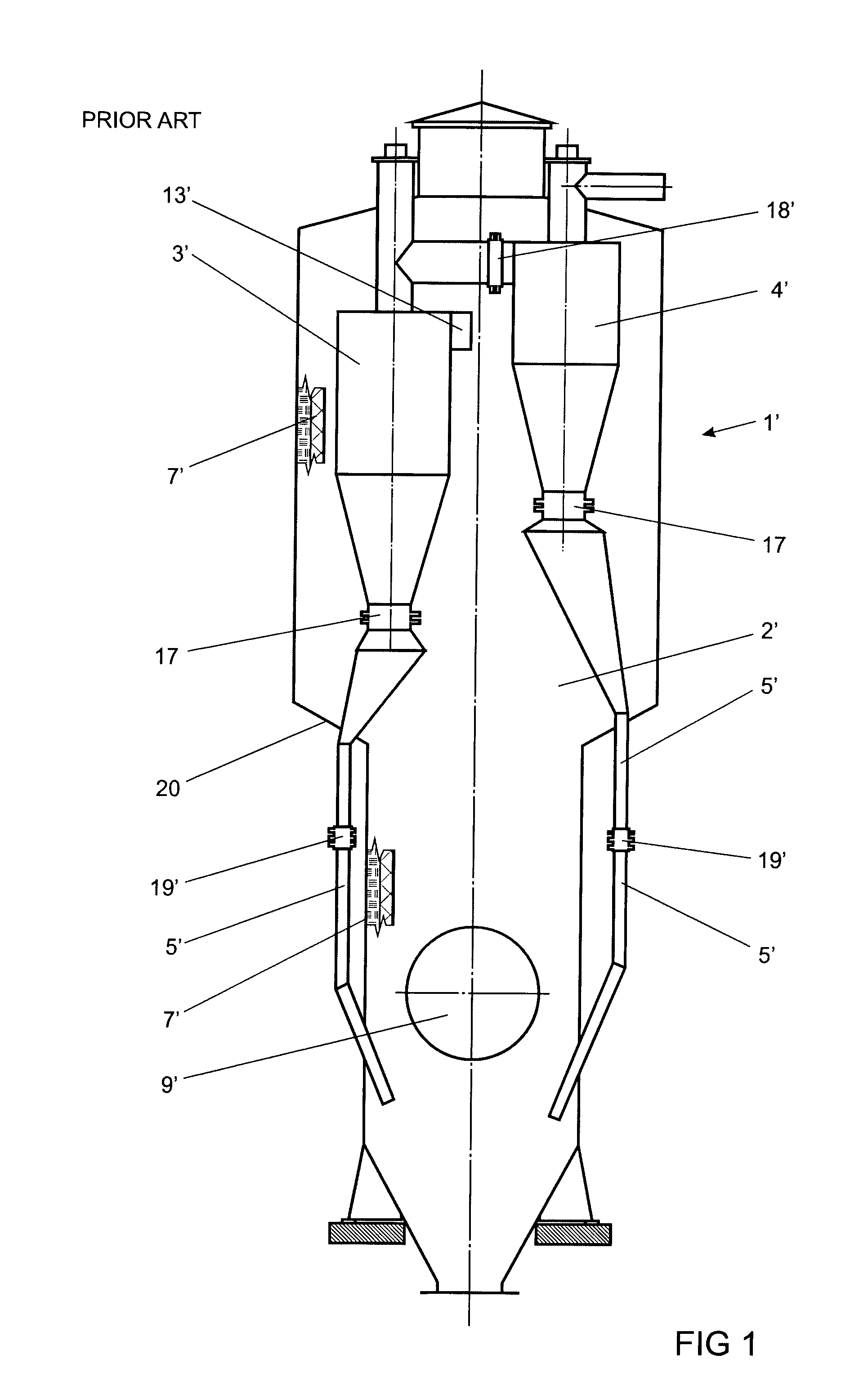

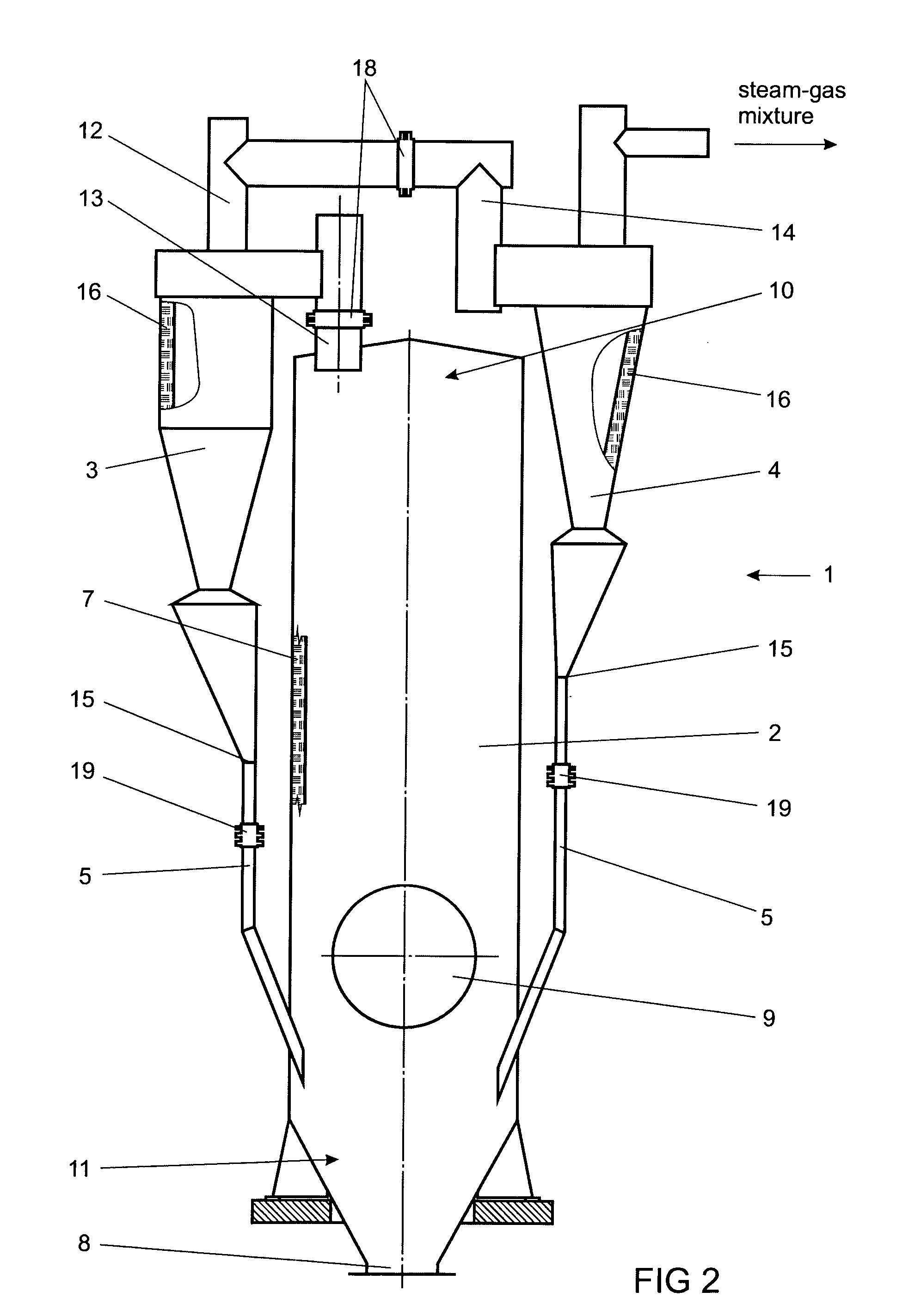

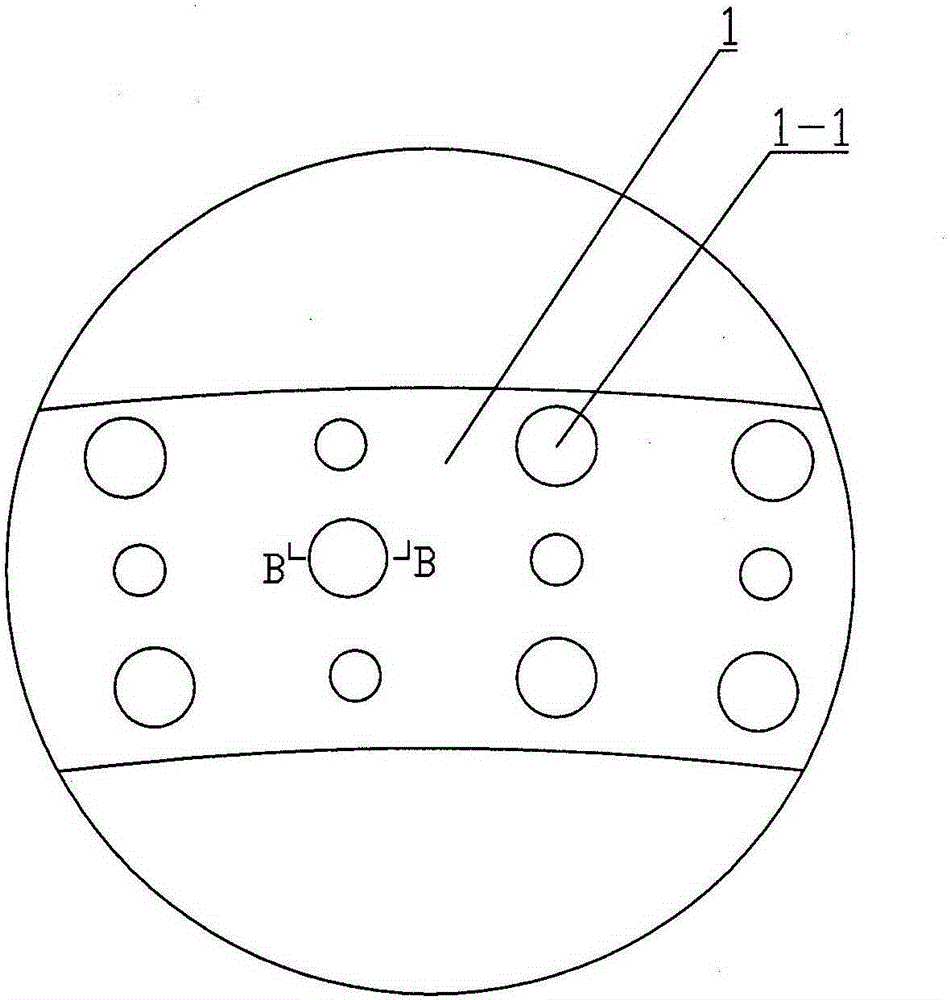

Separator of solid particles from steam-gas mixture

ActiveUS20100180557A1Reduce hydraulic resistanceImprove efficiencyCombination devicesReversed direction vortexThermodynamicsRefractory

The present invention is related to the separator (dust chamber) for separating solid particles from vapour-gas mixture, particularly to the structure of the dust chamber belonging amongst installation of the plant processing the fossil fuels or materials containing organic matter. The dust chamber (1) for separating solid particles from vapour-gas mixture comprises main body (2) with inner refractory lining (7) arranged to the inner surface of said main body, first and second stage cyclones (3, 4), lamella compensators (18, 19), dust removal conduits (5, 15) and inlet conduit (13) of the vapour-gas mixture into the first cyclone (3). The main body (2) of the dust chamber (1) is manufactured in all height from the cylinder of equal diameter and first and second stage cyclones (3, 4) are placed outside of the main body (2) of the dust chamber (1). For the refractory lining of the main body (2) of the dust chamber (1) and first and second stage cyclones (3, 4) the non-porous and wear proof material, for example concrete, is used.

Owner:EESTI ENERGIA OLITOOSTUS

Abrasion resistant dental composition product and process

InactiveUS20010012861A1Superior physical and aesthetic characteristicReduce abrasive wearCosmetic preparationsImpression capsSilanesProsthesis

Dental composition, product and process using a silicon containing abrasion resistant material. The dental products formed are abrasion resistant and self-lubricating across their entire cross sections. Dental compositions useful for forming dental products in accordance with the invention preferably includes an ethylenically unsaturated silane. The composition is formed into a dental prosthesis, such as an artificial tooth, inlay, onlay, facing, crown or bridge.

Owner:DENTSPLY RES DEVMENT

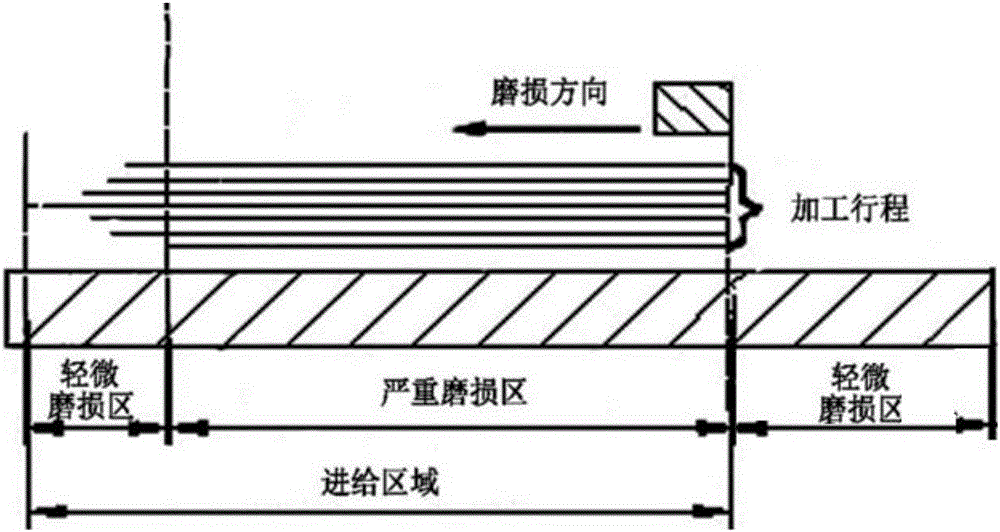

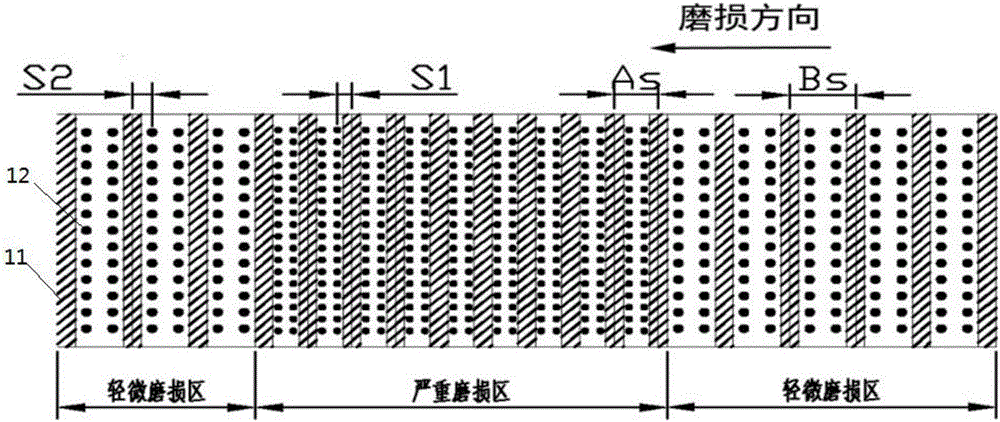

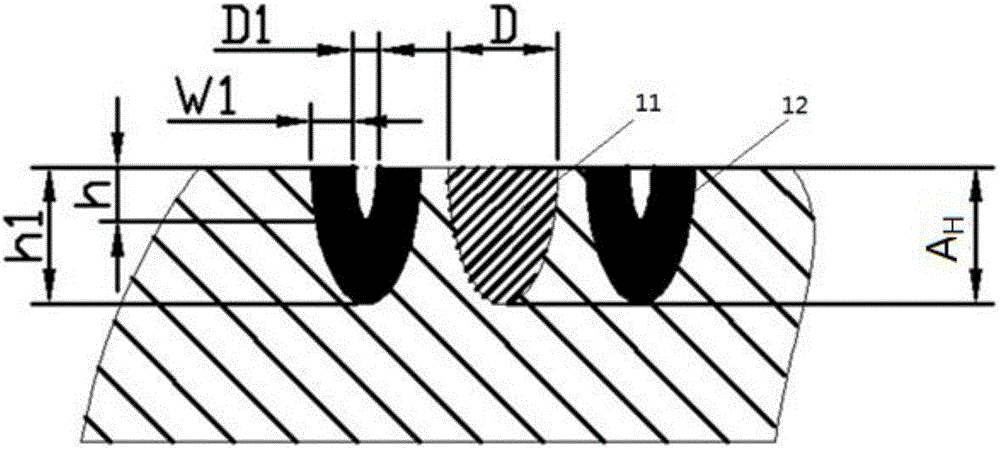

Multi-structure different-interval bionic surface combined cast-iron guide rail and regeneration method thereof

InactiveCN105108503AOvercoming Difficult-to-Regenerate ProblemsImprove wear resistanceLarge fixed membersStress distributionCoupling

The invention relates to a multi-structure different-interval bionic surface combined cast-iron guide rail and a regeneration method thereof. First bionic coupling elements and second bionic coupling elements are made on mild wear areas and a severe wear area of the guide rail working face; the first bionic coupling elements are strip-shaped or net-shaped bionic coupling elements, and intervals of the first bionic coupling elements in the mild wear areas are larger than those of the first bionic coupling elements in the severe wear area; the second bionic coupling elements are pit-shaped coupling elements and are distributed among the first bionic coupling elements. According to the multi-structure different-interval bionic surface combined cast-iron guide rail and the regeneration method thereof, according to the rigidity or stress distribution situations of the areas with different wear degrees, two double-coupling-element bionic surfaces with changeable intervals are set, a multi-structure different-interval bionic surface combination with different anti-wear performances is formed, and the surface of which the rigidity or the stress is distributed evenly is obtained, so that the effect that the overall anti-wear performance of the surface is uniform and stable for a long time is achieved. In addition, by means of the interaction between the two coupling elements and a machine body, the wear resistance of the sliding guide rail is further improved.

Owner:JILIN UNIV

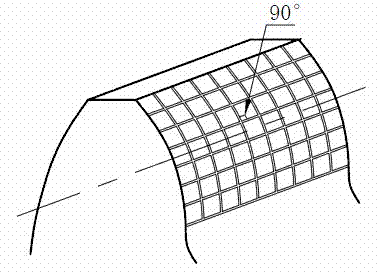

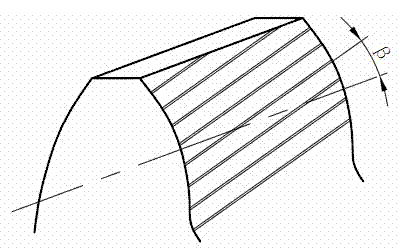

Gear with surface texture tooth surfaces

InactiveCN102889362AReduce abrasive wearAvoid Three-Body FrictionGear lubrication/coolingPortable liftingMachined surfaceLubrication theory

The invention discloses a gear with surface texture tooth surfaces. Uniformly arranged surface texture mark forms are arranged on each tooth surface of the gear. The surface texture mark forms are strip-type convex mark forms or strip-type concave mark forms which are parallel to gear engagement lines. Or, the surface texture mark forms are provided with grid-like convex mark forms or grid-like concave mark forms which are parallel and vertical to gear engagement lines. A surface texture is machined on a tooth surface, so that the gear with surface texture tooth surfaces can accommodate abrasive particles, and reduce the abrasive particle abrasion between the tooth surfaces; the gear with the surface texture tooth surfaces can store lubricating oil, take away friction heat generated between the tooth surfaces, reduce the tooth surface temperature, and prevent tooth surface agglutination from invalidation; and according to a partial film elastic fluid lubrication theory, the gear with surface texture tooth surfaces is favorable for forming an elastic fluid hydrodynamic lubricating oil film to improve the lubrication state. By the surface texture tooth surfaces, the wearing resistance of the gear can be improved, and the service life of the gear can be prolonged.

Owner:ZHEJIANG UNIV +1

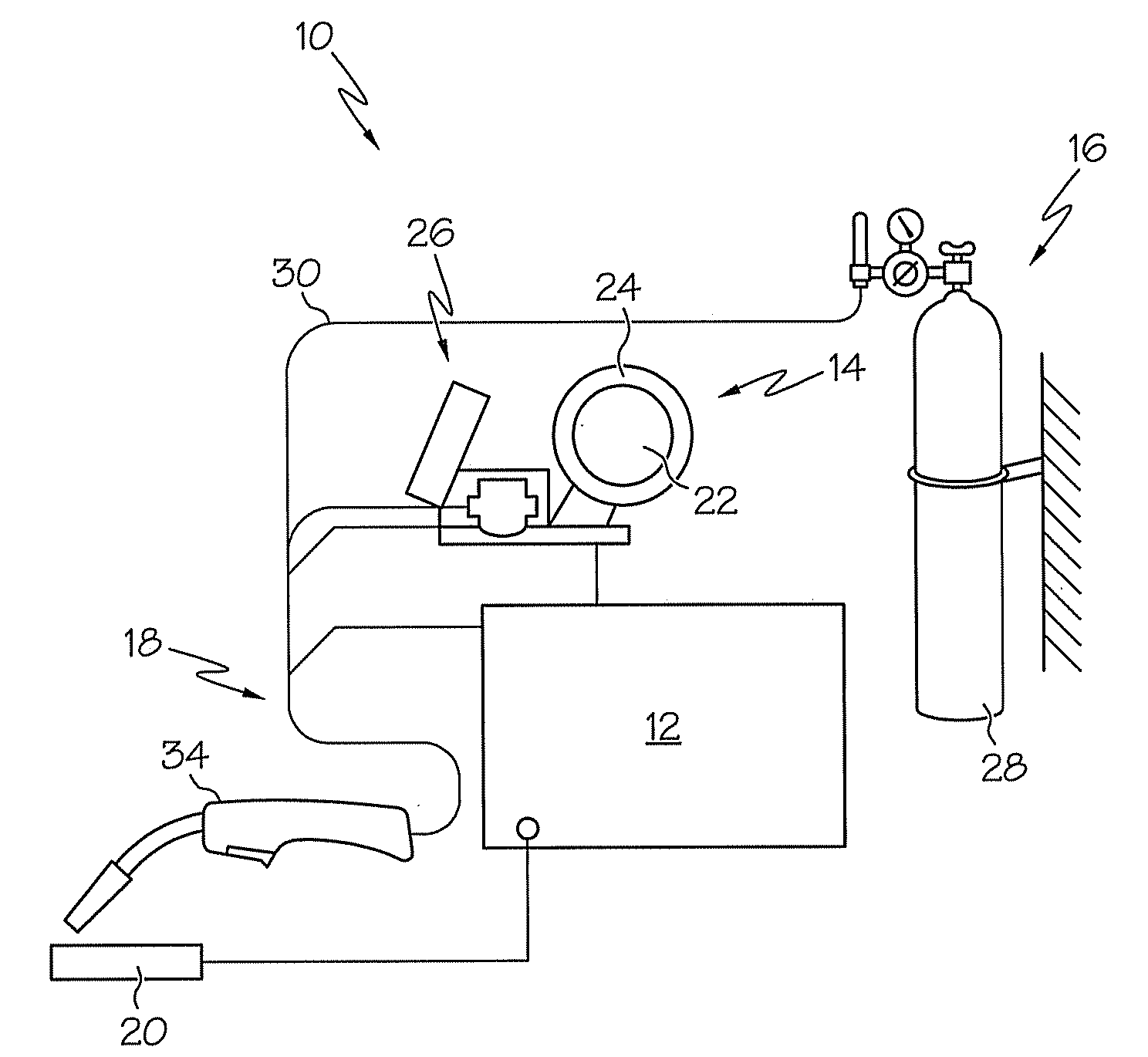

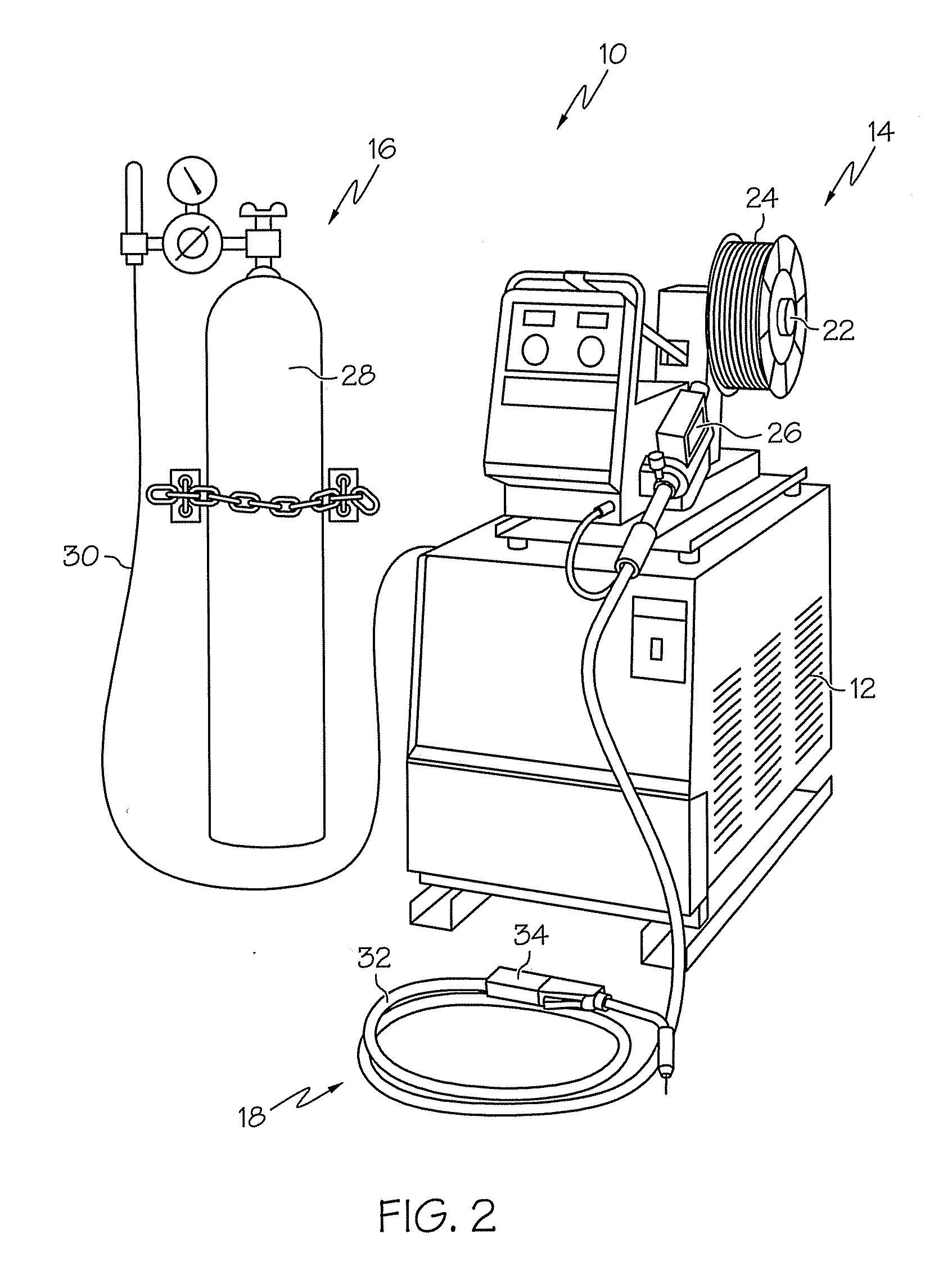

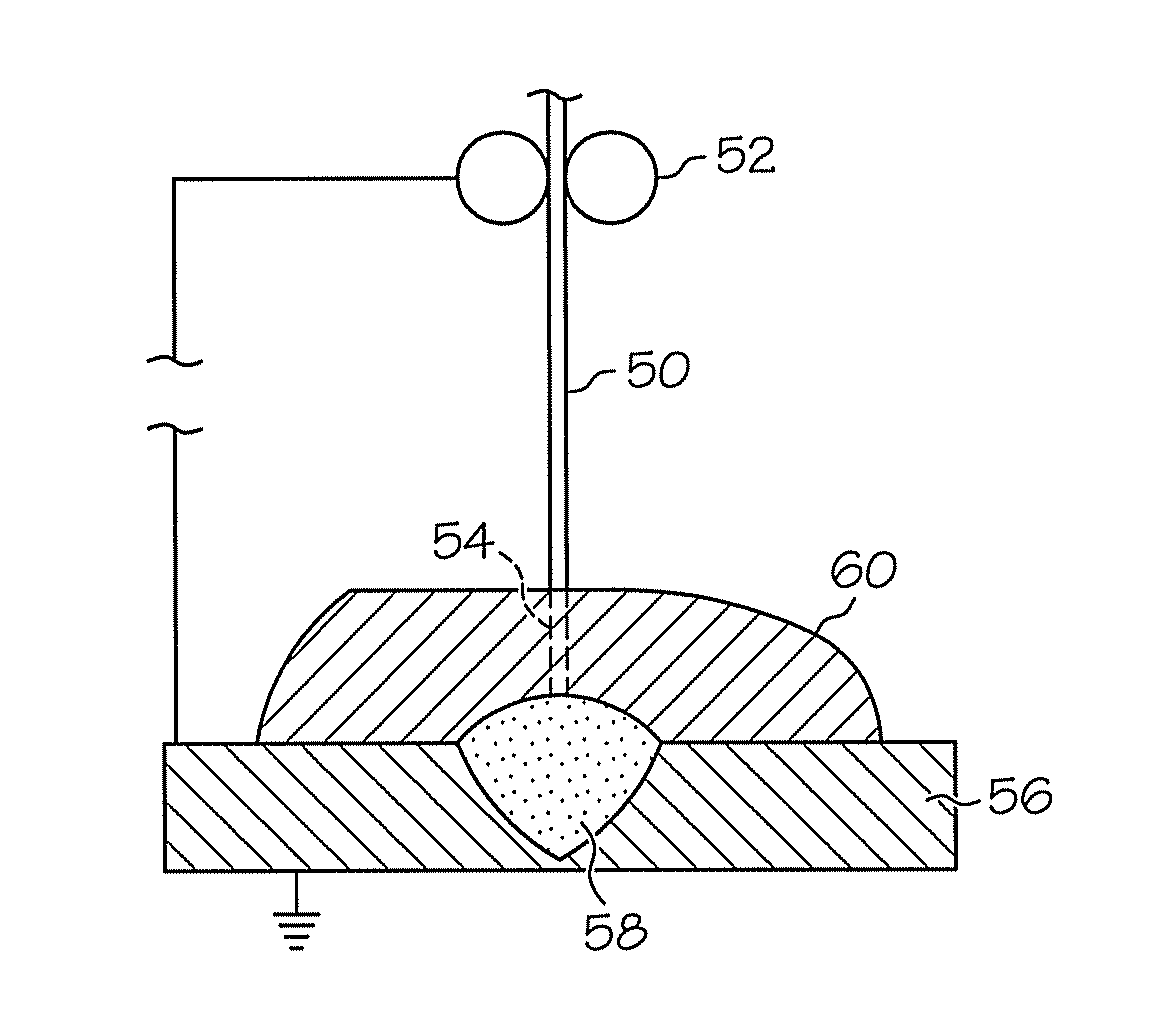

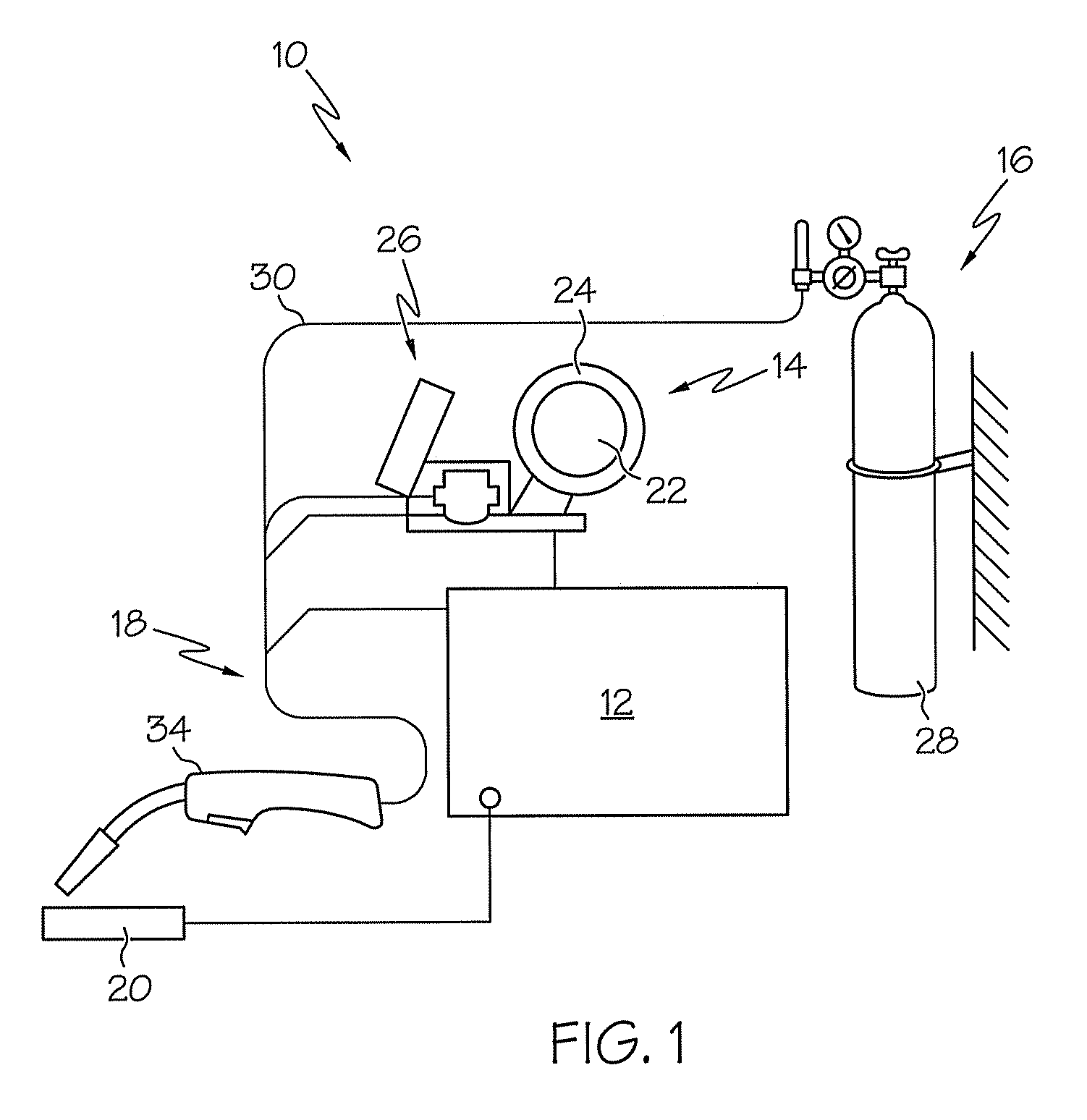

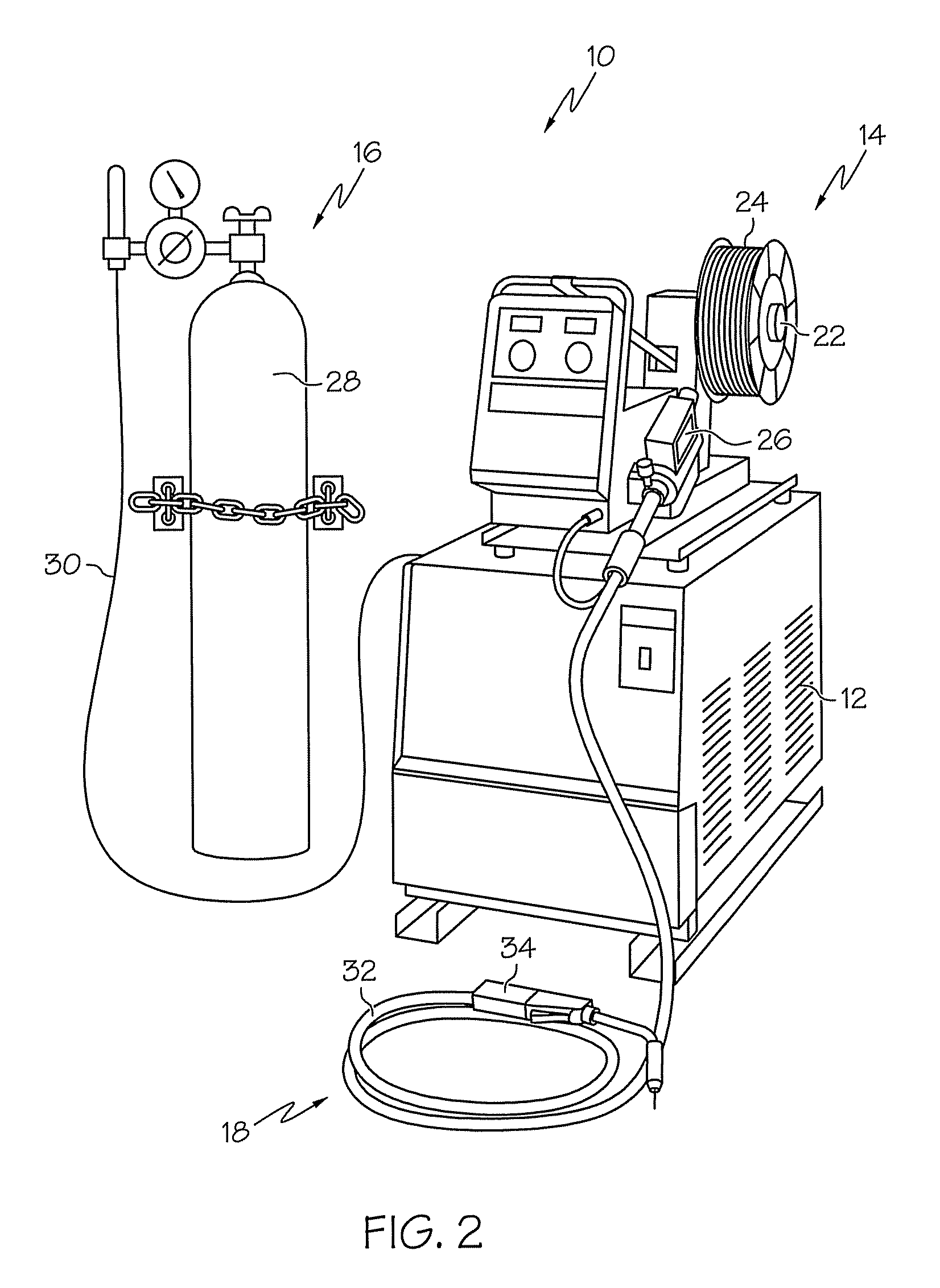

Welding wire for submerged arc welding

ActiveUS20090314756A1Reduce abrasive wearEliminate contaminationArc welding apparatusWelding/cutting media/materialsCopper contaminationLubricant

The copper cladding normally applied to the surfaces of a submerged arc welding wire for preventing weld gun contact tip abrasive wear is replaced with a solid lubricant. This eliminates copper contamination of the weld from the copper cladding while preserving the useful life of the contact tip.

Owner:LINCOLN GLOBAL INC

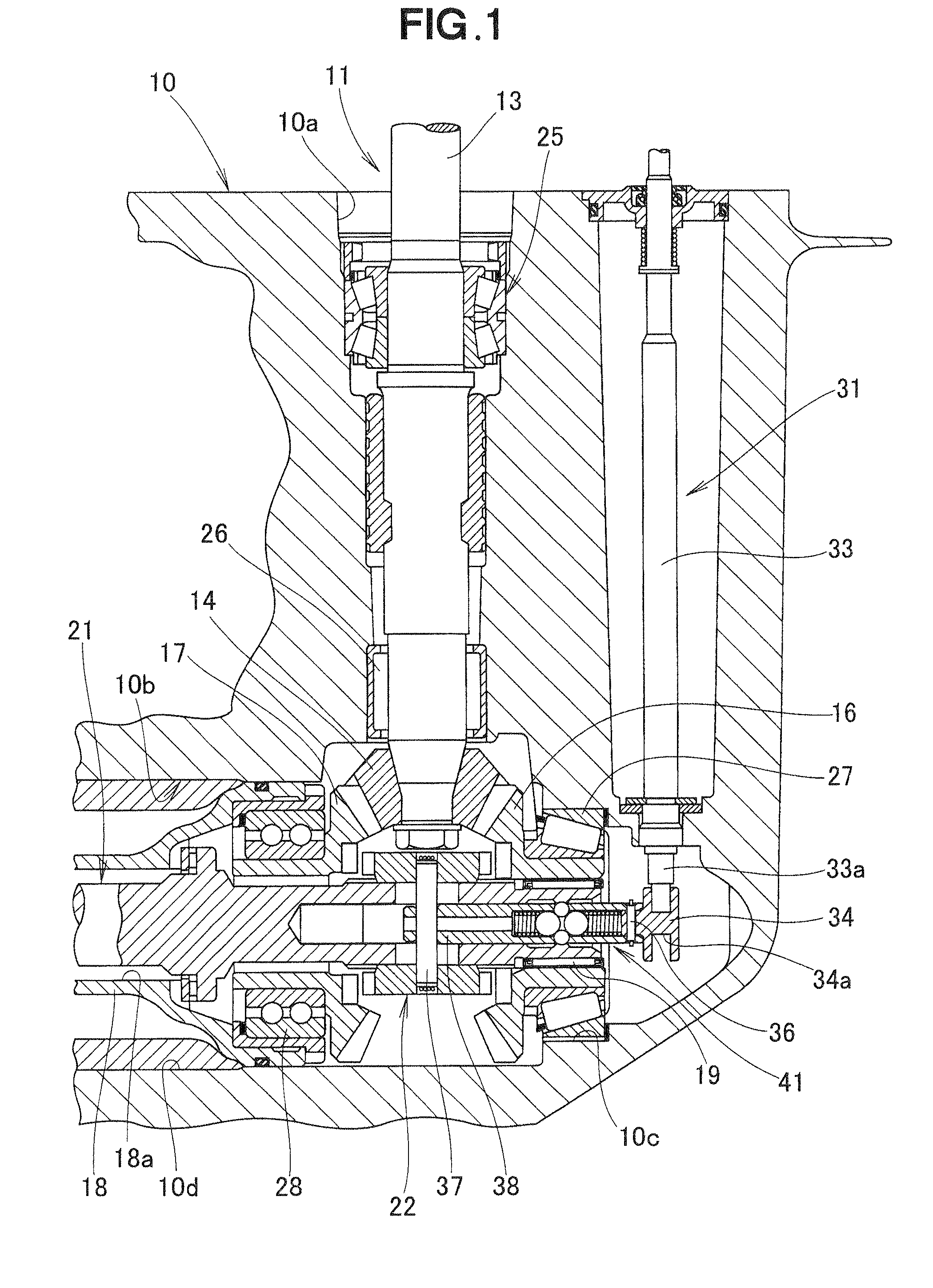

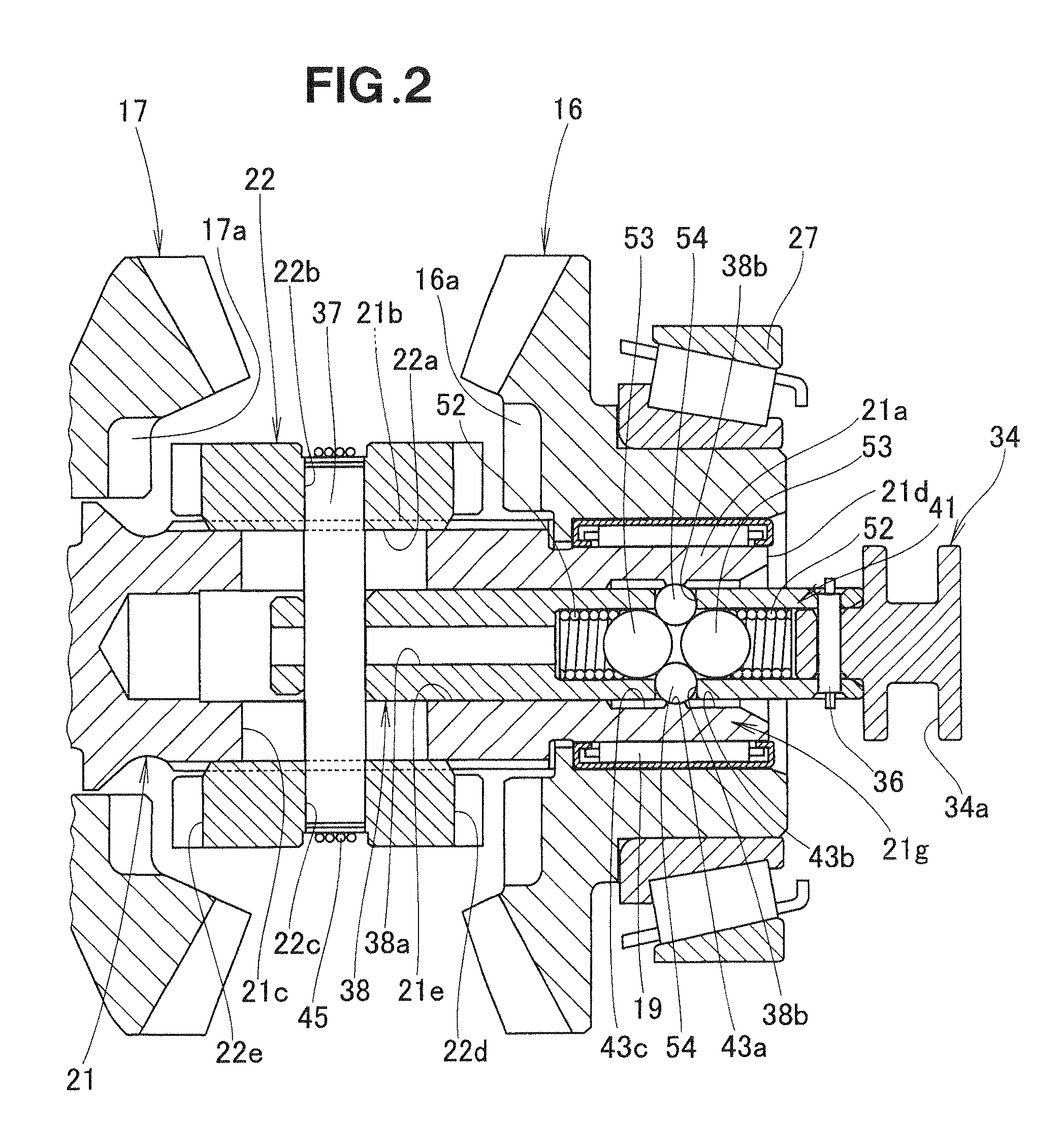

Dog clutch mechanism for outboard motor

InactiveUS8834217B2Low costZero clearancePropulsion power plantsOutboard propulsion unitsPropellerGear tooth

A dog clutch mechanism incorporated in an outboard motor includes a sliding clutch dog member splined to a propeller shaft and having recesses on each end face thereof, and a row of gear teeth formed on an end face of each of a pair of driven gears rotatably mounted on the propeller shaft. Each of the recesses has a bottom surface stepped to provide a corner edge at a stepped portion thereof. Each of the gear teeth has a beveled surface formed at a rear edge as viewed from a rotating direction of the driven gear. When the gear teeth are in mesh with the recesses of the clutch dog member, the corner edge of the stepped bottom surface of each recess is in contact with the beveled surface of the mating gear tooth.

Owner:HONDA MOTOR CO LTD

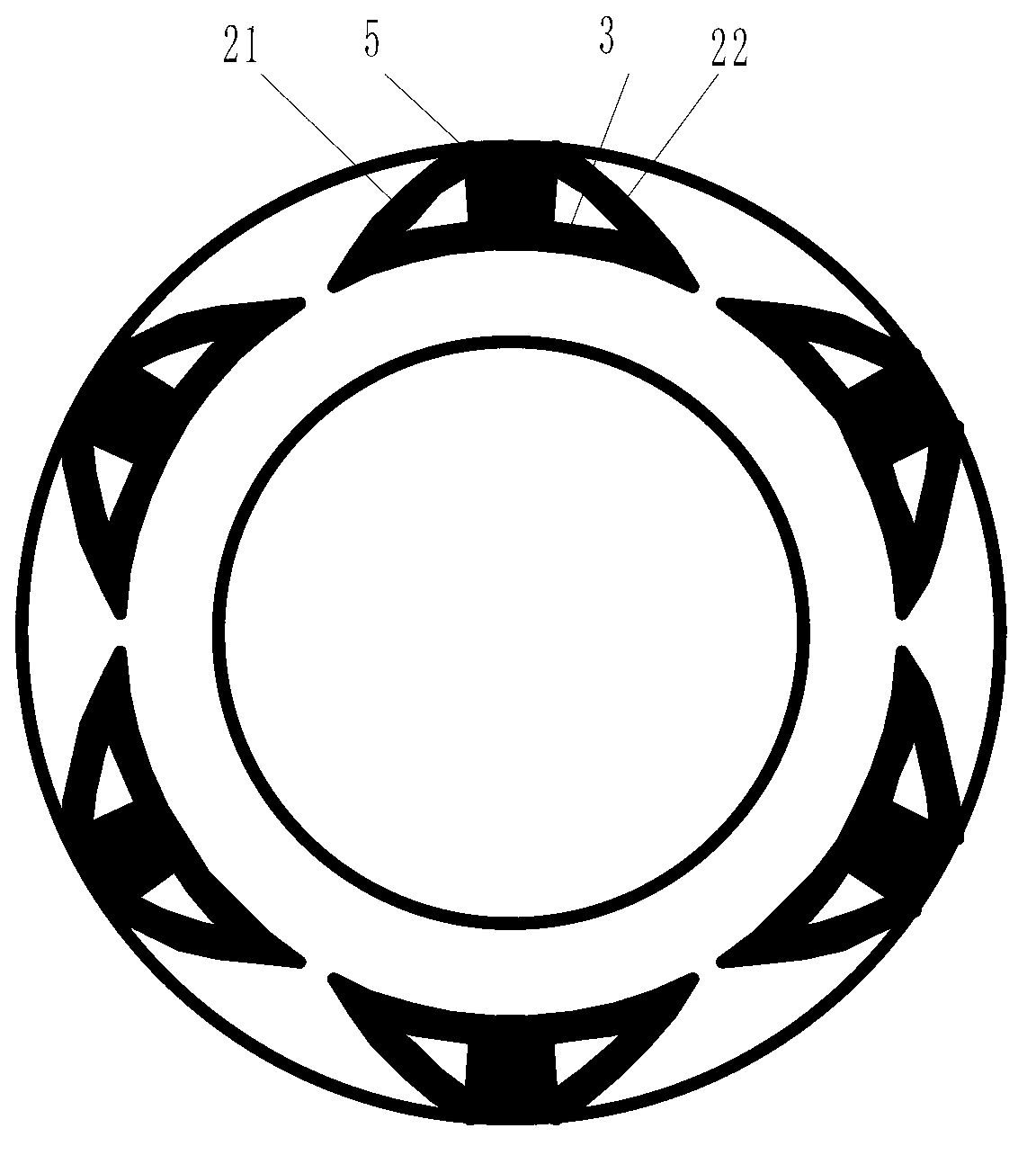

High-current plug-in connection with multi-arm contact lamellae

ActiveUS20160211590A1Reduce abrasive wearEvenly distributedCoupling contact membersClamped/spring connectionsEngineeringContact system

A socket for a high-current plug-in connection is provided, which includes a contact sleeve and a hollow cylindrical contacting system. The contacting system includes a plurality of elongated contact lamellae, is situated in an inner area of the contact sleeve, and is supported with at least a portion of its outer wall on the inner wall. The contact lamellae extend between a first collar and a second collar of the contacting system. The socket includes a contact lamella, in an area between the first collar and second collar, having an arm, via which the contact lamella is additionally connected to a collar of the contacting system in a supporting manner.

Owner:ROBERT BOSCH GMBH

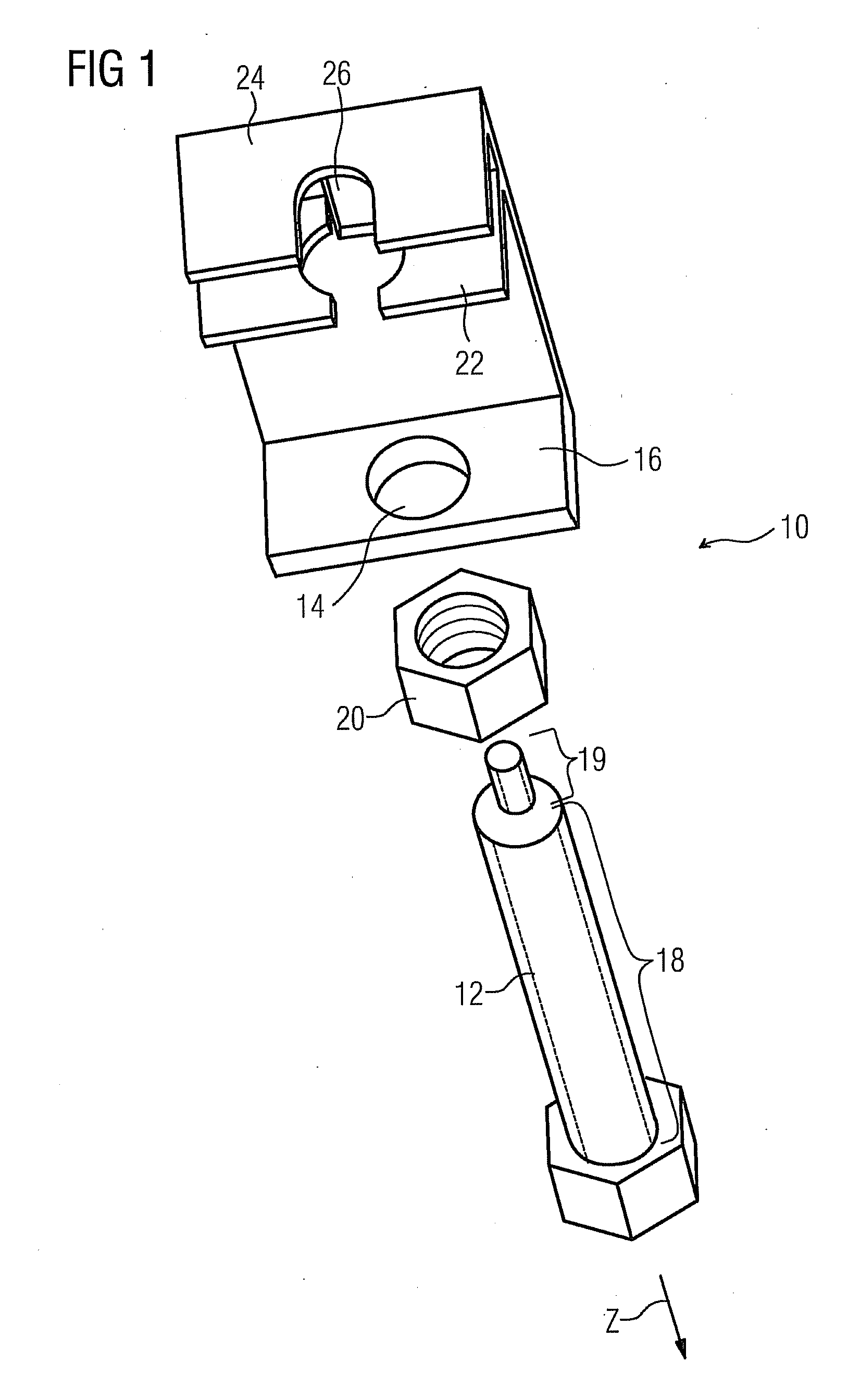

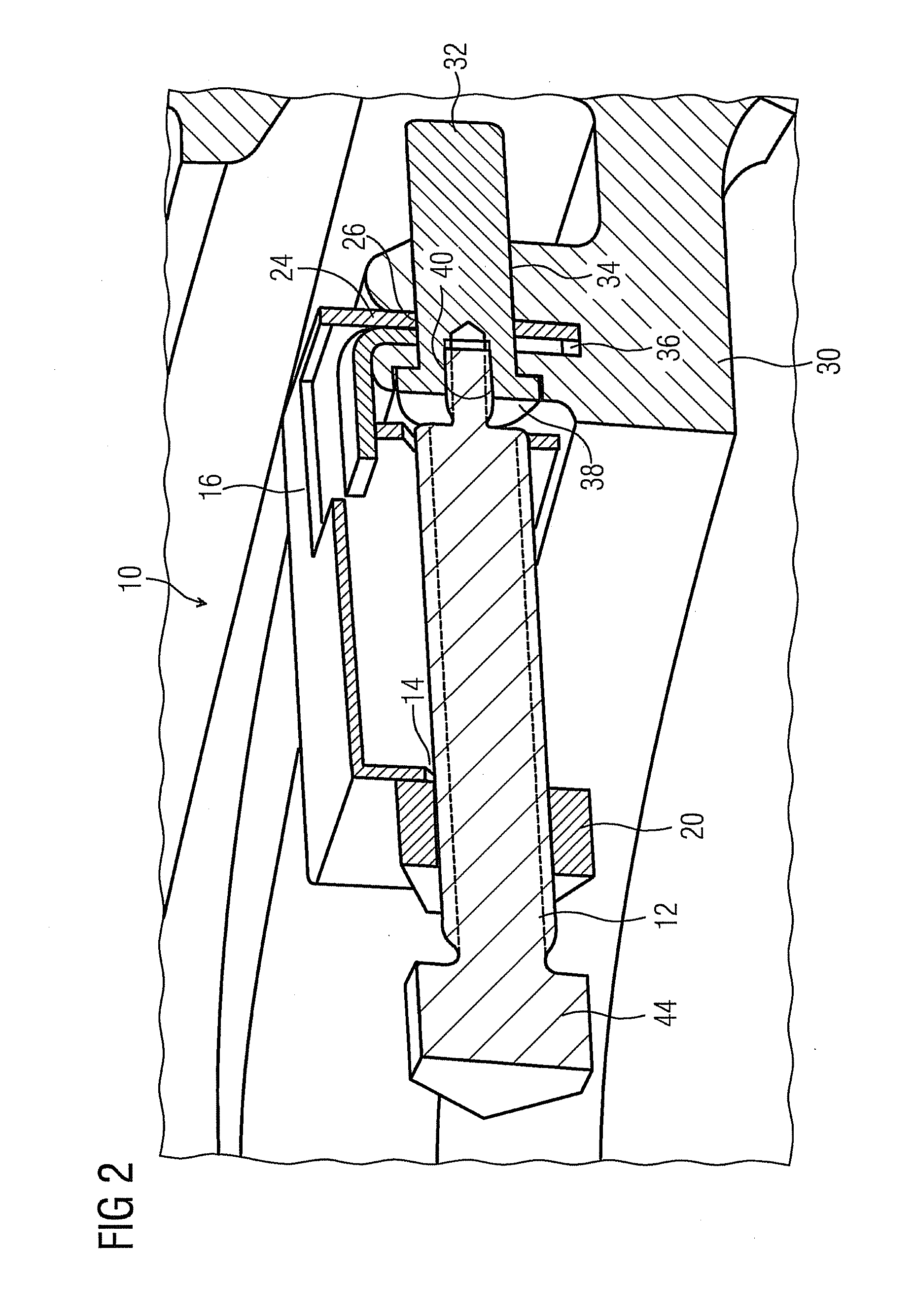

Multi-part pin remover for removing a pin or stud from a hole of a component

InactiveUS20100115747A1Quality unchangedNot to damageMetal working apparatusMetal-working hand toolsBiomedical engineering

Owner:SIEMENS AG

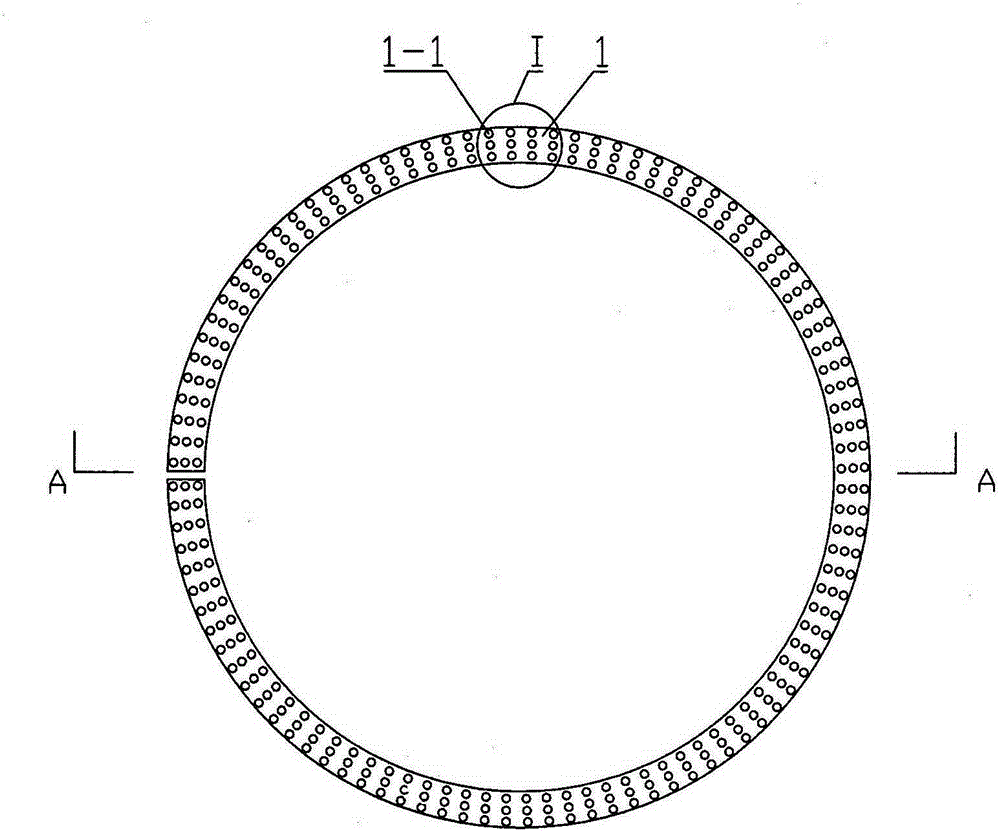

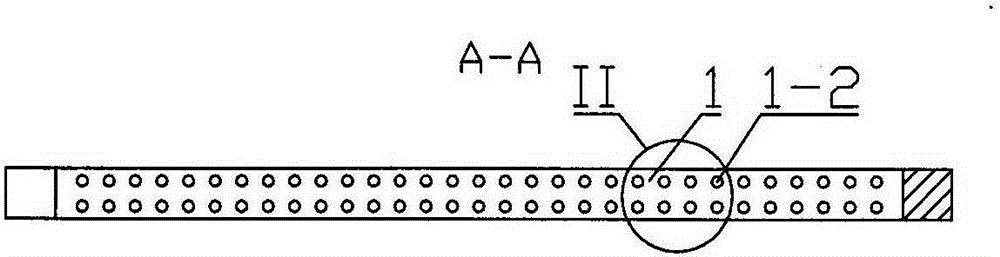

Turbocharger sealing ring subjected to laser surface texturing and machining method

InactiveCN105299233AHigh hardnessImprove protectionEngine sealsLaser beam welding apparatusFriction reductionOccupancy rate

The invention discloses a turbocharger sealing ring subjected to laser surface texturing and a machining method. After laser surface texturing, arc-shaped micro-concave cavities different in diameter and depth are formed in the left end face, the right end face and the inner circle surface of the turbocharger sealing ring and are distributed densely in a well-arranged manner. The machining method of the turbocharger sealing ring comprises the following steps that a surface fluid lubrication theoretical model of the turbocharger sealing ring is built to determine the diameters, depths and area occupancy rates of the arc-shaped micro-concave cavities in the left end face, the right end face and the inner circle surface with the optimal lubrication friction reduction effect through numerical calculation; and then a diode pumping Nd:YAG laser device is selected, under a laser machining graphic software interface, the geometrical parameters and distribution state of the arc-shaped micro-concave cavities are input, and laser surface texturing machining is carried out on the left end face, the right end face and the inner circle surface of the turbocharger sealing ring through a single pulse same-point interval repeated machining technology.

Owner:HUNAN TYEN MACHINERY

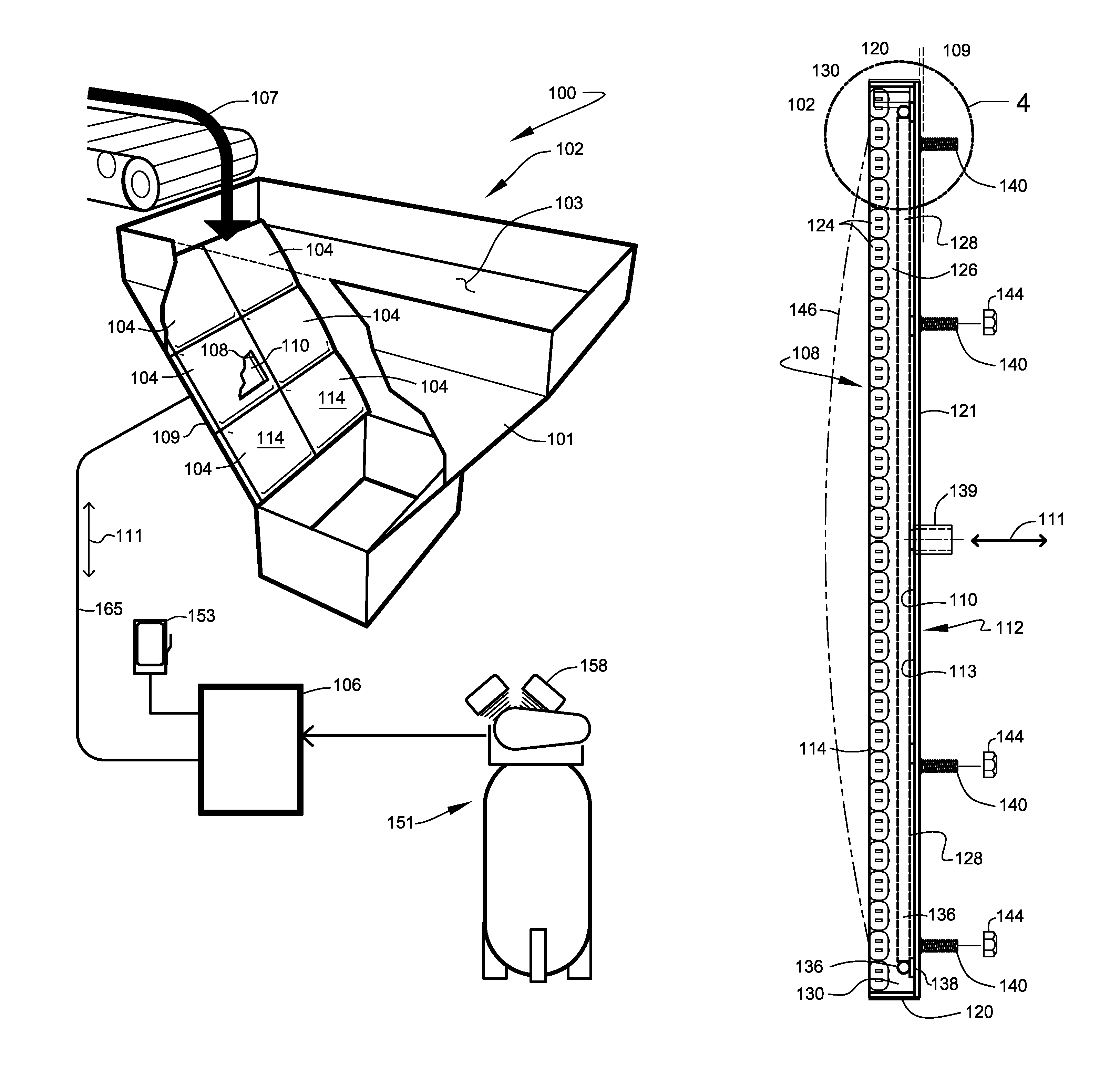

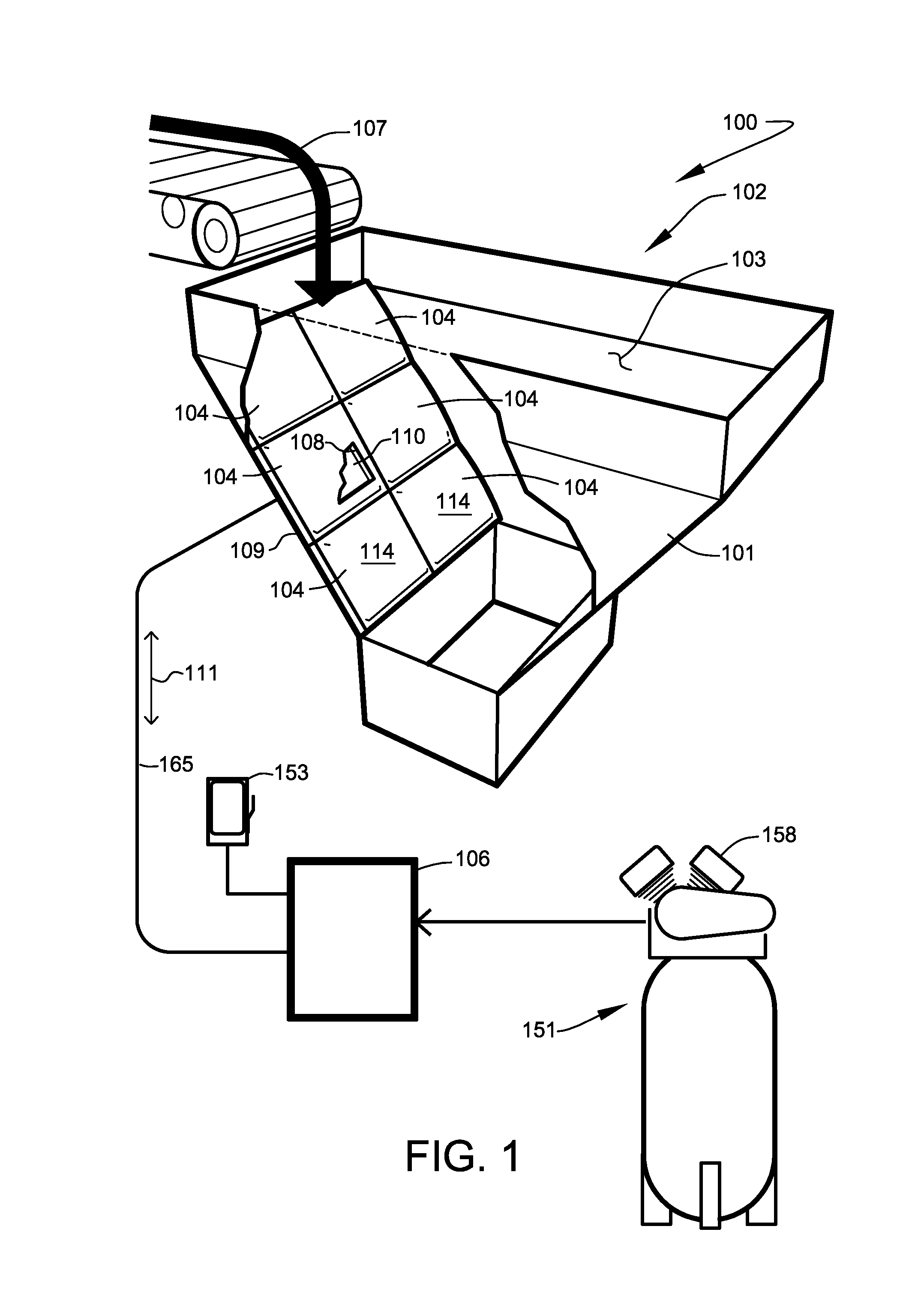

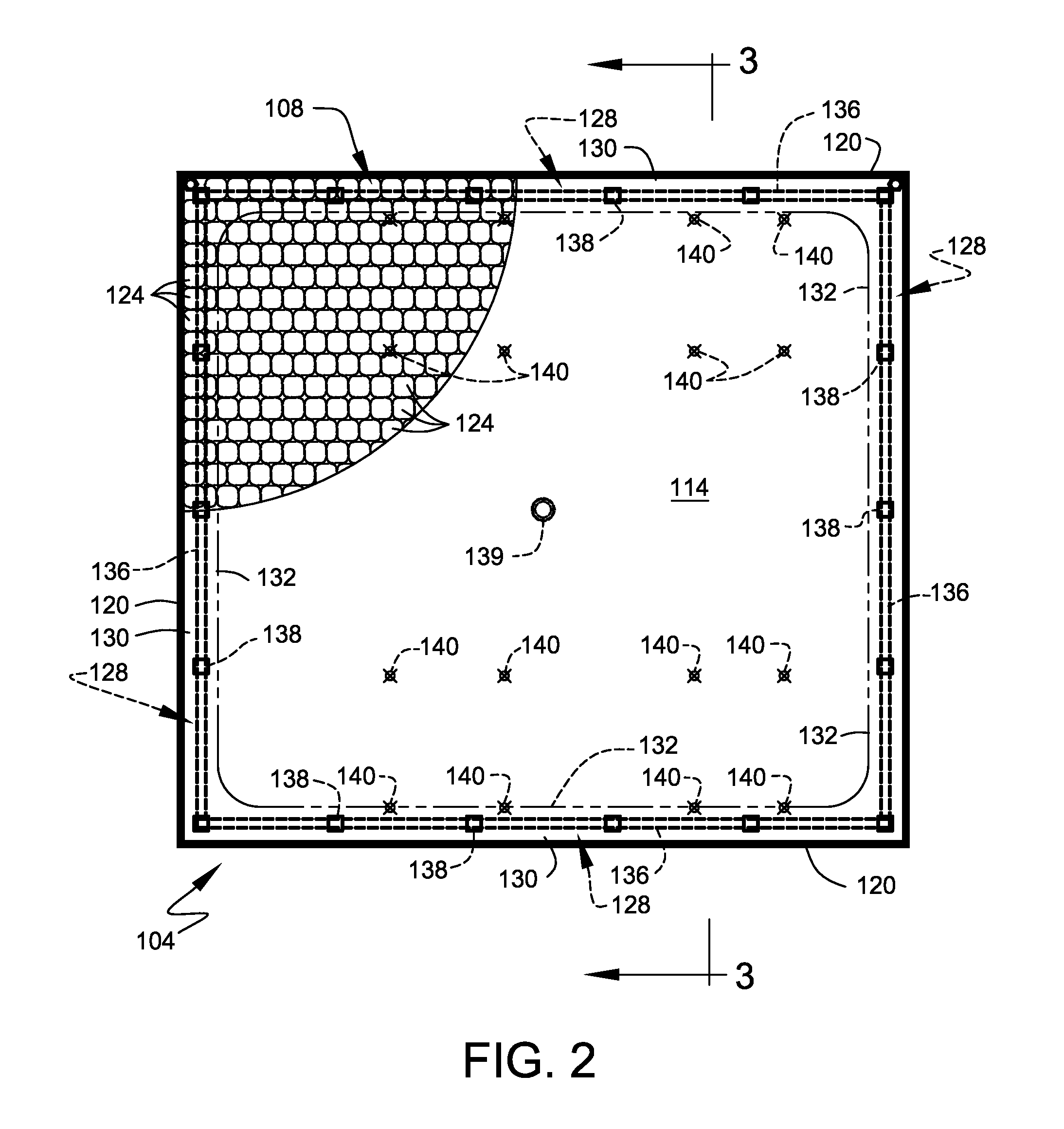

Inflatable liner systems

ActiveUS8616358B2Improves wear and durability and performance of wearReduce abrasive wearAircraft ejection meansLarge containersEngineering

Owner:CORROSION ENG

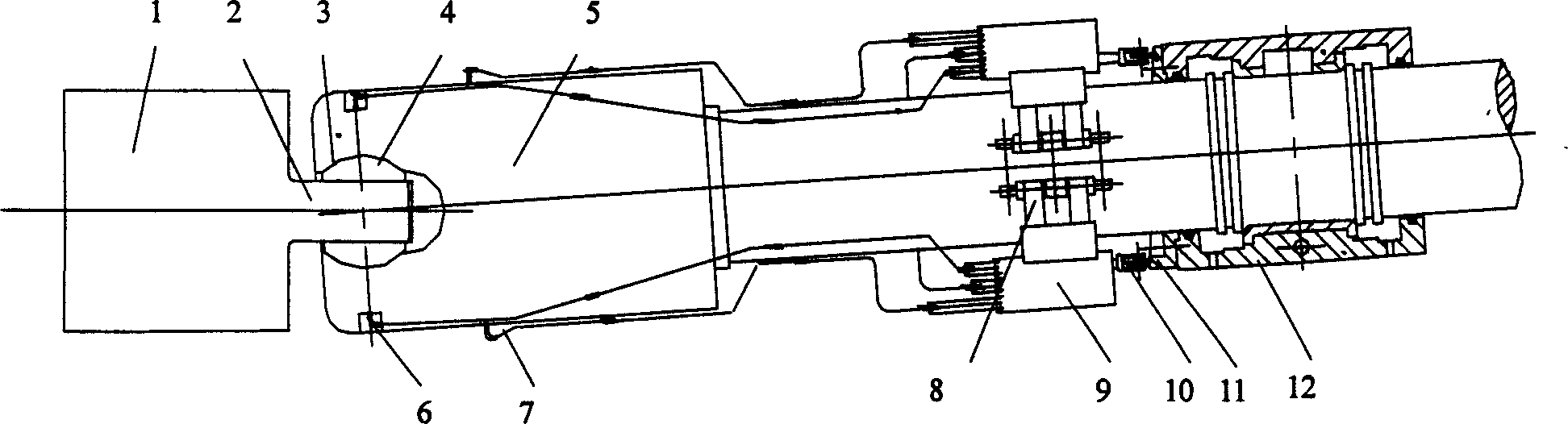

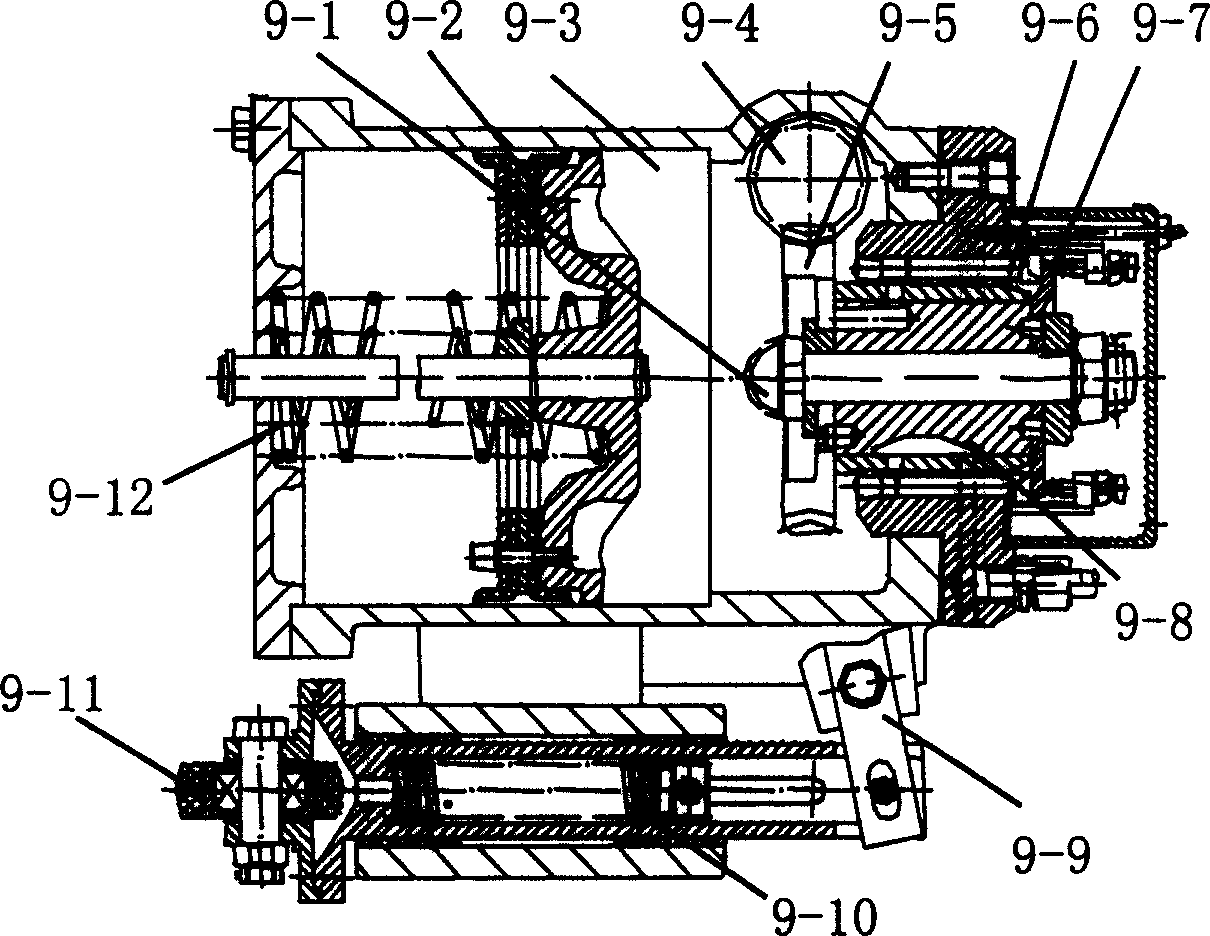

Slider type universal shaft automatic lubricating device

InactiveCN1546899ACompact structureEasy to adjustYielding couplingLubrication elementsUniversal jointEngineering

The invention is a kind of gliding block universal-joint spindle automatic lubricating device. The invention belongs to mechanical manufacturing field, especially refers to a kind of automatic lubricating device for middle board roller copper gliding block universal-joint. The device is made up of rollers, palm end, tiger's mouth, gliding block, universal-joint spindle, oil adding hole. The character lies in: there sets an automatic oil supplying device on the universal-joint spindle, the oil supplying device includes an oil pipe, a fixing clamp ring, a plunger pump, a plunger pump post rod, template, tile mold, the plunger pump is fixed with the universal-joint spindle with the fixing clamp ring, and rotates with the universal-joint spindle, from the plunger pump to the oil adding hole the invention uses copper oil pipe to connects them and fixes them on the universal-joint spindle. The template is fixed with the universal-joint spindle tile sides with screws. The structure is simple, and compact.

Owner:UNIV OF SCI & TECH BEIJING

Surface thermal treatment method of screw

InactiveCN103276350AHigh surface hardnessImprove wear resistanceSolid state diffusion coatingWater processingNitrogen gas

The invention relates to a surface thermal treatment method of a screw. The surface thermal treatment method comprises the following steps of: (1), carrying out degreasing, acid activating and deionized water-washing treatment onto a screw workpiece in sequence; (2), drying the screw pretreated in the step (2), and removing the residual water on the surface; (3), carrying out gas nitrogen-sulfur-chrome leakage treatment on the screw, placing the workpiece to an electric heating furnace with a gas mixture of gas complex of sulfur chrome and nitrogen gas to carry out nitrogen-sulfur-chrome leakage treatment; (4), carrying out sand blasting or shot blasting treatment on the screw workpiece, and removing a surface loose layer; (5), carrying out oxidation treatment on the screw workpiece, placing the workpiece to the electric heating furnace with liquid oxide salt, and immersing to oxide salt molten liquid; and (6), repeating the steps (3)-(5) by once or twice or more, forming a super-hard surface tissue on the surface of the wokpiece to complete the surface treatment of the screw workpiece. According to the surface thermal treatment method of the screw, a layer of nitrogen-sulfur-chrome-iron compound with a thickness of 15 microns-45 microns is formed on the surface of the screw, so that the surface hardness, the abrasion resistance and the corrosion resistance of the screw are improved.

Owner:FOSHAN HUAYAN LIHE SURFACE TECH

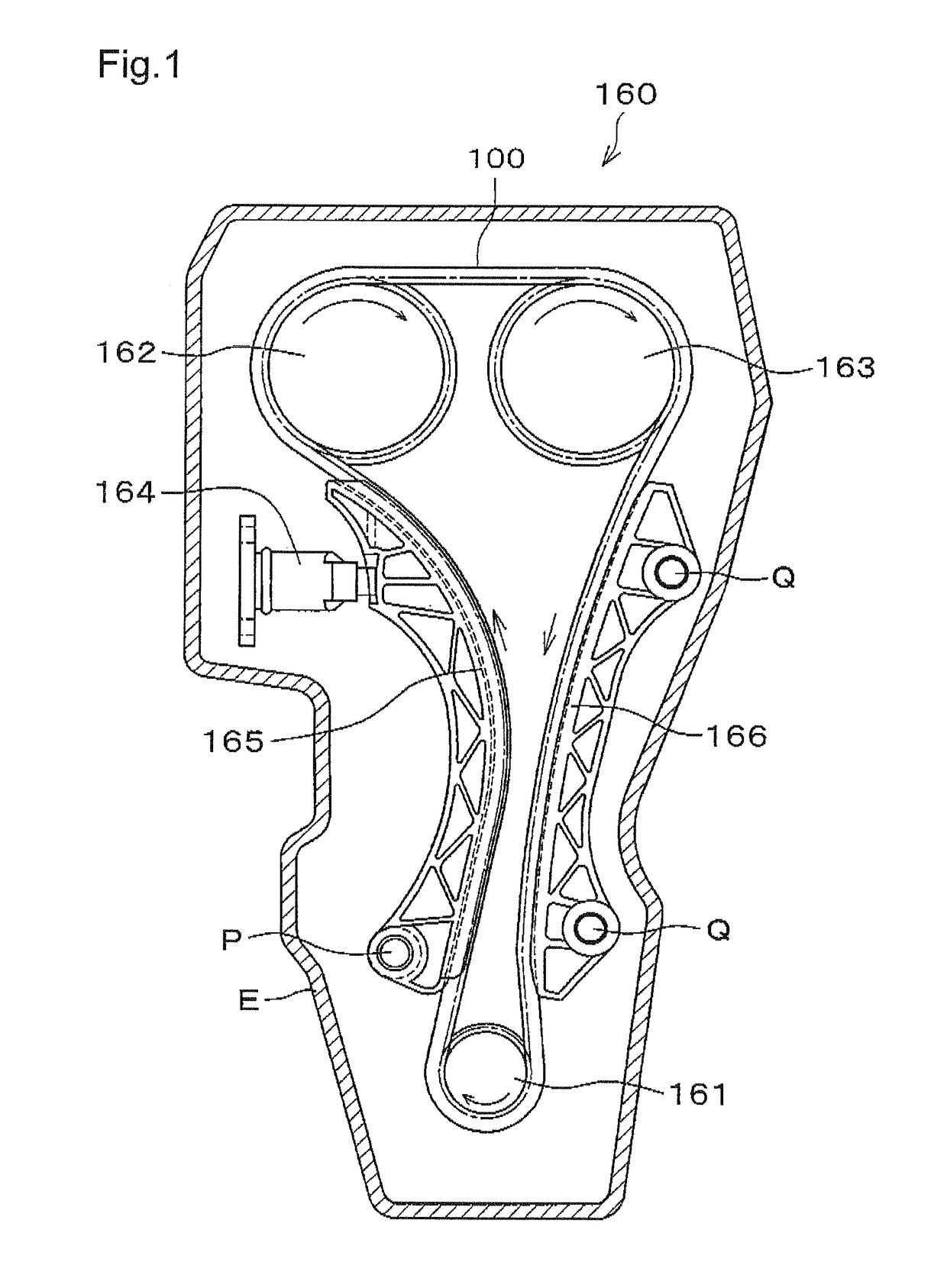

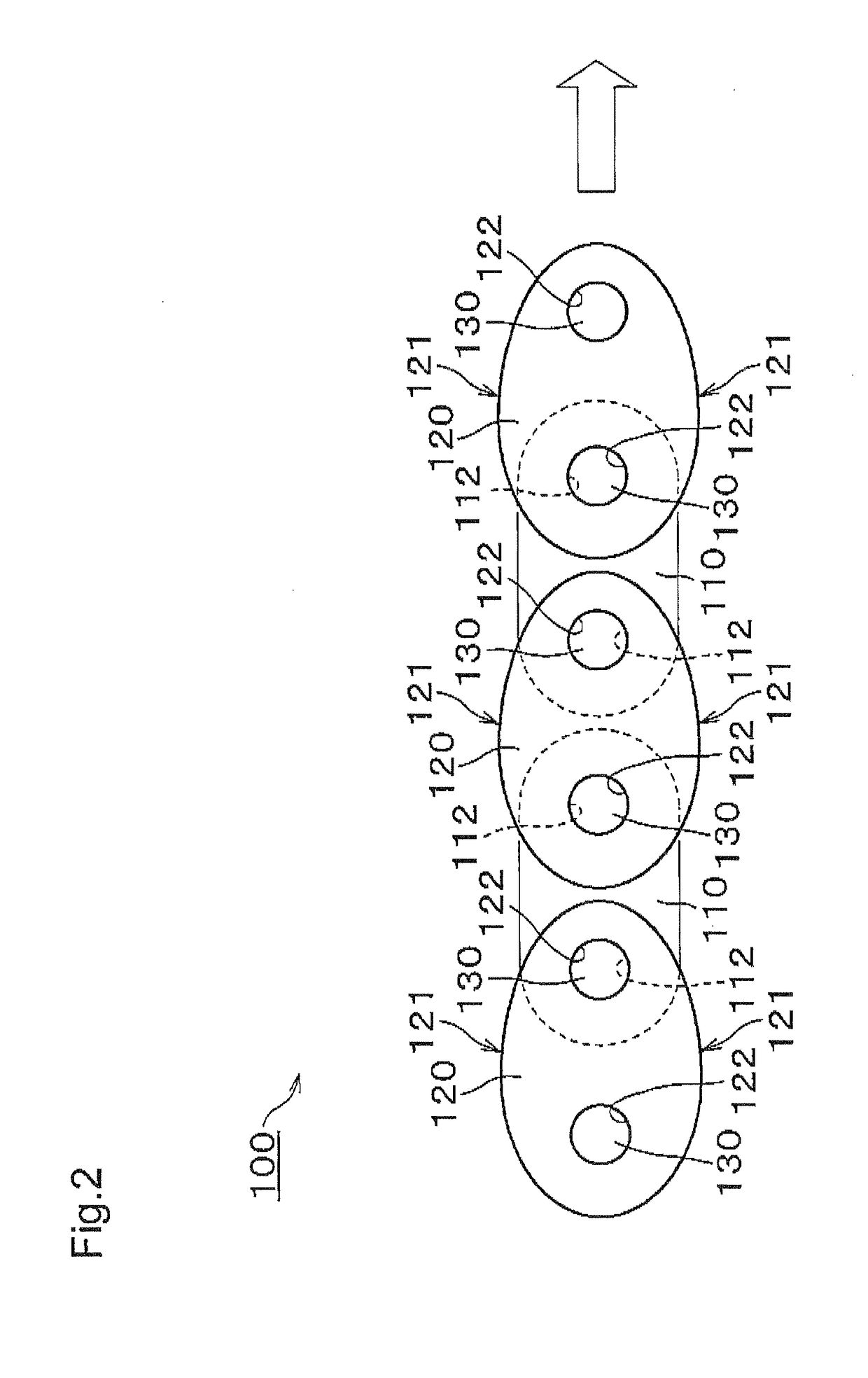

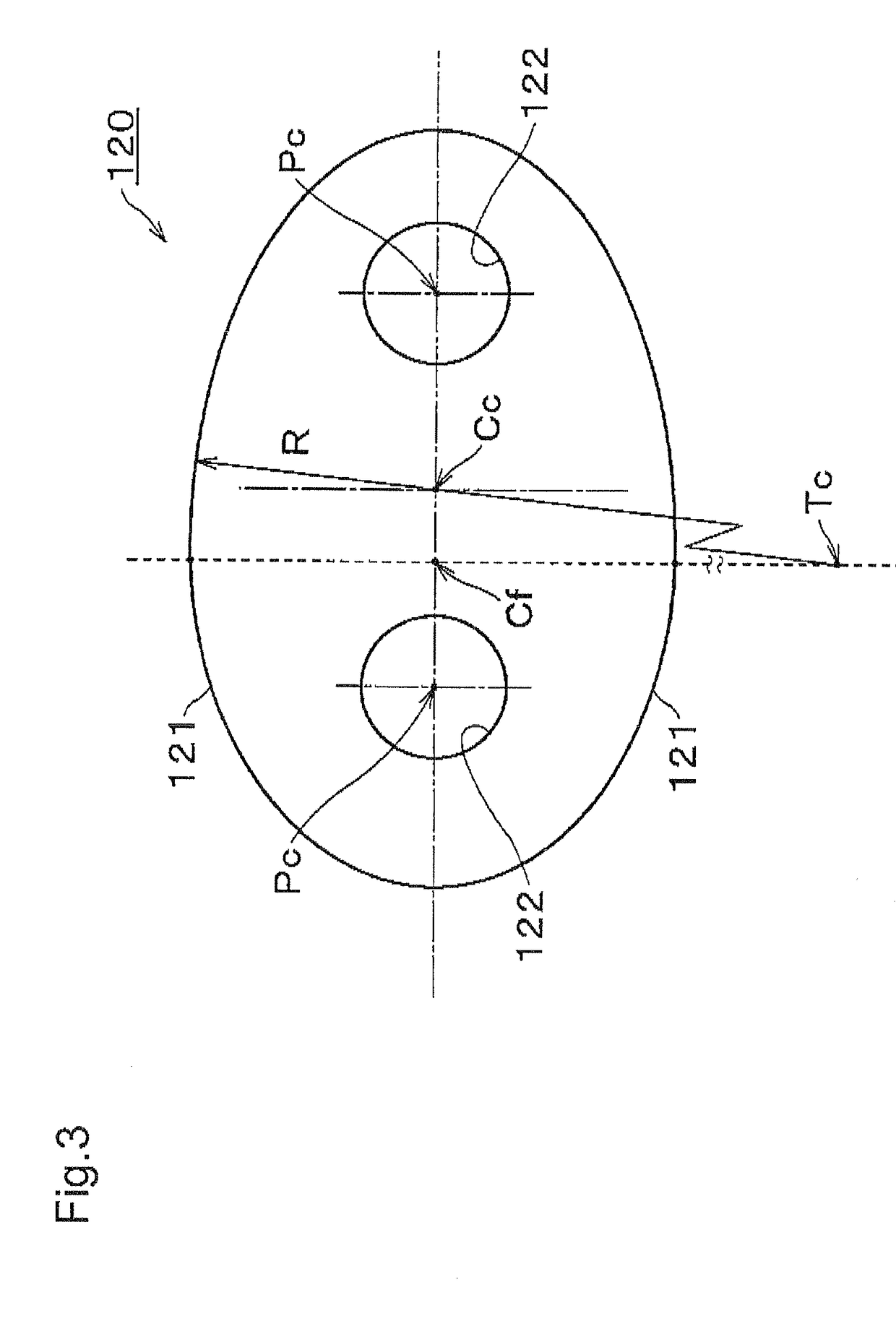

Chain

ActiveUS8469845B2Reduce contact areaReduce contact resistanceGearingDriving chainsEngineeringAbutment

In a transmission chain having link plates with convex edges for sliding contact with a guide surface, the plates are asymmetric in shape so that the distance from a line connecting the centers of the connecting holes and the convex edge is greatest at a position other than at the midpoint between the connecting holes. A pivoting action of the link plates takes place as they slide over a guide surface, changing the abutment point.

Owner:TSUBAKIMOTO CHAIN CO

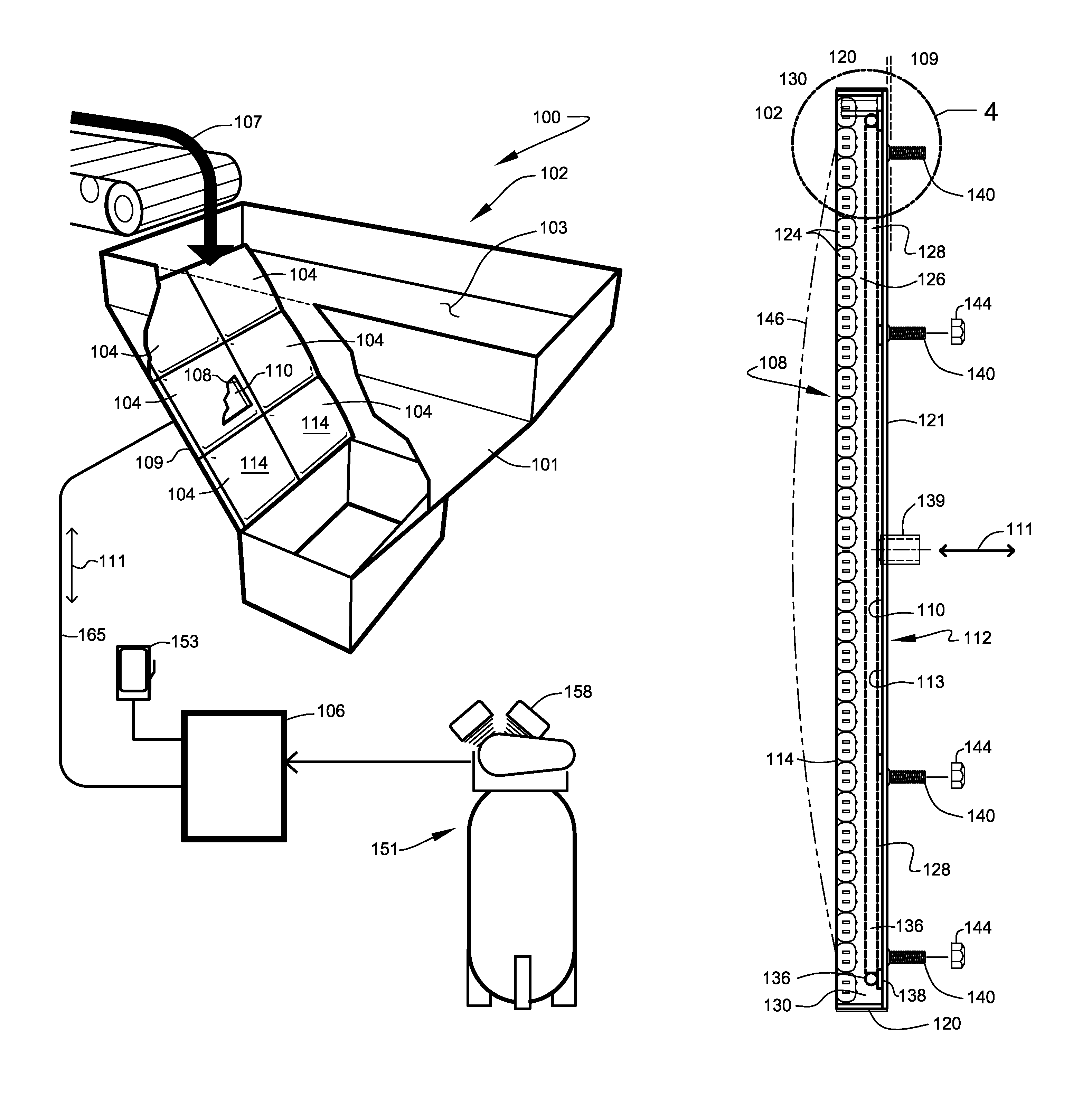

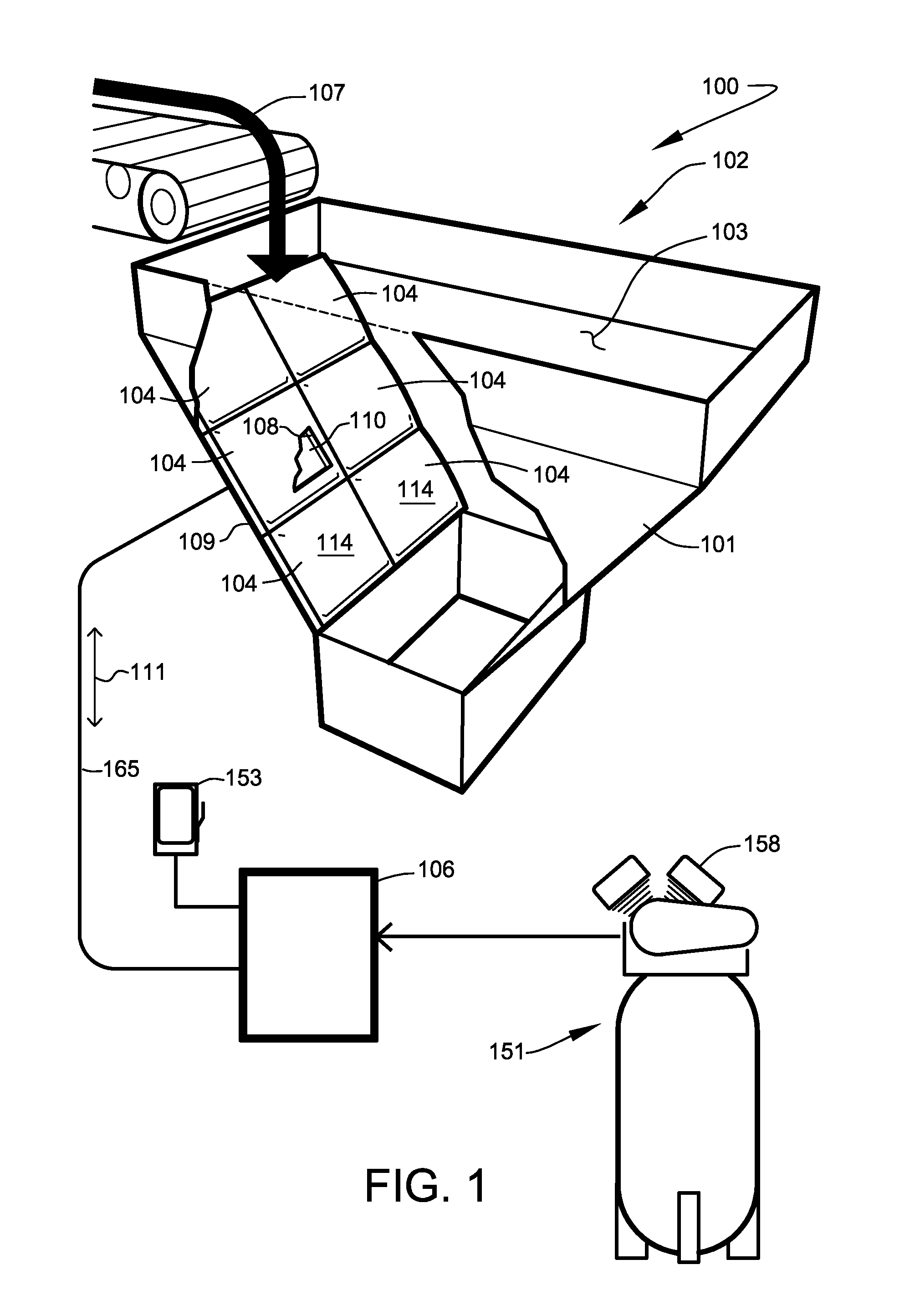

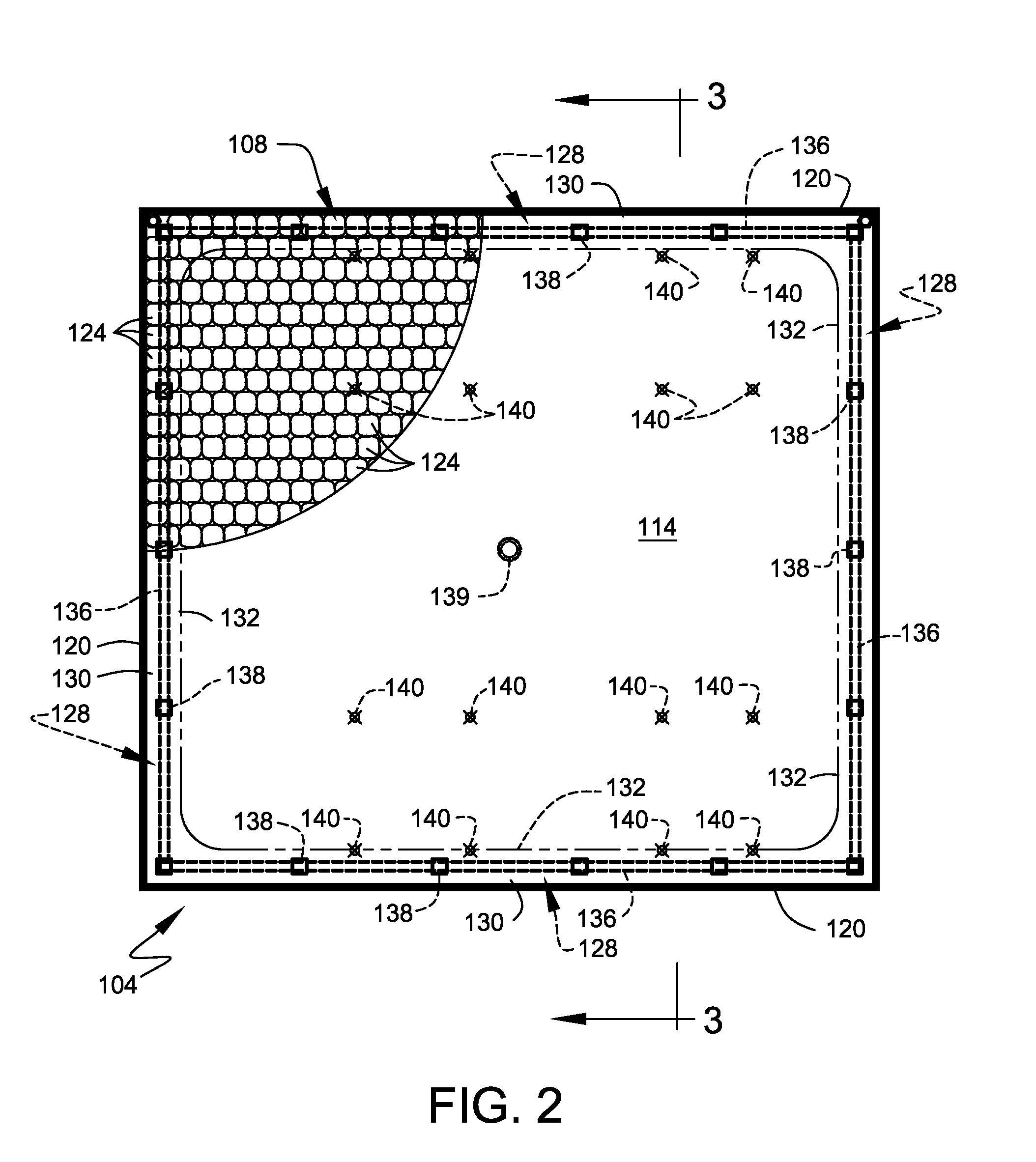

Inflatable liner systems

InactiveUS9038803B2Improves wear and durability and performance of wearReduce abrasive wearAircraft ejection meansLarge containersEngineering

An inflatable liner with vibratory function related to lining mining hoppers and other such devices. The inflatable liner has an exterior expandable layer and ceramic wear layer beneath that assists maintaining a long-use-life of the inflatable liner. Use of the air-control device to rapidly inflate and deflate exterior expandable layer vibrates in the exterior expandable layer and assist removing unwanted material / debris from the exterior lining of exterior expandable layer to further maintain a long-life use of the inflatable liner and lower maintenance of the machinery / hopper.

Owner:CORROSION ENG

Welding wire for submerged arc welding

ActiveUS8901455B2Reduce abrasive wearEliminate contaminationArc welding apparatusWelding/cutting media/materialsCopper contaminationLubricant

The copper cladding normally applied to the surfaces of a submerged arc welding wire for preventing weld gun contact tip abrasive wear is replaced with a solid lubricant. This eliminates copper contamination of the weld from the copper cladding while preserving the useful life of the contact tip.

Owner:LINCOLN GLOBAL INC

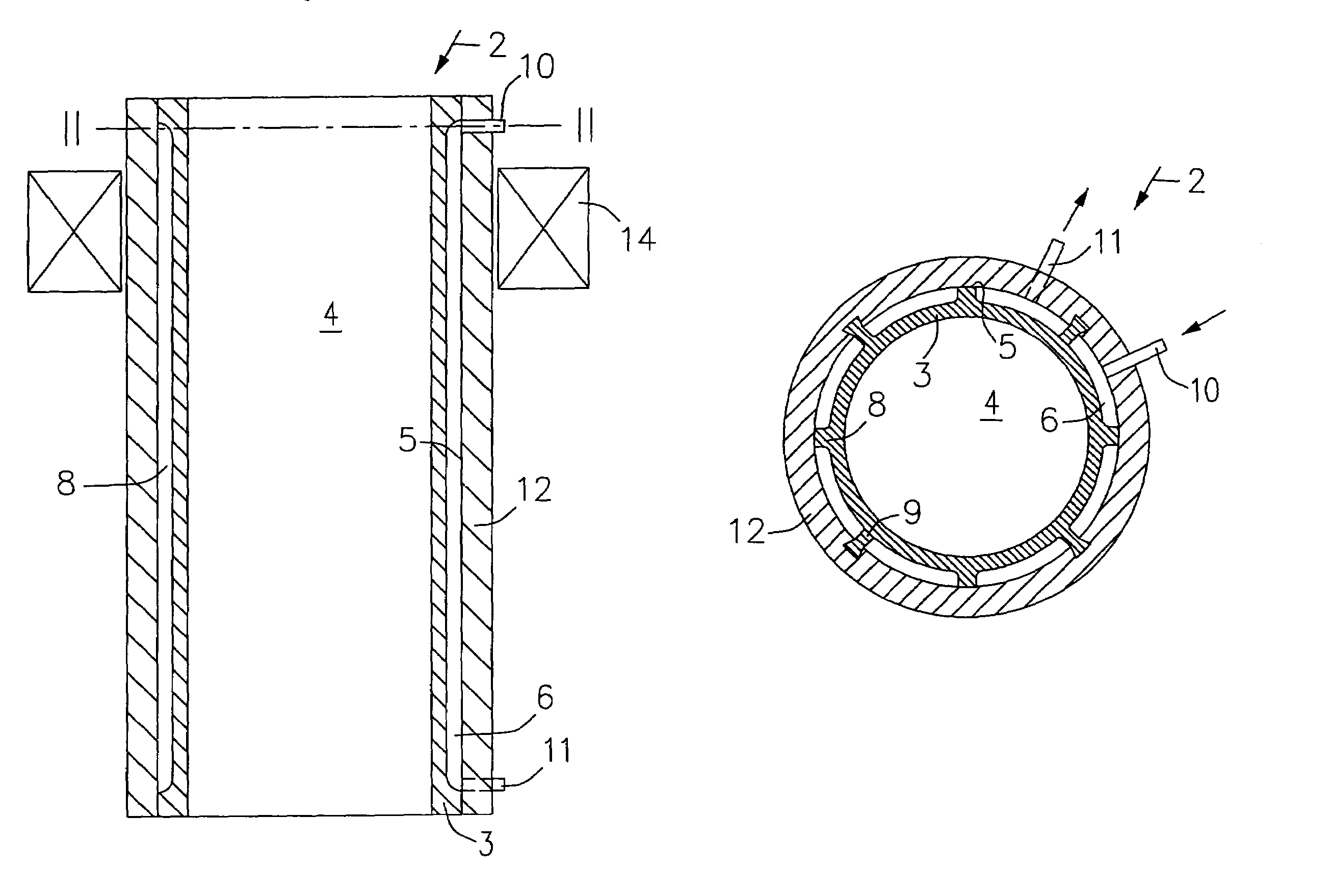

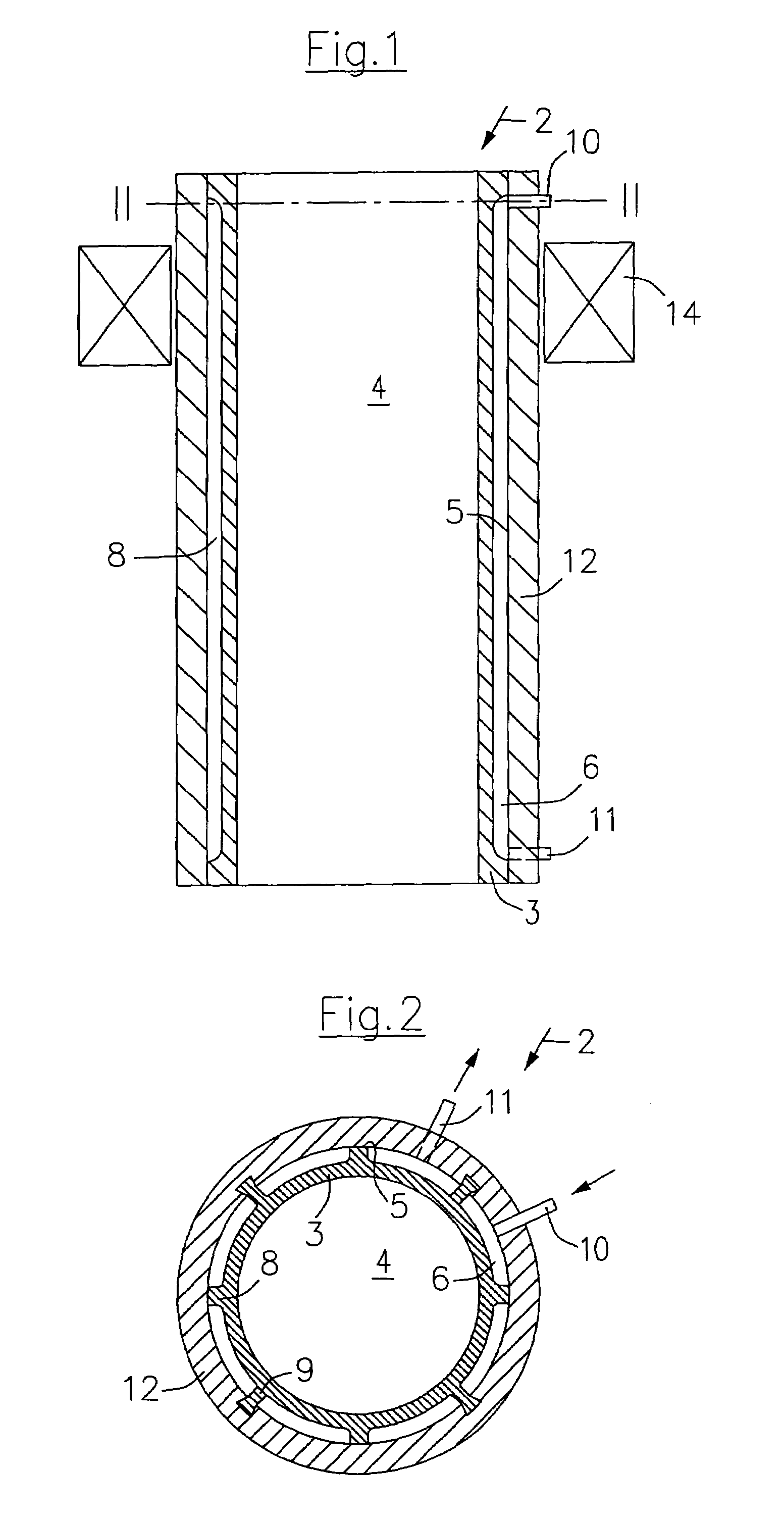

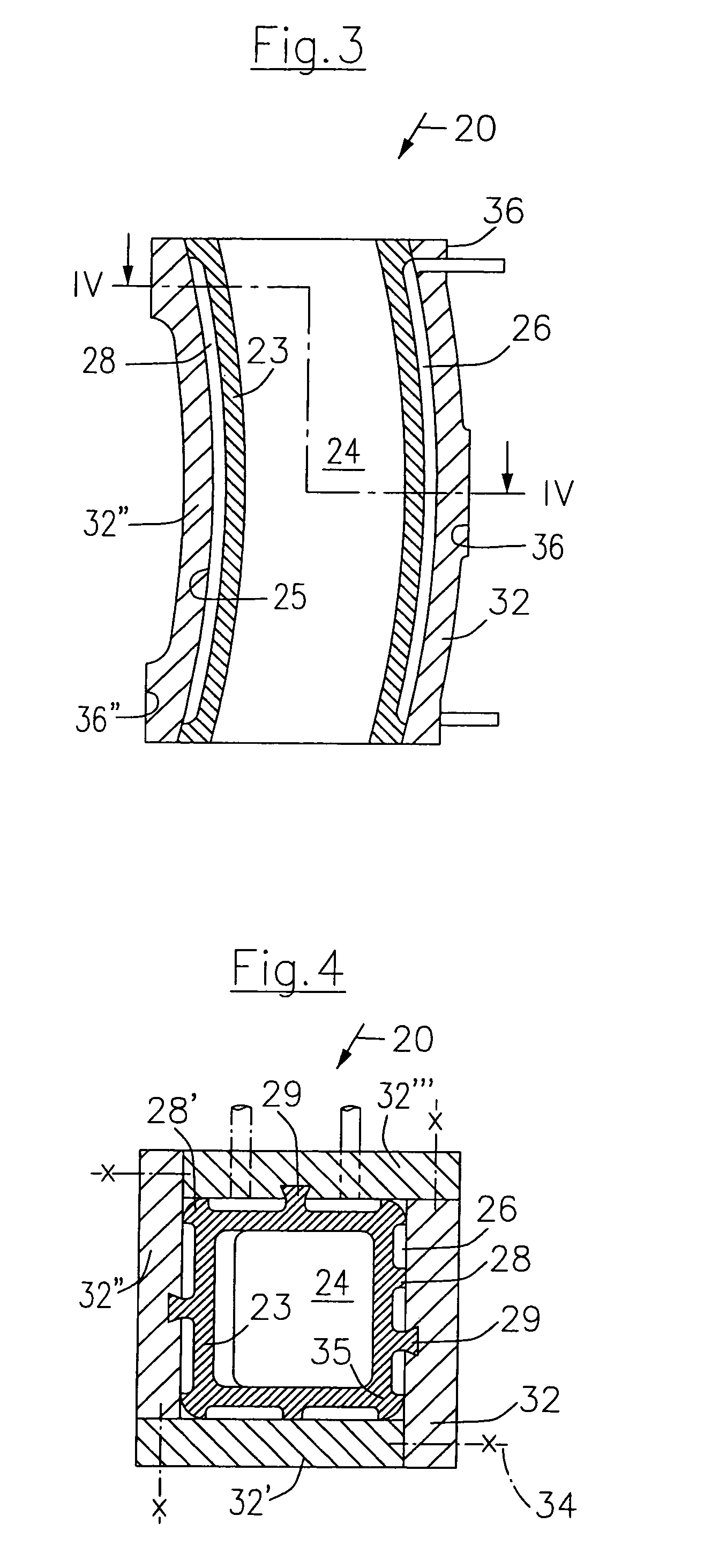

Tubular mould for continuous casting

ActiveUS7422049B2Prevent electrolytic corrosionGood dimensional stabilityPermanent magnetsElectromagnetsWater circulationCooling capacity

In the continuous casting of round or polygonal billet and bloom formats, use is made of moulds the mould cavity of which comprises a copper tube (3) which is intensively cooled by means of water-circulation cooling. In order to increase the cooling capacity on the one hand and the dimensional stability of the mould cavity (4) on the other hand, and also extend the total service life of the copper tube (3), it is proposed to provide the copper tube (3) with a supporting shell (12) or supporting plates over the entire circumference at the tube outer lateral surface (5). For the cooling of the copper tube (3), cooling ducts (6) for guiding the cooling water are arranged on the copper tube (3) or on the supporting shell (12). The cooling ducts (6) are distributed over the entire circumference at the tube outer lateral surface (5) and extend substantially over the entire mould length.

Owner:CONCAST AG

Device for continuous filtration of material blends

InactiveUS7124895B2Improve device stabilityReduce abrasive wearDough homogenizationFrozen sweetsMotor driveFiltration

A device for the continuous filtration of material blends, in particular for separating impurities from plastic melts. A housing has a hollow cylindrical filter disposed inside. An inside chamber is disposed inside the filter. An annular chamber is defined by the outer surface of the filter and an inside wall of the housing. A cleaning device removes the impurities retained on the filter by a motor driving about an axis coupled to pivot the filter inside the housing. The cleaning device has at least one wiper for removing in the radial direction impurities retained on the filter. A conveying device transports off the impurities removed from the filter by the wiper. The motor-driven filter and the conveying device are driven separately of each other.

Owner:ETTLINGER KUNSTSTOFFMANSCHINEN GMBH

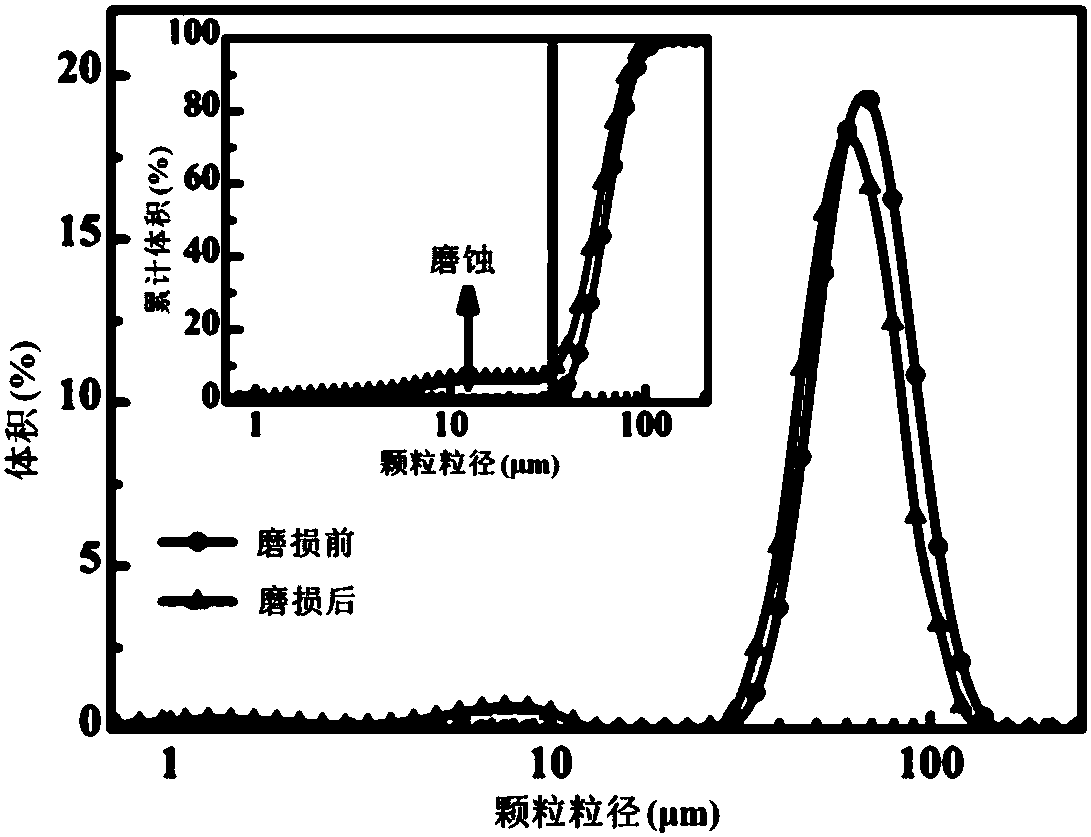

Nickel/aluminum oxide catalyst microsphere and preparation method thereof

InactiveCN108339548AReduce abrasive wearExtended use timeHydrocarbon from carbon oxidesCatalystsMethanationMicrosphere

The invention provides a nickel / aluminum oxide catalyst microsphere and a preparation method thereof. The method comprises the steps that a nickel source, an addition agent raw material and an aluminum source solution are mixed, then a sodium silicate or tetraethyl orthosilicate solution is added as a silicon source, a precipitant is added for adjusting the pH, and a coprecipitation reaction is conducted to obtain a precipitate; the precipitate is subjected to a hydrothermal reaction, and after the reaction is completed, the precipitate is washed and dried to obtain a catalyst precursor; the solid content of precursor slurry is adjusted, then spraying granulation is conducted, and after calcination, the Ni / Al2O3 catalyst microsphere is obtained. The Ni / Al2O3 catalyst microsphere with highwear resistance is obtained, abrasion and loss of a catalyst in the high-temperature high-pressure methanation process of a fluidized bed can be reduced, the production cost is lowered, the catalyticactivity and stability of the catalyst are improved at the same time, and the yield of methane is increased. The catalyst has the advantages that the treatment amount is high, the catalyst is quicklyformed, the reaction process is simple and easy to control, and the catalyst has good application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com