Slider type universal shaft automatic lubricating device

A universal joint shaft, automatic lubrication technology, applied in the direction of engine lubrication, lubricating parts, couplings, etc., can solve the problem of the protection cover oil supply and roller replacement and inspection of the shaft connection, increase the workload of the protection sleeve, pressure spray Large oil investment and other problems, to achieve the effect of low fuel consumption, simple and compact structure, and adjustable oil volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

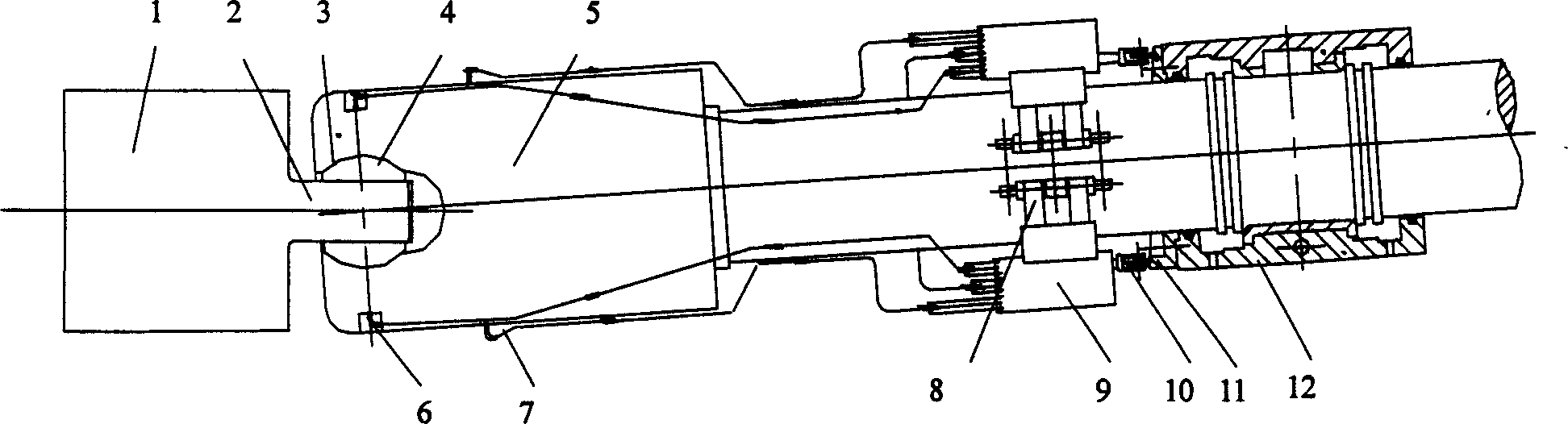

[0027] A slider type universal joint shaft automatic lubricating device, which is composed of a roll 1, a flat head 2, a tiger mouth 3, a slider 4, a universal joint shaft 5, and an oil filling hole 6, and an automatic lubrication device is designed on the universal joint shaft 5 Oil device, the oil supply device includes oil pipe 7, fixed snap ring 8, plunger pump 9, plunger pump ejector rod 10, template 11, balance support plate template 12, when connecting, plunger pump 9 is connected with fixed snap ring 8 and ten thousand It is fixed to the joint shaft 5 and rotates together with the universal joint shaft. From the plunger pump 9 to the oil filling hole 6, it is connected with the copper oil pipe 7 and then fixed on the universal joint shaft. The screw is fixed.

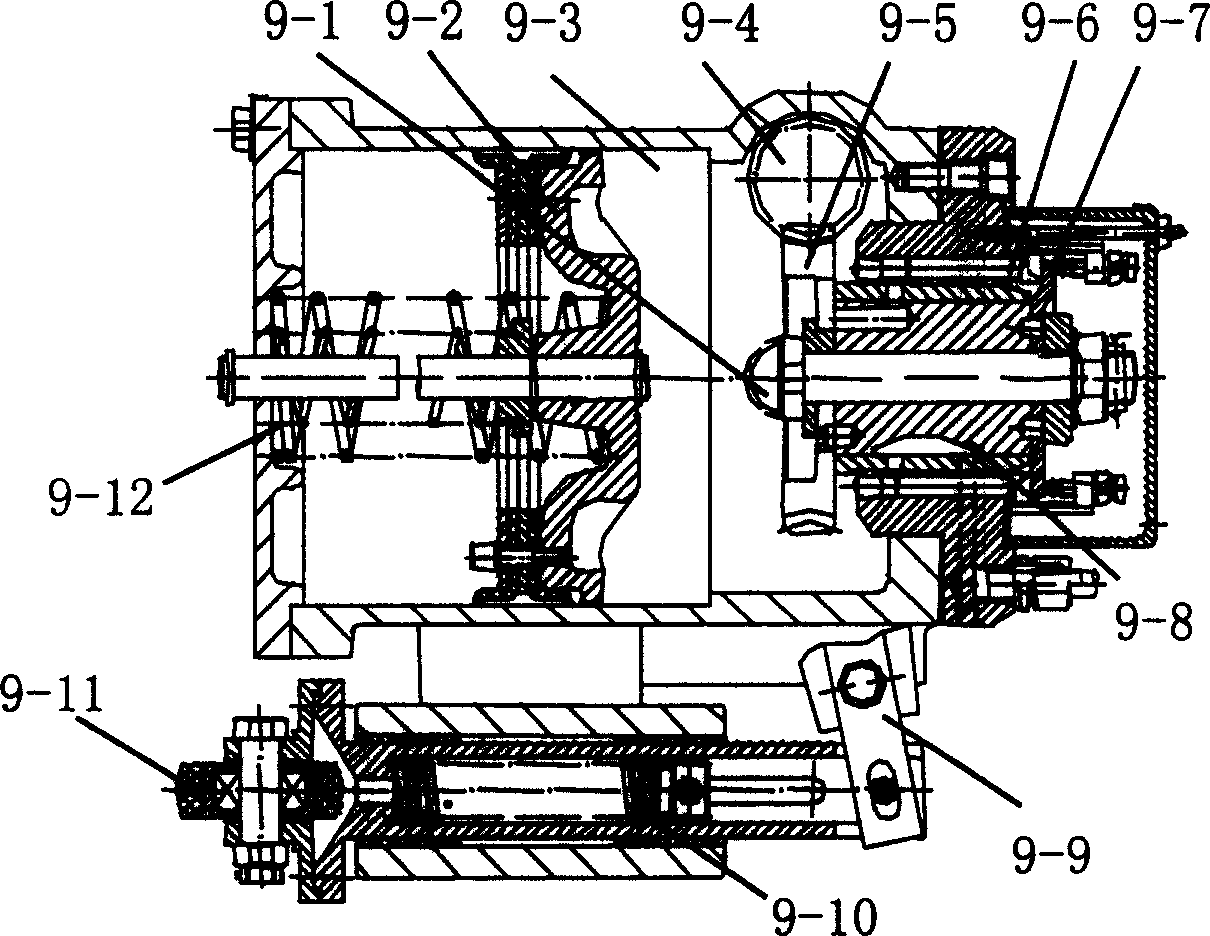

[0028] Piston pump 9 as figure 2 Shown, by filling hole 9-1, piston 9-2, oil storage cavity 9-3, worm rod 9-4, turbine 9-5, plunger 9-6, convex plate 9-7, cock 9-8, Rocking bar 9-9, return spring 9-10, roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com