Patents

Literature

997 results about "Dental prosthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A dental prosthesis is an intraoral (inside the mouth) prosthesis used to restore (reconstruct) intraoral defects such as missing teeth, missing parts of teeth, and missing soft or hard structures of the jaw and palate. Prosthodontics is the dental specialty that focuses on dental prostheses. Such prostheses are used to rehabilitate mastication (chewing), improve aesthetics, and aid speech. A dental prosthesis may be held in place by connecting to teeth or dental implants, by suction, or by being held passively by surrounding muscles. Like other types of prostheses, they can either be fixed permanently or removable; fixed prosthodontics and removable dentures are made in many variations. Permanently fixed dental prostheses use dental adhesive or screws, to attach to teeth or dental implants. Removal prostheses may use friction against parallel hard surfaces and undercuts of adjacent teeth or dental implants, suction using the mucous retention (with or without aid from denture adhesives), and by exploiting the surrounding muscles and anatomical contours of the jaw to passively hold in place.

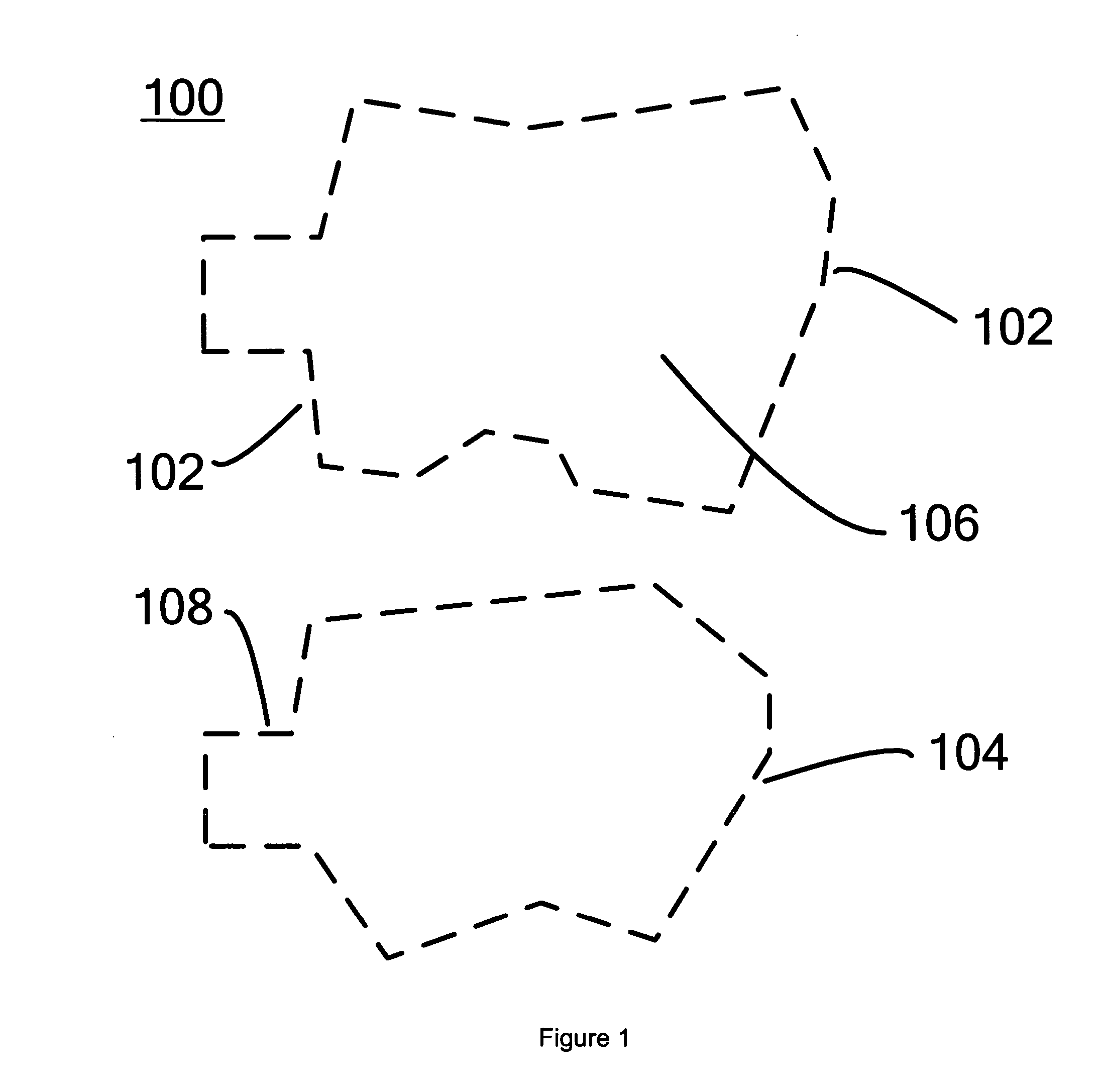

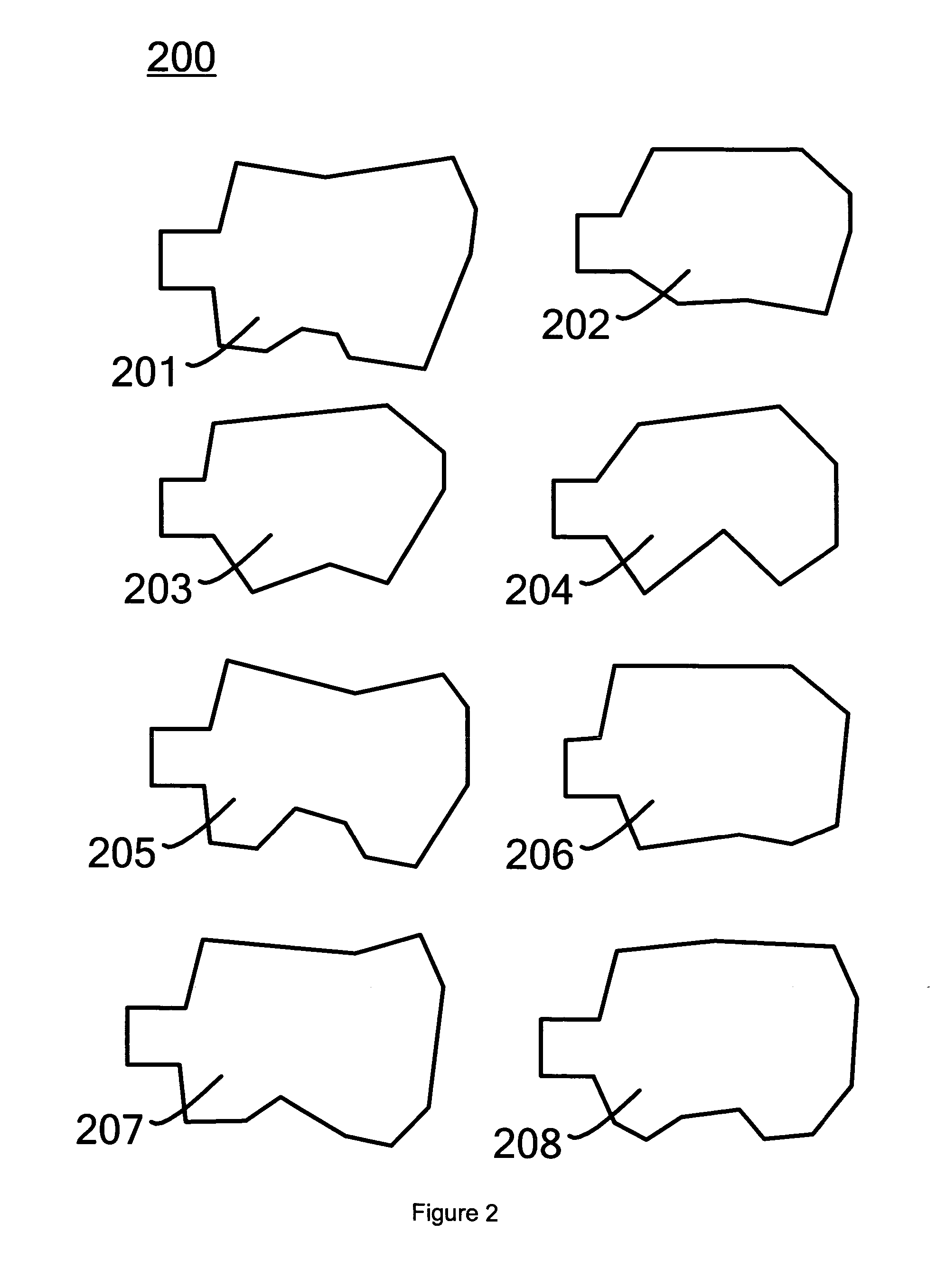

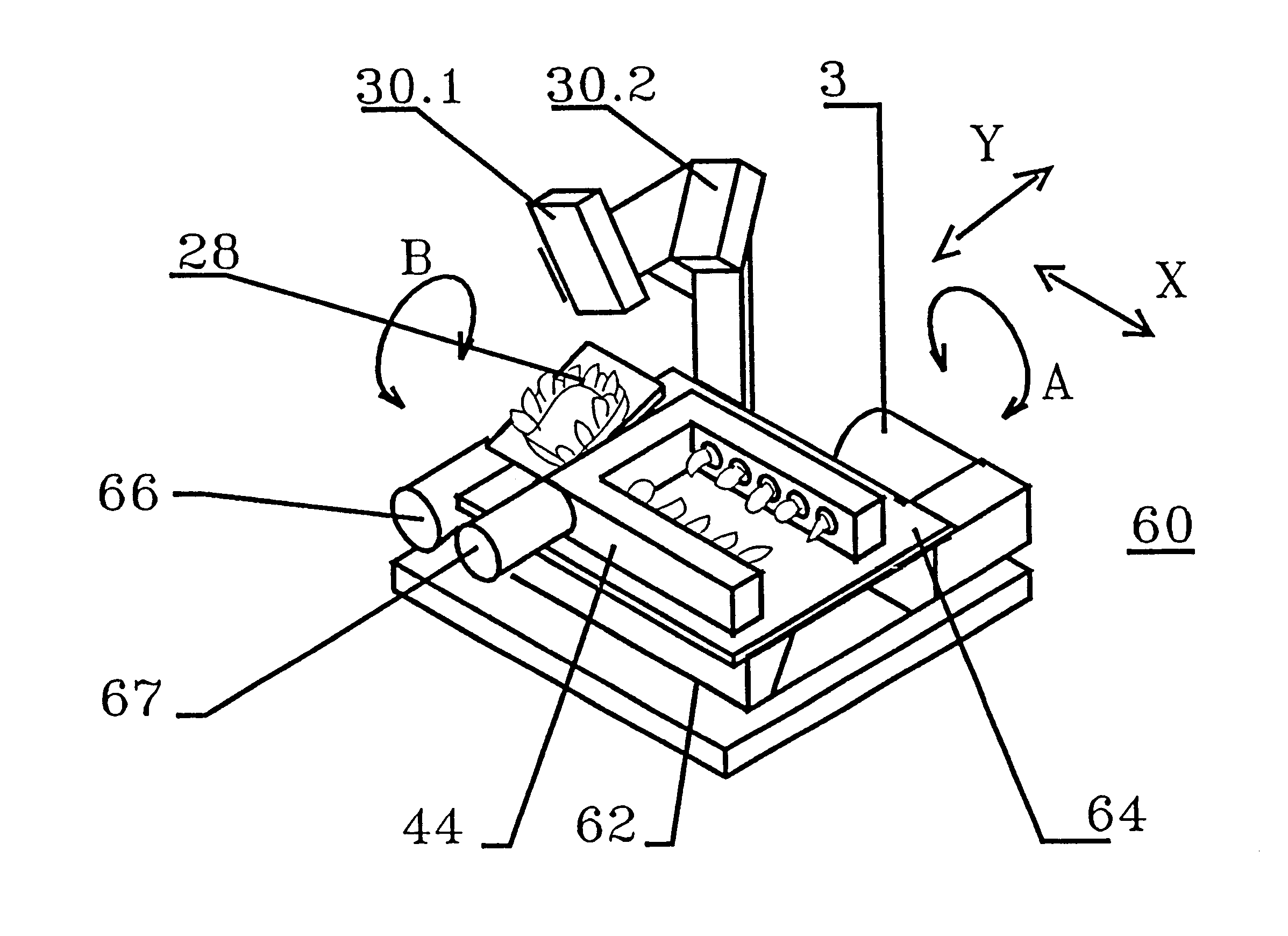

Mill blank library and computer-implemented method for efficient selection of blanks to satisfy given criteria

ActiveUS20050008887A1Easy to manufactureReduce material wasteDental implantsPerson identificationEngineeringInventory management

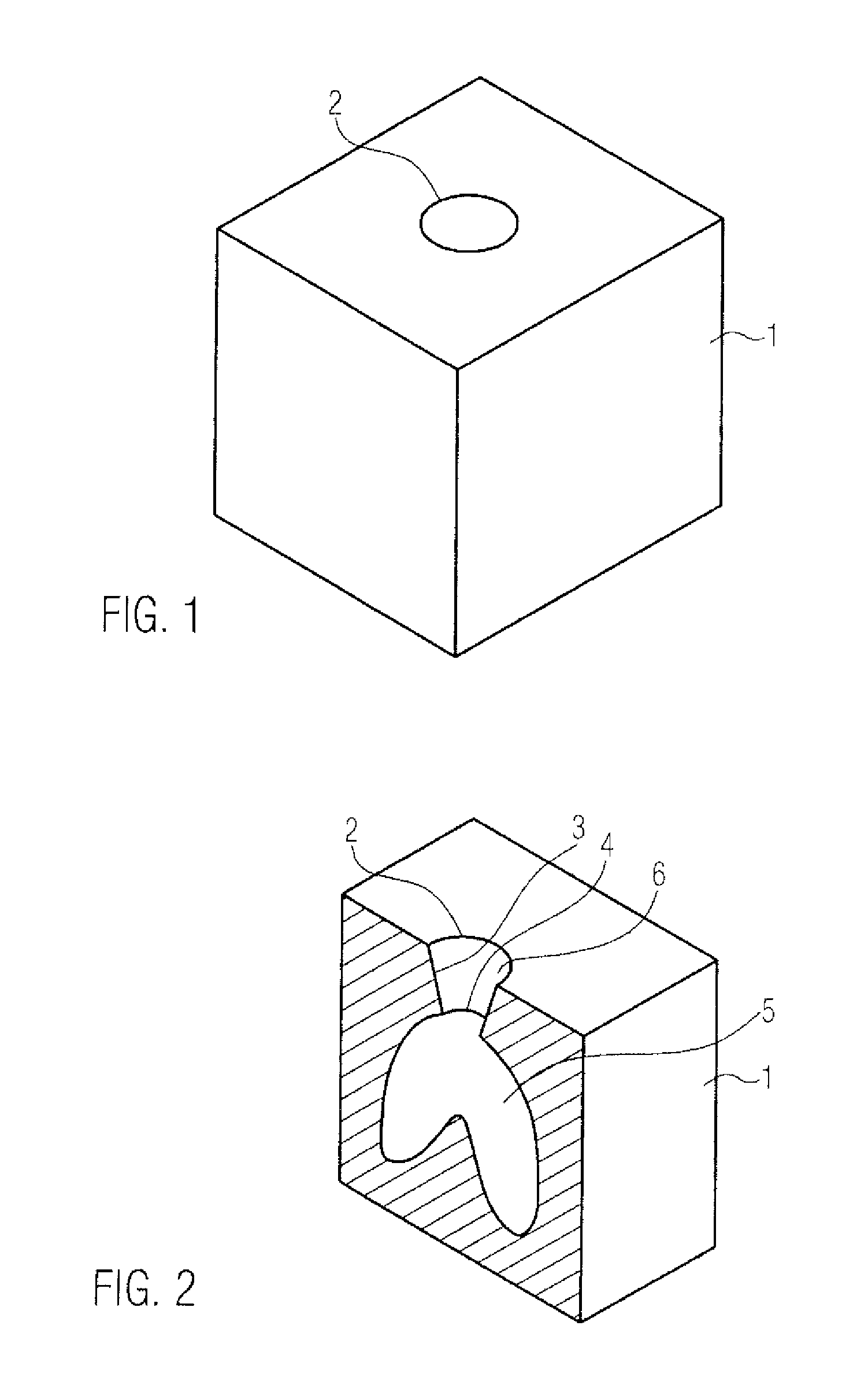

The present invention relates generally to mill blank constructions to facilitate the manufacture of dental restorations. A given mill blank is formed in a shape (i.e. with a given geometry) that has been predetermined to reduce material waste when the mill blank is machined into the final part. A set of two or more blanks each having such characteristics comprise a smart blank “library.” In one embodiment, a smart blank library includes a sufficient number of unique blanks such that, when the geometry of the designed restoration is known, the smart blank with a highest yield can be selected for use in milling the restoration. The “yield” of a given smart blank represents the amount of material of the smart blank that is actually used in the final restoration. Automated processes for smart blank inventory management and smart blank selection are also described.

Owner:D4D TECH LP

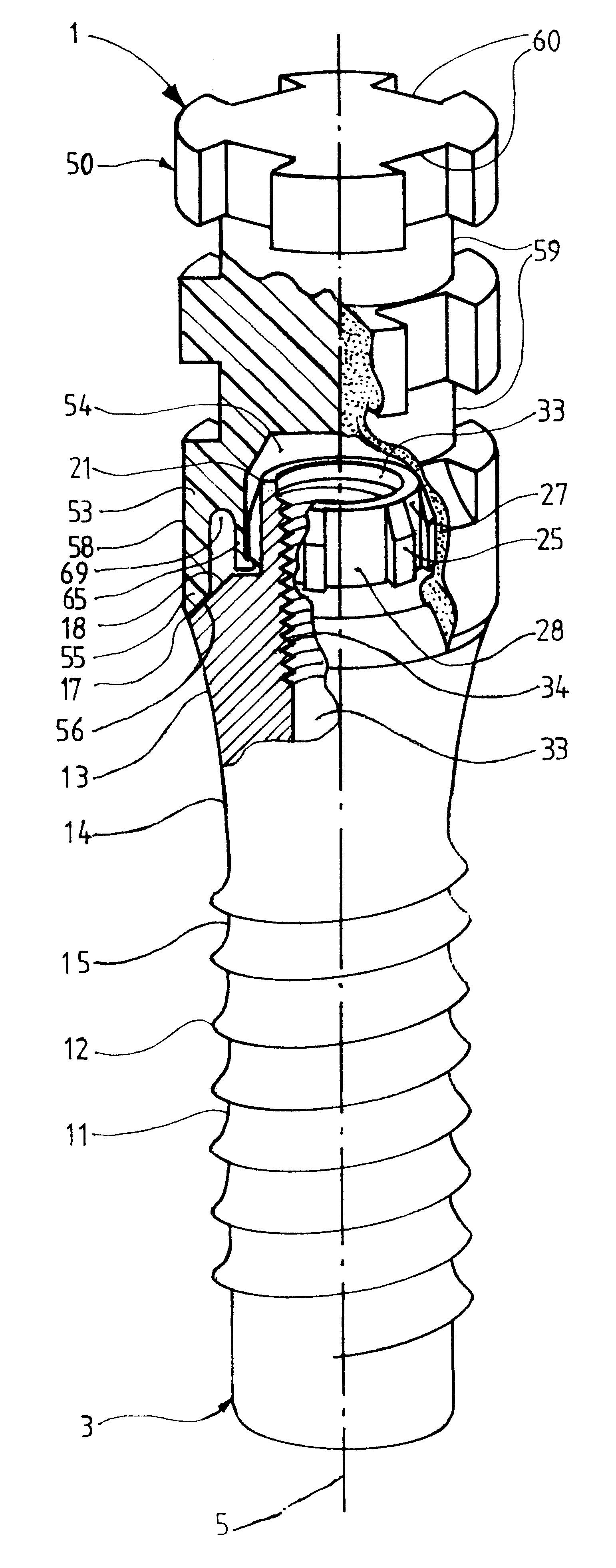

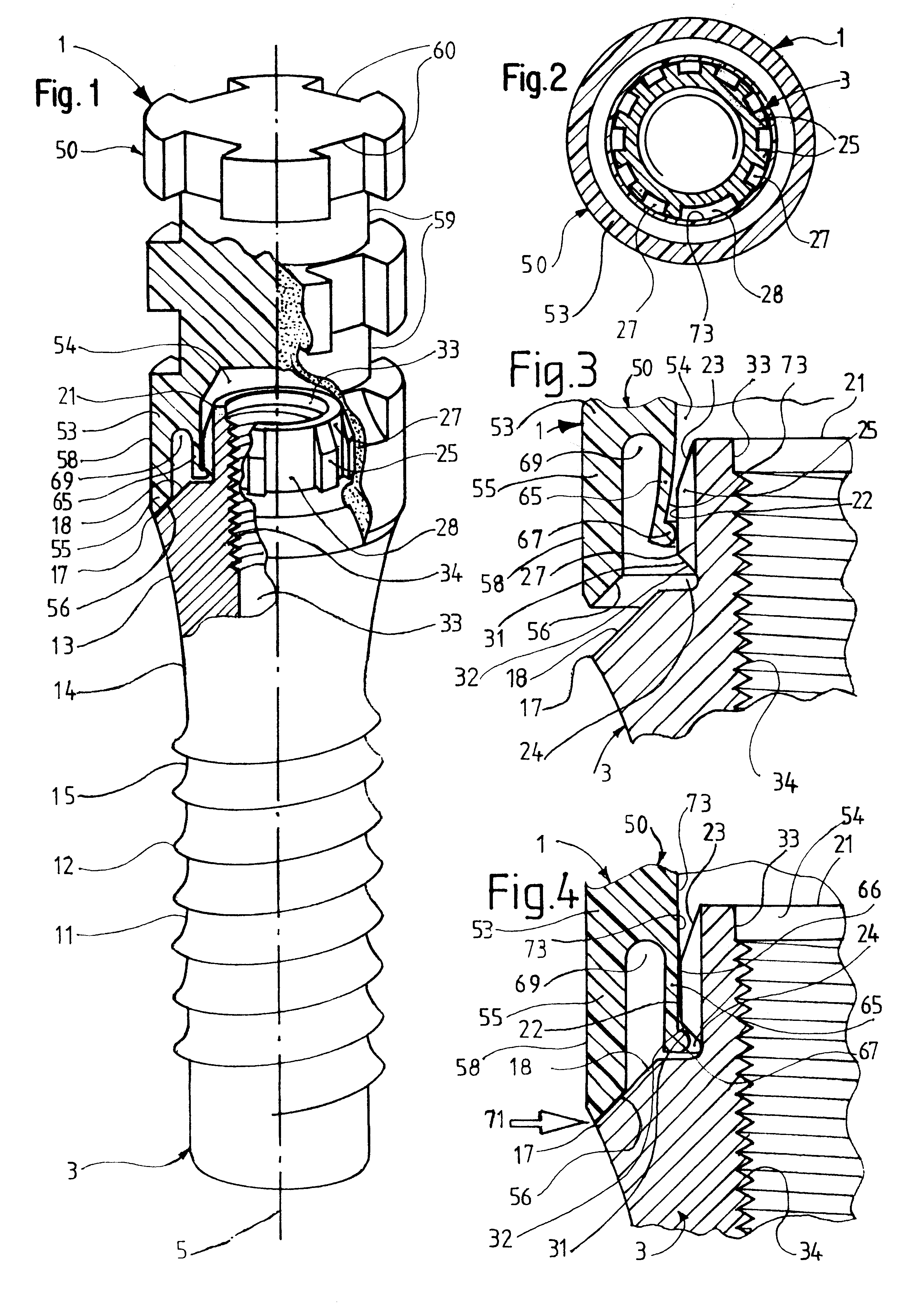

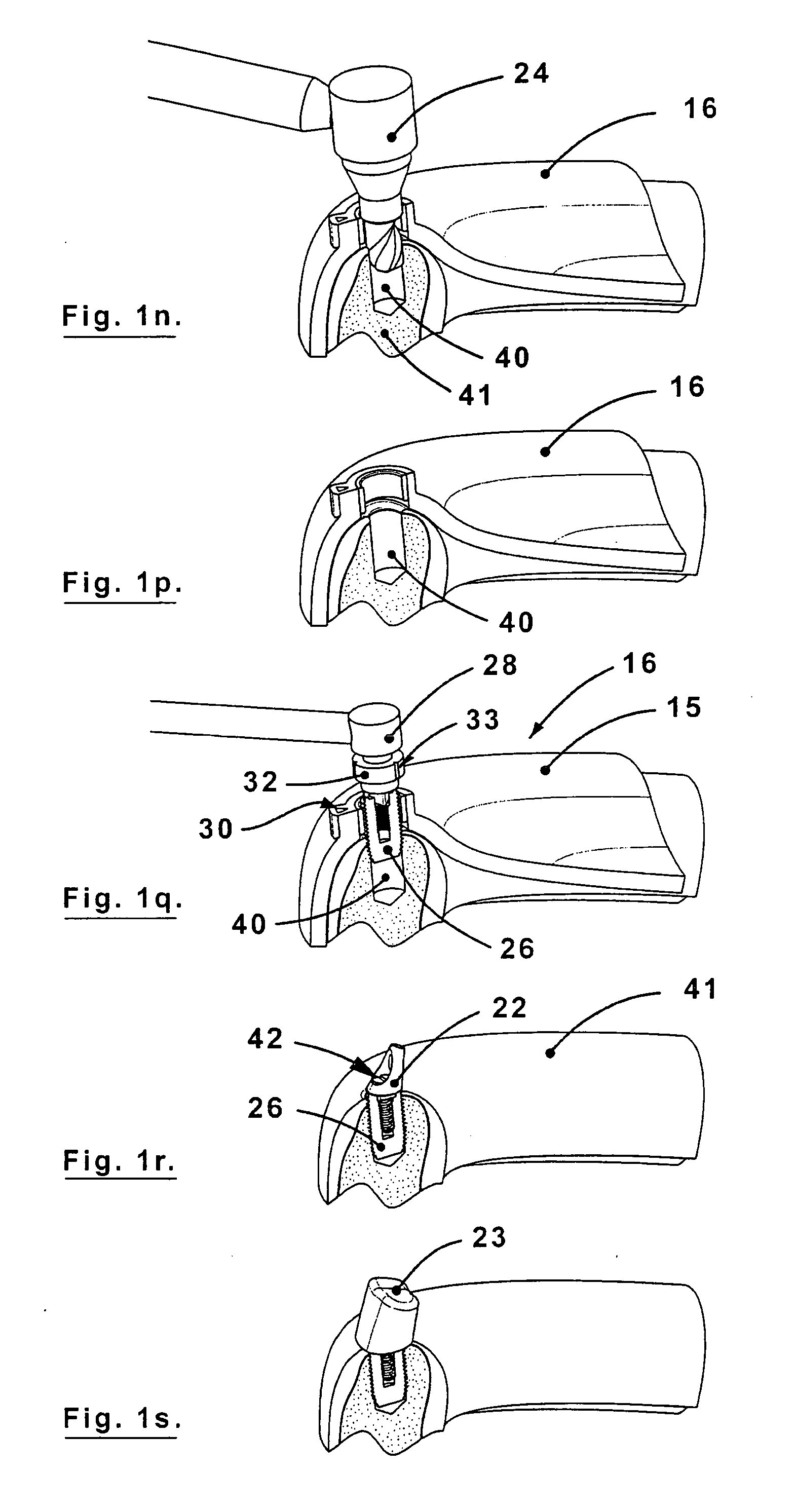

Device for forming a dental prosthesis

InactiveUS6332777B1Quick releaseOvercome the influence of errorDental implantsImpression capsEngineeringShoulder surface

A device for forming a dental prosthesis includes a support and an element which can be attached thereto, such as an impression element. The support has an anchoring part for anchoring in a bone or a master model, a shoulder with an annular shoulder surface, and a head. The impression element has an elastically deformable fixing agent. When the device is assembled, the fixing agent jams and / or latches with the support, either externally on the support, on the side of the shoulder facing the anchoring part, or in an axial hole of the support. The element can be quickly detachably connected to the support by placing it on top of the support, and can be quickly separated from the support by moving the support away. When the device is assembled, the support and the element can lay on top of each other with annular surfaces. The annular surfaces have fully circular outer edges which are visible from the outside in an approximately radial viewing direction.

Owner:STRAUMANN HLDG AG +1

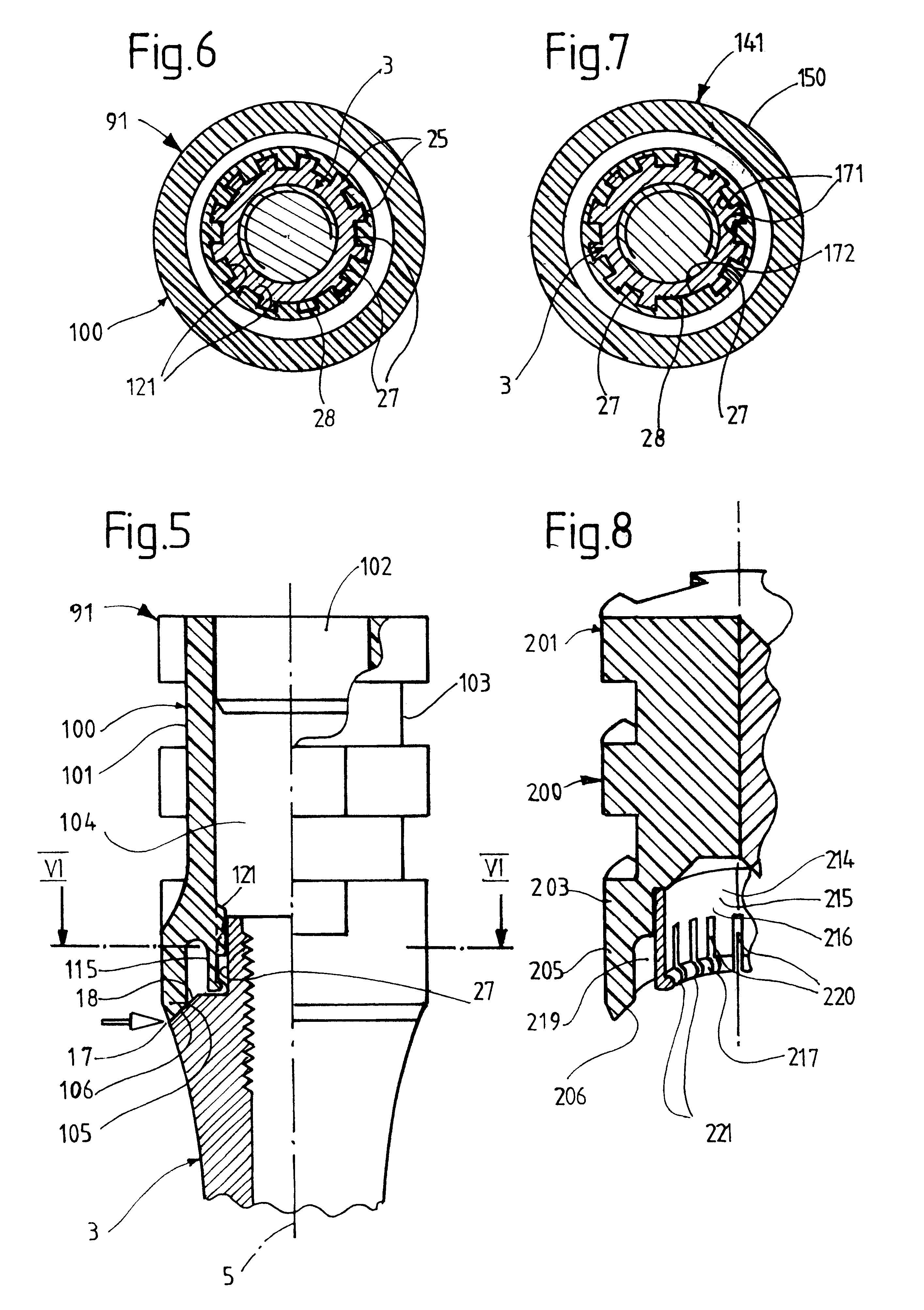

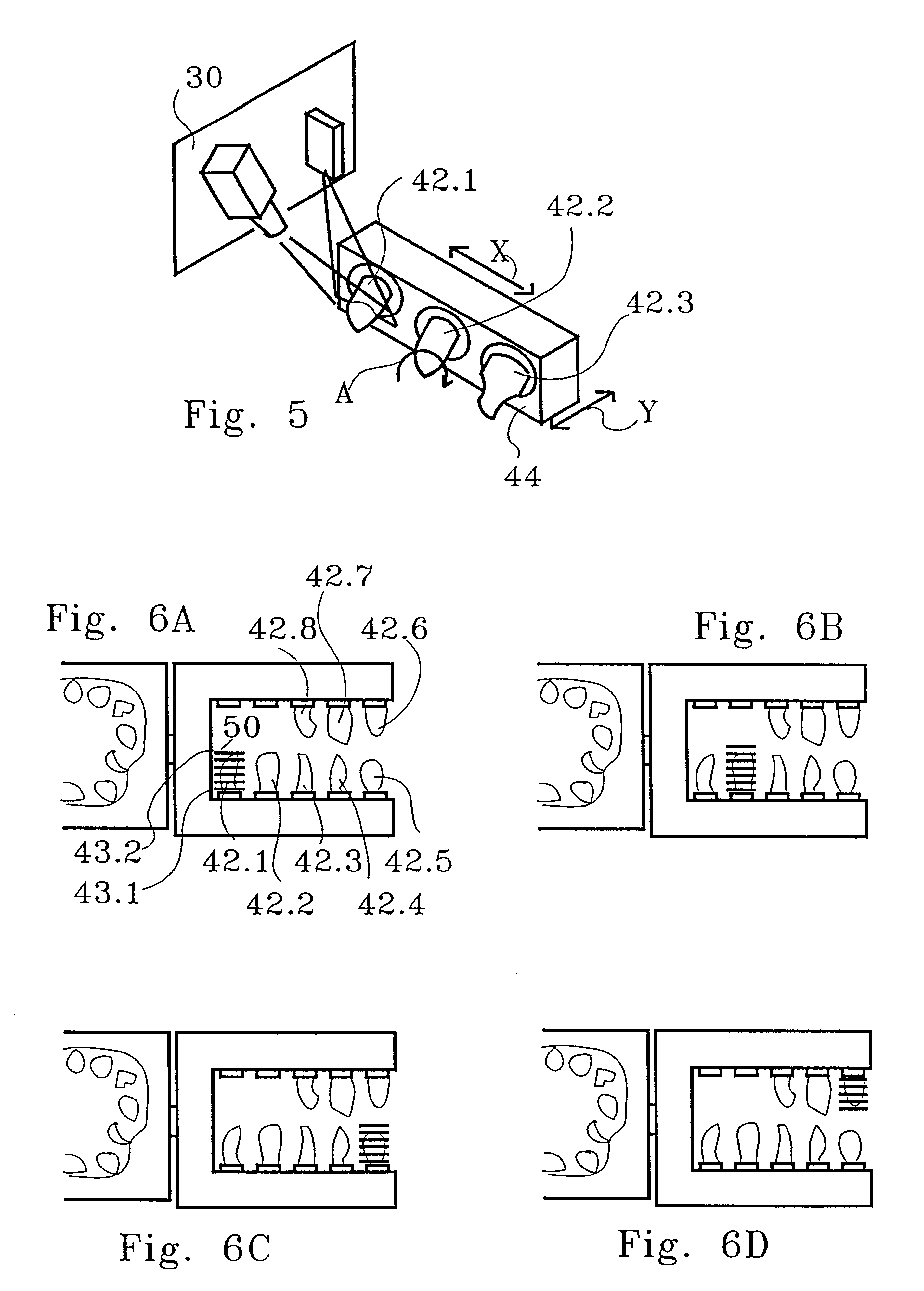

Material for a dental prosthesis, method and device for determining the shape of a remaining tooth area to be provided with a dental prosthesis, method and arrangement for producing a dental prosthesis and use of the arrangement

InactiveUS6287121B1Improve accuracySuitable for processingImpression capsTooth crownsDigital dataGlass fiber

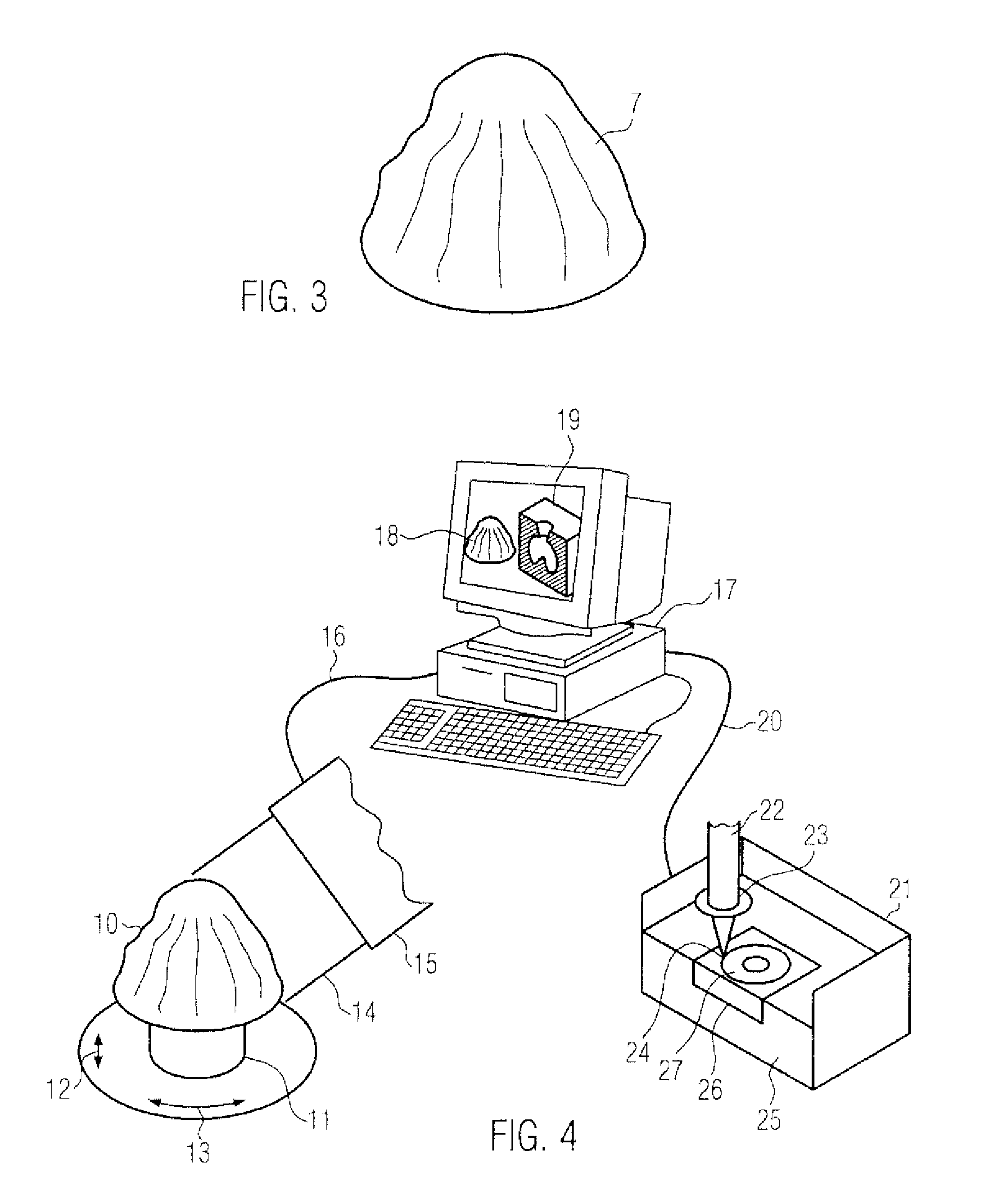

Material for a dental prosthesis consisting of fiber glass reinforced plastic. The material is used to produce a blank by means of a special injection-molding process, which can be worked by means of a machining process. A method and a device for determining the shape of a duplicate of a remaining tooth area to be provided with a dental prosthesis. The shape of the duplicate is determined, as is the shape of duplicate sections into which the duplicate has been divided, the determined data are stored and combined. A method and arrangement for producing a dental prosthesis. The shape of a duplicate (42) of a remaining tooth area to be provided with the dental prosthesis is determined by means of a shape determination device (110), the determined data are stored in the form of digital data (DD), and the dental prosthesis (143) is produced in a production machine (114), which is controlled by means of production data (FD). The shape determination device (110) and the production machine (114) are coupled by means of an EDP installation (118), which contains a memory unit for storing the digital data (DD) and performs the calculation of the production data (FD).

Owner:STRAUMANN HLDG AG +2

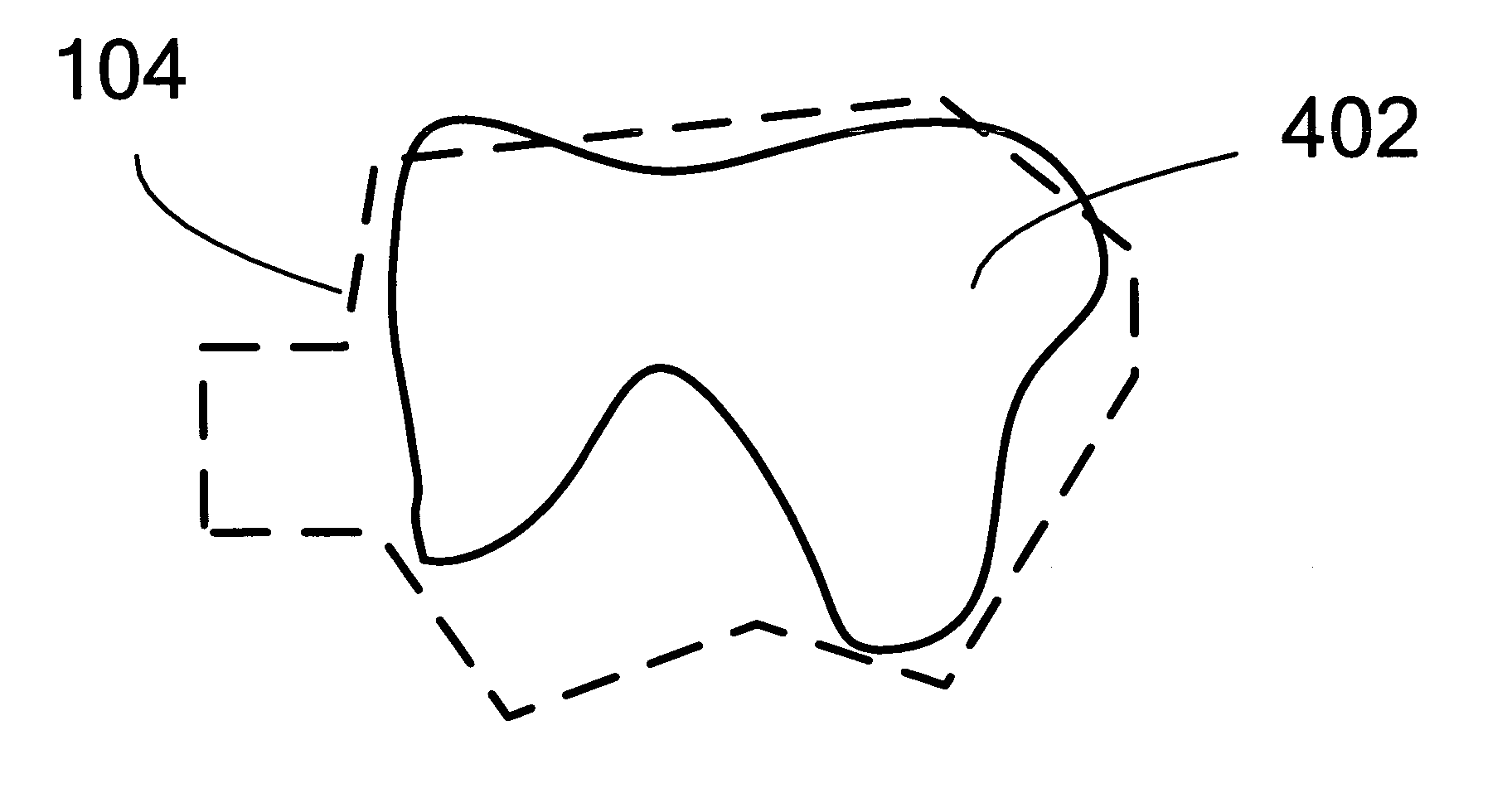

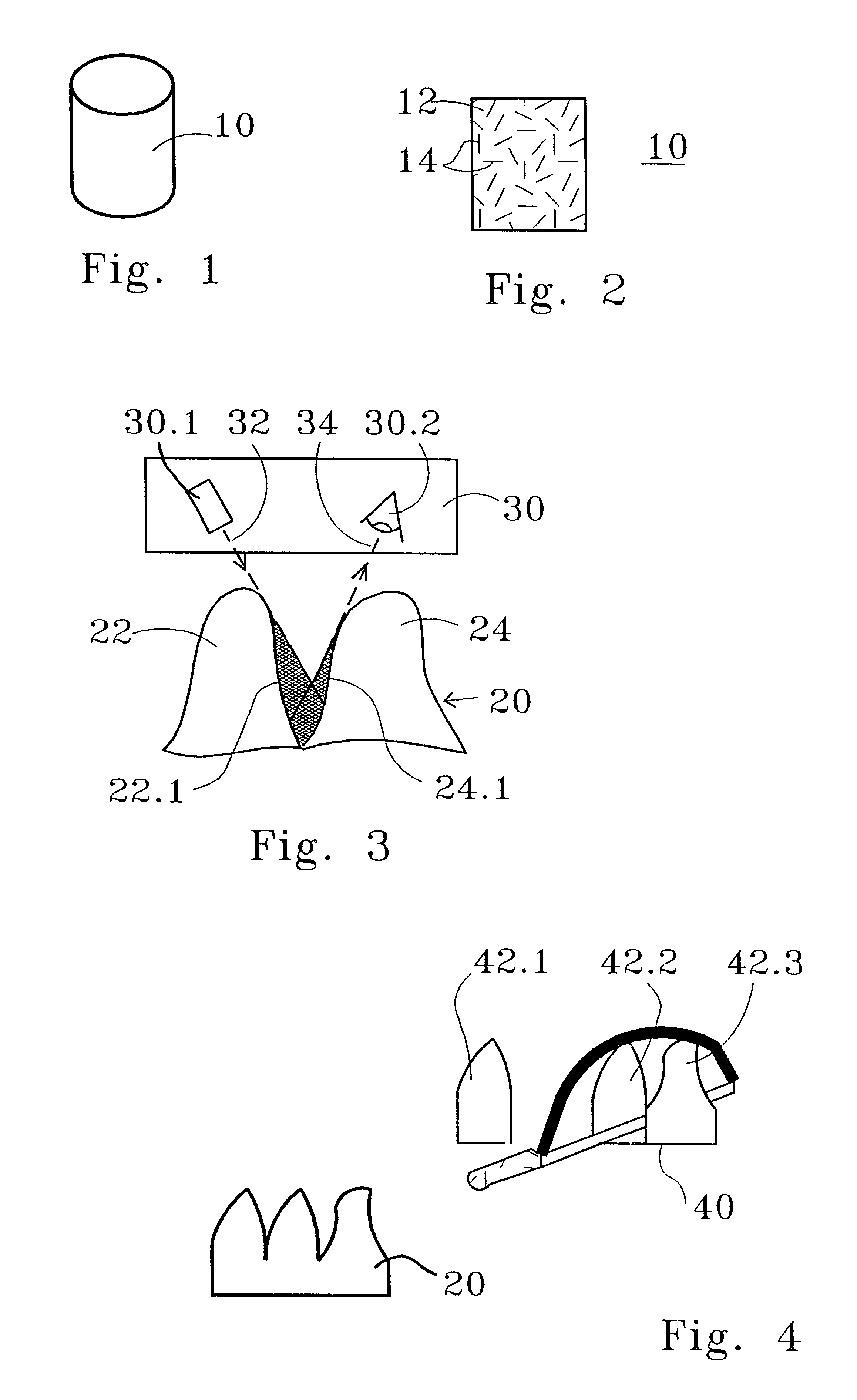

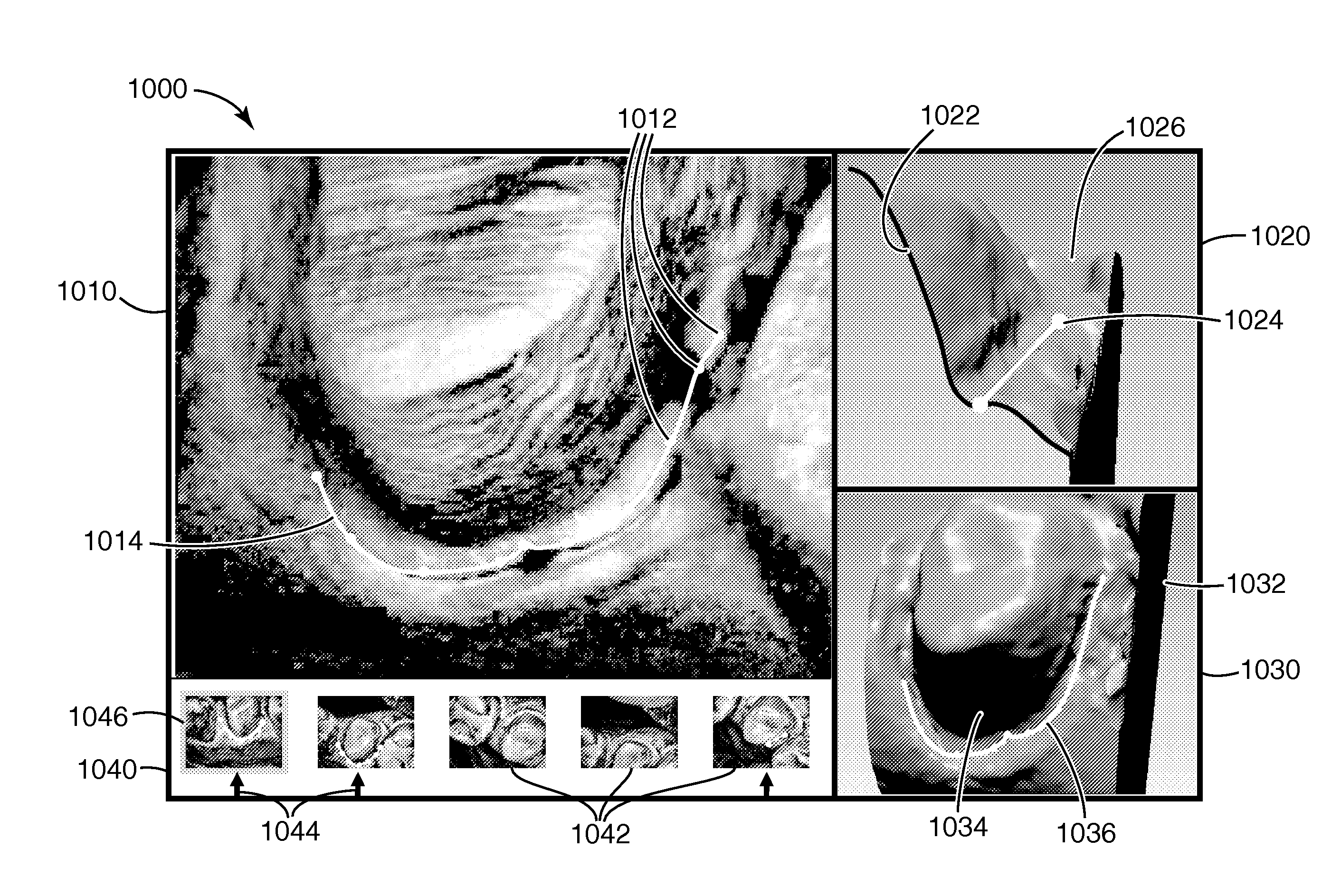

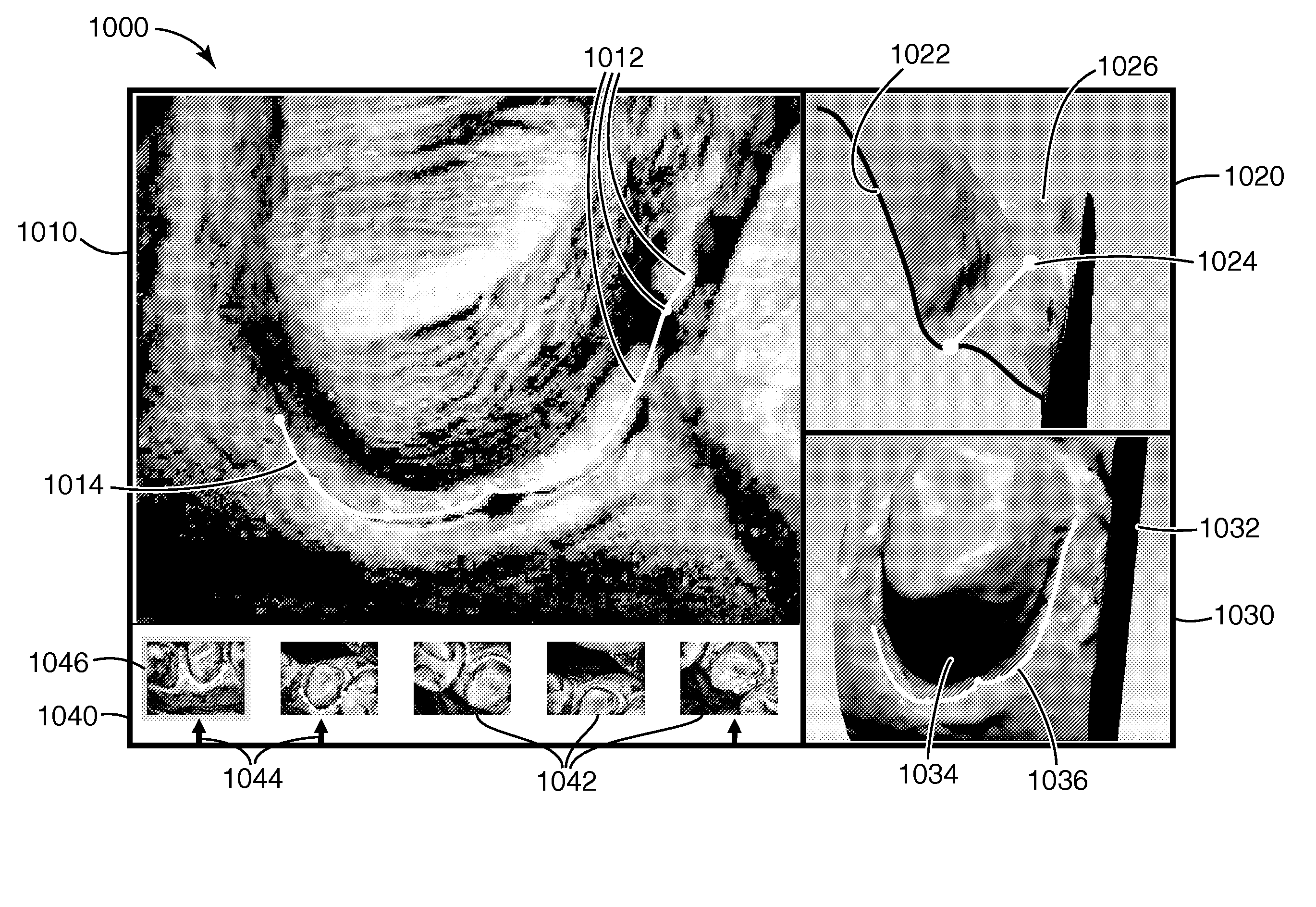

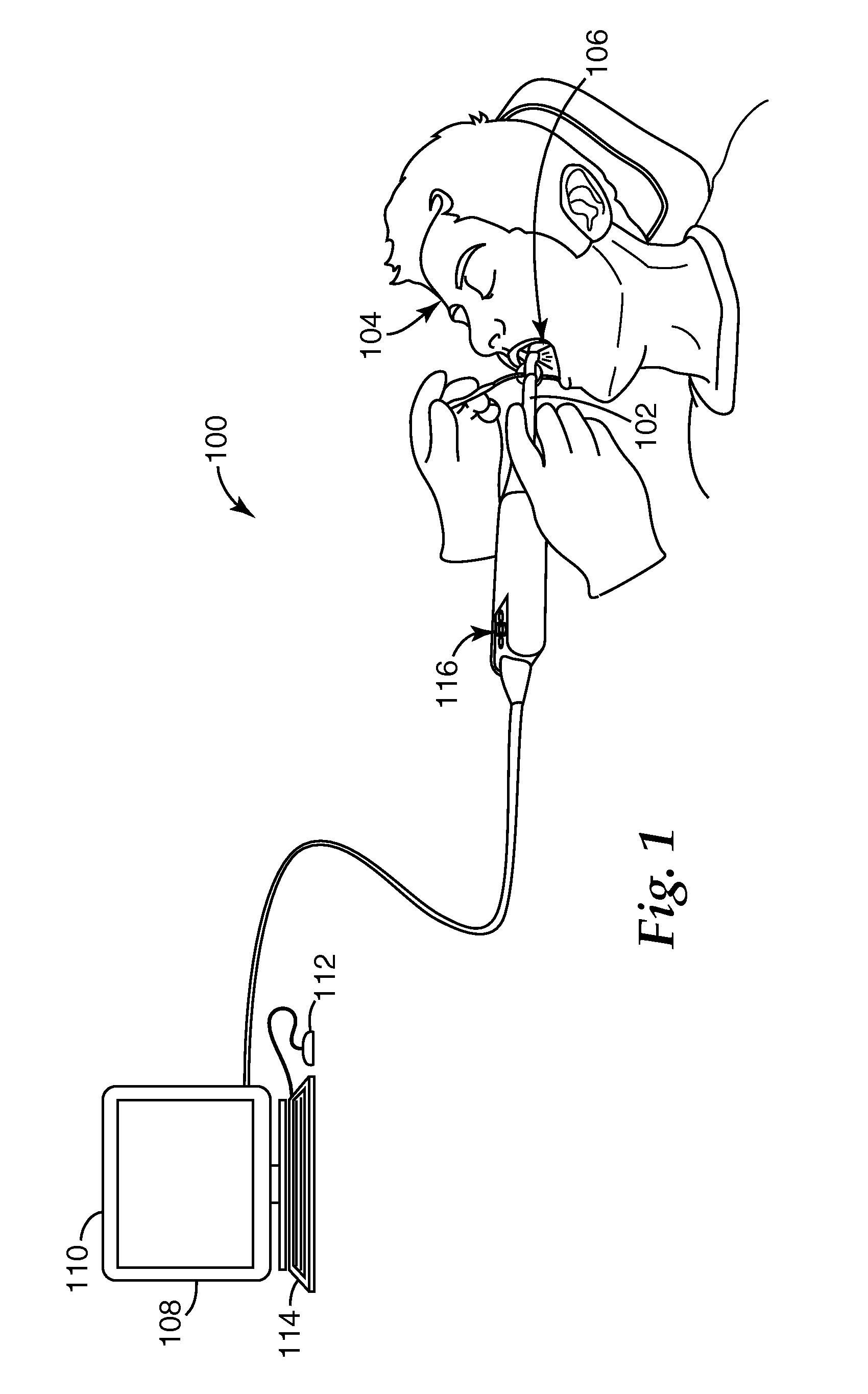

Video-assisted margin marking for dental models

InactiveUS20100281370A1Simple production processSpeed up the processInput/output for user-computer interactionImpression capsInteractive modelingAmbiguity

Tools are described for preparing digital dental models for use in dental restoration production processes, along with associated systems and methods. Dental modeling is improved by supplementing views of three-dimensional models with still images of the modeled subject matter. Video data acquired during a scan of the model provides a source of still images that can be displayed alongside a rendered three-dimensional model, and the two views (model and still image) may be synchronized to provide a common perspective of the model's subject matter. This approach provides useful visual information for disambiguating surface features of the model during processing steps such as marking a margin of a prepared tooth surface for a restoration. Interactive modeling tools may be similarly enhanced. For example, tools for margin marking may synchronize display of margin lines between the still image and the model so that a user can interact with either or both of the visual representations, with changes to a margin reflected in both displays.

Owner:3M INNOVATIVE PROPERTIES CO

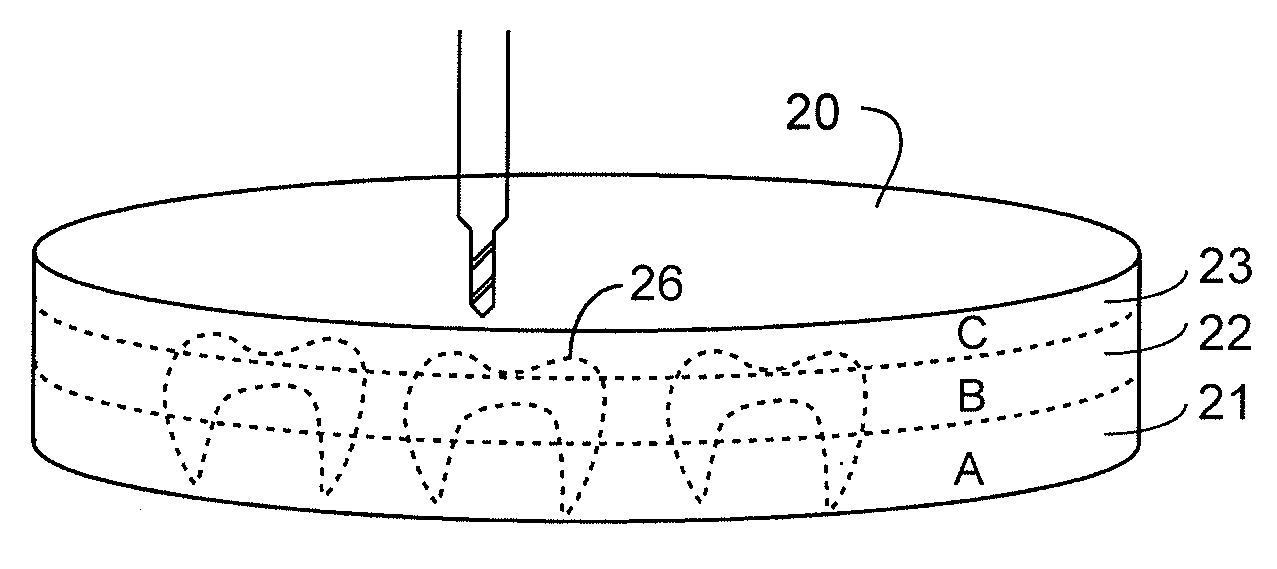

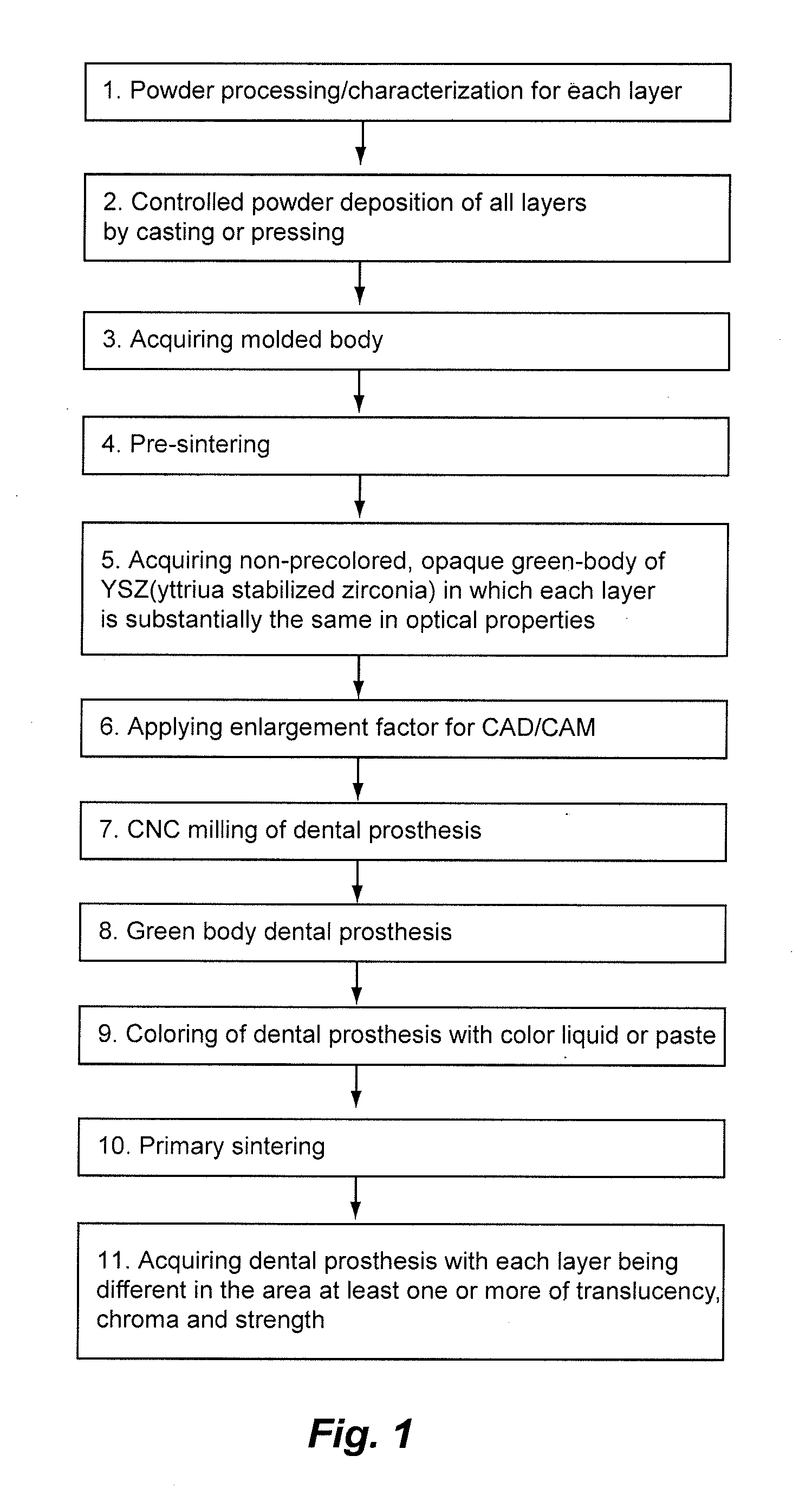

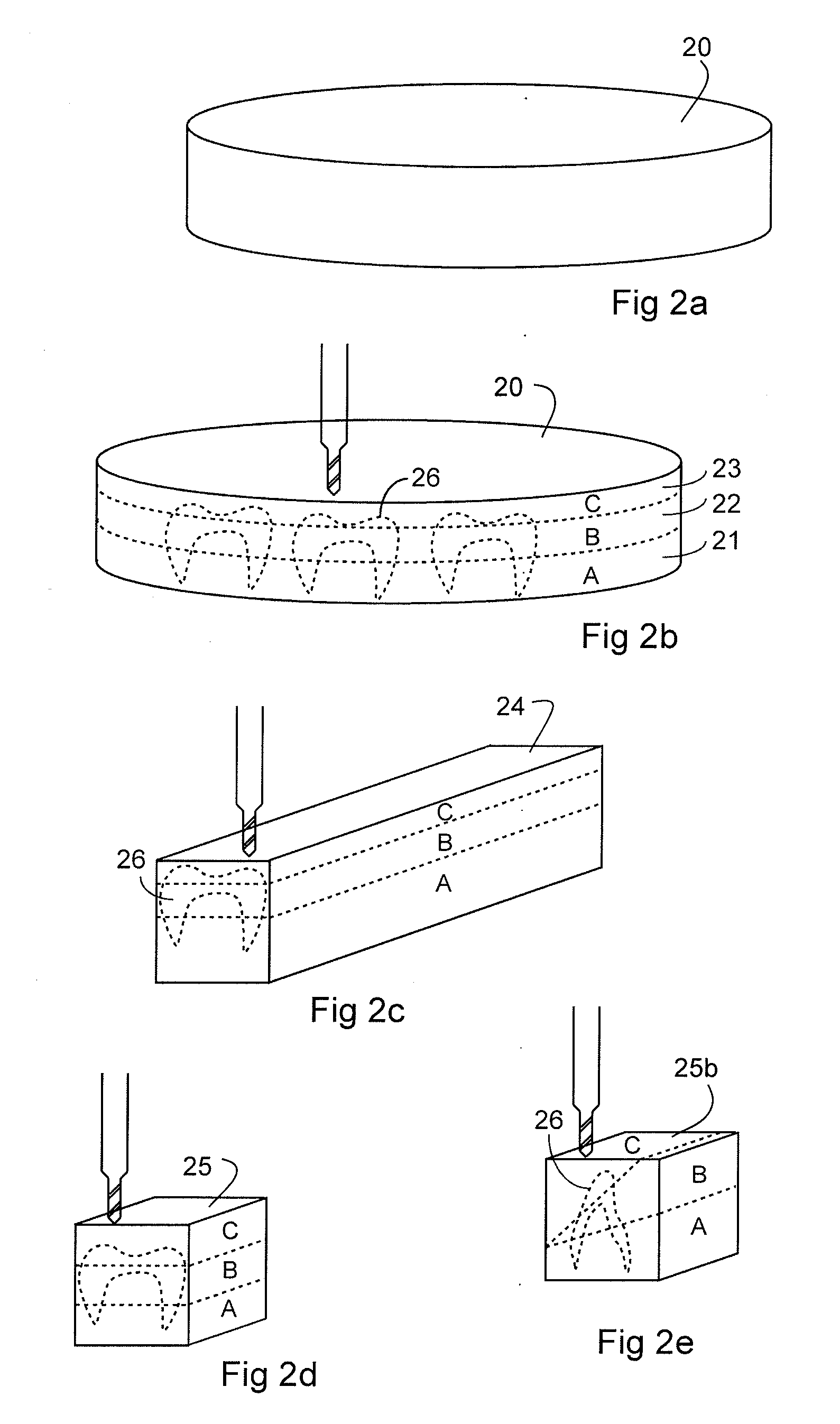

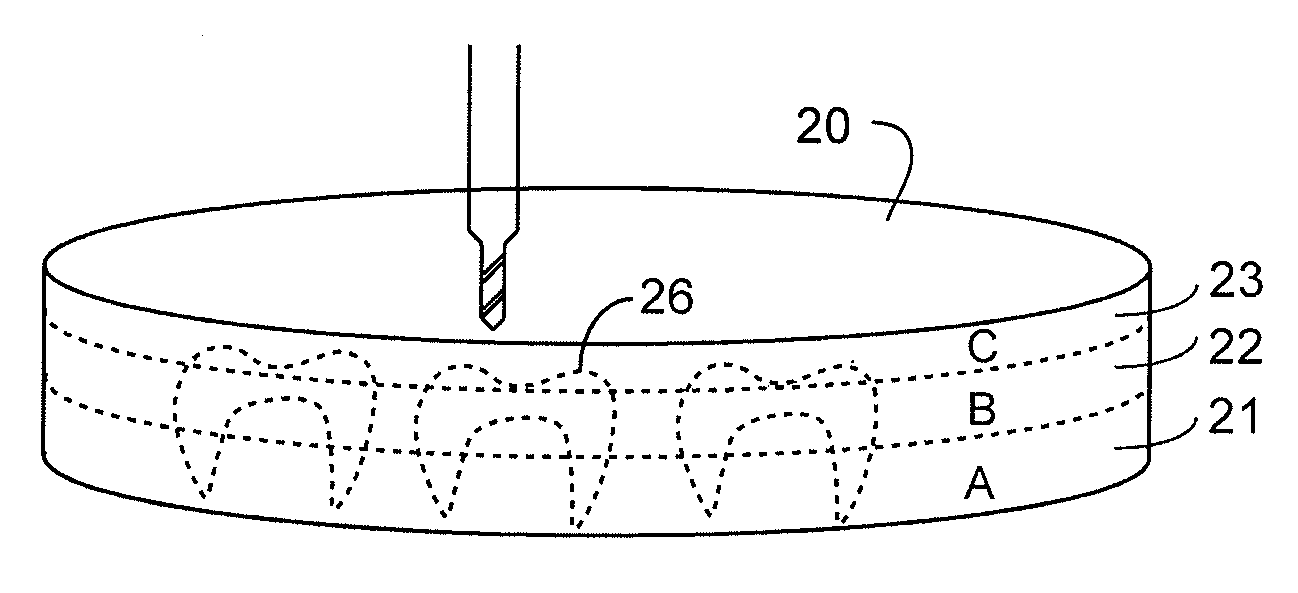

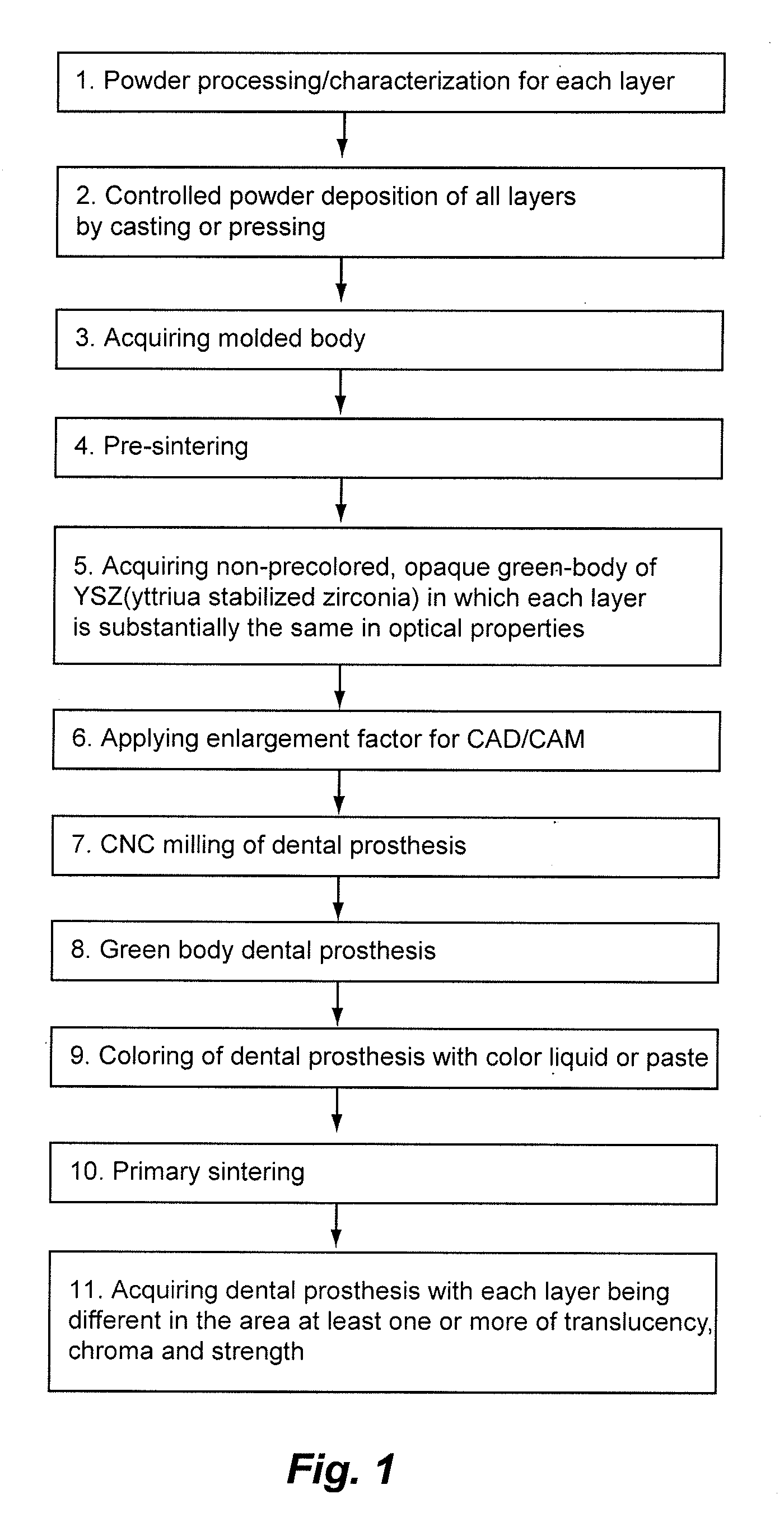

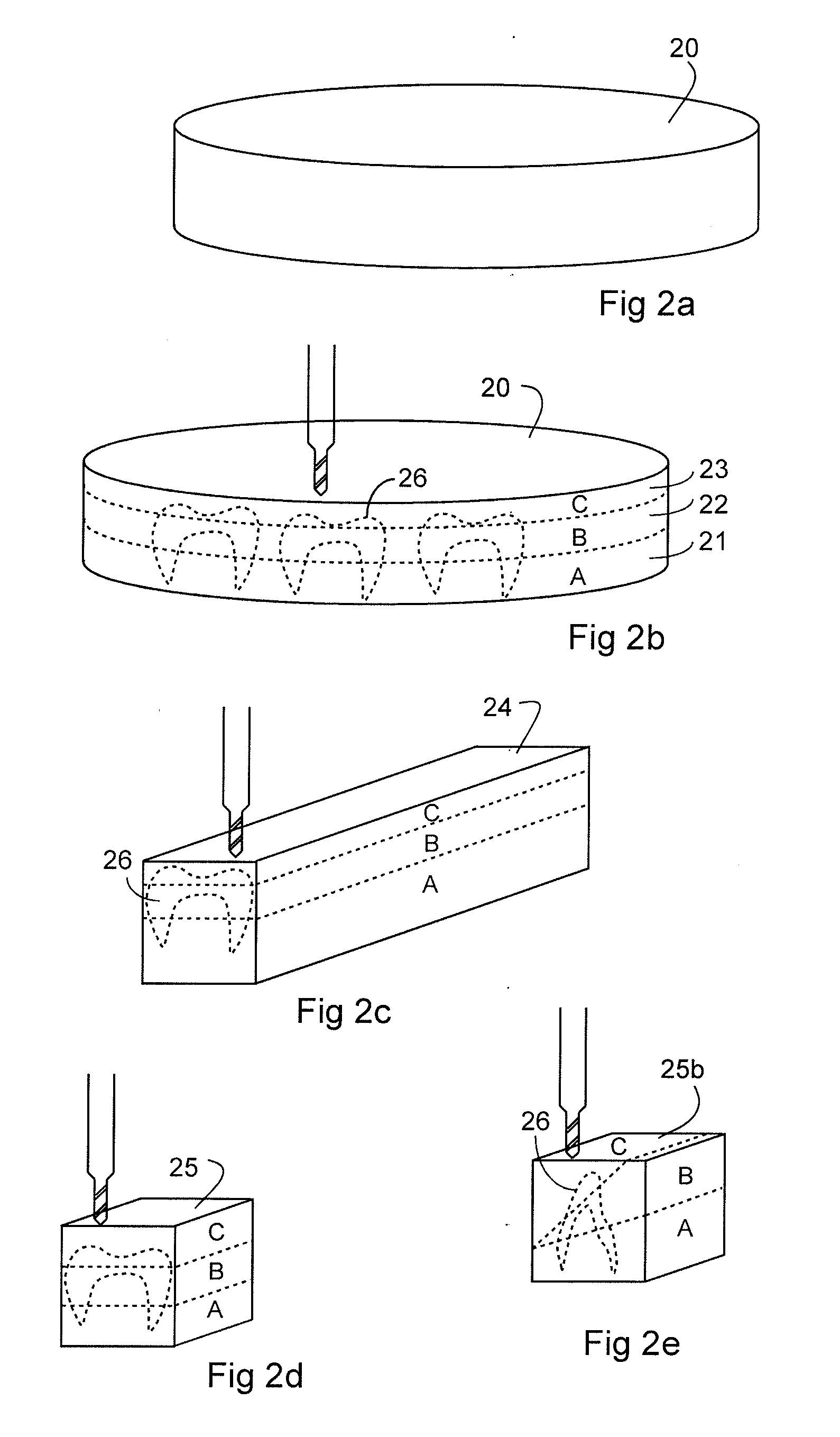

Non-Pre-Colored Multi-Layer Zirconia Dental Blank that has a Gradual Change in Translucency through a Thickness After Sintering

ActiveUS20130221554A1Small productImproved and more natural optical characteristicArtificial teethCeramic layered productsIncreased translucencyChemical composition

Owner:B & D DENTAL

Dental restorations formed by solid free-form fabrication methods

InactiveUS6994549B2Manufacture of restorationAdditive manufacturing apparatusImpression capsFree formThin layer

Solid free form fabrication techniques such as fused deposition modeling and three-dimensional printing are used to create a dental restoration. Three-dimensional printing comprises inkjet printing a binder into selected areas of sequentially deposited layers of powder. Each layer is created by spreading a thin layer of powder over the surface of a powder bed. Instructions for each layer may be derived directly from a CAD representation of the restoration. The area to be printed is obtained by computing the area of intersection between the desired plane and the CAD representation of the object. All the layers required for an aesthetically sound restoration can be deposited concurrently slice after slice and sintered / cured simultaneously. The amount of green body oversize is equivalent to the amount of shrinkage which occurs during sintering or curing. While the layers become hardened or at least partially hardened as each of the layers is laid down, once the desired final shaped configuration is achieved and the layering process is complete, in some applications it may be desirable that the form and its contents be heated or cured at a suitably selected temperature to further promote binding of the powder particles.

Owner:JENERICPENTRON

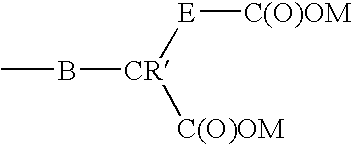

Oral care compositions comprising dicarboxy functionalized polyorganosiloxanes

InactiveUS7025950B2High retention ratePositive tooth feel benefitsCosmetic preparationsToilet preparationsPersonal careNatural tooth

Disclosed are compositions and methods for treating and modifying surfaces and for enhancing delivery of active agents to surfaces treated with the compositions, which comprise siloxane polymers functionalized with pendant moieties comprising anionic groups, specifically carboxylic acid groups. When applied to a suitable surface, the present composition comprising the carboxy functionalized siloxane polymers forms a substantially hydrophobic coating on the treated surface. These polymers effectively deposit on surfaces that have cationic sites, which are capable of forming bonds or linkages with the anionic groups of the polymer. The treated surface becomes hydrophobic due to the deposition of the carboxy functionalized siloxane polymer, which then imparts a variety of end use benefits to that surface such as ease of cleaning, stain removal and prevention, whitening, etc. The carboxy functionalized siloxane polymer further acts as a carrier to deposit active agents onto the surface and to improve retention and efficacy of said actives on the treated surface. The present compositions are useful in a variety of applications including oral care, hair and skin care, personal care, cosmetics, and fabric and hard surface cleaning and conditioning. Examples are oral compositions for use in cleaning and whitening of natural teeth and dental prosthesis; for preventing, reducing or removing plaque, calculus and surface deposited stains on teeth; and for providing shine, smoothness and positive feel benefits to teeth, the compositions comprising at least about 0.1% by weight of a dicarboxy functionalized siloxane polymer in a formulation that effectively deposits the polymer to teeth and other oral surfaces.

Owner:THE PROCTER & GAMBLE COMPANY

Methods for dental restoration

InactiveUS20040167646A1Additive manufacturing apparatusMechanical/radiation/invasive therapiesDentistryPreparation procedures

The present invention provides a method for preparing dental restorations, the method comprising the steps of (a) compiling a database of materials for use in preparing a dental restoration; (b) compiling a database of procedures for preparing the dental restoration; (c) determining the geometrical constraints of the dental restoration; (d) determining the aesthetic constraints of the dental restoration; and (e) inputting the geometrical constraints and the aesthetic constraints to a computer to mathematically select from the material database and the procedure database a recipe for producing the dental restoration.

Owner:CYNOVAD

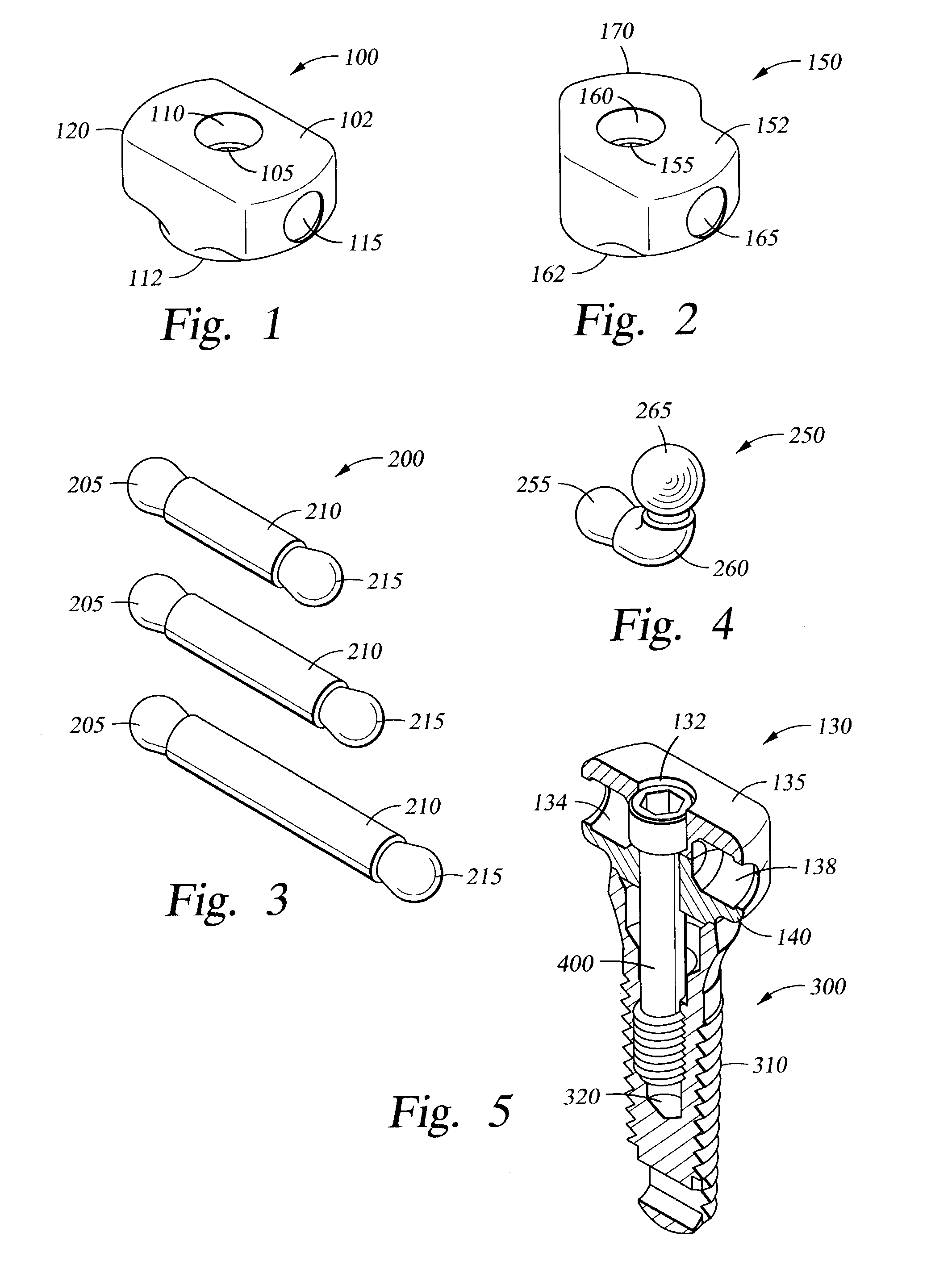

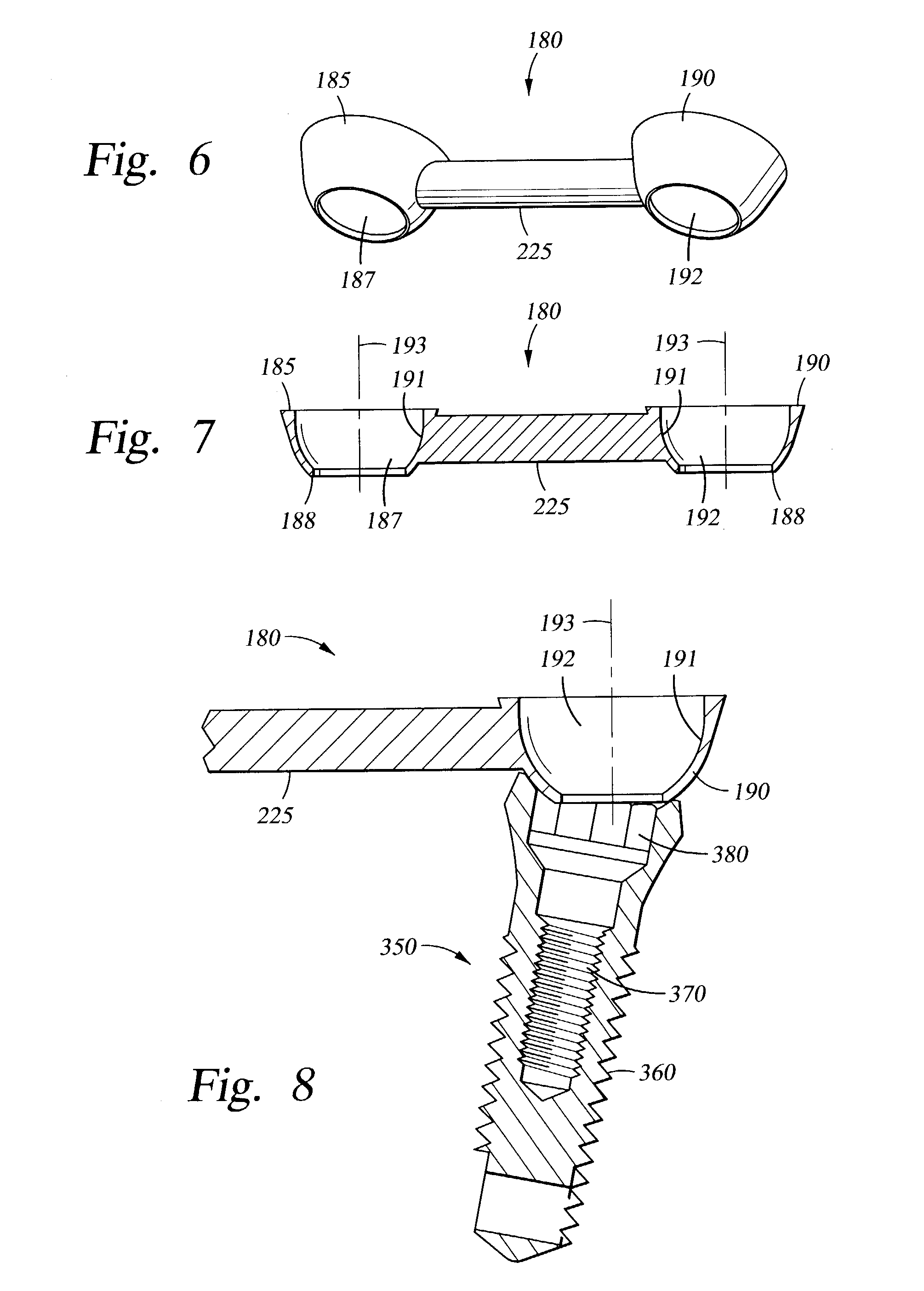

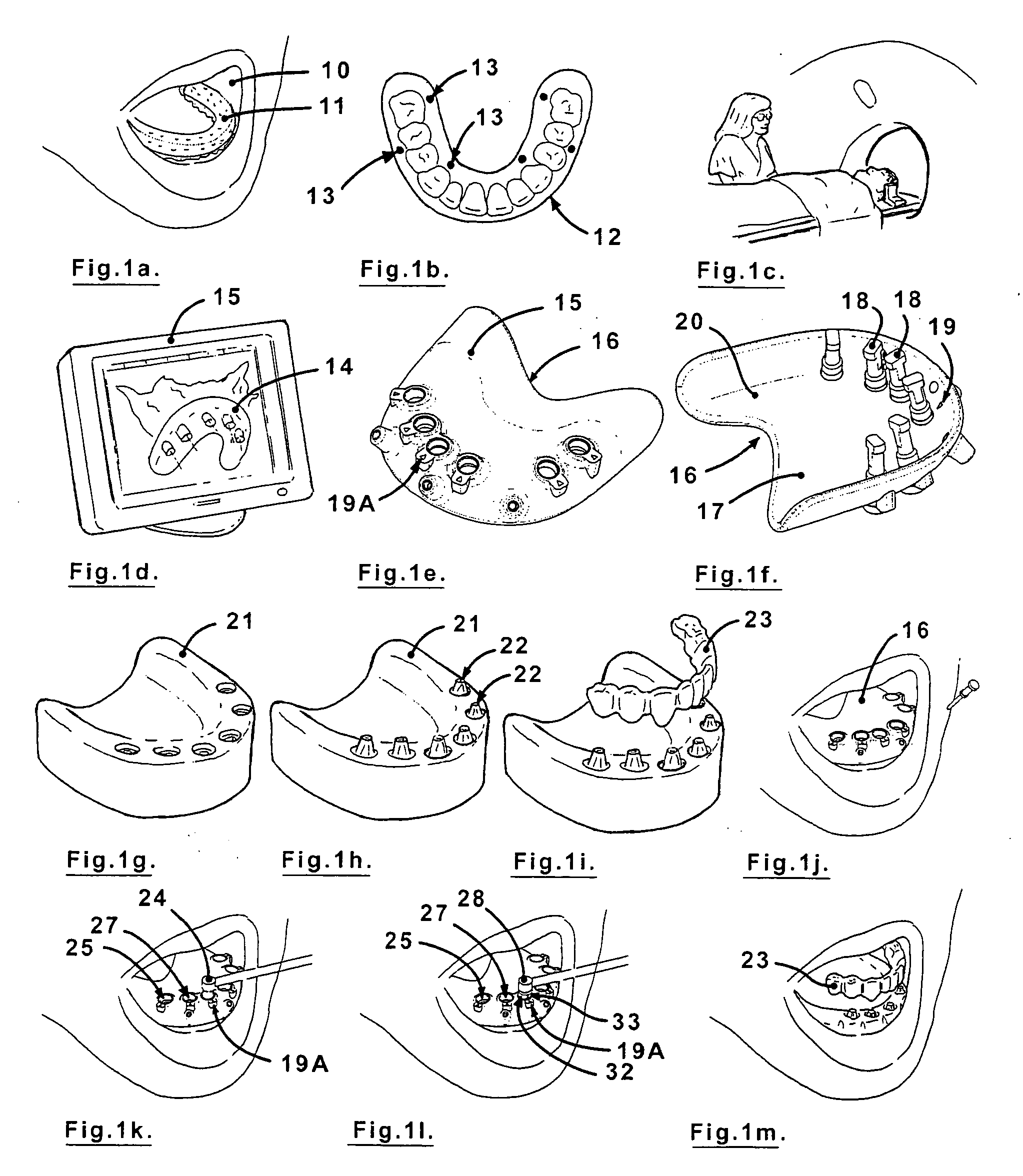

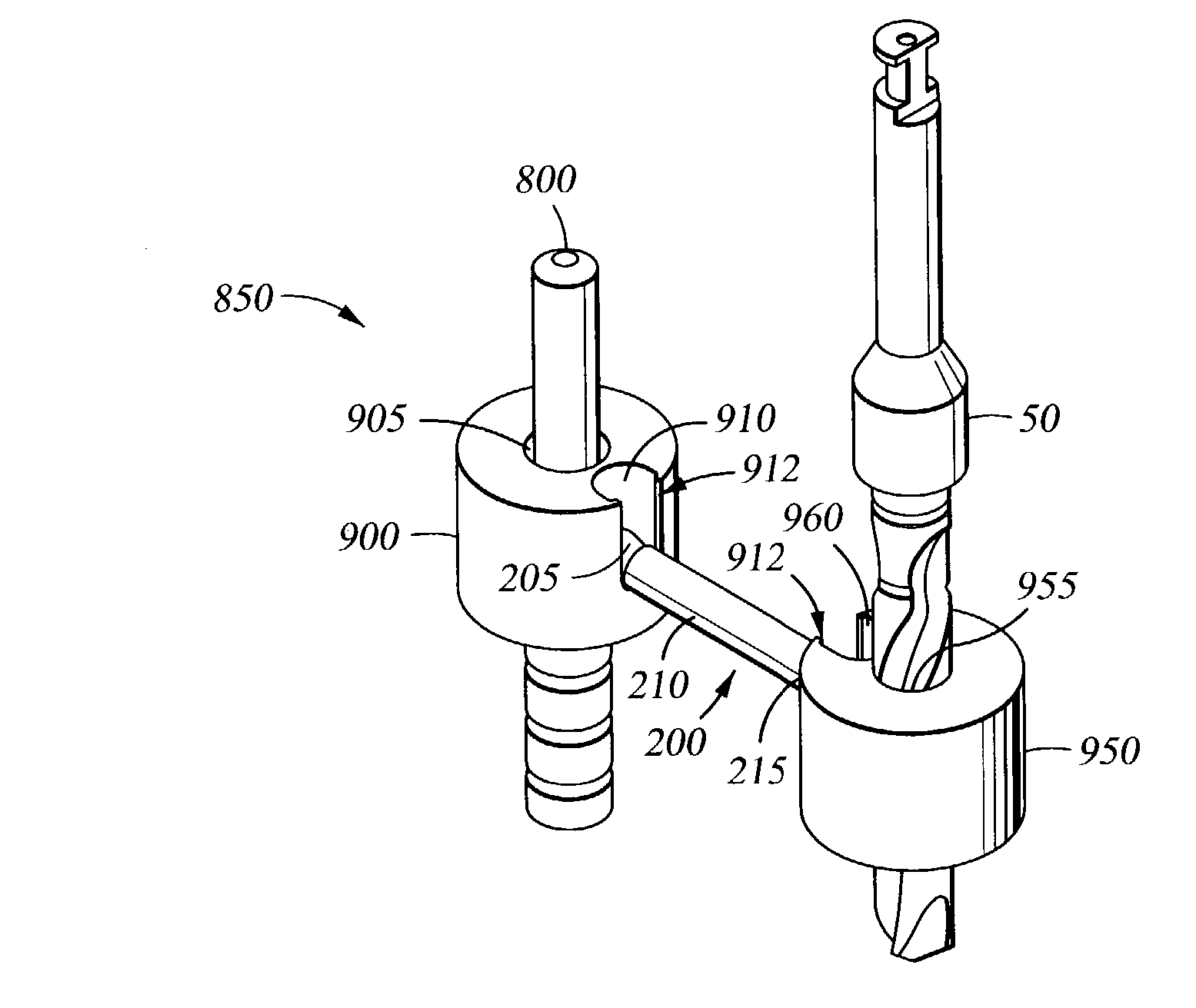

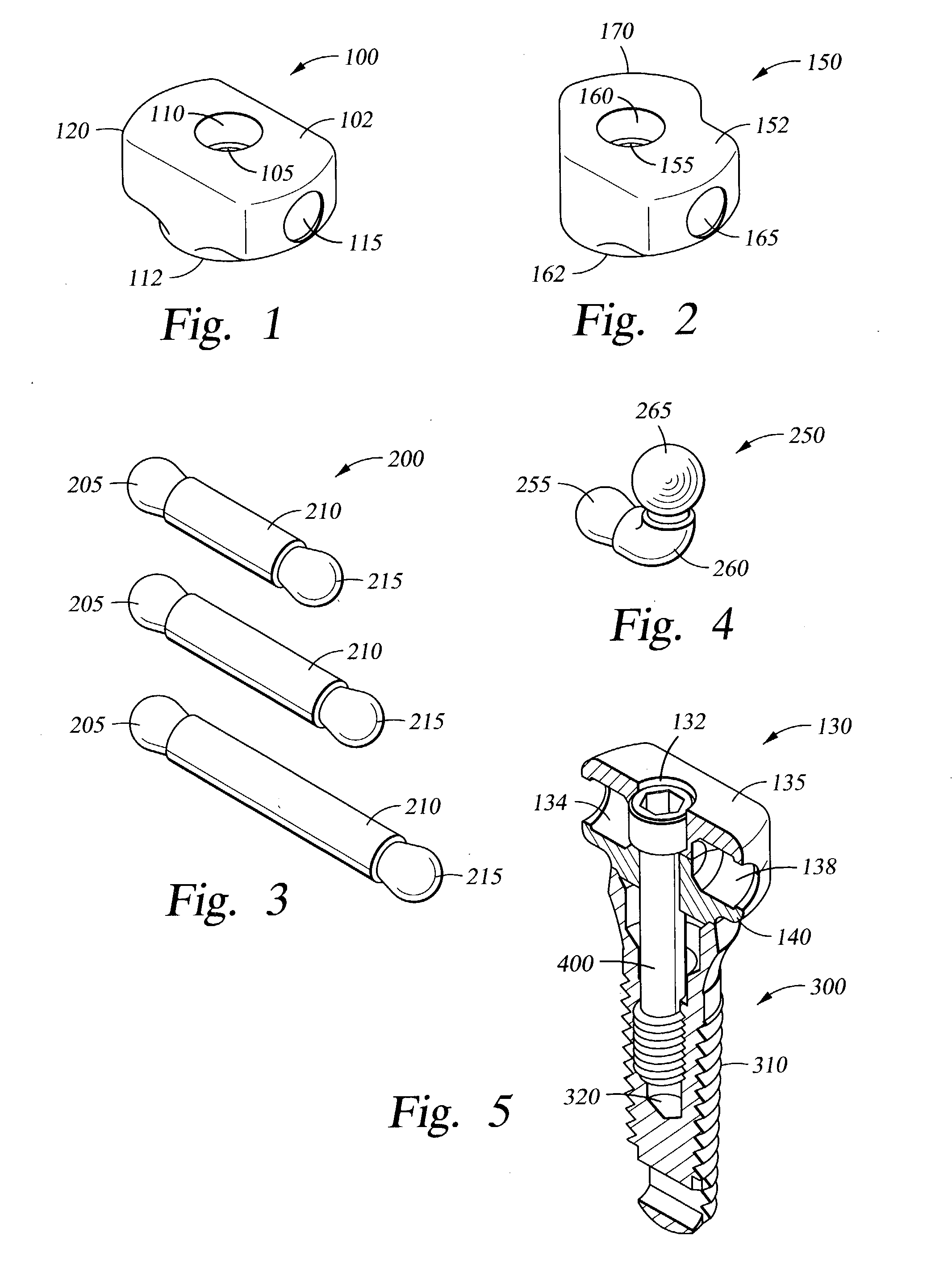

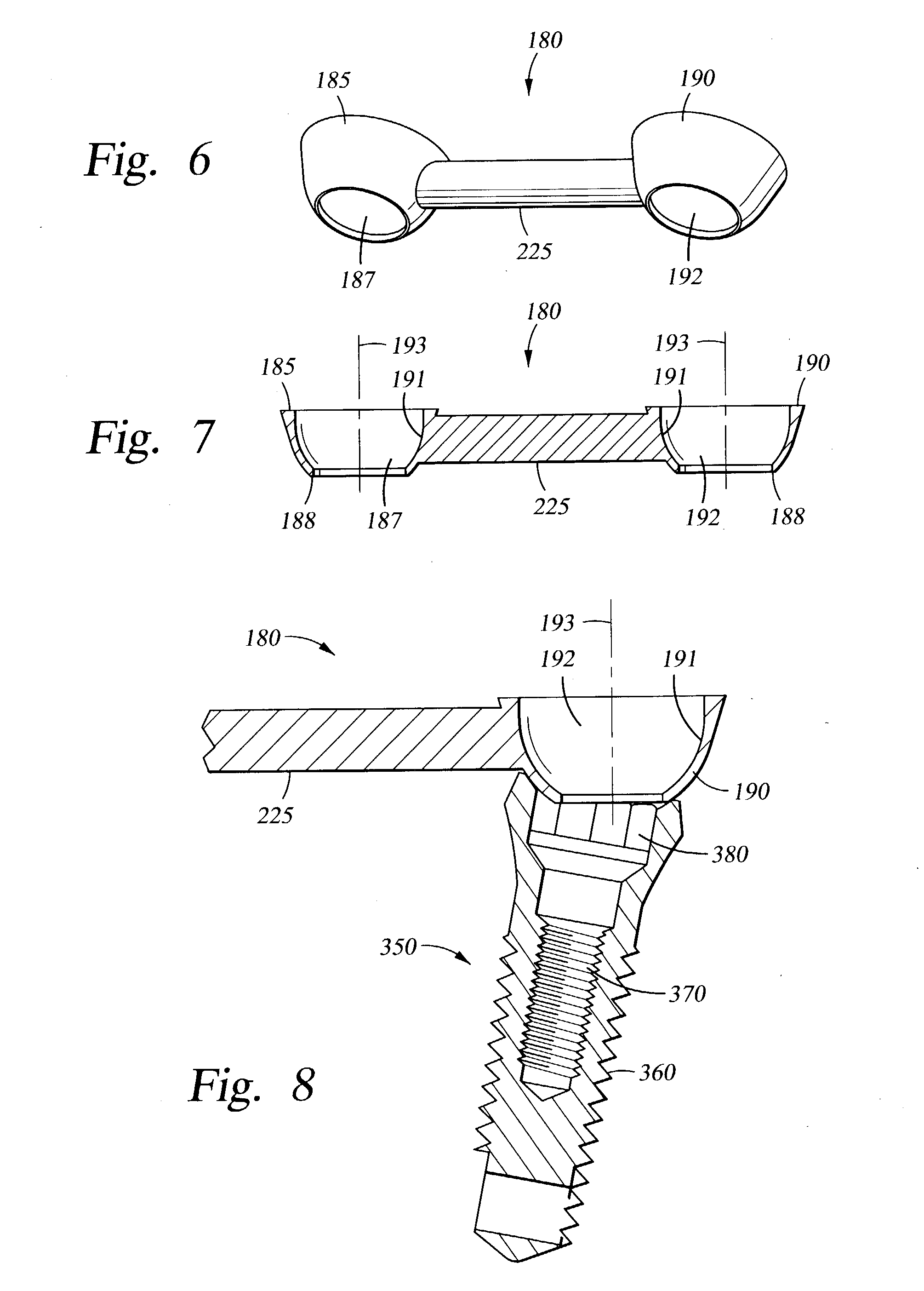

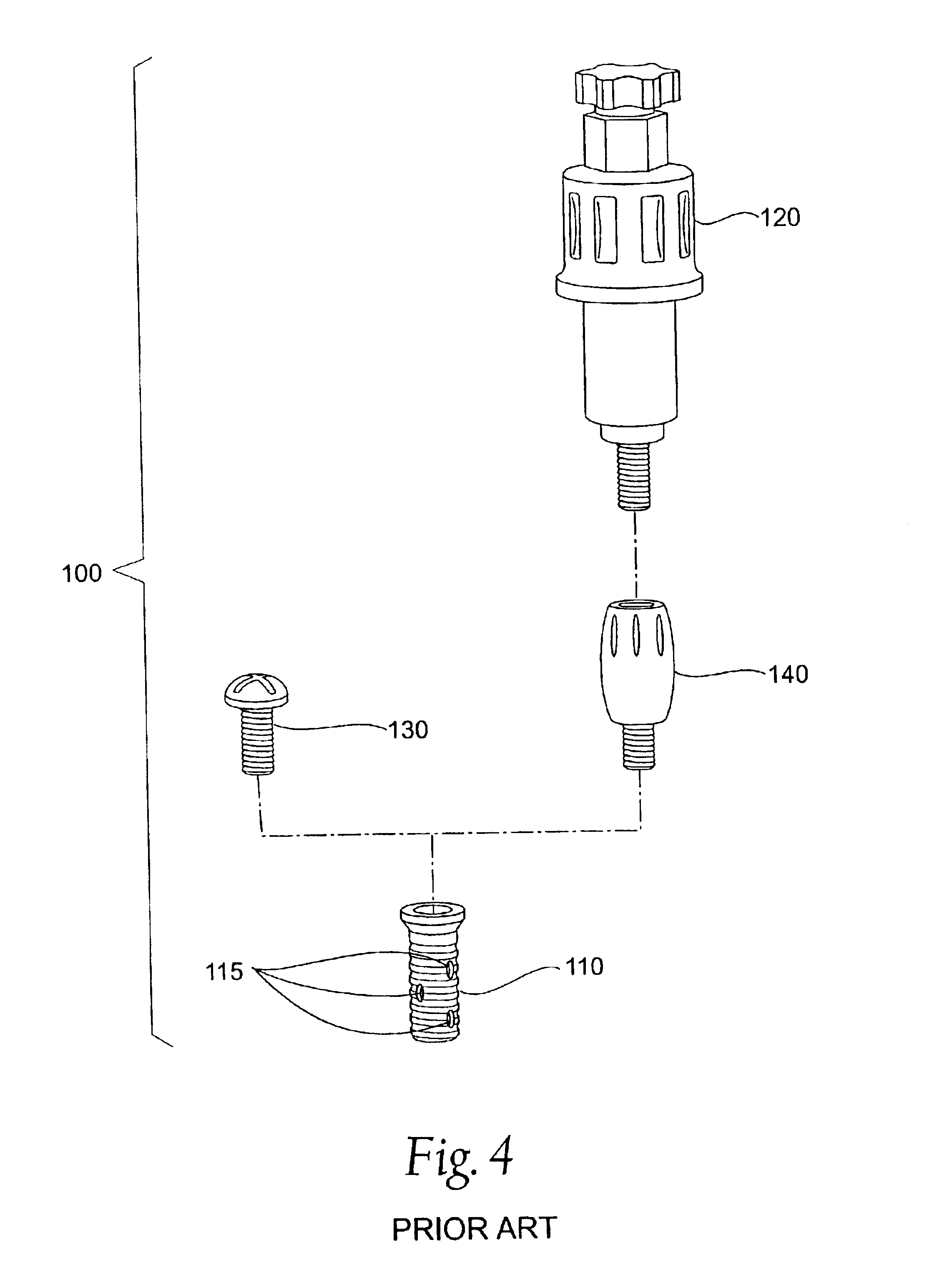

Multi-adjustable drill guide and framework system for dental prosthetics

InactiveUS7021934B2Reduce complexityLow costDental implantsDental toolsPermanent implantDental implant

In one aspect, a group of inter-connecting, prefabricated components of various shapes and sizes that can be assembled together to form a framework system directly onto dental implants installed in the patient's mouth is disclosed. In another aspect, a group of prefabricated components to form a drill guide system for drilling a properly spaced and oriented implant hole adjacent to another implant hole or adjacent to a fully-installed implant is disclosed. In yet another aspect, improved procedures for installing permanent, implant-supported dental restorations are disclosed, including an immediate loading procedure.

Owner:ZIMMER DENTAL INC

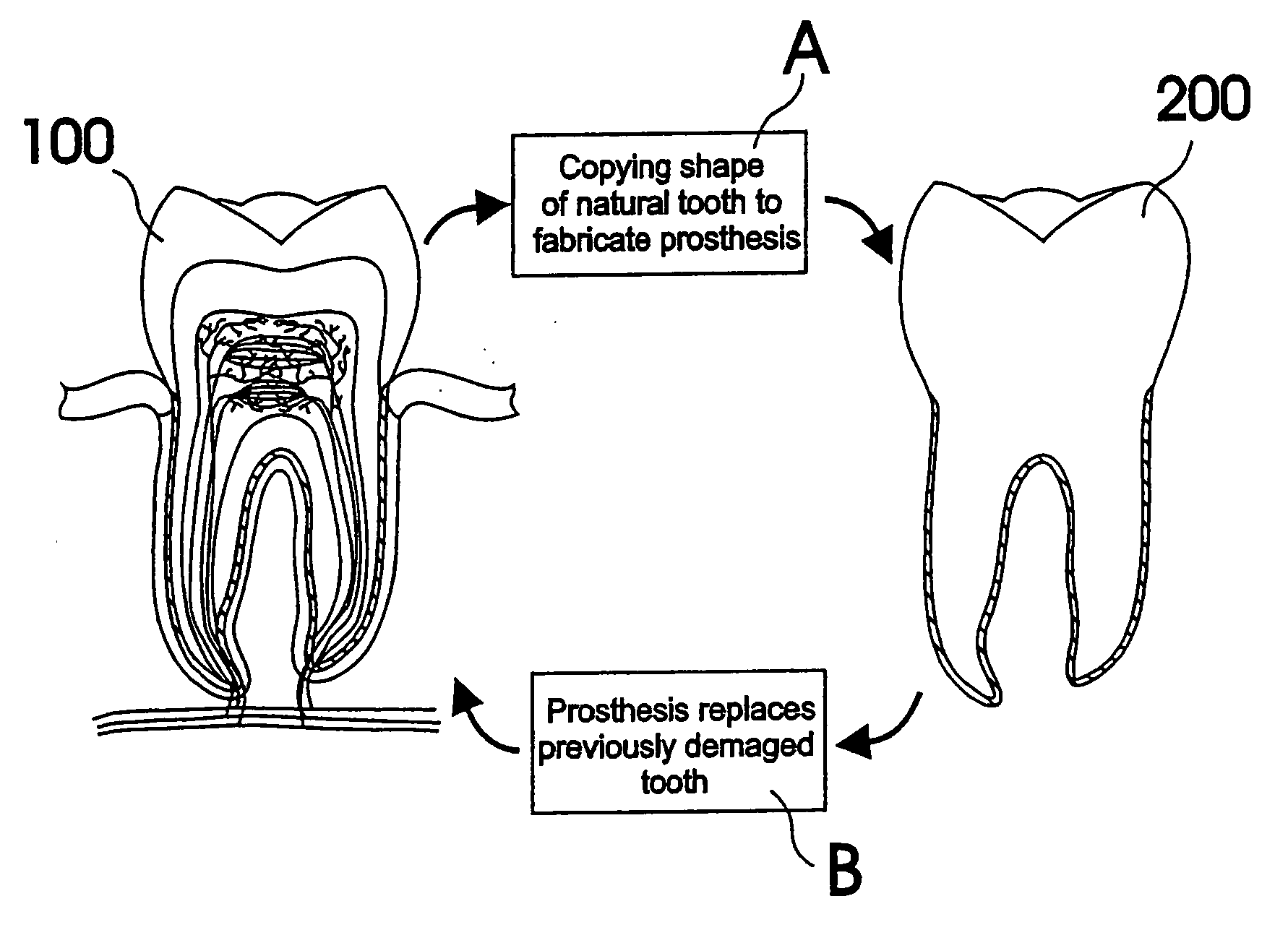

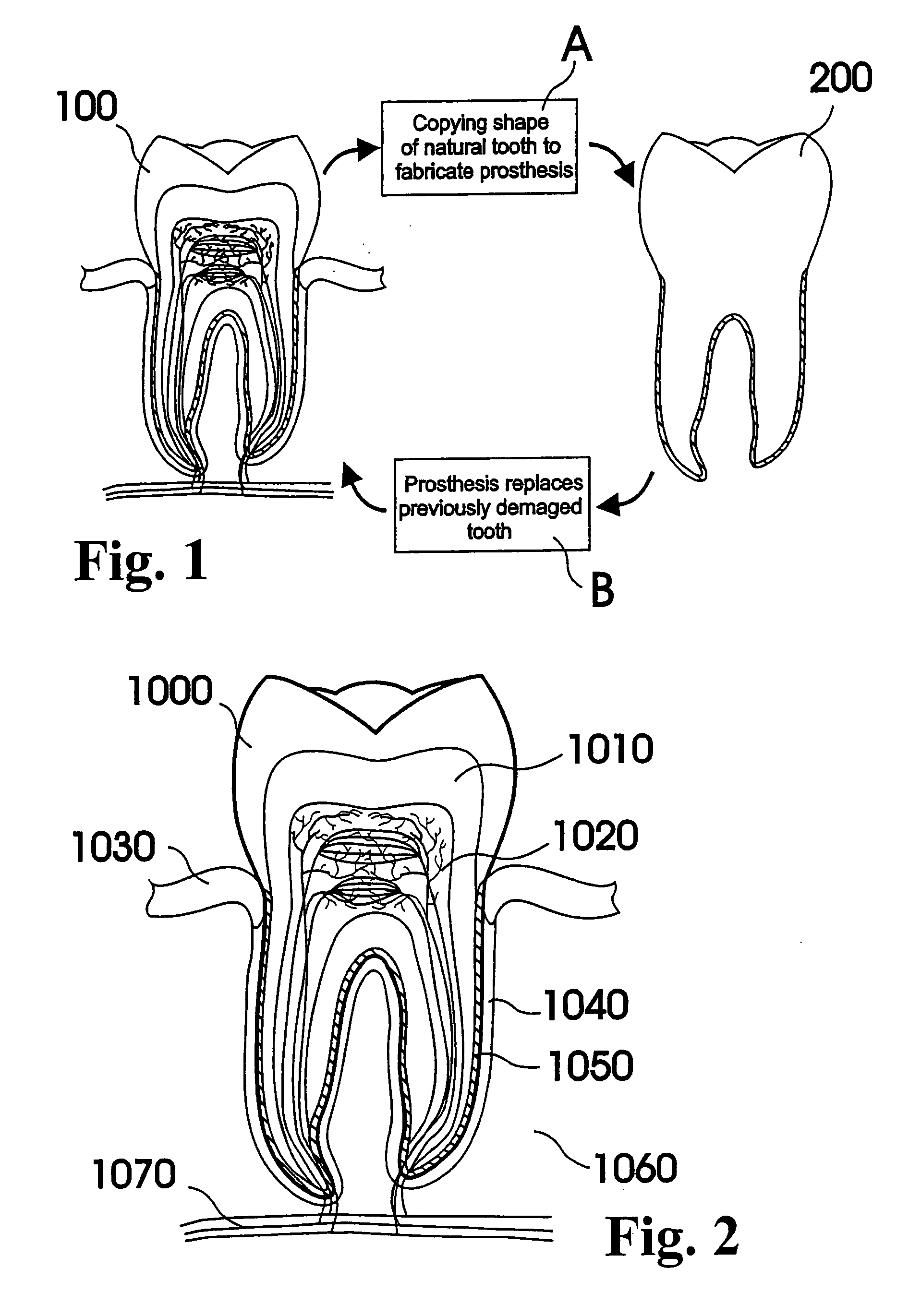

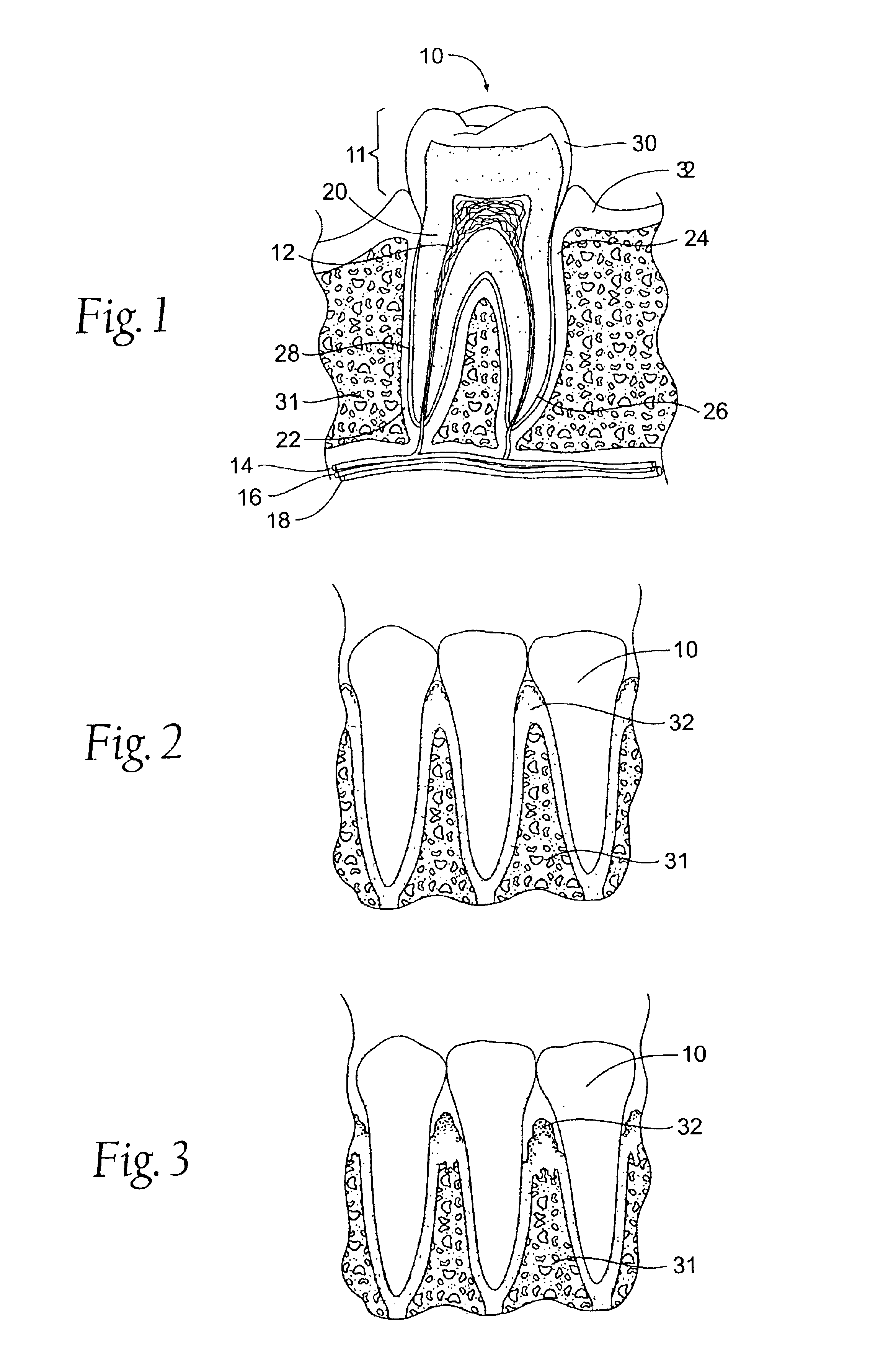

Customized dental prosthesis for periodontal- or osseointegration, and related systems and methods

ActiveUS20080090207A1None have achieved superiorQuality improvementDental implantsImpression capsOsseointegrationExtracted tooth

A dental prosthesis for periodontal integration is disclosed. Furthermore a customized dental prosthesis for osseointegration is disclosed having a first manufactured portion shaped to substantially conform to the three-dimensional surface of a root of a tooth to be replaced and a second manufactured portion shaped to substantially conform to the three-dimensional surface of a crown of a tooth to be replaced. Furthermore a customized manufactured splint is disclosed to position and fixate a tooth-shaped prosthesis. Furthermore a CAD / CAM based method of and a system for manufacturing a customized dental prosthesis replacing an extracted tooth is disclosed, where the extracted tooth is scanned regarding its three-dimensional shape and substantially copied using (a) an imaging system in-vitro like a 3D scanner or in-vivo like a cone beam CT system, (b) CNC machinery and (c) biocompatible material that is suitable to be integrated into the extraction socket and at least partially adopted by the existing tissue forming the socket.

Owner:NATURAL DENTAL IMPLANTS

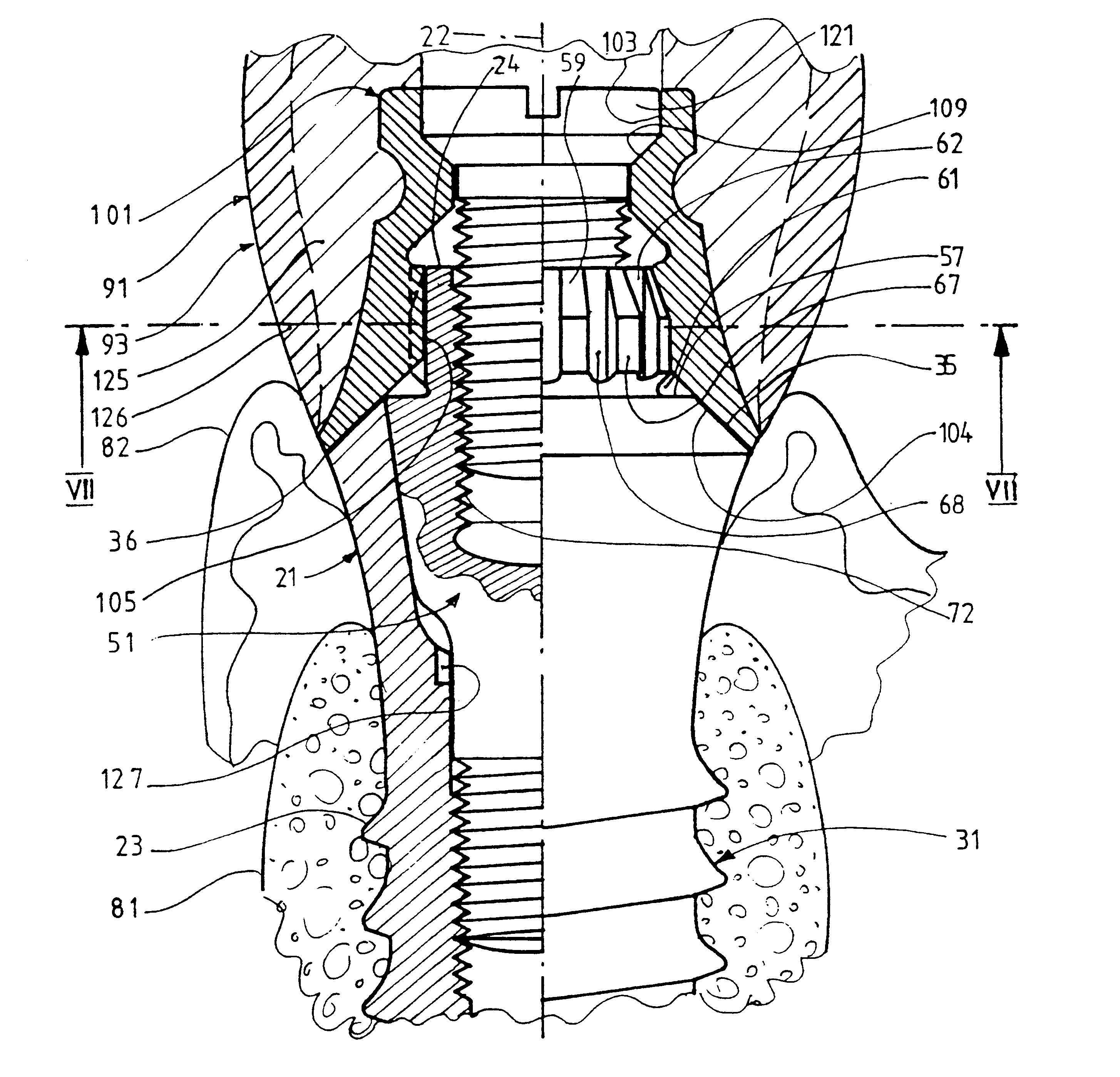

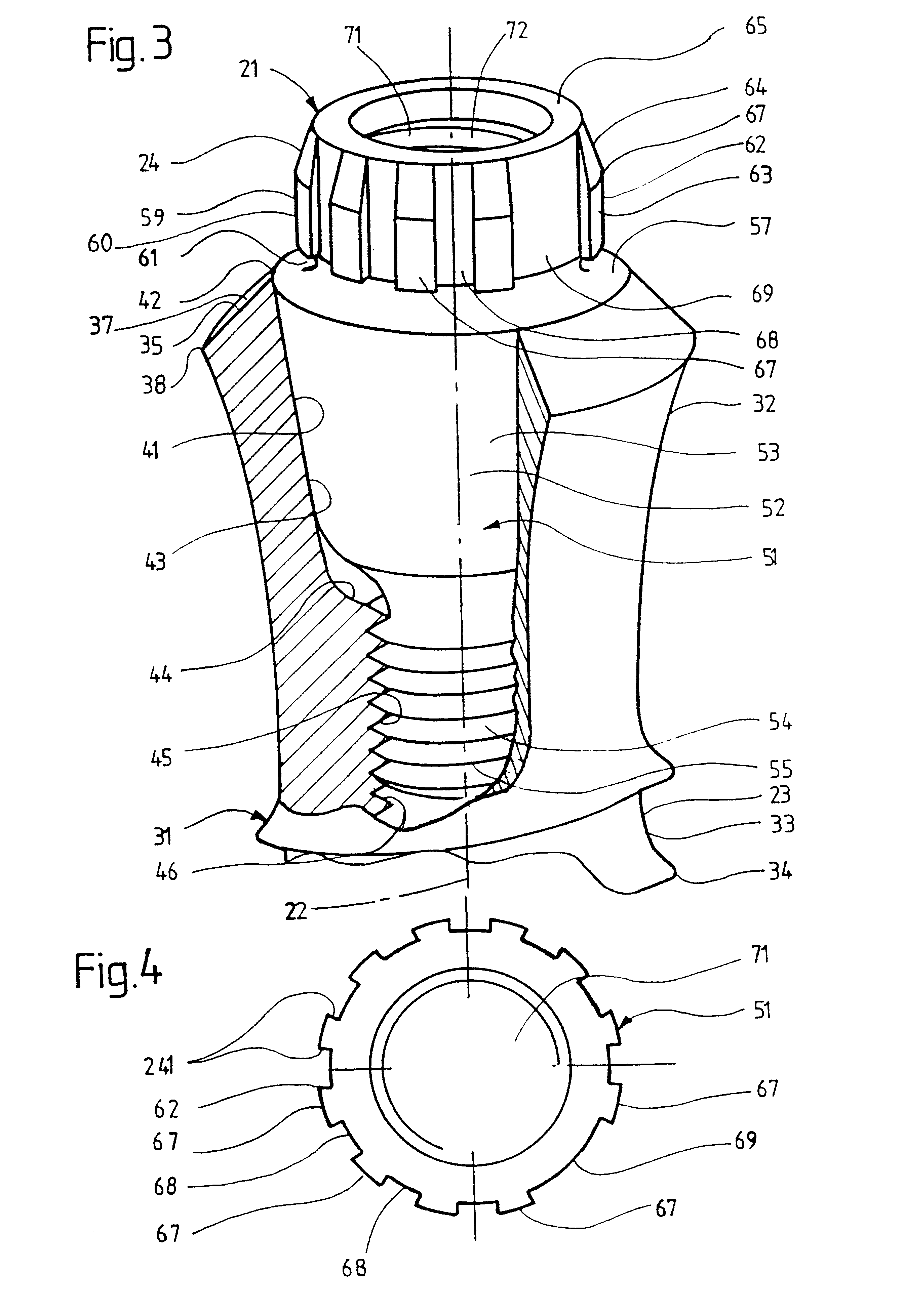

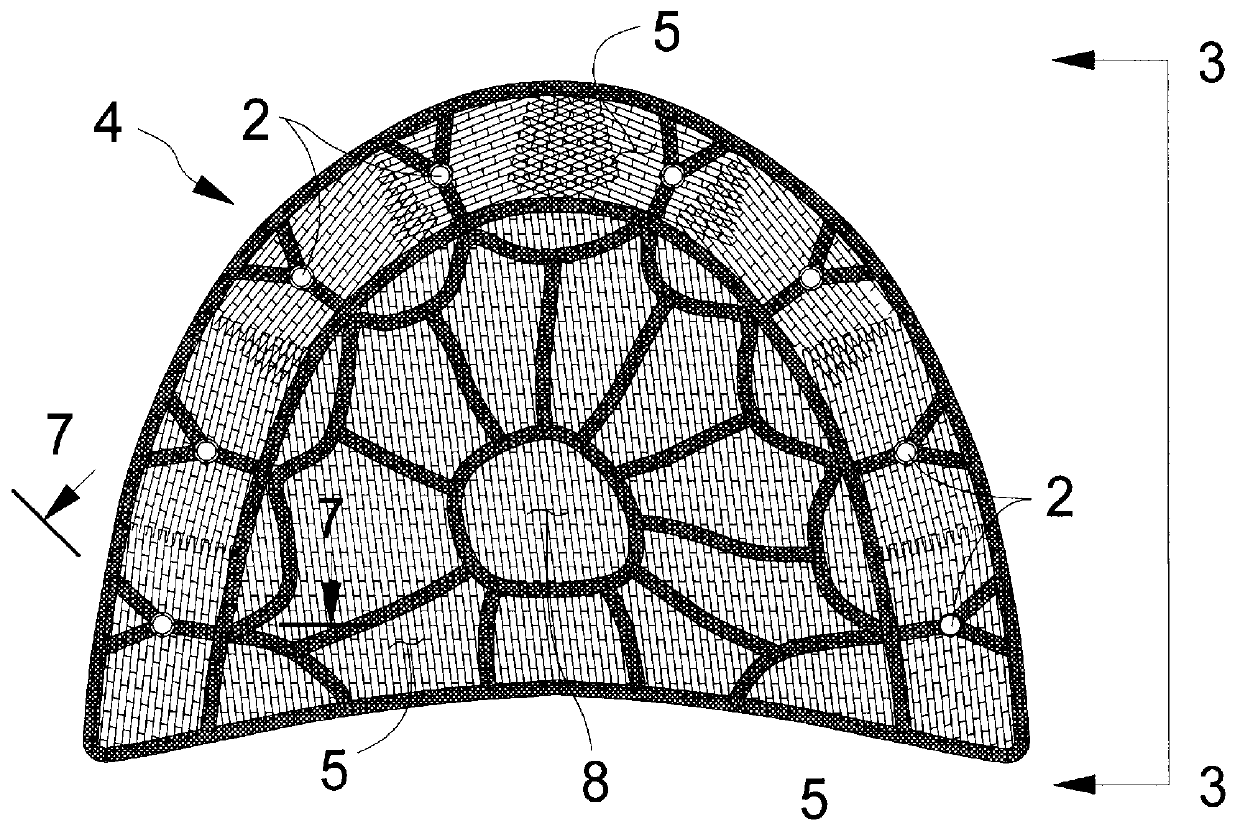

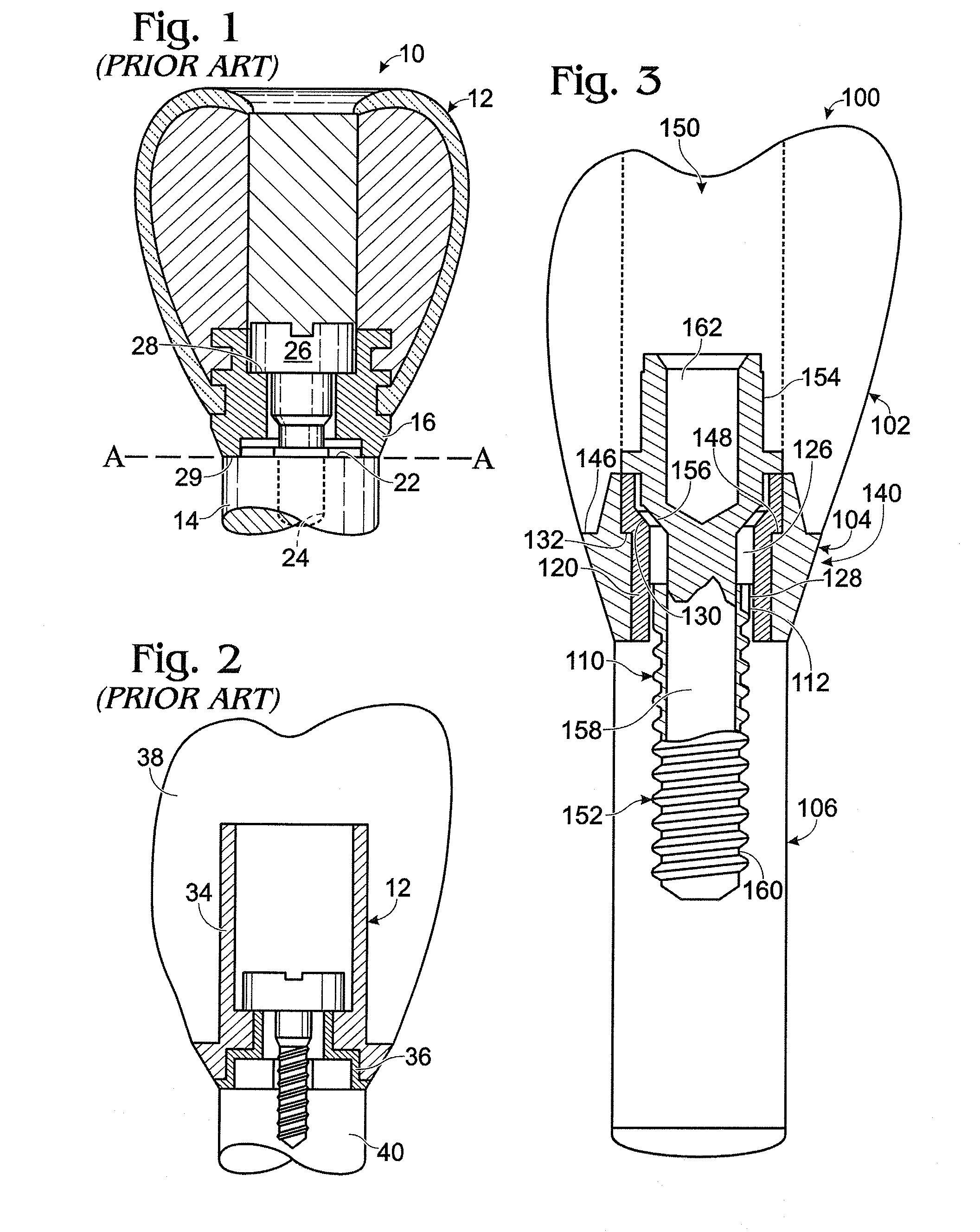

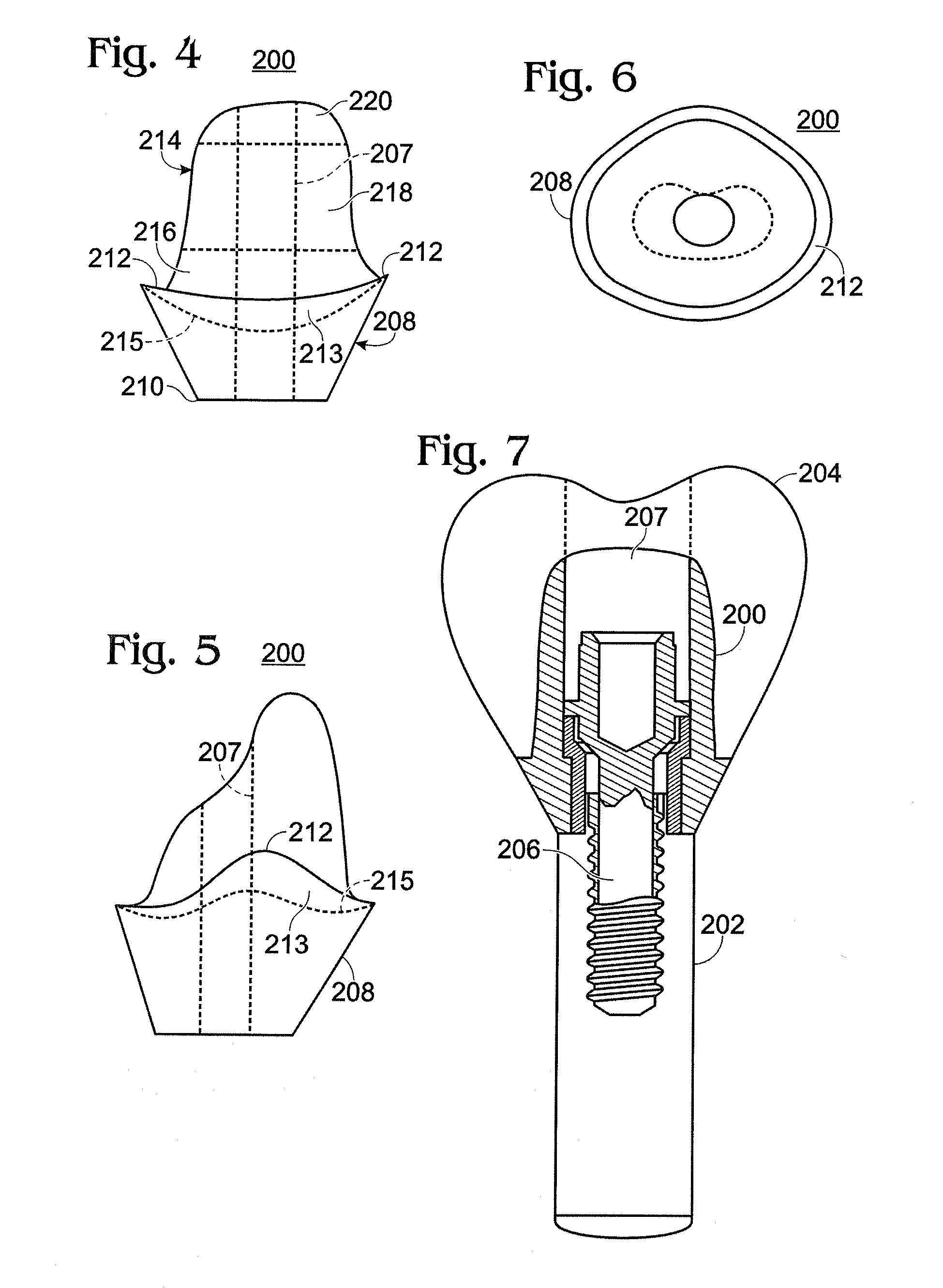

Support for sustaining and/or forming a dental prosthesis

InactiveUS6726480B1Avoid disadvantagesPrecise positioningDental implantsDental prostheticsDenturesEngineering

A support for sustaining and / or forming a dental prosthesis, comprises an axle, an anchoring part which can be anchored in a bone or a master model, and a head part which protrudes out of said bone or master mode. The head part has intermediate spaces distributed around the axis, i.e., several first intermediate spaces forming a divided circle, and a second, wider and / or deeper intermediate space. A cap can be fixed to the support. The cap has at least one projecting part for engaging in an intermediate space and, optionally, can be configured for fixing in several different rotational positions or a single rotational position, the support allowing exact positioning. The cap can also be produced without a projecting part of the type mentioned. The same support can be used to form different types of dental prostheses.

Owner:STRAUMANN HLDG AG +1

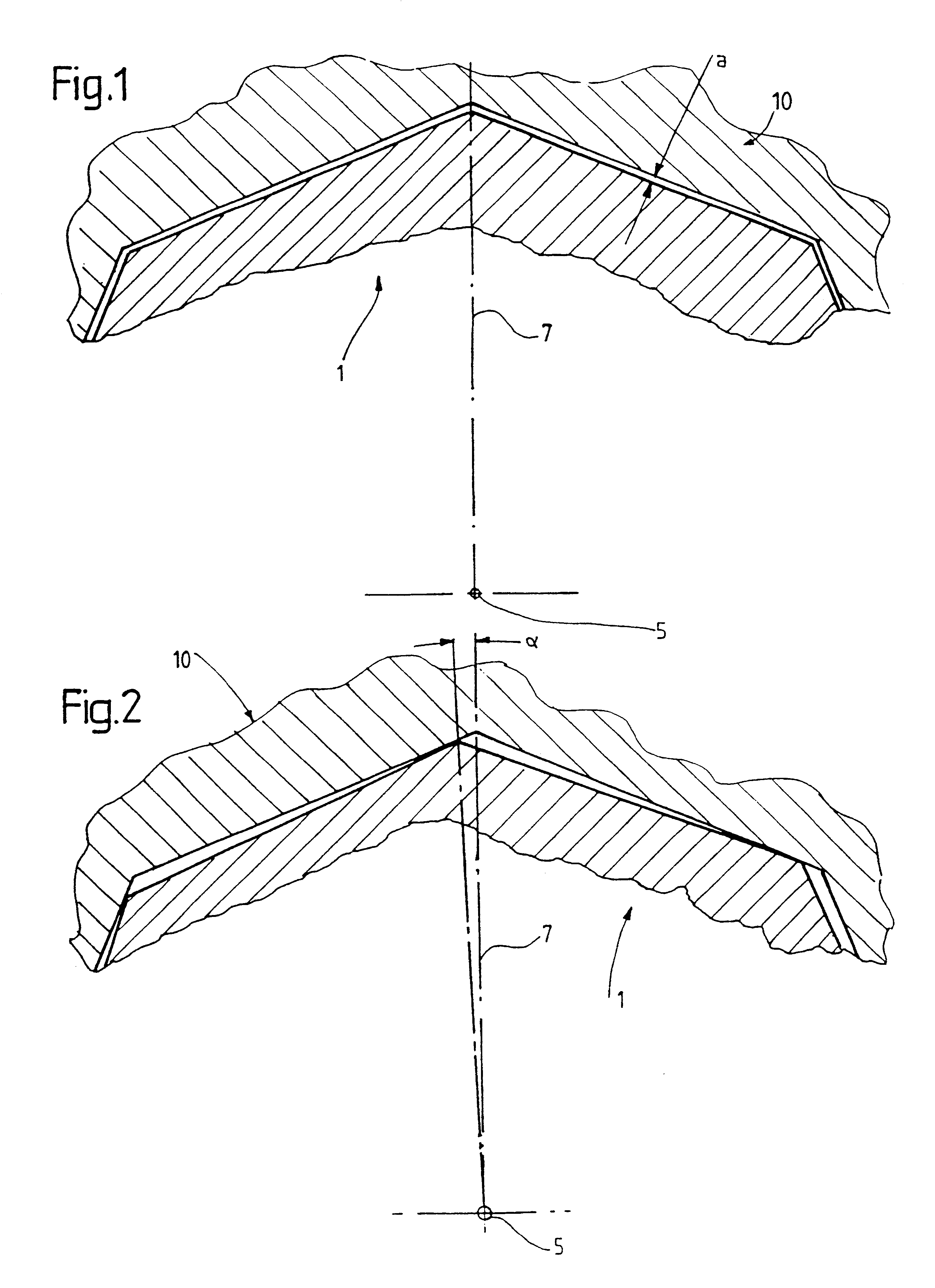

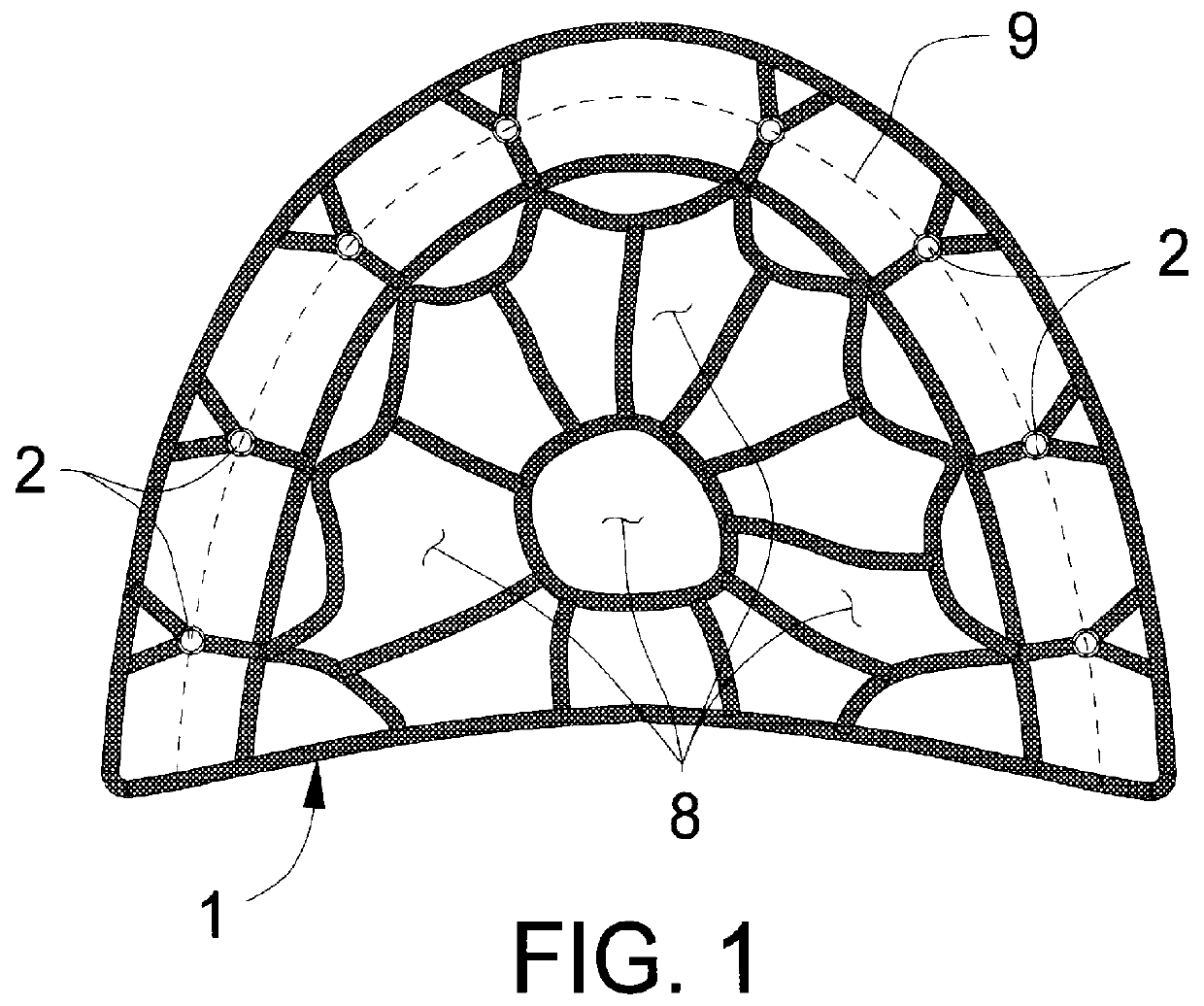

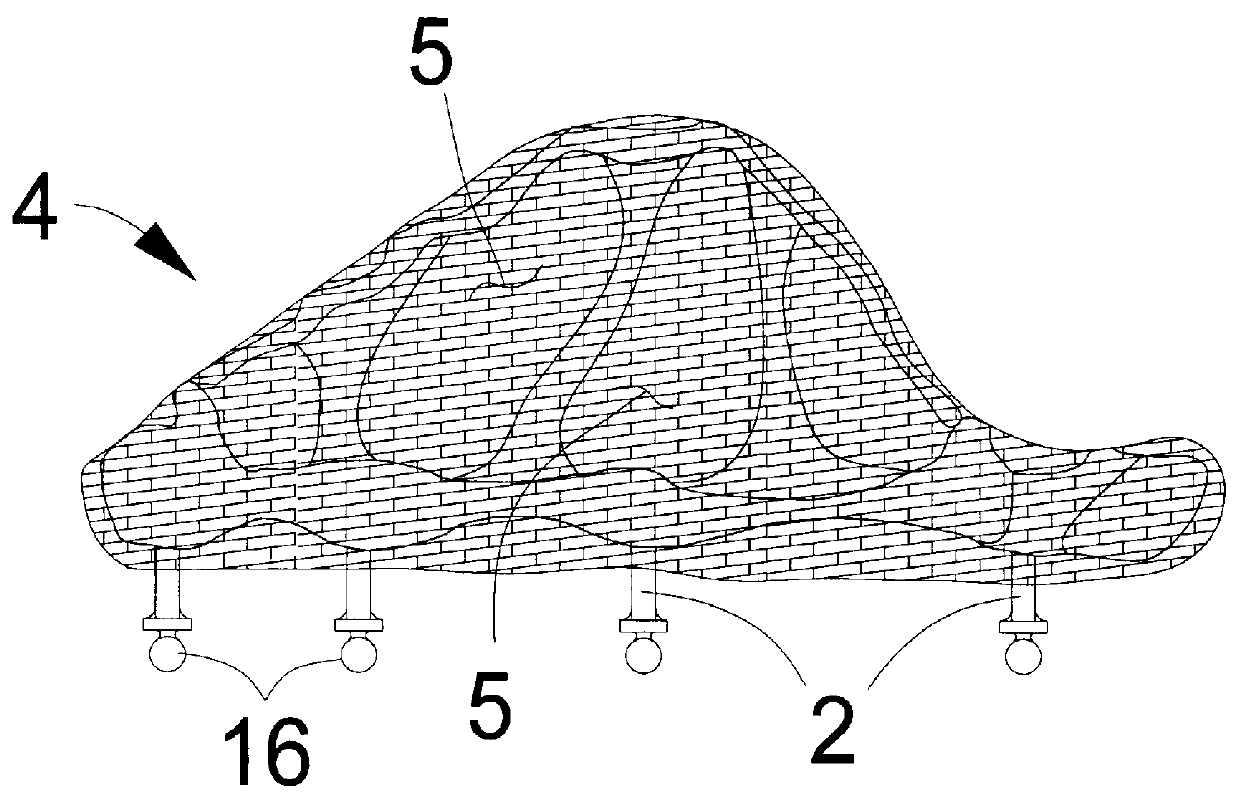

Osseo-integrated sub-periosteal implant

A sub-periosteally implantable prosthesis support structure for a fixed or detachable dental prosthesis includes a framework fitted to and generally conforming to the inner and outer contours of the bony ridge structures of a person. The framework is configured to provide a space extending generally normal to the bony ridge structure to an apex to provide space for subsequent bone growth. A plurality of denture support posts are distributed about the framework and depend outwardly from the apex in substantial alignment with the bony ridge structure. During the fabrication of the prosthesis support structure, a bio-compatible fine mesh screen is fixed to and spans, tent-like, the framework to substantially overlay the bone structure and the space provided for subsequent bone growth. After the support structure has been implanted, the growth of bone into the space and around the support structure is promoted to osseo-integrate the support structure with the person's bony ridge, thus providing a secure foundation for a denture or fixed dental prosthesis configured for detachable or fixed coupling with the denture support posts. The support structure may be made, partly or wholly, from either non-resorbable material, such as titanium stock and mesh, or from a resorbable material such as Vicryl TM .

Owner:ROBINSON DANE Q

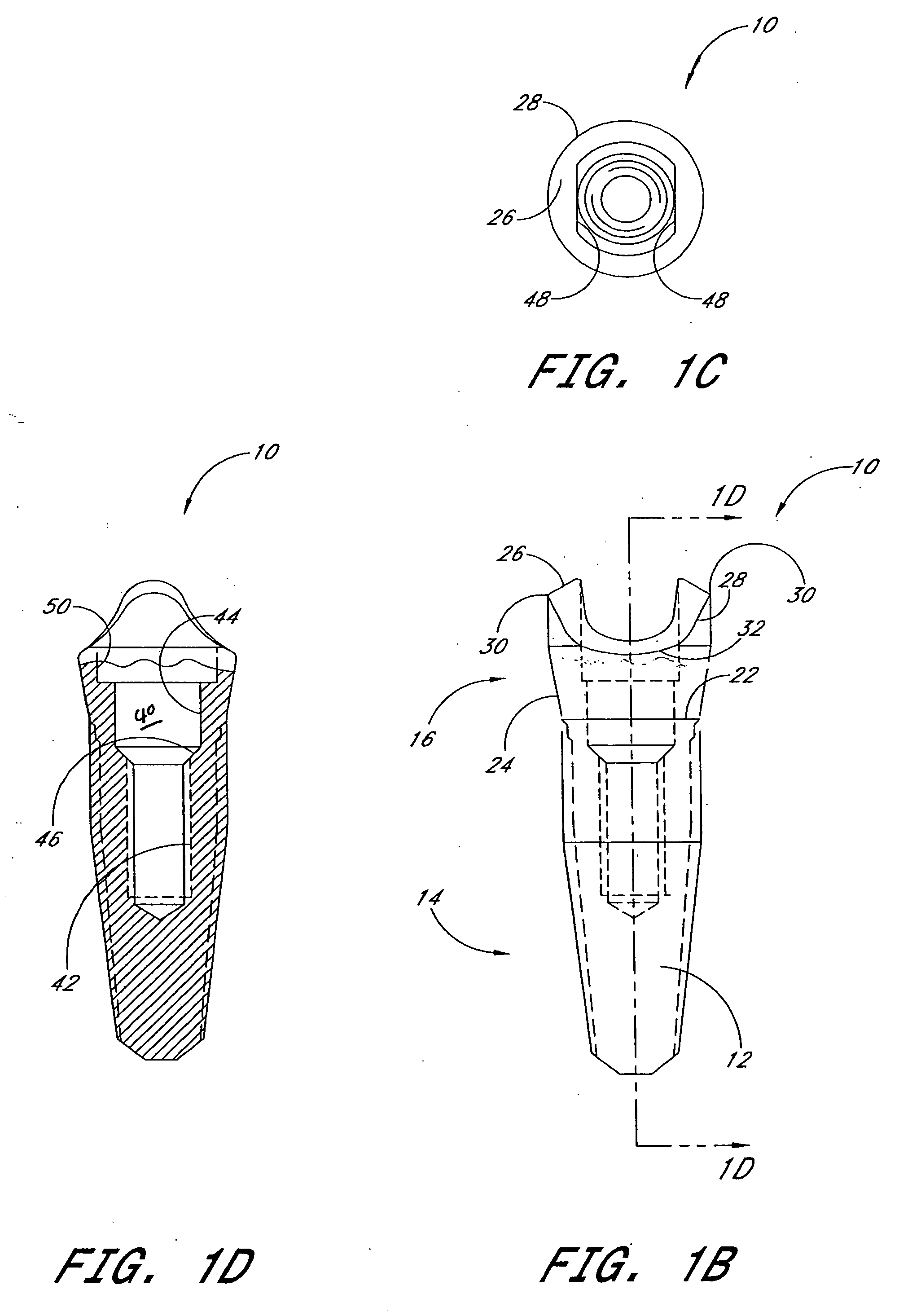

Dental Implant Abutment

A dental implant abutment for attaching a dental prosthesis within a patient's mouth. The abutment is a single unit structure fabricated of a ceramic material, multicolored throughout to match the color of the dental prosthesis, the surrounding dentition and the surrounding gingival tissue.

Owner:IVOCLAR VIVADENT AG

Synchronized views of video data and three-dimensional model data

ActiveUS20110050848A1Simple production processSpeed up the processTelevision system detailsImpression capsInteractive modelingSubject matter

Tools are described for preparing digital dental models for use in dental restoration production processes, along with associated systems and methods. Dental modeling is improved by supplementing views of three-dimensional models with still images of the modeled subject matter. Video data acquired during a scan of the model provides a source of still images that can be displayed alongside a rendered three-dimensional model, and the two views (model and still image) may be synchronized to provide a common perspective of the model's subject matter. This approach provides useful visual information for disambiguating surface features of the model during processing steps such as marking a margin of a prepared tooth surface for a restoration. Interactive modeling tools may be similarly enhanced. For example, tools for margin marking may synchronize display of margin lines between the still image and the model so that a user can interact with either or both of the visual representations, with changes to a margin reflected in both displays.

Owner:MEDIT CORP

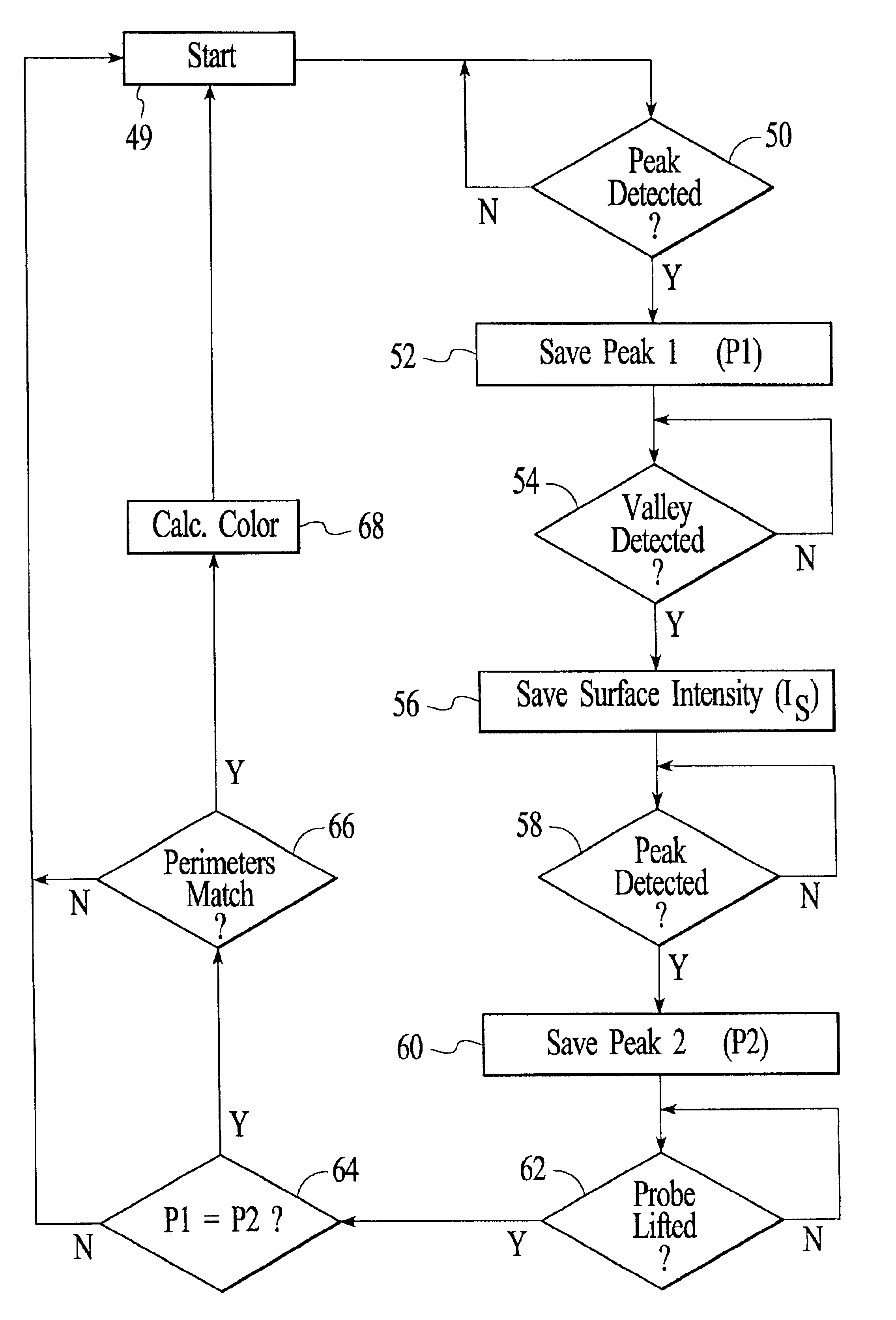

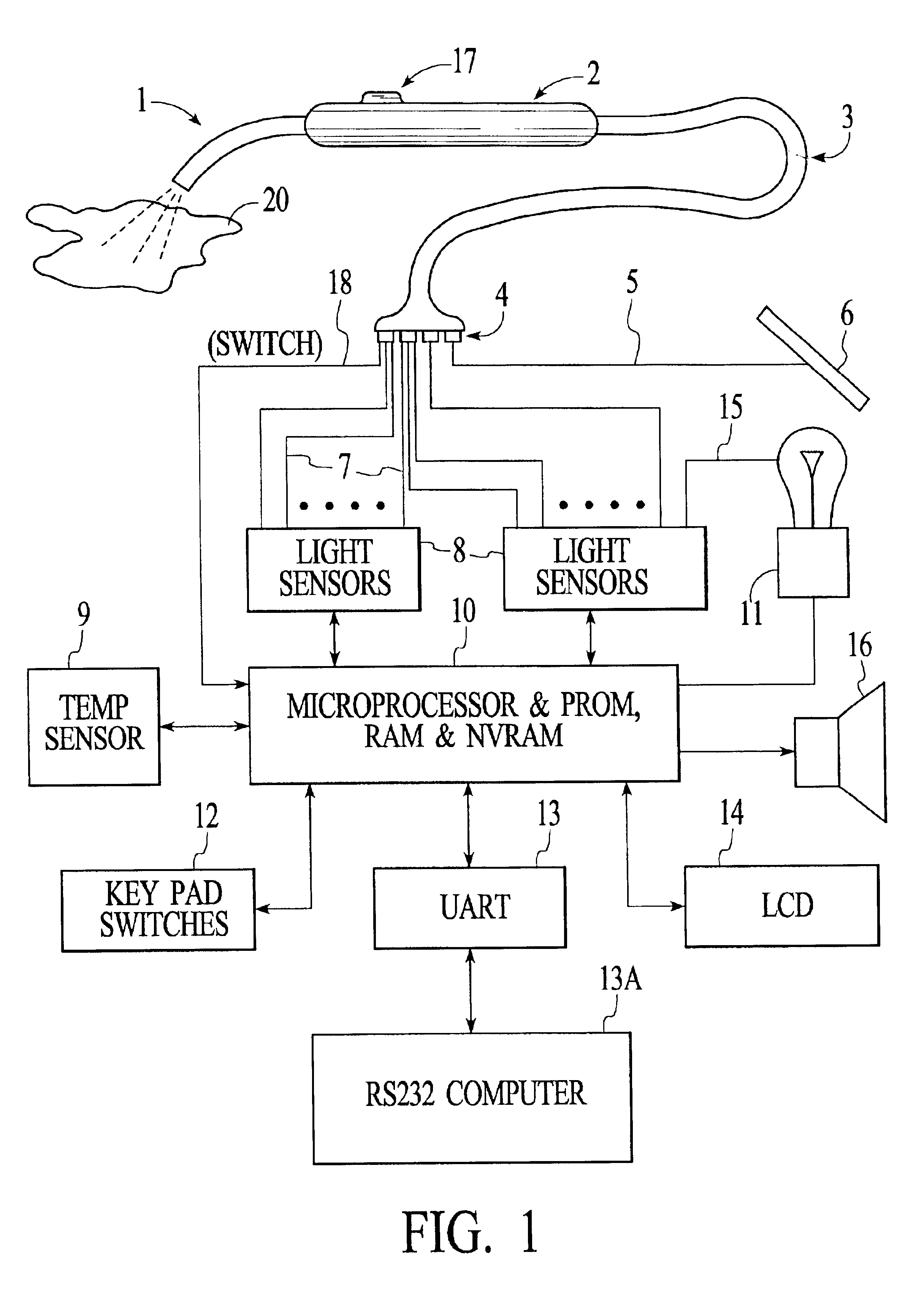

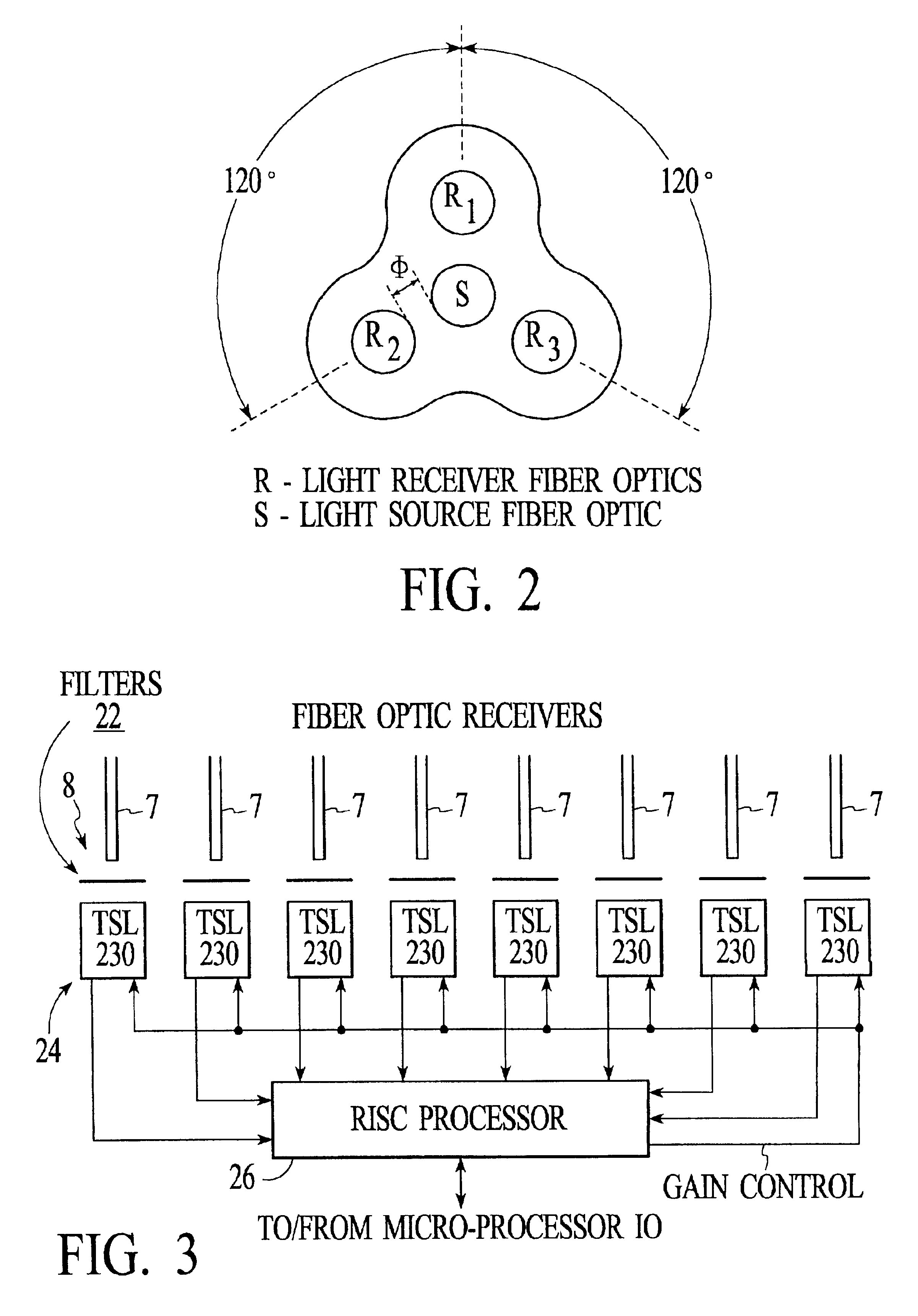

Apparatus for determining multi-bit data via light received by a light receiver and coupled to spectral sensors that measure light in spectral bands

Optical characteristic measuring systems and methods such as for determining the color or other optical characteristics of teeth are disclosed. Perimeter receiver fiber optics preferably are spaced apart from a source fiber optic and receive light from the surface of the object / tooth being measured. Light from the perimeter fiber optics pass to a variety of filters. The system utilizes the perimeter receiver fiber optics to determine information regarding the height and angle of the probe with respect to the object / tooth being measured. Under processor control, the optical characteristics measurement may be made at a predetermined height and angle. Various color spectral photometer arrangements are disclosed. Translucency, fluorescence, gloss and / or surface texture data also may be obtained. Audio feedback may be provided to guide operator use of the system. The probe may have a removable or shielded tip for contamination prevention. A method of producing dental prostheses based on measured data also is disclosed. Measured data also may be stored and / or organized as part of a patient data base. Such methods and implements may be desirably utilized for purposes of detecting and preventing counterfeiting or the like. Low cost and small form factor spectrometers, and methods for manufacturing the same, also are disclosed. Spectrometers and spectrophotometers embedded in printing and scanning and other type devices, as well as computer companion devices, scope-type devices and the like, also are disclosed. Data encoding based on such devices also may be implemented.

Owner:RPX CORP

Method and apparatus for color matching of slightly colored translucent objects such as teeth and dental prosthesis, in particular

The invention relates to a method and apparatus for color matching of slightly colored objects which are transparent, diffusing an absorbent, by acuminating a small error of the objects with a first bunch of optical fibers. A second bunch of optical fibers is used to pick up the light back scattered from the area of the objects. The second fibers are located inside of the illuminating fibers. The light is measured at 3 wavelengths that correspond to blue, green and red colors and the pigmentation of the object is calculated as a difference between the red and blue spectrum components. Presentation of the brightness is calculated to be proportional to the green spectrum component. The pigmentation and brightness is then compared with the same perimeters of a standard shape pallet. The invention is particularly suitable for color matching the teeth in the mouth with dental prosthesis and dental restorative materials.

Owner:RAWICZ ANDREW +2

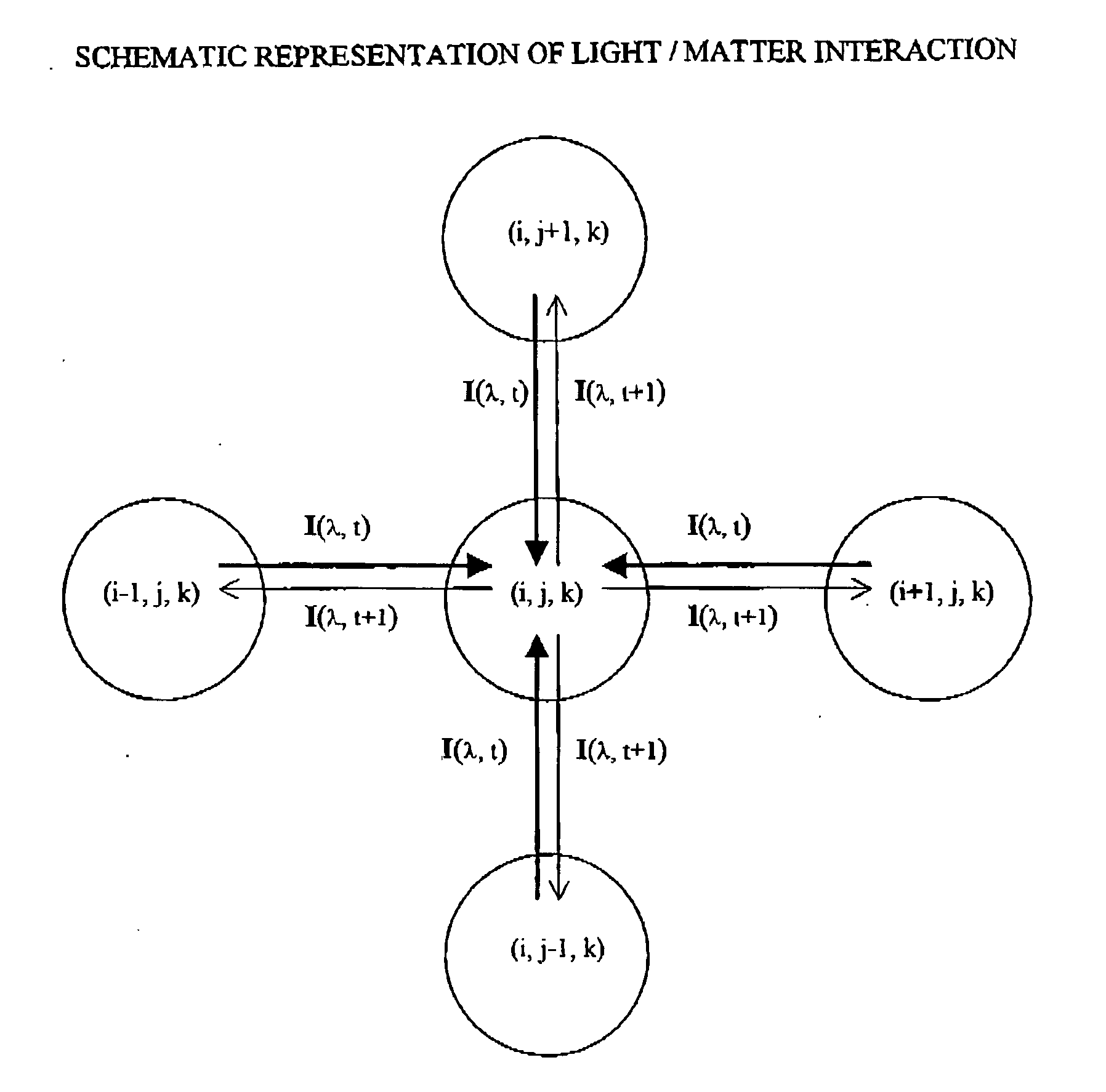

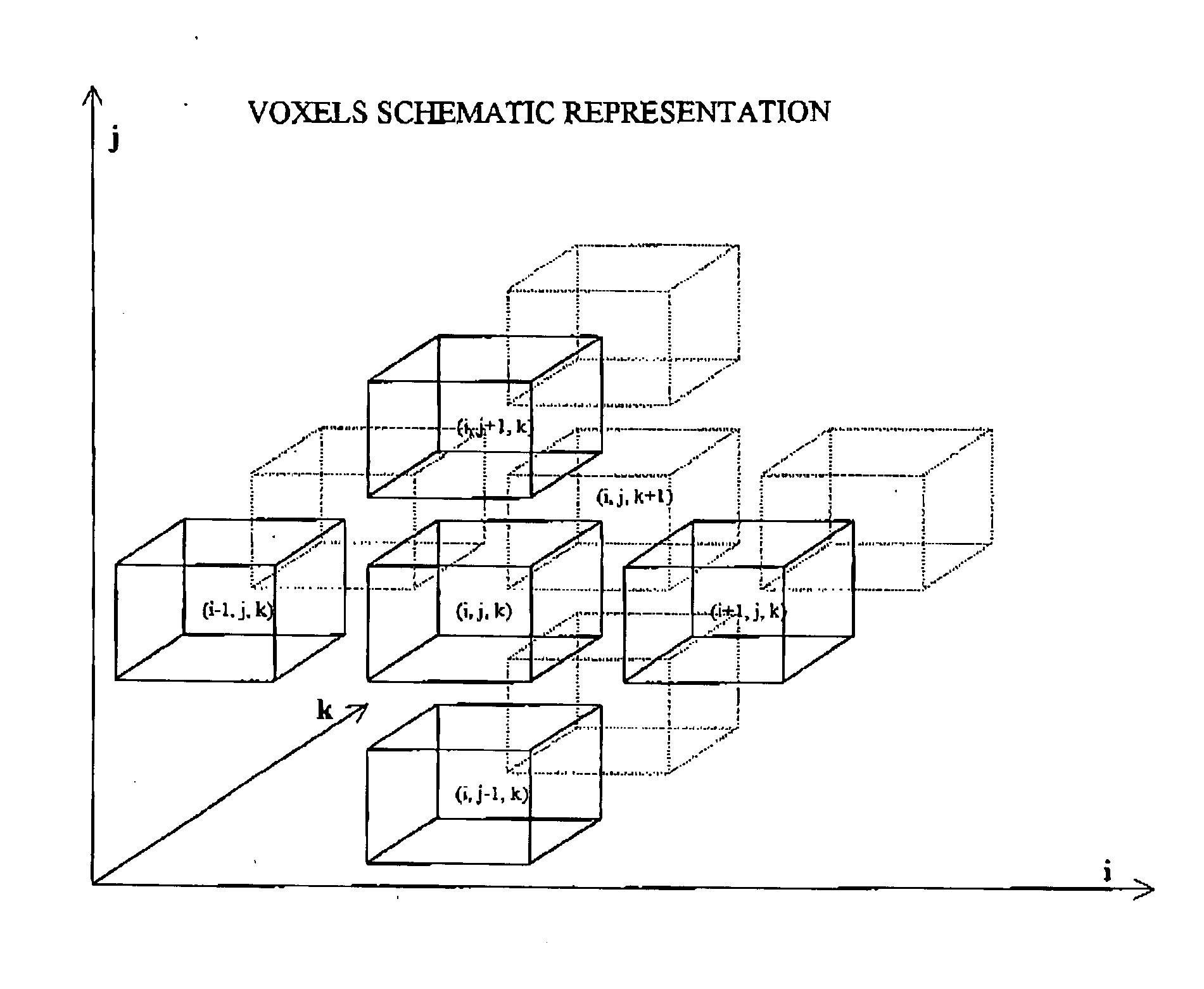

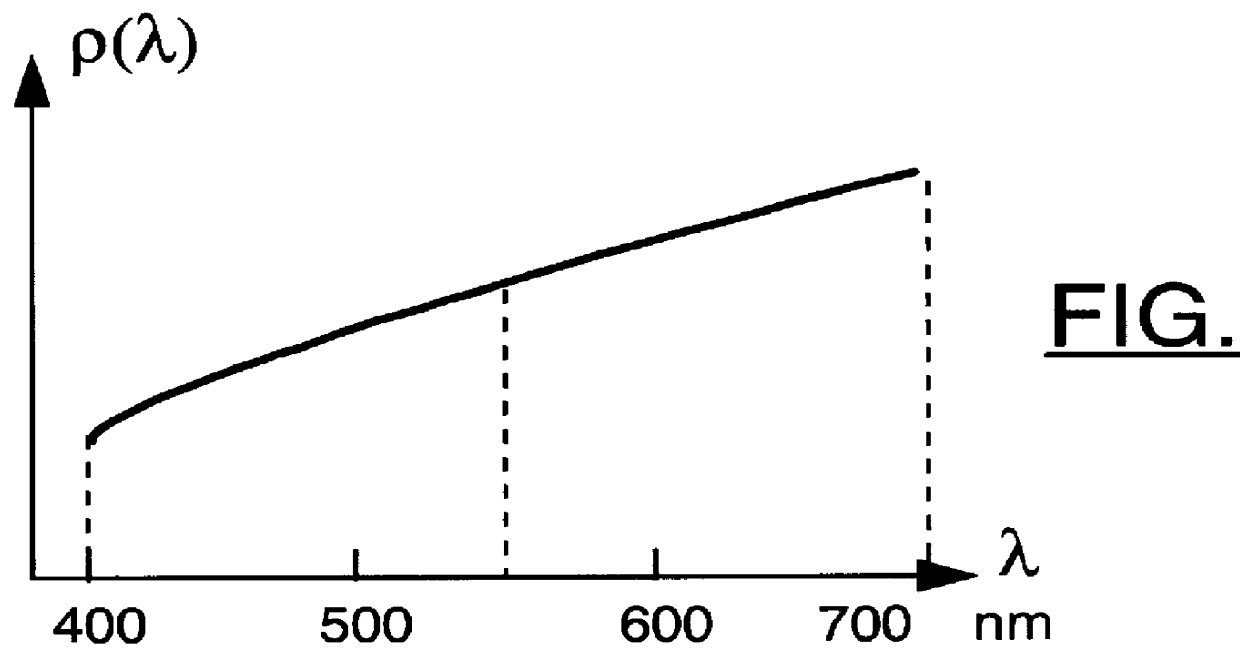

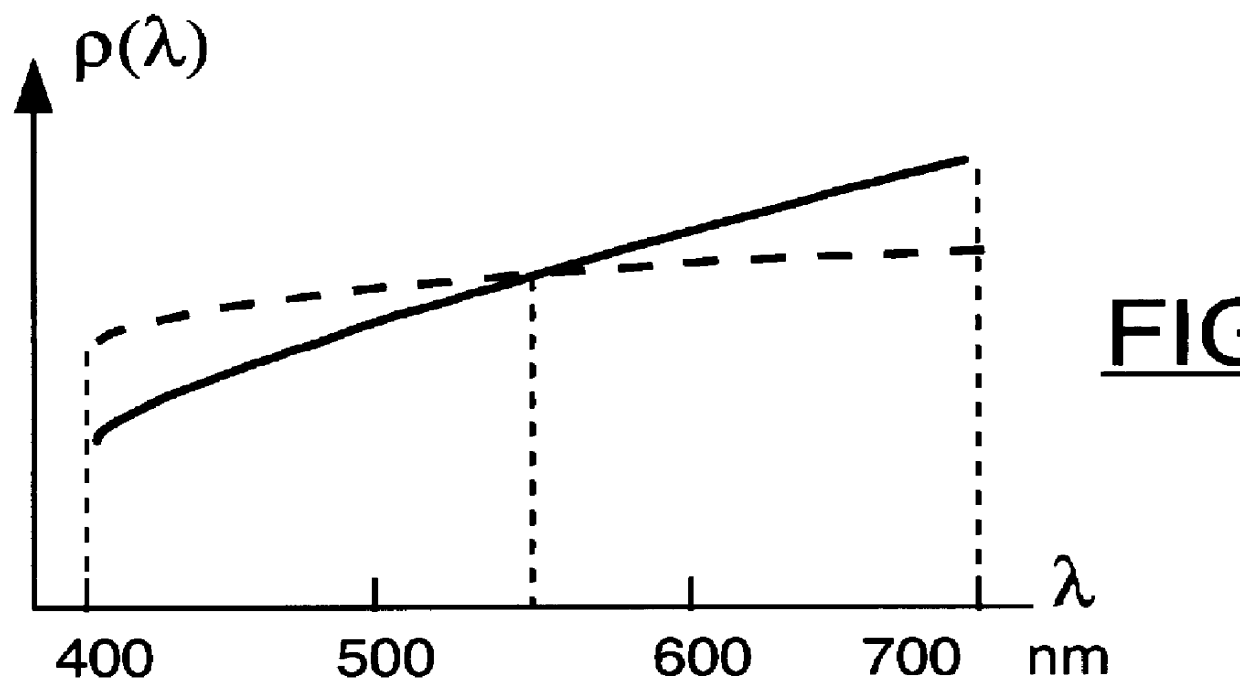

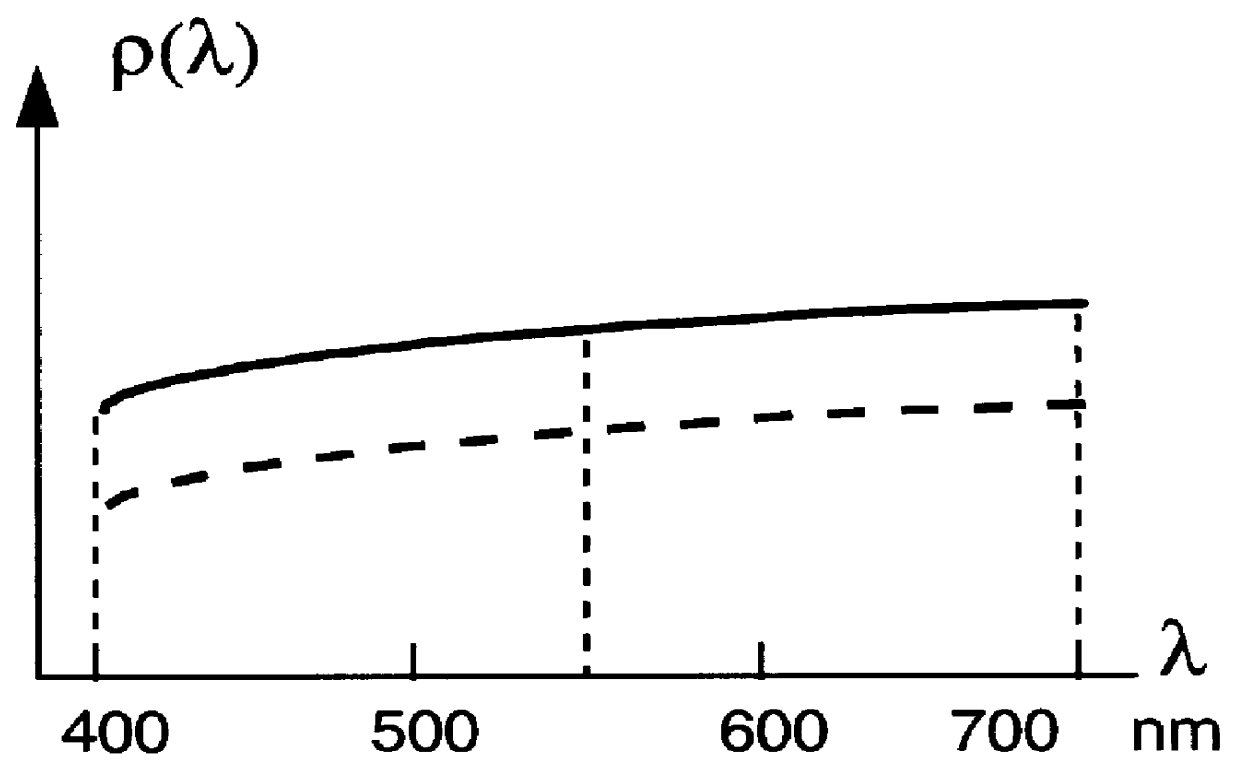

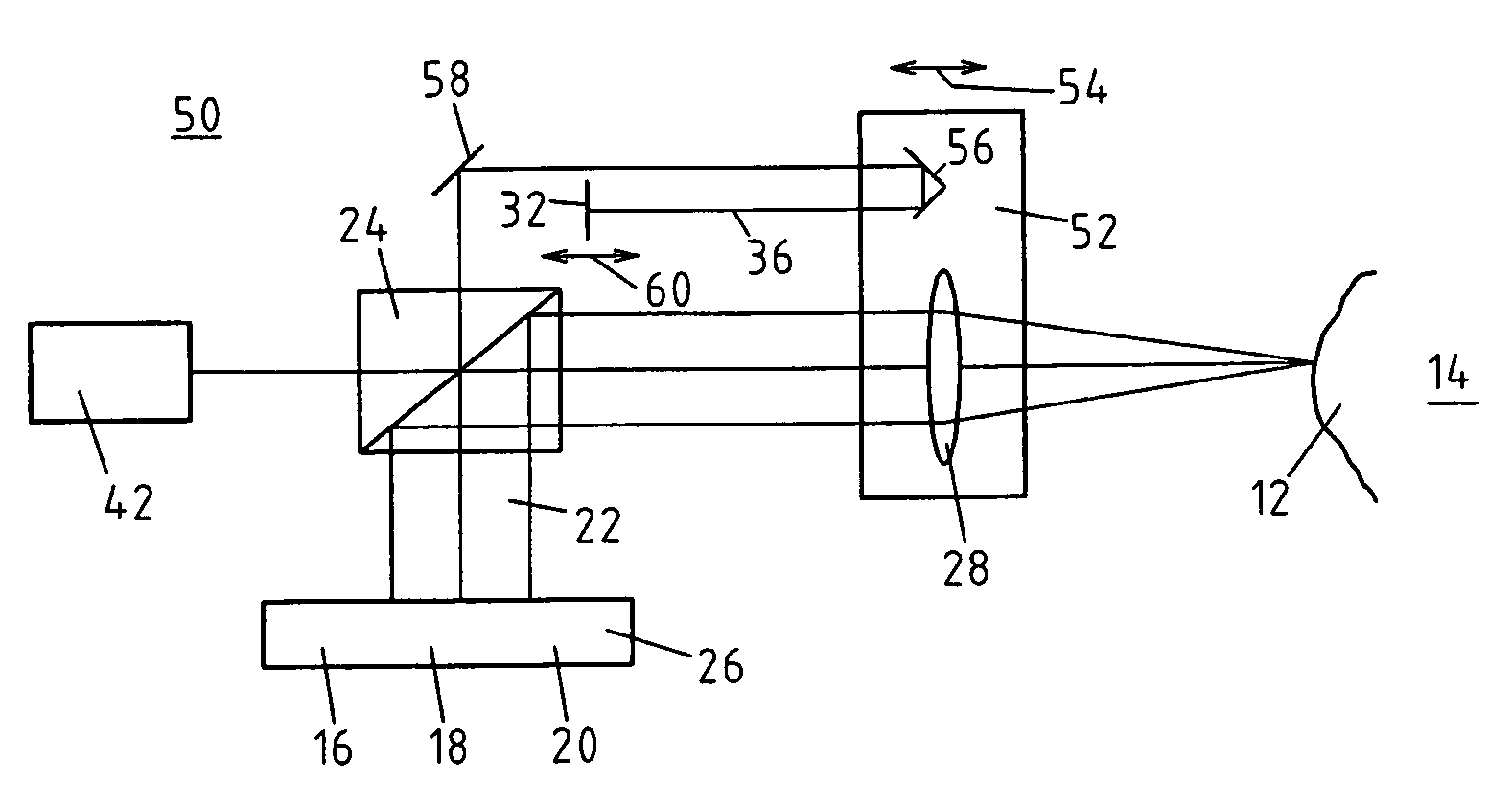

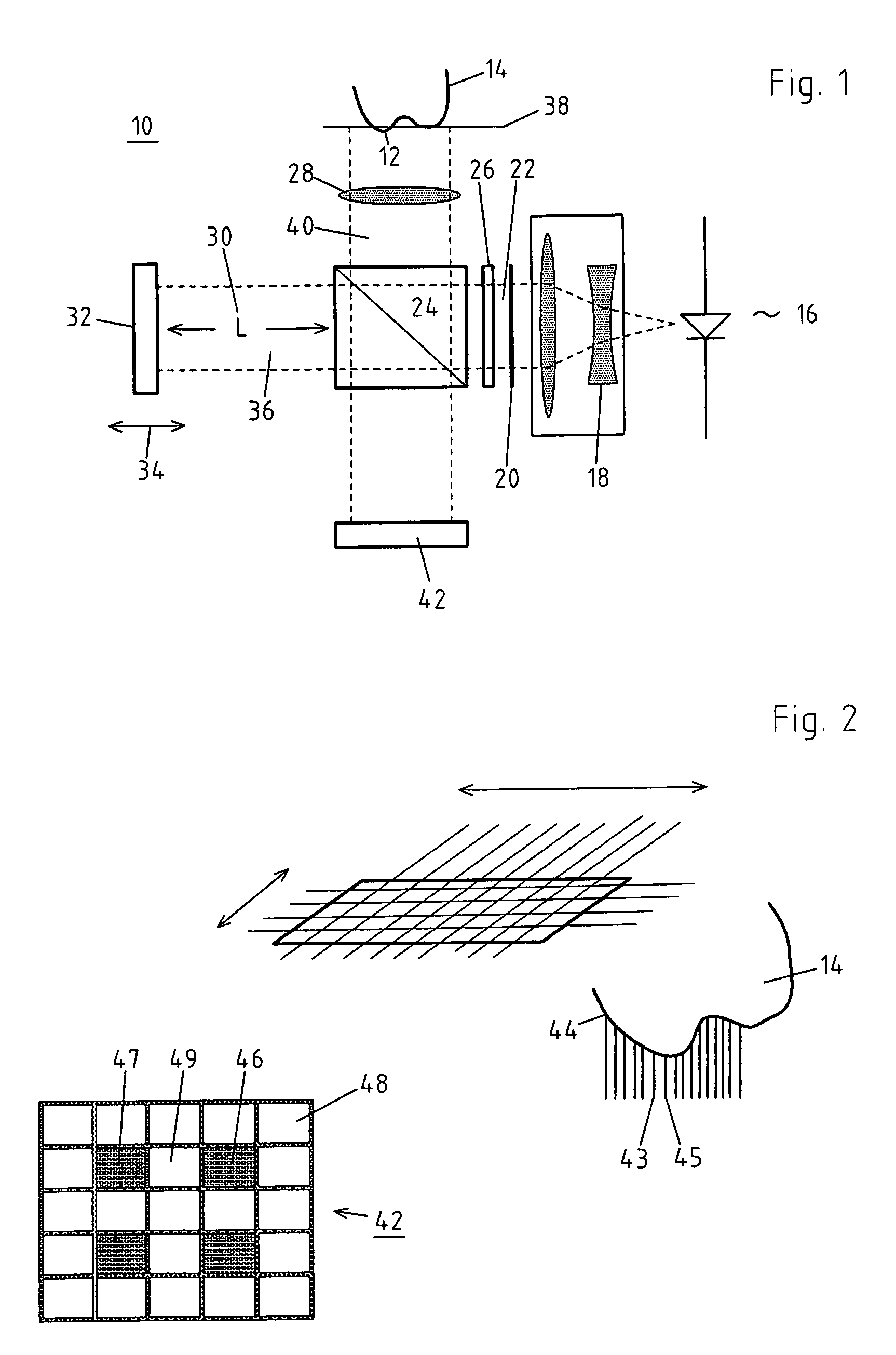

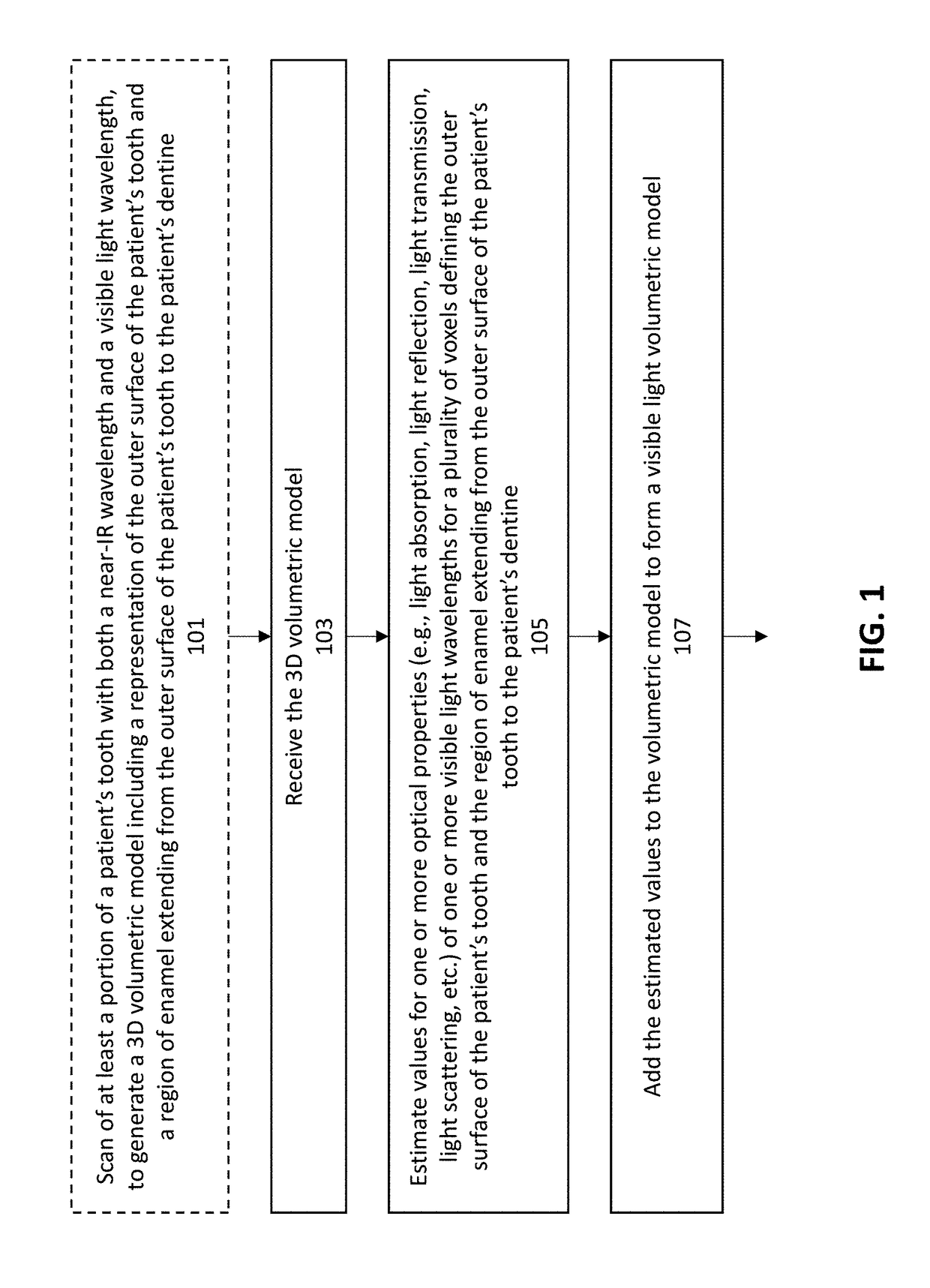

Method and device for detecting the contour data and/or optical characteristics of a three-dimensional semi-transparent object

ActiveUS7872760B2Improve signal-disturb signal ratioHigh resolutionImpression capsRadiation pyrometryOptical propertyLight beam

A method and device for detecting the contour data and / or optical characteristics of an object, such as a tooth or a tooth restoration, based on an interference and / or autocorrelation measurement using an image sensor. To permit an exact surface detection in addition to a determination of the optical characteristics of the object, individual light beams strike the object, which are located at a distance from one another in such a way that no impact of reflected individual light beams takes place on immediately adjacent pixels of the image sensor.

Owner:DEGUDENT

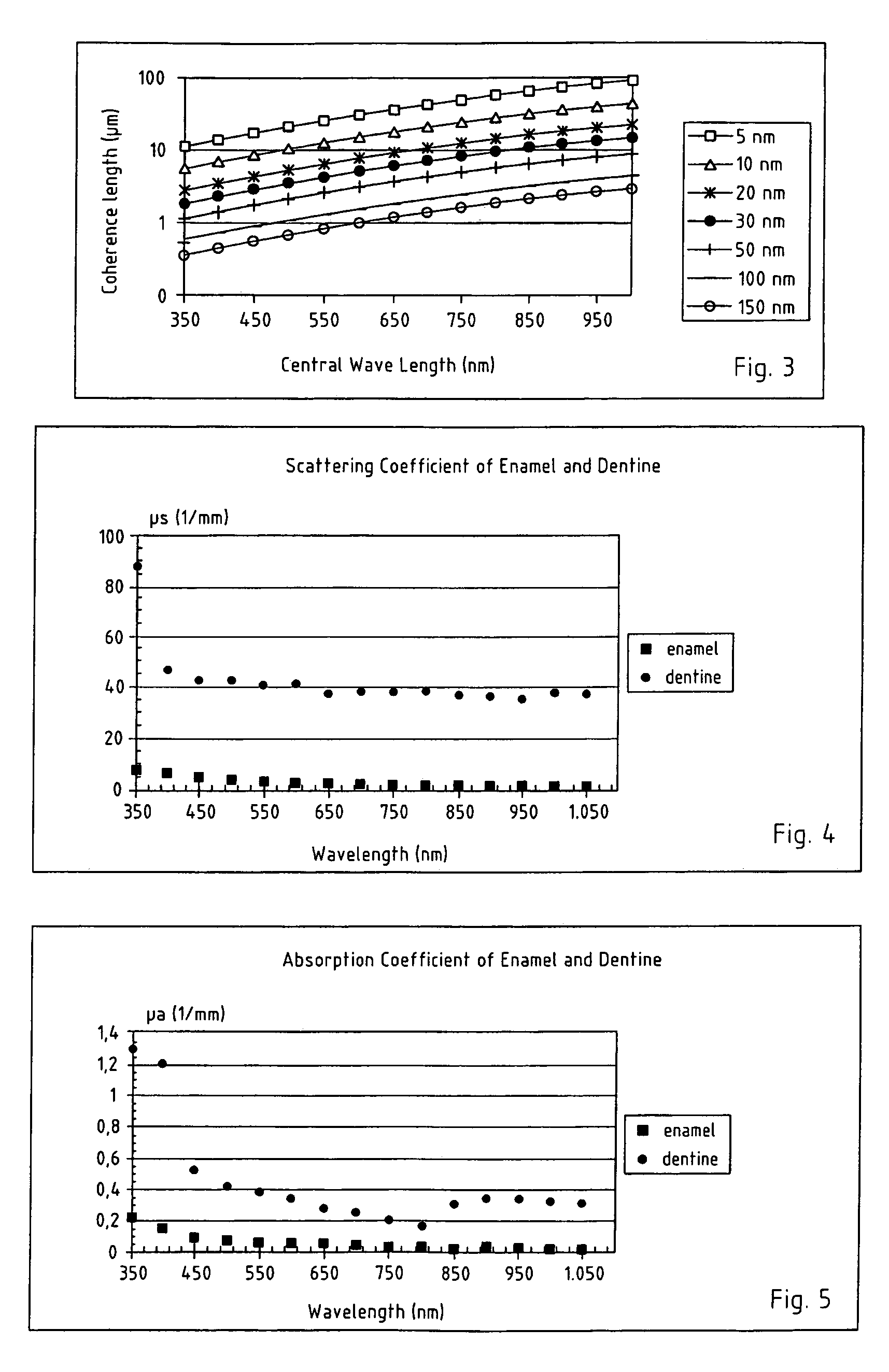

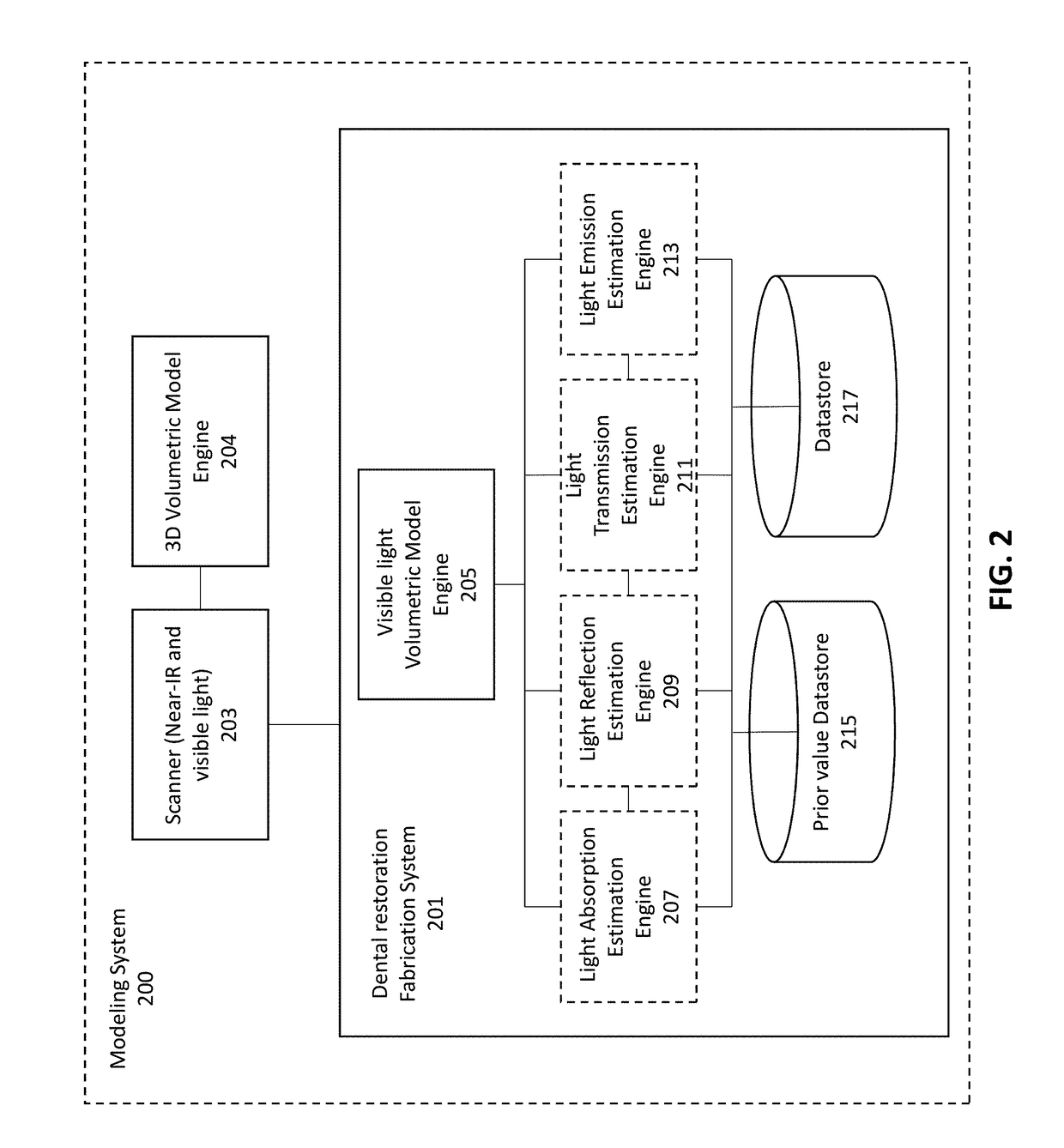

Tooth shading, transparency and glazing

ActiveUS20190029784A1Highly accurate three-dimensional modelImpression capsImage analysisNatural toothComputer science

Systems, methods, and / or computer-readable media described herein provide technical solutions to the highly technical problems of machine generation of dental restorations. In particular, these systems, methods and / or computer readable media may provide technical solutions to aid in the creation of dental restorations that more closely resemble a natural tooth (including its internal optical structure). These systems, methods and / or computer readable media may help in virtually rendering a tooth, including its internal optical structure, and apply these renderings (e.g., digital models) to the fabrication of the dental restoration.

Owner:ALIGN TECH

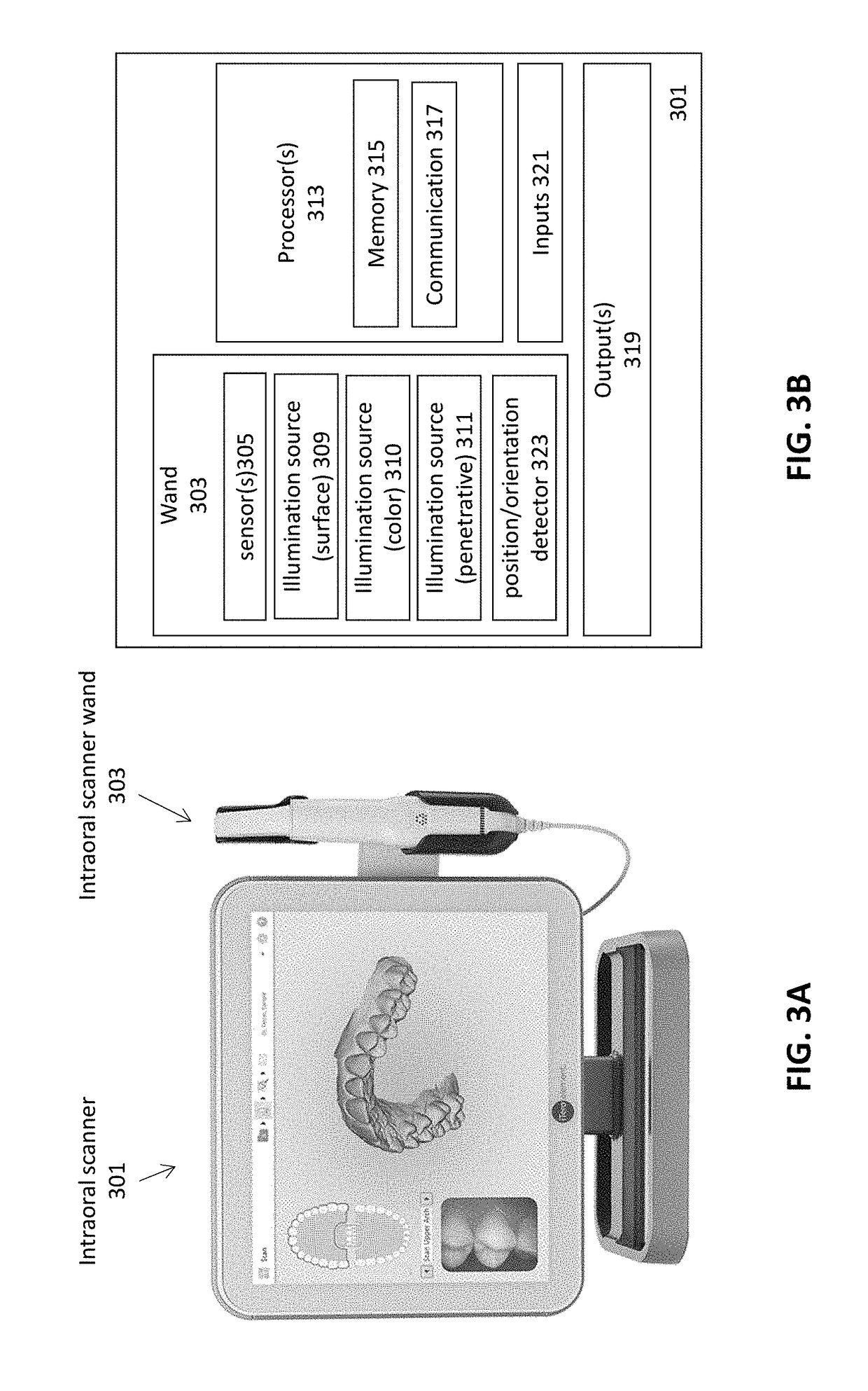

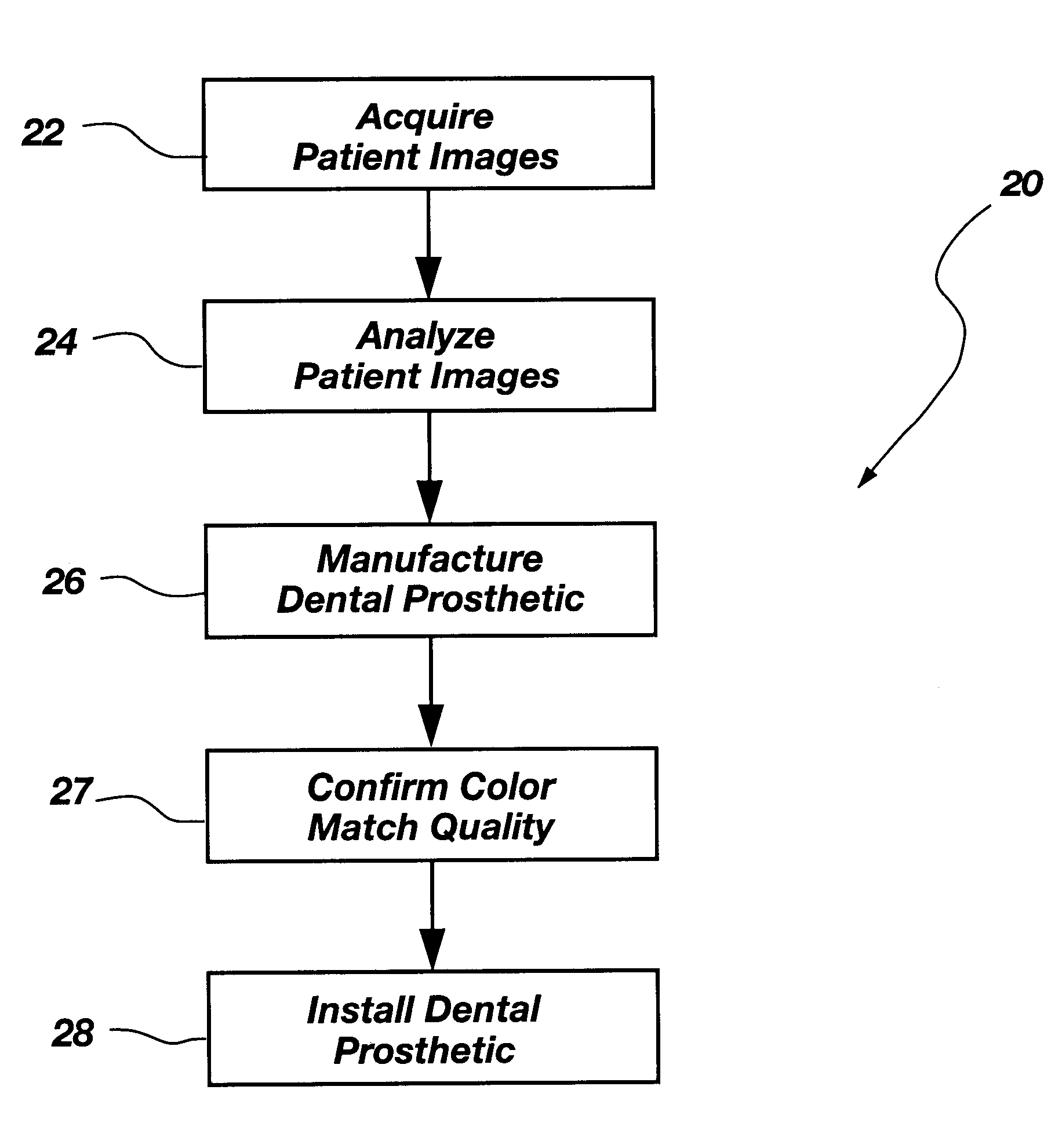

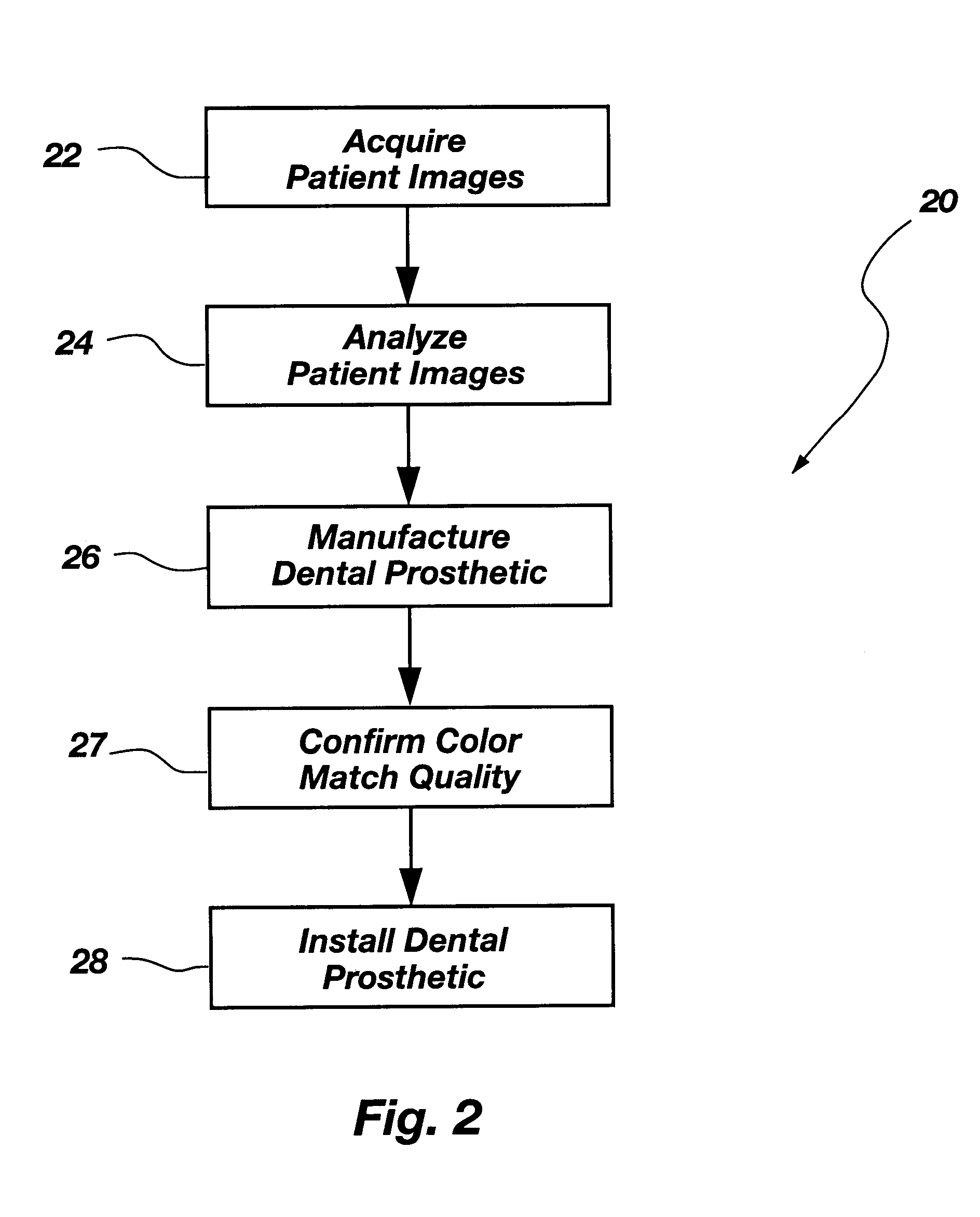

Method, apparatus and system for automated tooth shade analysis and matching

Methods, apparatuses and systems for tooth shade analysis and matching are disclosed. A method embodiment according to the invention includes acquiring at least one image, the image including one or more teeth of a patient and normalization references, normalizing the at least one image in accordance with the normalization references, determining the color of the teeth as composed of colors from one or more selected shade standards, communicating the standardized color information to a dental laboratory, manufacturing a dental prosthesis based on the standardized color information and installing the dental prosthetic. Normalization is performed to correct patient images for variations in lighting conditions and image source. Normalization references include a black reference, a white reference and at least one color reference. The normalized image is standardized by matching the pixels of the normalized image to selected shade standards. Selected shade standards may include incisal tooth shade standards. The standardized color image and / or analysis may be communicated to a dental laboratory according to aspects of the invention. The dental prosthesis can then be manufactured by a lab technician by referring to the standardized image. Color models according to the invention may include RGB, HSI and other models for representing color images. The methods, apparatuses and systems for tooth shade analysis and matching are also applicable to direct restorations of natural teeth, such as repair of chipped or broken teeth.

Owner:DENTECH

Method, machine-readable medium and computer concerning the manufacture of dental prostheses

InactiveUS20080153069A1Easy and inexpensive to manufactureEasy and inexpensiveTooth crownsTeeth cappingMaterials scienceDental prosthesis

The invention relates to a method by which a mold for casting, such as metal casting, of dental prostheses is prepared, with the step of: preparing the mold on the basis of mold model data with a CAM / CAD method. Furthermore, the invention relates to a method for the determination of a shape of a mold for casting, such as metal casting, of dental prostheses with the step of: creating mold model data describing the shape of the mold.

Owner:INSTITUT STRAUMANN AG

Non-Pre-Colored Multi-Layer Zirconia Dental Blank that has a Gradual Change in Chroma through a Thickness After Sintering

InactiveUS20130224454A1Small productImproved and more natural optical characteristicArtificial teethCeramic layered productsChemical compositionDentistry

Owner:B & D DENTAL

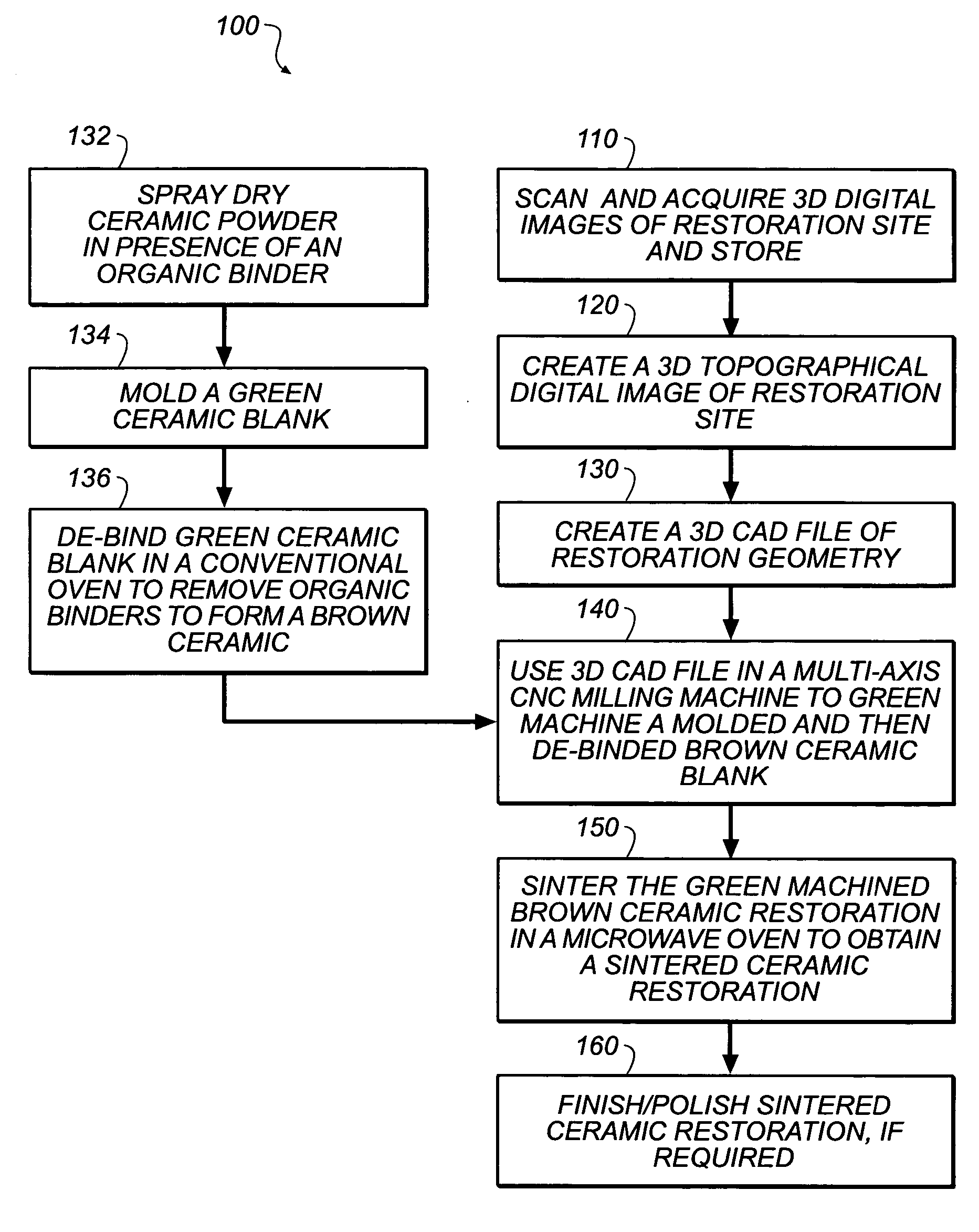

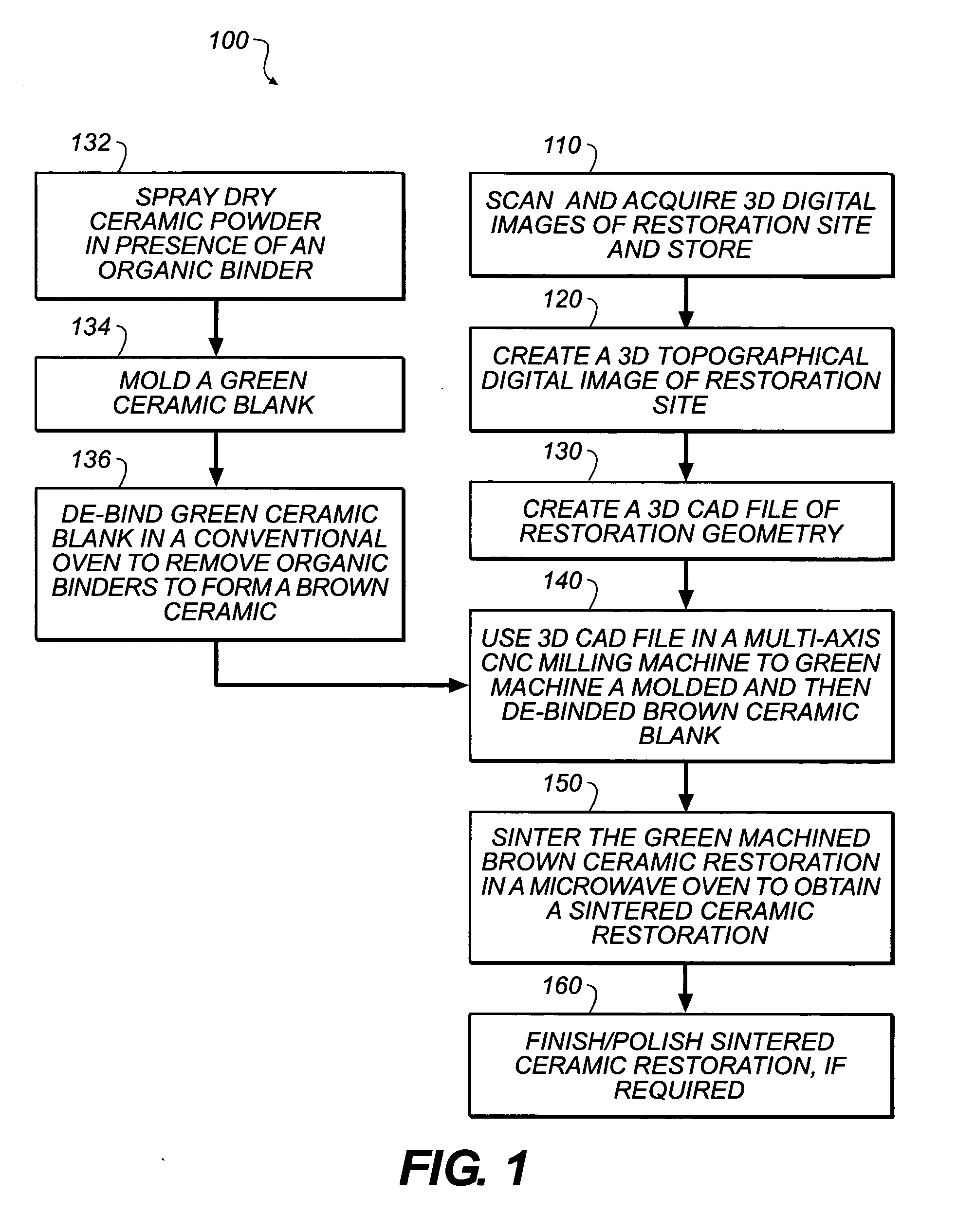

Method of making ceramic dental restorations

InactiveUS20050261795A1Without diminishing easeHigh speedTeeth fillingSpecial data processing applicationsHigh densityDental surgeon

Dental restorations can be made by acquiring a three-dimensional digitized image of a dental restoration site. A ceramic blank from which volatile organic binders have been removed, is then machined according to the three-dimensional digitized image to form a “brown” ceramic restoration. This material is then sintered using microwave energy to provide a high density ceramic dental restoration corresponding to the dental restoration site. This method can be carried out within a few hours thereby saving the patient several dental visits and enabling the dentist to better serve the patient directly in the office.

Owner:EASTMAN KODAK CO

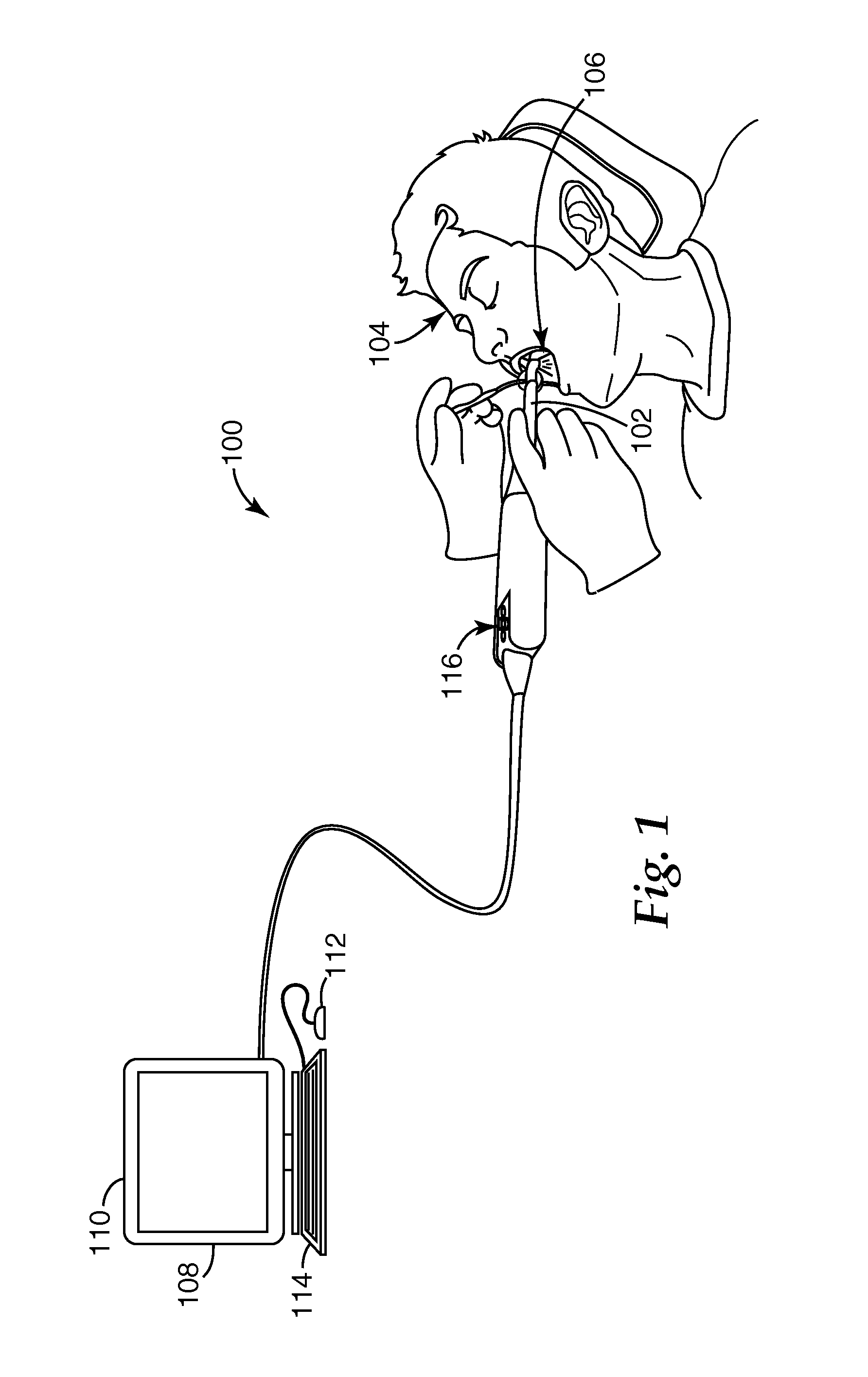

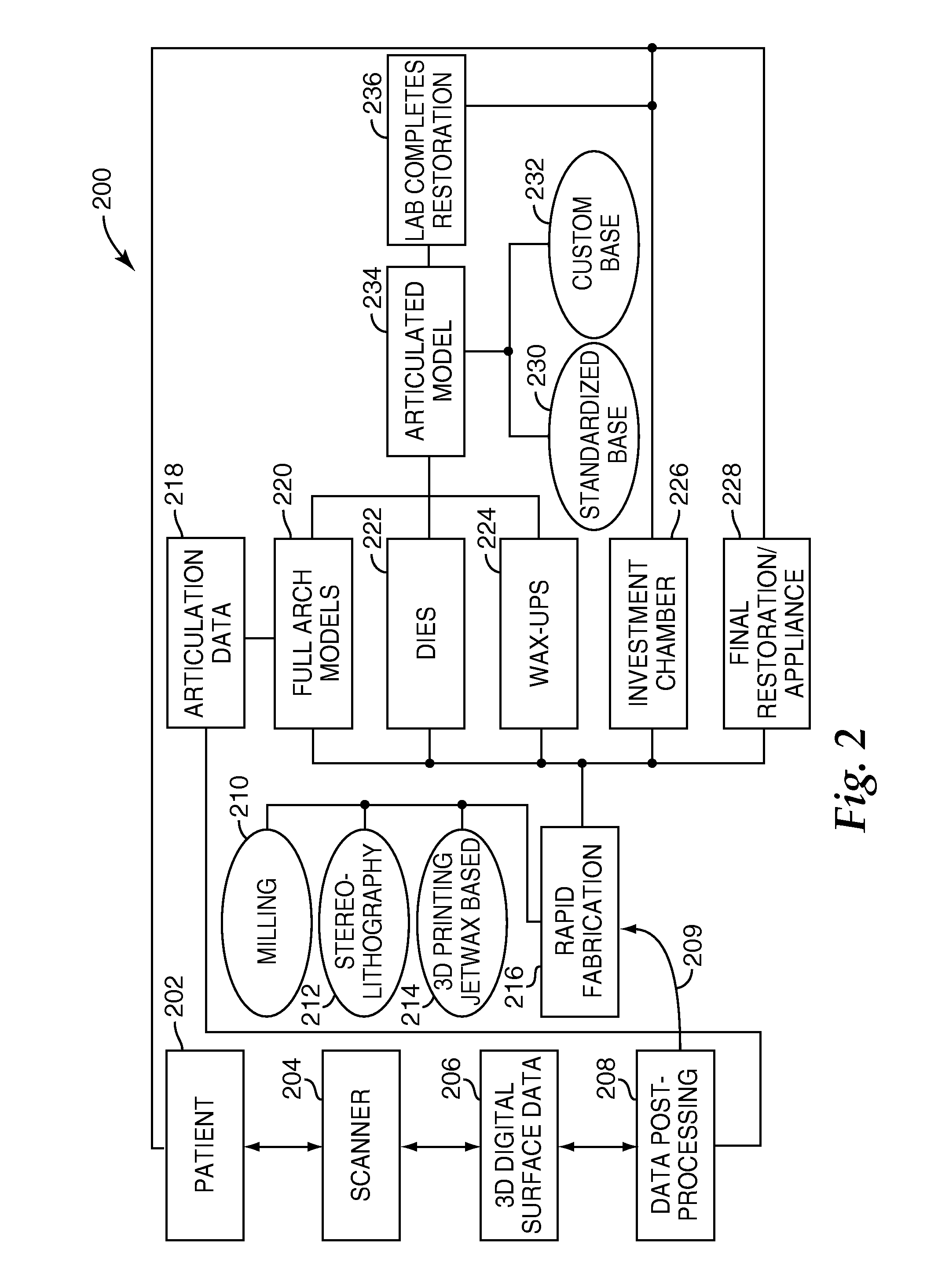

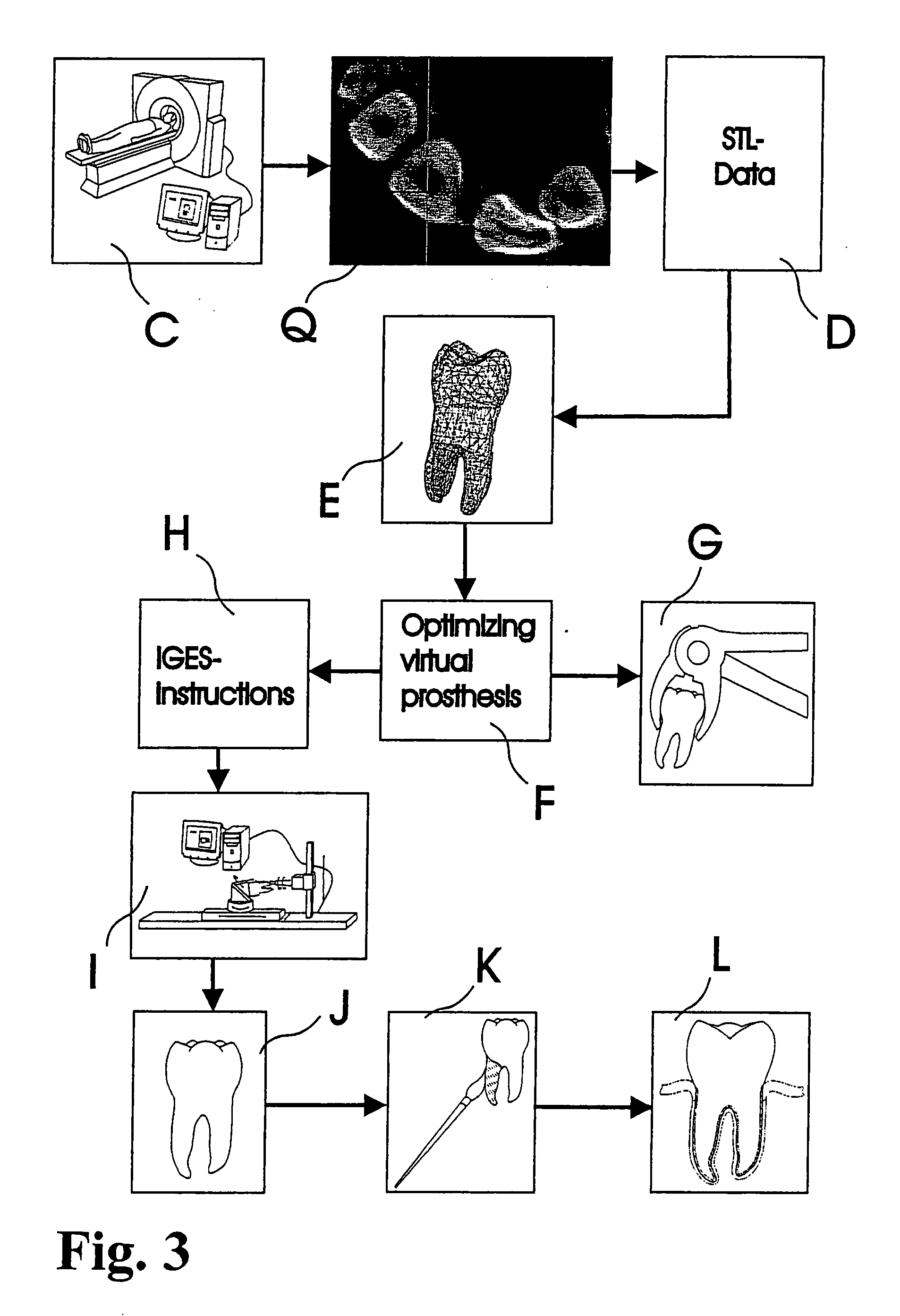

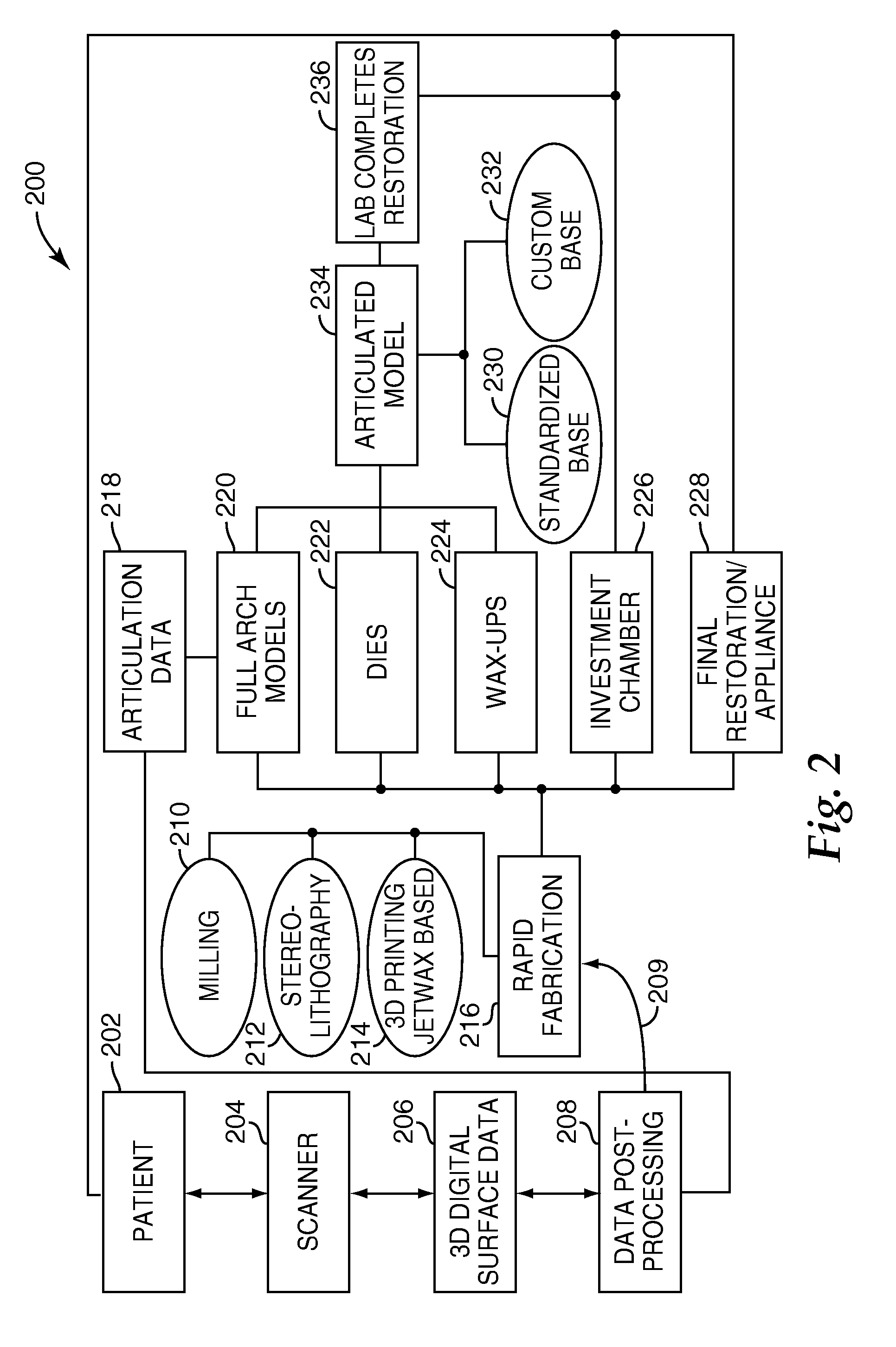

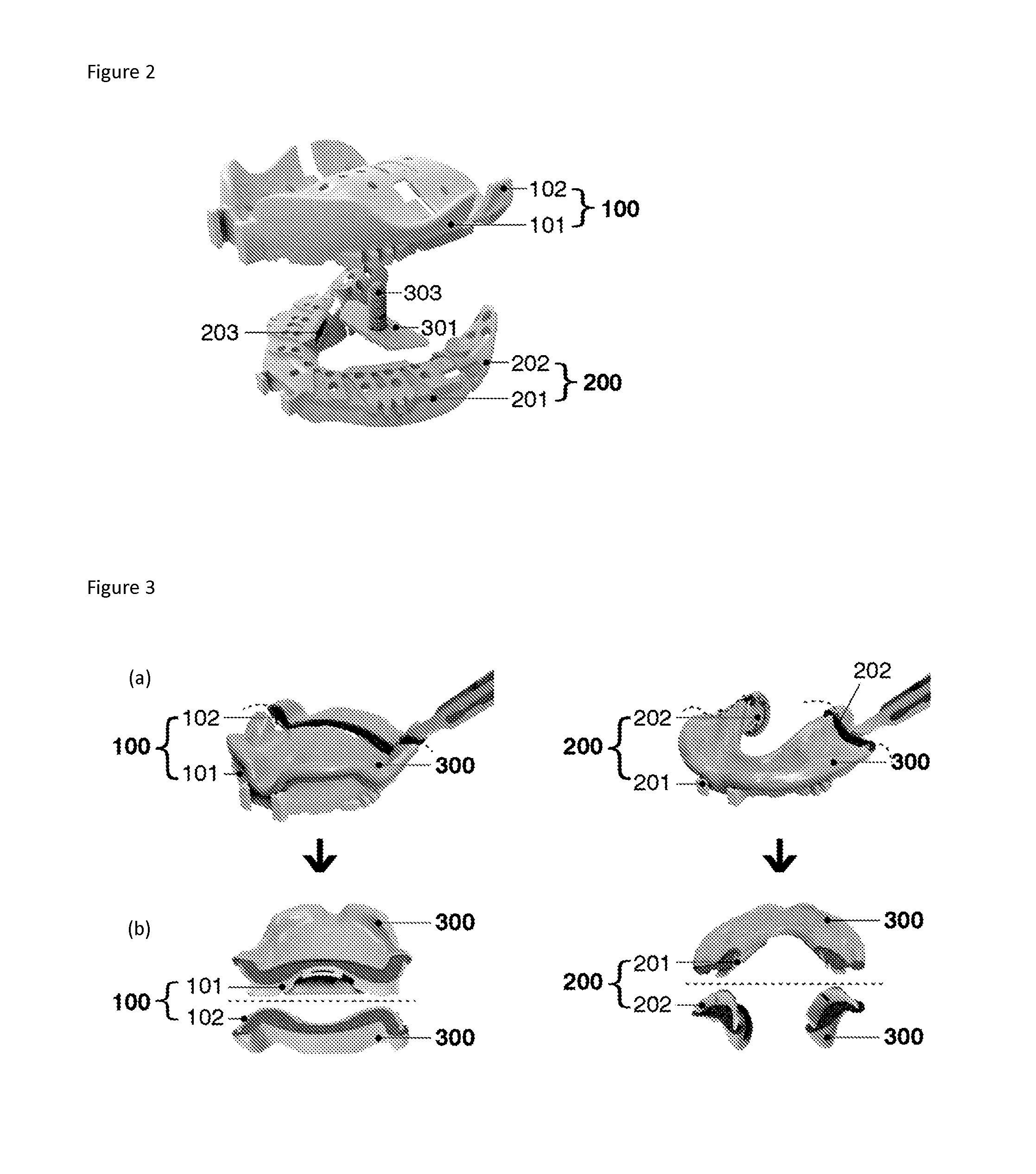

Computer-aided Fabrication Of A Removable Dental Prosthesis

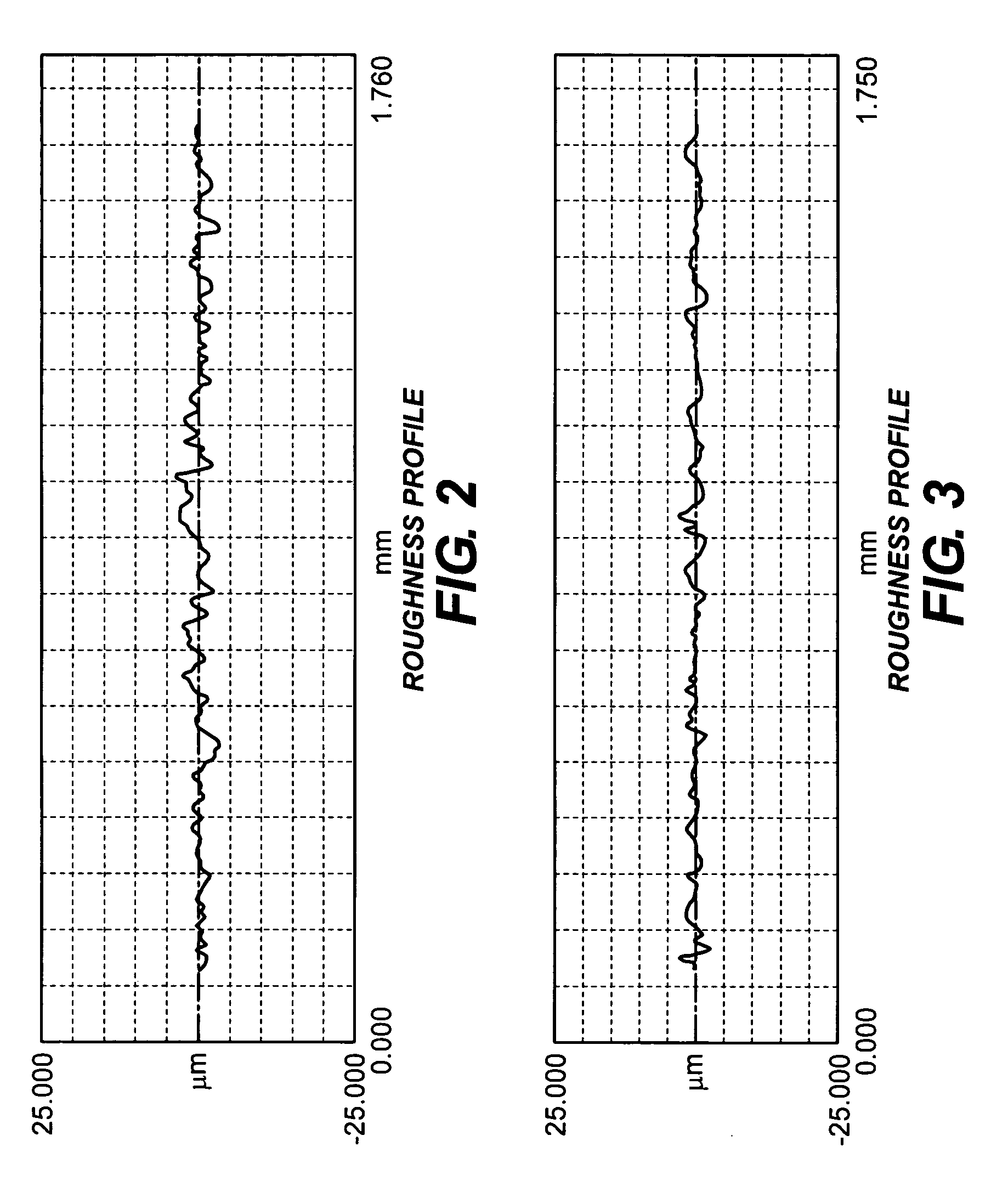

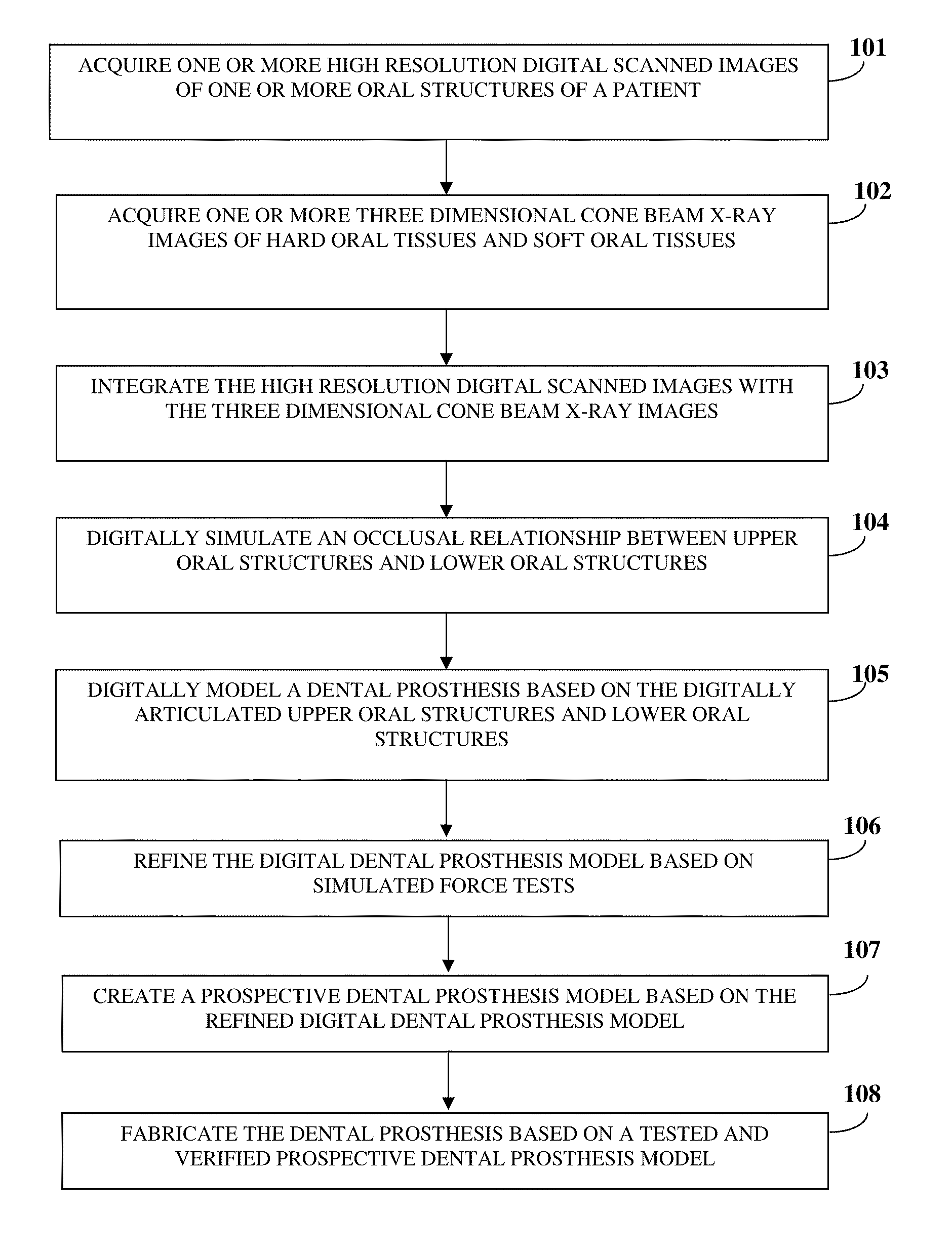

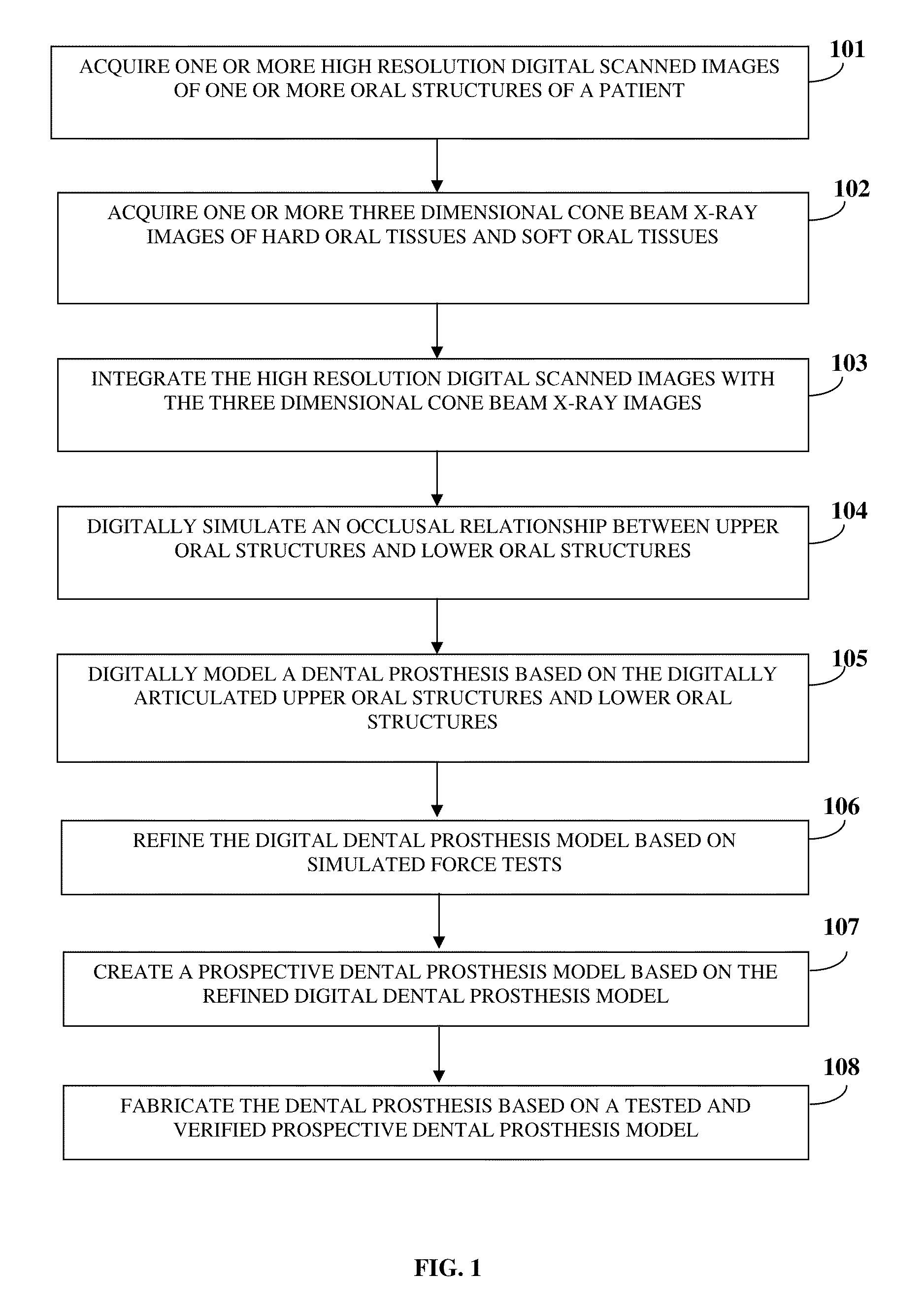

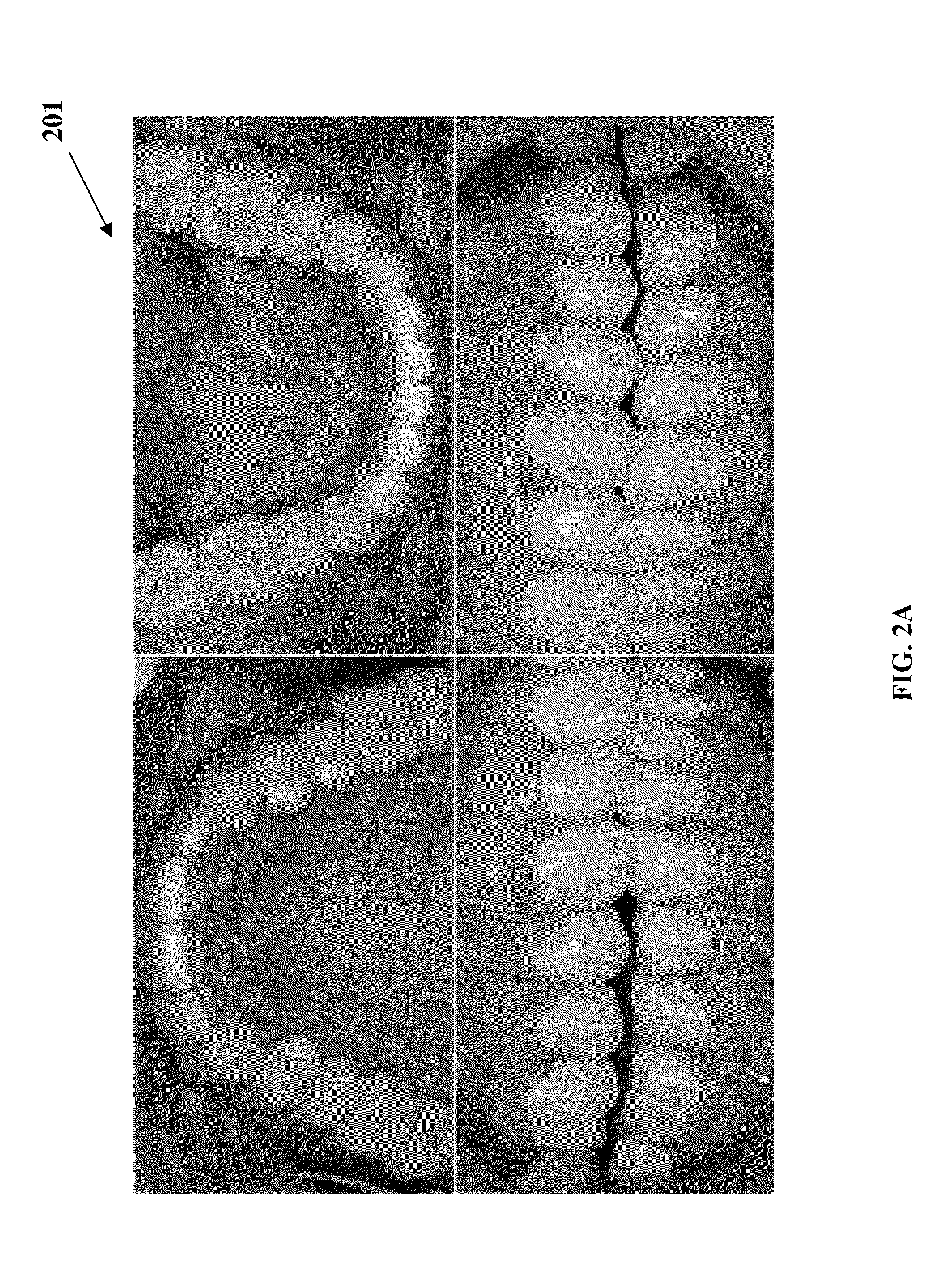

InactiveUS20110276159A1Maximizing retention and functionHighly accurate model-lessAdditive manufacturing apparatusDental articulatorsX-rayComputer aid

A method and system for fabricating a dental prosthesis are provided. High resolution digital scanned images of a patient's oral structures are acquired. Three dimensional (3D) cone beam X-ray images of hard and soft oral tissues are acquired. The scanned images are integrated with the 3D cone beam X-ray images in a 3D space to obtain combined three dimensional images of the oral structures. The occlusal relationship between upper and lower oral structures are digitally simulated using the combined three dimensional images. The dental prosthesis is digitally modeled for planning intra-oral positioning and structure of the dental prosthesis. The digital dental prosthesis model is refined based on simulated force tests performed for assessing interference and retention of the digital dental prosthesis model. A prospective dental prosthesis model is created based on the refined digital dental prosthesis model. The dental prosthesis is fabricated based on a verified prospective dental prosthesis model.

Owner:HANKOOKIN

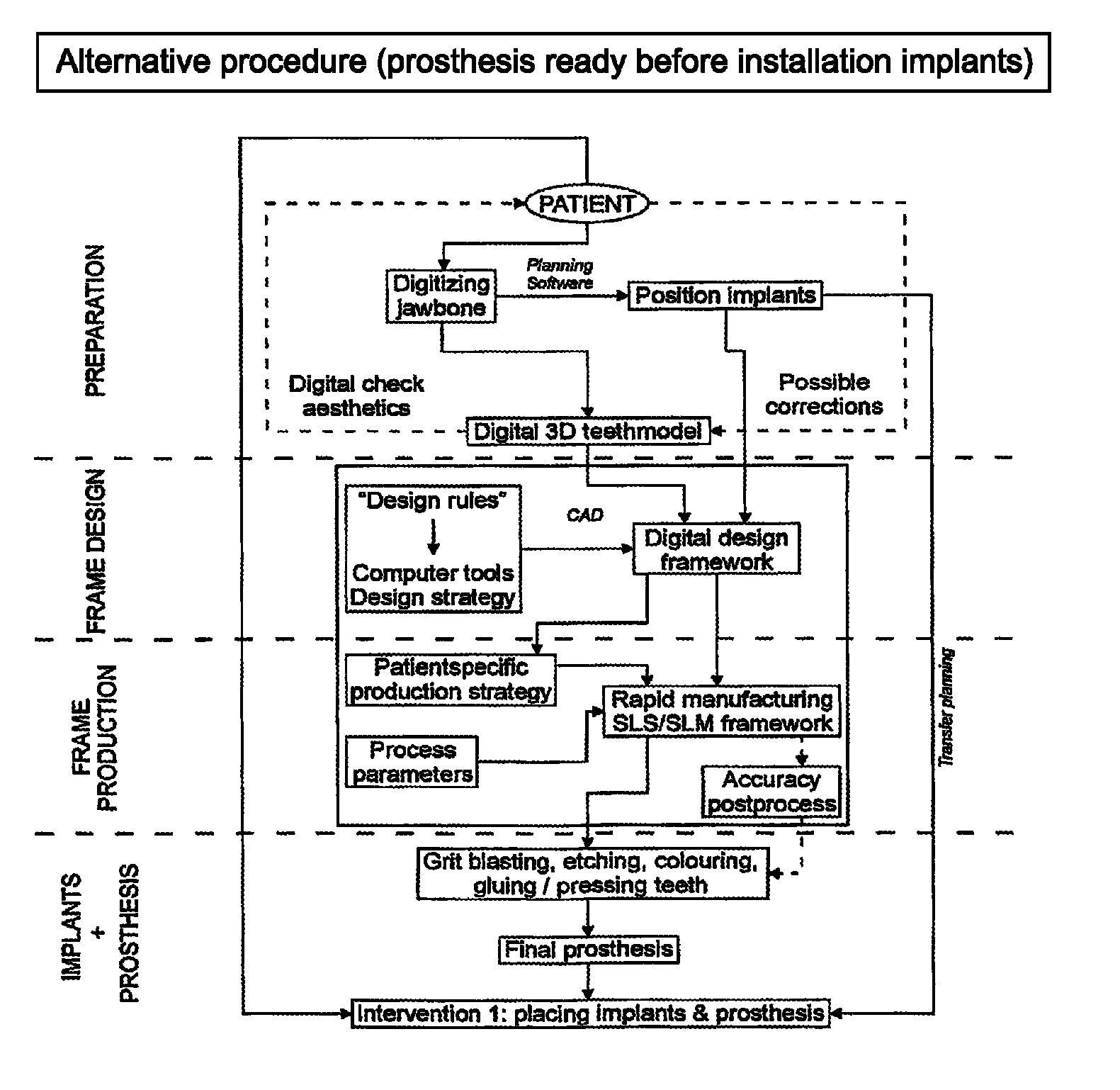

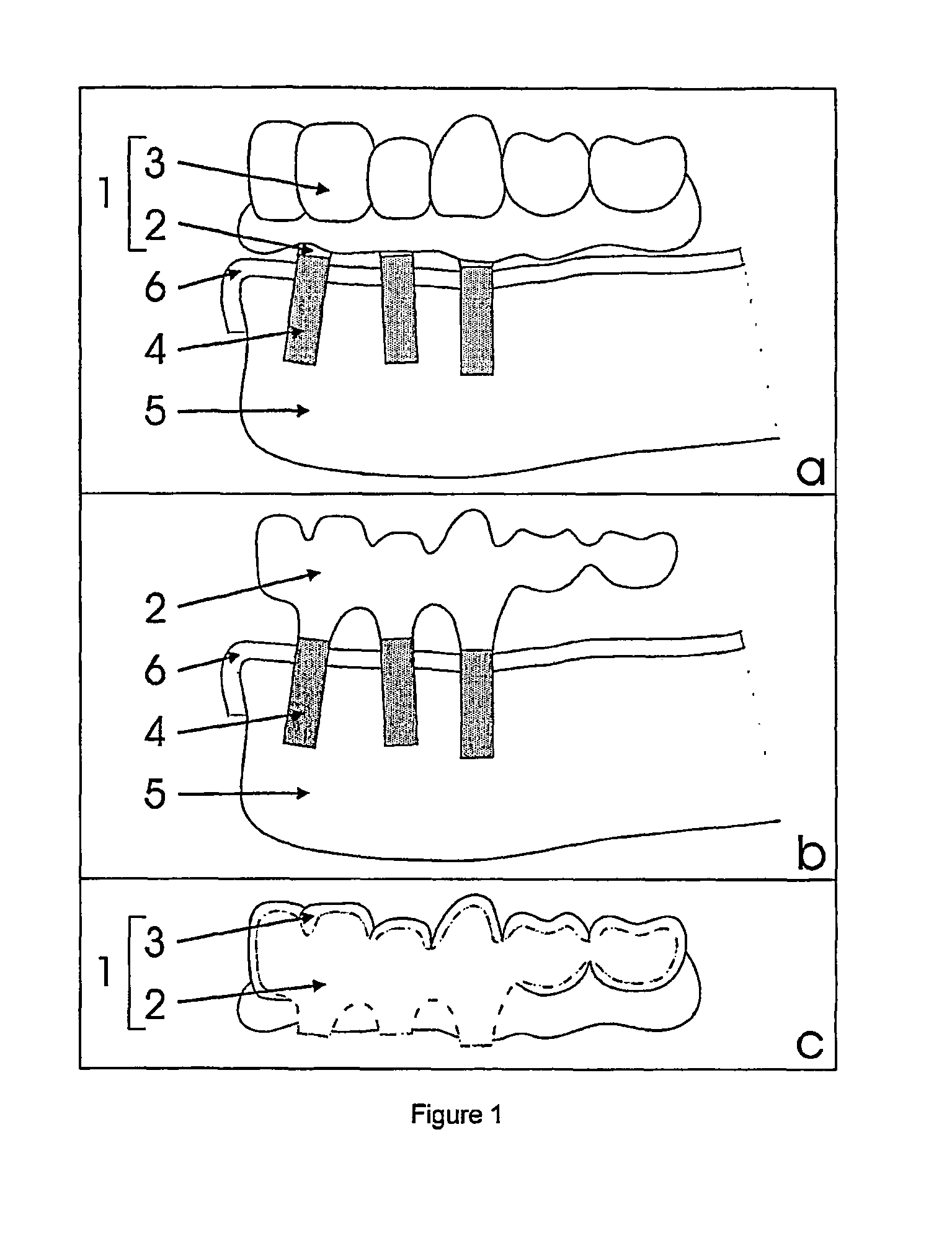

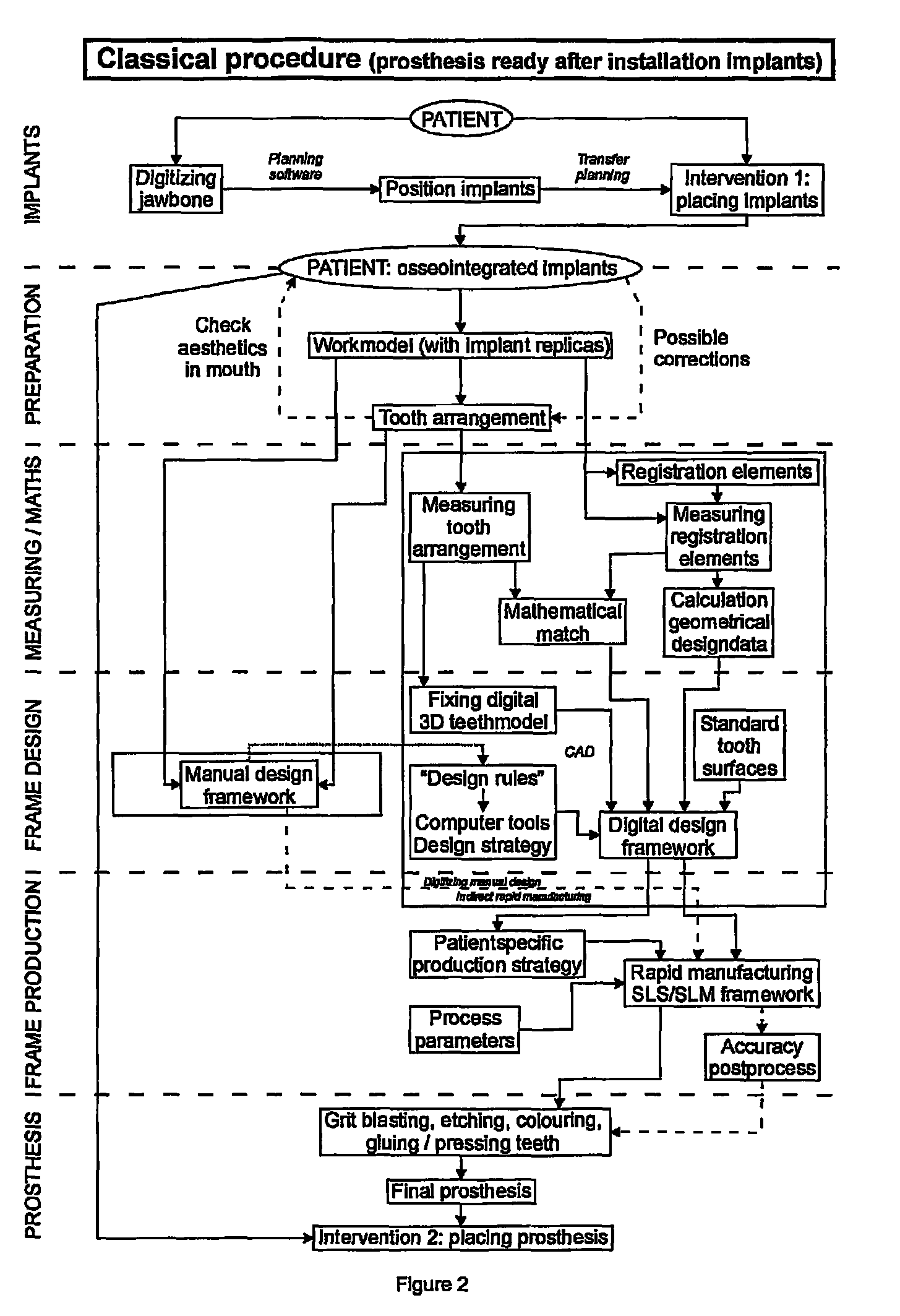

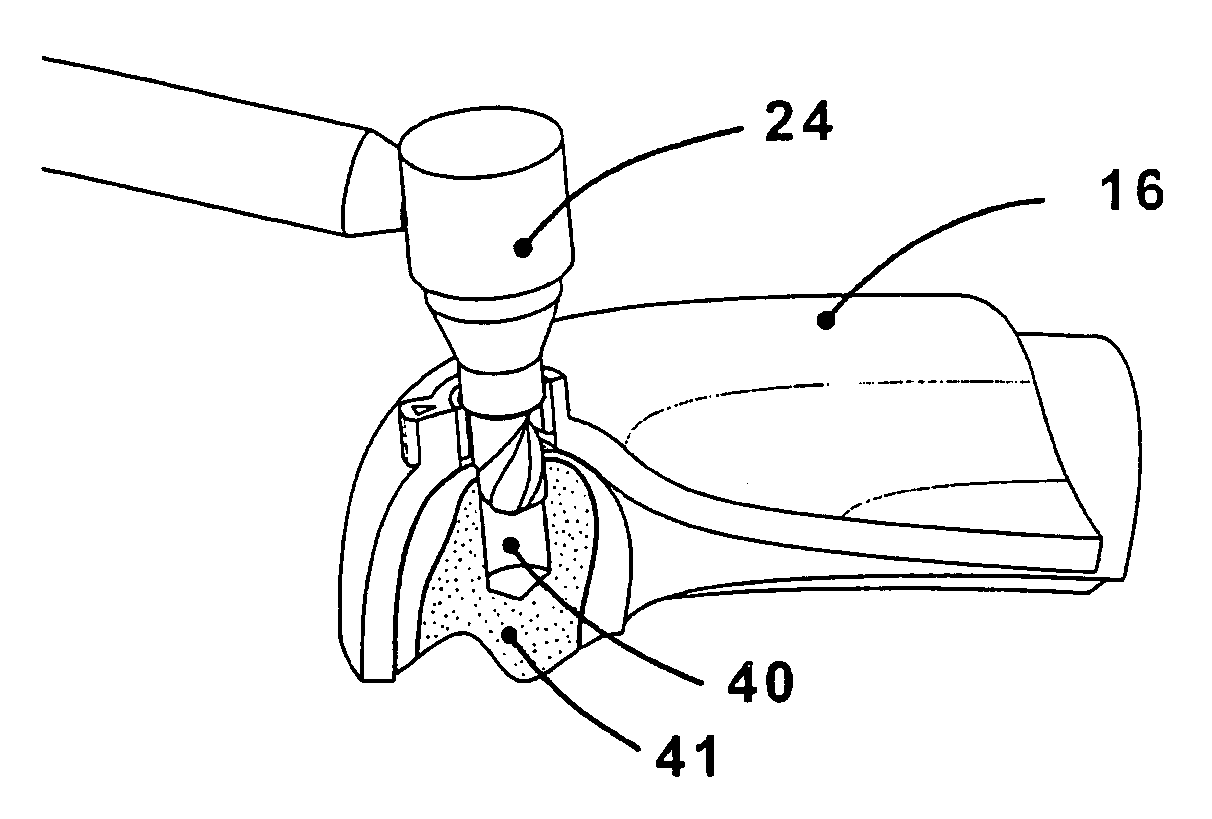

Procedure for design and production of implant-based frameworks for complex dental prostheses

The present invention provides methods allowing the use of selective laser powder processing techniques for the production of medically acceptable prosthetic dental frameworks. The frameworks produced according to the present invention have high grade mechanical properties as well as a high accuracy.

Owner:LAYERWISE

Surgical drill guide and index system

InactiveUS20090011382A1The process is convenient and fastMore accurateTeeth fillingDental toolsSurgical drillAngular orientation

A surgical drill guide for installing dental implants with predetermined angular alignment and rotational orientation for a dental prosthesis, formed of:a. a base part formed to correspond generally to the shape and contour of a patient's upper or lower mouth, the base part having peripheral edges and having opposite tissue and mouth sides and at least one drill guide hole extending through the base part from the tissue side to the mouth side, each of the drill guide holes having a central axis at a predetermined angular orientation relative to the mouth side and having lateral location relative to the peripheral edges, andb. a set of rotational position indicators on the tissue and mouth sides respectively of the base part for each of the drill guide holes, the rotational position indicators of each set being at the same rotational position about the central axis of the drill guide hole.

Owner:BAVAR TREVOR

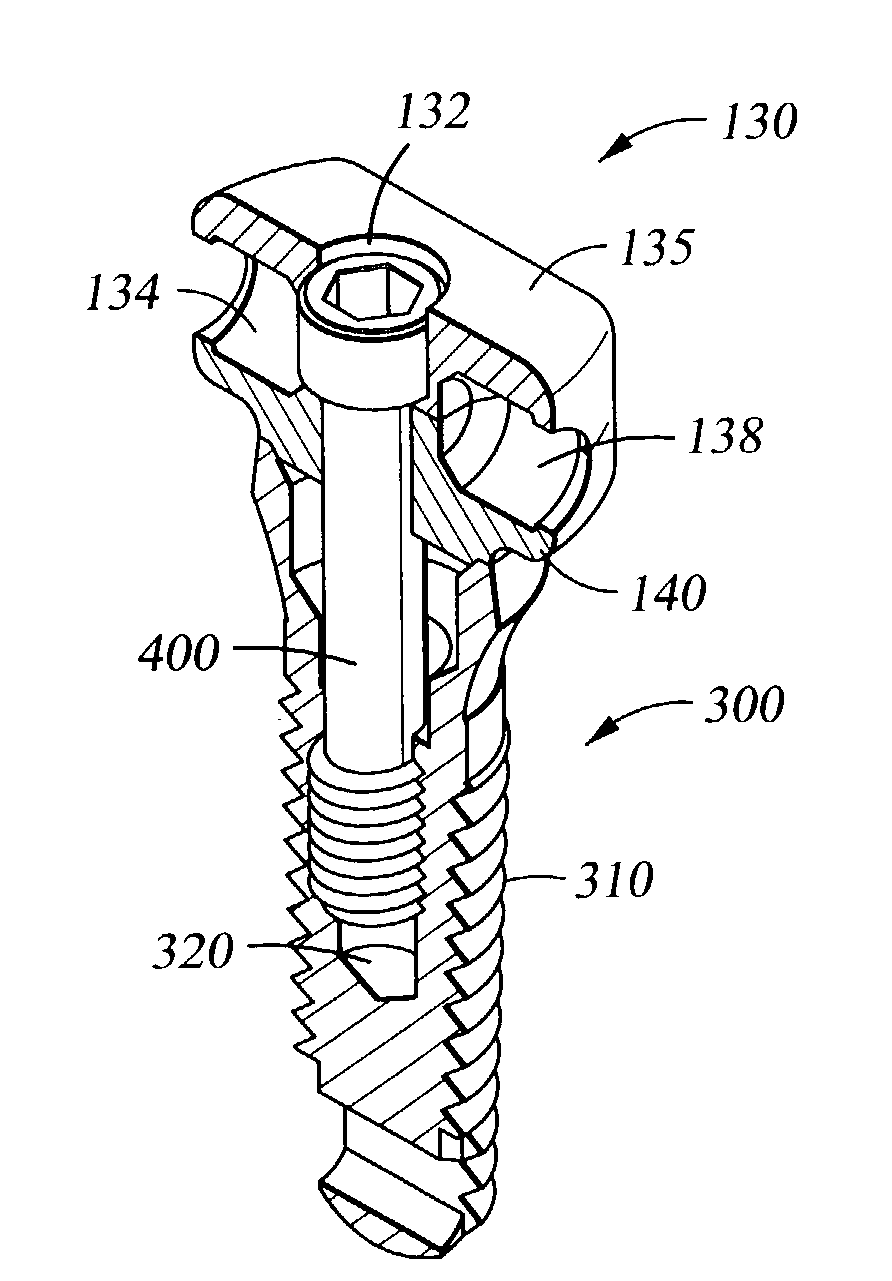

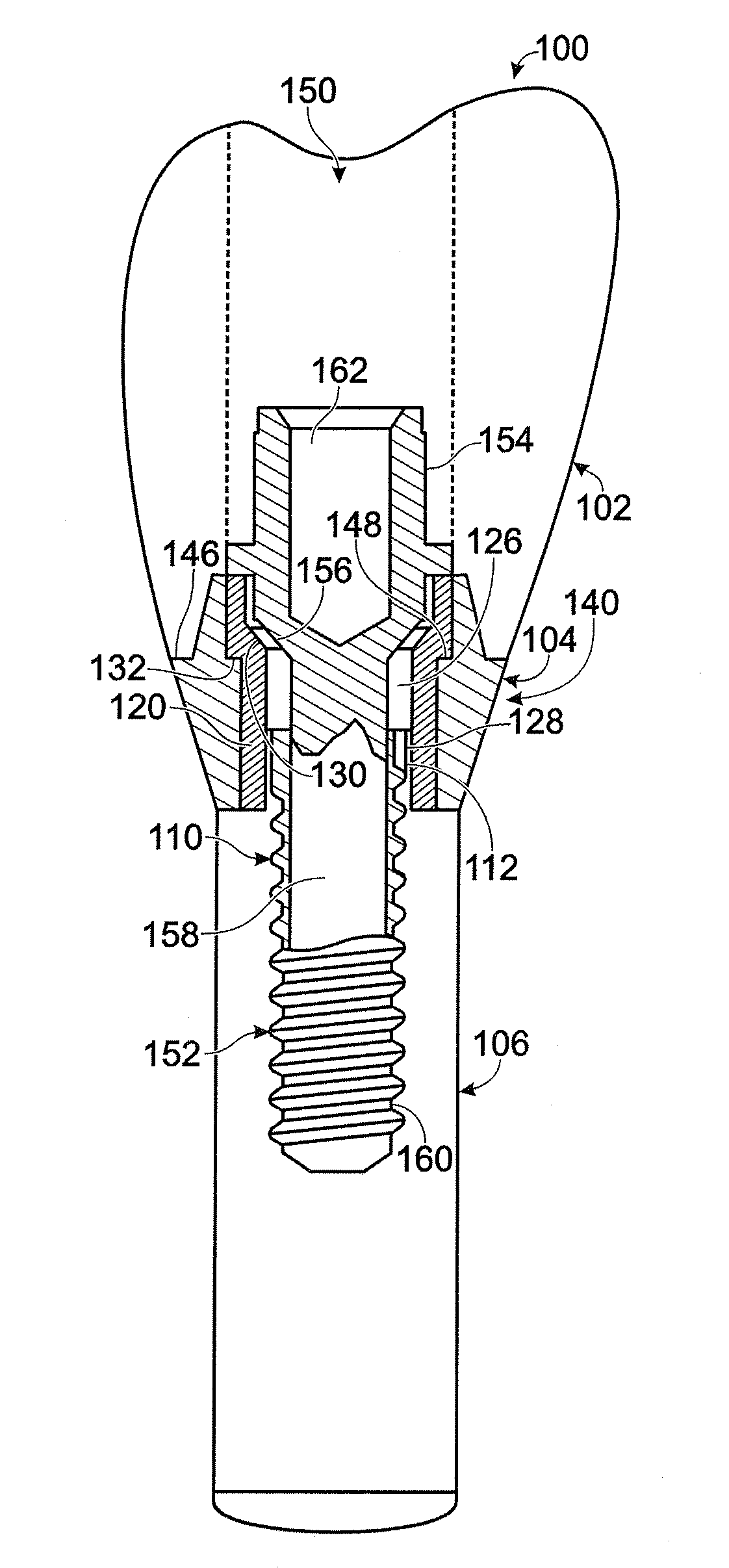

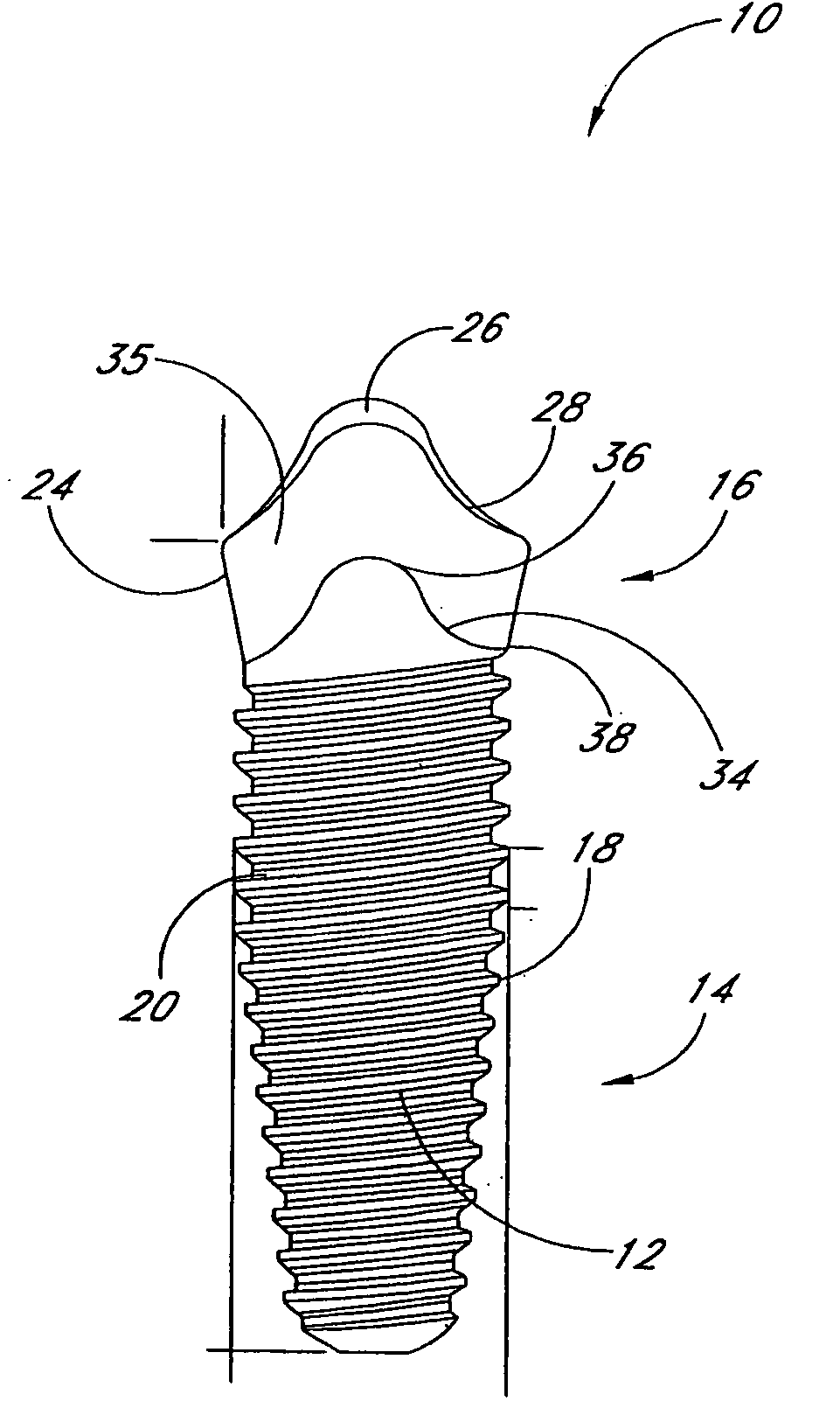

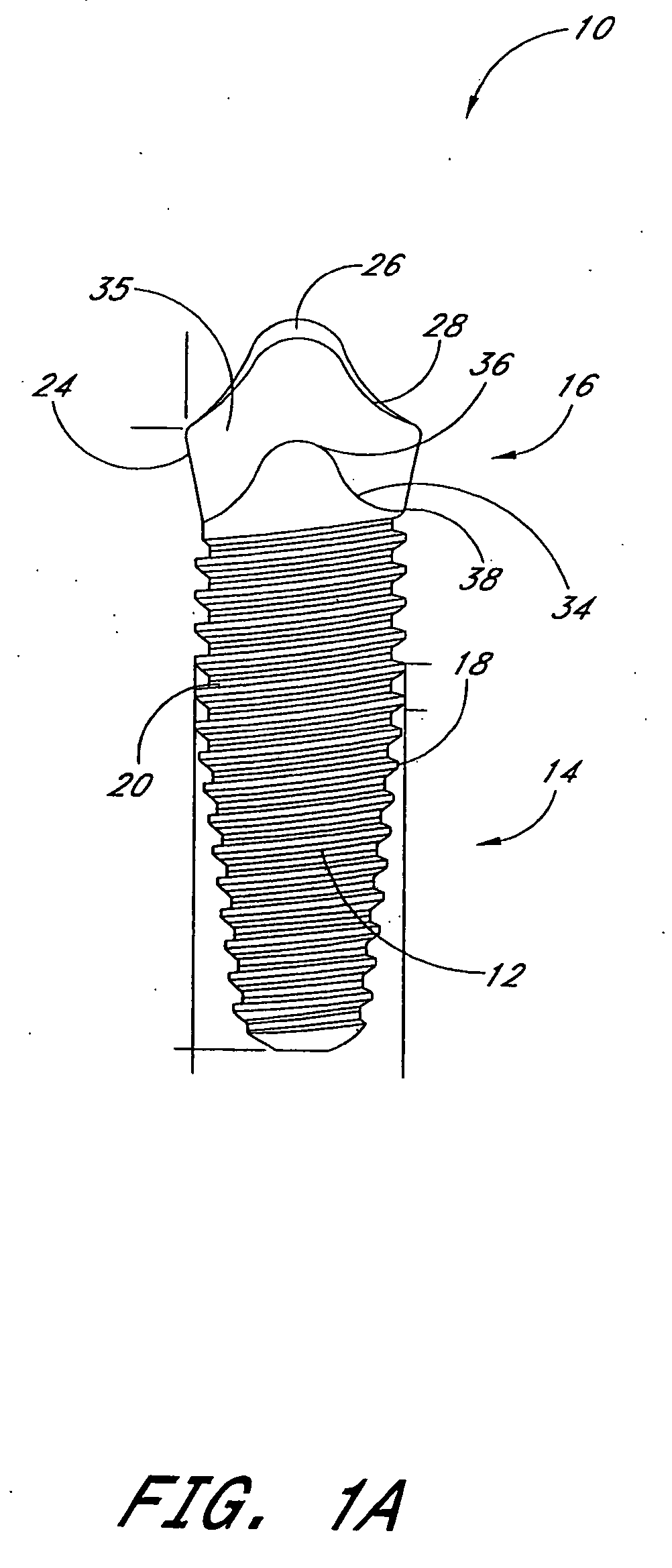

Dental implant system

A dental implant assembly for supporting a dental prosthesis. The assembly comprises a dental implant and an abutment. The dental implant comprises a body portion, a collar portion and a central bore. The body portion is located at a distal end of the dental implant and is configured to lie at least substantially below a crest of a patient's jawbone. The collar portion is located at a proximal end of the dental implant and forms an abutment mating surface which defines an outer edge that has a generally scalloped shape. The central bore extends through the collar portion and into the implant body portion. The central bore includes a threaded portion and a post portion. The abutment comprises a post configured to fit within the post portion of the central bore and an implant mating surface that is configured to mate with the abutment mating surface of the dental implant.

Owner:NOBEL BIOCARE SERVICES AG

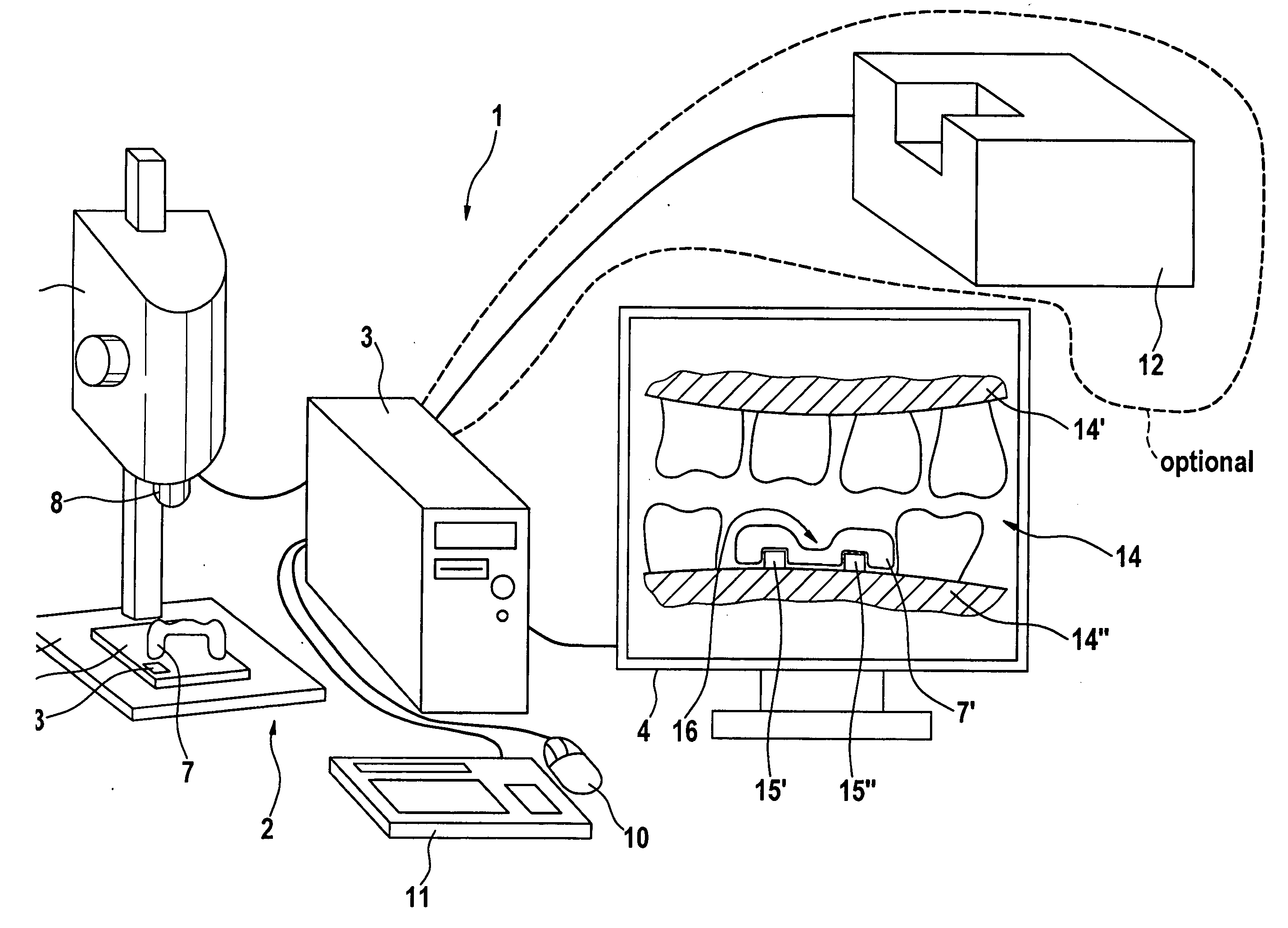

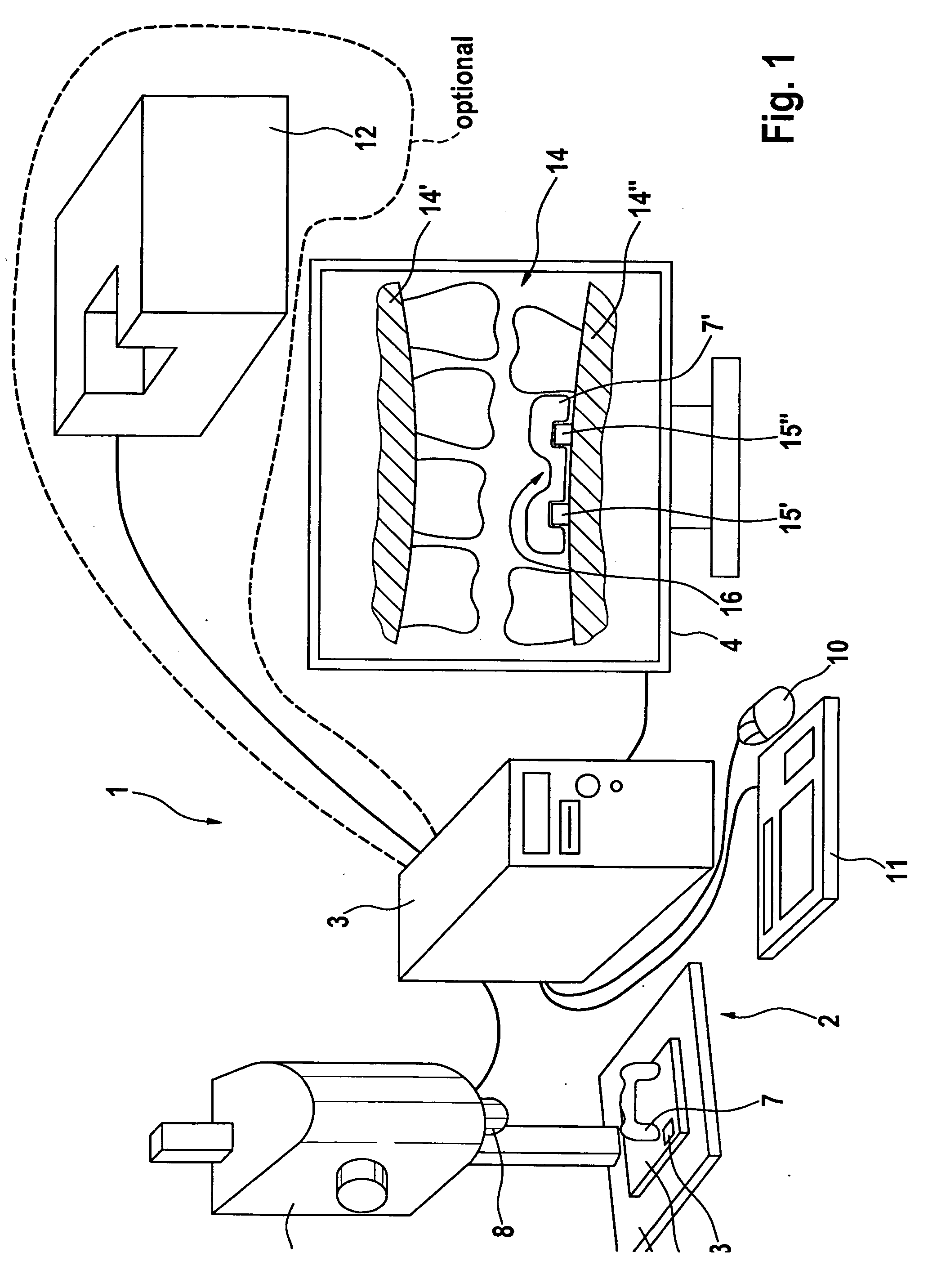

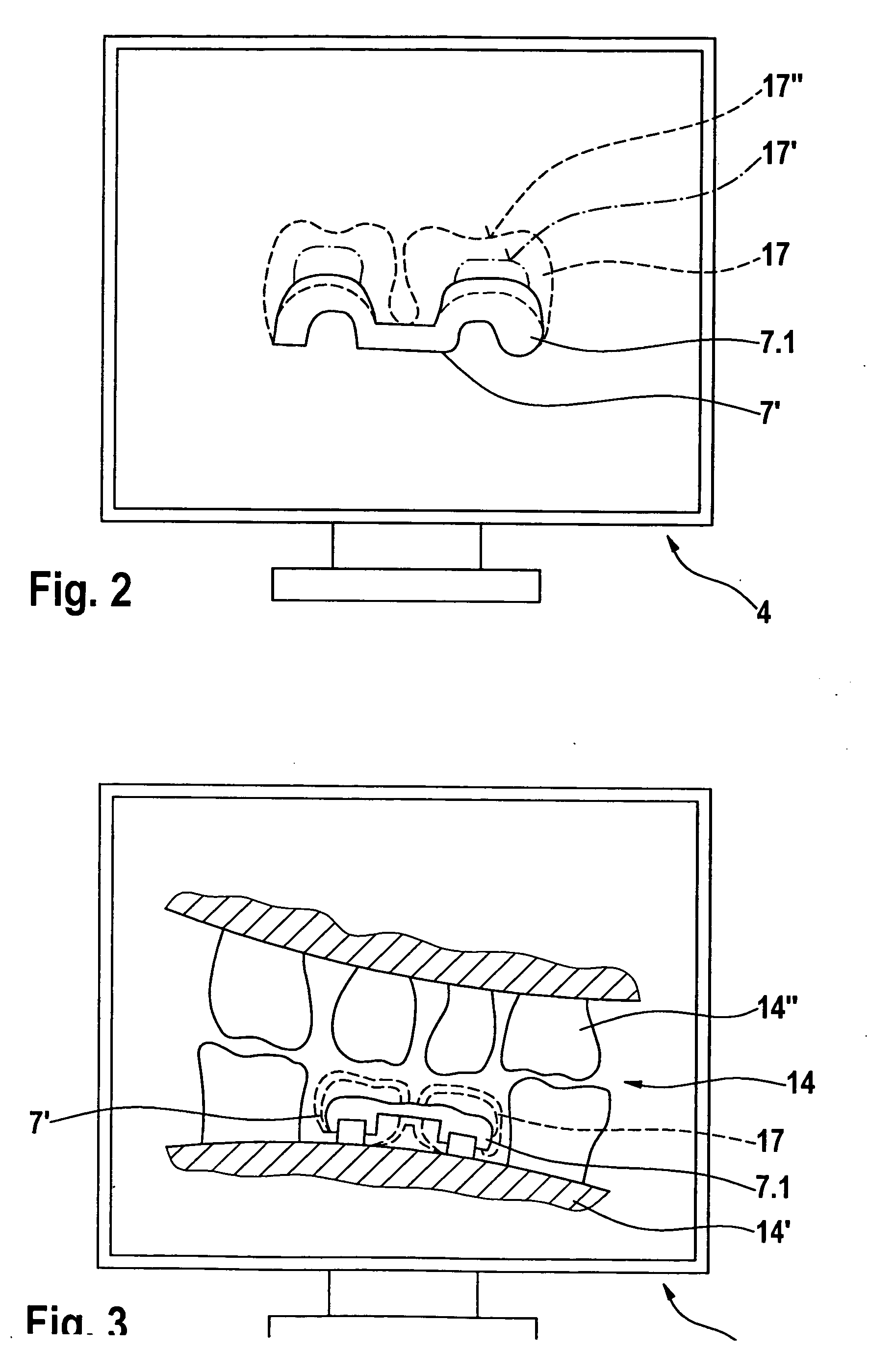

Method and Device for Producing Dental Prosthesis Elements

InactiveUS20090081616A1Easy to monitorAccurate fitDental implantsAdditive manufacturing apparatusDenturesProsthesis

The invention relates to a method for producing a dental prosthesis element (7), according to which the dental prosthesis element (7) is manually reworked. Construction data (17, 17′, 17″) relating to the dental prosthesis element to be produced is recorded together with measurement data (7′) relating to the dental prosthesis element (7) to be produced and is reproduced on a display (4), the measurement data having been recorded by means of a three-dimensional measurement device (2). The invention also relates to one such method whereby a 3D data record of the tooth situation (14) is reproduced on the display (4) instead of the construction data. The invention further relates to a device for the partial manual treatment of the dental prosthesis element. Said device comprises a three-dimensional measurement device (2), a display (4), and a computer unit (3) comprising means for the correlation and comparison of two data records and for graphically presenting the data generated by the comparison.

Owner:SIRONA DENTAL SYSTEMS

Multi-adjustable drill guide and framework system for dental prosthetics

InactiveUS20040142300A1Shorten the timeLow costDental implantsDental toolsPermanent implantEngineering

In one aspect, a group of inter-connecting, prefabricated components of various shapes and sizes that can be assembled together to form a framework system directly onto dental implants installed in the patient's mouth is disclosed. In another aspect, a group of prefabricated components to form a drill guide system for drilling a properly spaced and oriented implant hole adjacent to another implant hole or adjacent to a fully-installed implant is disclosed. In yet another aspect, improved procedures for installing permanent, implant-supported dental restorations are disclosed, including an immediate loading procedure.

Owner:ZIMMER DENTAL INC

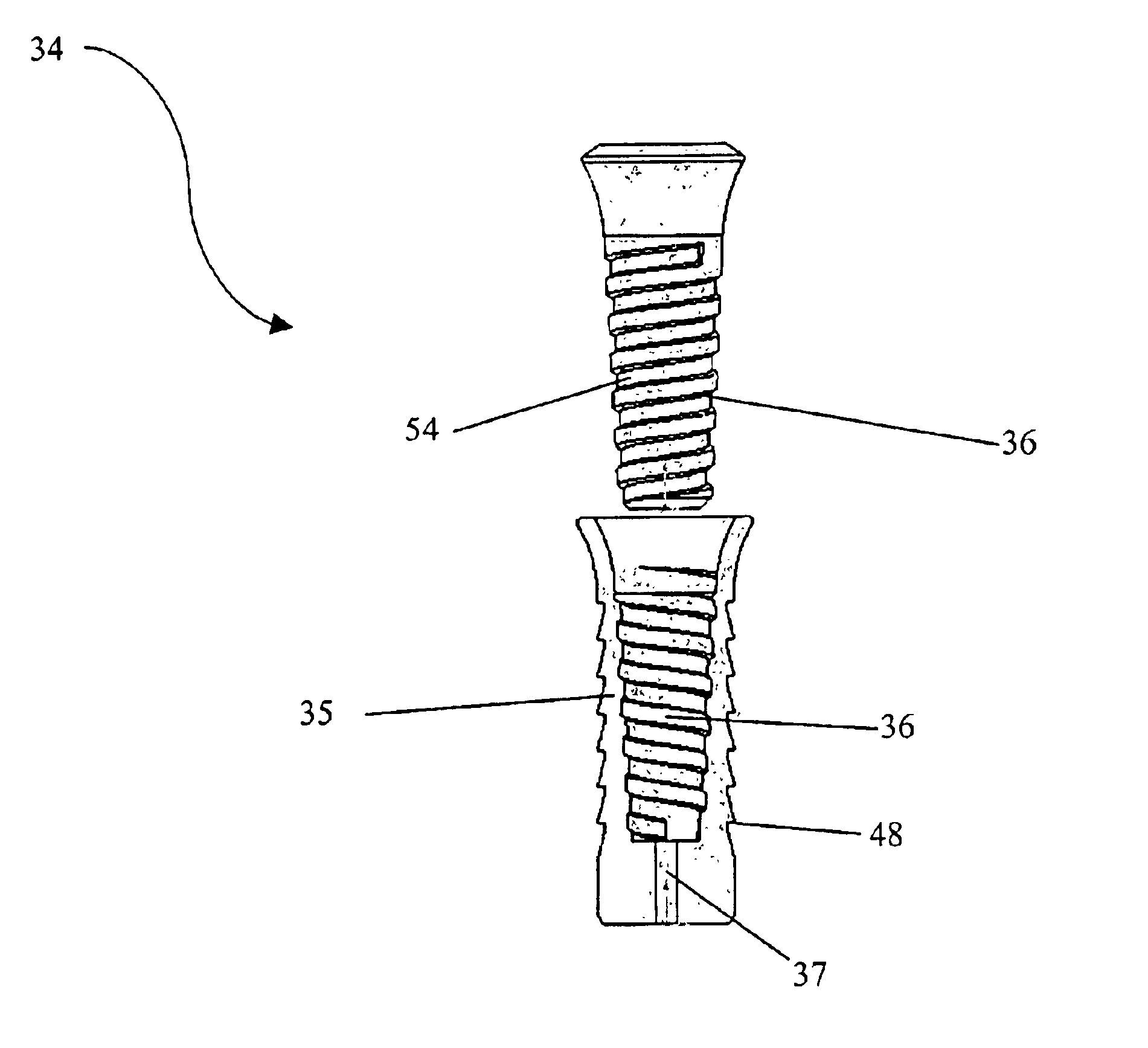

Expandable polymer dental implant and method of use

Systems and methods for a dental implant system suitable for an endosteal implant into a jawbone are provided. The systems and methods make use of an tapered, expandable polymer sheath insertable into a jawbone, a tapered implant insertable into the sheath and causing expansion of the sheath upon insertion, and an abutment adapted to be coupled to the implant and permitting the attachment of a dental prosthesis.

Owner:DYNAMIC IMPLANTS

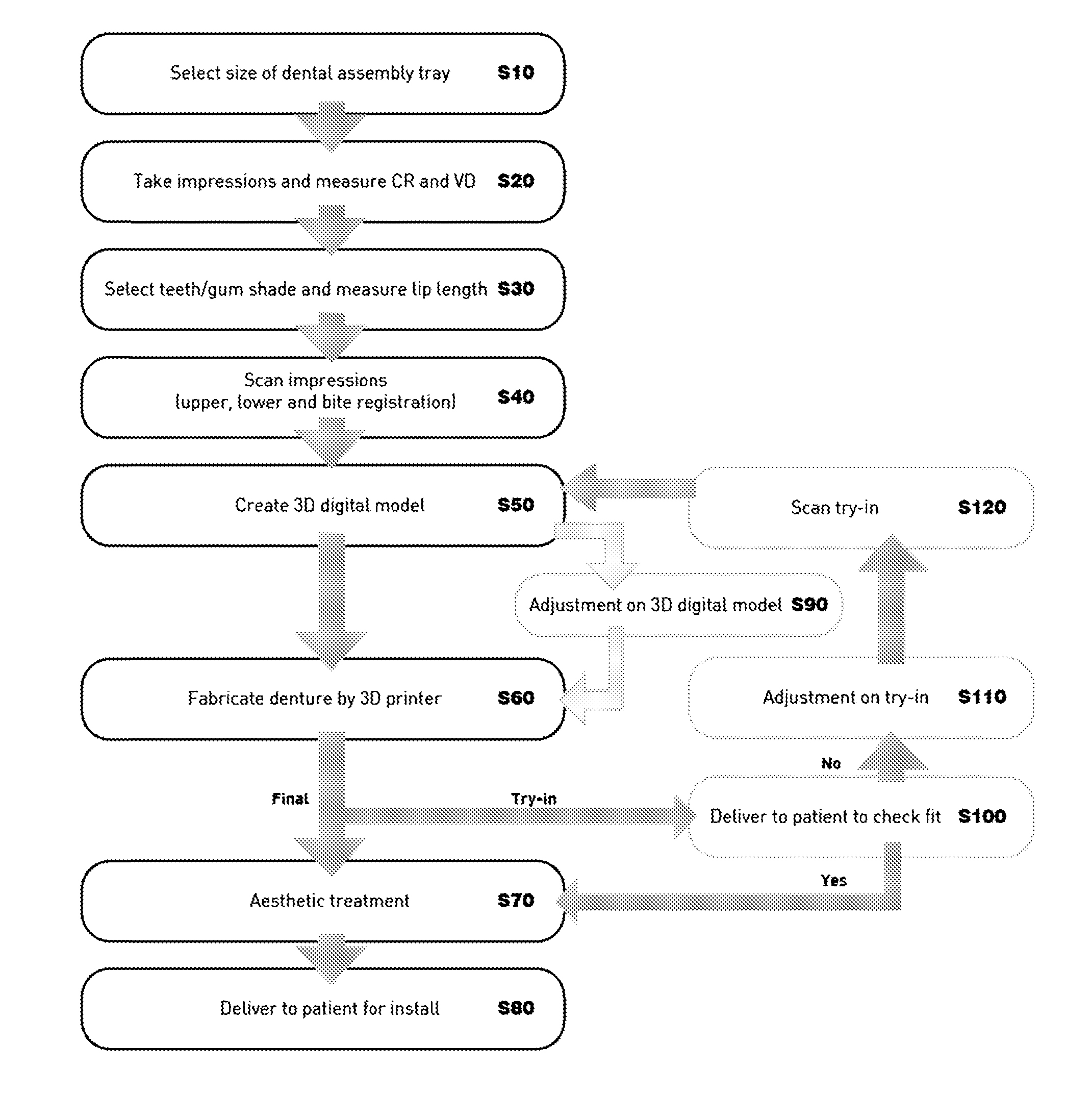

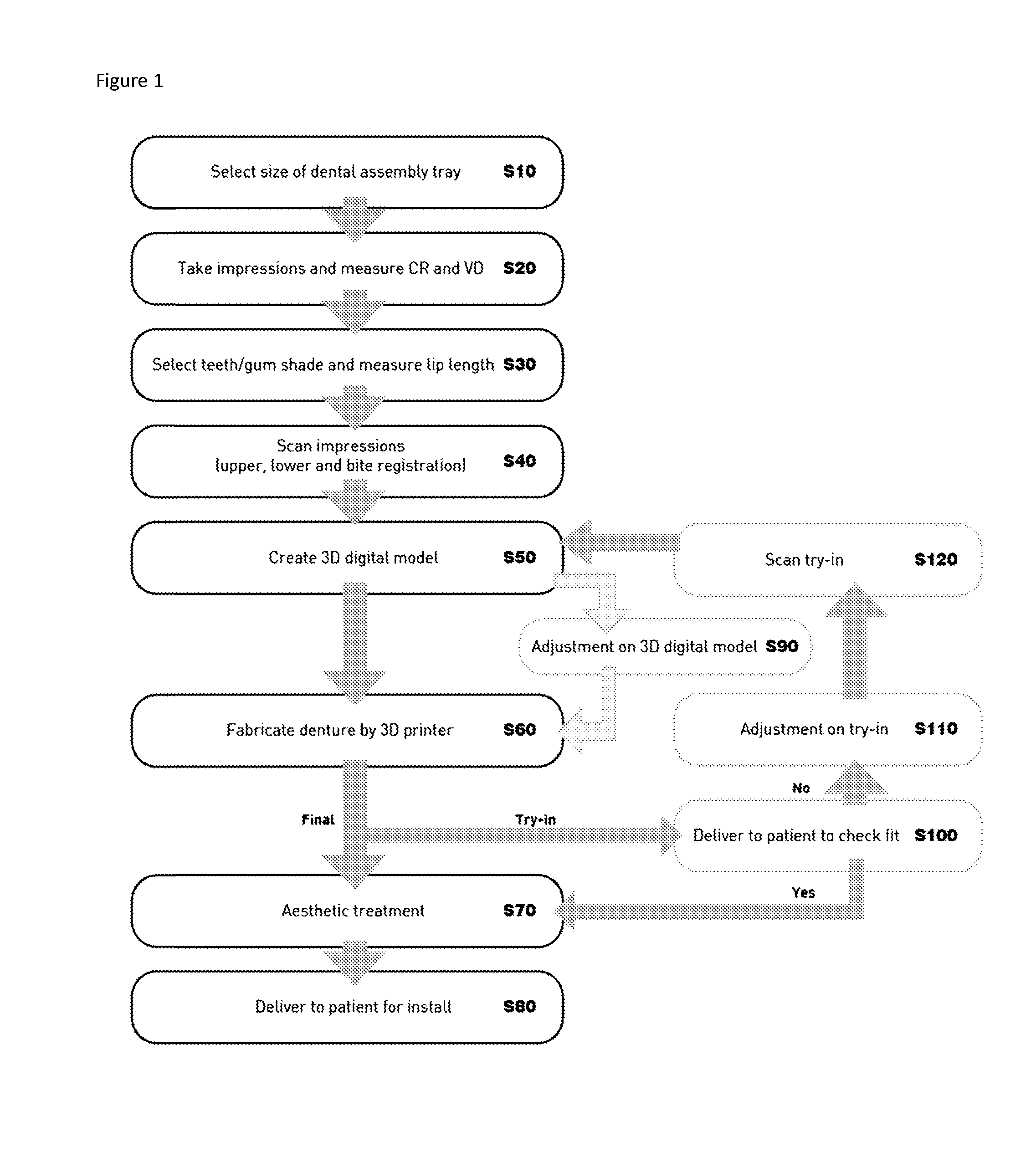

Method and apparatus for preparing removable dental prosthesis

ActiveUS20140308624A1Easy to operateAccurate manufacturing of a complete denture without intensive manual laborImpression caps3D printingSingle visit3d design

A method for manufacturing a removable dental prosthesis using a three-dimensional (3D) printer includes receiving dental impressions of a patient obtained using a dental impression tray assembly, the dental impressions including a bite registration and at least a mandibular impression or a maxillary impression; receiving information related to the patient's jaw relations obtained using the dental impression tray assembly, the jaw relations including a vertical dimension and a centric relation obtained during the patient's single visit to a dentist; scanning the received dental impressions with a 3D scanner to provide data representative of an edentulous shape of the patient; generating a 3D model of the dental prosthesis based on the data and the received information related to the patient's jaw relations using 3D design software; displaying the generated 3D model on a display, allowing customization of the 3D model; and 3D printing the dental prosthesis according to the 3D model.

Owner:DENTCA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com