Patents

Literature

51 results about "Broken teeth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

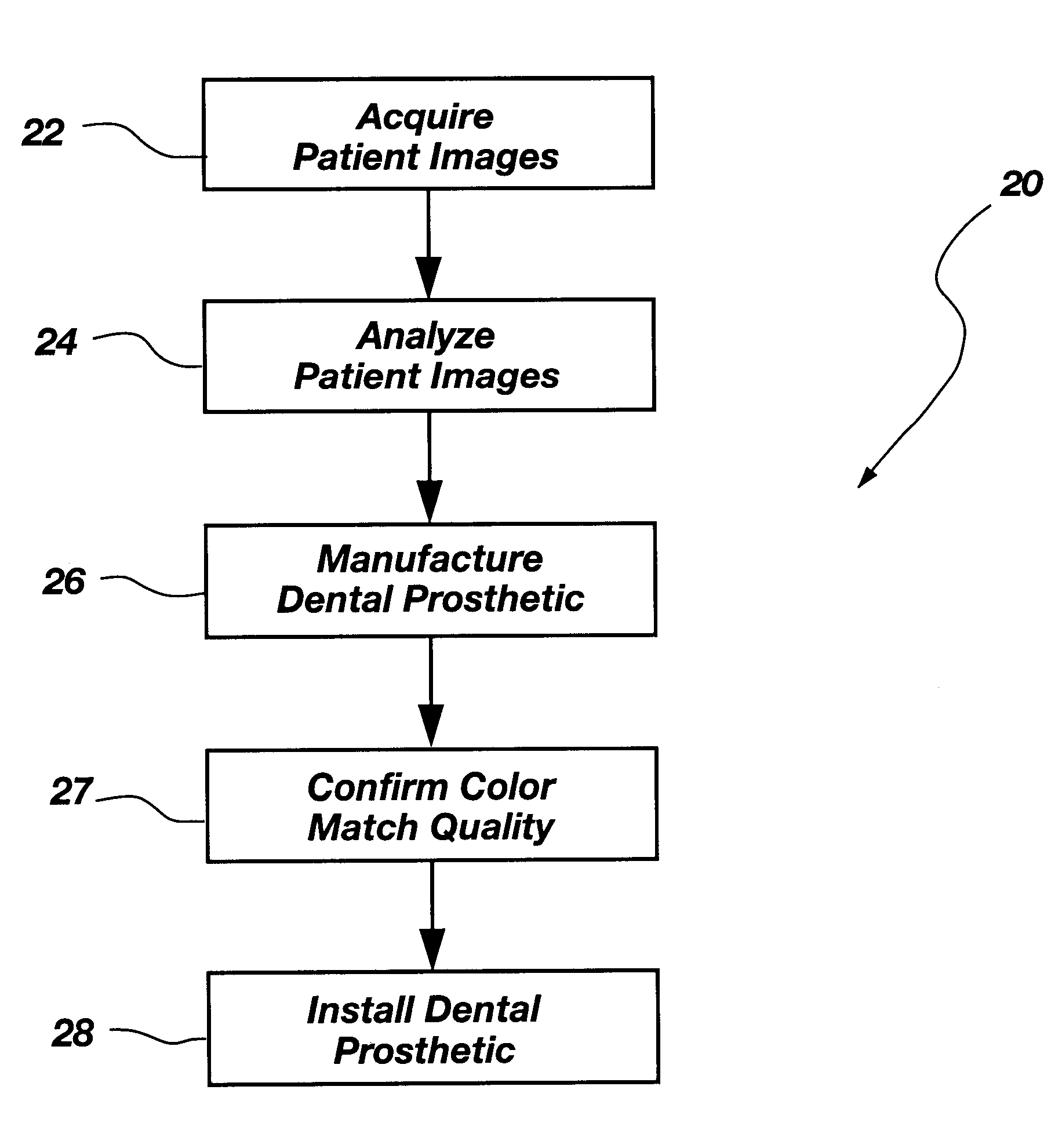

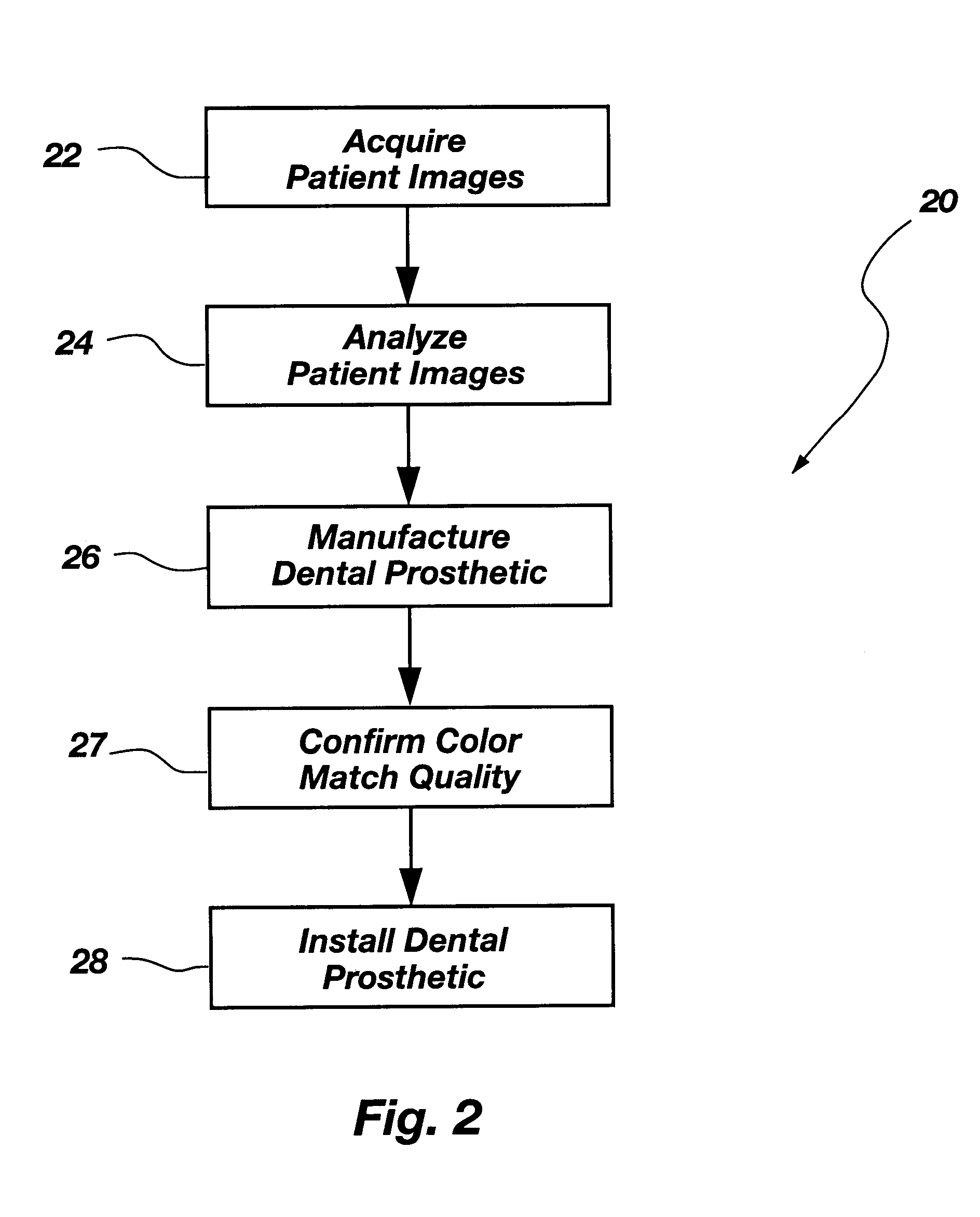

Method, apparatus and system for automated tooth shade analysis and matching

Methods, apparatuses and systems for tooth shade analysis and matching are disclosed. A method embodiment according to the invention includes acquiring at least one image, the image including one or more teeth of a patient and normalization references, normalizing the at least one image in accordance with the normalization references, determining the color of the teeth as composed of colors from one or more selected shade standards, communicating the standardized color information to a dental laboratory, manufacturing a dental prosthesis based on the standardized color information and installing the dental prosthetic. Normalization is performed to correct patient images for variations in lighting conditions and image source. Normalization references include a black reference, a white reference and at least one color reference. The normalized image is standardized by matching the pixels of the normalized image to selected shade standards. Selected shade standards may include incisal tooth shade standards. The standardized color image and / or analysis may be communicated to a dental laboratory according to aspects of the invention. The dental prosthesis can then be manufactured by a lab technician by referring to the standardized image. Color models according to the invention may include RGB, HSI and other models for representing color images. The methods, apparatuses and systems for tooth shade analysis and matching are also applicable to direct restorations of natural teeth, such as repair of chipped or broken teeth.

Owner:DENTECH

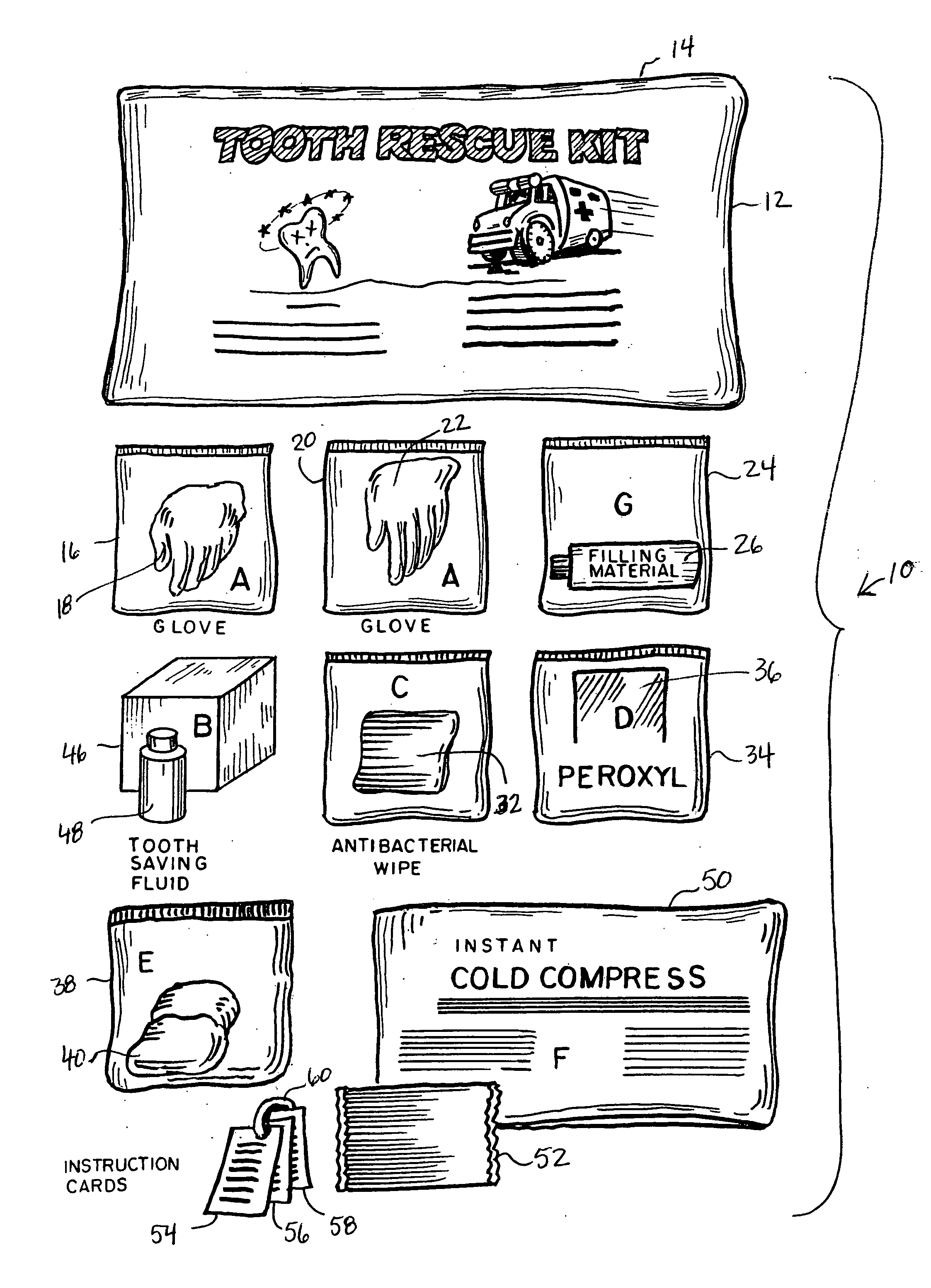

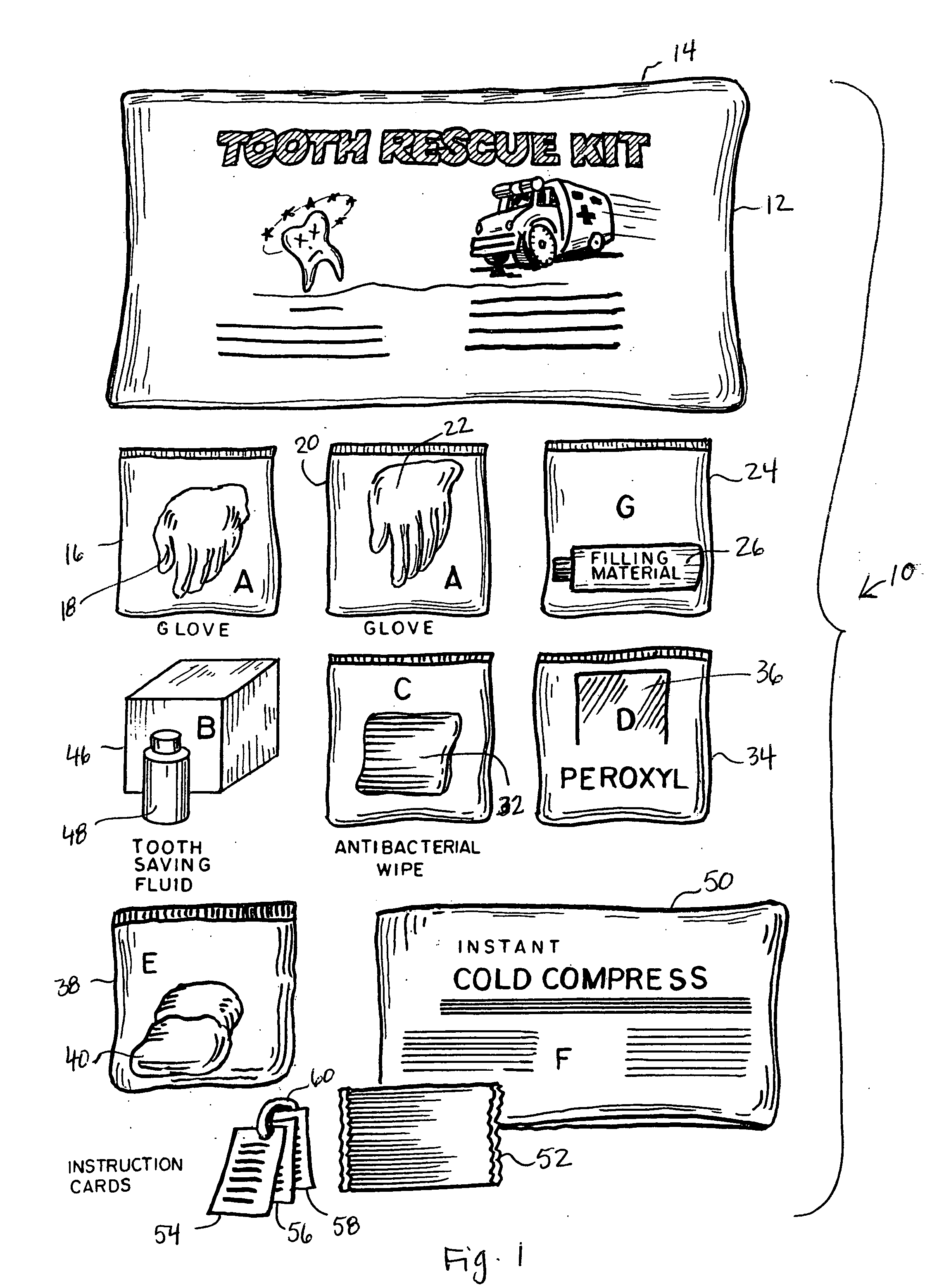

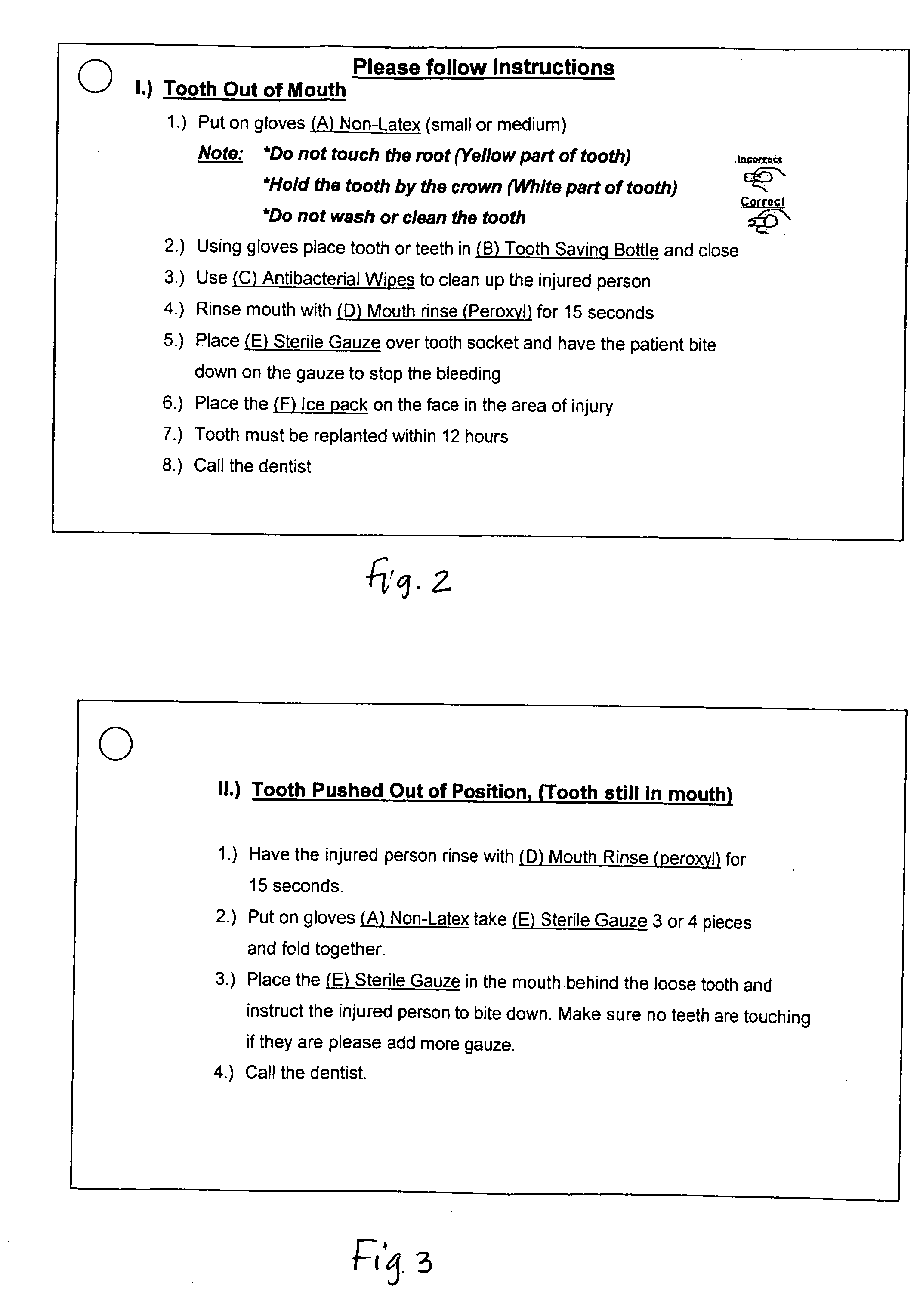

Tooth rescue kit

A portable compact emergency dental kit is provided for administering first aid in cases of avulsed, loose, or broken teeth. The kit contains step-by-step instructions for rendering the first aid even by persons untrained in dentistry. The kit contains a quantity of tooth-preserving fluid for temporary retaining knocked out teeth, as well as a tube of dental filling material that sets shortly after being dispensed from the tube. A quantity of gloves, sterile gauze, antiseptic mouth rinse, ice packs and antibacterial wipes is provided in the kit holder.

Owner:BEAR JOHNNY R

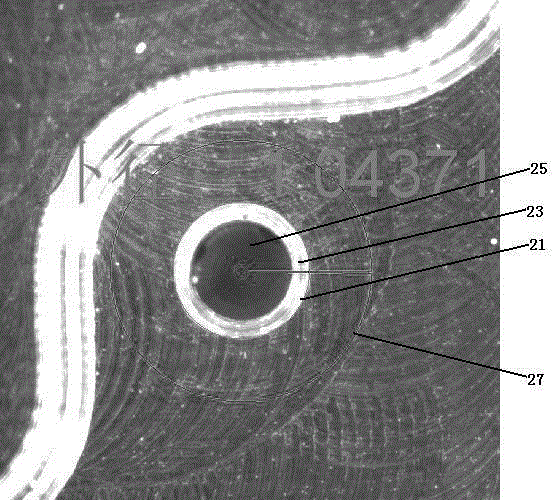

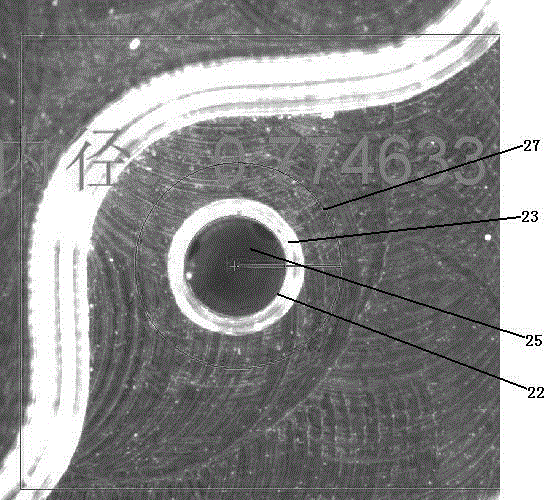

Threaded hole structure quality detection method

InactiveCN104990511AEffective shootingOptically investigating flaws/contaminationUsing optical meansMissing toothMissed tooth

The invention provides a threaded hole structure quality detection method. A CCD camera and an annular light source are used for quality detection of internal threads. The index items of the detection of the internal threads include external diameter, internal diameter, percentage of thread, number of thread teeth, tooth pitch, tooth depth, and the number of effective teeth. Identifiable ineffective teeth include broken teeth, missing teeth, foreign bodies and burr.

Owner:SUZHOU JQS INFO TECH CO LTD

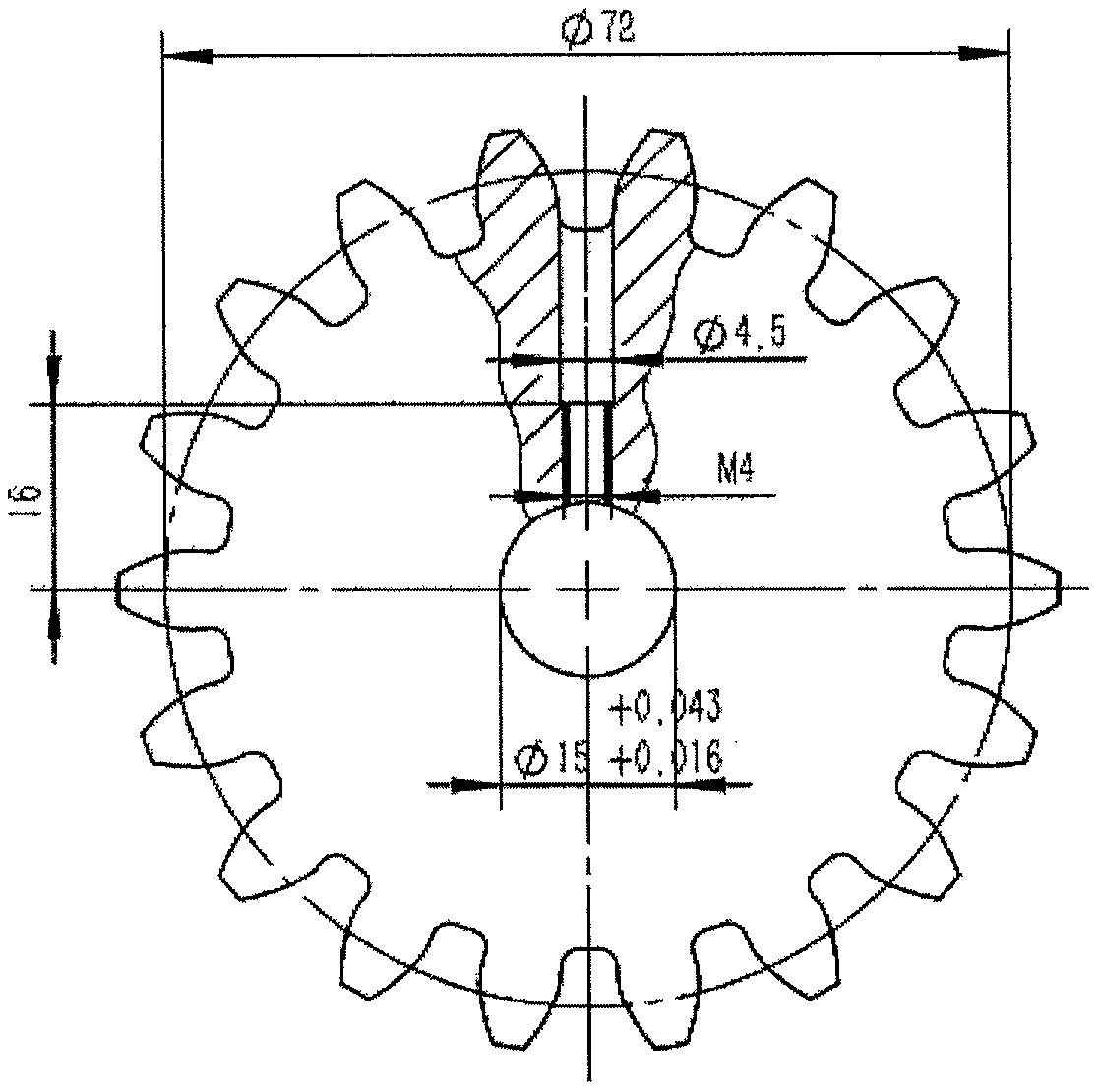

Refabrication method of waste chain wheels for mining

The invention relates to a refabrication method of waste chain wheels for mining. The refabrication method is characterized by including the following steps that (1) the waste chain wheels are selected and waste chain wheels which do not have broken teeth and fatigue cracks are picked out; (2) the waste chain wheels are milled by a numerical control high-speed milling machine according to the chain nest shape of waste chain wheels, irregularly-abraded fatigue layers and hardening layers are removed, the depth of equidistant machining based on the size of an original chain nest is 12-18 mm; (3) the waste chain wheels are arranged on a welding positioner and are matched with a welding robot, consumable electrode gas is used to protect welding technology, build-up-welding materials are used to achieve build-up welding layer by layer, welding requirements are that a back pass weld covers 1 / 3-2 / 5 of a front pass weld; (4) the build-up-welded chain wheel nest is milled by the numerical control high-speed milling machine, and the original size of the milled chain nest is recovered. Tests prove that according to the method, the repairing efficiency of the waste chain wheels can be obviously improved, the repaired wheel chains are reliable in quality, and the homogeneity of products is good.

Owner:NINGXIA TIANDI BENNIU IND GRP

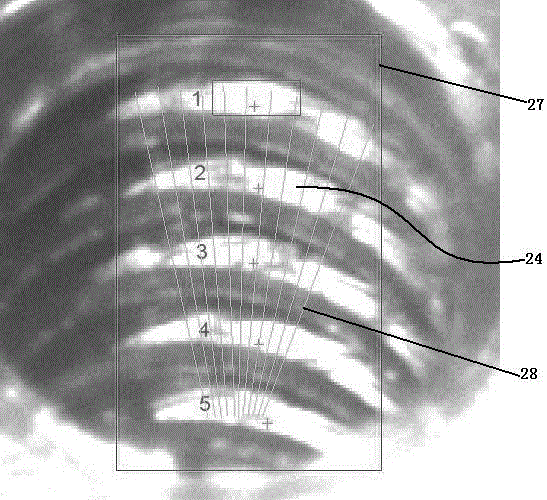

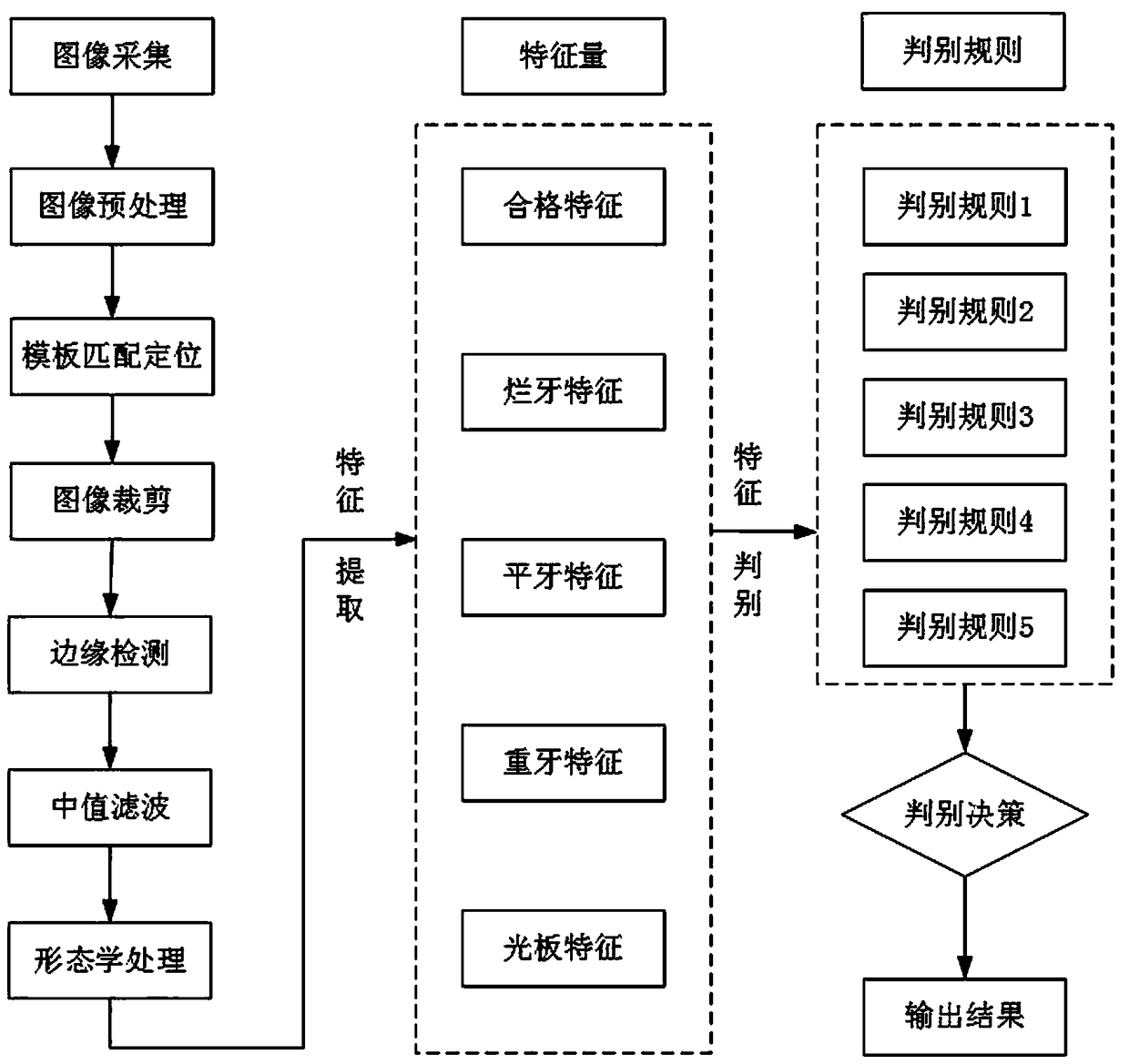

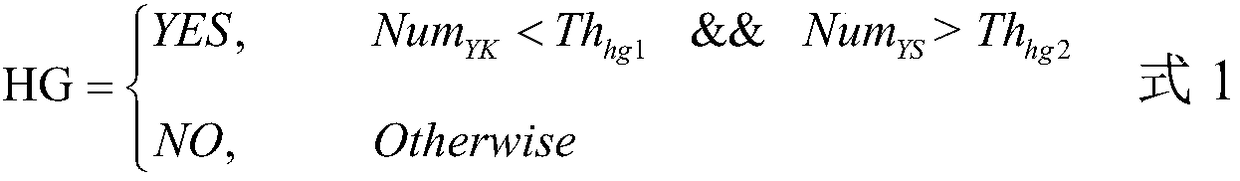

Method of detecting tooth defects of wedges based on edge detection

InactiveCN108280838AGood edge feature extractionHigh degree of production automationImage enhancementImage analysisTemplate matchingProduction line

The invention discloses a method of detecting tooth defects of wedges based on edge detection, comprising the steps of (1) acquiring an image of a wedge workpiece, and preprocessing the image; (2) subjecting the wedge workpiece to image template match positioning and image cutting; (3) subjecting the image to edge detection; (4) subjecting the image to median filtering and morphological processing; (5) performing characteristic extraction and judging. The method is capable of detecting and recognizing tooth defects (flat teeth, broken teeth, overlap teeth and polished plates) of wedges accurately on a production line site, the problem that existing manual detection has low speed, low efficiency and high cost is effectively solved, automation level of wedge production is increased, productquality is improved, and the method has good robustness.

Owner:GUILIN UNIV OF ELECTRONIC TECH

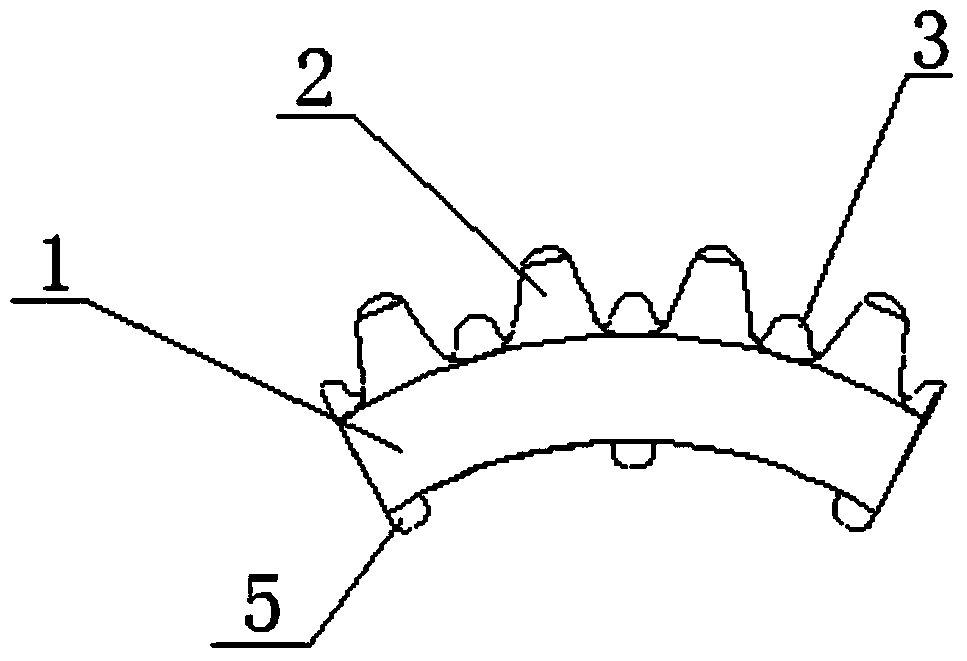

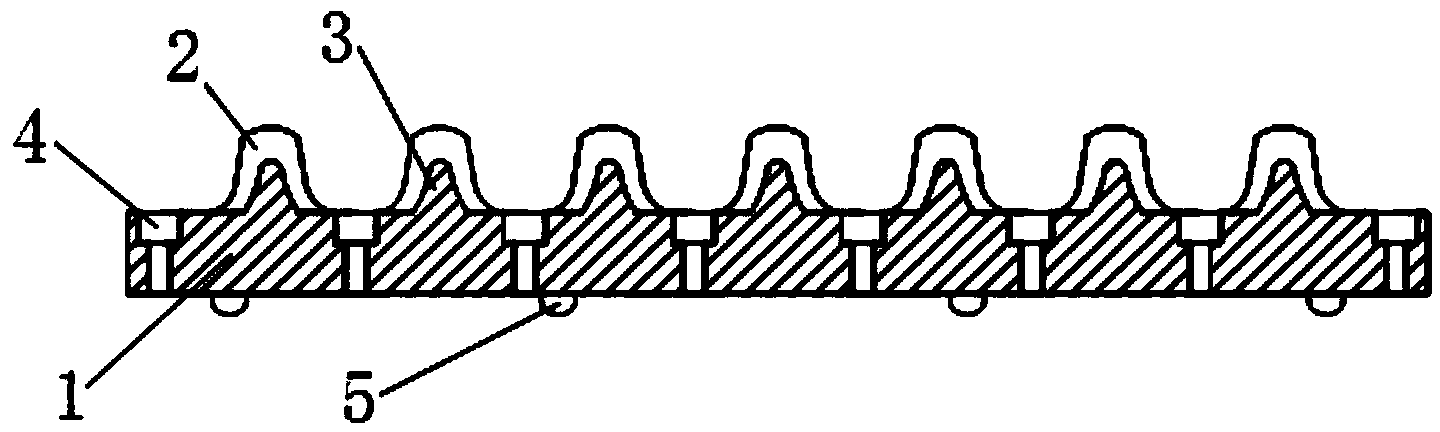

Arc-shaped toothed plate with large and small teeth on toothed roll crusher

InactiveCN104014392ASimple structureImprove crushing efficiencyGrain treatmentsLarge toothSmall tooth

The invention discloses an arc-shaped toothed plate with large and small teeth on a toothed roll crusher. The arc-shaped toothed plate comprises an arc-shaped plate, wherein a plurality of groups of toothed rows are arranged on the cambered surface of the excircle of the arc-shaped plate in a circumferential direction and comprise a plurality of large teeth and a plurality of small teeth, and the plurality of small teeth are located between two adjacent large teeth in the toothed row respectively; a plurality of T-shaped mounting holes are respectively arranged in the arc-shaped plate axially, and a plurality of locating bosses are arranged on the cambered surface of the inner circle of the arc-shaped plate axially. The arc-shaped toothed plate is simple in structure, can improve the crushing efficiency, can uniformly crush grains with low excessively-crushing quantity, and is low in energy consumption and high in capacity, and the arc-shaped toothed plate is stable in installation and operation, has low noise and less dust, is less in noble metal consumption, low in manufacture cost and convenient in adjustment and maintenance, particularly solves the repairing problem of broken teeth and greatly reduce the equipment running and maintaining costs.

Owner:盛金平

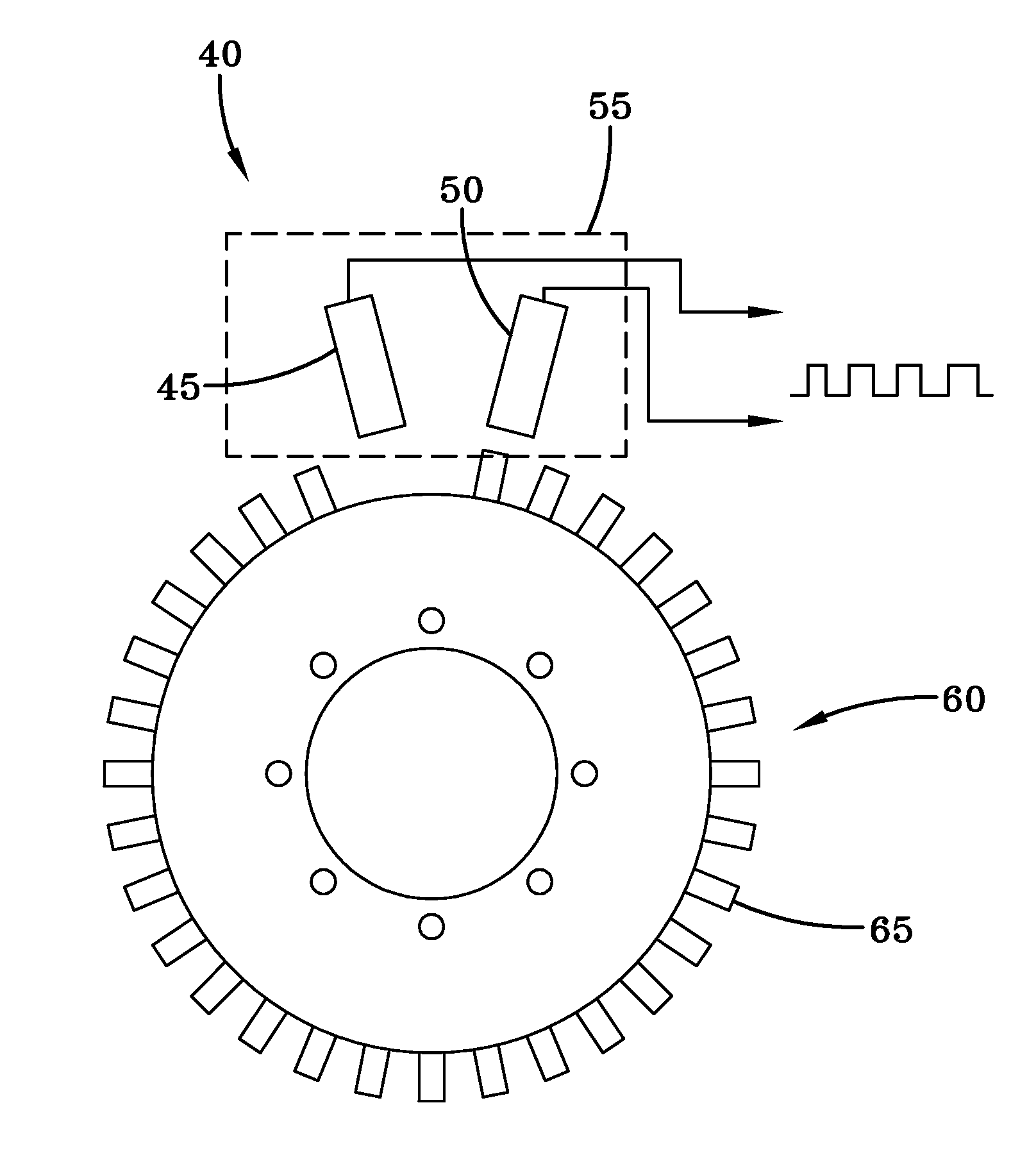

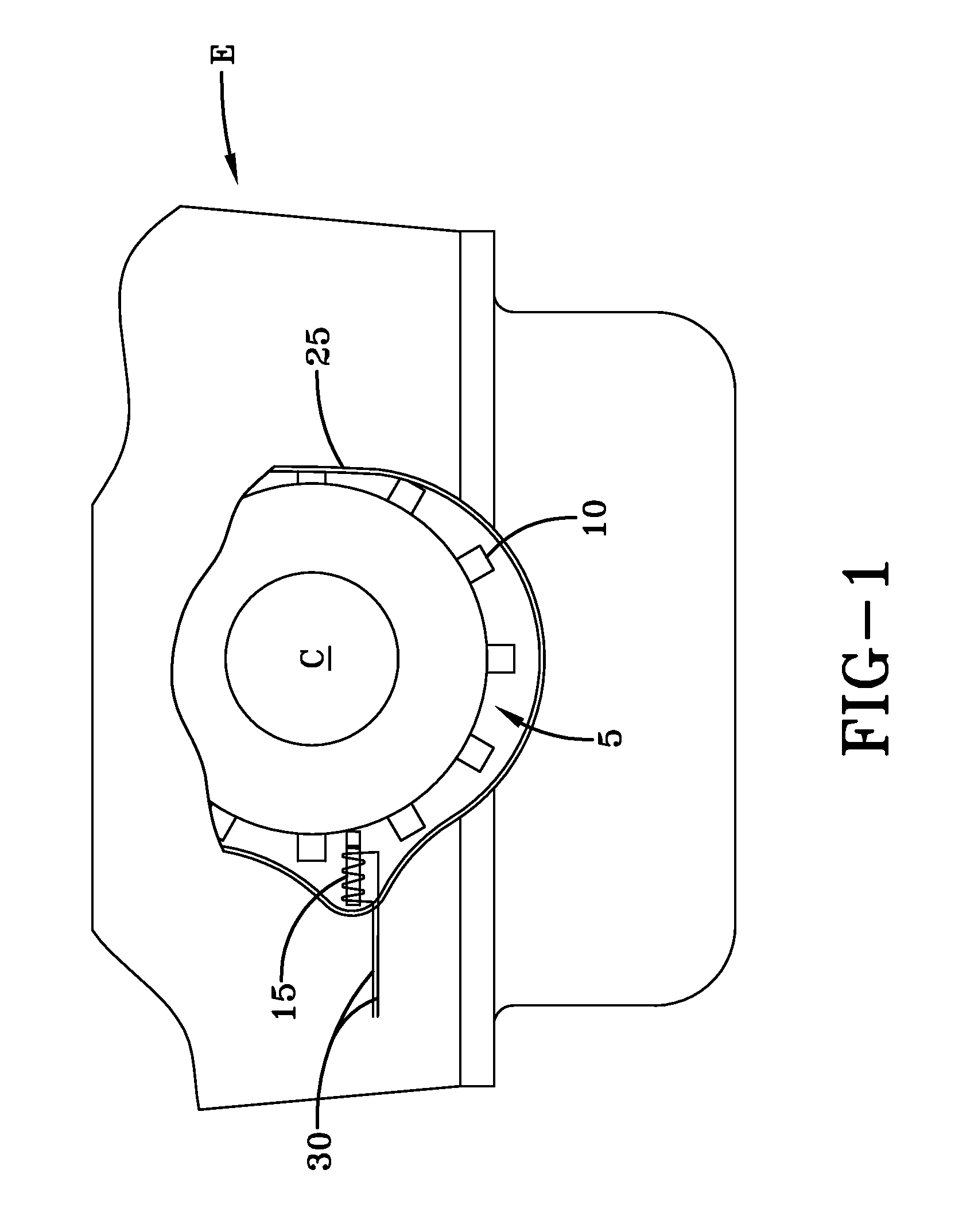

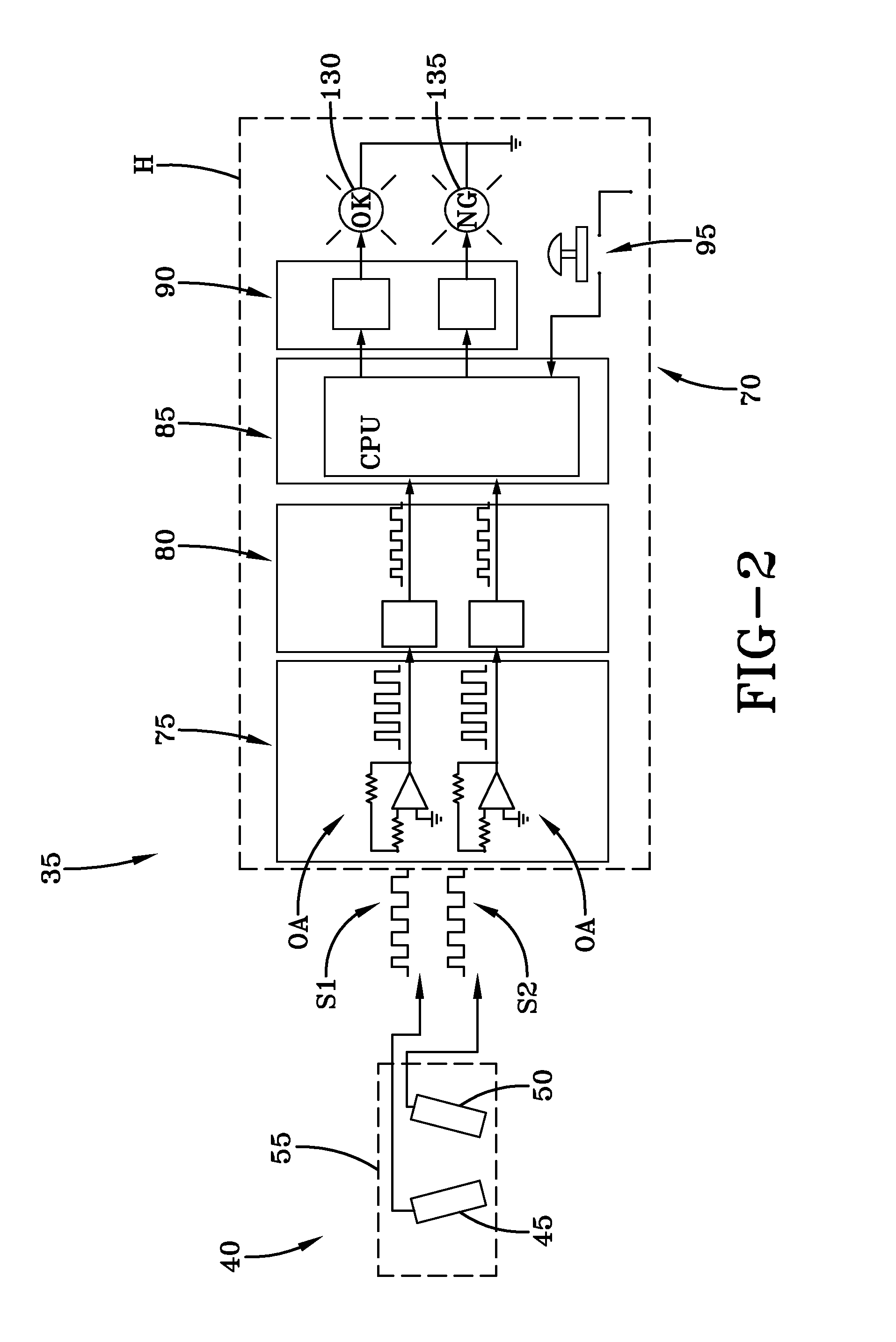

Device and method for detecting vehicle engine pulse generator plate tooth defects

InactiveUS8100000B1Easy to moveQuickly detect damagedElectric ignition installationEngine testingEngineeringPulse sequence

A device and its method of use for in situ detection of bent and / or broken teeth on a vehicle engine pulse generator plate. The device includes a pair of detection sensors adapted to detect pulse generator plate teeth during rotation of a pulse generator plate, and a controller in communication with the sensors. The sensors are arranged such that one sensor leads the other with respect to the detection of teeth on a rotating pulse generator plate. Rotation of a pulse generator plate in the presence of the sensors will cause the sensors to produce an output signal each time a tooth passes by. The signals from the sensors form associated pulse trains that are evaluated by a microprocessor device and associated program of the controller to determine if the pulse generator plate has any bent and / or broken teeth.

Owner:HONDA MOTOR CO LTD

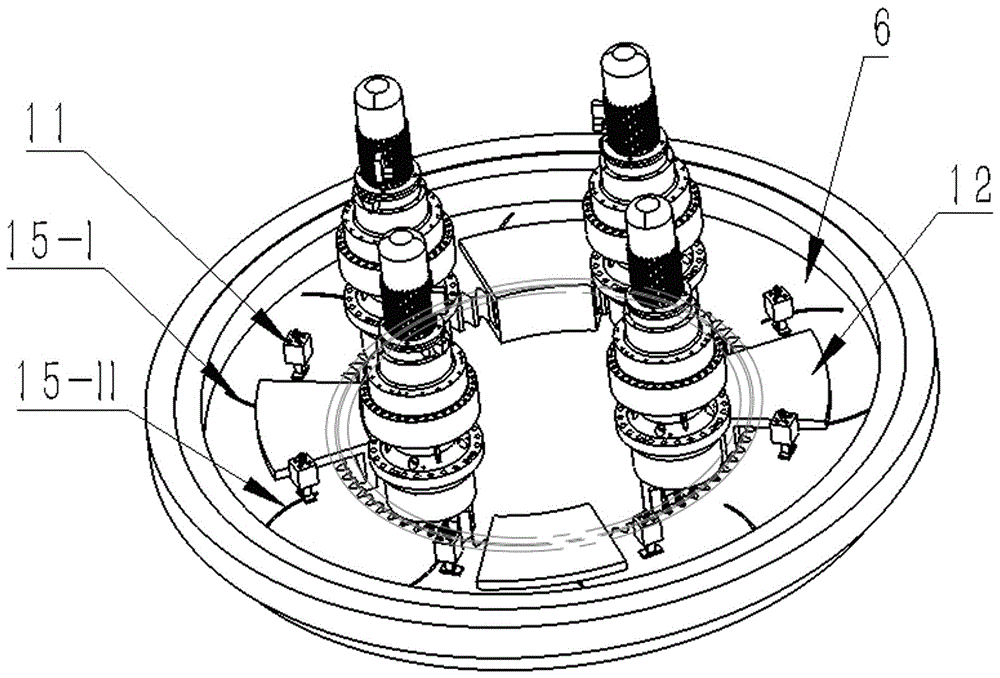

Wind generating set yawing device and wind generating set

The invention relates to a wind generating set yawing device. The device comprises a brake disc, a yawing gear, a yawing bearing and a yawing gearbox; the yawing gearbox is fixed to an engine room, the brake disc and an inner ring or an outer ring of the fixed yawing bearing are fixed together, and the yawing gear is arranged on the inner side of the brake disc, and is engaged with multiple output small gears at the bottom of the yawing gearbox. Due to the fact that the yawing gear is arranged on the inner side of the brake disc, when engaging tooth breaking appears in the position between the yawing gear and the small gears, broken teeth can fall down from the lower portion in time, and cannot be clamped in engaging portions of the yawing gear and the output small gears, and secondary damage of the gear is avoided. The invention further relates to a wind generating set with the yawing device.

Owner:XEMC WINDPOWER CO LTD

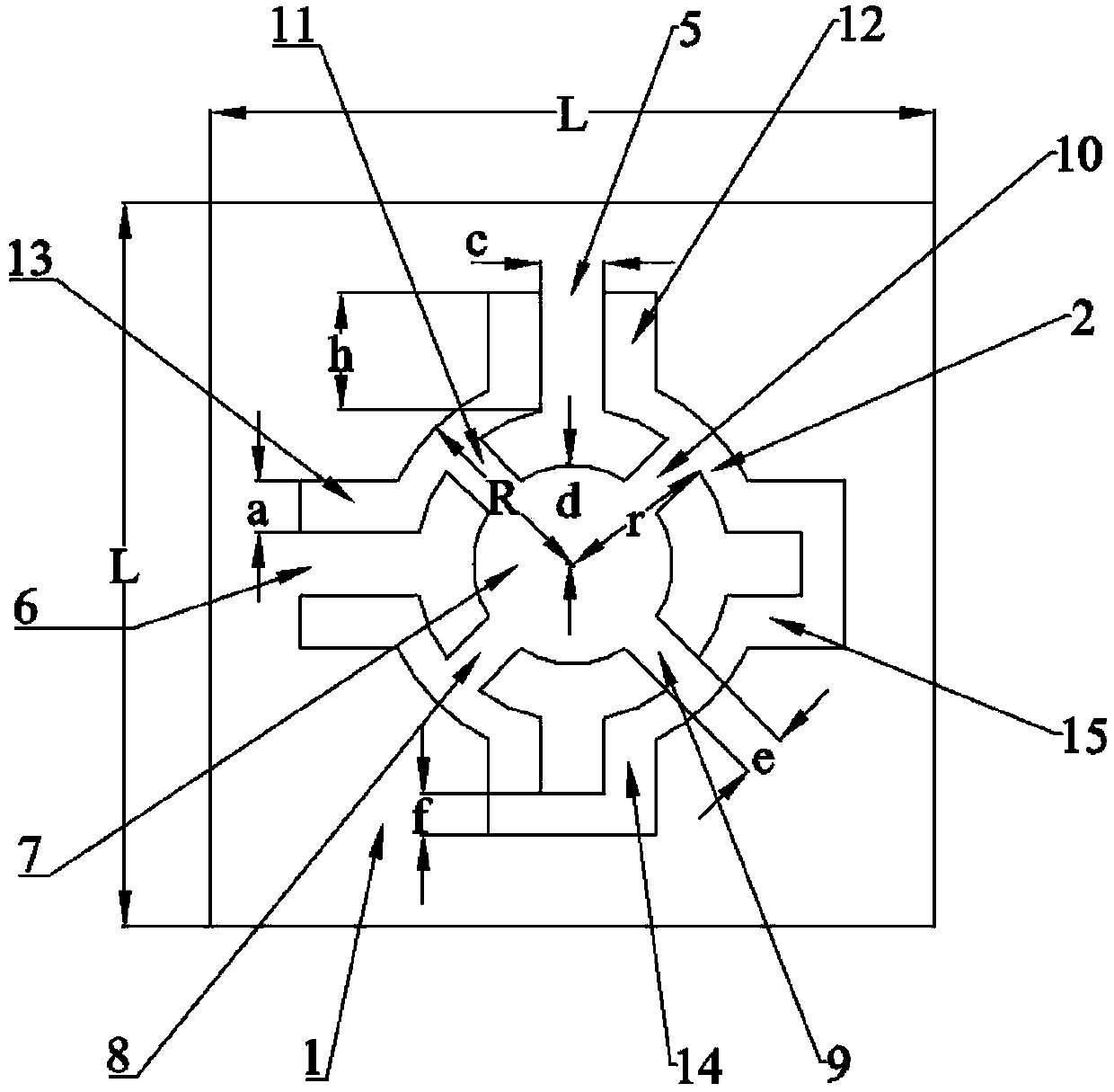

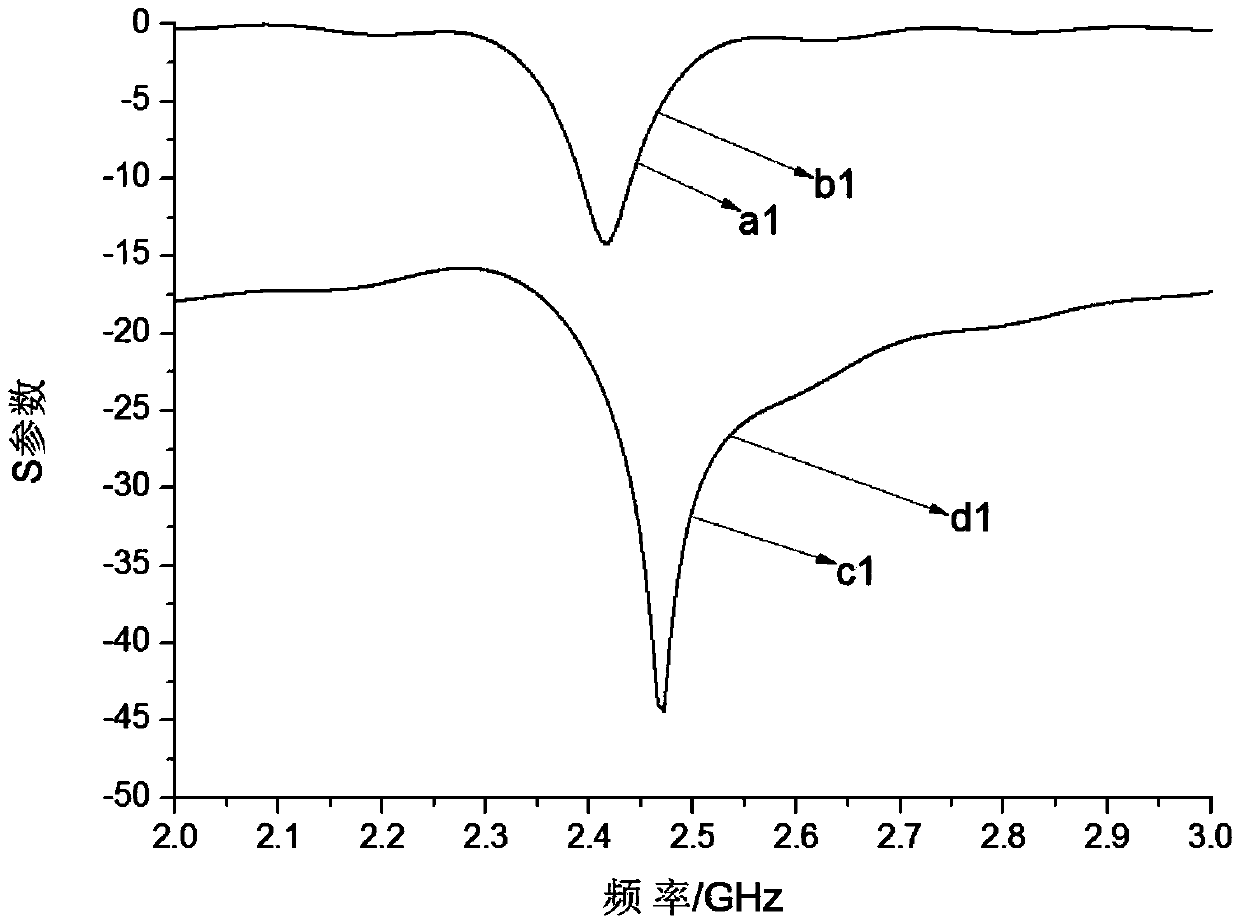

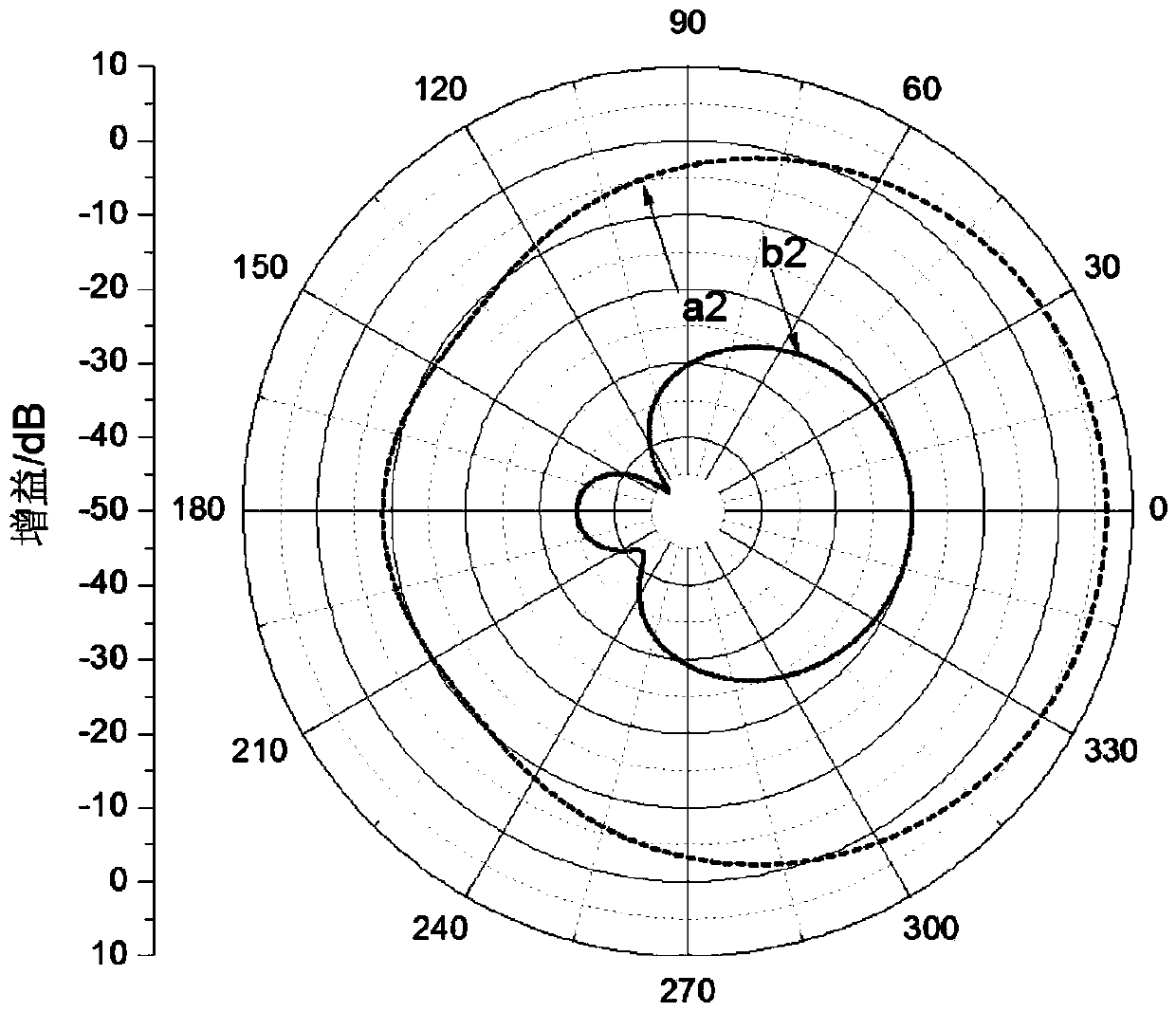

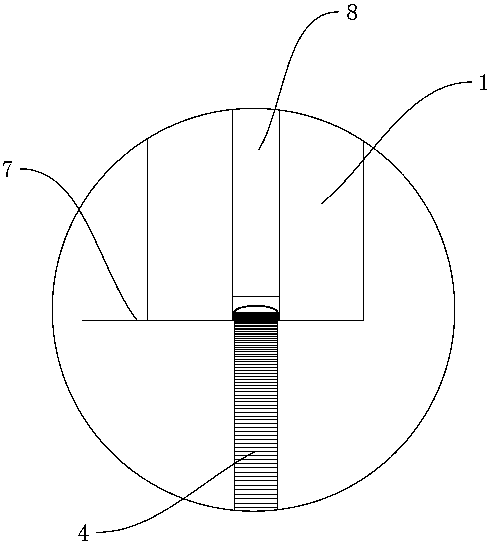

Double-fed dual-polarization microstrip antenna

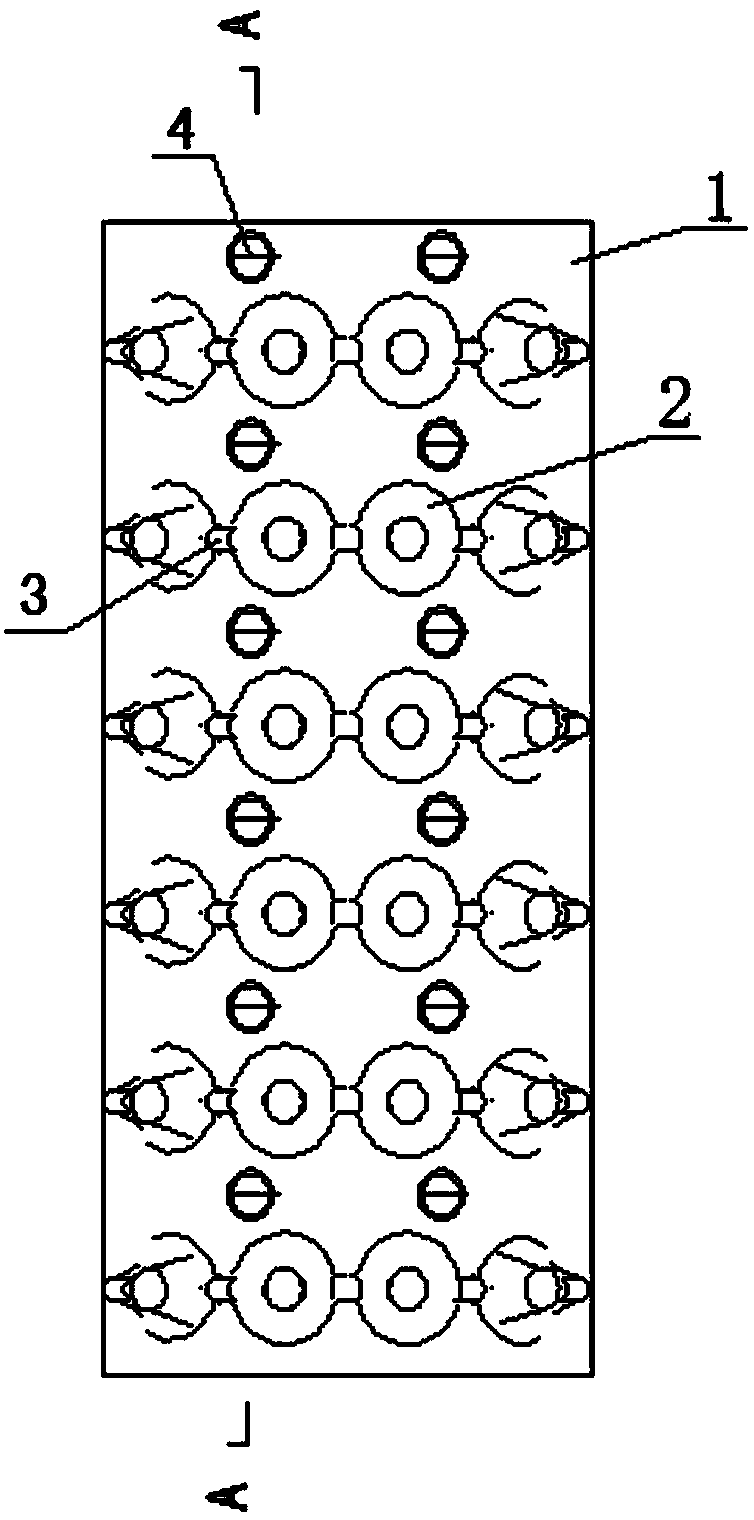

ActiveCN104201467AGood dual polarization characteristicsLow cross polarizationRadiating elements structural formsPolarised antenna unit combinationsDielectric substrateBroken teeth

The invention relates to a patch antenna, in particular to a double-fed dual-polarization microstrip antenna. The double-fed dual-polarization microstrip antenna comprises a dielectric substrate and a radiation patch arranged on the front face of the dielectric substrate, a geometric center of the radiation patch is coincided with that of the dielectric substrate 1, and the back face of the dielectric substrate is grounded. The radiation patch is in a shape of a toothed gear and comprises a central circular piece, four identical concentric arc pieces, four identical radial strip pieces and four teeth; the four concentric arc pieces and the four identical radial strip pieces are symmetrically arranged on the outer periphery of the central circular piece, and each concentric arc piece is connected with the central circular piece through one radial strip piece; the four teeth are uniformly distributed and orthogonally positioned at four ends of the radiation patch and are arranged at two ends of each concentric arc piece, two adjacent teeth of the four teeth are identical U-shaped teeth, and the other two adjacent teeth are identical broken teeth which are U-shaped teeth with radial middle openings serving as feed ports. The double-fed dual-polarization microstrip antenna is high in isolation and has excellent dual polarization characteristics.

Owner:XIAMEN UNIV

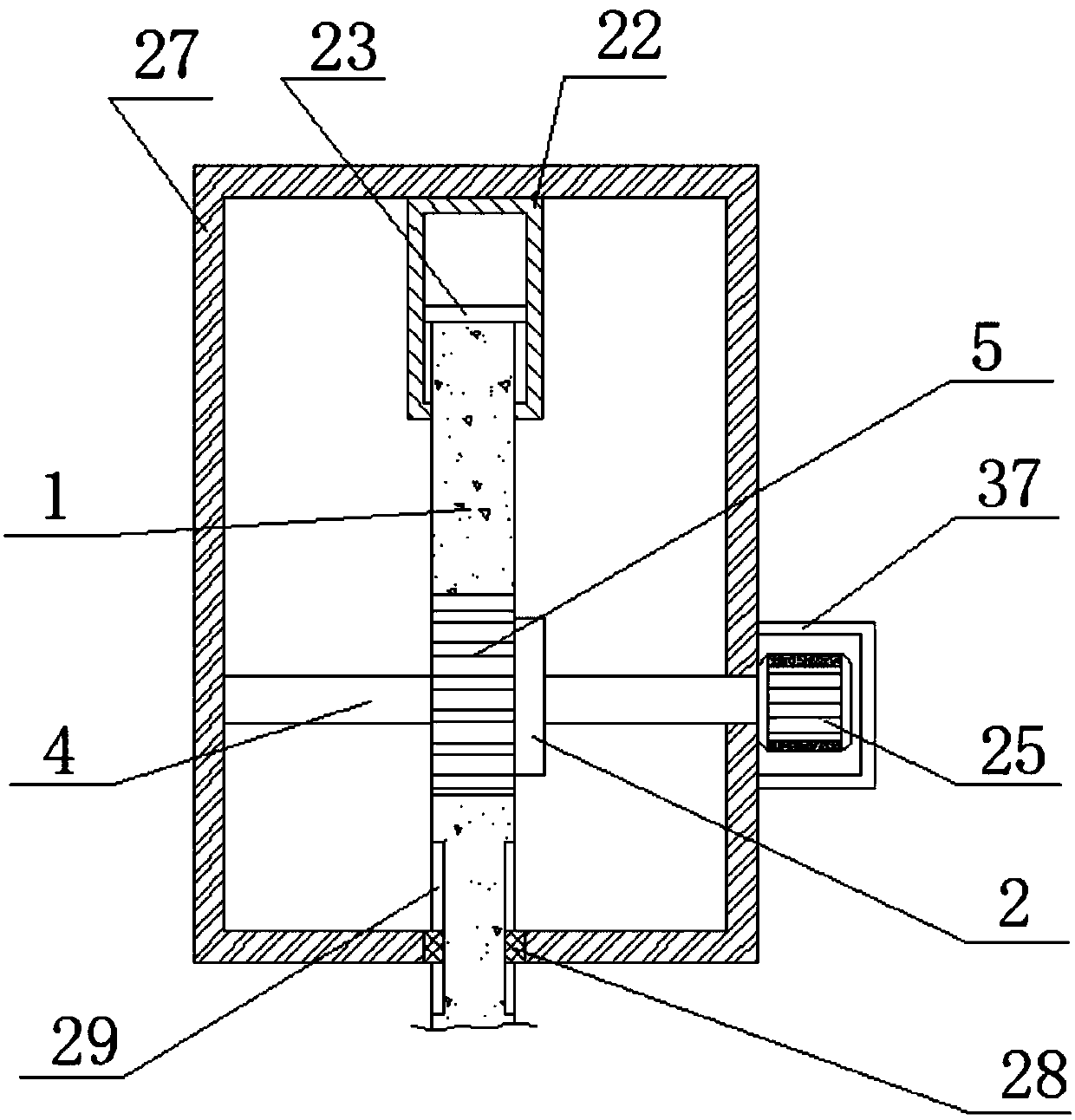

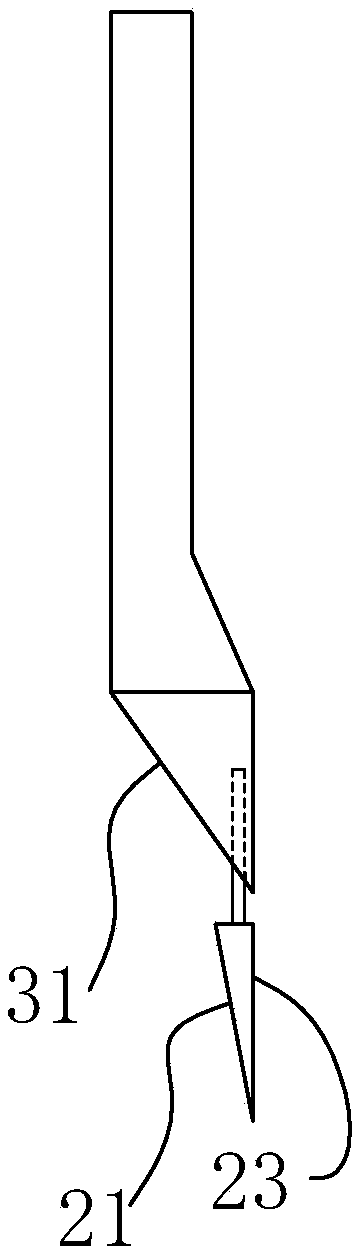

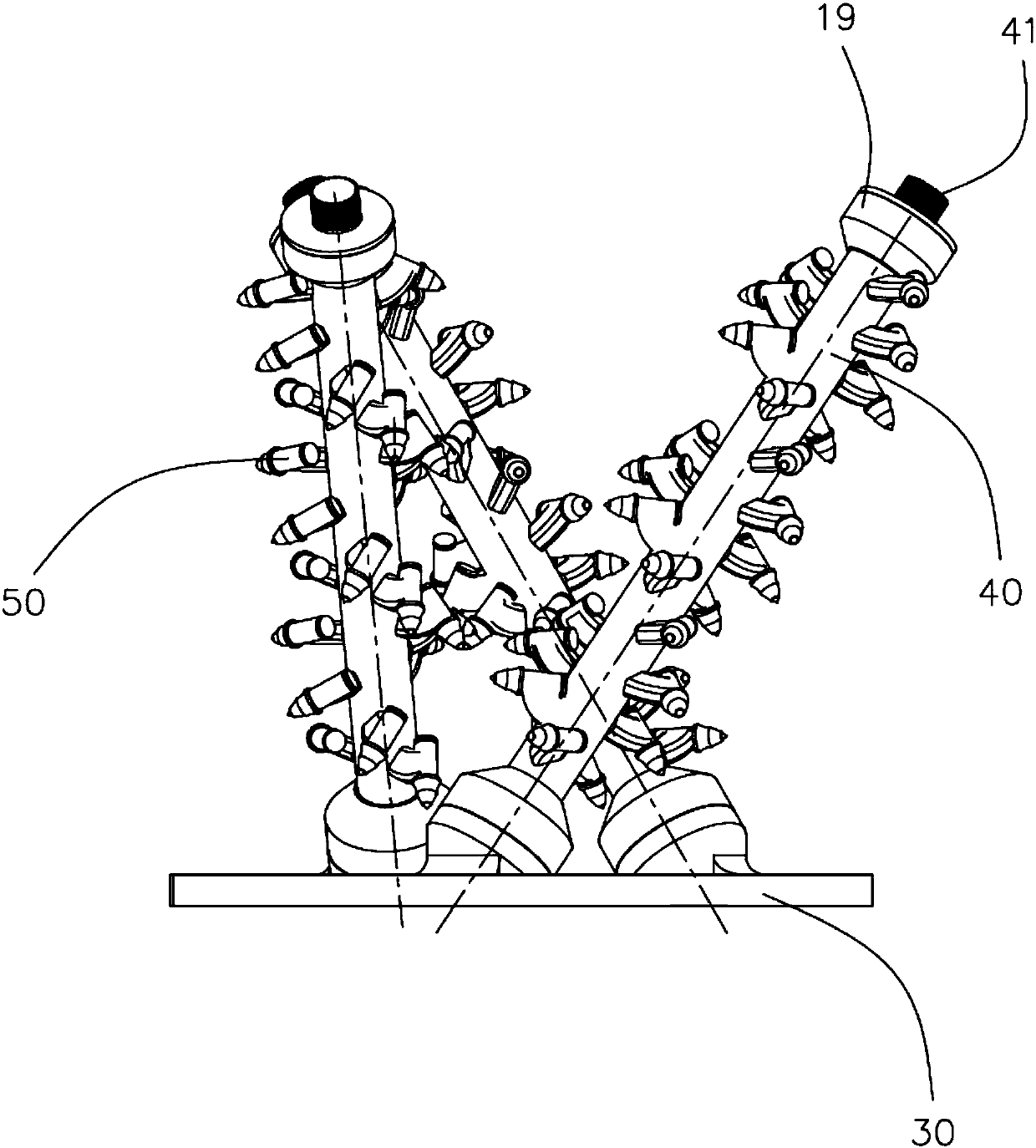

Combined feed processing and granulating device

InactiveCN107549858AImprove the problems of rough granulation and easy crushingStir wellFeeding-stuffEngineeringCrusher

The invention discloses a combined feed processing and granulating device, which comprises a feed crushing and feeding module, a mixing and stirring extrusion discharging module and an extrusion granulation discharging module. The upper end of the installation plate is provided with a crushing operation cylinder, and the upper end of the crushing operation cylinder is provided with a cone feeding cylinder. The upper and lower sides of the antiemetic city crushing operation cylinder are symmetrically and evenly provided with material guide holes, and the right side of the crushing operation cylinder is inlaid A crushing motor is provided, and the crushing motor is provided with a crushing shaft running through the crushing shaft to the left, and crushing teeth are uniformly arranged on the outside of the crushing shaft, and the crushing teeth on the crushing shaft are uniformly provided with passive crushing gears on the inside of the crushing shaft. The invention has the advantages of compact structure design, simple operation, simplified transmission structure design, stable transmission, uniform mixing, good granulation quality and fast speed.

Owner:胡永才

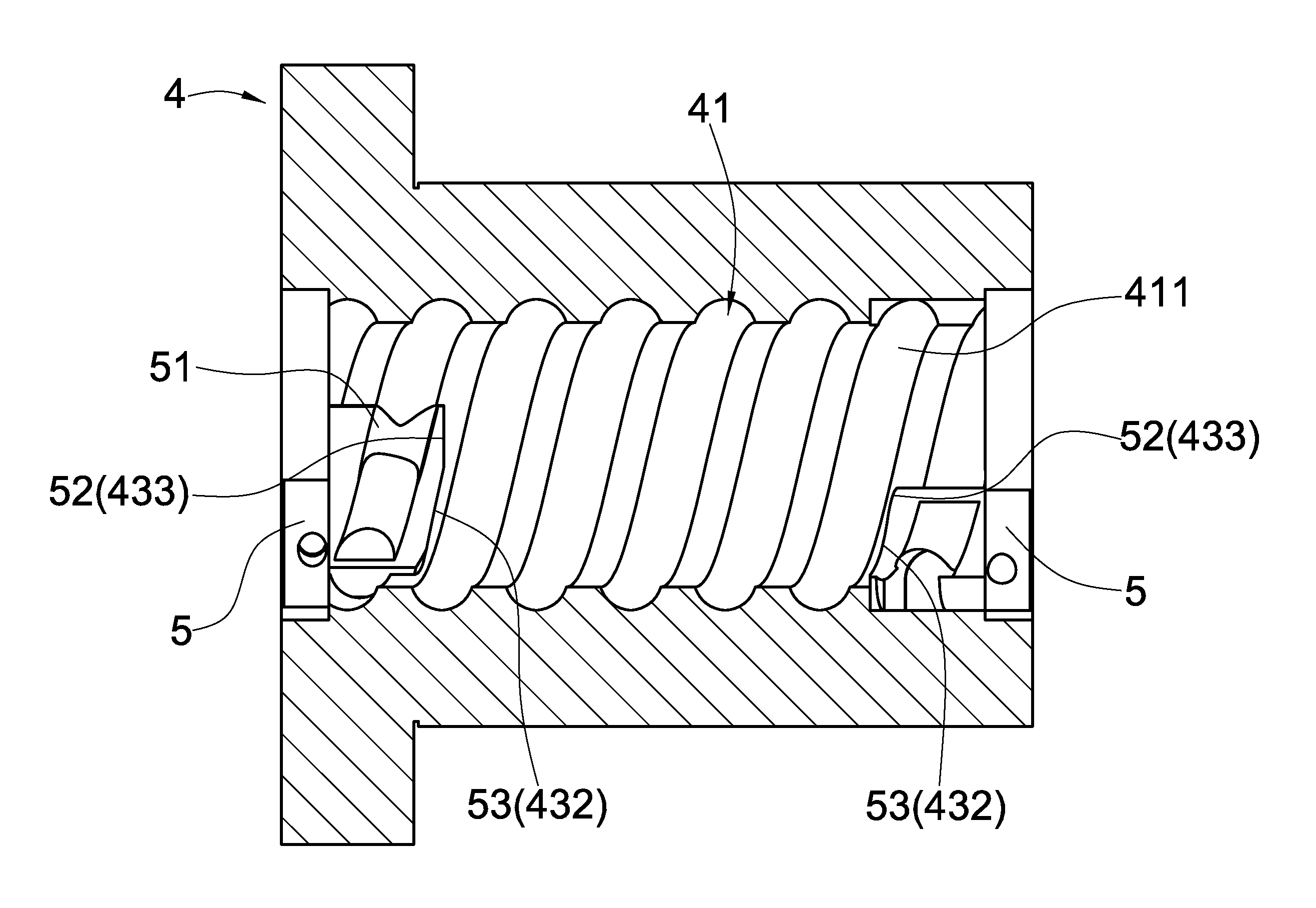

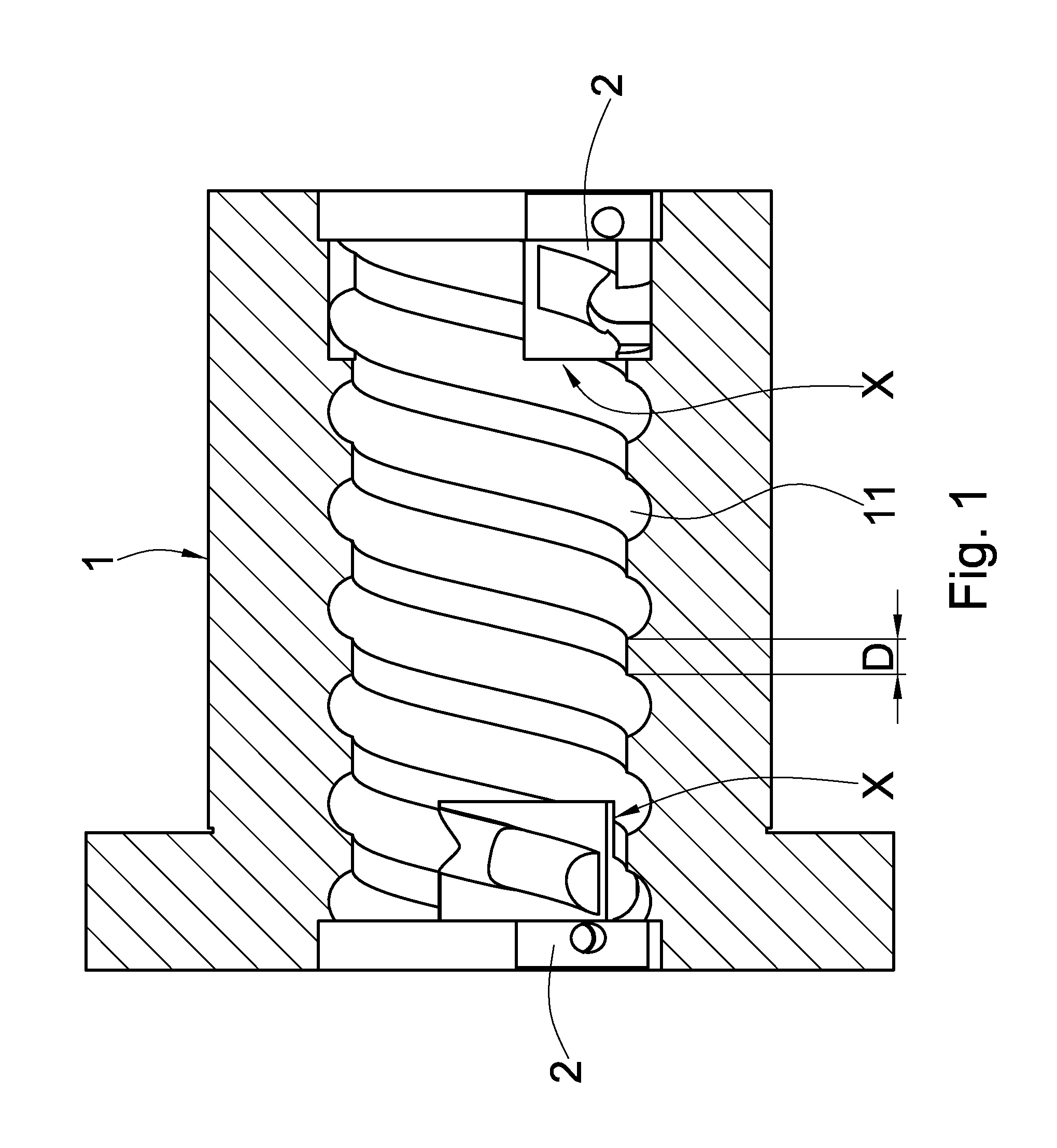

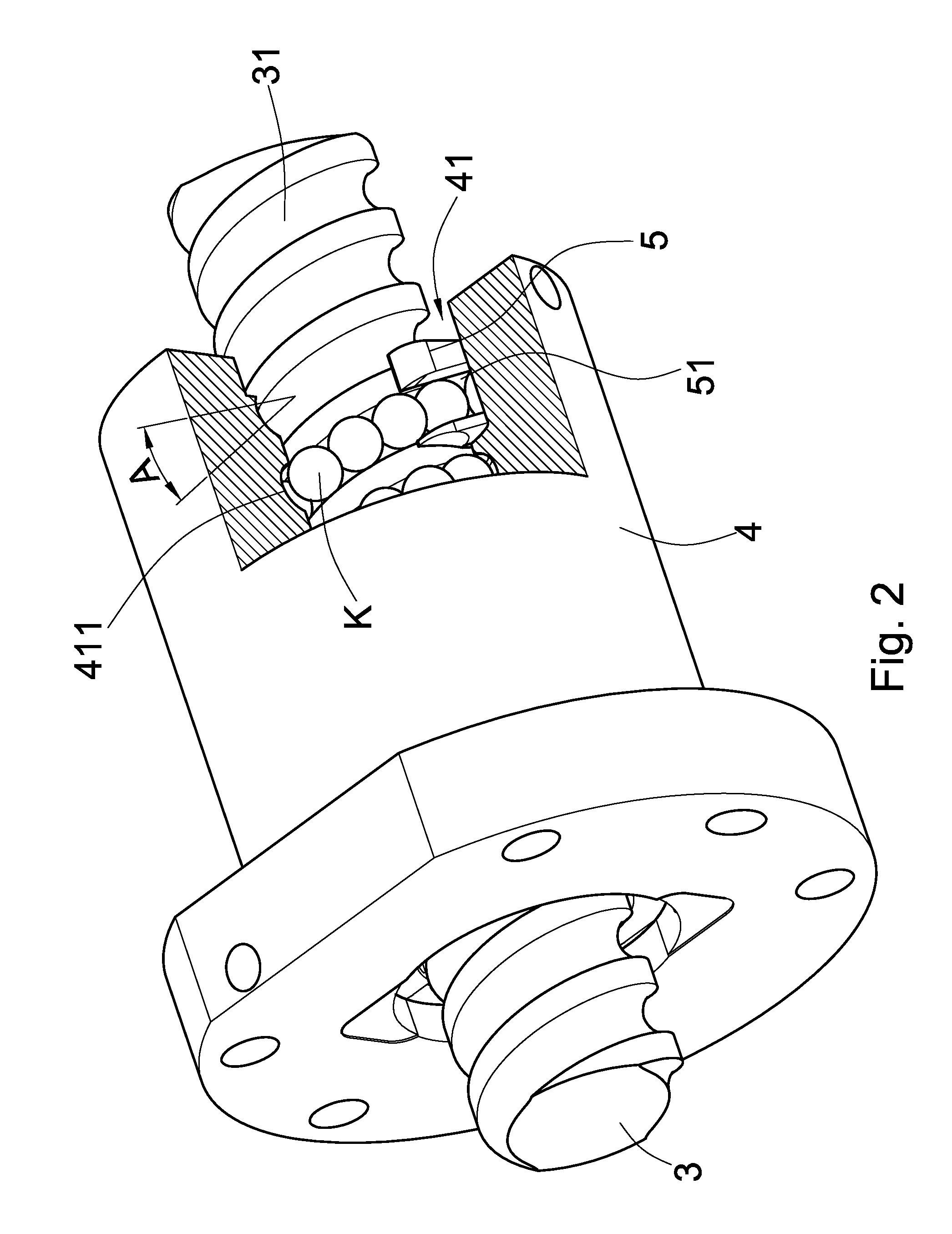

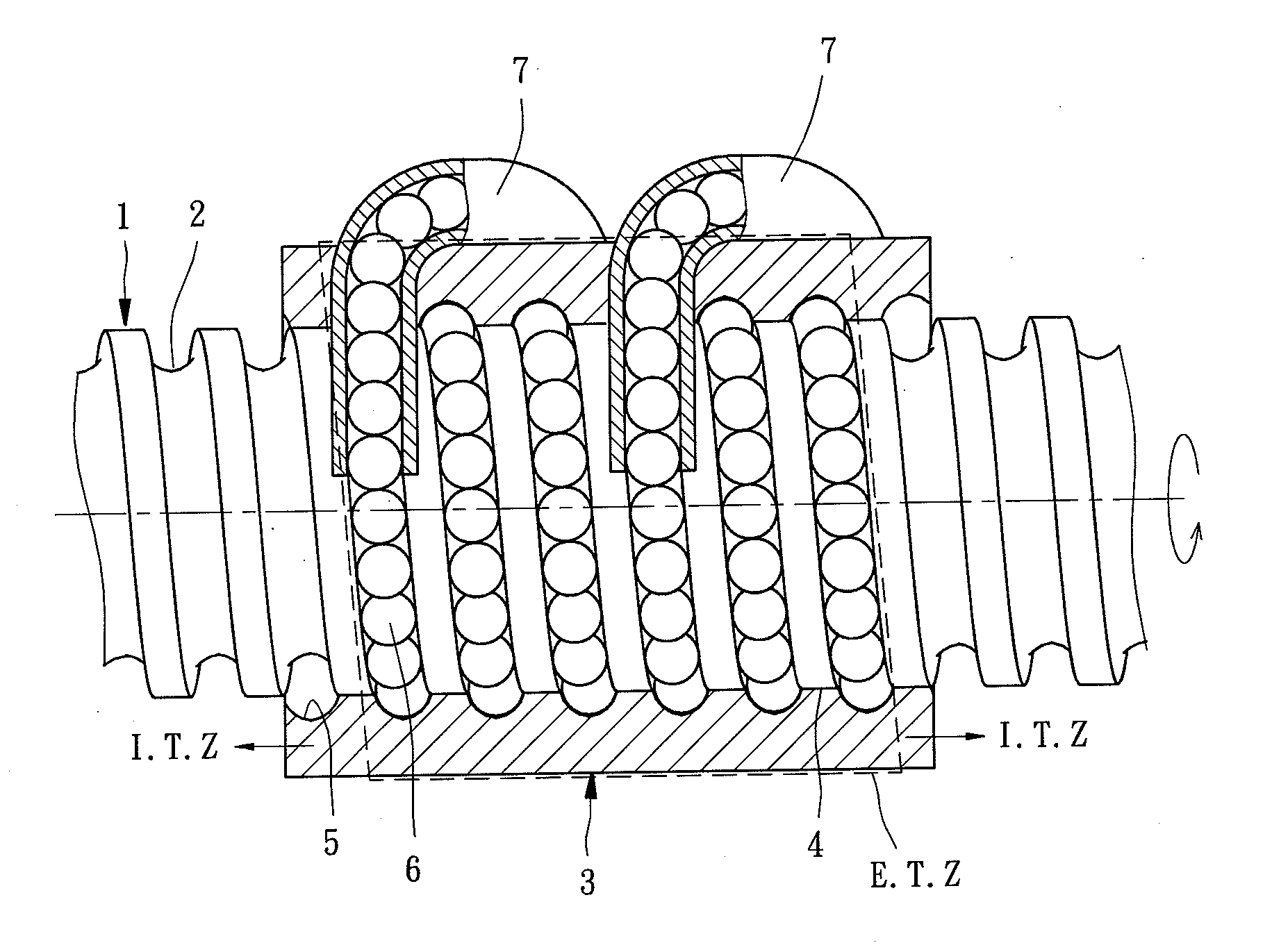

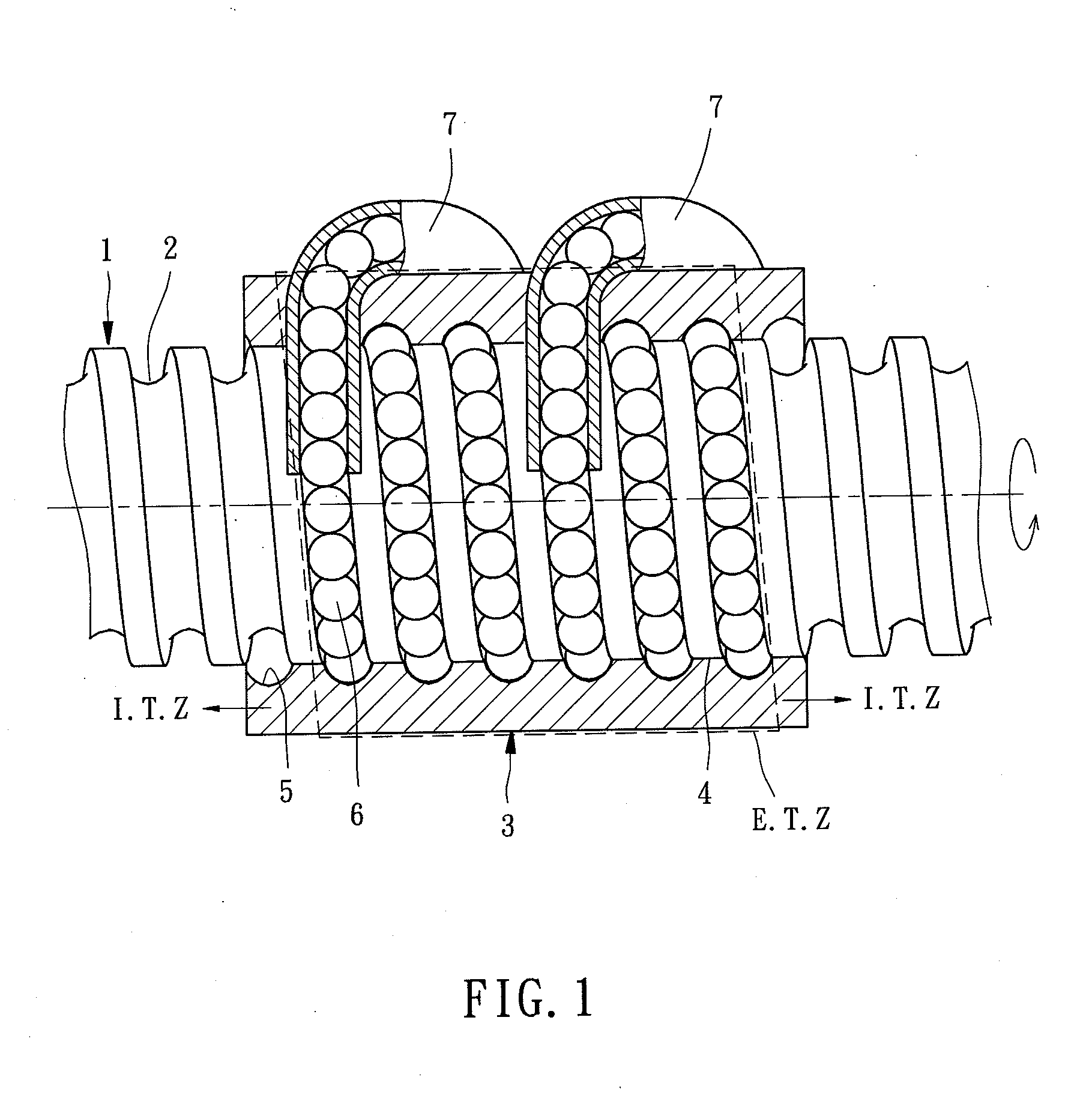

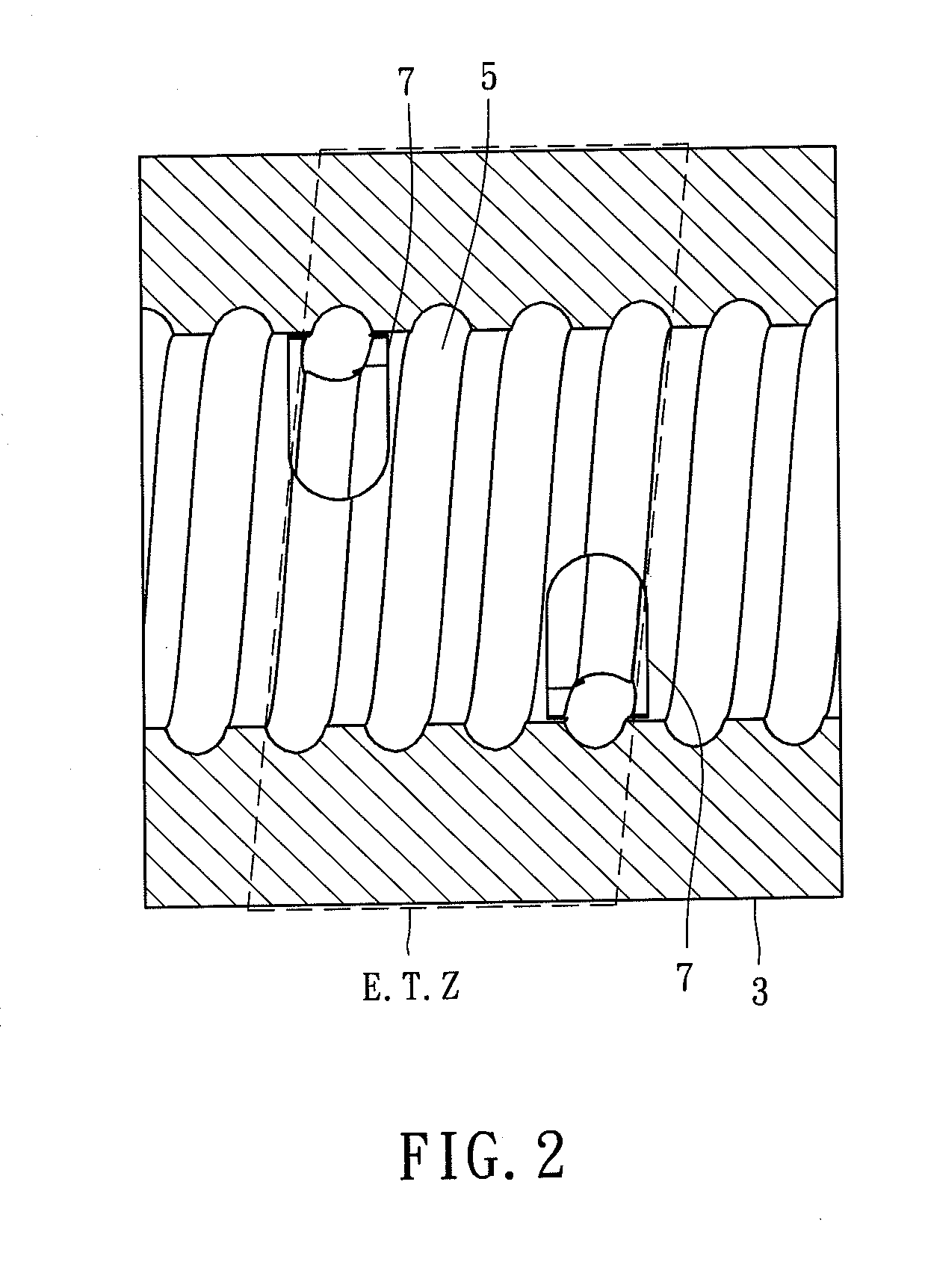

Circulation element for ball screw

ActiveUS8640564B2Reduce running noiseReduce manufacturing costPortable liftingToothed gearingsBall screwEngineering

This invention is revises the cap nut which the custom knows to suppose it to install trough's outline, will cause to install the dadoing to lead (lead angle to be small) lowly or on two above trundle ditch cap nut will not have the broken tooth's question, when will process should install the trough, only need use the face cutter then to process the forming, will reduce the production cost; And return circuit of this invention all establishes in the backflow part, therefore may promote and the cap nut supposes the backflow hole and the load way grade of fit, causes to roll the moving parts movement to be smoother, and reduces the noise production.

Owner:HIWIN TECH

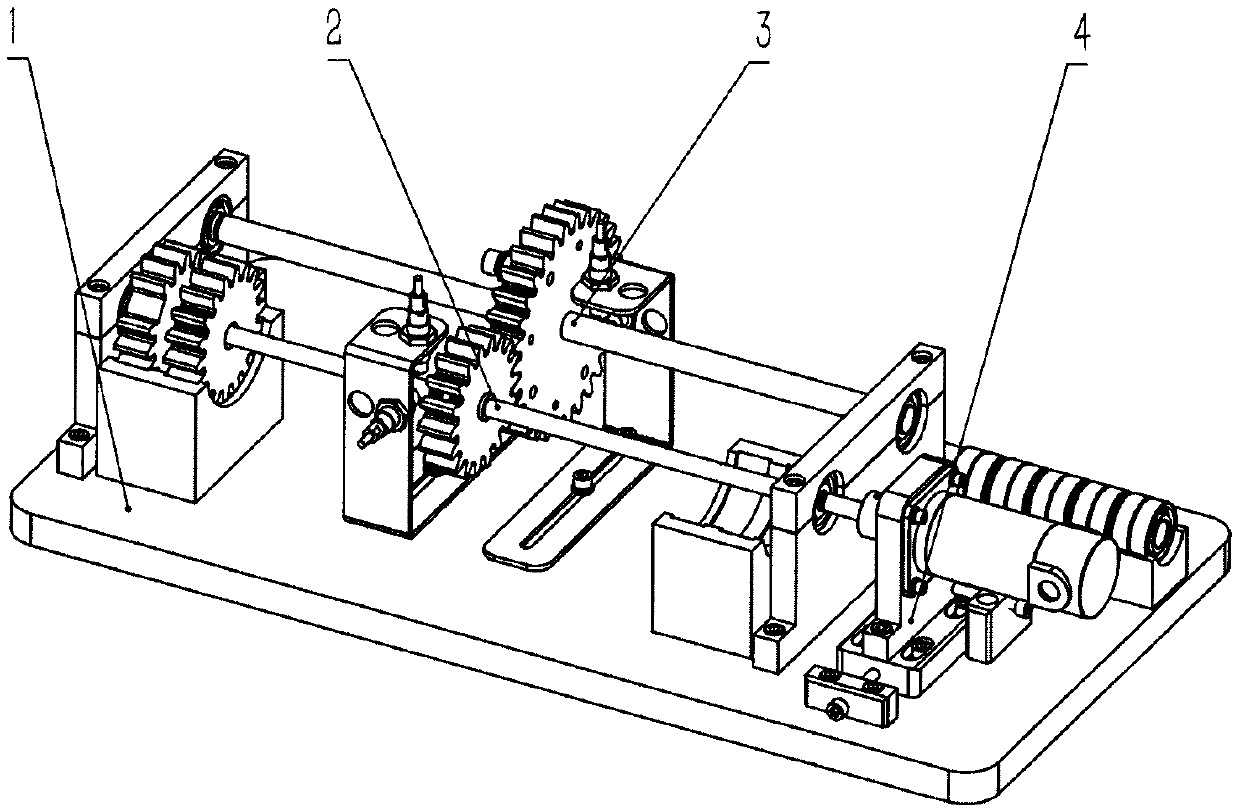

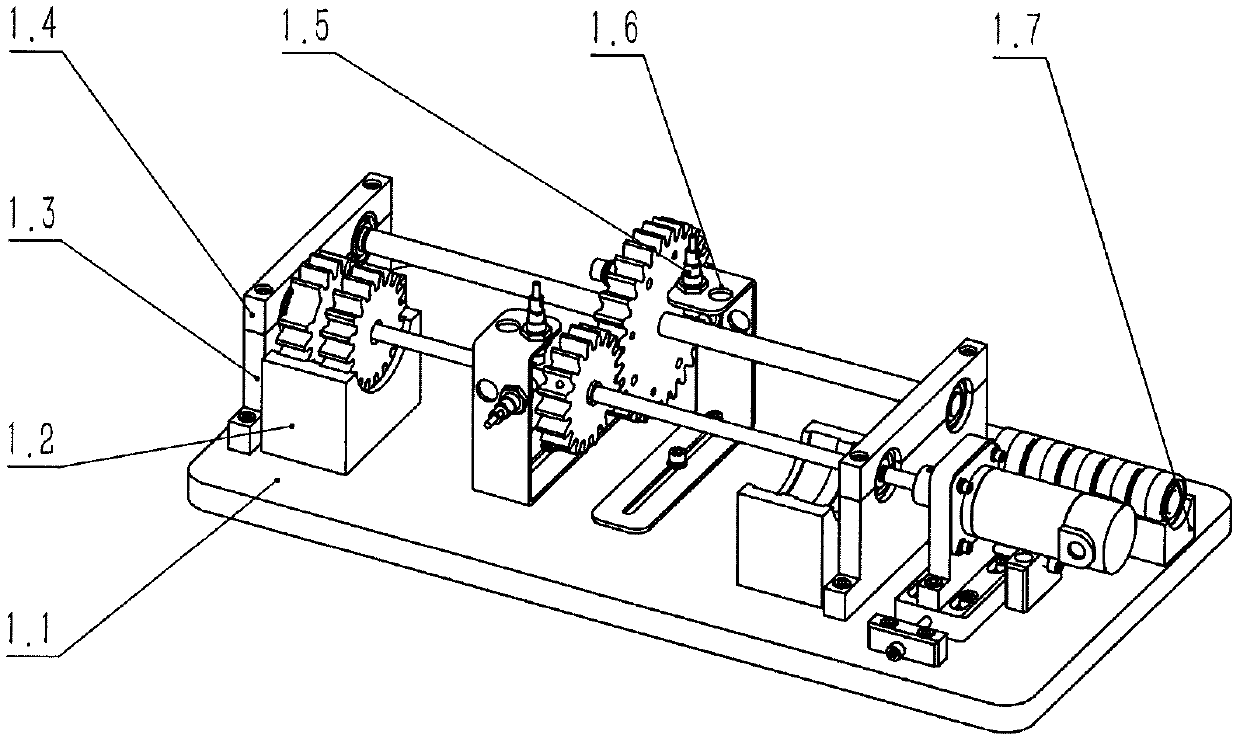

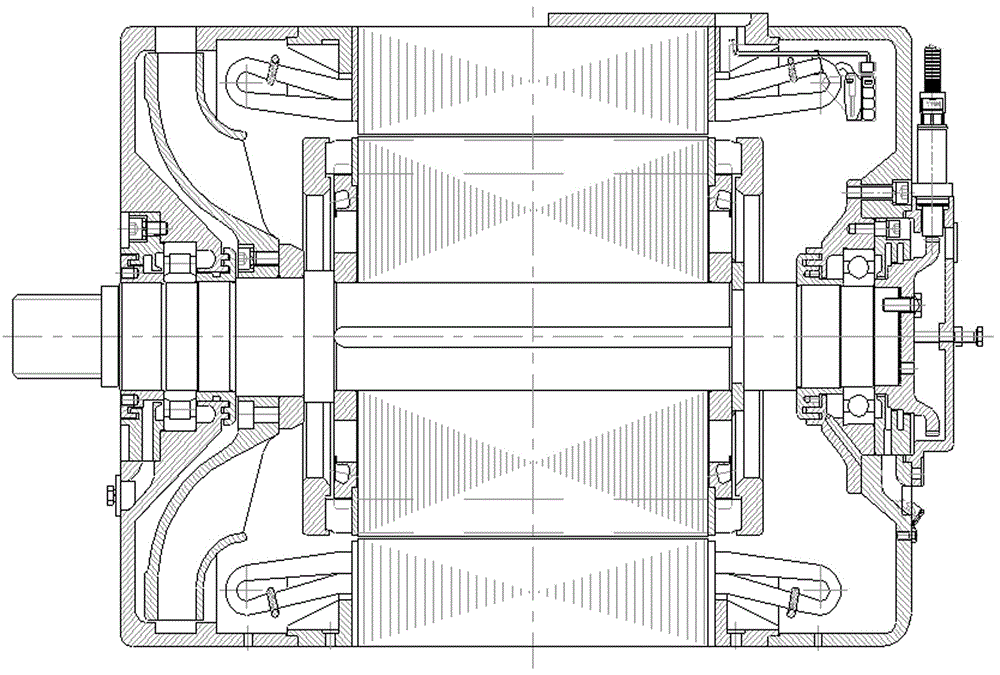

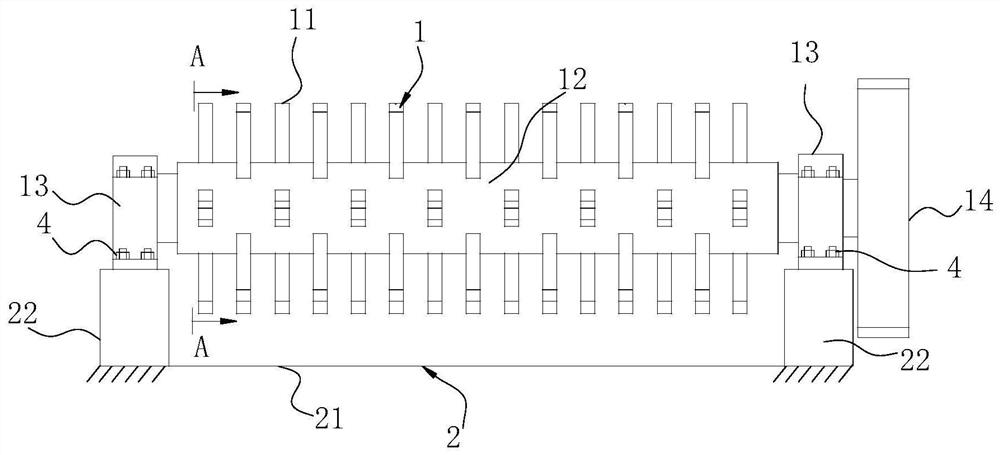

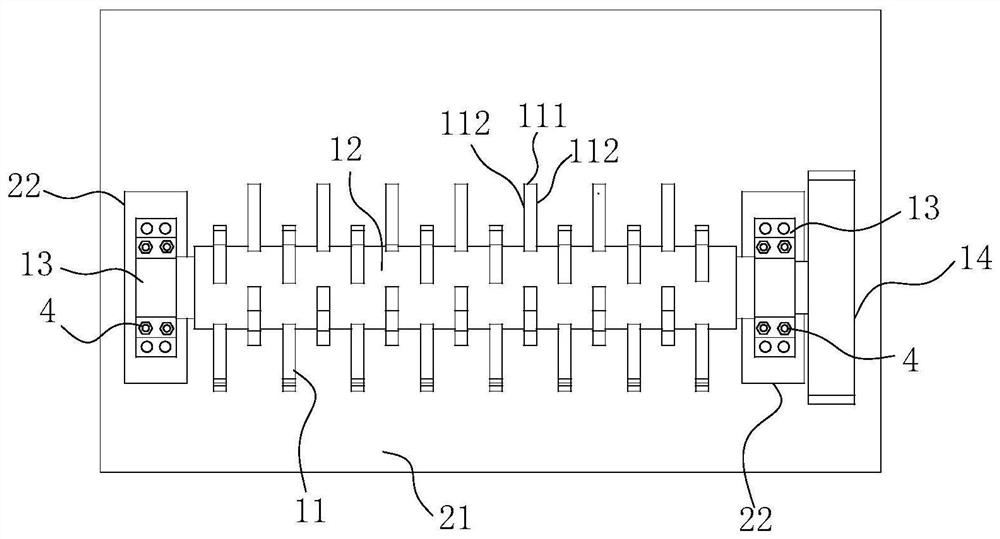

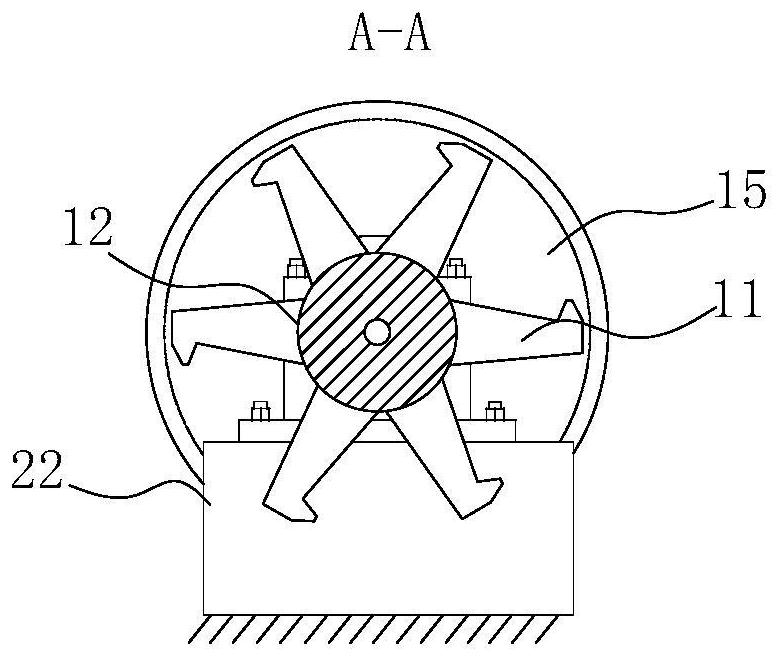

Gear driving system fault simulation experiment table with part quick replacement function

The invention provides a gear driving system fault simulation experiment table with a part quick replacement function and mainly relates to double-span double-rotor gear driving fault simulation systems capable of quickly replacing bearing and gear parts and setting and adjusting multiple faults. The experiment table can be applied to mechanical engineering and measurement and control instrument course experiment teaching and relevant scientific research. The experiment table can simulate a bearing normal state, a bearing rolling body fault, an inner ring fault, an outer ring fault, a holder fault, a gear normal state, gear broken teeth, a gear pitting fault, a mixing fault of two types of parts, gear rotation unbalance and other fault types. The experiment table provides an experiment basis and technical guidance for a state monitoring and fault diagnosis course of a rotating mechanical system driving system, fault type setting operation is quick and convenient, popularization is easy, and a guarantee is provided for relevant experiment teaching and scientific research in institutions of higher education.

Owner:TIANJIN POLYTECHNIC UNIV

Bedding soil tamping device for construction site

InactiveCN109610275AIt is convenient to pad the soilAvoid unevennessRoads maintainenceArchitectural engineeringBroken teeth

The invention, which belongs to the technical field of building construction, in particular relates to a bedding soil tamping device for a construction site, thereby solving a problem that the existing tamping device for flattening the municipal administration path does not have the functions of automatic filling and bedding. The tamping device comprises a mounting shell. A fixing cylinder is connected to the inner wall of one side of the top of the mounting shell by a bolt. First sliding slots are formed in the two sides of the fixing cylinder; a same horizontally arranged limiting rod is connected to the inner walls of the two sliding slots in a sliding manner; and the outer wall of the bottom of the limiting rod is connected with a support post by a bolt. A through hole is formed in theouter wall of one side of the bottom of the mounting shell; and limiting plates are connected to the inner walls of two ends of the through hole by bolts. According to the invention, with a servo motor, a driving gear, and a driven gear, tapered broken teeth on a rotating shaft are driven to make rotation and thus the soil entering a storing shell is smashed, so that the uneven roadbed can be filled with soil.

Owner:赵智慧

Method for repairing circular saw web of flying sawing machine

InactiveCN102500824ACutting costsReduce cutting areaSawing tools dressing arrangementsCold formedCircular saw

The invention relates to a method for repairing a circular saw web of a flying sawing machine. The method sequentially comprises the following technical processes of shaping the saw web, repairing broken teeth, shaping the tooth shape of a tooth grinding machine, quenching at high frequency and tempering at low temperature, so that the shortcoming of pure mechanical repairing of the tooth grinding machine is overcome; and saw teeth of the saw web have the original performance, and the service life of the saw web is not shortened; theoretically, the saw web can be repaired for over hundred times; the cutting area is reduced by about 0.1 to 0.5 percent every time when the saw web is repaired; therefore, the cost of the saw web during production of cold-formed sectional steel is reduced greatly; and the production cost is reduced.

Owner:SHANXI DINGRONG COLD FORMED SECTIONS

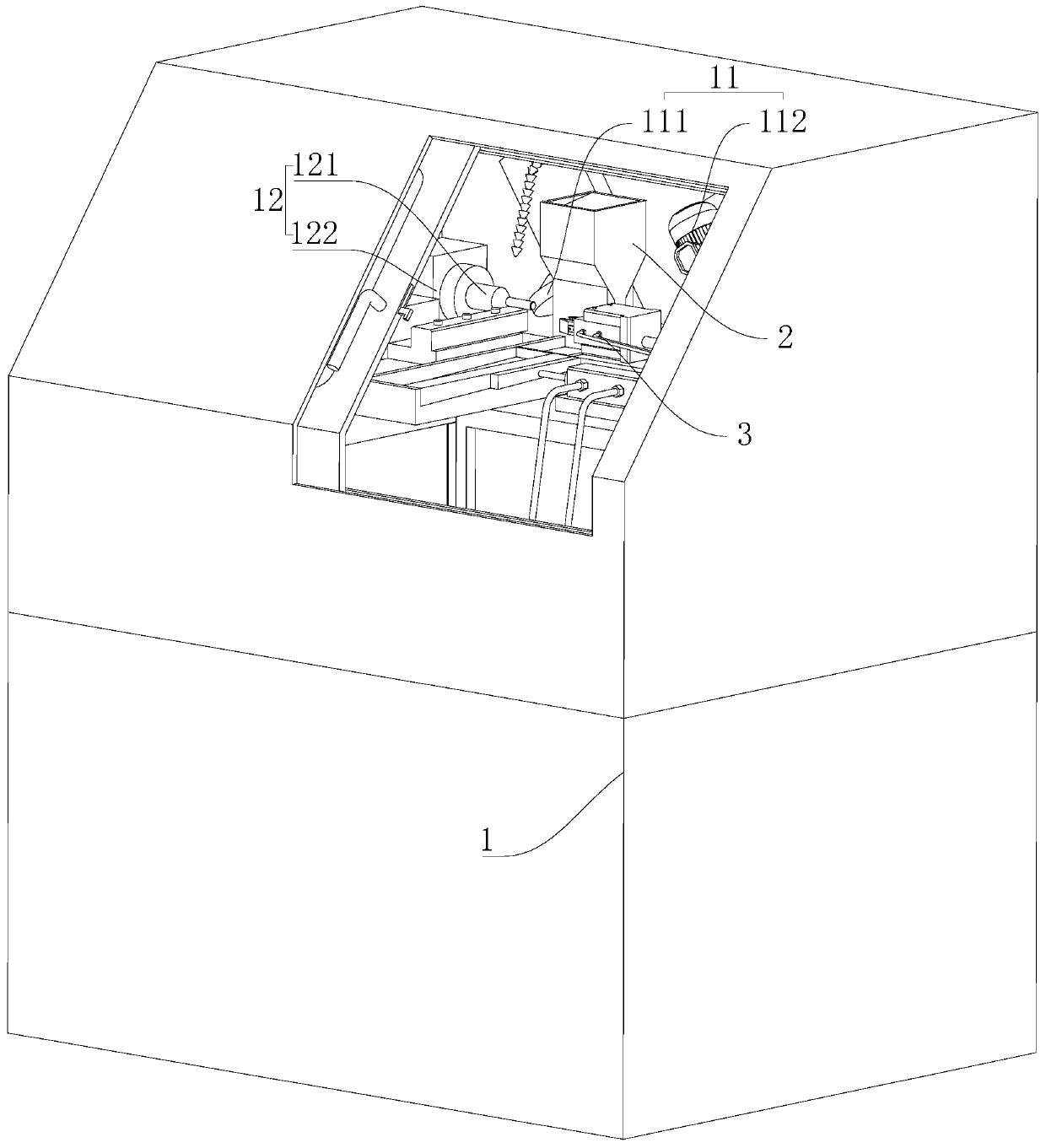

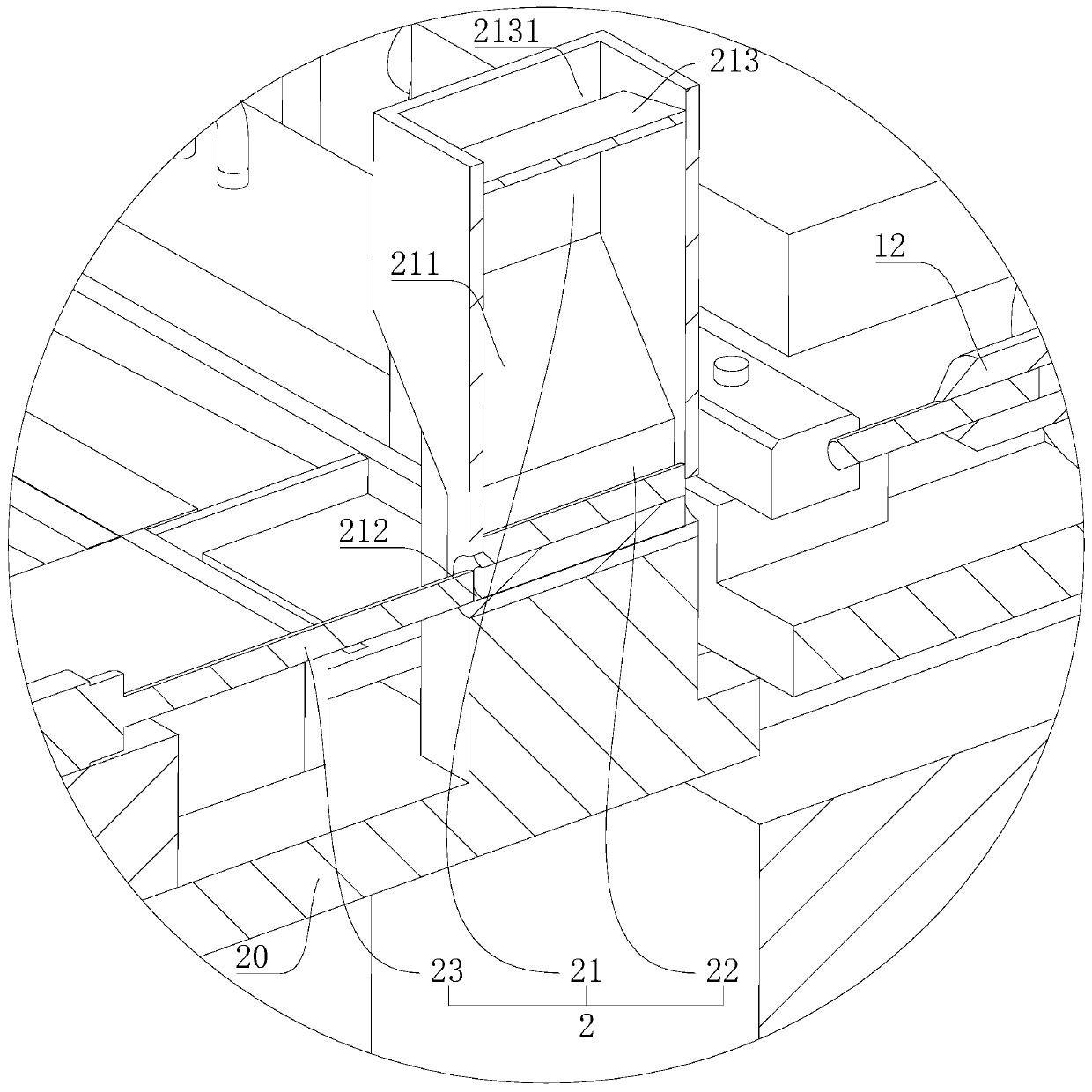

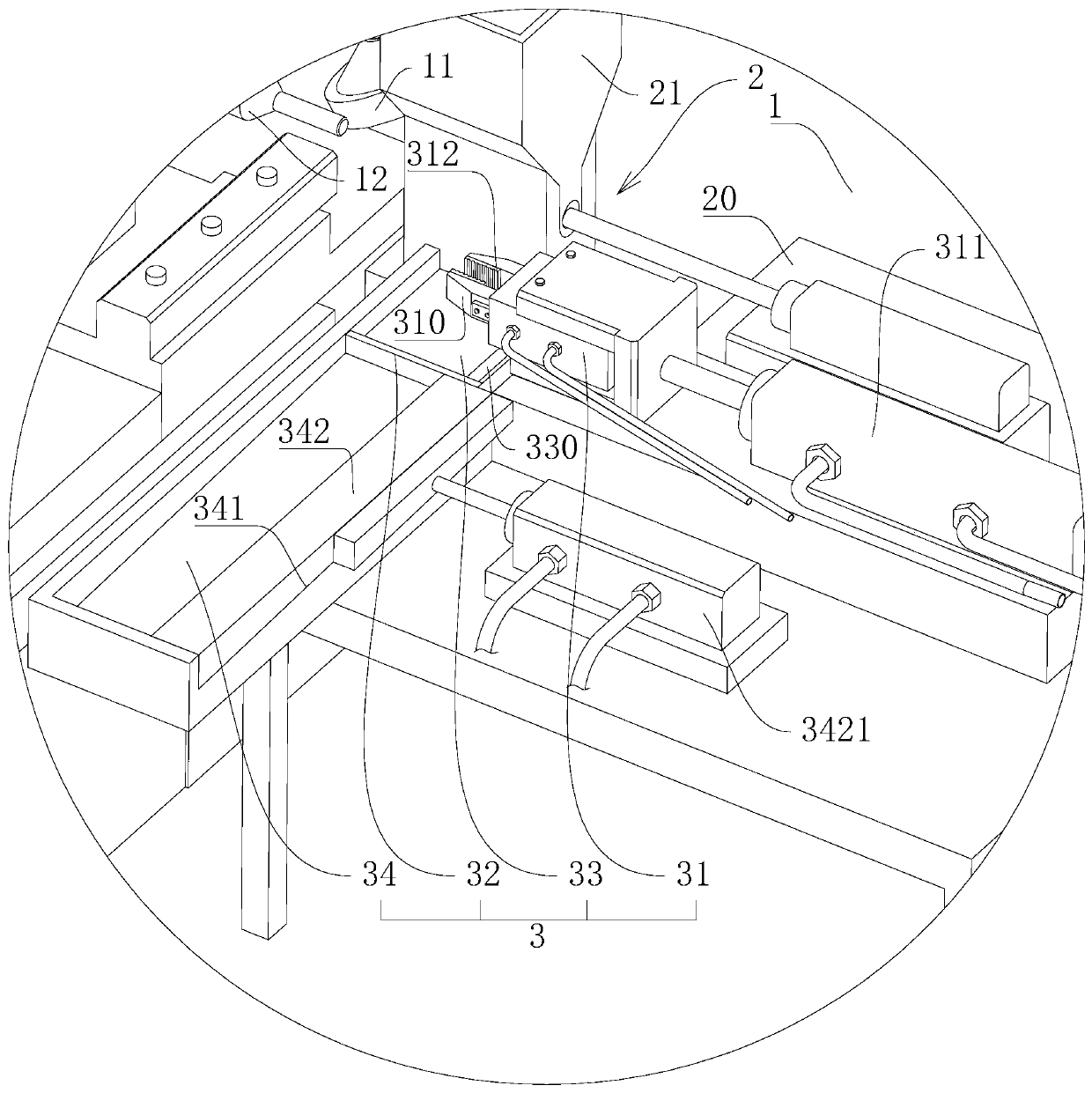

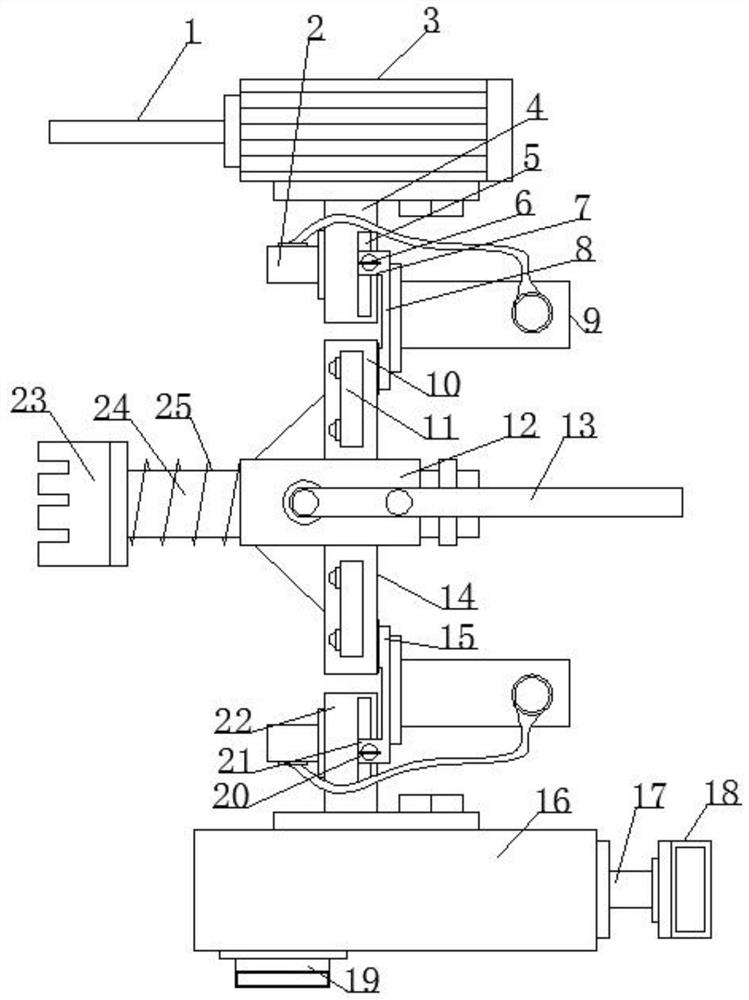

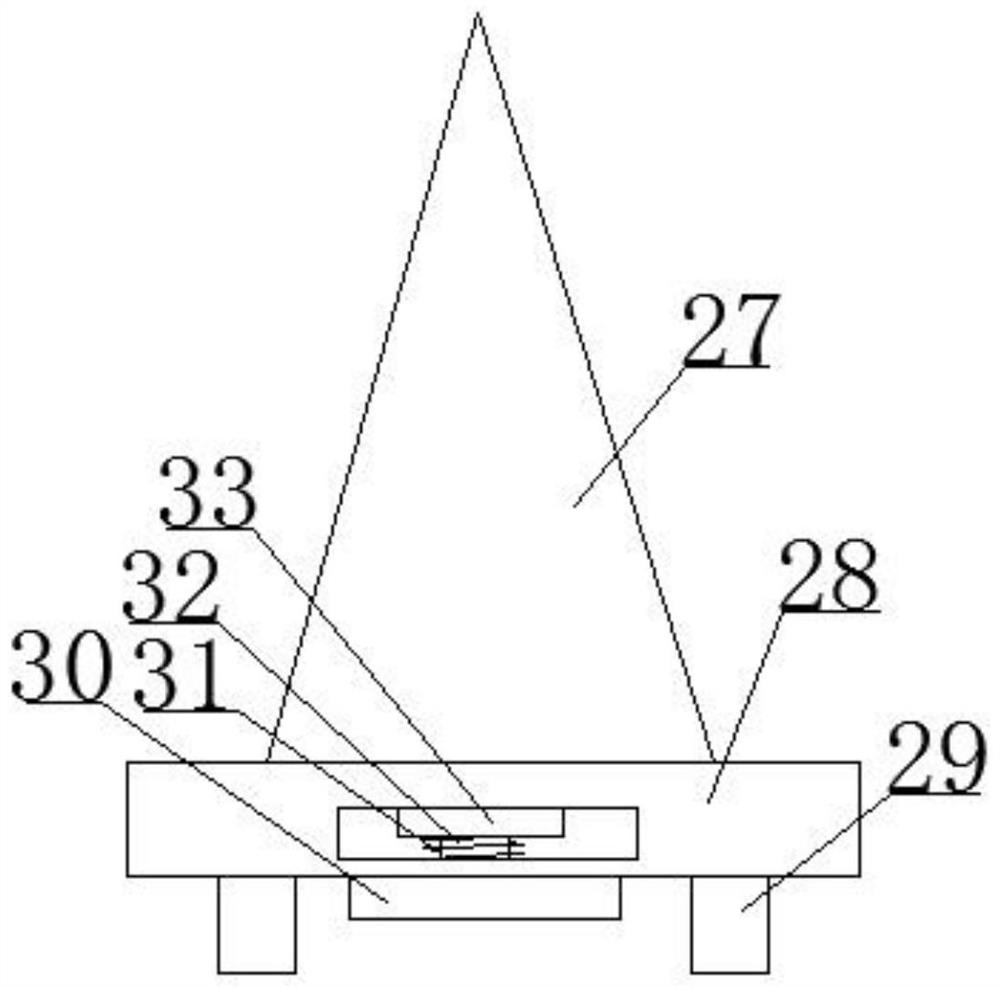

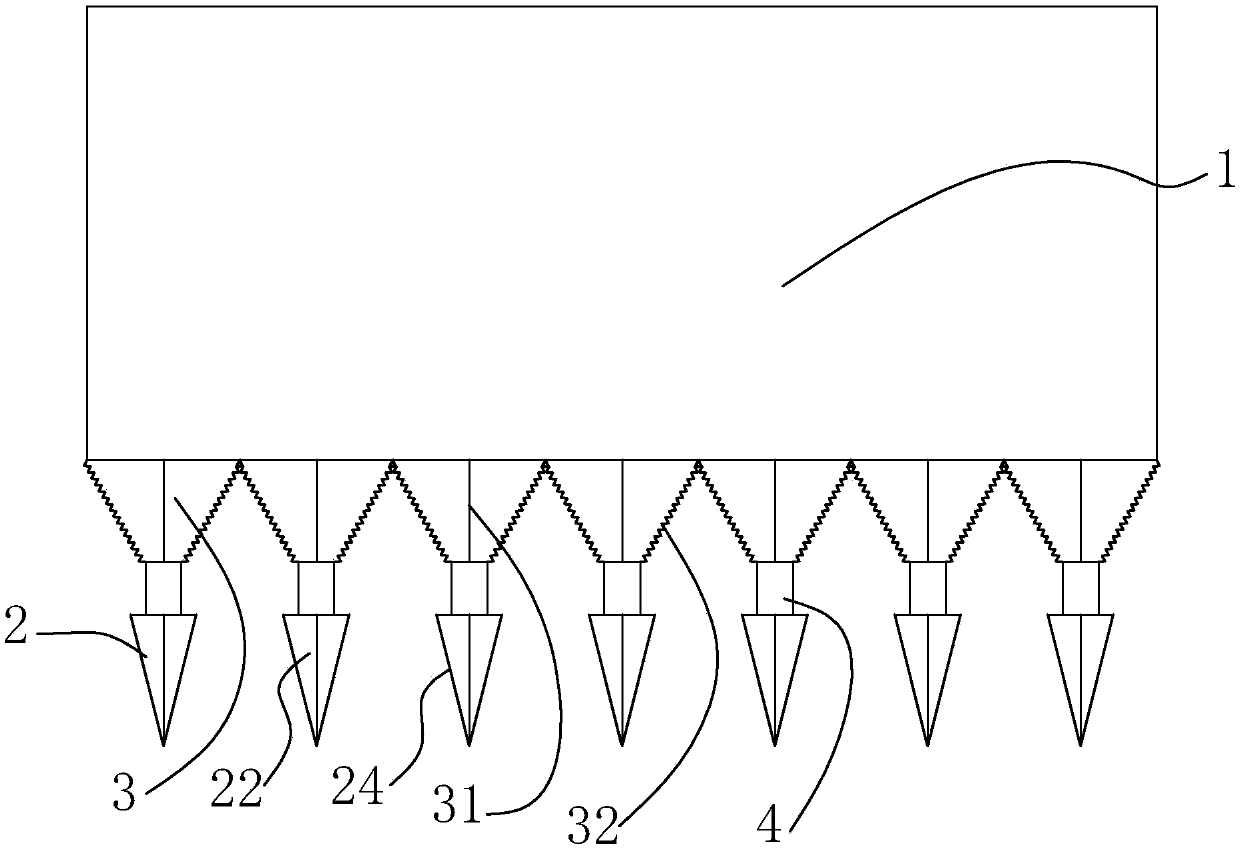

Machining system for milling cutter and machining method of machining system

InactiveCN110524323AHigh degree of automationProduce the effect of automatic feeding and dischargingMilling cuttersOther manufacturing equipments/toolsBroken teethTooth grinding

The invention discloses a machining system for a milling cutter and a machining method of the machining system, relates to the technical field of milling cutter manufacturing, and aims to solve the problems that in the using process of an existing milling cutter broken tooth grinding machine, a to-be-machined blank needs to be manually clamped to a clamping piece and the automation degree is quitelow; according to the technical scheme, the machining system is characterized by comprising a rack, a polishing mechanism and a clamping mechanism, the clamping mechanism is slidably connected to theinterior of the rack in the direction close to or away from the polishing mechanism, and the polishing mechanism is fixedly connected to the interior of the rack; a feeding mechanism used for automatically feeding blanks is arranged on the side, located on the grinding mechanism, of the rack, and a clamping discharging mechanism is arranged on the side, away from the grinding mechanism, of the feeding mechanism. The feeding mechanism comprises a storage bin, a feeding port and a feeding push rod, the storage bin is fixed to the side, located on the grinding mechanism, of the rack, the feedingport is formed in the bottom end of the storage bin, and the feeding push rod is connected to the bottom end of the feeding port in a sliding mode. The effects of automatically completing feeding ofthe steel blanks and improving the automation degree are achieved.

Owner:深圳市富吉真空技术有限公司

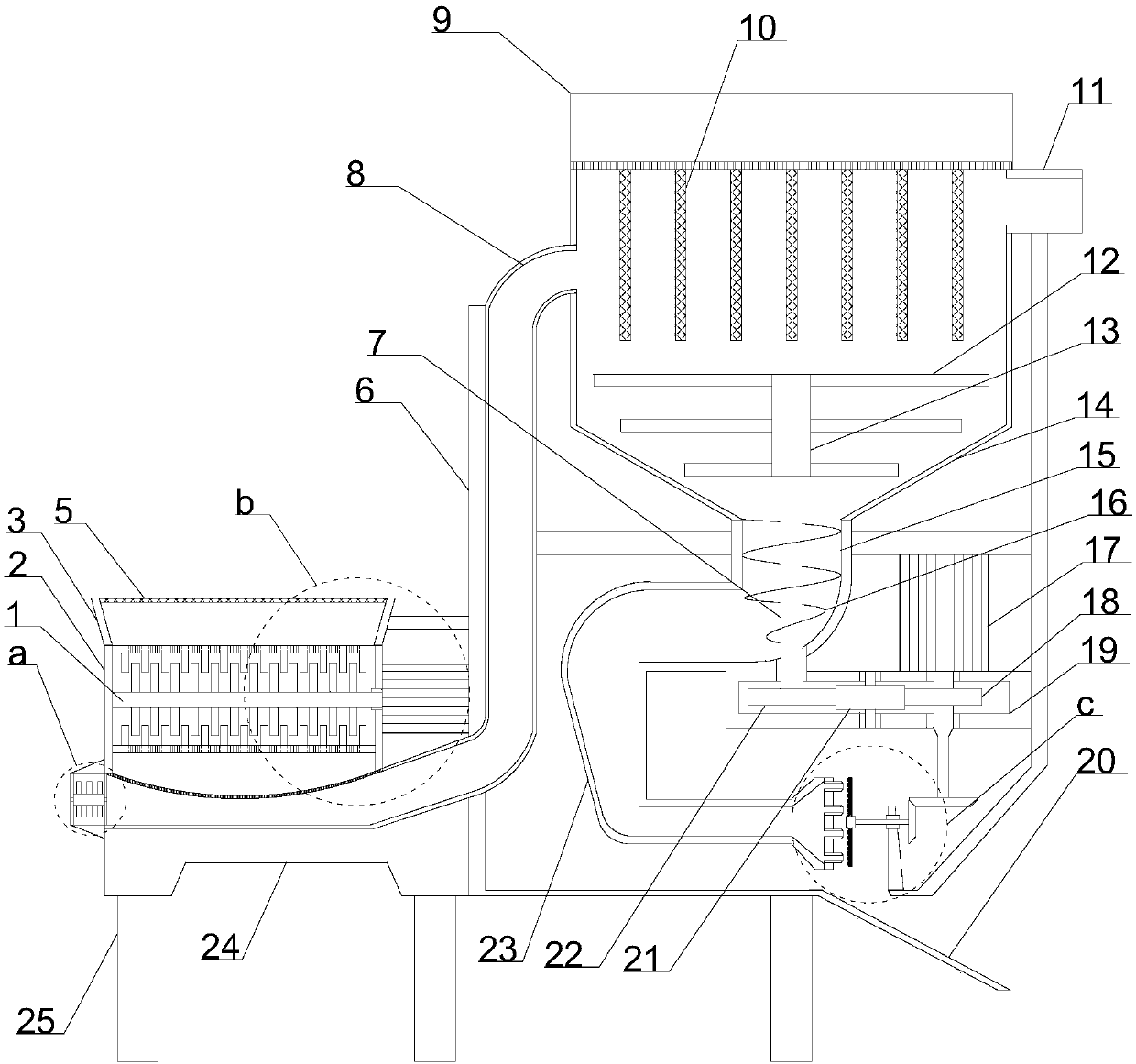

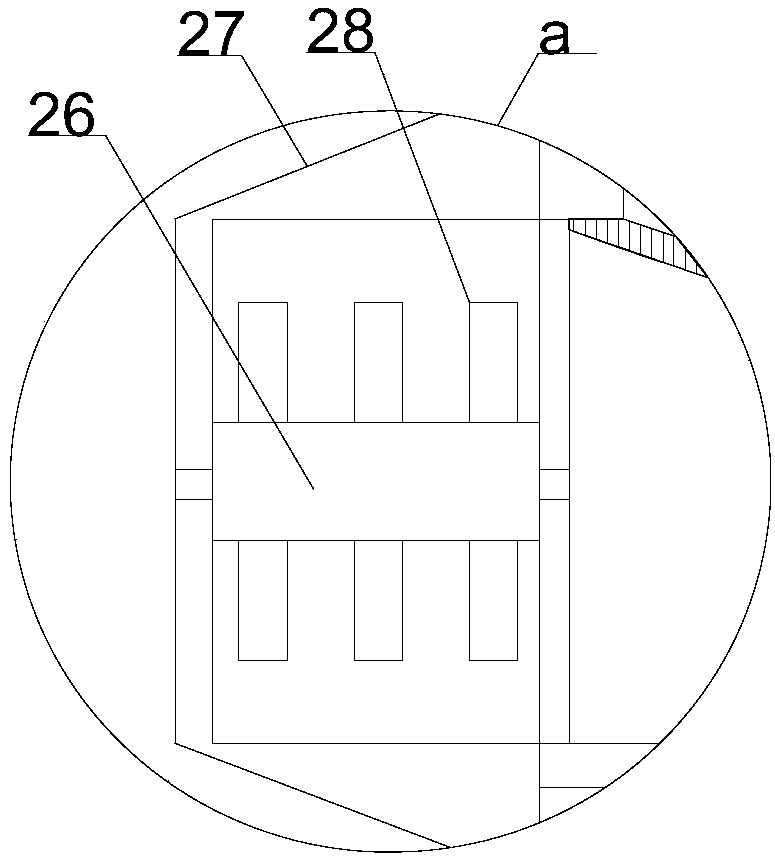

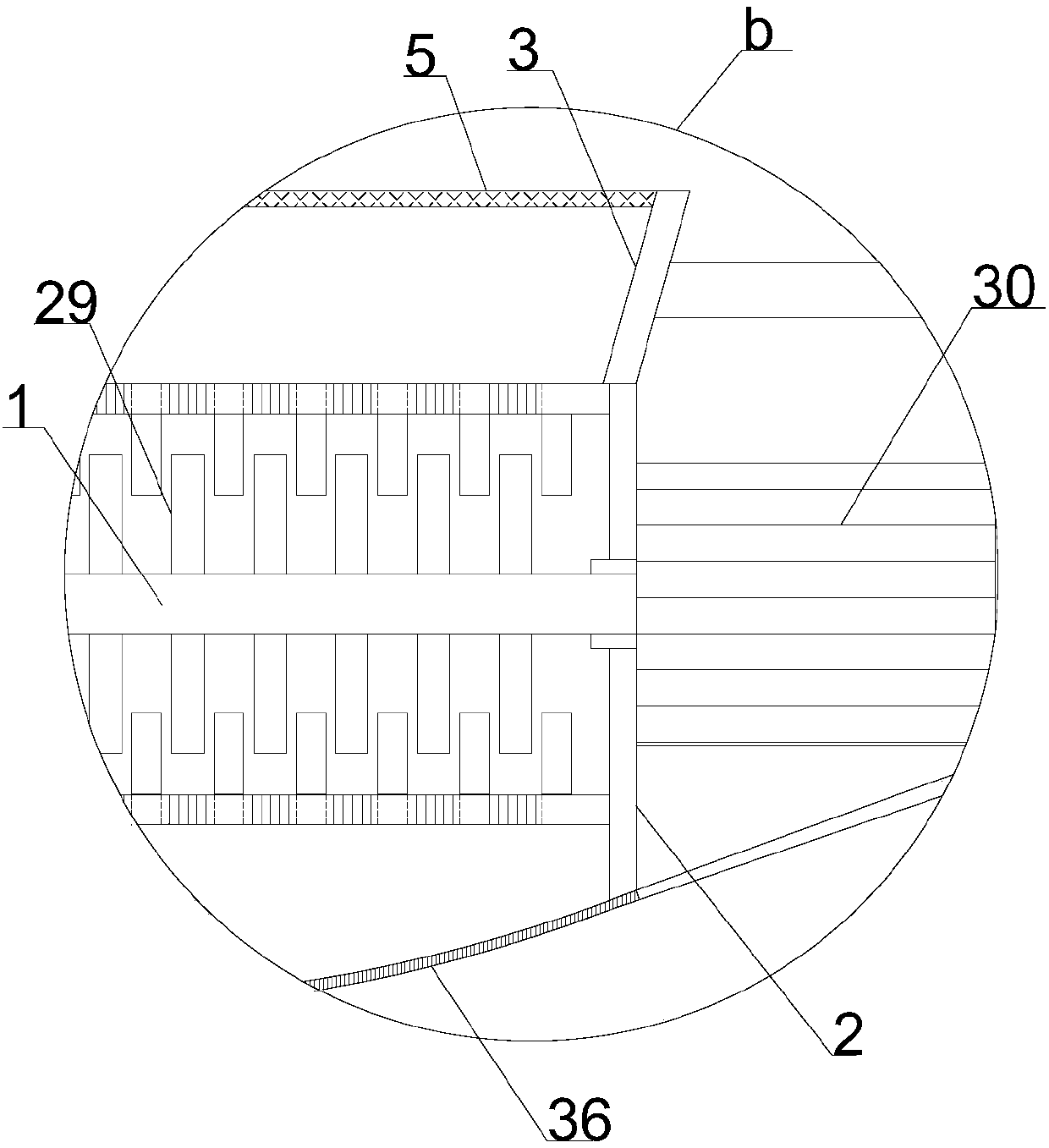

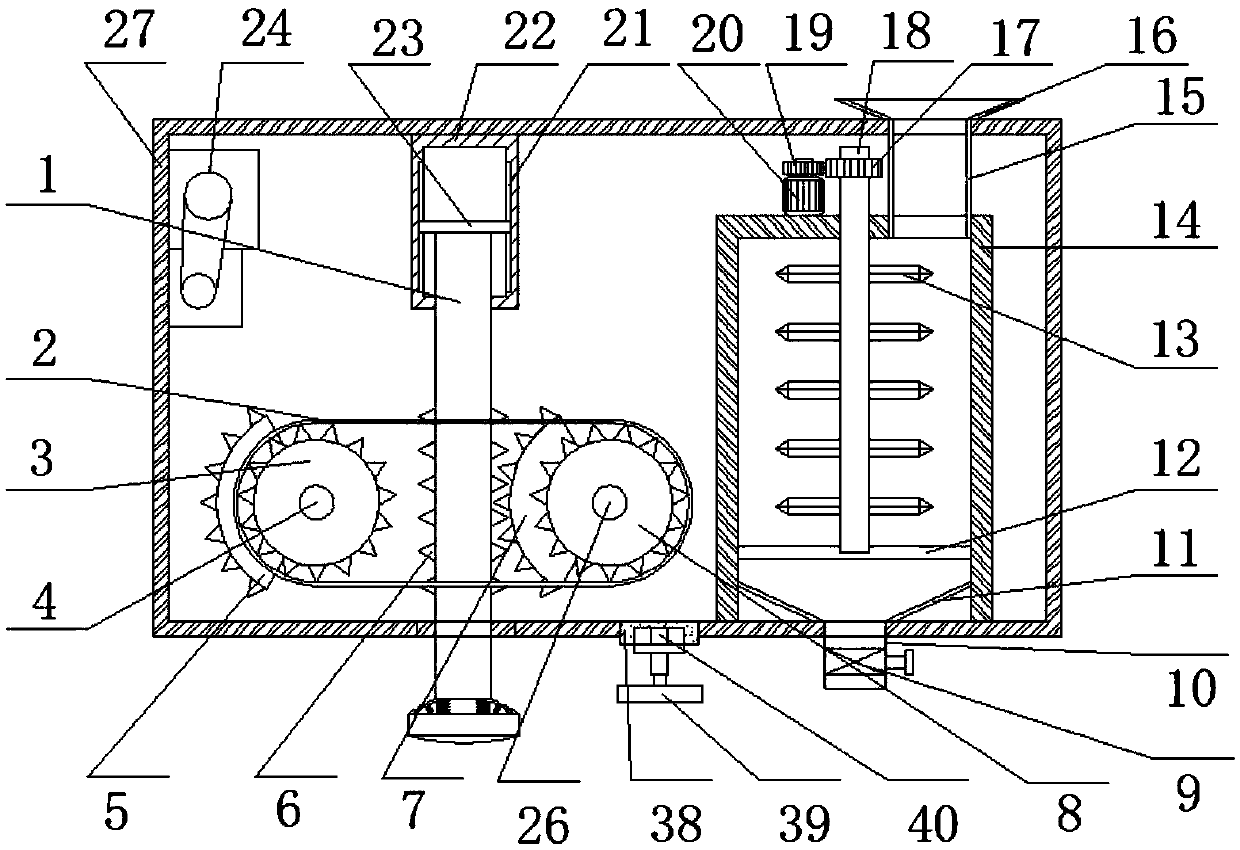

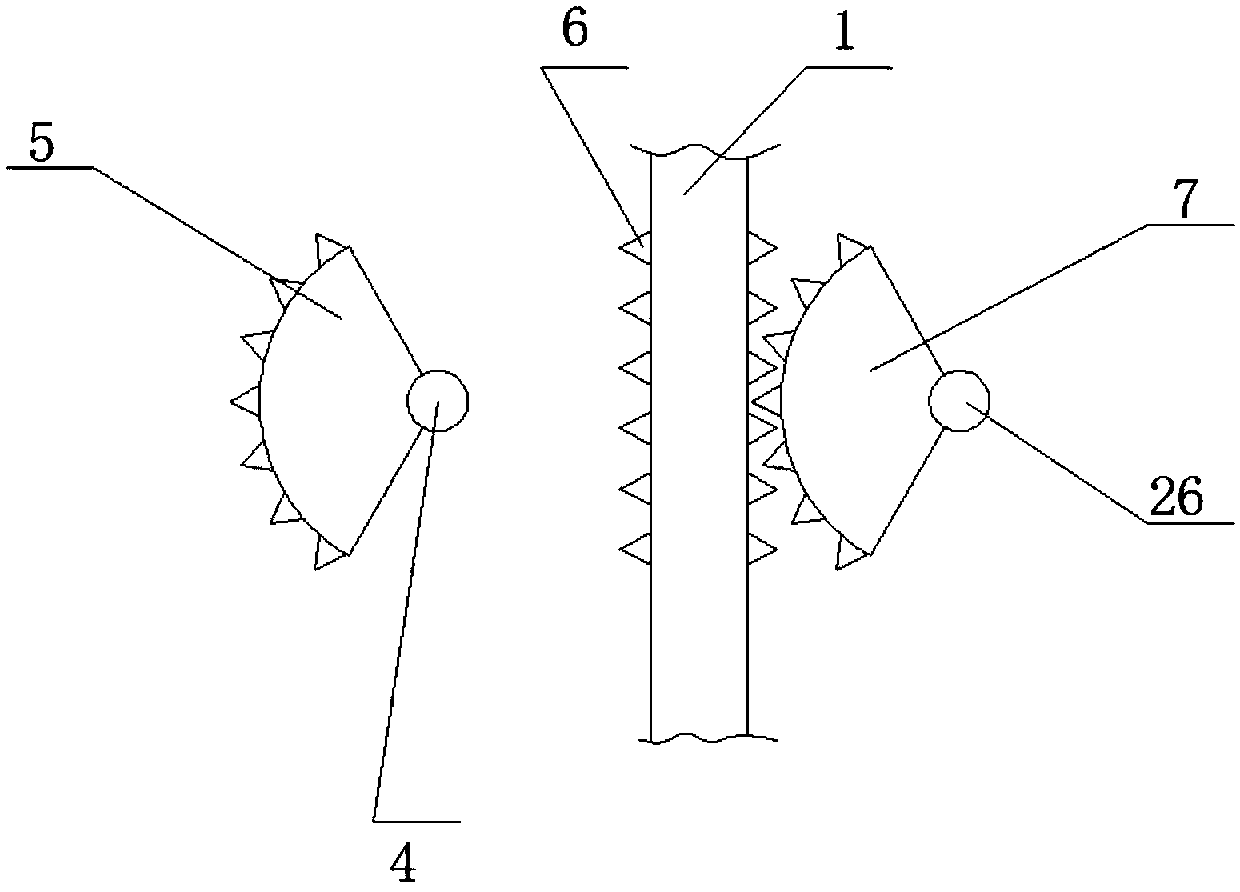

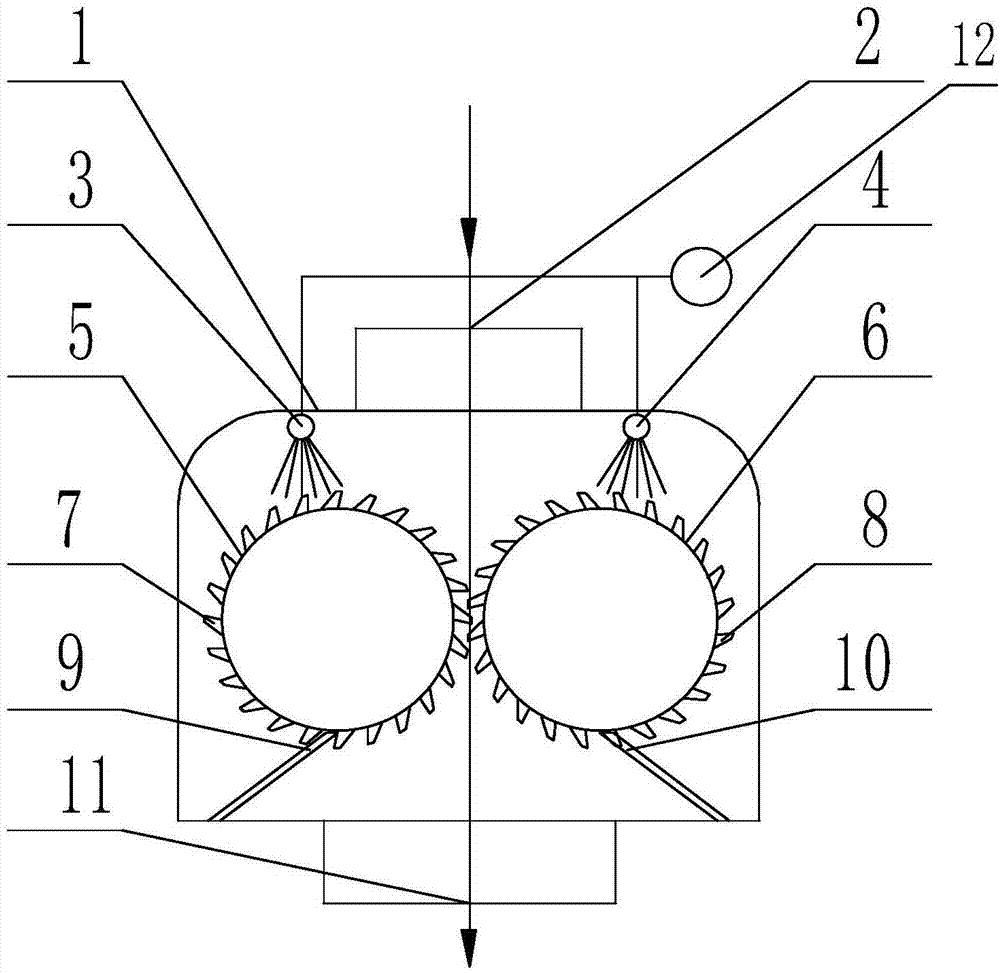

Use method for anti-adhesion crusher for crushing adhesive oil shale

ActiveCN107185637AReduce downtime for maintenanceIncrease productivityGrain treatmentsFree fallingQuality assurance

The invention discloses a use method for an anti-adhesion crusher for crushing adhesive oil shale. When the crusher crushes the adhesive oil shale, tailings dry powder conveyed by a scattering and feeding device through high pressure pipelines is continuously sprayed by spraying holes of a left scattering device and a right scattering device which respectively correspond to a left roller and left crushing teeth and a right roller and right crushing teeth to form adhesion layers; the crushed adhesive oil shale and the tailings dry powder adhesion layers naturally fall down and are discharged by a discharging hole; and meanwhile, scraper heads of a left scraper and a right scraper respectively clean occluded gaps of the left crushing teeth and the right crushing teeth and the roller walls of the left roller and the right roller. The oil shale tailings powder is uniformly sprayed on the surfaces of the rollers and teeth, a layer of tailings dry powder anti-adhesion layer is formed, the scrapers are correspondingly arranged between tooth pitches of the two rows of crushing teeth, the production efficiency of the crusher for the adhesive oil shale is improved, and a crushing quality of the adhesive oil shale is ensured.

Owner:LUOYANG CEMENT ENG DESIGN & RES INST

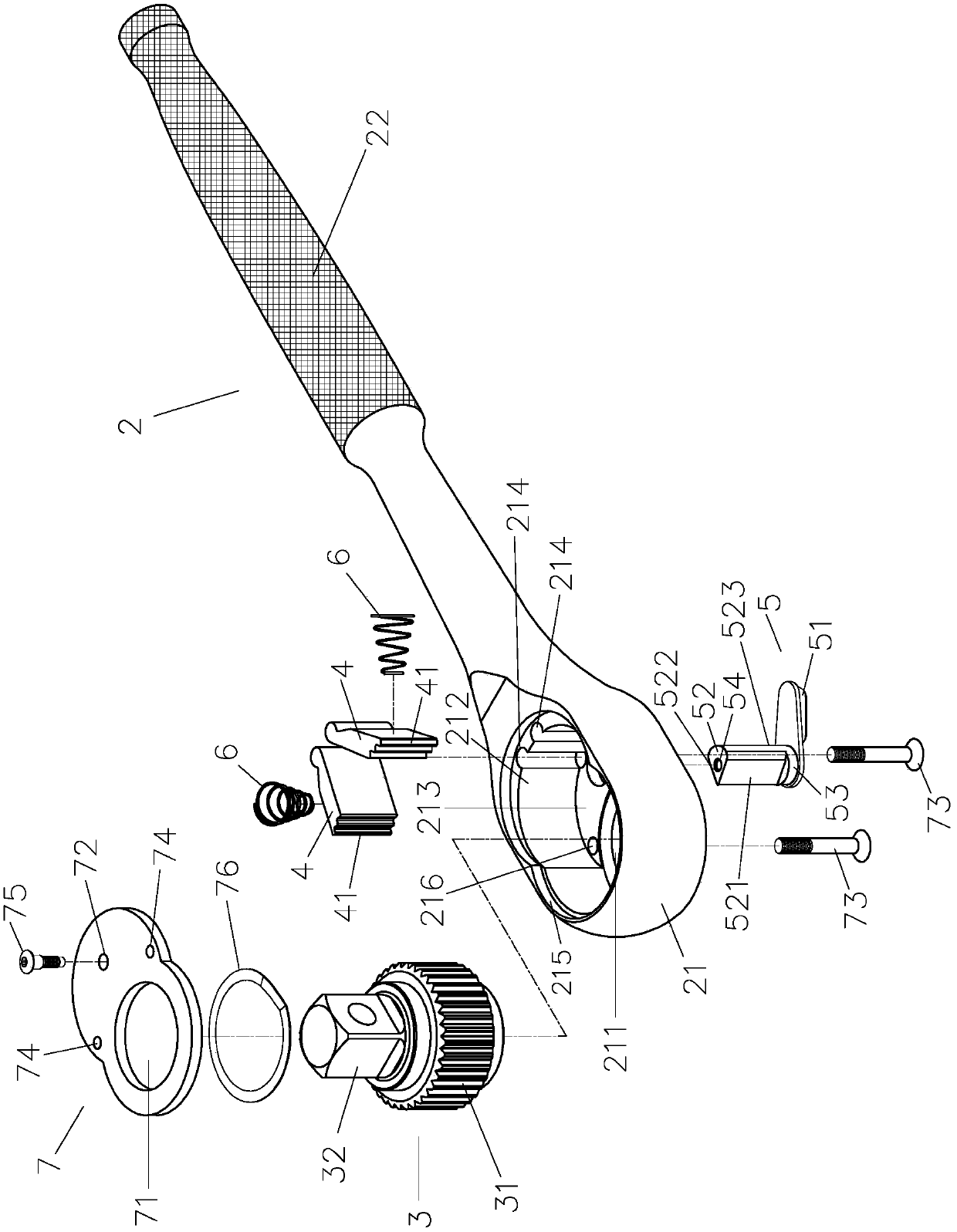

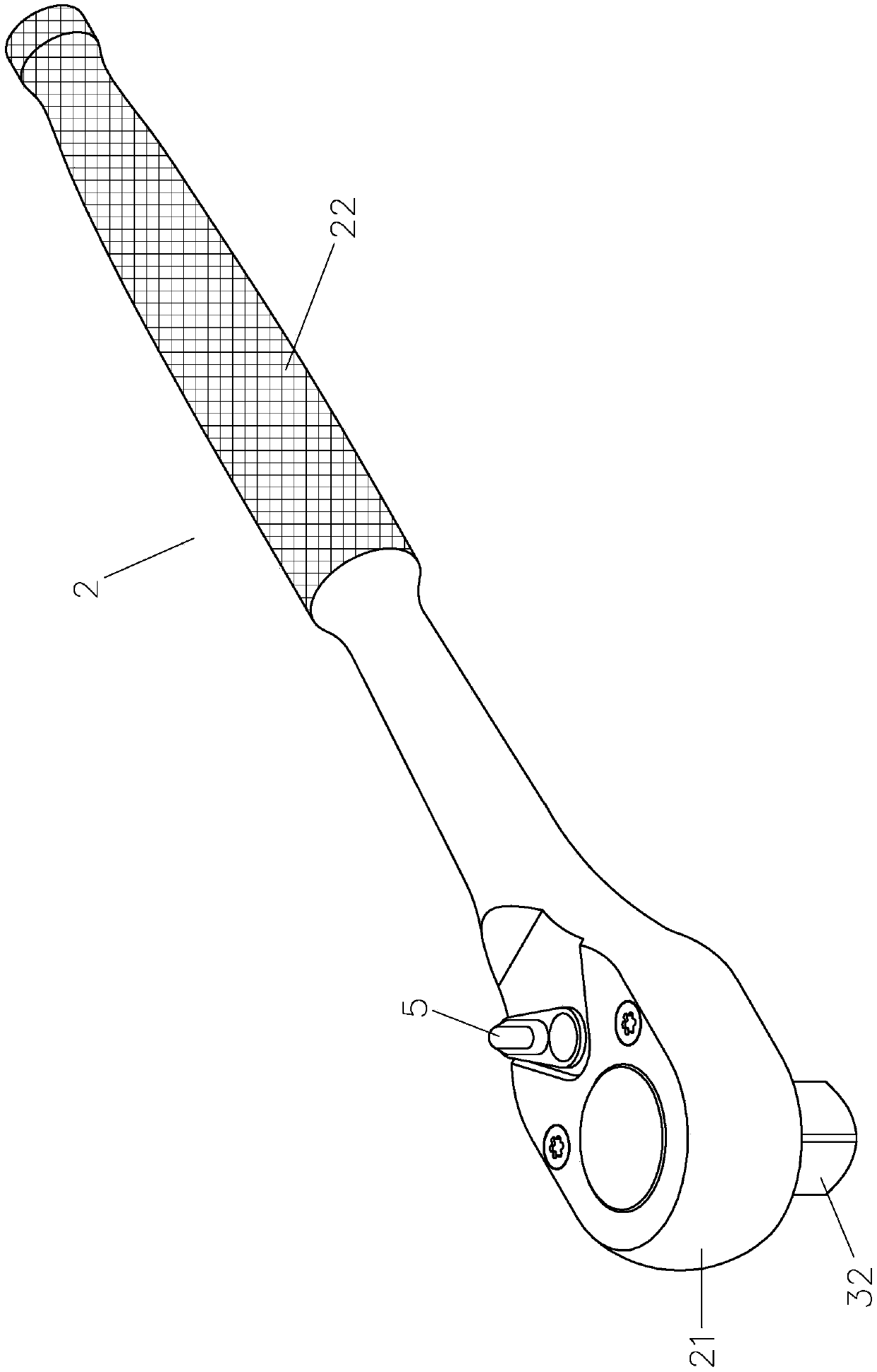

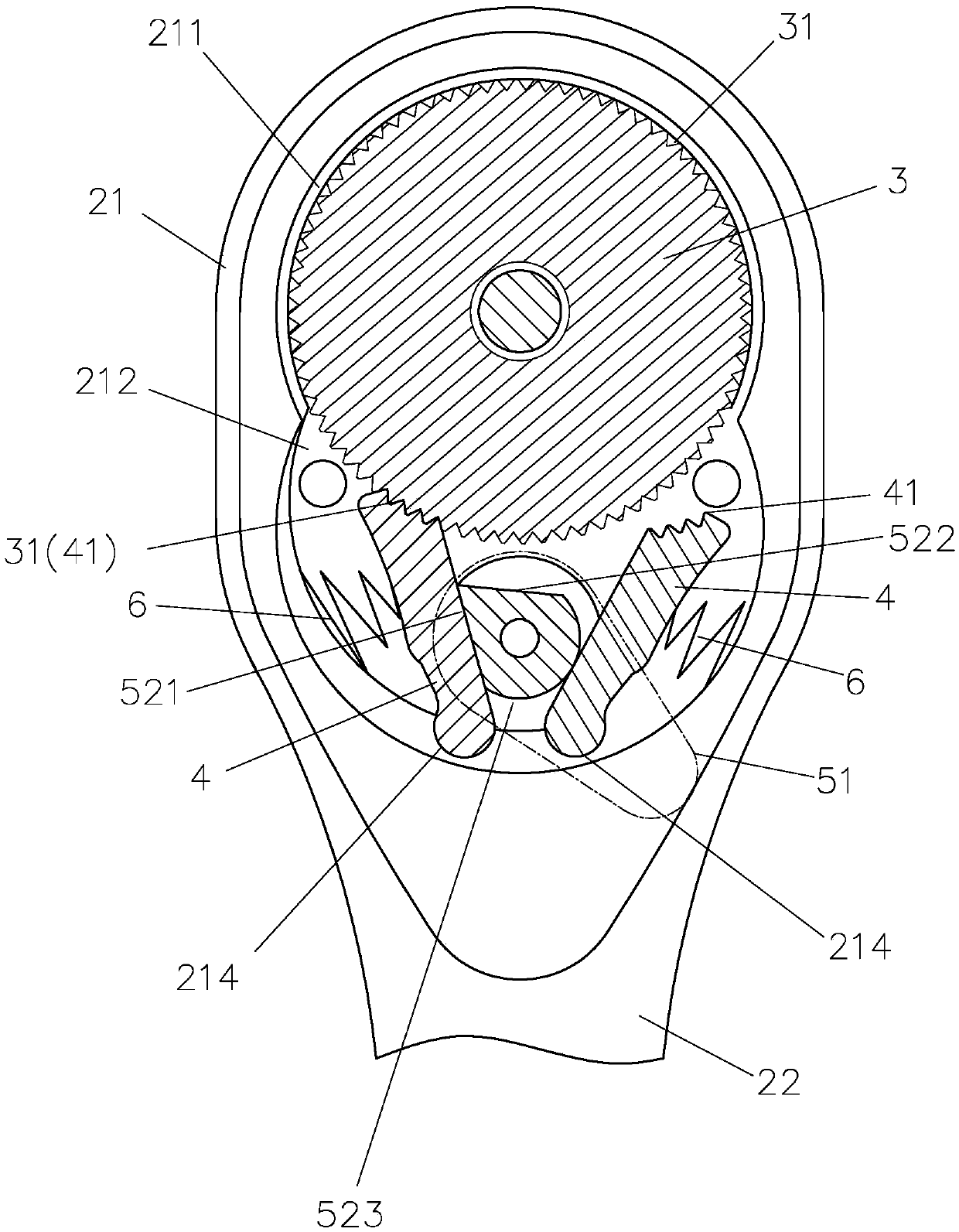

A ratchet wrench

The invention provides a ratchet wrench. The ratchet wrench comprises a body, a ratchet, two braking blocks, two elastic pieces and a reversing piece. The material strength of the braking block is greater than that of the ratchet; in a ratchet wrench pulling operation, if the applied force exceeds the limited and bearable torsion at the meshed part of the ratchet teeth of the ratchet and the teethpart of the braking block to cause tooth breakage, the tooth part of the braking block is instantly meshed and positioned with a good ratchet tooth which is positioned behind the broken tooth and isengaged again, so that the effect of ensuring the operation and personal safety of an operator is achieved.

Owner:AFICIAL CO LTD

External circulation type ball screw device

The invention provides an external circulation type ball screw device comprising screw shaft and nut having first and second screw grooves. A circulation member comprises first leg, second leg and connection portion. The first leg comprises a first end surface having first inner and outer points, and the second leg comprises a second end surface having second inner and outer points; first and second entrances formed on the first and second end surfaces of circulation passage; first and second thickness respectively provided between the first entrance and the first inner and outer points thereof; the second thickness being greater than the first; the third and fourth thickness respectively provided between the second entrance and the second inner and outer points thereof; the fourth thickness being greater than the third. The groove wall of the second screw groove occupied and the occurrence of broken teeth of the nut are reduced.

Owner:HIWIN TECH

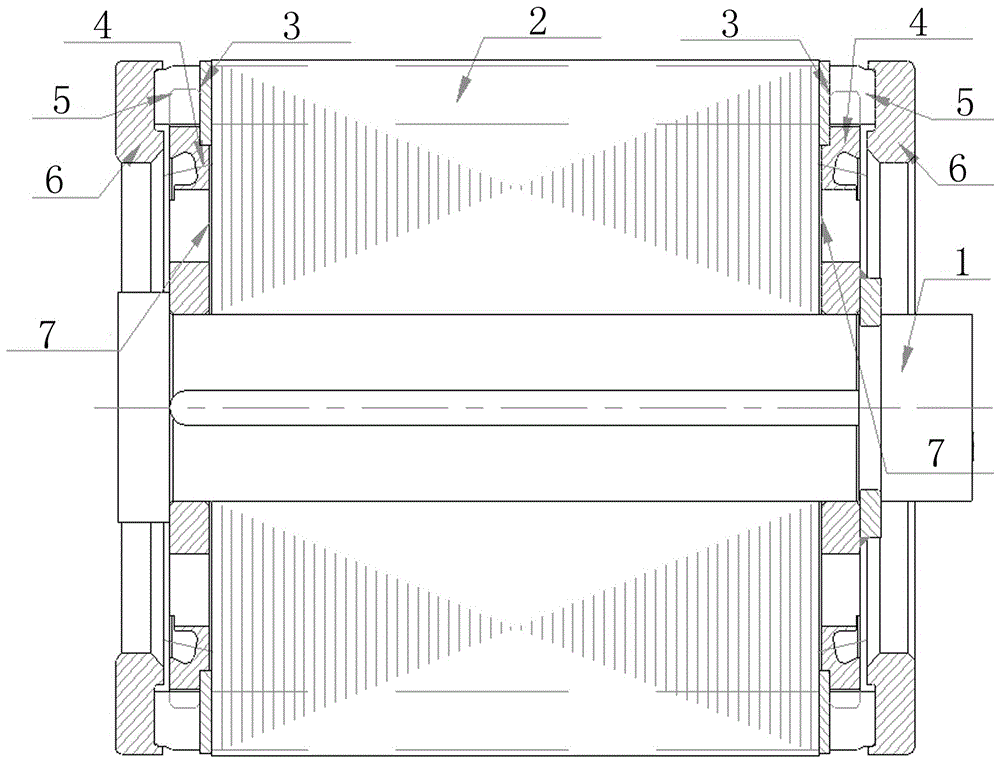

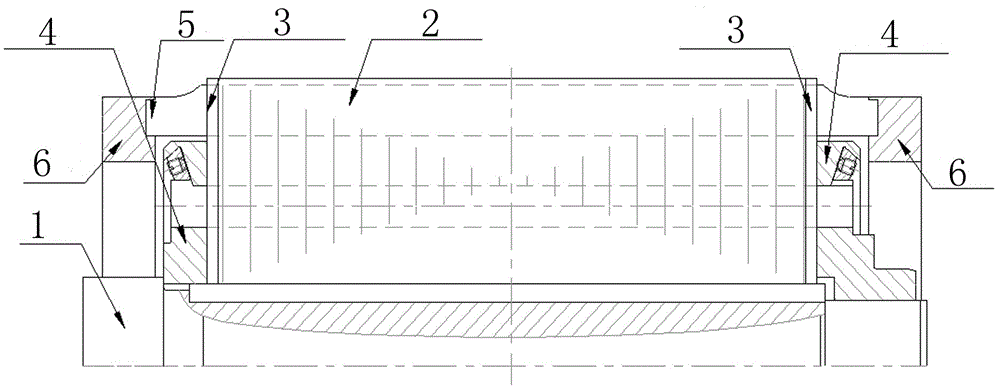

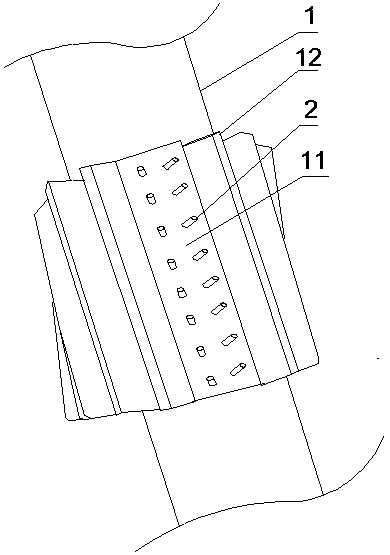

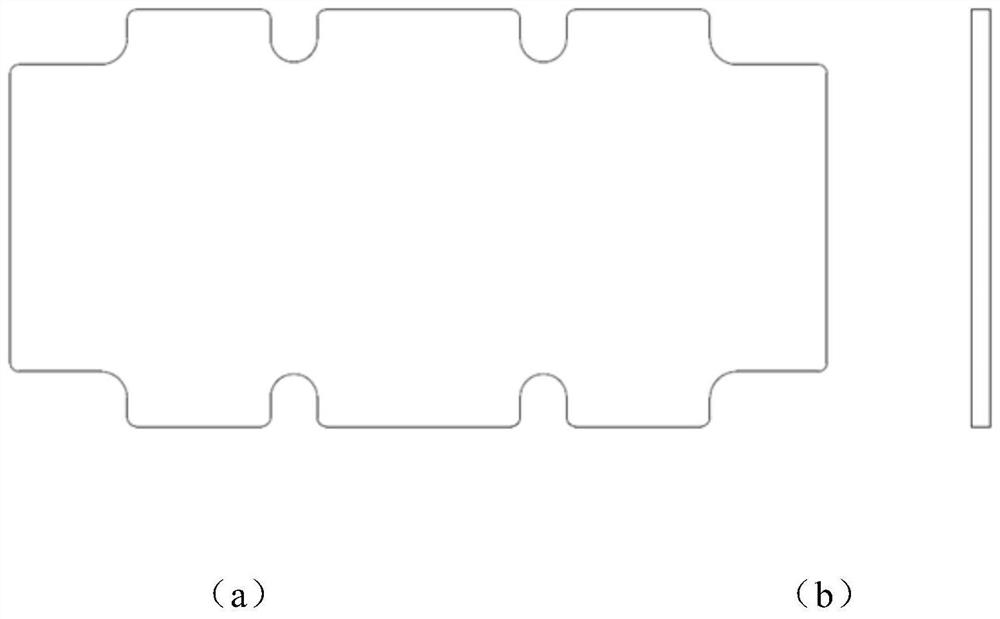

Rotor structure for reducing asynchronous motor cage rotor core punching tooth expansion

InactiveCN106026582AAvoid broken teethImprove operational reliabilityAsynchronous induction motorsPunchingEngineering

The invention relates to a motor rotor structure, in particular to a rotor structure for reducing asynchronous motor cage rotor core punching tooth expansion. The technical problems that an existing motor rotor is prone to quality problems such as rotor tooth expansion and broken teeth, and motor operation is affected are solved. The rotor structure for reducing asynchronous motor cage rotor core punching tooth expansion comprises a rotor punching which is arranged on a rotating shaft in a sleeving mode and rotates around the rotating shaft coaxially, a rotor end plate, a rotor pressing ring, a guide strip and an end ring. The rotor end plate compresses the external circle portion of the rotor punching. On the inner circle portion of the rotor punching, the rotor end plate is matched with the rotor pressing ring, and a gap is reserved between the rotor end plate and the rotor punching; the rotor pressing ring also compresses the outer circle tooth portion of the rotor. According to the motor rotor structure, the problem that rotor tooth expansion is caused by high temperature during welding of the motor rotor guide strip and the end ring is greatly solved, the problem of broken teeth possibly caused in the motor operation is avoided, and the motor operation reliability is improved. The guide strip and the punching are suitable in fit dimension, punching loosening is avoided, and reliability is improved.

Owner:CRRC YONGJI ELECTRIC CO LTD

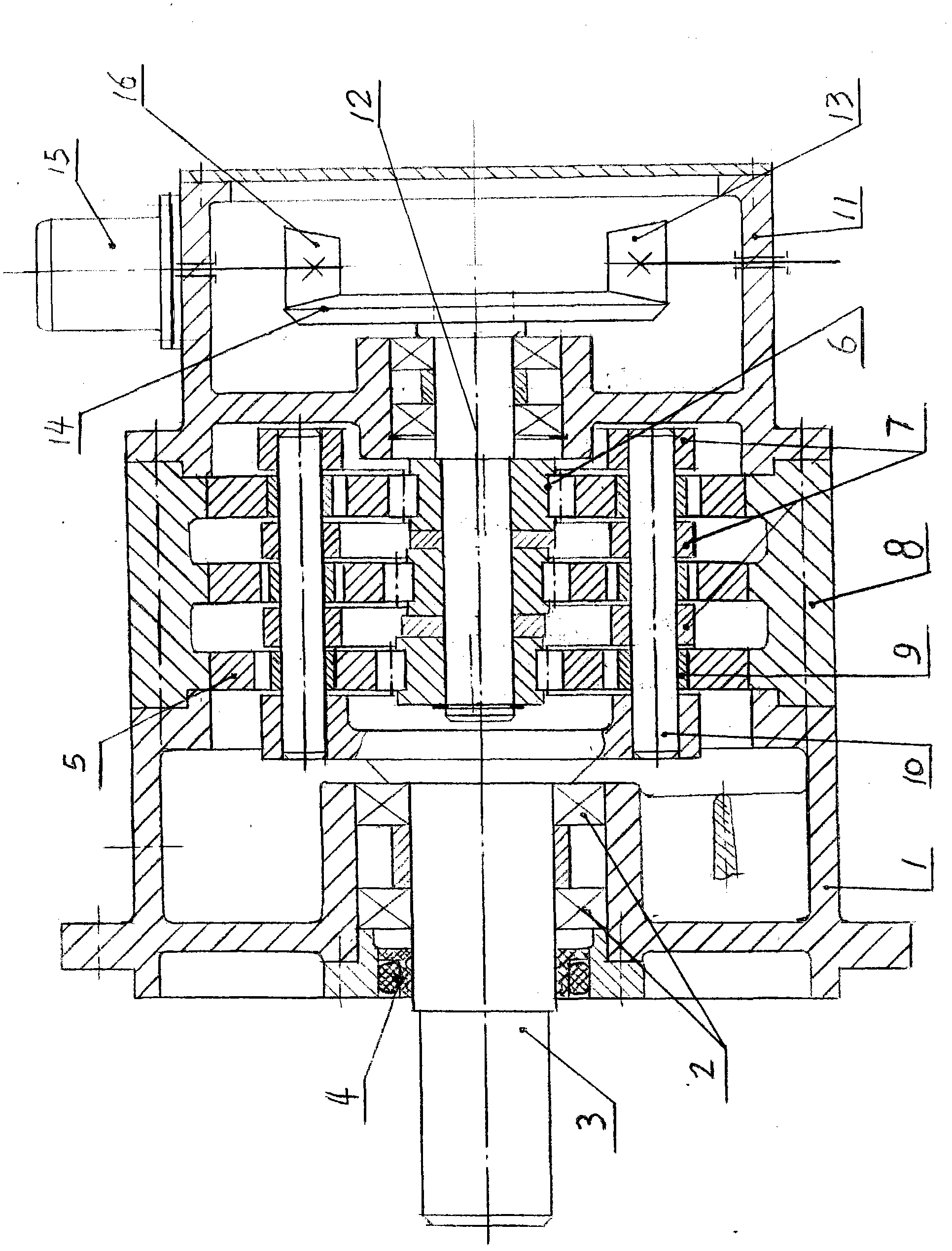

Large-torque bevel gear-double-cycloidal speed reduction device of rocket launching movable platform

InactiveCN102032322ASimple structureLarge single-stage reduction ratioRocket launchersToothed gearingsReduction driveRocket launch

The invention relates to the technical field of reducers, in particular to a large-torque bevel gear-double-cycloidal speed reduction device of a rocket launching movable platform. The speed reduction device is characterized in that a secondary speed reduction device is composed of a bevel gear pair and a double-cycloidal transmission, wherein (A) the double-cycloidal transmission consists of a frame, an output shaft, supporting bearings, three cycloidal gears with a phase angle of 120 degrees, an eccentric bearing, a hypocycloid gear ring, a front frame, an input shaft and a W output mechanism, the input shaft is supported in the inner hole of the front frame through the bearing, the shaft extension end of the input shaft is linked with the eccentric bearing, and the input end of the input shaft is linked with a large bevel gear; the front frame is sequentially linked with the hypocycloid gear ring and the frame into a whole; and the output shaft is supported in the inner hole of the frame through the bearing; and (B) two symmetrical devices of small bevel gear shafts, which are meshed with the large bevel gear are supported in box wall holes of the front frame through the bearings, one small bevel gear shaft is linked with a motor, and the other small bevel gear shaft is linked with a manual handle. The large-torque bevel gear-double-cycloidal speed reduction device has the following beneficial effects: (a) the double reduction is realized, the axial size is short, the weight is light, and high degree of lightweight is realized; (b) the cycloidal gears have no broken teeth, and the three cycloidal gears have the transmission bearing capacity greater than that of a planet with only four planetary gears; and (c) the cost is reduced by 40-55%.

Owner:吴声震

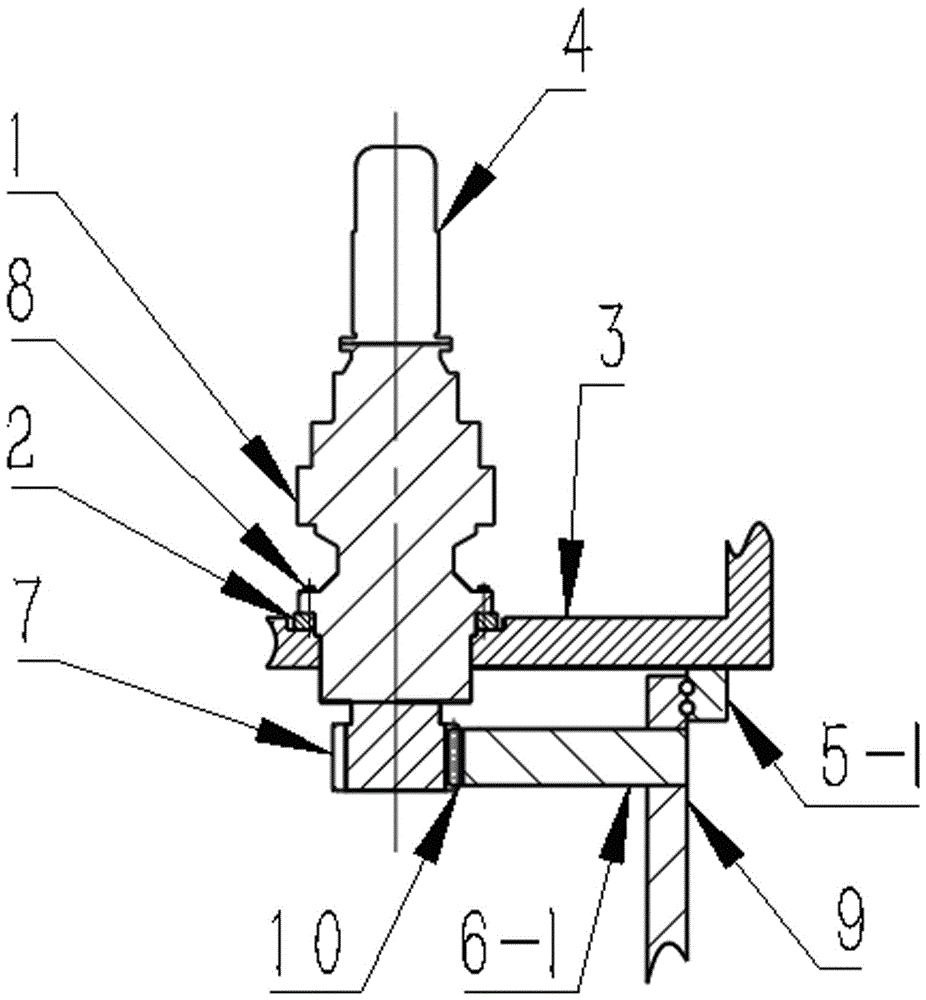

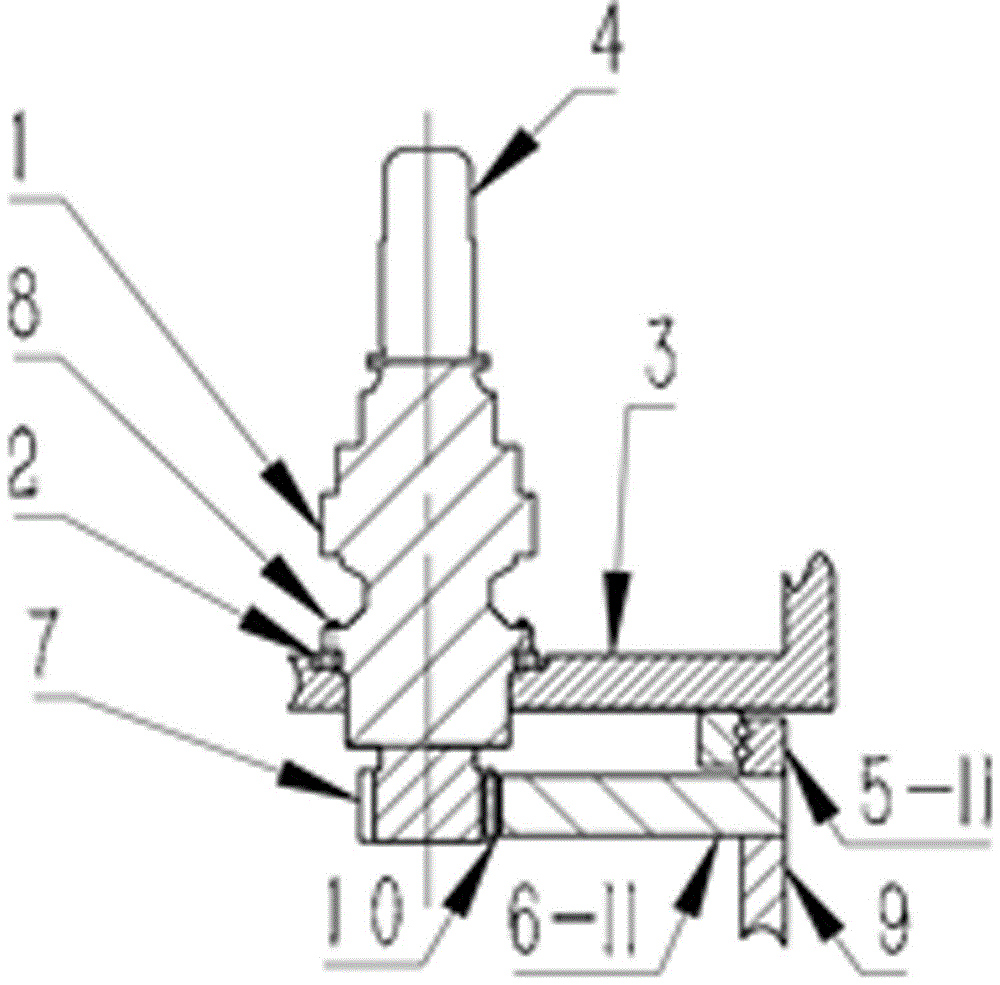

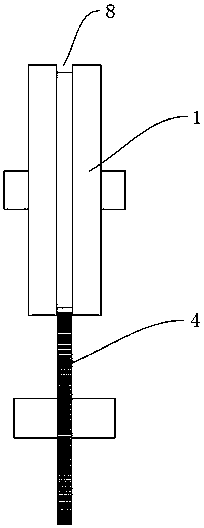

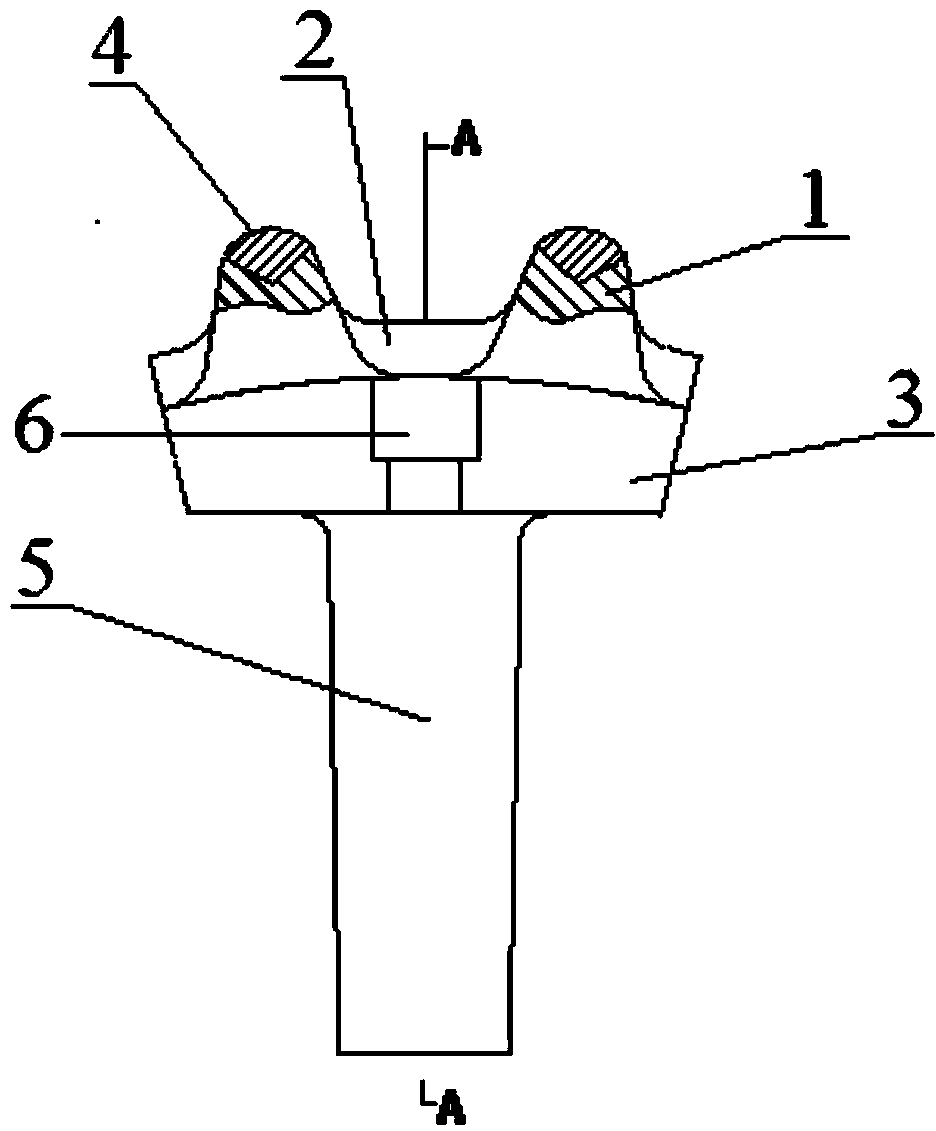

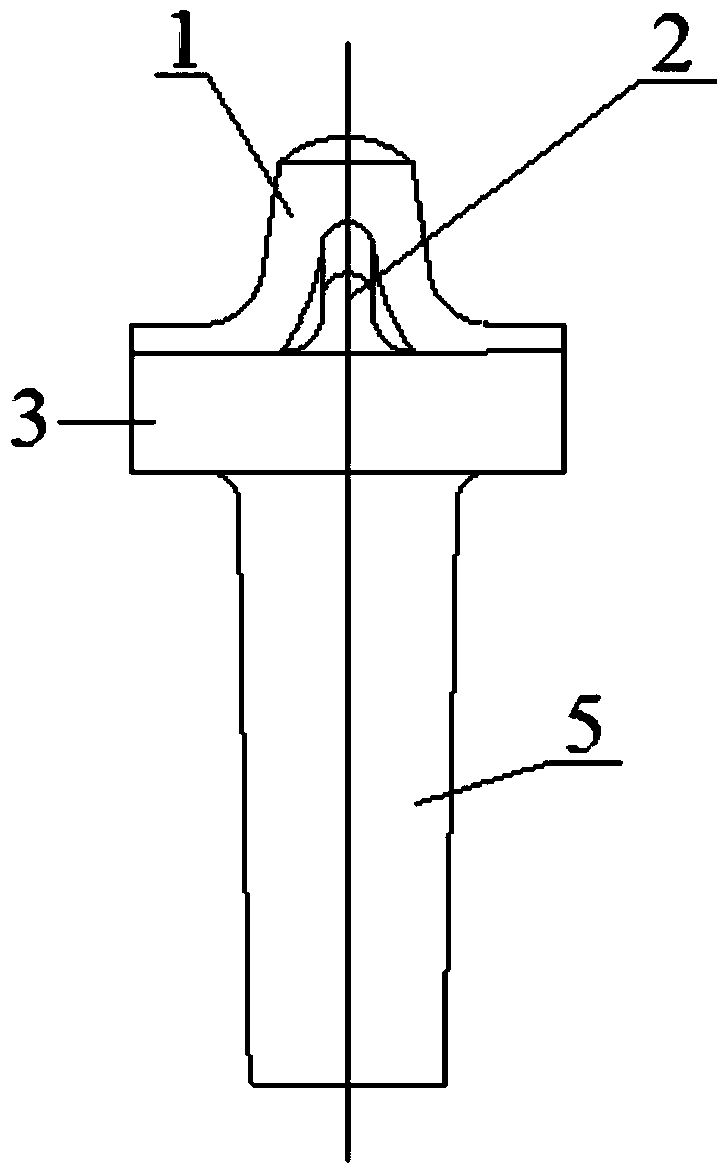

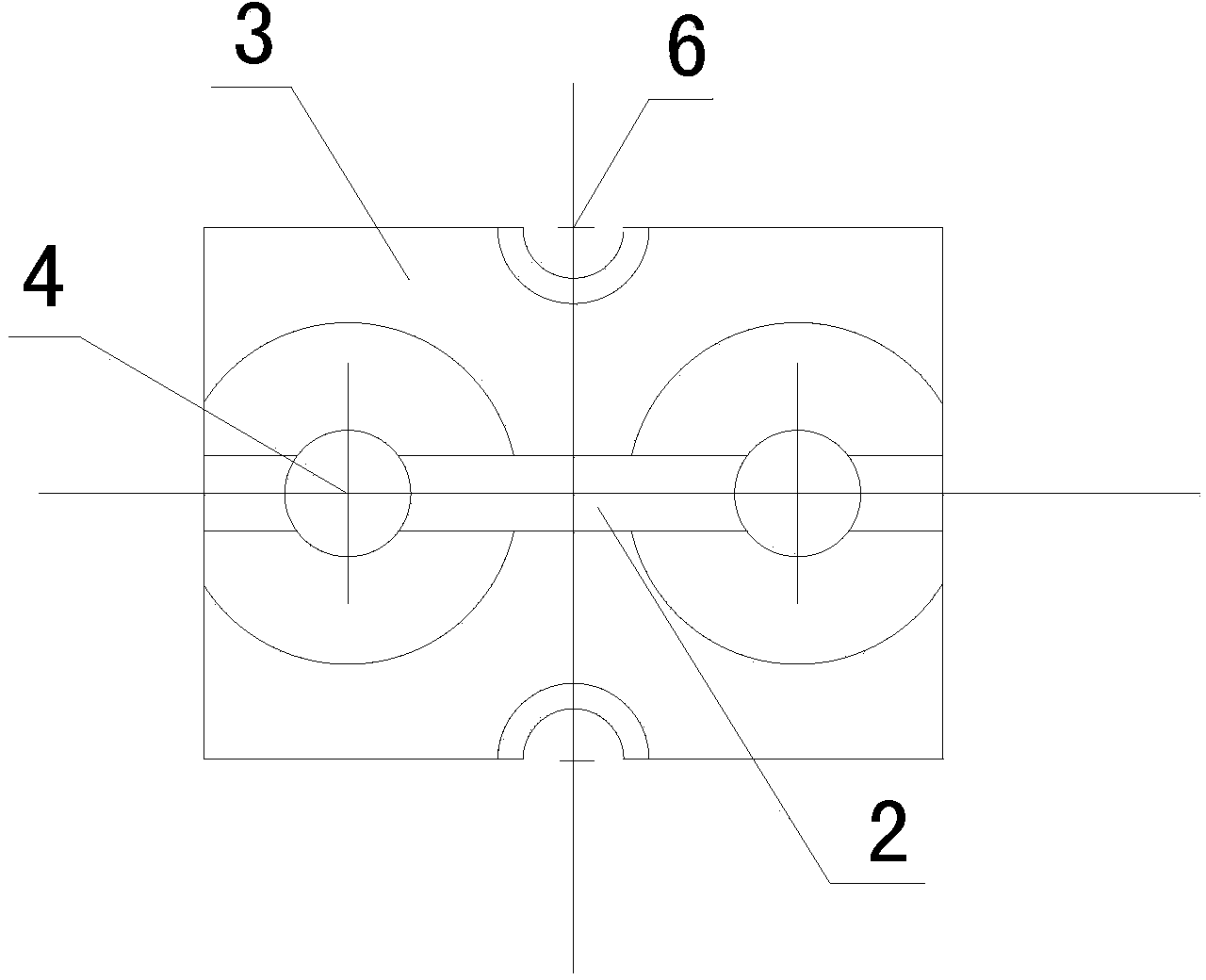

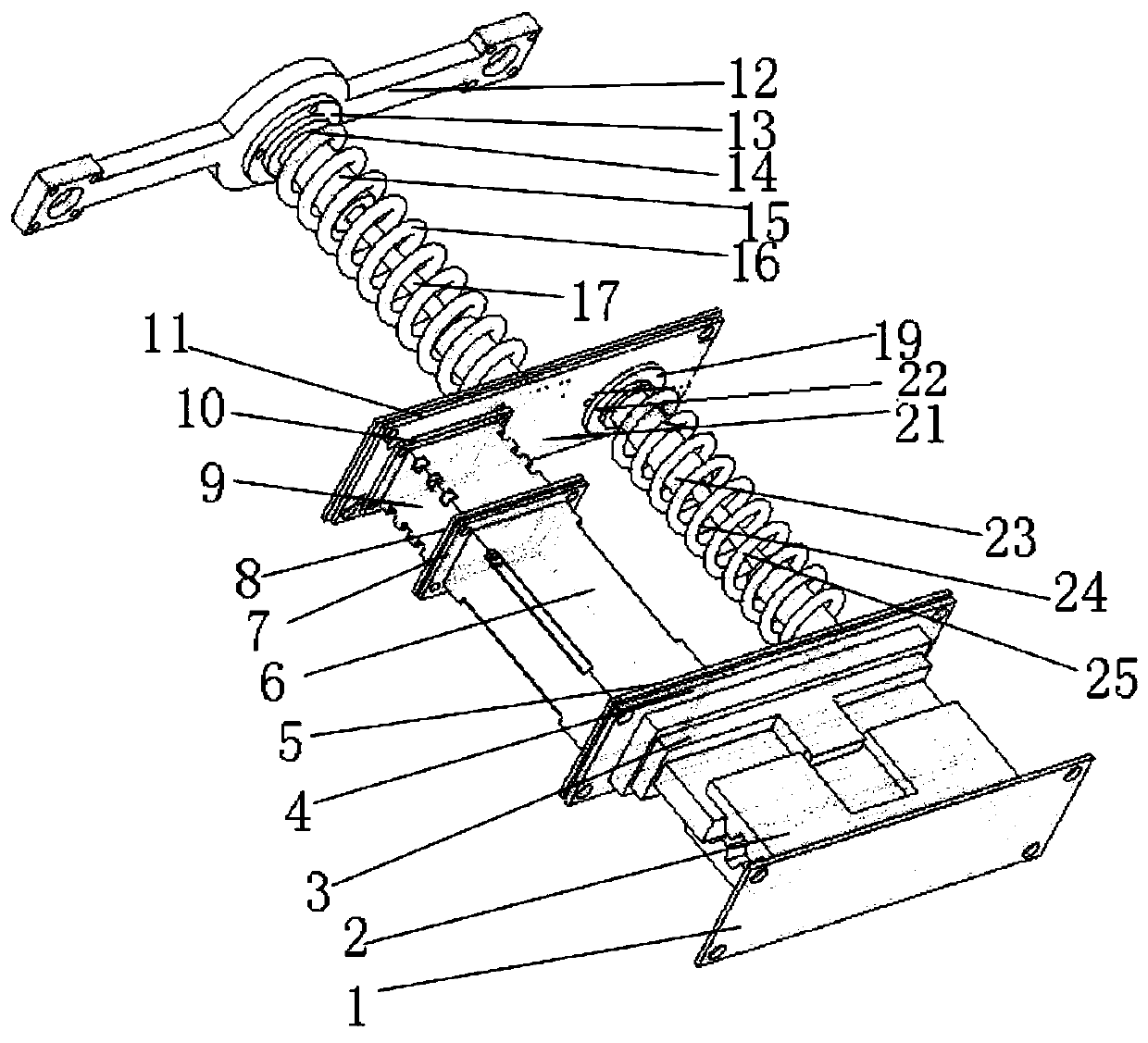

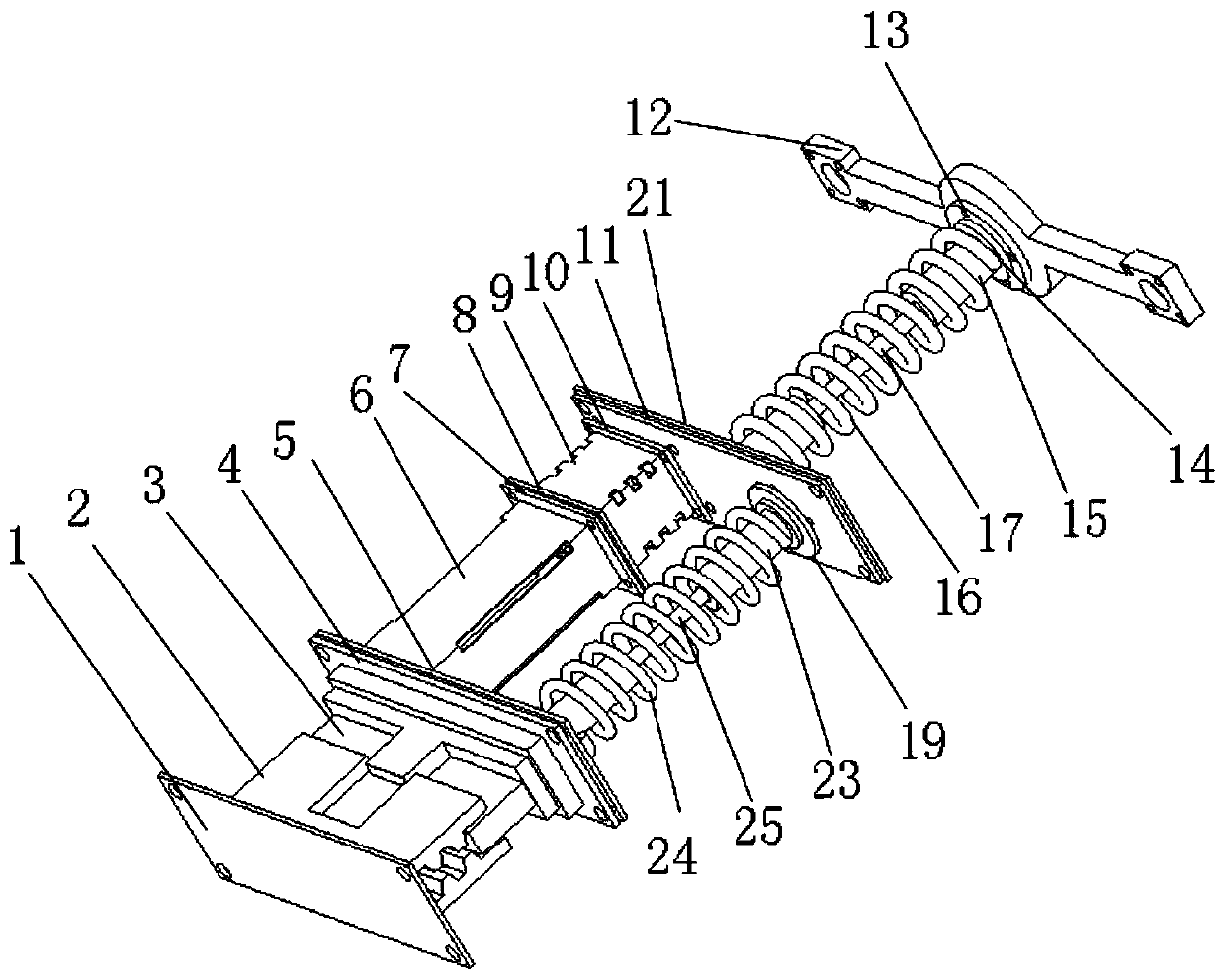

Quick repair device for broken teeth of gear

InactiveCN112222460AQuick installationConvenient lightingMeasurement/indication equipmentsBoring/drilling componentsGear wheelCoil spring

The purpose of the invention is to solve the problem in the prior art that broken teeth of a gear are not easy to quickly repair, and the invention discloses a quick repair device for the broken teethof the gear. The quick repair device for the broken teeth of the gear comprises a guide cylinder; a third sliding rod is sleeved in the guide cylinder; an inserting plate is fixedly installed at theleft end of the third sliding rod; a first spiral spring is fixedly connected between the inserting plate and the guide cylinder; a holding rod is fixedly installed on the side face of the guide cylinder; a first installing rod and a second installing rod are separately welded to the upper surface and the lower surface of the guide cylinder; illuminating lamps are fixedly installed on the side faces of the first installing rod and the second installing rod separately; a first sliding rod is arranged on the outer side of the first installing rod; a first connecting frame is connected between the first sliding rod and the first installing rod; and a first sliding block is installed between the first connecting frame and the first sliding rod. According to the invention, a manufactured toothis installed at the broken tooth location of a gear disc, and the stability of the teeth is improved through the cooperation of a hook and a top plate; and therefore, rapid repairing of the gear is achieved.

Owner:呼和牧仁

Asphalt shoveling plate for municipal engineering

The invention discloses an asphalt shoveling plate for municipal engineering. The asphalt shoveling plate comprises a plate body, a plurality of clearing teeth extending forward are closely arranged in parallel on the front side of the plate body, the clearing tooth comprises a front breaking tooth on the front side and a rear shoveling tooth on the rear side, the front breaking tooth is providedwith a prop-open ridge slanting from bottom to top, the front breaking tooth further comprises a flat pressing surface, the flat pressing surface and the prop-open ridge intersect to form a front cutting ridge, the front breaking tooth forms a triangular cone, and the rear shoveling tooth also takes the structure of the triangular cone. The front breaking tooth firstly breaks the position where the asphalt and the ground are in contact with each other, the adjacent two front breaking teeth form a weak zone if the rear shoveling tooth is ignored, the weak zone is not broken, the asphalt and theground are still tightly adhered on the weak zone, then the shoveling tooth breaks and shovels up the weak zone, the weak zone is isolated and is therefore easy to shovel up. The asphalt shoveling plate is used to clean the asphalt on the ground.

Owner:FOSHAN UNIVERSITY

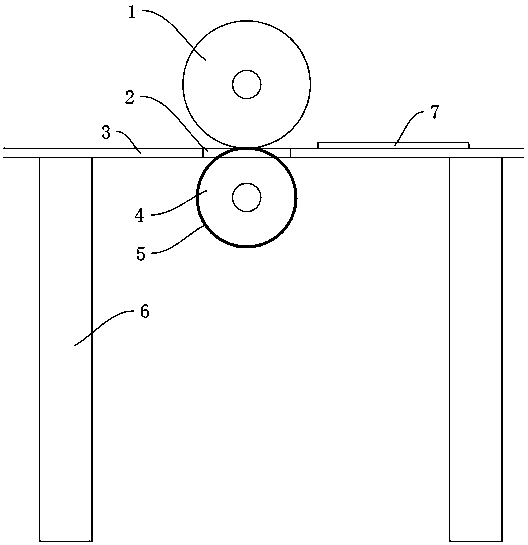

Medicine packaging box glue-coating surface breaking device

PendingCN110588063AImprove adhesionNot easy to disengageBox making operationsPaper-makingAdhesiveMechanical engineering

The invention relates to a medicine packaging box glue-coating surface breaking device. The device comprises a workbench, and a pressing wheel and a surface breaking wheel, wherein the pressing wheeland the surface breaking wheel are arranged at the upper and bottom relative to the workbench; rotating axes of the pressing wheel and the surface breaking wheel are parallel; surface breaking teeth are arranged on the periphery of the surface breaking wheel; a circle of groove is arranged in the middle of the periphery of the pressing wheel; the surface breaking wheel is opposite to the groove, and the surface breaking teeth of the surface breaking wheel extend into the groove. The broken teeth of the broken wheel is used for cutting a broken seam on the film covering surface of the paper piece, and a film covering layer on the surface of the broken seam paper piece is broken; in the subsequent gluing process, the adhesive can penetrate into the film covering layer and dip into the paperbody, so that the paper body of a packaging box can be bonded together after gluing, the bonding effect is good, and the paper body is not easy to separate.

Owner:浙江亚铭威印刷包装有限公司

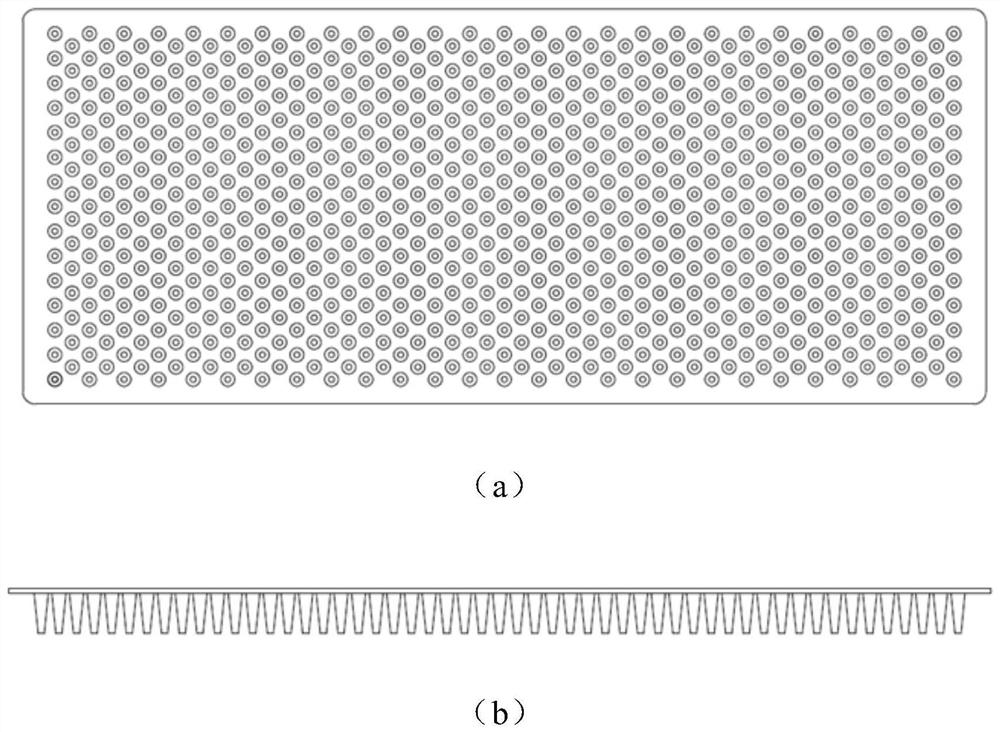

Roll teeth with wear-resisting metal for toothed roll crusher

The invention discloses roll teeth with wear-resisting metal for a toothed roll crusher. The roll teeth comprises a protection platform and a teeth handle, wherein teeth and reinforcing ribs which are distributed at intervals and are integrally connected are arranged on the protection platform, the upper parts of the teeth are integrally provided with the wear-resisting metal, a mounting hole is formed in the protection platform, and the teeth handle is integrally connected to the bottom of the protection platform. With the adoption of the roll teeth provided by the invention, grains of a product are uniform, number of over crushed grains is low, the energy consumption is low, the capacity is high, the crushing efficiency is high, the operation is table, the noise is small, little dust is generated, consumption of precious metal is little, the manufacturing price is low, the adjustment and maintenance are convenient, especially the broken teeth repairing problem is solved by virtue of the arrangement of the reinforcing ribs, and therefore, the operation and maintenance costs of equipment are greatly reduced.

Owner:盛金平

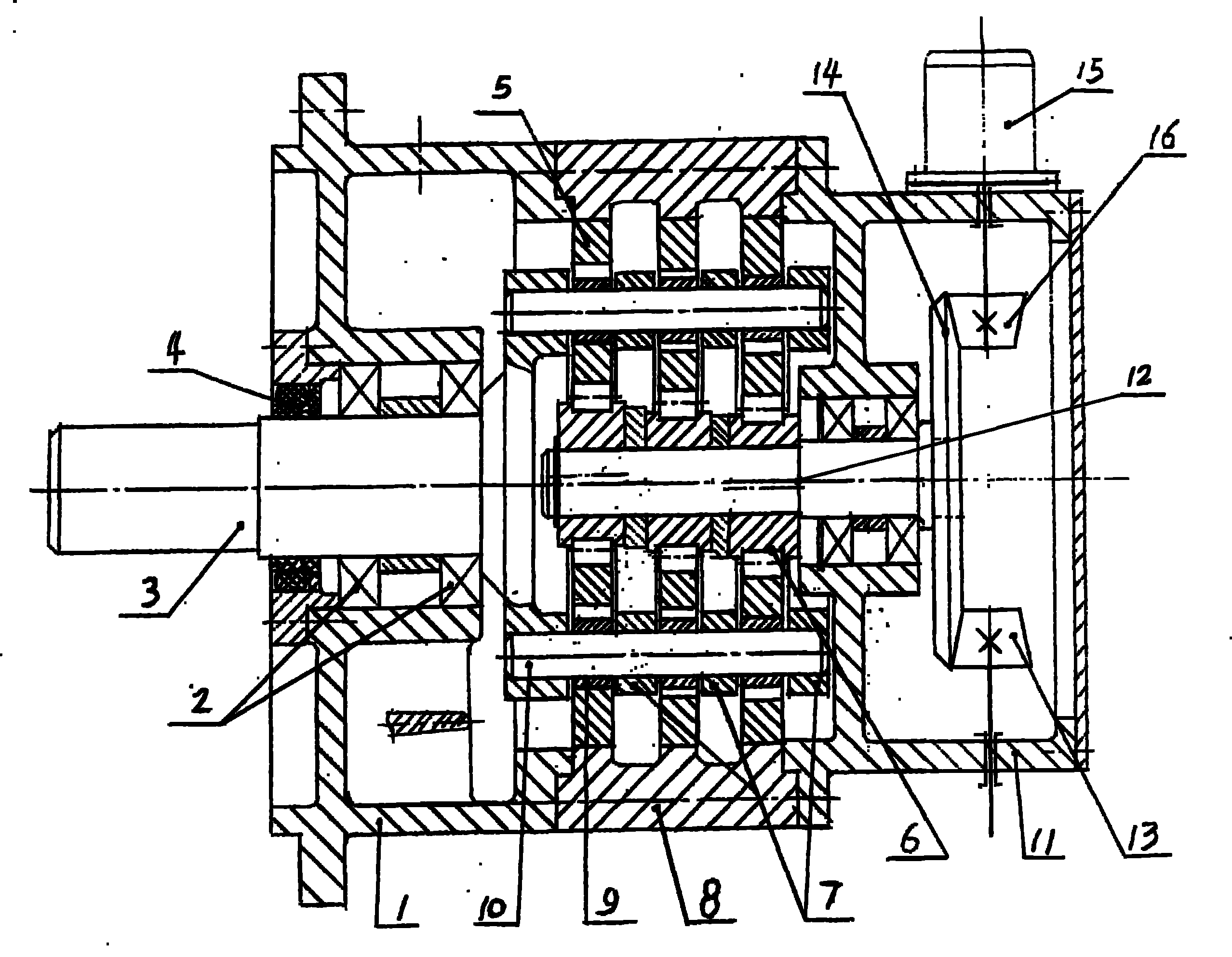

A broken tooth reinforcement device and repair method for giant gears

ActiveCN106064286BHigh hardnessImprove the strength of forceWelding accessoriesSocial benefitsEconomic benefits

The invention relates to a broken tooth fastening device of a giant gear and a repair method. The repair method comprises the following steps of (1) polishing; (2) detecting; (3) drilling: uniformly drilling at least three drilling holes in each tooth root repair surface of the gear; (4) fastening: respectively performing interference driving on metal bars into each drilling hole of the step (3), using the metal bars as reinforcing ribs in the repair gear, and welding the metal bars and the gear into a whole; (5) welding; (6) recovering. The invention further discloses the broken tooth fastening device of the giant gear. According to the broken tooth fastening device and the repair method, on one hand, the hardness and mechanical strength of the tooth surface of the gear can be greatly increased, thereby prolonging the service life of the gear, and the operating reliability is high; on the other hand, the operation is simple, the repair speed is high, and postweld heat treatment is not needed, so that equipment cannot be delayed for a long time so as not to cause heavy losses due to shutdown, the cost is greatly reduced, and economic benefits and social benefits are effectively increased.

Owner:HUANENG HUNAN YUEYANG POWER GENERATION CO LTD

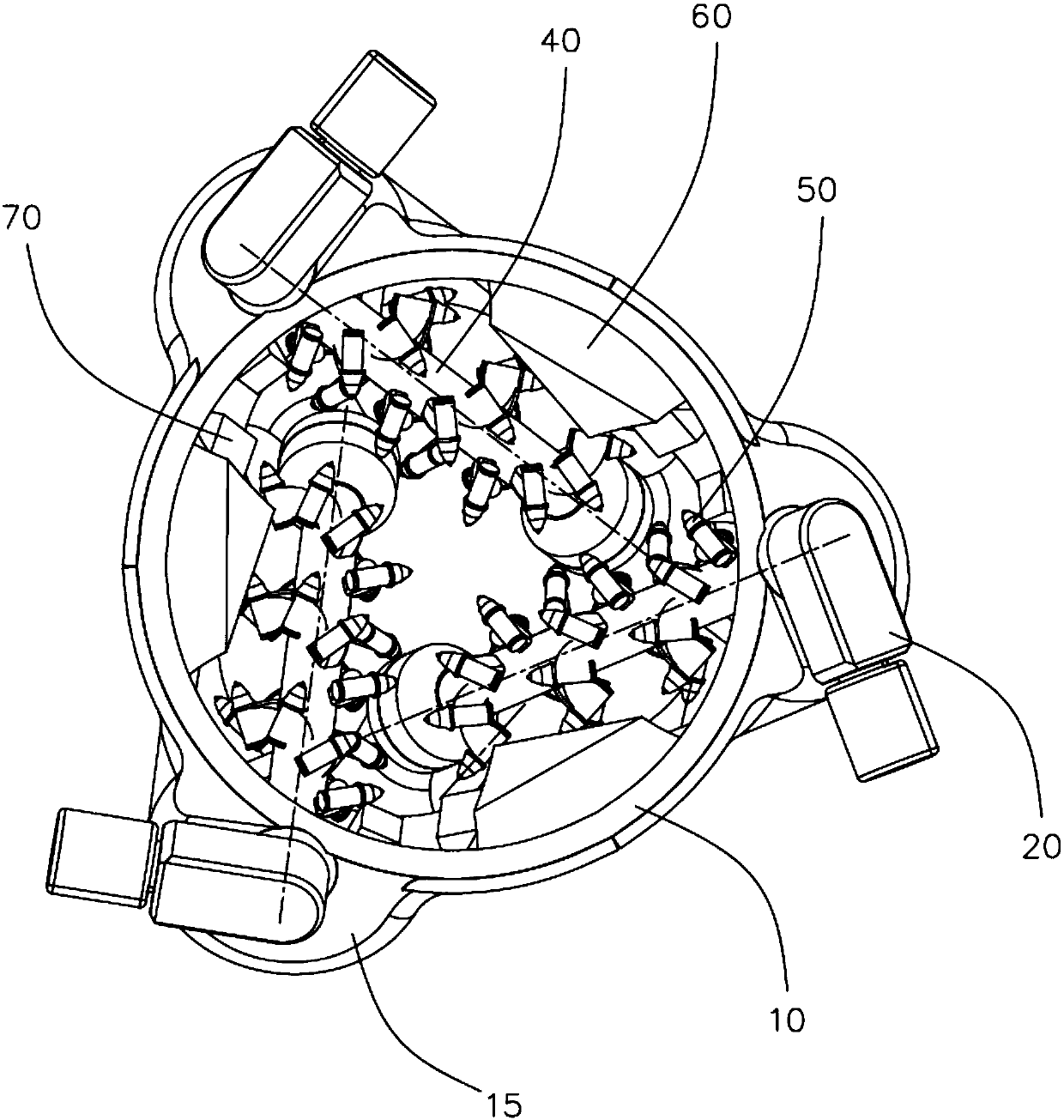

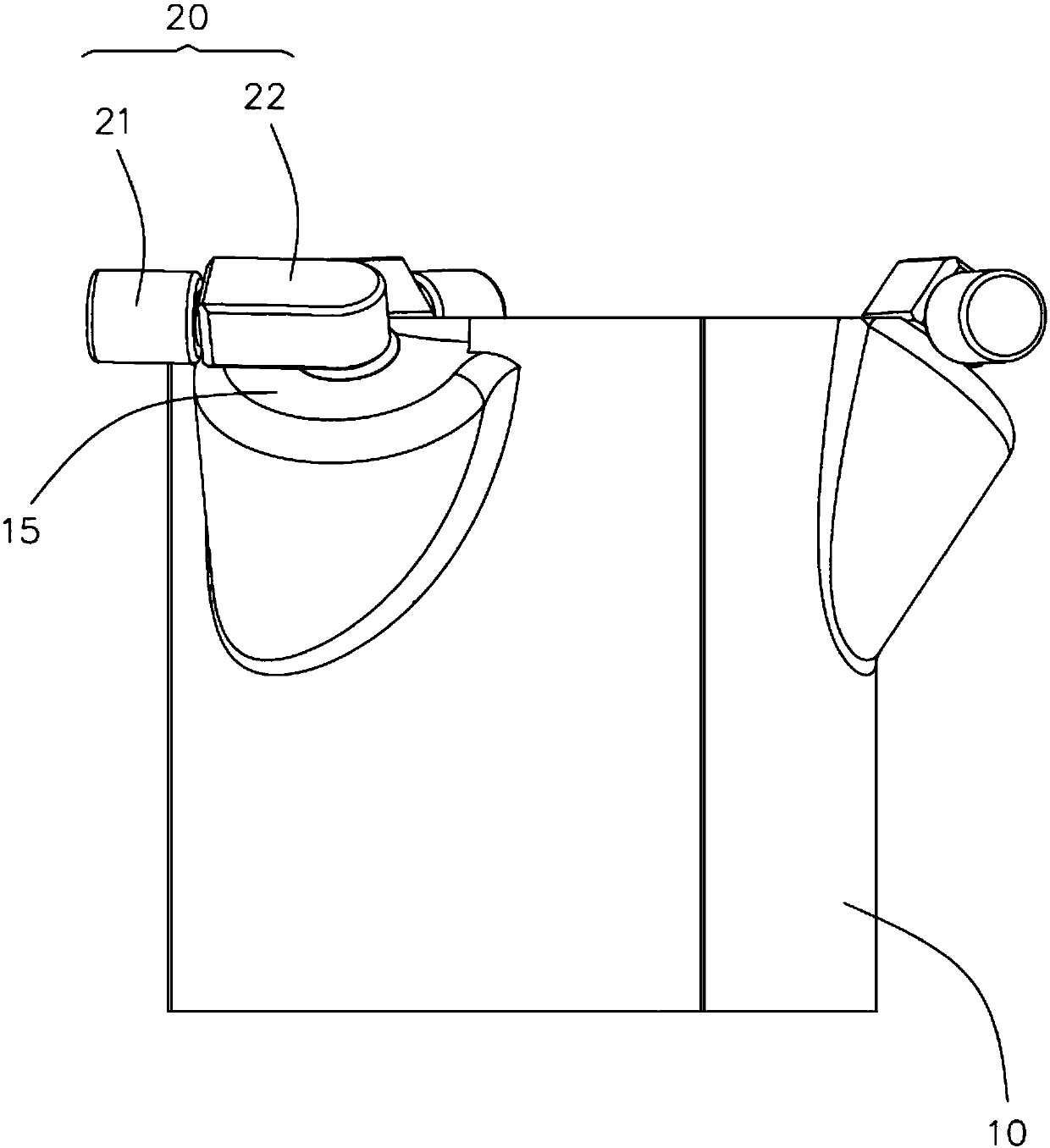

Vehicle collision energy-absorbing device and method based on elastic broken tooth base

ActiveCN107933695BProtect life safetyPromote absorptionUnderstructuresPost collisionEnergy absorption

The invention discloses a vehicle collision energy absorption device based on an elastic broken tooth base and belongs to the technical field of vehicle front longitudinal beam collision energy absorption. The vehicle collision energy absorption device comprises a broken tooth energy absorption device, a shock absorption device and an elastic energy absorption device. When a vehicle is crashed, energy generated due to collision is firstly transmitted to the broken tooth energy absorption device, the energy is absorbed through the broken tooth energy absorption device at the first level, and the stage has the beneficial effects that rigidity is small, and the energy absorption amount is large. The energy which cannot be absorbed by the broken tooth energy absorption device is transmitted tothe next step, the energy is absorbed through the shock absorption device at the second level, and the stage has the beneficial effects that the energy absorption amount is large, and flexibility islarge. The energy which cannot be absorbed by the shock absorption device is transmitted to the elastic energy absorption device and absorbed through the elastic energy absorption device at the thirdlevel, and the stage has the beneficial effects that flexibility is large so that personal safety can be well protected after the vehicle is crashed, and damage to other components of the vehicle is reduced as much as possible.

Owner:SHAANXI UNIV OF SCI & TECH

Three-dimensional inclined tooth roll crusher

Owner:NINGXIA TIANDI BENNIU IND GRP

A kind of hard tooth surface gear and hard tooth surface gear repair process

ActiveCN103075490BReduce generationPurify crystal mediaPortable liftingMetallic material coating processesSocial benefitsGear wheel

Owner:WUHAN KAIMING HIGH TECH

A method for repairing roller teeth of a crusher

ActiveCN112846638BImprove repair efficiencySimple and fast operationMeasurement devicesWork benchesStructural engineeringCrusher

The invention discloses a method for repairing roller teeth of a crusher, which includes the following steps: step S10, providing auxiliary tooling, the auxiliary tooling includes an operation platform, and drawing a theoretical pattern of the roller teeth and a reference point of the pattern of the roller teeth on the upper surface of the operation platform ; Step S20, making the orthographic projection of the reference point of the roller teeth coincide with the pattern reference point; Step S30, according to the wear condition of the crushing teeth on the roller teeth, replace the crushing teeth that need to be repaired or repair the wear-resistant layer on the crushing teeth; Step S41, select the first calibration point on the surface of the repaired broken tooth, measure the distance between the orthographic projection of the first calibration point on the working platform and the corresponding point on the theoretical drawing of the first calibration point, and obtain the first calibration point. Check the difference; step S42, judge whether the first check difference is within the set error range, if the first check difference is not within the set error range, adjust the installation position of the repaired broken tooth or adjust the repair The thickness of the wear-resistant layer on the final crushing teeth. It is easy to operate and the restoration quality is high.

Owner:SGIS SONGSHAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com