Gear driving system fault simulation experiment table with part quick replacement function

A technology of gear transmission and parts replacement, which is applied to the simulation device of space navigation conditions, the simulator, the test of mechanical parts, etc., and can solve the problems of difficulty in replacement, damage to test bench parts, and long experiment time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are listed, and the present invention is further described in detail in conjunction with the accompanying drawings.

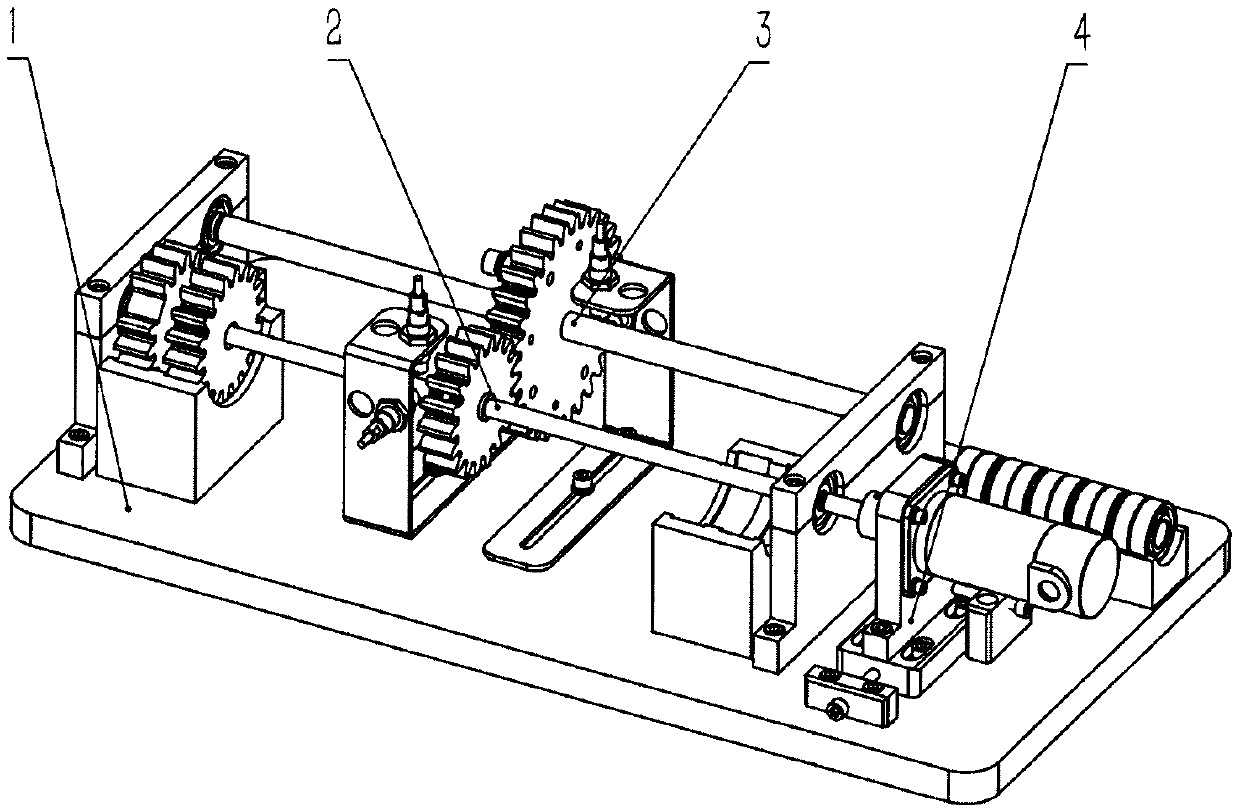

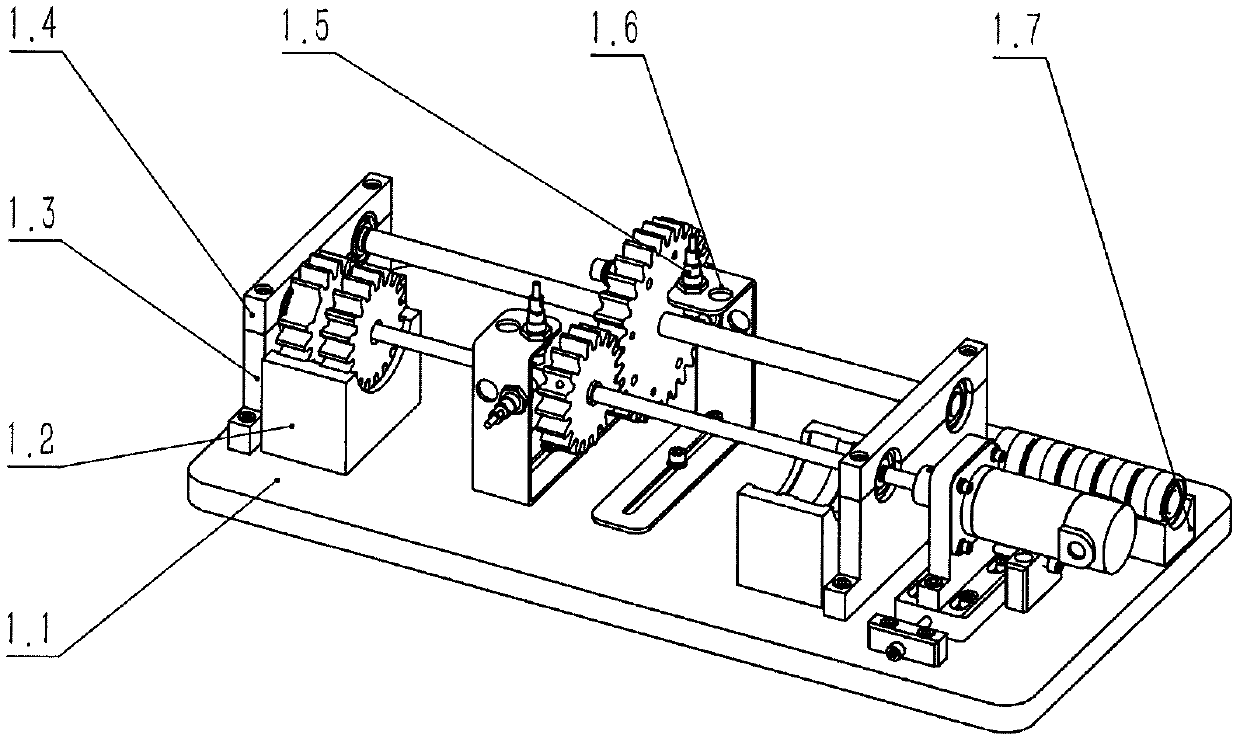

[0056] A kind of gear transmission system failure simulation experiment platform of quick replacement parts of the present invention can carry out following experiment:

[0057] (1) Gear fault simulation experiment

[0058] Gear fault adjustment module 2 includes pinion (broken tooth) 2.1, pinion (pitting) 2.2, pinion shaft 2.3, pinion (normal) 2.4, deep groove ball bearing 63002.5, elastic coupling (DR-6×10 -D25L40) 2.6, permanent magnet DC motor (55ZY06 / A3) 2.7.

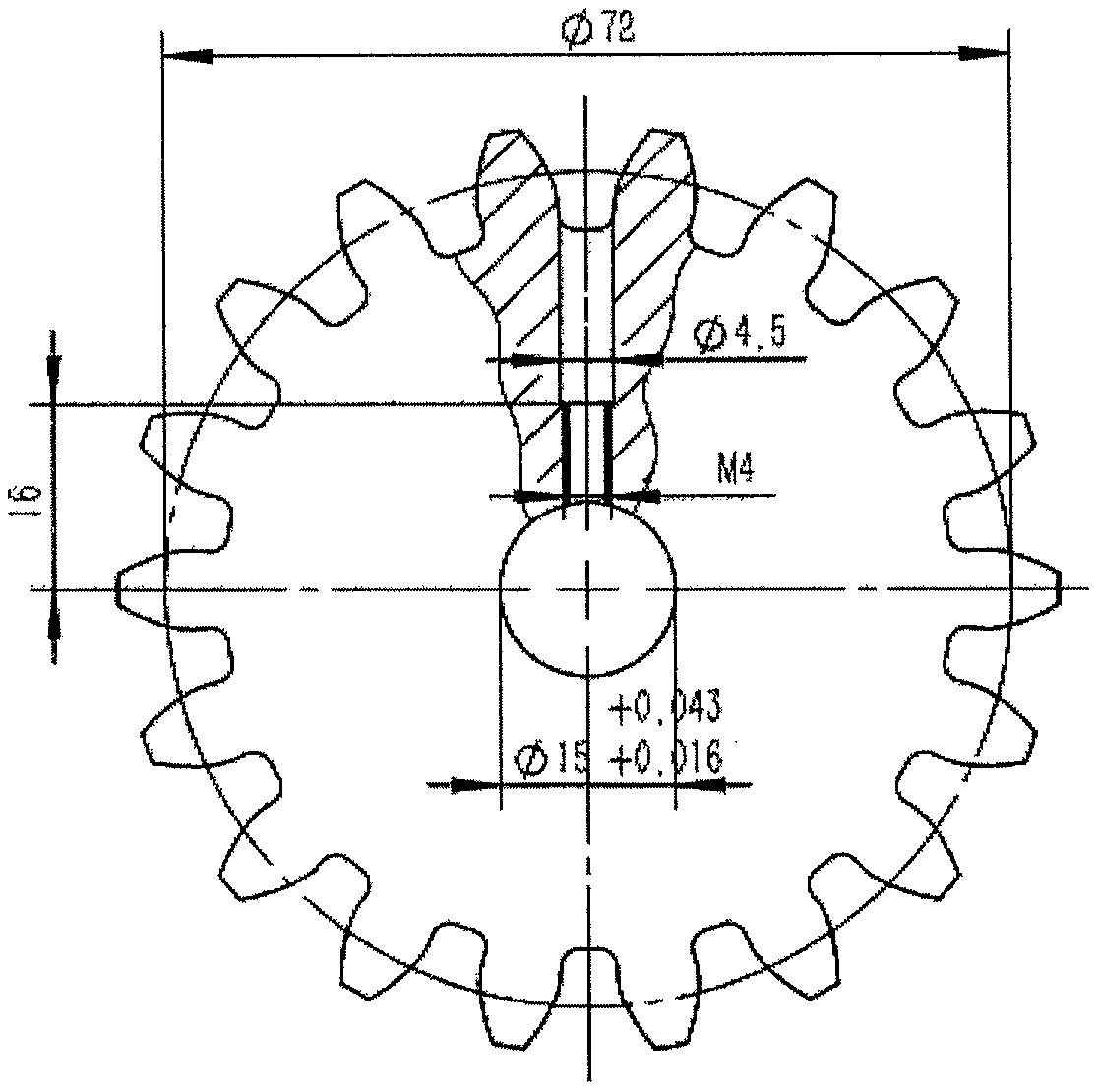

[0059] The gear fault adjustment module 2 is set on the pinion transmission shaft system, the pinion shaft 2.3 adopts a stepped shaft with thick middle and thin ends, the diameter of the shaft shoulder installed by the bearings 2.4 at both ends is 10 mm, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com