Patents

Literature

307 results about "Permanent magnet dc motor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Answered Mar 4, 2018. A DC Motor whose poles are made of Permanent Magnets is known as Permanent Magnet DC (PMDC) Motor. The magnets are radially magnetized and are mounted on the inner periphery of the cylindrical steel stator. The stator of the motor serves as a return path for the magnetic flux.

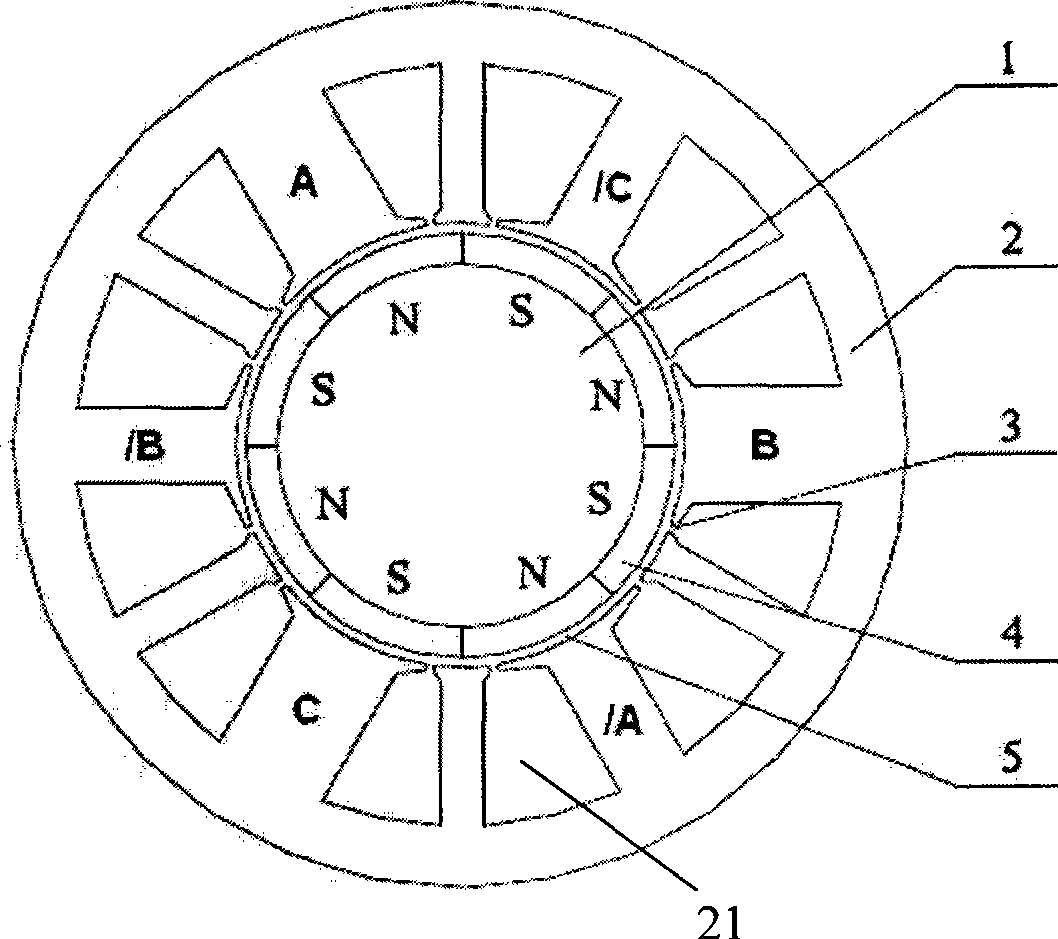

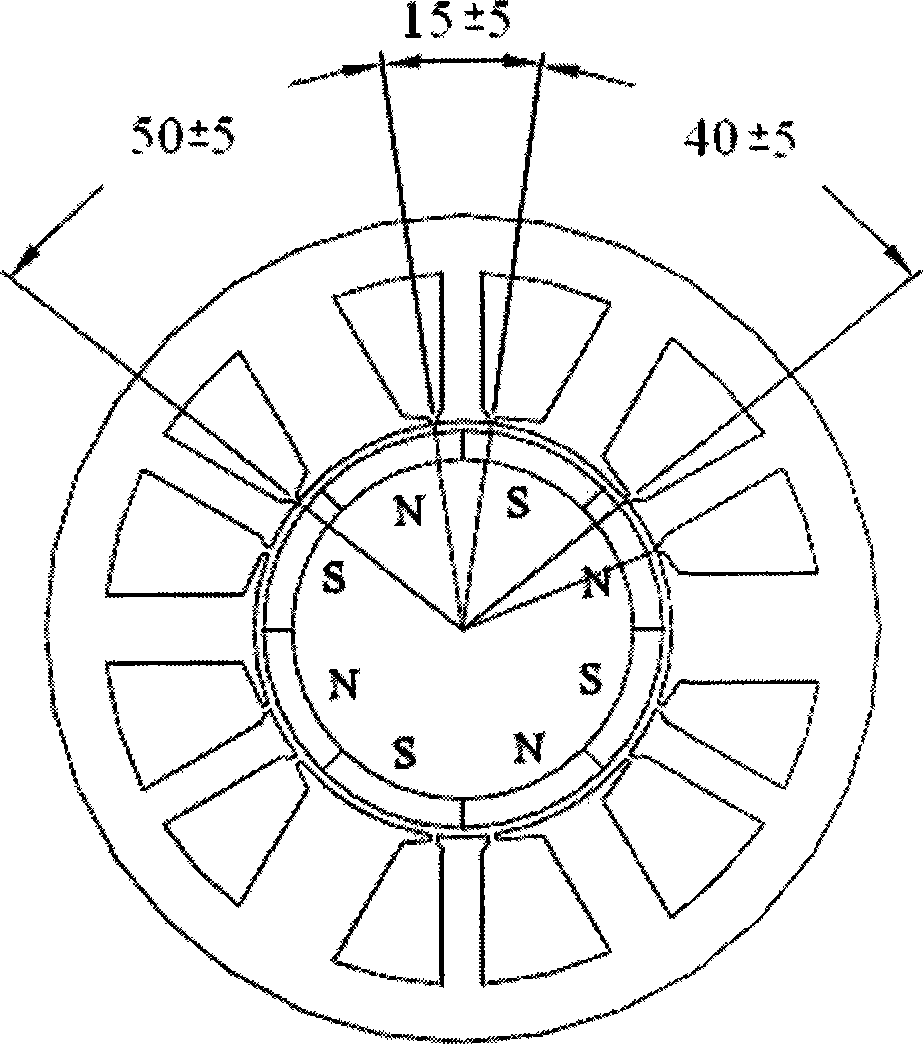

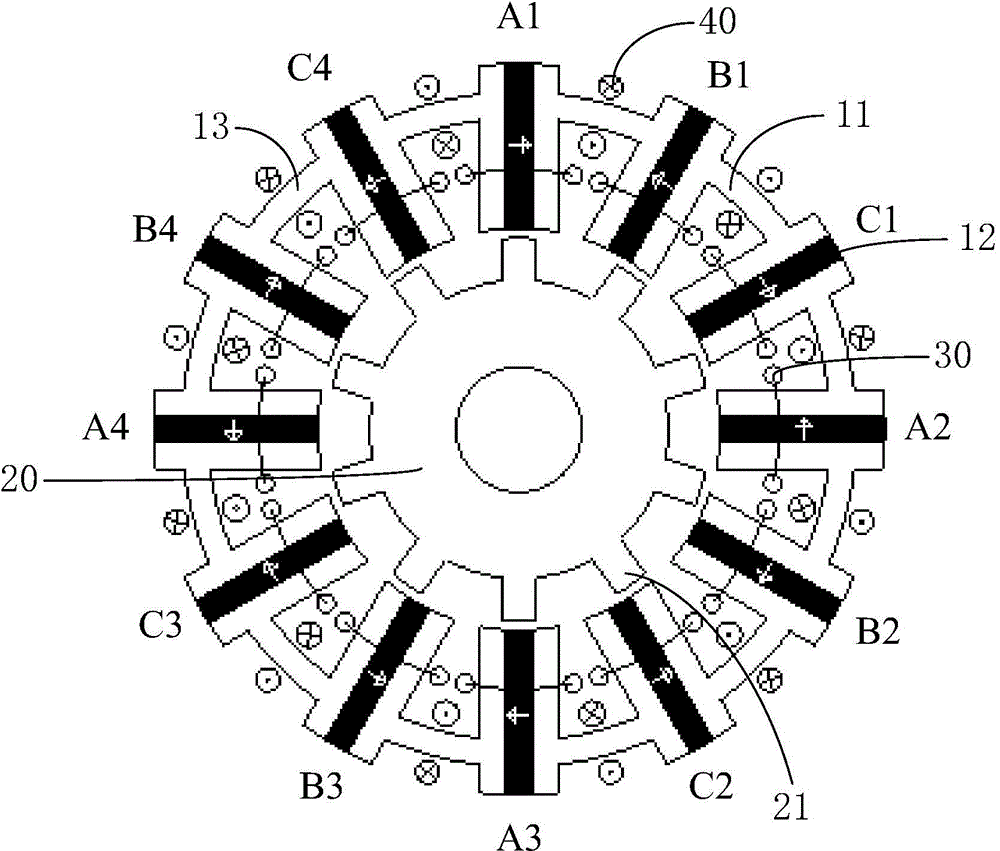

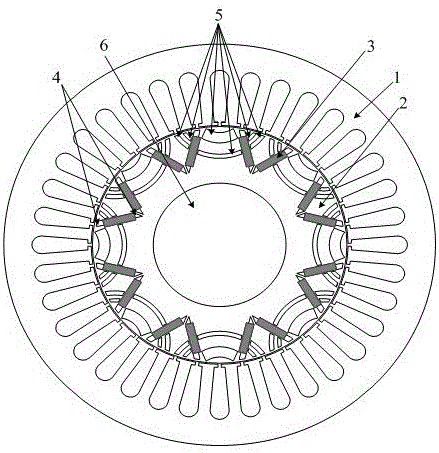

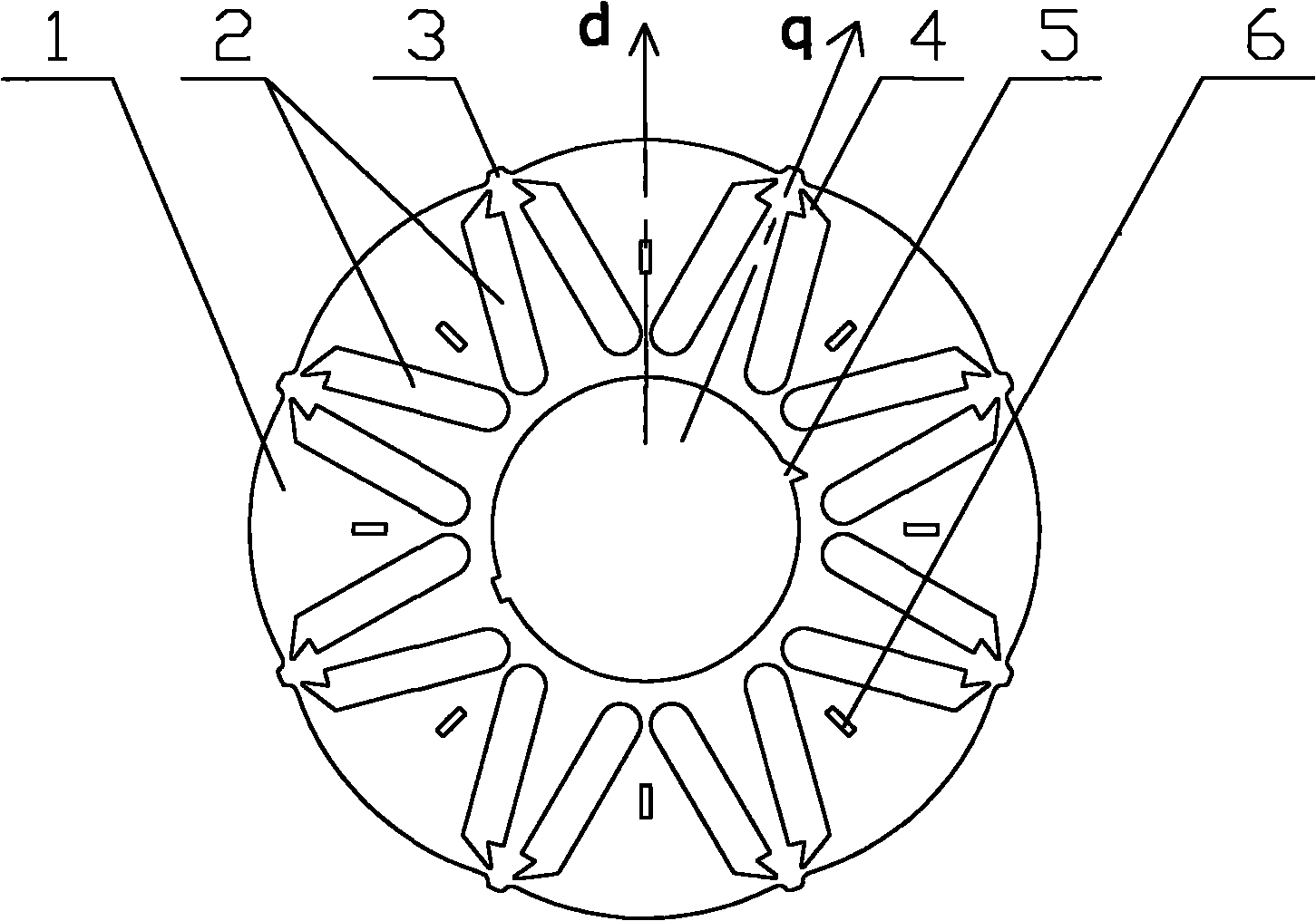

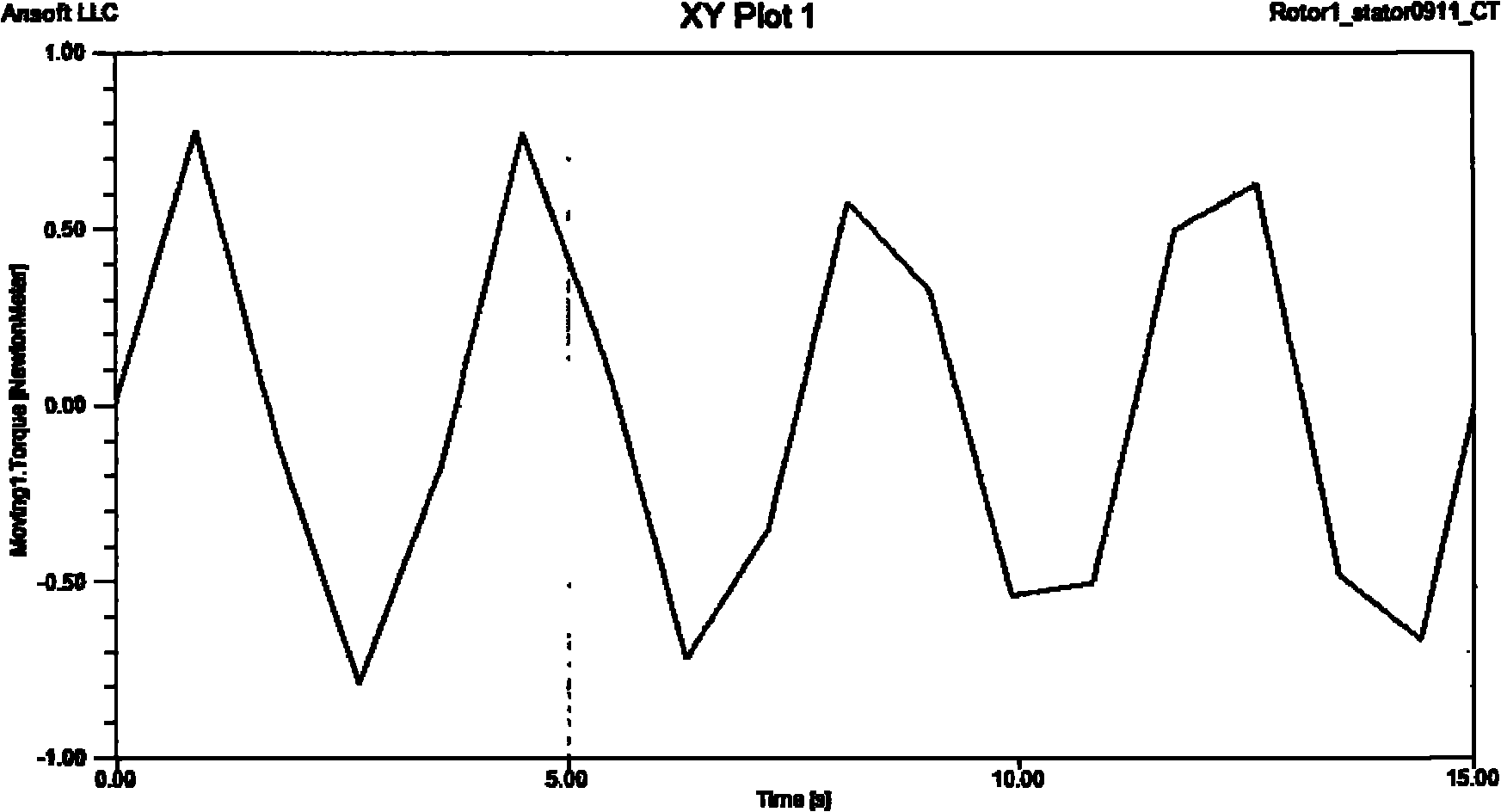

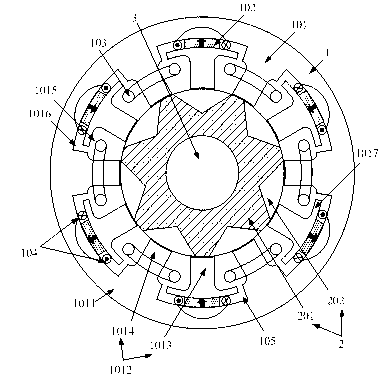

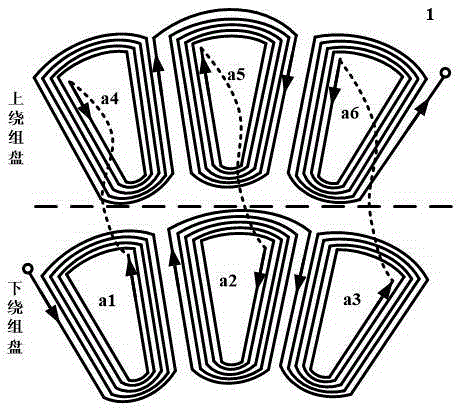

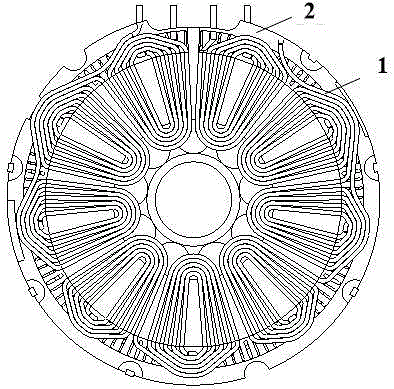

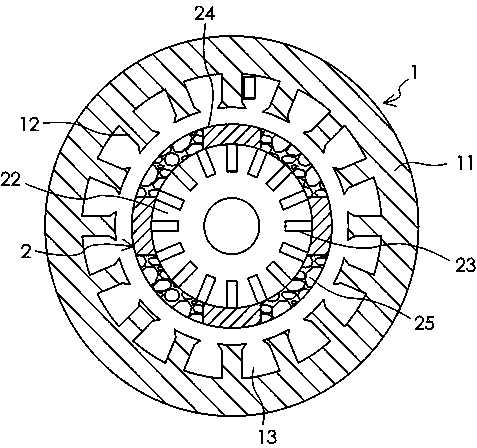

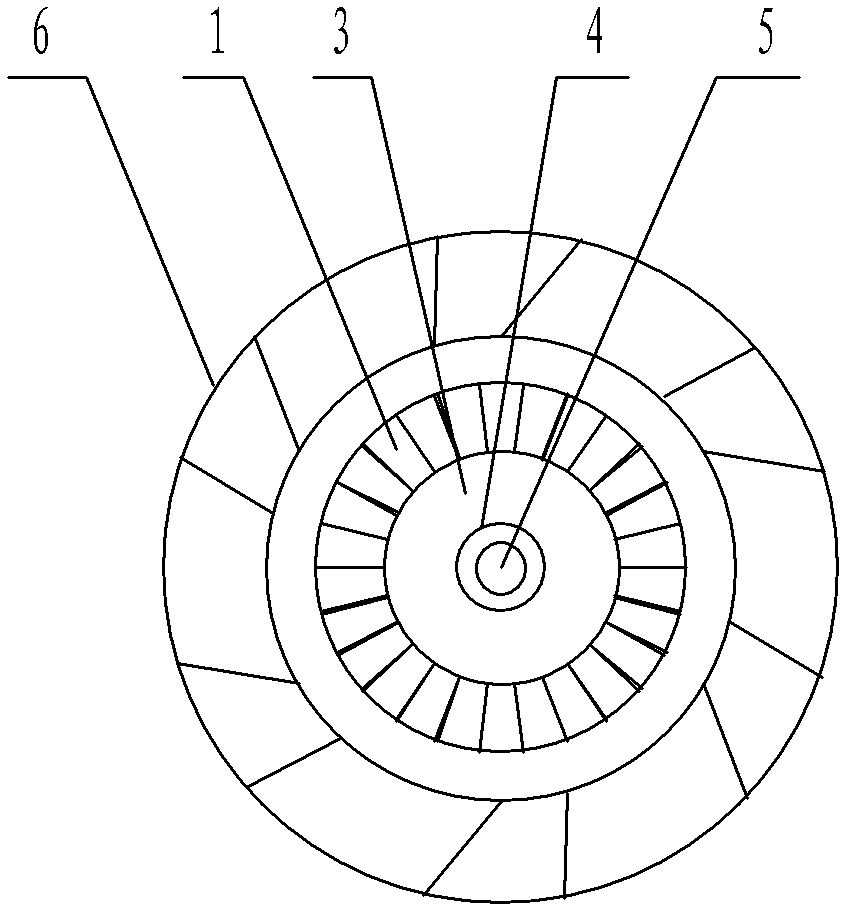

Square wave three-phase brushless permanent magnetic DC motor

ActiveCN101371425ASmall positioning torqueSimple structureMagnetic circuit rotating partsMagnetic circuit stationary partsLarge toothMagnetic poles

The invention relates to a square wave three phase brushless permanent magnet dc motor. In order to solve the problems existed in the prior square wave permanent magnet motor and sine wave permanent magnet motor, a magnetic pole number 2P is equal to 8 on a rotor iron core; a slot number Z is equal to 12 of a stator iron core, twelve teeth comprises three big teeth, three middle teeth and six small teeth;a mechanical angle ratio of the big teeth is 50 degree + / - 5 degree, the mechanical angle ratio of the middle teeth is 40 degree + / - 5 degree,the mechanical angle ratio of the small teeth is 15 degree + / - 5 degree,and a total mechanical angle ratio of one big tooth plus one middle tooth plus two small teeth is equal to 120 degree.The three phase concentrated windings respectively wind on the big teeth and middle teeth, each phase only has two concentrated windings and the three phase motor only has six concentrated windings. The motor can generate a stable torque when driven by a three phase square wave current and a torque fluctuation index is equivalent to that of the sine wave permanent magnet. The motor of the invention has a series of advantages of minimum winding end, minimum air gap, minimum material, minimum locating torque and minimum loss or the like.

Owner:SCBD (ANHUI) E TECH CO LTD

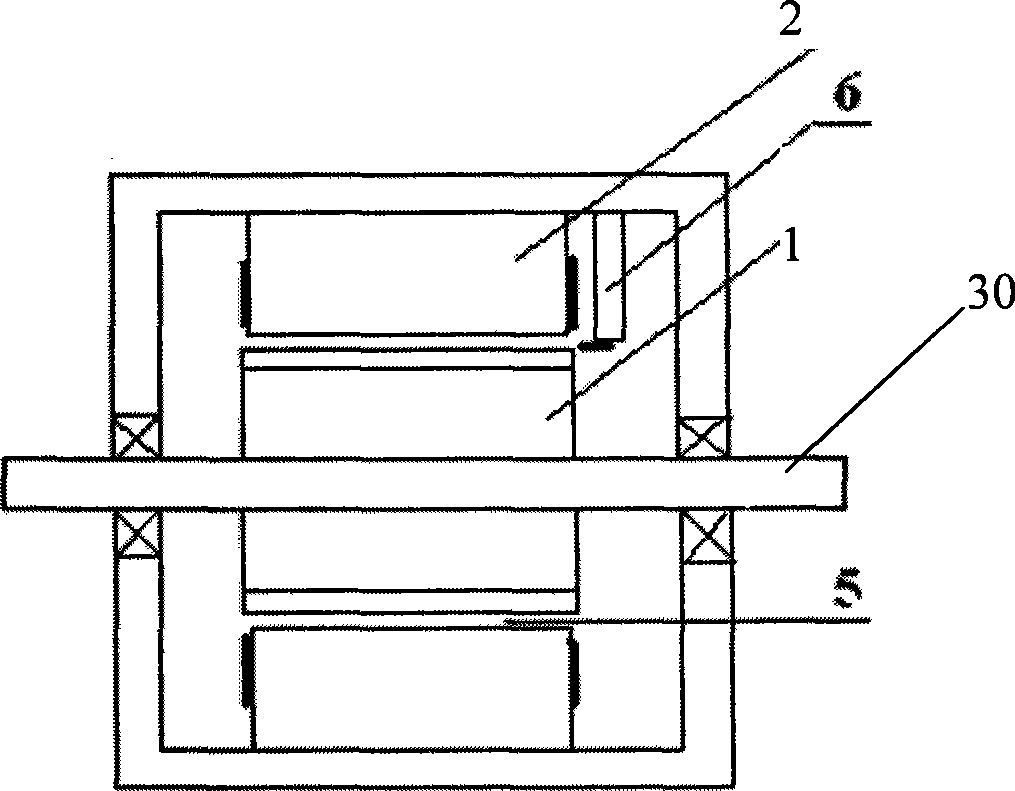

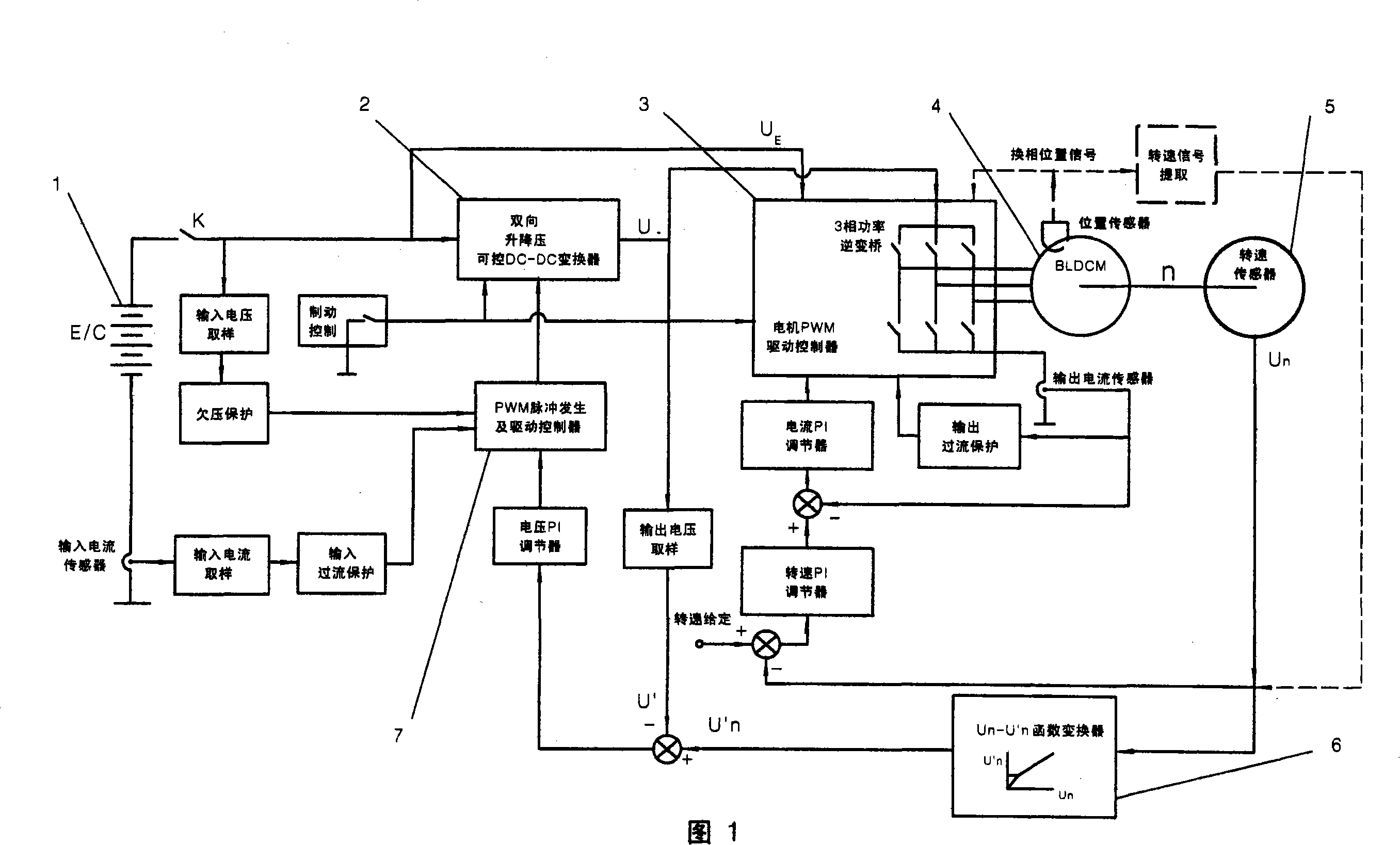

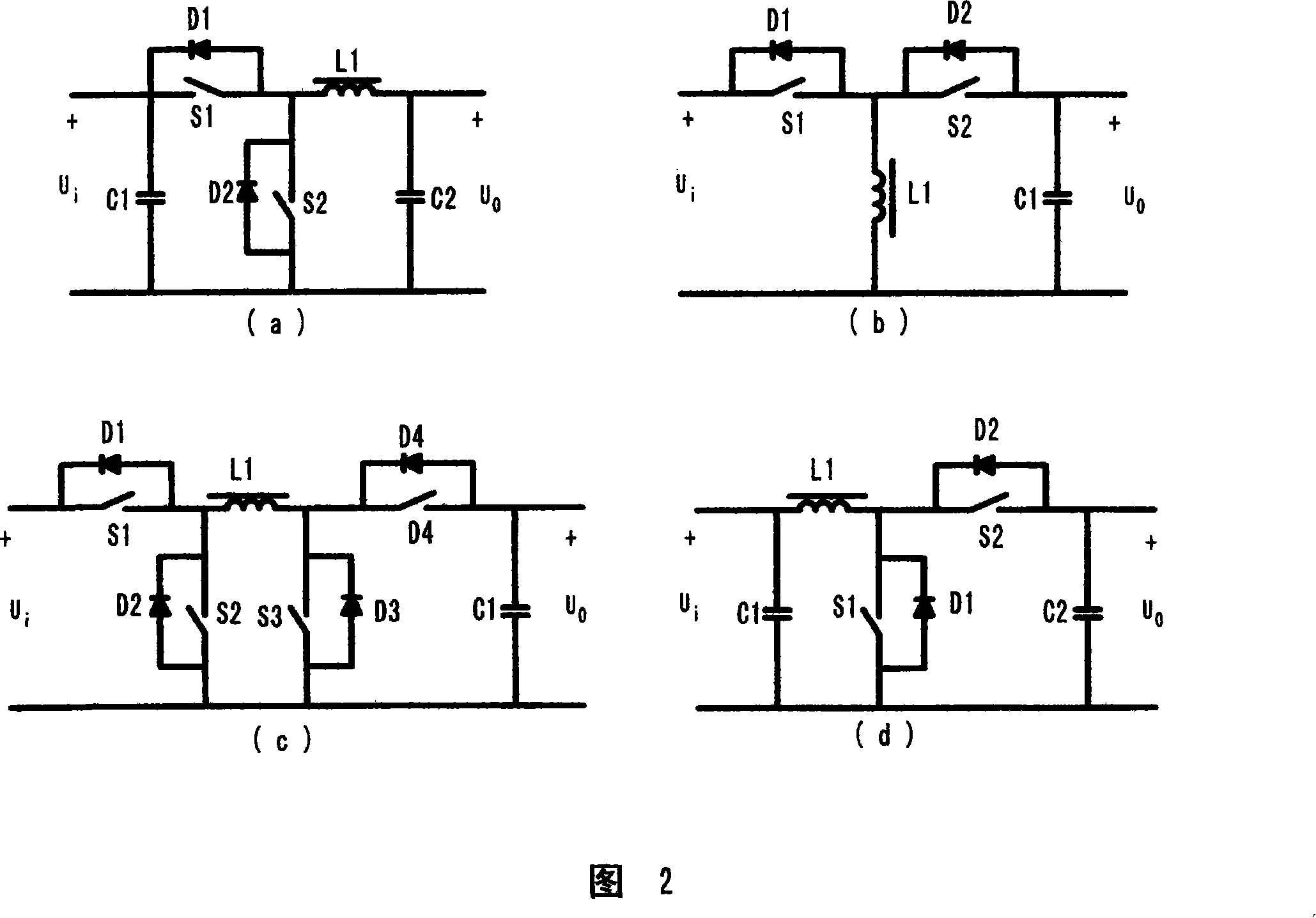

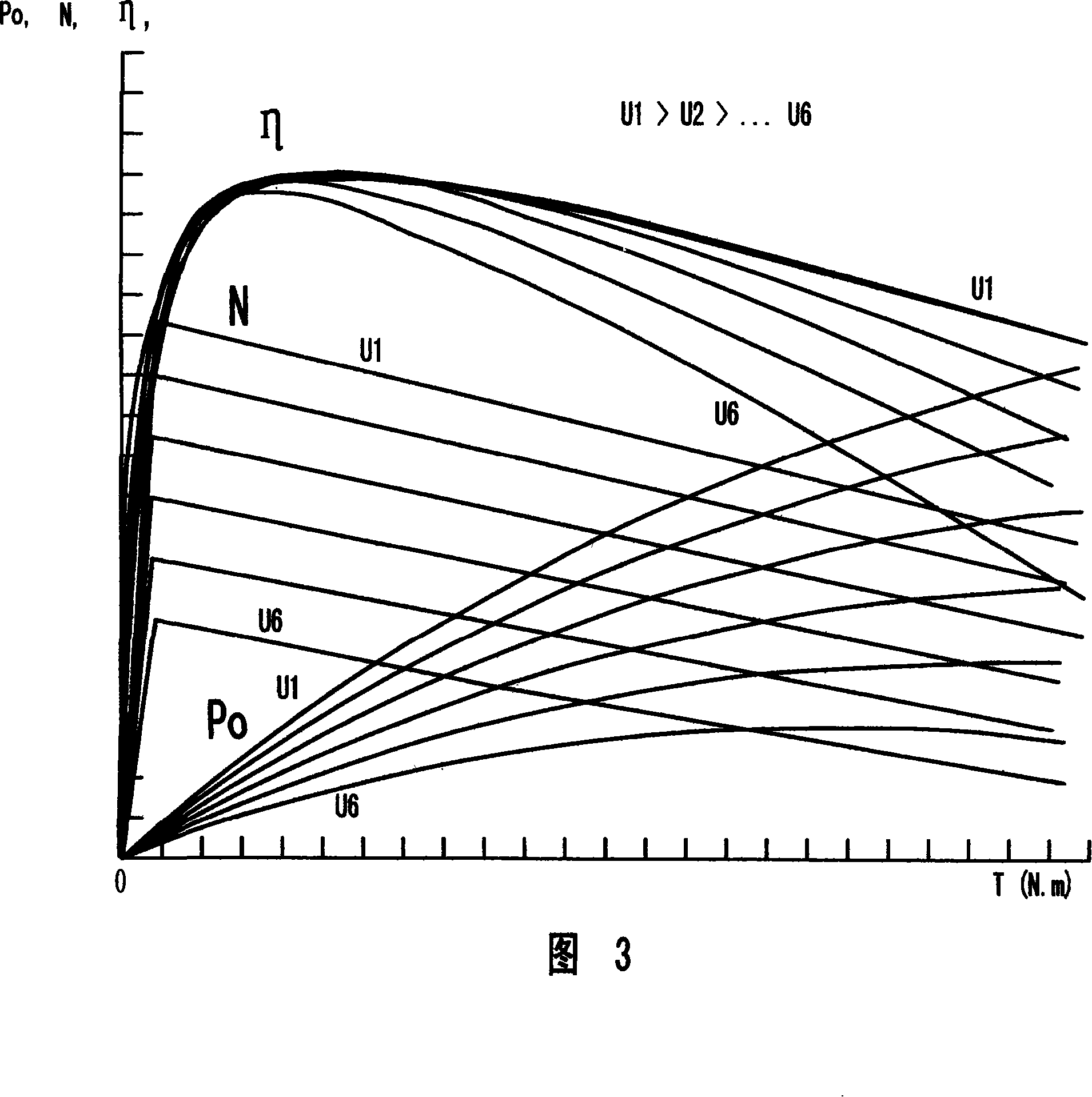

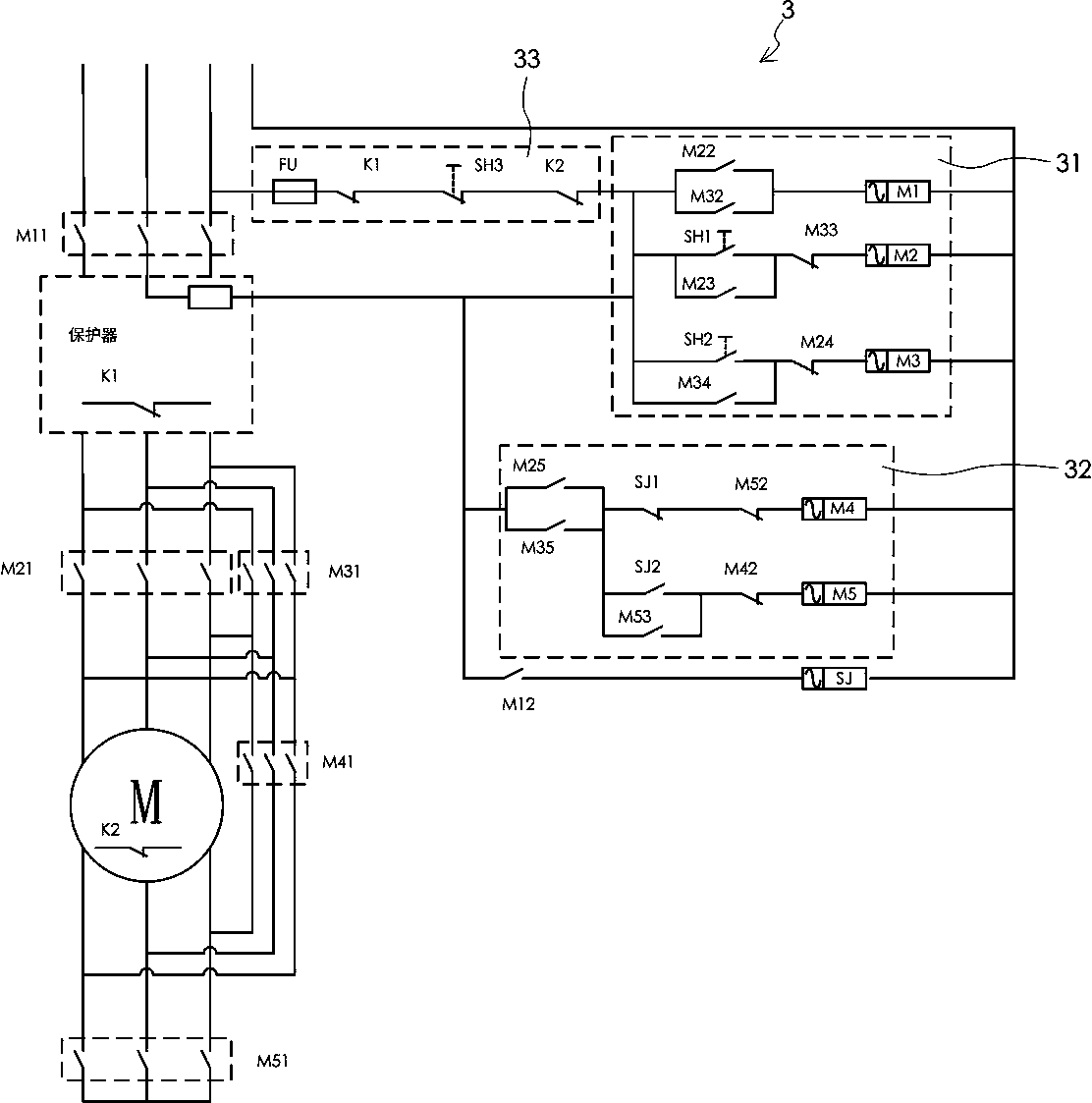

Permanent-magnet DC motor drive control system with approximate constant power pulling motor characteristics

InactiveCN101159422AIncreased complexityIncrease manufacturing costSingle motor speed/torque controlMechanical energy handlingCapacitanceBrushless motors

A permanent-magnetic DC motor bearing similar characteristics with the constant power pulling motor, in particular a new drive control system for brushless motor adopts new technologies of full electronic drive control and DC-DC transducer. The motor can generate great drive torque, i.e. high tractive force, climbing ability and better acceleration performance with low power consumption, and eliminate the needs for improvement to the motor structure, complication, high manufacture cost or weak magnetic control; the motor may further gain such performance as high speed, wide speed regulation and infinite variable speed under light load; the total voltage of the battery and the number of single series of connection can be reduced; controllable electric brake can be realized through fully utilizing the energy feedback during sliding and braking. The new system can significantly improve the kinetic performance, safety and reliability of electric vehicles and remarkably reduce operating costs, with ideal characteristics expected in various electric vehicles powered by rechargeable battery or / and super capacitance as well as significantly expanded work scope and capacity for conventional electrically driven system.

Owner:李平 +1

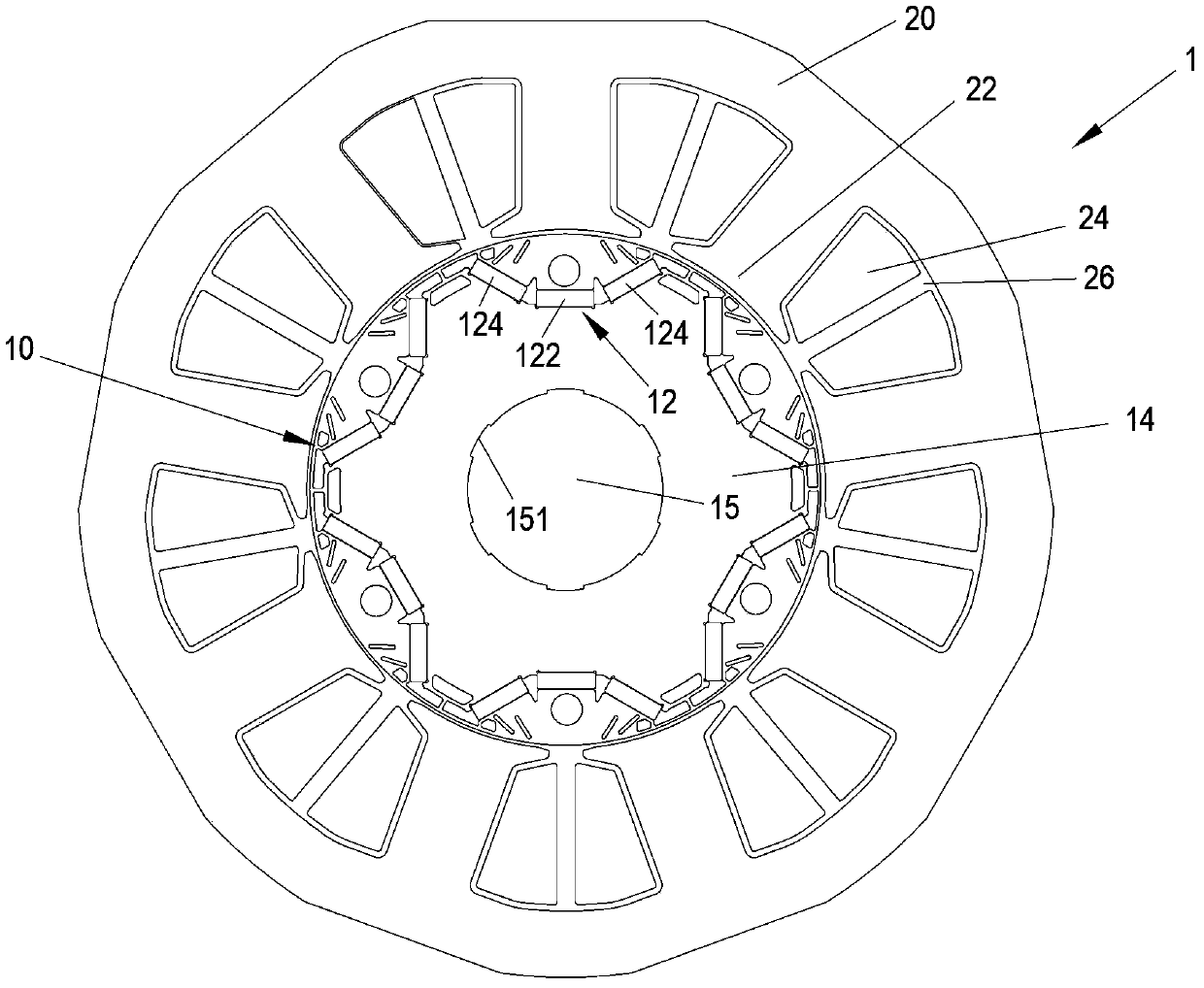

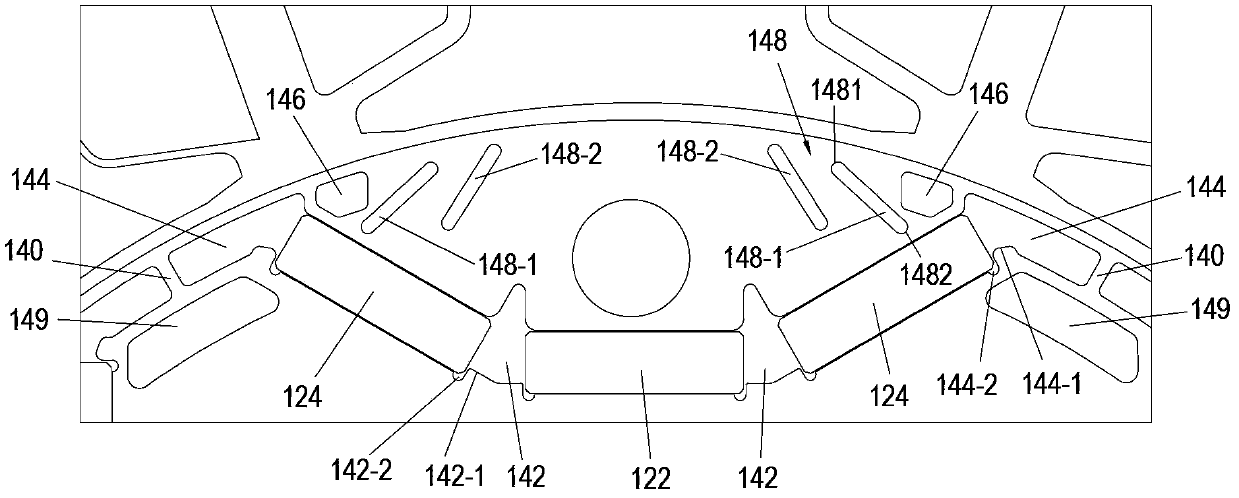

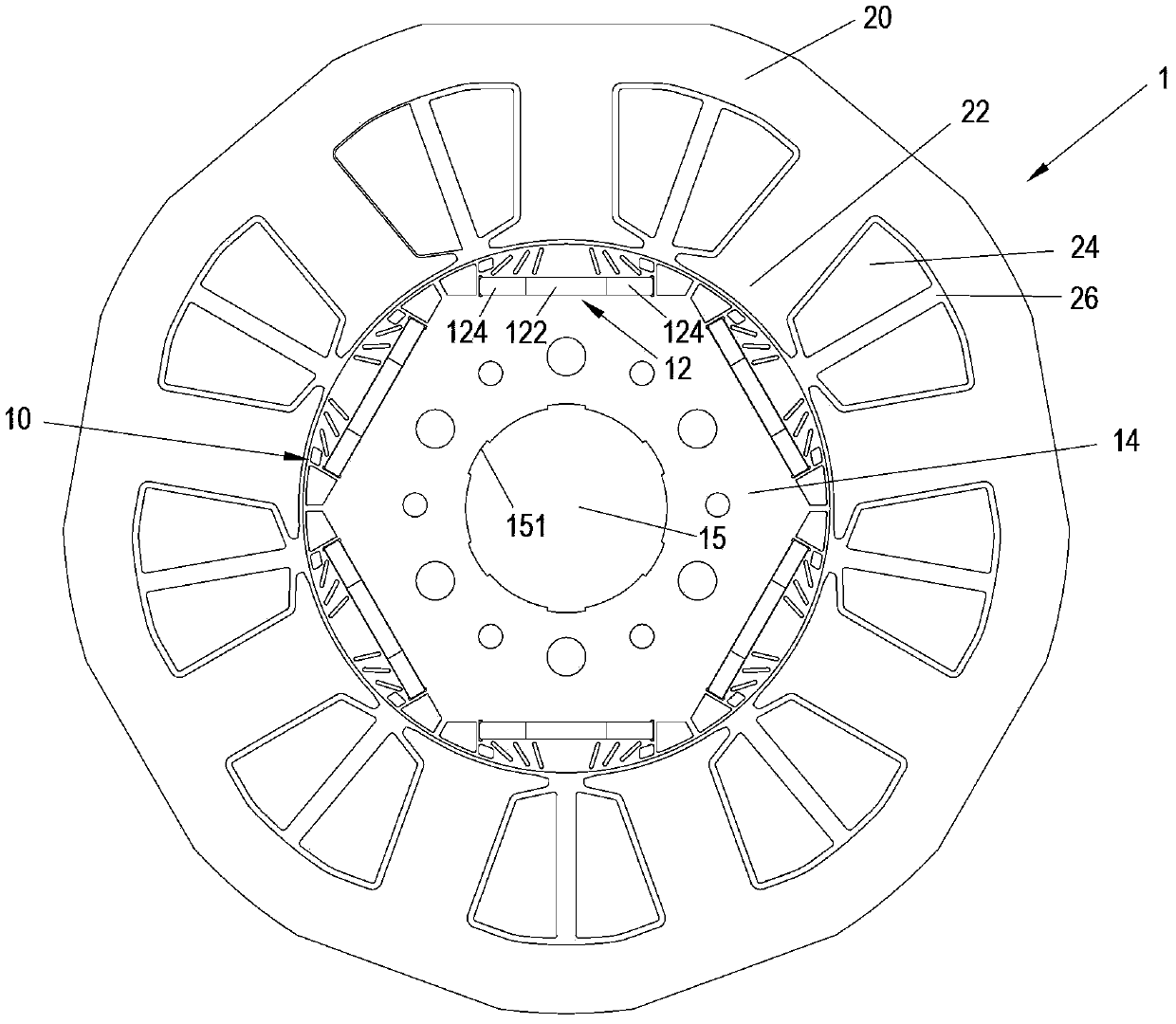

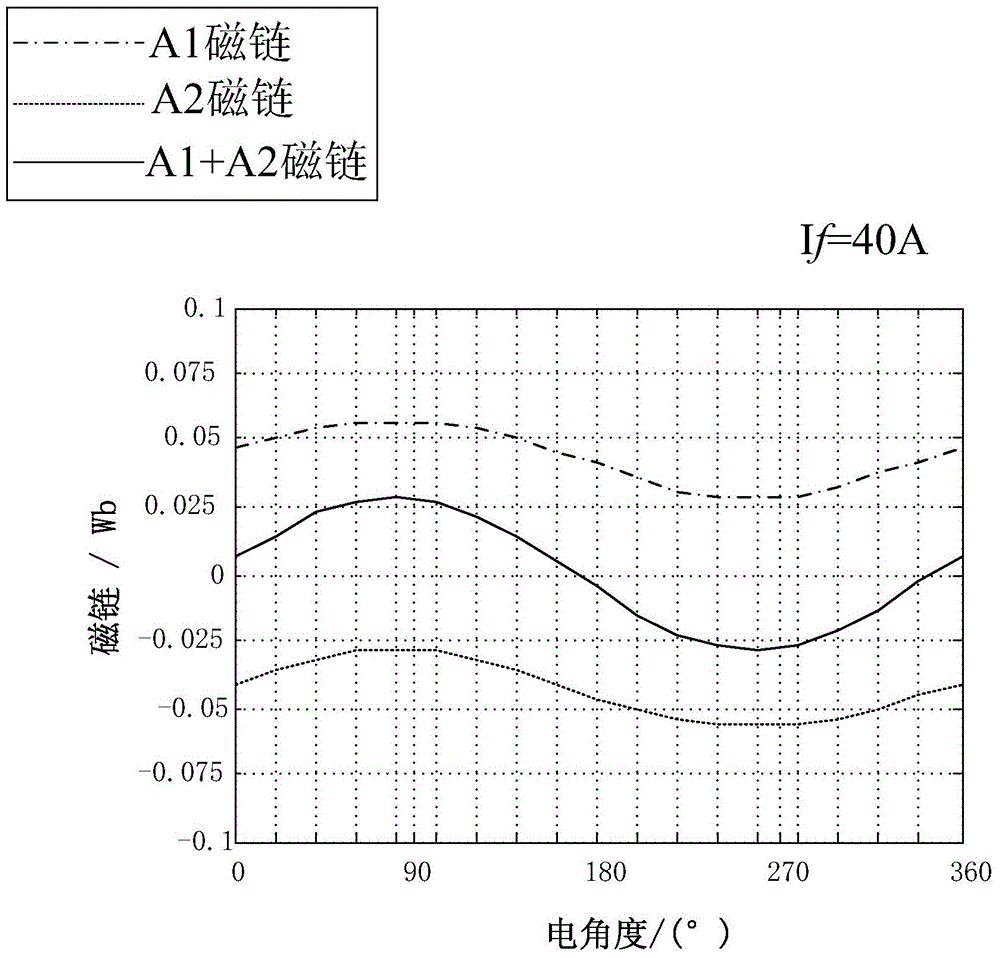

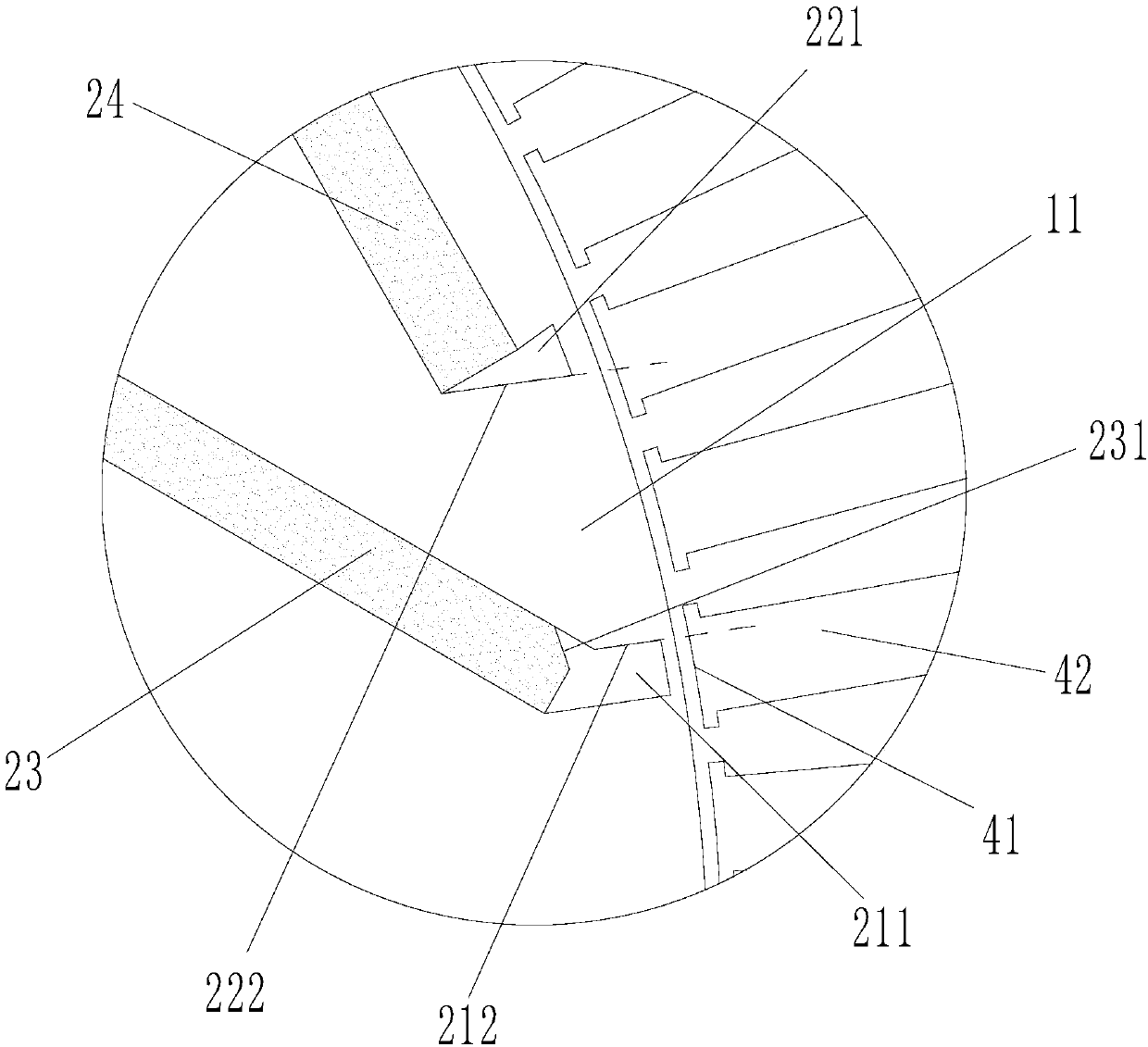

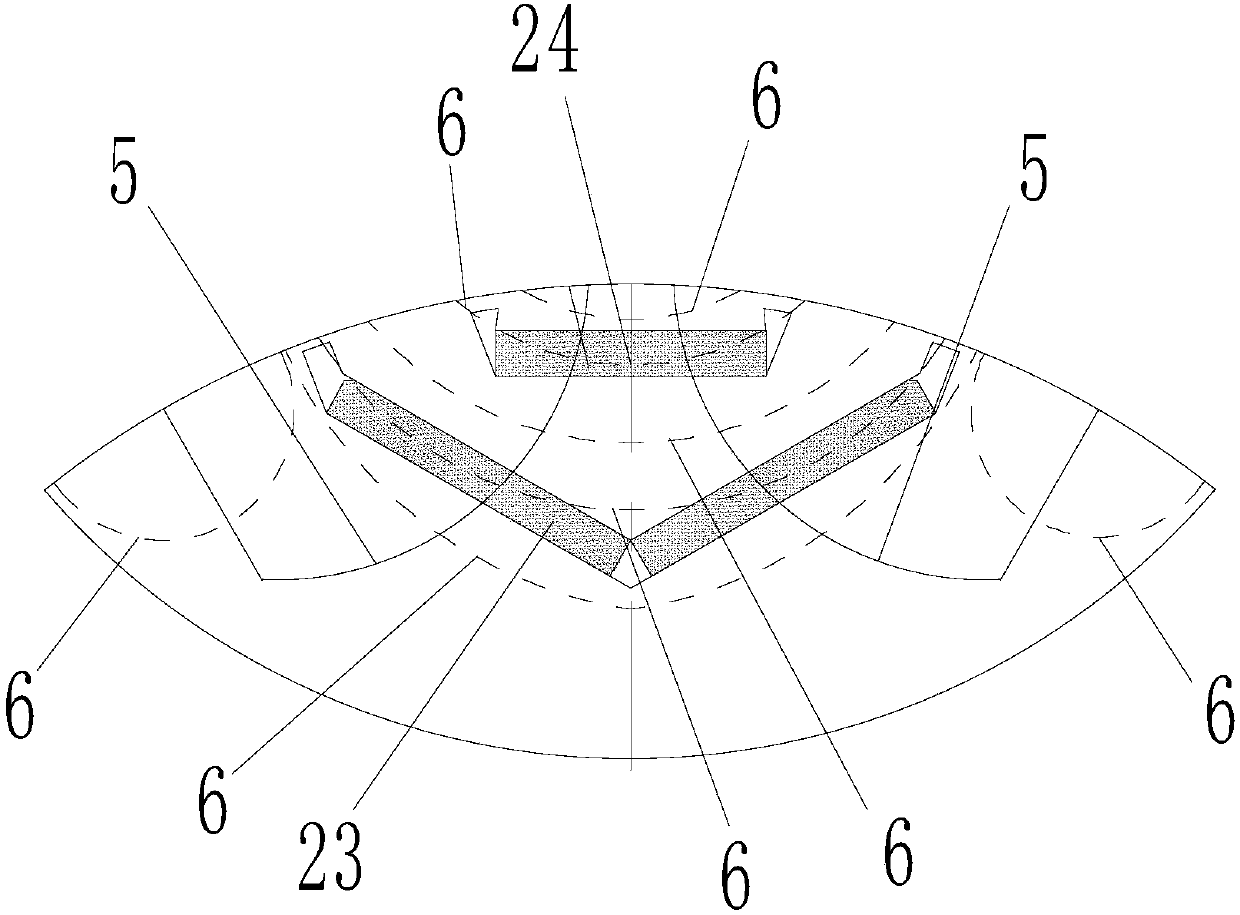

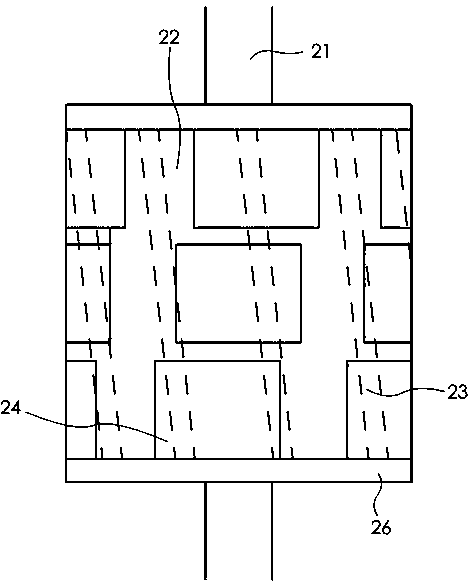

Rotor assembly and permanent magnet motor comprising same

The invention discloses a rotor assembly for a permanent magnet motor. The rotor assembly comprises a rotor iron core and multiple permanent magnet groups uniformly distributed along the peripheral direction of the rotor iron core; each of the permanent magnet group comprises a first permanent magnet positioned in the middle of the permanent magnet group and second permanent magnets positioned at the end parts of the permanent magnet group, wherein first magnet isolating slots are arranged between the end part edges, away from the first permanent magnet, of the second permanent magnets, and the outer periphery of the rotor iron core; the first magnet isolating slots extend along the outer periphery of the rotor iron core in the extension direction of the permanent magnets. According to the rotor assembly, magnetic fields between stator teeth and the rotor permanent magnets are optimized by the magnet isolating slots, and the reversing of the hysteresis magnetic field is effectively inhibited, so the magnetic field change is reduced and the pulse of the output torque of a motor is reduced; in addition, the magnet isolating slots can be used for reducing the density degree of magnetic lines, so the demagnetizing capacity of the permanent magnets in the rotor assembly is improved. The invention also relates to a permanent magnetic motor comprising the rotor assembly.

Owner:EMERSON CLIMATE TECH (SUZHOU) CO LTD

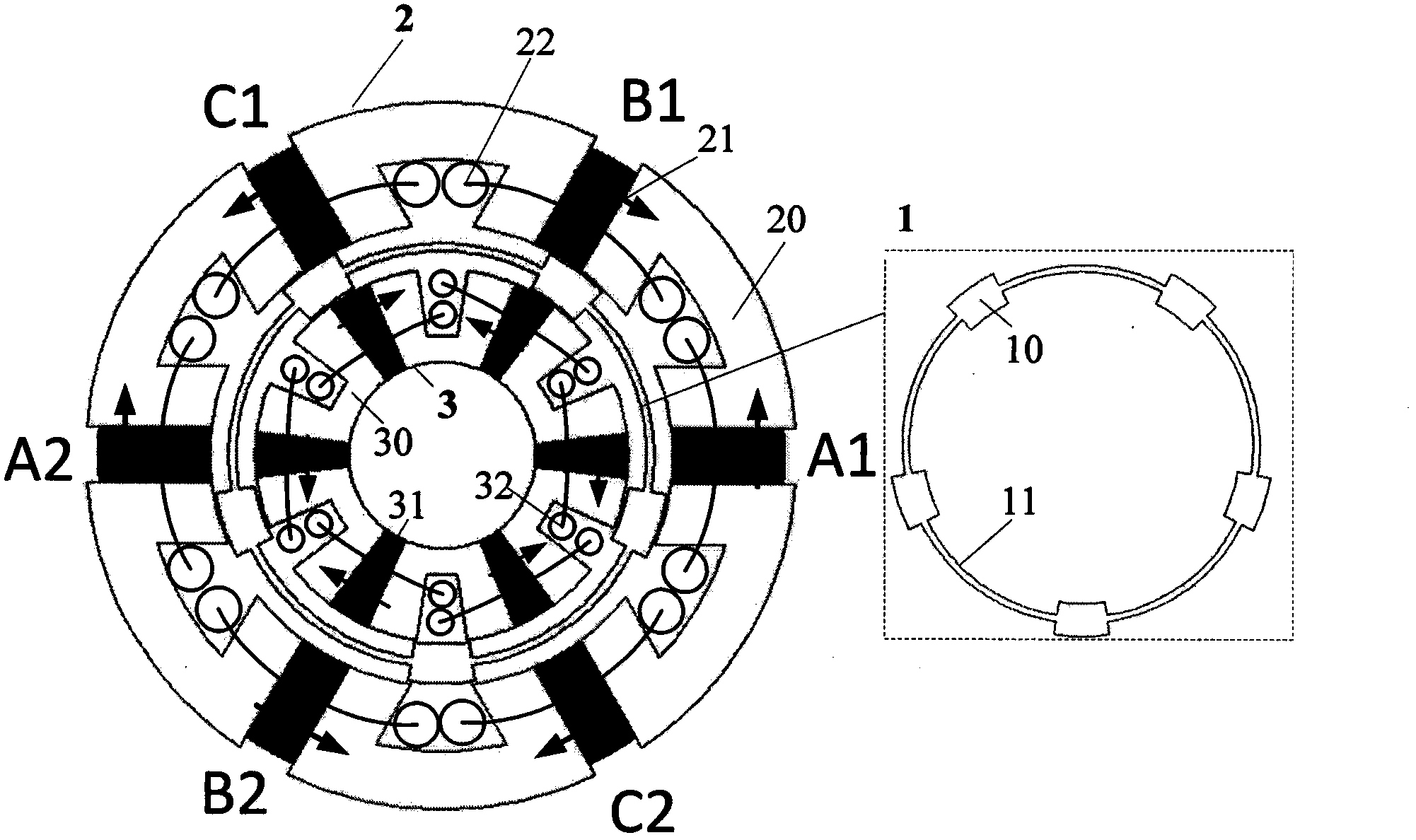

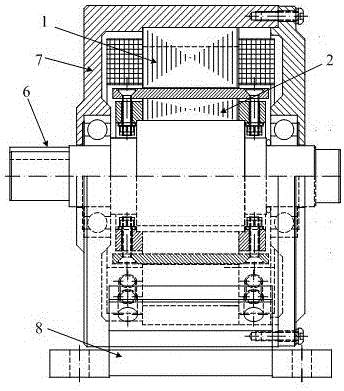

Double-stator high-power-density flux switching permanent magnet motor

ActiveCN103647382ASimple structureImprove reliabilityElectric machinesDynamo-electric machinesElectric machinePermanent magnet motor

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

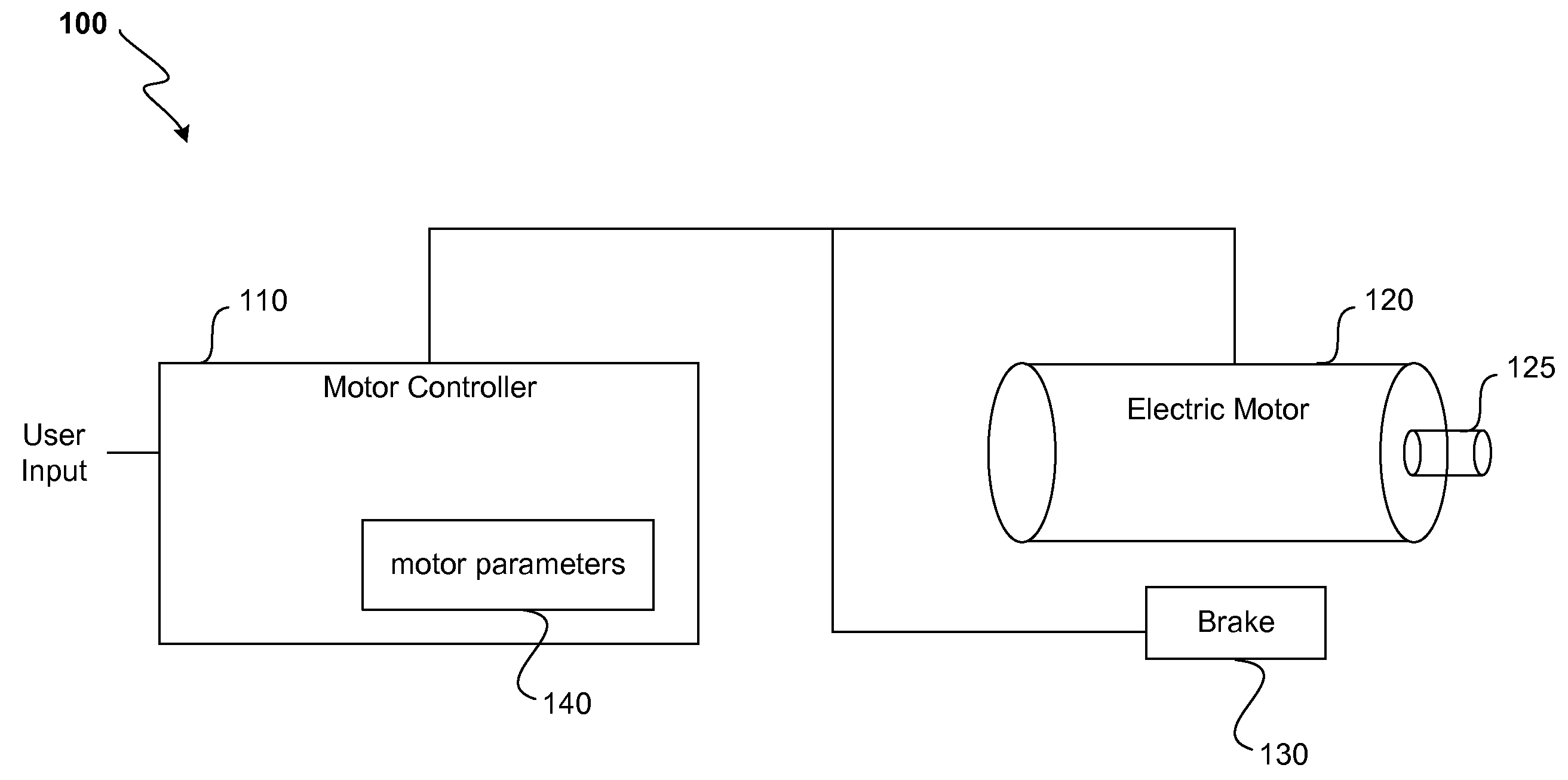

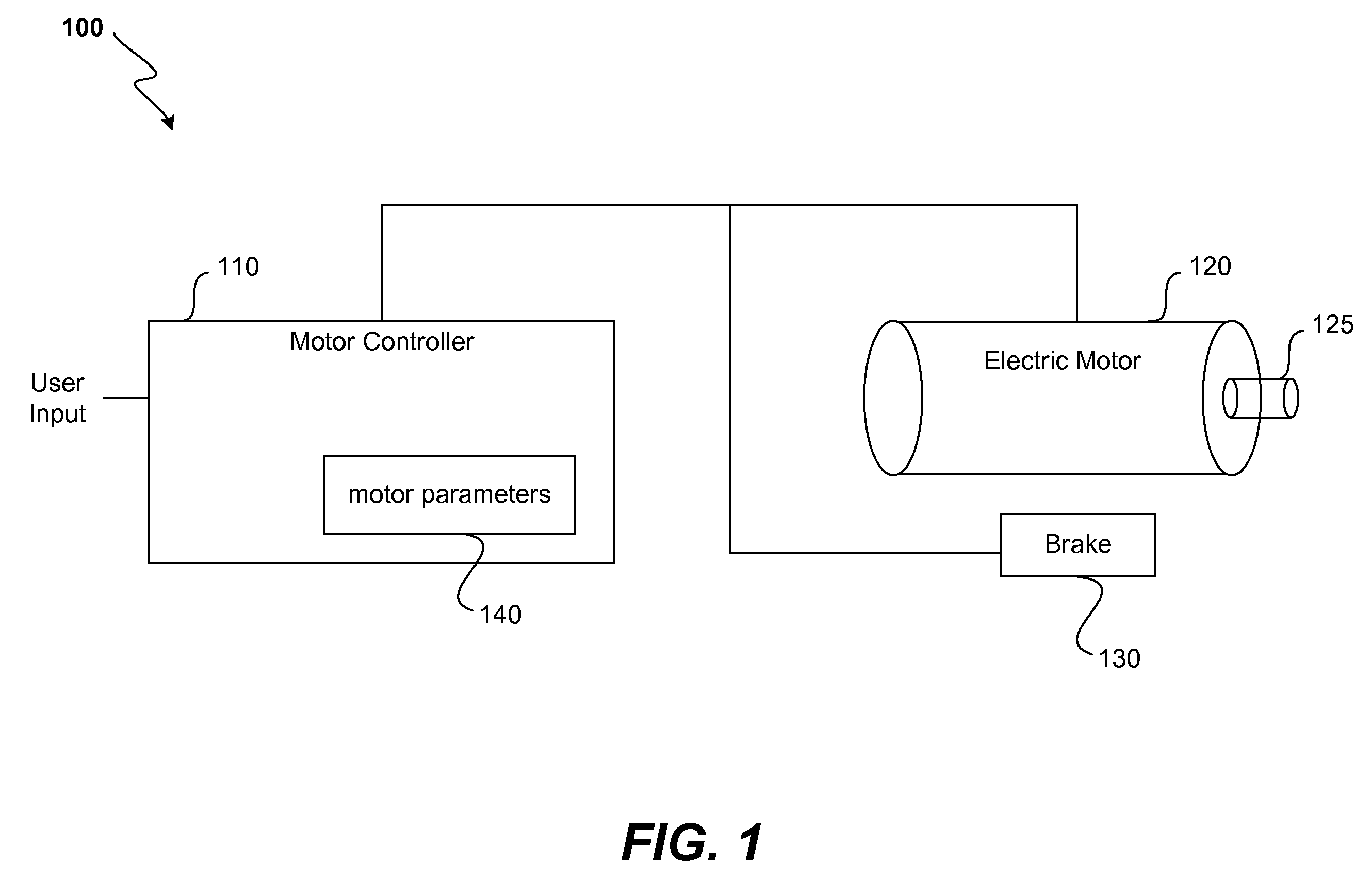

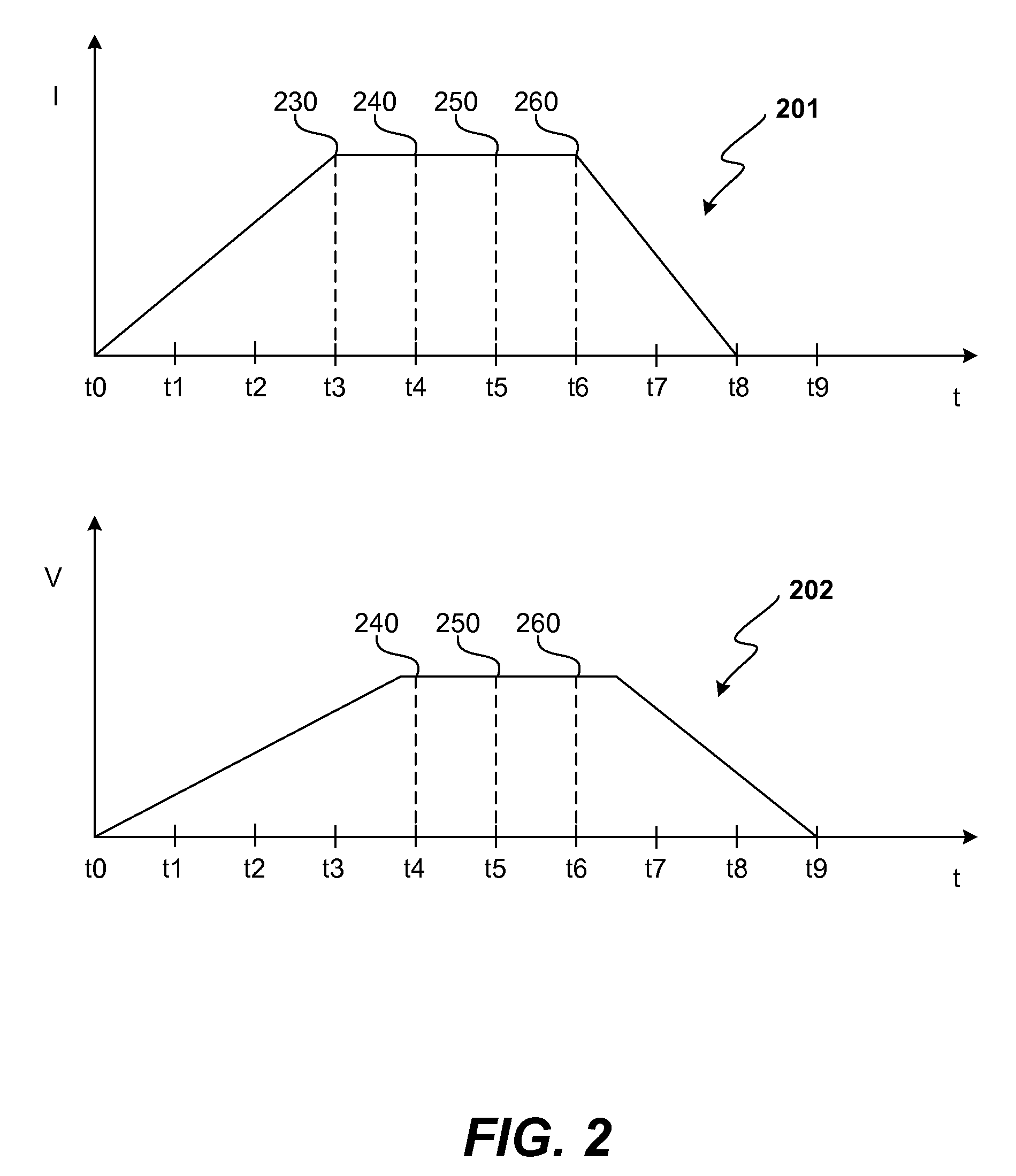

Systems and methods for dynamically compensating motor resistance in electric motors

ActiveUS20100007299A1Reduce trafficEasy to measureHybrid vehiclesMotor/generator/converter stoppersElectrical resistance and conductanceMotor controller

Electric motor controllers that dynamically adjust a motor resistance parameter are described. In order to adjust the motor resistance parameter, power is applied the electric motor while the controlled vehicle is stopped and its brake is set so that the vehicle remains stopped while a measurement is taken that can be used to determine motor resistance. A new motor resistance value is then generated based at least in part upon the measurement(s) and the motor resistance parameter is set to the new motor resistance value. The new motor resistance parameter may then be used in the control of the electric motor. In some embodiments, the measurements are taken after the controller receives a brake release request but before actually releasing the brake. The described arrangement can be used in a wide variety of motor controllers and is especially well suited for use in low cost controllers that control motors that are susceptible to wide variations in their resistance such as brushed permanent magnet DC motors.

Owner:CURTIS INSTRUMENTS INC

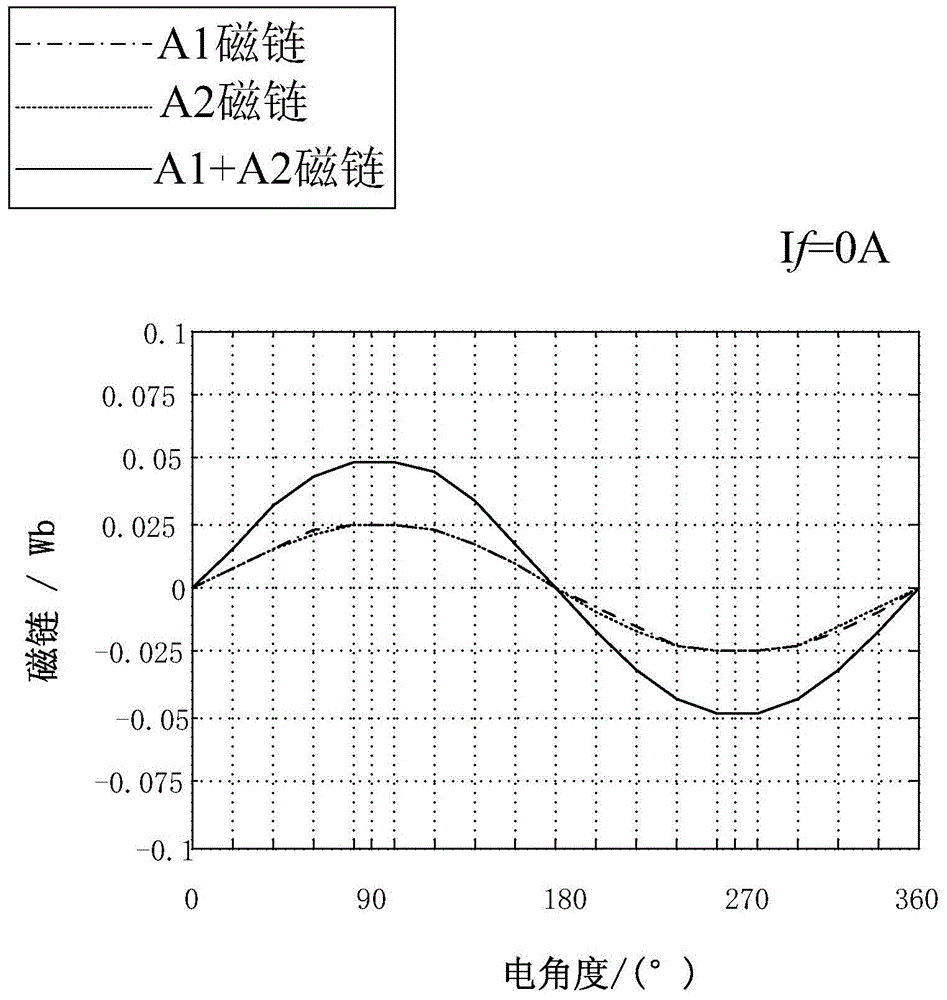

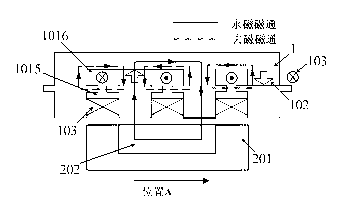

Mixed excitation flux switching motor

InactiveCN104539125AImprove power densityImprove efficiencySynchronous machine detailsMagnetic circuit rotating partsPower flowExcitation current

The invention relates to a mixed excitation flux switching motor which comprises a stator and a rotor, wherein multiple salient poles are uniformly distributed on the rotor; the stator comprises 12 H-shaped iron cores, 12 tangentially magnetizing permanent magnets, armature windings and exciting windings; the H-shaped iron cores and the permanent magnets are alternatively arranged; the magnetizing directions of two adjacent permanent magnets are opposite to each other; the exciting winding is wound on yoke retained magnetic bridges of the H-shaped iron cores; the exciting current directions applied by the exciting windings on two adjacent yoke retained magnetic bridges are opposite to each other; and each armature winding is arranged a stator pole consisting of two adjacent H-shaped iron cores and the sandwiched permanent magnet. According to the mixed excitation flux switching motor disclosed by the invention, the advantages of a flux switching permanent magnet motor are remained, extra copper consumption is not needed, the maximum gap flux density, torque and the like can be obtained, and the switching motor is good in adjustable flux performance and easy to process.

Owner:SHANGHAI DIANJI UNIV

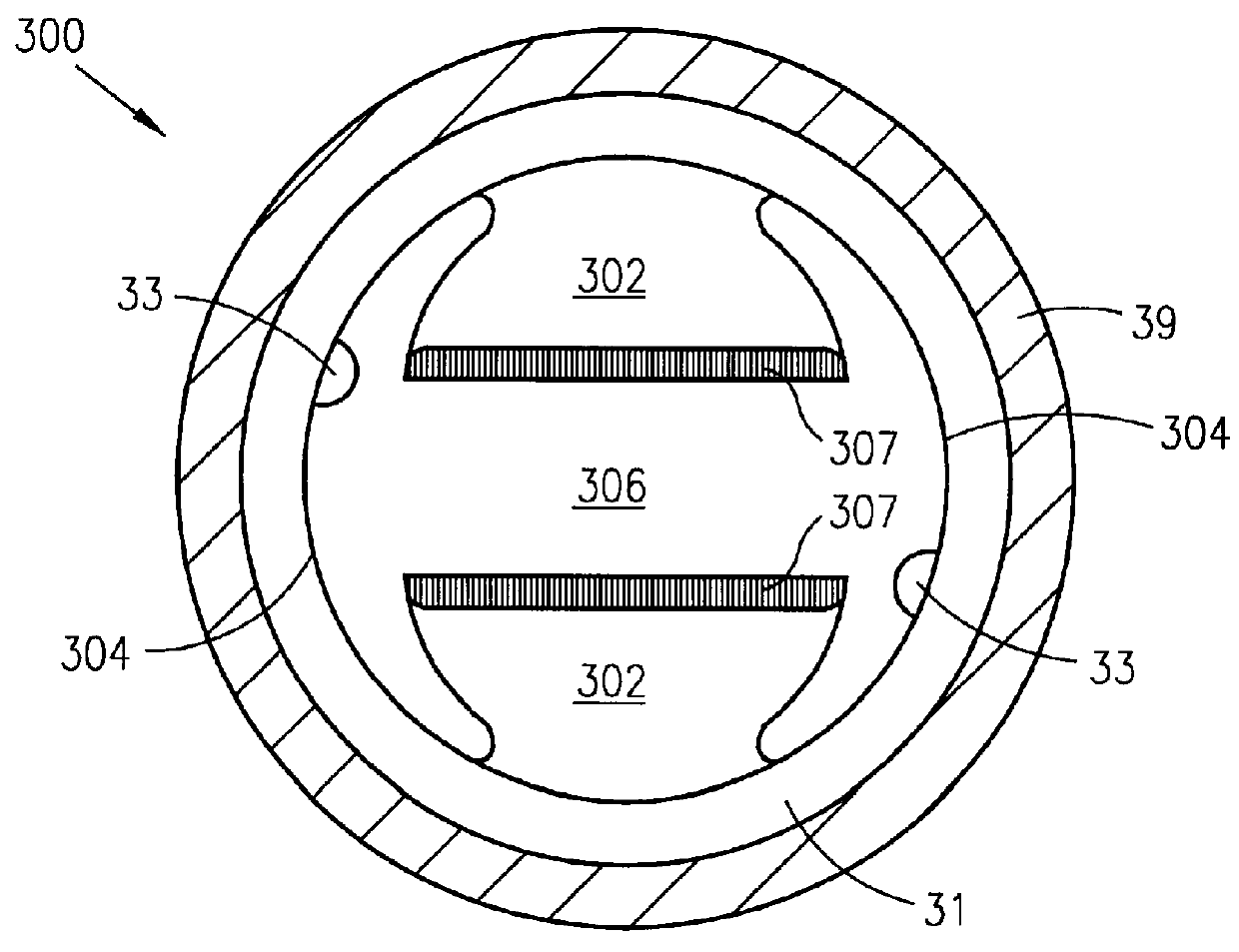

Method of magnetizing a ring-shaped magnet

InactiveUS6080352AAvoid missingLow costOther chemical processesInorganic material magnetismDetentMagnetization

A brushless permanent-magnet direct current motor has a permanent magnet which is magnetized to create an offset angle between detent and mutual torques for providing sufficient starting torque for all relative orientations between the stator and the rotor of the motor. This is accomplished by providing a permanent magnet in which the global magnetization of the magnet has been disrupted by the application of a local magnetic field to a portion of the magnet, thereby to provide a magnetic anomaly in the global magnetization. Also, a method of magnetization of the magnet is described.

Owner:SEAGATE TECH LLC

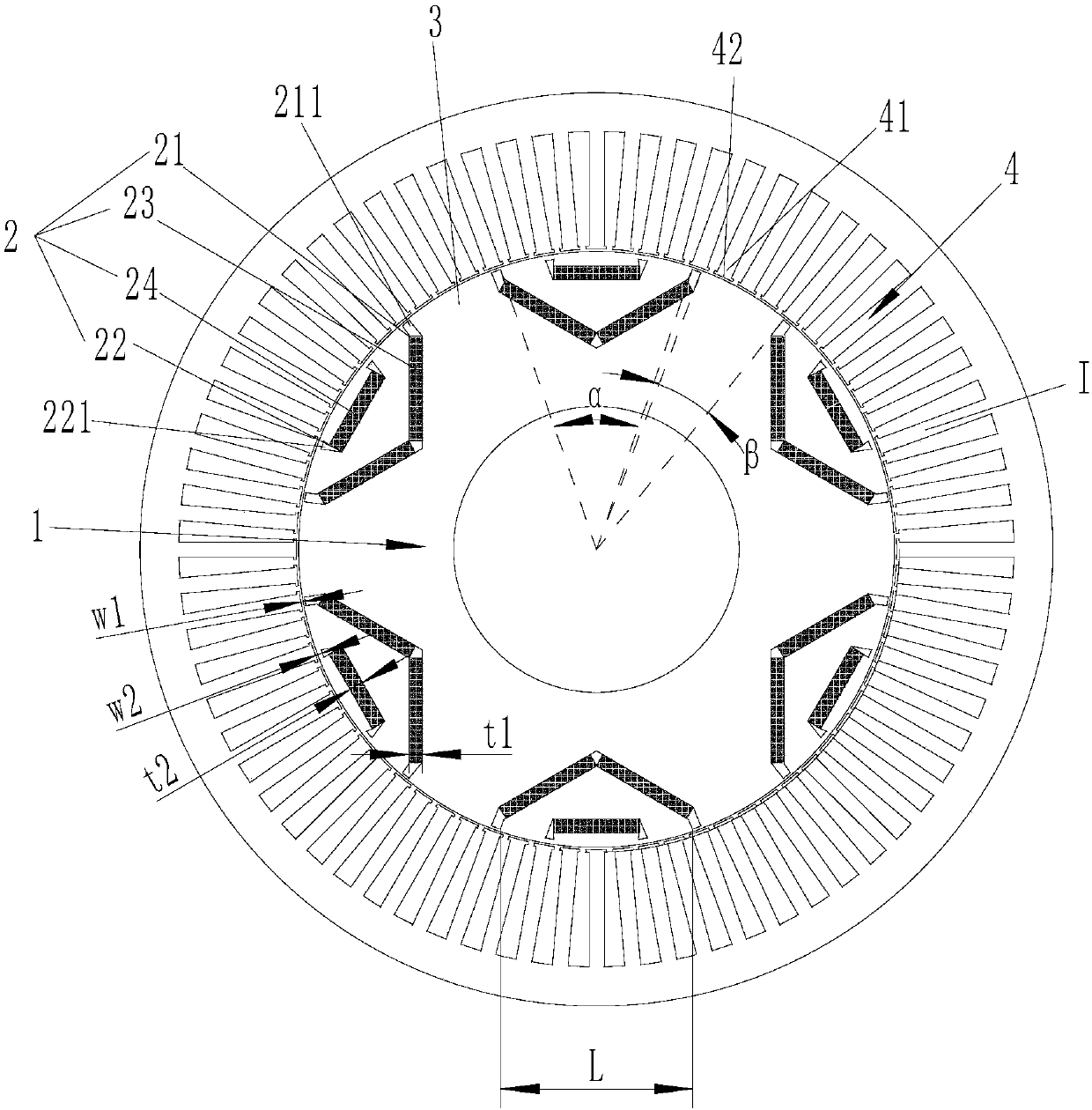

Built-in magnetic barrier type magnetic field enhanced permanent magnet brushless motor

ActiveCN106026597AIncrease profitModerate thicknessMagnetic circuit rotating partsSynchronous machine detailsMagnetic barrierBrushless motors

The invention discloses a built-in magnetic barrier type magnetic field enhanced permanent magnet brushless motor, comprising a stator and a rotor coaxially sleeved inside the stator. The rotor is evenly embedded with a plurality of pairs of permanent magnetic steels along the circumference, and each pair of the permanent magnetic steels are composed of two blocks of neodymium iron boron permanent steels of the same rectangular structure and placed in a V manner. The V-shaped opening faces an air gap and the adjacent two pairs of permanent magnetic steels are arranged symmetrically on the two sides of a cross axis; the inner part of the rotor between adjacent two pairs of permanent magnetic steels is provided with a first group of arc shaped built-in magnetic barriers whose arc openings face the air gap; a second group of arc shaped built-in magnetic barriers and a third group of arc shaped built-in magnetic barriers whose arc openings face the air gap and whose structures are identical and are symmetrically arranged around a straight axis are arranged between the two neodymium iron boron permanent steels of each pair of the permanent magnetic steels. Each group of the arc shaped built-in magnetic barriers contains an inner magnetic barrier and an outer magnetic barrier. The adjacent two pairs of permanent magnetic steels alternate for tangential magnetization, and the tangential magnetization directions of two blocks of neodymium iron boron permanent steels in each pair of the permanent magnetic steels are opposite to each other, which improves the driving performance and reliability of the motor.

Owner:SUMEC HARDWARE & TOOLS

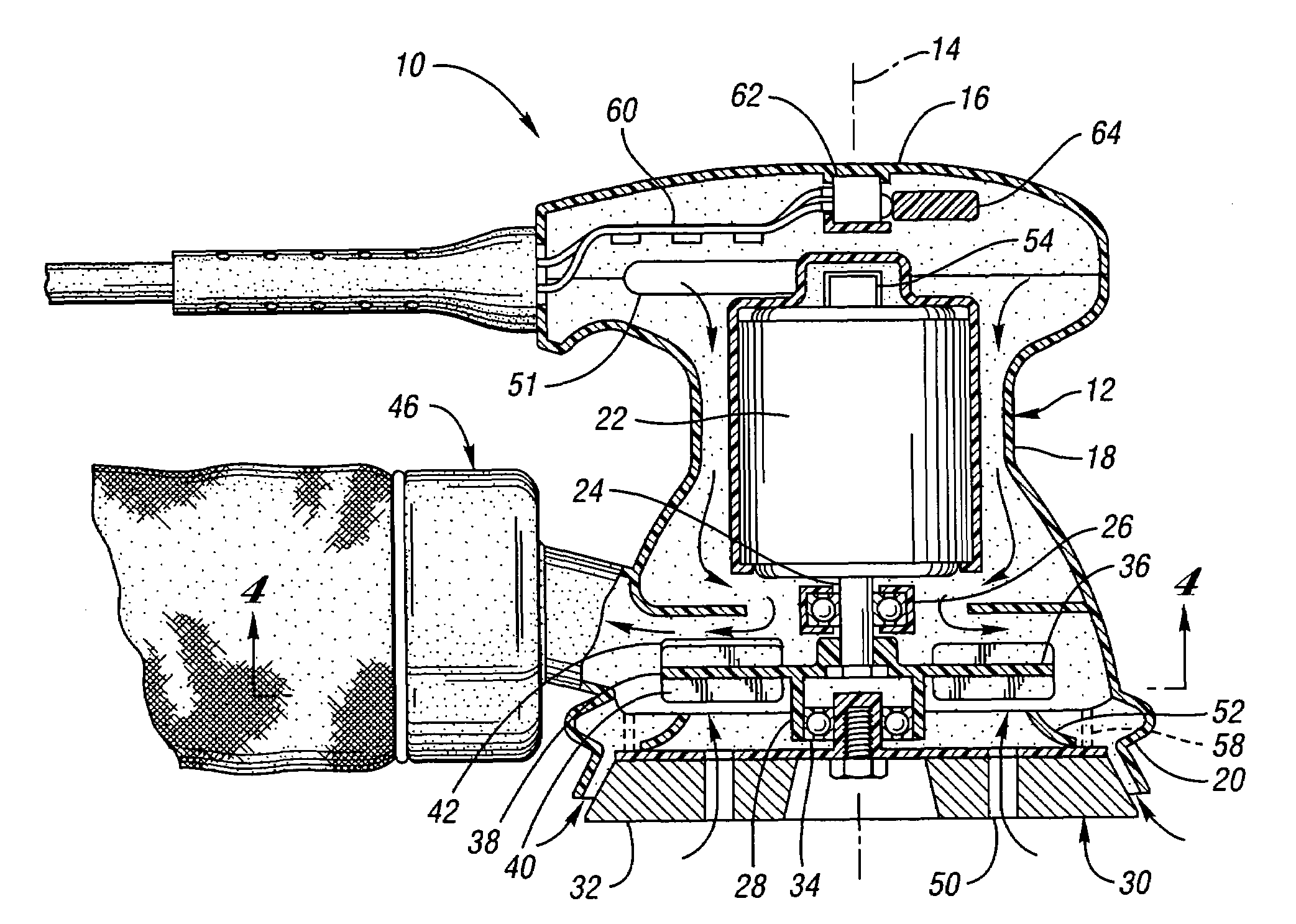

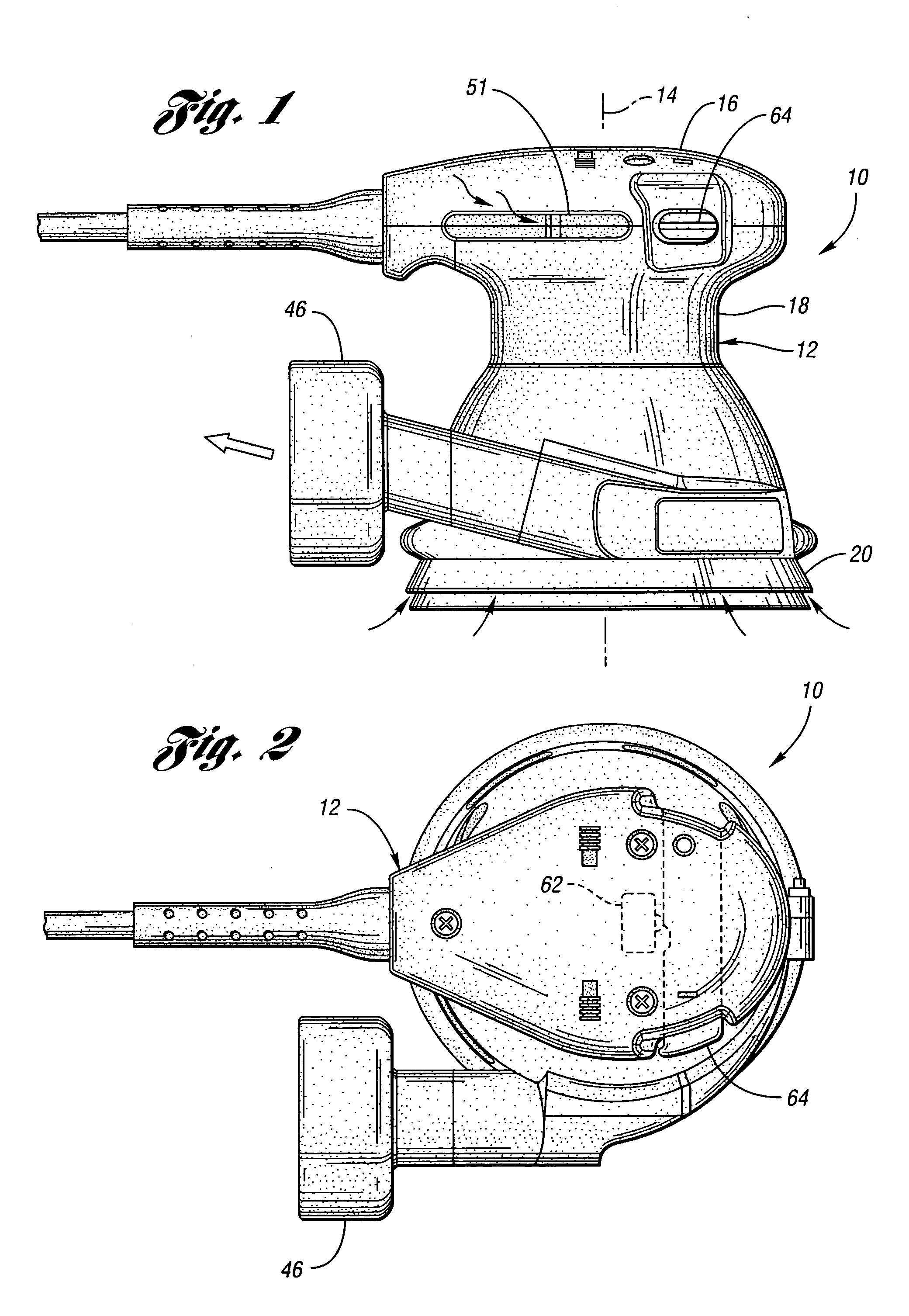

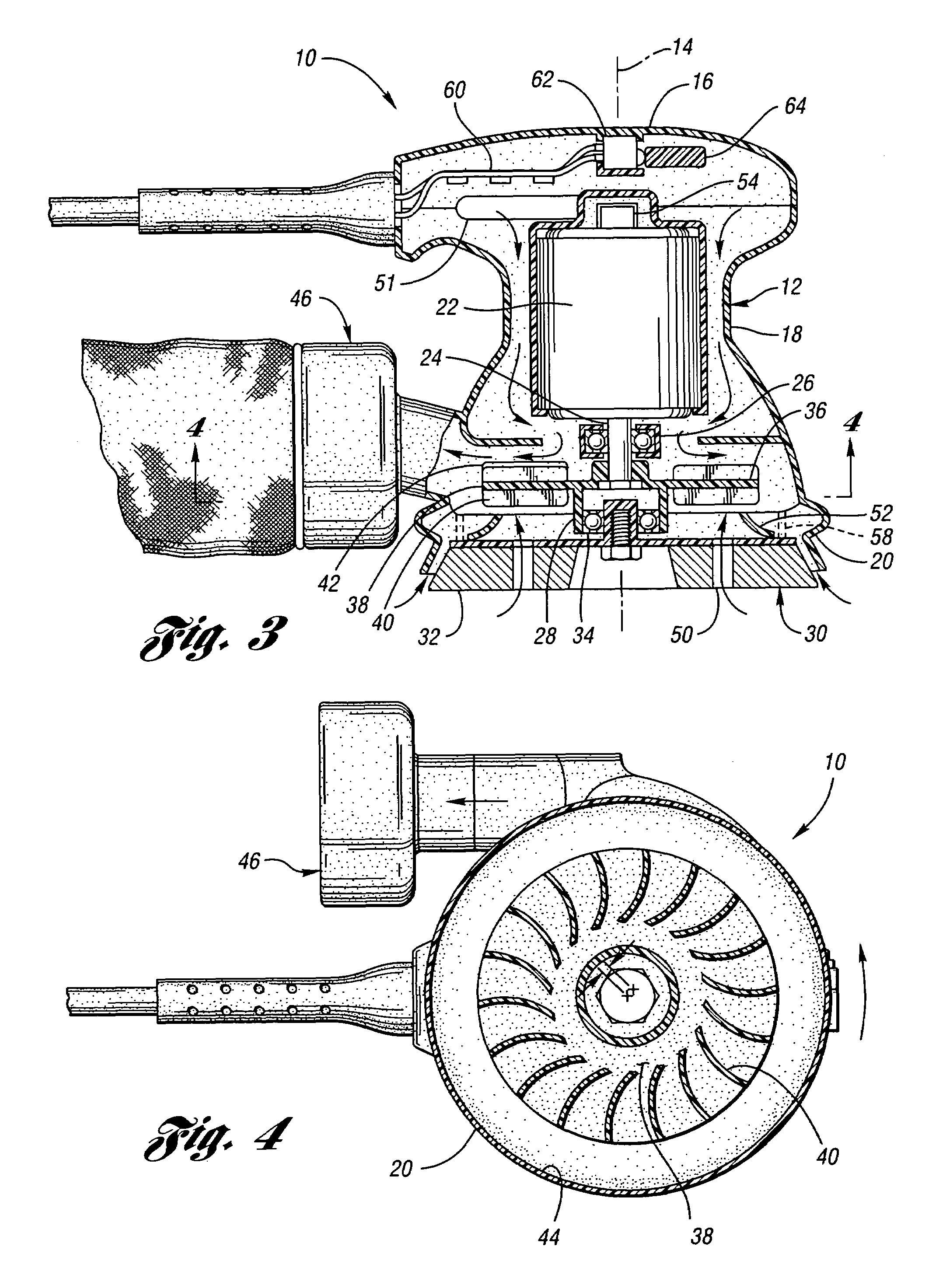

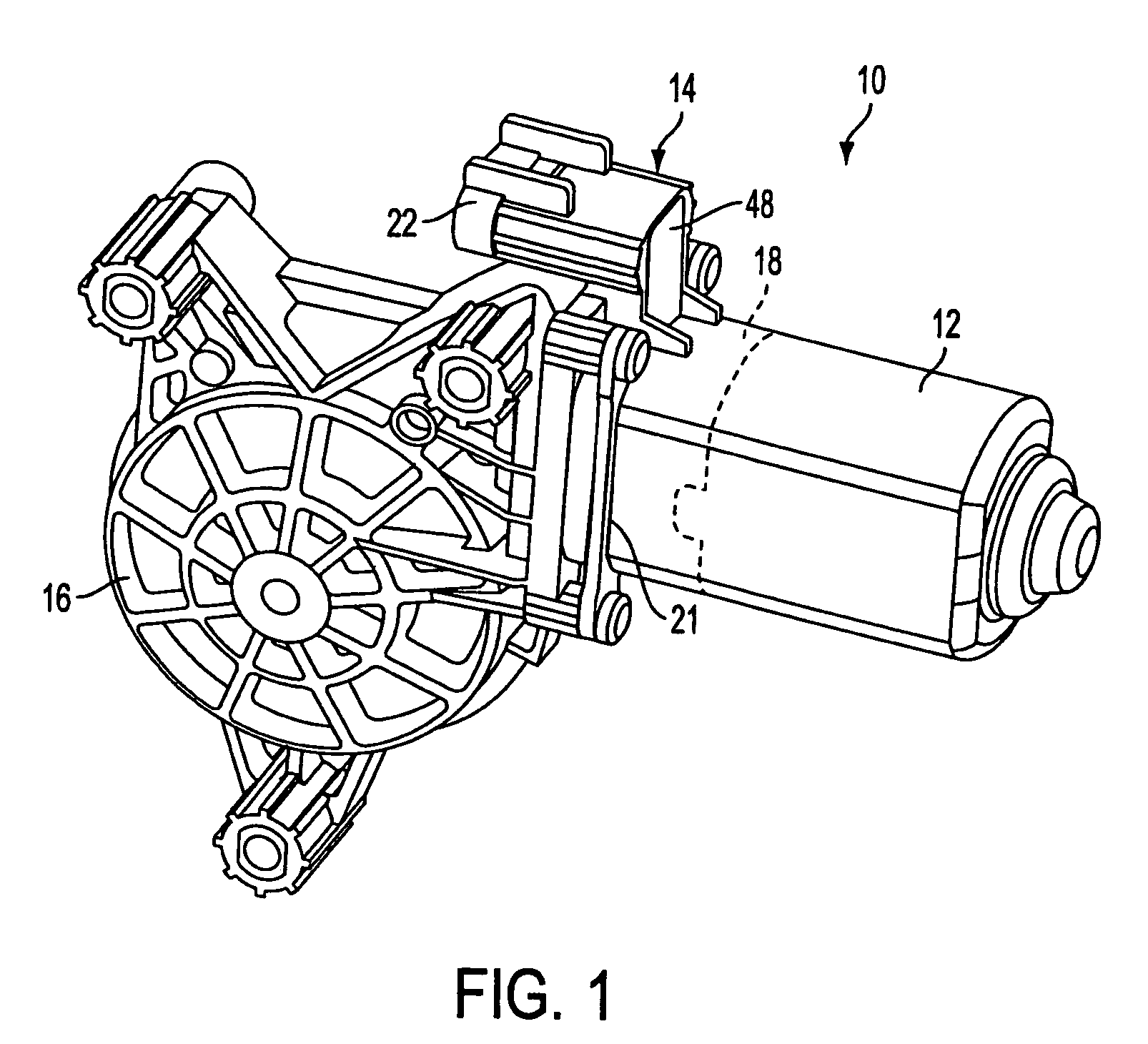

Orbital sander

InactiveUS7270598B2Avoid violationsEasy to useGrinding machine componentsPortable grinding machinesSanderEngineering

Owner:EASTWAY FAIR

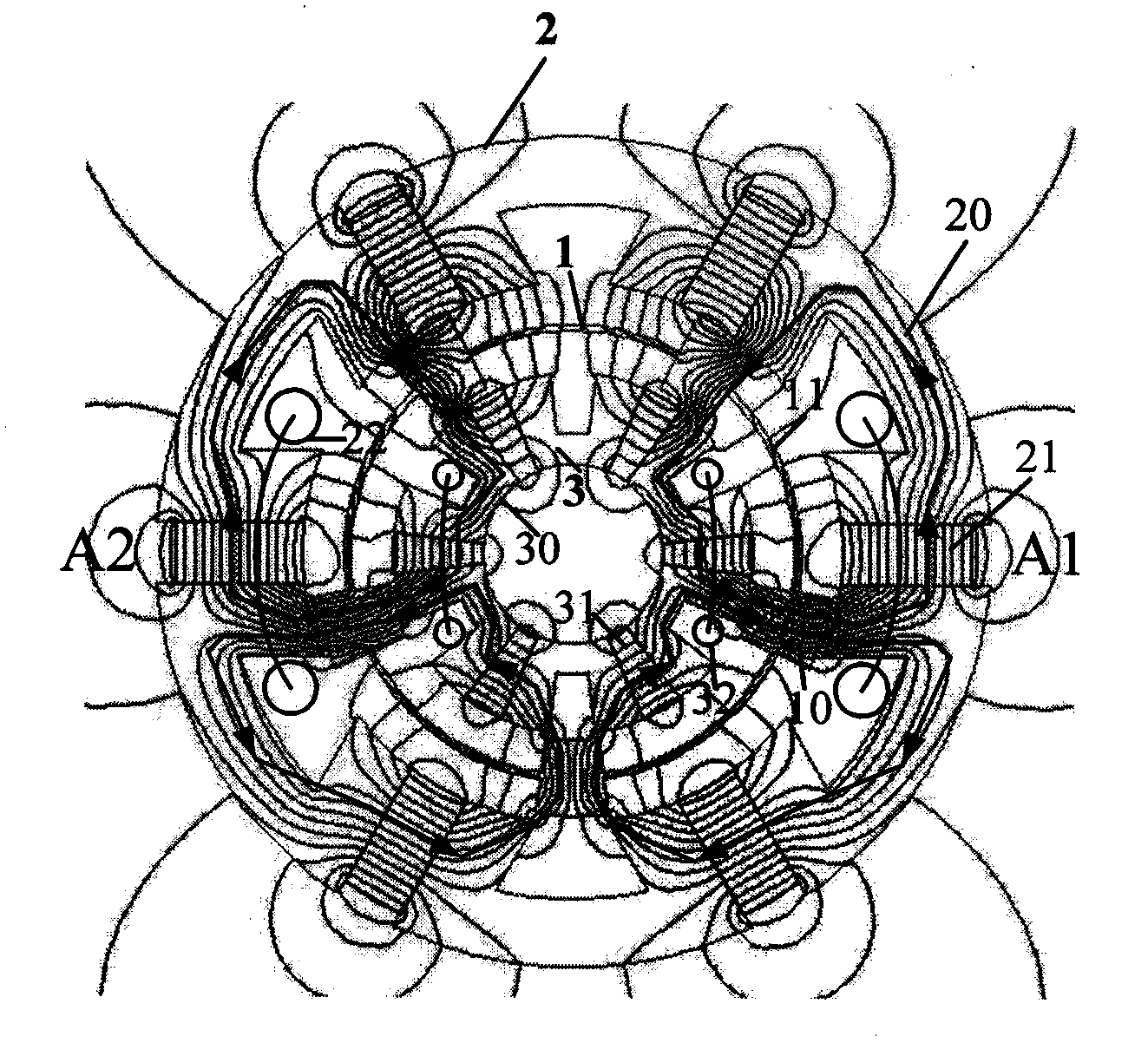

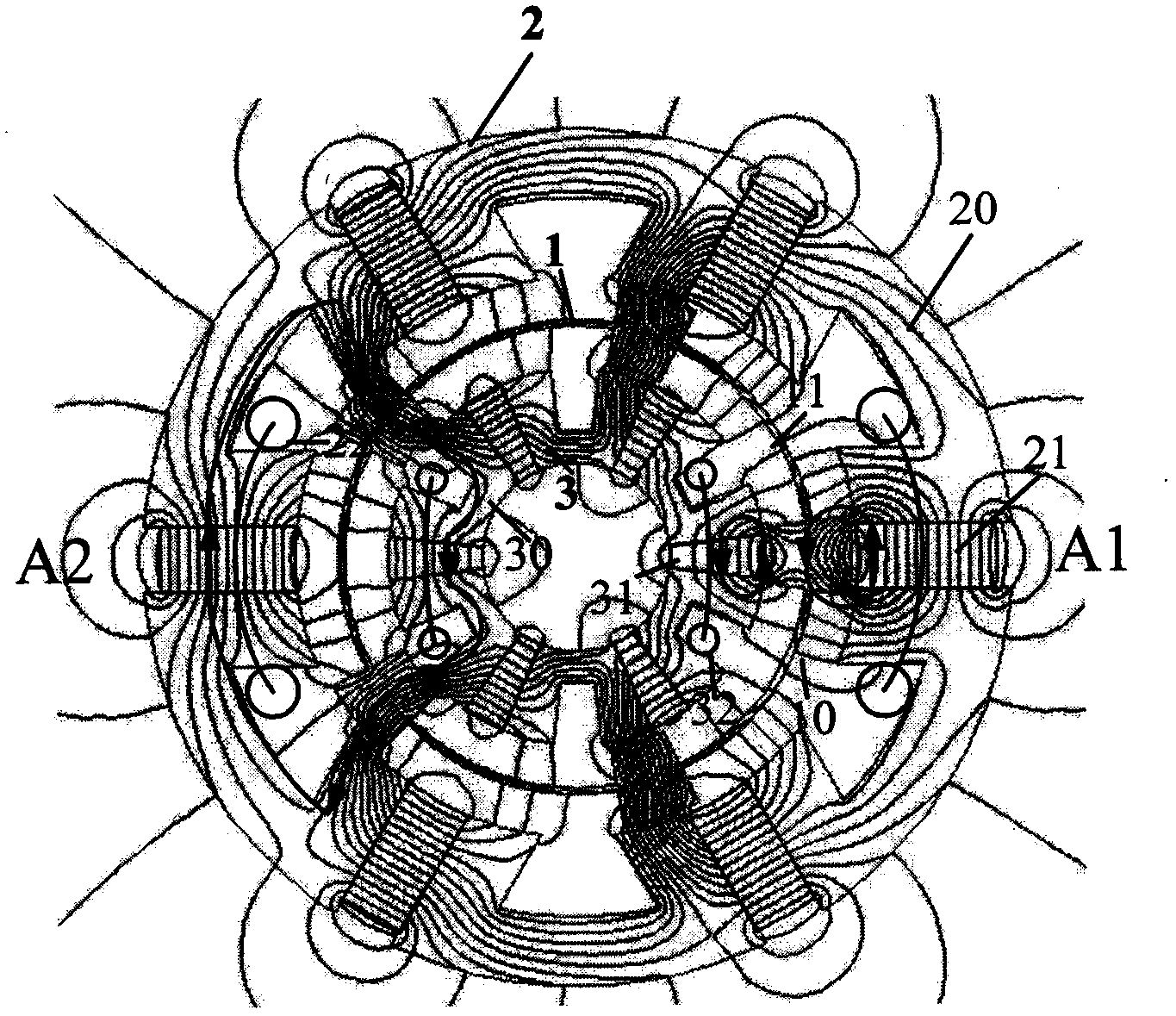

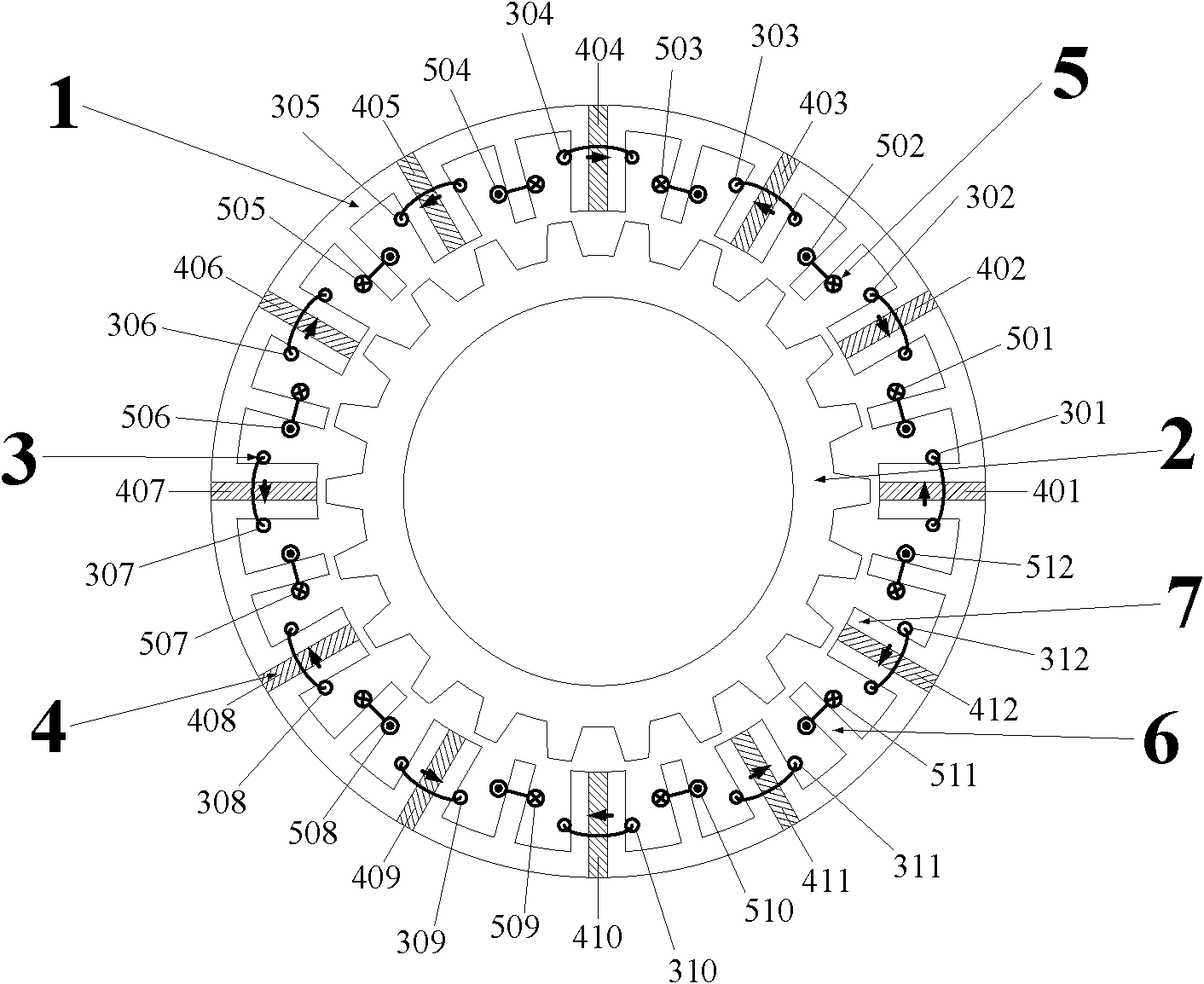

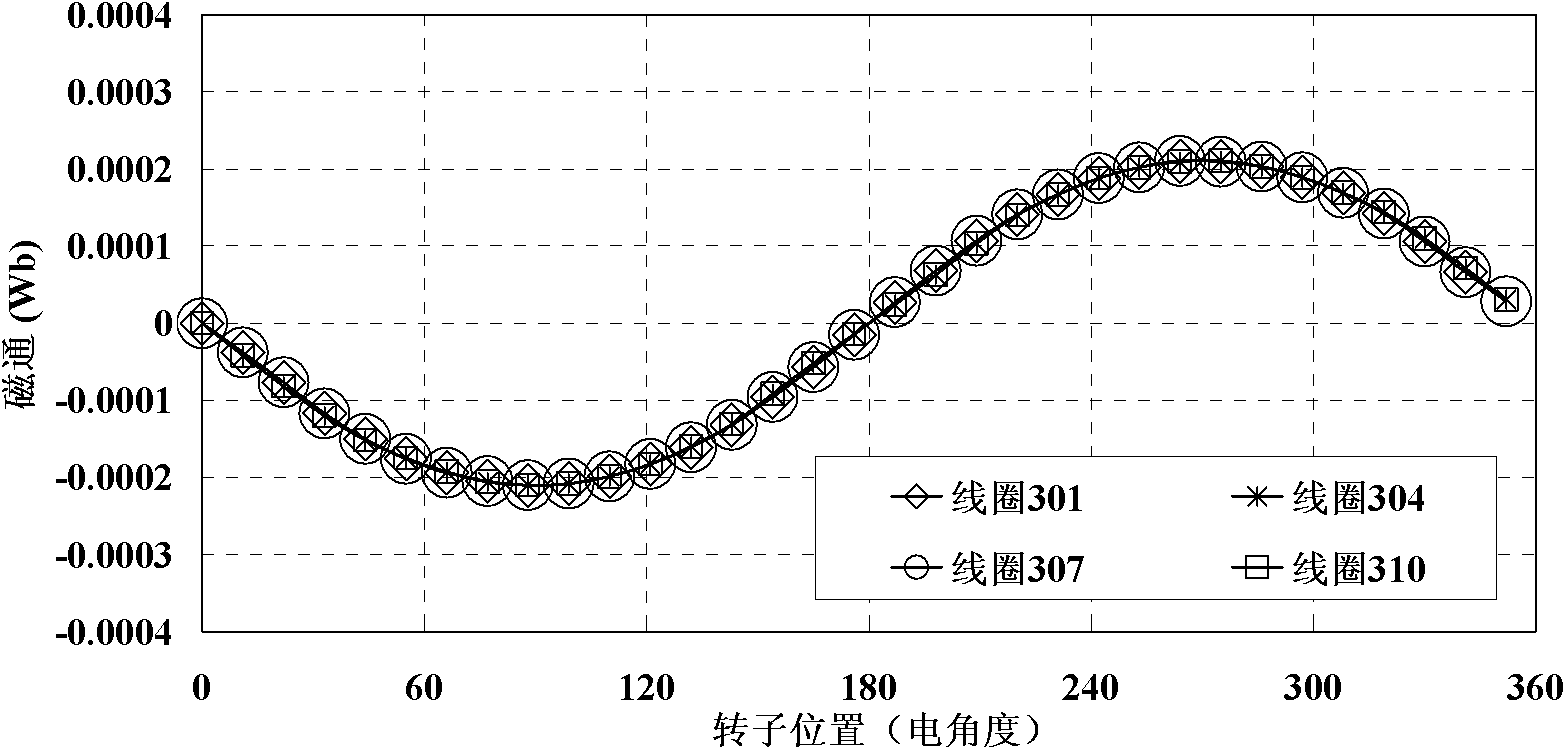

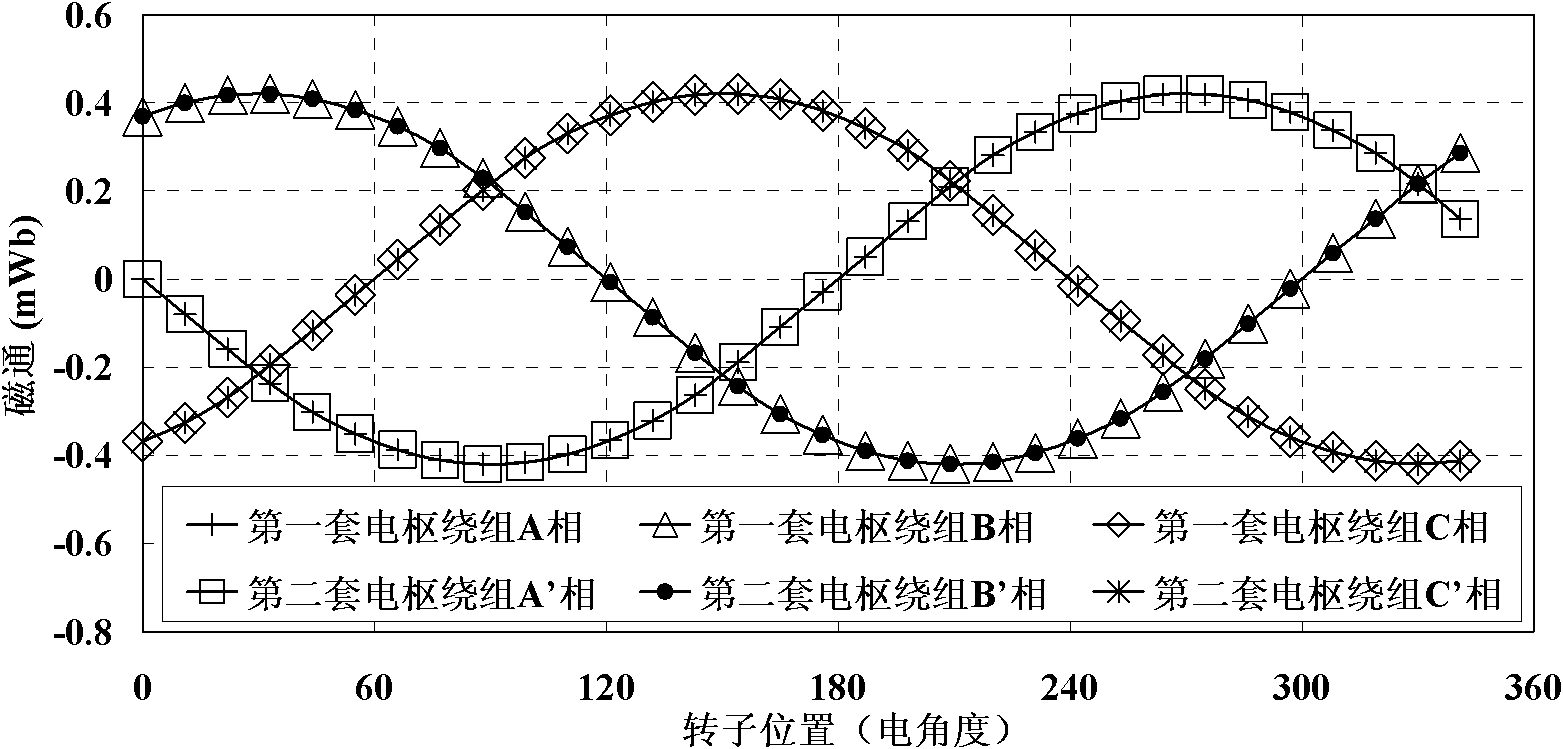

A Redundant Excitation Double Armature Winding Multiphase Flux Switching Motor with Fault Tolerant Teeth

ActiveCN102290883AImprove fault toleranceOvercoming irreconcilable difficultiesMagnetic circuit stationary partsWindings conductor shape/form/constructionFault toleranceElectric machine

The invention discloses a redundant excitation double-armature winding multiphase magnetic flux switching motor with fault-tolerant teeth, which comprises a stator core, a rotor core, 4m armature coils and magnetic exciting coils, wherein the stator core is formed by splicing 4m E-shaped iron core units and 4m permanent magnets in a staggering way; the magnetizing directions of the permanent magnets are tangential; the adjacent magnetizing directions are opposite; a raised tooth in the middle of each E-shaped iron core unit is a stator fault-tolerant tooth; raised teeth at both sides of each E-shaped iron core unit are permanent magnet teeth; one permanent magnet and two permanent magnet teeth which are in contact with the permanent magnet form a stator permanent magnet tooth; the armature coils are sheathed on the stator permanent magnet tooth; the 2m adjacent armature coils form a first set of symmetrical m-phase armature winding; the other 2m armature coils form a second set of symmetrical m-phase armature winding; the magnetic exciting coils are sheathed on a stator fault-tolerance tooth; and the magnetic exciting coils are sequentially connected in series from the head to thetail to form a set of single-phase central excitation winding. Compared with the prior art, the motor has the advantages that the fault tolerance and reliability of the motor are increased and the motor is provided with multiple operating modes.

Owner:SOUTHEAST UNIV

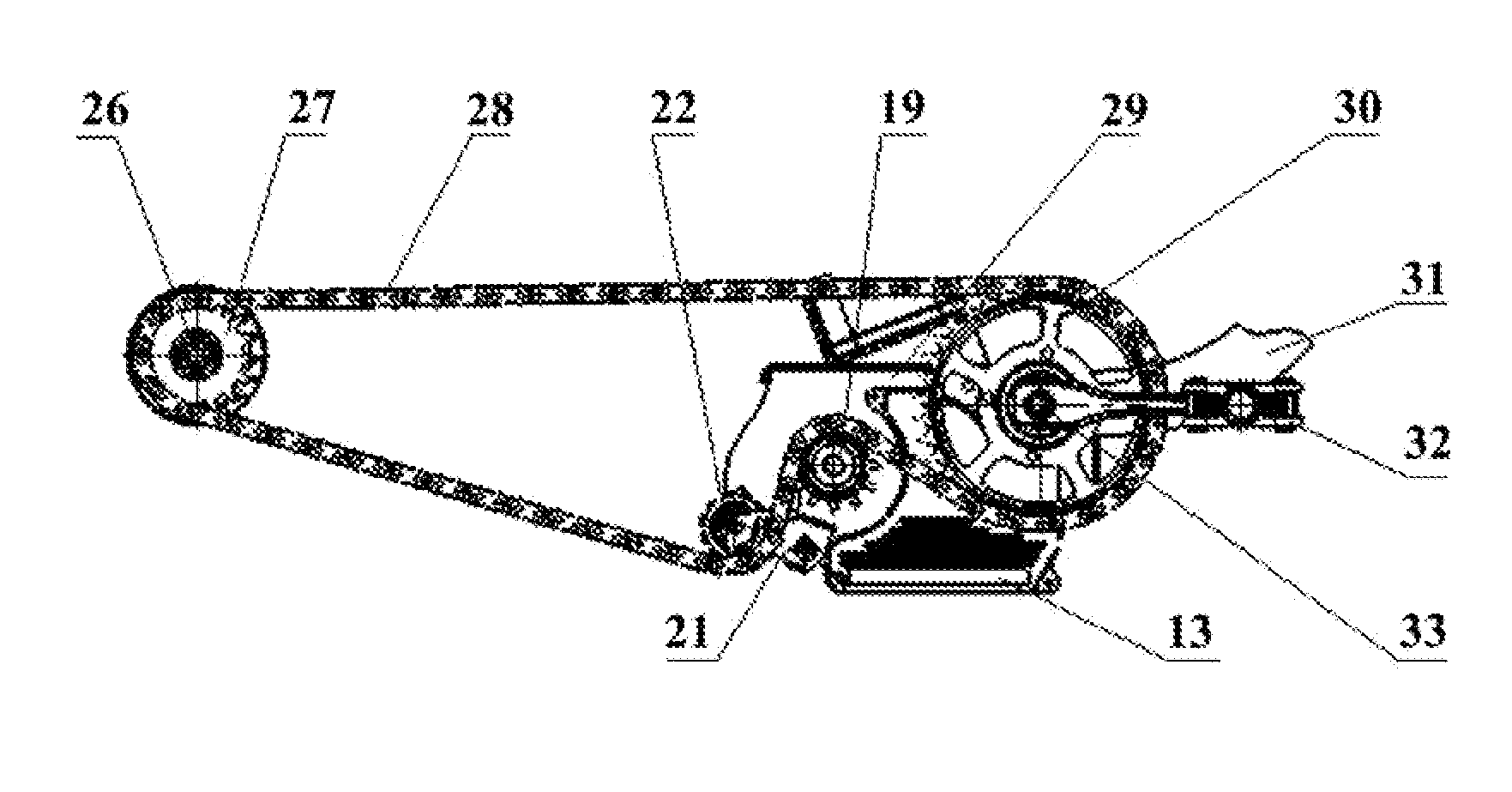

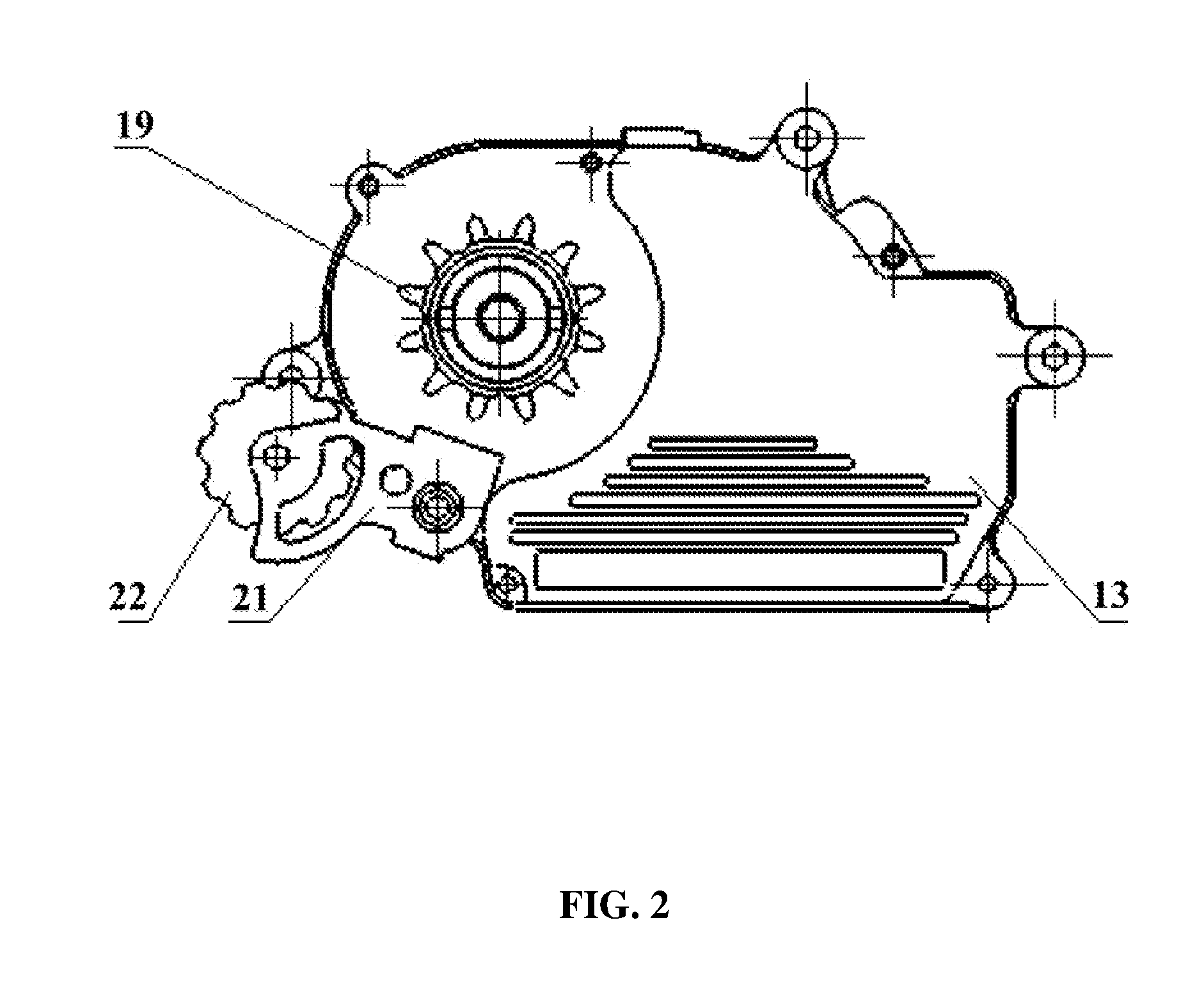

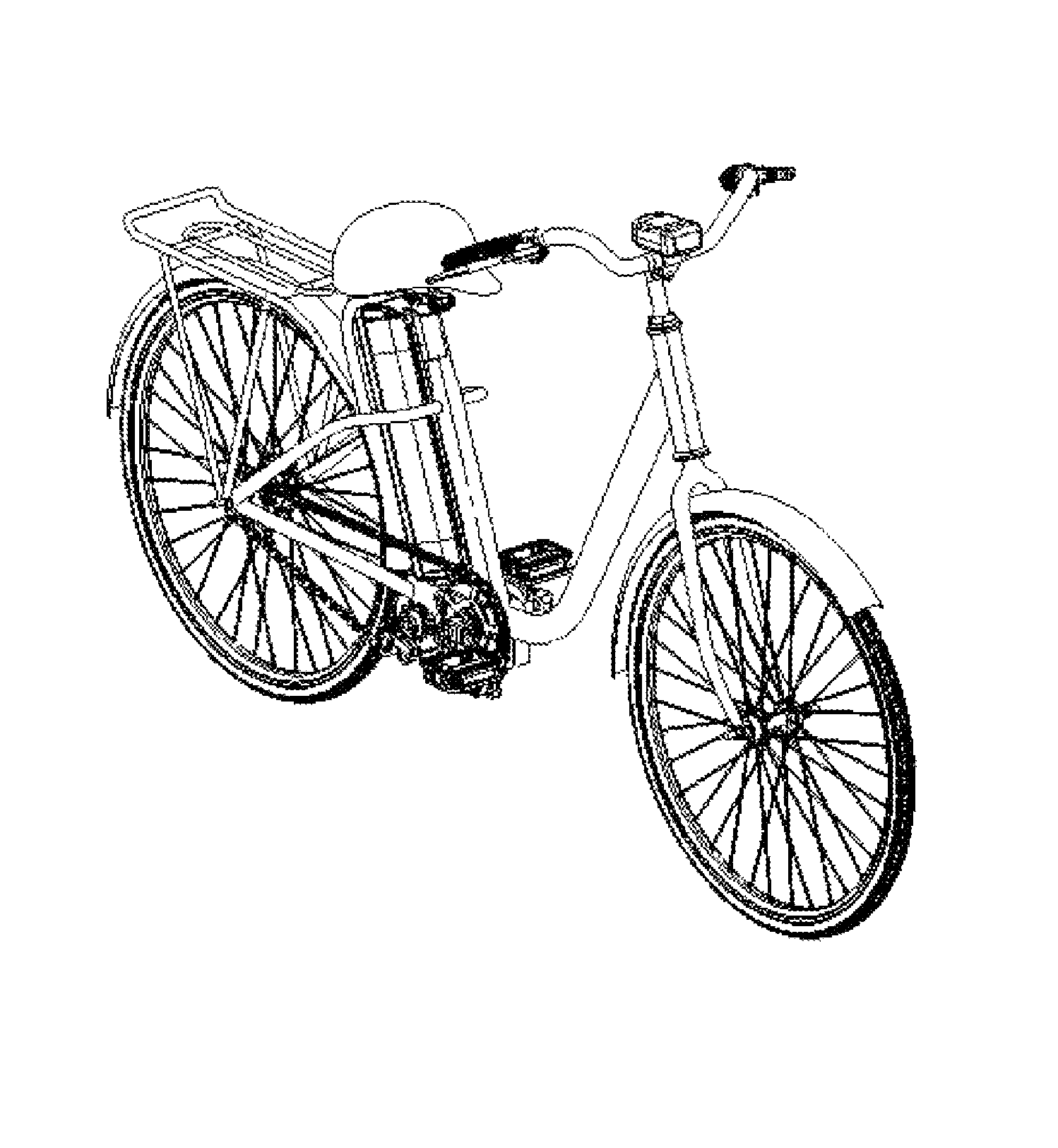

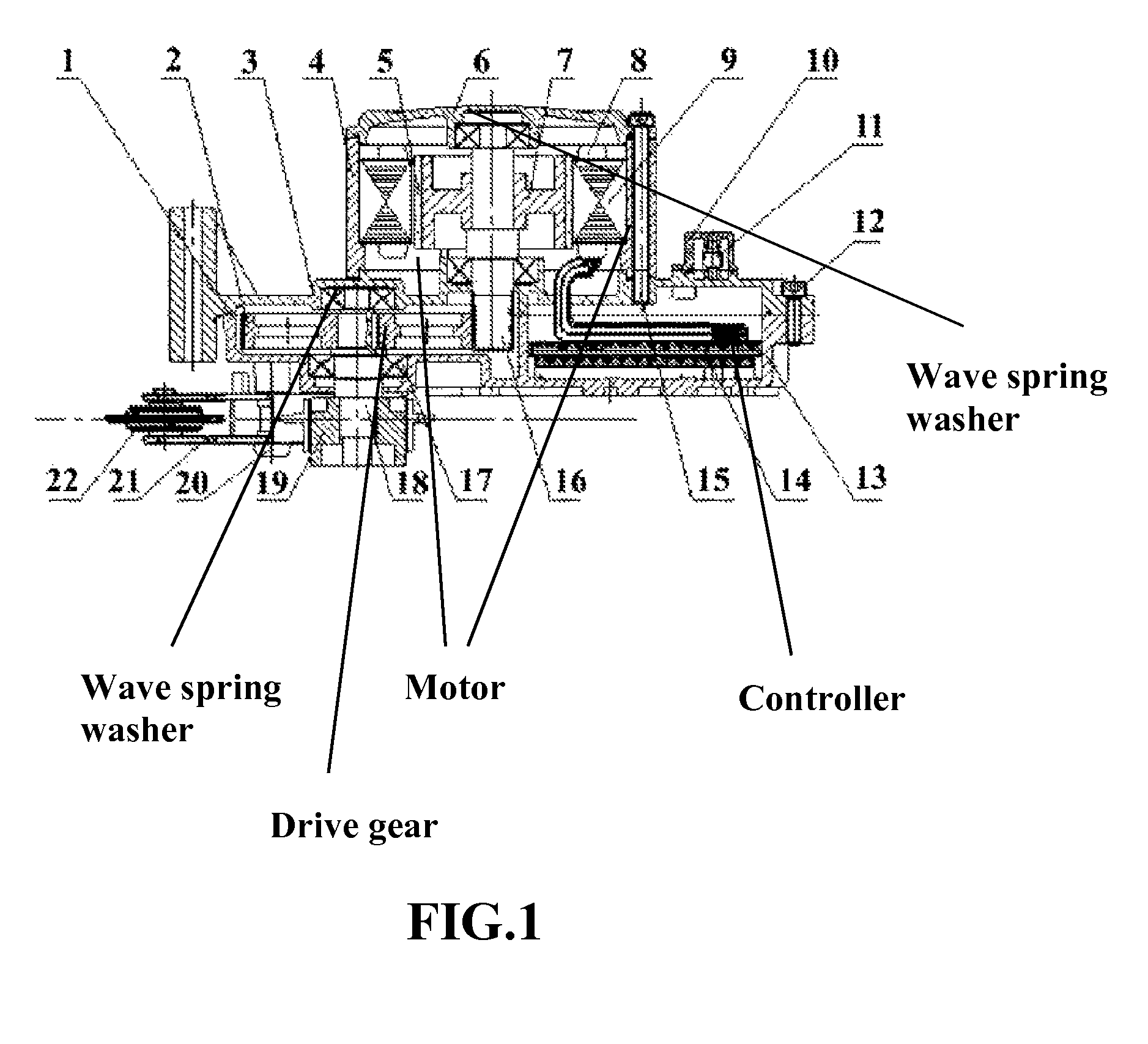

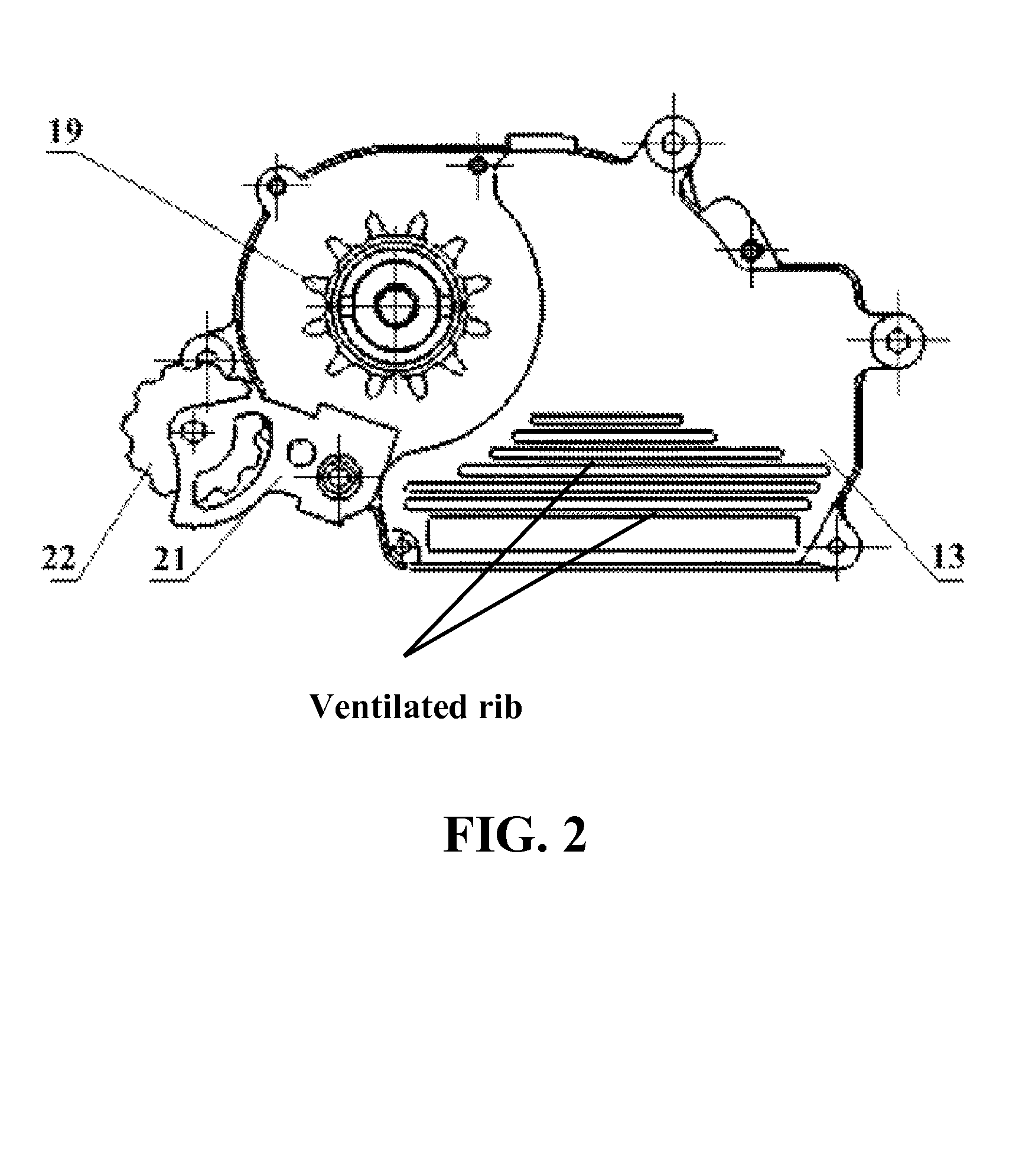

Middle electric motor drive unit for electric bicycle

InactiveUS20110168472A1Reduce drive costsLow production costSpeed controllerPropulsion by humans/animalsReducerControl theory

A middle electric motor drive unit for an electric bicycle, including a motor, a controller, a sensor, a gear reducer, a one-way clutch, a chain tightener, and a housing. The middle electric motor drive unit is disposed below a frame of the electric bicycle, and in the vicinity of a pedal shaft thereof. The middle electric motor drive unit is independent from the pedal shaft with respect to functions and structure. The motor is an internal rotor and permanent magnet DC motor. The motor shaft of the motor is parallel to a gear shaft and the pedal shaft. The controller is built-in, and disposed in or on the housing. The sensor is an internal sensor or an external pedal shaft sensor.

Owner:TIANJIN MINGDU TECH CO LTD

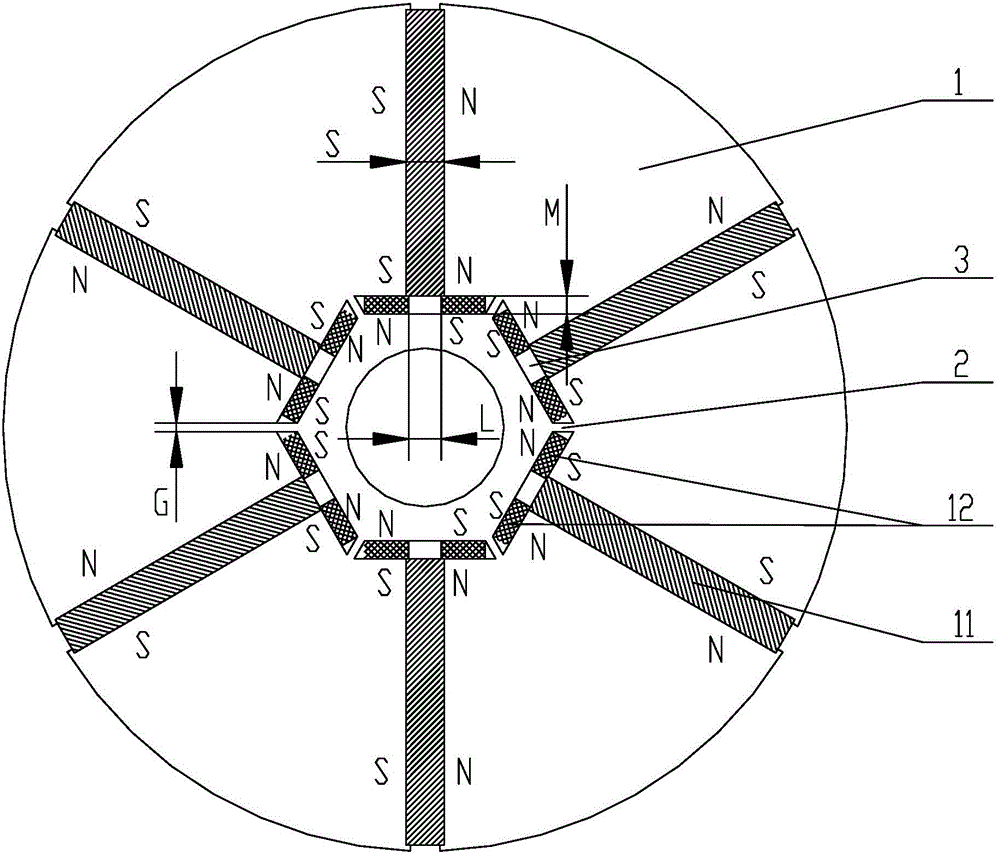

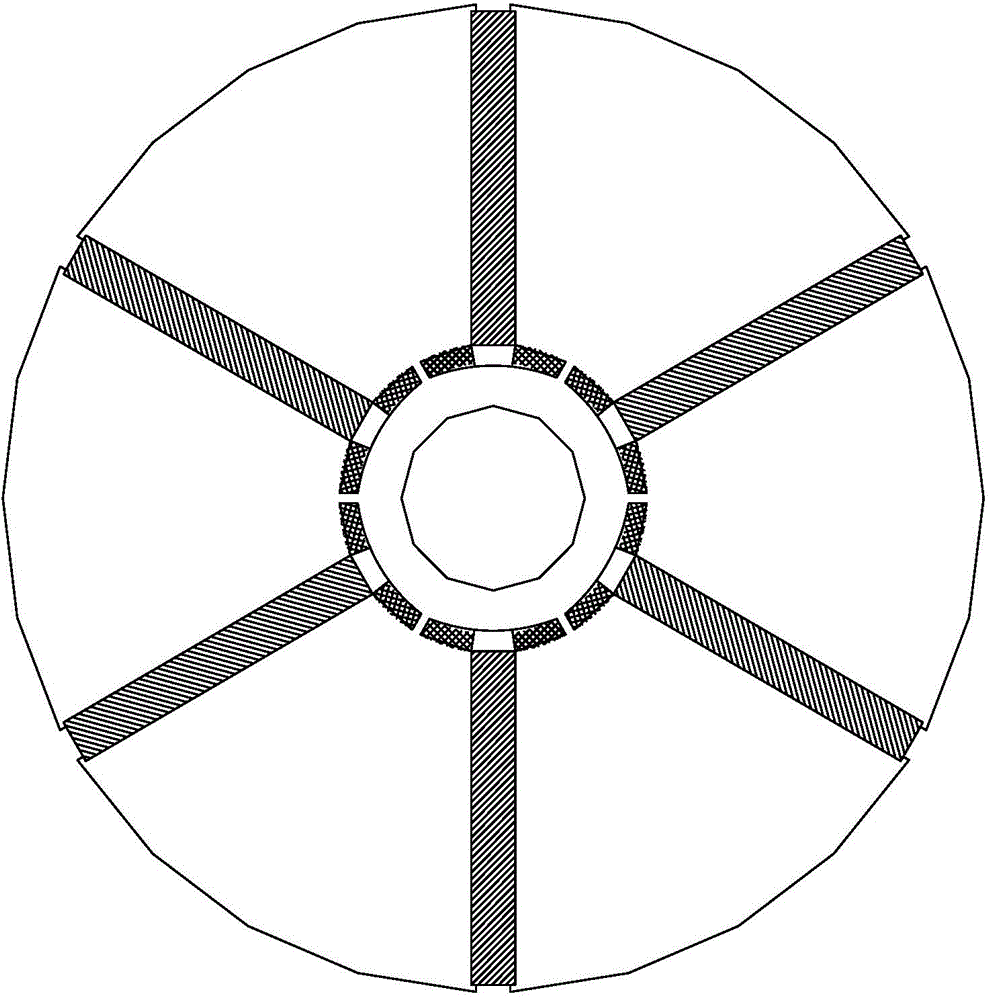

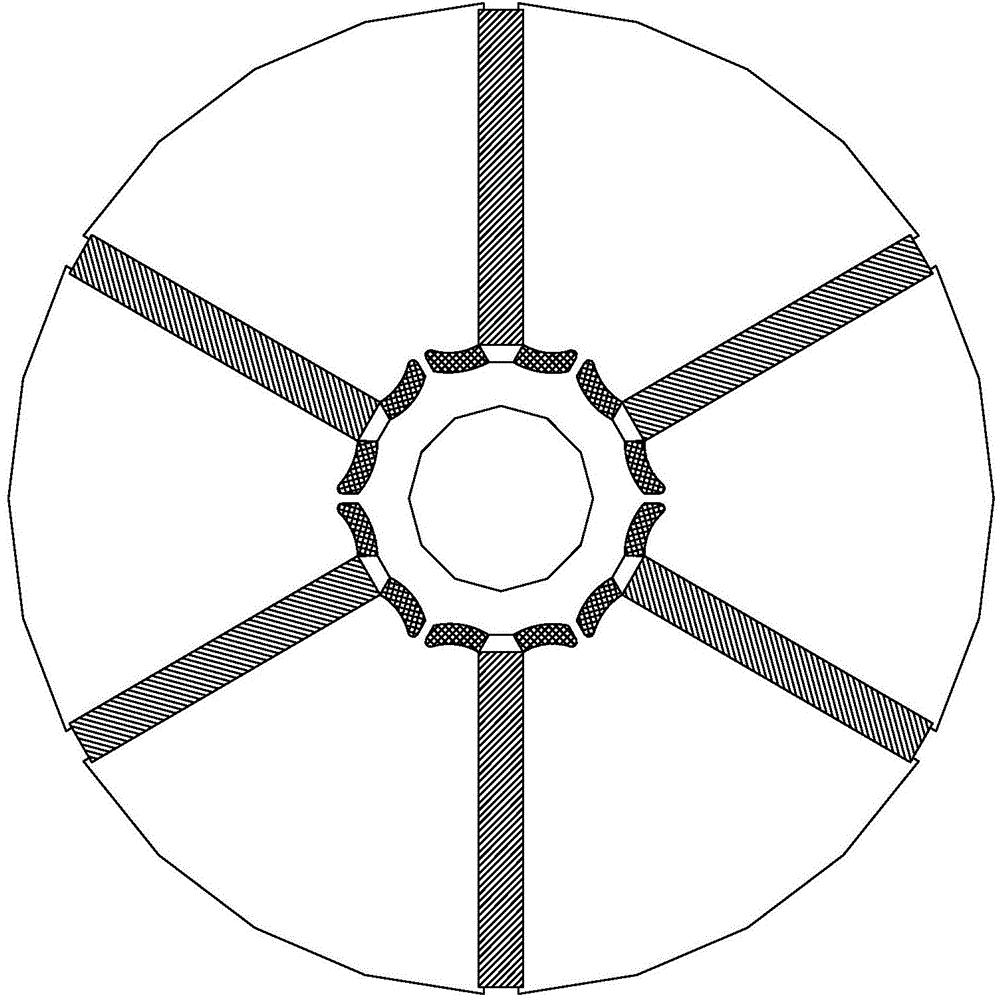

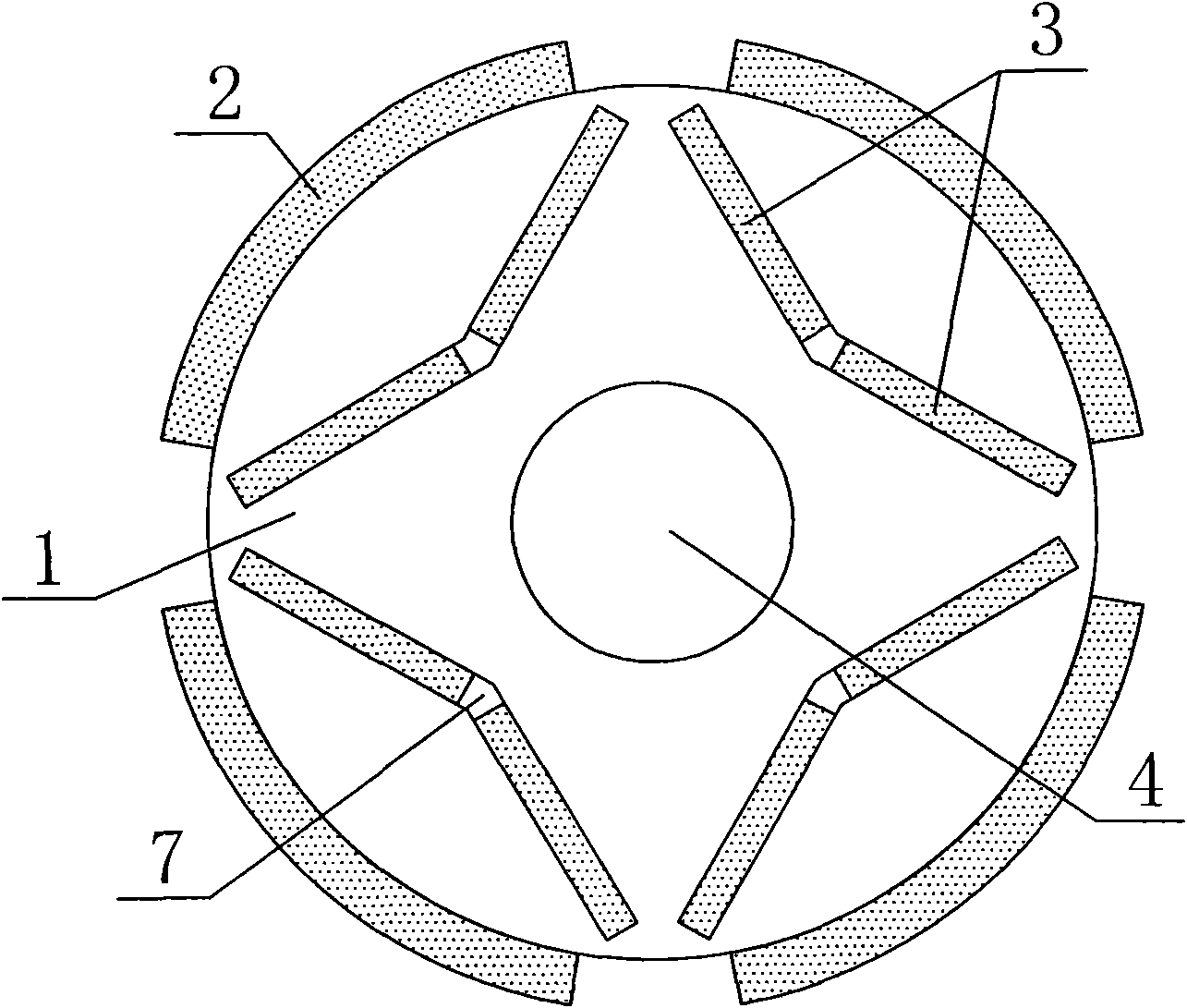

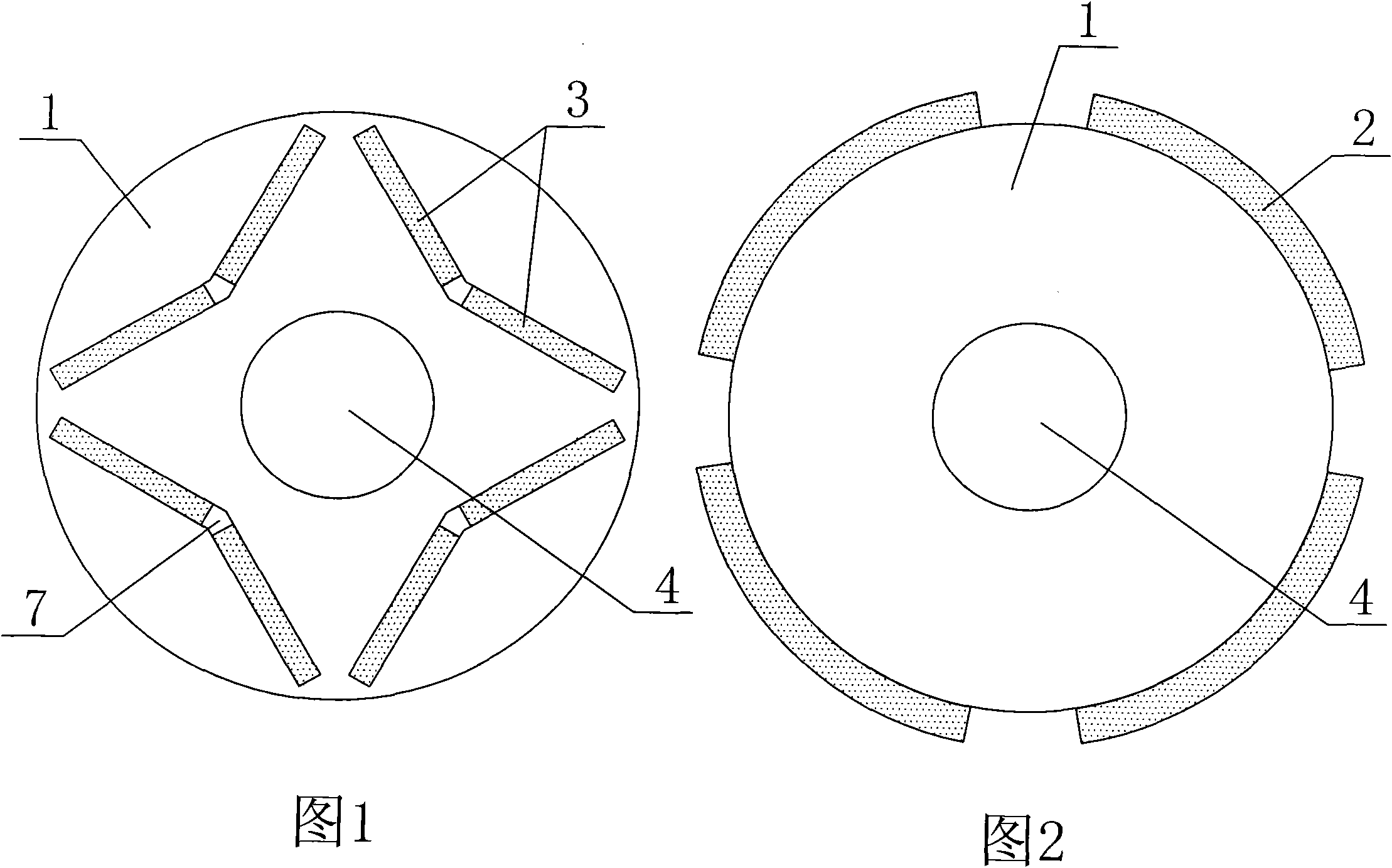

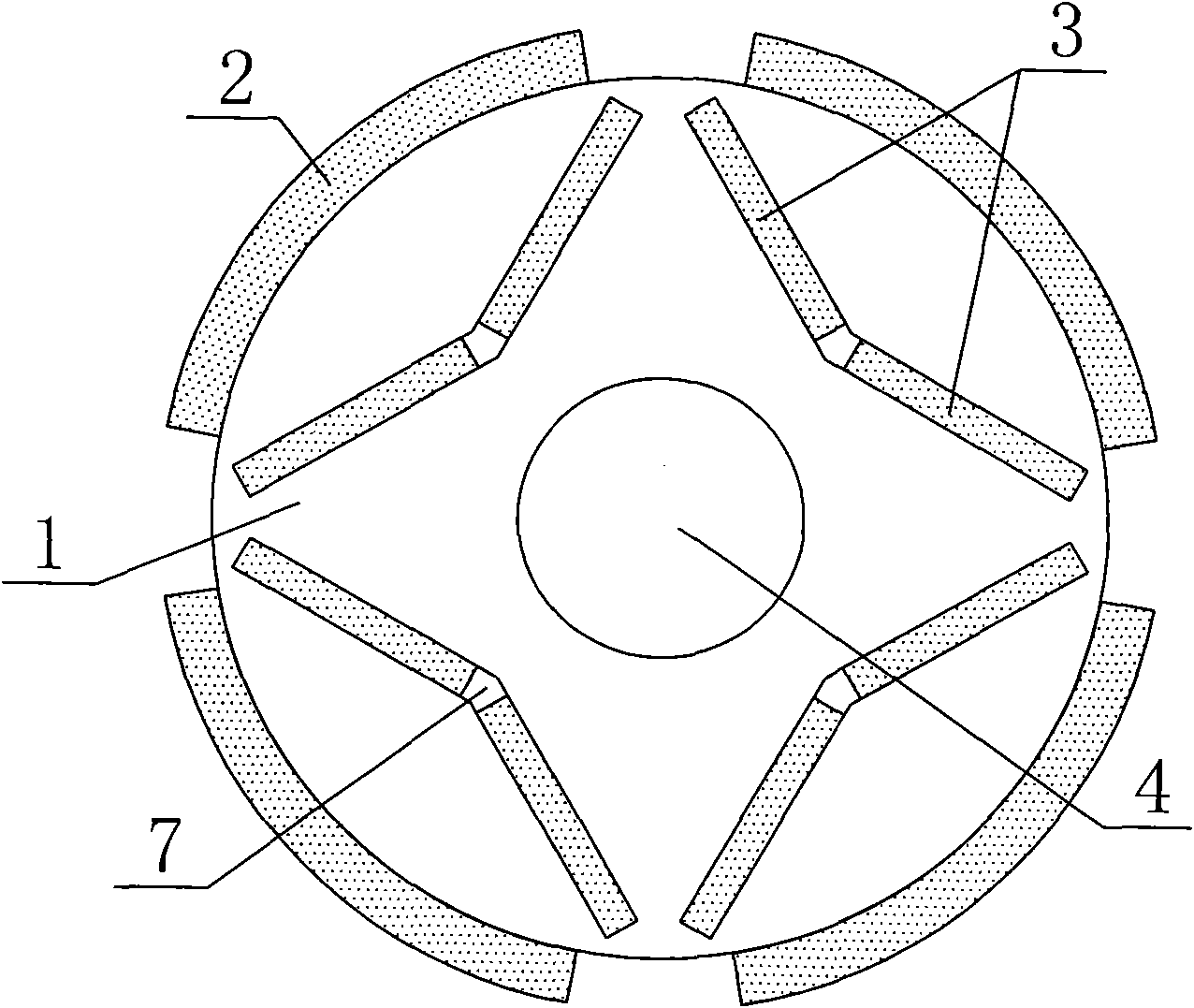

Rotor of permanent magnet synchronous motor and permanent magnet synchronous motor provided with same

ActiveCN104485762AHigh mechanical strengthReduce Flux LeakageSynchronous machine detailsMagnetic circuit rotating partsPermanent magnet synchronous motorPermanent magnet synchronous generator

The invention discloses a rotor of a permanent magnet synchronous motor and the permanent magnet synchronous motor, which belong to the technical field of the permanent magnet synchronous motors, and are designed in order to solve the problems of high leakage flux, low permanent magnet utilization rate, influence on motor performance and efficiency and the like in existing rotor of the permanent magnet synchronous motor. The rotor of the permanent magnet synchronous motor comprises a rotor core, wherein an even number n of tangential permanent magnets are distributed evenly in radial direction on the rotor core, and the same polarities of two adjacent tangential permanent magnets are opposite; radial permanent magnets are arranged symmetrically on two sides of one end of each tangential permanent magnet close to the inner side of the rotor core respectively; every two radial permanent magnets sandwiched between two adjacent tangential permanent magnets have the same polarity in the direction facing to a stator, and a magnetic isolating bridge is arranged between every two radial permanent magnets. The invention further discloses a permanent magnet synchronous motor provided with the rotor. By utilizing the rotor, the leakage flux of the tangential permanent magnets on the inner side of the rotor is reduced, the utilization rate of the permanent magnets is improved, and the motor efficiency and the motor structural intensity are enhanced.

Owner:GREE ELECTRIC APPLIANCES INC +1

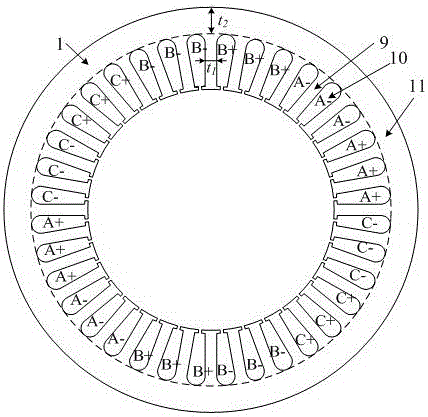

Permanent magnet synchronous motor

InactiveCN102420475AReduce cogging torqueEasy to manufacture and assembleMagnetic circuit rotating partsSynchronous machine detailsPermanent magnet synchronous motorMagnetic poles

A purpose of the present invention is providing a permanent magnet synchronous motor rotor structure which has high air gap flux density and is easy to generate back electromotive force with a sine wave. In a permanent magnet synchronous motor, a circumferential surface of the rotor is uniformly provided with a plurality of magnetic steel grooves which are independently enclosed and do not contact mutually. Every two magnetic steel grooves are arranged to form a V shape, an opening of the V shape faces excircle of the rotor, and a tip of the V shape faces a rotor center. Each magnetic steel groove is provided with magnetic steel. In each group of V-shaped magnetic steel grooves, two magnetic steel facing the excircle of the rotor core have a same magnetic pole, and magnetic poles of magnetic steel facing the excircle of the rotor core in two adjacent groups of V-shaped magnetic steel grooves are opposite with the magnetic pole of the two magnetic steel. The excircle of the rotor goes down toward the center with depth delta and smooth transition at a crossing position of axes, which means that air gap width at the crossing position is less than air gap width at a straight axis position by delta. Through improving the rotor, the permanent magnet synchronous motor rotor has high mechanical strength and a large salient pole ratio, and weakened magnetism speed expansion is facilitated.

Owner:TIANJIN SANTROLL ELECTRIC SCI & TECH

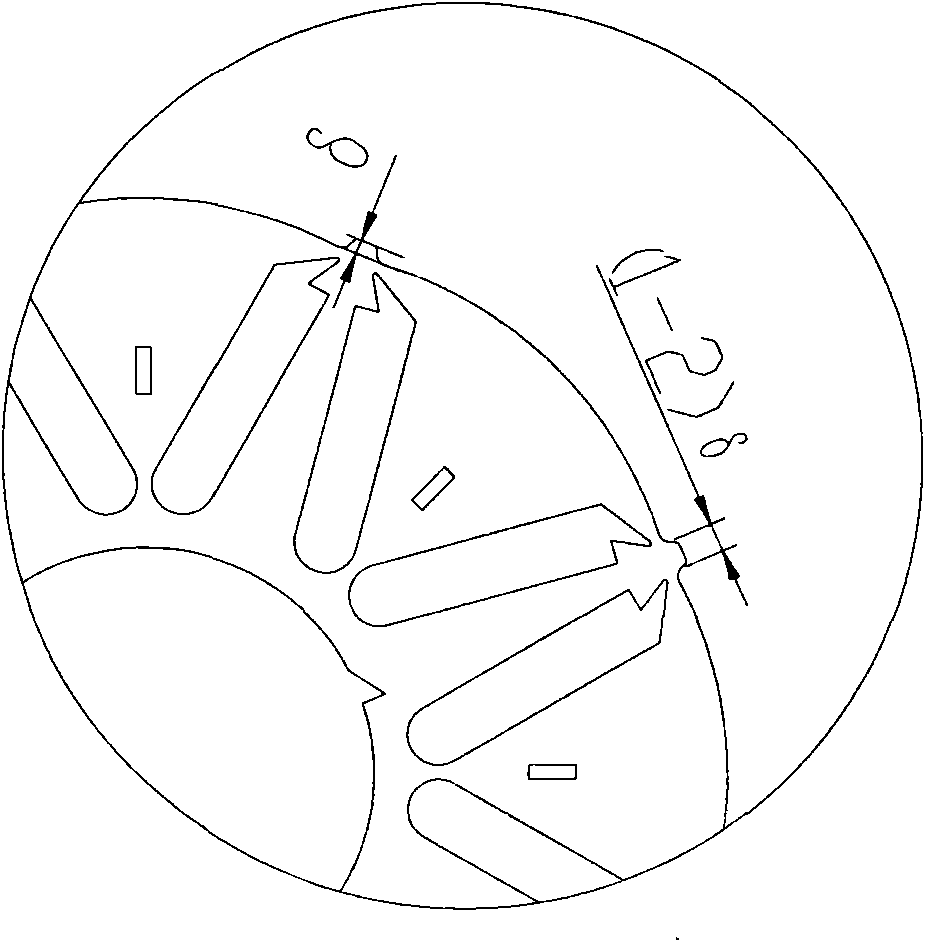

Reluctance type alternating pole permanent magnet motor

PendingCN107659101ATake advantage ofIncrease the q-axis inductanceMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPermanent magnet motorInductance

The invention provides a reluctance type alternating pole permanent magnet motor, which comprises a rotor, wherein the rotor is provided with at least two permanent magnet poles which take an axis ofthe rotor as a center and are uniformly distributed along the circumferential direction of the rotor, each permanent magnet pole comprises inner-layer magnetic slots and outer-layer magnetic slots which are sequentially arranged and mutually separated along the radial direction of the rotor; and each inner-layer magnetic slot is internally provided with an inner-layer permanent magnet matched withthe inner-layer magnetic slot, and each outer-layer magnetic slot is internally provided with an outer-layer permanent magnet matched with the outer-layer magnetic slot. The reluctance type alternating pole permanent magnet motor has the advantages that the difference between q-axis inductance and d-axis inductance can be improved, thus the reluctance torque is enabled to be fully utilized, and the electromagnetic torque is enabled to be improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Middle electric motor drive unit for electric bicycle

InactiveUS8205705B2Compact and reasonable structureConvenience to workSpeed controllerPropulsion by humans/animalsReducerControl theory

A middle electric motor drive unit for an electric bicycle, including a motor, a controller, a sensor, a gear reducer, a one-way clutch, a chain tightener, and a housing. The middle electric motor drive unit is disposed below a frame of the electric bicycle, and in the vicinity of a pedal shaft thereof. The middle electric motor drive unit is independent from the pedal shaft with respect to functions and structure. The motor is an internal rotor and permanent magnet DC motor. The motor shaft of the motor is parallel to a gear shaft and the pedal shaft. The controller is built-in, and disposed in or on the housing. The sensor is an internal sensor or an external pedal shaft sensor.

Owner:TIANJIN MINGDU TECH CO LTD

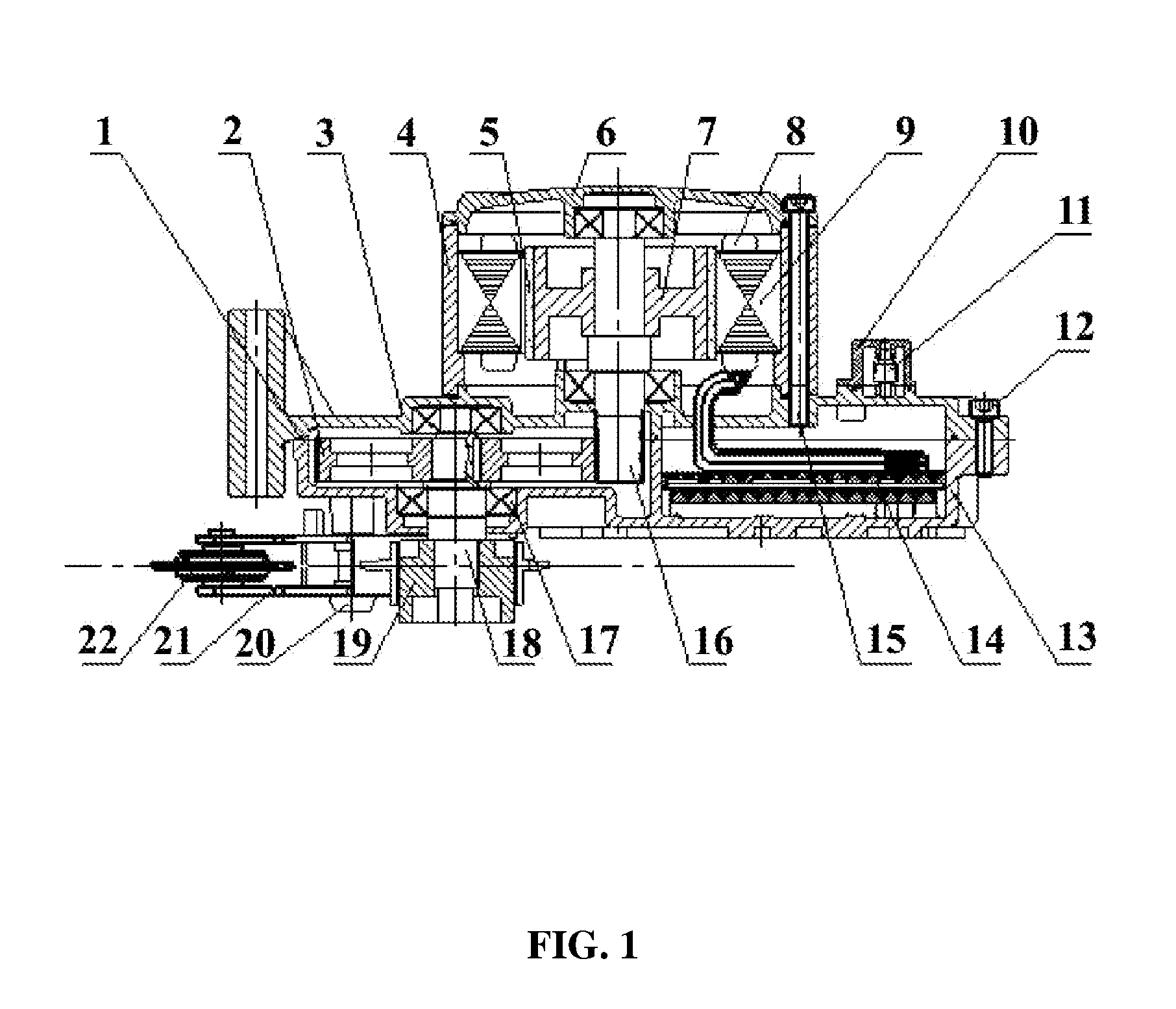

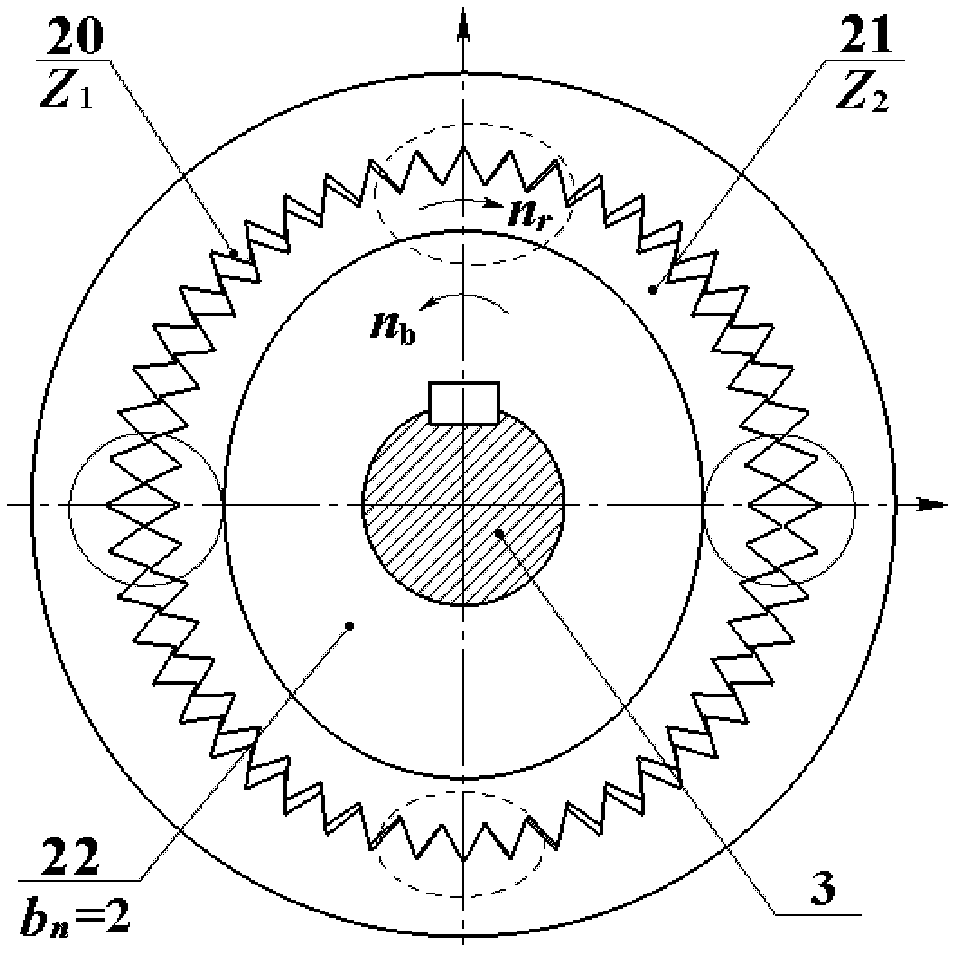

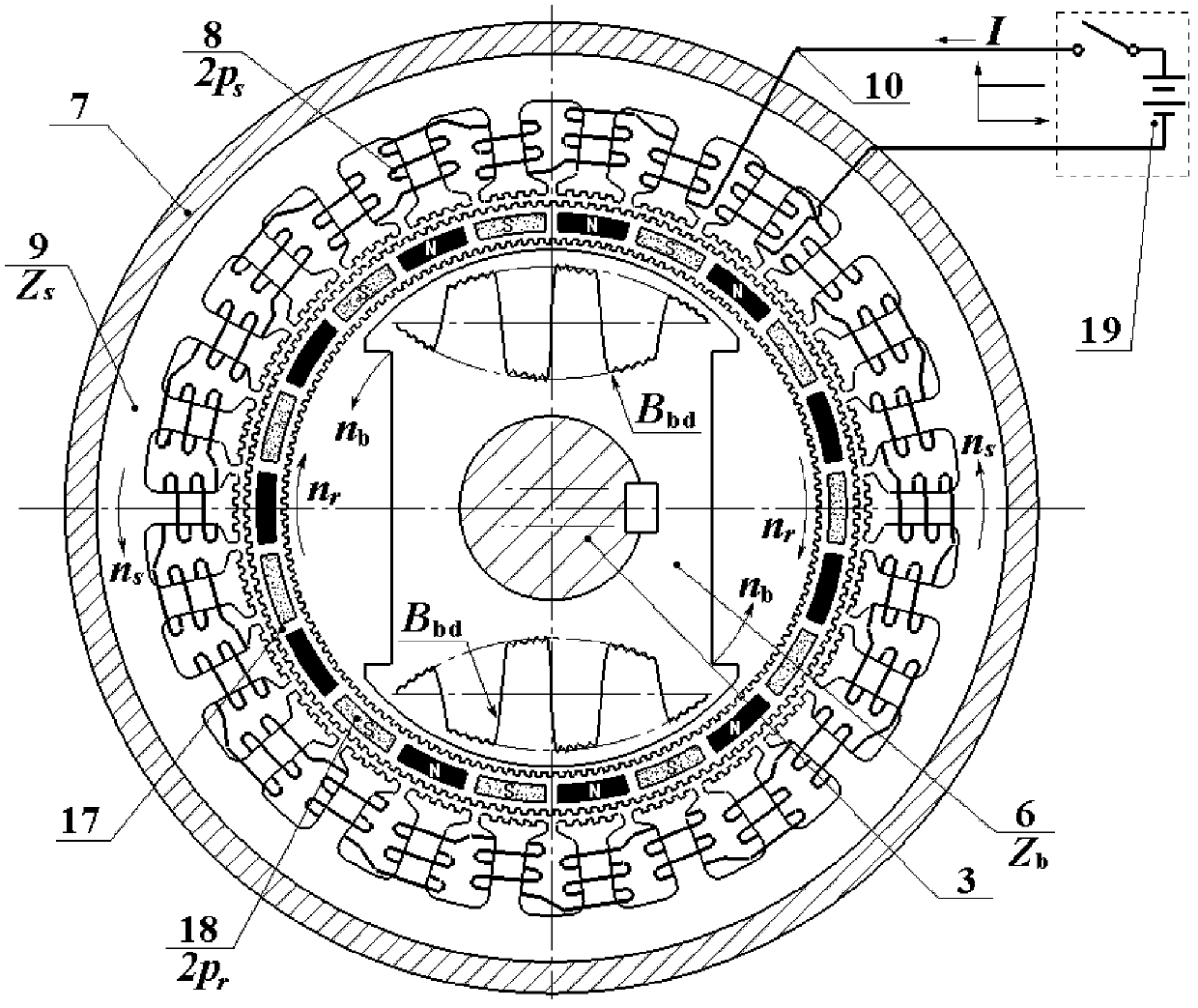

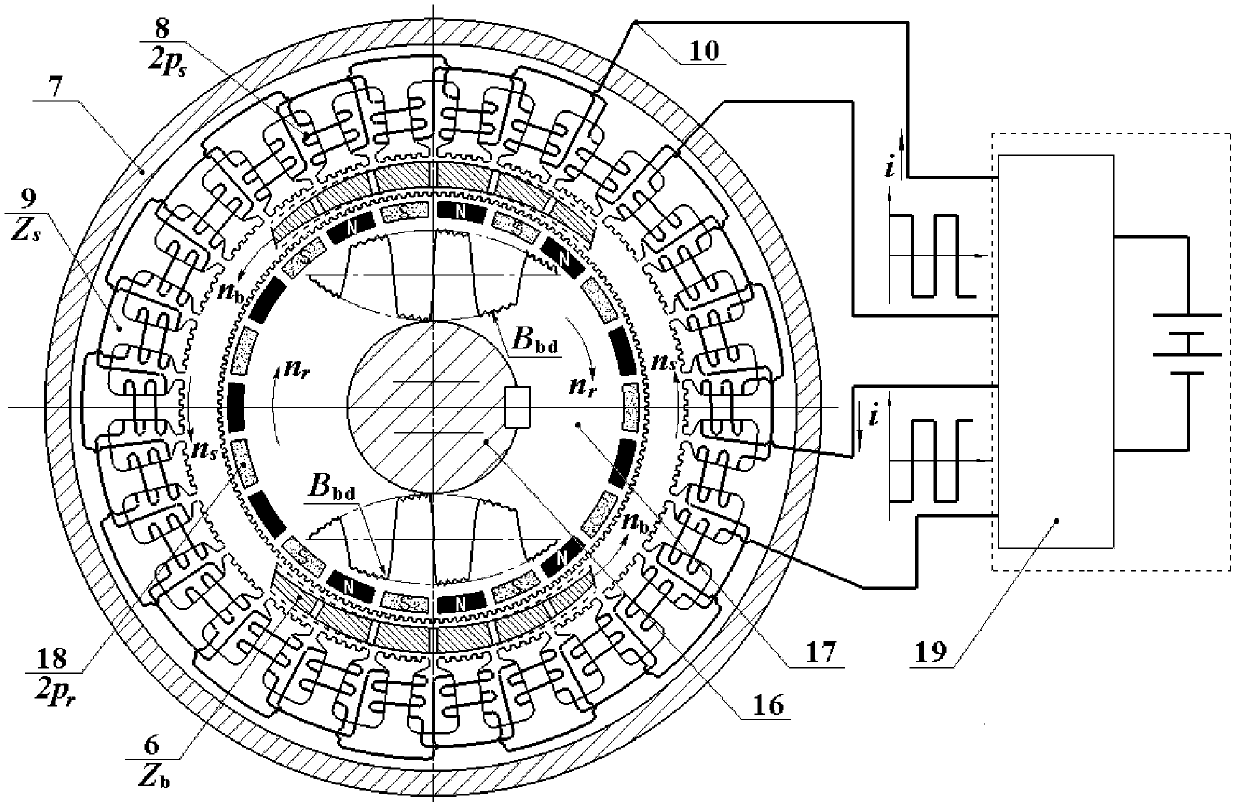

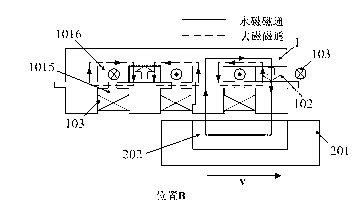

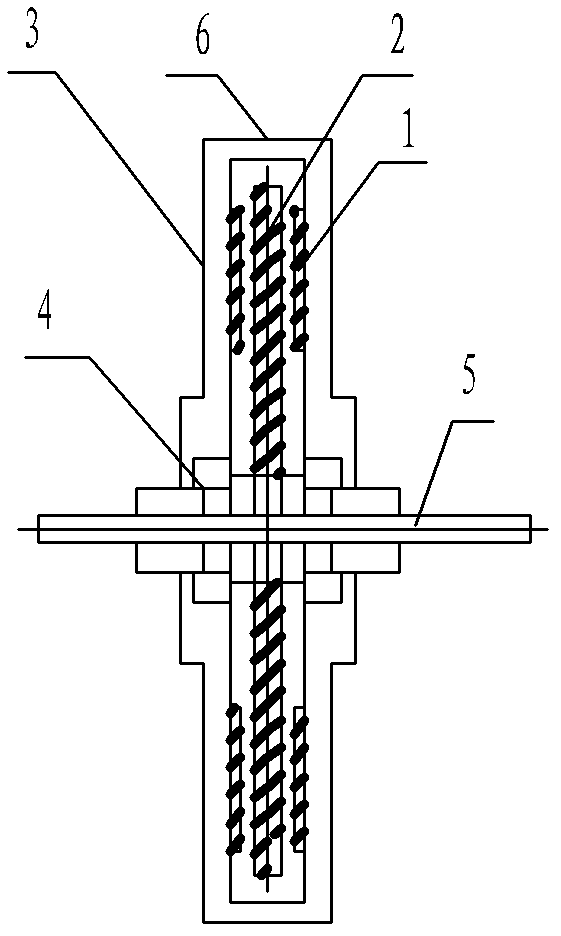

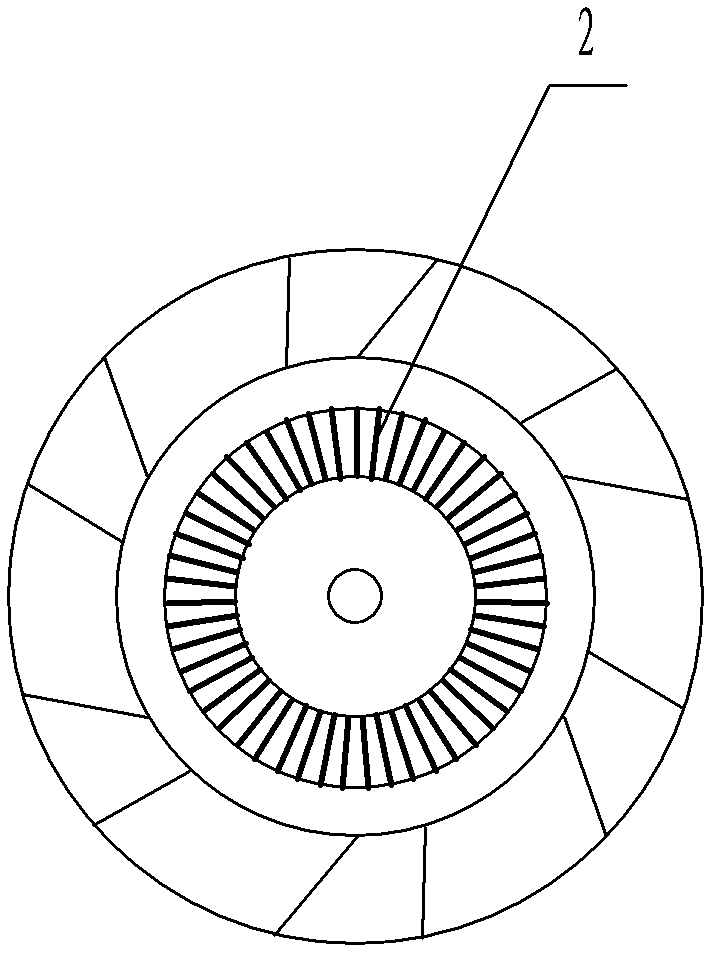

Dual mechanical port magnetic conductance harmonic type electromagnetic gear composite permanent magnet motor

InactiveCN103378711AEliminate contact frictionImprove transmission efficiencyDynamo-electric brakes/clutchesDynamo-electric gearsPermanent magnet rotorLow speed

Provided is a dual mechanical port magnetic conductance harmonic type electromagnetic gear composite permanent magnet motor which can be widely applied to industrial transmission fields such as wind power generation, electric automobiles, ship driving and server driving. The electromagnetic gear composite permanent magnet motor is characterized is that main transmission components of the electromagnetic gear composite permanent magnet motor consists of a stator formed of a stator iron core (9) and a stator winding (8) having 2ps poles, a permanent rotor formed of a rotor iron core (17) equipped with 2pr rotor permanent magnets (18) and an output shaft (16), and a salient pole magnetic conductance wave rotor (6) having Zb salient poles, wherein a numerical difference between the number of pole-pairs ps and pr is relatively small; and the stator, the permanent magnet rotor and the salient pole magnetic conductance wave rotor (6) are coaxially disposed, are mutually coupled through a radial air-gap magnetic field, and are mutually coupled in a salient pole straight axis area of the high-speed rotating salient pole magnetic conductance wave rotor (6) by using a principle of heteropolarity magnetic field attraction with a small pole difference so as to drive the permanent magnet rotor with a small pole difference to rotate at a low speed. Therefore, power speed changed and torque conversion controlled drive with no mechanical contact and no friction is realized.

Owner:余虹锦

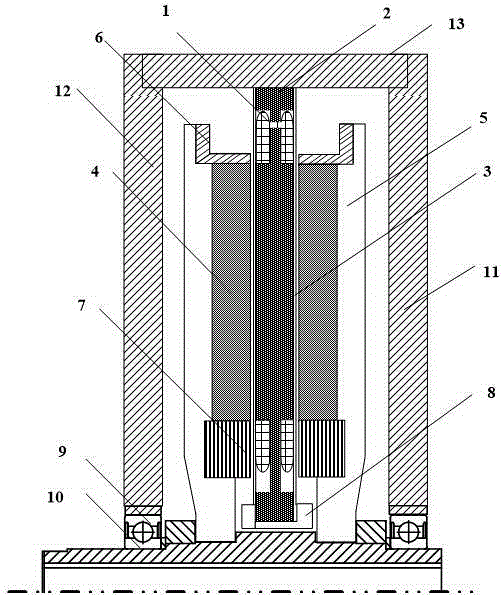

Built-in permanent magnet memory motor of magnetic flux switching type

InactiveCN103199661ASimple structureReduce wind resistanceMagnetic circuit rotating partsSynchronous machine detailsMechanical reliabilityElectric machine

The invention discloses a built-in permanent magnet memory motor of a magnetic flux switching type. The permanent magnet memory motor comprises a casing, a stator, a rotor and a rotating shaft, wherein the stator is a cylinder with a through hole and is formed by a star-shaped magnetic isolation block with a center through hole and partitioned rotor iron core discs; the rotating shaft is fixedly connected in the center through hole of the magnetic isolation block; and the partitioned rotor iron core discs are shaped like a fan and are uniformly distributed at the circumference of the rotor as well as fixedly connected to the outer surface of the magnetic isolation block. The stator comprises a stator iron core, permanent magnets, three-phase armature windings and pulse windings, wherein the stator iron core comprises a stator yoke and stator teeth formed by permanent teeth and armature teeth; the permanent magnets are shaped like a tile and radially magnetized, so that magnetic leakage factors are small; the magnetization directions of the two adjacent permanent magnets are opposite; the three-phase armature windings are wound on the armature teeth; and the pulse windings are wound on the permanent magnets. According to the permanent magnet memory motor, the weak magnetic ability and the rotation speed running range of the motor can be improved; and the no-load air gap magnetic field can be adjusted. In addition, the permanent magnet memory motor disclosed by the invention is strong in mechanical reliability, thereby being suitable for high-speed running.

Owner:SOUTHEAST UNIV

Axial flux motor of stator iron-core-free Halbach permanent magnet array

ActiveCN105305749AImprove structural strengthAchieve coolingMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet rotorMolecular materials

The invention discloses an axial flux motor of a stator iron-core-free Halbach permanent magnet array. The motor includes two permanent magnet rotors, the rotors are mounted on a rotating shaft in the manner that permanent magnets of the rotors face each other, and a circular ring made of a high-molecular material is mounted between the rotors; radial guide grooves are regularly arranged in the circumferential directions of the front and back sides of the circular ring, and used for mount a stator winding coil with excitation lines; each permanent magnet rotor is composed of a magnetic conductive yoke of the rotor and a segmented permanent magnet mounted in the yoke; and 12 permanent magnets whose magnetizing directions are different from one another are mounted under each pair of poles, the axial magnetizing direction of the first permanent magnet is 0 degree, the difference between the magnetizing directions of the adjacent permanent magnets is 30 degree, and, thus, the Halbach array is realized, and the content of harmonic waves of air-gap flux density is greatly reduced. The axial flux motor has the advantages of high air-gap flux density sine degree, low winding loss, high structural intensity of the stator, good heat radiation effect, and high power / volume ratio.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

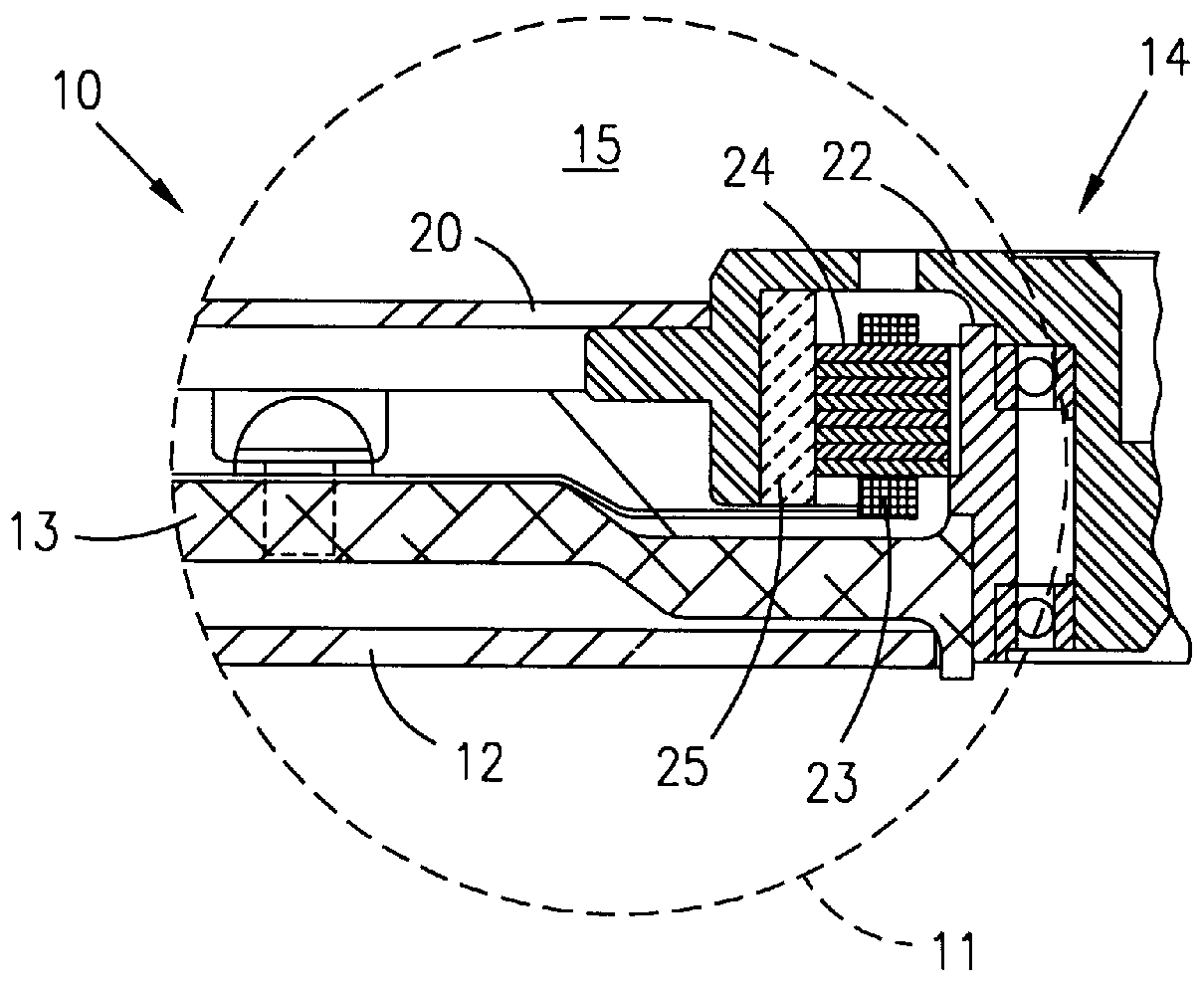

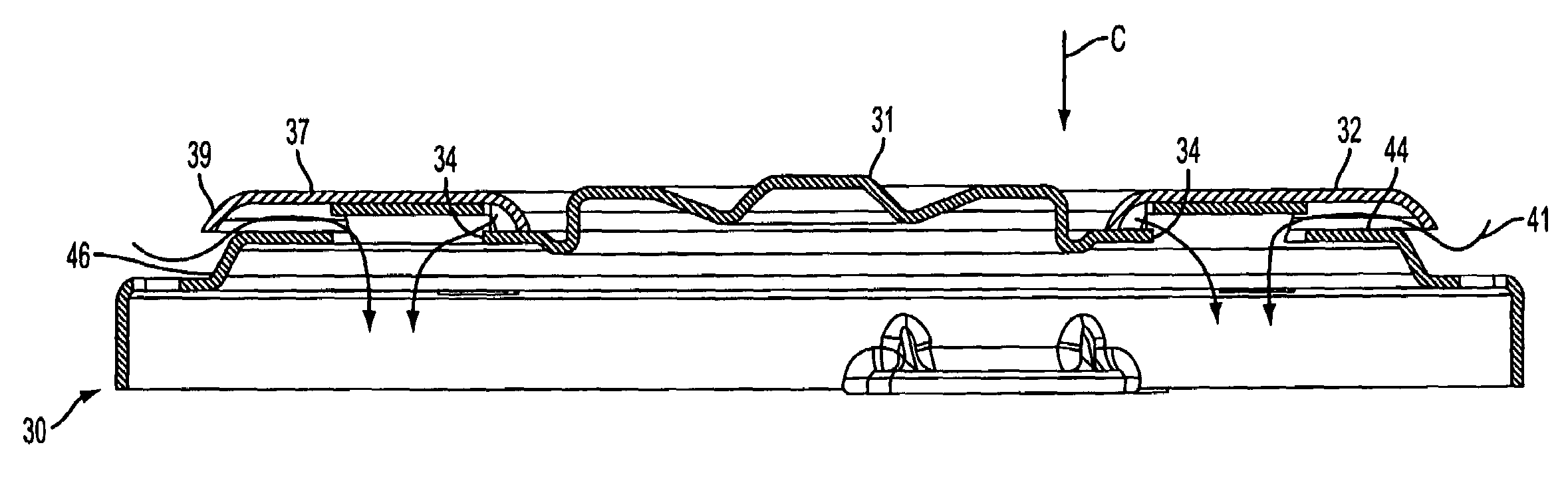

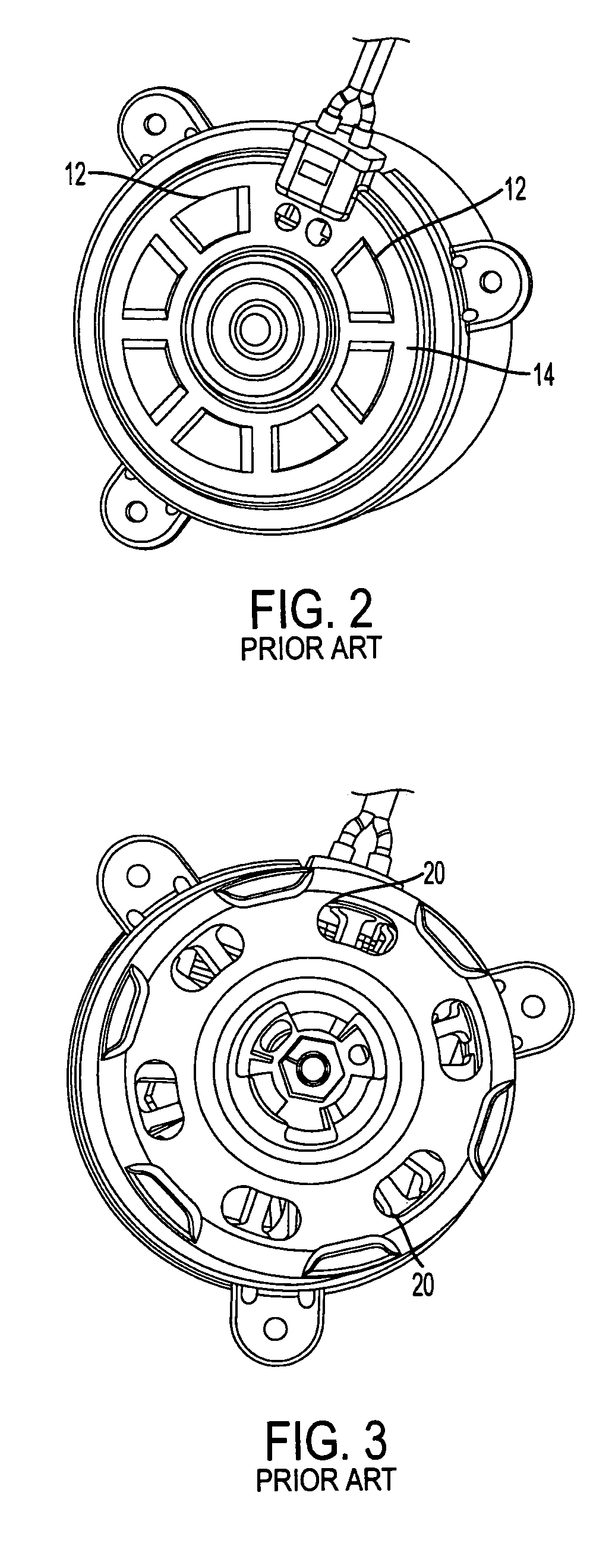

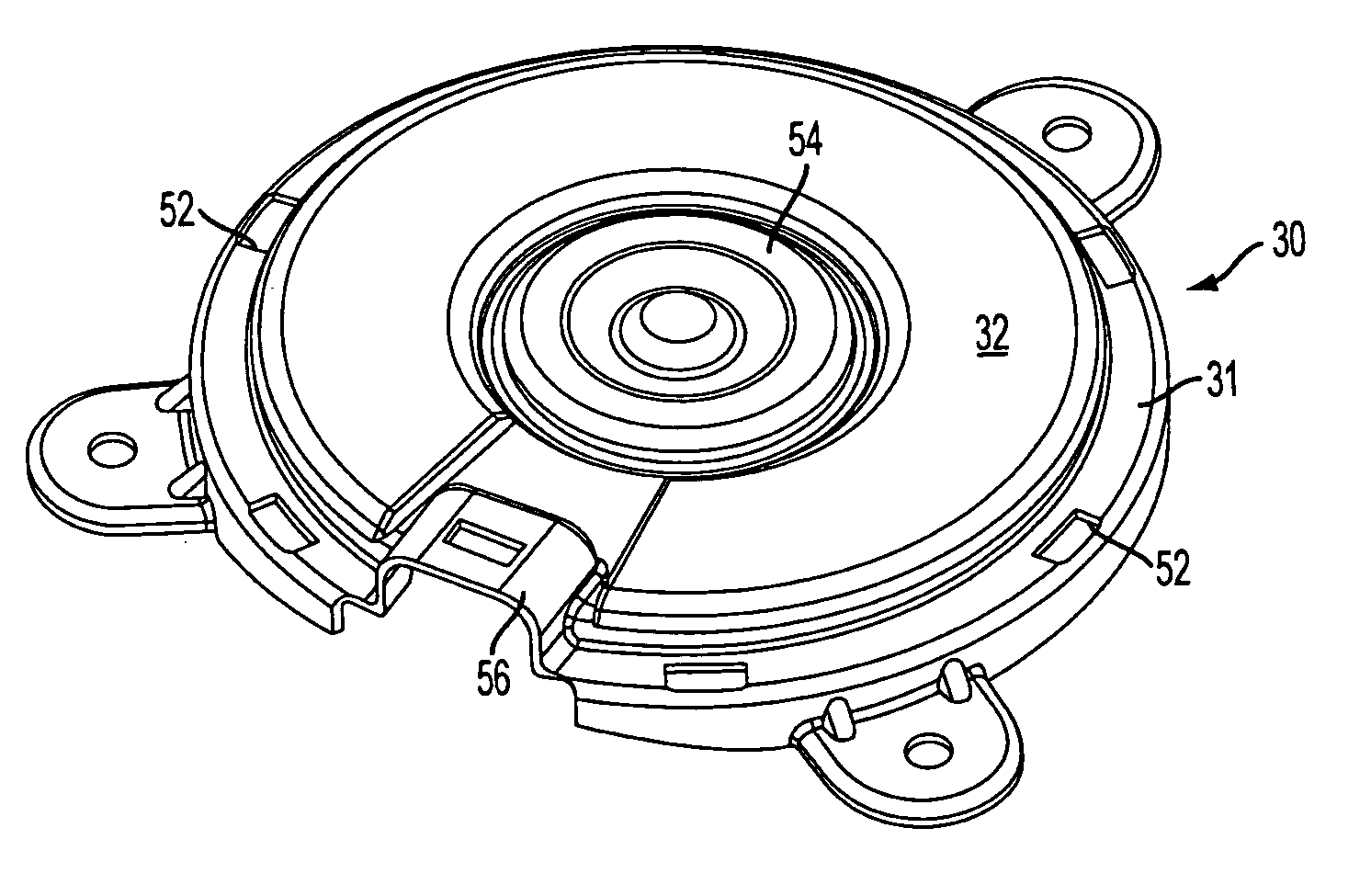

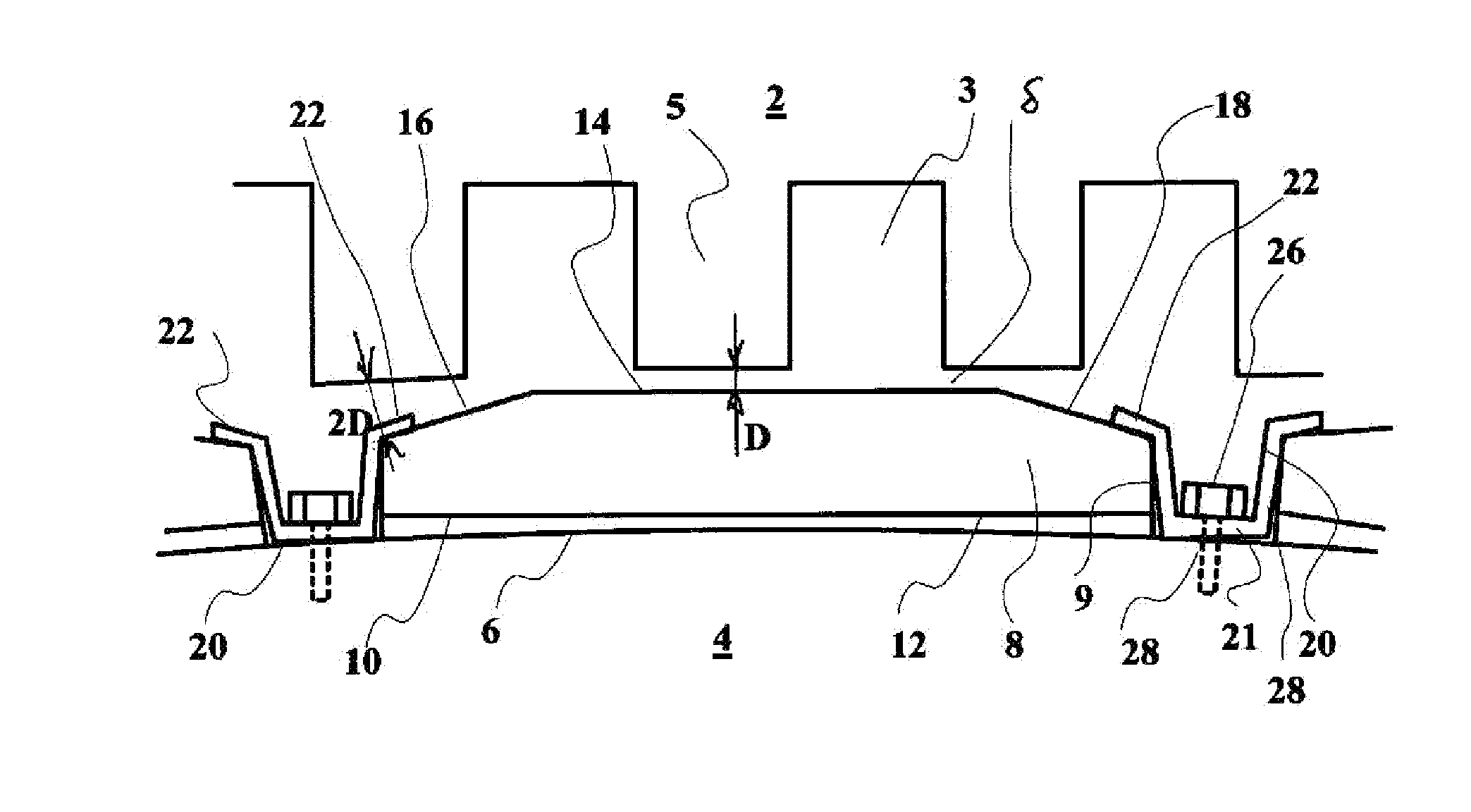

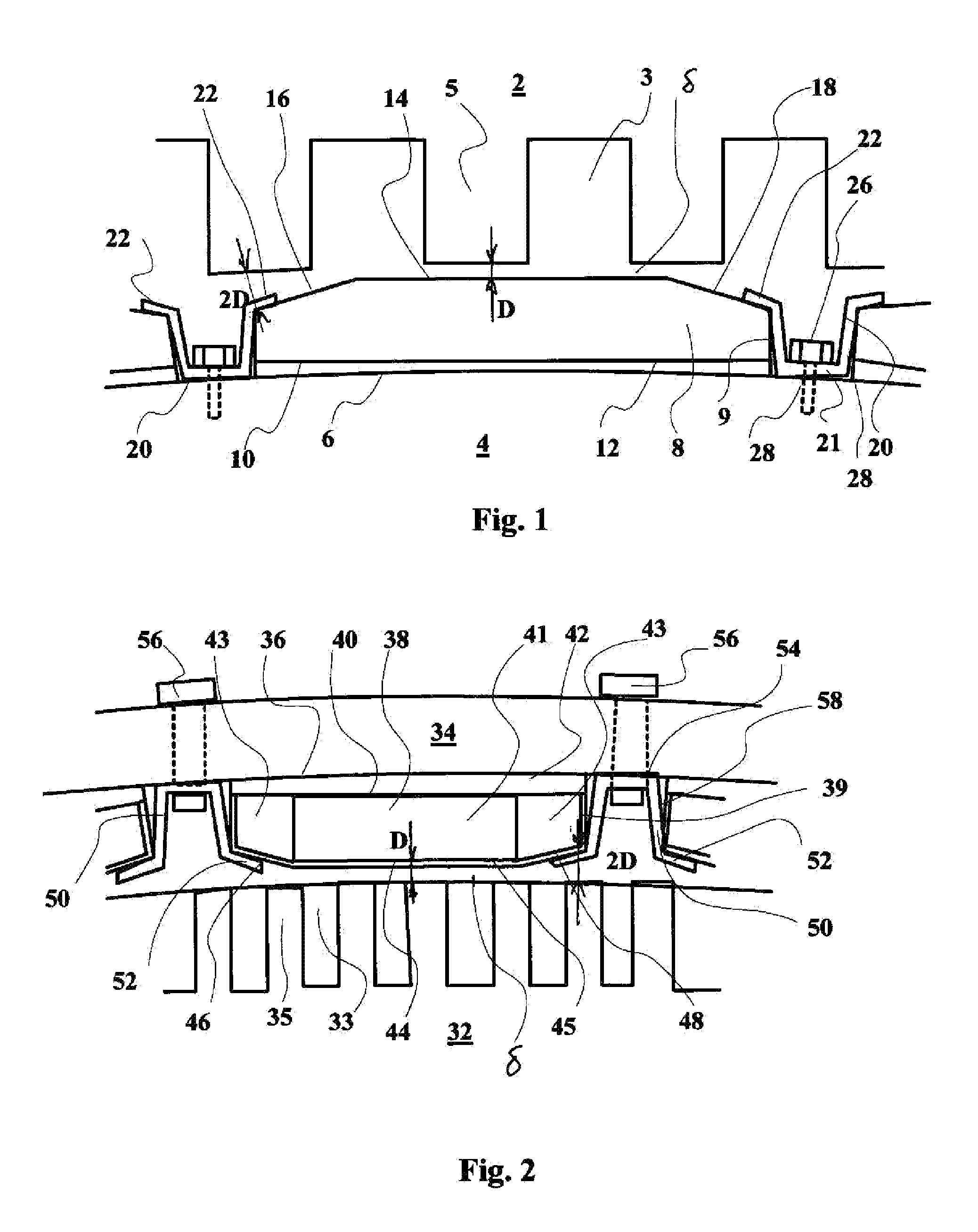

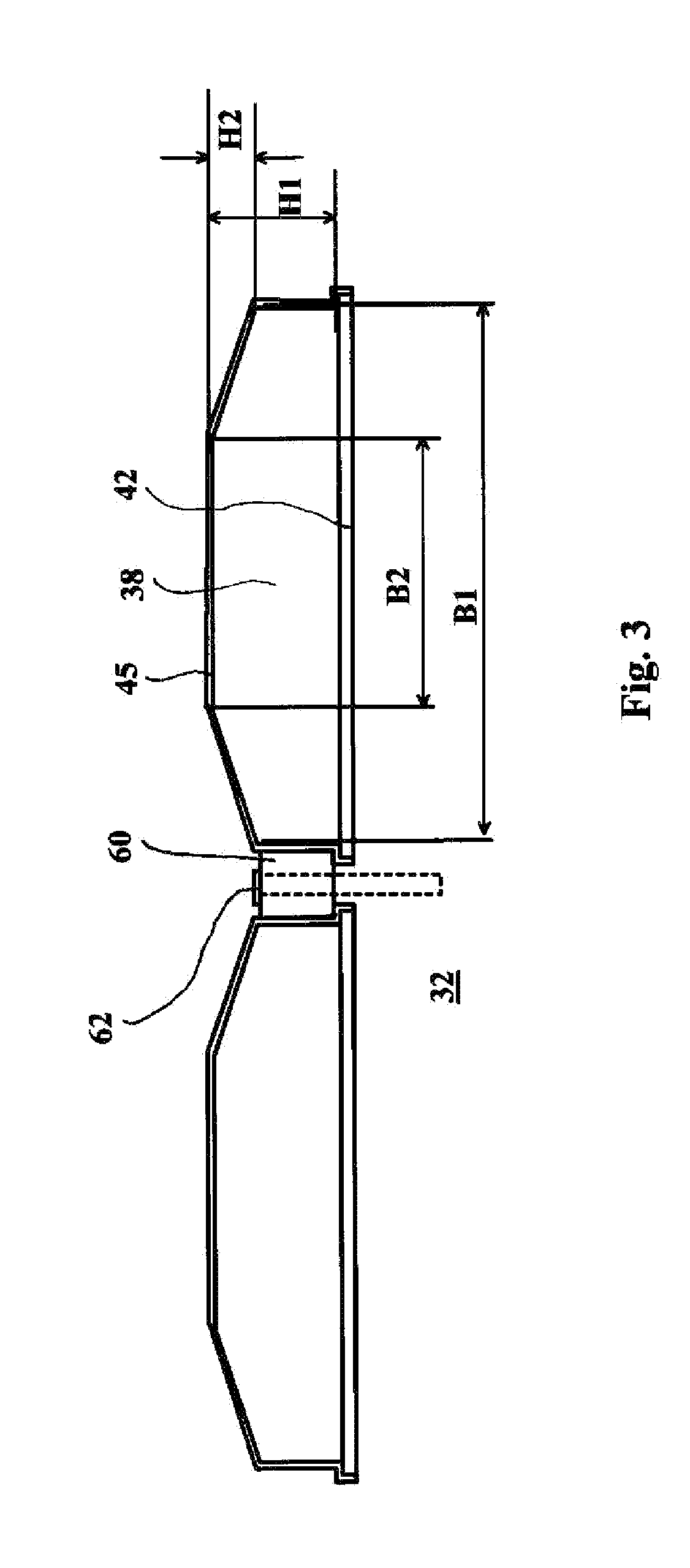

Vented end cap with integrated splash shield for permanent magnet DC motor

ActiveUS7034416B2Cooling/ventillation arrangementSupports/enclosures/casingsForeign matterEngineering

A permanent magnet D.C. electric motor 36 includes a motor housing 29 having first and second ends. The second end 42 is substantially closed and has an end of a shaft 35 extending there from. The second end includes vent holes 20 therein. The first end 27 is substantially open. An end cap 31 closes the first end of the housing. The end cap 31 has venting holes 34 therein for permitting air to pass there-through to cool the motor. A splash shield 32 is integral with the end cap 31 and covers the venting holes 34 in such a manner to limit foreign matter from entering the venting holes while permitting air to flow through the venting holes.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

Permanent magnet motor rotor

InactiveCN102097876AReduce Flux LeakageHigh mechanical strengthMagnetic circuit rotating partsSurface mountingPermanent magnet motor

The invention discloses a surface-mounted and interior mixed permanent magnet motor rotor. The rotor comprises a rotor core, tiled permanent magnets, interior permanent magnets and a rotating shaft. The rotor is characterized in that the tiled permanent magnets adhere to the surface of the rotor core, with N and S poles alternate; the interior permanent magnets are inserted into V-shaped slots in the rotor core; the polarity of the two permanent magnets in each V-shaped slot is opposite; and the two permanent magnets form series structure on a magnetic circuit with the corresponding tiled permanent magnet. The rotor has the beneficial effects of enhancing the mechanical strength of the permanent magnet motor, reducing the magnetic flux leakage, omitting the magnetism isolating bridge and improving the starting, braking and operating performances of the permanent magnet motor.

Owner:HENAN POLYTECHNIC UNIV

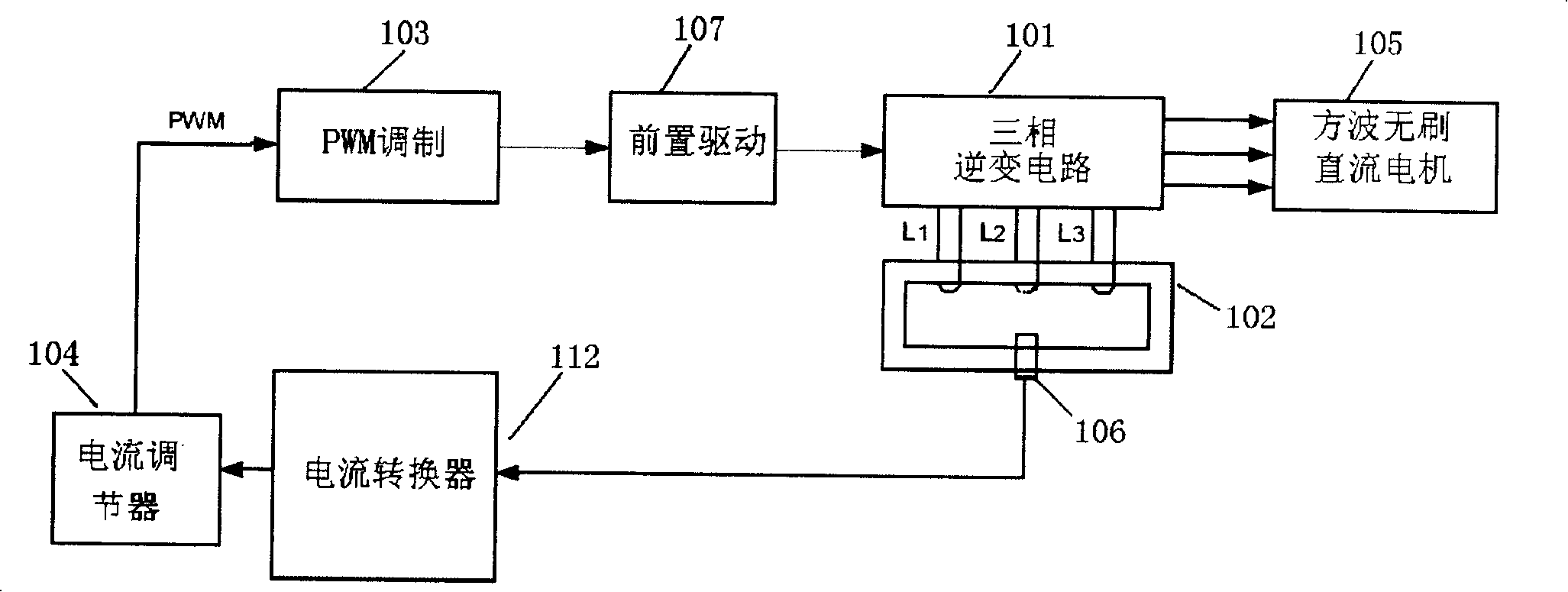

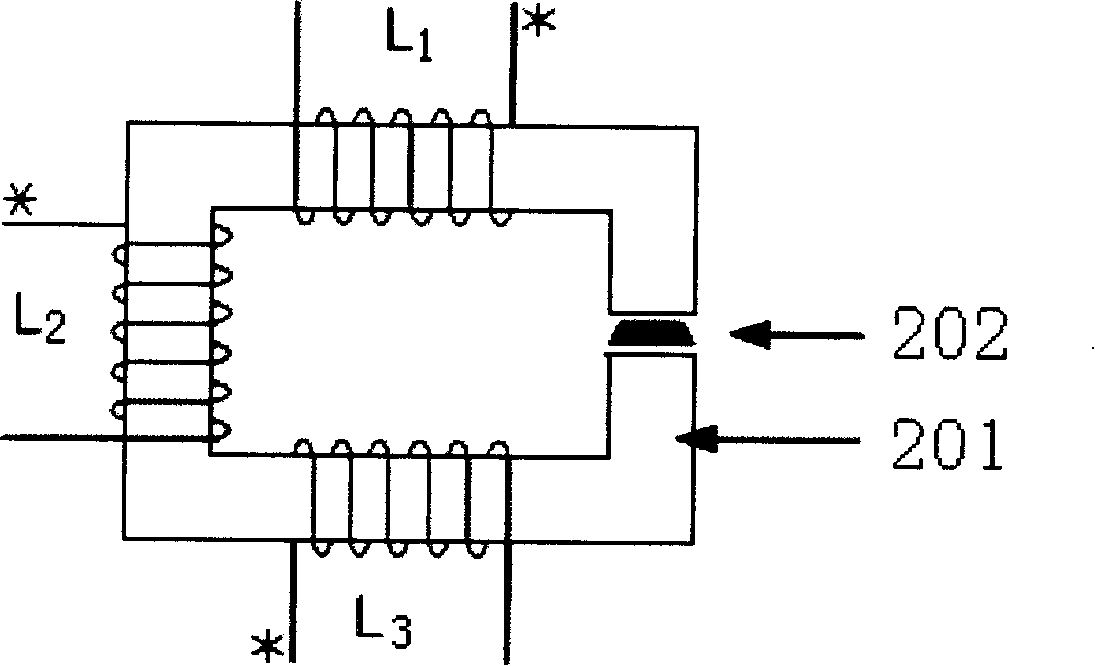

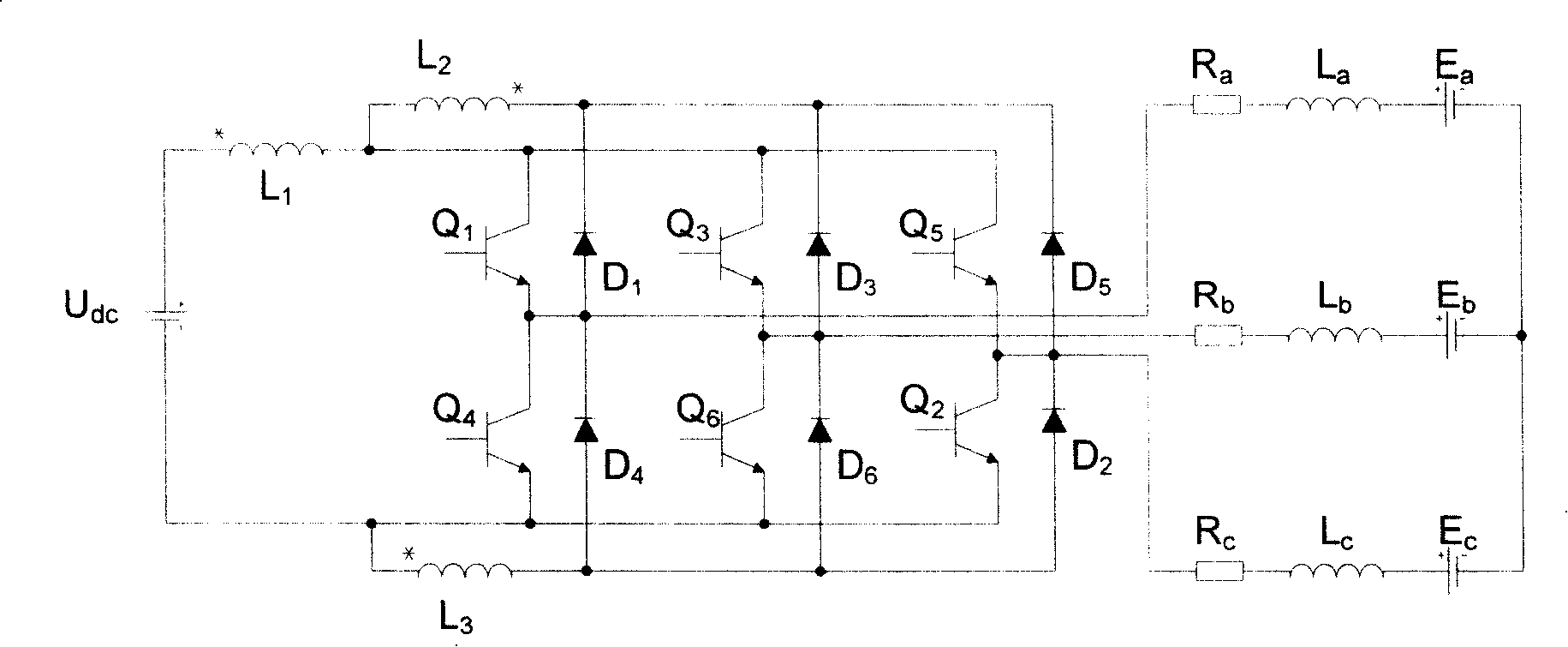

Control system and control method of brushless DC motor

ActiveCN101227163ASolve the problem of current closed-loop controlIncrease dynamicsSingle motor speed/torque controlAc-dc conversionPhase currentsLoop control

The invention relates to the controlling technique of a three-phase direct current motor, which aims at solving the problem that the existing technique can not realize good electric current closed-loop control of a three-phase square-wave brushless direct current motor. The invention provides a novel proposal for realizing electric current closed-loop control of the square-wave brushless permanent magnet direct current motor, particularly comprises a brushless direct current motor controlling system, a controlling method and a corresponding inversing module. The cathodes of freewheeling diodes D1, D3, D5 are independent from each input end of self switch pipe and mutually connected in parallel to a sample-taking coil L2, and / or the anodes of freewheeling diodes D4, D6, D2 are independent from each output end of self switch pipe and mutually connected in parallel to a sample-taking coil L3. The invention can adopt a single resultant current sensing device to completely continuously take sample of three-phase electric current when the motor is conducted and freewheeled, and continuous closed-loop control can be carried out to three-phase electric current by a single electric current closed-loop regulating device, and therefore, dynamic and static index of the motor are greatly increased.

Owner:SHENZHEN ACAD OF AEROSPACE TECH

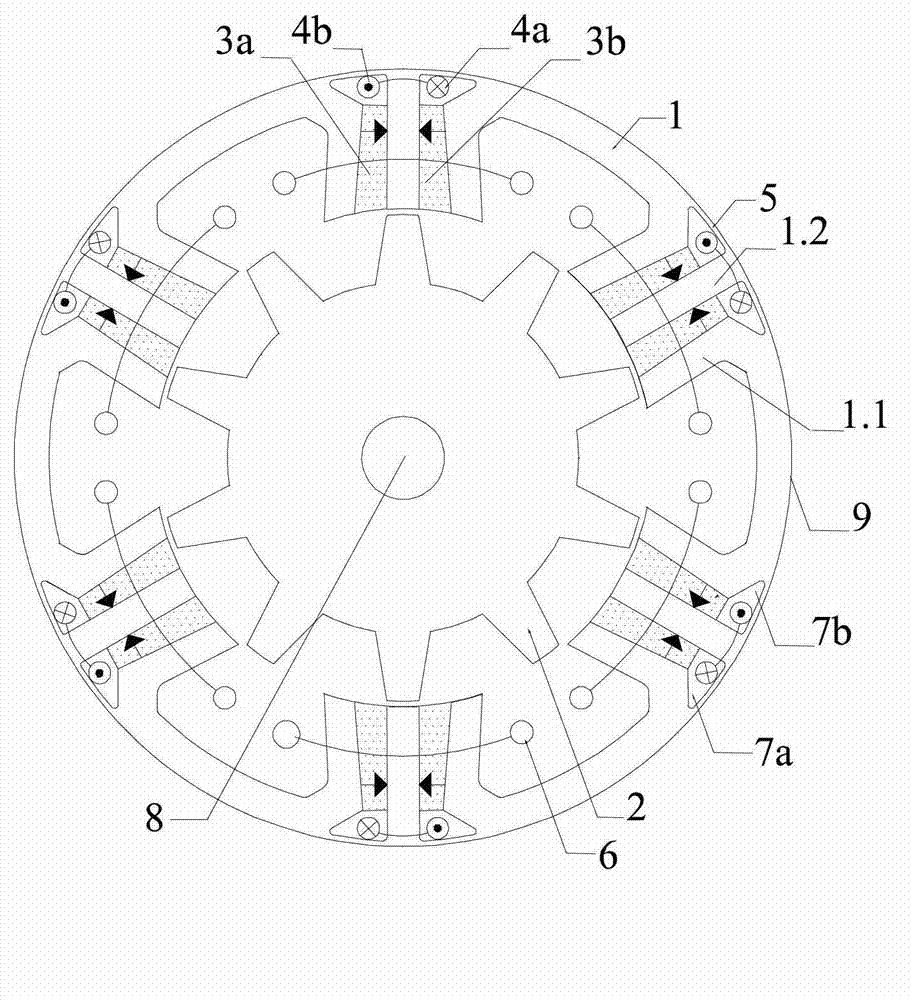

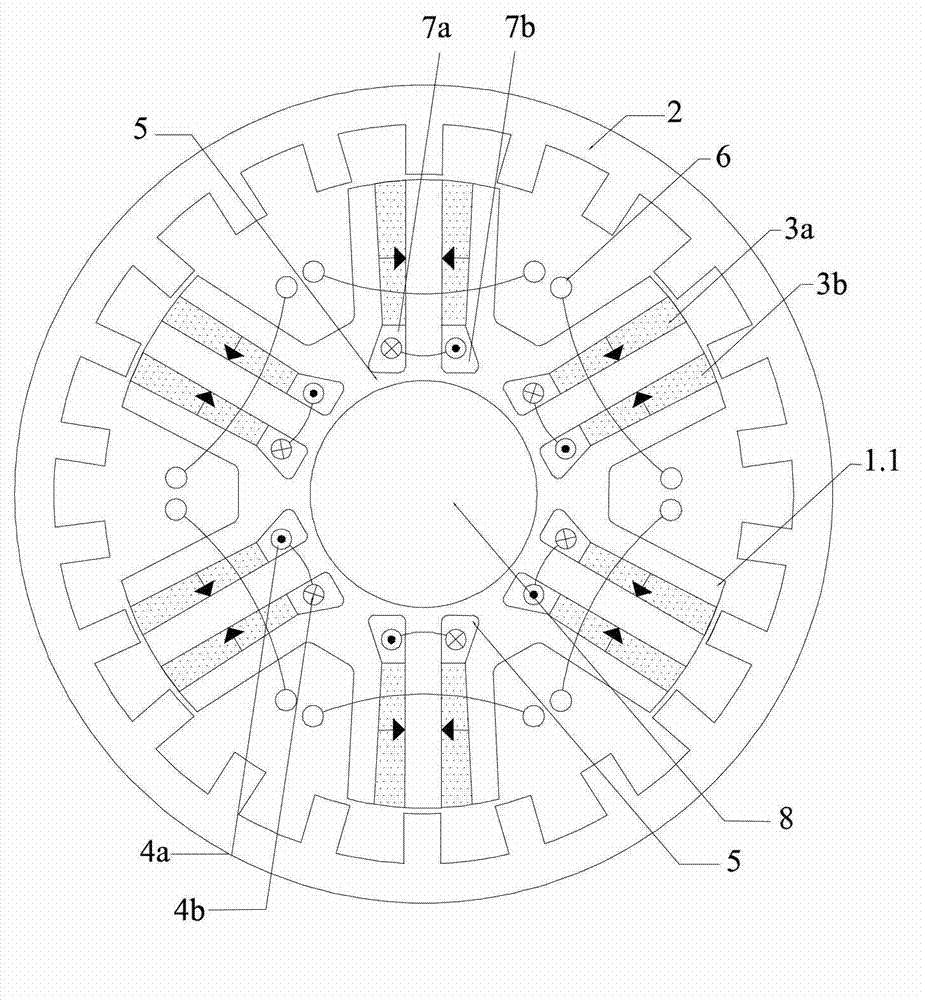

Magnetism-gathering-type magnetic flux switching permanent magnet memory motor

InactiveCN103078466ASimple structureStable structureMagnetic circuit stationary partsWindings conductor shape/form/constructionCopper lossPulse current

The invention discloses a magnetism-gathering-type magnetic flux switching permanent magnet memory motor, which comprises a stator, a rotor (2) and an un-conducted magnetic shaft (8), wherein the stator (1) is arranged outside the rotor (2); the rotor (2) is fixed on the un-conducted magnetic shaft (8) and is in a salient pole type; the stator comprises a stator core (1), a first permanent magnet (3a), a second permanent magnet (3b), a three-phase armature winding (6), a first pulsed winding (4a) and a second pulse winding (4b); the stator core (1) comprises a plurality of stator yokes and stator teeth protruding to the center direction of the stator core from the stator yokes; and a stator slot is formed between the adjacent stator teeth. With the adoption of the magnetism-gathering-type magnetic flux switching permanent magnet memory motor, the residual magnetization of the permanent magnet is adjusted through applying pulse current to a pulse winding; a motor no-load air-gap field can be adjusted; the weak magnetic ability of the motor and the rotating speed operation range are improved; and meanwhile, the torque and power density of the motor can be effectively improved through magnetism-gathering-type armature teeth, and the copper loss of the motor is reduced.

Owner:SOUTHEAST UNIV

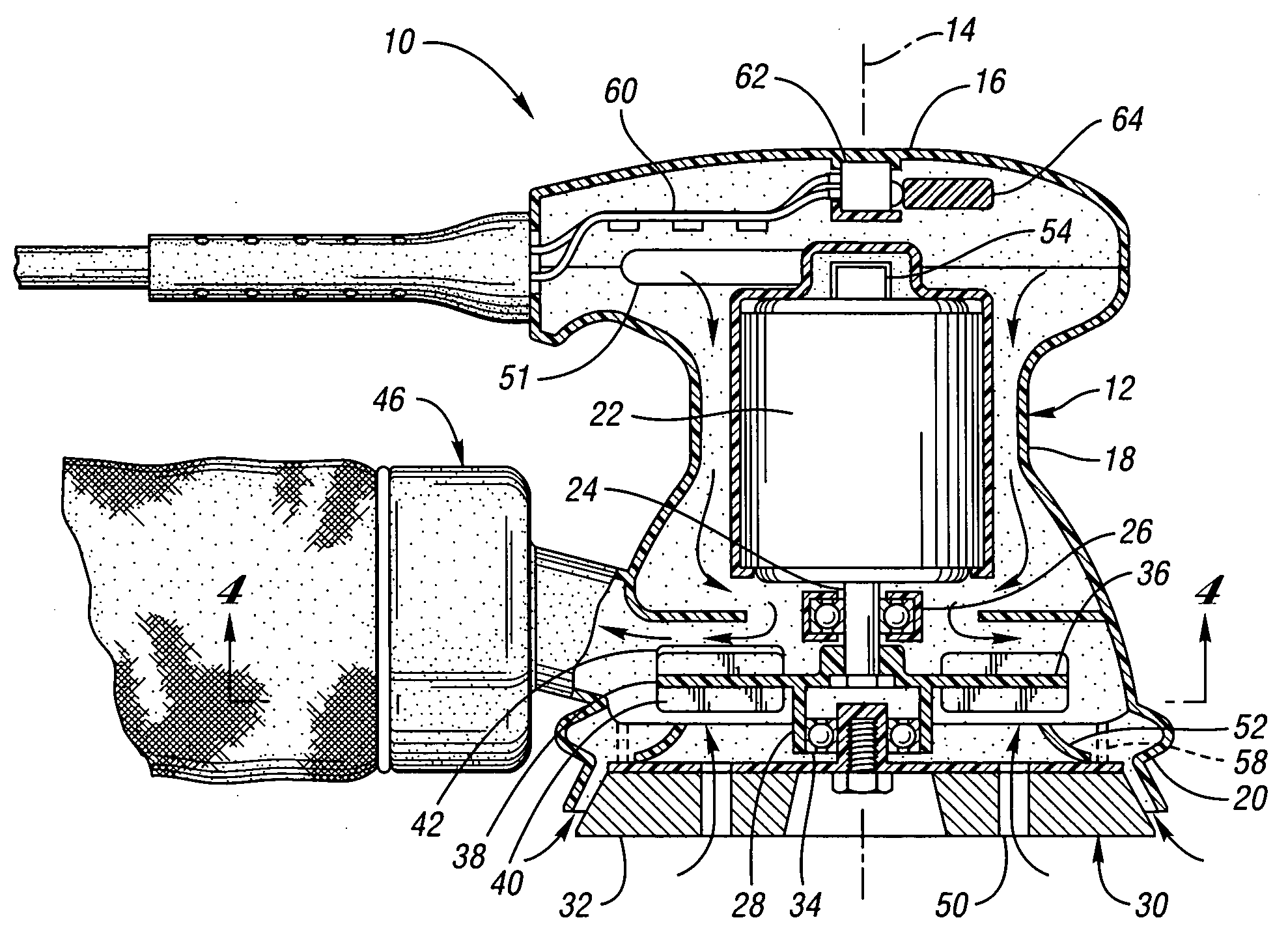

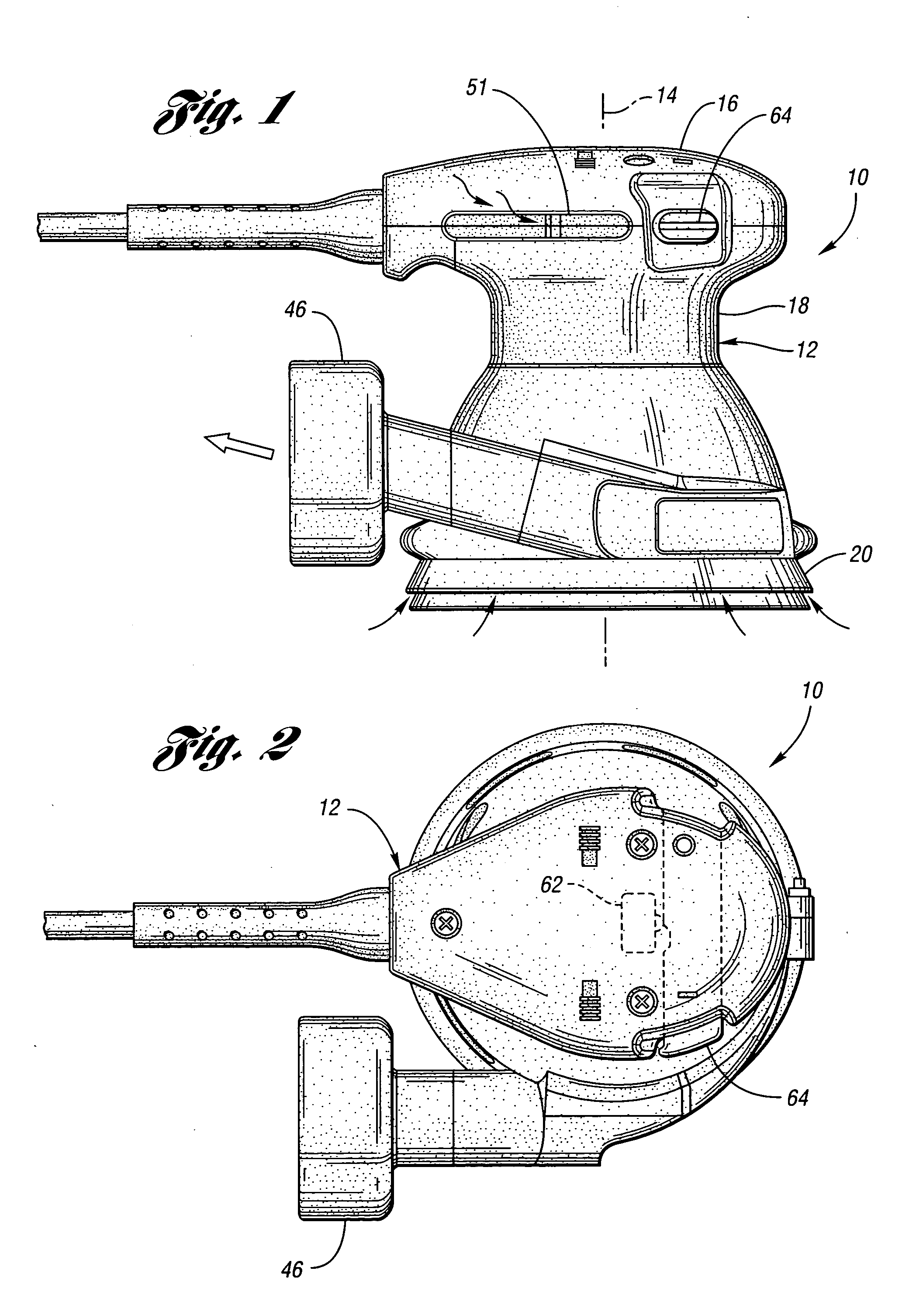

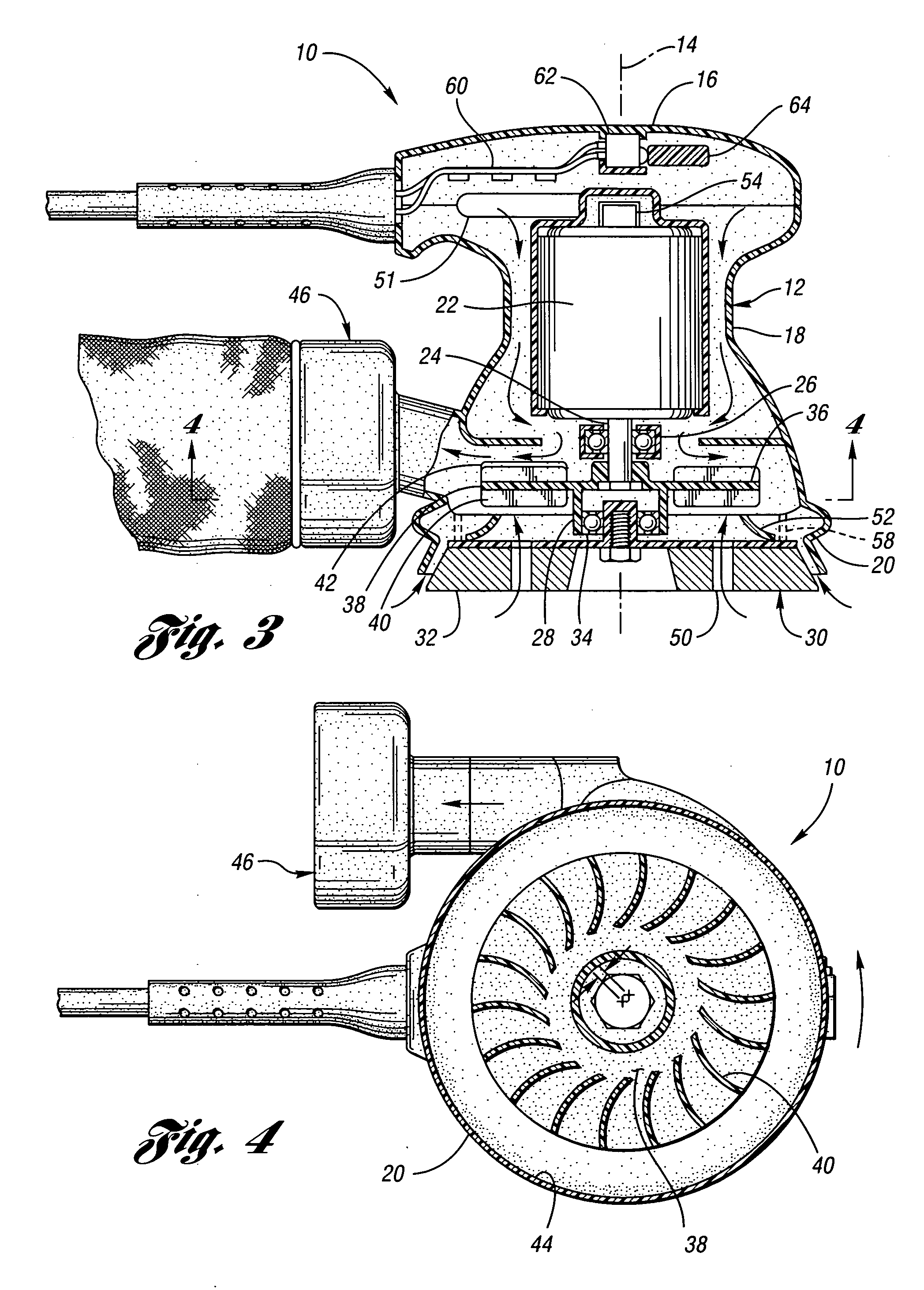

Orbital sander

InactiveUS20050003748A1Easy to useGrinding machine componentsPortable grinding machinesSanderActuator

An orbital sander is provided having a number of novel features including a high speed permanent magnet DC motor having a relatively flat rpm versus torque curve. The sander includes an AC to DC power supply, a remotely located on / off switch operated by a switch actuator bar extending transversely through the housing enabling the operator to actuate the on / off switch by alternatively pushing opposed ends of the actuator bar. The orbital sander further includes a fan having non-uniformly spaced blades, eliminating the need for a conventional counterweight, and a dust outlet adapted to be alternatively connected to a dust canister or alternate size collector vacuum hoses.

Owner:EASTWAY FAIR

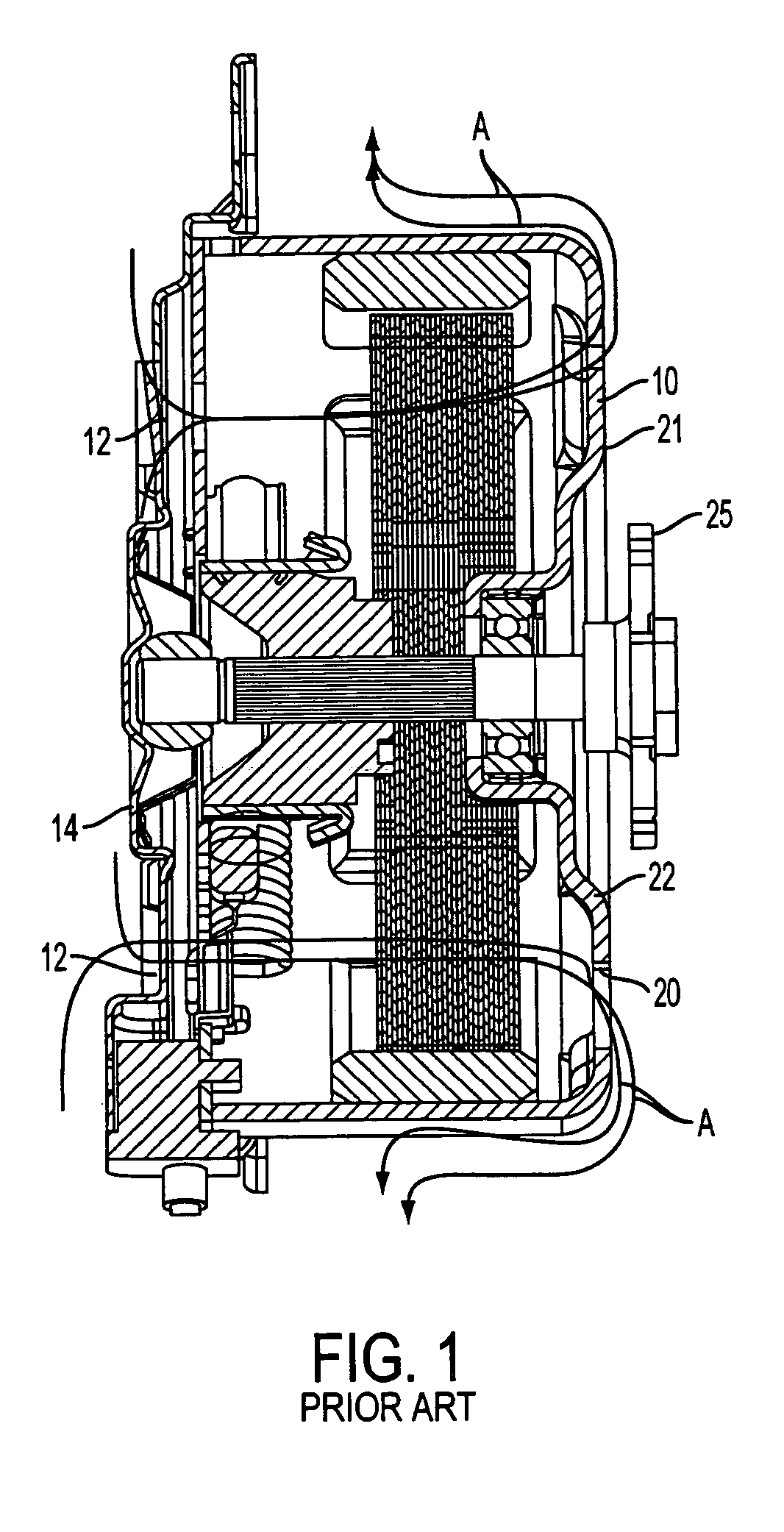

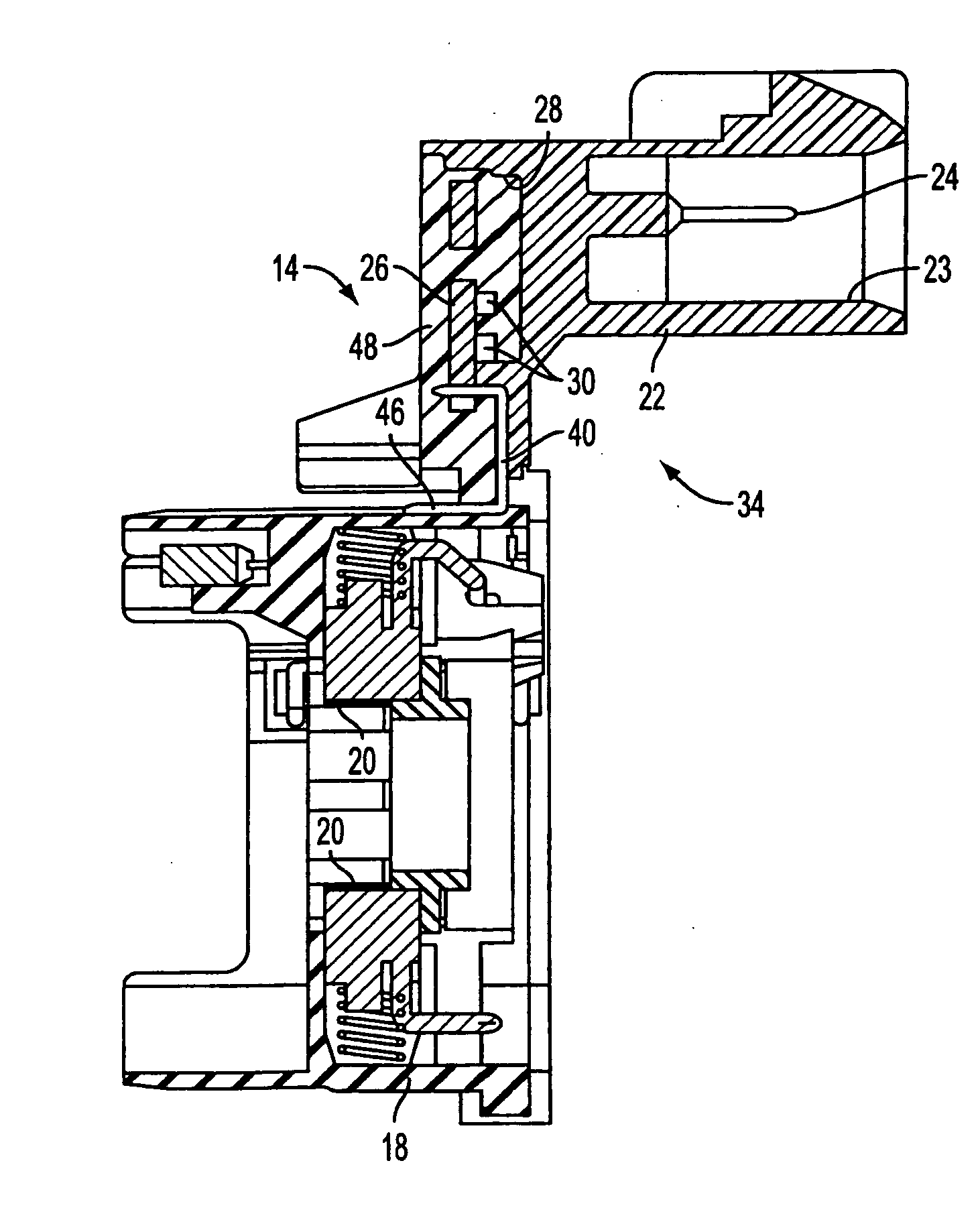

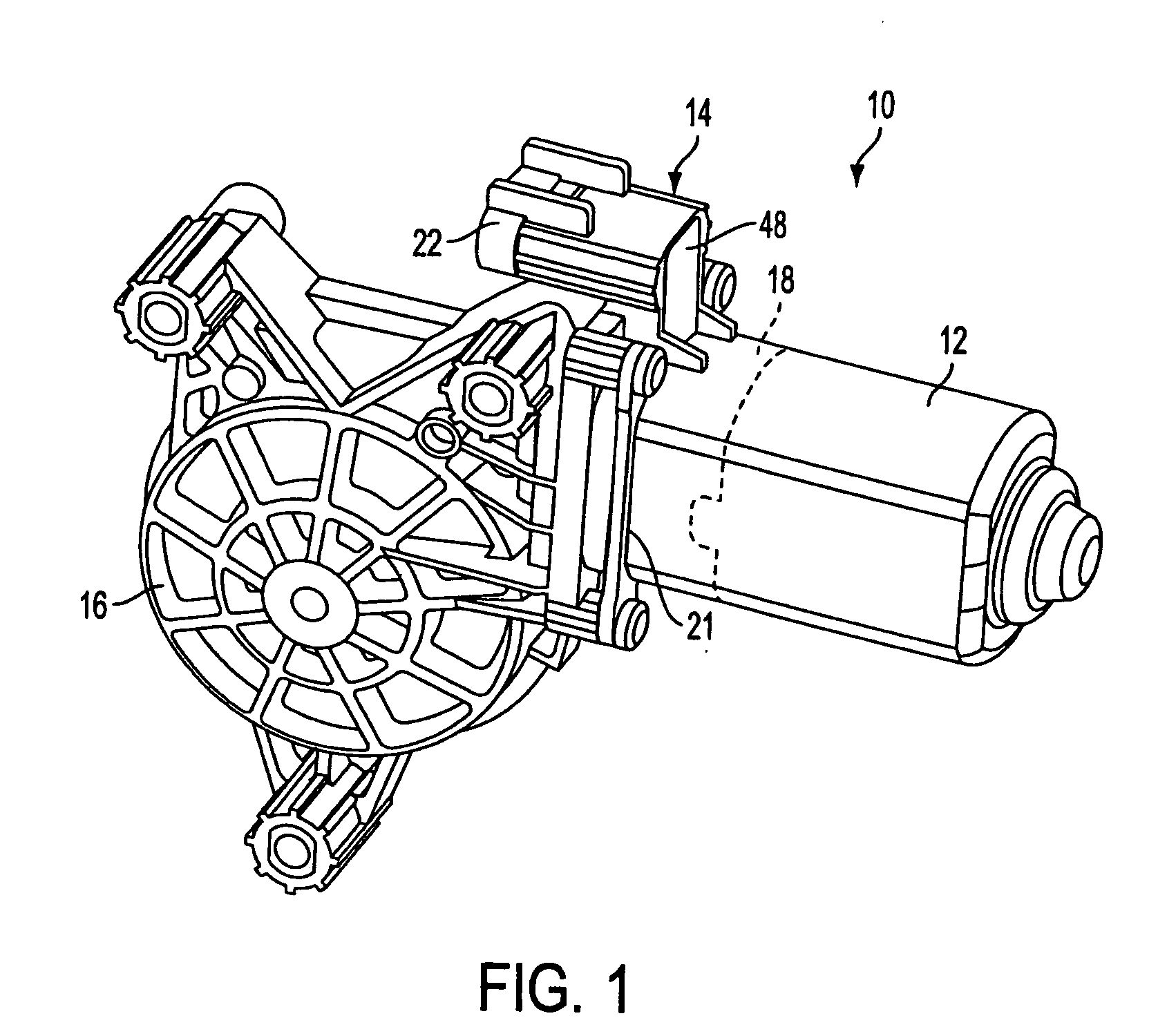

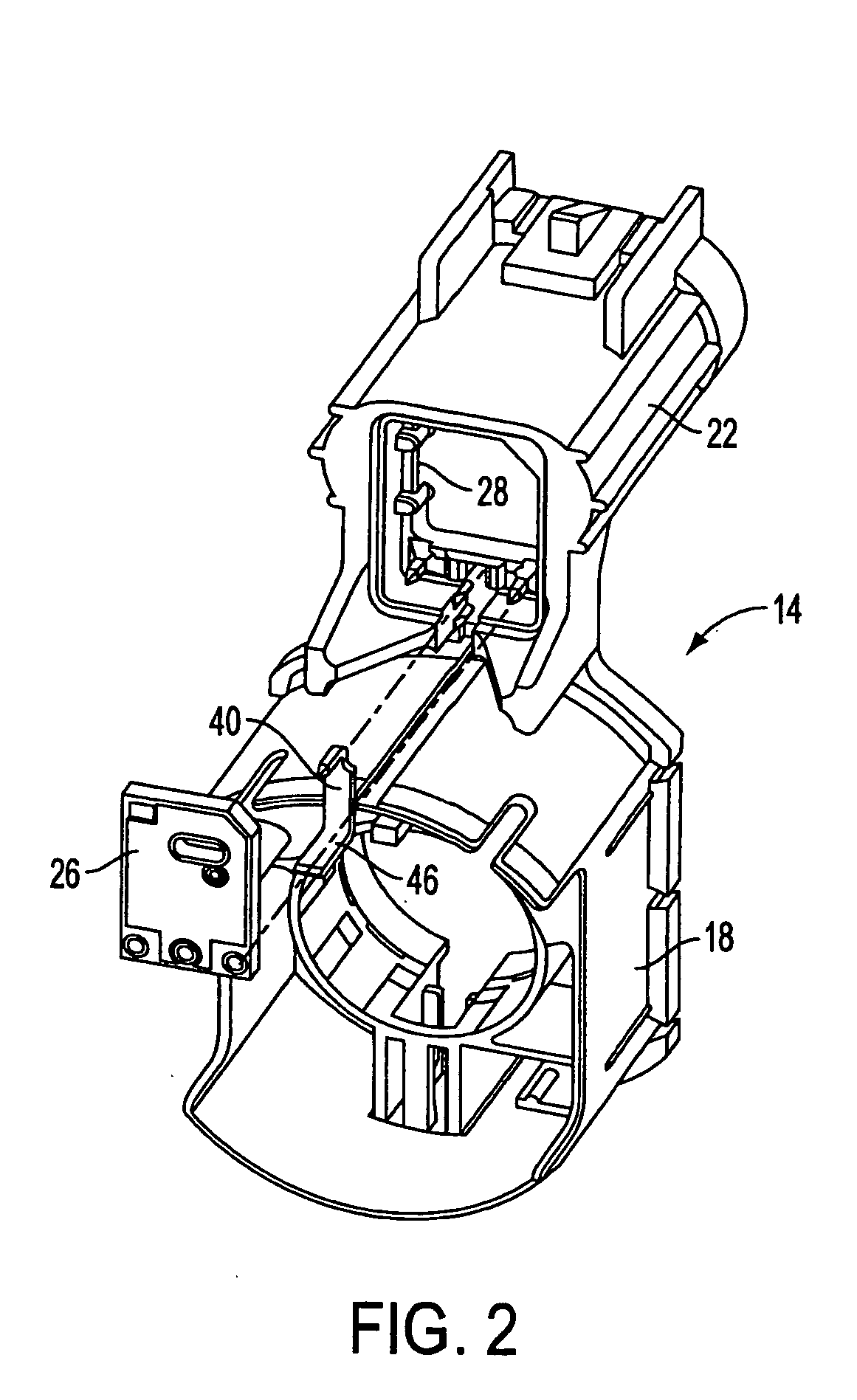

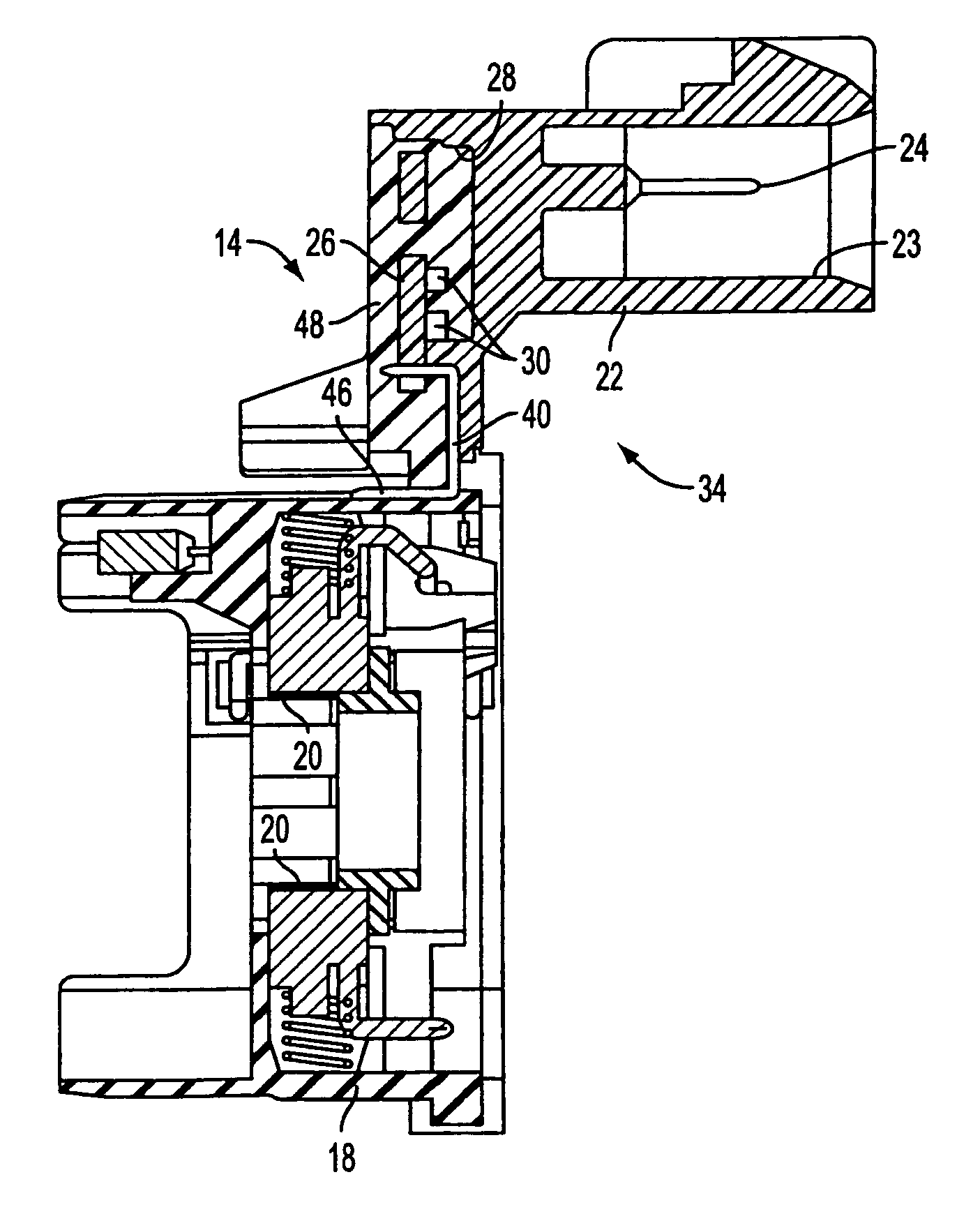

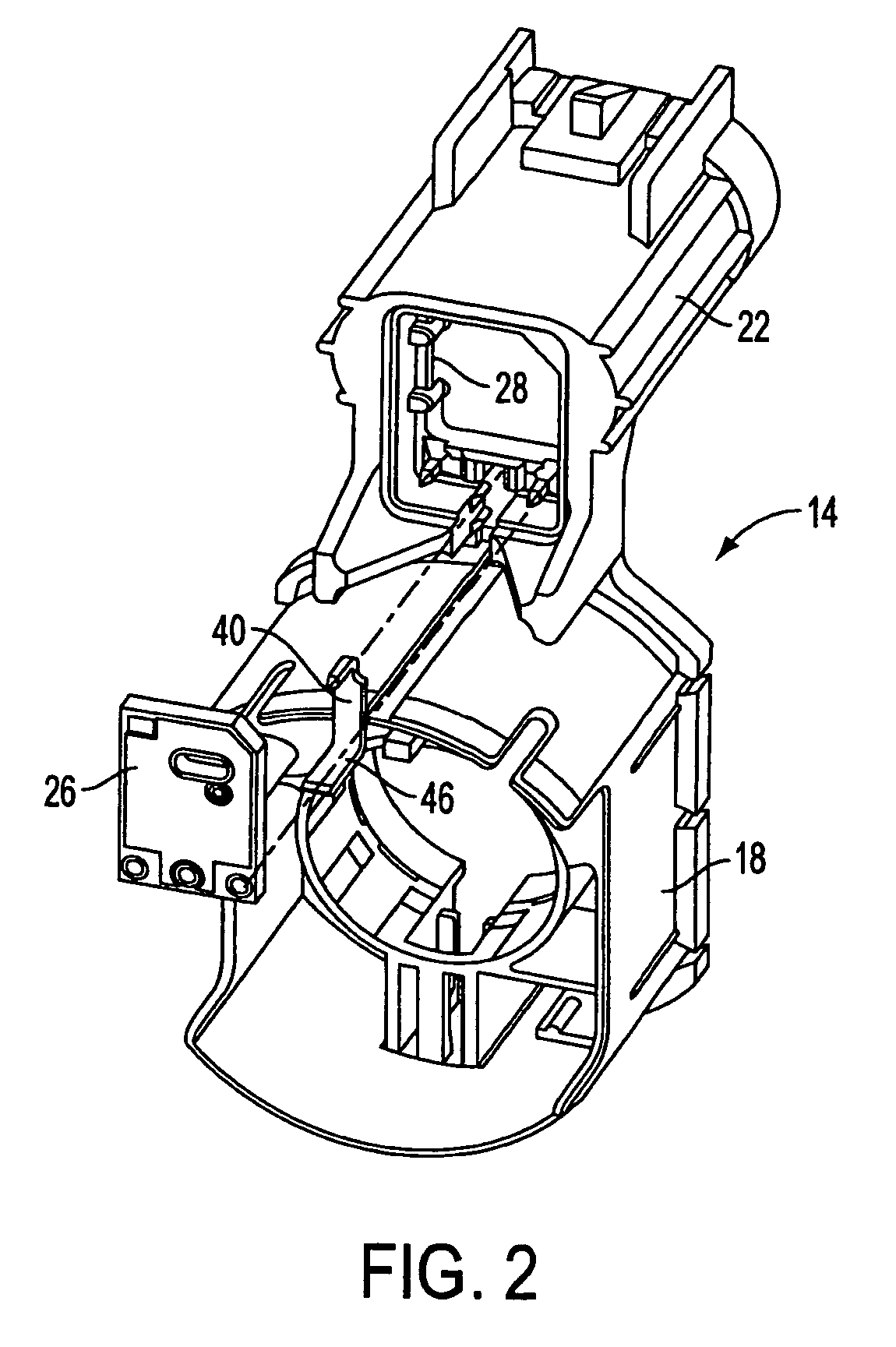

EMI suppression in permanent magnet DC motors having PCB outside motor in connector and overmolded

InactiveUS20050189829A1EMI suppressionRotary current collectorMagnetic/electric field screeningElectromagnetic interferenceEngineering

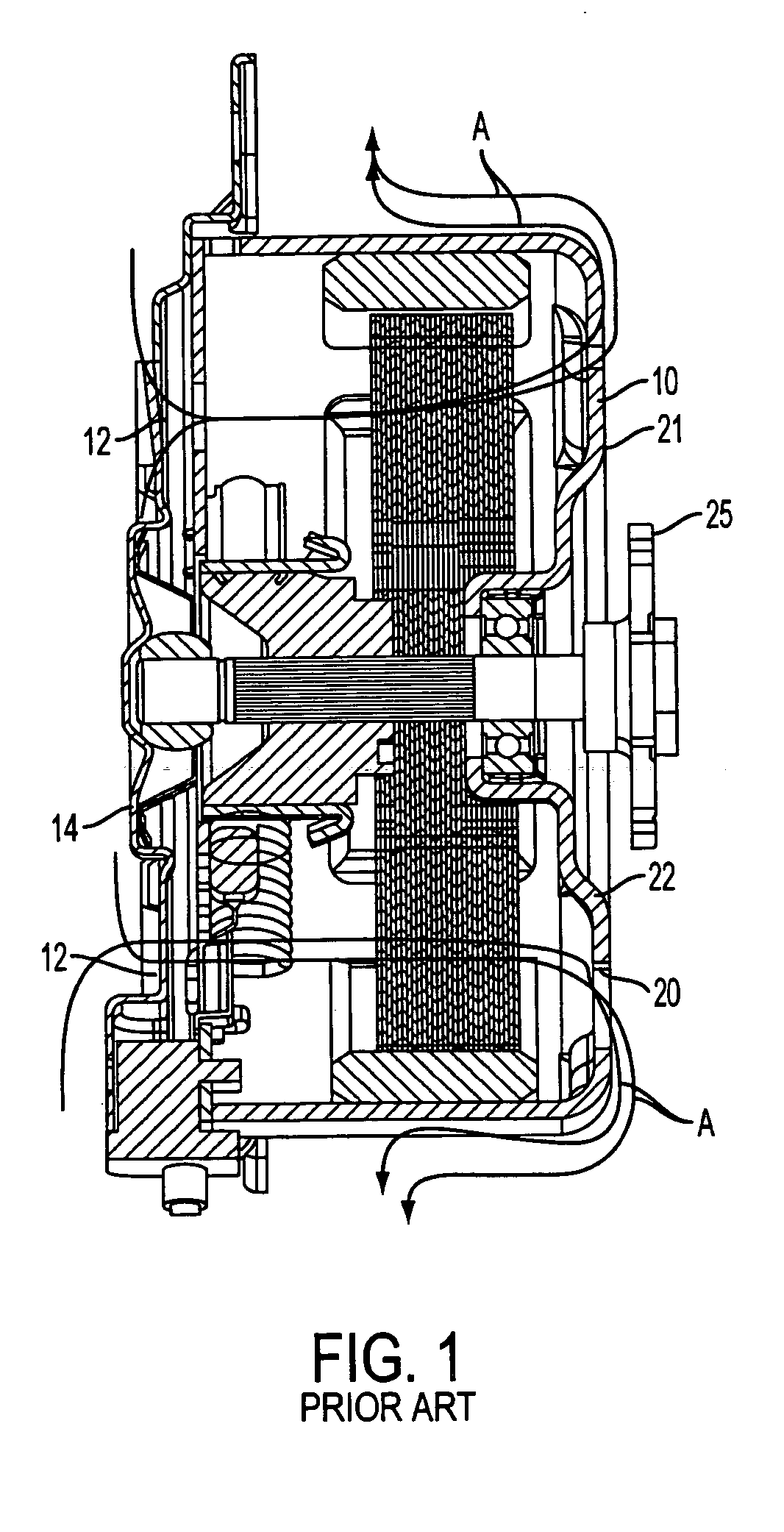

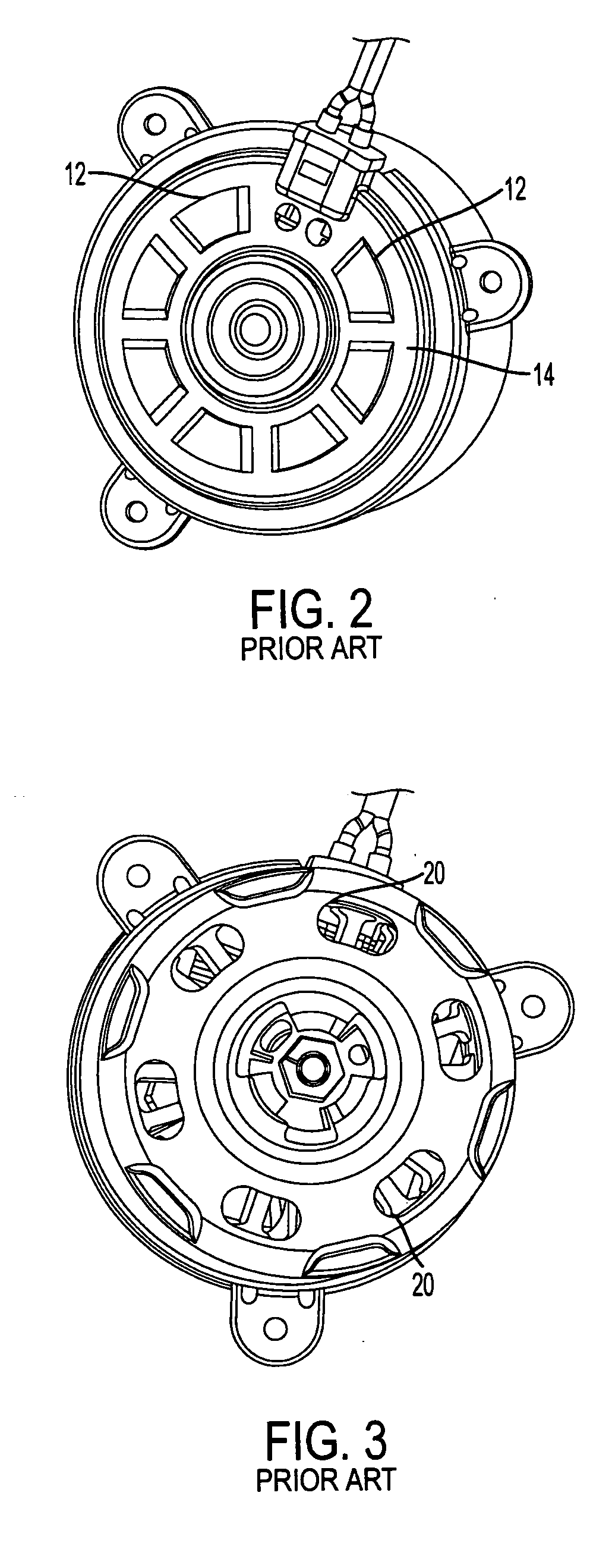

A permanent magnet DC motor 10 having electromagnetic interference (EMI) suppression includes a metal motor housing 12 and a brush card assembly 34. The brush card assembly includes brushes 20 and leads 24 constructed and arranged to be coupled with a source of power to power the motor. A brush card housing 14 has a first portion 18 housing the brushes and a second portion 22, integral with the first portion, and housing the leads. A printed circuit board 26 is mounted with respect to the second portion of the housing and carries at least one electromagnetic interference (EMI) suppression component 30 constructed and arranged to suppress EMI generated by the motor. The leads are electrically connected to the printed circuit board so that current can be provided through the printed circuit board to the brushes. A contact member 40 is electrically connected between the printed circuit board and the metal motor housing so that the at least one EMI suppression component couples the brushes to the metal motor housing thereby causing the metal motor housing to become an AC ground and EMI shield.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

EMI suppression in permanent magnet DC motors having PCB outside motor in connector and overmolded

InactiveUS6992414B2Rotary current collectorMagnetic/electric field screeningElectricityElectromagnetic interference

A permanent magnet DC motor 10 having electromagnetic interference (EMI) suppression includes a metal motor housing 12 and a brush card assembly 34. The brush card assembly includes brushes 20 and leads 24 constructed and arranged to be coupled with a source of power to power the motor. A brush card housing 14 has a first portion 18 housing the brushes and a second portion 22, integral with the first portion, and housing the leads. A printed circuit board 26 is mounted with respect to the second portion of the housing and carries at least one electromagnetic interference (EMI) suppression component 30 constructed and arranged to suppress EMI generated by the motor. The leads are electrically connected to the printed circuit board so that current can be provided through the printed circuit board to the brushes. A contact member 40 is electrically connected between the printed circuit board and the metal motor housing so that the at least one EMI suppression component couples the brushes to the metal motor housing thereby causing the metal motor housing to become an AC ground and EMI shield.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

Method for transforming three-phase asynchronous motor into permanent magnet motor

ActiveCN104052208AReliable startHigh mechanical strengthManufacturing stator/rotor bodiesDynamic balanceThree phase asynchronous motor

The invention provides a method for transforming a three-phase asynchronous motor into a permanent magnet motor. The method comprises the following steps that part of an iron core on the outer circumference of a rotor is cut off according to design needs, four sets of magnetic steel are attached to the outer circumference of the rotor, the clearances between the magnetic steel are coated with non-magnetic material layers, the outer sides of the magnetic steel are covered with non-magnetic metal layers, dynamic balance is detected, the transformed rotor is arranged in a stator, and the permanent magnet motor is formed.

Owner:王贤长

Core-free permanent magnet direct current motor with axial magnetic field for electric vehicle

InactiveCN102355101AImprove battery lifeImprove climbing abilityMagnetic circuit rotating partsElectric machinesElectric machineMetallic materials

The invention discloses a core-free permanent magnet direct current motor with an axial magnetic field for an electric vehicle. The motor comprises permanent magnets, magnetic conduction yokes, a bearing, a shaft core and a hub. A core-free inner stator is arranged coaxially on the shaft core. The two sides of the inner stator are coaxially provided with a rotor on which an even number of permanent magnets are uniformly distributed respectively. The inner edges of the rotors are connected with the magnetic conduction yokes on the two sides of the motor respectively, and are arranged together with the shaft core of the motor by the bearing. The outer edges of the rotors are connected together with the hub of the motor by the magnetic conduction yokes. The two sides of the stator are provided with the rotor respectively, a core and a toothed groove are not required, the dual rotors and the single stator form dual air gaps, and the magnetic field is axial. The efficiency of the motor is improved, effective metal materials are saved, the life mileage of the motor is increased, the climbing capability of the motor is improved and the battery replacement cycle of the electric vehicle is prolonged; and the motor is particularly suitable for use as a driving motor for the electric vehicle.

Owner:王春煜

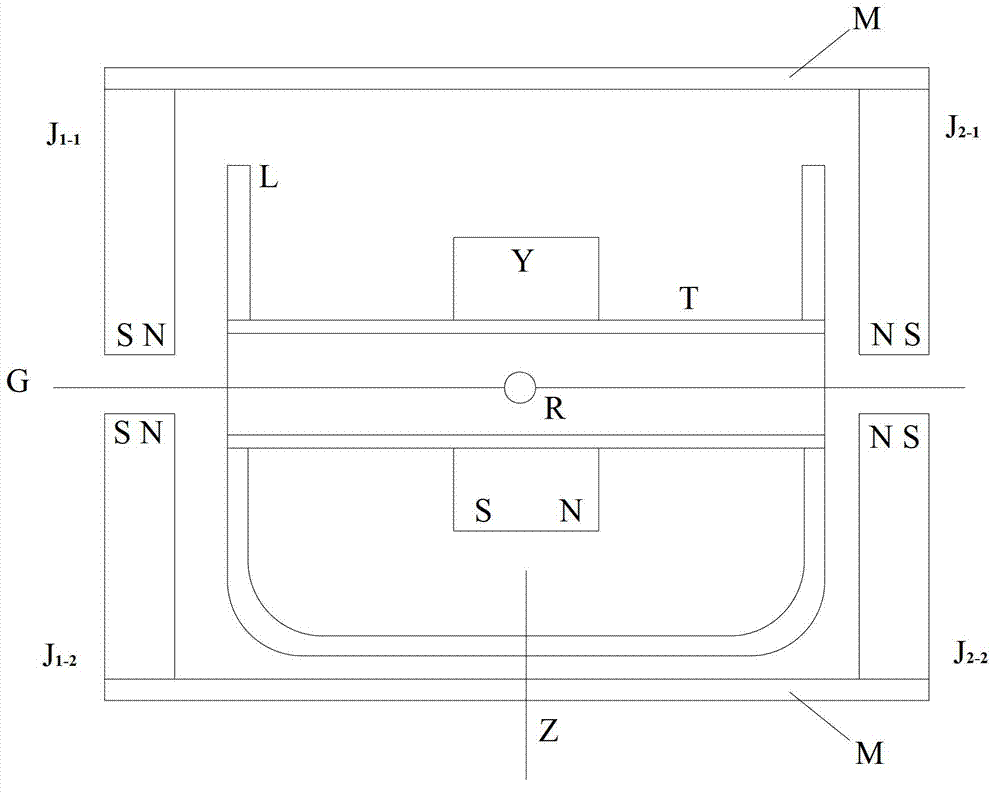

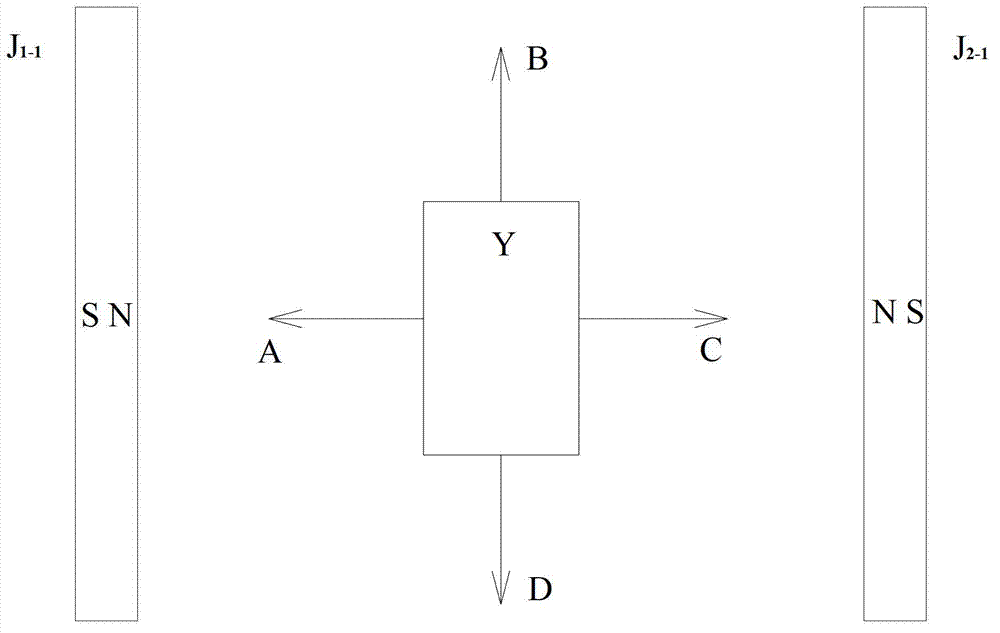

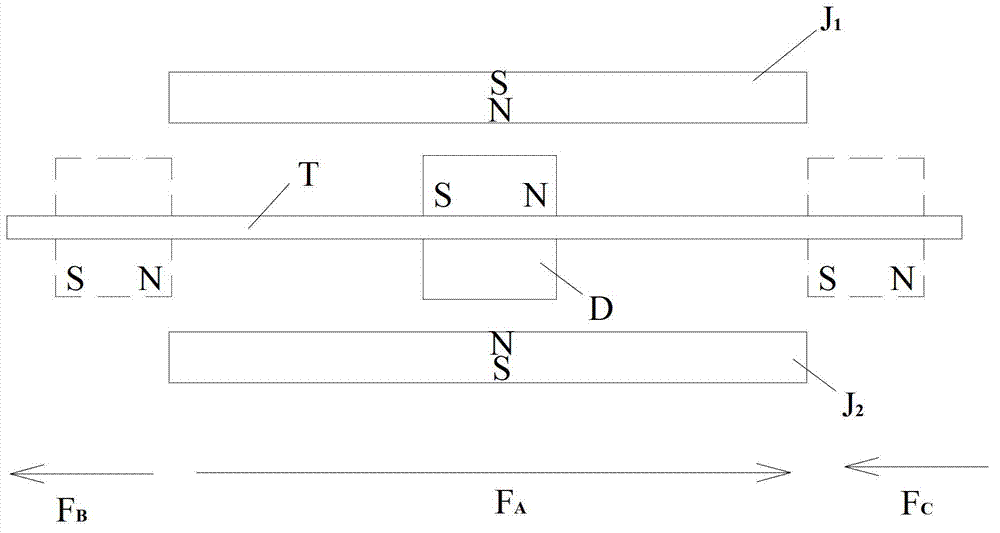

Magnet force device

The invention discloses a magnet force device and relates to an application of magnets in electromechanical devices. The magnet force device solves the problem of taking out energy from magnetic fields of the magnets and saves energy by means of the magnets. A force except for the attractive force and the repulsive force is further found out between two magnets, a movable magnet is arranged in the magnetic field of a static magnet, the included angle formed between the pole axis direction of the movable magnet and the pole axis direction of the static magnet is 90 degrees, the static magnet does not move, and the movable magnet moves due to the force which is called the magnet force. The attractive force and the repulsive force are respectively arranged on the outer side of the magnetic field of the static magnet. The attractive force, the repulsive force and the magnet force can serve as the pushing force, so that energy can be saved. The attractive force and the repulsive force can also be avoided, and only the magnet force of the magnets serves as the main power for motion to form a power device of linear motion or rotation motion, so that a large amount of energy can be saved. The magnetic field of the static magnet can be replaced by the magnetic field of an electromagnetic coil, and the movable magnet can move due to the magnet force, so that a power device the same as a permanent magnet direct current motor can be formed.

Owner:矫祥田

Vented end cap with integrated splash shield for permanent magnet DC motor

ActiveUS20050168080A1Cooling/ventillation arrangementSupports/enclosures/casingsForeign matterEngineering

A permanent magnet D.C. electric motor 36 includes a motor housing 29 having first and second ends. The second end 42 is substantially closed and has an end of a shaft 35 extending there from. The second end includes vent holes 20 therein. The first end 27 is substantially open. An end cap 31 closes the first end of the housing. The end cap 31 has venting holes 34 therein for permitting air to pass there-through to cool the motor. A splash shield 32 is integral with the end cap 31 and covers the venting holes 34 in such a manner to limit foreign matter from entering the venting holes while permitting air to flow through the venting holes.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

Permanent magnet electric machine and permanent magnet for an electric machine

ActiveUS20120001508A1Reduce manufacturing costHarmful impactMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPermanent magnet rotorElectric machine

The disclosure relates to an electric machine with a permanent magnet rotor, where permanent magnets have been fitted on an outer surface of a cylindrical rotor, and relates to a permanent magnet. The permanent magnets forming the electric machine's rotor pole are shaped so that the electric machine's air gap is substantially constant in a middle of the pole, and the air gap increases in an essentially straightforward manner when moving towards the edge of the pole. The permanent magnet is of an even thickness in the middle, and becomes thinner towards the edges. This can result in a decrease in the torque ripple and cogging torque of an electric machine.

Owner:ABB (SCHWEIZ) AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com