Method for transforming three-phase asynchronous motor into permanent magnet motor

A permanent magnet motor, three-phase asynchronous technology, applied in the manufacture of stator/rotor body, etc., can solve the problems of low energy efficiency level of permanent magnet rotor, high machining requirements, troublesome transformation, etc., to achieve enhanced mechanical strength, reliable start, and improved reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

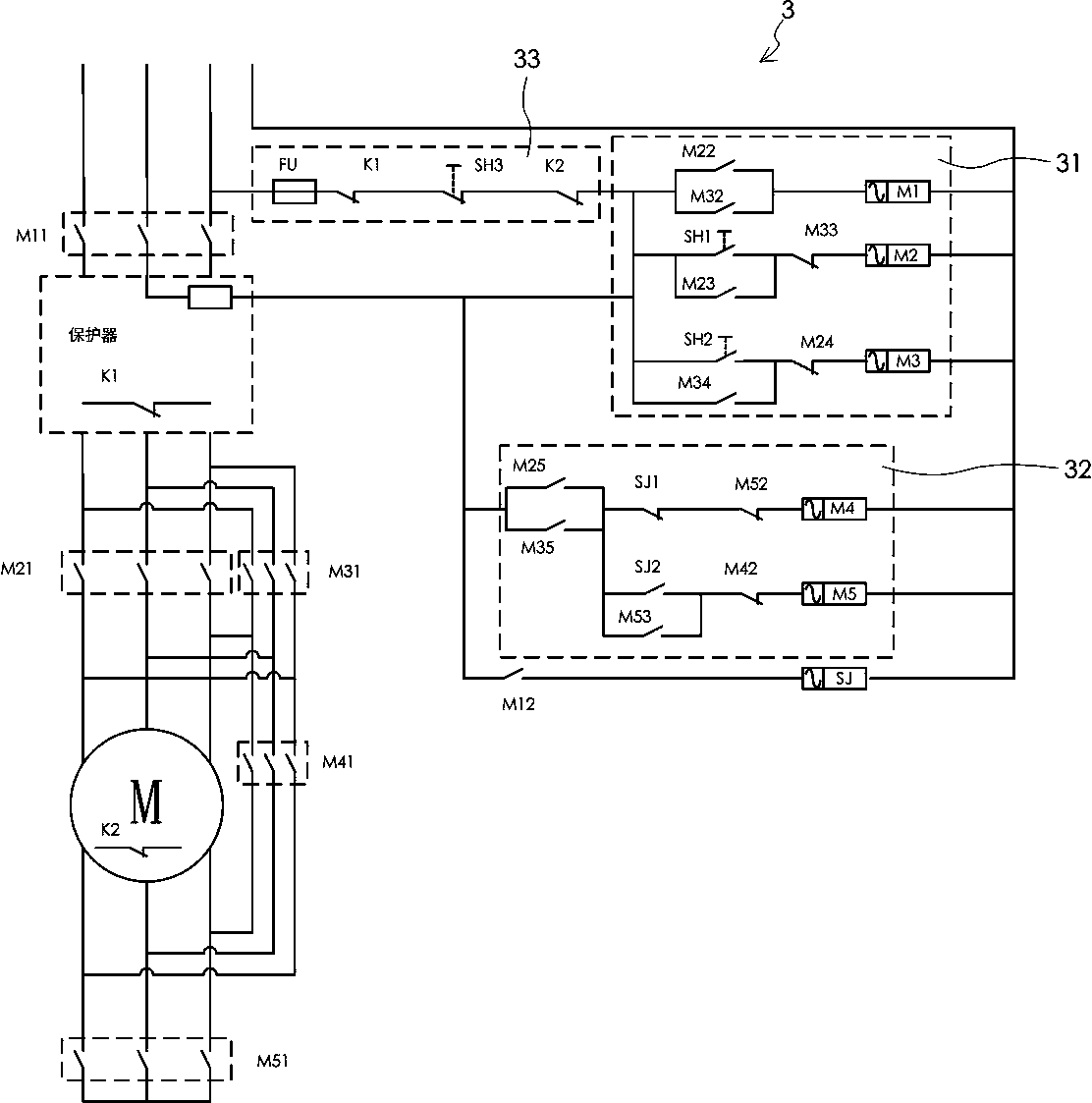

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0015] This method of transforming a three-phase asynchronous motor into a permanent magnet motor of the present invention comprises the following steps:

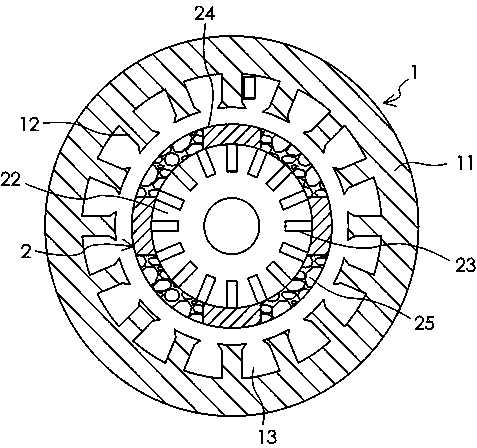

[0016] Cut off part of the iron core on the outer circumference of the rotor according to the design requirements, retain part of the copper / aluminum guide bars in the iron core, and retain part of the end rings at both ends of the iron core. The bars and end rings can still generate an induced magnetic field.

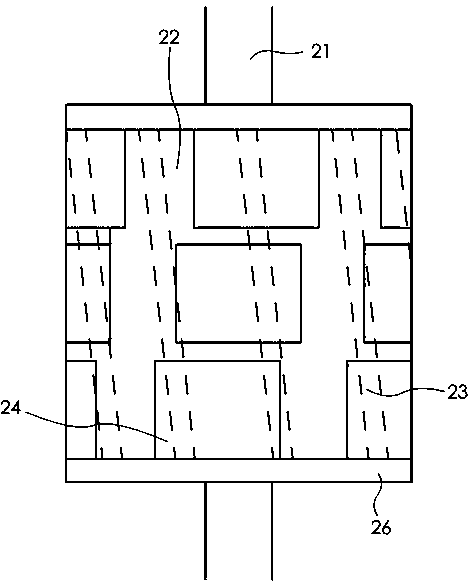

[0017] Paste four groups of magnetic steel on the outer circumference of the rotor, and the arrangement direction of each group of magnetic steel can be a straight line or an oblique line. Each group of magnets can be composed of 3, 3.5, 4 and other different numbers of magnets.

[0018] After pasting the magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com