Core-free permanent magnet direct current motor with axial magnetic field for electric vehicle

A DC motor, axial magnetic field technology, applied in electric vehicles, motors, electromechanical devices, etc., can solve the problems of motor efficiency restriction, too many electromagnetic wires, large moment of inertia, etc., to increase cruising range and climbing ability, and prolong replacement. Battery time, effect of saving effective metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

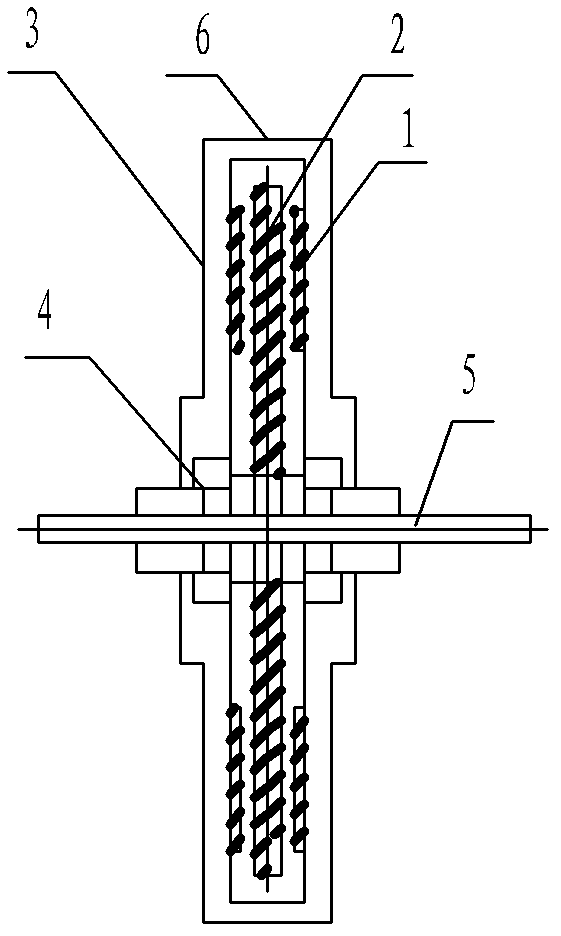

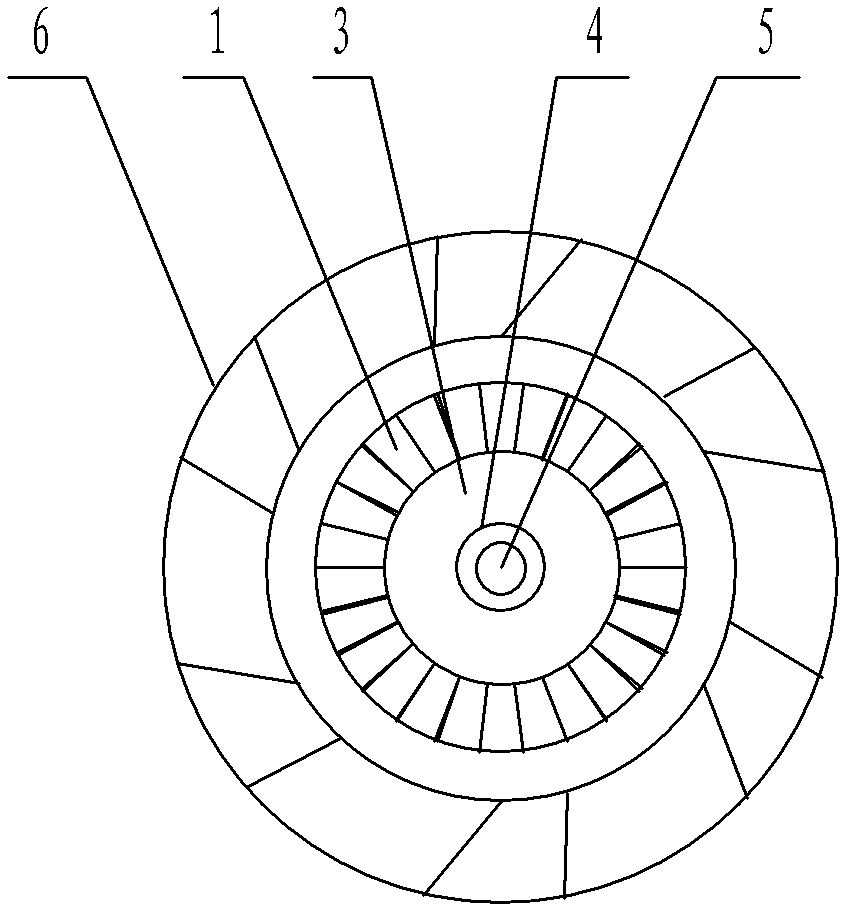

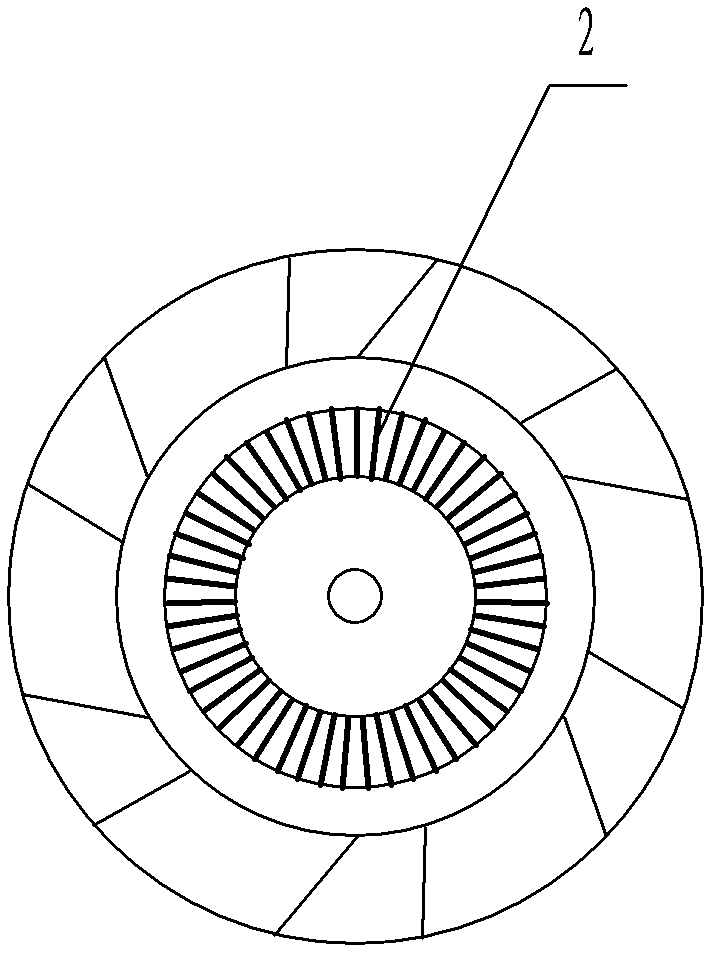

[0017] Such as Figure 1 to Figure 3 As shown, the high-efficiency permanent magnet DC motor for electric vehicles is composed of a shaft core 5, a casing, a stator, a rotor, a bearing 4, a magnetic yoke 3, a permanent magnet 1, and a motor outlet. An iron-less inner stator composed of electromagnetic wire windings and epoxy materials is coaxially installed; two rotors with an even number of permanent magnets are coaxially installed on both sides of the inner stator; the inner edge of the rotor is connected to the motor two The side end covers are respectively connected, installed with the shaft core of the motor through the bearing, and the outer edge of the rotor is connected with the hub of the motor through the end cover. It adopts a stator with two rotors on both sides. There is no iron core and no cogging. The double rotor and single stator form a double air gap, and the magnetic field is axial.

[0018] And: the stator is cast and pressed by winding and epoxy resin (or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com