Radiating and cooling device for power battery

A power battery, heat dissipation and cooling technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of inability to modularize expansion, bulky, complex structure of shell-and-tube heat dissipation devices, etc., to improve battery energy efficiency, volume, etc. Streamlined and guaranteed cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

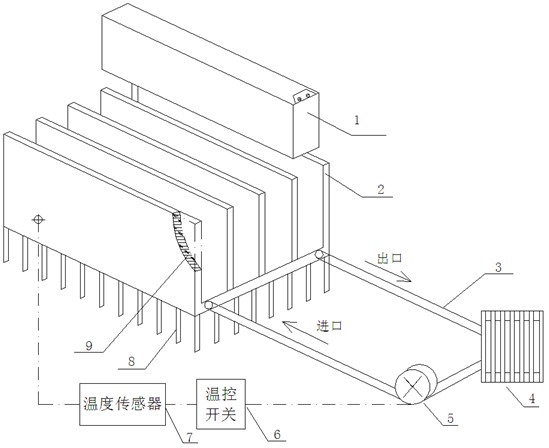

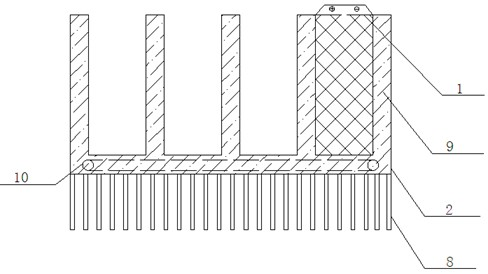

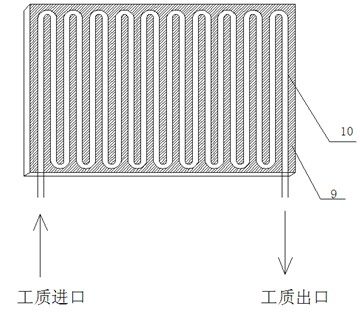

[0022] The hollow metal cold plate is used to improve the heat transfer effect between the battery pack and the phase change material, and the phase change material is filled in the metal cold plate shell, and the temperature of the battery pack is maintained in an appropriate working range through the heat absorption of the phase change material to ensure that the temperature of the battery is within the range. consistency between. And a coil radiator is arranged at the bottom of the hollow cold plate shell, and the liquid cooling working fluid is passed inside to take away the heat of the battery. Through the effective combination of the three cooling methods, the temperature of the battery pack can be significantly reduced to ensure the consistency of the temperature of the battery cells.

[0023] Such as figure 1 The schematic diagram of the heat dissipation and cooling device for the power battery is shown. The device includes two parts, one part is the power battery hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com