Patents

Literature

246results about How to "Improve utility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

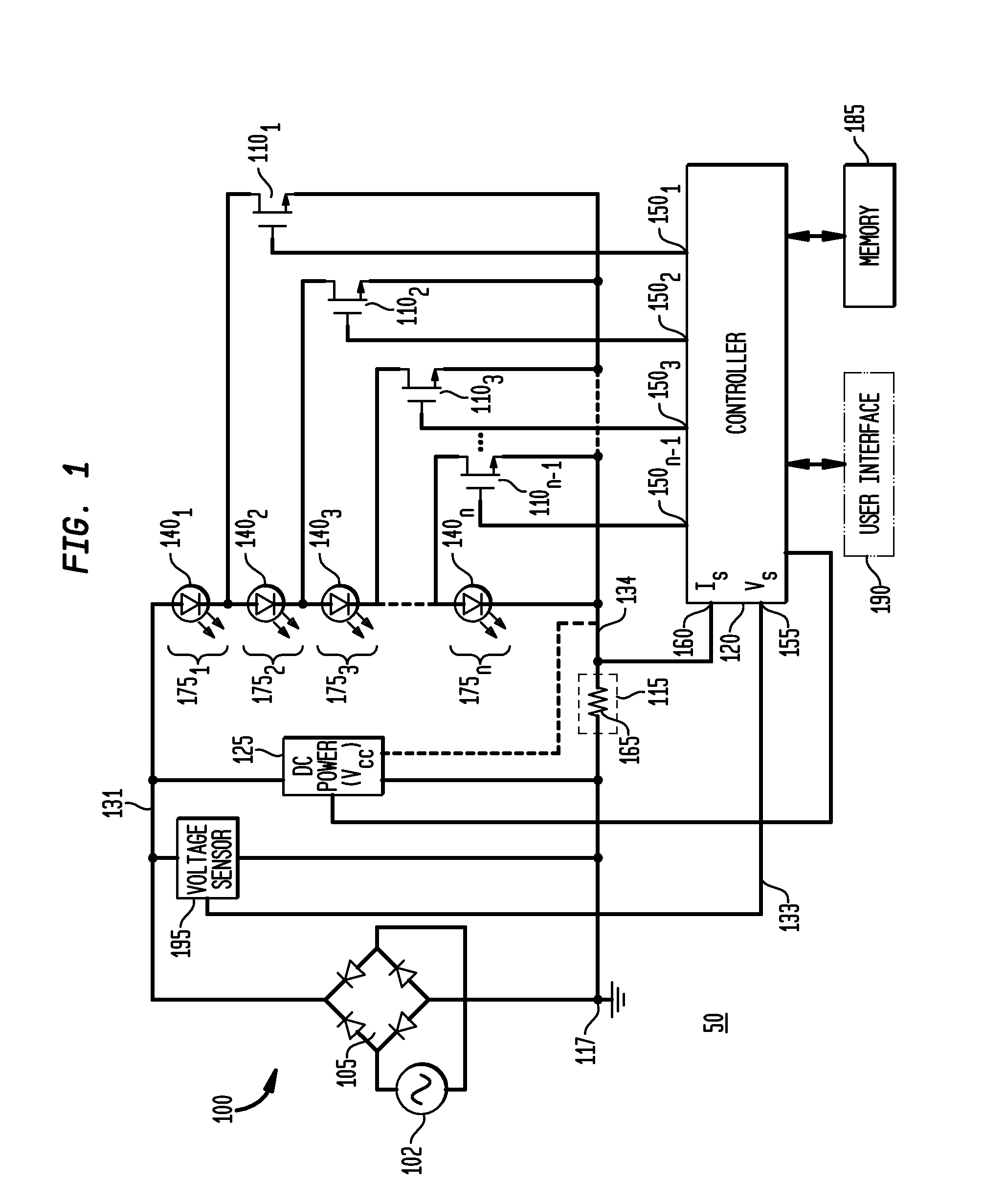

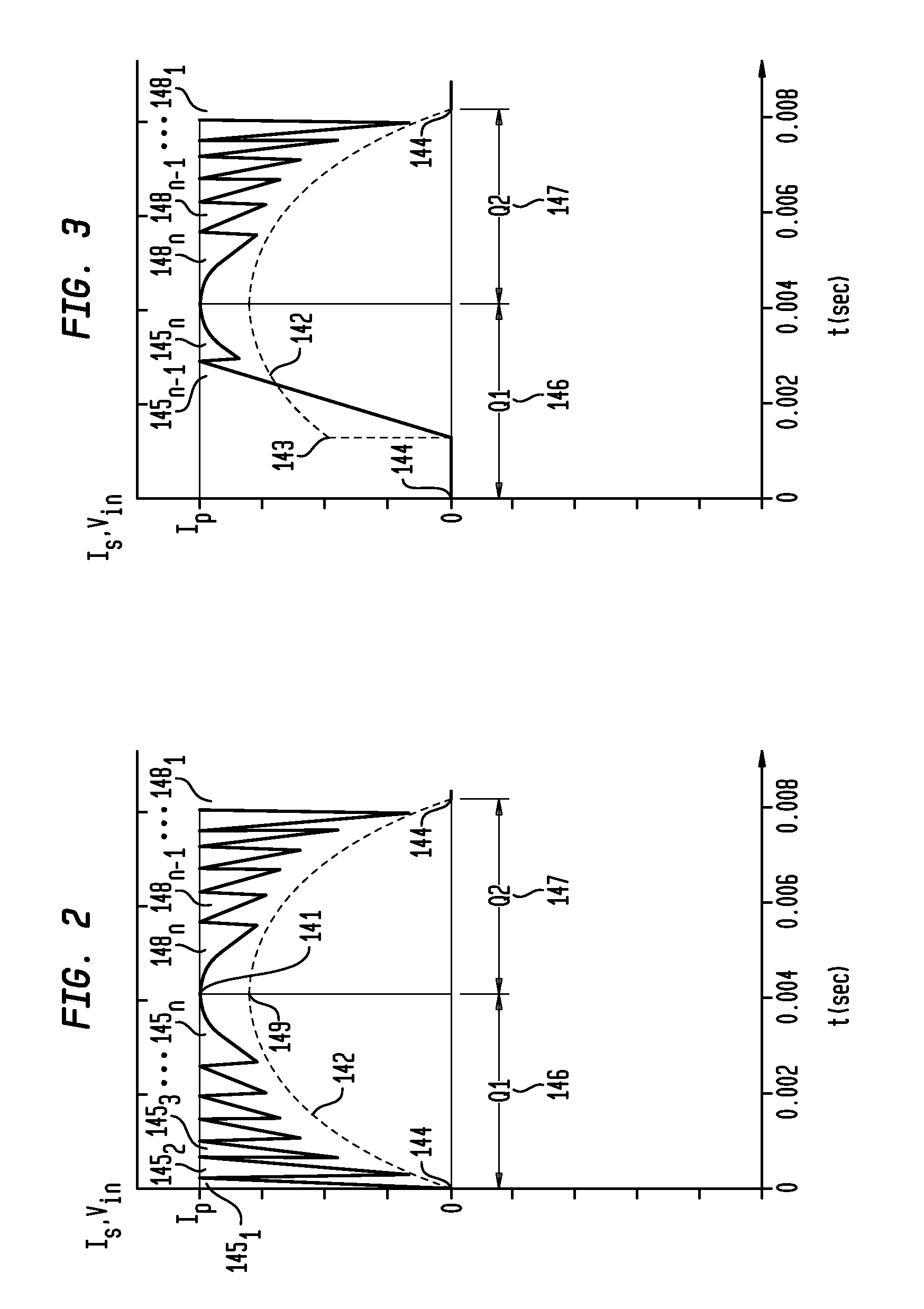

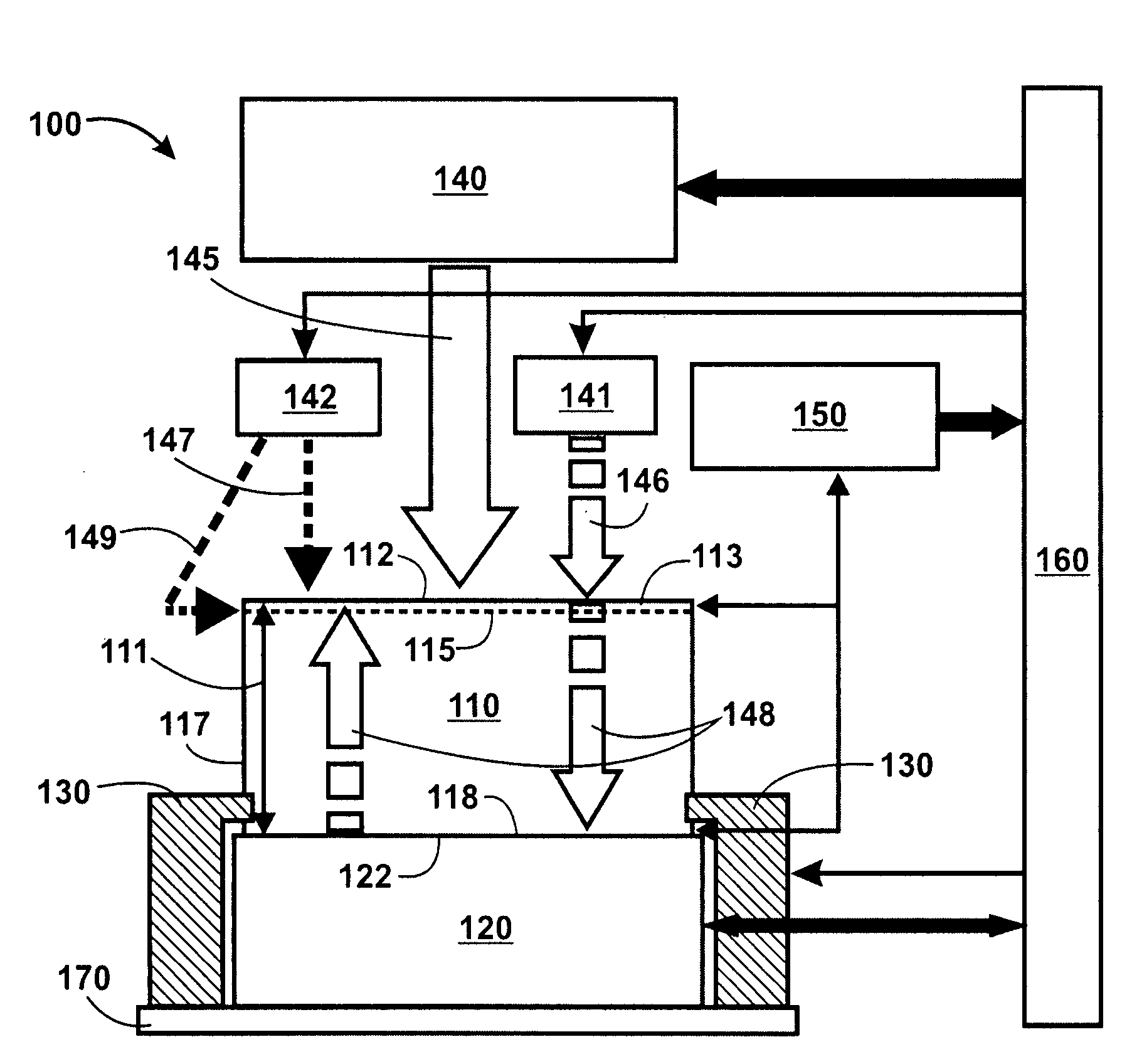

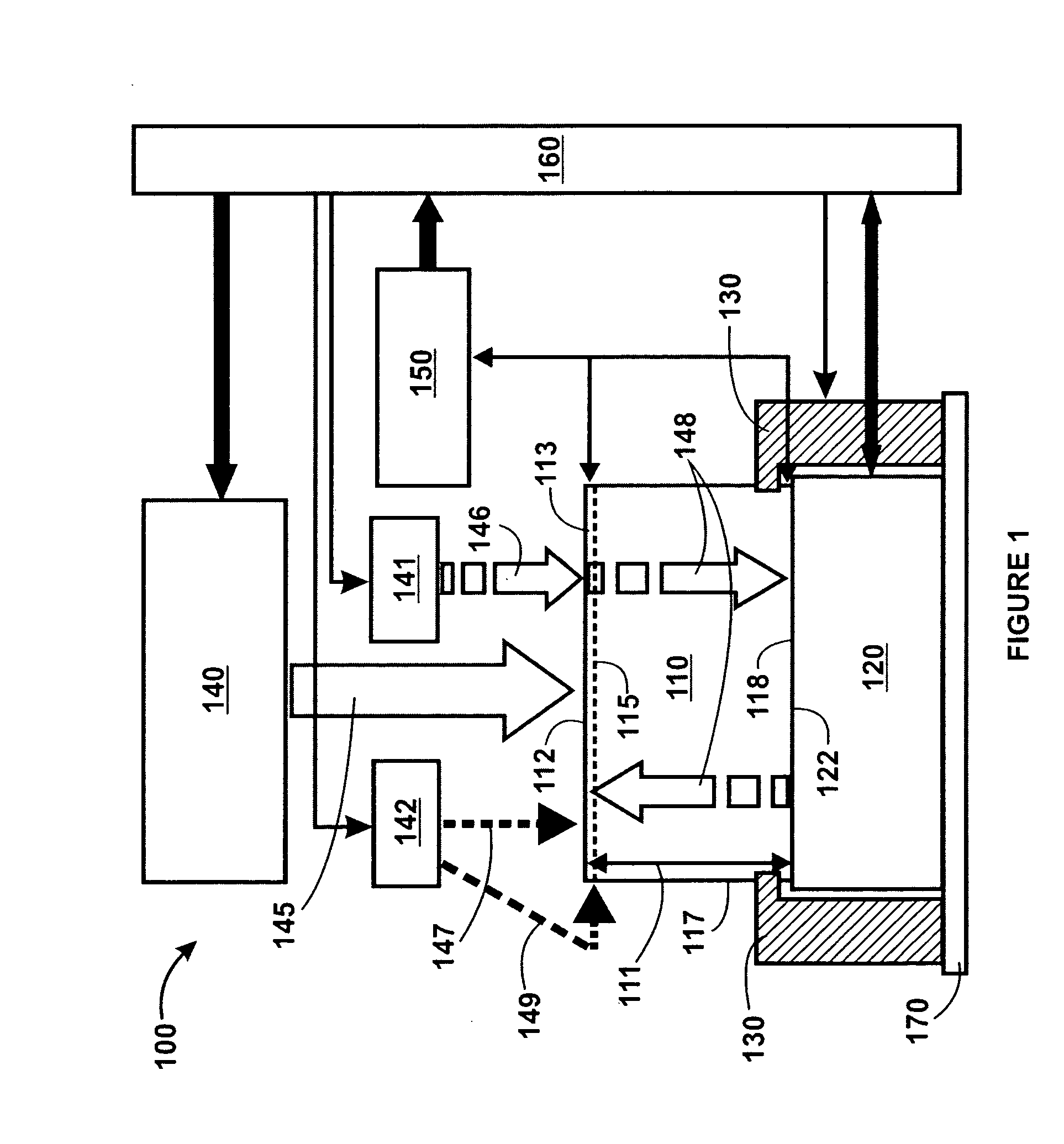

Apparatus, Method and System for Providing AC Line Power to Lighting Devices

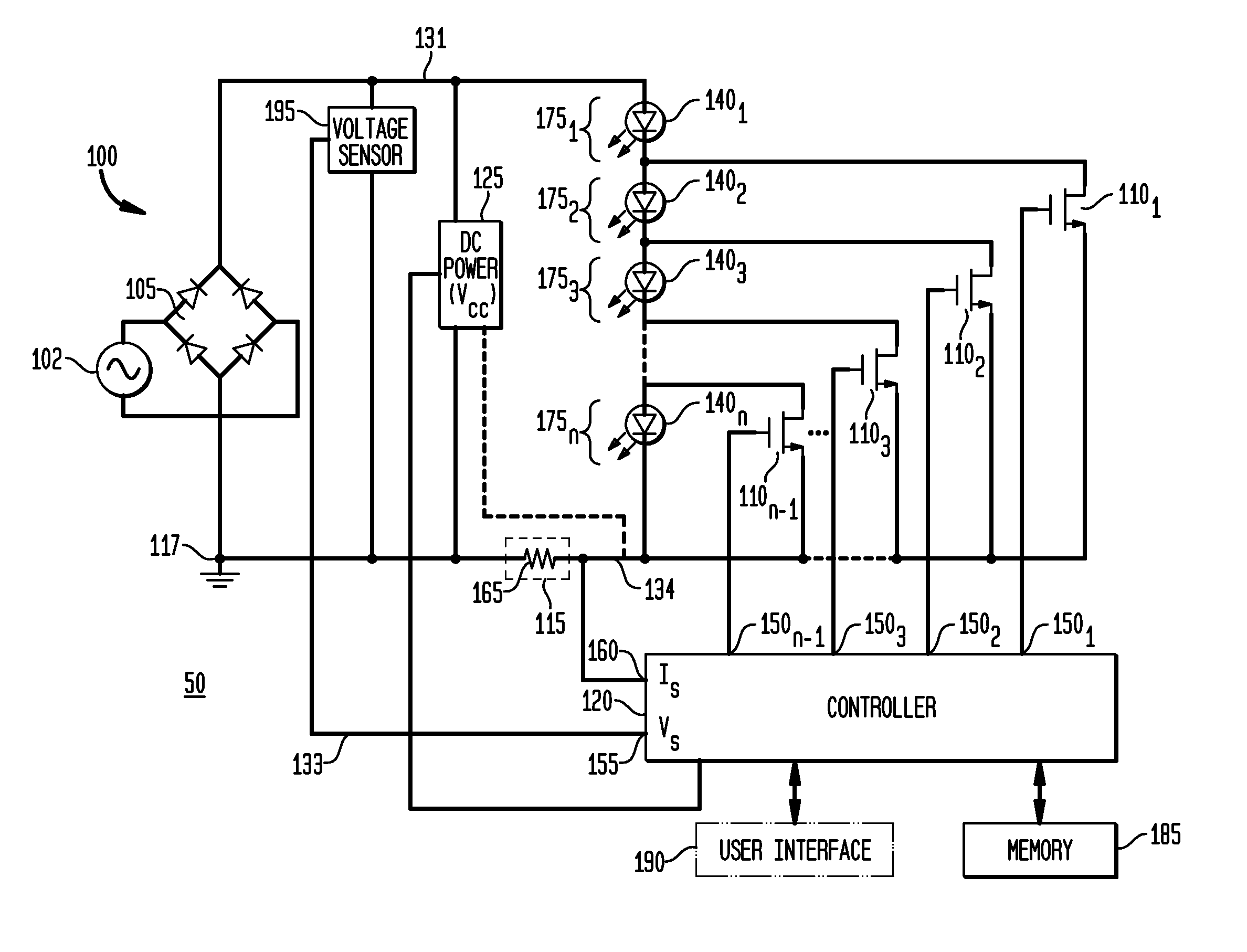

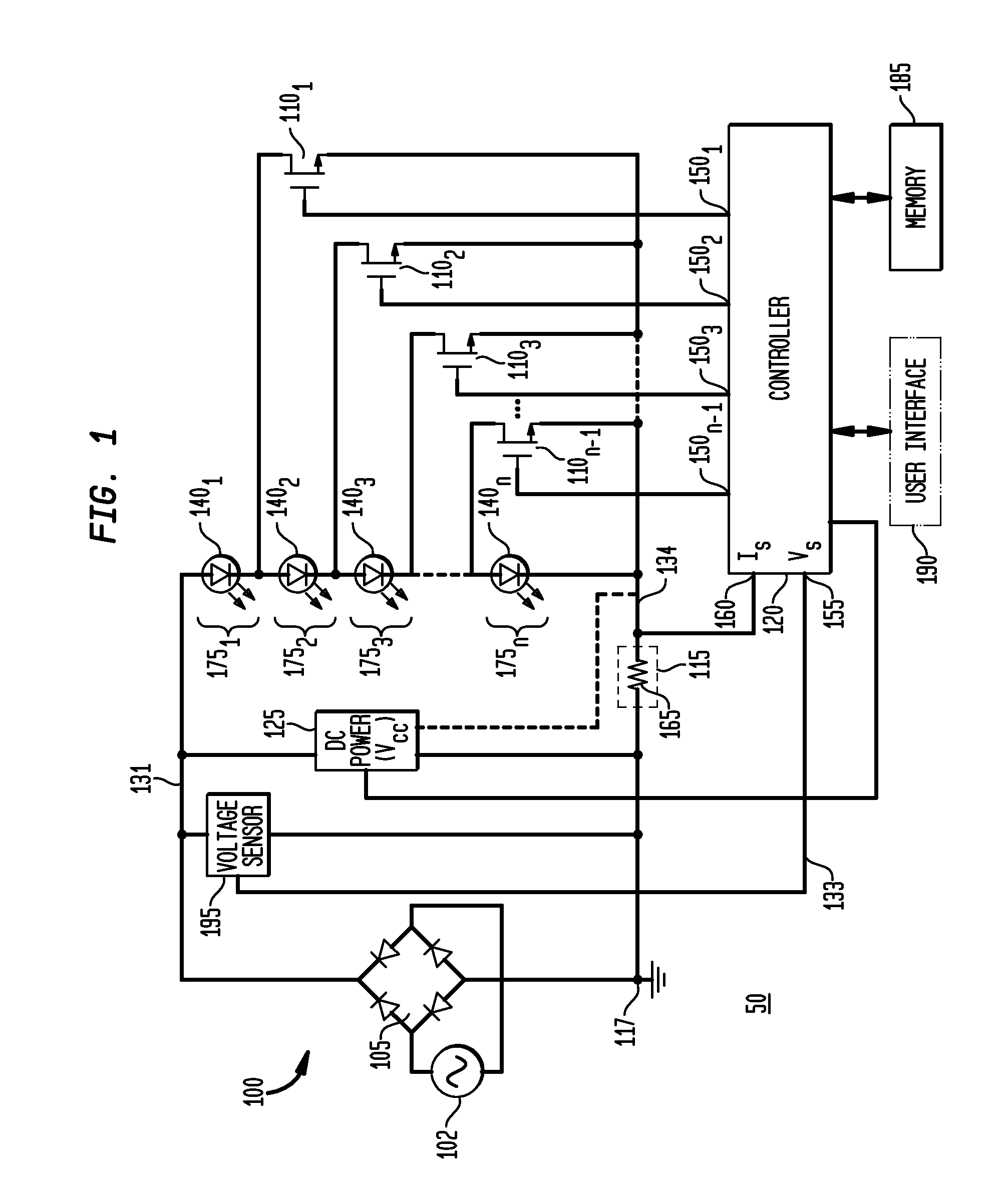

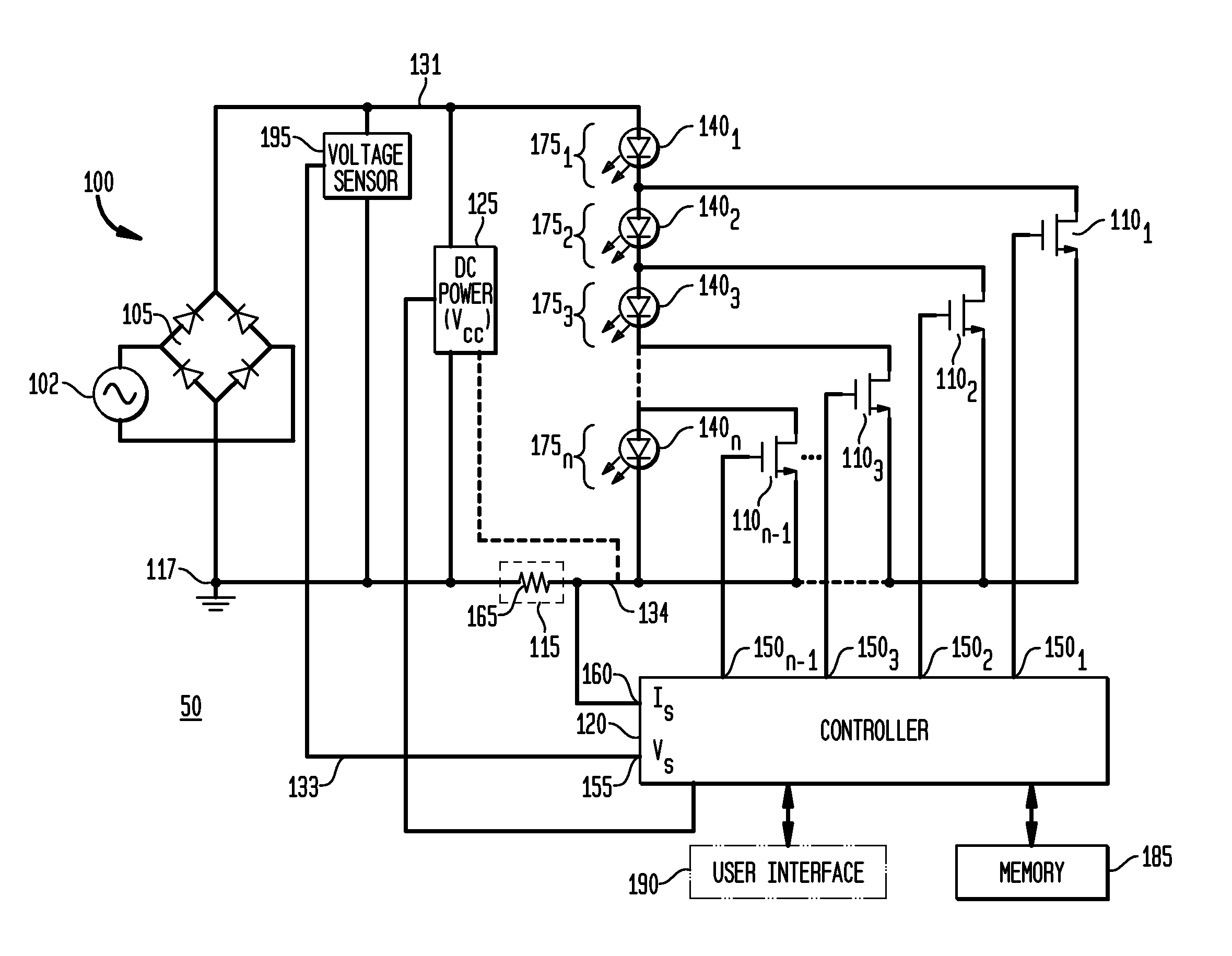

ActiveUS20120081009A1Reduction in size and costImprove Utilization and EfficiencyElectrical apparatusElectroluminescent light sourcesLight equipmentVoltage regulation

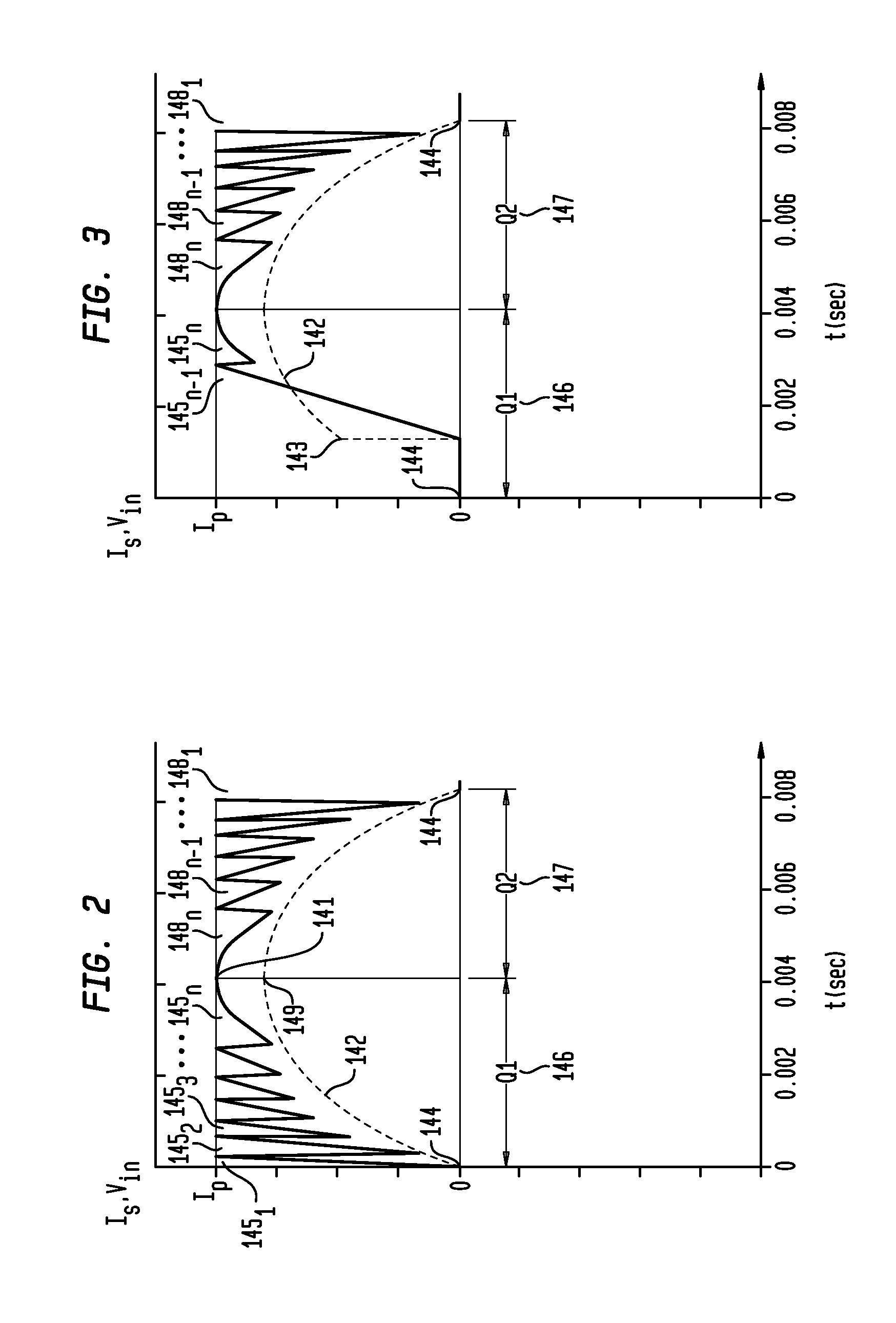

An apparatus, method and system are disclosed for providing AC line power to lighting devices such as light emitting diodes (“LEDs”). An exemplary apparatus comprises: a plurality of LEDs coupled in series to form a plurality of segments of LEDs; first and second current regulators; a current sensor; and a controller to monitor a current level through a series LED current path, and to provide for first or second segments of LEDs to be in or out of the series LED current path at different current levels. A voltage regulator is also utilized to provide a voltage during a zero-crossing interval of the AC voltage. In an exemplary embodiment, first and second segments of LEDs are both in the series LED current path regulated at a lower current level compared to when only the first segment of LEDs is in the series LED current path.

Owner:CHEMTRON RES

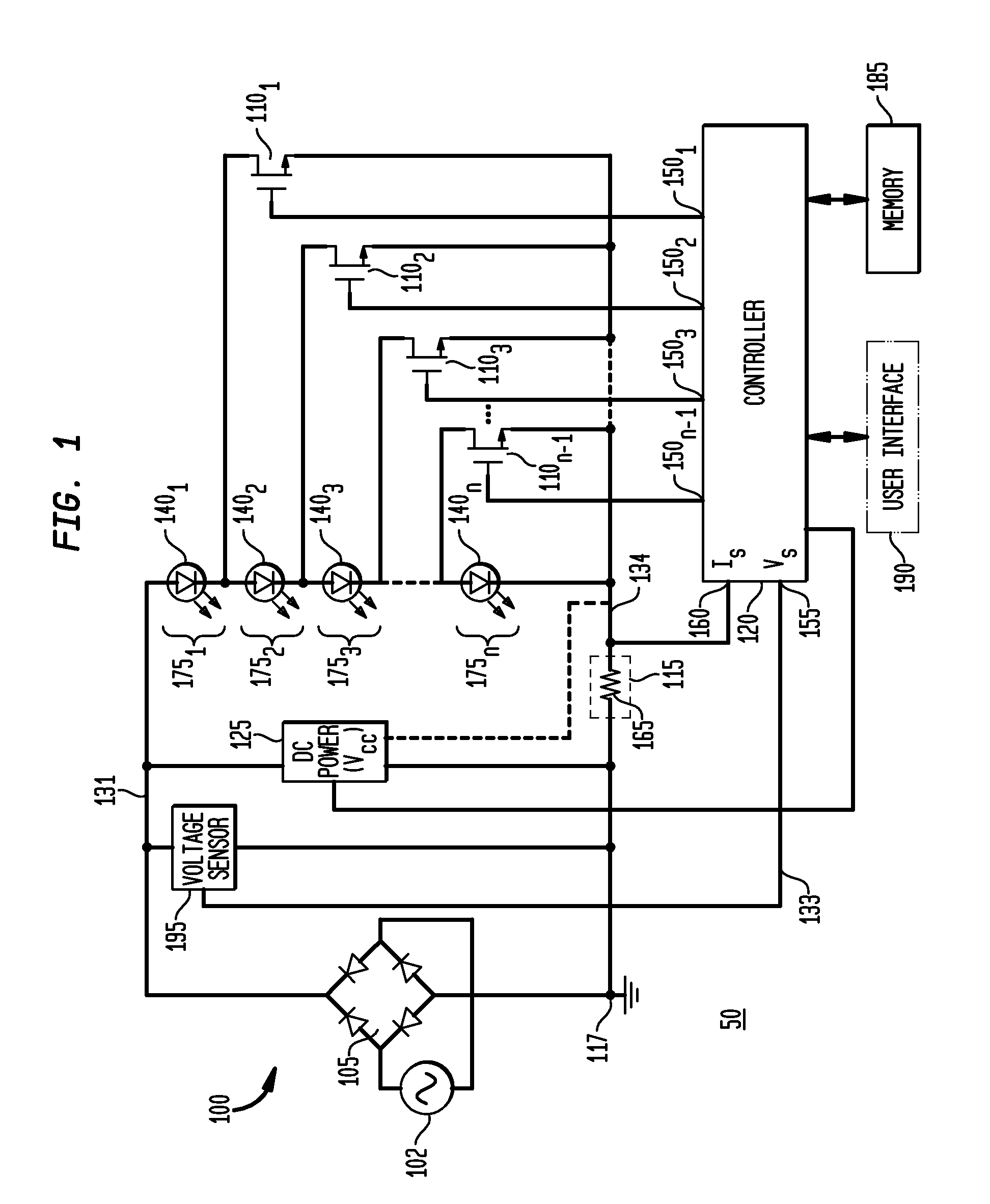

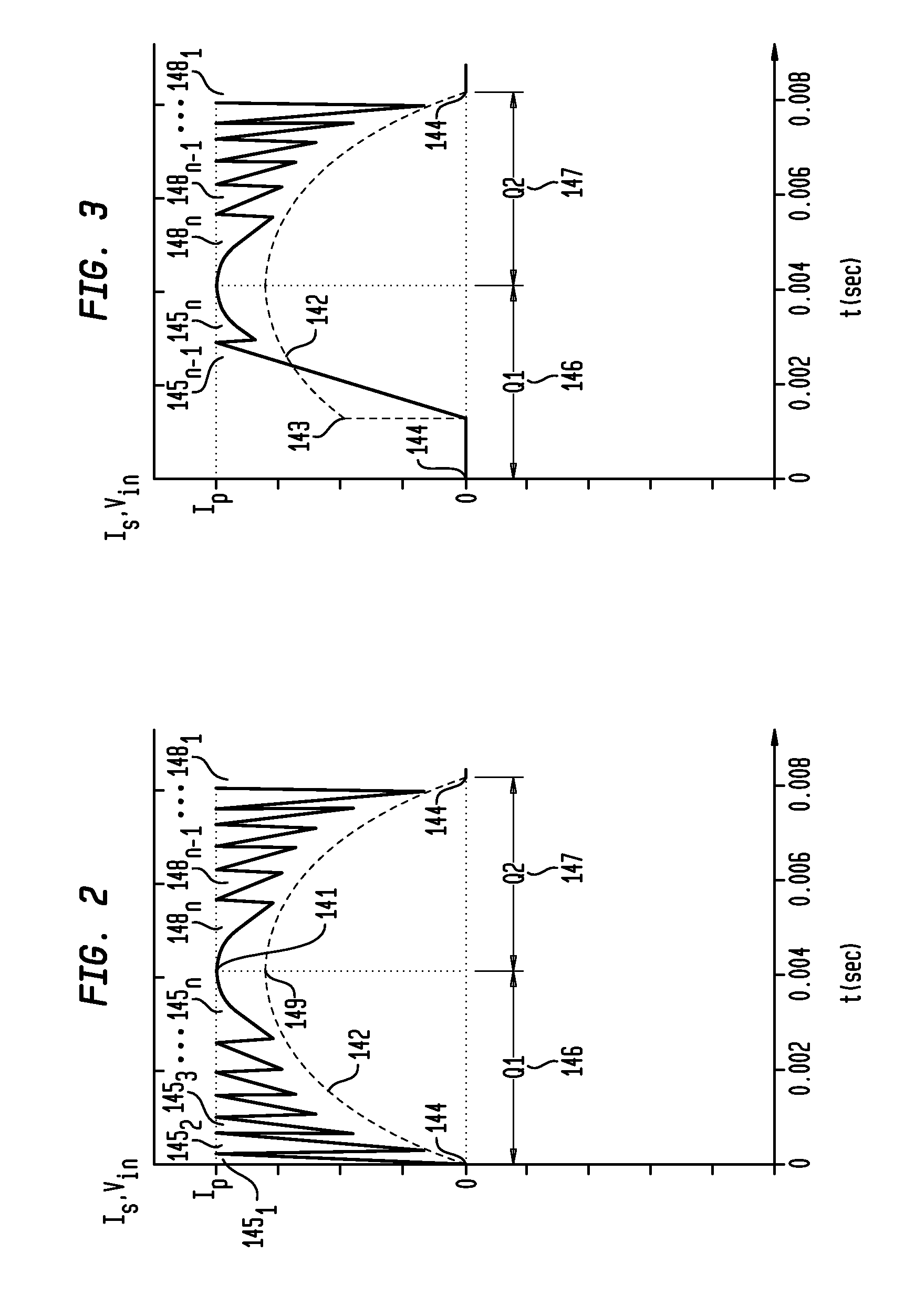

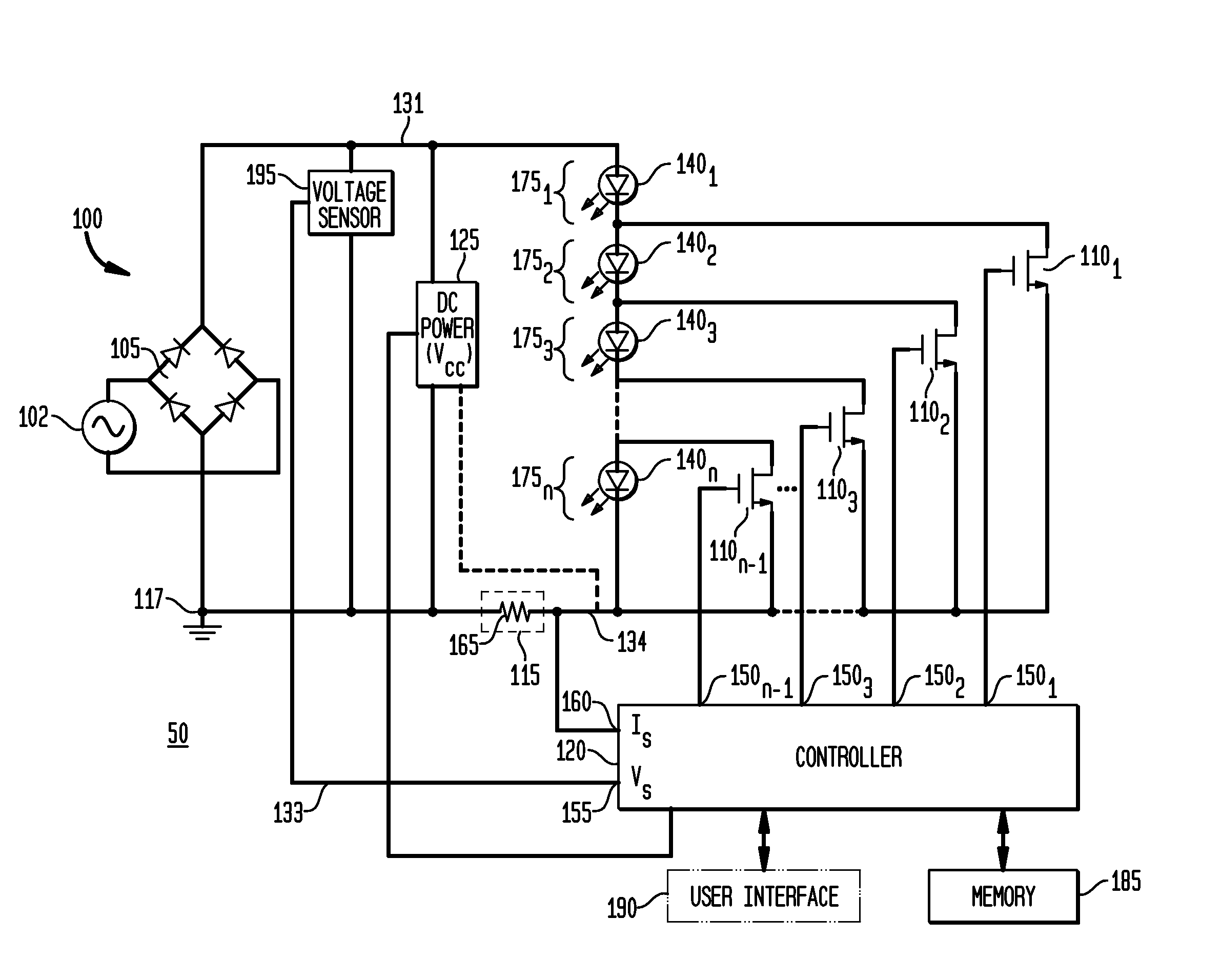

Apparatus, Method and System for Providing AC Line Power to Lighting Devices

ActiveUS20100308739A1Reduction in size and costImprove Utilization and EfficiencyElectrical apparatusElectroluminescent light sourcesLight equipmentControl signal

An apparatus, method and system are disclosed for providing AC line power to lighting devices such as light emitting diodes (“LEDs”). An exemplary apparatus comprises: a plurality of LEDs coupled in series to form a first plurality of segments of LEDs; a plurality of switches coupled to the plurality of segments of LEDs to switch a selected segment into or out of a series LED current path in response to a control signal; a memory; and a controller which, in response to a first parameter and during a first part of an AC voltage interval, determines and stores in the memory a value of a second parameter and generates a first control signal to switch a corresponding segment of LEDs into the series LED current path; and during a second part of the AC voltage interval, when a current value of the second parameter is substantially equal to the stored value, generates a second control signal to switch a corresponding segment of LEDs out of the first series LED current path.

Owner:CHEMTRON RES

Apparatus, Method and System for Providing AC Line Power to Lighting Devices

ActiveUS20100308738A1Small sizeLow costElectrical apparatusElectroluminescent light sourcesLight equipmentControl signal

An apparatus, method and system are disclosed for providing AC line power to lighting devices such as light emitting diodes (“LEDs”). An exemplary apparatus comprises: a plurality of LEDs coupled in series to form a first plurality of segments of LEDs; a plurality of switches coupled to the plurality of segments of LEDs to switch a selected segment into or out of a series LED current path in response to a control signal; a current sensor; and a controller which, in response to a first parameter and during a first part of an AC voltage interval, generates a first control signal to switch a corresponding segment of LEDs into the series LED current path; and during a second part of the AC voltage interval, generates a second control signal to switch a corresponding segment of LEDs out of the first series LED current path.

Owner:CHEMTRON RES

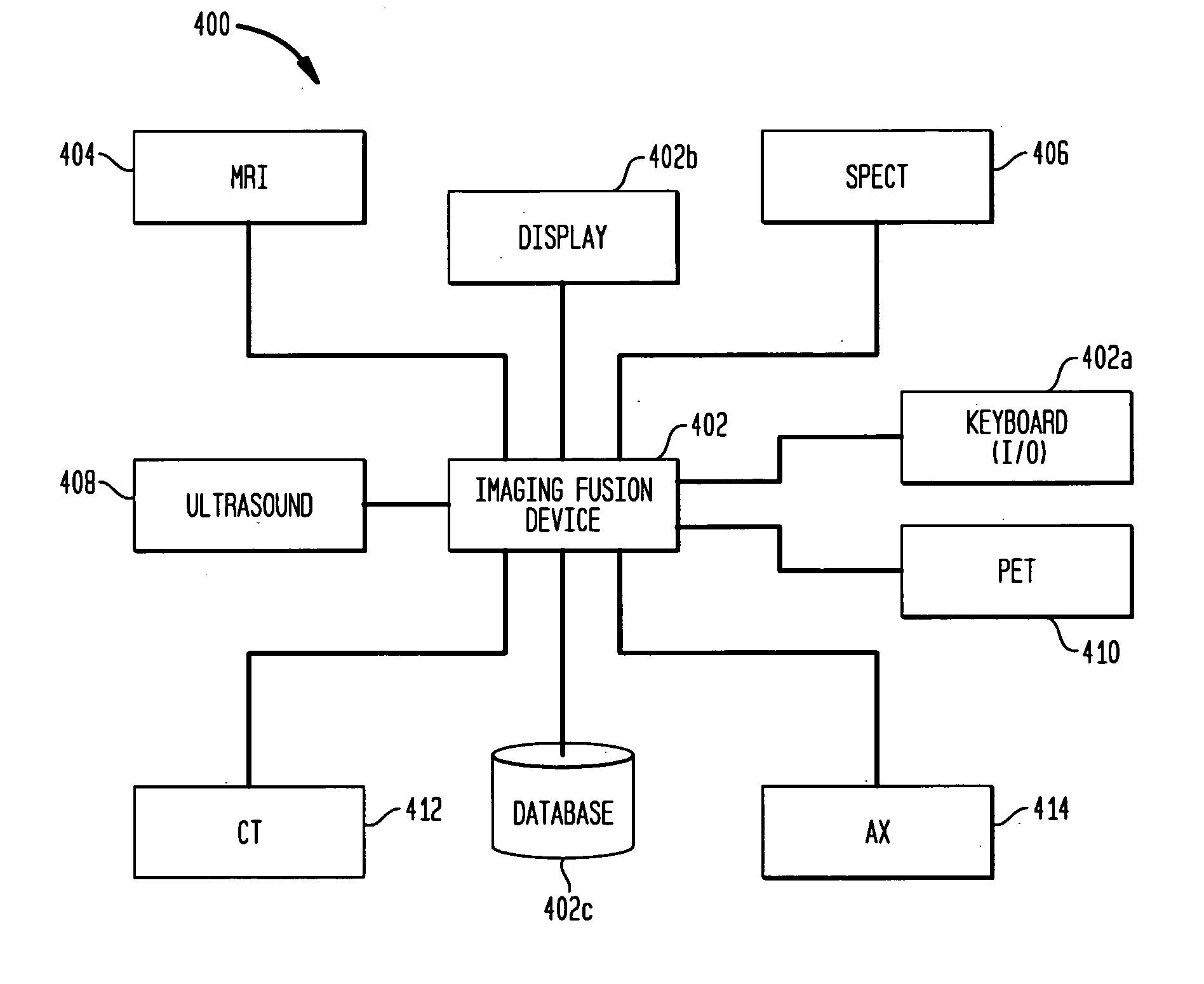

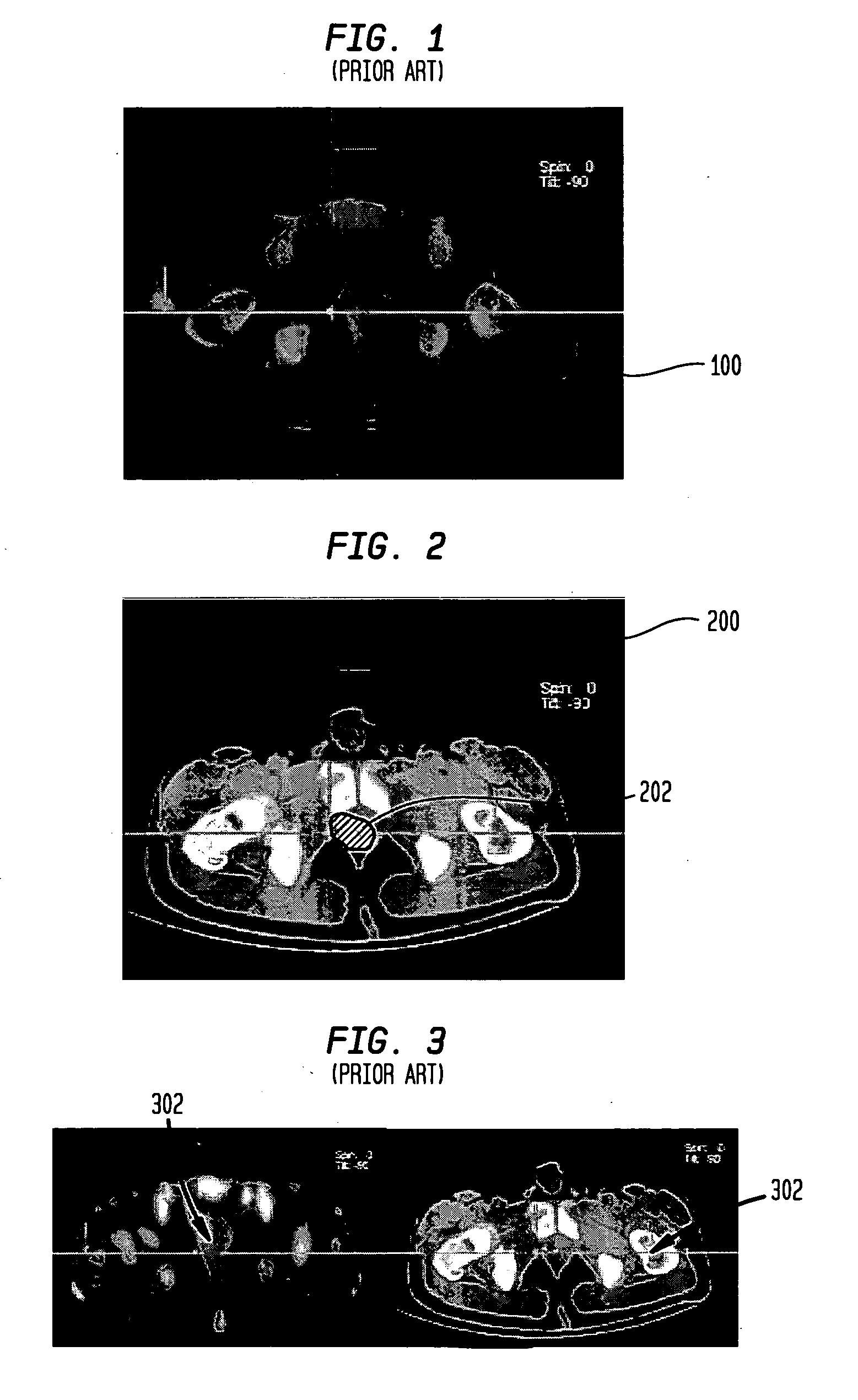

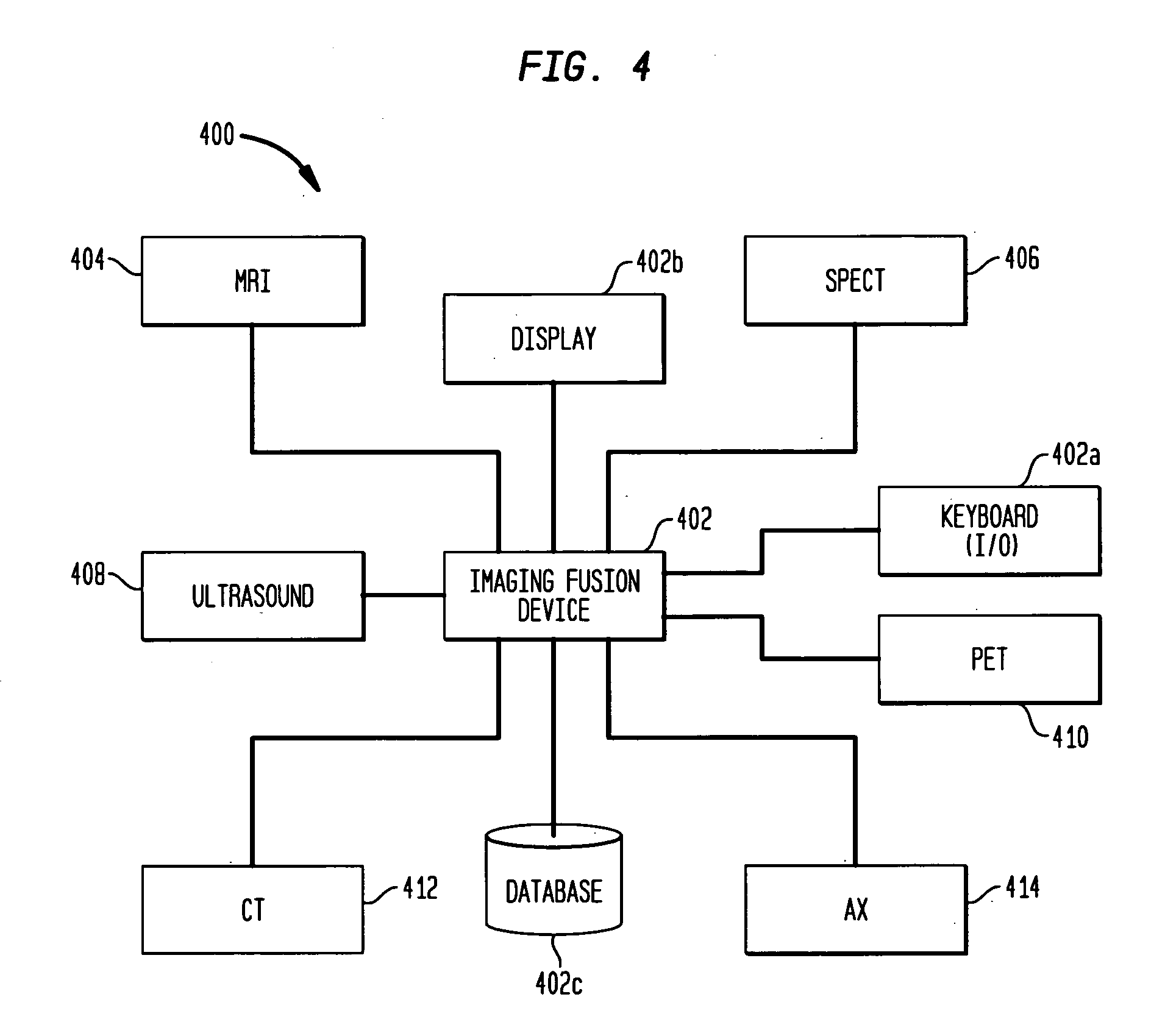

Systems and methods for localized image registration and fusion

ActiveUS20060004275A1Improve utilityReduce processing2D-image generationSurgeryRegion of interestCo registration

Systems and methods are described for co-registering, displaying and quantifying images from numerous different medical modalities, such as CT, MRI and SPECT. In this novel approach co-registration and image fusion is based on multiple user-defined Regions-of-Interest (ROI), which may be subsets of entire image volumes, from multiple modalities, where the each ROI may depict data from different image modalities. The user-selected ROI of a first image modality may be superposed over or blended with the corresponding ROI of a second image modality, and the entire second image may be displayed with either the superposed or blended ROI.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

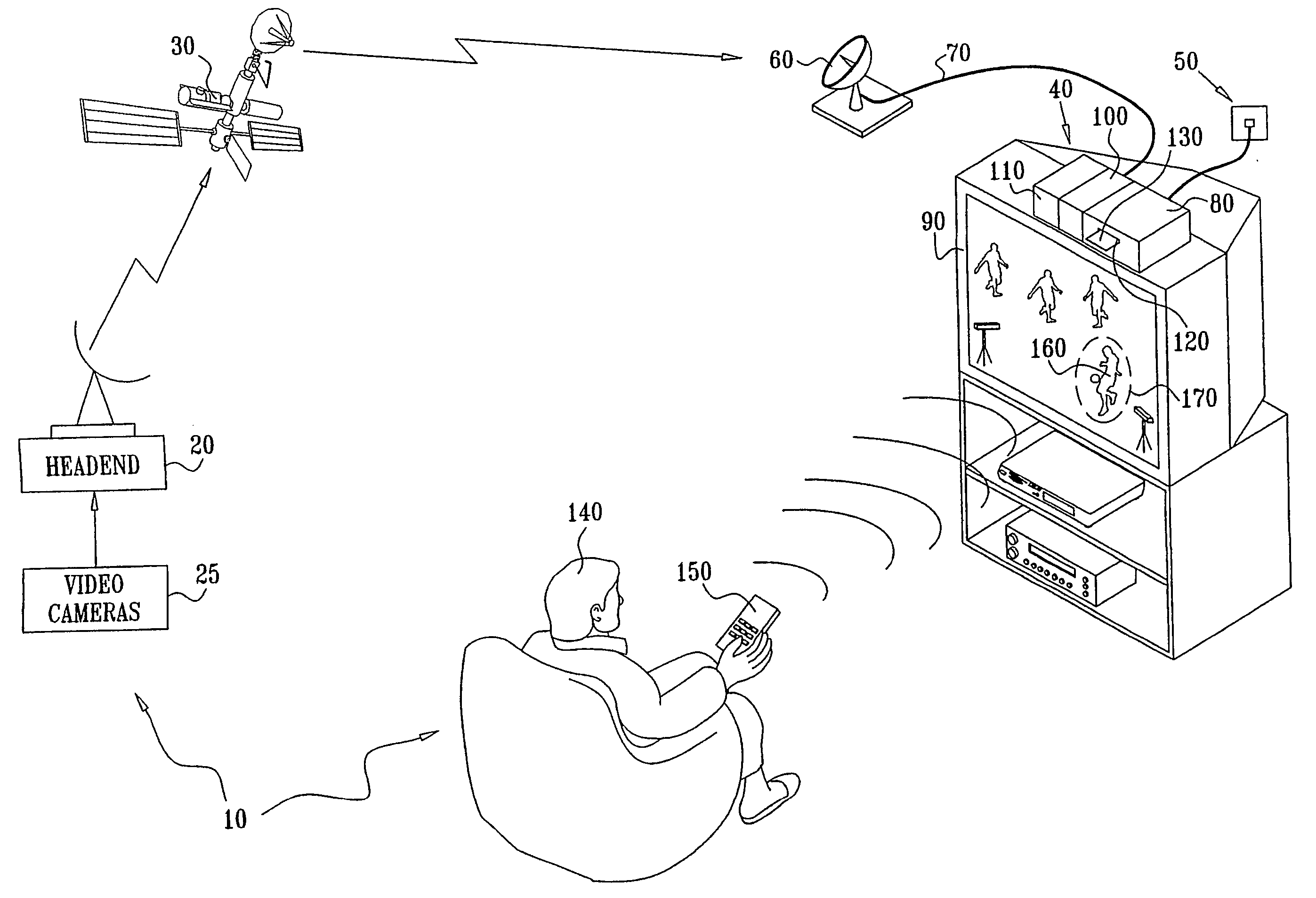

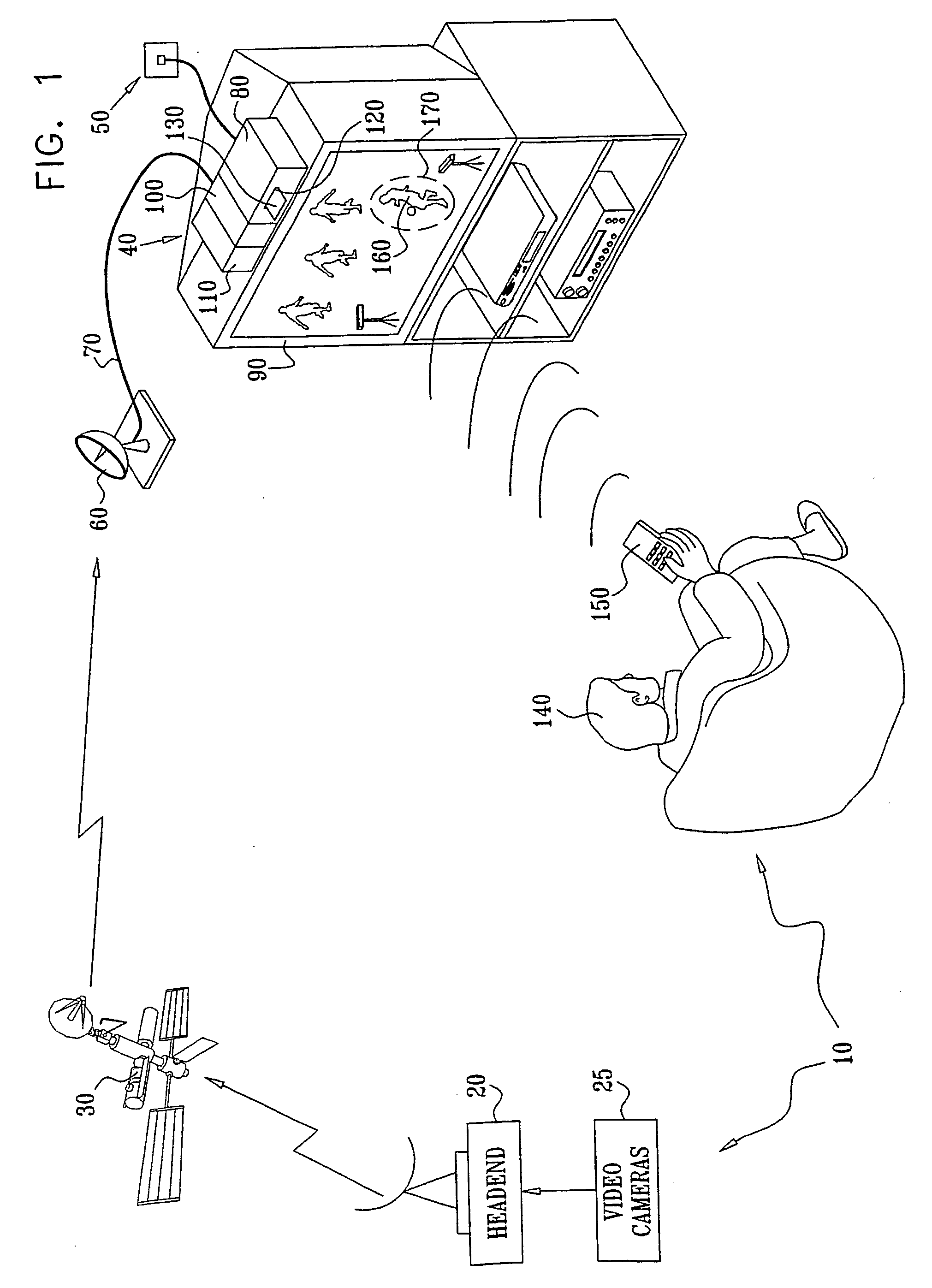

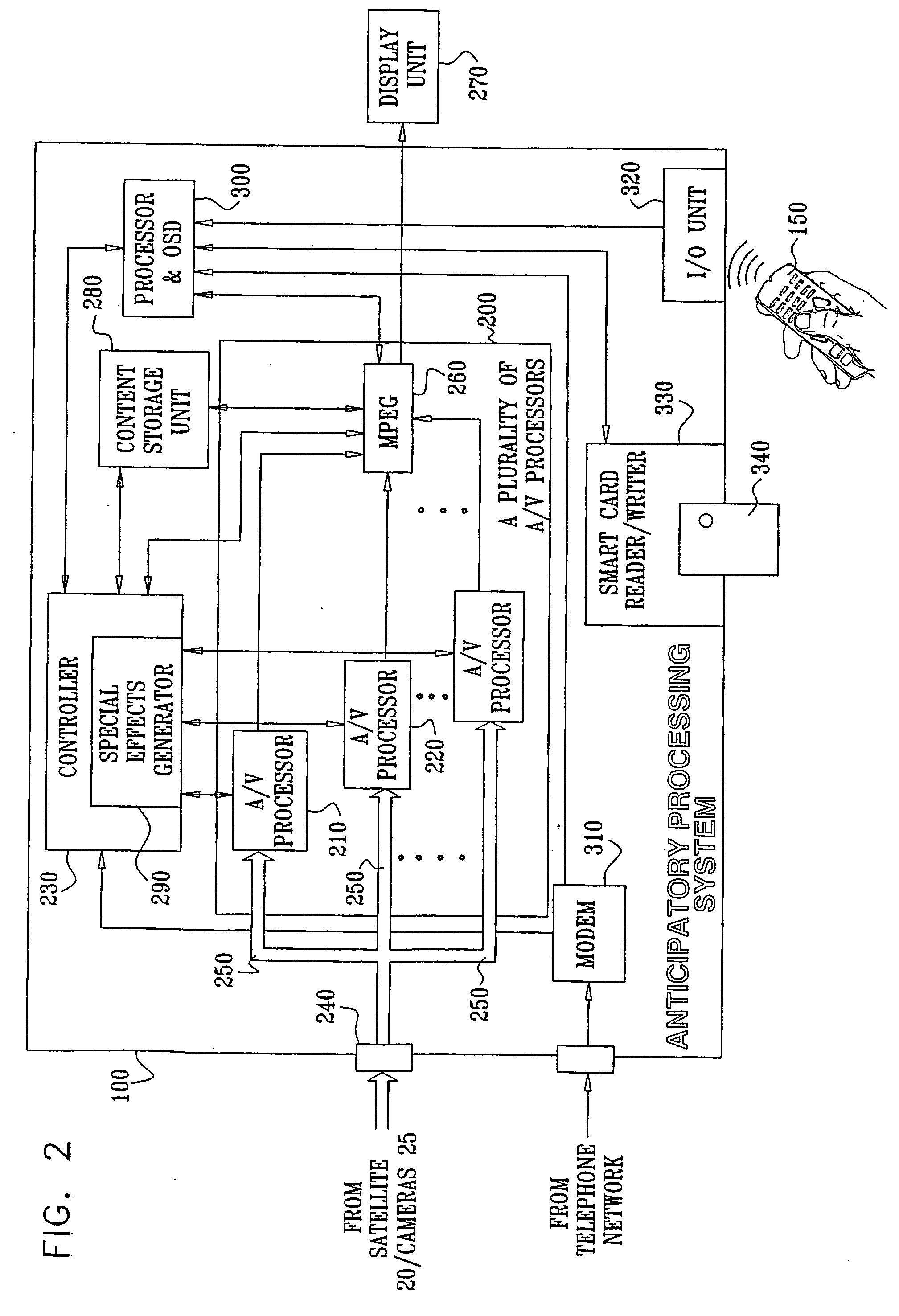

Interactive broadcast system

InactiveUS20050273830A1Improve utilityImprove controlTelevision system detailsPulse modulation television signal transmissionBroadcast systemComputer science

An anticipatory processing system is described. The anticipatory processing system includes a controller generating a prediction of an event determining program material to be displayed, and an audiovideo (A / V) processor controlled by the controller for preparing a digital stream for use in response to the prediction of the of the event. Related apparatus and methods are also described.

Owner:CISCO TECH INC

Apparatus and method of temperature conrol during cleaving processes of thick film materials

InactiveUS20080188011A1Improve utilityCost reductionSemiconductor/solid-state device testing/measurementElectric discharge tubesFilm materialEngineering

An apparatus for temperature control of manufacture of thick film materials includes a stage comprising a planar surface for supporting a bulk material to be implanted and subsequently cleaved. The bulk material has a surface region, a side region, and a bottom region which provides a volume of material and defines a length between the bottom region and the surface region. The apparatus further includes a mechanical clamp device adapted to engage the bottom region to the planar surface of the stage such that the bulk material is in physical contact with the planar surface for thermal energy to transfer through an interface region between the bulk material and the stage while the surface region is substantially exposed. Additionally, the apparatus includes a sensor device configured to measure a temperature value of the surface region and generate an input data. The apparatus further includes an implant device configured to perform implantation of a plurality of particles through one or more portions of the surface region of the bulk material and a controller configured to receive and process the input data to increase and / or decrease the temperature value of the surface region through at least the interface region between the planar surface of the stage and the bottom region of the bulk material.

Owner:SILICON GENERAL CORPORATION

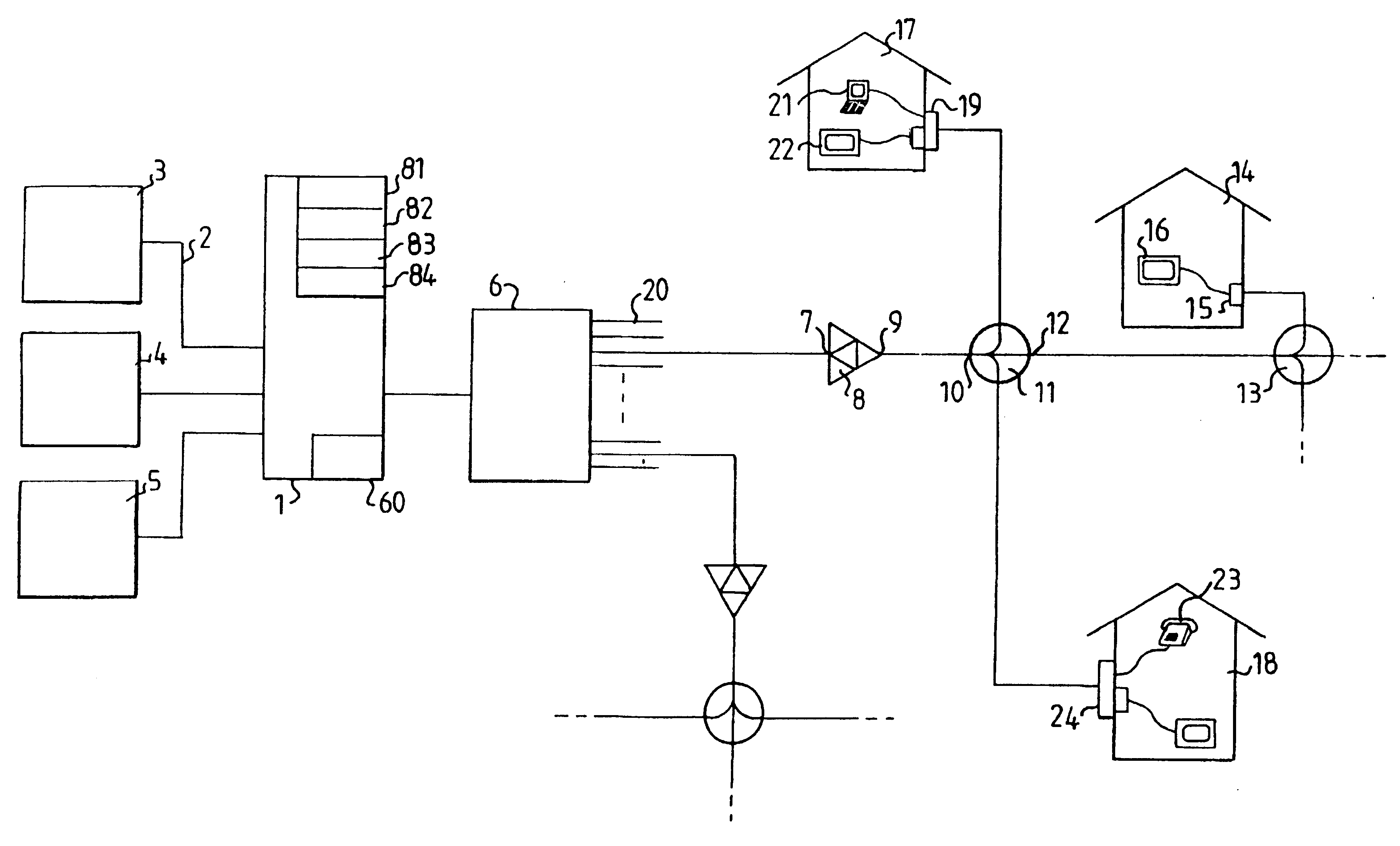

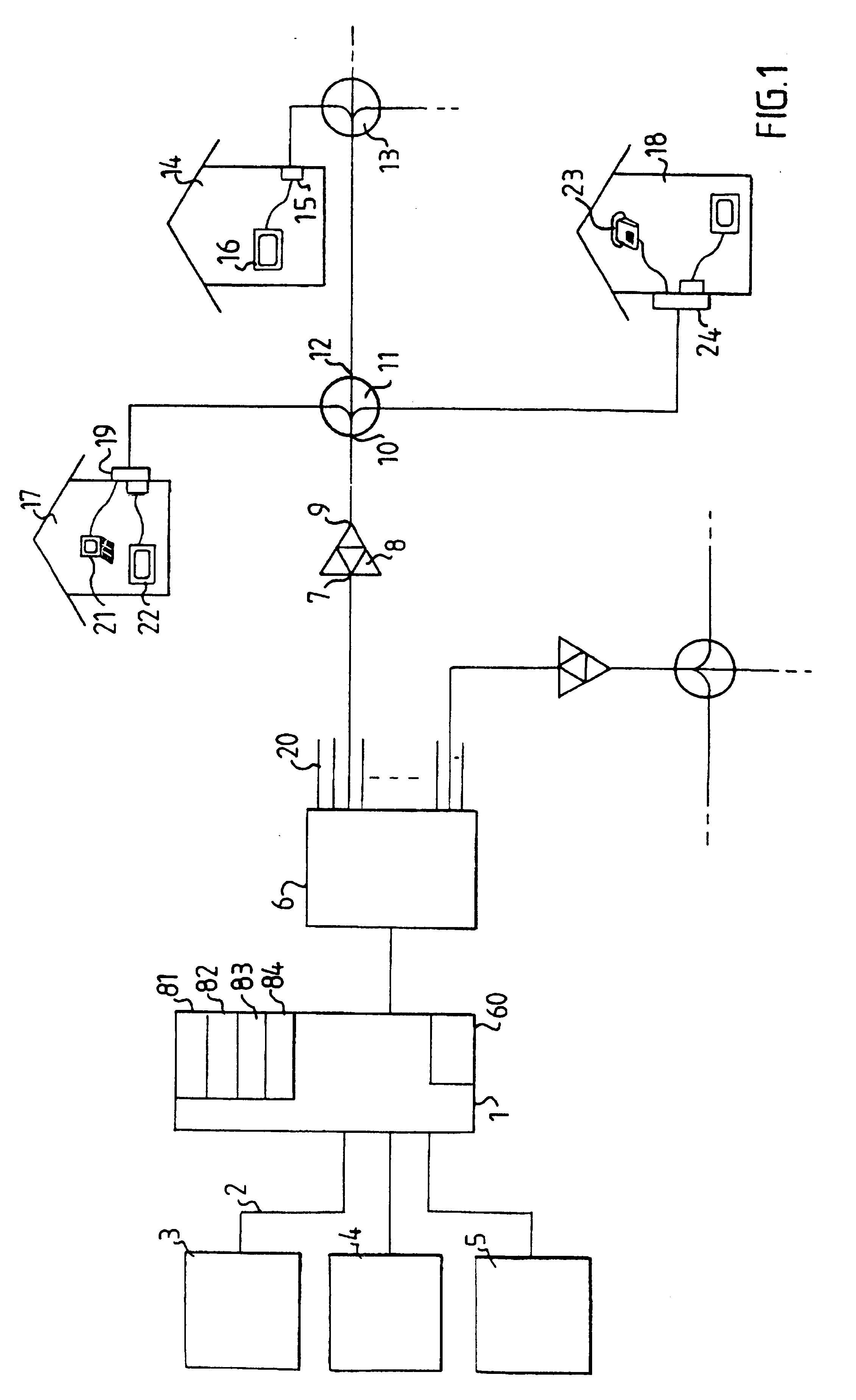

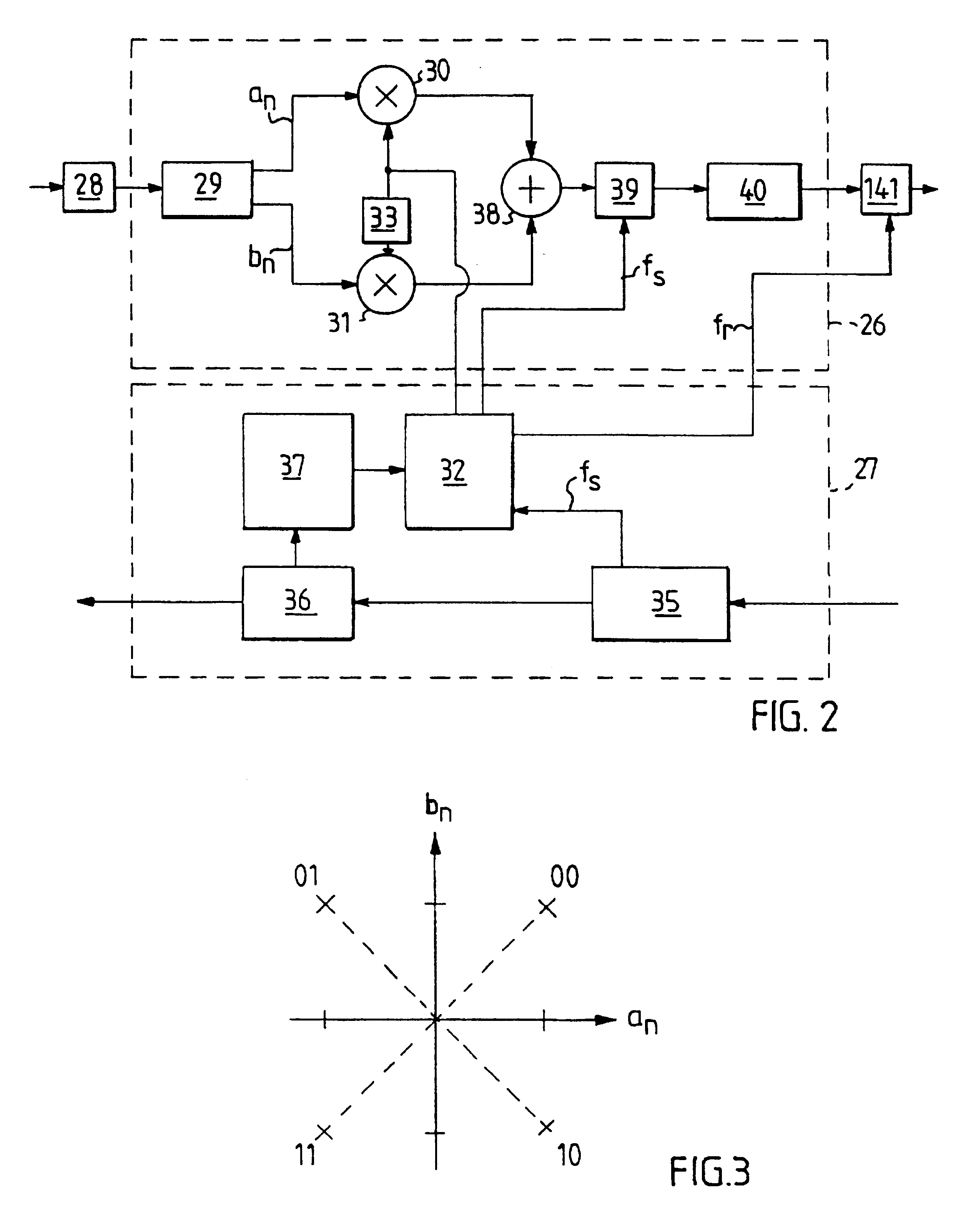

Device and method relating to cable TV networks

InactiveUS6496982B1Improve utilityOvercome problemsResource management arrangementsBroadcast-related systemsBroadbandTransmitter

A method and an apparatus transmit and receive information in a cable TV network including at least one base station connected to a branching cable network, branching from the base station to at least two subscribers, provided with transmitters. A unique carrier frequency is assigned to each of the subscriber's transmitters, the carrier frequencies being orthogonal. Signals from the subscriber's transmitters are transmitted simultaneously, received in the base station as a broadband signal, and separated using a common algorithm.

Owner:TELEFON AB LM ERICSSON (PUBL)

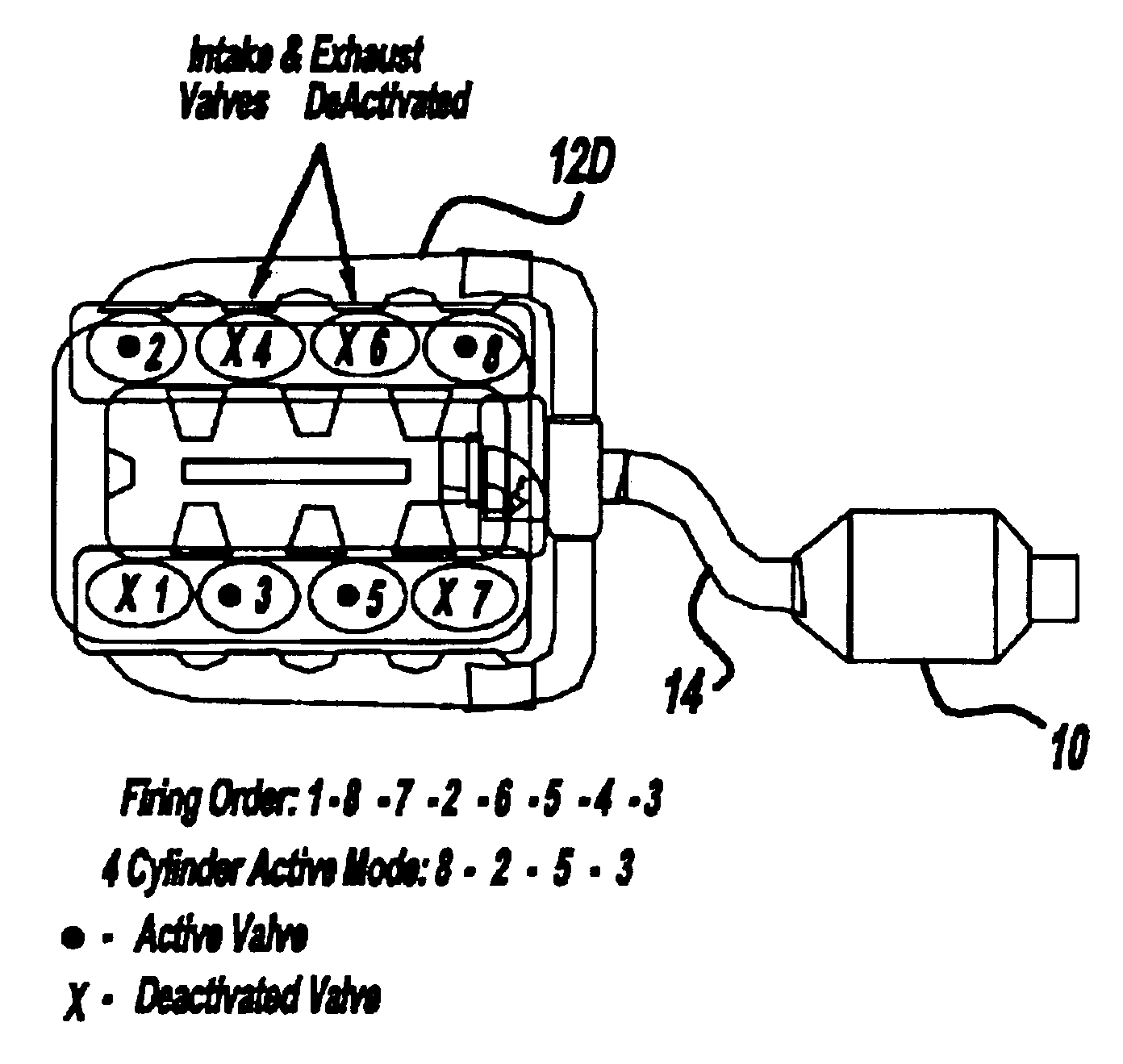

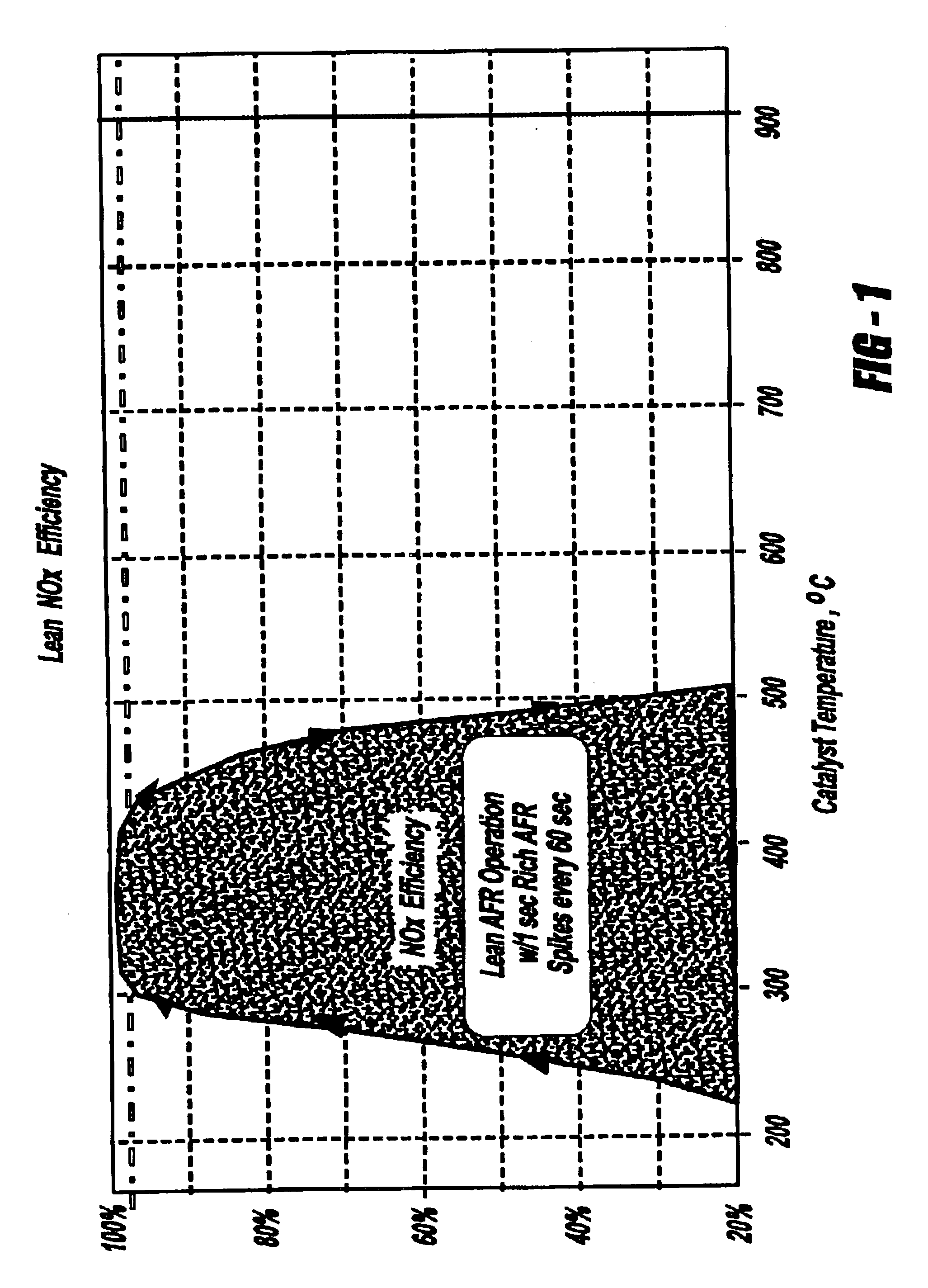

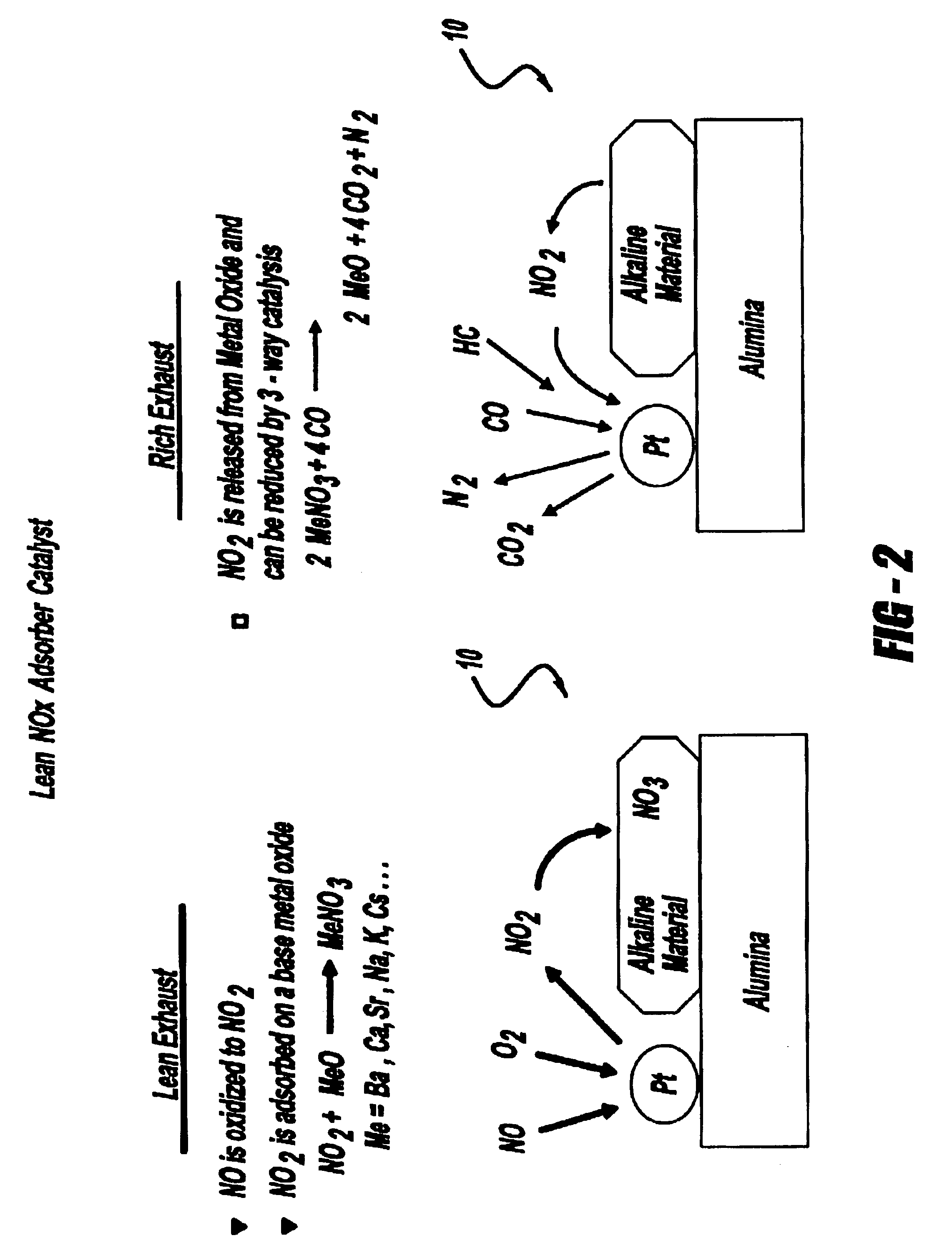

Exhaust emission aftertreatment

InactiveUS6857264B2Raise temperatureImprove utilityElectrical controlNon-fuel substance addition to fuelExhaust gasExhaust fumes

An engine control system in a vehicle including a variable displacement internal combustion engine, a controller for controlling the displacement of the variable displacement internal combustion engine, and where the controller operates the variable displacement internal combustion engine in a partially displaced operating mode upon startup to increase exhaust gas temperature.

Owner:GM GLOBAL TECH OPERATIONS LLC

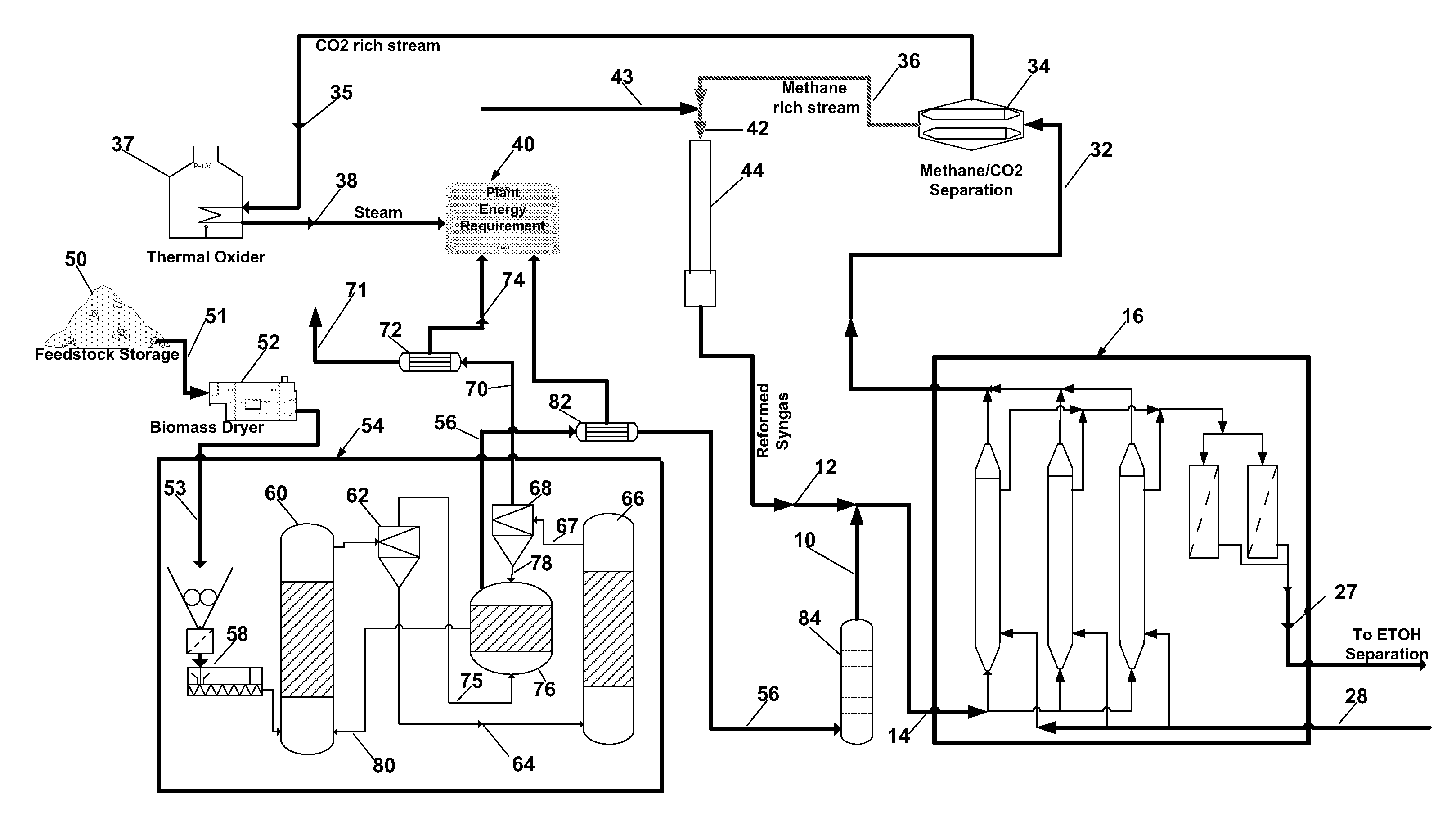

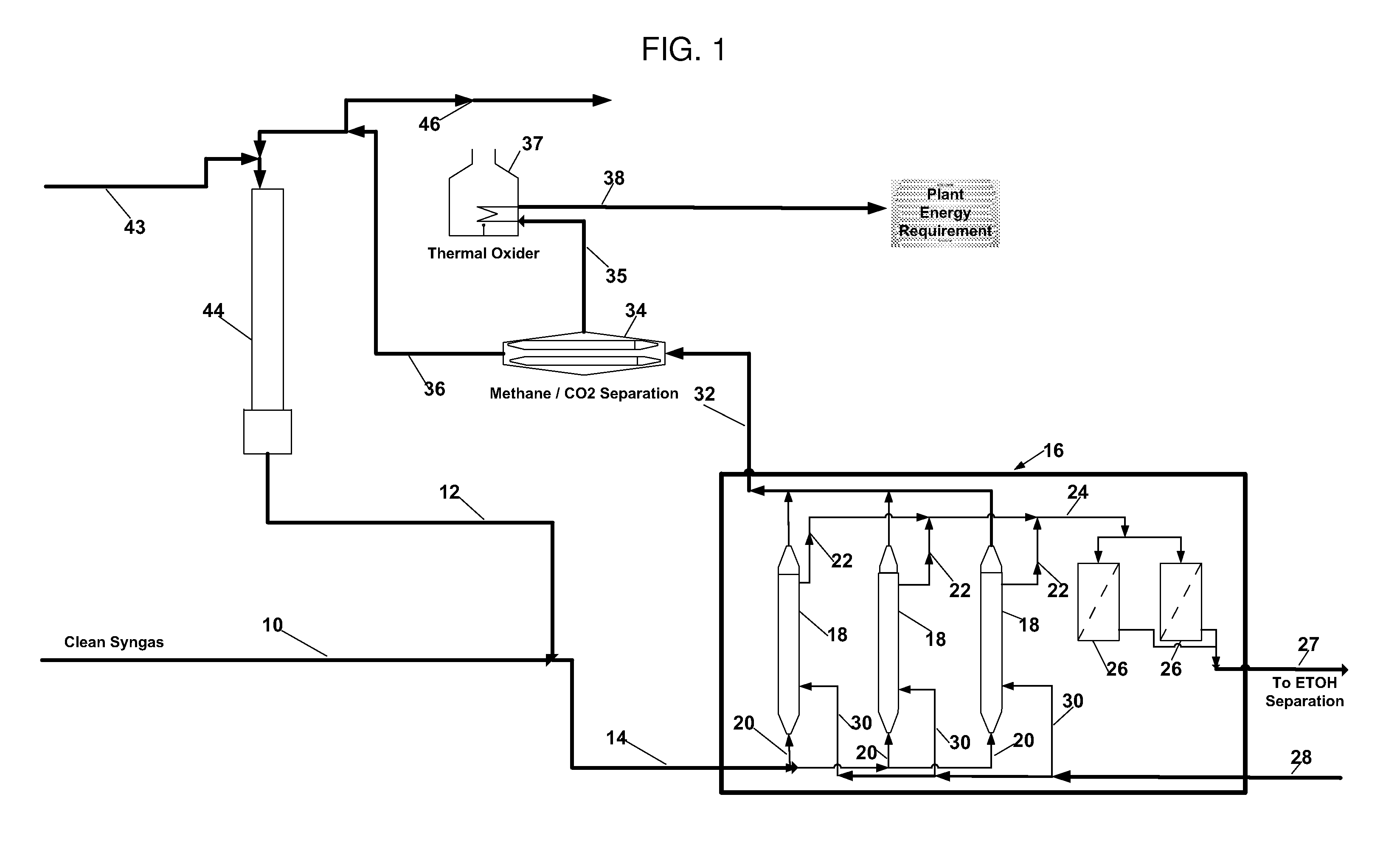

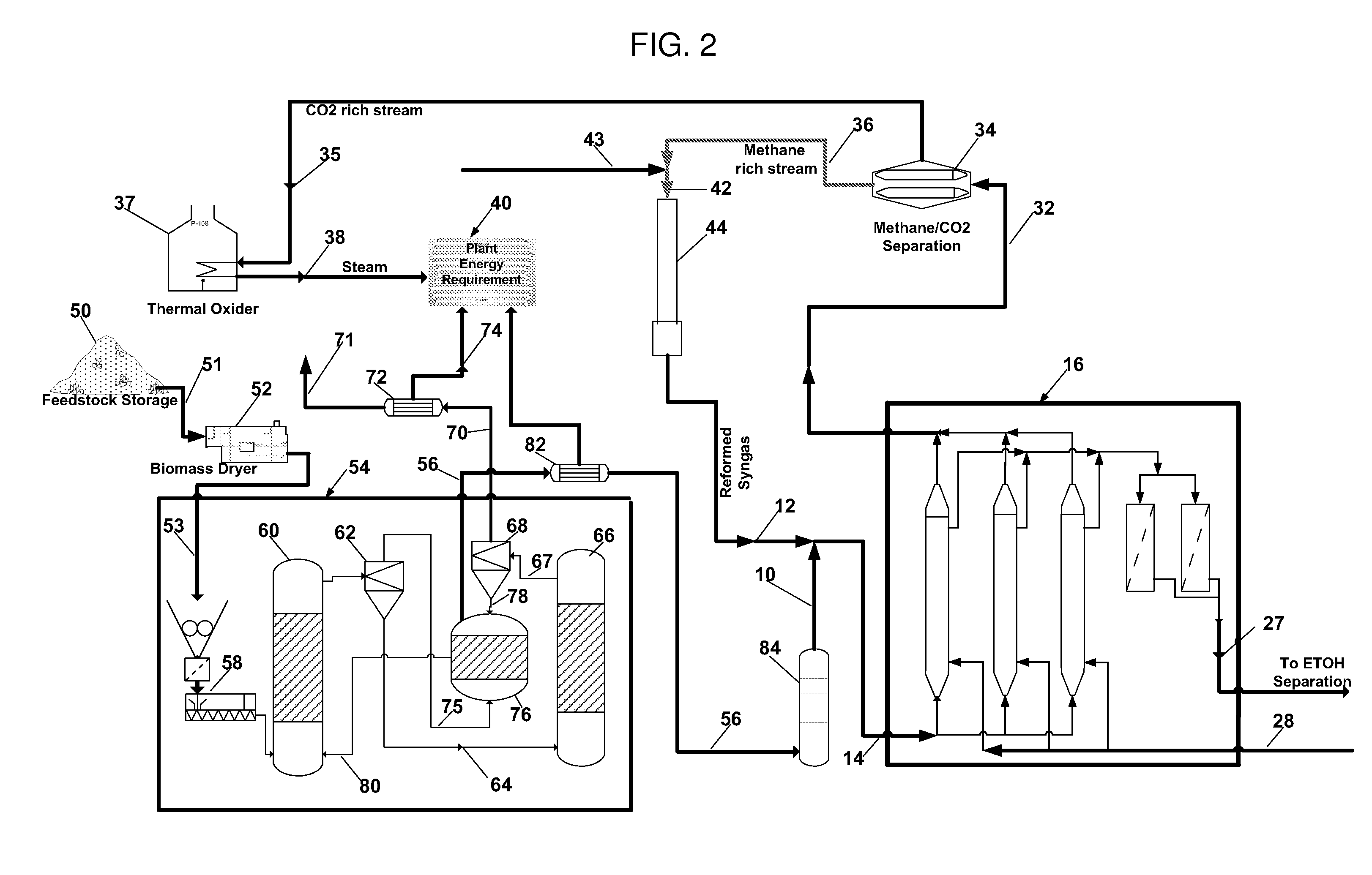

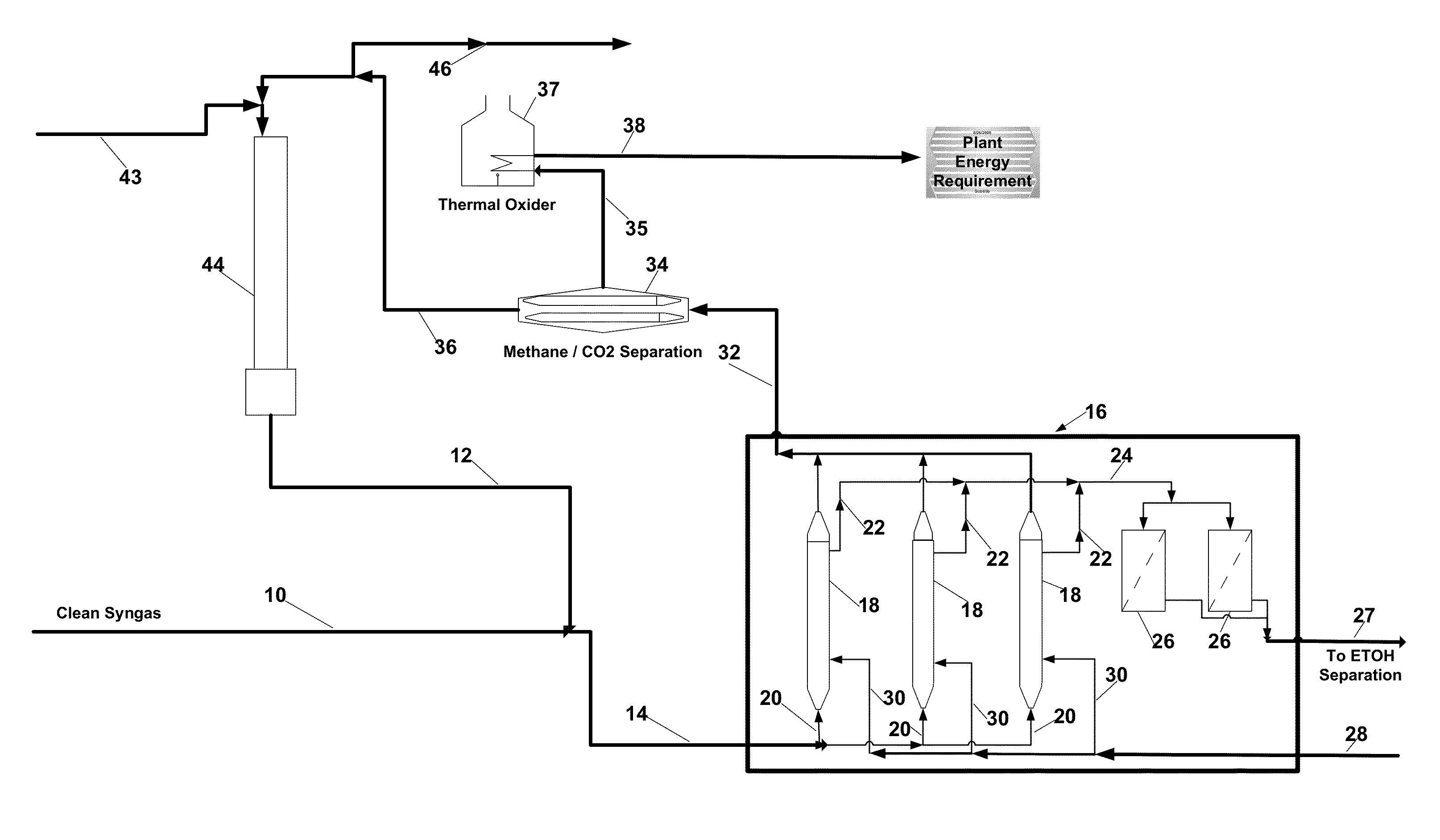

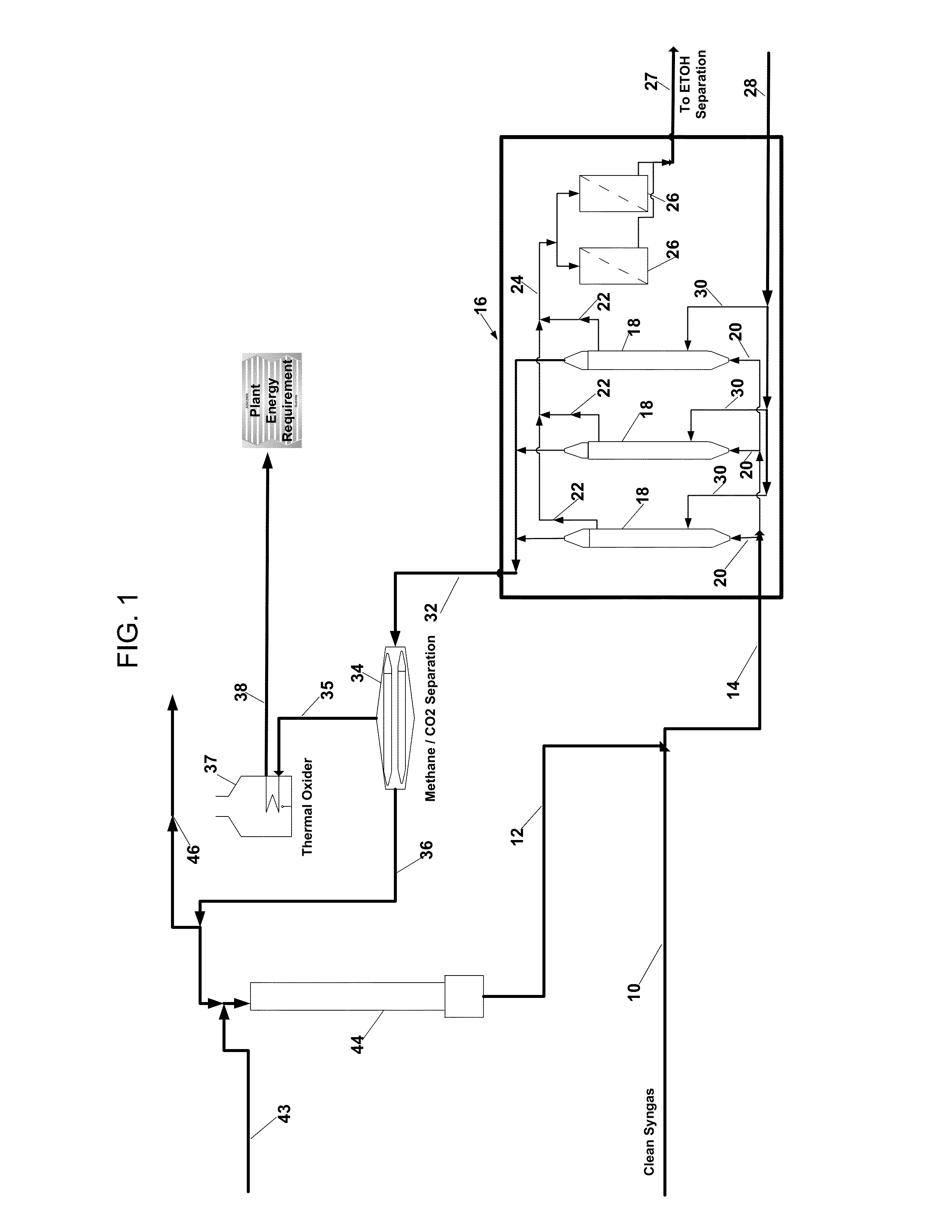

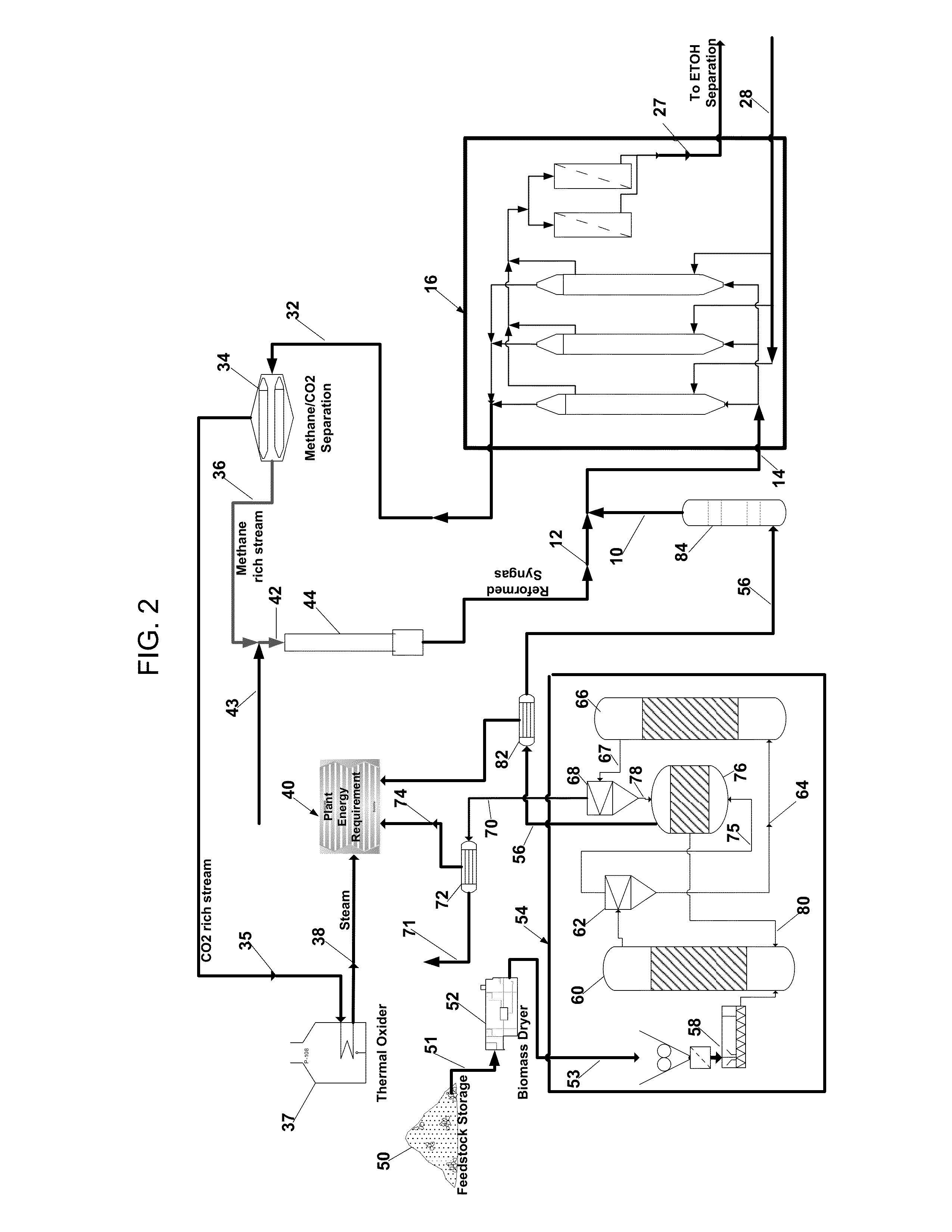

Process for fermentation of syngas from indirect gasification

ActiveUS20100298450A1Easy to separateEffective recoveryDirect heating destructive distillationBiofuelsSyngasLiquid product

Ethanol and other liquid products are produced from biomass using indirect gasification of the biomass to produce a syngas containing CO2, CO, H2 and methane that passes the syngas without substantial removal of the methane to a fermentation zone for the conversion of the CO and CO2 and H2 to ethanol and the production of a methane rich stream followed by the methane reforming of the methane rich stream to produce additional CO and CO2 and H2 that passes to the fermentation zone.

Owner:SYNATA BIO INC

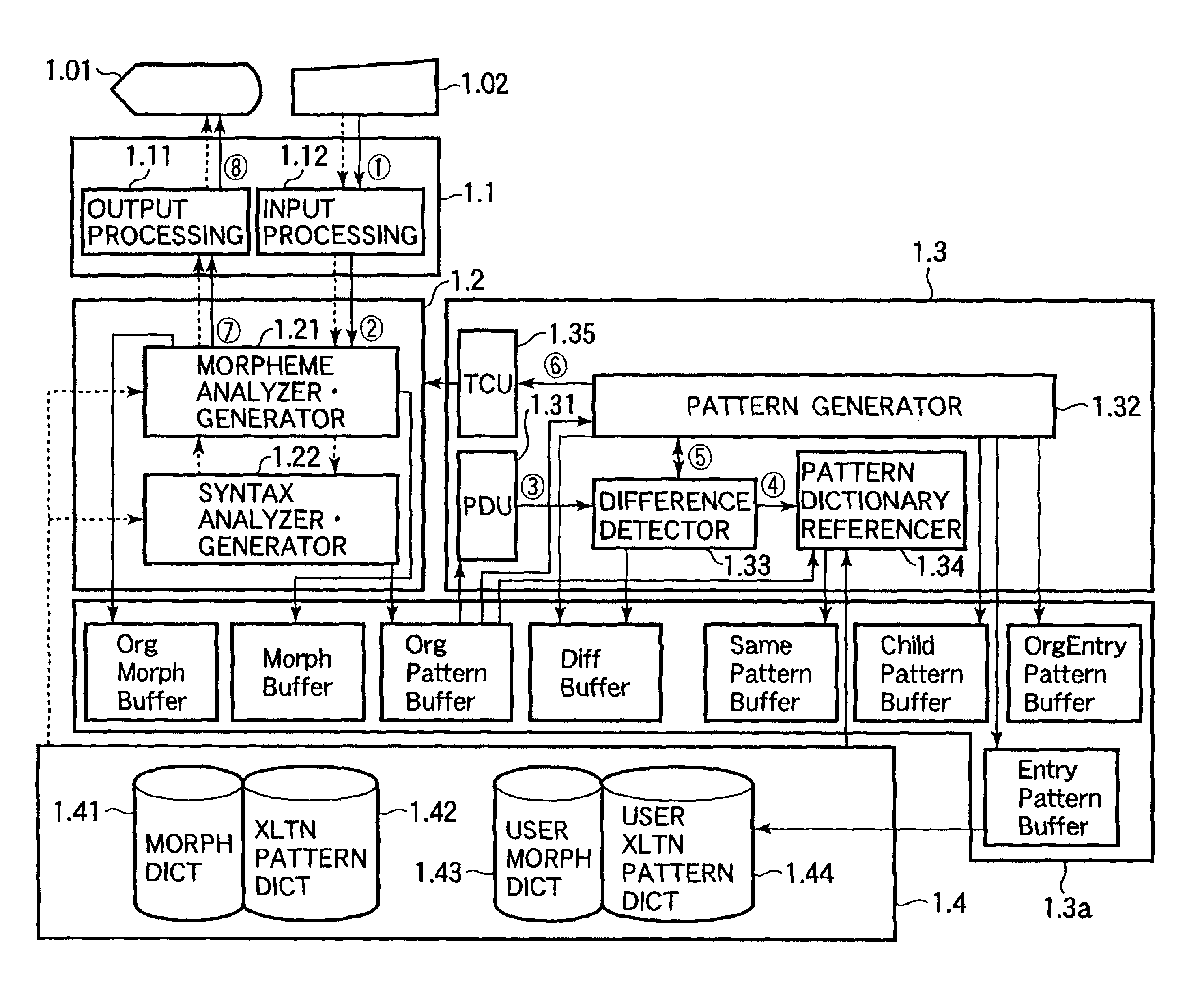

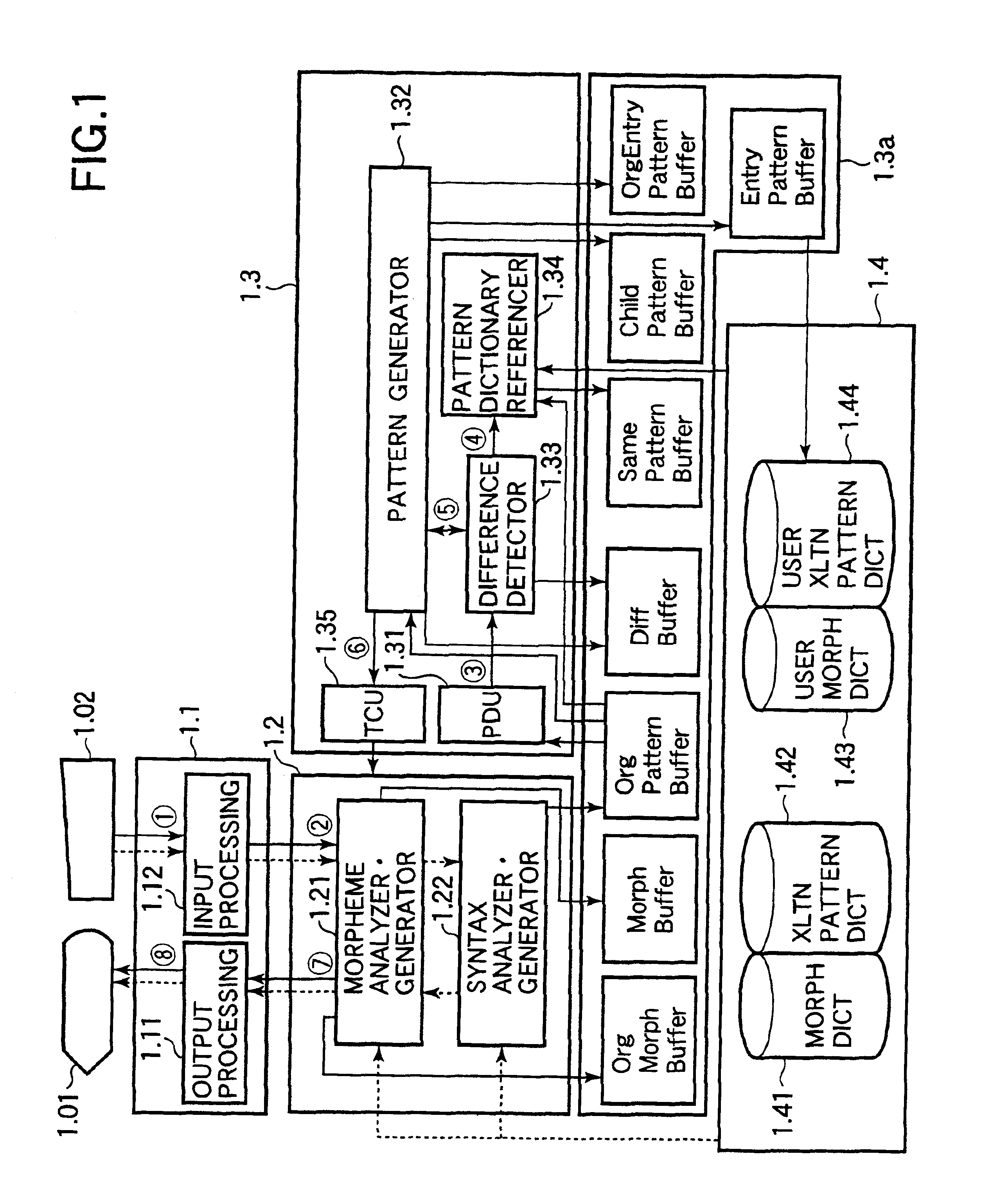

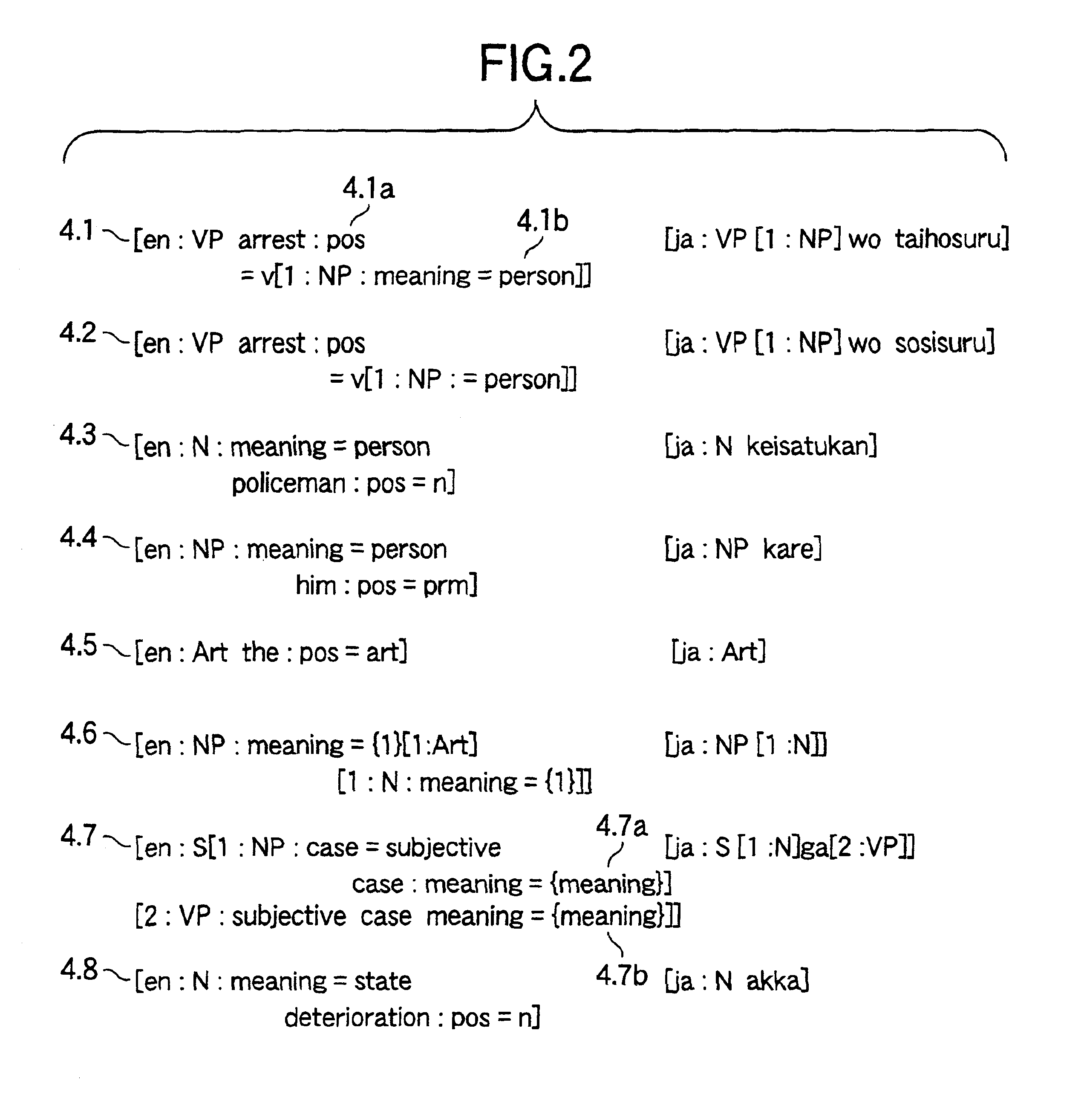

Apparatus and method for adding information to a machine translation dictionary

InactiveUS6920419B2Efficiently derivedImprove utilityNatural language translationSpeech analysisMachine-readable dictionaryMorpheme

Given a source text, a desired translation of the source text into a target language, and a machine-readable dictionary, a first set of morphemes in the target language is generated from the source text, typically by using the dictionary to perform a machine translation of the source text. The second text is analyzed into a second set of morphemes in the target language. Differences between the first and second sets of morphemes are found, and morphemes corresponding to the differences are taken from the source text. Existing information including these source-text morphemes is extracted from the dictionary, and new information to be added to the dictionary is automatically generated from the extracted information and the differences. This process generates comparatively short dictionary entries, corresponding only to the differences between the two set of morphemes, and therefore creates useful dictionary entries while saving dictionary space.

Owner:OKI ELECTRIC IND CO LTD

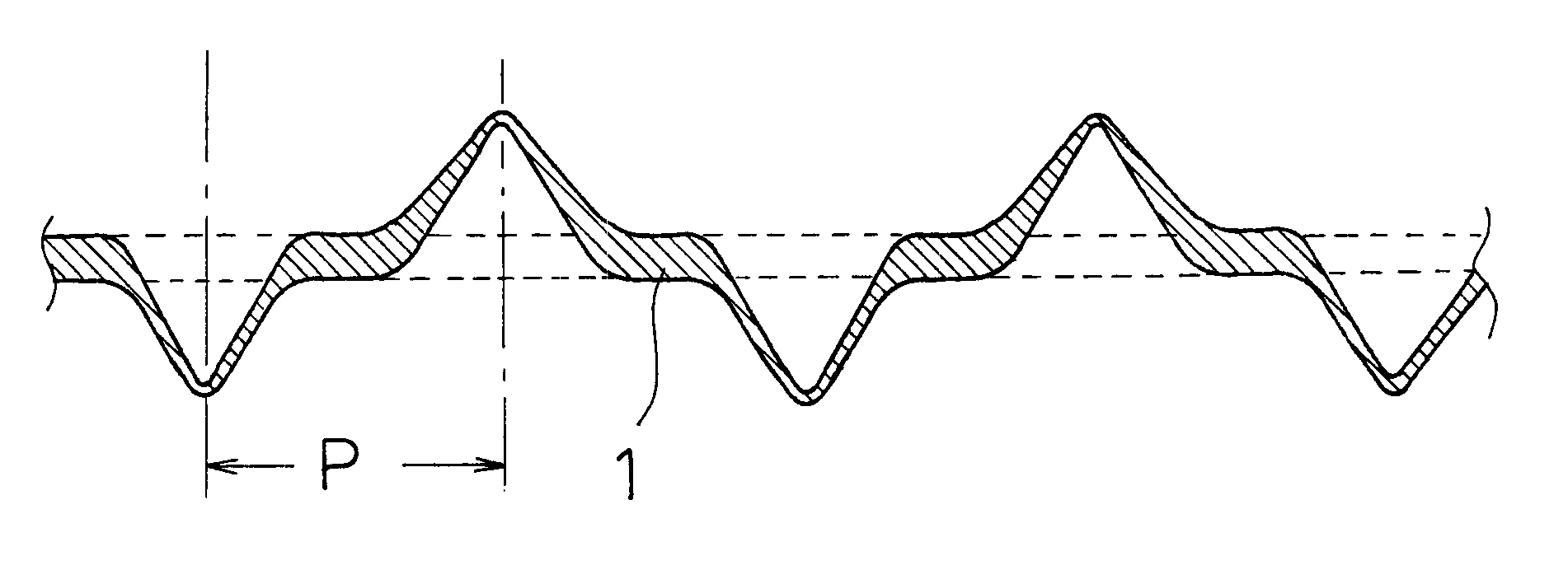

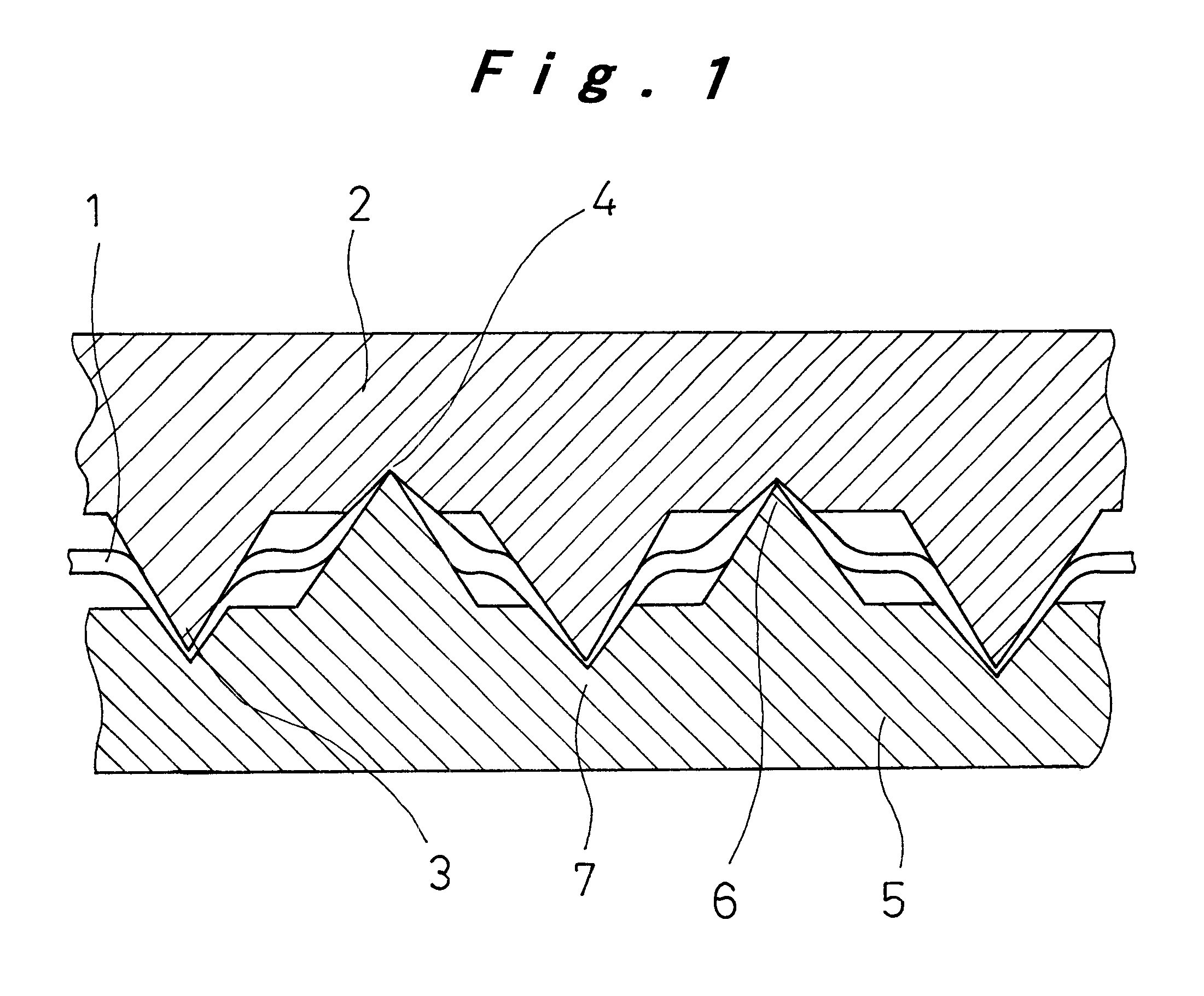

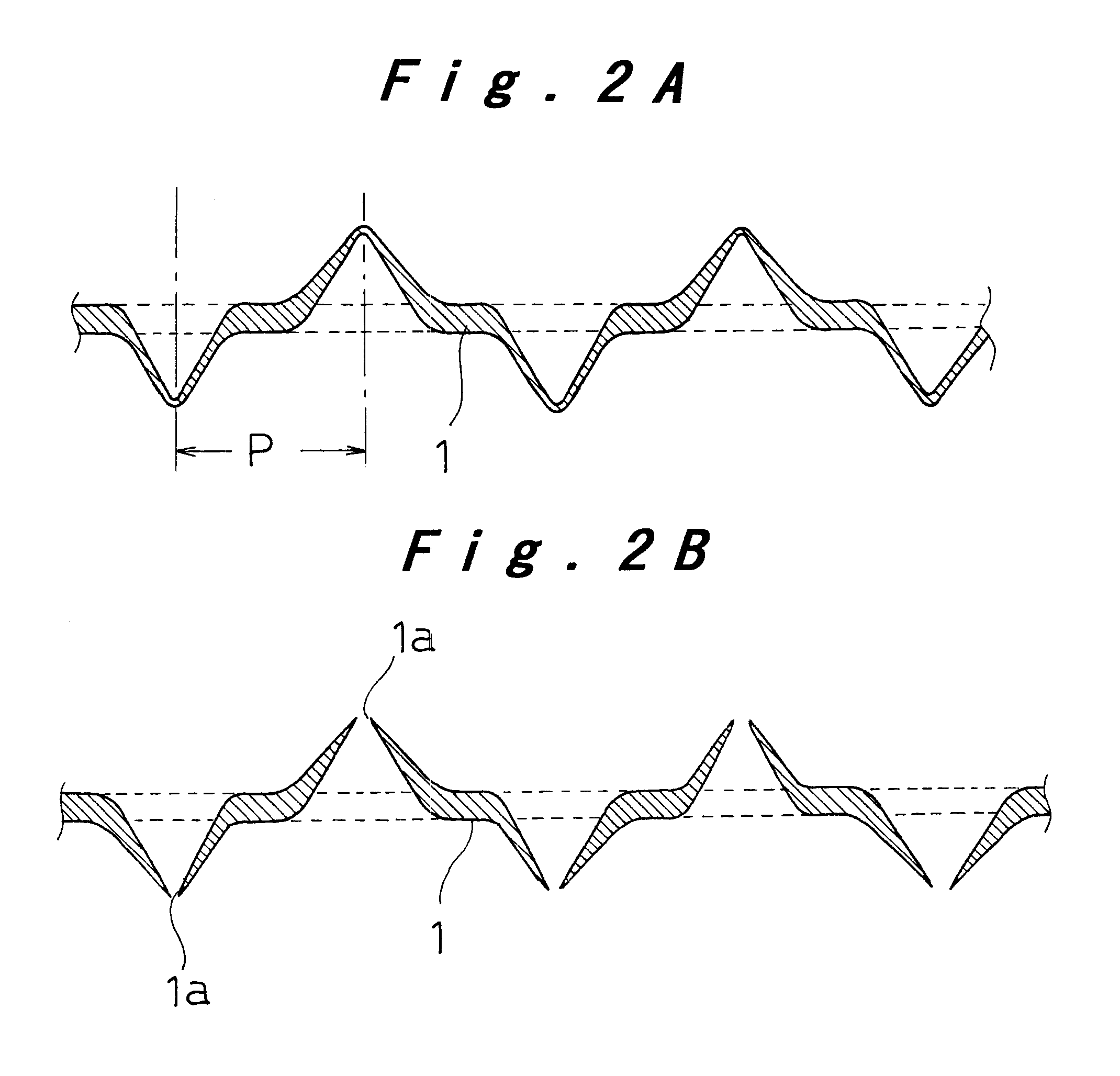

Non-sintered electrode and method of manufacturing same

InactiveUS6444366B1Improve overall utilizationQuality improvementPrimary cellsElectrode carriers/collectorsMaterials scienceMetal sheet

A metal sheet (1) which constitutes a non-sintered type electrode support is processed to have minute irregularities on its surface. The irregularities are formed by a mechanical method such that protrusions (9) and indentations (8) are configured with a center-to-center pitch (P) in the range of from 50 to 300 mum and such that the apparent thickness after processing is at least three times as large as the unprocessed material thickness.

Owner:PANASONIC CORP

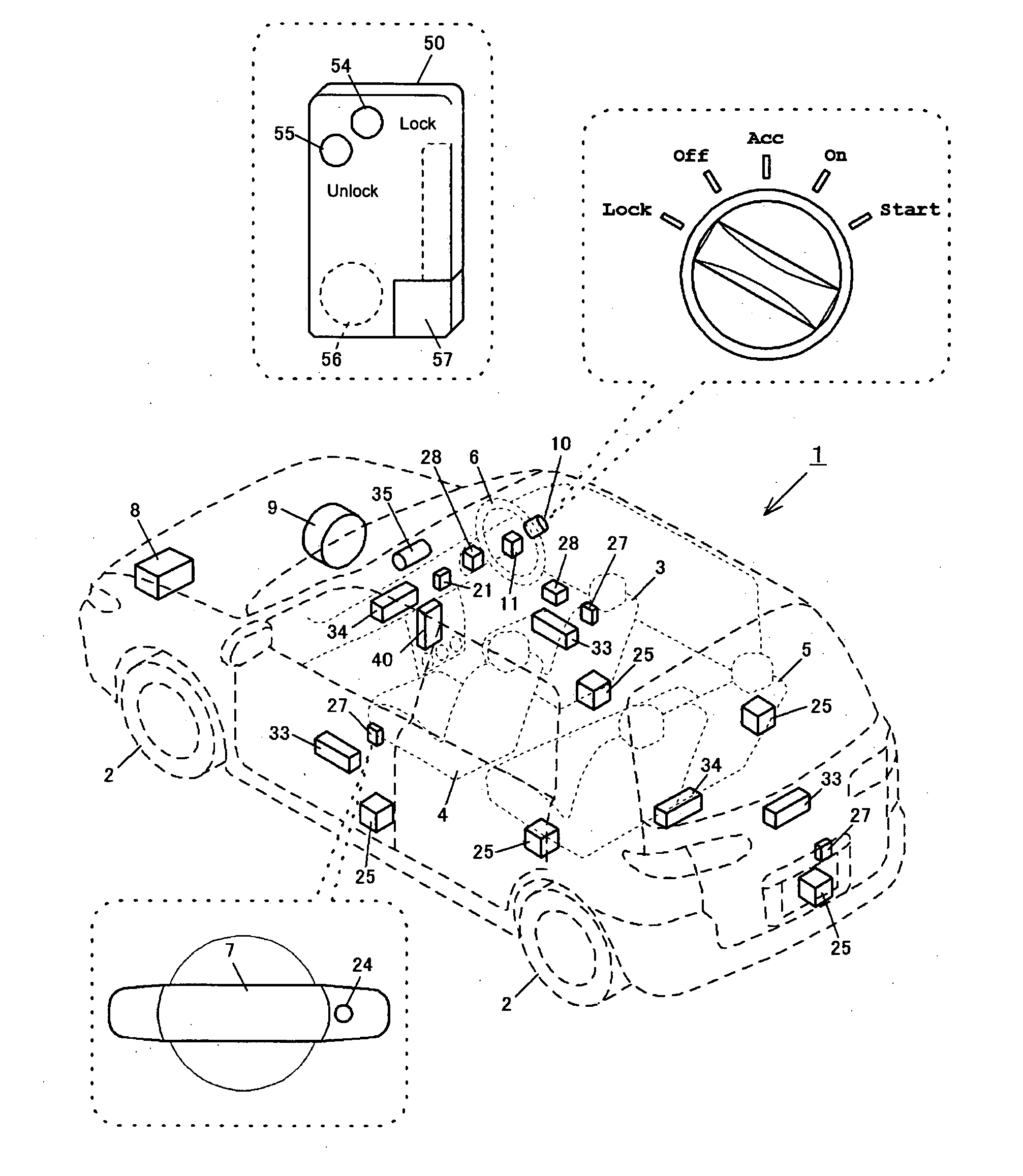

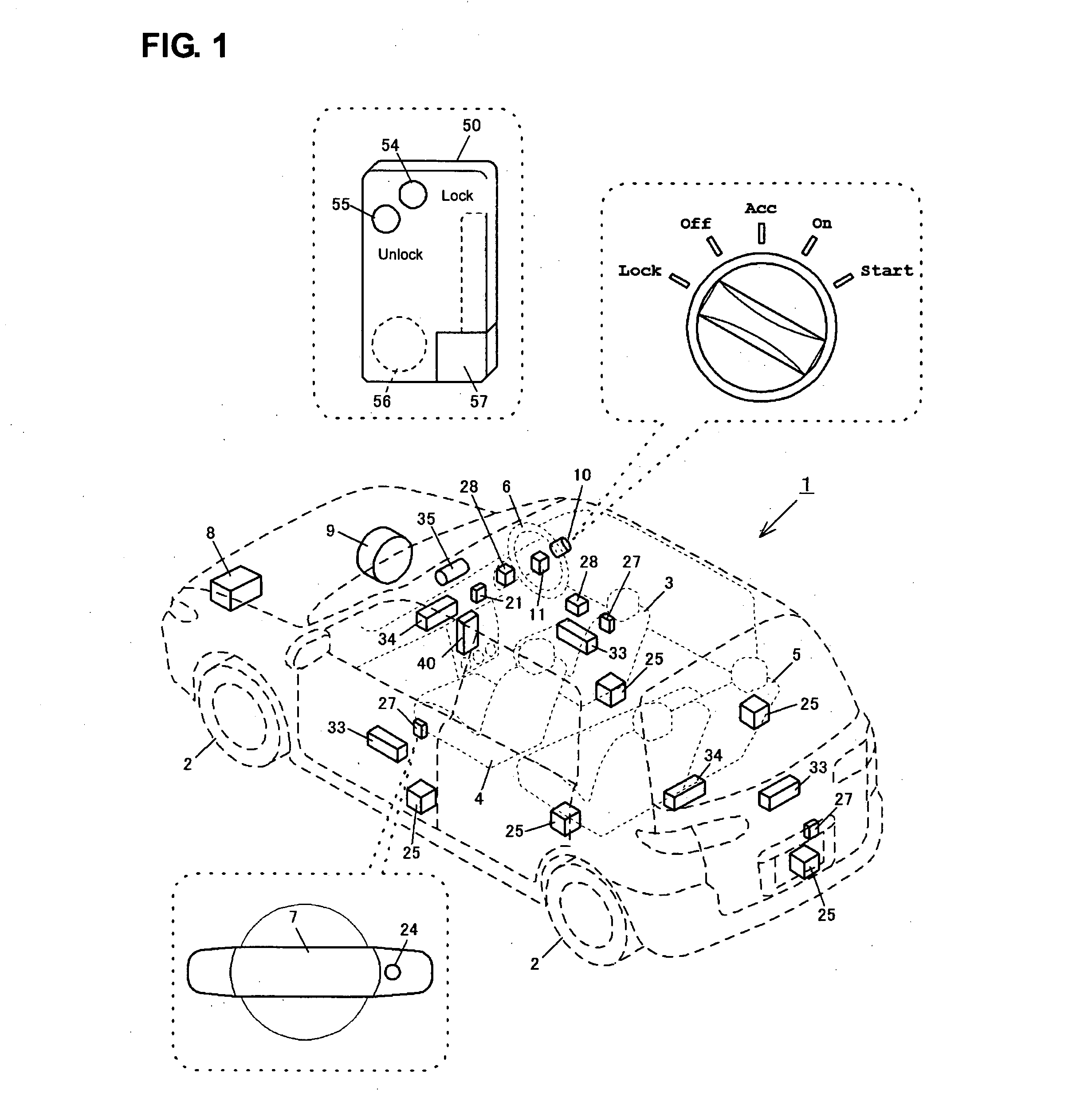

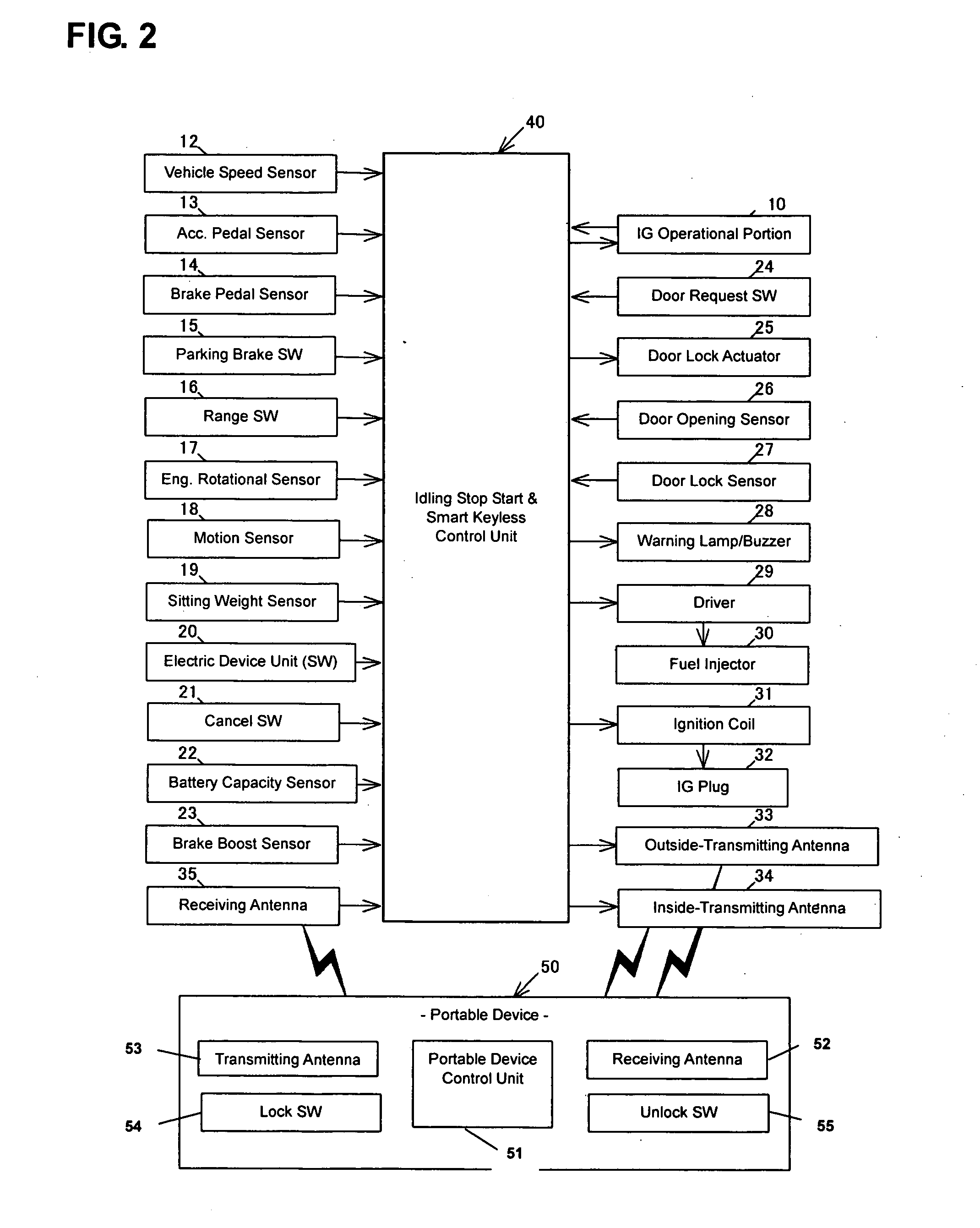

Control system for vehicle

InactiveUS20060236970A1Improve utilityPrecise functionElectrical controlInternal combustion piston enginesControl systemControl unit

A control unit automatically stops an engine when a vehicle is stopped and automatically starts the engine in a case where operation for a vehicle start is conducted by a passenger or a specified emergency start is required. Herein, in the case where the operation for the vehicle start is conducted by the passenger, the engine is automatically started when ID verification with a portable device is confirmed, and in the case where the specified emergency start is required, the engine is automatically started without the confirmation of the ID verification with the portable device. Accordingly, a proper antitheft function of a smart engine starter (SES) system and a proper engine-start function of an idling stop start (ISS) system.

Owner:MAZDA MOTOR CORP

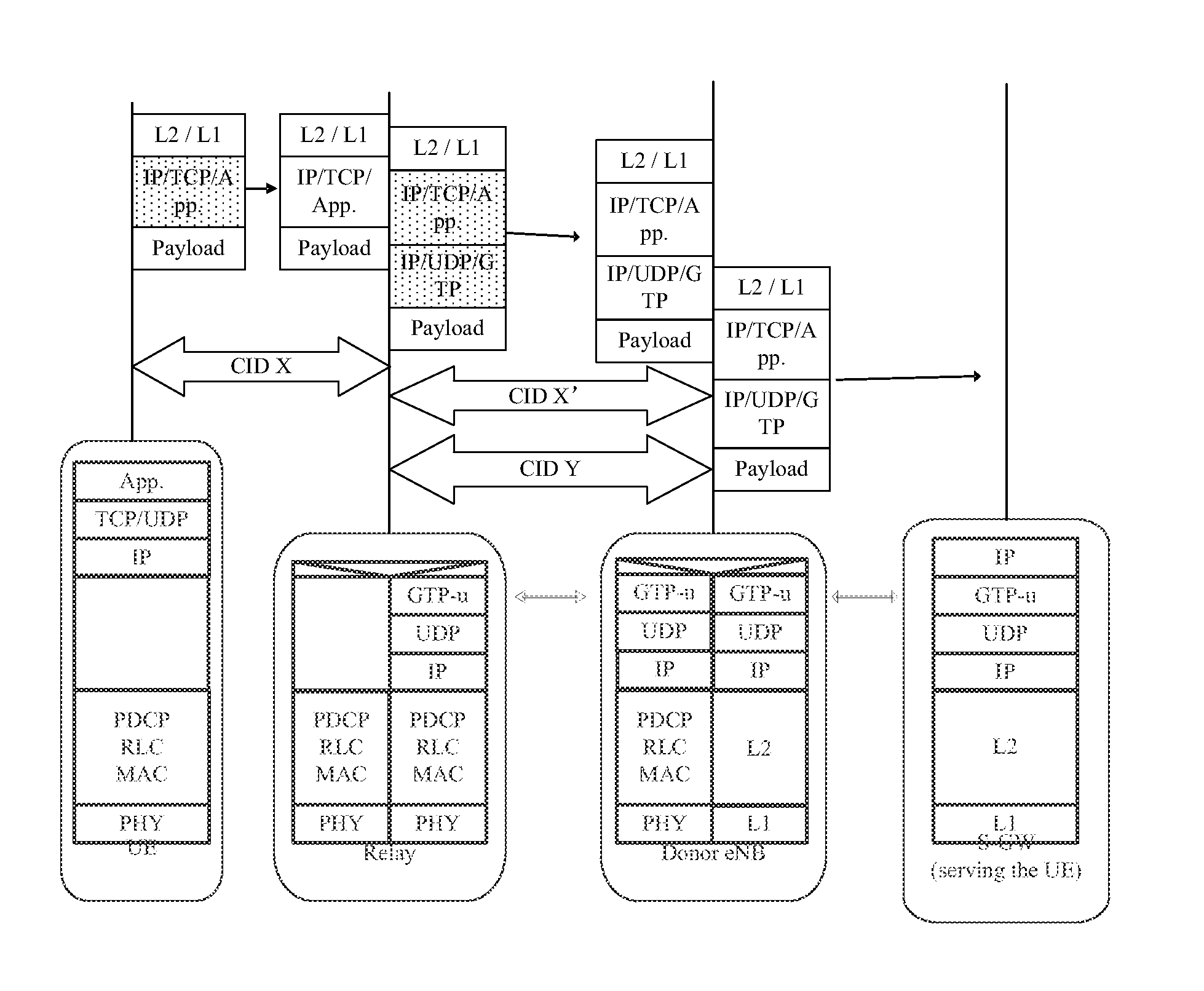

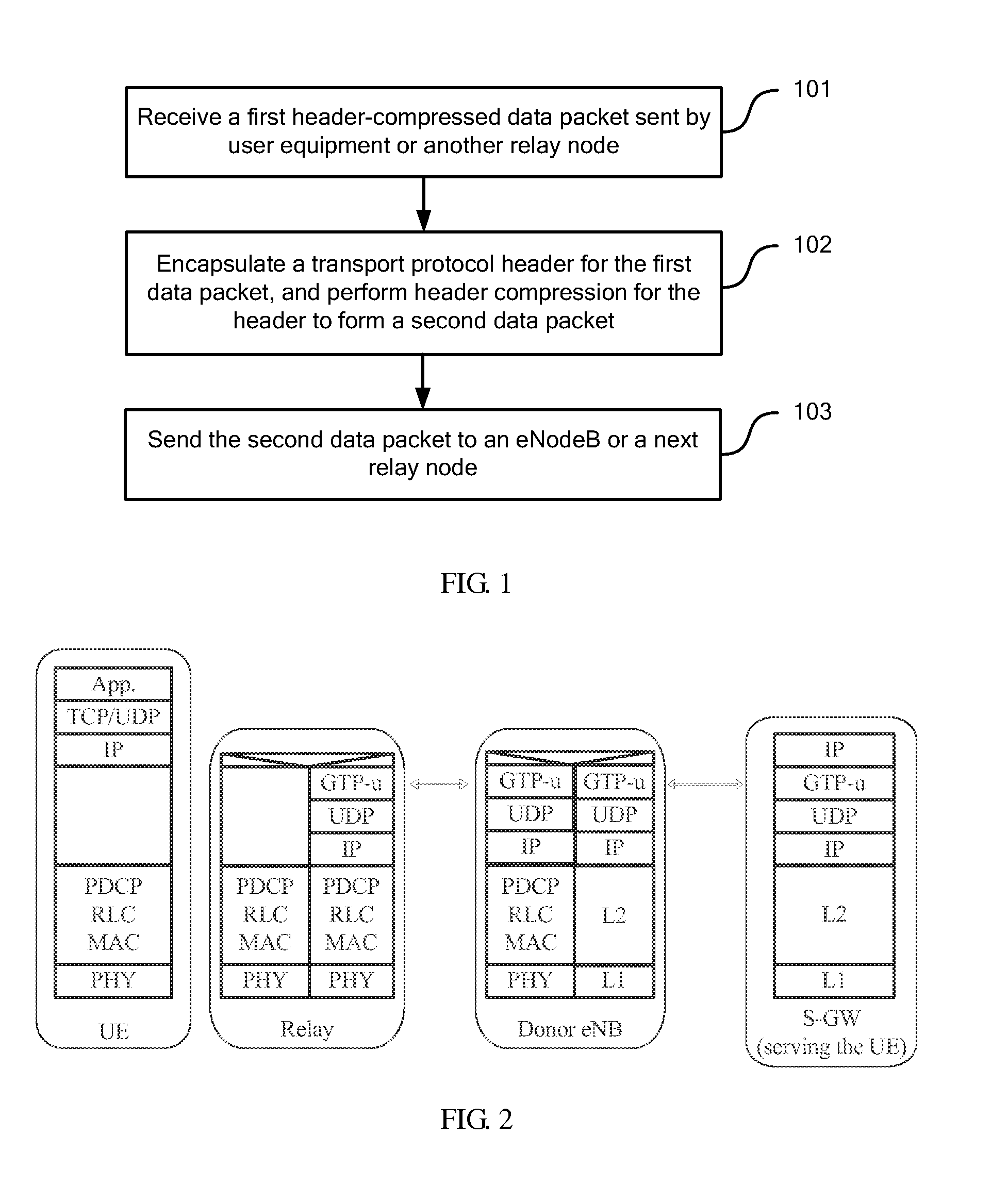

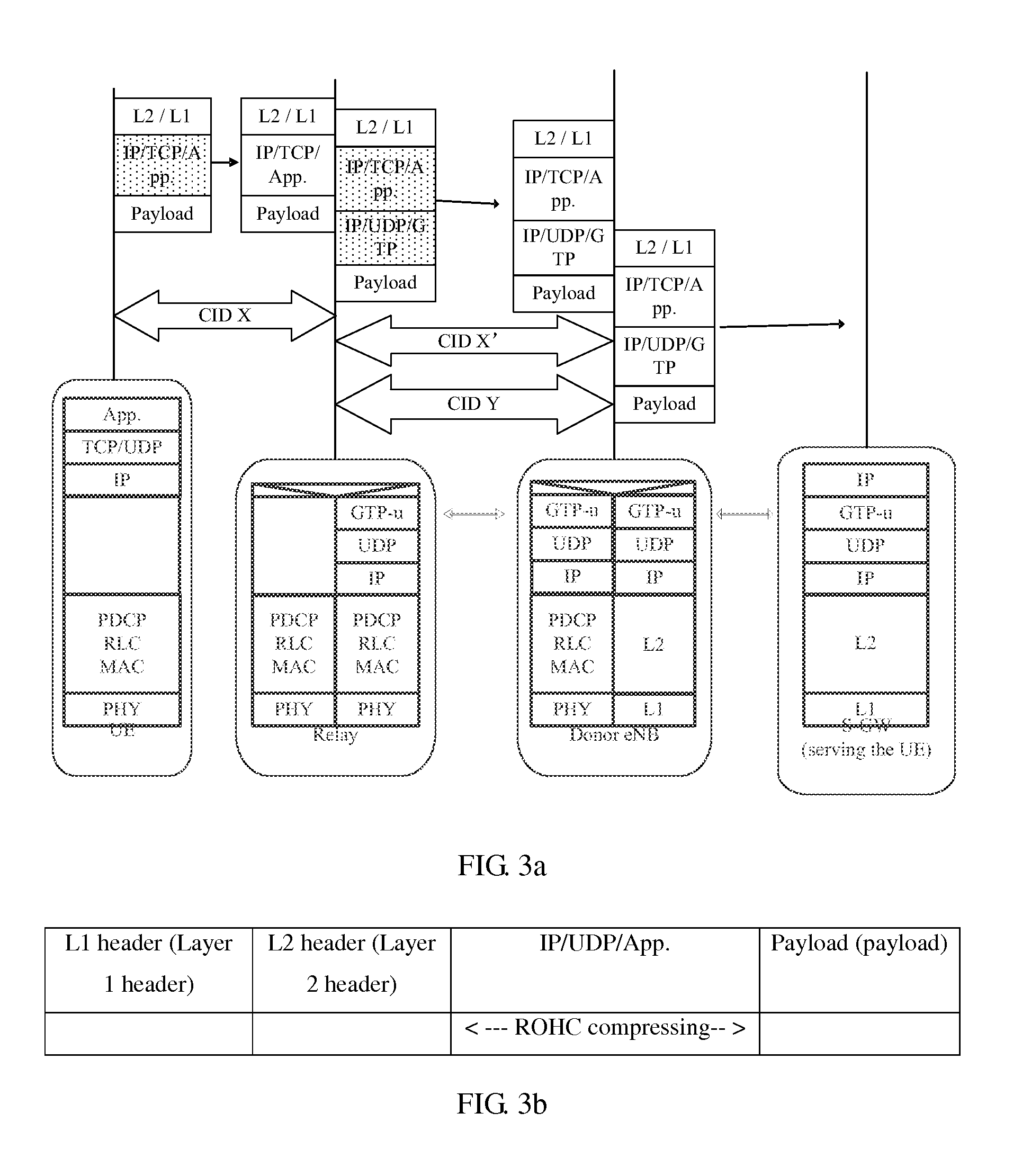

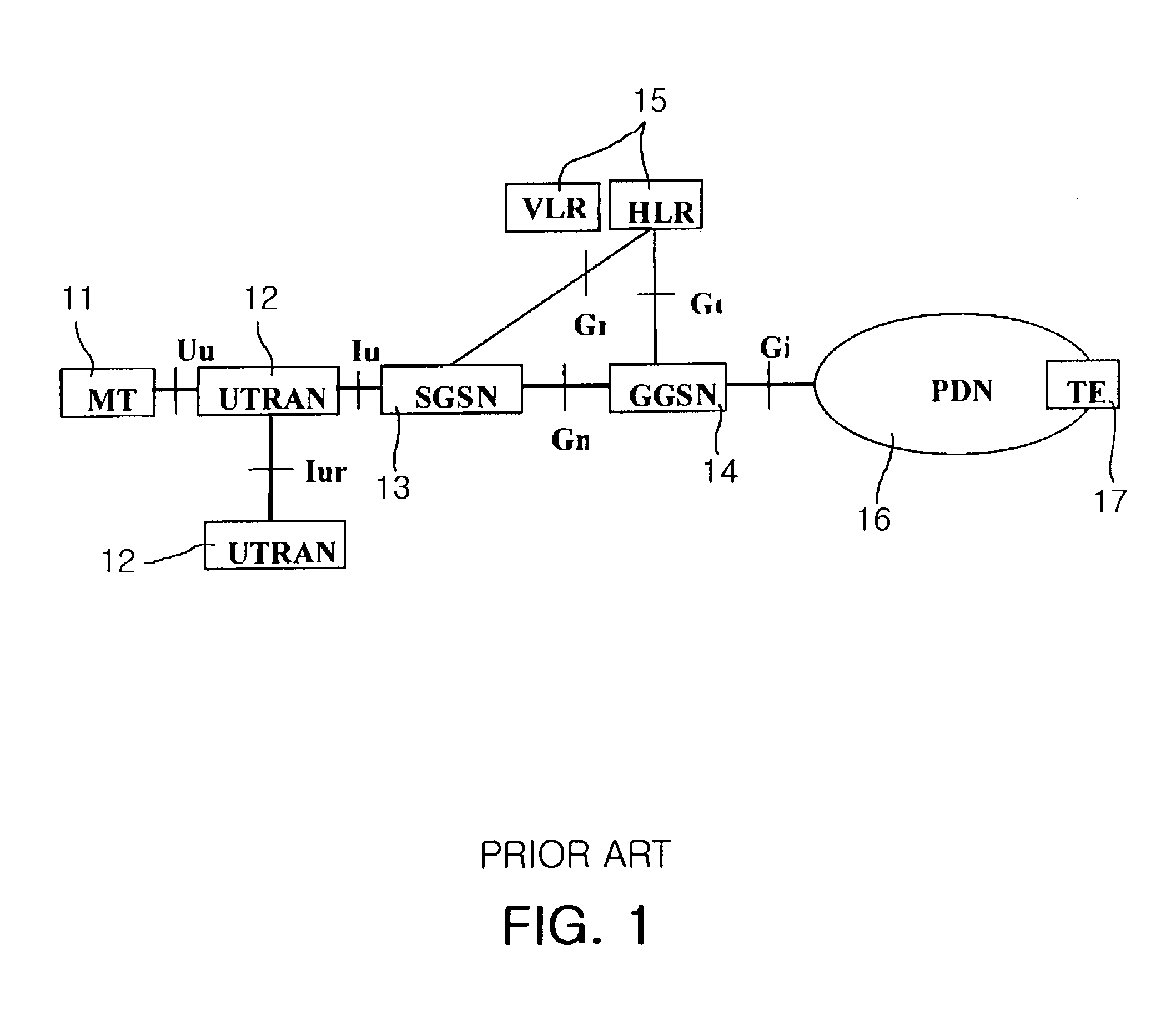

Method and Apparatus for Header Compression in Network Relay Scenario

InactiveUS20120155375A1Occupation be reduceImprove utilityFrequency-division multiplex detailsNetwork traffic/resource managementProtocol for Carrying Authentication for Network AccessEnodeB

Embodiments of the present application disclose a method and an apparatus for header compression in a network relay scenario. The method includes: receiving, by a relay node, a first header-compressed data packet sent by user equipment or another relay node; encapsulating a transport protocol header for the first data packet and performing header compression for the header to form a second data packet; and sending the second data packet to an eNodeB or a next relay node in an uplink direction.

Owner:HUAWEI TECH CO LTD

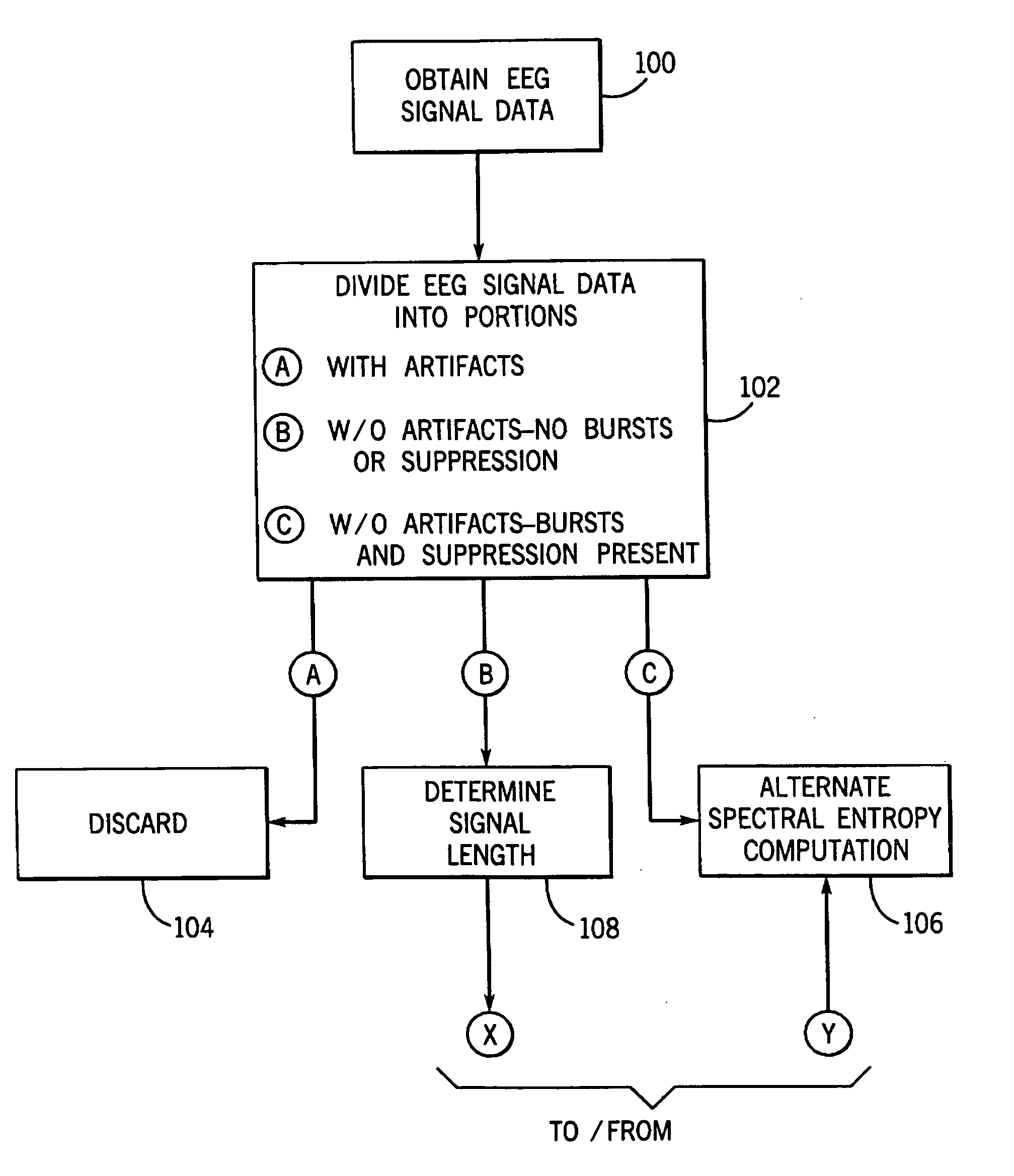

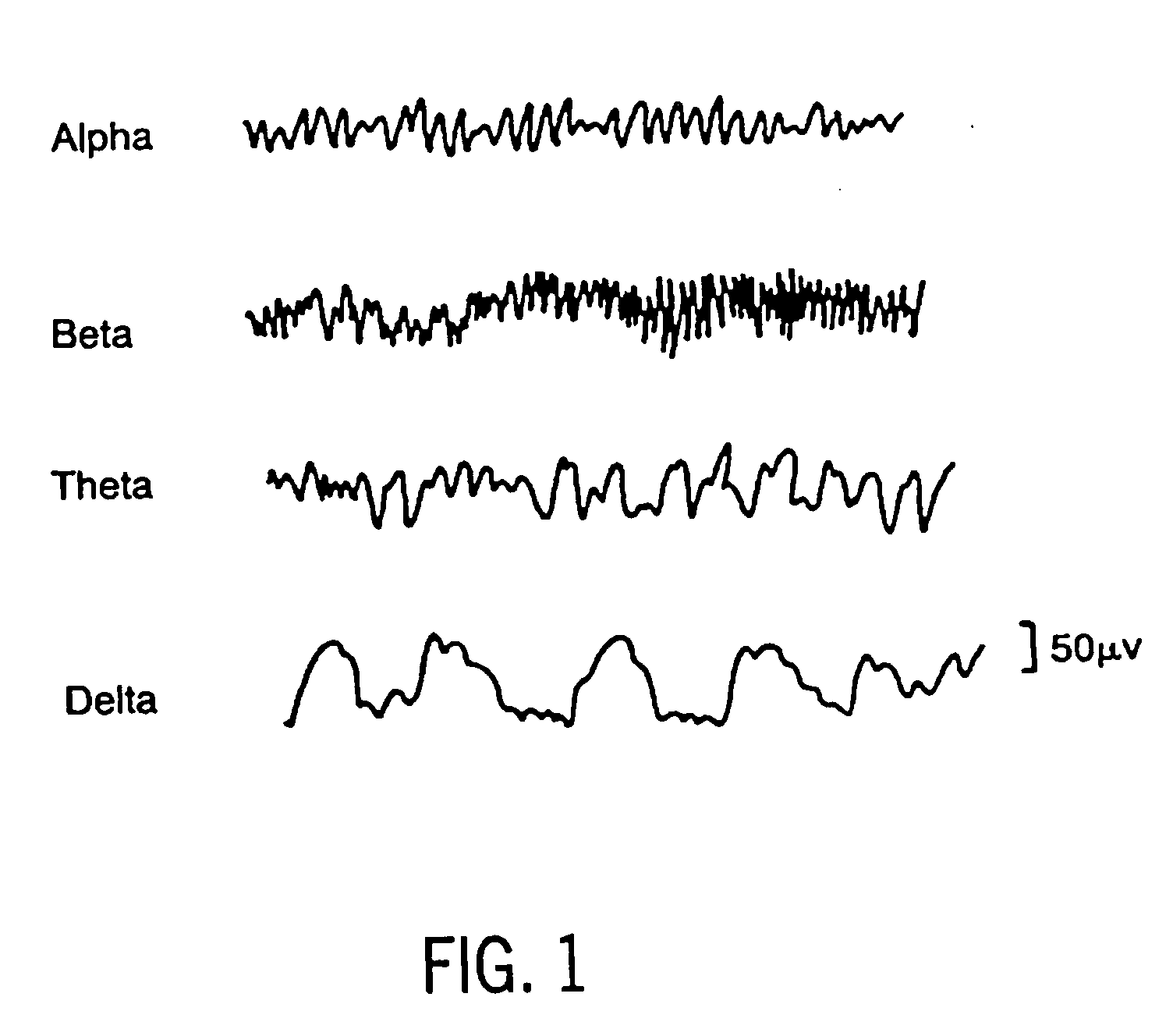

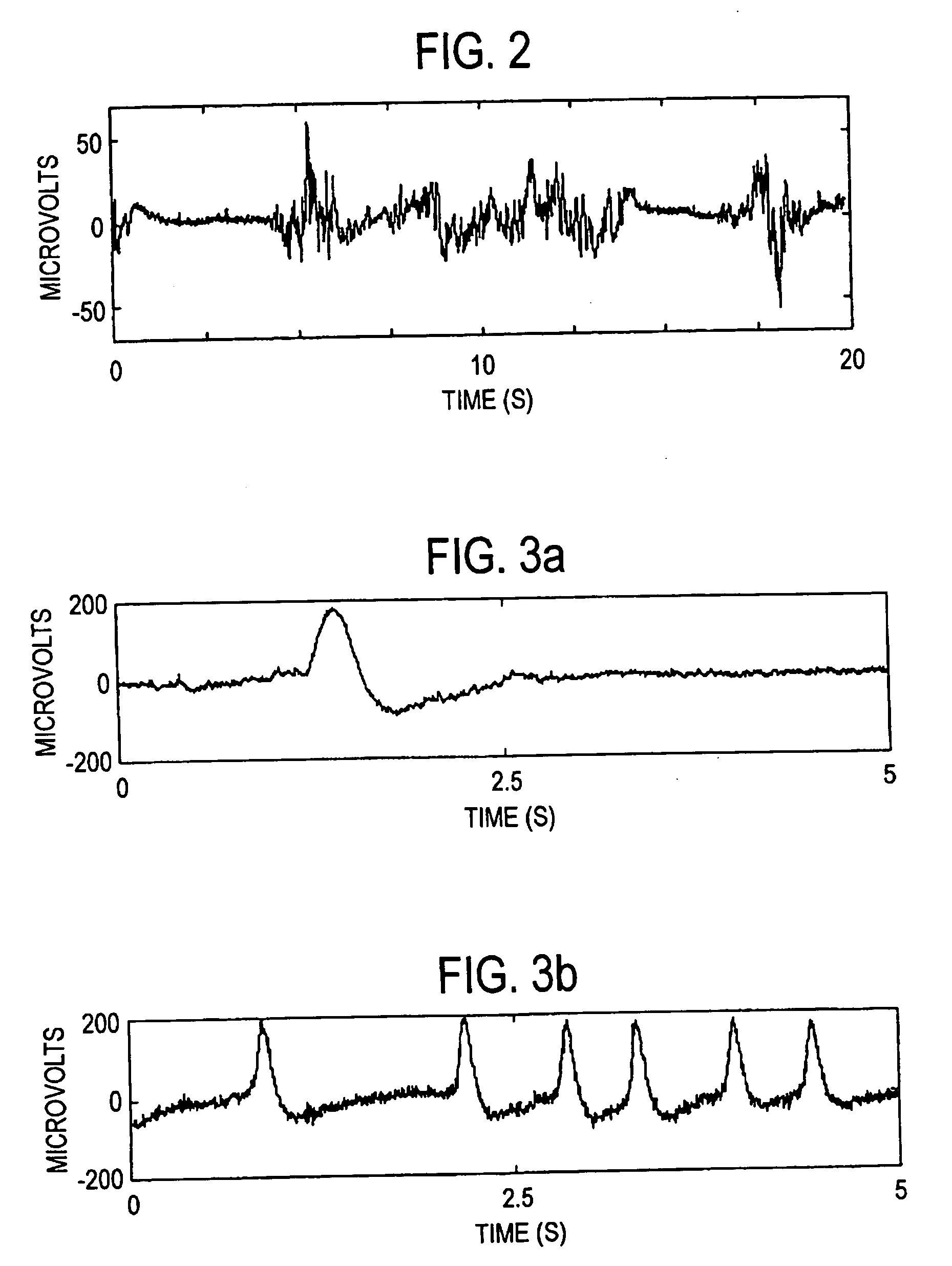

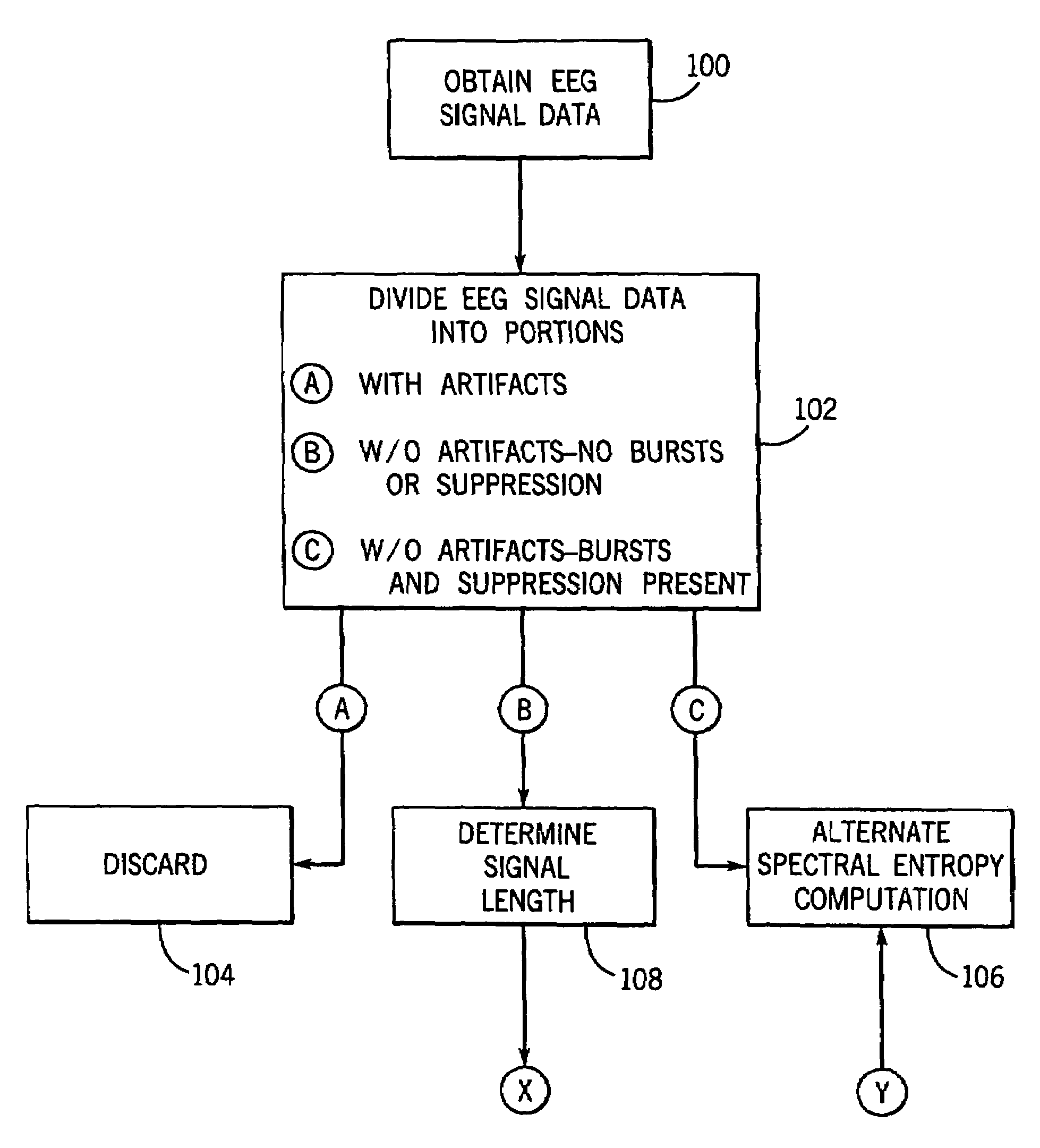

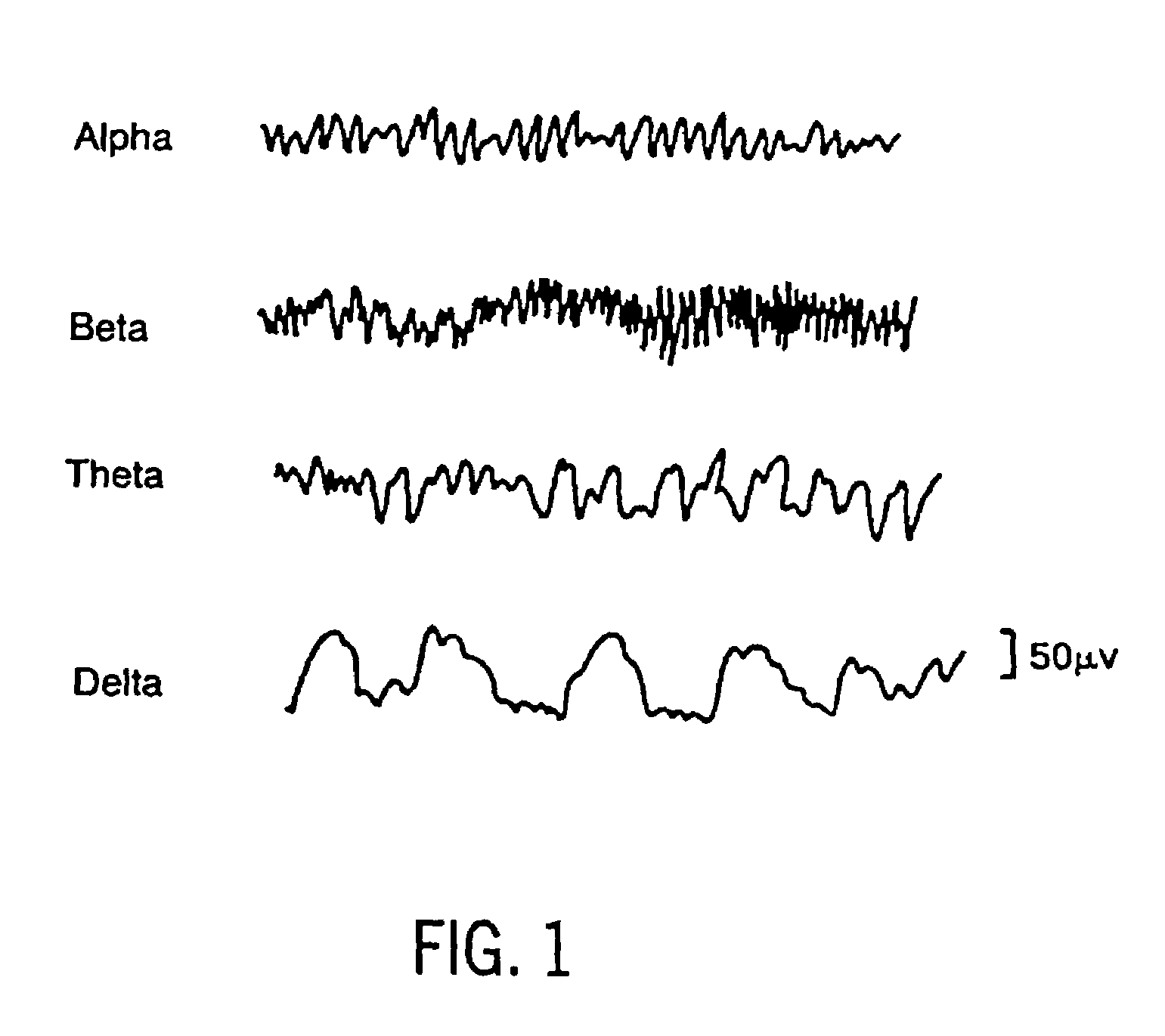

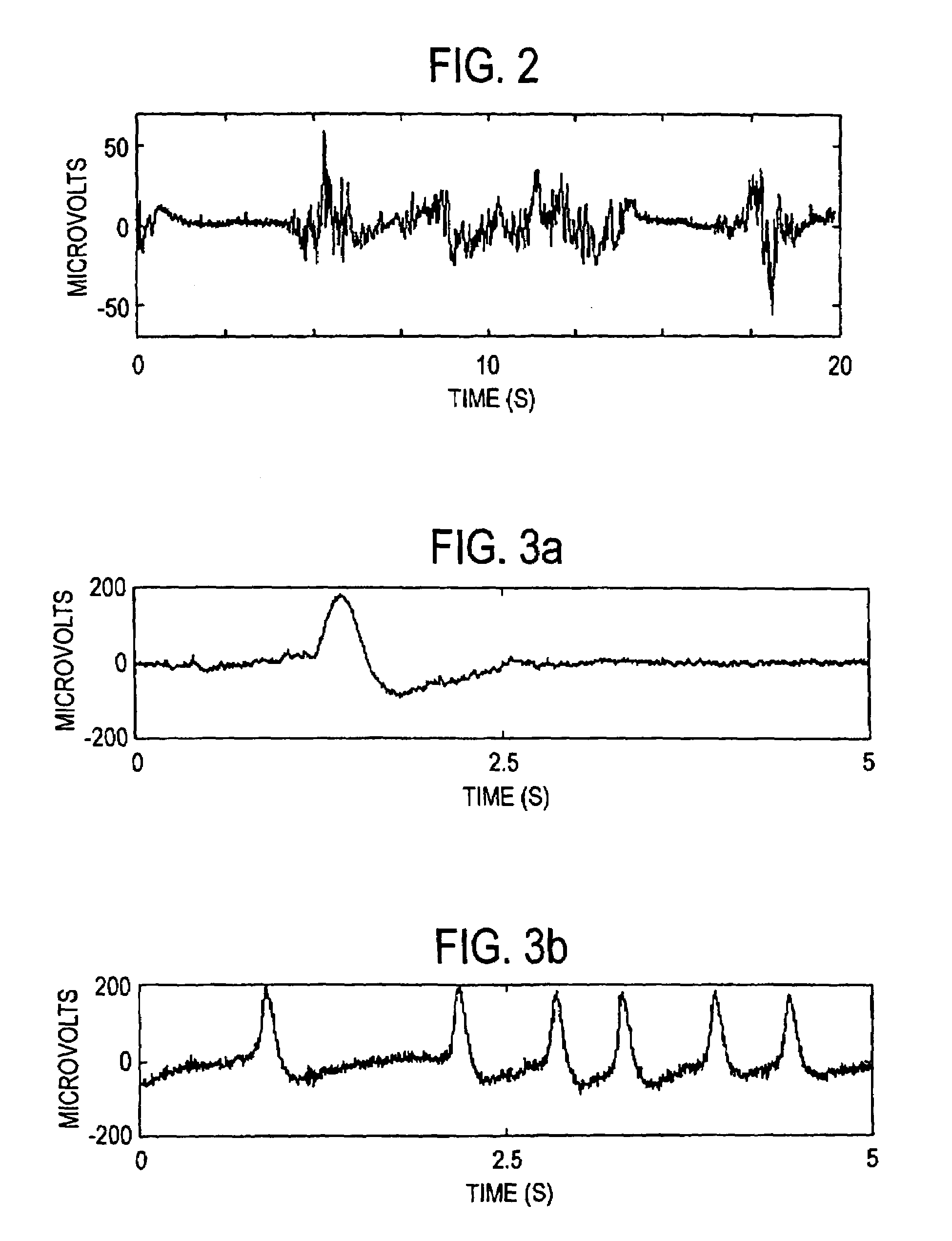

Method and apparatus for determining the cerebral state of a patient using generalized spectral entropy of the EEG signal

A method and apparatus for ascertaining the cerebral state of a patient using generalized spectral entropy of the EEG signal.

Owner:INSTRUMENTARIUM CORP

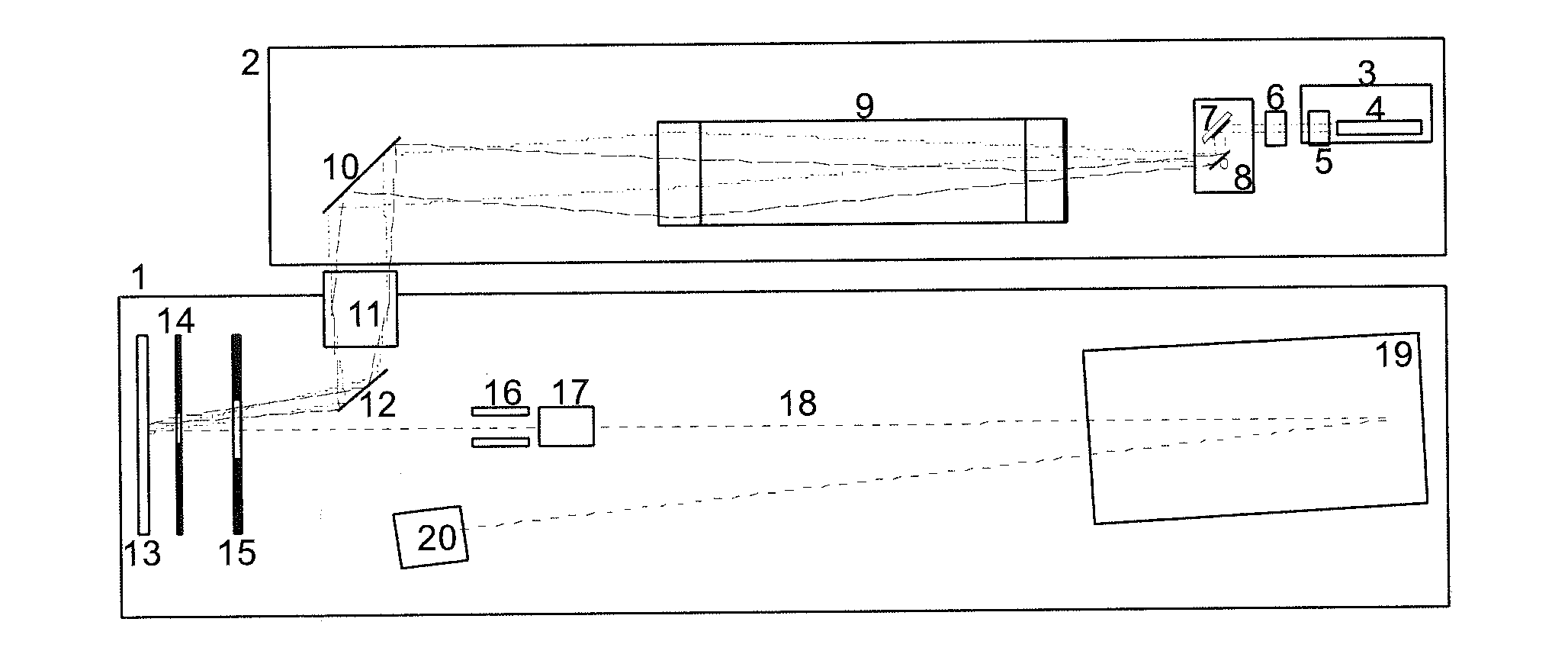

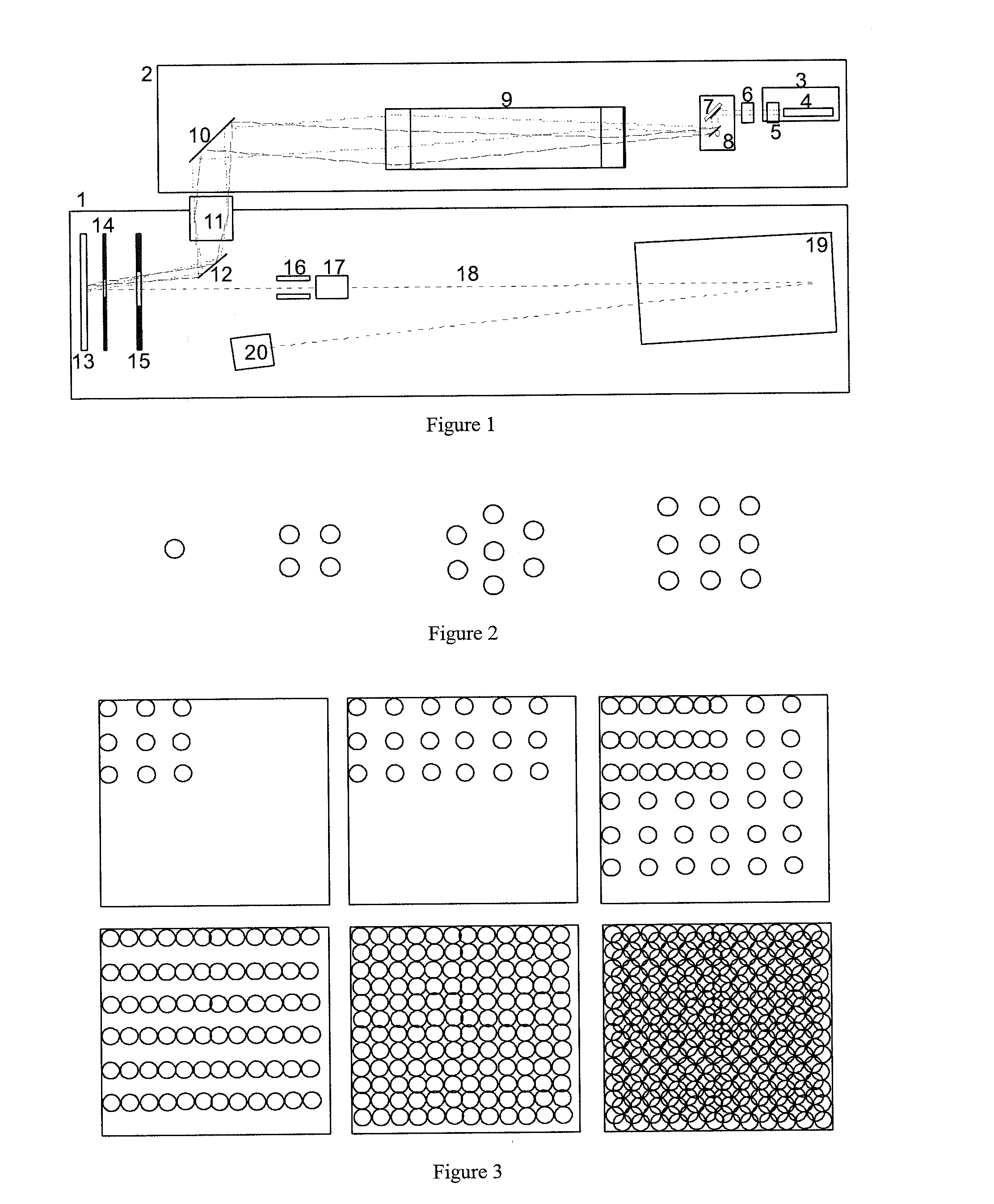

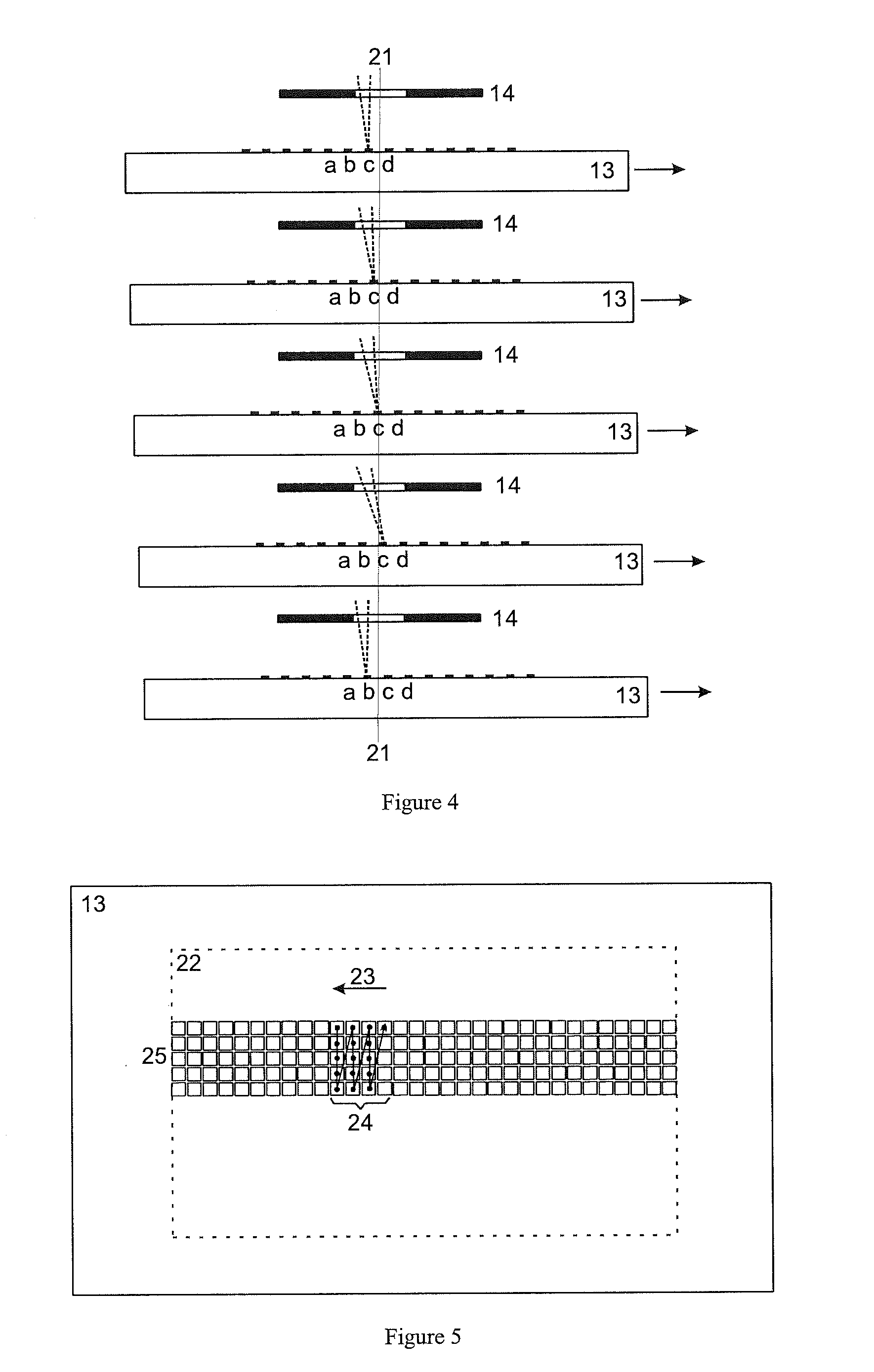

Laser spot control in maldi mass spectrometers

ActiveUS20130056628A1Improve overall utilizationImprove utilityTime-of-flight spectrometersIsotope separationDesorptionLight beam

Mass spectrometers ionize samples by matrix-assisted laser desorption (MALDI). The samples are located on a moveable support plate, and irradiated by a pulsed laser. A fast positional control of laser spots is provided via a system of rotatable mirrors to relieve strain on a support plate motion drive. If the spot position is finely adjusted by the mirror system and follows the movement of the sample support plate, the intermittent movement of the sample support can be replaced with a continuous uniform motion. The fast positional control allows more uniform ablation of a sample area. Galvo mirrors with low inertia may be used between the beam generation and a Kepler telescope in the housing of the laser. The positional control can also provide a fully automatic adjustment of MALDI time-of-flight mass spectrometers, at least if the ion-optical elements are equipped with movement devices.

Owner:BRUKER DALTONIK GMBH & CO KG

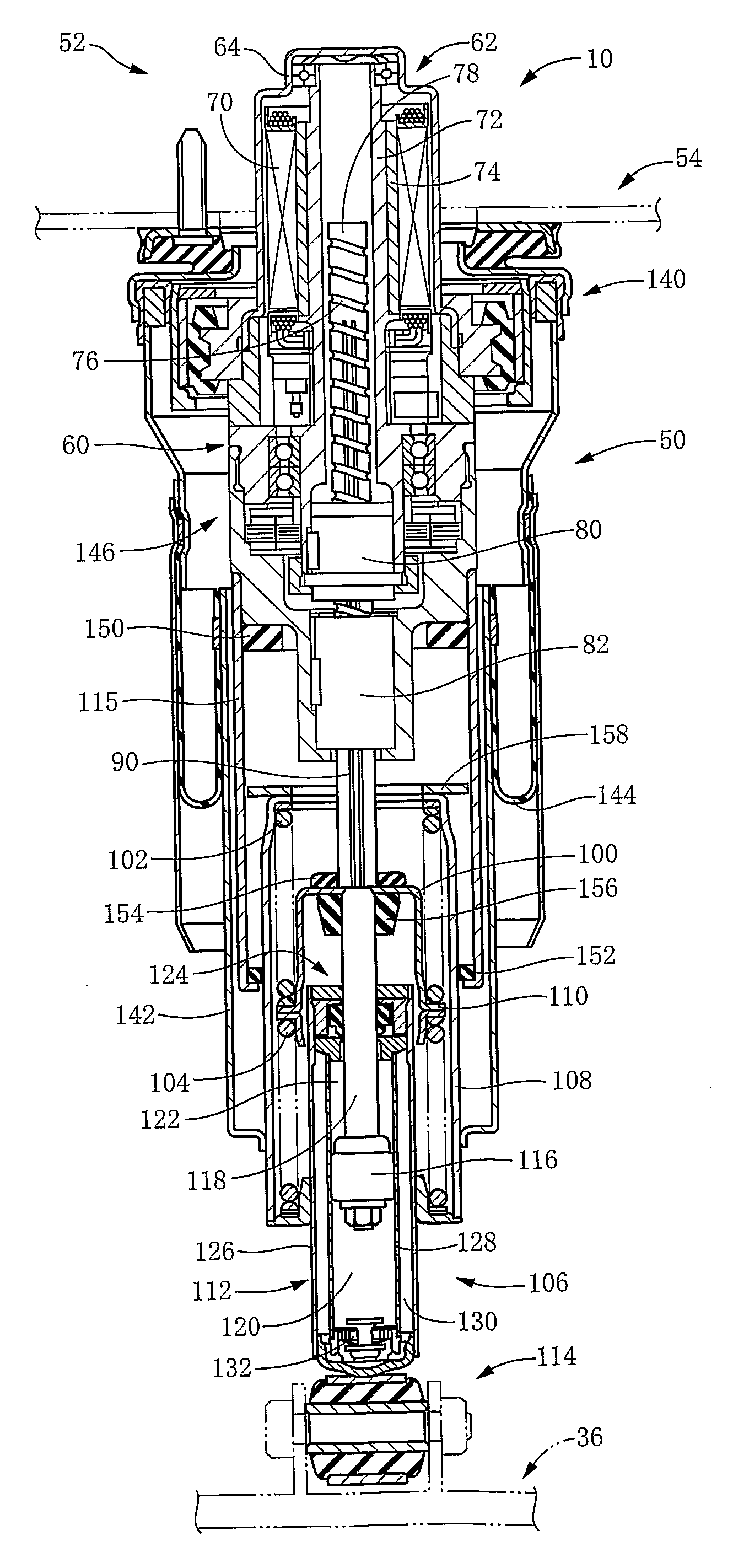

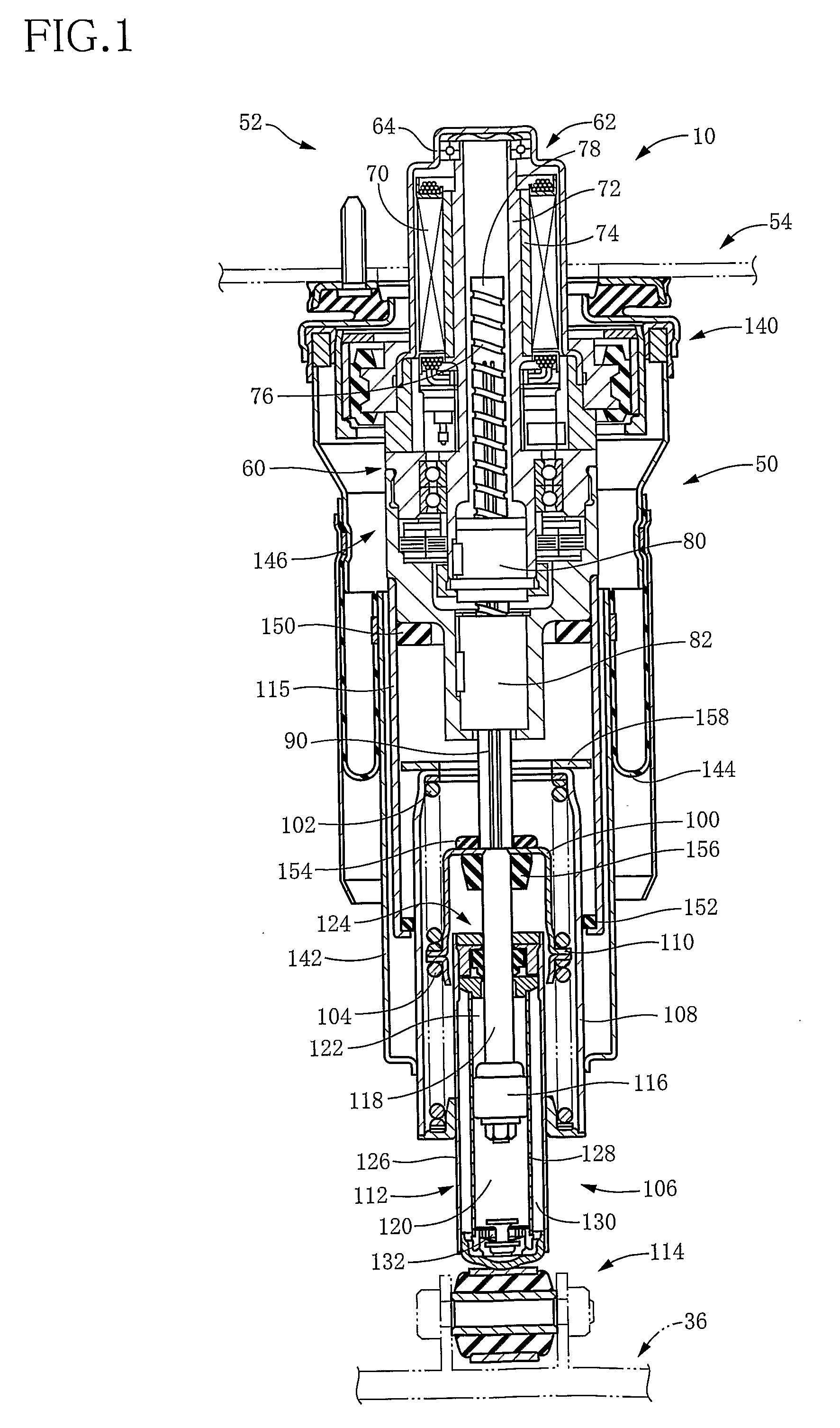

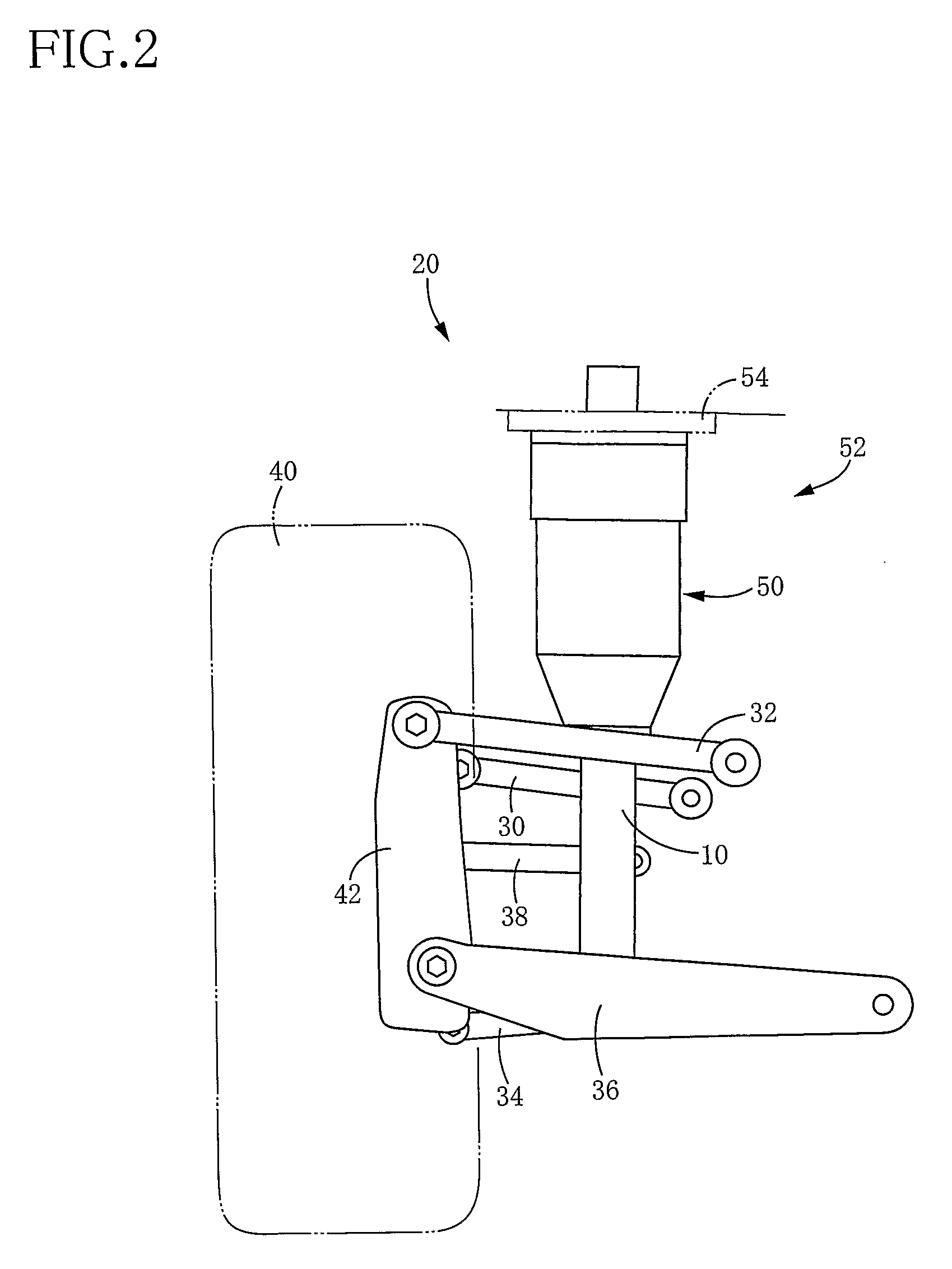

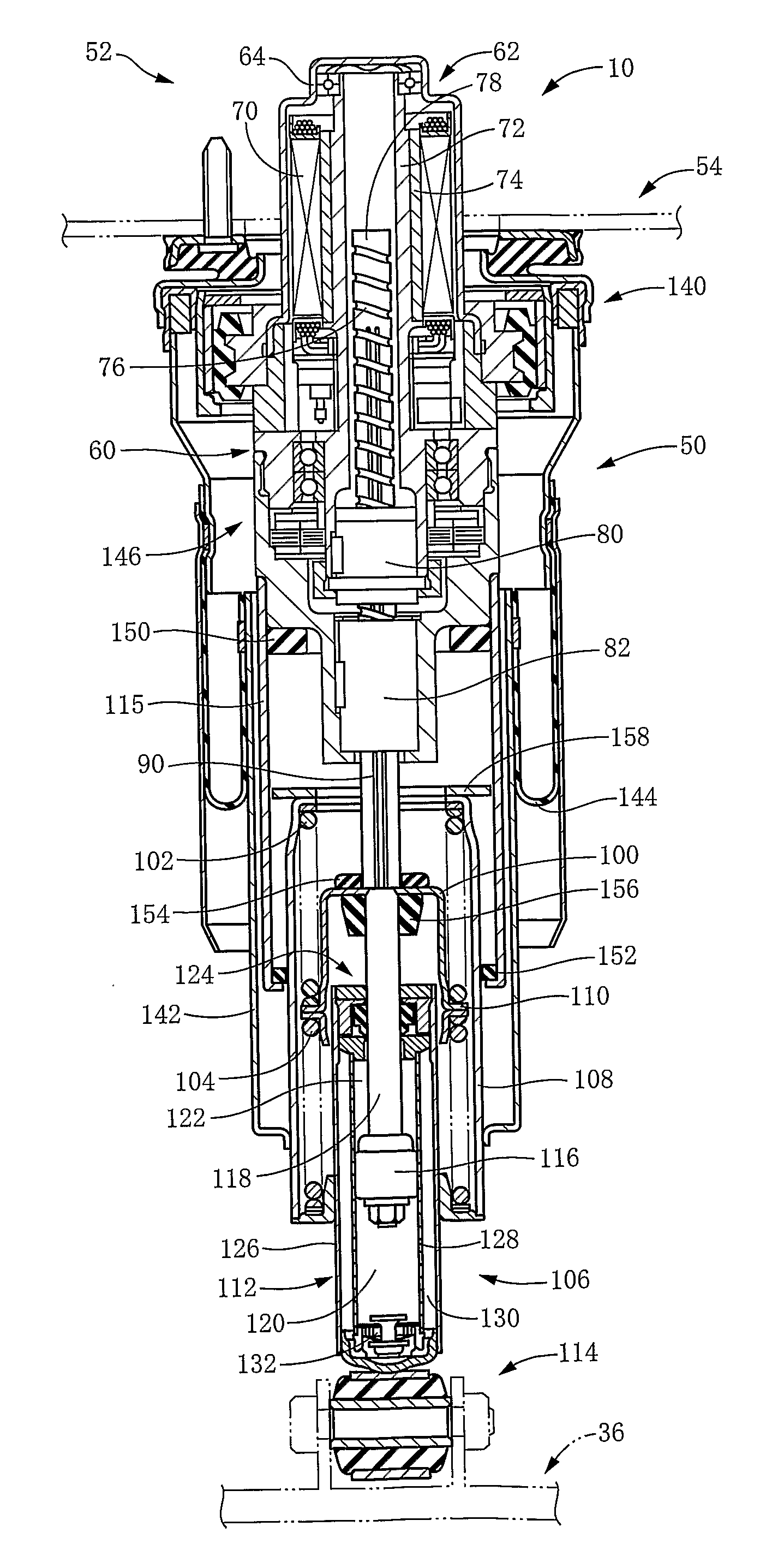

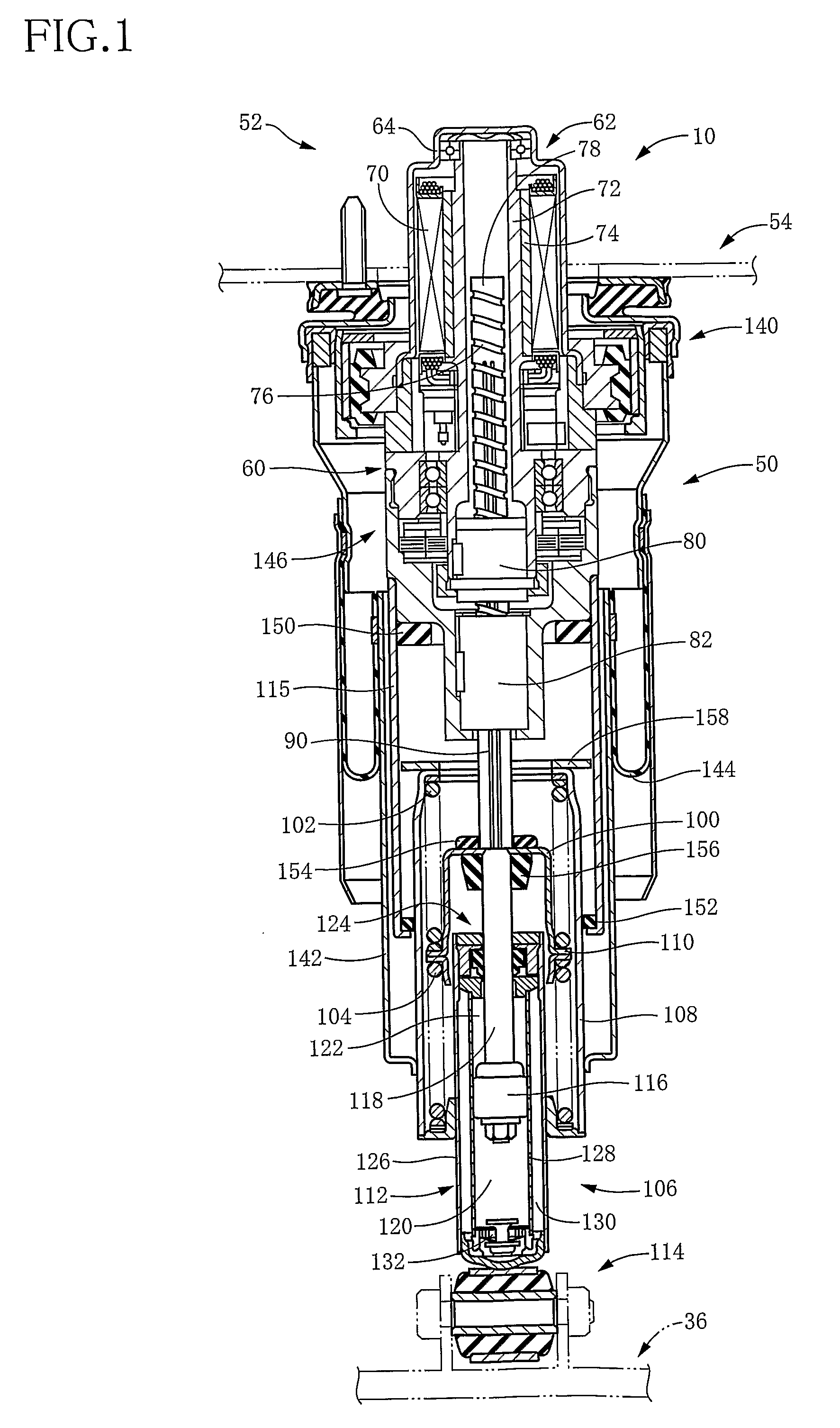

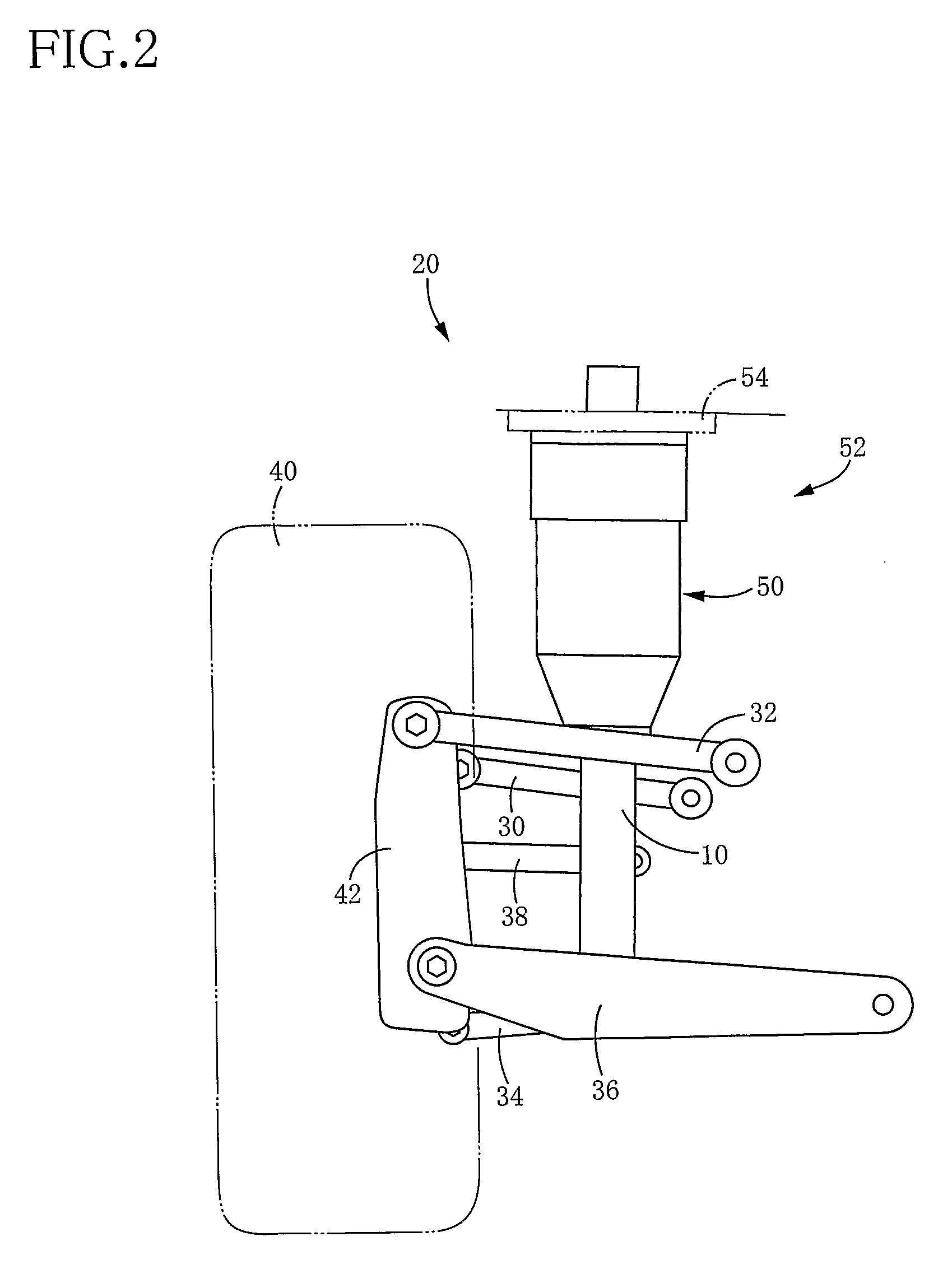

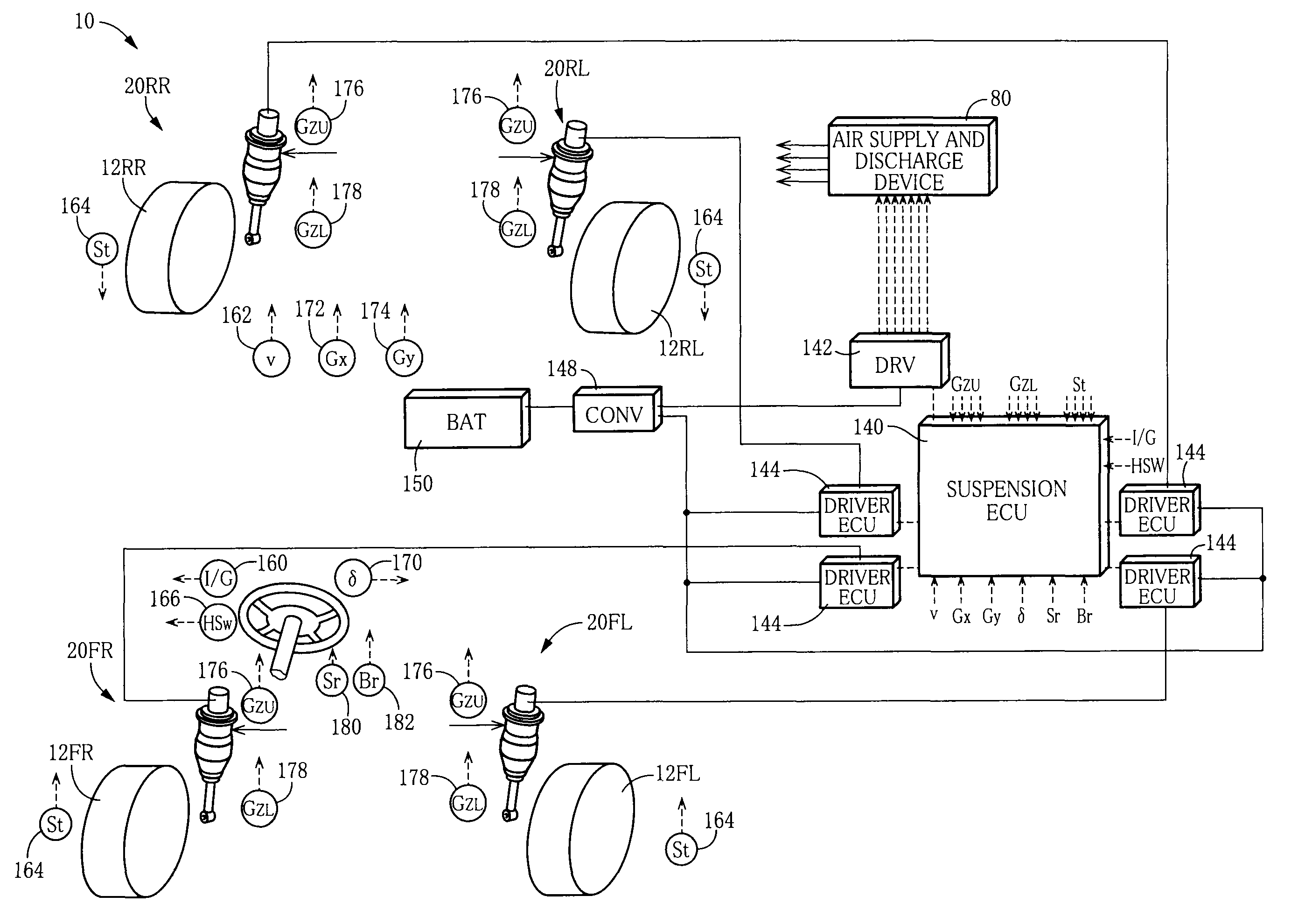

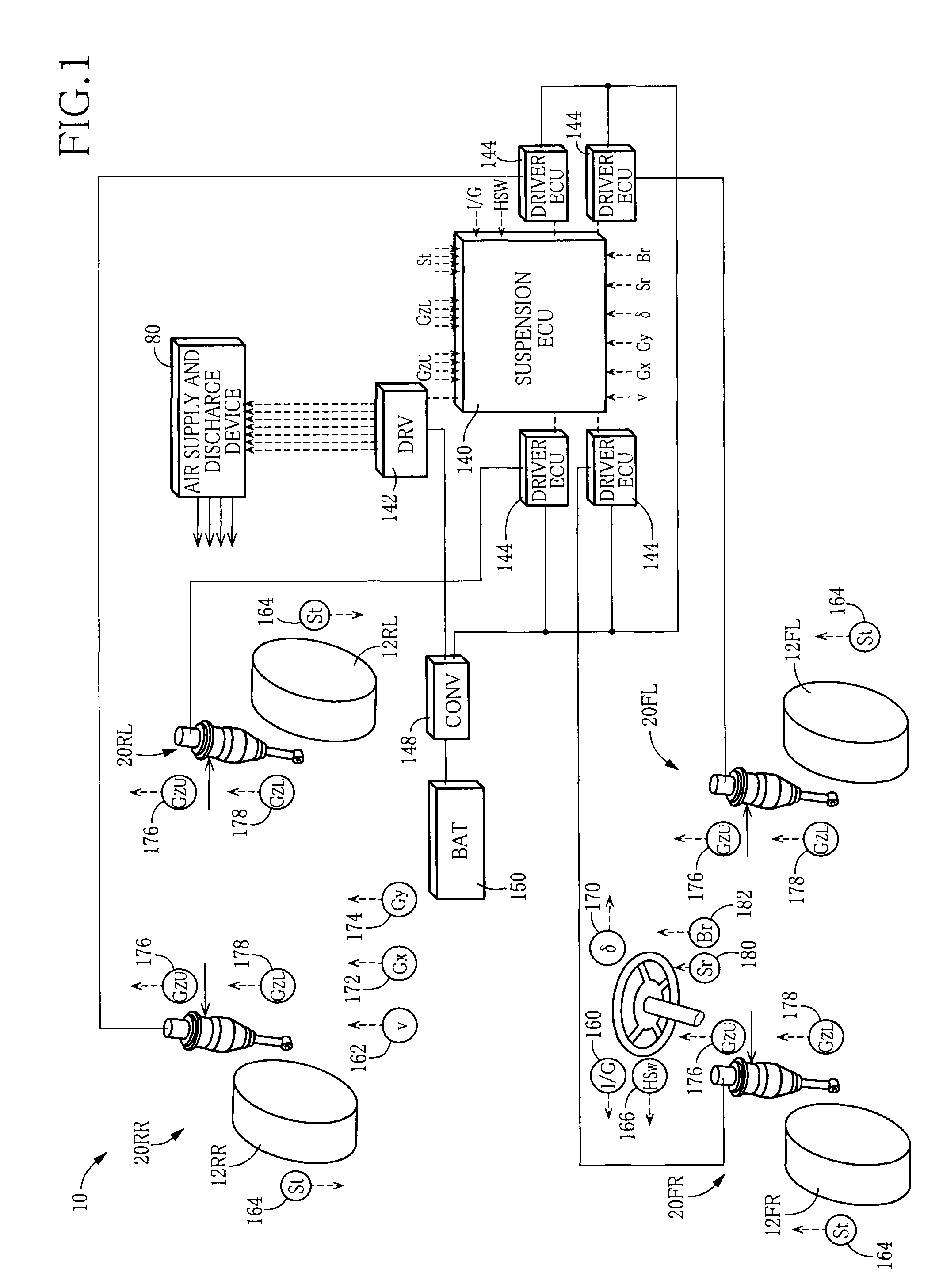

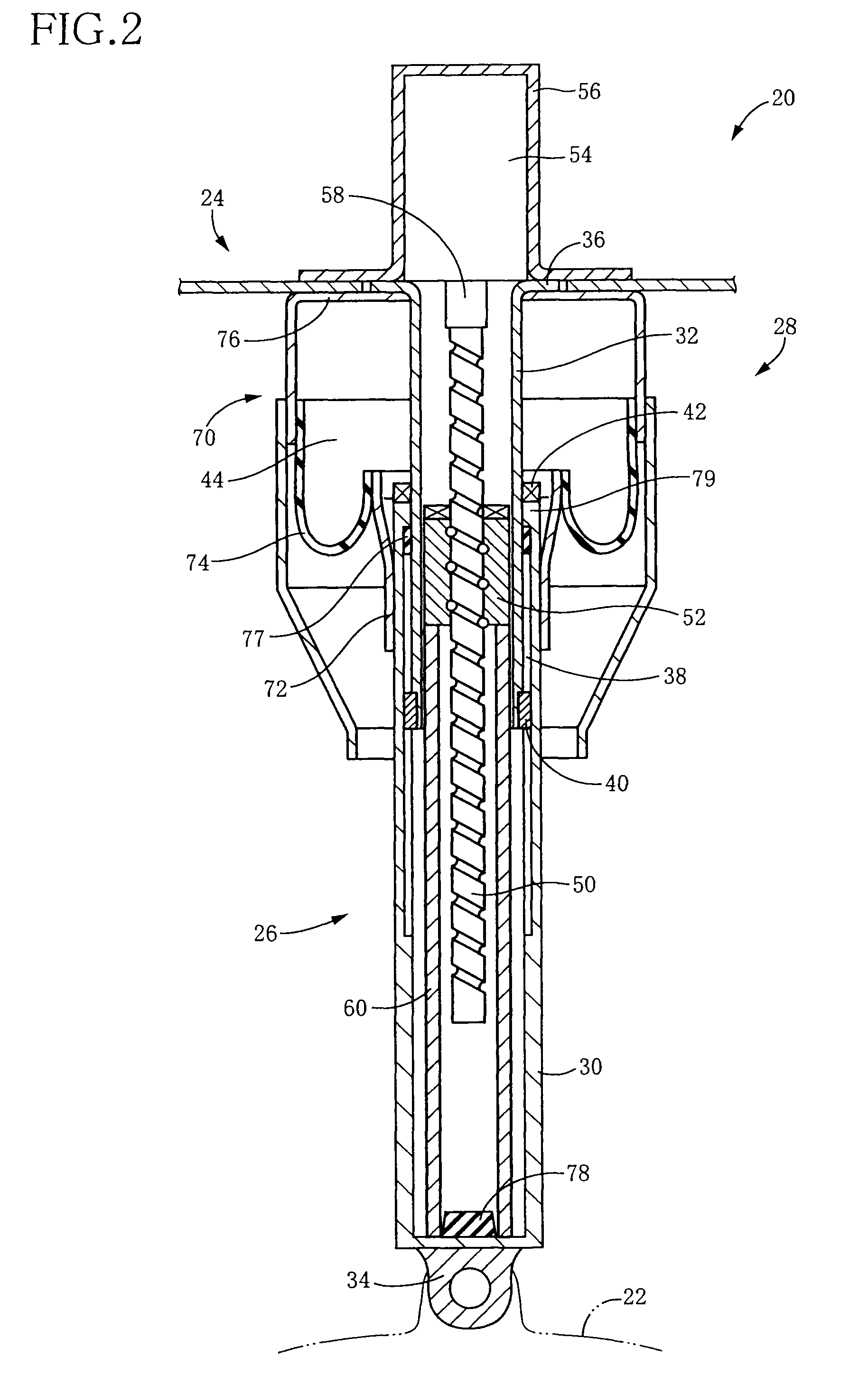

Electromagnetic shock absorber for vehicle

InactiveUS20100200343A1Improve utilityHigh degree of utilitySpringsVibration dampersEngineeringElectromagnetic absorbers

An electromagnetic absorber (10) for a vehicle including (a) a threaded rod (78) which is disposed on one of a sprung portion and an unsprung portion and which has a threaded groove (76) formed in its outer circumferential portion and an axial groove (90) extending in its axis direction (b) a nut (80) which is rotatably disposed on the other of the sprung portion and the unsprung portion and which is screwed with the threaded rod and (c) a rod-rotation inhibiting member (82) which includes a fitting portion configured to be fitted in the axial groove and which is disposed on the other of the sprung portion and the unsprung portion, the rod-rotation inhibiting member being configured to inhibit the threaded rod from rotating while permitting the threaded rod to move in the axis direction. In the electromagnetic absorber, the threaded groove is not formed at a section of a fitting range at which the fitting portion is fitted in the axial groove when the fitting portion is located at an end of the fitting range that extends in the axis direction on the outer circumferential portion of the threaded rod.

Owner:TOYOTA JIDOSHA KK +2

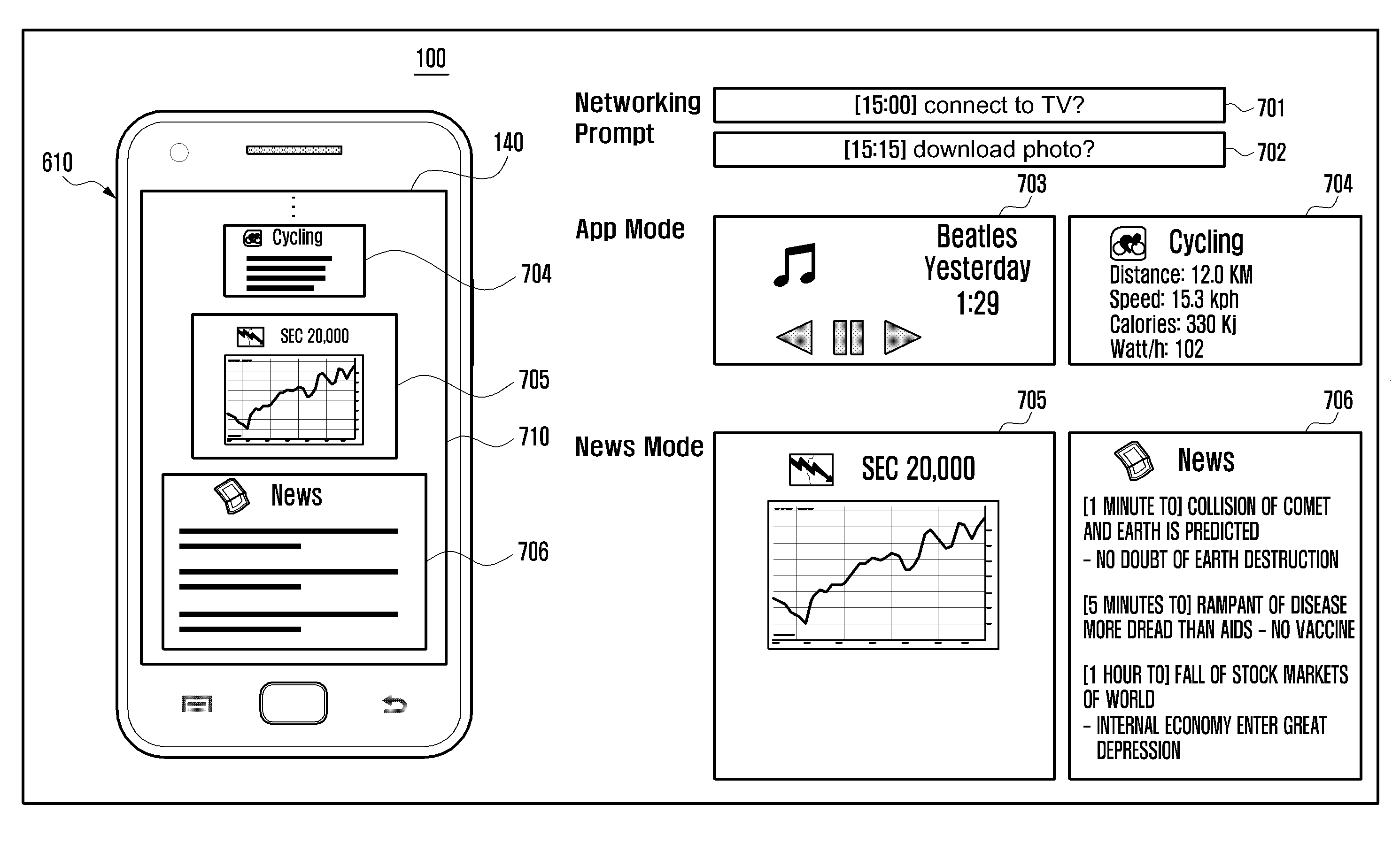

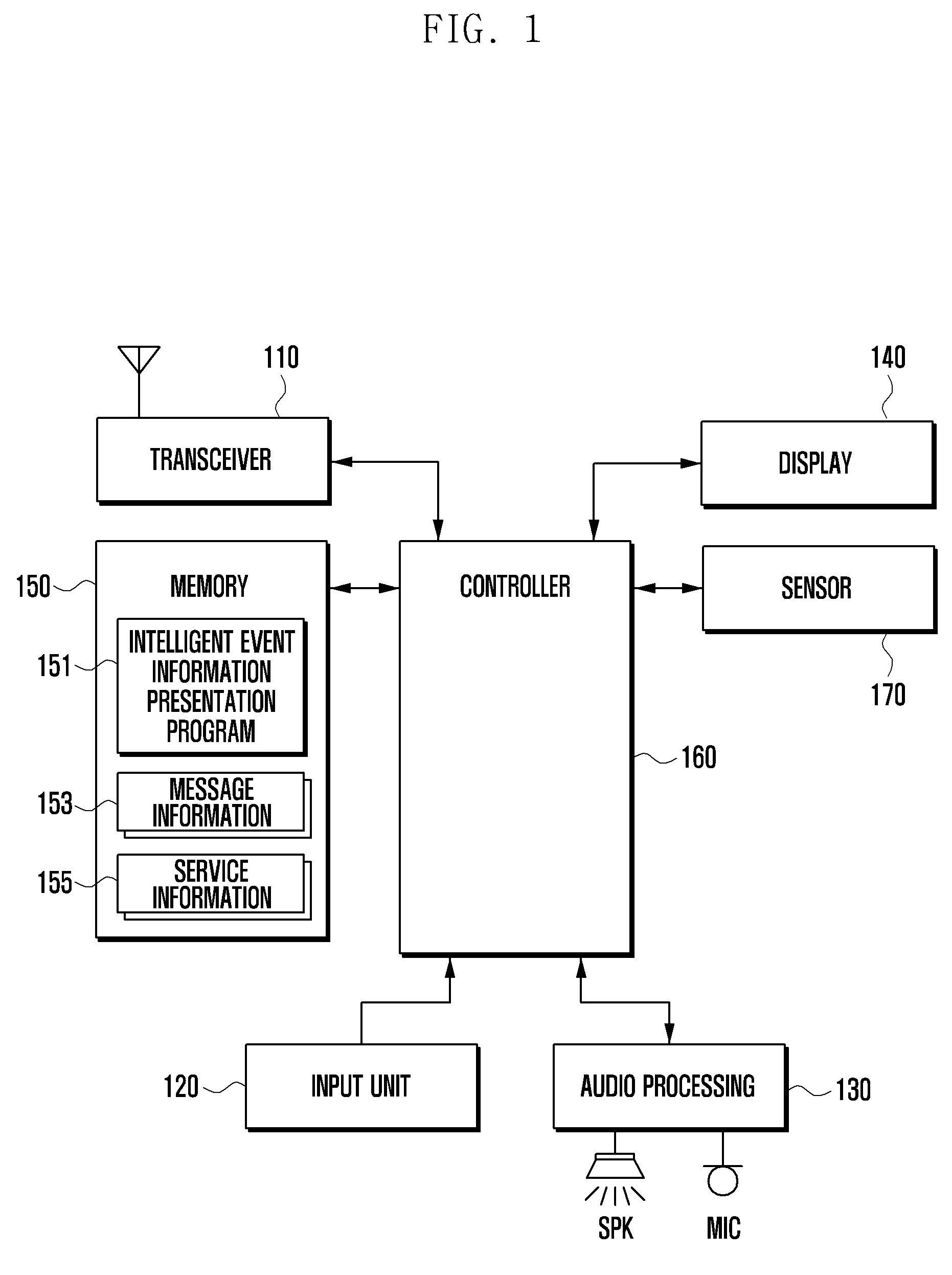

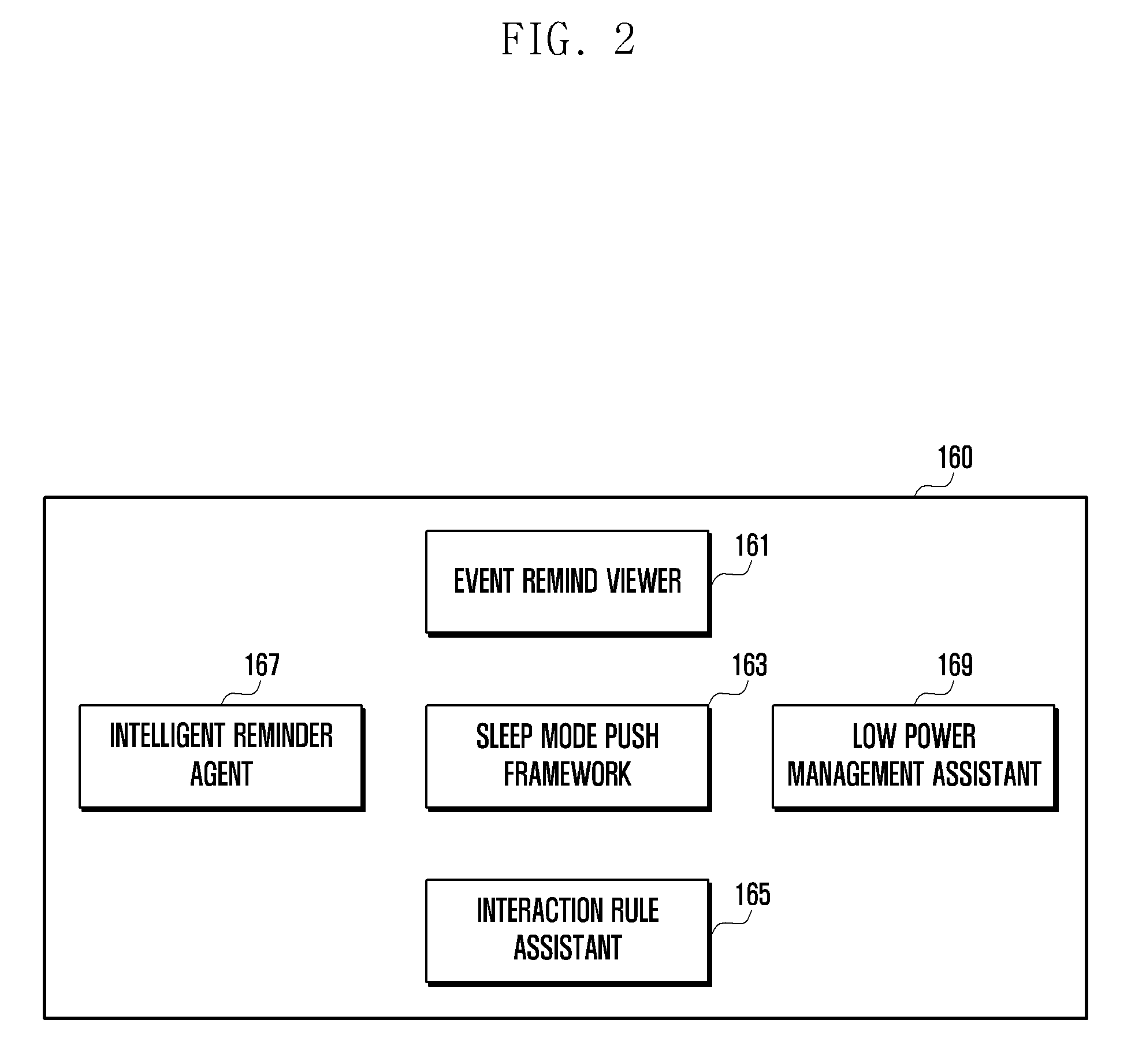

Intellegent event information presentation method and terminal

ActiveUS20130268865A1Improve utilityEnhanced informationUnauthorised/fraudulent call preventionDigital data processing detailsReal-time computingOperation mode

An intelligent event information presentation method and terminal is provided for facilitating information utilization by processing various event information, intelligently generated in association with a function of the terminal. The event information presentation method of the present invention includes collecting event information; and presenting at least one of the collected event information, according to a current operation mode.

Owner:SAMSUNG ELECTRONICS CO LTD

Electromagnetic shock absorber for vehicle

InactiveUS8668060B2Valid conversionIncrease profitVibration dampersSpringsElectromagnetic absorbersScrew thread

An electromagnetic absorber (10) for a vehicle including (a) a threaded rod (78) which is disposed on one of a sprung portion and an unsprung portion and which has a threaded groove (76) formed in its outer circumferential portion and an axial groove (90) extending in its axis direction (b) a nut (80) which is rotatably disposed on the other of the sprung portion and the unsprung portion and which is screwed with the threaded rod and (c) a rod-rotation inhibiting member (82) which includes a fitting portion configured to be fitted in the axial groove and which is disposed on the other of the sprung portion and the unsprung portion, the rod-rotation inhibiting member being configured to inhibit the threaded rod from rotating while permitting the threaded rod to move in the axis direction. In the electromagnetic absorber, the threaded groove is not formed at a section of a fitting range at which the fitting portion is fitted in the axial groove when the fitting portion is located at an end of the fitting range that extends in the axis direction on the outer circumferential portion of the threaded rod.

Owner:TOYOTA JIDOSHA KK +2

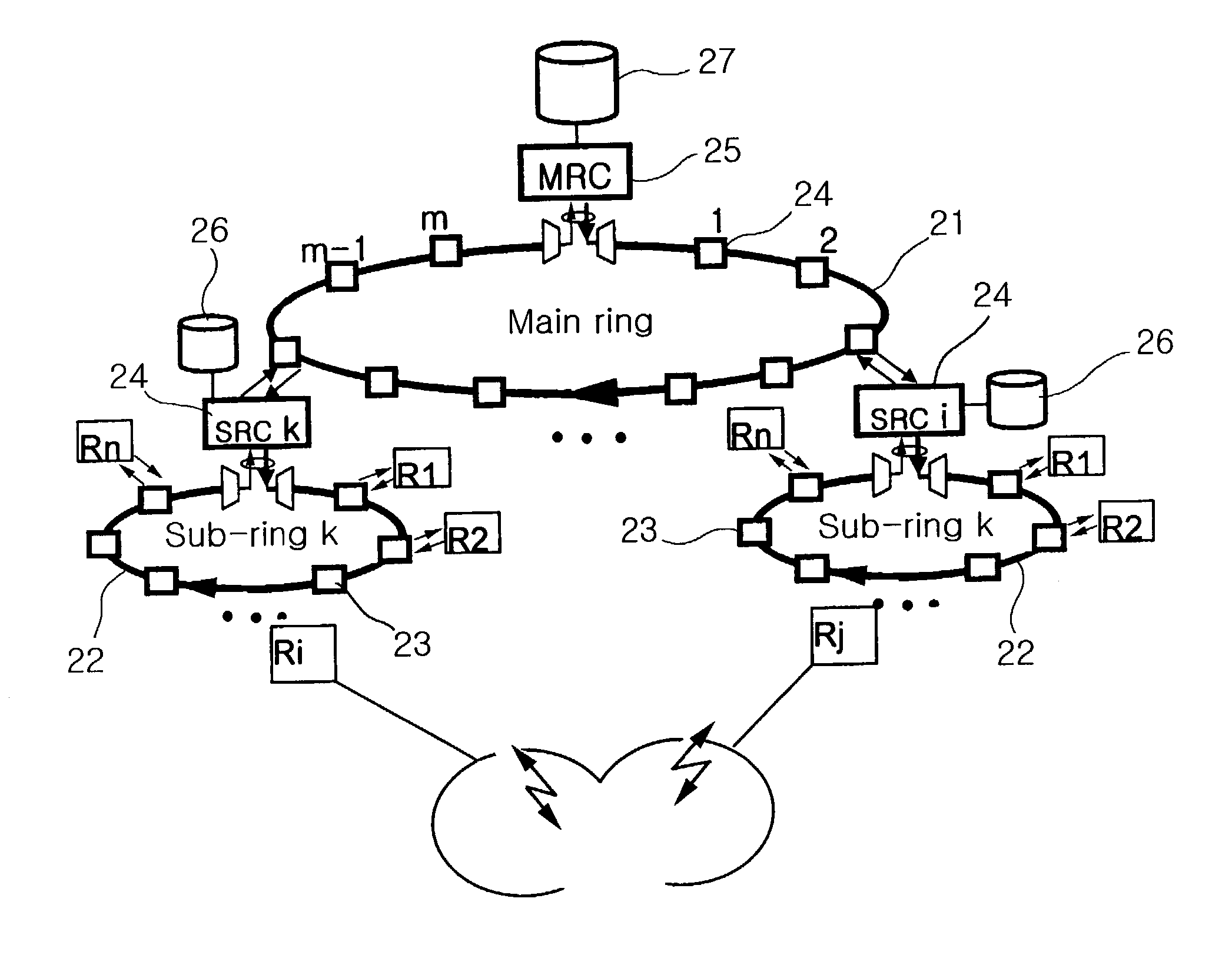

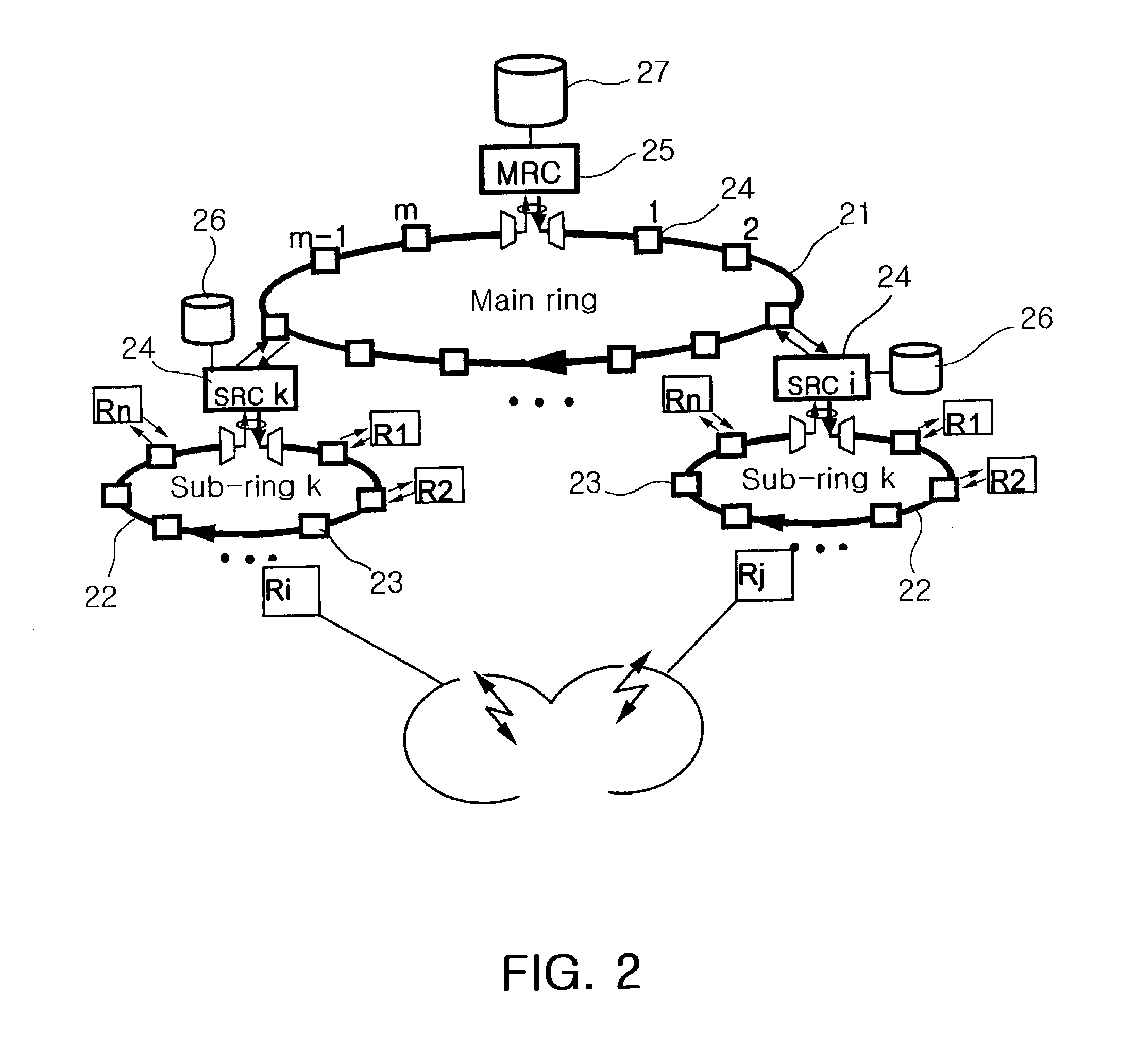

Method for transmitting packet in wireless access network based on wavelength identification code scheme

InactiveUS7421203B2Improve utilityTransmission process be simplifyError preventionFrequency-division multiplex detailsRadio networksRadio Network Controller

A method for transmitting a packet in a wireless access network based on a wavelength identification code scheme. The method comprises the steps of connecting n number of RNCs (Radio Network Controllers) to one sub-ring where the “n” is a positive integer, and assigning a unique wavelength to each RNC; identifying a packet to be transmitted between the RNCs located within a same sub-ring using the assigned unique wavelength, and transmitting the packet through an SRC (Sub-Ring Controller); connecting m number of SRCs to one main-ring where the “m” is a positive integer, and assigning a unique wavelength to each SRC; and detaching a wavelength identification code from the packet to be transmitted between the RNCs located within different sub-rings, and transmitting the packet having the encapsulated wavelength identification code through an MRC (Main-Ring Controller).

Owner:ELECTRONICS & TELECOMM RES INST

Suspension system for vehicle

InactiveUS7887064B2Increase profitImprove utilityVibration dampersSpringsAttitude controlBody posture

Owner:TOYOTA JIDOSHA KK

Manufacturing method of embossed gold art porcelain

ActiveCN104589887AImprove utilityEasy to viewDecorative surface effectsSpecial ornamental structuresManufacturing engineering

The invention discloses a manufacturing method of embossed gold art porcelain. Based on an 'addition process embossment technology', the manufacturing method comprises design and drawing of embossment decoration patterns at the early stage, digital treatment and film manufacturing, and is characterized by sequentially comprising the following steps: 1) manufacturing a silk screen plate of an embossment decoration pattern; 2) manufacturing ceramic transfer paper of embossment decoration patterns; 3) manufacturing a silk screen plate of gold decoration patterns; 4) manufacturing ceramic transfer paper of the gold decoration patterns; 5) pasting flowers; 6) baking flowers; 7) carrying out gold decoration; and 8) carrying out gold baking. Based on the 'addition process embossment' technology, the manufacturing method of embossed gold art porcelain can be applied to large-scale and standardized production of embossed gold art porcelain with extremely high practical, ornamental and collection value; products are dignified, graceful and gorgeous; the embossment pattern surface has the thickness of 120microns, has concave and convex handfeel, and is high in sense of layering. Compared with the traditional 'addition process embossment' technology, the production efficiency and the finished product rate of products are improved obviously.

Owner:SHENZHEN STECHCOL CERAMIC CRAFTS

Method and apparatus for determining the cerebral state of a patient using generalized spectral entropy of the EEG signal

A method and apparatus for ascertaining the cerebral state of a patient using generalized spectral entropy of the EEG signal.

Owner:INSTRUMENTARIUM CORP

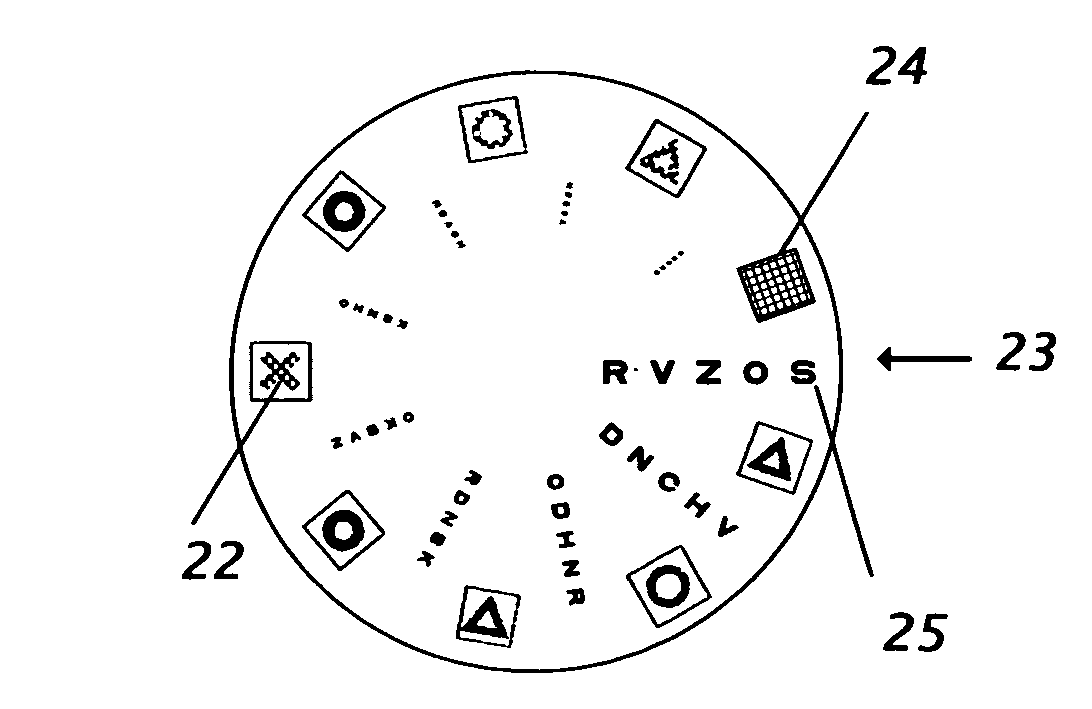

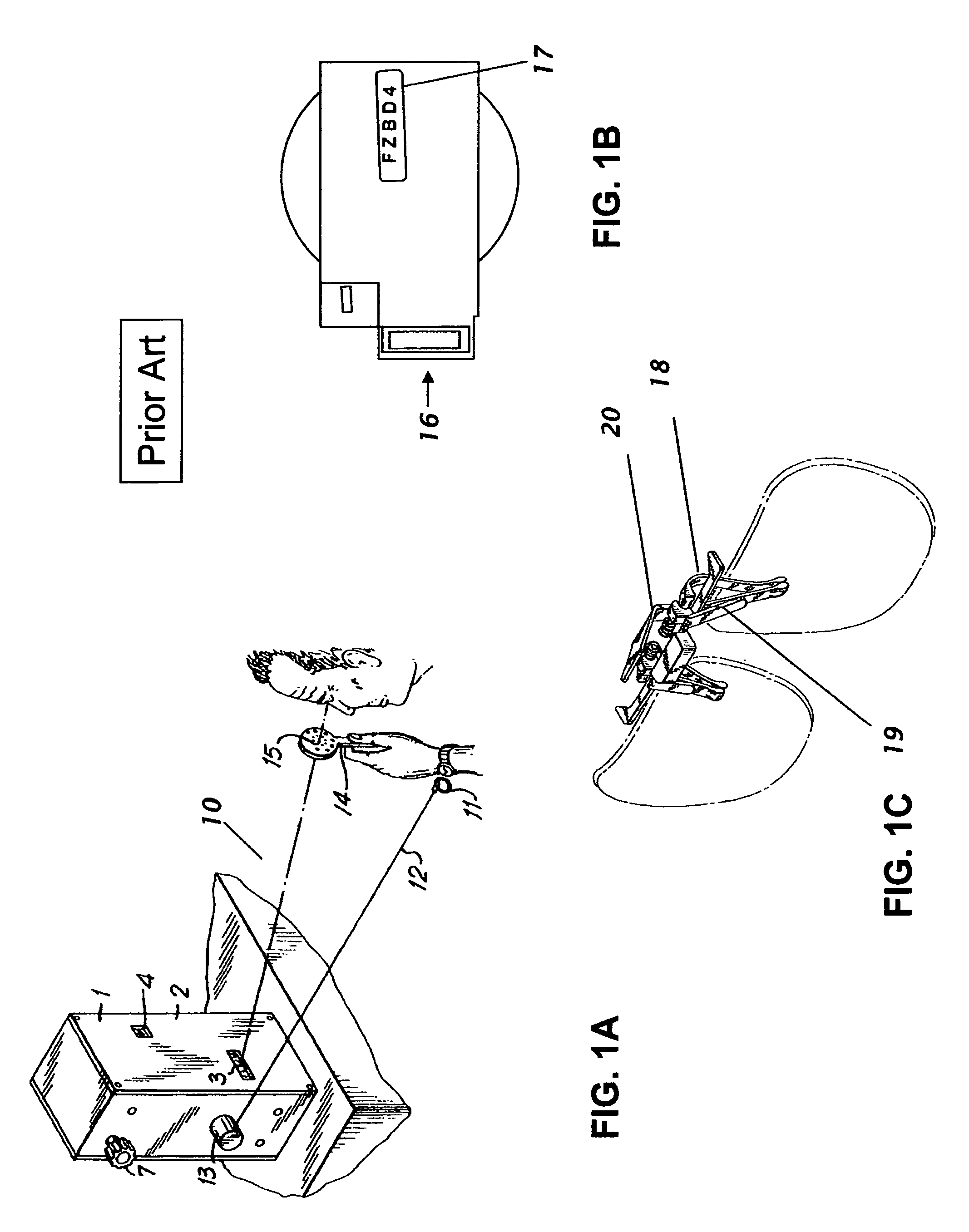

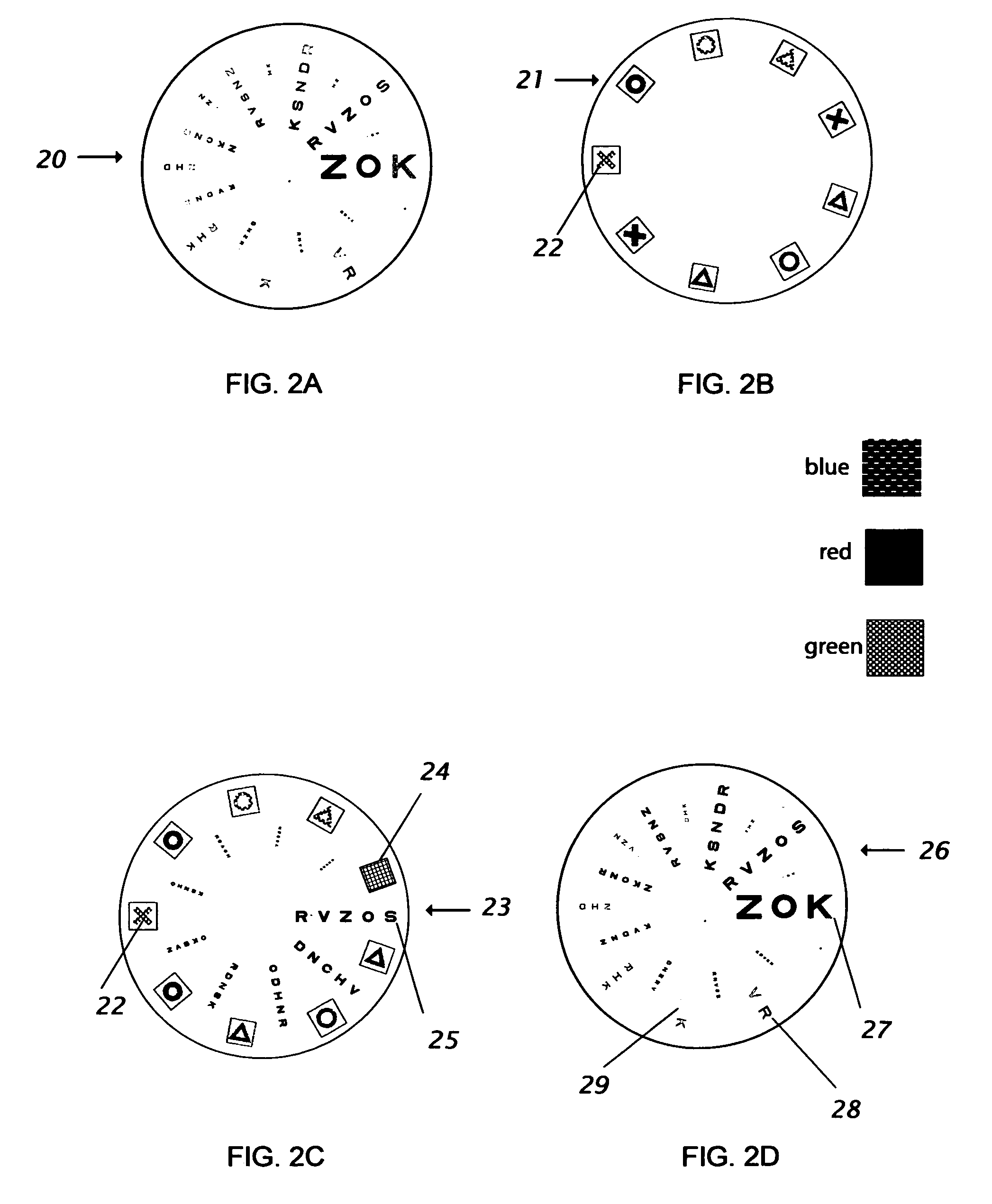

Hand-held device for contrast and multifunction vision testing

A vision testing device for measuring single or multiple visual functions consisting of an internally illuminated hand-held instrument, vision charts, vision correcting and occluding elements, a testing frame for holding combined vision correcting and blocking elements, and modular accessories.

Owner:HOFELDT ALBERT JOHN

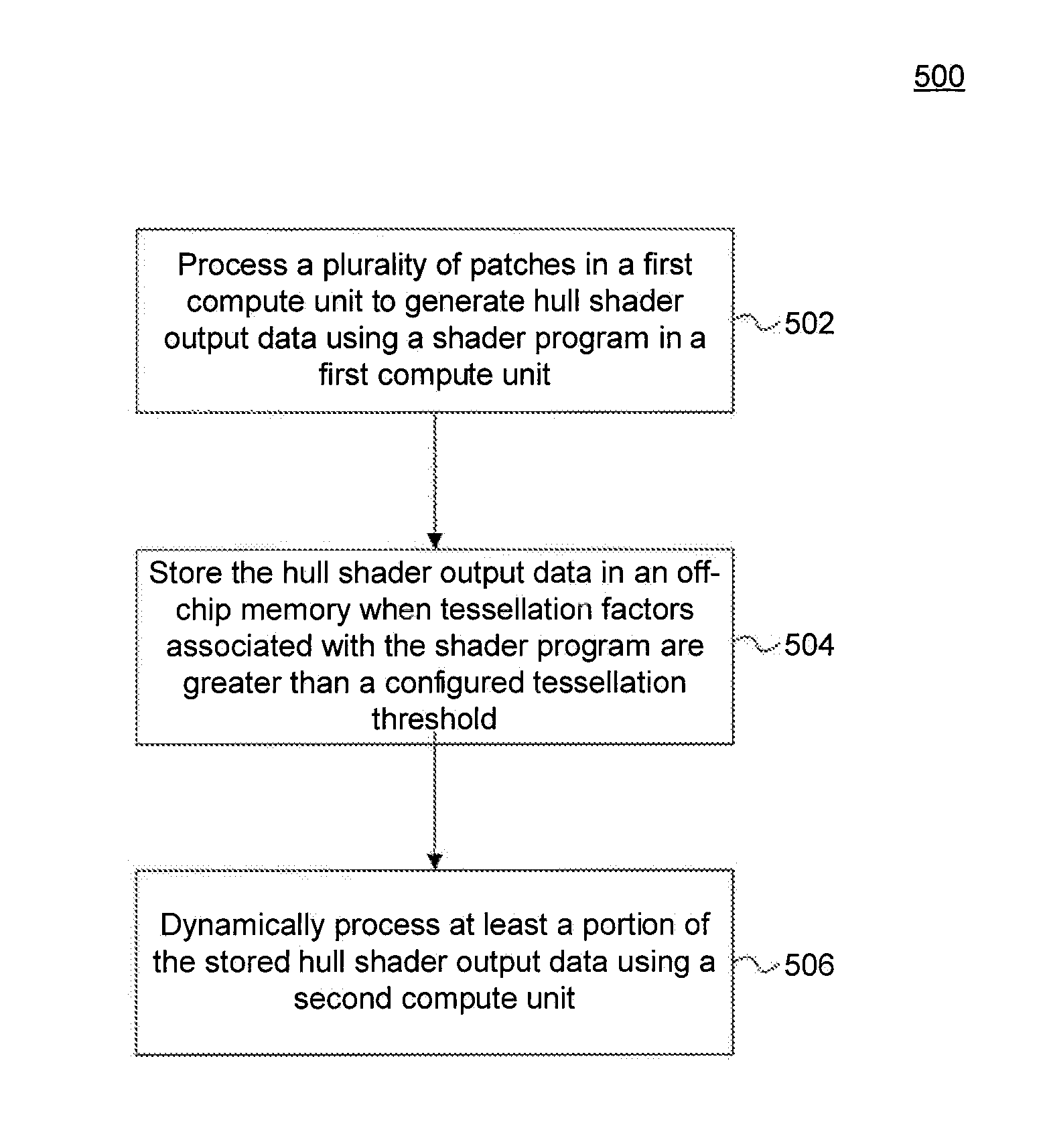

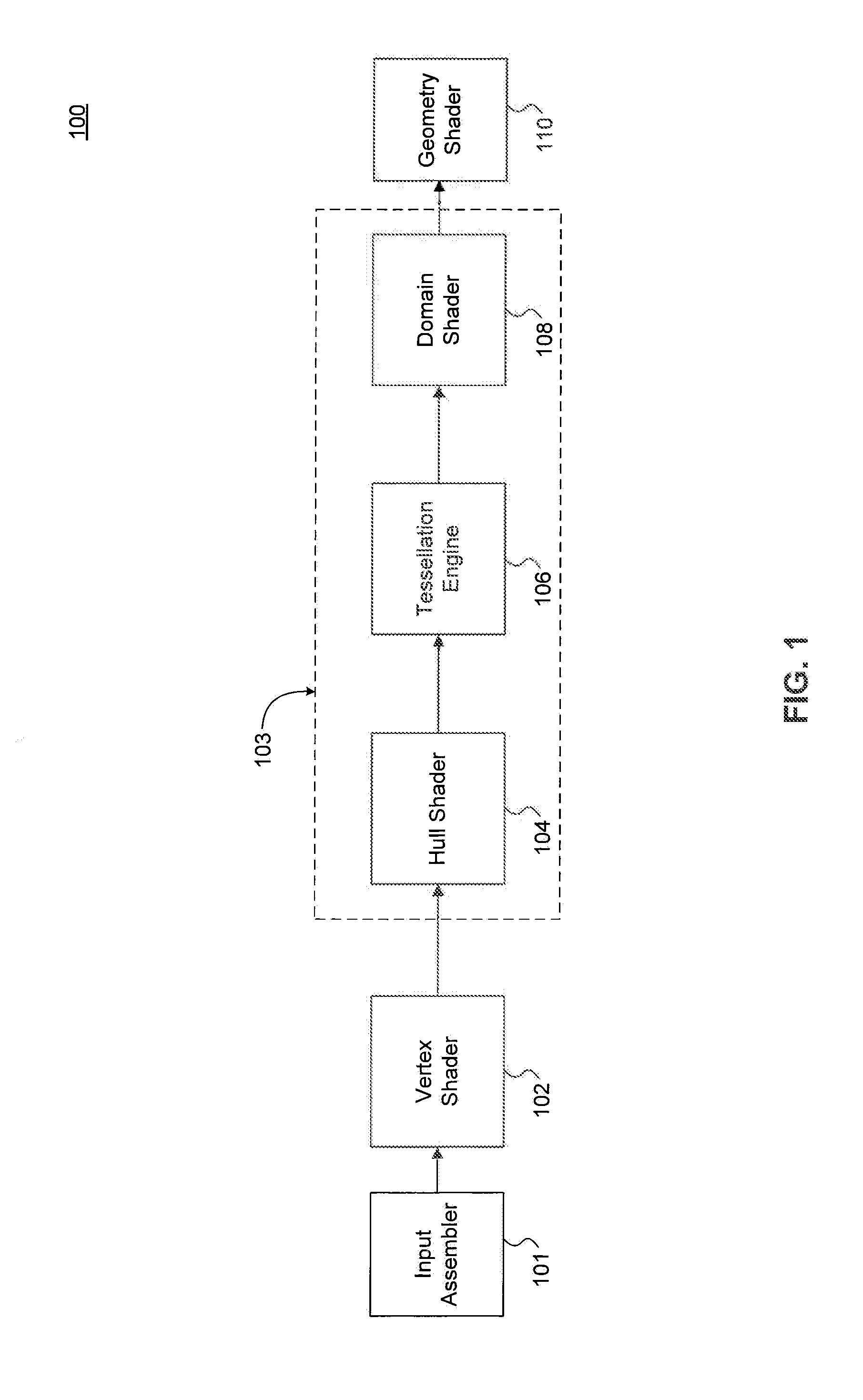

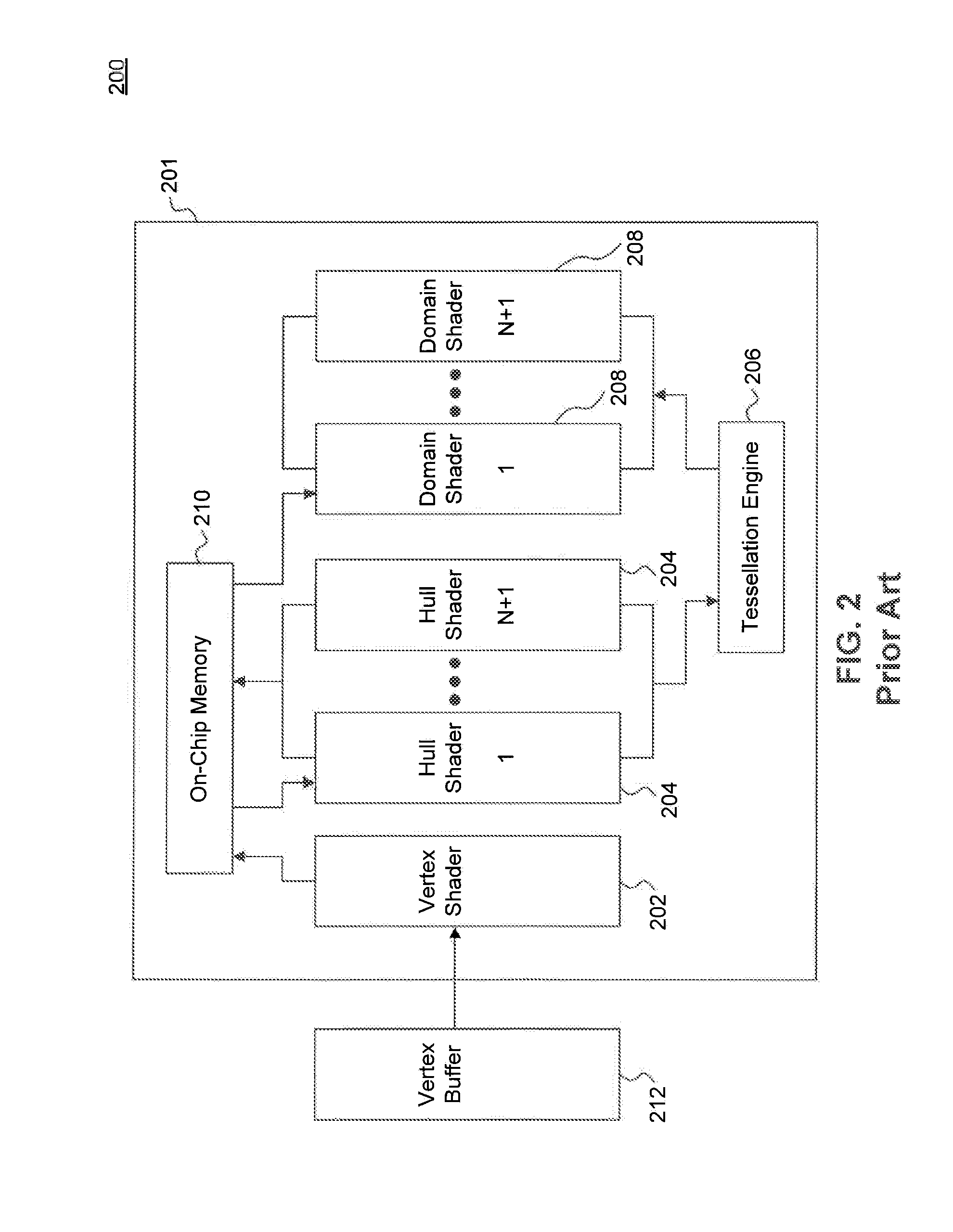

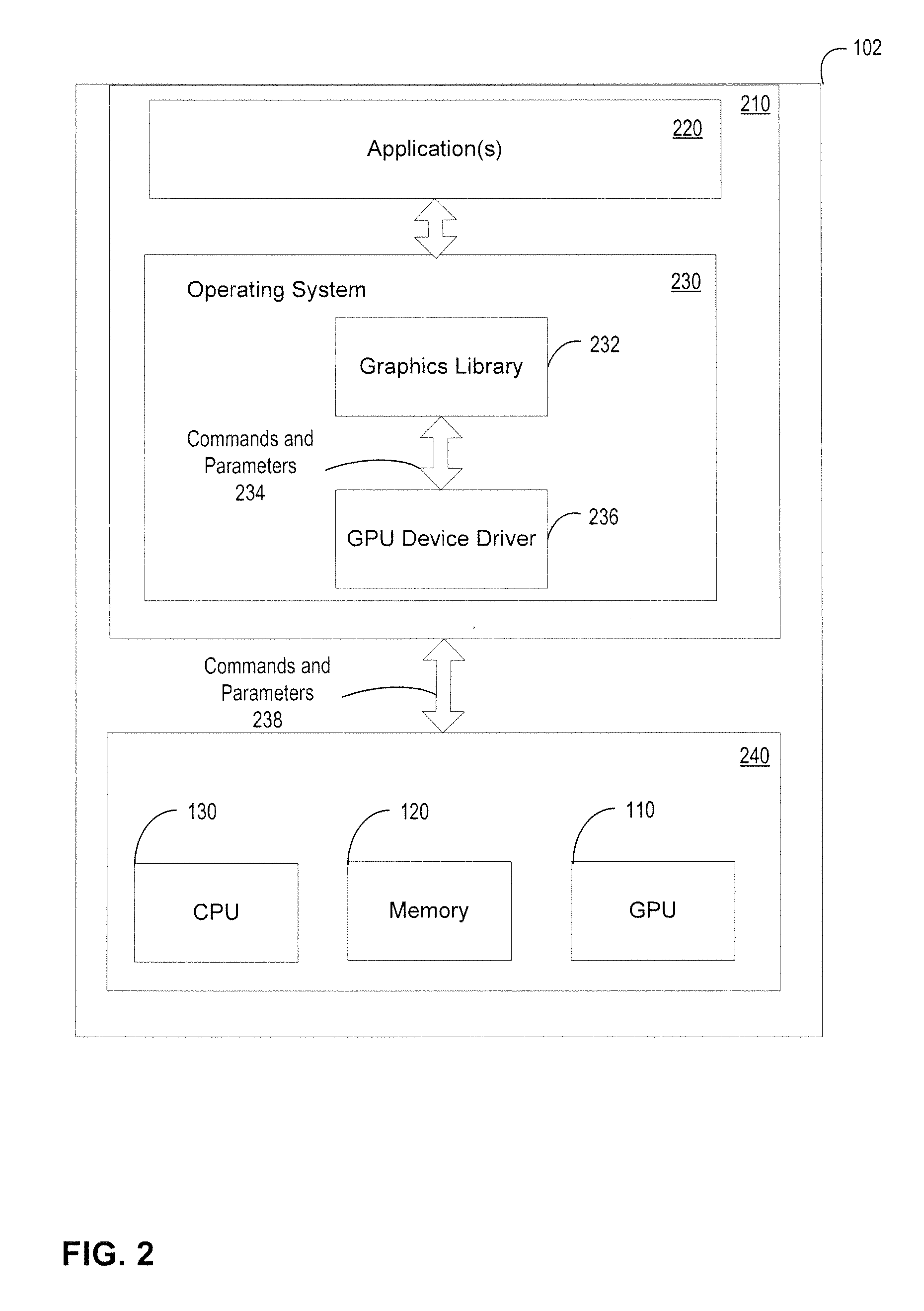

Off Chip Memory for Distributed Tessellation

Embodiments include an apparatus, a computer readable medium and a method for distributing tessellations within an accelerated processing device (APD) including at least two compute units. Embodiments include processing a plurality of patches in a first compute unit using a hull shader to generate hull shader output data. Once generated, hull shader output data is stored to an off-chip memory when tessellation factors associated with the shader program are greater than a configured threshold. Once stored in the off-chip memory, at least a portion of the hull shader output data is dynamically processed using a second compute unit.

Owner:ADVANCED MICRO DEVICES INC

Process for fermentation of syngas from indirect gasification

ActiveUS8759047B2Easy to separateEffective recoveryDirect heating destructive distillationBiofuelsLiquid productSyngas

Owner:SYNATA BIO INC

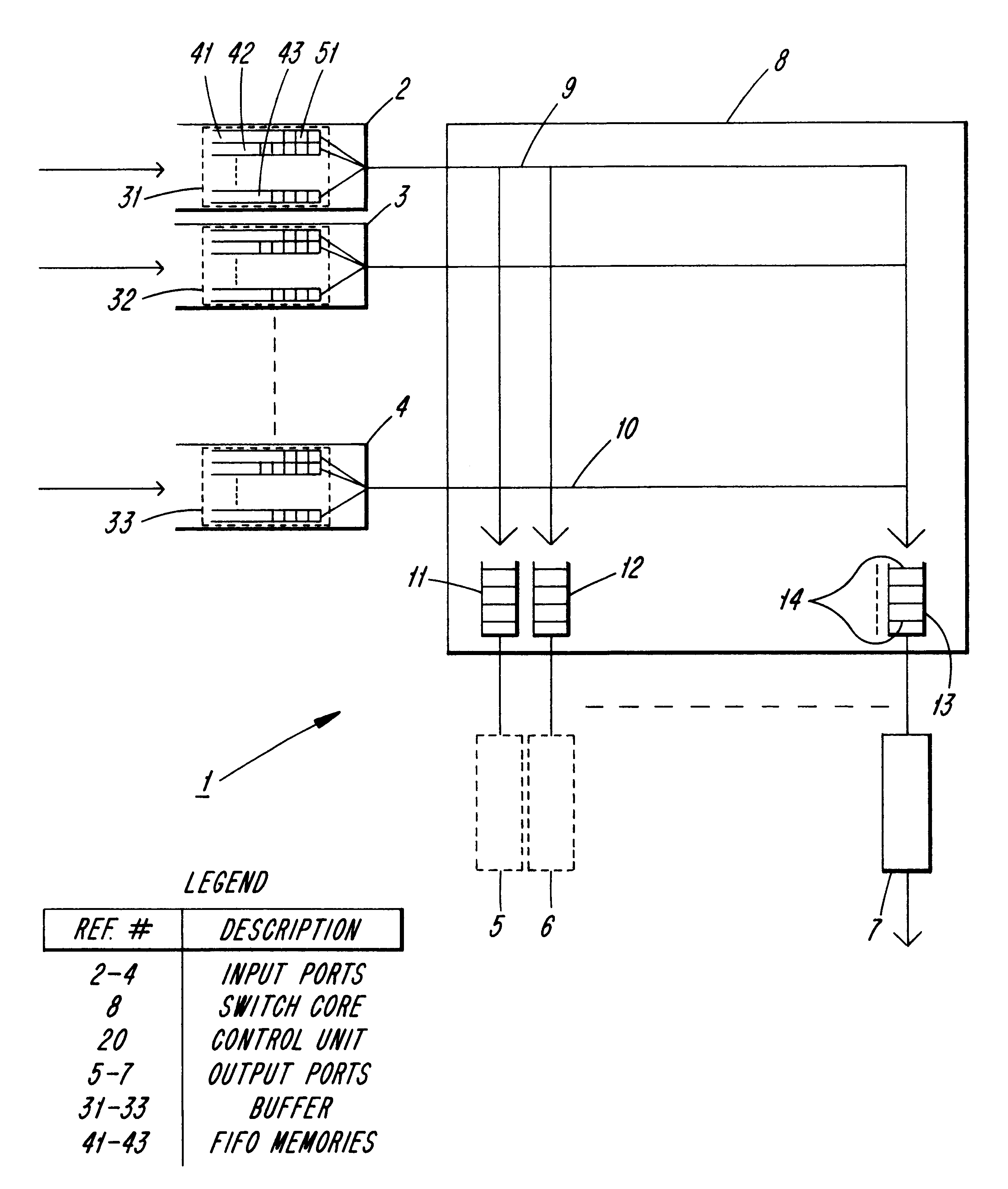

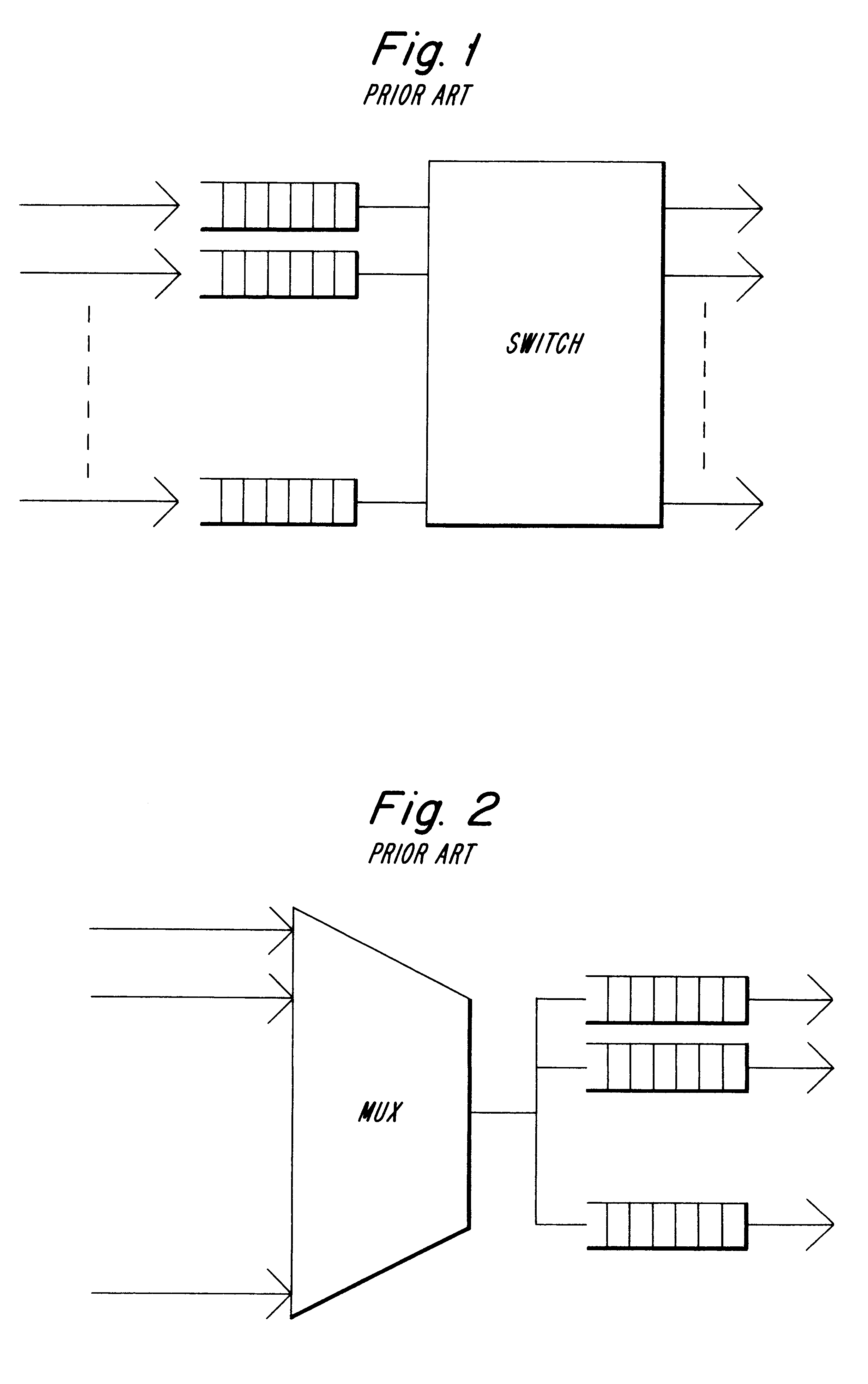

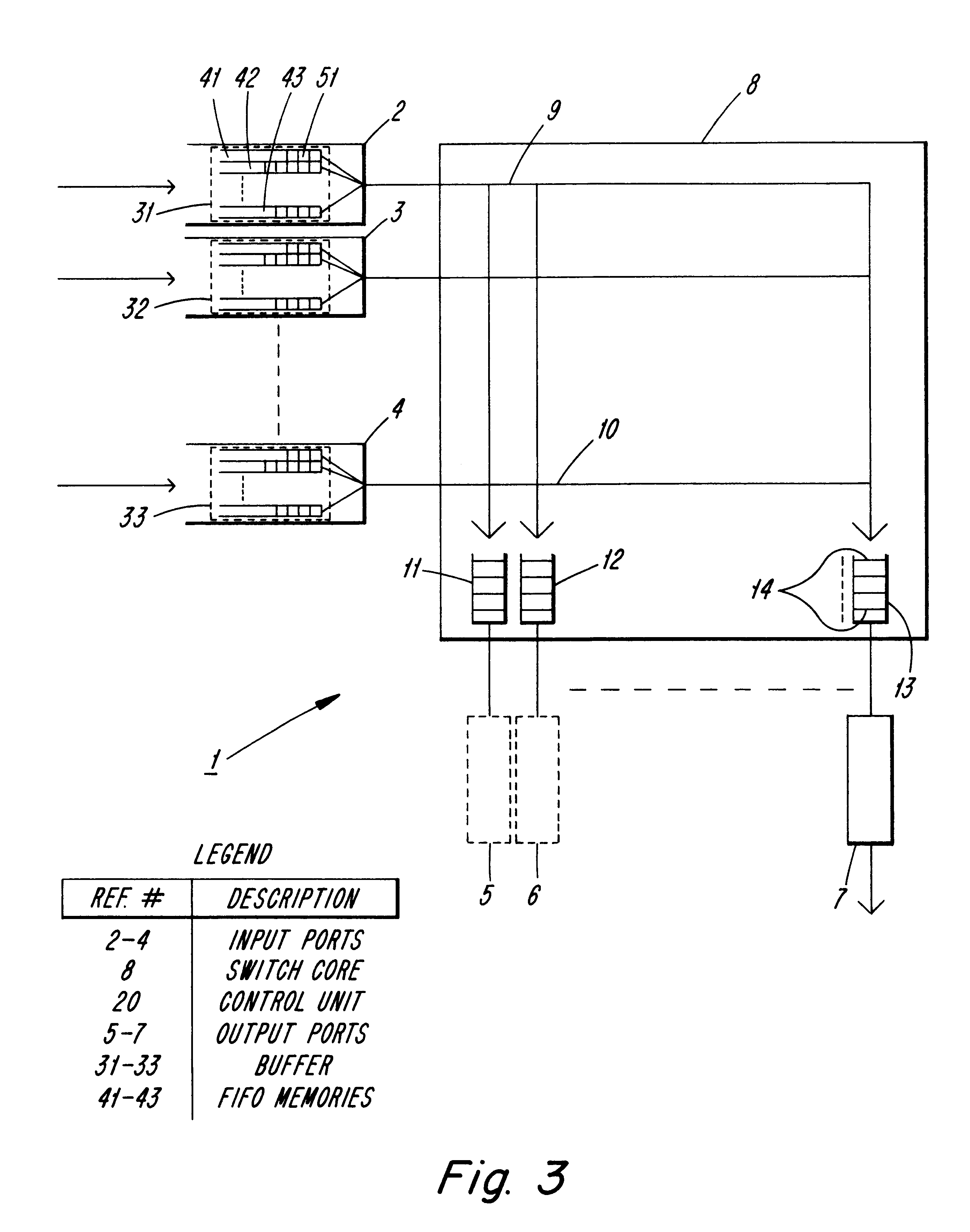

Flow control for switching

InactiveUS6172963B1Reduce utilizationImprove utilityError preventionFrequency-division multiplex detailsTraffic capacityEngineering

Owner:TELEFON AB LM ERICSSON (PUBL)

Granular whole grain flour

InactiveCN104116051AHas nutritional propertiesIncrease nutritionFood ingredient functionsFood preparationBiotechnologyEdible mushroom

The invention relates to a granular whole grain flour. A production process is as below: screening the whole grains and accessories, removing impurities, cleaning, baking at low temperature, sterilizing, blending according to a formula and grinding; and granulating the ground and cooked whole grain flour according to a conventional food and condiment granulation process through a food granulator, and packing the granular whole grain flour respectively. The granular whole grain flour comprises the following components by weight percentage: 50-100% of cereals and 0-50% of an auxiliary material. The auxiliary material is a food material or a mixture of many kinds of raw materials, and the auxiliary material is added to regulate the taste and nutrition of the whole grain flour; the whole grain flour has the nutritional characteristics of whole grains, and is supplemented with the nutrition of fruits, vegetables, meat, eggs, seafood, edible mushroom and Chinese herbal medicines; therefore, the granular whole grain flour can reach dietetic invigoration effect, is easy to drink and nonstick, and simplifies the production process.

Owner:程长青

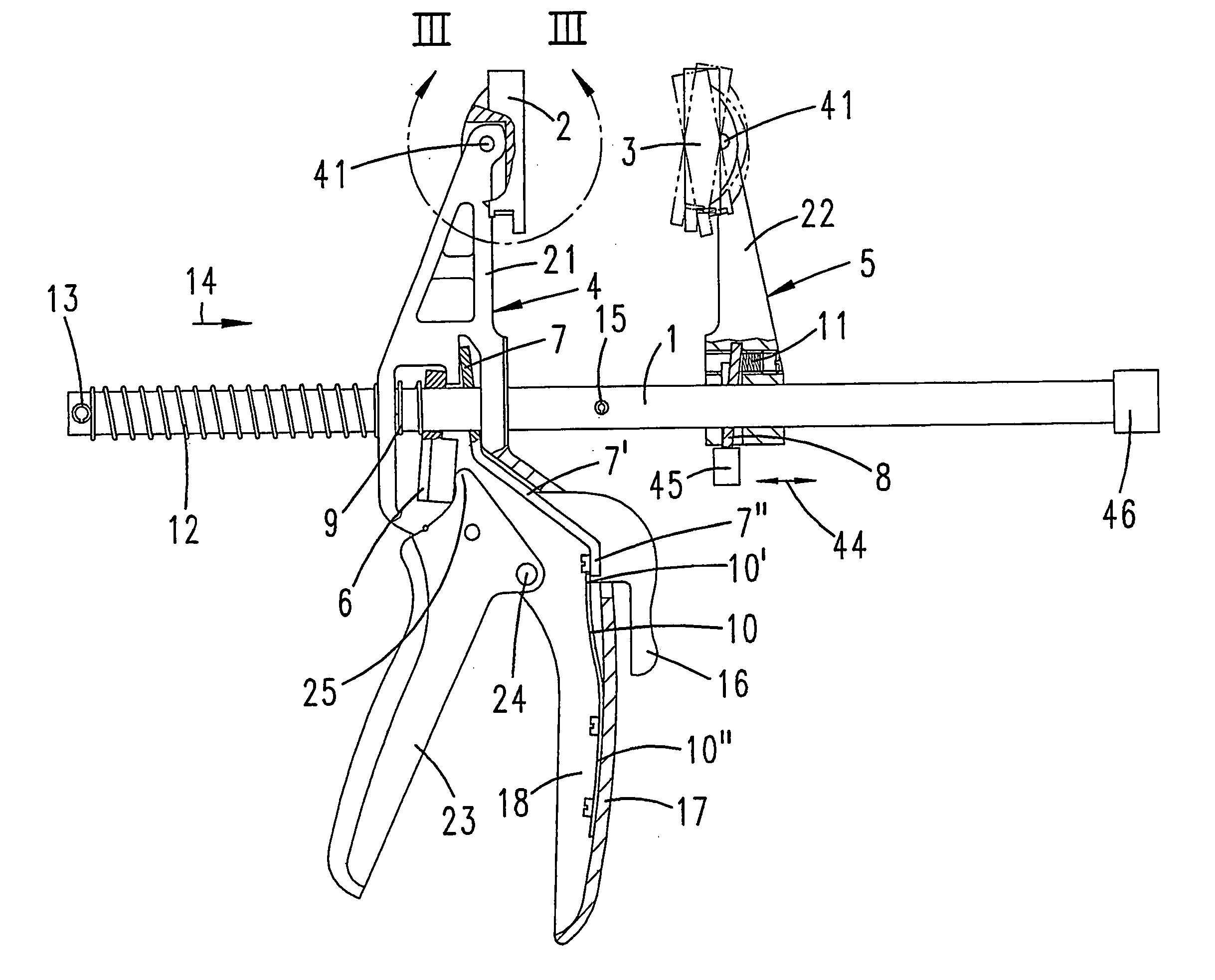

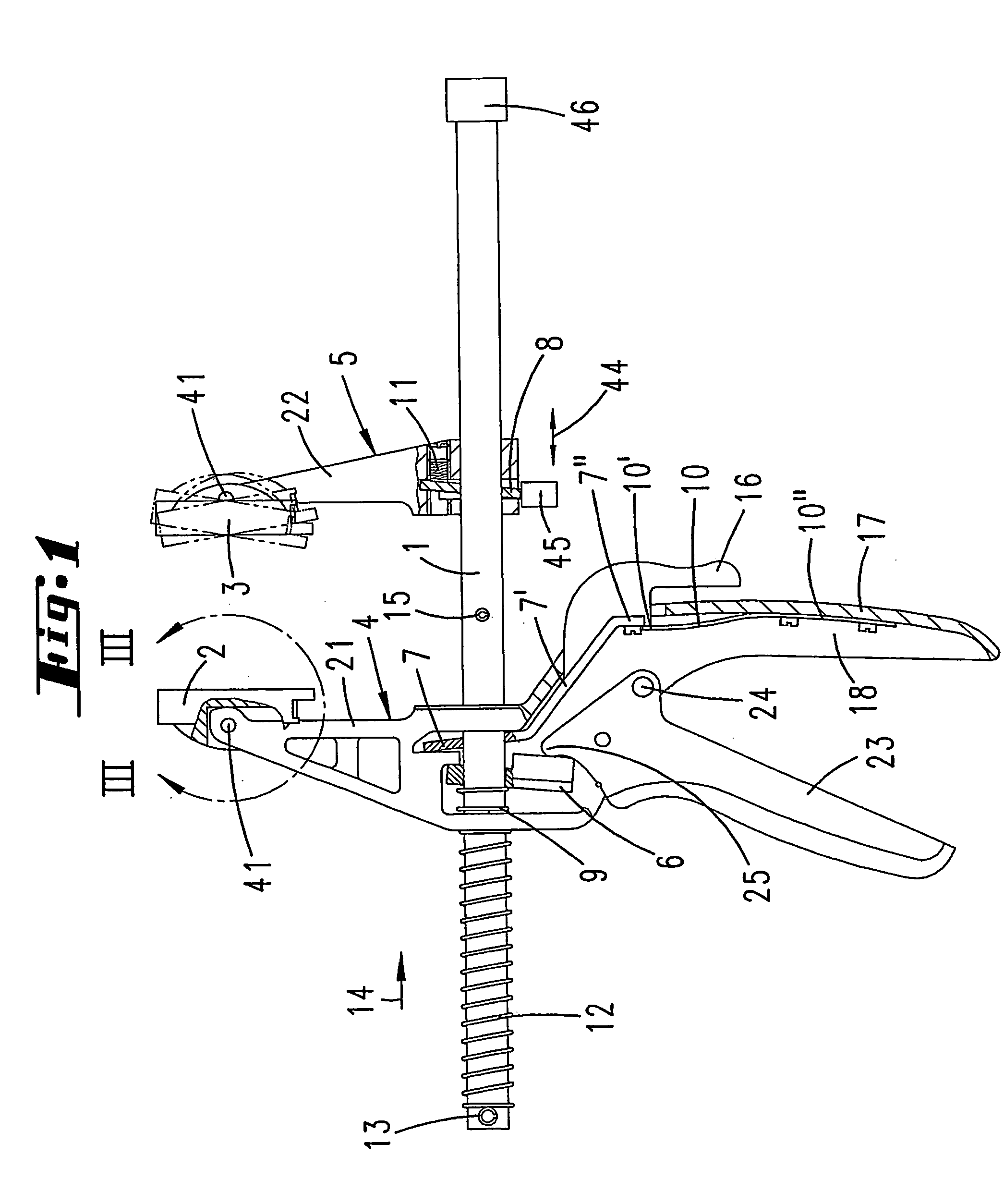

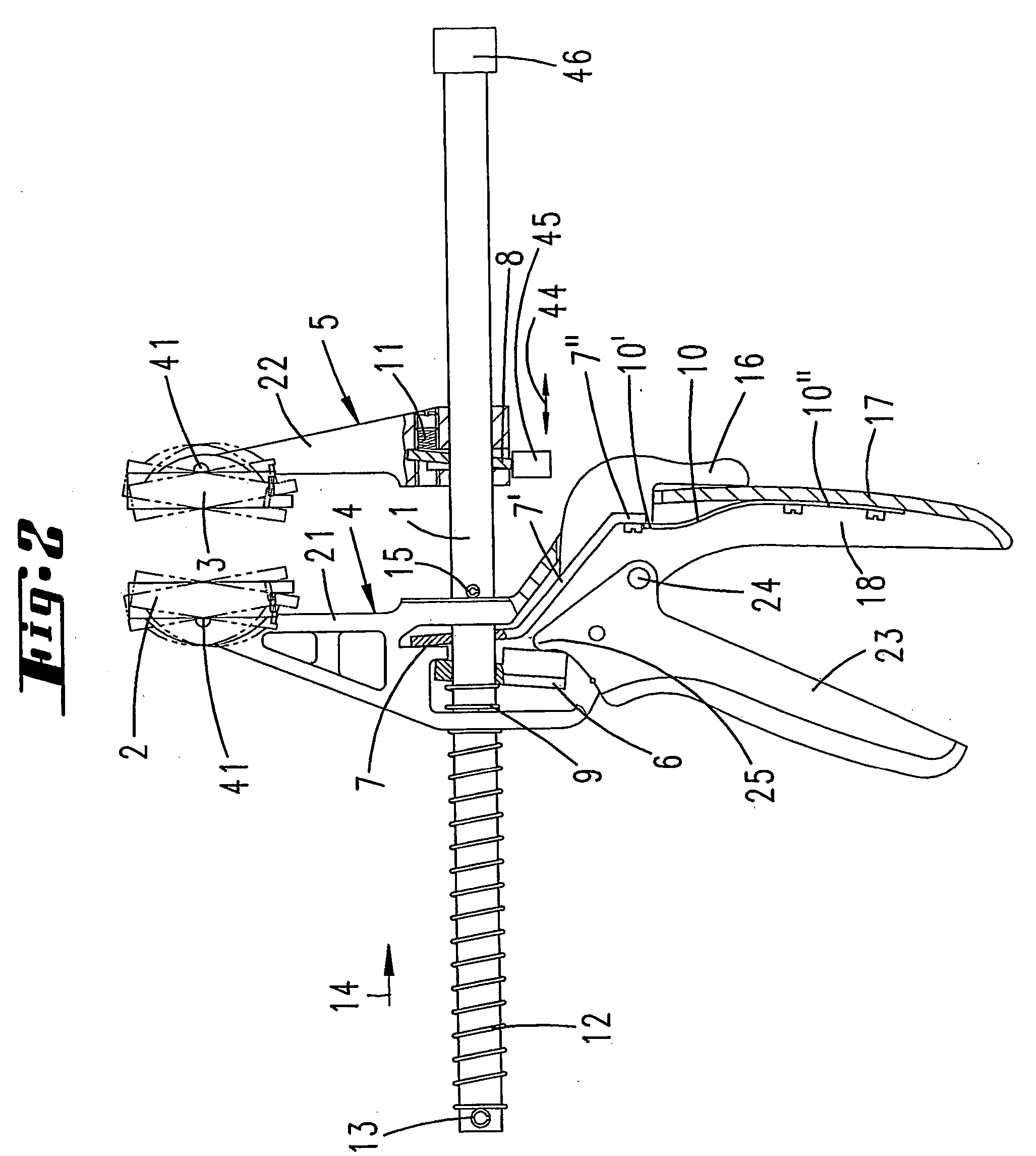

Single-handed clamp clip

Owner:WOLFCRAFT

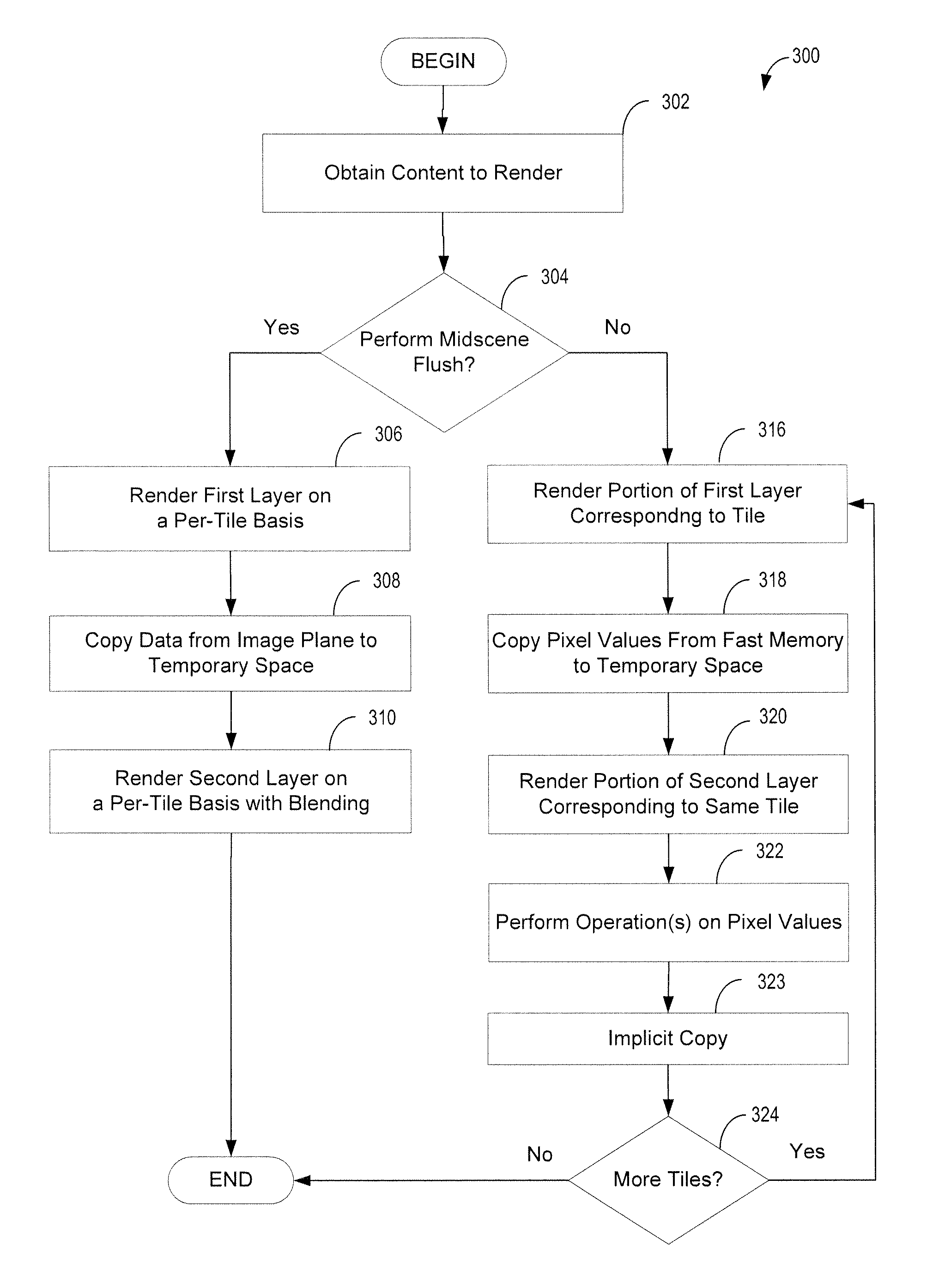

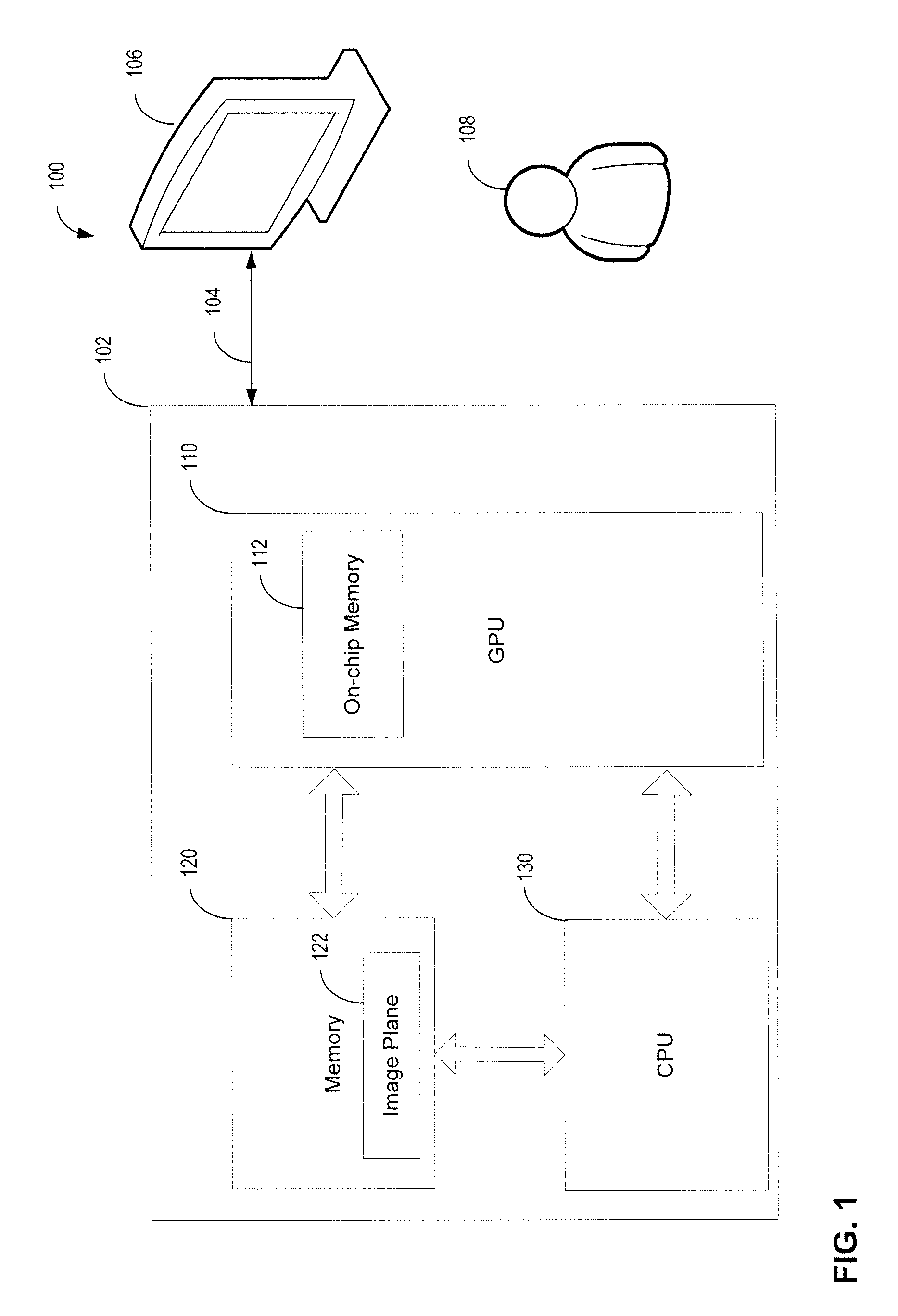

System and method for layering using tile-based renderers

ActiveUS20130063473A1Improve utilityPoor performanceCathode-ray tube indicatorsProcessor architectures/configurationAccess timeImage layer

A method for tile-based rendering of content. Content may be rendered in a memory region organized as multiple tiles. In scenarios in which content is generated in layers, for operations that involve compositing image layers, an order in which portions of the image are processed may be selected to reduce the aggregate number of memory accesses times, which in turn may improve the performance of a computer that uses tile-based rendering. An image may be processed such that operations relating to rendering portions of different layers corresponding to the same tile are performed sequentially. Such processing may be used in a computer with a graphics processing unit that supports tile-based rendering, and may be particularly well suited for computers with a slate form factor. An interface to a graphics processing utility within the computer may provide a flag to allow an application to specify whether operations may be reordered.

Owner:MICROSOFT TECH LICENSING LLC

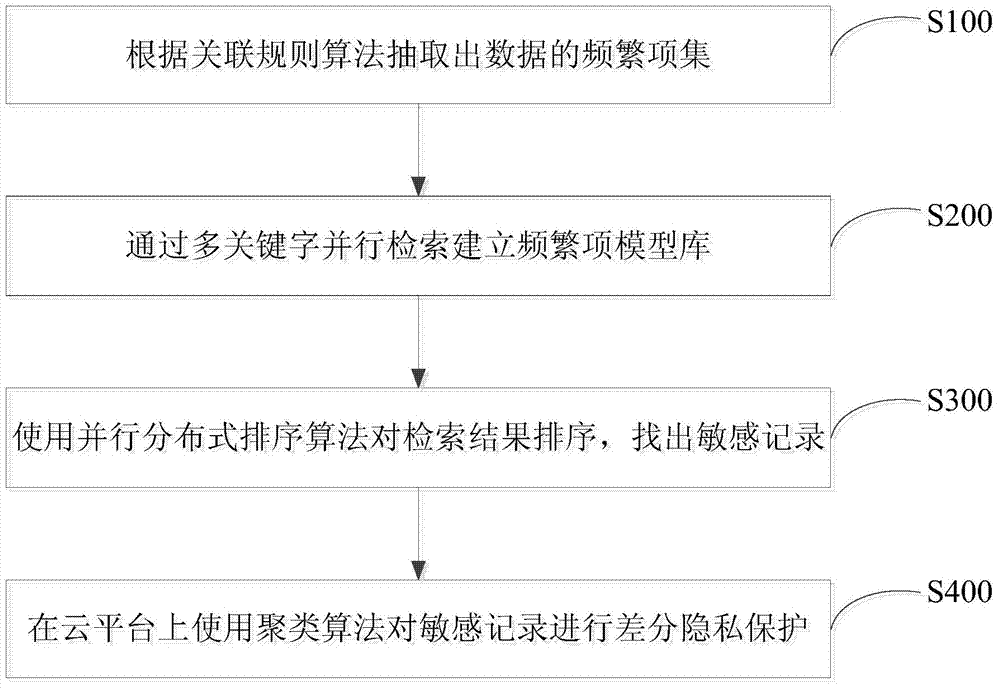

Cloud platform privacy protection method based on frequent item retrieval

InactiveCN104123504AImprove utilityReduce risk of data leakageDigital data protectionSpecial data processing applicationsSorting algorithmPrivacy protection

The invention relates to a cloud platform privacy protection method based on frequent item retrieval. The cloud platform privacy protection method comprises the steps of extracting a frequent item set of data according to an association rule algorithm; establishing a frequent item model library by performing parallel retrieval on multiple key words; sorting retrieval results by means of a parallel distributed sorting algorithm to find sensitive records; performing difference privacy protection on the sensitive records on a cloud platform through a clustering algorithm. According to conditions of frequent items of the data, the sensitive records revealing user information are retrieved, and difference privacy protection is performed on the sensitive records in a targeted mode. Therefore, relevant sensitive information cannot be speculated according to known non-sensitive information. By means of the cloud platform privacy protection method based on frequent item retrieval, the sensitive records are protected only, other information contents are not affected, therefore, data leakage risk is reduced while effectiveness of published data is increased, and safety of the data on the cloud platform is ensured.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com