Patents

Literature

618 results about "Whole grains" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

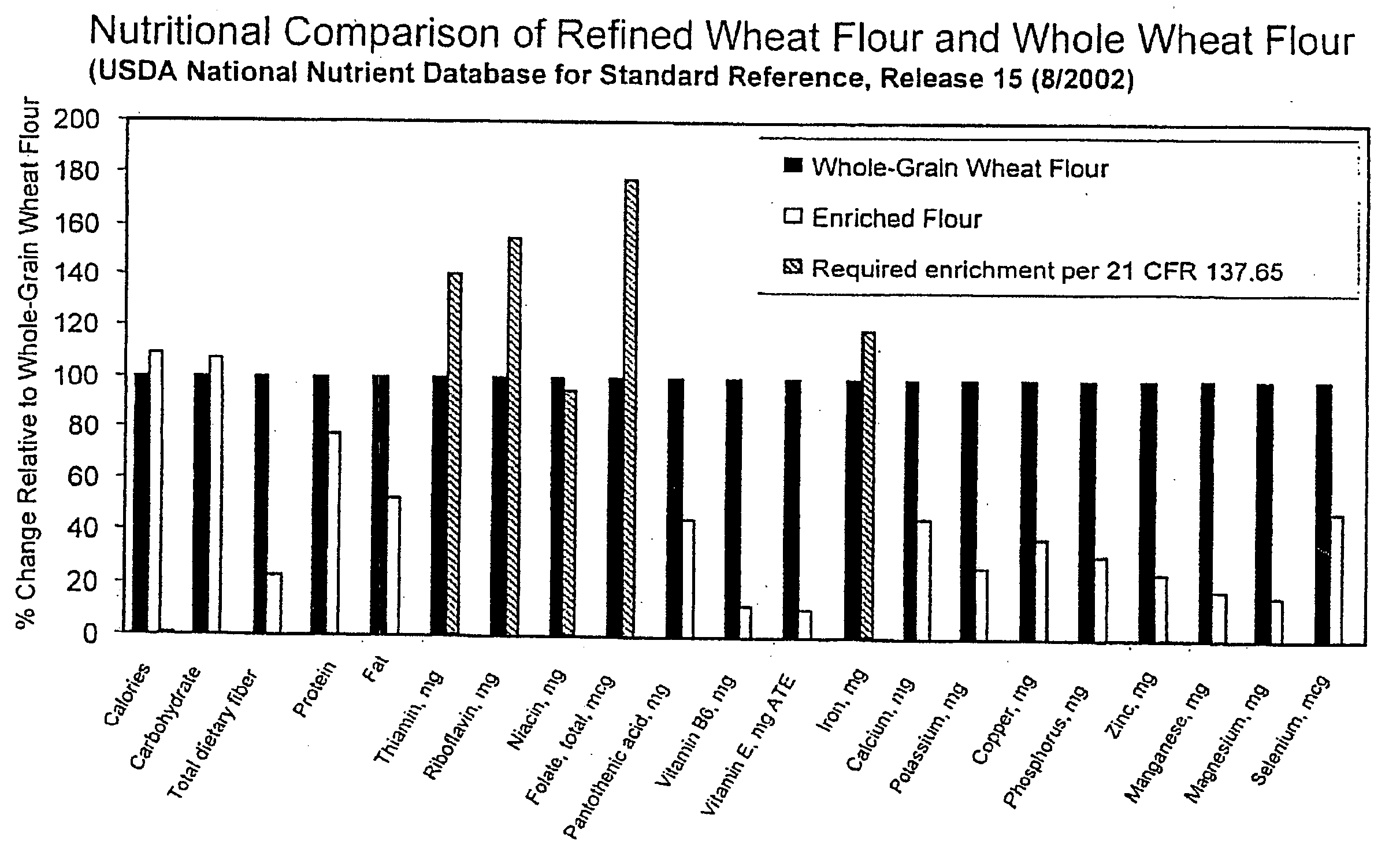

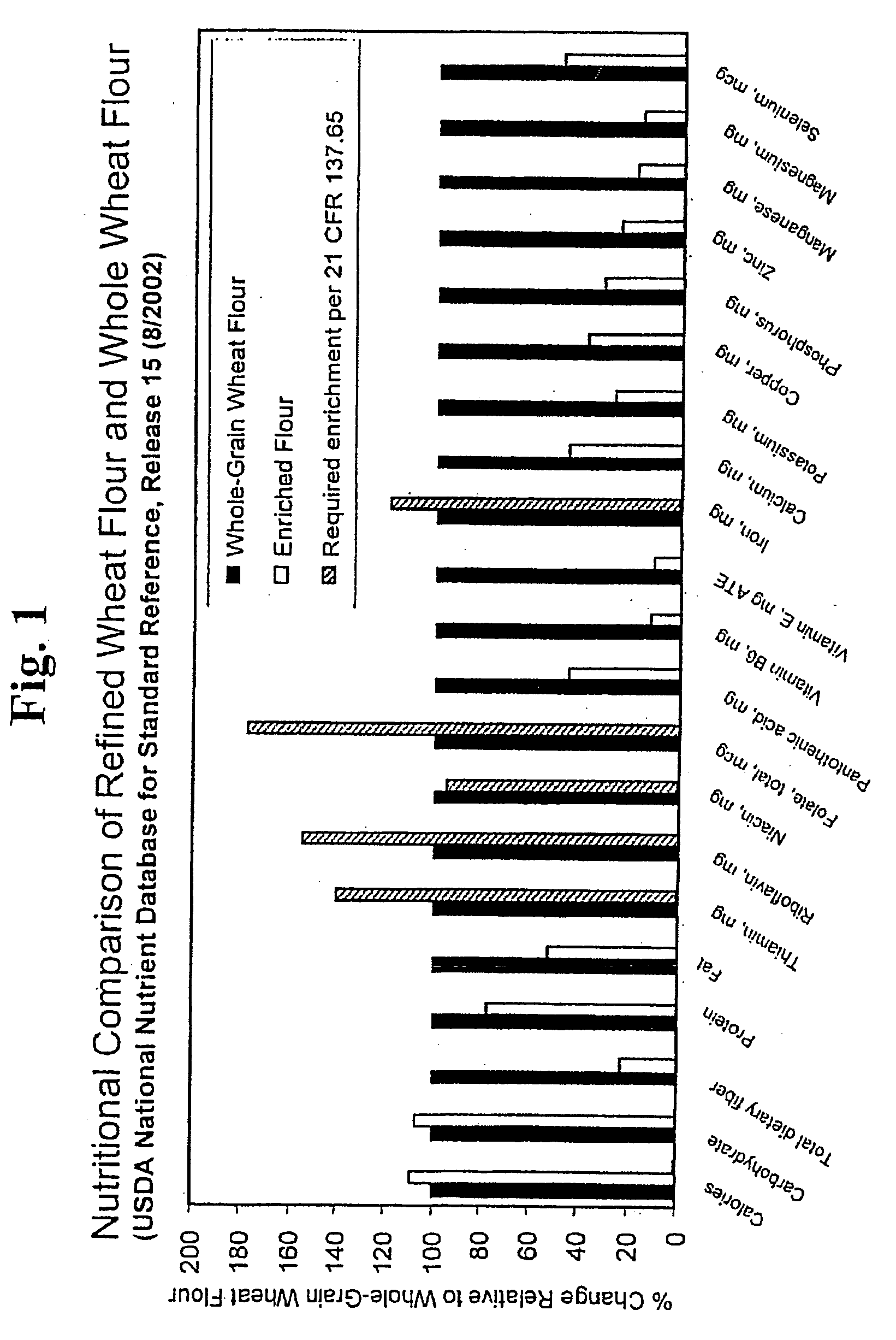

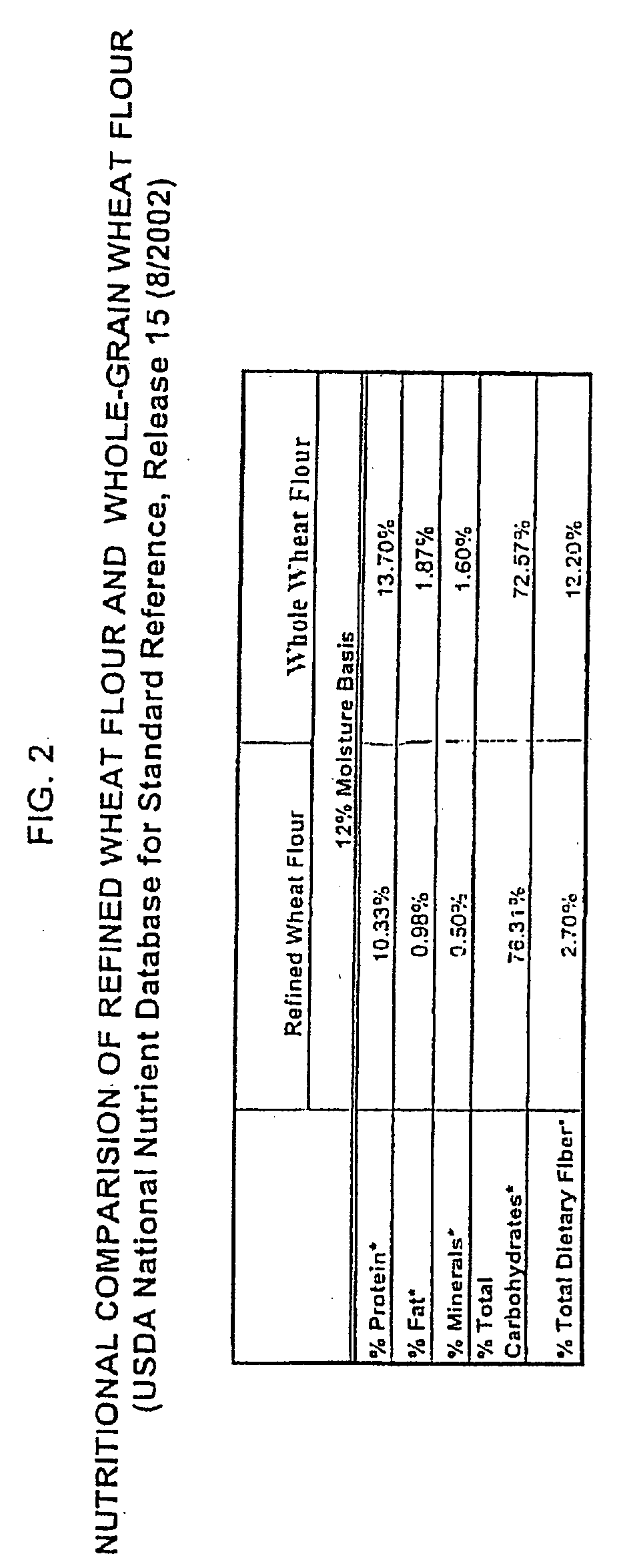

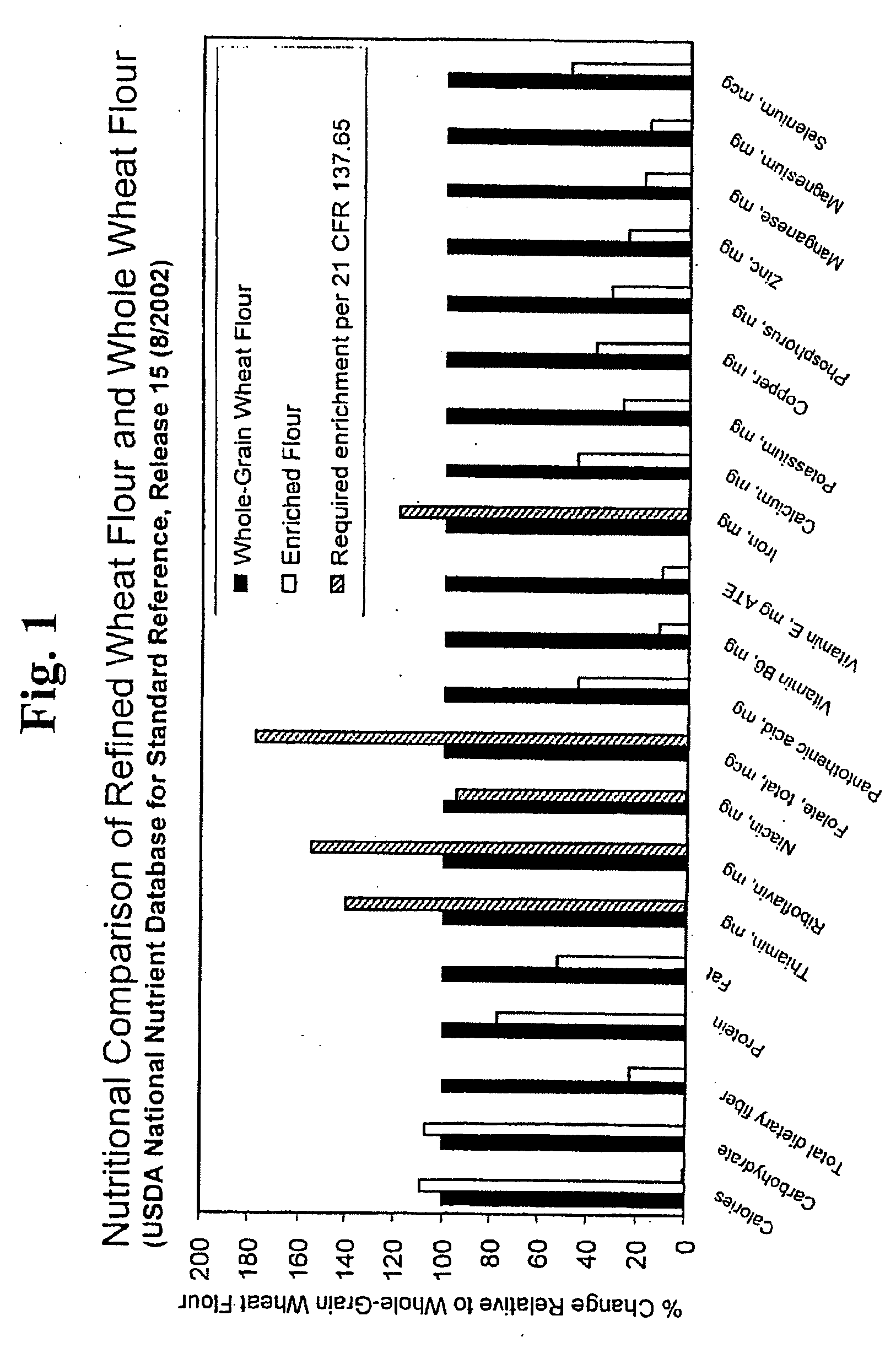

Whole grain. A whole grain, also called a wholegrain, is a grain of any cereal and pseudocereal that contains the endosperm, germ, and bran, in contrast to refined grains, which retain only the endosperm. As part of a general healthy diet, consumption of whole grains is associated with lower risk of several diseases.

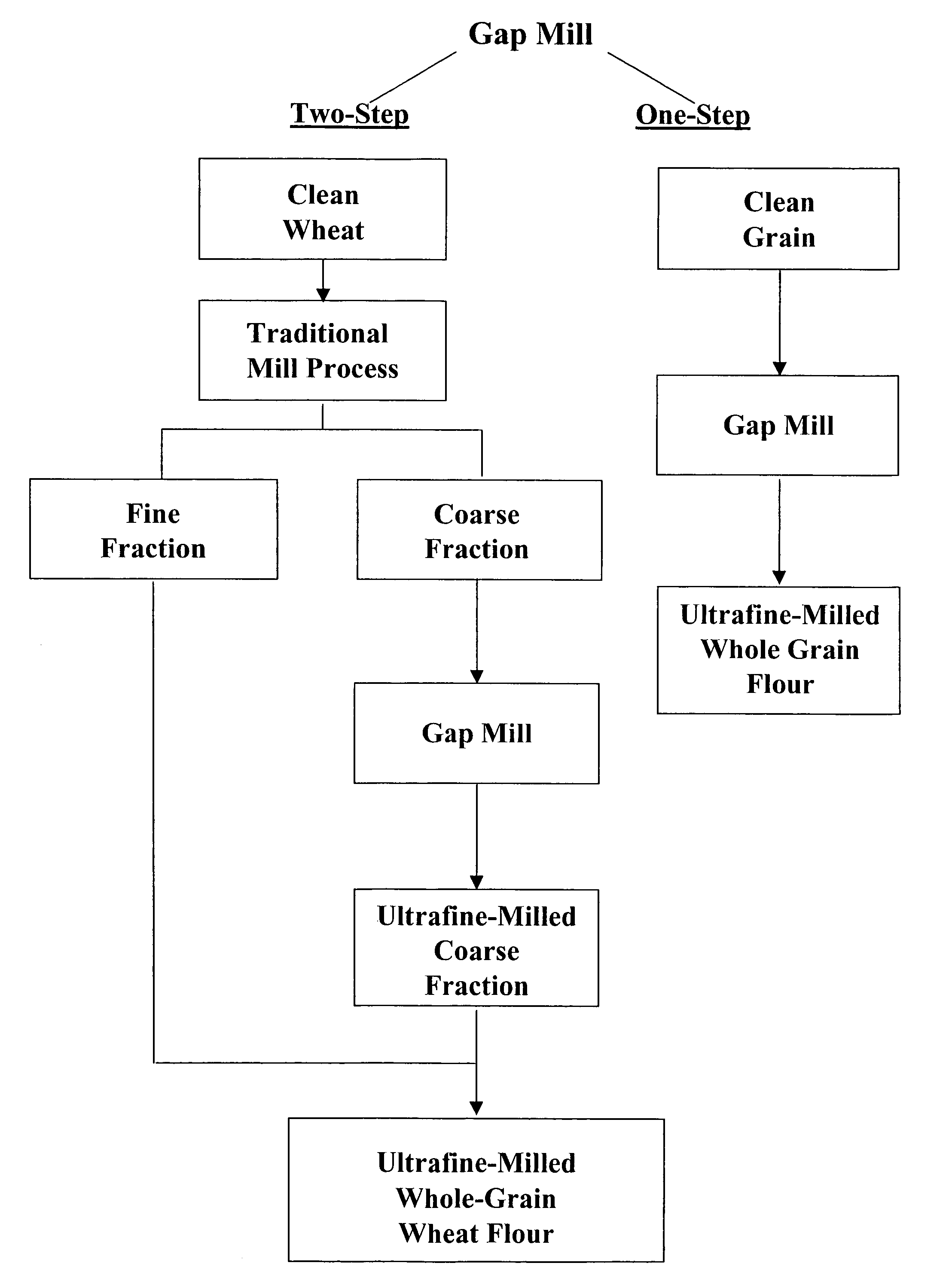

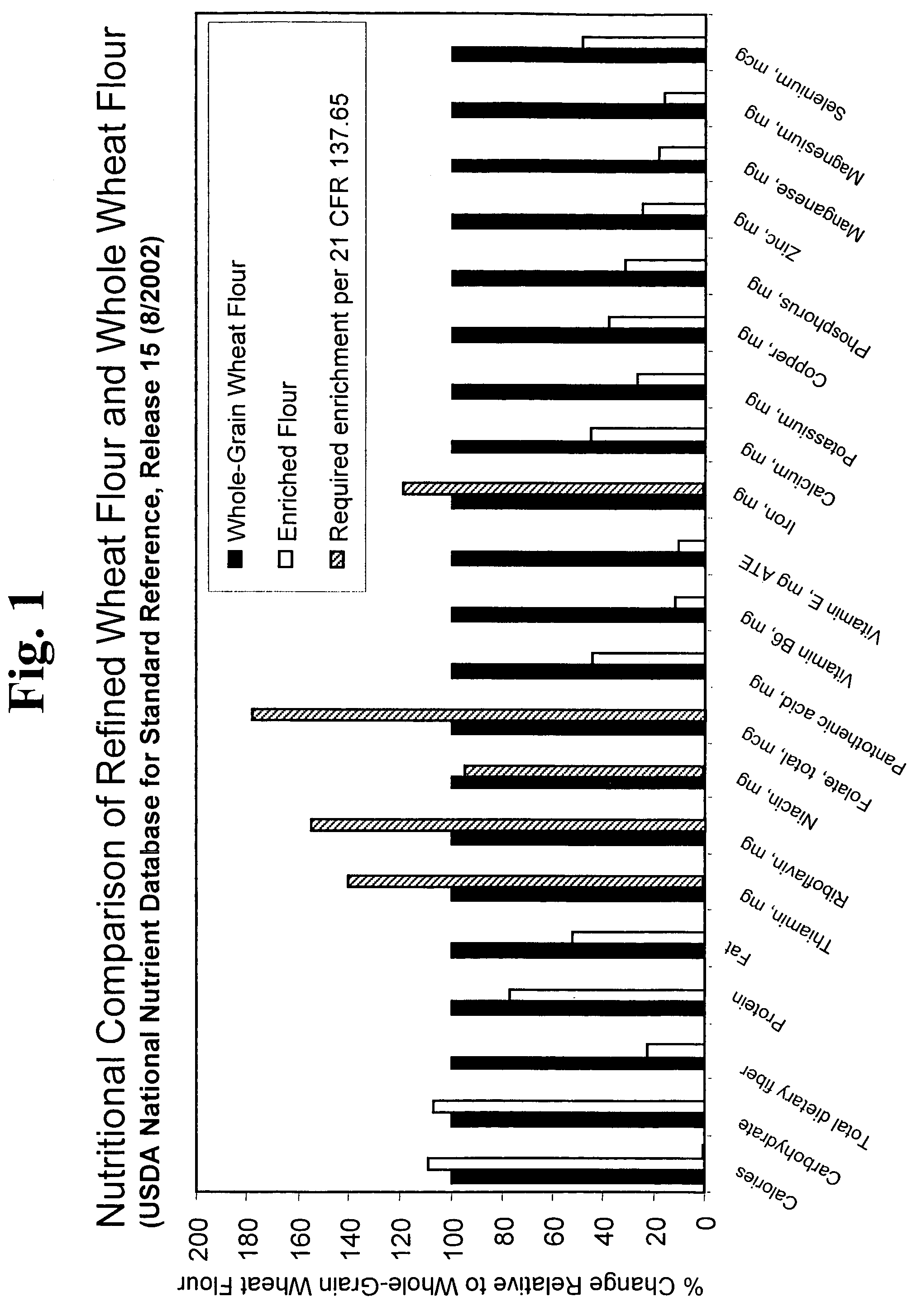

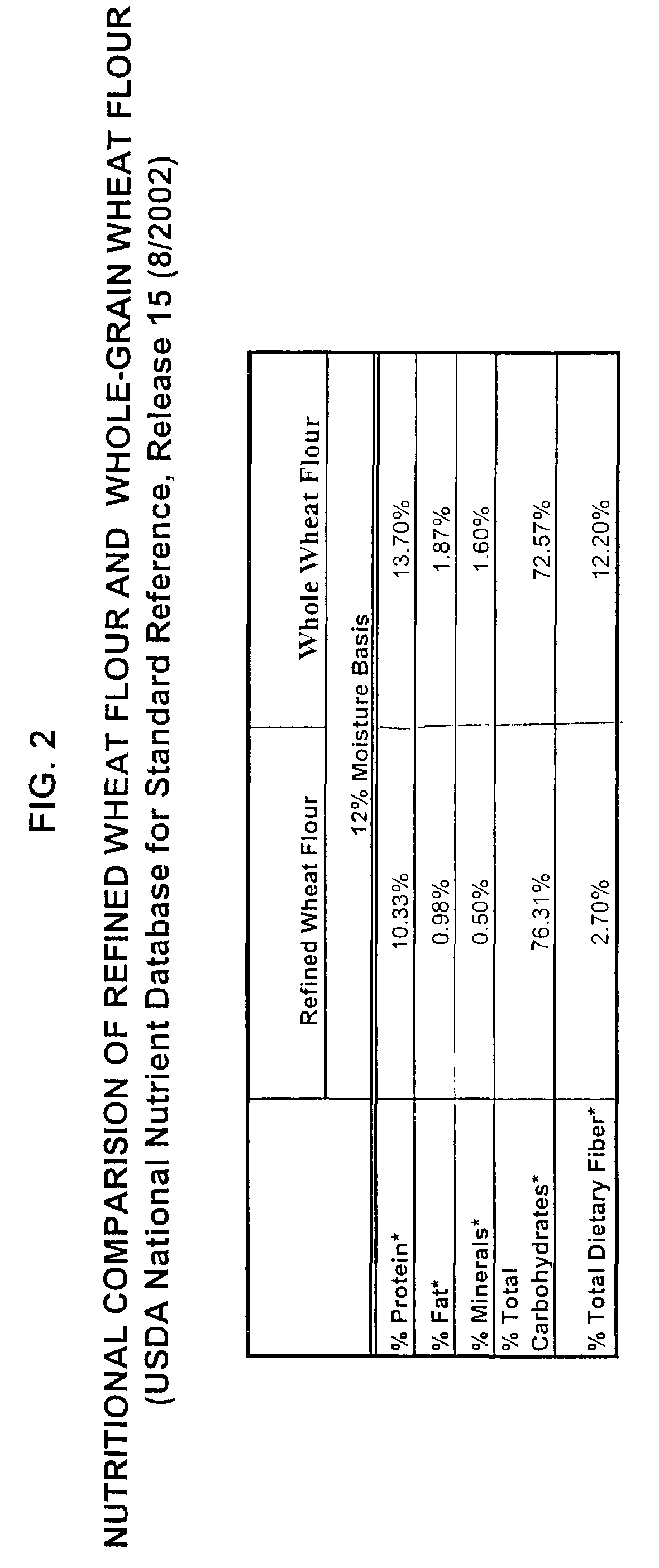

Process for producing an ultrafine-milled whole-grain wheat flour and products thereof

InactiveUS20060073258A1High nutritional valueHigh in fiberDough treatmentGrain treatmentsSnack foodUltra fine

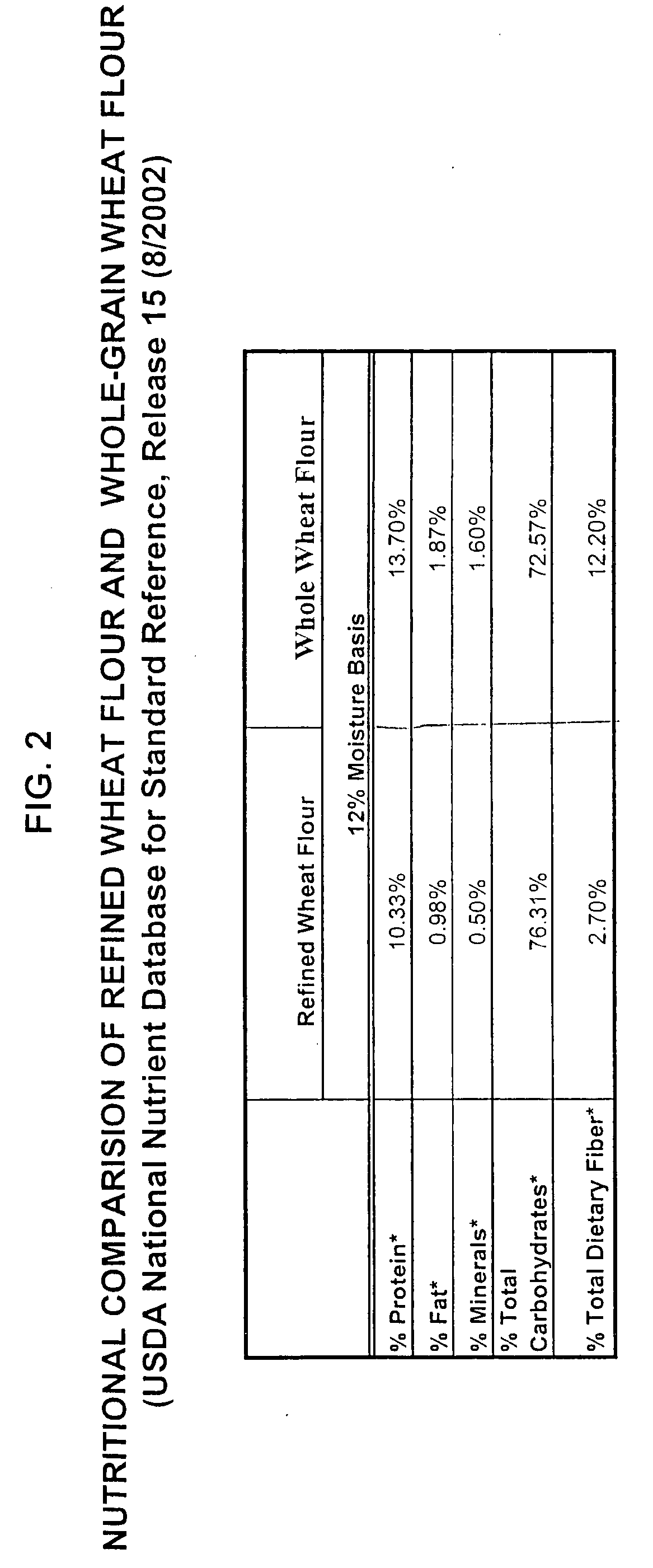

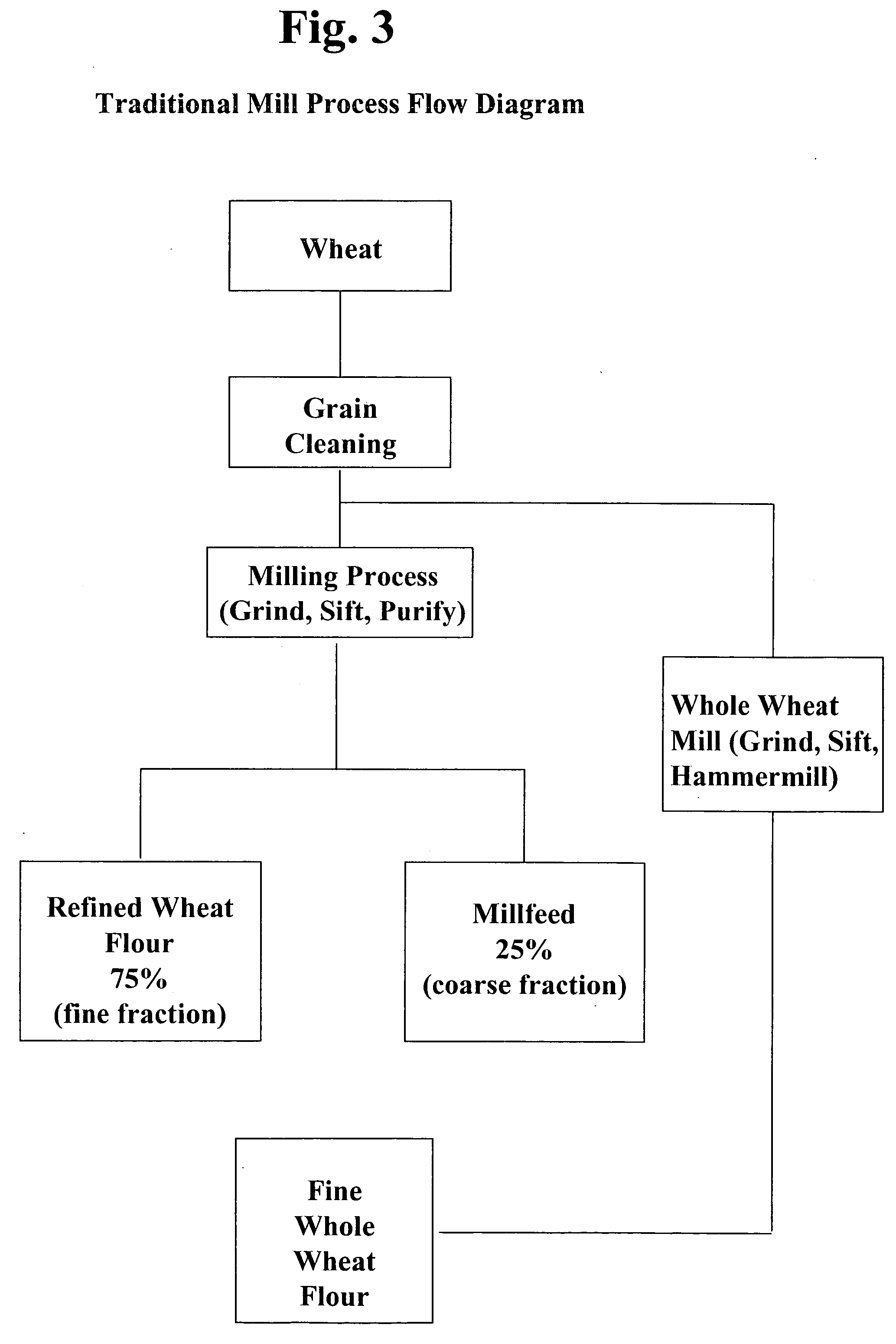

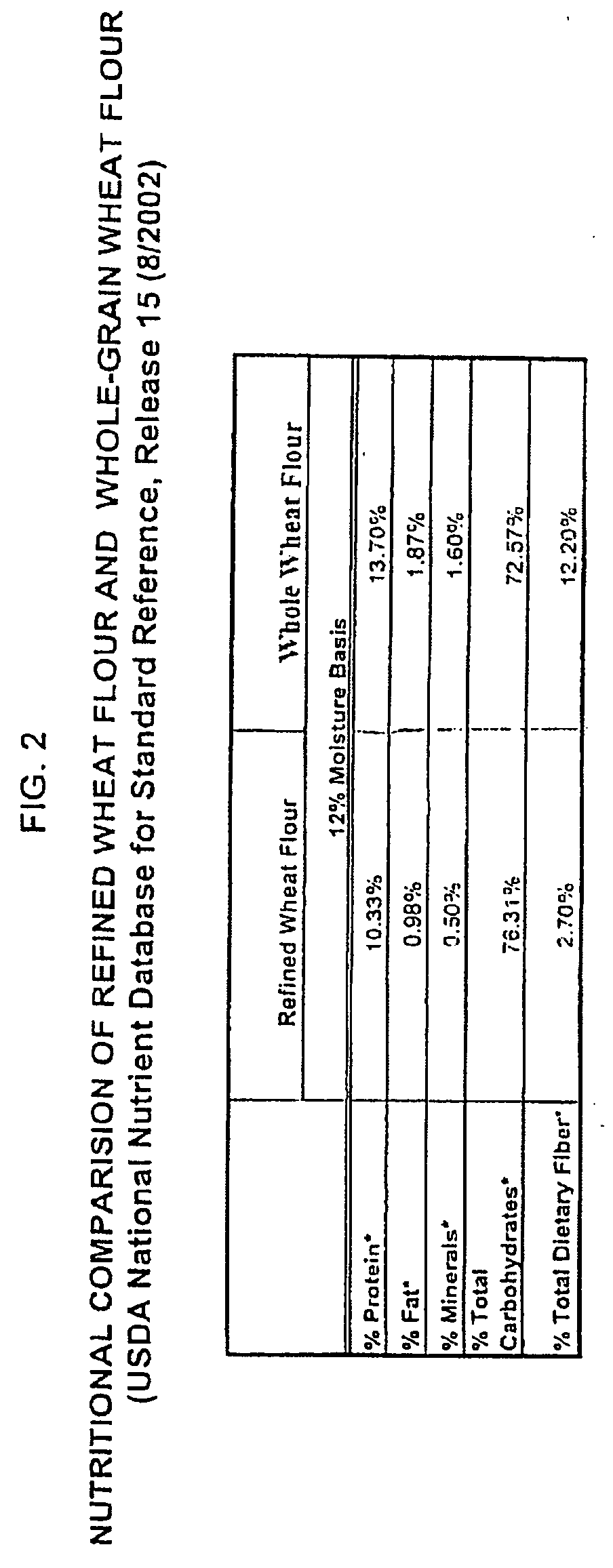

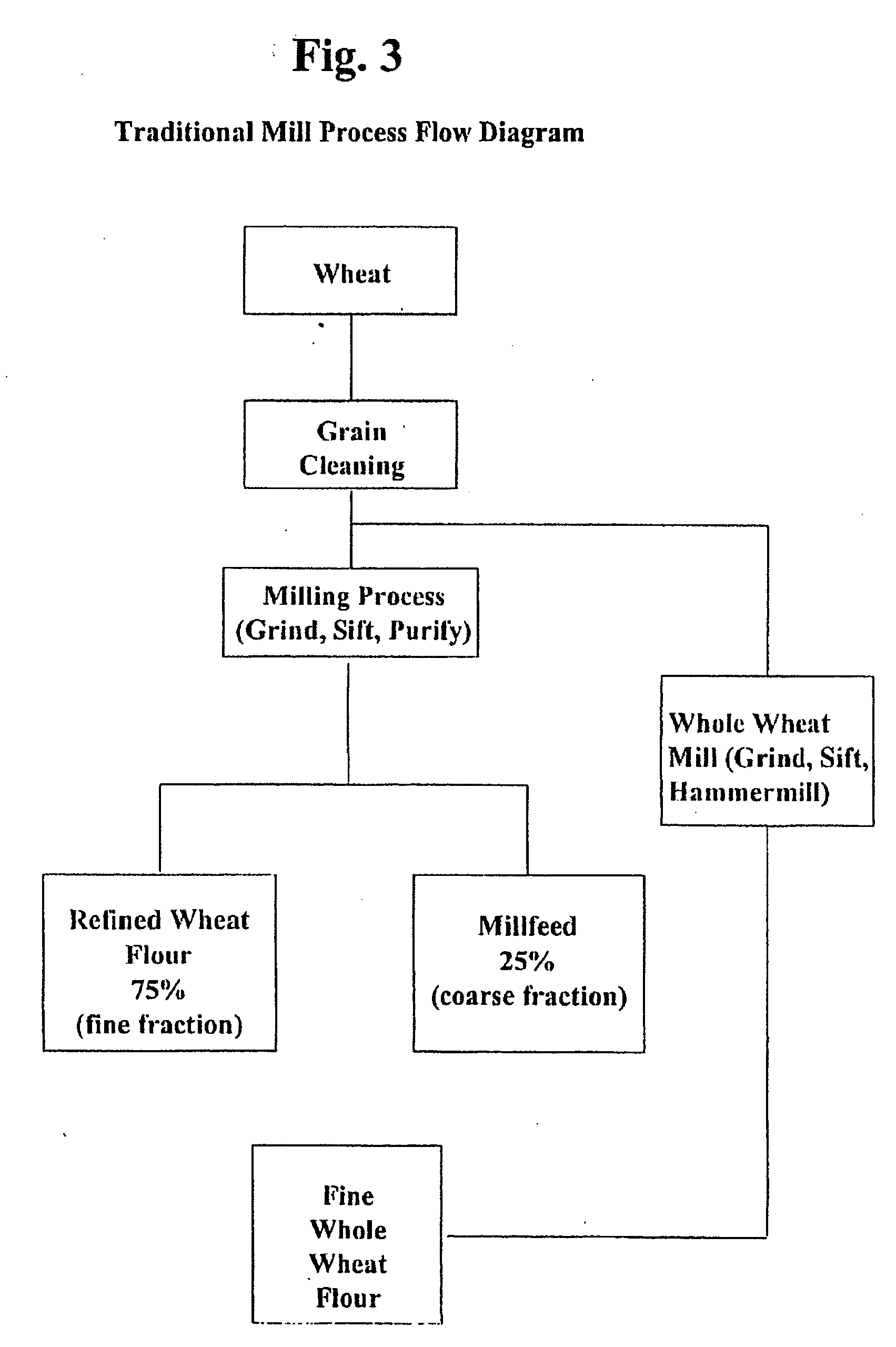

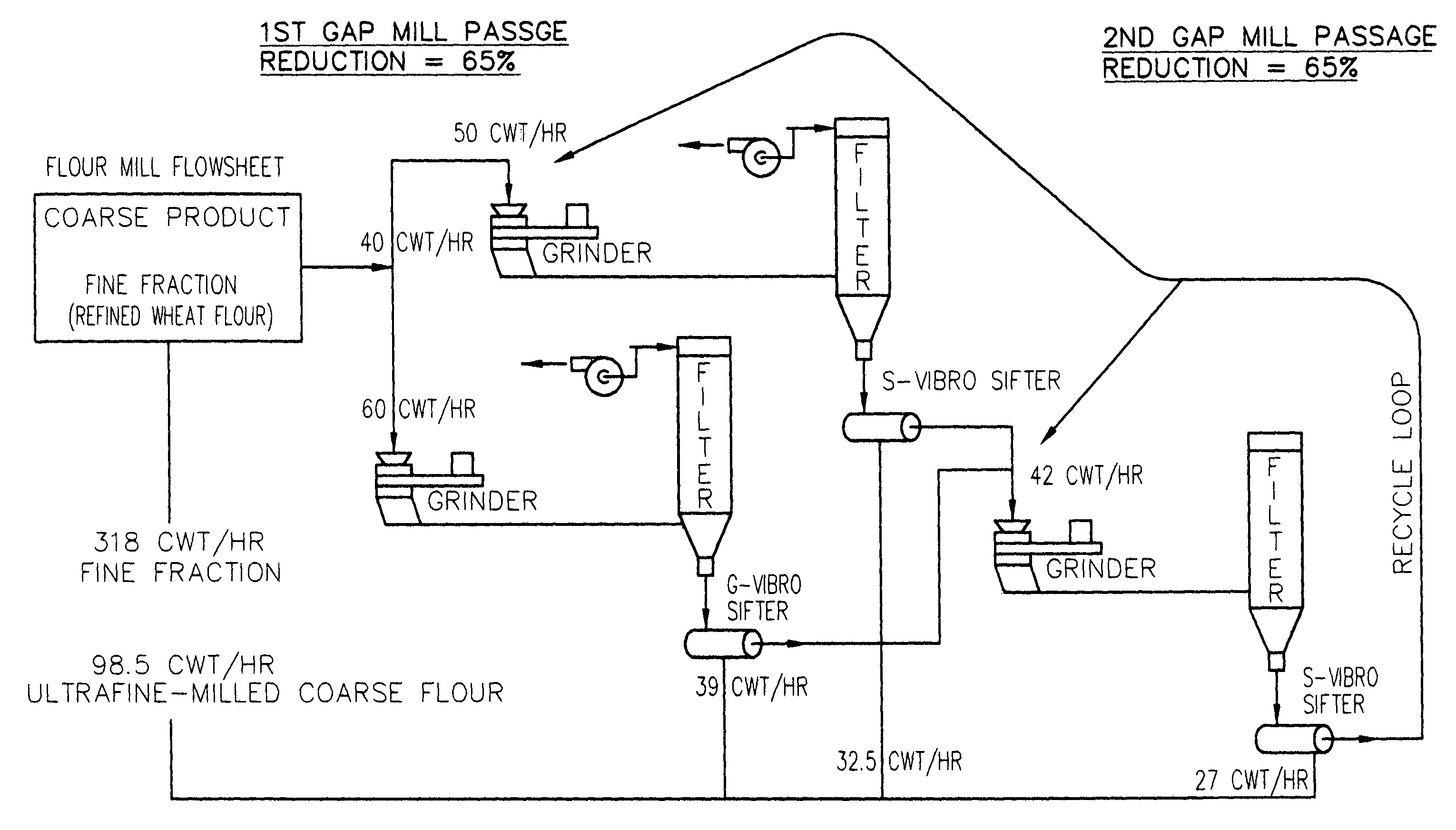

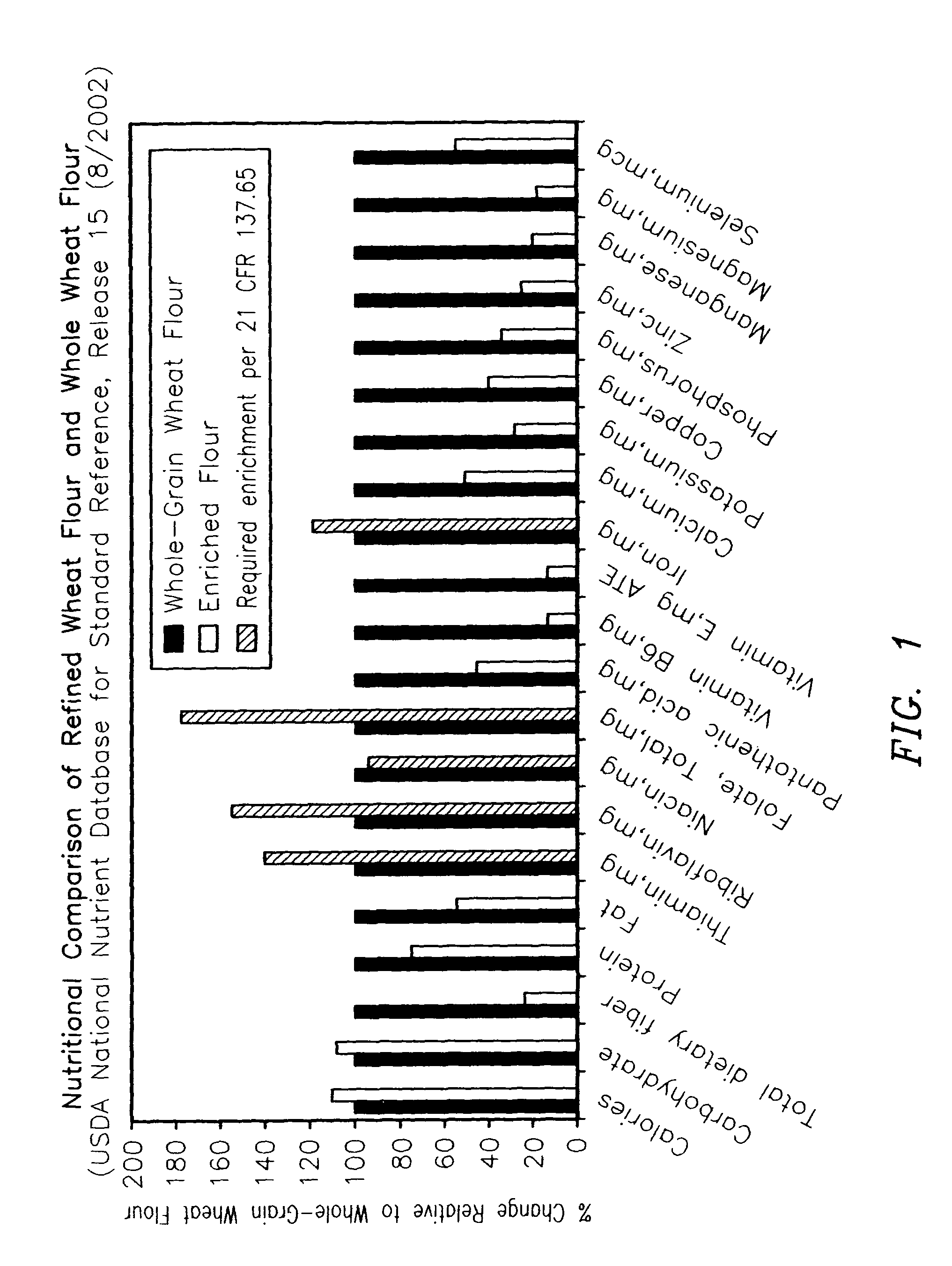

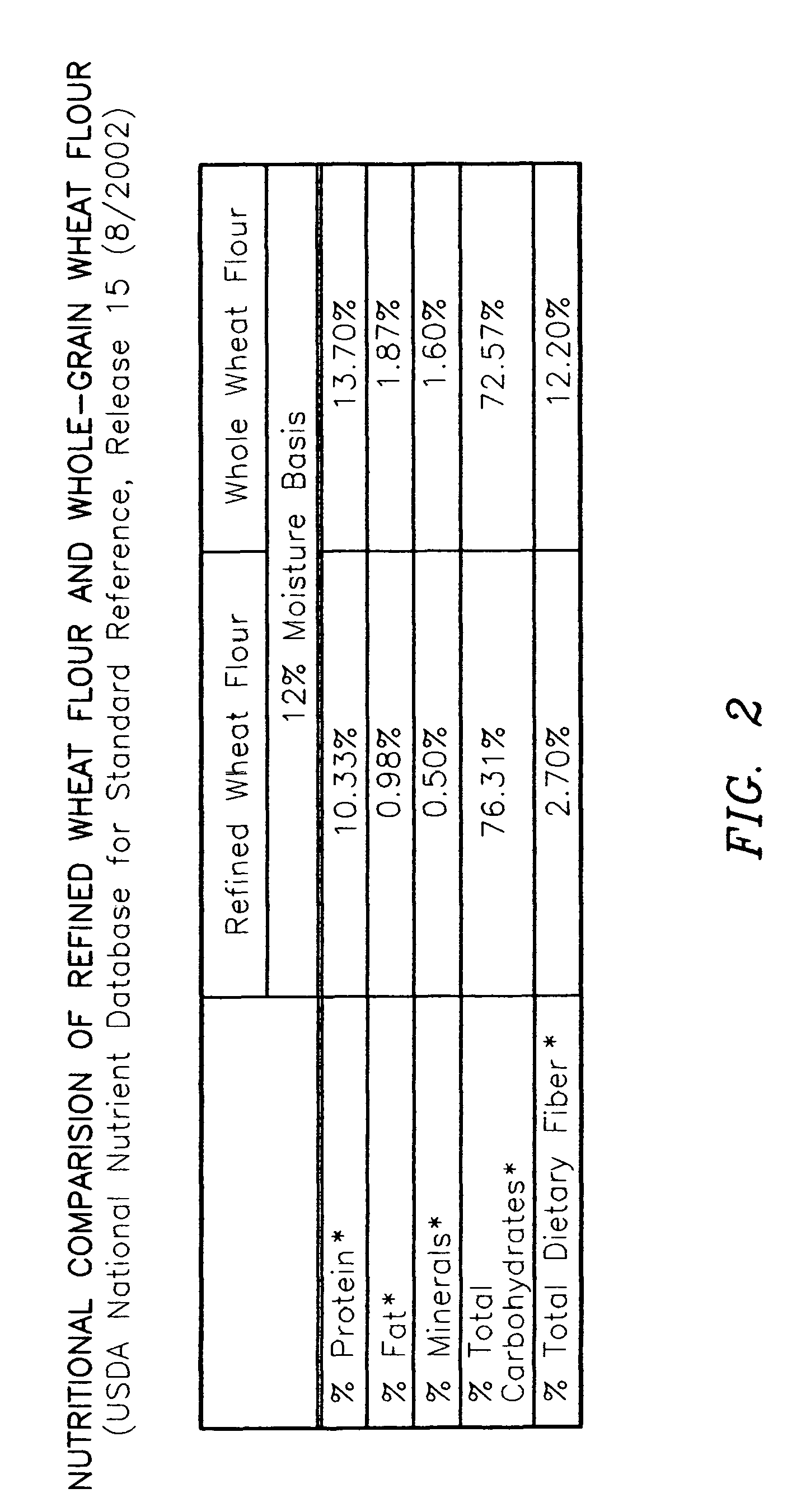

A process for producing an ultrafine-milled whole-grain wheat flour which has the full nutritional value of wheat kernels, while retaining the texture of refined wheat flour and an appearance similar to refined wheat flour, and the products which can be made from the ultrafine-milled whole-grain wheat flour. The process can also be used for producing an ultrafine-milled coarse fraction, which can be used as a replacement and to fortify refined wheat flour. The ultrafine-milled coarse fraction can be used in bakery products, snack products and food products.

Owner:CONAGRA FOODS

Whole grain non-dairy milk production, products and use

ActiveUS20070014892A1Increase coverageReserved functionDough treatmentWort preparationSlurryWhole milk

A method comprising selection of unbroken whole grain rice that are first washed, or whole grain corn that is first reduced in size, and then making an aqueous slurry that is subsequently wet milled to release all the protein, fat, fiber, and starch components normally held in the structure of the grain. The resulting slurry can be reacted with heat to gelatinize the starch and the subsequent product dried. Also, the heated slurry containing the liberated components can be treated to enzymatic hydrolysis via the process of liquefaction and optionally saccharification, producing whole grain rice milk products having diverse carbohydrate compositions. The whole grain milk products are characterized by a nutritional composition containing substantially all the nutritional components of the whole grain, being an opaque whole milk colloid, having smooth texture versus pulpiness, lacking in all bitterness normally associated with whole grain products, and having a variety of sweetness levels from non-sweet to very sweet.

Owner:STEUBEN FOODS

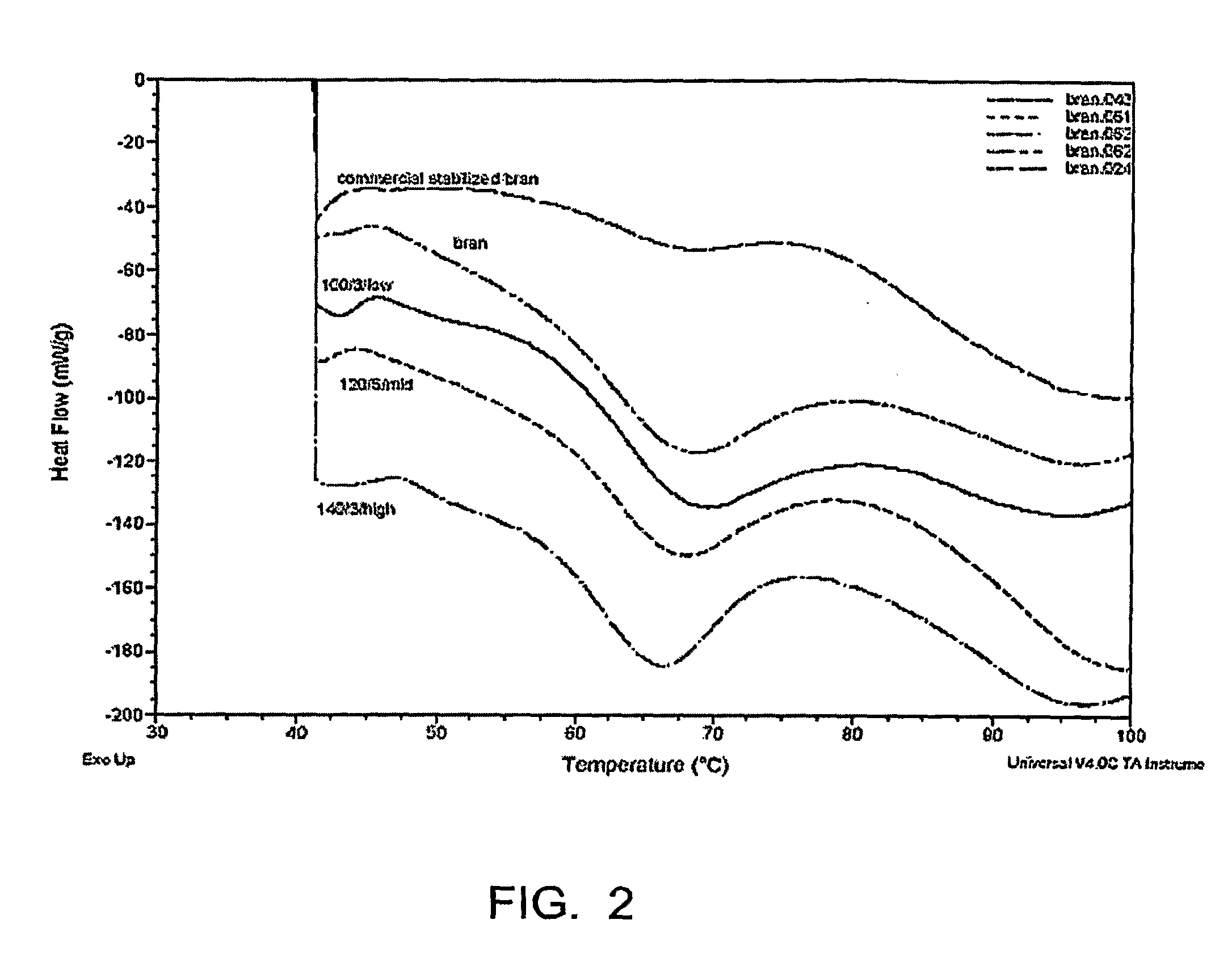

Production of stabilized whole grain wheat flour and products thereof

ActiveUS20070292583A1Superior oven spreadNice appearanceDough treatmentBaking mixturesAntioxidantLipoxygenase activity

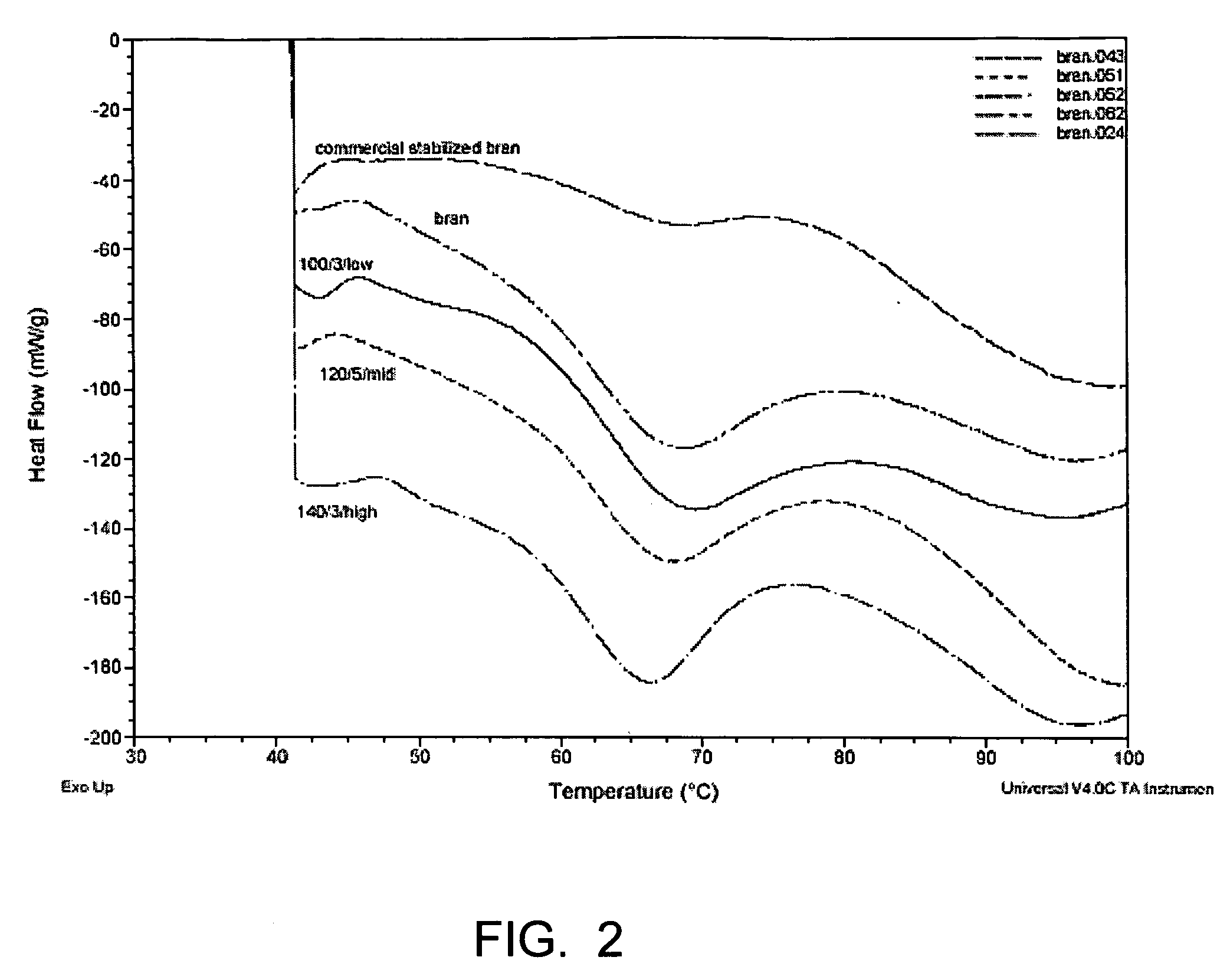

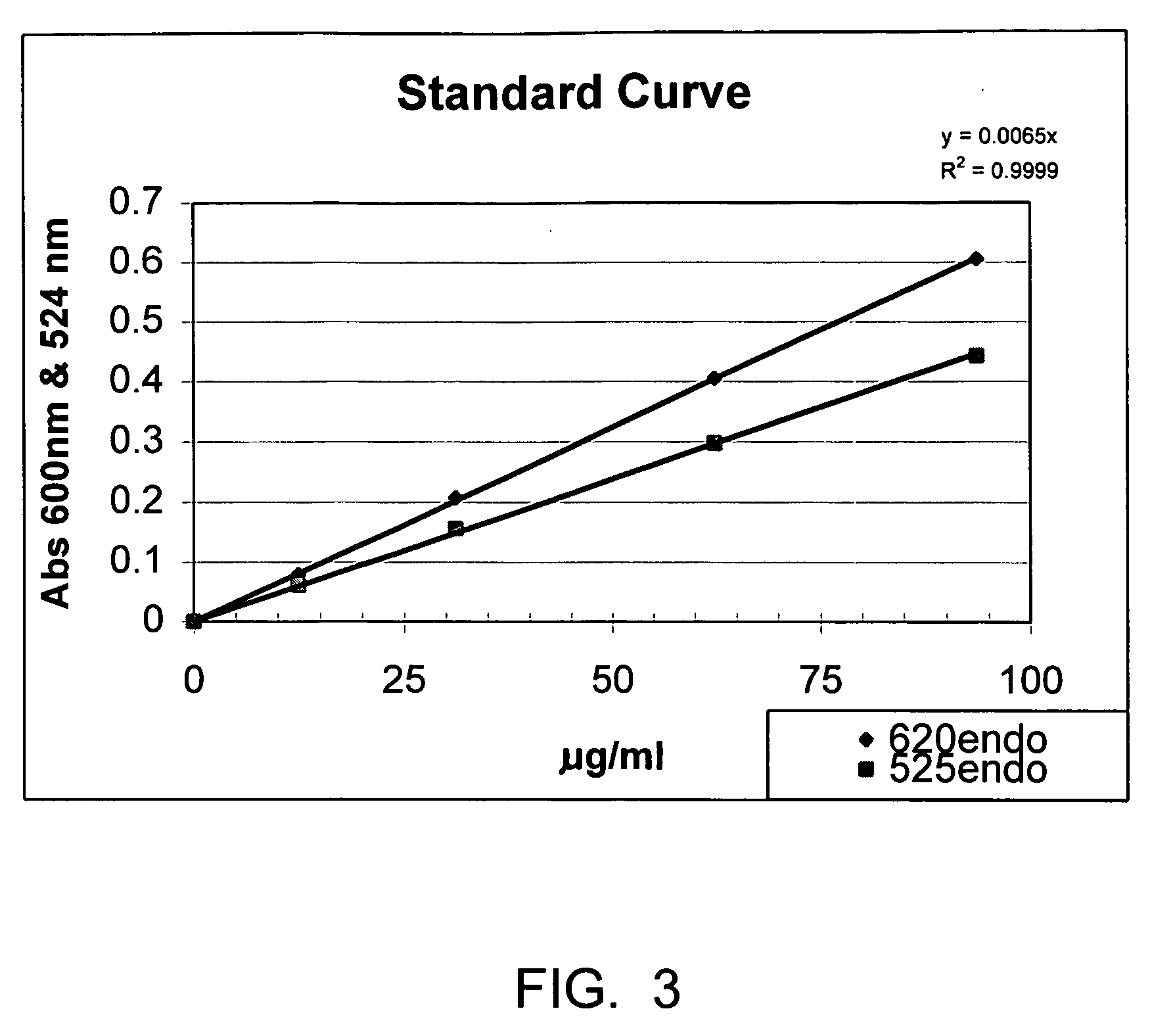

A stabilized bran component and a stabilized whole grain wheat flour containing the component are produced by subjecting a bran-enriched coarse fraction which contains bran, germ and starch to grinding or milling to reduce grittiness of the coarse fraction without substantially damaging the starch due to abrasion. The coarse fraction may be stabilized by heating to substantially reduce the lipase and lipoxygenase activity of the coarse fraction without substantial gelatinization of the starch. High levels of natural antioxidants and vitamins are retained while avoiding substantial acrylamide formation during the stabilization. The stabilized coarse fraction or stabilized bran component may be combined with a fine fraction which contains predominantly endosperm to obtain a stabilized whole grain wheat flour. The stabilized whole grain wheat flours and the stabilized bran component exhibit extended shelf life and may be used for making baked goods, such as cookies, with desirable oven spread, and a non-gritty mouthfeel.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Whole grain products made with whole grain durum wheat

ActiveUS20060073240A1Eliminating visually distinct particulate matterBaking mixturesConfectioneryCereal grainWhole grains

Owner:GENERAL MILLS INC

Chia seed composition

InactiveUS20090181127A1Enhancing gastrointestinal regularityEnhancing heart healthMilk preparationDough treatmentVitamin antagonistGlycoside formation

A composition of matter is disclosed and formed from a stable, defatted whole grain flour derived from Salvia hispanica L. whole ground seed using a suitable solvent that is free of cyanogenic glycosides, vitamin antagonists, and gluten. The composition includes minerals, about 30% wt / wt protein, about 30-40% insoluble fiber and about 2-3% of fructo-oligosaccarides.

Owner:US NUTRACEUTICALS LLC

Process for producing an ultrafine-milled whole-grain wheat flour and products thereof

A process for producing an ultrafine-milled whole-grain wheat flour which has the full nutritional value of wheat kernels, while retaining the texture of refined wheat flour and an appearance similar to refined wheat flour, and the products which can be made from the ultrafine-milled whole-grain wheat flour. The process can be used for producing an ultrafine-milled coarse fraction. Further, using the process with a variety of other grains is discussed.

Owner:CONAGRA FOOD INGREDIENTS

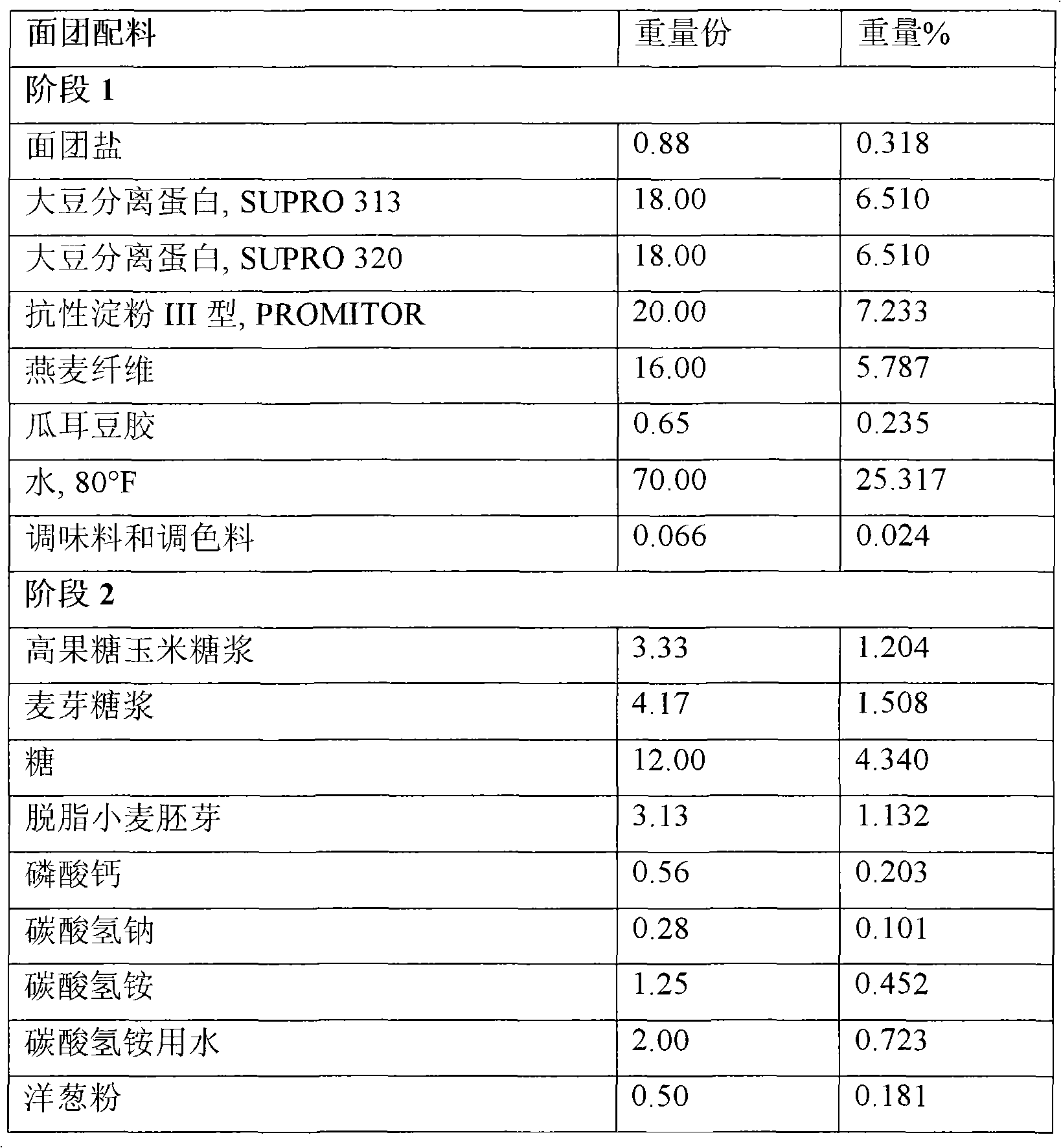

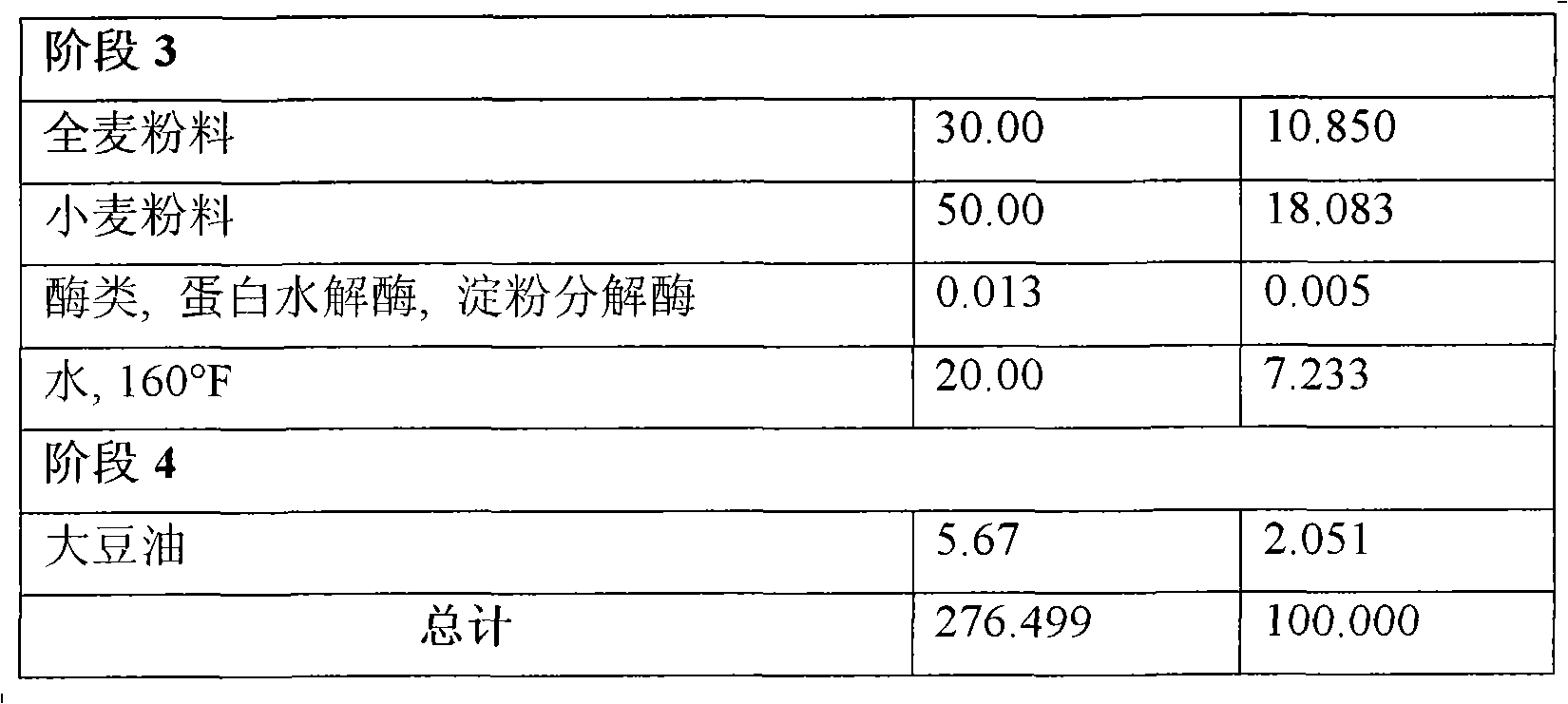

High fiber and high protein baked goods production

InactiveUS20100303991A1Pleasant tastePotential healthDough/pre-mixesConfectioneryStarch gelatinizationHigh protein food

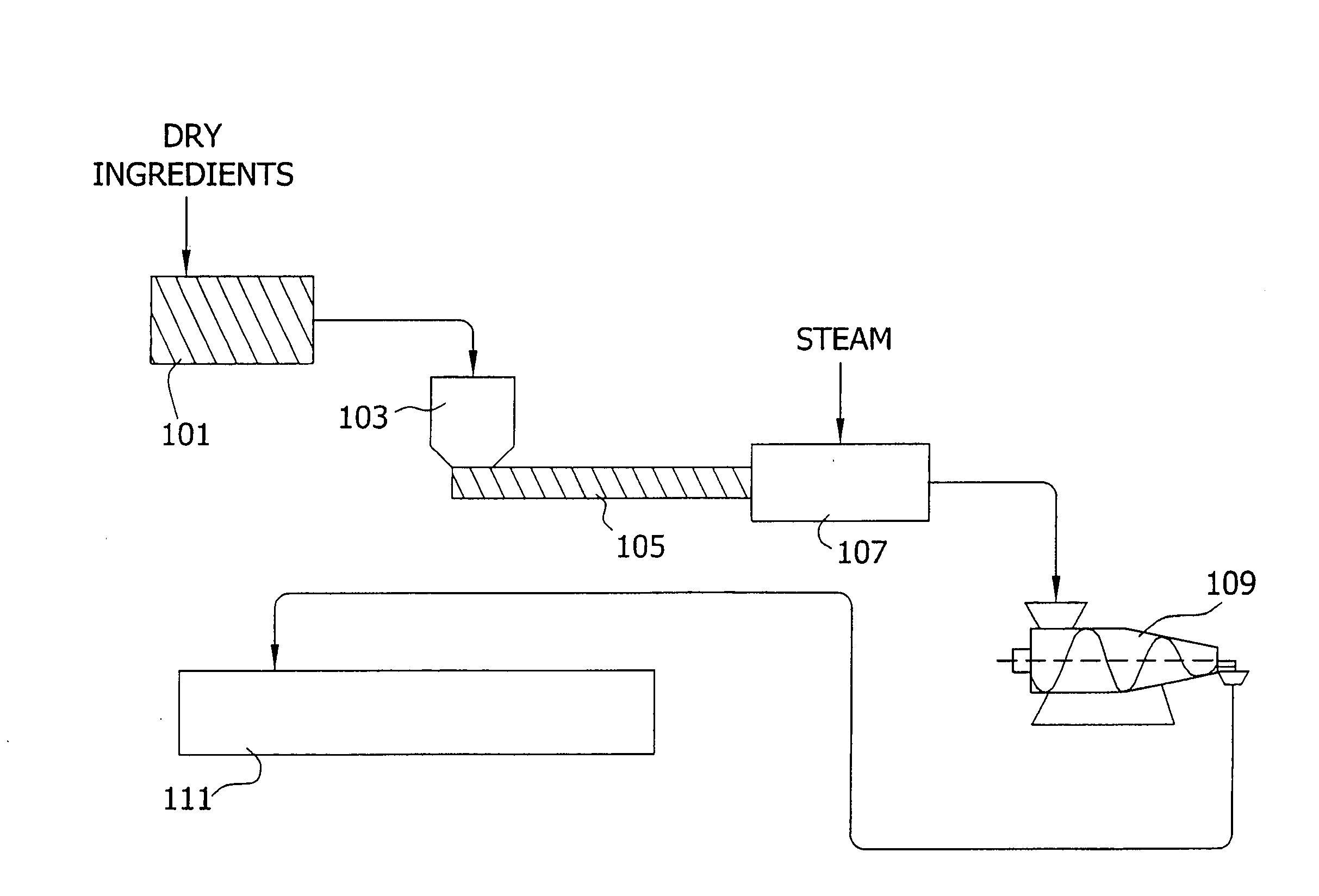

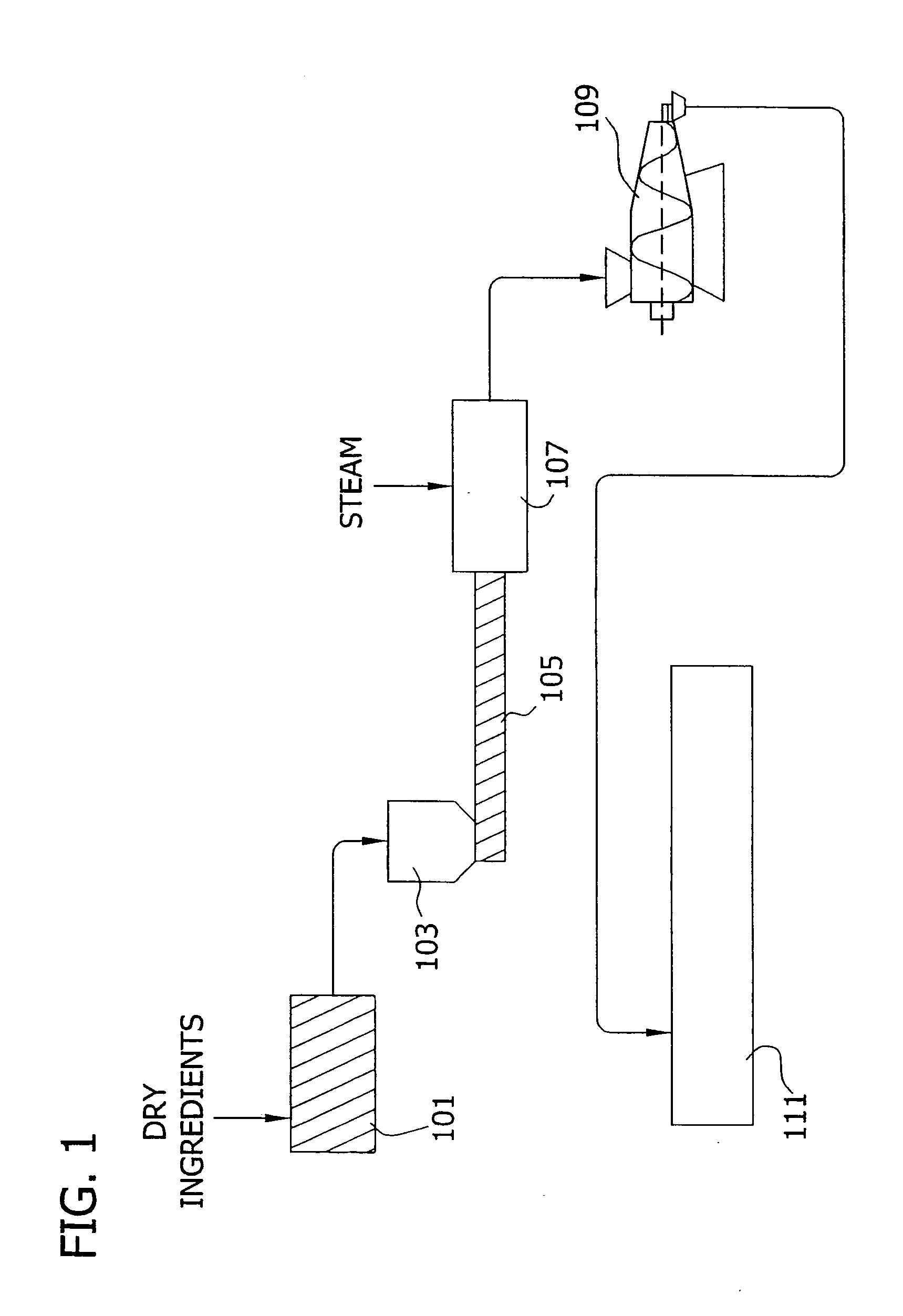

Substantially uniform hydration and dispersion of high amounts of protein and fiber are achieved while avoiding lump formation, hard textures, and off-tastes in the continuous, mass production of high protein and high fiber content sheetable doughs, and baked goods such as crackers, snacks, and cookies made from the sheeted doughs, by hydrating the protein and fiber with water at a temperature below the denaturization temperature of the proteins, and steaming the hydrated mixture without substantial gelatinization of starch during dough production. The steamed, hydrated mass may be admixed with ingredients comprising at least one flour comprising starch to obtain a dough while avoiding substantial gelatinization of starch of the at least one flour during mixing. The baked goods may have a protein content of at least about 4 g, a fiber content of at least about 4 g, and a whole grain flour content of at least about 4 g per 30 g serving.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Process for producing an ultrafine-milled whole-grain wheat flour and products thereof

A process for producing an ultrafine-milled whole-grain wheat flour which has the full nutritional value of wheat kernels, while retaining the texture of refined wheat flour and an appearance similar to refined wheat flour, and the products which can be made from the ultrafine-milled whole-grain wheat flour. The process can be used for producing an ultrafine-milled coarse fraction. Further, using the process with a variety of other grains is discussed.

Owner:CONAGRA FOOD INGREDIENTS

Frozen confectionary products comprising hydrolyzed whole grain

The present invention relates to frozen confectionary product comprising up to 20% wt fat, up to 25% milk solids non fat (MSNF), from 5 to 40% wt sweetening agent and up to 3% of stabiliser and / or emulsifier, wherein said frozen confectionery further comprises a hydrolysed whole grain composition and an alpha-amylase or fragment thereof, which alpha-amylase or fragment thereof shows no hydrolytic activity towards dietary fibers when in the active state.

Owner:SOC DES PROD NESTLE SA

Recombined whole grain having visually indistinguishable particulate matter and related baked products

InactiveUS20070269579A1Minimal visual impactEliminate the effects ofDough treatmentBakery productsParticulatesMicroparticle

A recombined whole grain flour for use in preparing whole grain products such that whole grain particulates provide minimal visual impact to the whole grain product. By selectively controlling the particle size of the milled bran and germ constituents used in the recombined whole grain flour, the visual and color impact associated with bran and germ particulates can be substantially eliminated from the whole grain product. In particular, whole grain products such as whole grain breads, dough products, mixes and biscuits can be made with recombined whole grain flour. Whole grain products made with recombined whole grain flour are advantageous in that they incorporate the health advantages associated with whole grains while eliminating the characteristic, visual color differences noticeable within a whole grain crumb due to visually identifiable bran and germ particulates found in traditional whole grain products.

Owner:GENERAL MILLS MARKETING INC

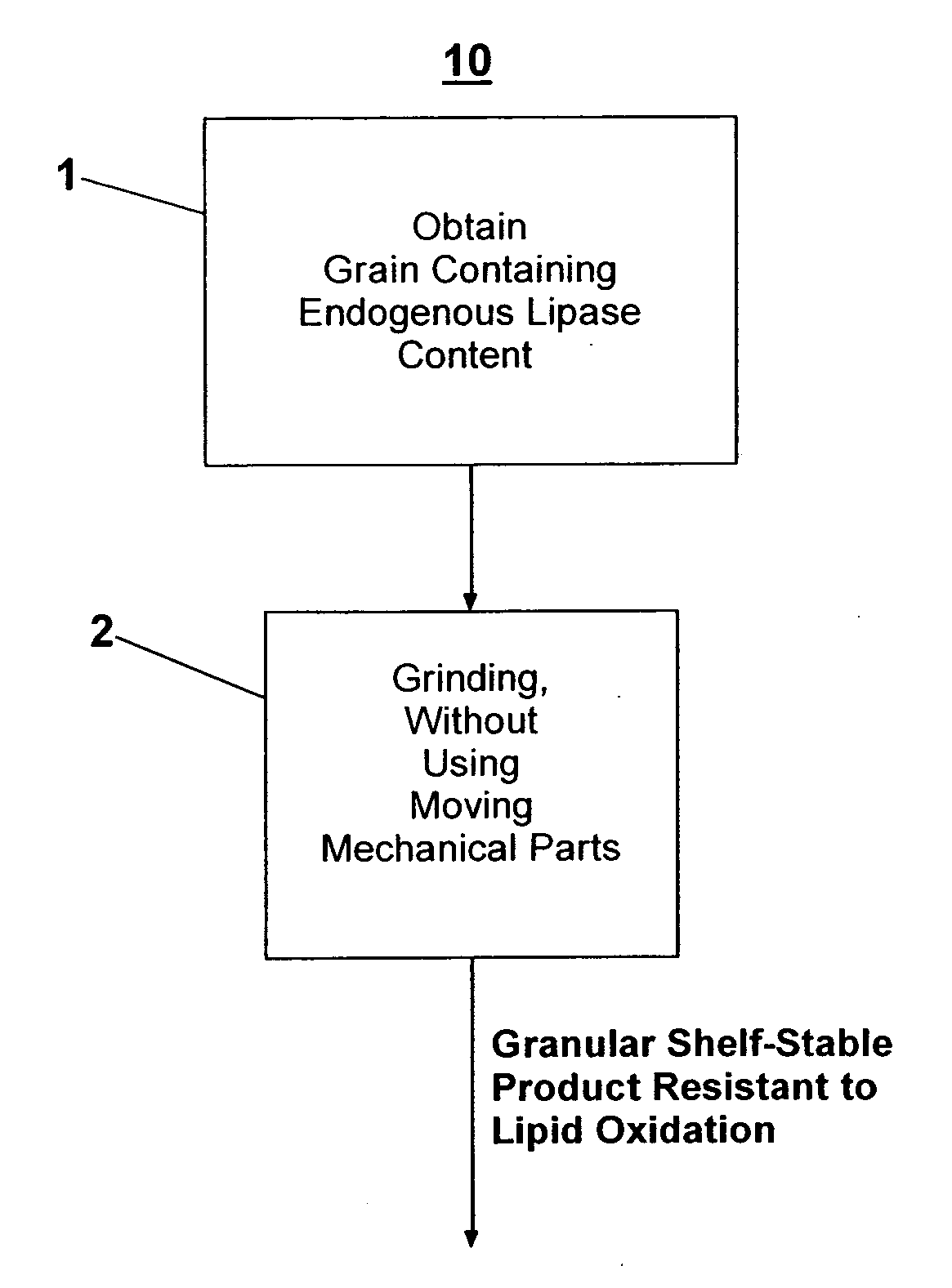

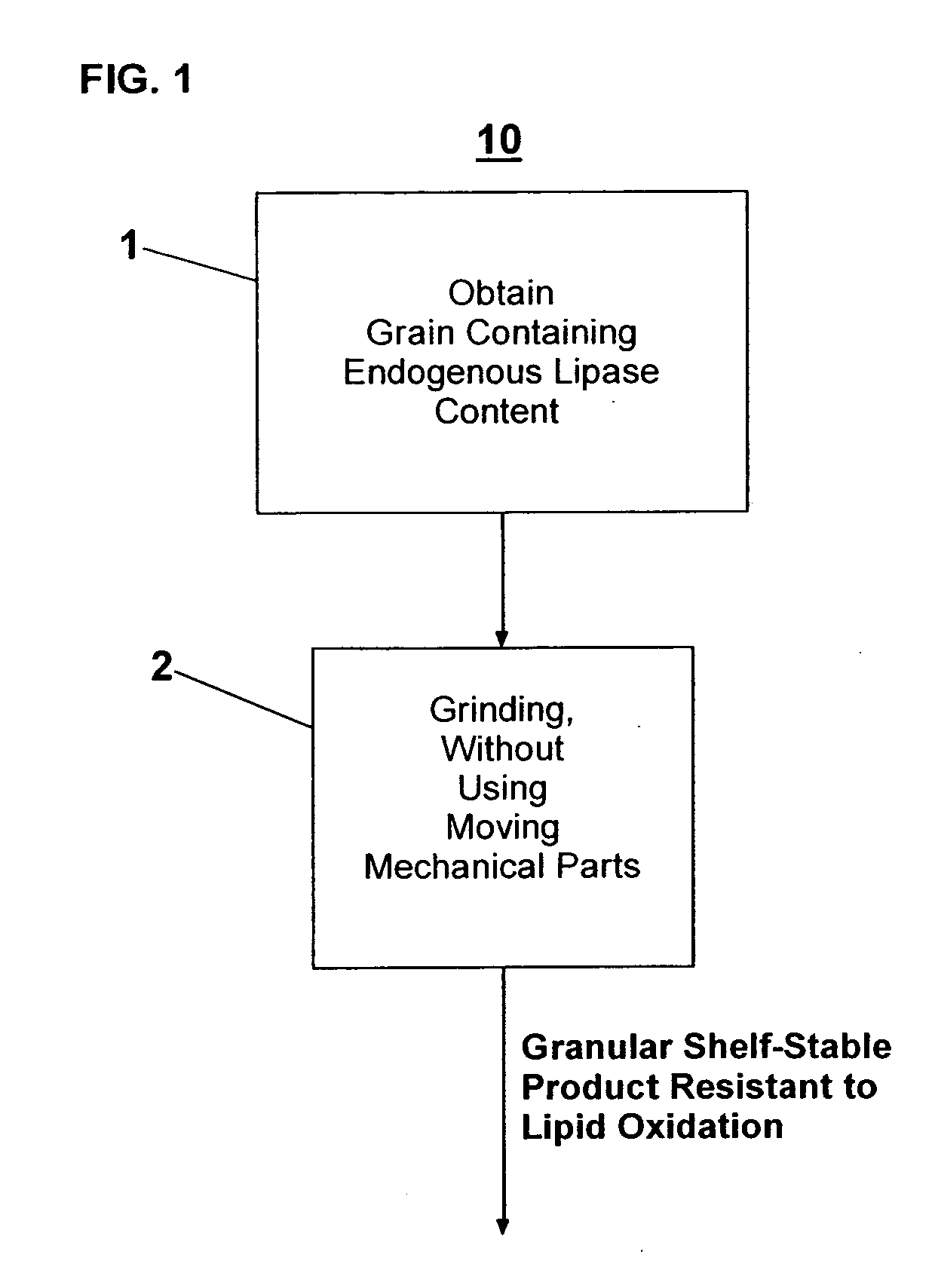

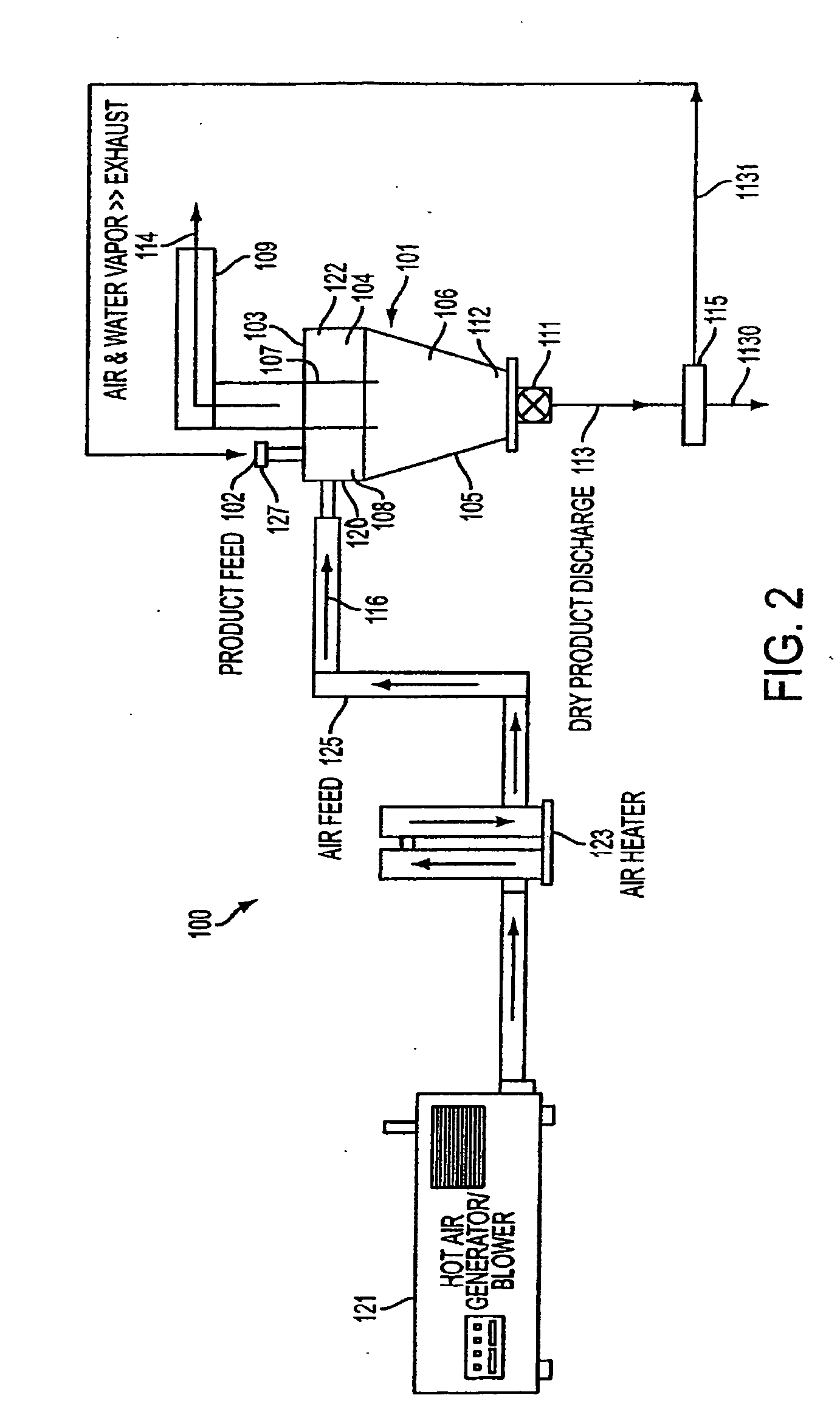

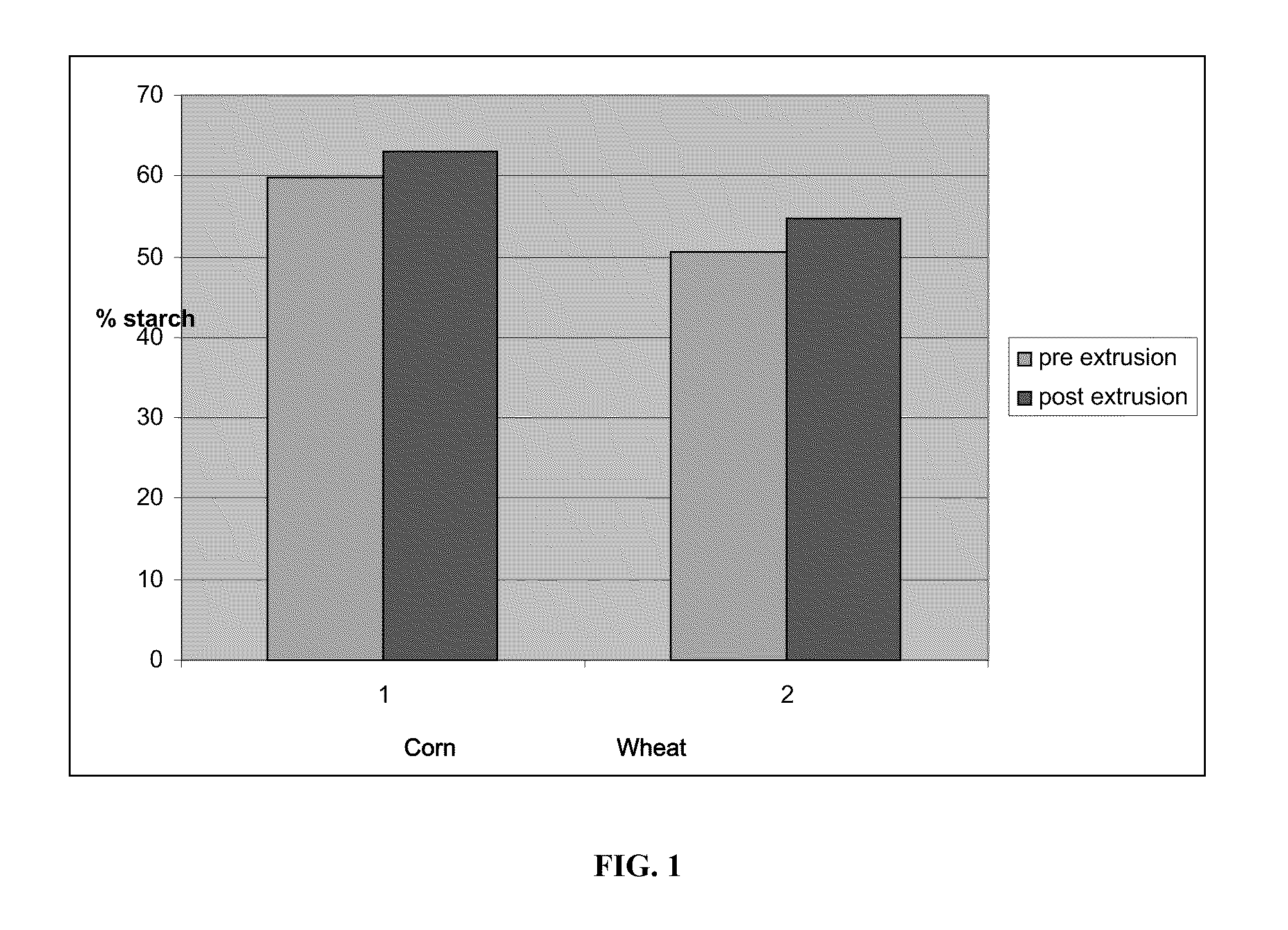

Process for granulation of edible seeds

InactiveUS20060286269A1Less-prone to lipid oxidationStable and resistant to lipid oxidationCosmetic preparationsToilet preparationsUnit operationLipid oxidation

A process for grinding edible seeds, such as grain and / or pulses, in a single unit operation in a continuous, short-duration controlled-temperature manner. Grinding may be effected without the need for moving mechanical parts. The granulated product obtained from the grinding treatment is stable to lipid oxidation. It also may be used in preparing instant whole grain food products.

Owner:KRAFT FOODS INC

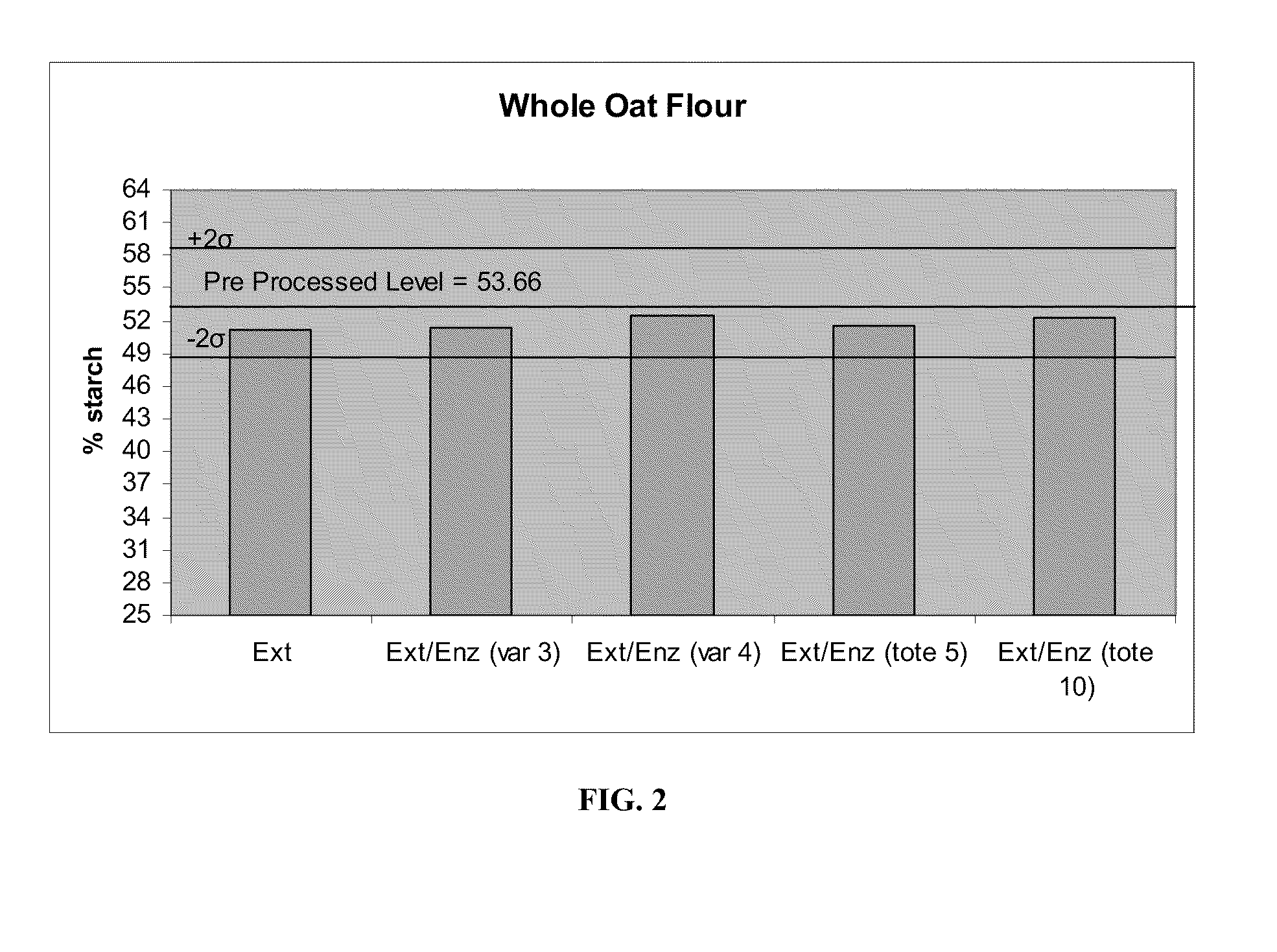

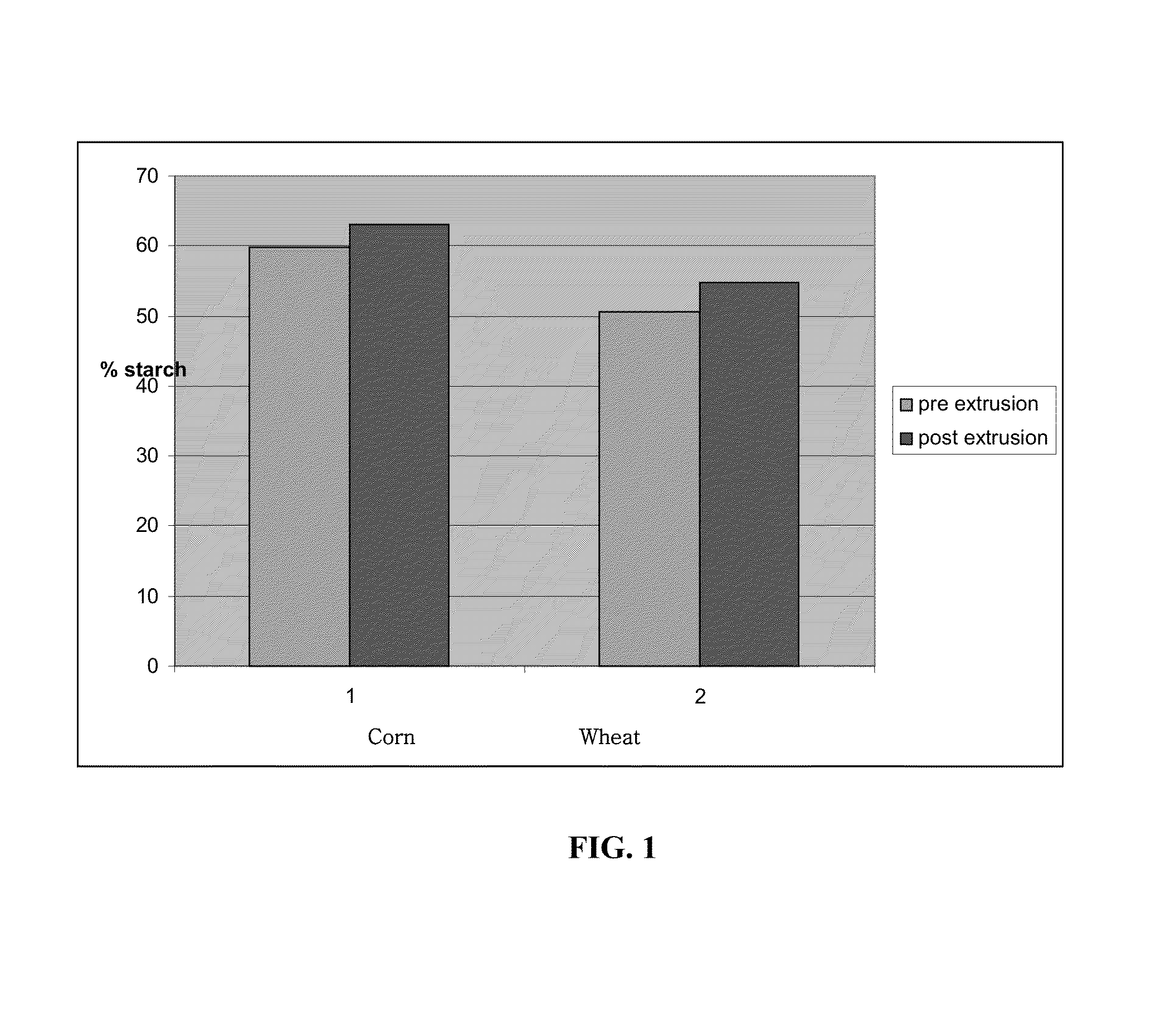

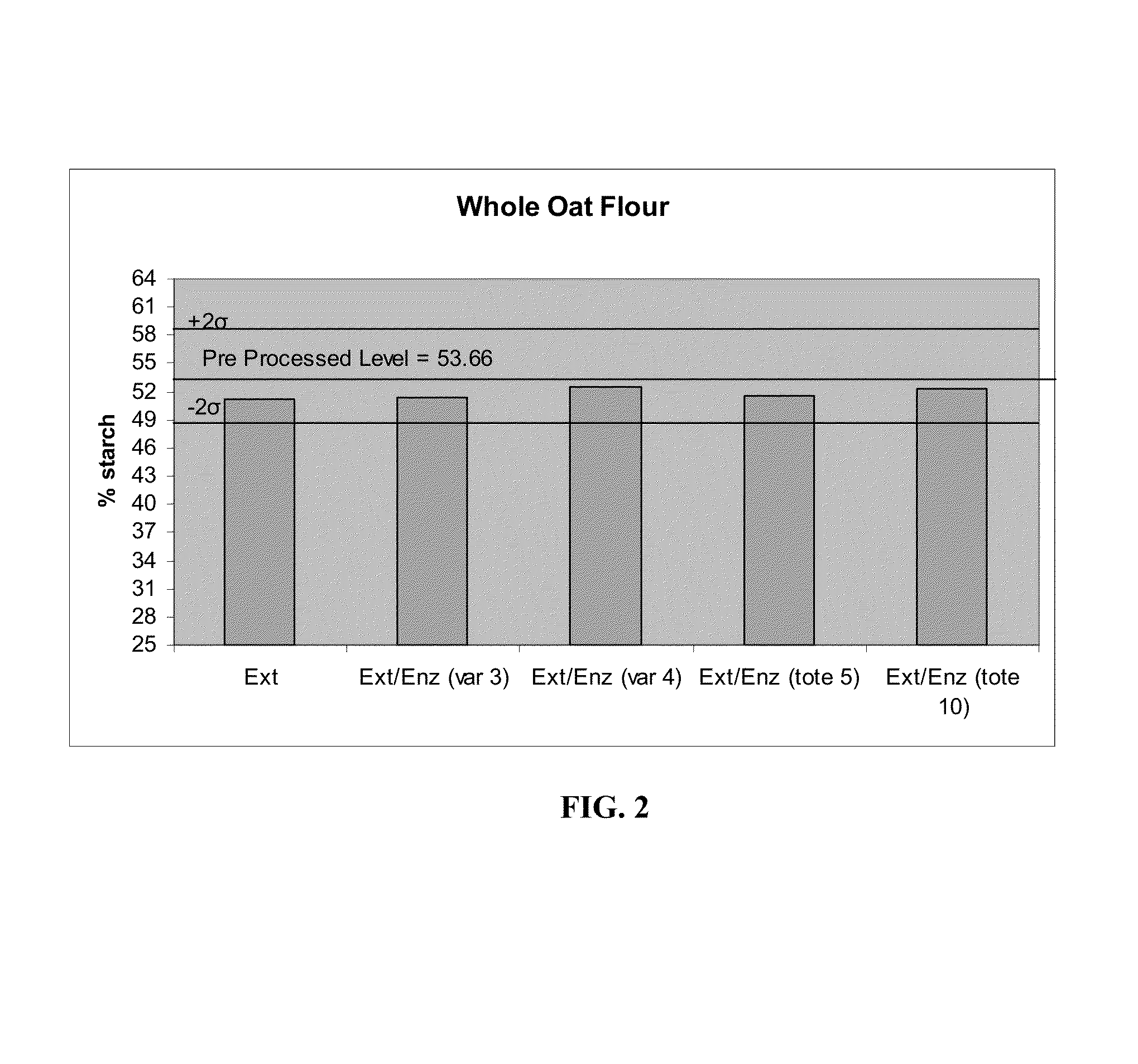

Method of producing modified whole grain oat flour and products containing modified whole grain oat flour

A method of producing modified whole grain oat flour that includes the digestion of oat fiber using fiber-digesting enzymes, is described. The resulting modified whole grain oat flour contains the whole oats, including the digested fiber, as well as the fiber-digesting enzymes. In addition, topical formulations and food products that include modified whole grain oat flour as an ingredient are described.

Owner:21ST CENTURY GRAIN PROCESSING

Method of Preparing Highly Dispersible Whole Grain Flour

A method of preparing a highly dispersible whole grain flour by hydrolyzing, milling and agglomerating grain flour. Highly dispersible hydrolyzed whole grain flours made in accordance with the present invention include an enzyme that hydrolyzes the whole grain flour while maintaining the integrity of the whole grain throughout processing. The whole grain flours of the present invention are highly dispersible in liquid and semi-solid media.

Owner:THE QUAKER OATS CO

Protein Extrudates Comprising Whole Grains

InactiveUS20090155444A1Increase concentrationDough treatmentProteins working-up by texturisingHigh concentrationAdditive ingredient

The present invention relates to food materials containing a high concentration of vegetable protein and whole grains and processes for their manufacture. More particularly, the present invention relates to protein extrudates containing high concentrations of soy protein and whole grains, processes for manufacturing such protein extrudates, and the use of such protein extrudates as food ingredients.

Owner:SOLAE LLC

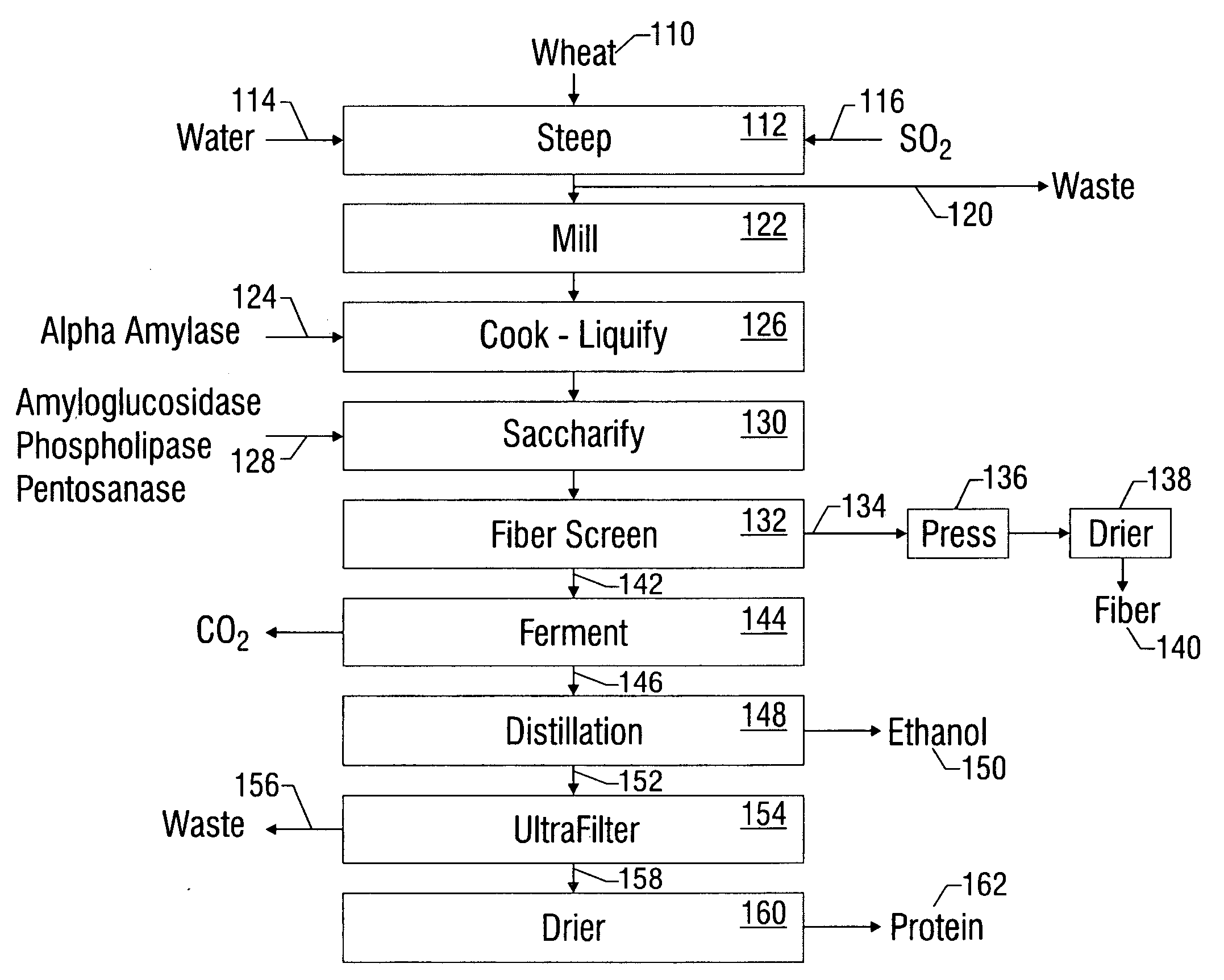

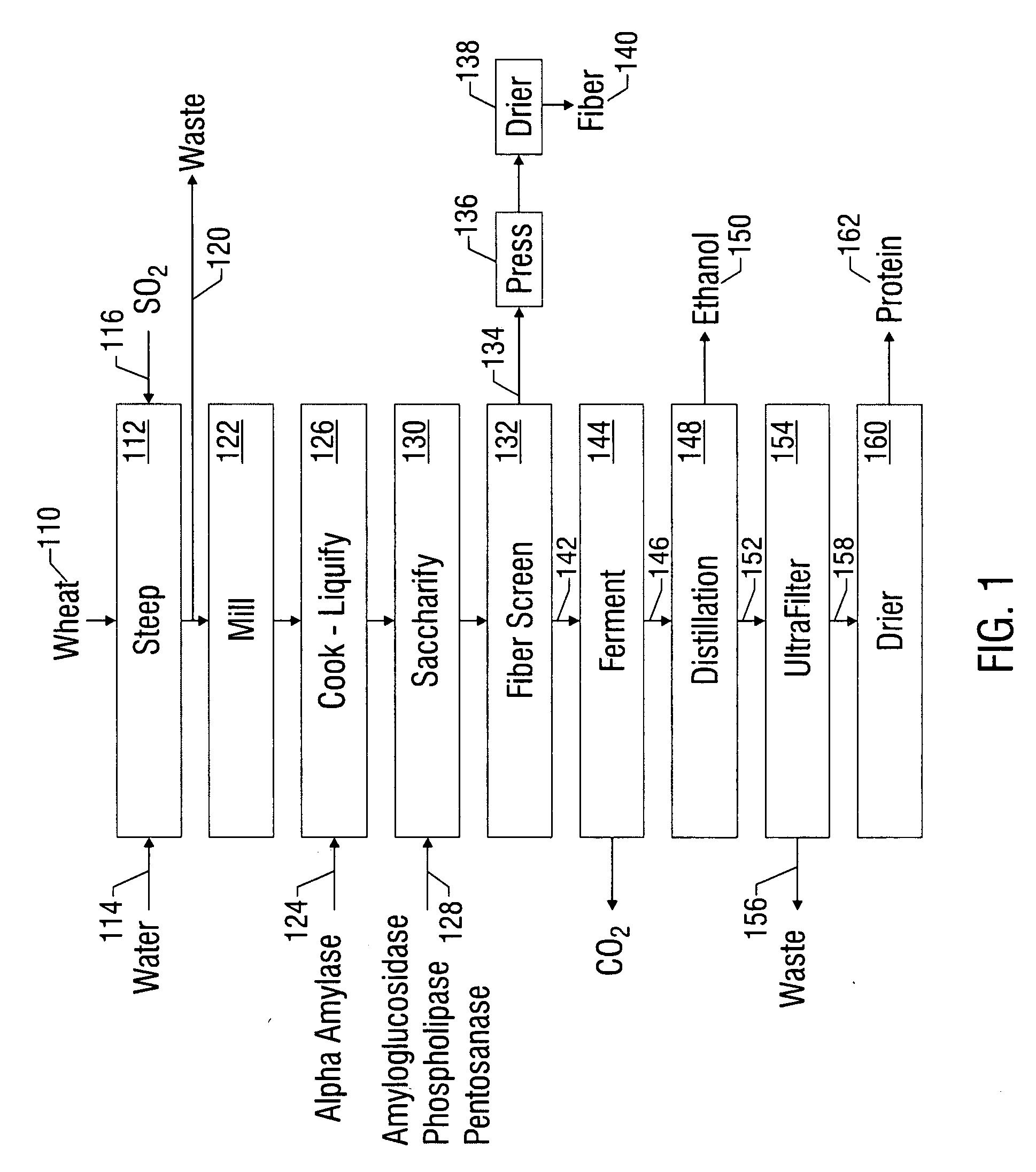

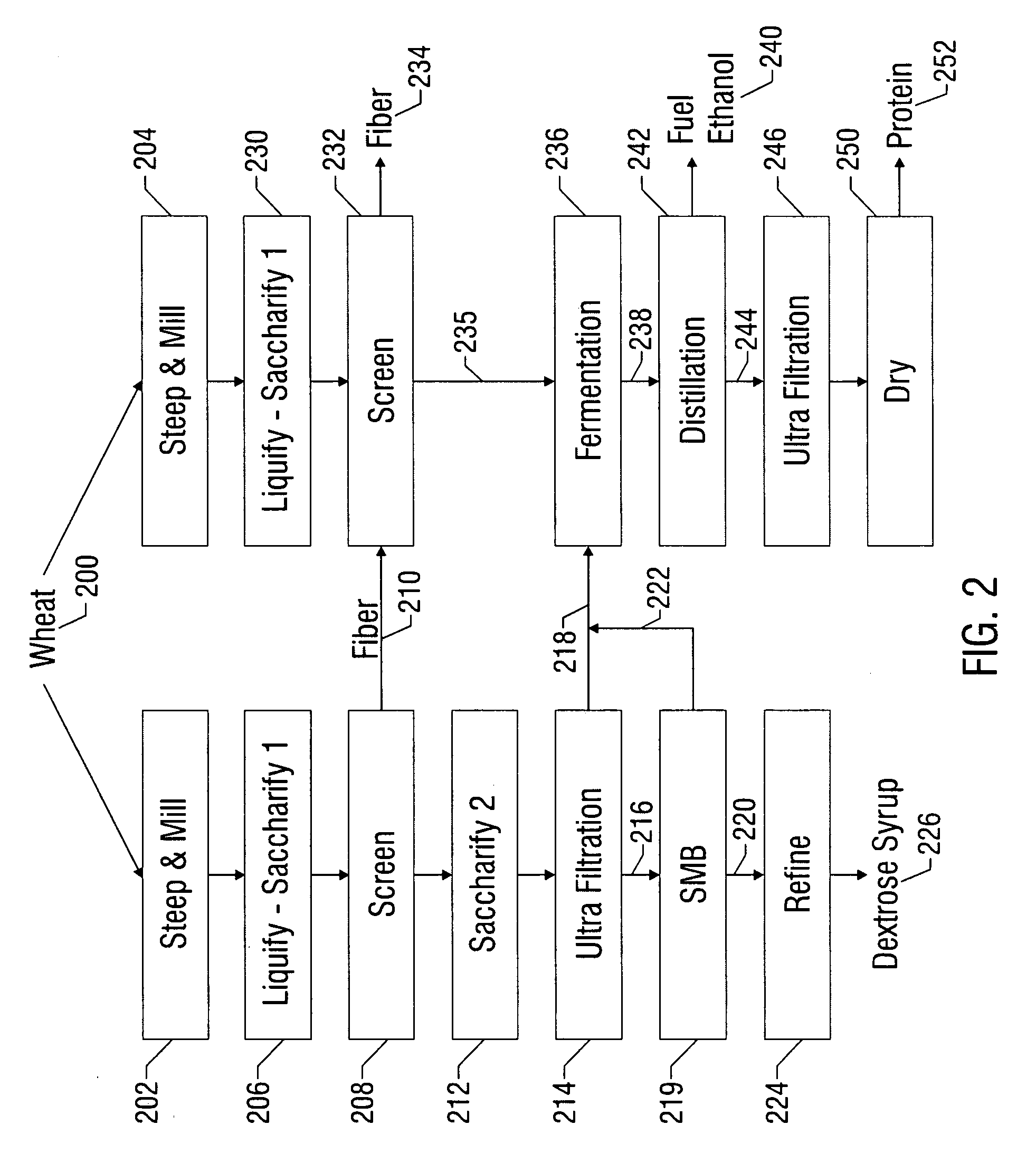

Grain wet milling process for producing ethanol

Whole grain, such as wheat, barley, rye, and / or rice, can be processed by (a) steeping the grain in an aqueous liquid to produce softened grain, (b) milling the softened grain to produce milled grain, (c) liquefying the milled grain by contacting it with amylase and heating it to a temperature of at least about 50° C., producing a liquefied material, (d) at least partially saccharifying the liquefied material by contacting it with amyloglucosidase at a temperature of at least about 50° C., producing a first saccharified material, and (e) separating fiber and germ from the first saccharified material, producing a screened material that is substantially free of fiber and germ. The process also includes the steps of (f) further saccharifying and fermenting the screened material with a microorganism that produces ethanol, thereby producing a broth that comprises ethanol, soluble protein, and insoluble protein, and (g) separating ethanol from the broth. A protein-rich product can be recovered from the broth that comprises both gluten from the grain and microorganism from the fermenting step.

Owner:TATE & LYLE INGREDIENTS AMERICAS INC

Special diet edible for patients with kidney yin deficiency

The invention belongs to the technical field of medicinal and edible formula foodstuffs, and specifically relates to a special diet edible for patients with kidney yin deficiency. Kidney yin means yin-qi and yin-fluid of kidney self, is the yin basis all over the body, and has effects of cooling, moistening, soggy nourishing and limiting excess yang-heat on the whole body. According to the special diet, traditional Chinese medicines with characteristics of whole grains, homology of medicine and food, and new resource foodstuffs are combined together, diet and health preserving are organically combined, so that kidney yin deficiency is conditioned, prevented and resisted. According to the special diet, disease treatment methods as motherland traditional Chinese medicine treasures are inherited, probiotics is creatively utilized as a pioneer and is promoted in propagation, so that microecological balance in intestines is regulated, splenic and gastric motility is enhanced, and drug absorption is accelerated. Probiotics is abundant in multiple active factors, biological immune factors and multiple vitamins. Also according to constitution characteristics of the patients with kidney yin deficiency, multiple natural original-ecological medicinal and edible food materials are added, so that the special diet of the invention has the unique advantage of integration of triple-efficacy comprising dietotherapy, prevention and conditioning.

Owner:浙江永葆康安医疗科技有限公司

Agricultural fibre fuel pellets

A method of preparing fuel pellets includes the steps of providing a feedstock in the form of agricultural hull fibres having a moisture content of about 10 to about 16%; and compressing and extruding the agricultural fibre feedstock through a die to obtain fuel pellets in the form of small cylinders having a diameter of about ⅜ inch to ¾ inch or more, said pellets having an ash content of about 1.1% to about 20% by weight and a calorific value of about 7,000 BTUs per pound of fuel on a dry basis. The agricultural hull fibres may be derived from all whole grains and seeds. For example, are comprised of at least one of corn bran fibre, rye bran fibre; oat bran fibre, rice bran fibre, soy bran fibre, canola bran fibre and wheat bran fibre. The method may include the step of pre-treating the agricultural whole grain and seed hull fibre feedstock with high temperature steam before being formed into pellets at a sufficient temperature and sufficient time to activate hemicellulose within the fibre as a binding agent. The method may include the step of mixing the agricultural whole grain and seed hull fibre feedstock with a sequestering agent before being formed into pellets for sequestering alkali metal vapors and raising the fusion point of the inorganic elements during combustion of the pellets. The sequestering agent may be calcium carbonate added in amounts up to about 0.5% by weight. The pellets contain additives comprised of ammonium nitrate, calcium, manganese, magnesium, aluminum, barium, iron, potassium and amorphous silicate, which sequester potassium and chlorides and alter the fusion point of the inorganic elements present in the fuel.

Owner:EVERGREEN BIOFUELS

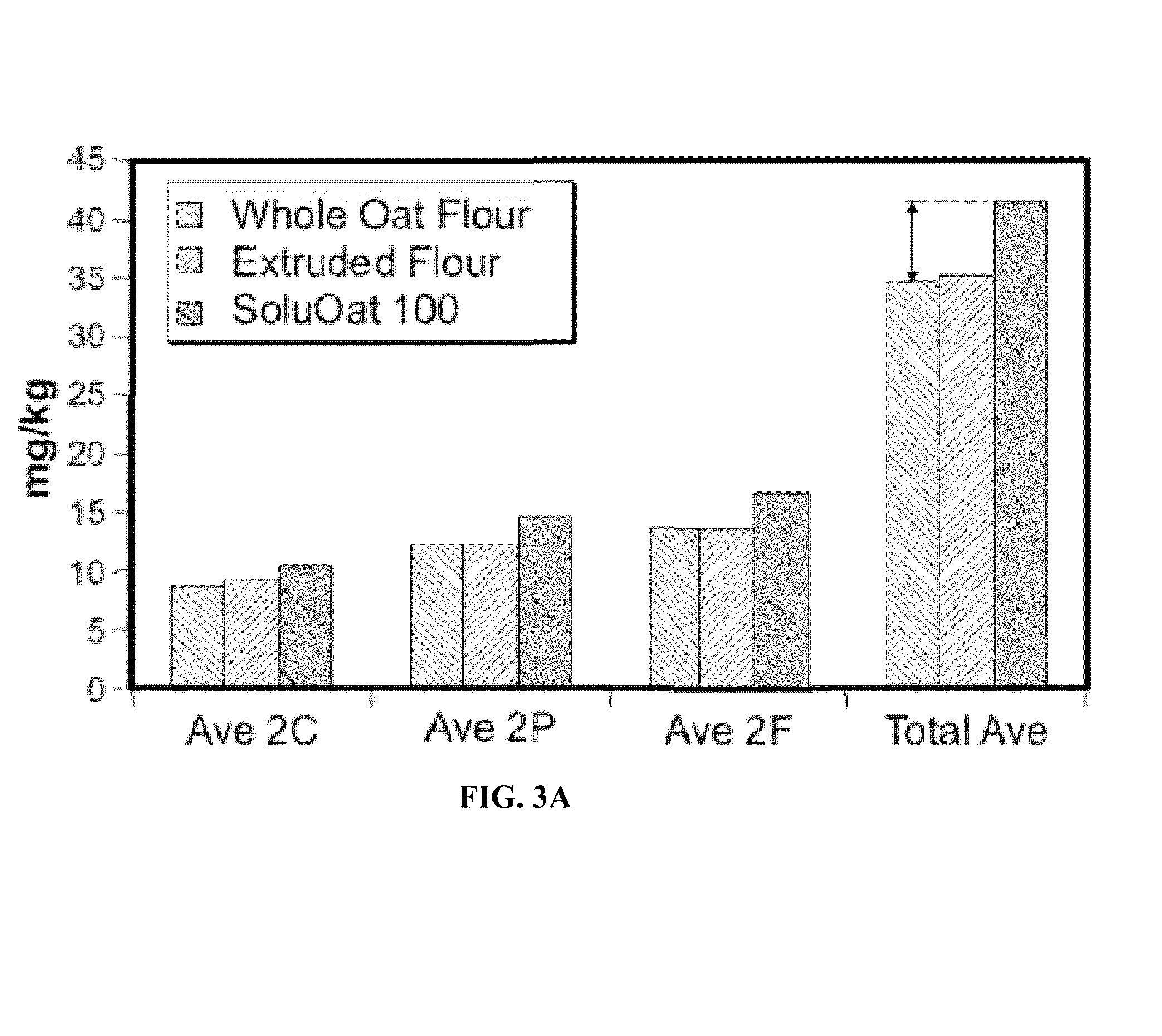

Method of Preparing Highly Dispersible Whole Grain Flour with an Increased Avenanthramide Content

ActiveUS20130209610A1Increased avenanthramide contentMaintain integrityWort preparationMetabolism disorderWhole grainsAvenanthramide

A method of preparing a highly dispersible whole grain oat flour by hydrolyzing, milling and agglomerating grain flour to arrive at a whole grain oat flour having an increased avenanthramide content compared to native oat flour.

Owner:THE QUAKER OATS CO

Chia seed composition

InactiveUS8652544B2Good for healthImprove regularityBiocideDough treatmentVitamin antagonistAdditive ingredient

Owner:US NUTRACEUTICALS LLC

Production of whole grain hot cereal products

InactiveUS20080131582A1Promote hydrationReduced activityDough treatmentFood preparationHot cerealBran

A dry, whole grain hot cereal product which readily hydrates into a creamy, non-gritty, non-pasty, whole grain hot cereal is produced by milling whole cereal grains or combining separate streams or sources of endosperm, bran and germ to obtain a milled whole grain mixture having a particle size distribution of 100% by weight through a No. 16 (1,190 micron), preferably a No. 18 (1,000 micron), most preferably a No. 20 (841 micron) U.S. Standard Sieve, and less than or equal to about 7% by weight through a No. 100 (149 micron) U.S. Standard Sieve. The endosperm, the bran and the germ may be stabilized before or after milling of the whole grains or the endosperm, the bran and the germ, to avoid insect infestation and to at least substantially inactivate lipase and lipoxygenase. The dry, whole grain hot cereal product may be a cook-on-stove or instant hot cereal product.

Owner:BURNHAM & MORRILL CO

Production of stabilized whole grain flour and products thereof

ActiveUS20090238935A1Reduces lipase and lipoxygenase activityLow levelDough treatmentMilk preservationAntioxidantLipoxygenase activity

A stabilized bran component and a stabilized whole grain flour containing the component are produced by subjecting a bran-enriched coarse fraction which contains bran, germ and starch to grinding or milling to reduce grittiness of the coarse fraction without substantially damaging the starch due to abrasion. The coarse fraction may be stabilized by heating to substantially reduce the lipase and lipoxygenase activity of the coarse fraction without substantial gelatinization of the starch. High levels of natural antioxidants and vitamins are retained while avoiding substantial acrylamide formation during the stabilization. The stabilized coarse fraction or stabilized bran component may be combined with a fine fraction which contains predominantly endosperm to obtain a stabilized whole grain flour. The stabilized whole grain flours and the stabilized bran component exhibit extended shelf life and may be used for making baked goods, such as cookies, with desirable oven spread, and a non-gritty mouthfeel.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Process for producing an ultrafine-milled whole-grain wheat flour and products thereof

ActiveUS20050136174A1High nutritional valueHigh in fiberDough treatmentFood shapingWheat flourFood products

A process for producing an ultrafine-milled whole-grain wheat flour which has the full nutritional value of wheat kernels, while retaining the texture of refined wheat flour and an appearance similar to refined wheat flour, and the products which can be made from the ultrafine-milled whole-grain wheat flour. The process can also be used for producing an ultrafine-milled coarse fraction, which can be used as a replacement and to fortify refined wheat flour. The ultrafine-milled coarse fraction can be used in bakery products, snack products and food products.

Owner:ARDENT MILLS

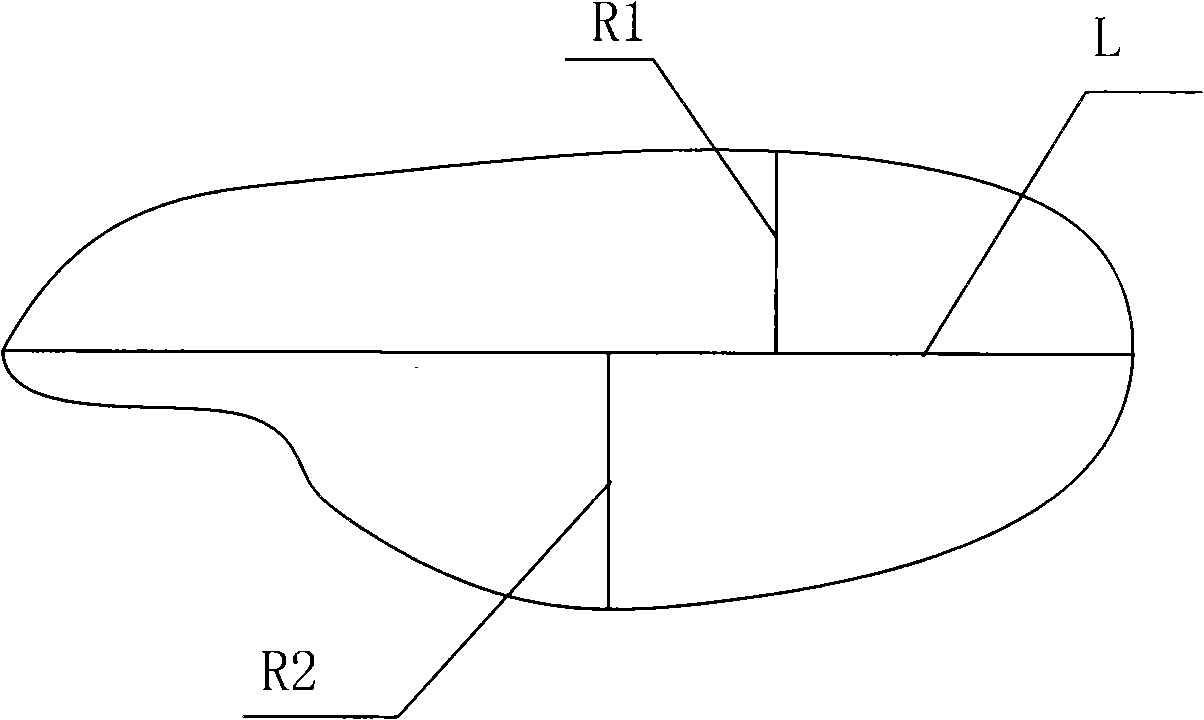

Method for detecting rice granule type

InactiveCN101275824AQuick checkEasy to operateTesting starch susbtancesCharacter and pattern recognitionRice grainPurchasing

The invention discloses a detection method of large grain of rice, comprising placing a rice sample in the image acquisition system for collecting original image information; reading the original image information and detaching the background from the rice sample; identifying whole grain rice and crushed rice; randomly selecting for a required amount in the whole grain rice according to rice varieties of set parameters and the whole grain rice amount required for detection, and searching point by point. The invention is used for the large grain of rice detection process of on-the-spot rice purchasing and market deal, achieving a rapid detection.

Owner:CHINA AGRI UNIV

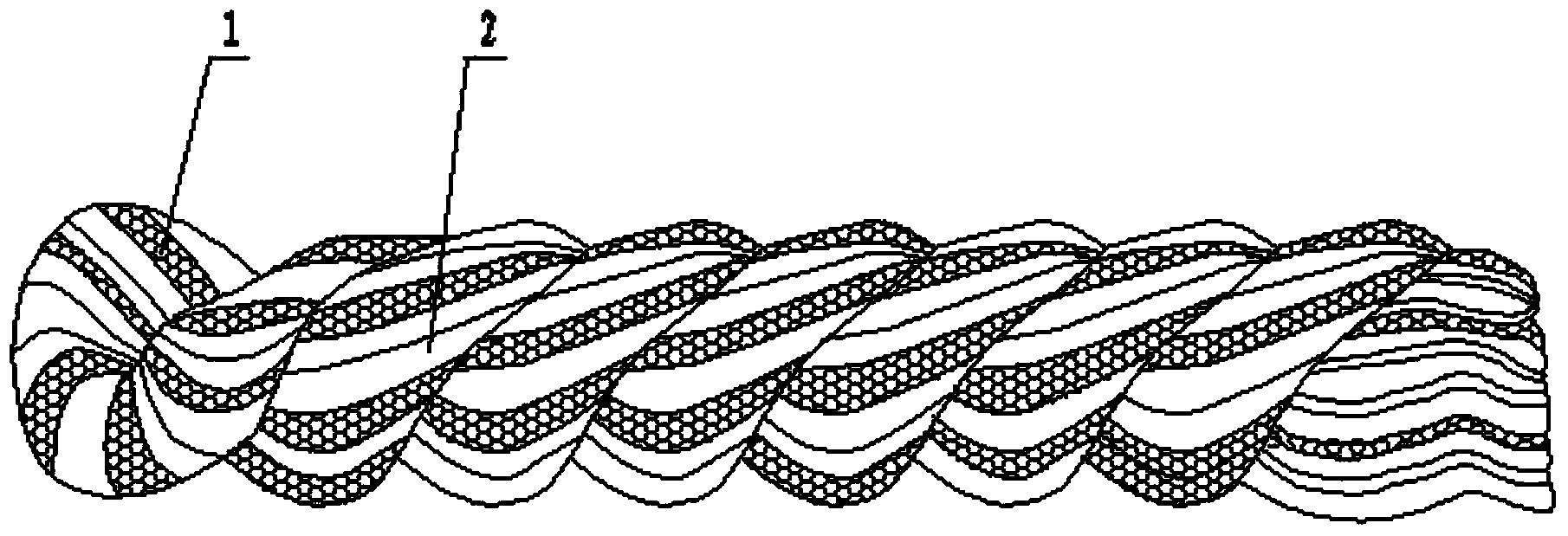

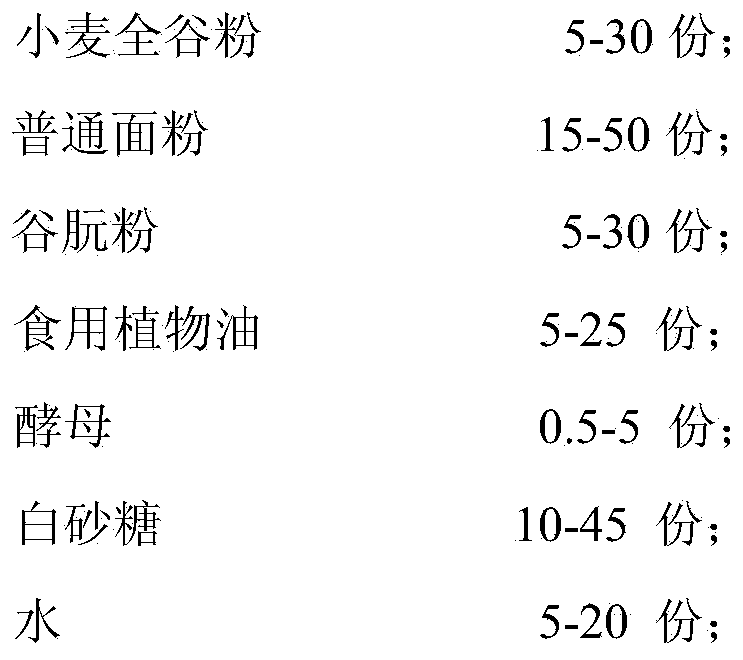

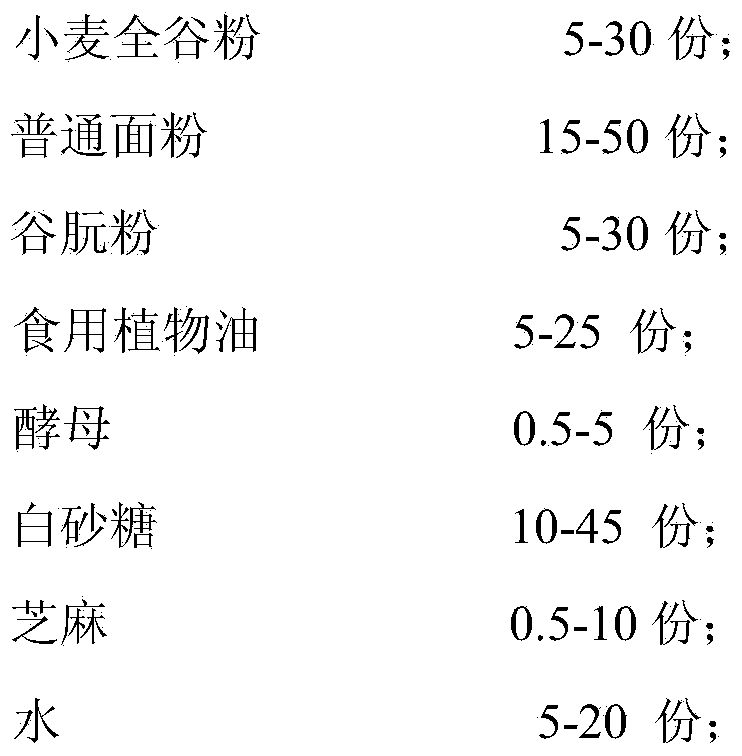

Fried dough twist with high dietary fiber content and fillings and method for making fried dough twist

ActiveCN103749630AEasy to operateQuality improvementDough treatmentBakery productsDietary fiberSweetness

The invention relates to fried dough twist with a high dietary fiber content and fillings. The fried dough twist comprises dough strips of the fried dough twist, sesame strips and the fillings. A ratio of a sum of the mass the dough strips of the fried dough twist and the mass of the sesame strips to the mass of the fillings is 10:2-8. The fried dough twist has the advantages that common flour is proportionally replaced by wheat whole-grain flour, so that the dietary fiber content can be increased; a part of the common flour is innovatively replaced by gluten powder in the aspect of a process for making the fried dough twist, so that the bonding ability of the fillings of the fried dough twist can be improved, the tensile property of the dough strips of the fried dough twist can be enhanced, the traditional manual fried dough twist twisting technological operability is high, the quality of finished fried dough twist products can be improved, the manufacturing process can be simplified, and the manufacturing cost can be reduced; characteristics such as fragrance, sweetness, crispness and softness-free long storage life of the fried dough twist can be kept by a method for making the fried dough twist with the high dietary fiber content and the fillings, the crunching degree and the dietary fiber content of the fried dough twist can be increased, and a market gap can be filled.

Owner:天津桂发祥十八街麻花食品股份有限公司

High fiber and high protein baked goods production

ActiveCN101897353APleasant tasteNo smellDough/pre-mixesConfectioneryHigh protein foodAdditive ingredient

Substantially uniform hydration and dispersion of high amounts of protein and fiber are achieved while avoiding lump formation, hard textures, and off-tastes in the continuous, mass production of high protein and high fiber content sheetable doughs, and baked goods such as crackers, snacks, and cookies made from the sheeted doughs, by hydrating the protein and fiber with water at a temperature below the denaturization temperature of the proteins, and steaming the hydrated mixture without substantial gelatinization of starch during dough production. The steamed, hydrated mass may be admixed with ingredients comprising at least one flour comprising starch to obtain a dough while avoiding substantial gelatinization of starch of the at least one flour during mixing. The baked goods may have a protein content of at least about 4 g, a fiber content of at least about 4 g, and a whole grain flour content of at least about 4 g per 30 g serving.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

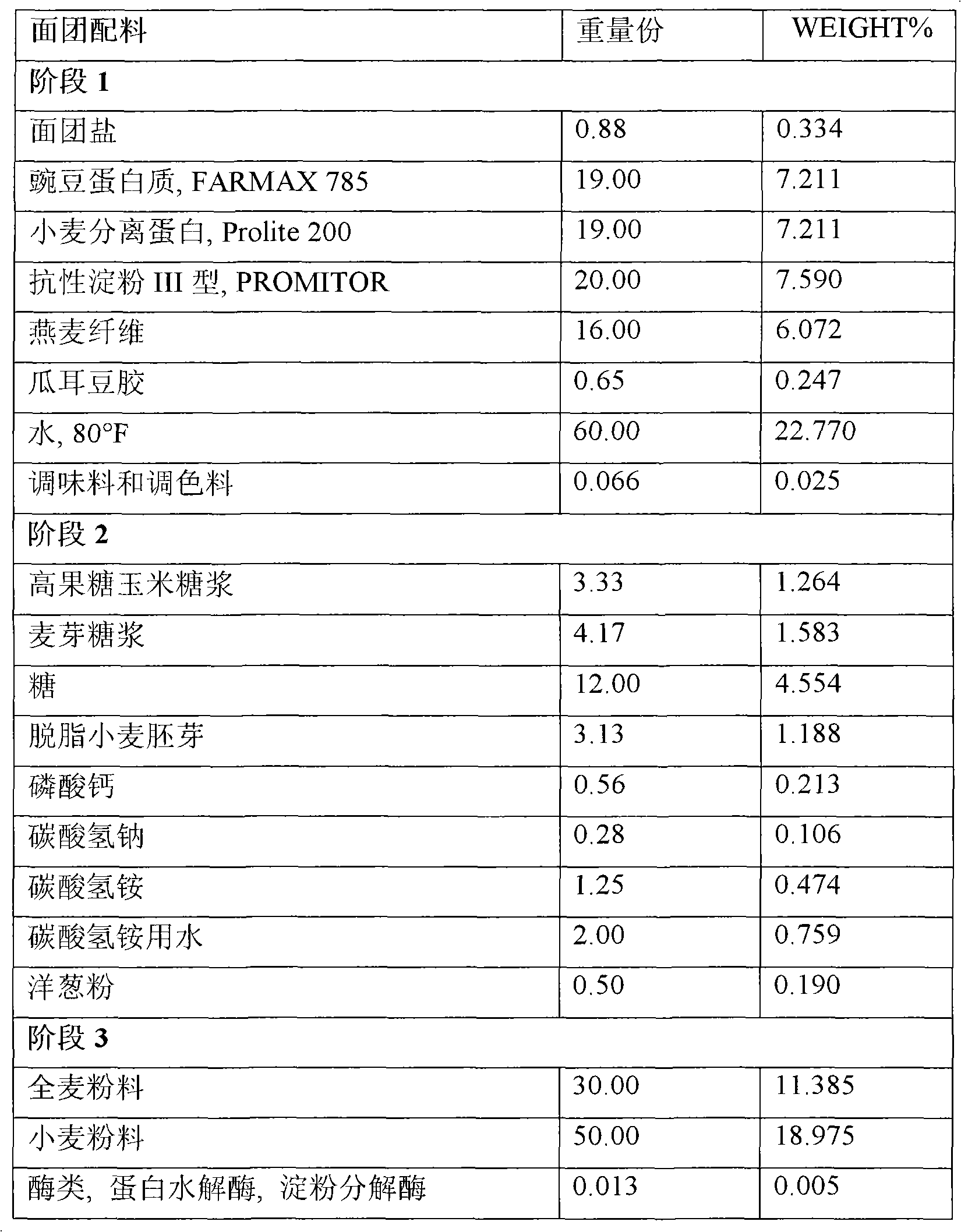

Thin parts made of beta or quasi-beta titanium alloys; manufacture by forging

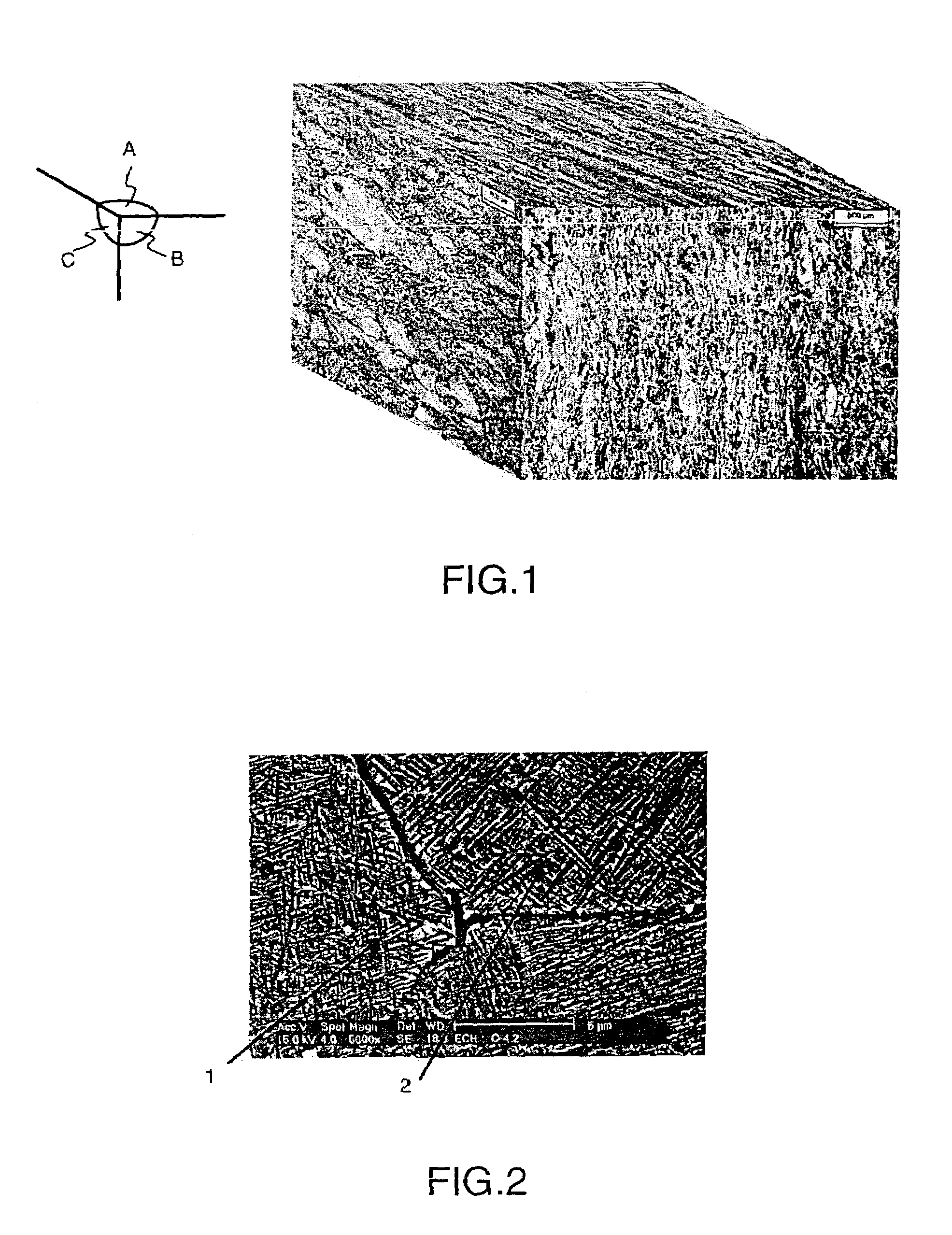

The present invention provides non-axially symmetrical manufactured parts of thickness less than 10 mm, made of β or quasi-β titanium alloy, having a core microstructure constituted by whole grains presenting a slenderness ratio greater than 4 and an equivalent diameter lying in the range 10 μm to 300 μm. The invention also provides a method of manufacturing the parts by forging.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Whole grain food

The invention discloses whole grain food which is prepared by the following raw materials according to parts by weight: 30-50 parts of corn, 5-10 parts of rice, 5-10 parts of sticky rice, 5-10 parts of black kerneled rice, 5-10 parts of millet, 5-10 parts of glutinous millet, 5-10 parts of soybeans, 5-10 parts of black beans, 5-10 parts of mung beans, 5-10 parts of red beans, 5-10 parts of peas, 5-10 parts of wheat, 5-10 parts of buck wheat, 5-10 parts of barley, 5-10 parts of oats, 5-10 parts of fragrant rice, 5-10 parts of sorghum and 5-10 parts of peanuts. The preparation method is as follows: selecting various raw materials according to composition, puffing or popping after cleaning, then smashing and stirring, and finally vacuum packaging to obtain the whole grain food. The invention is prepared by a plurality of farmhouse eighteen rice whole grain raw materials which are easy to obtain; the invention not only has comprehensive and abundant nutrition, but is also easy to store and convenient to use after being puffed or popped, and has soft and smooth mouthfeel, fragrant and sweet taste, thus being an invention result which is worthy of being promoted vigorously to improve the dietary structure of the whole people and improve human quality at present.

Owner:许洪昌

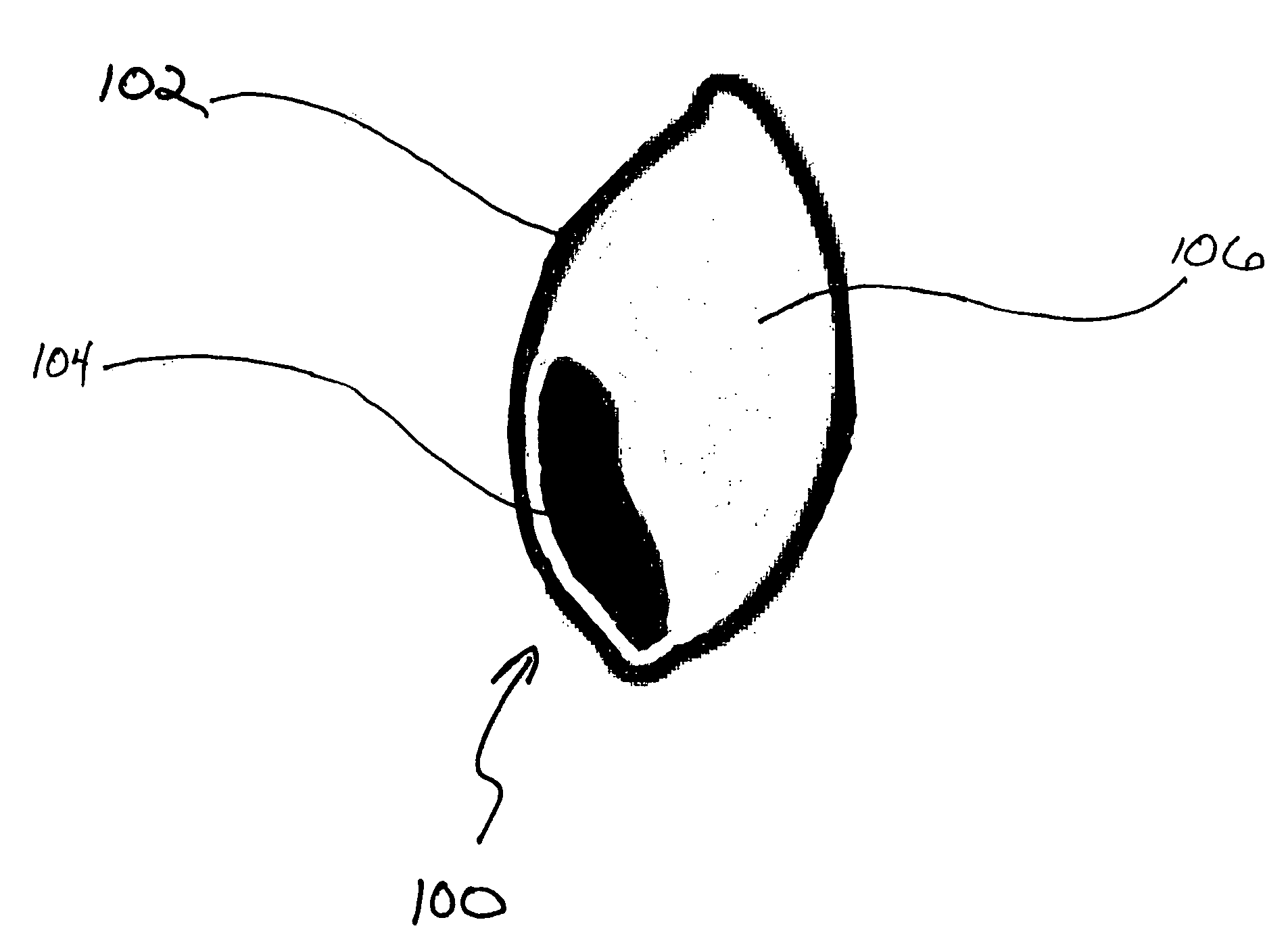

Whole grain flour and products including same

The present invention is a grain product. The grain product includes a first fraction including bran. The first fraction is milled to a first particle size of less than 500 micrometers. The grain product also includes a second fraction including germ. The second fraction is milled to a second particle size of less than 500 micrometers. The grain product is at least one of: a food product, a nutritional supplement, a dietary supplement, a fiber supplement, a digestive supplement, a functional food, and a medical food.

Owner:ARDENT MILLS

Germinated whole grain and preparation method thereof

InactiveCN104855837AMaintain the content of heat-sensitive substancesAvoid pollutionFood processingFood ingredient functionsFiberOrganoleptic

The invention discloses a germinated whole grain and a preparation method thereof, and belongs to the technical field of deep processing of grains. The whole grain is subjected to ultrasonic washing, high-voltage pulsed electric field treatment, biological enzymolysis or combined high-voltage pulsed electric field and biological enzymolysis treatment in a soaking process, and a segmented soaking and germination manner for germination is adopted, so that the sensory quality, germination yield and quality of a germinated whole grain product are improved, and germination loss is reduced. The preparation method is simple, low in soaking and germination temperature, short in cycle, energy-saving and environment-friendly. The content of functional, nutritional and bioactive substances in the germinated whole grain product is remarkably increased, and food safety is remarkably improved. For example, for brown rice, germinated brown rice prepared by the preparation method has gamma-aminobutyric acid content of 303.8 to 312.6 mg / 100 g, glutathione content of 16.8 to 18.3 mg / 100 g, IP6 content of 460.8 to 484.4 mg / 100 g and dietary fiber content of 3.5 to 3.6 mg / 100 g.

Owner:宁夏家道回乡农业开发有限公司

Special diet for hyperglycemia patients

ActiveCN103404757AStable healthEffect on reducing the development of coronary heart disease-related conditionsFood preparationAcute hyperglycaemiaChinese traditional

The invention belongs to the technical field of medicine-food homologous formula food and particularly relates to special diet for hyperglycemia patients. The reason inducing hyperglycemia is that hepatic glycogen output is increased, too much high-fat food is ingested, the pancreatic islet function can not excellently secrete insulin, and then, the blood sugar content is increased. The traditional Chinese medical science always stresses that dietotherapy is better than medication, so as to avoid injection and medication and even pain of surgery. According to the special diet, whole grains are perfectly combined with medicine-food homologous and new-resource-food traditional Chinese medicines, and diet and health preserving are organically combined so as to regulate, prevent and resist hyperglycemia; probiotics are creatively utilized as a pioneer based on the inheritance of Chinese traditional Chinese medicine treasure treatment methods, and the proliferation of the probiotics is promoted, so that the movement functions of the spleen and stomach are enhanced; and meanwhile, various natural and original ecological medicine-food homologous edible materials are added according to the physical characteristics of hyperglycemia patients, so that the special diet has the unique advantage of integrated dietotherapy, prevention and regulation effects.

Owner:杭州劲膳美健康管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com