Patents

Literature

163 results about "Cereal product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nutrient clusters for food products and methods of preparation

Nutrient clusters for food products, such as for addition to Ready-To-Eat cereals, are made in the form of aggregates or clusters comprising a first particulate component; a nutrient powder blend, and sufficient binder to adhere the powder to the particulates. The nutrient clusters are in the form of pieces each weighing from about 0.3 to 5 g. and having a moisture content of about 2% to 10%. Such nutrient clusters are prepared by applying a liquid binder to the particulates to form sticky particulates, adding a powdered nutrient blend, and curing the mixtures to form hardened dried nutrient clusters. The nutrient cluster can contain 100% US recommended daily allowance of essential vitamins and minerals and can contain added macronutrients such as soy proteins, soluble fiber, and / or calcium in nutritionally dense form in as little as 5 to 15 g of nutrient clusters. The clusters find particular suitability for use in providing to-order customized cereal products in response to particular customer requirements for nutrition.

Owner:GENERAL MILLS INC

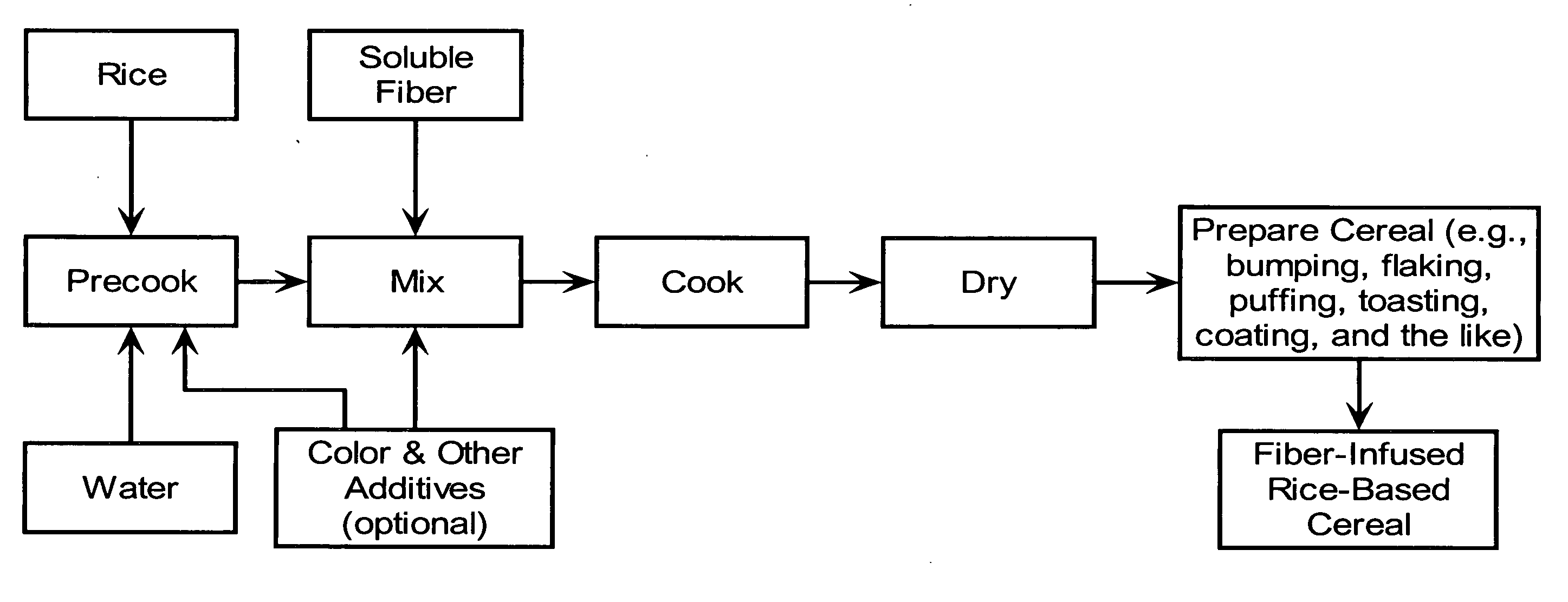

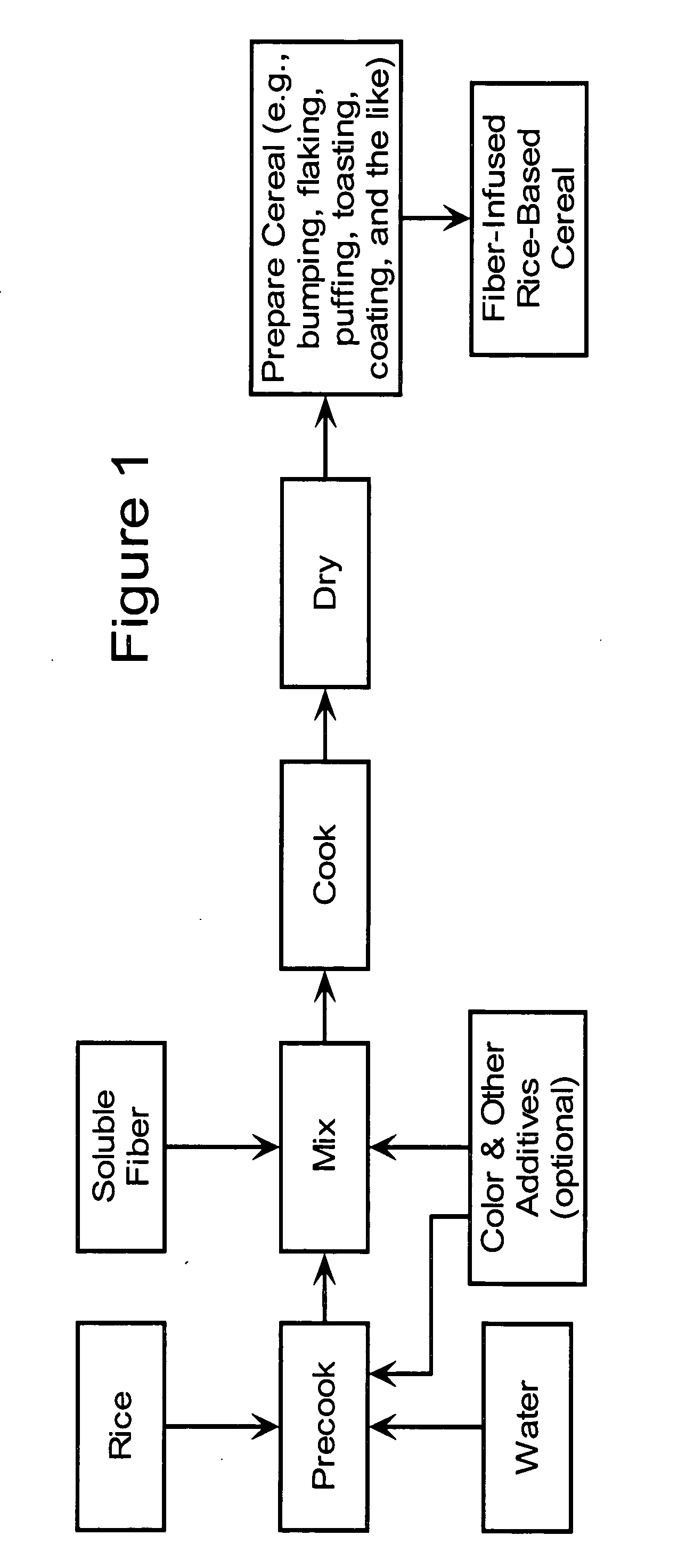

Fiber-containing rice-based cereals and methods of preparation

Methods for providing cooked rice with enhanced levels of fiber, wherein the fiber-containing cooked rice is suitable and especially adapted for use in preparing fiber-containing rice-based cereal products and especially for preparing fiber-containing puffed rice-based cereal products, are provided.

Owner:POST HOLDINGS

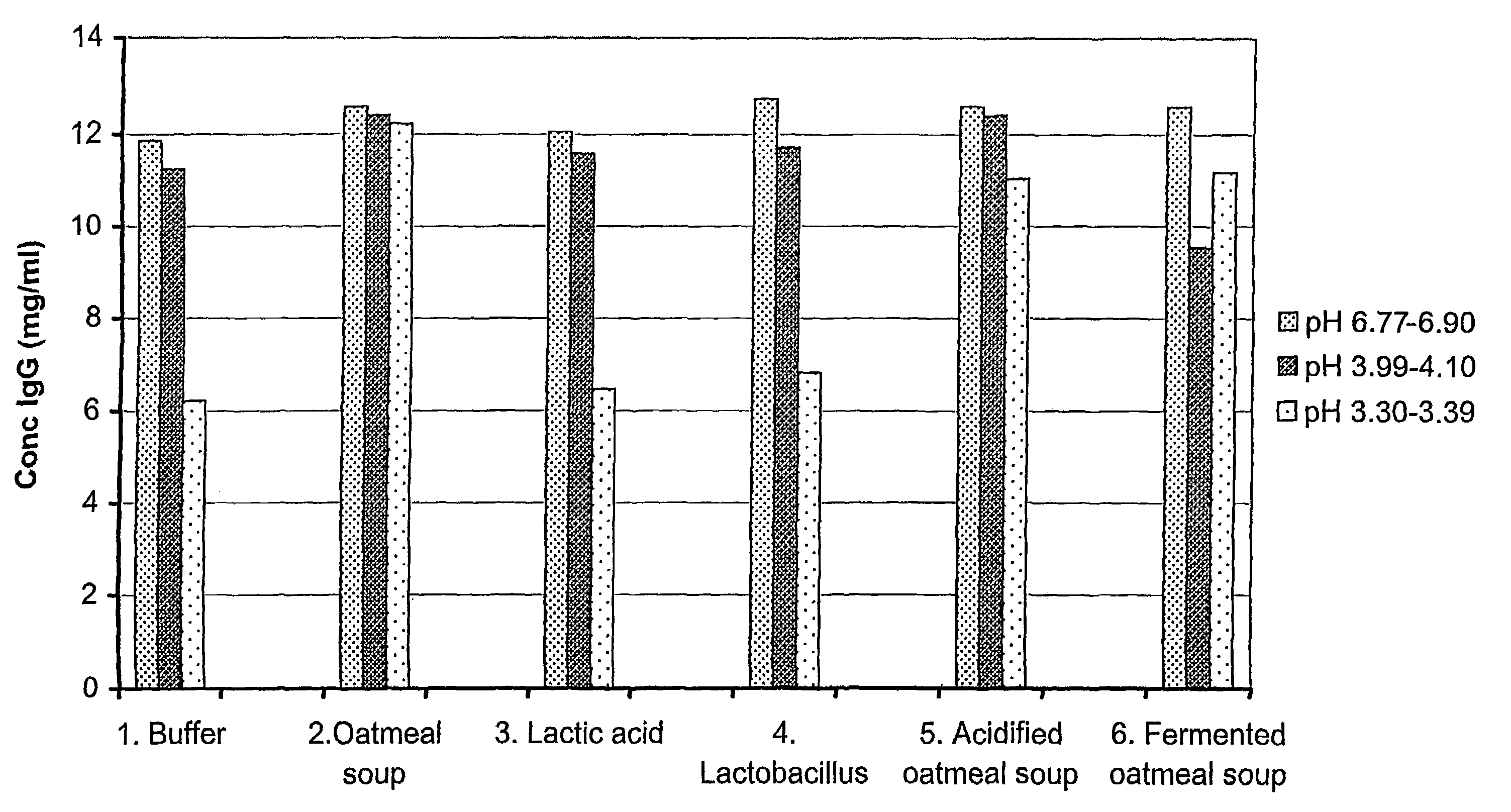

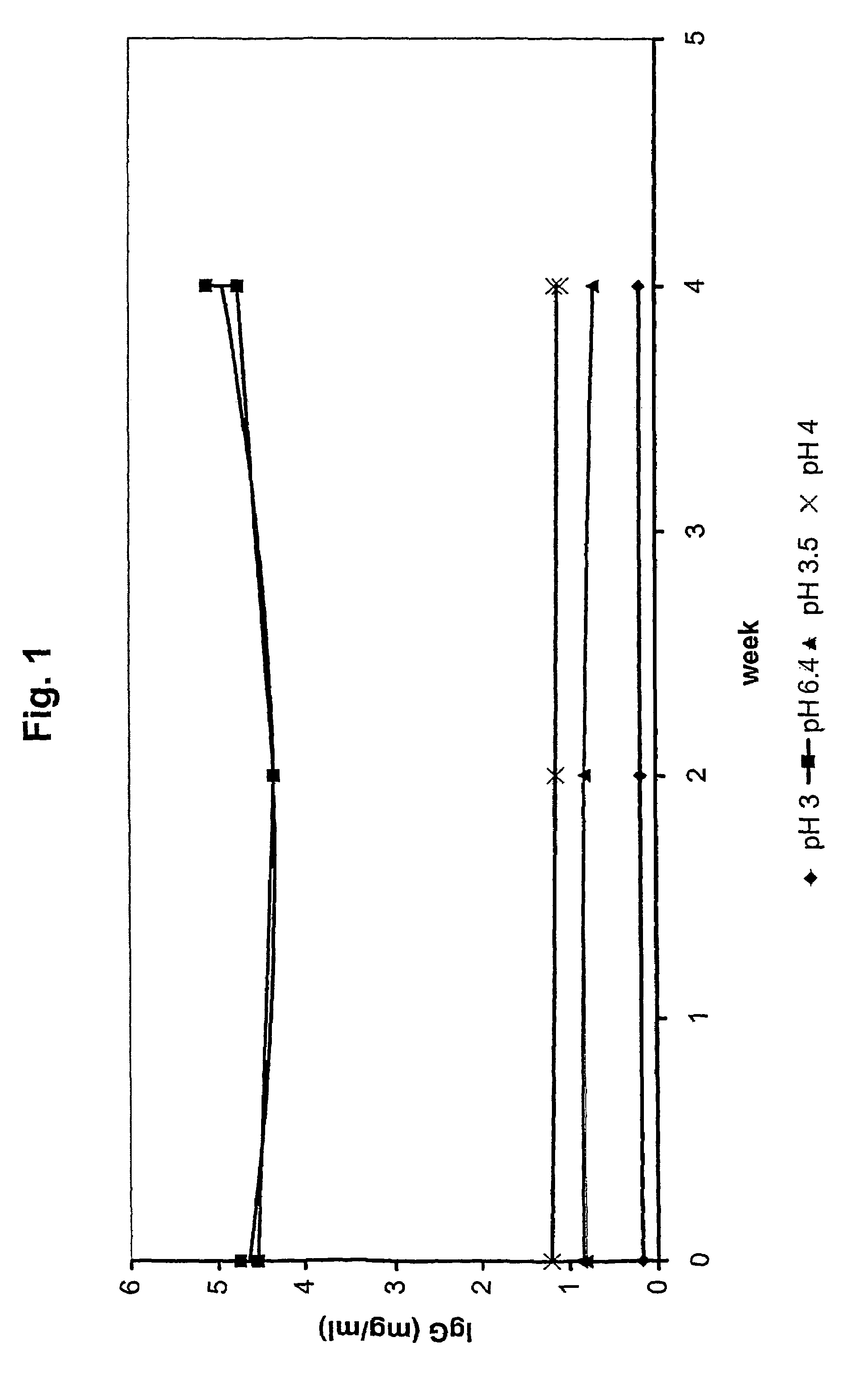

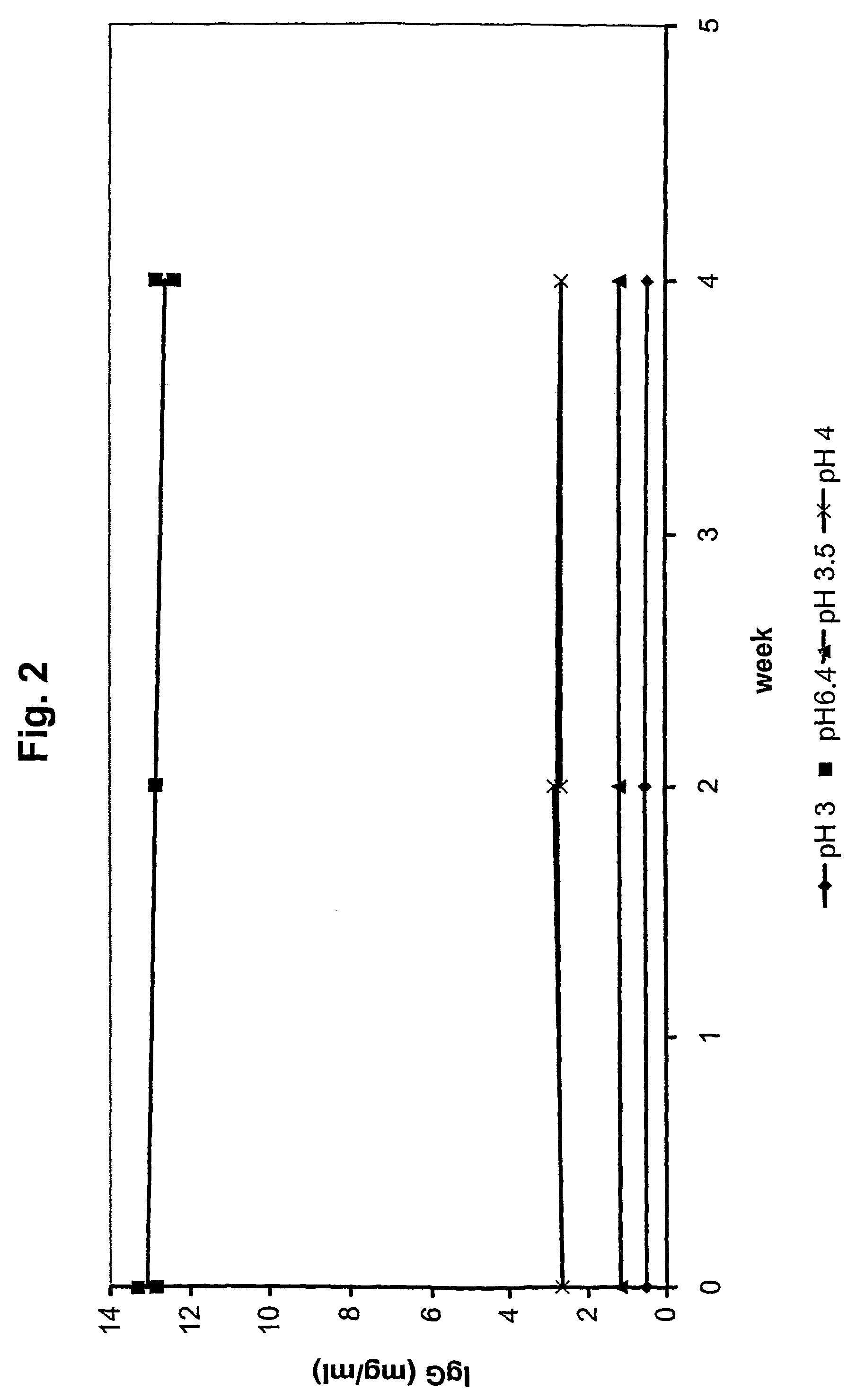

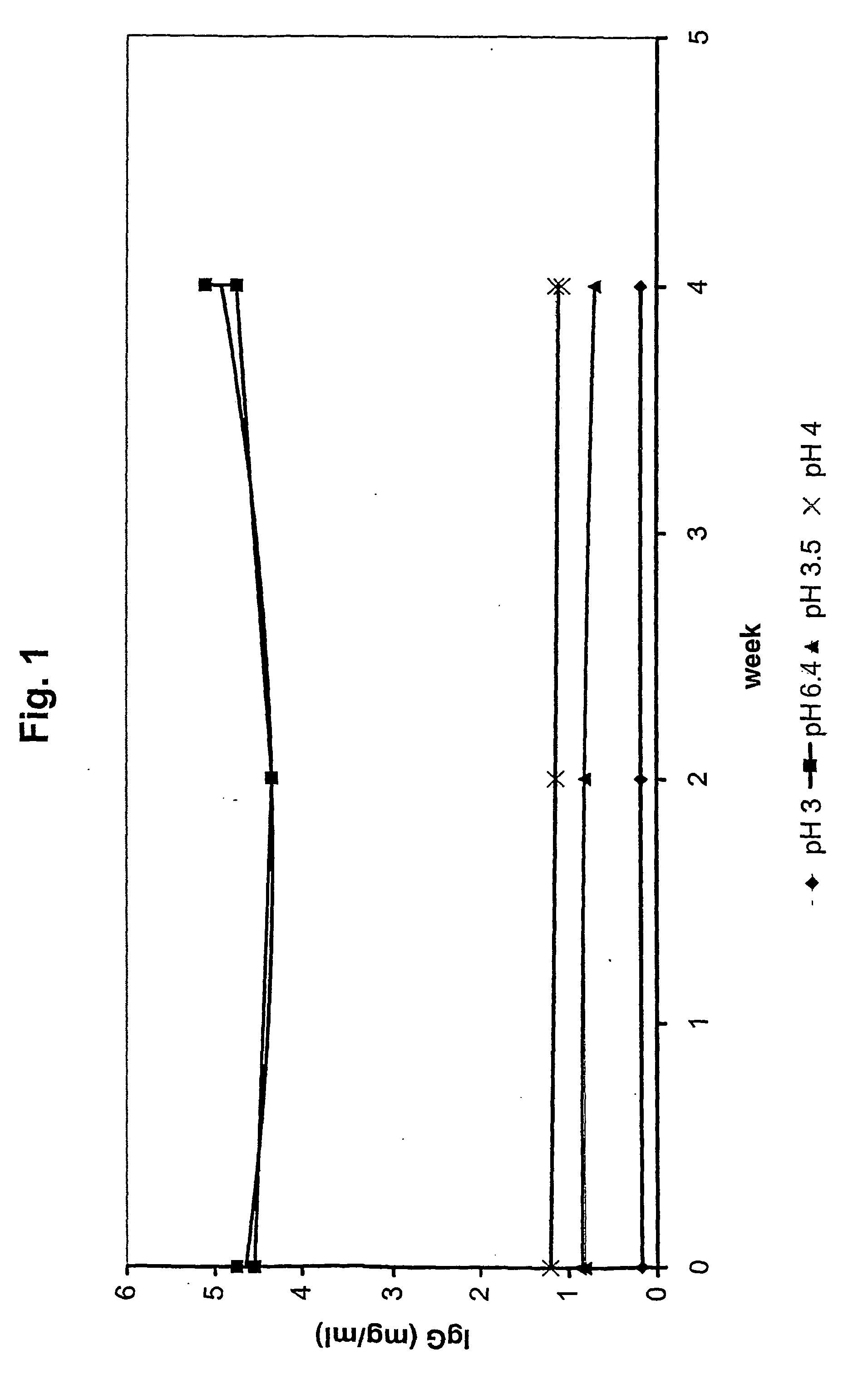

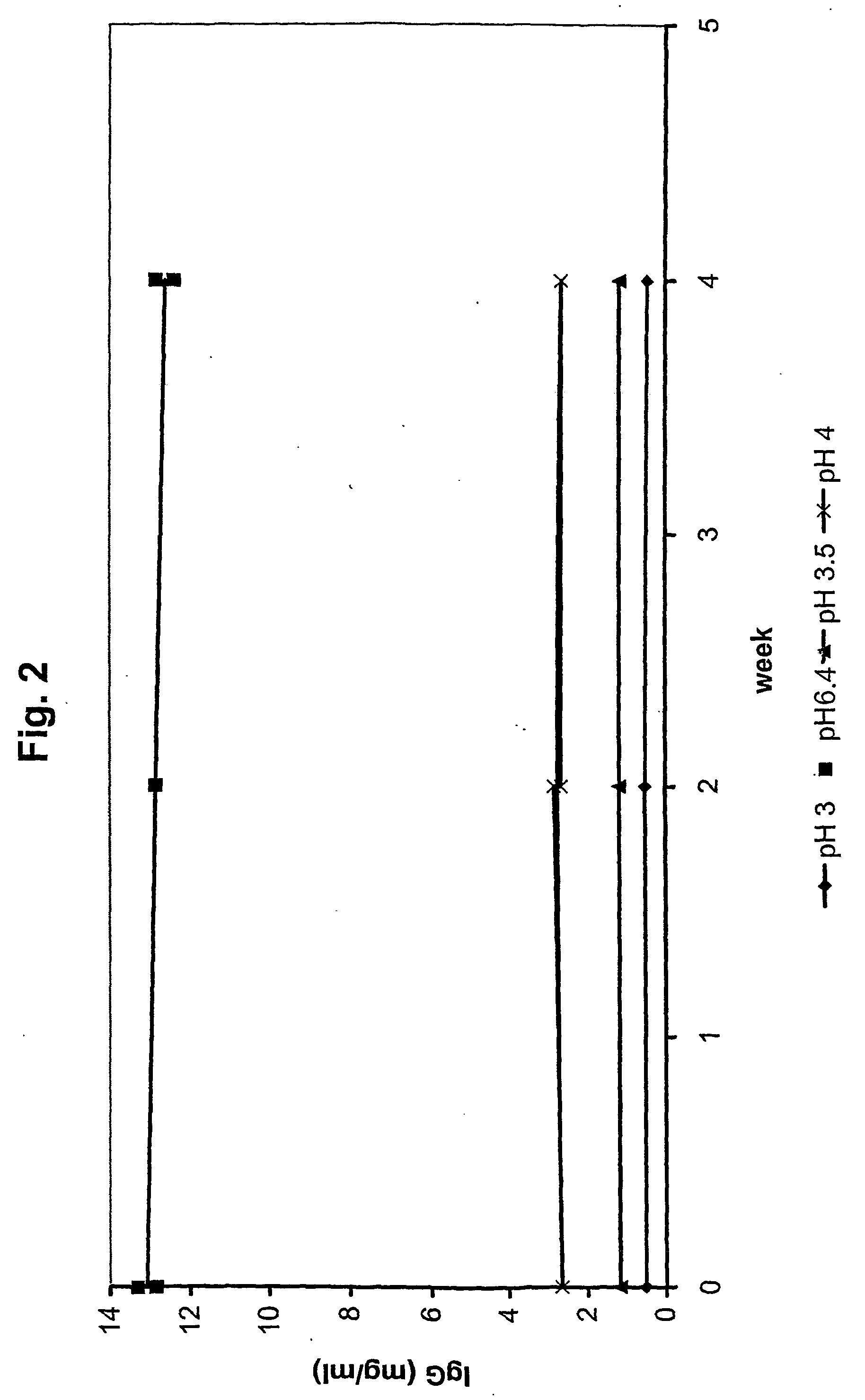

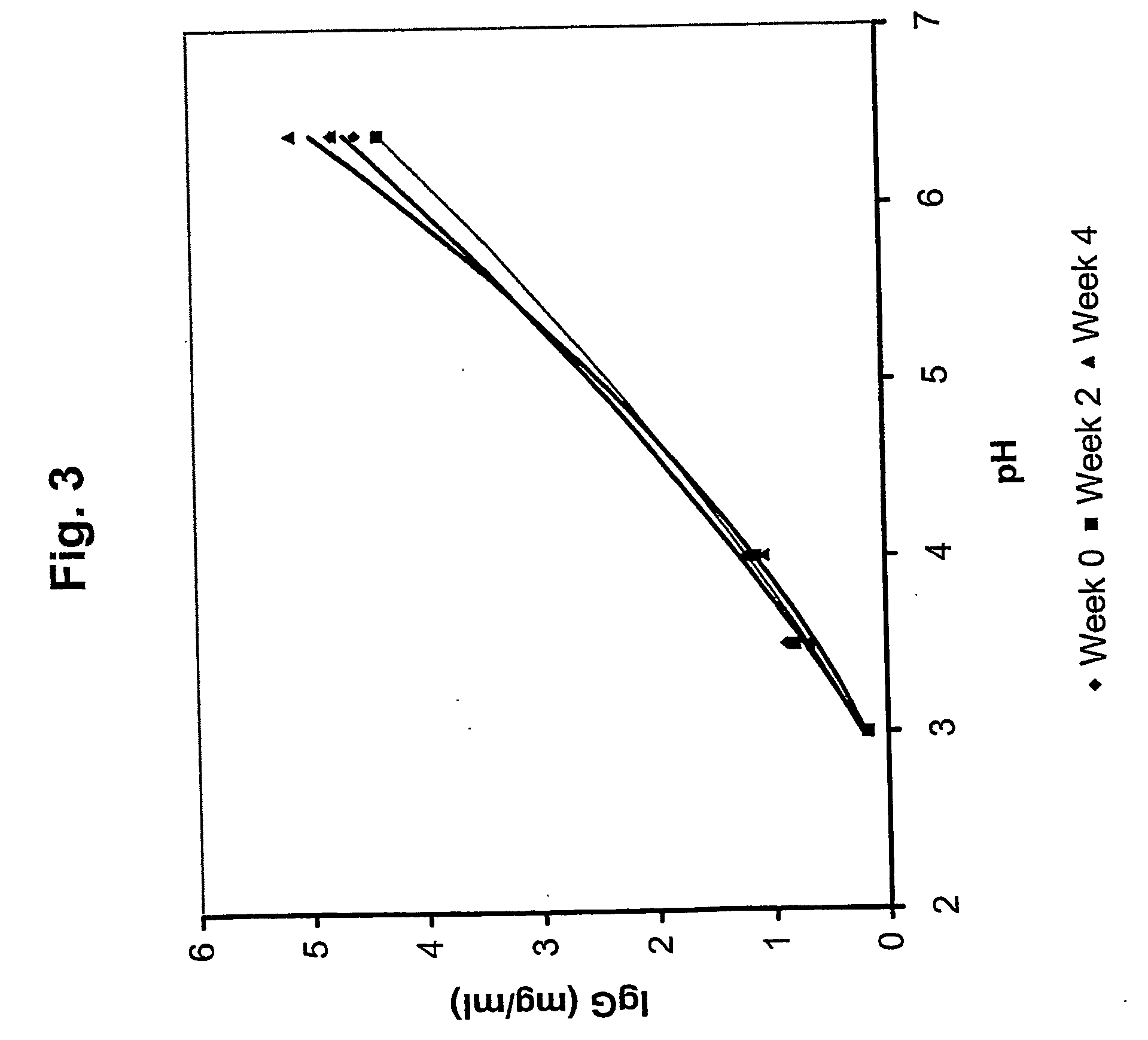

Stabilization of immunoglobulins at low pH

The present invention provides a method of stabilizing immunoglobulins in a solution having a pH below 4 by adding cereals or hydrolysed cereal products in an amount sufficient to prevent degradation. The present invention also provides a health drink or sports drink comprising immunoglobulins in a solution having a pH of 2.7–3.8 containing cereals or hydrolysed cereal products in an amount sufficient to prevent degradation of the immunoglobulins.

Owner:PROBI AB LUND SE

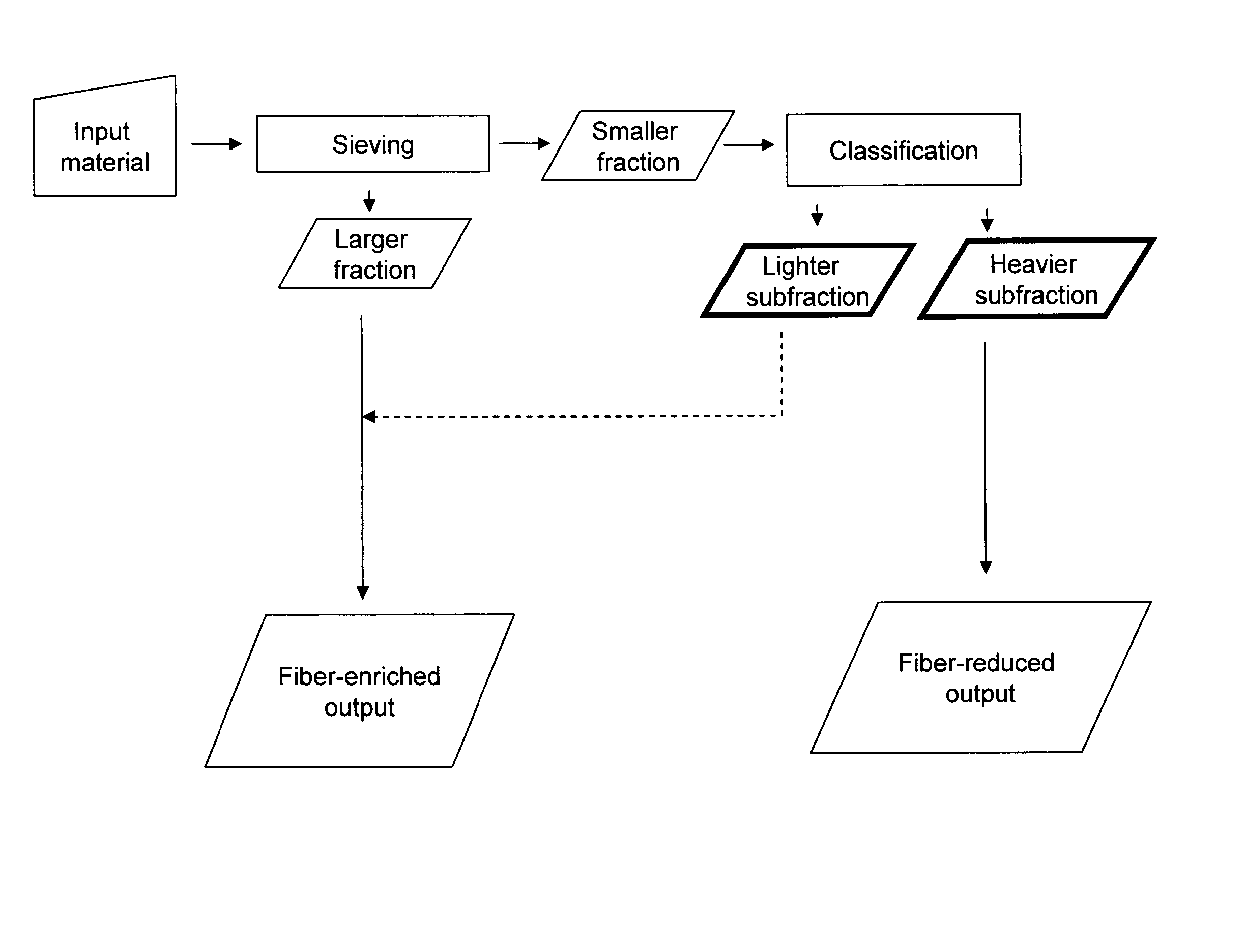

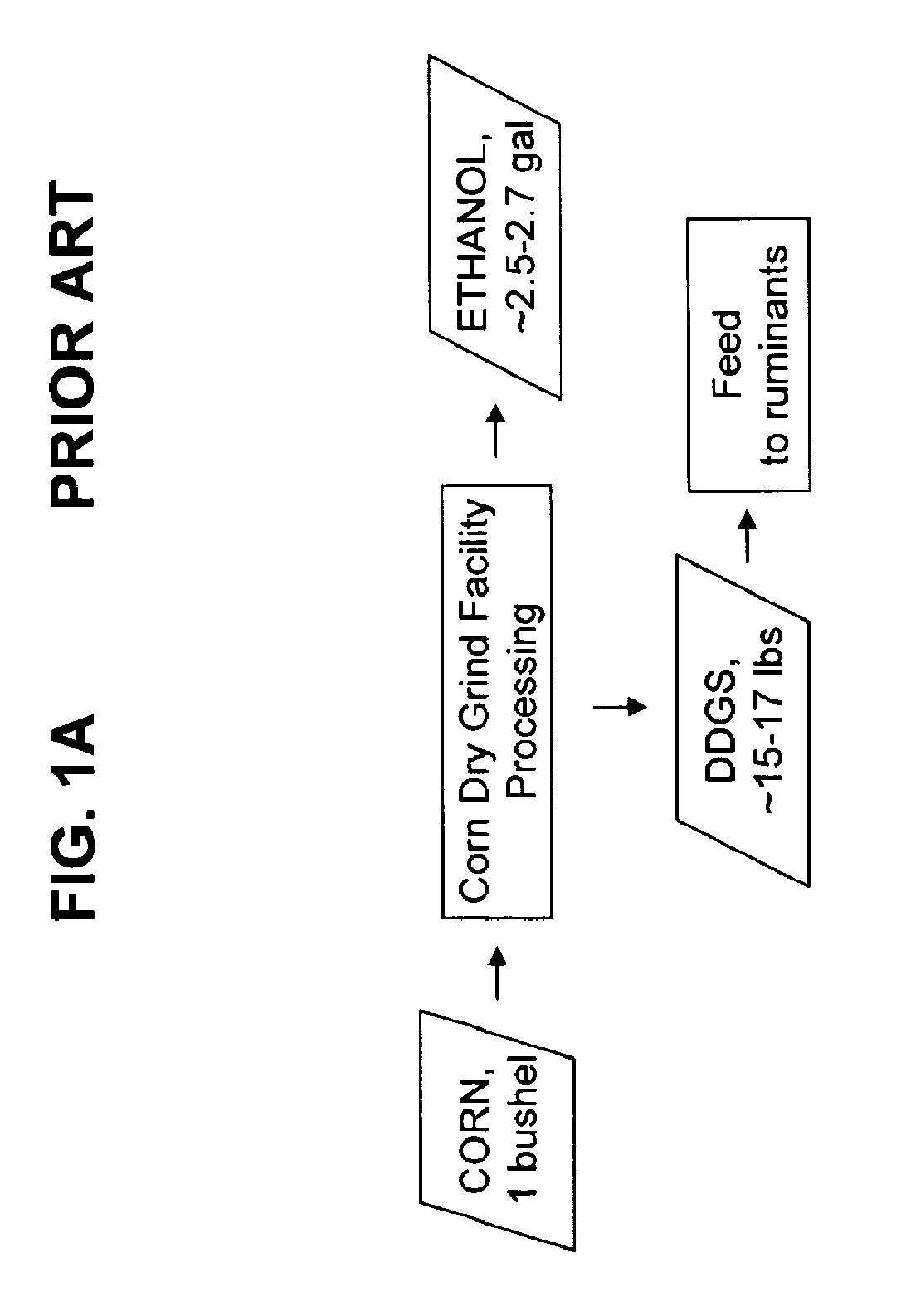

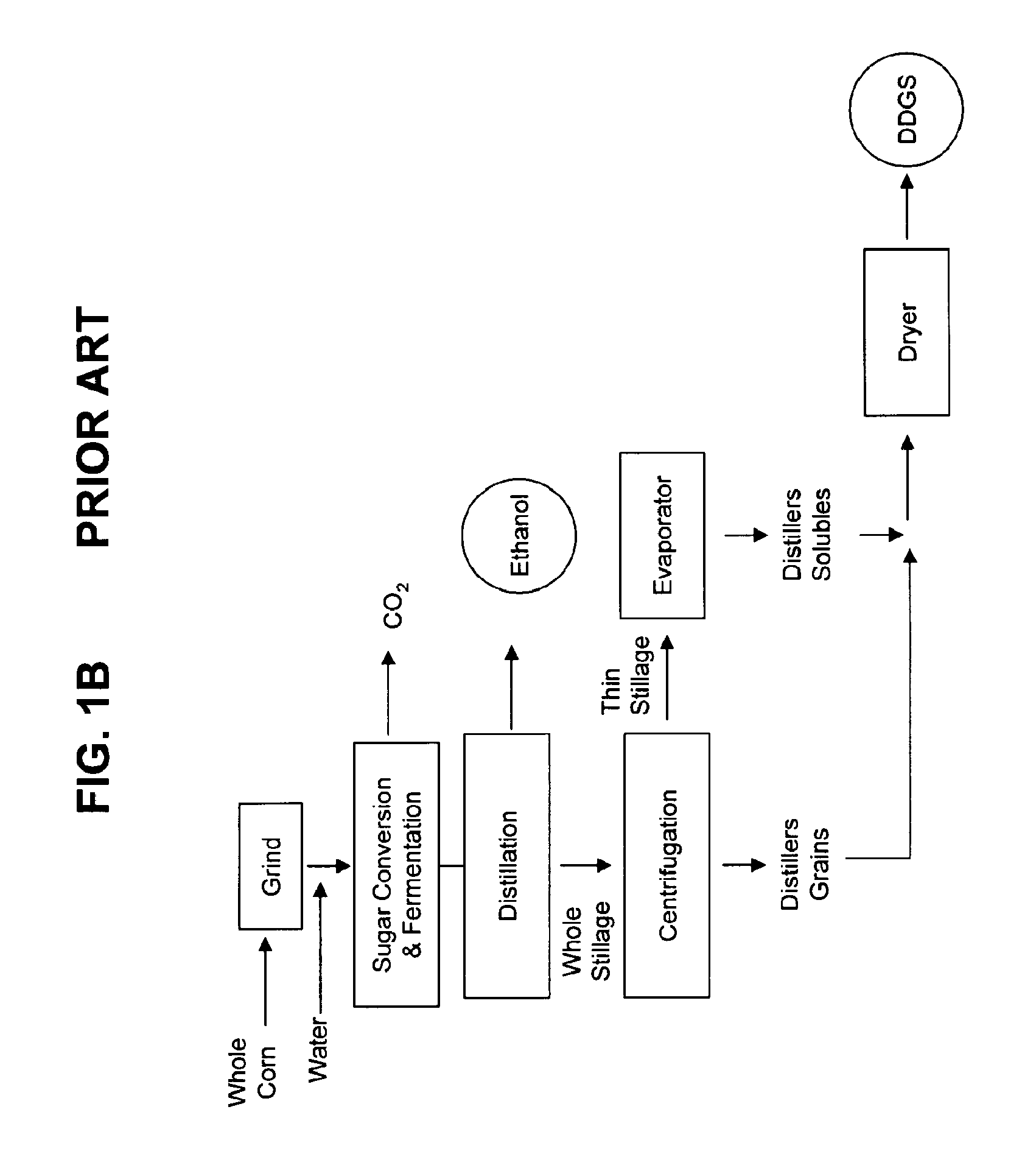

Removal of fiber from grain products including distillers dried grains with solubles

Methods, devices, and compositions relating to processed grain products are disclosed. An exemplary method disclosed is a fiber separation process for the ethanol industry corn products of Distillers Dried Grains (DDG) and Distillers Dried Grains with Solubles (DDGS) resulting from the widely used dry grind technology. A disclosed process and apparatus allows the removal and separate recovery of fiber-reduced DDG or DDGS products with expanded potential for use as a non-ruminant feed product in addition to the removal and separate recovery of a fiber-enriched product. The specific processes, devices, and compositions disclosed are readily adaptable to modern ethanol production plants.

Owner:MISSISSIPPI STATE UNIV RES TECH

Natural Extract Containing Xanthohumol, and Method for the Production Thereof Products Produced Therefrom

The invention relates to a method for producing an extract containing xanthohumol (XN), which is obtained from toasted cereal products, cereal malt, coffee or cocoa. The XN-content in said extract is in the region of 10 mg / kg-2 g / kg xanthohumol. The use of XN-toasted extracts enables the XN-content of foodstuffs and pharmaceutical products to be increased in a natural manner.

Owner:ARCAINI ANTONIO

Modified oilseed material

InactiveUS6841184B2Lower contact angleSuitable for useMilk preparationProtein composition from vegetable seedsCereal grainCereal product

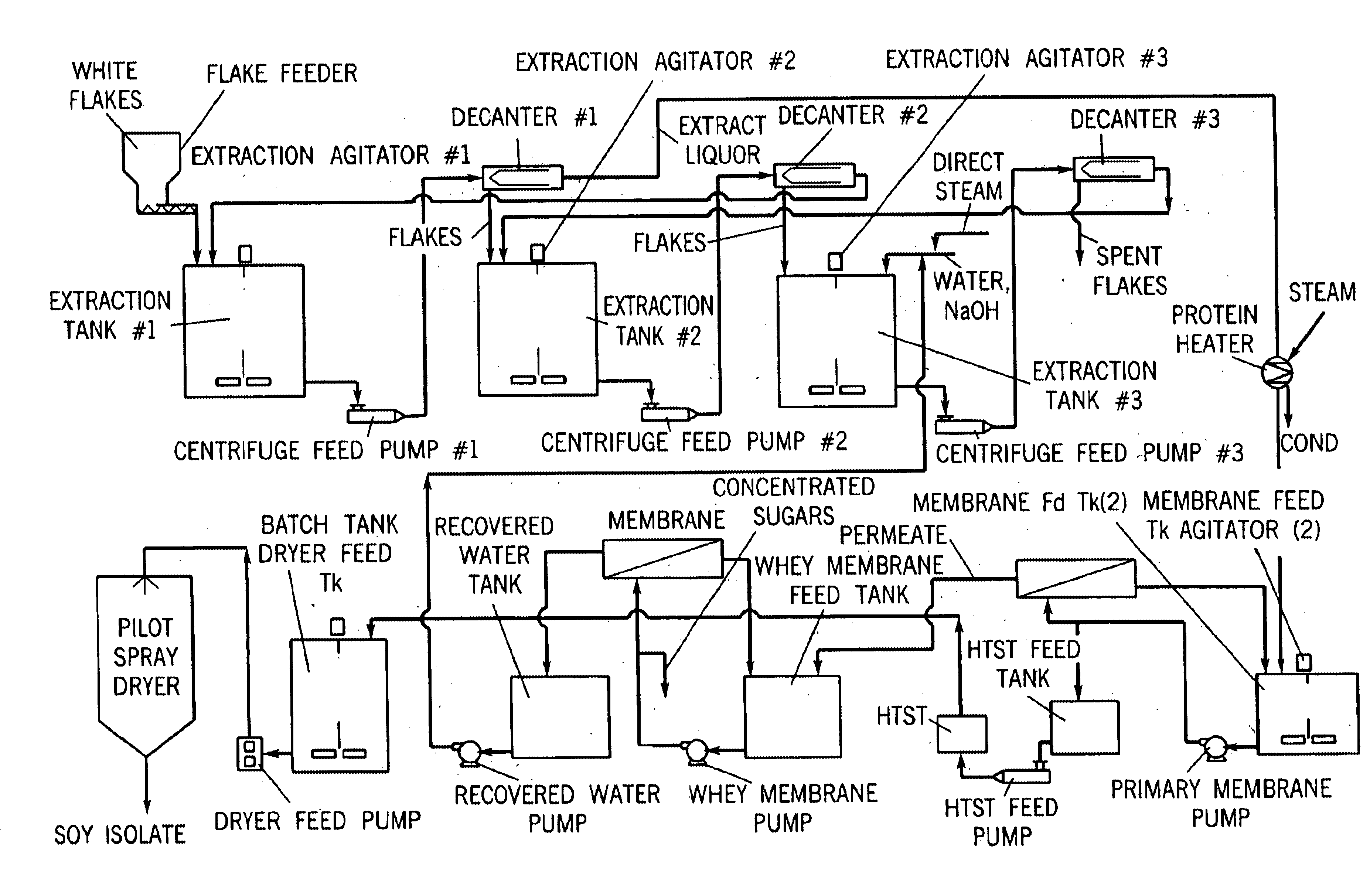

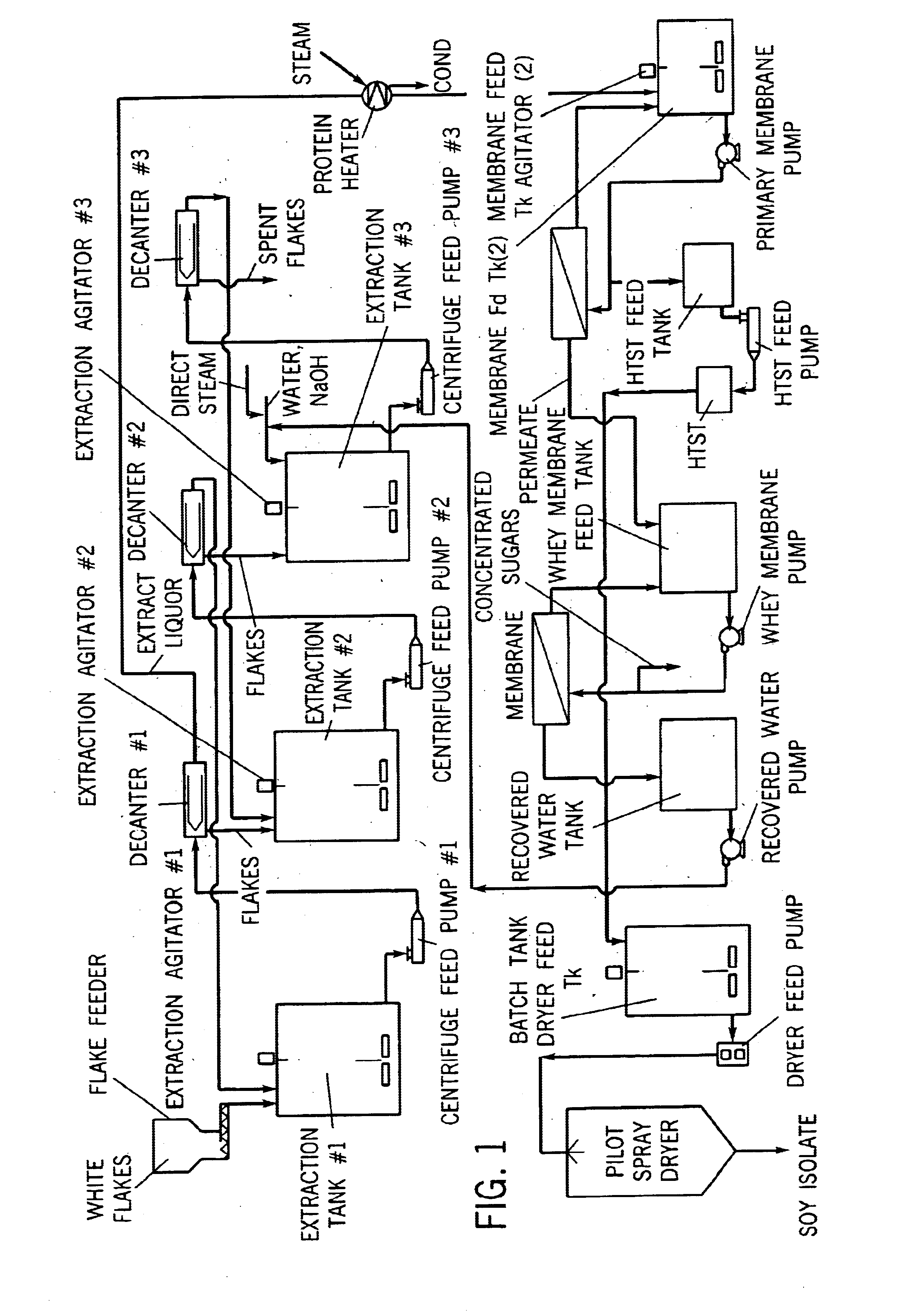

A modified oilseed material formed from oilseed-based material is described. The modified oilseed material can be utilized in a variety of nutritional applications, including the preparation of protein supplemented food products such as beverages, processed meats, frozen desserts, confectionery products, dairy-type products, and cereal grain products. The modified oilseed material typically includes at least 85 wt. % protein (dry solids basis), at least about 40% of the modified oilseed material has an apparent molecular weight of greater than 300 kDa, and / or a MW50 of at least about 200 kDa.

Owner:CARGILL INC

Production of whole grain hot cereal products

InactiveUS20080131582A1Promote hydrationReduced activityDough treatmentFood preparationHot cerealBran

A dry, whole grain hot cereal product which readily hydrates into a creamy, non-gritty, non-pasty, whole grain hot cereal is produced by milling whole cereal grains or combining separate streams or sources of endosperm, bran and germ to obtain a milled whole grain mixture having a particle size distribution of 100% by weight through a No. 16 (1,190 micron), preferably a No. 18 (1,000 micron), most preferably a No. 20 (841 micron) U.S. Standard Sieve, and less than or equal to about 7% by weight through a No. 100 (149 micron) U.S. Standard Sieve. The endosperm, the bran and the germ may be stabilized before or after milling of the whole grains or the endosperm, the bran and the germ, to avoid insect infestation and to at least substantially inactivate lipase and lipoxygenase. The dry, whole grain hot cereal product may be a cook-on-stove or instant hot cereal product.

Owner:BURNHAM & MORRILL CO

Extruded, highly cooked, non-sticky starch products

Owner:WENGER MANUFACTURING INC

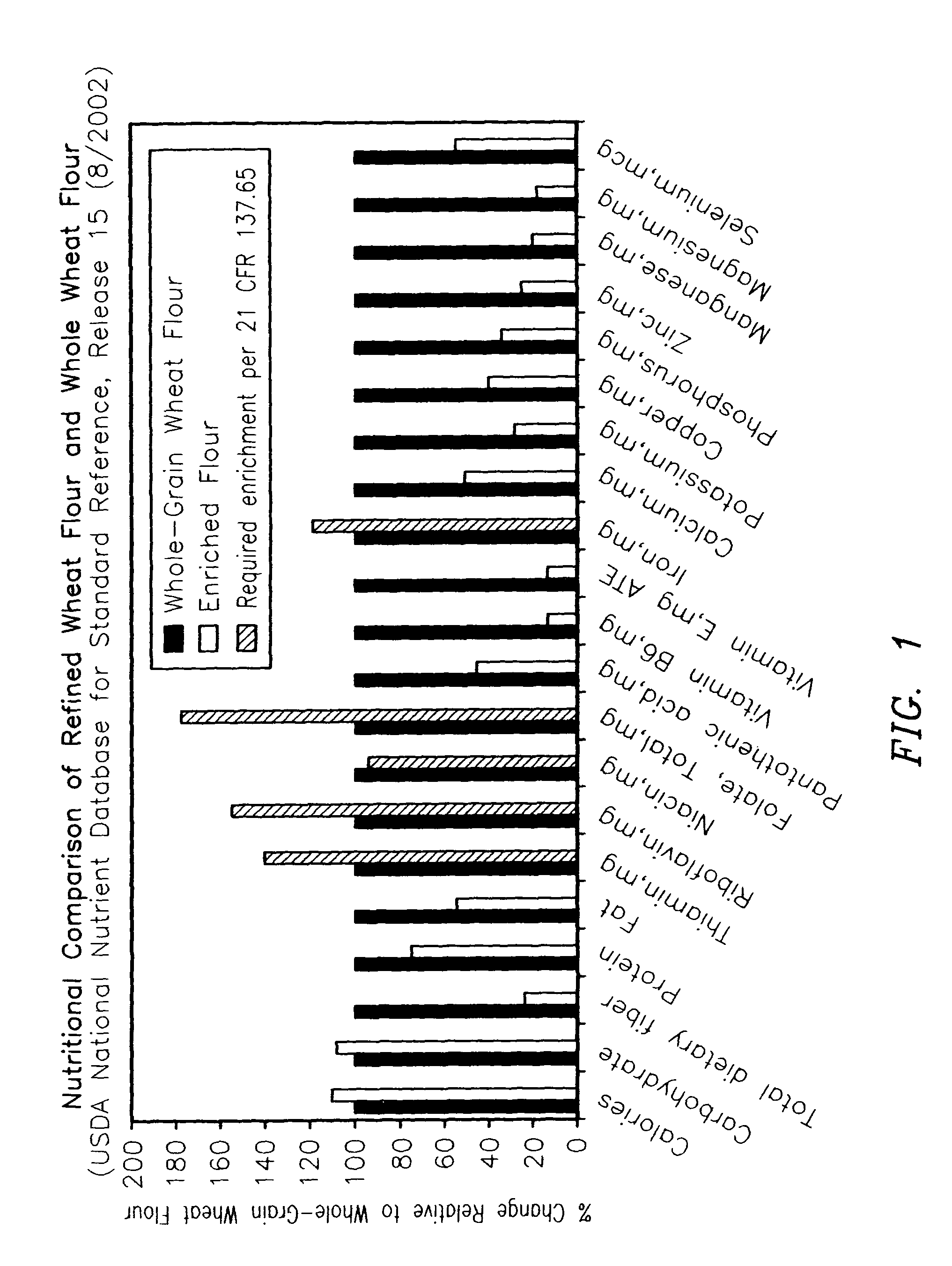

Whole grain flour and products including same

The present invention is a grain product. The grain product includes a first fraction including bran. The first fraction is milled to a first particle size of less than 500 micrometers. The grain product also includes a second fraction including germ. The second fraction is milled to a second particle size of less than 500 micrometers. The grain product is at least one of: a food product, a nutritional supplement, a dietary supplement, a fiber supplement, a digestive supplement, a functional food, and a medical food.

Owner:ARDENT MILLS

Germinated whole grain and preparation method thereof

InactiveCN104855837AMaintain the content of heat-sensitive substancesAvoid pollutionFood processingFood ingredient functionsFiberOrganoleptic

The invention discloses a germinated whole grain and a preparation method thereof, and belongs to the technical field of deep processing of grains. The whole grain is subjected to ultrasonic washing, high-voltage pulsed electric field treatment, biological enzymolysis or combined high-voltage pulsed electric field and biological enzymolysis treatment in a soaking process, and a segmented soaking and germination manner for germination is adopted, so that the sensory quality, germination yield and quality of a germinated whole grain product are improved, and germination loss is reduced. The preparation method is simple, low in soaking and germination temperature, short in cycle, energy-saving and environment-friendly. The content of functional, nutritional and bioactive substances in the germinated whole grain product is remarkably increased, and food safety is remarkably improved. For example, for brown rice, germinated brown rice prepared by the preparation method has gamma-aminobutyric acid content of 303.8 to 312.6 mg / 100 g, glutathione content of 16.8 to 18.3 mg / 100 g, IP6 content of 460.8 to 484.4 mg / 100 g and dietary fiber content of 3.5 to 3.6 mg / 100 g.

Owner:宁夏家道回乡农业开发有限公司

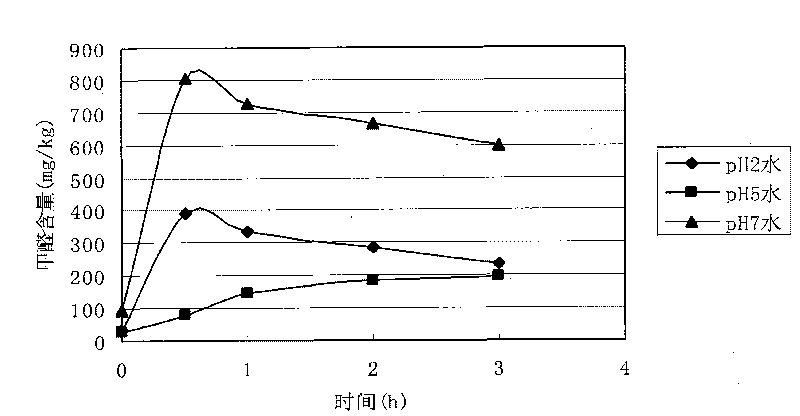

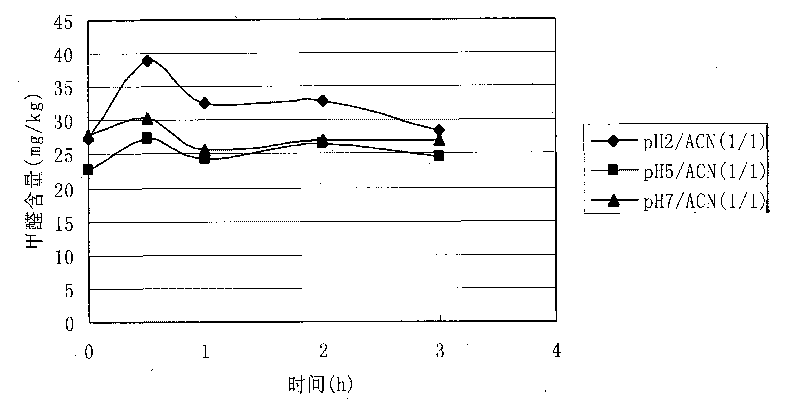

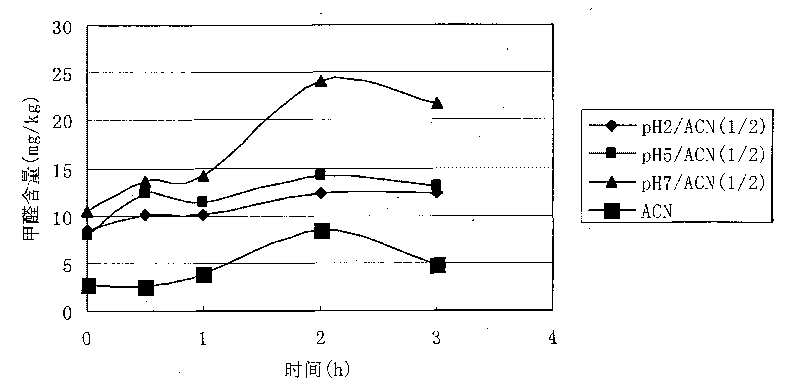

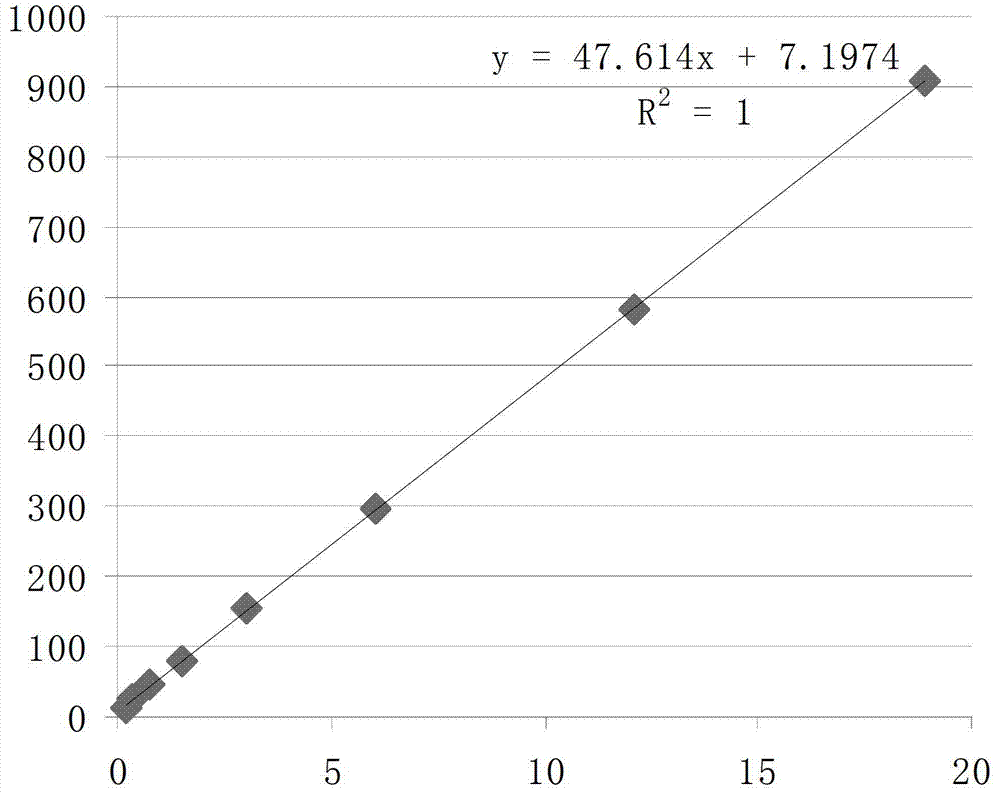

Method for testing formaldehyde in food by means of derivation extraction

InactiveCN101762660AEfficient extractionHigh recovery rateComponent separationWater bathsAquatic product

The invention relates to a method for testing the content of formaldehyde in food by means of liquid chromatography, in particular to a method for testing the formaldehyde in import and export aquatic products, vegetables (including mushroom), cereal products, dairy products and beers, etc. The method for testing the content of the formaldehyde in the food by means of liquid chromatography comprises the steps of: (1) extracting; (2) purifying; (3) preparing formaldehyde standard work solution; (4) testing; (5) blank testing; and (6) computing and expressing a result. The method adopts acetonitrile / pH 5 ethylic acid buffer solution (1 / 1, v / v) of 2, 4-dinitrophenylhydrazine to directly derive and extract the formaldehyde in a sample and test by means of the liquid chromatography. The formaldehyde is extracted from the sample under water bath at the temperature of 60 DEG C and the derivatization reaction is performed. The 2, 4-dinitrophenylhydrazine and the group in protein compete for the formaldehyde in the reaction solution, thereby being capable of effectively preventing the formaldehyde from combining with the protein in the sample and having higher formaldehyde recovery ratio than that of by using an immersion method.

Owner:THE INSPECTION & QUARANTINE TECH CENT ZHEJIANG ENTRY EXIT INSPECTION & QUARANTINE BUREAU

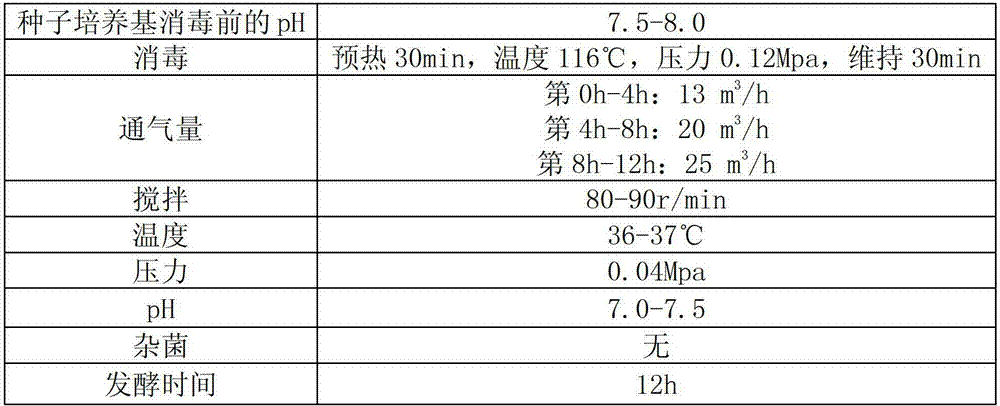

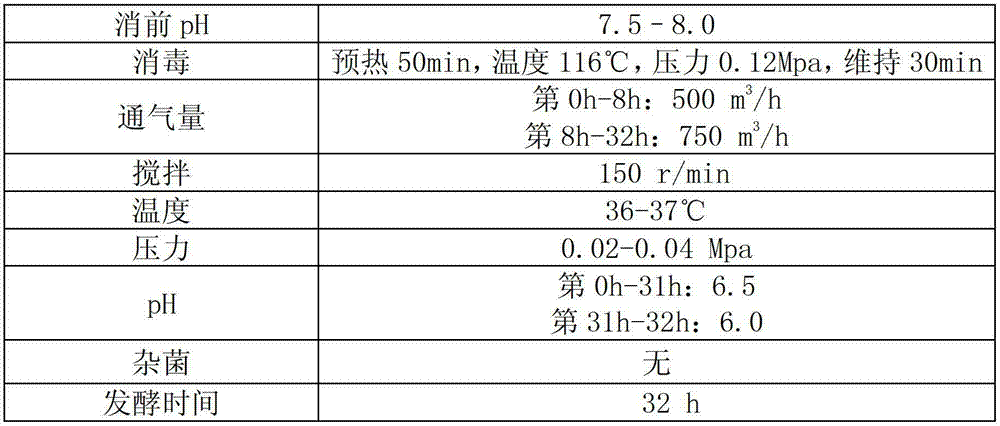

Bacillus subtilis and application of bacillus subtilis to production of antimicrobial peptide

ActiveCN103194411ALower requirementRealize industrial productionBacteriaMicroorganism based processesAntimicrobial peptidesBacillus subtilis

The invention discloses bacillus subtilis and an application of the bacillus subtilis to production of antimicrobial peptide. The preservation number of the bacillus subtilis BF168 provided by the invention is CGMCC No. 7200. The invention further provides the application of the bacillus subtilis BF168 to the production of sublancin antimicrobial peptide or antibiotic substance. The application of the bacillus subtilis has the following specific advantages that (1) cereal products, such as corn and soybean processed goods, are taken as the main raw materials to replace the raw materials of chemical reagent grade in a laboratory, so that the production cost is reduced; (2) the industrial production of the sublancin antimicrobial peptide or antibiotic substance can be realized; (3) the production efficiency of the sublancin antimicrobial peptide or antibiotic substance can be improved, and the content of the sublancin antimicrobial peptide in a fermentation liquid can be up to 80-150mg / L; and (4) the yield is high, the cost is low, the purity of product is high, the requirements on operators during production are low, the process is simple, and the popularization is easy.

Owner:LINZHOU SINAGRI YINGTAI BIOLOGICAL PEPTIDES CO LTD

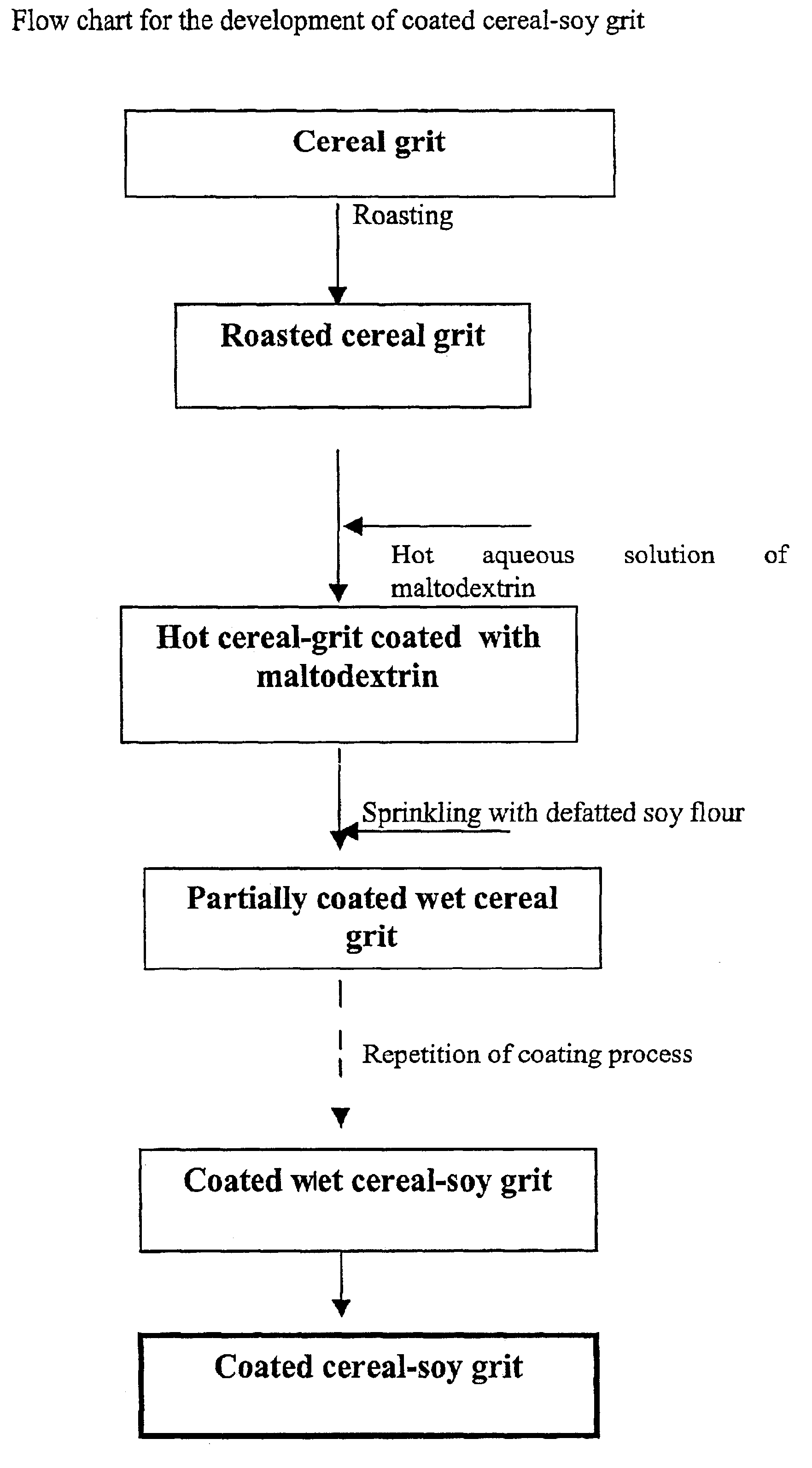

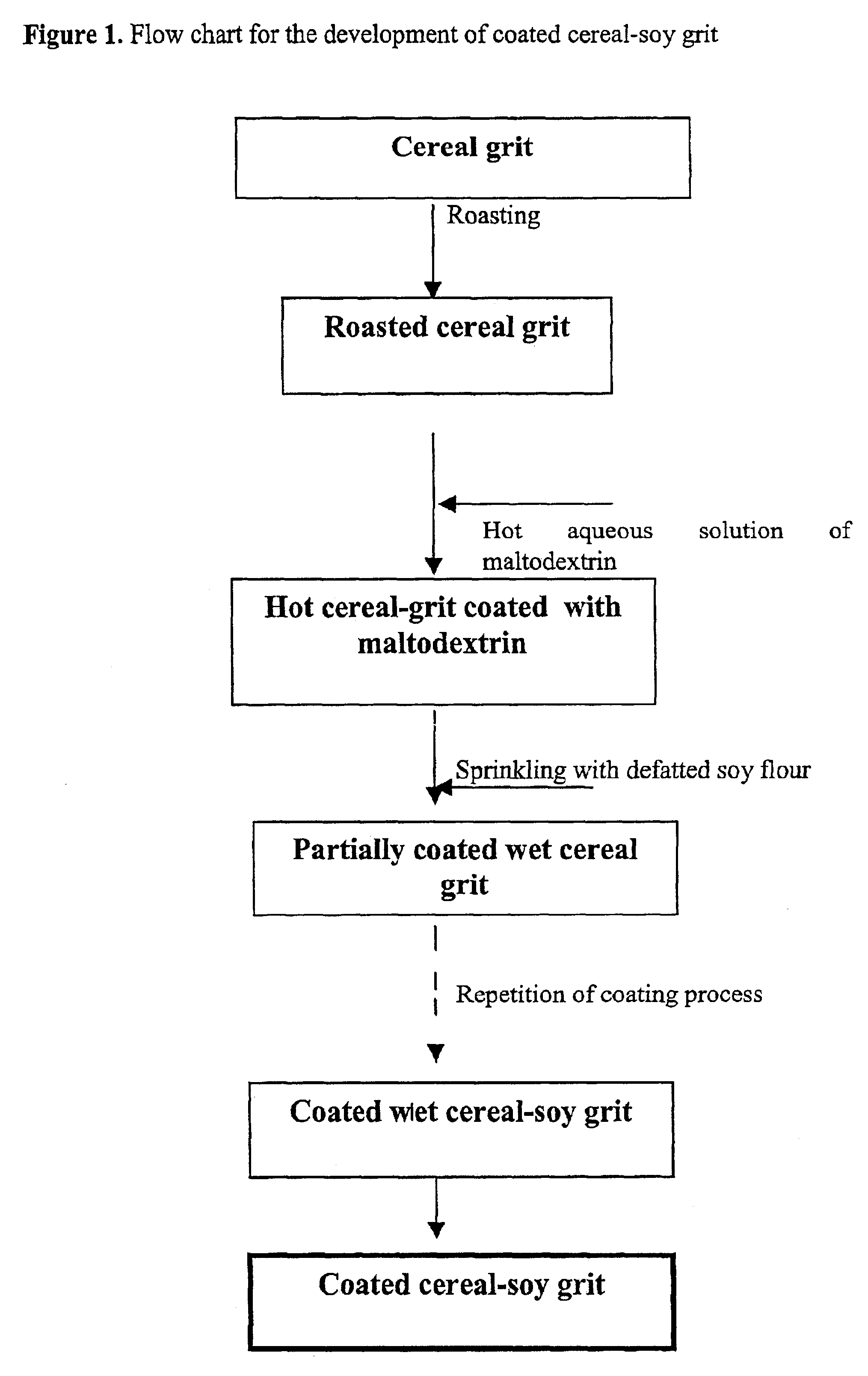

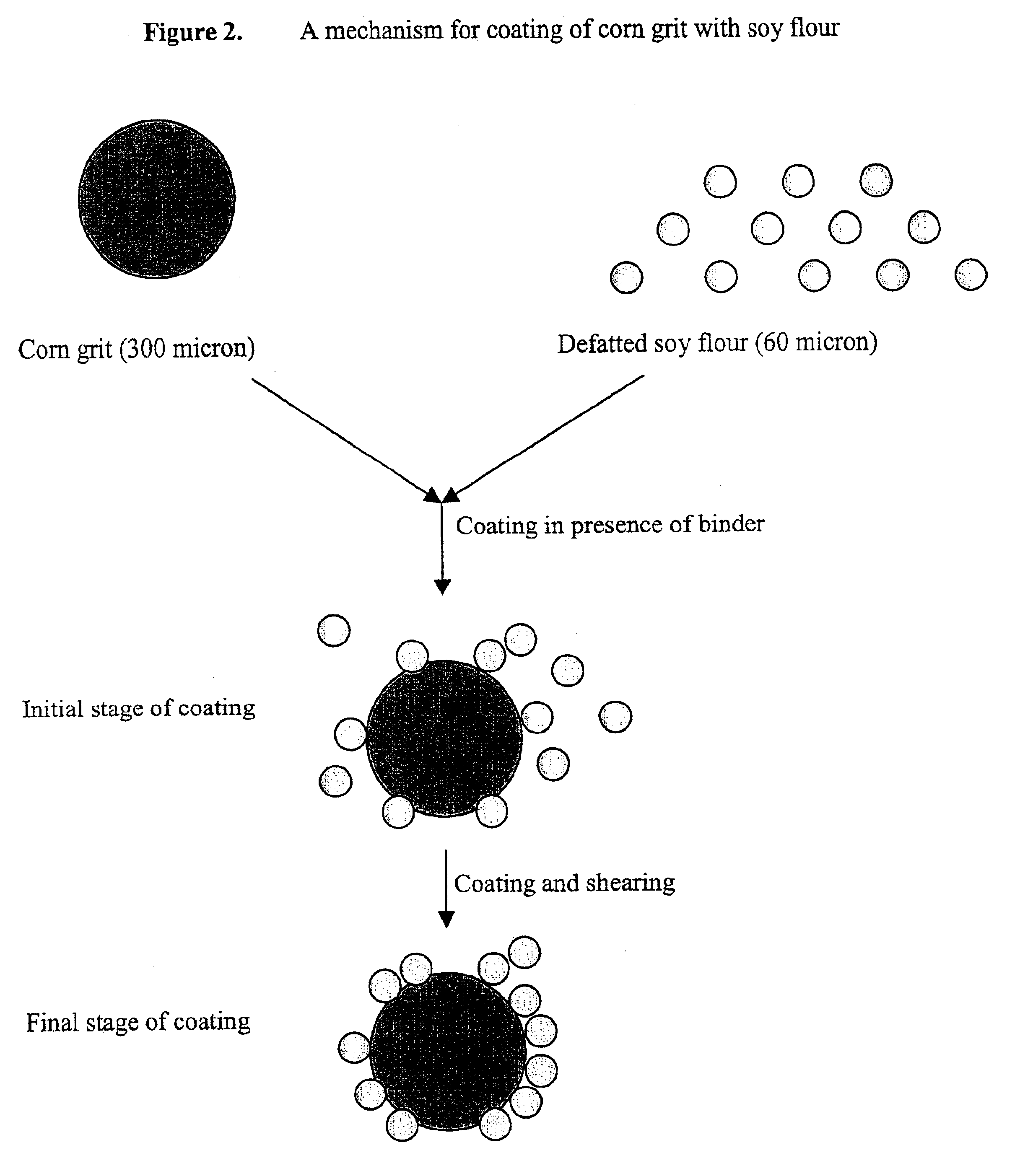

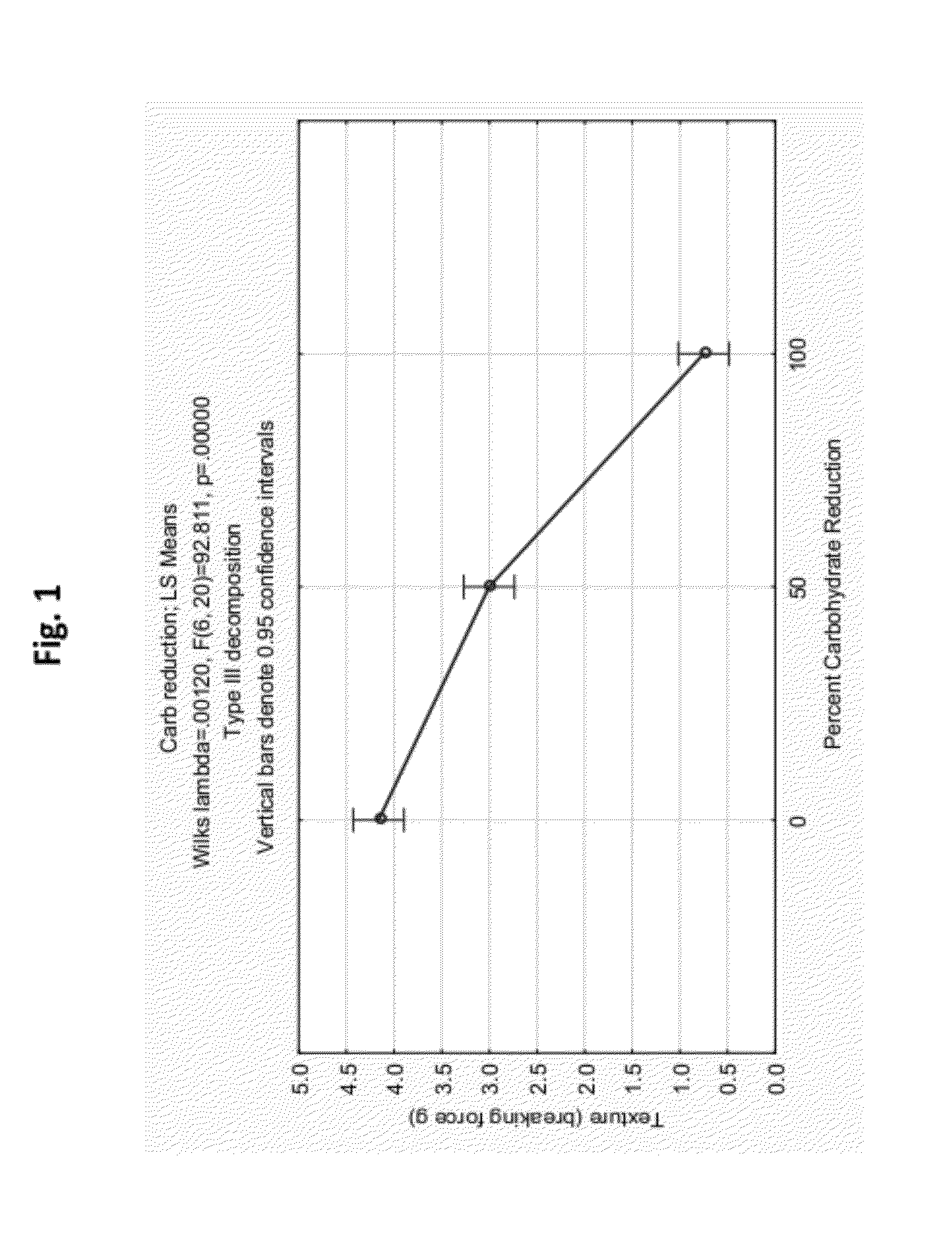

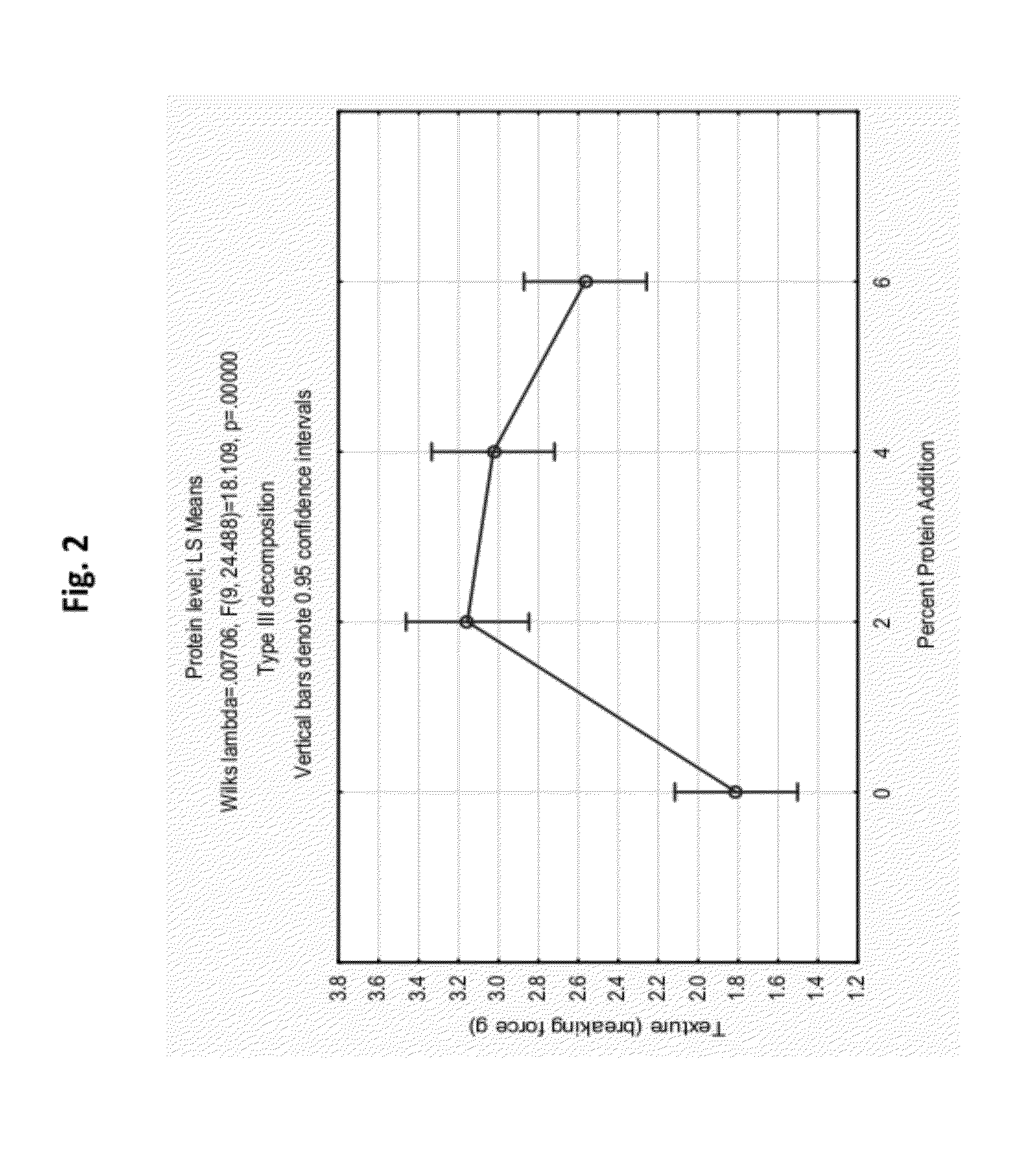

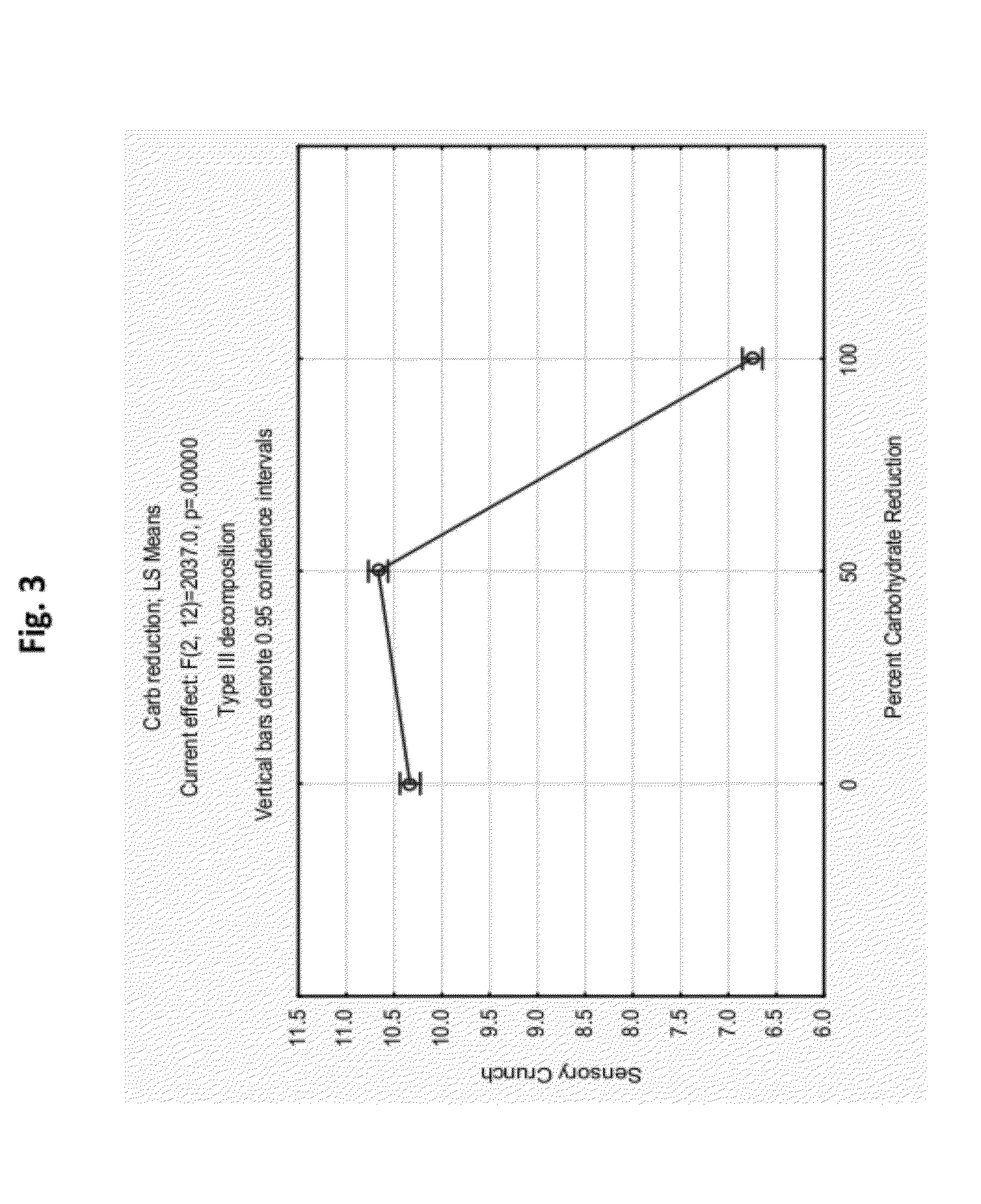

Cereal grit food product having enhanced shelflife and high protein content

InactiveUS6866880B2Extended shelf lifeHigh in proteinDough treatmentConfectioneryBiotechnologyCereal grain

The present invention provides a cereal based protein rich product having good texture and taste and having an enhanced shelf life; the present invention also provides a process for the production of the cereal product.

Owner:COUNCIL OF SCI & IND RES

Cereal Binder Compositions and Methods for Making Cereal Bars and Cereal Clusters

InactiveUS20120269939A1Improving shelf-lifeImprove textureMilk preparationSugar food ingredientsBiotechnologyCereal grain

Disclosed are cereal binder compositions having reduced carbohydrate content as compared to present carbohydrate binders. Also disclosed are methods for producing agglomerated cereal products using binders comprising a substantially gluten-free protein in combination with carbohydrate.

Owner:GLANBIA NUTRITIONALS IRELAND

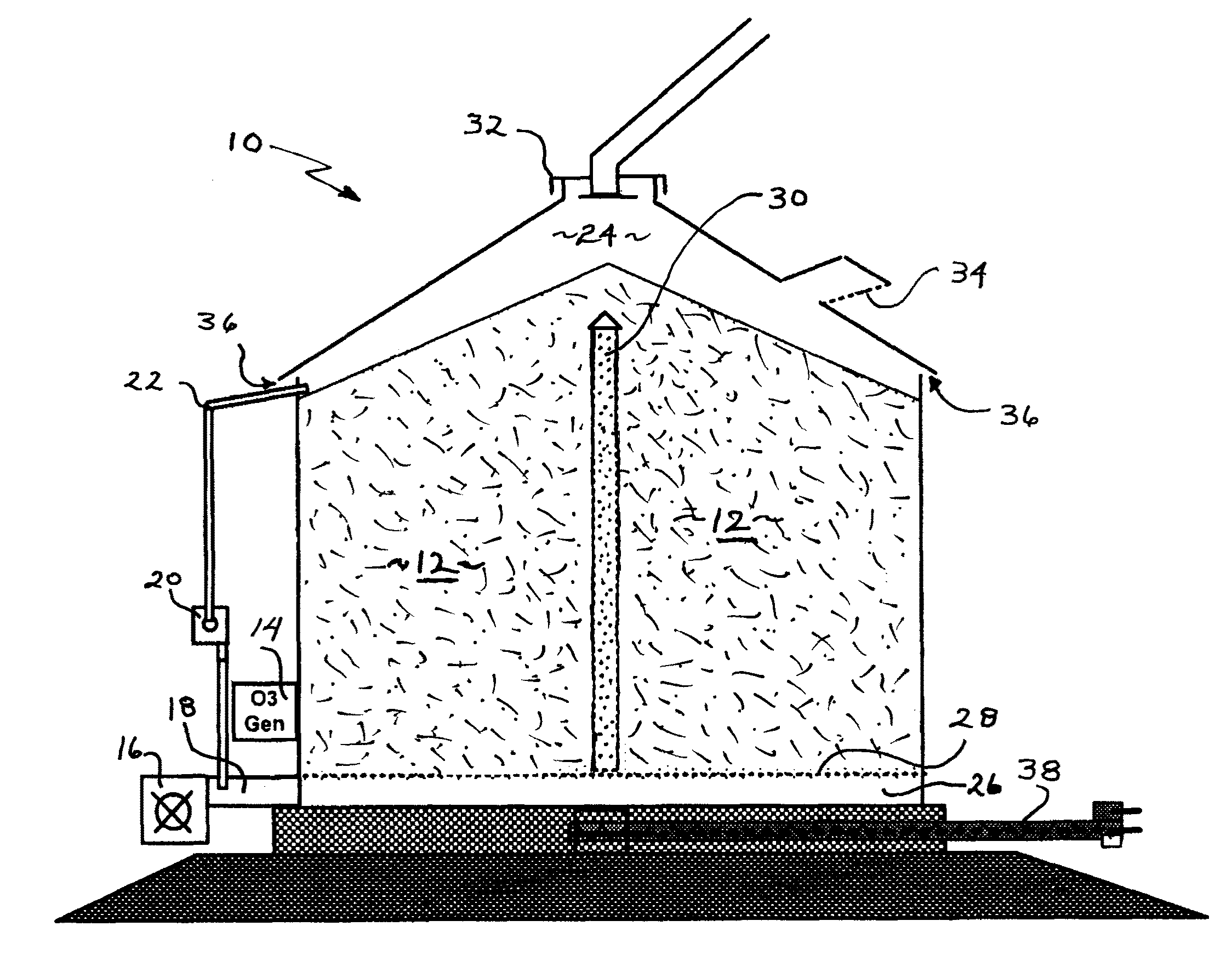

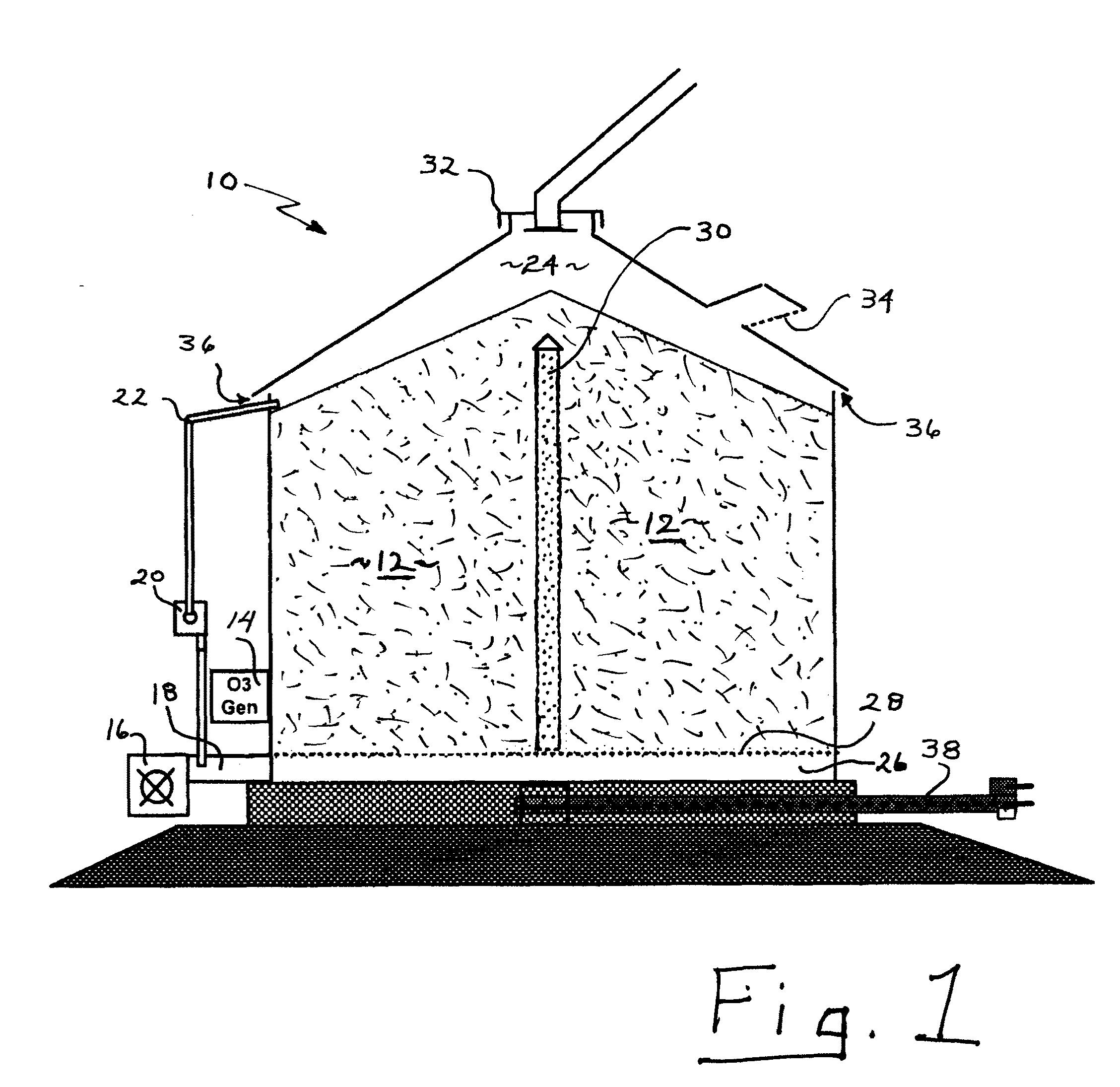

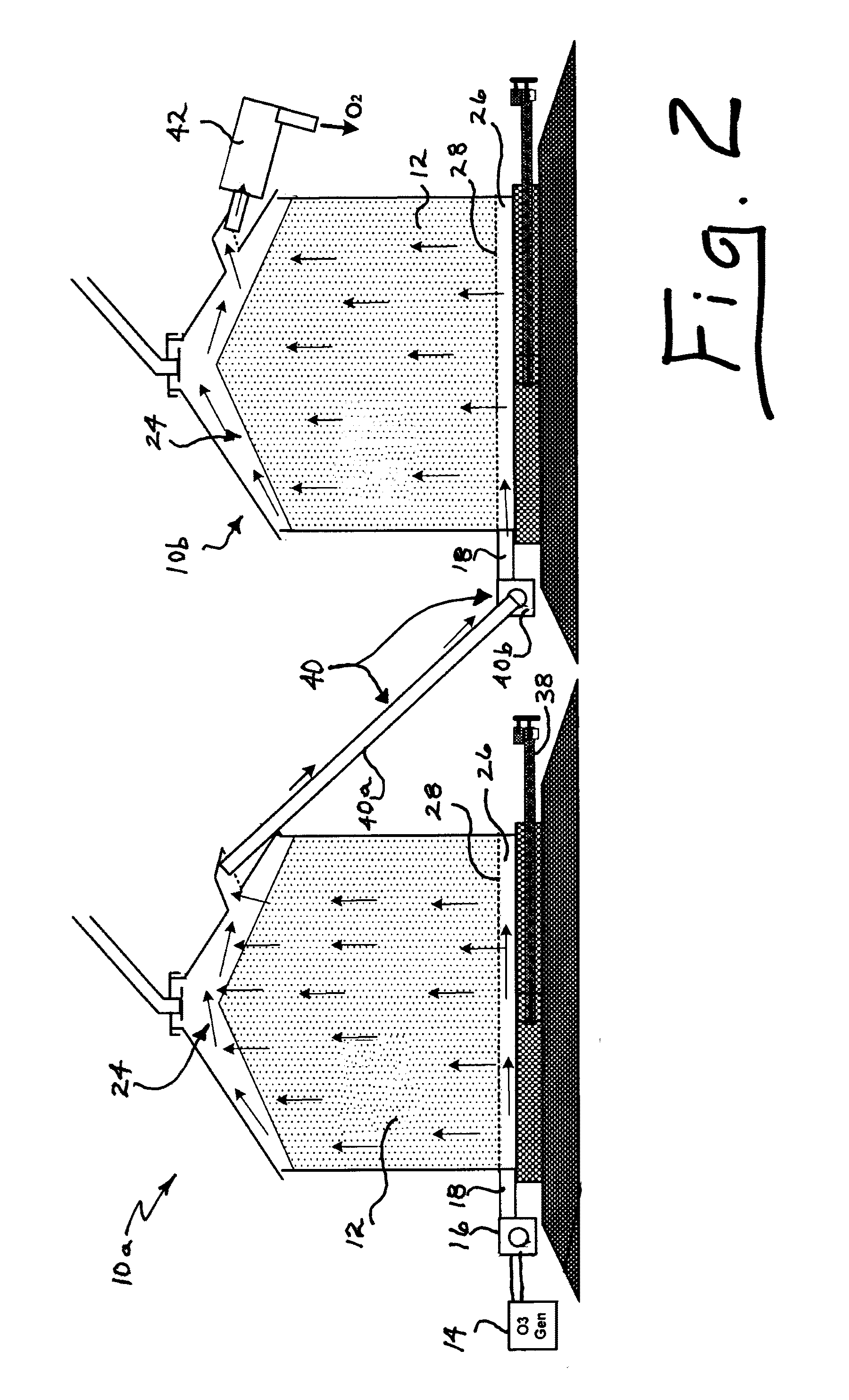

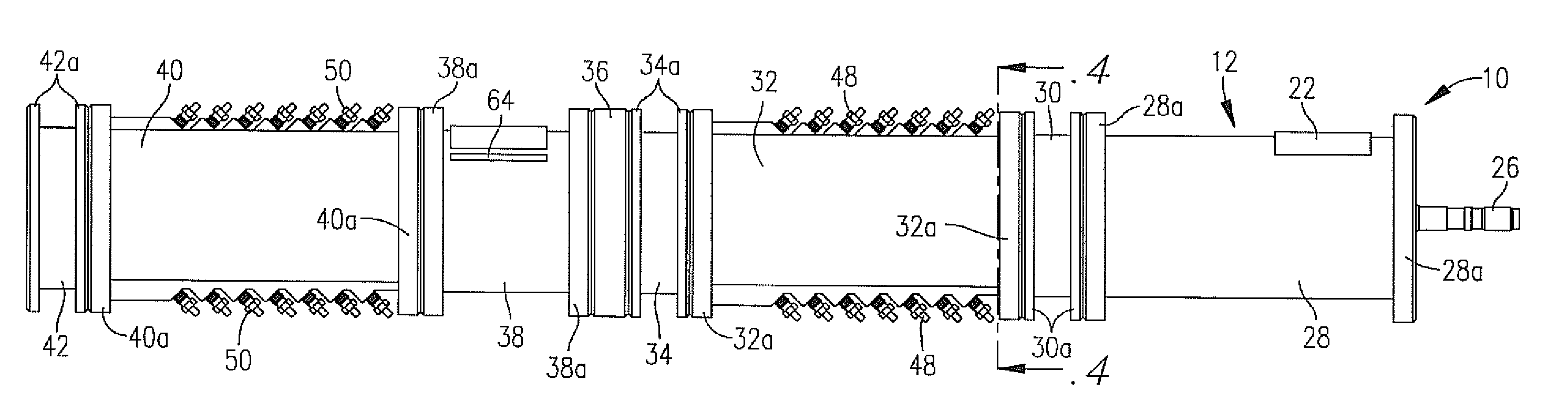

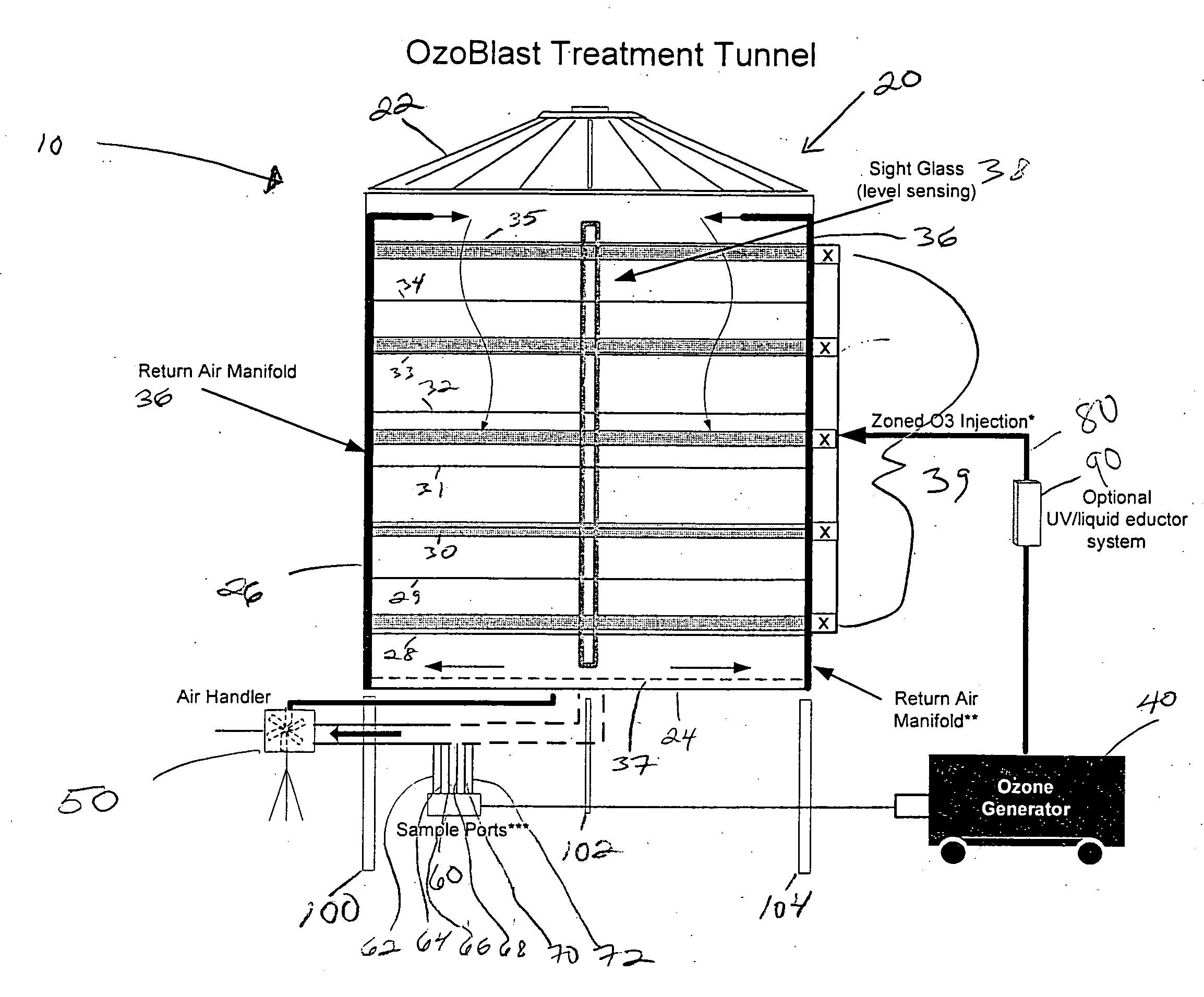

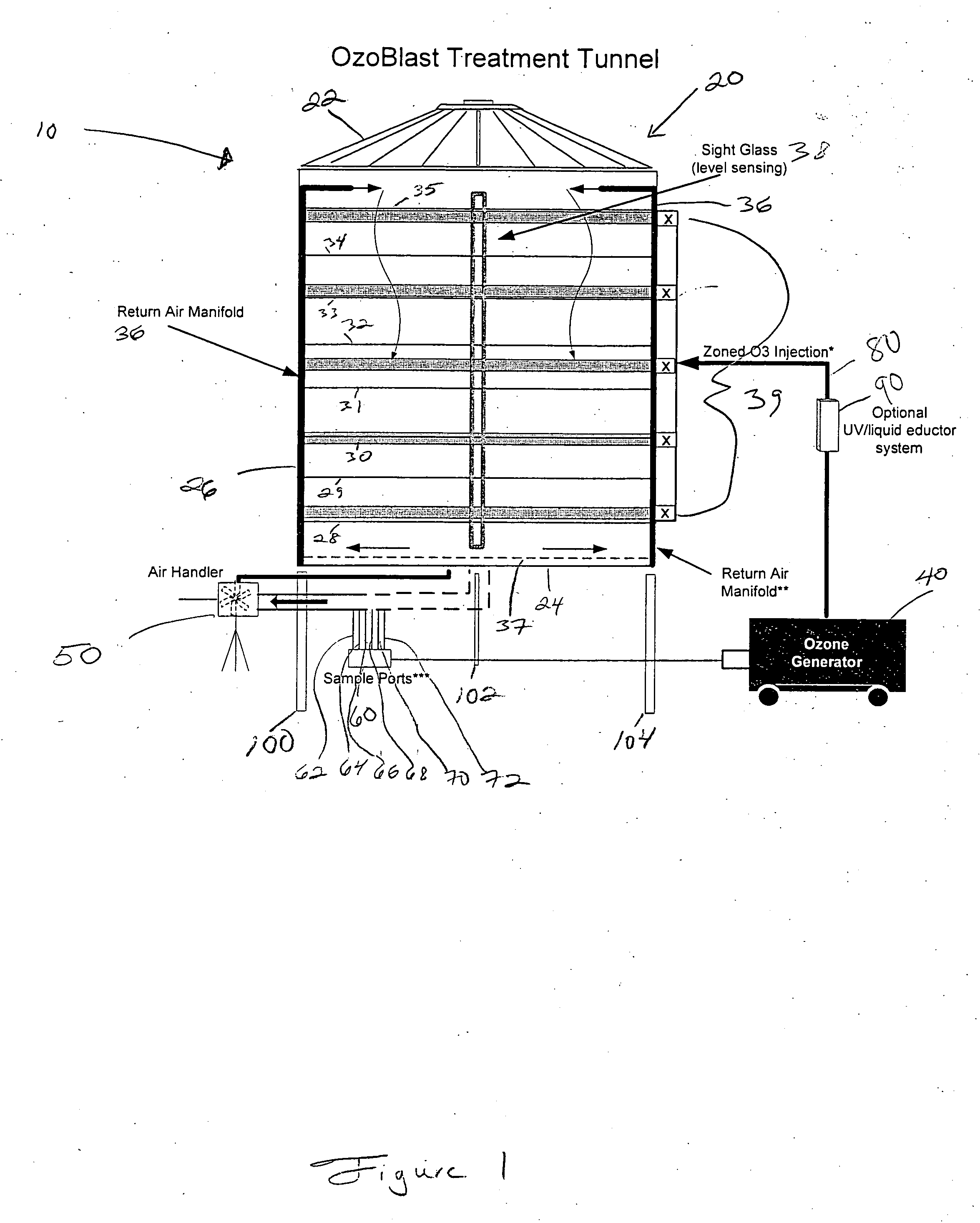

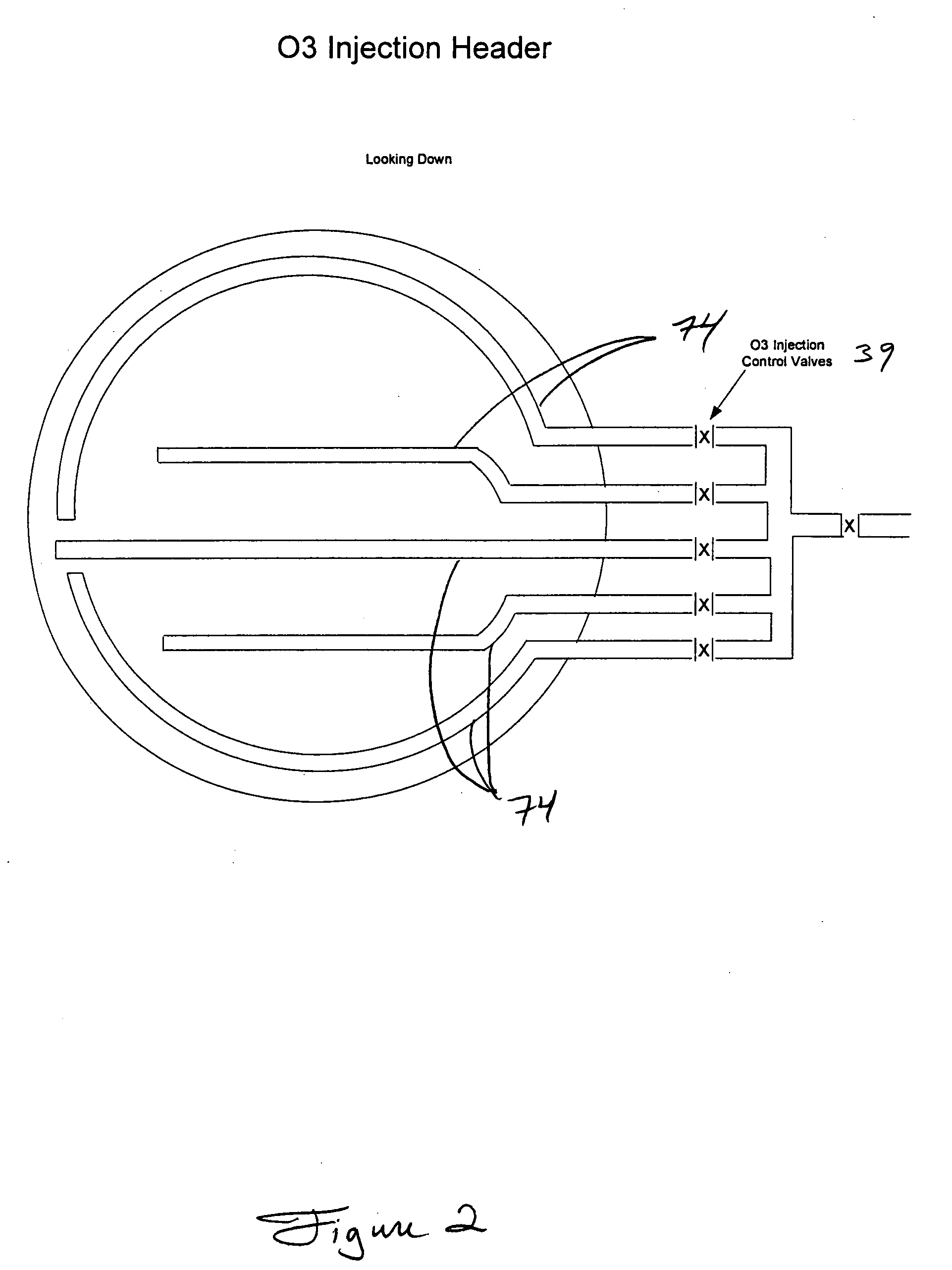

Fumigation and sanitation of biological products storage systems using ozone

InactiveUS20090117016A1Avoid damageFood preservationEnergy based chemical/physical/physico-chemical processesEngineeringBiologic Products

An apparatus and method are provided for elimination of mold, pests, insects and the like from bulk, stored grain and milled grain products and other biological items by pushing an ozone-containing atmosphere up through the grain or biological items and providing and maintaining an ozone-containing atmosphere in contact with the upper surface of the grain or biological items and maintaining an ozone-containing atmosphere in the spaces of the storage contained that are below the grain or biological items.

Owner:ADAPTIVE OZONE SOLUTIONS

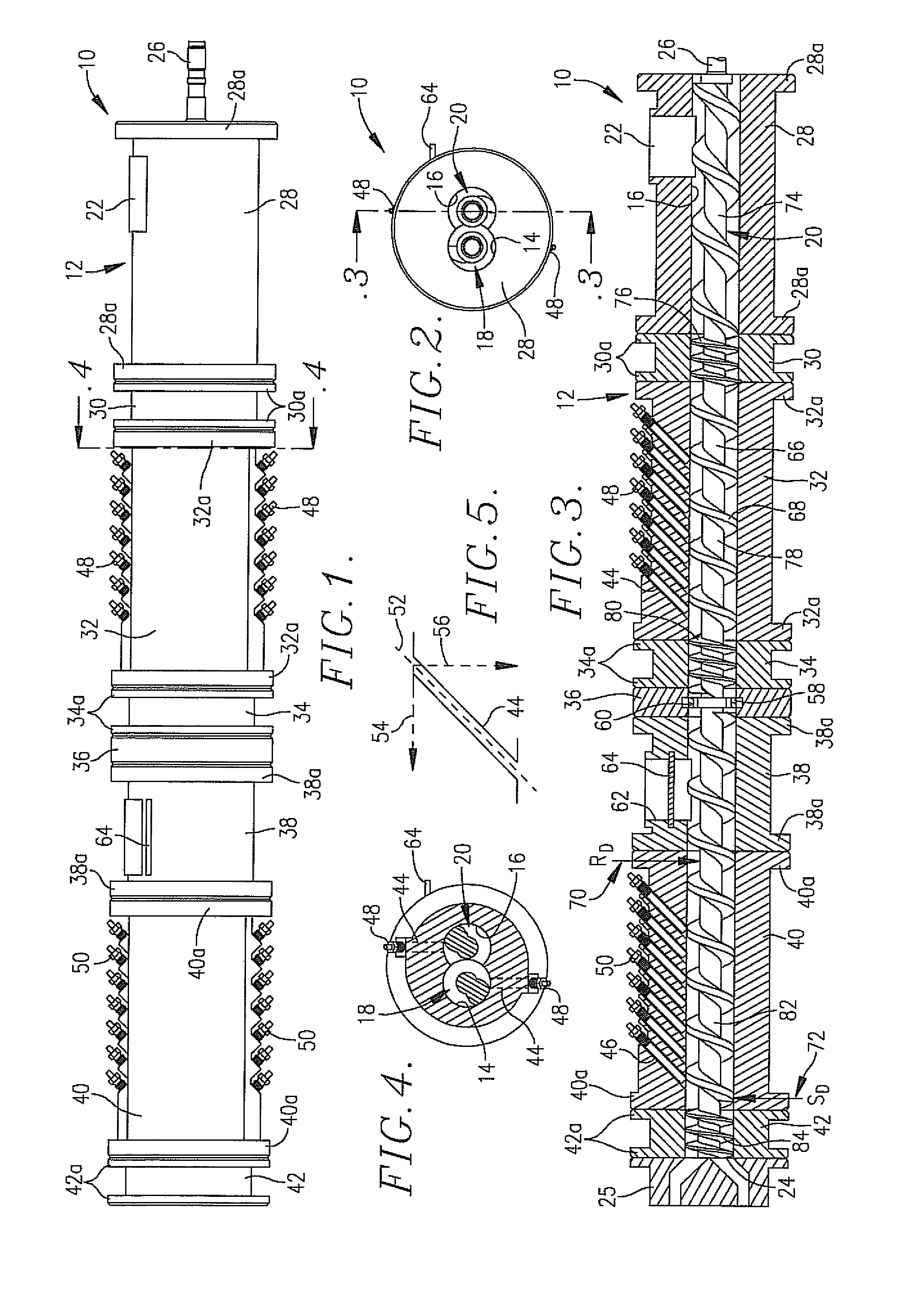

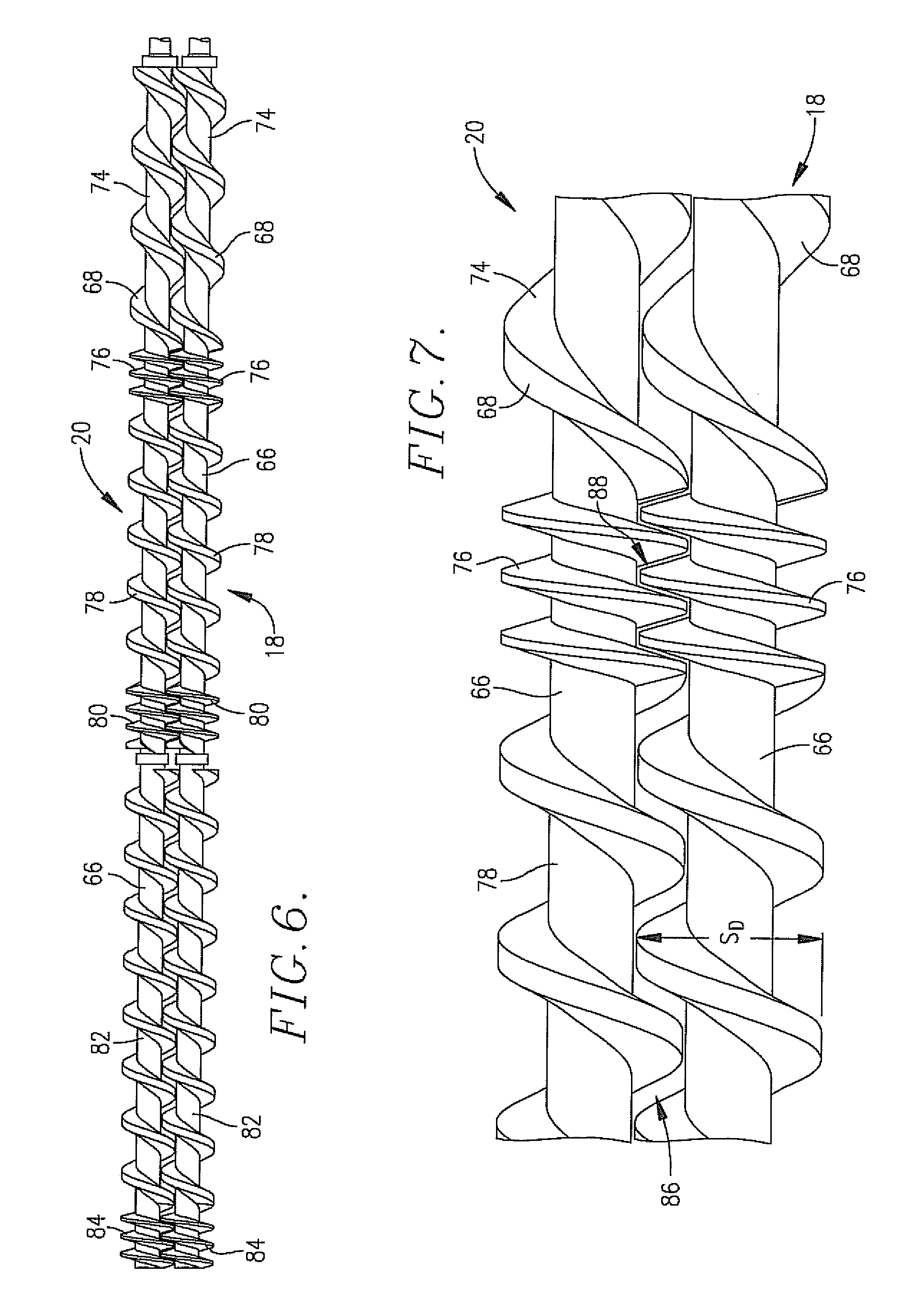

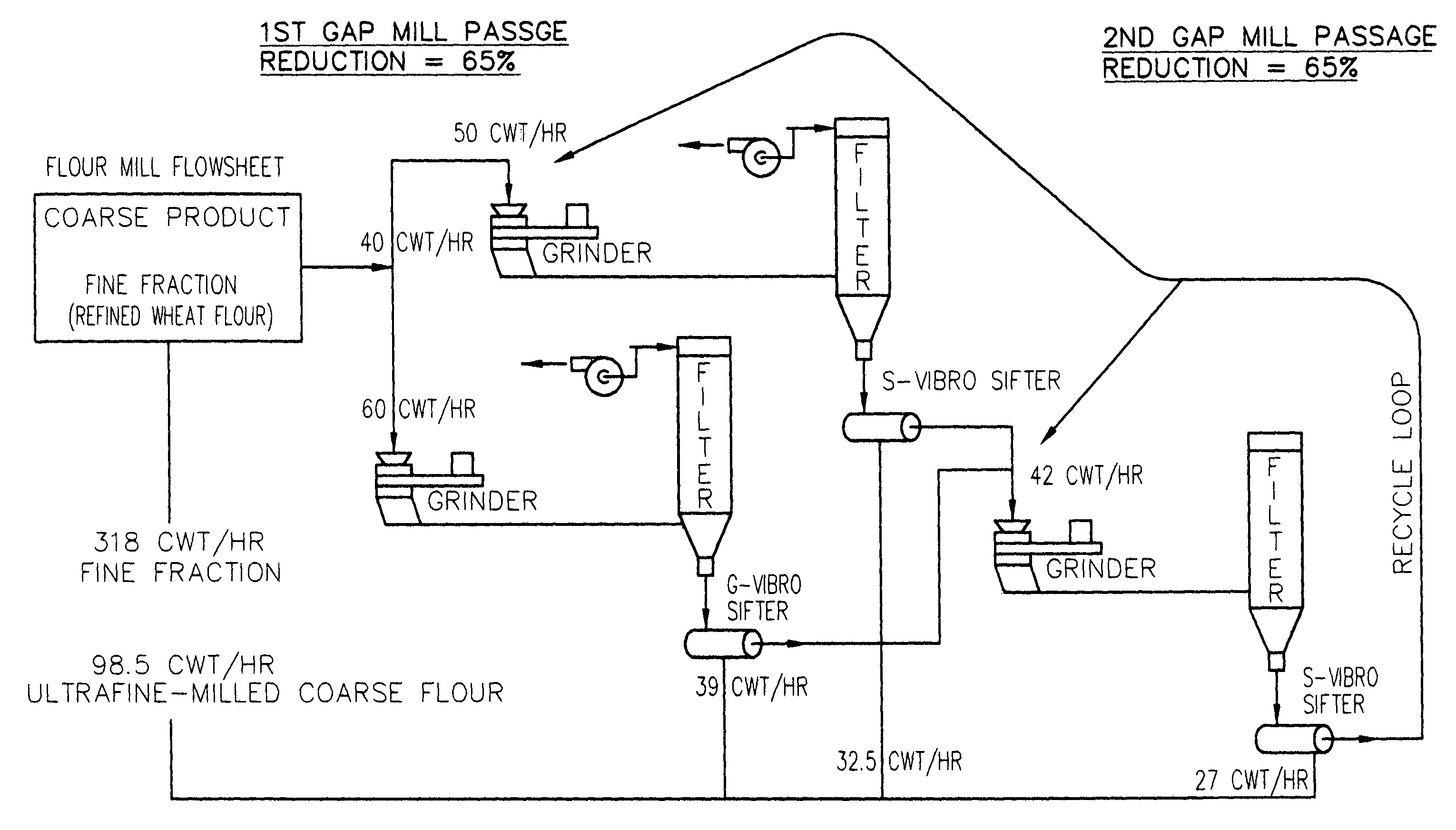

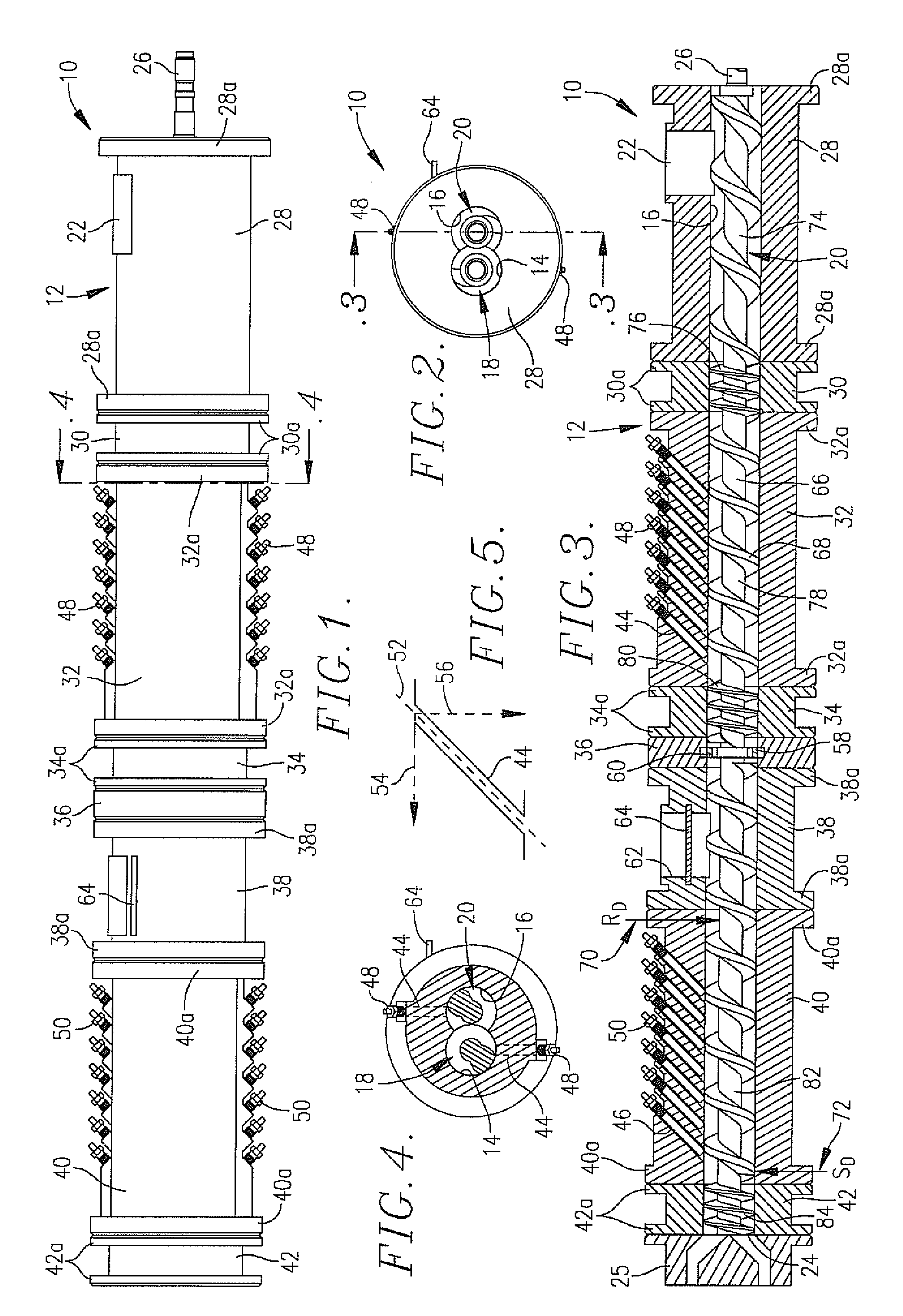

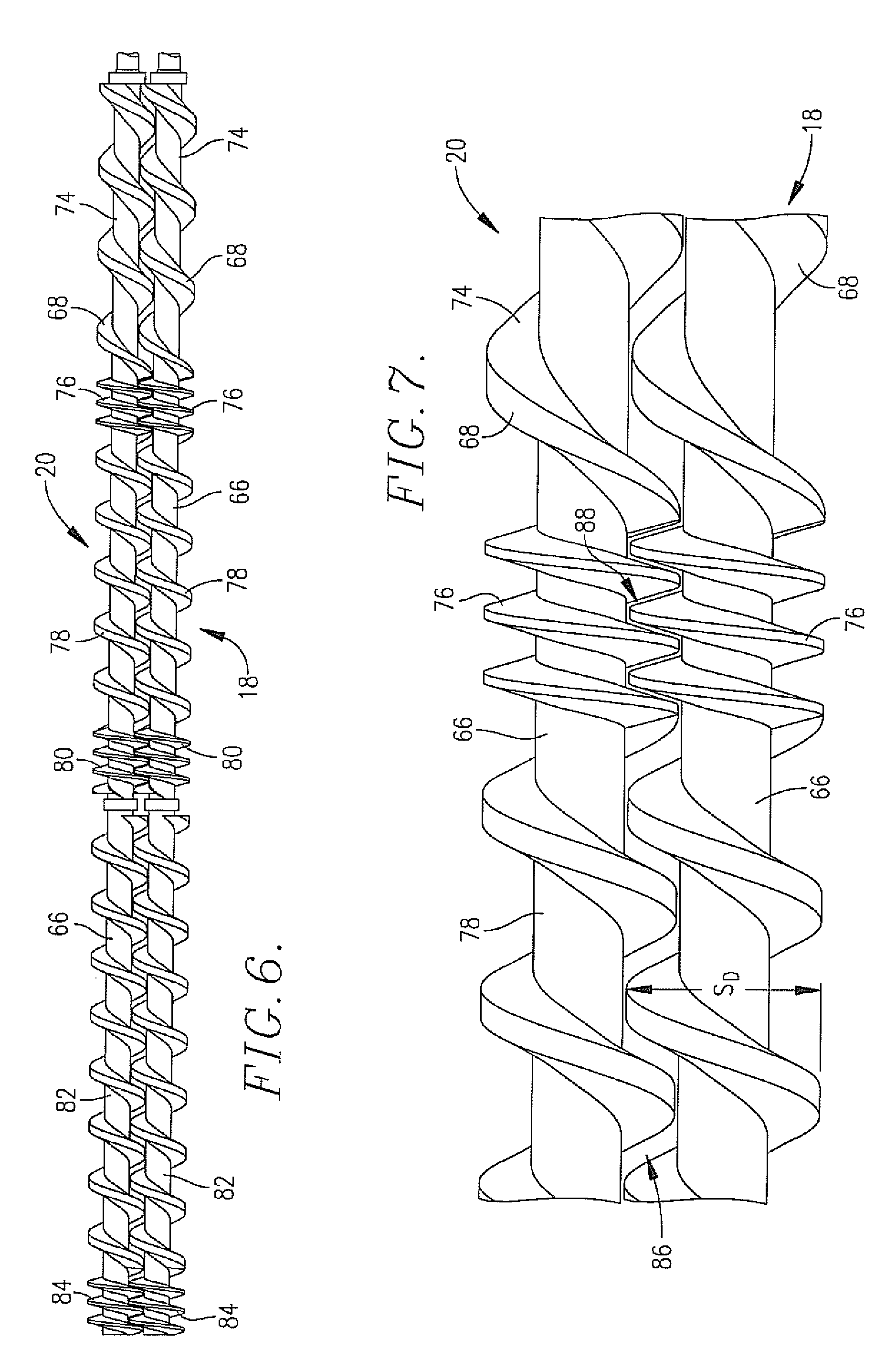

Extruded, highly cooked, non-sticky starch products

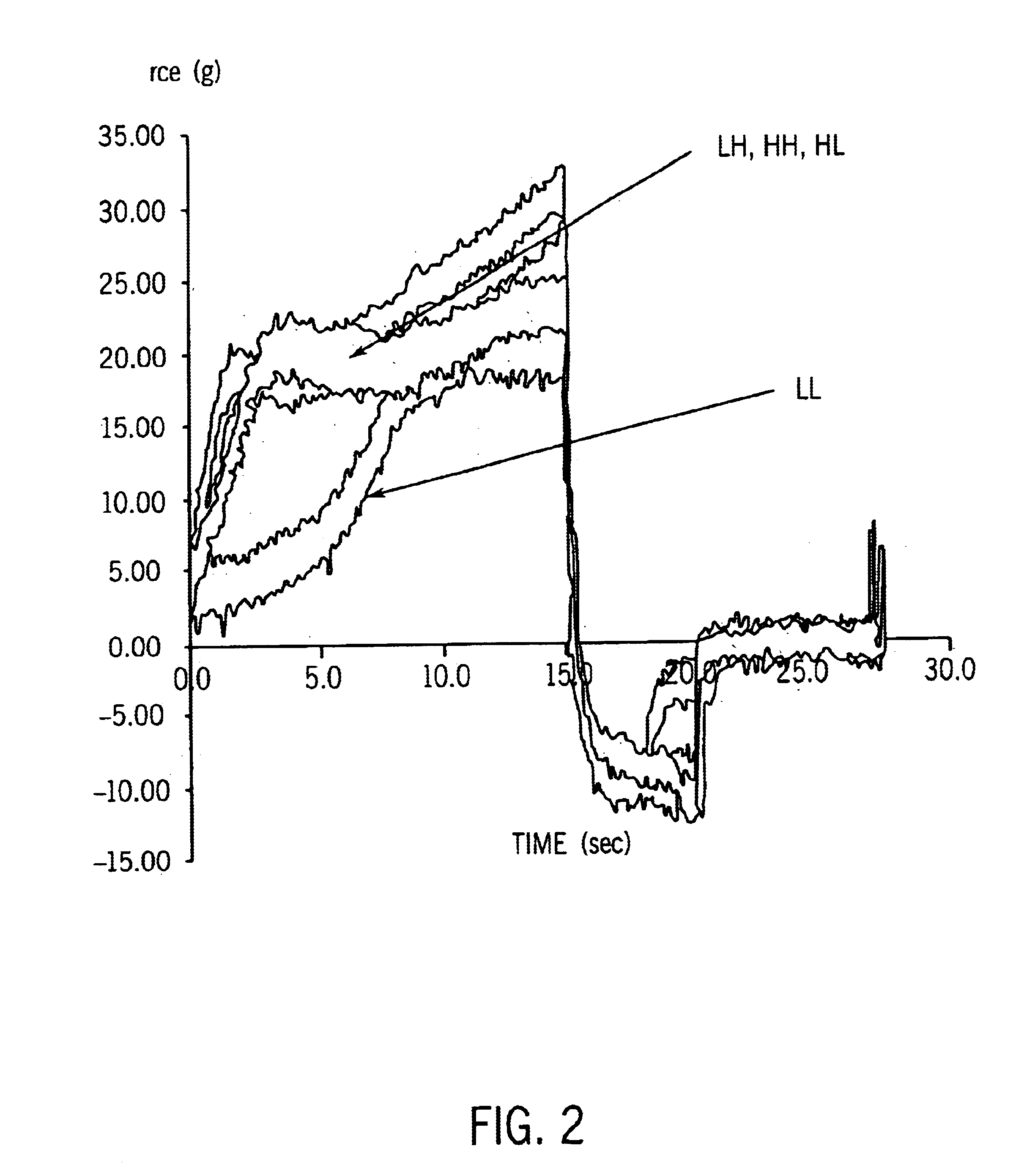

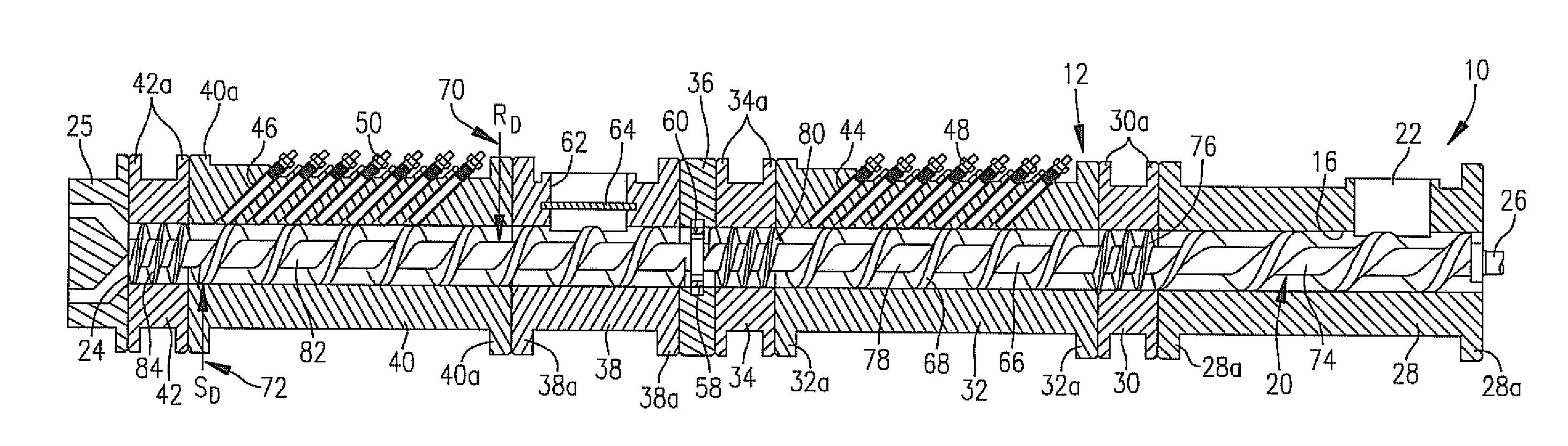

ActiveUS7749552B1High degreeLow viscosityMilk preservationMeat/fish preservation by heatingPre treatmentViscosity

Improved extruded starch-bearing grain products (e.g., corn and wheat) are provided having relatively high cook values and low cold water viscosities. The products are prepared by initial preconditioning to partially cook the starting material(s), followed by low shear extrusion cooking, with a total STE / SME ratio of at least about 4.

Owner:WENGER MFG LLC

Diet therapy nutritional household porridge

The invention which belongs to the porridge filed concretely relates to a nutritional household porridge which realizes health preserving and healthcare through diet therapy. The nutritional household porridge provided in the invention has a high nutritive value and a diet therapy effect. The porridge is obtained by treating a cereal product as a main material and proper amounts of one to three of Lycium Chinense, walnut, edible tree fungus, red date, longan, lotus seed, lily, Chinese yam, peanut, Semen Euryales, chestnut and Polygonum multiflorum Thunb as ingredients, then respectively independently packaging the main material and the ingredients, and packaging in a finished product packaging bag.

Owner:王东新

Low carbohydrate flour substitute

A low carbohydrate flour substitute for making food product having the mouth feel of a typical grain product with minimal carbohydrate content comprises in combination hydrogenated starch hydrolysate, vegetable protein, and fibers having a length determined to provide the desired mouth feel. High intensity sweetners, albumin, and other additives are added in appropriate amounts which provide taste, texture, and coloration.

Owner:MULLER THYM HAROLD TOY JR

Stabilisation of immunoglobulins at a low ph

InactiveUS20040028667A1Significant positive effectOrganic active ingredientsBiocideSports drinkProbiotic bacterium

The invention refers to a method of stabilising immunoglobins in a solution havin a pH below 4, wherein cereals or hydrolysed cereal products are added in an amount sufficient to prevent degradation. The invention also refers to a health drink or sports drink comprising immunoglobins in a solution having a pH of 2.7-3.8, which are stabilised by the addition of cereals or hydrolysed cereal products, and which can optionally also contain a probiotic bacterium.

Owner:PROBI AB LUND SE

Omega-3 enriched cereal, granola, and snack bars

InactiveUS20100272875A1Improve nutritional qualityNegative tasteDough treatmentEdible oils/fats with fatty acid estersStearidonic acidProduct mix

The present disclosure provides for improved cereal products, specifically snack bars, and methods of producing such products by incorporating healthy lipids containing stearidonic acid into the product compositions. In one embodiment of the disclosure, a cereal product including a SDA-enriched oil is disclosed. In another embodiment of the disclosure, a snack bar including a SDA-enriched soybean oil is disclosed.

Owner:MONSANTO TECH LLC

Method and system for sanitization of grain products

InactiveUS20070134380A1Eliminate odorEliminate moldSeed preservation using chemicalsAgricultural scienceCereal product

Owner:THE O3 ZONE

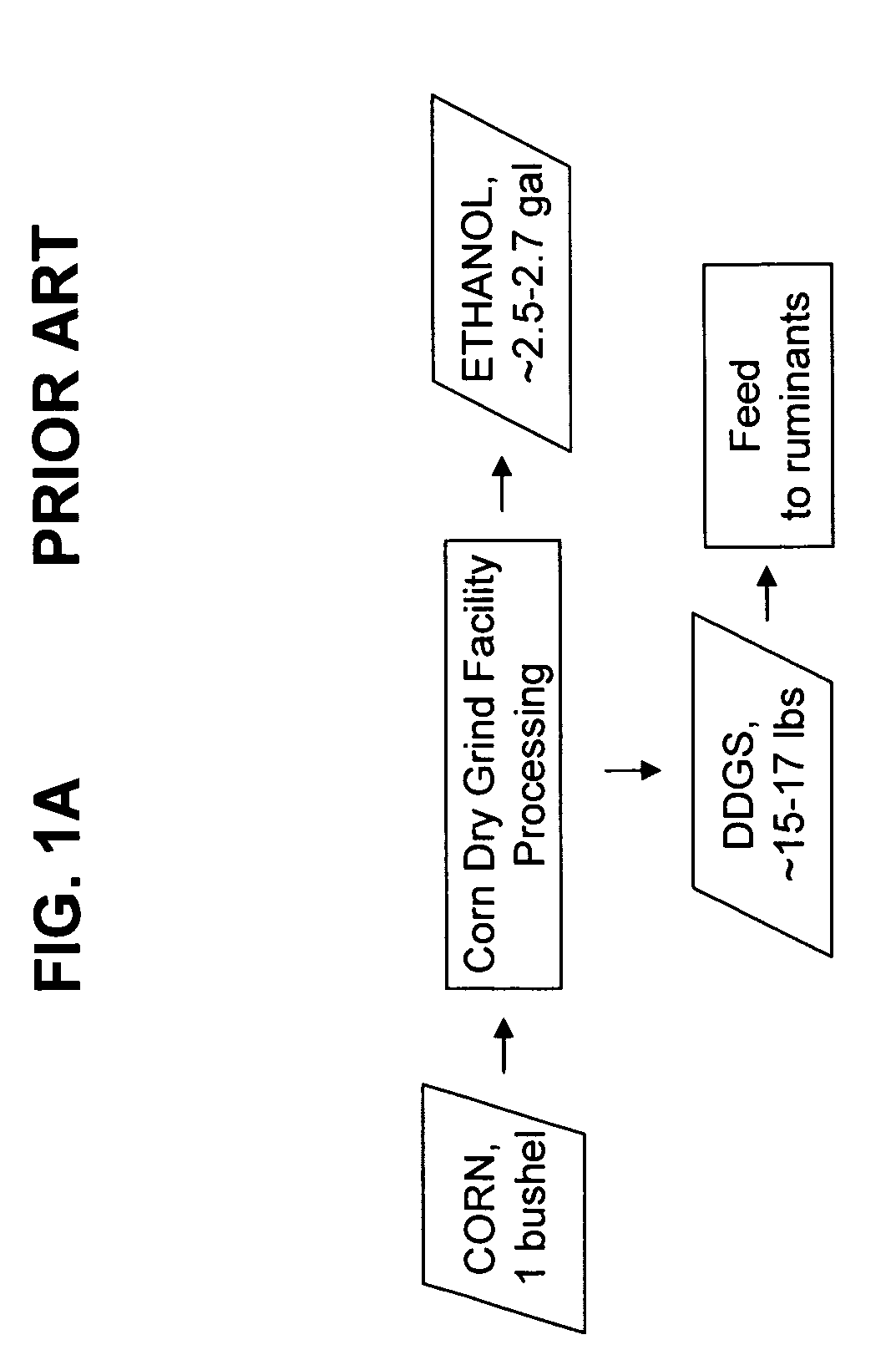

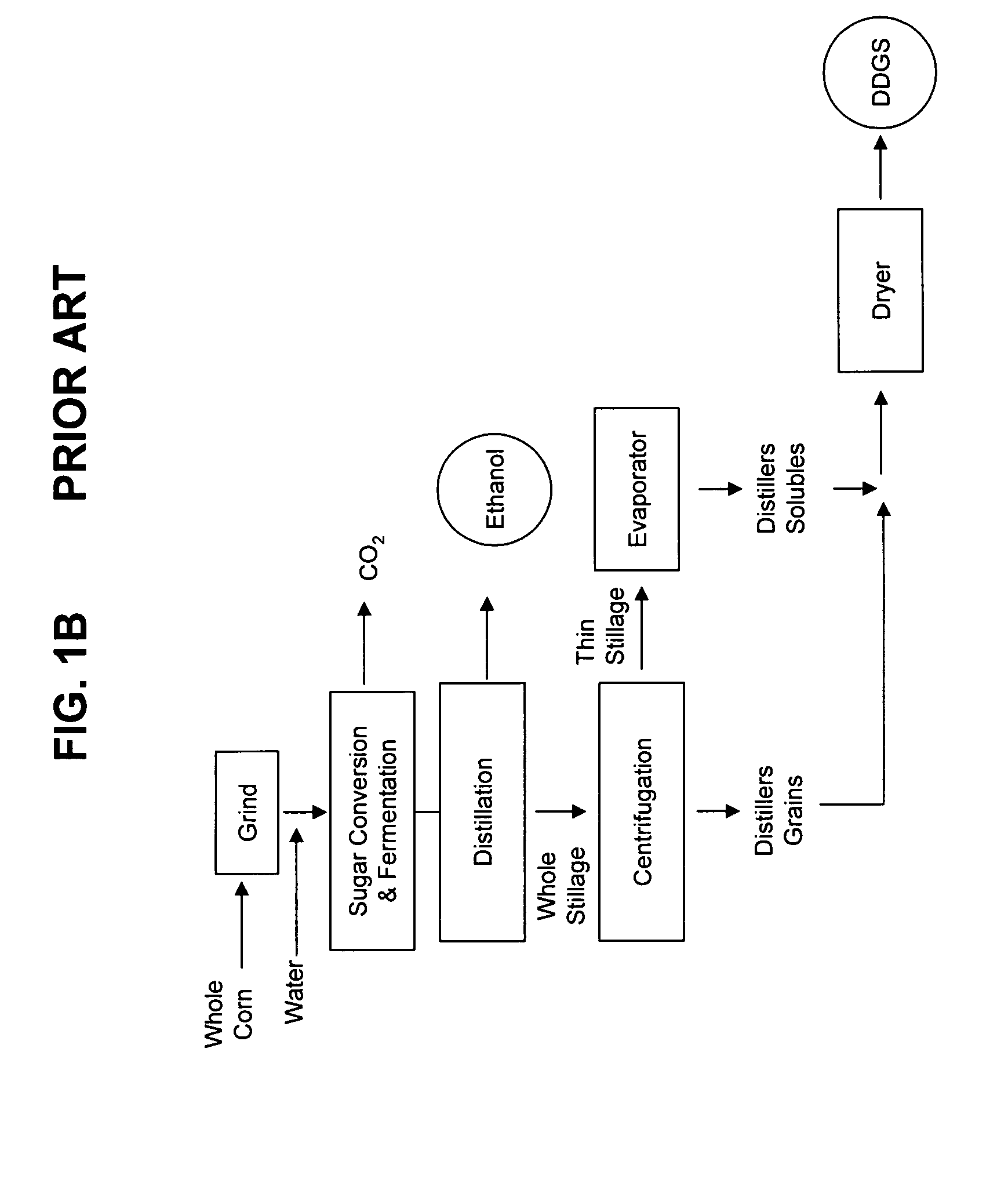

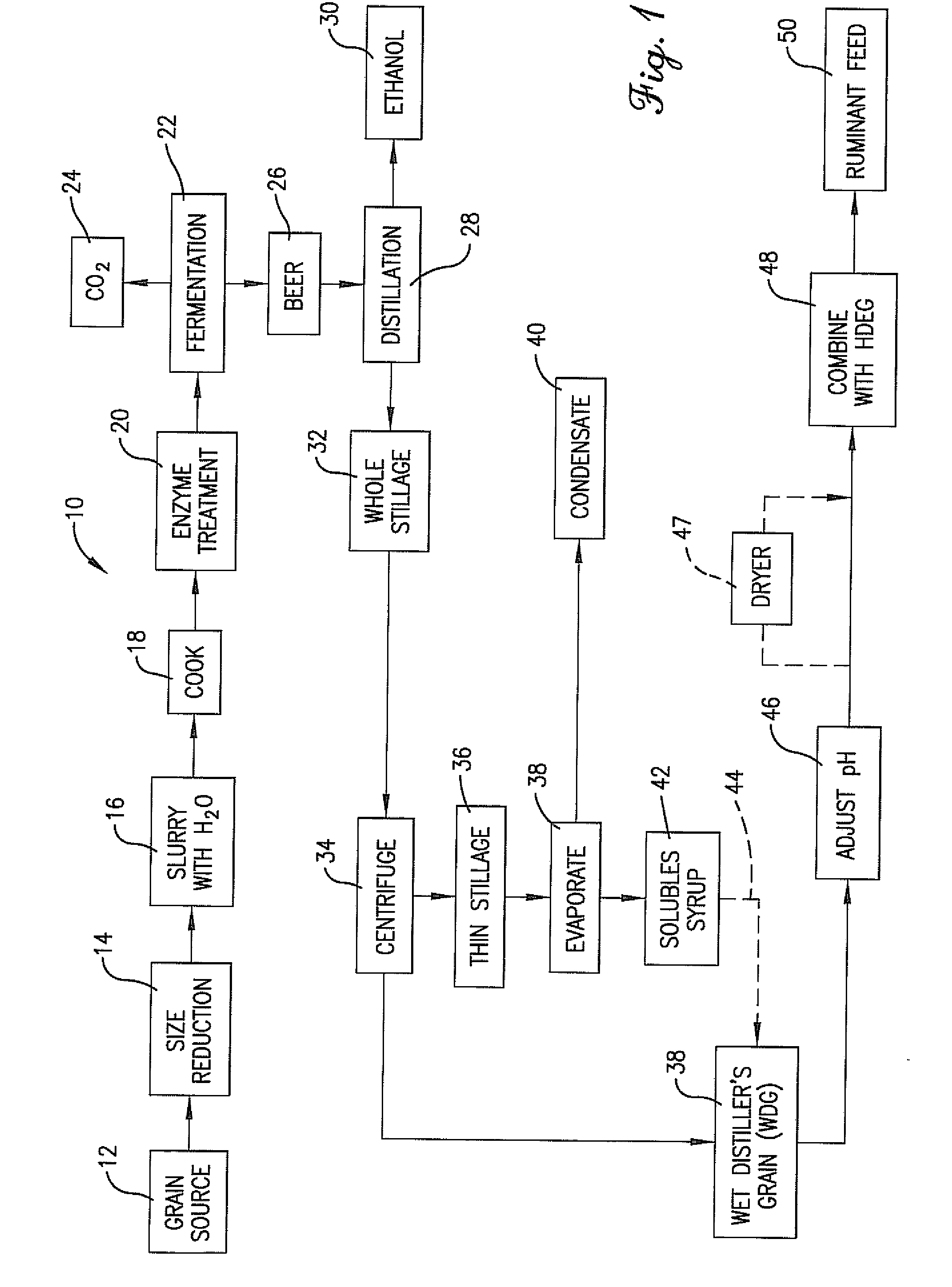

RUMINANT FEEDS CONTAINING pH-ADJUSTED EDIBLE BYPRODUCTS AND HIGH DIGESTIVE EFFICIENCY GRAINS

InactiveUS20080279981A1Improve digestion efficiencyAvoid the needWort preparationFood processingBiotechnologyAdditive ingredient

Improved ruminant feeds are provided which include a pH-adjusted first ingredient selected from the group consisting of ruminant-edible, initially low pH commercial byproducts and initially low pH grain or forage-derived products, combined with a second ingredient comprising a high digestive efficiency feed grain such as flaked corn. An improved process (10) for the production of a ruminant feed (50) as an adjunct to a fuel ethanol plant is also provided wherein starch-bearing grain (12) is processed to yield ethanol (30) and whole stillage (32). The whole stillage (32) is then treated to remove water and to yield a wet distiller's grain product (WDG) (38). The pH of the WDG (38) is then elevated (46) by the addition of base to a pH of from about 5-8, and the pH-adjusted WDG (46) is optionally dried (47) and combined with a high digestive efficiency feed grain (HDEG) such as flaked grain (48). The ruminant feeds (50) of the invention do not generate low rumen pH levels when consumed, and thus avoid rumen acidosis and related problems.

Owner:BYPROD FEED TECH

Method of bleaching cereal grains

InactiveUS7101580B2White colorIncrease volumeDough treatmentEdible seed preservationFiberFood flavor

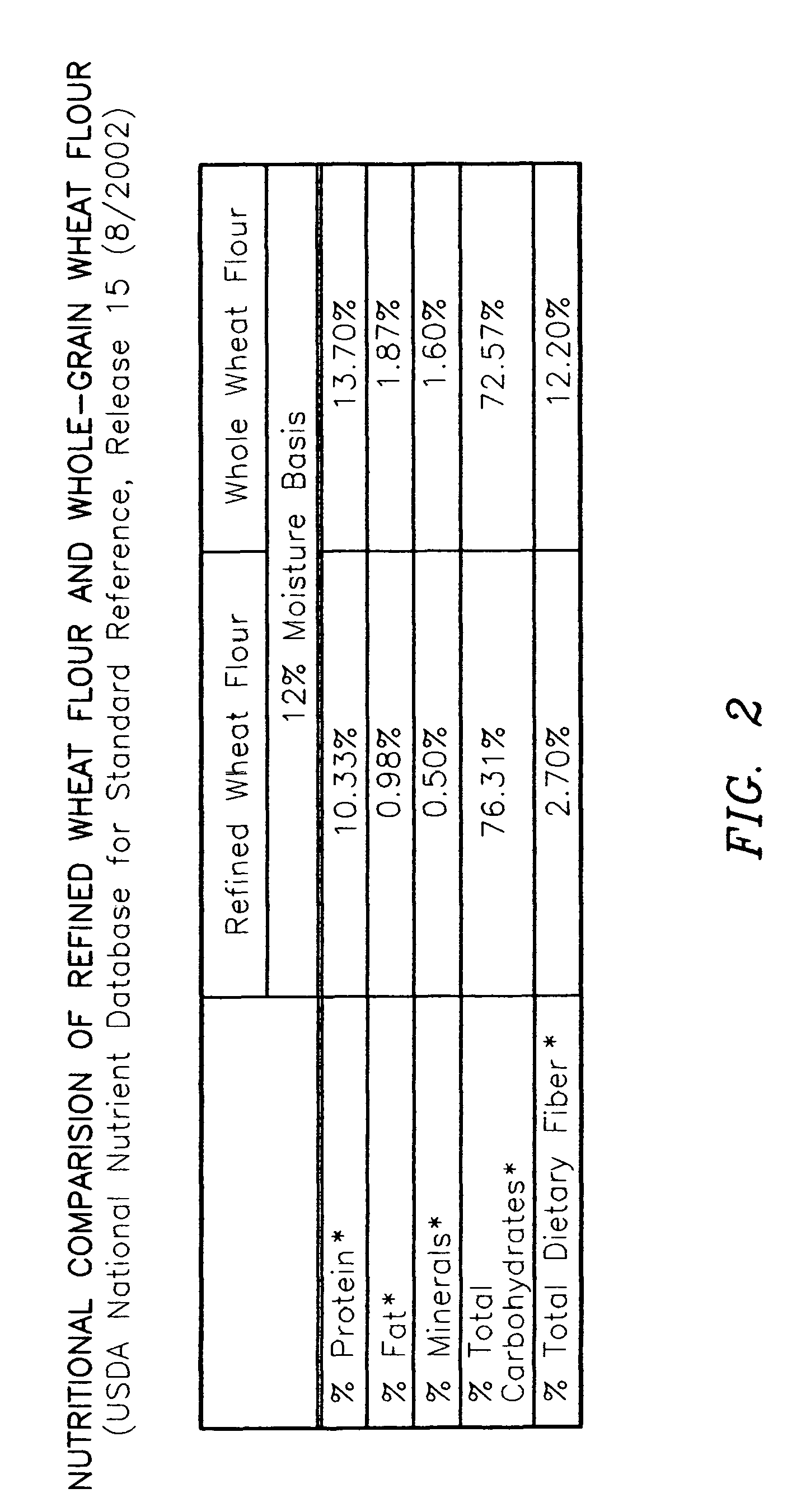

The present invention describes bleached grain products such as bleached whole wheat flour that are obtained having the color and taste of white flour by bleaching whole wheat kernels prior to conventional flour milling. The wheat kernels are treated with a peroxide solution to lighten the color of the bran layers. The bleached grain kernels can be tempered and milled into whole grain flours having 10% to 12% dietary fiber from the bran but which are white in color and bland in flavor. The whitened, high fiber whole wheat flours can be used to prepare good tasting, and nutritious products such as baked goods such as breads and pastries as well as pasta product, and ready-to-eat cereals or grain based snacks.

Owner:GENERAL MILLS INC

Method for processing cereal potato powder into rice grain products by using konjak flavor powder to prevent starch gelatinization

The invention relates to a method for processing cereal potato powder into rice grain products by using konjak flavor powder to prevent starch gelatinization, in particular to a processing method for cereal products. In the method, the cereal potato powder is used as a major ingredient which consists of one or more of cereal powder or / and potato powder; and special-grade konjak flavor powder is used as a critical ingredient, wherein the used amount of the special-grade konjak flavor powder accounts for 1 to 10 percent of the total amount of raw materials, and the water consumption accounts for 18 to 30 percent of the total weight of the raw materials. The method comprises the following steps of: preparing the special-grade konjak flavor powder, the cereal potato powder raw materials and the water respectively according to a ratio; dissolving the special-grade konjak flavor powder in hot water at the temperature of between 55 and 60 DEG C to prepare serous fluid; mixing and stirring the serious fluid and the cereal potato powder fully to form uniform dough wet grains, and curing; processing the cured materials in the same direction at different speeds by adopting a double screw extruder, and wrapping by glucomannan serving as a special-grade konjak flavor powder aid, so that the gelatinization degree of cereal potato starch is limited within the range of between 75 and 78 percent effectively, and forming strip colloid to be extruded; and cutting the colloid to form the rice grain products with full grains.

Owner:湖北富程魔芋产业发展有限公司

Methods and compositions employing pomegranate extracts and fementation products of statin-producing fungi

InactiveUS20070104730A1Lower systolic blood pressureReduced activityBiocideFungi medical ingredientsHMG-CoA reductaseFungal microorganisms

Dietary supplements useful for treating or preventing cardiac disease are disclosed According to some embodiments, the presently disclosed supplement includes a pomegranate product fermented with a statin-producing fungus such one or more of Monascus, Aspergillus, Penicillium, Pleurotus, Pythium, Hypomyces, Paelicilomyces, Eupenicillium, and Doratomyces. Alternatively or additionally, the presently disclosed supplement includes a pomegranate product in combination with a plant product, such as a grain product and a legume, fermented with the statin-producing fungus. Optionally, the supplement includes at least one of coenzymeQ10 and a tocopherol. The presently disclosed dietary supplements include both a COX-2 inhibitor and a HMG-CoA reductase inhibitor, and in some embodiments, the supplement is useful for reducing or controlling blood cholesterol for managing atherosclerotic disease, and / or for managing blood pressure. Methods of preparing the presently disclosed dietary supplement are also provided.

Owner:RIMONEST

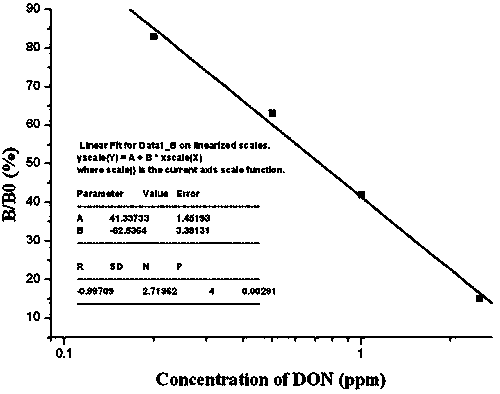

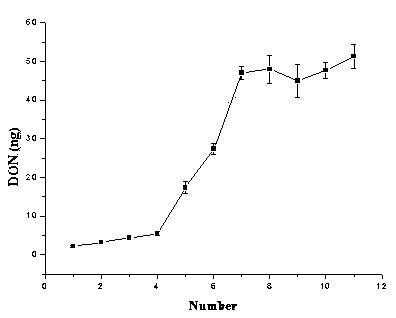

Preparation of ELISA kit for detecting deoxynivalenol

The invention relates to preparation of an ELISA kit for detecting deoxynivalenol. The kit with sensitive detection, accuracy, fastness, simple operation and strong specificity is suitable for determination of a large number of samples. The kit includes an ELISA plate coated with deoxynivalenol antigens, a deoxynivalenol standard sample, a deoxynivalenol antibody working solution, an enzyme-labeled?second antibody working solution, a substrate solution A, a substrate solution B, a stop solution, a concentrating sample weak solution and a washing concentrate. The principle of the deoxynivalenol detection kit is solid phase indirect competitive enzyme-linked immunosorbent assay. An extracted sample, the enzyme-labeled?standard second antibody working solution and the antibody working solution are added to corresponding enzyme-labeled holes; after incubation for a period of time, the substrate solution A and the substrate solution B are added into a washing plate; under the action of the enzyme, blue color occurs in the holes; and the stop solution adding is added in, and the color changes from blue to yellow. The degree of color is in inverse proportion relationship with the content of deoxynivalenol in the standard substance or sample. The method can be directly used for detecting deoxynivalenol in cereals and cereal products.

Owner:JIANGSU WISE SCI & TECH DEV

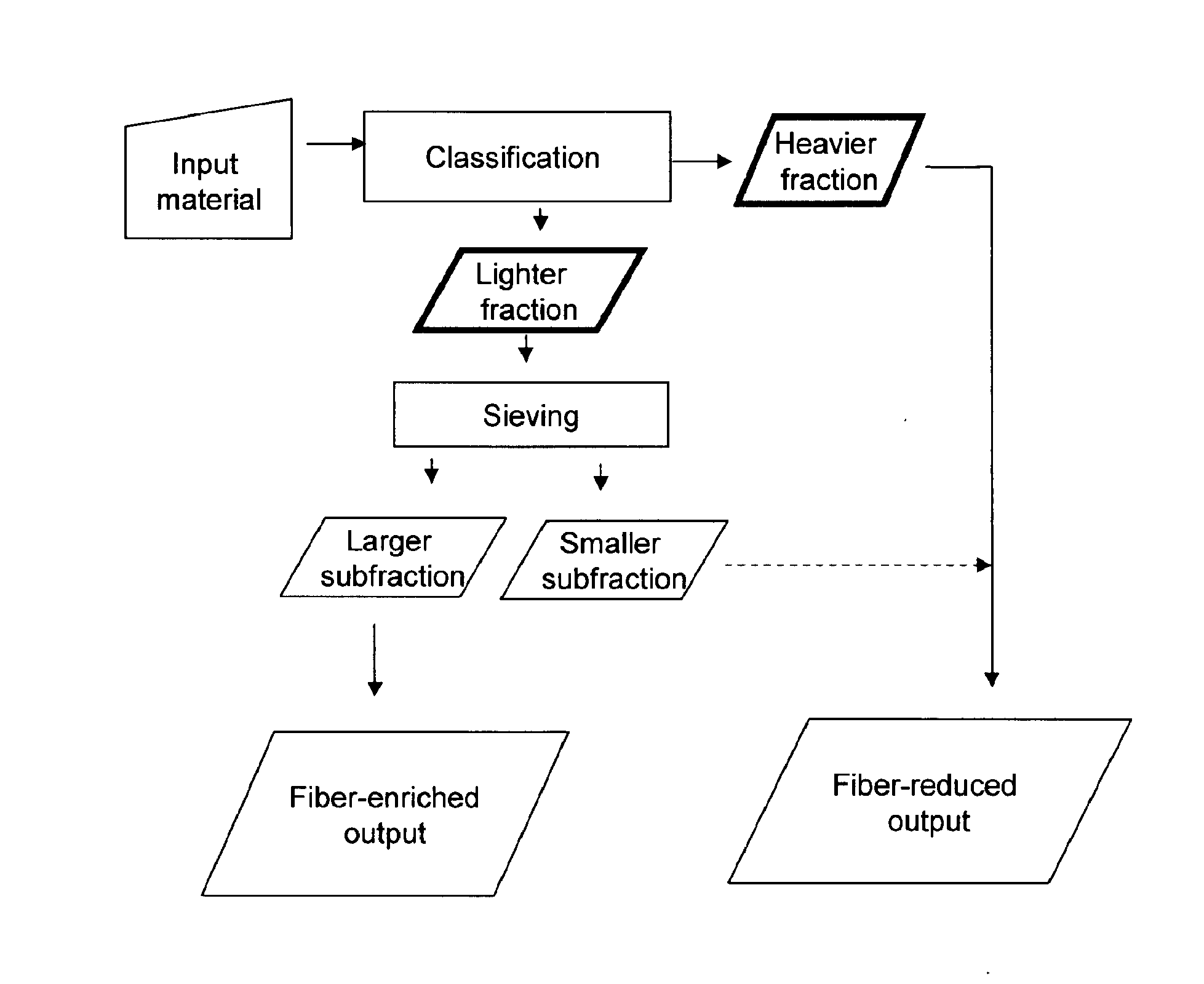

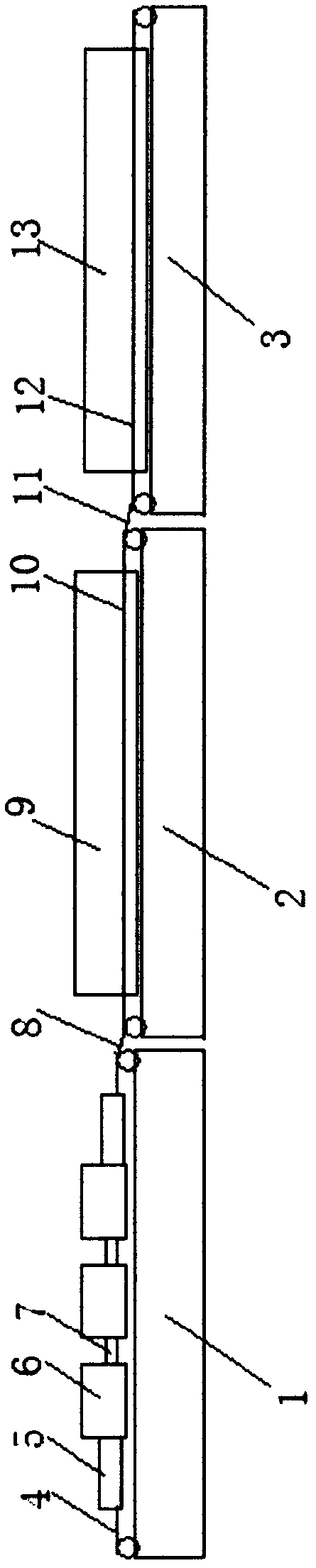

Fiber separation using elusieve process

ActiveUS20100206780A1Easy to adaptLower blood cholesterol levelsFood processingBiofuelsFiberWheat middlings

Methods, devices, and compositions relating to processed grain products are disclosed for ground corn flour, soybean meal, cottonseed meal, and wheat middlings. An exemplary method disclosed is a fiber separation process for the ethanol industry corn products of Distillers Dried Grains (DDG) and Distillers Dried Grains with Solubles (DDGS) resulting from the widely used dry grind technology. A disclosed process and apparatus allows the removal and separate recovery of fiber-reduced products with expanded potential for use as a non-ruminant feed product in addition to the removal and separate recovery of a fiber-enriched product. The fiber enriched and fiber reduced products each have uses in the feed industry. The specific processes, devices, and compositions disclosed are readily adaptable to feed mills.

Owner:MISSISSIPPI STATE UNIV RES TECH

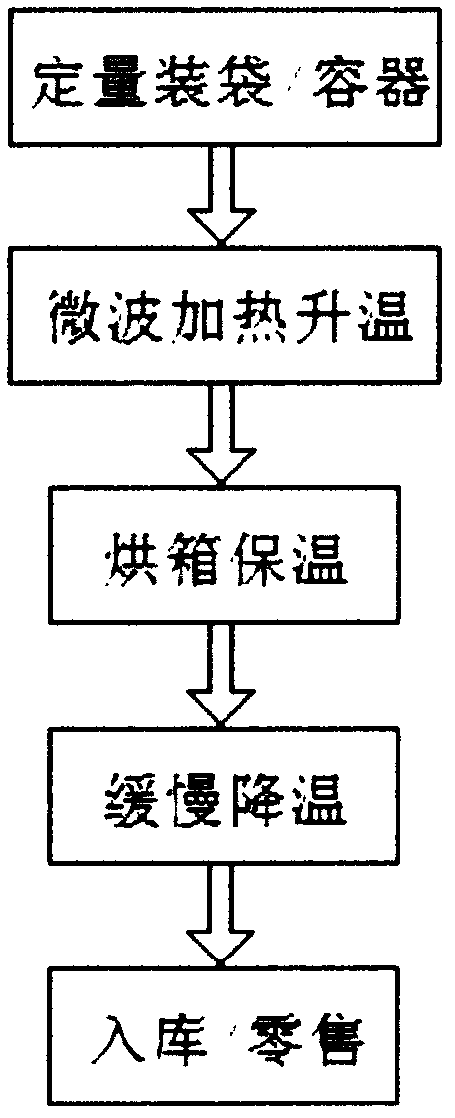

Microwave pest killing method for grain products such as rice, beans, wheat

InactiveCN102986864AAchieve pest controlComplete production processSeed preservation by heatingCold airAgricultural science

The invention discloses a microwave pest killing method for grain products such as rice, beans, wheat and the like for grain raw material or processed grain, which is applicable to the grain products before being put in storage or taken out of storage. The microwave pest killing method for grain comprises the following steps: (1) quantitatively putting the grain product into a pored packing bag or nonmetal container; (2) uniformly heating to 40-70 DEG C in a box-type or tunnel-type industrial microwave oven; (3) setting temperature to 50-70 DEG C in a tunnel-type thermal insulation oven, and keeping the temperature for 3-15 minutes; (4) slowly reducing the temperature of the container or the packing bag to below 40 DEG C in a cooling channel in a cold air environment; and (5) storing the product or selling at retail. The method disclosed by the invention is a pure physical pest killing technology, and can completely kill the adults, larvae and eggs in the grains of rice and beans while maintaining the original quality and flavor of the grain products such as rice, beans, wheat and the like.

Owner:SHANGHAI MAIFENG MICROWAVE EQUIP

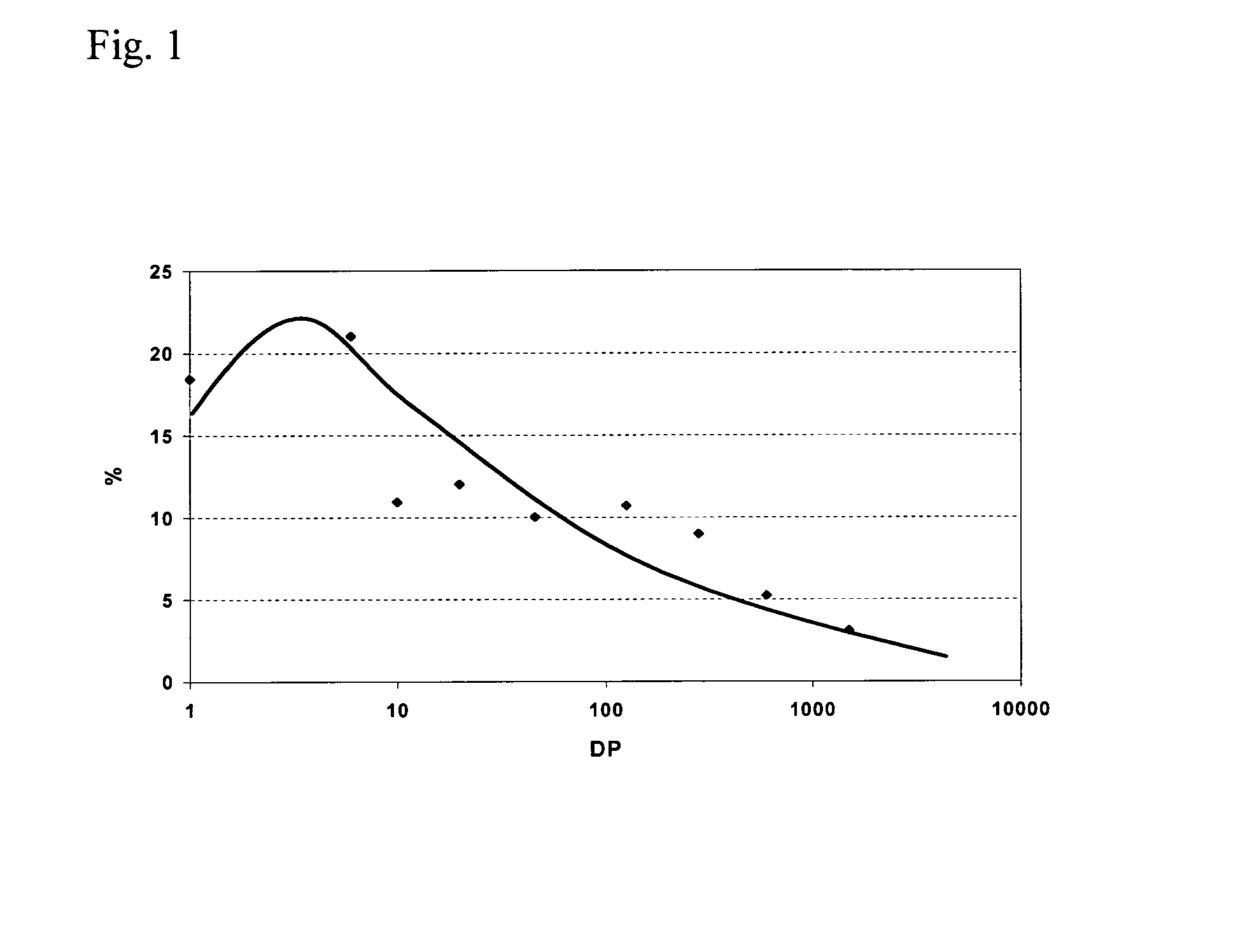

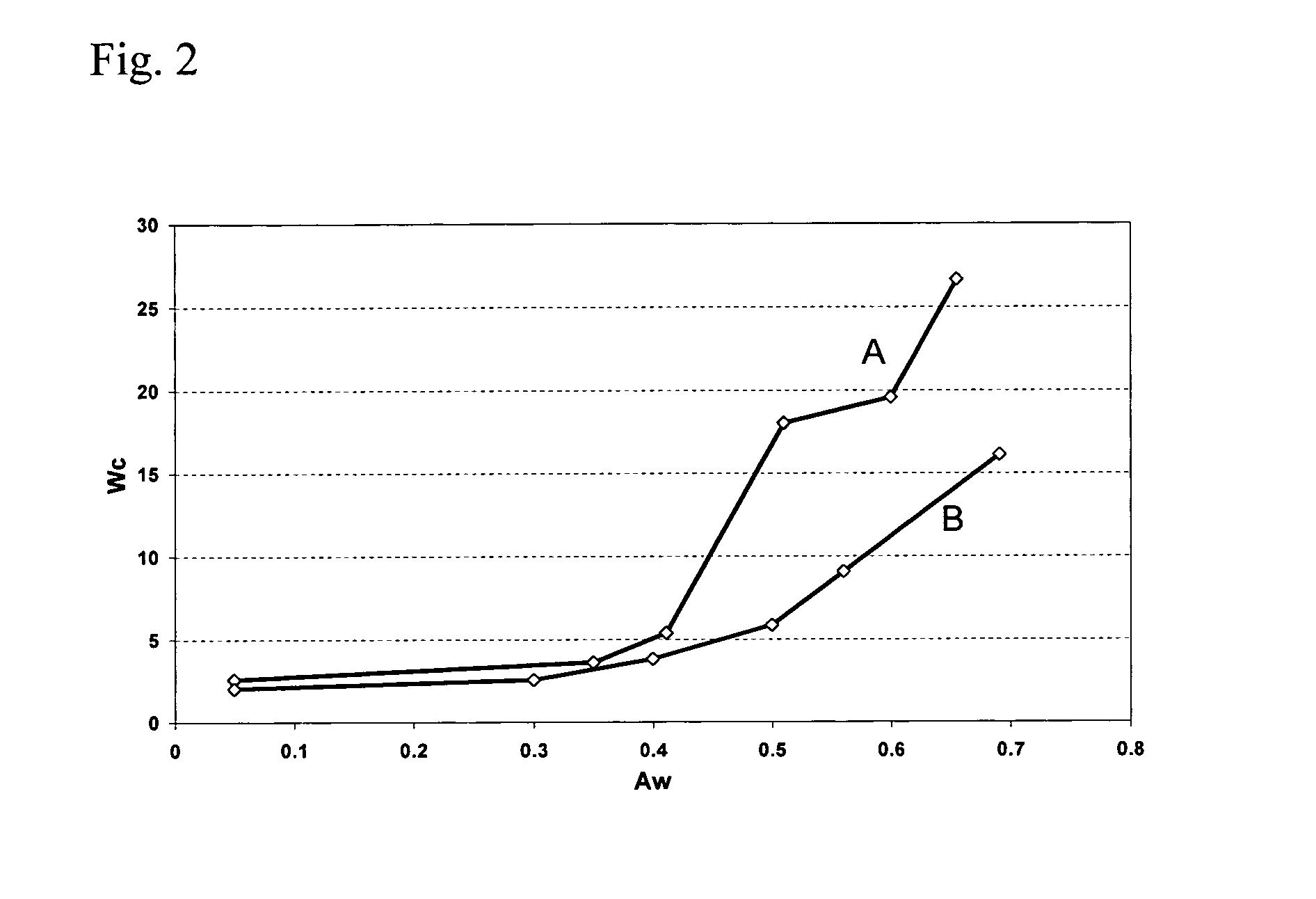

Food product

InactiveUS20110165292A1Improve moisture resistanceDough treatmentBaking mixturesSugarFructooligosaccharide

A no- or low-sugar wafer or an expanded extruded cereal product comprising monodisperse maltodextrins or fructooligosaccharides, methods of making these compositions and food products containing these compositions.

Owner:NESTEC SA

Preparation method of deoxynivalenol immunoaffinity column

InactiveCN103801110AReduce exposureOther chemical processesPreparing sample for investigationSpecific adsorptionPretreatment method

The invention discloses a preparation method of an immunoaffinity column based on deoxynivalenol monoclonal antibodies. An affinity adsorbent obtained through coupling of monoclonal antibodies obtained through cell fusion and cyanogen bromide activated agarose 4B is filled in a solid phase extraction tube to obtain the immunoaffinity column capable of specific adsorption of deoxynivalenol. The immunoaffinity column prepared by the invention can specifically combine with deoxynivalenol, has a maximal binding capacity of about 240ngDON, and reaches recovery rate of no less than 90% for three times of repeated usage. The invention can be used in the pretreatment method of detection of deoxynivalenol residues in cereals and cereal products.

Owner:JIANGSU WISE SCI & TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com