Patents

Literature

733results about How to "Lower contact angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coating composition for multiple hydrophilic applications

InactiveUS20030203991A1Tough and durable and printable surfaceImprove wettabilityOther chemical processesSynthetic resin layered productsColloidWear resistance

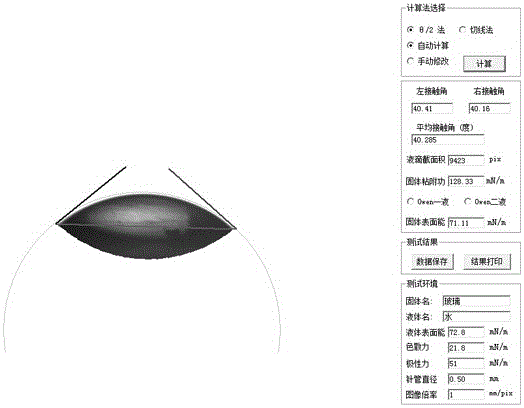

A coating composition is disclosed which comprises an aqueous polymeric matrix, a hydrophilic polymer, a colloidal metal oxide and a crosslinker. The coating composition when applied on medical devices is hydrophilic, shows improved lubricity, abrasion resistance and substrate adhesion on metallic or plastic substrates. The coating also shows improved water sheeting thus providing the coated substrates with anti-fog properties. The coating absorbs aqueous dye or stain solutions making the substrate suitable for printing.

Owner:HYDROMER INC

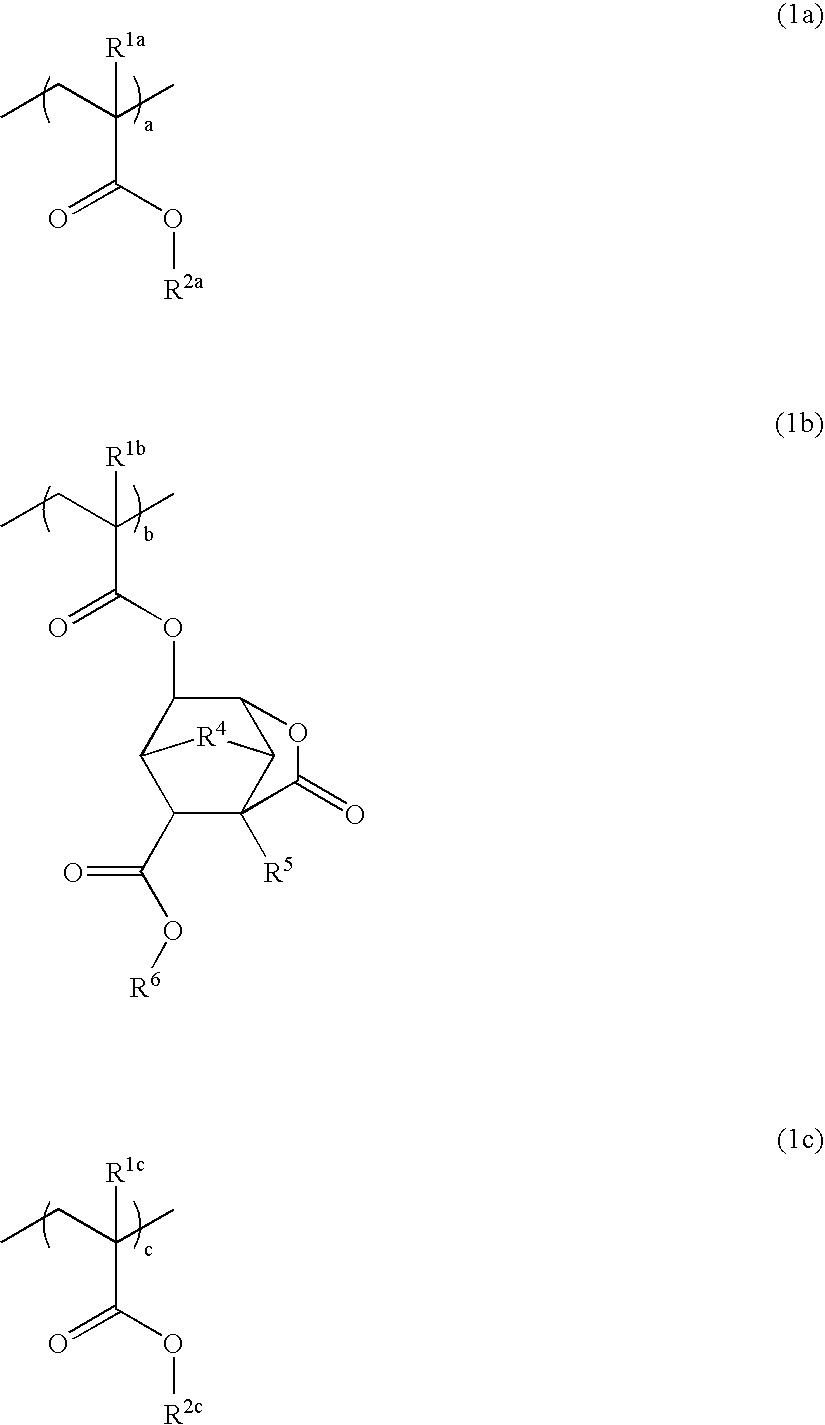

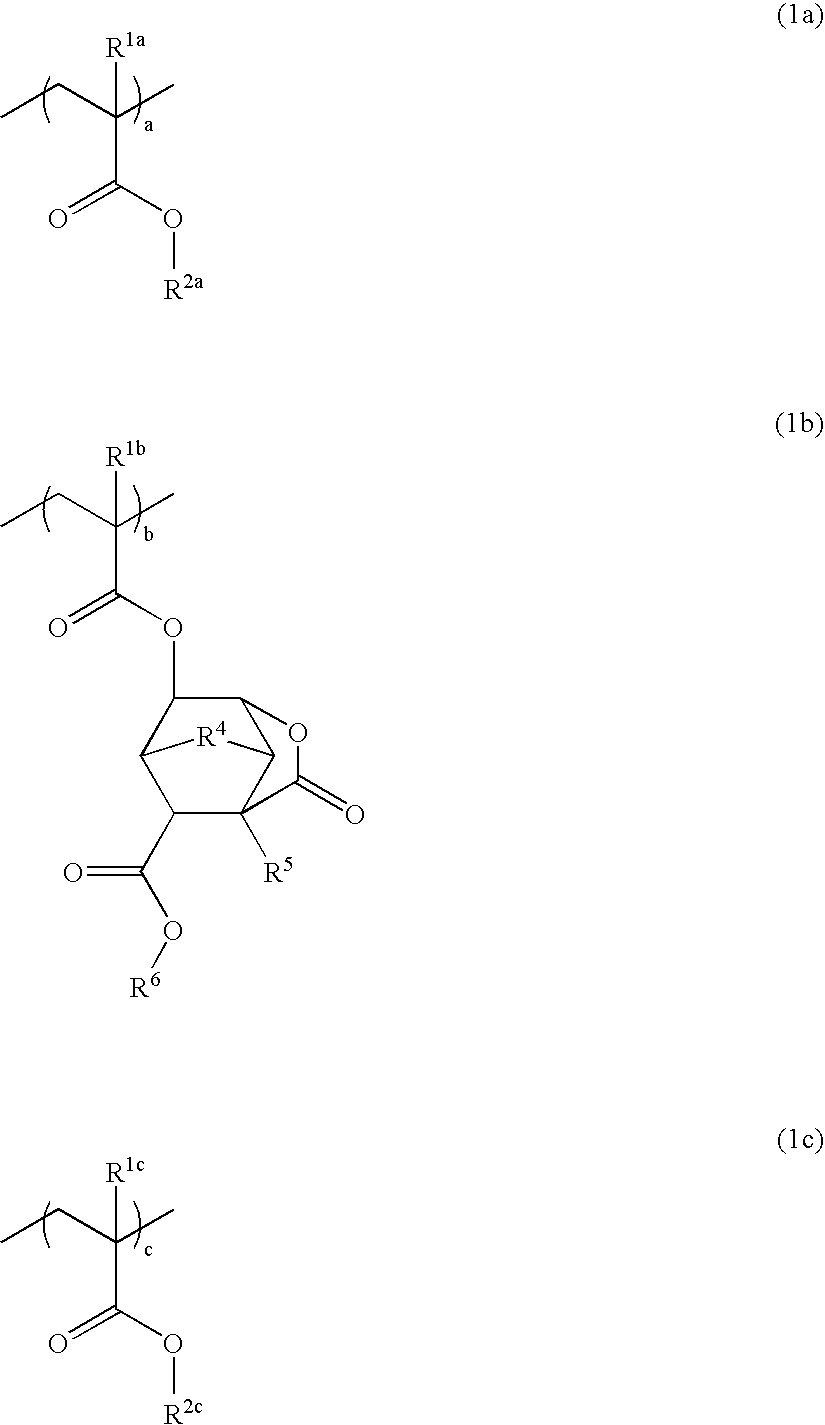

Polymer, resist composition, and patterning process

ActiveUS20080118860A1Lower contact anglePromote resultsPhotosensitive materialsRadiation applicationsPolymer chemistrySoluble polymer

To a resist composition, an alkali-soluble polymer having fluorinated ester-containing lactone units incorporated therein is included as an additive. The resist composition forms a resist film having a reduced contact angle after development. The resist film prevents water penetration during immersion lithography.

Owner:SHIN ETSU CHEM IND CO LTD

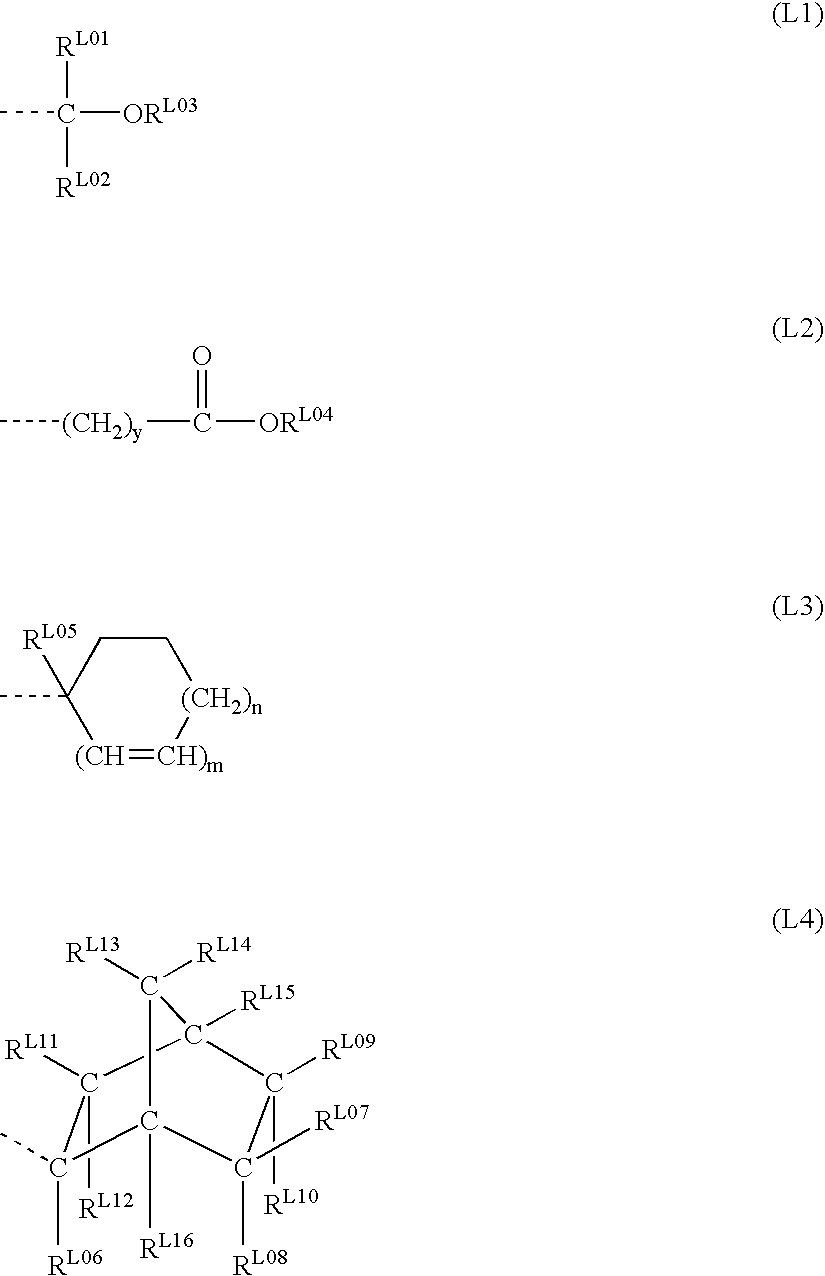

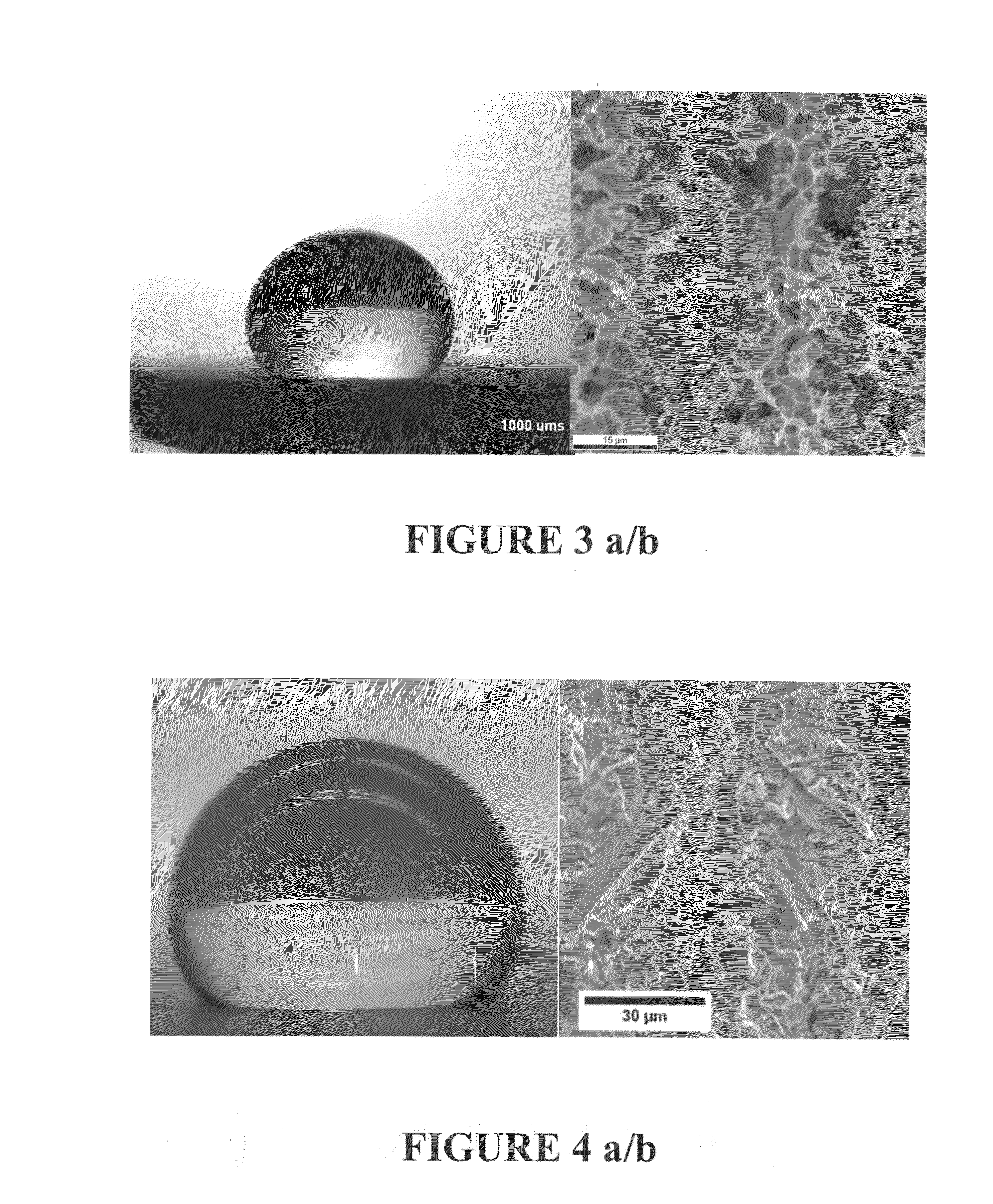

Articles with super-hydrophobic and/or self-cleaning surfaces and method of making same

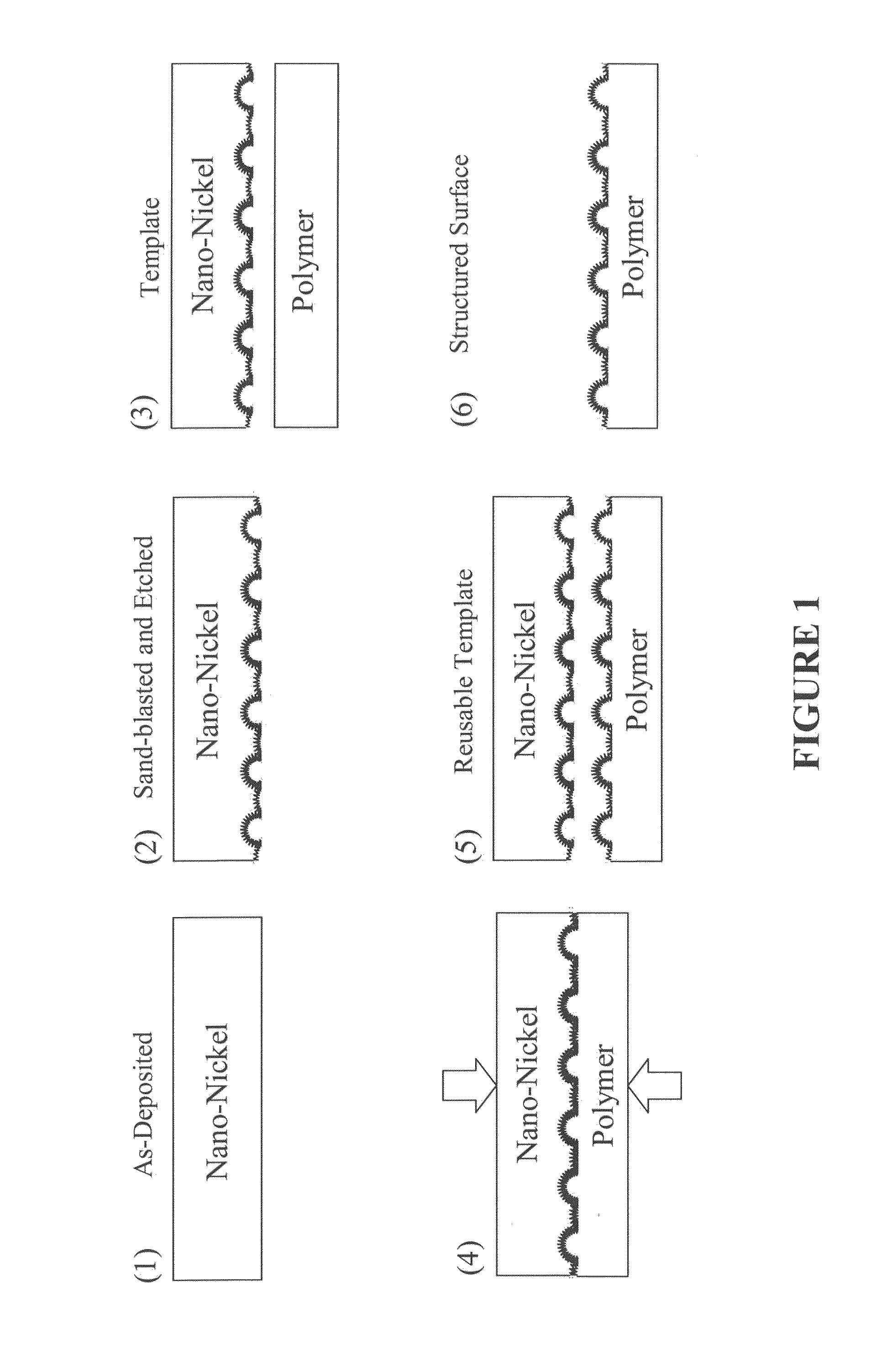

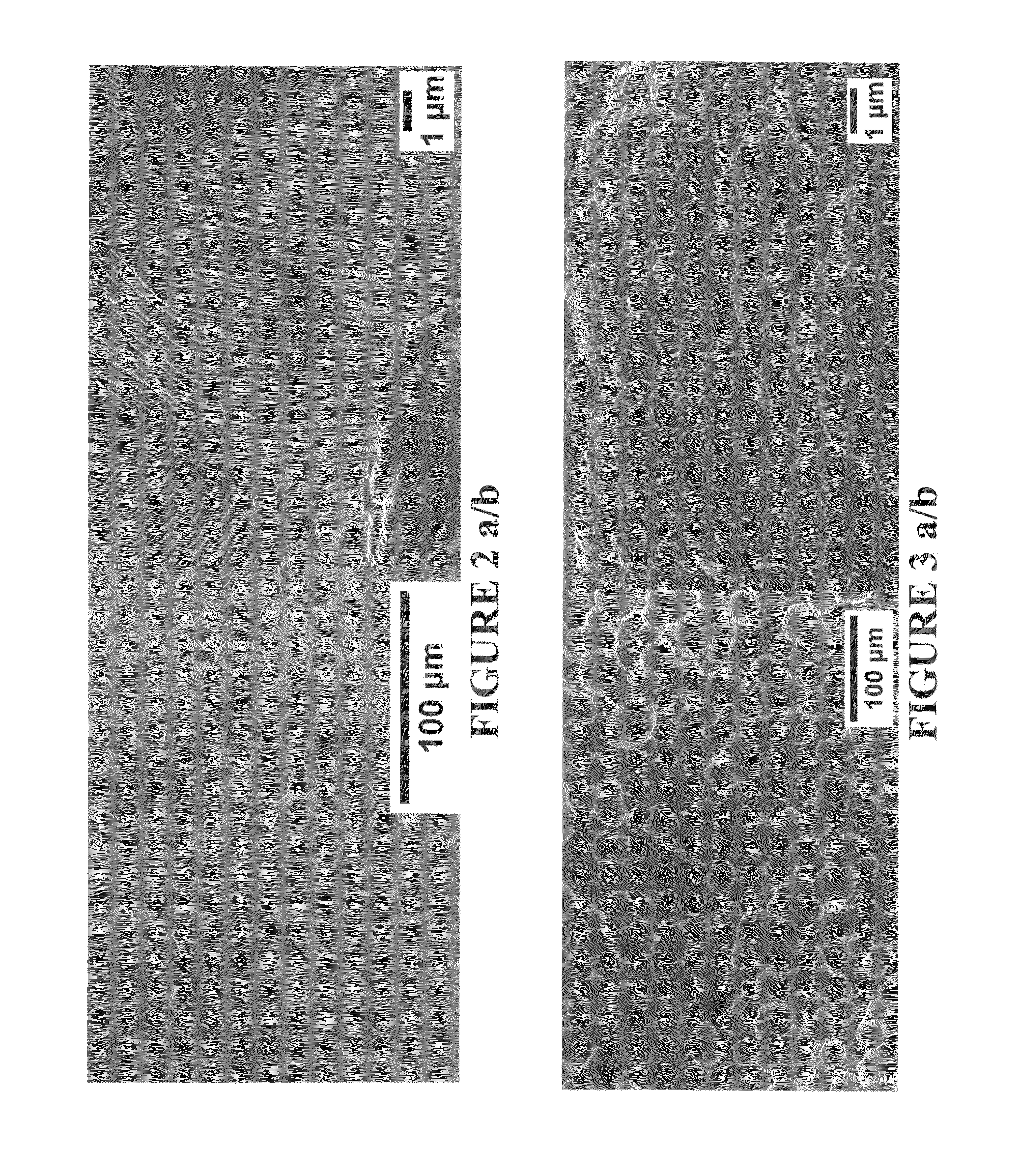

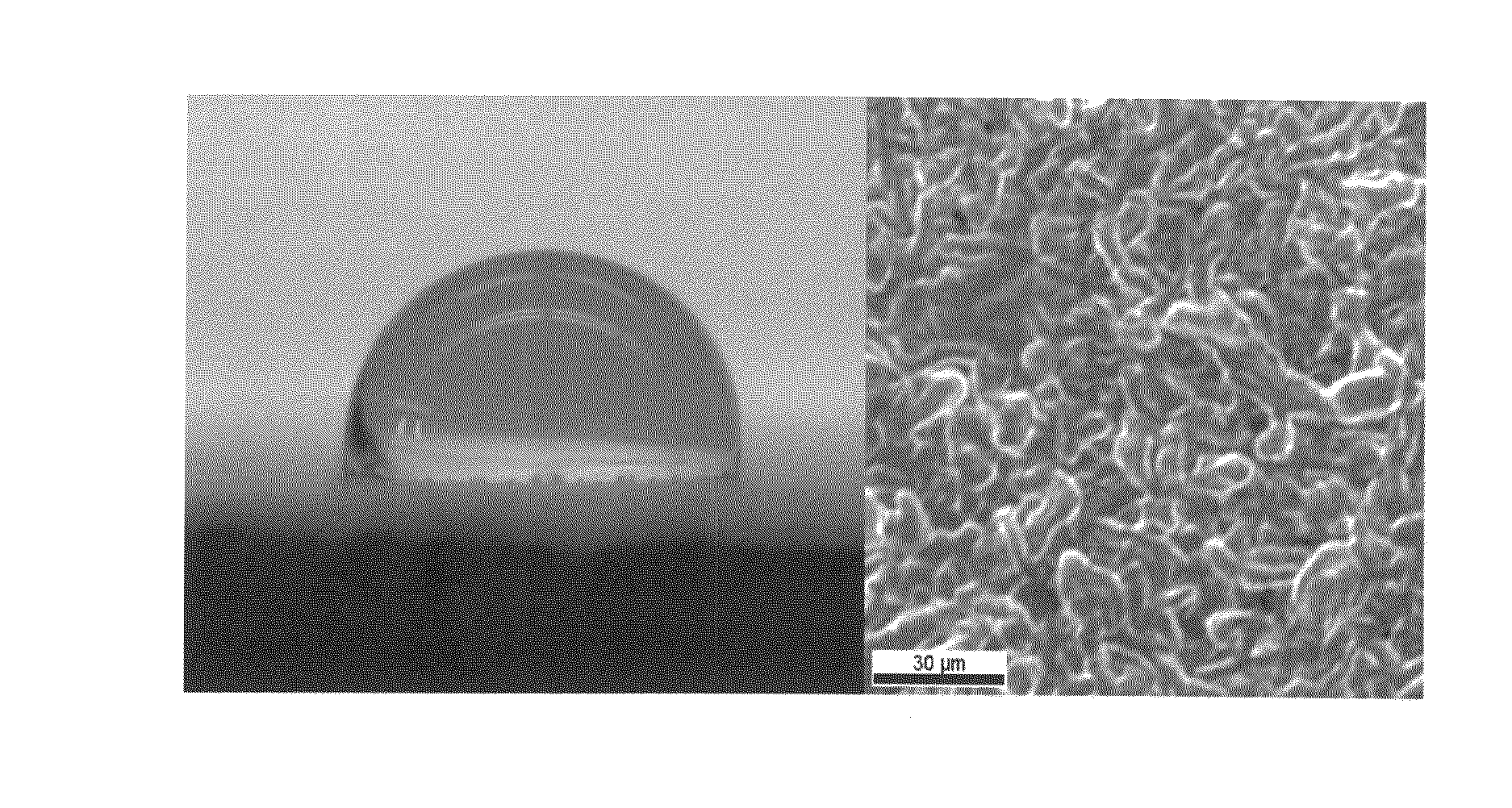

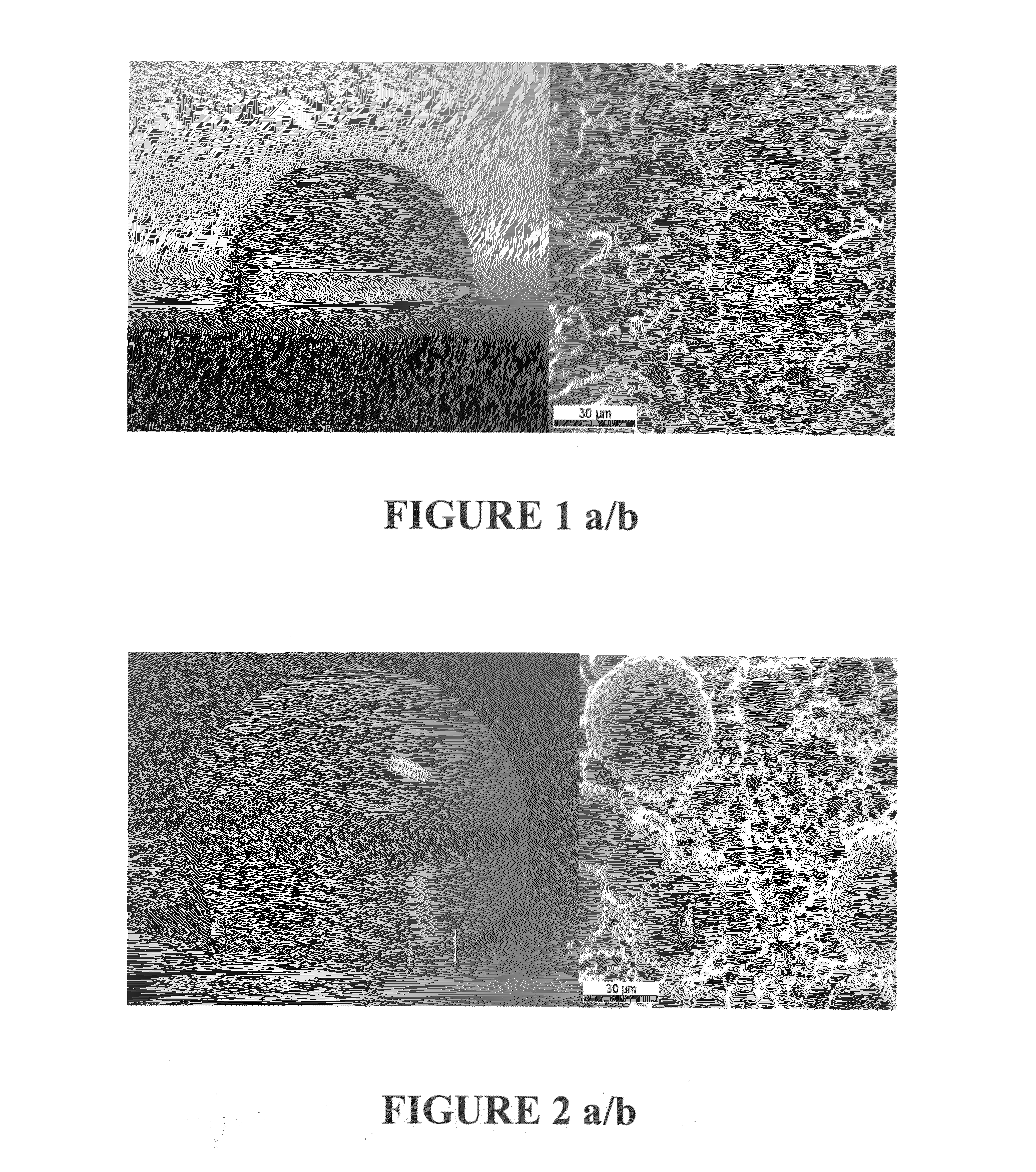

ActiveUS20110287203A1Lower contact angleLarge scaleDischarging arrangementMouldsFine grainSelf-cleaning surfaces

Super-hydrophobic and self-cleaning articles produced by imprinting exposed surfaces with suitable fine-grained and / or amorphous metallic embossing dies to transfer a dual surface structure, including ultra-fine features less than or equal to 100 nm embedded in and overlaying a surface topography with macro-surface structures greater than or equal to 1 micron are disclosed.

Owner:INTEGRAN TECH

Metallic articles with hydrophobic surfaces

ActiveUS20110287223A1Lower contact angleLarge scaleElectrolysis componentsPretreated surfacesMetal coatingMetallic materials

Articles containing fine-grained and / or amorphous metallic coatings / layers on at least part of their exposed surfaces are imprinted with surface structures to raise the contact angle for water in the imprinted areas at room temperature by equal to or greater than 10°, when compared to the flat and smooth metallic material surface of the same composition.

Owner:INTEGRAN TECH

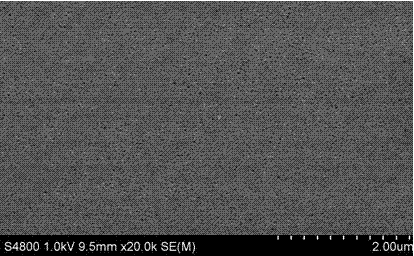

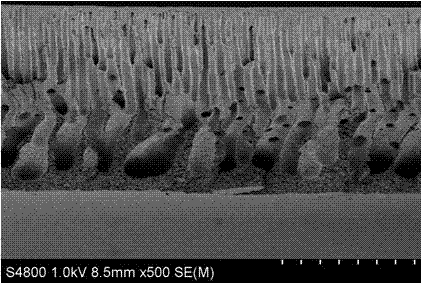

Super-hydrophobic and super-oleophobic surface preparation technology

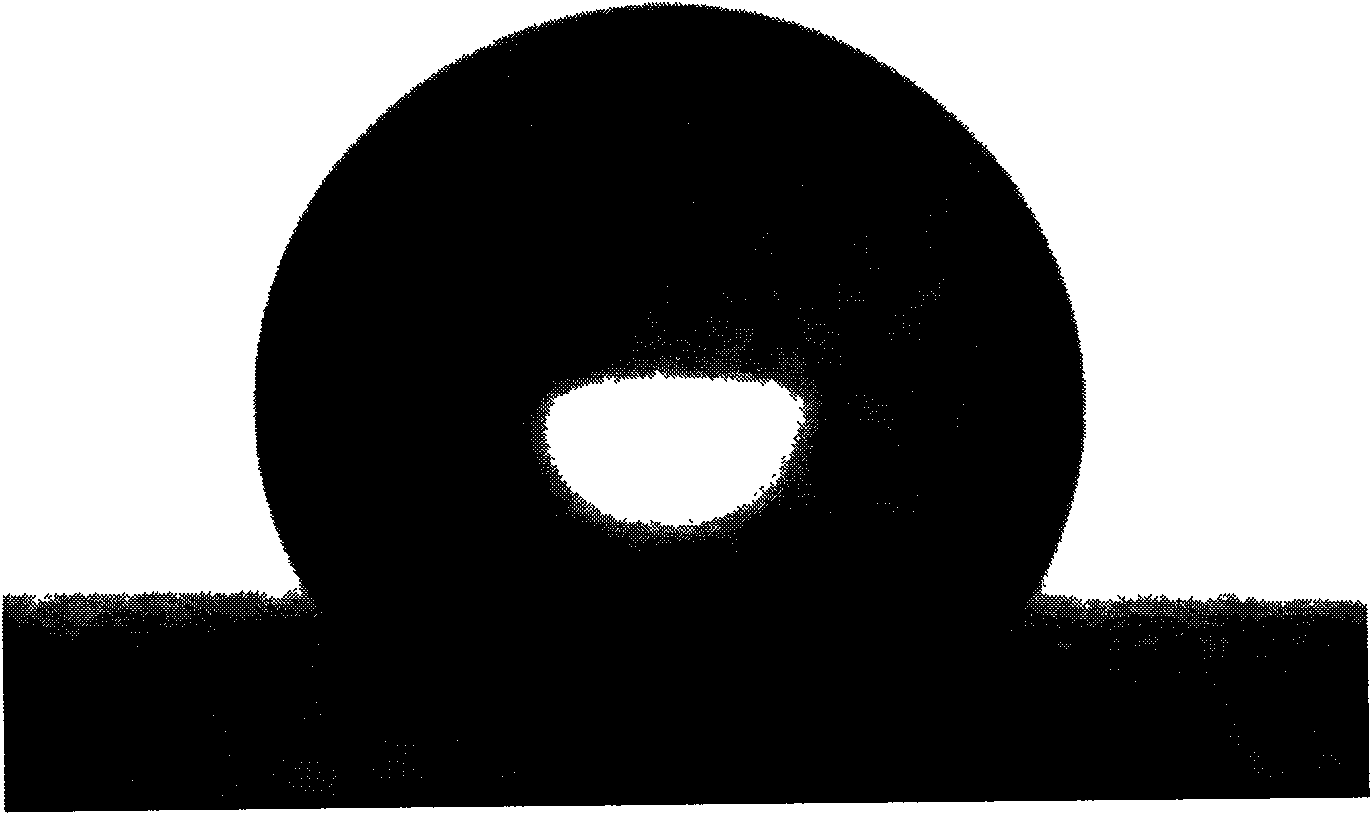

The invention discloses super-hydrophobic and super-oleophobic surface preparation technology. In the preparation technology, aluminum or aluminum alloy sheets are subjected to two-step electrochemical treatment, and then are modified by using perfluorinated octadecyl trichlorosilane or perfluorinated polymethacrylate to prepare the super-hydrophobic and super-oleophobic surface. The surface has super-hydrophobic property on aqueous solution of which the pH value is between 1 and 14 and super-oleophobic property on various oil drops, wherein a contact angle of the surface on water is 171 degrees, and a rolling angle is less than 1 degree; the surface expresses the super-oleophobic property on various oil drops except for perfluorinated polymer liquid, and all contact angles between the oil drops and the surface are more than 150 degrees, and rolling angles are generally less than 10 degrees; and the surface can also be put in air for a long time and can still maintain the super-hydrophobic property and super-oleophobic property.

Owner:中科润泉(烟台)工业科技有限公司

Method of hydrocarbon recovery

InactiveUS20100096129A1Increase contact angleLower contact angleFluid removalRecovery methodWater flow

A method is given for treating a wellbore to increase the production of hydrocarbons from a subterranean formation penetrated by a wellbore, involving a period of injecting into the formation an aqueous injection fluid having a different chemical potential than the aqueous fluid in the formation. If there is water blocking, an osmotic gradient is deliberately created to cause flow of water into the injected fluid; hydrocarbon is then produced by imbibition. If the pore pressure in the water-containing pores in the formation is too low, an osmotic gradient is deliberately created so that water flows from the injected fluid into the water-containing pores, increasing the pore pressure and facilitating hydrocarbon production by imbibition. The method may be repeated cyclically. A semipermeable membrane may be created to enhance the osmosis. Wetting agents may be used to influence imbibition.

Owner:SCHLUMBERGER TECH CORP

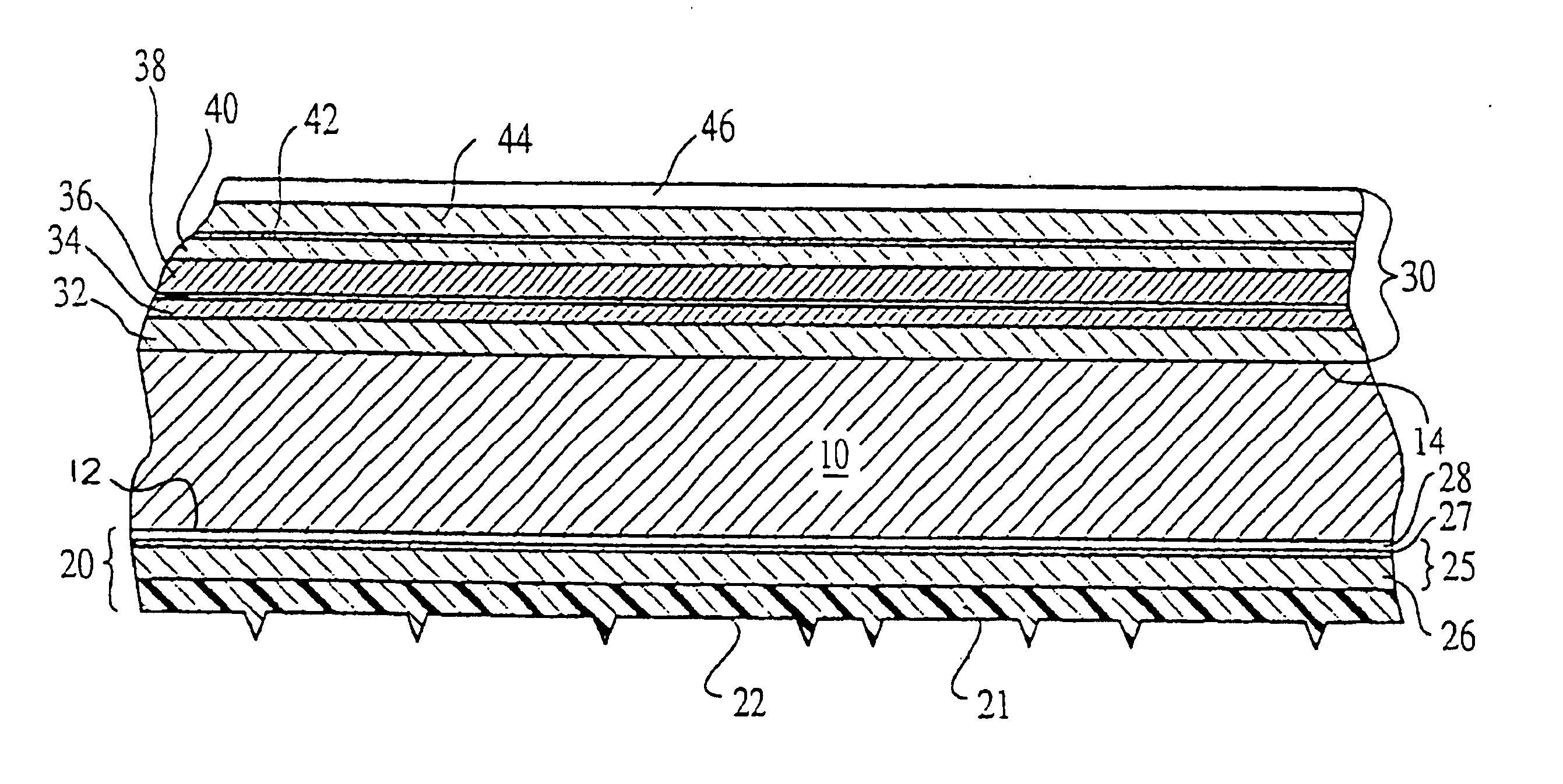

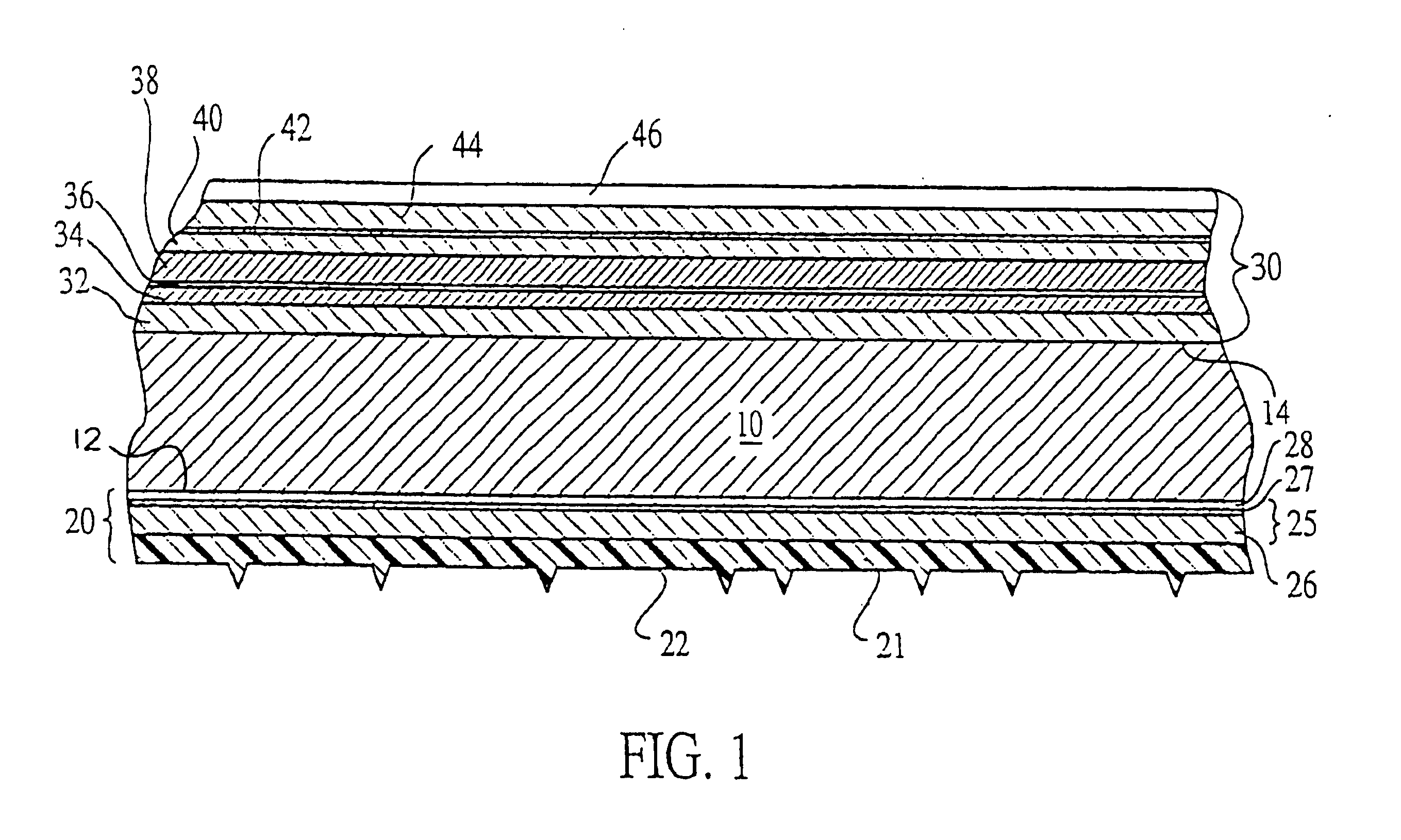

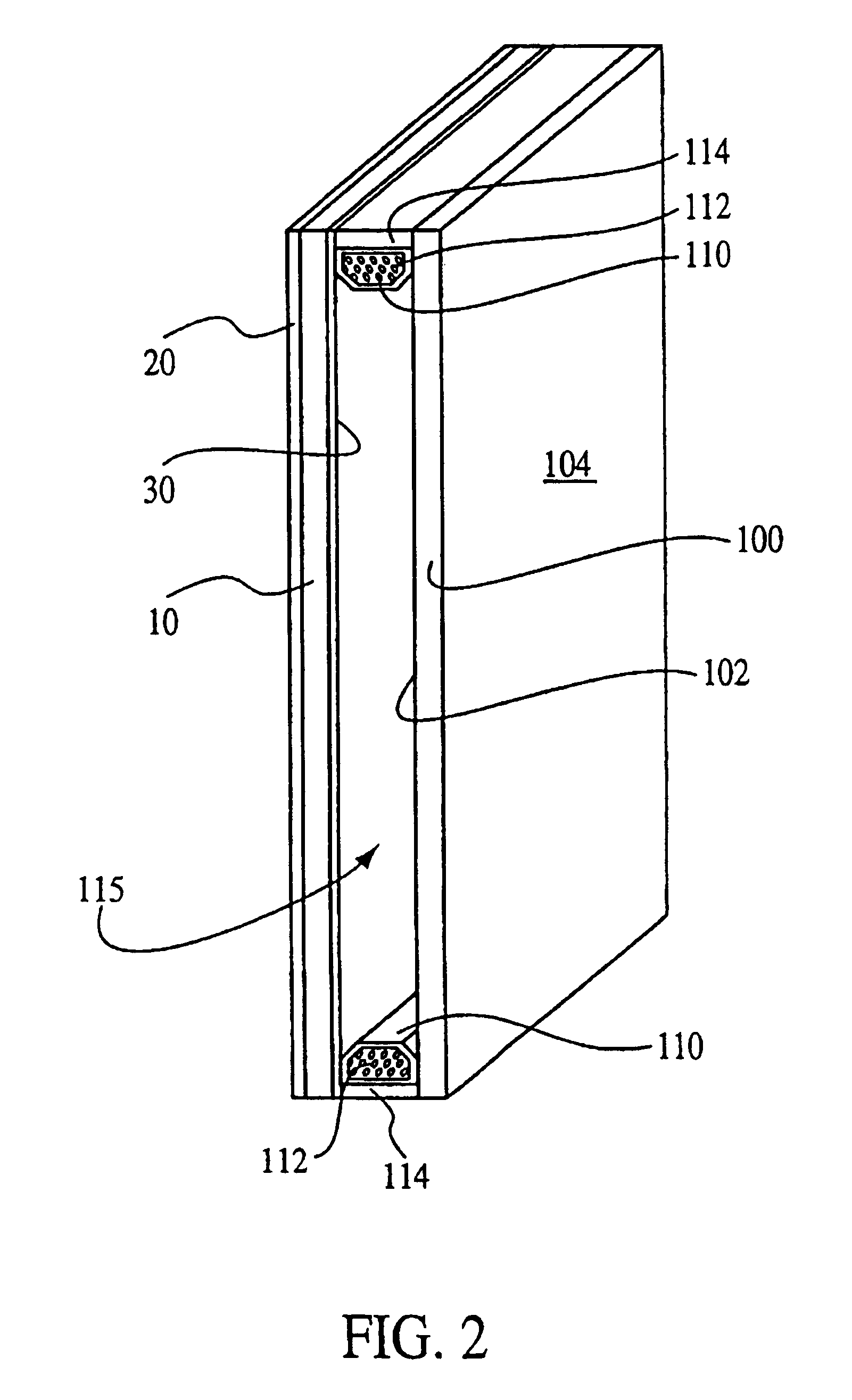

Low-emissivity, soil-resistant coating for glass surfaces

InactiveUS6974629B1Low-emissivity coatingLow emissivityVacuum evaporation coatingSputtering coatingSputteringLow emissivity

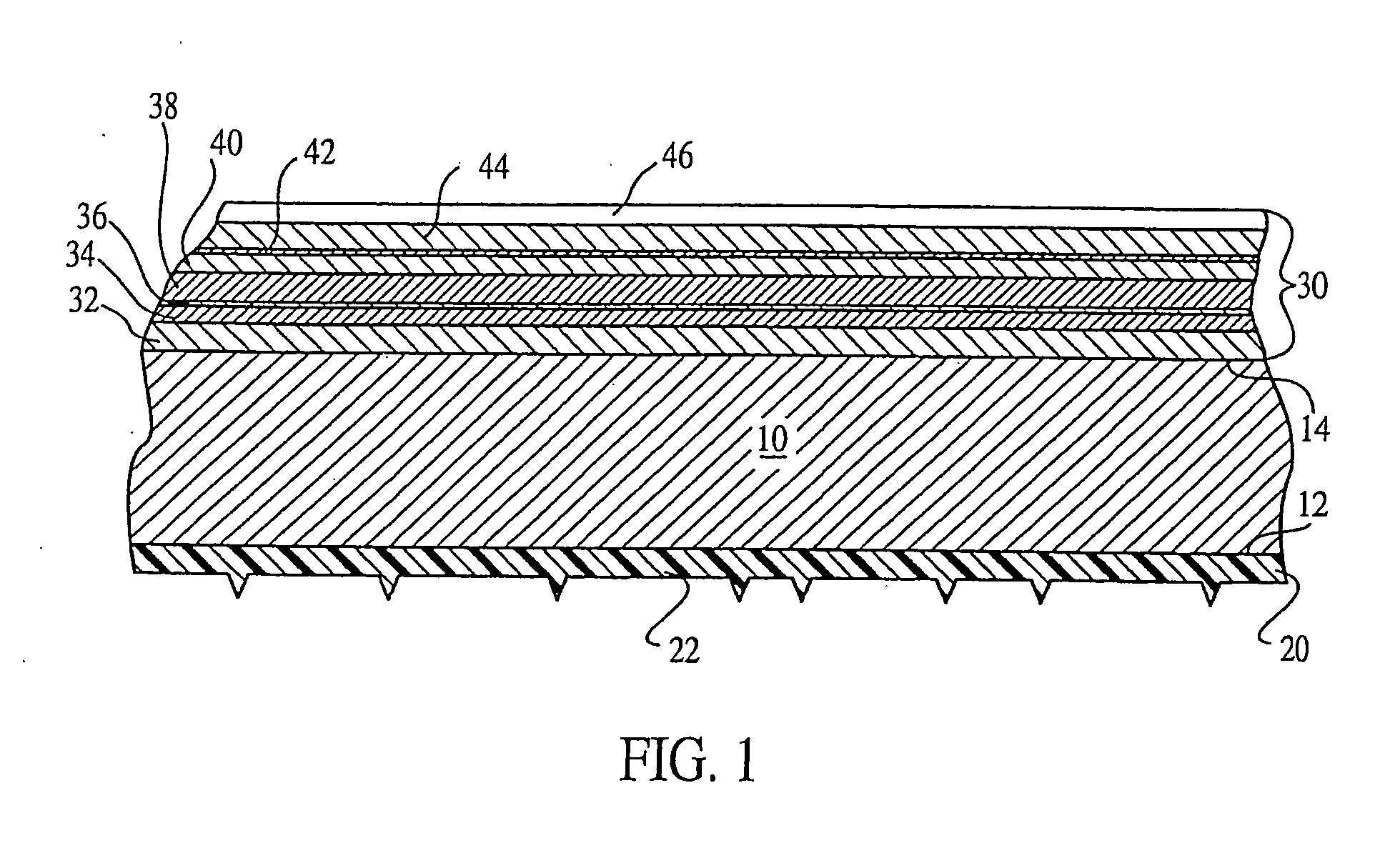

A coated article (e.g., a coated glass article) is provided with a low-emissivity, water-sheeting coating. The coating comprises a sputtered silica layer over a pyrolytically-applied dielectric layer. In certain embodiments, an automobile windscreen is provided with a low-emissivity, water-sheeting coating. Also provided are methods of rendering a surface of a substrate (e.g., a pane of glass) resistant to soiling and staining, such as by depositing on the substrate a low-emissivity, water-sheeting coating.

Owner:CARDINAL CG

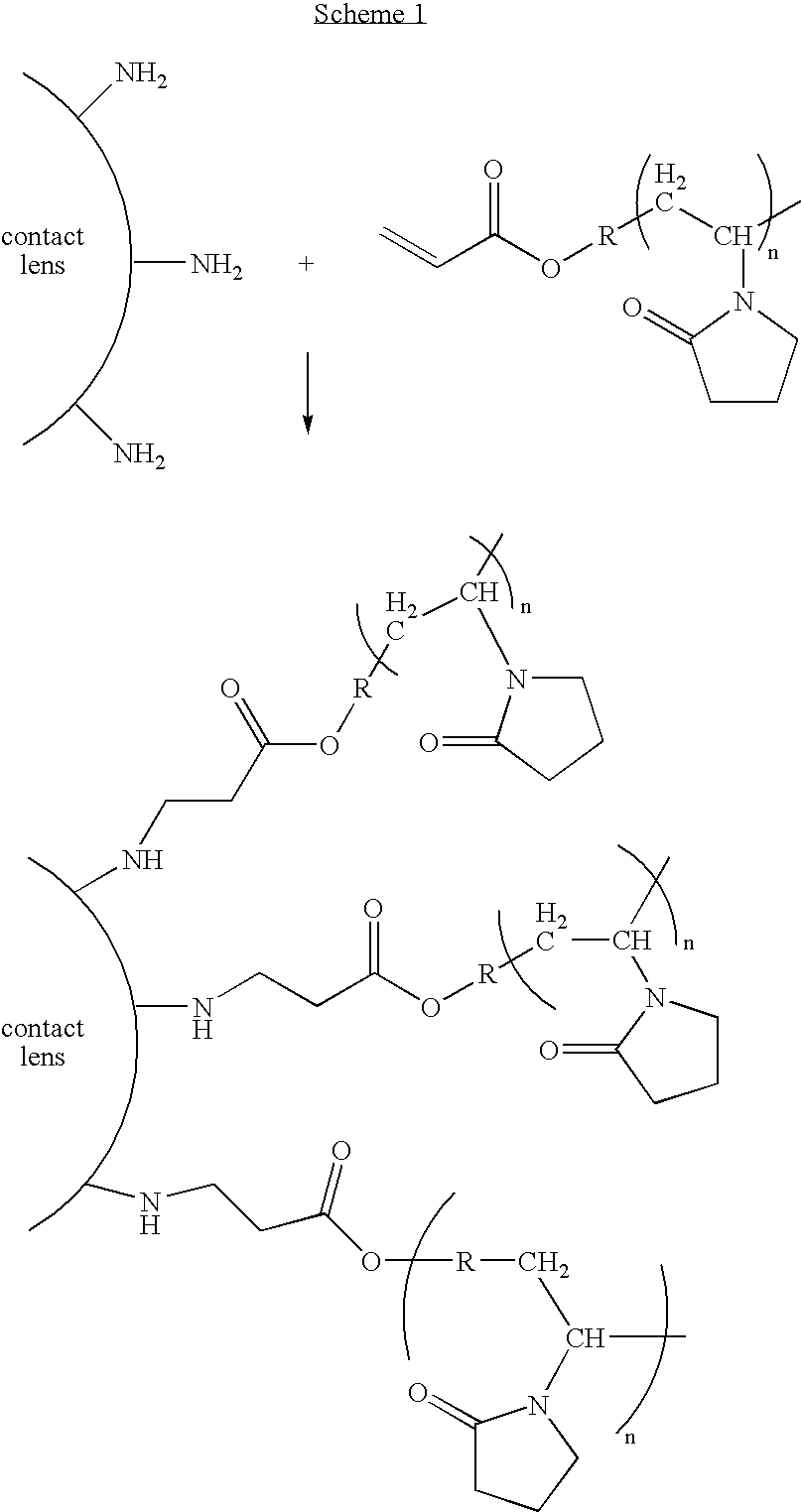

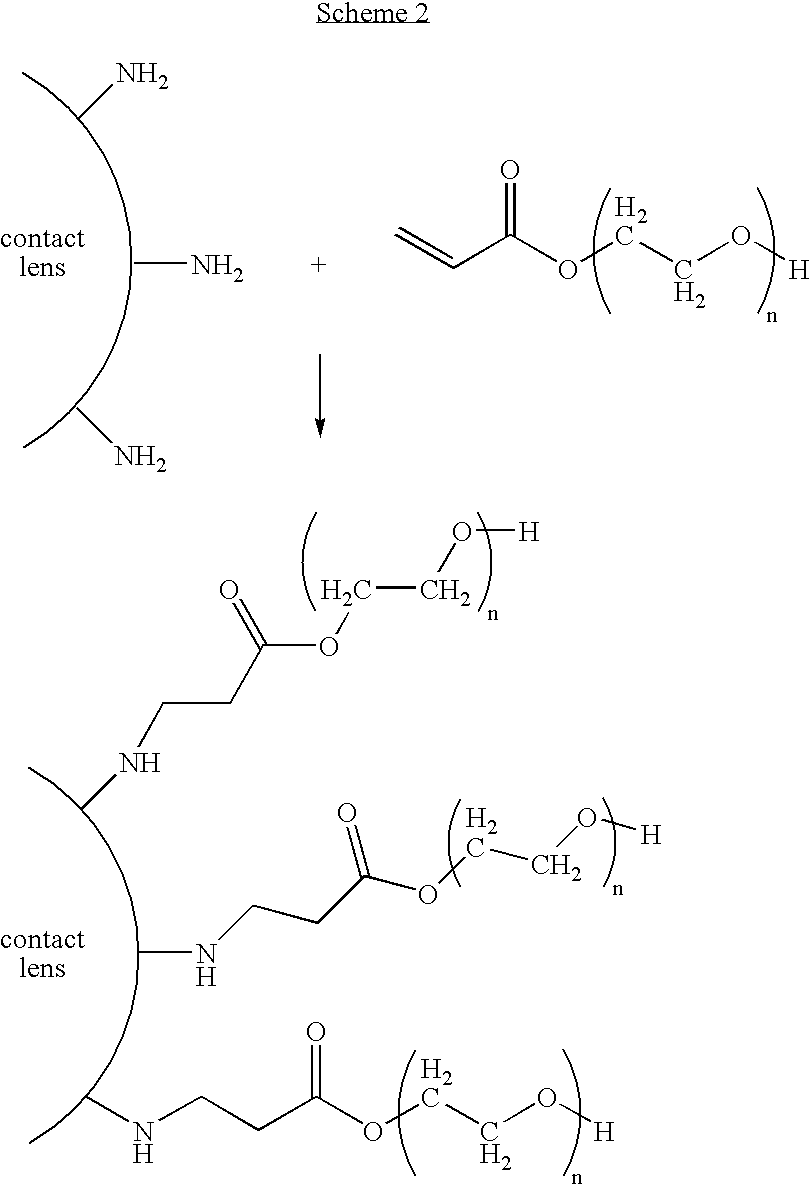

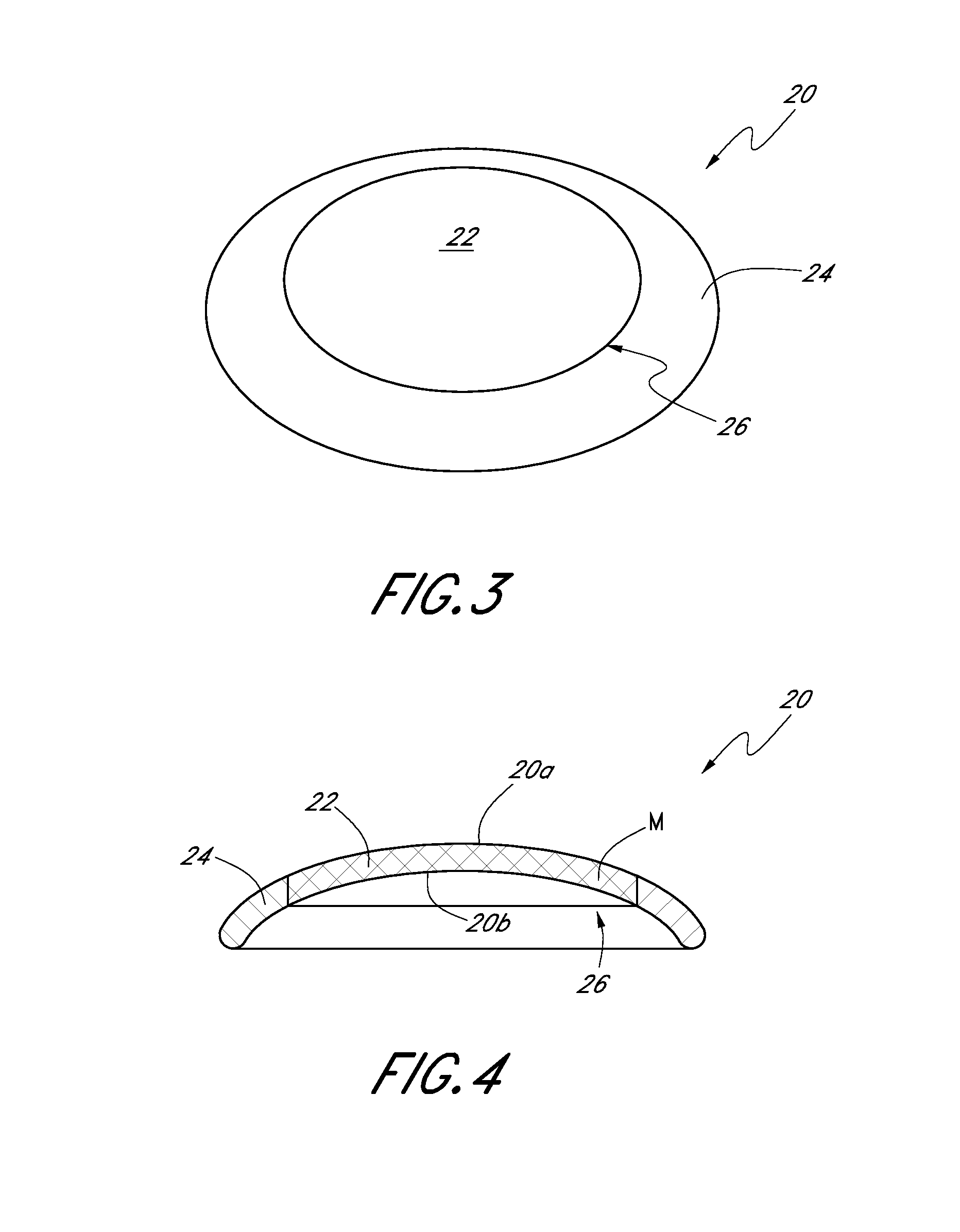

Modification of surfaces of polymeric articles by Michael addition reaction

InactiveUS20080003259A1Reduce contact angleHigh level of performance quality and comfortCoatingsProsthesisChemistryPopulation

A medical device having an increased surface hydrophilicity comprises a coating polymer comprising units of a polymerizable hydrophilic compound that is attached to the surface of the medical device via the Michael addition reaction. The coating polymer can be applied to a medical device comprising a hydrogel material. The attachment of the coating polymer may be enhanced by increasing the population of the medical-device surface functional groups before contacting the medical device with the coating polymer.

Owner:BAUSCH & LOMB INC

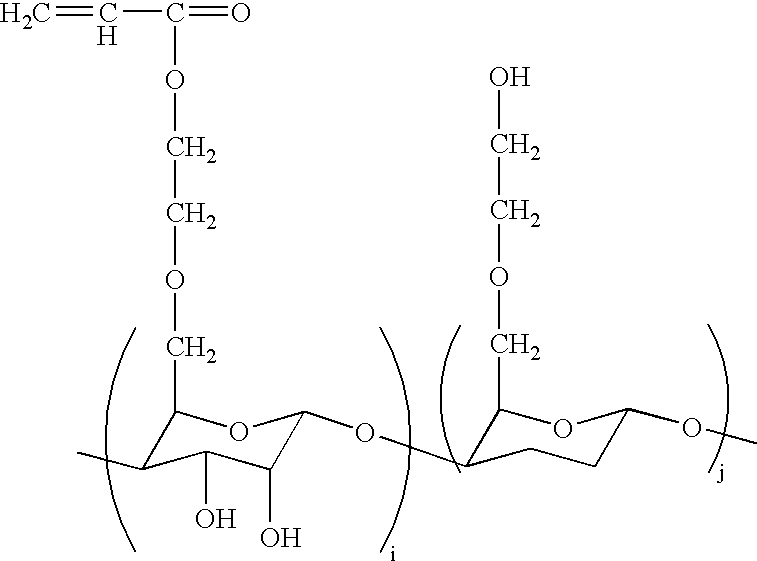

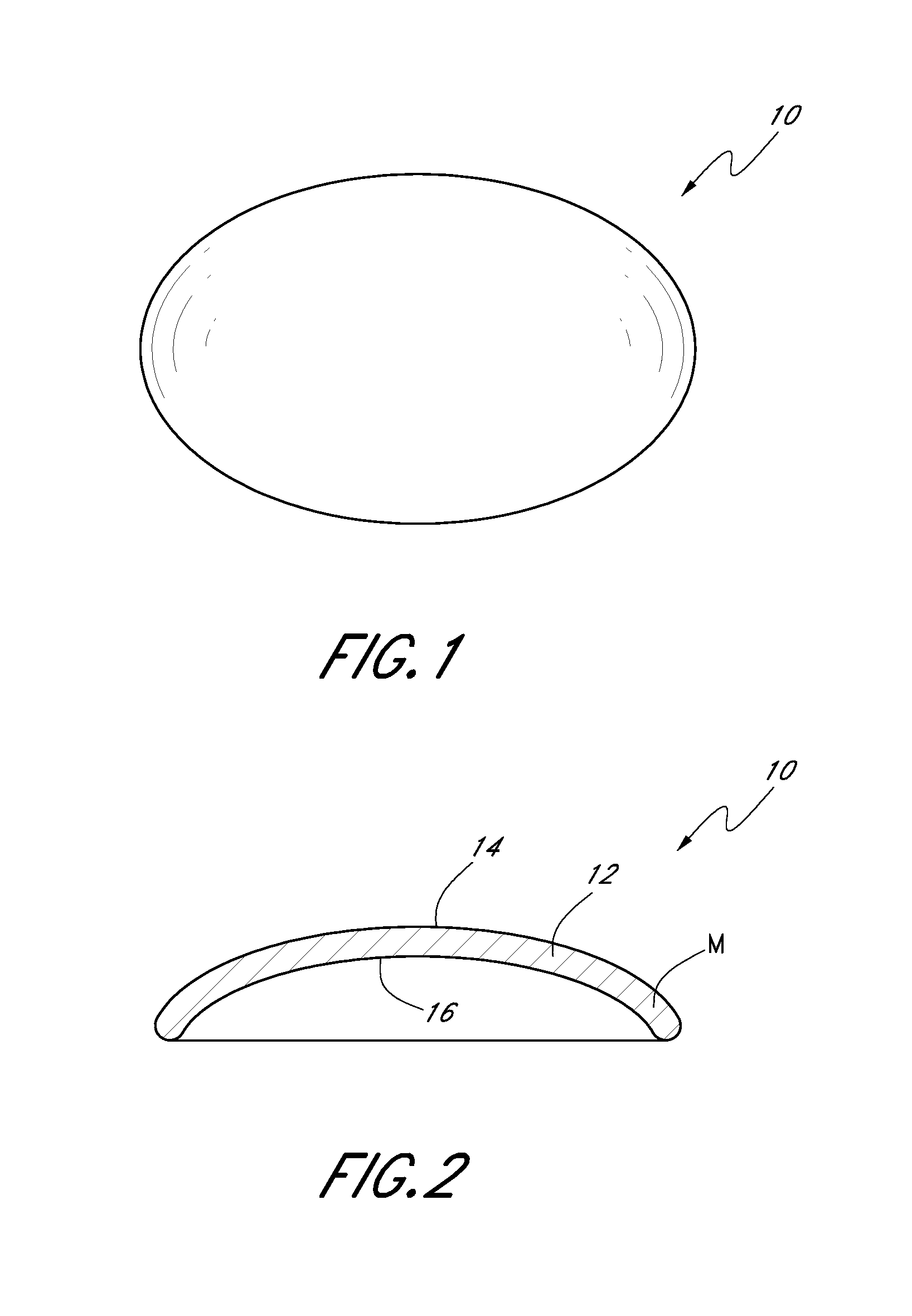

Methods for improving the hydrophilicity of contact lenses and contact lenses having the same

ActiveUS7329001B2Improve wettabilitySmooth connectionSpectales/gogglesOptical partsGas-permeable contact lensChemical agent

Owner:SYNERGEYES

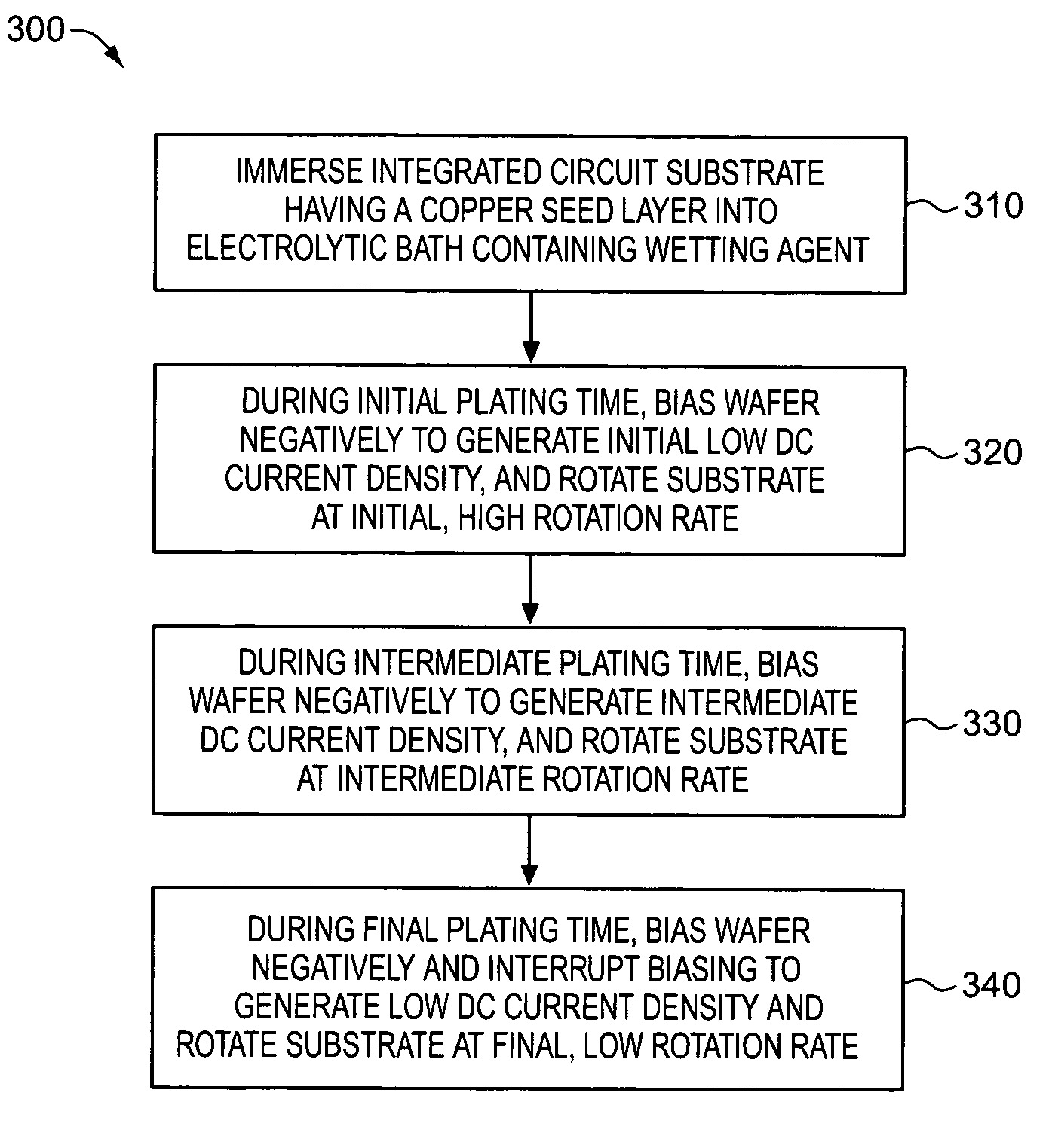

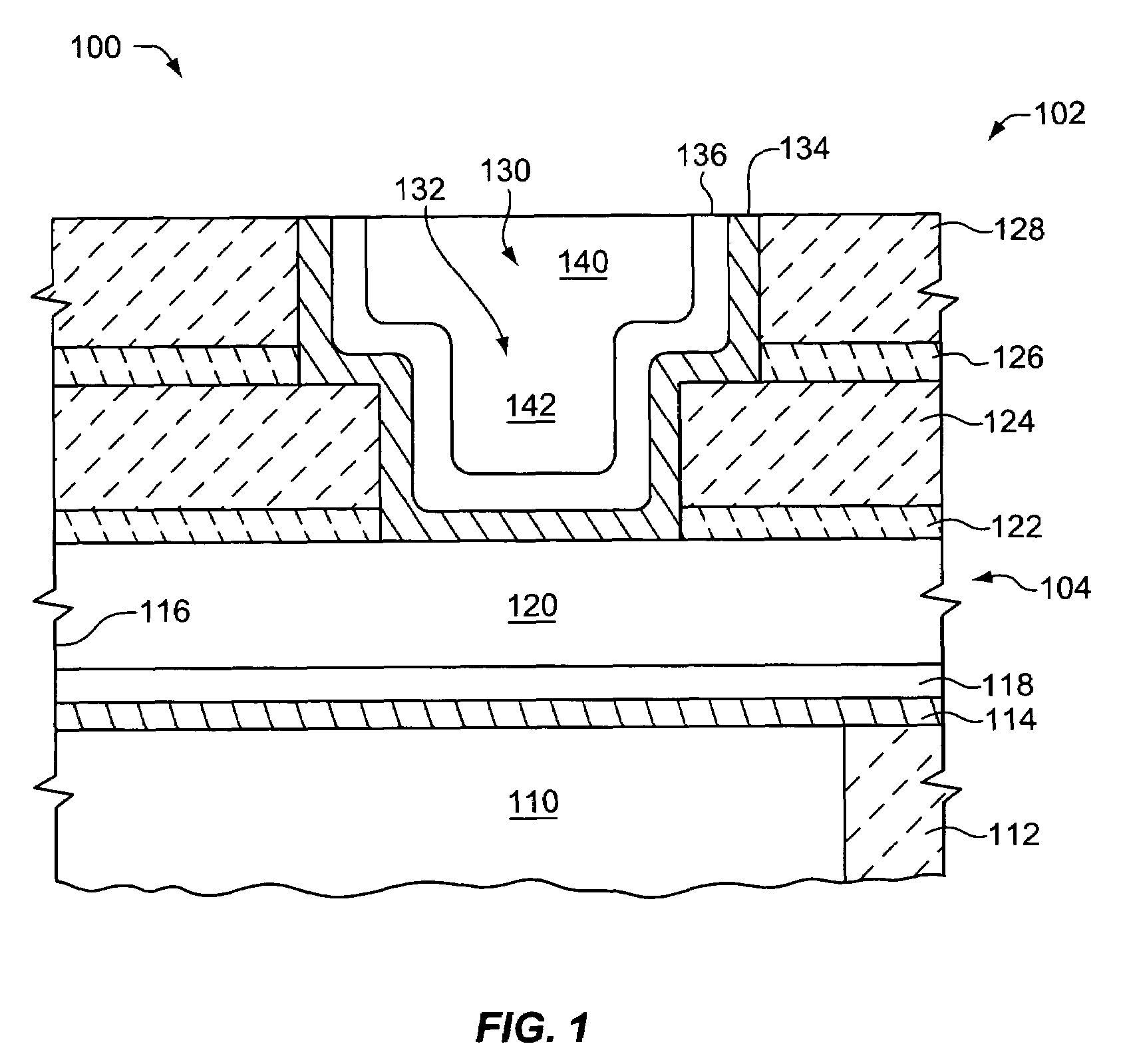

Electroplating bath containing wetting agent for defect reduction

InactiveUS7232513B1Wetting of substrate surfaceReducing pit defectSemiconductor/solid-state device manufacturingSuppressorDyne

An electroplating solution contains a wetting agent in addition to a suppressor and an accelerator. In some embodiments, the solution has a cloud point temperature greater than 35° C. to avoid precipitation of wetting agent or other solute out of the plating solution. In some embodiments, the wetting agent decreases the air-liquid surface tension of the electroplating solution to 60 dyne / cm2 or less to increase the wetting ability of the solution with a substrate surface. In some embodiments of a method for plating metal onto substrate surface, the electroplating solution has a measured contact angle with the substrate surface less than 60 degrees.

Owner:NOVELLUS SYSTEMS

Thermoplasticity sizing agent for carbon fiber and preparation and usage thereof

The invention provides a thermoplasticity sizing agent for a carbon fiber as well as a preparation method and a usage method thereof and relates to solvent sizing agent for a carbon fiber as well as a preparation method and a usage method thereof. According to the invention, the problems that the existing thermoplastic sizing agent is complicate in preparation process and pollutes the environment are solved. The preparation method is as follows: the thermoplastic resin, an organic solvent A and an adjuvant are mixed and stirred uniformly so as to obtain the thermoplastic sizing agent, when being used, the carbon fiber is dipped in the thermoplasticity sixing agent, then fractioning is carried out on the carbon fiber with agent and the treated carbon fiber is dipped in an organic solvent B, and finally the carbon fiber is dried. According to the invention, the wettability of the carbon fiber and the high performance thermoplasticity resin of polyarylether can be improved, the boundary bonding performance of the carbon fiber or the resin matrix composite of thermoplasticity polyarylether can be improved, and the thermoplasticity sizing agent has the advantages that the cost is low, the performance is stable, the utilization is stable and the environment is not polluted. The thermoplasticity sizing agent for the carbon fiber is used for the surface treatment of a carbon fiber material.

Owner:HARBIN INST OF TECH

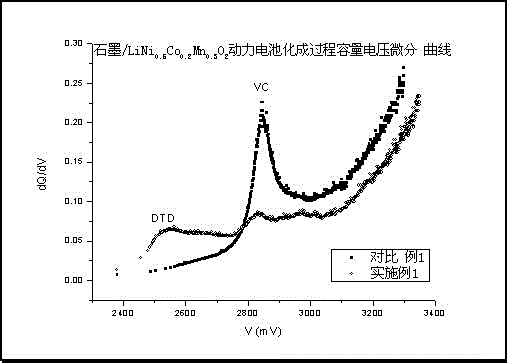

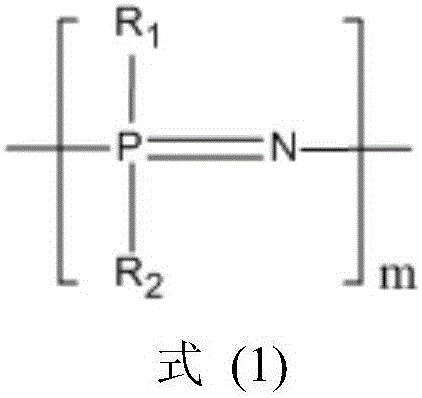

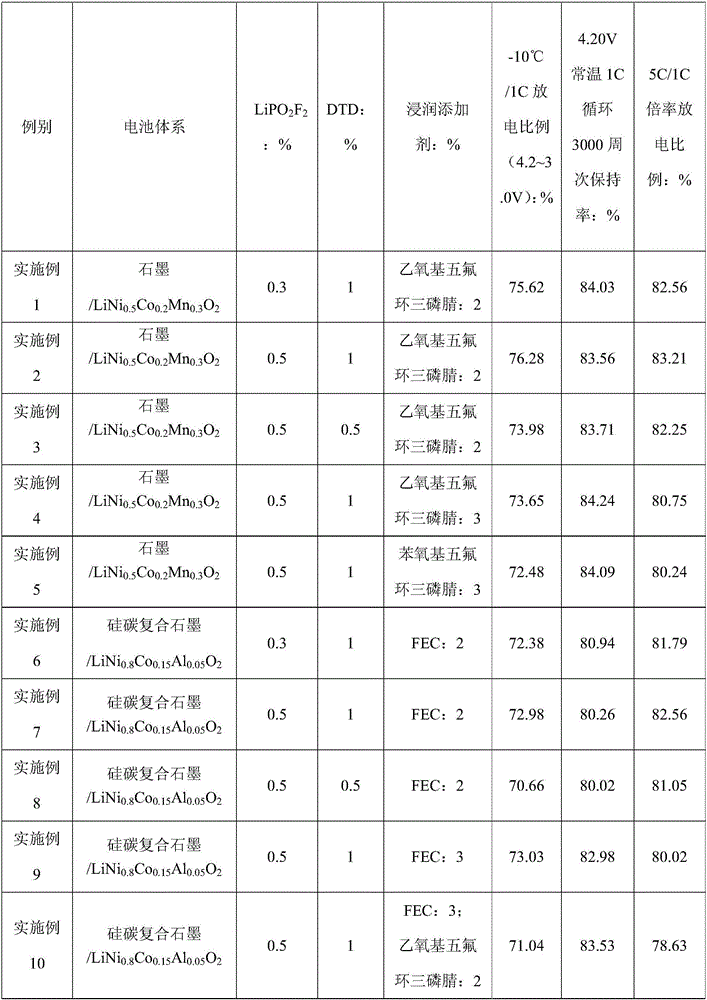

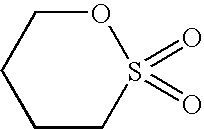

High-nickel ternary lithium ion power battery electrolyte and high-nickel ternary lithium ion power battery

InactiveCN106058316AImprove transmission characteristicsImprove dynamic propertiesSecondary cellsBatteriesDifluorophosphatePower battery

The invention discloses a high-nickel ternary lithium ion power battery electrolyte and a high-nickel ternary lithium ion power battery. The electrolyte includes a non-aqueous organic solvent, a lithium salt, a conductive additive, a film forming additive and an infiltration additive, wherein the conductive additive is lithium difluorophosphate, the film forming additive is ethylene sulfate, and the infiltration additive is at least one of fluorophosphazene and fluoroethylene carbonate; and synergism and mutual promotion of the three additives makes an excellent SEI film be formed on the surface of an electrode and effectively promotes all dynamic processes in the lithium ion battery. The power battery electrolyte has the advantages of good lithium ion transmission characteristic, good oxidation resistance, guaranteeing of high power characteristic and good cycle performances of the power battery, and high safety.

Owner:GUANGZHOU TINCI MATERIALS TECH

Hard surface cleaning compositions, premoistened wipes, methods of use, and articles comprising said compositions or wipes and instructions for use resulting in easier cleaning and maintenance, improved surface appearance and/or hygiene under stress conditions such as no-rinse

InactiveUS20050153857A1Easy to useImprove hygieneNon-ionic surface-active compoundsOrganic detergent compounding agentsHydrophilic polymersSurface cleaning

Owner:PROCTER & GAMBLE CO

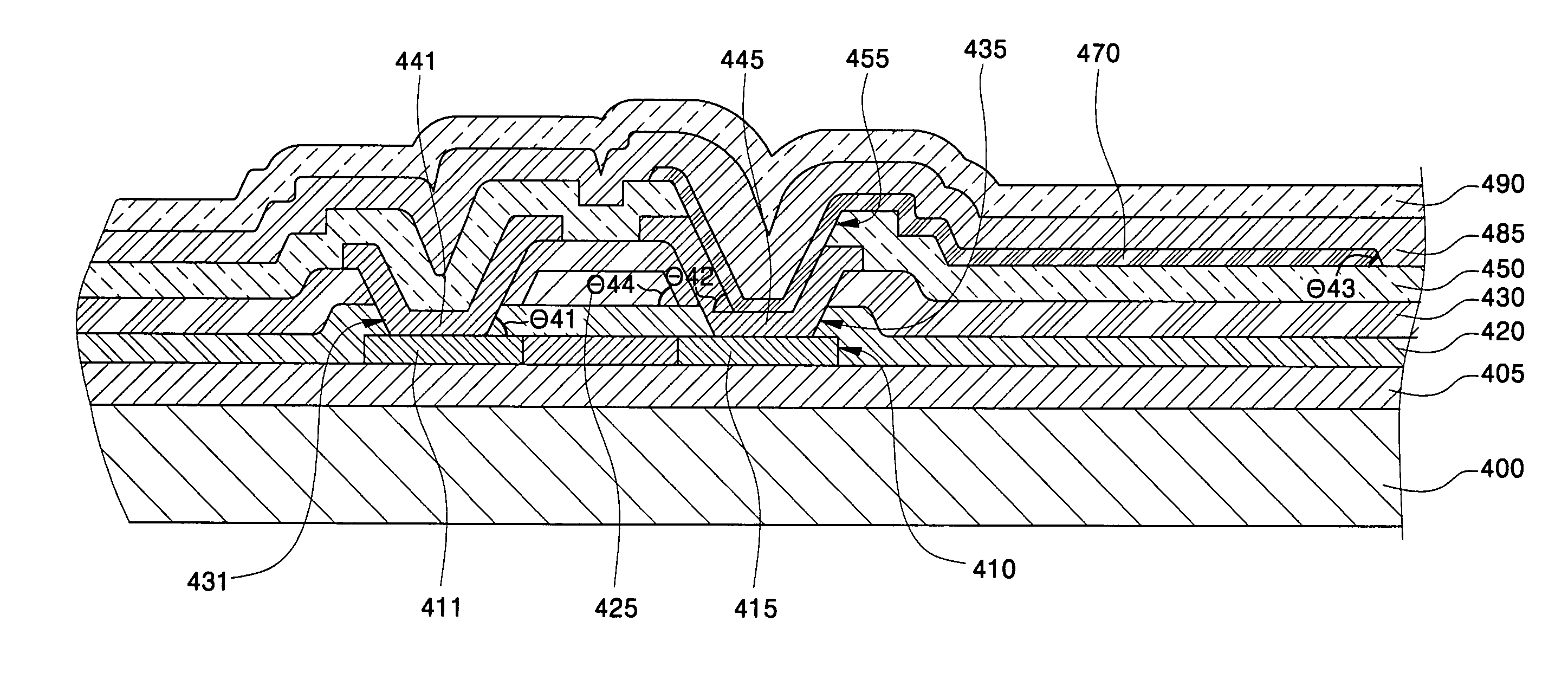

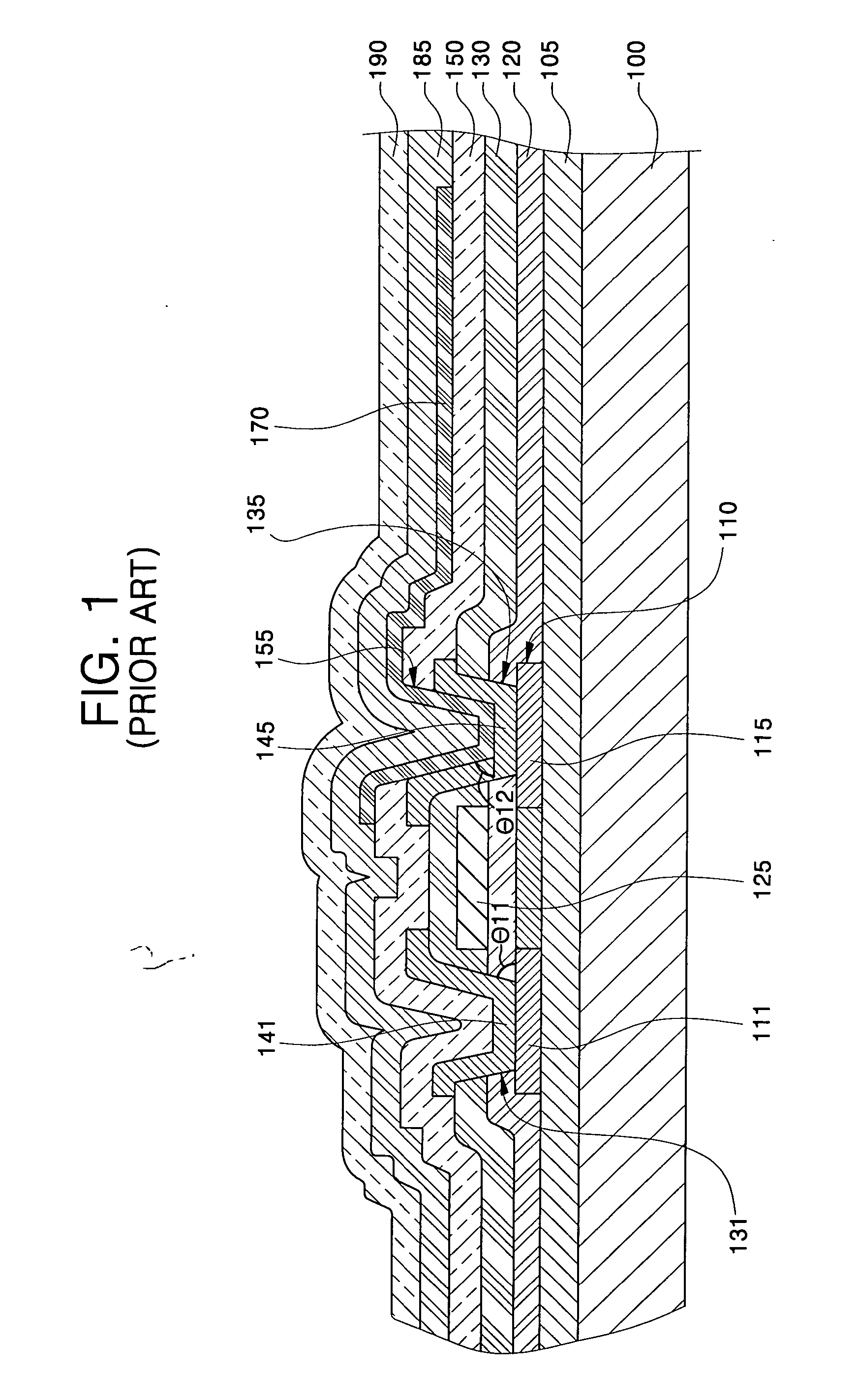

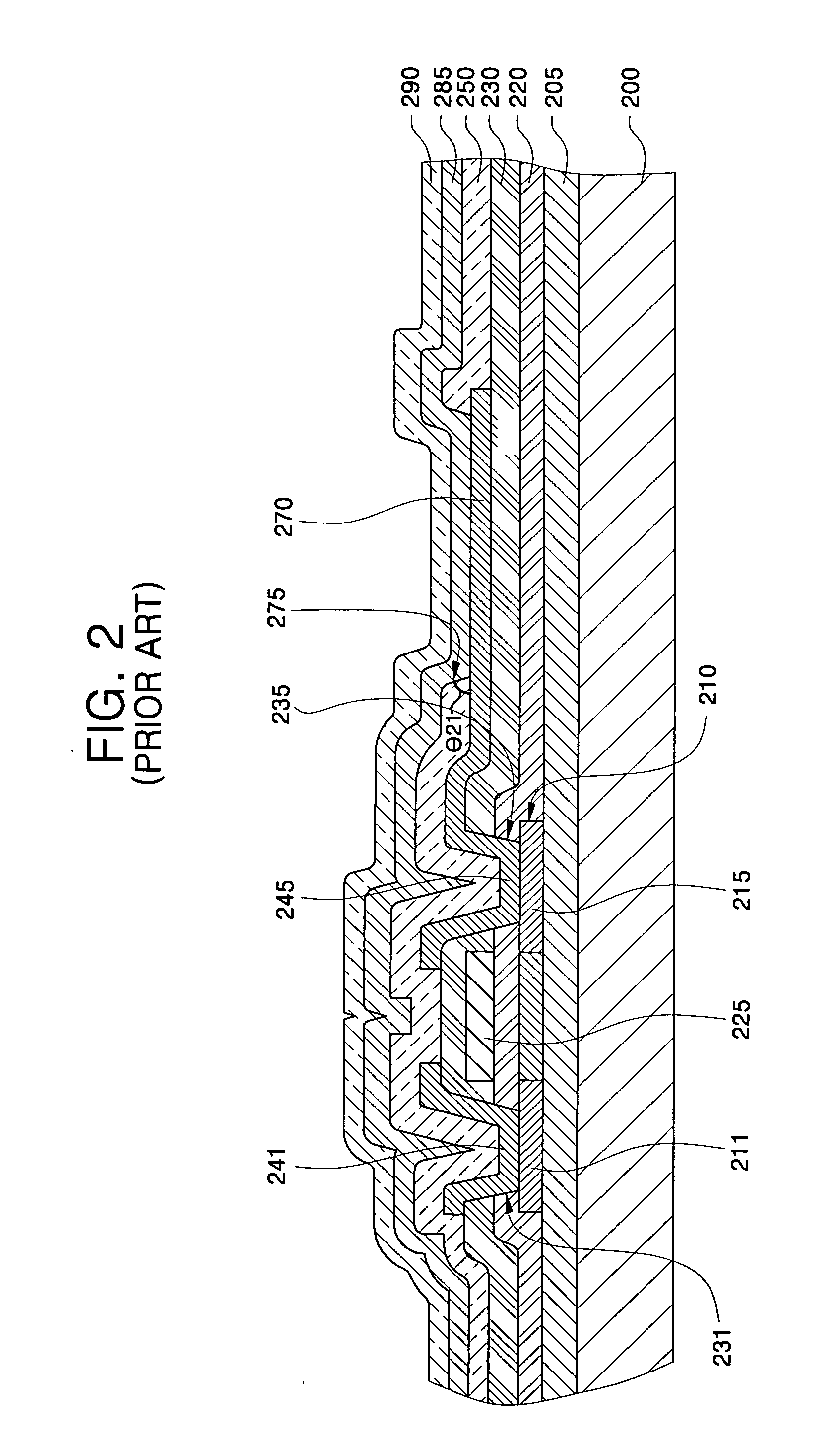

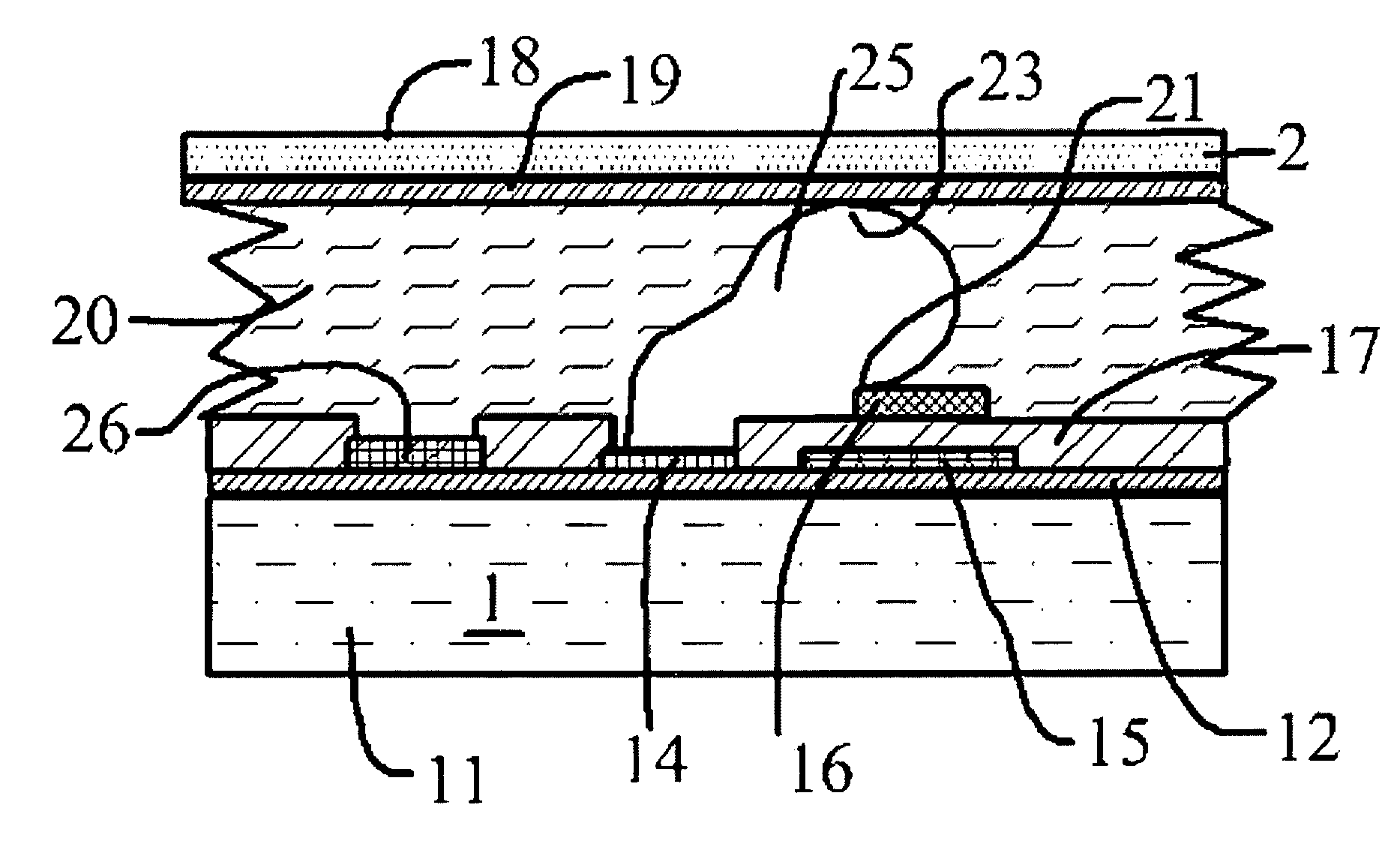

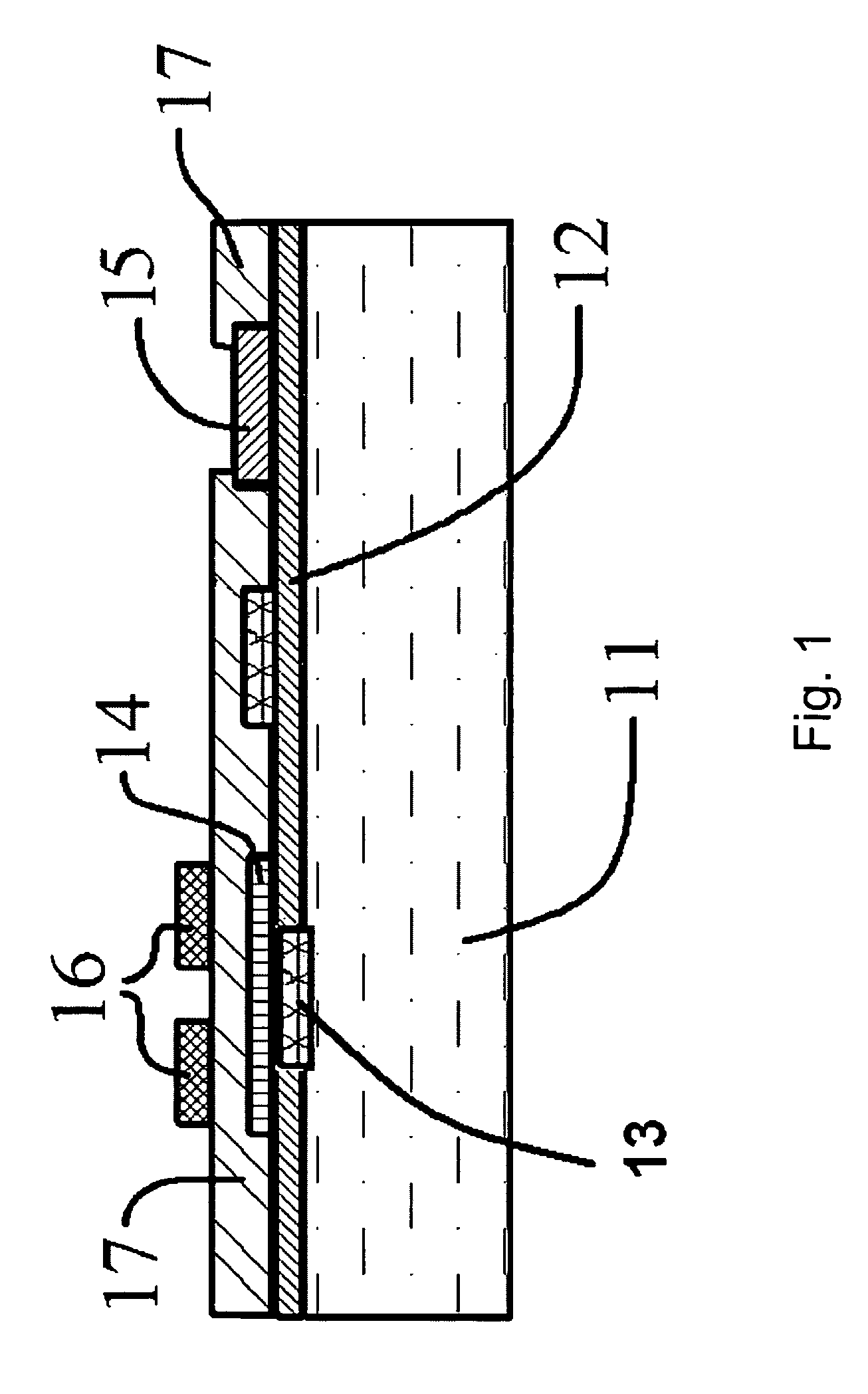

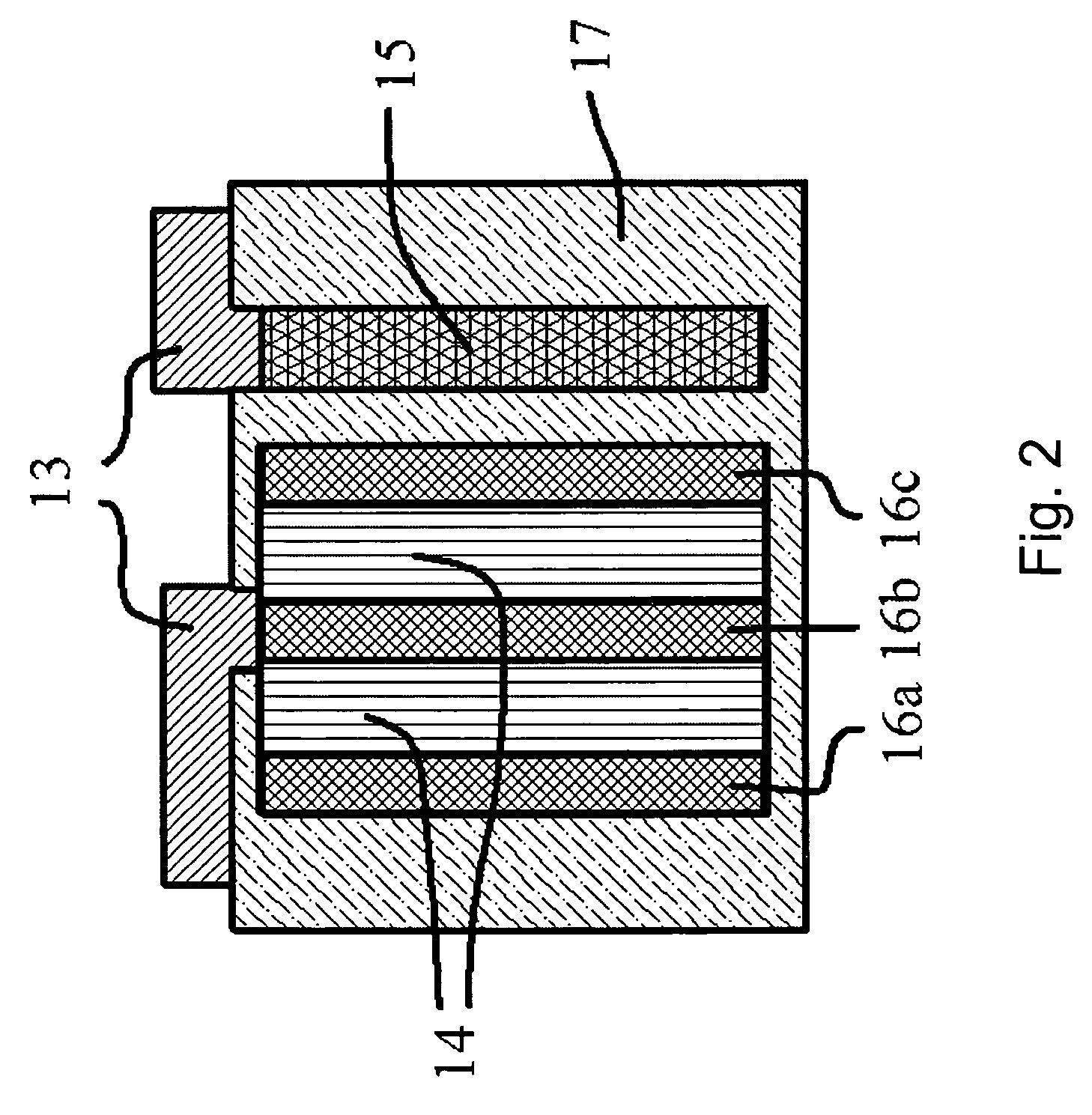

Flat panel display

ActiveUS20050116630A1Avoid defectsLower contact angleTransistorDischarge tube luminescnet screensDisplay deviceEngineering

A flat panel display capable of reducing element defects by decreasing taper angles of contact holes and a via hole. The flat panel display includes a thin film transistor having at least source and drain electrodes formed over an insulating substrate, an insulating layer having a via hole for exposing one of the source and drain electrodes, and an anode connected to said one of the source and drain electrodes through the via hole. The via hole and the anode are tapered with taper angles of 60° or less. The source and drain electrodes are connected respectively to source and drain regions of the thin film transistor through the contact holes. The contact holes are also tapered with taper angles of 60° or less.

Owner:SAMSUNG DISPLAY CO LTD

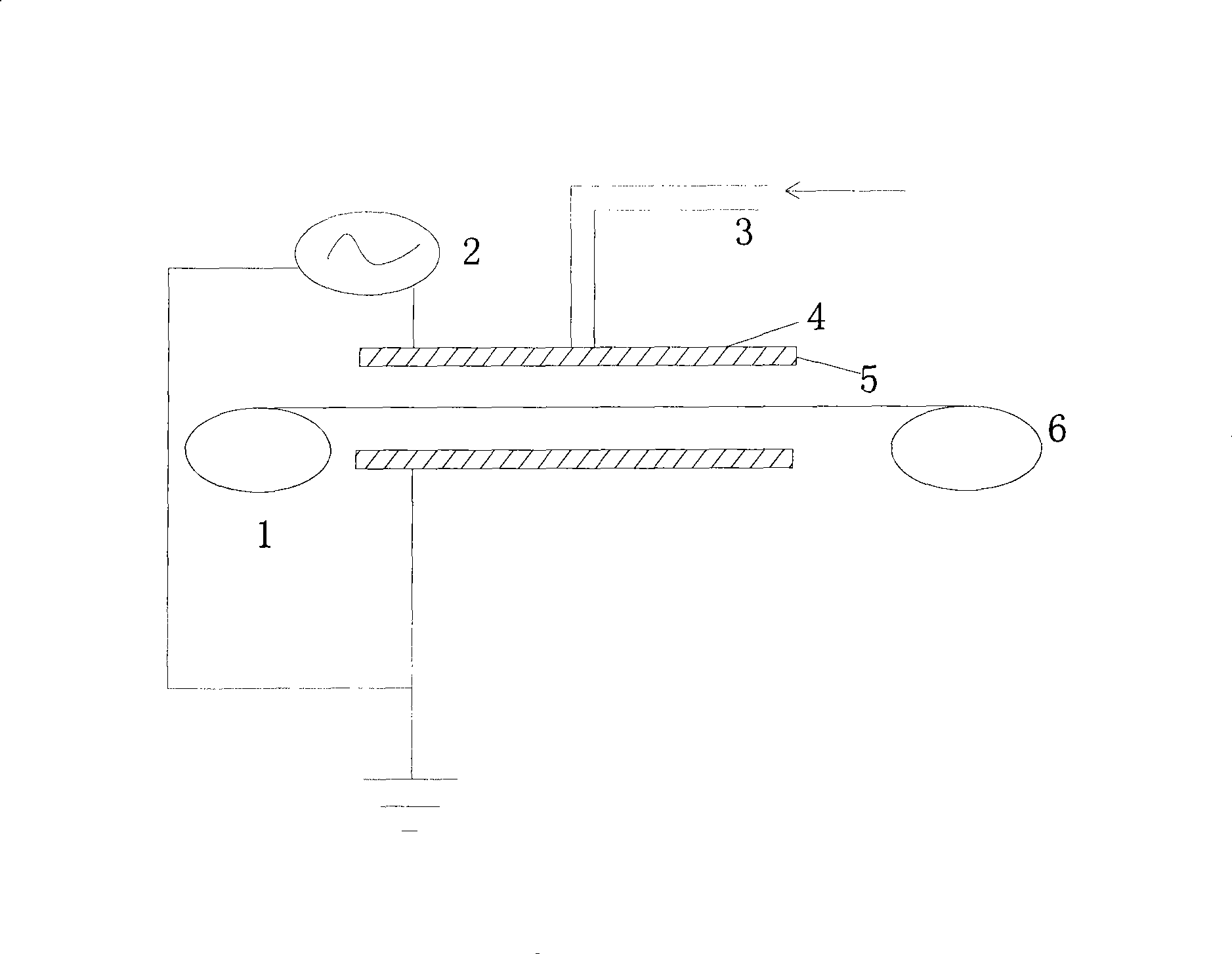

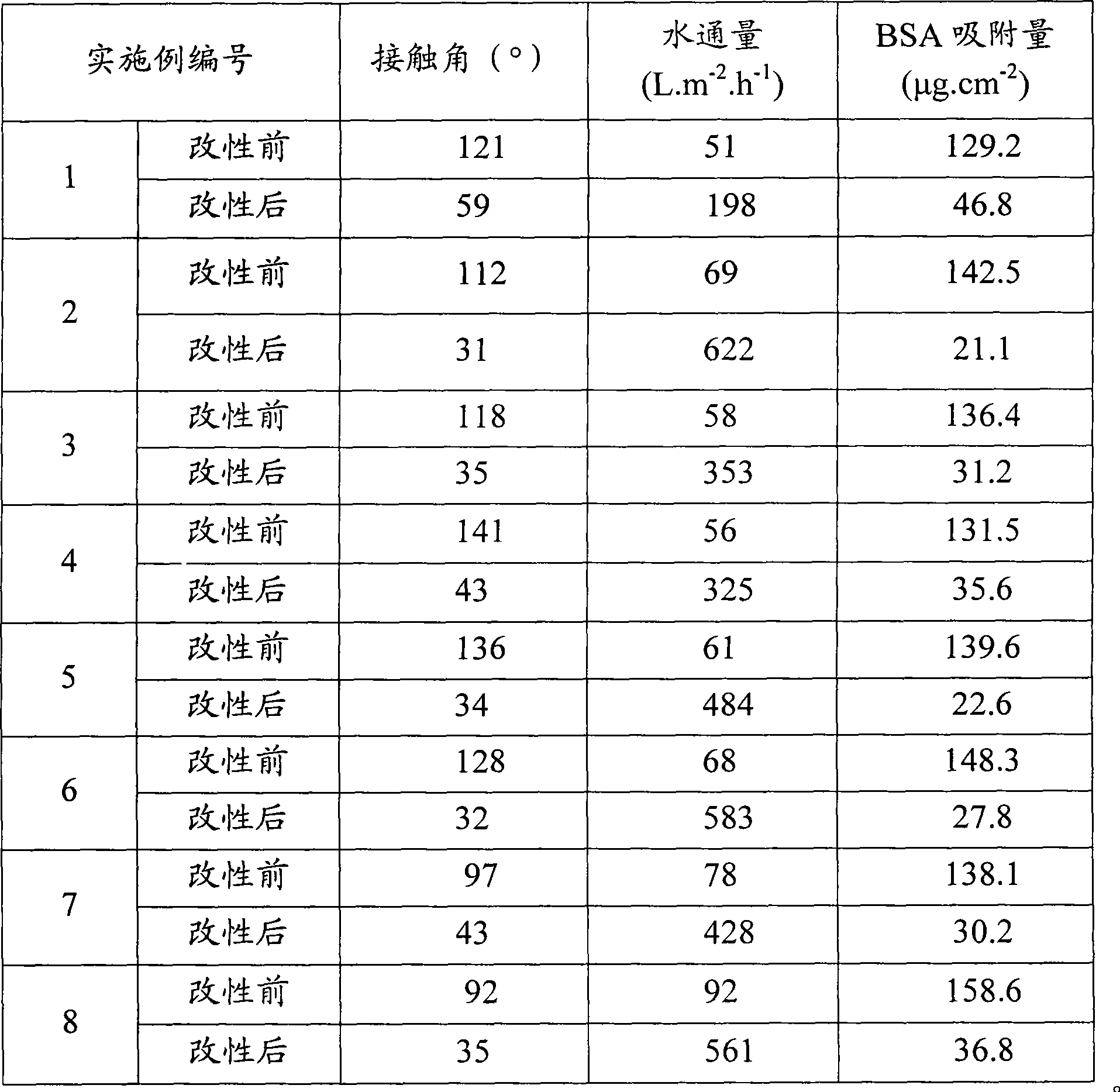

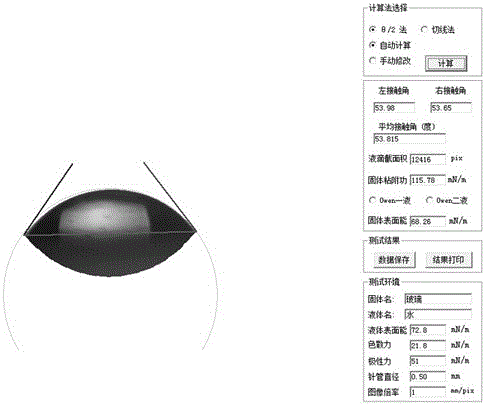

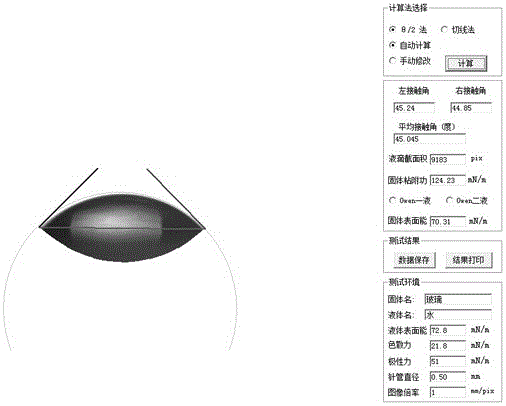

Hydrophilic modification method of polymer microporous film

InactiveCN101439265ANot easy to cause pollutionEasy to achieve continuous modificationSemi-permeable membranesPolymer scienceMonomer

The invention discloses a method of atmospheric dielectric barrier discharge plasma to carry out polymer microporous membrane hydrophilic modification. The method comprises the following steps: (1) the polymer microporous membrane is cleaned clearly, dried and then arranged into the solution of an organic monomer for dipping; after the surface of the microporous membrane absorbs the organic monomer, the microporous membrane is taken out and aired; (2) the polymer microporous membrane treated by the step (1) is arranged between the two discharge electrodes of the dielectric barrier discharge to carry out atmospheric dielectric barrier discharge plasma treatment; (3) the polymer microporous membrane treated by step (2) is cleaned and then dried. The method has the characteristics of simple technique, convenient operation, quick processing speed, good and durable processing effect, low cost, being not easy to cause environment pollution, energy saving, and the like.

Owner:ZHEJIANG UNIV

High-hydrophilic compound reverse osmosis membrane and preparation method of high-hydrophilic compound reverse osmosis membrane

InactiveCN105688694ALower contact angleSimple preparation processMembranesSemi-permeable membranesReverse osmosisPolyamide

The invention discloses a high-hydrophilic compound reverse osmosis membrane and a preparation method of the high-hydrophilic compound reverse osmosis membrane. Graphene oxide containing abundant oxygen-containing functional groups including carboxyl, hydroxyl, carbonyl and the like is used as a modifying agent, is added into a polysulfone porous supporting layer and is used for changing an inner pore structure of the polysulfone porous supporting layer, so that the hydrophilic performance of the prepared polysulfone porous supporting layer modified by graphene oxide is remarkably improved, and furthermore, the hydrophilic performance of the compound reverse osmosis membrane is improved, and the high-hydrophilic compound reverse osmosis membrane is prepared. The preparation method of the high-hydrophilic compound reverse osmosis membrane mainly comprises the following two steps: (1) preparing the polysulfone porous supporting layer modified by graphene oxide; (2) preparing a polyamide desalting layer. With the adoption of the high-hydrophilic compound reverse osmosis membrane and the preparation method of the high-hydrophilic compound reverse osmosis membrane, the problem that the hydrophilic performance of an existing polyamide reverse osmosis membrane is poor is solved and the industrial application prospect is good.

Owner:唐山海清源科技股份有限公司

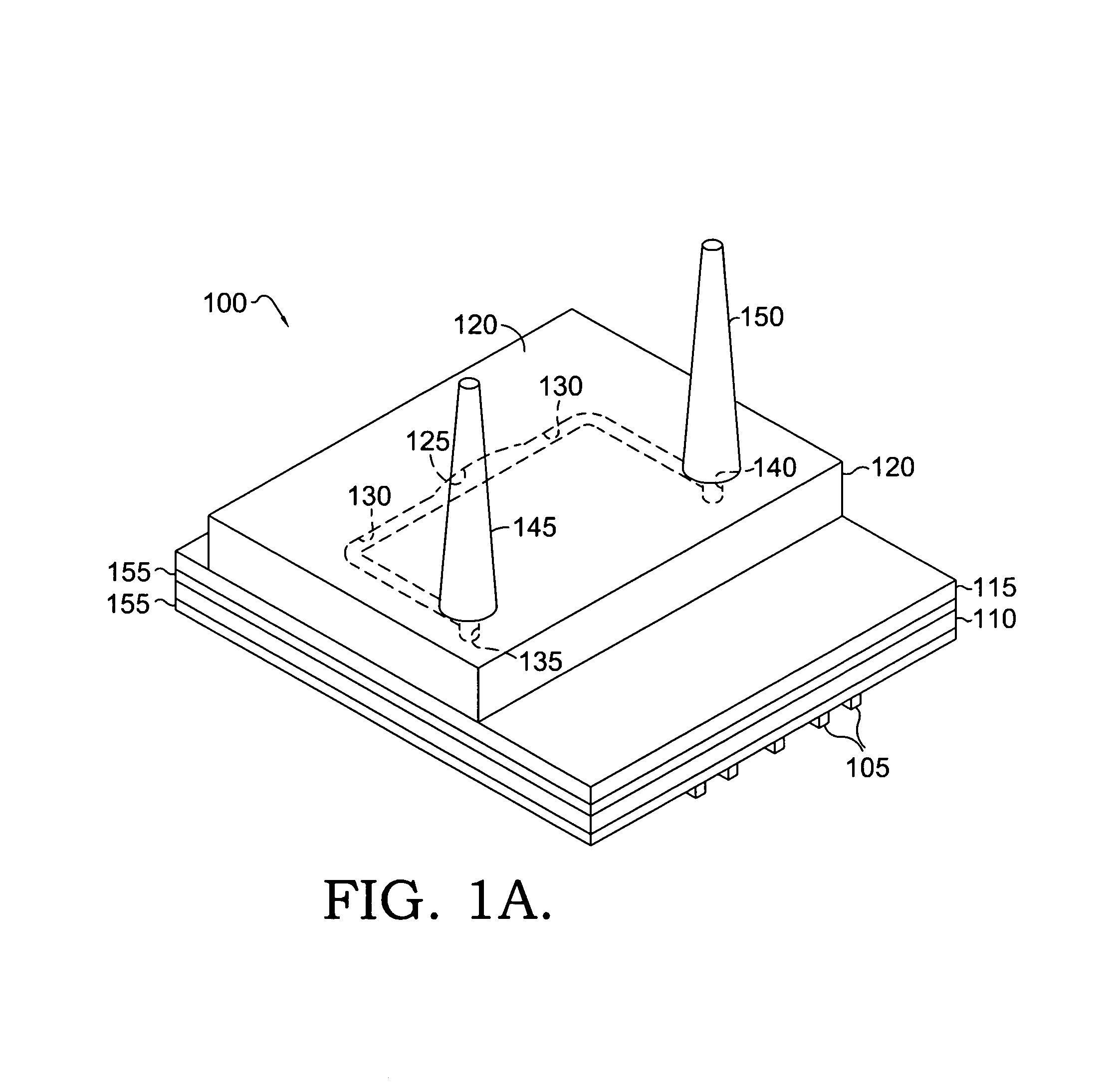

Micromachined electrowetting microfluidic valve

ActiveUS8037903B2Reduce resistanceSolve the lack of tensionValve arrangementsCircuit elementsEngineeringMicrofluidic channel

This invention relates to a systems and methods of controlling the flow of a fluid in a capillary or microfluidic channel. A first pair of electrodes can influence the wetting of a fluid front at a relatively hydrophobic surface in the channel. A second pair of electrodes can electrolytically generate a bubble that can stop fluid flow when it contacts the hydrophobic surface. Flow of a fluid in a channel can be stopped on contact with the hydrophobic surface and restarted when an electrostatic field reduces the contact angle of the fluid at the hydrophobic surface. The electrostatic field can be removed and the fluid stopped again when an electrolytically generated bubble contacts the hydrophobic surface to reestablish the blocking contact angle of the fluid, gas and surface.

Owner:MICROPOINT BIOTECHNOLOGIES CO LTD

Soil-resistant coating for glass surfaces

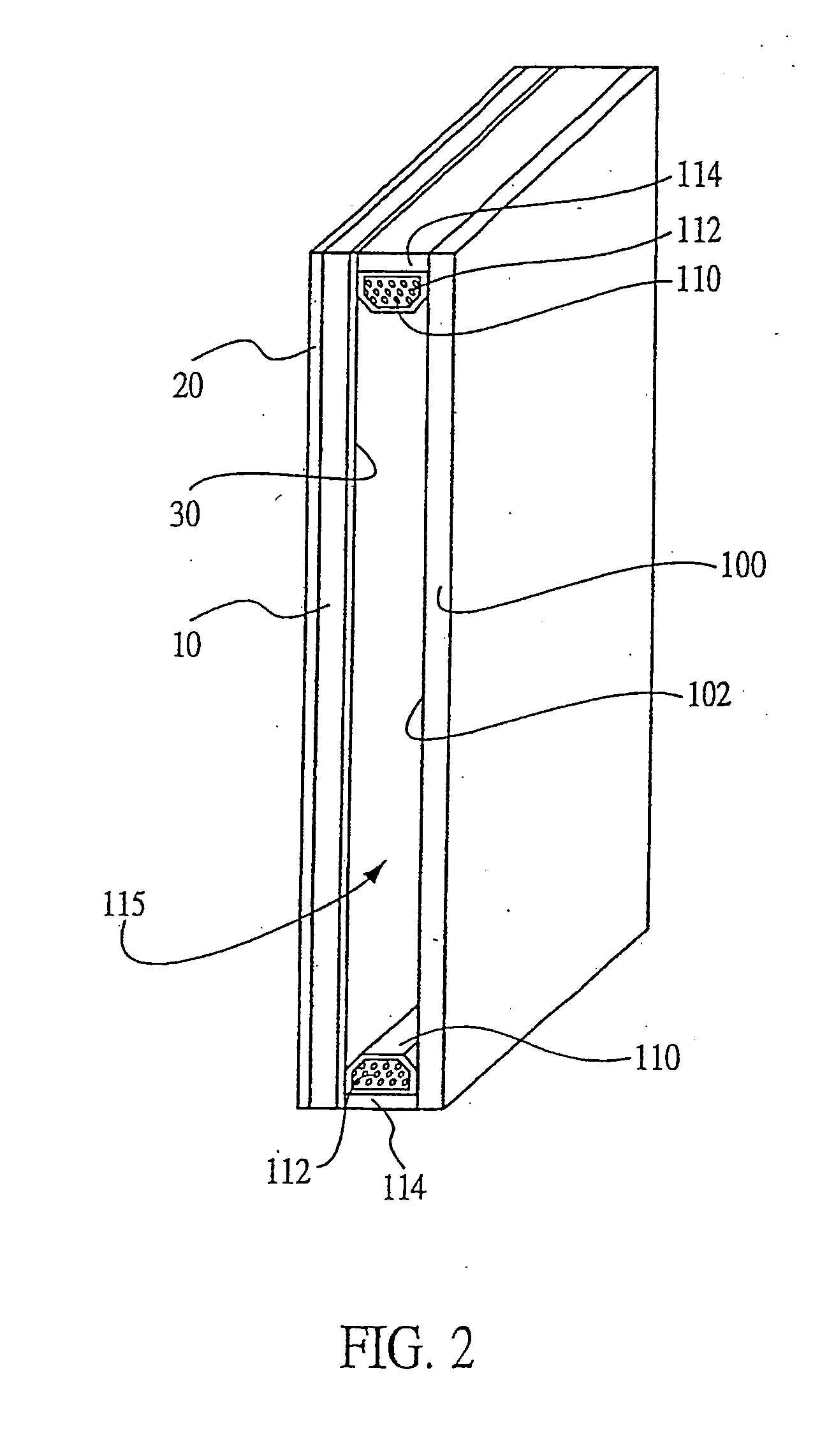

InactiveUS20050025982A1Lower contact angleDoors/windowsVacuum evaporation coatingSputteringSilicon dioxide

A glass article which has a water-sheeting coating. In one embodiment, a glass sheet is provided bearing a sputtered water-sheeting coating comprising silica on an exterior surface and bearing a reflective coating on an interior surface. The interior surface of a sheet of glass can be coated with a reflective coating by sputtering, in sequence, at least one dielectric layer, at least one metal layer, and at least one dielectric layer. The exterior surface of the glass can be coated with a water-sheeting coating by sputtering silica directly onto the exterior surface of the sheet of glass. Both the reflective coating and the water-sheeting coating can optionally be applied during the same pass through the same sputter coating apparatus.

Owner:CARDINAL CG

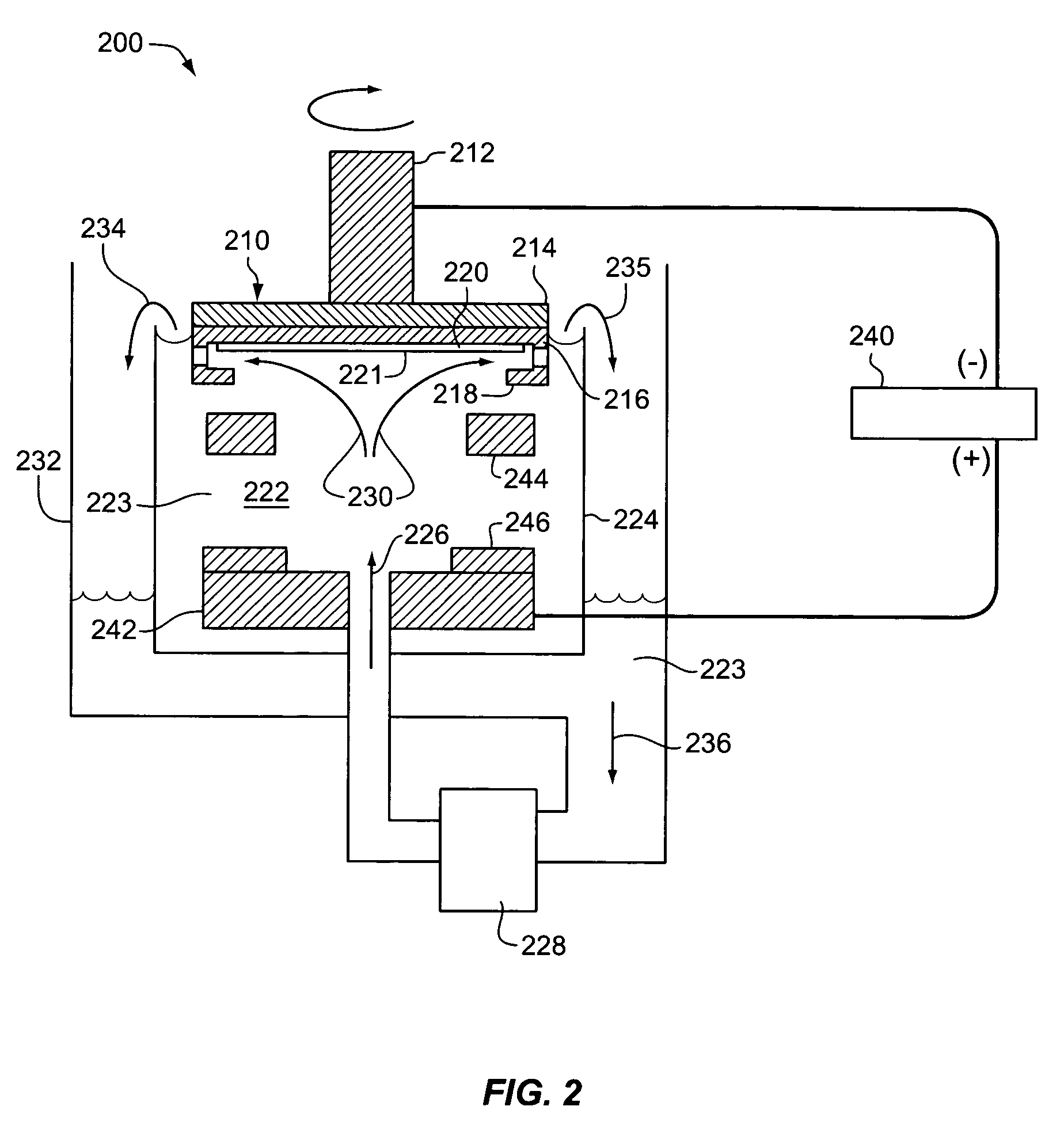

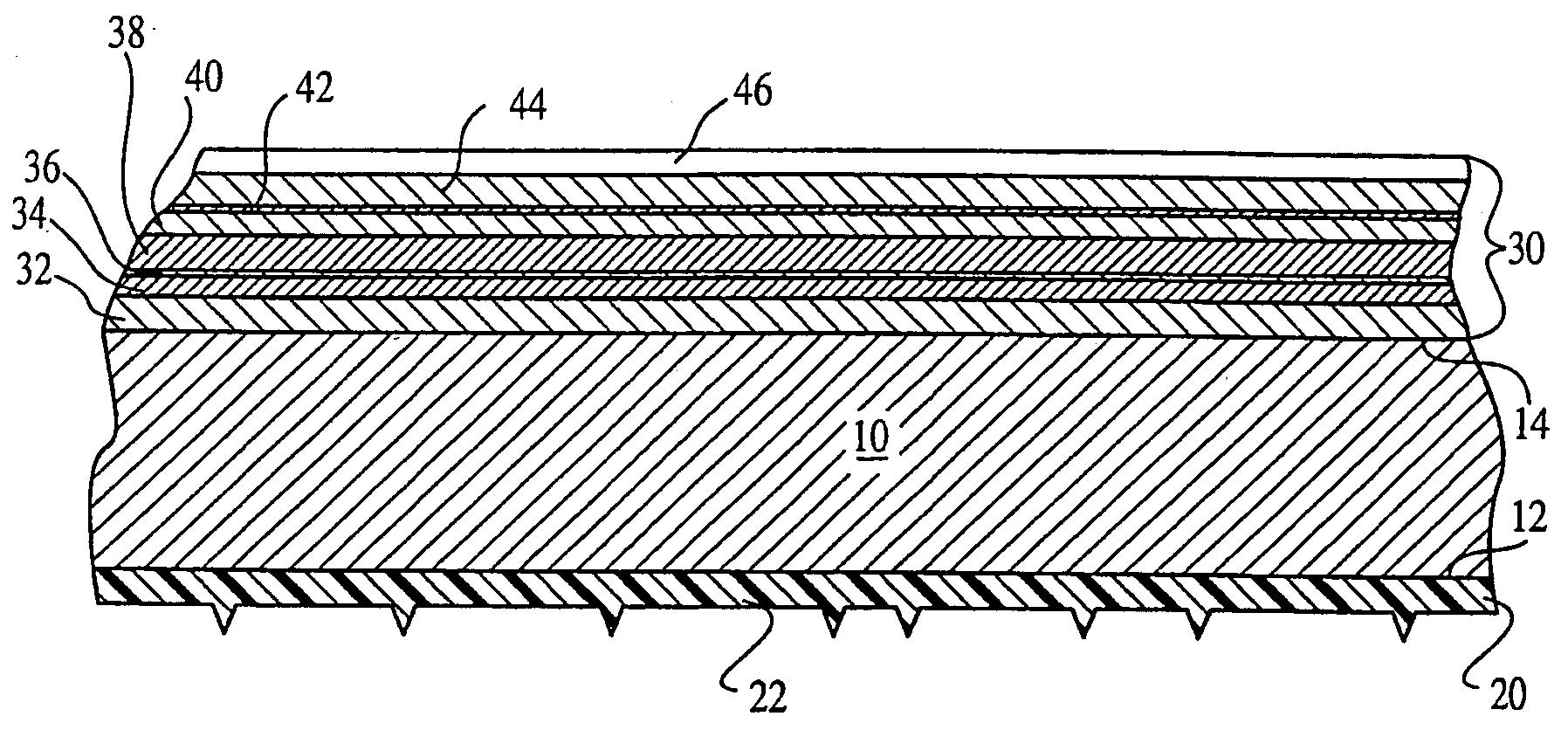

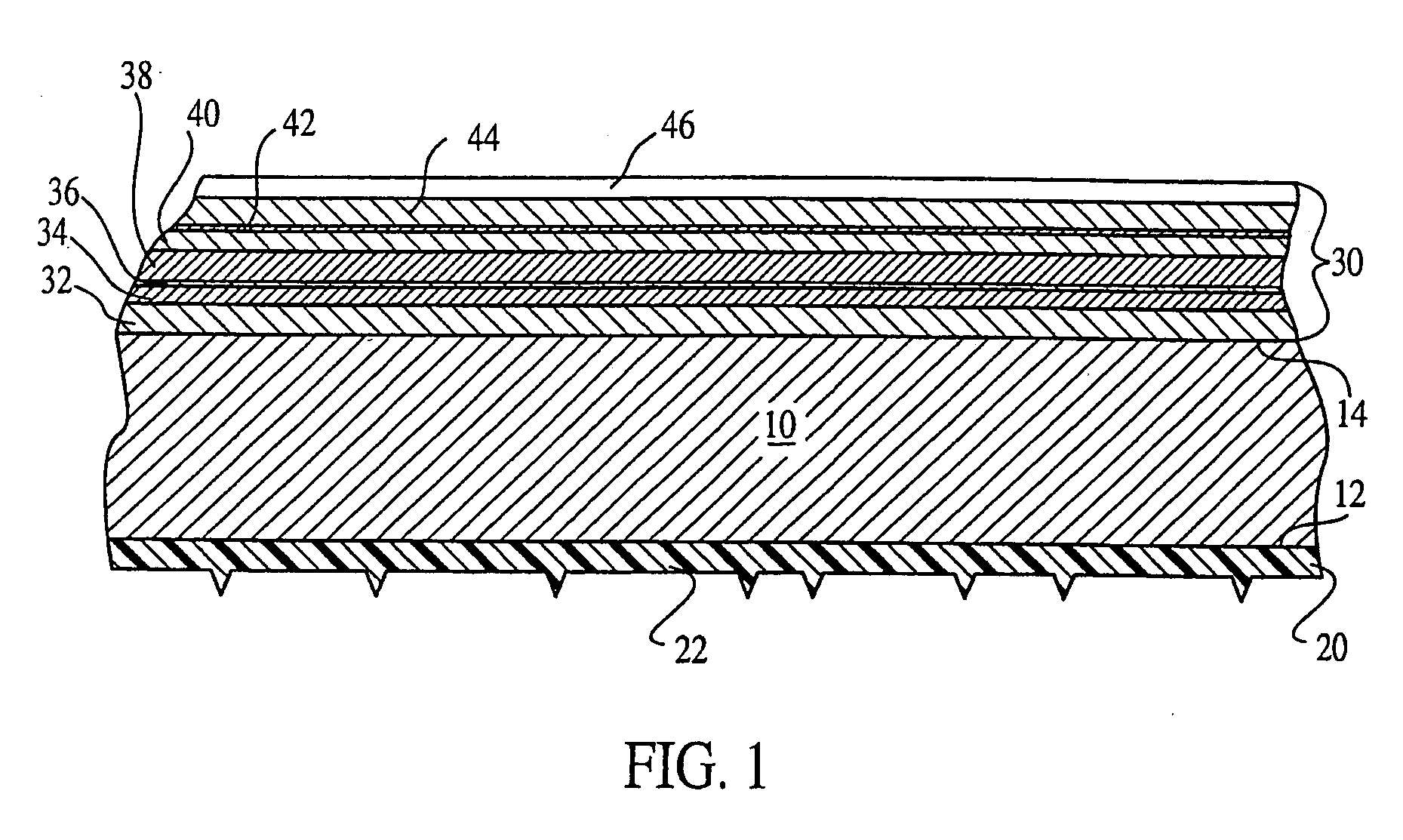

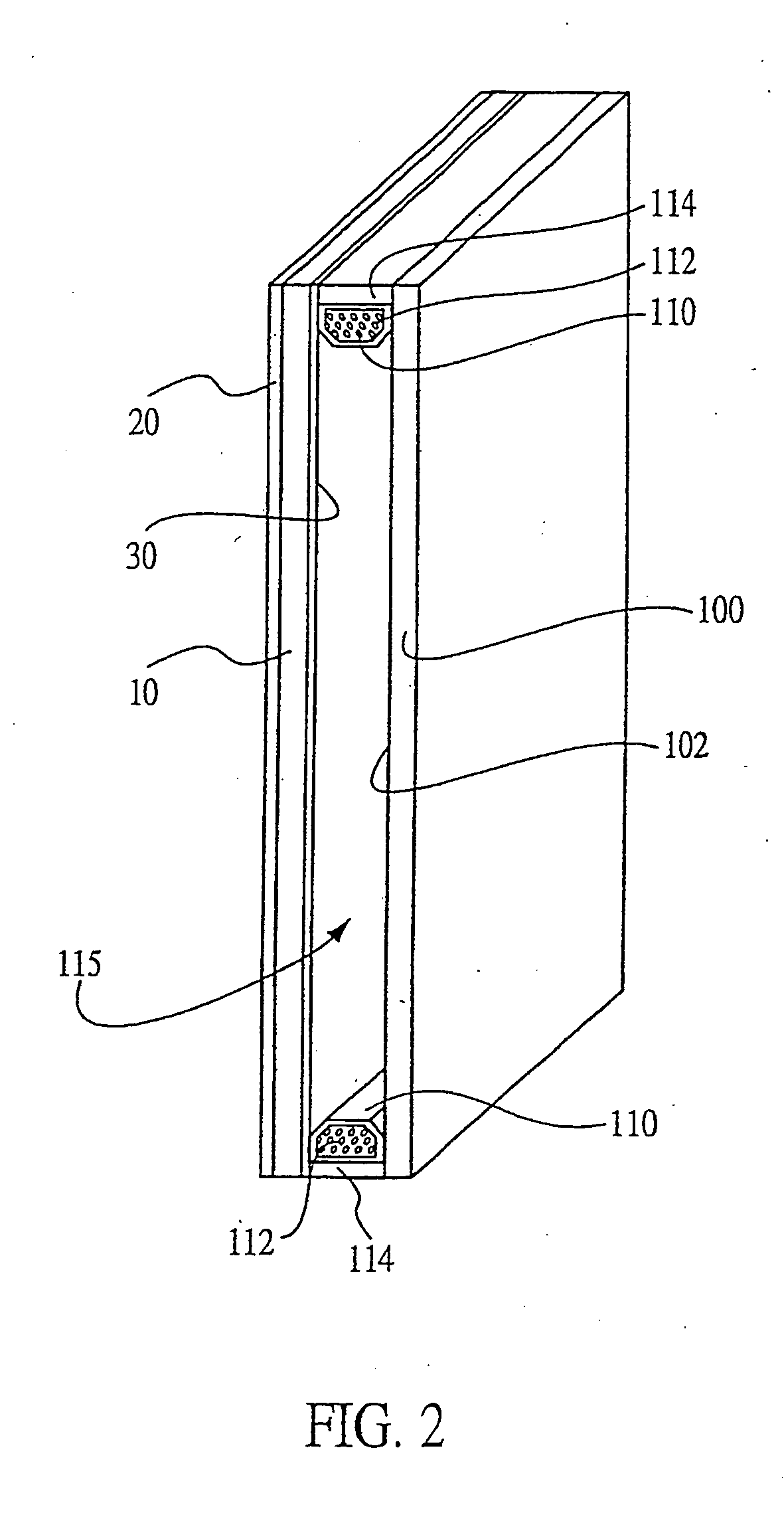

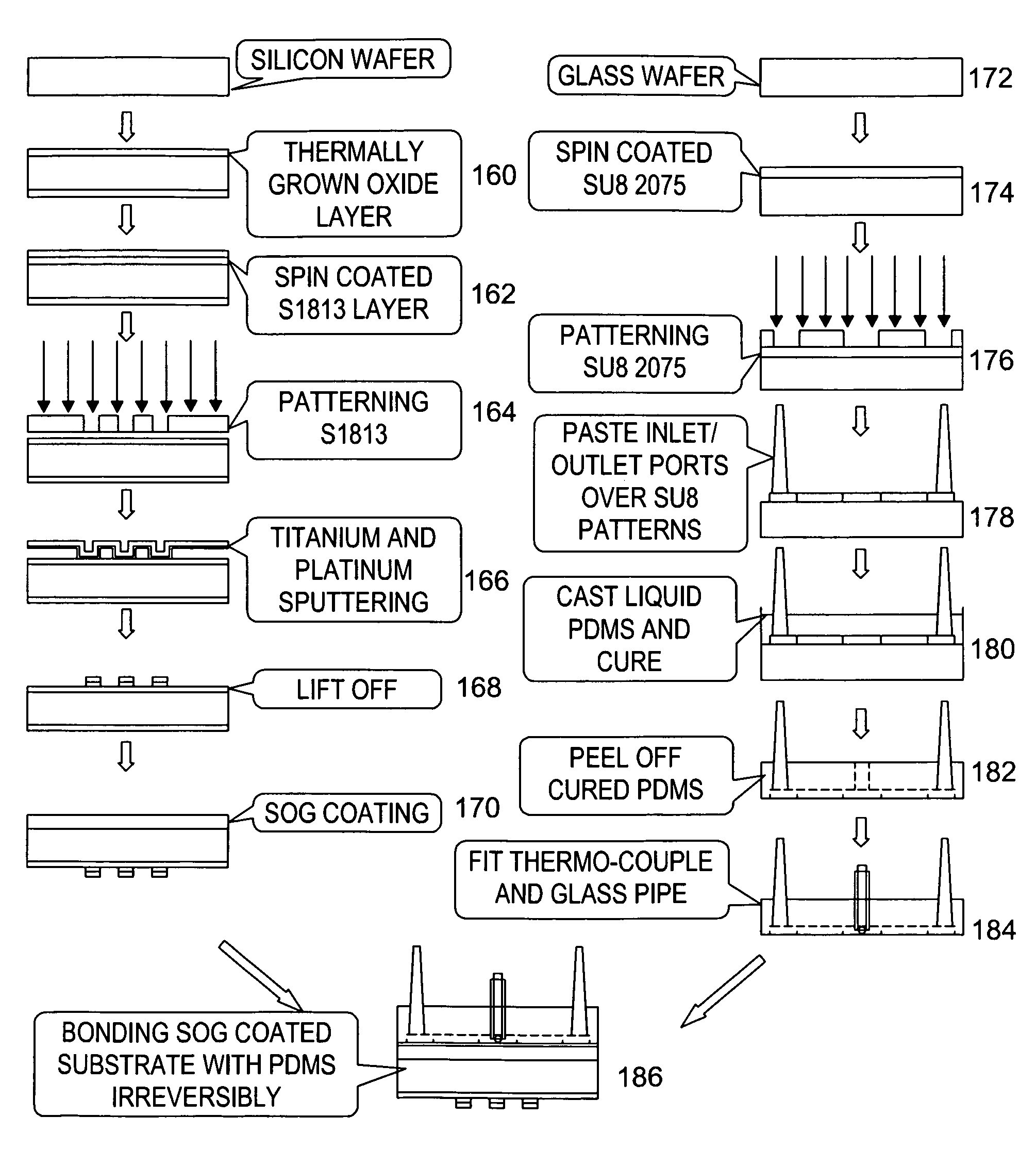

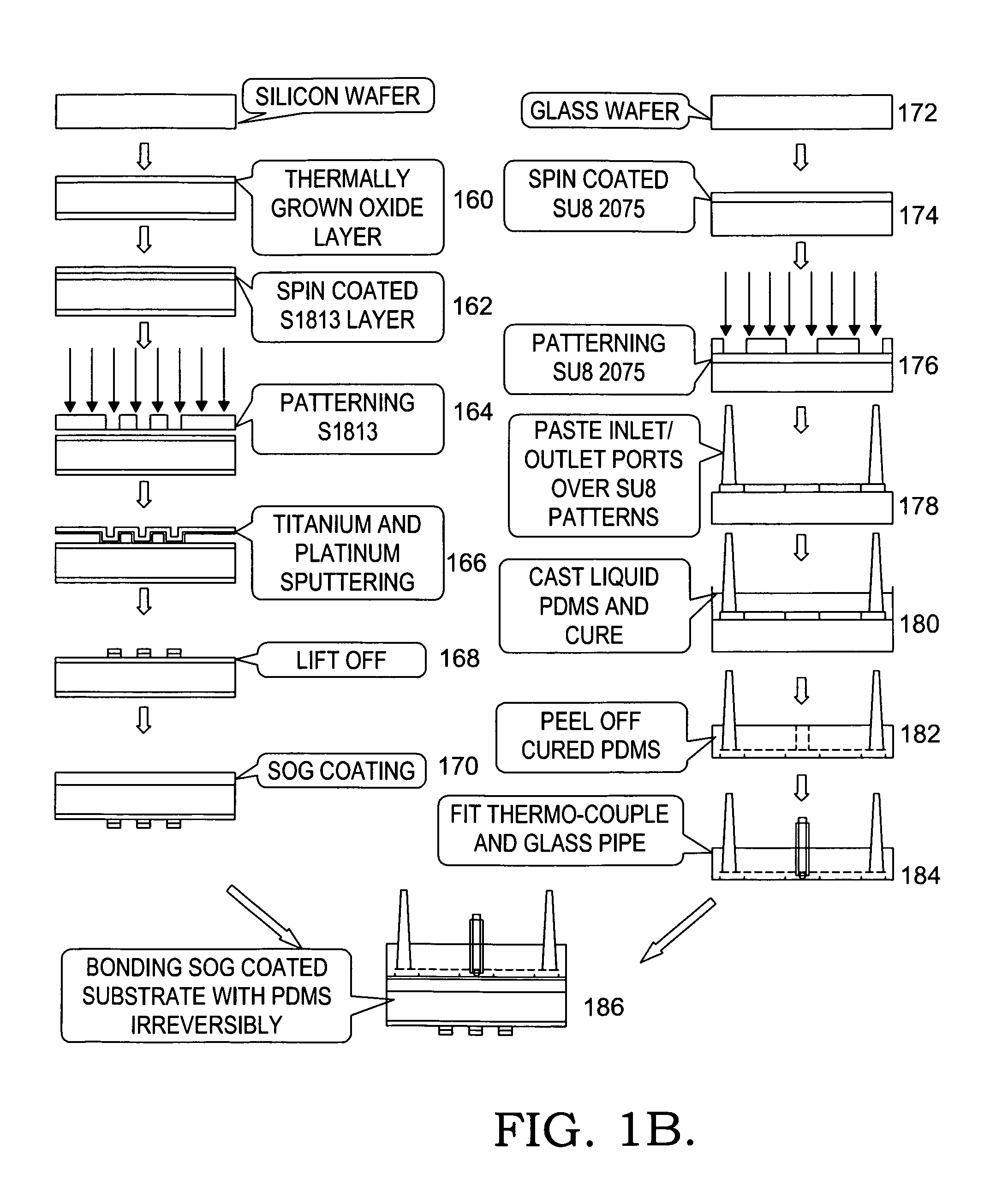

Reusable PCR amplification system and method

InactiveUS8173077B2Lower contact angleIncrease contact angleBioreactor/fermenter combinationsBiological substance pretreatmentsOxygen plasmaSpins

A DNA amplification device utilizing a polydimethylsiloxane (PDMS) and silicon substrate coated with spin-on glass (SOG) is provided. This PDMS layer is irreversibly bonded to the SOG layer of the silicon substrate using oxygen plasma. The amplification device is an inexpensive, microfluidic device, which can be utilized as a portable thermo-cycler to perform PCR amplification of DNA in the field.

Owner:UNIVERSITY OF MISSOURI

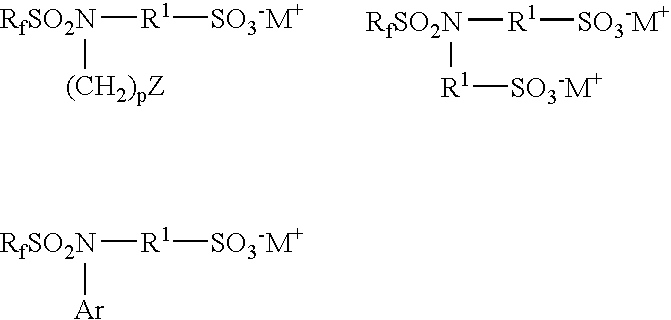

Fluorinated surfactants for aqueous acid etch solutions

ActiveUS6890452B2Reduce surface tensionImprove permeabilityDecorative surface effectsSemiconductor/solid-state device manufacturingEtchingSilicon oxide

Owner:3M INNOVATIVE PROPERTIES CO

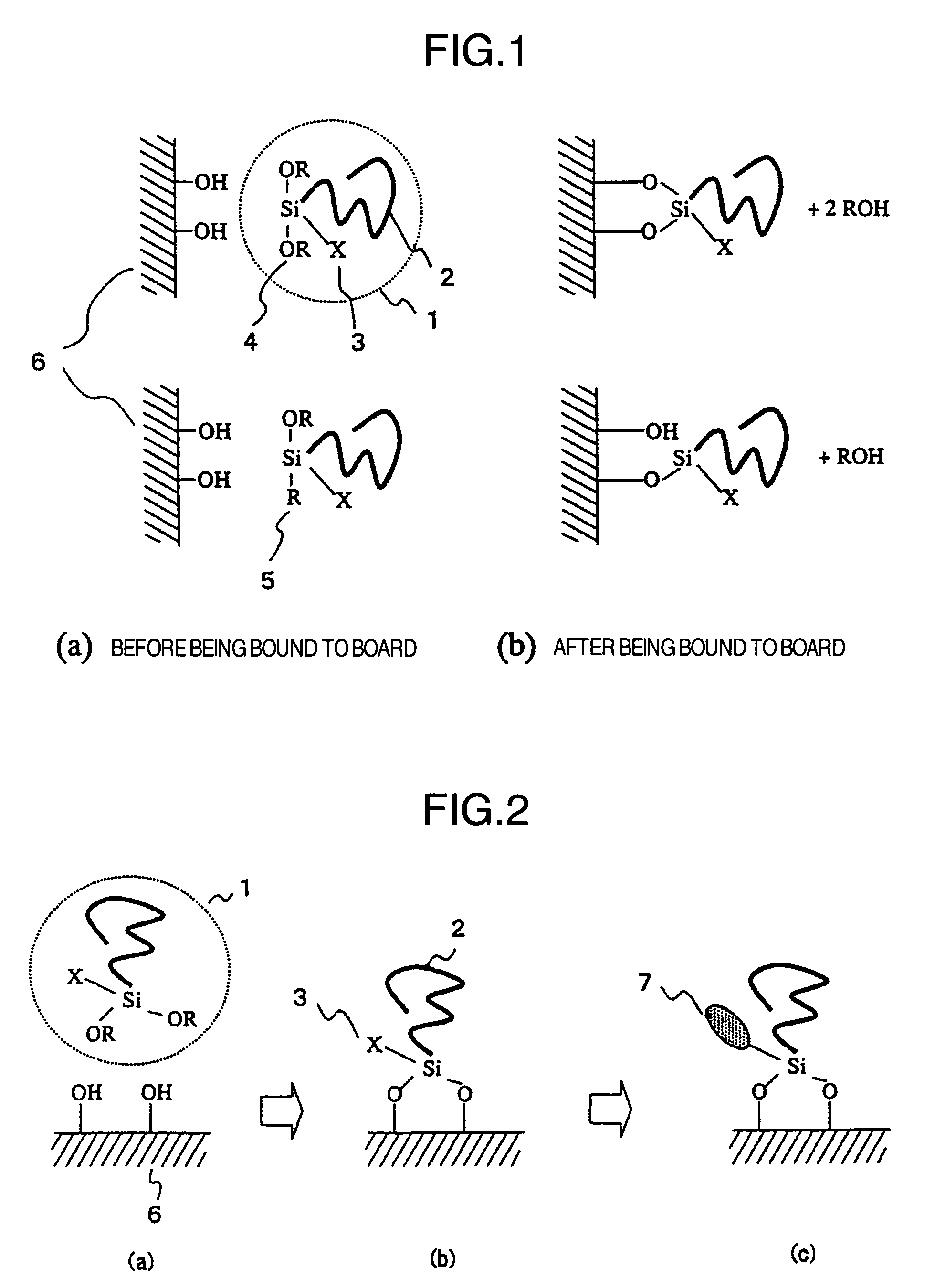

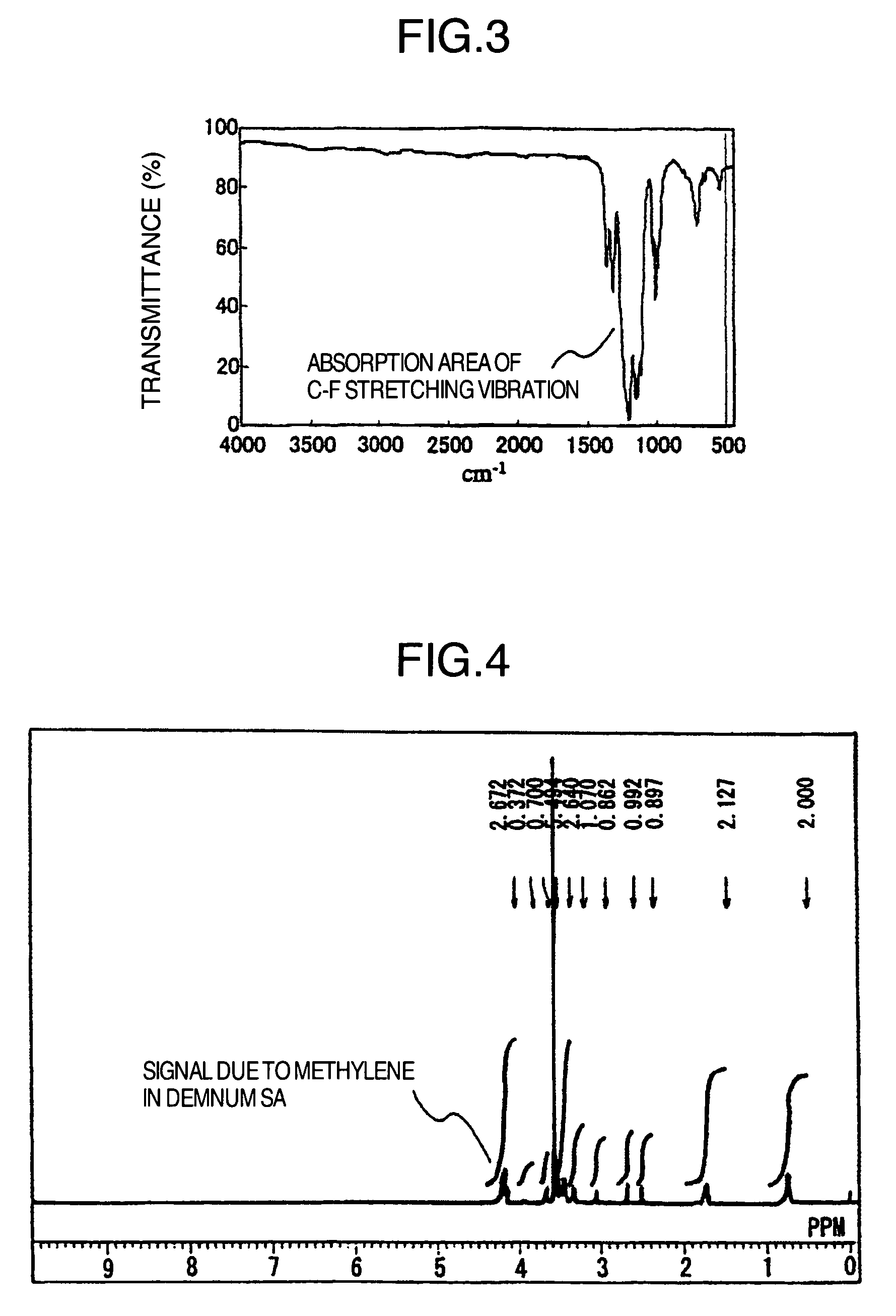

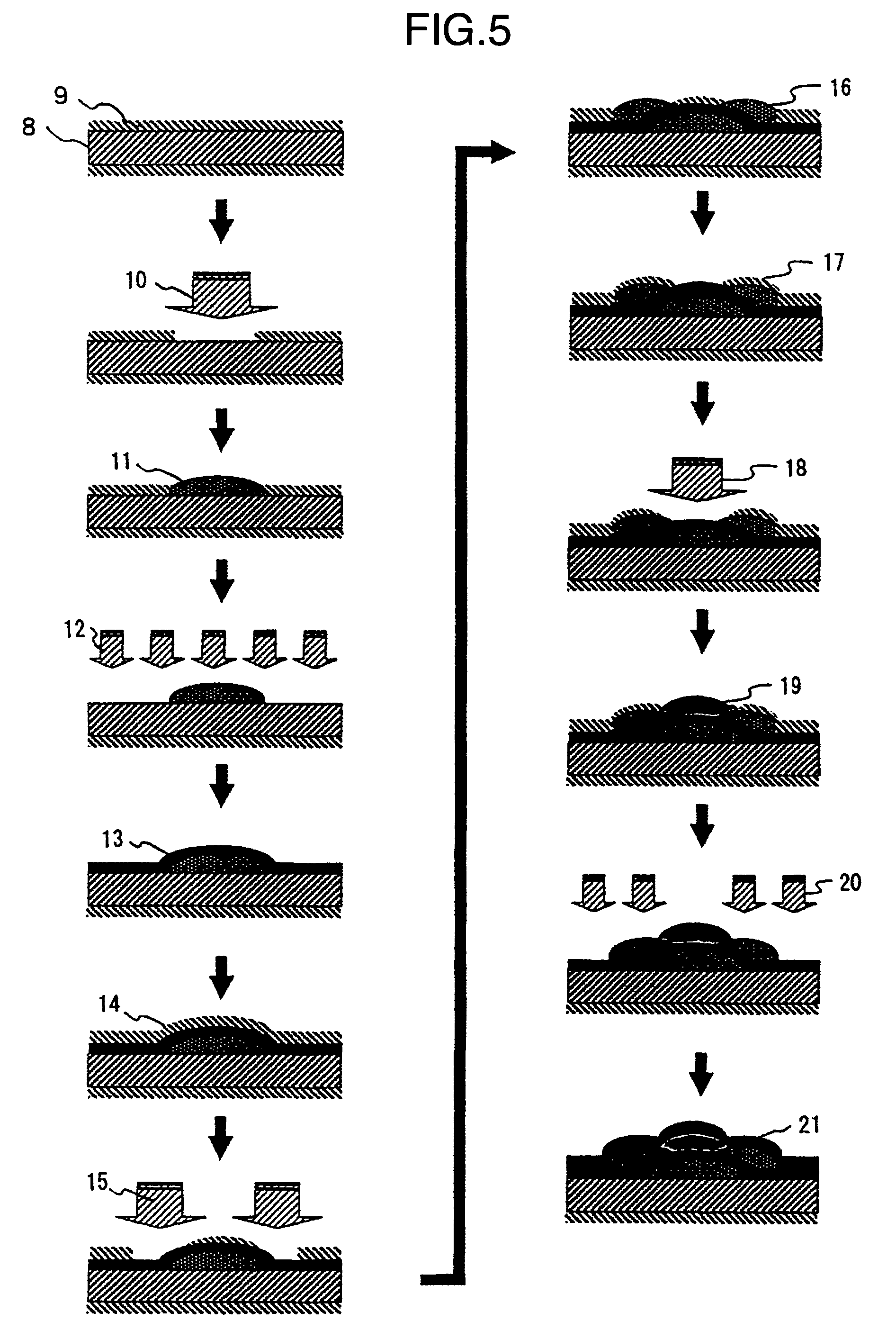

Fluorine compound, liquid repellent membrane using the same and product using the same

InactiveUS20050194588A1Reduce rejectionDecreased repellencySilicon organic compoundsOther chemical processesDisplay deviceUltraviolet

The present invention provides a liquid repellent membrane whose liquid repellency can be controlled by a varying physical stimulation; a novel fluorine compound which can be formed into the liquid repellent membrane; an electrical board, display device and color filter for display devices which are formed using the liquid repellent membrane by a method involving irradiation of visible light, which may be combined with a heating step, but needing no vacuum or ultraviolet ray irradiation process; methods for producing an electrical board, display device and color filter for display devices; and a pH sensor and ion sensor working on measurement of changed liquid repellency. The fluorine compound having liquid repellency is provided with a site at which it can be bound to a functional group, e.g., compound having a pigment unit.

Owner:HITACHI LTD

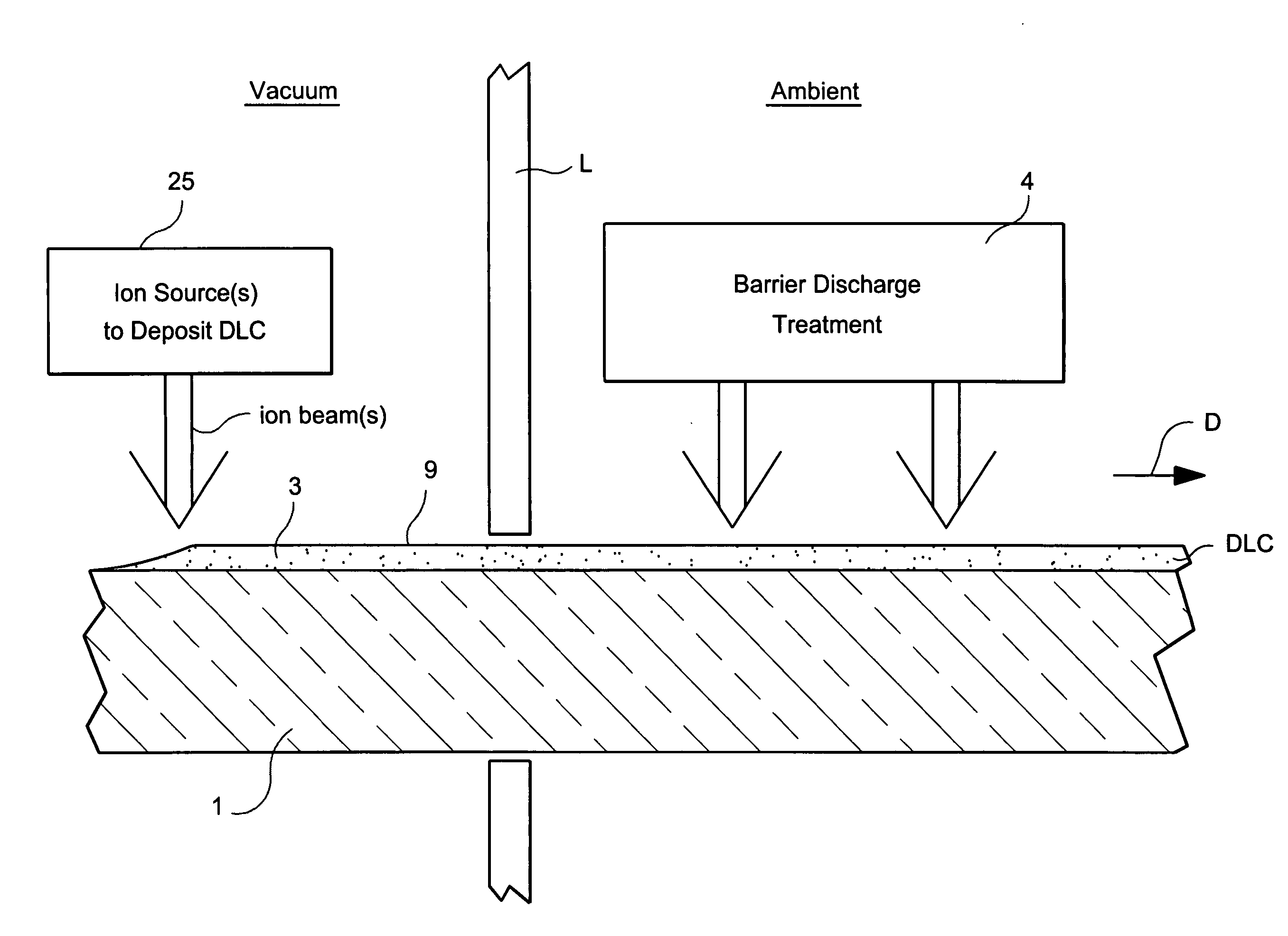

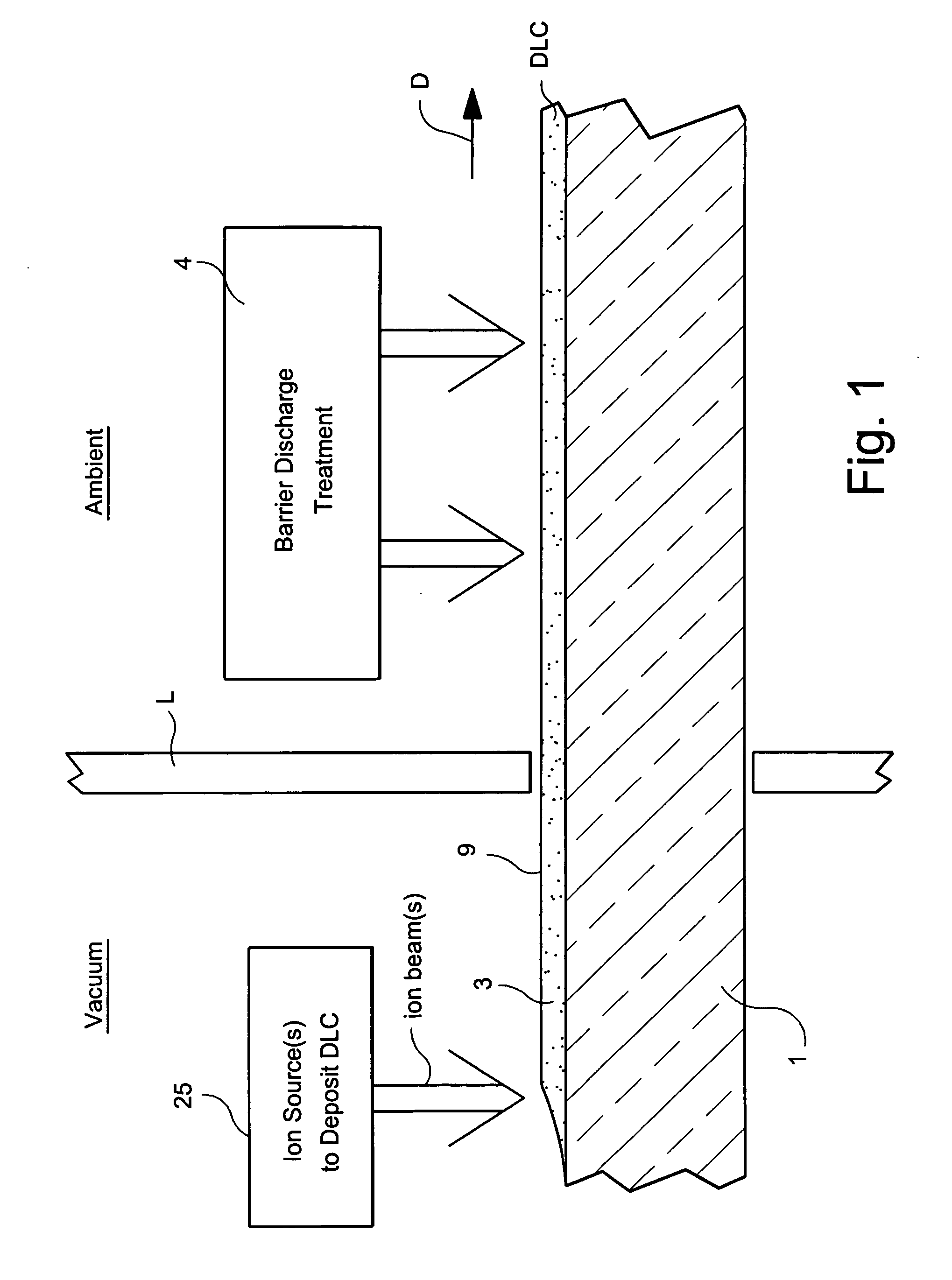

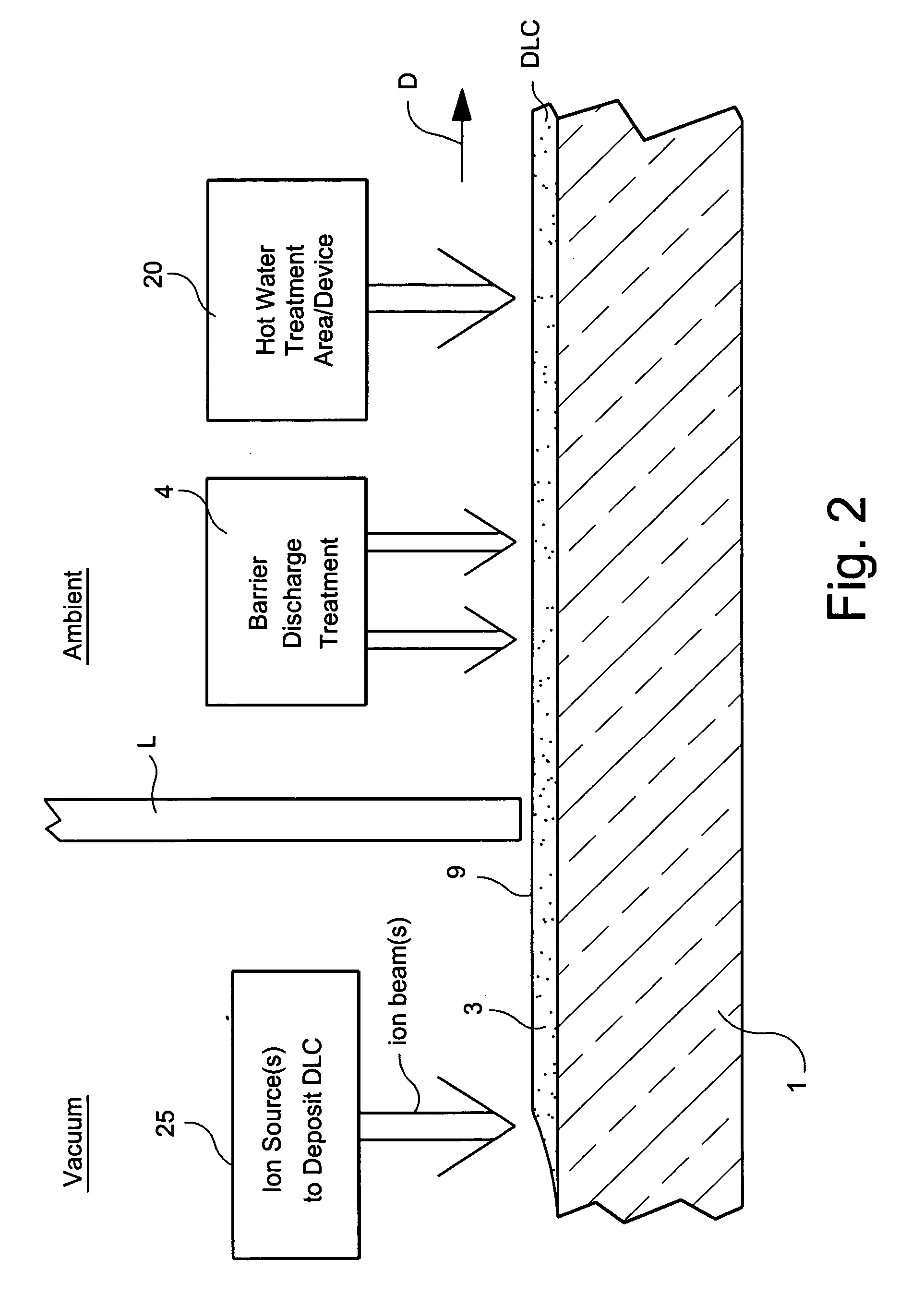

Hydrophilic DLC on substrate with barrier discharge pyrolysis treatment

InactiveUS20060246218A1Short timeLower contact anglePretreated surfacesChemical vapor deposition coatingDiamond-like carbonOxygen

A substrate is coated with a layer(s) or coating(s) that includes, for example, amorphous carbon in a form of diamond-like carbon (DLC). The DLC is then subjected to barrier discharge treatment (or some other type of plasma treatment) in order to cause the contact angle θ thereof to decrease. In certain example embodiments, an atmospheric plasma is used in the barrier discharge treatment, and the glow discharge produces oxygen radicals which impinge on the DLC and cause the contact angle to decrease.

Owner:GUARDIAN GLASS LLC

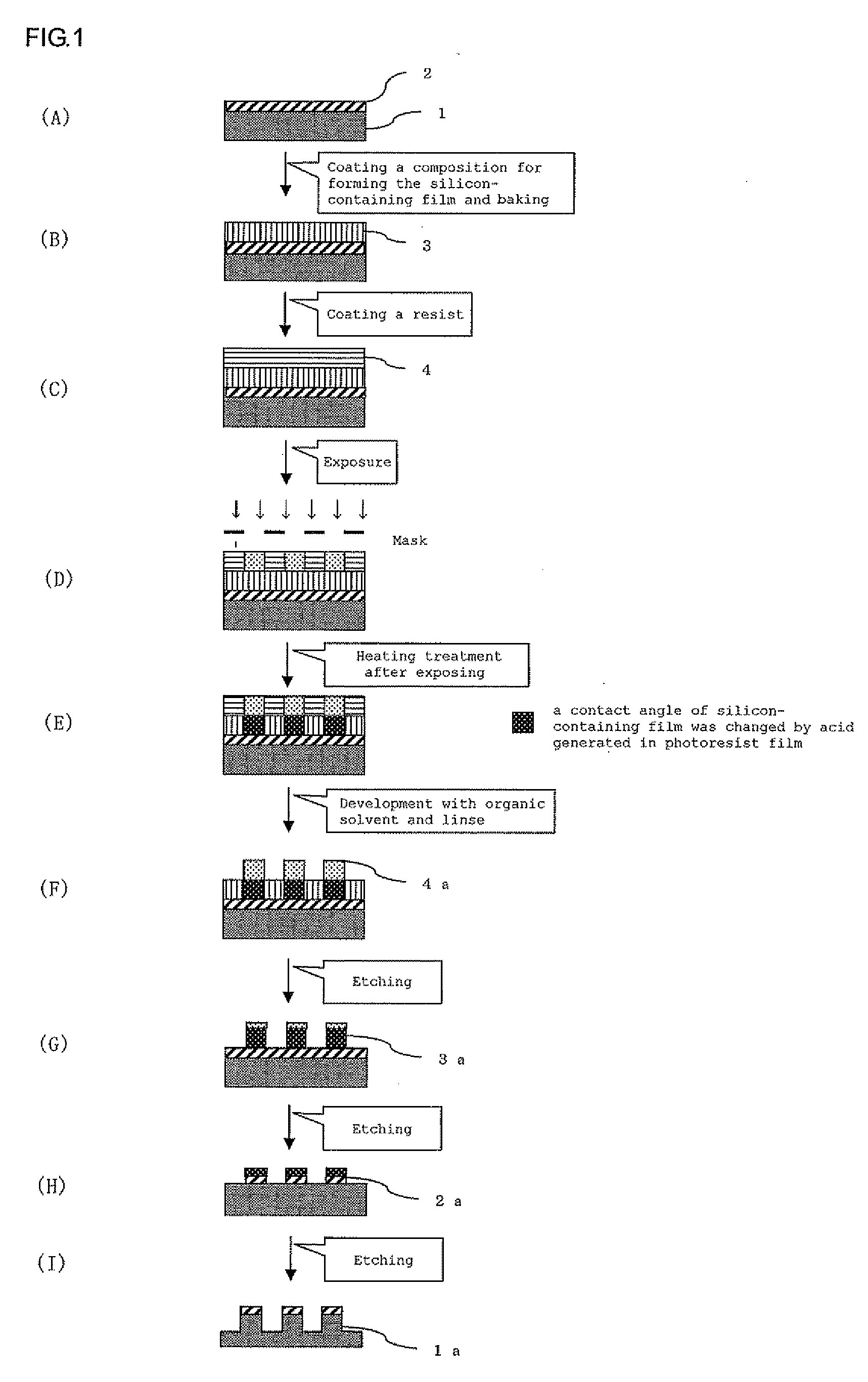

Patterning process

ActiveUS20120276483A1Improve adhesionReduce surface roughnessSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusOrganic solventPhotoresist

The invention provides a patterning process, comprising at least a step of forming a silicon-containing film on a body to be processed by using a composition for the silicon-containing film, a step of forming, on the silicon-containing film, a photoresist film by using a resist composition, a step of exposing to the photoresist film after heat treatment thereof, and a step of forming a negative pattern by dissolving an unexposed area of the photoresist film by using a developer of an organic solvent; wherein a composition giving the silicon-containing film whose pure-water contact angle in the part corresponding to the exposed area of the photoresist film becomes in the range of 35° or more to lower than 70° after exposure is used as the composition. There can be optimum patterning process as a patterning process of a negative resist pattern to be formed by adopting organic solvent-based development.

Owner:SHIN ETSU CHEM IND CO LTD

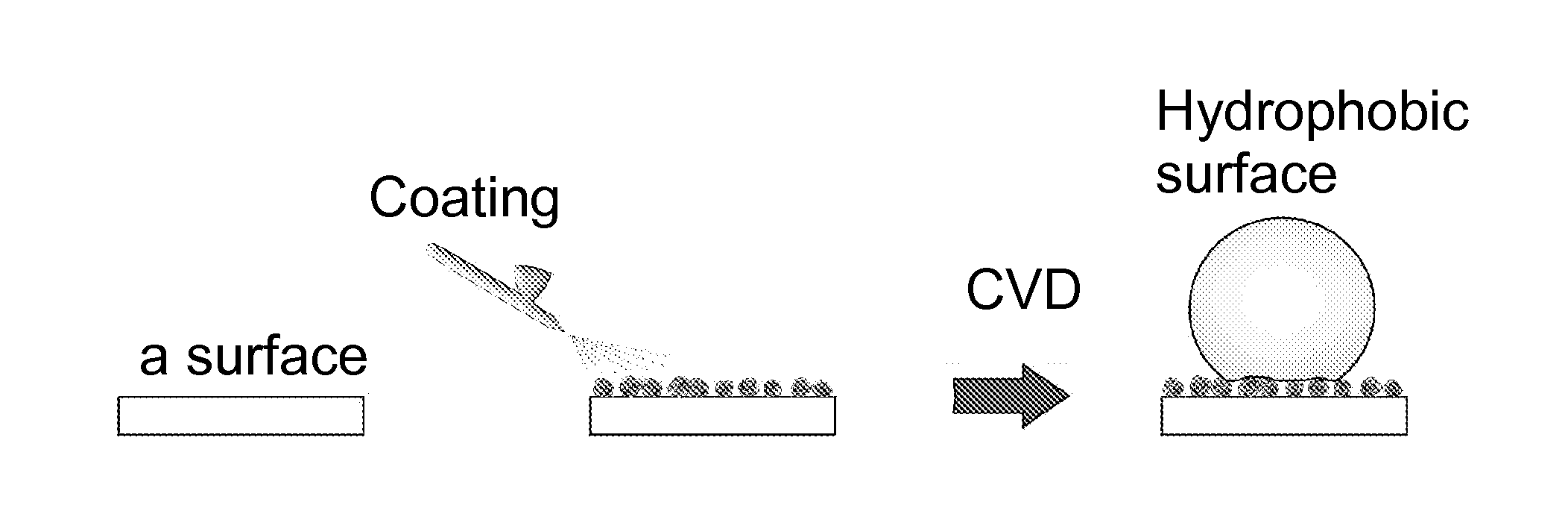

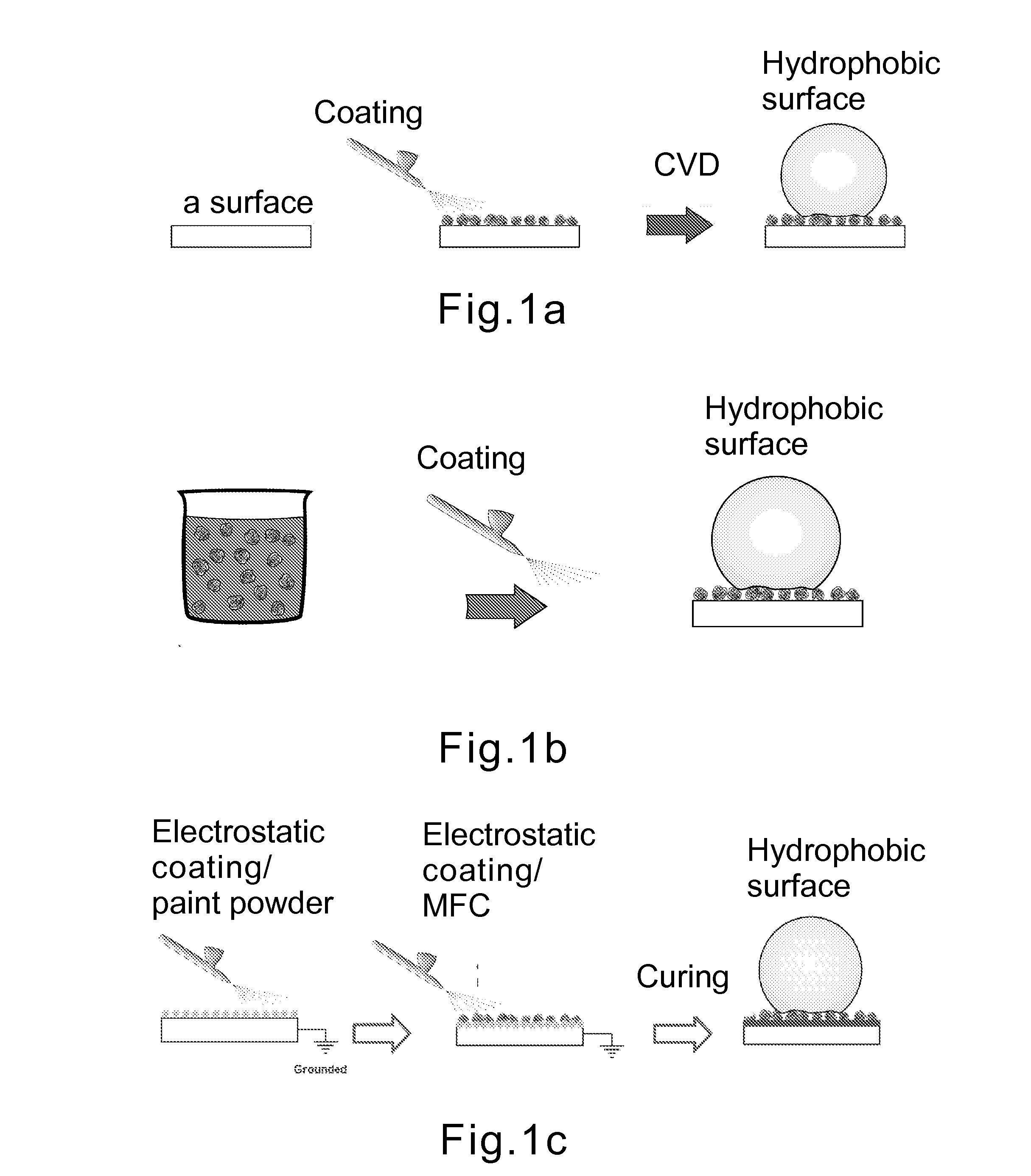

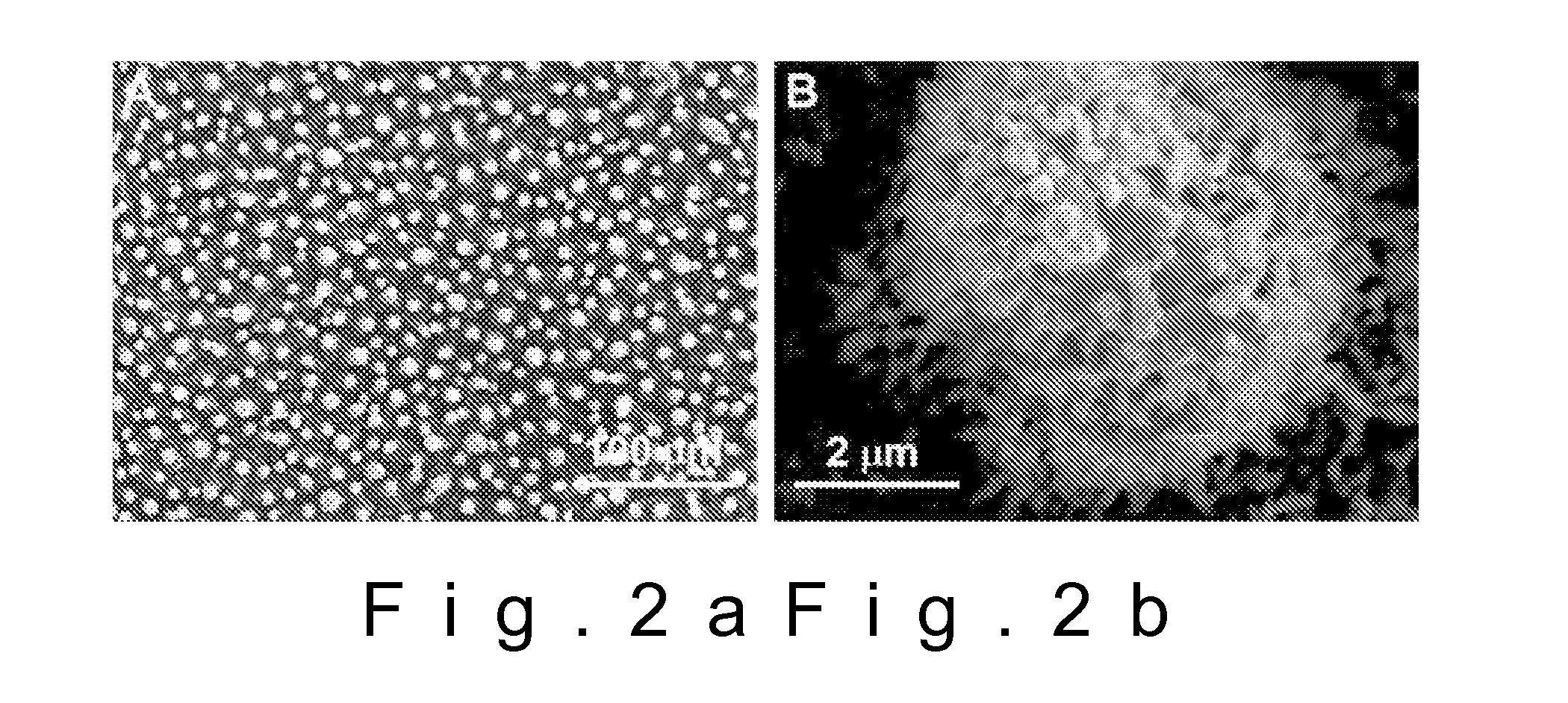

Hydrophobic coating and a method for producing hydrophobic surface

InactiveUS20140130710A1Similar in sizeIncrease contact angleElectric shock equipmentsWater-repelling agents additionPolymer chemistryHydrophobic surfaces

A method for producing a superhydrophobic surface, which includes cellulosic material. The cellulosic material includes nanocellulose particles and the method includes adding the nanocellulose particles to a surface and hydrophobizing the nanocellulose particles with a modifier before, during and / or after the addition of the particles. The invention further relates to a hydrophobic coating.

Owner:UPM-KYMMENE OYJ

Soil-resistant coating for glass surfaces

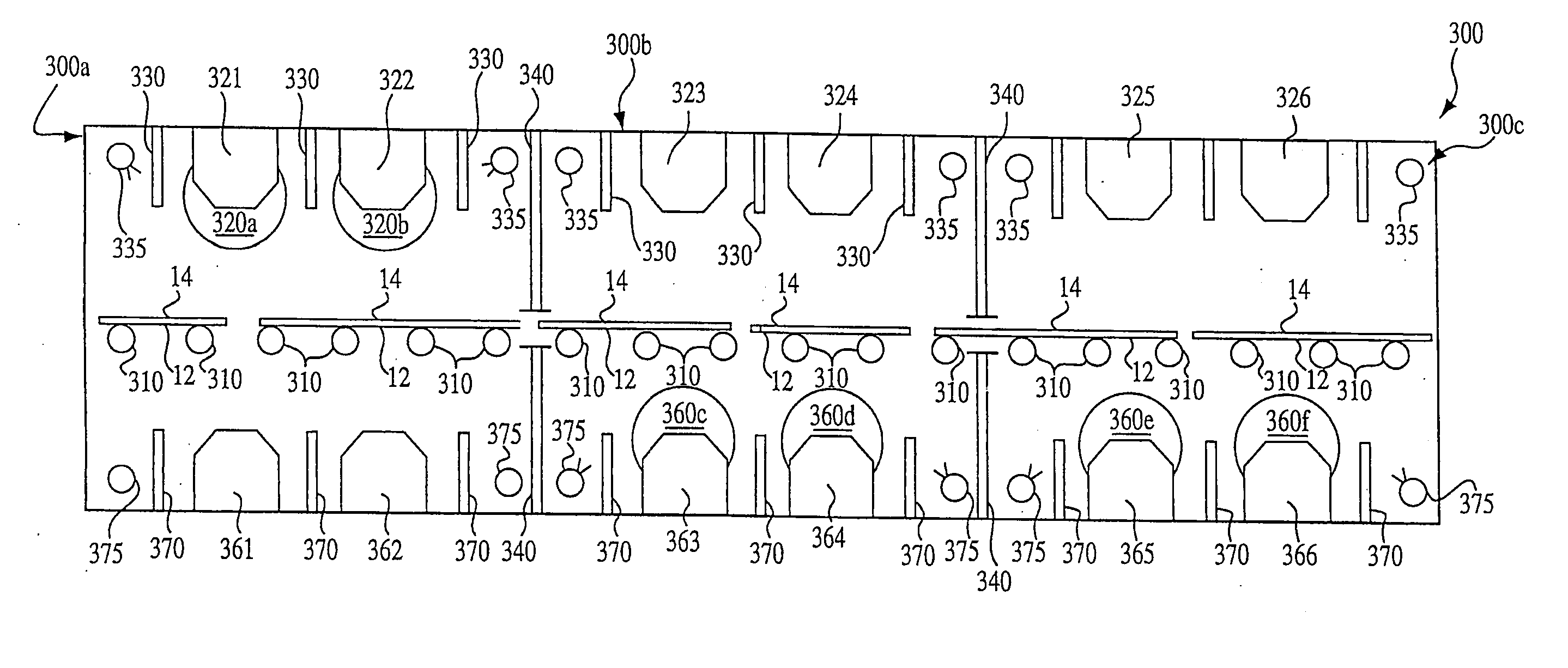

A method and apparatus for coating two sides of a single pane of glass or other substrate in a single pass through a coating apparatus. A sputtering line is provided, this line comprising a series of sputtering chambers. At least one of the chambers comprises a downward sputtering chamber having an upper target. At least one of the chambers comprises an upward sputtering chamber having a lower target. In some embodiments, the upper and lower targets are rotary targets. The coating apparatus advantageously has a plurality of transport rollers for conveying the substrate along the sputtering line. In certain embodiments, a majority of the chambers of the sputtering line are downward sputtering chambers each having only an upper target with no lower target.

Owner:CARDINAL CG

Surface modification method for polytetrafluoroethylene product

ActiveCN101979429AImprove permeabilityImprove wettabilityCoatingsPolyethylene glycolTherapeutic effect

The invention discloses a surface modification method for a polytetrafluoroethylene product. The method comprises the following steps of: coating polyethylene glycol on the surface of the polytetrafluoroethylene product, and then performing surface modification on the polytetrafluoroethylene product coated with the polyethylene glycol by adopting a plasma treatment method. Compared with the prior art, the polyethylene glycol element is introduced on the surface of the polytetrafluoroethylene product so as to effectively improve the surface activity of the polytetrafluoroethylene product, reduce the contact angle, improve the surface energy, remarkably improve the wetting property and the adhesion property of the polytetrafluoroethylene product and keep the polytetrafluoroethylene product for long time; and in addition, the method has little influence on the chemical property of the polytetrafluoroethylene product, has the advantages of convenient for operation, simple process, high processing speed, good treatment effect, low cost, energy conservation and emission reduction, is not easy to cause environmental pollution, and is more suitable for industrialized production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

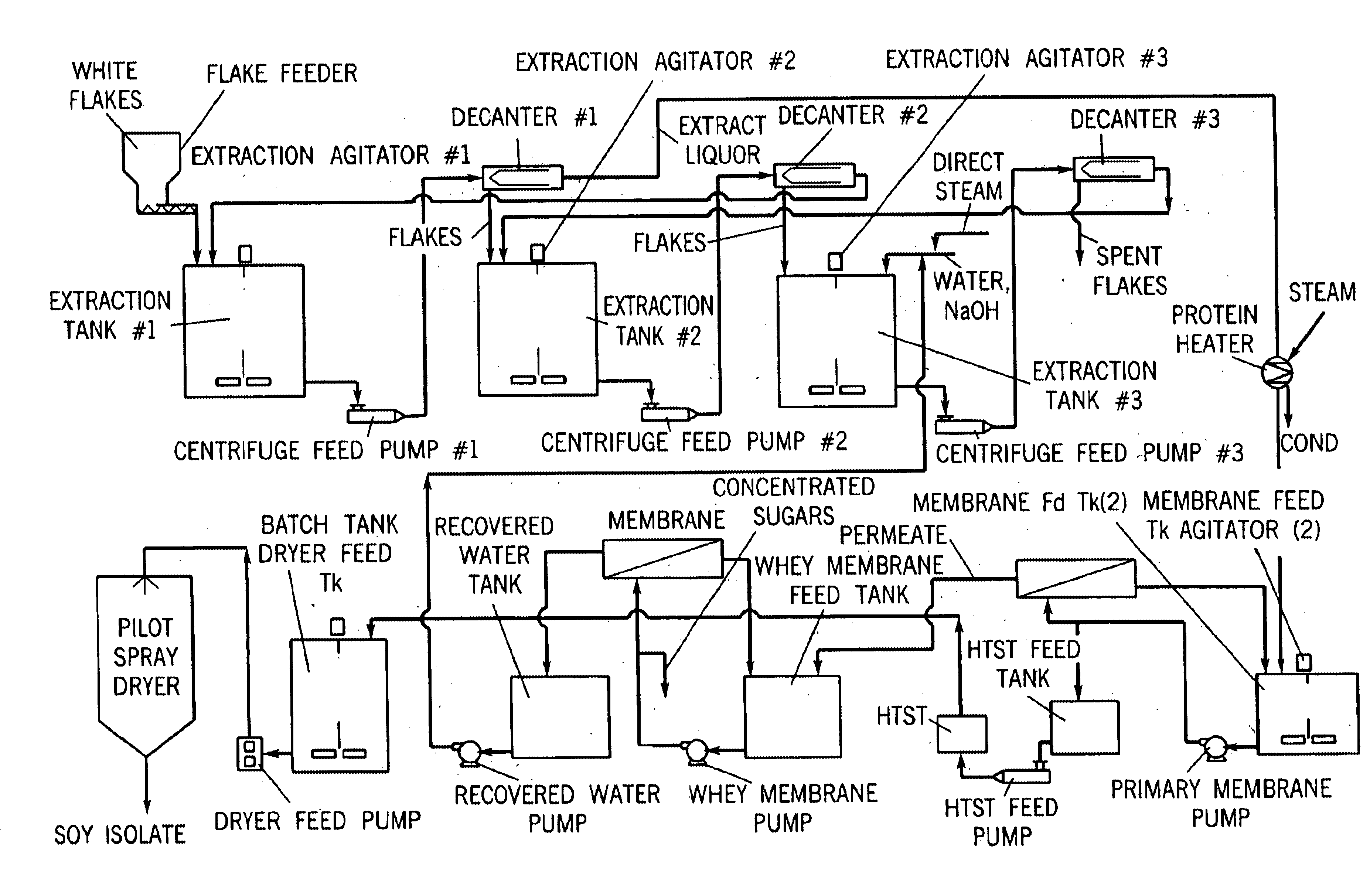

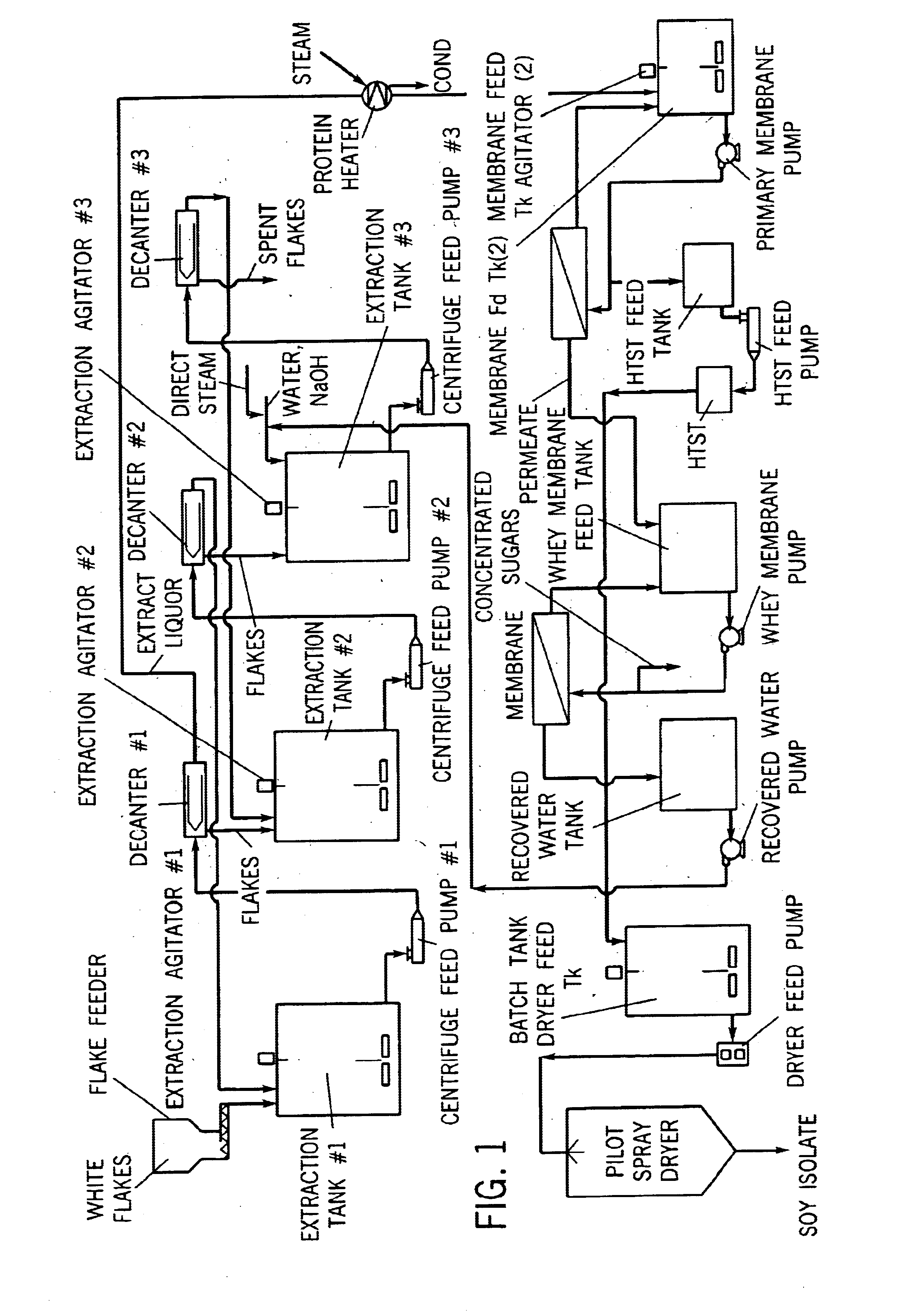

Modified oilseed material

InactiveUS6841184B2Lower contact angleSuitable for useMilk preparationProtein composition from vegetable seedsCereal grainCereal product

A modified oilseed material formed from oilseed-based material is described. The modified oilseed material can be utilized in a variety of nutritional applications, including the preparation of protein supplemented food products such as beverages, processed meats, frozen desserts, confectionery products, dairy-type products, and cereal grain products. The modified oilseed material typically includes at least 85 wt. % protein (dry solids basis), at least about 40% of the modified oilseed material has an apparent molecular weight of greater than 300 kDa, and / or a MW50 of at least about 200 kDa.

Owner:CARGILL INC

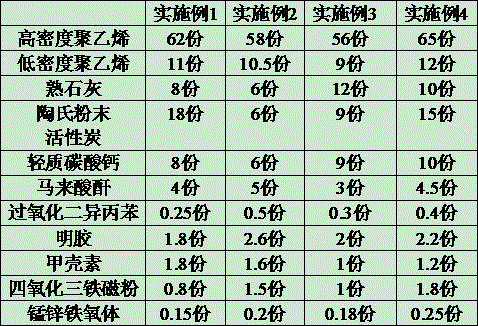

Hydrophilic carrier for microbial biofilm formation

InactiveCN105621595ANot easy to fall offPromote sheddingTreatment with microorganism supports/carriersLow-density polyethyleneMicrobial Biofilms

The invention discloses a hydrophilic carrier for microbial biofilm formation. The hydrophilic carrier comprises a hollow short tube, and a first concentric ring and a second concentric ring which are sequentially concentrically arranged outside the hollow short tube, wherein the surface of the outermost second concentric ring is toothed; and the microbial filler is composed of the following components in parts by weight: high-density polyethylene, low-density polyethylene, white lime, Dow powder activated carbon, light calcium carbonate, maleic anhydride, dicumyl peroxide, gelatin, chitin, ferroferric oxide magnetic powder and manganese-zinc ferrite. The density of the microbial filler is 0.96-0.98 g / cm<3>. The hydrophilic carrier for microbial biofilm formation prolongs the contact time between microbes and organic matters, so that the organic matters are degraded quickly and thoroughly; and the biological oxidation can restore the surface adsorption capacity of the activated carbon.

Owner:KOOVINE ENVIRONMENTAL PROTECTION TECH CO LTD

Volatile stamping cutting oil composite for machining for machining of moderate-thickness aluminum plate and preparation method thereof

InactiveCN102199476AImprove the lubrication effectImprove rust resistanceLubricant compositionIrritationPhosphate

The invention relates to volatile stamping cutting oil composite for machining of a moderate-thickness aluminum plate and a preparation method thereof. The stamping cutting oil composite comprises the following raw materials in percentage by weight: 90-95 percent of solvent oil, 1-4 percent of antiwear additive, 1-4 percent of oiliness additive, 0.5-2 percent of antirust additive and 0.2-1 percent of antioxidant; the solvent oil has low sulphur content, low aromatic hydrocarbon content, no toxicity and smell and has the kinematic viscosity of 1.5-3.5mm<2> / s at 20 DEG C; the antiwear additive is selected from phosphates; the oiliness additive contains more than one of fatty alcohol and fatty acid methyl ester; the antirust additive is sodium alkylsulfonate; and the antioxidant is an antioxidant BHT (butylated hydroxytoluene). The preparation method of the volatile stamping cutting oil composite for the machining of the moderate-thickness aluminum plate, provided by the invention, is simple and convenient; and the composite provided by the invention does not contain a chlorine extreme pressure agent, is a biological environment-friendly product and has the advantages of excellent extreme pressure lubrication performance and favorable demoulding performance, volatilization completeness, no trace leaving, no clean, extremely low smell, no irritation to skin, time and labor saving and capability of greatly prolonging the service life of a mould.

Owner:上海德润宝特种润滑剂有限公司

Preparation method for surface ionization modified polysulfone ultrafiltration membrane

ActiveCN102755844AImprove hydrophilicityLower contact angleSemi-permeable membranesMethacrylatePhase conversion

The invention discloses a preparation method for a surface ionization modified polysulfone ultrafiltration membrane. The preparation method comprises the following steps: 1) dissolving polysulfone, poly-2-(dimethylamino) ethyl methacrylate- polysulfone-2-(dimethylamino) ethyl methacrylate triblock copolymer into a solvent to obtain casting membrane solution; 2) leading the casting membrane solution to flow through a film forming machine, soaking in a coagulating bath to obtain polysulfone membrane; 3) soaking the polysulfone membrane in bromoacrtic solution to carry out surface quaternization treatment; and 4) cleaning and drying to obtain the surface ionization modified polysulfone ultrafiltration membrane. According to the invention, the polysulfone ultrafiltration membrane is prepared by carrying out solution mixing to poly-2-(dimethylamino) ethyl methacrylate-contained amphipathic block copolymer with polysulfone through an immersion sediment phase conversion method, the membrane surface has anion and cation after the surface quaternization treatment is carried out by the bromoacrtic solution, and the hydrophilcity and anti-pollution capability of the membrane are greatly improved. The preparation method is simple and convenient, mild in modification conditions, obvious in effect and the like, and can prepare high-hydrophilcity, large-flux and anti-pollution polysulfone ultrafiltration membrane.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com