Patents

Literature

158 results about "Self-cleaning surfaces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

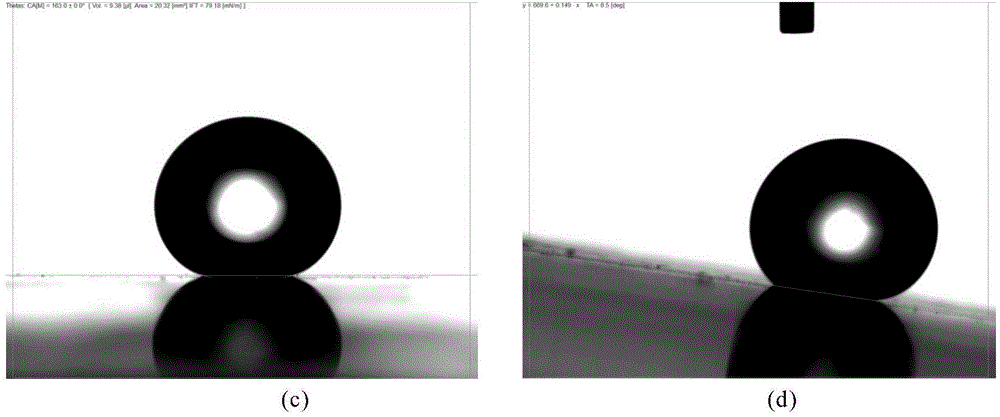

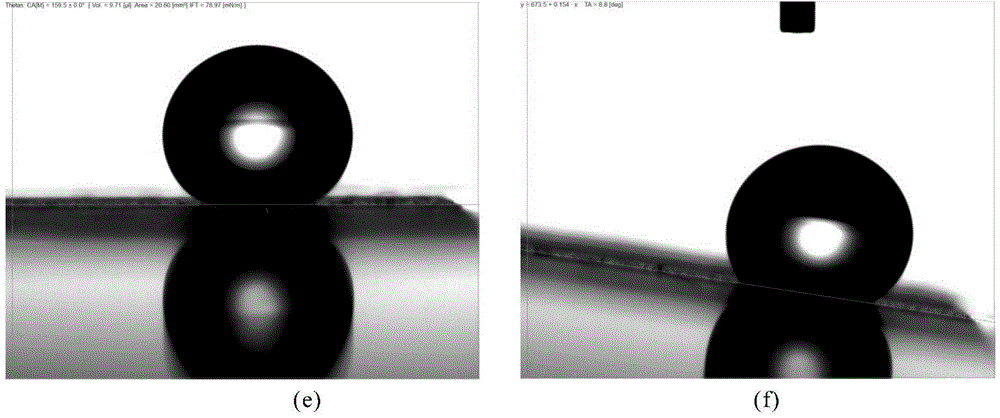

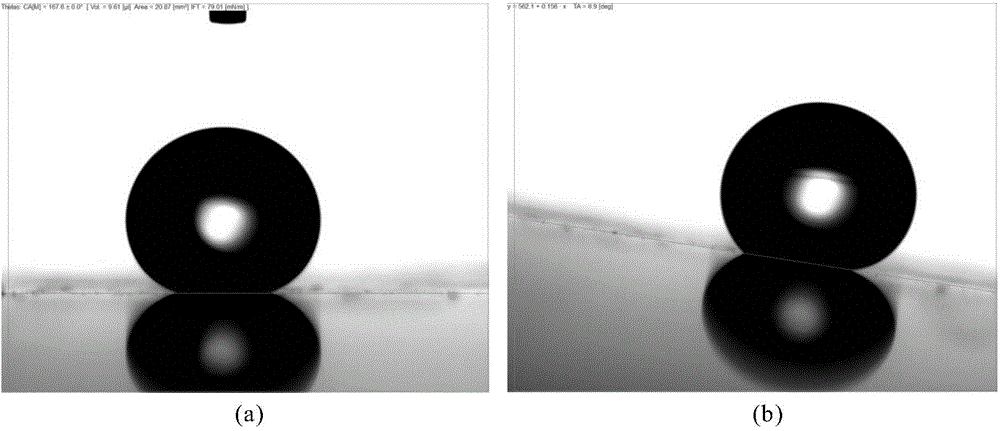

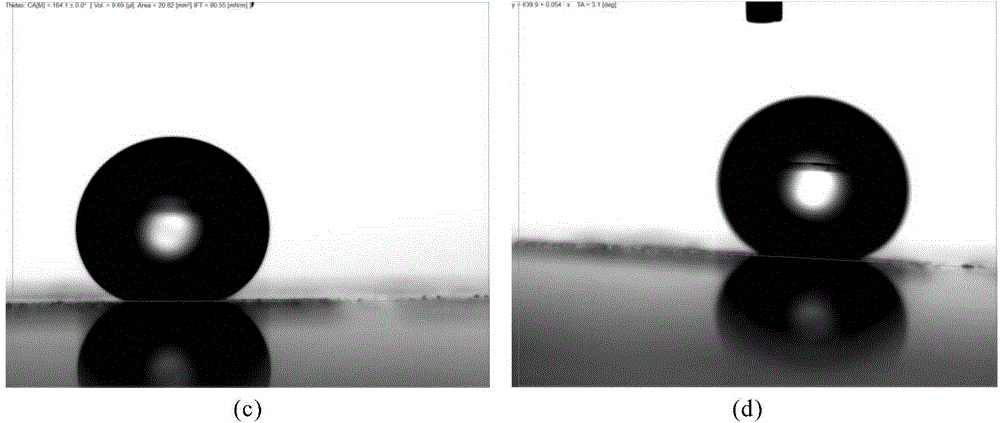

Self-cleaning surfaces are a class of materials with the inherent ability to remove any debris or bacteria from their surfaces in a variety of ways. The self-cleaning functionality of these surfaces are commonly inspired by natural phenomena observed in lotus leaves, gecko feet, and water striders to name a few. The majority of self-cleaning surfaces can be placed into three categories: 1) Superhydrophobic, 2) Superhydrophilic, and 3) Photocatalytic.

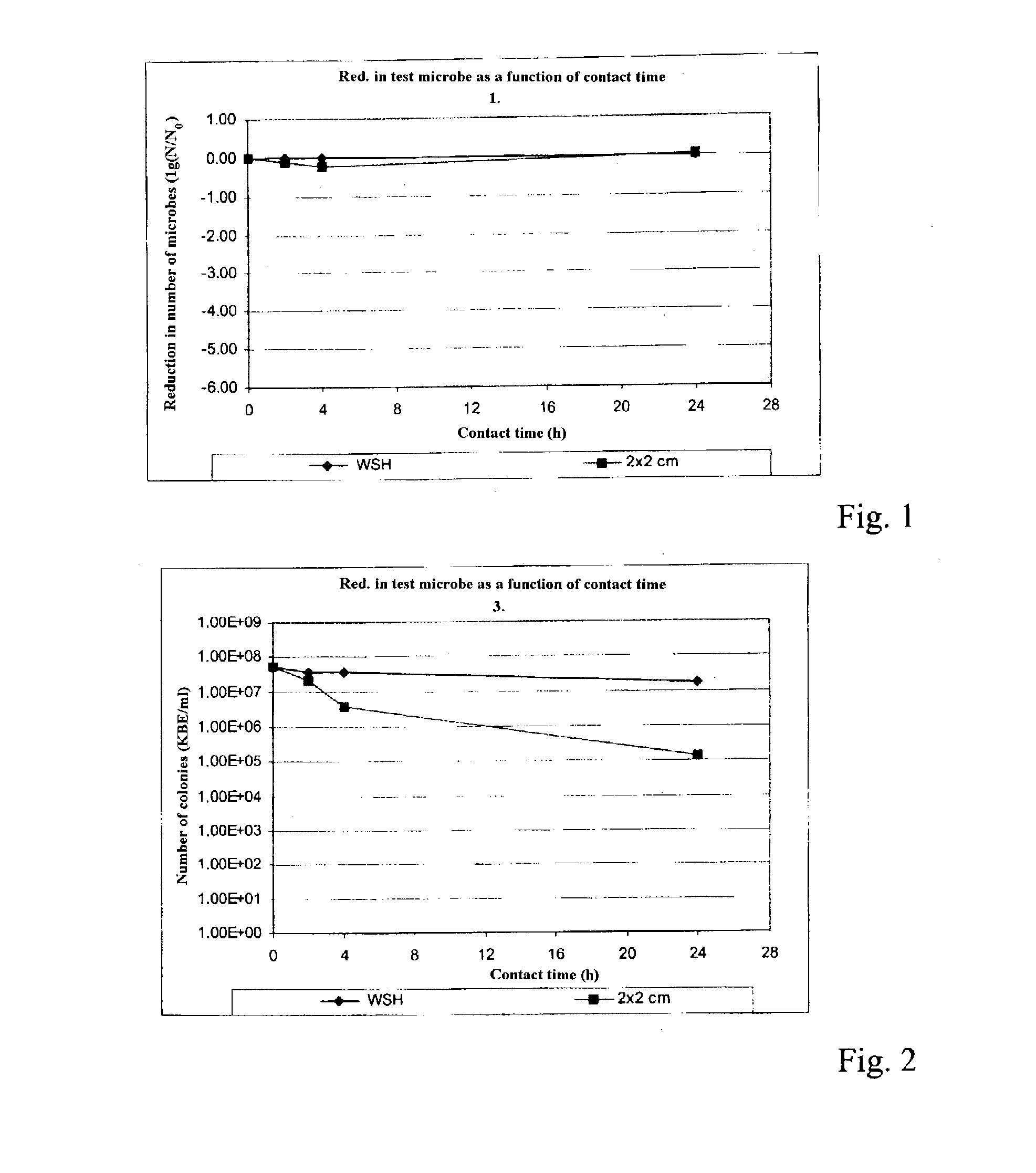

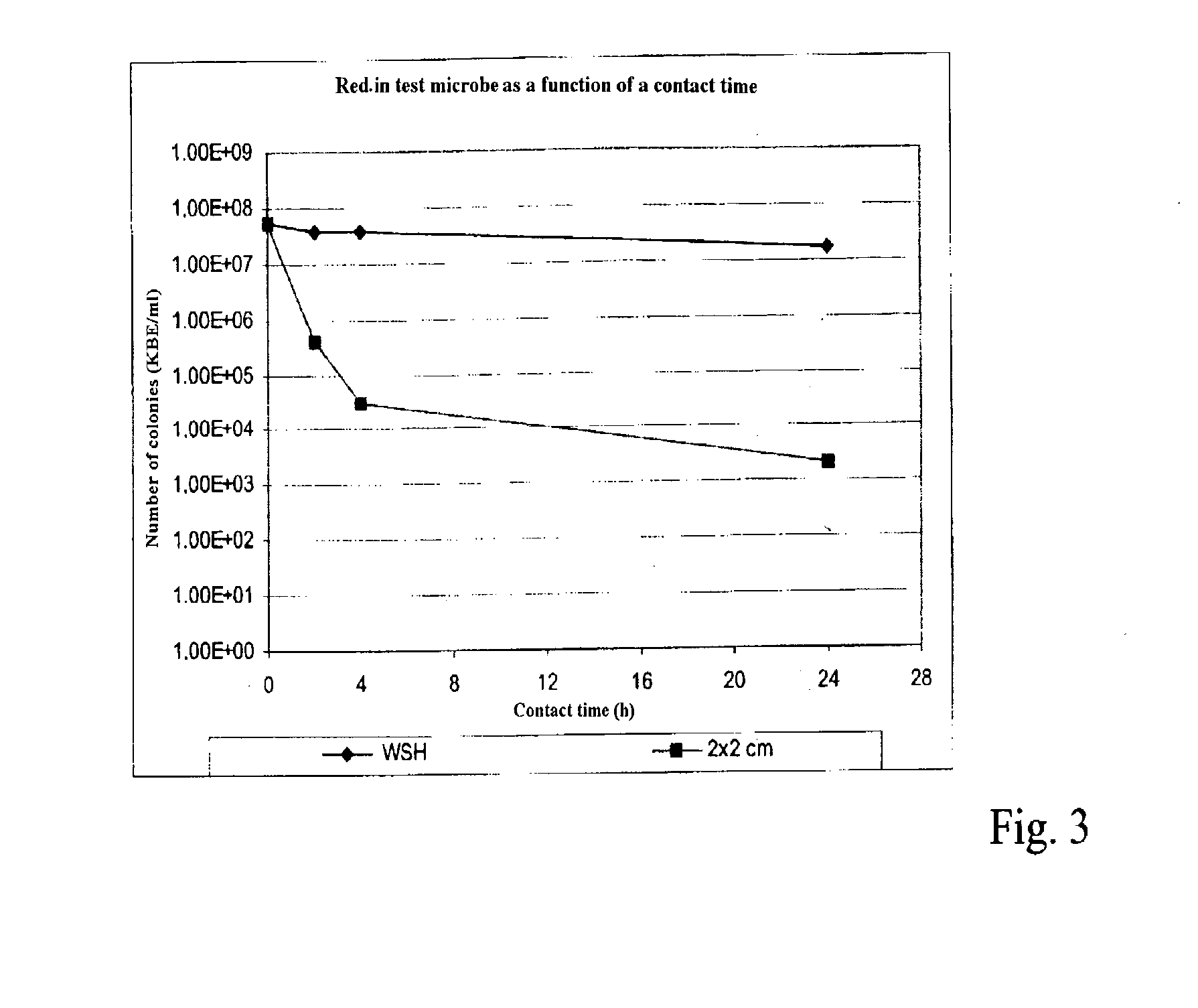

Self-cleaning lotus effect surfaces having antimicrobial properties

A self-cleaning or lotus-effect surface that has antimicrobial properties, commercial products comprising such a surface, and uses thereof. A process for the production of an antimicrobial self-cleaning or lotus-effect surface in which one or more antimicrobial polymer(s) is secured to a surface-coating system for securing structure-formers to generate a self-cleaning surface. This method lastingly binds antimicrobial polymers to the self-cleaning surface. Commercial products comprising an antimicrobial self-cleaning or lotus-effect surface.

Owner:CREAVIS GES FUER TECH

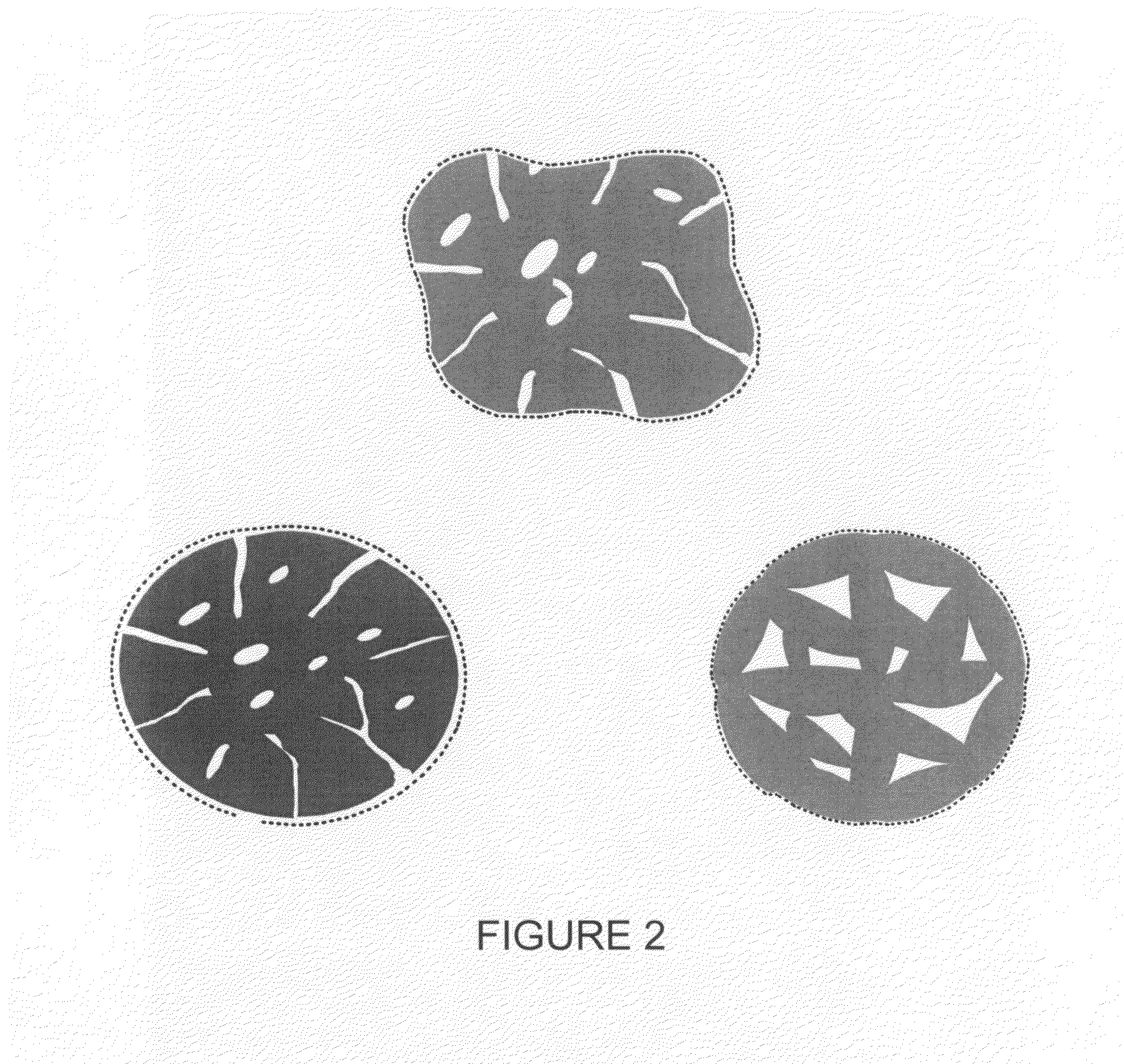

Surfaces rendered self-cleaning by hydrophobic structures, and process for their production

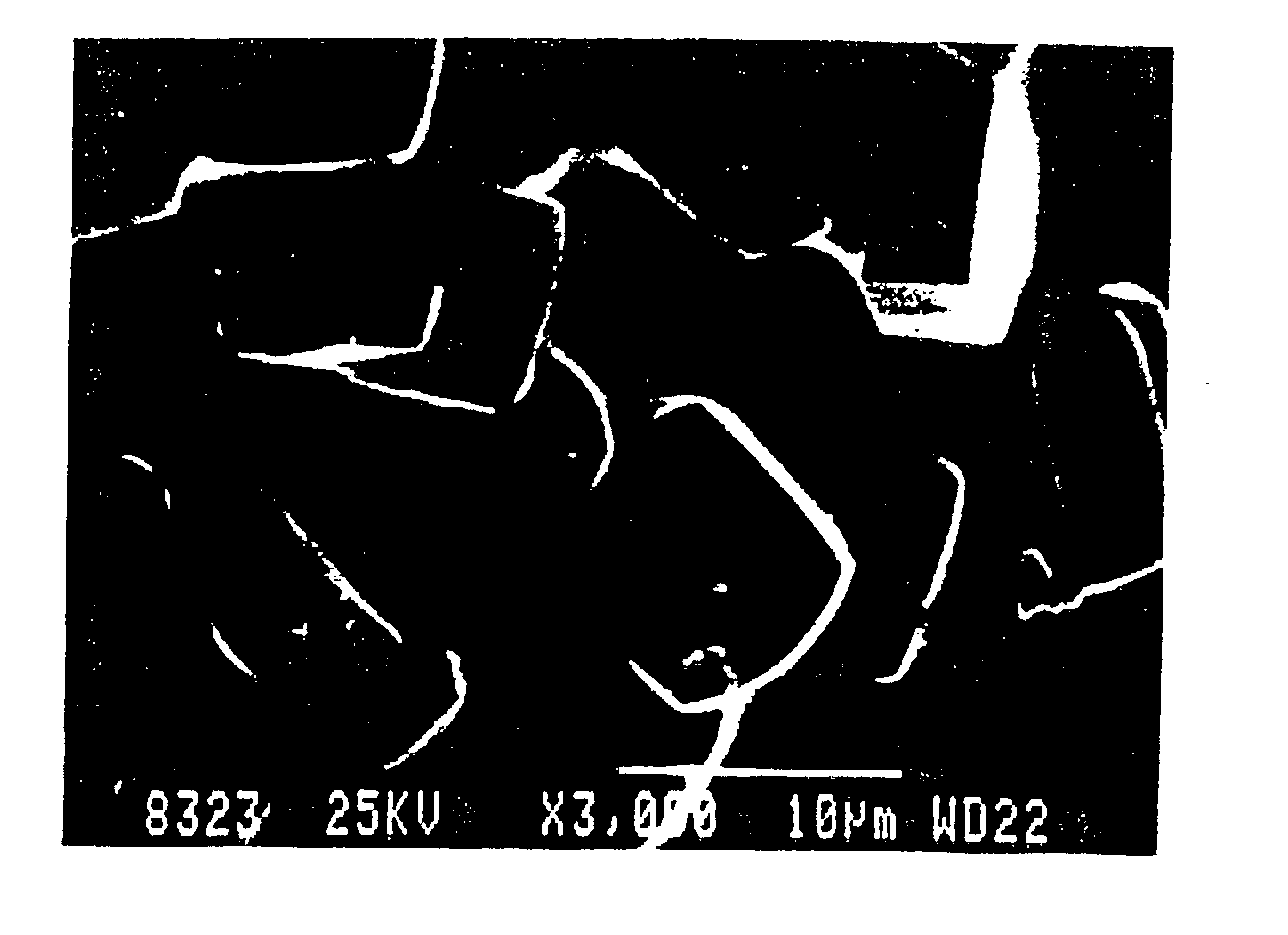

InactiveUS6852389B2Effectively self-cleaningSimple processNanotechSpecial ornamental structuresFissured structureFumed silica

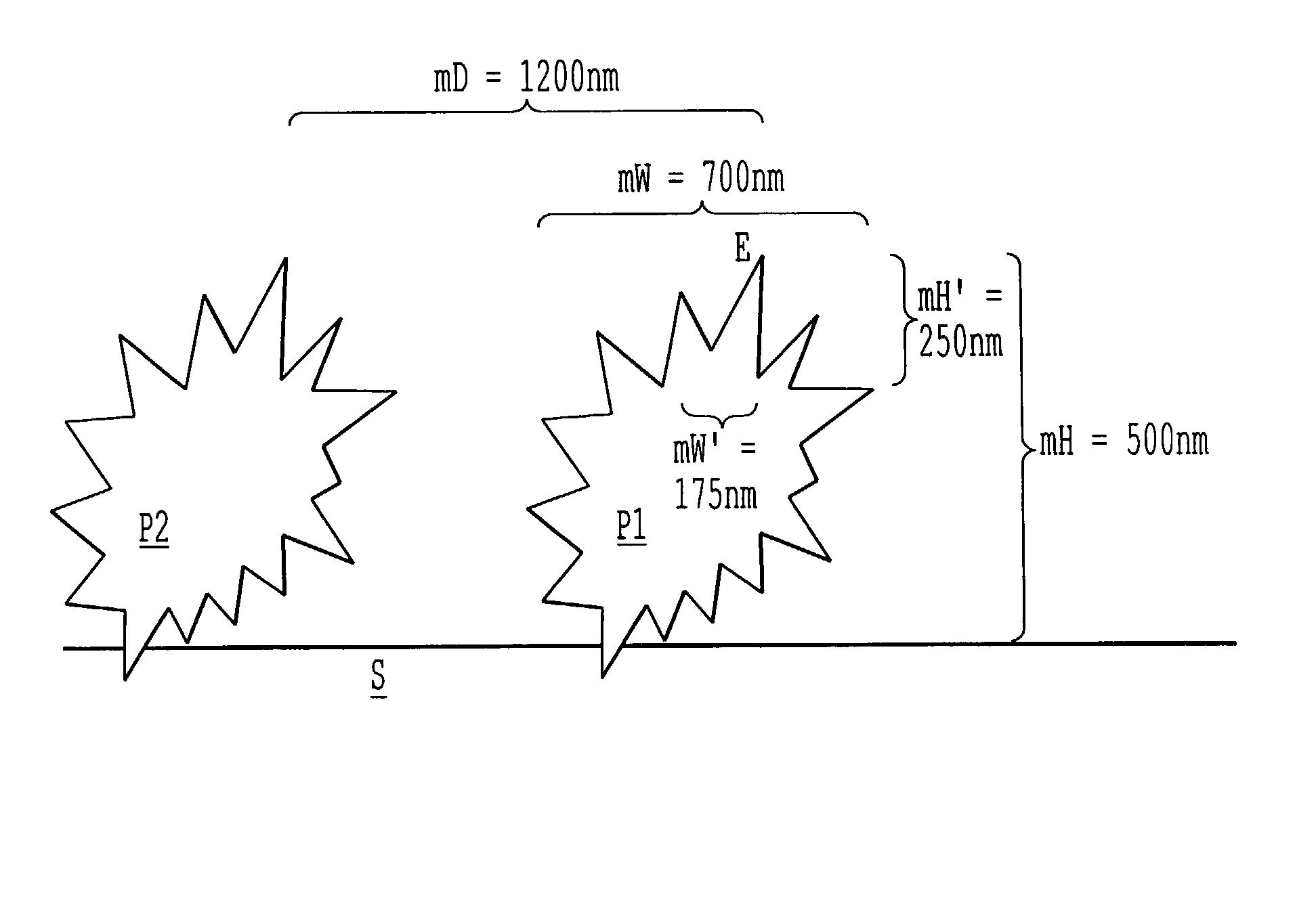

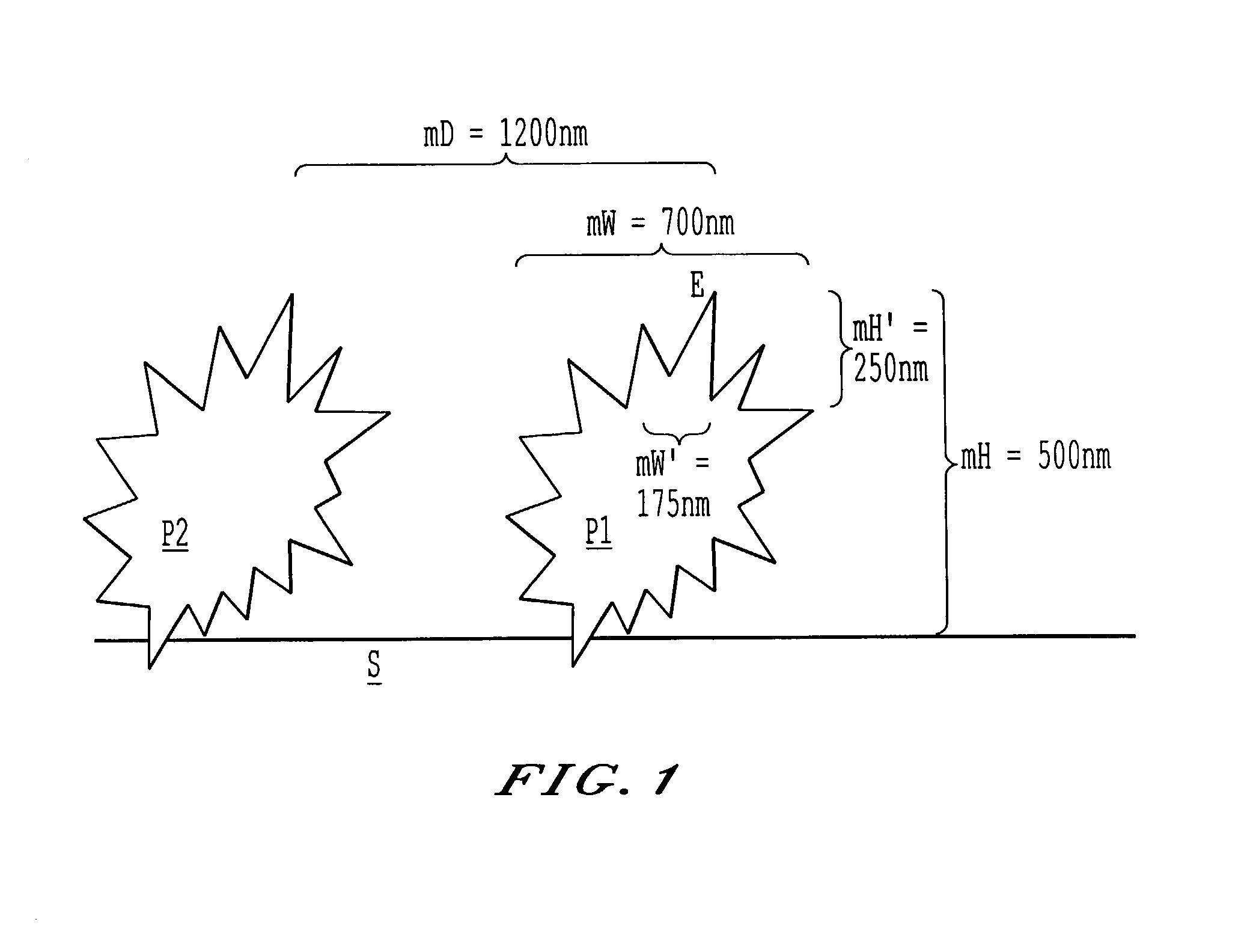

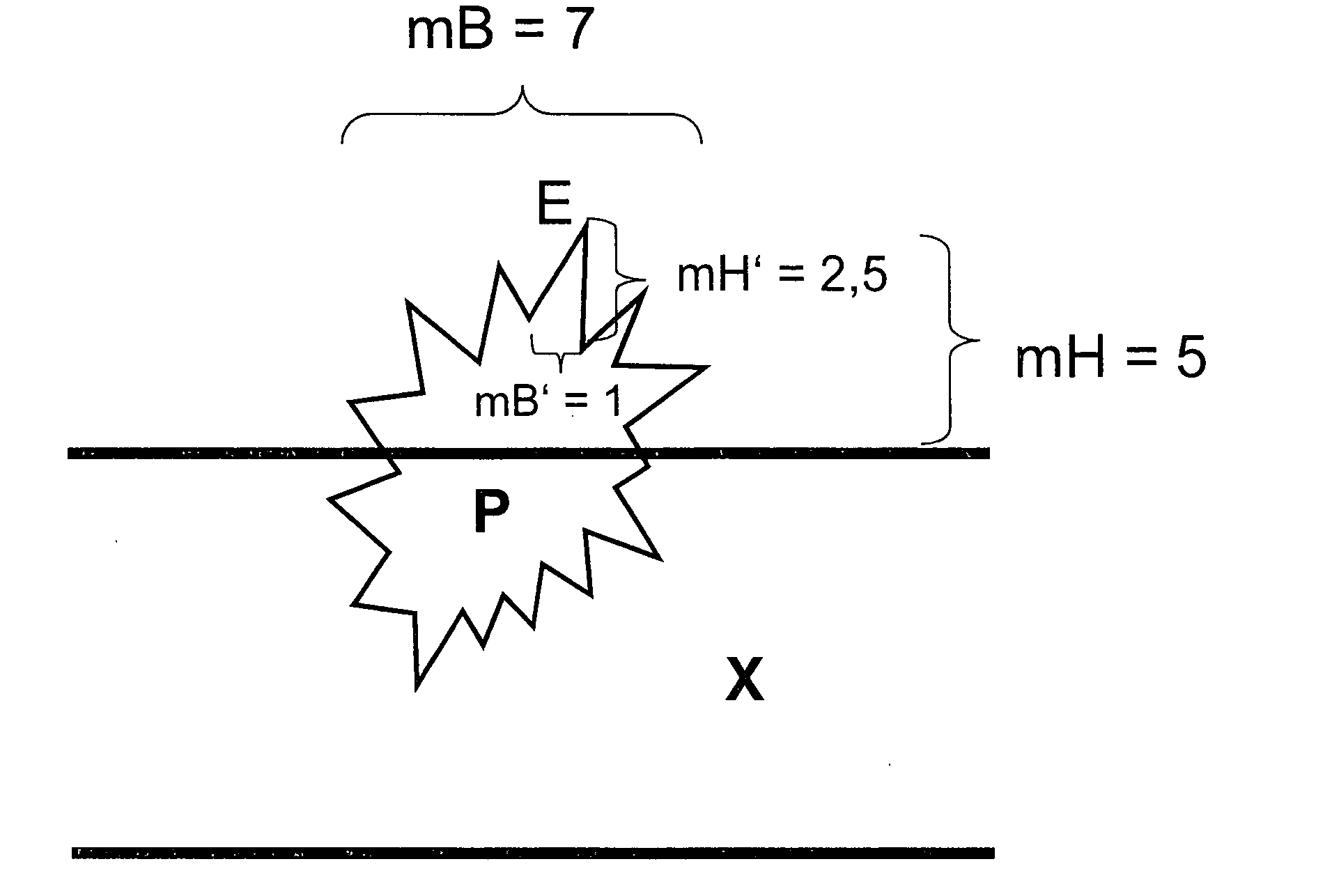

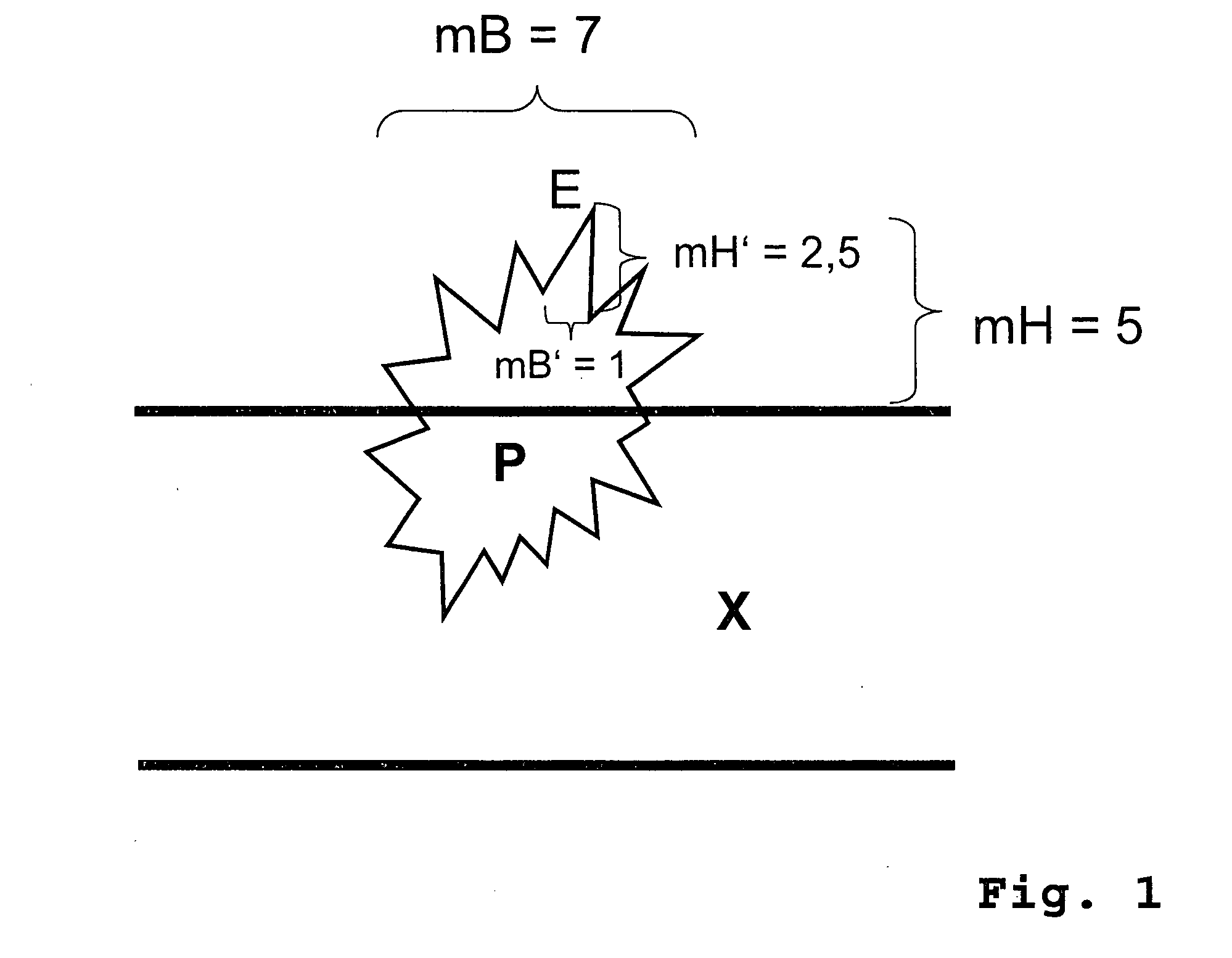

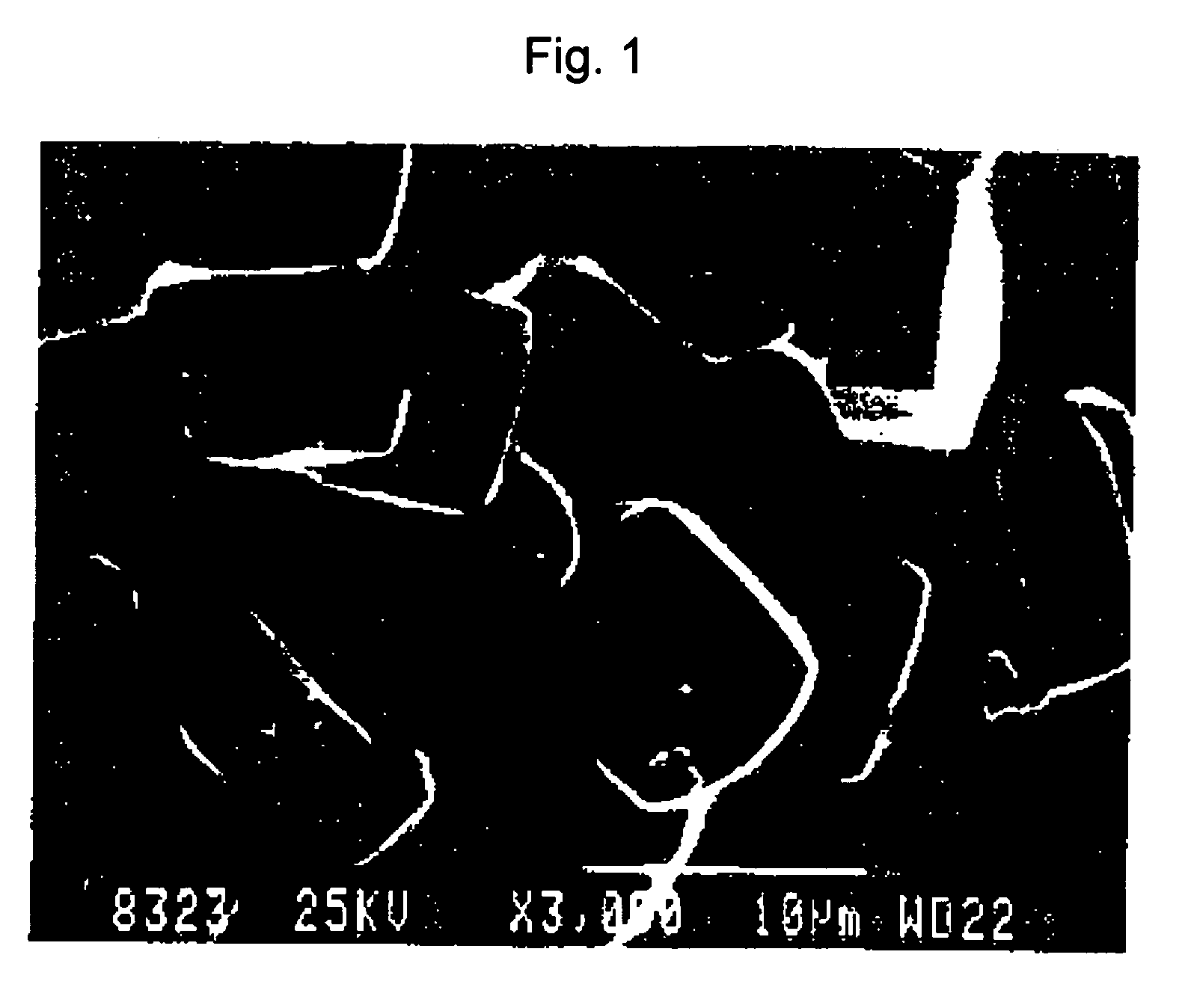

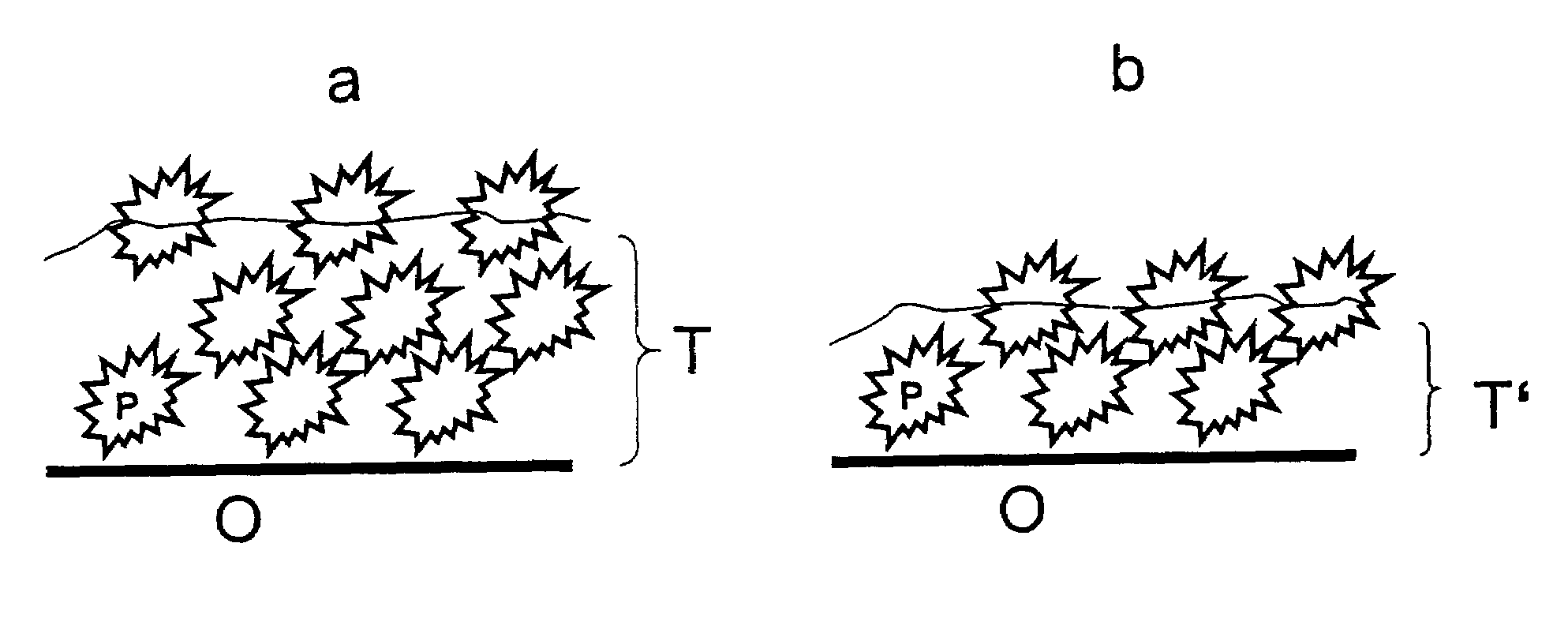

A self-cleaning surface which has an artificial, at least partially hydrophobic, surface structure containing elevations and depressions, which comprises a surface having structure-forming particles, which are formed of hydrophobic, fumed silica, adhered thereto by way of fixative particles applied to the surface, whereby the structure-forming particles and the fixative particles have elevations and depressions ranging in dimensions of 1 to 1000 nm and the particles themselves having an average size of less than 50 μm, the particles providing said surface structure of elevations and depressions, wherein, by incipient melting of the fixative particles, only partial melting of the fixative particles occurs which is sufficient to bond the structure forming particles without substantial wetting of the particles by the fixative particles to said surface while retaining, the fissured structure of the structure-forming particles in the nanometer range.

Owner:DEGUSSA AG

Surfaces rendered self-cleaning by hydrophobic structures, and process for their production

InactiveUS6858284B2Effectively self-cleaningSimple processNanotechSpecial ornamental structuresMeth-Gas phase

A self-cleaning surface which has an artificial, at least partially hydrophobic, surface structure containing elevations and depressions, which comprises an at least partially hydrophobic surface formed from structure-forming particles of hydrophobic fumed silica having elevations and depressions ranging in dimensions of 1 to 1000 nm and the particles themselves having an average size of less than 50 μm adhered to the surface by way of a viscous, curable carrier material selected from the group consisting of polyurethane, polyurethane acrylates, silicone acrylates and singly and / or multiply unsaturated (meth)acrylates applied to the surface, which is sufficient to bond the structure forming particles without substantial wetting of the particles by the carrier material while retaining the fissured structure of elevations and depressions of the structure-forming particles in the nanometer range.

Owner:DEGUSSA AG

Articles with super-hydrophobic and/or self-cleaning surfaces and method of making same

ActiveUS20110287203A1Lower contact angleLarge scaleDischarging arrangementMouldsFine grainSelf-cleaning surfaces

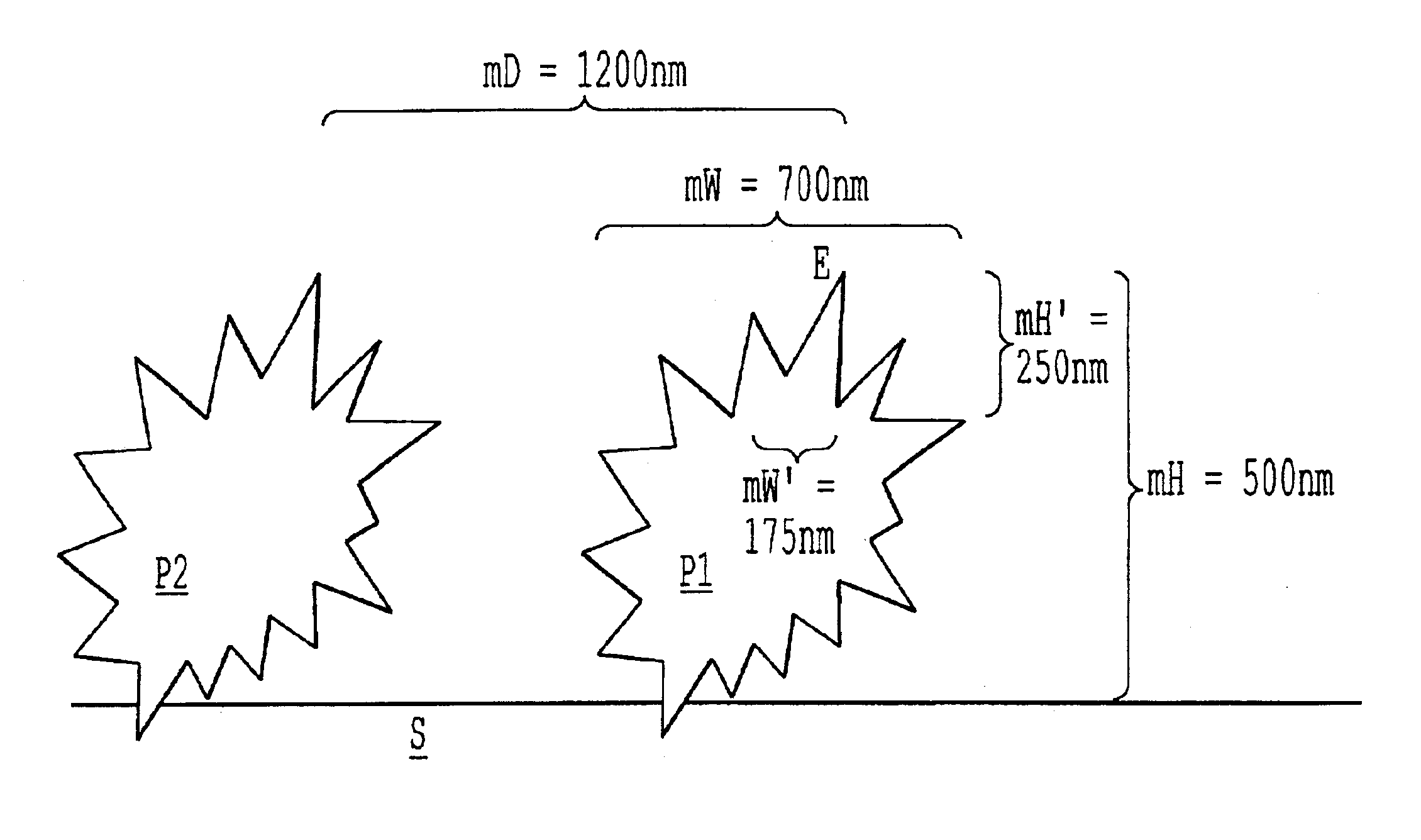

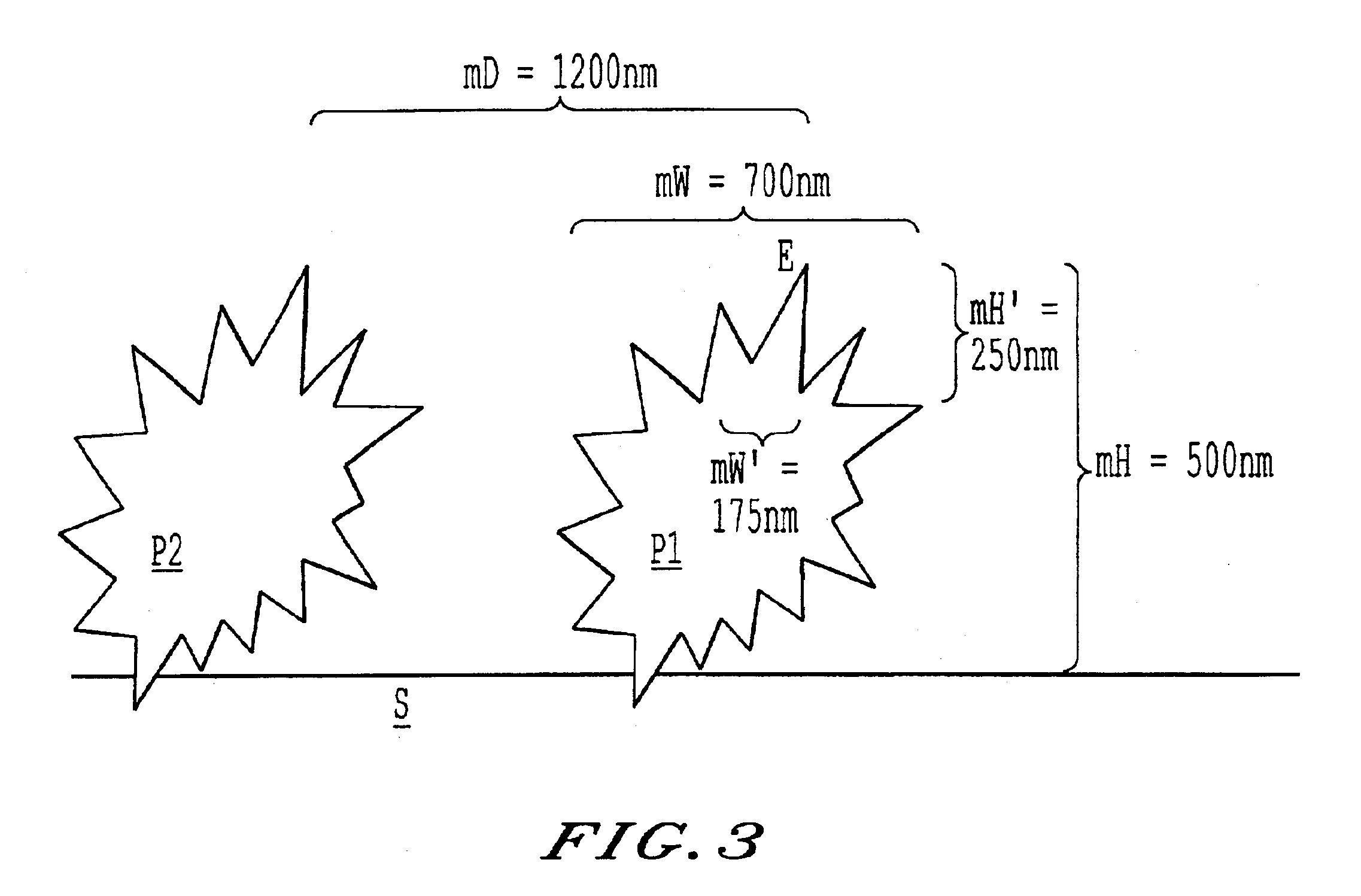

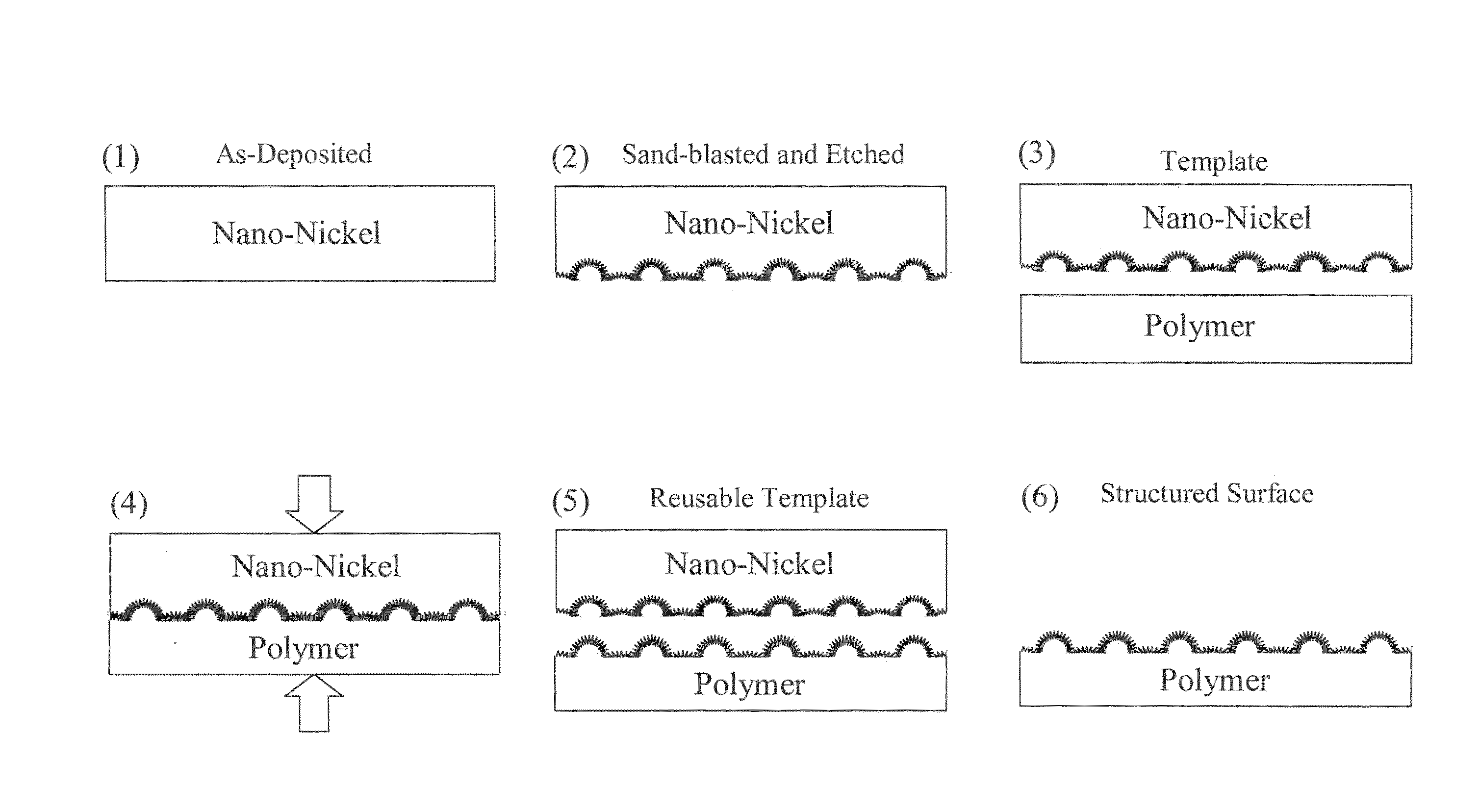

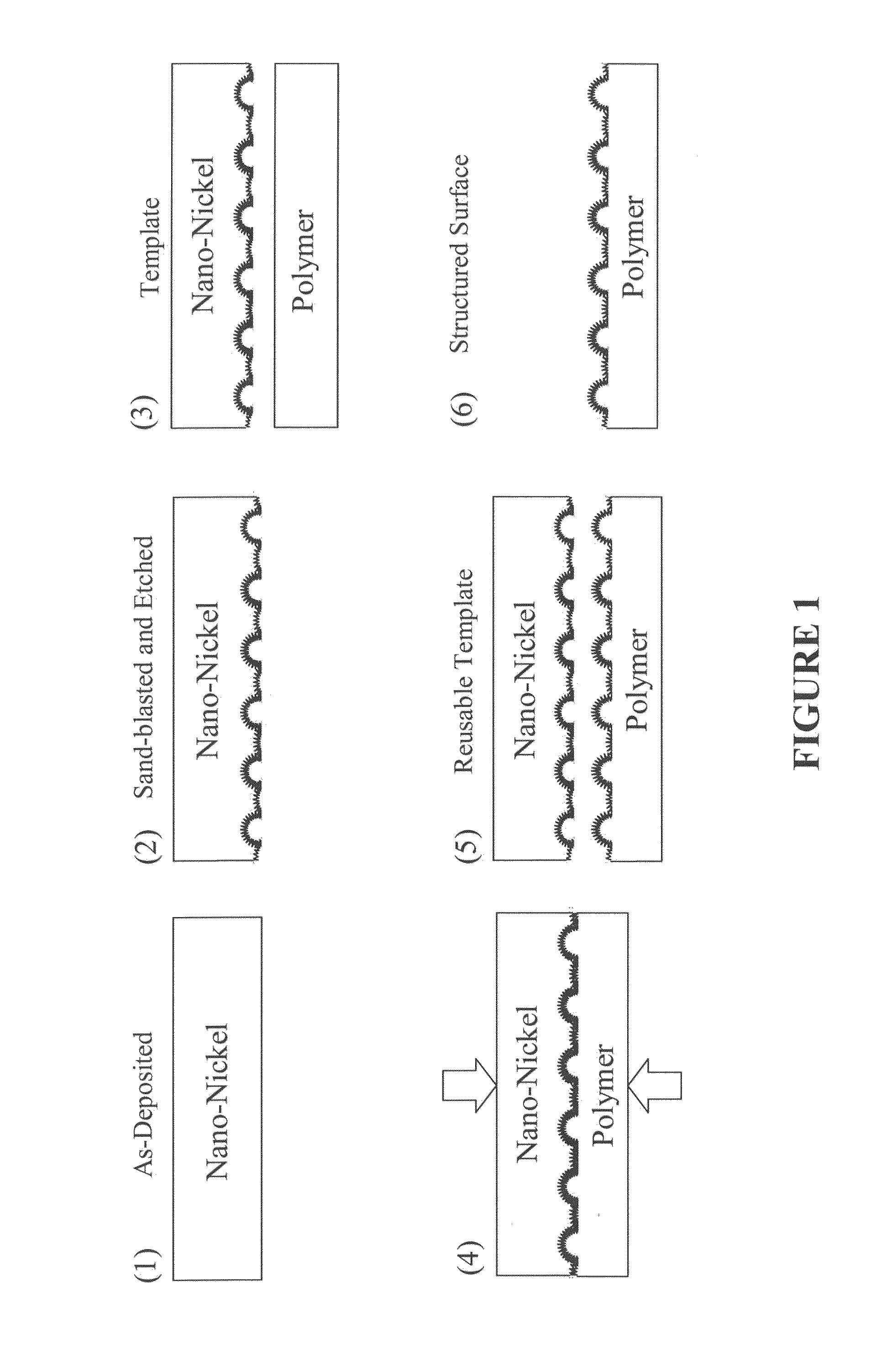

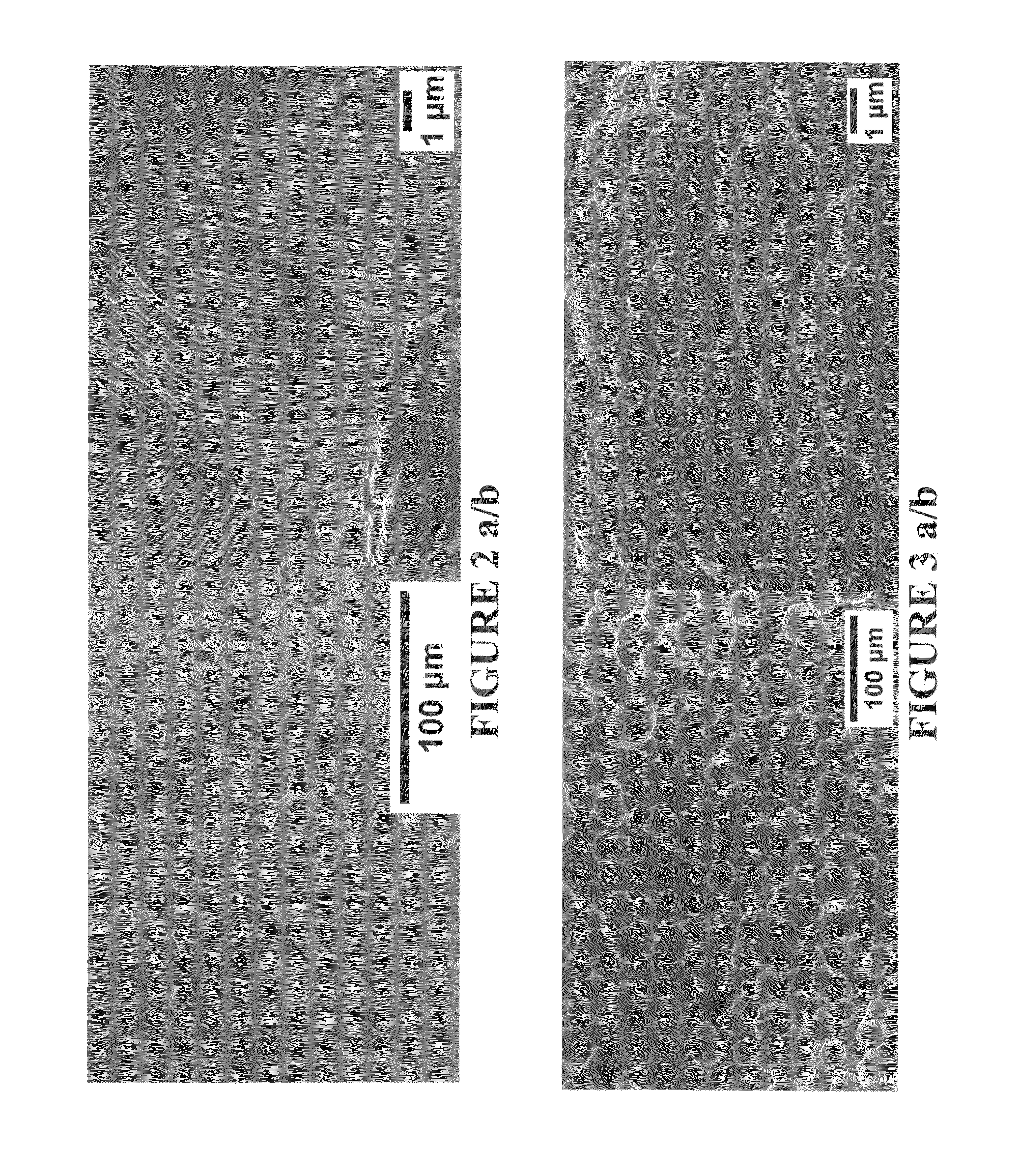

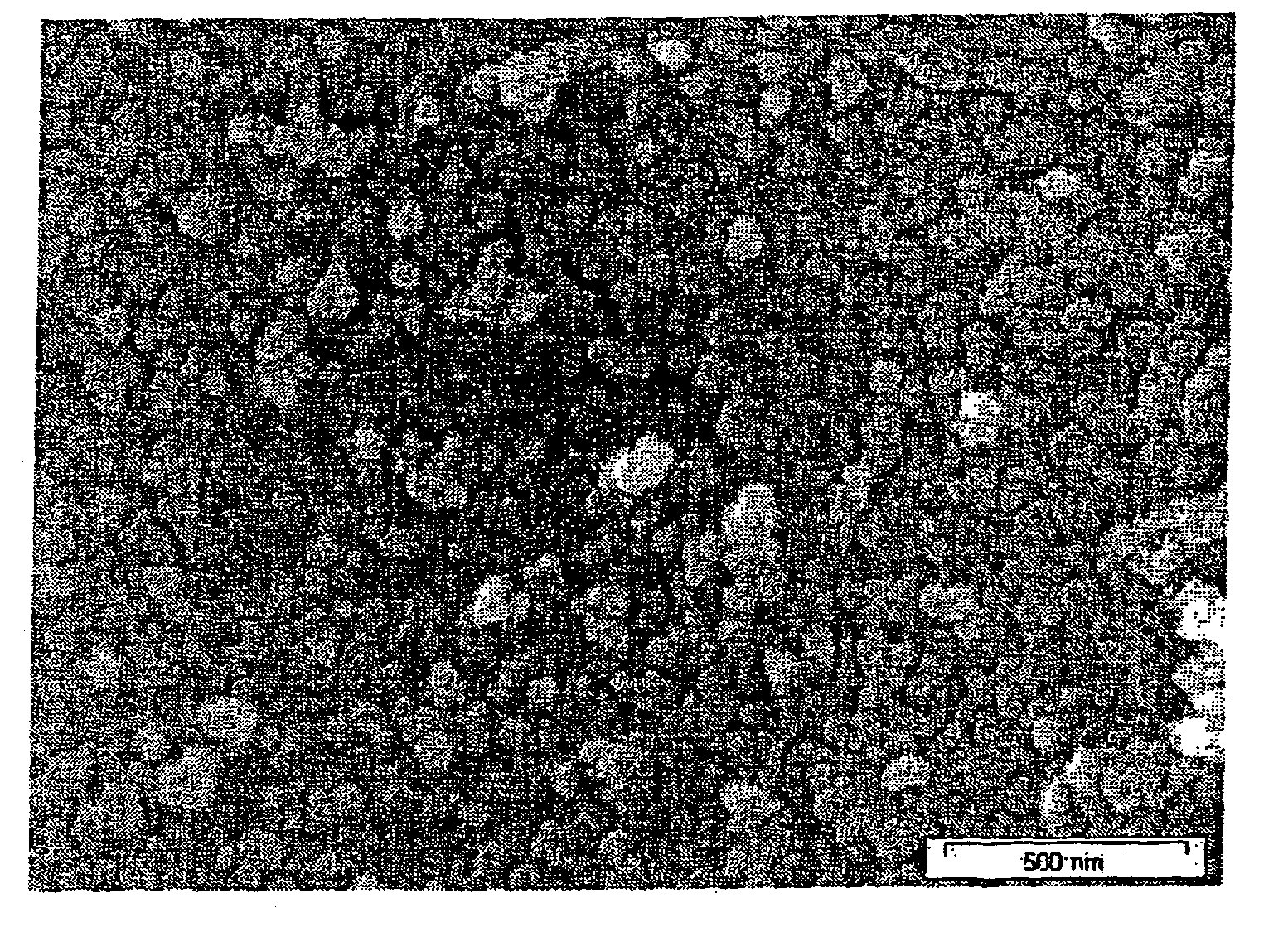

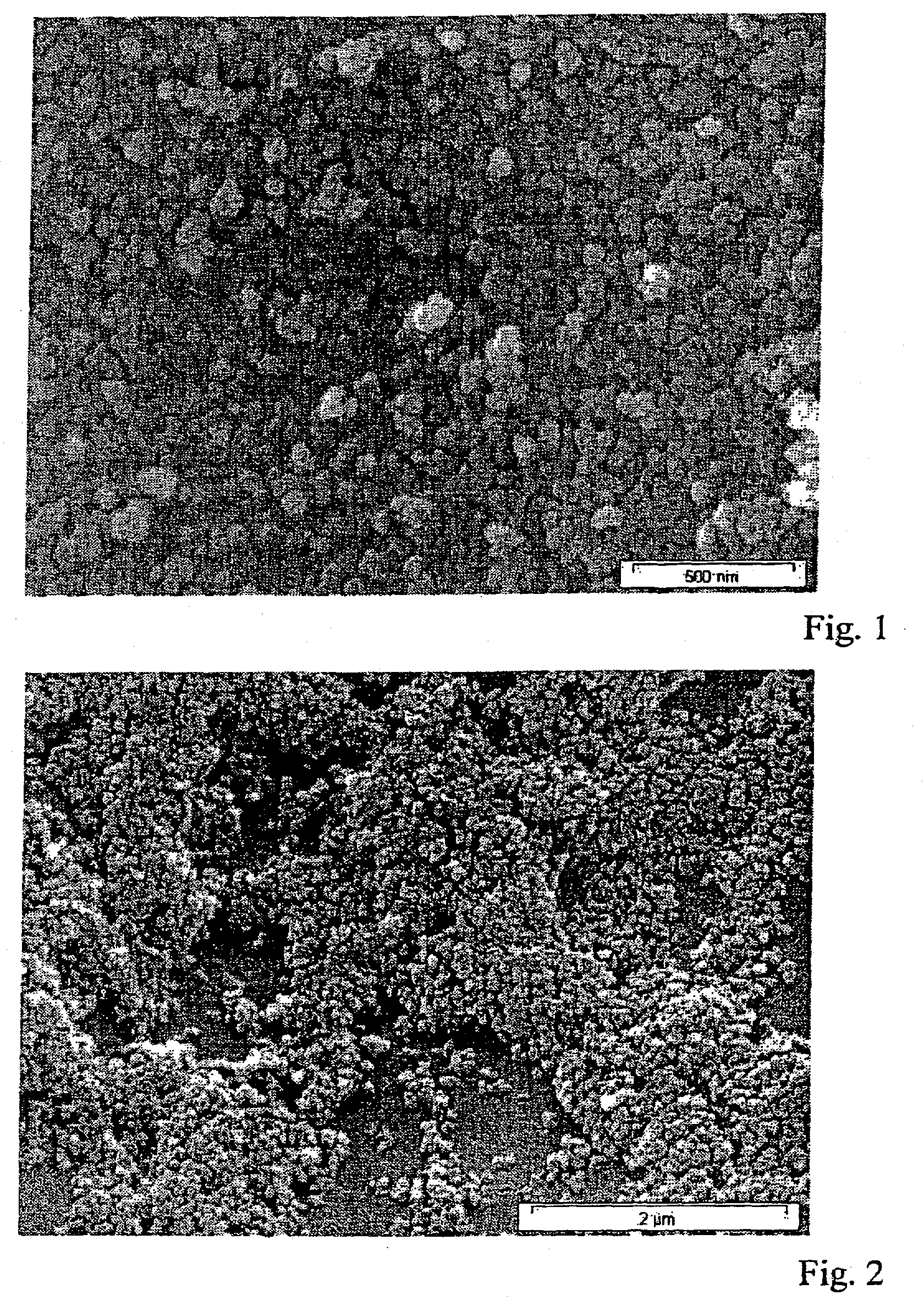

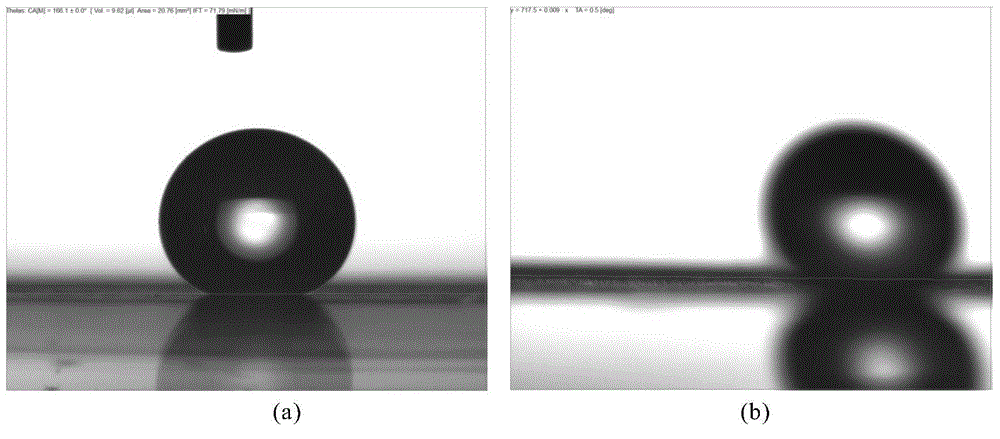

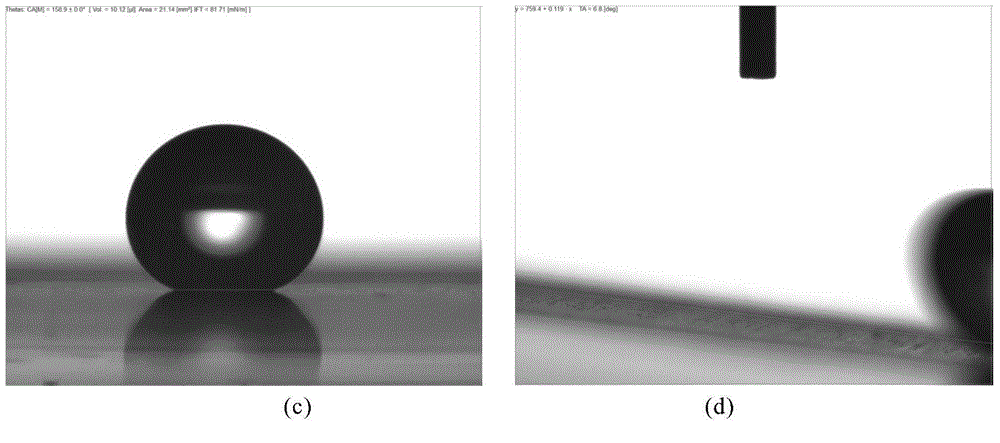

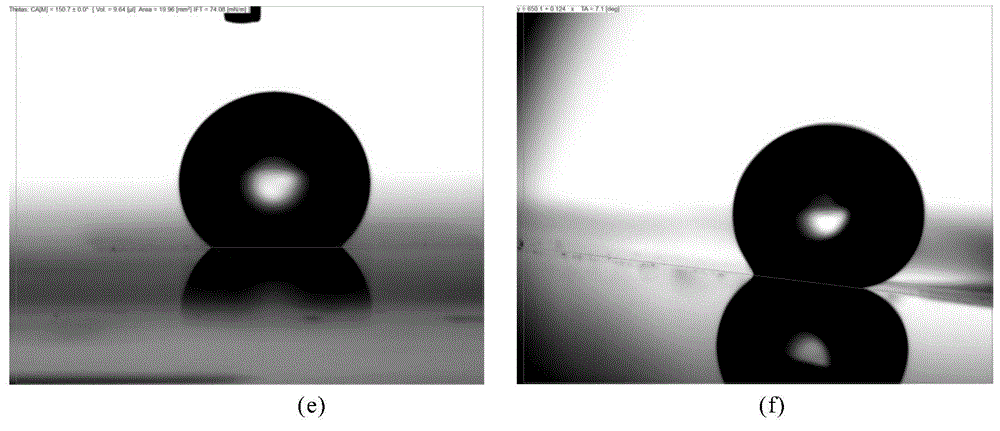

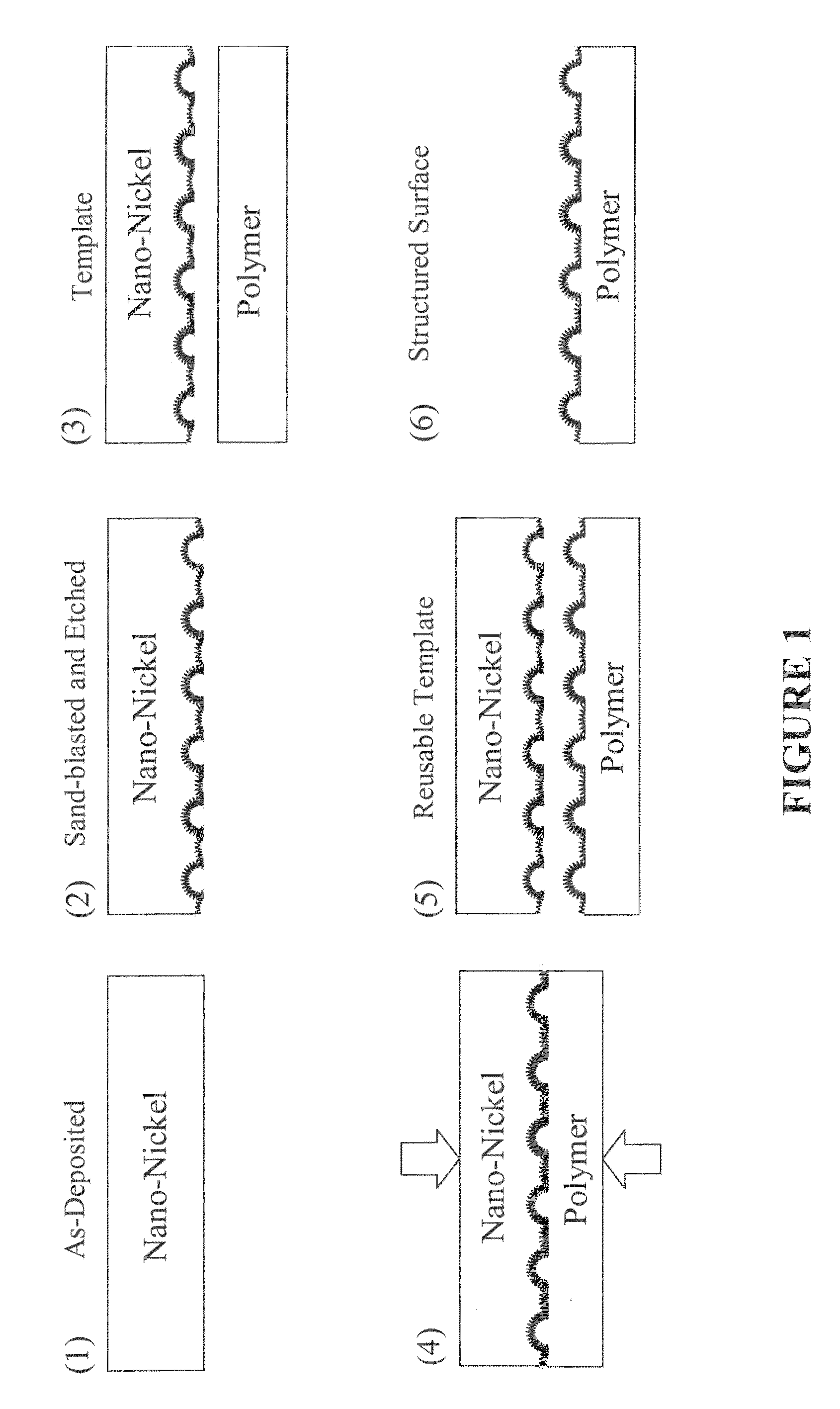

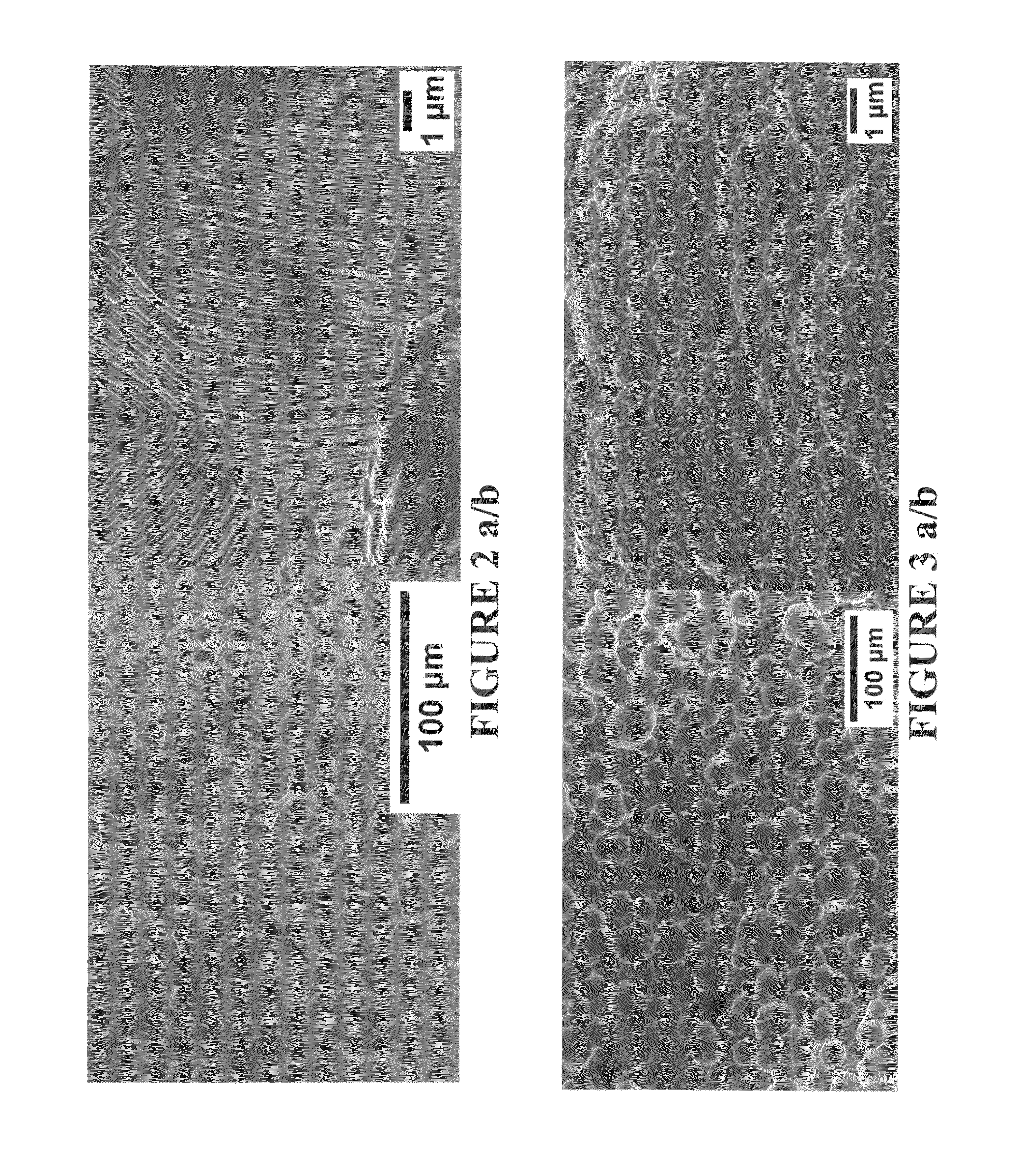

Super-hydrophobic and self-cleaning articles produced by imprinting exposed surfaces with suitable fine-grained and / or amorphous metallic embossing dies to transfer a dual surface structure, including ultra-fine features less than or equal to 100 nm embedded in and overlaying a surface topography with macro-surface structures greater than or equal to 1 micron are disclosed.

Owner:INTEGRAN TECH

Surfaces which are self-cleaning by hydrophobic structures, and a process for their production

A process for producing self-cleaning surfaces, in which an at least partially hydrophobic, surface structure is formed by securing particles on a polymer surface, which comprises applying, to the polymer surface, at least one solvent which comprises the particles and which solvates the polymer surface, and securing at least part of the particles to the polymer surface by removing the solvent; self-cleaning surfaces obtained by the process; and objects containing self-cleaning surfaces obtained by the process.

Owner:CREAVIS GES FUER TECH

Compositions and processes for producing durable hydrophobic and/or olephobic surfaces

InactiveUS20100004373A1Reduce contact areaProtection is in progressGroup 4/14 element organic compoundsSpecial tyresPowder coatingMaterials science

Coating compositions for producing hydrophobic or super-hydrophobic surfaces and olephobic or super-olephobic surfaces, and to processes for producing such surfaces. In particular, the present invention relates to hydrophobic or olephobic powder coatings and their use for transforming surfaces of articles into hard-to-wet and self-cleaning surfaces.

Owner:UNIV OF WESTERN ONTARIO

Hydrophobic self-cleaning coating composition

InactiveUS20080250978A1Efficient use ofSolve the lack of resistanceSemiconductor/solid-state device manufacturingMixingWater basedMineral spirit

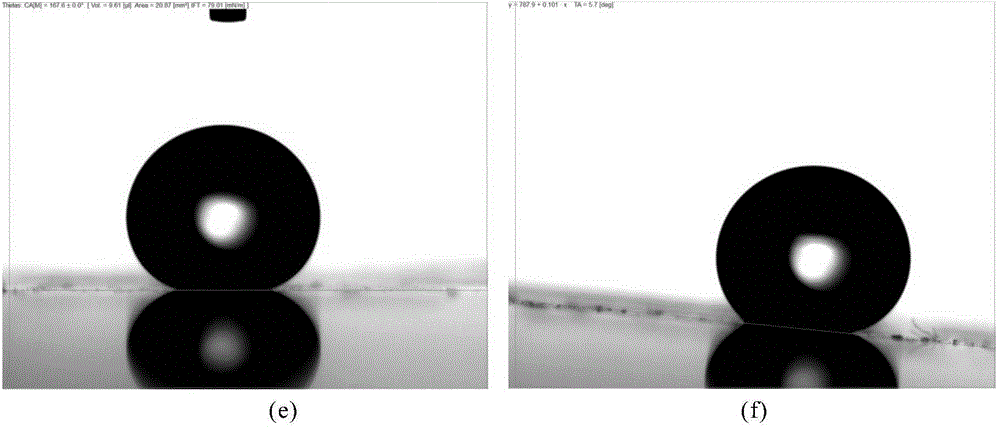

The present invention provides a water based, low VOC super hydrophobic coating composition that can be used to make wet and dry dirt repellent surfaces to keep the surfaces clean for a reasonable period of time. The coating utilizes hydrophobic nanoparticles dispersed in water. This treatment produces a virtually transparent coating releasing very little or no VOC compounds whereas previous coatings of comparable hydrophobicity release up to 99 percent VOC compounds. The coating can be applied by a simple, single application method and the super hydrophobic property can be achieved by drying at room temperature for 5 to 10 minutes. A preferred coating can be easily removed and renewed when desired. The aqueous hydrophobic self cleaning coating composition that can be applied by conventional methods such as by spraying the composition onto a surface creating a wet and dry dirt repellent coating on the surface. The hydrophobic self cleaning coatings are used on exterior automotive and boat surfaces, and in many other applications, to produce a self cleaning surface, reduce adherence of dirt and contaminants to a treated surface, and reduce drag in some applications providing an energy savings. The coating solves the problem of poor resistance to UV light, opaque appearance, and / or abrasion found in previous coatings of similar nature. A preferred coating has good resistance to UV light and some resistance to abrasion. Clear, nearly transparent and translucent coatings are produced as compared to conventional coatings of comparable hydrophobicity which are typically white or opaque. The coating can be applied by a single and easy spraying method and the super hydrophobic property can be achieved by drying the film by evaporation of the solvent wetting solution and water based carrier at ambient temperature for 5 to 10 minutes. Embodiments of the hydrophobic self-cleaning coating composition can be produced resulting in a clear coating or in some cases a translucent dirt repellant film or coating on painted material, plastic, metal, glass, ceramic, fiberglass or a polymer substrate. The coating typically utilizes hydrophobic nanoparticles of fumed silica and / or titania wetted by a hydrophilic solvent such as acetone for no VOC applications, or with mineral spirits, alcohol or a light distillate if VOC are not a consideration, together with a selected surfactant typically having an HLB value in a range of from 9 to 13.At least one preferred coating composition comprising an effective amount of a treated fumed silica wetted with a solvent and dispersed in water, upon drying, resulted in a coated surface providing a contact angle of at least 165 degrees and a surface energy below 12 dynes / centimeter as compared to water having a contact angle of from 65 to 80 degrees on a noncoated surface. The composition imparts a degree of hydrophobicity to a surface so that the surface will have a tilt angle of sliding of less than 2 degrees as compared to water on a noncoated surface having a tilt angle of sliding of 90 degrees or higher. The coating composition is removed by washing with a detergent or applying pressure to the coating wiping same from the treated surface. Exposure to water in the form of rain or snow does not remove the coating composition.

Owner:ASHLAND LICENSING & INTPROP LLC

Glass ceramic and metal substrates with a self-cleaning surface, method for the production and use thereof

InactiveUS6872441B2Improve self-cleaningExcellent abrasion resistanceFouling preventionPretreated surfacesRough surfaceGlass-ceramic

The invention relates to glass, ceramic and metal substrates with at least one self-cleaning surface, comprising a layer with a micro-rough surface structure which is arranged on the substrate and made at least partly hydrophobic. The layer contains a glass flux and structure-forming particles with a mean particle diameter within the 0.1 to 50 μm range; the glass flux and structure-forming particles are present in a volume ratio within the 0.1 to 5 range, and the micro-rough surface structure has a ratio of mean profile height to mean distance between adjacent profile tips within the 0.3 to 10 range.To produce the subject of the invention the substrate is coated with a composition containing a glass flux and structure-forming particles, and the layer is burnt in and made hydrophobic.

Owner:FERRO GMBH

Preparation method of aqueous super-hydrophobic/super-hydrophobic and oileophobic coating

InactiveCN106811114AExcellent superhydrophobicityExcellent super amphiphobic propertiesAntifouling/underwater paintsPaints with biocidesNanoparticles dispersionSolvent

The invention discloses a preparation method of a water-based super-hydrophobic or super-amphiphobic coating. Nano-particles are ultrasonically dispersed into water, the pH of the solution is adjusted to obtain a nano-particle dispersion; The silane coupling agent is hydrolyzed under stirring to obtain an organosilane polymer / nanoparticle composite suspension; and then applied to the surface of the base material by spraying or dipping to obtain a water-based superhydrophobic / superamphiphobic coating. The present invention successfully prepares a water-based super-hydrophobic or super-amphiphobic coating with excellent performance without using any additives (organic solvent, surfactant and water-based solvent), and has many advantages such as water-based environmental protection, low price and excellent performance. , It has broader application prospects in the fields of self-cleaning surface, anti-corrosion coating, oil pollution prevention and oil transportation.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Surfaces rendered self-cleaning by hydrophobic structures, and process for their production

InactiveUS20020150725A1Pretreated surfacesRecord information storageSurface structureMaterials science

A self-cleaning surface which has an artificial, at least partially hydrophobic, surface structure containing elevations and depressions, wherein the elevations and depressions are formed by structure-forming particles and fixative particles applied to the surface, wherein the fixative particles act to secure the structure-forming particles to the surface and the fixative particles are also secured to the surface; and a process for making such a surface.

Owner:DEGUSSA AG

Hydrophobic self-cleaning coating compositions

InactiveUS20080221009A1Not to damageEfficient use ofNon-ionic surface-active compoundsNon-surface-active detergent compositionsEvaporationEngineering

A super hydrophobic self cleaning coating composition that can be applied by conventional methods such as by spraying the composition onto a surface creating a wet and dry dirt repellent coating on the surface. The super hydrophobic self cleaning coatings are used on exterior automotive and boat surfaces, and in many other applications, to produce a self cleaning surface, reduce adherence of dirt and contaminants to a treated surface, and reduce drag in some applications providing an energy savings. The coating utilizes a blend of organic and / or inorganic polymers with hydrophobic nanoparticles of fumed silica and / or titania in a volatile solvent which evaporates at ambient temperature. The coating solves the problem of poor resistance to UV light, opaque appearance, and / or some abrasion resistance not found in previous coatings of similar nature. A preferred coating has good resistance to UV light and some resistance to abrasion. Clear, nearly transparent and translucent coatings are produced as compared to conventional coatings of comparable hydrophobicity which are typically white or opaque. The coating can be applied by a single and easy spraying method and the super hydrophobic property can be achieved by drying the film by evaporation of the solvent at ambient temperature for 5 to 10 minutes. Embodiments of the super hydrophobic self-cleaning coating composition result in a clear coating or in some cases a translucent dirt repellant film for coating on painted material, plastic, metal, glass, ceramic, fiberglass or a polymer substrate. The coating utilizes a blend of organic and / or inorganic polymers with hydrophobic nanoparticles of fumed silica and / or titania in a volatile solvent. At least one preferred coating composition comprising an effective amount of a treated fumed silica in a solvent resulting in a coated surface providing a contact angle of at least 165 degrees as compared to water having a contact angle of from 10 to 15 degrees on a noncoated surface. The composition imparts a degree of hydrophobicity to a surface so that the surface will have a tilt angle of sliding of less than 2 degrees as compared to water on a noncoated surface having a tilt angle of sliding of 90 degrees or higher. The coating composition is removed by washing with a detergent or applying pressure to the coating wiping same from the treated surface. Exposure to water in the form of rain or snow does not remove the coating composition.

Owner:ASHLAND LICENSING & INTPROP LLC

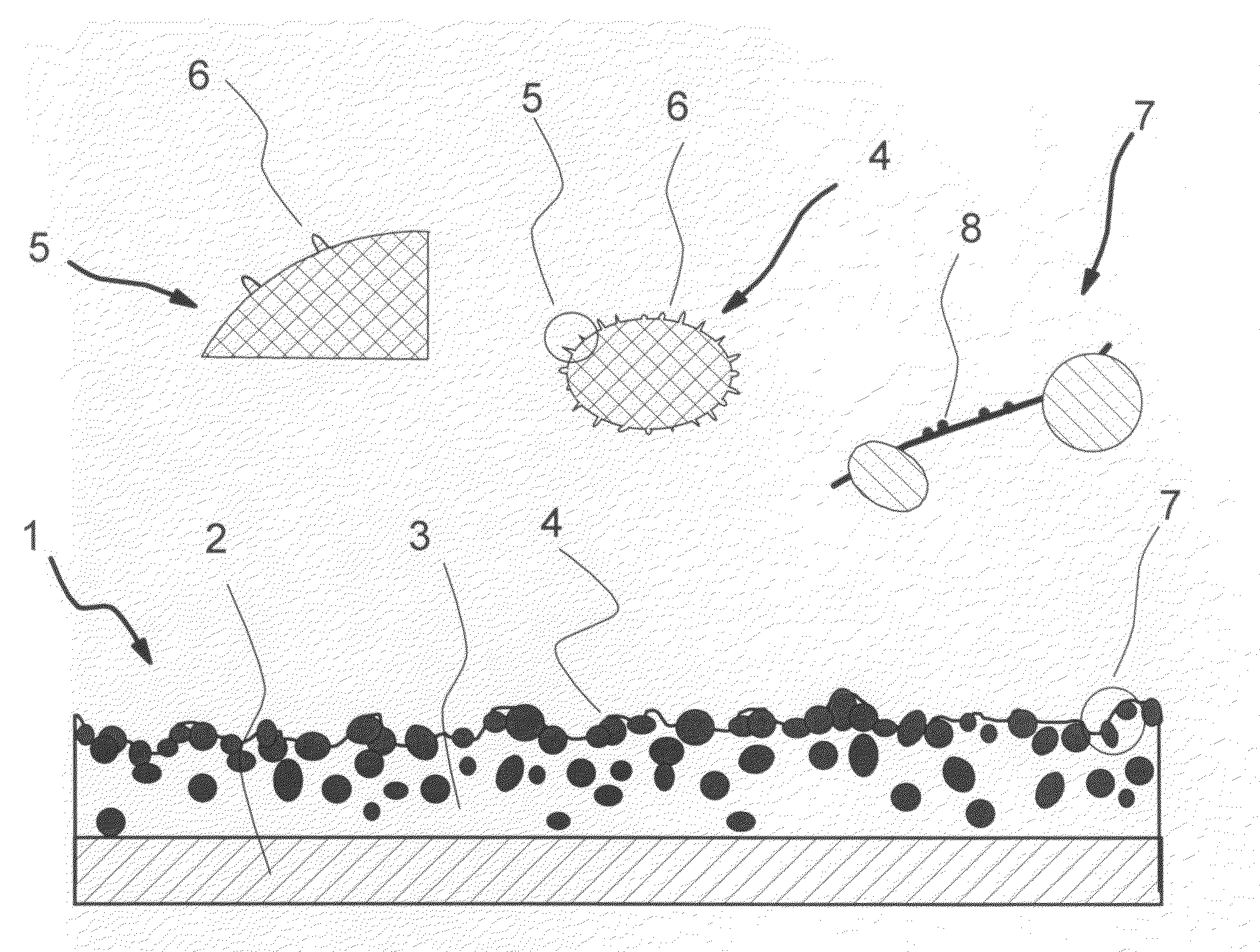

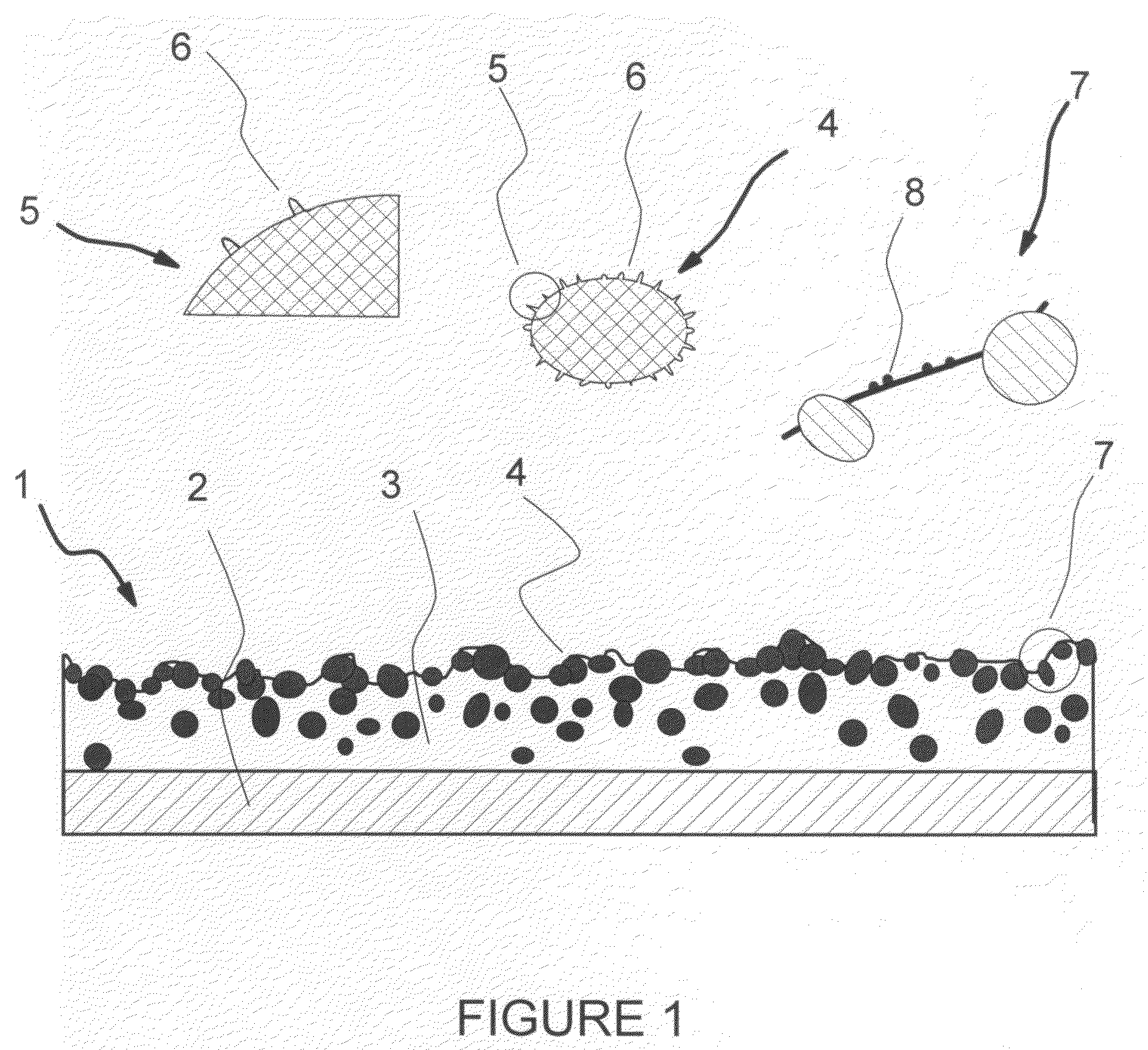

Self-cleaning surfaces comprising elevations formed by hydrophobic particles and having improved mechanical strength

The present invention relates to self-cleaning surfaces having improved mechanical stability and a process for the production thereof. The present invention is achieved by producing self-cleaning, hydrophobic, structured surfaces having mixtures of particles, which are fixed on their surface and which comprise structure-producing particles selected from semimetal or metal oxides, silicas and metal powders, and wax particles. Structured surfaces that are structured by such mixtures of particles are distinguished by substantially higher mechanical stability of the structure and are therefore especially suitable for the production of self-cleaning surfaces, which are exposed to relatively high mechanical loads, such as, for example, the surfaces of tarpaulins, awnings, greenhouse elements, conservatories or truck tarpaulins.

Owner:EVONIK OPERATIONS GMBH

Glass, ceramic and metal substrates with a self-cleaning surface, method of making them and their use

Owner:FERRO GMBH

Surfaces rendered self-cleaning by hydrophobic structures and a process for their production

InactiveUS7211313B2Improve mechanical stabilitySimple processLayered productsPretreated surfacesMaterials scienceHydrophobic surfaces

A self-regenerating, self-cleaning hydrophobic surface is formed when particles are secured on a carrier that is itself a mixture of particles and binder. When particles on the surface are ablated by erosion, new particles in the carrier are exposed to regenerate the self-cleaning surface, resulting in a long-lasting self-cleaning action. The self-cleaning surface may be used with particular advantage outdoors, e.g. on vehicles, where self-cleaning materials are particularly exposed to the effects of the environment.

Owner:DEGUSSA AG

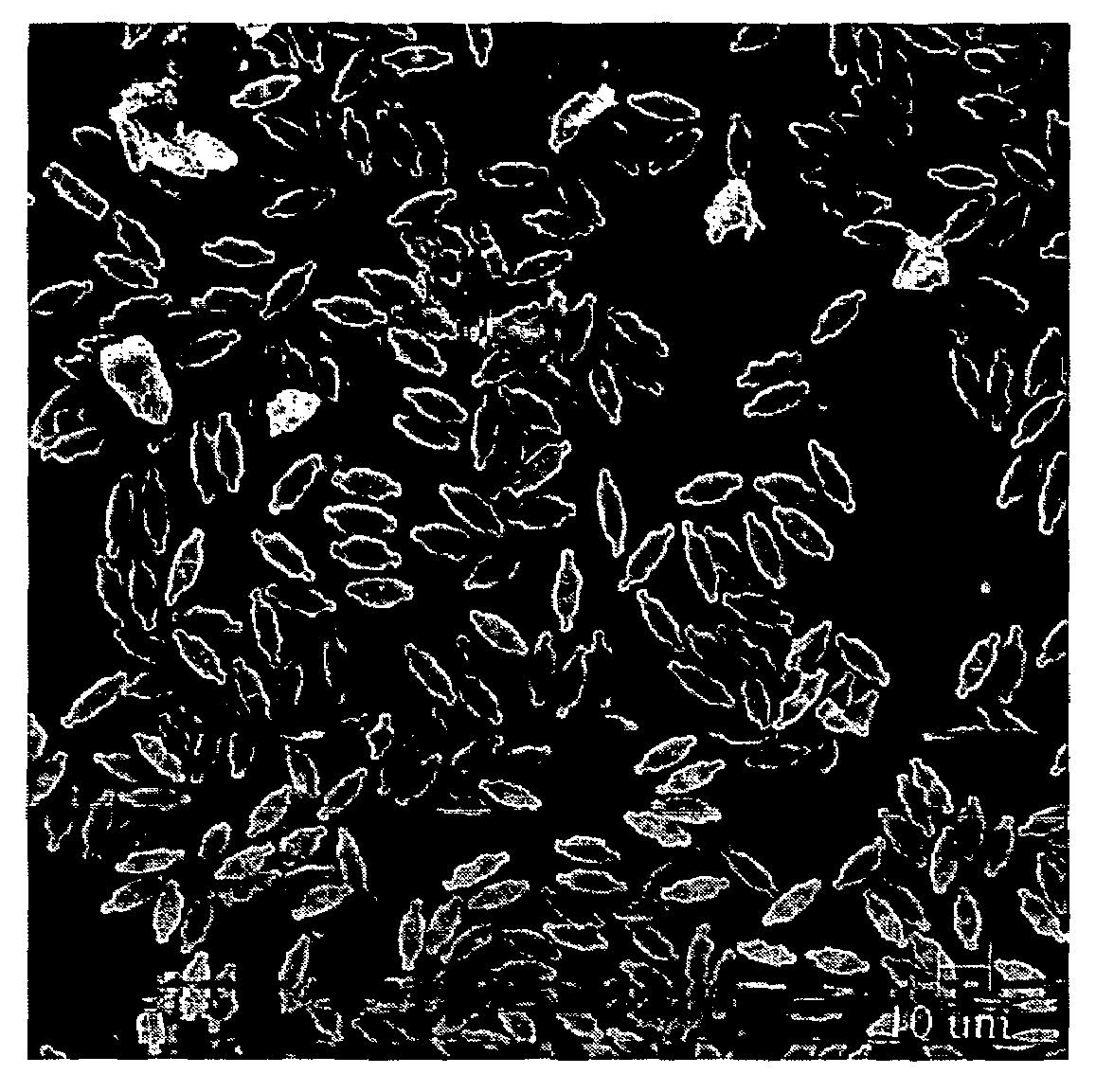

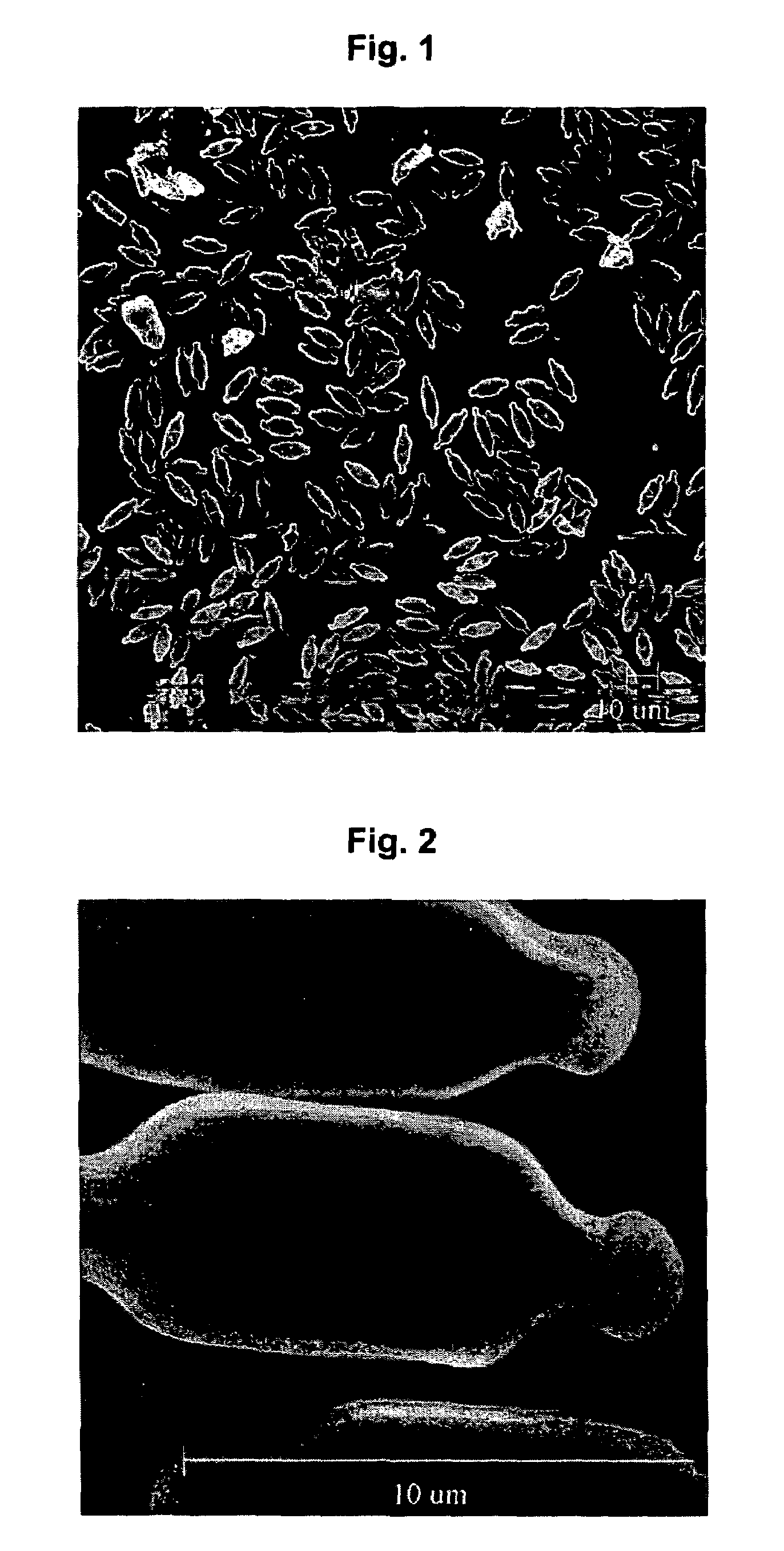

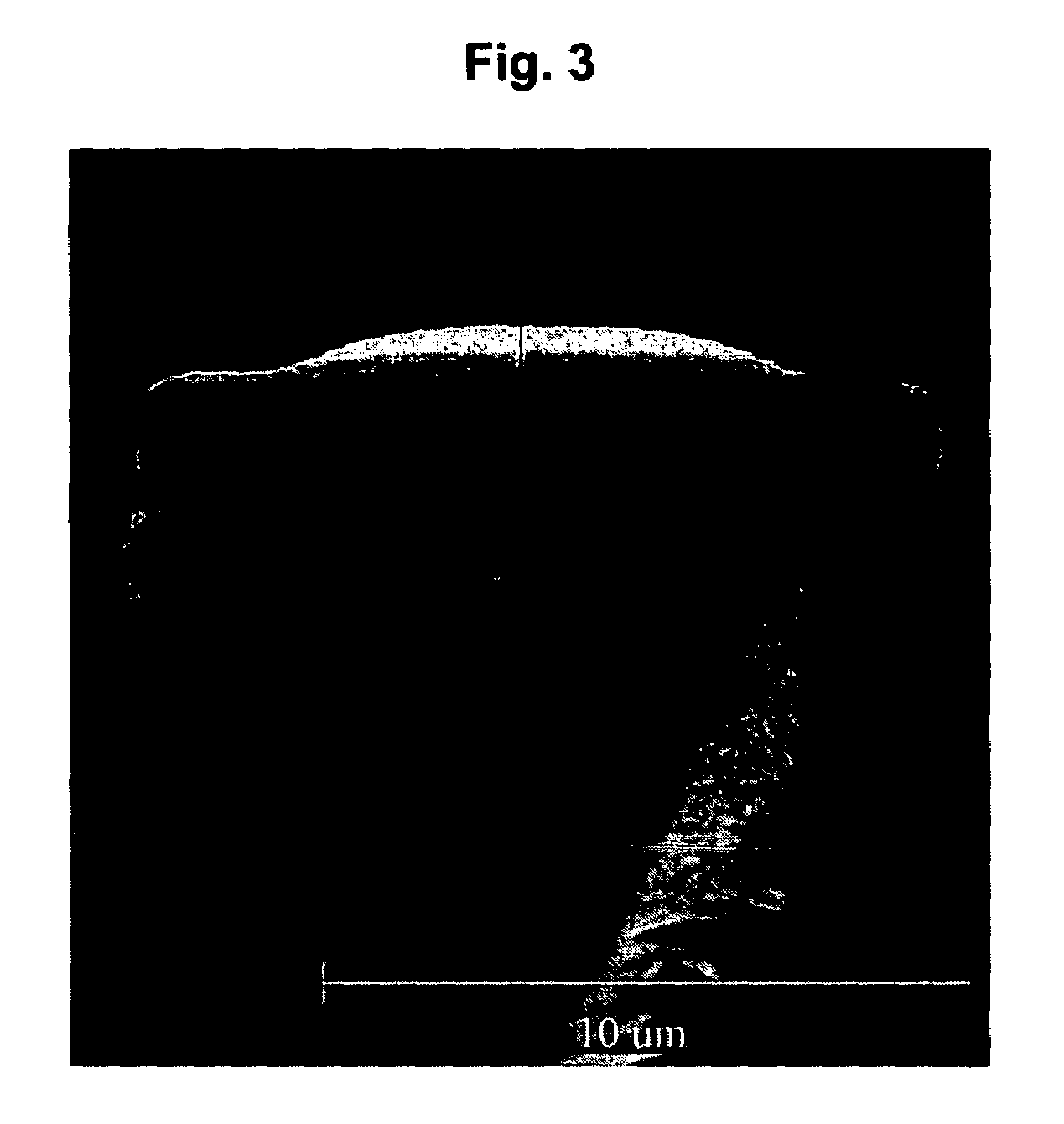

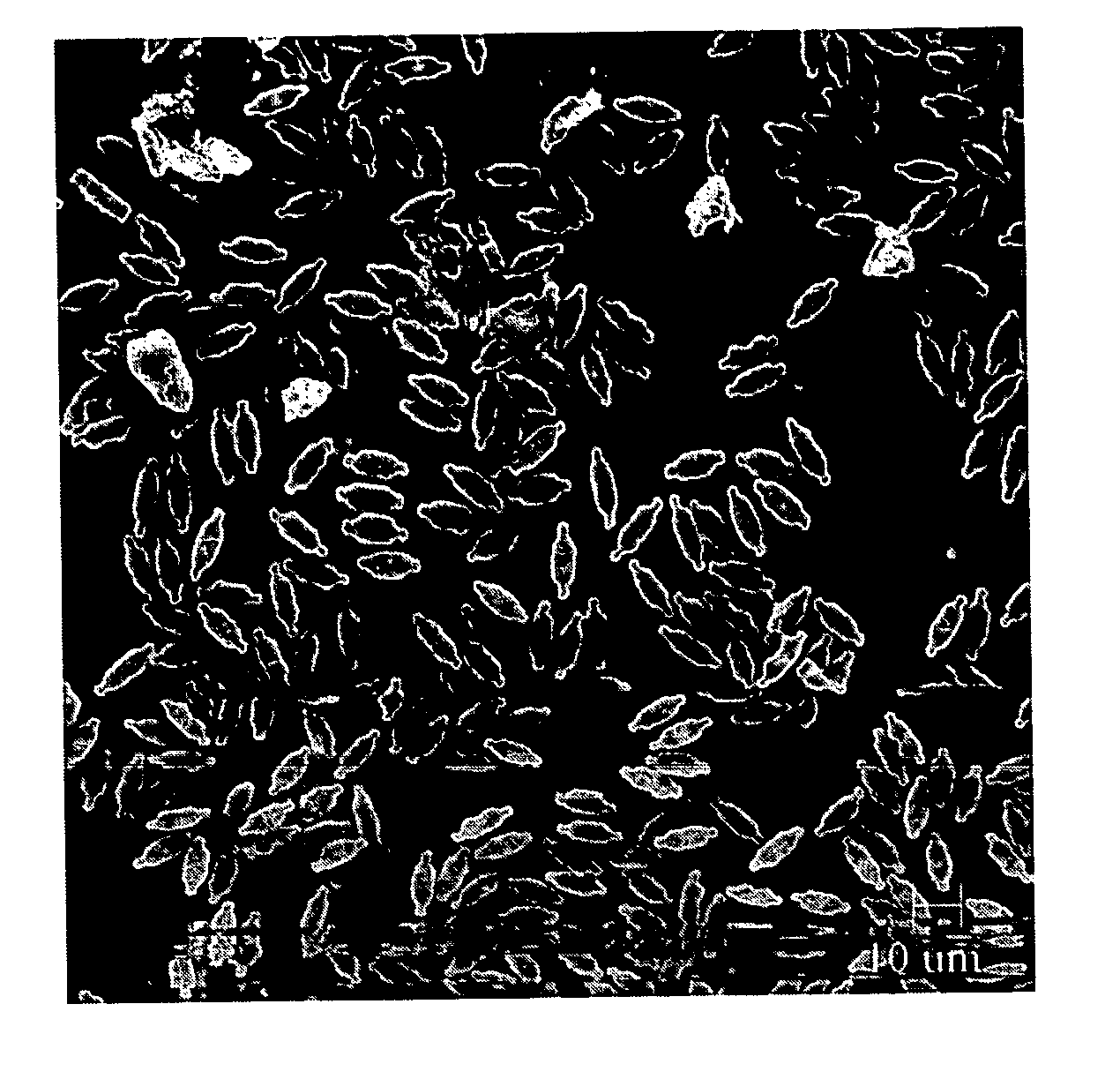

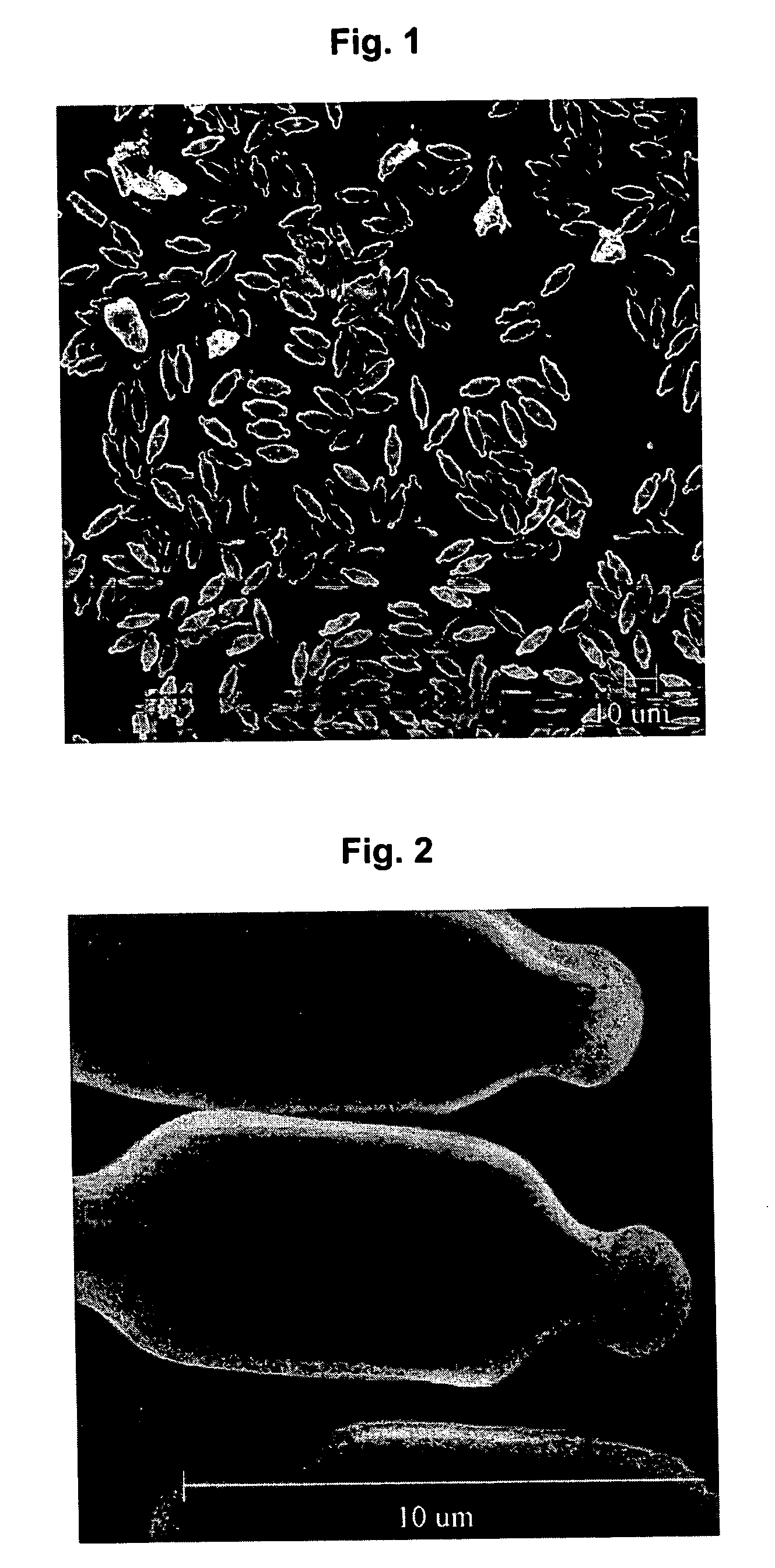

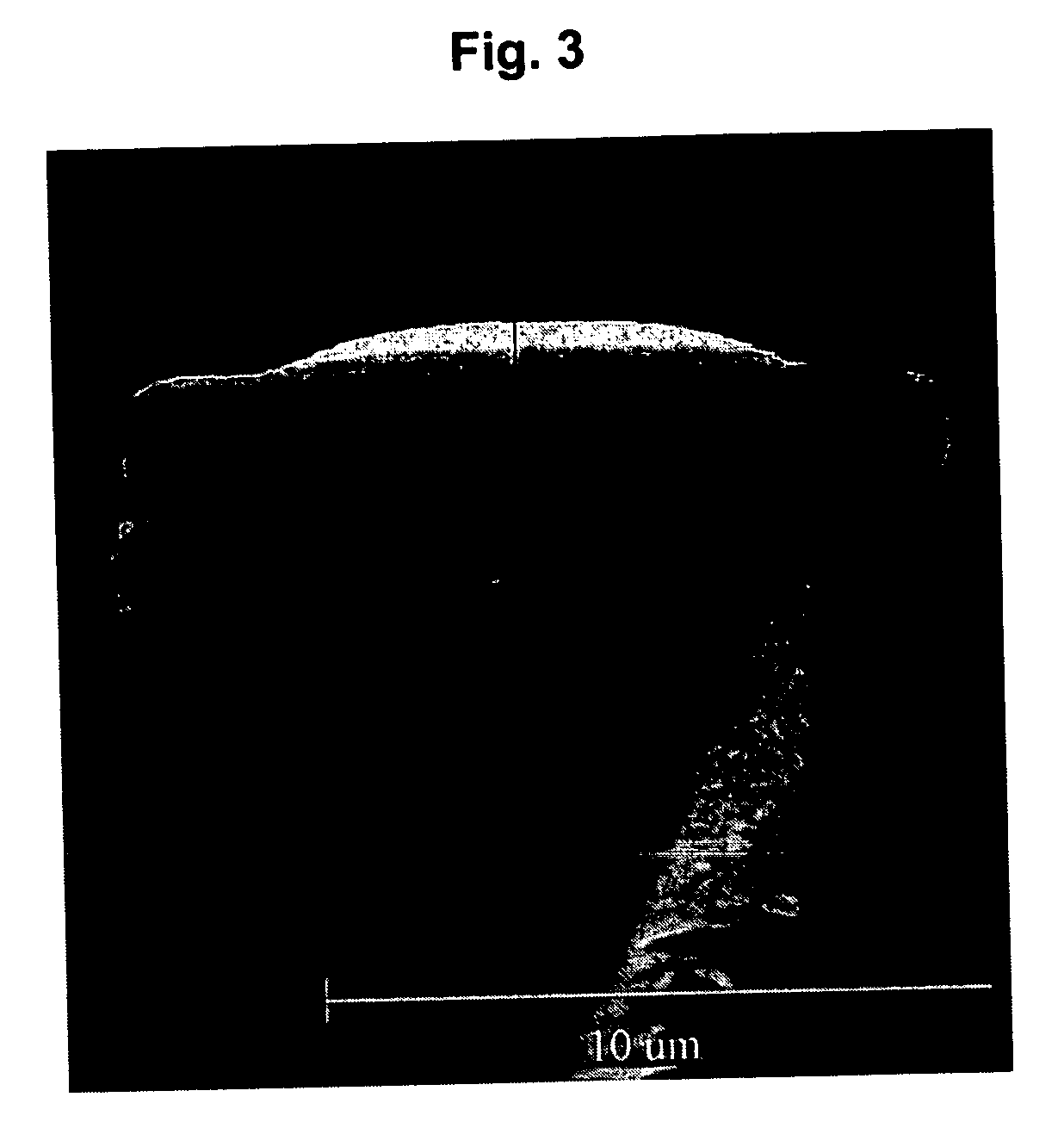

Structured self-cleaning surfaces and method of forming same

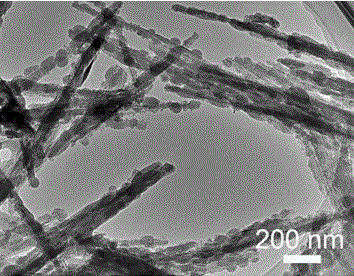

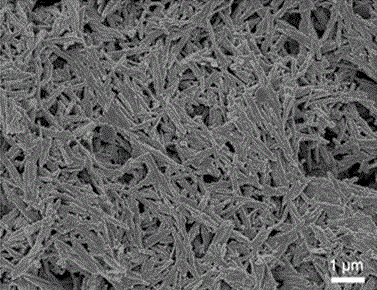

InactiveUS7524531B2Limited degreeSimple and flexiblePretreated surfacesCoatingsFilm-forming agentNanometre

The present invention involves growing diatoms on a surface for the purpose of forming nanoscale-sized siliceous structures on the surface. In accordance with the invention, diatom films are grown on various substrates, which are then fired to remove all organic material from the diatoms and produce a surface coated with intricate, nanoscale-sized structures. The nanoscale-sized structured surface is subsequently treated with a hydrophobic film-forming agent to form a structured self-cleaning surface.

Owner:FERRO CORP

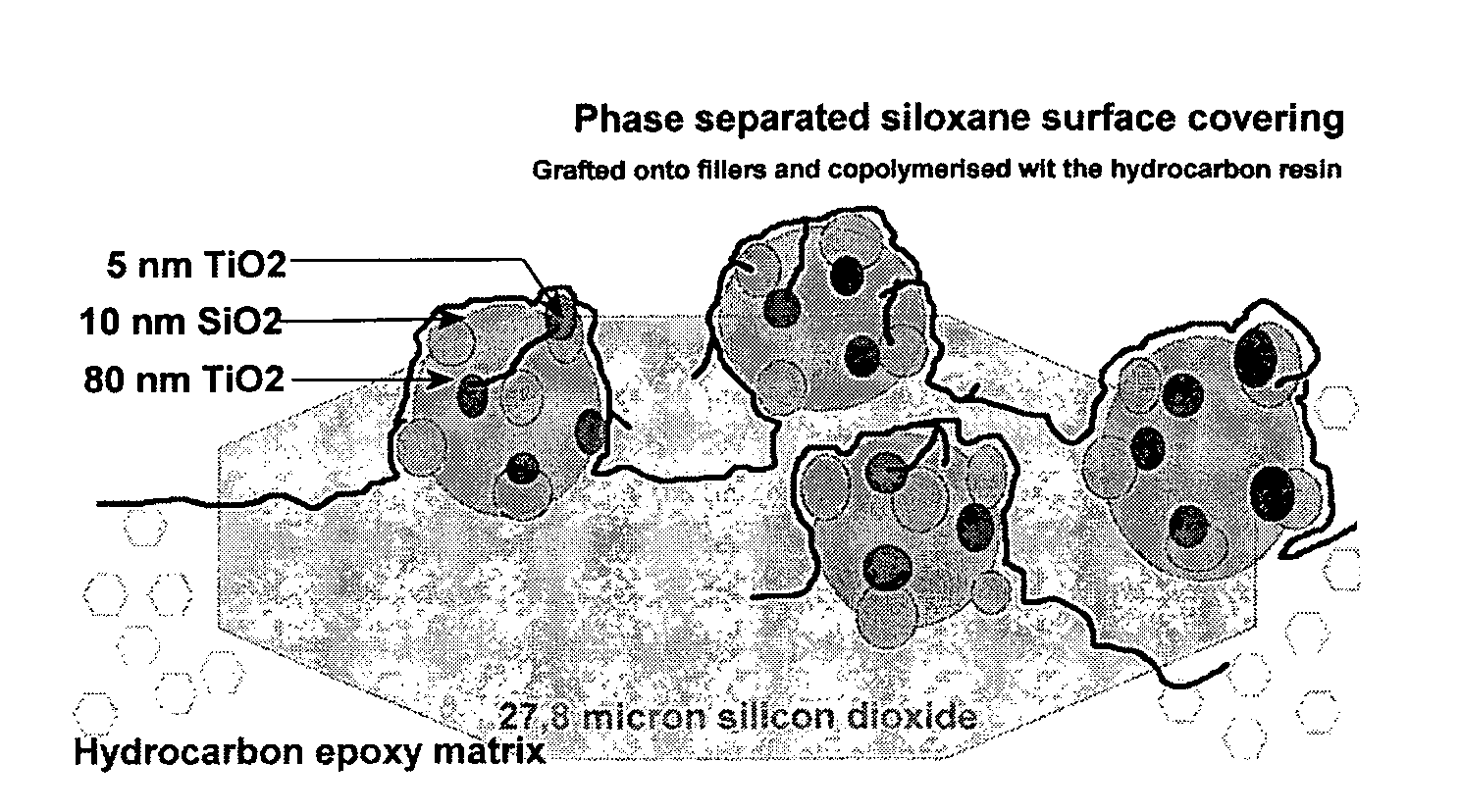

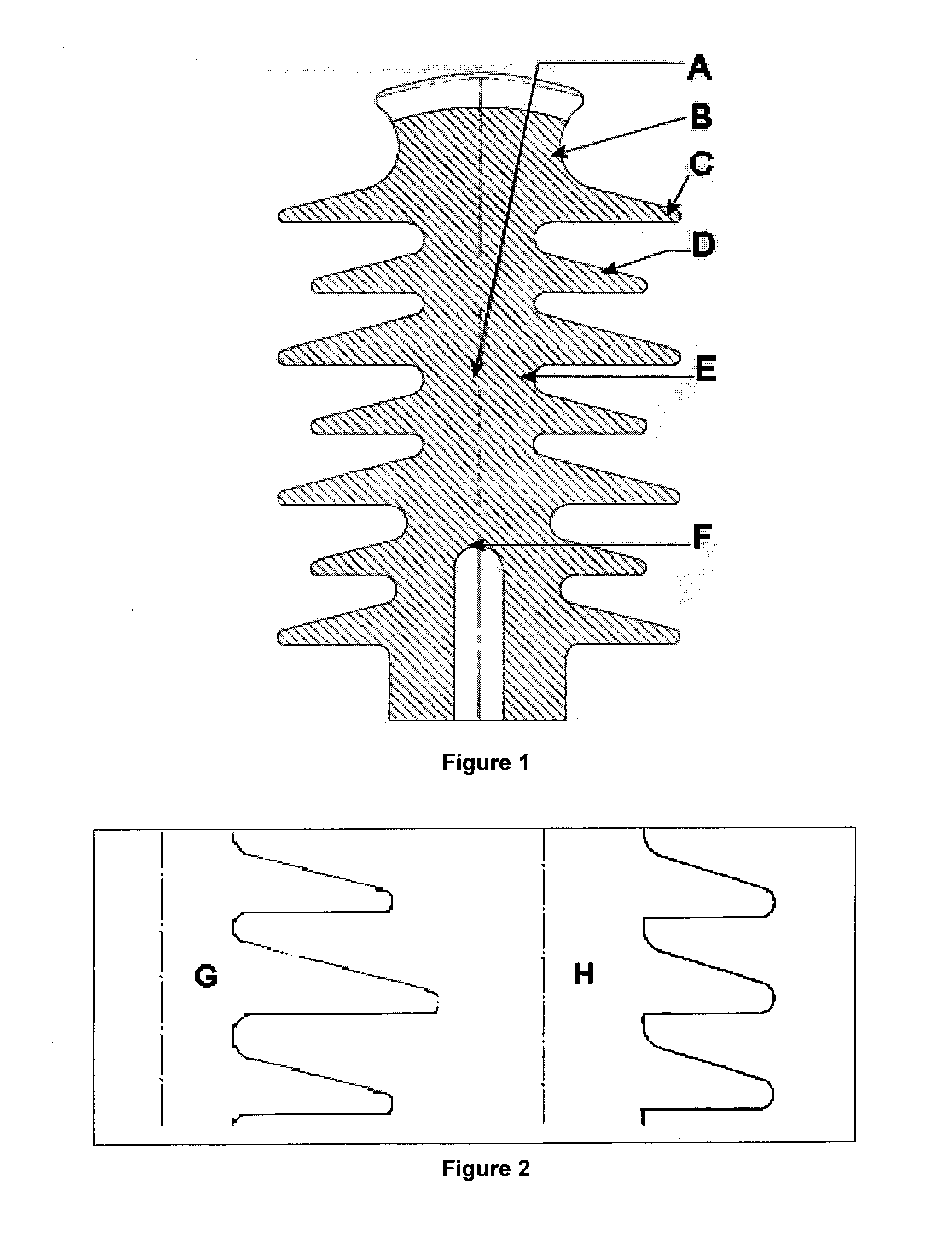

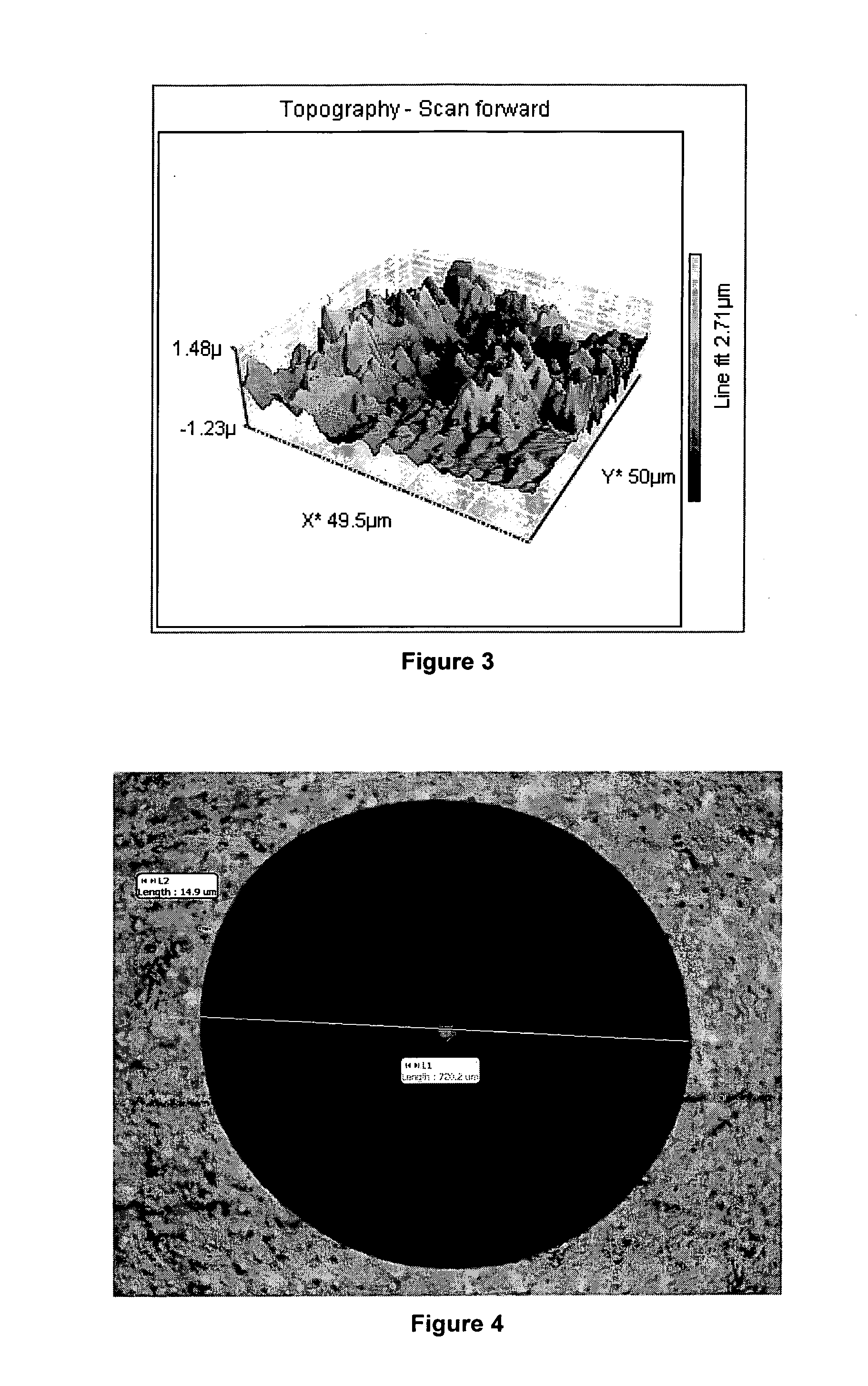

Polymeric High Voltage Insulator with a Hard, Hydrophobic Surface

InactiveUS20100326699A1Reduce weightLow costLiquid surface applicatorsElectric discharge heatingChemical reactionLow leakage

The present invention relates to phase separated siloxane-hydrocarbon copolymer surfaces which are hard and hydrophobic and can be superhydrophobic by the addition of nanoparticles. More specifically the siloxane oligomer / polymer precursor is terminated with (a) chemically reactive group(s). The bond between the siloxane moiety and the hydrocarbon functional moiety is a Si atom directly bonded to a carbon atom. It is applied (for example) to the entire surface of a fibre reinforced and void-free polymer concrete core with 60 to 88% polymeric and inorganic fillers for application as a high voltage insulator. The product has high mechanical strength, impact resistance and good electrical insulation properties. The coating provides good UV resistance, hydrophobicity and a hard self-cleaning surface for use as outdoor high voltage electrical insulator in areas of high pollution with low leakage currents when energised and can also be applied to other products.

Owner:NANONCI

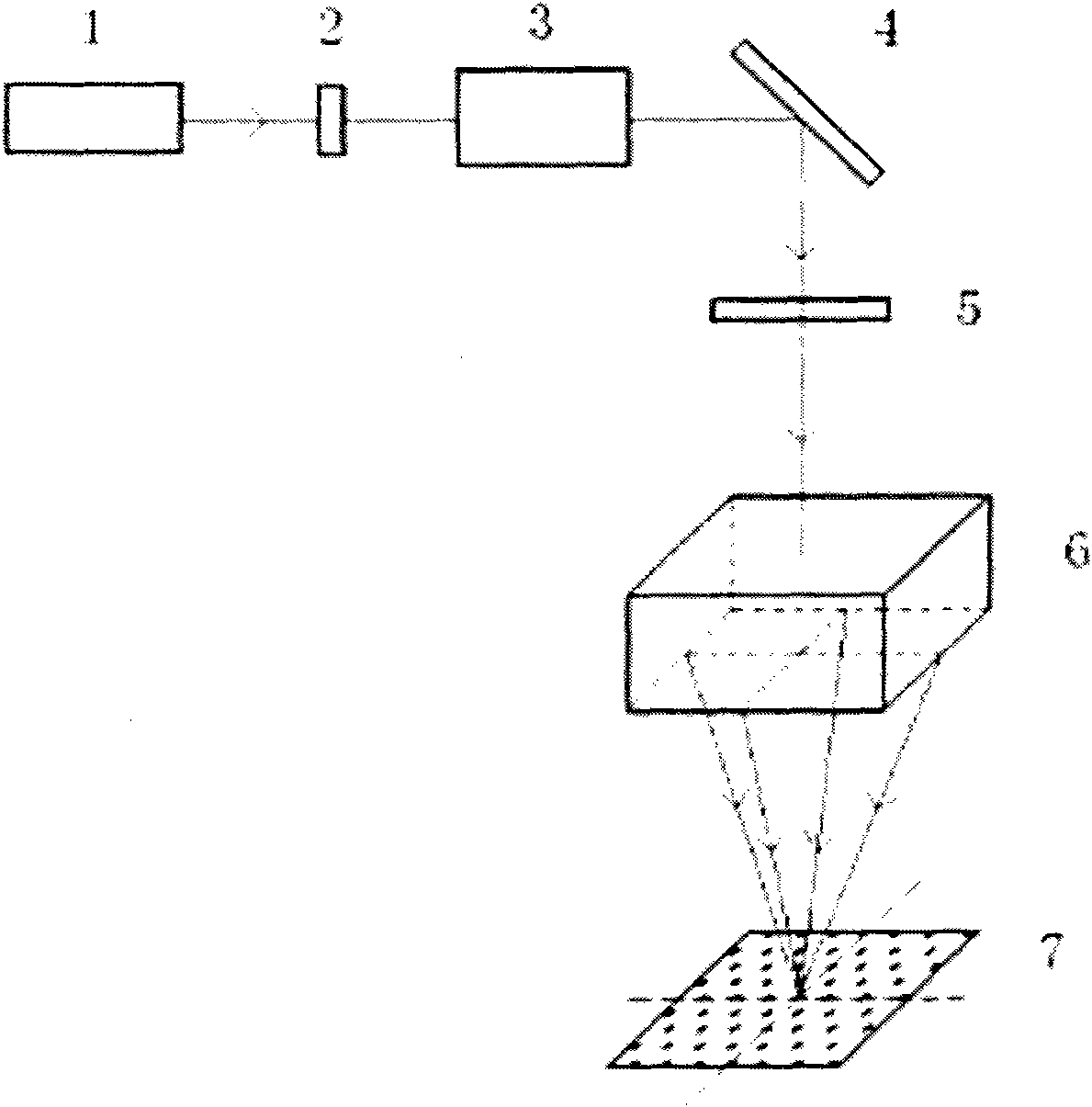

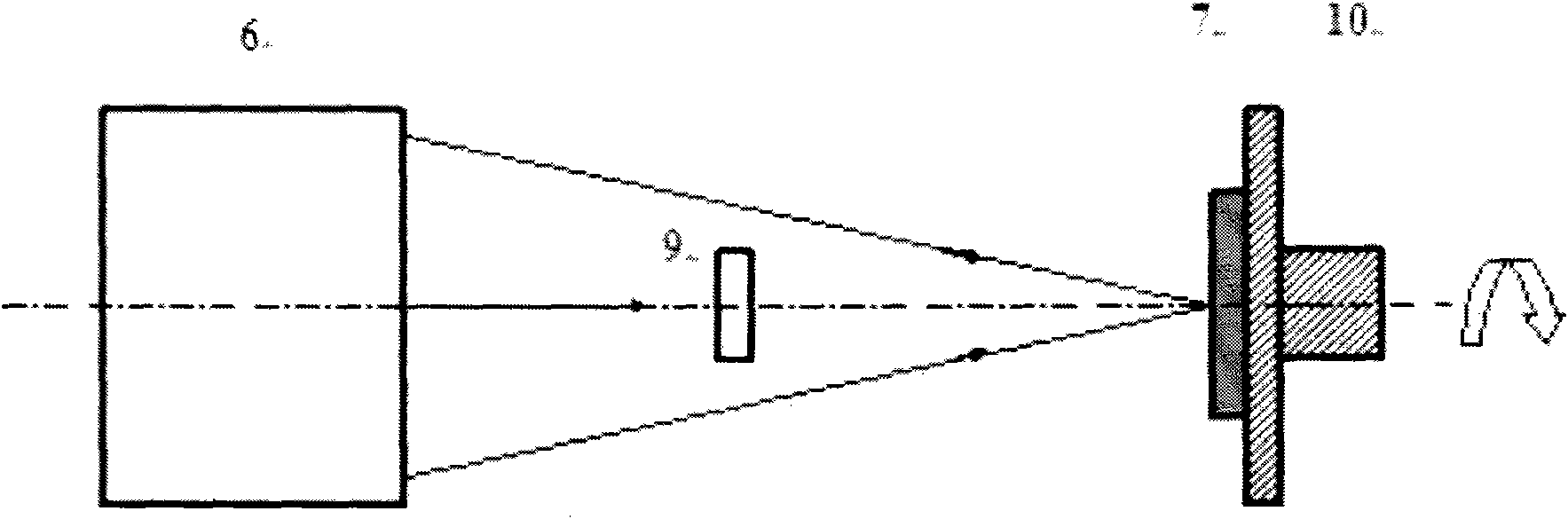

Method and system for manufacturing self-cleaning surface structure by adopting laser interference photolithography technology

InactiveCN101844272AParameters can be adjustedGood controllability of structural parametersPhotomechanical exposure apparatusMicrolithography exposure apparatusMicro nanoMicron scale

The invention relates to method and system for manufacturing a self-cleaning surface structure by adopting a laser interference photolithography technology. The method is characterized in that a plurality of coherent laser beams are combined by using a laser interference photolithography system, weakness modulation is carried out on light intensity distribution in an interference field, redistributed laser energy after modulation is used for ablating the surface of optics materials, and a micron-size or nanoscale dense cylindrical or conical anaglyph structure is generated within a large area range, thereby obtaining a super-hydrophobic film, greatly lowering the viscous phenomenon, benefiting to attachments including dusts, liquid and the like on the surface of the materials detaching from the surface of the materials and fulfilling a self-cleaning function. Without external materials, the self-cleaning fine structure generated on the surface of the materials is more stable and durable and can continuously regulate the period and the size from the nanoscale to the micron size by regulating an incidence angle of the interference photolithography system to enable dual structure of nanometer, micro and micro nanometer to become possible.

Owner:CHANGCHUN UNIV OF SCI & TECH +1

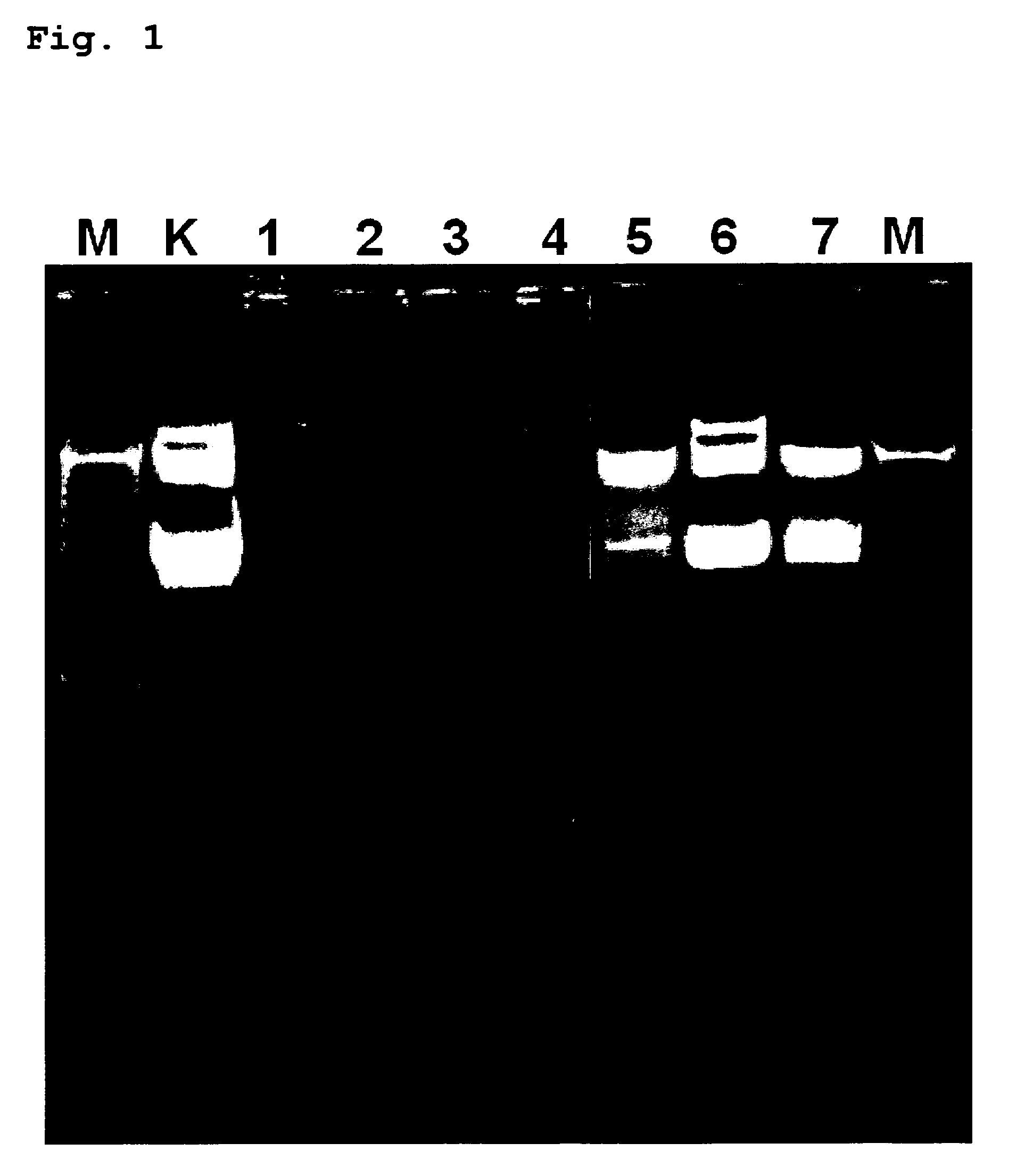

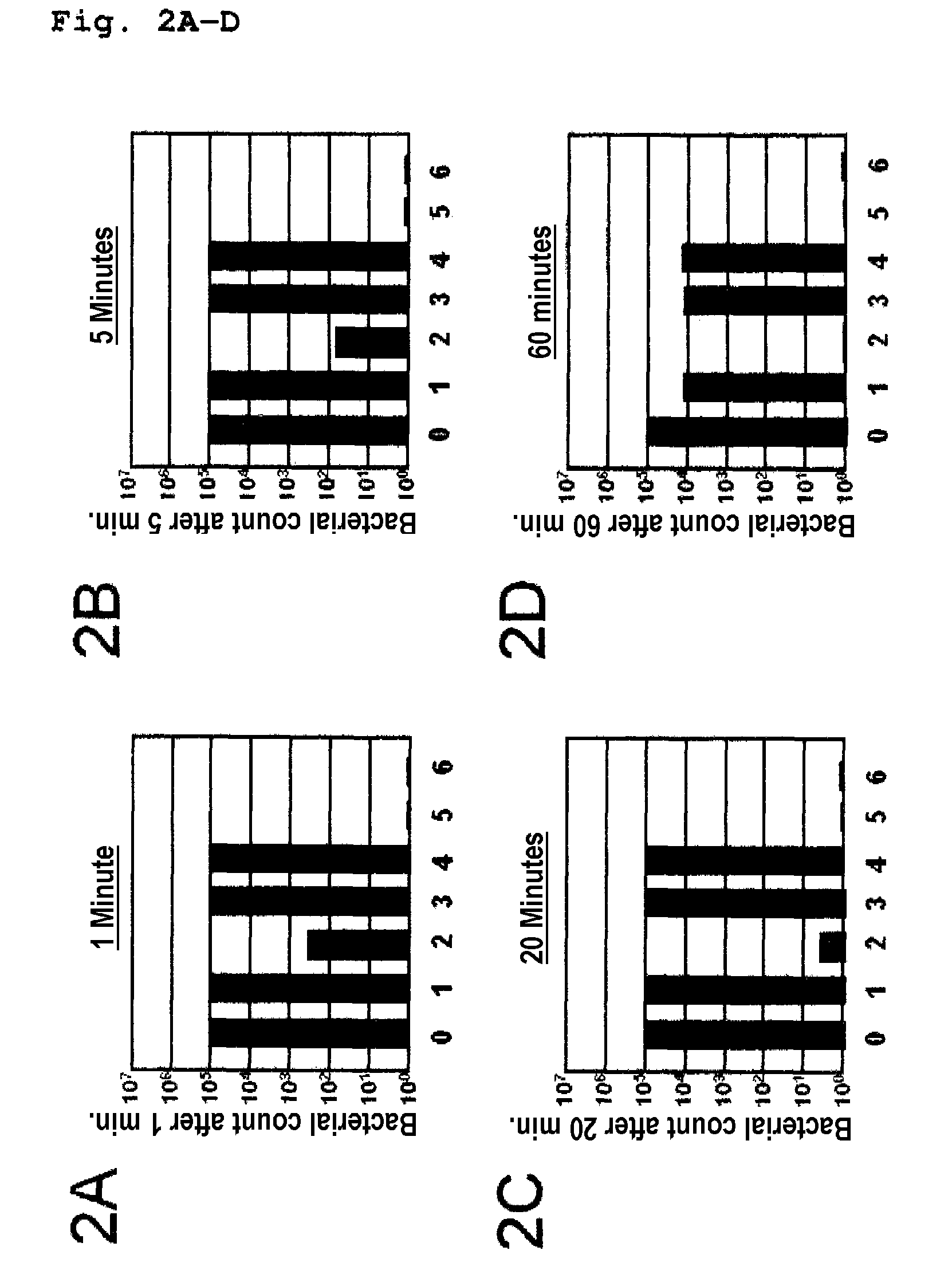

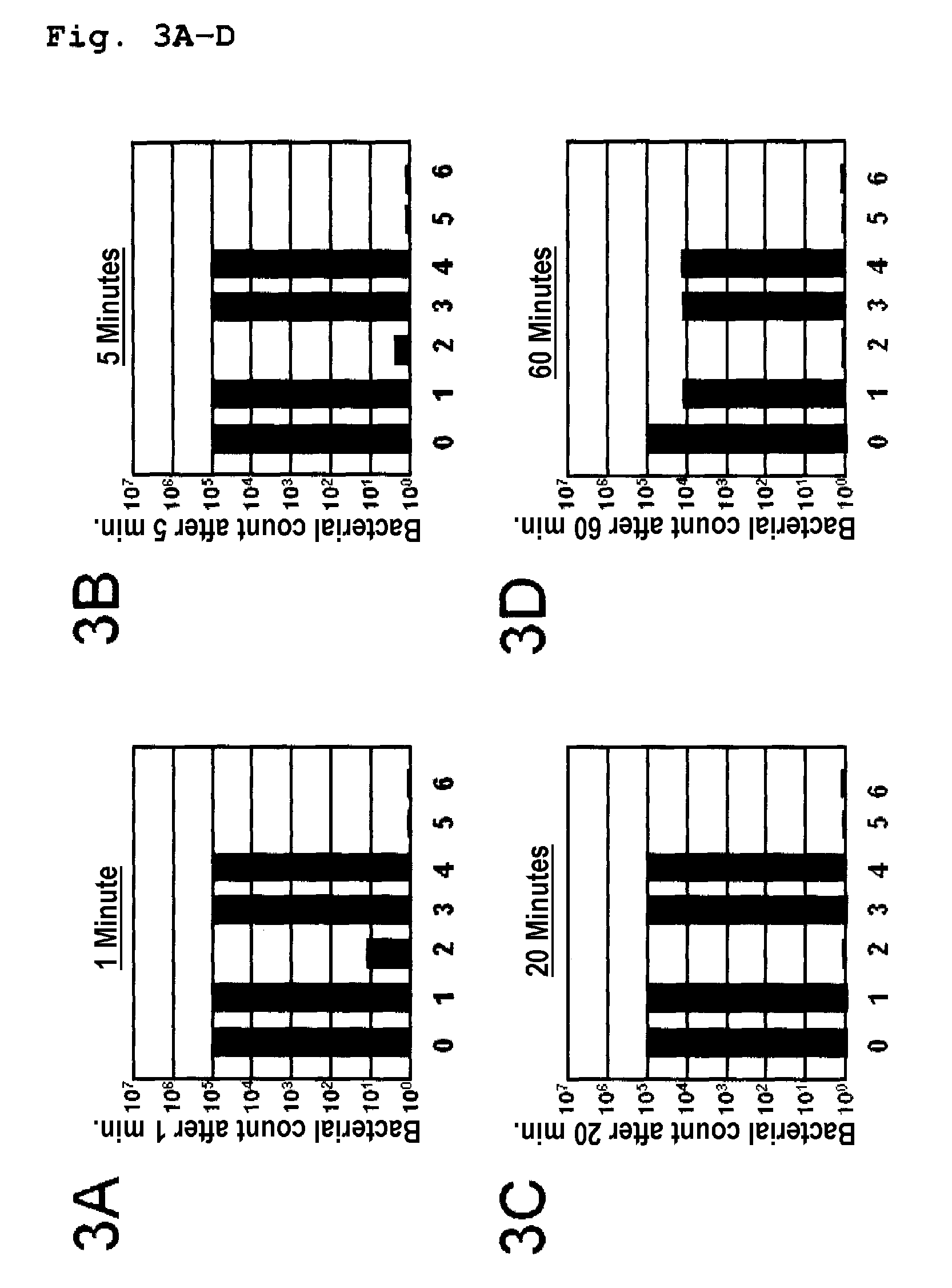

Bioactive, ruthenium-containing coating and device

ActiveUS20100143431A1Quicker releaseFaster and efficient sterilizationBiocideInorganic active ingredientsOligodynamic effectRuthenium

The invention relates to the production and use of novel bioactive devices and metallic coatings for example for sterilizing, disinfecting, and decontaminating water or aqueous solutions. The known oligodynamic effect of silver for reducing the amount of germs is thereby improved and increased by combining silver with ruthenium and a vitamin or derivative thereof. The novel properties of these bioactive metal surfaces lead to faster and more efficient killing of microorganisms. Simultaneously, these novel bioactive metal surfaces prevent infestation by microorganisms and attachment or permanent deposition of problematic biomolecules such as for example DNA, RNA, or proteins. A self-cleaning surface is thus obtained, which very quickly and efficiently and over extended periods of time sterilizes water and aqueous solutions when they come in contact with said surface.

Owner:AGXX INTPROP HLDG

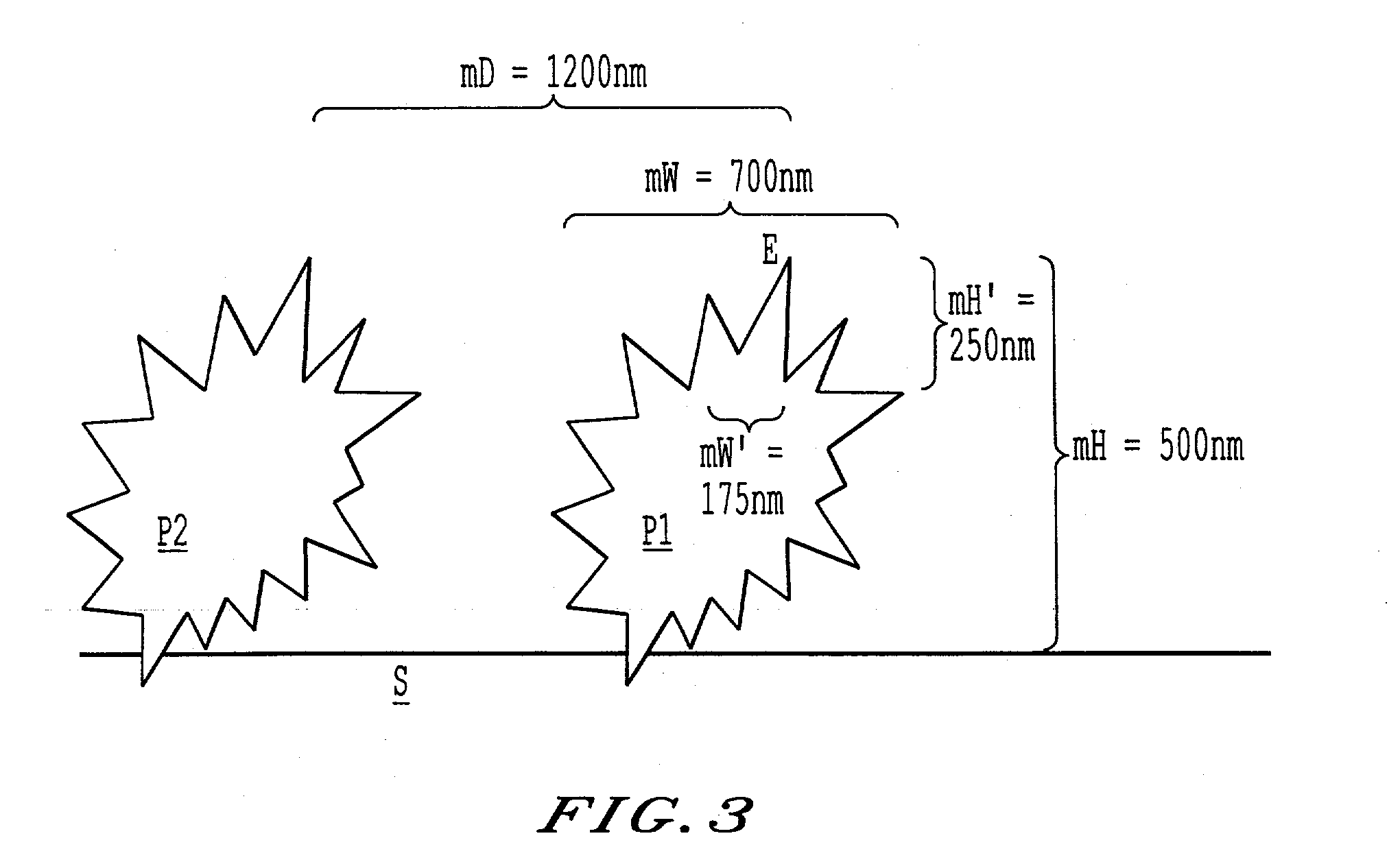

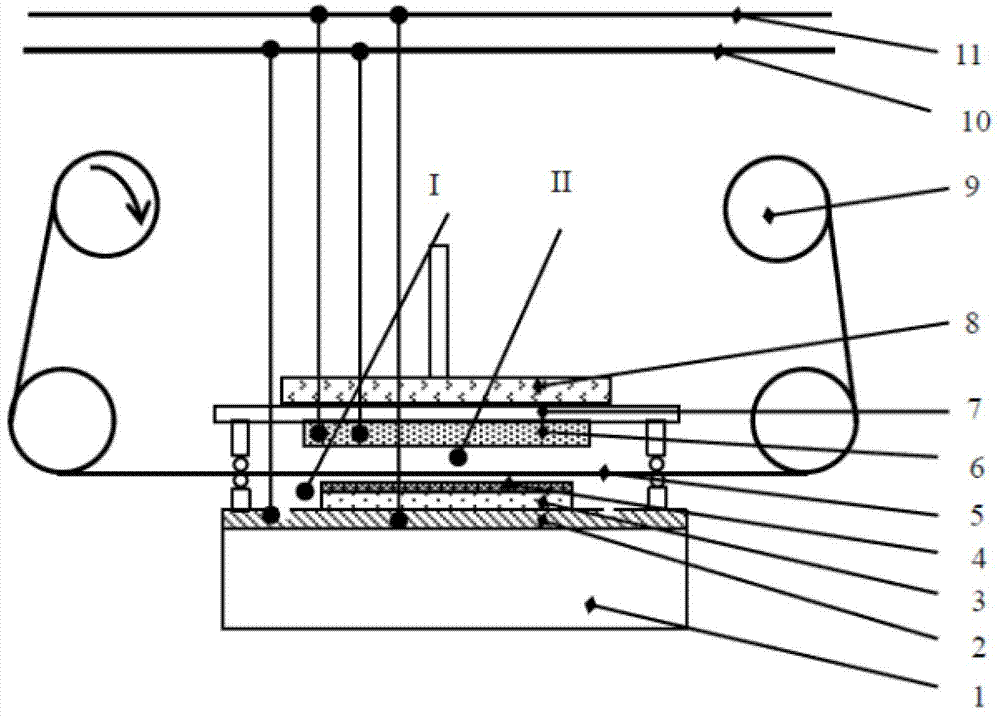

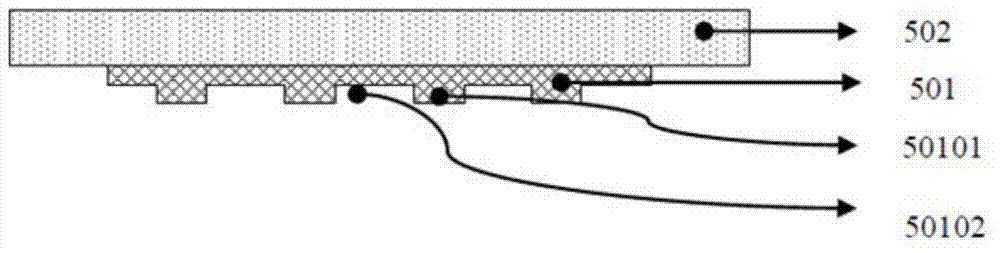

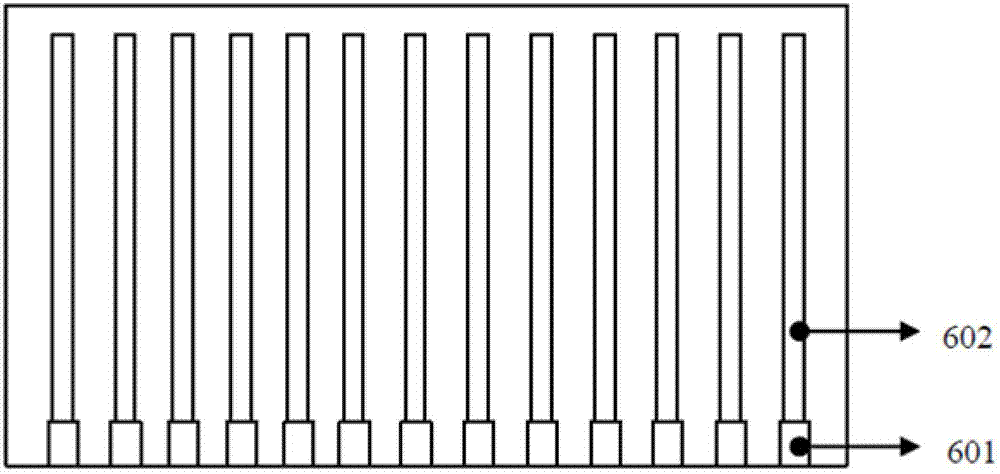

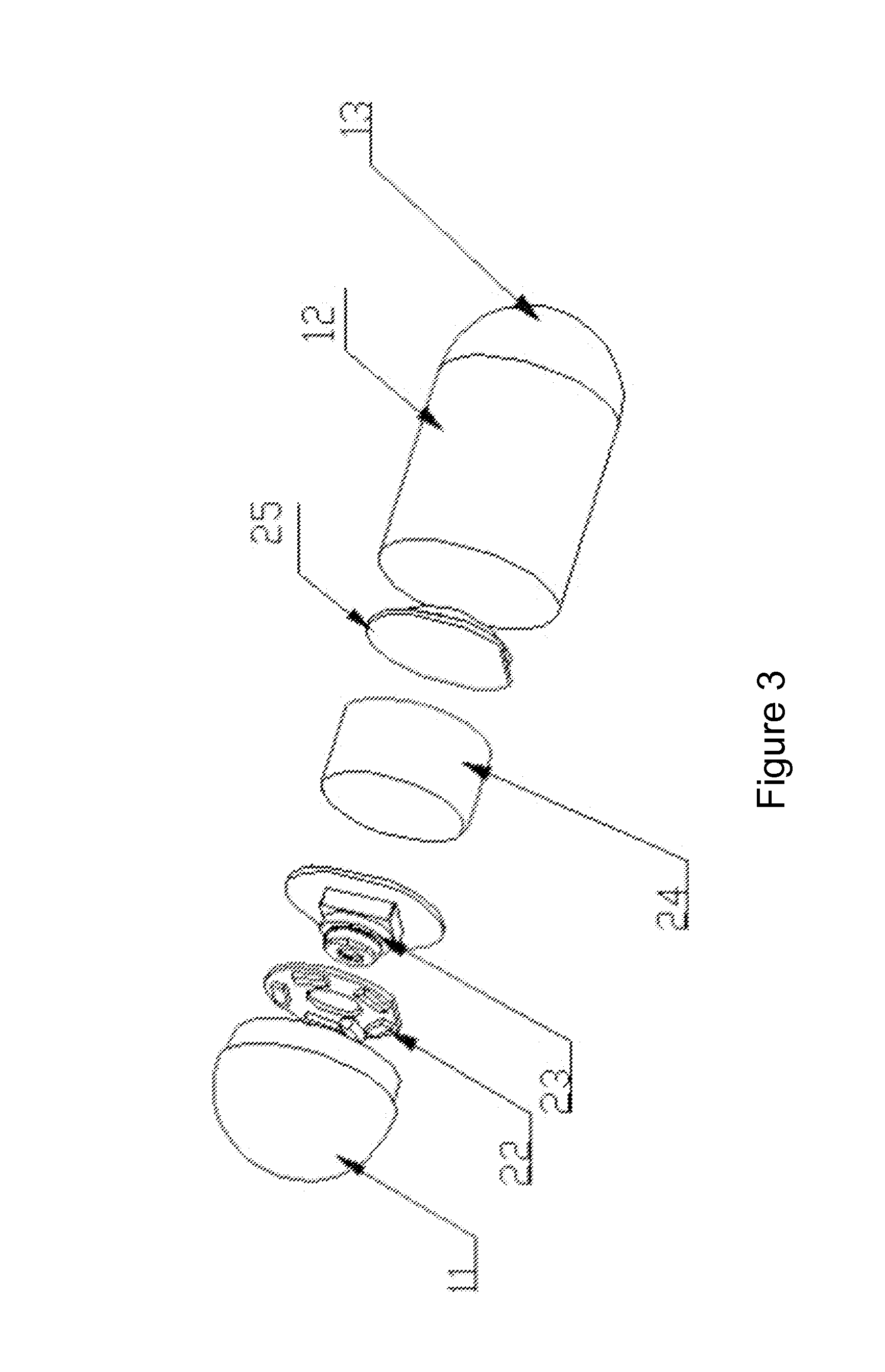

Nanometer impression device and nanometer impression method for high-brightness light-emitting diode (LED) graphics

ActiveCN102866582AReduce defectsGood removal effectNanoinformaticsPhotomechanical exposure apparatusSolubilityGraphics

The invention discloses a nanometer impression device and a nanometer impression method for high-brightness light-emitting diode (LED) graphics. The nanometer impression device comprises a wafer bearing platform, a vacuum sucking disc, a substrate, a ultraviolet light cured nanometer impression slushing compound and the like. A die is a thin film elastic composite flexible die and comprises a graphical layer and a supporting layer, wherein the graphical layer has the characteristics of water solubility, thin-film structure, elasticity and high transparency, and the die is manufactured by adopting a rolling impression process. The nanometer impression method for achieving high-brightness LED graphics based on the device comprises the steps of (1) pre-processing, (2) impression, (3) curing, (4) demoulding, (5) post-processing and (6) transferring of impression graphics. By means of the nanometer impression device and the nanometer impression method, a large-area, high-aspect-ratio micro-nanometer structure is efficiently manufactured on an unsmooth surface or a curved surface substrate or a fragile substrate with low cost. The nanometer impression device and the nanometer impression method are suitable for large-scale manufacture of optical devices, three-dimensional miniature batteries, micro-electromechanical system (MEMS) devices, photovoltaic devices, anti-reflecting layers, self-cleaning surfaces and the like and are especially suitable for the LED graphics and industrial-grade large-scale production of wafer-level splicing-free micro-optical devices.

Owner:兰红波

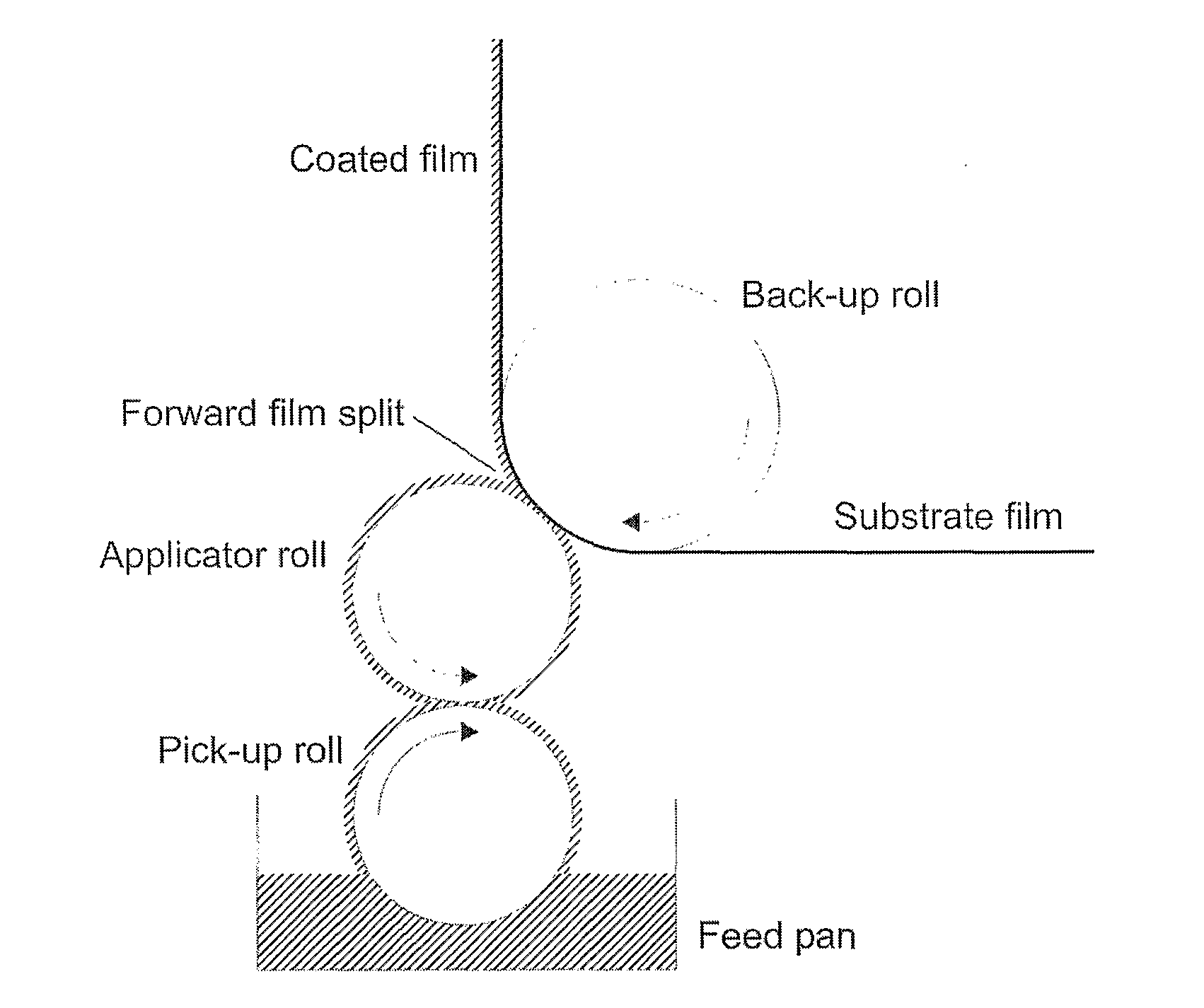

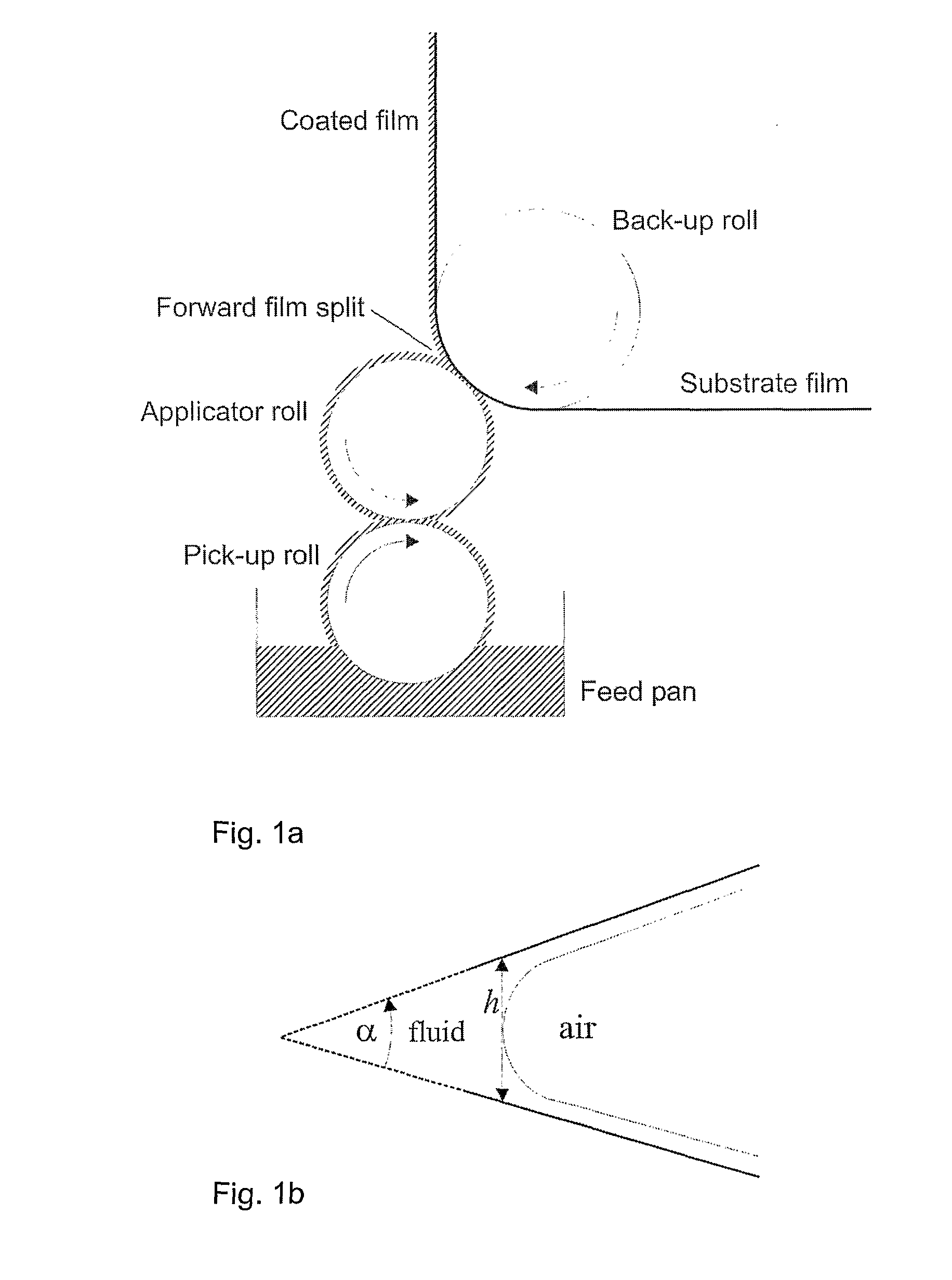

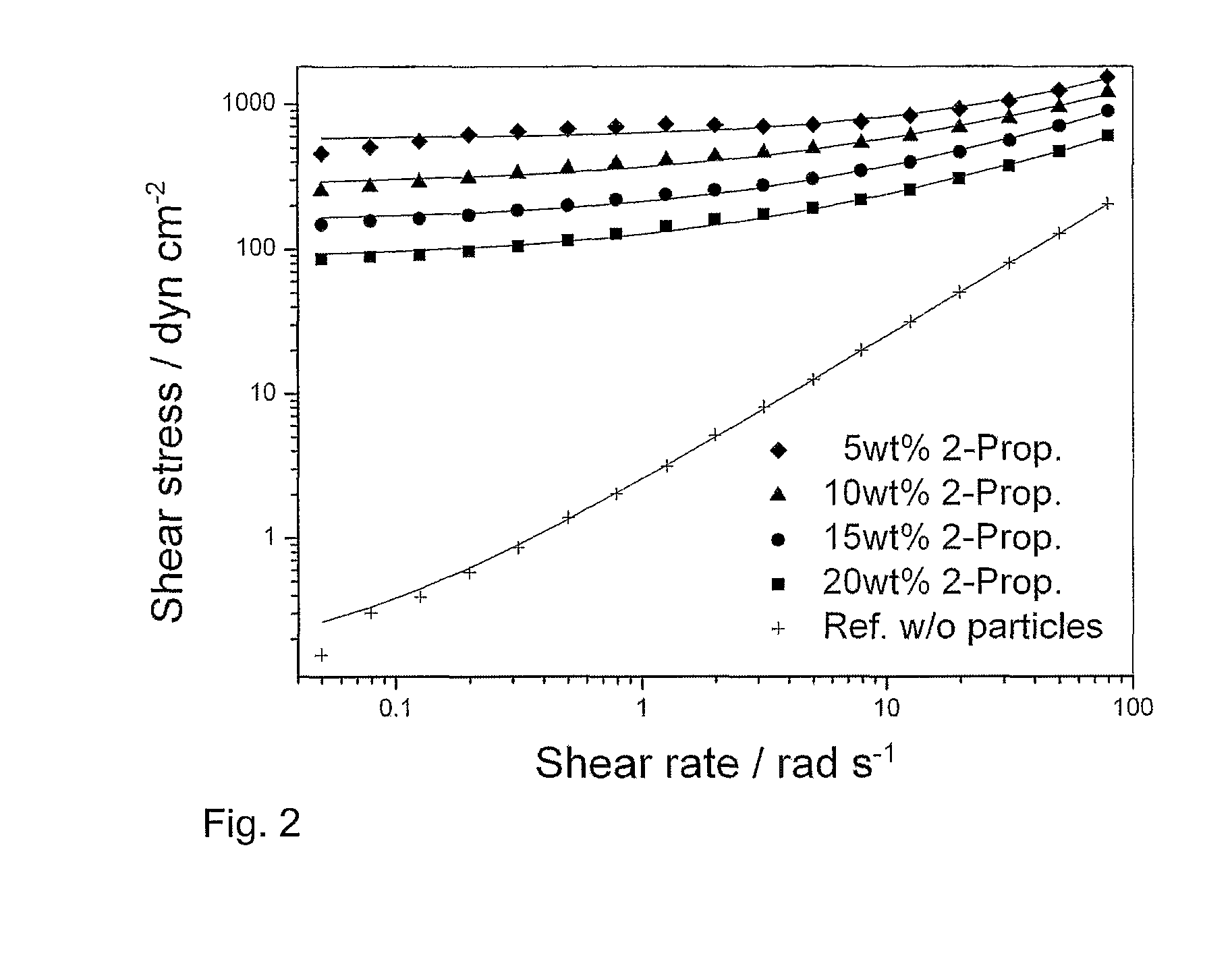

Method for the Application of a Structured Coating Upon a Smooth Surface

InactiveUS20080233356A1Well formedSmall surface areaLayered productsPretreated surfacesControlled releaseShear stress

A roll coating method for preparing a coated substrate with structured surface of the coating is described. Said method comprises application of a polymer based coating fluid to a substrate surface by means of a coating fluid application roll and then curing the applied coating, wherein the polymer based coating fluid is a fluid showing Bingham or Herschel-Bulkley flow behavior with a yield stress τ0>10 dyn cm−2, in particular a fluid having low viscosity at high shear rate, fast viscosity enhancement in the absence of shear stress and a high yield stress. Applications of such produced surfaces are release films, e.g. for pressure sensitive adhesives, controlled release adhesives and self-cleaning surfaces and friction coefficient reducing surfaces.

Owner:PERLEN CONVERTING +1

Substrates with self-cleaning surface, process for their prodn. and their use

InactiveCN1481342AHas a self-cleaning surfaceImprove self-cleaning effectFouling preventionSuperimposed coating processMaterials scienceMetal

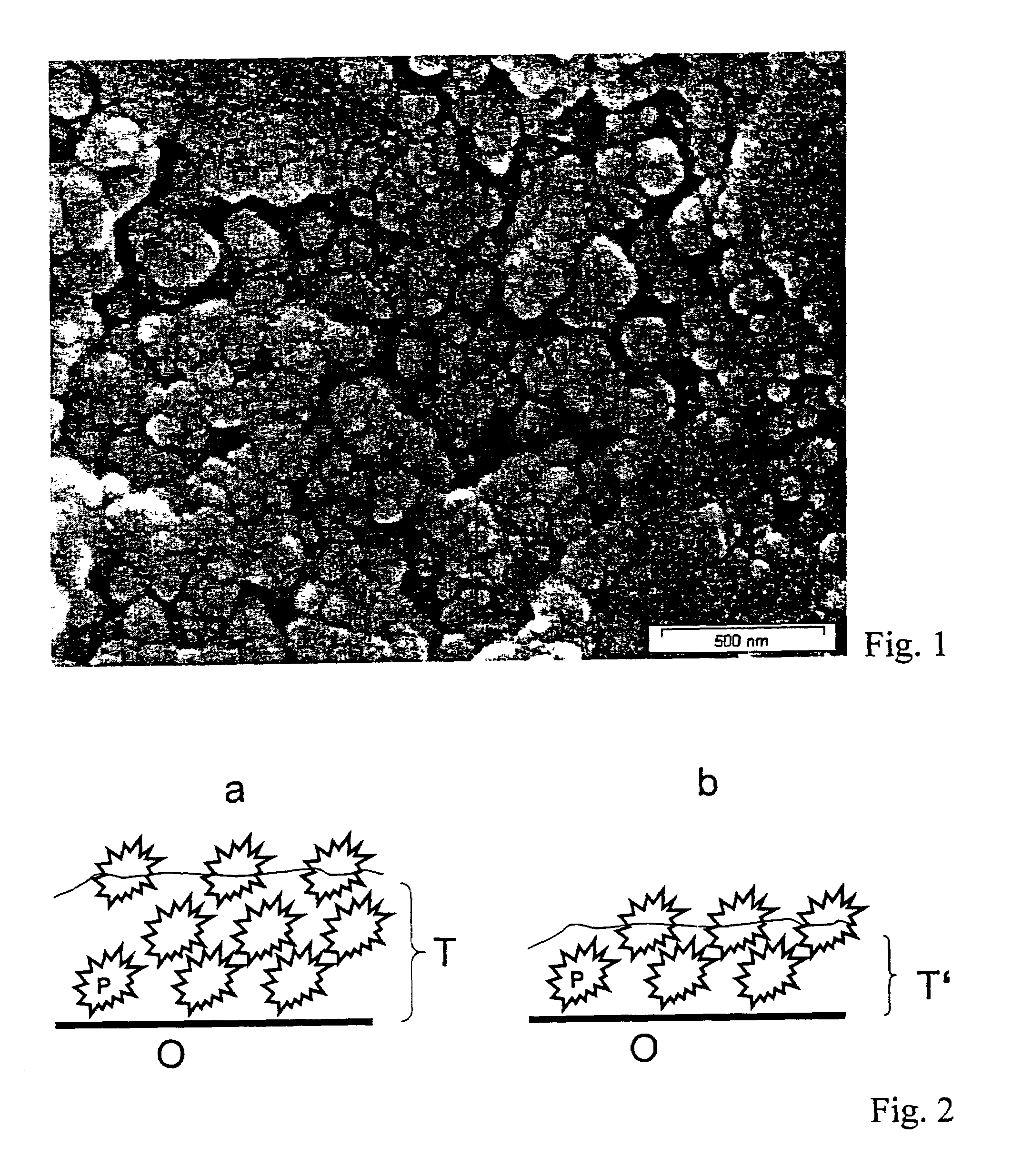

Substrates, in particular a substrate of glass, ceramic, plastic and metal and glazed or enamelled substrates, with a self-cleaning surface comprise an at least partly superficially hydrophobic structured (elevations and depressions) coating located on the substrate. Substrates according to the invention comprise particles with an average diameter of less than 100 nm, in particular 5 to less than 50 nm, for formation of the structure of the coating. Compositions according to the invention which are employed for the production of the structured coating of substrates according to the invention comprise, in addition to the structure-forming particles, a layer-forming material in a weight ratio of 100:1 to 1:2, in particular 20:1 to 1:1. In addition to having good self-cleaning properties, the coating is distinguished by its transparency. The use of the substrates is aimed in particular at the most diverse glass articles.

Owner:FERRO CORP

Capsule endoscope having a self-cleaning surface and method of using the same

The present invention discloses a capsule endoscope and a method to prevent the capsule from being covered by a residue or mucous in a patient's digestive tract. The capsule endoscope comprises an improved surface, preventing a residue or mucous to adhere onto the surface of the capsule, and in the unlikely event that a residue or a mucous is collected by the capsule the improved surface can allow an easy and successful clean before an image is taken.

Owner:ANKON MEDICAL TECH (SHANGHAI) CO LTD

Structured self-cleaning surfaces and method of forming same

InactiveUS20060246277A1Increased durabilityLess durabilityPretreated surfacesGlass/slag layered productsFilm-forming agentMaterials science

The present invention involves growing diatoms on a surface for the purpose of forming nanoscale-sized siliceous structures on the surface. In accordance with the invention, diatom films are grown on various substrates, which are then fired to remove all organic material from the diatoms and produce a surface coated with intricate, nanoscale-sized structures. The nanoscale-sized structured surface is subsequently treated with a hydrophobic film-forming agent to form a structured self-cleaning surface.

Owner:FERRO CORP

Method for manufacturing stainless steel super-hydrophobic self-cleaning surface through ultra-fast lasers

InactiveCN104907701AExcellent superhydrophobic propertiesSimple processWelding/soldering/cutting articlesLaser beam welding apparatusMetallic substrateHydrophobic effect

The invention relates to a method for manufacturing a stainless steel super-hydrophobic self-cleaning surface through ultra-fast lasers, and belongs to the technical field of metal base material surface modification. According to the method, firstly, polishing pretreatment is carried out on a stainless steel sample; then, the surface of the sample is cleaned in an ultrasonic cleaning device through deionized water, and the surface of the sample is blow-dried through cold air or is air-dried; the laser processing technology is used, the surface of the sample is treated by adjusting relative process parameters through an ultra-fast laser device, innumerable microstructures are processed in the surface of the sample, the processed sample is placed into an electrically heated drying oven to be baked after processing, and the stainless steel super-hydrophobic self-cleaning surface with nanoscale granulated or flaky or protrusion-shaped structures is obtained. The surface has the self-cleaning function and is excellent in friction resistance and corrosion resistance. The method for manufacturing the stainless steel super-hydrophobic self-cleaning surface through the ultra-fast lasers is simple in process, convenient to operate, high in efficiency, little in energy consumption, low in cost and environmentally friendly, and industrial application is easy to implement.

Owner:HUBEI UNIV OF TECH

Articles with super-hydrophobic and/or self-cleaning surfaces and method of making same

Owner:INTEGRAN TECH

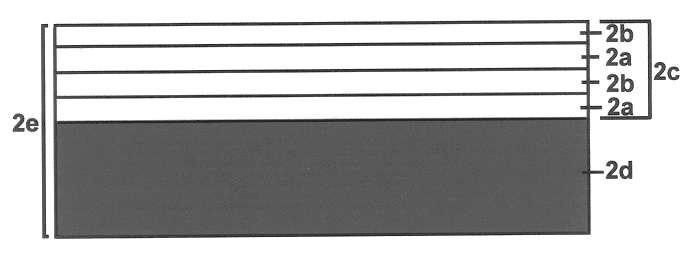

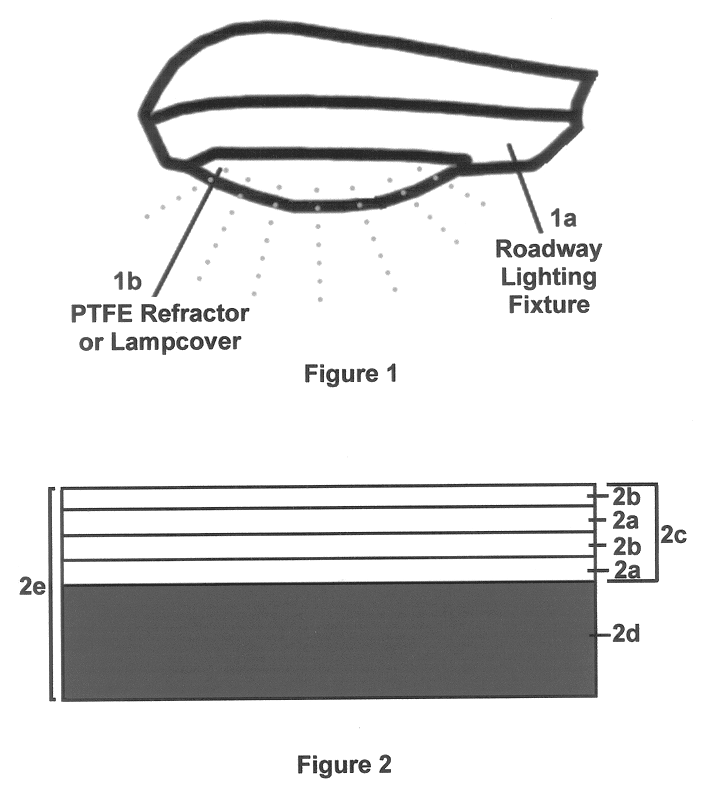

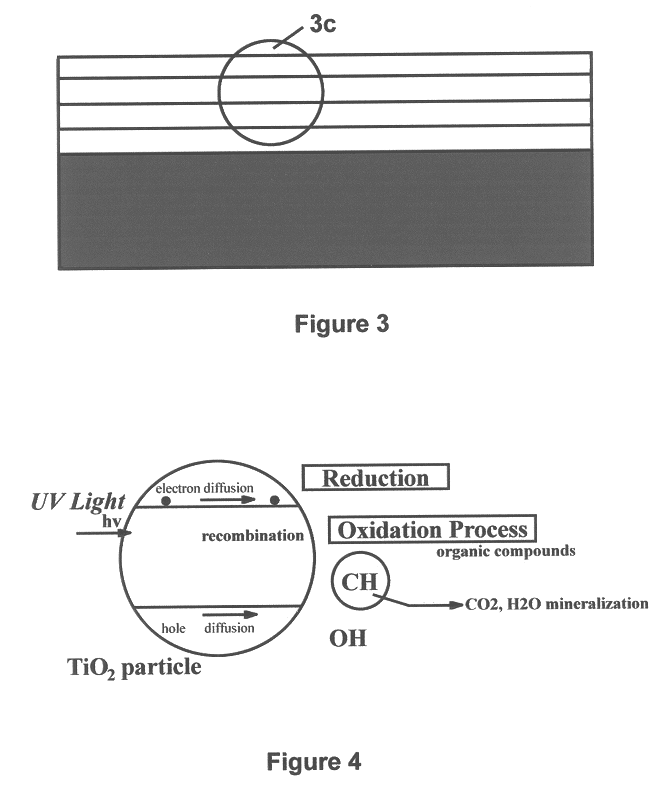

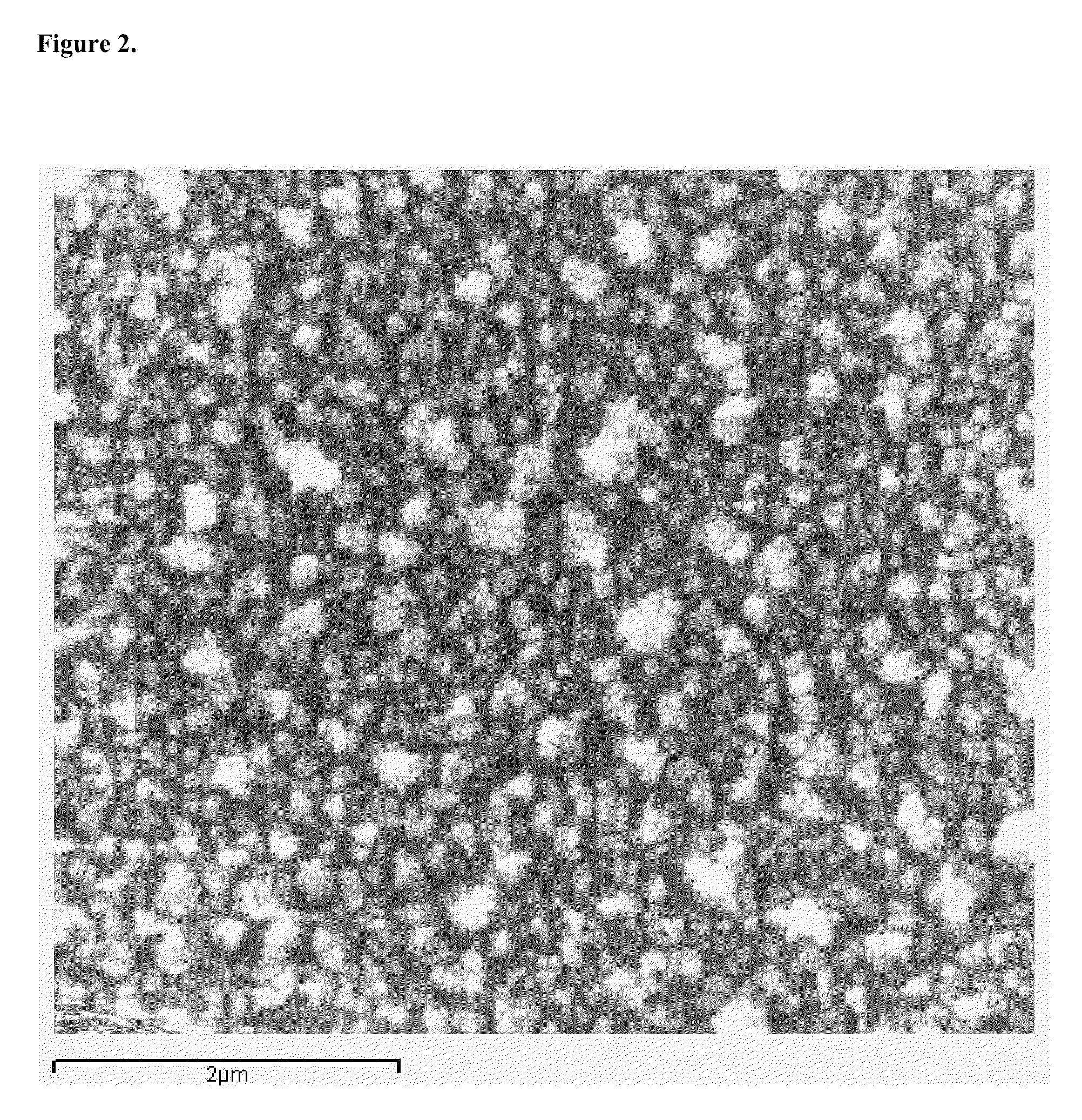

Wavelength selective photocatalytic dielectric elements on polytetrafluoroethylene (PTFE) refractors having indices of refraction greater than 2.0

InactiveUS6599618B1Fouling preventionPhysical/chemical process catalystsPhotocatalytic reactionEffect light

This invention relates to a photocatalytic dielectric element placed upon polytetrafluoroethylene (PTFE) refractors and lamp covers to provide a self-cleaning surface for use on roadway lighting fixtures. The photocatalytic dielectric element is comprised of a series of hard durable thin dielectric film layers that can be tailored to selectively reflect UV with a plurality of dielectric layers having indices of refraction greater than 2.0. The photocatalytic dielectric element is otherwise transmissive to light at all other wavelengths. In addition, the photocatalytic dielectric element can concentrate photons generating from the light fixture, or from direct sunlight within a narrow range of wavelengths on the outer surface of the polytetrafluoroethylene refractor or lamp cover. In turn this promotes photocatalytic reactions that decompose bacteria and other organic contaminates that contact the polytetrafluoroethylene refractor or lamp cover where the photocatalytic dielectric element is placed upon, thus, making the light fixture self cleaning. The photocatalytic dielectric element can be placed on what is termed as, "difficult to adhere to substrate materials", such as the polytetrafluoroethylene, while maintaining good adhesion without delamination, in addition to most any other substrate material. The photocatalytic dielectric element preferably has been deposited on the surface of the polytetrafluoroethylene refractor by dual alternating low-pressure environment deposition techniques.

Owner:SIMMON JR FREDERICK LEE

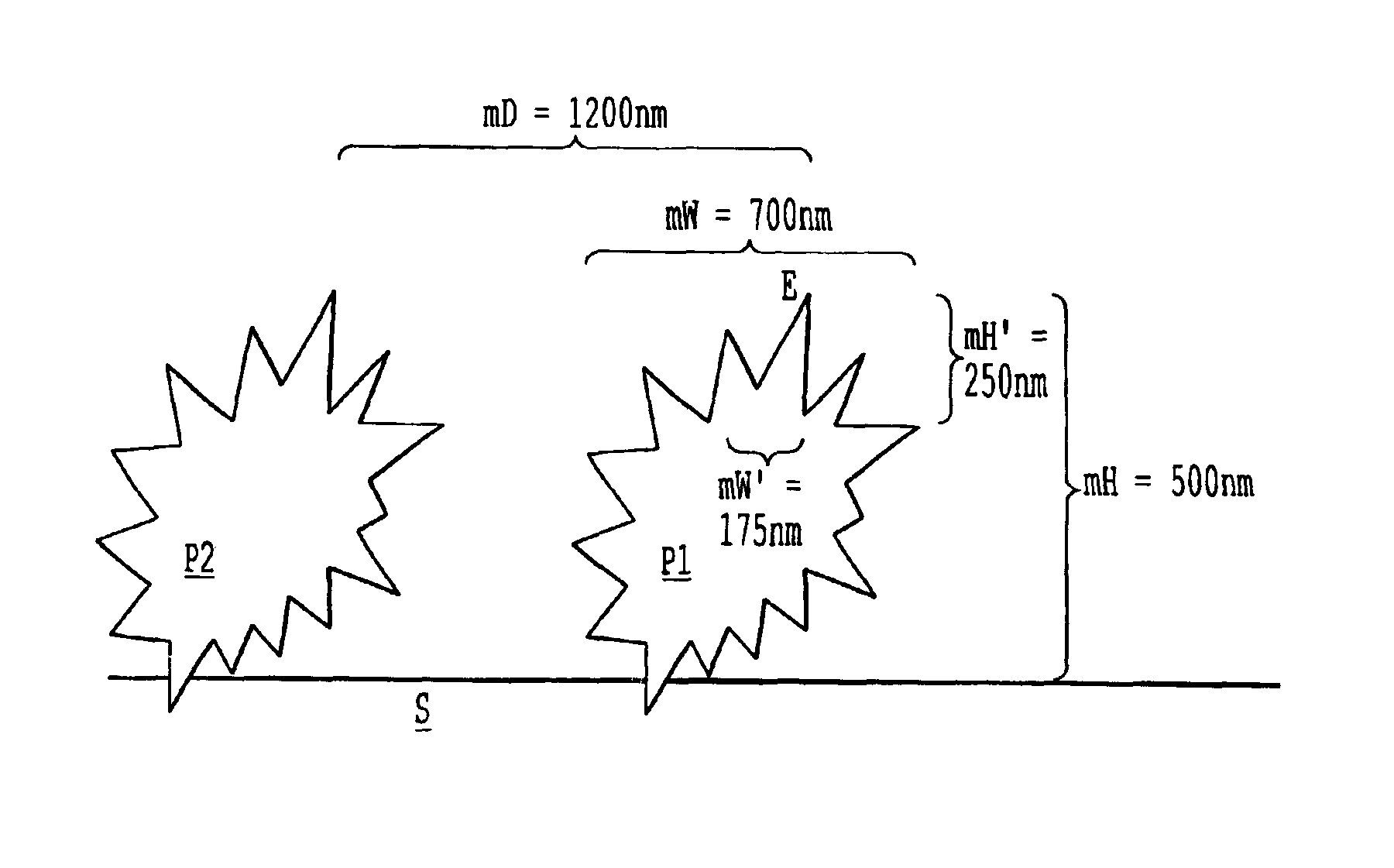

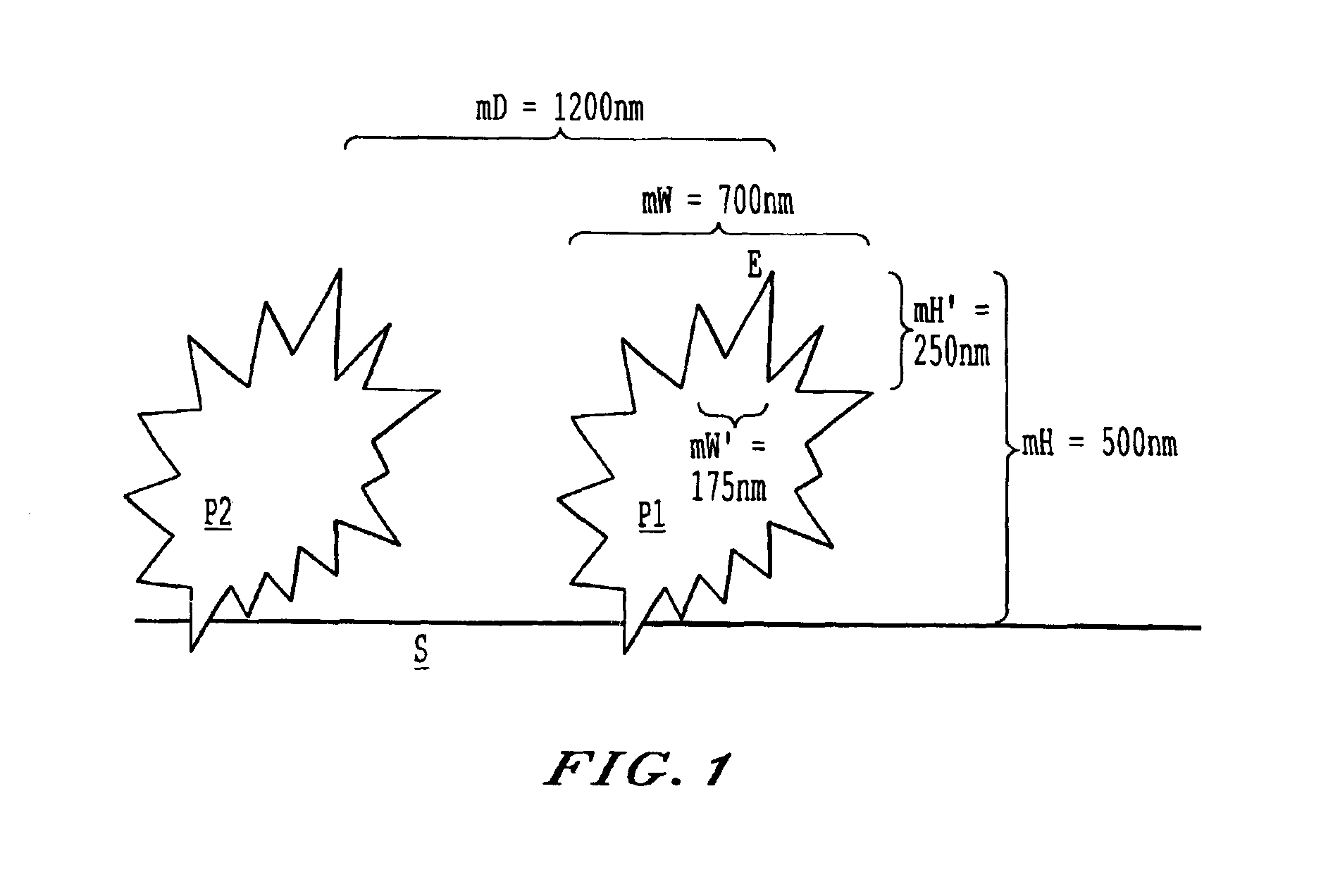

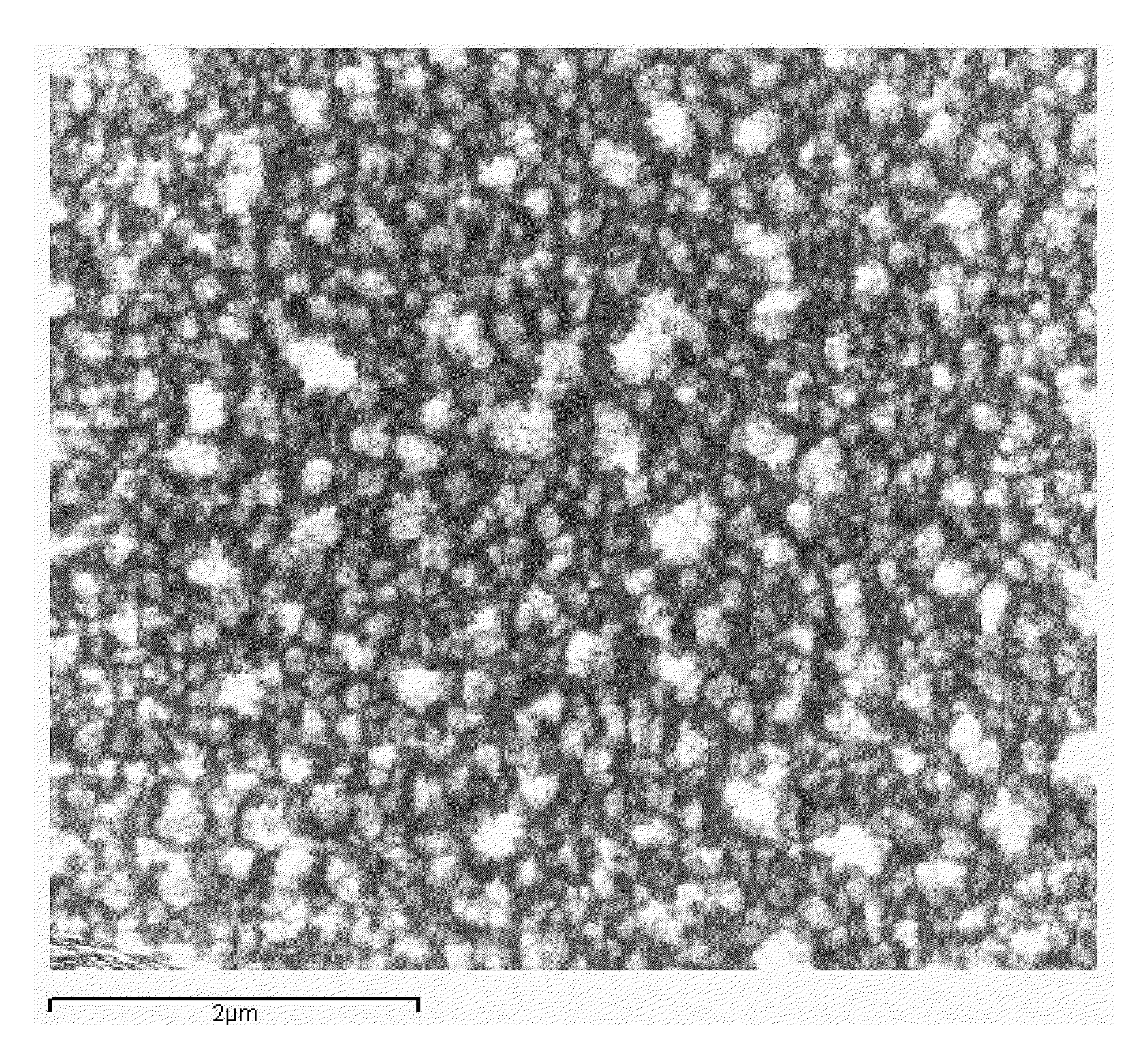

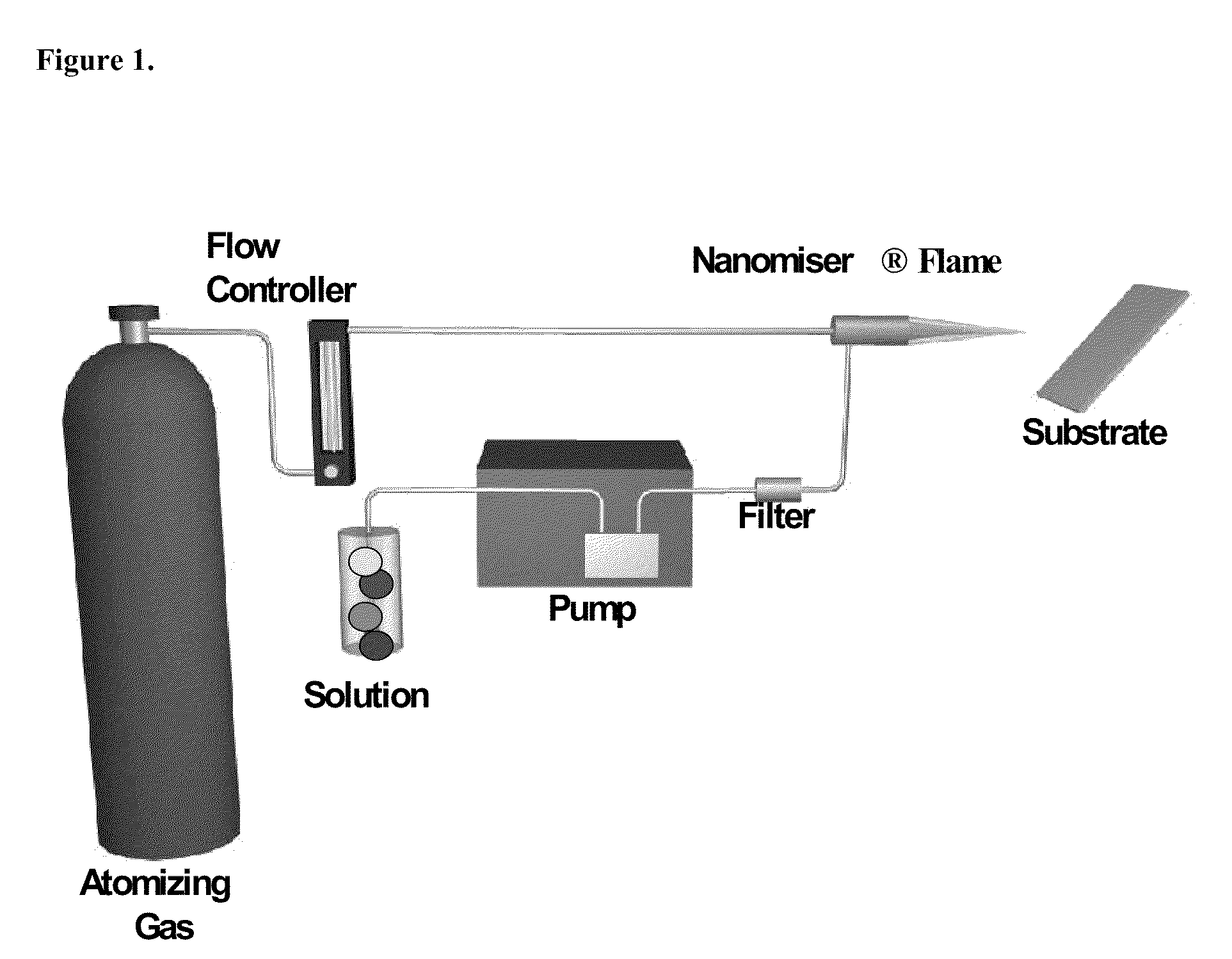

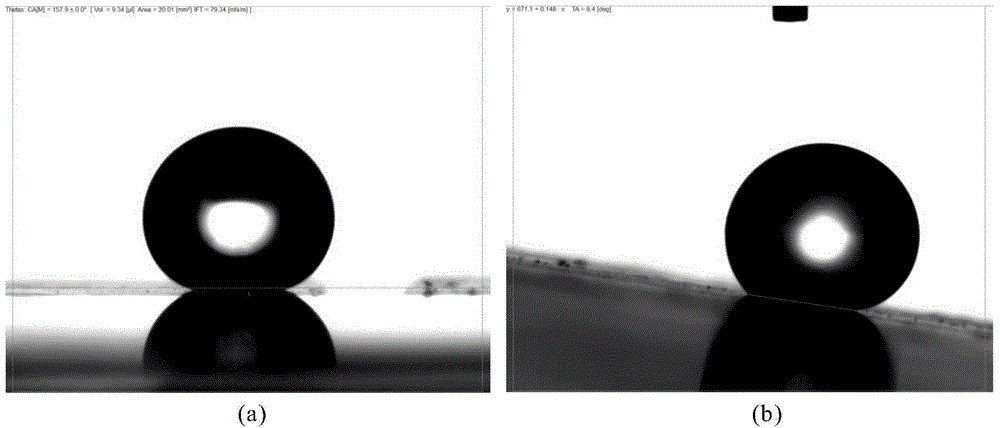

Hypertransparent Nanostructured Superhydrophobic and Surface Modification Coatings

InactiveUS20100203287A1Liquid surface applicatorsLayered productsSuperhydrophobic coatingChemical vapor deposition

Hydrophobic and self-cleaning surfaces have wide applications, including glasses, camera covers, windows, solar panels and high-end finished surfaces. Many existing hydrophobic coatings either have low transmittance, making them unsuitable for high light transmission applications, or are insufficiently hydrophobic. The present invention concerns high-quality hypertransparent superhydrophobic coatings, for example SiO2-based, with double-roughness microstructure that were deposited on to, for example, glass substrates using, for example, the combustion chemical vapor deposition (CCVD) technique. Embodiments of the invention include coatings with a contact angle of higher than 165°, a rolling angle of <5°, a haze of <0.5%, and an increased transmittance by 2% higher and a reflectance of 2% lower than bare glass. The double roughness can improve wear resistance. Additionally, other surface chemistries can be applied to yield hydrophilic, oliophobic, or oliophobic surfaces.

Owner:NGIMAT CO

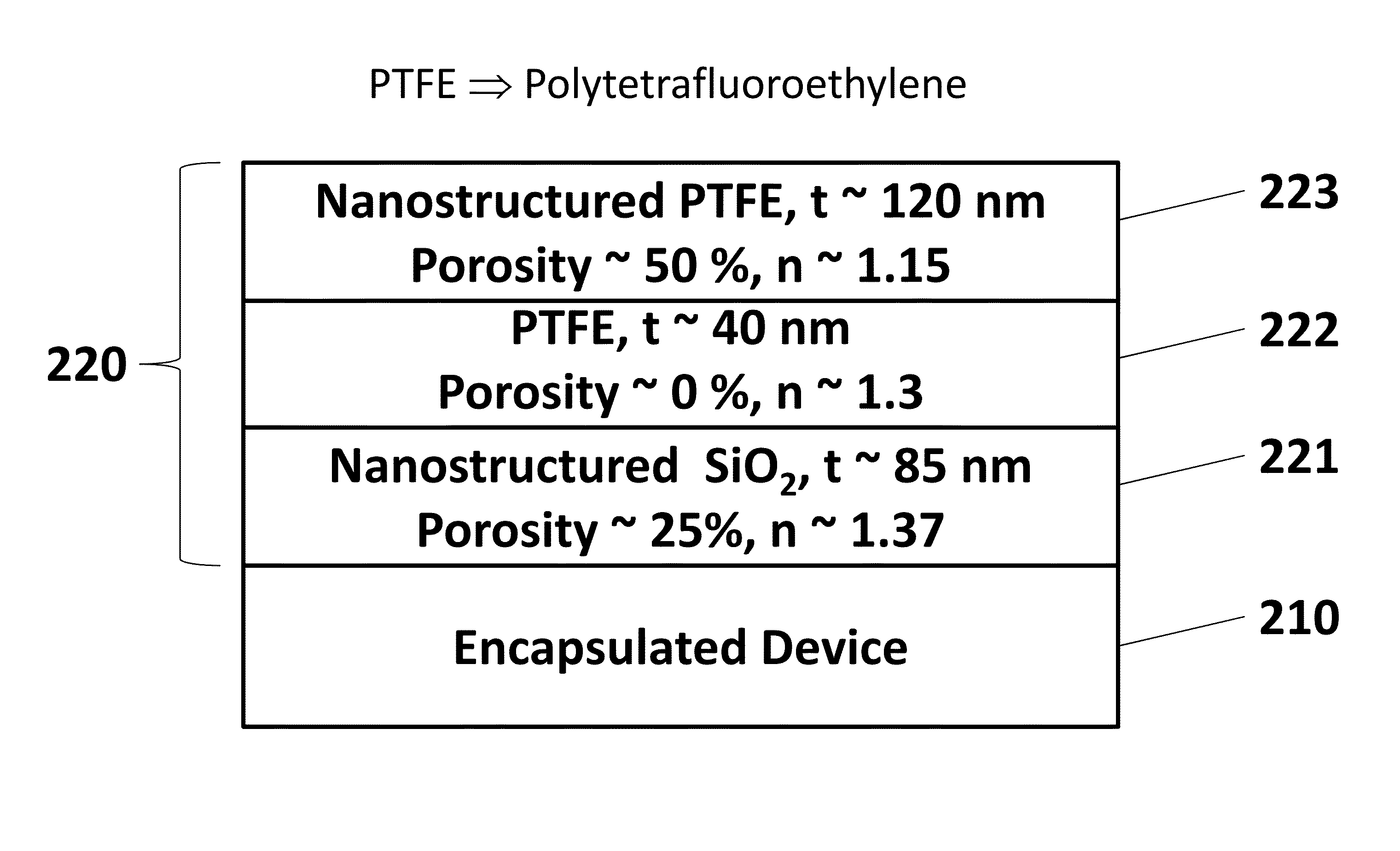

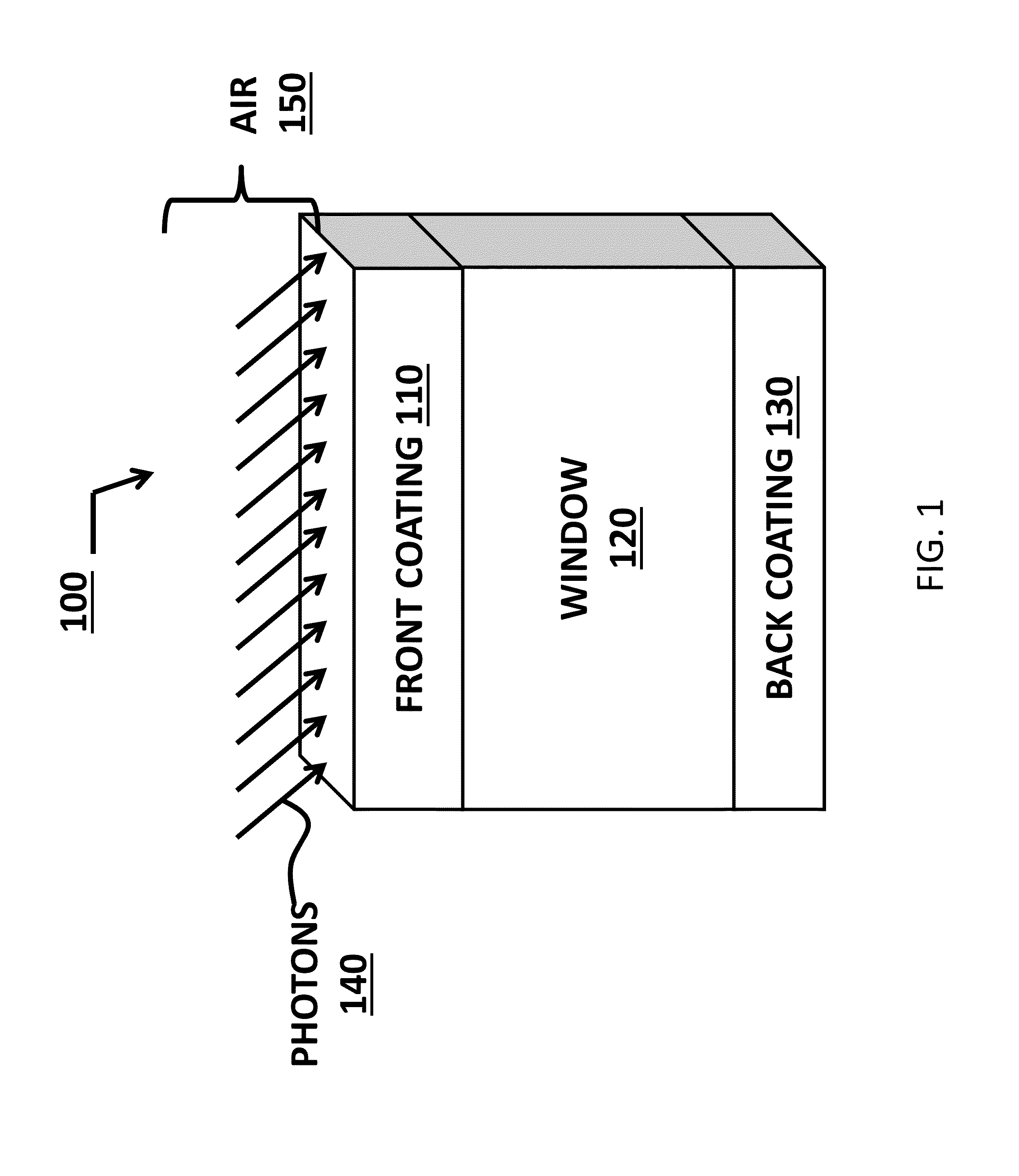

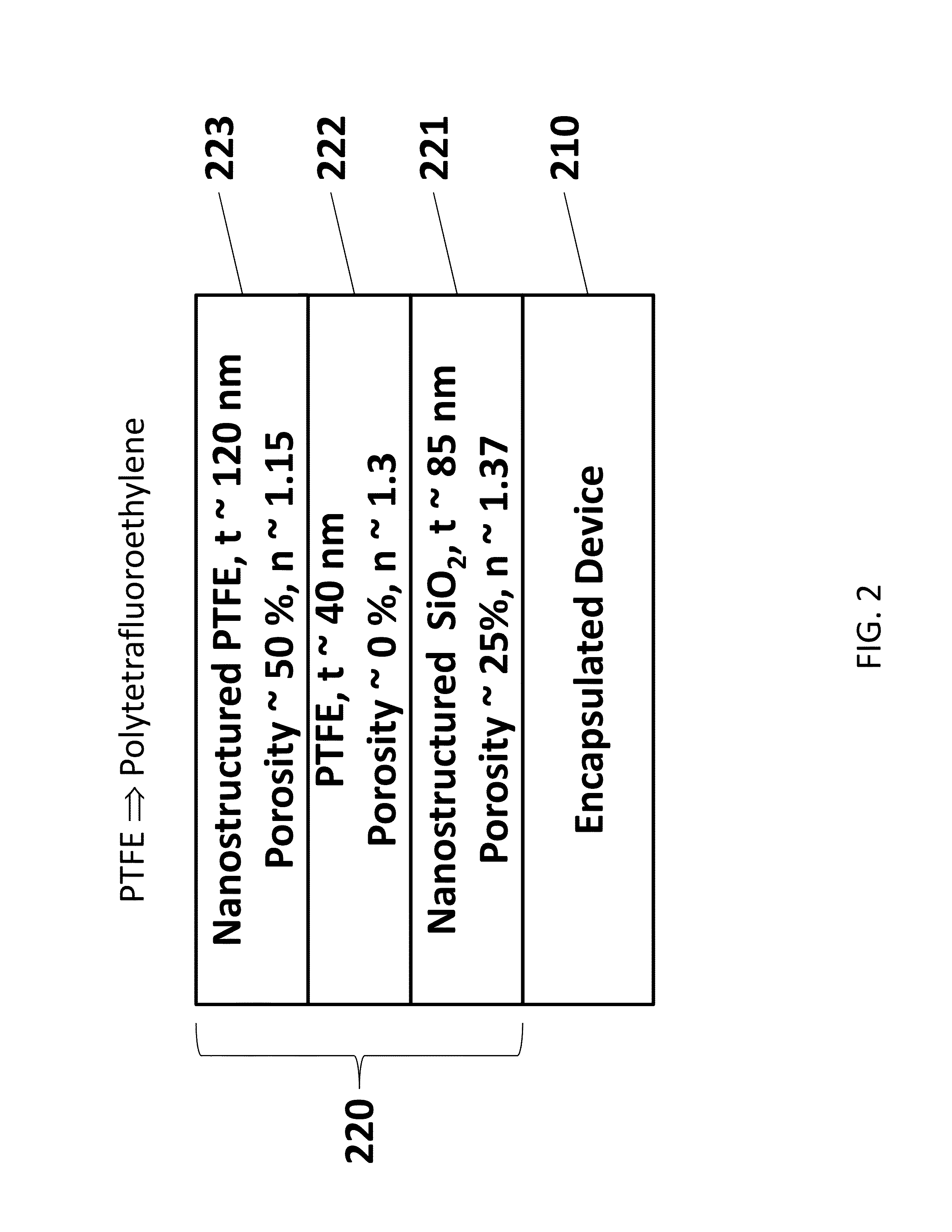

Highly durable hydrophobic antireflection structures and method of manufacturing the same

ActiveUS9400343B1Minimize reflection lossGood broadbandCoatingsPhotovoltaic energy generationReflection lossRefractive index

Durable hydrophobic antireflection structures for optical elements, optical windows, and front sheets of encapsulated photovoltaic and photonic devices are disclosed which can minimize reflection losses over the entire accessible portion of the solar spectrum simultaneously provide self-cleaning and finger-print-free surface. Reduced reflectance and self-cleaning surfaces are resulted from coating the front sheet of encapsulated device with combination of nonporous and porous nanostructured materials such as silicon dioxide nanorods and PTFE. Step-graded antireflection structures can exhibit excellent omnidirectional performance, significantly outperforming conventional quarter wavelength and low-high-low refractive index coatings. Methods of constructing nanostructured durable optical coatings with hydrophobic surfaces are disclosed that can cover large-area ridged and flexible substrates.

Owner:MAGNOLIA OPTICAL TECH

Method for preparing aluminum alloy superhydrophobic self-cleaning surface by using ultrashort pulse laser

InactiveCN104947116AExcellent superhydrophobic propertiesSimple processMetallic substrateSurface modification

The invention relates to a method for preparing an aluminum alloy superhydrophobic self-cleaning surface by using an ultrashort pulse laser, belonging to the technical field of metal substrate surface modification. The method comprises the following steps: carrying out polishing pretreatment on an aluminum alloy sample, cleaning the sample surface respectively with deionized water and anhydrous ethanol, blow-drying with cool air or drying in air, and carrying out surface treatment on the sample by using a laser processing technique after adjusting related technological parameters by an ultrashort pulse laser so as to obtain countless microstructures on the sample surface; and after finishing processing, putting the processed sample into an electrothermal drying box, and baking to obtain the aluminum alloy superhydrophobic surface with a micron-sized mastoid or porous structure on the surface, wherein the surface has the self-cleaning function and has excellent friction resistance and corrosion resistance. The preparation method has the advantages of simple technique, high efficiency, low energy consumption, low cost and environment friendliness, is convenient to operate, and can easily implement industrial application.

Owner:HUBEI UNIV OF TECH

Method for preparation of aluminium alloy superhydrophobic self-cleaning surface by use of ultrafast laser

The present invention relates to a method for preparation of aluminium alloy superhydrophobic self-cleaning surface by use of ultrafast laser, and belongs to the metal substrate surface modification technical field. The method is as follows: first, an aluminium alloy sample is polished for pretreatment, the sample surface is cleaned with deionized water and absolute ethyl alcohol, after the sample surface is cleaned, the sample is blow-dried by cold air or dried in air, and then by use of laser processing technique, after regulation of relevant process parameters by use of the ultrafast laser, the sample surface is processed, the sample surface is processed to form countless micro structures, after the processing is completed, the processed sample is put into an electrically heated drying oven for baking to obtain aluminium alloy super hydrophobic surface provided with micron-scale or nanoscale mastoid-shaped structures. The surface has the function of self-cleaning and excellent friction resistance, and corrosion resistance. The preparation method is simple in process, convenient in operation, high in efficiency, less in energy consumption, low in cost, green, and environmentally friendly, and the industrial application is easy to realize.

Owner:金顿激光科技(佛山)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com