Patents

Literature

211 results about "Partial melting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Partial melting occurs when only a portion of a solid is melted. For mixed substances, such as a rock containing several different minerals or a mineral that displays solid solution, this melt can be different from the bulk composition of the solid.

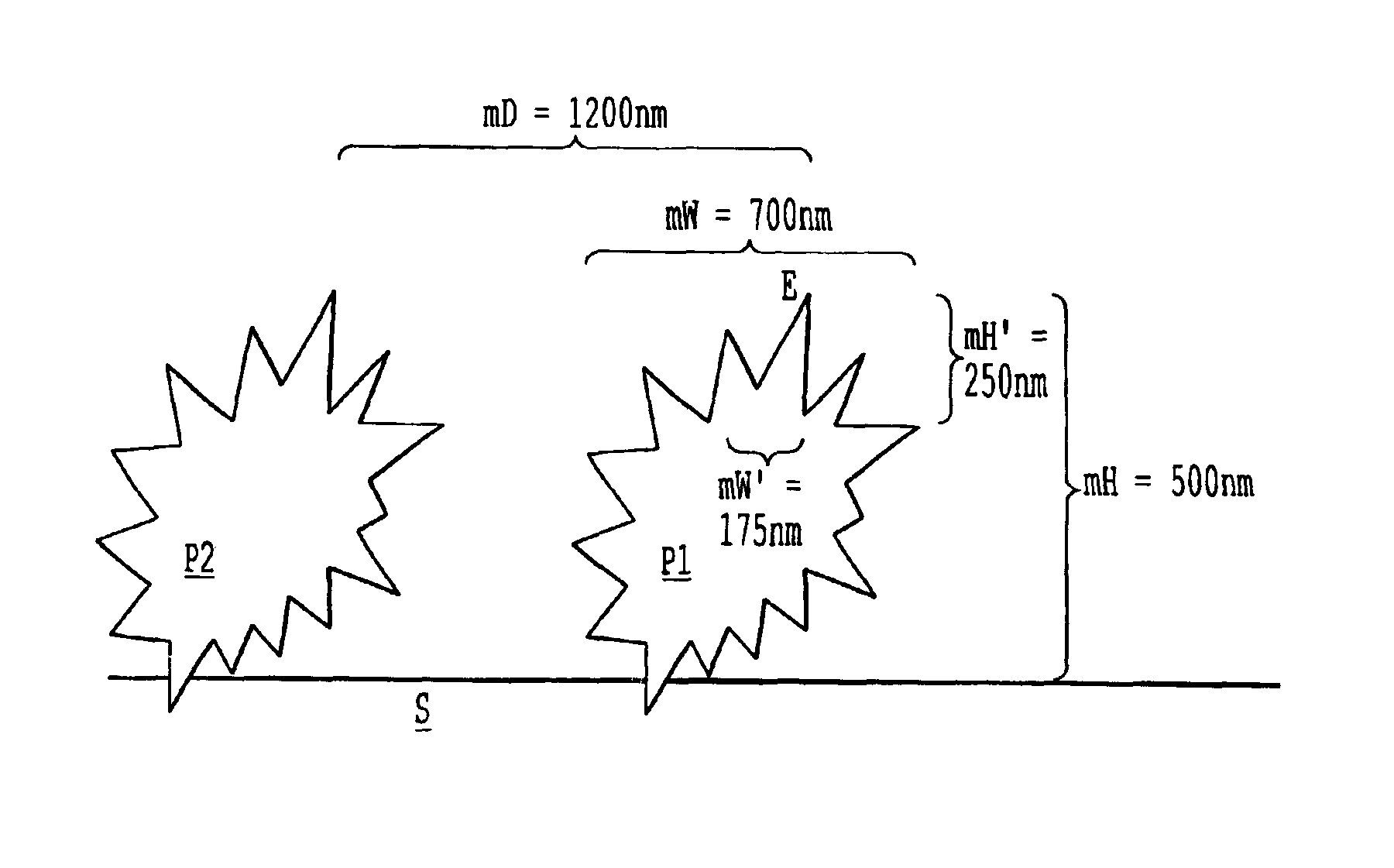

Surfaces rendered self-cleaning by hydrophobic structures, and process for their production

InactiveUS6852389B2Effectively self-cleaningSimple processNanotechSpecial ornamental structuresFissured structureFumed silica

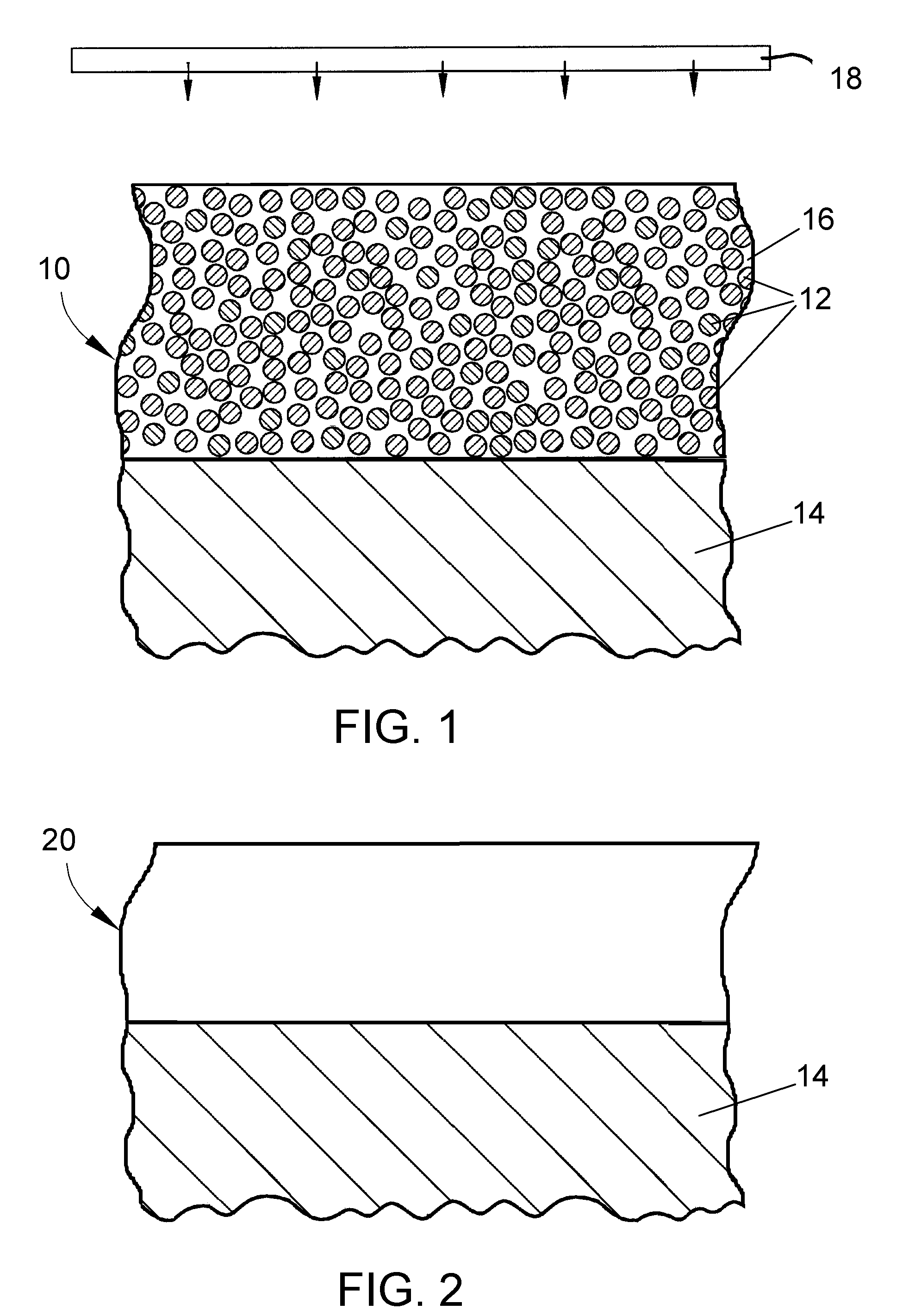

A self-cleaning surface which has an artificial, at least partially hydrophobic, surface structure containing elevations and depressions, which comprises a surface having structure-forming particles, which are formed of hydrophobic, fumed silica, adhered thereto by way of fixative particles applied to the surface, whereby the structure-forming particles and the fixative particles have elevations and depressions ranging in dimensions of 1 to 1000 nm and the particles themselves having an average size of less than 50 μm, the particles providing said surface structure of elevations and depressions, wherein, by incipient melting of the fixative particles, only partial melting of the fixative particles occurs which is sufficient to bond the structure forming particles without substantial wetting of the particles by the fixative particles to said surface while retaining, the fissured structure of the structure-forming particles in the nanometer range.

Owner:DEGUSSA AG

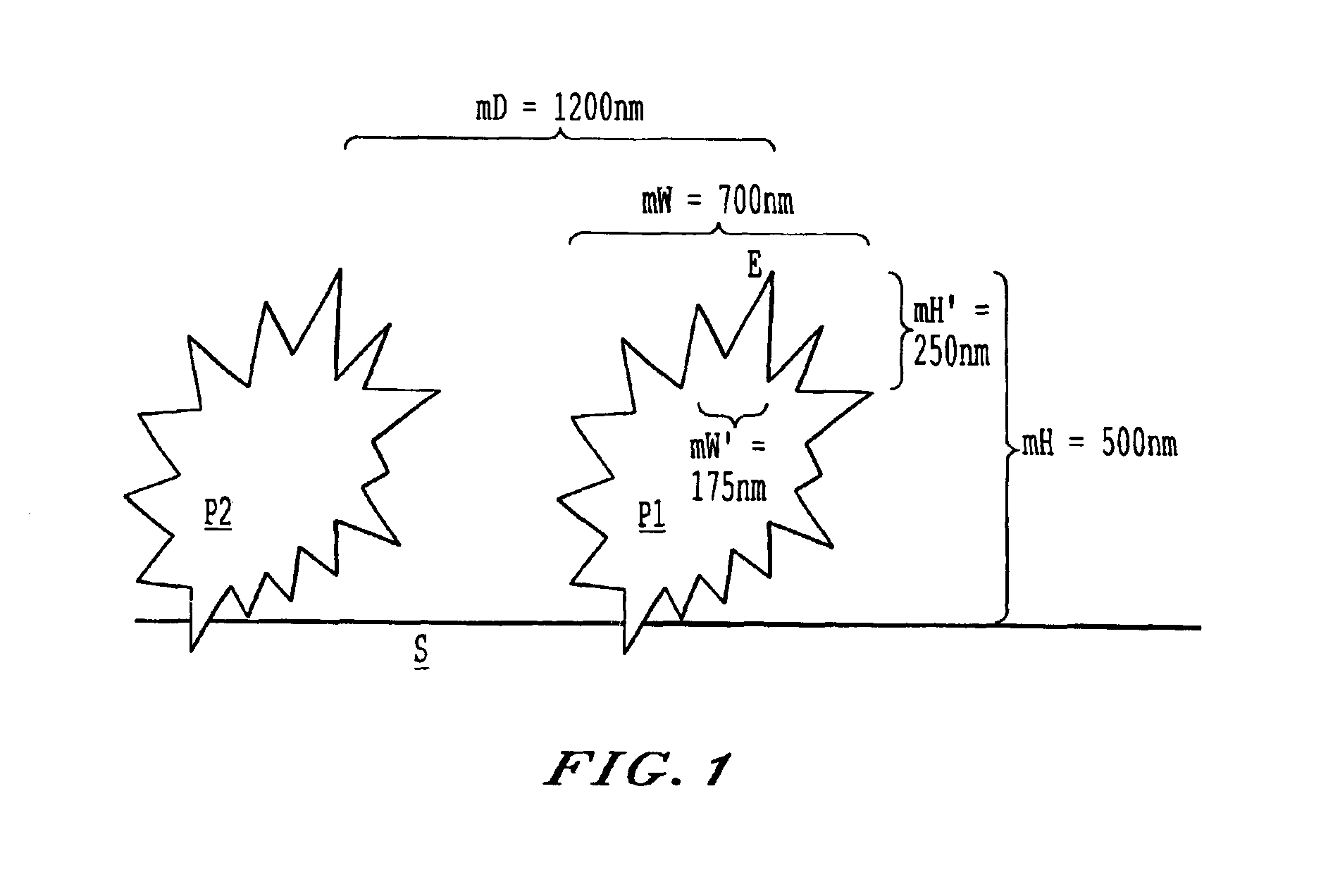

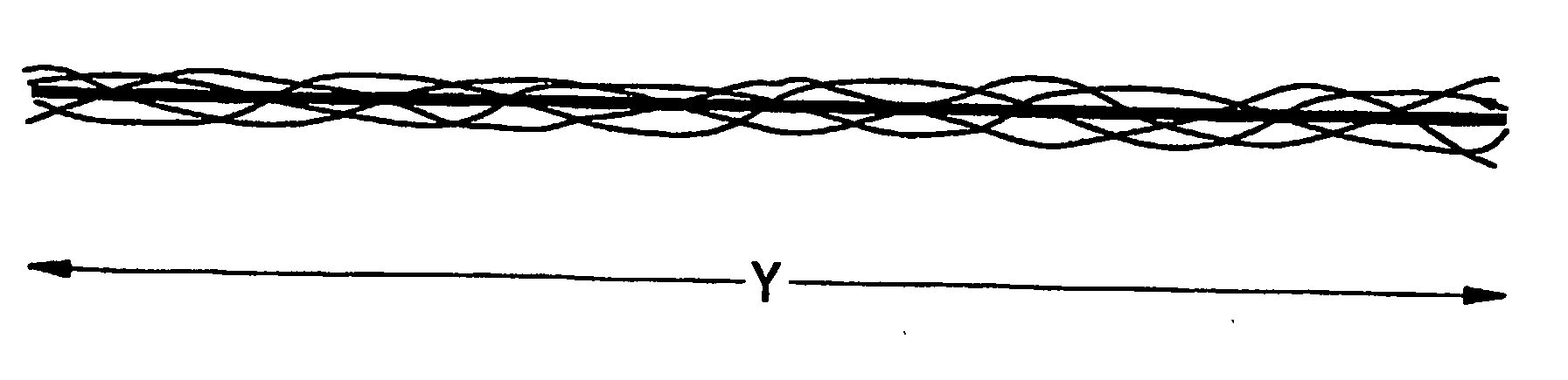

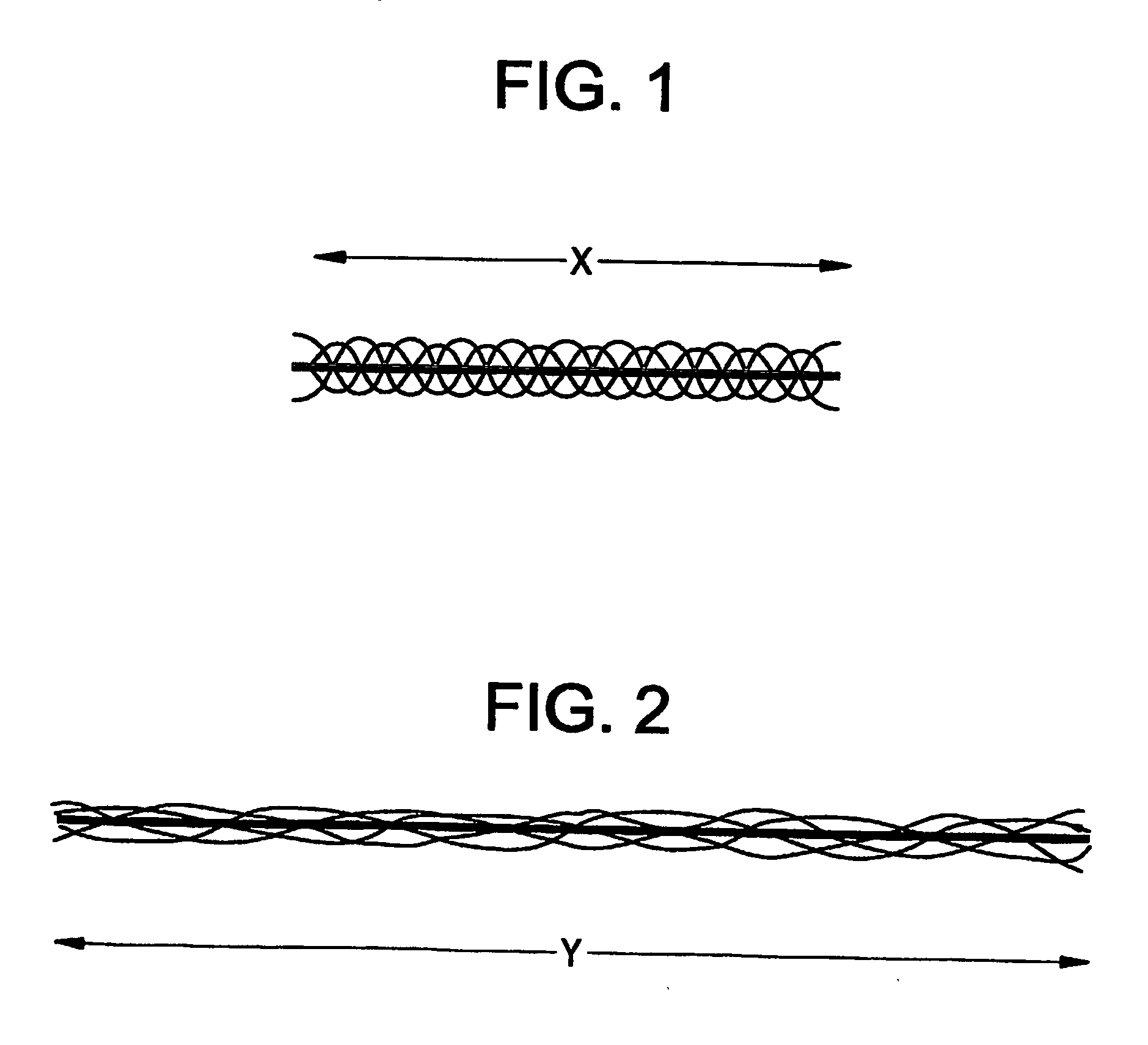

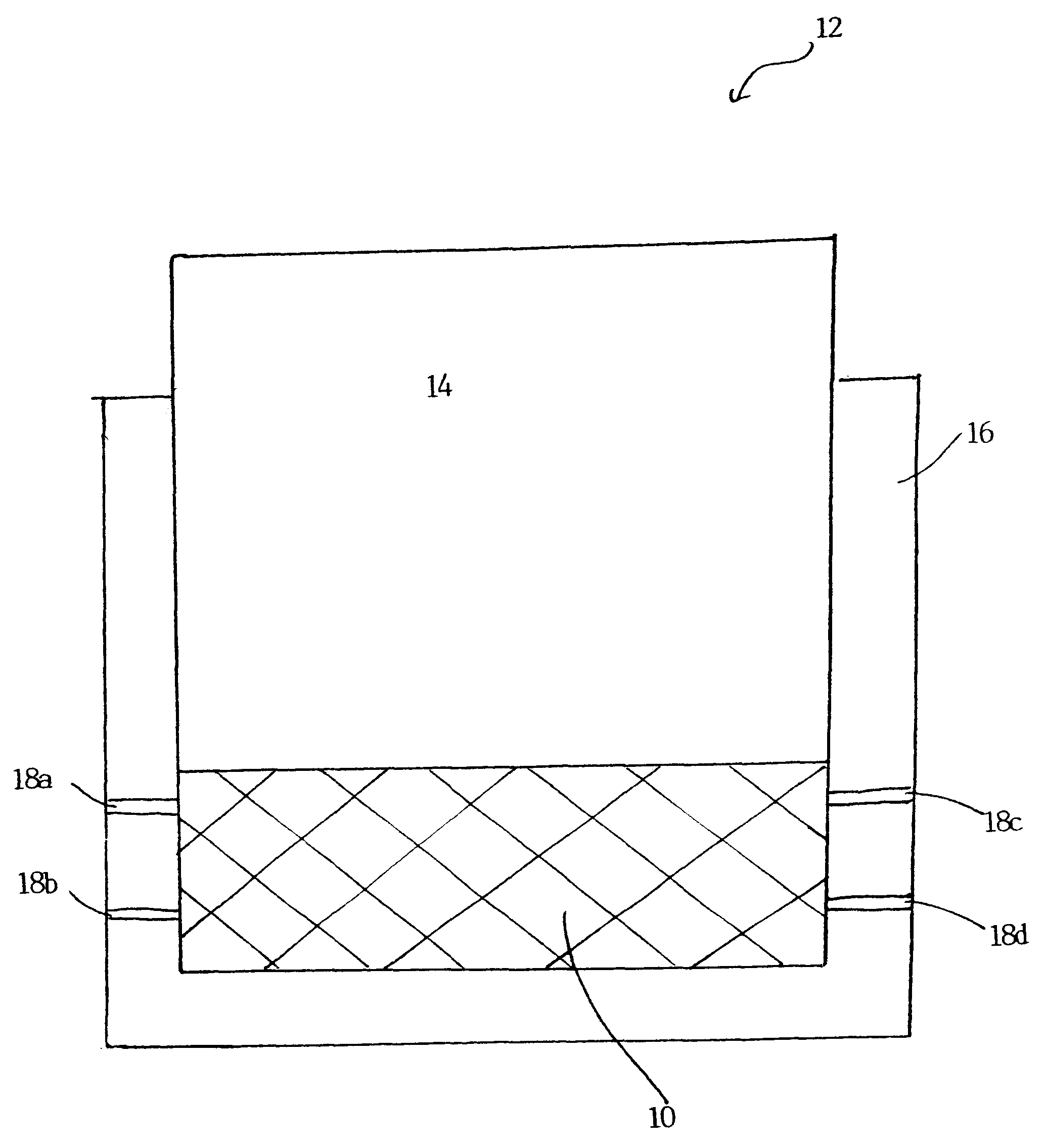

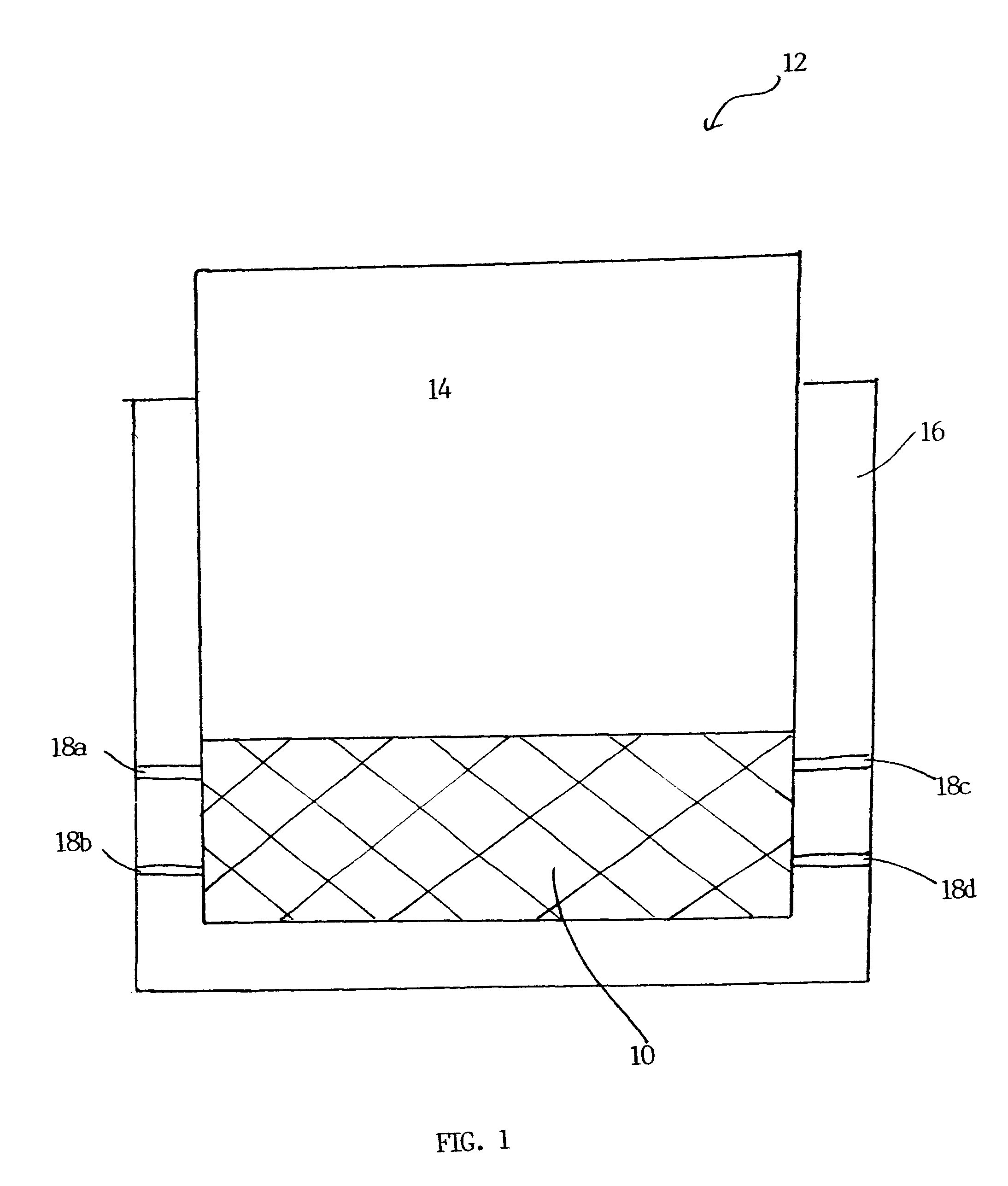

Manufacture of polyolefin fishing line

InactiveUS6148597AReduce resistanceReduce wearAgriculture tools and machinesFilament/thread formingYarnPolyolefin

Yarns and fishing lines are made by a process that includes the step of exposing an opaque yarn made from ultrahigh molecular weight, gel spun polyolefin filaments to a temperature within the melting point range of the filaments for a time sufficient to at least partially fuse the contact surfaces of adjacent filaments. For ultrahigh molecular weight, gel spun polyethylene, this temperature is preferably within the range from about 150 DEG -157 DEG C. The surface fusion between and among filaments imparts desirable handling characteristics to the ultrahigh molecular weight, gel spun polyolefin yarns and fishing lines that are similar to those of a conventional monofilaments. Preferably, the temperature, residence time, and stretching ratio at the selected temperature are chosen to provide a fishing line exhibiting a tensile modulus within the range from about 230 g / d to about 780 g / d with a tenacity of at least 15 g / d.

Owner:PURE FISHING

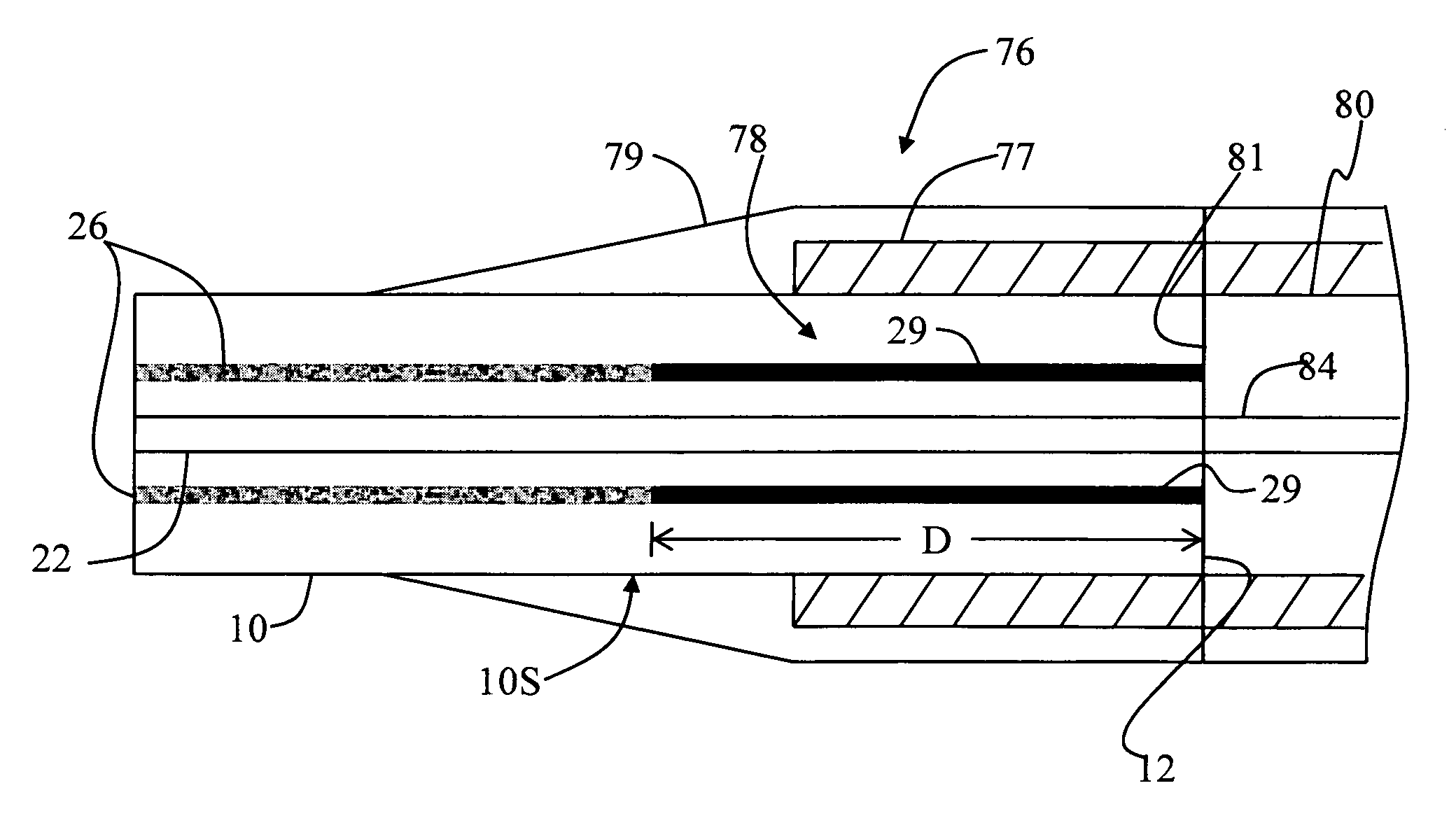

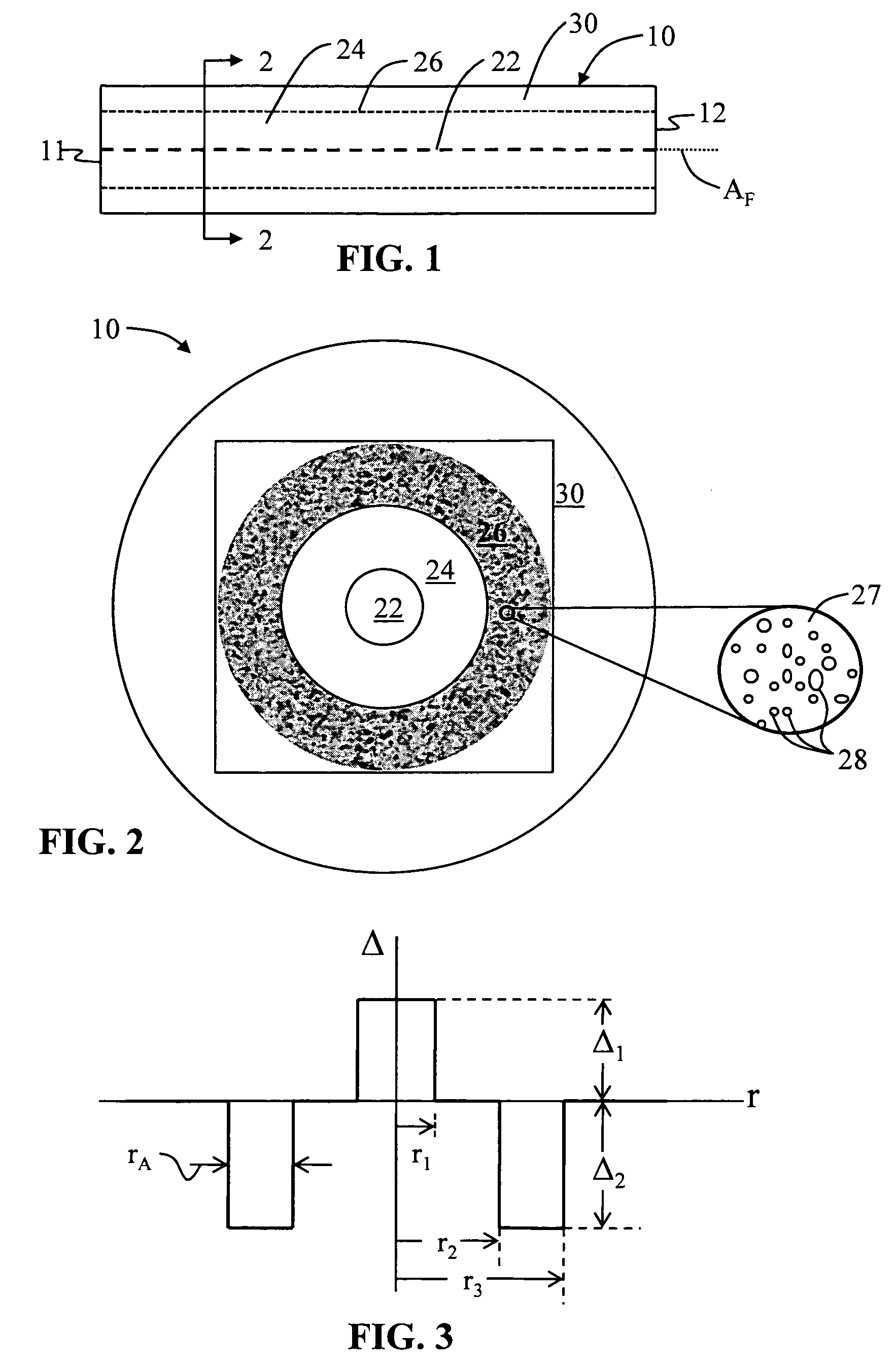

Airline optical fiber with reduced multipath interference and methods of forming same

InactiveUS7542645B1Reduce multipath interferenceReducing MPICladded optical fibreOptical waveguide light guideFiberMultipath interference

An airline (AL) optical fiber (“AL fiber”) that has an AL region with airlines, with the AL region arranged relative to the fiber core so as to make the fiber bend insensitive. The AL region is capable of supporting one or more higher-order optical modes. One method of reducing multipath interference (MPI) includes accessing a section of the AL fiber and closing at least one of the airlines in the section. This serves to attenuate one or more higher-order modes, which reduces MPI. In one example, the AL fiber has an end section wherein the airlines are filled with a blocking material. An example blocking material is a curable adhesive that is wicked into the airlines via capillary action and then cured when the adhesive reaches a certain depth from the fiber end. In another example, the blocking material is formed by heating the AL fiber section to cause the section to melt and block the airlines, so that the melted AL fiber serves as the blocking material. The AL fiber with reduced MPI is particularly useful as a “jump” fiber, whose length is too short to rely on attenuating higher-order modes via a cable cut-off wavelength.

Owner:CORNING OPTICAL COMM LLC

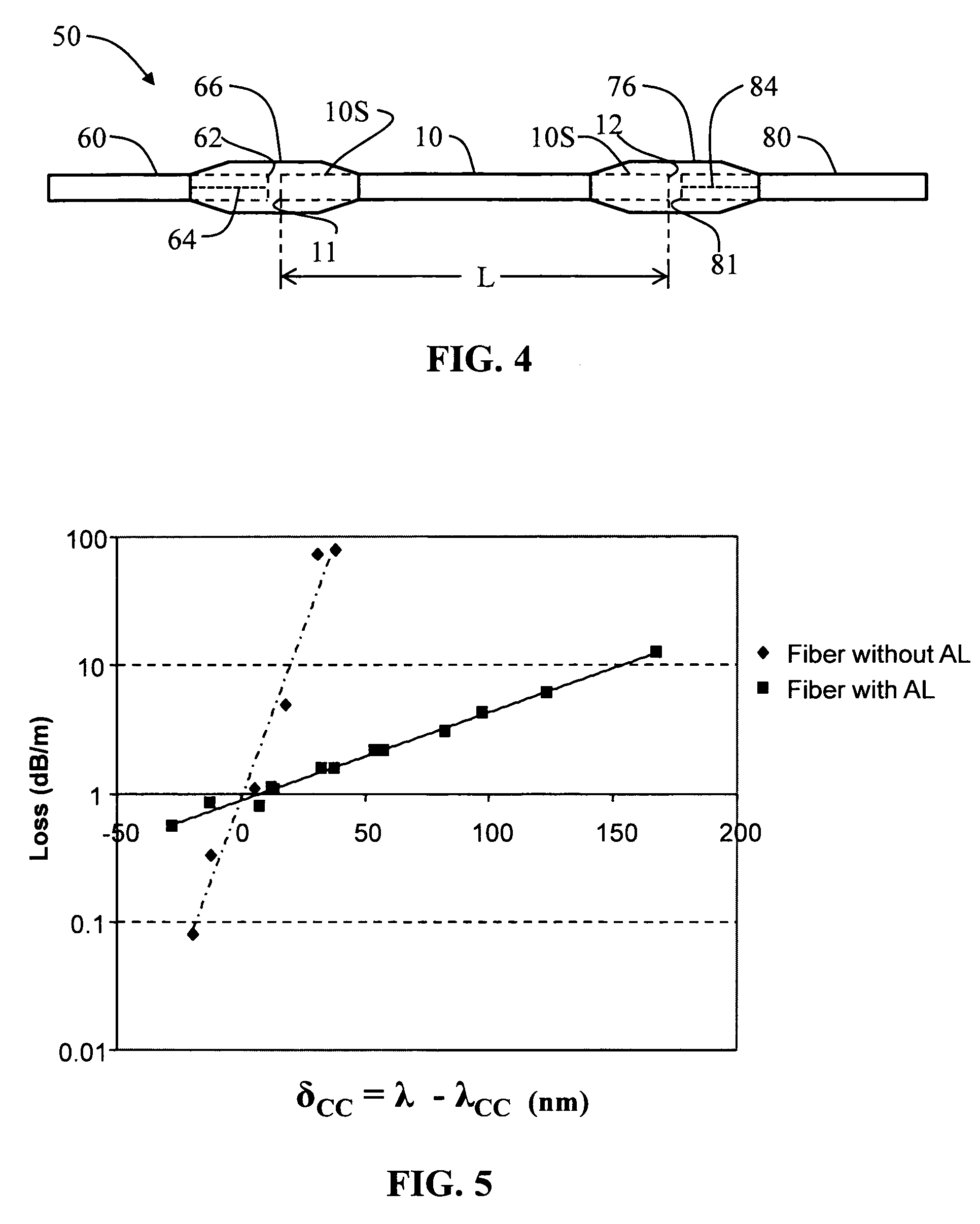

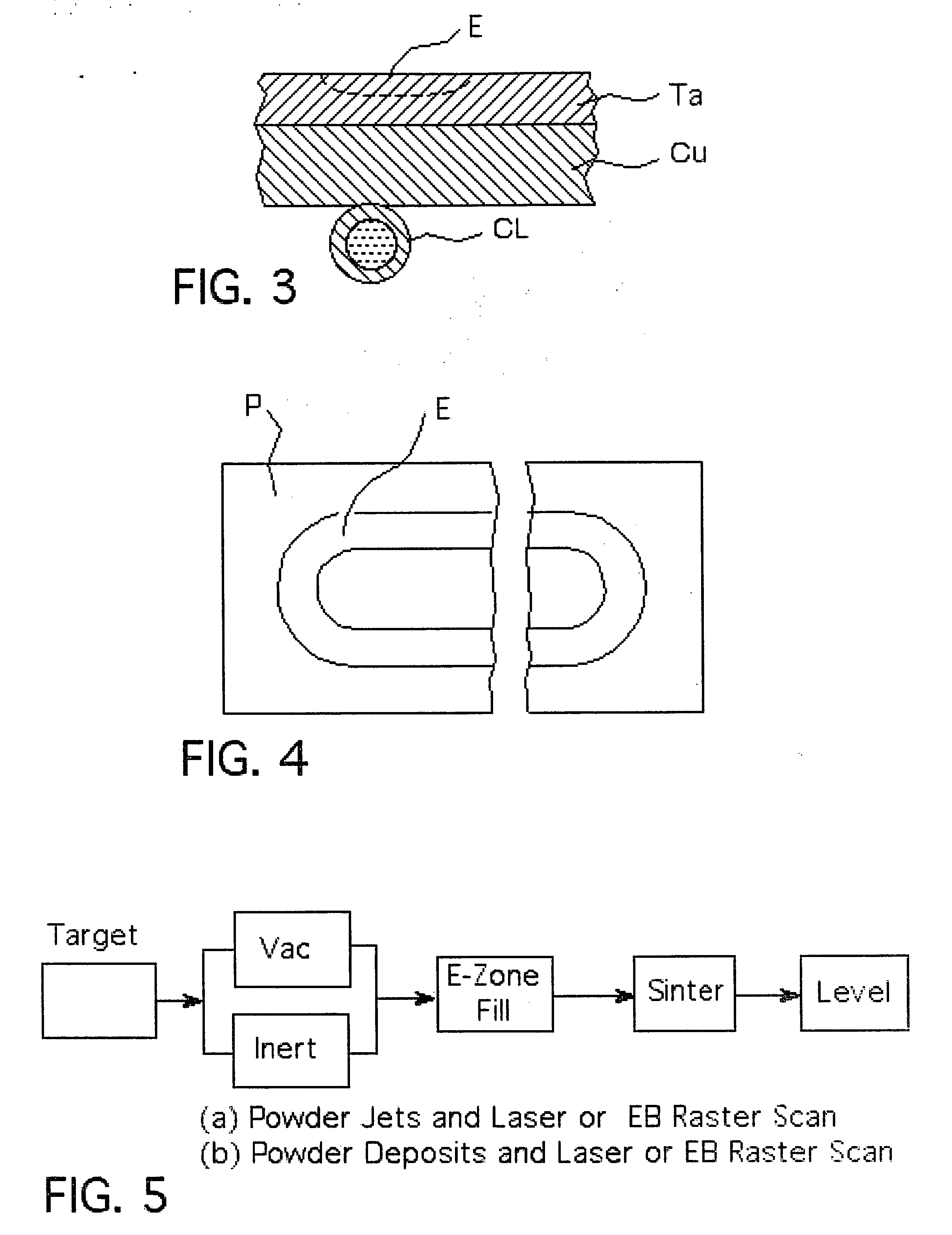

Refractory metal and alloy refining by laser forming and melting

ActiveUS20050142021A1Shorten cycle timeRadiation applicationsVacuum evaporation coatingNiobiumLinearity

Owner:MATERION NEWTON INC

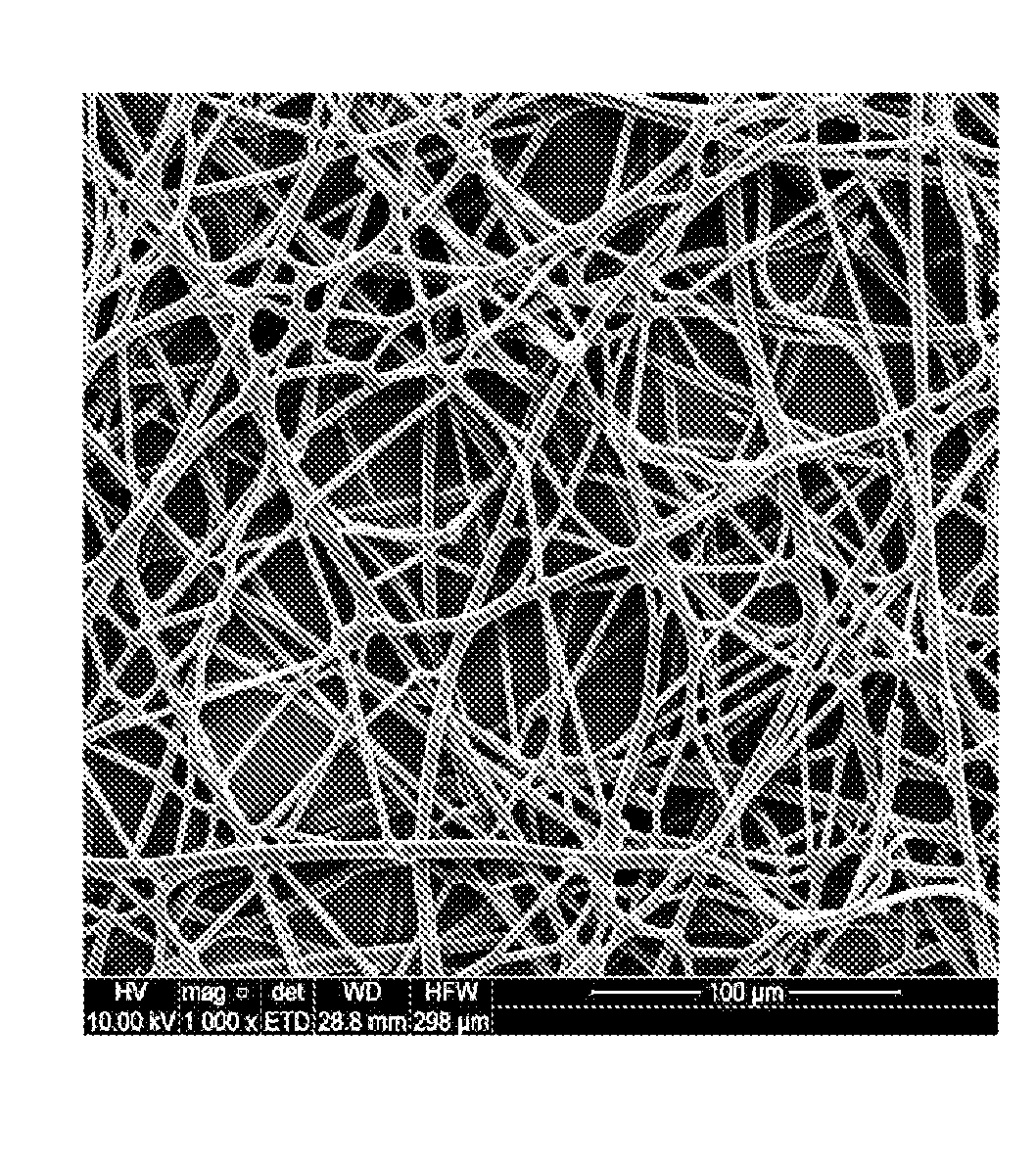

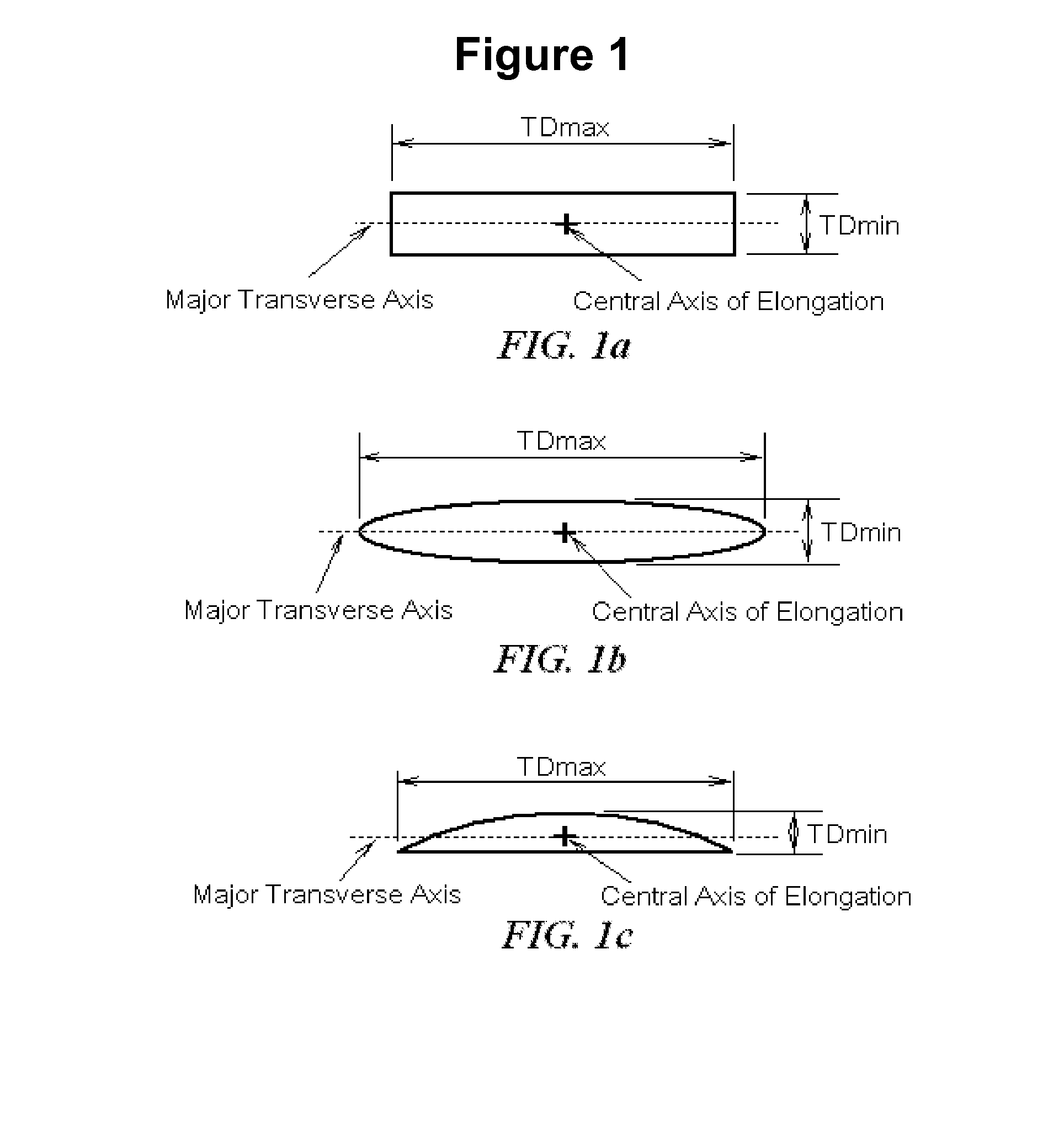

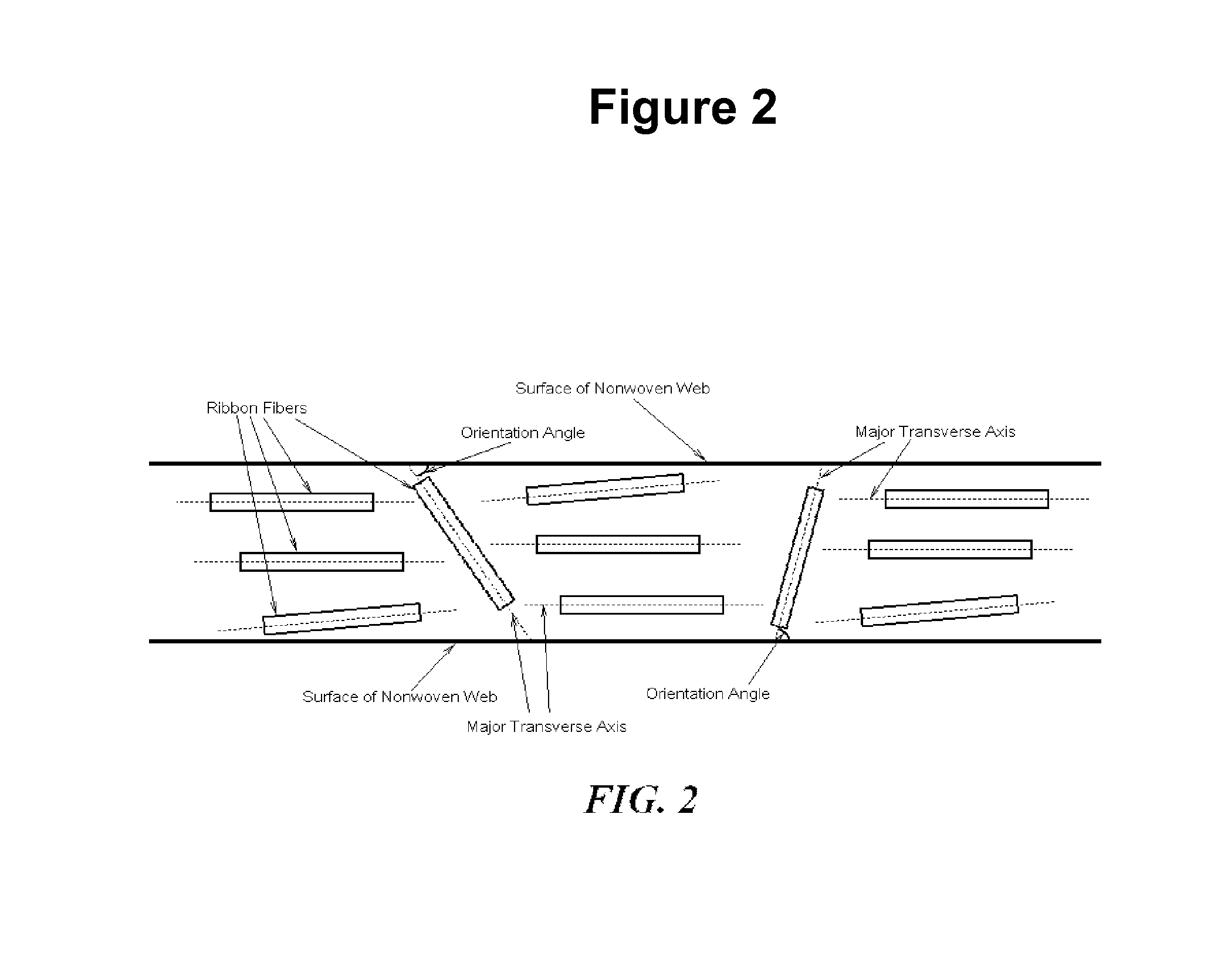

Paper and nonwoven articles comprising synthetic microfiber binders

InactiveUS20140311695A1Inorganic fibres/flakesNon-fibrous pulp additionPolymer scienceMelting temperature

A process of making a paper or nonwoven article is provide. The process comprising:a) providing a fiber furnish comprising a plurality of fibers and a plurality of binder microfibers, wherein the binder microfibers comprise a water non-dispersible, synthetic polymer; wherein the binder microfibers have a length of less than 25 millimeters and a fineness of less than 0.5 d / f; and wherein the binder microfibers have a melting temperature that is less than the melting temperature of the fibers;b) routing the fiber furnish to a wet-laid nonwoven process to produce at least one wet-laid nonwoven web layer;c) removing water from the wet-laid nonwoven web layer; andd) thermally bonding the wet-laid nonwoven web layer after step (c); wherein the thermal bonding is conducted at a temperature such that the surfaces of the binder microfibers at least partially melt without causing the fibers to melt thereby bonding the binder microfibers to the fibers to produce the paper or nonwoven article.

Owner:EASTMAN CHEM CO

Articulating build platform for laser additive manufacturing

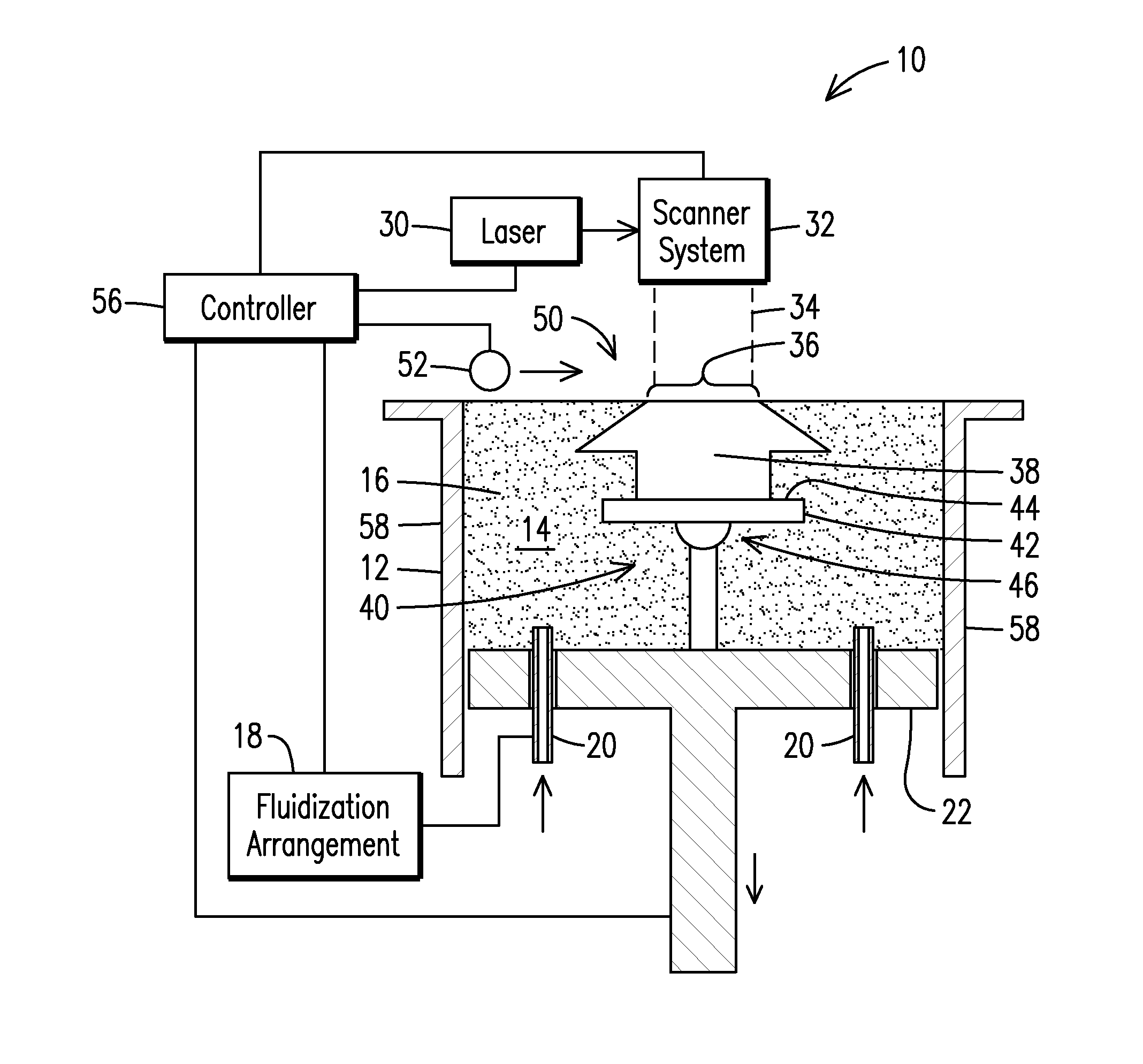

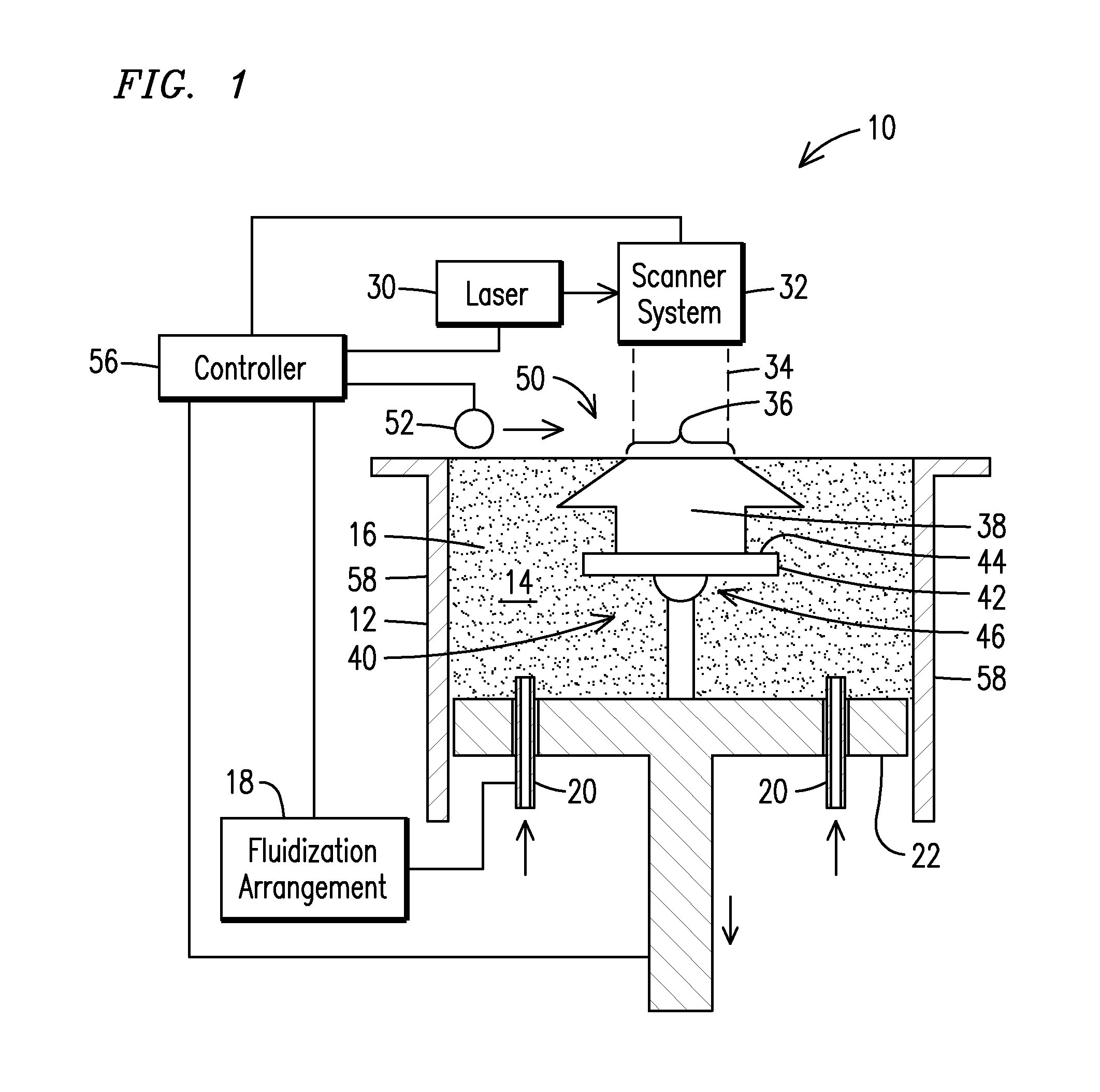

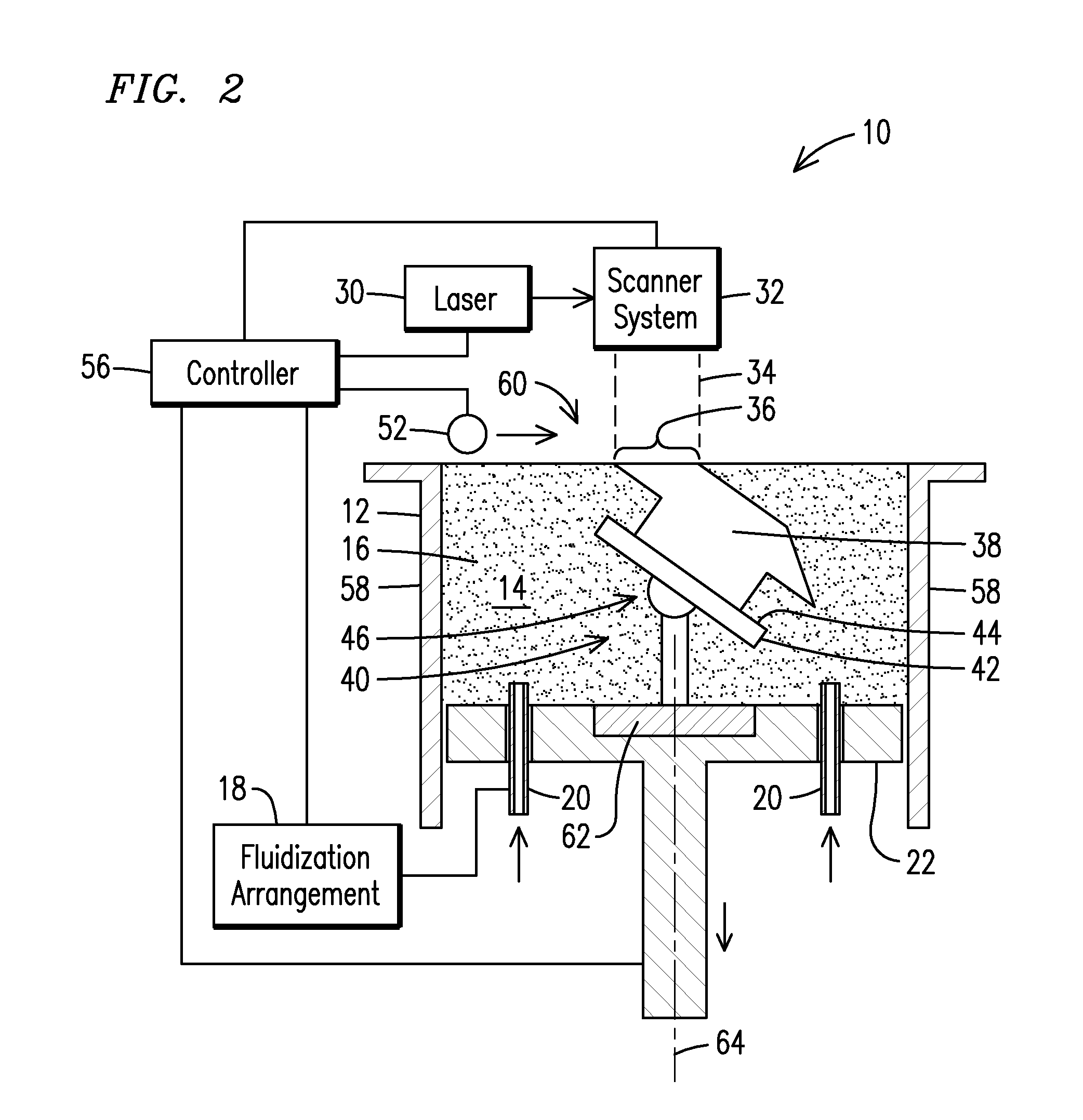

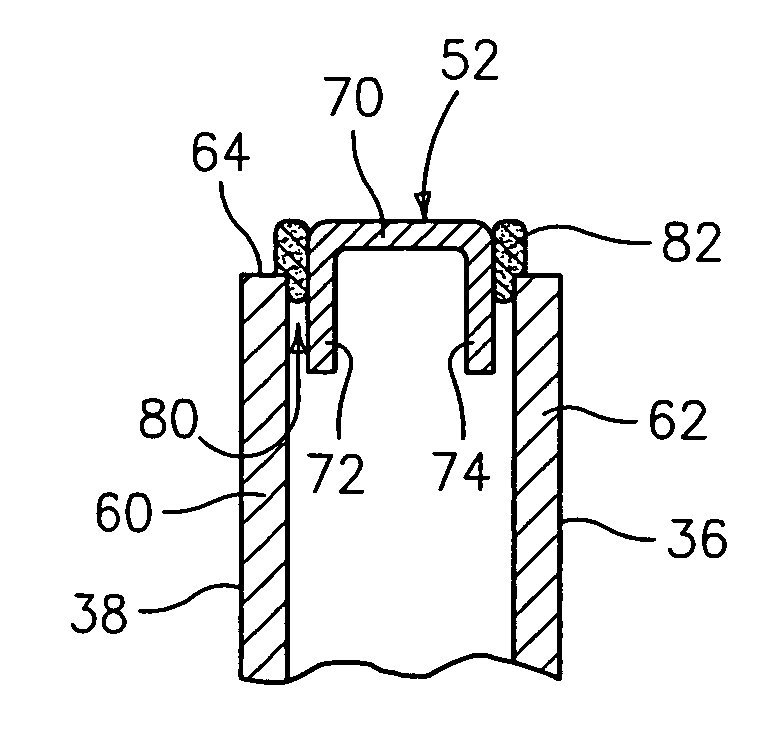

ActiveUS20160067923A1Additive manufacturing apparatusAuxillary shaping apparatusMarine engineeringMetallic materials

An additive manufacturing apparatus (10) including: a container (12) configured to bound a bed of powdered metal material; a fluidization arrangement (18) configured to fluidize the bed of powered material; an articulation mechanism (40) disposed within the container and configured to support and to rotate a component (38) about at least one horizontal axis; and an energy beam (34) configured to selectively scan portions (36) of a surface of the bed of powdered metal material to melt or sinter the selectively scanned portions onto the component.

Owner:SIEMENS ENERGY INC

Superalloy repair methods

InactiveUS20070044306A1Improve the immunityArc welding apparatusWelding/cutting media/materialsInterior spaceSuperalloy

A method for forming or remanufacturing a component to have an internal space. A refractory metal blocking element is formed, in situ, with at least a portion to be within the internal space. The formation includes an at least partial melting. A material is added, the blocking element at least partially blocking entry of the material to the internal space. The blocking element is removed.

Owner:UNITED TECH CORP

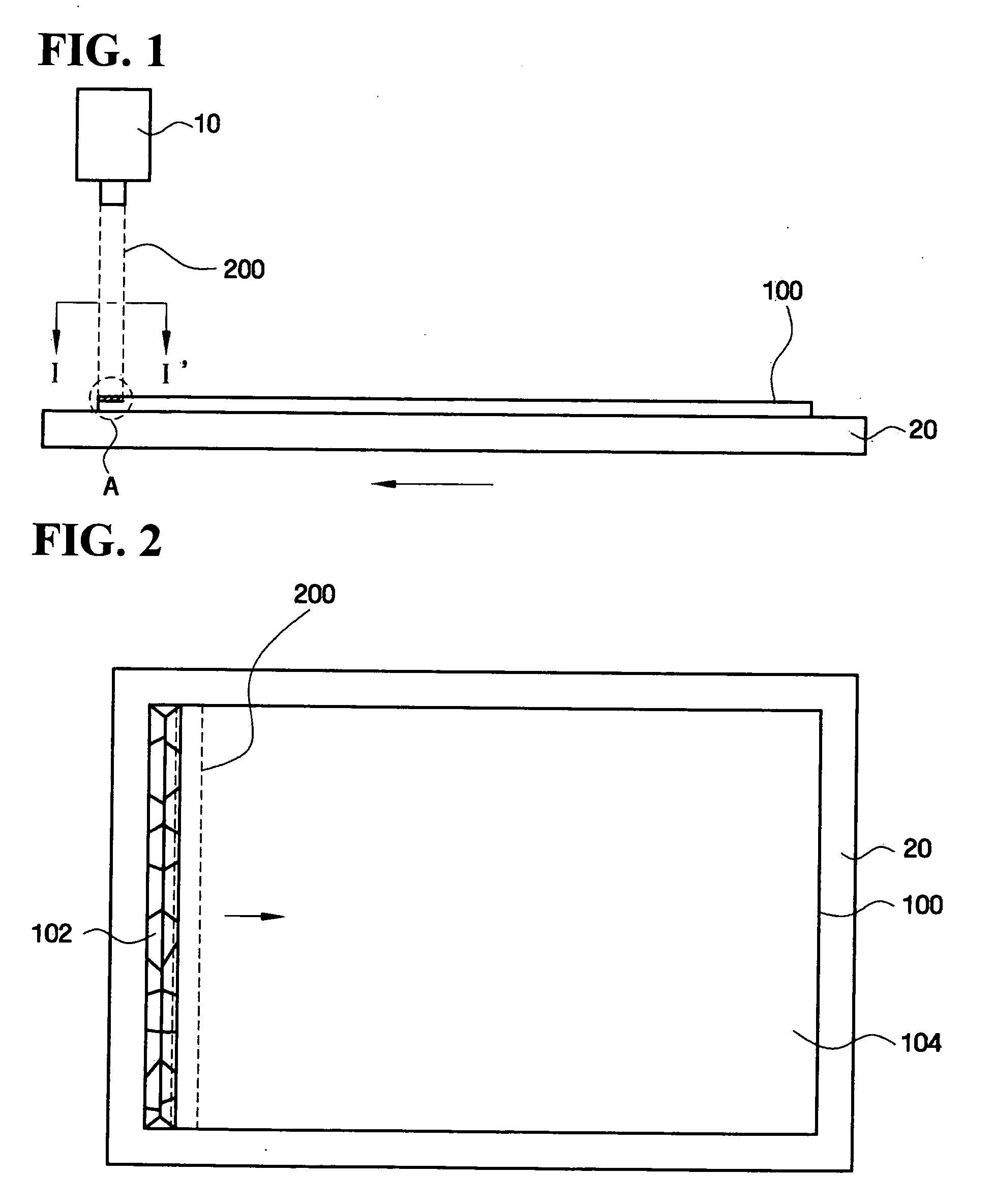

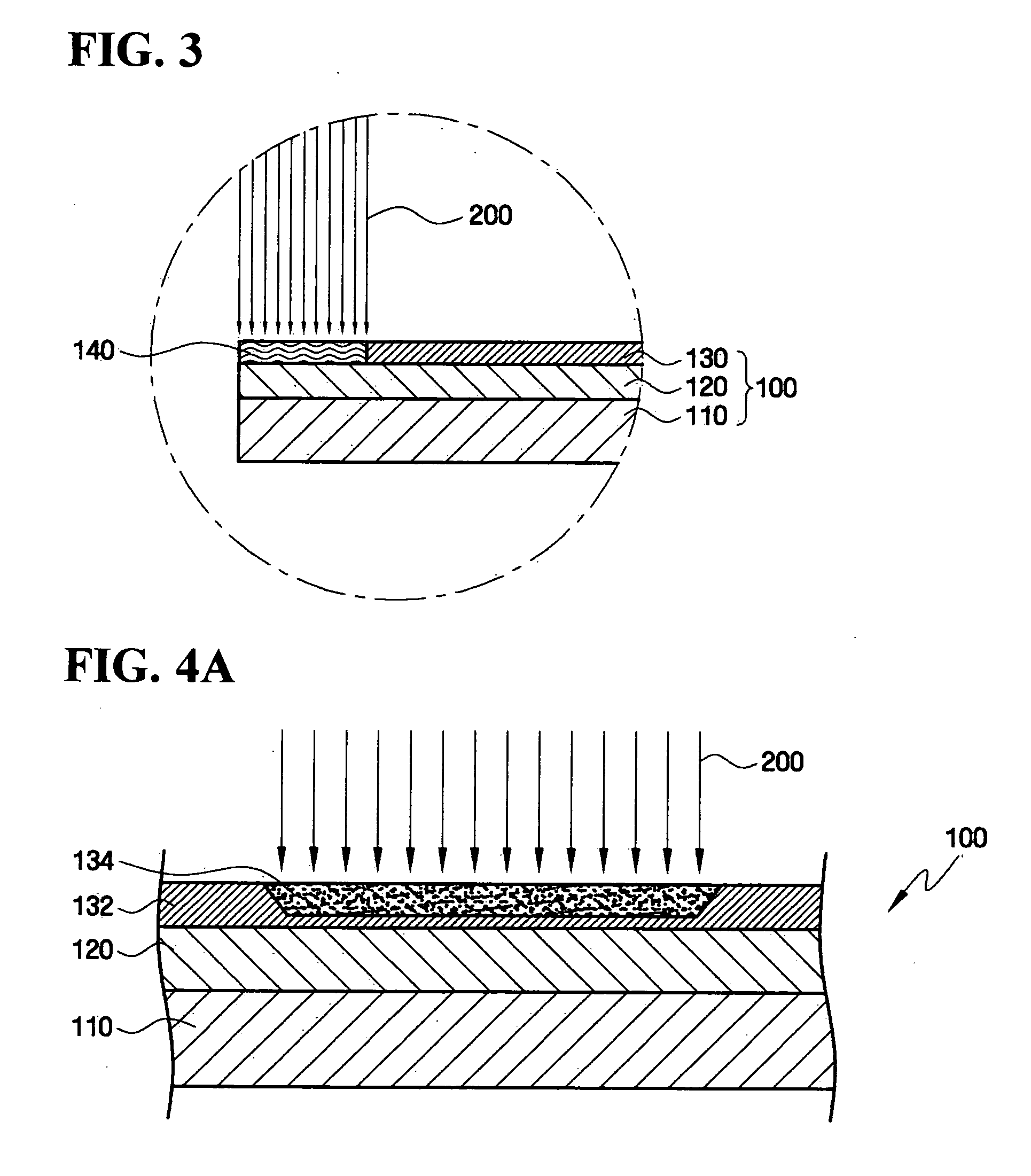

Method of forming polycrystalline silicon thin film and method of manufacturing thin film transistor using the method

ActiveUS20070054477A1Excellent electrical propertiesSolid-state devicesSemiconductor/solid-state device manufacturingHigh energyLaser beams

Provided are a method of forming a polycrystalline silicon thin film with improved electrical characteristics and a method of manufacturing a thin film transistor using the method of forming the polycrystalline silicon thin film. The method includes forming an amorphous silicon thin film on a substrate, partially melting a portion of the amorphous silicon thin film by irradiating the portion of the amorphous silicon thin film with a laser beam having a low energy density, forming polycrystalline silicon grains with a predetermined crystalline arrangement by crystallizing the partially molten portion of the amorphous silicon thin film, completely melting a portion of the polycrystalline silicon grains and a portion of the amorphous silicon thin film by irradiation of a laser beam having a high energy density while repeatedly moving the substrate by a predetermined distance, and growing the polycrystalline silicon grains by crystallizing the completely molten silicon homogeneously with the predetermined crystalline arrangement.

Owner:SAMSUNG DISPLAY CO LTD

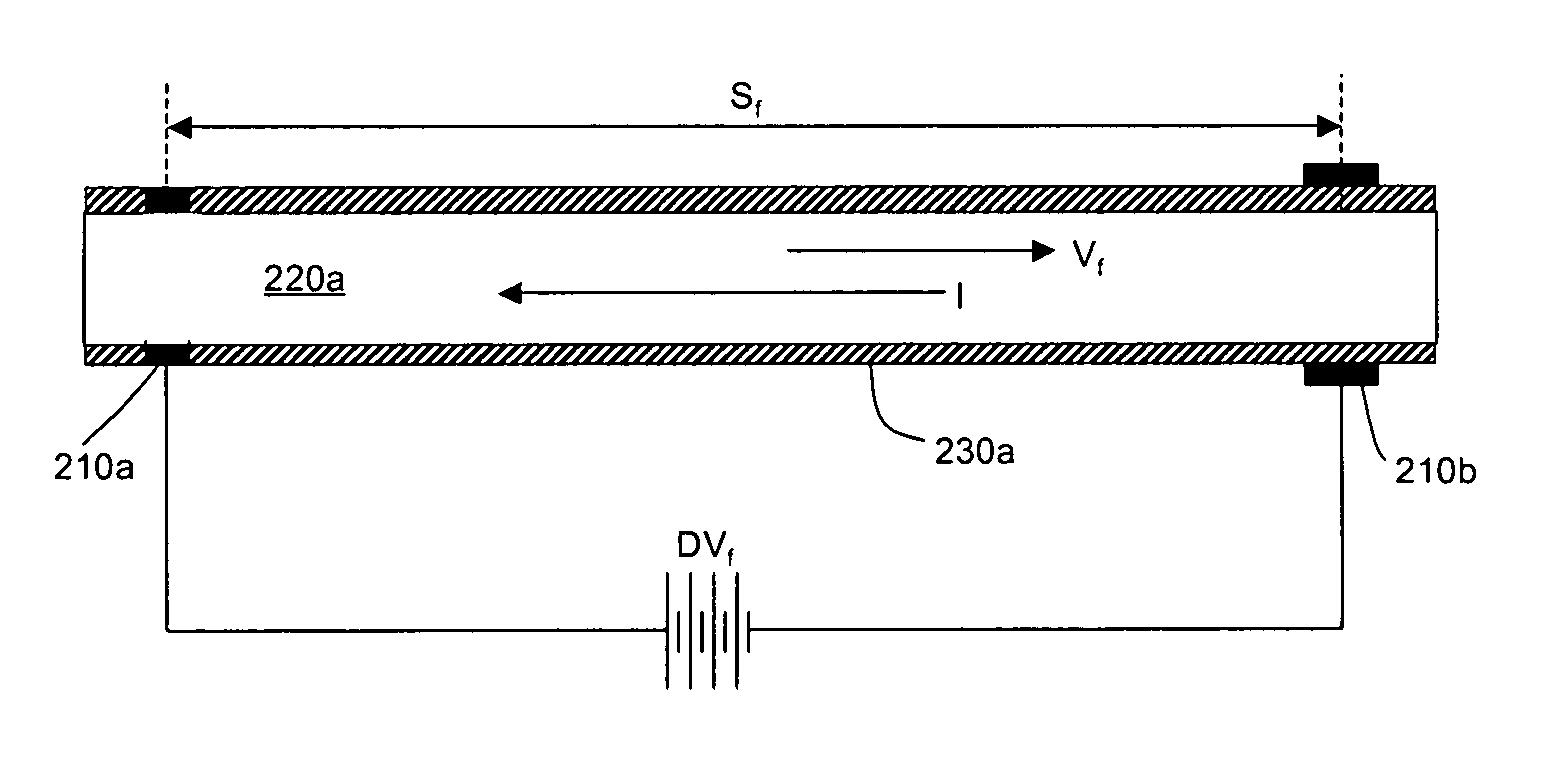

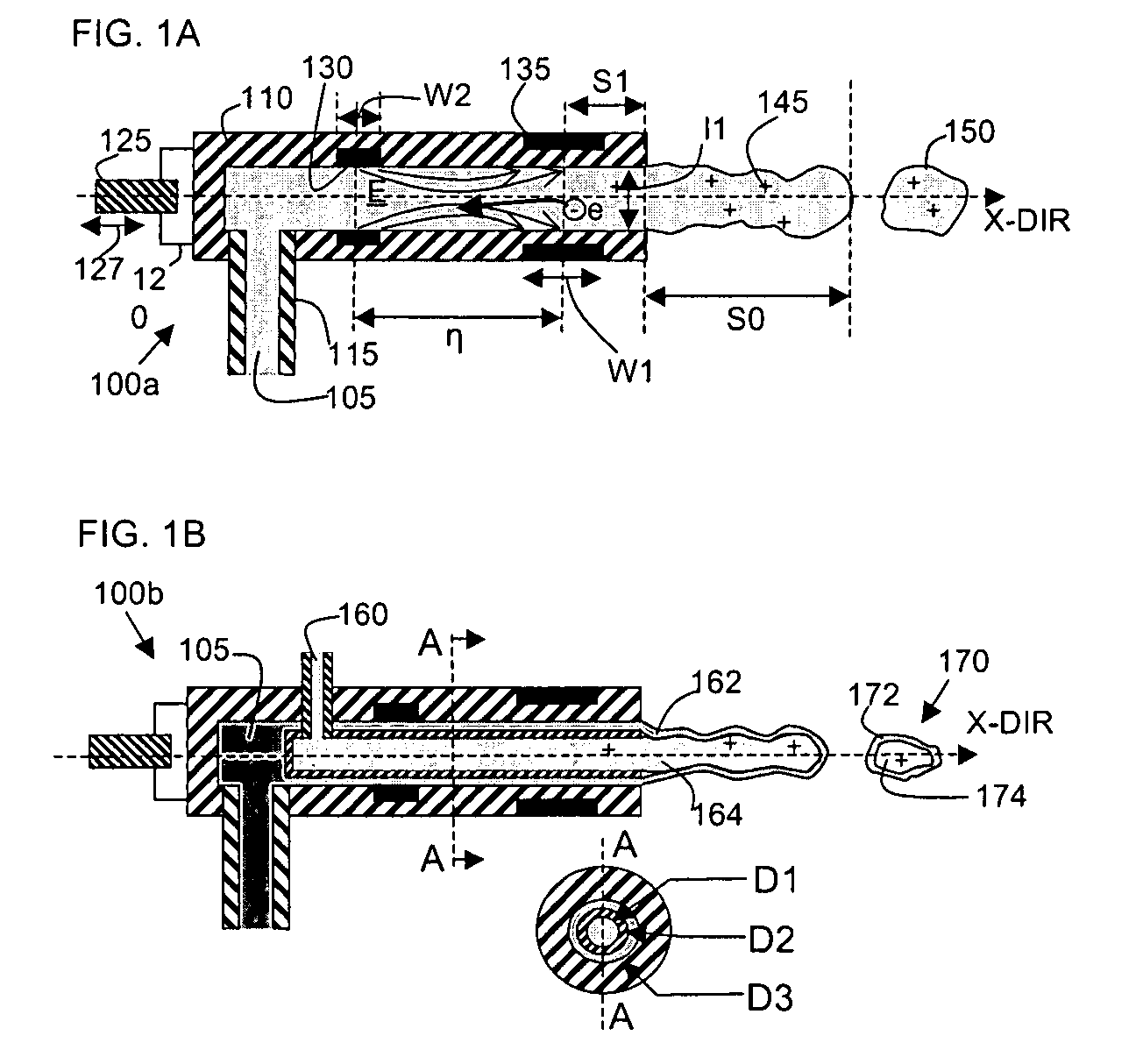

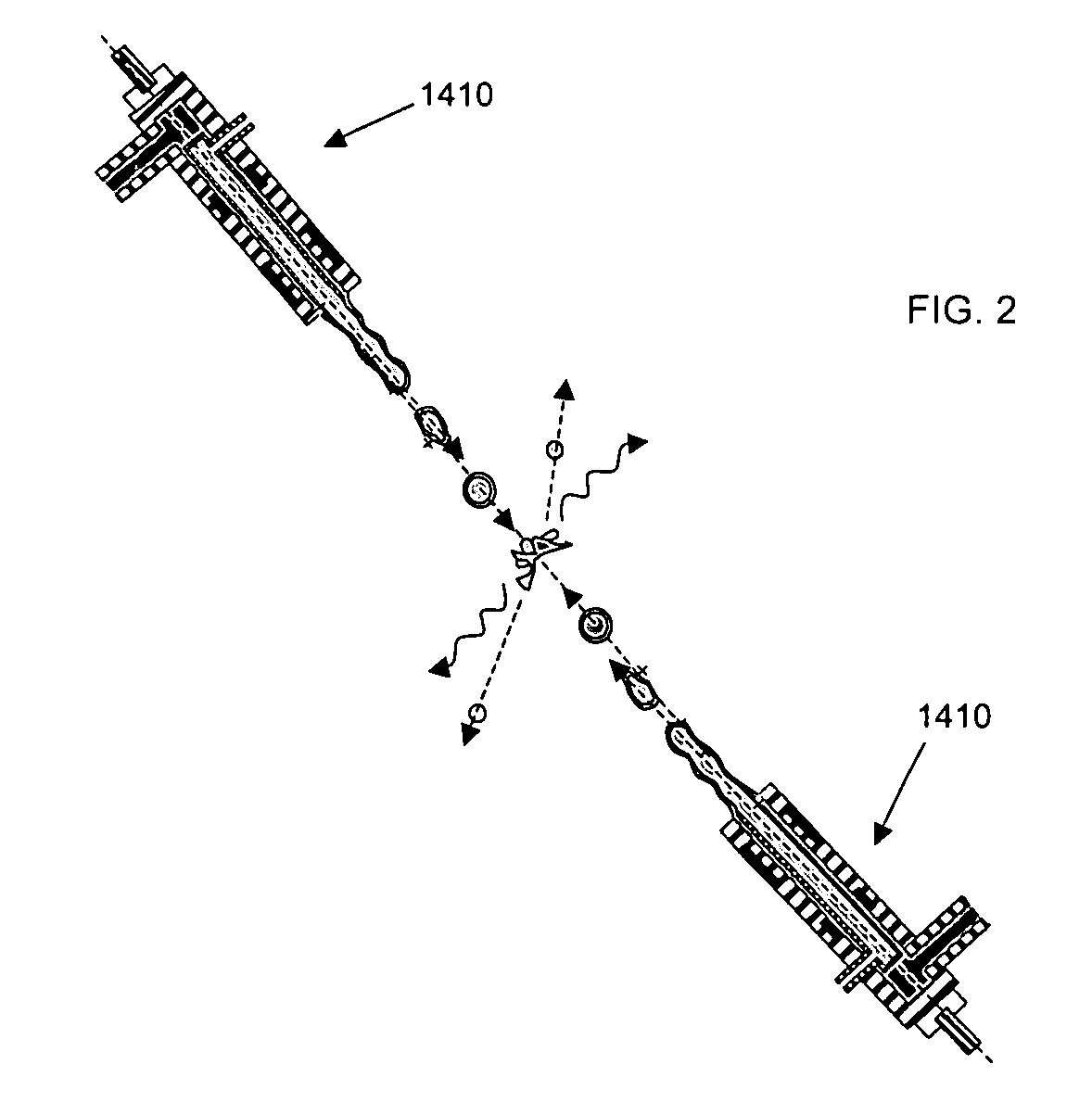

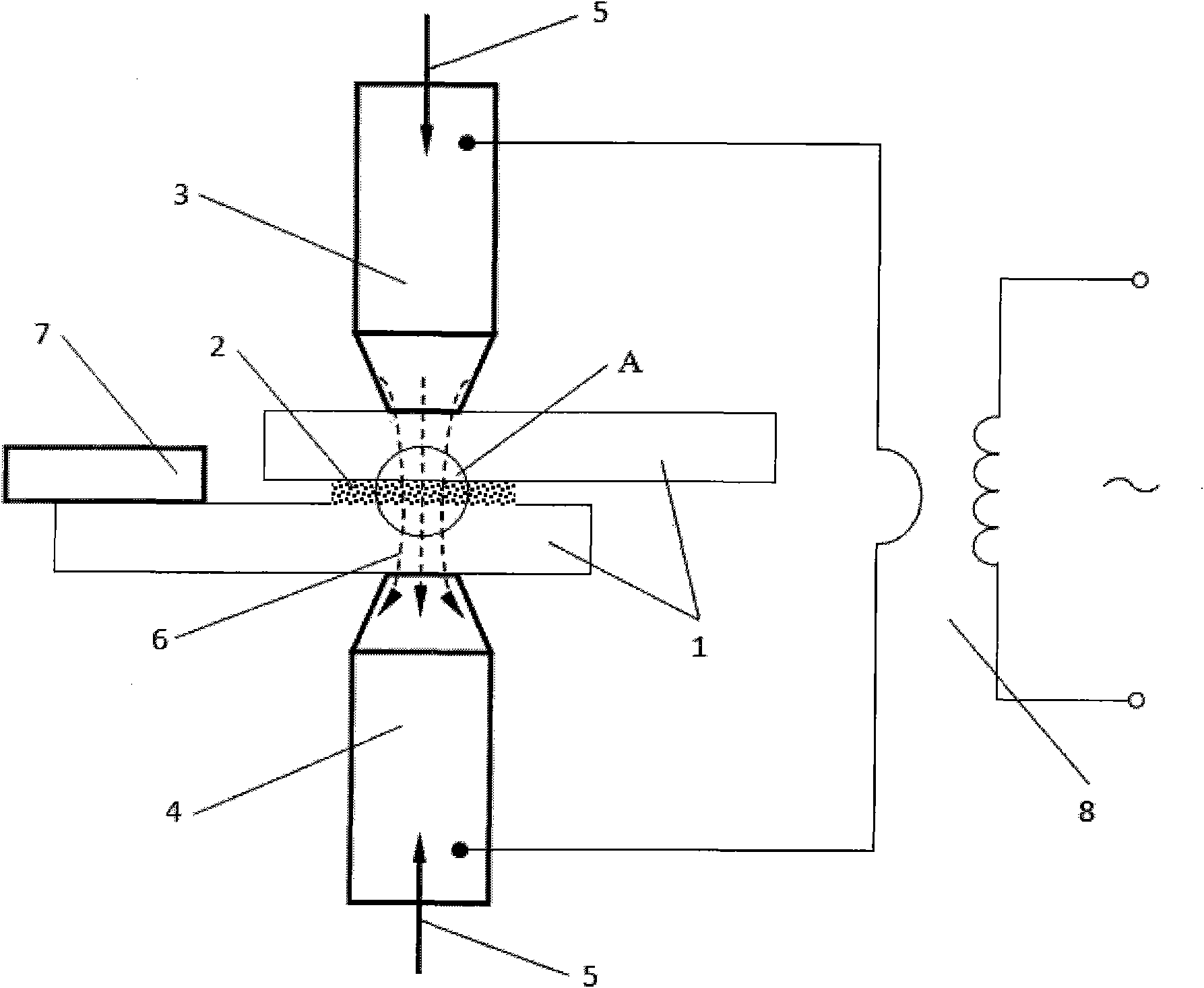

Eletrofluid collisional accelerator and fusion reactor

At least one exemplary embodiment is directed toward accelerating charged hydrogenated fluid into collisions of sufficient energy to initiate at least partial fusion of the collisional hydrogenated fluid, where one of the products of the collision is a product including an element higher in the periodic tables than at least one of the colliding fluids, and where, optionally, the at least partial fusion heats a coolant loop which in turn generates electricity.

Owner:KEADY JOHN P

Method for producing welded resin material and welded resin material

ActiveUS20080254242A1Good welding performanceMechanical working/deformationDoors/windowsEngineeringLaser light

A method for producing a welded resin material contains steps of: superimposing a resin member having transmissibility to laser light and a resin member having absorptivity to laser light to form a contact part where the resin members are in contact with each other; forming a closed space that is adjacent to the contact part and faces one end of the contact part; and radiating the laser light from the resin member having transmissibility while pressing the resin members to each other through the contact part, so as to heat the contact part to melt a resin at the contact part, housing a resin excluded from the contact part through melting in the closed space, solidifying the resin melted at the contact part to weld the resin members.

Owner:MITSUBISHI ELECTRIC CORP

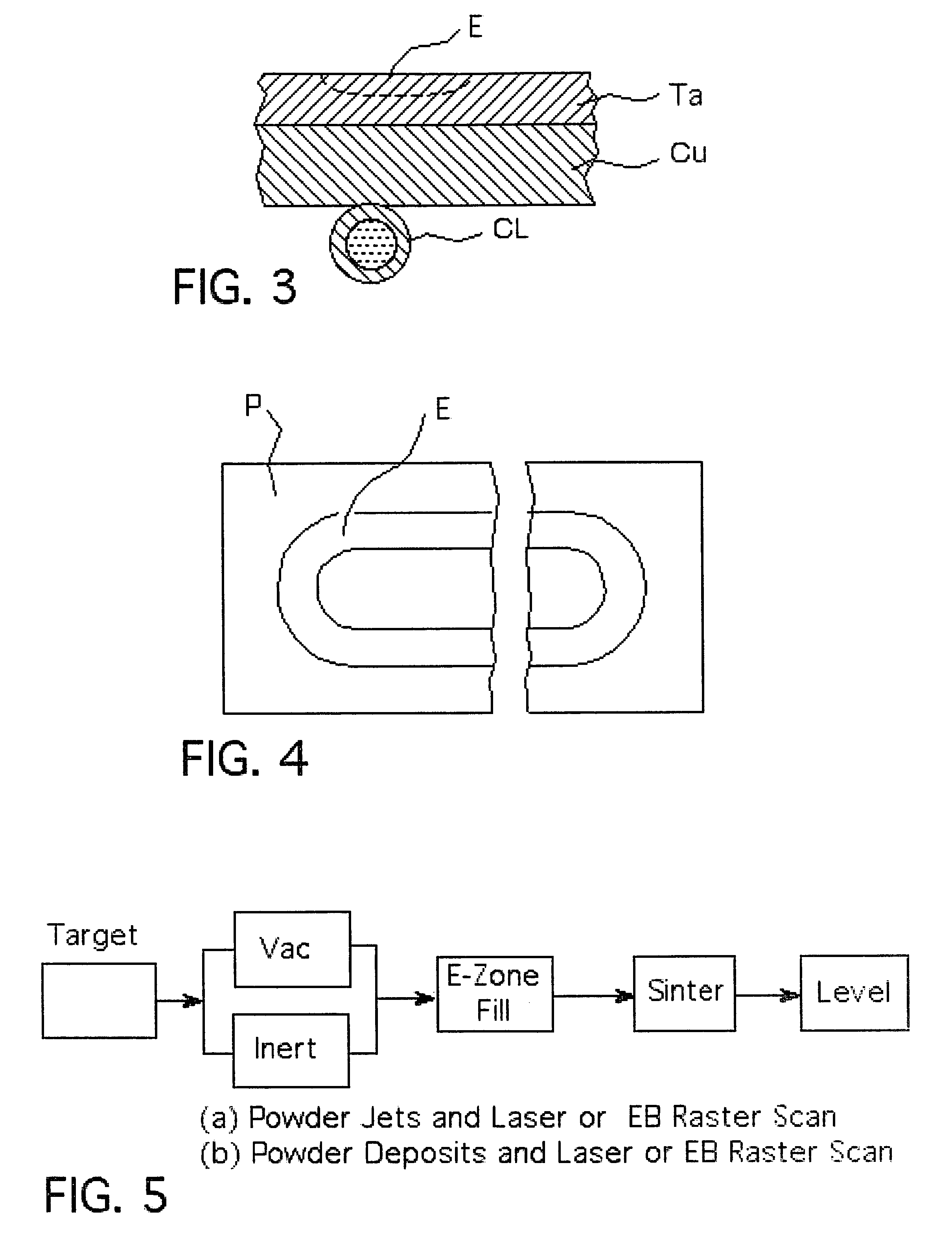

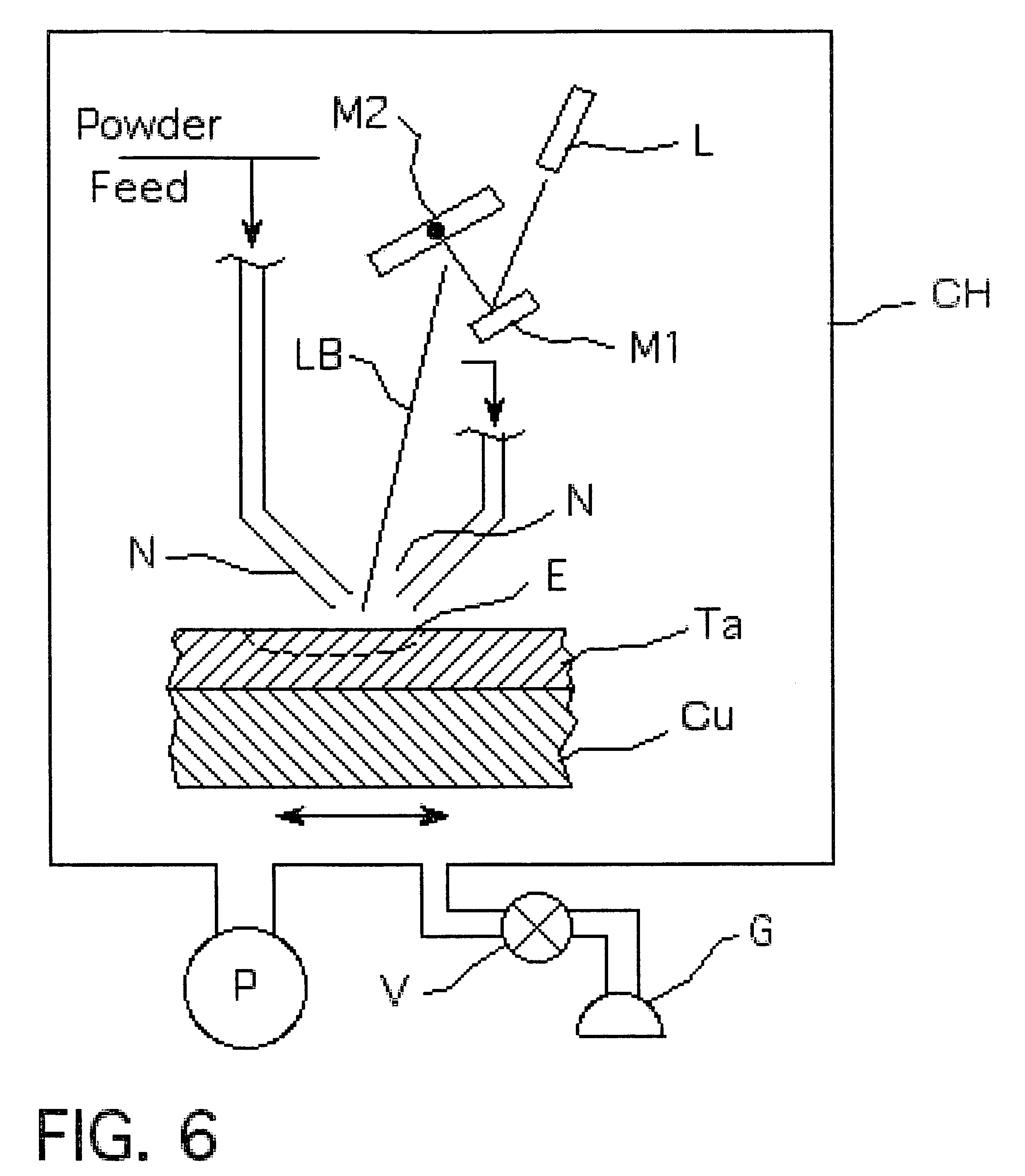

Refractory metal and alloy refining by laser forming and melting

ActiveUS7651658B2Improve throughputMore consistencyRadiation applicationsVacuum evaporation coatingNiobiumNear net shape

A process to chemically refine and consolidate tantalum, niobium and their alloys to a fabricated product of net shape or near-net shape with higher throughput, more consistency, and lower manufacturing costs compared to prior art routes or rejuvenate damaged and deteriorated refractory metal parts. Powder metal is loaded into hoppers to be fed into laser forming / melting equipment. A suitable substrate is loaded into a laser forming / melting chamber onto which the powder will be deposited and consolidated in a point-scan process. As the powder is fed onto successive points of the surface of the substrate in linear traces, the laser is used to heat and partially melt the substrate and completely melt the powder. A combined deposition and melt beam traces the substrate surface repeatedly over a selected area to build up a dense coating of controlled microstructure in multiple layers. A fully dense deposit is built up that becomes the desired shape.

Owner:MATERION NEWTON INC

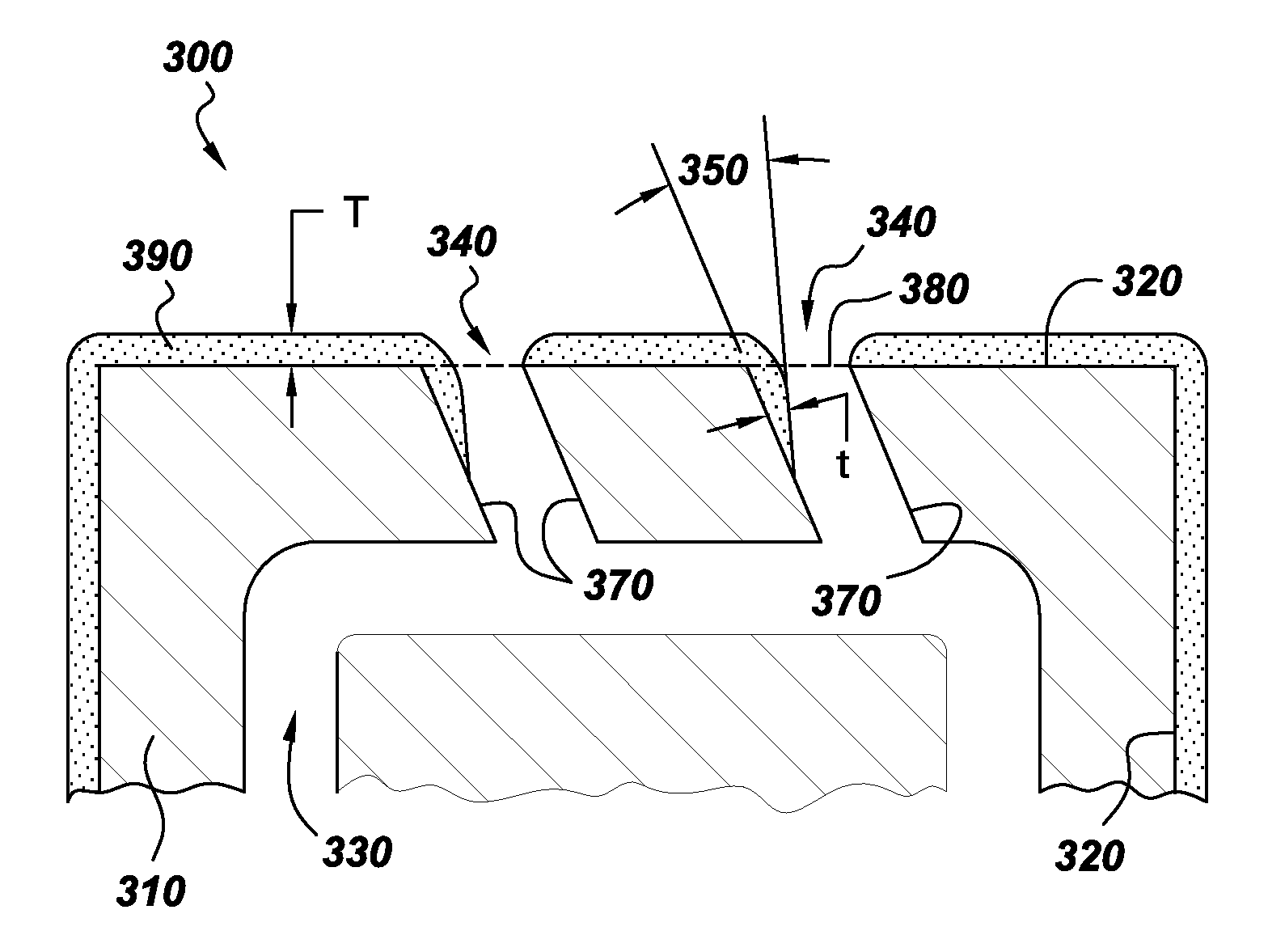

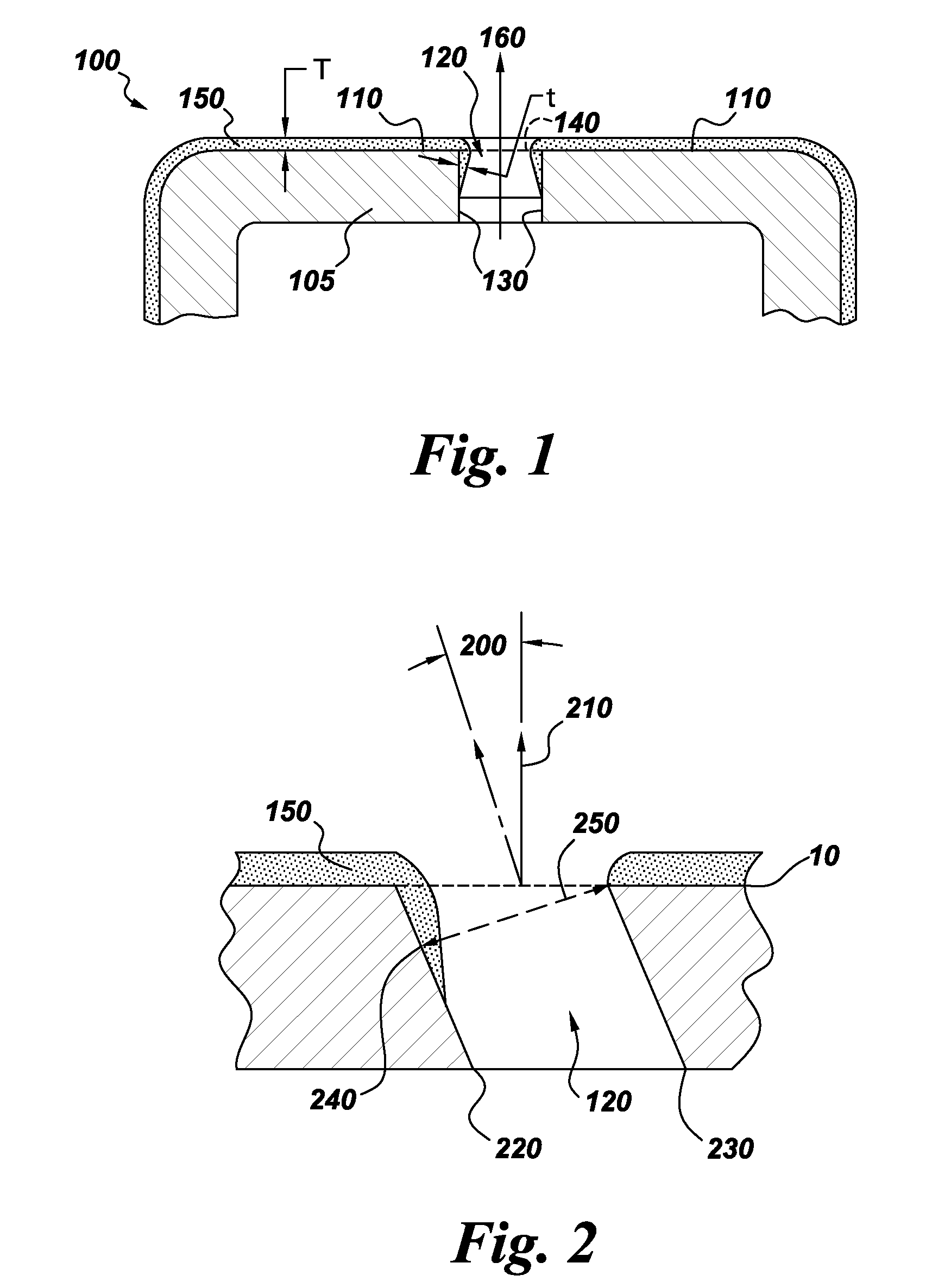

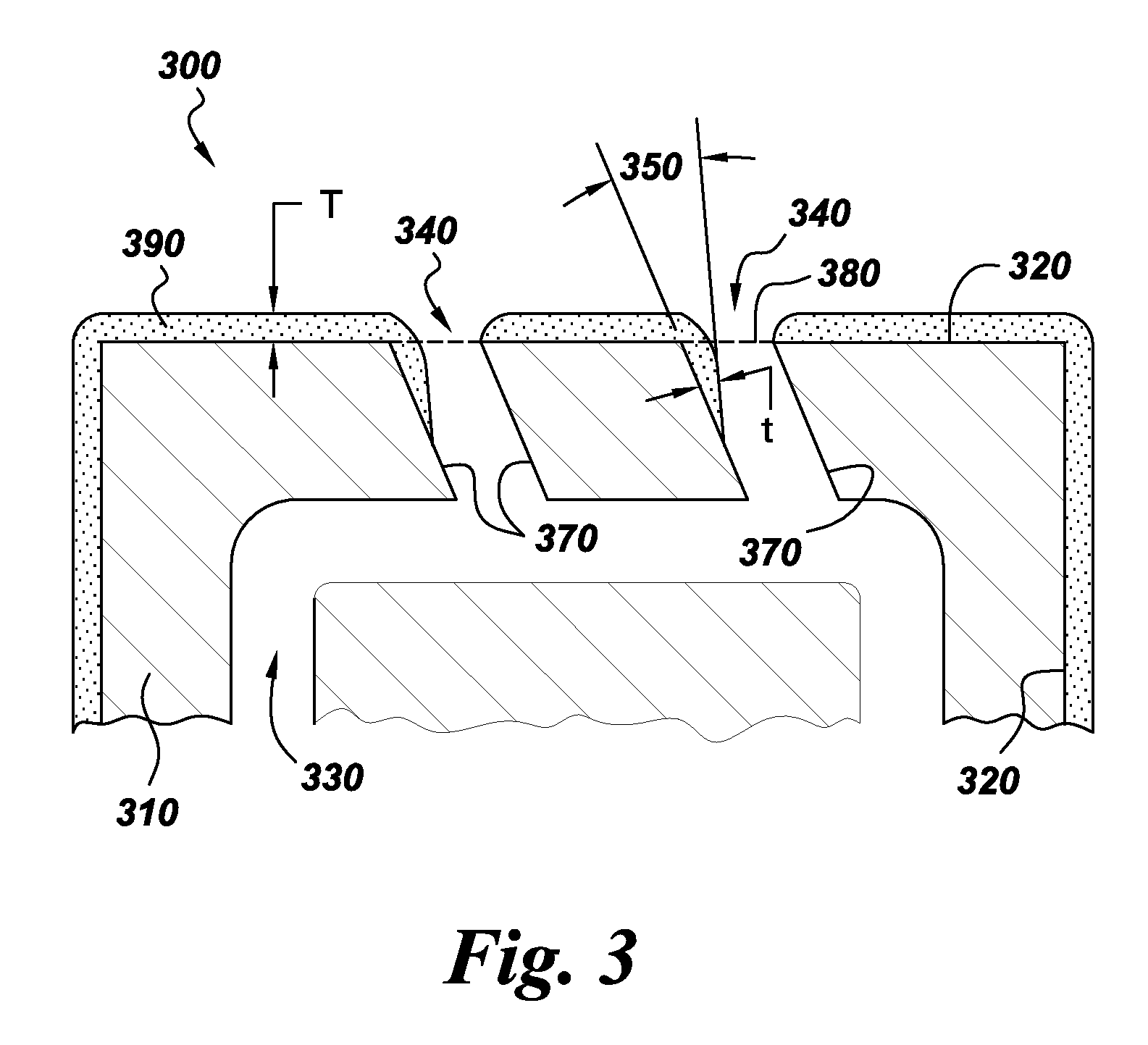

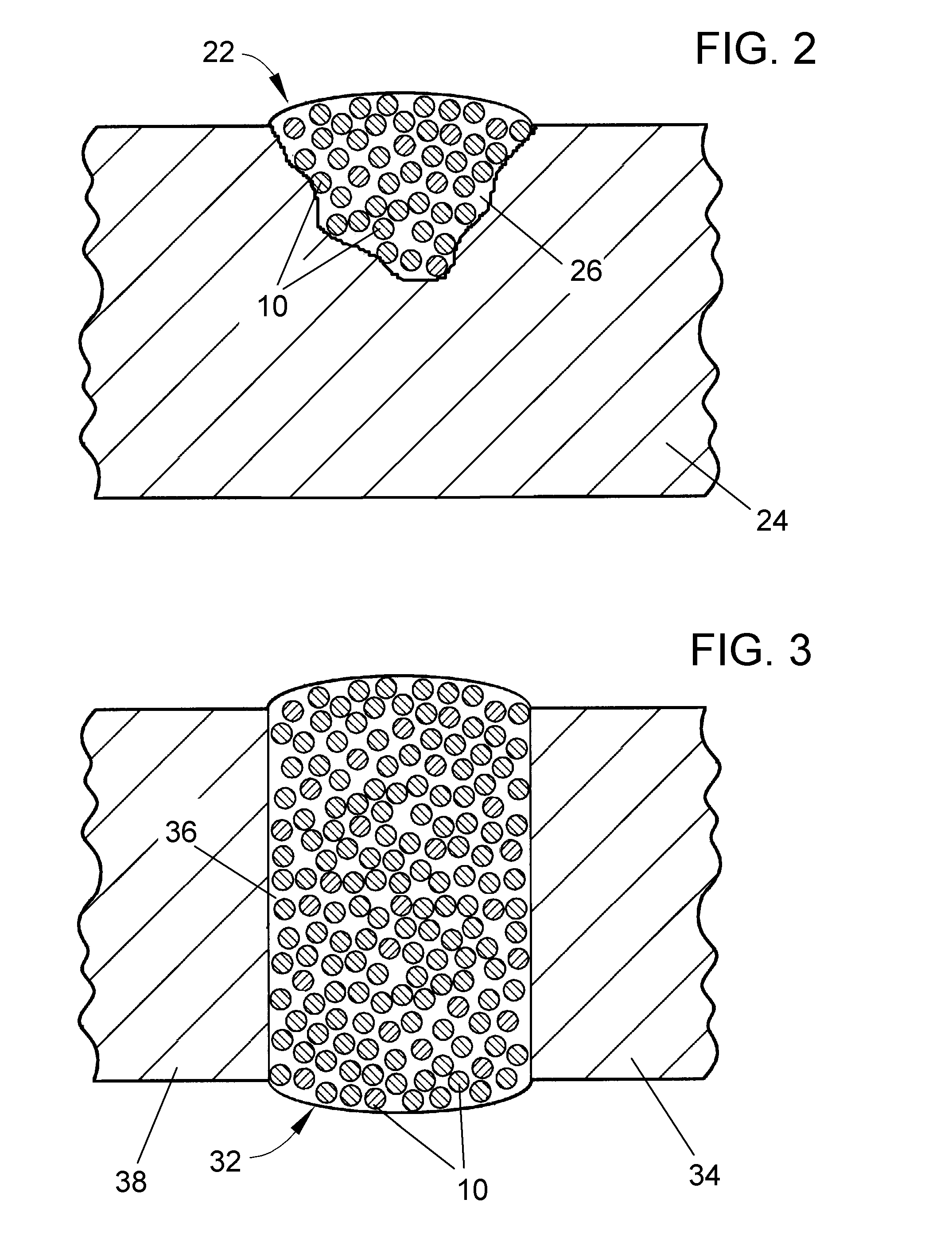

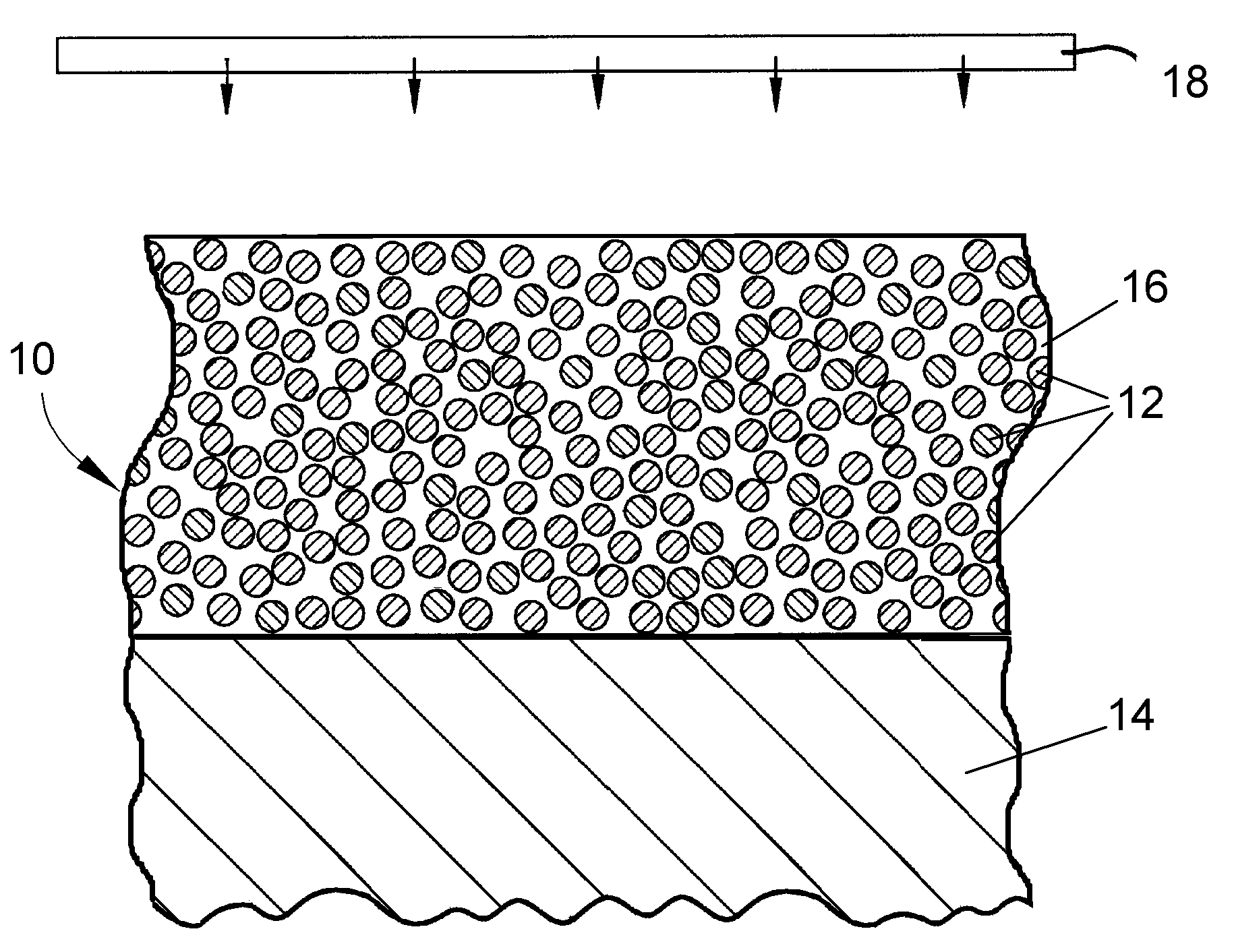

Articles for high temperature service and methods for their manufacture

Articles coated via a plasma spray process, and methods for making such articles, are presented. For example, one embodiment is an article comprising a substrate comprising a top surface and a channel disposed in the substrate. The channel is defined by an internal channel surface disposed beneath the top surface and having a terminal end at an orifice at the top surface. A coating is disposed on the top surface and on at least a portion of the internal channel surface. A coating thickness at any point on the internal channel surface is less than a nominal coating thickness on the top surface, and the coating comprises a plurality of at least partially melted and solidified particles.

Owner:GENERAL ELECTRIC CO

Method for producing electrical contacts using selective melting and a low pressure kinetic spray process

A new kinetic spray process is disclosed that enables the coating to withstand severe bending and stress without delamination. The method includes use of a low pressure kinetic spray supersonic nozzle having a throat located between a converging region and a diverging region. A main gas temperature is raised to from 1000 to 1300 degrees Fahrenheit and the coating particles are directly injected into the diverging region of the nozzle at a point after the throat. The particles are entrained in the flow of the gas and accelerated to a velocity sufficient to result in partial melting of the particles upon impact on a substrate positioned opposite the nozzle and adherence of the particles to the substrate. The coating also has a desirable shinny surface. The method finds special application in coating substrates for use in formation of electrical connections.

Owner:DELPHI TECH INC

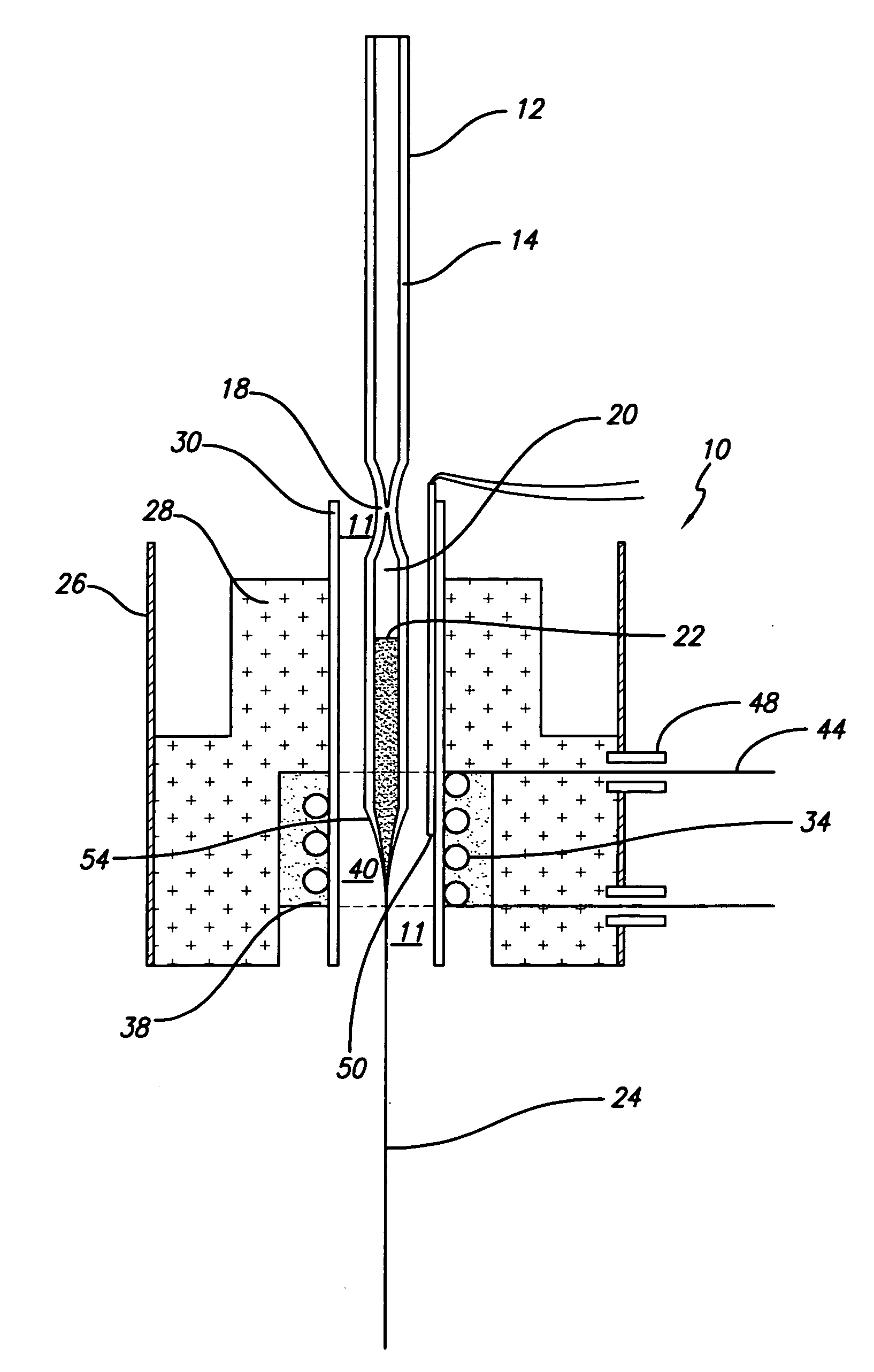

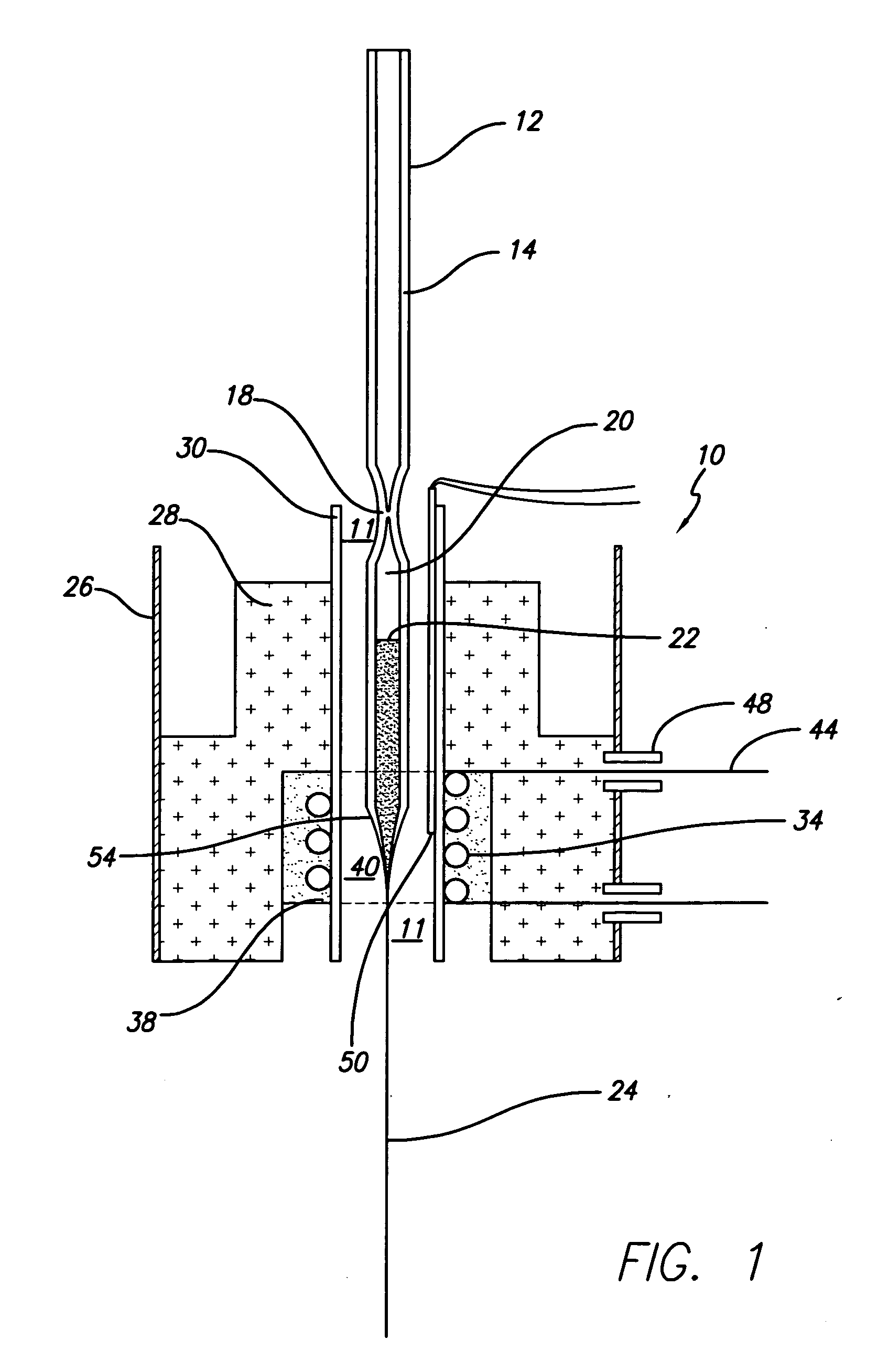

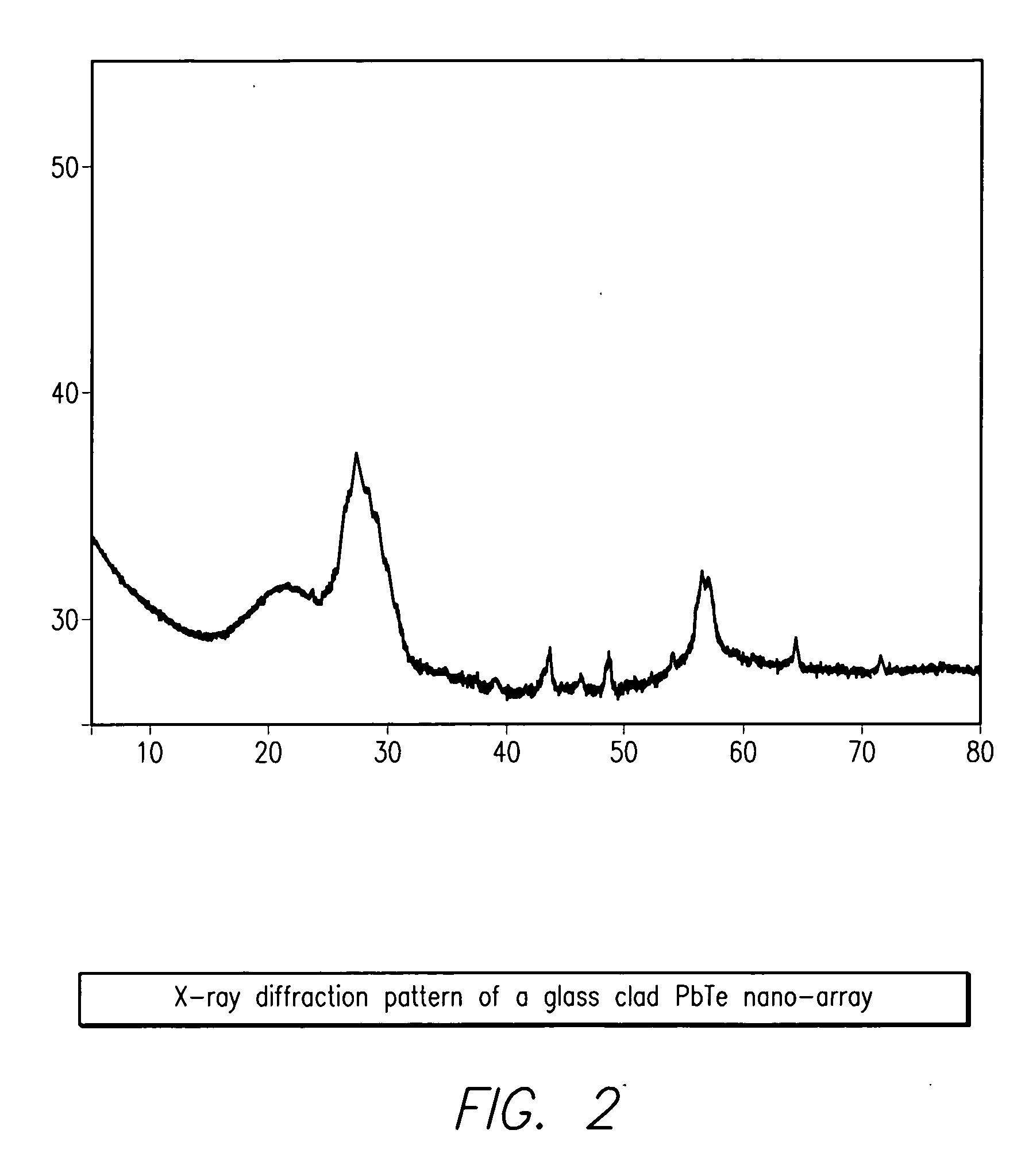

Methods of drawing high density nanowire arrays in a glassy matrix

InactiveUS20070131266A1Reduce variationExpand the populationGlass making apparatusThermoelectric device with peltier/seeback effectThermoelectric materialsFiber

The present invention provides a method of drawing a thermoelectrically active material in a glass cladding, comprising sealing off one end of a glass tube such that the tube has an open end and a closed end, introducing the thermoelectrically active material inside the glass tube and evacuating the tube by attaching the open end to a vacuum pump, heating a portion of the glass tube such that the glass partially melts and collapses under the vacuum such that the partially melted glass tube provides an ampoule containing the thermoelectric material to be used in a first drawing operation, introducing the ampoule containing the thermoelectric material into a heating device, increasing the temperature within the heating device such that the glass tube melts just enough for it to be drawn and drawing fibers of glass clad thermoelectrically active material. The invention further provides a method for bunching together such fibers and re-drawing them one or more times to produce arrays of thermoelectric nanowires clad in glass.

Owner:ZT3 TECH INC

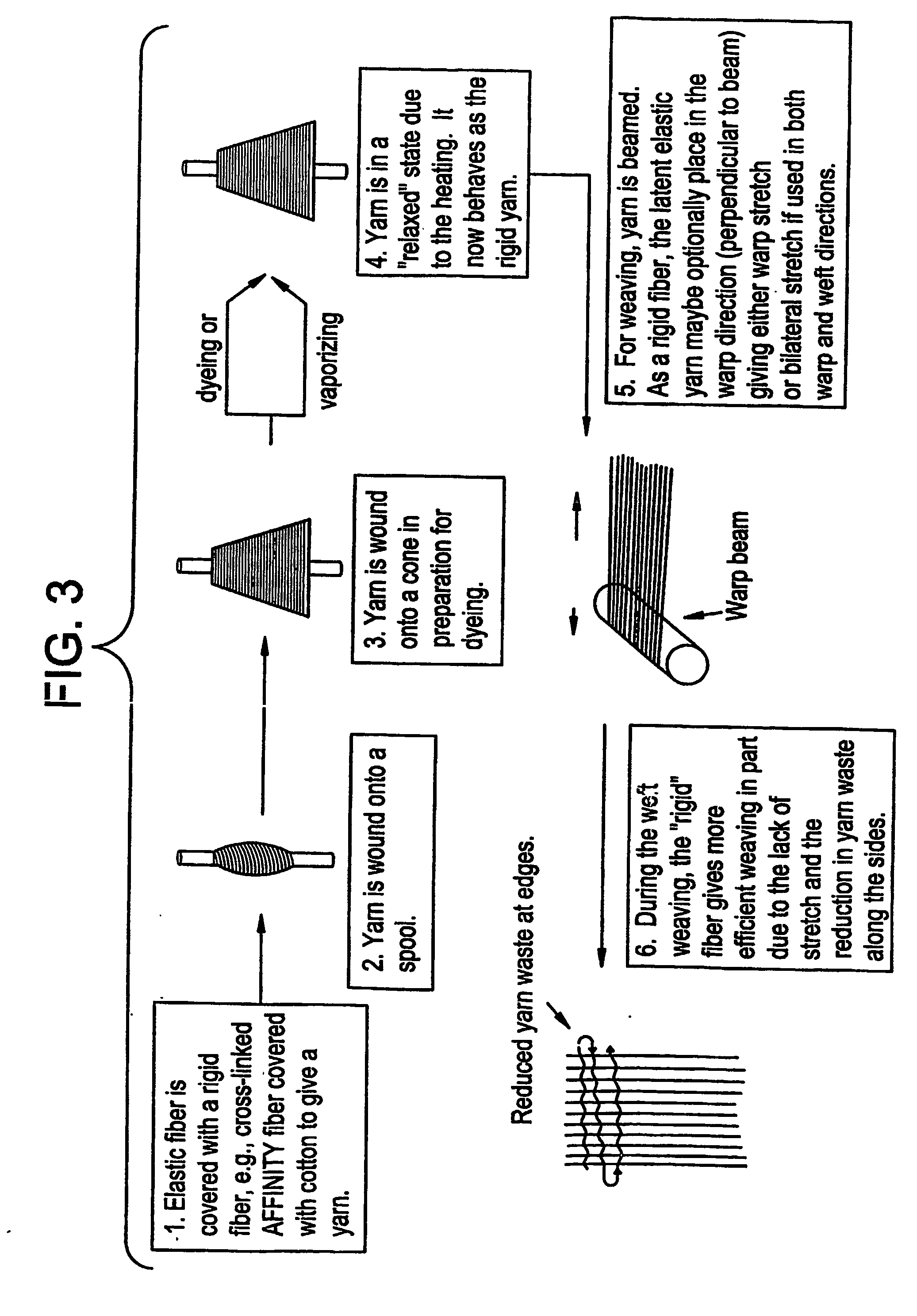

Reversible, heat-set, elastic fibers, and method of making and articles made from same

ActiveUS20050165193A1Reduce stepsReduce the amount requiredShrinkingMonocomponent polyurethanes artificial filamentFiberElastic fiber

A reversible, heat-set covered fiber is described, the covered fiber comprising: A. A core comprising an elastic fiber comprising a substantially crosslinked, temperature-stable, olefin polymer, and B. A cover comprising an inelastic fiber. The fiber is head set by a method comprising: (a) Stretching the covered fiber by applying a stretching force to the covered fiber; (b) Heating the stretched covered fiber of (a) to a temperature in excess of the crystalline melting point of the olefin polymer for a period of time sufficient to at least partially melt the olefin polymer; (c) Cooling the stretched and heated covered fiber of (b) to a temperature below the crystalline melting point of the olefin polymer for a period of time sufficient to solidify the polymer; and (d) Removing the stretching force from the covered fiber.

Owner:DOW GLOBAL TECH LLC

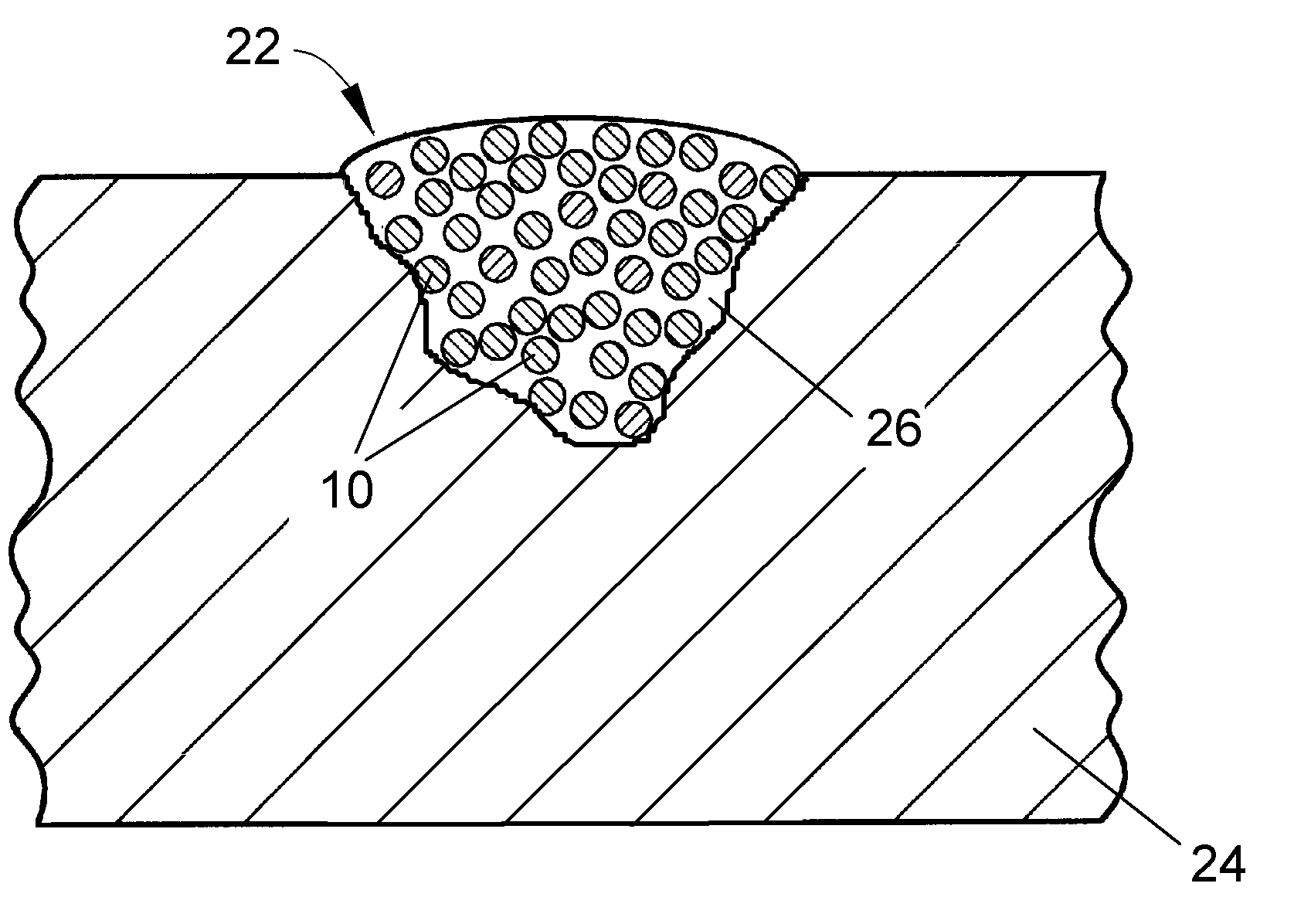

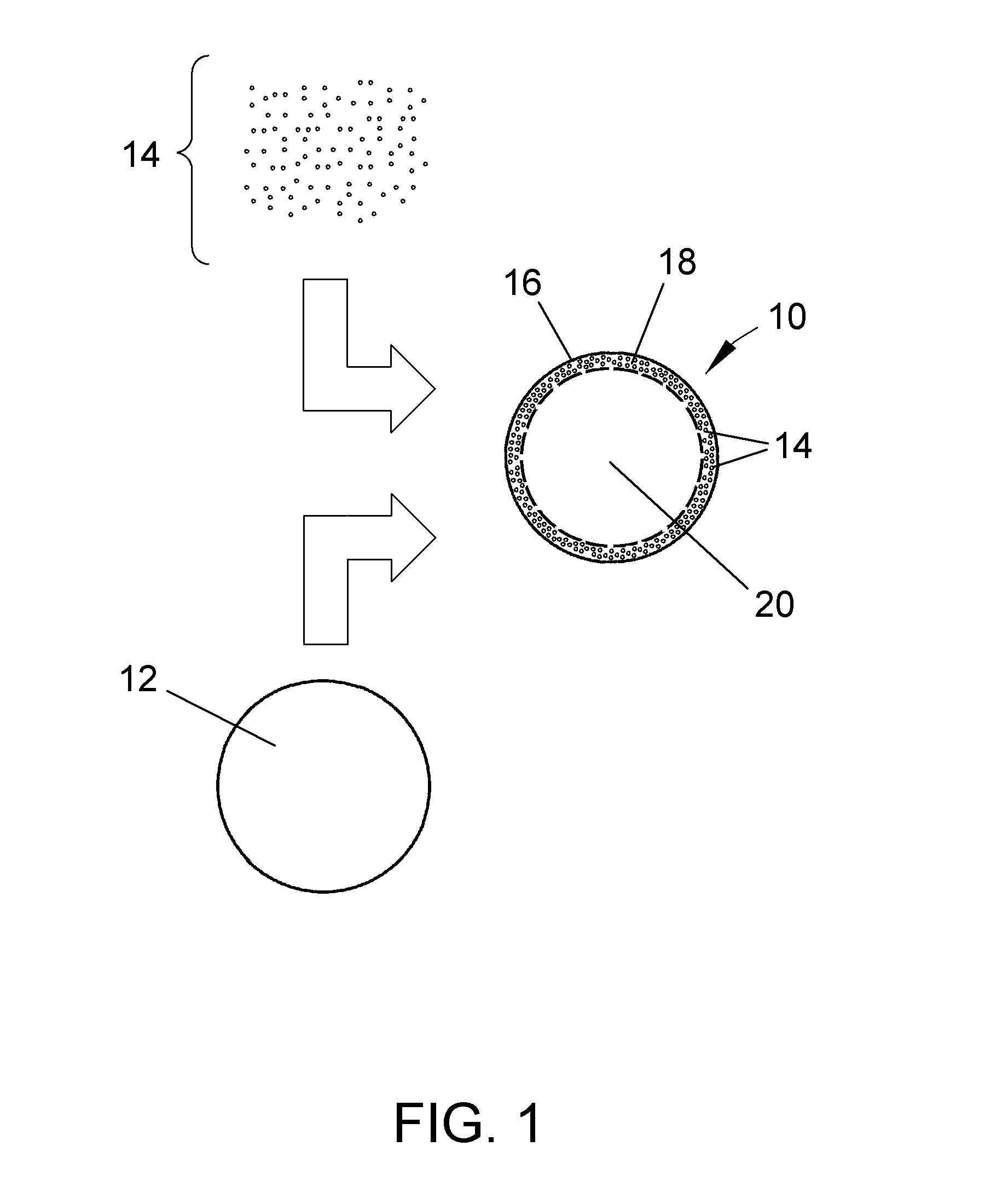

Braze material and processes for making and using

ActiveUS20080142575A1Improve mechanical propertiesImprove the heating effectWelding/cutting media/materialsThin material handlingParticulatesSuperalloy

A braze material and processes for making and using the material, such as for use in the manufacturing, coating, repair, and build-up of superalloy components. The braze material is composed of particles with melt-modifying constituents that are limited to the surfaces of the particles, yet are capable of sufficiently promoting the heating of the particles by conventional means and microwave radiation to achieve at least partial melting of the particles. The melt-modifying constituents are in the form of particulates embedded in the outer surface region of each particle. The particulates are formed of melting point depressant(s) and / or microwave coupling enhancer(s), are much smaller than the particle in which they are embedded.

Owner:GENERAL ELECTRIC CO

Polymeric materials and process for producing same

InactiveUS6482343B1Low mechanical strengthPromote resultsLamination ancillary operationsLaminationFiberTransition pressure

An improved process for producing a consolidated polymeric monolith from an assembly of thermoplastic polymer. The assembly is placed under pressure to fill a majority of the voids thereof by mechanical deformation of the fibers, and heated to a temperature too low to melt the fibers at the deformation pressure but sufficiently high to at least partly melt the fibers at a lower transition pressure. While maintaining the assembly at this temperature, the pressure is reduced to the transition pressure long enough for partial melting of the fibers to fill the rest of the voids, and then is increased to a consolidation pressure at least as high as the deformation pressure. The assembly is cooled slowly to ambient temperature at the consolidation pressure. The process allows accurate control of thermal expansion coefficients of the product. Further, products of manufacture produced by the process exhibit improved strength, thermal stability, infrared transparency and unique intrinsic physical characteristics.

Owner:POLYEITAN COMPOSITES

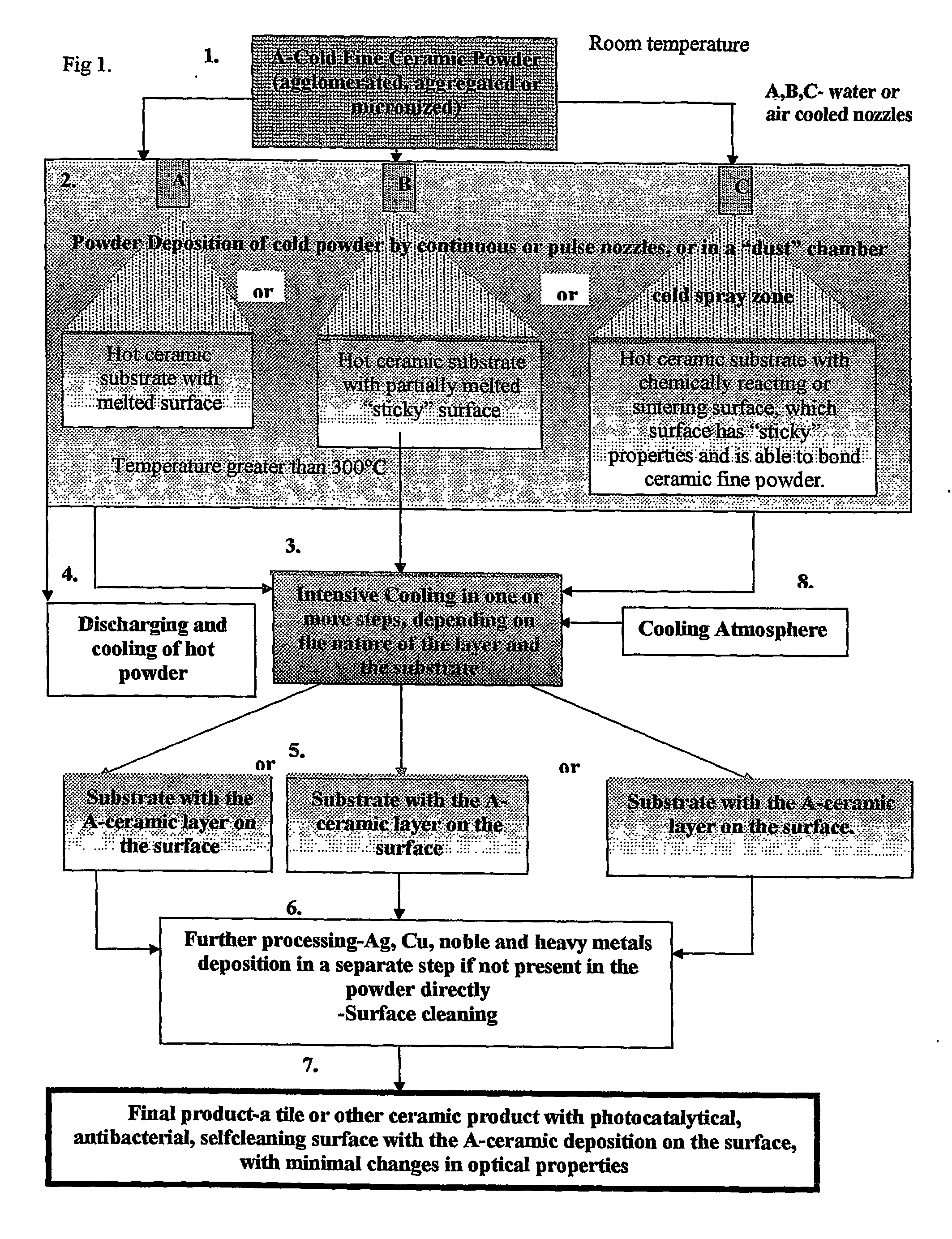

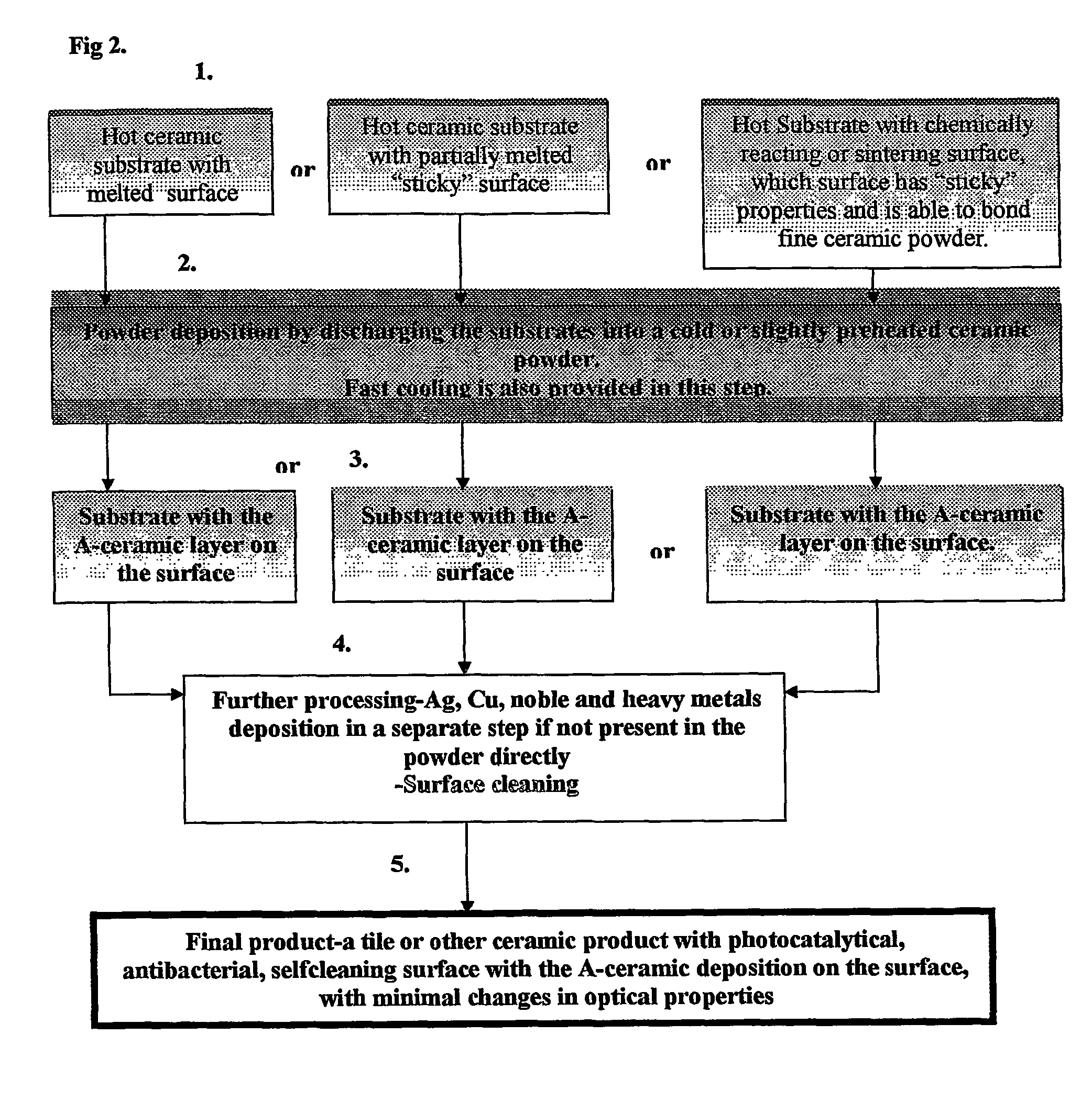

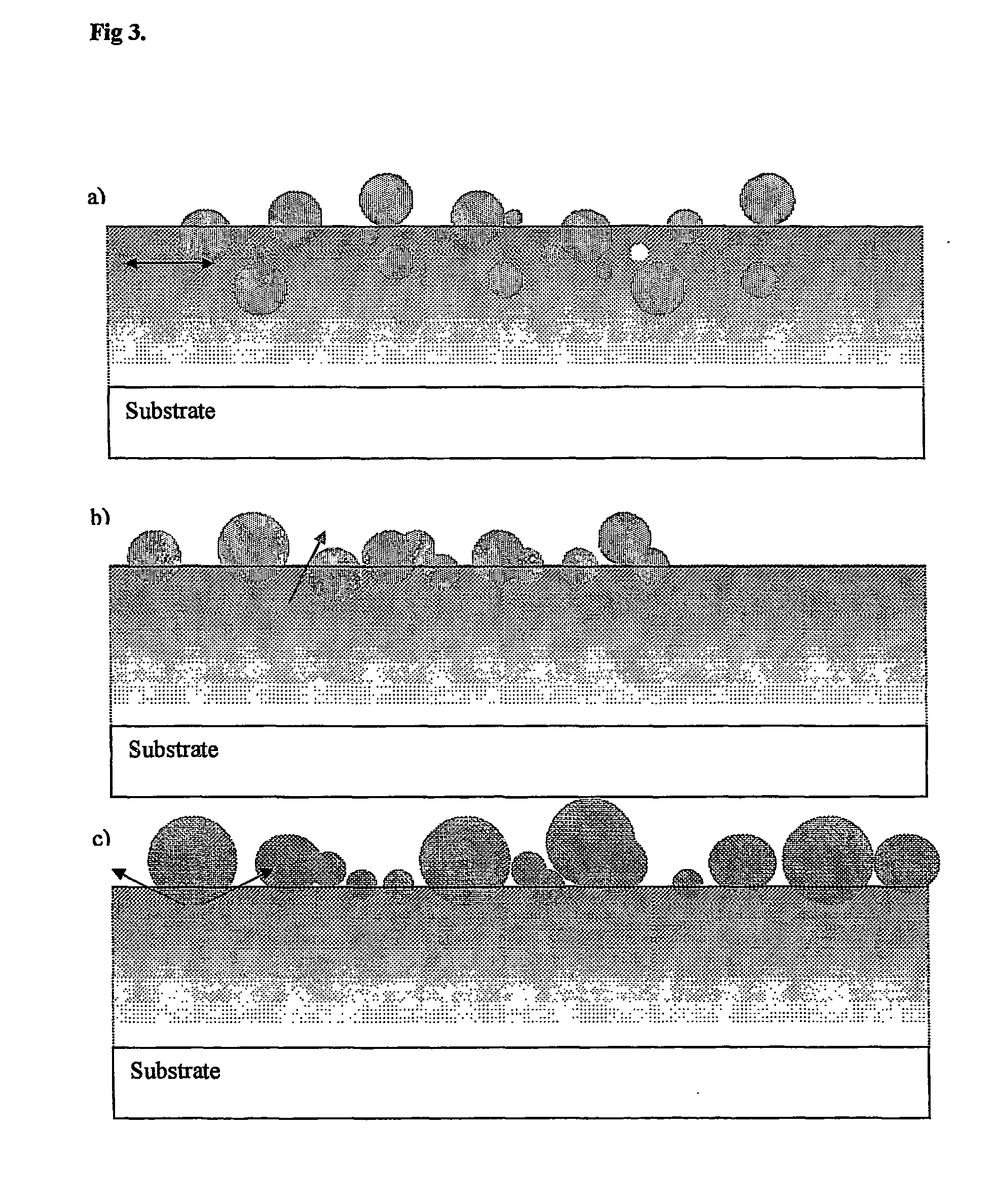

Manufacturing of Photocatalytic, Antibacterial, Selfcleaning and Optically Non-Interfering Sufaces on Tiles and Glazed Ceramic Products

InactiveUS20070275168A1Cheap productionOptimizationPretreated surfacesCoatingsOptical propertyCooling down

The principle of the deposition technique uses ultrafine crystals of ceramic oxides deposited relatively cold on melted or partially melted surfaces of ceramic tiles and other glazed ceramics, creating a spotty deposition without a significant change of optical properties of the surface. Because the desired nano-substance is deposited cold in a solid state form on the hot “sticky” surfaces and rapidly cooled down, deposited material is directly melted into the substrate surface, but its outer side remains unchanged. It allows creating a deposition with the desired parameters, for amplifying and extending the antibacterial protection in the dark, these surfaces may contain noble and heavy metals, deposited either dry as a part of the powder, or in a separate step, directly on the surface by wet depostion followed by drying and calcination.

Owner:PROCHAZKA JAN

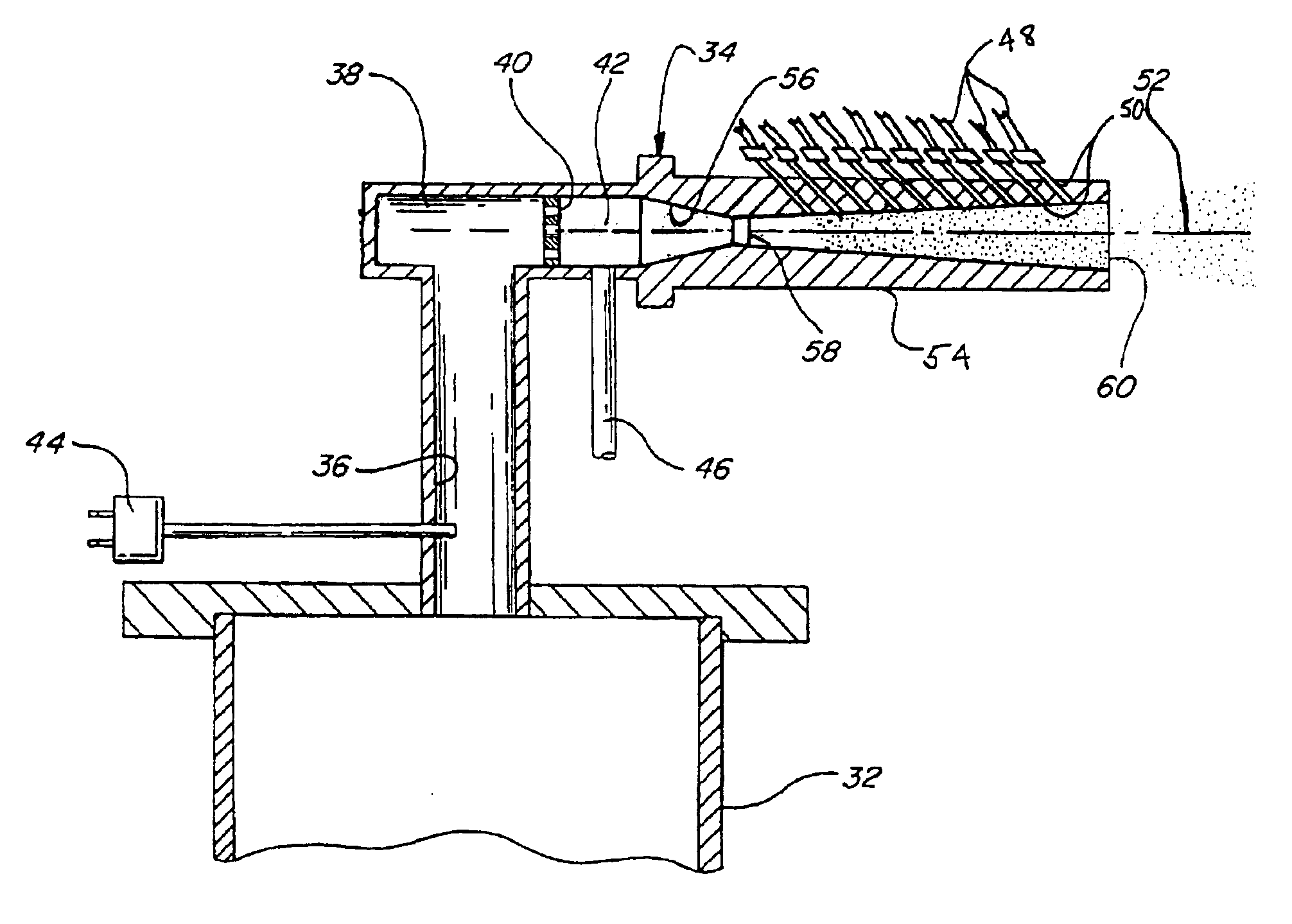

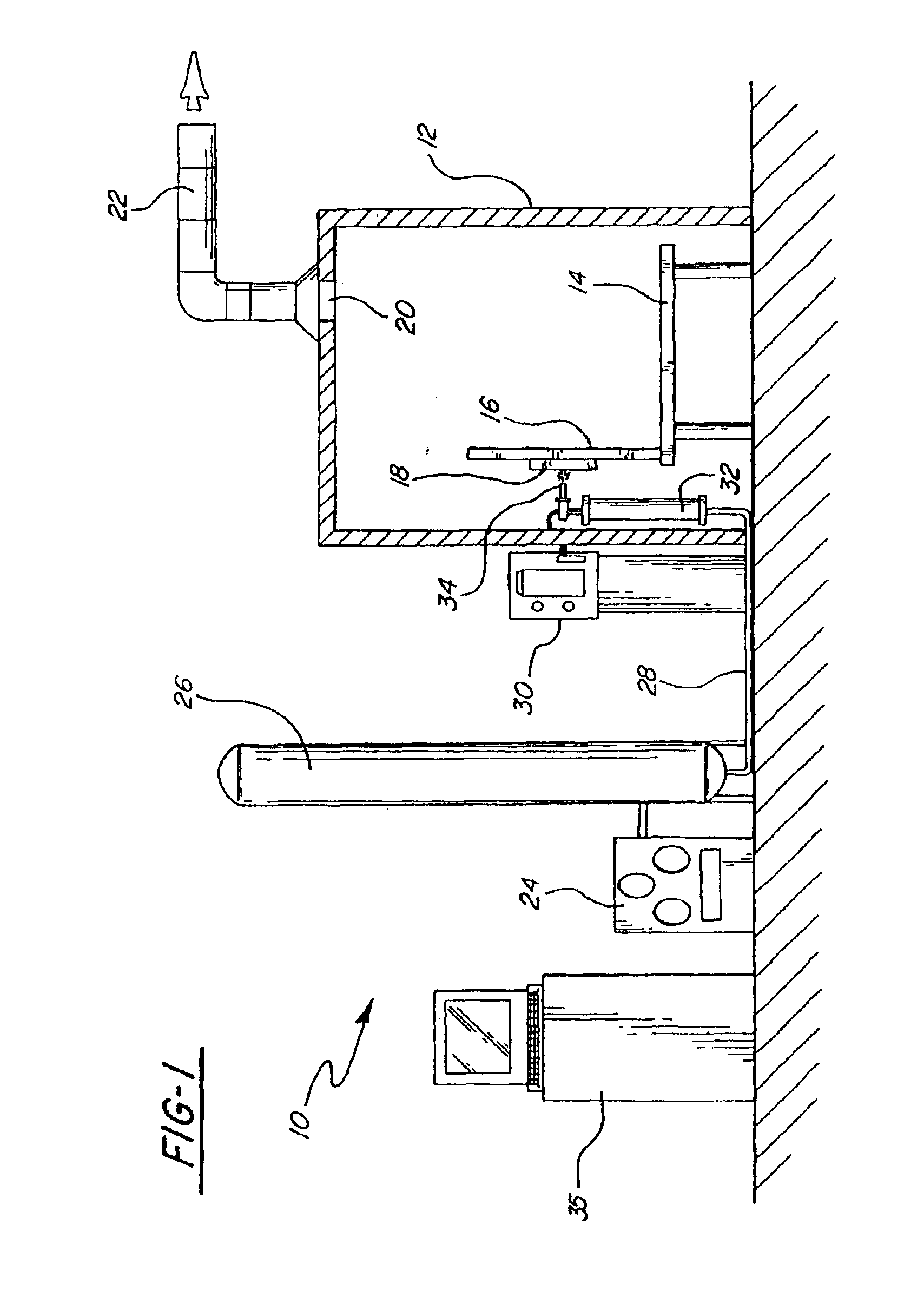

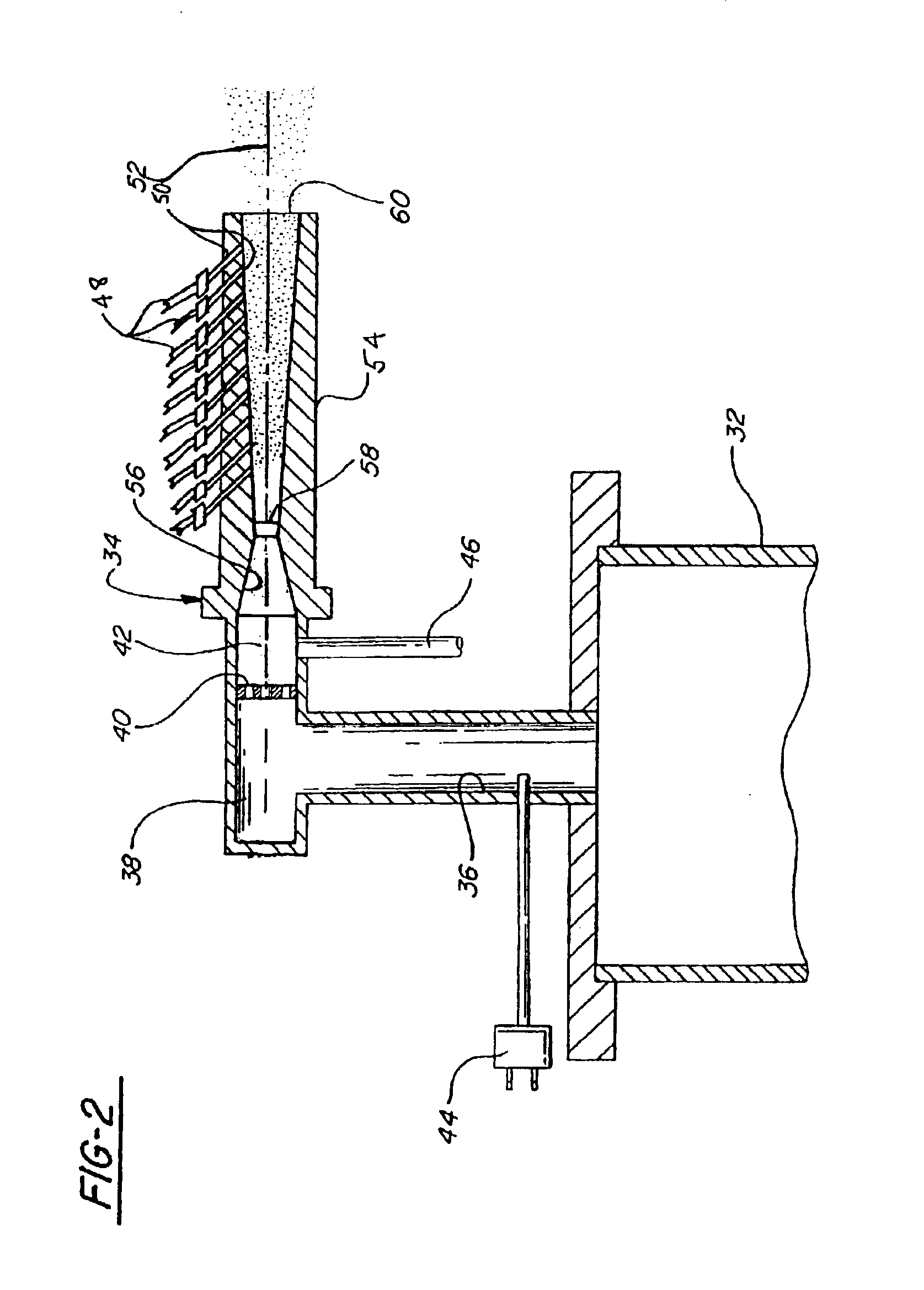

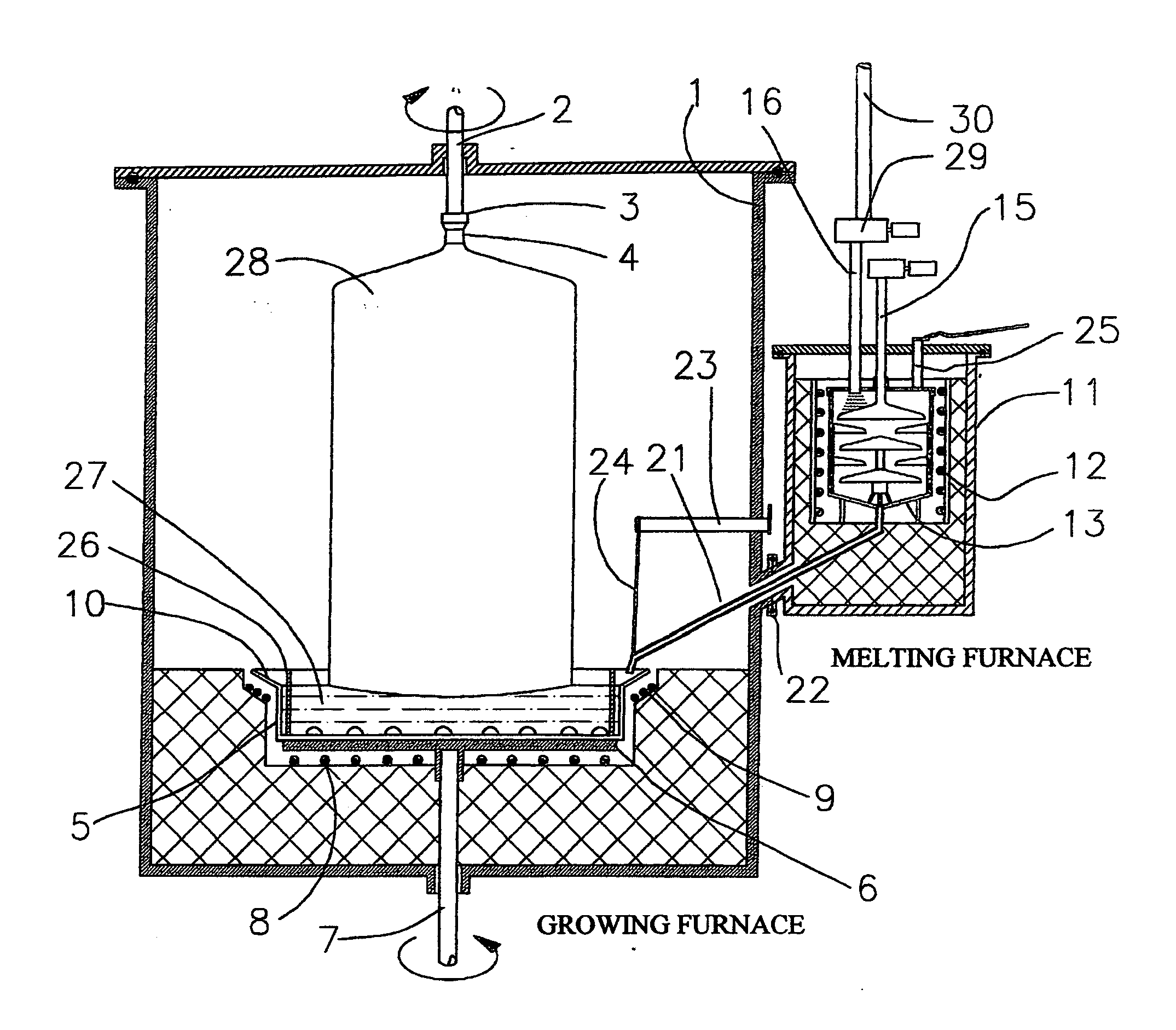

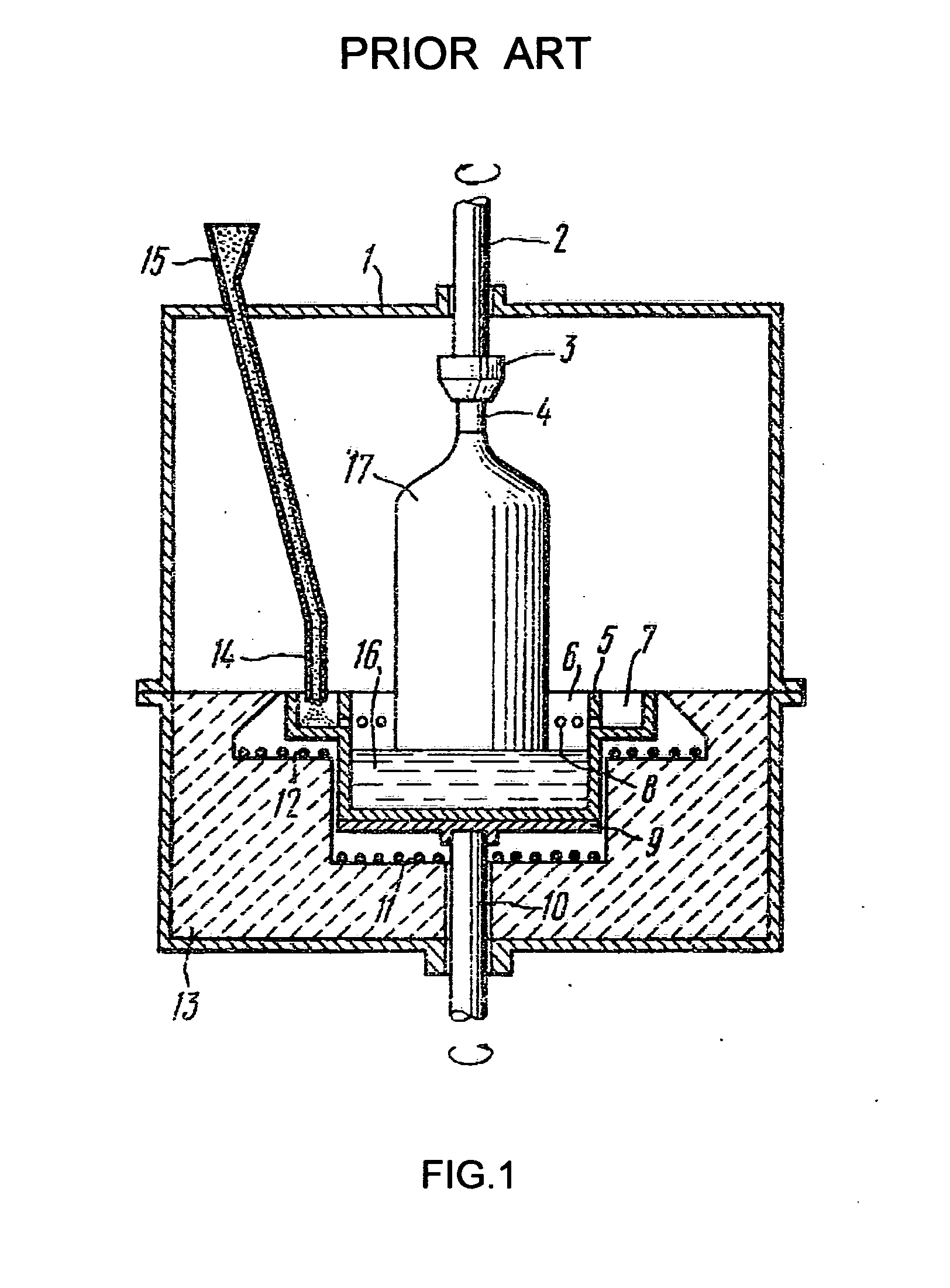

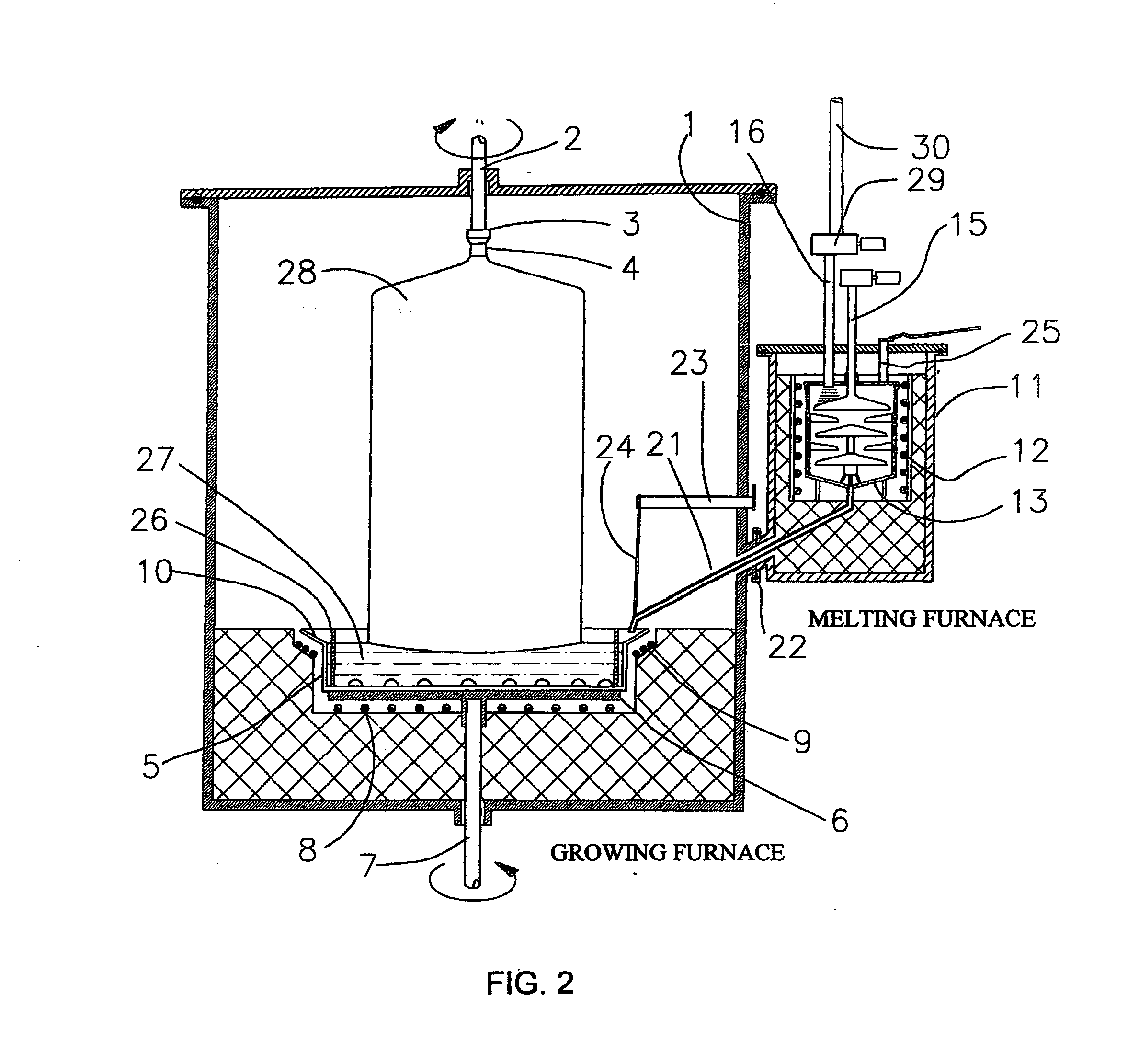

Controlled gravity feeding czochralski apparatus with on the way melting raw material

InactiveUS20130220215A1Independent controlPolycrystalline material growthBy pulling from meltLiquid stateCrucible

A melting furnace is mounted adjacent a growth furnace in which a single crystal ingot is pulled from the melt according to the Czochralski method. The melting furnace comprises a receiving container for melting therein raw material in a particle or powder form falling in it from a feeder. The receiving container accommodates a set of slope-wise plates providing a distributed sliding of partially melted raw material particles over the surface of these plates and their complete melting while moving downward; eventually the melted raw material flows into the crucible of the growth furnace through a heated conveying tube extending slantingly from the conical bottom of the receiving container to the crucible through coaxial openings in housings of both furnaces. The rate of feeding is defined solely by a feeder, and at continuous feeding the raw material flows continuously by gravity from the feeder to the crucible of the growth furnace, first in a solid state (powder, granules, pellets, etc.) and then in a liquid state.

Owner:LGS INNOVATIONS

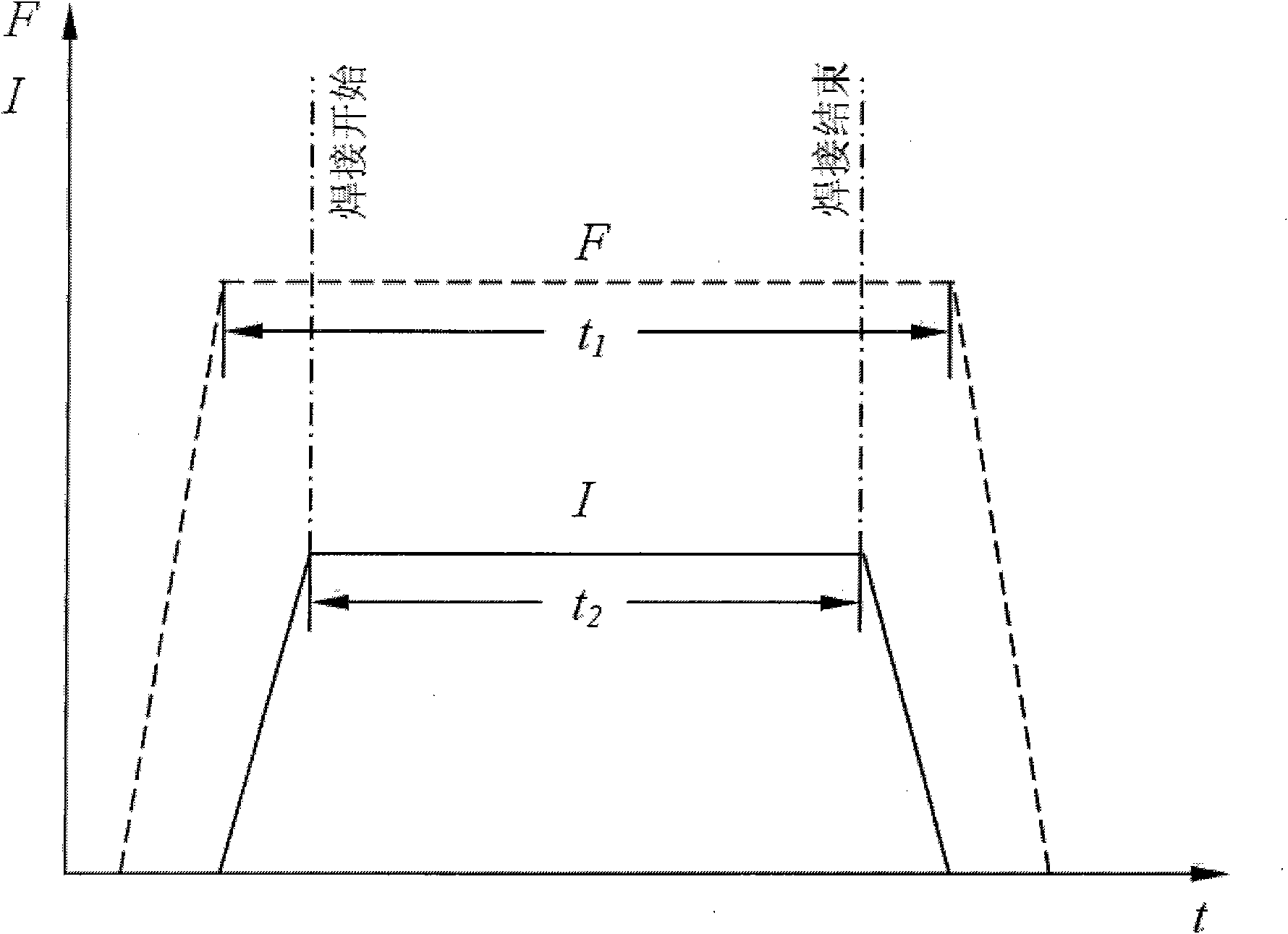

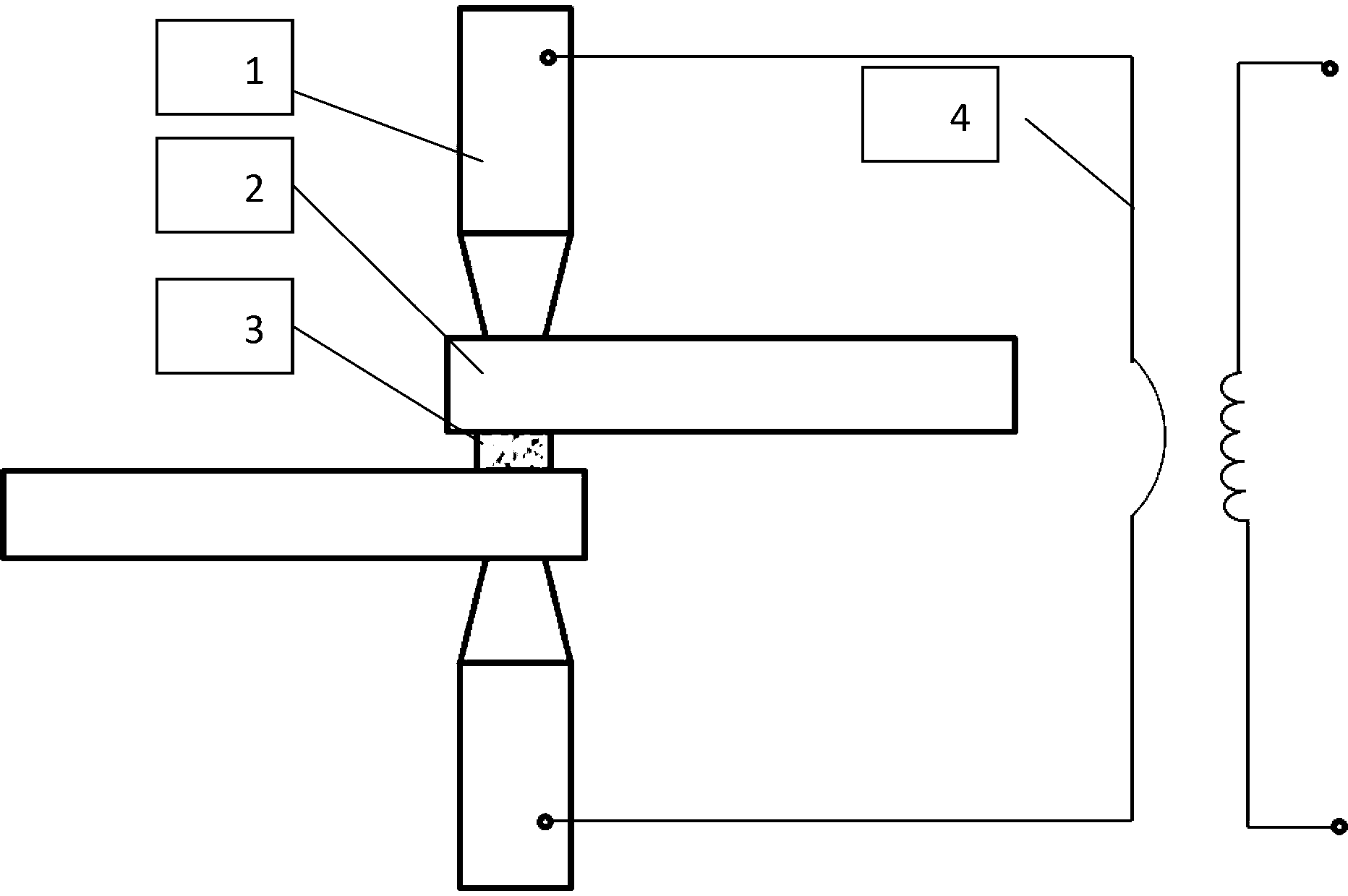

Powder medium diffusion reaction resistance brazing method of magnesium alloy

InactiveCN101885095AWelding processing methods are enriched and supplementedReliable weldingSoldering apparatusShielding gasContact resistance

The invention discloses a powder medium diffusion reaction resistance brazing method of magnesium and a magnesium alloy material, applying in welding of the magnesium and the magnesium alloy material. In the method, a magnesium base powder medium is used as a filling layer, thus improving the problem that contact resistance of the magnesium alloy material is difficult to be welded at the initial stage of the welding; and resistance heat is used as a welding heat source, under the protection of a protective gas and the action of the resistance heat, the partial melting of the surface to be welded of the material and the rapid melting of the powder medium are synchronized to form an alloy solder. Under the impact action of an electrode voltage with a proper magnitude, an oxide film smashes, the powder medium generates an eutectic reaction on the interface of the material to be welded and an eutectic is formed on the interface by virtue of a diffusion action among dissimilar metals, thereby realizing the reliable connection of the materials. The method is mainly used for achieving the welding under the environment of inert gas protection and has strong flexibility and relative ideal project meaning.

Owner:CHONGQING UNIV OF TECH

Technique method for filling spot welding stainless steel high-entropy alloy powder and for filling spot welding stainless steel with high-entropy alloy powder

InactiveCN103252568AIncrease current densityFormula flexibleResistance welding apparatusHigh entropy alloysShielding gas

The invention discloses a technique method for filling spot welding stainless steel high-entropy alloy powder and for filling spot welding stainless steel with high-entropy alloy powder. According to the technique method for filling the spot welding stainless steel high-entropy alloy powder and for filling the spot welding stainless steel with the high-entropy alloy powder, the high-entropy alloy powder is mainly composed of AlFeCuCoNiTiCrx, wherein the x is molar ratio of the Al to the Cr and is between 0 to 0.3, and the size of the powder is 100-300 meshes. When high-entropy alloy powder media are used as a filling layer, the contact resistance of a stainless steel material which are different to weld at the early welding stage is improved, resistance heat is used as a welding heat source, partial melting of the surface of the material to be welded is achieved under the protection of protective air and under the action of the resistance heat, an oxidation film can be broken under the impact effect of proper electrode pressure, refining of the high-entropy alloy powder media can be achieved on the interface of the material to be welded, a molten core and a single face-centered cubic tissue are formed on the interface, and then the strength and the corrosion resistance of a connector are improved. The technique method for filling the spot welding stainless steel high-entropy alloy powder and for filling the spot welding stainless steel with the high-entropy alloy powder has the advantages that welding can be achieved under the thermal compensation condition, the flexibility is strong, and ideal engineering significance is achieved.

Owner:SHANGHAI UNIV OF ENG SCI

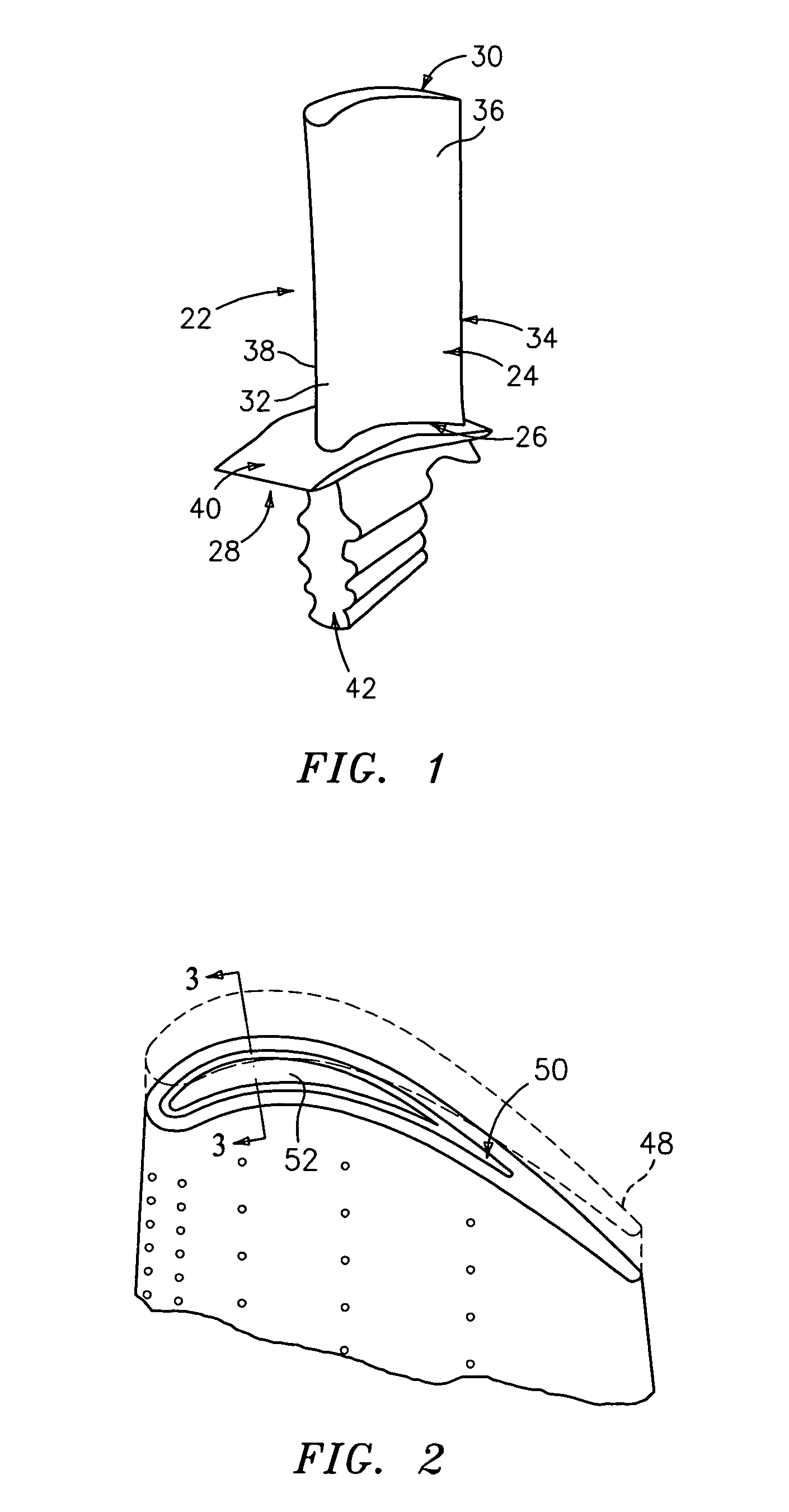

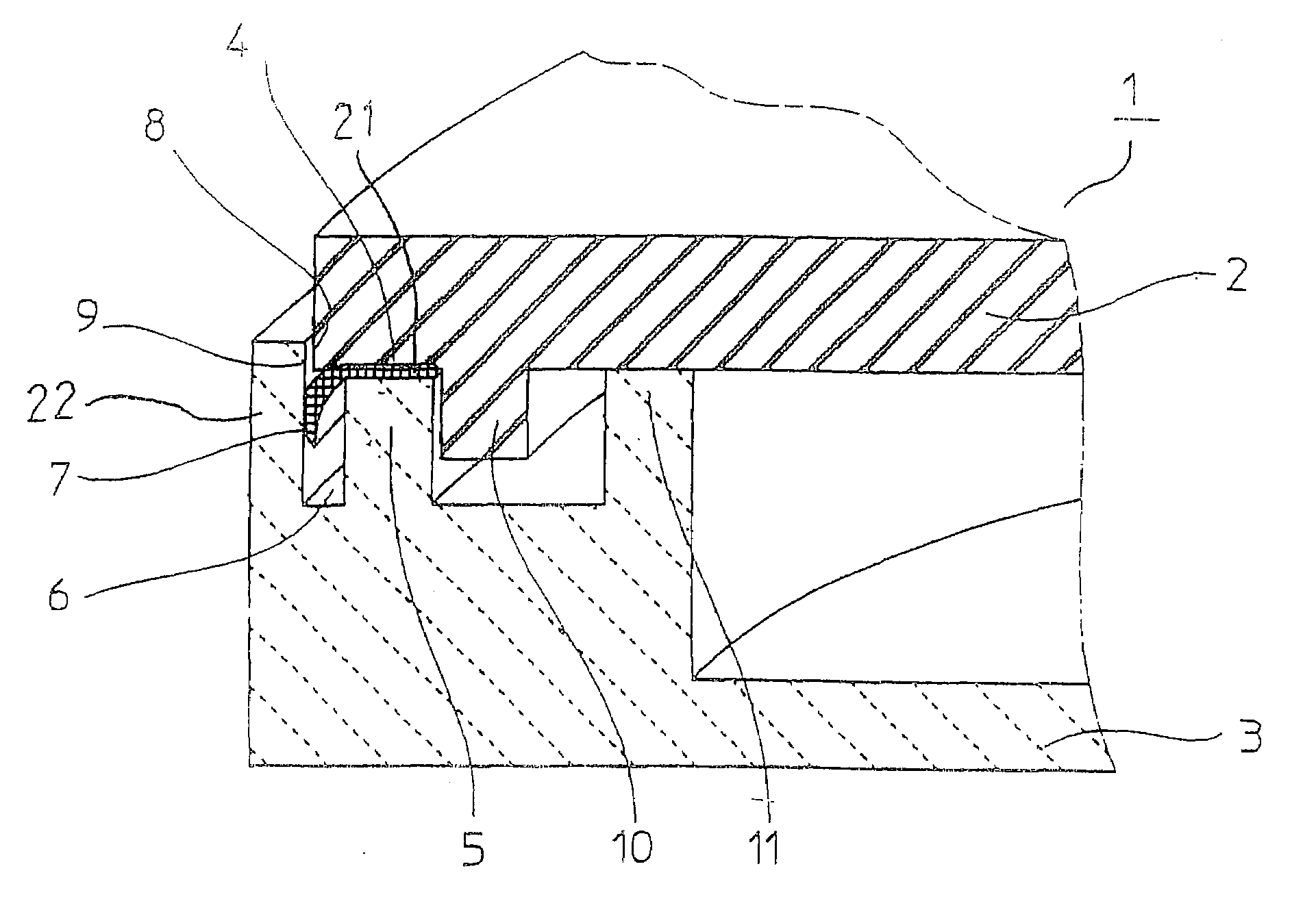

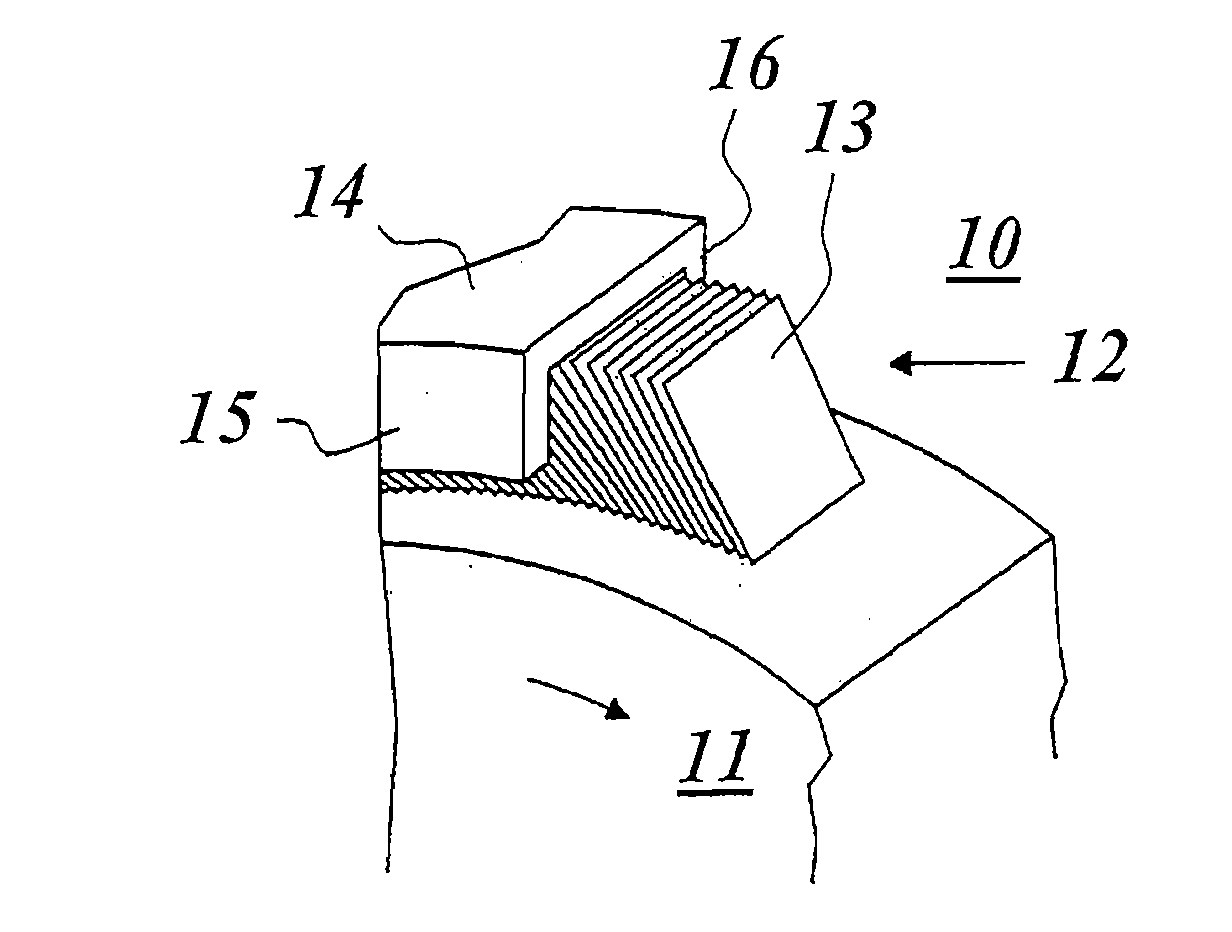

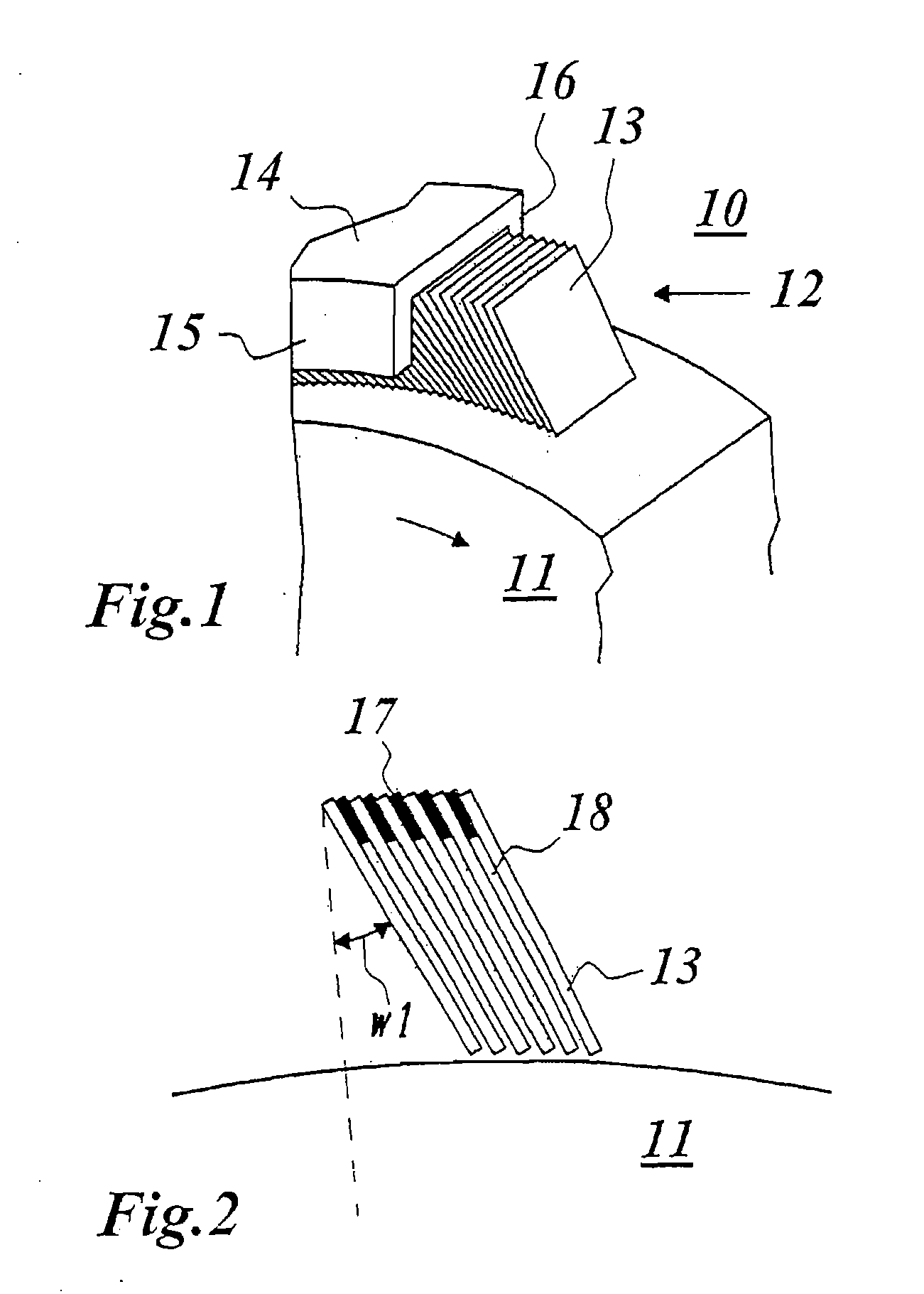

Leaf seal, in particular for a gas turbine, and method of producing it

InactiveUS20070120326A1DistanceAccurate settingEngine sealsLeakage preventionLiquid stateBraze alloy

A leaf seal for sealing a shaft rotating about an axis, in particular in a gas turbine, includes a plurality of spaced-apart leaves arranged in a concentric circle around the axis and fixed in position by brazing, the leaves having surfaces oriented essentially parallel to the axis. The leaves are brazed to one another via intermediate spacers made of a brazing foil, so that a brazed joint is produced by brazing alloy from the brazing foils. The brazing temperature may be set to an optimum value just above the solidus temperature of the brazing foil, at which partial melting of the brazing foil occurs and penetration of liquid brazing alloy into the gap between the leaves is avoided.

Owner:ANSALDO ENERGIA IP UK LTD

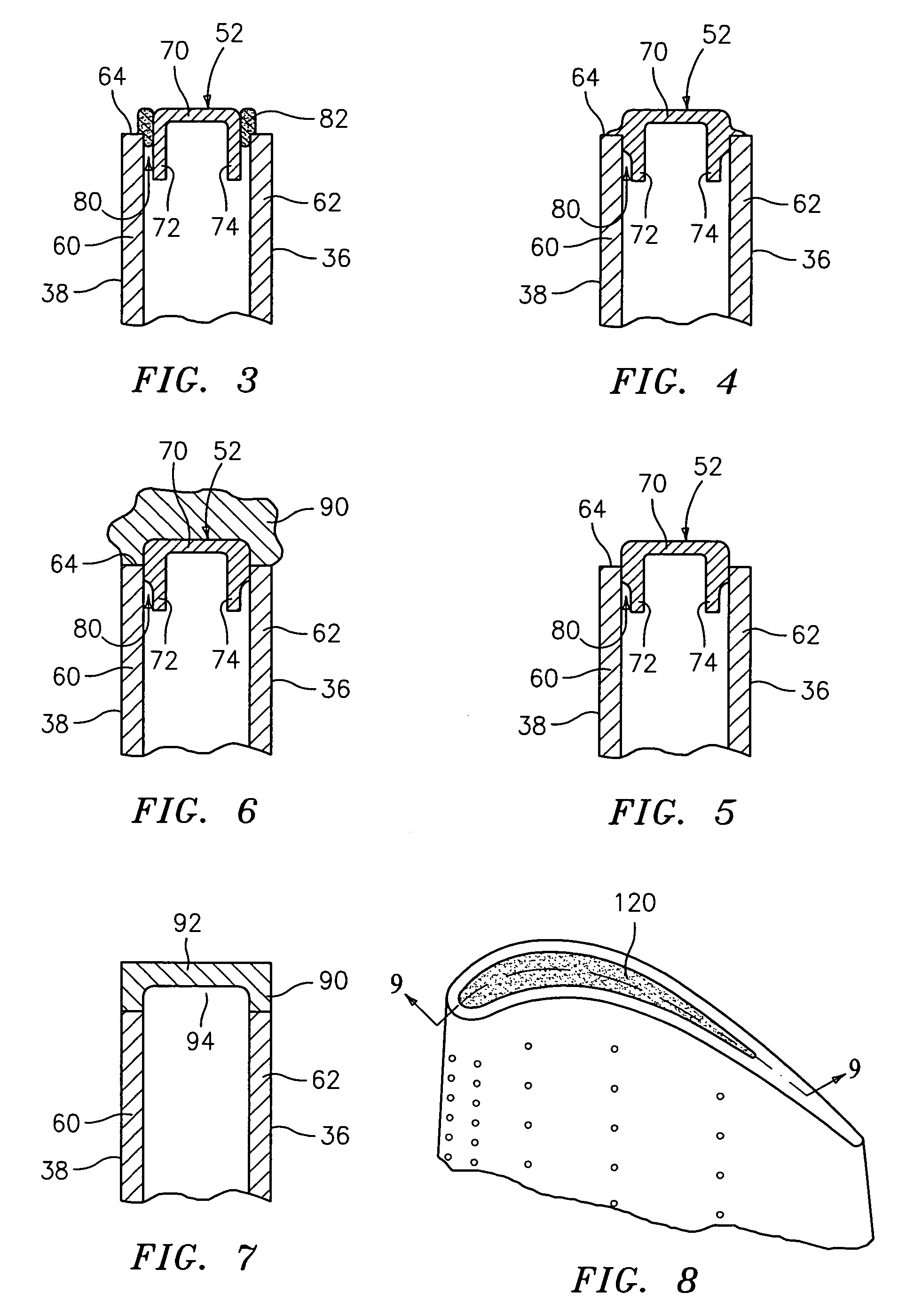

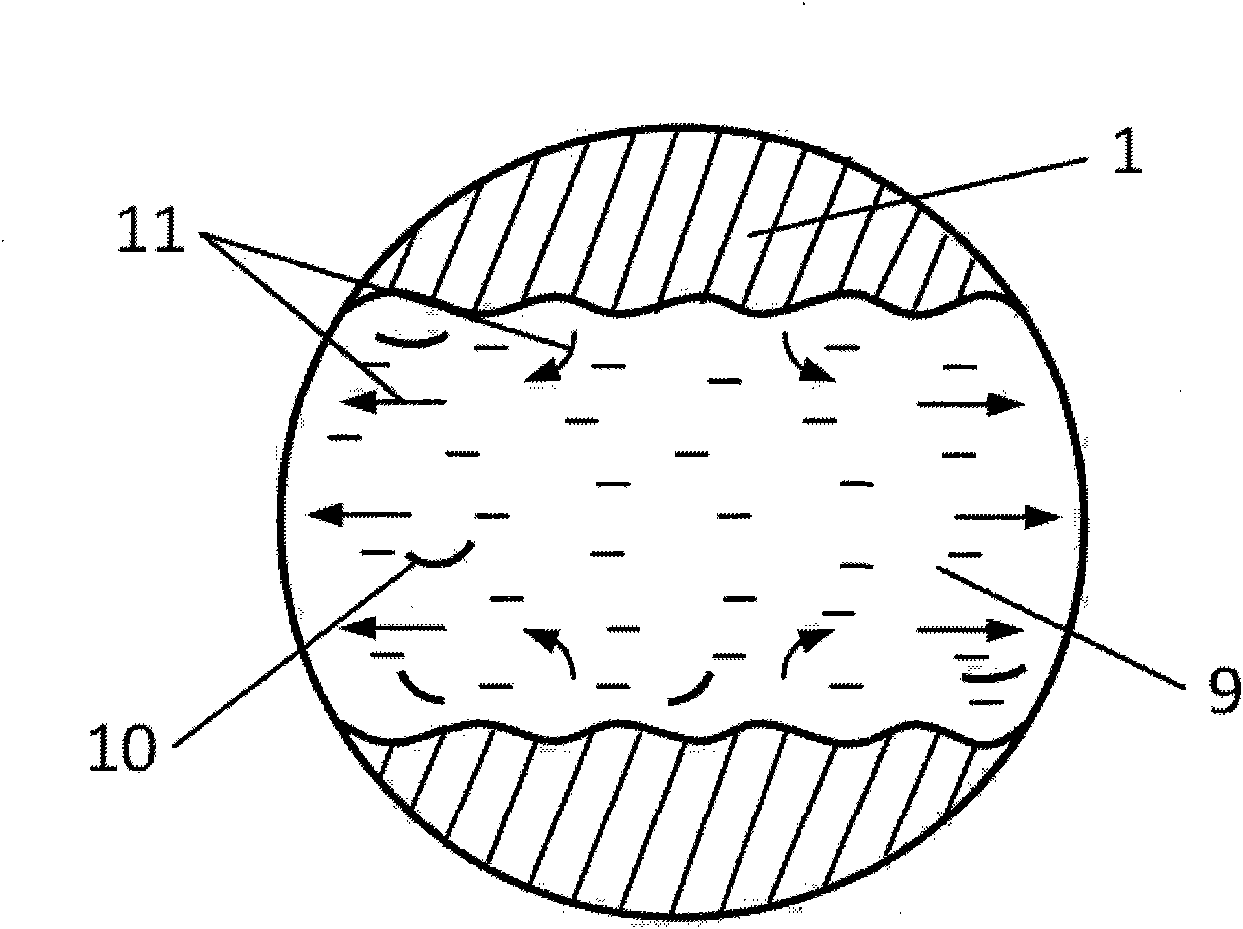

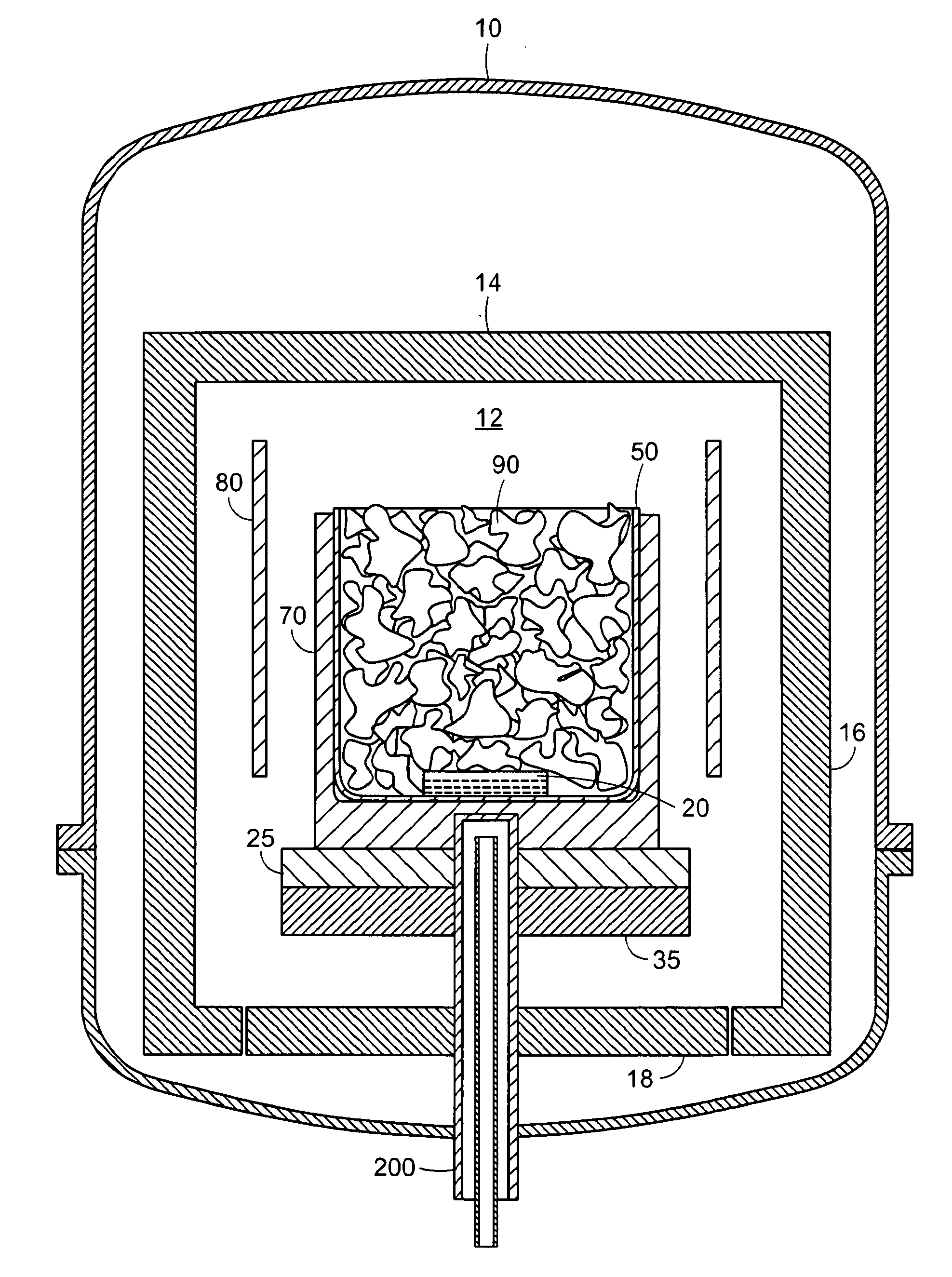

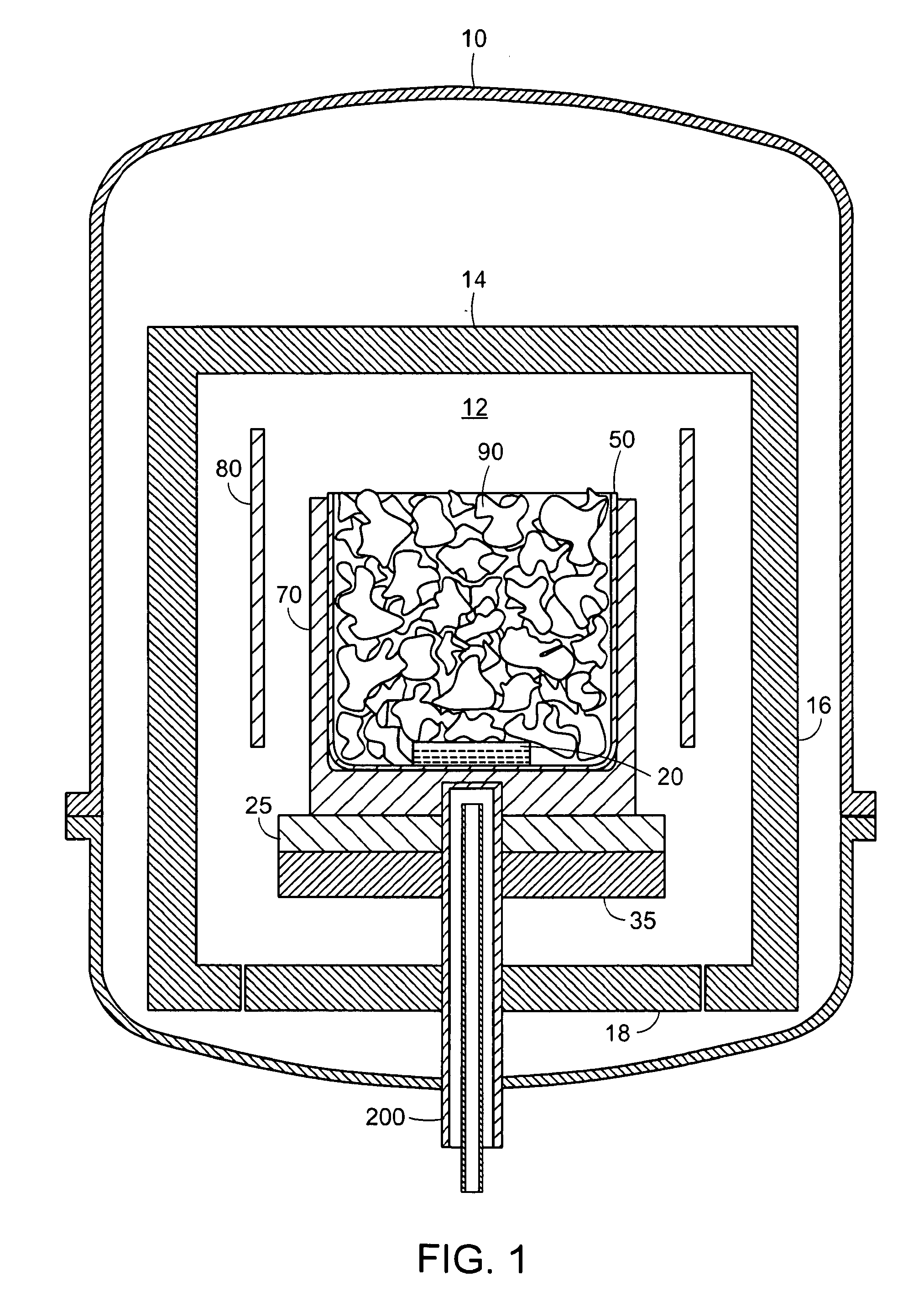

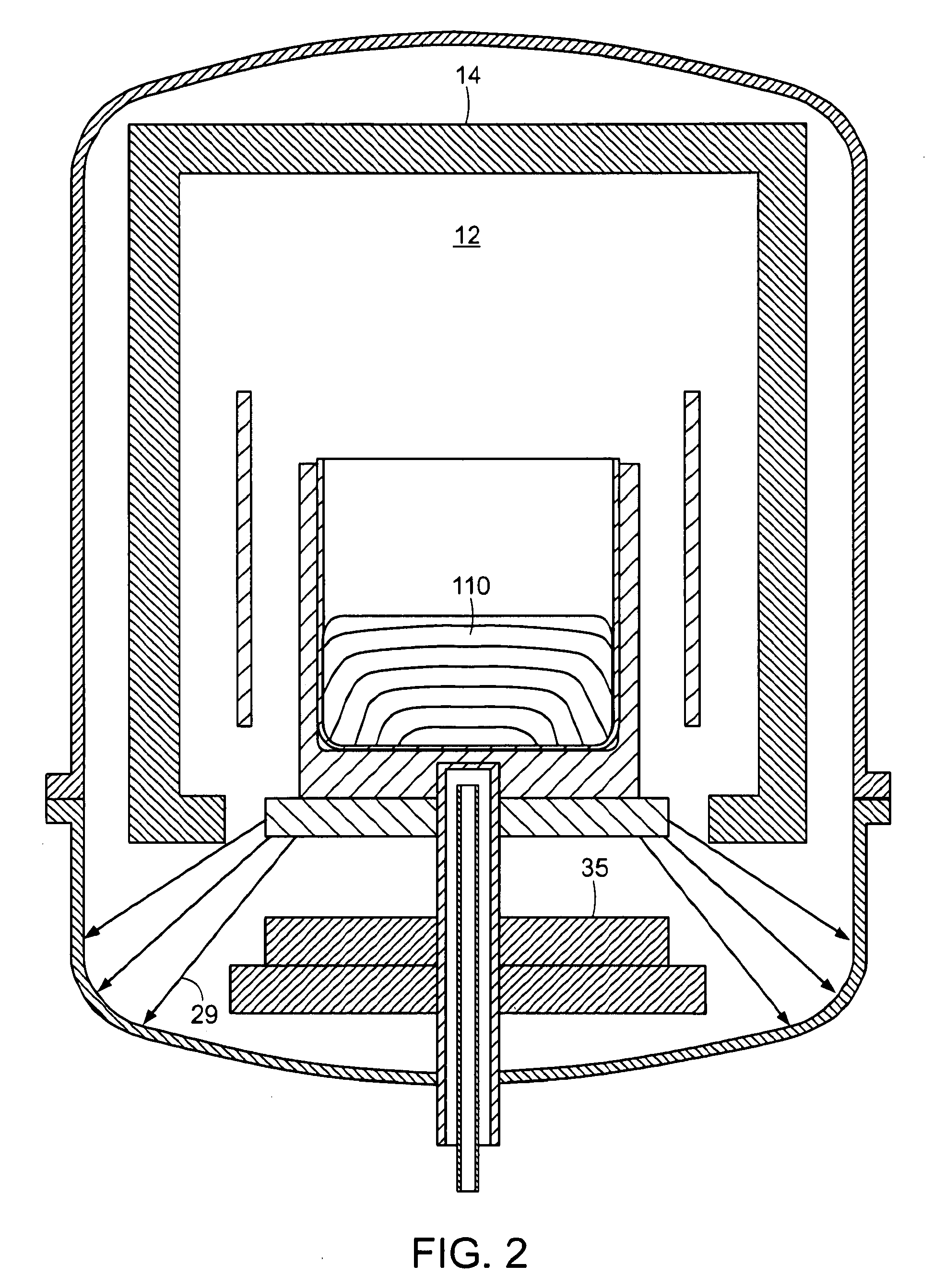

Systems and methods for growing monocrystalline silicon ingots by directional solidification

InactiveUS20110259262A1Quality improvementEfficiency savingPolycrystalline material growthBy zone-melting liquidsGrowth phaseCrucible

Systems and methods are provided for producing monocrystalline materials such as silicon, the monocrystalline materials being usable in semiconductor and photovoltaic applications. A crucible (50) is received in a furnace (10) for growing a monocrystalline ingot, the crucible (50) initially containing a single seed crystal (20) and feedstock material (90), where the seed crystal (20) is at least partially melted, and the feedstock material (90) is completely melted in the crucible (50), which is followed by a growth and solidification process. Growth of monocrystalline materials such as silicon ingots is achieved by directional solidification, in which heat extraction during growth phases is achieved using insulation (14) that is movable relative to a crucible (50) containing feedstock (90). A heat exchanger (200) also is provided to control heat extraction from the crucible (50) during the growth and solidification process to achieve monocrystalline growth.

Owner:GT SOLAR INC

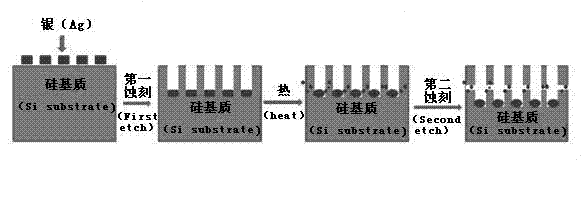

Large-area layering etching and transferring method of auxiliary metal silicon nanometer line array

InactiveCN102701138ATake advantage ofDecorative surface effectsChemical vapor deposition coatingSilicon nanowiresMetal

The invention discloses a large-area layering etching and transferring method of an auxiliary metal silicon nanometer line array. The method comprises the steps: carrying out heating treatment on an Si (silicon) sheet which is etched once by a wet process in air; partially fusing an Ag (silver) nanometer particle catalyst on the bottom part of the silicon nanometer line array; attaching a part of Ag nanometer particles to the lateral wall of the silicon nanometer line array; transversely etching the attached Ag nanometer particles in a re-etching process; carrying out secondary etching reaction on the silicon nanometer line array to generate a regular fault; and stripping off the silicon nanometer line array on the fault by an adhesive tape. The invention provides a layering etching and transferring method of the silicon nanometer line array for industrial production, so that full utilization of a body silicon substrate material and manufacture of a flexible silicon nanometer device can be achieved.

Owner:SUZHOU UNIV

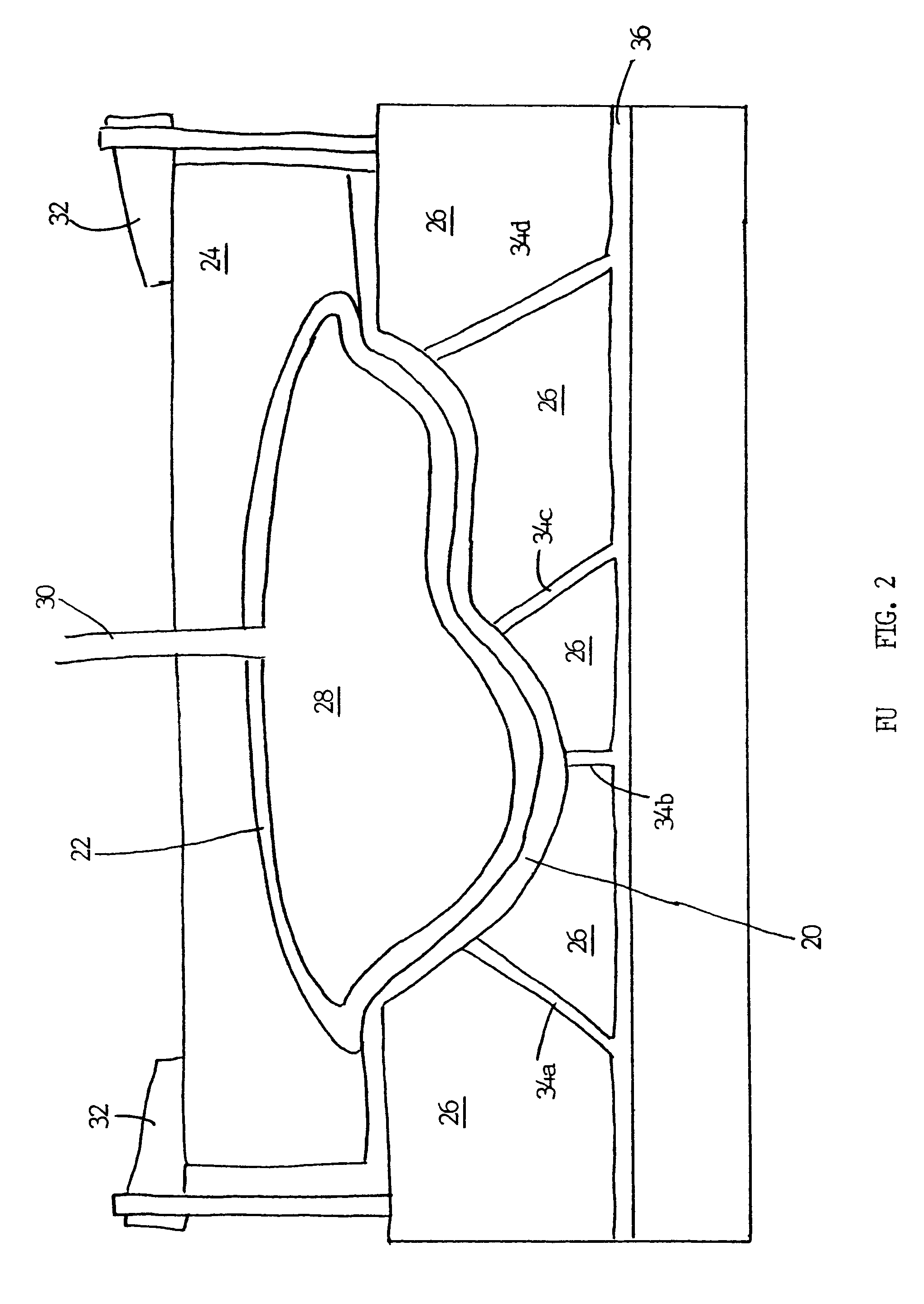

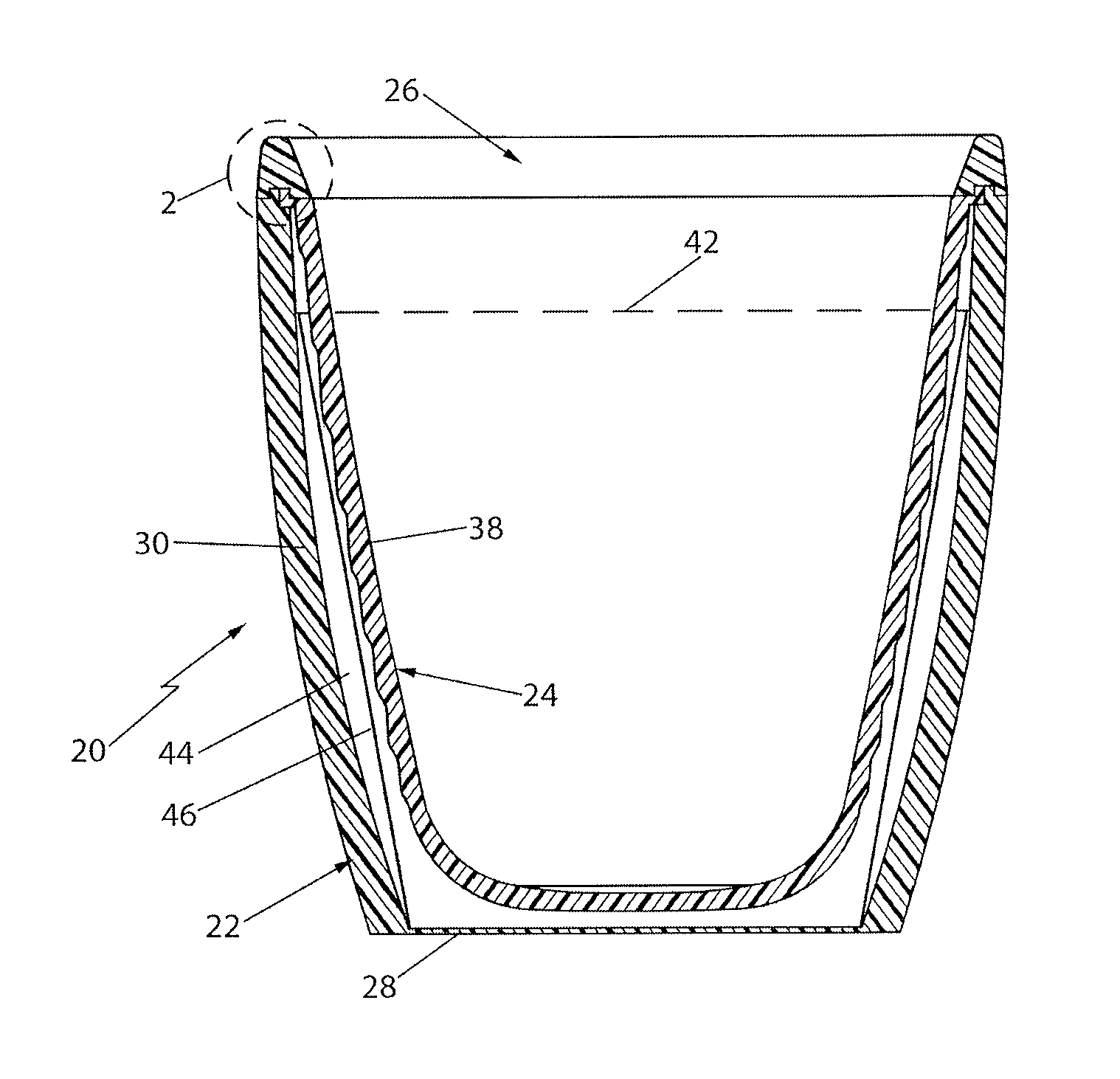

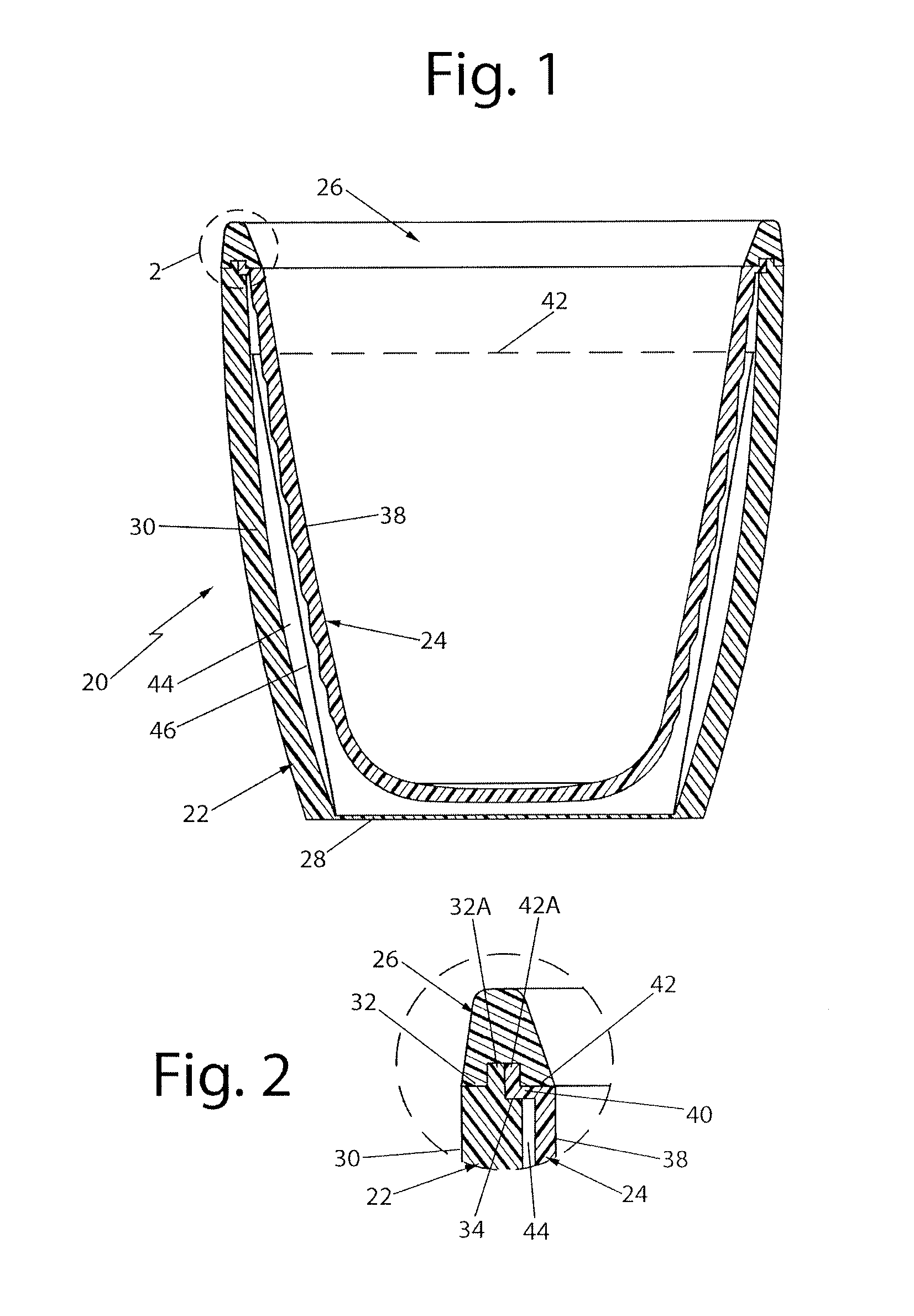

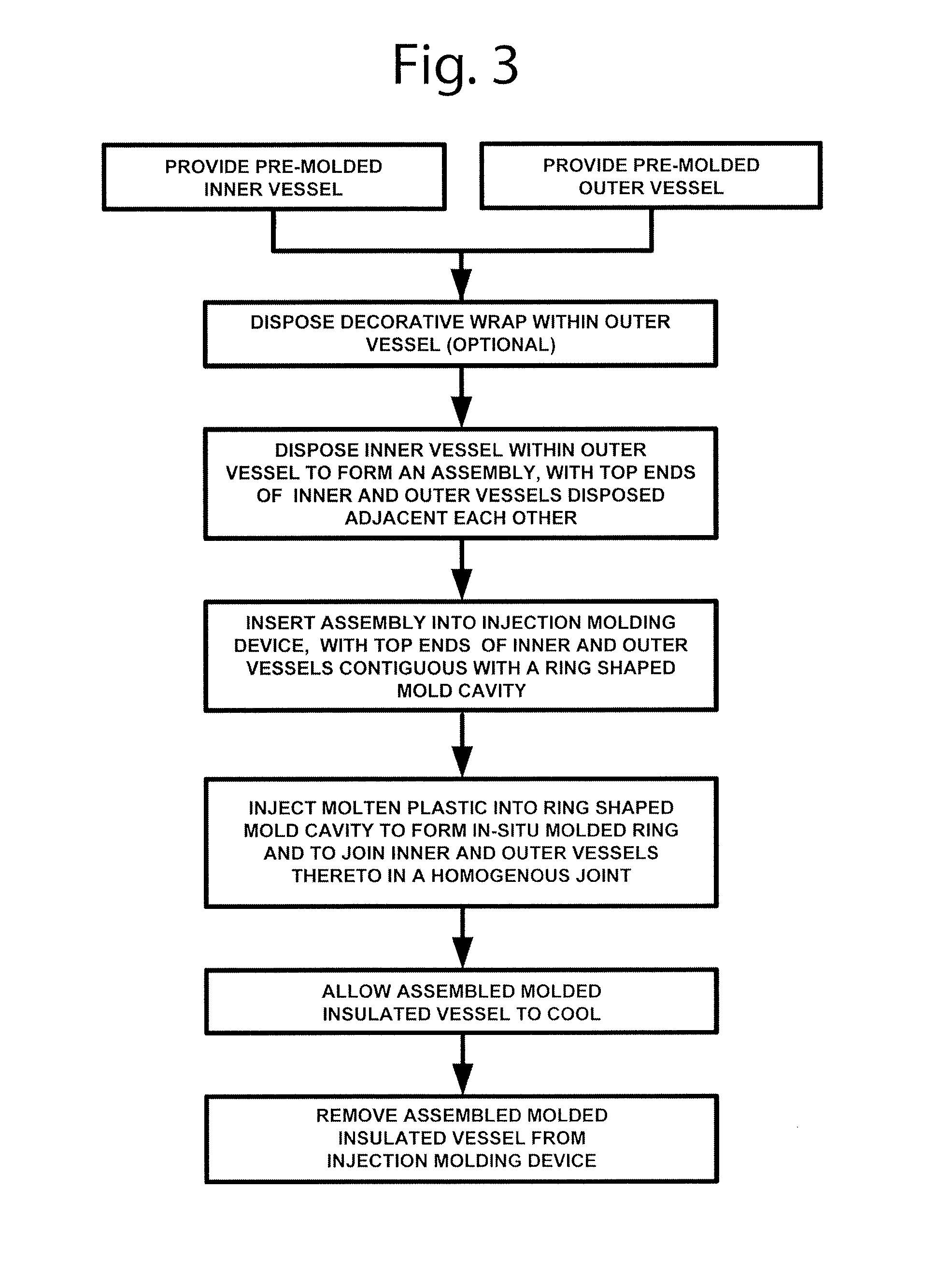

Insulated double walled drinking vessel and method of making the same

An insulated drinking vessel, e.g., a tumbler, and method of making the same is disclosed. The vessel basically comprises a pre-molded inner vessel formed of a plastic material having a sidewall is disposed within a pre-molded outer vessel formed of a plastic material having a sidewall to form a subassembly having an insulating air space between the sidewalls. Each of the vessels includes a contoured surface including at least one projection or depression. A ring of plastic material is molded in-situ on the contoured surfaces to cause portions thereof to melt and intermingle with the plastic material of the ring to form a homogenous joint having a depth no greater than approximately 0.003 inch. The ring forms the rim or lip of the insulated drinking vessel.

Owner:TERVIS TUMBLER

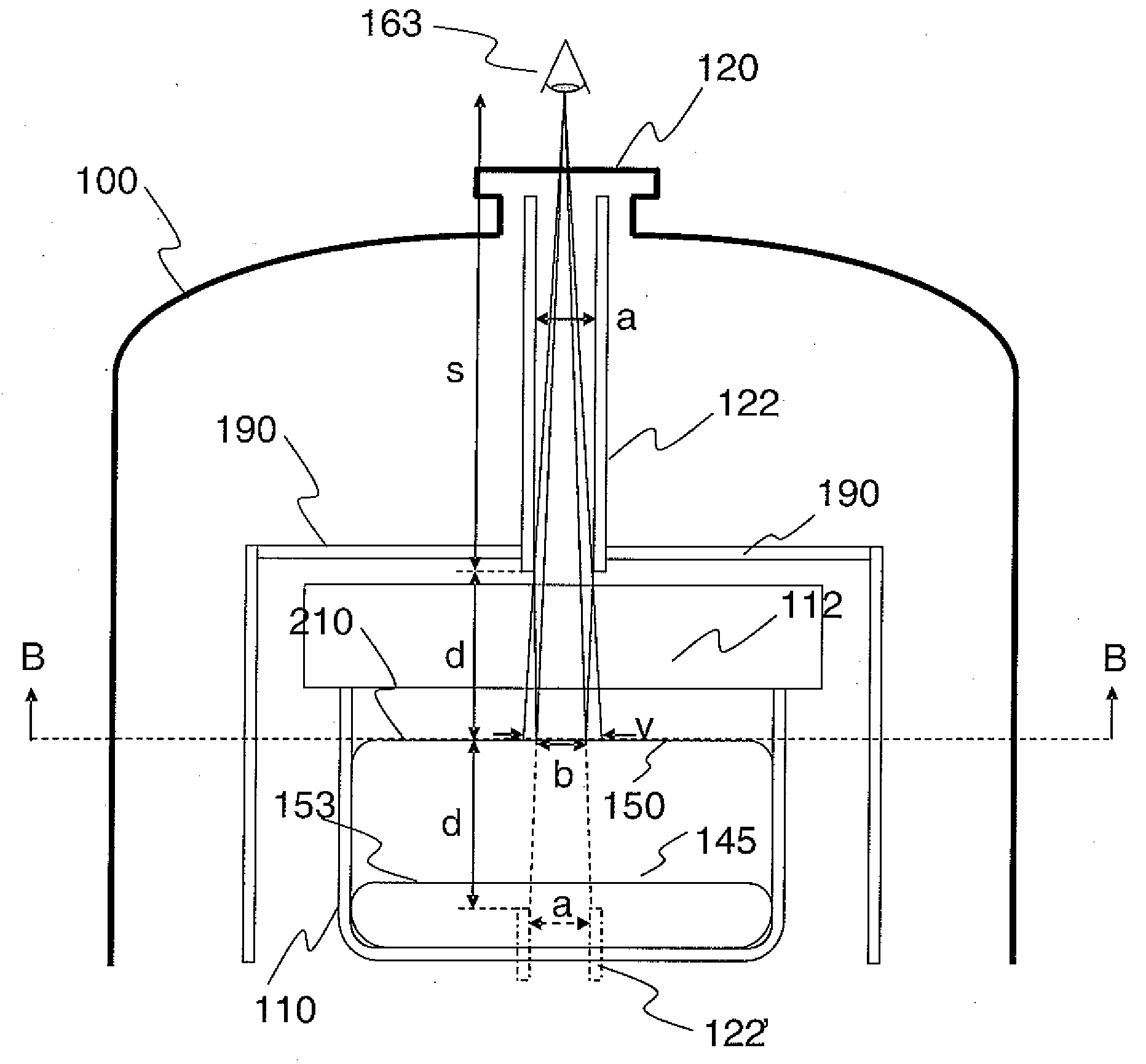

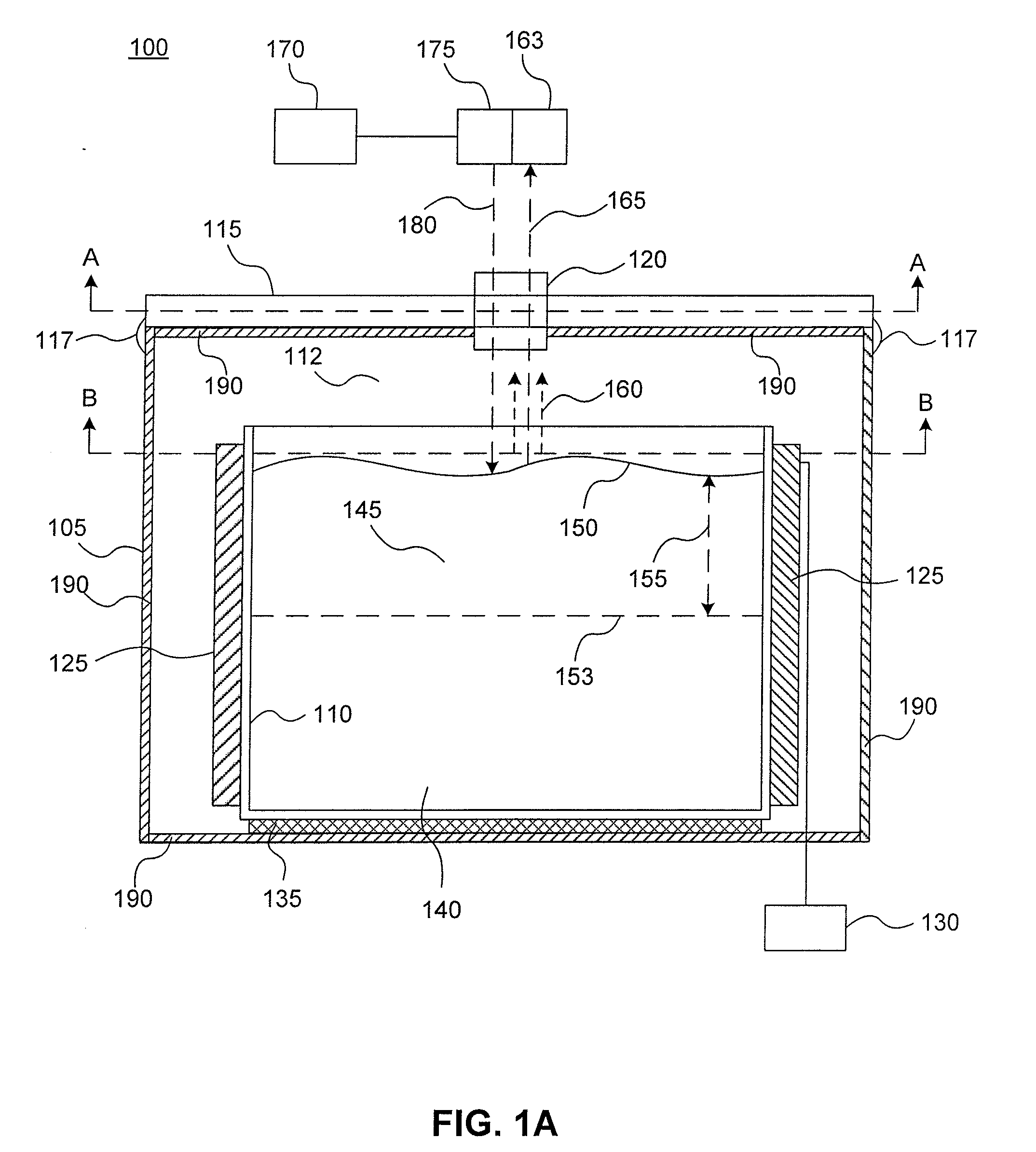

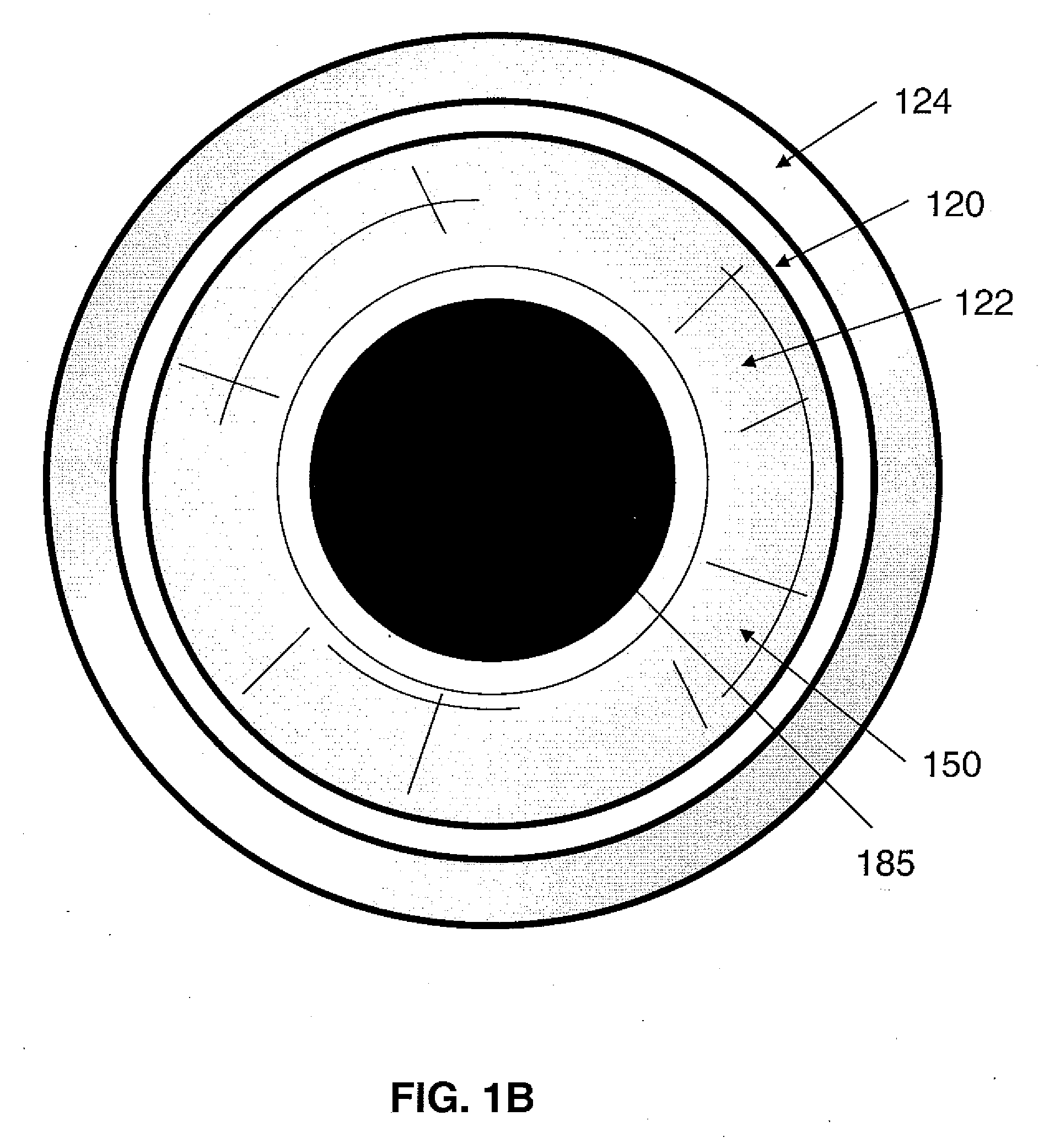

Methods and Systems for Monitoring a Solid-Liquid Interface

InactiveUS20090116019A1Vibration measurement in solidsOptical radiation measurementGravitational constantLiquid surfaces

Methods and systems are provided for monitoring a solid-liquid interface, including providing a vessel configured to contain an at least partially melted material; detecting radiation reflected from a surface of a liquid portion of the at least partially melted material that is parallel with the liquid surface; measuring a disturbance on the surface; calculating at least one frequency associated with the disturbance; and determining a thickness of the liquid portion based on the at least one frequency, wherein the thickness is calculated based onL=f2w2g,where g is the gravitational constant, w is the horizontal width of the liquid, and f is the at least one frequency.

Owner:BP CORP NORTH AMERICA INC

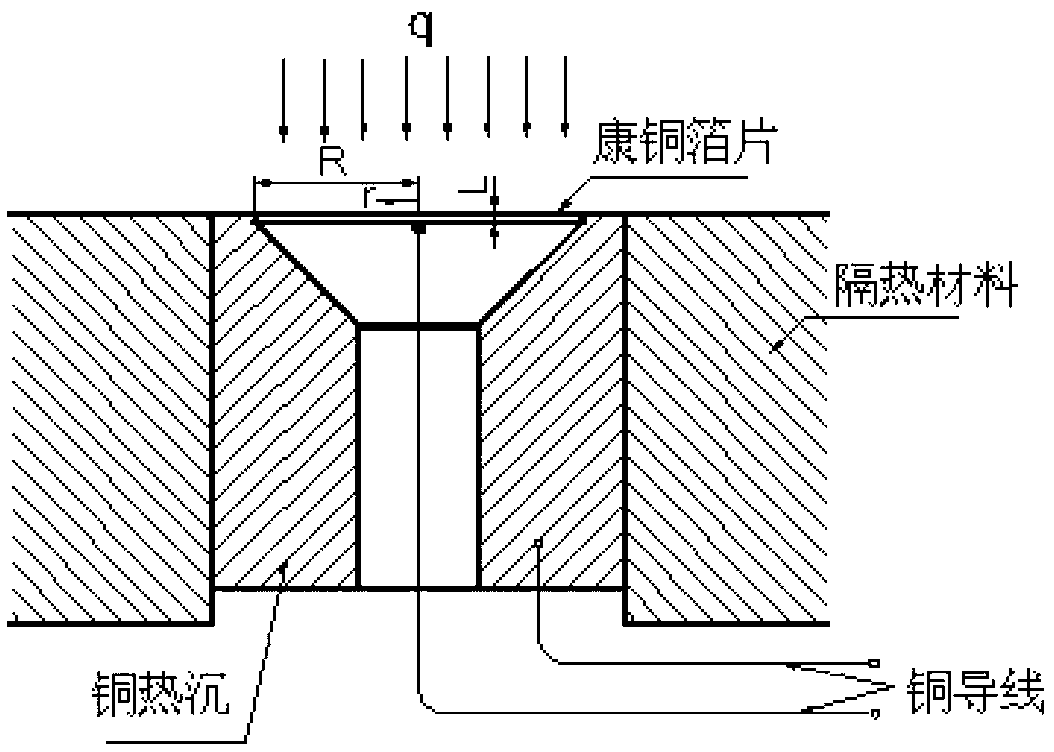

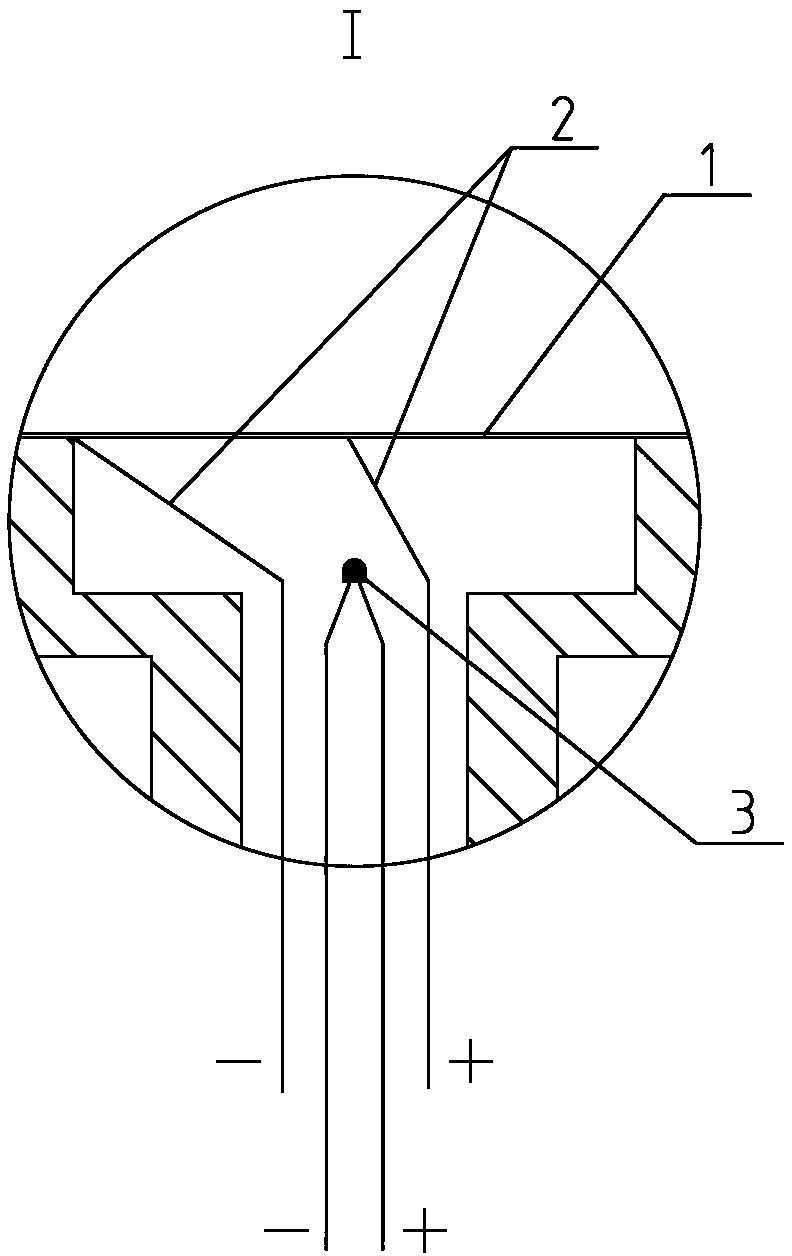

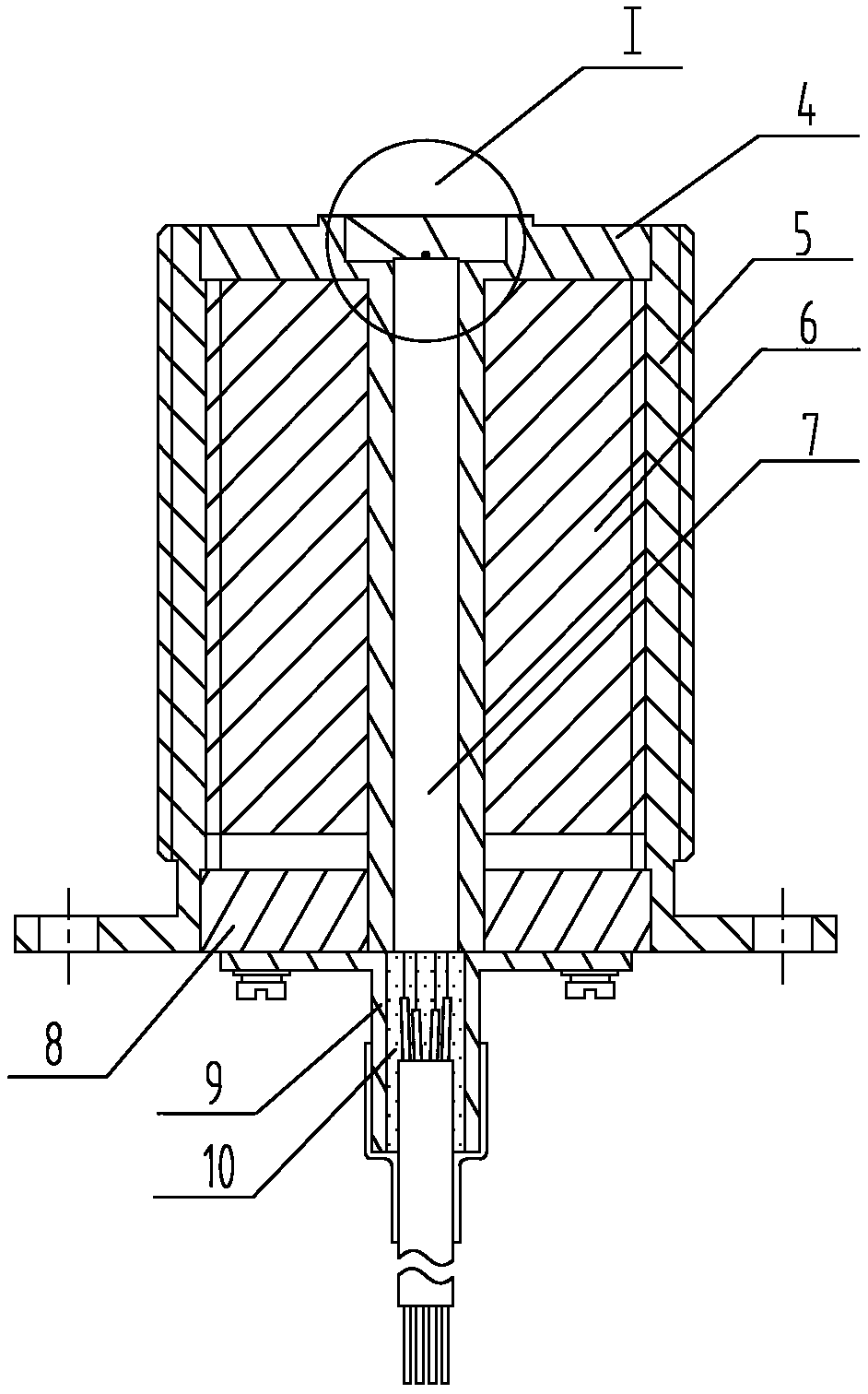

Phase-change heat accumulation type heat flow sensor

ActiveCN103217233AExtended working hoursAbsorb moreThermometers using electric/magnetic elementsUsing electrical meansHeat flowTemperature monitoring

The invention relates to a phase-change heat accumulation type heat flow sensor mainly consisting of a shell, an upper cover, a lower cover, a back cover, a phase-change heat accumulation body, a constantan circular foil, two nickel chrome wires, a thermoelectric couple, a four-hole aluminum oxide ceramic tube and the like, wherein the surface of the constantan circular foil is blacked, the constantan circular foil and the two nickel chrome wires form a measurement end surface sensitive body, the upper cover is welded with the shell after being welded with the measurement end surface sensitive body; after the phase-change heat accumulation body is screwed in, the lower cover is welded with the shell; and the two nickel chrome wires at the constantan circular foil and the thermoelectric couple are drawn out by the back cover in a fastening manner after passing through the four-hole aluminum oxide ceramic tube. According to the phase-change heat accumulation type heat flow sensor disclosed by the invention, by utilizing the phase-change heat accumulation principle, the working time is remarkably prolonged; by utilizing an E-shaped difference thermocouple, the high temperature resistance of the measurement end surface is largely improved; and by utilizing the thermocouple, a measurement end part is added with a temperature monitoring function and the situations that the measurement end part is molten, burn and the like are avoided.

Owner:BEIJING RES INST OF TELEMETRY +1

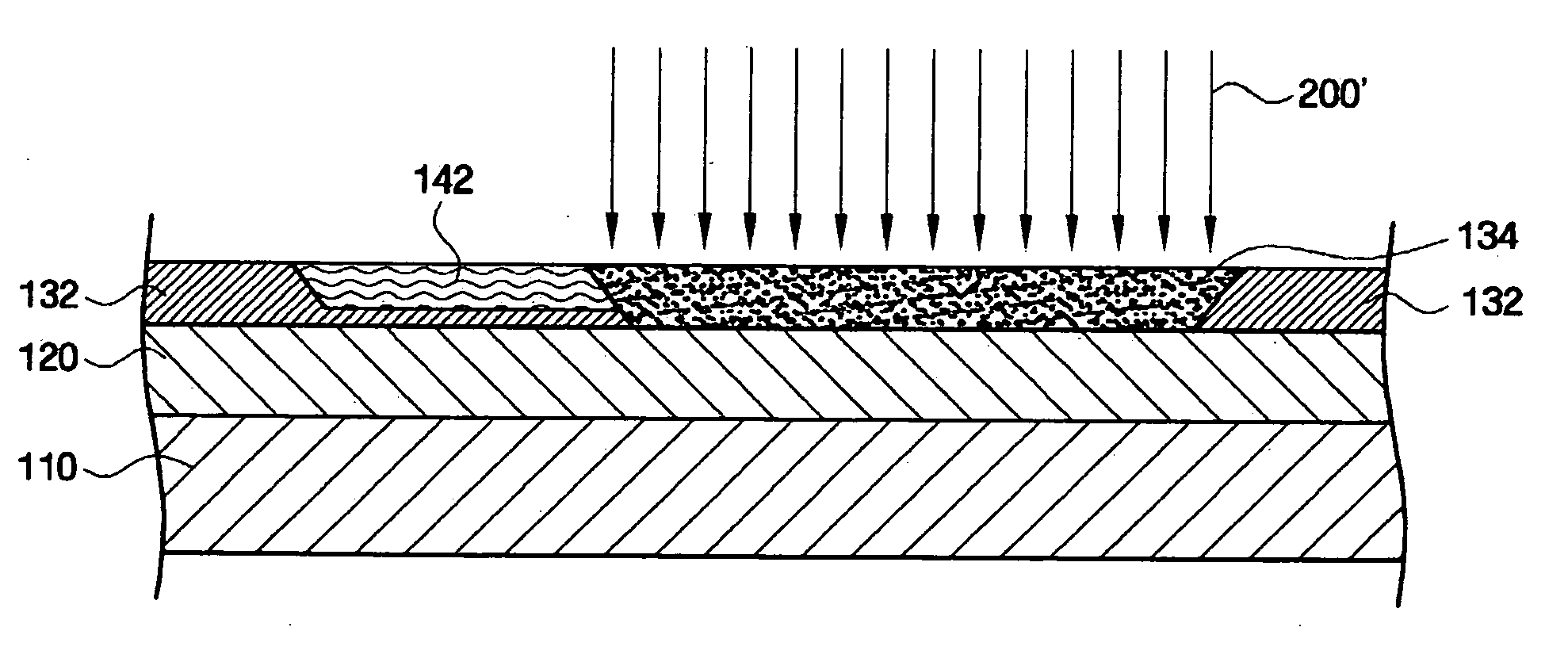

Microwave brazing process for forming coatings

ActiveUS20080145566A1Not to significantly degradeSelective heatingTurbinesRadiation applicationsMetallurgyMicrowave irradiation

A process for forming a coating on a surface of a substrate, so that heating of the coating material is selective and sufficient to cause at least partial melting of the coating material and permit bonding to the substrate without excessively heating the substrate so as not to significantly degrade its properties. The process generally entails forming a brazing paste containing powder particles dispersed in a binder. The particles are formed of a composition that is susceptible to microwave radiation. The brazing paste is then applied to the surface of the substrate and subjected to microwave radiation so that the particles couple with the microwave radiation and are sufficiently heated to burn off the binder and then at least partially melt to form an at least partially molten layer on the substrate. The microwave radiation is then interrupted to allow the at least partially molten layer to cool, solidify, and form the coating.

Owner:GENERAL ELECTRIC CO

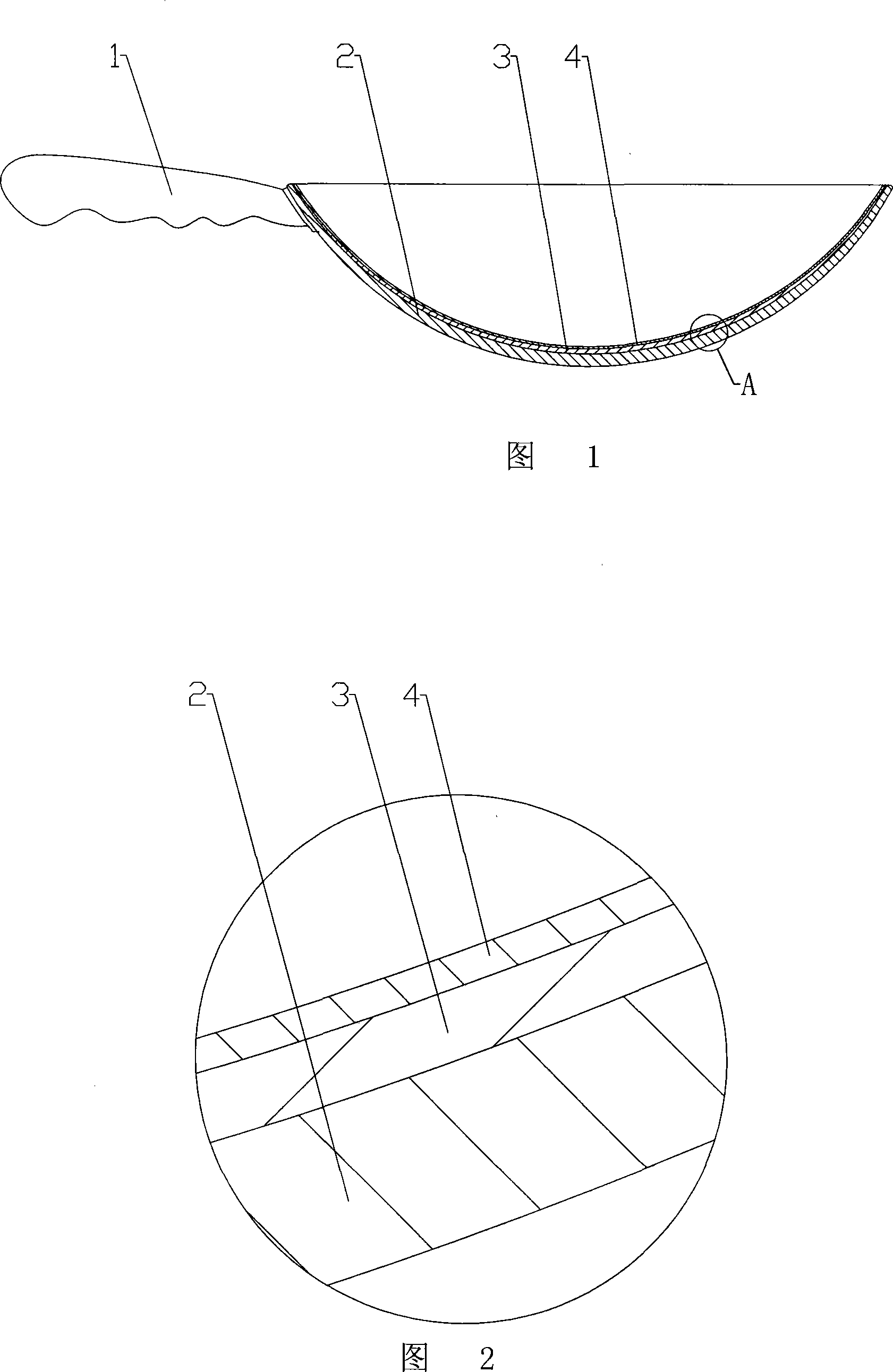

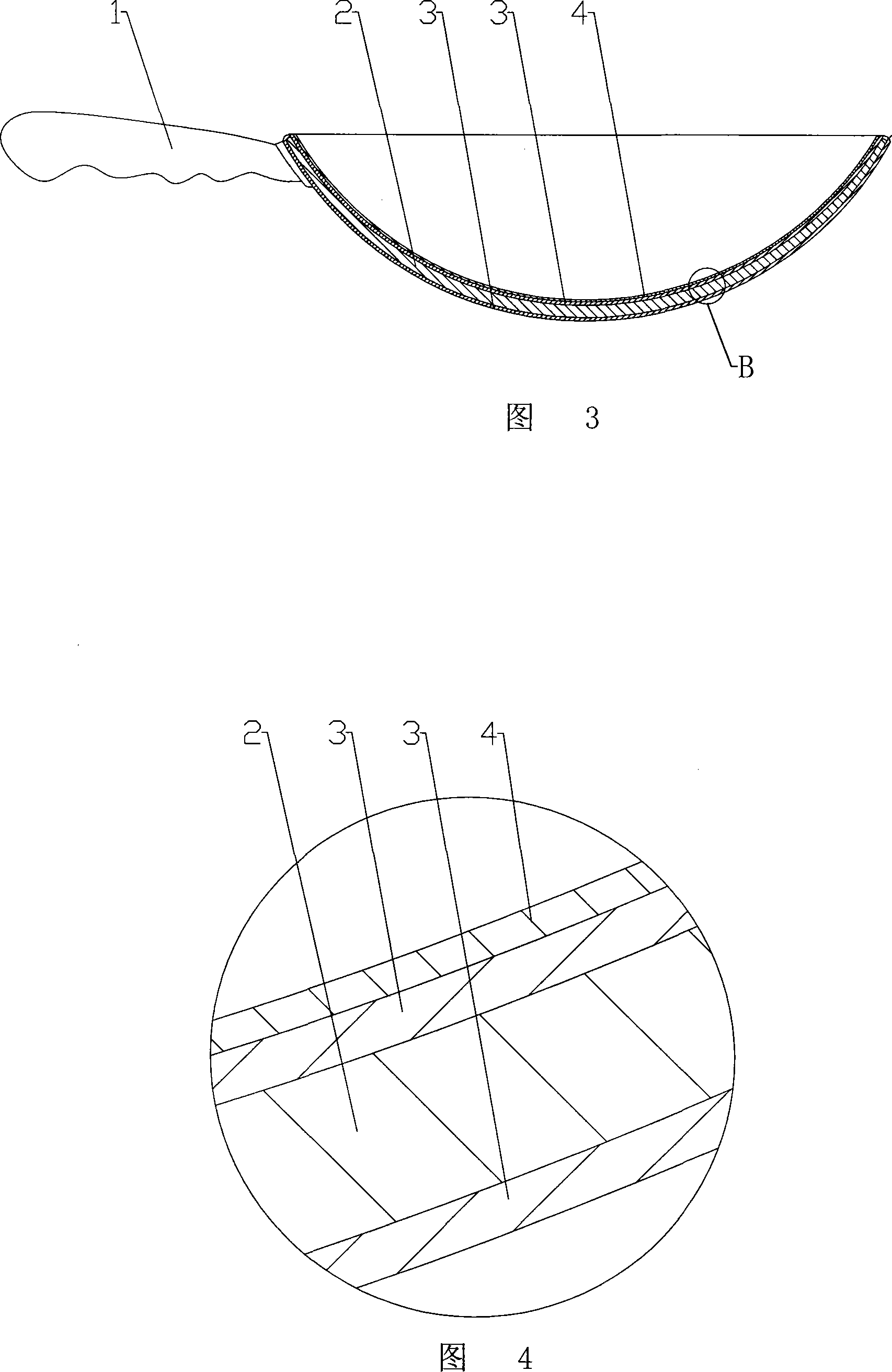

Cooker

InactiveCN101176616ADoes not cause peelingStrong adhesionCooking-vessel materialsMetallurgyCooking process

The invention relates to a pan, comprising a pan body; wherein, a handle is arranged on the pan body, which comprises a metallic layer and a ceramic layer compounded as a whole. The metallic layer and the ceramic layer are close compounded as a whole through partial fusing or fusing; the ceramic layer on the inner surface of the pan body is covered with a non-stick layer with the component of ceramic, which is bound on the ceramic layer through 200 to 420 DEG C baking. The invention has the advantages that: since the metallic layer and the ceramic layer are close compounded as a whole through partial melting or melting, and the adhesive power between the metallic layer and the ceramic layer is strong, the desquamation of the ceramic layer is avoided after the using of metallic spade in the cooking process or a long-time using of the pan; the non-stick layer and the ceramic layer are hard connected since the non-stick layer comprises the component of ceramic.

Owner:卢雄文

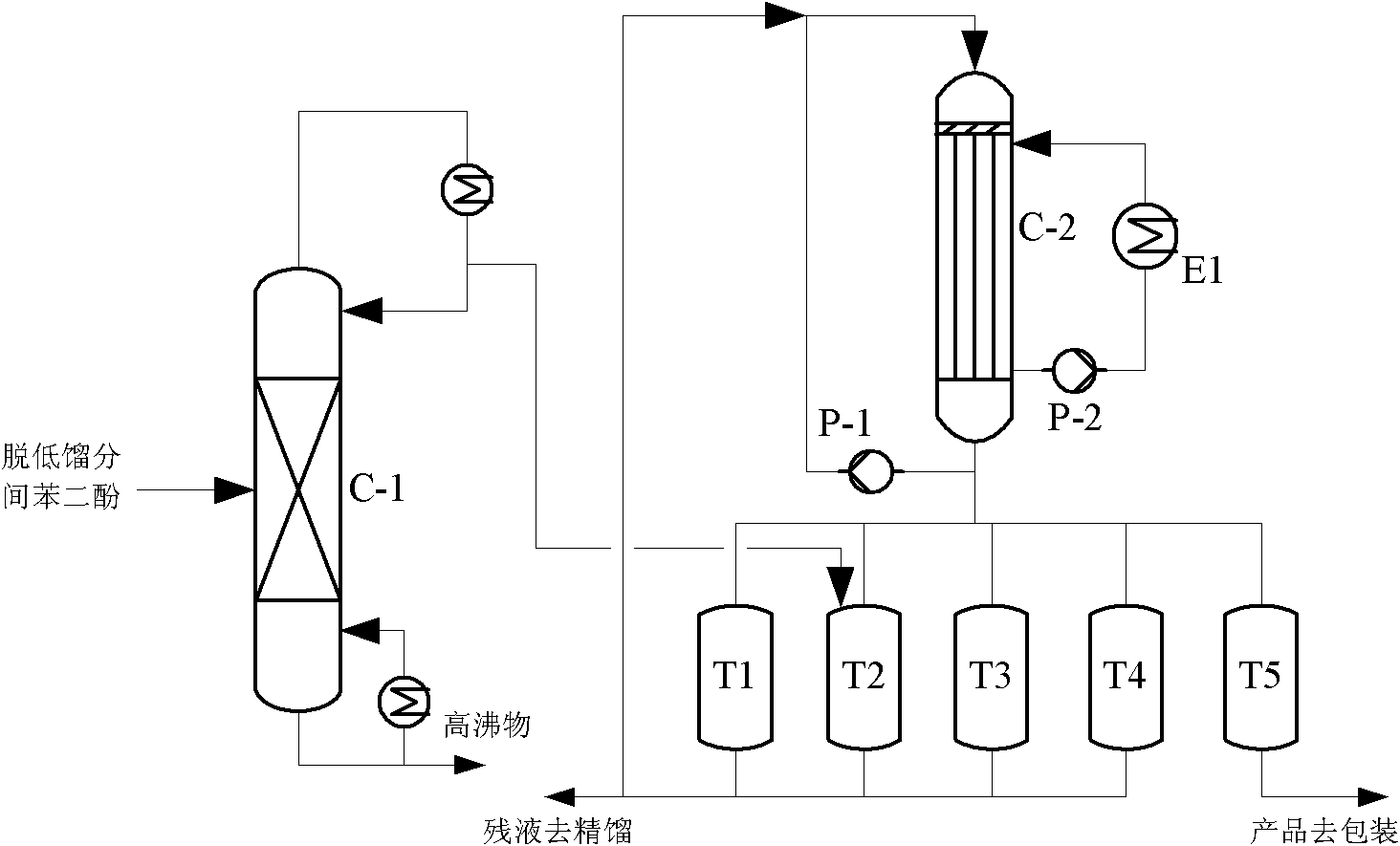

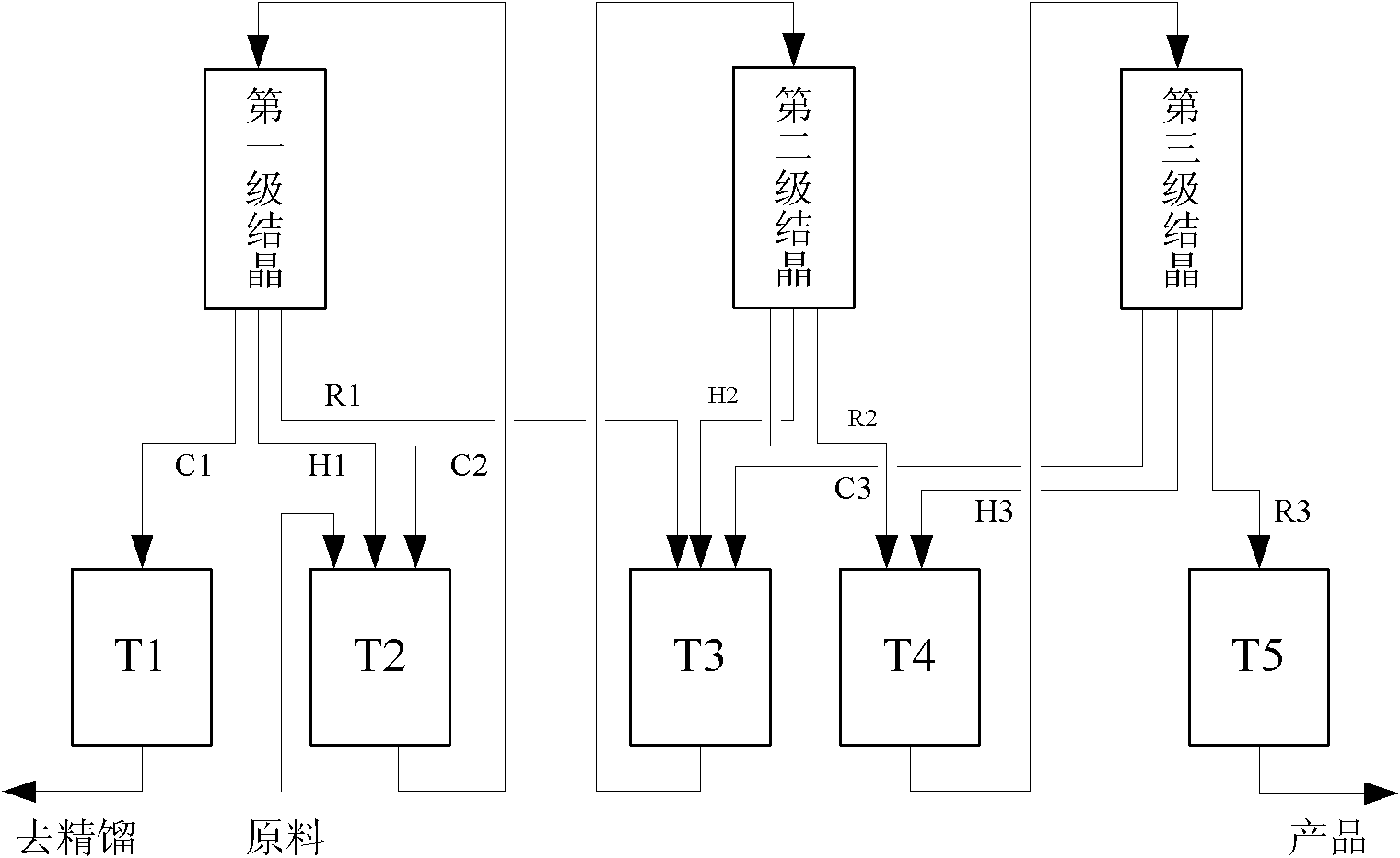

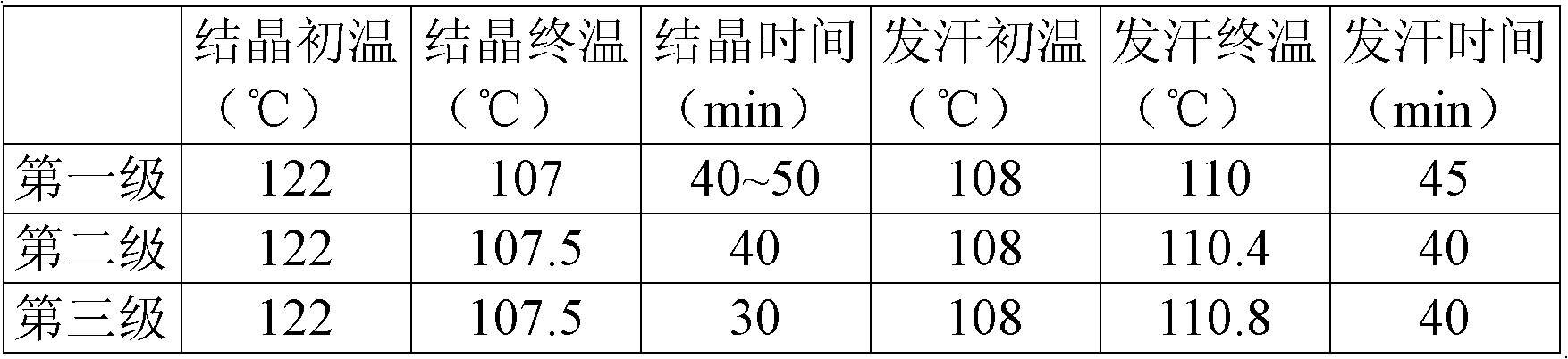

Method for preparing high-purity resorcinol through melt crystallization

ActiveCN102464573AHigh purityHigh yieldOrganic chemistryOrganic compound preparationWastewaterSolvent

The invention provides a method for preparing high-purity resorcinol through melt crystallization. The method mainly comprises steps of melt crystallization, partial melting (sweating) and melting. According to the invention, a graded melt crystallization method is adopted, and the process is carried out in a falling film dynamic crystallization device, such that non-pure resorcinol is purified. The adopted grade number should satisfy a final purity expectation obtained with a high yield. At least one grade is adopted, and commonly several grades are adopted. The grade number varies from 1 to 4, such that a complete resorcinol product crystallization refining circulation is formed. The method is advantaged in that: no solvent is required by melt crystallization, such that the product is prevented from being polluted by exterior solvents or other materials. Especially, latent pollution to resorcinol caused by back-mixing of solution crystallization impurities and degradation reactions caused by high rectification temperature can be prevented, and the influence of waste water caused by solution crystallization to the environment can be avoided. The product yield is high, the product purity is high, and the production efficiency is high.

Owner:ZHEJIANG HONGSHENG CHEM IND +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com