Powder medium diffusion reaction resistance brazing method of magnesium alloy

A diffusion reaction and resistance brazing technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of high thermal conductivity of magnesium alloys, difficult welding process, large coefficient of linear expansion, etc., to improve metallurgical behavior, formula Flexible, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

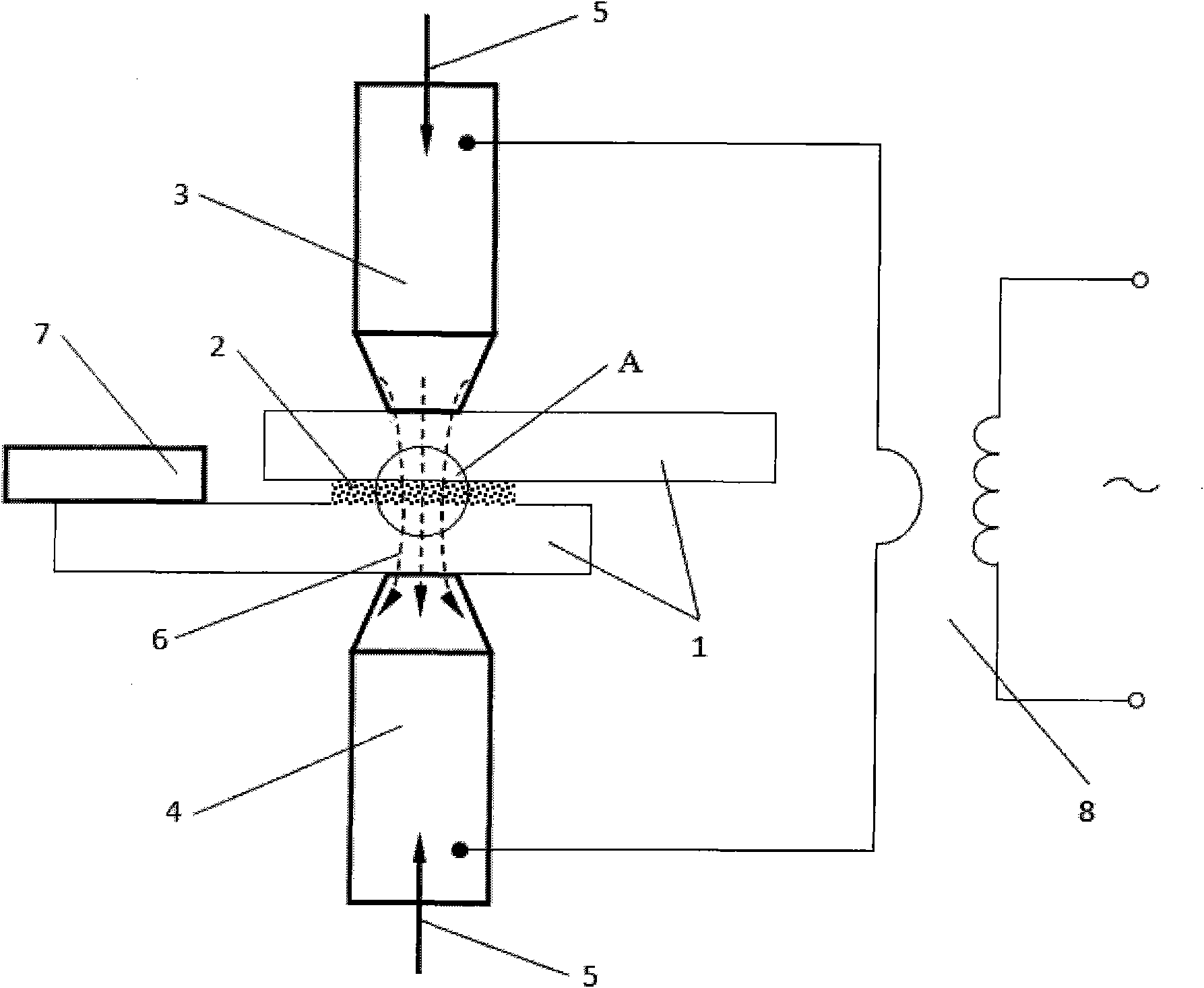

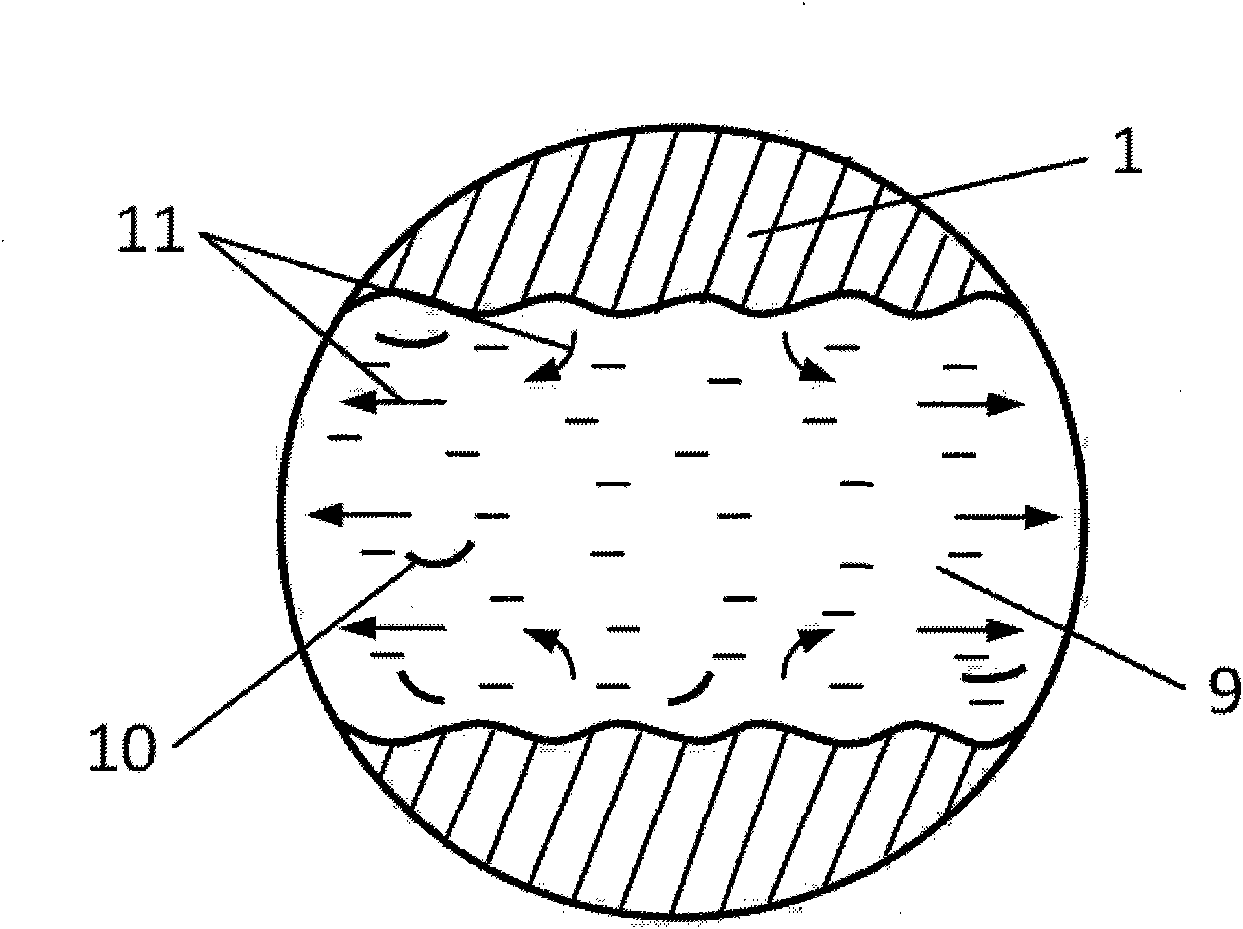

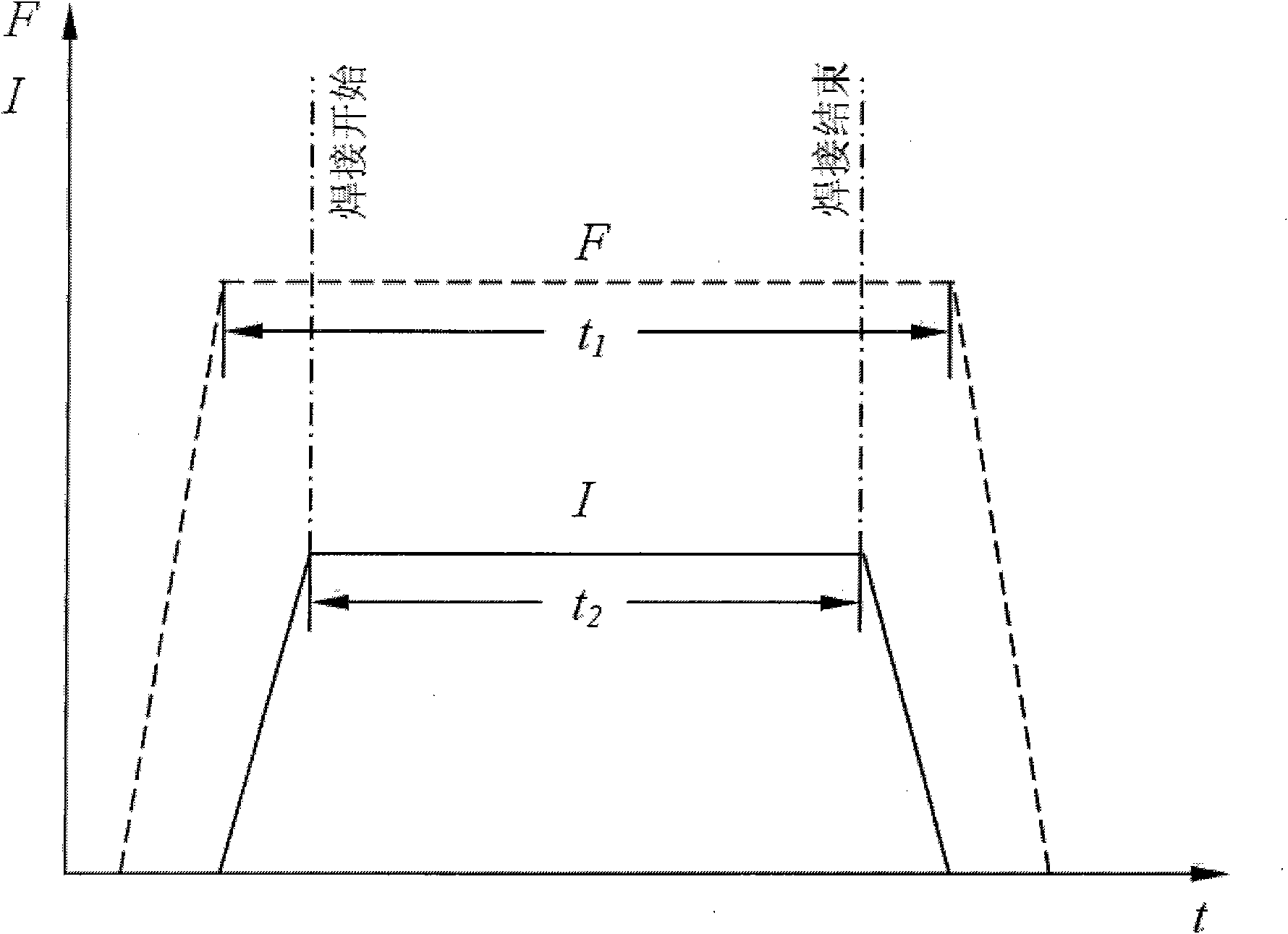

[0040] Embodiment 1: The clamping and welding process of the materials to be welded are as follows figure 1 , image 3 As shown, it is a single pulse current welding process. The AZ31B magnesium alloy workpiece 1 is the overlapping joint of two flat plates with a thickness of 1 mm. After the magnesium-based powder medium is uniformly mixed with acetone, the pressure sprayer is evenly sprayed on the surface of the magnesium alloy workpiece 1 to be welded to form a powder medium filling layer 2 . Set the main welding parameters as: welding current I=12000A, electrode pressure F=1570N, welding current duration t 2= 1.5s. After the acetone in the powder filling layer is volatilized, the flat plate workpieces to be welded are overlapped and clamped between the upper and lower electrodes 3 and 4. Aim the protective gas nozzle 6 at the welding area, turn on the argon gas protection, and the gas flow rate is 4L / min. Apply electrode pressure F to make the workpieces to be welded t...

Embodiment 2

[0041] Embodiment 2: The clamping of materials to be welded and the welding process are as follows figure 1 , Figure 4 As shown, it is a double pulse current welding process. and image 3 Compared with the process flow shown, Figure 4 The process flow increases the auxiliary welding current I 2 , keep the filling layer of the welded joint at a higher temperature for a certain period of time to facilitate the diffusion of dissimilar metals. The AZ31B magnesium alloy workpiece 1 is the overlapping joint of two flat plates with a thickness of 1 mm. After the magnesium-based powder medium is uniformly mixed with acetone, it is uniformly sprayed on the surface of the workpiece 1 to be welded by a pressure sprayer to form a filling layer 2 . Set the main welding parameters as: main welding current I 1 =12000A, auxiliary welding current I 2 =8000A, electrode pressure F=1570N, main welding current duration t 2 = 1.5s, the auxiliary welding current duration t3 = 1.5s. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com