Patents

Literature

56results about How to "Increase soldering temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

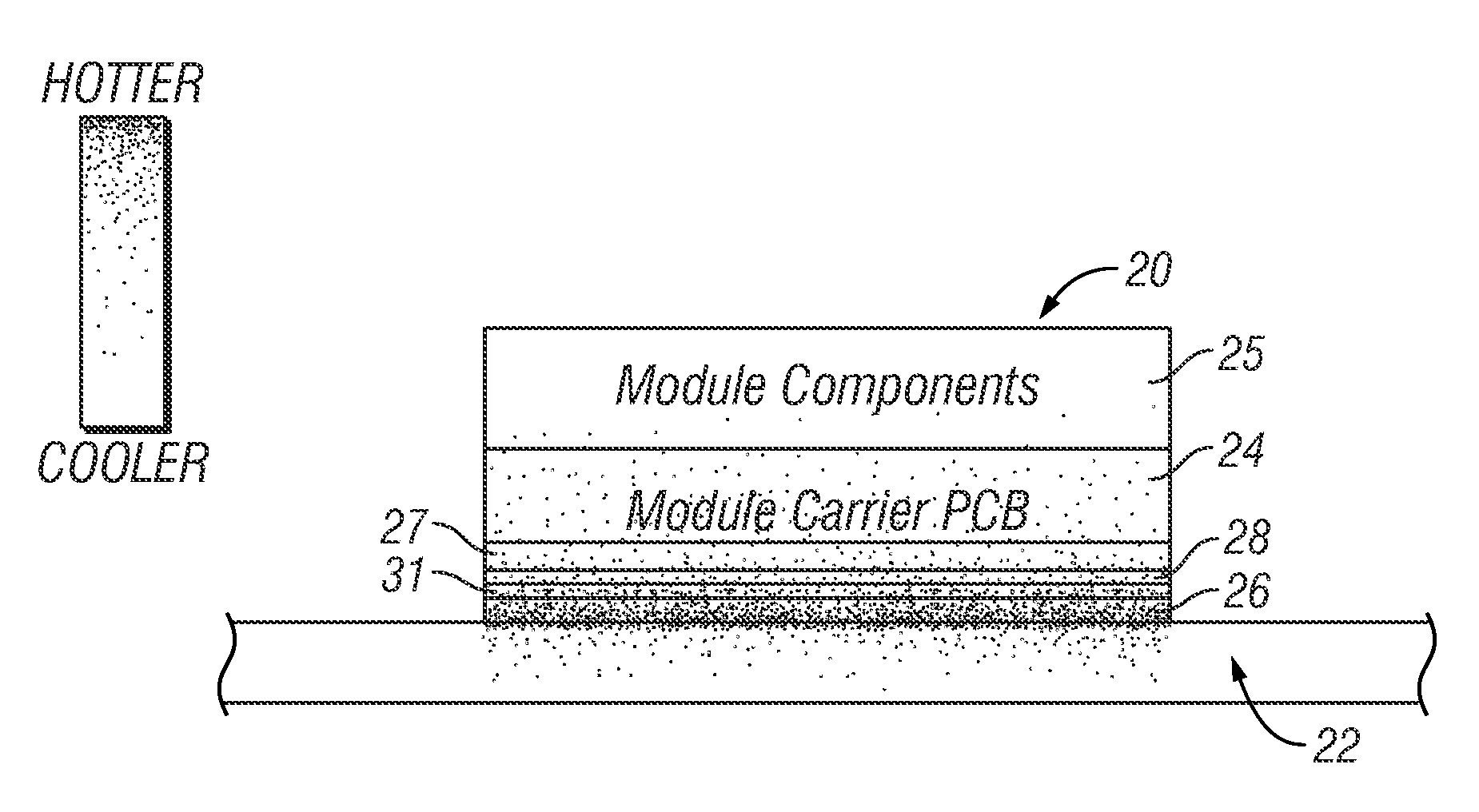

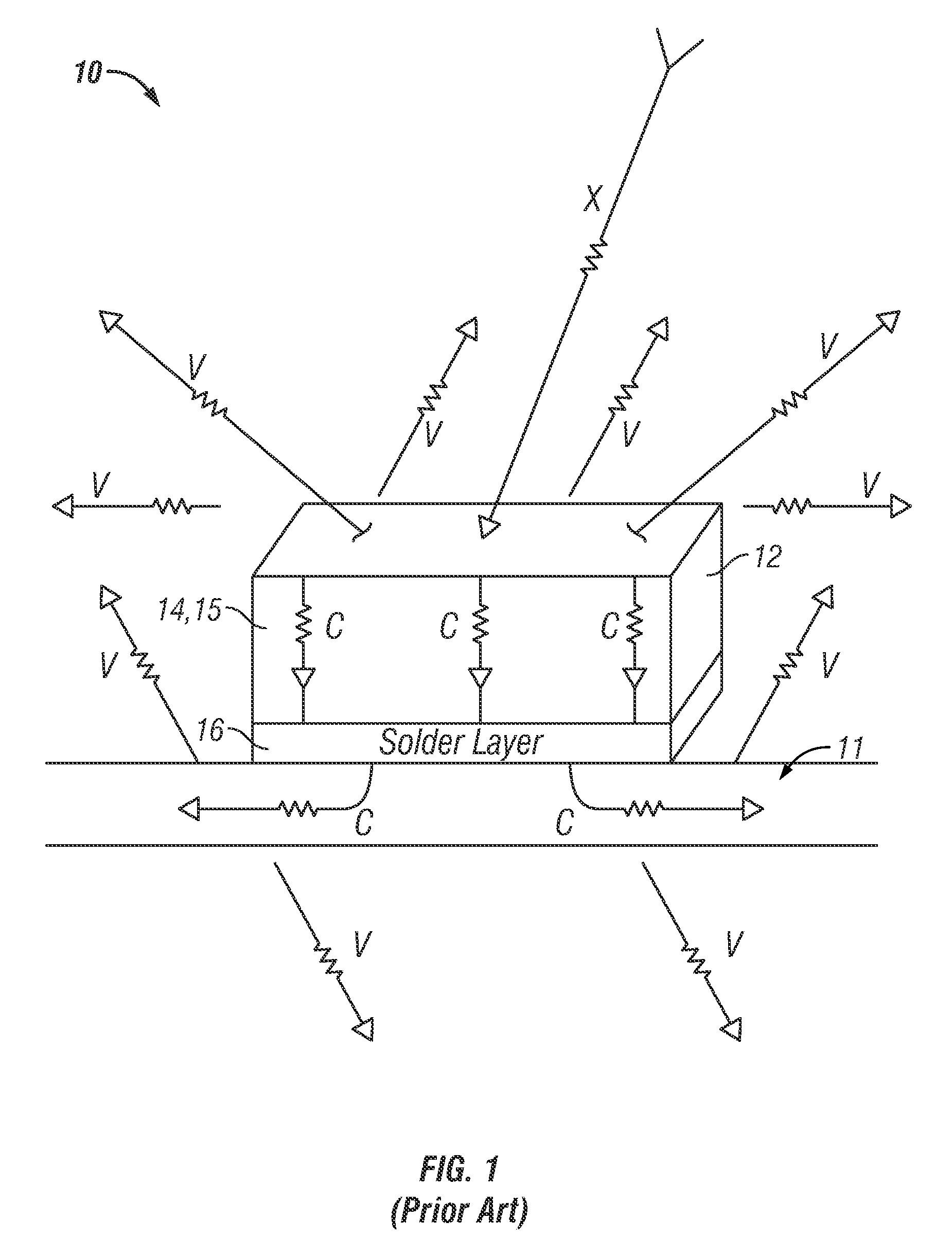

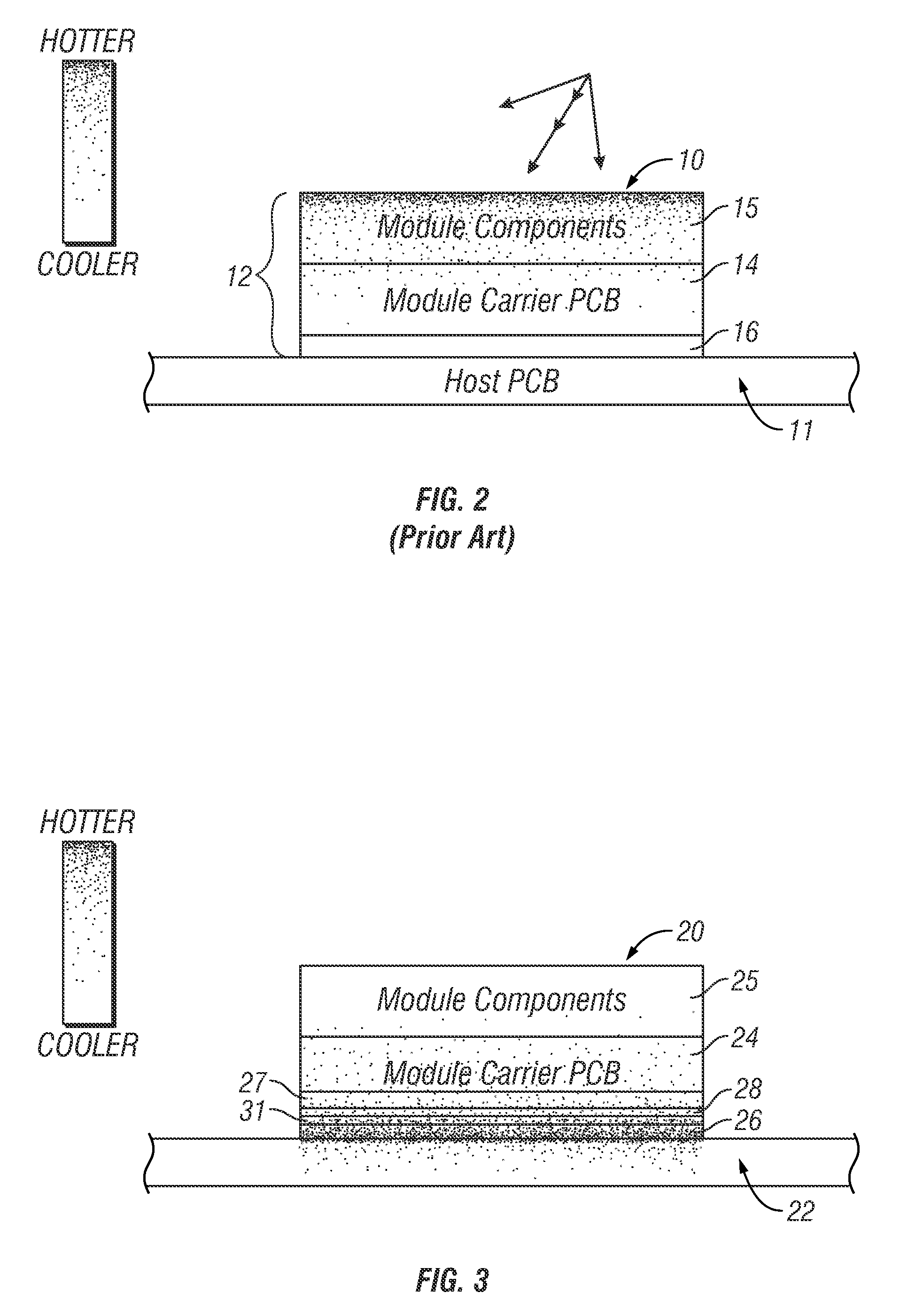

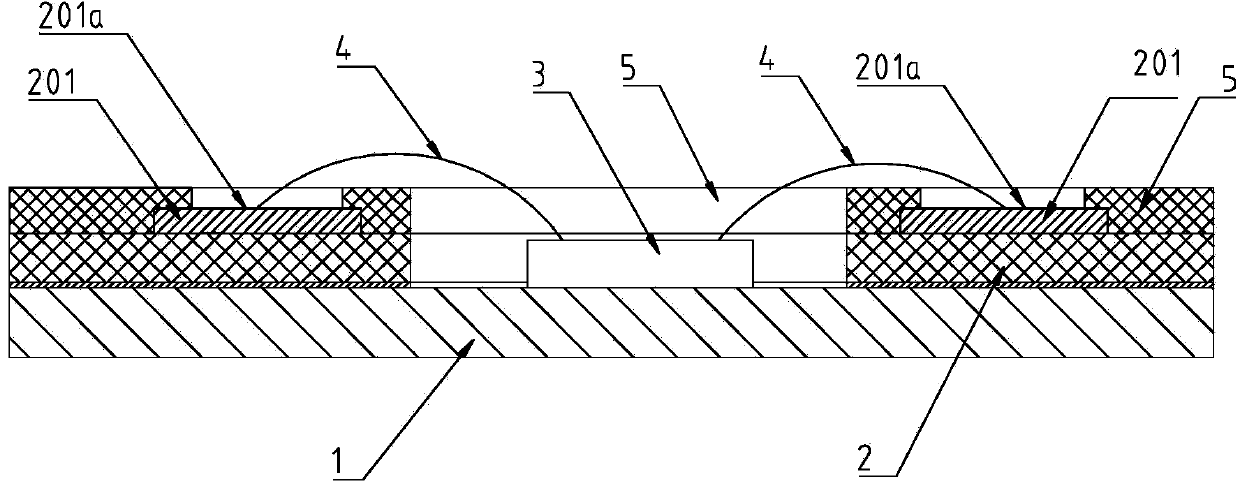

Integral heater assembly and method for carrier or host board of electronic package assembly

InactiveUS20130094148A1Easy to processLow costHeater elementsPrinted resistor incorporationLow voltageEngineering

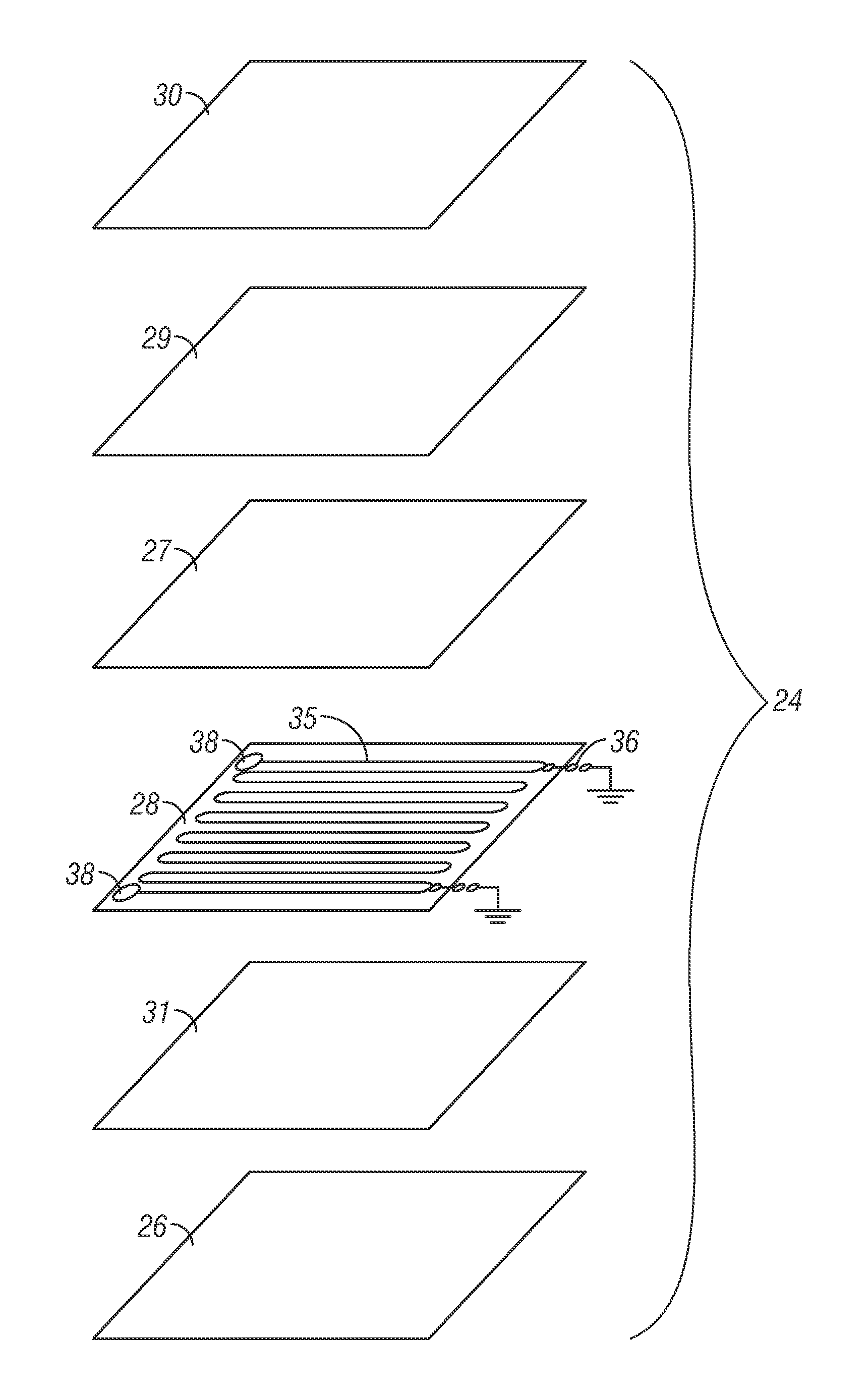

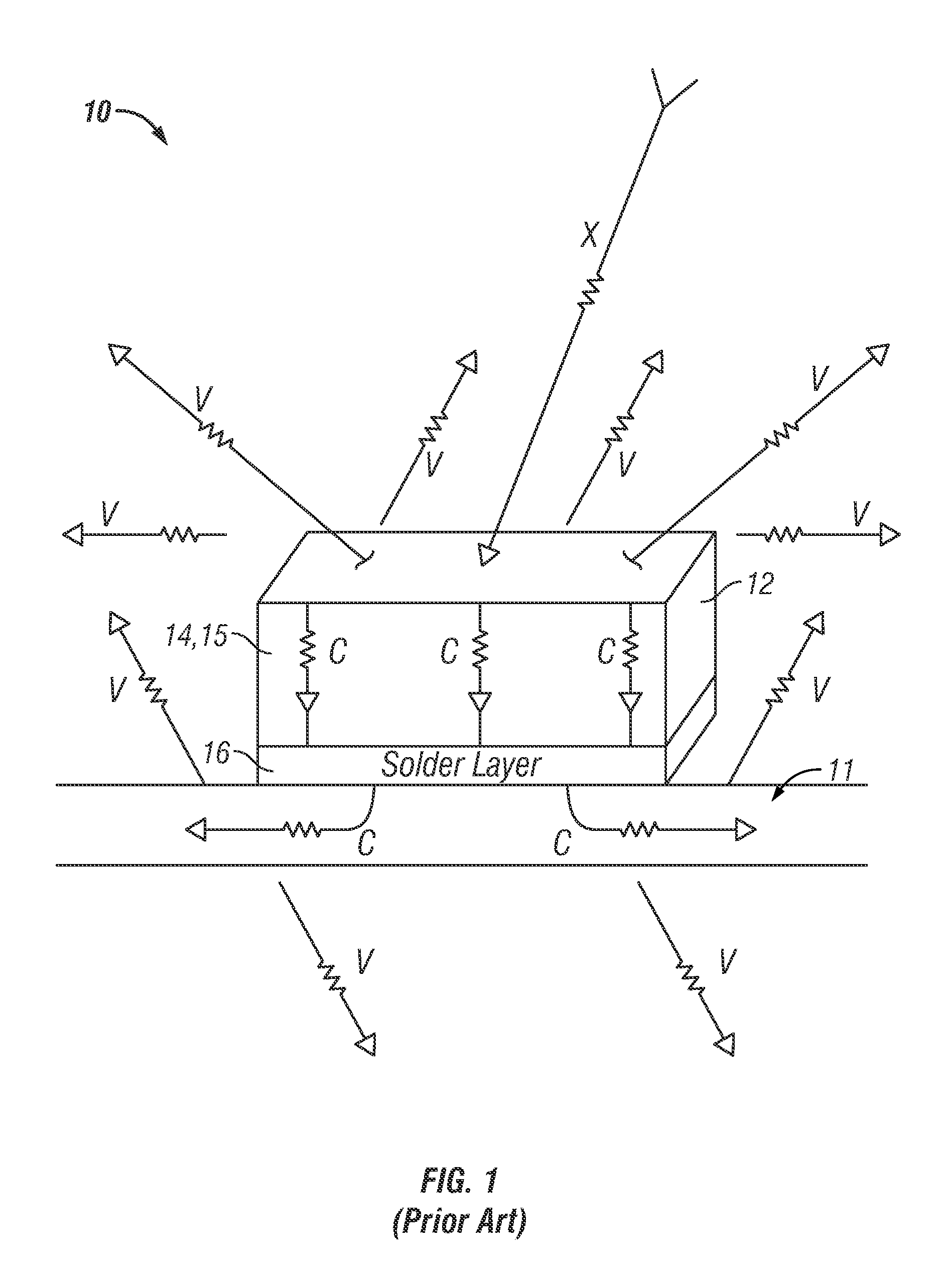

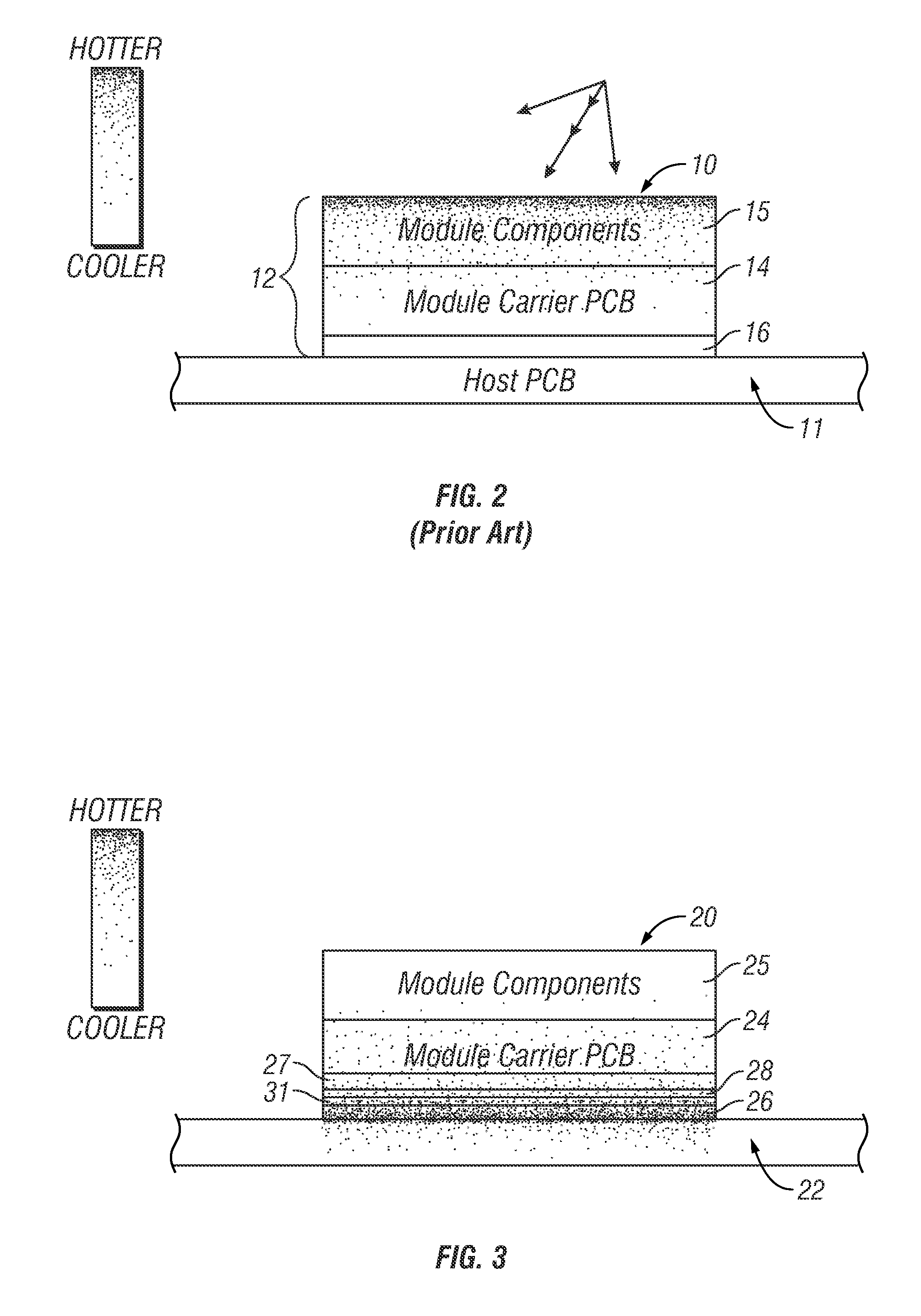

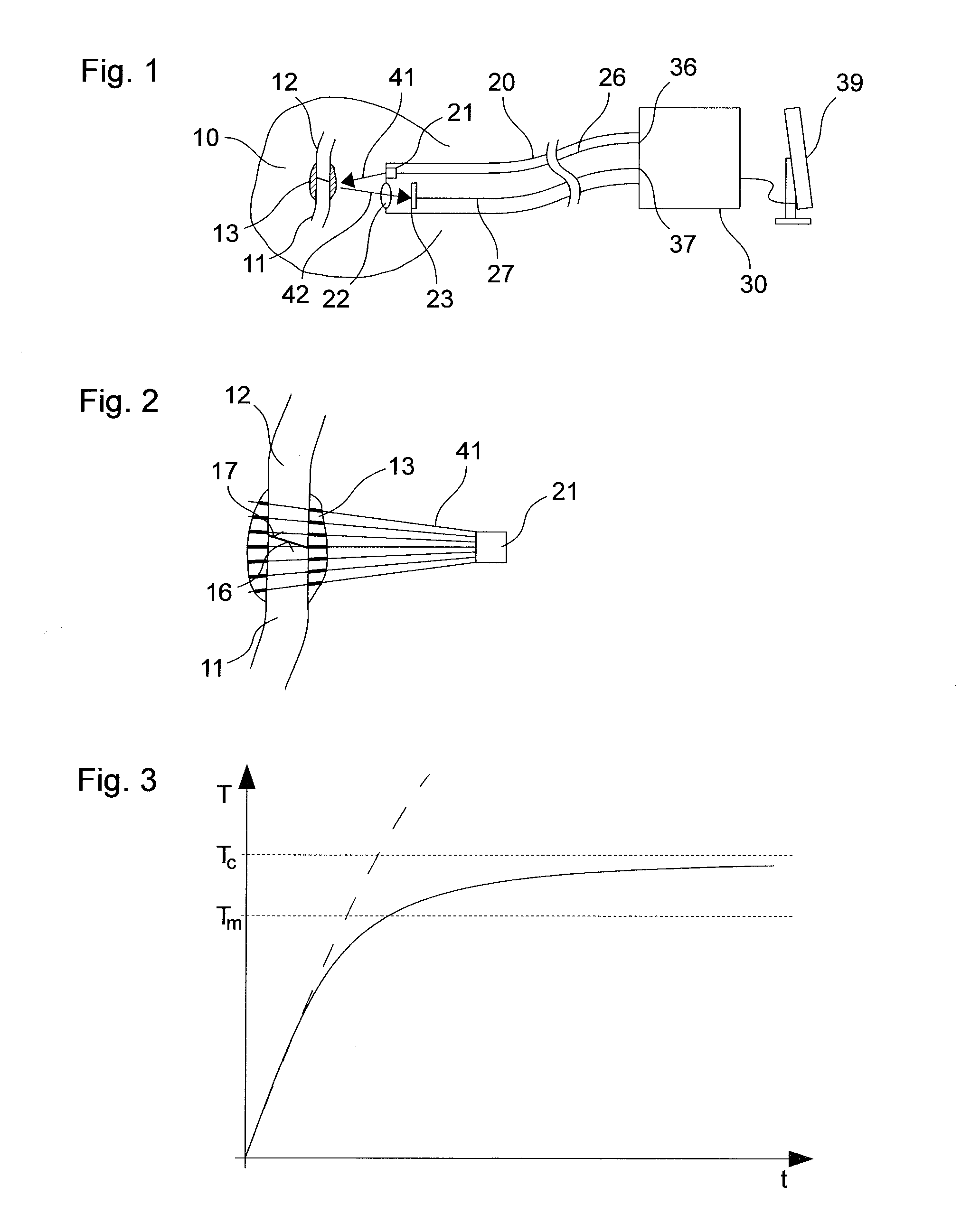

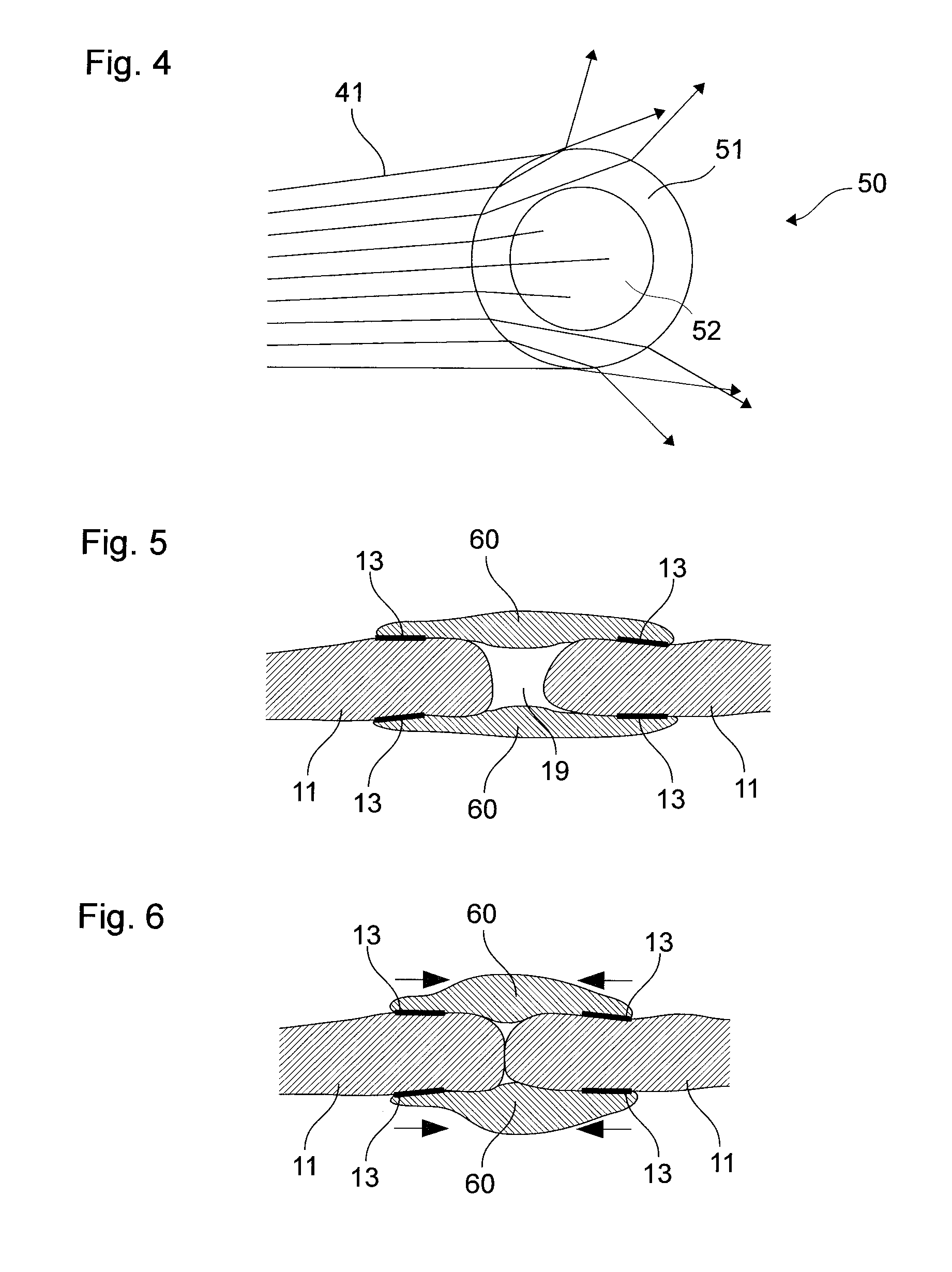

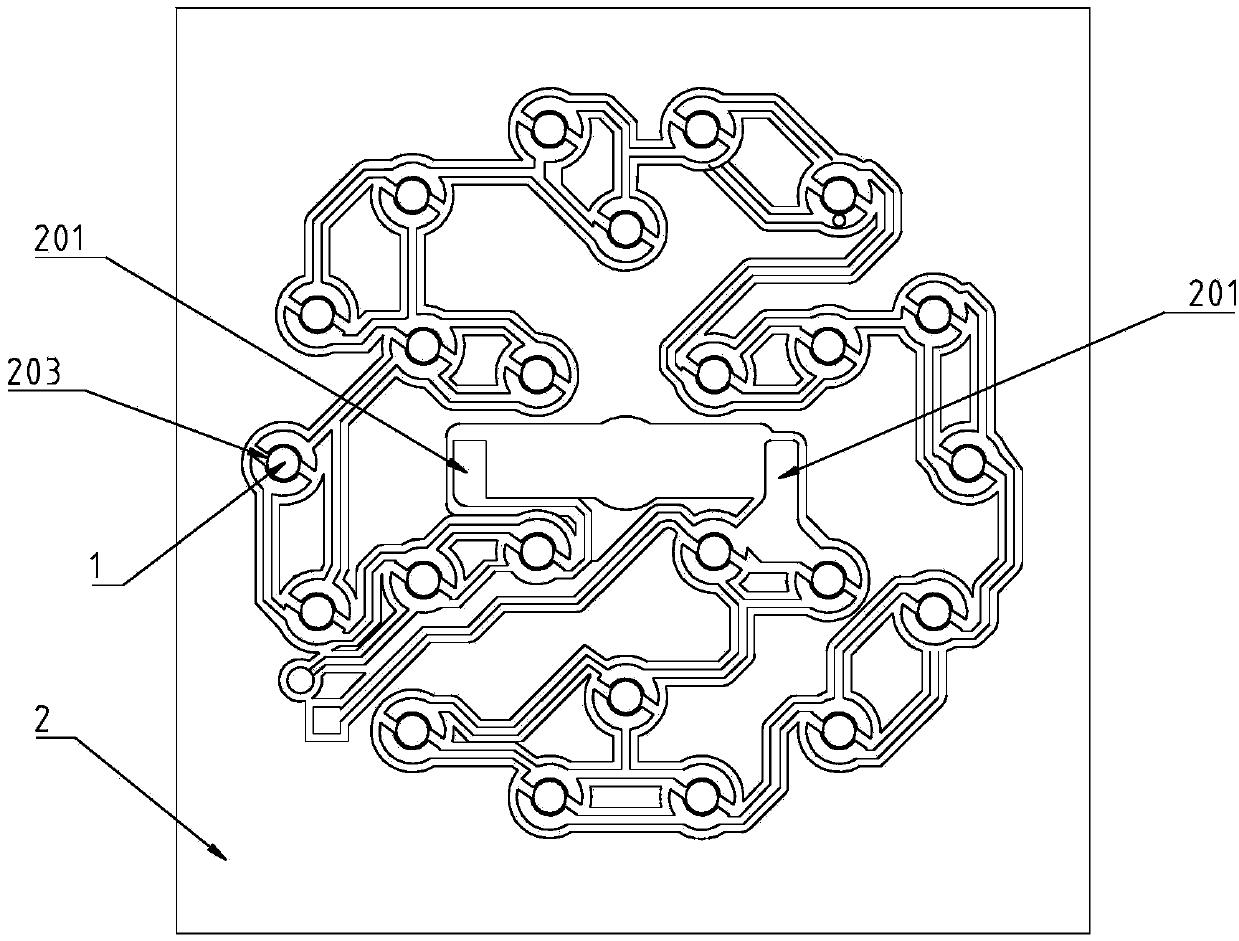

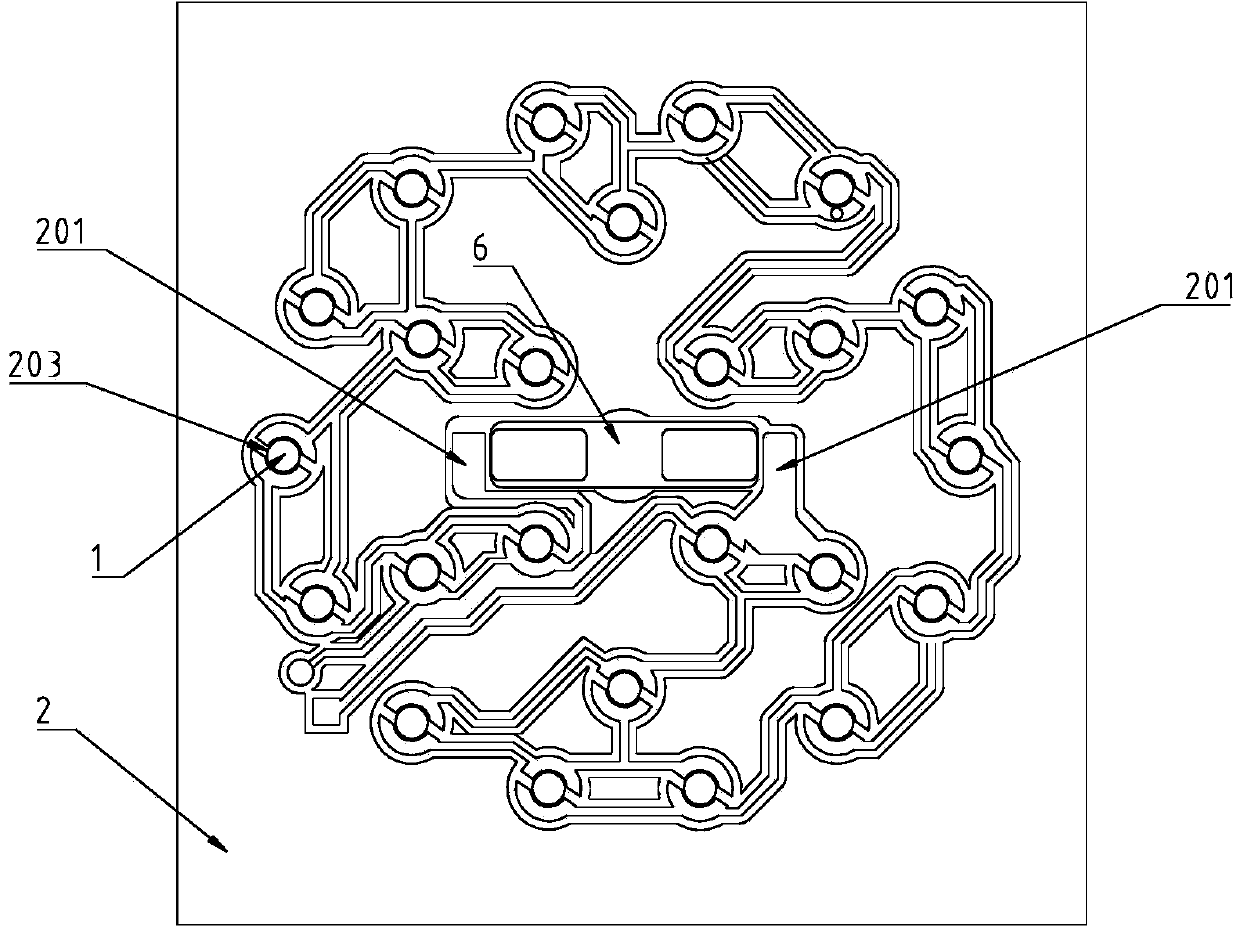

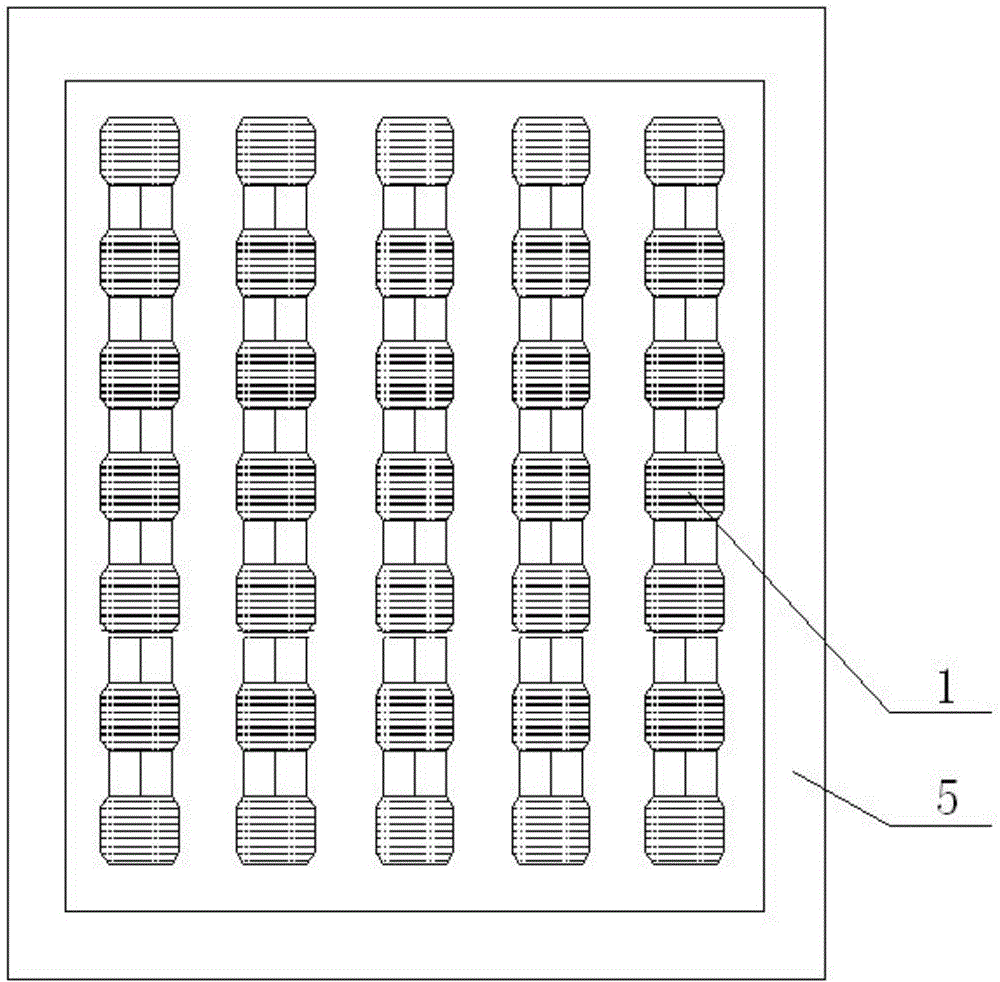

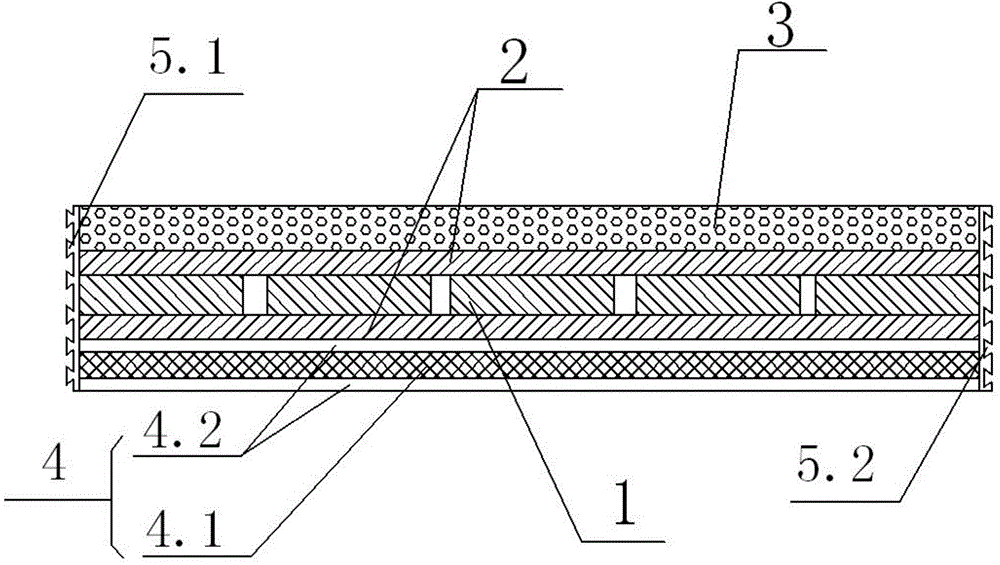

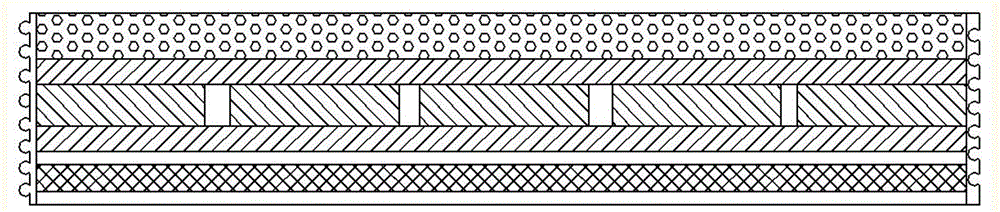

A multilayer printed circuit board has an embedded heater layer having at least one elongated heater element trace of copper which is densely arranged in a predetermined circuitous path over at least part of the area of the board. The heater element has inputs configured for connection to a standard high current, low voltage power supply, and may also have ground connections for selective connection to a ground layer. The heater layer may be embedded in a carrier board of a surface mount module close to the lower solder interface layer, or may be embedded in a host board of an electronics assembly close to the mounting surface.

Owner:INTEGRATED MICROWAVE

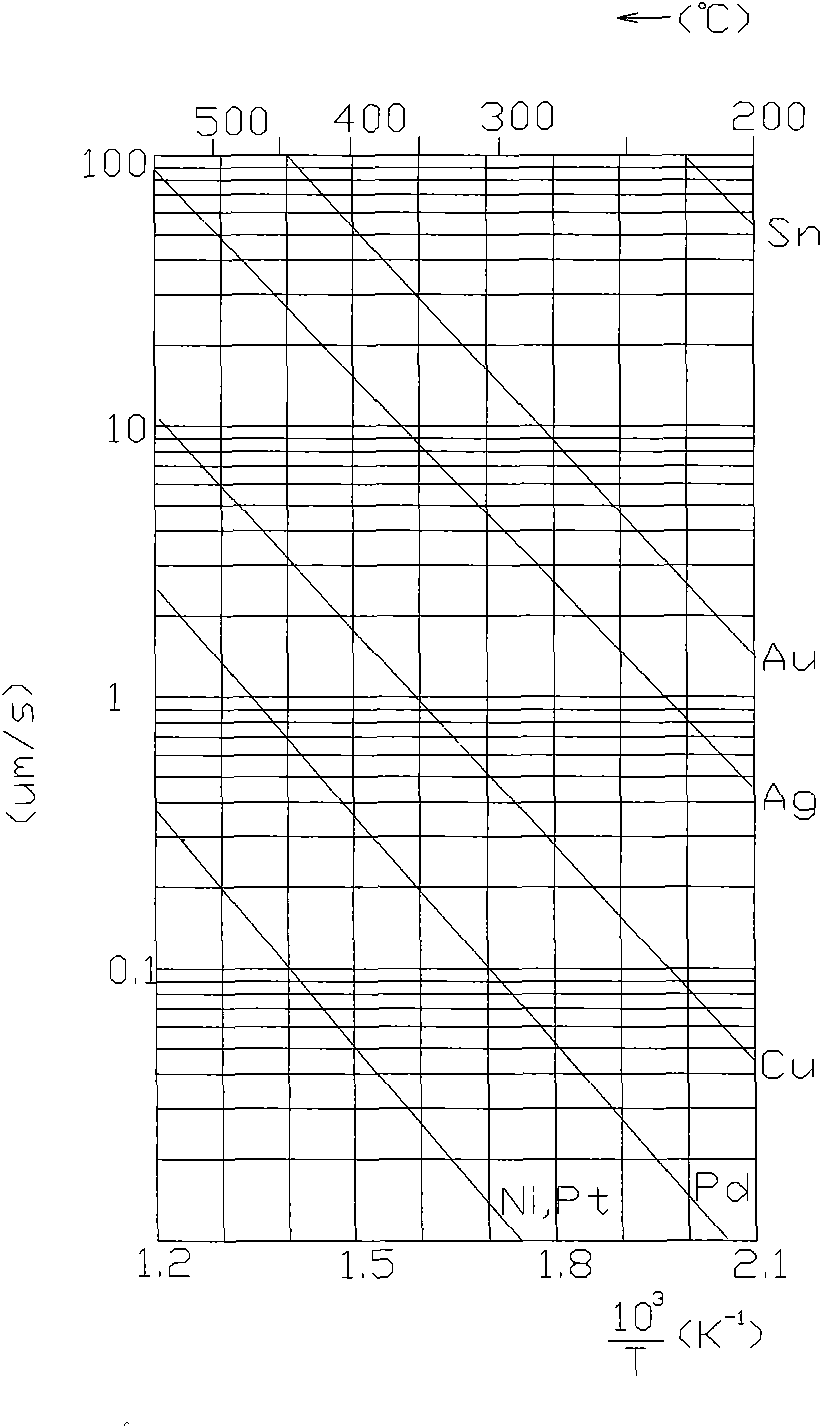

Lead-free solder

InactiveCN1398697AImprove mechanical propertiesIncrease soldering temperatureWelding/cutting media/materialsSoldering mediaIndiumCopper

A lead-free solder material for soldering in electronic, instrument, lamp and other fields consists of: In 0.003-5 wt%, Sb 0.2-5 wt%, Cu 0.5-3 wt% Ag 0.2-5 wt% and Sn the rest. Compared with the traditional solder, the present invention has equal or even higher mechanical performance, soldering temperature and electric performance, and may be drawn into 0.5 mm diameter lead-less solder wire, and it is harmless to human body and environment.

Owner:郴州金箭焊料有限公司

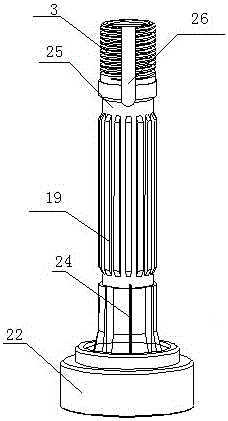

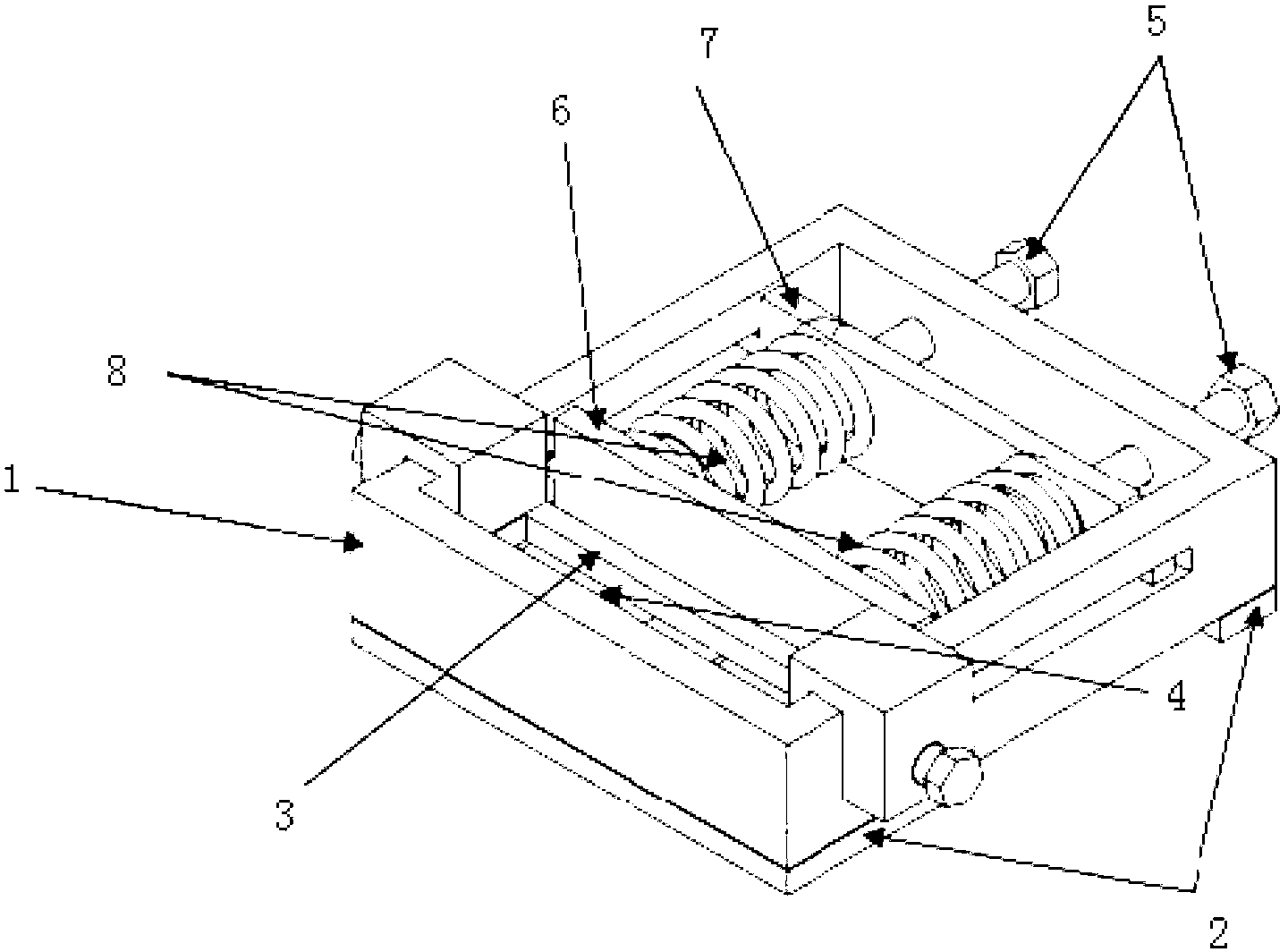

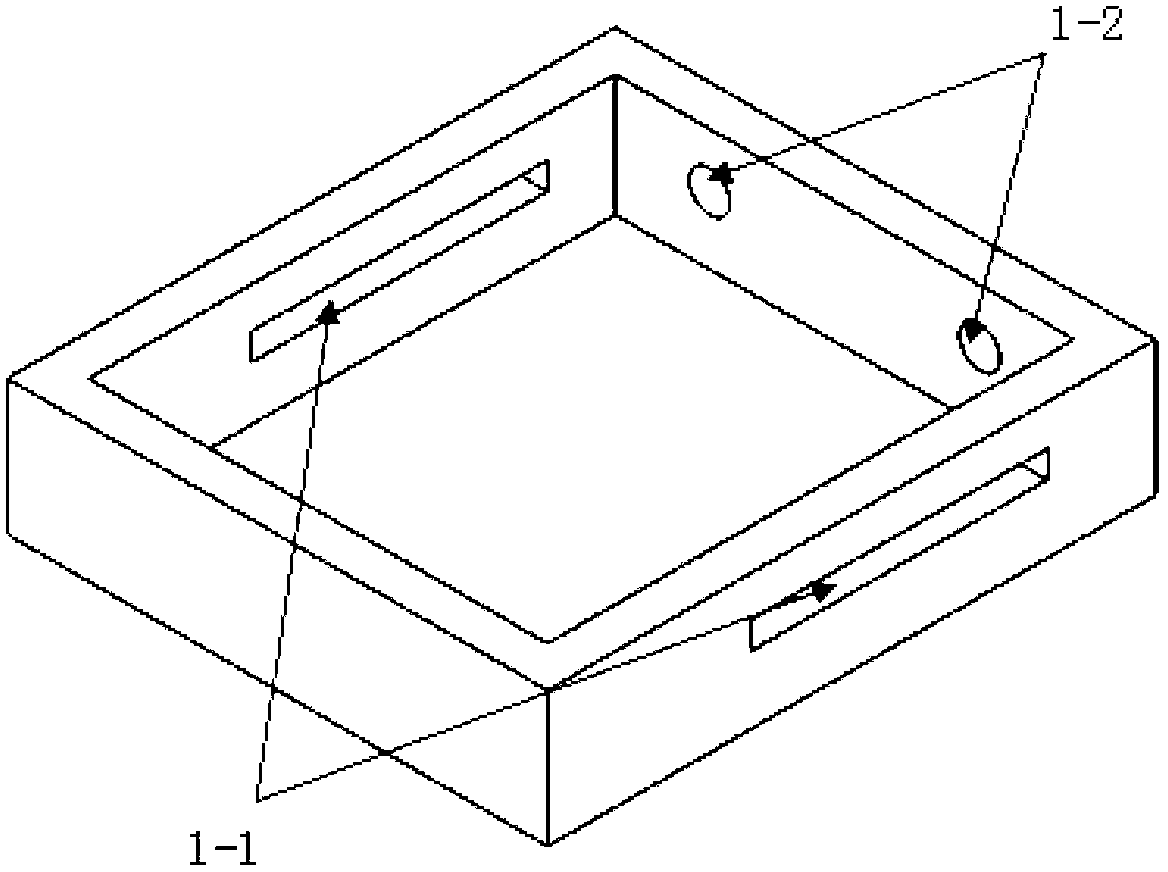

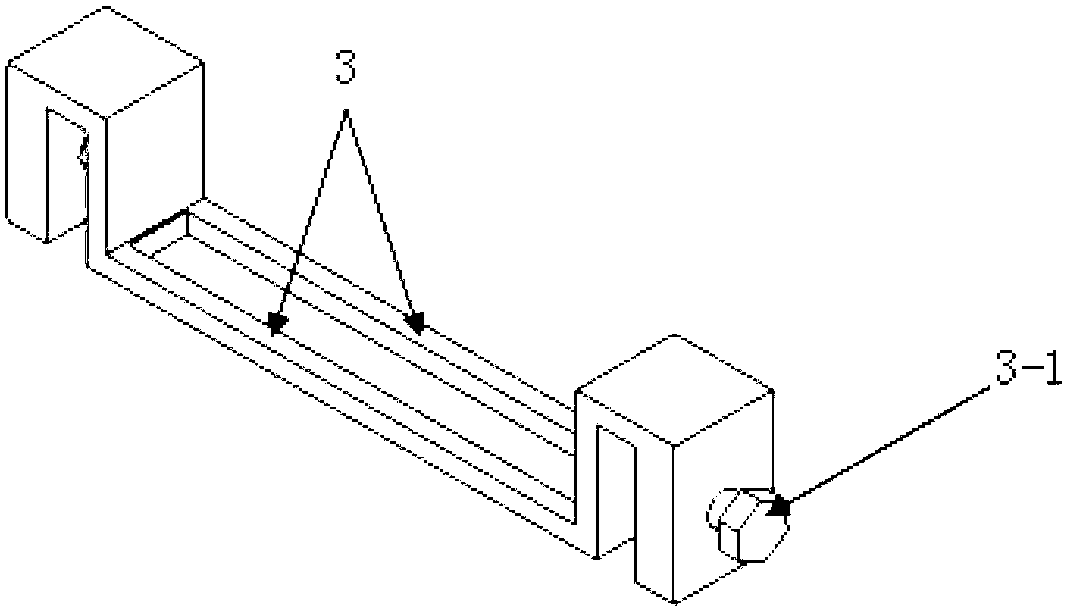

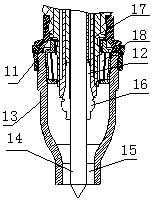

Electromagnetic vibrating, stirring and friction-welding stirring-head and welding method thereof

InactiveCN101574756ALarge plastic deformationChanging the plastic flow modeNon-electric welding apparatusFriction weldingEngineering

The invention discloses an electromagnetic vibrating, stirring and friction-welding stirring-head and a corresponding welding method thereof. An electromagnetic vibrating device is adopted to assist electromagnetic vibration during the process of stirring, and friction-welding to lead the stirring-head to vibrate at high frequency simultaneously when the stirring-head rotates at a high speed to transfer energy to the metals in a stirring and friction area so as to lead the metals to achieve plastic state more quickly; the thermoplastic metals receive the composite effects of a friction force and the high-frequency vibrating energy during the rotating process of a stirring needle, thus being capable of effectively improving the velocity of the thermoplastic metal flow, improving the forming efficiency and quality of welding seams and being more effectively used for the welding and processing of high-melting point materials and thick boards.

Owner:CHONGQING UNIV

Method for overlaying welding of duplex stainless steel

ActiveCN102941394AEnough temperaturePrevent hot and cold cracksArc welding apparatusFurnace typesThermal insulationRoom temperature

A method for the overlaying welding of a duplex stainless steel comprises the following steps: A, integral preheating: the preheating temperature is 250-300 DEG C, and thermal insulation is carried out for 0.8-1.2 hours; B, overlaying welding implementation: the welding current is 180-220A, the welding voltage is 25-29V, the welding velocity is 350-450mm / min, and the interlayer temperature is 250-300 DEG C; C, annealing heat treatment: the initial temperature is 200-300 DEG C and is gradually increased to 700-750 DEG C, and thermal insulation is carried out for 1.8-2.5 hours; and D, a workpiece is cooled in a furnace to below 150 DEG C and then is discharged to be naturally cooled to the room temperature in the air. According to the method for the overlaying welding of the duplex stainless steel, the parameters of the welding temperature, heat treatment temperature after the welding and the like are reasonably selected, cracks due to hot and cold are obviously reduced, the toughness and the machinability of the duplex stainless steel are increased, and when the method is used for the overlaying welding of the duplex stainless steel of a ship lift guide wheel, all the performance indexes can satisfy the requirements.

Owner:WUHAN MARINE MACHINERY PLANT

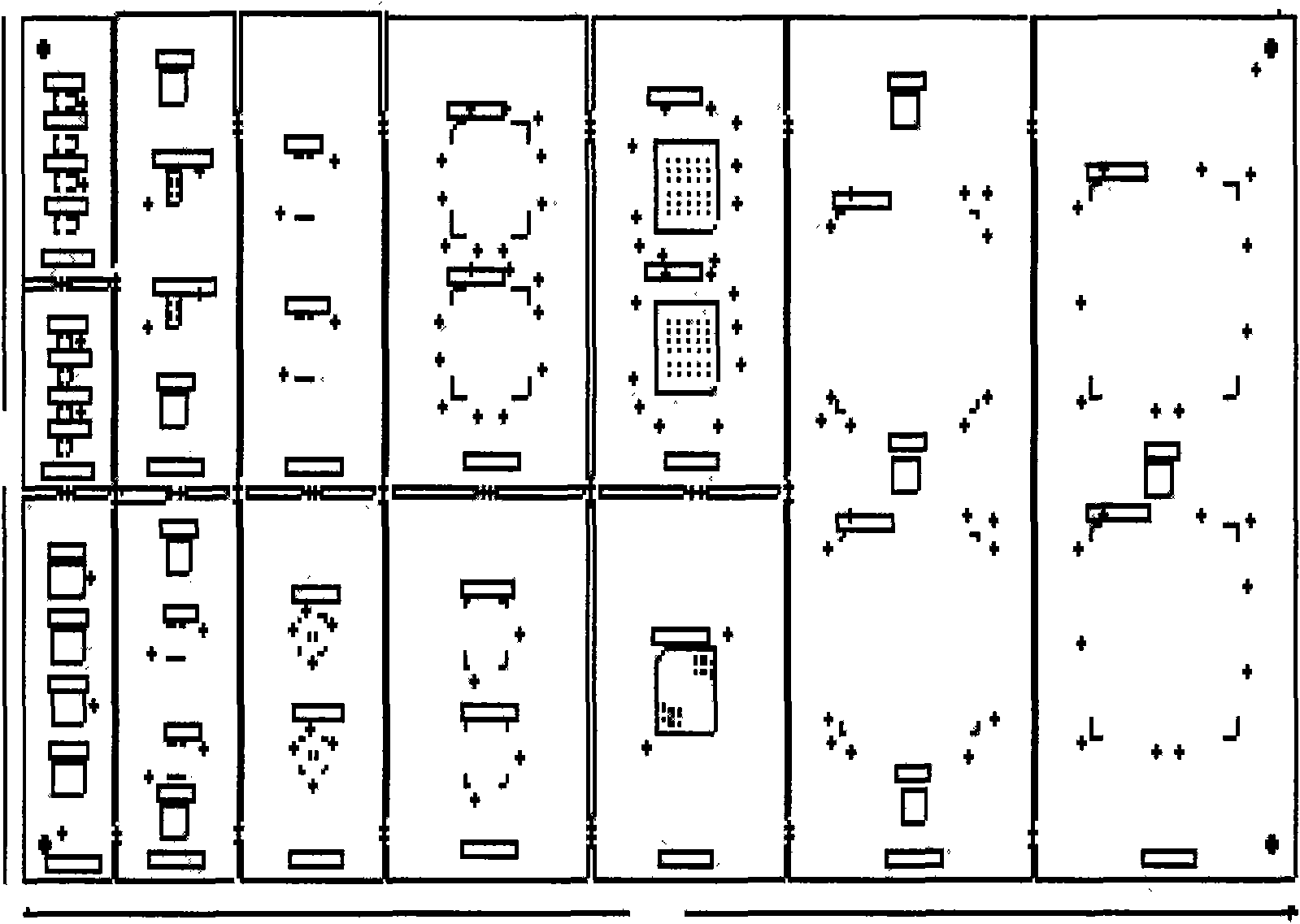

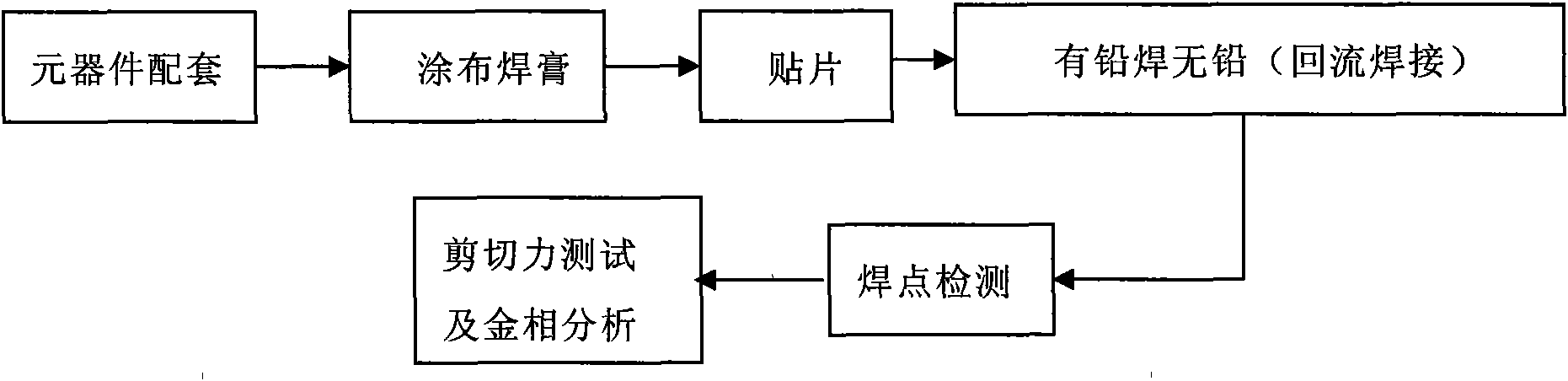

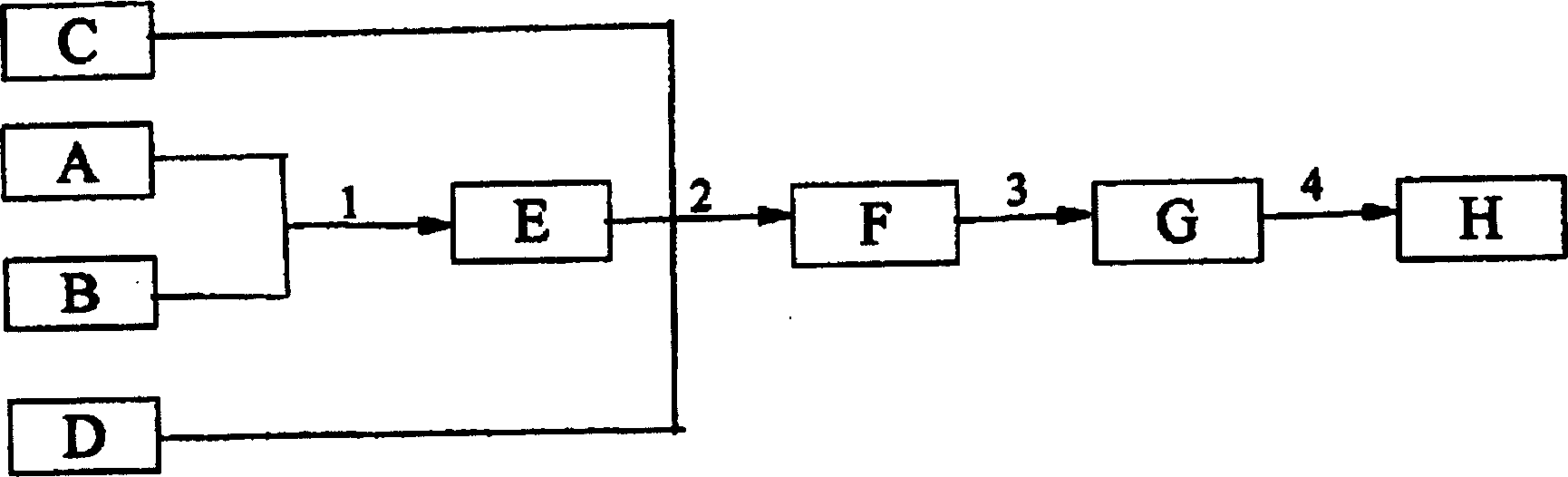

Method of welding printed circuit board containing mixed lead components and leadless components

ActiveCN101553092AIncrease soldering temperatureReliable weldingPrinted circuit assemblingWelding/cutting media/materialsTemperature curveEngineering

The present invention relates to a method of welding printed circuit board containing mixed lead components and leadless components, using lead solder and controlling welding temperature curve to improve welding peak temperature and prolong solder liquid phase time properly on the base of conventional lead welding technics to implement reliable welding of leadless components. Applying the invention provided technical scheme can implement solder paste coating, patching and welding in one time of most lead components and leadless components, of which the production efficiency is far higher than separate welding technics of lead components and leadless components. The invention provided method improves production efficiency and reduces materials control difficulty of production field while shorts production period of mixed products and reduces production cost.

Owner:BEIJING RES INST OF TELEMETRY +1

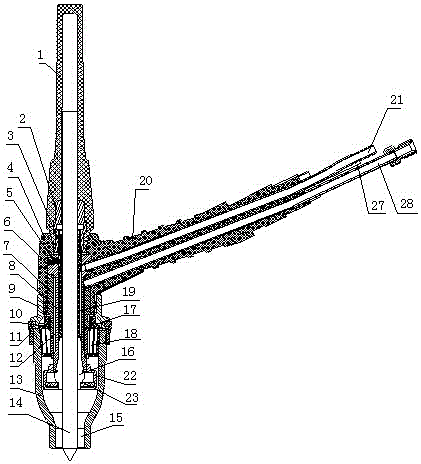

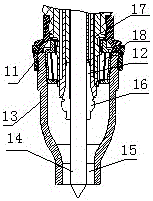

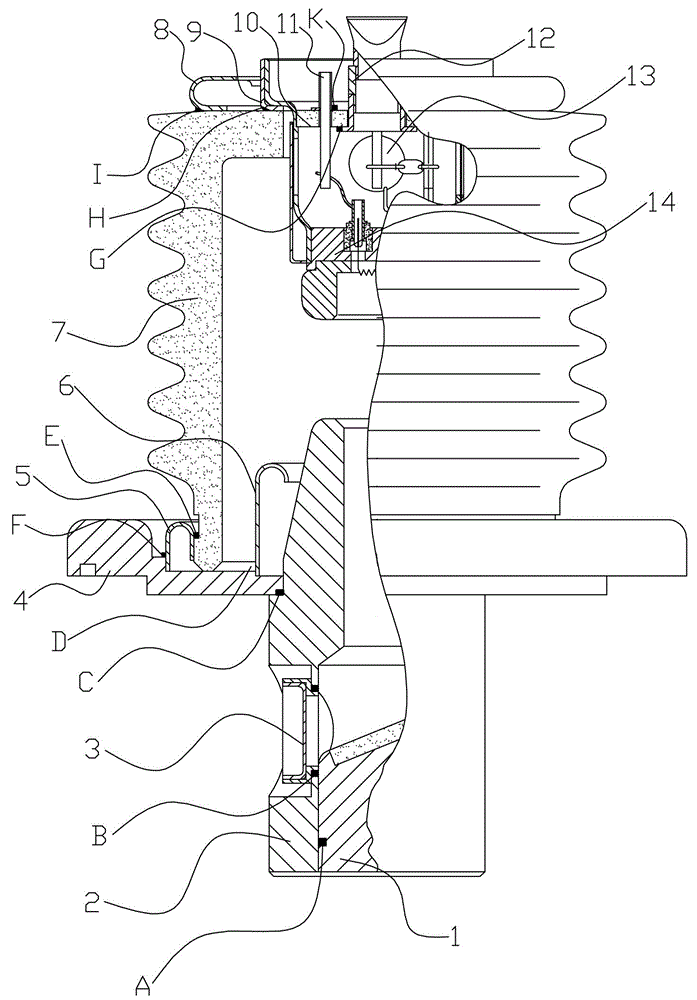

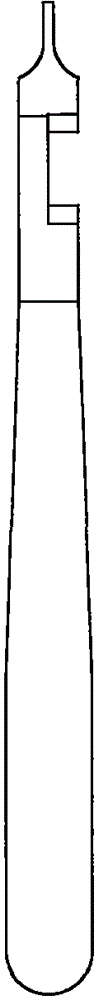

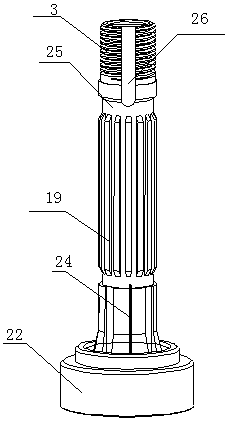

Efficient water-cooling argon arc welding gun

The invention provides an efficient water-cooling argon arc welding gun. The efficient water-cooling argon arc welding gun is composed of a handle, a gun head body, a gun head body protecting sleeve, a rear cap, a tungsten electrode rod, a tungsten electrode clamp, an inner heat insulation sleeve, an outer heat insulation sleeve, an outer connection sleeve, a spray nozzle connection ring and a ceramic spray nozzle, wherein the middle of the handle is provided with a gas inlet pipe, a water inlet pipe and a water outlet pipe; the right end of the handle is connected with a machine head body outer sleeve covering the exterior of the gun head body; the lower end of the gas inlet pipe is connected with a gas inlet hole in the side face of the upper end of the gun head body; the gas inlet hole communicates with a vertical through hole in the center of the gun head body; the tungsten electrode clamp is arranged in the middle of the vertical through hole; the tungsten electrode rod penetrates a middle hole of the tungsten electrode clamp; an annular groove is machined in the middle of the outer circle of the gun head body; the exterior of the annular groove is closely sleeved with the inner circle of the inner heat insulation sleeve, and the annular groove is closed into a water-cooling sleeve; the water inlet pipe and the water outlet pipe communicate with the water-cooling sleeve; the outer heat insulation sleeve is arranged outside the inner heat insulation sleeve; the exterior of the outer heat insulation sleeve and the inner circle at the upper end of the ceramic spray nozzle are connected together in a sleeving manner; the outer connection sleeve is arranged at the lower end of the gun head body protecting sleeve; the spray nozzle connection ring is connected to the lower end of the outer connection sleeve and connected with the outer circle at the upper end of the ceramic spray nozzle in a thread screwing manner; and the rear cap is arranged at the top end of the gun head body.

Owner:济南尼克焊接技术有限公司

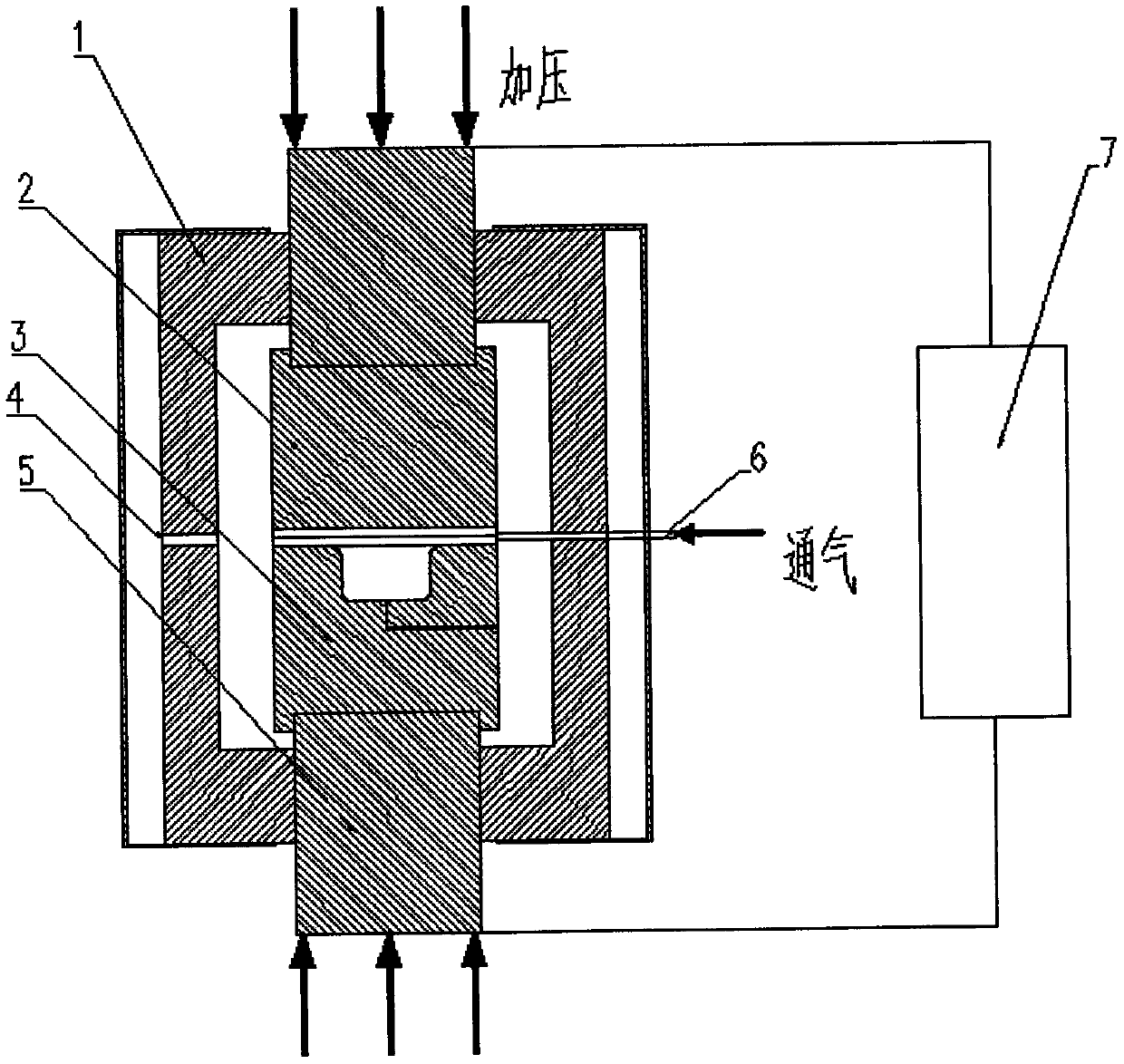

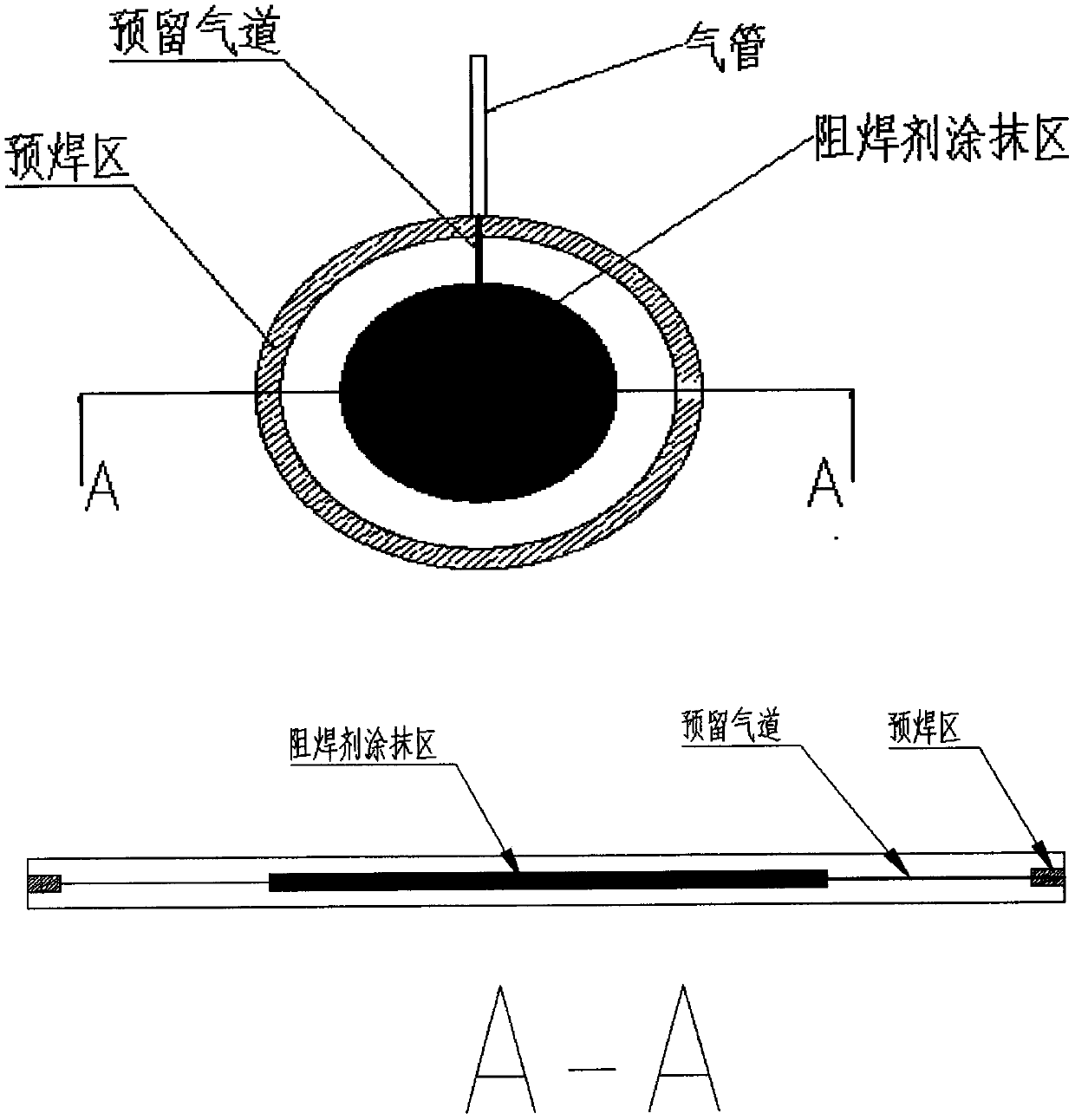

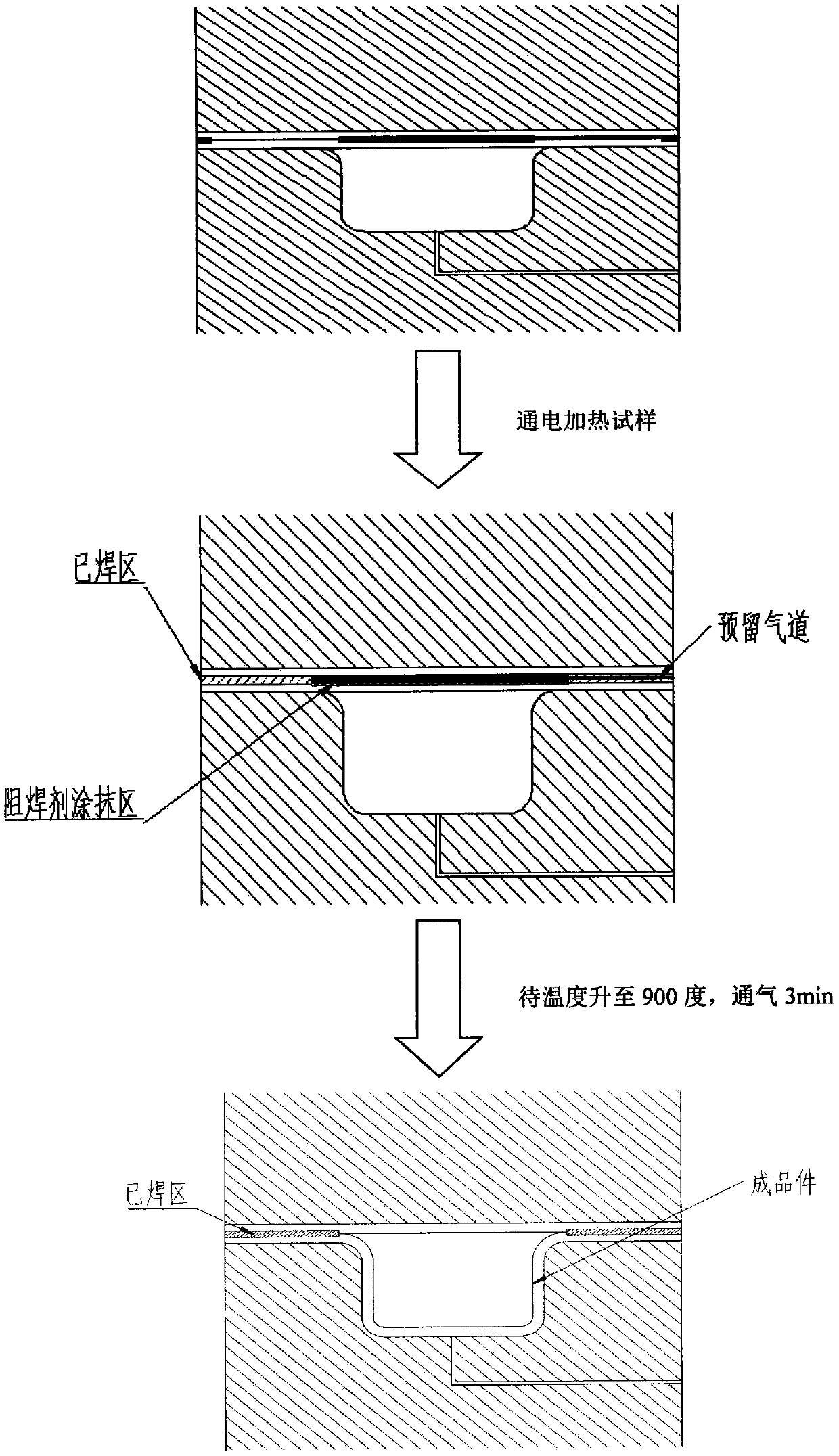

Quick forming device for titanium alloy multi-layered plate and forming method thereof

The invention designs a quick forming device for a titanium alloy multi-layered plate and a forming method thereof. The device comprises upper and lower graphite molds, a graphite electrode, a pulse direct current power supply, a pressurizing device and a test sample. The method comprises the following steps of generating a lot of resistance heat and discharging heat with a short time, as a directcurrent pulse current directly passes the test sample coated with a solder resist in a special area, wherein the test sample is heated quickly to enter an ultra-plastic state; then introducing gas, wherein the area, coated with the solder resist, of the test sample is swelled quickly; and meanwhile, achieving diffusion bonding by atom exchange in the area which is not coated with the solder resist so as o further form the multi-layered plate quickly. The device can remarkably shorten the forming time of the titanium alloy multi-layered plate and has the advantages of being high in forming speed, low in forming cost and suitable for forming various titanium alloy multi-layered plates.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Novel copper-based dip brazing alloy for drilling bit

InactiveCN101890588AReasonable typeReasonable contentWelding/cutting media/materialsSoldering mediaChemical compositionBraze alloy

The invention discloses a novel copper-based dip brazing alloy used in drilling bit production. Cutting drill teeth and a drill body form a whole by dip brazing. The dip brazing copper alloy has excellent mechanical property and high strength, toughness and abrasion resistance. A brazing process is simple and convenient and suitable for brazing drill bits of multiple types. When the brazing temperature is between 900 and 1,000 DEG C, the alloy comprises the following chemical components in percentage by weight: 5 to 10 percent of Ni, 3 to 9 percent of Mn, 3 to 5 percent of Fe, 7 to 13 percent of Sn, 0.1 percent of sigma RE and the balance of Cu. When the brazing temperature is between 950 and 1,150 DEG C, the alloy comprises the following chemical components in percentage by weight: 8 to 15 percent of Ni, 10 to 13 percent of Mn, 5 to 10 percent of Zn, 1 to 2 percent of Fe, 0.05 to 0.1 percent of Ce and the balance of Cu. When the brazing temperature is between 1,100 and 1,250 DEG C, the alloy comprises the following chemical components in percentage by weight: 15 to 20 percent of Ni, 5 to 10 percent of Mn, 3 to 5 percent of Fe, 0.05 to 0.1 percent of sigma RE and the balance of Cu.

Owner:TIANJIN SANTIAOSHI NONFERROUS METAL FOUNDRY

Electron beam pressurizing connection method for aluminum alloy and particle-reinforced aluminum matrix composite material

InactiveCN103008869AIncrease soldering temperature and holding timeWell formed weldWelding/cutting auxillary devicesAuxillary welding devicesAluminum matrix compositesVacuum cooling

The invention provides an electron beam pressurizing connection method for aluminum alloy and a particle-reinforced aluminum matrix composite material, and relates to an electron beam assisted heat source diffusion welding method for the aluminum alloy and the particle-reinforced aluminum matrix composite material, aiming at solving the problems of serious metal burning loss, interface reaction, air pores and the like existing in the traditional fusion welding technique of the particle-reinforced aluminum matrix composite material. The electron beam pressurizing connection method for the aluminum alloy and the particle-reinforced aluminum matrix composite material comprises the following steps of: 1) conducting pretreatment to two base metal blocks to be welded; 2) putting the two base metal blocks into a welding fixture and applying pressure to squeeze the base metal blocks; 3) conducting vacuum pumping treatment; 4) conducting welding for the first time by adopting an upward defocusing mode; 5) conducting welding for the second time; and 6) conducting vacuum cooling to complete the electron beam pressurizing connection of the aluminum alloy and the particle-reinforced aluminum matrix composite material. The electron beam pressurizing connection method for the aluminum alloy and the particle-reinforced aluminum matrix composite material belongs to the field of pressurizing assisted welding.

Owner:HARBIN INST OF TECH

Highly-efficient, energy-saving and environmentally-friendly manufacturing method of metal ceramic X ray tube

ActiveCN104889519AIncrease soldering temperatureConducive to environmental protectionSoldering apparatusGetterHigh energy

The invention provides a highly-efficient, energy-saving and environmentally-friendly manufacturing method of a metal ceramic X ray tube. All parts are processed and manufactured at first, and then cleaned and assembled. The manufacturing method is characterized in that during the assembling, AgGu28 soldering flux sheets or rings are arranged in 10 to-be-welded welding places of a part, and titanium molybdenum getter is arranged in the cathode of a metal ceramic X ray tube; the assembled metal ceramic X ray tubes are vertically arranged in a material rack then sent into a vacuum welding furnace, vacuumized, heated to 650-750 DEG C, kept warm for 10-12 hours, heated to 800 DEG C and kept warm for 7-10 minutes until the welding materials are fused, so soldering and sealing are finished; a cooling system of the vacuum welding furnace is started, temperature is reduced to 60 DEG C in 4-6 hours, vacummization is stopped, and the welding materials are taken out of the furnace; and degassing, vacuum exhausting and welding for the materials are finished at a time, then performing the stress test for 8 hours, and at last qualified products are examined and put in storage. According to the invention, problems of low efficiency, insecurity, severe environmental pollution and high energy consumption of the current manufacturing technique are solved.

Owner:HUANGSHI SHANGFANG INSPECTION EQUIP

Solder paste applied to signal distributor and preparation method of solder paste

InactiveCN107309577AHigh activation temperatureEnhanced ability to deoxidizePrinted circuit assemblingWelding/cutting media/materialsAlloyCleansing Agents

The invention relates to solder paste applied to a signal distributor. The solder paste is composed of flux paste and tin-based alloy welding powder. The flux paste is obtained after 25%-40% of solvent, 42%-50% of modified rosin, 2%-5% of organic acid, 2%-5% of borofluoride, 7%-10% of a thixotropic agent and 5%-10% of an antioxidant are added in a reaction kettle to be stirred, heated to 150 DEG C and dissolved. The flux paste is evenly mixed with any one of several types of solder powder, including Sn96.5Ag3.0Cu0.5, Sn97.5Ag2.0Cu0.5, Sn98.5Ag1.0Cu0.5, Sn99Ag0.3Cu0.7, Sn99Cu0.7, Sn42Bi58, Sn64Bi35Ag1.0, Sn64.7Bi35Ag0.3 and Sn64.9Bi35Ag0.1, in a mixing machine according to the weight ratio being (10-15):(85-90) to obtain the solder paste suitable for the signal distributor. The solder paste is particularly suitable for the signal distributor, the production cost can be reduced, and the production efficiency can be improved; viscosity is appropriate, thixotropy is high, the solder paste is not likely to be layered when a glue dispenser conducts dispensing, and the solder paste can be uniformly sprayed on an assigned welding area; an oxidation film of an electroplated coating on the surface of the solder powder can be completely removed within 5-8 seconds, and false solder and missing solder can be prevented; and the storage life of the solder paste is long, and the solder paste can bear a high welding temperature. Post-soldering residues are few, and cleaning can be easily conducted through an environment-friendly cleaning agent.

Owner:赛伦(厦门)新材料科技有限公司

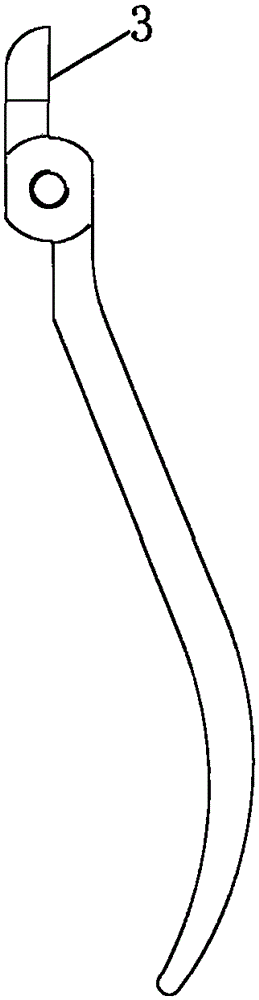

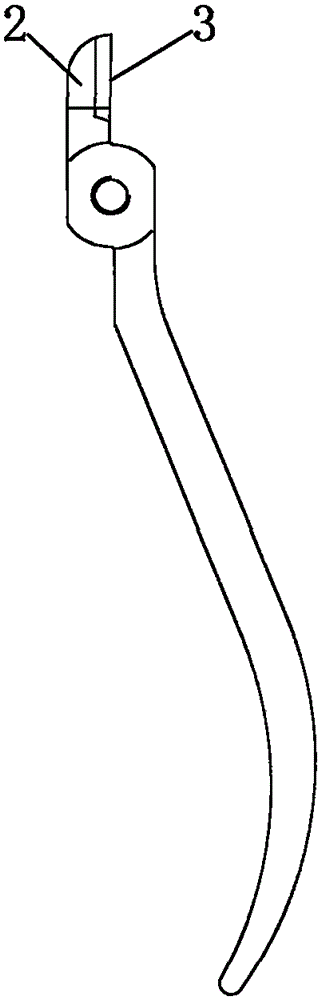

Medical clamp and processing method thereof

InactiveCN105149886AFulfil requirementsIncrease soldering temperatureSurgical scissorsSurgical forcepsProduct gasHardness

The invention discloses a medical clamp and a processing method thereof. The medical clamp comprises a clamp head, a jaw and soldering flux, wherein the clamp head is made of a medium-low hardness stainless steel material; the jaw is made of a higher hardness stainless steel material; the soldering flux is used for splicing the clamp head and the jaw; and when the clamp head and the jaw are quenched, the soldering flux is melted to weld the clamp head and the jaw integrally. The processing method comprises the following steps: the clamp head and the jaw are clamped together to form a combination, the combination is coated with the soldering flux, the combination coated with the soldering flux is placed in a vacuum furnace or a tracked furnace with the gas protection function to be quenched, and at the same time, the soldering flux is melted to weld the clamp head and the jaw, so as to connect the clamp head with the jaw integrally, and at last, after excess materials of the clamp head and the jaw are cut with a wire or cut off by a grinding machine, a finished product is manufactured. The jaw is made of the higher hardness stainless steel, and a handle and a clamp body are made of the medium-low hardness stainless steel material, so that the problems of blackening and rusting of the jaw are solved well.

Owner:王光良

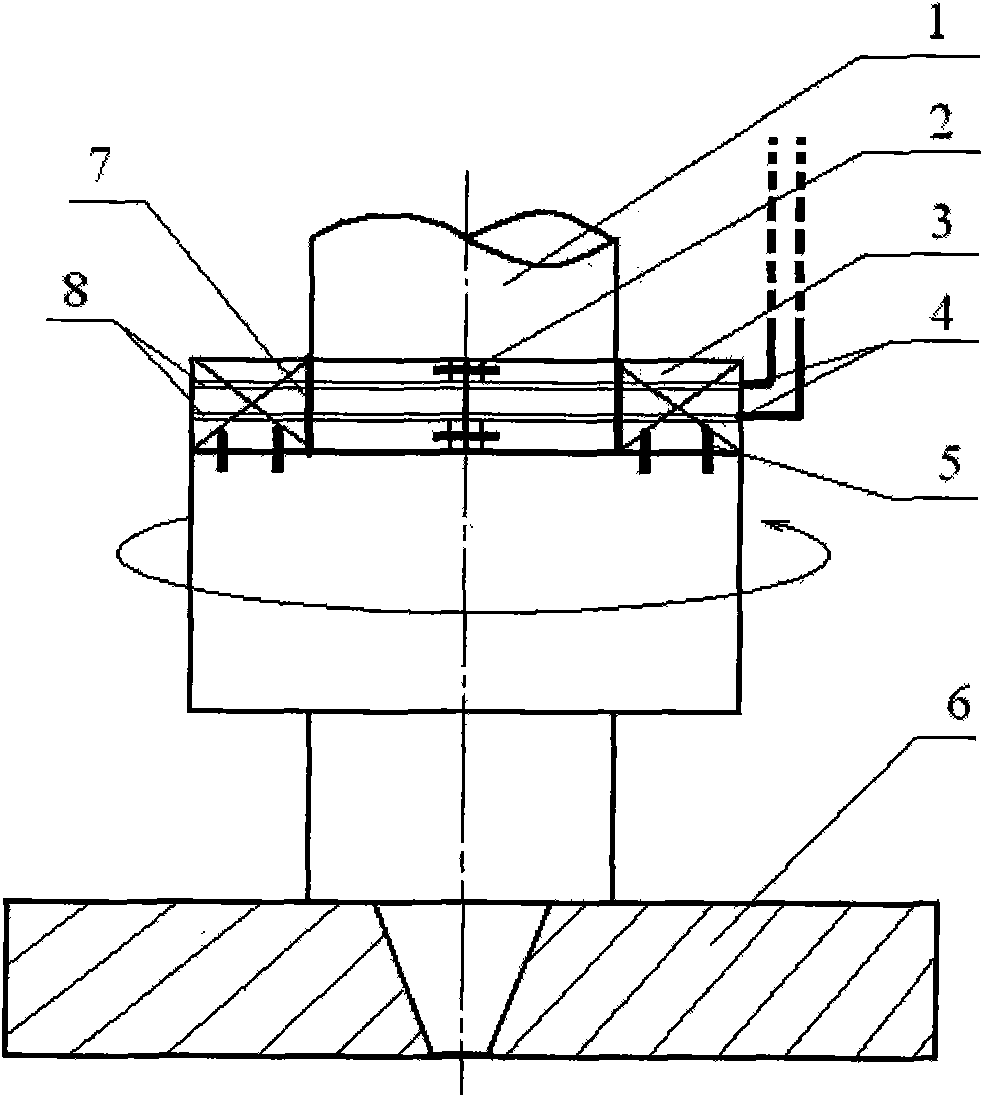

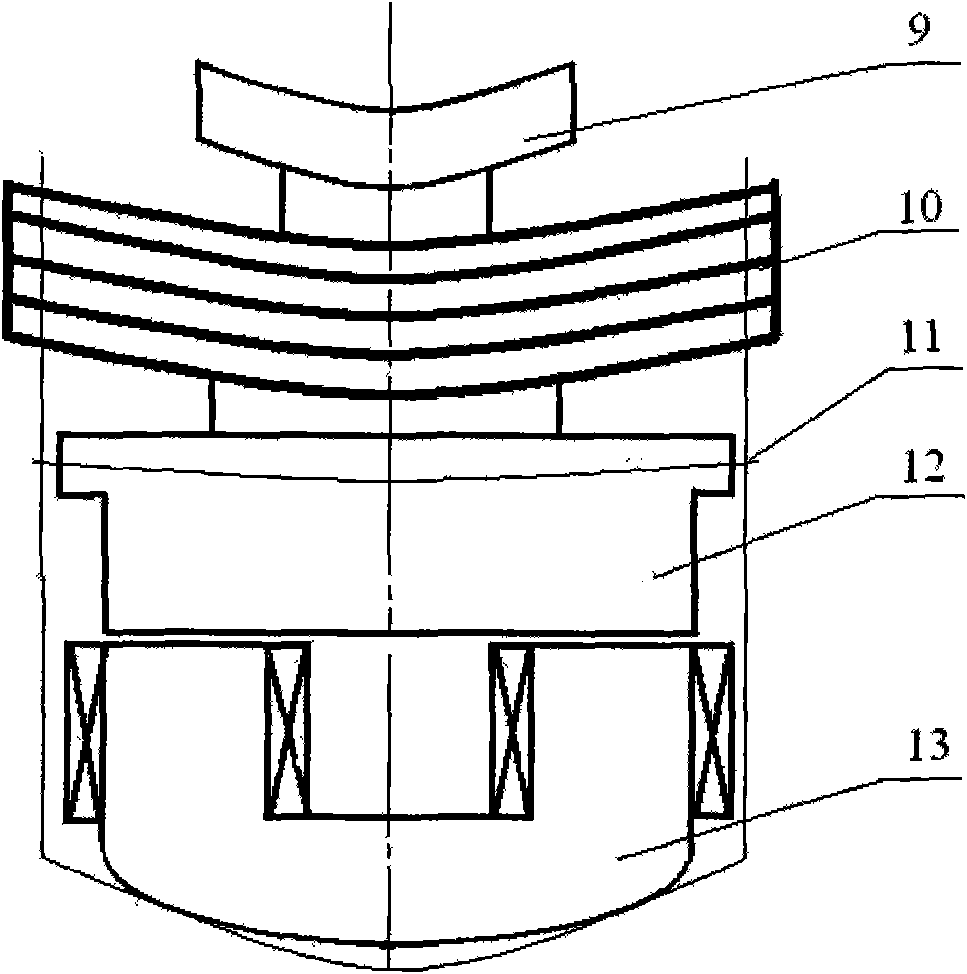

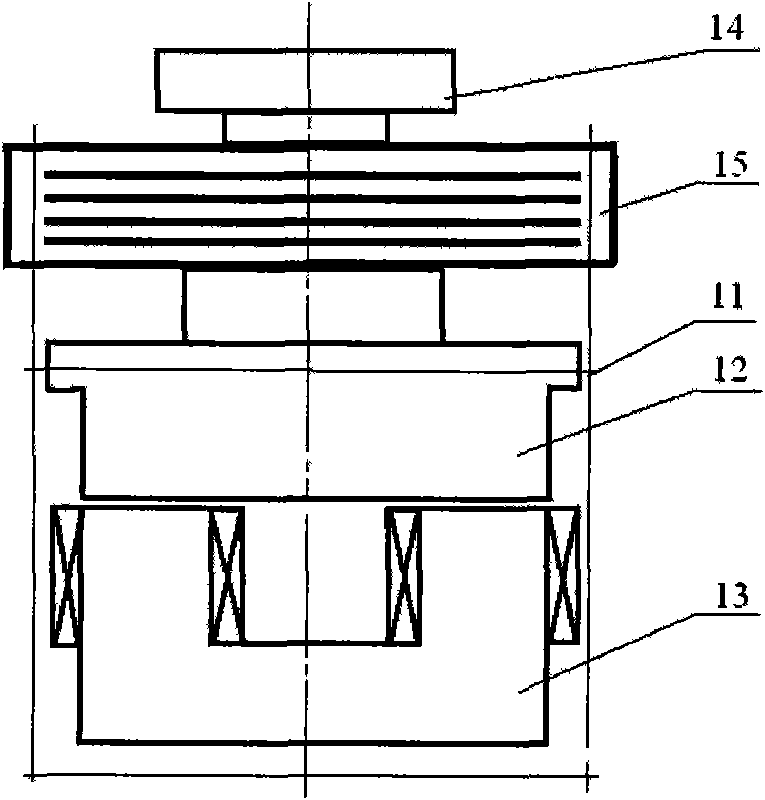

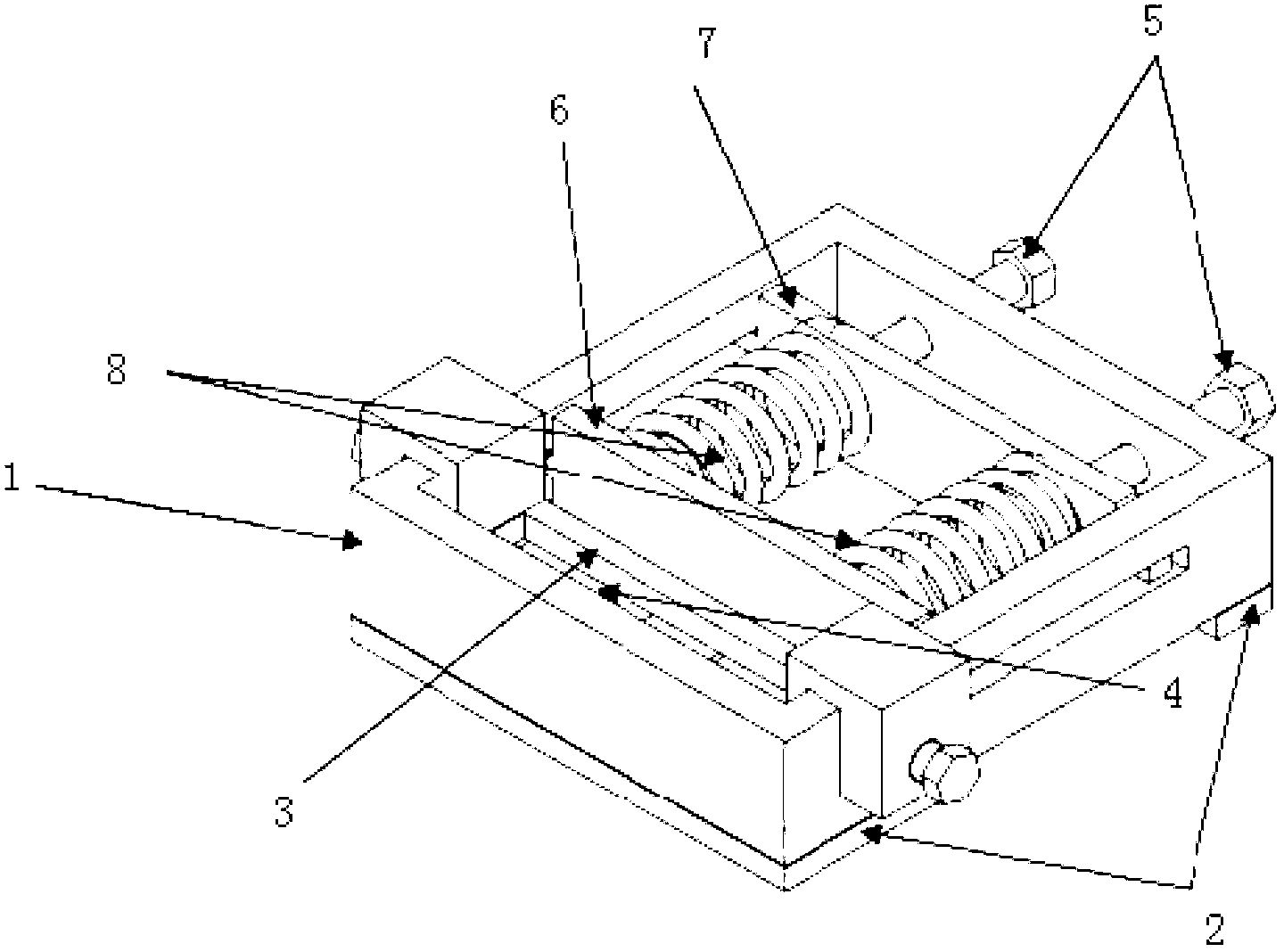

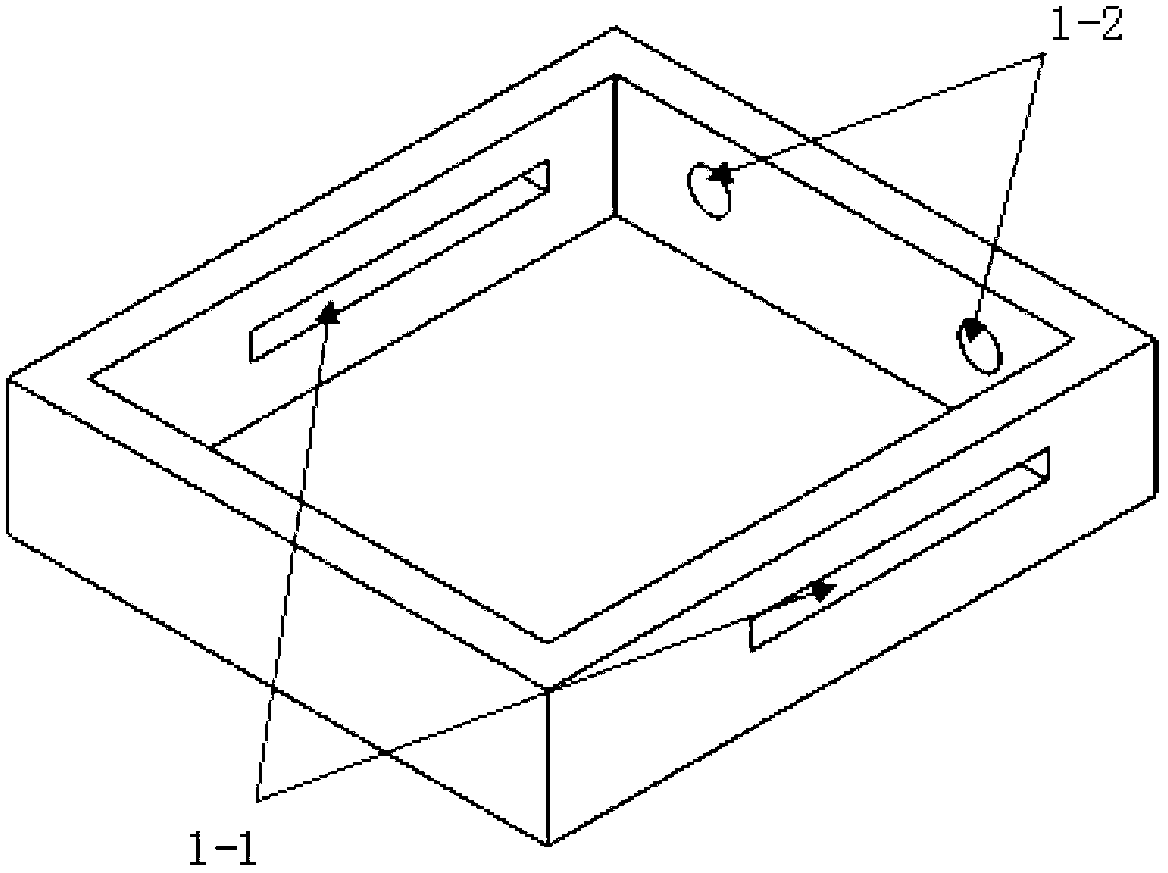

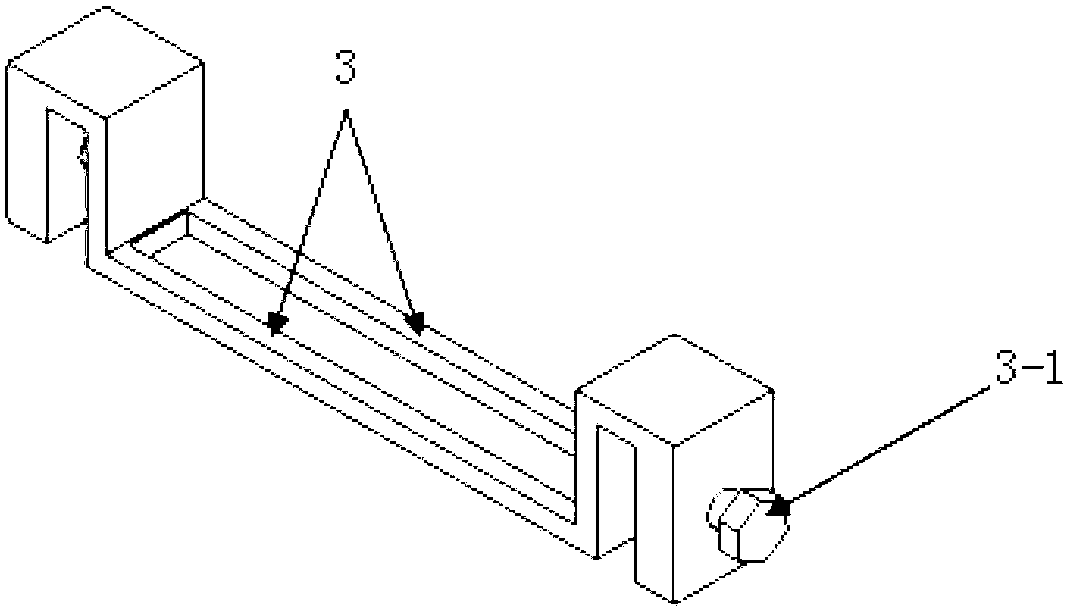

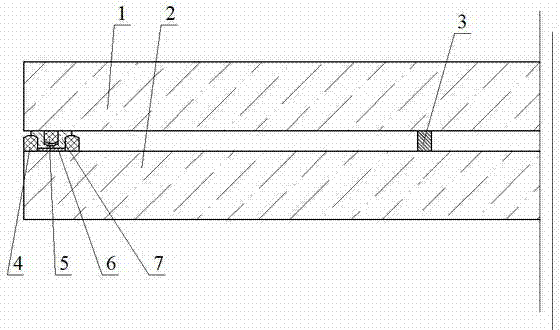

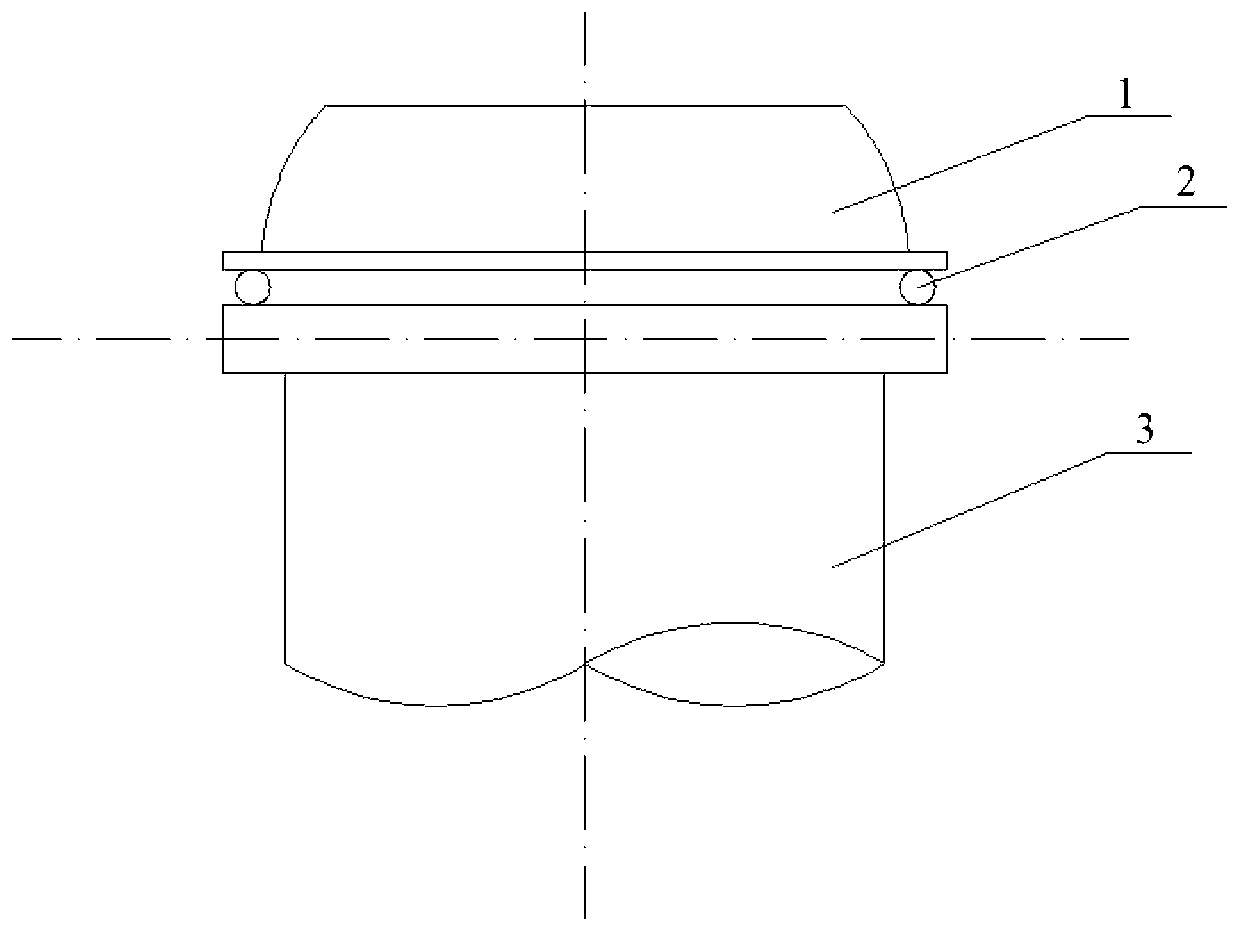

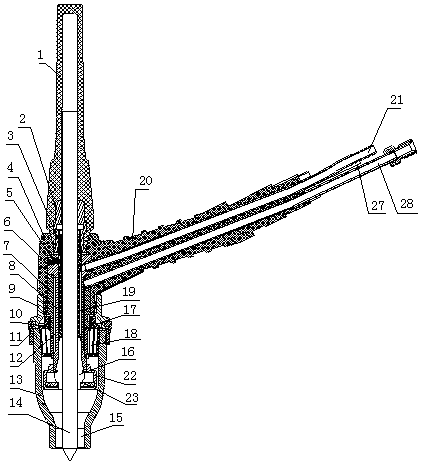

Tool capable of applying pressure to carry out electron beam auxiliary heat action connection

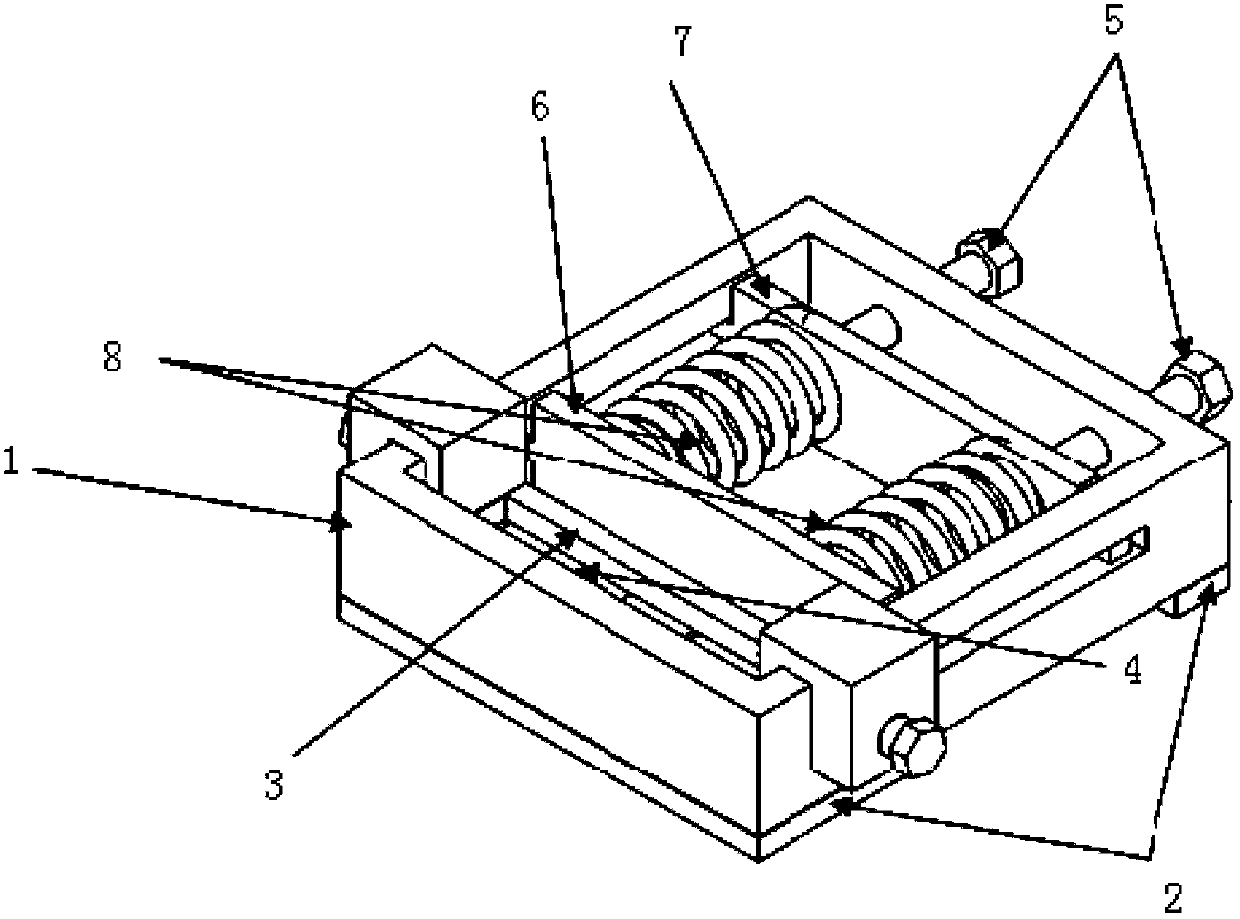

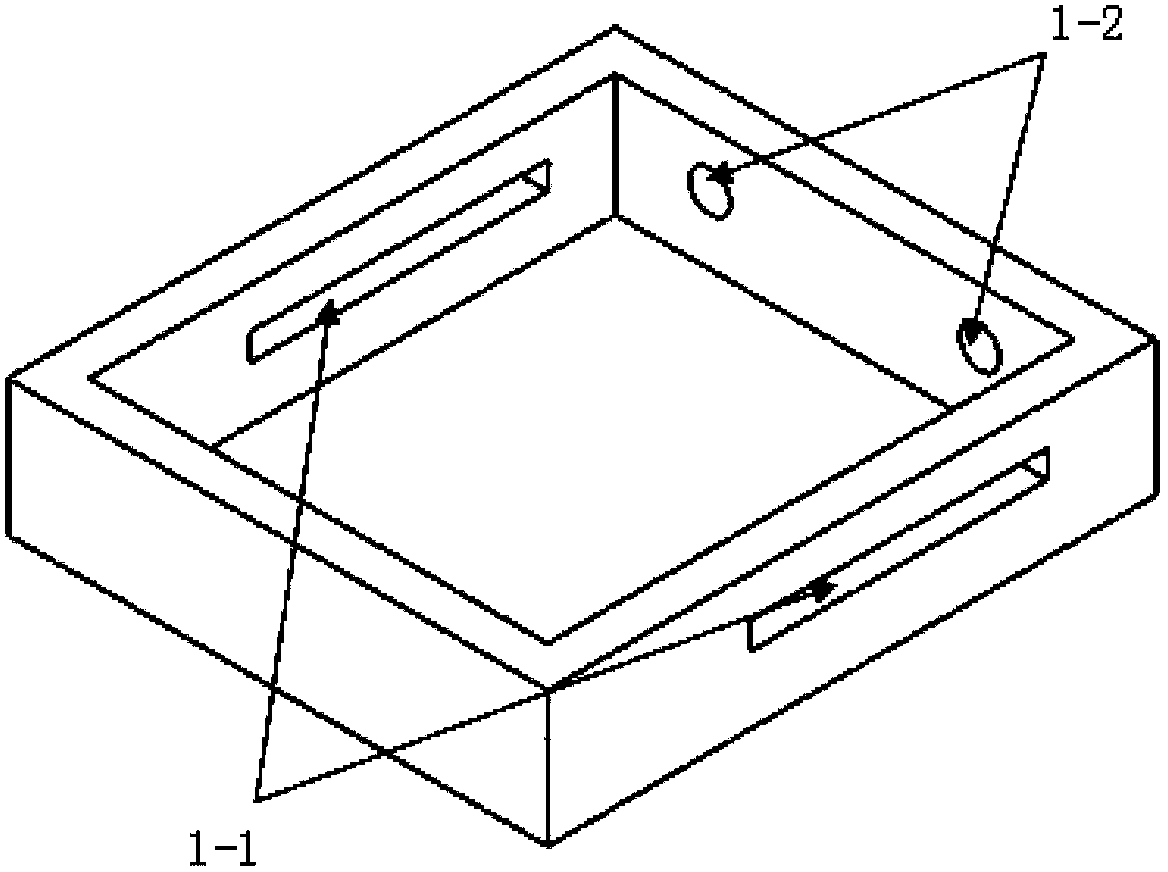

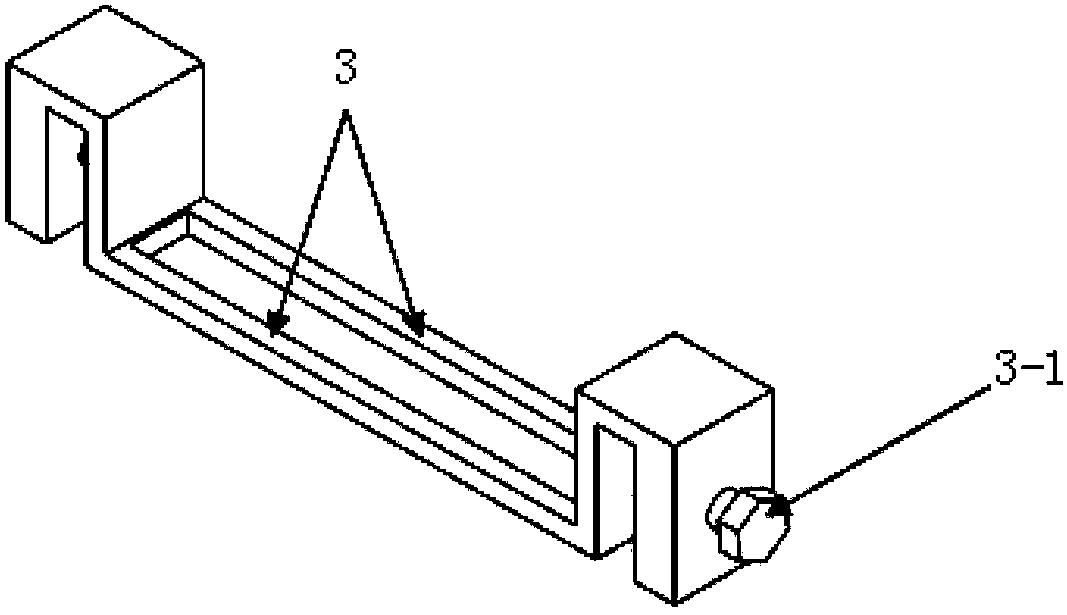

InactiveCN103008950ALocal connectionIncrease soldering temperatureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFusion welding

The invention relates to a tool capable of applying a pressure to carry out electron beam auxiliary heat action connection. The invention relates to a welding fixture for an electron beam auxiliary heat source action connection method. The invention aims to solve the problems of serious metal fire waste, interface reaction and the like, which are generated when a conventional fusion welding technology is adopted to process certain materials, so as to provide the tool capable of applying the pressure to carry out electron beam auxiliary heat action connection. The tool capable of applying the pressure to carry out electron beam auxiliary heat action connection is formed by a fixture housing, a fixture base, a vertical fixing device and a horizontal fixing device. The tool has the following working principle that the welding fixture disclosed by the invention is used by applying a certain pressure to a contact surface of a base metal, simultaneously utilizing a defocused electron beam to carry out circular scanning on a weld joint, repeatedly scanning in a reciprocating manner and controlling the welding speed so as to implement effects of raising the welding temperature and prolonging the heat preservation time, i.e. the defocused electron beam is used as a heat source to implement local connection of the base metal. The tool belongs to the field of a welding auxiliary tool.

Owner:HARBIN INST OF TECH

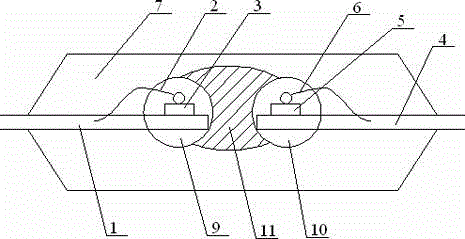

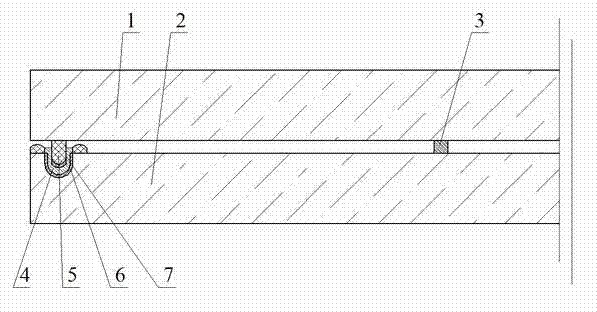

Metal-welded plain vacuum glass provided with edges sealed by sealing strips and manufacturing method thereof

Metal-welded plain vacuum glass provided with edges sealed by sealing strips is disclosed. The plain vacuum glass comprises upper glass and lower glass, and is characterized in that: the upper glass is provided with at least one sealing strip; the periphery of the lower glass is provided with at least two sealing strips; the sealing strip of the upper glass is inserted between the sealing strips of the lower glass; and after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by metal solder in a vacuum furnace. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Integral heater assembly and method for carrier or host board of electronic package assembly

InactiveUS9125301B2Easy to processLow costPrinted circuit assemblingHeater elementsLow voltageSurface mounting

Owner:INTEGRATED MICROWAVE

Low-Ti high-strength silver-based middle-temperature active brazing filler metal and preparation method thereof

ActiveCN109590634AUniform compositionUniform tissueWelding/cutting media/materialsSoldering mediaAlloyHigh pressure

The invention relates to low-Ti high-strength silver-based middle-temperature active brazing filler metal and a preparation method thereof. The brazing filler metal is prepared from 20 to 25 percent by weight of Cu, 15 to 25 percent by weight of Sn, 1 to 5 percent by weight of Pd, 1.0 to 3.0 percent by weight of Ti, and the balance Ag. The preparation method comprises the steps of adopting variousmetal for smelting according to the alloy proportion, then atomizing through high-pressure gas and carrying out deposition modeling, carrying out hot extrusion treatment on a modeled blank so as to enable an alloy to be densified, then rolling the densified blank, and finally obtaining an AgCuSnPdTi alloy sheet. The alloy brazing filler metal prepared through the method is uniform in compositionsand segregation-free, and can be processed into the sheet, and the welding temperature is lowered by about 200 DEG C compared with conventional AgCuTi active brazing filler metal, so that the residual heat stress of an Si3N4 ceramic welded joint is reduced, and the welding strength and the reliability of Si3N4 ceramics are improved.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

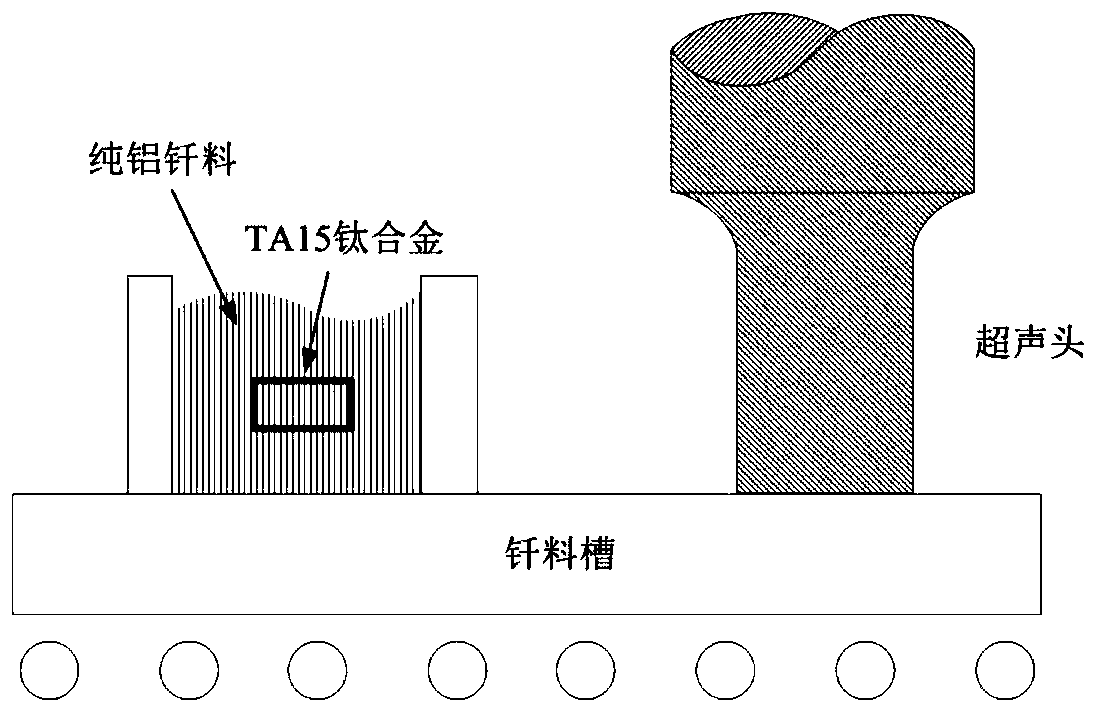

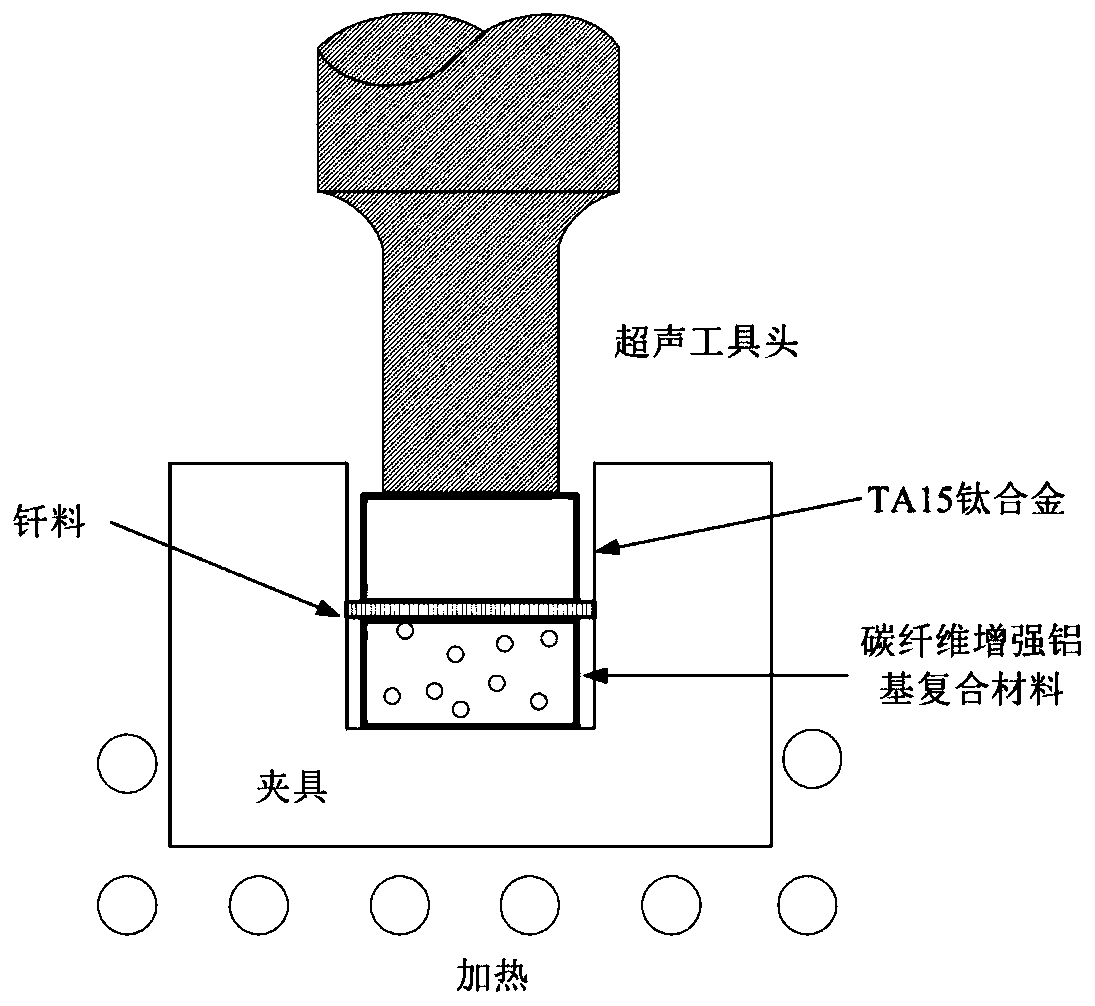

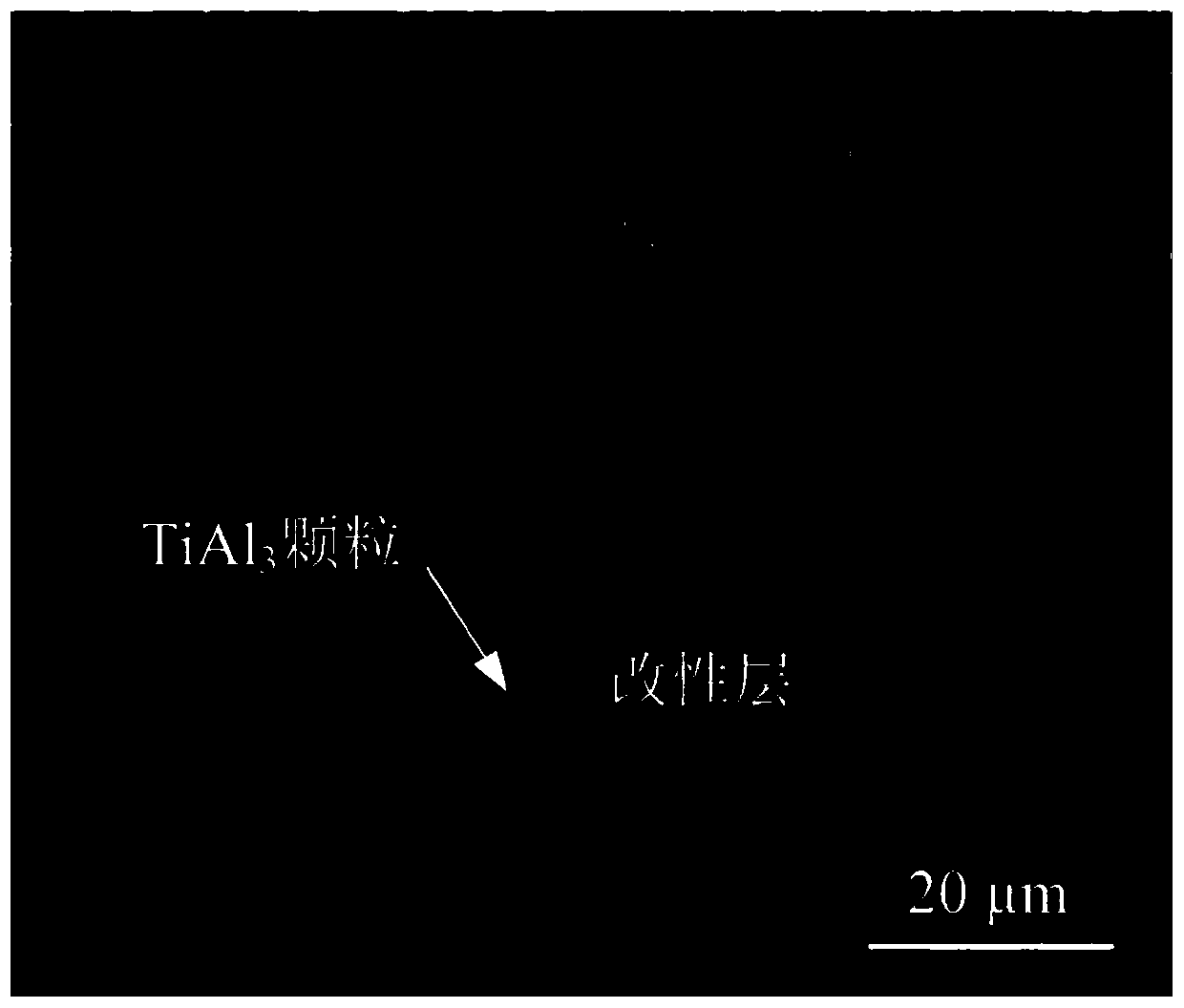

Braze soldering method for welding aluminum-base composite materials and titanium alloys and enabling intermetallic compound particles in weld seams to be dispersed and reinforced

ActiveCN110860754ALarge particle sizeHigh strengthSoldering apparatusWelding/soldering/cutting articlesUltrasonic weldingWeld seam

The invention provides a braze soldering method for welding aluminum-base composite materials and titanium alloys and enabling intermetallic compound particles in weld seams to be dispersed and reinforced, and relates to the field of braze soldering of the aluminum-base composite materials and the titanium alloys. The method solves the technical problem that performance of a connector obtained through an existing aluminum-base composite material and titanium alloy method is low. The method comprises the steps that firstly, a pure aluminum ingot is fused; secondly, the surface of a titanium alloy is modified; and thirdly, ultrasonic welding is carried out. According to the method, the welding temperature of the titanium alloys and the aluminum-base composite materials can be lowered obviously, the situation that a base material is heated and softened in the welding process is effectively prevented, TiAl3 particles entering the weld seams can have the dispersing and reinforcing function,and a welding connector with high strength is obtained beneficially. The method is used for braze soldering of the aluminum-base composite materials and the titanium alloys.

Owner:HARBIN INST OF TECH

Glass-metal heat sealing material and method of heat-pipe evacuated solar collector tube

The invention discloses glass-metal heat sealing material and method of a heat-pipe evacuated solar collector tube. One end of a glass tube is sintered into a glass flange; the end face of the flange and the surface of a Fe-Ni expansion alloy end cover are respectively cleaned and deoiled; an annular welding wire prepared from the glass-metal heat sealing material is clamped in the middle, wherein the sealing temperature is 0.6-0.9 times of the melting point of the welding wire, the exerted impact pressure is 70-500kg / cm<2>, and the time is 0.5 seconds to 2 minutes; the glass-metal heat sealing material is selected from any one of metal substances or metal alloy of Mg, Be, V, Co and Ni,the metal alloy contains nickel and silicon, the mass fraction of the nickel in the metal alloy is 1-30%, the mass fraction of the silicon is 1-30%, and base metal is selected from any one of Mg, Be, V and Co. The corrosion resistance, the welding temperature, the fatigue strength and the malleability of the welding line disclosed by the invention are improved; the welding wire is more tightly combined with glass and metal; the air leak rate is reduced; and the service life is prolonged.

Owner:西藏中科阳光新能源科技股份有限公司

Method and solder for form-fitted joining of two surfaces

ActiveUS20110100545A1Increase soldering temperatureHeating evenlyImpression capsLamination ancillary operationsMating connectionOptical property

A method for form-fitted joining of two surfaces, where a metallic or non-metallic solder is applied to at least one of the two surfaces, where the solder has a temperature-dependent optical property. The solder is radiated with electromagnetic radiation with a predetermined spectrum, such that the solder reaches a predetermined temperature above its melting temperature and moistens the surfaces, such that the temperature-dependent optical property is modified reversibly or irreversibly at the predetermined temperature of the solder. The solder is cooled to below its melting temperature, such that the solder solidifies and connects the surfaces in form-fitted manner.

Owner:STORZ ENDOSKOP PROD GMBH

Method for overlaying welding of duplex stainless steel

ActiveCN102941394BEnough temperaturePrevent hot and cold cracksArc welding apparatusFurnace typesThermal insulationRoom temperature

Owner:WUHAN MARINE MACHINERY PLANT

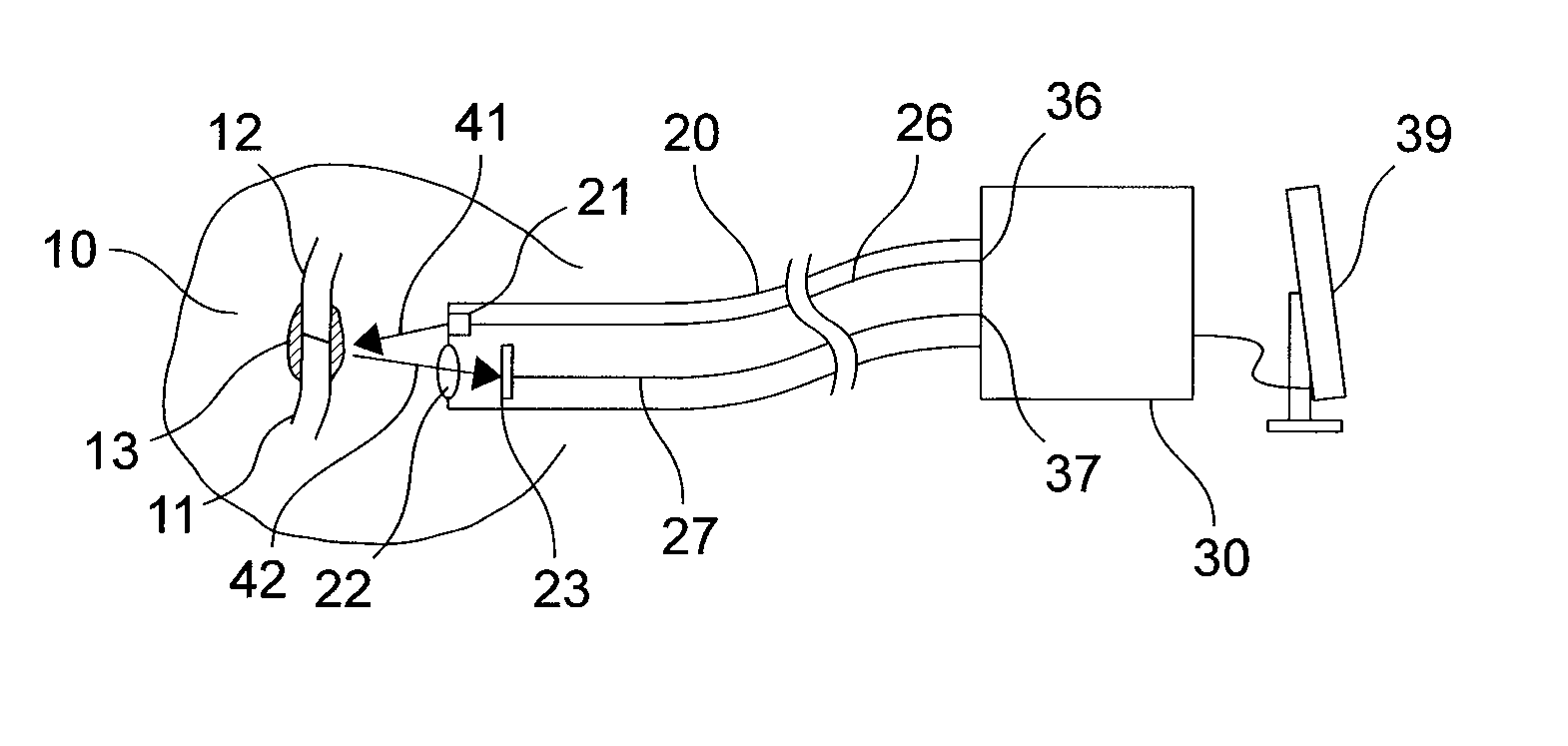

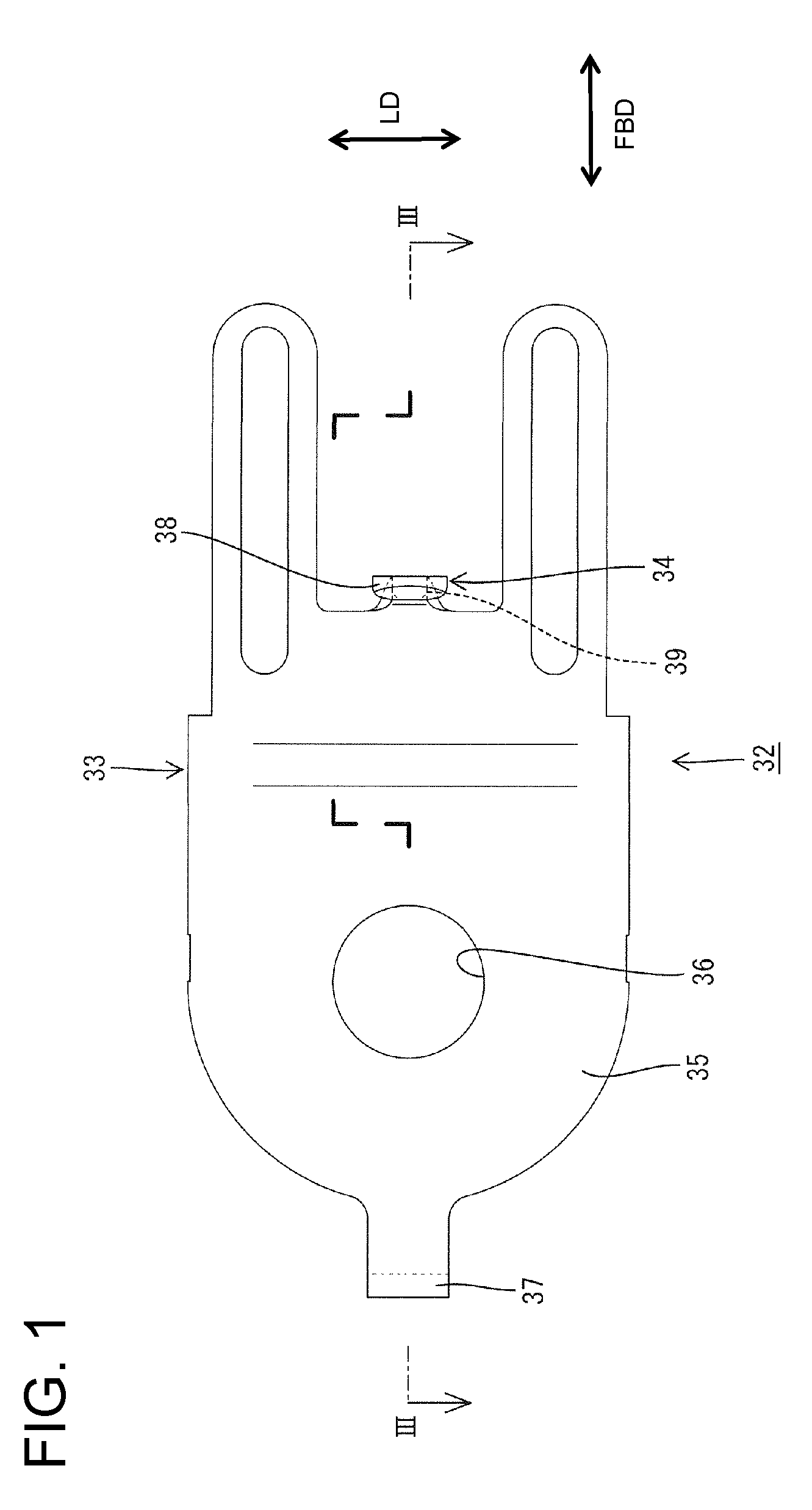

Packaging structure and packaging technology improving optical coupler reliability

ActiveCN104867919AStress reliefEliminates high voltage breakdown pathsSemiconductor/solid-state device detailsSolid-state devicesEngineeringHigh pressure

The invention discloses a packaging structure and a packaging technology improving optical coupler reliability; the packaging technology specifically comprises the following steps: coupling, aligning and racking; packing an input end and an output end; setting a high voltage block layer; and mould pressing. The high voltage block layer is arranged between an input end transparent silica gel layer and an output end transparent silica gel layer; a mould pressing material is filled between the input end transparent silica gel layer and the output end transparent silica gel layer, and between an outer wall of the high voltage block layer and a housing. The packaging technology can improve a soldering temperature, so SMT paster soldering technology can be applied to an optical coupler welding process; a stress between a chip welding gold thread and the silica gel and mould pressing material and a high voltage breakdown path in the optical coupler can be removed without needing a silica gel surface treatment complex technology condition, thus reducing production difficulty and production cost, and effectively ensuring product reliability.

Owner:NINGBO QUNXIN MICRO-ELECTRONICS CO LTD

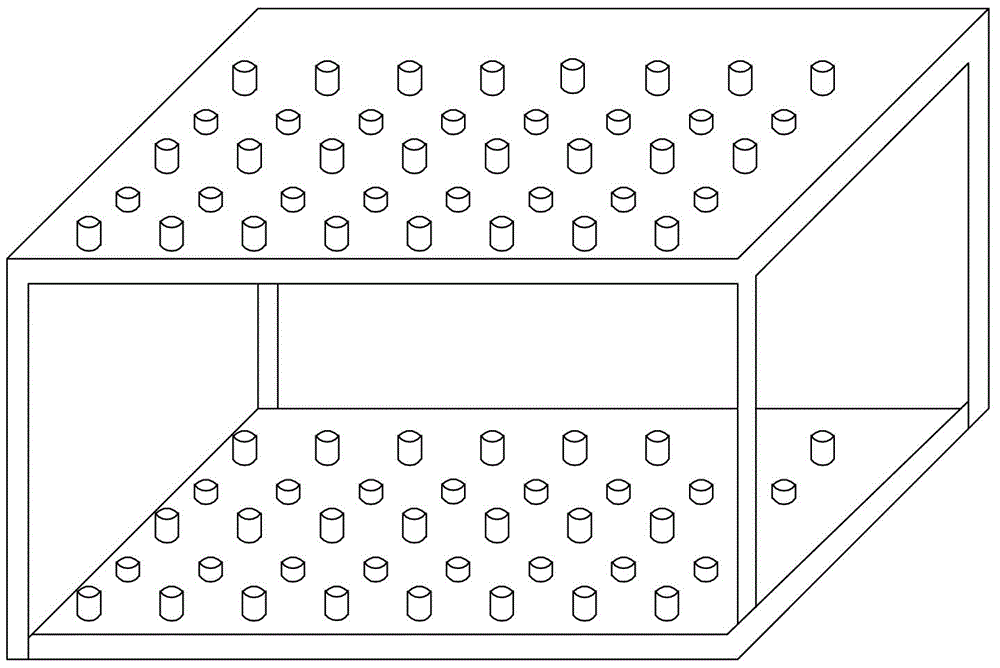

Metal-welded plain vacuum glass provided with edges sealed by sealing grooves and sealing strips and manufacturing method thereof

Metal-welded plain vacuum glass provided with edges sealed by sealing grooves and sealing strips is disclosed. The plain vacuum glass comprises upper glass and lower glass, and is characterized in that: the periphery of the upper glass is provided with sealing strips; corresponding positions of the periphery of the lower glass are provided with the sealing grooves and sealing strips; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by metal solder in a vacuum furnace; a sealed vacuum layer is formed between the upper glass and the lower glass; and supports arranged in a point array are disposed in the vacuum layer. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

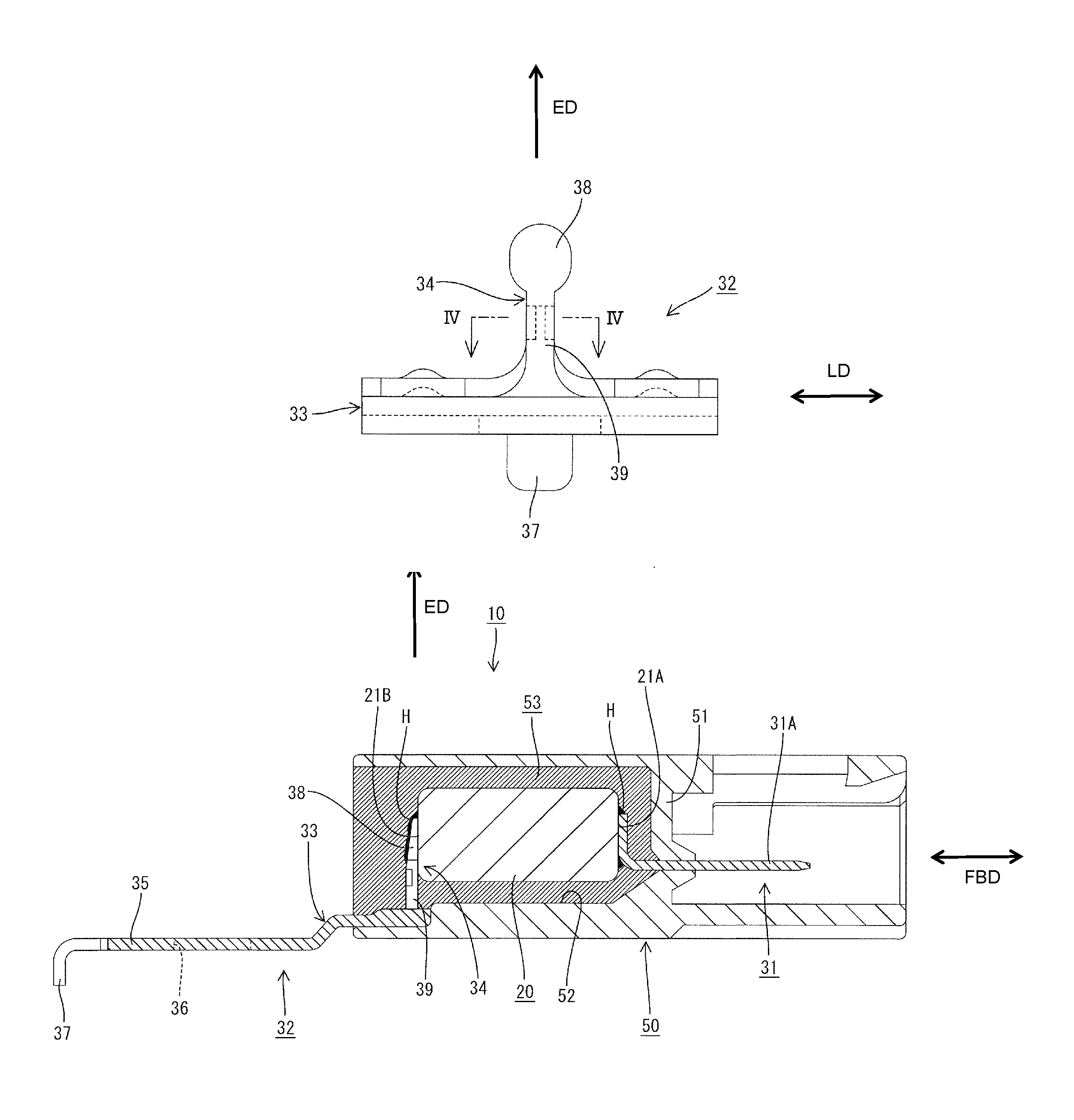

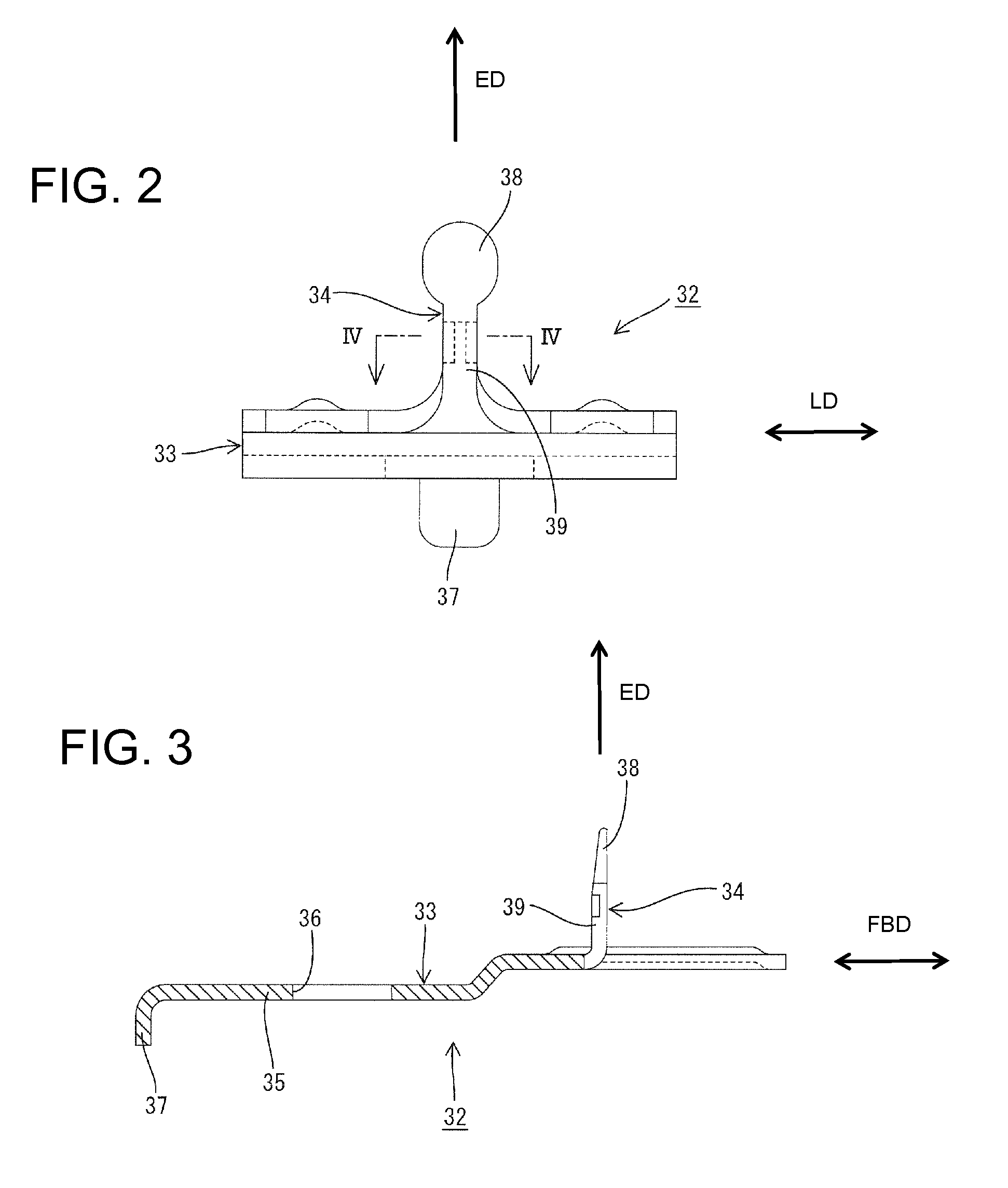

Electrical connector having an electronic device

ActiveUS8602821B2Increase soldering temperatureShort timeRelieving strain on wire connectionContact member assembly/disassemblyEngineeringElectrical connector

Owner:SUMITOMO WIRING SYST LTD

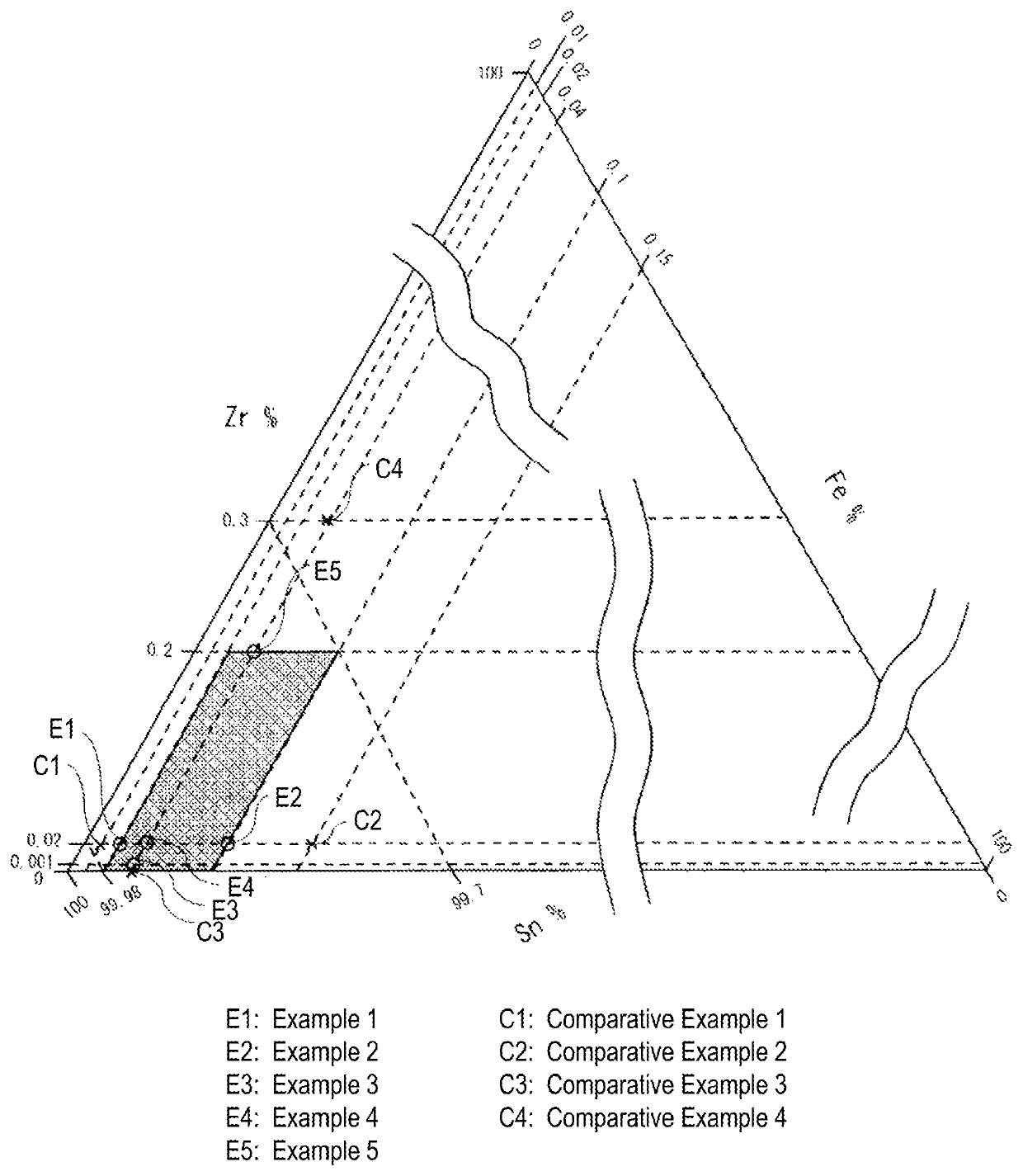

Solder alloy for preventing Fe erosion, resin flux cored solder, wire solder, resin flux cored wire solder, flux coated solder, solder joint and soldering method

ActiveUS10717158B2Reduced elutionAvoid leachingWelding/cutting media/materialsSoldering mediaCarbideFlux-cored arc welding

Provided are a solder alloy for preventing Fe erosion, a resin flux cored solder, a wire solder, a resin flux cored wire solder, a flux coated solder, a solder joint, and a soldering method which, in order to prolong the life of a soldering iron tip, suppress erosion of the soldering iron tip and by which adhesion of carbide to the soldering iron tip is suppressed. The present invention has an alloy composition comprising, by mass %, 0.02-0.1% Fe, more than 0% and equal to or less than 0.2% Zr, with the remainder being Sn, and is used to prevent Fe erosion.

Owner:SENJU METAL IND CO LTD

Lead-free solder

InactiveCN1242869CImprove mechanical propertiesIncrease soldering temperatureWelding/cutting media/materialsSoldering mediaIndiumCopper

A lead-free solder material for soldering in electronic, instrument, lamp and other fields consists of: In 0.003-5 wt%, Sb 0.2-5 wt%, Cu 0.5-3 wt% Ag 0.2-5 wt% and Sn the rest. Compared with the traditional solder, the present invention has equal or even higher mechanical performance, soldering temperature and electric performance, and may be drawn into 0.5 mm diameter lead-less solder wire, and it is harmless to human body and environment.

Owner:郴州金箭焊料有限公司

Circuit board of LED lamp, LED lamp board and processing technology of circuit board

ActiveCN104185371AIncrease soldering temperatureGood welding performanceSolid-state devicesMultilayer circuit manufactureAbrasive blastingSolder mask

The invention discloses a circuit board of an LED lamp, an LED lamp board and a processing technology of the circuit board. The LED lamp board includes LED wafers, wafer lead wires and the circuit board. The circuit board includes mirror boards, a substrate and a solder mask layer. The substrate includes wafer installation holes. The mirror boards are bonded on the back of the substrate. The solder mask layer covers the front face of the substrate. The front face of the substrate includes aluminum conductive lines. The outer surfaces of the conductive lines include abrasive blasting rough layers. The wafer lead wires are ultrasonically welded with bonding pads on the aluminum conductive lines of the circuit board. The LED wafers are pasted on the mirror boards in the wafer installation holes of the substrate. The outer surfaces of the conductive lines are provided with the rough layers formed through abrasive blasting, and during ultrasonic welding with metal lead wires, especially aluminum lead wires, the fusion degree of the lead wires and the bonding pads is high. Compared with aluminum alloy bonding pads which do not undergo the abrasive blasting processing, the lead wires are capable of bearing a higher tension. The manufactured LED lamp board is high in good rate and low in fault rate in a use process.

Owner:深圳市鼎华芯泰科技有限公司

Solar cell module for sunlight room and preparation method thereof

InactiveCN104701400AHigh light transmittanceNo pollution in the processFinal product manufacturePhotovoltaic energy generationWater leakageTransmittance

The invention discloses a solar cell module for a sunlight room and a preparation method thereof. The solar cell module for the sunlight room comprises a tempered glass layer, EVA film layers, a cell piece layer and a backboard; the EVA film layer is arranged at each of the upper and lower surfaces of the cell piece layer, the tempered glass layer adheres the upside of the cell piece, and the backboard adheres to the downside of the cell piece; a side frame is arranged at the periphery; the backboard comprises a PET layer at the middle, a fluorine-containing weather-resistant layer coats each of the upper and lower surfaces of the PET layer, the PET layer is 0.15 to 0.30 millimeters in thickness, the upper fluorine-containing weather-resistant layer is 0.008-0.014 millimeters in thickness, and the lower fluorine-containing weather-resistant layer is 0.015 to 0.025 millimeters in thickness; the side frame of each component is provided with a bump or a groove having sliding fit with the adjacent side frame, and the bump of the side frame is sleeved in the groove of the adjacent side frame in a sliding mode to realize component connection. The solar cell module for the sunlight room has advantages that the sunlight is soft, the indoor air flow and human settlement maintenance are facilitated, the sealing property is good, water leakage is avoided, and the conversion efficiency and light transmittance of the cell are high.

Owner:JIANGXI RIPUSHENG ENERGY TECH

Tool capable of applying pressure to carry out electron beam auxiliary heat action connection

InactiveCN103008950BLocal connectionIncrease soldering temperatureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFusion welding

The invention relates to a tool capable of applying a pressure to carry out electron beam auxiliary heat action connection. The invention relates to a welding fixture for an electron beam auxiliary heat source action connection method. The invention aims to solve the problems of serious metal fire waste, interface reaction and the like, which are generated when a conventional fusion welding technology is adopted to process certain materials, so as to provide the tool capable of applying the pressure to carry out electron beam auxiliary heat action connection. The tool capable of applying the pressure to carry out electron beam auxiliary heat action connection is formed by a fixture housing, a fixture base, a vertical fixing device and a horizontal fixing device. The tool has the following working principle that the welding fixture disclosed by the invention is used by applying a certain pressure to a contact surface of a base metal, simultaneously utilizing a defocused electron beam to carry out circular scanning on a weld joint, repeatedly scanning in a reciprocating manner and controlling the welding speed so as to implement effects of raising the welding temperature and prolonging the heat preservation time, i.e. the defocused electron beam is used as a heat source to implement local connection of the base metal. The tool belongs to the field of a welding auxiliary tool.

Owner:HARBIN INST OF TECH

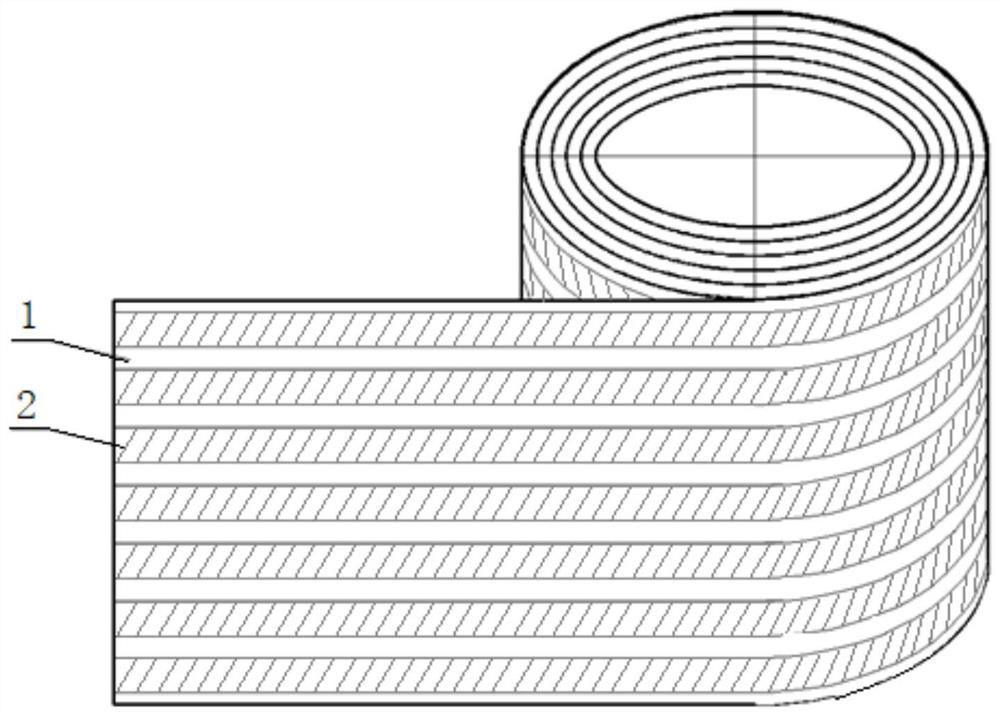

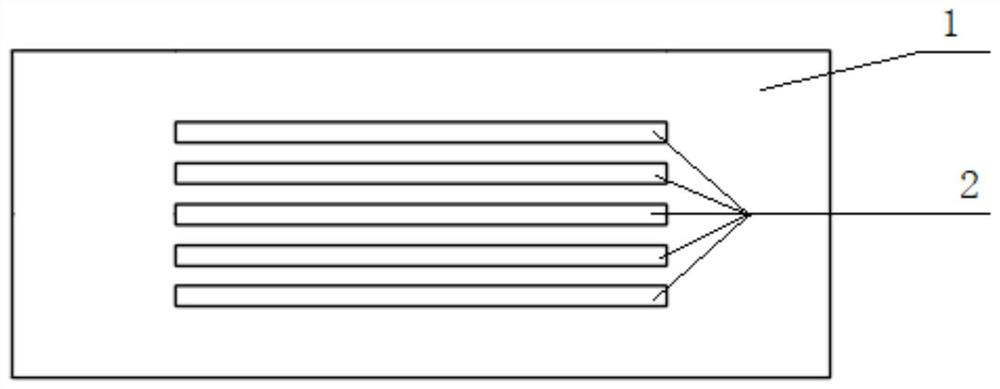

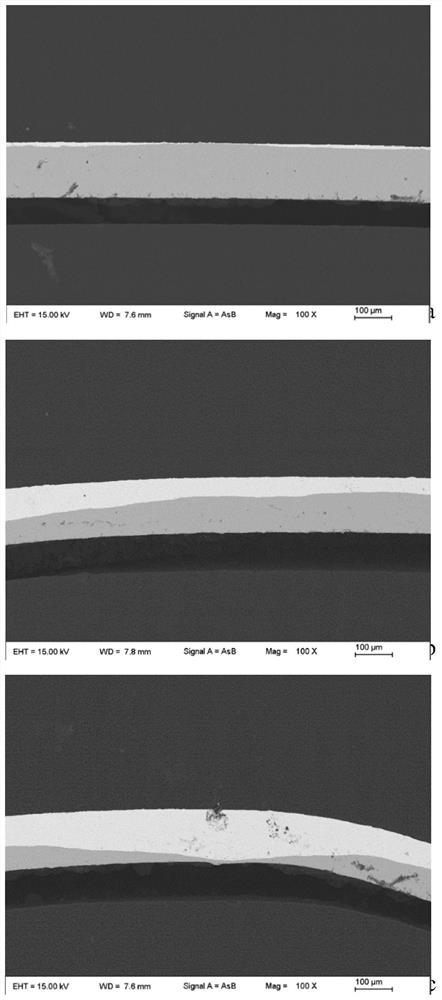

High-tin-content copper-tin brazing filler metal grid-shaped composite strip and preparation method thereof

ActiveCN113941797AIncrease soldering temperatureLow soldering temperatureWelding/cutting media/materialsSoldering mediaCopperFiller metal

The invention discloses a high-tin-content copper-tin brazing filler metal grid-shaped composite strip. The tin content is 10wt%-60wt%; the high-tin-content copper-tin brazing filler metal grid-shaped composite strip comprises a strip-shaped copper base body, a plurality of grooves which are arranged in parallel at intervals are formed in one surface of the strip-shaped copper base body, the grooves are filled with tin to form tin bars, and the tin bars and copper around the grooves are connected into a whole. The invention further discloses a preparation method of the high-tin-content copper-tin brazing filler metal grid-shaped composite strip. According to the method, the influence of the tin adding amount on the machining forming performance can be avoided, when the tin content reaches 10wt%-60wt%, the high-tin-content copper-tin brazing filler metal strip can still be obtained through a conventional pressure machining method, and the brazing temperature is reduced.

Owner:ZHEJIANG ASIA GENERAL SOLDERING & BRAZING MATERIAL

A high-efficiency water-cooled argon arc welding torch

ActiveCN106001861BImprove protectionDesign scienceCooled electrode holdersSpray nozzleAgricultural engineering

The invention provides a high-efficiency water-cooled argon arc welding torch, which is composed of a handle, a torch head body, a torch head body sheath, a rear cap, a tungsten pole rod, a tungsten pole clamp, an inner heat insulation sleeve, an outer heat insulation sleeve, an outer connection sleeve, The nozzle connection ring is composed of ceramic nozzles, in which the middle of the handle is provided with an air inlet pipe, an inlet pipe and an outlet pipe, the right end of the handle is connected with the outer casing of the gun head body, and the lower end of the air inlet pipe is connected with the upper end of the gun head body The air intake hole on the side is connected, and the air intake hole is connected with the vertical through hole in the center of the gun head body. A tungsten pole clip is set in the middle of the vertical through hole. The ring groove, the inner circle of the inner heat insulation sleeve is tightly fitted on the outside of the ring groove to seal the ring groove into a water cooling jacket, the water inlet pipe and the water outlet pipe are connected with the water cooling jacket, and an outer insulation Heat sleeve, the outer heat insulation sleeve is connected with the inner circle of the upper end of the ceramic nozzle, the lower end of the gun head body sheath is provided with an outer connecting sleeve, the lower end of the outer connecting sleeve is connected to the nozzle connecting ring, and the connecting ring and the outer circle of the upper end of the ceramic nozzle pass through the thread Screwed together, the rear cap is set on the top of the gun head body.

Owner:济南尼克焊接技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com